Patents

Literature

170 results about "Venturi scrubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively referred to as wet scrubbers.

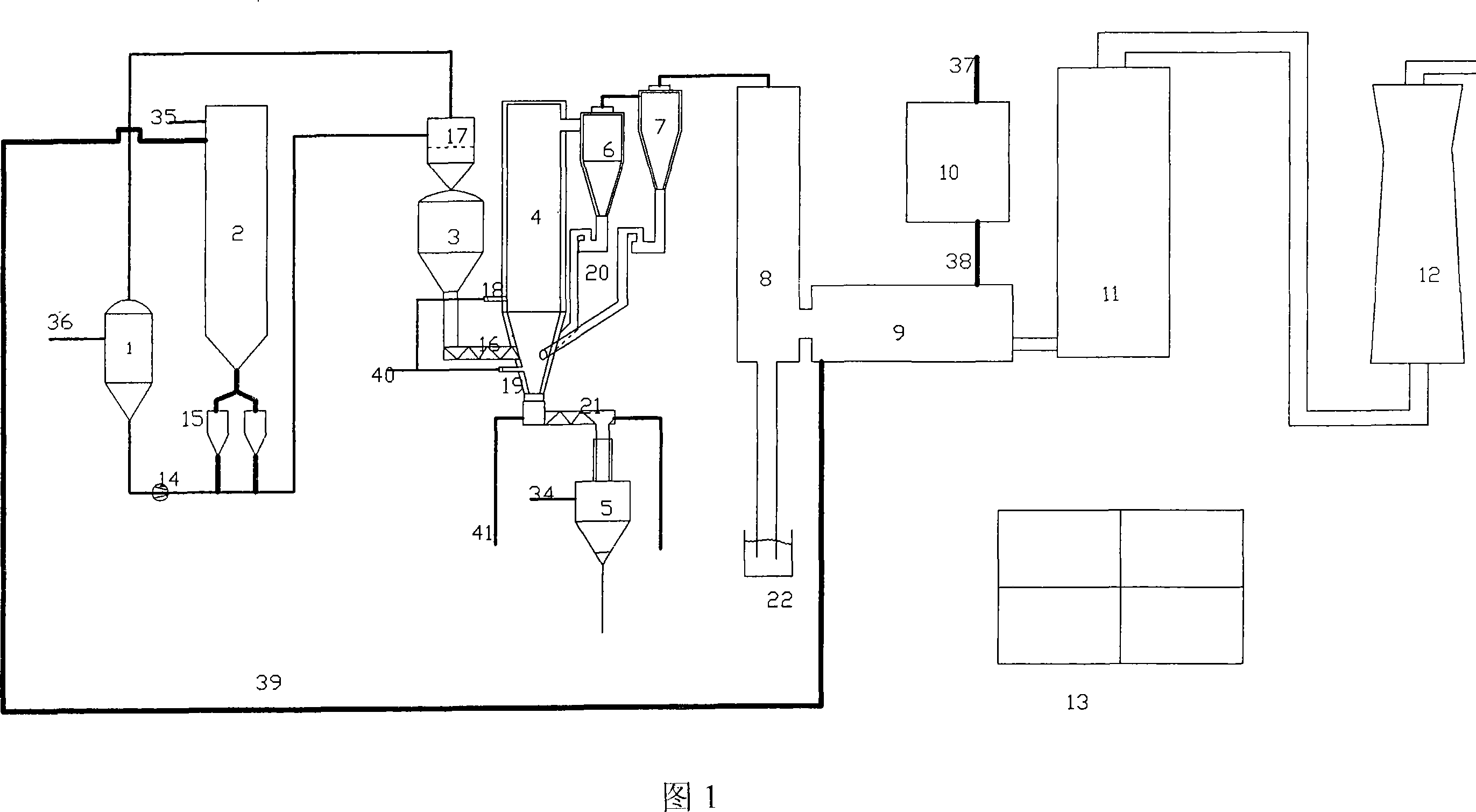

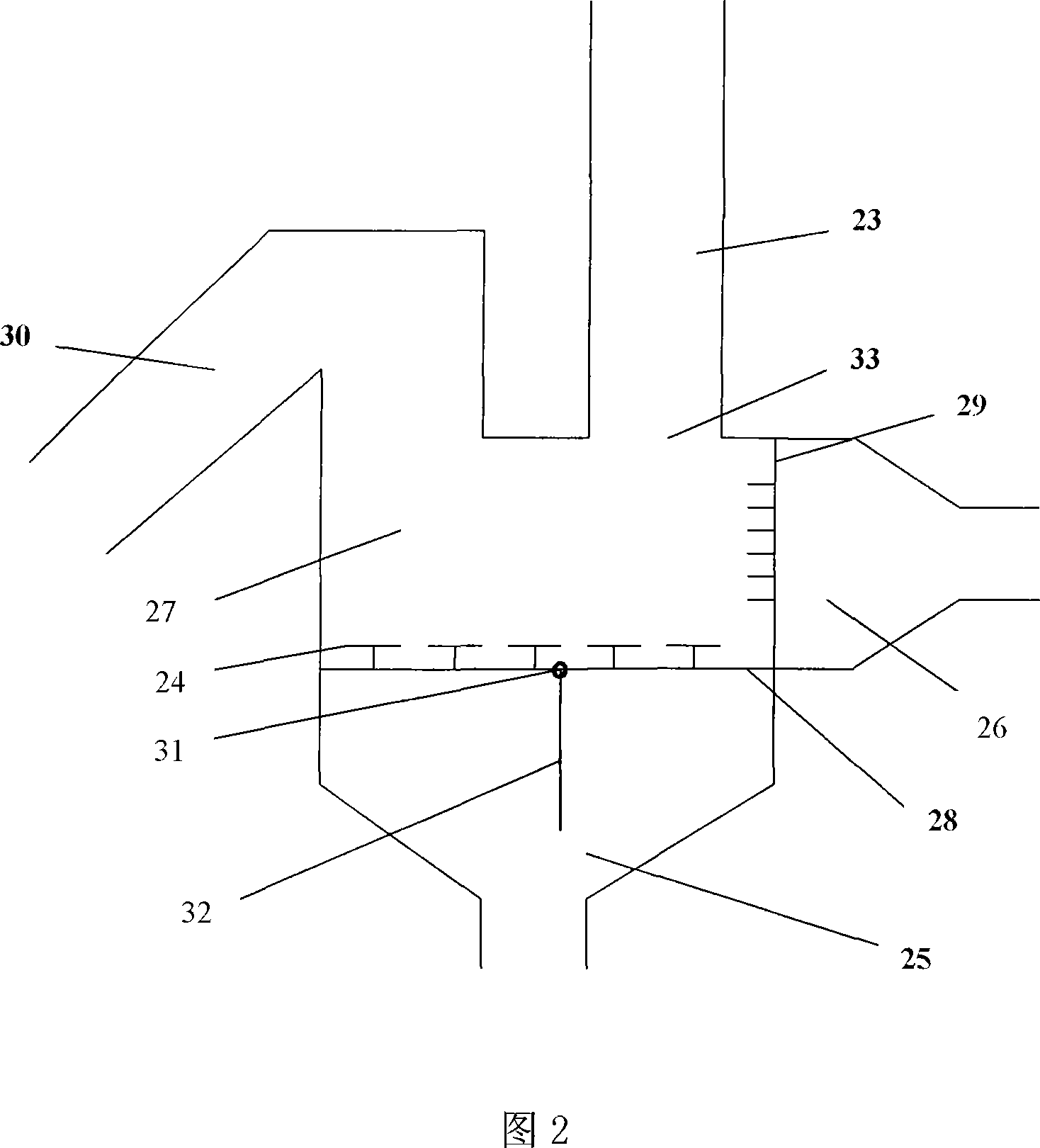

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

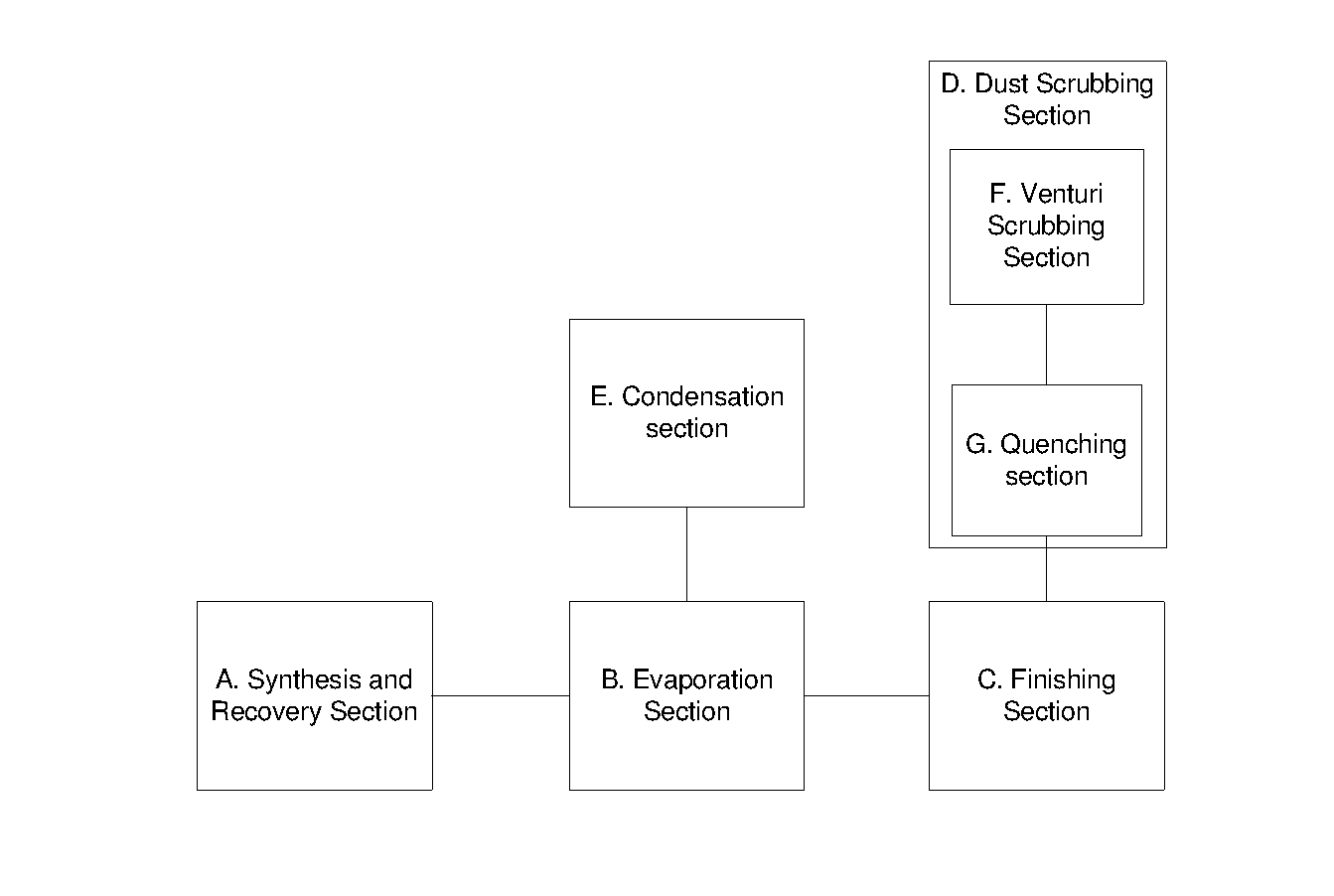

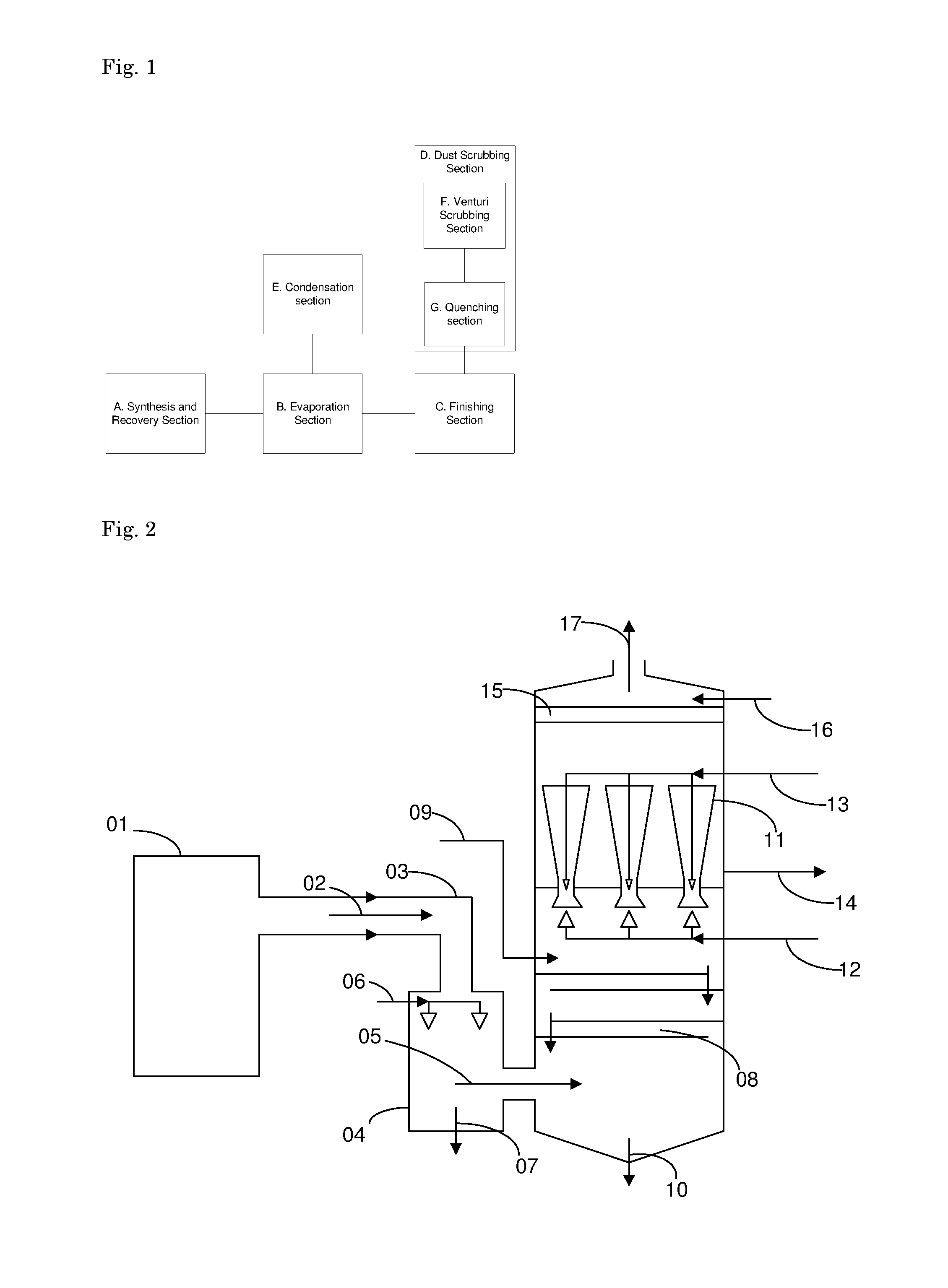

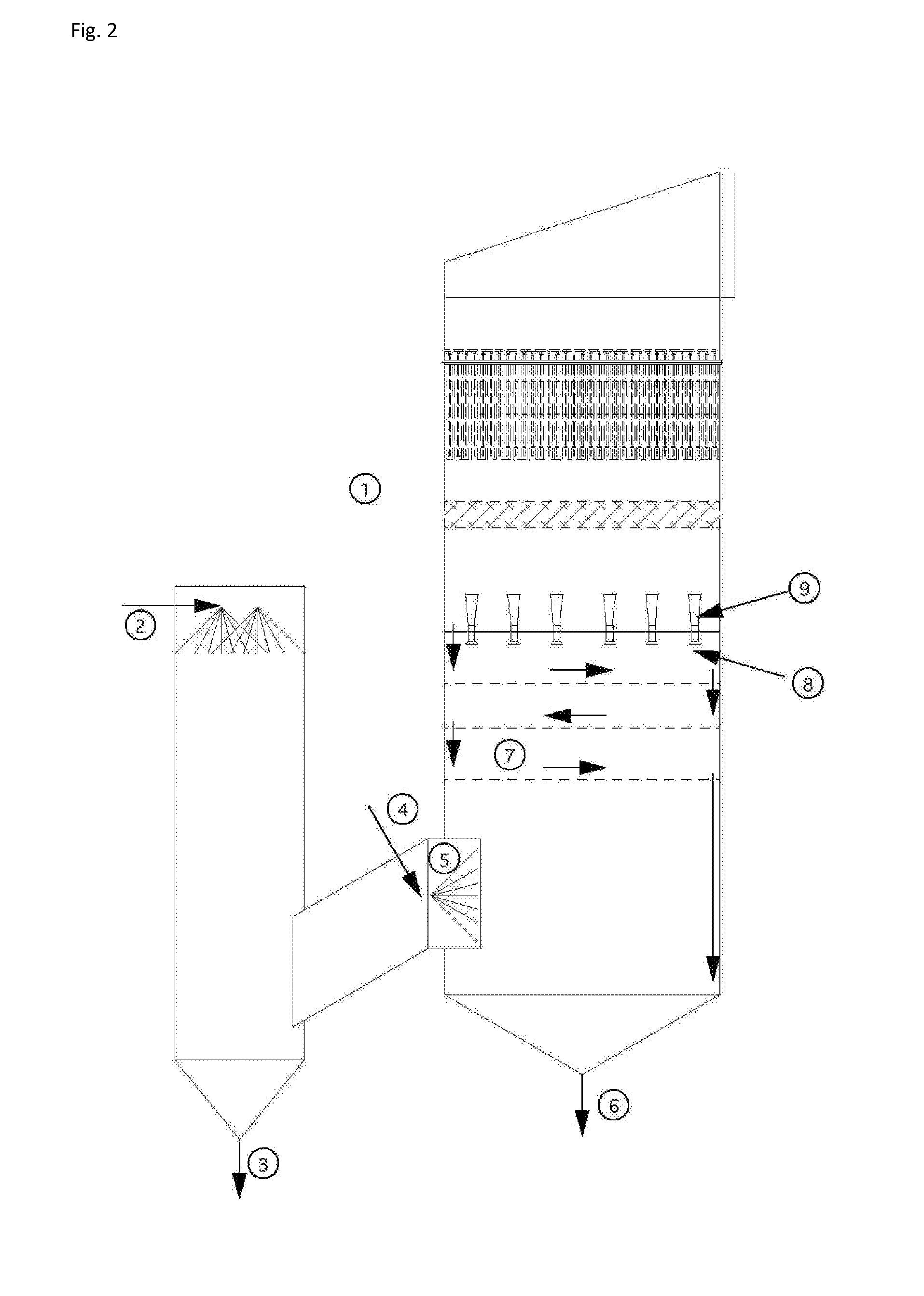

Removal of dust in urea finishing

Disclosed is a method for the removal of urea dust from the off- gas of a finishing section (1) of a urea production plant, the method comprises subjecting the off-gas to quenching with water (06) so as to produce quenched off-gas, and subjecting the quenched off-gas to scrubbing using at least one venturi scrubber (11). As a result, a lower pressure drop over the scrubber is attained, and a more efficient growth of urea particles, facilitating the removal thereof.

