Patents

Literature

35 results about "Rocket-based combined cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

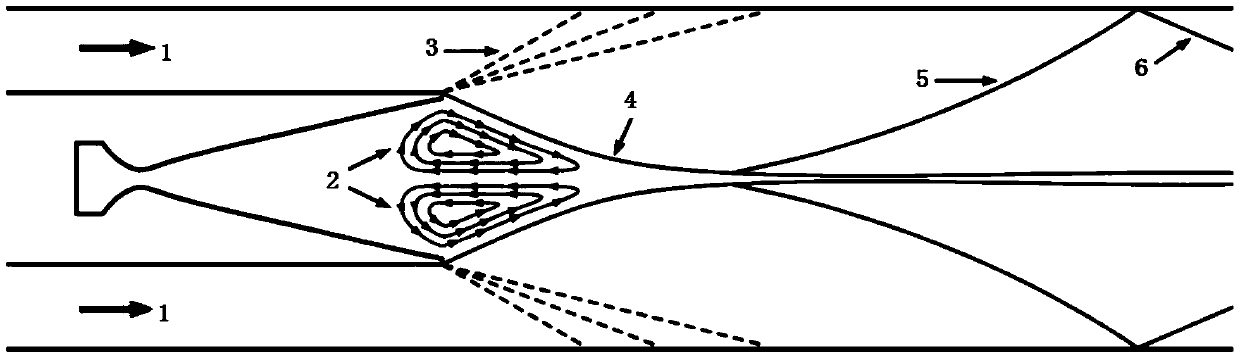

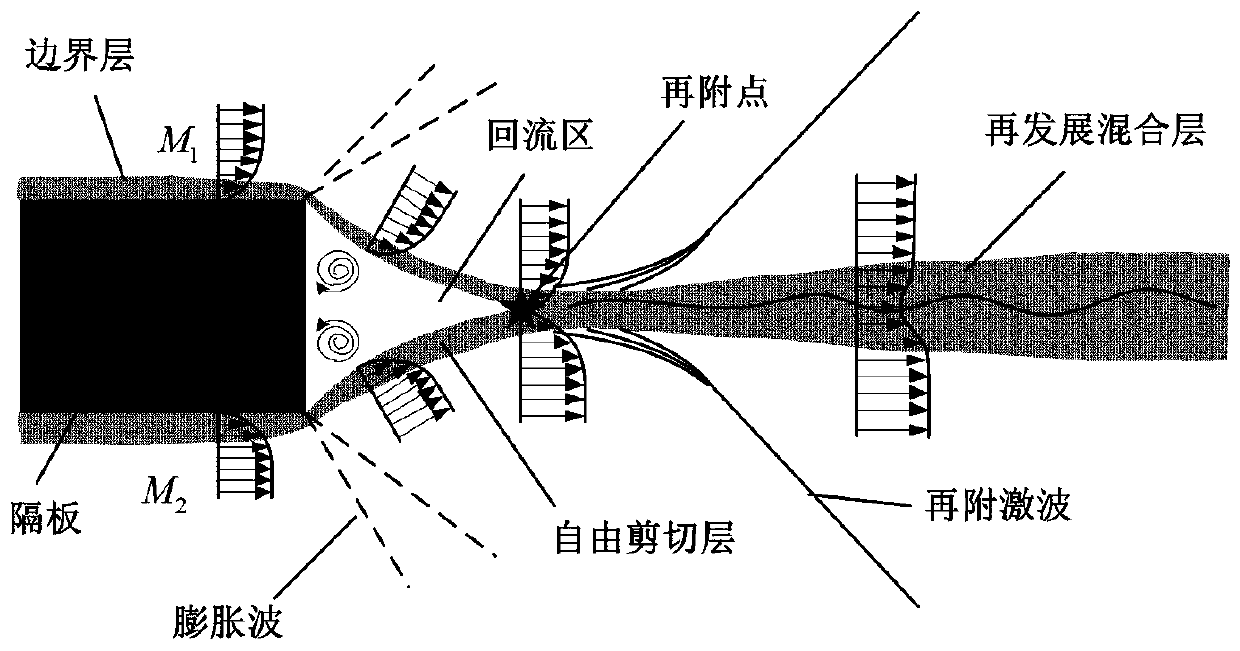

The RBCC, or Rocket-Based Combined Cycle propulsion system, is one of the two types of propulsion systems that may be tested in the Boeing X-43 experimental aircraft. The RBCC, or strutjet as it is sometimes called, is a combination propulsion system that consists of a ramjet, scramjet, and ducted rocket, where all three systems use a shared flow path.

Variable working condition type primary rocket system of rocket based combined cycle engine

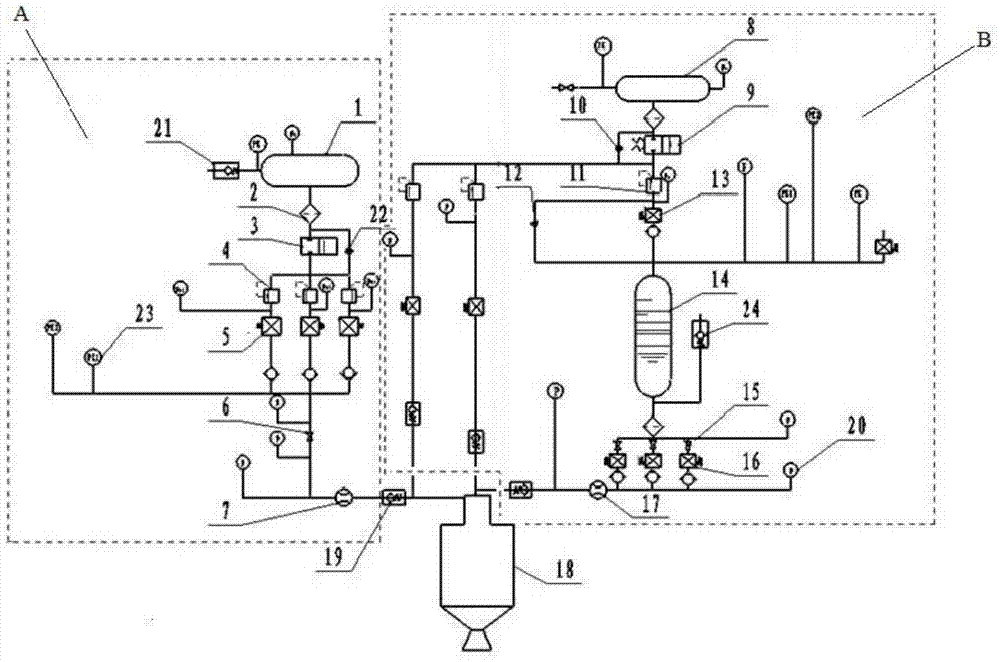

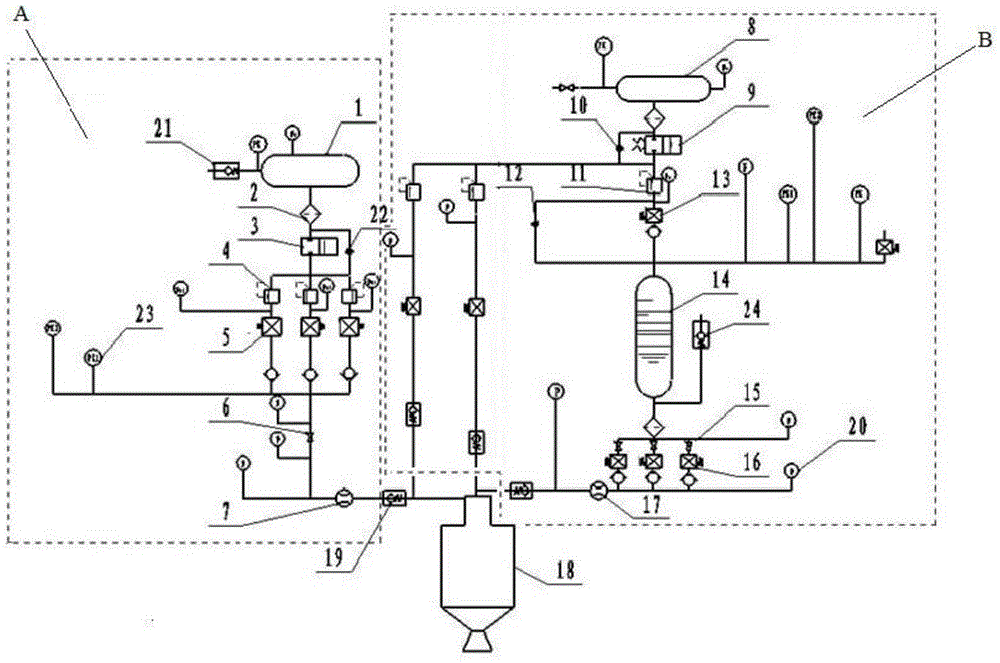

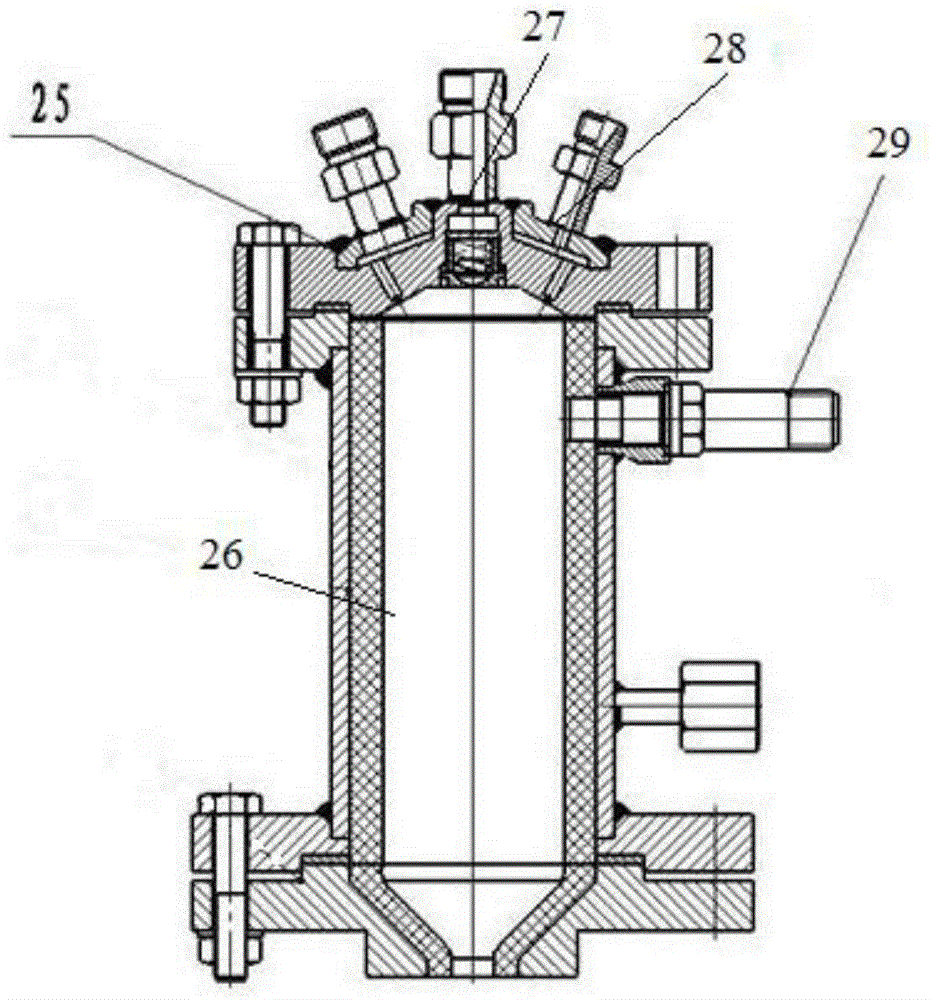

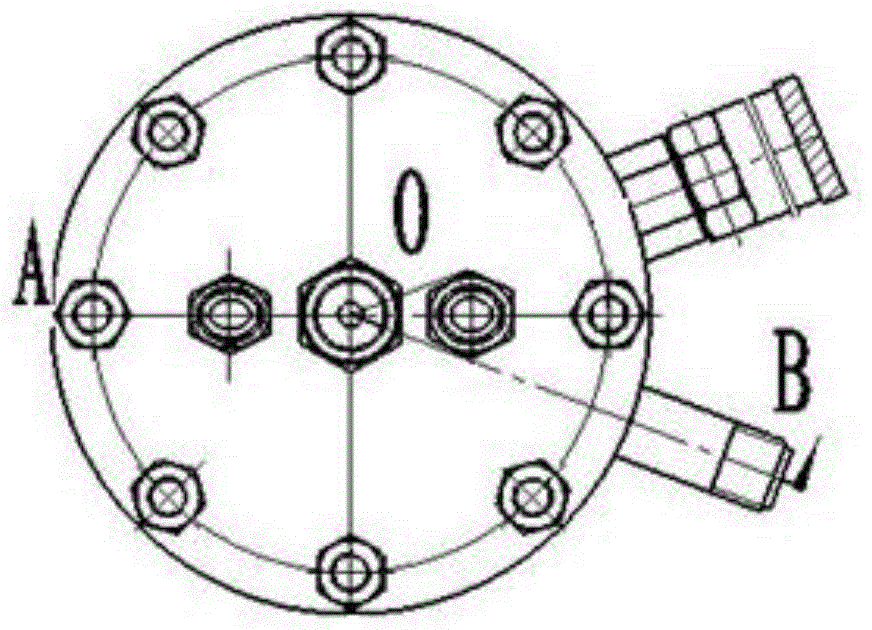

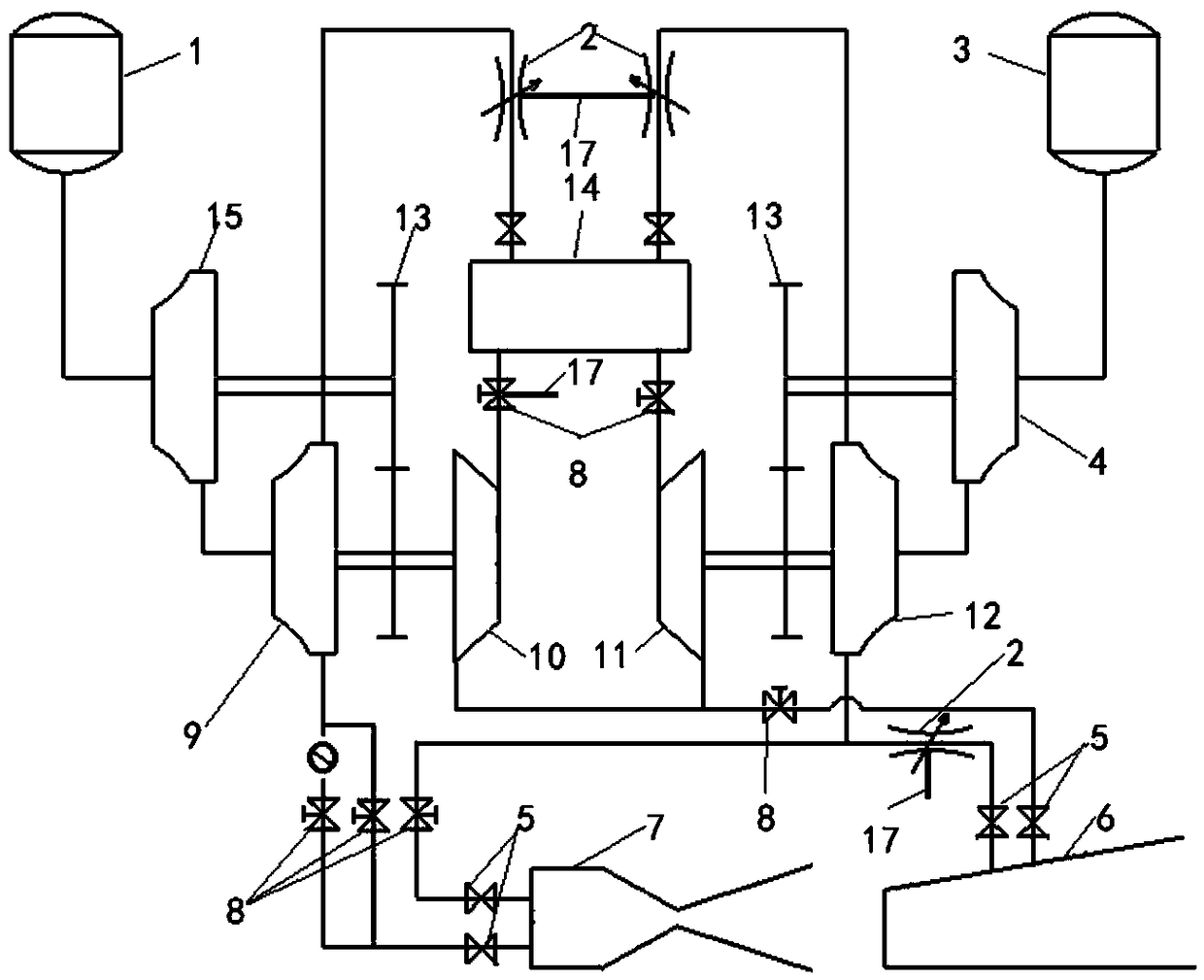

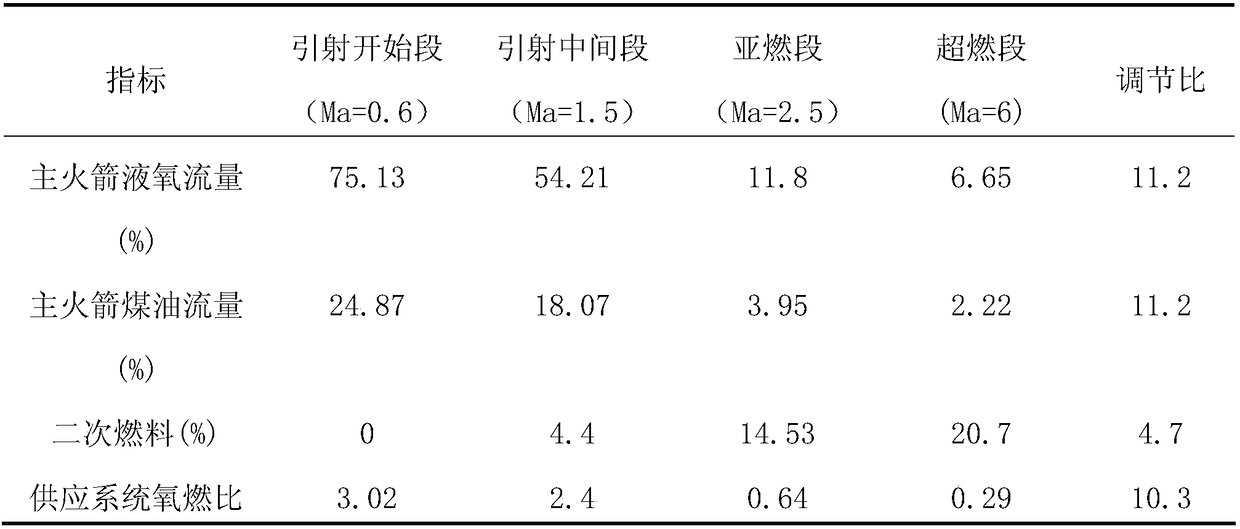

The invention discloses a variable working condition type primary rocket system of a rocket based combined cycle engine. The variable working condition type primary rocket system comprises a propellant supply system and a primary rocket engine thrust chamber which are connected through a pipeline, wherein the propellant supply system comprises an oxidant supply system and a fuel supply system, the oxidant supply system comprises an oxygen flow rate control system, the oxygen flow rate control system comprises a plurality of oxygen conveying pipelines, each oxygen conveying pipeline is provided with an oxygen pressure relief valve for opening and closing the corresponding oxygen conveying pipeline, an outlet of each oxygen conveying pipeline is connected with an oxygen perforating plate, the fuel supply system comprises a plurality of fuel conveying pipelines, an outlet of each fuel conveying pipeline is provided with a cavitation venturi pipe, and an inlet of each fuel conveying pipeline is connected with a nitrogen pressure relief device. The variable working condition type primary rocket system of the rocket based combined cycle engine has the advantages that the flow rate of a propellant can be accurately, controllably, stably and quickly adjusted, the complexity is low, and the operation is simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

