Patents

Literature

82results about How to "High gas velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

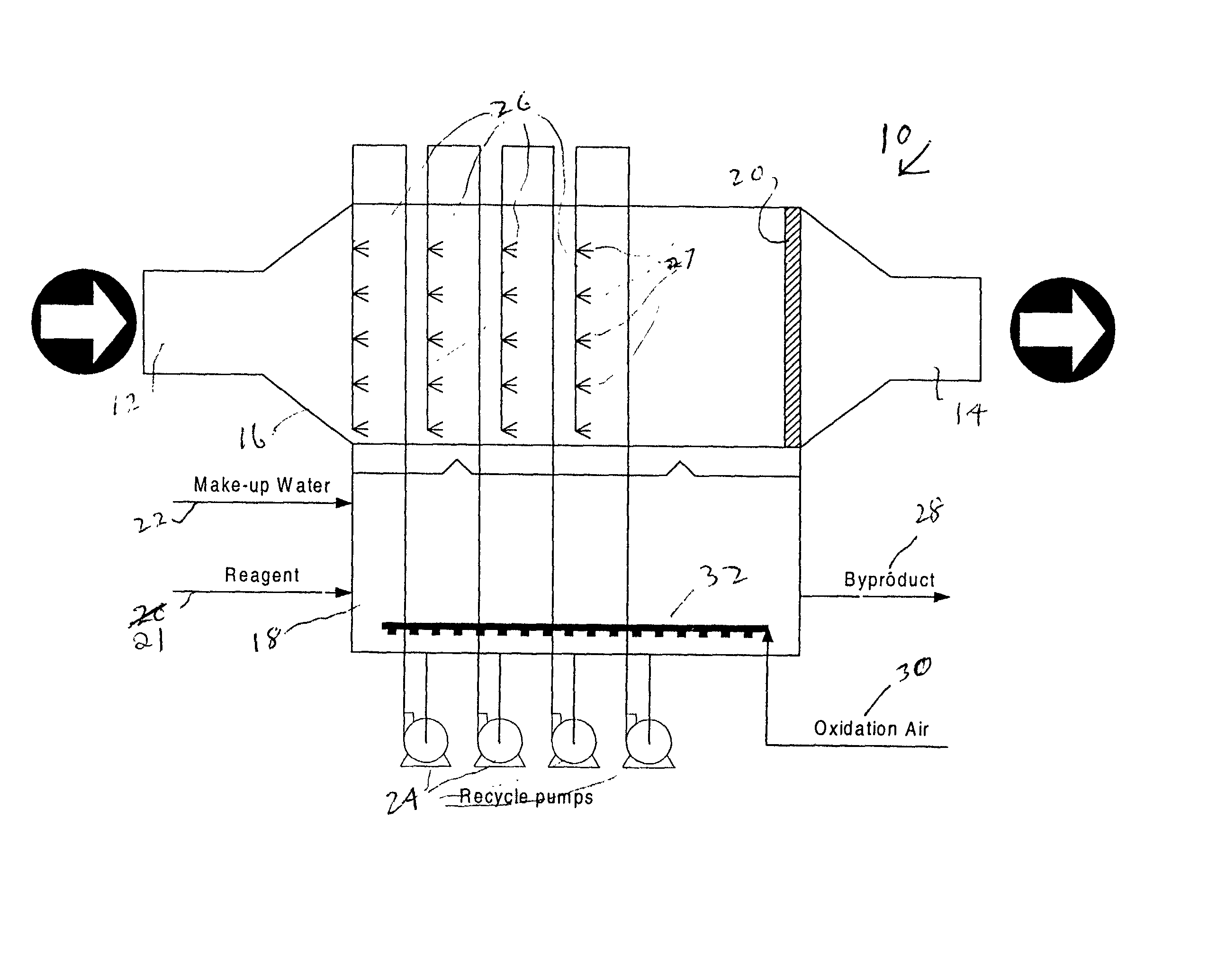

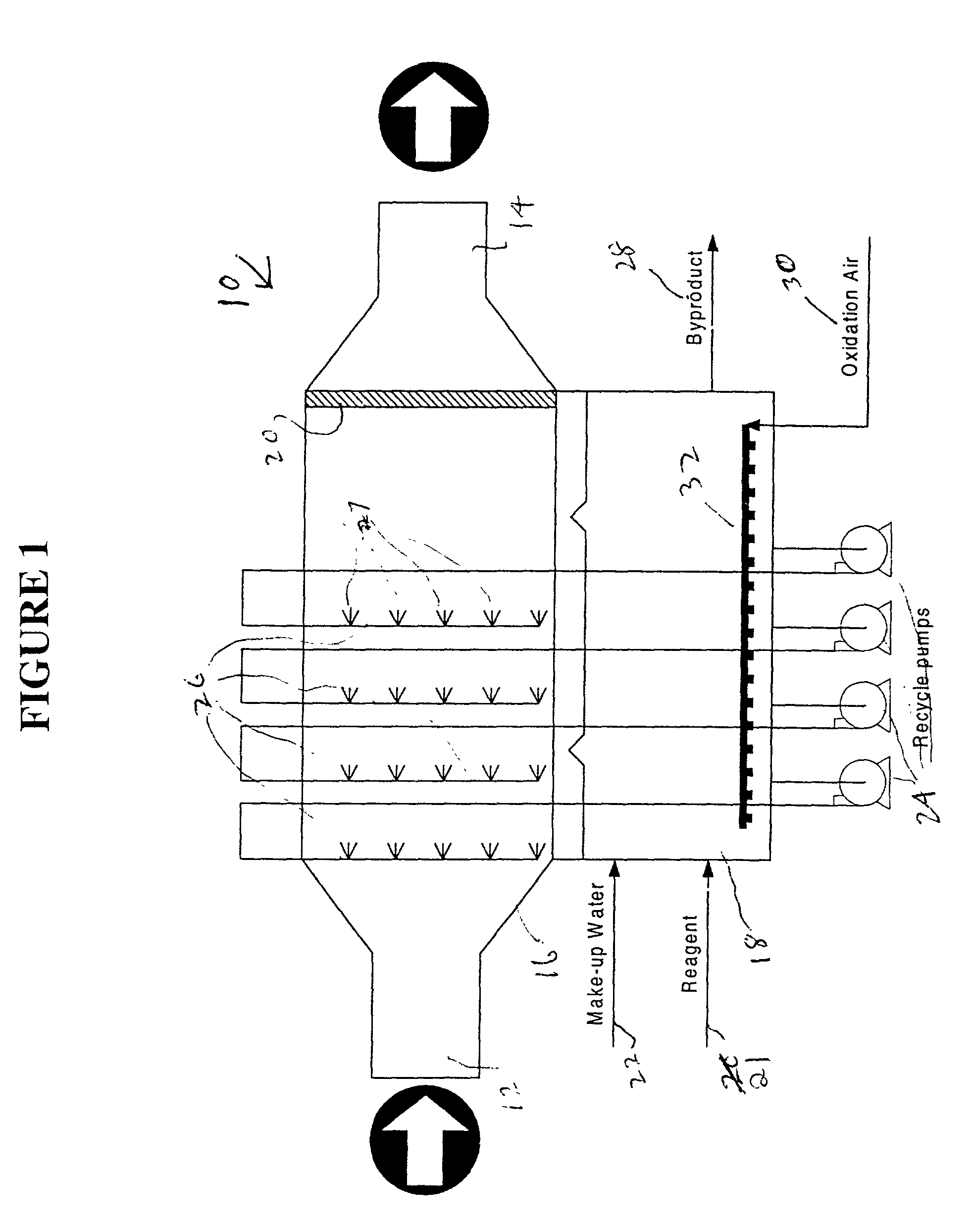

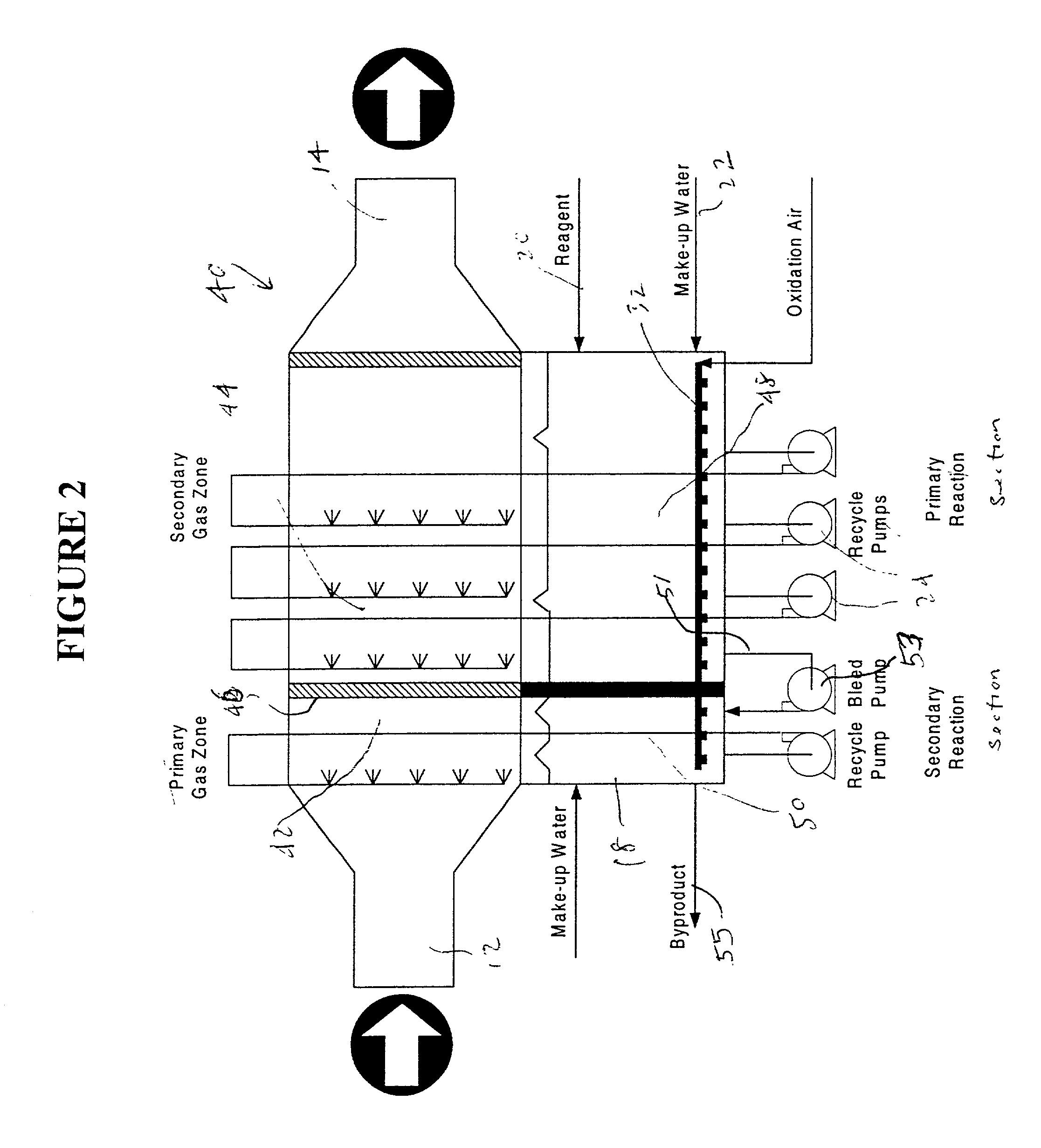

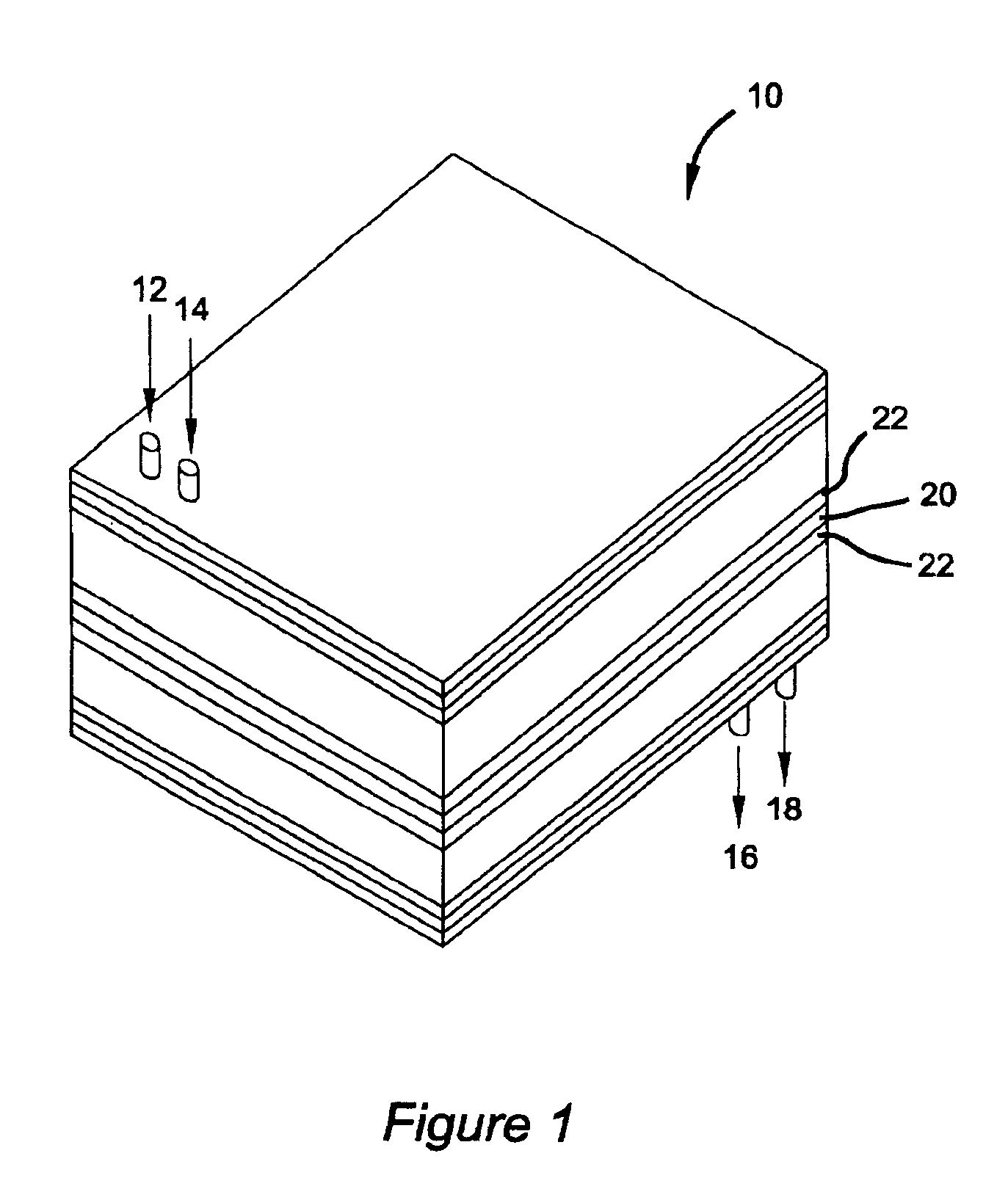

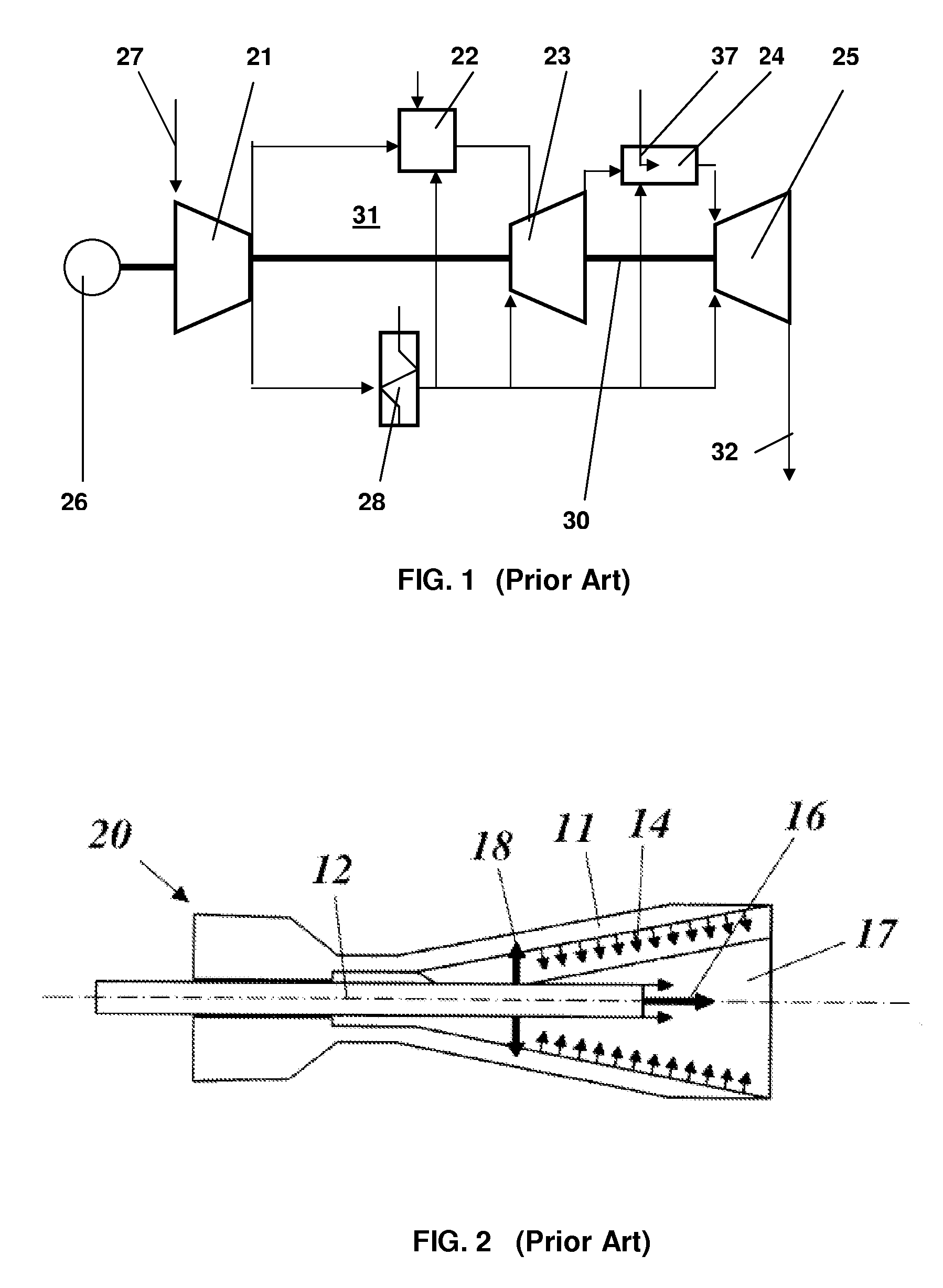

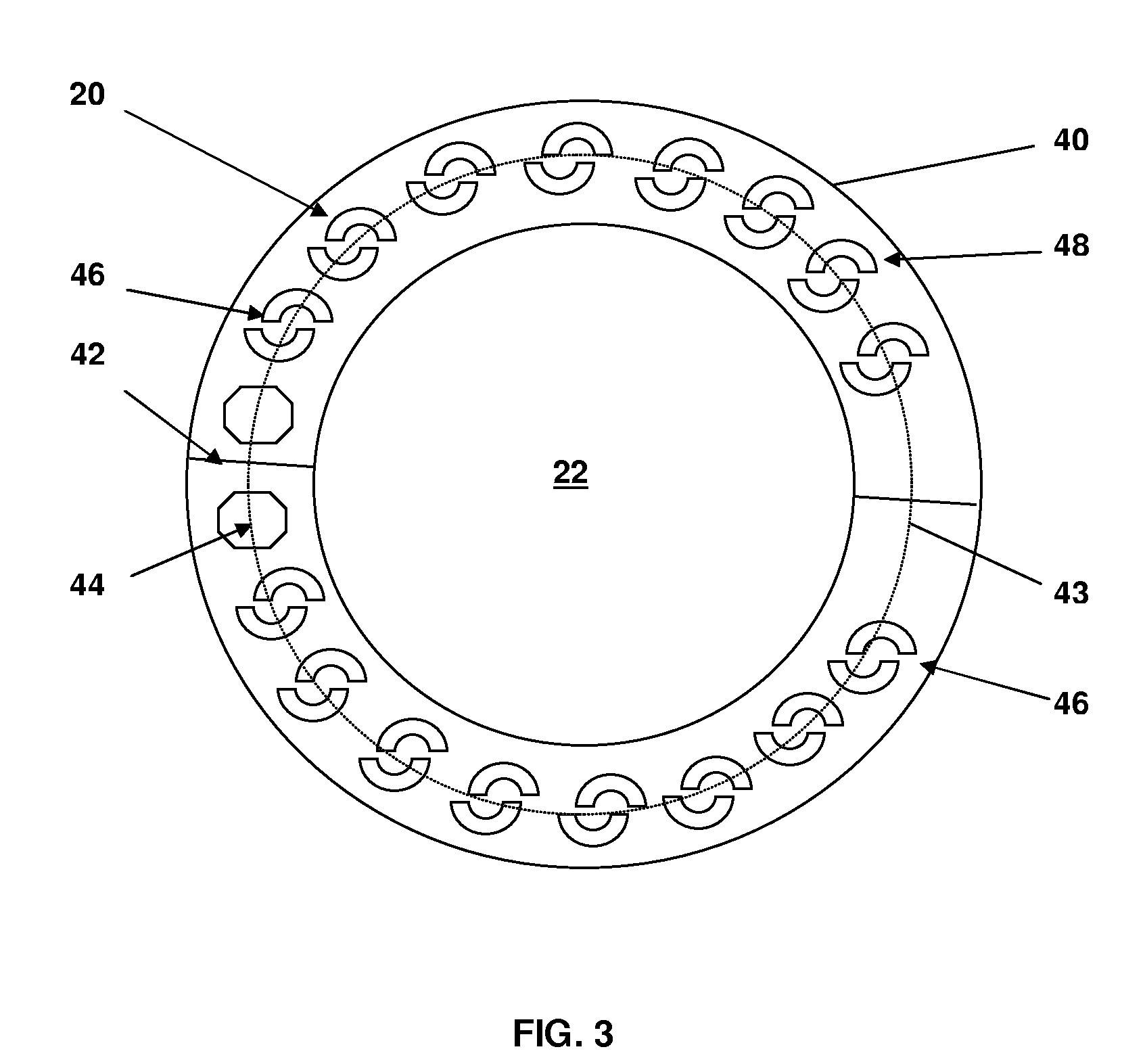

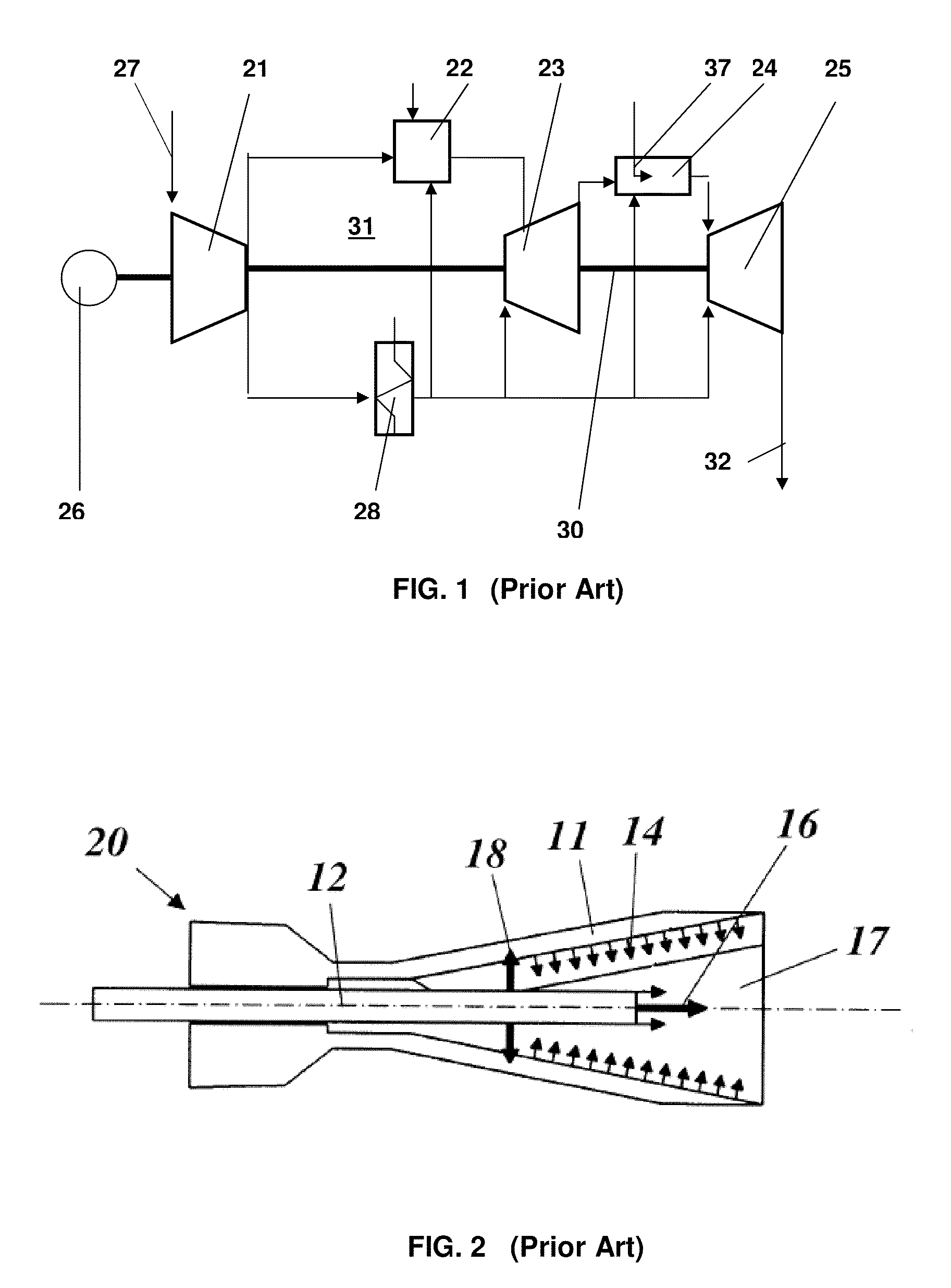

Horizontal scrubber system

InactiveUS20020110511A1Eliminate needHigh gas velocityElectrostatic separationUsing liquid separation agentDifferential pressureProduct gas

A scrubber system is provided which enables a substantially horizontal flow path for the gas which is being subjected to scrubbing. Among other advantages, this permits operation of the absorber with a differential pressure of zero or less. Scrubber composition spray means are positioned in the horizontal gas flow path for spraying an aqueous scrubber composition in a direction which is generally cocurrent with said gas flow. The system is free of means which spray the scrubber composition in directions countercurrent to said gas flow.

