Rocket based combined cycle engine combustion chamber

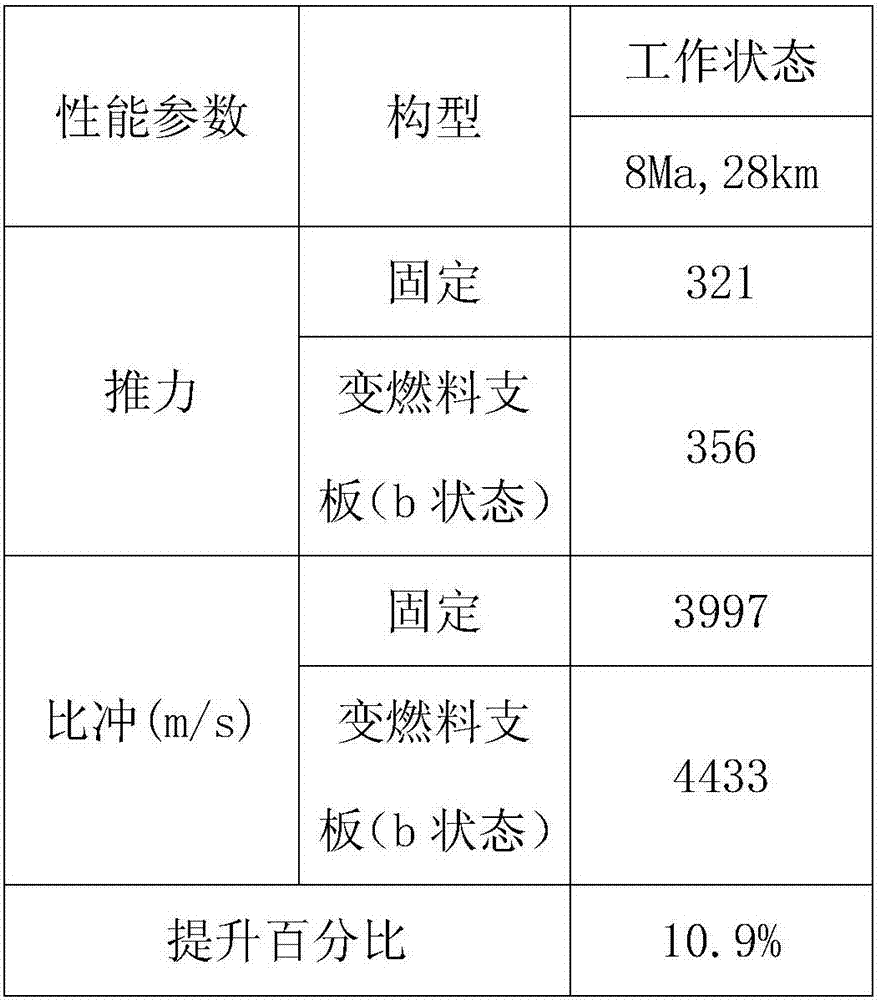

A combustion chamber and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as large variation range and complex actuating mechanism, and achieve the effect of improving thrust and specific impulse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

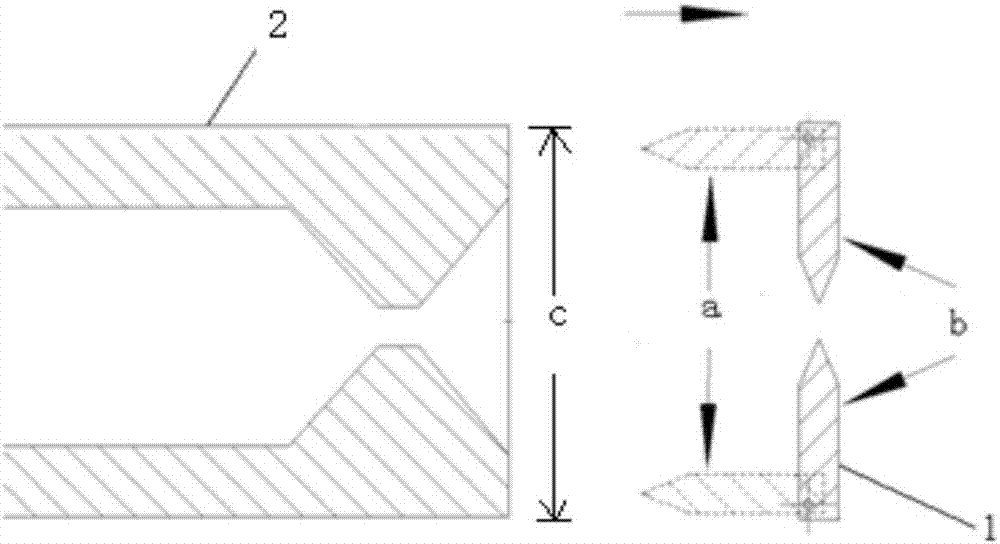

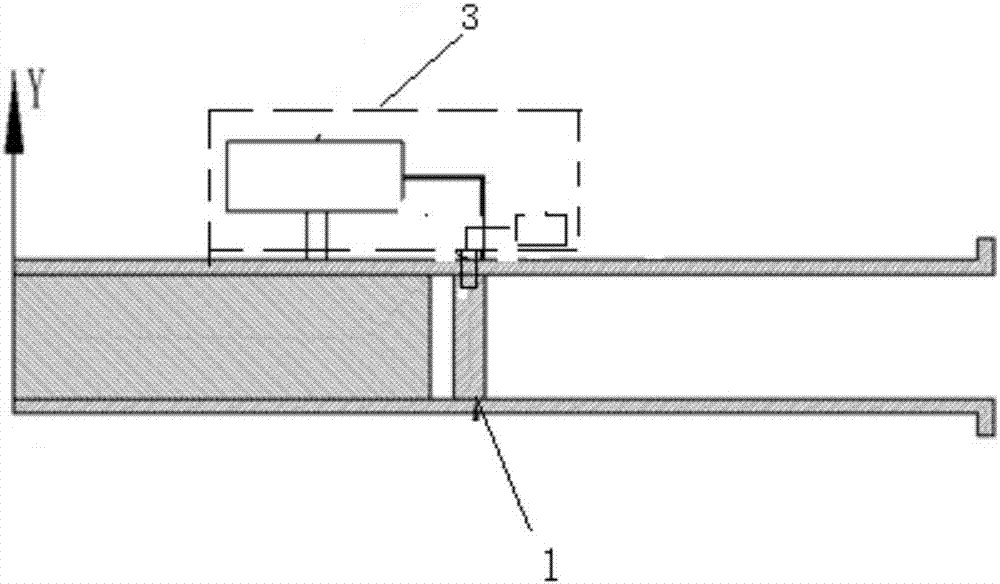

[0010] Rocket-based combined cycle engine combustion chamber of the present invention, such as figure 1 and figure 2 As shown, including the combustion chamber cavity, two fuel support plates 1 are vertically arranged in the combustion chamber cavity, and their heights are consistent with the height of the combustion chamber cavity; the rear ends of the two fuel support plates 1 pass through The rotating shaft is installed in the combustion chamber cavity; when the support plate rocket combustion chamber is working and the high-temperature gas enters the combustion chamber cavity through the exit of the support plate rocket nozzle, the two fuel support plates 1 are consistent with the direction of the combustion chamber cavity , and their front and rear ends are all on the corresponding same cross-section; when the support plate rocket combustion chamber stops working, and when the support plate rocket nozzle outlet no longer ejects high-temperature gas, the two fuel support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com