Owner:STAMICARBON BV

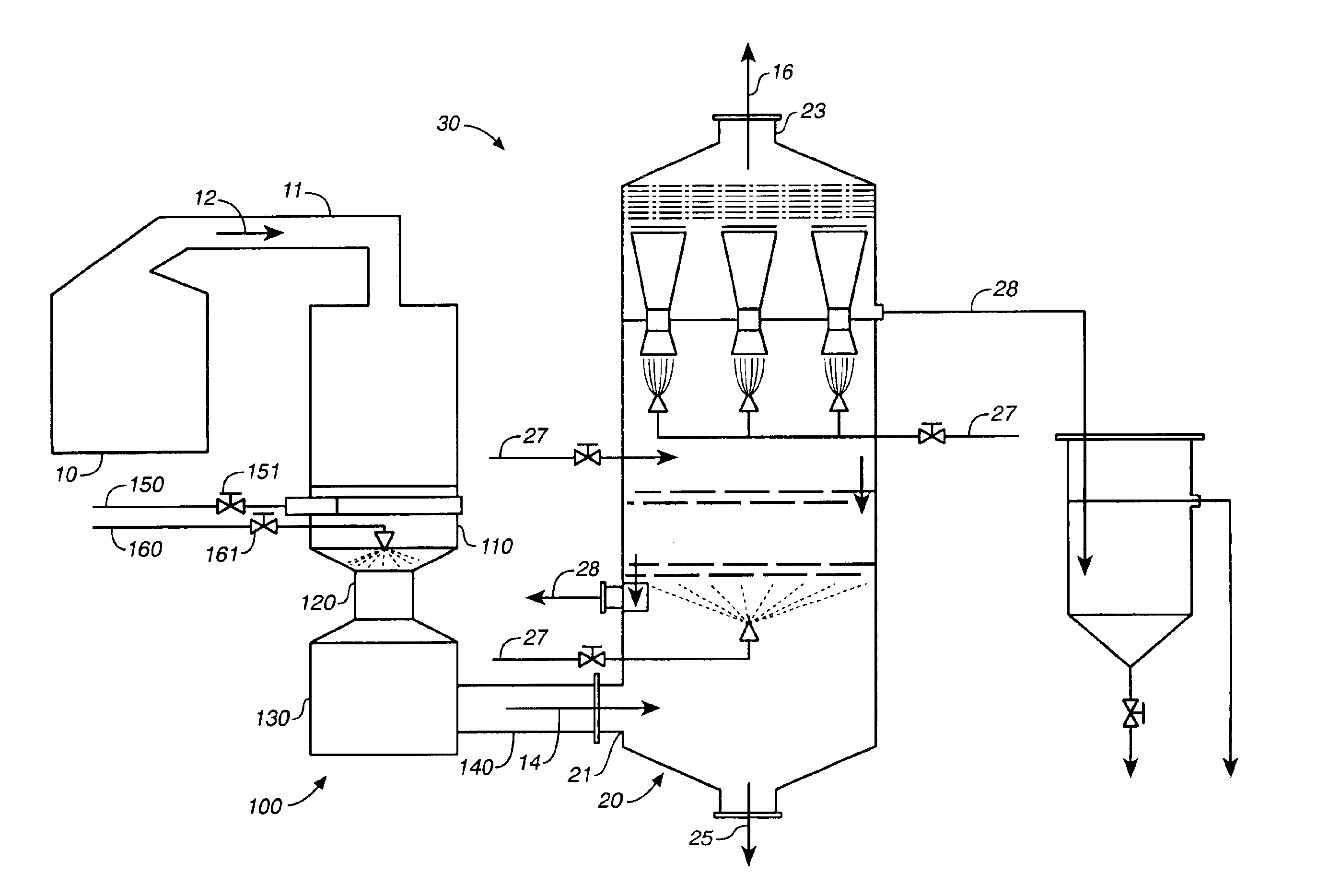

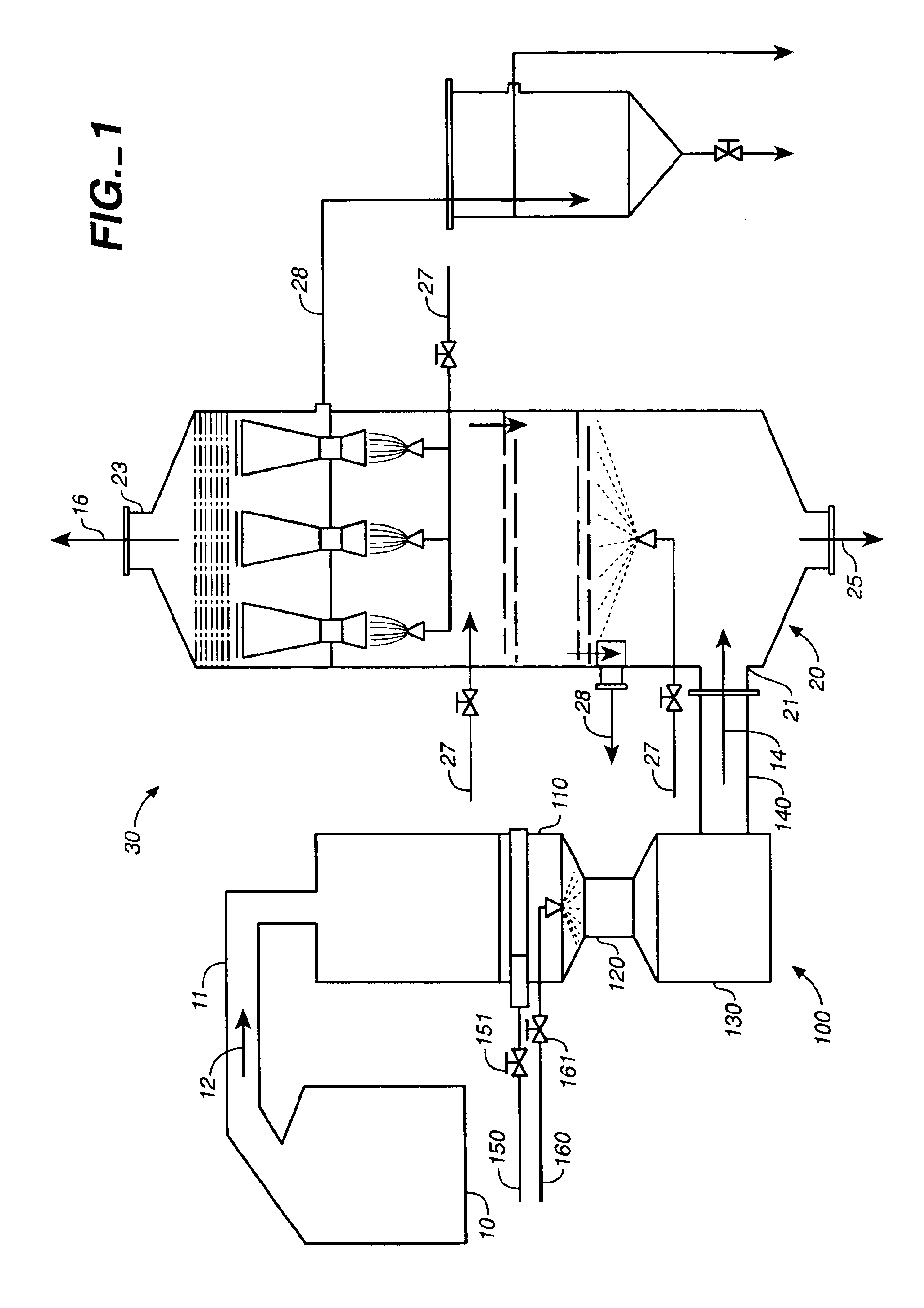

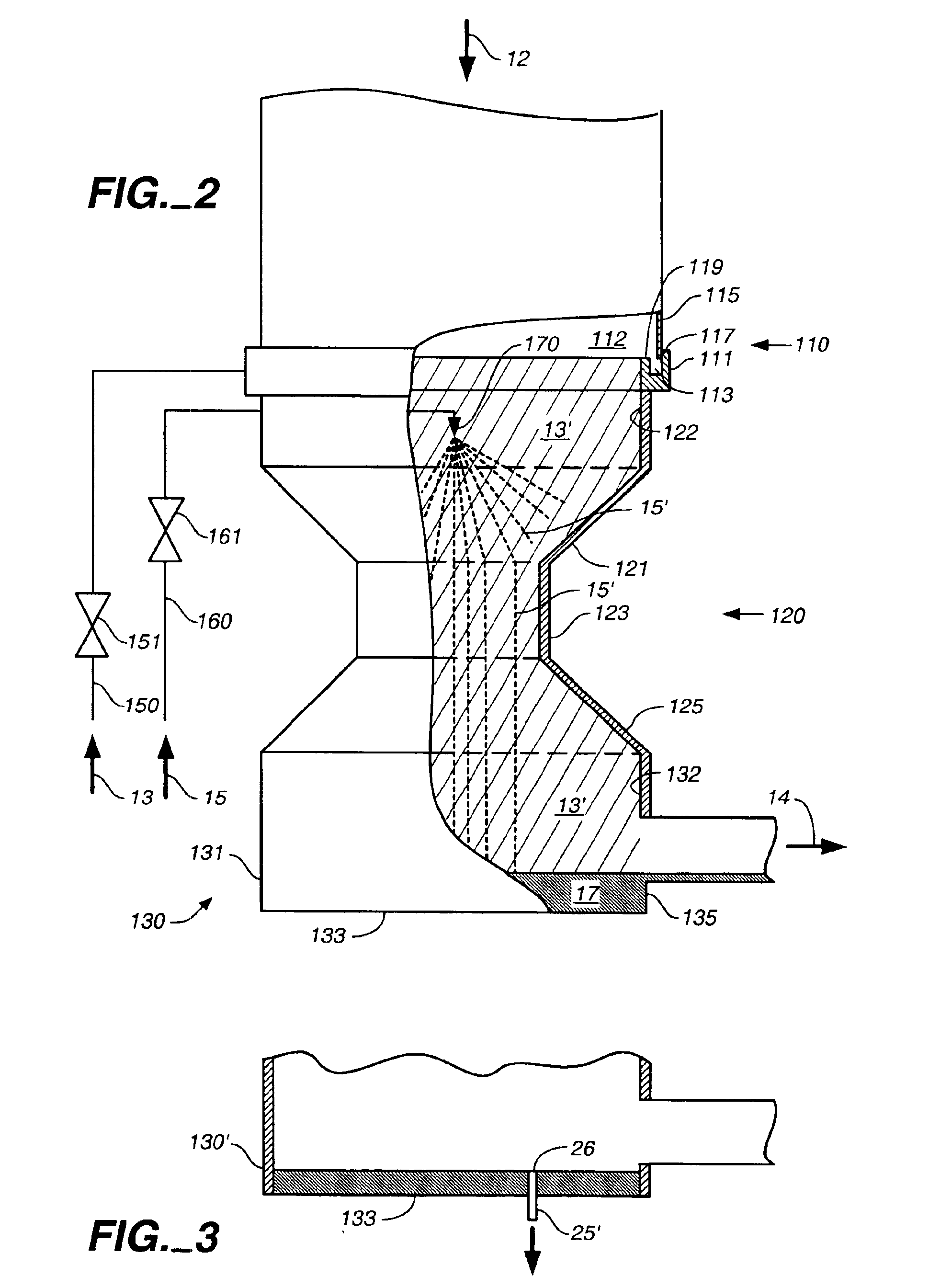

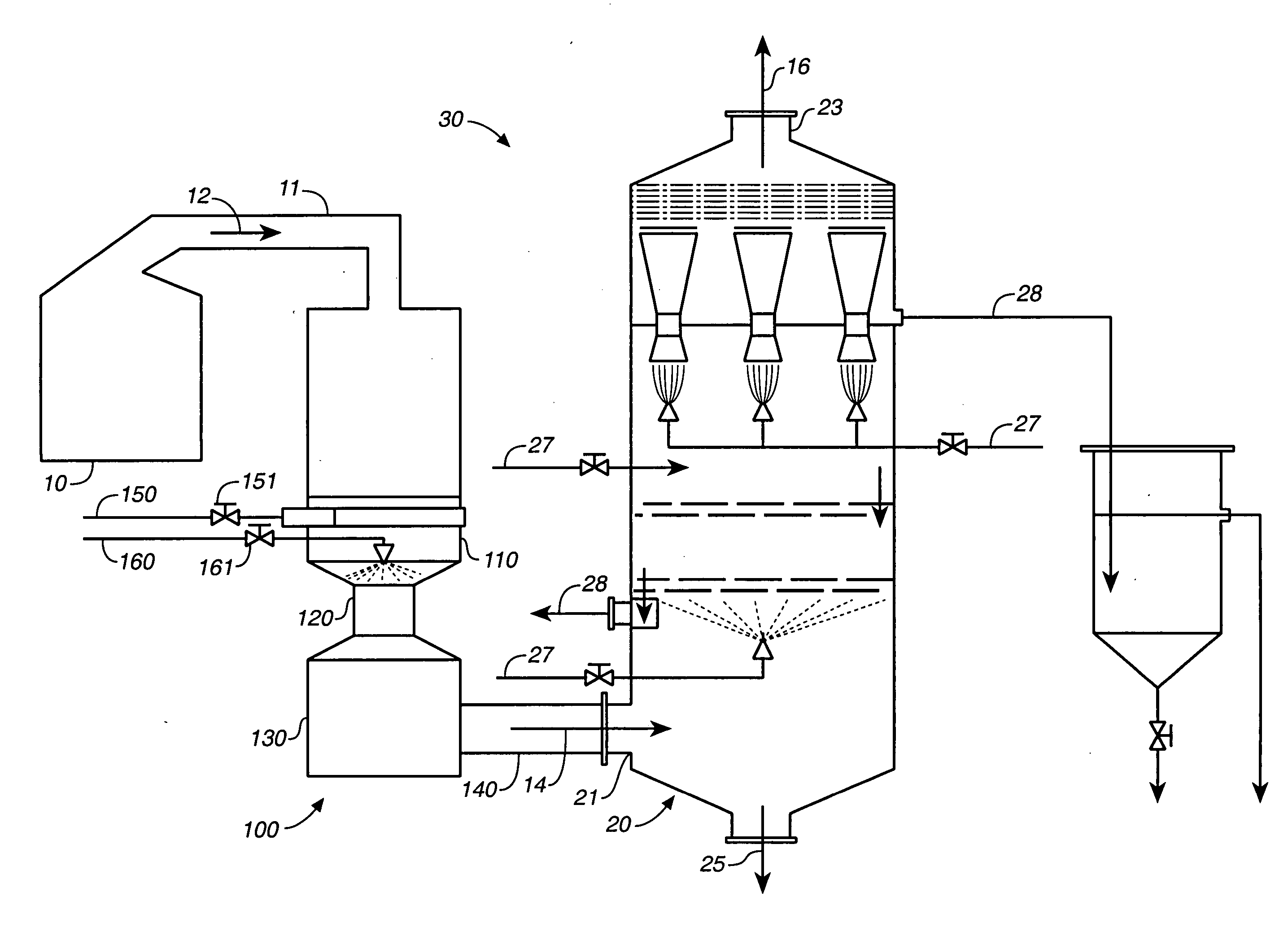

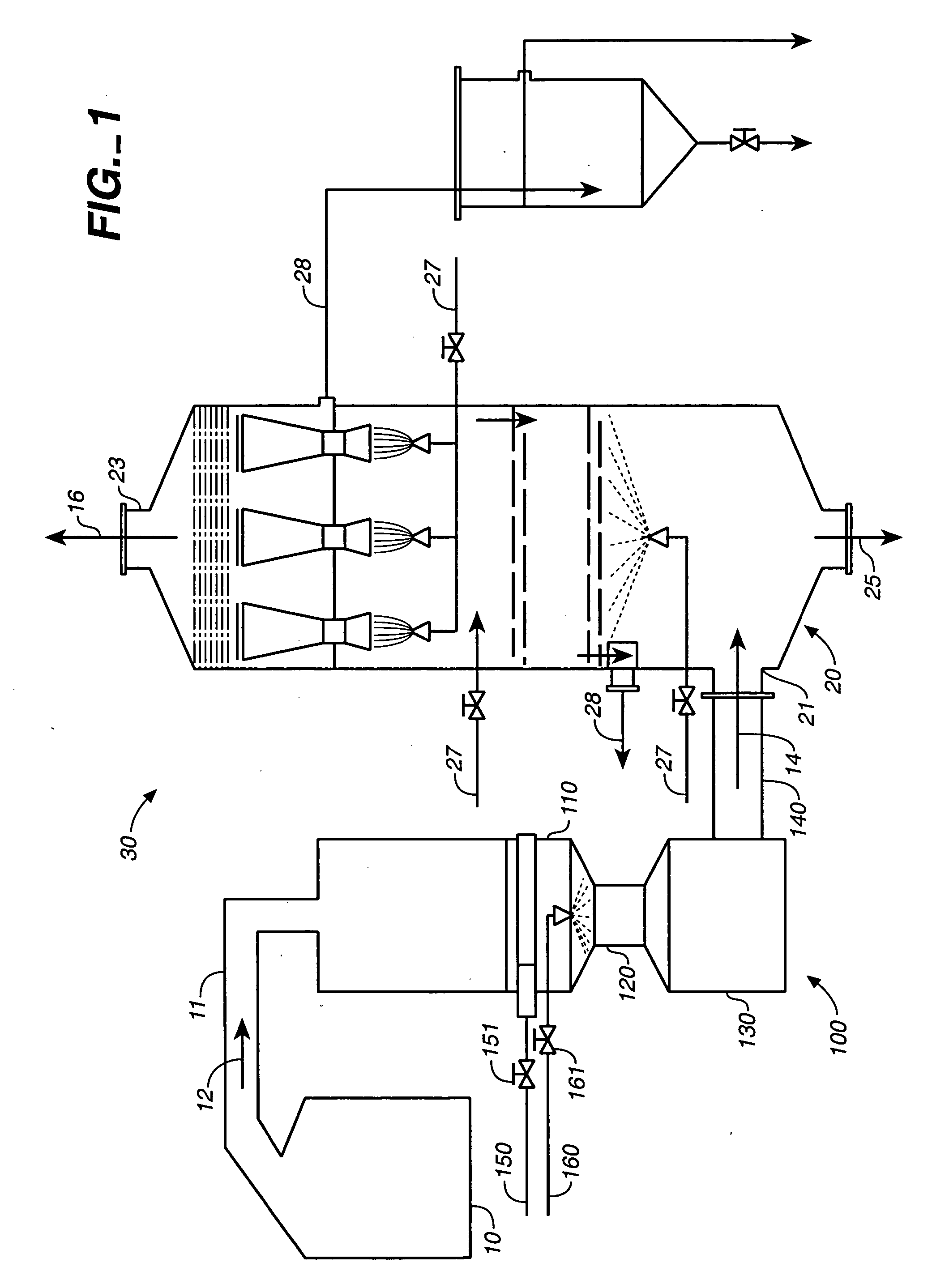

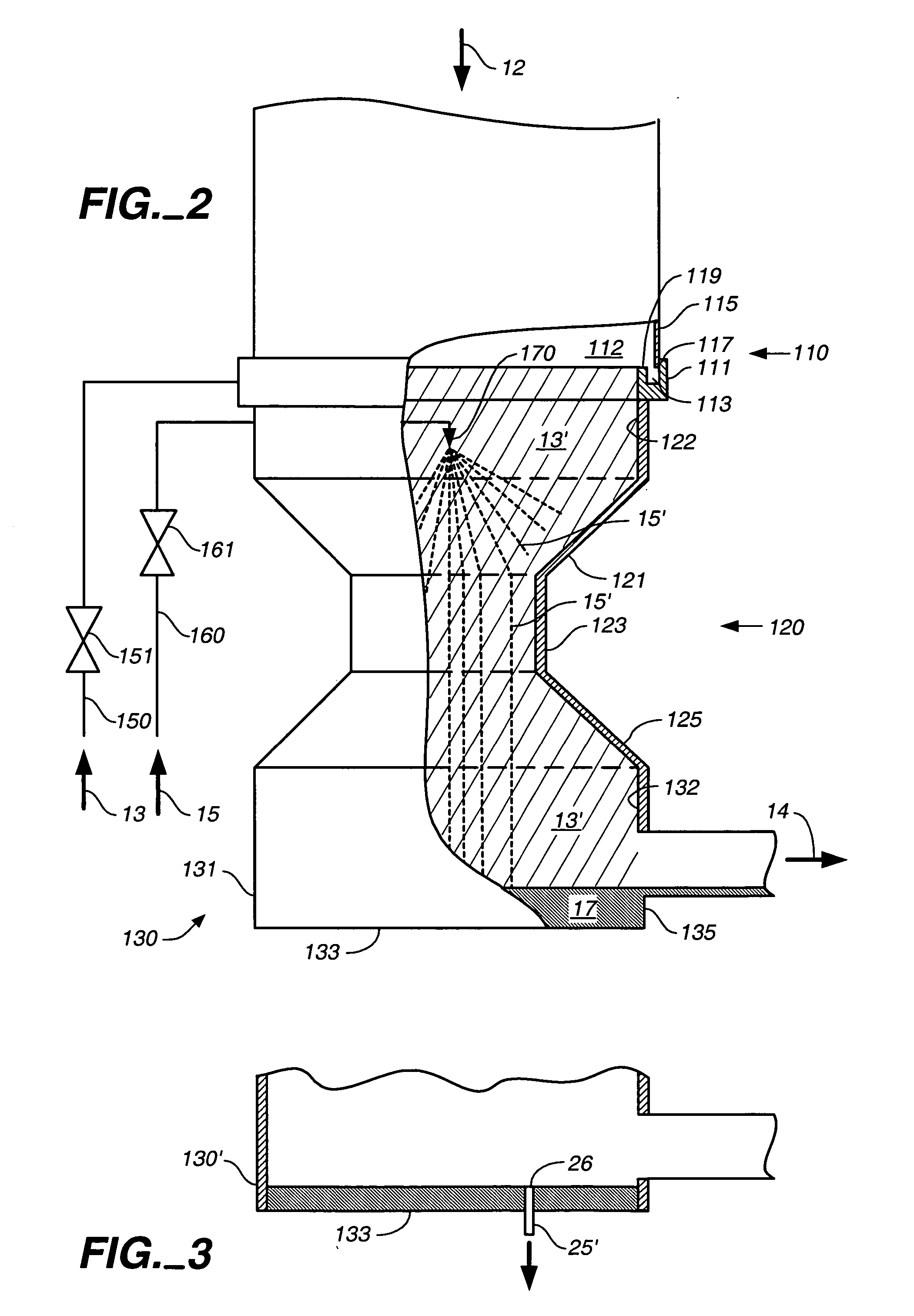

Low-energy venturi pre-scrubber for an air pollution control system and method

InactiveUS6953495B2High percentage of ashWeaken energyHuman health protectionUsing liquid separation agentEvaporative coolerParticulates

Owner:ENVIROCARE INT

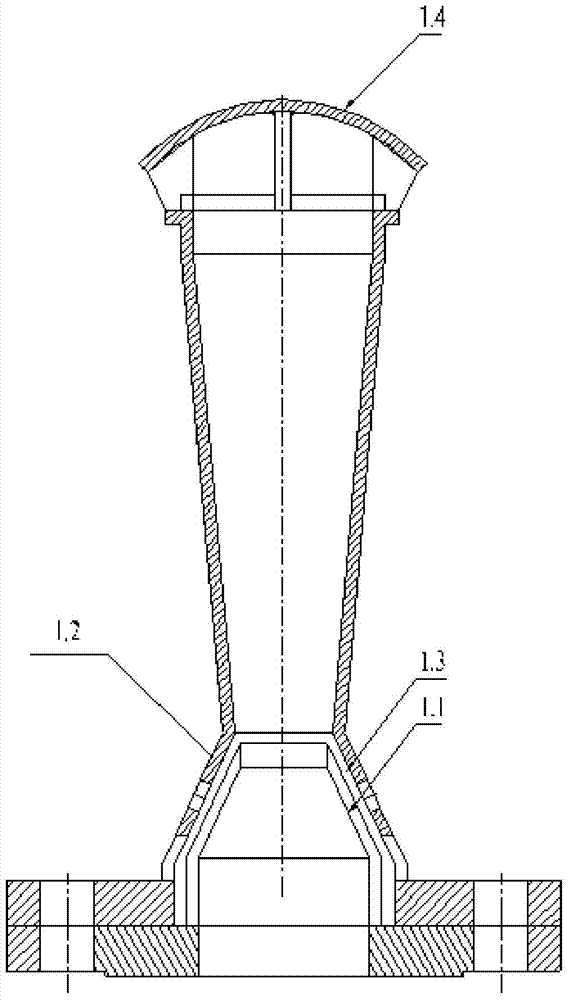

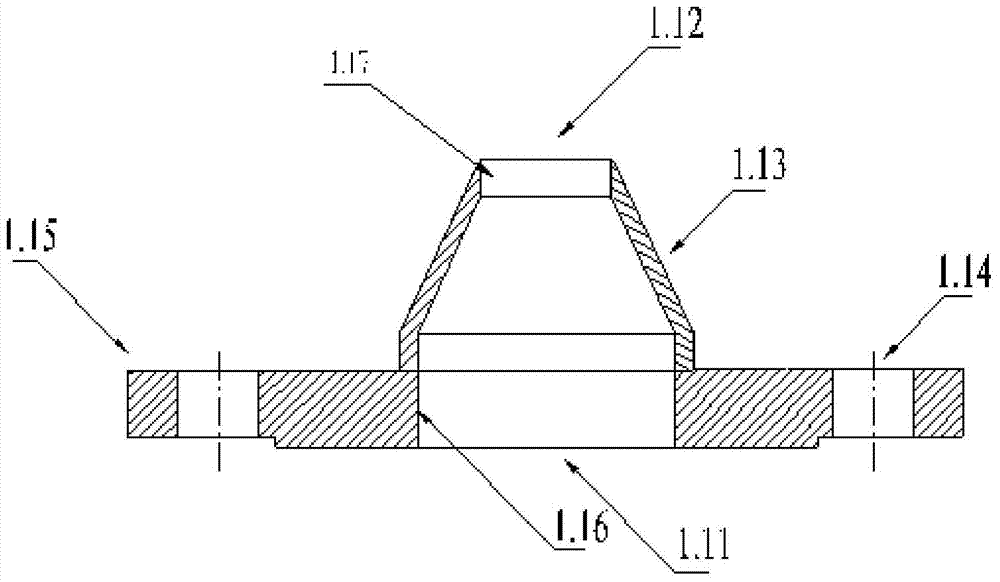

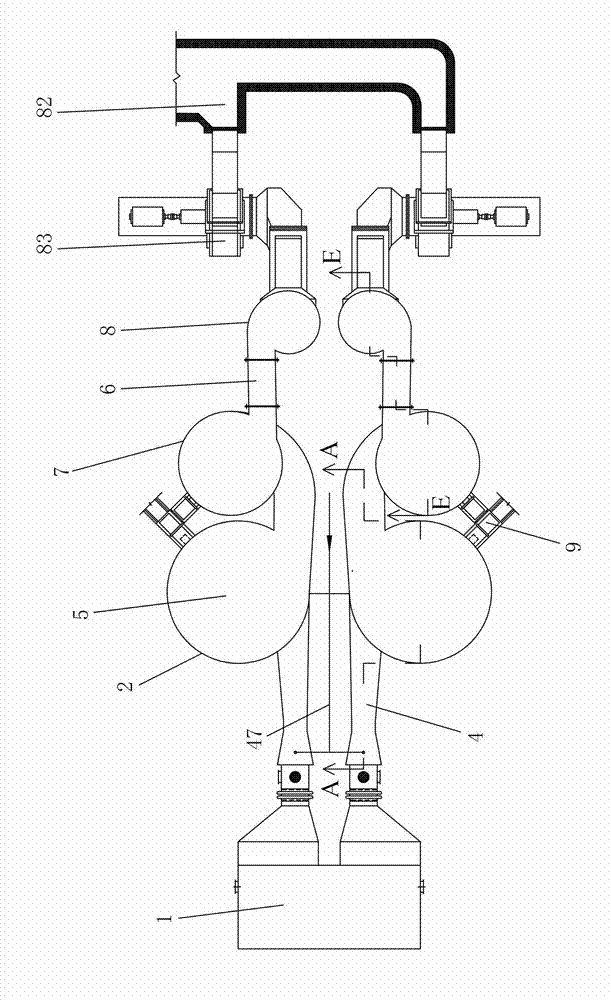

Split self-suction type Venturi tube washer

ActiveCN103566683AFully atomizedImprove gas bubblingUsing liquid separation agentPressurized water reactorFiltration

The invention provides a split self-suction type Venturi tube washer which comprises an outer sleeve mainly comprising a contraction section and an expanding section, and further comprises a conical independent contraction section, wherein the conical independent contraction section is of a conical structure and is the same as the contraction section of the outer sleeve in shape, the conical independent contraction section is sleeved in the contraction section of the outer sleeve, and is connected with the contraction section of the outer sleeve through flanges at respective inlet ends, an annular liquid flowing channel is formed between the conical independent contraction section and the contraction section, a liquid sucking hole is formed in the contraction section of the outer sleeve, and an outlet baffle plate is arranged at the outlet end of the expanding section of the outer sleeve. Compared with a common Venturi tube washer, the split self-suction type Venturi tube washer is higher in removing efficiency. The split self-suction type Venturi tube washer is suitable for being used as a Venturi tube washer required by a filtration and emission system of pressurized water reactor containment, and is also suitable for an industrial dust removing process.

Owner:CHINA NUCLEAR POWER ENG CO LTD

An apparatus and method for particulate capture from gas streams and a method of removing soluble particulate from a gas

ActiveUS20160303502A1Reduce concentrationUrea derivatives preparationOrganic compound preparationHigh concentrationParticulates

Disclosed is a method for the removal of soluble particulate matter from a gas stream, such as urea dust from the off-gas of a finishing section of a urea production plant. The method comprises subjecting the off-gas to at least two quenching stages an aqueous quenching liquid. The quenching liquid used in a first, upstream quench stage, is allowed to have a higher concentration of dissolved particulate matter than the quenching liquid in the second, downstream quench stage. The quenched gas is led through a particle capture zone, typically comprising one or more of a wet scrubber, a Venturi scrubber, and a wet electrostatic precipitator.

