Patents

Literature

31results about How to "High specific impulse performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

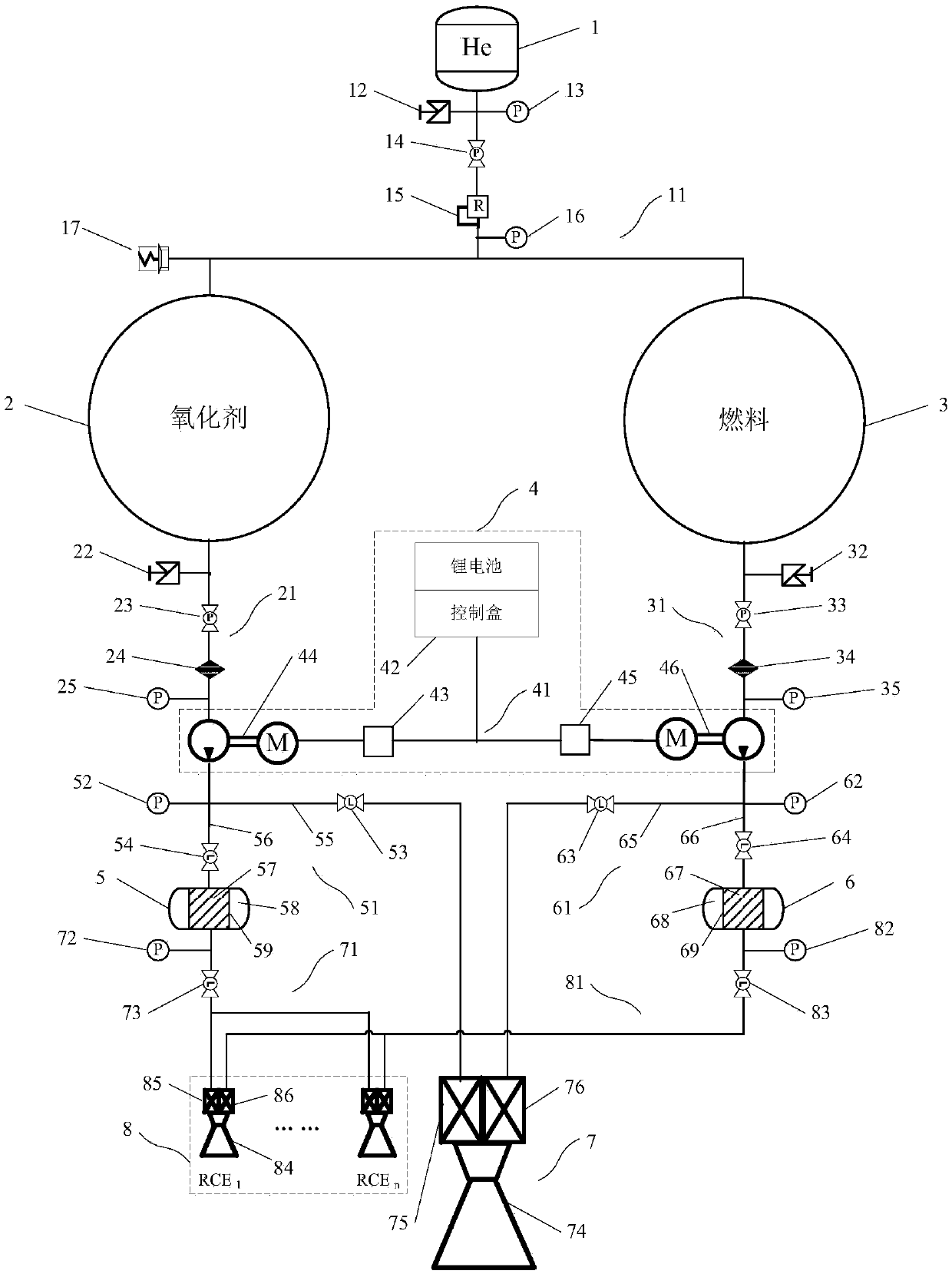

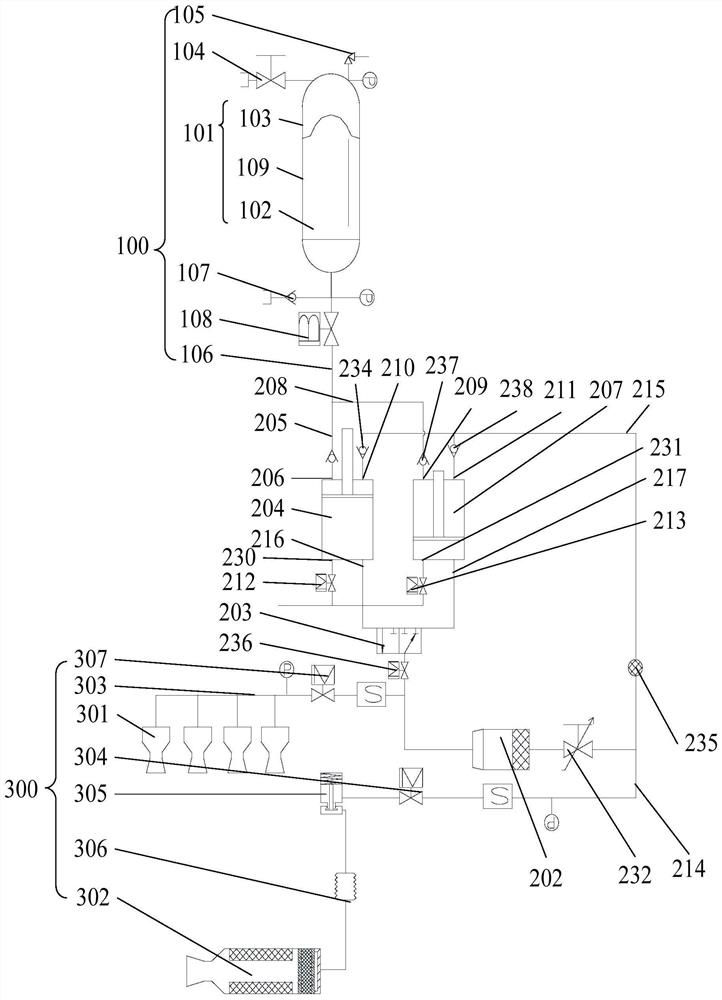

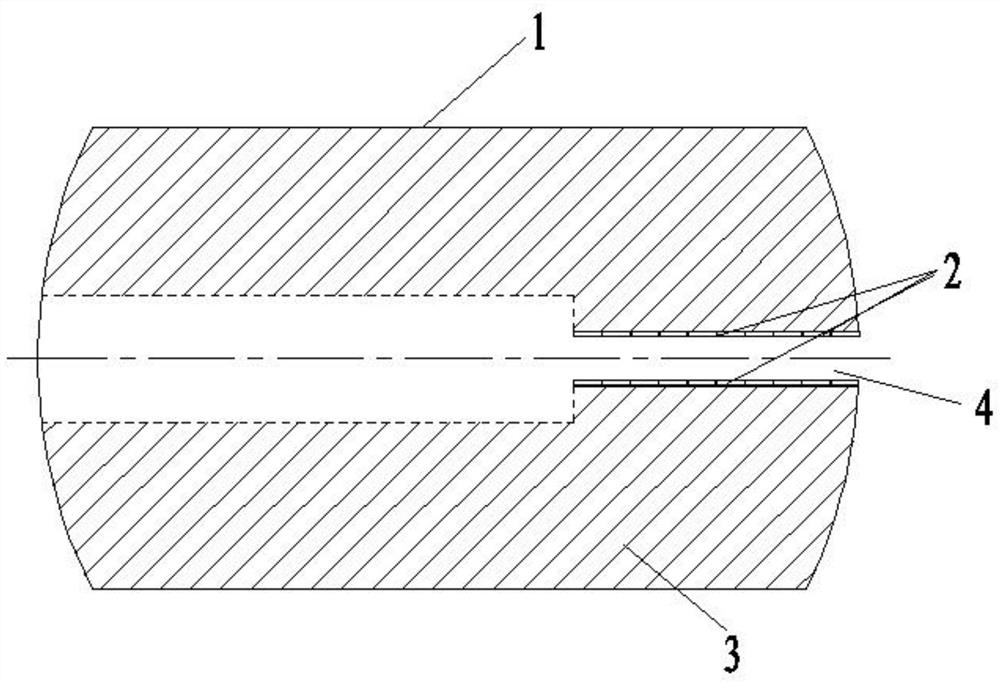

Orbit and attitude control integrated space marching system based on electric pump

ActiveCN109630317AHigh specific impulse performanceReduce carryRocket engine plantsAttitude controlGas cylinder

