Patents

Literature

387results about How to "Reduce the amount of adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

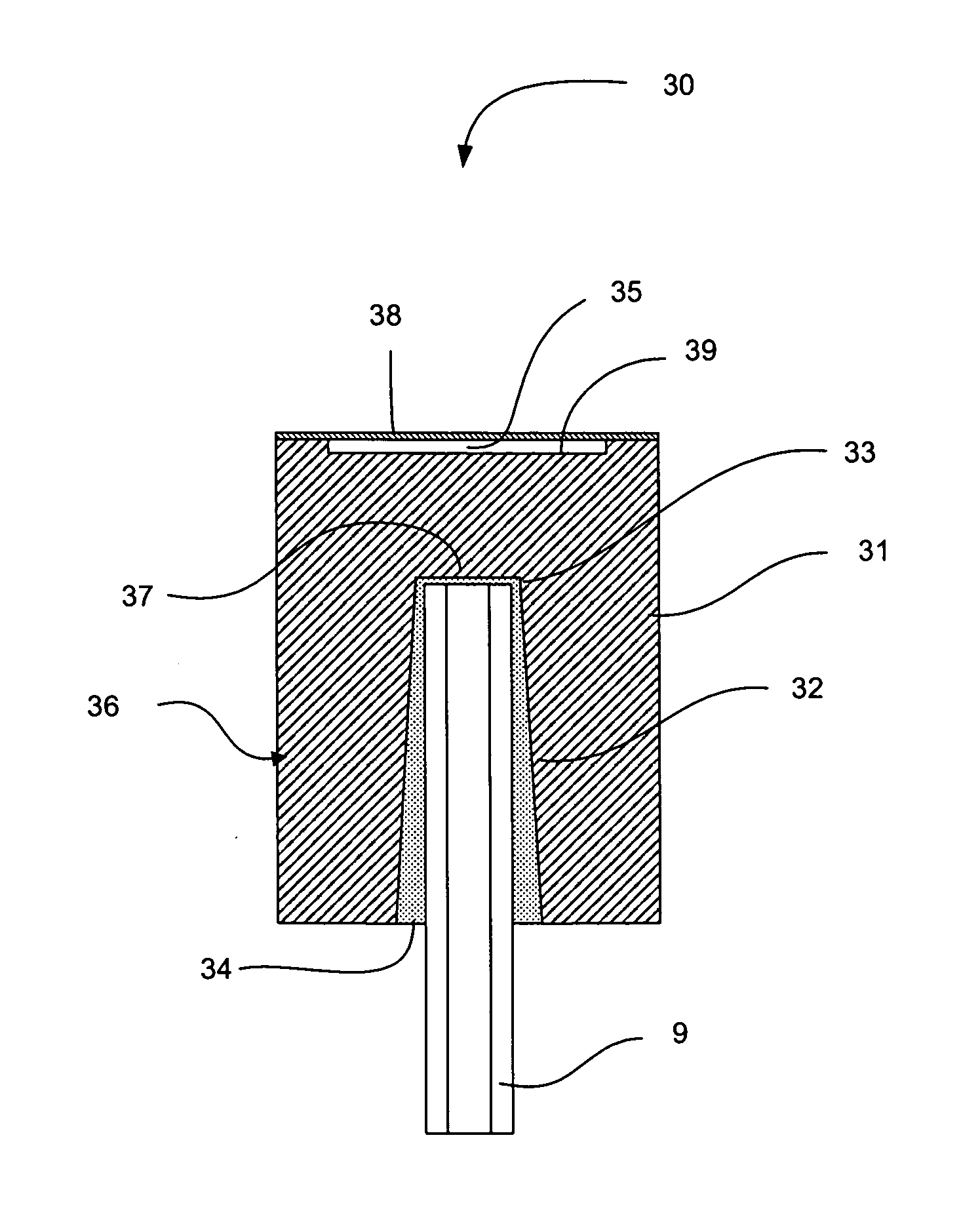