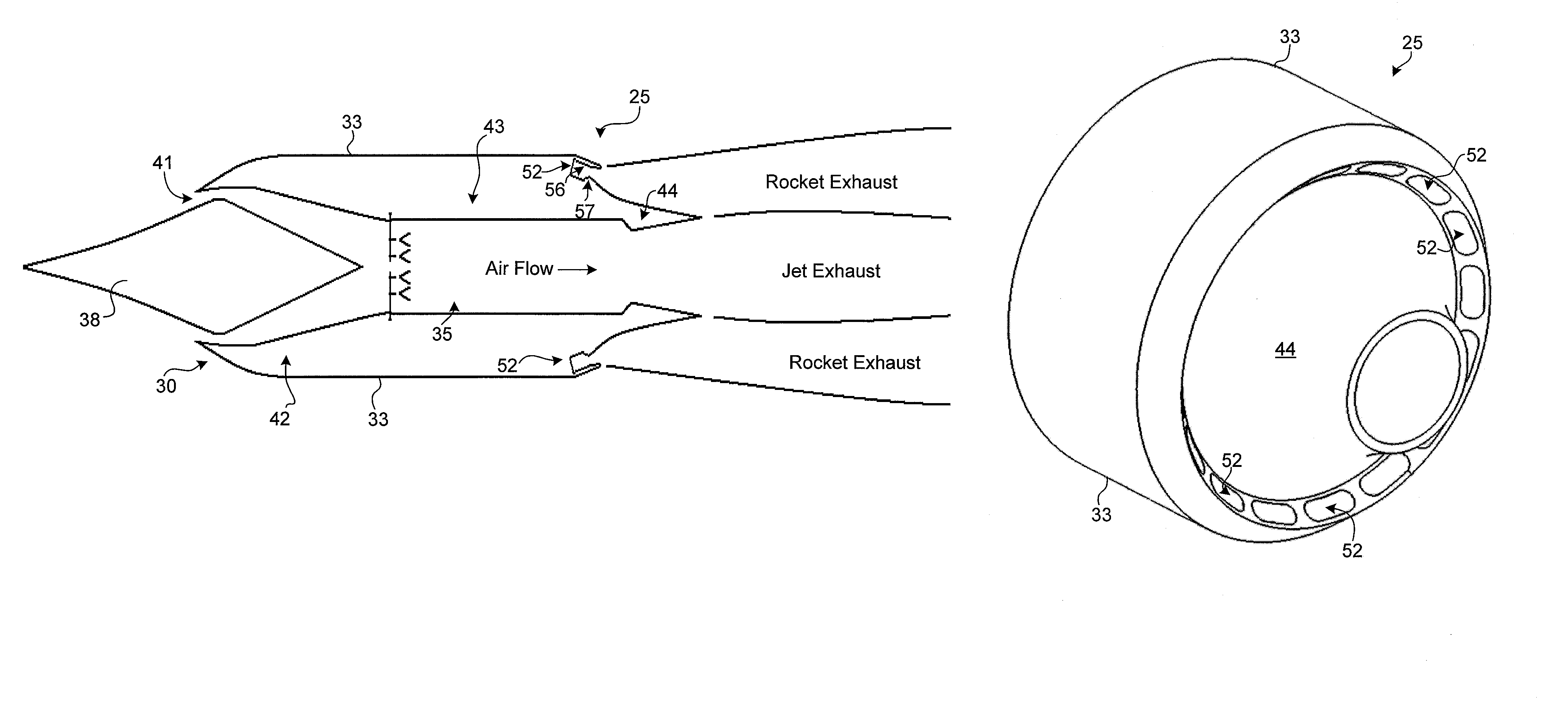

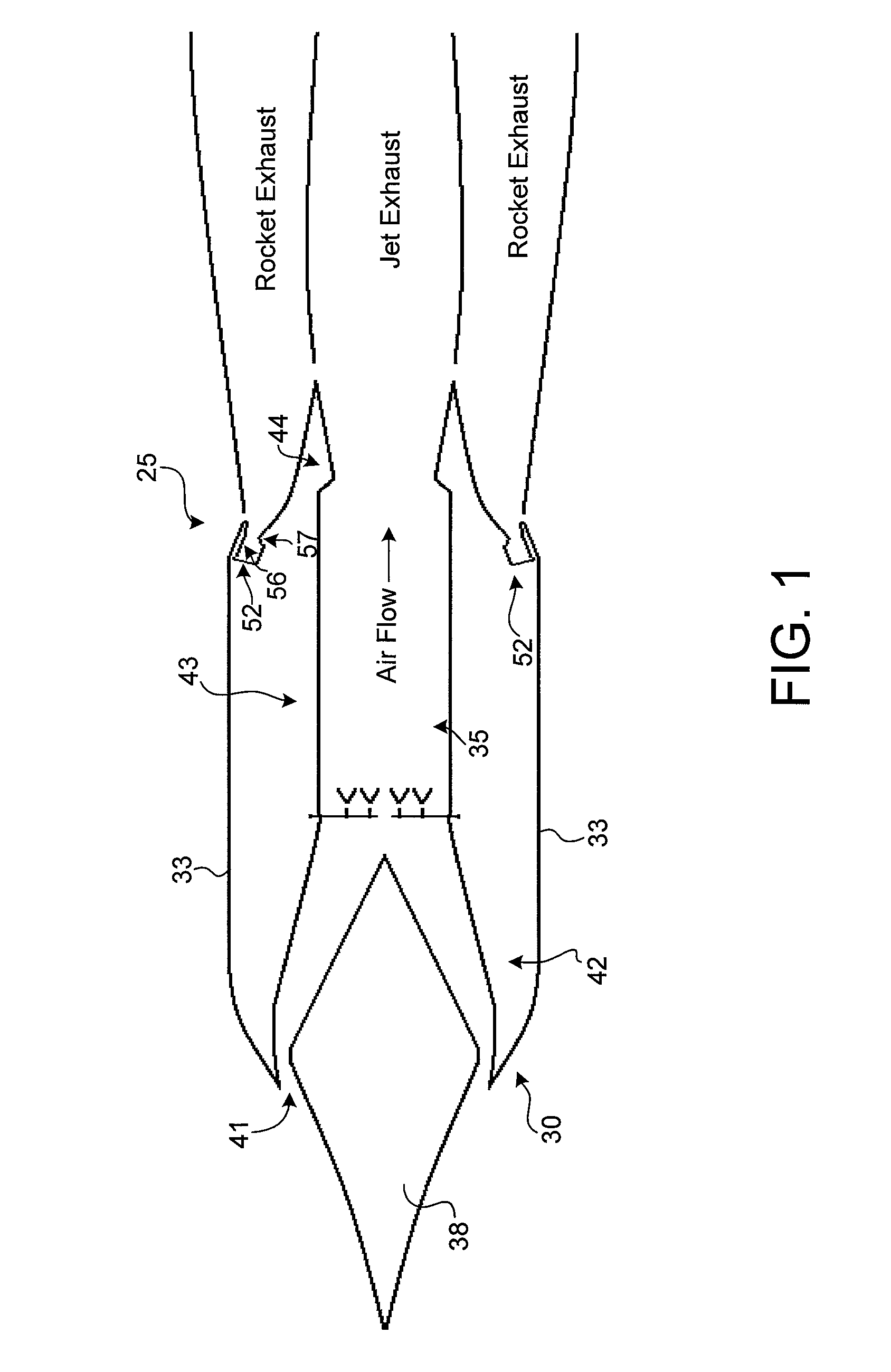

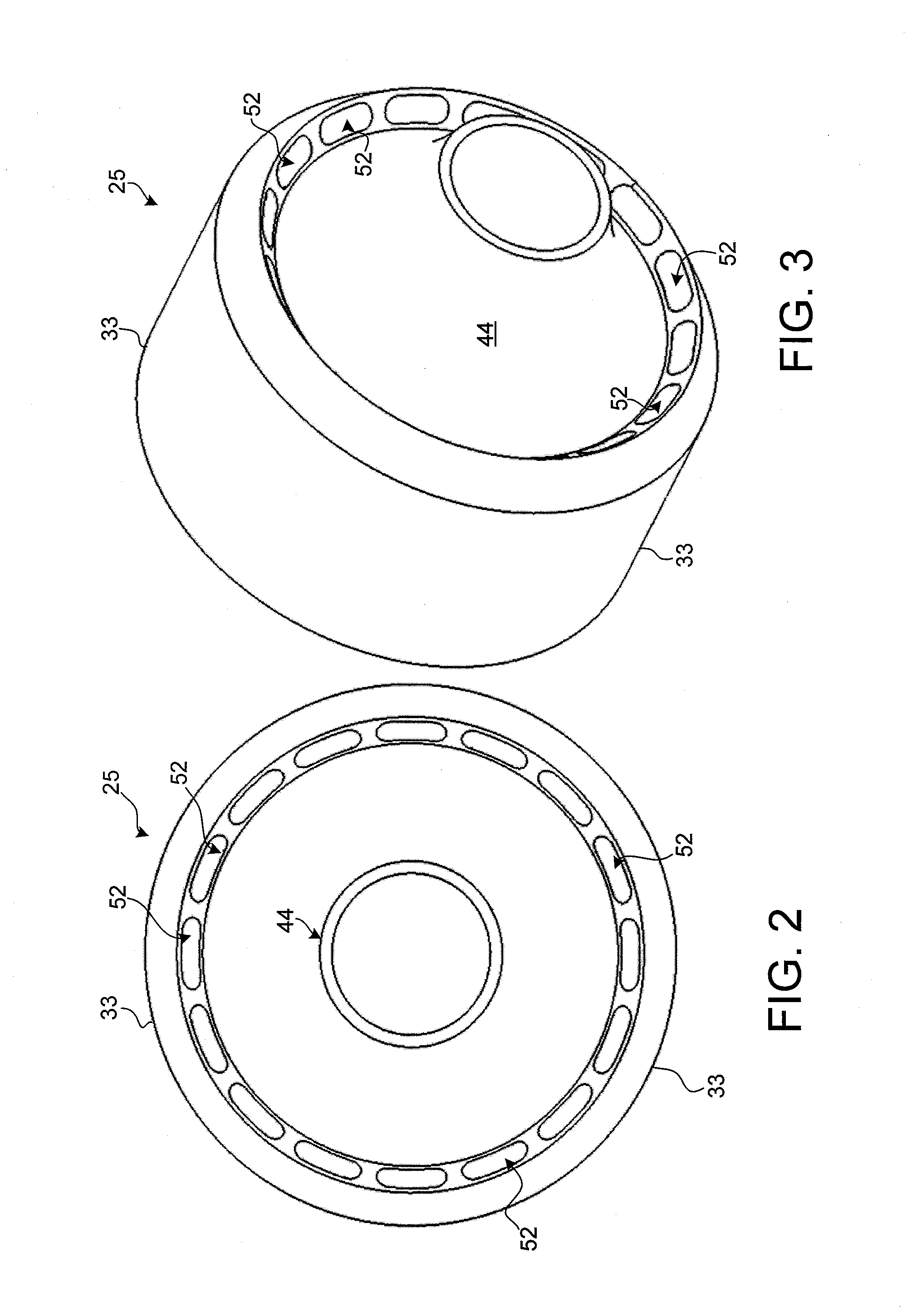

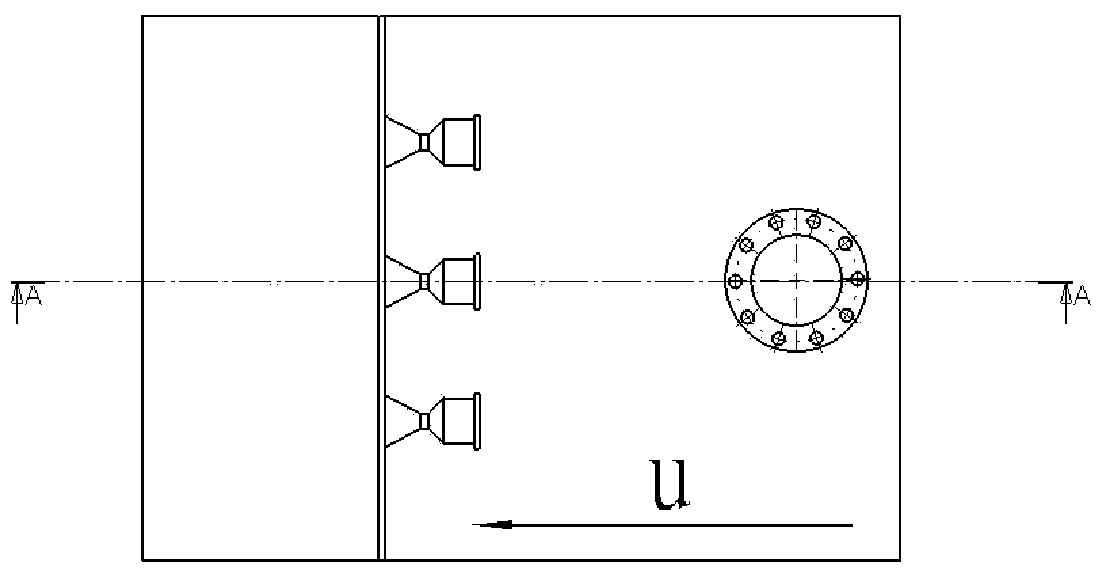

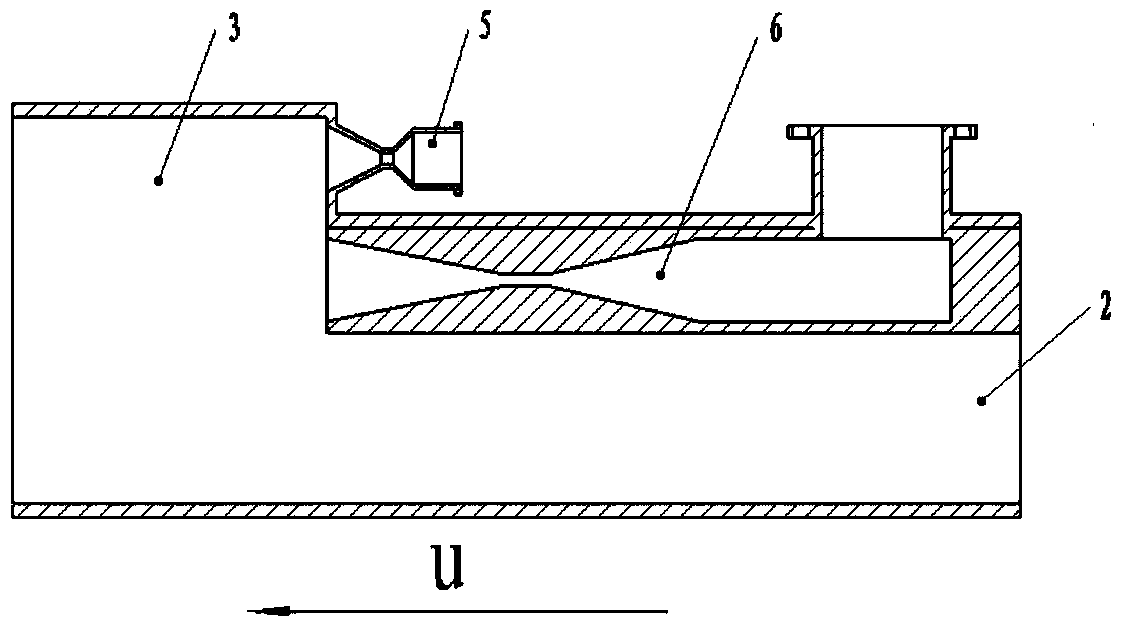

Rocket based combined cycle propulsion unit having external rocket thrusters

The present disclosure generally pertains to rocket based combined cycle (RBCC) propulsion units. In one exemplary embodiment, at least one rocket thruster is integrated with a jet engine but is external to the flow path of the jet engine, forming an altitude compensating plug nozzle. Since the rocket thruster is external to such flow path, the rocket flow from the rocket thruster interacts with the jet flow from the jet engine aft of the nozzle of the jet engine. Such interaction occurs without a significant performance penalty in the operation of the jet engine. In fact, it is possible that the interaction of the rocket flow with the jet flow may actually improve the efficiency of the jet engine under some conditions. Moreover, having the rocket thrusters positioned external to the flow path of the jet engine helps to avoid many of the problems plaguing conventional RBCC propulsion units.

Owner:UNIVERSITY OF ALABAMA

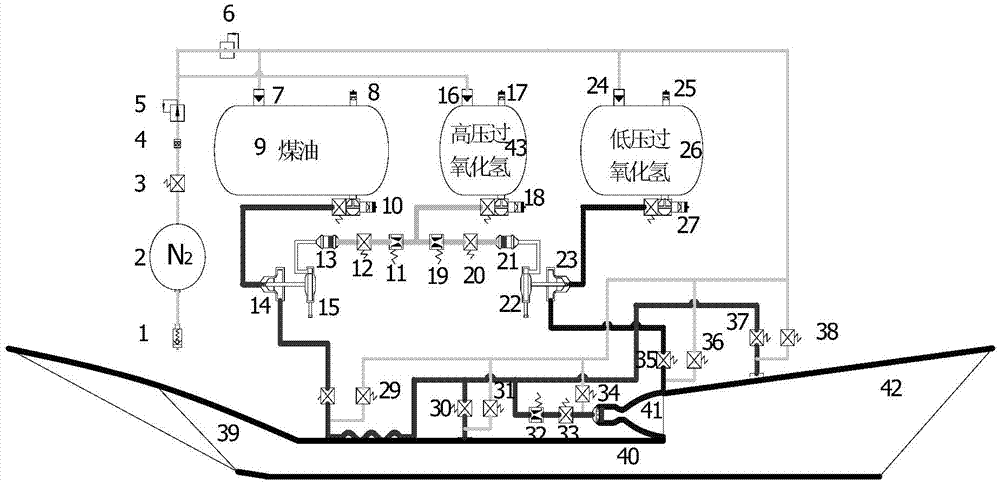

Hydrogen-peroxide-based RBCC (Rocket Based Combined Cycle) engine pressure pumping and squeezing integrated fuel system

ActiveCN103696883AOvercoming complexityOvercome the huge disadvantageRocket engine plantsCombustion chamberKerosene

The invention provides a hydrogen-peroxide-based RBCC (Rocket Based Combined Cycle) engine pressure pumping and squeezing integrated fuel system. The hydrogen-peroxide-based RBCC engine pressure pumping and squeezing integrated fuel system comprises a pressurization unit, a supplying unit, an engine body and a connecting pipeline unit; the pressurization unit is used for performing pressurization on the supplying unit; the supplying unit which is connected with the engine body through the connecting pipeline unit supplies propellant to the engine body. The hydrogen-peroxide-based RBCC engine pressure pumping and squeezing integrated fuel system has the advantages of overcoming disadvantages of a complex and huge system due to the fact that a rocket thrust chamber and a stamping combustion chamber separately supply fuel, synthesizing respective advantages of the hydrogen peroxide and kerosene propellant, being high in density specific impulse, satisfying combination engine design requirements for integrated fuel supplying and an integrated cooling structure and being mature in utilization and maintenance technology, relatively simple in system composition and easy to achieve.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

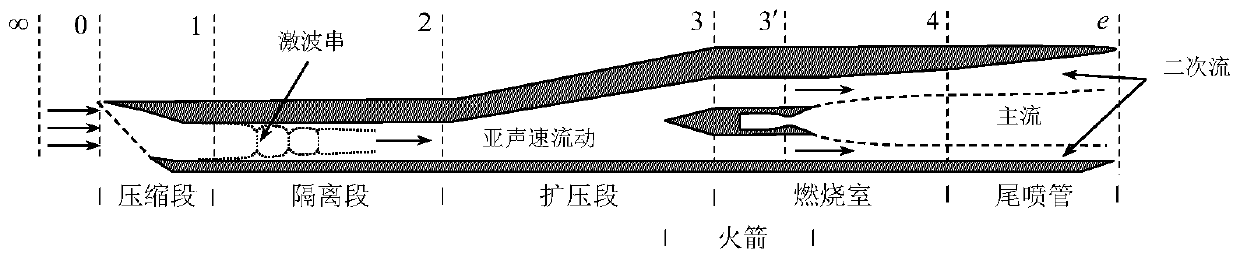

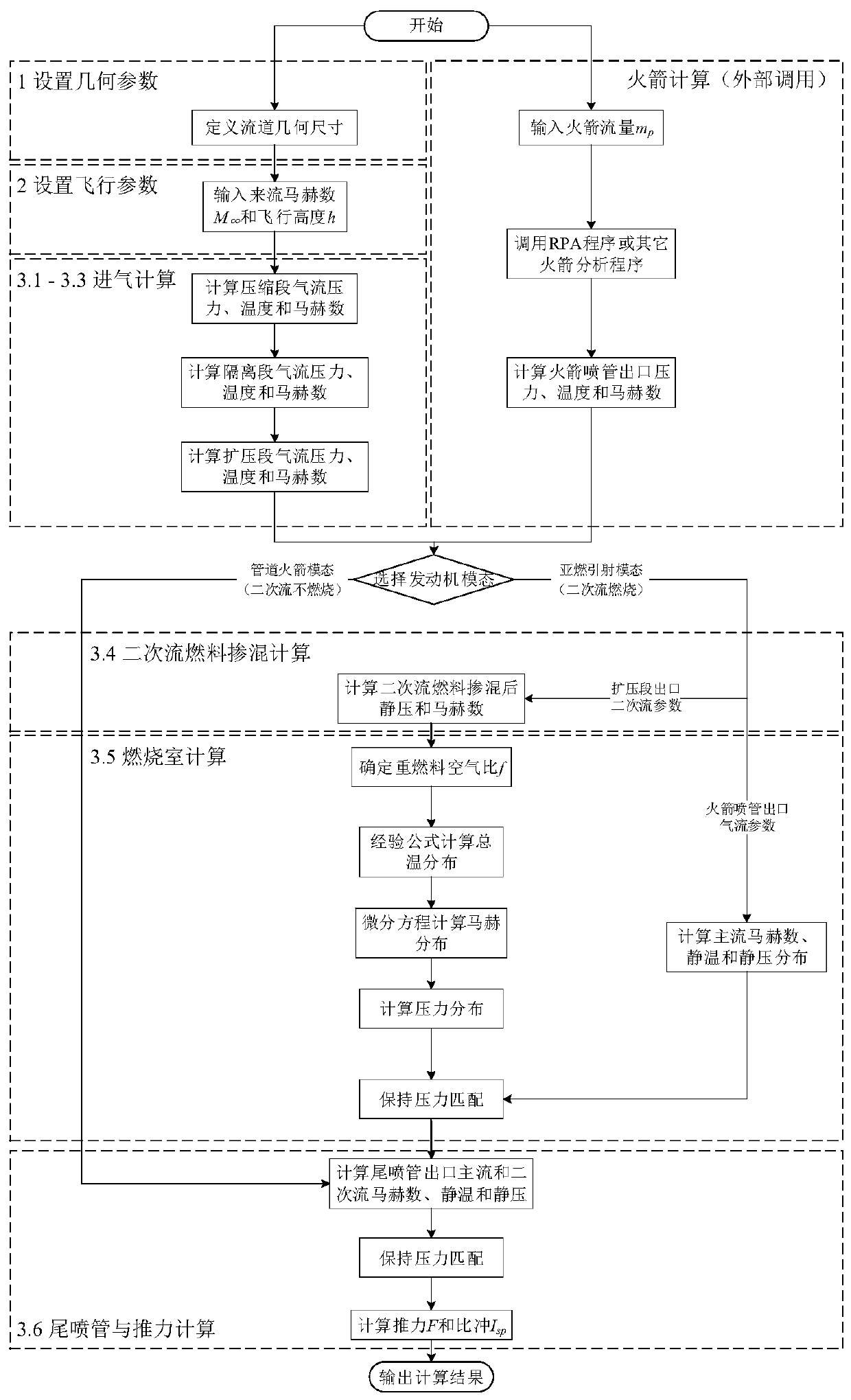

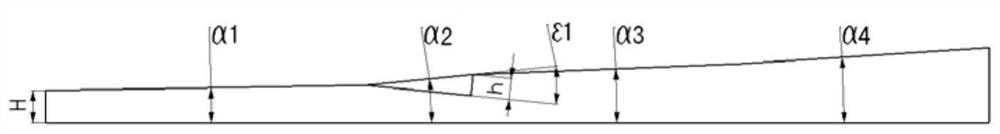

Rocket-based combined cycle engine thrust calculation method

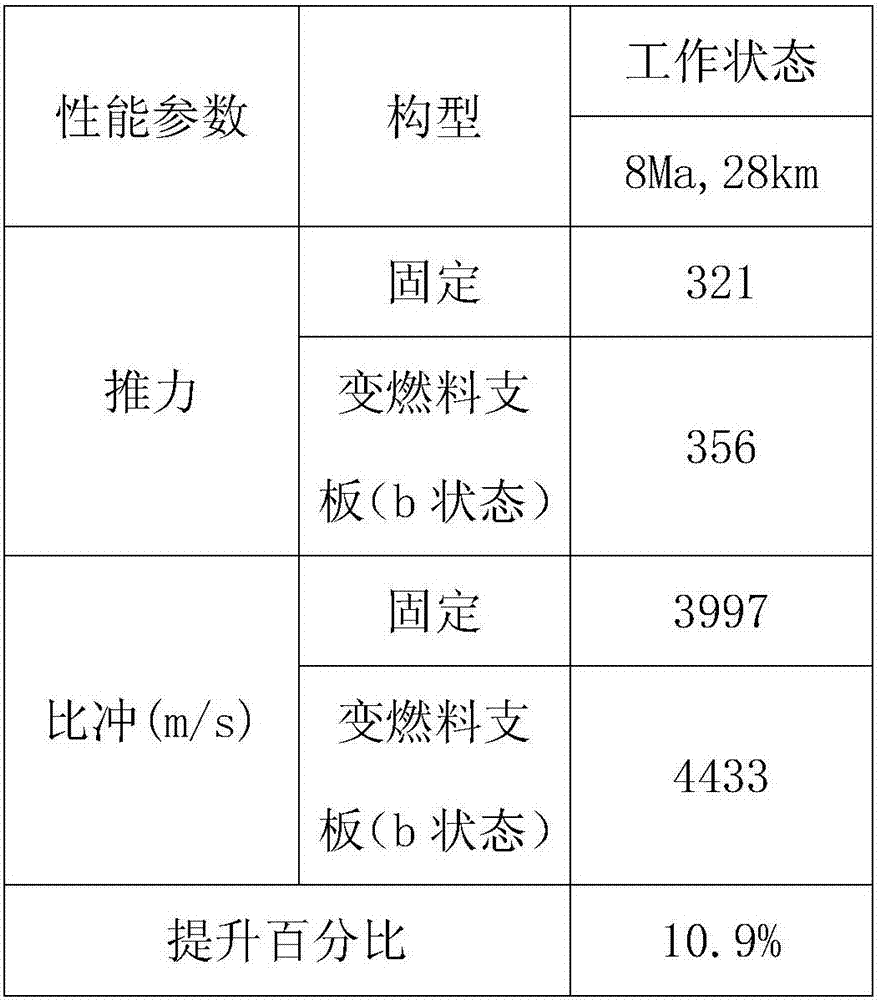

InactiveCN110362783AThrust Quick EstimationQuick Estimation of Specific Impulse PerformanceComplex mathematical operationsFlight heightCombustion chamber

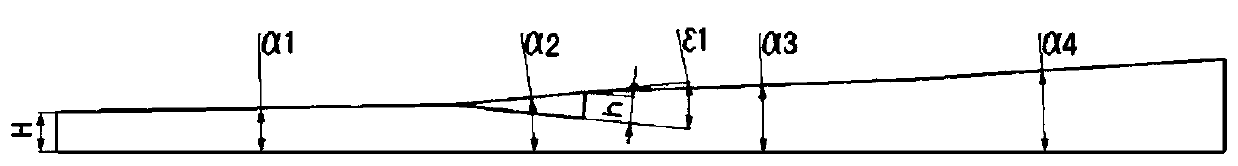

The invention provides a rocket-based combined cycle engine thrust calculation method. Firstly, one-dimensional geometrical parameters of an inner flow channel of the rocket-based combined cycle engine are determined and include an air inlet channel inlet sectional area, an air inlet channel compression angle, an e isolation section sectional area, a sub-expansion section expansion ratio, a combustion chamber expansion ratio, a rocket combustion chamber sectional area, a rocket nozzle size and an engine exhaust nozzle expansion ratio; the flight height, the flight Mach number and the mainstream flow are input; and then thrust estimation is conducted on the rocket-based combined cycle engine, and the final thrust of an outlet of an exhaust nozzle of the rocket-based combined cycle engine and the specific impulse of the engine are obtained. According to the method, rapid estimation of thrust and specific impulse performance of the rocket-based combined cycle engine is achieved, and a newtool is provided for initial design of the engine and trajectory planning of an aircraft.