Owner:URS

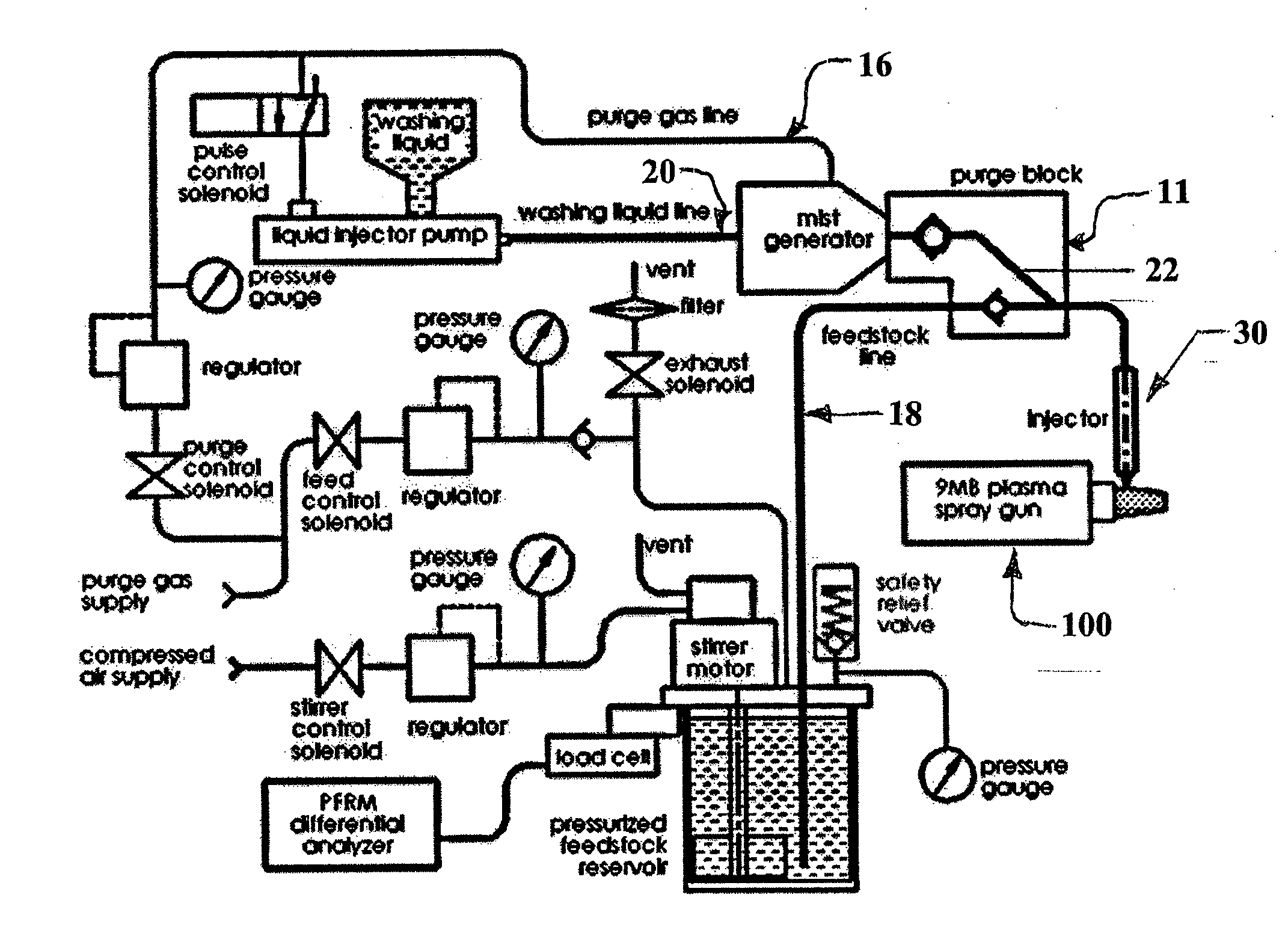

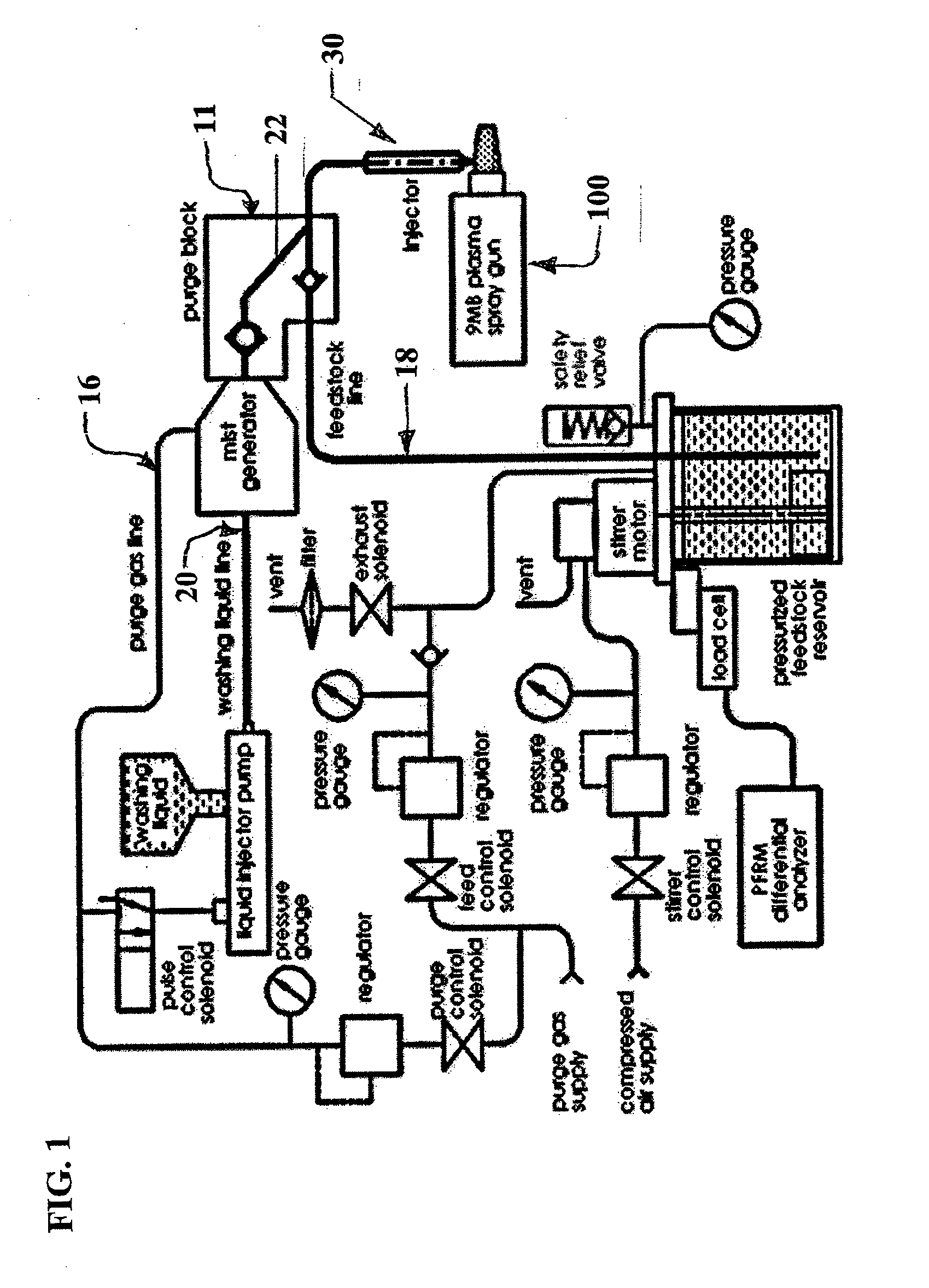

Pressure based liquid feed system for suspension plasma spray coatings

ActiveUS20130270355A1Avoid accumulationReduce cooling effectLiquid surface applicatorsMolten spray coatingLiquid jetLiquid medium

Apparatus (1) for injecting a liquid in an area of a thermal spray gun (100). The apparatus (1) includes an injector cleaning device (10) having an inlet connectable (19) to at least one feedstock supply line (18), an inlet connectable (17) to at least one gas supply line (16), and an inlet connectable (21) to at least one liquid medium supply line (20). An injector (30) orifice is coupled to the injector cleaning device (10) and is adapted to at least one of inject a liquid jet into a hot stream created in the area of the thermal spray gun (100) and receive feedstock, gas and liquid passing into the inlets.

Owner:SULZER METCO (US) INC

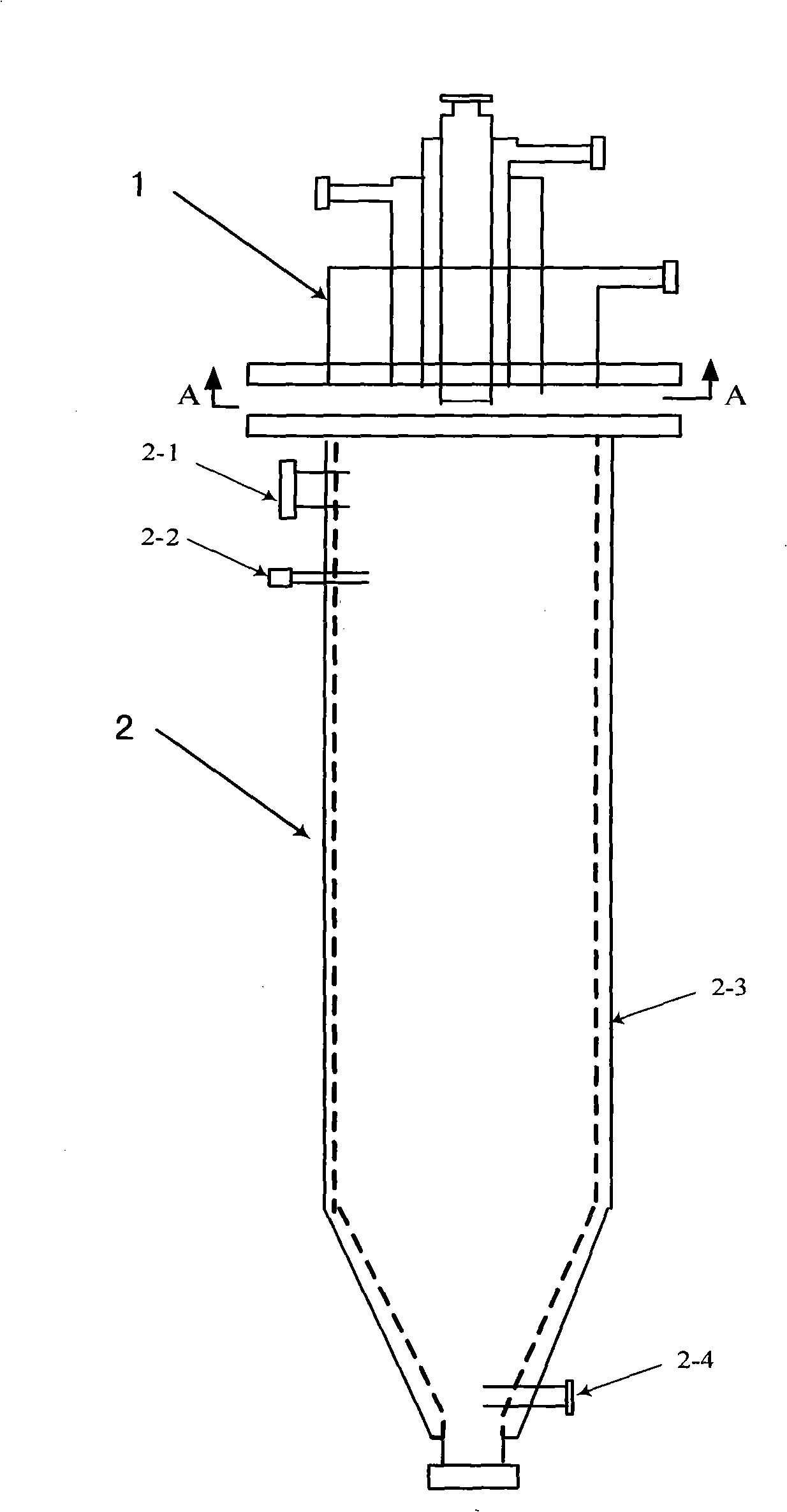

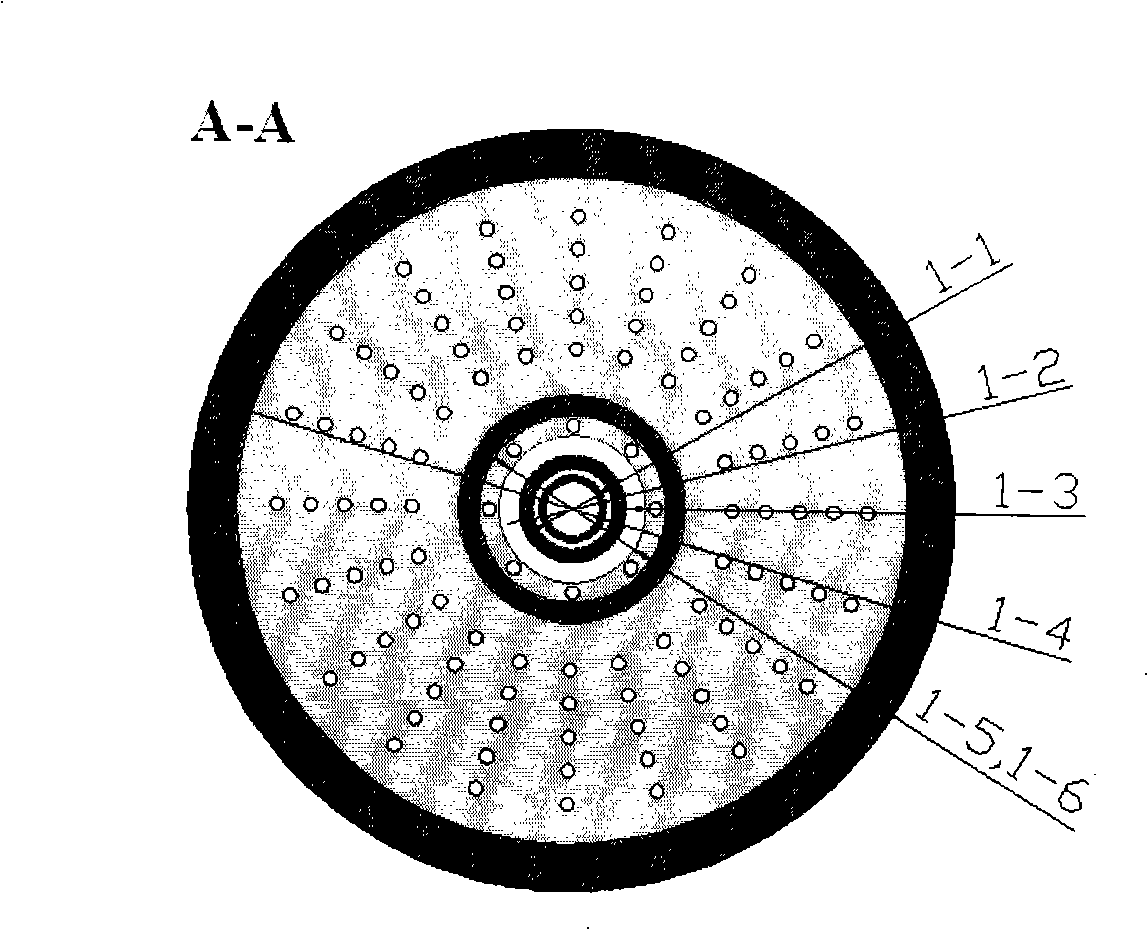

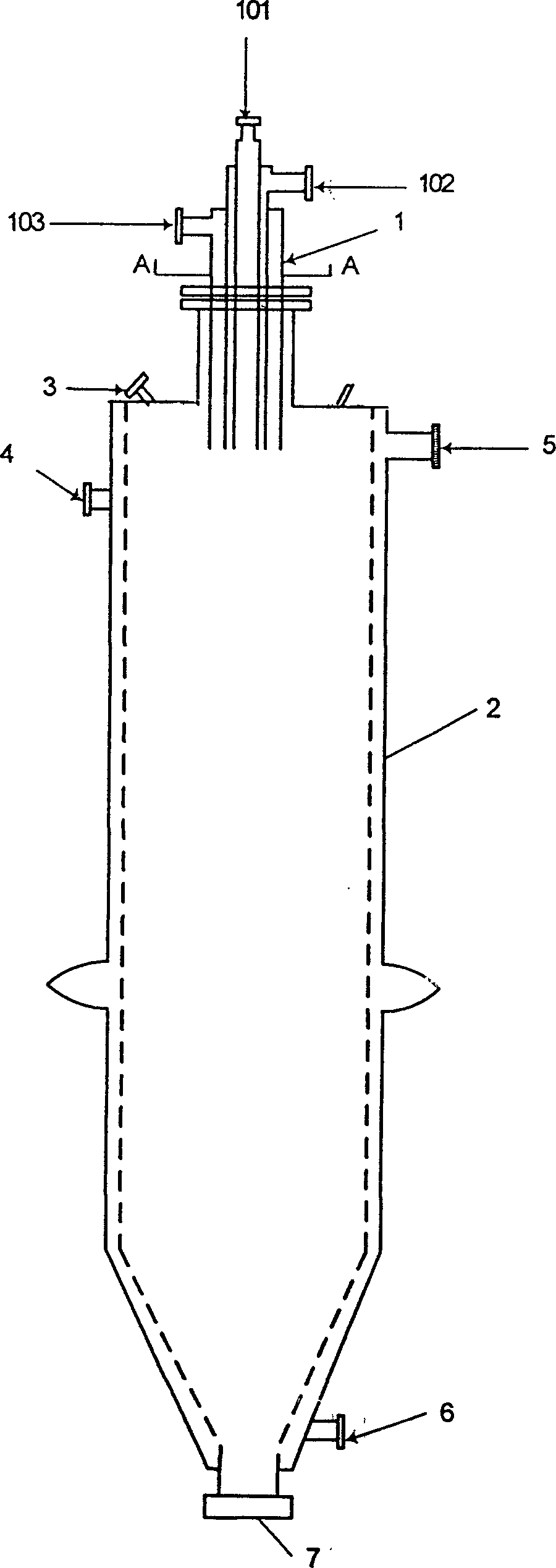

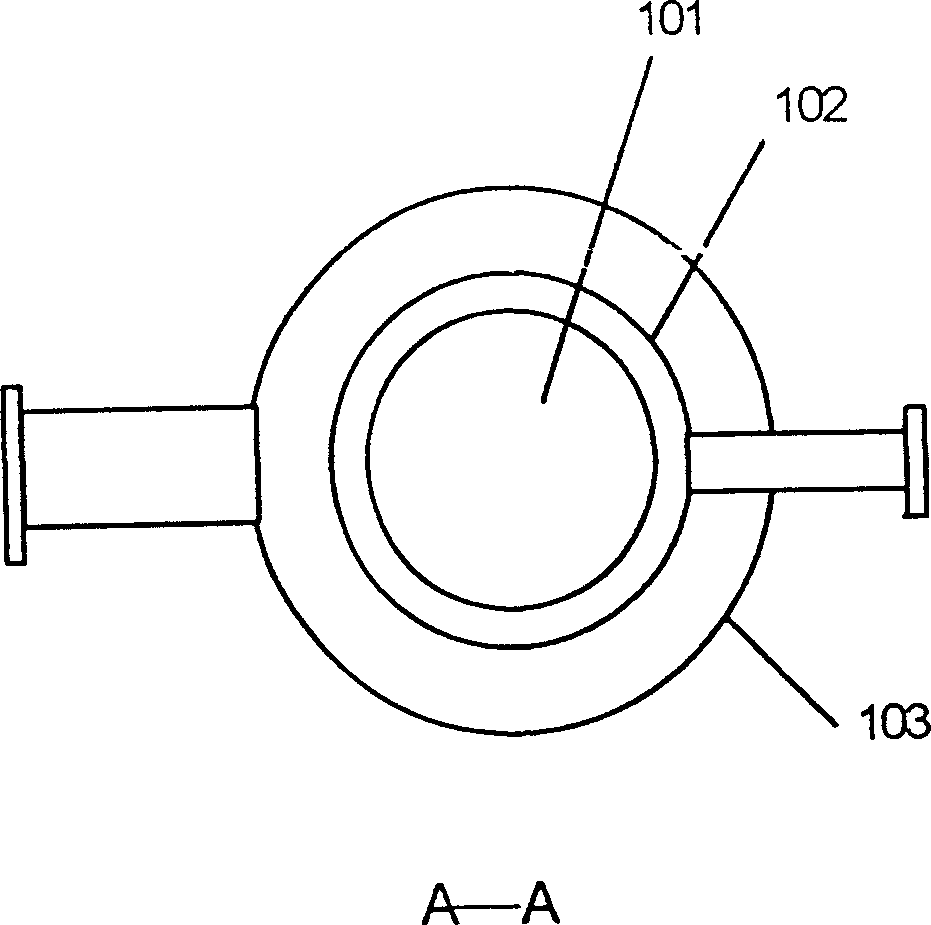

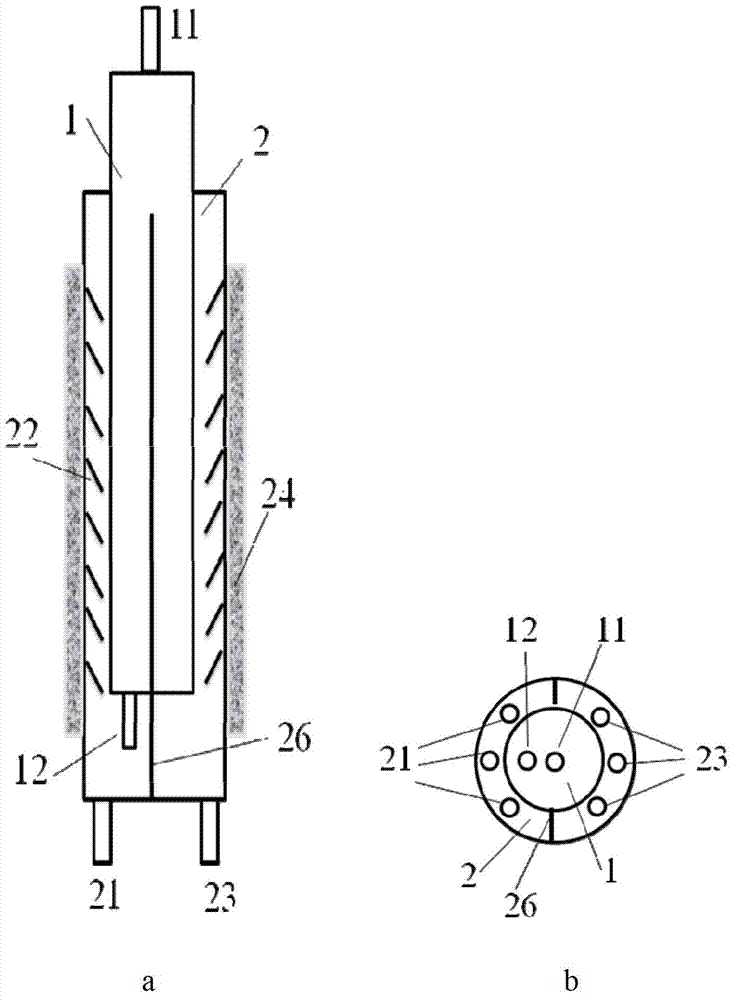

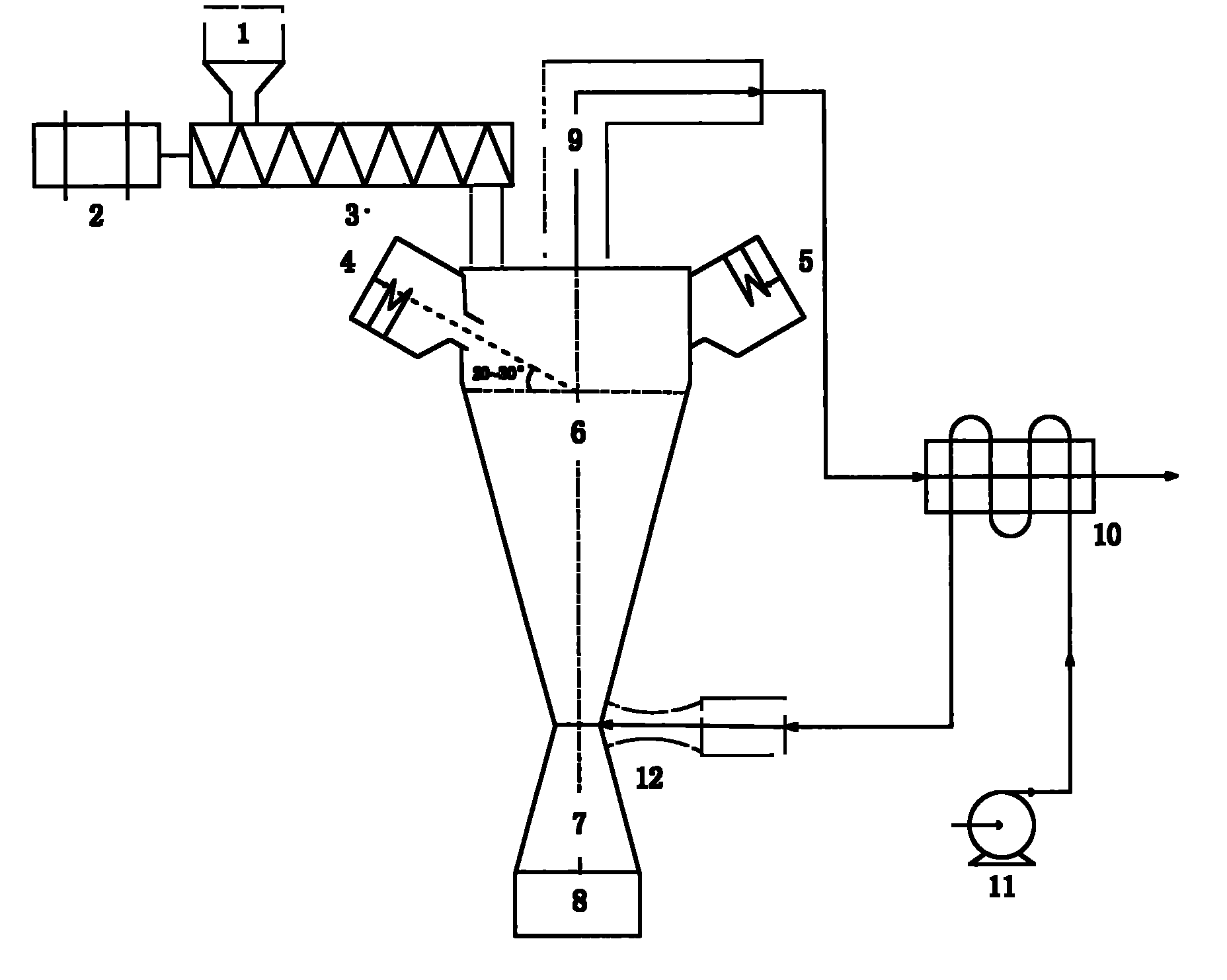

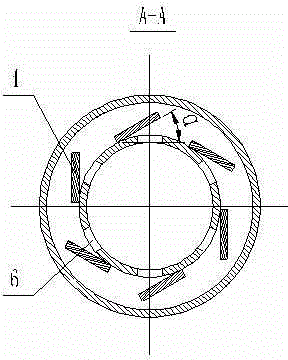

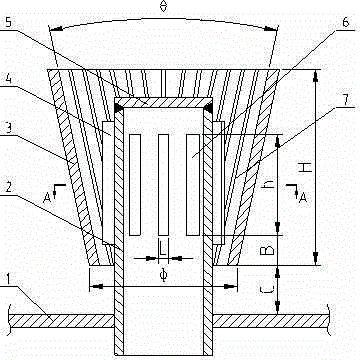

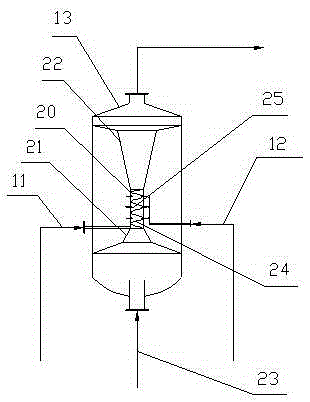

Gas-phase combustion reactor for preparing nano granule and its industrial application

ActiveCN101264433AAvoid scaringOvercome temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTin dioxideGas phase

The invention discloses a gas phase combustion reactor for preparing nanometer particles and the industrial application method. By changing the nozzle structure of the reactor in the prior art, the reactor enables the reaction material and the combustion gas to be evenly mixed to form ultrahigh speed jet flame, overcomes the defects of uneven temperature field and concentration field and liability to scab of nozzle, and enables continuous production for long period. The gas phase combustion reactor can be used for industrial and continuous preparation of various oxide nanometer particles such as nanometer titanium dioxide, silicon dioxide, aluminum oxide, and antimony doped tin dioxide.