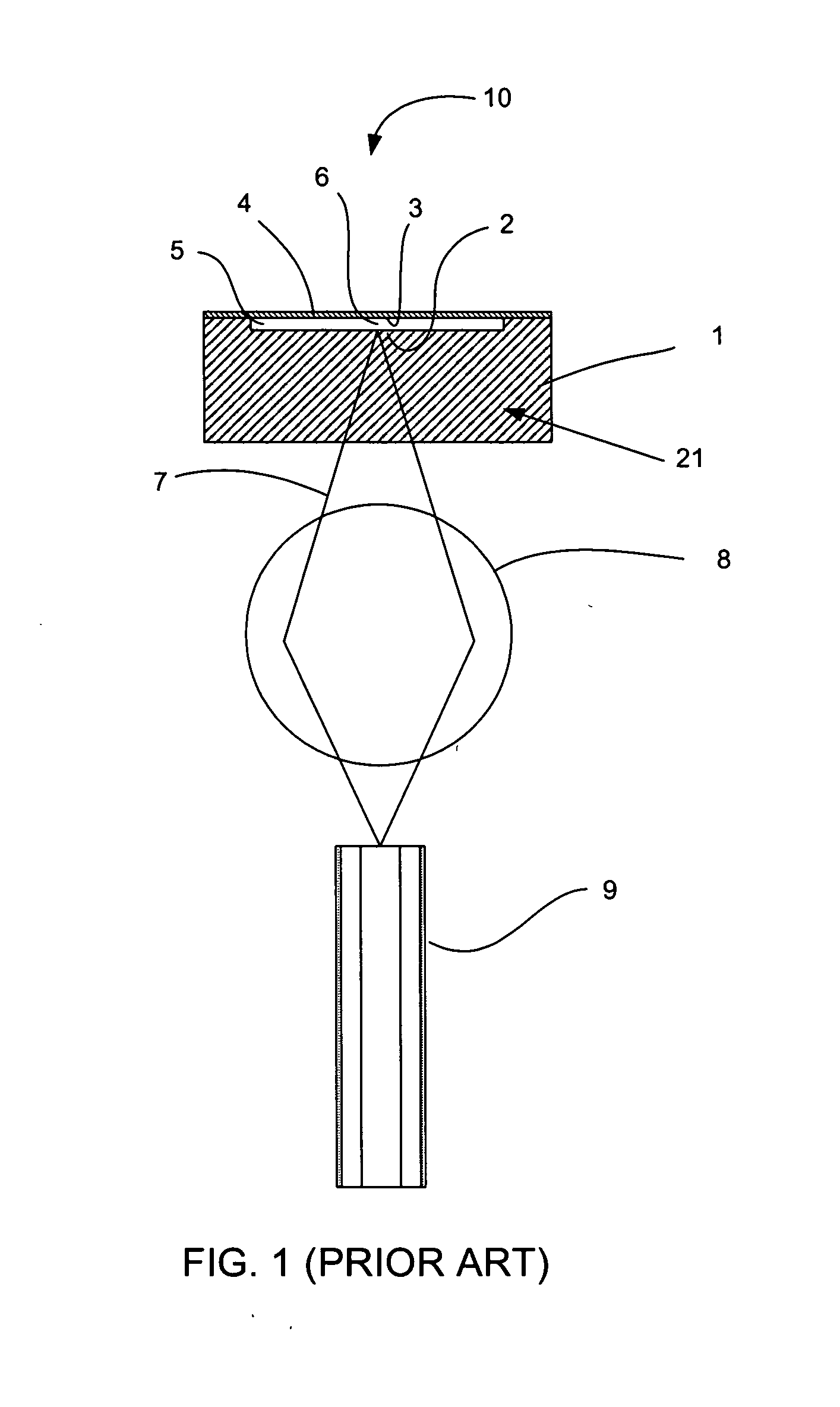