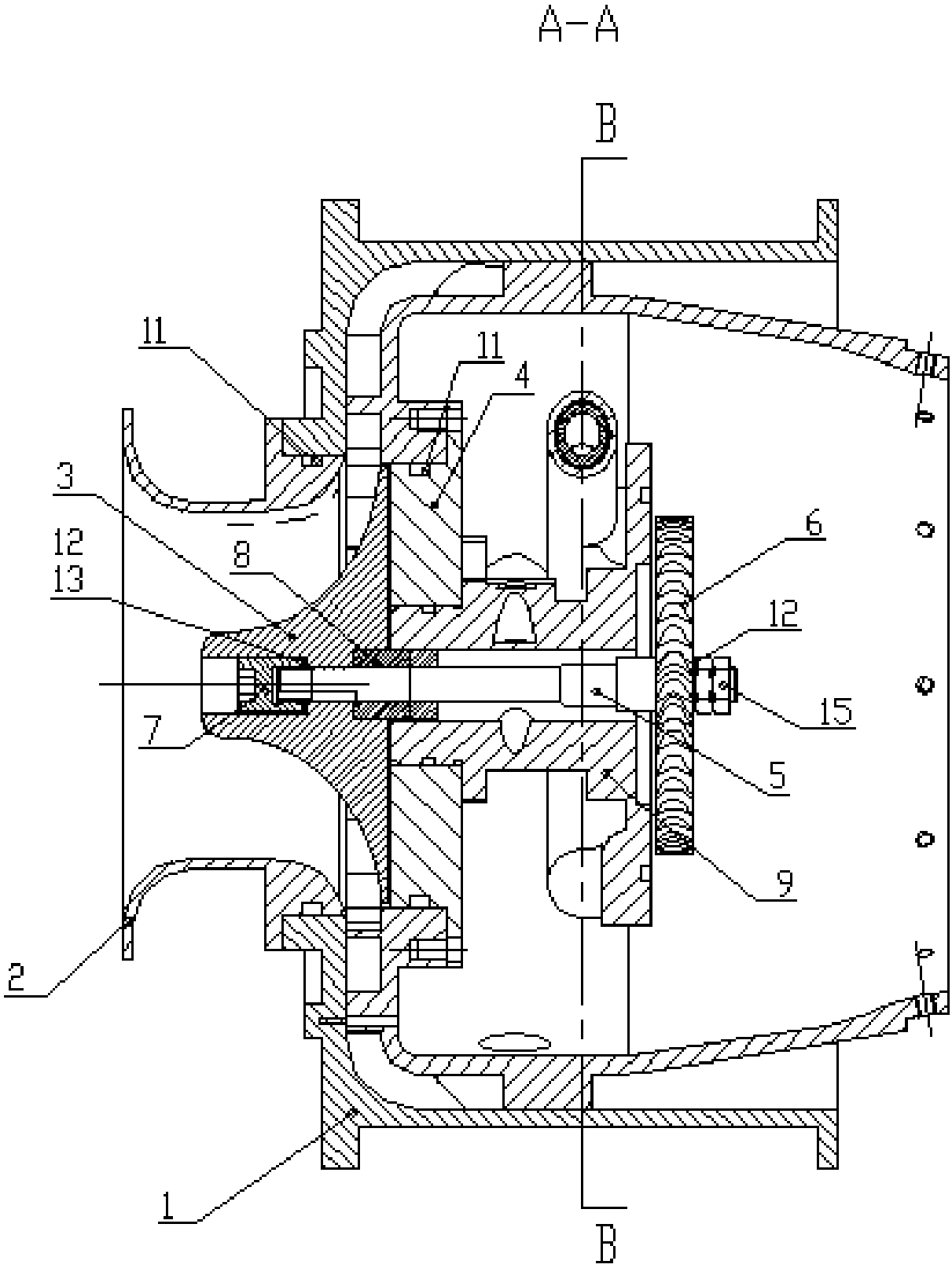

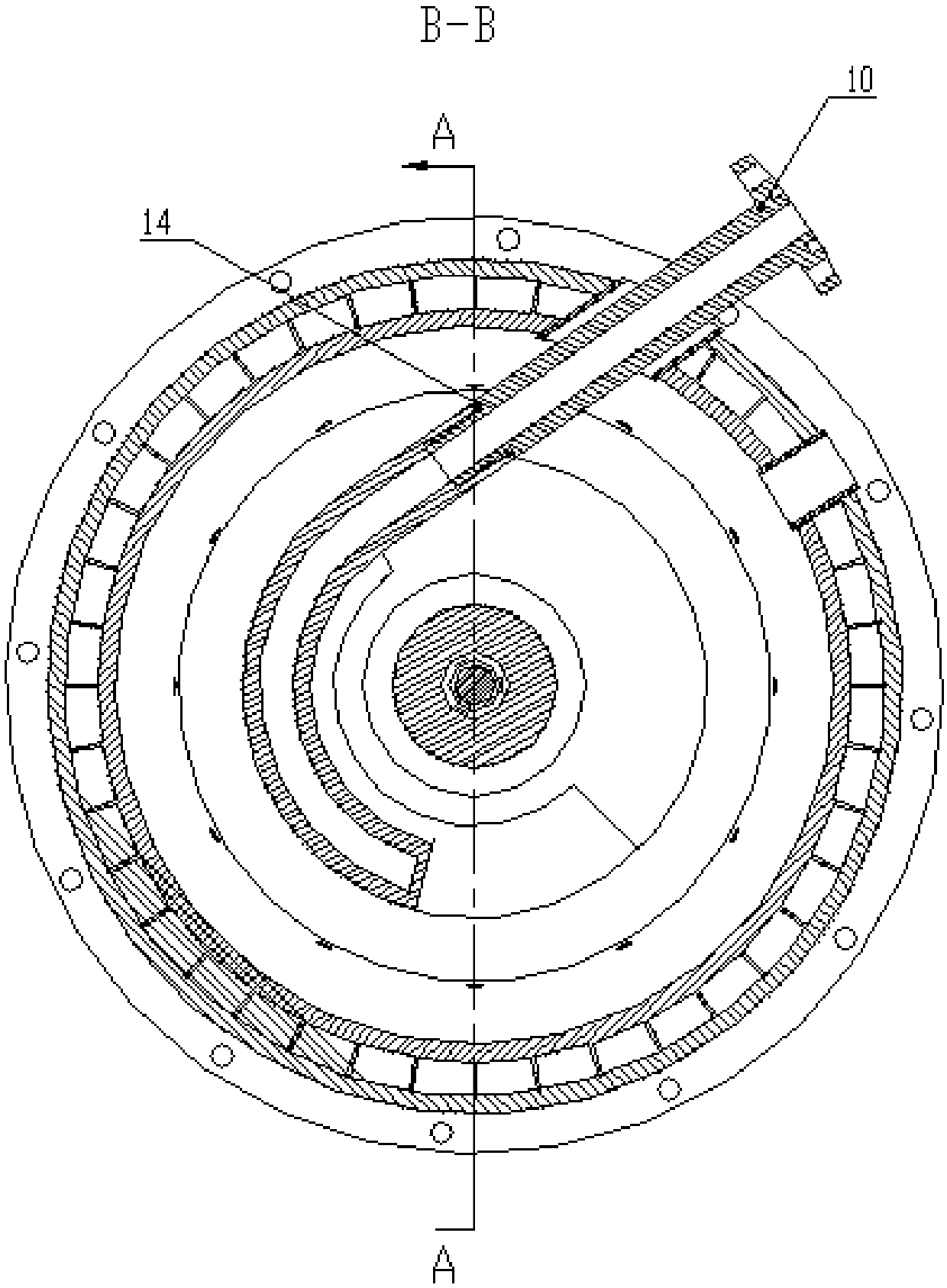

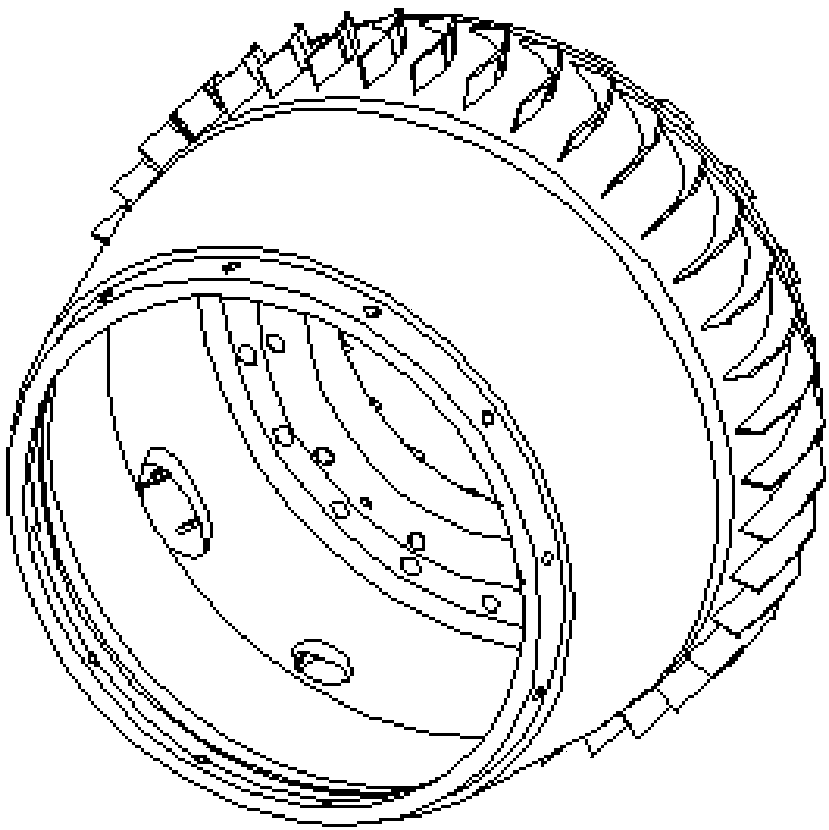

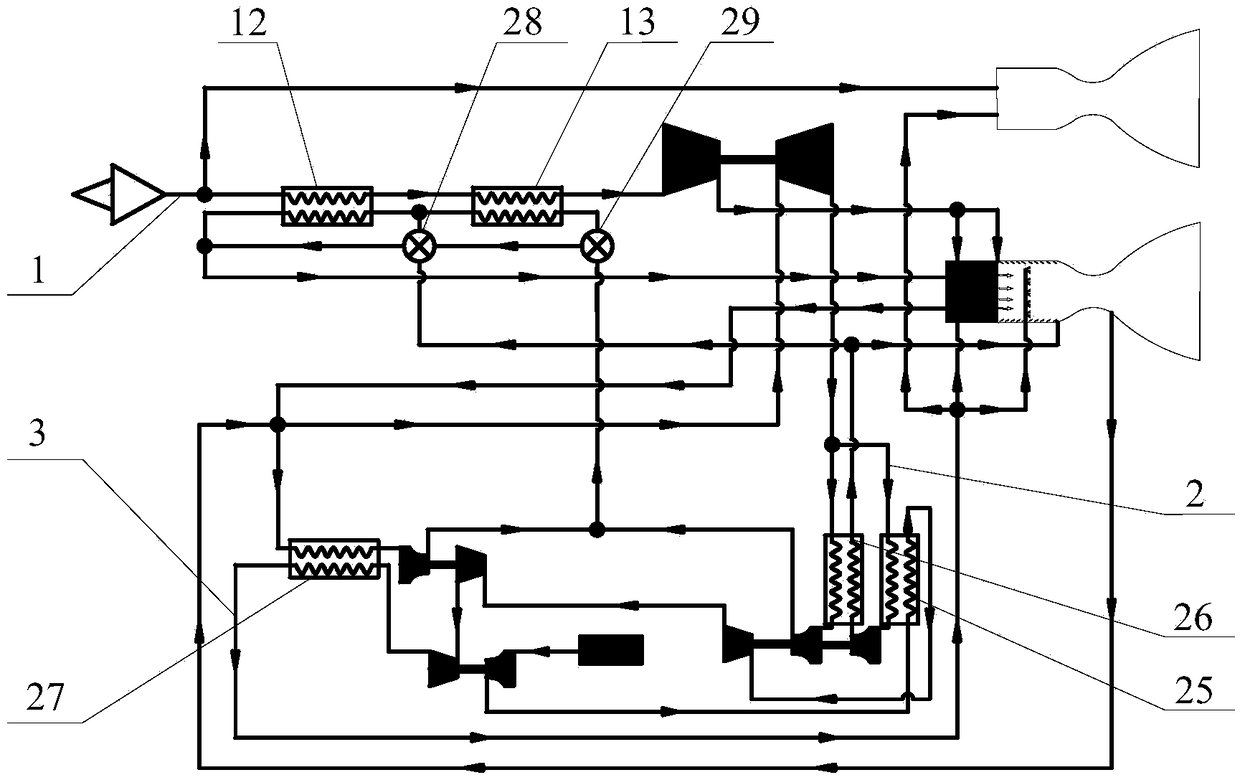

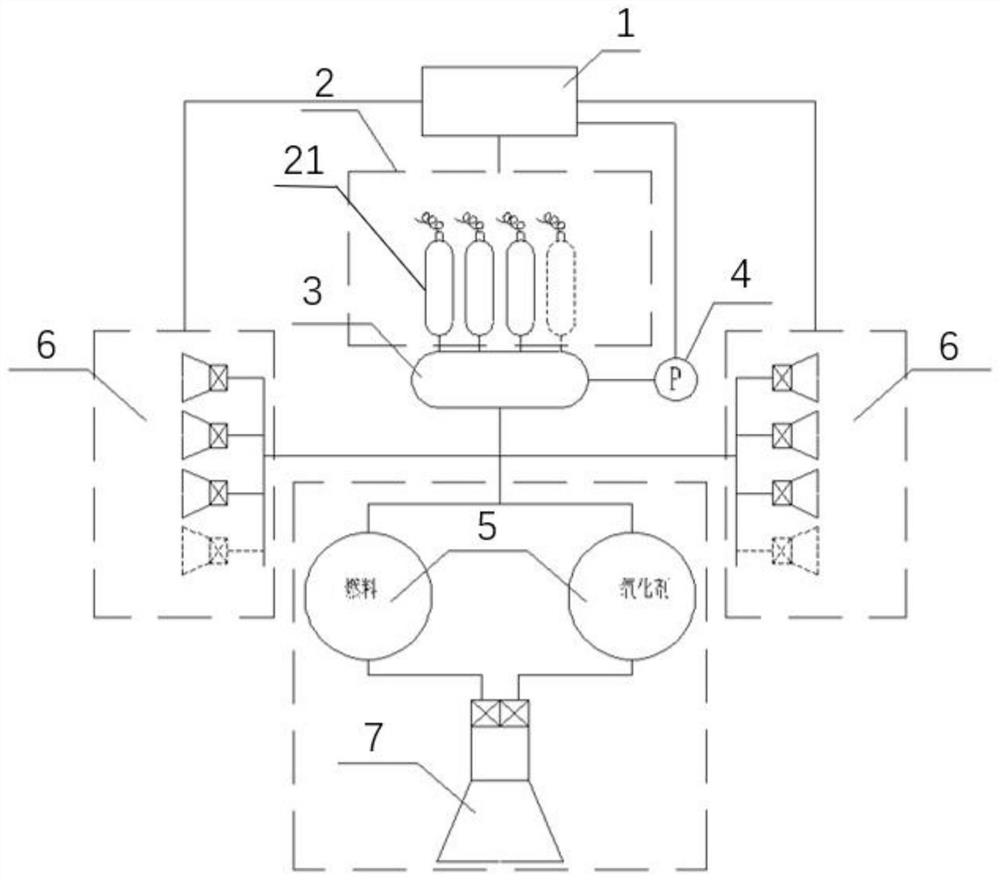

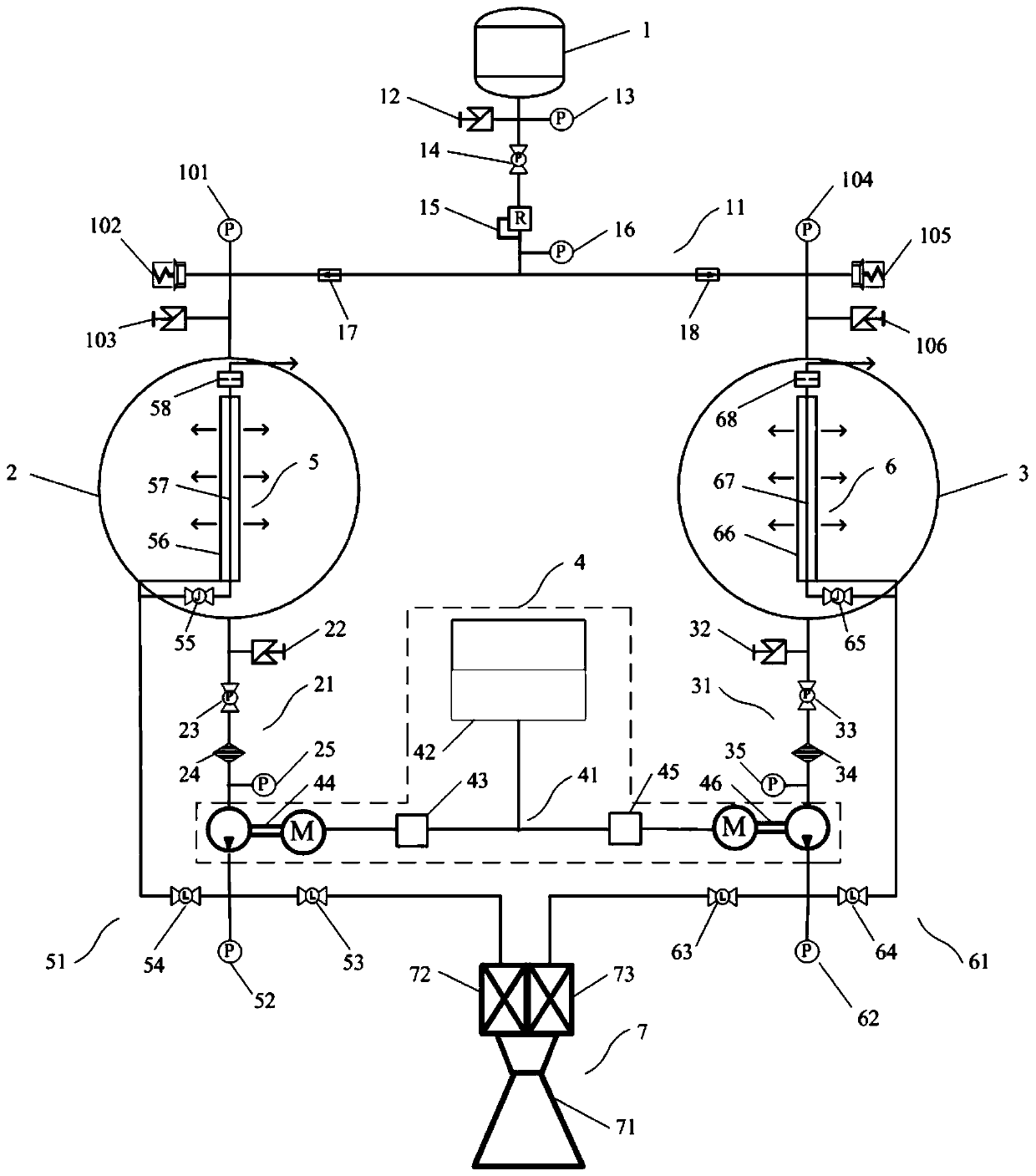

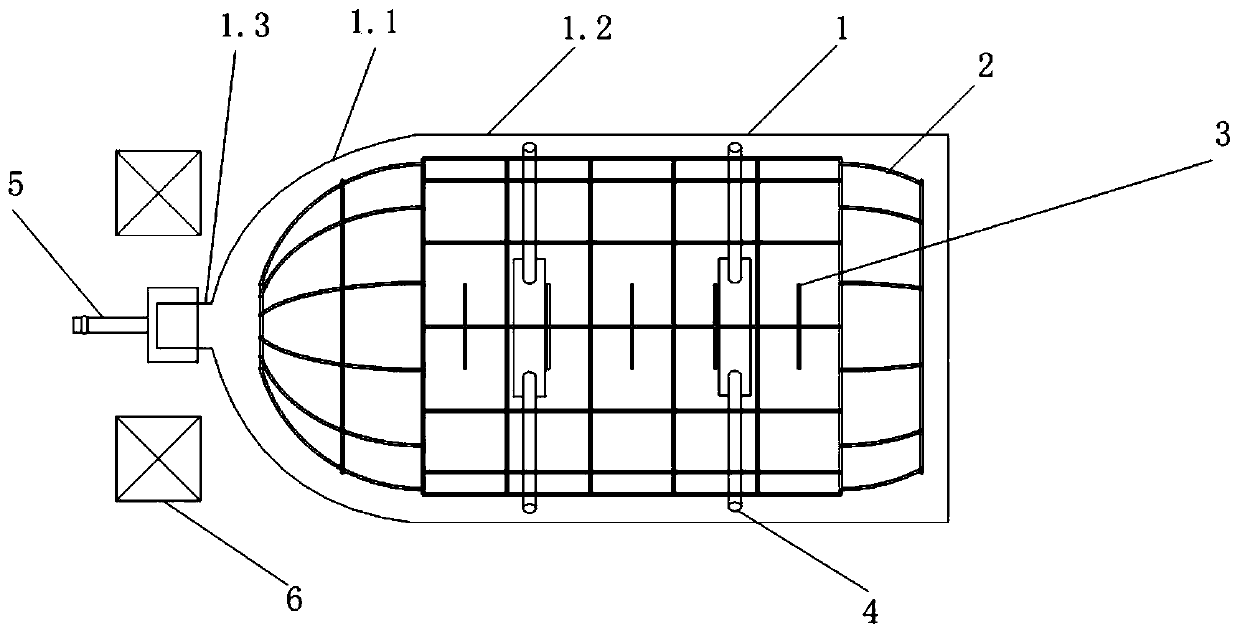

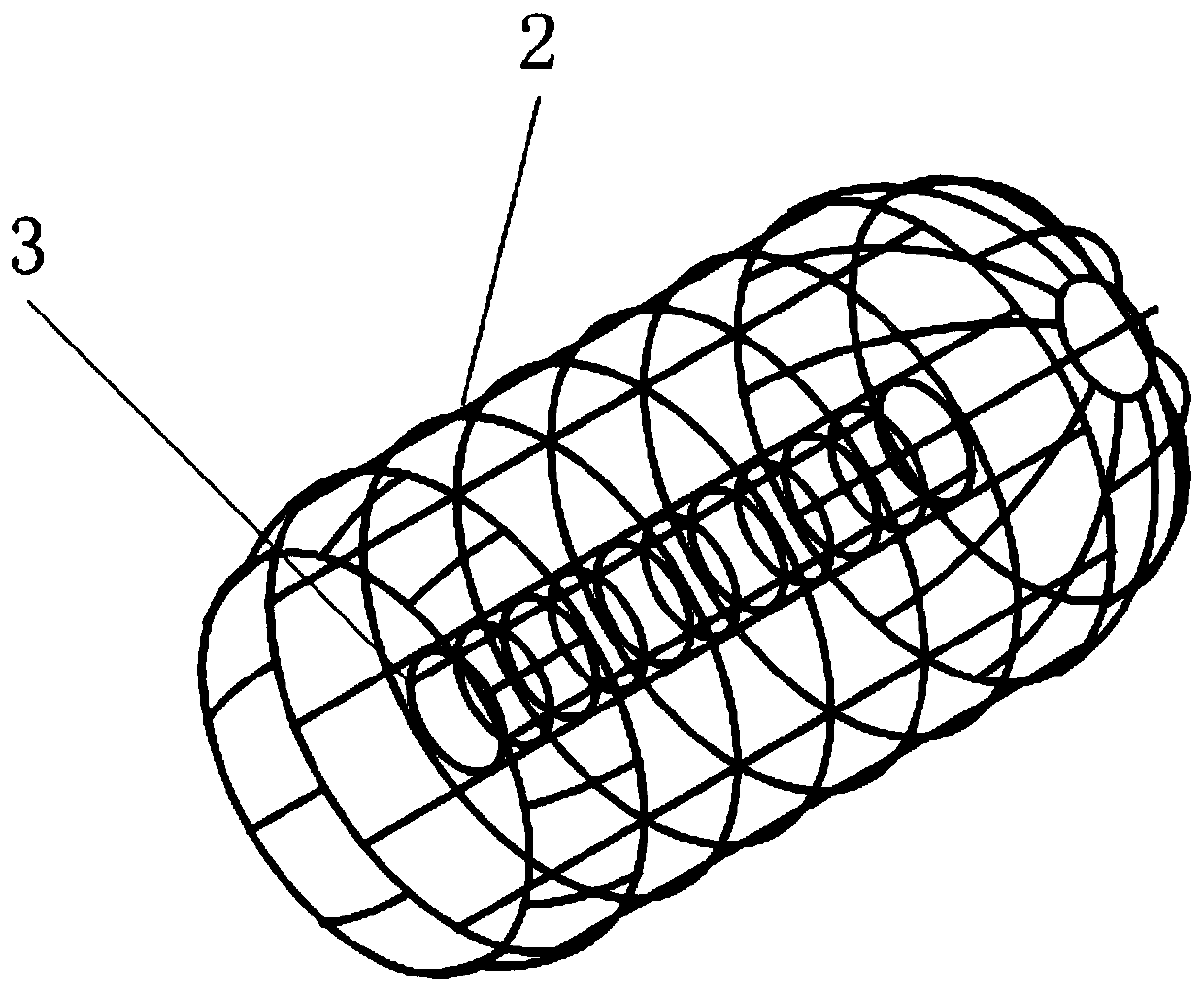

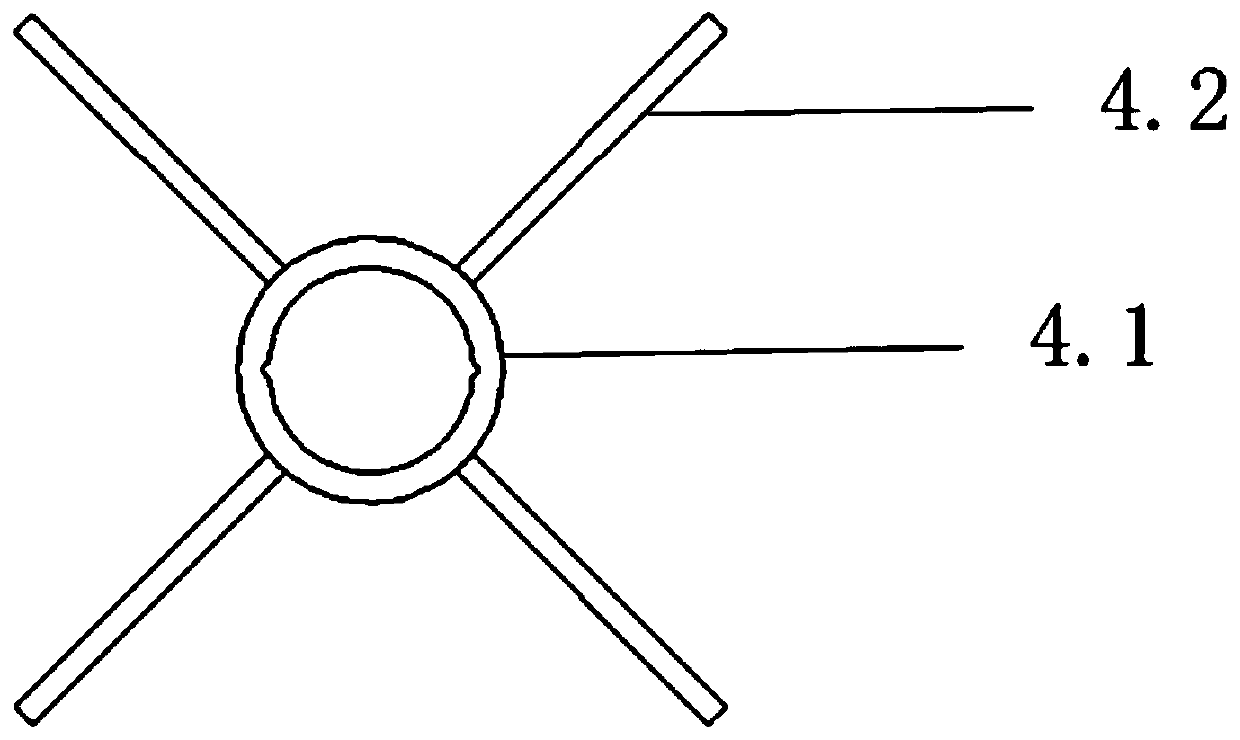

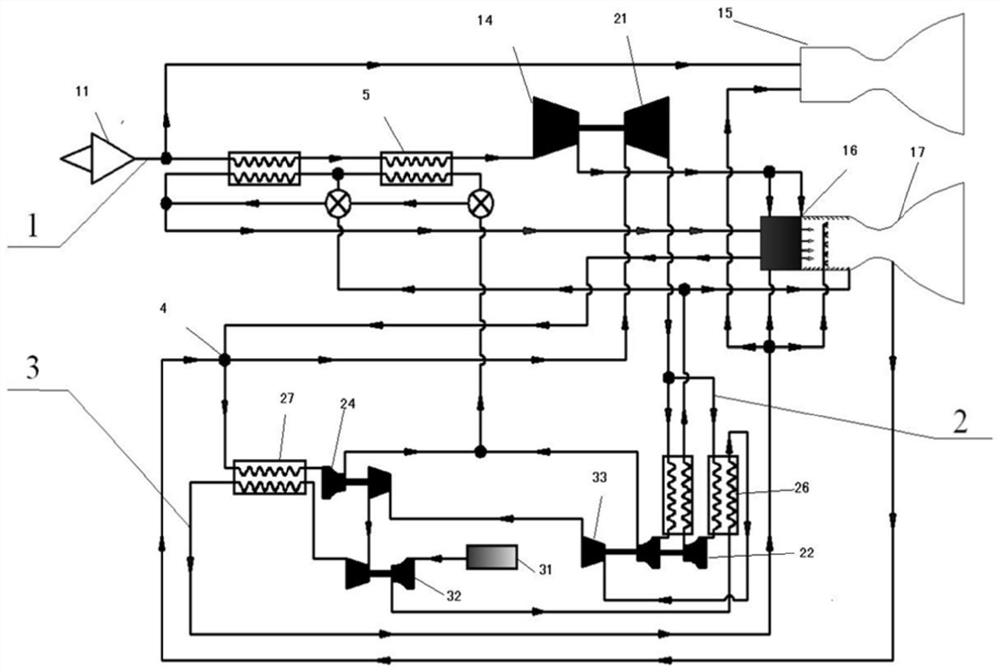

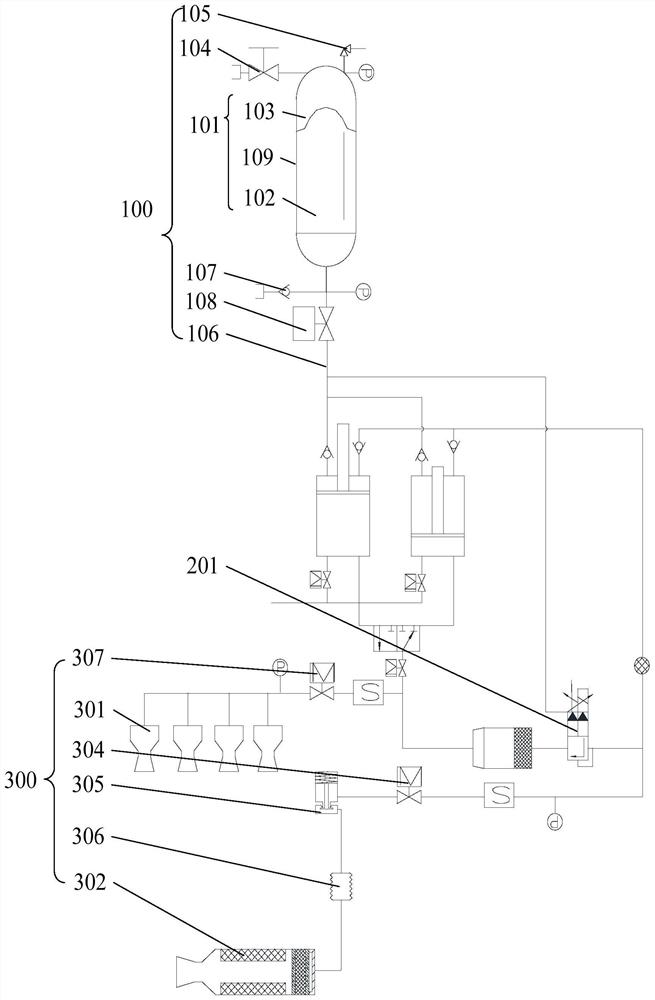

The invention discloses an orbit and attitude control integrated space marching system based on an electric pump. The orbit and attitude control integrated space marching system comprises a high-pressure air bottle, an oxidizing agent storage tank, a fuel storage tank, an electric pump system, an oxidizing agent pressure accumulator, a fuel pressure accumulator, an orbit-control engine and attitude-control engines; the high-pressure air bottle is connected with the oxidizing agent storage tank and the fuel storage tank through a pipeline I, the oxidizing agent storage tank and the fuel storagetank are connected with the electric pump system through a pipeline II and a pipeline III correspondingly, the electric pump system is connected with the orbit-control engine and the oxidizing agentpressure accumulator and the fuel pressure accumulator through a pipeline V and a pipeline VI correspondingly, and the oxidizing agent pressure accumulator and the fuel pressure accumulator are connected with the attitude-control engines through a pipeline VII and a pipeline VIII correspondingly. The electric pump system controls the rotating speed and the lift of a motor pump through an actuator,the pressure and flow of an oxidizing agent and fuel supplied for the engines are controlled, the adjustment is convenient, and the supplying requirements for a propellant of large-range thrust adjustment and multi-time starting and stopping of the orbit-control engine can be met.