Owner:EAST CHINA UNIV OF SCI & TECH

Auxiliarily burning reactor and its application in vapor process of preparing nano SiO2

The auxiliarily combustion reactor of the present invention has improved nozzle structure, and the vapor process of preparing nano SiO2 is superior to available process, which has non-homogeneous temperature field and concentration field in combustion reactor, uneven retention time of material in the combustion reaction area, and easy scaling in the nozzle outlet and other demerits. The present invention has raised nano SiO2 product quality.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Methane and oxygen pre-mixer

InactiveCN101125282AEvenly distributedRemove in timeHydrogenFlow mixersNuclear engineeringPartial oxidation

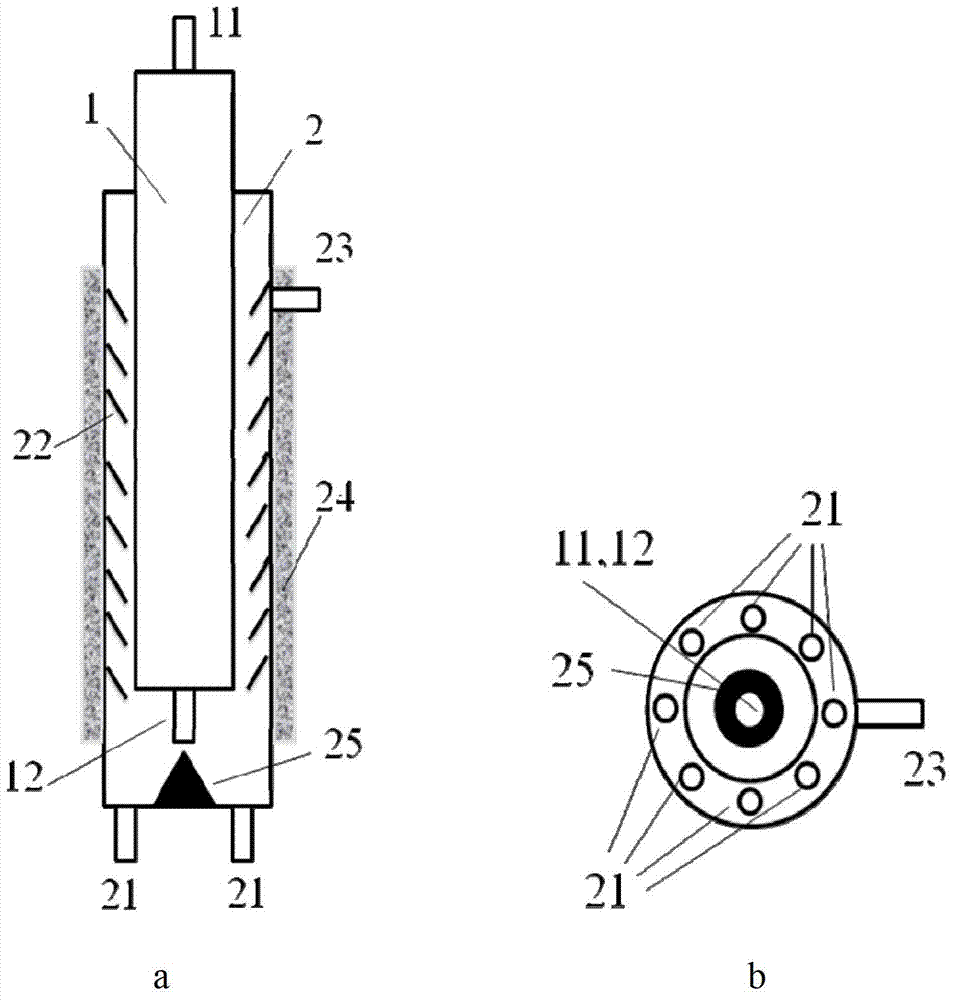

The present invention relates to a methane and oxygen pre-mix device, mainly consists of a casing, a gas distributed system, a heat exchange system and a multiorifice gas distribution plate; the gas distributed system adopts the rotational flow or the circular flow gas distributed system; the rotational flow gas distributed system consists of a methane air intake system, an oxygen air intake system, an upper distributor and a lower distributor; the circular flow gas distributed system consists of center feed pipes, cross feed pipes and ring gas distributor of the methane and the oxygen; the heat exchange system consists of an upper separator, a lower separator, a centre internal pipe, an external pipe, a metal fin, a heat exchange medium inlet pipe and a heat exchange medium outlet pipe; via the gas distributed system, the methane and the oxygen have a preliminary mixture in a smaller space, then by the stimulant fluidized bed consisting of the centre internal pipe, the external pipe and the metal fin, circuitously flowing upwards, achieving a molecular level mixture at the exit. The present invention effectively increases the pre-mix effect and guarantees the inflaming retarding and explosion prevention of the pre-mix chamber, having a good function in the industry of methane partial oxidation to syngas.

Owner:TSINGHUA UNIV

Process of synthesizing gasoline and coproducting aromatic hydrocarbon by synthetic gas

InactiveCN101016475AHigh gas velocityImprove heat transfer performanceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoverySyngasReaction temperature

The invention discloses a synthetic craft of petrol co generating aromatic hydrocarbons with synthesis gas, which comprises the following steps: mixing methanol synthesis and methanol-watering activator; loading into plasm-stating bed reactor; loading ZSM-5 activator into fixed bed reactor at normal pressure; leading into diluting hydrogen gas (H2 / N2); proceeding programmed temperature deacidize for activator in plasm-stating bed; getting tail gas; proceeding preheat for fixed bed activator with the tail gas; leading synthesis gas with H2 / CO at 1-5 : 1 into plasm-stating bed after finishing reduction under 3.0-7.0MPa; controlling reacting temperature at 260-300 deg.c and gas space velocity at 30000-120000h-1; making the reacting product enter into fixed bed with equal pressure; setting the reacting temperature at 300-400 deg.c and gas space velocity at 10000-40000h-1; proceeding synthetic reacting. This invention possesses merits of big gas speed, good heat diffusion and minor equipment investment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Apparatus and method for continuously preparing thin-layer grapheme or hybrid combining thin-layer grapheme with thin-walled carbon nanotube

InactiveCN102730673ASimple structureLow equipment costMaterial nanotechnologyGrapheneCvd grapheneThin walled

The invention discloses an apparatus for continuously preparing thin-layer grapheme or a hybrid combining the thin-layer grapheme with thin-walled carbon nanotube and a preparation method of the thin-layer grapheme or the hybrid combining the thin-layer grapheme with the thin-walled carbon nanotube by utilizing the apparatus, which belongs to the field of multiphase flow reactor technology and carbon nanomaterial preparation. The apparatus provided by the invention comprises a downer, a riser and a heating system wrapped on the outside of the riser for heating up. According to the method, the heating system is started; reaction gas and a template are led through the entrance of a gas-solid mixture of the downer to grow thin-layer grapheme, or the reaction gas and a catalyst are led to grow hybrid of thin-layer grapheme and thin-walled carbon nanotube; and then the reaction gas is led through the a gas inlet of the riser; all gas-solid mixture moves forward, passes through a member area, gets out of the riser and enters a subsequent gas-solid separation section and a cooling and storage section. The apparatus provided by the invention has the advantages of simplicity in structure and low cost of equipment. The method provided by the invention has low environmental pollution and the obtained product has high quality.

Owner:TSINGHUA UNIV

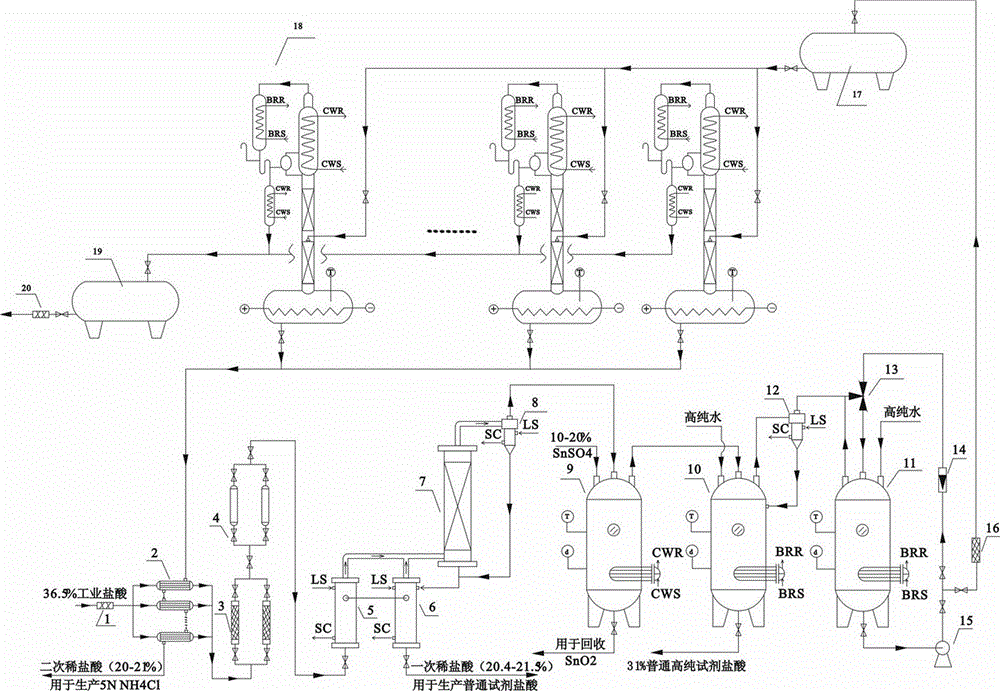

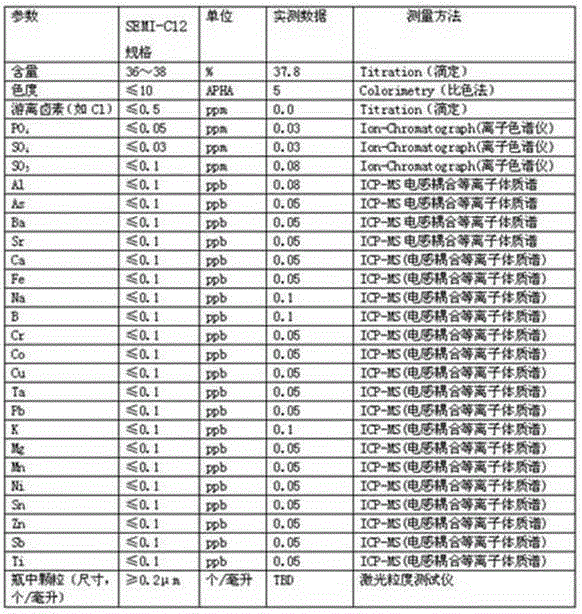

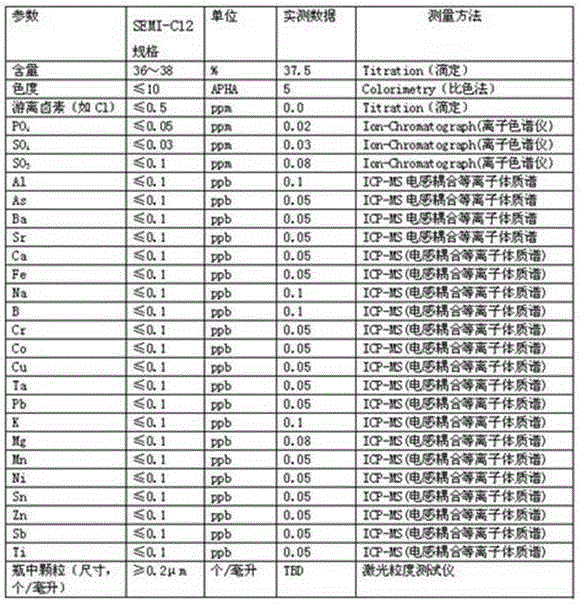

Method for preparing ultra-clean high-purity hydrochloric acid

ActiveCN103979497AReduce pollutionReduce oxidationChlorine/hydrogen-chloride purificationActivated carbonFiber

The invention discloses an industrial method for preparing ultra-clean high-purity reagent-grade hydrochloric acid from industrial hydrochloric acid through purification. The method comprises the following steps: filtering the industrial hydrochloric acid, dechlorinating activated carbon fibers, performing ion exchange through an anion exchange resin column, heating and evaporating; removing high-boiling-point substances out of gas-phase fractions through a super-pure polytetrafluoroethylene-dipped graphite packing tower, washing the gas-phase fractions in a stannous mono-sulfate solution, washing with high-purity water, then absorbing the high-purity water , thus obtaining the ultra-clean high-purity hydrochloric acid product. The method also can comprise a step of second distillation. The aim of realizing high-quality high-efficiency industrial batch production of ultra-clean high-purity reagent hydrochloric acid is reached.

Owner:XILONG SCI CO LTD

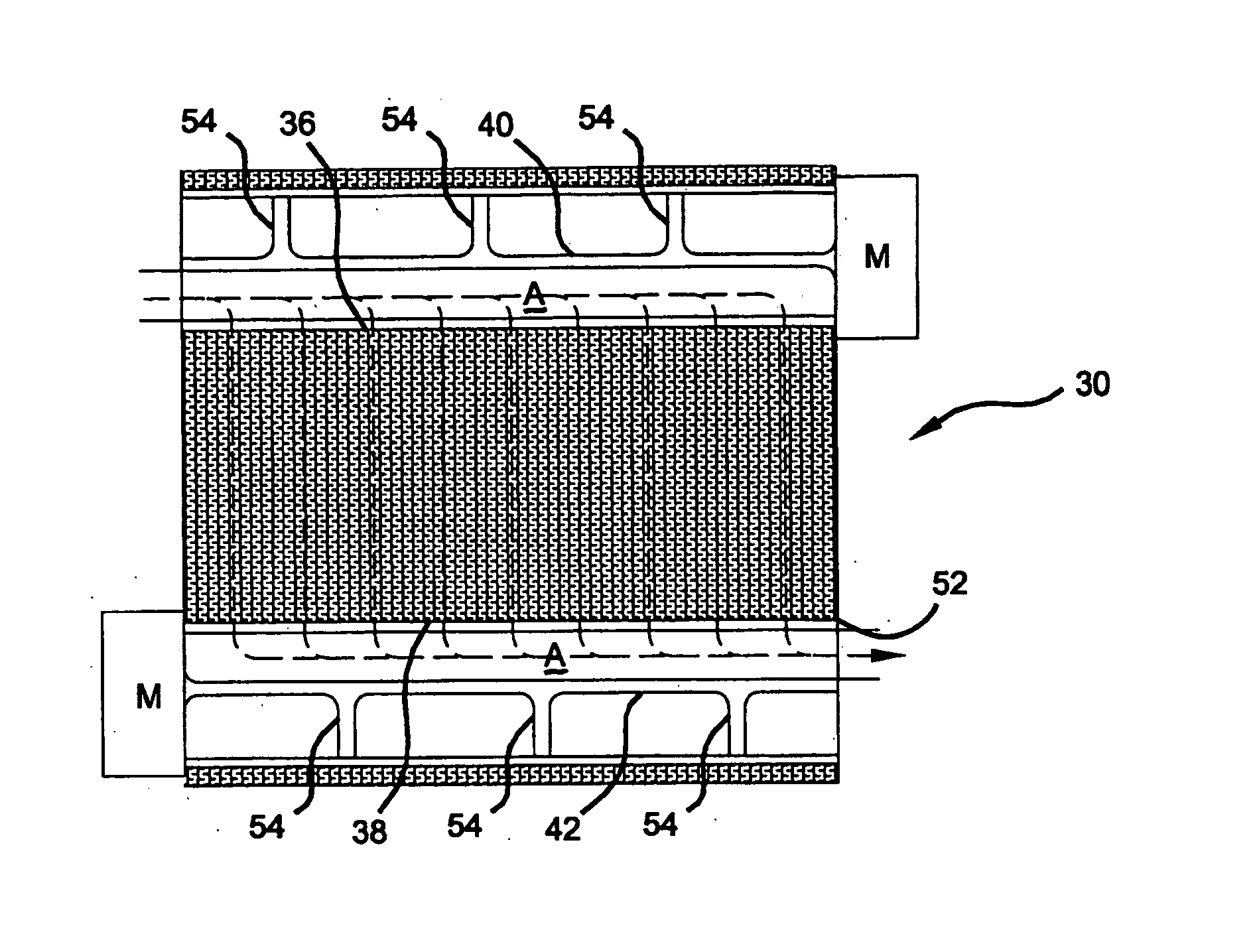

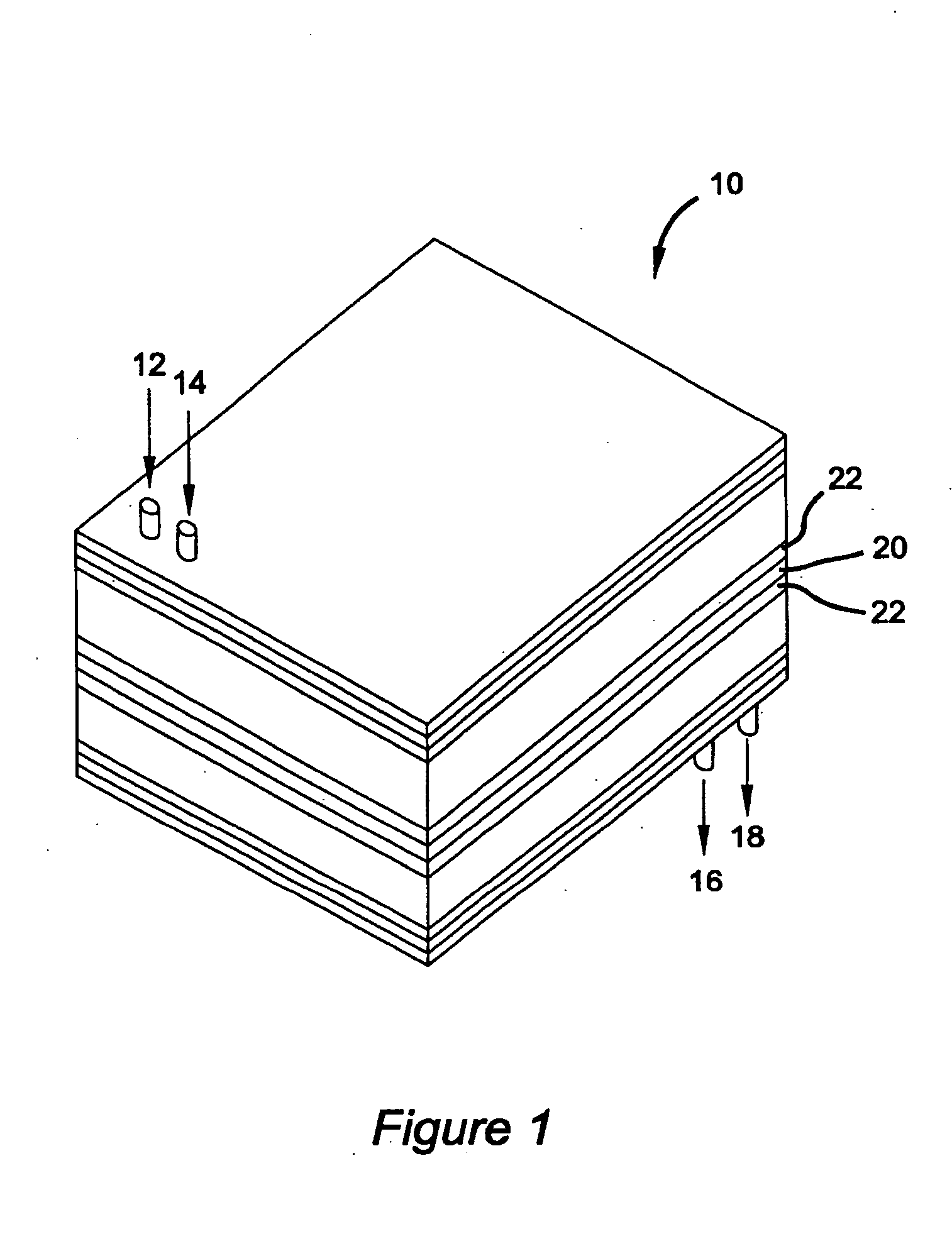

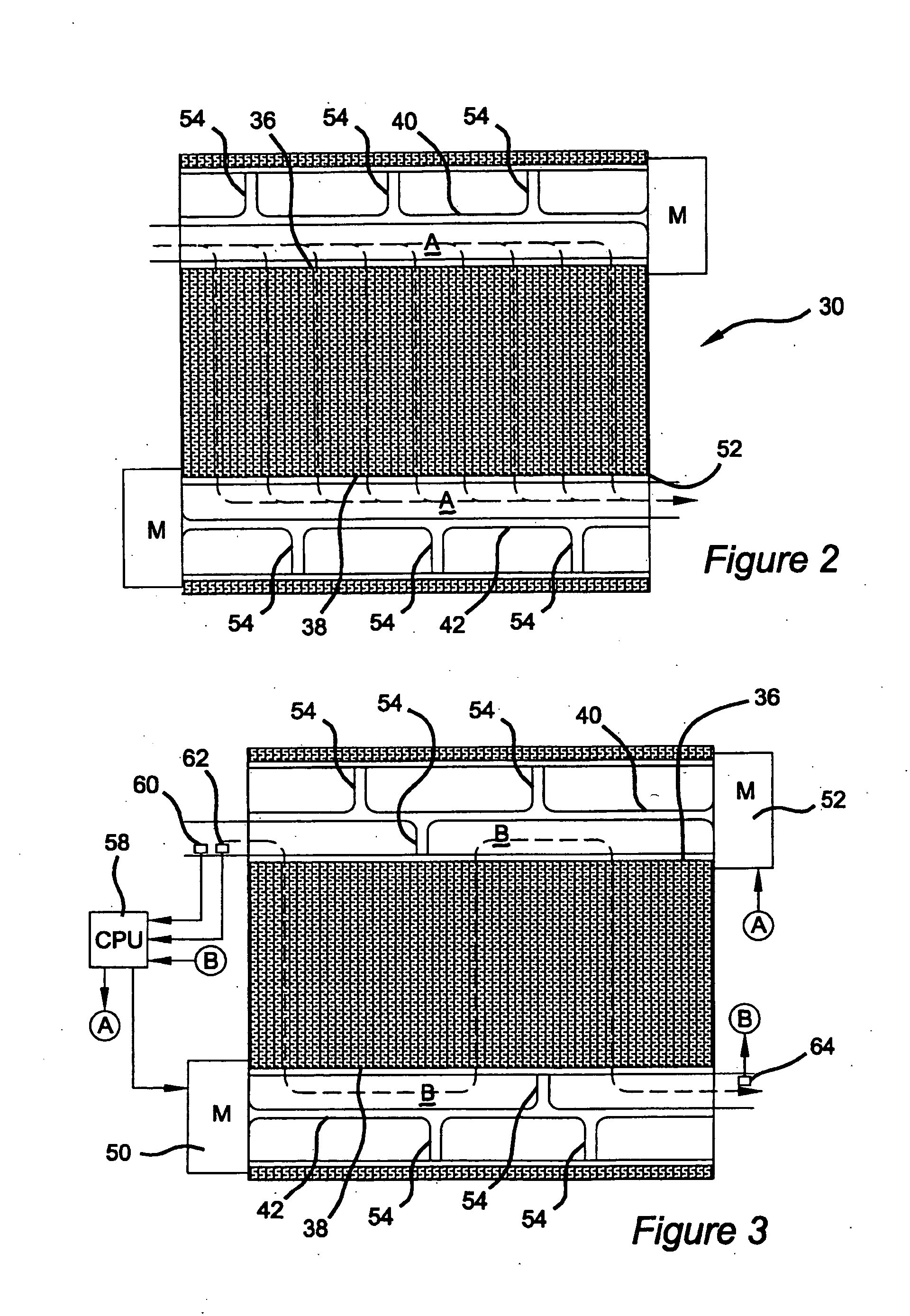

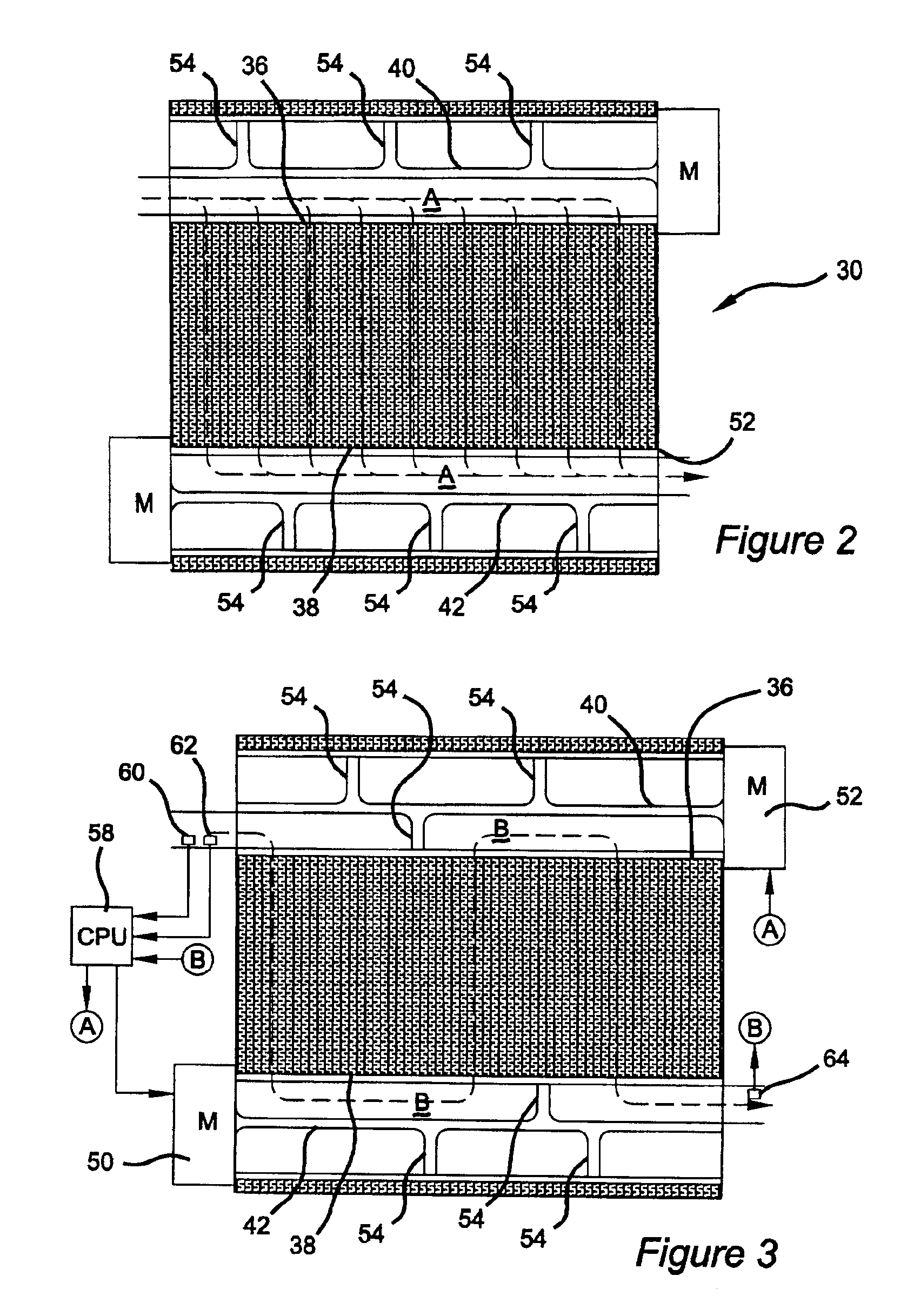

Device and method to expand operating range of a fuel cell stack

InactiveUS20050037254A1Expand the scope of operationHigh gas velocityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A device and method are provided to allow the flowpaths in a fuel cell stack to be reconfigured dependent on reactant gas throughput in order to maintain appropriate pressure drop, sufficient velocities, and reactant concentrations of each cell of a fuel cell stack.