Owner:STAMICARBON BV

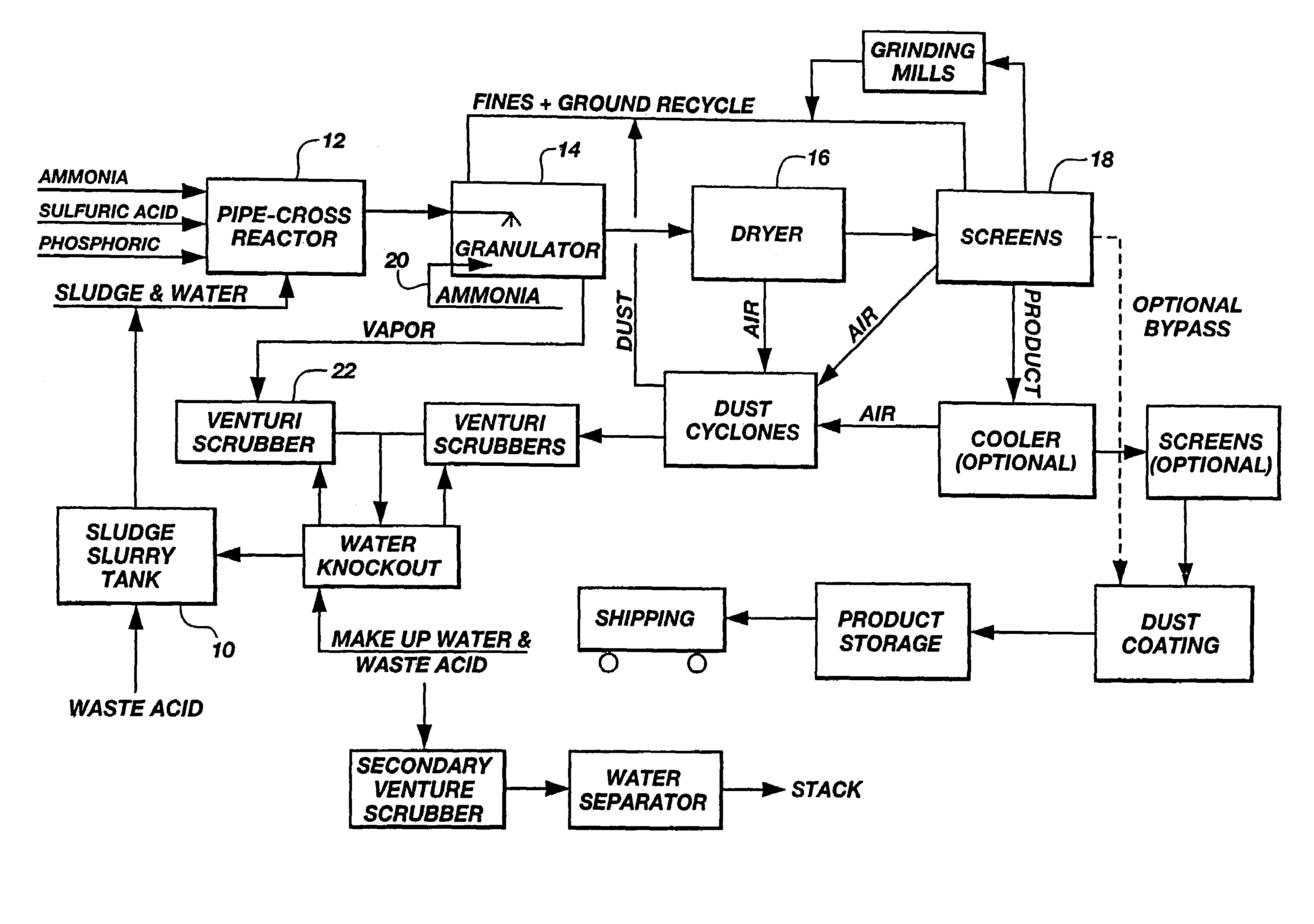

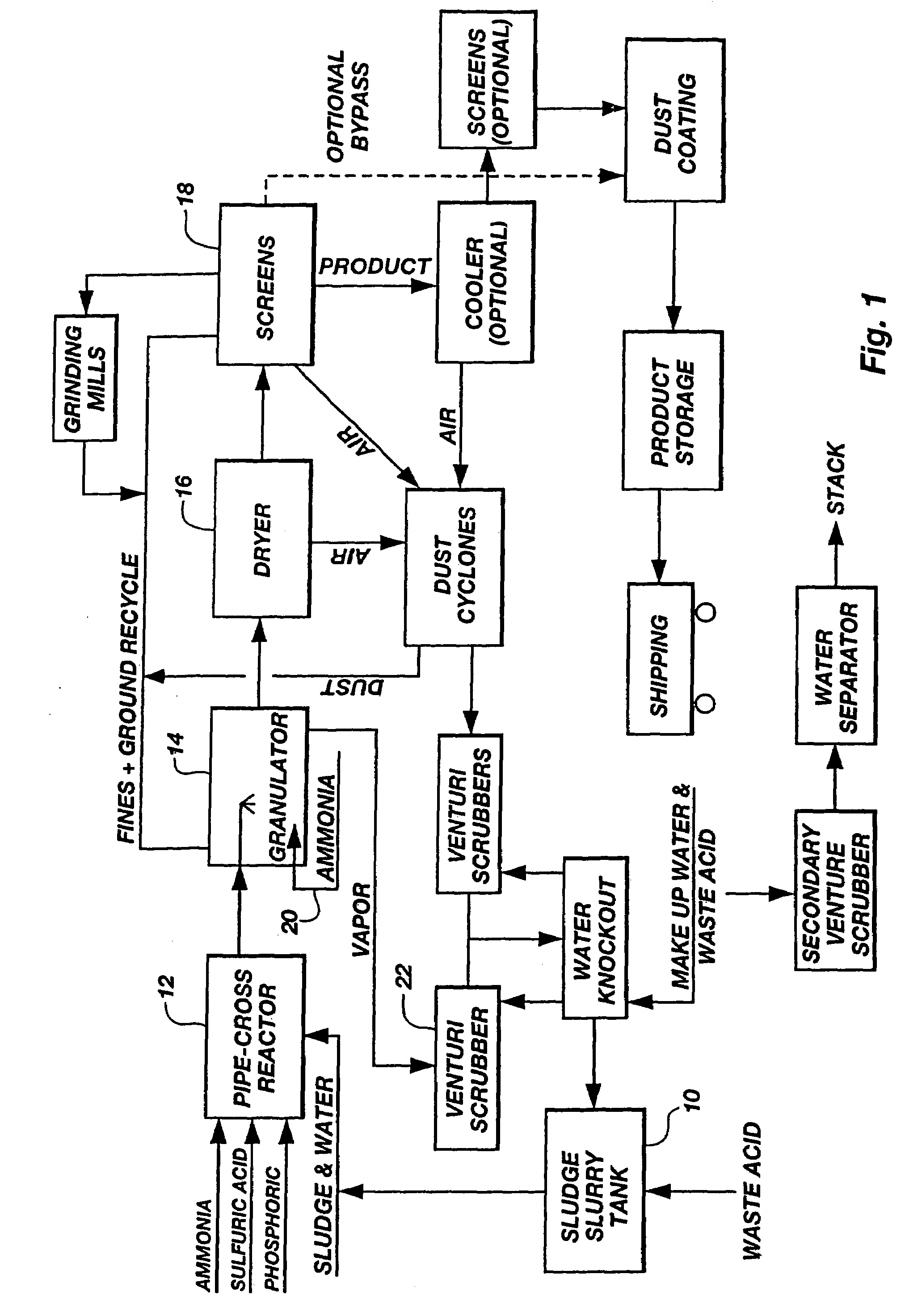

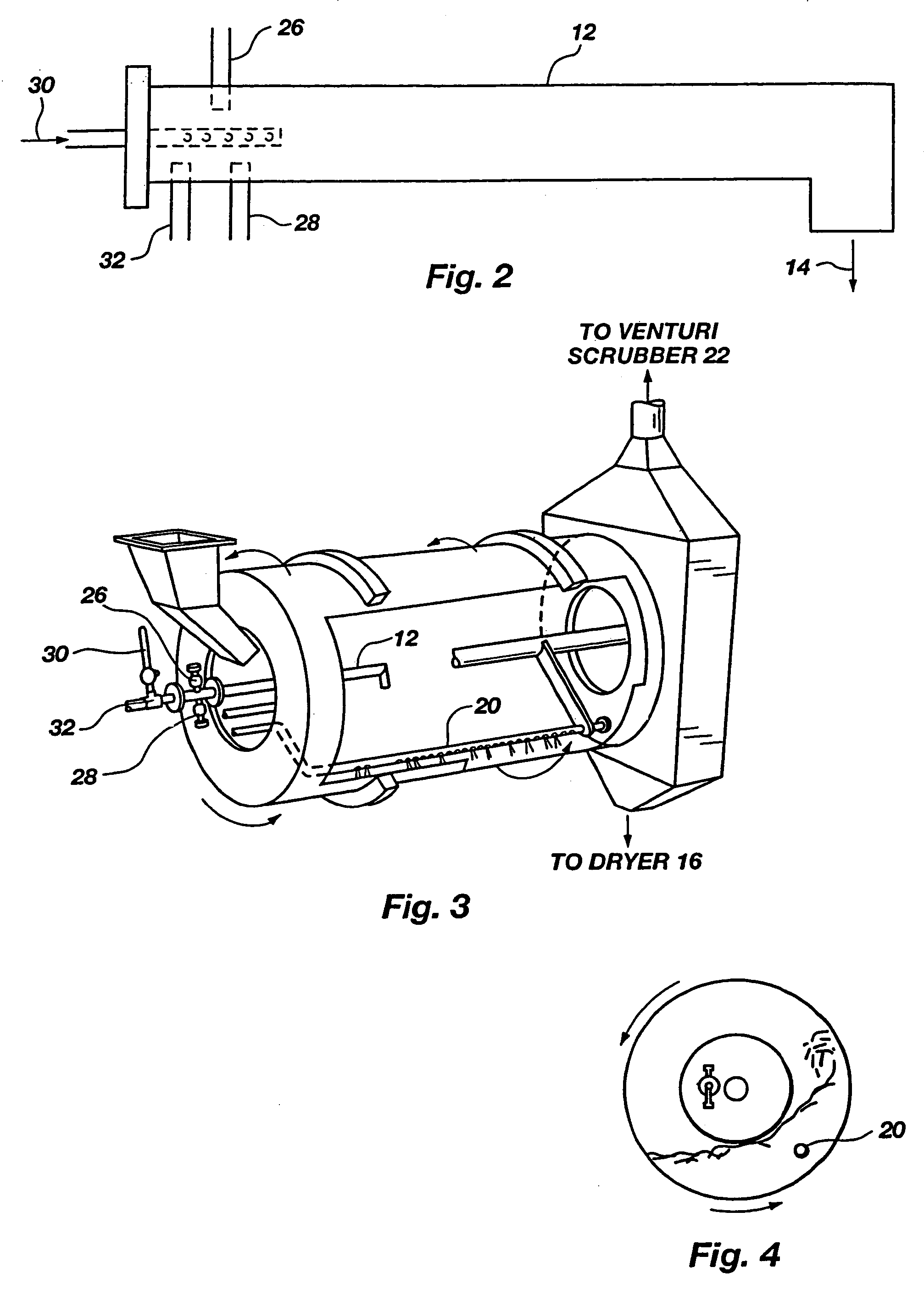

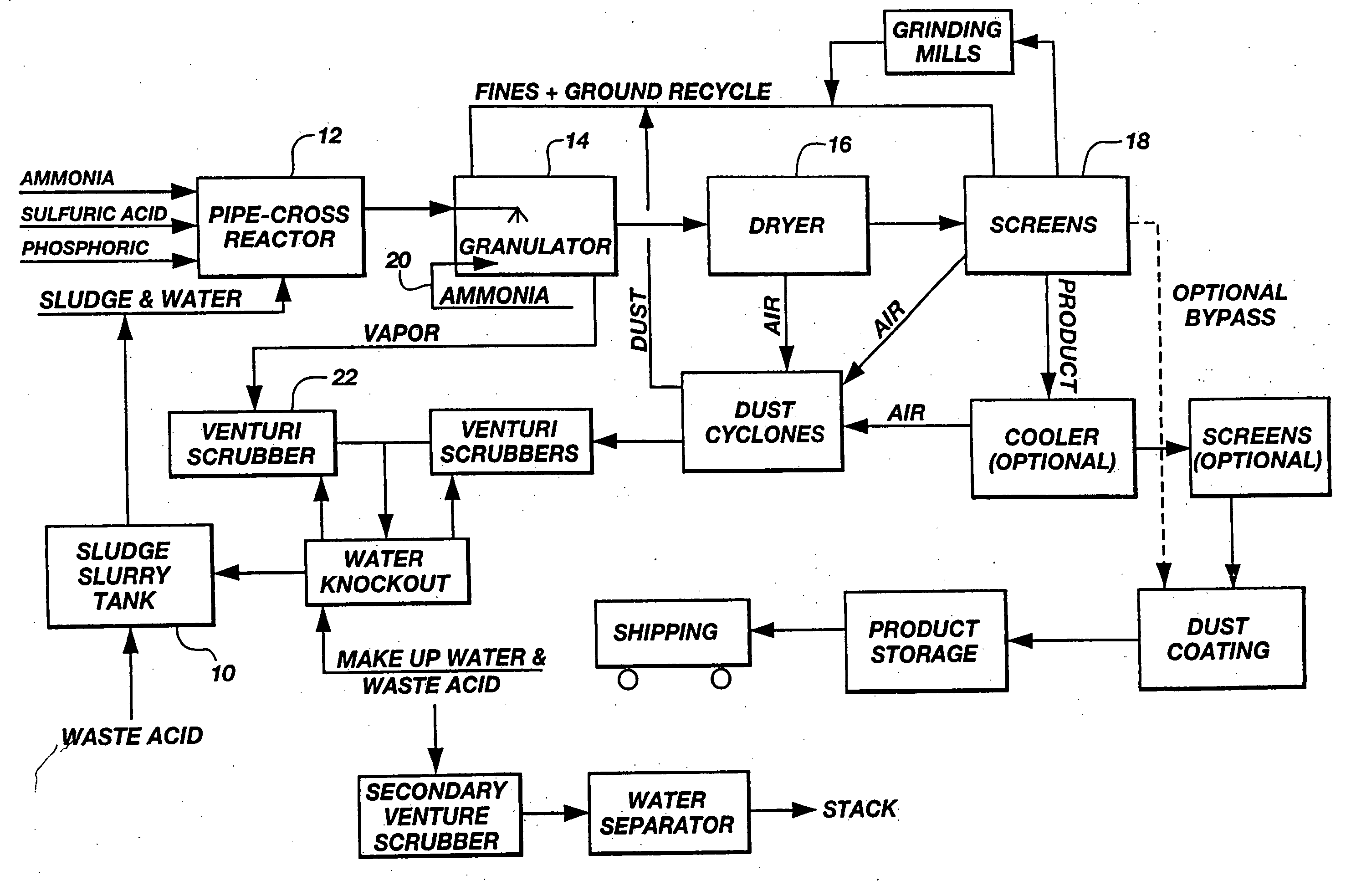

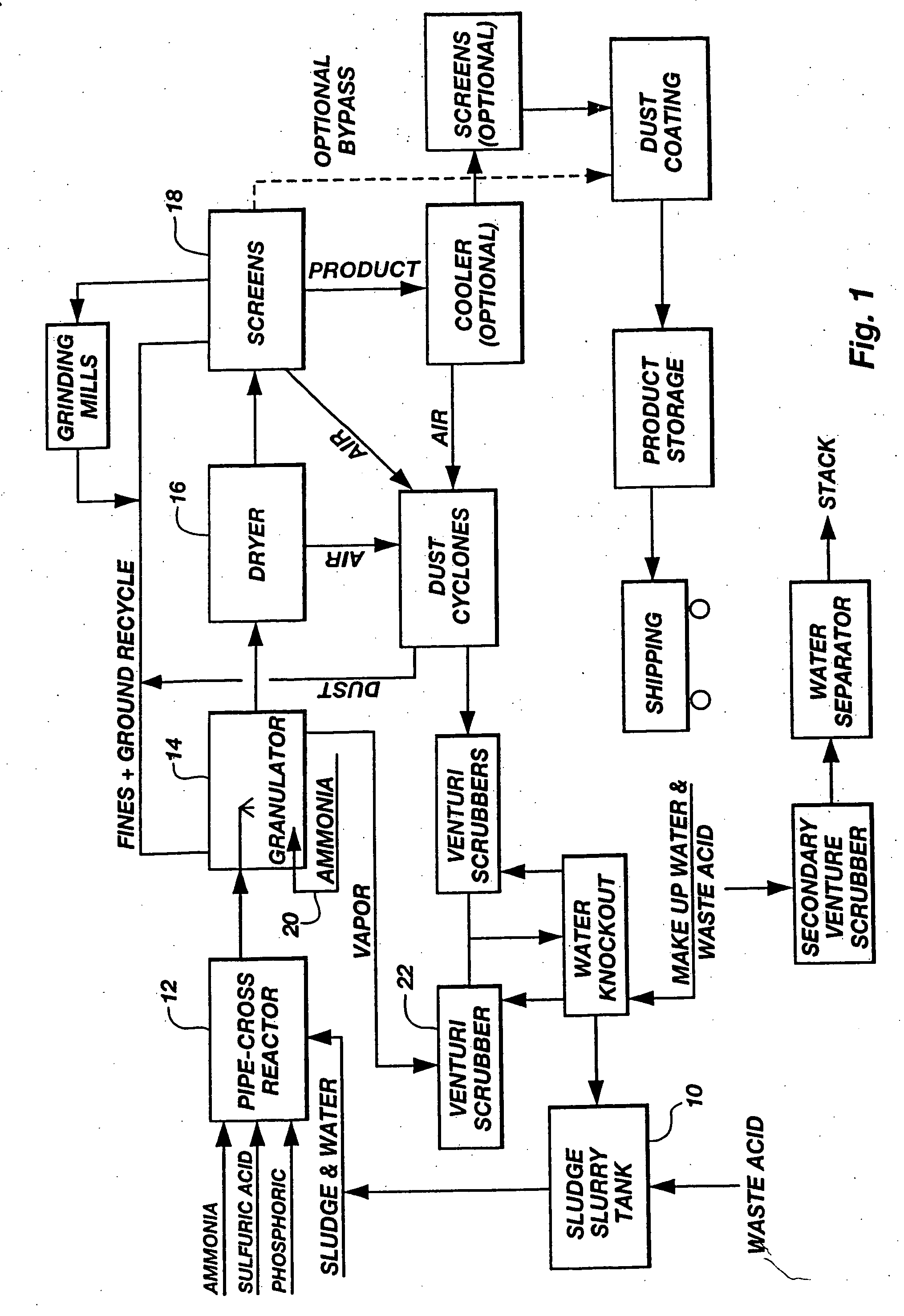

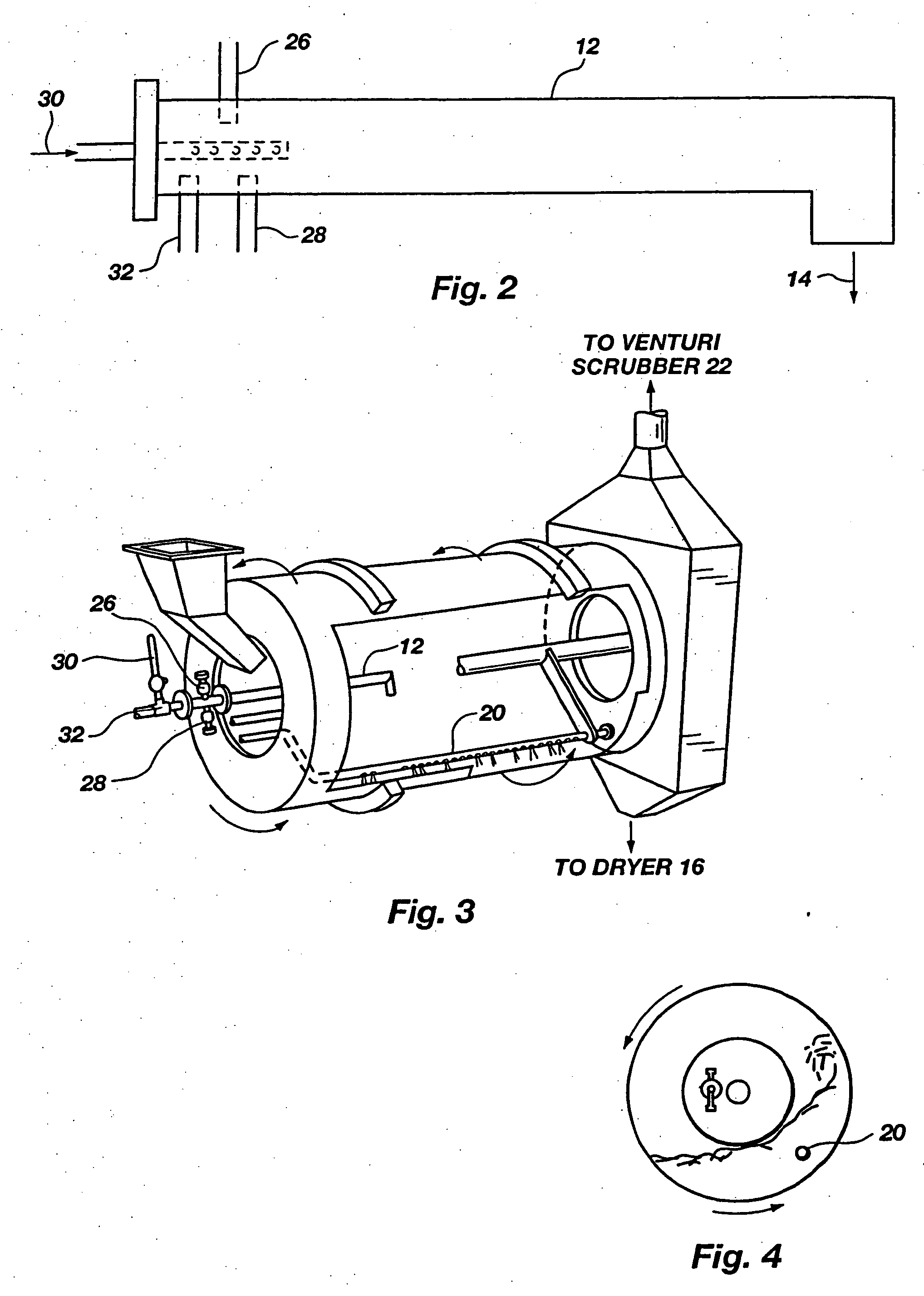

Sewage sludge recycling with a pipe cross-reactor

InactiveUS7169204B2Increase valueReduce moisture contentBio-organic fraction processingSludge treatmentSludgeVolumetric Mass Density

An improved process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g., sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor. The process more particularly involves mixing the waste material with water to form a slurry (or initially taking the waste material as a slurry); pumping the slurry to a pipe-cross reactor for reaction with a base, acid, and water to form a melt; spraying the melt onto a recycling bed of fines in a granulator, and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g., a fertilizer or soil conditioner having a greater “NPK” value than the original relatively low analysis organic waste material). The invention also includes fertilizers produced according to the improved process, which fertilizers are of the same size and shape and density of commonly used fertilizers. The method advantageously utilizes the heat generated by the exothermic acid-base reaction in the pipe-cross reactor to remove the approximately 80% water from sludge, thus saving large amounts of energy normally used in conventional drying or burning methods, while, at the same time, conserving the intrinsic values of the nutrients and humates contained in the sludge. In one embodiment, the process includes a method of disposing of spent acid from a hot dip galvanizing process or a steel pickling process involving incorporating the spent acid to maintain the low pH of a venturi scrubber used in the improved process.

Owner:UNITY FERTILIZER LLC

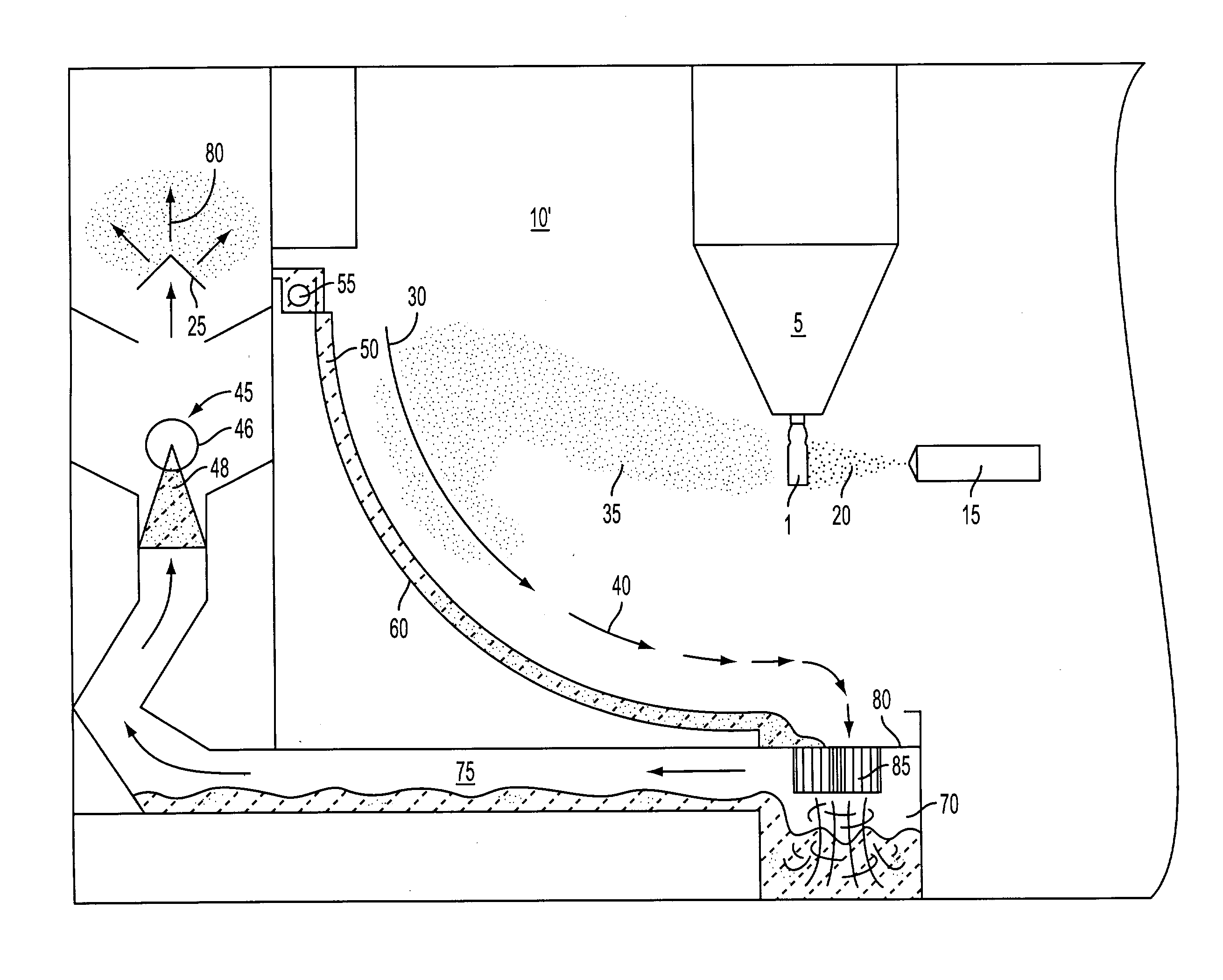

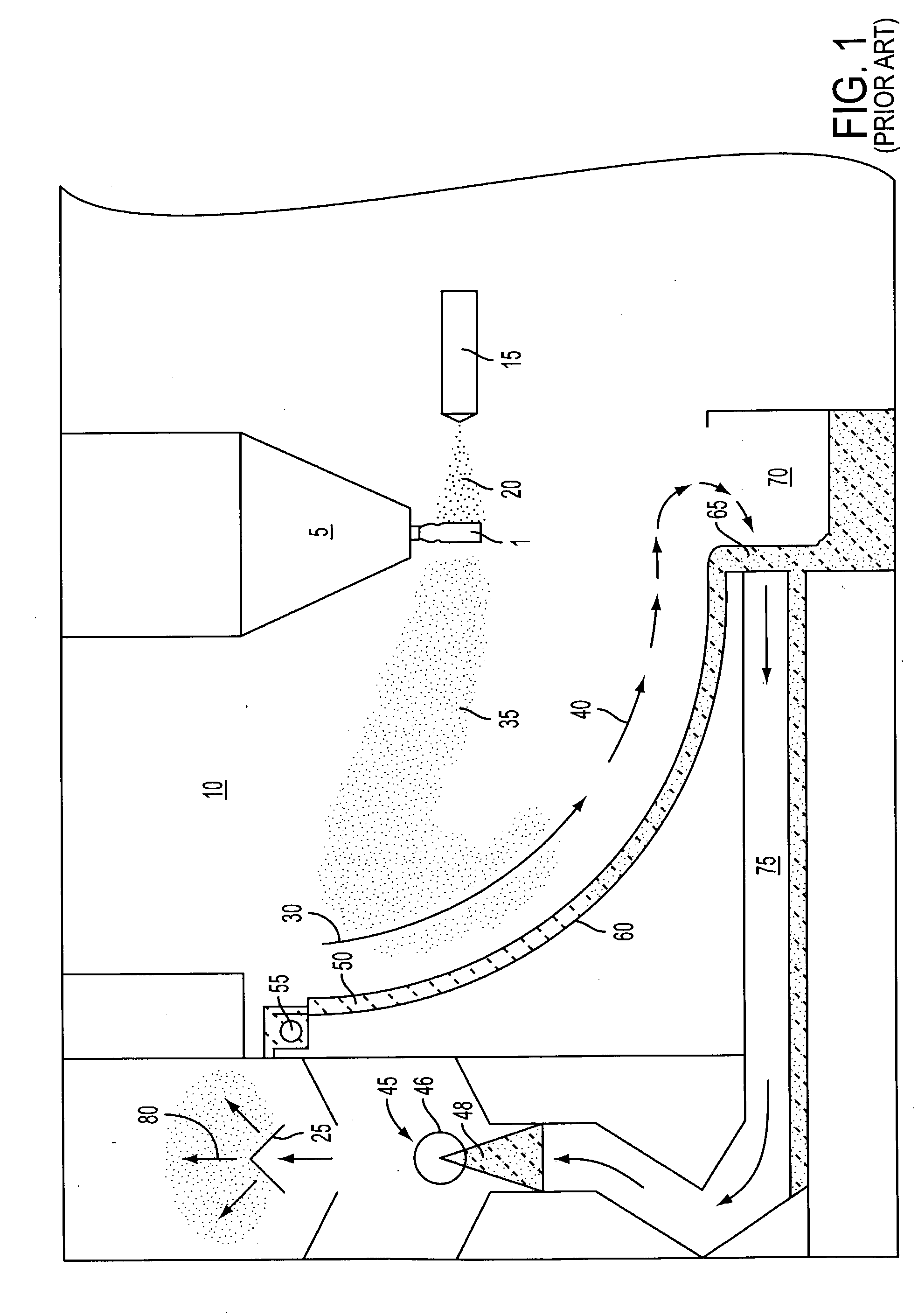

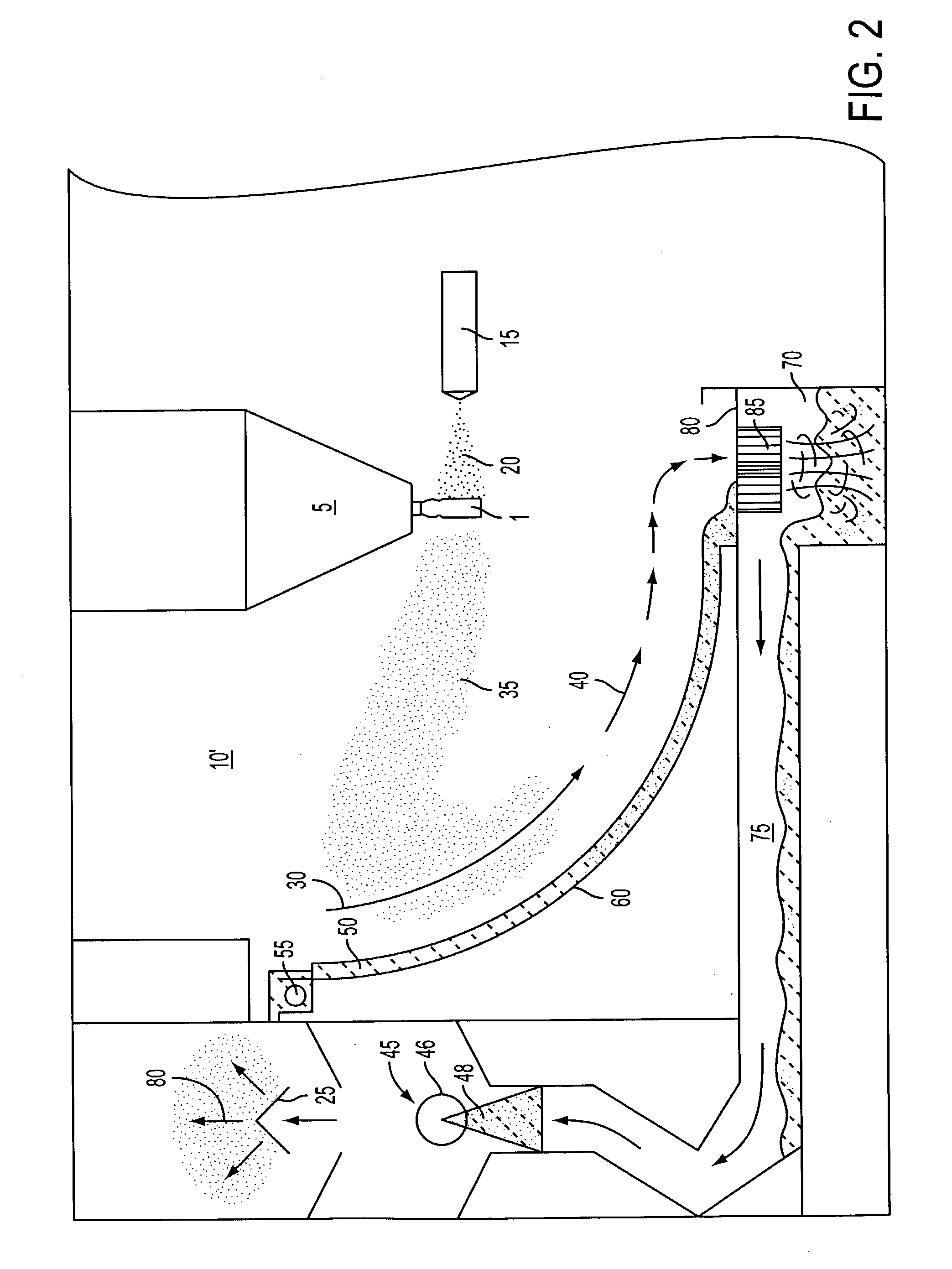

Low-energy venturi pre-scrubber for an air pollution control system and method

InactiveUS20050022667A1High percentage of ashWeaken energyHuman health protectionUsing liquid separation agentParticulatesEvaporative cooler

A low-energy venturi pre-scrubber optimized for removing abrasive particles from a gaseous effluent is disclosed. While venturi scrubbers are efficiently used for at removing entrained particulates in air pollution control systems, they can be damaged due to the abrasive characteristics of entrained particles, such as silica particles greater than a micrometer in diameter. According to the present invention, high scrubbing efficiencies can be obtained in equipment that is not damaged by the abrasive particles by first removing the abrasive particles in a low-energy venturi, and then removing the remaining particles in a second scrubber. In addition to improving the lifetime and reducing the maintenance costs of the venturi, scrubbing fluids have fewer large particles, allowing their use in downstream components, such as evaporative coolers.