Owner:NAT UNIV OF DEFENSE TECH

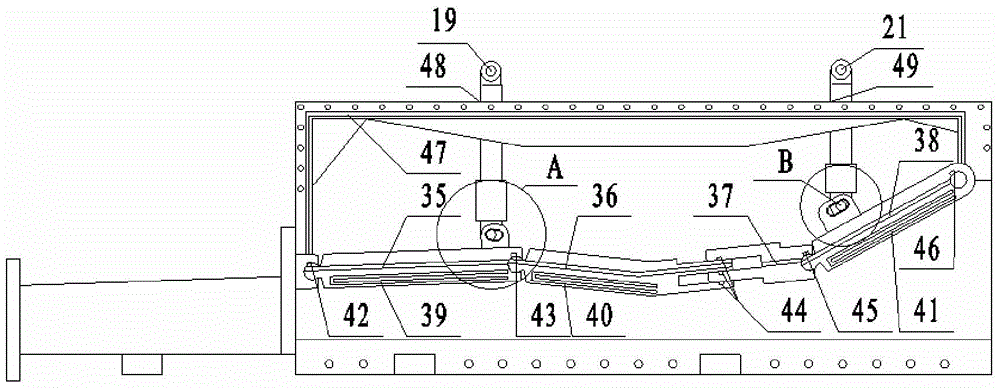

Variable structure combustion chamber of rocket-based-combined-cycle engine

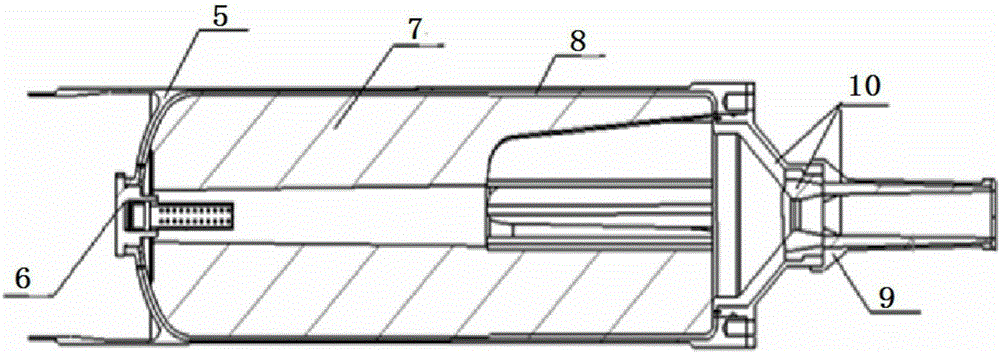

InactiveCN105240160AIncrease thrustHigh specific impulse performanceRocket engine plantsCombustion chamberDivergence angle

The invention discloses a variable structure combustion chamber of a rocket-based-combined-cycle engine. The variable structure combustion chamber is composed of a drive system, a back pressure cavity and a combustion chamber body. The drive system is located at the upper portion of the back pressure cavity. The back pressure cavity is fixed to the portion above variable sections of the combustion chamber body and forms an integral structure with the combustion chamber body. A combustion chamber fixed section is sequentially connected with variable sections of the combustion chamber body. The variable sections are connected through cooperation of ball head hinge convex faces and ball head hinge concave faces. Two sets of hydraulic drive mechanisms drive the first variable section and the third variable section of the combustion chamber body through drive rods and connecting rods. Axial sealing grooves of the variable sections are filled with graphite strips so as to isolate high-temperature fuel gas in the combustion chamber body, and sealing is guaranteed. According to the variable structure combustion chamber, stable transition among different modes is achieved through grade adjustment. In the injection mode and the subsonic combustion mode, the variable sections of the combustion chamber body are adjusted by a hydraulic drive mechanism to generate different divergence angles and throat heights, so that the combustion chamber body is in the optimal work state, and the thrusting force and specific impulse performance of the combustion chamber body are obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

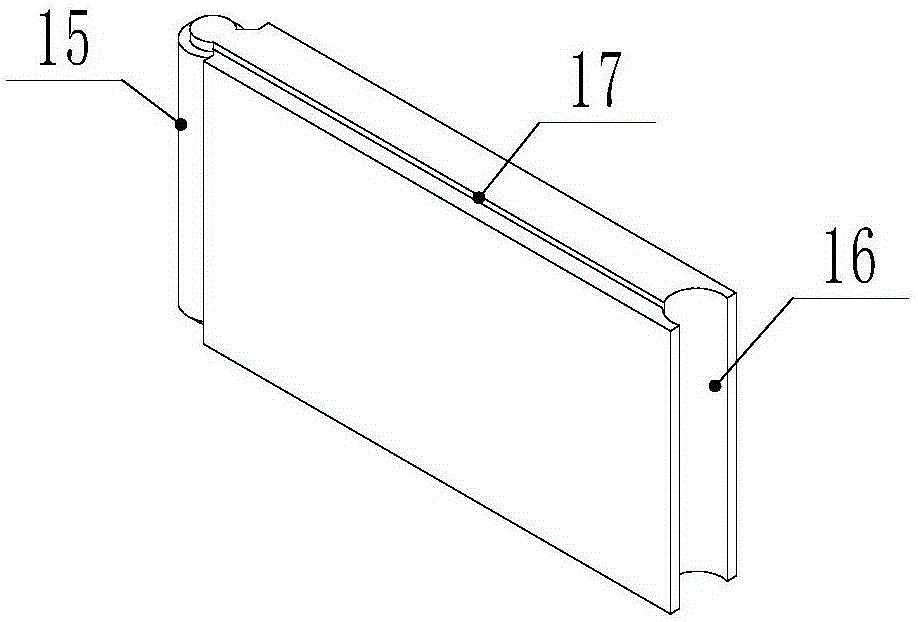

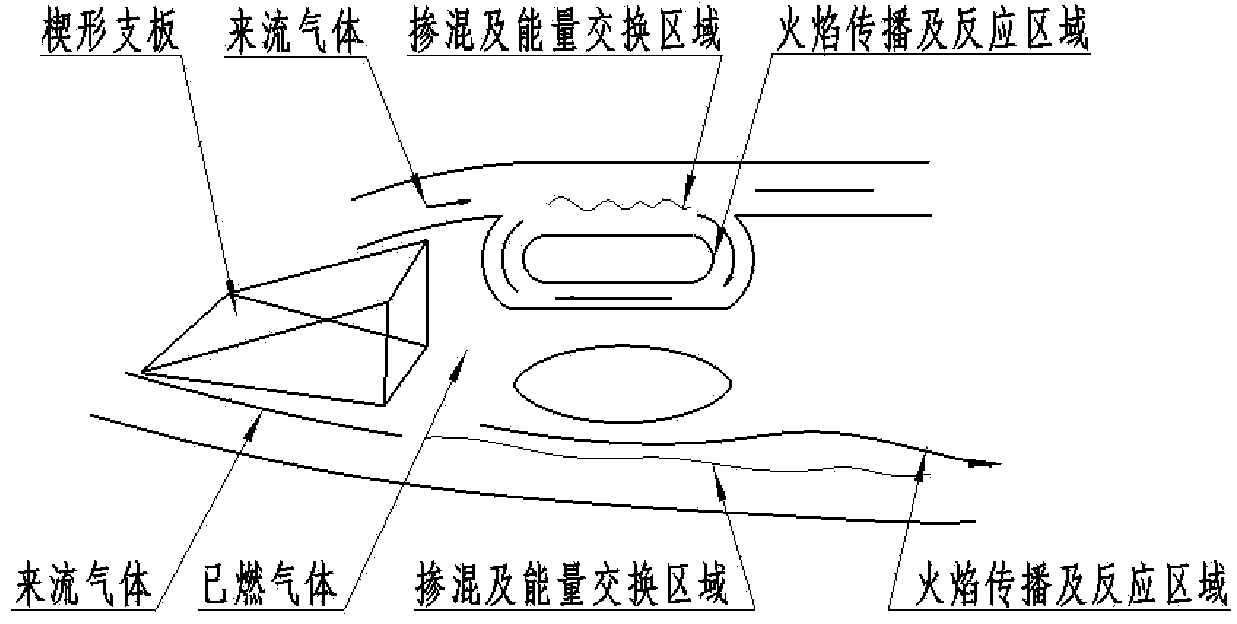

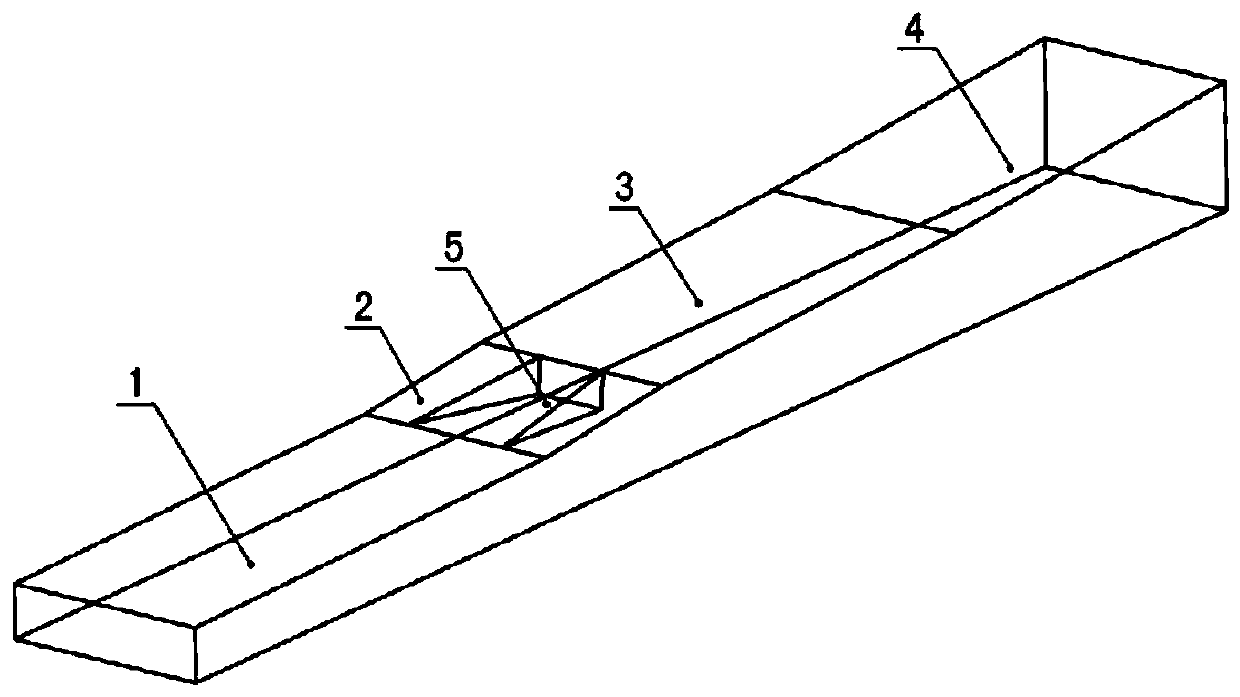

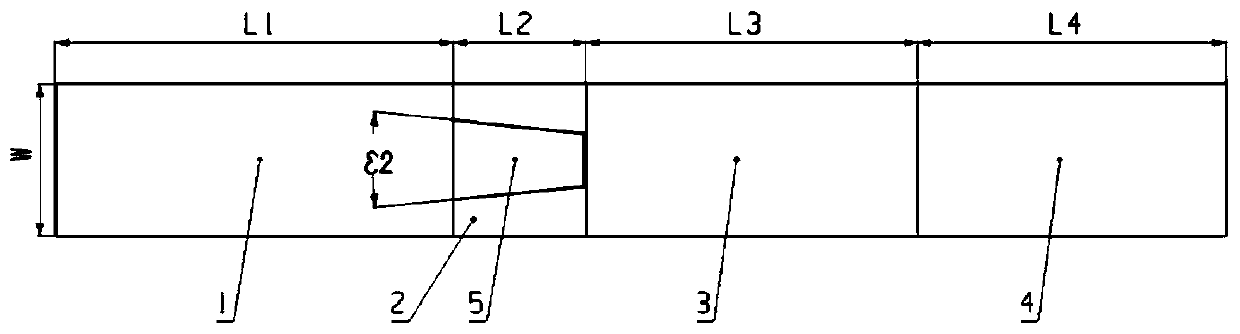

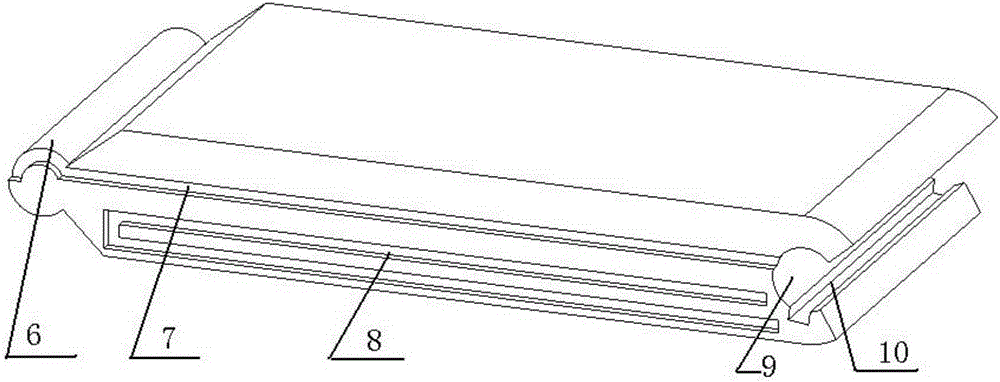

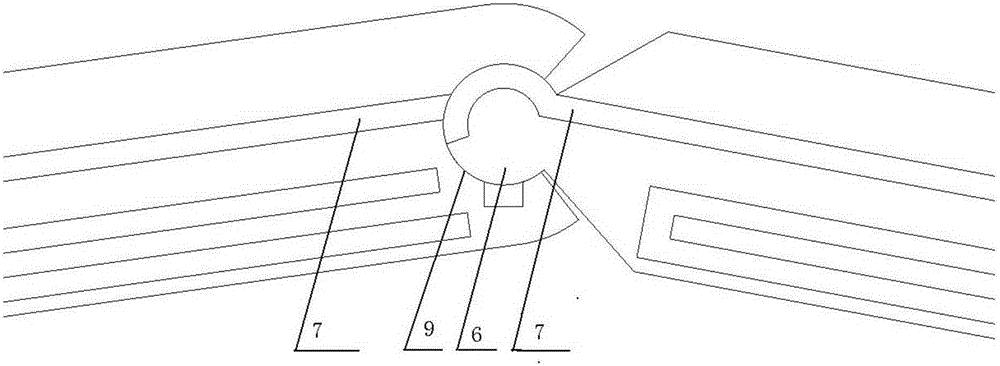

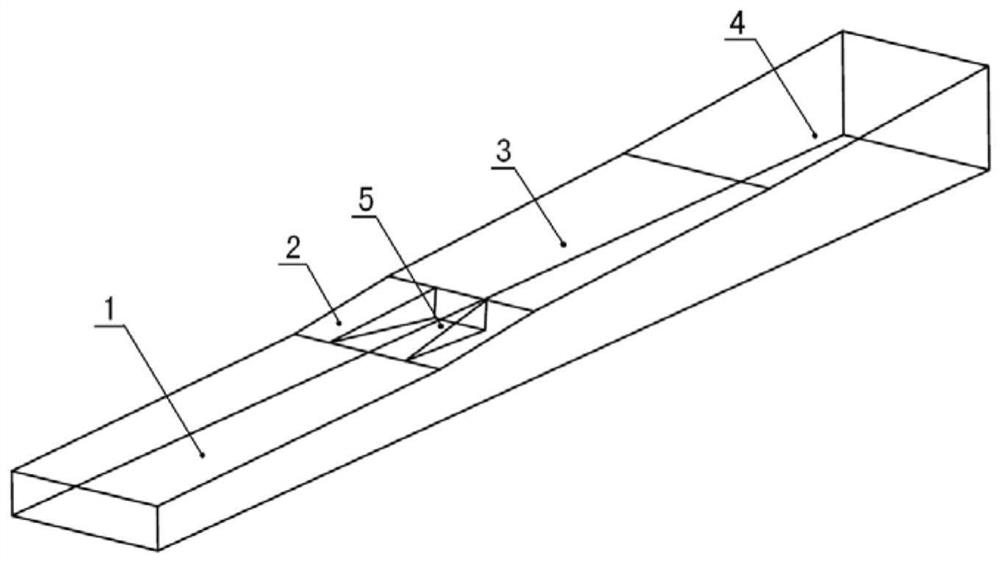

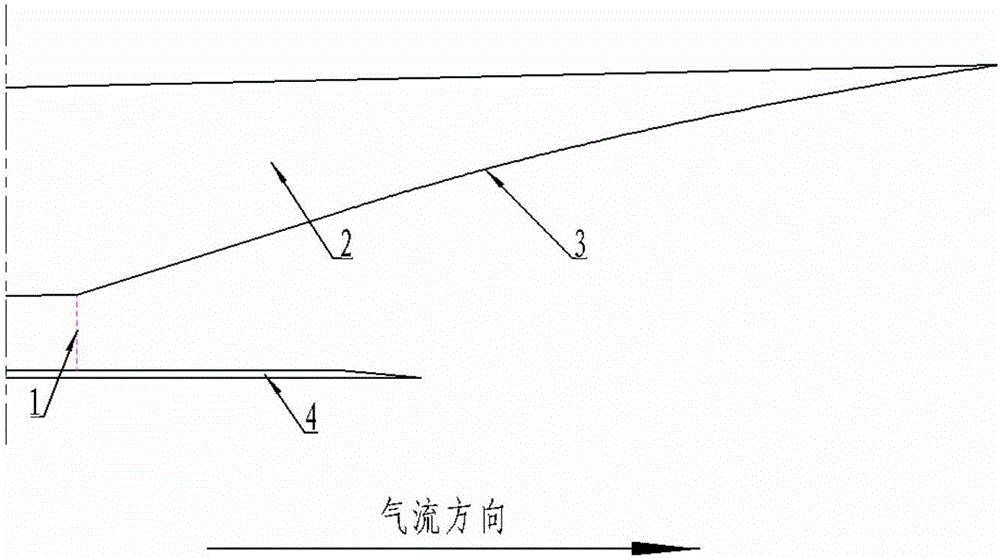

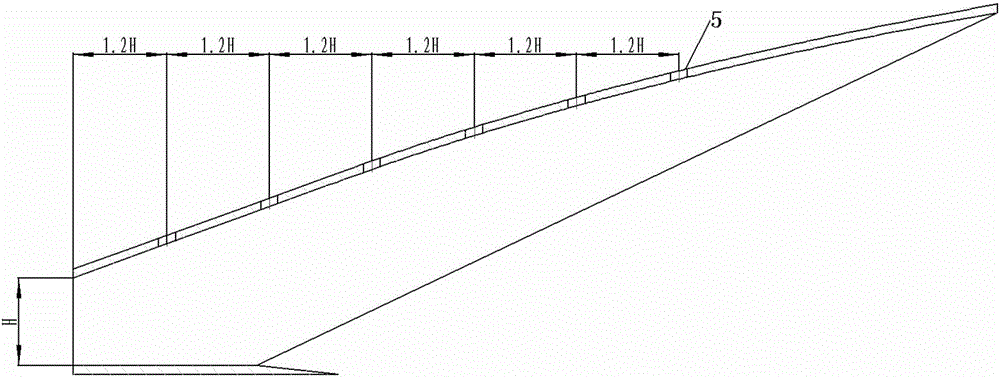

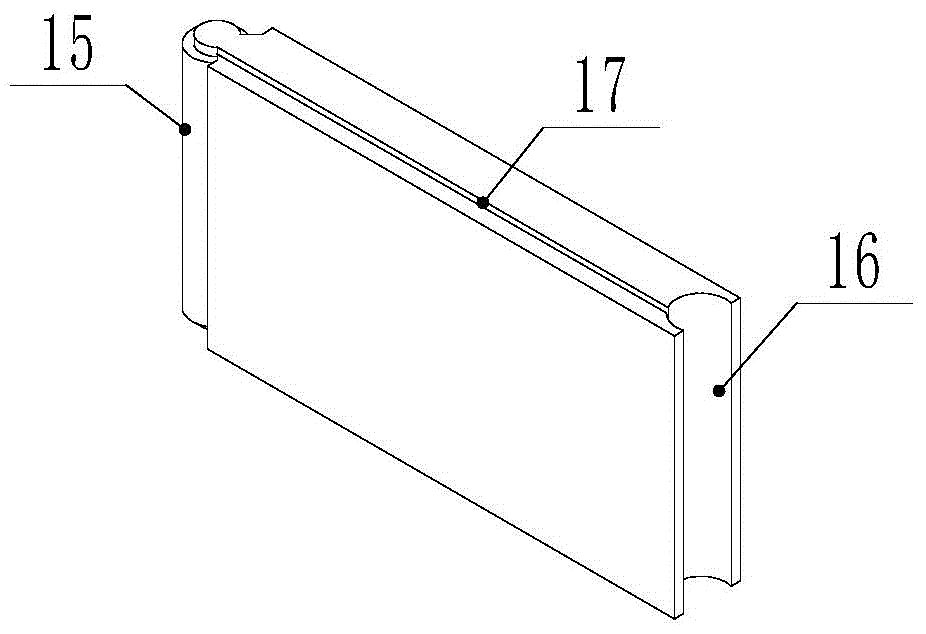

Fuel supporting plate for improving non-premixed combustion of RBCC (rocket-based combined cycle) bimodal combustion chamber

InactiveCN103727562ACompact structureEnhanced guiding vortexContinuous combustion chamberCombustion chamberRocket

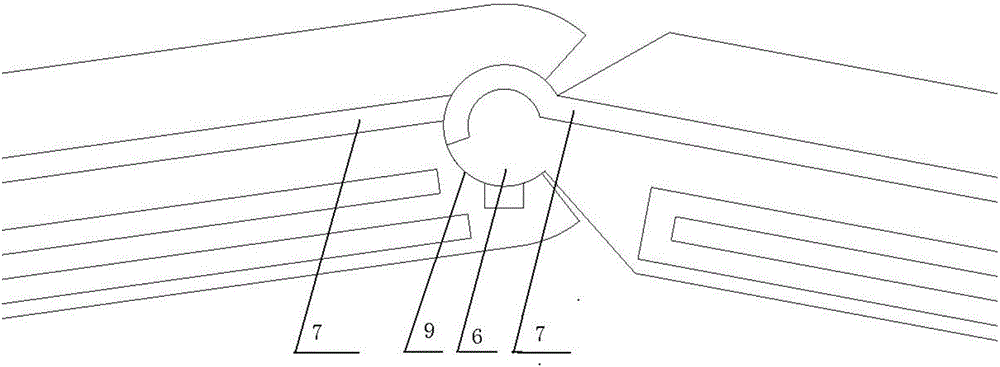

The invention discloses a fuel supporting plate for improving non-premixed combustion of a RBCC (rocket-based combined cycle) bimodal combustion chamber. The streamwise vortex fuel supporting plate is in a structure with unilateral wedged bosses, and two fuel supporting plate bodies are symmetrically distributed on two sides of a rocket. The front portion of the fuel supporting plate is wedged, the rear portion of the fuel supporting plate is straight, and three wedged bosses at equal intervals are arranged on the outer side of the front portion and fixedly connected with the supporting plate. The upper portion of a fuel jet block is provided with two screw holes connected with fuel jet hoses, fuel passage holes in the fuel jet block are communicated with the screw holes, and the lower portion of the fuel jet block is connected with a passage on the fuel supporting plate. The fuel jet block is fixed onto an engine, and jet positions can be changed in different experimental operating conditions. By means of the structure of the fuel supporting plate, guide vortexes of fluids on the lateral sides of the supporting plate can be intensified to enable fuel mixing to be more effective, a regular shear layer on the rear side of the supporting plate is reasonably destroyed to achieve higher turbulence level of the shear layer on the rear side of the supporting plate, the area of a combustion boundary layer is broadened, and the fuel can be better mixed with an incoming flow to form a larger combustion area.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