Owner:GM GLOBAL TECH OPERATIONS LLC

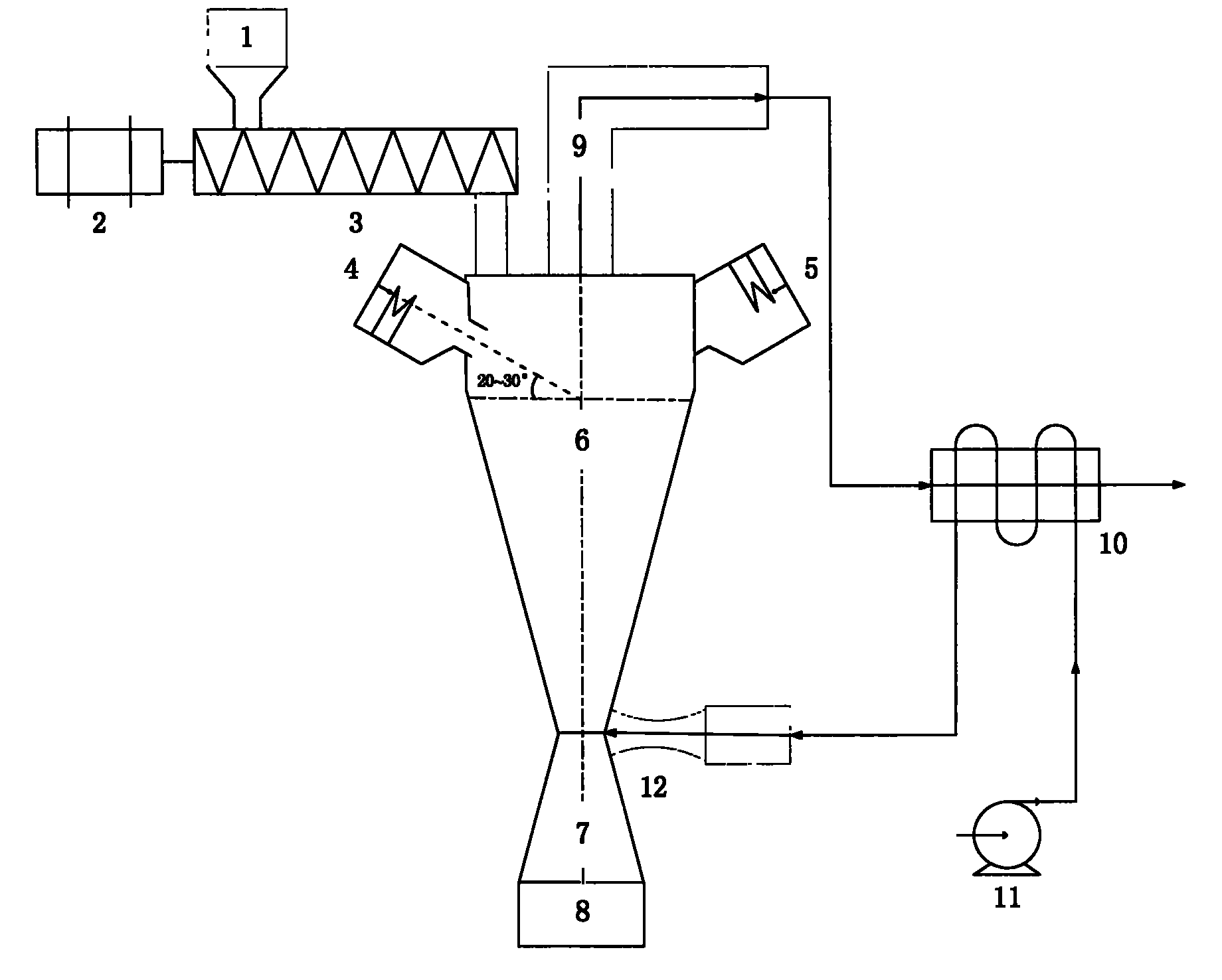

Two-section biomass cyclone high-temperature pyrolysis gasification furnace

The invention discloses a two-section biomass cyclone high-temperature pyrolysis gasification furnace comprising an upper-section cyclone high-temperature pyrolysis gasification chamber, a lower-section vapour spraying pyrolysis gasification chamber, a screw feeder, a biomass gas exhaust pipe, a gas fuel high-velocity burner and a slab box. When the two-section biomass cyclone high-temperature pyrolysis gasification furnace disclosed by the invention is operated, the gas fuel high-velocity burner generates a high-temperature anaerobic flue gas, and the high-temperature anaerobic flue gas is spayed into the upper-section cyclone high-temperature pyrolysis gasification chamber at high velocity along a tangential direction and close to an inner wall side to form a strong cyclonic vortex; meanwhile, biomass materials fall into the upper-section cyclone high-temperature pyrolysis gasification chamber through the screw feeder and are mixed, heated and pyrolyzed with the high-temperature anaerobic flue gas, wherein fixed carbon is gasified, and a generated biomass gas is exhausted through the biomass gas exhaust pipe; the biomass gas heats fed water into vapours through a heat exchanger;and the vapours enter the lower-section vapour spraying pyrolysis gasification chamber through a Venturi tube so as to further pyrolyze and gasify carbon residues, and finally formed slag is discharged into the slag box. According to the invention, the content of tars contained in the biomass gas can be greatly reduced and the effective utilization of biomass energy is realized.

Owner:HARBIN INST OF TECH

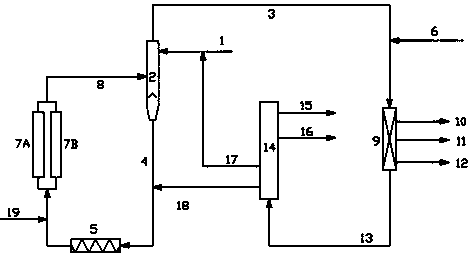

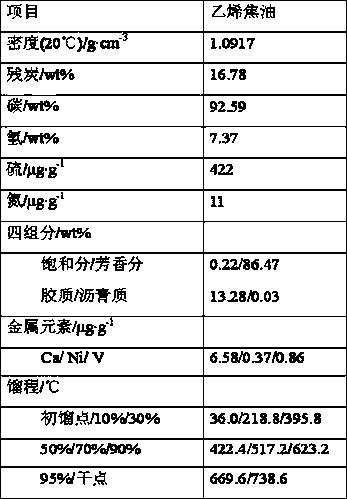

Process and system for treating ethylene tar

ActiveCN109929592APlay a role in strippingRestricted accessTreatment with hydrotreatment processesCracking reactionTreatment system

The invention discloses a process and a system for treating ethylene tar. According to the process, preheated ethylene tar contacts a coking reaction effluent from a delayed coking reaction system ina pretreatment reactor, and a light component and a heavy component are obtained after separation; the heavy component enters the delayed coking reaction system, and the generated coking reaction effluent enters the pretreatment reactor; the light component and hydrogen enter a hydrogenation reaction system, and the reaction effluent is separated to obtain gas, gasoline distillate, diesel oil distillate and heavy oil distillate; and the heavy oil distillate enters a catalytic cracking reaction system, and the catalytic diesel oil obtained after separation enters the pretreatment reaction. Thetreatment system comprises the pretreatment reactor, the coking reaction system, the hydrogenation reaction system, and the catalytic cracking reaction system. With the process and the system of the present invention, the stable long-cycle operation of the whole treatment system can be ensured, and the yield of the light oil product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

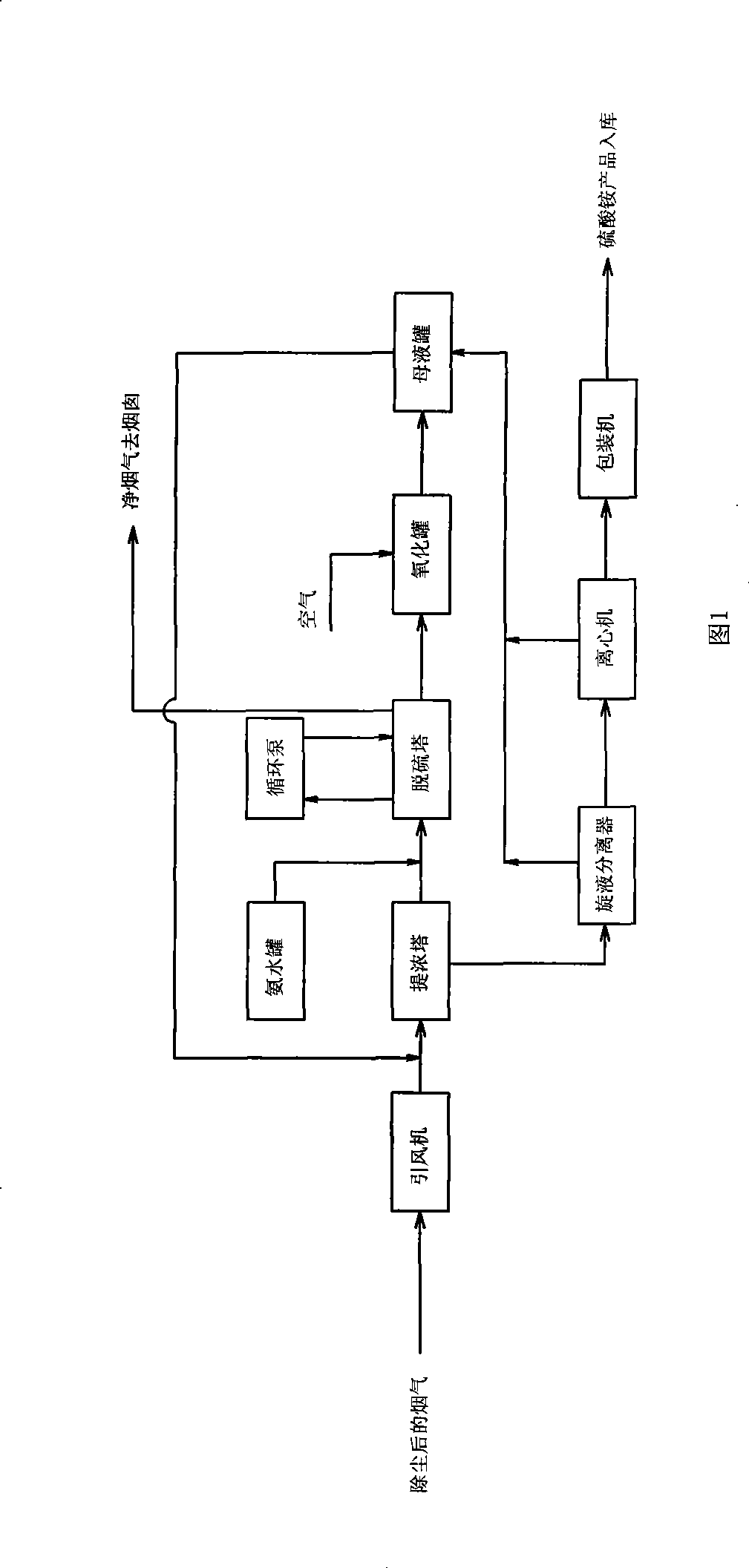

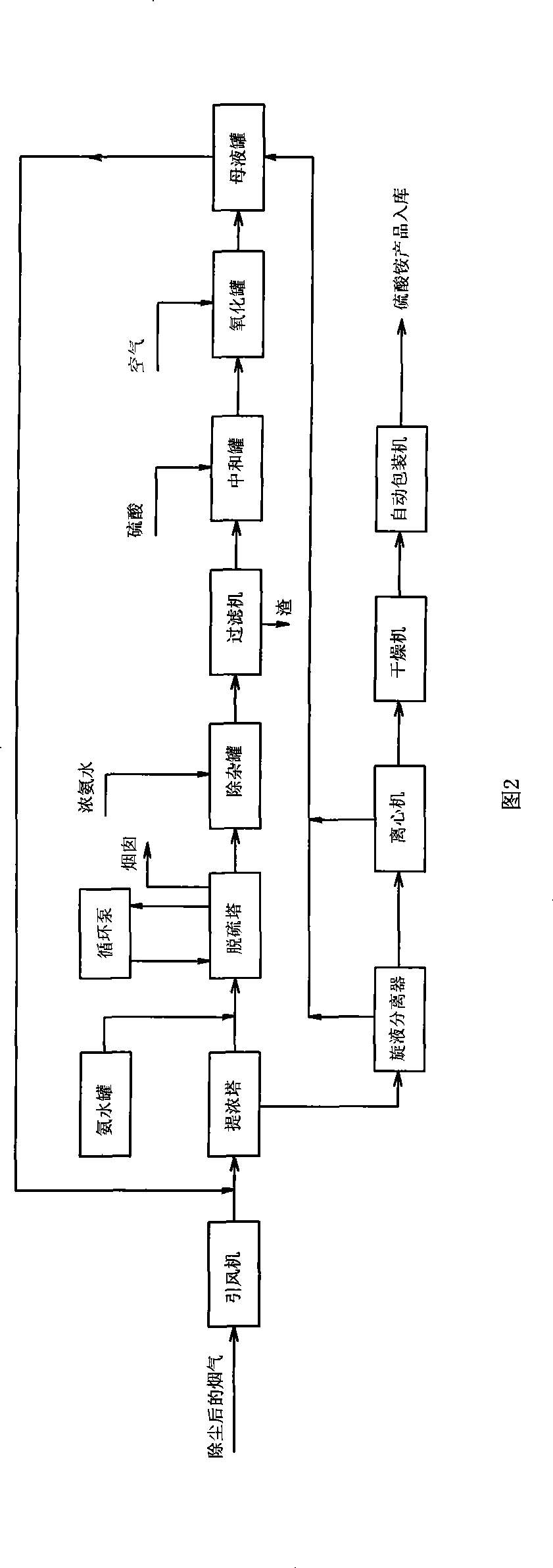

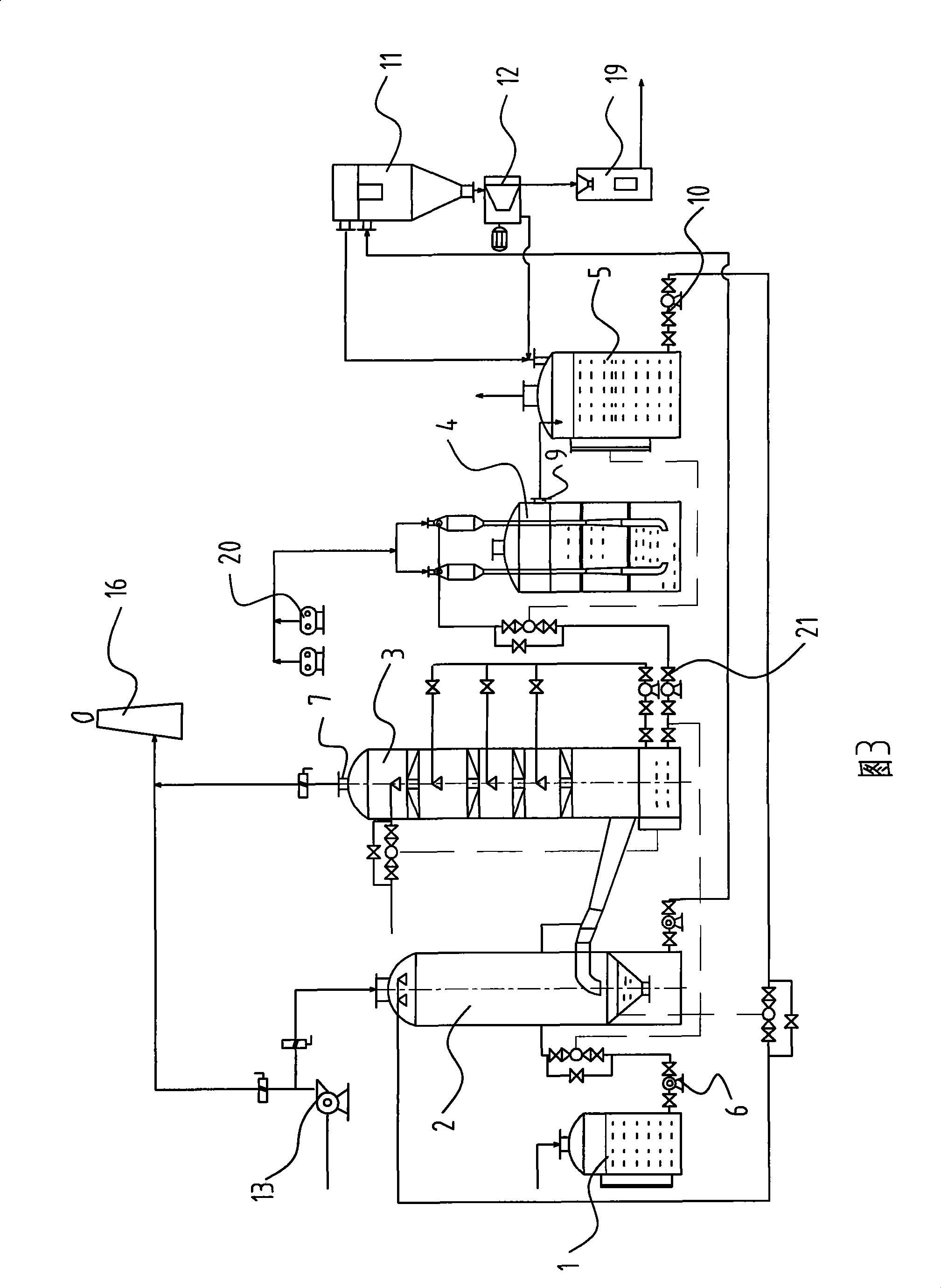

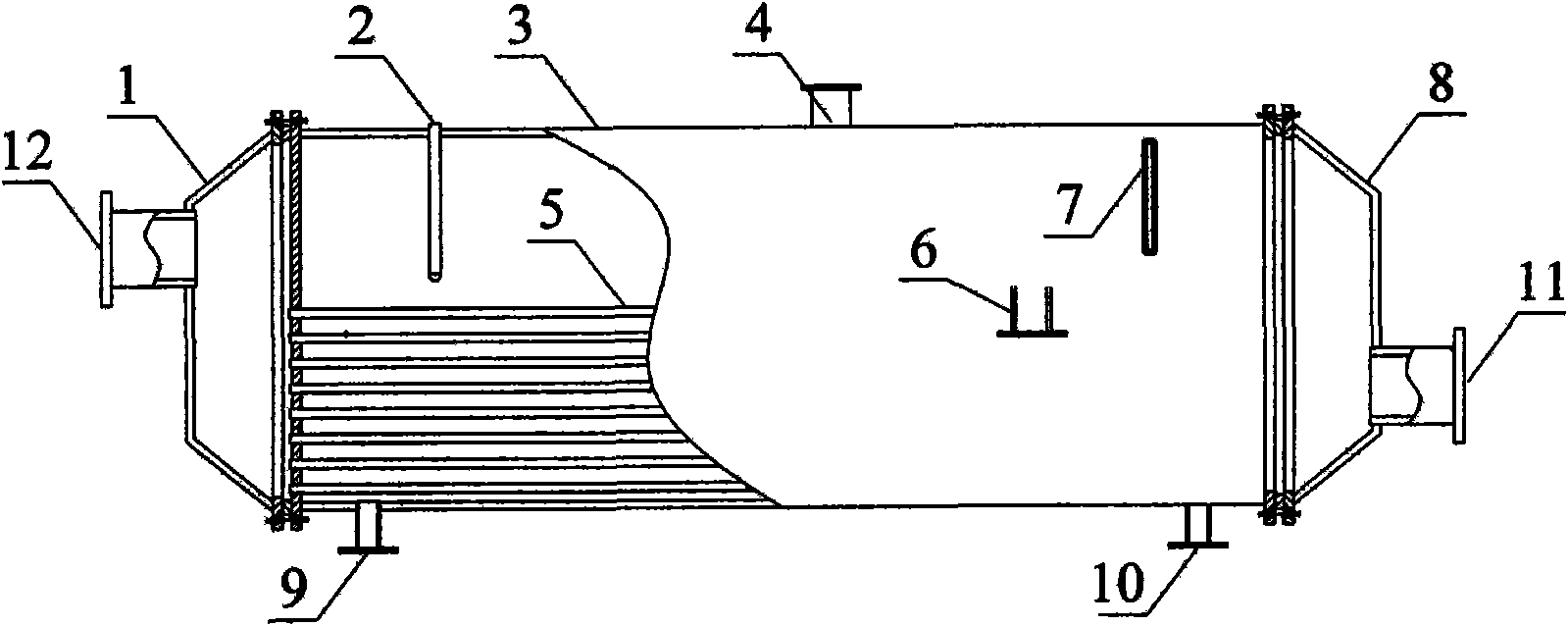

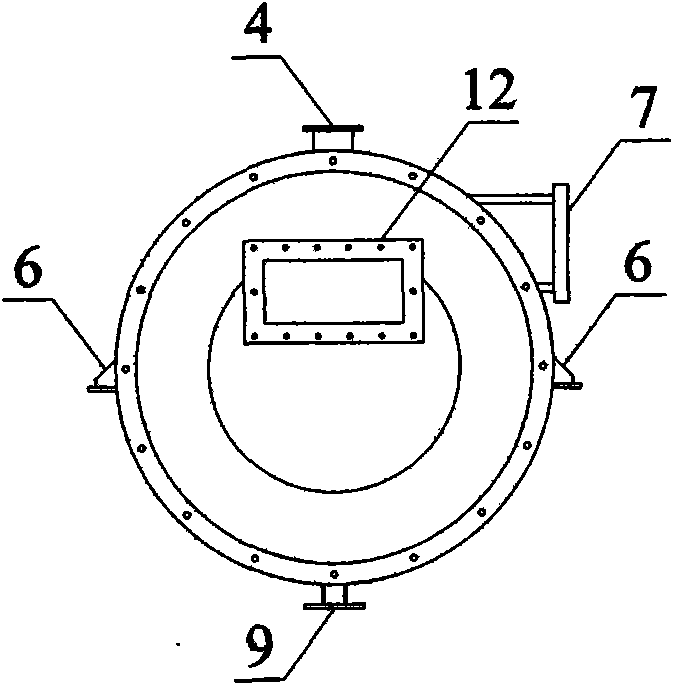

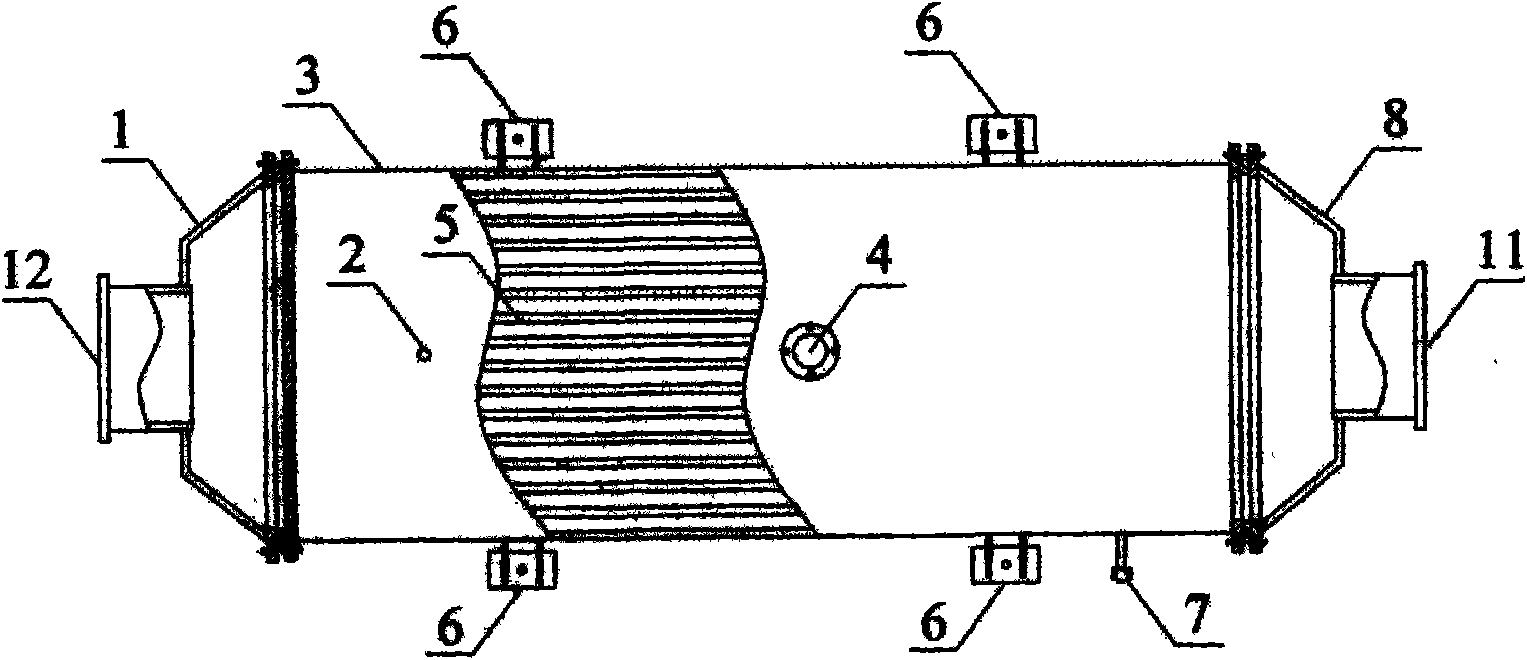

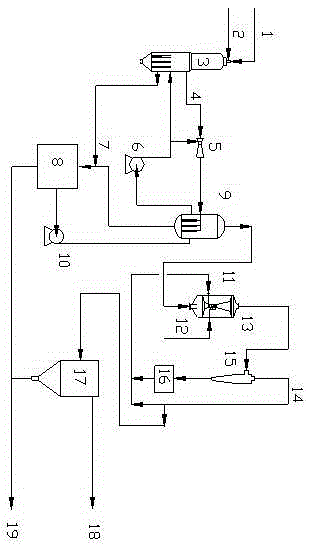

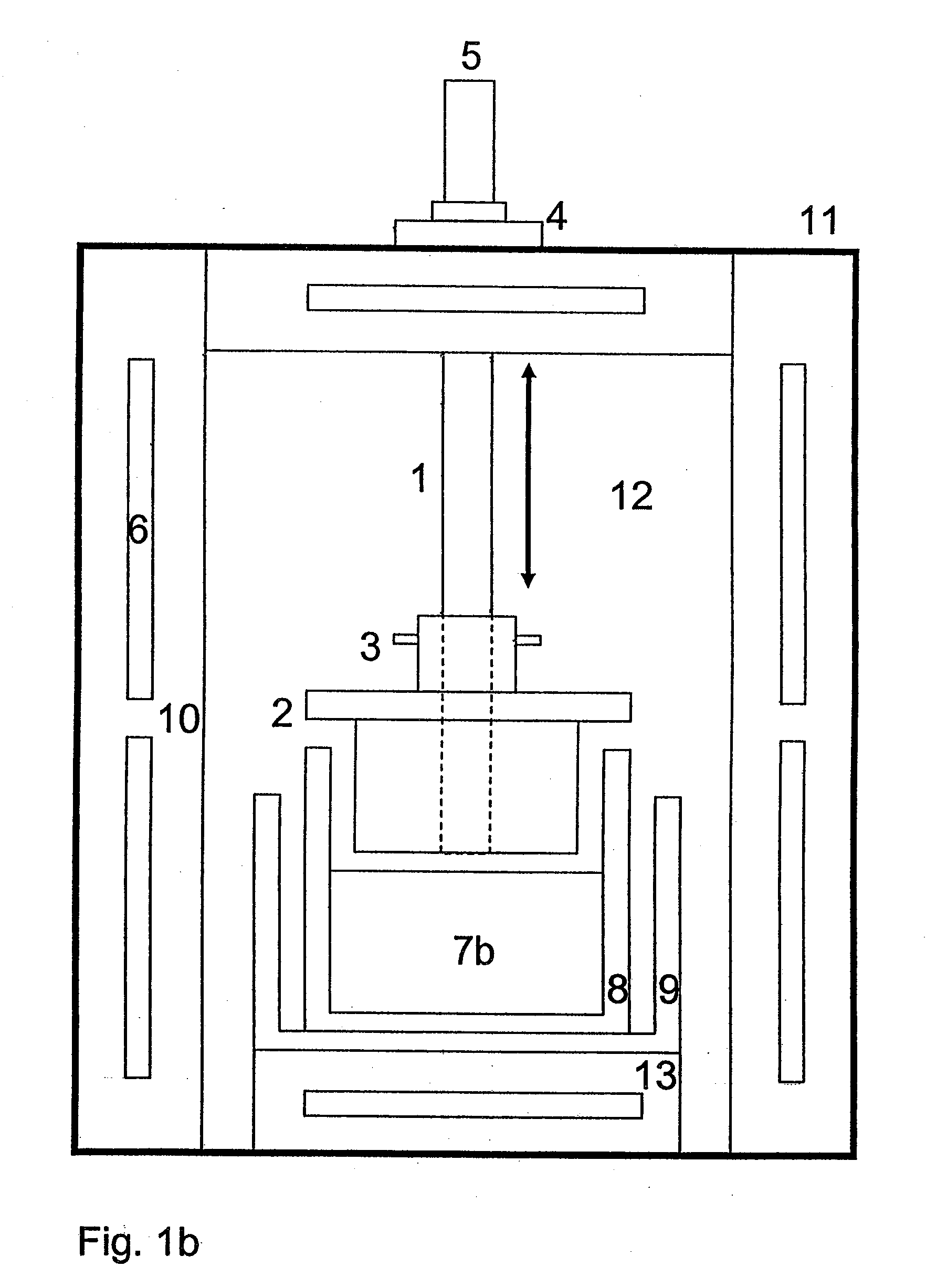

High-efficient wet-type ammonia recovering method desulfuration method with oxidation and concentration processes outside tower and device thereof

InactiveCN101433798AReduce the chance of being corrodedHigh gas velocityDispersed particle separationCycloneRecovery method

The invention discloses a high efficiency wet-type desulfurization method through ammonia recovery method for oxidation and concentration outside a tower, and a device thereof. The method comprises the following steps: (1) feeding flue gas into the top part of a concentrating tower after dust removal, cooling down and humidifying the flue gas, then feeding the flue gas into a first level venturi section of a desulfurization absorption system to contact atomized ammonia water so as to have the first level absorption reaction, performing the second level and the third level desulfurizations, and discharging the flue gas after the purification; (2) oxidizing the ammonium sulfite solution generated in a desulfurizing tower and then overflowing the ammonium sulfite solution into a mother liquor tank from the top part of an oxidation tank; and (3) pumping the ammonium sulfate solution in the mother liquor tank to the top part of the concentrating tower through a mother liquor pump to perform heat exchange with the high temperature flue gas after atomization so as to form a supersaturated solution containing 3 to 5 percent of crystal, wherein the supersaturated solution flows out of the bottom of the concentrating tower and is pumped into a hydraulic cyclone through a slurry pump to perform the first level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; the crystal-liquid mixed solution flowing out of the bottom of the concentrating tower automatically flows into a centrifugal machine to perform the second level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; and solid ammonia sulfate is fed into an automatic packaging machine to be packaged and put into storage. The method has simple processes, greatly reduces investment, and can reclaim agricultural level ammonia sulfate and industrial level ammonia sulfate.

