Single-element micro-propulsion module device and pressurization method based on additive manufacturing technology

An additive manufacturing and single-group technology, which is applied to jet propulsion devices, aerospace vehicle propulsion system devices, rocket engine devices, etc., can solve the problems of heavy weight, unfavorable for long-term storage, and large volume, so as to increase the loading capacity, High-efficiency space utilization and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

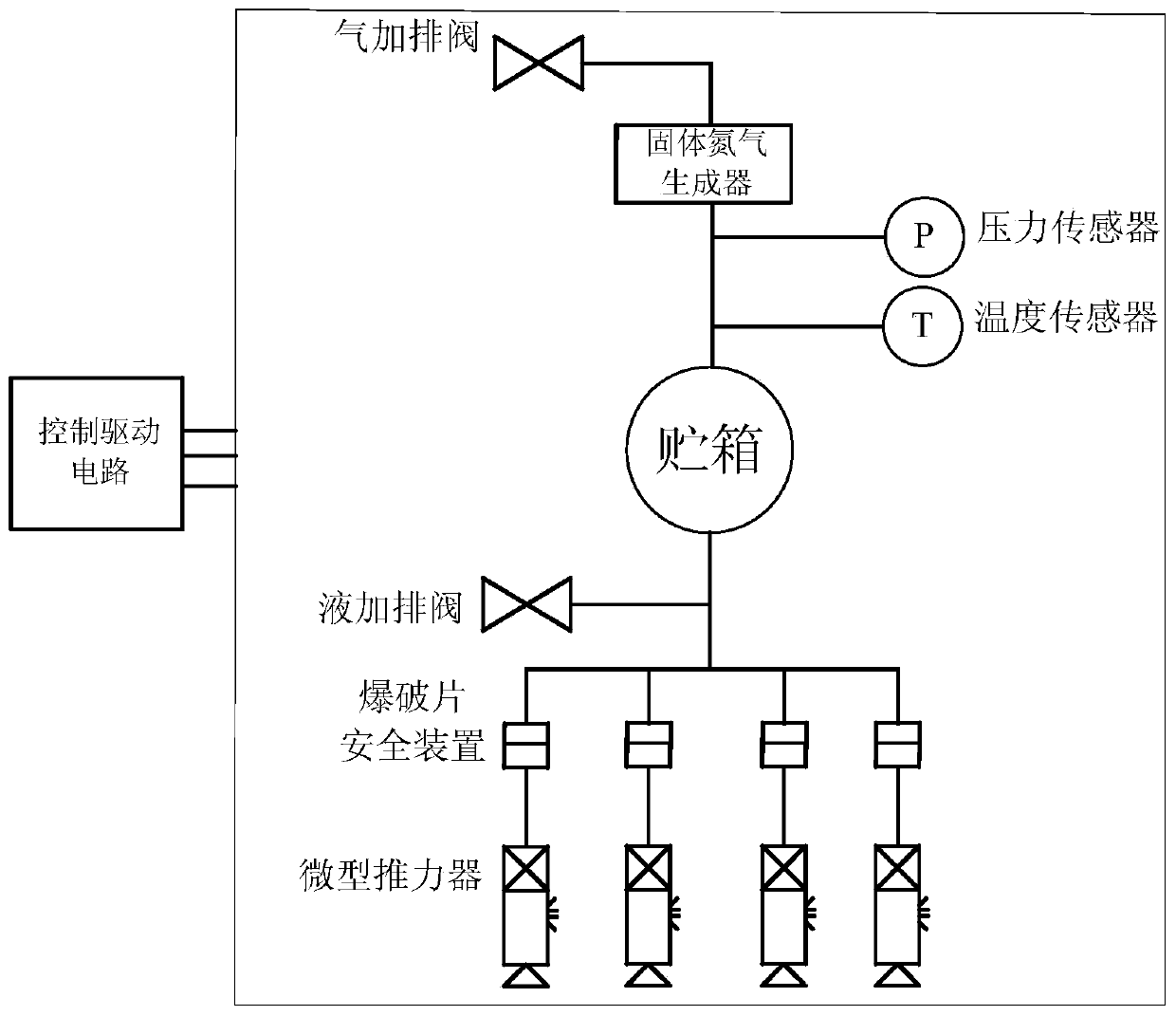

[0026] Such as figure 1 As shown, a single-component micro-propulsion module device based on additive manufacturing technology, including 4 micro-thruster components, 1 gas addition and discharge valve, 1 liquid addition and discharge valve, multiple nitrogen generators, and a temperature sensor, a pressure sensor, burst disc safety device, storage tank components, control drive circuit, etc. The shell materials of the gas adding and discharging valve, liquid adding and discharging valve, bursting disc safety device and storage tank assembly are all made of titanium alloy. The mounting interfaces of the individual components are realized by additive manufacturing. The micro thruster assembly consists of micro valves and micro thrusters. The bursting disc safety device consists of a bursting disc and a mounting structure. The tank assembly consists of a tank diaphragm and a diaphragm skeleton. The propellants of the single-component micro-propulsion module device include an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com