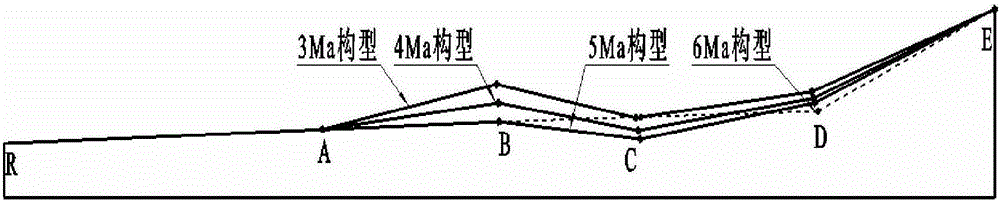

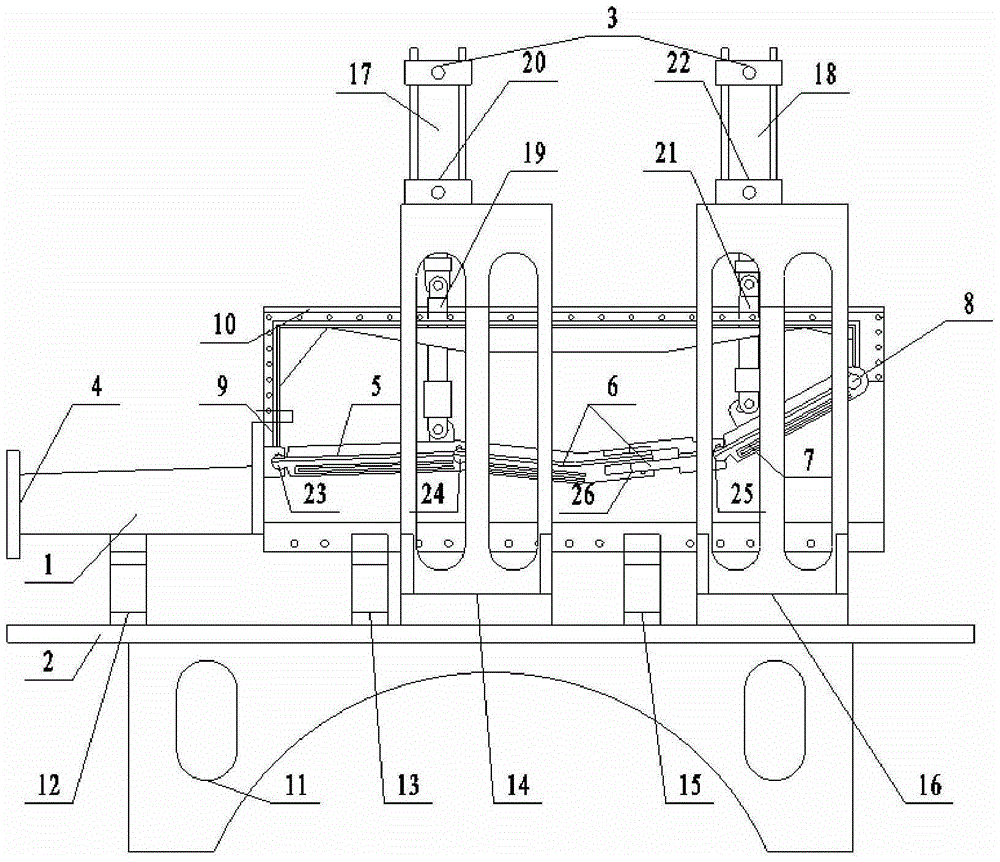

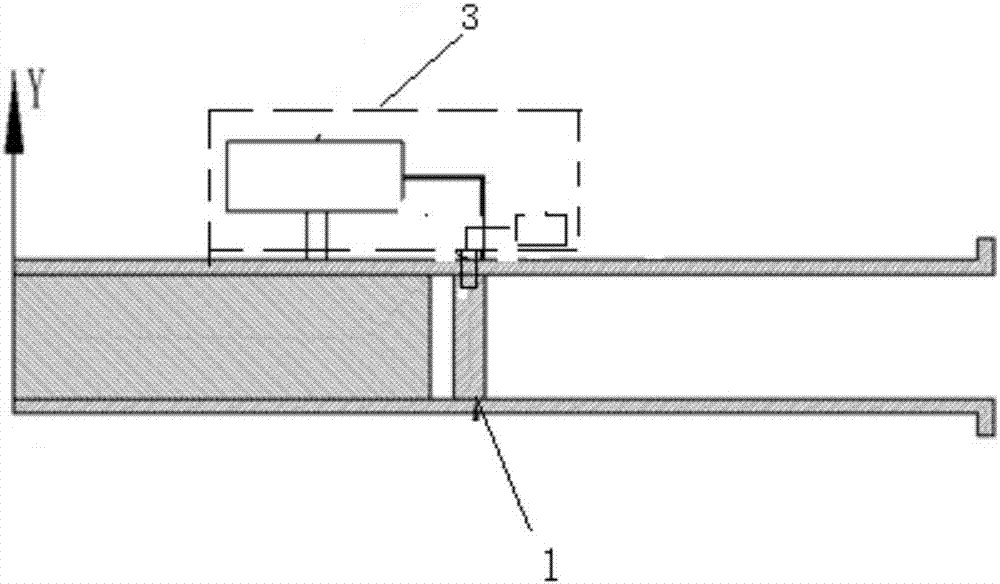

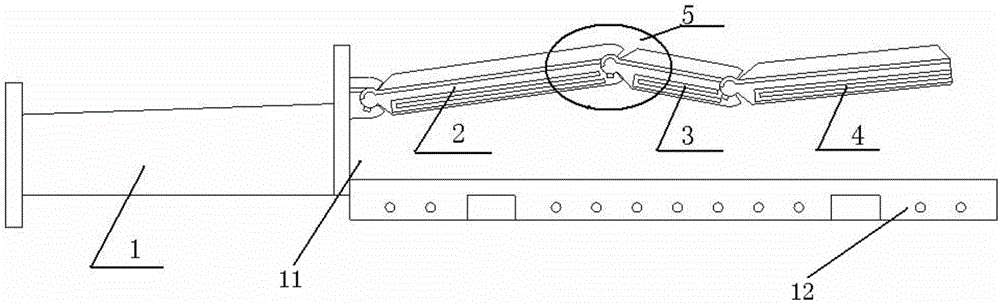

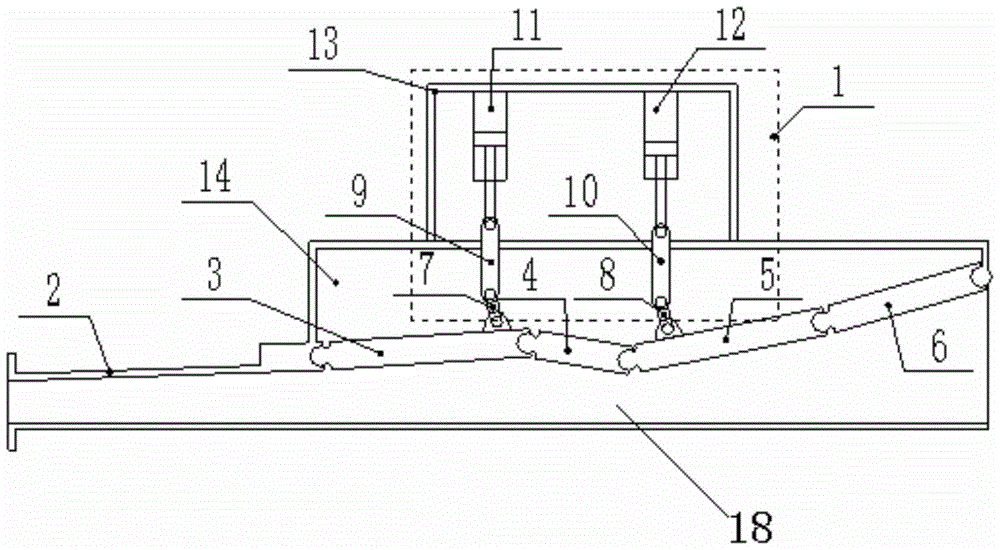

Variable-geometry RBCC (rocket based combined cycle) engine for ground experiment

InactiveCN105201689AImplement configuration changesRealize regulationRocket engine plantsHydraulic cylinderCombustor

The invention discloses a variable-geometry RBCC (rocket based combined cycle) engine for a ground experiment. A mechanical structure adopting variable-geometry combustor grading adjustment is adopted, an engine is fixed on an experiment table, two actuating mechanisms are perpendicularly mounted on the experiment table at an equal interval, and the engine is located in brackets of the two actuating mechanisms; a fixed section combustor and a variable section combustor are fixedly connected, an inner cavity bottom plate of the fixed section combustor and an inner cavity bottom plate of the variable section combustor adopt an integrated structure, a flame stabilization device is mounted in the fixed section combustor, a variable geometry mechanism is simplified, and a pressed cavity cover plate is mounted above the variable section combustor; two actuating mechanisms drive upper cavity plates to move up and down in the vertical direction through hydraulic cylinder pistons and connecting rods respectively, four-level adjustment of the combustor in different Mach number ranges is completed, and combustor structures in different inlet Mach numbers are adjusted and kept. The engine is used for research of combustors in different Mach numbers and research of combustion dynamic response characteristics in the combustor structure adjusting process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

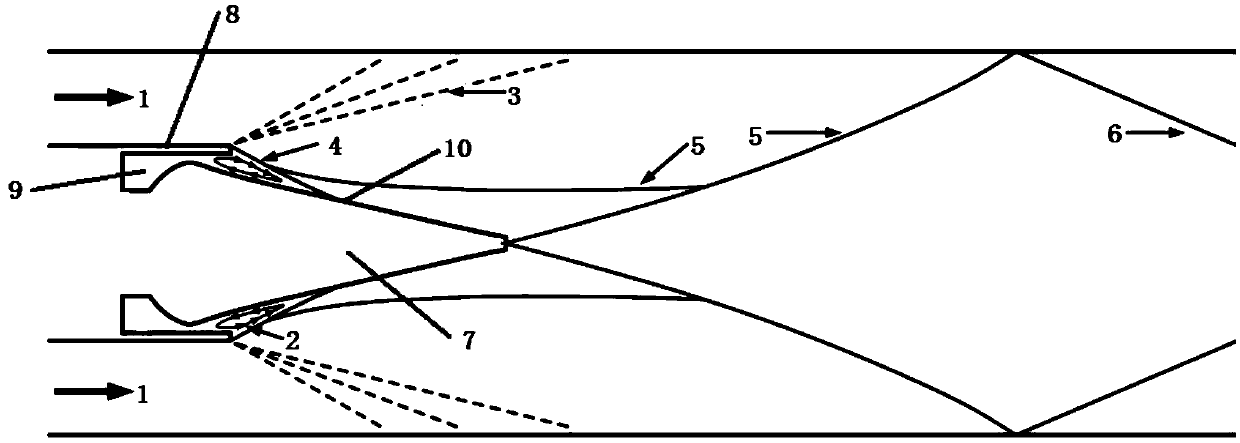

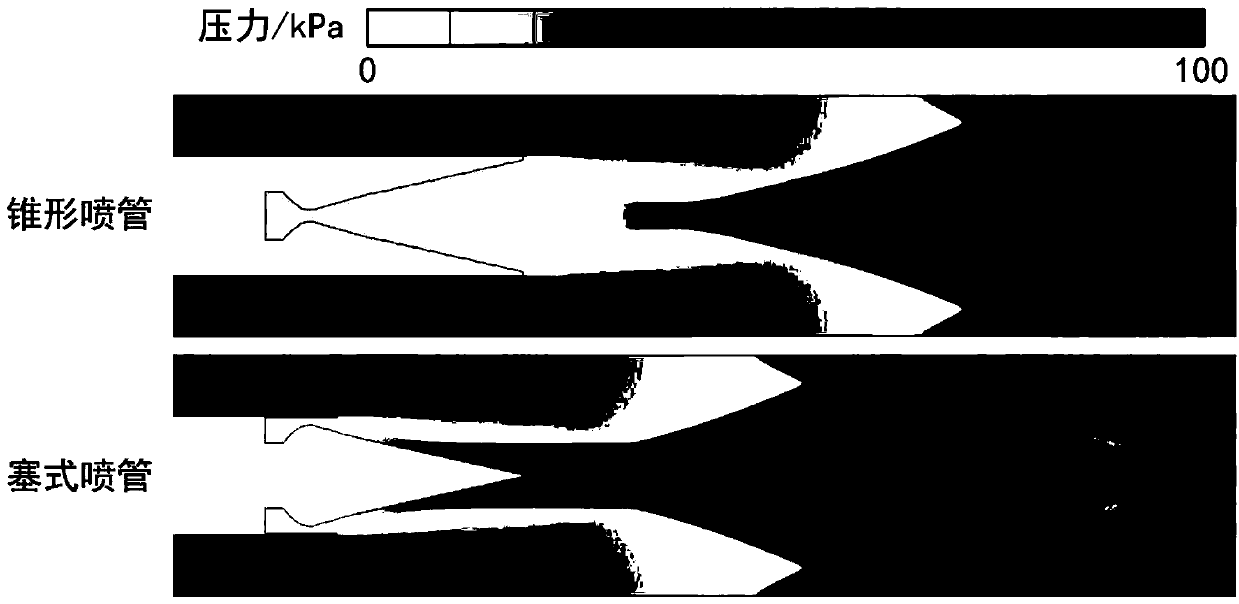

Ejector rocket for rocket-based combined cycle engine

ActiveCN109538375AIncrease the areaIncrease resistanceRocket engine plantsRocketRocket-based combined cycle

The invention provides an ejector rocket for rocket-based combined cycle engine. The ejector rocket includes a jet pipe. The jet pipe is a plug type jet pipe. According to the invention, in the ejector rocket, the plug type jet pipe is adopted instead of a conical or bell-shaped jet pipe in the prior art so as to improve the pressure at the bottom of the jet pipe of the ejector rocket in a stamping mode and reduce the bottom resistance. Therefore, a recirculation zone at the bottom of the ejector rocket is reduced and the total pressure loss is reduced. Meanwhile, in the stamping mode, the plug type jet pipe can reduce the area of a high temperature zone and reduce thermal protection requirements.

Owner:NAT UNIV OF DEFENSE TECH

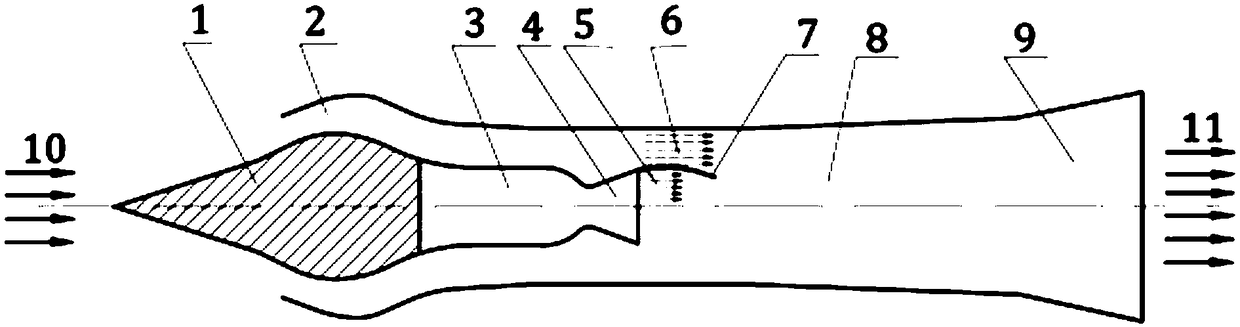

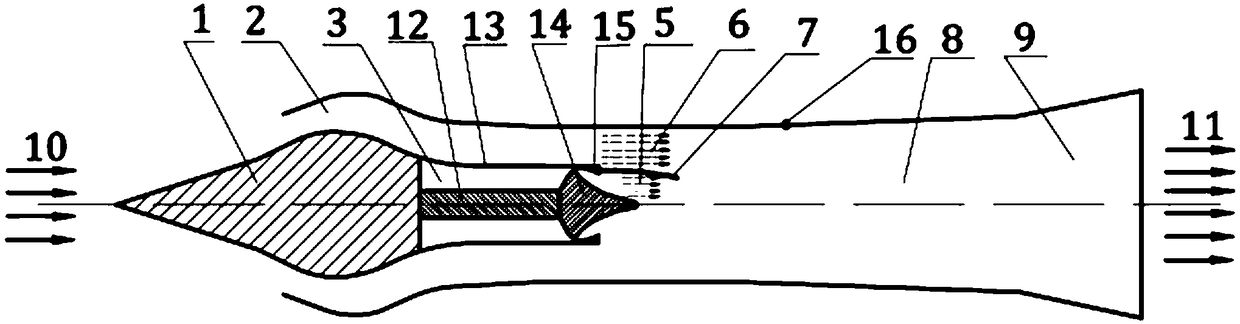

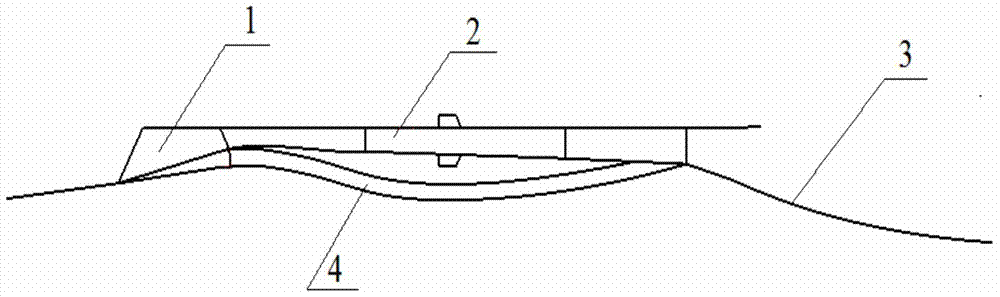

Rocket-based combined cycle engine

ActiveCN109139296AWith automatic matching featureWide range of workRocket engine plantsRam jet enginesCombustion chamberAmbient pressure

The invention relates to a rocket-based combined cycle engine. The rocket-based combined cycle engine comprises a shell body, an air inlet, a central cone, a rocket combustion chamber, a supersonic-combustion combustion chamber and a supersonic-combustion spray pipe. The air inlet and the supersonic-combustion combustion chamber are arranged in the shell body sequentially, the central cone is arranged in the air inlet, the tail end of the central cone is connected with the rocket combustion chamber, and the tail end of the rocket combustion chamber is connected with the plug-type spray pipe. The rocket combustion chamber comprises a cylindrical shell and a rocket combustion chamber inner core arranged in the cylindrical shell, wherein one end of the cylindrical shell is connected with thecentral cone and is in smooth transition connection with the central cone; one end of the rocket combustion chamber inner core is connected with the central cone; and the rocket combustion chamber inner core coincides with the central axis of the cylindrical shell. Incoming flow air enters the supersonic-combustion combustion chamber from an inlet of the air inlet through the air inlet, and the tail end of the supersonic-combustion combustion chamber is connected with the supersonic-combustion spray pipe. According to the rocket-based combined cycle engine, a traditional rocket engine bell-shaped spray pipe is changed into the plug-type spray pipe, and it is guaranteed that the engine has higher performance in a wide range by utilizing the automatic matching characteristic of the plug-typespray pipe and ambient pressure.