Owner:HENAN XUHUI ENVIRONMENT PROTECTION ENG

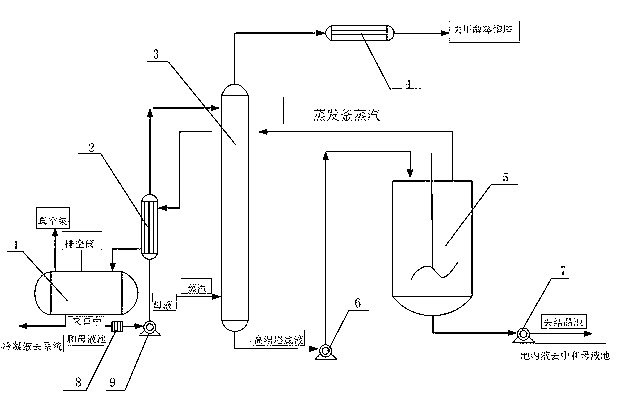

Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

ActiveCN103253819AReduce maintenance workloadExtend the life cycleMultistage water/sewage treatmentAlkali metal sulfites/sulfatesThermodynamicsDistillation

The invention discloses a device and a production technology for treating ternary-monomer wastewater and extracting sodium sulfate. The device comprises a plate-and-frame filter press, a mother liquid heat exchanger, a stripping tower and a condenser which are sequentially communicated through a pipeline, wherein the condenser is communicated with a methane distillation tower through the pipeline. The production technology comprises the following steps of: (1) pumping neutralized mother liquid into the plate-and-frame filter press, preheating the mother liquid through the mother liquid heat exchanger, and then pumping the mother liquid into the stripping tower from the top of the stripping tower; (2) pumping steam into the stripping tower from the bottom of the stripping tower, after methane in the mother liquid is brought out by the steam, condensing the steam through the condenser, then entering the methane distillation tower, and separating to obtain methane; (3) pumping liquid at the bottom of a high-temperature tower into an evaporation and concentration kettle to be concentrated, steaming out moisture, and using the steam generated by the evaporation and concentration kettle for heating the mother liquid heat exchanger; and (4) after concentrating a material in the evaporation and concentration kettle, placing the concentrated material in a crystallizing pond, and feeding the mother liquid, Na2SO4.10H2O in which is separated out in the crystallizing pond, into a mother liquid neutralization pond to be reused.

Owner:WEIFANG WORLD CHEM

Device and method to expand operating range of a fuel cell stack

InactiveUS6911277B2Expand the scope of operationHigh gas velocityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

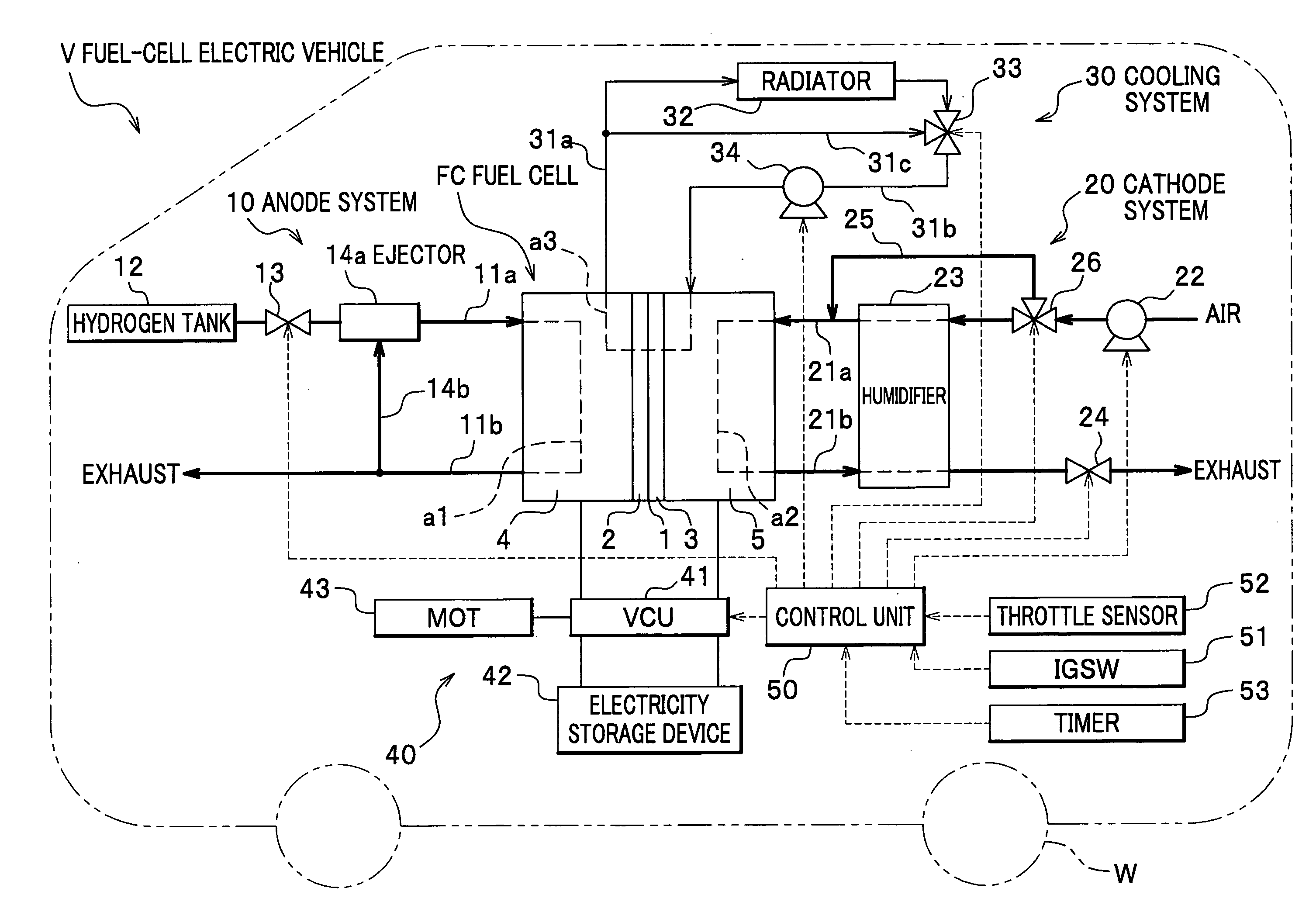

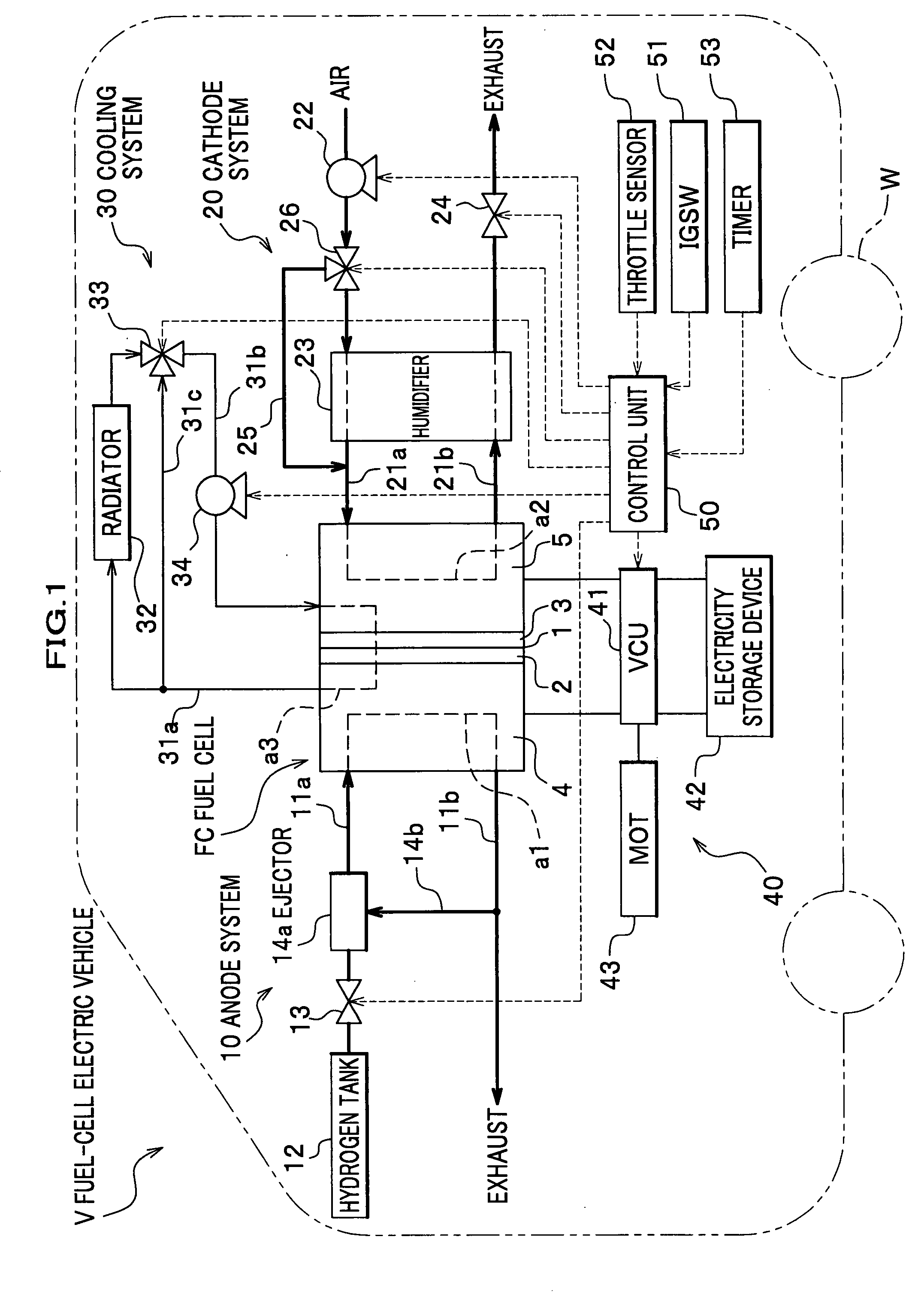

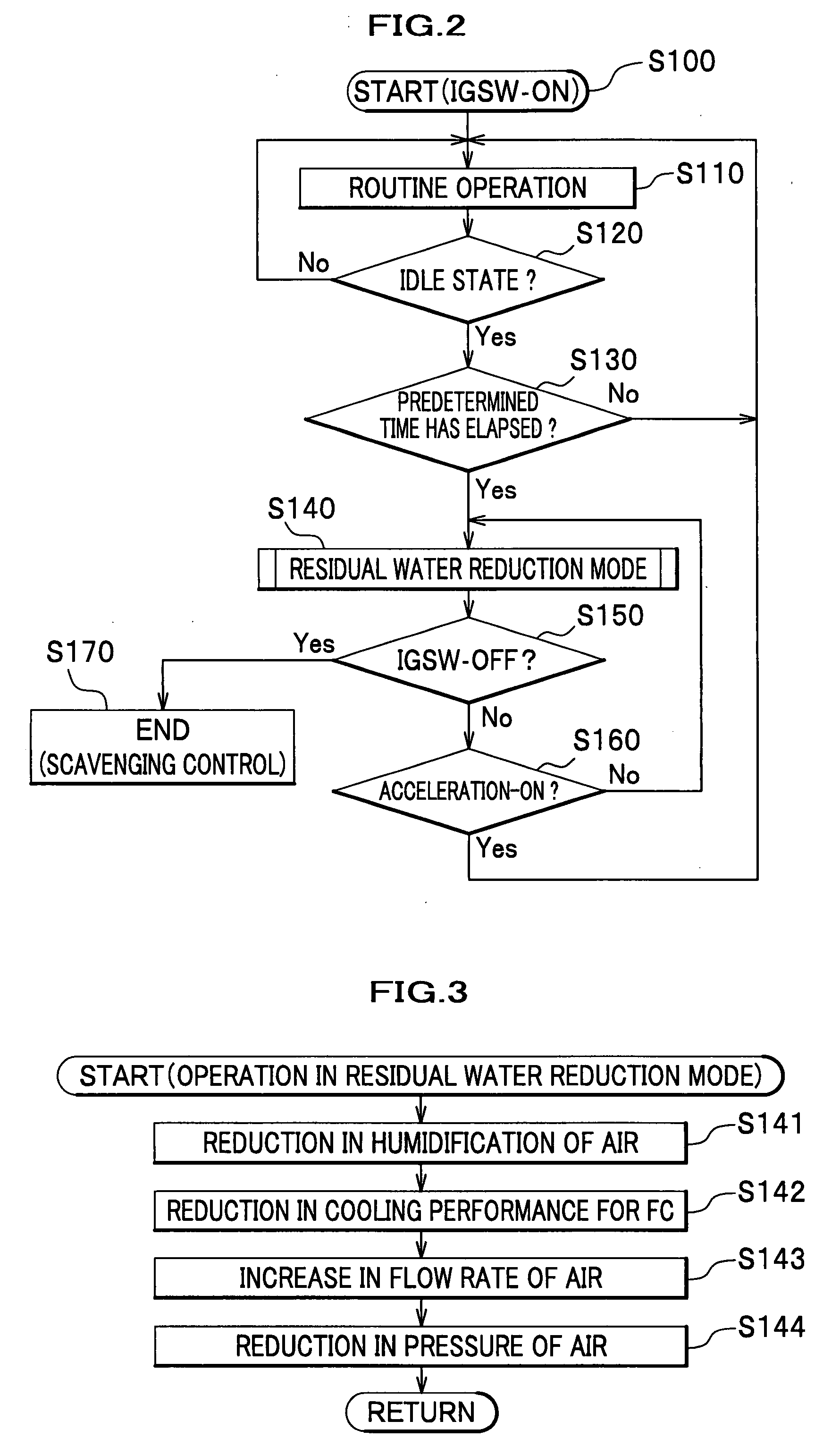

Fuel-cell electric vehicle

InactiveUS20070231639A1Facilitate flow velocityIncrease flow volumeOperating modesFuel cell auxillariesFuel cellsOperation mode

When a fuel-cell electric vehicle is running at idle, and a predetermined period of time has elapsed since the vehicle comes into the idle state, forthcoming stopping of an operation of the vehicle is predicted, and the operation mode of a fuel cell is shifted to a residual water reduction mode in which residual water remaining inside the fuel cell is reduced. In the residual water reduction mode, for example, the amount of humidification for air to be supplied to the fuel cell is reduced, so that the air with reduced humidity passes through the fuel cell, to thereby increase the amount of residual water removed by the air. Accordingly, the residual water inside the fuel cell can be reduced before the actual stopping of the operation of the vehicle.