Owner:SHANGHAI INST OF SPACE PROPULSION

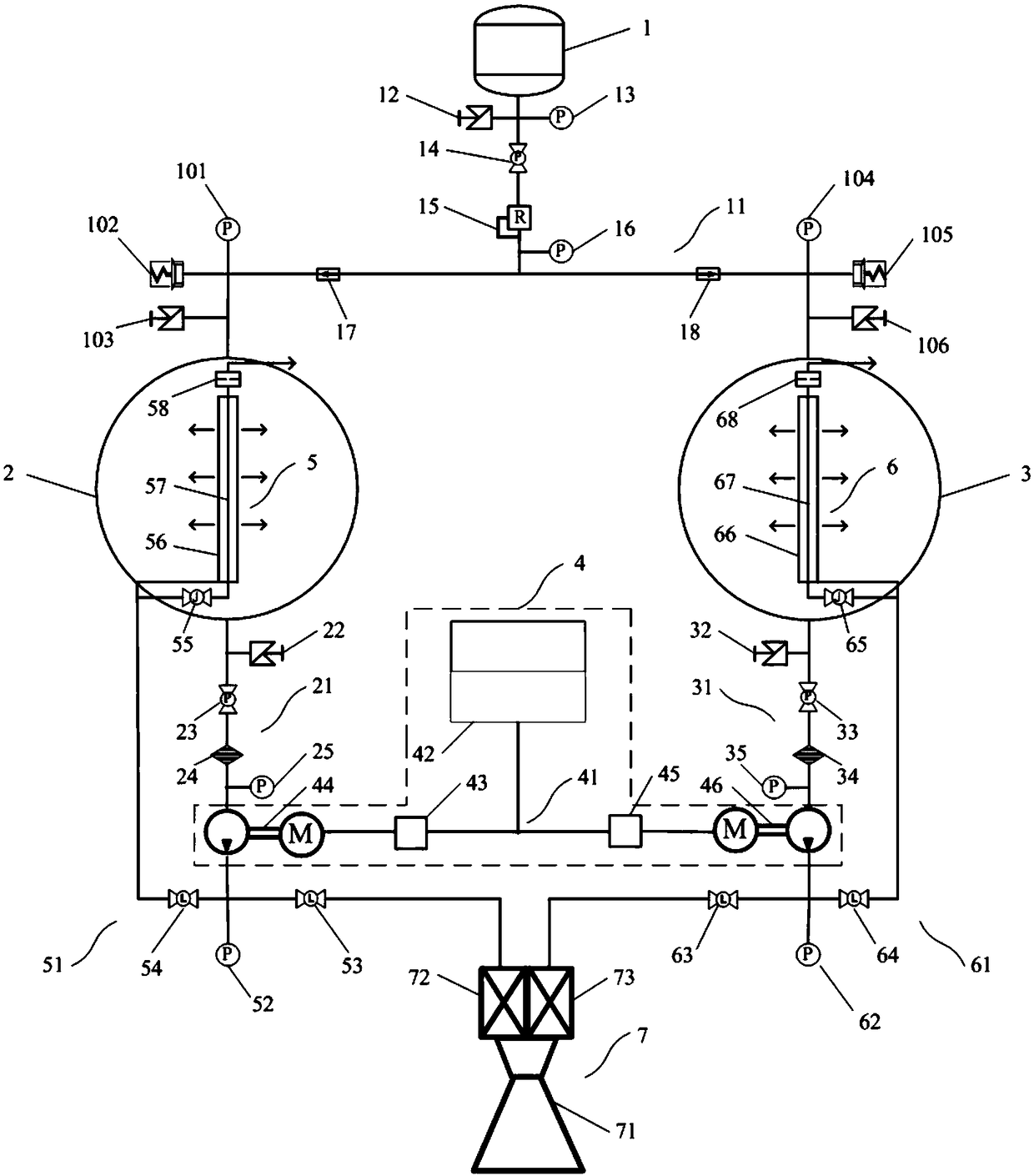

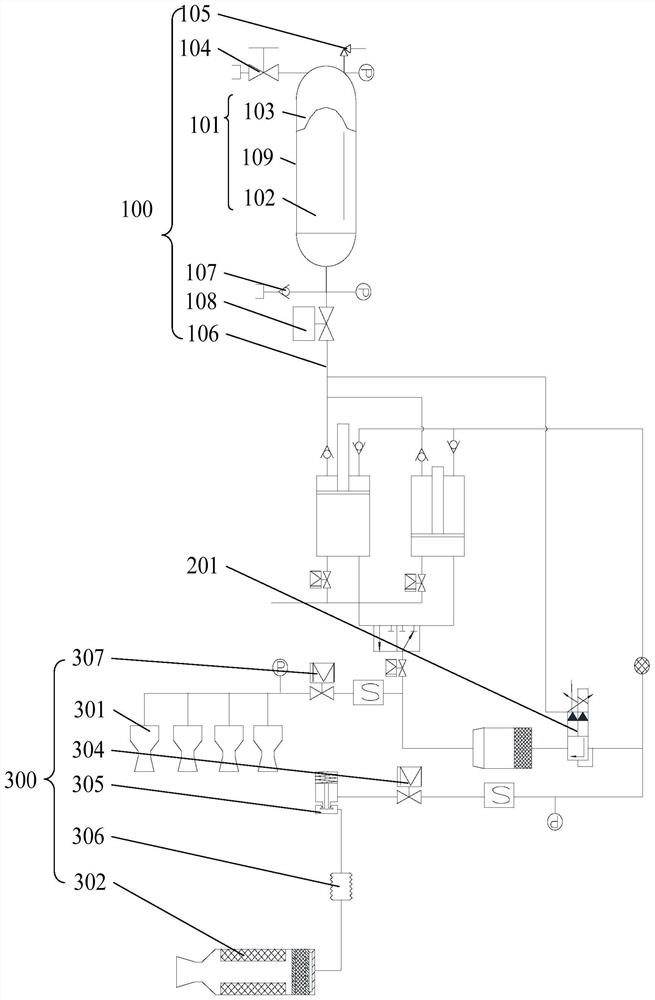

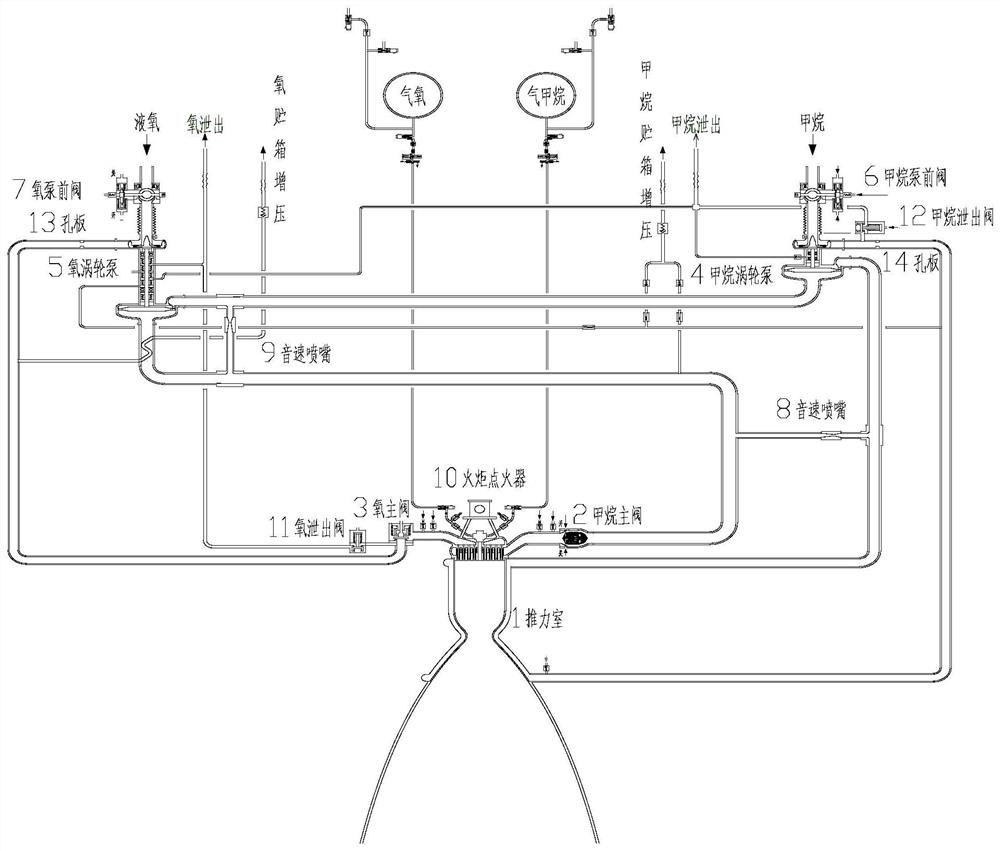

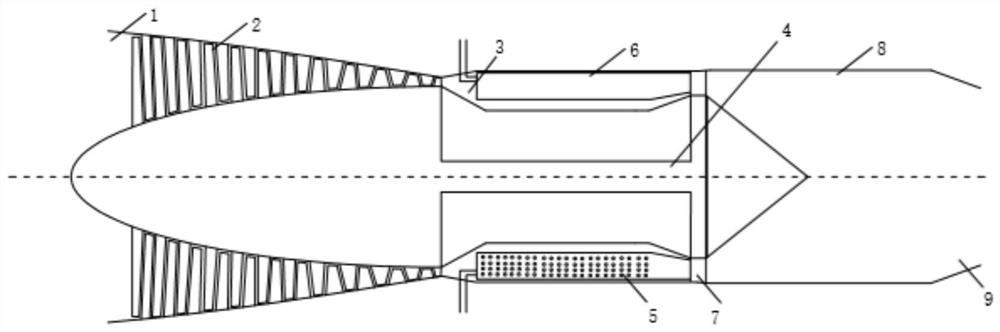

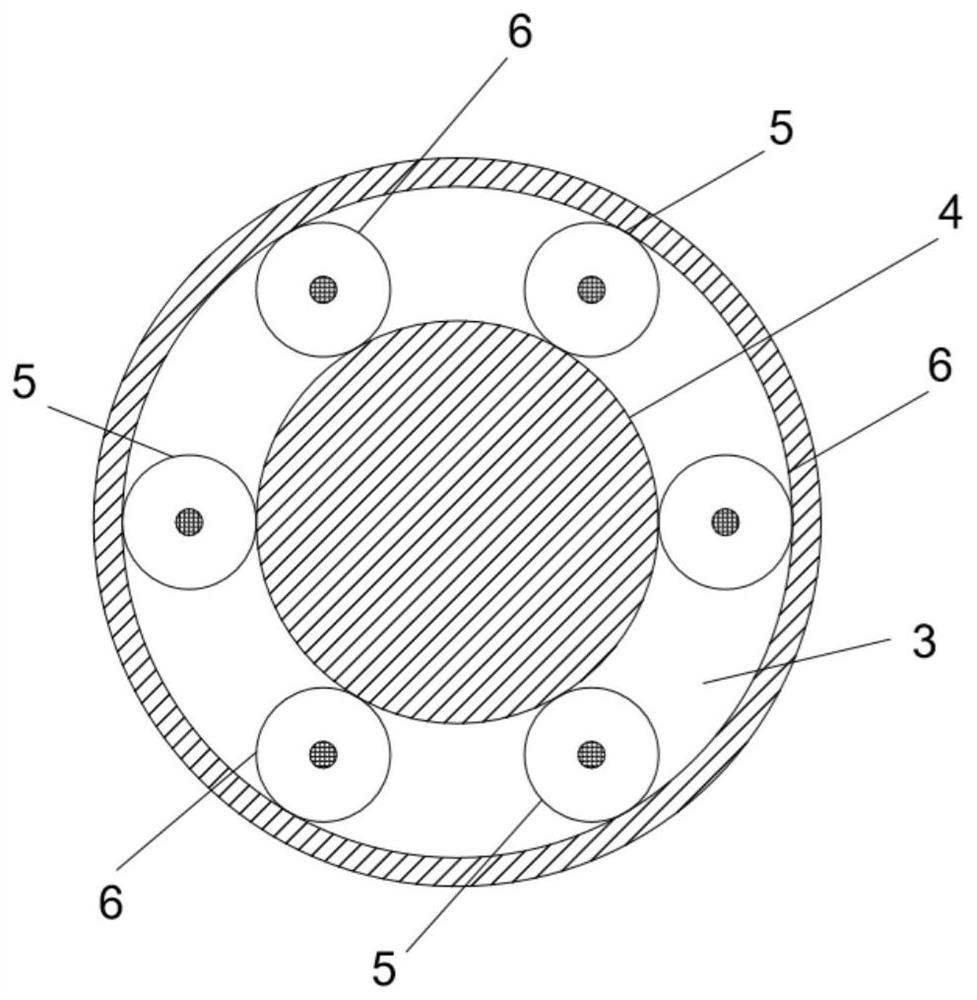

Electric pump pressure type liquid oxygen methane space propelling system

ActiveCN109281774AHigh specific impulse performanceReduce carryCosmonautic vehiclesCosmonautic propulsion system apparatusLiquid oxygenEngineering

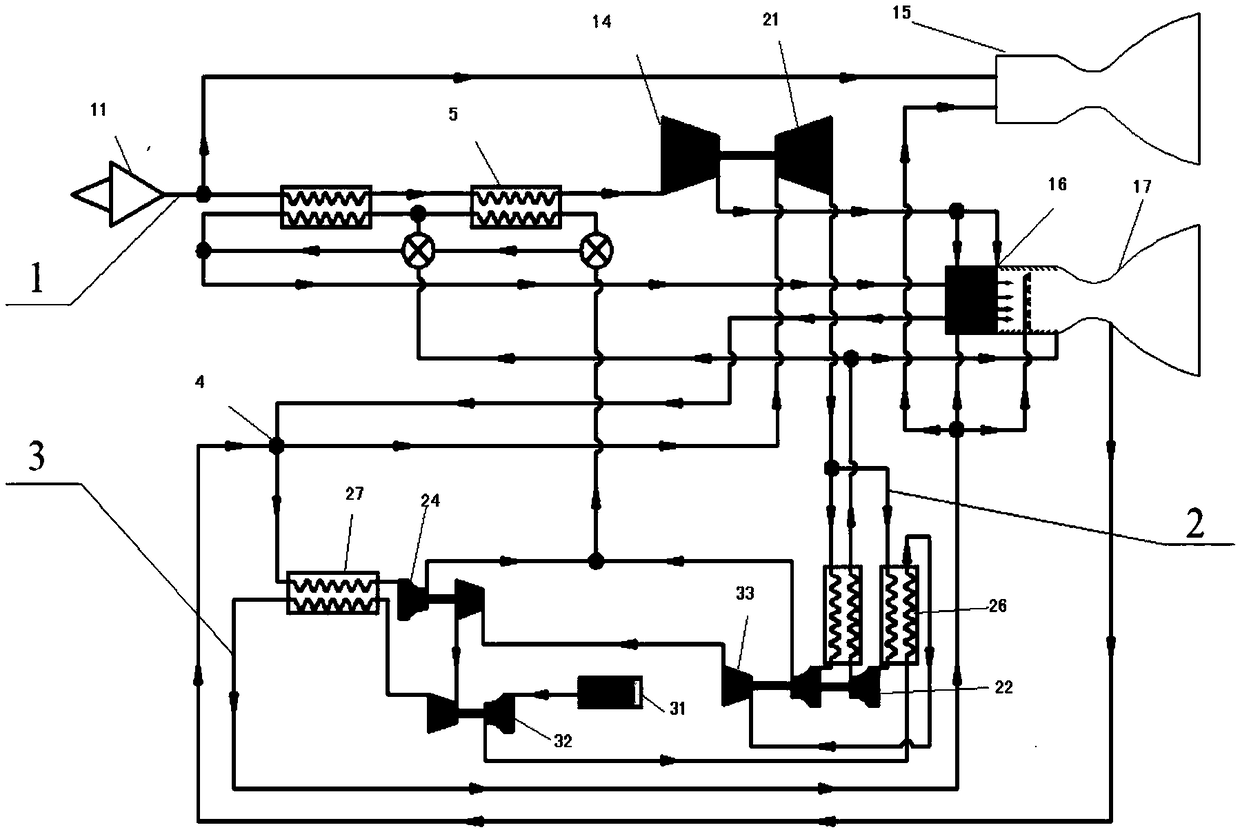

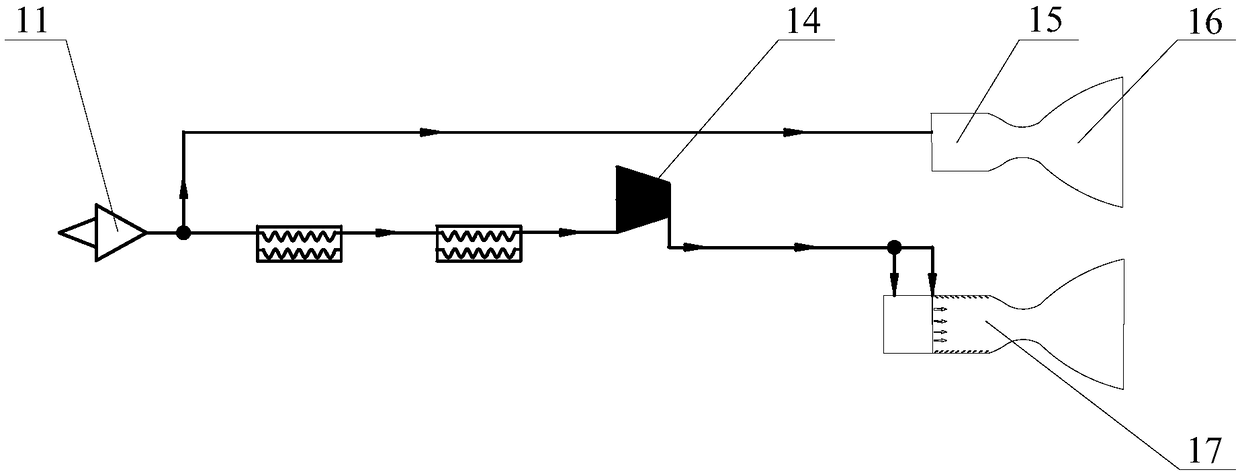

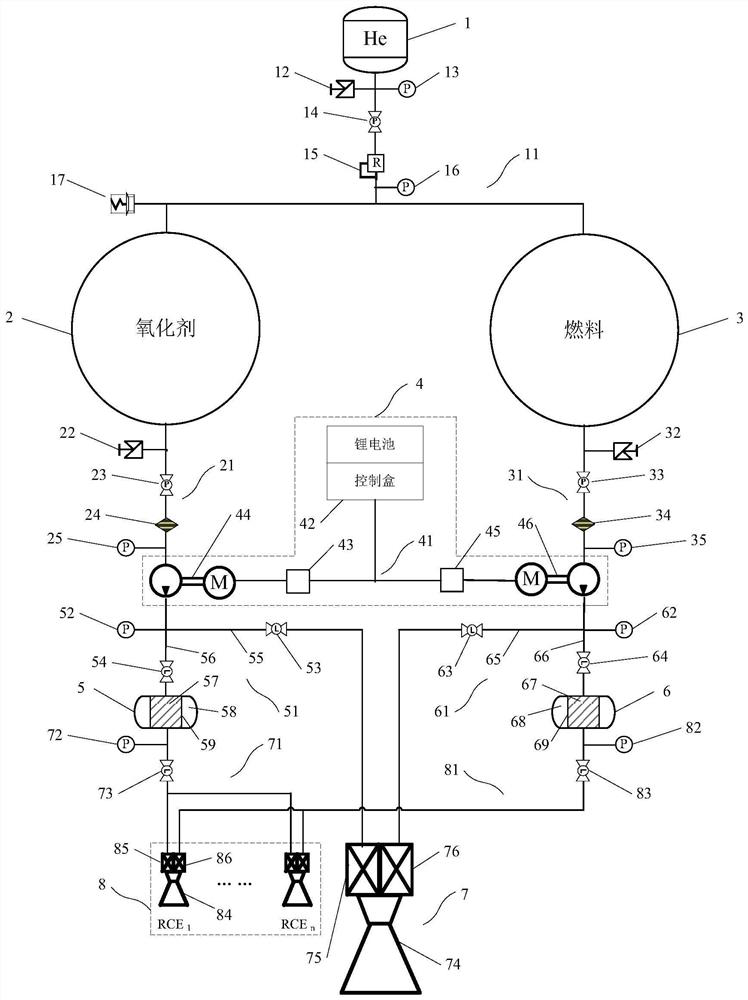

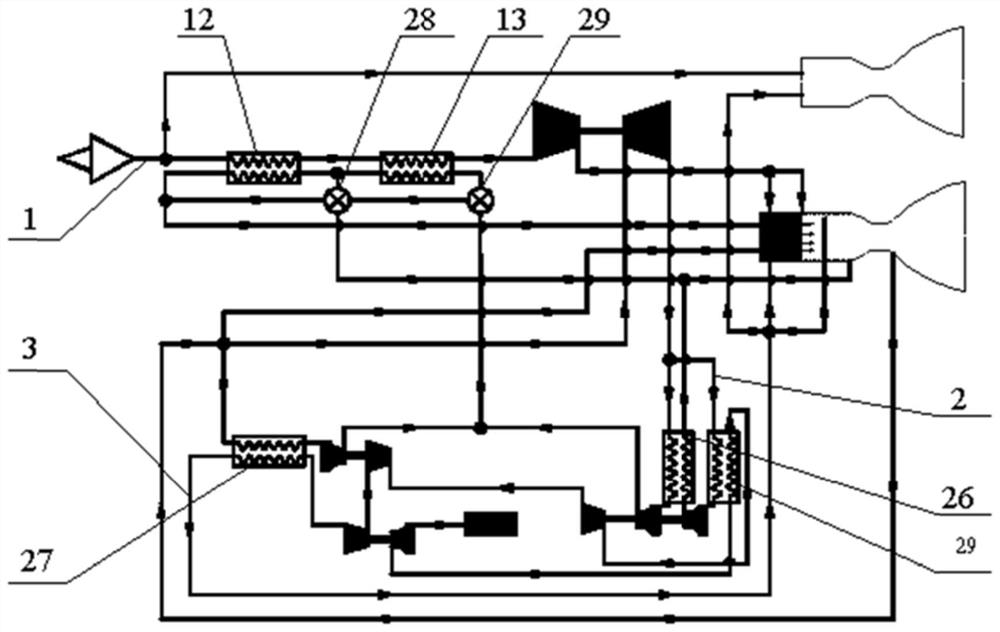

The invention provides an electric pump pressure type liquid oxygen methane space propelling system. The electric pump pressure type liquid oxygen methane space propelling system comprises a high-pressure gas cylinder, a liquid oxygen storage tank, a methane storage tank, an electric pump system, an oxygen heat exchange injection rod, a methane heat exchange injection rod and a track control engine; the high-pressure gas cylinder is connected with the liquid oxygen storage tank and the methane storage tank through a first pipeline; the liquid oxygen storage tank and the methane storage tank are connected with an electric pump system through a second pipeline and a third pipeline; the oxygen heat exchange injection rod is arranged in the liquid oxygen storage tank; the methane heat exchangeinjection rod is arranged in the methane storage tank; the electric pump system is connected with the oxygen heat exchange injection rod and the track control engine through a fourth pipeline; and the electric pump system is connected with the methane heat exchange injection rod and the track control engine through a fifth pipeline. The electric pump pressure type liquid oxygen methane space propelling system is suitable for a space aircraft propulsion system, and particularly has obvious application advantages on a space propelling system which has large propellant filling amount and whose track control engine needs to be started for a plurality of times..