Owner:NAT UNIV OF DEFENSE TECH

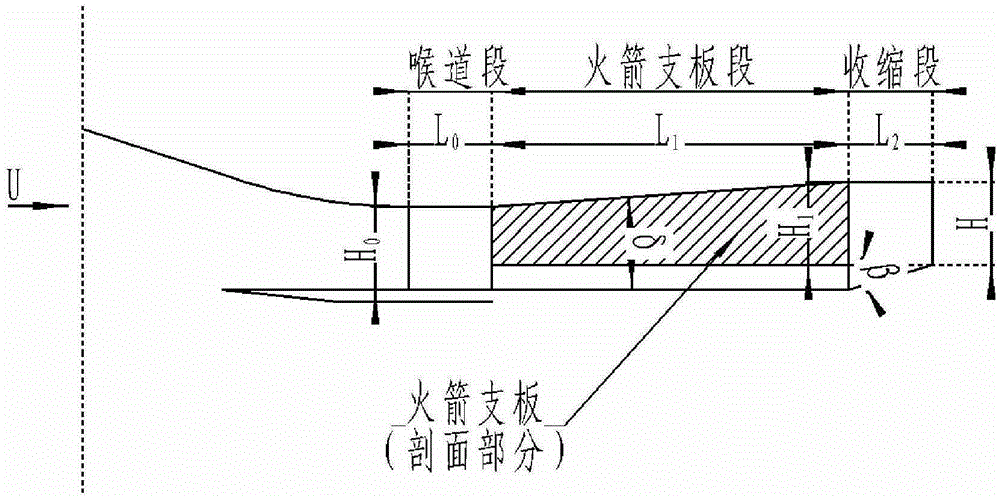

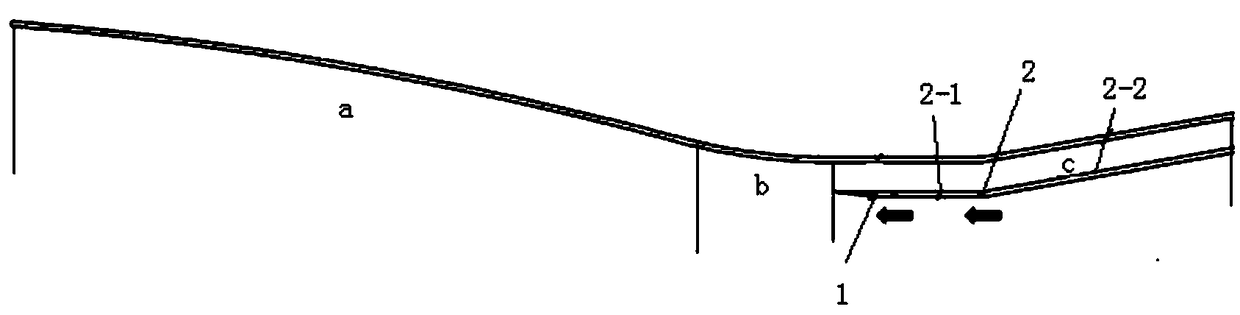

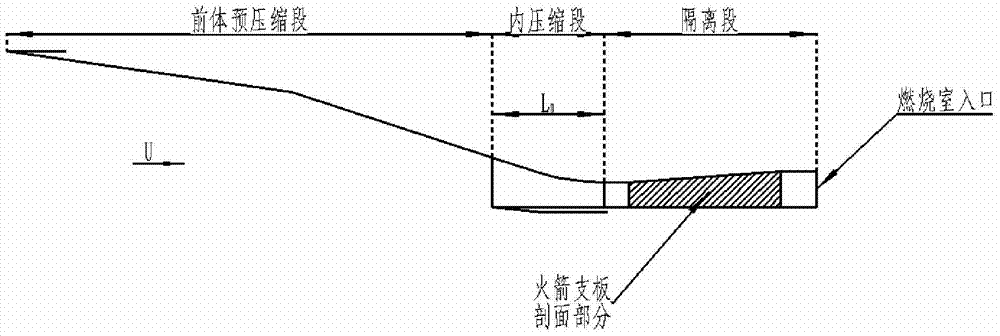

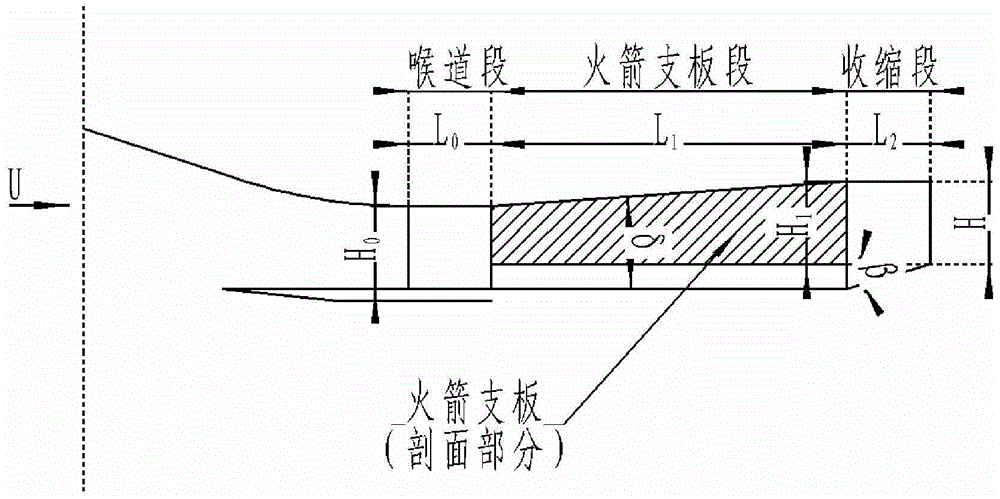

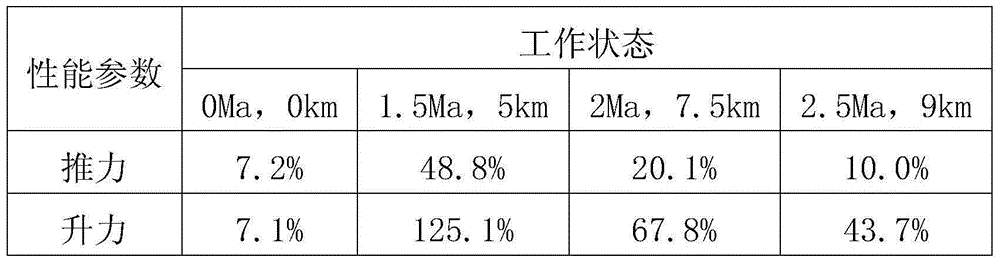

Structural design of inlet isolation segment of rocket-based-combined-cycle engine

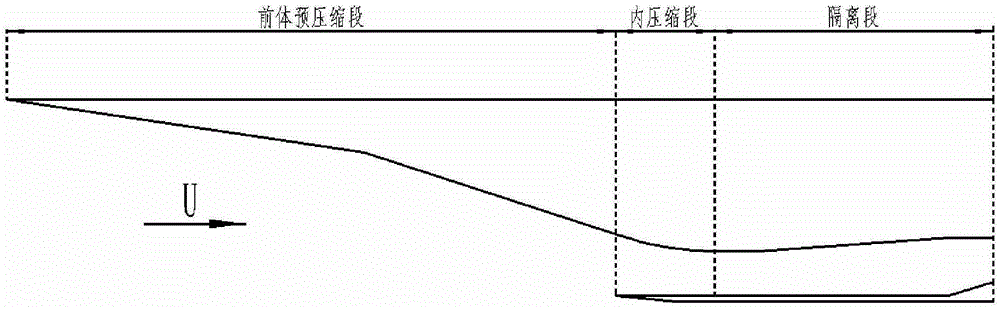

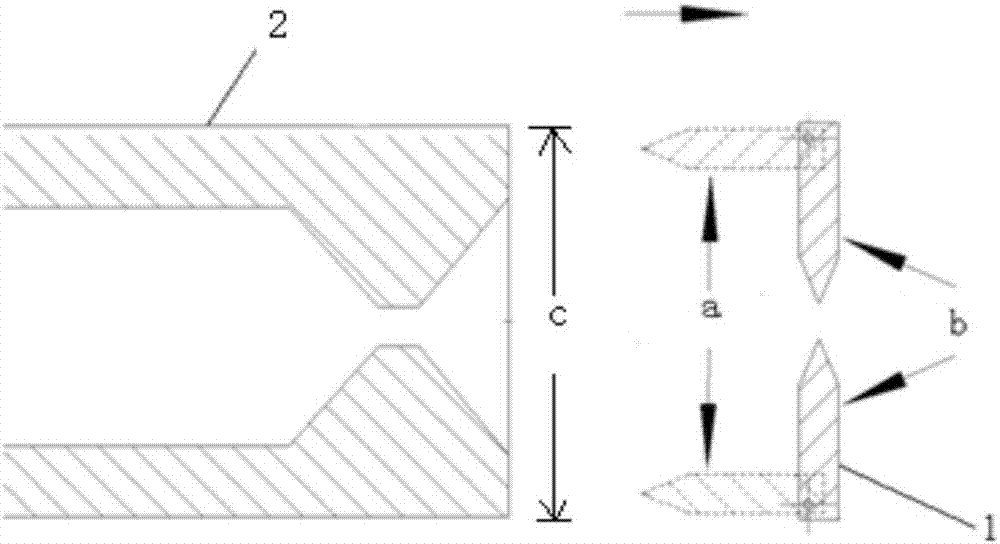

ActiveCN105351100AReduce the starting Mach numberImprove flow coefficientGas turbine plantsRam jet enginesCombustion chamberEngineering

The invention discloses structural design of an inlet isolation segment of a rocket-based-combined-cycle engine. Under the restraint that the minimal section of the inlet isolation segment is located in a throat segment, the sectional area of an effective circulation area of the isolation segment is improved, so that the sectional area of the inlet throat segment is increased to be equal to the sectional area of an intake of a combustion chamber, effective circulation area equal-sectional-area circulation is achieved on an inlet rocket supporting plate segment, and an equal straight segment behind the inlet rocket supporting plate segment is improved into a contraction segment so as to be matched with the section of the intake of the combustion chamber. It is ensured that the minimal section area of the inlet isolation segment is located in the throat segment. By means of the inlet isolation segment, the start mach number of an inlet is lowered, and the flow coefficients of the inlet in an injection mode and a ramjet mode and other performance parameters are increased. The design of the inlet isolation segment of the rocket-based-combined-cycle engine is high in development performance, the inlet isolation segment is designed according to different sectional sizes of the intake of the combustion chamber, the work range of the inlet can be effectively expanded, and the overall performance of the engine can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

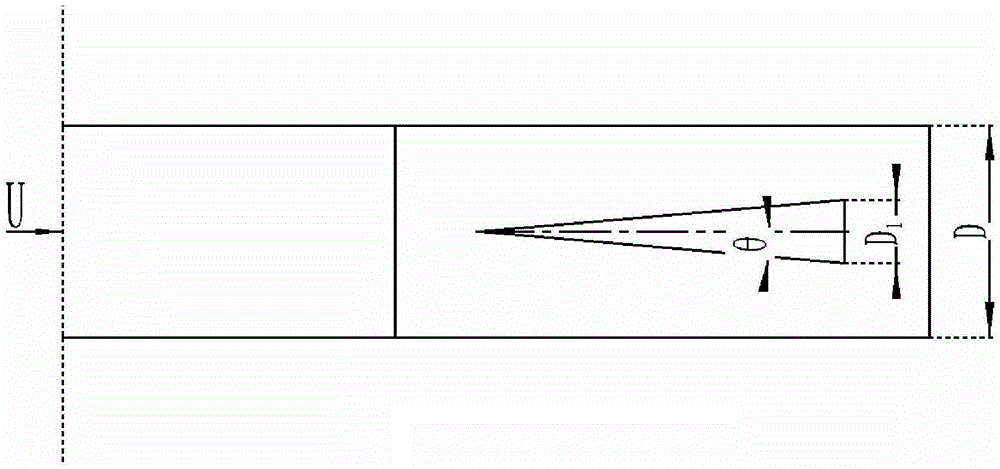

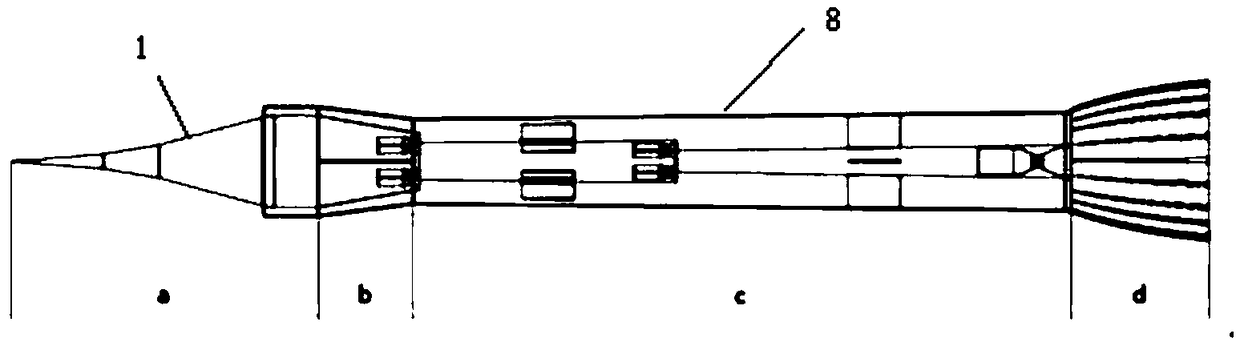

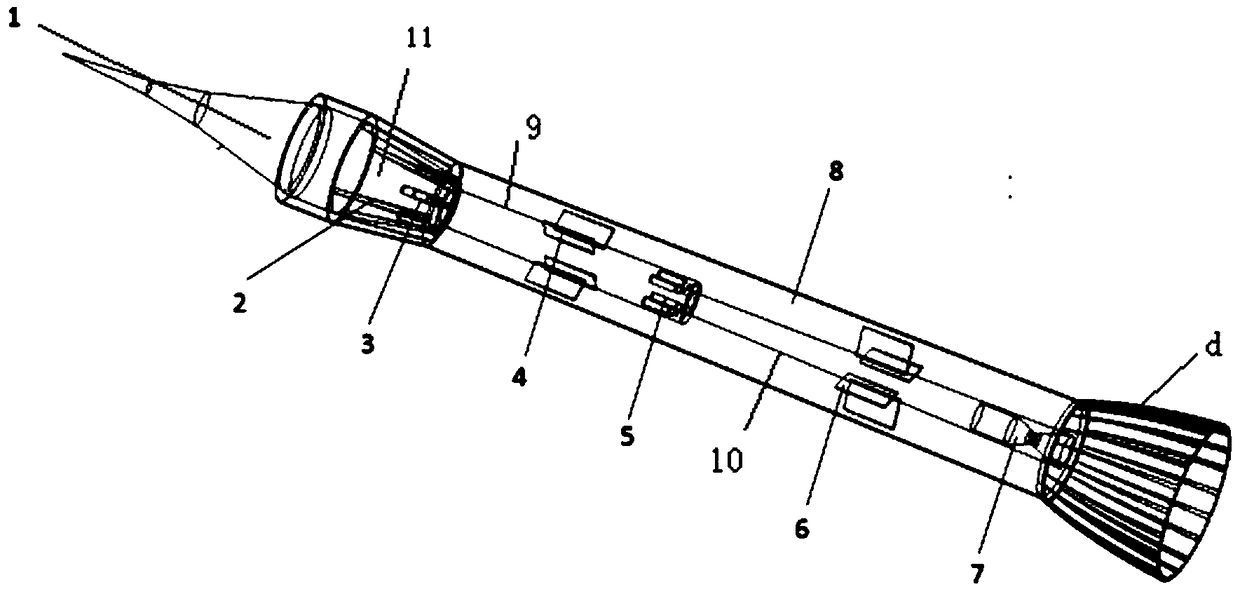

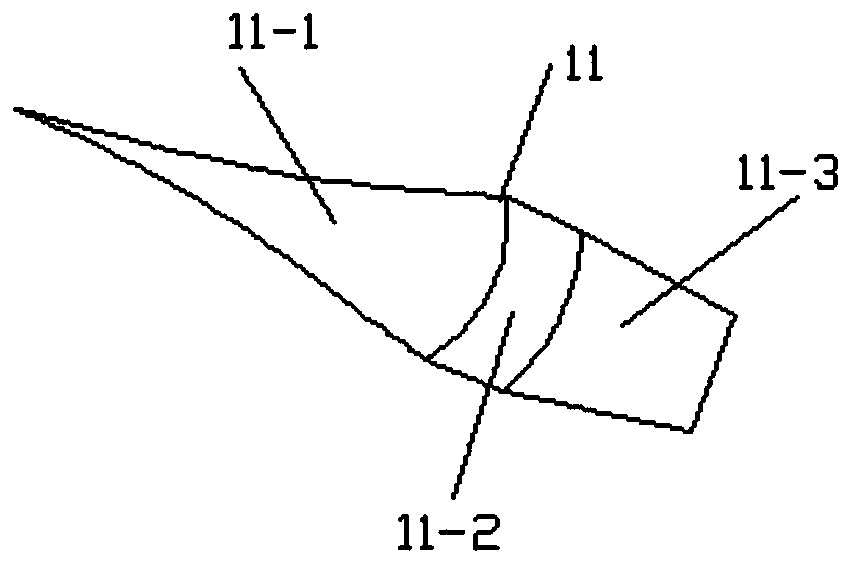

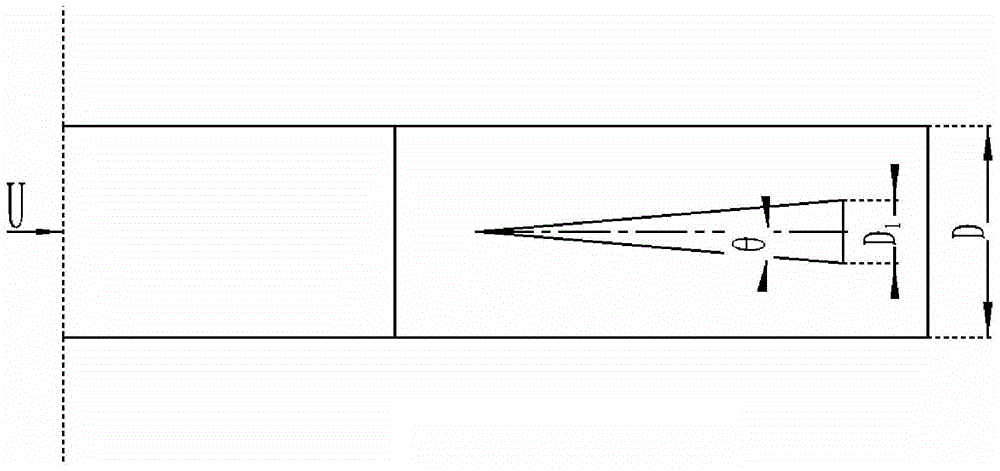

Axis-symmetric structure RBCC (rocket based combined cycle) whole flow passage with multistage rocket

ActiveCN108825405ALarge expansion ratio adjustment rangeImprove expansion efficiencyGas turbine plantsRam jet enginesCombustion chamberRocket-based combined cycle

The invention discloses an axis-symmetric structure RBCC (rocket based combined cycle) whole flow passage with a multistage rocket. The whole flow passage comprises a shell, a center cone is axially arranged in the shell in a sleeving manner, one section of the front end of the center cone goes through the shell, an outer compression section of an air inlet section is formed between the portion going through the shell and an inlet of the shell, an annular passage is formed between the shell and the center cone, an inner compression section of the air inlet section, an isolation section and a combustion chamber section are sequentially formed in the annular passage from front to back, the rear end of the shell is slidably connected with a tail pipe, and the tail pipe is communicated with the annular passage. The shell is slidably connected with the center cone and can slide front and back relative to the center cone in different rocket modes. According to the axis-symmetric structure RBCC whole flow passage with the multistage rocket, structural weight and pneumatic resistance are effectively decreased, corresponding rocket ejectors are selected in different modes, and the performance of the rocket is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

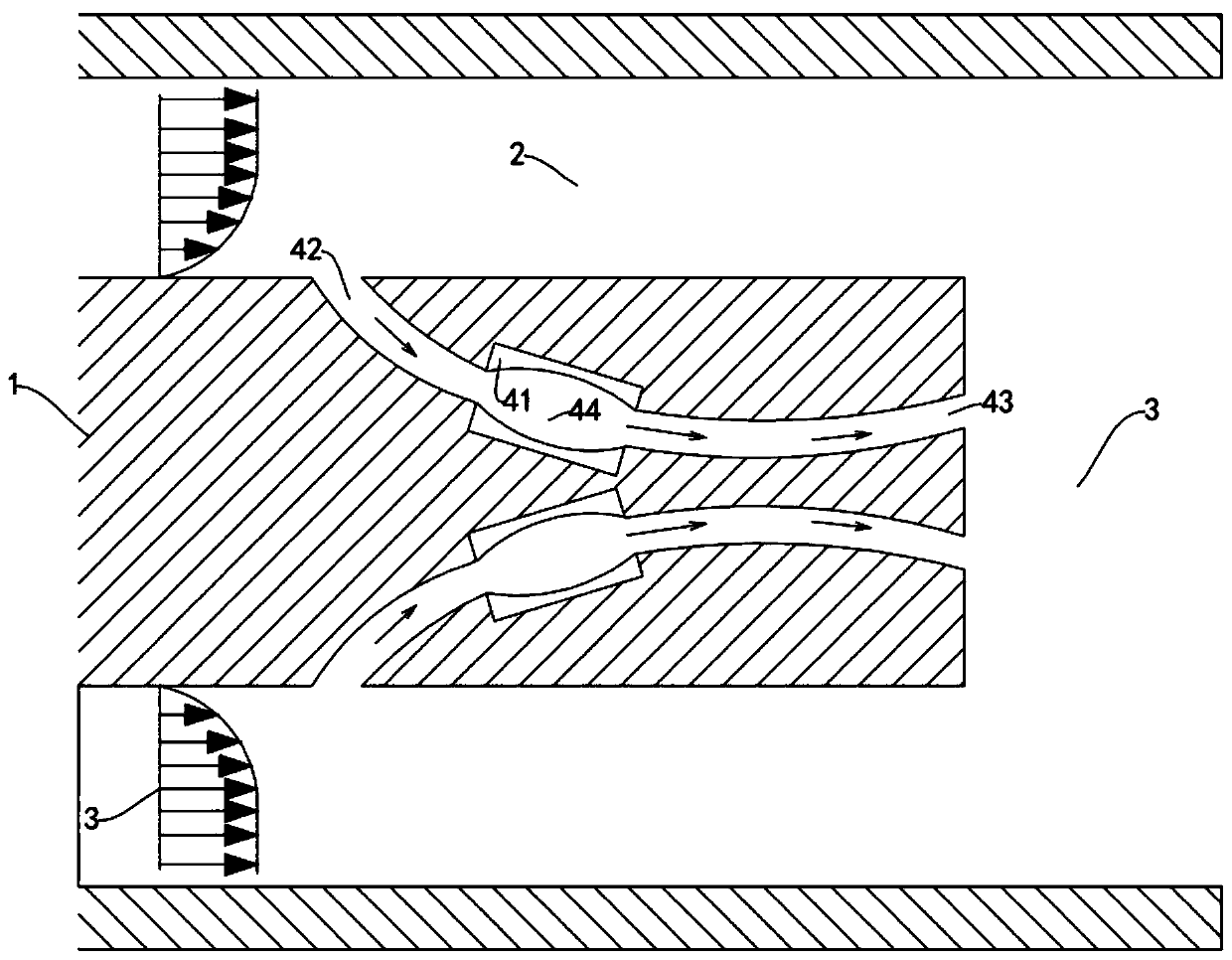

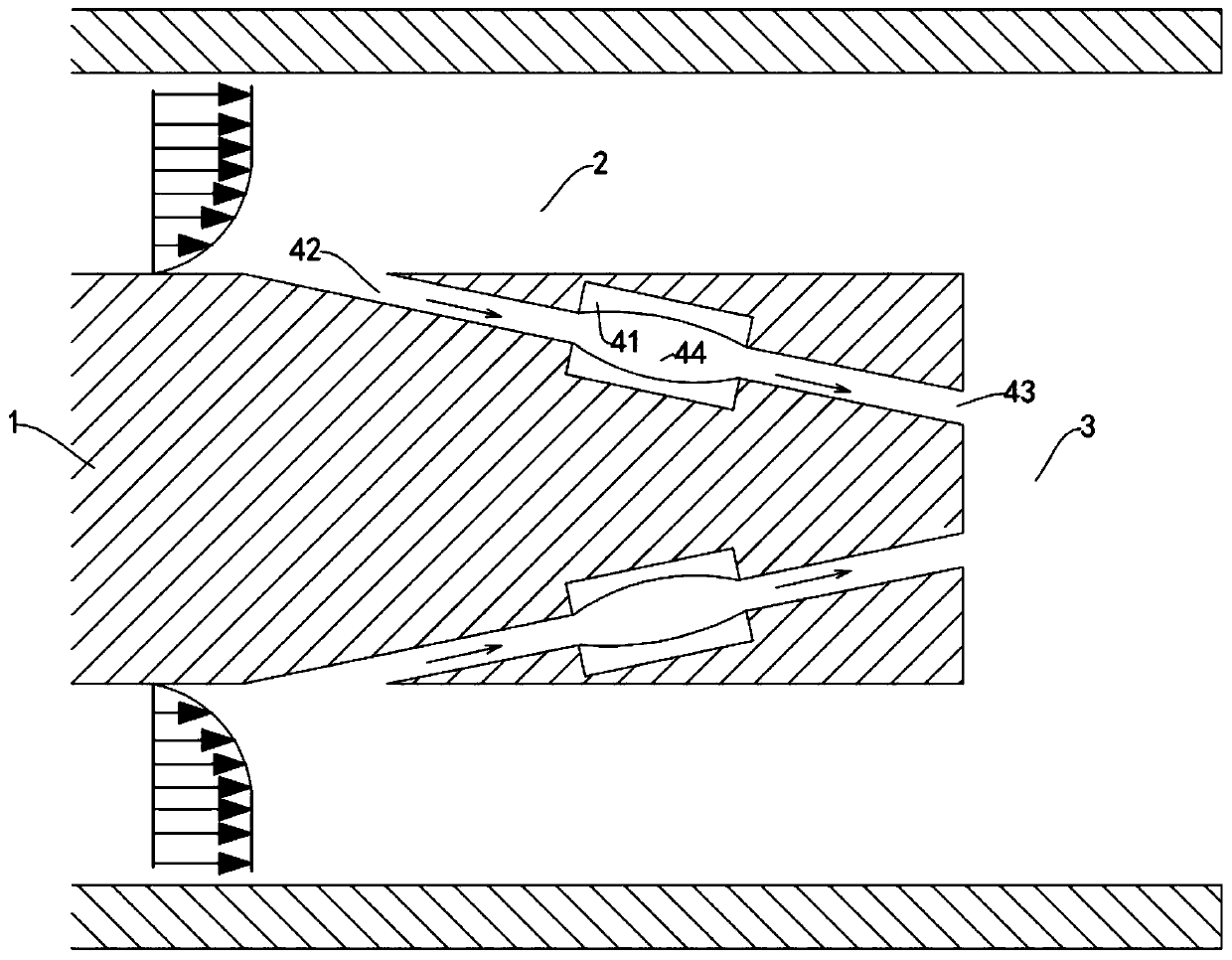

Rocket based combined cycle (RBCC) engine combustion chamber adopting slope-type rocket layout mode, and design method of RBCC engine combustion chamber

ActiveCN109882886AAvoid supersonic inflow aerodynamic problemsStable combustionContinuous combustion chamberJet flowCombustion chamber

The invention discloses a rocket based combined cycle (RBCC) combustion chamber adopting a slope-type rocket layout mode, and a design method of the RBCC combustion chamber. The combustion chamber issequentially provided with an isolation section, a rocket slope mounting section and an expansion section from an air inlet to an outlet of gas generated by combustion. The isolation section, the rocket slope mounting section and the expansion section are sequentially arranged from the air inlet to the outlet of the gas generated by combustion. A rocket thrust chamber is mounted at the rocket slope mounting section, so that a rocket jet flow is in three-side contact with a stamping main flow and is located in front of a front peak of a fire flame of the expansion section, ignition and flame stability of the combustion chamber are achieved through the rocket jet flow, and the problem that through a step rocket layout mode, rocket high-temperature and high-enthalpy activity jet flow ignitionand flame stability cannot be effectively utilized is avoided.