Owner:HONDA MOTOR CO LTD

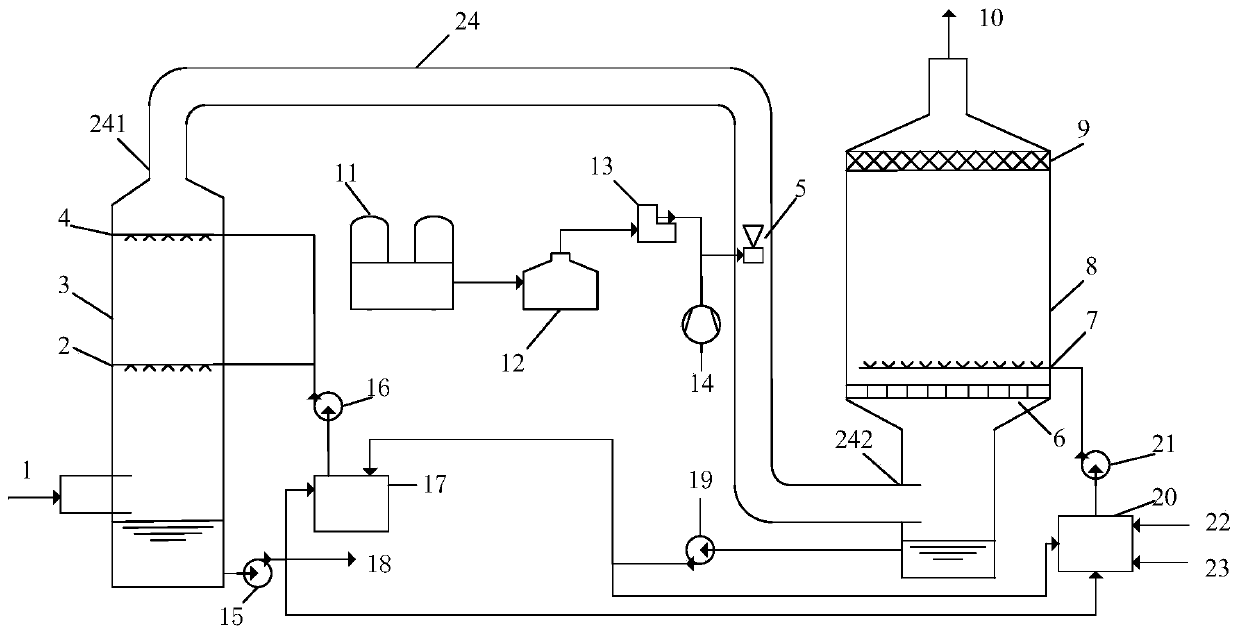

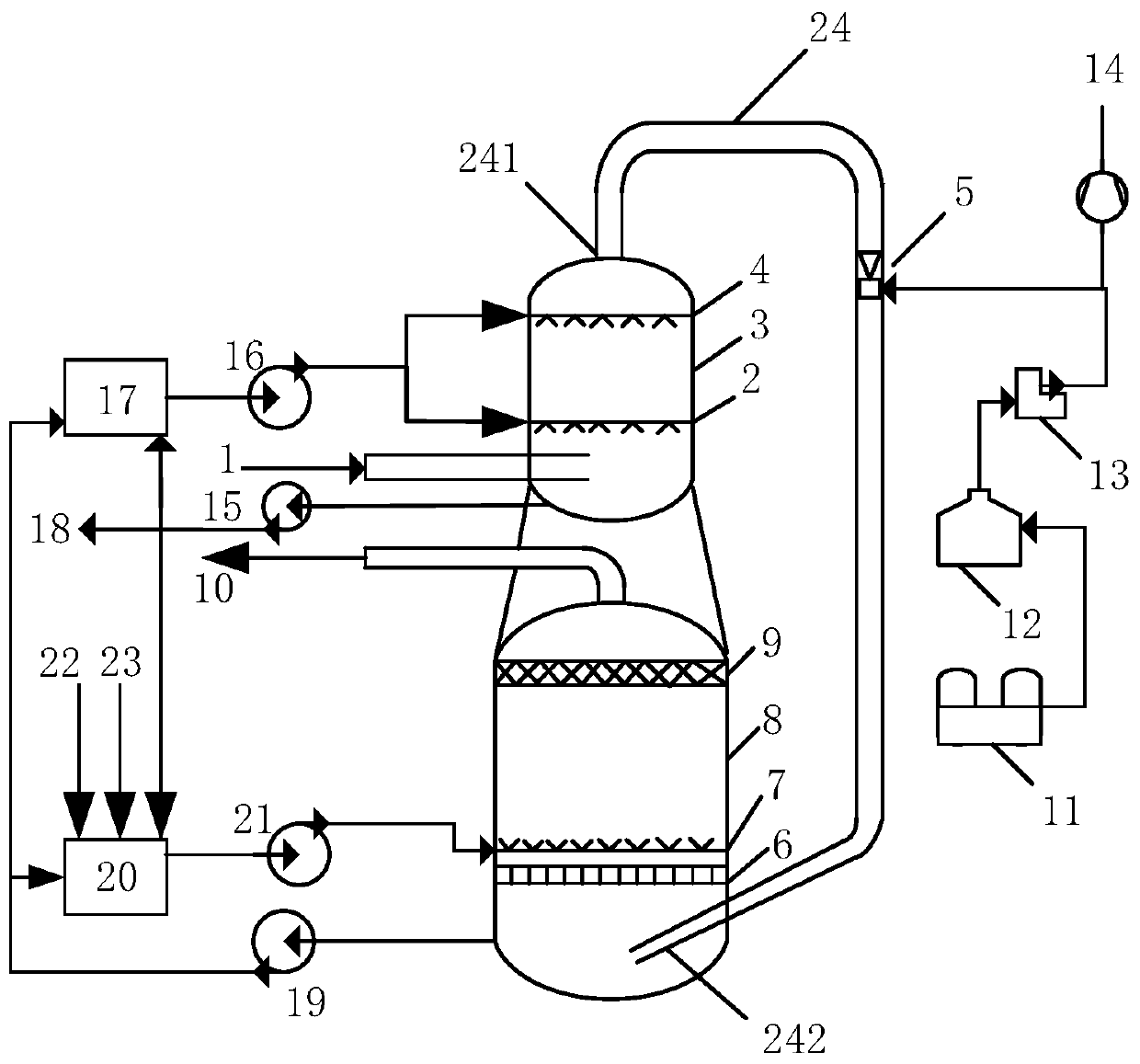

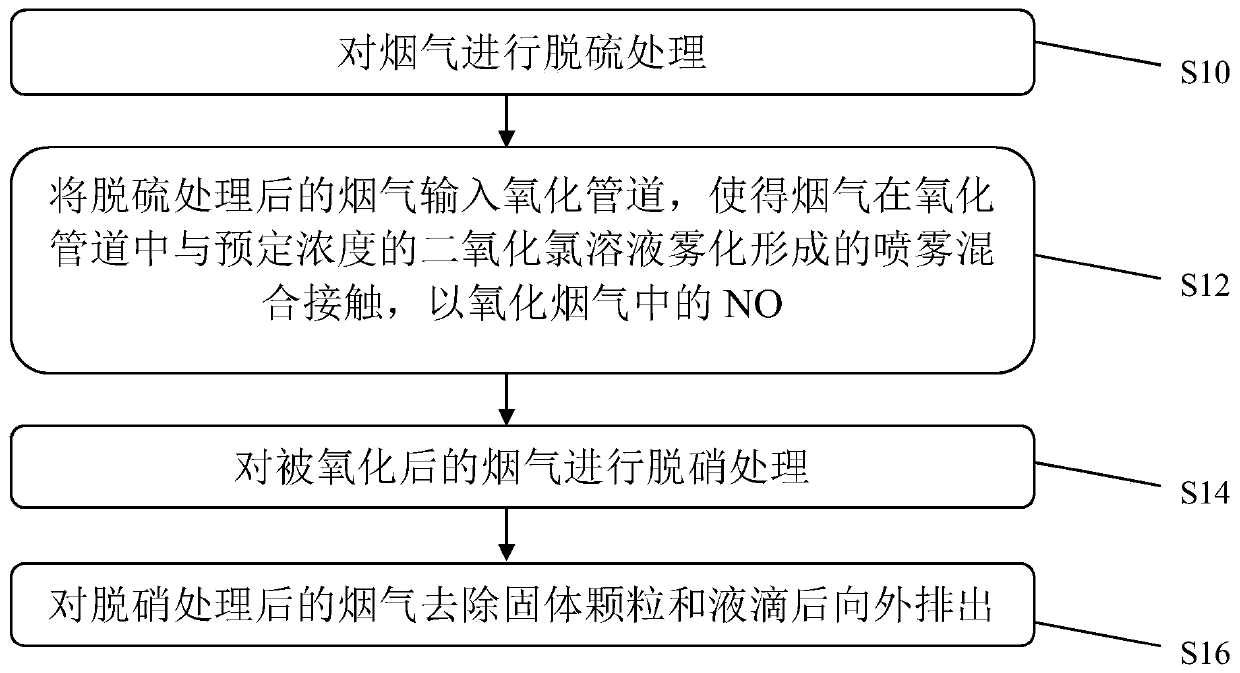

Flue gas desulfurization and denitration device and method

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

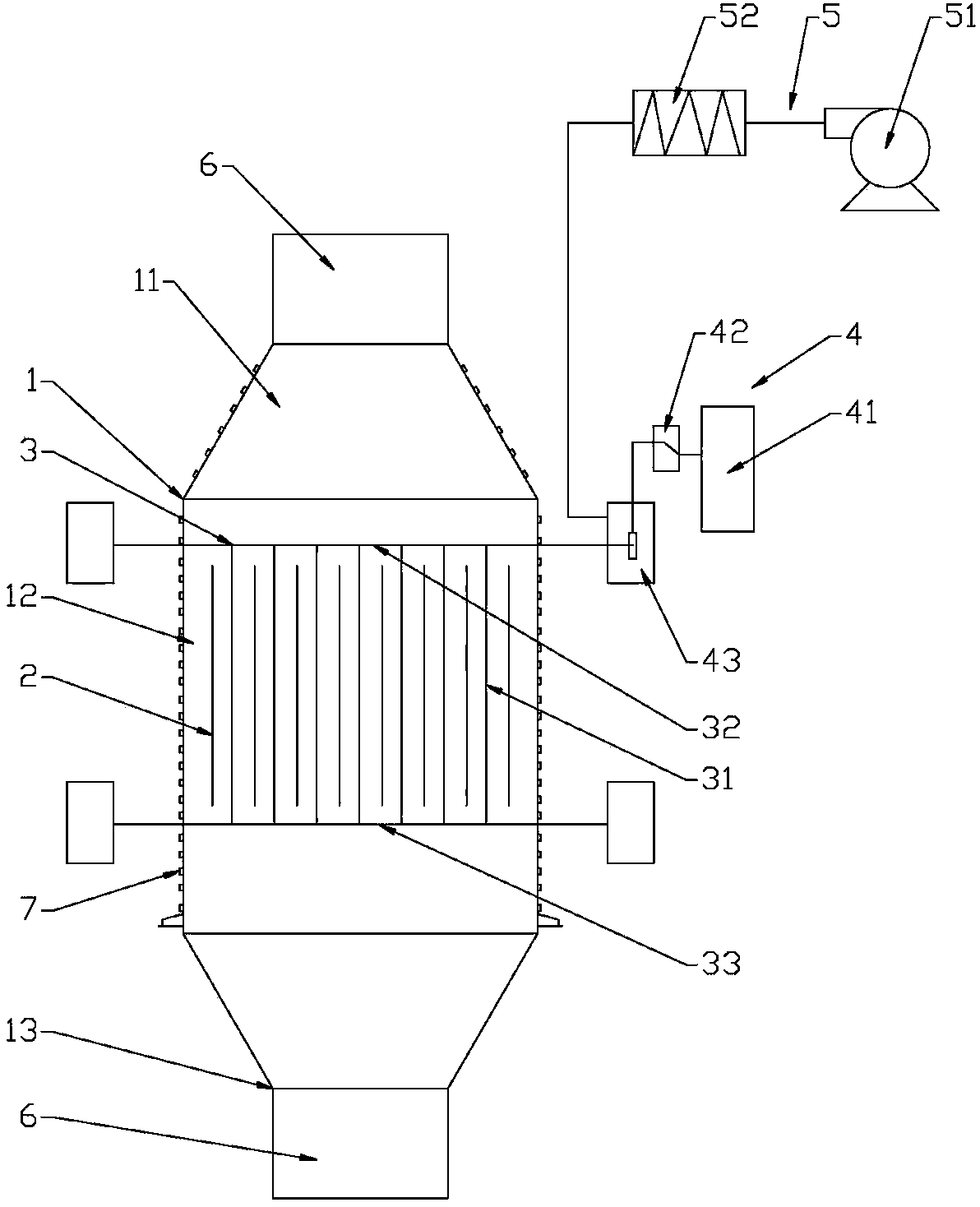

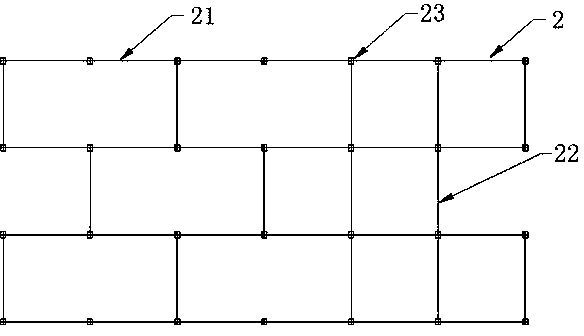

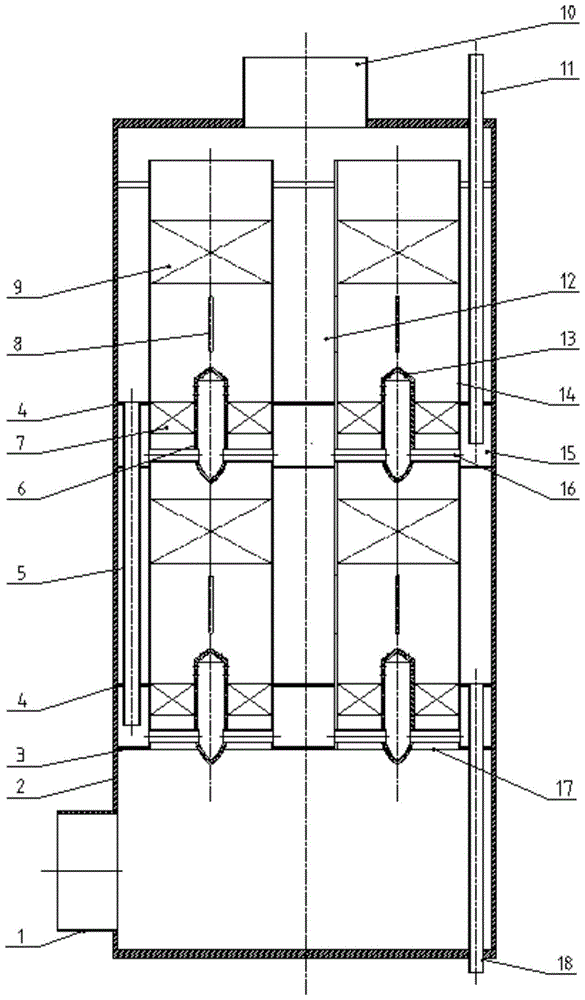

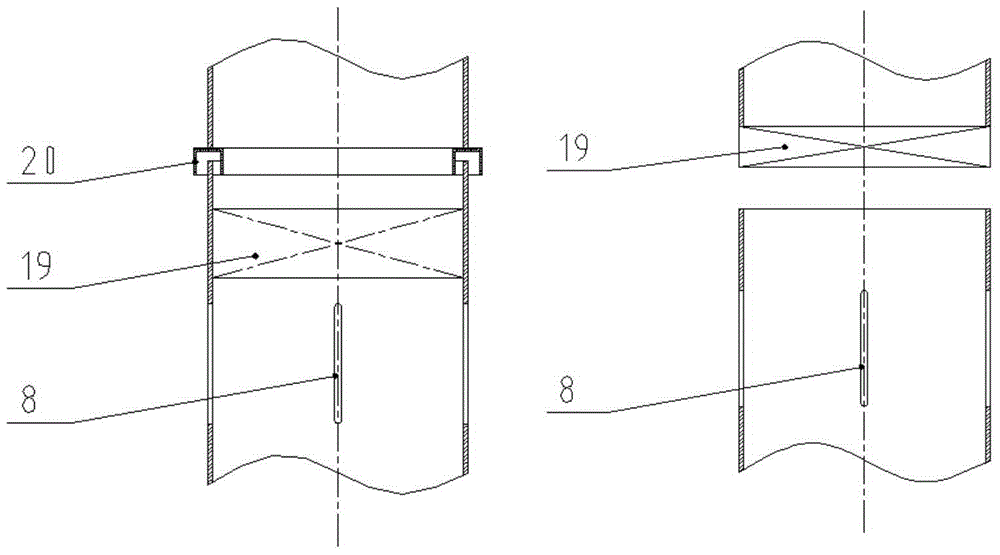

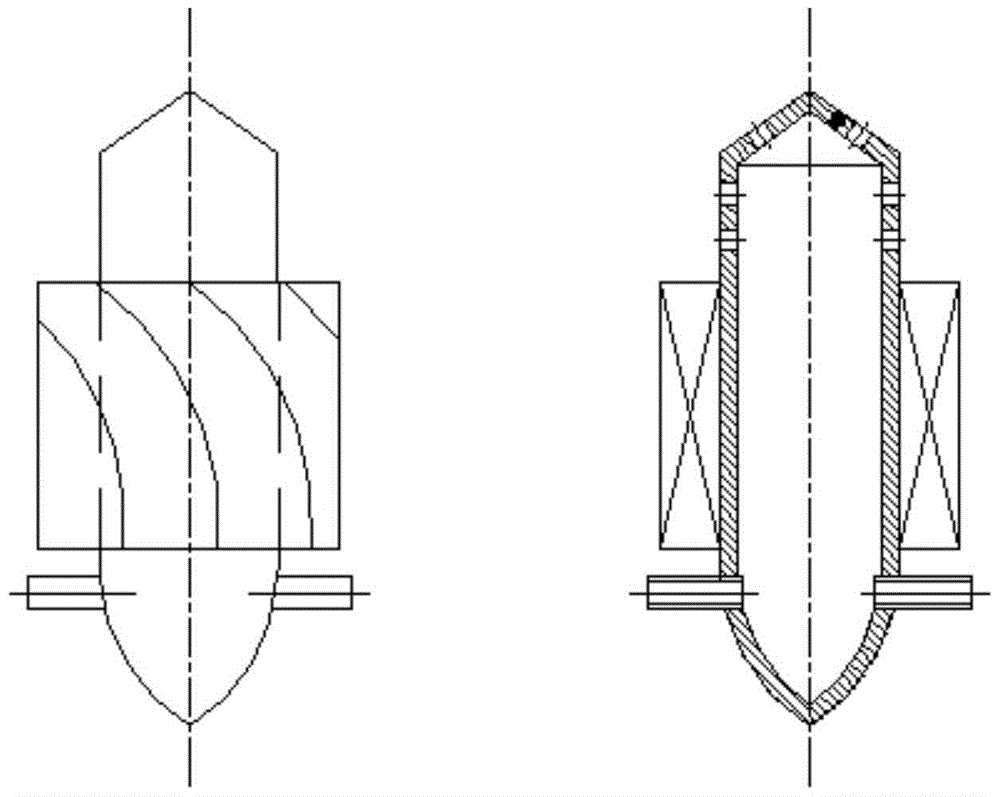

Efficient tubular plate vertical current wet-type electrostatic dust collector

InactiveCN103817005AEasy to driveImprove dust removal efficiencyExternal electric electrostatic seperatorElectric supply techniquesEngineeringHigh pressure

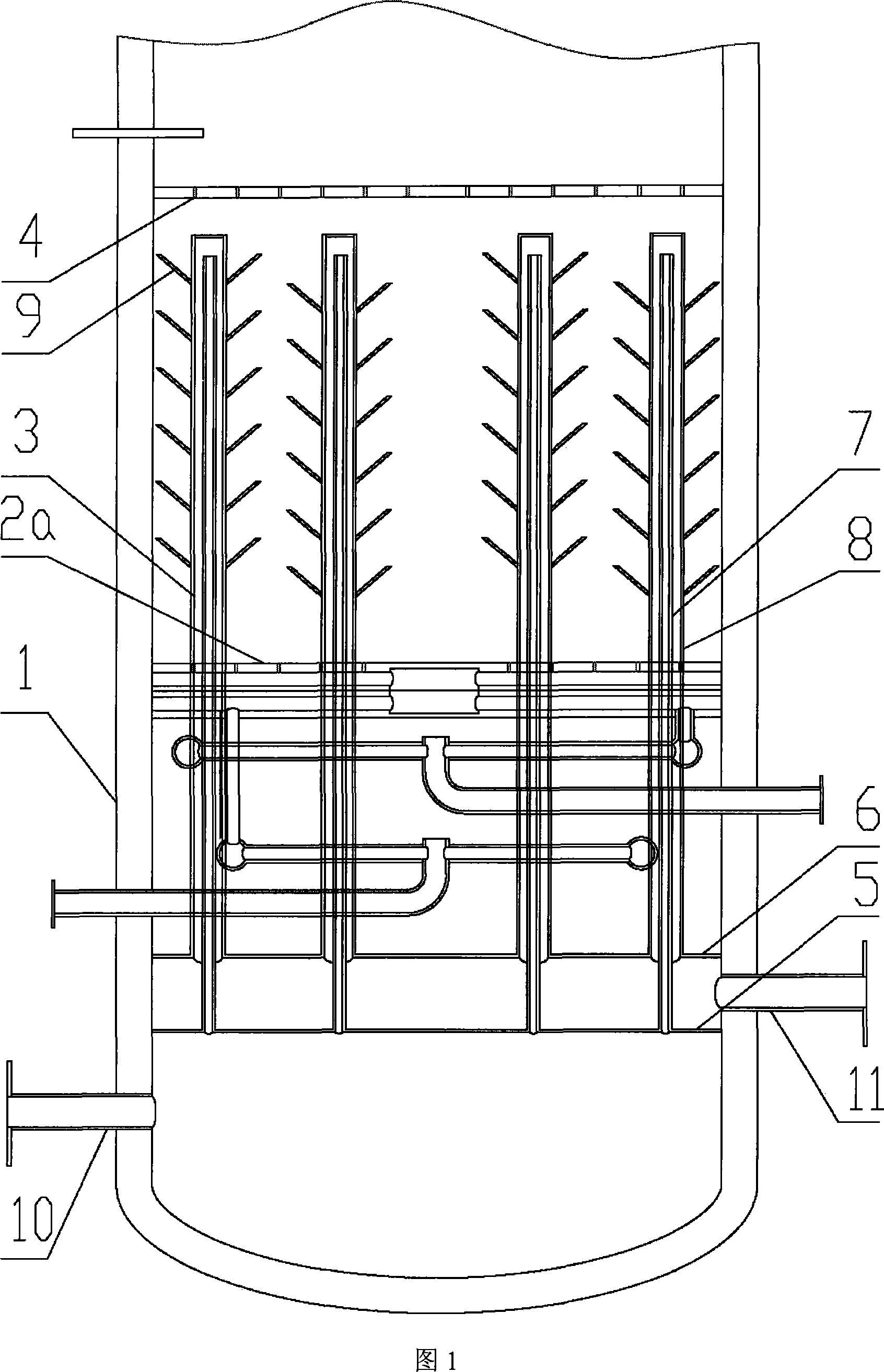

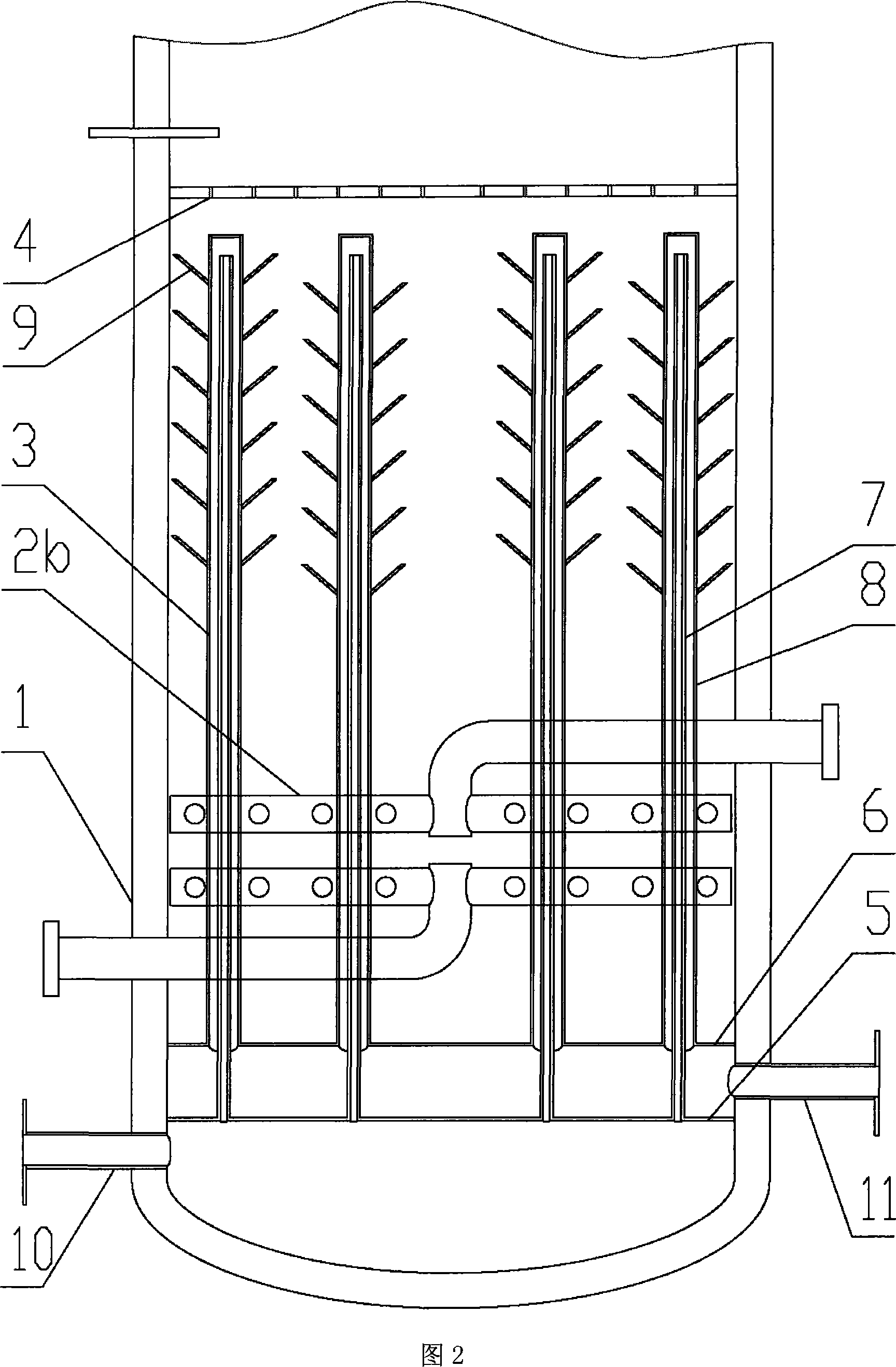

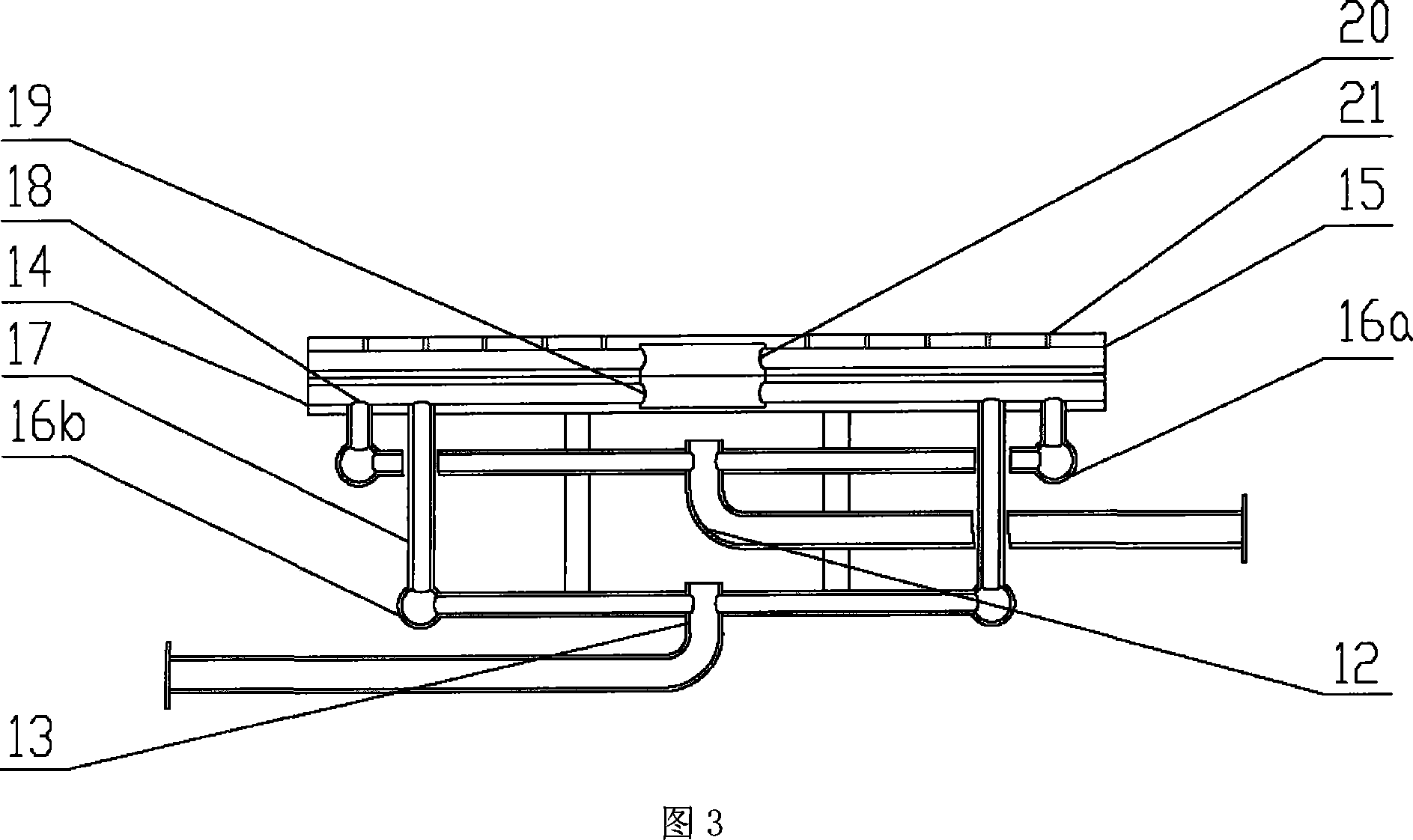

The invention discloses an efficient tubular plate vertical current wet-type electrostatic dust collector. The efficient tubular plate vertical current wet-type electrostatic dust collector comprises a shell (1), wherein an anode dust collecting mechanism (2) arranged vertically is arranged in the shell (1) and adopts a tubular plate structure formed by dust collecting boards; a vertically arranged cathode wire (31) with discharge points is arranged between the tubular plates of the anode dust collecting mechanism (2); the upper end of the cathode wire (31) is fixed on a cathode girder (32) above the cathode wire (31); the lower end of the cathode wire (31) is fixed on a tension frame (33) blow the cathode wire (31); the cathode girder (32) is connected with a high voltage power supply system (4) through conductive wires; a cathode system is formed by the cathode girder (32), the cathode wire (31) and the tension frame (33). As an electrostatic field formed by the tubular plate anode dust collecting mechanism and the cathode wires, effectively solves the problem of difficult removing of PM2.5 tiny particles, acid mist, liquid drops, aerosol, heavy metals and the like from the smoke, and the efficient tubular plate vertical current wet-type electrostatic dust collector is widely used.

Owner:双盾环境科技有限公司

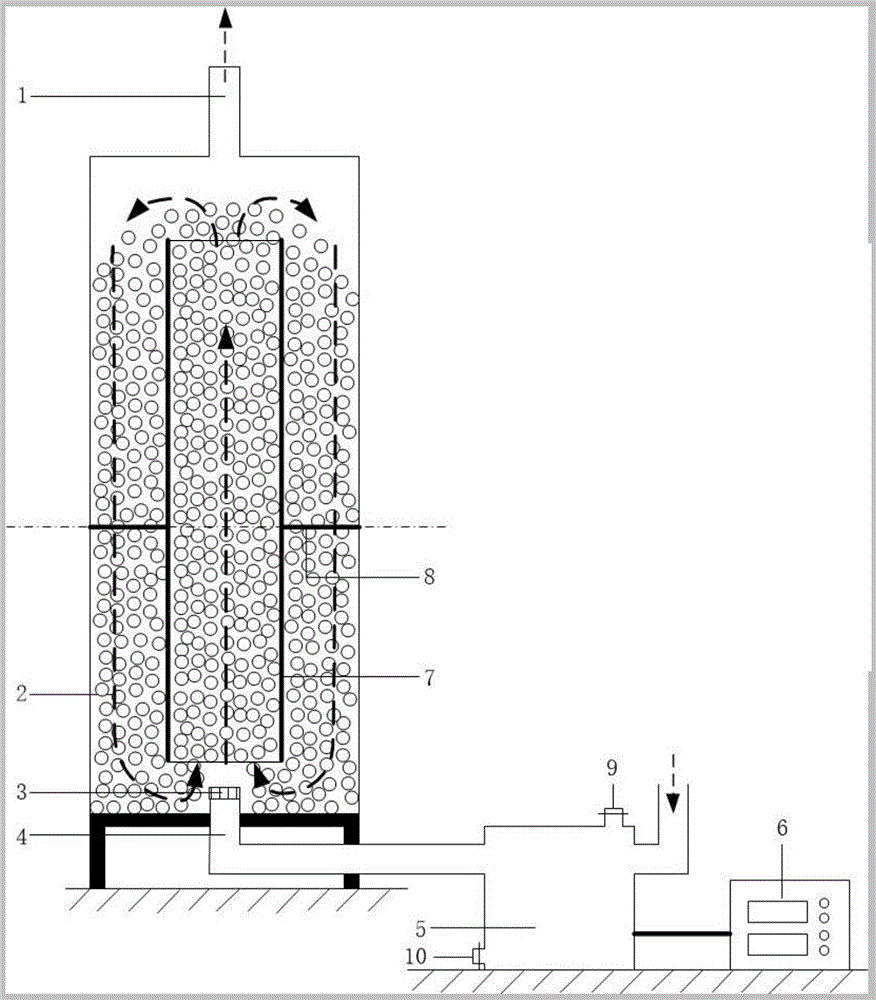

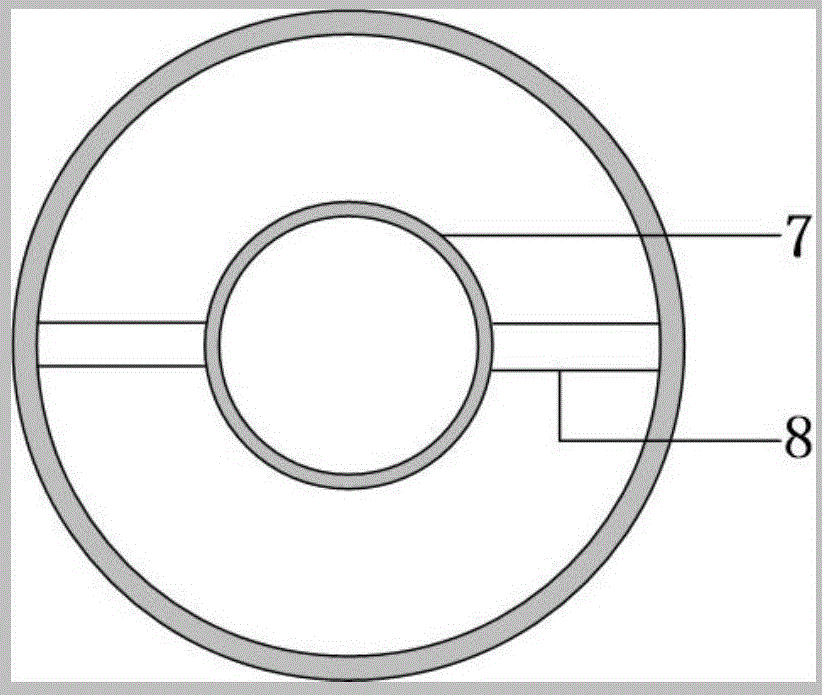

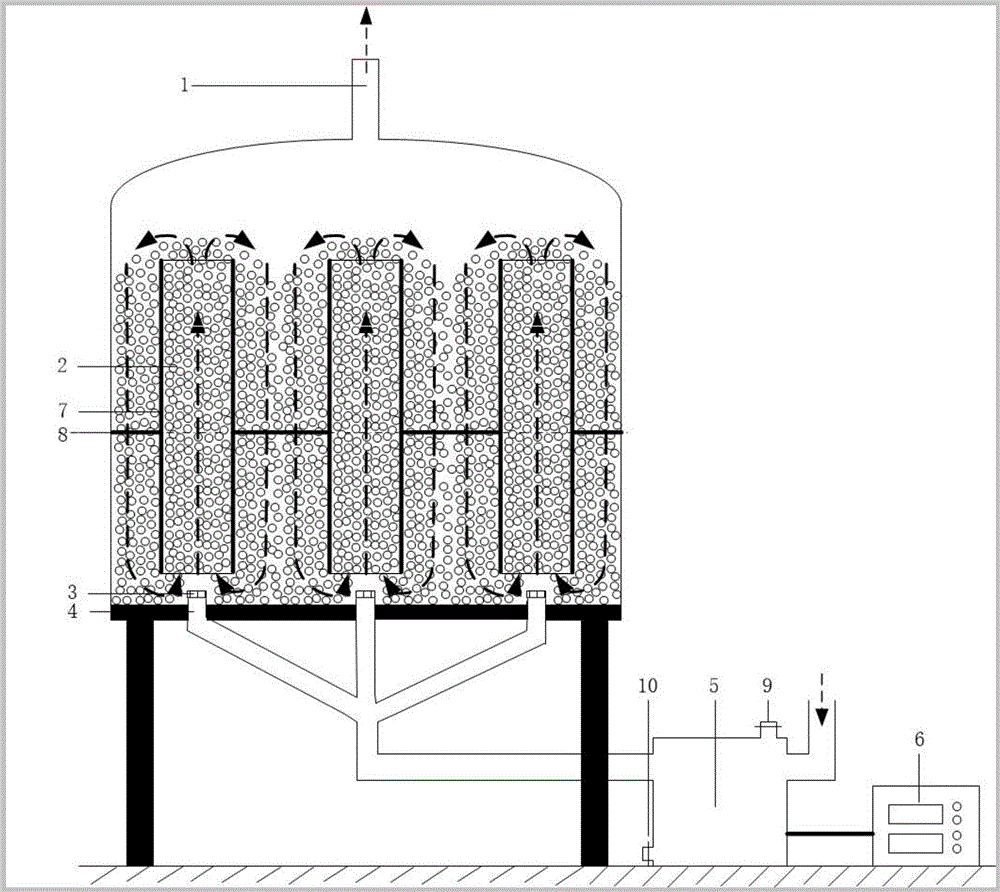

Internal-circulation biological fluidized bed system used for VOCs and malodorous gas treatments

ActiveCN106621792AImprove efficiencyExtend stable running timeDispersed particle separationAir quality improvementEngineeringProduct gas

The invention discloses an internal-circulation biological fluidized bed system used for VOCs and malodorous gas treatments. The internal-circulation biological fluidized bed system used for the VOCs and malodorous gas treatments comprises a biological fluidized bed reactor which adopts a structure comprising an inner sleeve and an outer sleeve; the inner sleeve is used for forming an up-flow area of fluidized fillers, and the outer sleeve is used as a down-flow area of fluidized fillers, and the fillers are high-molecular light fillers; the air inlet of the biological fluidized bed reactor is located at the bottom, and is connected with a humidifying unit; the fillers in the reactor are in fluidized state; microorganisms attach on the surfaces of the fillers, so that the VOCs and the malodorous gas are removed by mass transfer and degradation processes when the VOCs and the malodorous gas pass through the reactor; and moisture and nutrients are uniformly transported into the gas by the humidifying unit. The fillers have the characteristics of light weight and easy fluidization property; the internal-circulation sleeve reactor structure is capable of ensuring fluidization of the fillers at a relatively low gas velocity; and the pressure drop of the reactor is relatively low. The internal-circulation biological fluidized bed system used for VOCs and malodorous gas treatment overcomes disadvantages of traditional biological waste-gas purification devices, namely low mass transfer efficiency and uneven microbial distribution, and can be used for purifying the VOCs and the malodorous gas in the fields of industry, municipal administration, agriculture and the like.