Owner:SHANGHAI INST OF SPACE PROPULSION

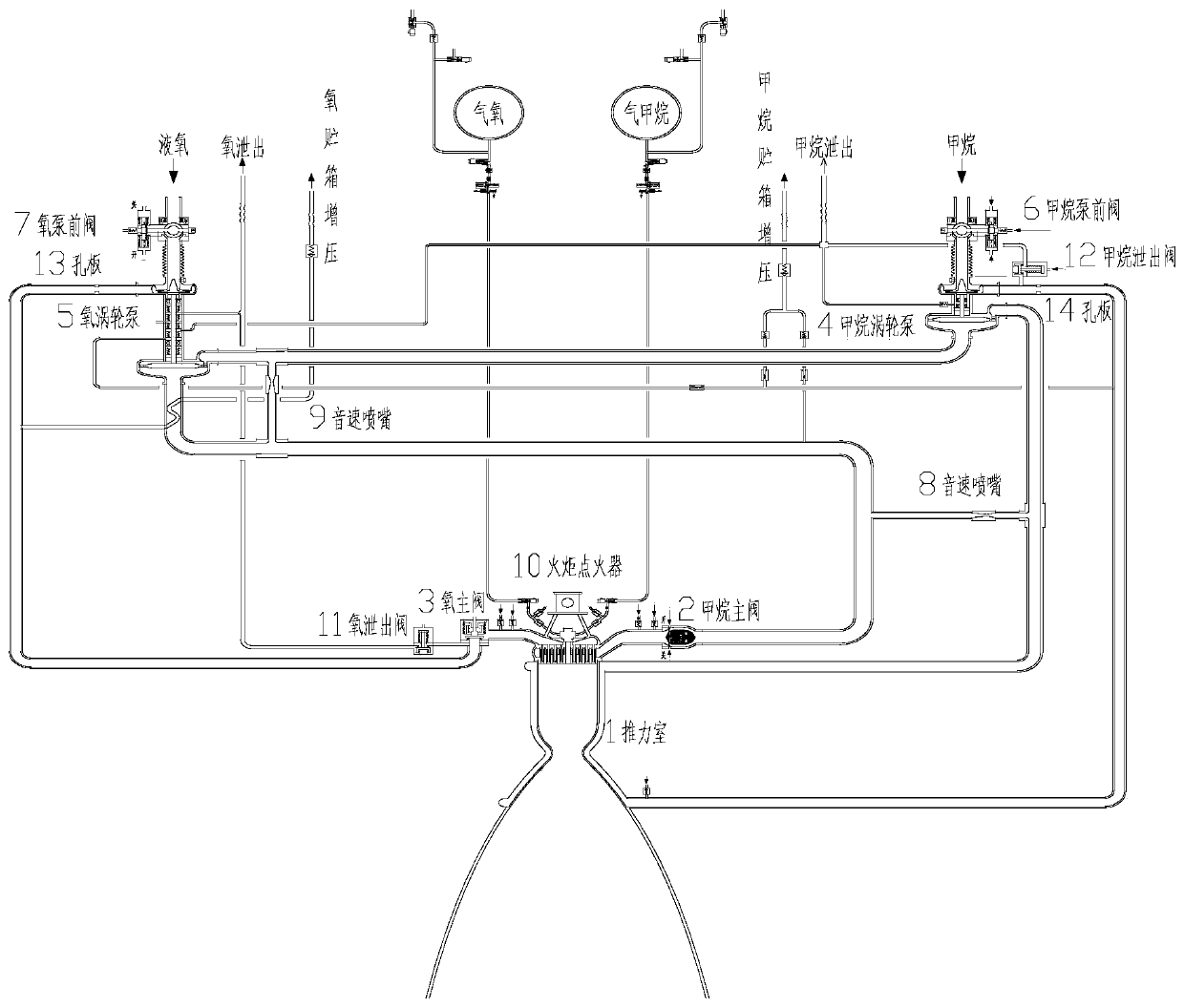

Expansion cycle liquid oxygen and methane upper-stage engine system

ActiveCN111005821ANo pollution in the processEasy to storeRocket engine plantsThrust chamberControl system

An expansion cycle liquid oxygen and methane upper-stage engine system comprises a propellant supply system, an ignition system and a thrust chamber. The propellant supply system comprises a methane supply system and a liquid oxygen supply system, the methane supply system pressurizes low-temperature liquid methane from an external storage tank and then supplies the low-temperature liquid methaneto the thrust chamber; the liquid oxygen supply system pressurizes the low-temperature liquid oxygen from the external storage tank and then supplies the low-temperature liquid oxygen to the thrust chamber; and the ignition system is located at the head of the thrust chamber and ignites under the control of a control system, liquid oxygen and methane entering the thrust chamber are ignited, and generated high-temperature gas is sprayed out of the nozzle of the thrust chamber to generate thrust force. The liquid oxygen and liquid methane are used as a propellant combination, and a closed expansion circulation system scheme is adopted, so the system is simple, the inherent reliability is high, the specific impulse performance is high, and repeated starting is easy to achieve.

Owner:BEIJING AEROSPACE PROPULSION INST

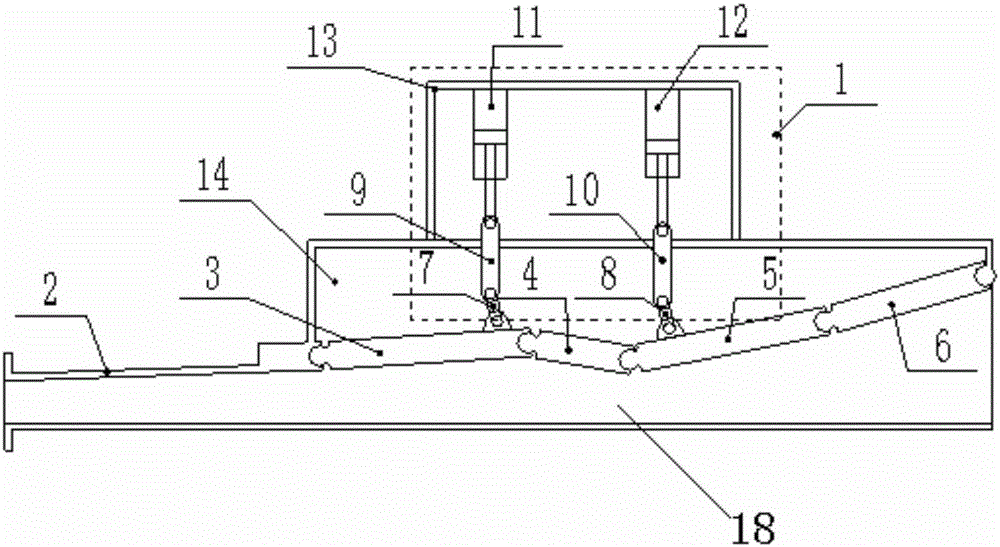

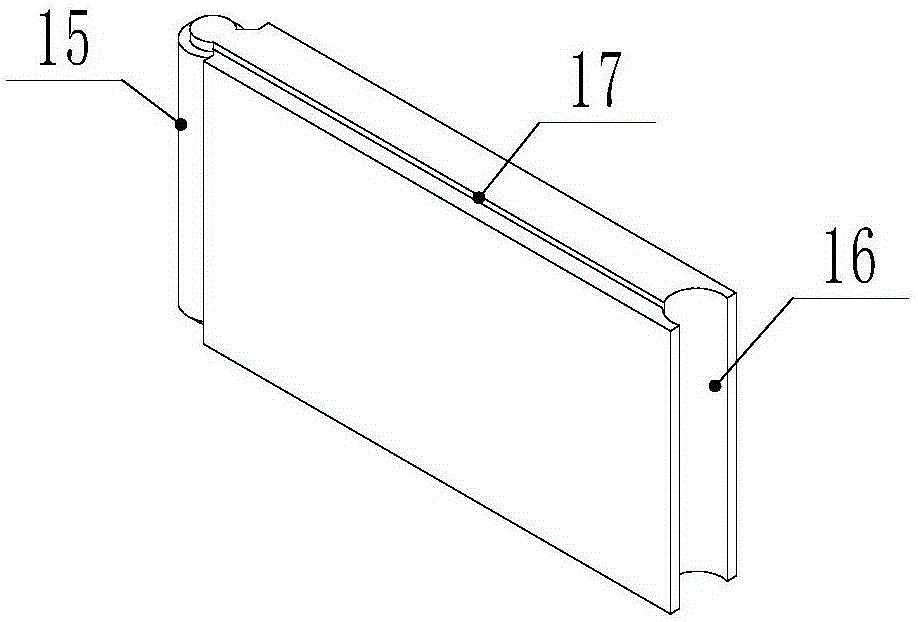

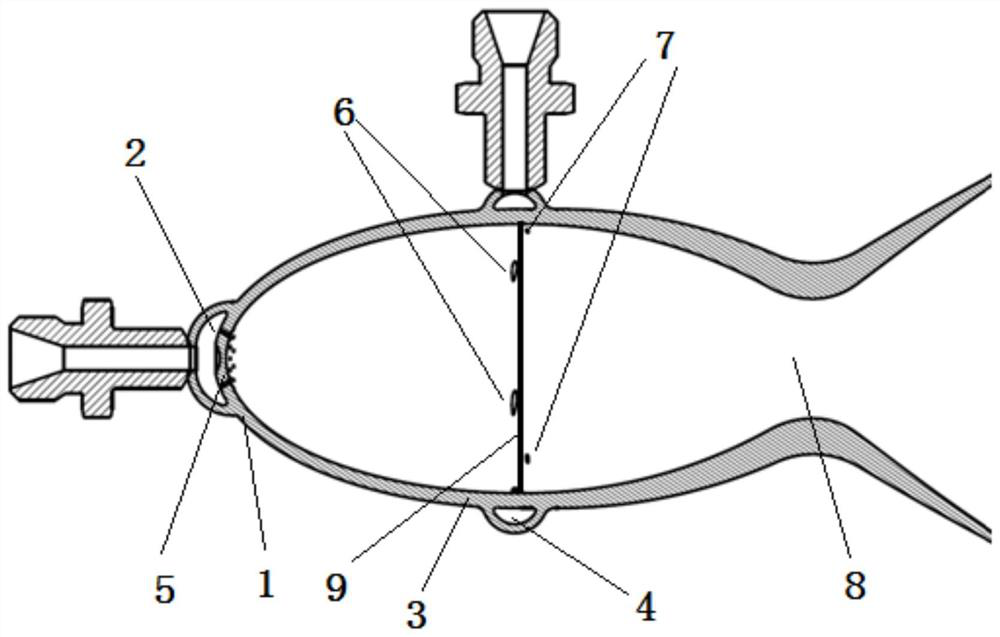

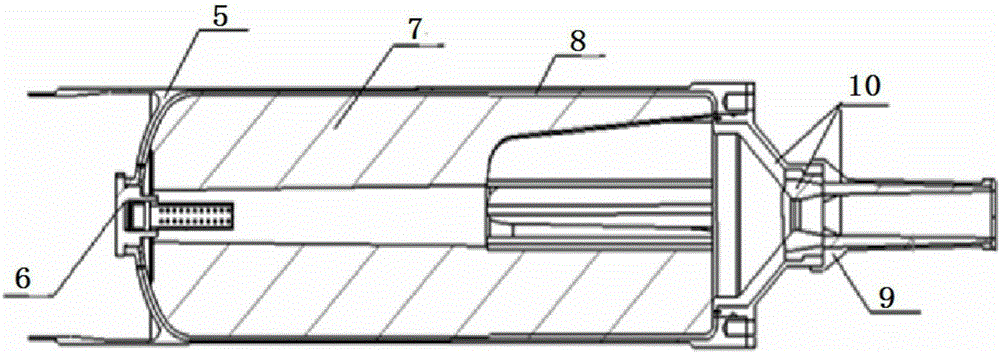

Sample machine on basis of principle of nitrous oxide mono-component thruster and use method thereof

The invention relates to a sample machine on the basis of the principle of a nitrous oxide mono-component thruster and a use method thereof. The invention utilizes the characteristics of the nitrous oxide gas such as no toxicity, no pollution, high catalytic decomposition temperature and capability of self-maintaining decomposition reaction, and applies the nitrous oxide gas in the propulsion field of aerospace micro-satellites. Compared with the existing commonly-used hydrazine mono-component thruster, the invention can effectively reduce the risk and cost of land disposal with a propellant, and also can realize higher specific impulse performance compared with the cold gas thruster. The invention can conduct principle demonstration verification for mono-component thruster adopting the nitrous oxide as the propellant, and provide technical support for research and development of a non-toxic micro-thruster applied in posture control of the micro-satellite.

