Phosphoric acid production tail gas recovery method

A tail gas recovery and phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacids, separation methods, etc., can solve the problems of large amount of non-condensable gas, high temperature of reaction tank, frequent shutdown of the system, etc., to increase the efficiency of washing and absorption, strengthen Washing absorption effect, long-term stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

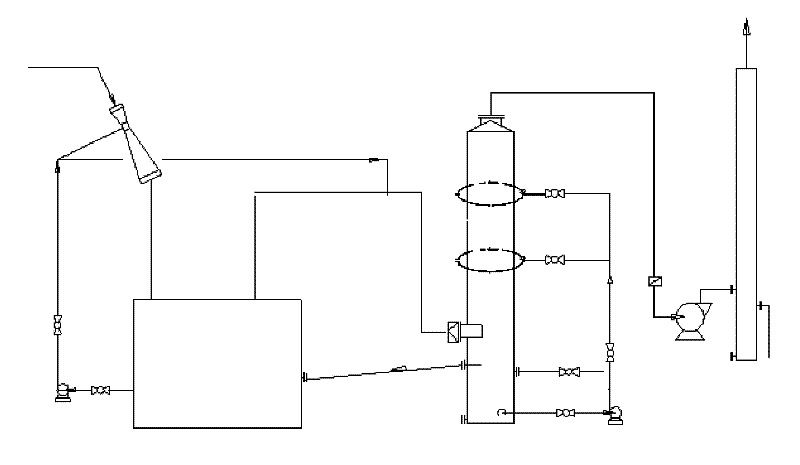

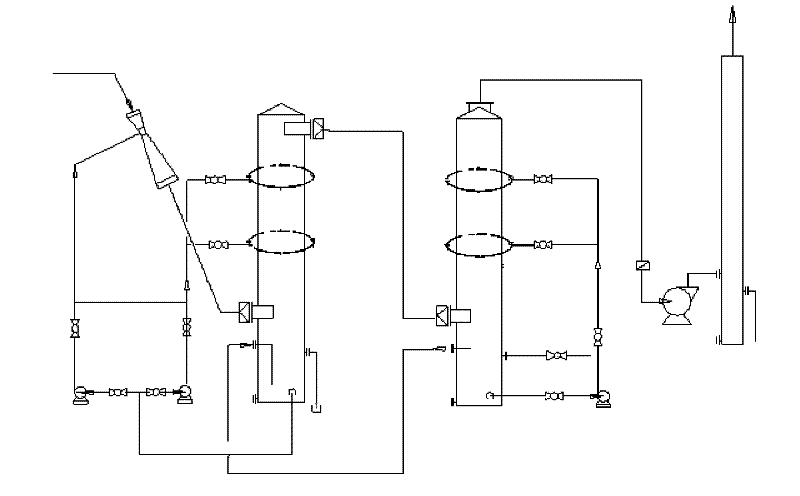

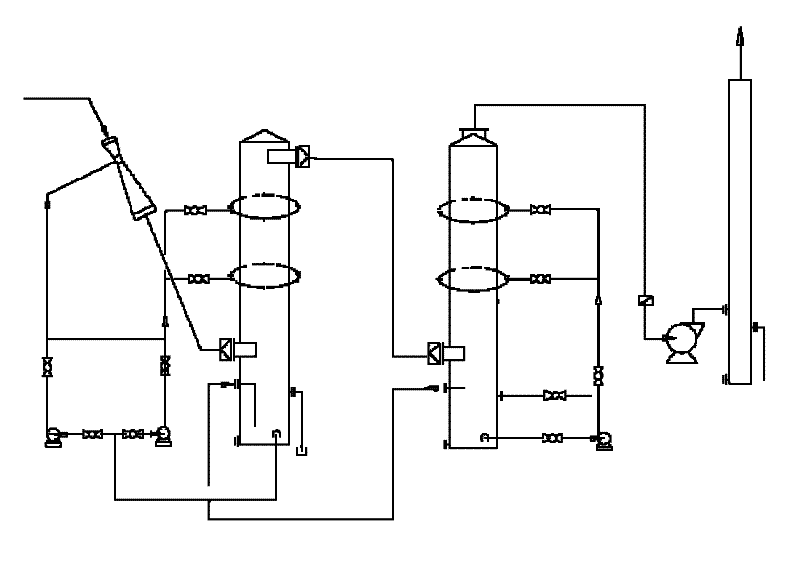

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] like figure 2 As shown, the process flow of the present invention is that the fluorine-containing gas enters the venturi scrubber through the tail gas duct, and performs the first-stage downstream spray washing with the washing liquid from the first washing pump, and the washed gas enters the first washing The washing liquid sent by the first washing pump is subjected to the first-stage counter-current two-layer spray washing again, and the gas after washing enters the second washing tower and the second-stage counter-current two-layer spraying After leaching and washing, it is pumped by the tail gas fan into the defoaming tower for defoaming, and finally discharged into the atmosphere through the chimney. The process water for washing is firstly added to the second washing tower for preheating spray washing by the second washing pump, then overflows from the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com