Owner:TSINGHUA UNIV

Graphene oxide/polymer composition for manufacturing inner liners and inner tubes of tires and method for preparing the same

ActiveUS20140309331A1Increase flexibilityImprove adhesionOther chemical processesSpecial tyresEpoxyPolymer science

A composition for manufacturing the inner liners and inner tubes of tires, and a method of preparing the same. The composition includes the following two phases: A) a continuous phase of a composition of graphene oxide / rubber including graphene oxide, a reactive rubber, and a solid rubber; and B) a dispersion phase of an epoxy natural rubber or a thermoplastic resin. In the composition of graphene oxide / rubber, the graphene oxide leads to low gas permeability and remarkably reinforces the rubber composition. The epoxy natural rubber or thermoplastic resin is dispersed in the composition of graphene oxide / rubber and forms an islands-in-the-sea structure. The composition has low gas permeability, excellent mechanical properties, and flexibility, and is adhesive to adjacent rubber.

Owner:BEIJING UNIV OF CHEM TECH

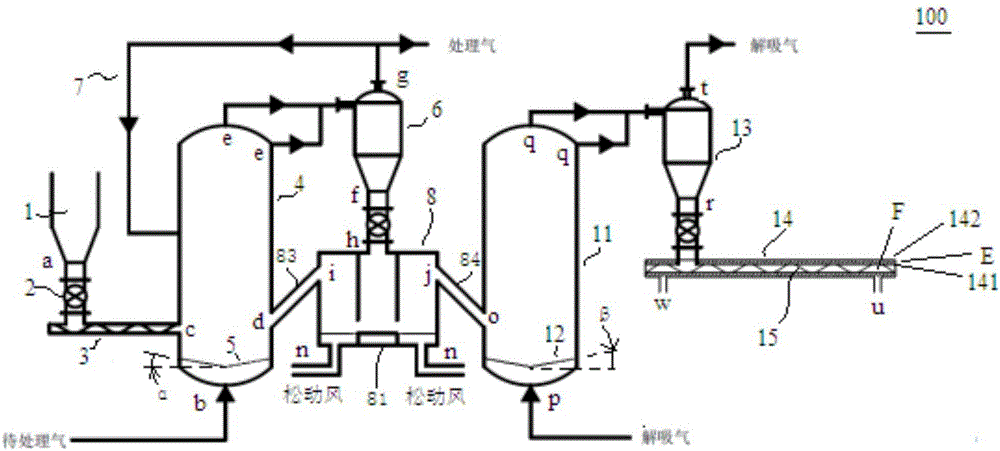

Fluidized bed gas adsorption-desorption system and treatment method thereof

ActiveCN105903314AHigh gas velocityReduce labor intensityDispersed particle separationGas solidFluidized bed

The invention discloses a fluidized bed gas adsorption-desorption system and a treatment method thereof. The system includes an adsorption fluidized bed, a regeneration fluidized bed, an adsorption side gas-solid separator, a desorption side gas-solid separator and a feed divider. The adsorption fluidized bed has an adsorbent inlet, a to-be-treated gas inlet, a first returned material inlet and a first mixture outlet. The adsorption side gas-solid separator is connected to the first mixture outlet. The regeneration fluidized bed has a second returned material inlet, a desorption gas inlet, and a second mixture outlet. The desorption side gas-solid separator is connected to the second mixture outlet. The feed divider has a feed inlet, an adsorption side divided material outlet and a desorption side divided material outlet, the feed inlet is connected to an adsorption side solid-discharge port of the adsorption side gas-solid separator, the adsorption side divided material outlet is connected to the first returned material inlet, and the desorption side divided material outlet is connected to the second returned material inlet. The system provided by the invention is easy to operate, the system treatment ability is enhanced, and the adsorption efficiency, adsorption economical efficiency and operation continuity are improved.

Owner:SHENWU TECH GRP CO LTD

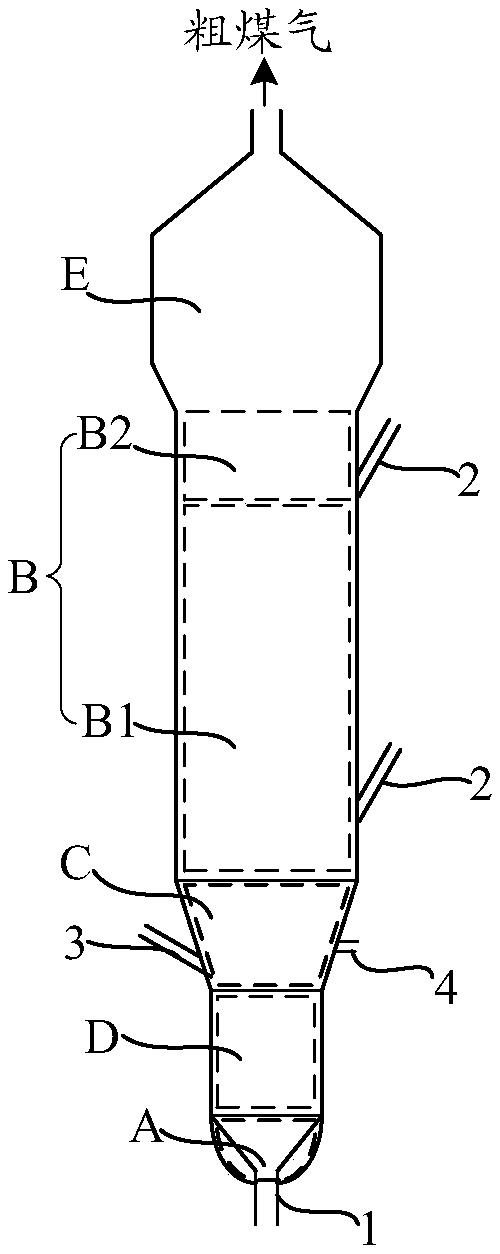

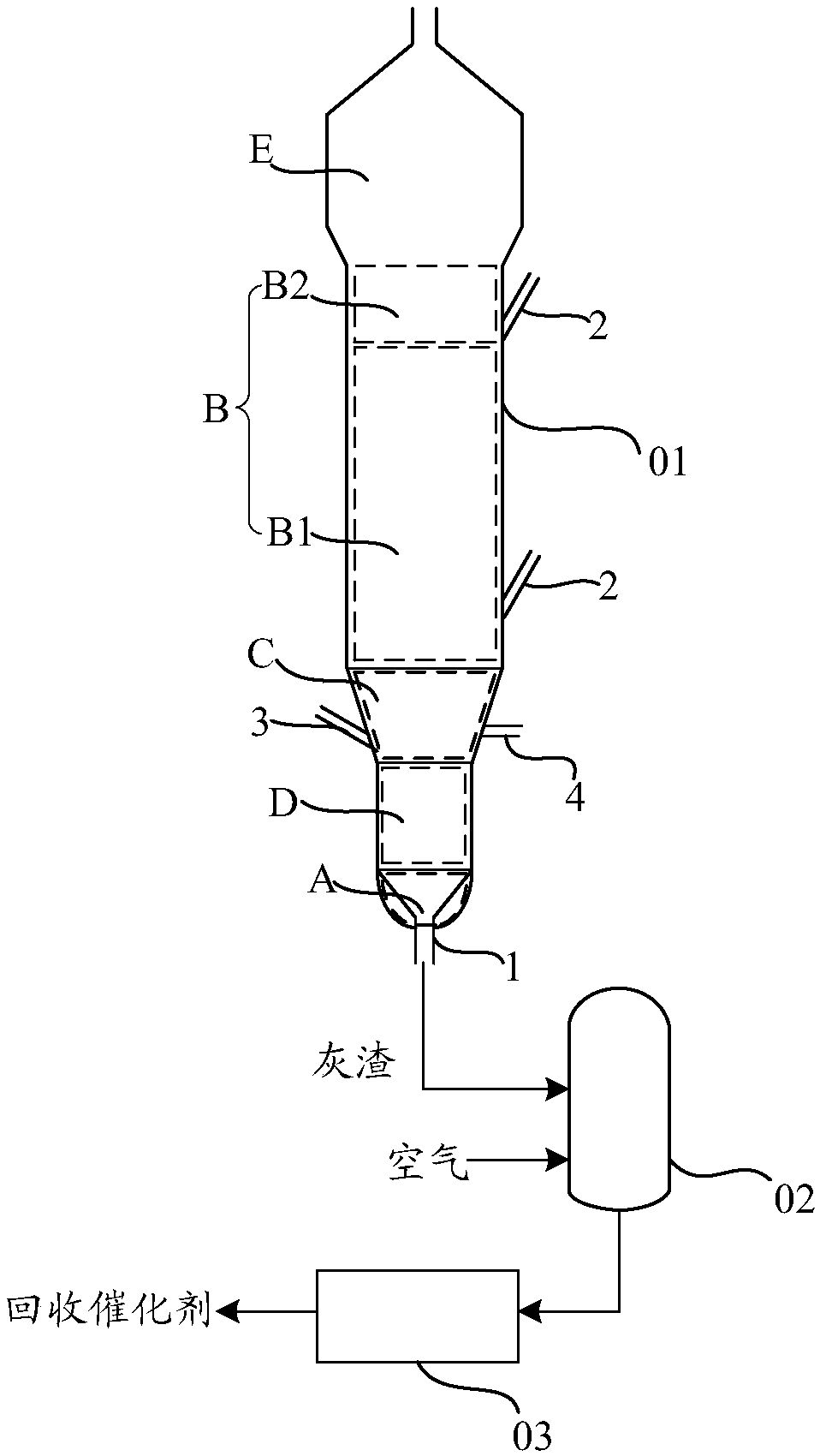

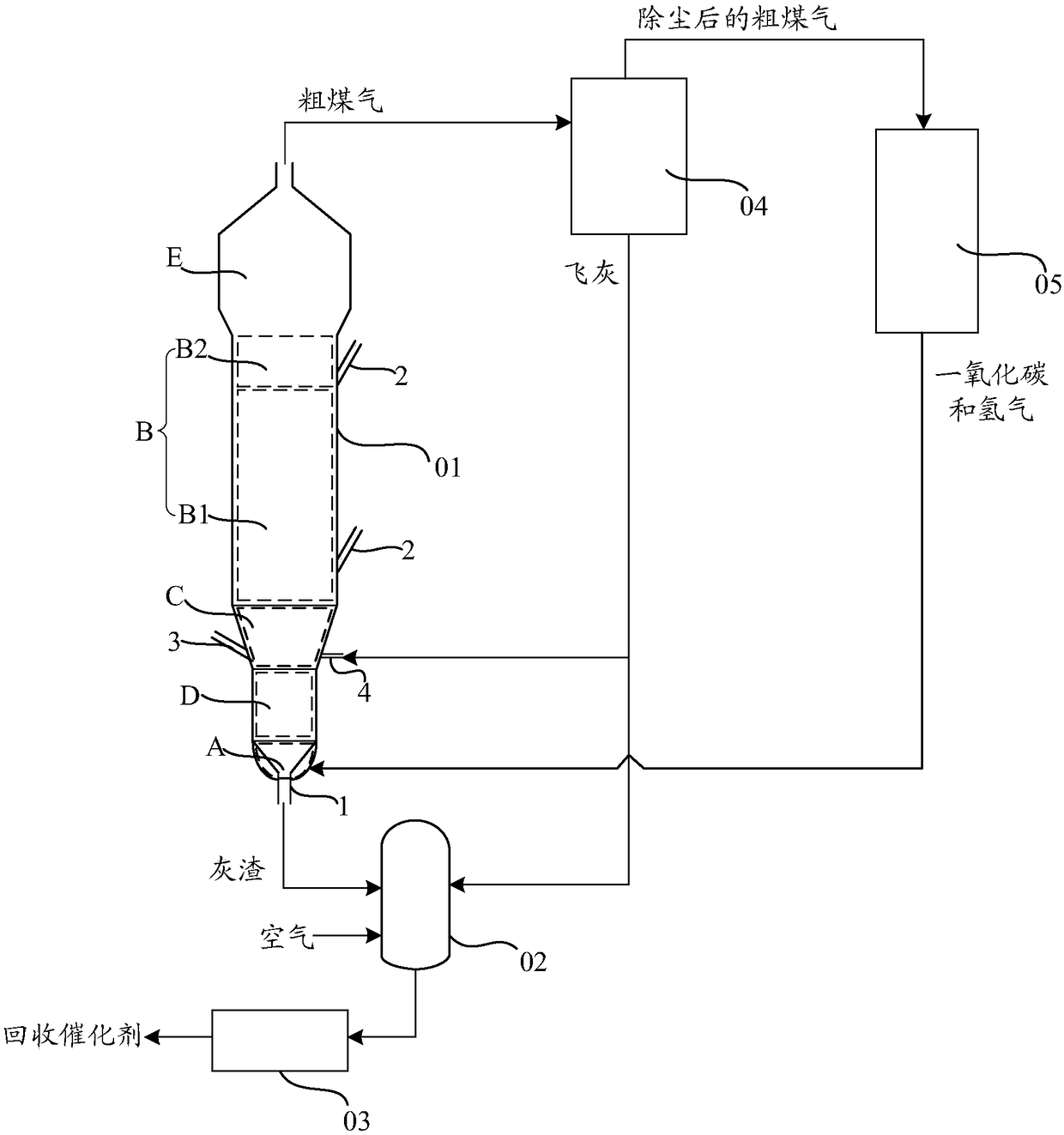

Fluidized bed gasifier, coal gasification system and method

InactiveCN108179032AHigh yieldStable furnace temperatureGasification processes detailsGranular/pulverulent flues gasificationSyngasFluidized bed gasifier

The invention relates to the technical field of coal gasification, in particular to a fluidized bed gasifier, a coal gasification system and a method, can satisfy the heat requirement of overall reaction in the furnace, have no need for introducing oxygen burning coal to provide heat, lower the risk of easy slagging in the gasifier due to introduction of oxygen, at the same time can promote forward overall reaction in the furnace, have no need for returning substantial synthesis gas to the furnace to increase the methane yield, and lower the risk of inhibition on overall reaction in the furnace caused by return of synthesis gas to the furnace. According to the fluidized bed gasifier, the bottom is a gas distribution plate area, a fluidized bed reaction area is disposed above the gas distribution plate area, a variable diameter section with a gradually enlarging inner diameter from the bottom up is disposed between the fluidized bed reaction area and the gas distribution plate area, thebottom of the fluidized bed gasifier is equipped with deslagging port, the side wall of the fluidized bed gasifier corresponding to the fluidized bed reaction area is equipped with coal inlets, and the lower part of the variable diameter section is equipped with a carbon carrier inlet.

Owner:ENN SCI & TECH DEV

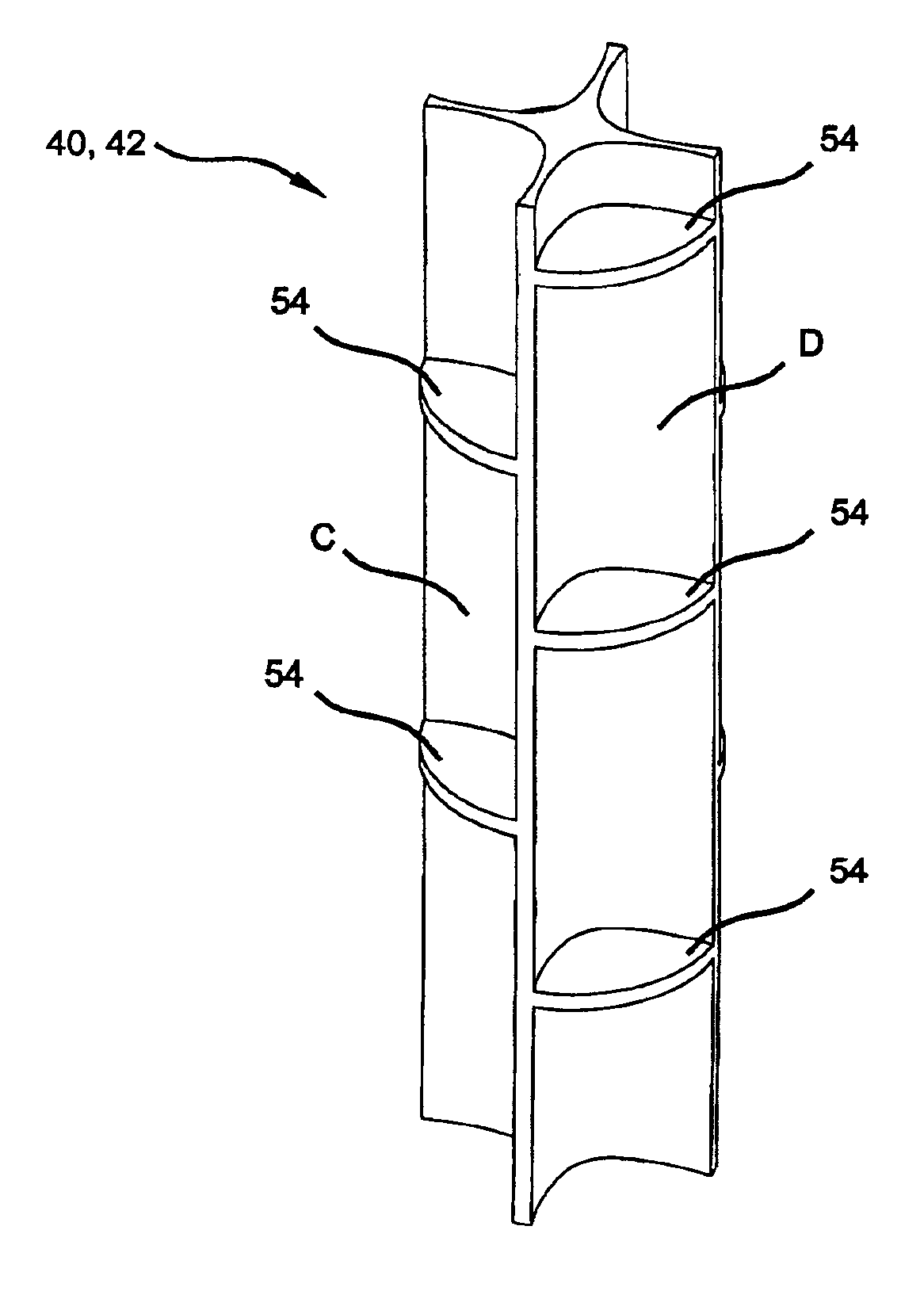

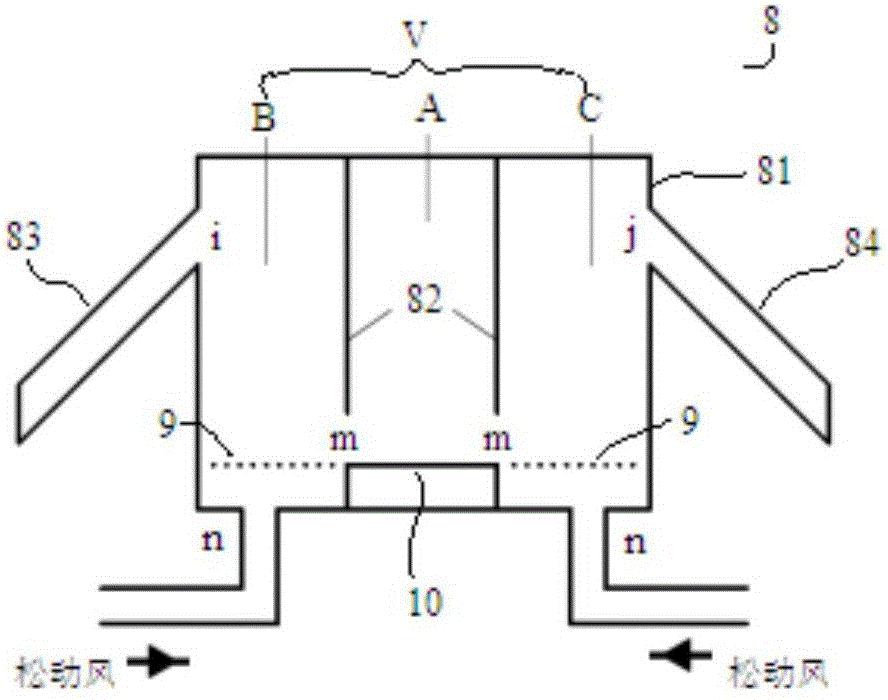

Airlift Cyclone Suction and Downcomer Isolation Tray

ActiveCN104959106BAvoid contactPrevent floodingDispersed particle separationChemical/physical/physico-chemical processesCycloneGas phase

The invention relates to an air-lift cyclone liquid absorption and liquid falling isolation-type tower plate. A sandwiched plate as well as a liquid flow falling guide pipe and a gas-phase rising pipe independent to each other, are additionally arranged below the tower plate. The rising airflow after transferring the mass by a centrifugal cyclone flow field is completely isolated from liquid phase flow after gas-phase mass transferring, so that the problem that the rising air flow causes flooding for the pushing of the falling liquid in an ordinary plate-type tower can be thoroughly avoided, the air speed of the tower plate can be greatly increased, the air-phase cyclone strength can be improved, the capability for breaking liquid drops can be improved, the mass transfer efficiency can be improved, and the tower path can be reduced. Since the rising airflow is isolated from the falling liquid phase, the air phase and the liquid phase after the high-speed cyclone contact mass transferring can be separated by virtue of a short height distance of the tower plate under the centrifugal action of the high-speed eddy flow, so that the distance between two adjacent layers of tower plates can be greatly reduced, and the height of the tower can be greatly reduced. The novel tower plate has the characteristics of small tower diameter, low tower height and high efficiency and has a prominent advantage in the field of high-air-flow effective mass transfer.