Owner:ENVIROCARE INT

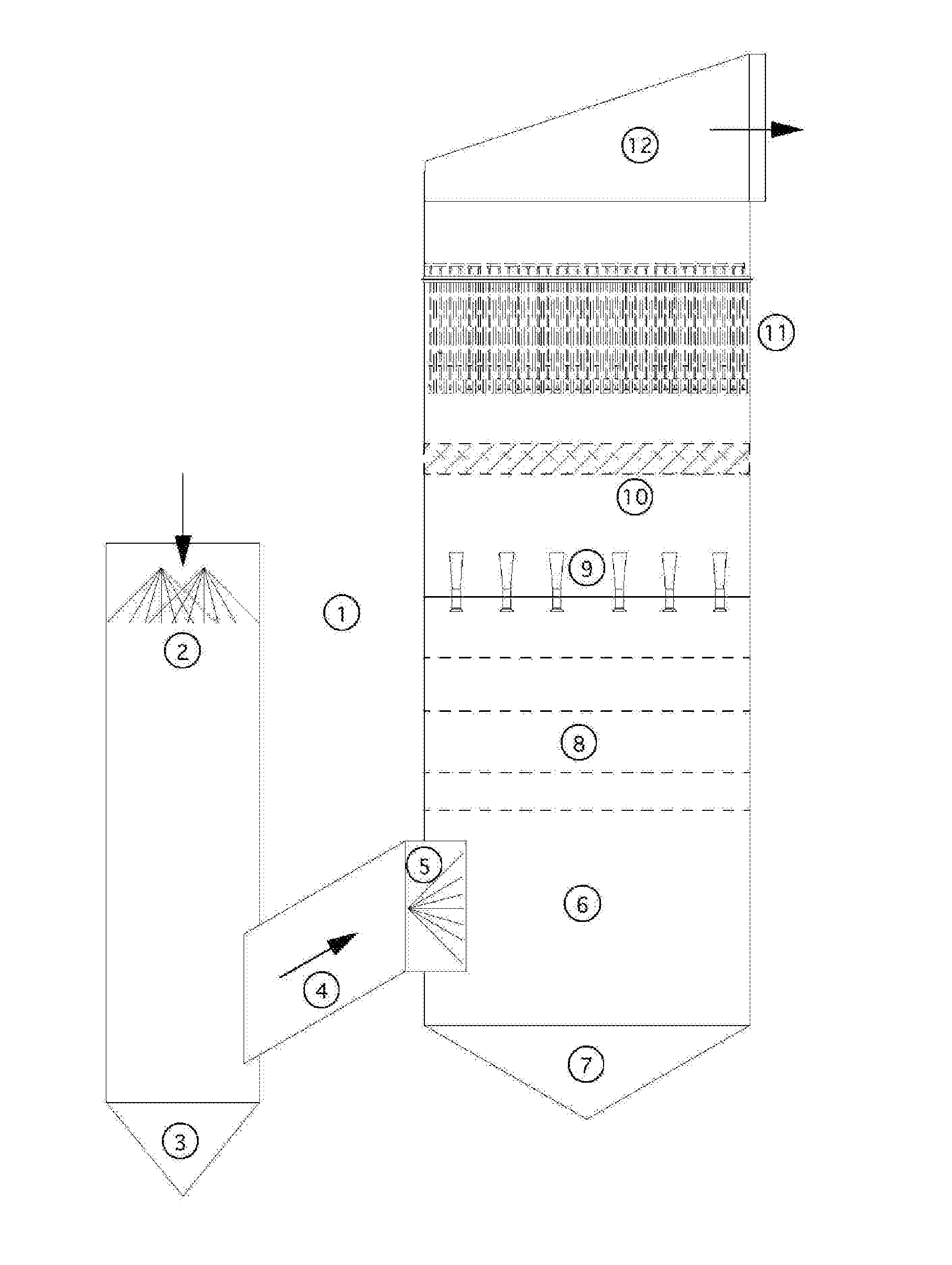

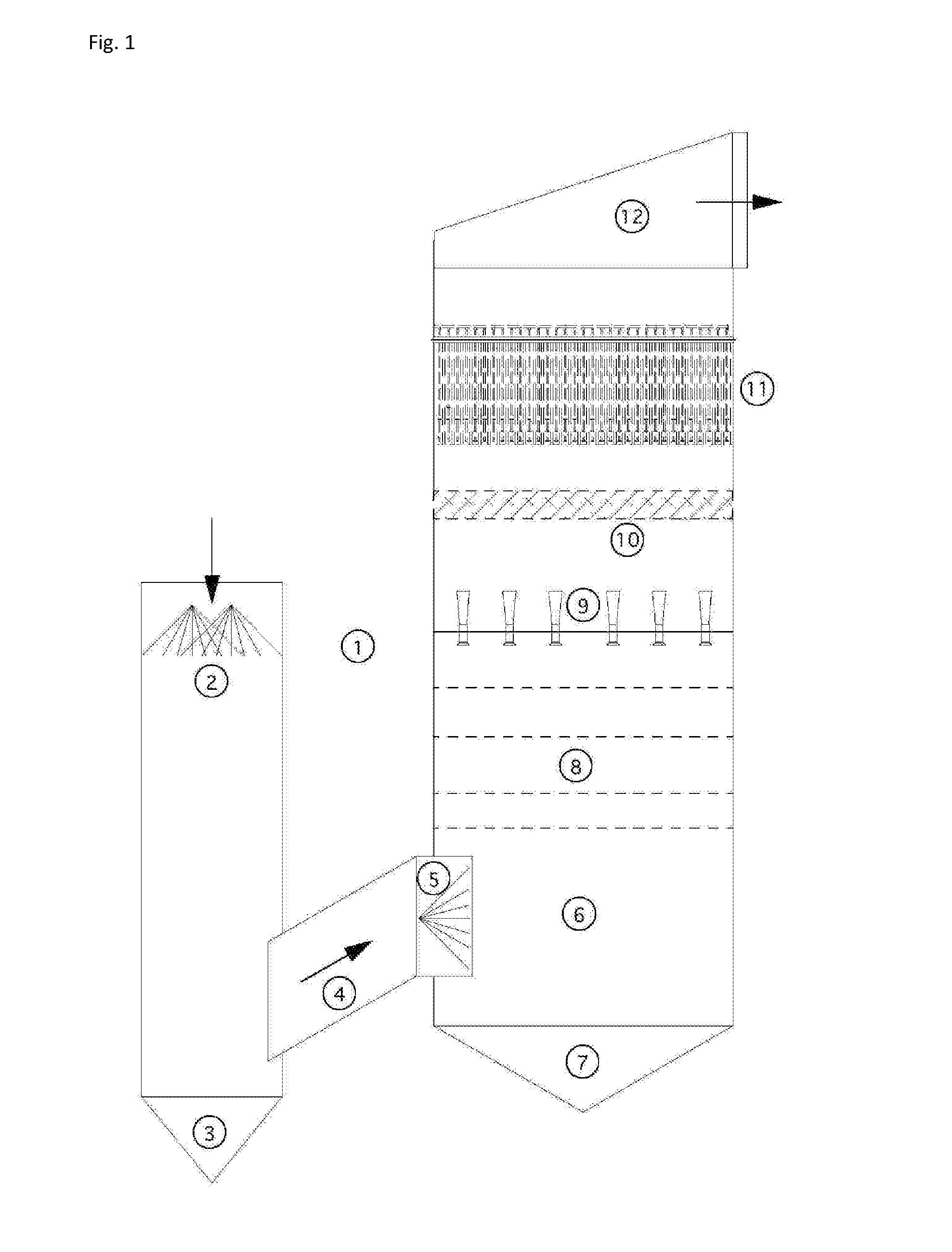

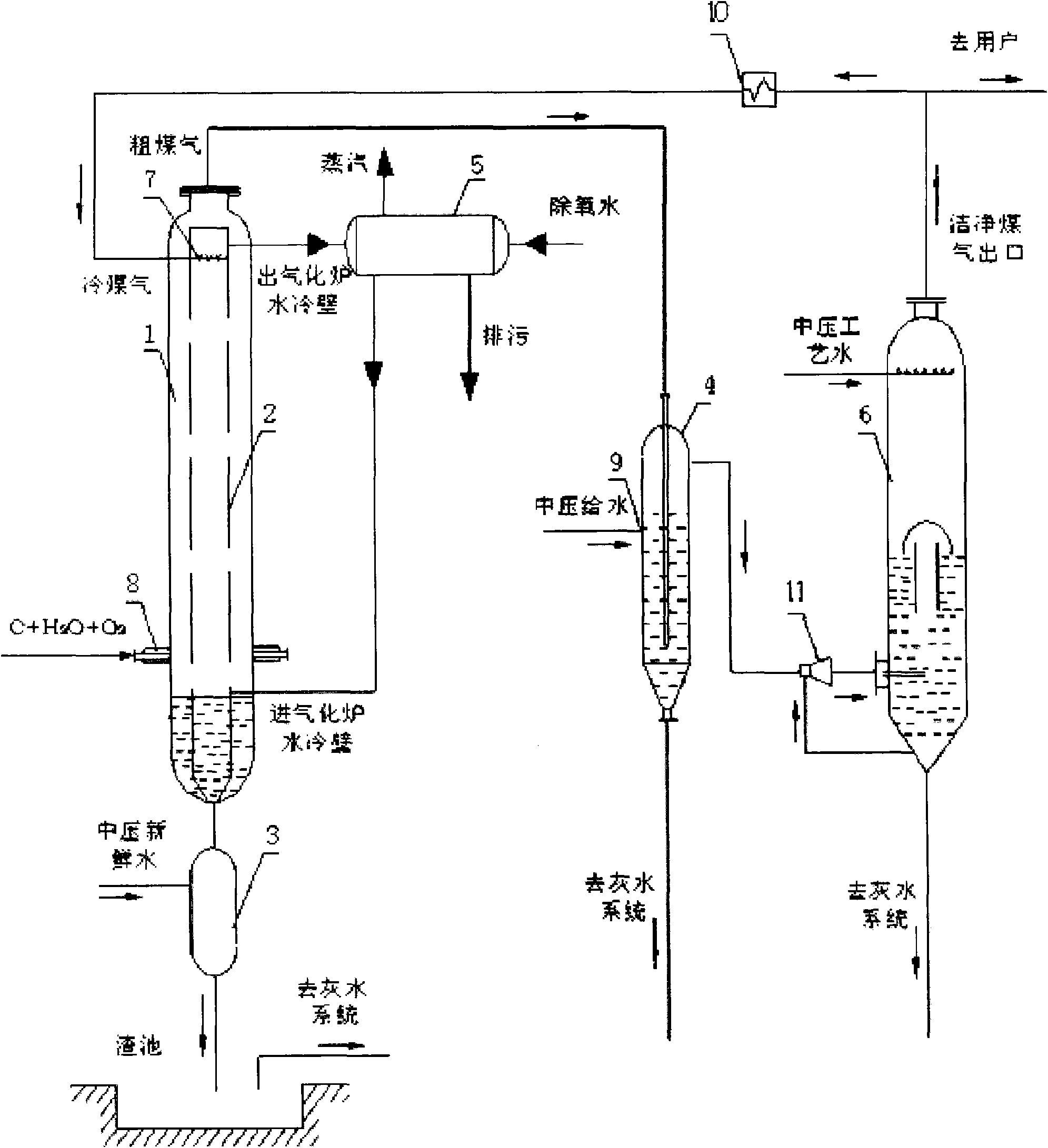

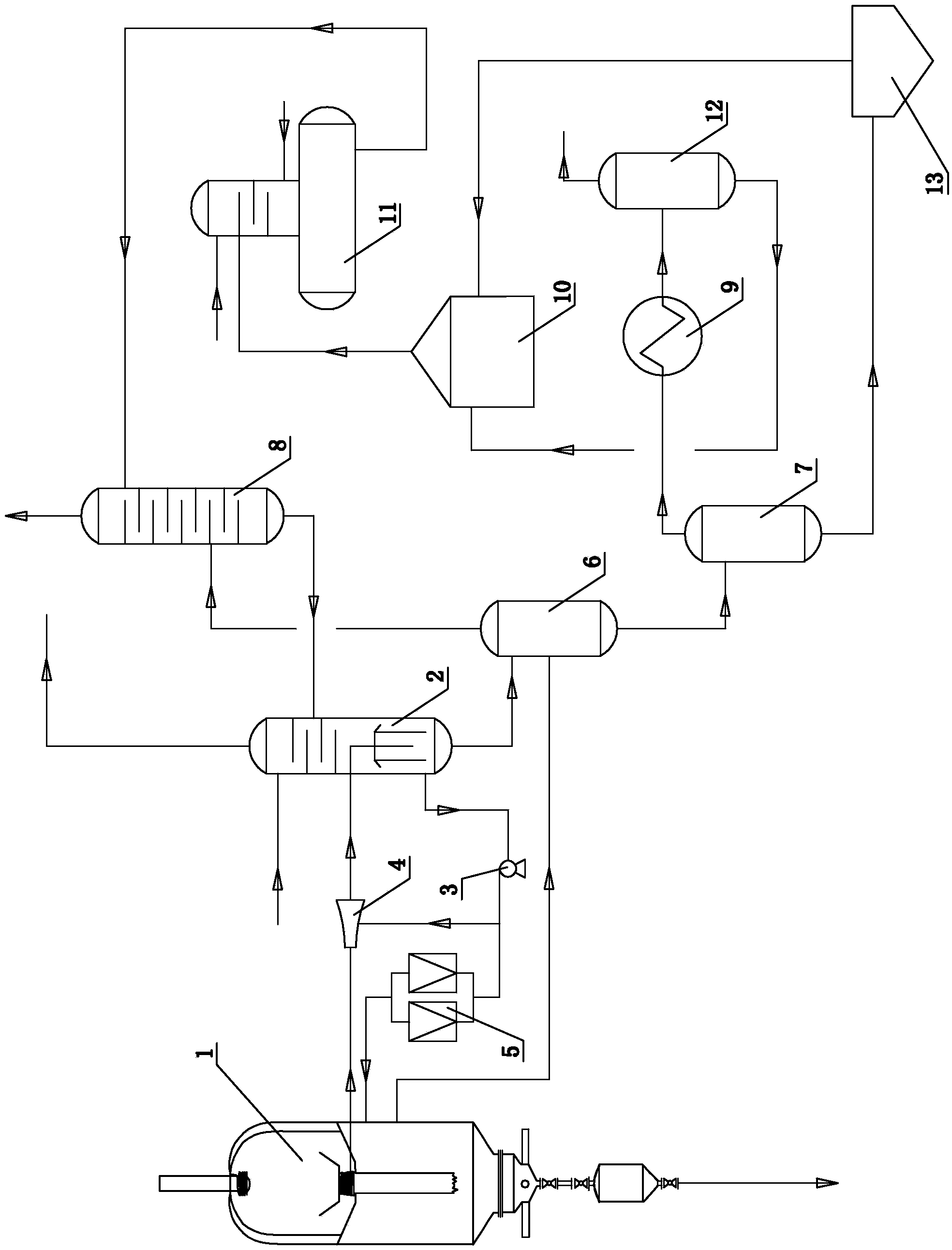

Under nozzle-type entrained flow gasification shock chilling device and shock chilling technology

InactiveCN101550361AIrritable cold curingLow costCombined combustion mitigationGranular/pulverulent flues gasificationWater vaporSlurry

The invention relates to an under nozzle-type entrained flow gasification shock chilling device and a shock chilling technology; the shock chilling device comprises a gasification furnace 1; a nozzle 8 is arranged at the lower part of the gasification furnace 1; wherein a gas outlet of the gasification furnace 1 is communicated with the raw gas inlet of a shock chilling tank 4; a gas outlet of the shock chilling tank 4 is connected with the raw gas inlet of a Venturi washer 11; and a gas outlet of the Venturi washer 11 is communicated with the gas inlet of a washing tower 6. Powdered or slurry coal powder and a gasification agent are sprayed to the gasification furnace 1 through the nozzle 8 to react and generate raw gas; the raw gas flows up and down in the gasification furnace 1; the raw gas is mixed with cool gas through a gas shock chiller 7 and then enters the shock chilling tank 4 to carry out water shock chilling; the gas enters the Venturi washer 11 and the washing tower 6 to be washed and purified; a part of the purified gas is conveyed to the user for use, and the other part thereof flows to the gas chiller 7 at the upper part of the gasification through thermal circulation to carry out shock chilling to the raw gas; therefore, the raw gas contains more water vapor. The device and the technology are characterized by low construction cost and high system overall efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

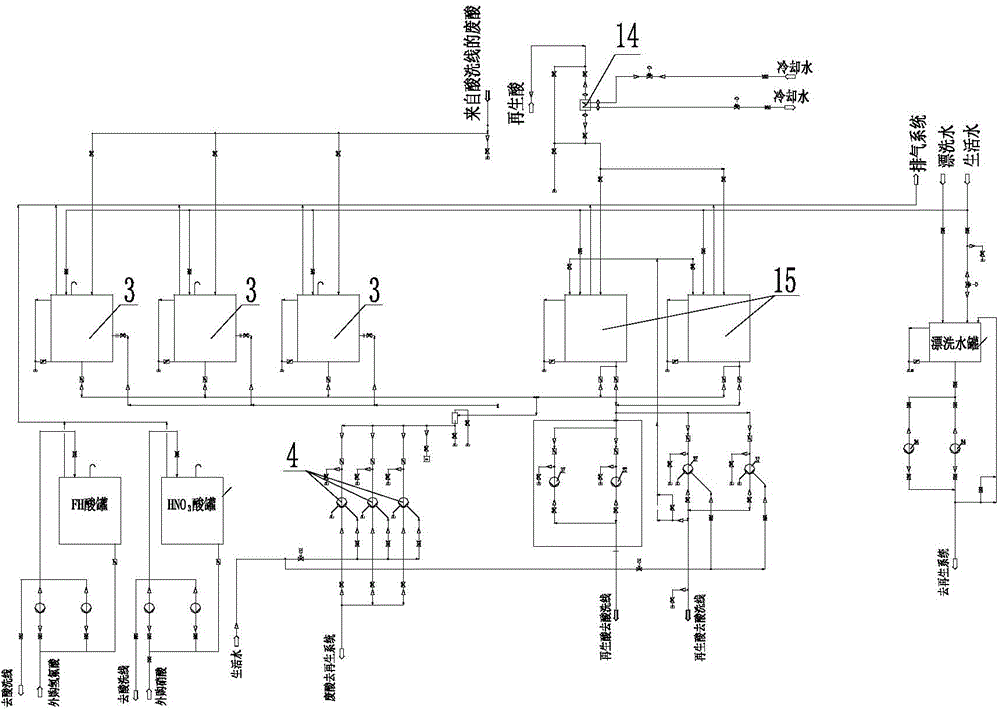

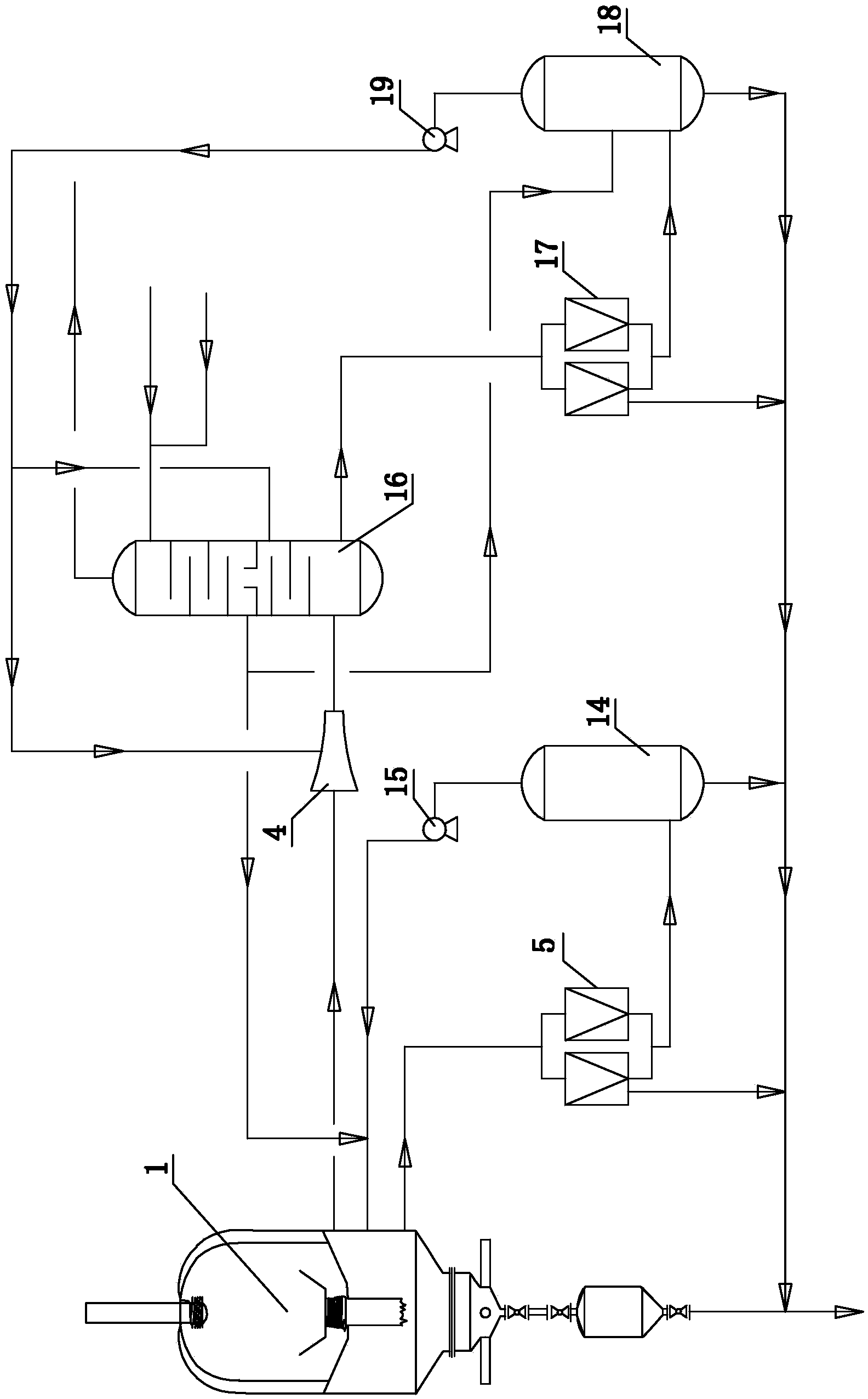

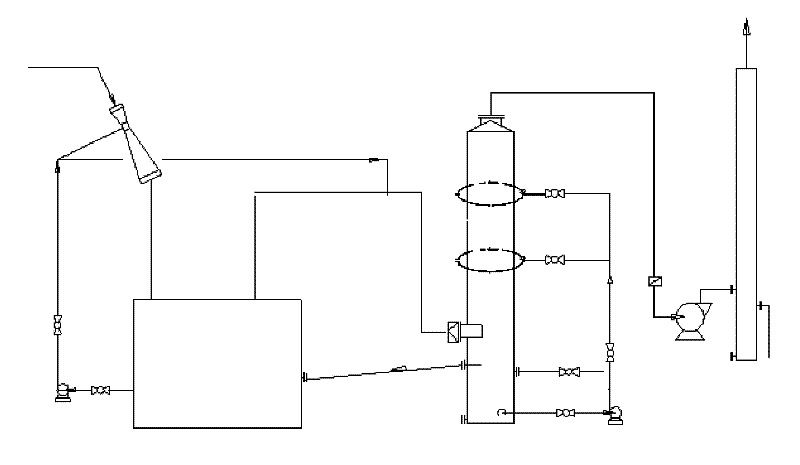

Method and device for regeneration of stainless steel mixed acid pickling waste acid by spray roasting process

The invention relates to a method and device for regeneration of stainless steel mixed acid pickling waste acid by a spray roasting process. The method comprises that waste acid is oxidized at a high temperature by a roasting furnace so that solid iron powder and acidic gas are produced, and the products are subjected to spraying absorption so that mixed acids are produced. The device comprises the roasting furnace, a raking machine, a pelletizer, a venturi scrubber, an absorption tower and a washing device. The top of the roasting furnace is provided with two spray guns, the spray guns can be lifted by a pneumatic device, the bottom of the roasting furnace is connected to the raking machine, the raking machine is connected to the pelletizer by a rotary valve, the roasting furnace is connected to the venturi scrubber, the venturi scrubber is connected to the absorption tower, the absorption tower is connected to the washing device, and the washing device is connected to a denitrification system by a smoke exhaust fan and a transverse liquid drop separator. Waste acid is roasted and decomposed at a high temperature to produce iron oxide powder and recovered acid, stainless steel metal ions and free acid capable of chemical combination with acid in pickling are recovered, and the recovered acid is returned to a pickling line for recycle so that acid consumption is reduced.