Owner:XIAN AEROSPACE PROPULSION INST

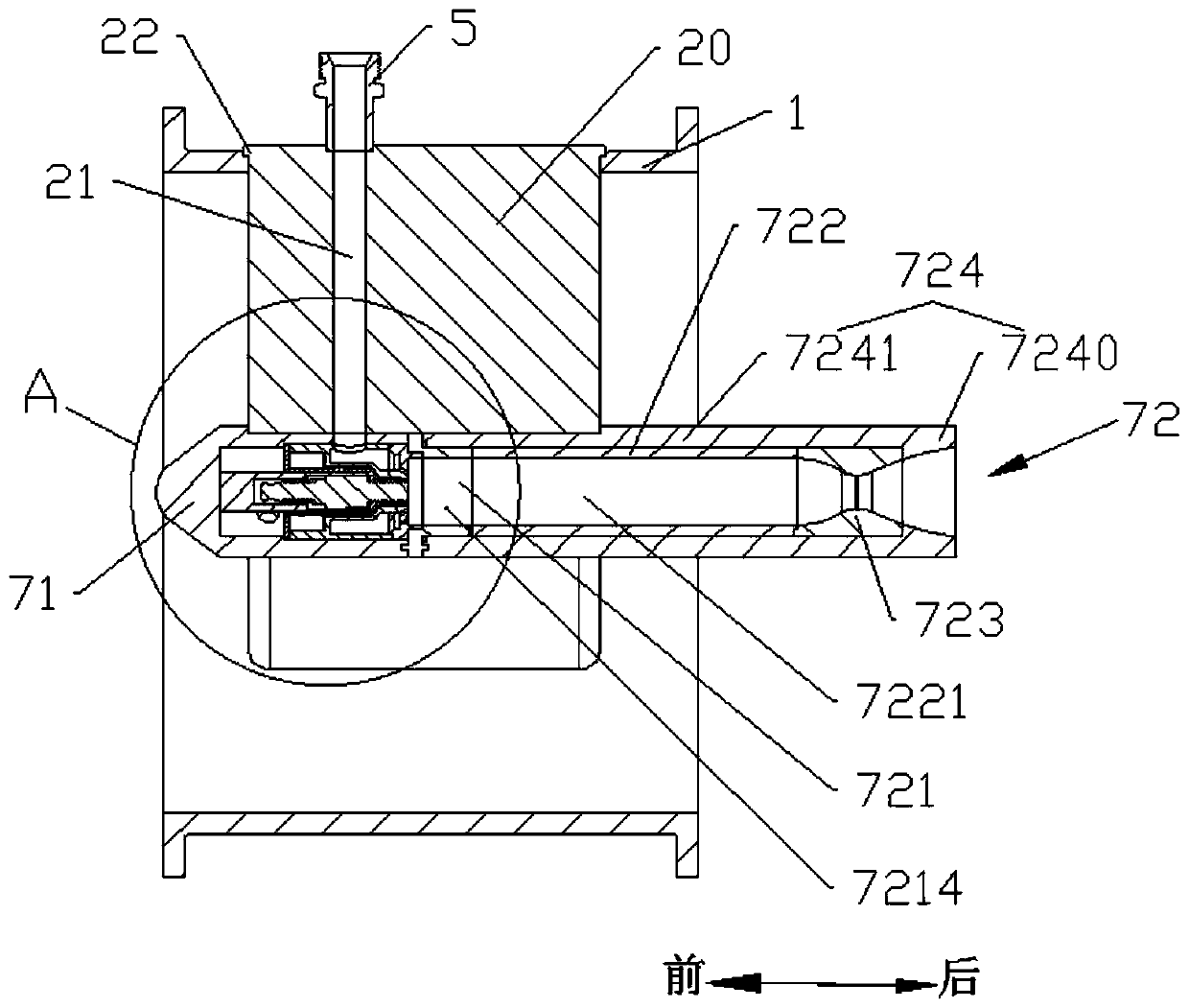

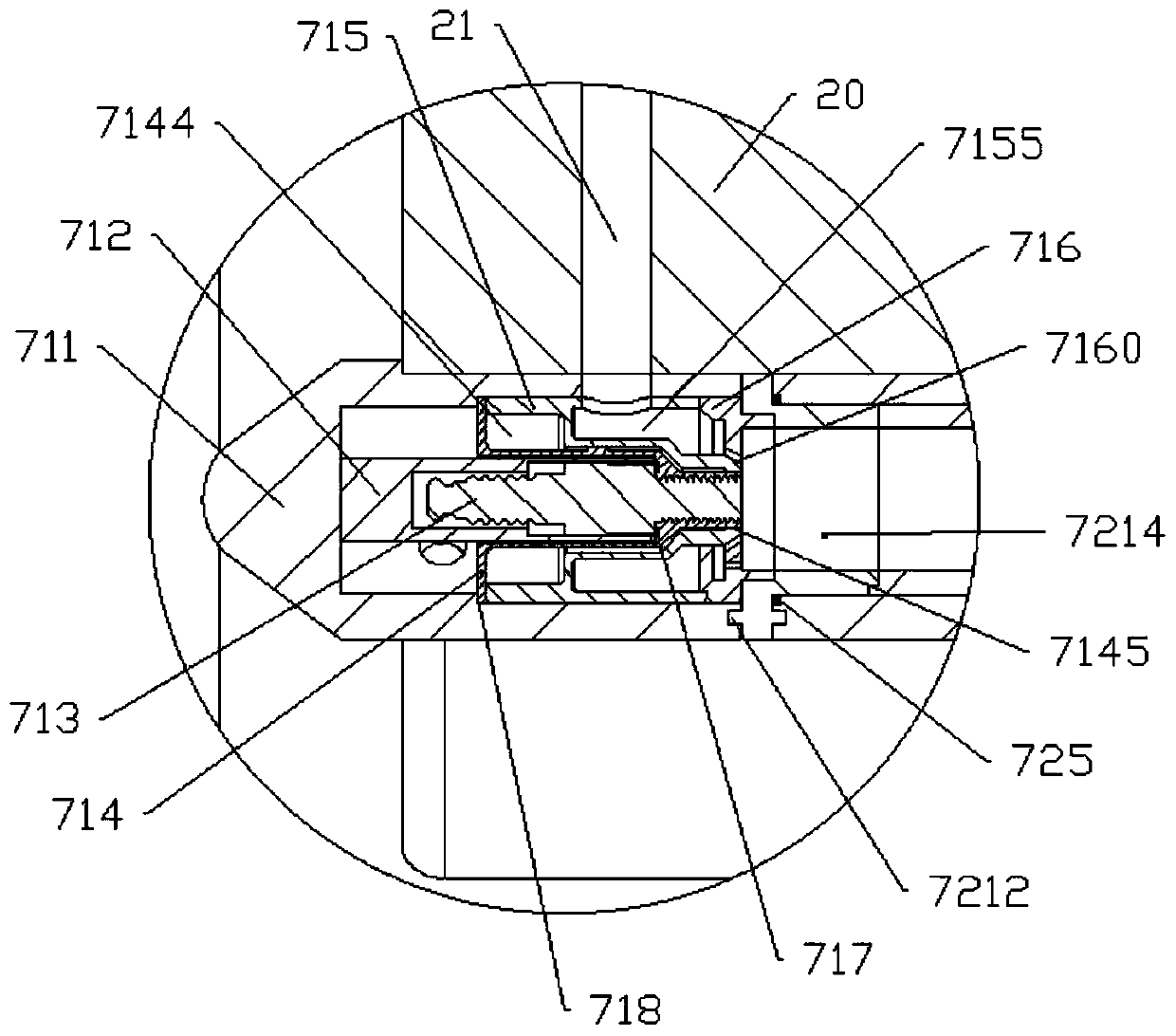

Motive sealing structure of variable-geometry combustor of rocket based combined cycle engine

InactiveCN105179107ASolve the technical problems of high temperature and high pressure dynamic sealingContact seal achievedRocket engine plantsCombustion chamberCombustor

The invention discloses a motive sealing structure of a variable-geometry combustor of a rocket based combined cycle engine. The mode that contact type sealing and non-contact type sealing are combined is adopted, so that rotary motive sealing of the joint of hinges and transverse motive sealing of all top plates and side plates of the combustor are achieved. A sealing groove is formed in the end face of a connection flange between the fixed section and the variable section of the combustor. Sealing grooves are formed in the two side edges of a bottom plate of an inner cavity of the combustor. The top plates of the inner cavity of the variable section of the combustor are connected with arc grooves to form mechanical sealing. Graphite bars in longitudinal grooves and a rotation shaft are sealed through packing. The top plates of the variable section of the combustor are provided with labyrinth channels. The top plates and the side plates are in transverse motive sealing. Red copper bars in the horizontal grooves formed in the side faces of the top plates and the side plates are sealed through packing. The red copper bars of every two top plates are attached to the joints of the top plates to achieve mechanical sealing. The sealing structure can meet the sealing requirement of the engine and also has the advantages of being simple in structure, convenient to machine, and easy to implement.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

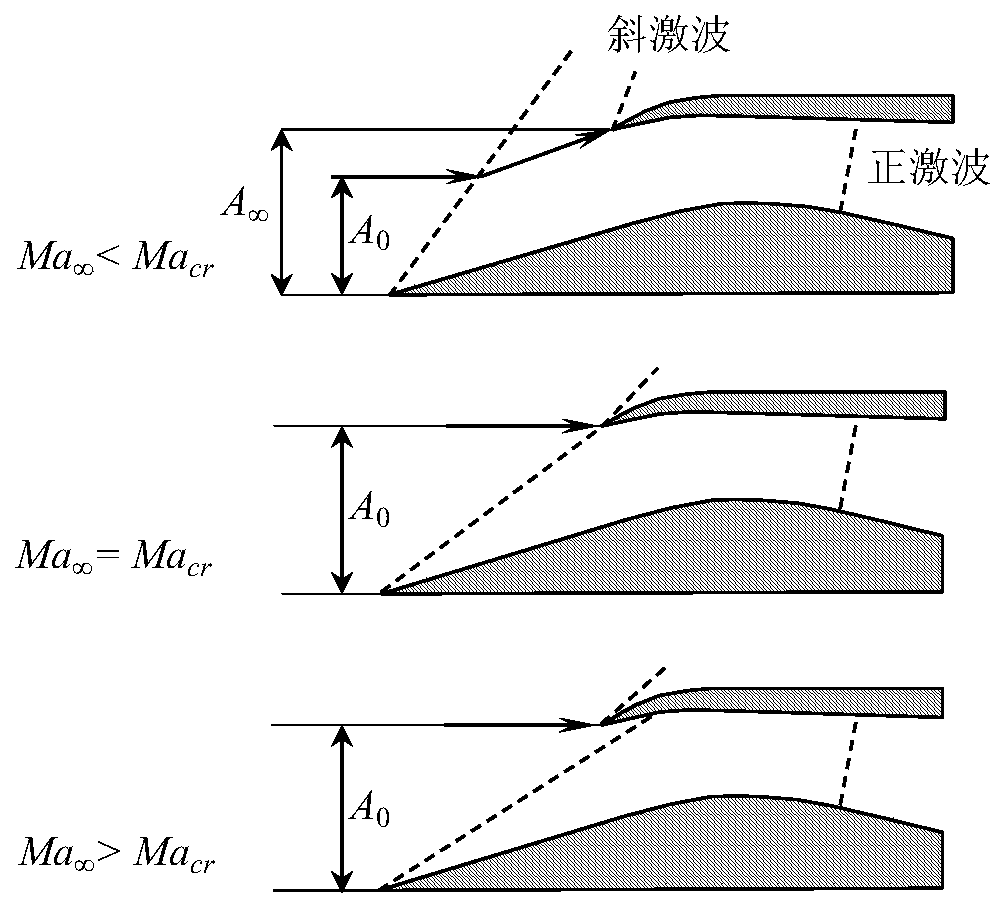

Variable-structure air inlet channel of rocket-based-combined-cycle engine

ActiveCN107061010AImprove work performanceIncrease the effective working rangeGas turbine plantsJet propulsion plantsThroatCombustion

The invention discloses a variable-structure air inlet channel of a rocket-based-combined-cycle engine. The variable-structure air inlet channel comprises a variable-structure air inlet channel inner compression section, and a bottom plate of the variable-structure air inlet channel inner compression section comprises an inner contraction section bottom plate and a throat section bottom plate which are connected through a second rotating device from front to back; the front end of the air inlet channel inner compression section communicates with an air inlet channel front body section, a bottom plate of the air inlet channel front body section is an air inlet channel front body bottom plate, and the rear end of the air inlet channel front body bottom plate is connected to the front end of the inner contraction section bottom plate through a first rotating device; when the mach number of the free jet is increased, the inner contraction section bottom plate rotates towards a cavity of the air inlet channel inner compression section by taking the first rotating device as a rotating shaft; and meanwhile, the throat section bottom plate takes the second rotating device as a rotating shaft and rotates in the direction far away from the cavity of the air inlet channel inner compression section. According to the variable-structure air inlet channel of the rocket-based-combined-cycle engine, the working performance under the injection and subsonic-combustion modes is effectively improved, and meanwhile, the performance loss of the air inlet channel under the supersonic-combustion mode is not caused.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A rocket-based combined cycle engine primary rocket system with variable operating conditions

The invention discloses a variable working condition type primary rocket system of a rocket based combined cycle engine. The variable working condition type primary rocket system comprises a propellant supply system and a primary rocket engine thrust chamber which are connected through a pipeline, wherein the propellant supply system comprises an oxidant supply system and a fuel supply system, the oxidant supply system comprises an oxygen flow rate control system, the oxygen flow rate control system comprises a plurality of oxygen conveying pipelines, each oxygen conveying pipeline is provided with an oxygen pressure relief valve for opening and closing the corresponding oxygen conveying pipeline, an outlet of each oxygen conveying pipeline is connected with an oxygen perforating plate, the fuel supply system comprises a plurality of fuel conveying pipelines, an outlet of each fuel conveying pipeline is provided with a cavitation venturi pipe, and an inlet of each fuel conveying pipeline is connected with a nitrogen pressure relief device. The variable working condition type primary rocket system of the rocket based combined cycle engine has the advantages that the flow rate of a propellant can be accurately, controllably, stably and quickly adjusted, the complexity is low, and the operation is simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

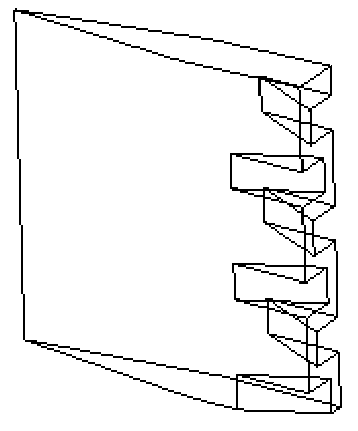

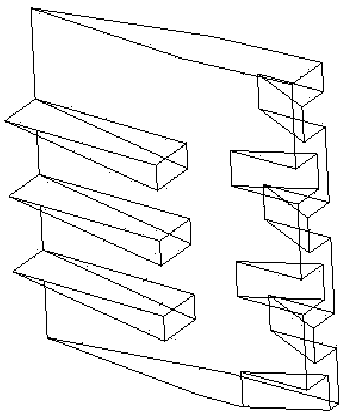

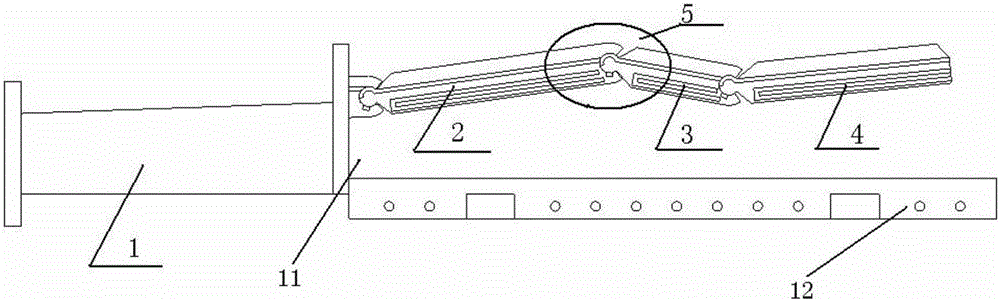

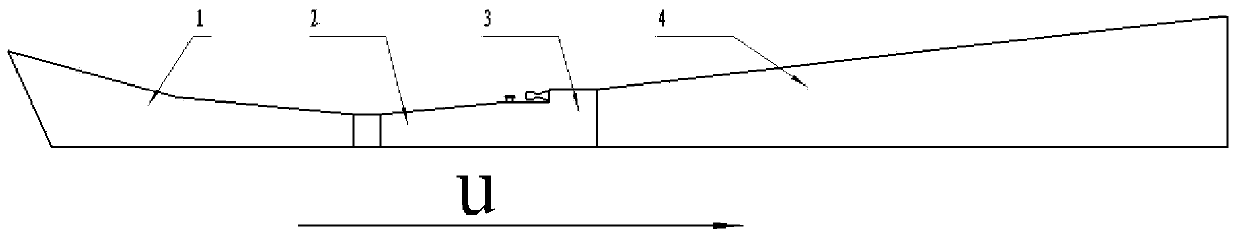

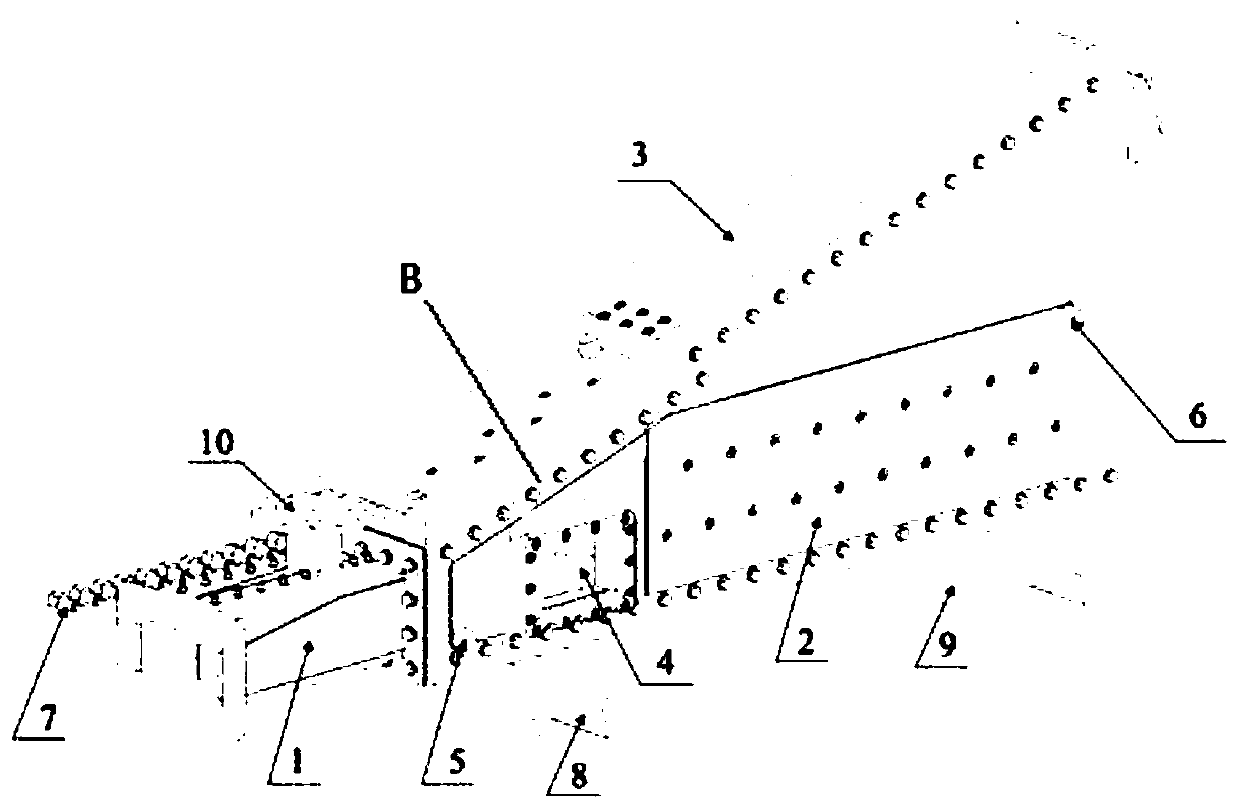

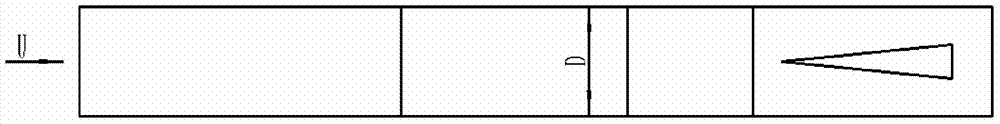

Rocket based combined cycle engine rocket ejector T-type layout

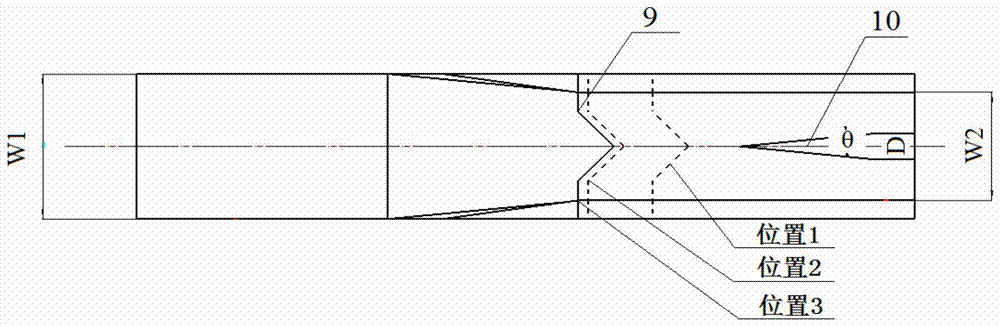

InactiveCN103726954AImprove scalabilityImprove performanceRocket engine plantsCombustion chamberScramjet

The invention discloses a rocket based combined cycle engine rocket ejector T-type layout comprising a central supporting plate rocket ejector and a plurality of side-wall rocket ejectors. The side-wall rocket ejectors are located above the central supporting plate rocket ejector. The front portions of the side-wall rocket ejector are connected to rocket combustion chamber pipelines, the central supporting plate rocket ejector is connected to a combustion chamber through upper-side pipelines, and the section of two sets of rockets is the interface of an insulating segment and a mixing segment. By means of limitation on T-type rocket ejector layout size, and a layout manner with smaller duty ratio than a full throughout central supporting plate layout manner and larger wetted perimeter than a side-wall layout manner is provided; congestion effect on the insulating segment of a full throughout supporting plate type rocket ejector and flight drag of scramjet mode are reduced, and cutting area of a primary jet flow and secondary jet flow are increased; the scalability of the rocket ejector T-type layout is high, and the rocket ejector layout is designed according to different mixing segment inlet section sizes so as to acquire excellent engine performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

