Method for controlling plasma flow of wing lift-rising apparatus

A plasma and high-lift device technology, applied in the direction of aircraft control, affecting the air flow flowing through the surface of the aircraft, aircraft parts, etc., can solve the problems of limited response speed and bandwidth, and achieve shortened run distance and short excitation response time , The effect of frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

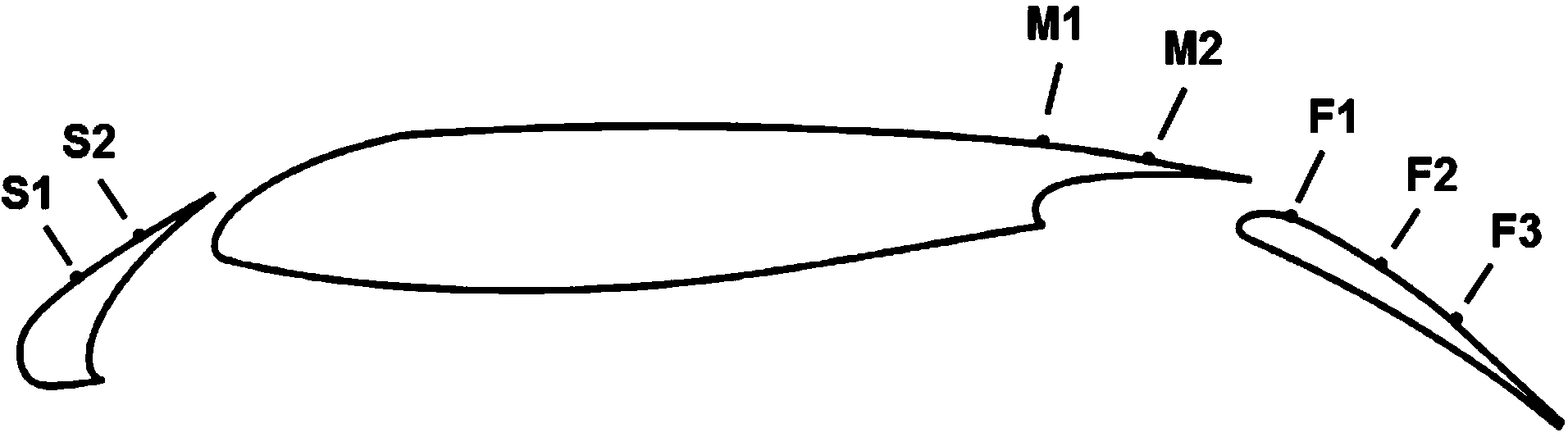

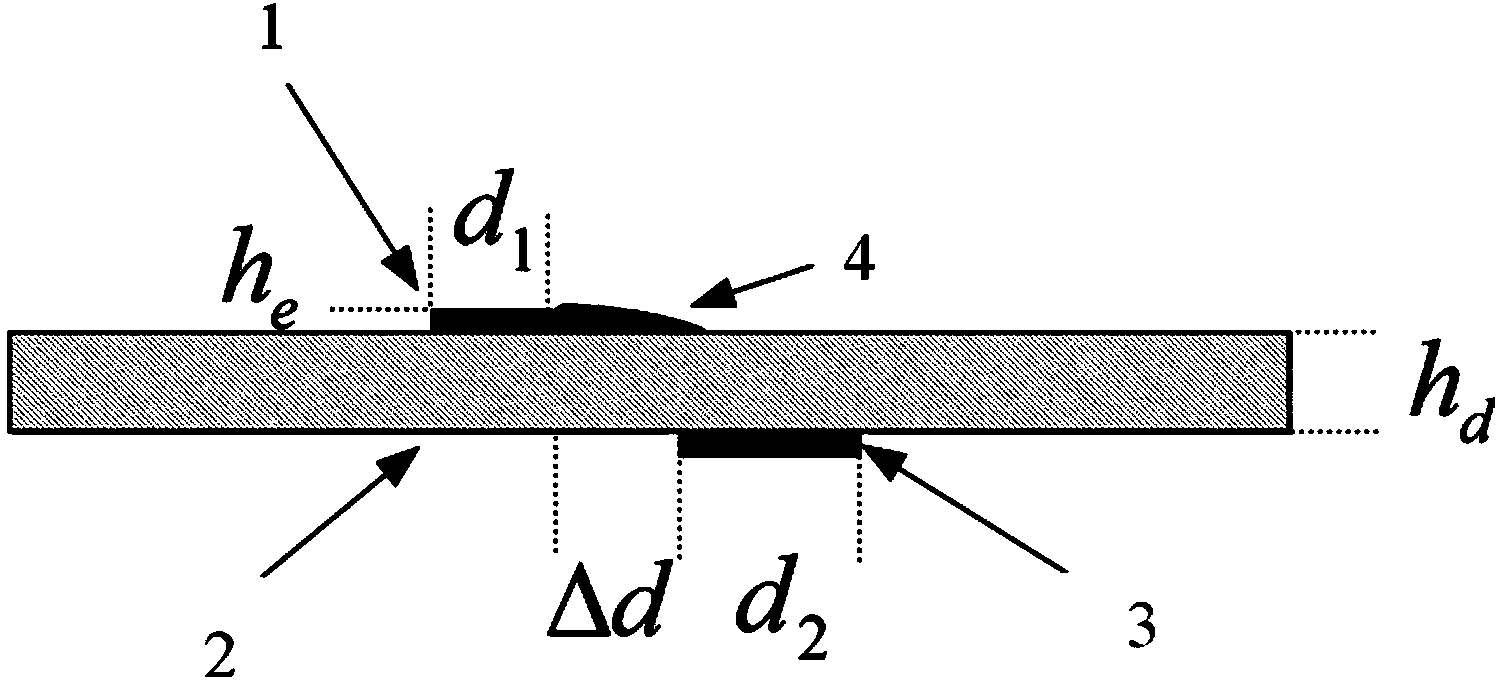

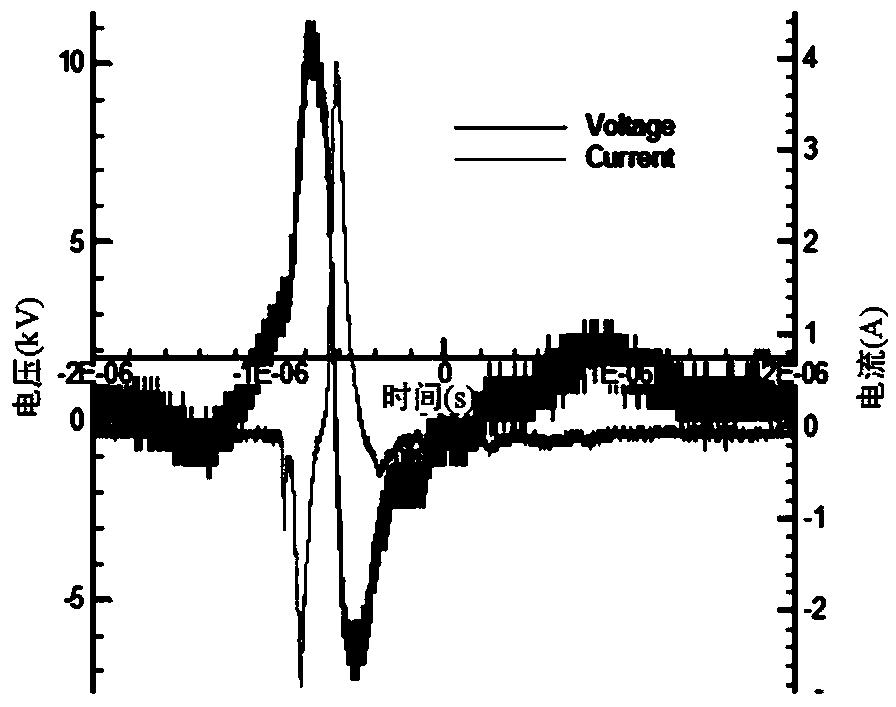

[0027] In the control method of this embodiment, the plasma exciter is laid on the suction surface of the leading edge slat, the suction surface of the trailing edge of the main wing and the suction surface of the trailing edge flap. The plasma exciter is composed of asymmetric layout electrodes separated by insulating material, the upper surface electrode of the insulating material is connected with the high-voltage end of the pulse plasma power supply, and the lower surface electrode is grounded. The laying position of the plasma actuator is at the leading edge and the trailing edge of the separation point. When the aircraft takes off and lands and opens the leading edge slats and trailing edge flaps, it sends an "on" signal to turn on the plasma actuator, and when the aircraft retracts the leading edge slats and trailing edge flaps, it sends out an "off" signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com