Owner:鞍山创鑫环保科技股份有限公司

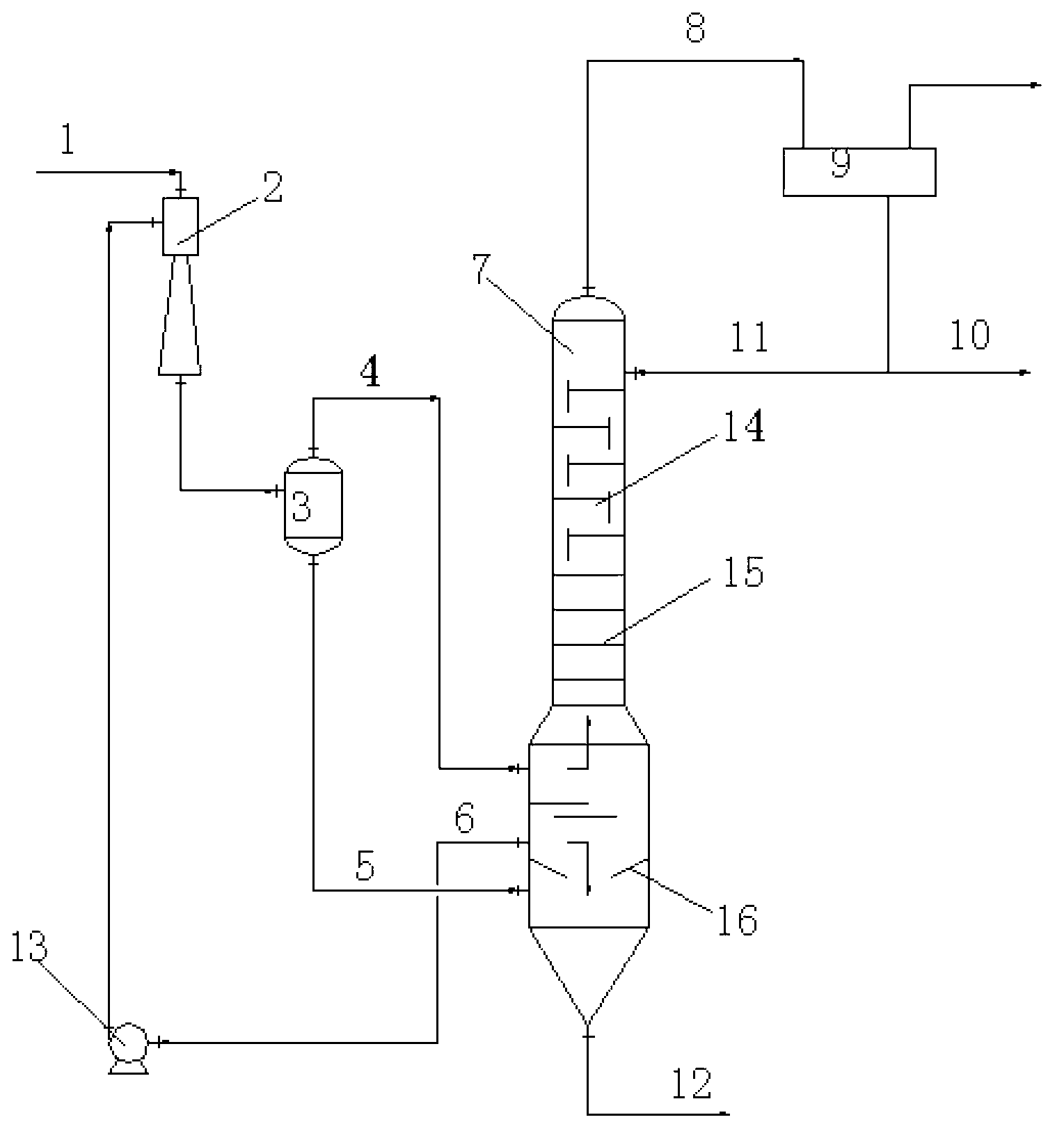

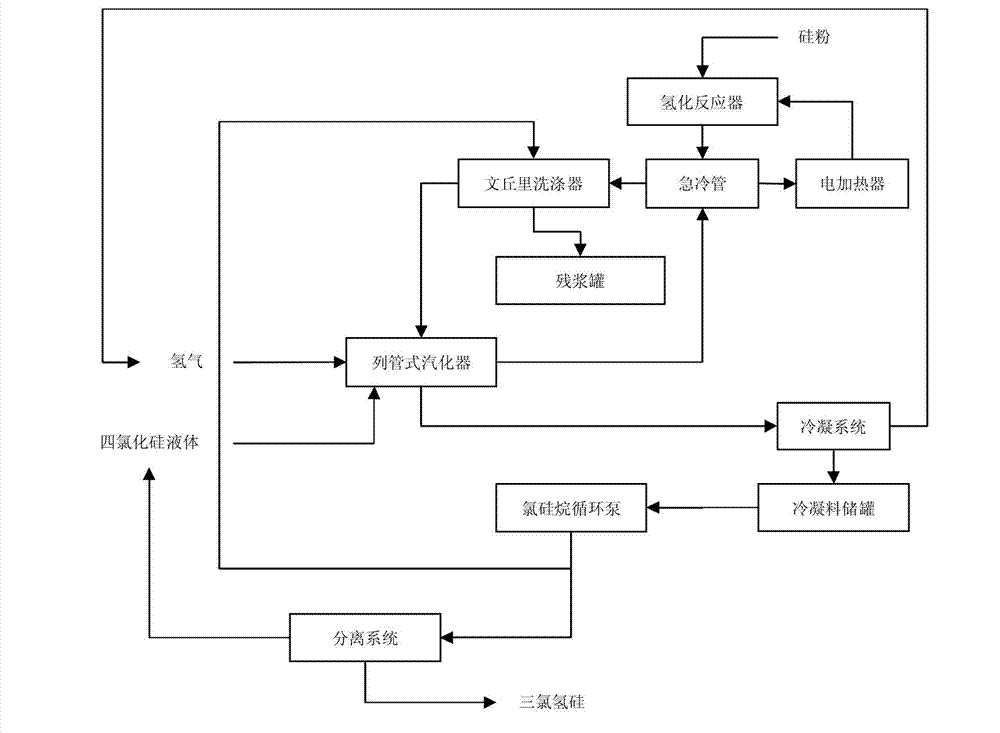

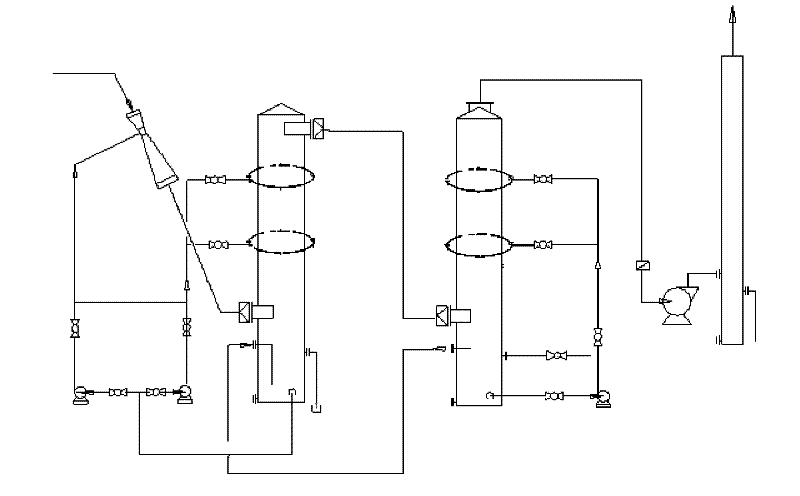

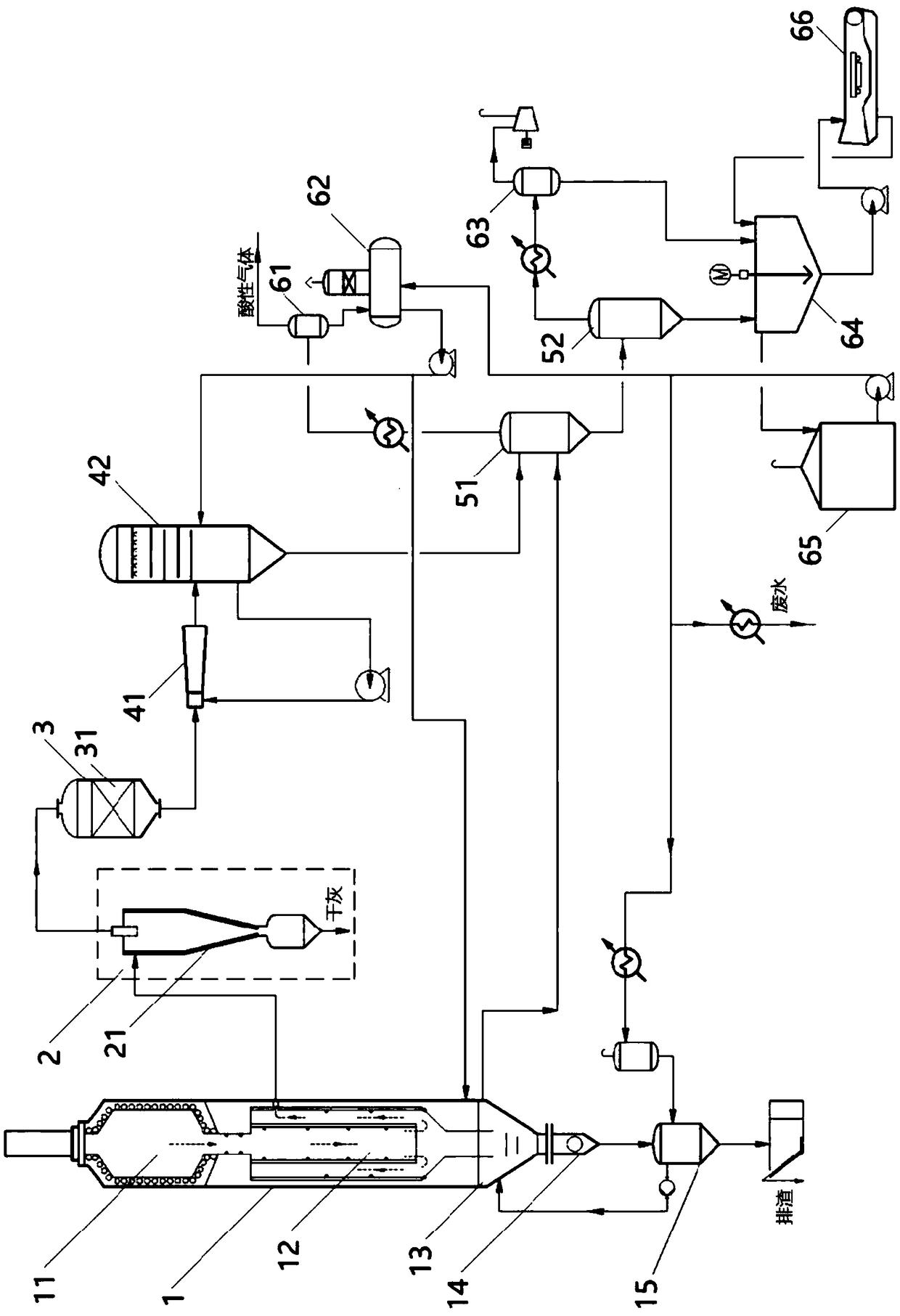

Dust removal process and system for trichlorosilane production

The invention provides a dust removal process and a system for trichlorosilane production. A dust containing reaction gas from a fluidized bed firstly enters into a venturi scrubber for scrubbing, a washed gas phase and a washed liquid phase are separated in a gas-liquid separation tank, the gas enters into a scrubbing tower from a gas inlet on the lower portion of the scrubbing tower, a liquid enters into the scrubbing tower from a liquid inlet on the lower portion of the scrubbing tower, the gas which is subjected to scrubbing purification is discharged from a gas outlet on the upper portion of the scrubbing tower, the gas discharged out of the scrubbing tower is subjected to condensation by a condenser, a part of condensate liquid serving as a scrubbing liquid of the scrubbing tower enters into the scrubbing tower again from the top, the other part of the condensate liquid is sent to a rectification device, and a slag slurry which contains high concentration silica powders, metal chlorides and high-boiling residues is discharged from a slurry port. According to the dust removal process and the system for the trichlorosilane production, the reaction gas which is subjected to cyclone dust removing is further processed, the high-boiling residues, the metal chlorides and a trace of refine silica powders contained in the reaction gas are removed by the device, when the reaction gas enters into the condensation system, pipelines and equipment can not be blocked, pollutions of the metal chlorides and high-boiling residues trichlorosilane are reduced, and the continuous and stable operation of the device is guaranteed.

Owner:HUALU ENG & TECH

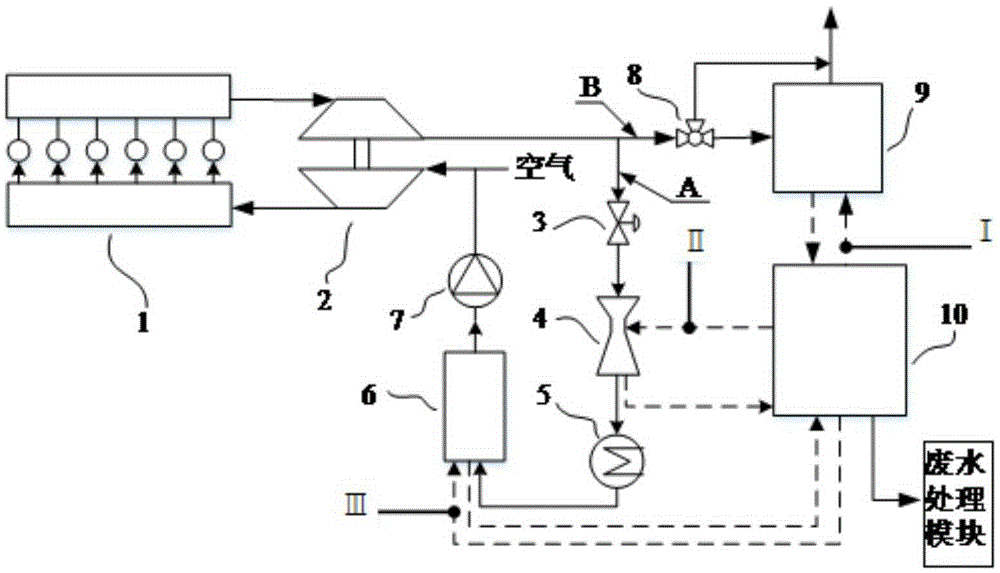

Combined desulphurization and denitration device and method of marine diesel engine

InactiveCN105289241AEfficient removalAvoid high pressureUsing liquid separation agentAtmospheric airFresh air

The invention discloses a combined desulphurization and denitration device and method of a marine diesel engine. The exhaust gas of the diesel engine is divided into two paths, wherein one path enters a denitration channel A and is recirculated to an air cylinder to participate in burning so as to lower the NOx emission of an engine; the other path enters a desulphurization channel B and is discharged to ambient atmosphere after being subjected to desulphurization processing. In the denitration channel A, the exhaust gas flows through components including a one-way stop valve, a Venturi scrubber, a cooler, a cleaning device, a blower and the like, particles and SO2 in the exhaust gas are removed through processing processes including pre-washing, cooling, washing, pressurizing and the like, and finally, the exhaust gas is mixed with fresh air from the intake channel of the diesel engine to enter the air cylinder and participate in burning; in the desulphurization channel B, the exhaust gas is discharged into the environment atmosphere after being subjected to particle removal by washing tower desulphurization. The Tier III requirement of IMO (International Maritime Organization) on marine fuel sulphur content and NOx emission in the exhaust gas can be met, and meanwhile, the corrosion and the abrasion on an engine compressor, a cylinder liner and the like by the exhaust gas can be lowered.

Owner:HARBIN ENG UNIV

Washing treatment process for synthesis gas

ActiveCN103435005ASimple processNo row lessHydrogen separationHydrogen productionReduction treatmentWater vapor

The invention discloses a washing treatment process for synthesis gas. The washing treatment process comprises the following steps: after black water from a shock chilling chamber of a gasification furnace is filtered and ash dreg is removed, the black water enters a buffering pot; after shock chilling water from the buffering pot passes through a circulating pump, the shock chilling water enters the shock chilling chamber of the gasification furnace; after synthesis gas is contacted with introduced washing water by a washing tower and enters a follow-up conversion working section after being contacted with converted condensing water and desalting and oxygen-removing water for dust removal; part of the washing water from the washing tower enters the shock chilling chamber of the gasification furnace; after dreg is filtered by a filter, the black water from the washing tower and the other part of the washing water are combined and then enter the buffering pot; after the washing water from the buffering pot is pressurized by a circulating pump, part of the washing water enters a venturi scrubber and the other part of the washing water enters the washing tower to be circularly used. According to the washing treatment process for the synthesis gas, the black water is not discharged out so that the pollution and the water consumption can be relieved; the wastewater discharge is reduced by 0.36 ton; the operation period of a device is prolonged and the treatment of ash water is very simple and common; the ash water does not need to be subjected to temperature reduction treatment so that the system has the relatively high water vapor content and the temperature of the synthesis gas is increased; the washing treatment process of the synthesis gas is good for the follow-up conversion working section.

Owner:刘金成

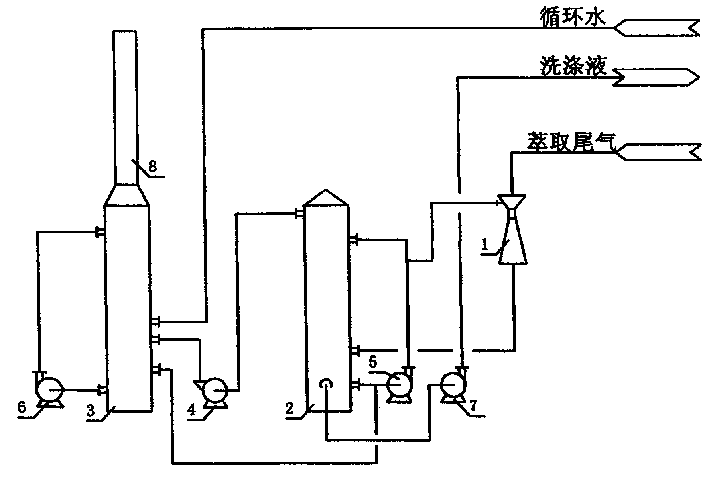

Washing method and apparatus for phosphoric acid reacting trough extracting tail gas

InactiveCN1471997ALess process equipmentEasy to manufactureUsing liquid separation agentPhosphorus compoundsCycloneProcess equipment

A method for washing the extractable tail gas of phosphoric acid reactor features that a venturi washer and two shower-cyclone washing towers are searially arranged and under the action of external circulating pumps, said tail gas is serially washed. Its advantages are no discharge of sewage, and high effect to remove F from tail gas (9 mg / cu.m).

Owner:EAST CHINA ENG SCI & TECH

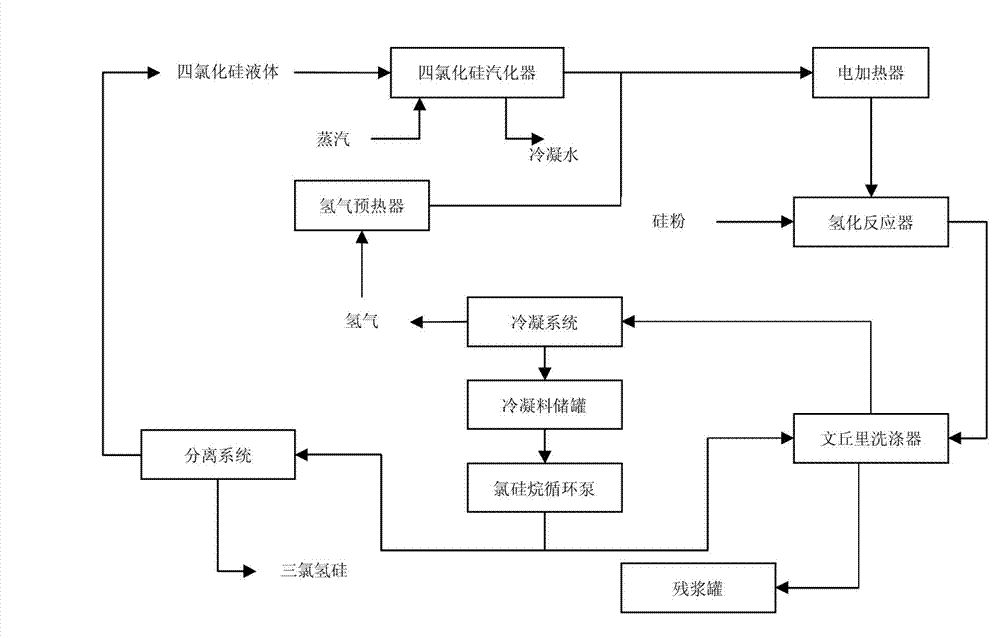

Energy utilization in polysilicon hydrogenation process

ActiveCN102730691AIncrease temperatureReduce the temperatureSilicon halogen compoundsSiliconSilanesHydrogenation process

The invention provides a method for utilizing energy in polysilicon cold-hydrogenation process, which improves the traditional cold-hydrogenation process and recycles the reaction heat to realize the effect of reducing the energy consumption. The method comprises the following steps: silicon tetrachloride liquid and hydrogen gas are introduced in a tubular vaporizer and mixed, and then enter a quenching pipe; the heat exchange is implemented for the mixed gas entering the quenching pipe and the reaction generated gas coming from a hydrogenation reactor; the mixed gas enters in an electric heater and is electrically heated, and then enters the hydrogenation reactor to react with silicon powders in the reactor; after the heat exchange of the reaction generated gas is implemented, the reaction generated gas enters a Venturi scrubber, and the silicon powder particles obtained by washing and a little chloro-silicane residual pulp are periodically discharged to a residual pulp tank; the gas which comes from the Venturi scrubber and is washed enters the tubular vaporizer; and the mixture of the hydrogen and the silicon tetrachloride after being heated enters a condensation system.

Owner:巴彦淖尔聚光硅业有限公司

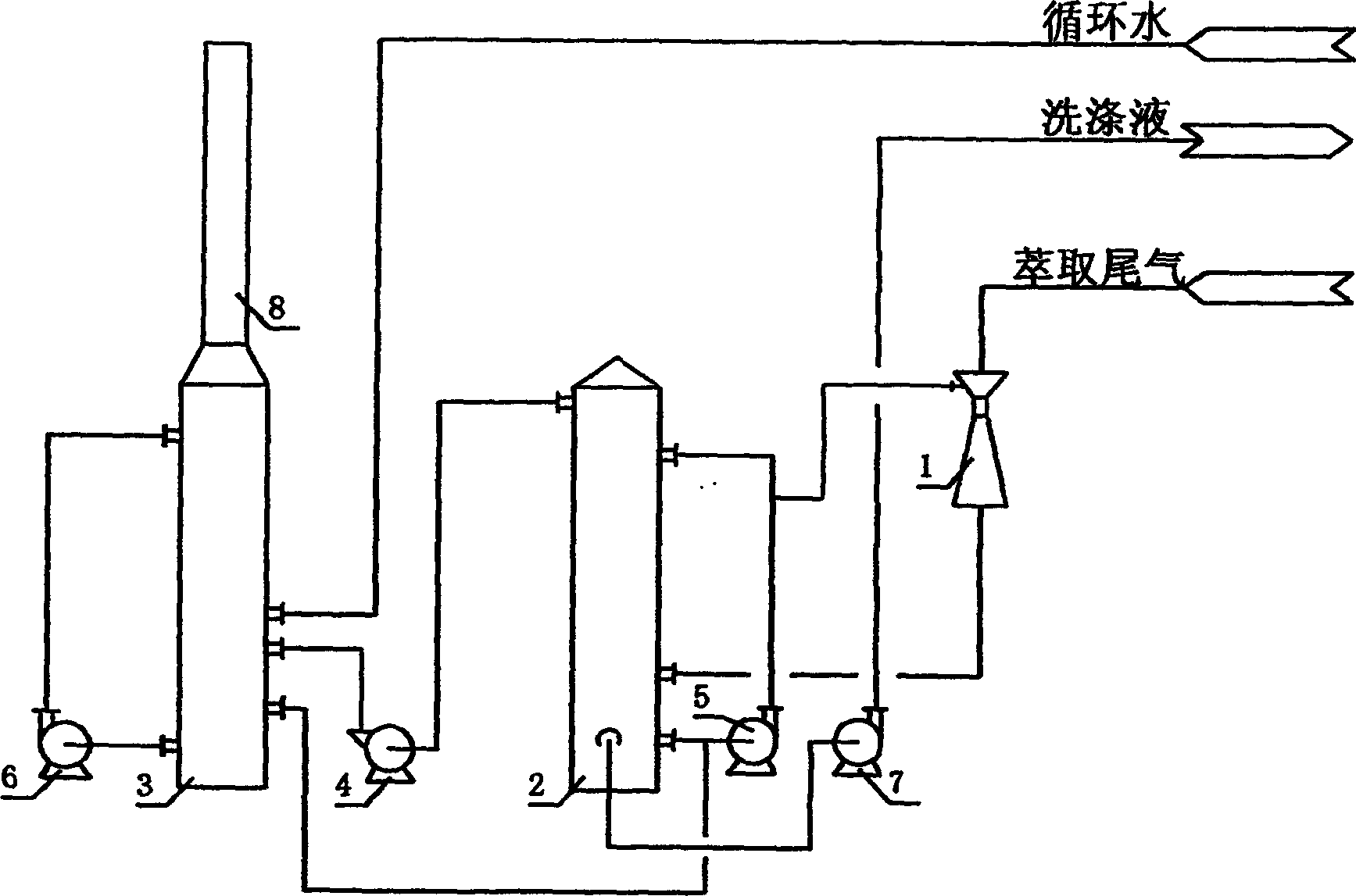

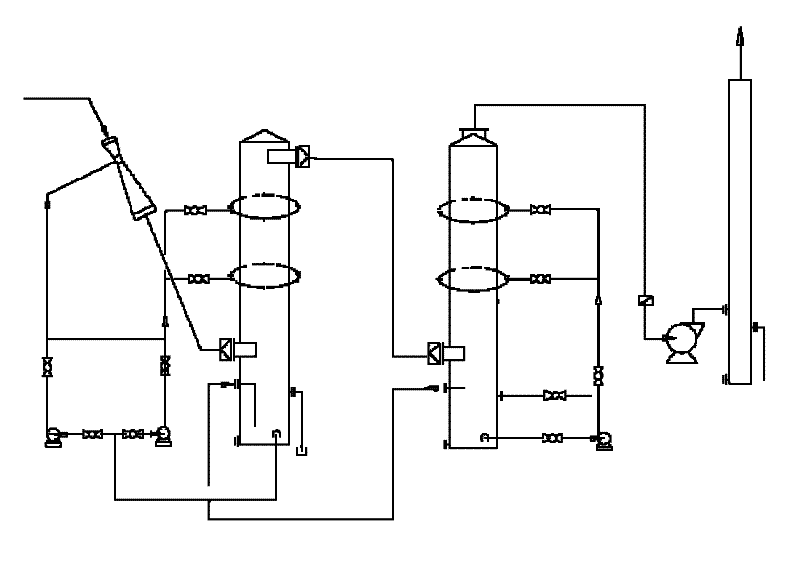

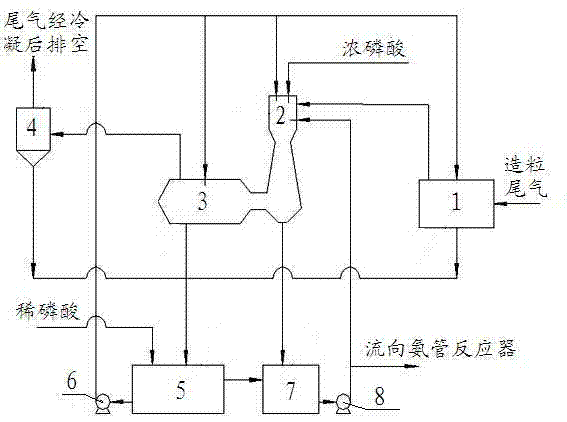

Phosphoric acid production tail gas recovery method

InactiveCN102258929AIncrease flow rateThe beneficial effect of increasing the first-level scrubber is: 1) reduce the flow rateDispersed particle separationPhosphoric acidRecovery methodPhosphoric acid

The invention relates to a method for recovering tail gas from phosphoric acid production. The process flow is as follows: the fluorine-containing gas enters the Venturi scrubber through the tail gas duct, and performs first-stage downstream spray washing with the washing liquid from the first washing pump, and the washed gas enters the first washing tower and the first washing tower. The washing liquid sent by the washing pump is subjected to the first-stage countercurrent two-layer spray washing again, and the gas after washing enters the second washing tower and the washing liquid sent by the second washing pump is subjected to the second-stage countercurrent two-layer spray washing. After being pumped by the tail gas fan, it enters the defoaming tower for defoaming, and finally discharges into the atmosphere through the chimney; the process water for washing first enters the second washing tower and is preheated and sprayed by the second washing pump, and then overflows from the second washing tower into The first washing tower is sent to the Venturi scrubber and the spraying device of the first washing tower by the first washing pump for spray washing and absorption. The beneficial effects of the present invention are: 1) reduce the gas flow rate, increase the washing and absorption efficiency; 2) preheat the washing liquid through the second washing tower, accelerate the formation of H2SiF6, and further strengthen the washing and absorption effect; 3) reduce the adhesion of the fan impeller, Reduce fan failures and corrosion of related equipment; 4) Strengthen the stability of operating indicators and increase the operating rate.

Owner:WUHAN ZHONGDONG PHOSPHATE TECH

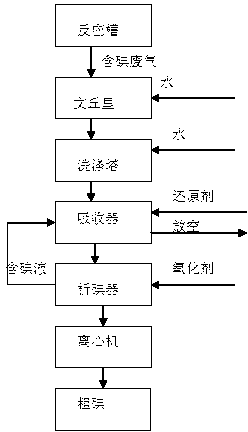

Method for extracting iodine from dehydrate wet method diluted phosphoric acid reaction iodic waste gas

InactiveCN103011084AEfficient recyclingImprove efficiencyDispersed particle separationIodineIodinePhosphoric acid

The invention discloses a method for extracting iodine from a dehydrate wet method diluted phosphoric acid reaction iodic waste gas. The method comprises the following steps: (1) collecting an iodic waste gas, and scrubbing in water by using a venturi scrubber and a scrubbing tower; (2) feeding the iodic waste gas subjected to defluorination into an iodine absorbing tower filled with materials, wherein a sealing tank is installed at the lower part of the tower and is filled with water and added with absorbent; (3) pumping the liquid in the sealing tank by using a washing circulation pump into the absorbing tower to be washed in circulation; (4) discharging the washed waste gas into the atmosphere through a fan; (5) after the concentration of the iodine in the liquid in the sealing tank achieves 50g / L, pumping the iodic liquid into an iodine precipitation tank, and adding hydrogen peroxide so as to precipitate the iodine in a crystal mode; and (6) filtering the liquid of iodic crystal, feeding back the liquid into the sealing tank of the absorbing tower, and obtaining 90% of crude iodine in a centrifugal mode. By utilizing the method, the iodine in the dehydrate wet method phosphoric acid reaction waste gas is effectively recycled, so that larger benefits are brought to enterprises, and meanwhile the on-site atmosphere environment is improved with good environmental-protection effect.