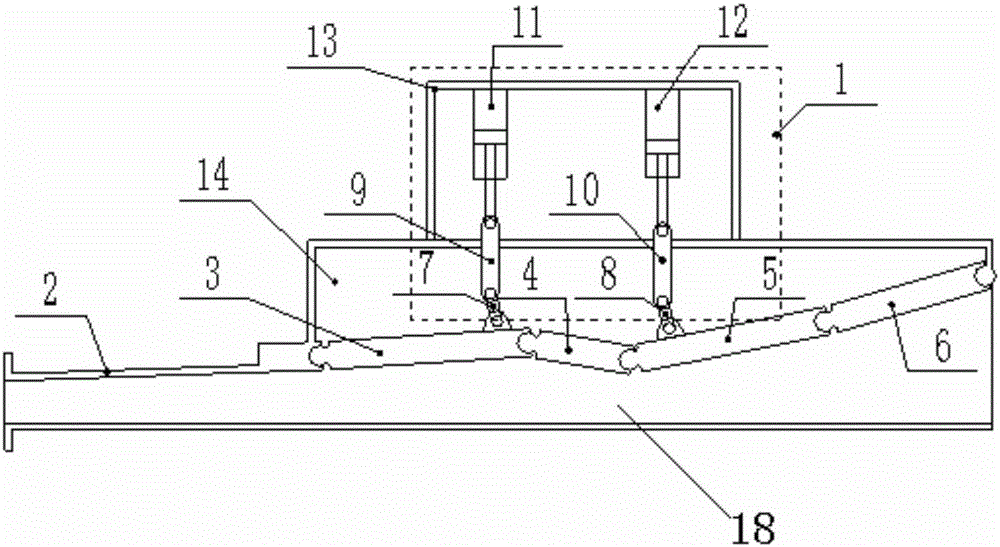

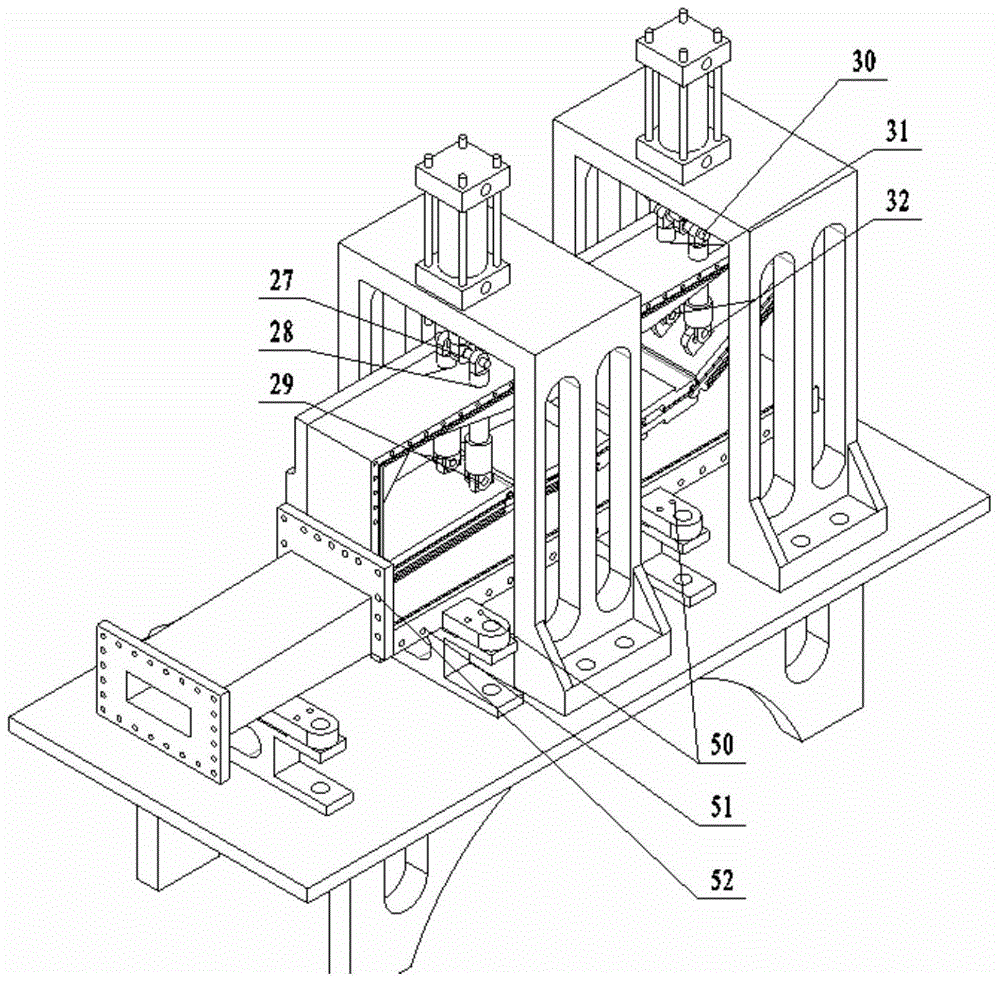

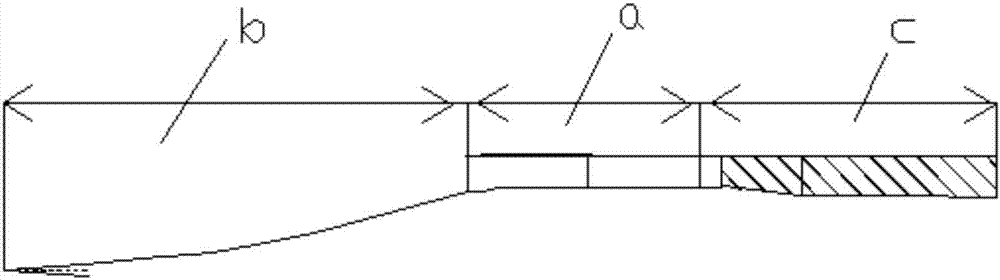

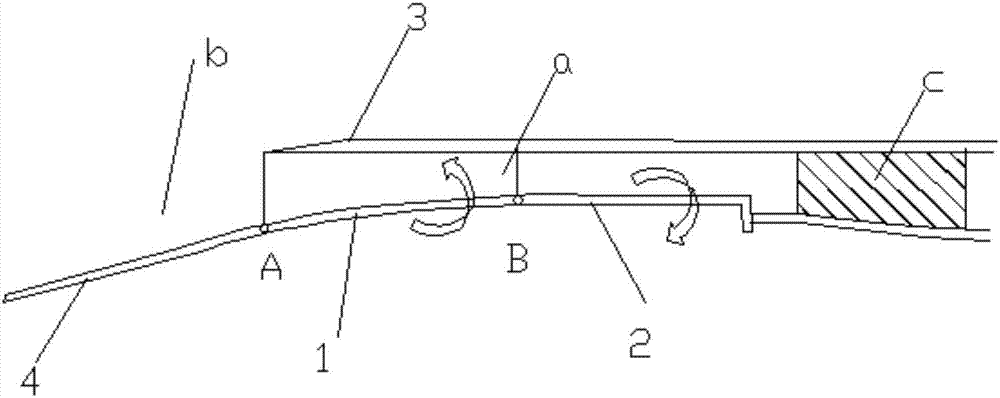

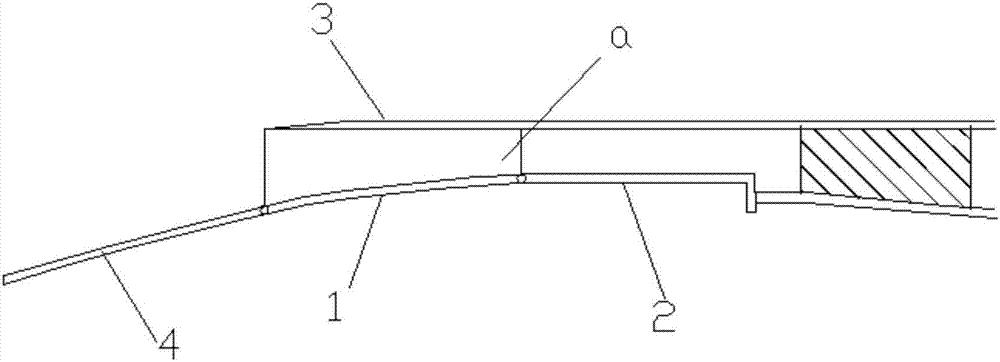

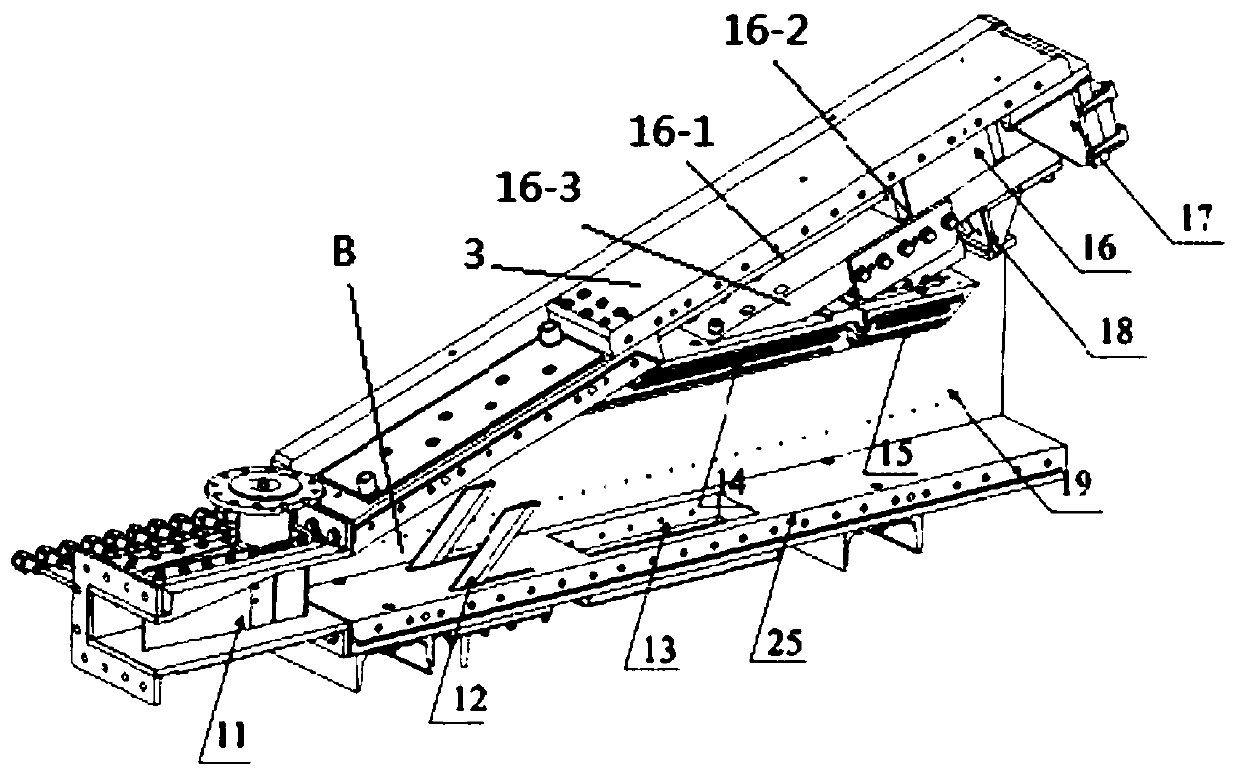

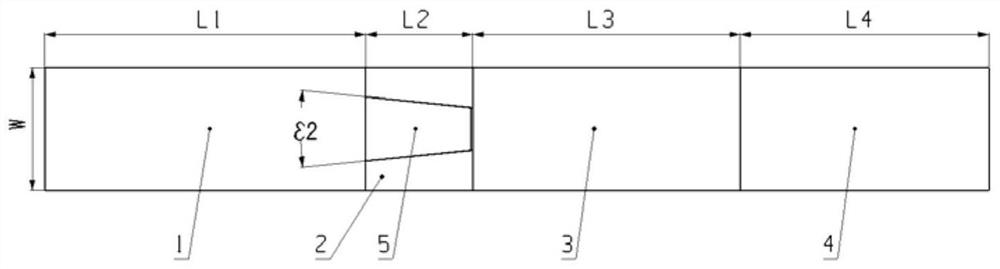

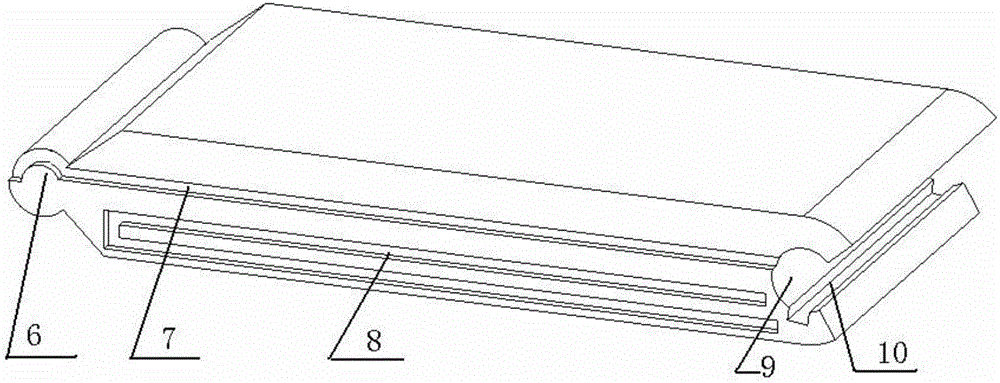

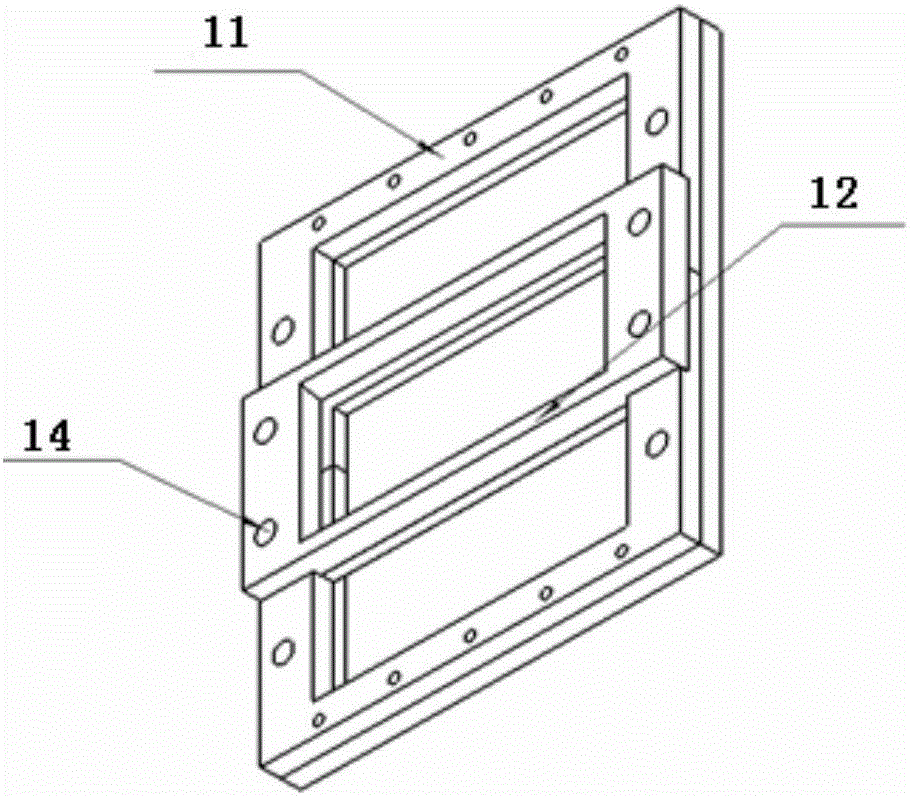

Experimental device of variable-structure rocket-based-combined-cycle combustion chamber

ActiveCN110307987AImprove performanceImprove the realization effectGas-turbine engine testingJet-propulsion engine testingCombustion chamberPower cycle

The invention discloses an experimental device of a variable-structure rocket-based-combined-cycle combustion chamber. The experimental device comprises a combustion chamber isolation section being ahollow shell with two open ends and a combustion chamber expansion section being a hollow shell with two open ends. The combustion chamber expansion section is encircled by a top plate assembly, a side plate and a bottom plate; and the front end of the combustion chamber expansion section is communicated with the outlet end of the combustion chamber isolation section. The top plate assembly includes a fixed plate, a translation top plate, and a rotating top plate. The front end of the fixed plate is fixedly connected with the top plate of the combustion chamber expansion section; and the fixedplate is inclined upwardly from the front to back. The front end of the translation top plate is in sliding connection with the lower surface of the front section of the fixed plate; and the translation top plate can slide back and forth along the front section of the fixed plate to change the expansion ratio of the combustion chamber. The front end of the rotating top plate is hinged to the tailof the translation top plate and a rotating shaft can be arranged at the hinged part; and the rear end of the rotating top plate can rotate in a direction away from or close to the fixed plate so asto change the geometric throat area of the combustion chamber. Therefore, the adjustment of the configuration of the combustion chamber under different incoming flow Mach number conditions can be realized; and a problem of dynamic sealing in the process of adjusting the structure of the combustion chamber is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rocket based combined cycle engine combustion chamber

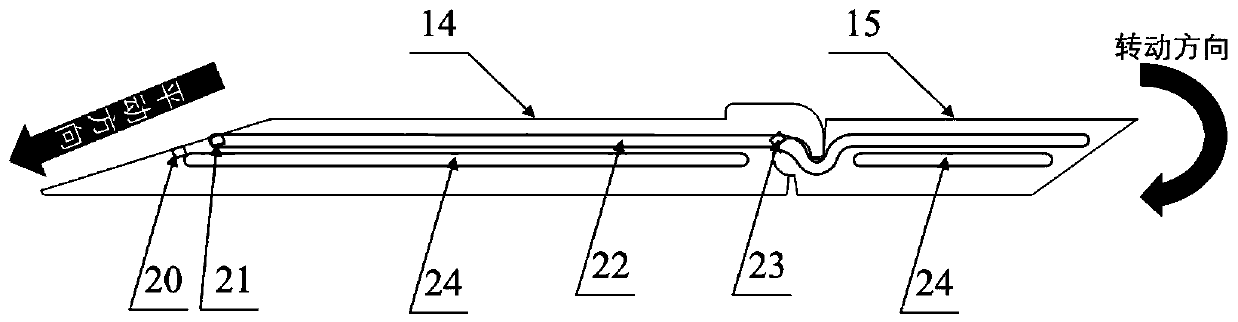

ActiveCN107100760AIncrease thrustHigh specific impulse performanceRocket engine plantsStopped workCombustion chamber

The invention discloses a rocket based combined cycle engine combustion chamber which comprises a combustion chamber cavity. Two fuel support plates are vertically arranged in the combustion chamber cavity, and the height of the fuel support plates is consistent with that of the combustion chamber cavity. The rear ends of the two fuel support plates are mounted in the combustion chamber cavity through rotary shafts. When the support plate rocket combustion chamber works, the two fuel support plates are consistent with the incoming flow direction, the front ends of the two fuel support plates are on the corresponding same cross section, and the rear ends of the two fuel support plates are on the corresponding same cross section. When the support plate rocket combustion chamber stops working, the two fuel support plates rotate around the rotary shafts in different directions to be perpendicular to the incoming flow direction, and the two fuel support plates are on the same straight line so as to divide the combustion chamber cavity into a first-stage return flow zone in front of the fuel support plates and a second-stage return flow zone behind the fuel support plates. The rocket based combined cycle engine combustion chamber meets air flow matching under different incoming flow conditions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

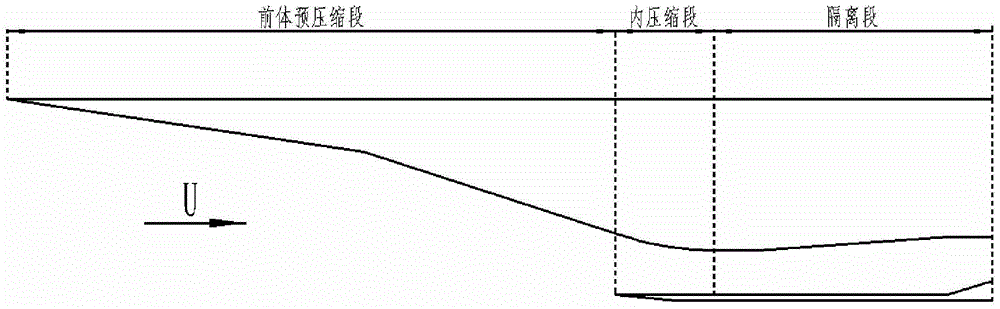

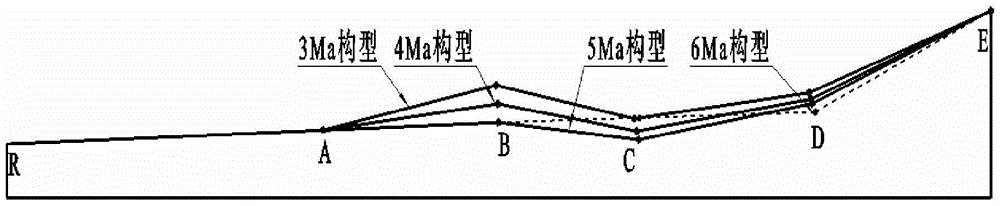

Curved-compression variable geometric gas inlet channel of rocket-based-combined-cycle engine

ActiveCN108825381AImprove performanceStart Mach number reductionGas turbine plantsJet propulsion plantsInlet channelCombustion

The invention discloses a curved-compression variable geometric gas inlet channel of a rocket-based-combined-cycle engine, the curved-compression variable geometric gas inlet channel comprises a precursor section of the gas inlet channel, an inner contraction section of the gas inlet channel, and an isolation section of the gas inlet channel, which are connected in sequence from front to back; theisolation section of the gas inlet channel is provided with a lip cover plate and a throat plate which are connected with each other. The throat plate comprises a front throat plate and a back throatplate from front to back. The front throat plate is fixed on a frame, and the back throat plate and the lip cover plate can slide back and force along the side wall of the gas inlet channel. Under the premise of improving the startability of the gas inlet channel, the working performance under ejector and sub-combustion modes is effectively improved, and the performance loss of the gas inlet channel in a super-combustion mode is not caused at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Combustion chamber of an rbcc engine with ramped rocket layout and its design method

ActiveCN109882886BAvoid supersonic inflow aerodynamic problemsStable combustionContinuous combustion chamberCombustion chamberJet flow

The invention discloses a rocket based combined cycle (RBCC) combustion chamber adopting a slope-type rocket layout mode, and a design method of the RBCC combustion chamber. The combustion chamber issequentially provided with an isolation section, a rocket slope mounting section and an expansion section from an air inlet to an outlet of gas generated by combustion. The isolation section, the rocket slope mounting section and the expansion section are sequentially arranged from the air inlet to the outlet of the gas generated by combustion. A rocket thrust chamber is mounted at the rocket slope mounting section, so that a rocket jet flow is in three-side contact with a stamping main flow and is located in front of a front peak of a fire flame of the expansion section, ignition and flame stability of the combustion chamber are achieved through the rocket jet flow, and the problem that through a step rocket layout mode, rocket high-temperature and high-enthalpy activity jet flow ignitionand flame stability cannot be effectively utilized is avoided.