Owner:BEIHANG UNIV

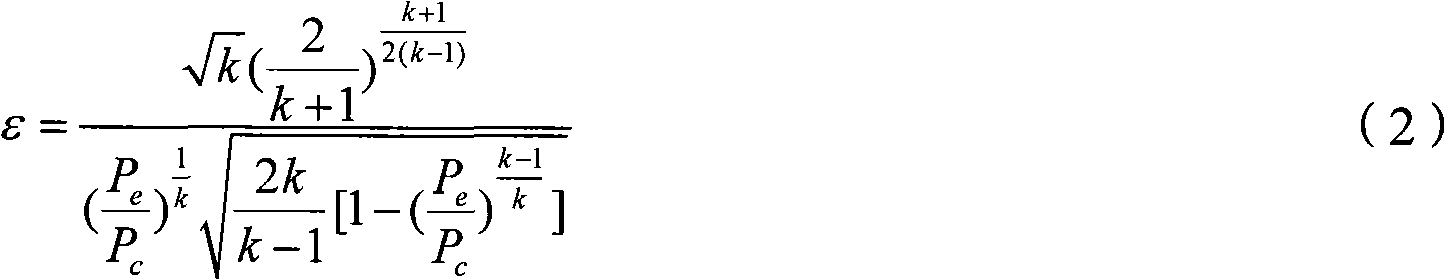

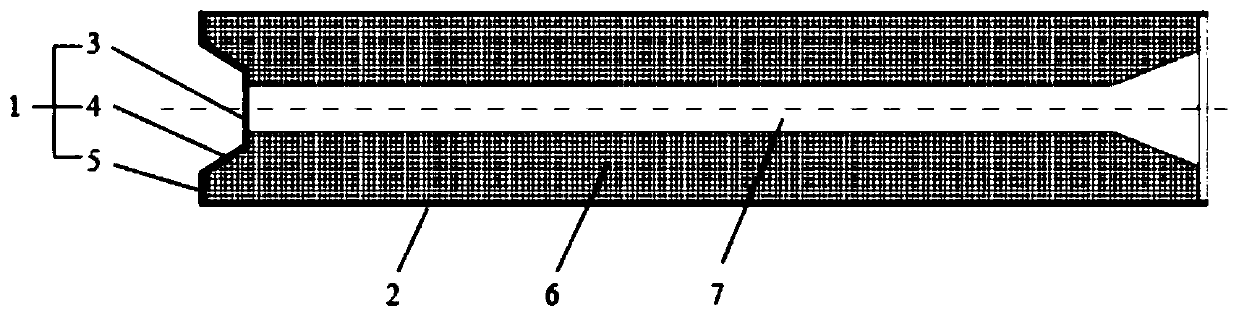

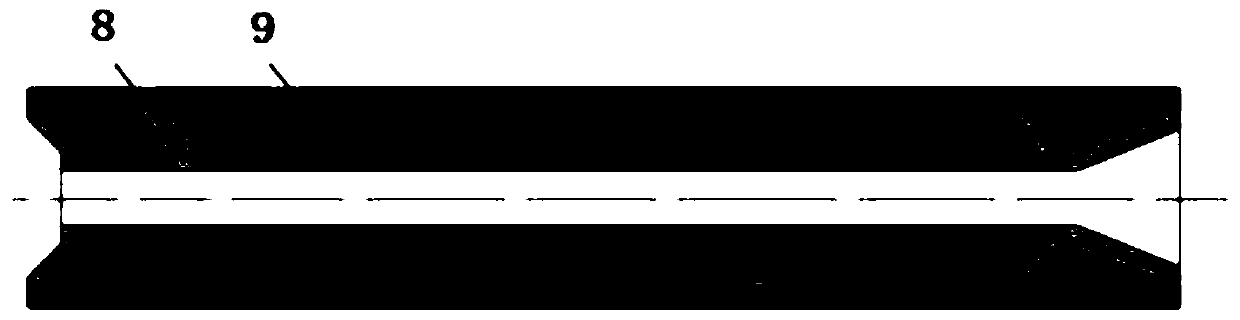

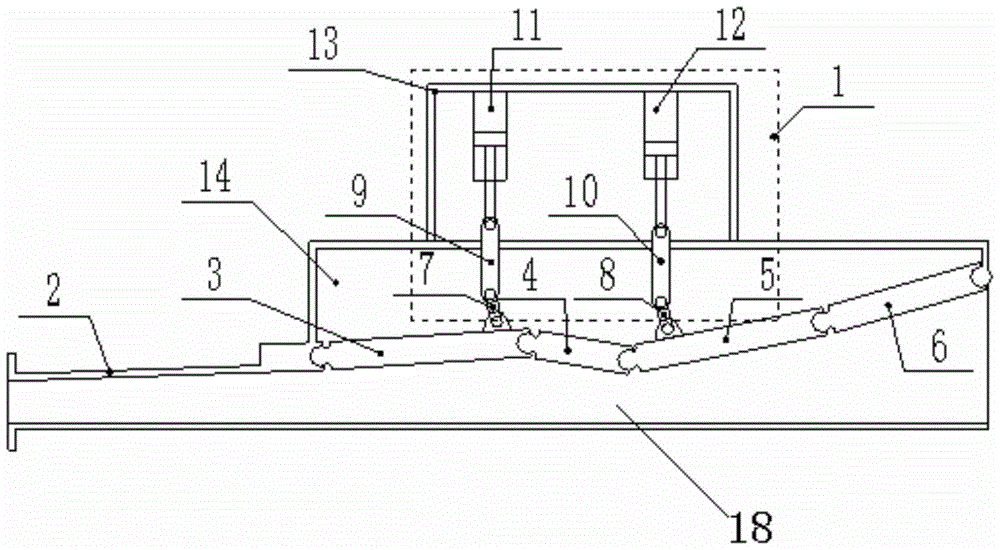

Variable structure combustion chamber of rocket-based-combined-cycle engine

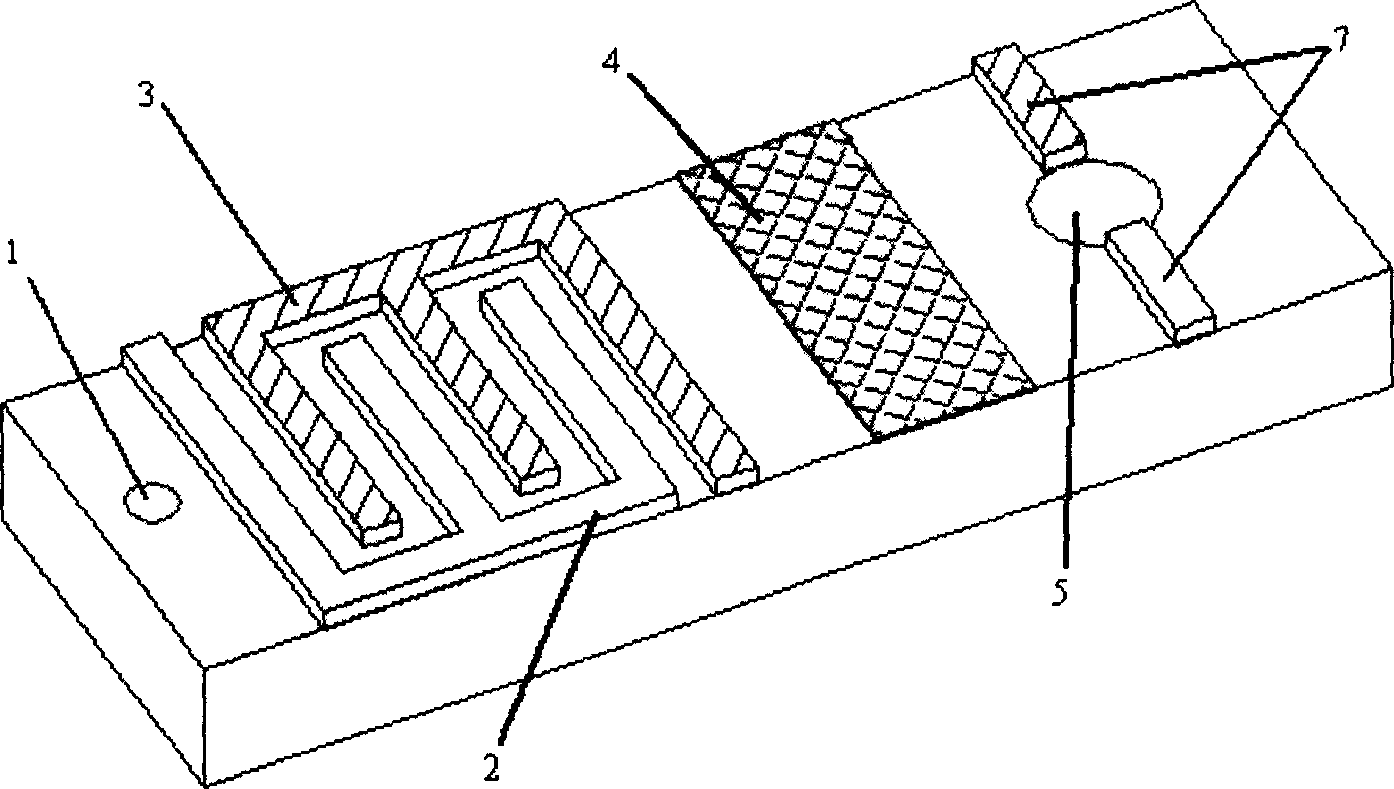

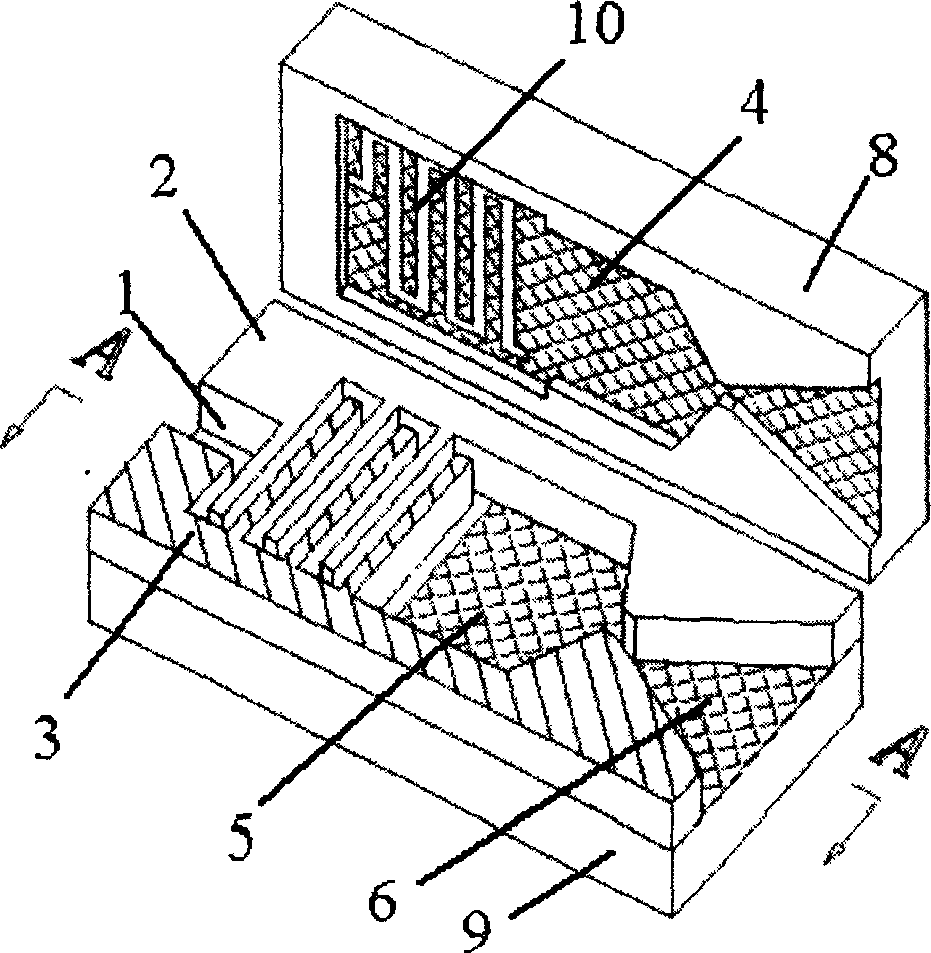

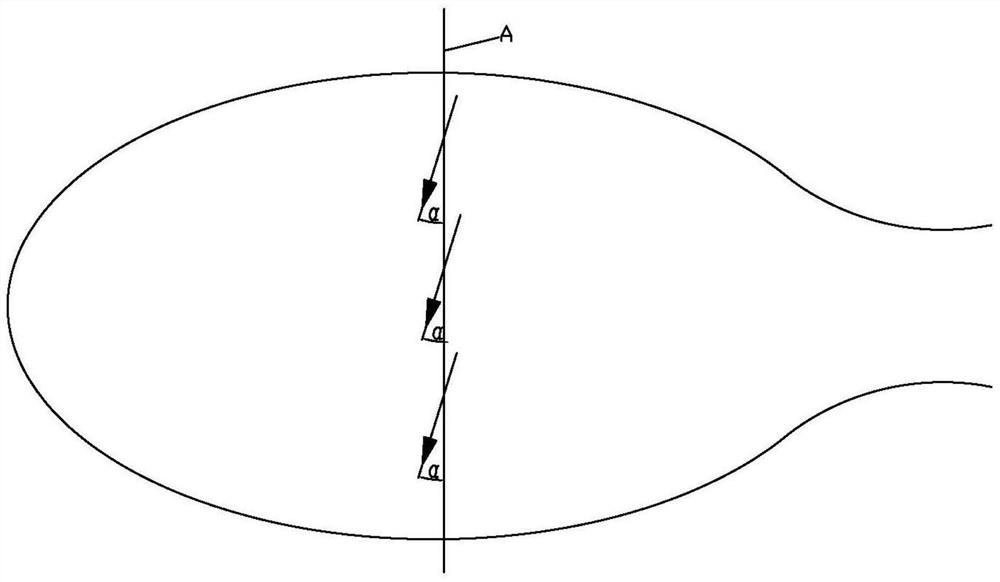

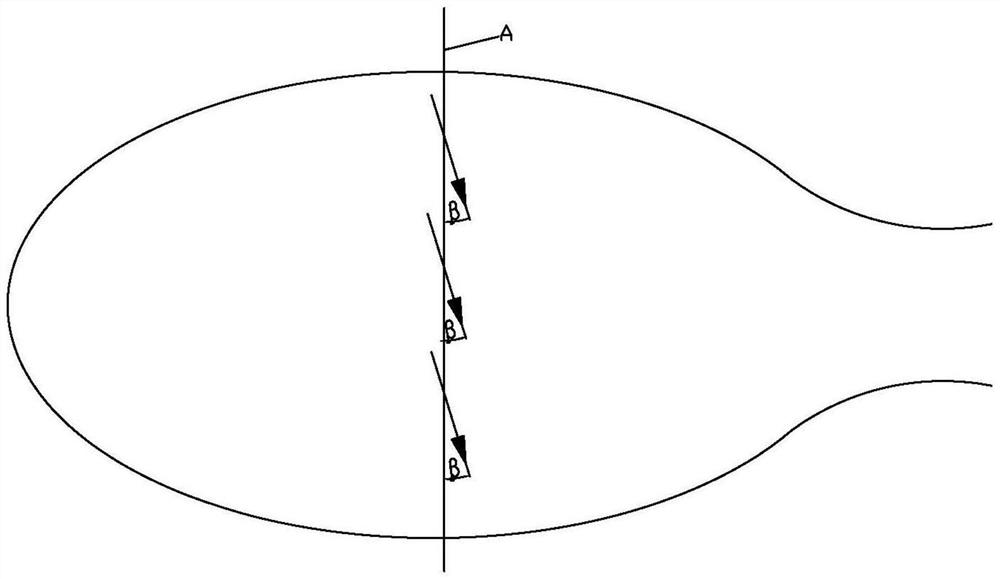

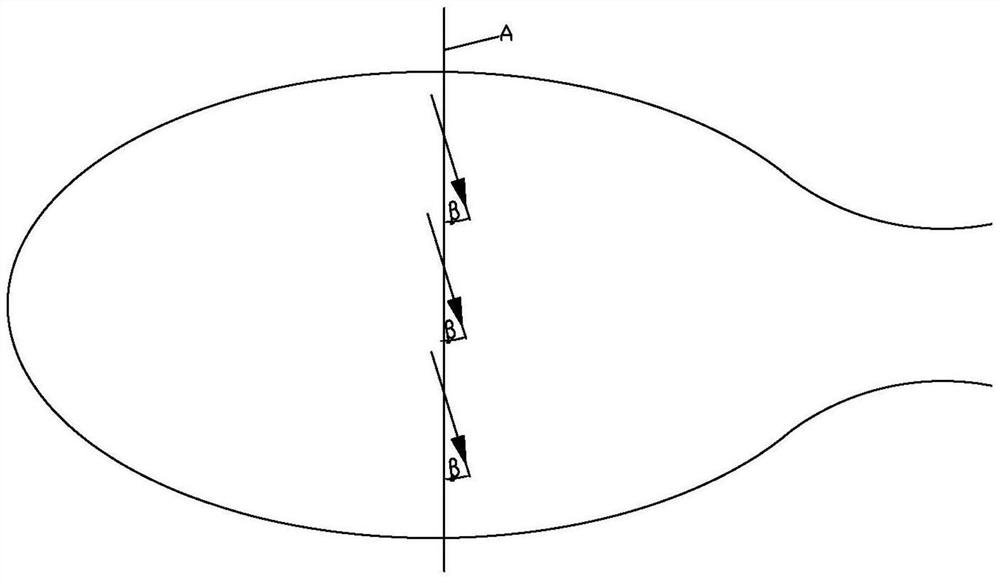

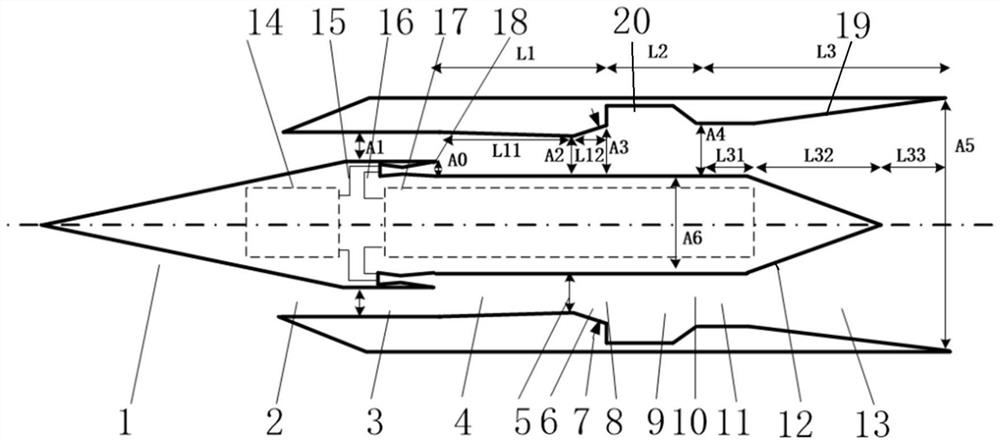

InactiveCN105240160AIncrease thrustHigh specific impulse performanceRocket engine plantsCombustion chamberDivergence angle

The invention discloses a variable structure combustion chamber of a rocket-based-combined-cycle engine. The variable structure combustion chamber is composed of a drive system, a back pressure cavity and a combustion chamber body. The drive system is located at the upper portion of the back pressure cavity. The back pressure cavity is fixed to the portion above variable sections of the combustion chamber body and forms an integral structure with the combustion chamber body. A combustion chamber fixed section is sequentially connected with variable sections of the combustion chamber body. The variable sections are connected through cooperation of ball head hinge convex faces and ball head hinge concave faces. Two sets of hydraulic drive mechanisms drive the first variable section and the third variable section of the combustion chamber body through drive rods and connecting rods. Axial sealing grooves of the variable sections are filled with graphite strips so as to isolate high-temperature fuel gas in the combustion chamber body, and sealing is guaranteed. According to the variable structure combustion chamber, stable transition among different modes is achieved through grade adjustment. In the injection mode and the subsonic combustion mode, the variable sections of the combustion chamber body are adjusted by a hydraulic drive mechanism to generate different divergence angles and throat heights, so that the combustion chamber body is in the optimal work state, and the thrusting force and specific impulse performance of the combustion chamber body are obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

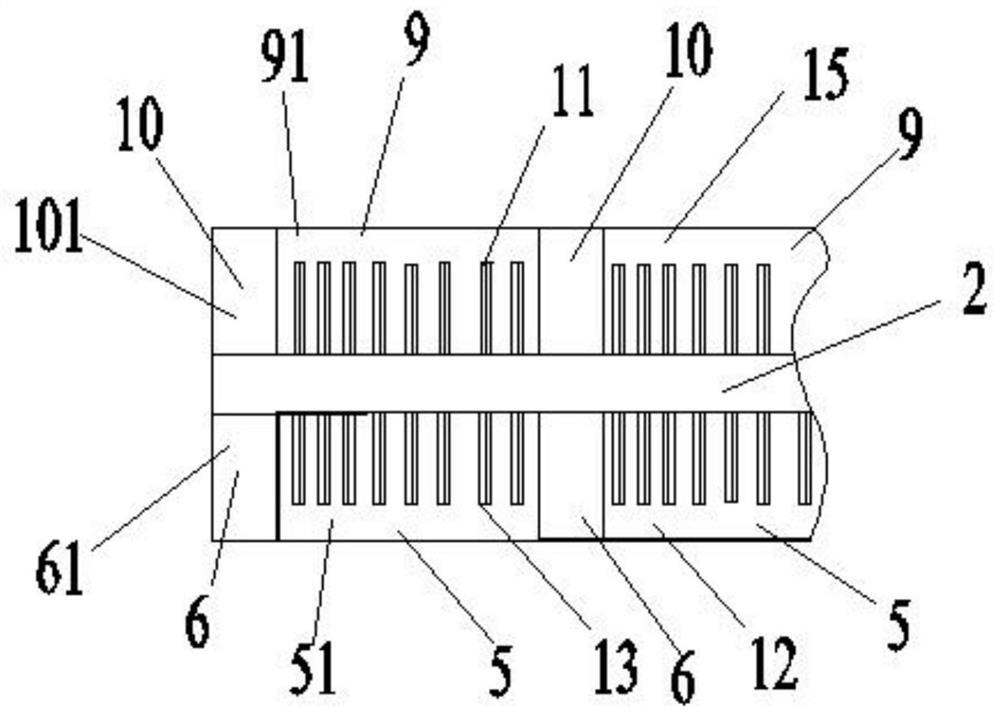

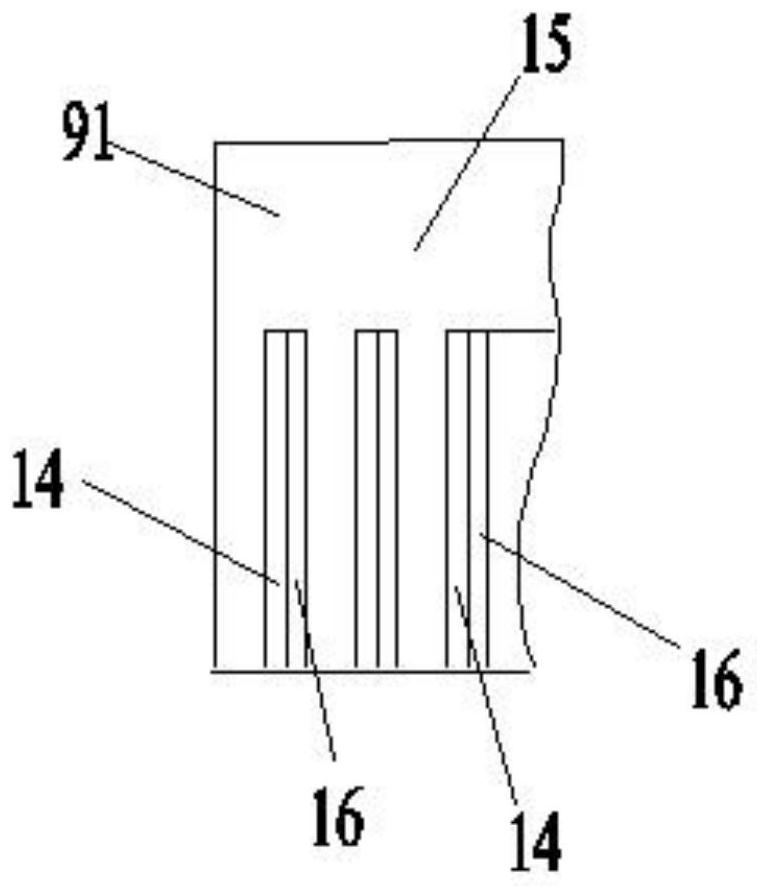

Novel high-pressure ratio large-flow turbocharging device for air turbine rockets

InactiveCN109723576AIncrease thrustHigh specific impulse performanceLeakage preventionRocket engine plantsImpellerHigh pressure

The invention belongs to the technical field of air turbine rocket combined engines, and particularly relates to a novel high-pressure ratio large-flow turbocharging device for air turbine rockets. When the novel high-pressure ratio large-flow turbocharging device for the air turbine rockets works, the fuel gas generated by a fuel gas generator is discharged through a convergent-divergent type drilling hole inclined nozzle to drive a symmetrical blade type pure impact turbine to rotate, and a working wheel drives a compressor impeller to pressurize the incoming flow air in an axial air inlet;and then the air flows through a diffuser in a compressor shell assembly, and the direction of the air is changed from radial direction to axial direction by a turning section in the outer wall of thediffuser, and finally the air flow is rectified by a flow-guiding cascade in the diffuser. The air flow discharged from the turbine working wheel and the compressor flow-guiding cascade is mixed andcombusted behind the turbo charger. The novel high-pressure ratio large-flow turbocharging device for the air turbine rockets provides a core power device capable of generating large thrust and high specific impulse performance for the air turbine rocket combined engines.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Novel pre-cooling air combined engine

ActiveCN109372657AReduce consumption rateAvoid wastingRocket engine plantsLiquid hydrogenPre cooling

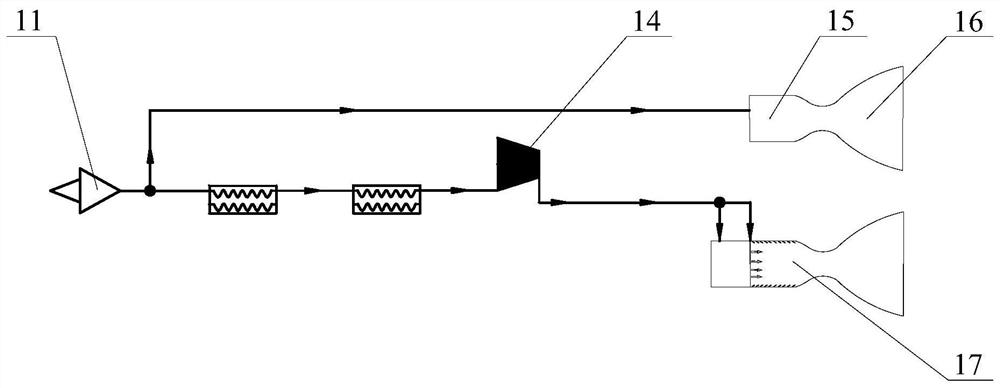

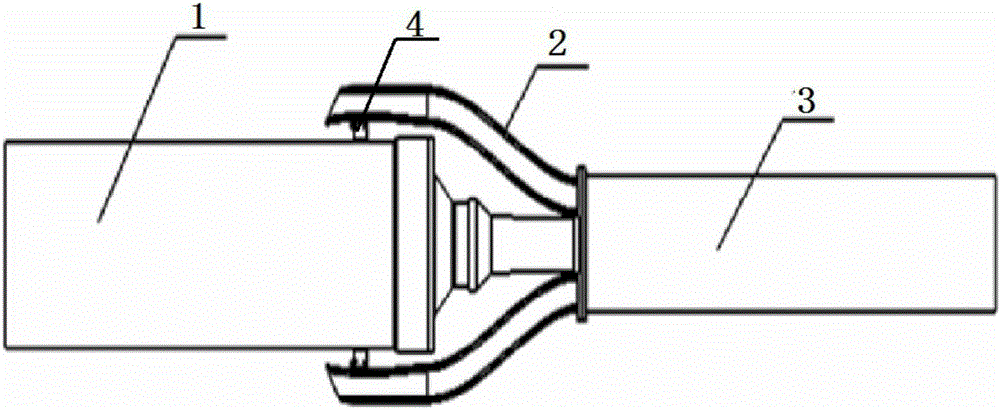

The invention provides a novel pre-cooling air combined engine. The engine comprises an air combustion path (1), a helium cooling path (2), and a hydrogen energy supply path (3); and the ultralow temperature characteristic of the liquid hydrogen fuel is utilized to cool the high-temperature incoming flow air after being stagnated through an air inlet channel, the helium cooling path (2) is introduced to be used as an intermediate circulation to carry out energy transfer and conversion between the hydrogen energy supply path (3) and the air combustion path (1), and thus the fuel required by cooling and the fuel combustion rate are reduced; and meanwhile, the concurrent heating power of a heater is reduced. The engine has the characteristics that the flight envelope is large, the mode conversion is simple and convenient, the air pre-cooling efficiency is high, and the system specific impulse is high; and the engine can be used as one stage of a horizontal take-off and landing repeatabletwo-stage to-orbit vehicle and as a power system of near-air hypersonic velocity launching platform.

Owner:XIAN AEROSPACE PROPULSION INST

Minisize propeller with electrolyzing water function

InactiveCN1804386AImprove thermal efficiencyHigh specific impulse performanceElectrolysis componentsRocket engine plantsPropellerThermal efficiency

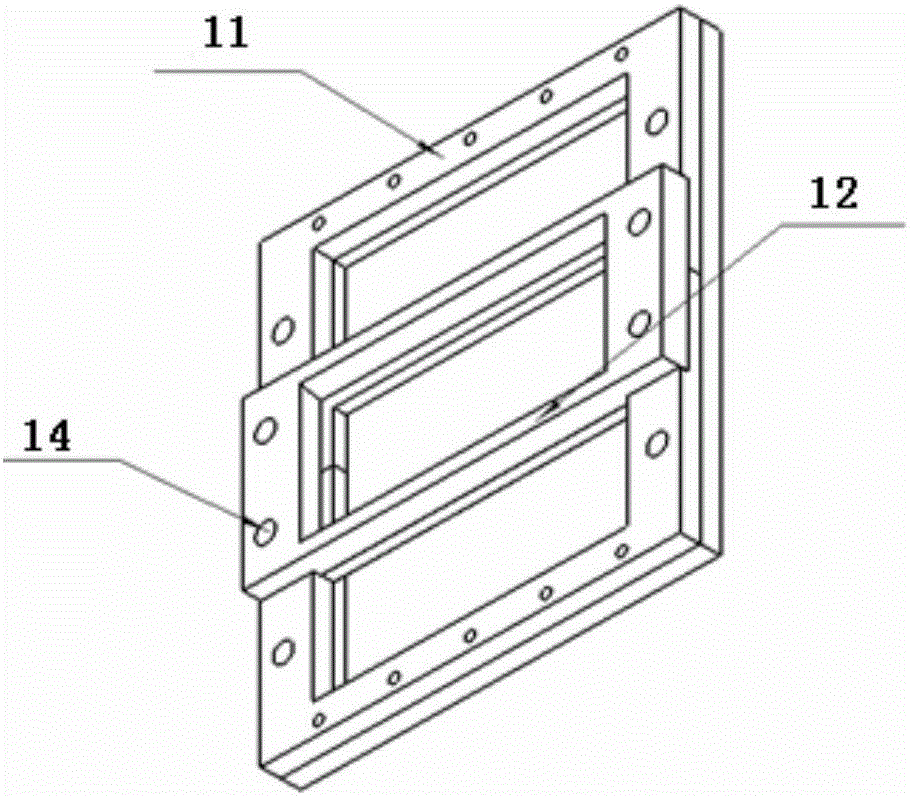

The invention relates to a micro-electrolysis water thruster which can utilize water or water solution, belonging to the micro-mechanical technique. It comprises: (1) a micro-electrolysis water thruster formed by three layered plates as a top plate, a bottom plate and spray plate with a one-way valve; (2) and a micro-electrolysis water thruster formed by layering top plate and bottom plate with high depth-width rate electrode or plane electrode without one-way valve. Wherein, the electrolysis reaction chamber is between the top and bottom plates which comprises an electrolysis anode and a electrolysis cathode; the burning chamber has a fire electrode; the hydrophobic film is plated on the inner surfaces of electrolysis reaction chamber and the burning chamber; and the one-way valve is between the burning chamber and the micro-spray pipe. The invention can generate hydrogen-oxygen mixed gas via the electrolyte of water to be fired to generate high-temperature high-pressure steam to be sprayed outside the spray pipe to form pushing power, which can improve the specific thrust property, thermal efficiency, responding speed and control accuracy, while its structure is compatible with MEMS to apply the micromation and integration.