Owner:WENGFU (GRP) CO LTD

Methods and Equipment for Treatment of Odorous Gas Steams

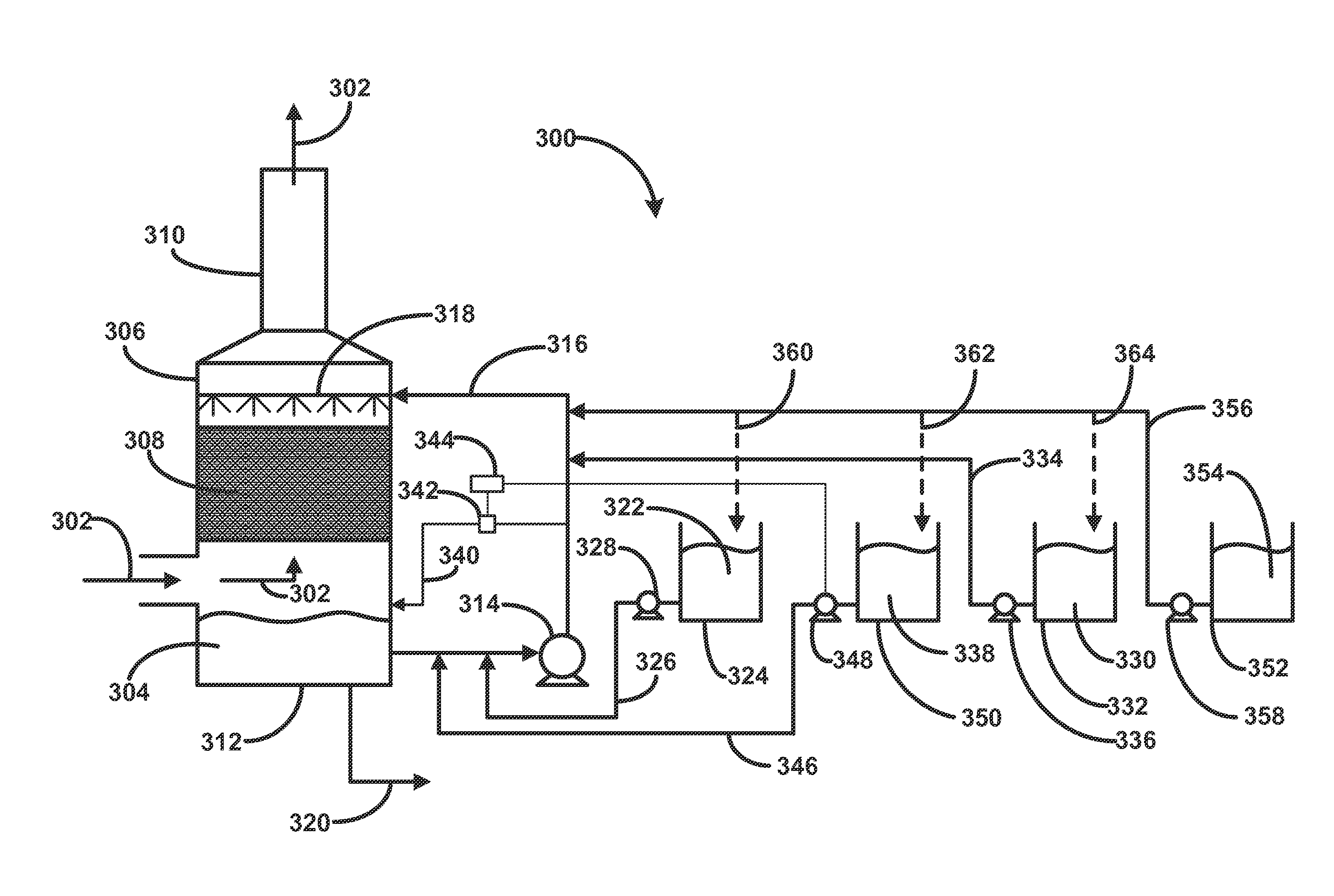

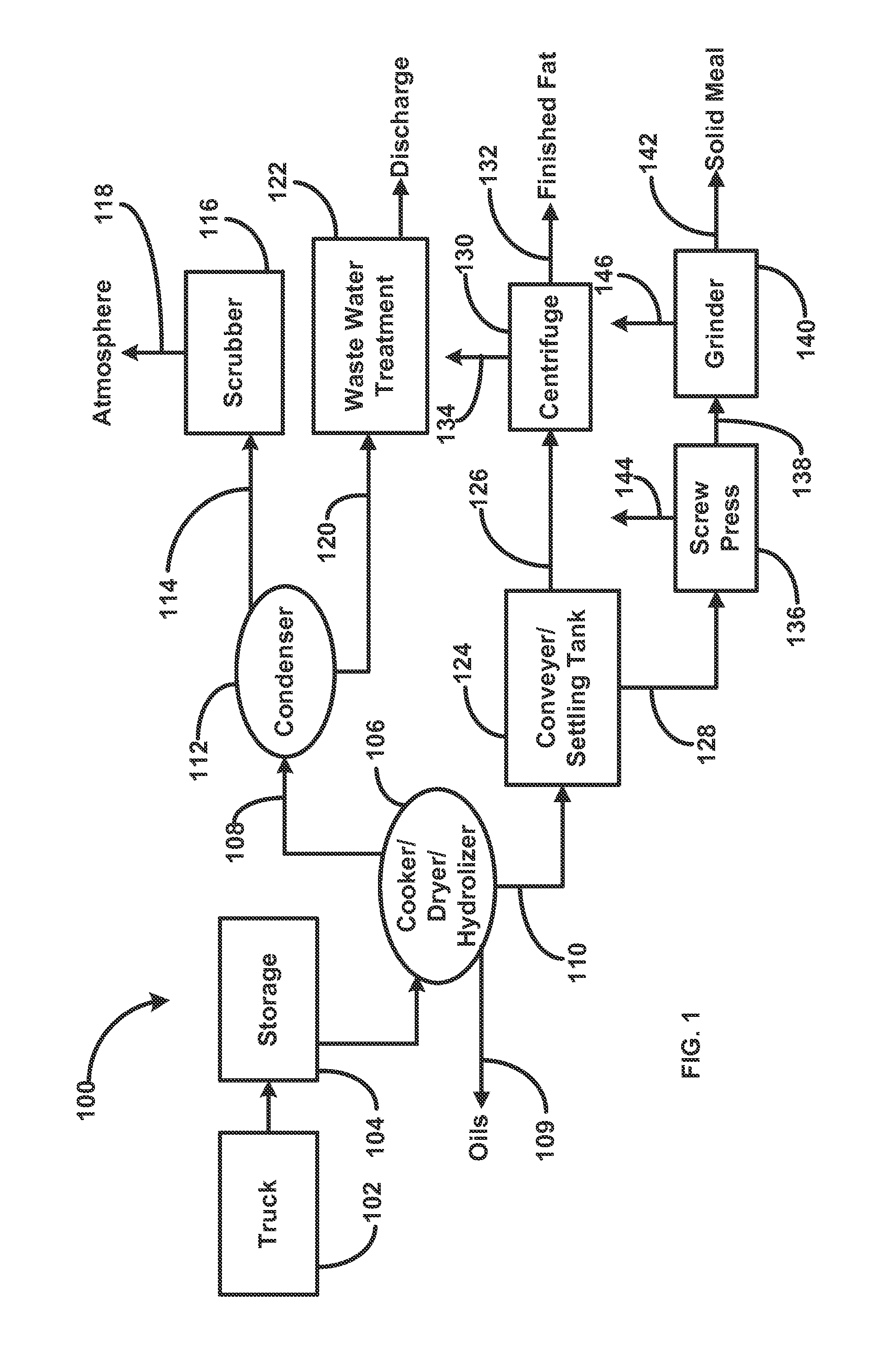

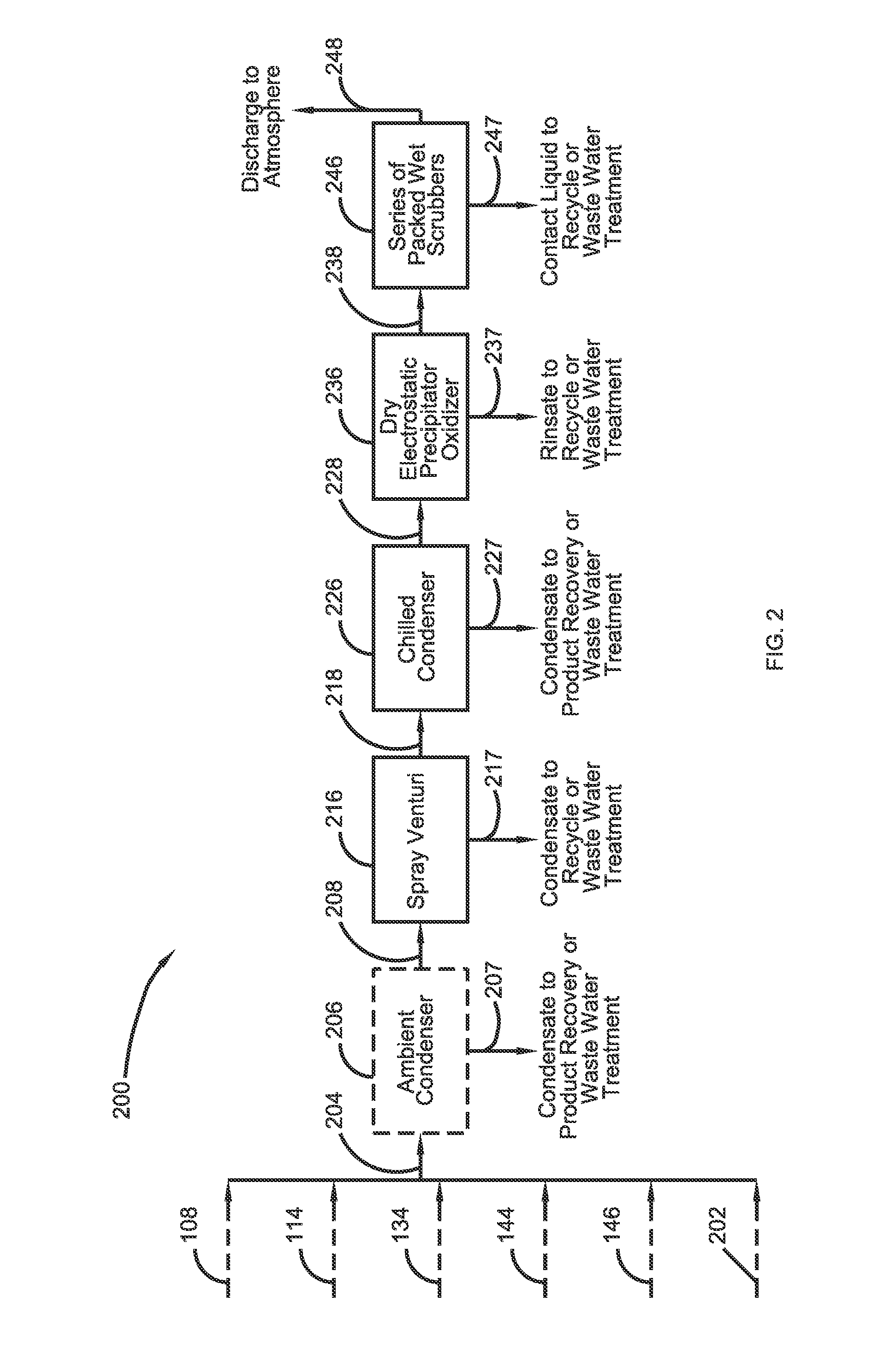

ActiveUS20140202206A1Reduce concentrationReduce the total massSolidificationGas treatmentCarcinogenic chemical compoundVenturi scrubber

A method for removing noxious, hazardous, toxic, mutagenic, and / or carcinogenic compounds and / or precursor compounds from a comingled gas, liquid and / or solid stream is described. In one embodiment, the method includes optionally passing the stream through an ambient temperature condenser followed by passing the stream through a spray venturi scrubber, a chilled condenser, a gas / solid separator, and a series of wet scrubbers to remove at least a portion of the compounds.

Owner:TEMPLE STEPHEN R +2

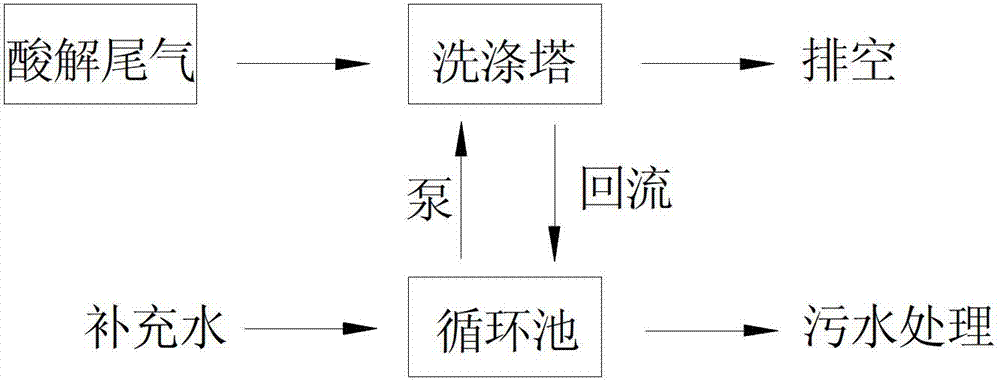

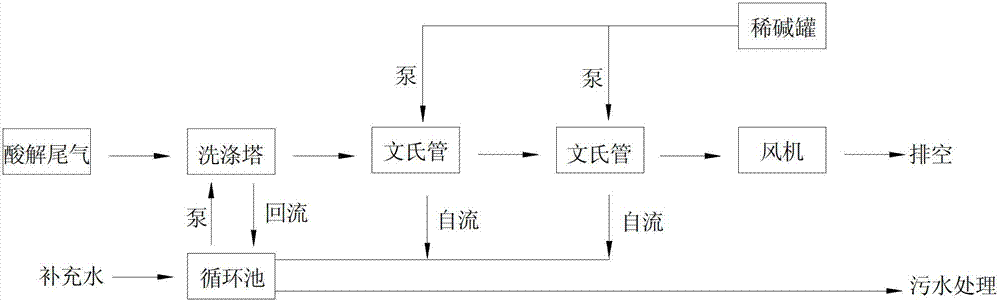

Titanium dioxide acidolysis tail gas treatment method

InactiveCN102755815ALess dilute alkali consumptionRealize cleaner productionUsing liquid separation agentTowerCleaner production

The invention belongs to the technical field of environmental protection, and particularly provides a titanium dioxide acidolysis tail gas treatment method. The titanium dioxide acidolysis tail gas treatment method comprises the following steps of: absorbing and cooling high temperature acidolysis tail gas generated by a titanium dioxide process adopting a sulfuric acid method through a washing tower, and processing the tail gas, the volume of which is reduced, through a venturi, so as to realize the tail gas treatment discharge standard, and realize clean production. According to the invention, a Ph value of a liquid in a circulating pool is kept more than or equal to 4.5, and the temperature of the tail gas is ensured to drop to be below 90 DEG C when a main reaction is generated; the tail gas which is greatly reduced in volume after cooling is processed through the venturi, the venturi adopts alkali waste generated by the titanium dioxide process adopting a sulfuric acid method, so as to realize the tail gas treatment discharge standard and realize the clean production; and most of sulfuric acid mist and sulfur dioxide gas of the tail gas are absorbed in the washing tower because of washing of a great quantity of circulating liquid, and the consumption of thin alkali in a follow-up venturi scrubber is less.

Owner:江苏恒丰伟业科技工程有限公司

Venturi scrubber plate, waste capture system, and method

InactiveUS20040112215A1Liquid surface applicatorsUsing liquid separation agentWaste materialVenturi scrubber

A venturi scrubber plate for a waste capture system and method for a waste material entrained in a fluid flow includes an enclosure having a flood sheet over which a liquid flows into a collection trough, an exhaust device which draws the fluid flow from the enclosure, across the collection trough, and through a throat section to a primary scrubber section, the venturi scrubber plate including a plate which is mounted on and substantially covers the collection trough, which has defined therein a plurality of holes, and through which the fluid flow containing the waste material flows, wherein the plate imposes a venturi effect on the fluid flow effective to accelerate the fluid flow so that turbulent mixing of the fluid flow containing the waste material and the liquid takes place and results in improved capture of waste material by the liquid ahead of the primary scrubber section.