Owner:XIAN AEROSPACE PROPULSION INST

A rocket-based combined cycle engine with variable suction and removal control inlet port

InactiveCN105221266BReduce the starting Mach numberImprove flow coefficientGas turbine plantsJet propulsion plantsRocketRocket-based combined cycle

The invention discloses a variable-gettering control air inlet passage for a rocket based combined cycle engine. The variable-gettering control air inlet passage comprises a precursor precompression section, an inner compression section and an air inlet passage profile of an isolation section, wherein an area-adjustable gettering region is arranged on the upper surface of the inner compression section of the air inlet passage. Under the constraint that the engine totally gives the air inlet passage profile, according to the structural scheme of variable-gettering control provided by a non-viscous air inlet passage theory, in the premise without adding a complex device, the start mach number of the air inlet passage is lowered. Before the rocket based combined cycle engine a shifted to a ramjet mode, an inner contraction section of the air inlet passage as the gettering region is totally opened. After the rocket based combined cycle engine a shifted to the ramjet mode, the inner contraction section of the air inlet passage as the gettering region is gradually closed. According to the structure of the variable-gettering control air inlet passage, the flow coefficient and other performance parameters under an ejecting mode and the ramjet mode are increased; the working range of the air inlet passage for rocket based combined cycle is widened; meanwhile, the air inlet passage still has a good performance under the supersonic mode.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Structural design of the isolation section of the intake port of a rocket-based combined cycle engine

ActiveCN105351100BReduce the starting Mach numberImprove flow coefficientGas turbine plantsRam jet enginesCombustion chamberEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A rocket-based combined cycle engine variable structure tail nozzle

InactiveCN103790735BImprove work performanceNo lossRocket engine plantsDiagnostic Radiology ModalityWork performance

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Supersonic hybrid enhanced structure with adjustable frequency characteristics and rocket-based combined engine

ActiveCN109488485BVariable volumeAchieve blending enhancement controlRocket engine plantsRam jet enginesJet flowRocket

The invention provides a supersonic blending reinforcing structure with an adjustable frequency characteristic and a rocket based combined cycle. The supersonic blending reinforcing structure comprises a supersonic incoming flow baffle, supersonic incoming flow channels are arranged on both sides of the supersonic incoming flow baffle, and the two supersonic incoming flow channels are in communication with each other at the tail end of the supersonic incoming flow baffle and form a supersonic incoming flow blending zone. The supersonic incoming flow blending zone communicates with the supersonic incoming flow channels through flow guiding pipes, the flow guiding pipes comprise expansion cavities formed in the supersonic incoming flow baffle, and expansion pipes with adjustable volume are arranged in the expansion cavities. Due to a pressure difference between the two ends of the flow guiding pipes, jet flow can be formed in the supersonic incoming flow blending zone without providing an additional air source, and blending reinforcing control of the supersonic incoming flow blending zone is realized; and meanwhile, the expansion pipes are arranged in the flow guiding pipes, the jetflow ejected by flow guiding rear pipes has a certain frequency characteristic, and moreover, the volumes of the expansion pipes are adjustable, so that the frequency of the jet flow ejected by the flow guiding rear pipes is adjustable. The supersonic blending reinforcing structure with the adjustable frequency characteristic and the rocket based combined cycle are applied to the field of supersonic incoming flow blending control.

Owner:NAT UNIV OF DEFENSE TECH

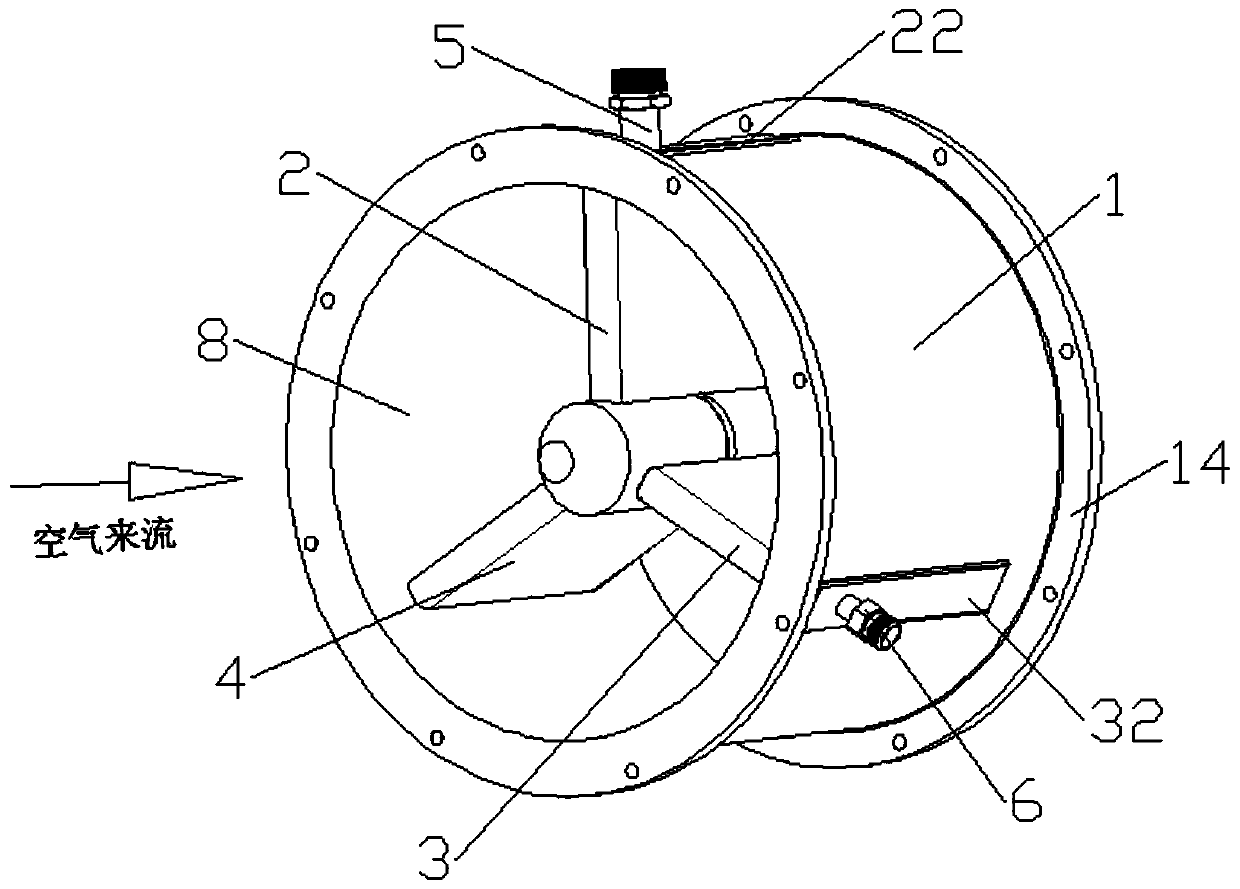

Integrated rocket ejector engine assembly and engine thereof

PendingCN110594037AReduce the impactSmall structure sizeRocket engine plantsRam jet enginesRam-air intakeRocket

The invention provides an integrated rocket ejector engine assembly. The integrated rocket ejector engine assembly comprises a stamping gas inlet path, three support plates and a rocket ejector, wherein the three support plates are separately an oxidant support plate, a fuel support plate and a voltage test circuit board; and the three support plates are used for hanging the rocket ejector in thestamping gas inlet path. The invention further provides a rocket based combined cycle engine. The integrated rocket ejector engine assembly can reduce the structural dimension, so that influences on air incoming flow are reduced.

Owner:HUNAN AIRTOPS INTELLIGENT TECH CO LTD

Dynamic sealing structure of variable geometry combustor of rocket-based combined cycle engine

InactiveCN105179107BSolve the technical problems of high temperature and high pressure dynamic sealingContact seal achievedRocket engine plantsCombustion chamberCombustor

The invention discloses a motive sealing structure of a variable-geometry combustor of a rocket based combined cycle engine. The mode that contact type sealing and non-contact type sealing are combined is adopted, so that rotary motive sealing of the joint of hinges and transverse motive sealing of all top plates and side plates of the combustor are achieved. A sealing groove is formed in the end face of a connection flange between the fixed section and the variable section of the combustor. Sealing grooves are formed in the two side edges of a bottom plate of an inner cavity of the combustor. The top plates of the inner cavity of the variable section of the combustor are connected with arc grooves to form mechanical sealing. Graphite bars in longitudinal grooves and a rotation shaft are sealed through packing. The top plates of the variable section of the combustor are provided with labyrinth channels. The top plates and the side plates are in transverse motive sealing. Red copper bars in the horizontal grooves formed in the side faces of the top plates and the side plates are sealed through packing. The red copper bars of every two top plates are attached to the joints of the top plates to achieve mechanical sealing. The sealing structure can meet the sealing requirement of the engine and also has the advantages of being simple in structure, convenient to machine, and easy to implement.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A rocket-based combined cycle engine variable structure combustion chamber

InactiveCN105240160BIncrease thrustHigh specific impulse performanceRocket engine plantsCombustion chamberDivergence angle

The invention discloses a variable structure combustion chamber of a rocket-based-combined-cycle engine. The variable structure combustion chamber is composed of a drive system, a back pressure cavity and a combustion chamber body. The drive system is located at the upper portion of the back pressure cavity. The back pressure cavity is fixed to the portion above variable sections of the combustion chamber body and forms an integral structure with the combustion chamber body. A combustion chamber fixed section is sequentially connected with variable sections of the combustion chamber body. The variable sections are connected through cooperation of ball head hinge convex faces and ball head hinge concave faces. Two sets of hydraulic drive mechanisms drive the first variable section and the third variable section of the combustion chamber body through drive rods and connecting rods. Axial sealing grooves of the variable sections are filled with graphite strips so as to isolate high-temperature fuel gas in the combustion chamber body, and sealing is guaranteed. According to the variable structure combustion chamber, stable transition among different modes is achieved through grade adjustment. In the injection mode and the subsonic combustion mode, the variable sections of the combustion chamber body are adjusted by a hydraulic drive mechanism to generate different divergence angles and throat heights, so that the combustion chamber body is in the optimal work state, and the thrusting force and specific impulse performance of the combustion chamber body are obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

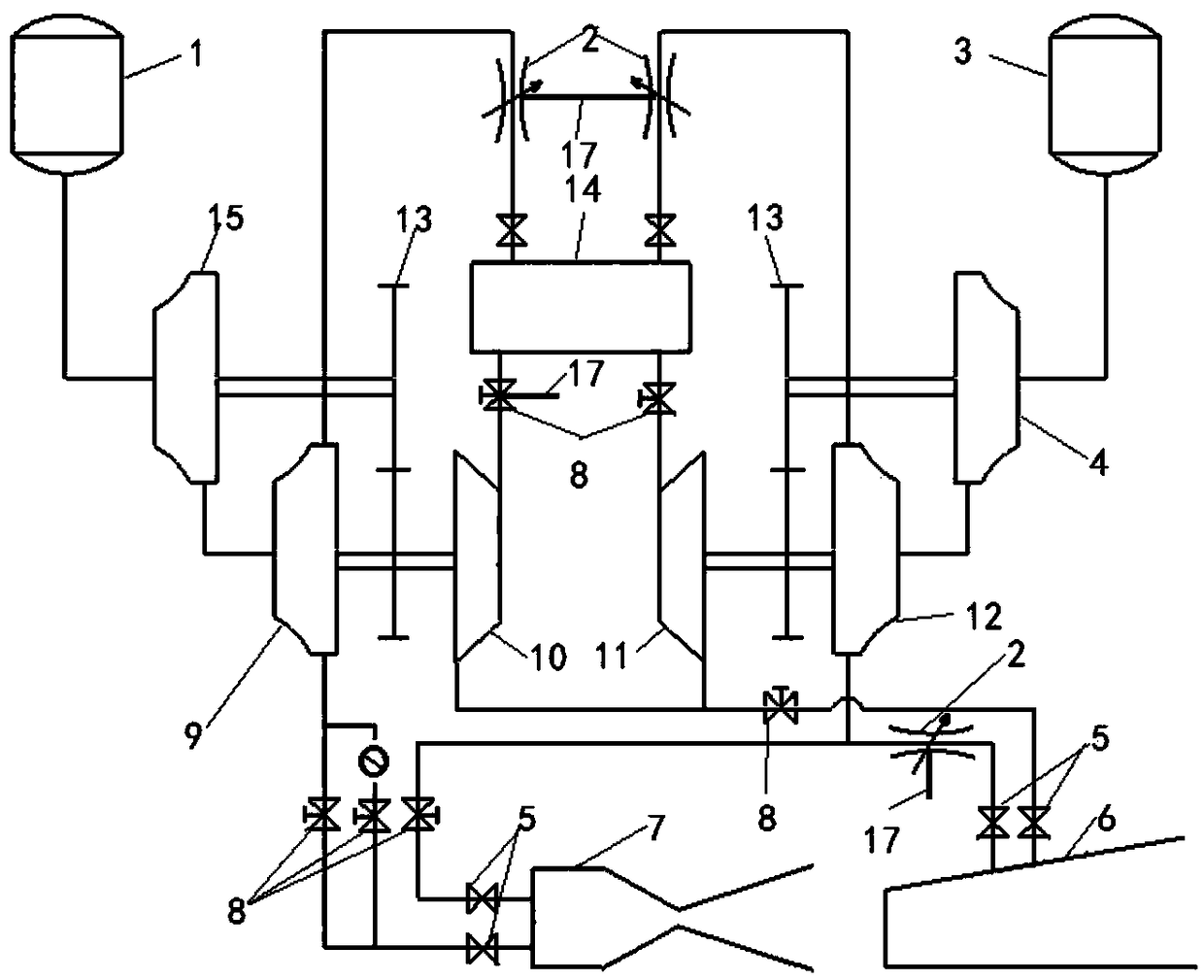

An integrated propellant supply system for a rocket-based combined cycle engine

InactiveCN106321284BImprove performanceSimple structureRocket engine plantsRam jet enginesKeroseneRocket-based combined cycle

The invention discloses an integrated propellant supply system of a rocket based combined circulating engine. The integrated propellant supply system consists of a liquid oxygen path supply system, a kerosene path supply system and a fuel gas system; the liquid oxygen path supply system provides an oxidant for the engine; the kerosene path supply system provides fuels for the engine; the fuel gas system provides turbine driving fuel gas for a turbine; and the liquid oxygen path supply system and the kerosene path supply system are symmetrically arranged with respect to a fuel gas generator 14. The supply system takes a fuel gas generator circulating system with a simple structure as a basic structural form for discharging the turbine driving fuel gas into a low-pressure ramjet flow path to carry out complementary combustion, so that an engine complementary combustion circulating system with a relatively simple structure and excellent performance is formed; moreover, the system has a large range of regulating capacity, and also meets supply needs of a main rocket propellant and engine secondary fuels of the rocket based combined circulating engine. The propellant supply system increases an energy utilization rate and improves engine performance, and can be used for wide-envelop multi-mode RBCC engine system integrating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A rocket-based combined cycle engine variable geometry side pressure inlet

InactiveCN105156212BImprove performanceReduce resistanceGas turbine plantsJet propulsion plantsAir volumeCombustion chamber

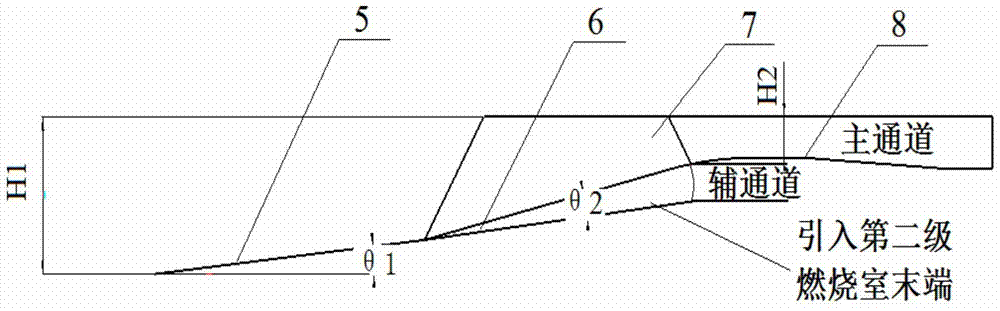

The invention discloses a variable geometry side pressure type air inlet passage of a rocket-based-combined-cycle (RBCC) engine. Grading adjustment is conducted with the adoption of a variable geometry mode to ensure that the air inlet passage has good properties within the working range of 1.5-7 Ma. The variable geometry side pressure type air inlet passage captures the air volume by lowering the low Mach number to achieve low Mach number start of the air inlet passage; an auxiliary passage is opened by rotating a second pressure pushing plate; part of airflow is introduced into the tail end of a combustion chamber, so that the resistance of the air inlet passage in an ejecting mode is lowered, and meanwhile the airflow introduced into the tail end of the combustion chamber restrains a tail ejecting pipe from overexpansion to increasing thrust, and accordingly the performance of the whole engine is improved by a large margin, and the rate of fuel consumption in the ejecting mode is lowered. The auxiliary passage is closed during the operation in a subsonic-supersonic-combustion mode, and a lip opening plate is moved forward or backward to cover and shelter a certain part of a pressure difference overflow window, so that the flow coefficient of the air inlet passage and the total pressure recovery coefficient are effectively increased. The side pressure type air inlet passage has the advantages of being simple and easy to achieve, and it is ensured that the air inlet passage has good performance during the operation interval of the whole engine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

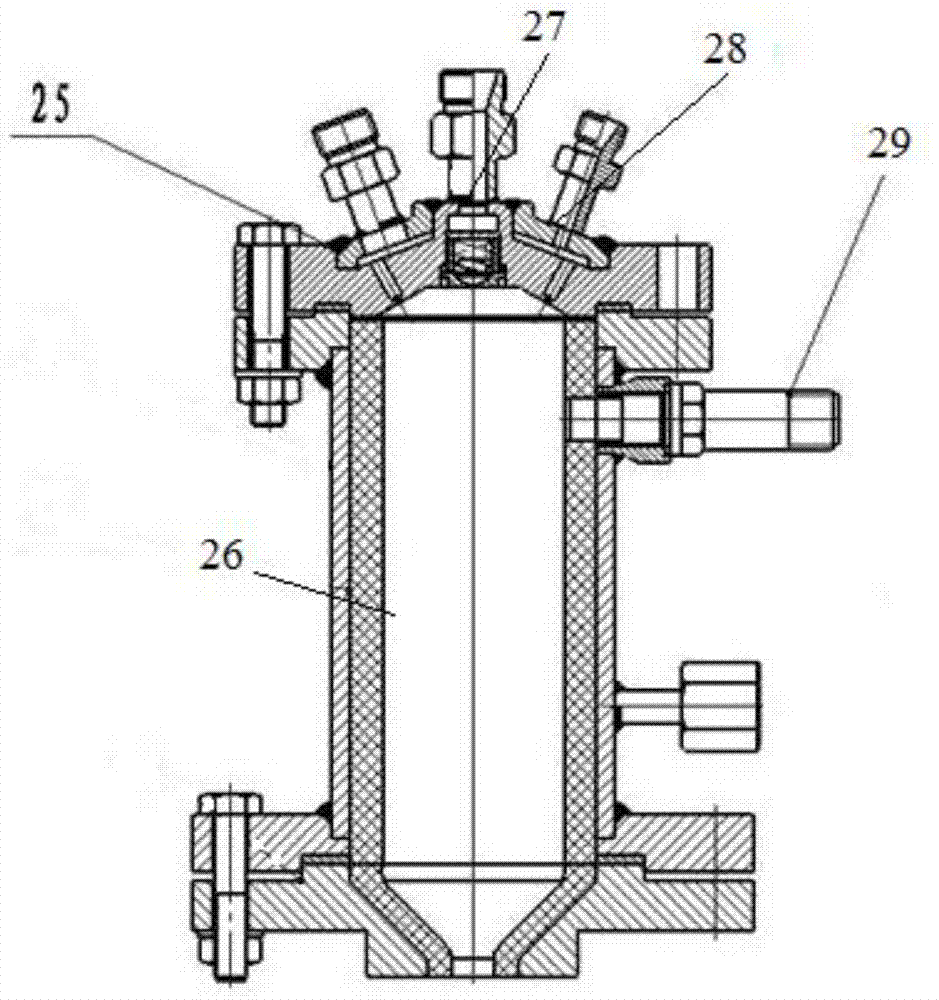

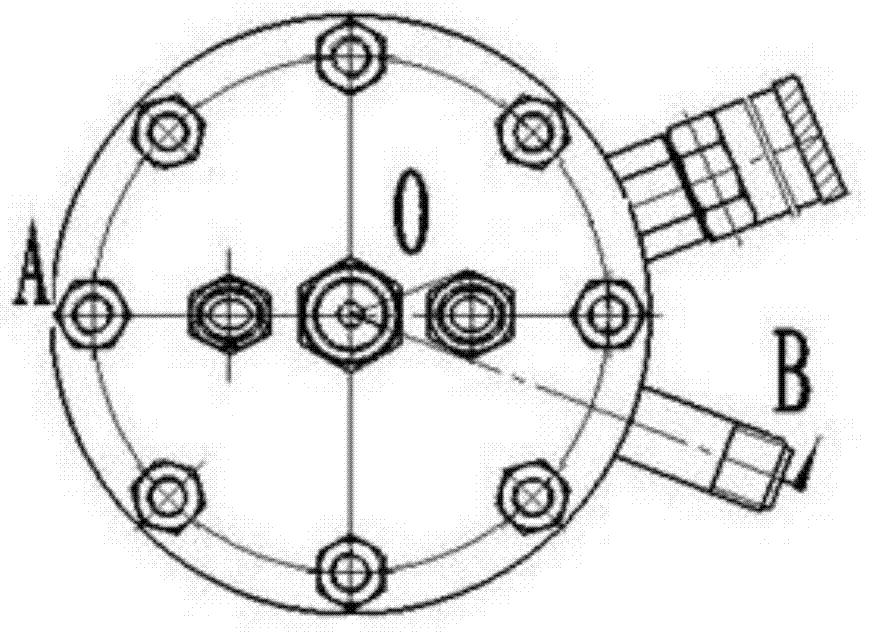

A Rocket-Based Combined Cyclic Ejection Modal Performance Experimental Engine

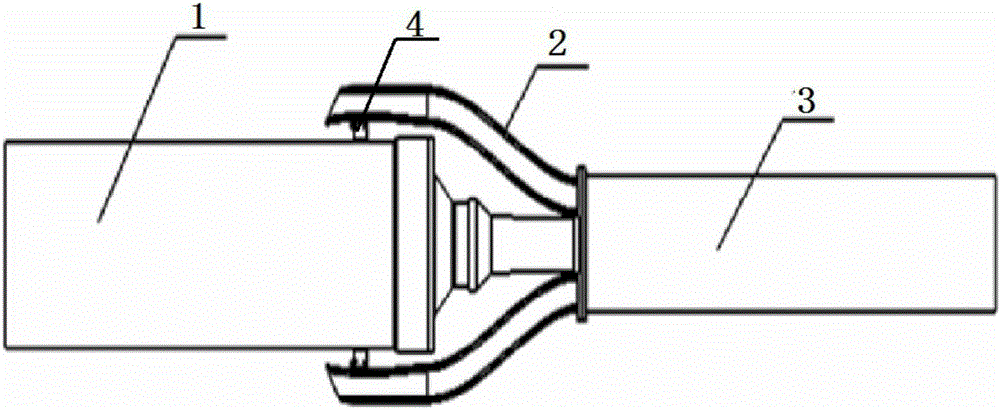

InactiveCN103758663BHigh specific impulse performanceLarge thrustRocket engine plantsCombustorCombustion chamber

The invention discloses a rocket-based combined cycle ejector mode performance test engine. A main rocket combustor is fixed in the front of a secondary combustor; intake ducts are mounted above and below the main rocket combustor respectively; intake ends of the intake ducts are fixed in the rear of the main rocket combustor through support lugs; the rear ends of the intake ducts are connected with the secondary combustor through an intake duct flange and a second combustor flange; the secondary combustor is in a divergent straight structure; the main rocket combustor is fitly connected with the secondary combustor; a flue of a nozzle divergent segment gradually changes from round to square. The main rocket combustor is charged through the combination of seven-pointed star shape and inner holes by close-to-wall pouring; after ignition, the flow of gas in a main rocket is kept basically unchanged; variation pattern of the rocket-based combined cycle ejector mode performance along with flight Mach number and height is verified; the basis is provided for passage design. The rocket-based combined cycle ejector mode performance test engine is simple in structure and convenient to maintain, and the influence of gas composition upon engine performance and trajectory climb can be extensively researched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com