Solid rocket engine without spray pipe

A solid rocket and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of limited exit velocity of combustion products, avoid a large amount of energy loss, improve specific impulse performance, and reduce structural quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

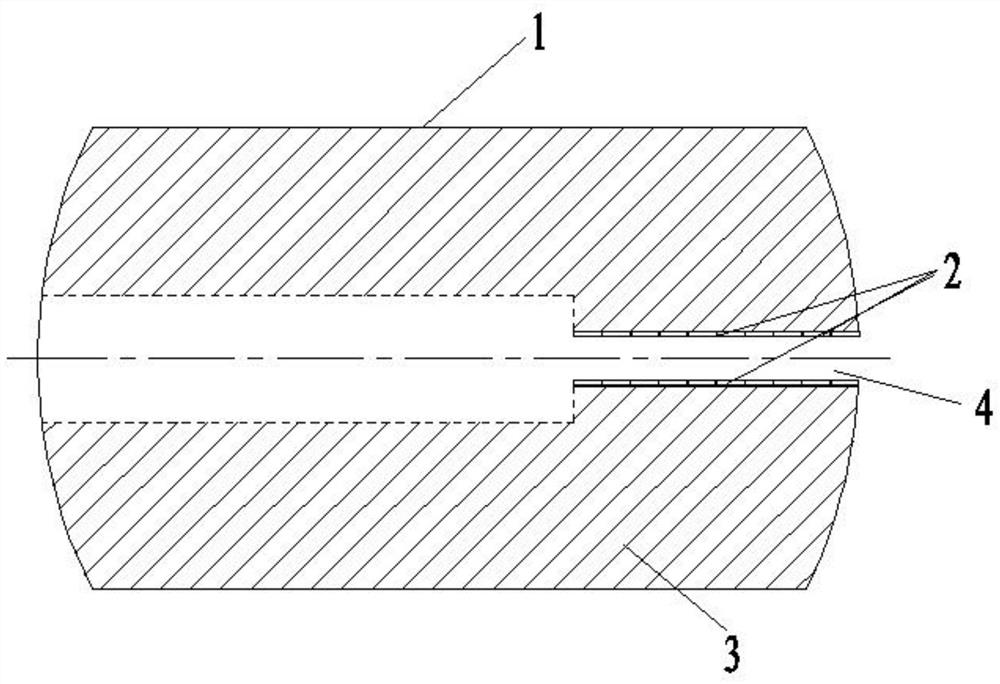

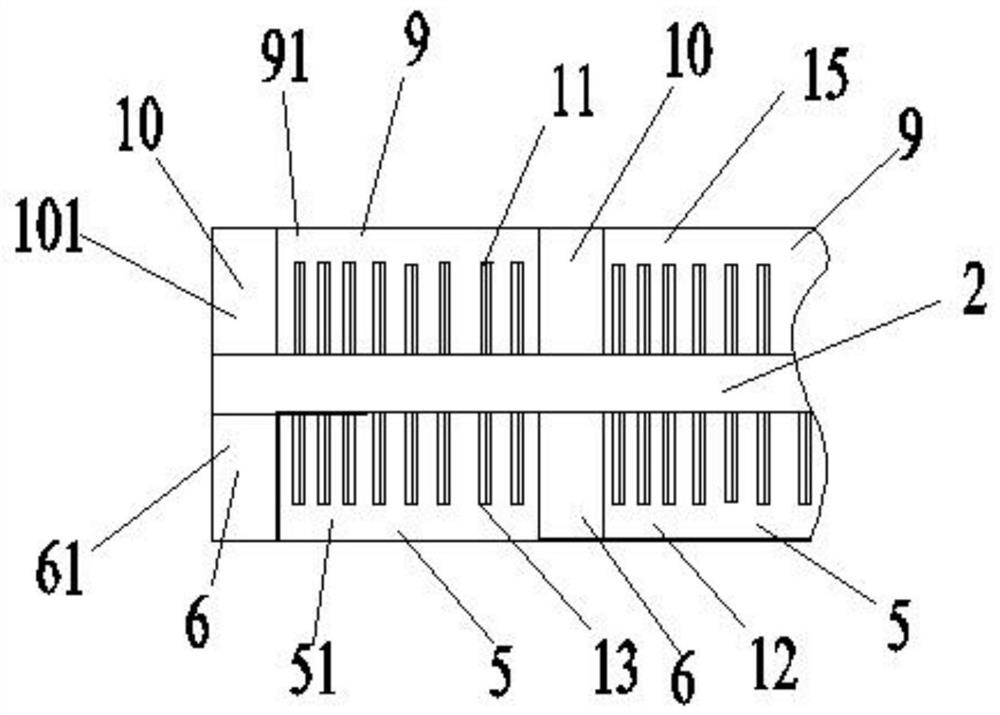

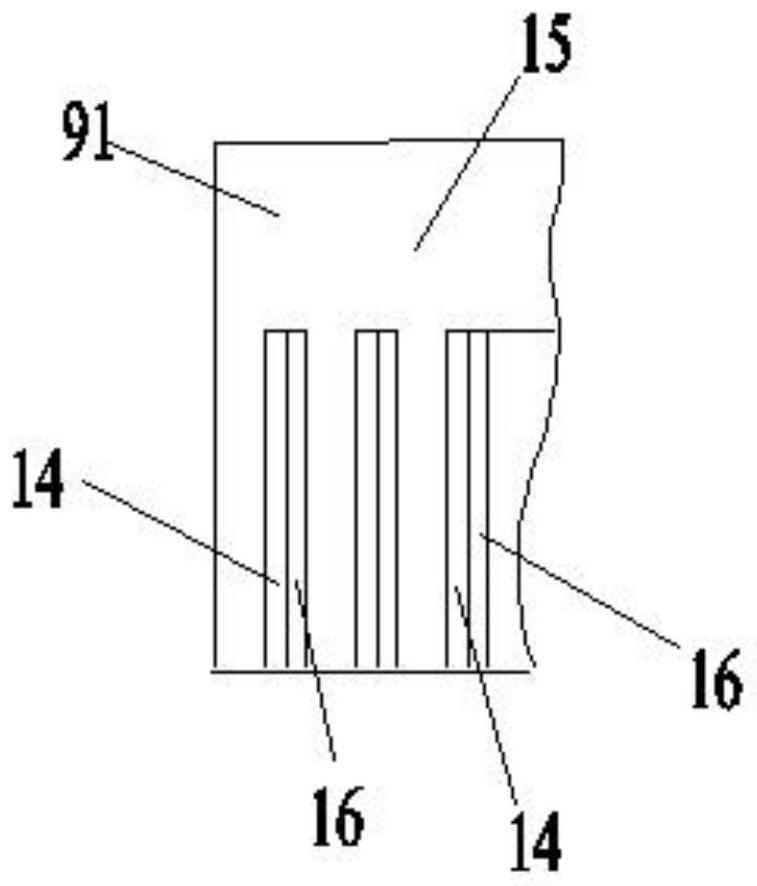

[0035] The invention discloses a nozzleless solid rocket motor, such as figure 1 with 2 As shown, it includes a shell 1, a propellant grain 3, a support tube 2, and an inner cavity electromagnetic field mechanism 6 and an inner cavity high-voltage thermoelectric mechanism 5 located on the inner wall of the support tube 2. The shell 1 is columnar, and the propellant grain 3 Filled in the inner cavity of the shell 1, a gas channel 4 is opened along the centerline of the propellant grain 3, the support tube 2 is cylindrical, the support tube 2 is sleeved in the gas channel 4, and is close to the outlet of the gas flow, the support tube 2 A plurality of inner cavity electromagnetic field mechanisms 6 and a plurality of inner cavity high-voltage thermoelectric mechanisms 5 are arranged at intervals in sequence on the inner wall, and the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com