Owner:DALIAN UNIV OF TECH

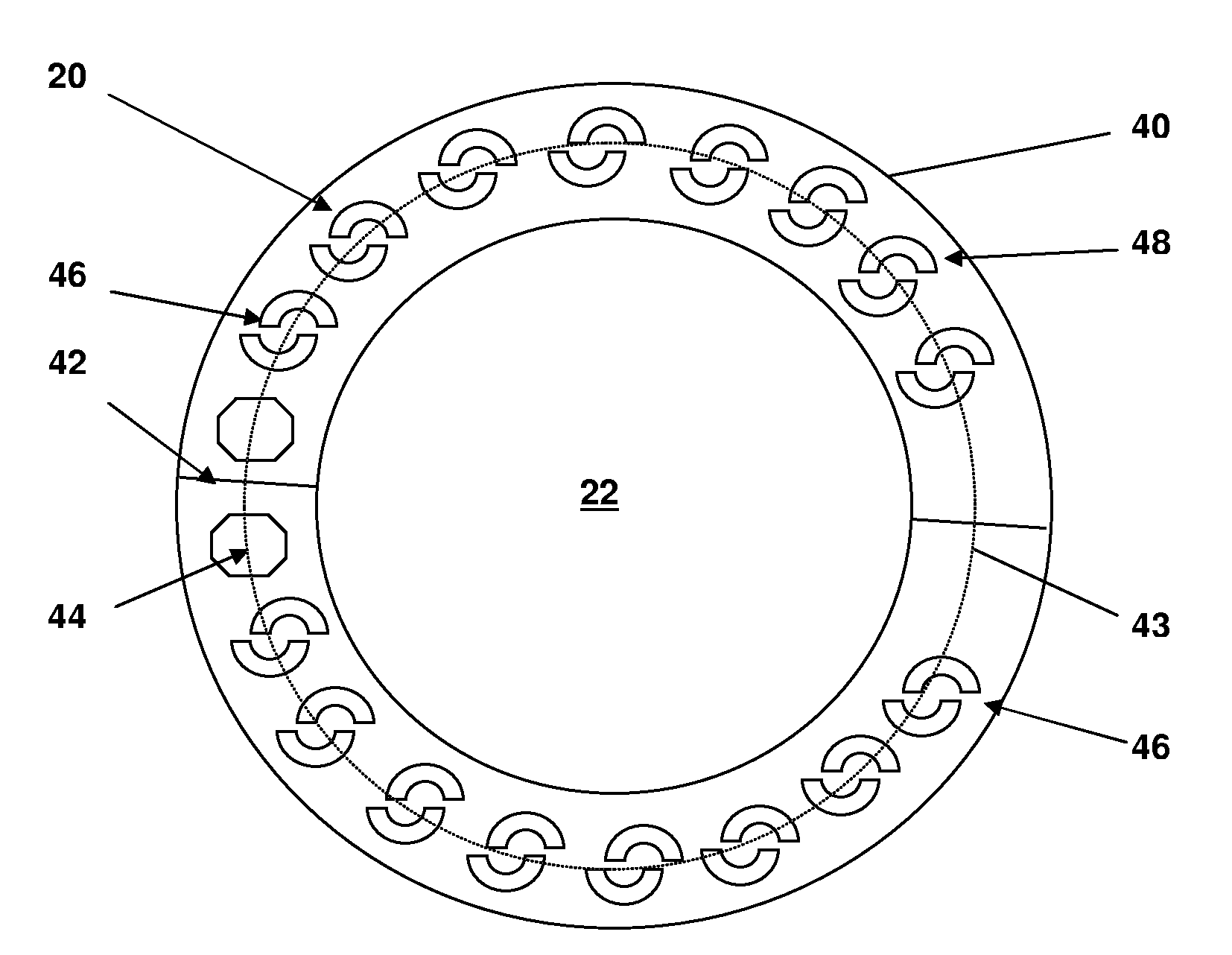

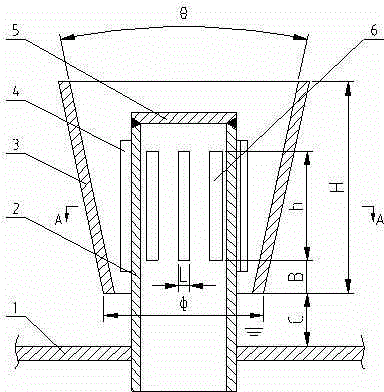

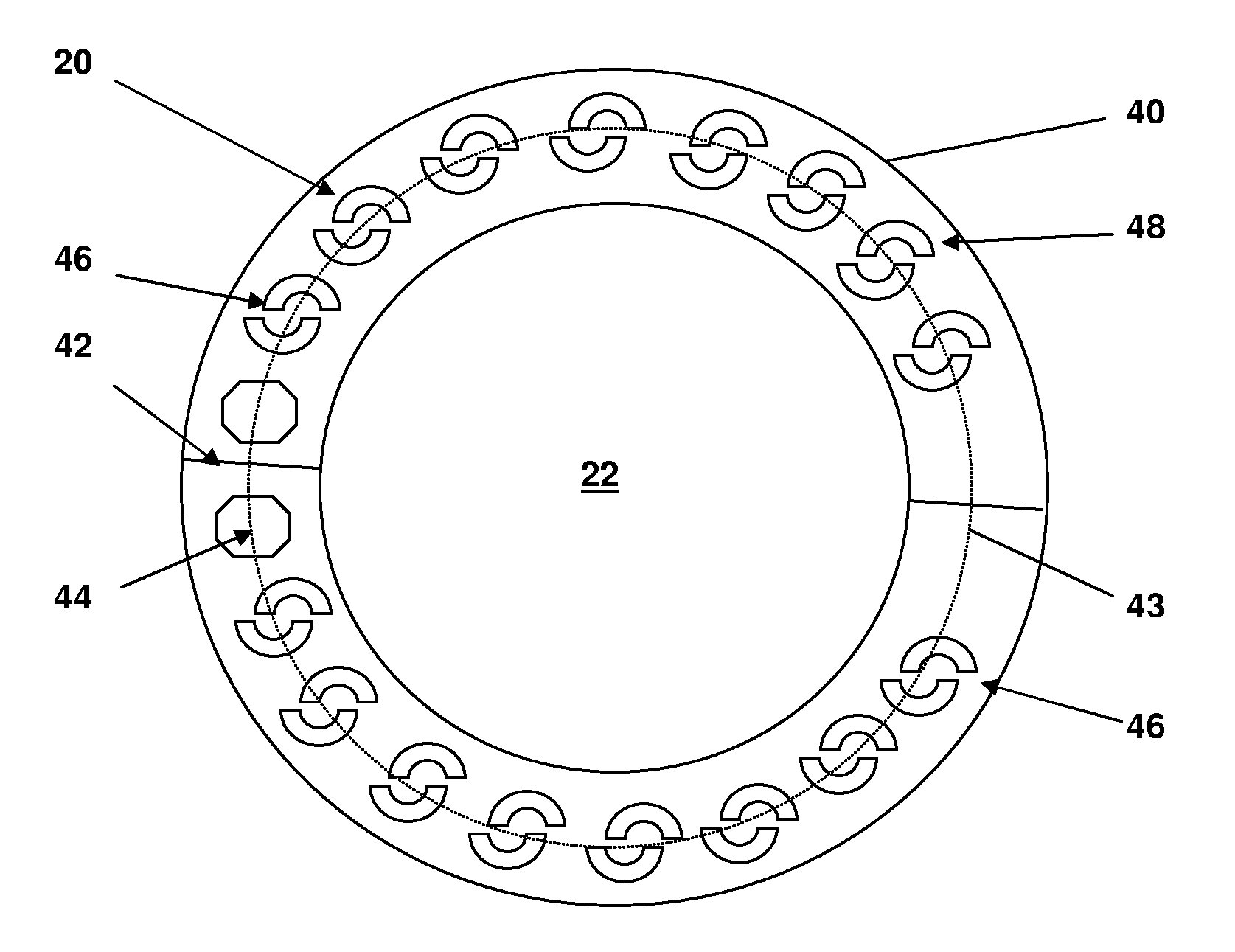

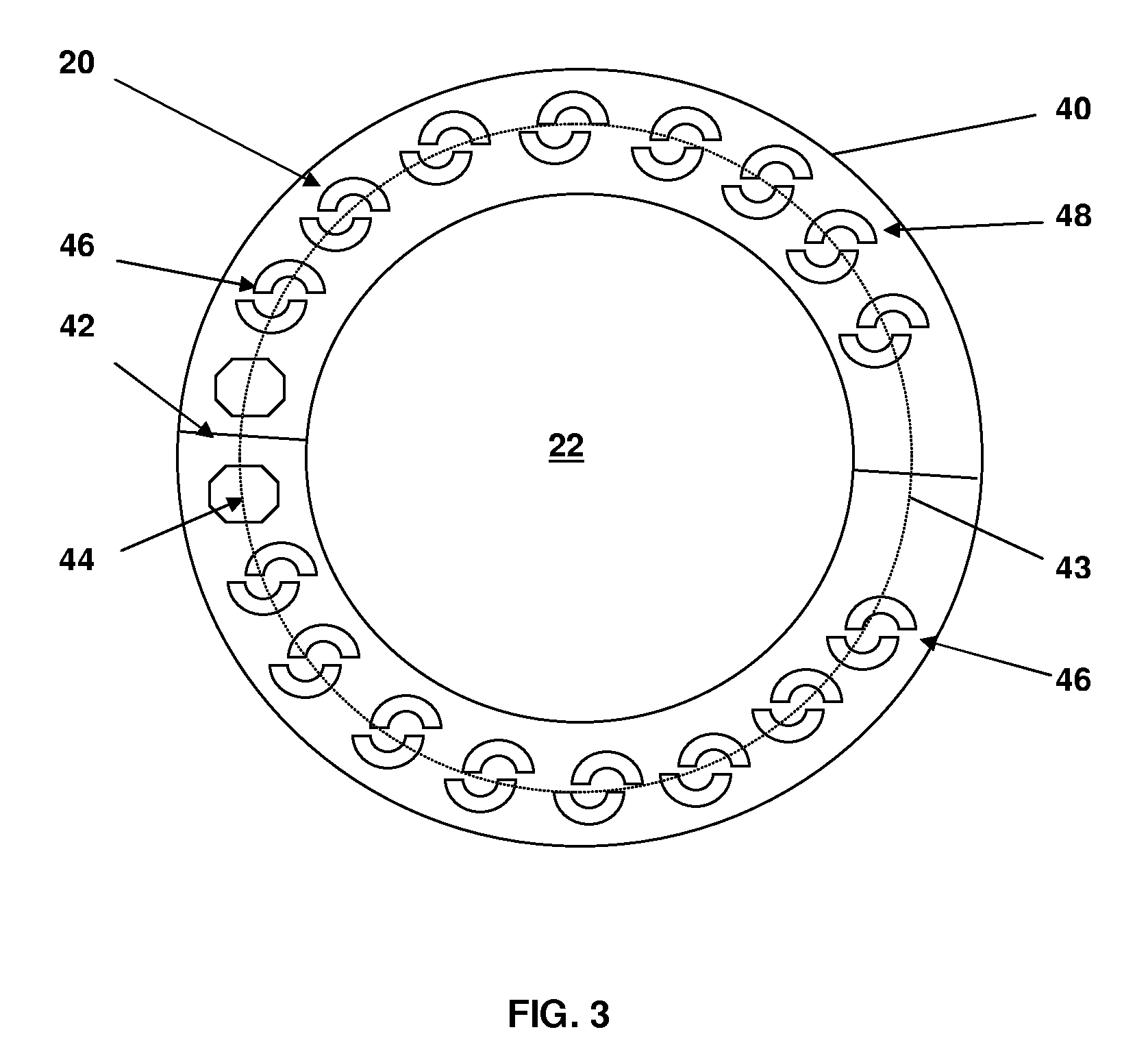

Combustor with reduced carbon monoxide emissions

InactiveUS20090282830A1Reduce carbon dioxide emissionsLarge spacingContinuous combustion chamberGas turbine plantsSplit linesCombustor

A combustor arrangement for a gas turbine engine (31) has a split line (42) and a plurality of burners (20,37) arranged in an annular ring (40). The burners (46) of the combustor on either side of the split line (42) have a separation distance of at least two times the average separation distance between burners (48) distant from the split line (42).

Owner:ANSALDO ENERGIA SWITZERLAND AG

Inverted cone-shaped flow baffling demister

ActiveCN104606958AEfficient removalAchieve separationDispersed particle separationChemical industryEngineering

The present invention discloses an inverted cone-shaped flow baffling demister, which comprises a plurality of demisting assemblies, wherein each demisting assembly comprises a gas rising pipe and an inverted cone cylinder, the inverted cone cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided with a sealing cover plate, the circumference of the gas rising pipe is provided with a plurality of seams, and the gas rising pipe circumference close to each seam is provided with tangential diversion wings. According to the inverted cone-shaped flow baffling demister, the separation of the liquid droplet and the gas is achieved through the multiple flow baffling during the fluid flowing process; and the inverted cone-shaped flow baffling demister has characteristics of simple structure, easy installation and effective gas-liquid separation achieving, and is suitable for the gas-liquid separation process in the fields of chemical industry, environmental protection, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combustor with reduced carbon monoxide emissions

InactiveUS7827777B2Reduce carbon dioxide emissionsLarge spacingContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

Owner:ANSALDO ENERGIA SWITZERLAND AG

Row tube type normal-pressure coal economizer

InactiveCN101639213AImprove heat transfer effectNo dust accumulationFeed-water heatersFlue gasWater flow

The invention relates to a row tube type normal-pressure coal economizer comprising a tube box, a flue gas inlet colleting box and a flue gas outlet collecting box, wherein the flue gas inlet colleting box and the flue gas outlet collecting box are connected with both ends of the tube box in screw joint, a flue gas interface is arranged on the flue gas inlet colleting box, a fan interface is arranged on the flue gas outlet collecting box, the lower part of the tube box is provided with a water outlet near the flue gas inlet colleting box, a water inlet is arranged near the flue gas outlet collecting box, a row tube is arranged in the tube box, one end of the row tube is connected with the flue gas interface, the other end of the row tube is connected with the fan interface, flue gas flowsin the row tube, and water flows in a space formed by an outer tube of the row tube and the tube box. The row tube type normal pressure coal economizer can effectively increase flue gas speed, increase a heating coefficient between the flue gas and a tube wall, obviously improve the heat exchange effect of a coal economizer, do not generate dust collecting phenomenon and become a maintenance-freecoal economizer.

Owner:杨益明

Process of synthesizing gasoline and coproducting aromatic hydrocarbon by synthetic gas

InactiveCN100529023CHigh gas velocityImprove heat transfer performanceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoveryReaction temperatureFixed bed

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Dust removal process of coal gas and process gas

ActiveCN106675664AWeight increaseHigh gas velocityChemical industryGasification processes detailsCoal waterSorbent

The invention discloses a dust removal process of coal gas and process gas. The dust removal process comprises the following steps of (1) putting the process gas produced by a combustion reaction of coal water slurry in a gasification furnace into a first-stage venturi scrubber, removing most of dust particles, putting the process gas into a water knockout drum for rinsing and water knockout, and enabling the process gas to enter second-stage venturi scrubbers from the bottom; (2) respectively injecting an adsorbent into a throat pipe or a reducing pipe of the second-stage venturi scrubber, wetting the adsorbent particles with spraying water at the throat pipe, and enabling the adsorbent particles to impact and adsorb the rest of the dust particles in the process gas from bottom to top along the scrubbers; and (3) separating the adsorbent particles adsorbed with dust through a cyclone separator, then regenerating the adsorbent particles, conveying the process gas into a bag dust remover for filtering and dust removal, and enabling the process gas to enter the next process unit. By means of the process, tiny dust particles can be effectively removed from the process gas, so that the dust content of the process gas is reduced, the operating period of a device is prolonged, and the aims of saving energy and improving the efficiency are fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

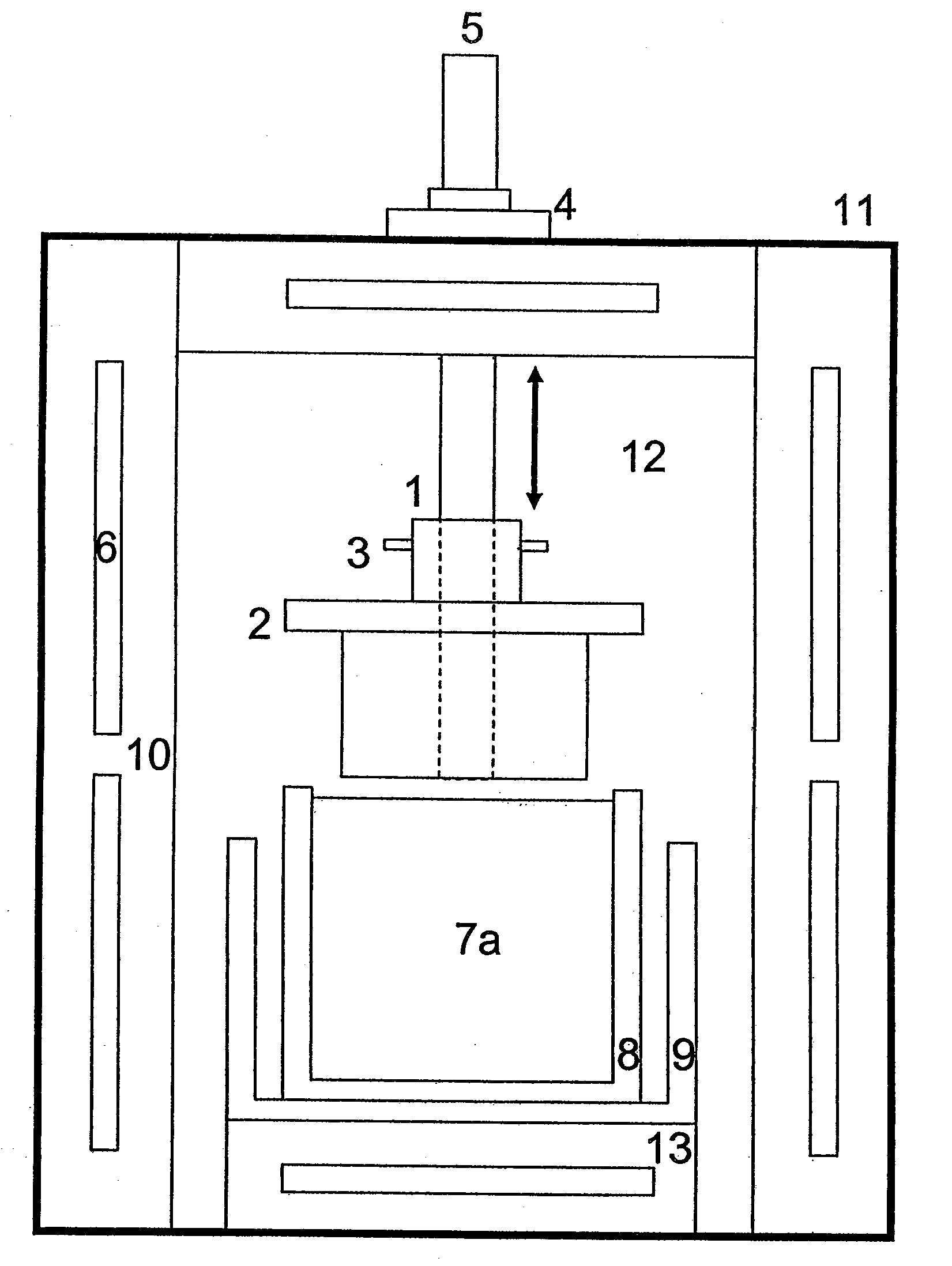

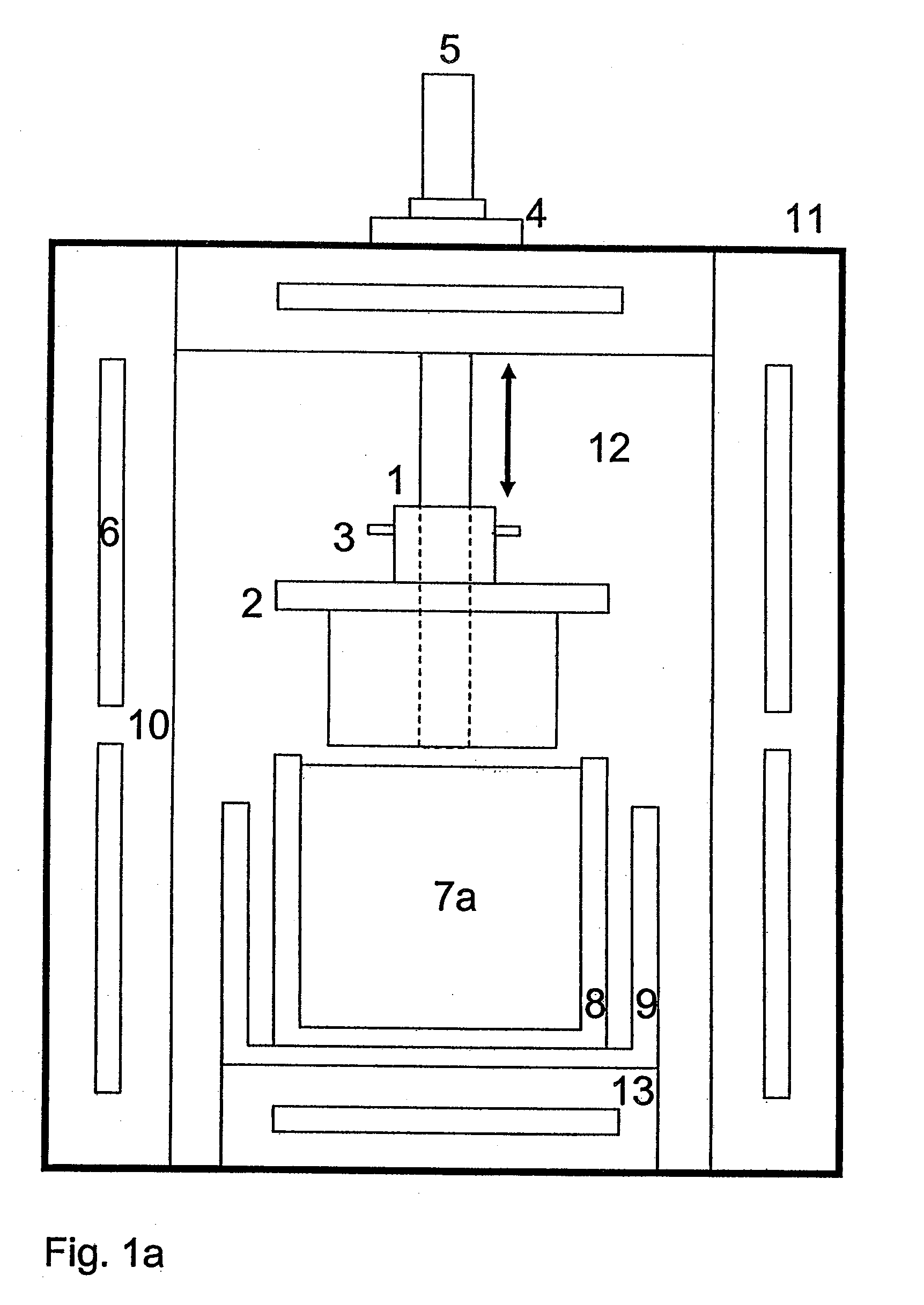

Device and method for producing crystalline bodies by directional solidification

InactiveUS20100320638A1Avoid transportMore effectively and controllablyPolycrystalline material growthConfectioneryThermodynamicsCrucible

The invention relates to a device and a method for producing crystalline bodies by directional solidification. The device comprises a melting furnace (11) having a heating chamber (12) in which at least one supporting surface (13) for a crucible (8) and at least one gas purging device arranged above the supporting surface (13) and having a gas outlet facing the supporting surface (13) are defined. An embodiment of the device is characterized in that the gas outlet is defined by one or more openings in a lower plunger surface of a plunger-shaped element (2) which has a geometry adapted to the inner shape of the crucible (8), said shape allowing an at least partial insertion of the plunger-shaped body (2) into the crucible (8). The gas purging device and / or the supporting surface (13) comprise an adjusting mechanism or are designed to be adjustable in such a manner that they allow an adjustment of a perpendicular distance between the supporting surface (13) and the plunger-shaped body (2). The device and the corresponding method allow carbon- and oxygen-containing materials to be discharged from the melt more efficiently and in a controlled manner. The device and the method thus allow—within certain limits—a specific adjustment of the carbon and oxygen content of the crystalline bodies.

Owner:SOLARWORLD IND GMBH

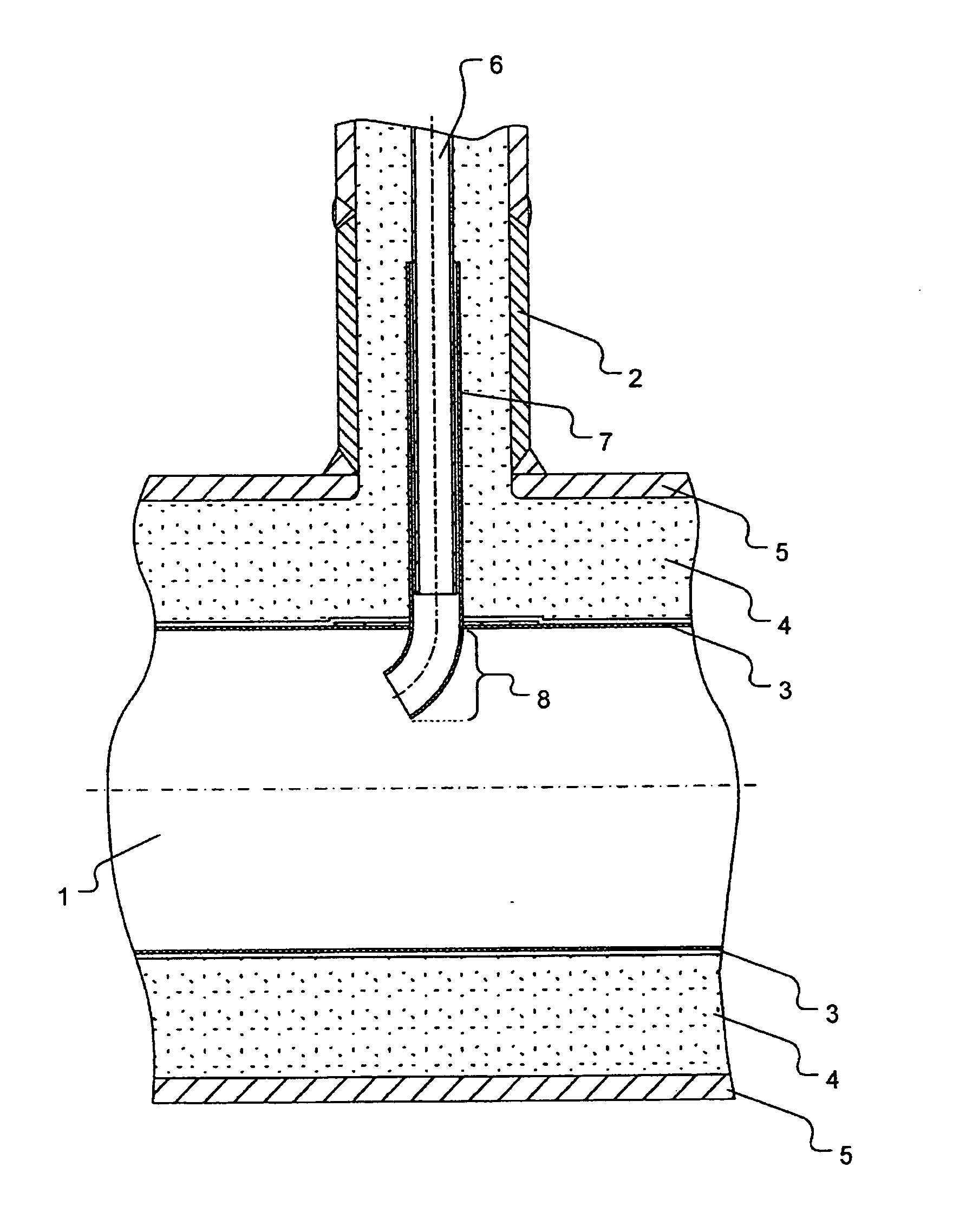

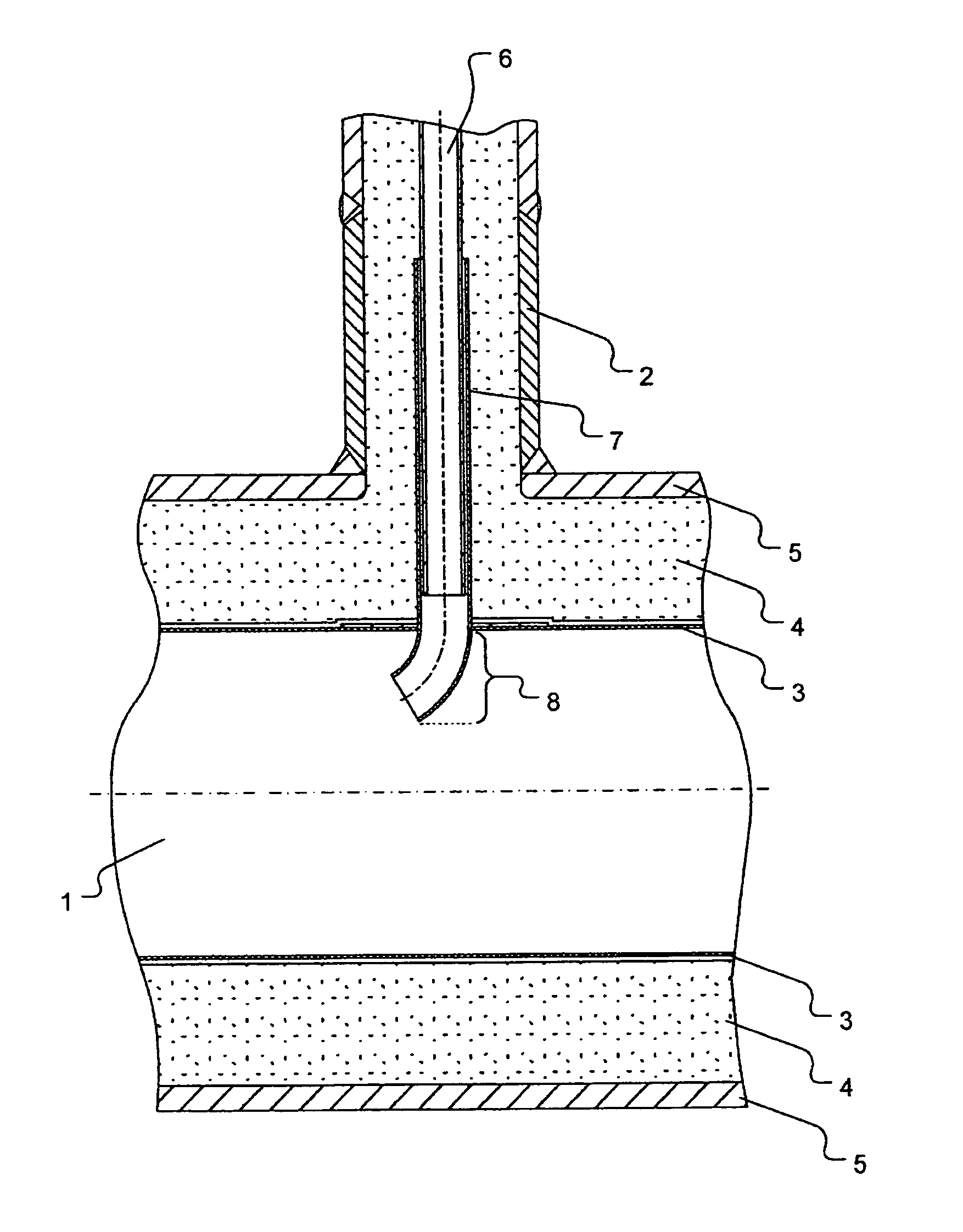

Collecting main for tubular cracking furnaces

ActiveUS8236252B2Reduce creep flowReduce the driving forceThermal non-catalytic crackingFlow mixersInsulation layerBrick

Collecting line for removing hot process gases conducted in process gas tubes from tubular reformers, wherein the collecting line has on the inside at least one insulation layer made of fire-resistant concrete or fire-resistant brick, and on the outside a wall made of a metallic outer tube, comprises a plurality of stubs via which the process gas tubes of the tubular furnace can be connected to the collecting line, wherein in the region of the stubs, the process gas tubes are at least in part conducted in guide tubes, and each gas outlet connected to the respective process gas tube projects into the collecting line, by means of which the process gas is introduced into the collecting line in correct functioning, and at least one gas outlet is constructed as a pipe bend.

Owner:UHDE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com