Hypersonic aircraft aero-propulsive integrated layout method based on combined power

A hypersonic, aerodynamic propulsion technology, which is applied to combined engines, jet propulsion devices, and air inlets of turbine/propulsion devices, etc., can solve the problems of large take-off weight, discontinuous thrust, and poor economy of aircraft, and can solve the problem of modal The thrust is discontinuous during conversion, reducing adverse effects and solving the effect of poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

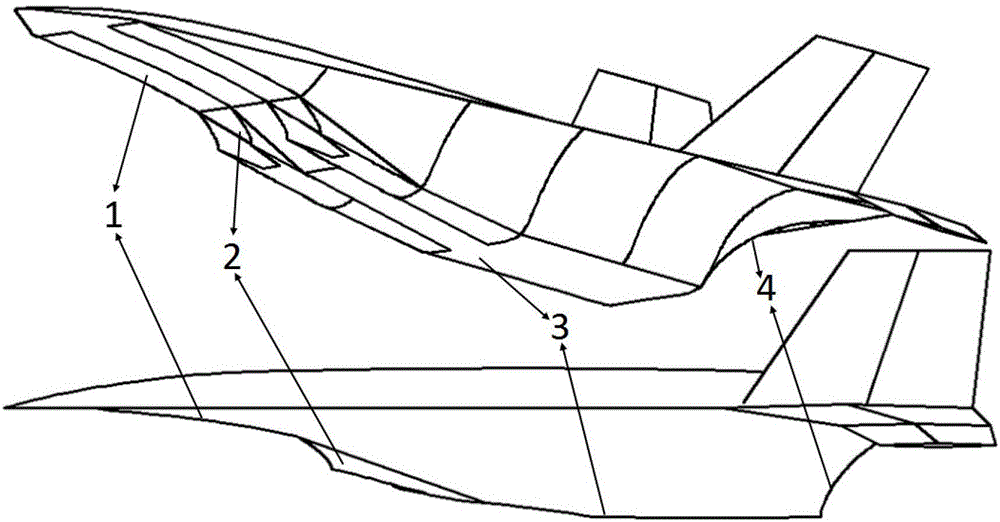

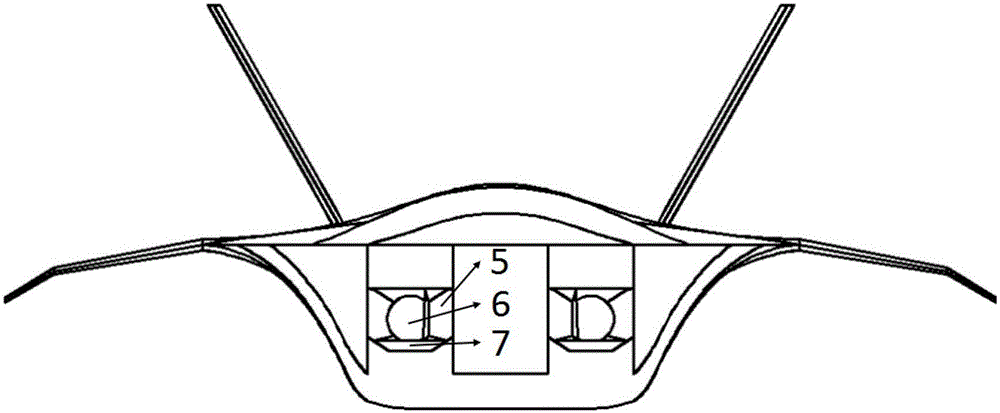

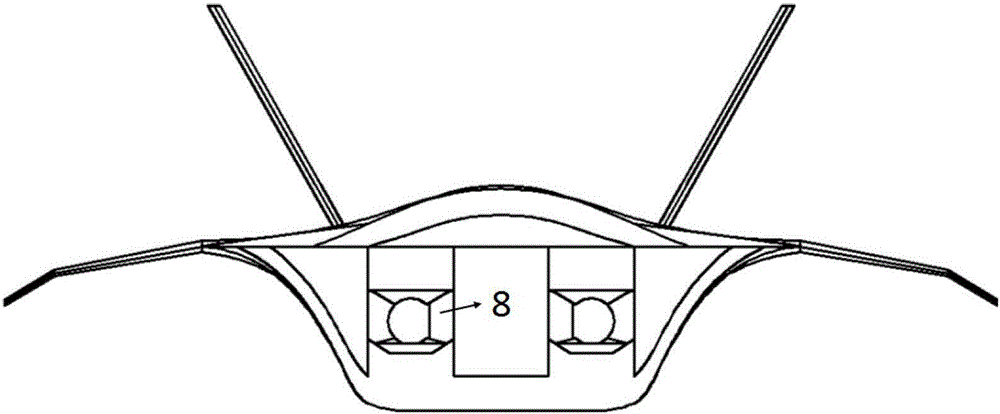

[0021] An integrated layout method for aerodynamic propulsion of a hypersonic aircraft based on combined power of the present invention integrates the design of the body of the hypersonic aircraft and the TRBCC propulsion system, wherein the hypersonic inlet and tail nozzle of the dual-mode ramjet It is integrated with the front body and rear body of the aircraft respectively; the turbine engine channel, the rocket ejection ramjet channel and the dual-mode ramjet channel are arranged in parallel, and work in coordination with each other to ensure that the aircraft rolls, takes off, and accelerates from transonic climb to cruise. The entire process of the stage has a large residual thrust and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com