Owner:TSINGHUA UNIV

Rocket ramjet wide-speed-range engine based on annular pressurization center body tail confluence

ActiveCN112682219AImprove thrust performanceReduce nozzle exit areaRam jet enginesComposite engine plantsRamjetCombustion chamber

The invention discloses a rocket ramjet wide-speed-range engine based on annular pressurization center body tail confluence. The engine comprises a center body, an air inlet channel, a combustion chamber with a concave cavity and a spray pipe. An embedded rocket in a conventional rocket ramjet engine is arranged on the outer side of the center body, the rocket gas and air are mixed in an annular mixing channel, and the contact area of rocket jet flow and the air is increased, so that the mixing distance of two air flows can be effectively shortened. Meanwhile, annular airflow is converted into central pipe flow through a central body contraction section at the spray pipe, the outlet area of the engine spray pipe can be reduced, and therefore the structural size of the engine is reduced, and the overall thrust performance of the rocket ramjet engine can be effectively improved by adopting the scheme.

Owner:NAT UNIV OF DEFENSE TECH

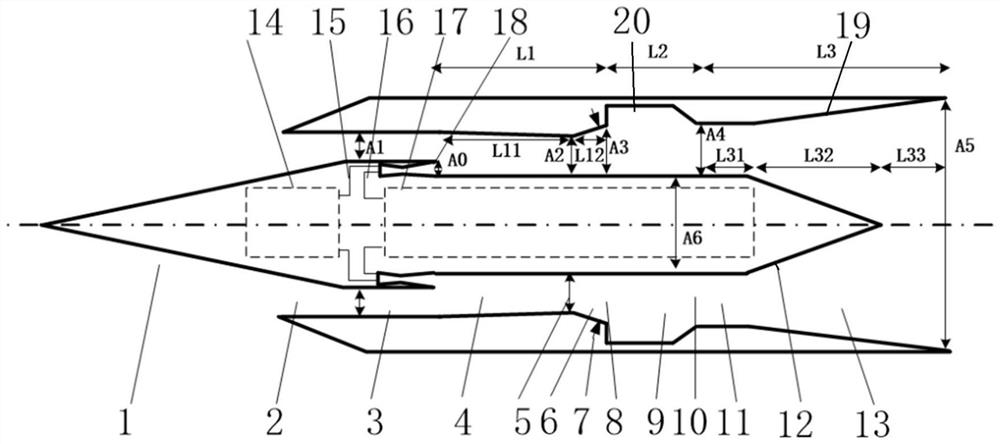

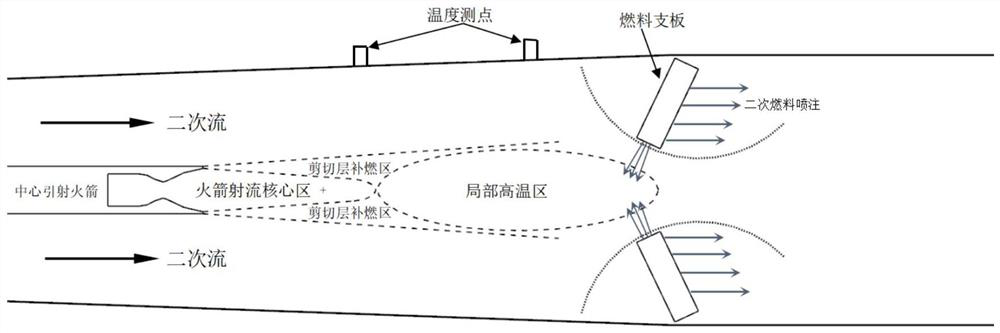

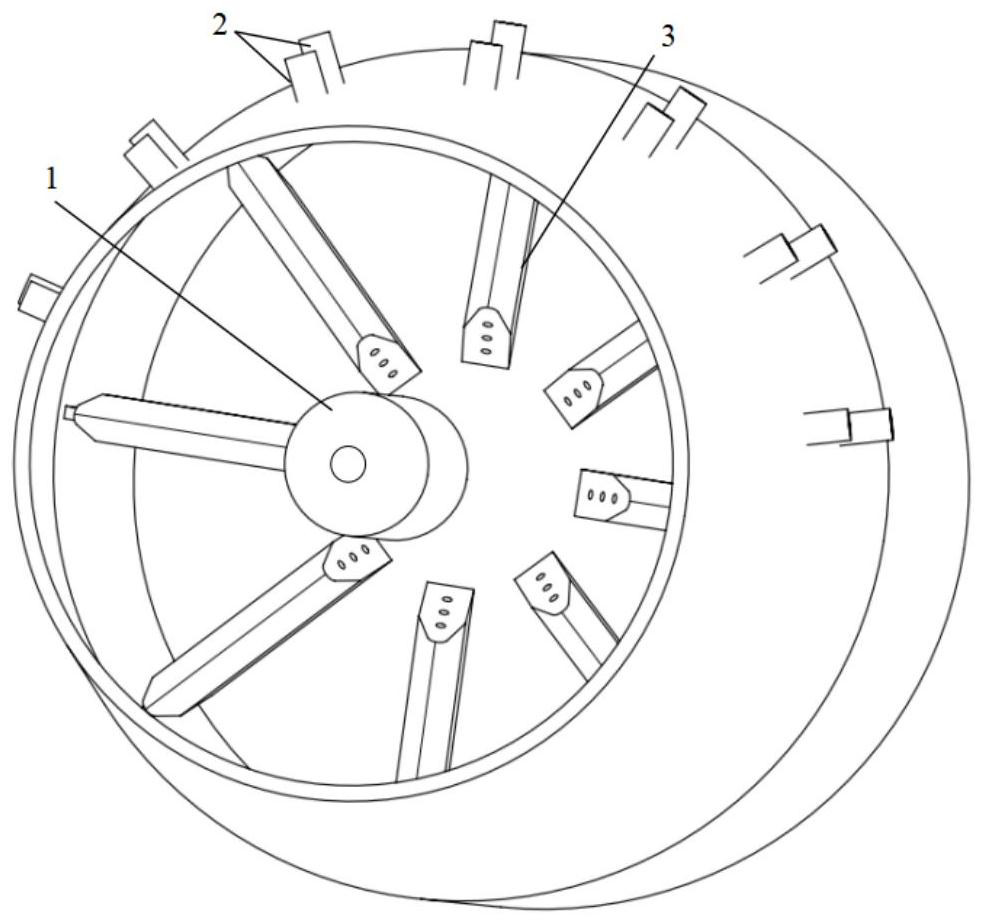

Rocket ejector ramjet combustion chamber and self-adaptive fuel injection method

ActiveCN114165361AShorten the lengthStable and efficient workRocket engine plantsRamjetThermodynamics

The invention discloses an ejector rocket ramjet combustion chamber and a self-adaptive fuel injection method, and relates to a rocket-based combined cycle engine. The combustion chamber is composed of a rocket ejector, a temperature sensor, a fuel supporting plate and an actuating mechanism. The rocket ejector is arranged in the center of the engine; the temperature sensors are symmetrically distributed in the width direction of the combustion chamber around the central axis at certain intervals; the fuel supporting plates are annularly distributed in the combustion chamber around the central axis, the tail ends of the fuel supporting plates are connected with the actuating mechanism, and the injection angle of the fuel supporting plates is adjusted. A rich-combustion ejector rocket serves as an ignition source of secondary fuel in different working modes, the area where a rocket jet flow local high-temperature area is located is judged based on temperature sensors, the injection angle of a fuel supporting plate is adjusted, the secondary fuel injected to the bottom of the supporting plate is injected into the local high-temperature area to be rapidly combusted, and the effect of guiding flames is achieved; secondary fuel ignition and stable combustion in the downstream backflow area of the support plate are realized. The rocket injection ramjet engine works efficiently and stably in different speed domain ranges, and the thrust and specific impulse performance is improved.

Owner:XIAMEN UNIV

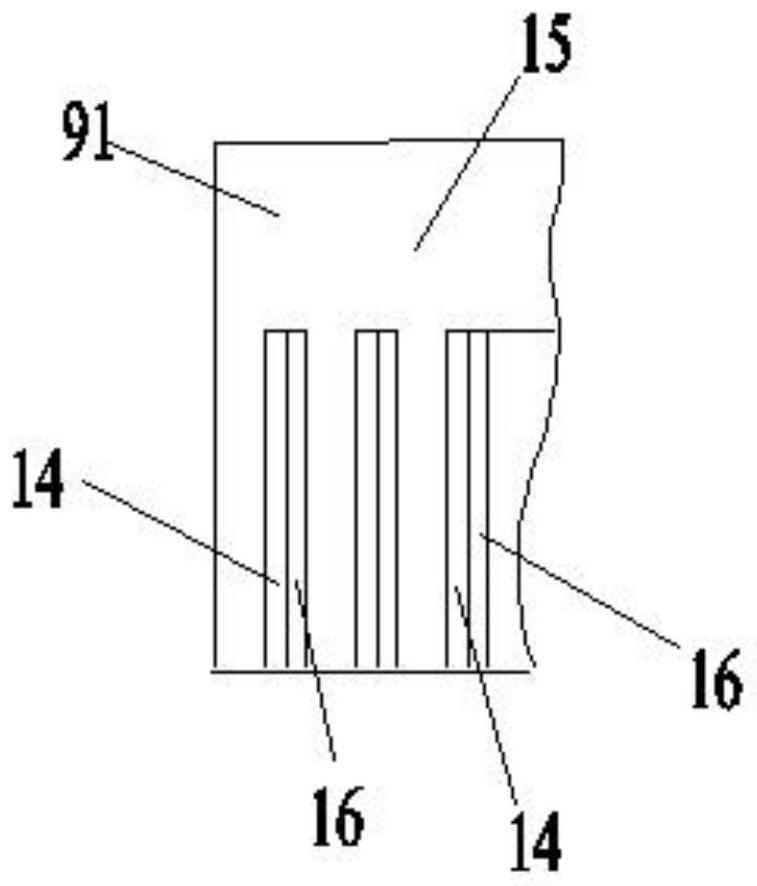

Control system for reciprocating displacement pump of solid-liquid rocket engine

ActiveCN112594093AQuick responseHigh specific impulse performanceRocket engine plantsGas cylinderControl system

The invention relates to the technical field of aerospace, in particular to a control system for a reciprocating type positive displacement pump of a solid-liquid rocket engine. The system comprises astorage mechanism and a liquid pressurizing mechanism; the storage mechanism is used for storing propellant; and the liquid pressurizing mechanism comprises a reciprocating type positive displacementpump, the storage mechanism is communicated with the reciprocating type positive displacement pump, and the reciprocating type positive displacement pump is used for pressurizing propellant and supplying the pressurized propellant to the attitude and orbit control engine mechanism. The liquid pressurizing mechanism is different from a traditional extrusion type or turbine pump pressure type conveying system, a high-pressure gas cylinder and a turbine pump assembly are not used any more, the propellant flowing out of the storage mechanism is pressurized through the light reciprocating type positive displacement pump, and the propellant can have high specific impulse performance.

Owner:BEIHANG UNIV

Liquid-film cooled thrust chamber for rail posture control engine

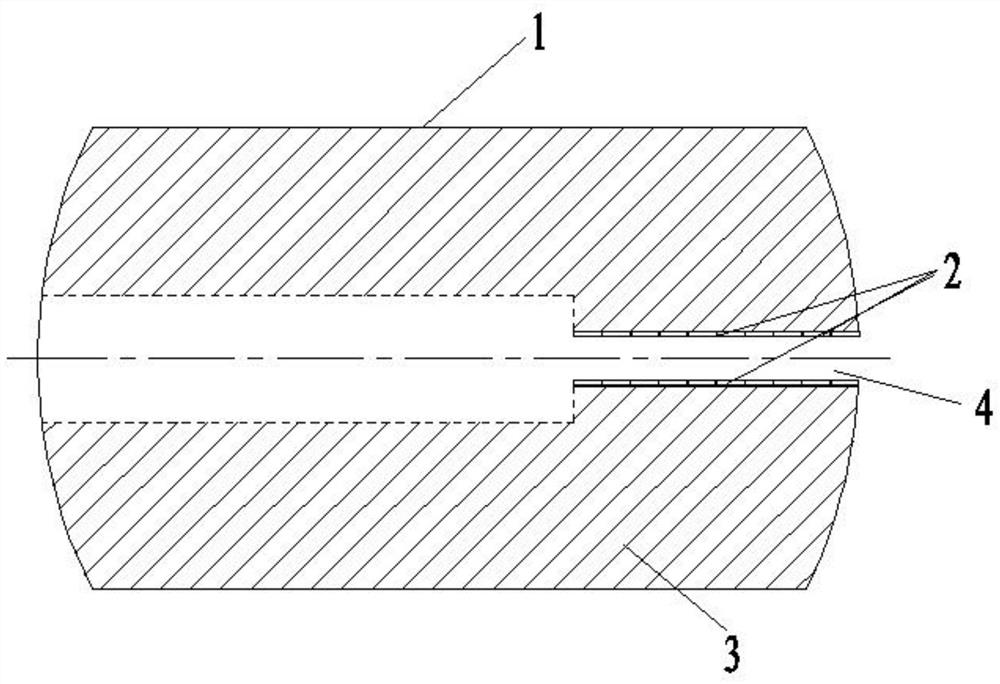

ActiveCN111963339APerfect for whole body coolingAchieve whole body coolingRocket engine plantsThrust chamberWhole body

The invention discloses a liquid-film cooled thrust chamber for a rail posture control engine. A first propellant chamber is arranged on the outer side of the head of the thrust chamber, and a secondpropellant chamber is arranged on the outer side of the middle position of the body of the thrust chamber. A plurality of first spray holes communicating with the first propellant chamber are formed in the shell wall of the head of the thrust chamber. A plurality of combustion jet holes and a plurality of liquid film jet holes are evenly formed in the shell wall of the body of the thrust chamber in the circumferential direction. A second propellant is sprayed to the head and the throat of the thrust chamber through the combustion jet holes and the multiple liquid film jet holes respectively, aliquid film is sprayed towards the throat of the thrust chamber, and a tangential liquid feeding mode is adopted, so that loss of the liquid film can be reduced. The cooling performance of the liquidfilm is given full play to. In addition, the combustion jet holes face the head of the thrust chamber, a tangential liquid feeding mode is adopted, the cooling performance of the liquid film can be achieved, meanwhile, the liquid film can react with the first propellant, therefore the proportion of the liquid film in the propellant can be reduced, and whole-body cooling of the thrust chamber is achieved.

Owner:XIAN AEROSPACE PROPULSION INST

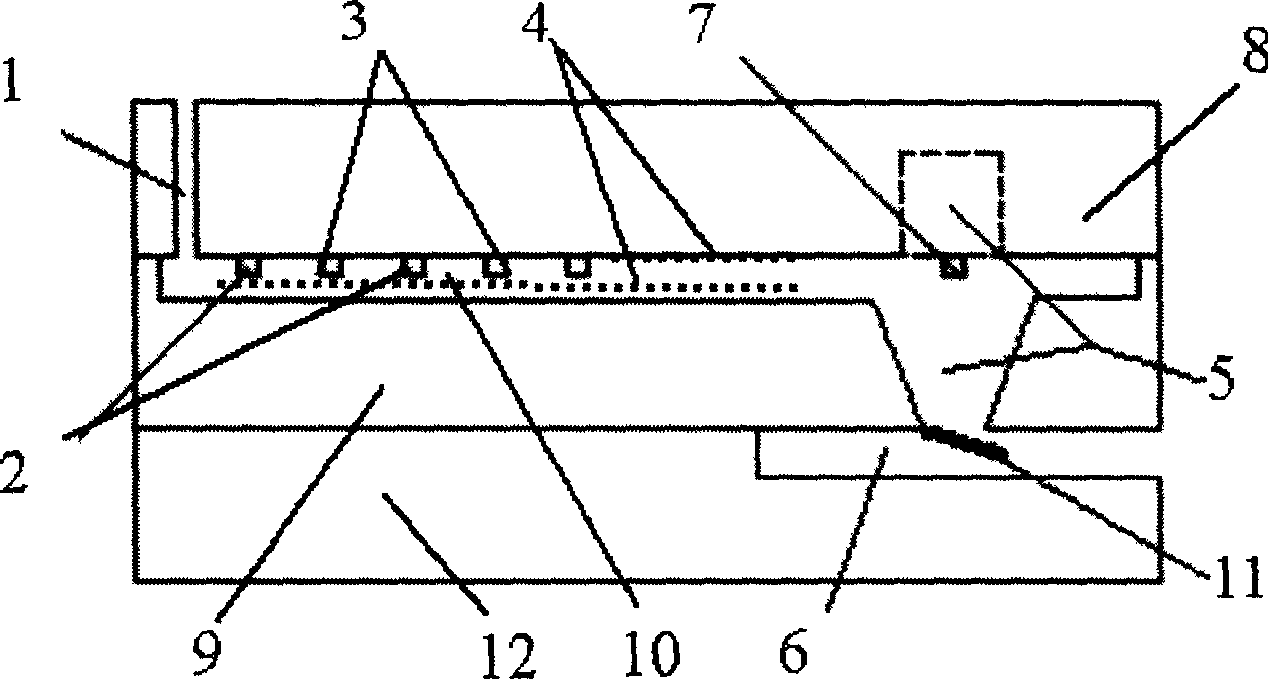

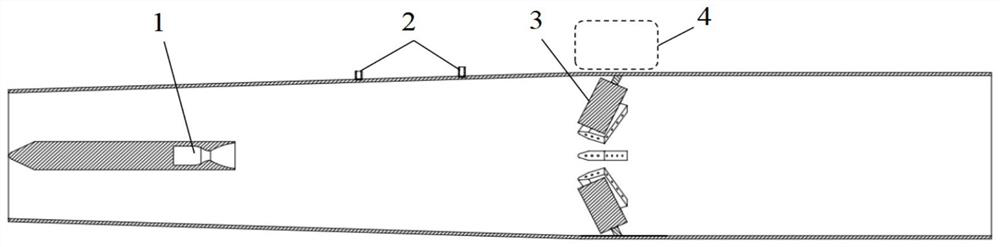

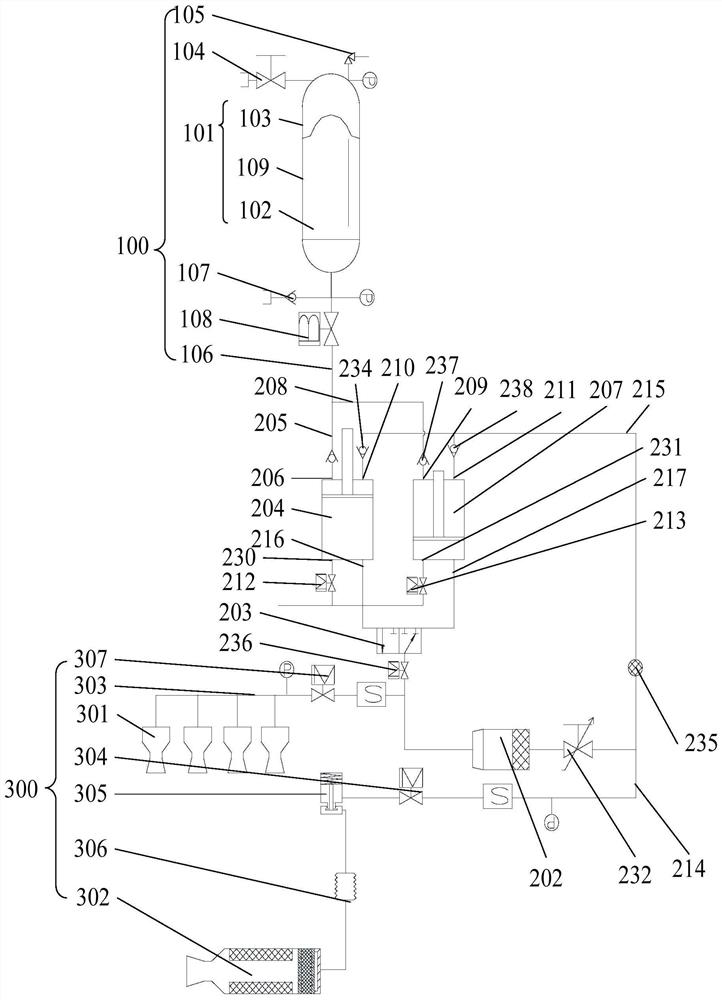

Solid-liquid dual-mode attitude and orbit control power system and control method thereof

ActiveCN114291299AImprove securityHigh specific impulse performanceCosmonautic propulsion system apparatusRocket engine plantsThermodynamicsControl power

The invention relates to a solid-liquid dual-mode attitude and orbit control power system and a control method thereof in the field of space propulsion systems. The solid-liquid dual-mode attitude and orbit control power system comprises a controller, a fuel gas generator, a gas collection tank, a propellant storage tank, a fuel gas attitude control thruster and a liquid orbit control engine. A solid grain is arranged in the fuel gas generator, the fuel gas generator, the gas collecting tank, the propellant storage tank and the liquid orbit control engine are sequentially communicated through pipelines, the gas collecting tank is communicated with the fuel gas attitude control thruster through a pipeline, and the controller is used for controlling the system. The controller controls the fuel gas generator to ignite the solid grain, the solid grain combusts to generate high-pressure fuel gas, the high-pressure fuel gas is filled into the gas collecting tank, one path of the high-pressure fuel gas in the gas collecting tank enters the fuel gas attitude control thruster, and the other path of the high-pressure fuel gas in the gas collecting tank enters the propellant storage box to extrude a propellant into the liquid orbit control engine. The advantages of a solid gas pressurization system and a liquid propelling system are combined, normal-pressure prepackaging storage of the propelling system is achieved, and the safety of prepackaging storage is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

Integrated space propulsion system with orbit and attitude control based on electric pump