Owner:GRAHAM PACKAGING CO LP

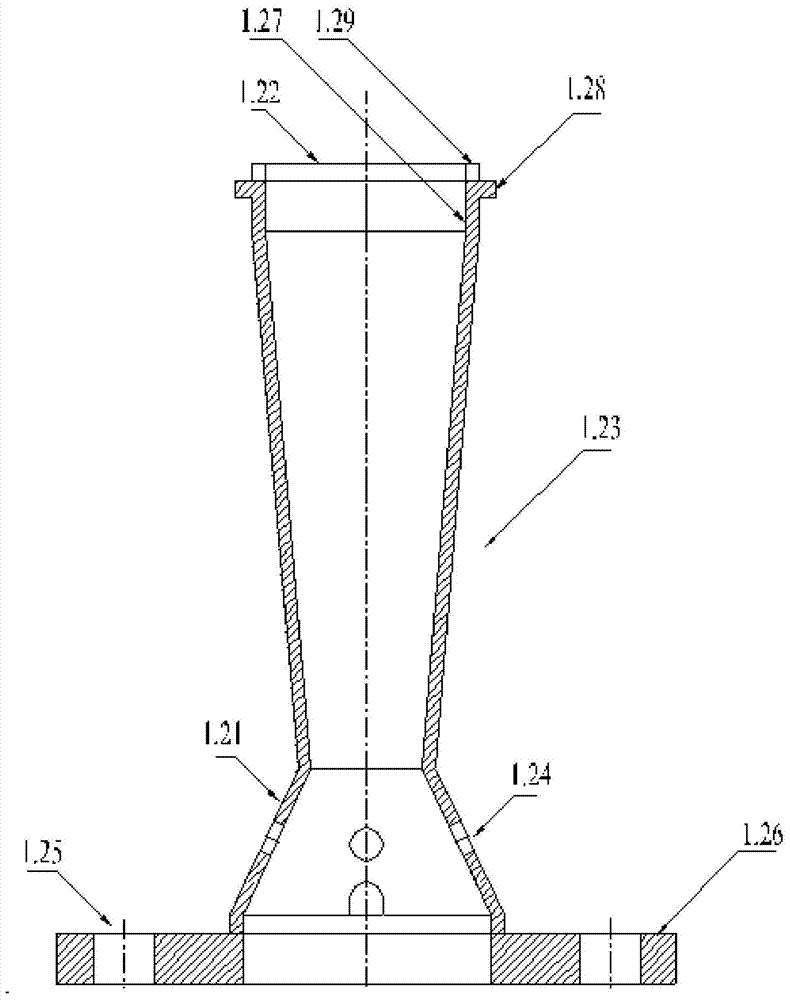

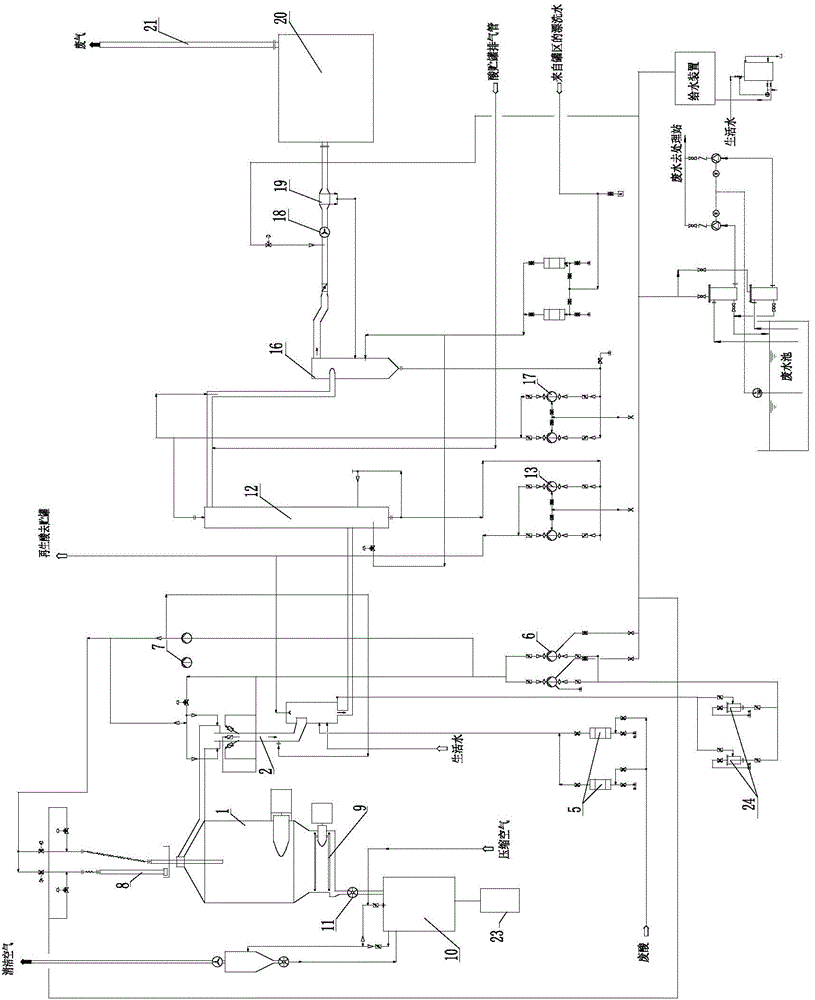

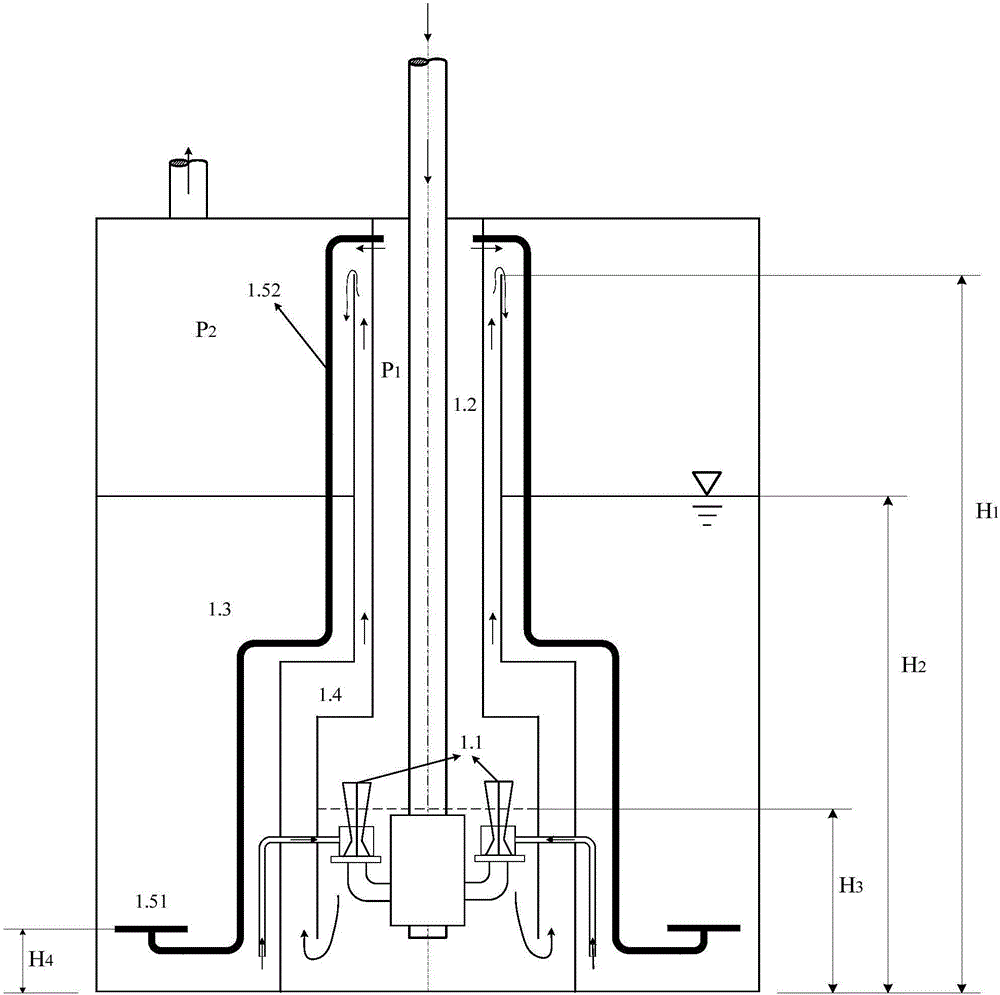

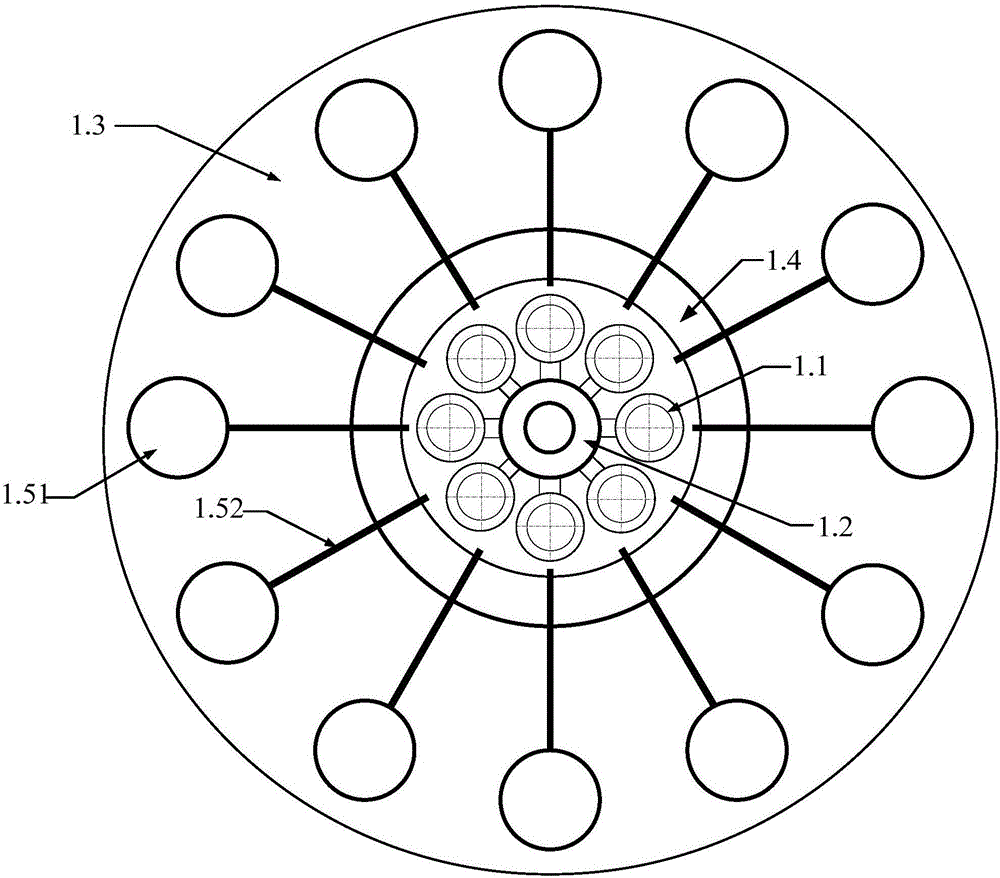

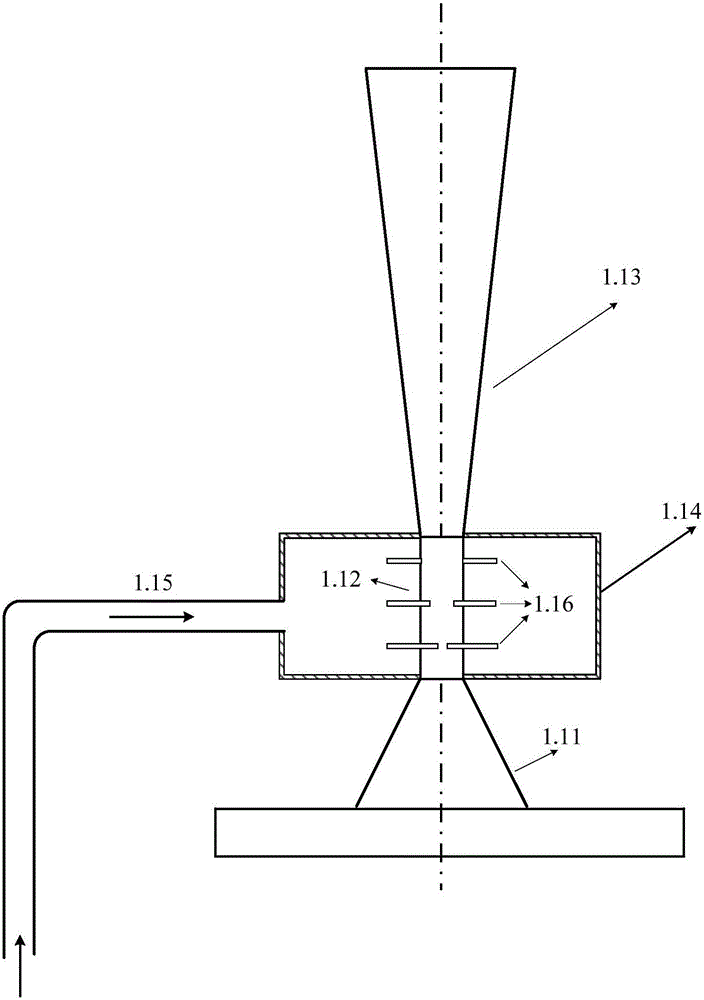

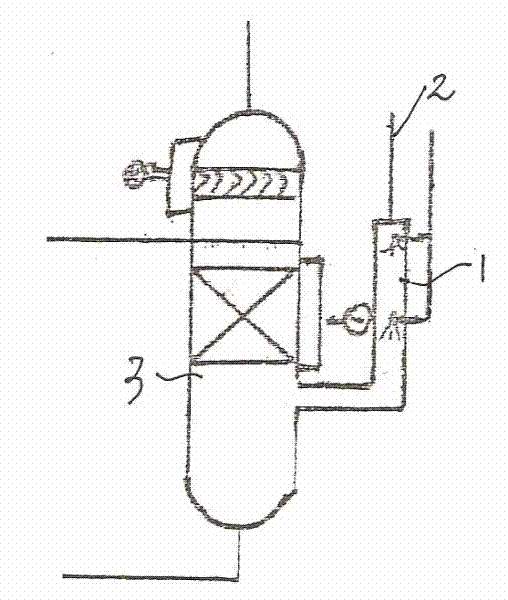

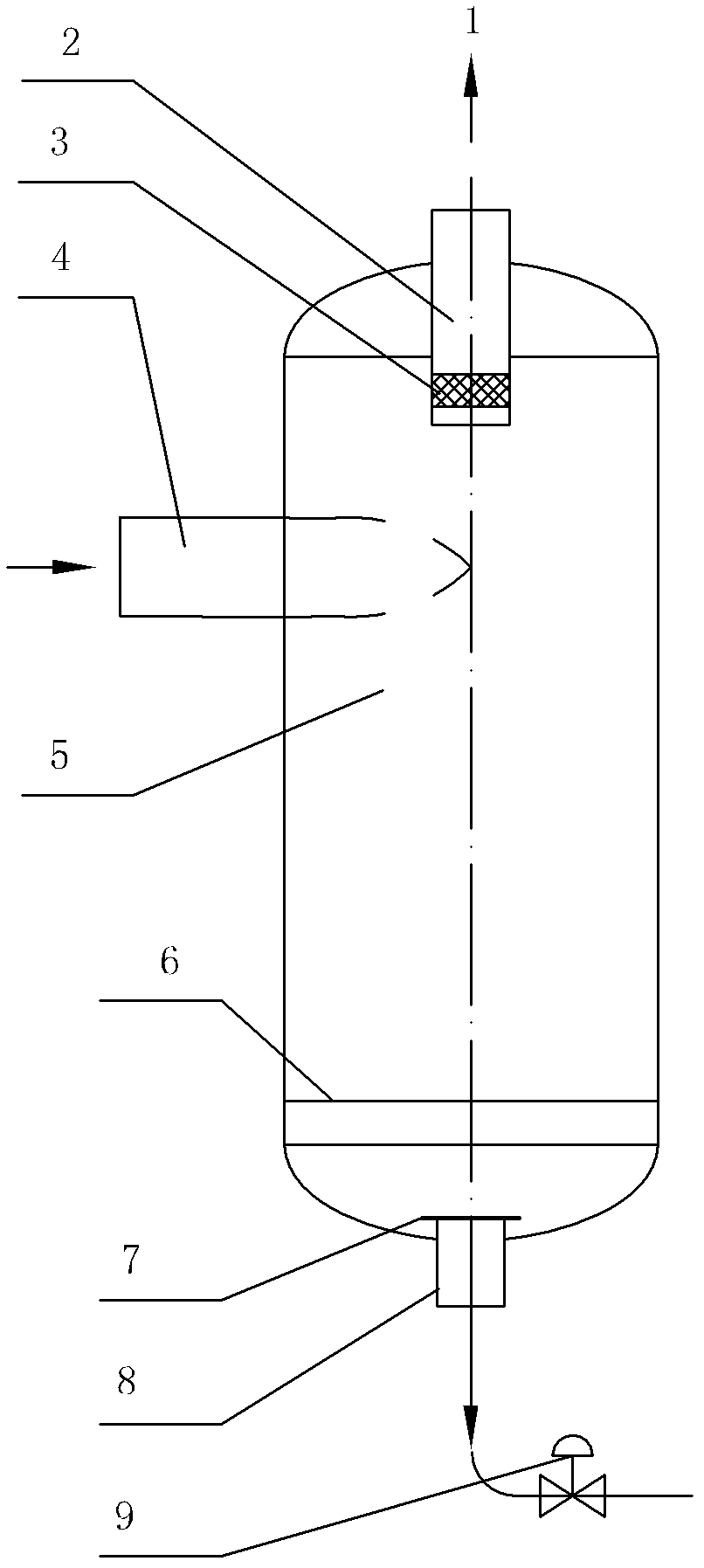

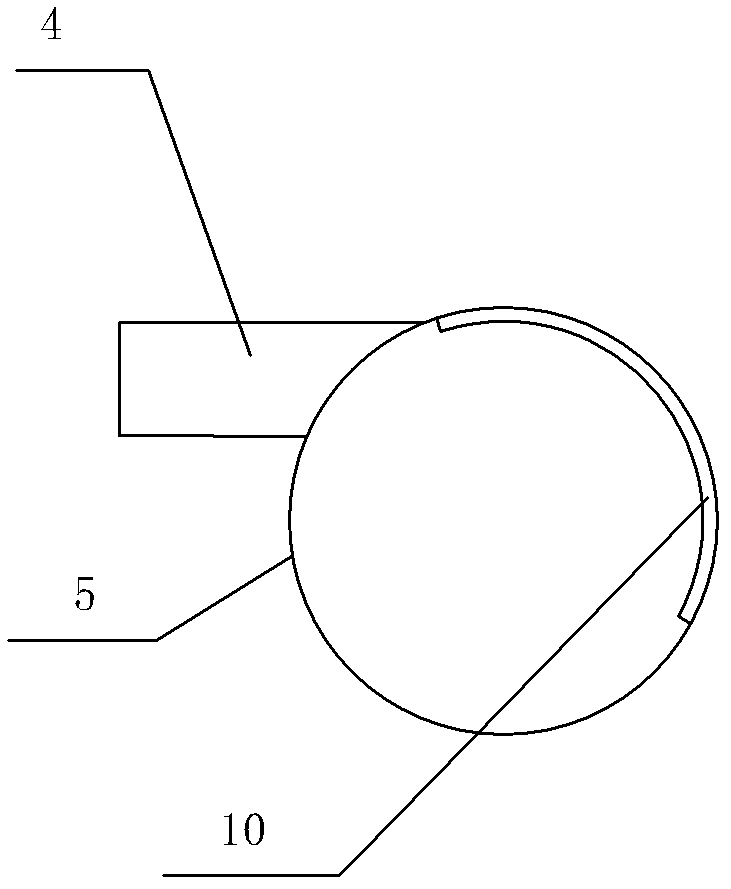

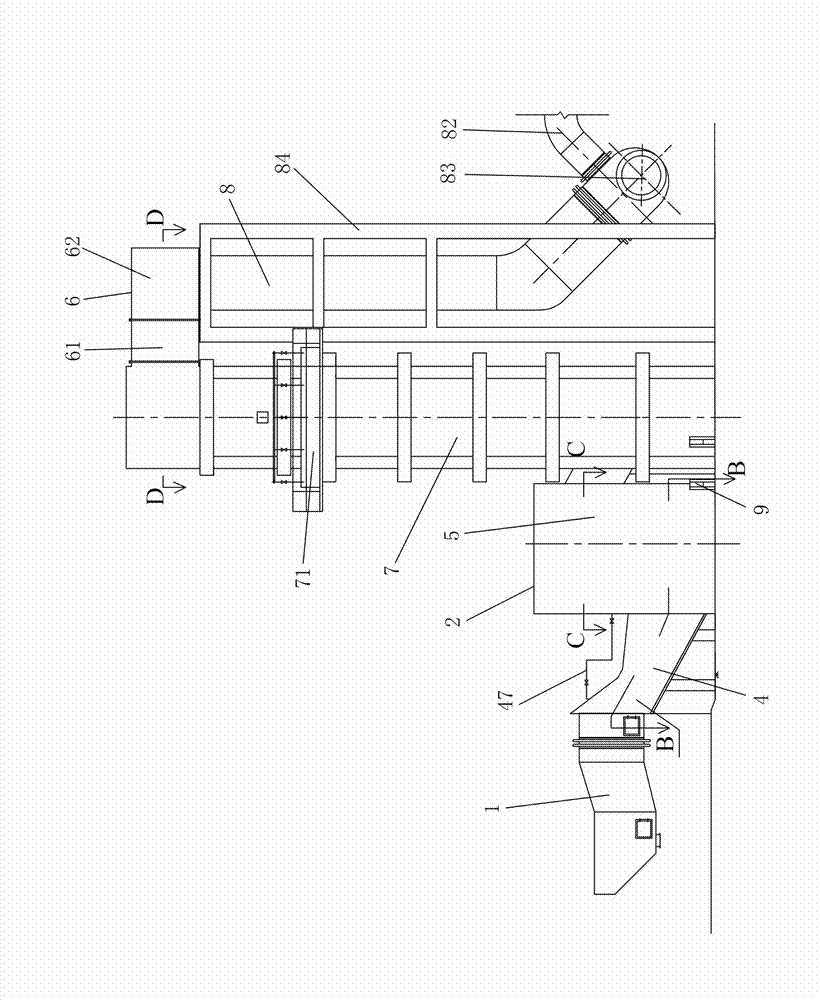

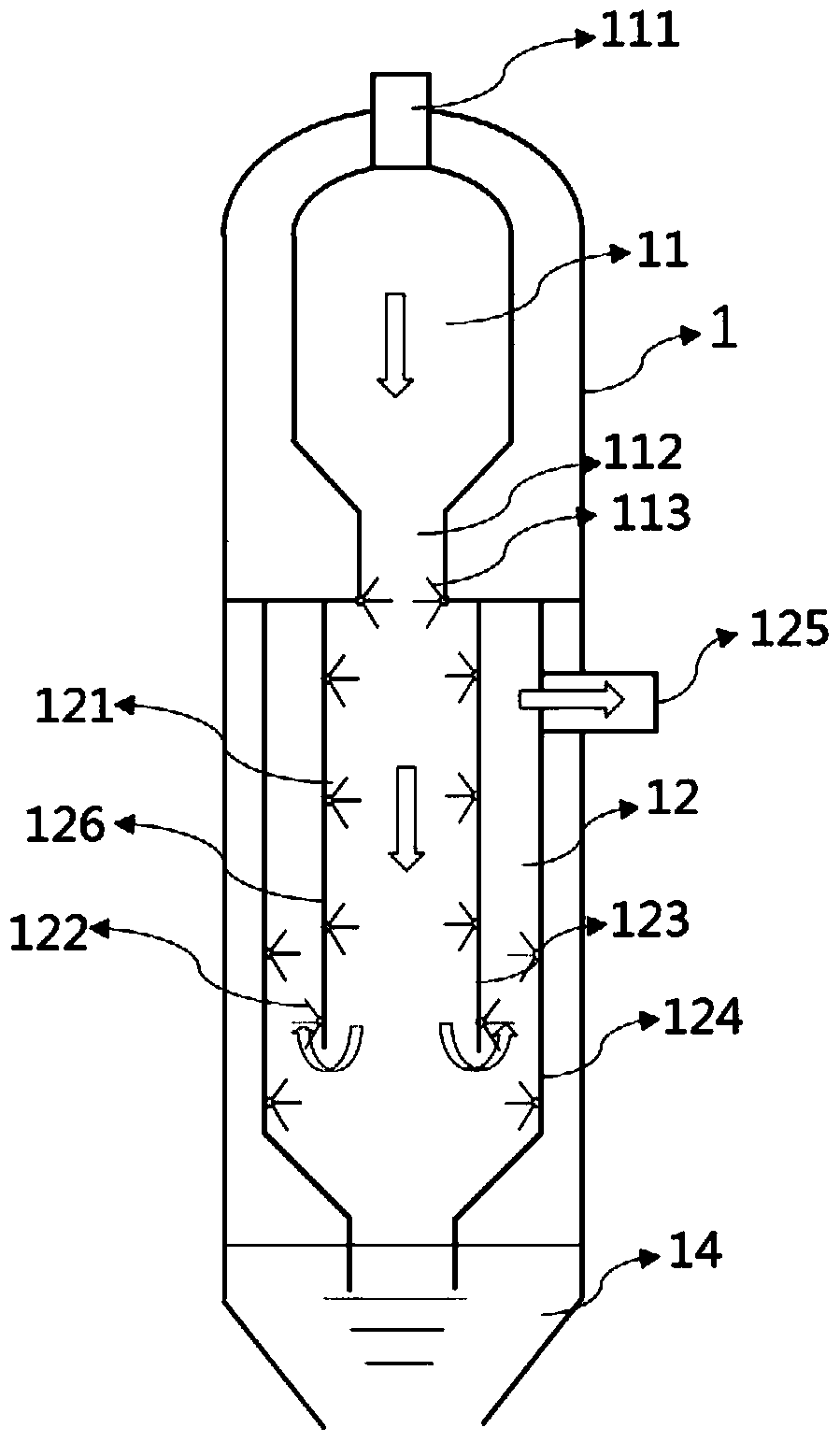

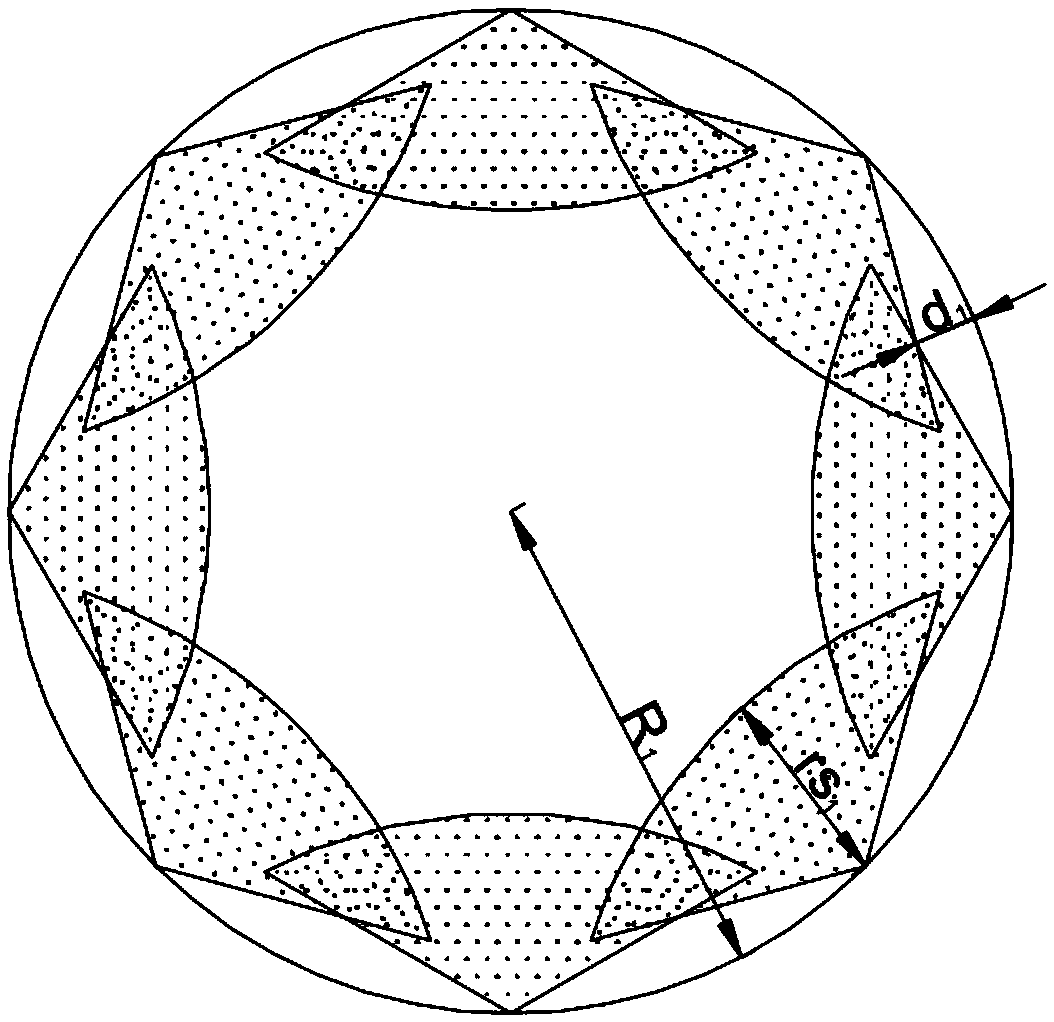

Containment vessel long-term pressure relief filtration system

ActiveCN106504811AGood removal effectImprove removal efficiencyNuclear energy generationEmergency protection arrangementsFiltrationBubble chamber

The invention provides a containment vessel long-term pressure relief filtration system. A circular liquid flowing channel is arranged in a housing; a bubbling chamber is formed between an outer wall of the circular liquid flowing channel and an inner wall f the housing; an inversed T-shaped cylindrical venturi scrubber chamber is formed in the inner wall of the circular fluid flowing channel; the bottom of the venturi scrubber chamber communicates with the lower end of the circular fluid flowing channel; self-suction venturi scrubbers are evenly arranged in the circumference direction of the venturi scrubber chamber; the lower inlet of each self-suction venturi scrubber communicates with a gas discharging pipe of a containment vessel; the upper end of the circular fluid flowing channel communicates with the bubbling chamber; bubbling systems are evenly arranged the circumference direction of the bubbling chamber; each bubbling system includes bubbling hole plates and communication pipes; and one end of each communication pipe is connected to the corresponding bubbling hole plate, and the other end of each communication pipe communicates with the upper part of the venturi scrubber chamber. The containment vessel long-term pressure relief filtration system has a higher removing efficiency, and can especially and remarkably improve the removing efficiency of methyl iodide gas.

Owner:HARBIN ENG UNIV

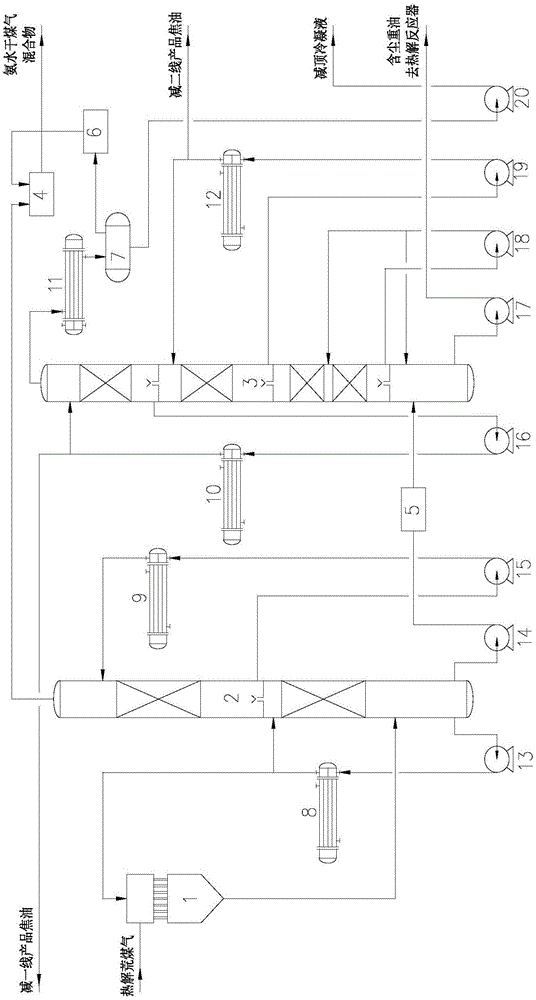

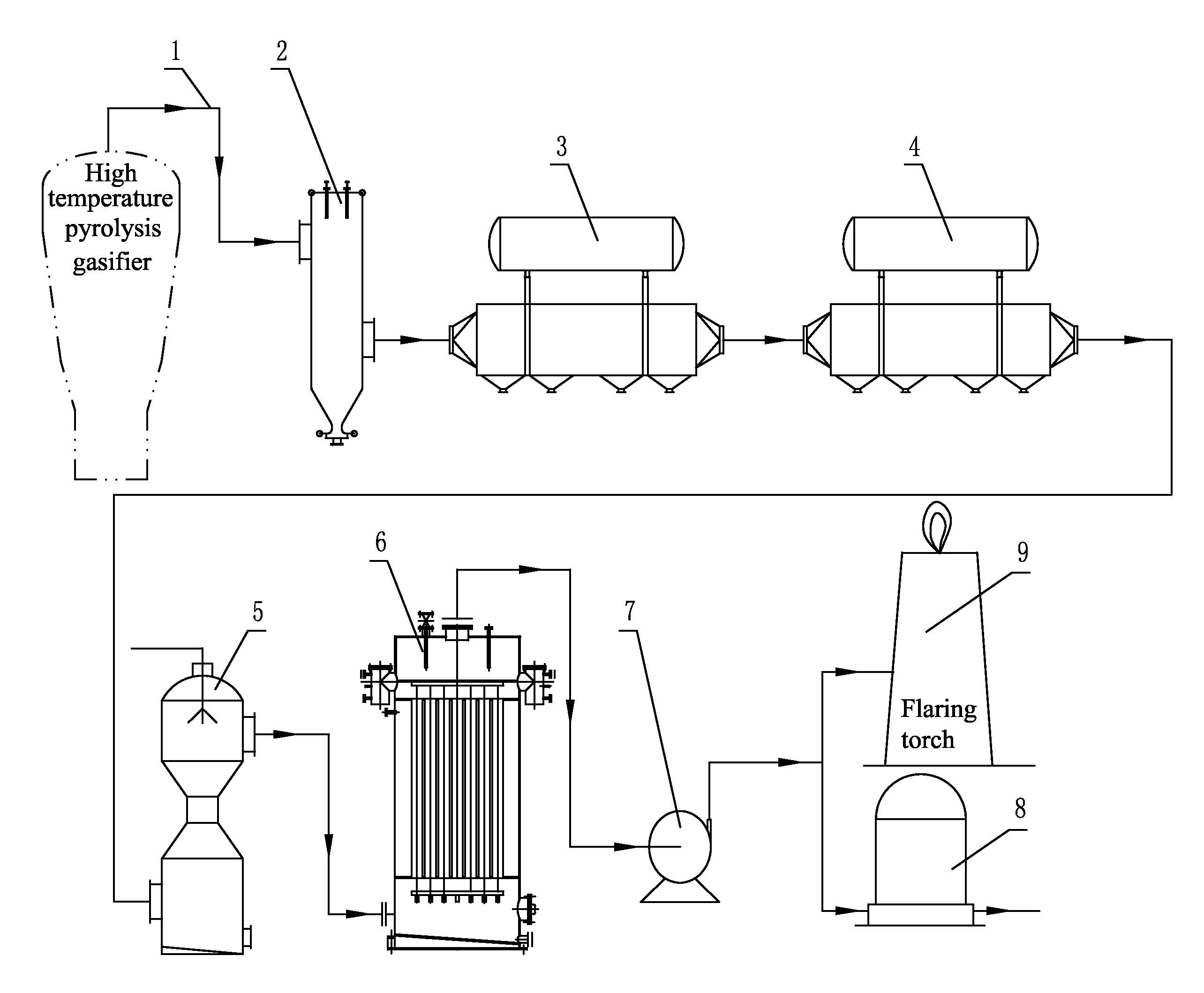

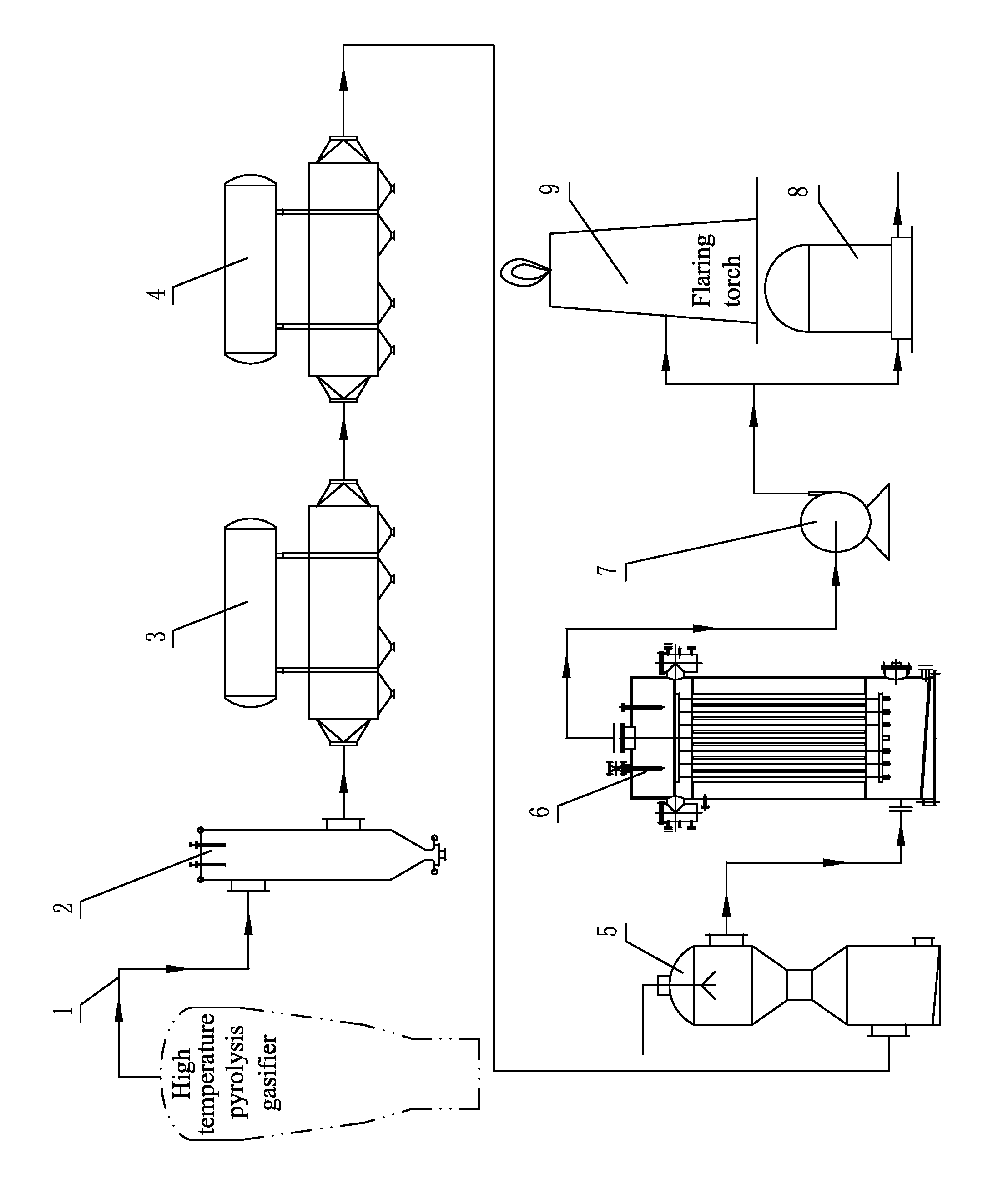

Liquid-phase dust removing system and liquid-phase dust removing method of pyrolysis coke-oven gas

ActiveCN105132041ASimple designSimple dust removal methodGas dust removalHigh concentrationDistillation

The present invention relates to a liquid-phase dust removing system and a liquid-phase dust removing method of pyrolysis coke-oven gas. The system comprises a venturi washer, an oil washing tower and a pressure reducing tower, wherein the tar and the dust in the coke-oven gas are condensed into the washing oil through the quenching cooling of the Venturi washer and the cooling dust removing of the oil washing tower, and the dust-containing washing oil is subjected to pressure reducing distillation to obtain the qualified tar product. According to the present invention, the system has characteristics of simple design, stable operation, economy, efficient and good safety, the dust removing method has characteristics of simpleness, high dust removing efficiency and stable and reliable dust removing effect, the quinoline insoluble substance content in the product oil can be less than 0.5%, the quinoline insoluble substance content in the dry coal gas is less than 1%, and the high concentration dust-containing heavy oil is circulated to the reactor so as to be subjected to pyrolysis again, such that the good dust removing purpose is achieved.

Owner:SHENMUFUYOU ENERGY TECH

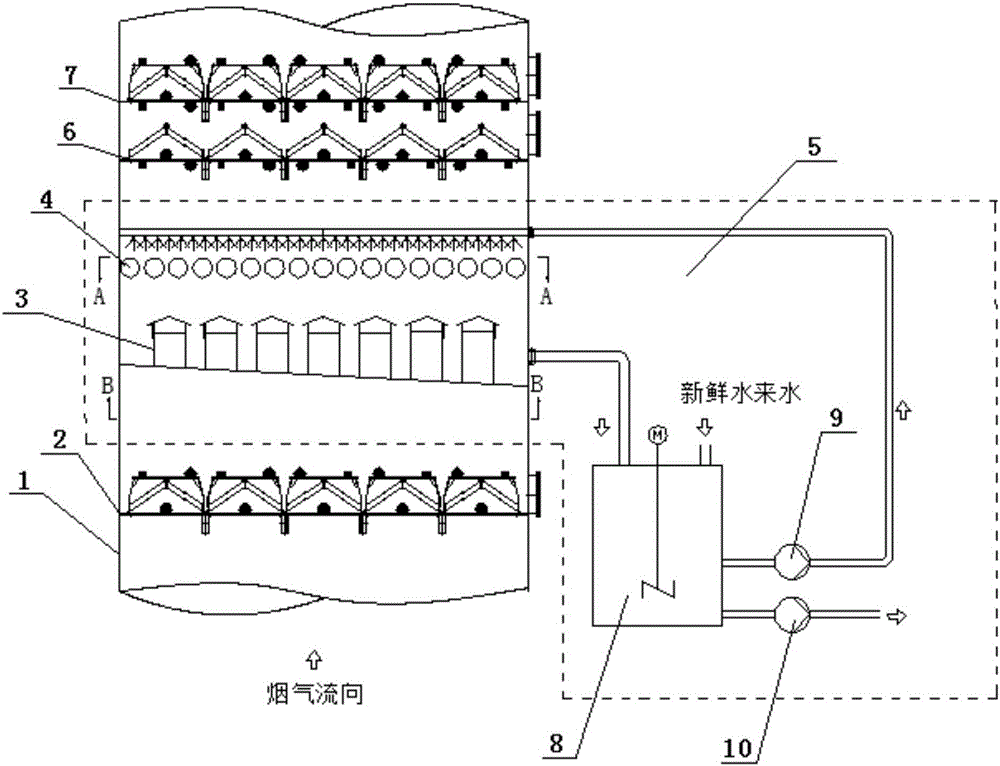

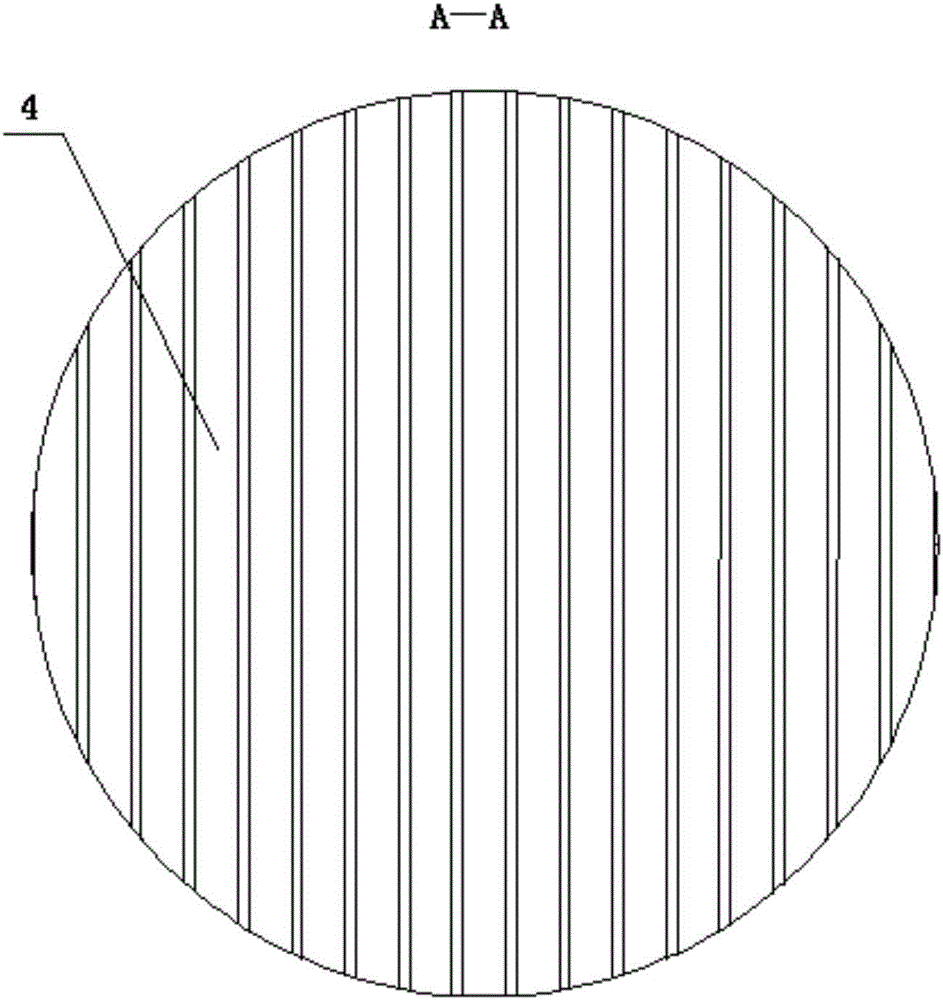

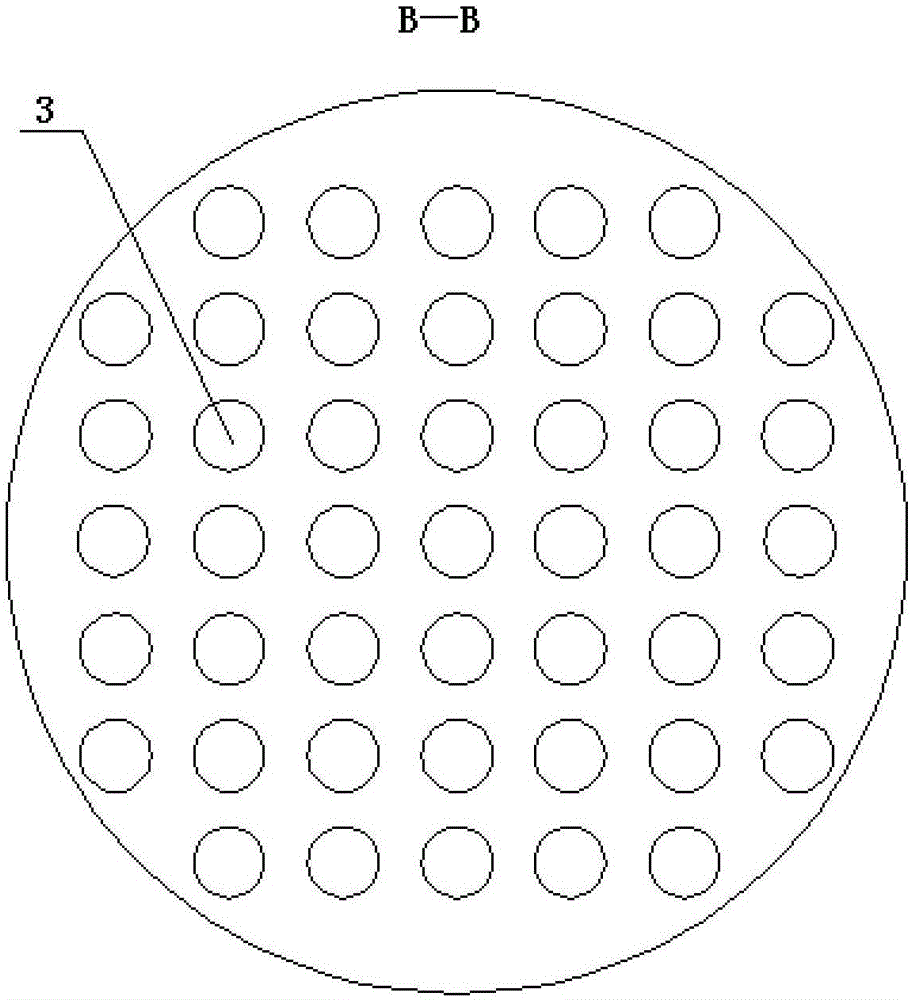

Dust growing combined dust removal and demisting integrated device of desulfurization tower

InactiveCN106731422AImprove the effect of collaborative dust removalReduce carryCombination devicesGas treatmentFlue gasGas lift

The invention provides a dust growing combined dust removal and demisting integrated device of a desulfurization tower and belongs to the technical field of dust removal and demisting of flue gas, aiming at solving the problems that flue gas at an outlet of a traditional desulfurization tower carries fine dust and gypsum mist drops and a gypsum rain phenomenon of a chimney is extremely easily caused. A first-grade roof ridge type demister is mounted at the upper part in the desulfurization tower; a gas lifting cap water reflowing layer, a novel venturi scrubber, a water spraying layer, a second-grade roof ridge type demister and a third-grade roof ridge type demister are mounted above the first-grade roof ridge type demister in sequence; a circulating water tank is arranged at the outer part of the desulfurization tower; the gas lifting cap water reflowing layer is communicated with the circulating water tank through a water returning pipeline; the gas lifting cap water reflowing layer is composed of a plurality of gas lifting caps; the circulating water tank is communicated with the water spraying layer through a circulating water pipeline; the water spraying layer is composed of a pipeline and a plurality of atomization nozzles. According to the dust growing combined dust removal and demisting integrated device of the desulfurization tower, provided by the invention, the cooperated dust removal capability of the desulfurization tower can be improved and the gypsum rain phenomenon of the chimney is completely eliminated.