Owner:SHANGHAI INST OF SPACE PROPULSION

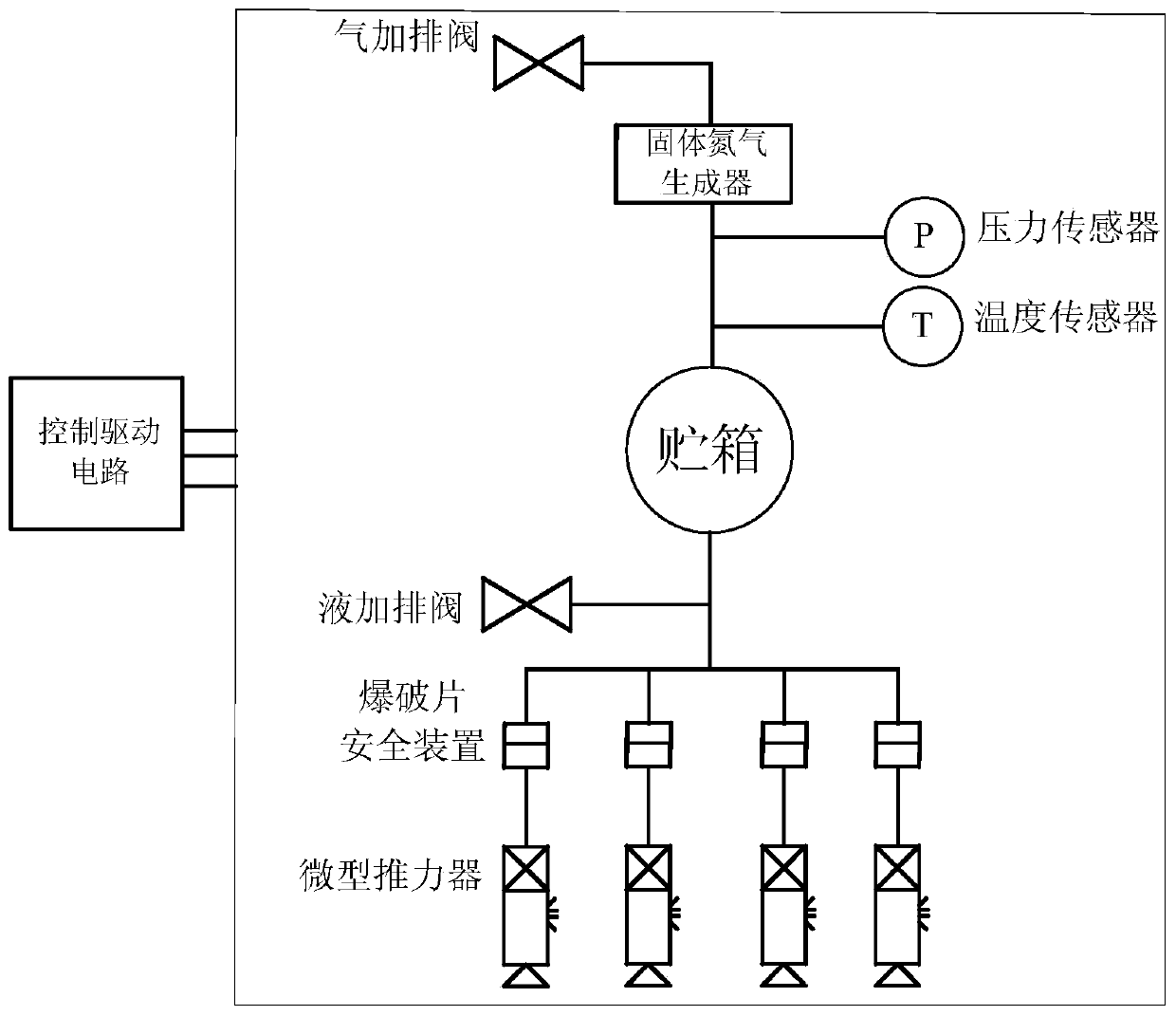

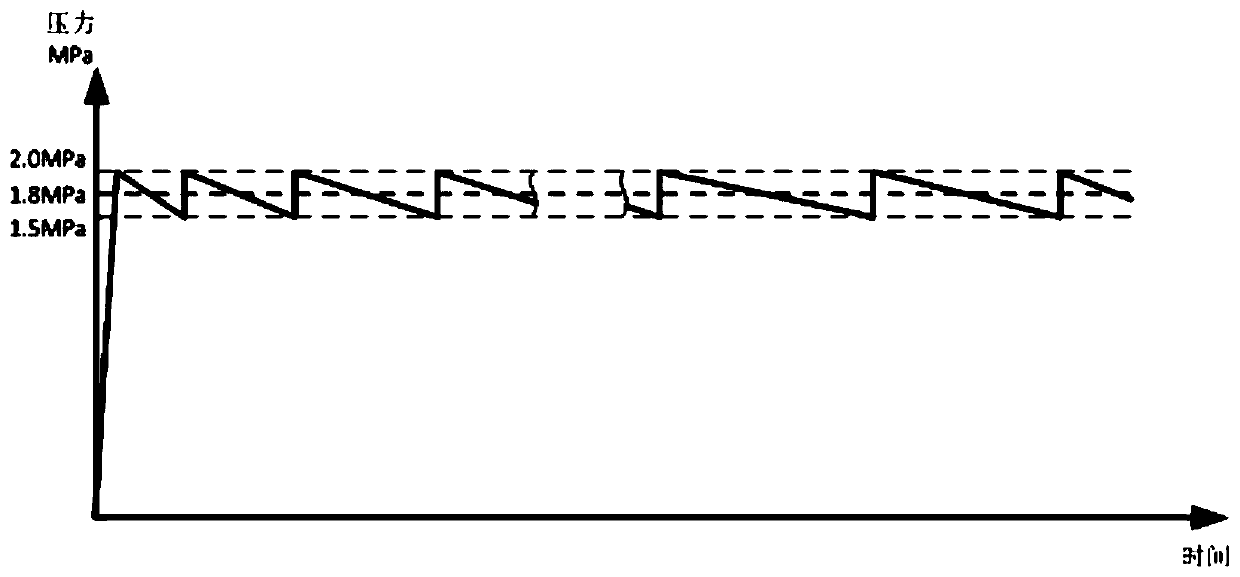

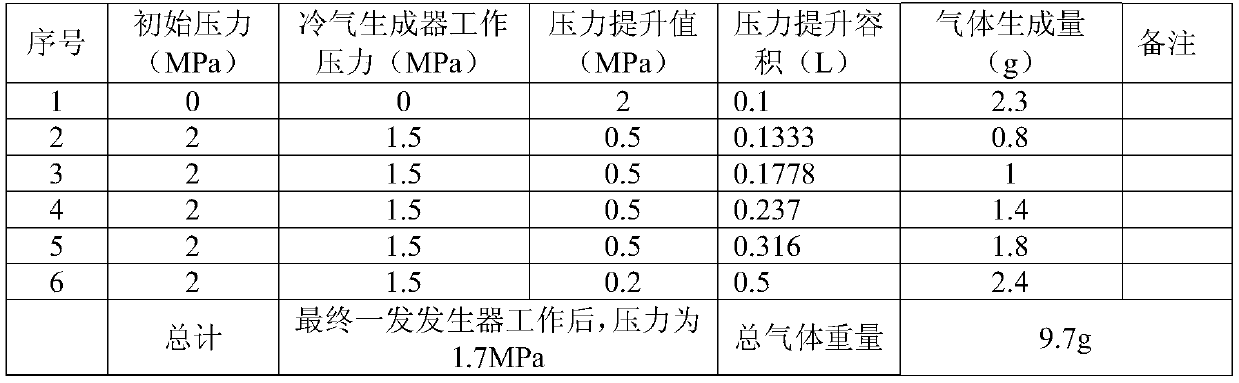

Single-element micro-propulsion module device and pressurization method based on additive manufacturing technology

ActiveCN107891999BHigh module integrationHigh work pressureCosmonautic vehiclesCosmonautic propulsion system apparatusManufacturing technologyProcess engineering

The invention relates to a single component micro-propulsion module device based on additive manufacturing technology. The device is characterized by comprising a micro-thruster assembly, a gas addingand discharging valve, a liquid adding and discharging valve, a solid nitrogen generator, a temperature sensor, a pressure sensor, a bursting disc safety device, a tank assembly and a control drive circuit; the gas adding and discharging valve, the solid nitrogen generator, the temperature sensor, the pressure sensor, the tank assembly, the liquid adding and discharging valve, the bursting disc safety device and the micro-thruster assembly are installed in series in a module gas room. The invention provides a novel device and method for safety isolation of a propulsion system, the high integration is facilitated, the system complexity is reduced, the reliable operation of an entire system is guaranteed, and the work performance of the entire system is improved.

Owner:BEIJING INST OF CONTROL ENG

An expansion cycle liquid oxygen methane upper stage engine system

ActiveCN111005821BNo pollution in the processEasy to storeRocket engine plantsThrust chamberControl system

An expansion cycle liquid oxygen methane upper stage engine system including a propellant supply system, an ignition system and a thrust chamber. The propellant supply system includes a methane supply system and a liquid oxygen supply system. The methane supply system pressurizes the cryogenic liquid methane from the external storage tank and supplies it to the thrust chamber; the liquid oxygen supply system pressurizes the cryogenic liquid oxygen from the external storage tank. After pressurization, it is provided to the thrust chamber; the ignition system is located at the head of the thrust chamber, and is ignited under the control of the control system to ignite the liquid oxygen and methane entering the thrust chamber, and the high-temperature gas generated is ejected from the nozzle of the thrust chamber to generate thrust. The present invention uses liquid oxygen and liquid methane as a propellant combination, and adopts a closed expansion cycle system scheme. The system is simple, has high inherent reliability, high specific impulse performance, and is easy to realize multiple starts.

Owner:BEIJING AEROSPACE PROPULSION INST

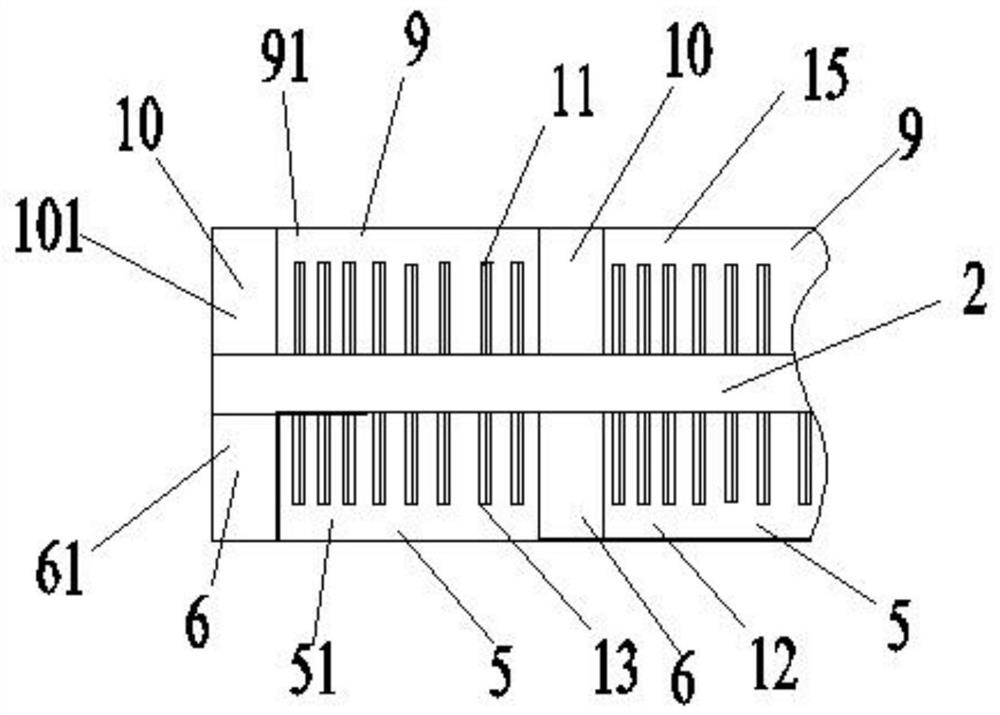

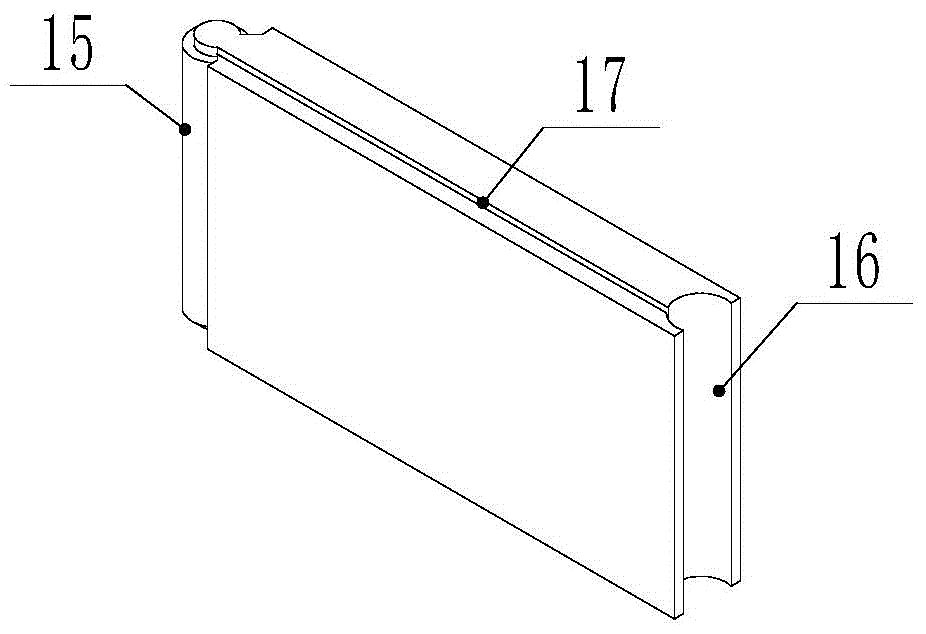

Nozzleless rocket motor stepped combustion chamber and inner wall thereof

ActiveCN110617160AIncrease the burning areaImprove acceleration performanceRocket engine plantsCombustion chamberStructural engineering

The invention provides a nozzleless rocket motor stepped combustion chamber and an inner wall thereof. The inner wall of the nozzleless rocket motor stepped combustion chamber includes a head radial wall surface and an axial wall surface; the head radial wall surface is composed of an initial step wall surface, a transition wall surface and a voltage stabilizing step wall surface, the initial stepwall surface and the voltage stabilizing step wall surface are both plane and perpendicular to the motor axis, and the transition wall surface has a certain slope and connects the initial step wall surface with the voltage stabilizing step wall surface to be a whole; the axial wall surface is connected to the outer edge of the initial step wall surface extends in the axial direction of the combustion chamber; and the axial wall surface and the head radial wall surface together form the combustion chamber.

Owner:NANJING UNIV OF SCI & TECH

A thrust chamber of a liquid-film-cooled orbital attitude control engine

ActiveCN111963339BPerfect for whole body coolingAchieve whole body coolingRocket engine plantsThrust chamberWhole body

The invention discloses a thrust chamber of a liquid film cooling rail attitude control engine. A first propellant chamber is arranged on the outside of the head of the thrust chamber, and a second propellant chamber is arranged on the outside of the body of the thrust chamber and is located outside the middle position; the thrust chamber The shell wall of the head is provided with a plurality of first injection holes communicating with the first propellant chamber; the shell wall of the thrust chamber body is evenly provided with a plurality of combustion injection holes and a plurality of liquid film injection holes along the circumferential direction ; The second propellant is sprayed to the head and throat of the thrust chamber through the combustion injection hole and a plurality of liquid film injection holes, because the liquid film injection is directed towards the throat of the thrust chamber, and the tangential liquid inlet method is adopted , so it can reduce the loss of the liquid film and give full play to the cooling performance of the liquid film; at the same time, the combustion injection hole faces the head of the thrust chamber, and adopts a tangential liquid inlet method, which can exert the cooling performance of the liquid film. The reaction of the first propellant not only reduces the proportion of liquid film to propellant, but also realizes the whole body cooling of the thrust chamber.

Owner:XIAN AEROSPACE PROPULSION INST

Electric pump pressure liquid oxygen methane space propulsion system

ActiveCN109281774BReduce operating costsReduce maintenance costsCosmonautic vehiclesCosmonautic propulsion system apparatusGas cylinderEngineering

The invention provides an electric pump pressure type liquid oxygen methane space propelling system. The electric pump pressure type liquid oxygen methane space propelling system comprises a high-pressure gas cylinder, a liquid oxygen storage tank, a methane storage tank, an electric pump system, an oxygen heat exchange injection rod, a methane heat exchange injection rod and a track control engine; the high-pressure gas cylinder is connected with the liquid oxygen storage tank and the methane storage tank through a first pipeline; the liquid oxygen storage tank and the methane storage tank are connected with an electric pump system through a second pipeline and a third pipeline; the oxygen heat exchange injection rod is arranged in the liquid oxygen storage tank; the methane heat exchangeinjection rod is arranged in the methane storage tank; the electric pump system is connected with the oxygen heat exchange injection rod and the track control engine through a fourth pipeline; and the electric pump system is connected with the methane heat exchange injection rod and the track control engine through a fifth pipeline. The electric pump pressure type liquid oxygen methane space propelling system is suitable for a space aircraft propulsion system, and particularly has obvious application advantages on a space propelling system which has large propellant filling amount and whose track control engine needs to be started for a plurality of times..

Owner:SHANGHAI INST OF SPACE PROPULSION

Solid rocket engine without spray pipe

ActiveCN112177797AReduce structural massHigh specific impulse performanceRocket engine plantsMechanical engineeringThermoelectric effect

The invention discloses a spray-pipe-free solid rocket engine which comprises a shell, a columnar propellant grain, a fuel gas channel and a supporting pipe. An inner cavity of the shell is filled with the propellant grain, and the fuel gas channel and the supporting pipe are arranged along the middle line of the propellant grain, are cylindrical, are arranged in the fuel gas channel in a sleevedmode and are close to a fuel gas flow outlet. A plurality of inner cavity electromagnetic field mechanisms and a plurality of inner cavity high-voltage thermoelectric mechanisms are sequentially arranged on the inner wall of the supporting pipe at intervals, and the inner cavity electromagnetic field mechanisms and the inner cavity high-voltage thermoelectric mechanisms are matched with one another to be used for generating millivolt-level thermoelectric potential due to the thermoelectric effect when fuel gas passes through a fuel gas channel of an inner cavity of the supporting pipe, and then high-voltage thermoelectric potential is formed. The fuel gas containing a large number of ionization products is greatly accelerated through the thermoelectric potential and is discharged through the inner cavity of the supporting pipe to push the rocket to operate; A spray pipe structural part of a conventional solid rocket engine is omitted, the structural weight of the engine is greatly reduced, and the probability of failure faults is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A compound mechanism full-flow circulation supersonic propulsion system and its working method

ActiveCN111594315BWork status is not affectedSolving the Thrust Trap ProblemRocket type power plantsContinuous combustion chamberTurbineSpecific impulse

The present invention proposes a composite mechanism full-flow cycle supersonic propulsion system and its working method, including an air inlet, a compressor, a diffuser duct, a shaft, an open pre-combustion driver, a closed pre-combustion driver, a turbine, a post-combustion Thruster, tail nozzle; the inlet, compressor, shaft, turbine, afterburning thruster, and tail nozzle are connected in sequence; the compressor and turbine are connected through a shaft; the turbine is located on the side of the inlet of the afterburning thruster, The tail nozzle communicates with the outlet of the afterburner thruster; the open pre-combustion driver and the closed pre-combustion driver are located behind the compressor, and the outlet is facing the turbine; the open pre-combustion driver and the closed pre-combustion driver are alternately distributed on the outer ring of the shaft Into the expansion duct of the space. The system maximizes the propulsion advantages of each subsystem in terms of specific impulse and thrust-to-weight ratio, so as to realize the rapid self-starting of the propulsion system, multi-degree-of-freedom, compound working mechanism, efficient and economical supersonic combined propulsion system.

Owner:浙江省涡轮机械与推进系统研究院

A Nozzleless Solid Rocket Motor

ActiveCN112177797BReduce structural massHigh specific impulse performanceRocket engine plantsThermoelectric effectCylinder (engine)

The invention discloses a nozzleless solid rocket motor, comprising: a shell, which is in the shape of a column, propellant grains filled in the inner cavity of the shell, a gas channel is opened along the central line, a support tube, which is in the shape of a tube, and is sleeved on the In the gas channel and close to the outlet of the gas flow, a plurality of inner cavity electromagnetic field mechanisms and a plurality of inner cavity high-voltage thermoelectric mechanisms are sequentially arranged on the inner wall, and the inner cavity electromagnetic field mechanisms and the inner cavity high-voltage thermoelectric mechanisms cooperate with each other for the gas to pass through. When supporting the gas channel in the inner cavity of the tube, a millivolt-level thermoelectric potential is generated due to the thermoelectric effect, and then a high-voltage thermoelectric potential is formed. The thermoelectric potential greatly accelerates the gas containing a large number of ionized products, and is discharged through the inner cavity of the supporting tube to propel the rocket. Operation; the invention cancels the nozzle structure of the conventional solid rocket motor, greatly reduces the structural quality of the motor, and reduces the probability of failure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A stepped combustion chamber and inner wall of a nozzleless engine

ActiveCN110617160BIncrease the burning areaImprove acceleration performanceRocket engine plantsCombustion chamberEngineering

The invention provides a stepped combustion chamber and an inner wall of a nozzleless engine. The inner wall of the combustion chamber includes a radial wall surface and an axial wall surface of the head; , the initial step wall and the pressure-stabilizing step wall are the same plane and perpendicular to the engine axis, the transition wall has a certain slope, and the initial step wall and the stabilizing step wall are connected as a whole; the axial wall is connected with the outer edge of the initial step wall and along the The combustion chamber extends axially; the axial wall and the radial wall of the head jointly form the combustion chamber.

Owner:NANJING UNIV OF SCI & TECH

Composite mechanism full flow circulation supersonic velocity propulsion system and working method thereof

ActiveCN111594315AWork status is not affectedSolving the Thrust Trap ProblemRocket type power plantsContinuous combustion chamberEngineeringAir compressor

The invention discloses a composite mechanism full flow circulation supersonic velocity propulsion system and a working method thereof. The system comprises an air admission passage, an air compressor, a diffusion duct, a shaft, an open type pre-burning driver, a closed type pre-burning driver, a turbine, an afterburning thruster and a jet nozzle; the air admission passage, the air compressor, theshaft, the turbine, the afterburning thruster and the jet nozzle are sequentially connected; the air compressor is connected with the turbine through the shaft; the turbine is positioned on the air inlet side of the afterburning thruster; the jet nozzle communicates with the outlet of the afterburning thruster; the open type pre-burning driver and the closed type pre-burning driver are positionedbehind the air compressor, and outlets directly face the turbine; and the open type pre-burning driver and the closed type pre-burning driver are alternately distributed in the diffusion duct in an annular space on the outer side of the shaft. The system gives play to propulsion advantages of all subsystems in the aspects of specific impulse and thrust-weight ratio as much as possible, so that asupersonic velocity combined propulsion system which is rapidly started by self, has multiple degrees of freedom and composite working mechanism and is efficient and economic is realized.

Owner:浙江省涡轮机械与推进系统研究院

A rocket-based combined cycle engine variable structure combustion chamber

InactiveCN105240160BIncrease thrustHigh specific impulse performanceRocket engine plantsCombustion chamberDivergence angle

The invention discloses a variable structure combustion chamber of a rocket-based-combined-cycle engine. The variable structure combustion chamber is composed of a drive system, a back pressure cavity and a combustion chamber body. The drive system is located at the upper portion of the back pressure cavity. The back pressure cavity is fixed to the portion above variable sections of the combustion chamber body and forms an integral structure with the combustion chamber body. A combustion chamber fixed section is sequentially connected with variable sections of the combustion chamber body. The variable sections are connected through cooperation of ball head hinge convex faces and ball head hinge concave faces. Two sets of hydraulic drive mechanisms drive the first variable section and the third variable section of the combustion chamber body through drive rods and connecting rods. Axial sealing grooves of the variable sections are filled with graphite strips so as to isolate high-temperature fuel gas in the combustion chamber body, and sealing is guaranteed. According to the variable structure combustion chamber, stable transition among different modes is achieved through grade adjustment. In the injection mode and the subsonic combustion mode, the variable sections of the combustion chamber body are adjusted by a hydraulic drive mechanism to generate different divergence angles and throat heights, so that the combustion chamber body is in the optimal work state, and the thrusting force and specific impulse performance of the combustion chamber body are obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

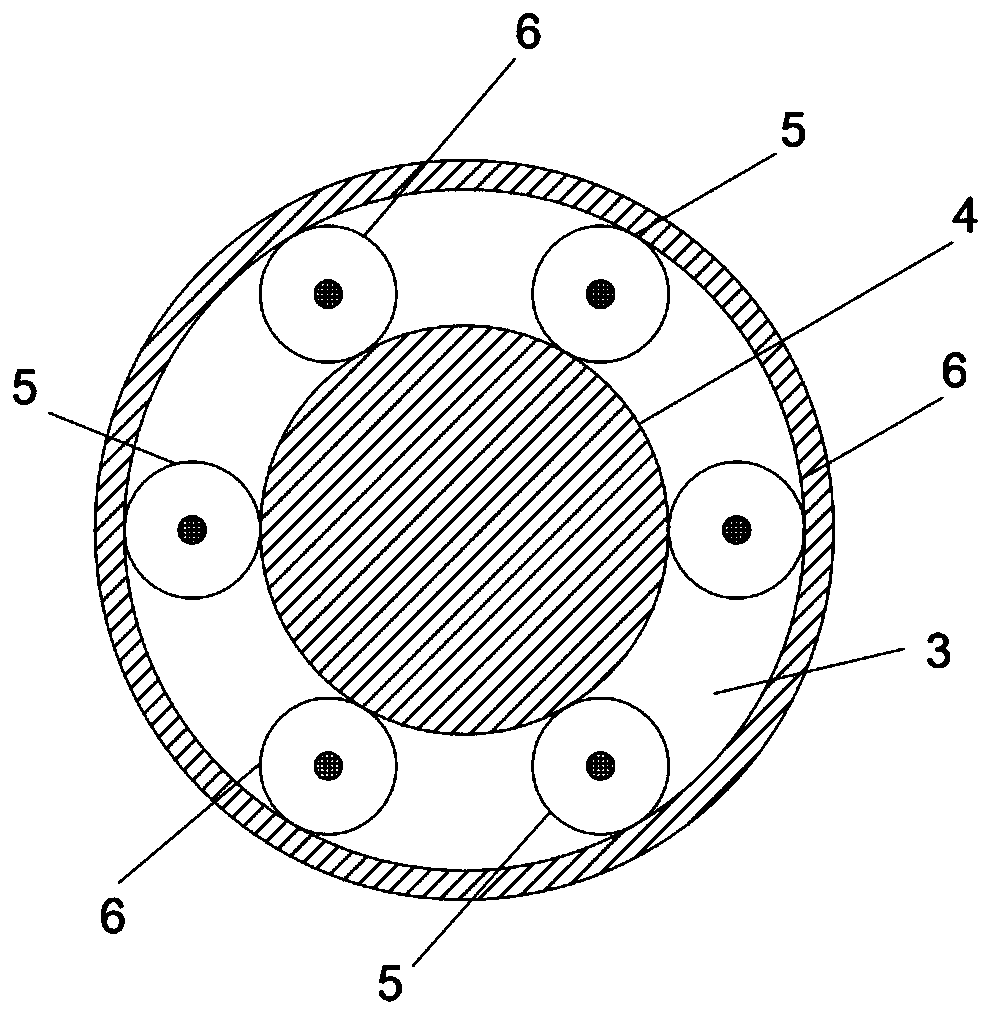

Ion collision accelerated electric thruster device

InactiveCN106286178BImprove specific impulseHigh specific impulse performanceMachines/enginesUsing plasmaElectricityOrbit

The invention discloses an ion collision acceleration type electric thruster device and relates to the field of aspiration type electric propulsion of low-orbit spacecraft. The ion collision acceleration type electric thruster device comprises a quartz tube, an anode grid, a cathode grid, a cathode support rack, an electric inlet and a permanent magnetic ring, wherein the cylindrical quartz tube comprises a tube cylinder part, a semi-sphere part and a guide hole part, the semi-sphere part is mounted at one end of the tube cylinder part, the guide hole part is mounted at the top of the semi-sphere part and is coaxial with the tube cylinder part, the anode grid attaches to the inner wall of the quartz tube, the cathode grid is mounted in the quartz tube through the cathode support rack, the cathode grid, the anode grid and the quartz tube are coaxial, the electric inlet is fixedly connected to the guide hole part, and the permanent magnetic ring is mounted outside the guide hole part and coaxially assembled with the anode grid and the cathode grid. The novel ion collision acceleration type electric thruster device is novel in structure, simple to produce and machine, stable in performance, safe, reliable, widely applicable, economic and practical.

Owner:DALIAN UNIV OF TECH

A ramjet wide-velocity engine based on an annular supercharged center body confluence rocket ramjet

ActiveCN112682219BImprove thrust performanceReduce nozzle exit areaRam jet enginesComposite engine plantsRamjetCombustion chamber

A rocket ramjet wide-velocity range engine based on an annular pressurized center body tail confluence rocket, the engine includes a center body, an air inlet, a concave cavity combustion chamber and a nozzle. The embedded rocket in the conventional rocket ramjet is put forward to the outside of the center body, and the rocket and air are mixed in the annular mixing channel. Since the contact area between the rocket jet and the air increases, the mixing distance of the two airflows can be effectively shortened , at the same time, the annular airflow is transformed into a central pipe flow through the central body convergence section at the nozzle, which can reduce the outlet area of the engine nozzle, thereby reducing the structural scale of the engine. Adopting this scheme can effectively improve the thrust performance of the rocket ramjet as a whole.

Owner:NAT UNIV OF DEFENSE TECH

A New Type of Precooling Air Combined Engine

ActiveCN109372657BReduce consumption rateAvoid wastingRocket engine plantsGas passingLiquid hydrogen

A new type of pre-cooled air combined engine, including air combustion path (1), helium cooling path (2), hydrogen energy supply path (3), by using the ultra-low temperature characteristics of liquid hydrogen fuel to cool the stagnant air through the intake port The final high-temperature incoming air is introduced into the helium cooling circuit (2) as an intermediate cycle to carry out energy transfer and conversion between the hydrogen energy supply circuit (3) and the air combustion circuit (1), reducing the fuel and cooling requirements Fuel combustion rate, while reducing the heating power of the heater, has the characteristics of large flight envelope, simple mode conversion, high air pre-cooling efficiency and high system specific impulse, and can be used as a repeatable two-stage orbiting aircraft for horizontal take-off and landing The power system of the first stage and adjacent air hypersonic launch platform.

Owner:XIAN AEROSPACE PROPULSION INST

Control system of reciprocating positive displacement pump for solid-liquid rocket motor

ActiveCN112594093BQuick responseHigh specific impulse performanceRocket engine plantsGas cylinderControl system

The present application relates to the field of aerospace technology, in particular to a control system for a reciprocating displacement pump of a solid-liquid rocket engine. The system includes a storage mechanism and a liquid pressurization mechanism; the storage mechanism is used to store the propellant; the liquid pressurization mechanism includes a reciprocating positive displacement pump, the storage mechanism communicates with the reciprocating positive displacement pump, and the reciprocating positive displacement pump is used to pressurize the propellant, And it is used to supply the pressurized propellant to the attitude and orbit control engine mechanism. The liquid pressurization mechanism is different from the traditional extrusion or turbo pump delivery system. This application no longer uses high-pressure gas cylinders and turbo pump components, and uses a lightweight reciprocating positive displacement pump to boost the propellant flowing out of the storage mechanism. The pressure can make the propellant have higher specific impulse performance.

Owner:BEIHANG UNIV

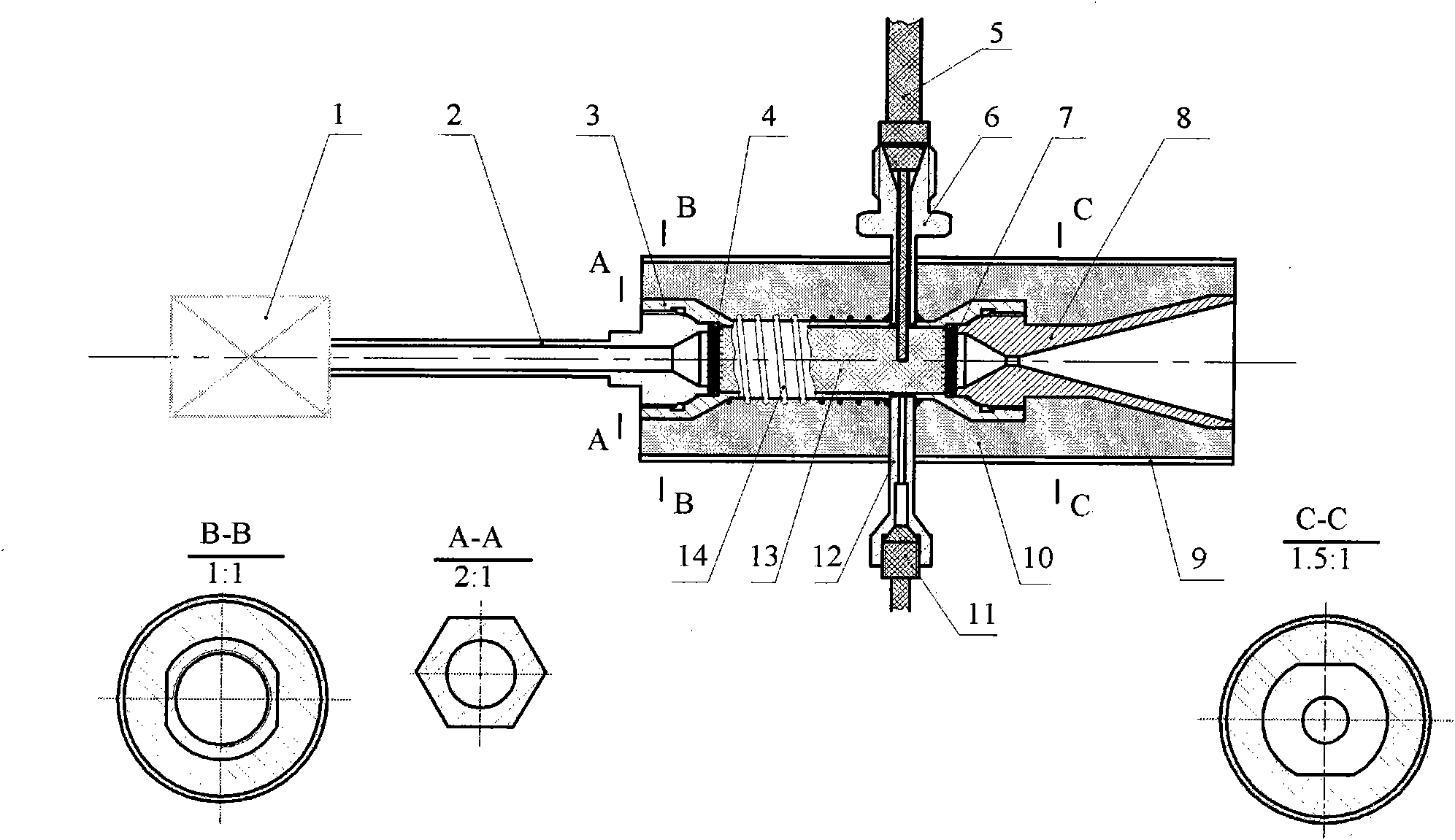

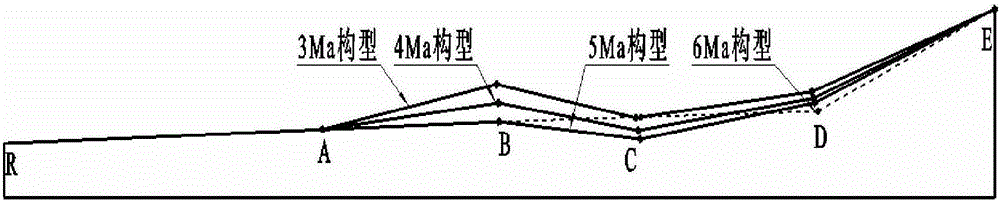

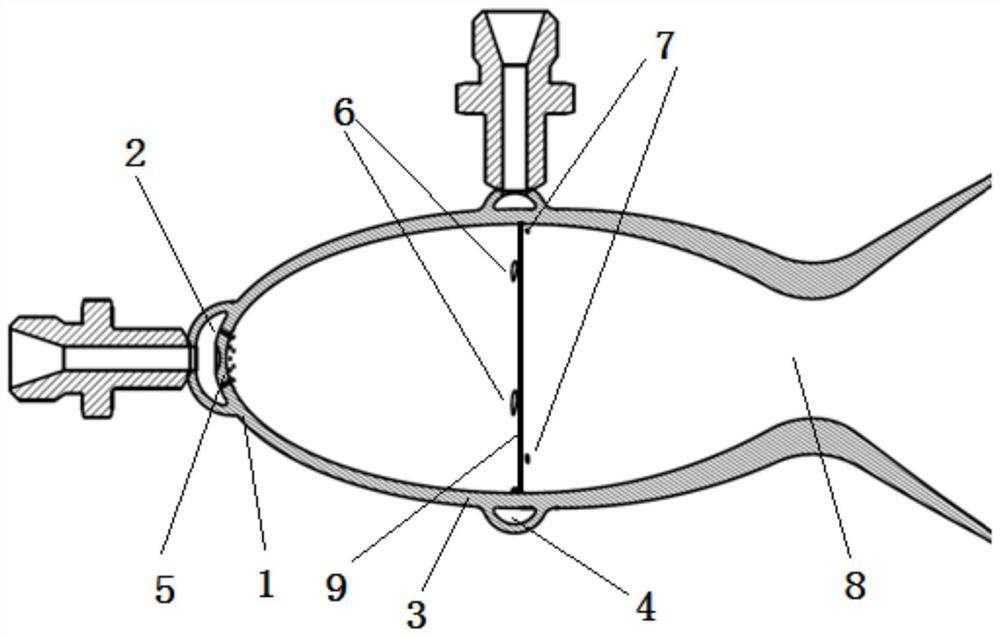

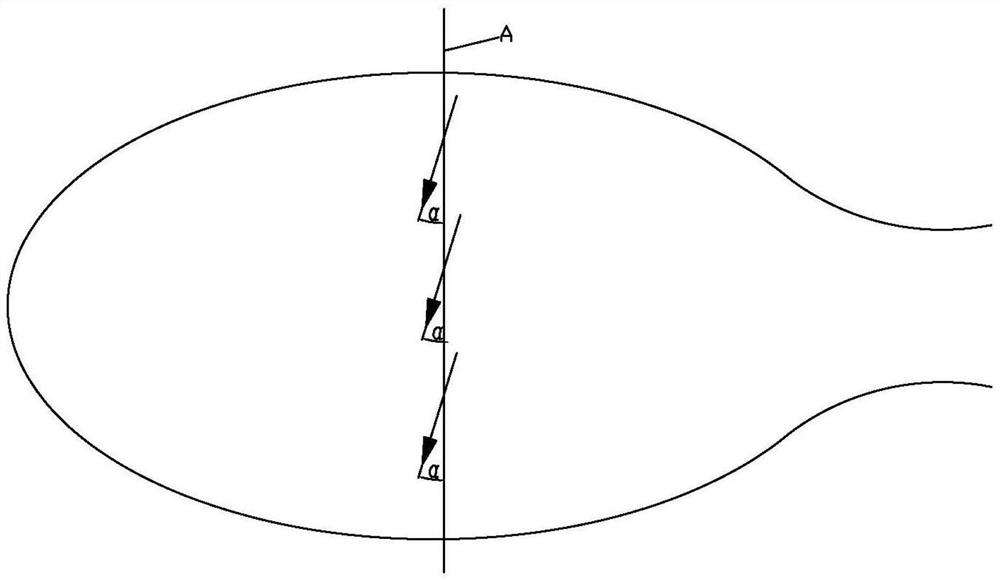

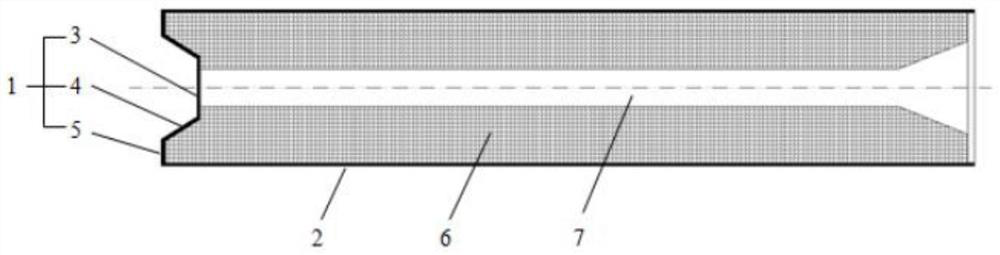

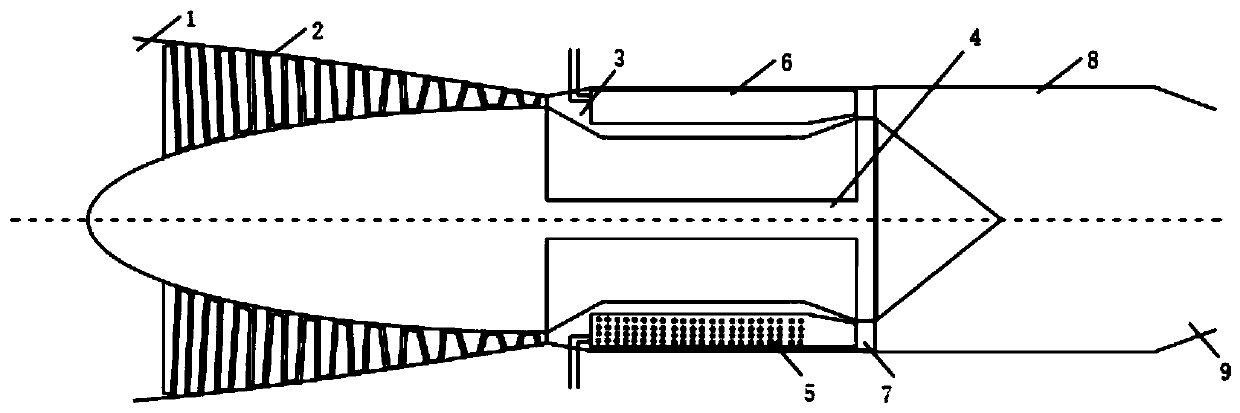

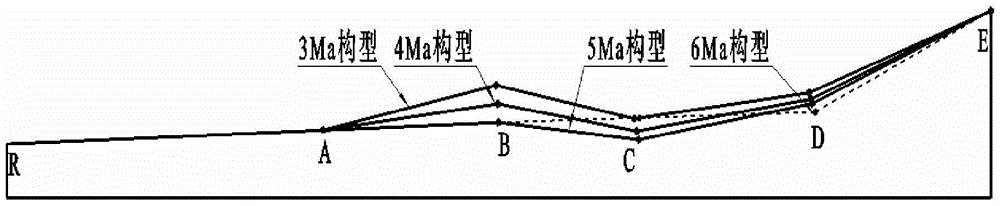

A Rocket-Based Combined Cyclic Ejection Modal Performance Experimental Engine

InactiveCN103758663BHigh specific impulse performanceLarge thrustRocket engine plantsCombustorCombustion chamber

The invention discloses a rocket-based combined cycle ejector mode performance test engine. A main rocket combustor is fixed in the front of a secondary combustor; intake ducts are mounted above and below the main rocket combustor respectively; intake ends of the intake ducts are fixed in the rear of the main rocket combustor through support lugs; the rear ends of the intake ducts are connected with the secondary combustor through an intake duct flange and a second combustor flange; the secondary combustor is in a divergent straight structure; the main rocket combustor is fitly connected with the secondary combustor; a flue of a nozzle divergent segment gradually changes from round to square. The main rocket combustor is charged through the combination of seven-pointed star shape and inner holes by close-to-wall pouring; after ignition, the flow of gas in a main rocket is kept basically unchanged; variation pattern of the rocket-based combined cycle ejector mode performance along with flight Mach number and height is verified; the basis is provided for passage design. The rocket-based combined cycle ejector mode performance test engine is simple in structure and convenient to maintain, and the influence of gas composition upon engine performance and trajectory climb can be extensively researched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com