Owner:哈尔滨电气环保有限公司

Pretreatment device of seawater desulphurization apparatus

InactiveCN102363092AEfficient captureReduce the temperatureUsing liquid separation agentBiochemical engineeringTower

The invention discloses a pretreatment device of a seawater desulphurization apparatus. The pretreatment device is characterized in that: the pretreatment device is a prespray device; the inlet of the prespray device is communicated with a smoke inlet pipeline; the outlet of the prespray device is communicated with a desulfurization tower; and the prespray device adopts a Venturi scrubber or an atomizing nozzle scrubber. The pretreatment device, which has the characteristics of reasonable structure and high work efficiency and can effectively capture dusts and oil stains in the smoke and reduce the temperature of the smoke penetrating to the desulfurization tower, creates good operation conditions for the desulfurization tower, and has the advantages of convenient manufacture and maintenance, and low cost.

Owner:顾忠华 +1

Method of purification of biomass syngas under negative pressure

InactiveUS20150041720A1Easy to detectImprove securityHydrocarbon from carbon oxidesHydrogen separation at low temperatureTubing typesScrubber

A method for purifying biomass syngas, including: a) introducing syngas out of a gasifier, through a water-cooling flue to a water-cooling quench tower; b) introducing the syngas from the water-cooling quench tower to a waste heat boiler of a water-tube type and a waste heat boiler of a heat-tube type; c) washing the syngas from the waste heat boiler of the heat-tube type in a Venturi scrubber in the absence of a filler to remove dust; d) introducing the syngas from the Venturi scrubber to a wet electrical dust precipitator for conducting dust removal and tar mist removal; and e) extracting the syngas by a coal gas draft fan, and transporting the syngas to a wet gas tank for storage or to a downstream process for use.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Sewage sludge recycling with a pipe cross-reactor

InactiveUS20050279146A1Enhance plant nutrient valueIncrease valueBio-organic fraction processingSludge treatmentSludgeSlurry

An improved process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g., sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor. The process more particularly involves mixing the waste material with water to form a slurry (or initially taking the waste material as a slurry); pumping the slurry to a pipe-cross reactor for reaction with a base, acid, and water to form a melt; spraying the melt onto a recycling bed of fines in a granulator, and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g., a fertilizer or soil conditioner having a greater “NPK” value than the original relatively low analysis organic waste material). The invention also includes fertilizers produced according to the improved process, which fertilizers are of the same size and shape and density of commonly used fertilizers. The method advantageously utilizes the heat generated by the exothermic acid-base reaction in the pipe-cross reactor to remove the approximately 80% water from sludge, thus saving large amounts of energy normally used in conventional drying or burning methods, while, at the same time, conserving the intrinsic values of the nutrients and humates contained in the sludge. In one embodiment, the process includes a method of disposing of spent acid from a hot dip galvanizing process or a steel pickling process involving incorporating the spent acid to maintain the low pH of a venturi scrubber used in the improved process.

Owner:UNITY FERTILIZER

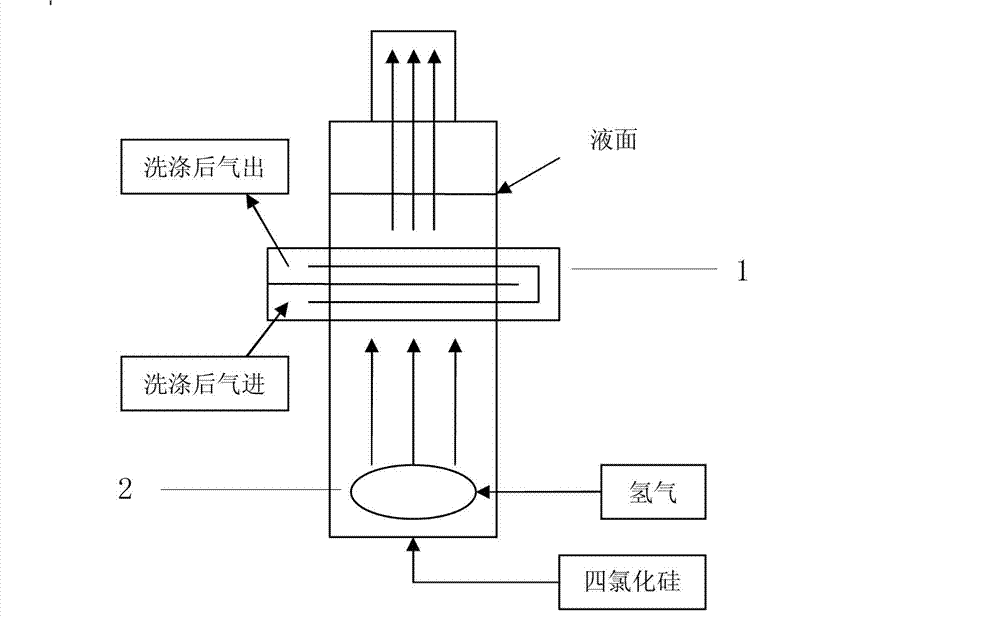

Gas-liquid separation tank for cold hydrogenation process

The invention relates to a gas-liquid separation tank for a cold hydrogenation process. The gas-liquid separation tank comprises a vertical tank body, a gas phase outlet, a liquid phase outlet, a liquid-level regulating valve and a two-phase outlet, wherein the gas phase outlet is formed above the tank body, the liquid phase outlet is formed below the tank body, the liquid-level regulating valve is arranged at the liquid phase outlet, and the two-phase outlet is formed in the middle of the tank body along the horizontal direction and is tangent with the inner wall of the tank body. According to the gas-liquid separation tank for the cold hydrogenation process, the technical problems that the conventional gas-liquid separation tank is relatively large in size and huge in occupied space are solved; and by adopting the vertical gas-liquid separation tank, the separation between reaction gas washed by utilizing a Venturi scrubber and scrubbing solution in the cold hydrogenation process can be realized, and the size of the device is minimized, so that the space is saved, and the cost is lowered.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

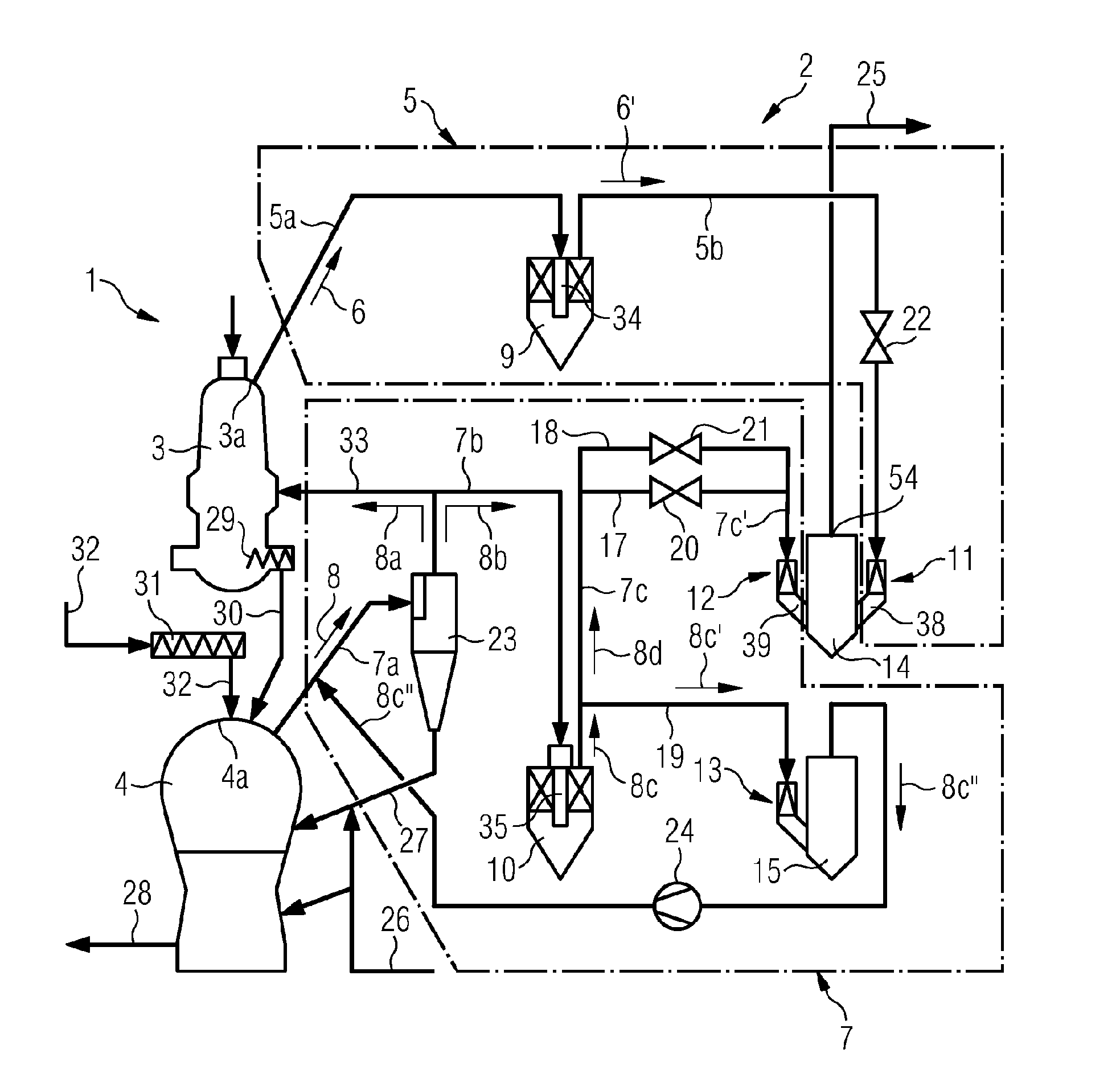

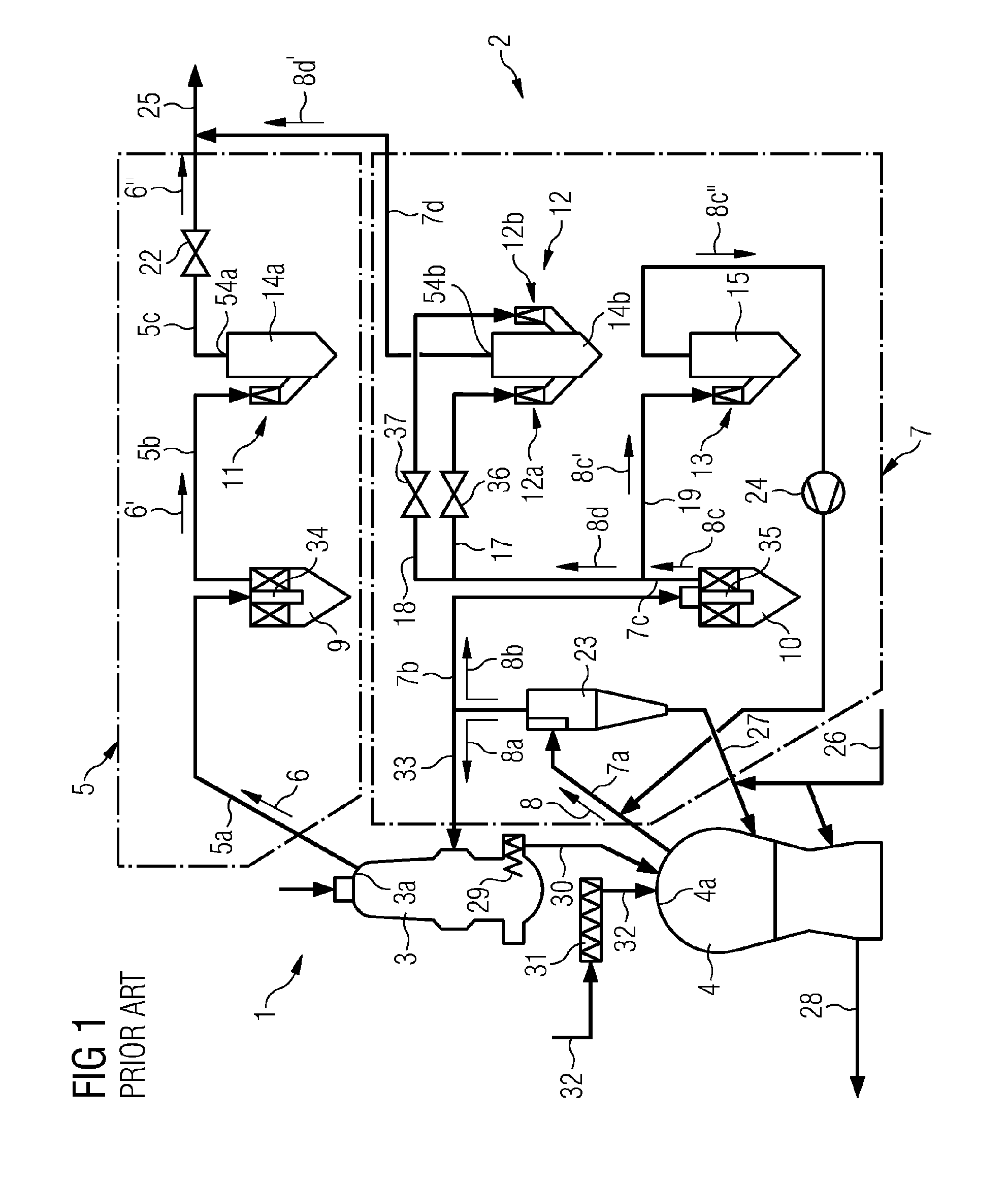

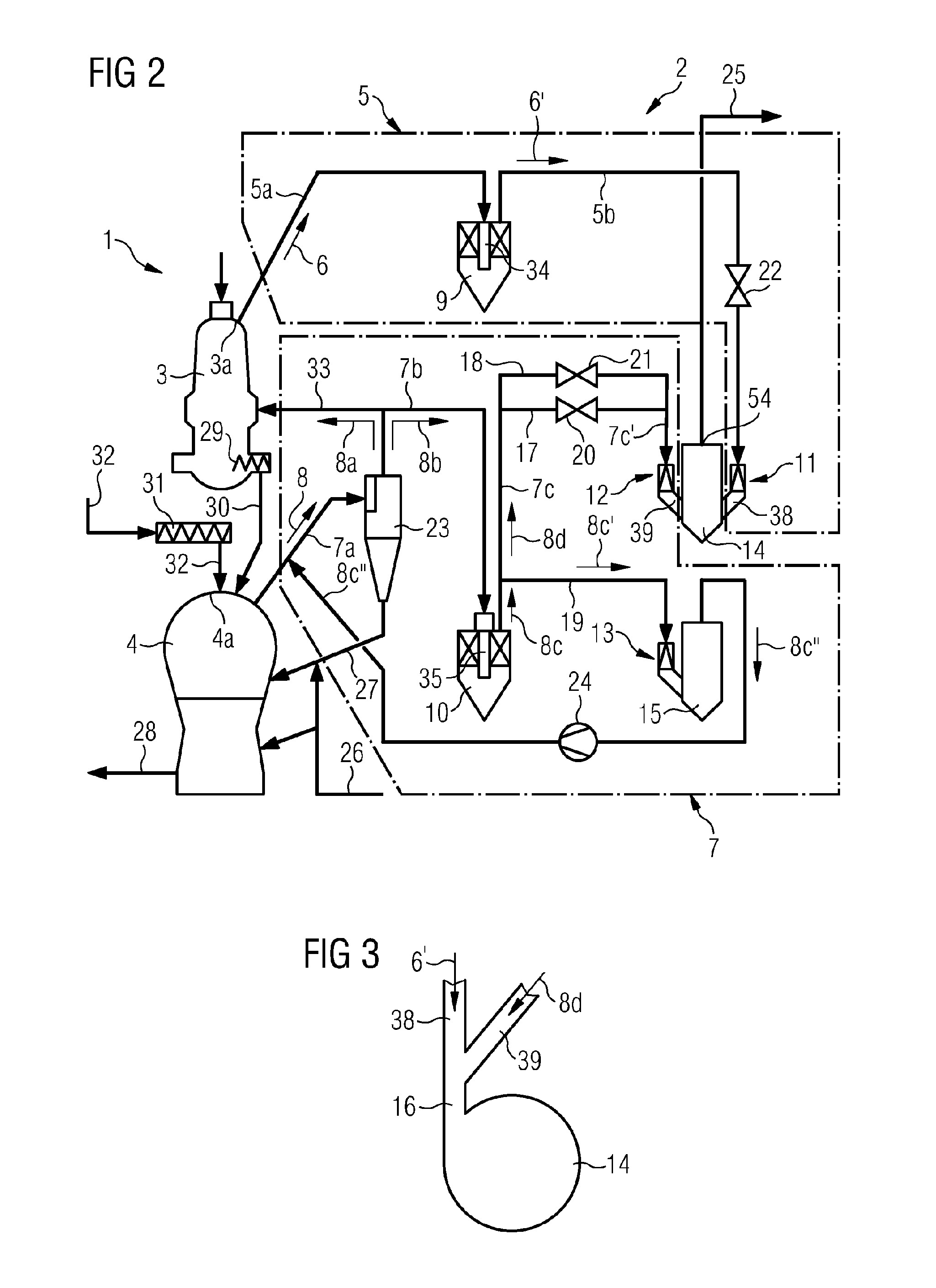

Process gas purification device for a melt reduction system for extracting pig iron

InactiveUS20110146485A1Simple and efficient process gas cleaningSimple and efficient processCombination devicesLiquid degasificationProcess engineeringProduct gas

Process gas purification device (2) for a melt reduction system (1) comprising at least one reduction reactor (3) and a melting gasification reactor (4), a first line system (5) for discharging a furnace gas (6) from the reduction reactor (3) and a second line system (7) for discharging a generator gas (8) from the melting gasification reactor (4) wherein both line systems (5,7) lead to a respective wet scrubbing system (11, 12). The furnace gas or generator gas flow can be throttled preferably by way of a control element (41) that varies a control gap (40) and the scrubber or cooling liquid (49) can be collected and drained. The first wet scrubber system (11) of the first line system (5) for routing the furnace gas (6) and the second Venturi scrubber system (12) of the second line system (7) for routing the generator gas (8) both discharge into a common mist elimination device (14).

Owner:POHANG IRON & STEEL CO LTD +1

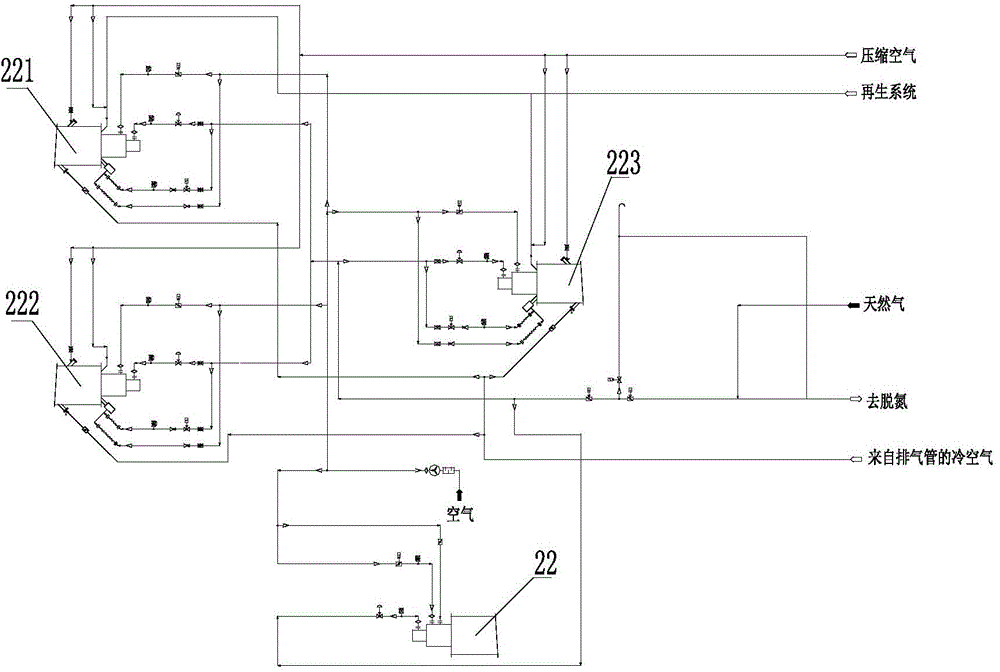

Spiral venturi scrubber and wet-method desulphurization and denitration dust-collecting system

InactiveCN102886189AHigh speed flowImprove centrifugal effectCombination devicesDust controlProcess engineering

The invention discloses a spiral venturi scrubber comprising a venturi pipe and a first water-sealing type water discharging device, wherein the venturi pipe is formed by connecting a retractable pipe, a compressed throat pipe and a spiral gradually-expanded pipe in sequence; the retractable pipe and the spiral gradually-expanded pipe are internally and respectively provided with first and second spraying and washing devices; and the bottom of the scrubber is provided with a water outlet which is connected with the first water-sealing type water discharging device. The invention further discloses a wet-method desulphurization and denitration dust-collecting system comprising a main desulphurization dust-collecting tower, a secondary desulphurization dust-collecting tower, a dehydrator and the spiral venturi scrubber; and the scrubber is communicated with the bottom end of the main desulphurization dust-collecting tower through a connecting flue; the top of the main desulphurization dust-collecting tower is communicated with the top of the secondary desulphurization dust-collecting tower through the dehydrator; and an air inlet of the secondary desulphurization dust-collecting tower is higher than the bottom surface of the dehydrator. The spiral venturi scrubber has the advantages of small volume, low energy consumption, high dust-collecting efficiency, good desulphurization and denitration effects and the like.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE

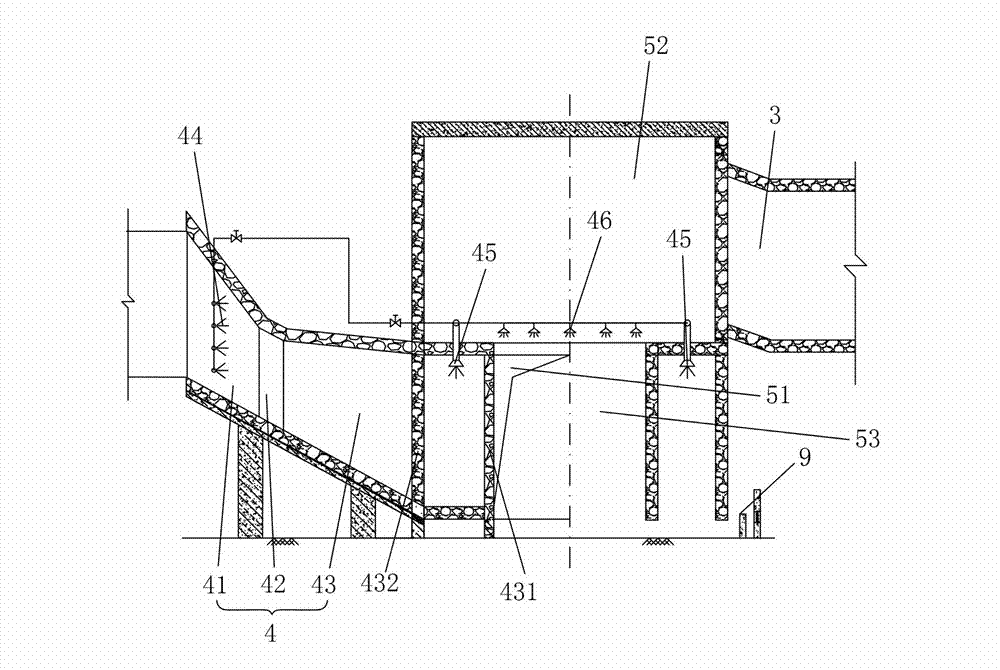

Method for improving washing effect of ammonium phosphate granulation tail gas

InactiveCN104511239APromote absorptionReduce neutralizationUsing liquid separation agentPresent methodAtmospheric air

The invention discloses a method for improving the washing effect of ammonium phosphate granulation tail gas. The method comprises the following steps: the granulation tail gas sequentially flows through a Venturi pre-stage washer, a Venturi washer and a horizontal washer and is washed by a washing liquid from the front chamber of a cycle tank in a cycle manner, the washed tail gas flows through a condenser to remove water, the water removed tail gas flows through a demister and undergoes solid-liquid separation, and the obtained tail gas is discharged to the atmosphere through a chimney; most of the washing liquid in the front chamber of the cycle tank enters the rear chamber of the cycle tank, and is mixed with the washing liquid overflowing from the front chamber of the cycle tank, and the obtained washing liquid mixture is sent to an ammonia tube reactor to participate in a reaction; concentrated phosphoric acid is added to the Venturi washer; and diluted phosphoric acid is introduced into the front chamber of the cycle tank. The method can solve the problems of low ammonia absorption and poor washing effect of present methods.

Owner:广西鹿寨化肥有限责任公司

Gasification system and technology for efficient heat recovery

PendingCN108795500AImprove heat recoveryEnsure safetyChemical industryGasification processes detailsThermal energyDistillation

The invention provides a gasification system for efficient heat recovery. The system comprises a gasification furnace, gas-solid separation and ash cooling equipment, a convective heat exchange device, gas scrubbing equipment and a black water treatment system, wherein a spraying device is arranged on a heat transfer surface in a radiation heat transfer chamber of the gasification furnace, so as to form a lower temperature zone close to the heat transfer surface and a core high temperature zone on one side, far from the heat transfer surface, of the lower temperature zone; the gas-solid separation and ash cooling equipment is communicated with a synthesis gas outlet of the gasification furnace; the convective heat exchange is used for recycling sensible heat of synthesis gas and producingpower steam; the gas scrubbing equipment comprises a venturi scrubber and a scrubbing tower which are connected in series; the black water treatment system comprises a primary flash distillation device and a secondary flash distillation device. The invention further provides a gasification technology for efficient heat recovery. The scheme adopts a radiation heat exchange chamber adopting a borderland temperature control technology, not only guarantees the safety of a heat exchange tube, but also guarantee high heat recovery efficiency, higher yield of saturated steam and smaller equipment volume under high radiation intensity.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com