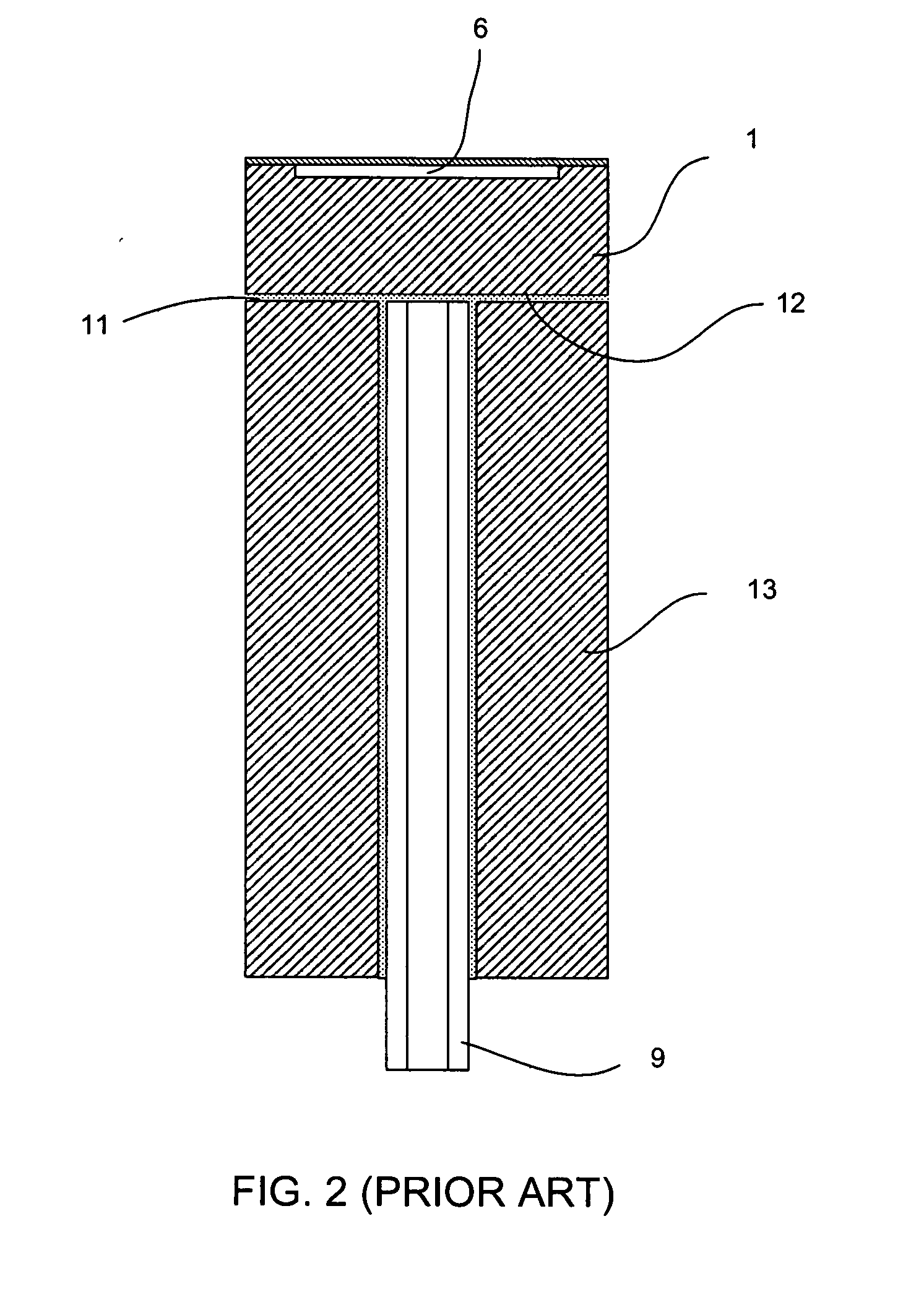

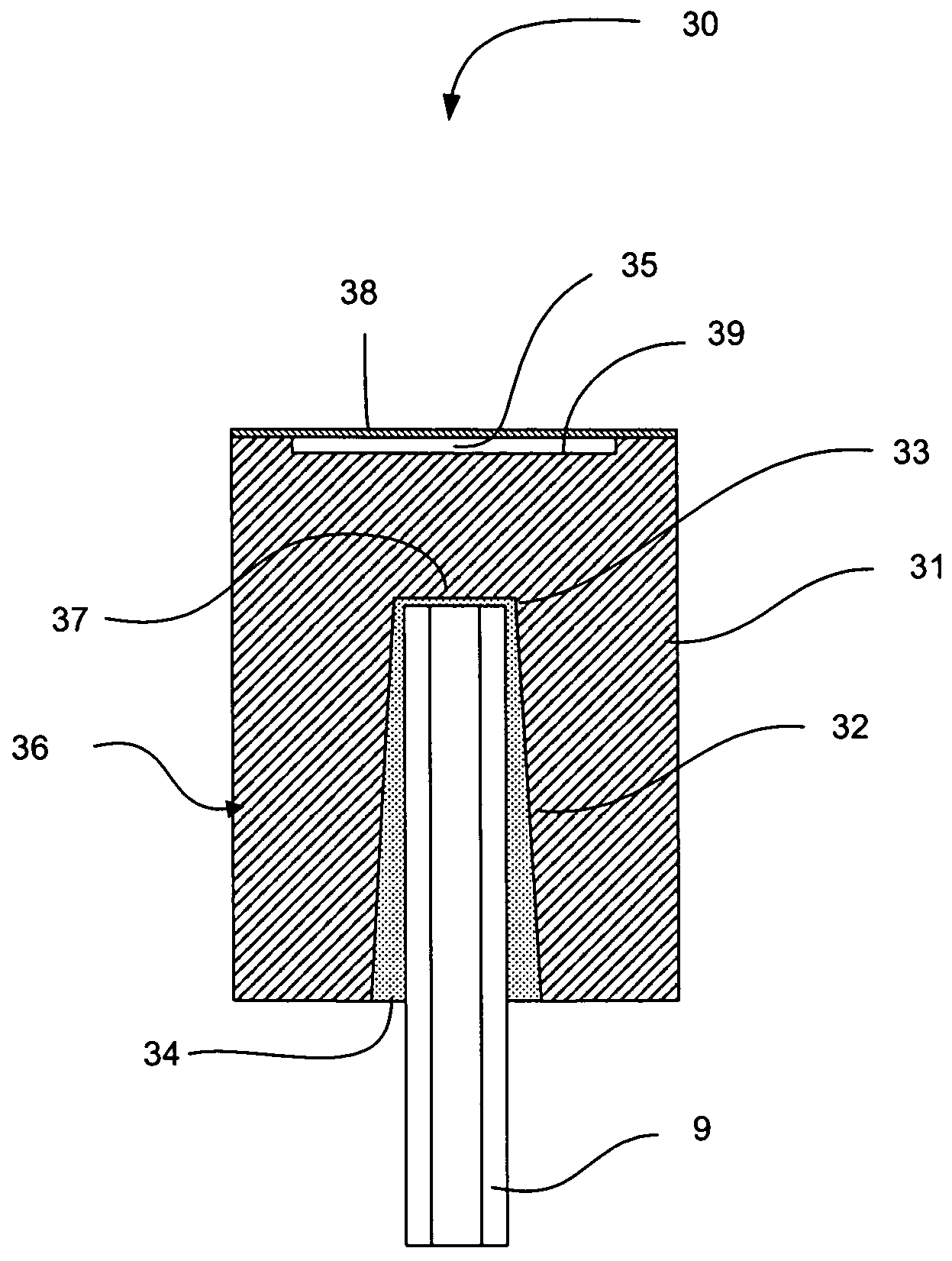

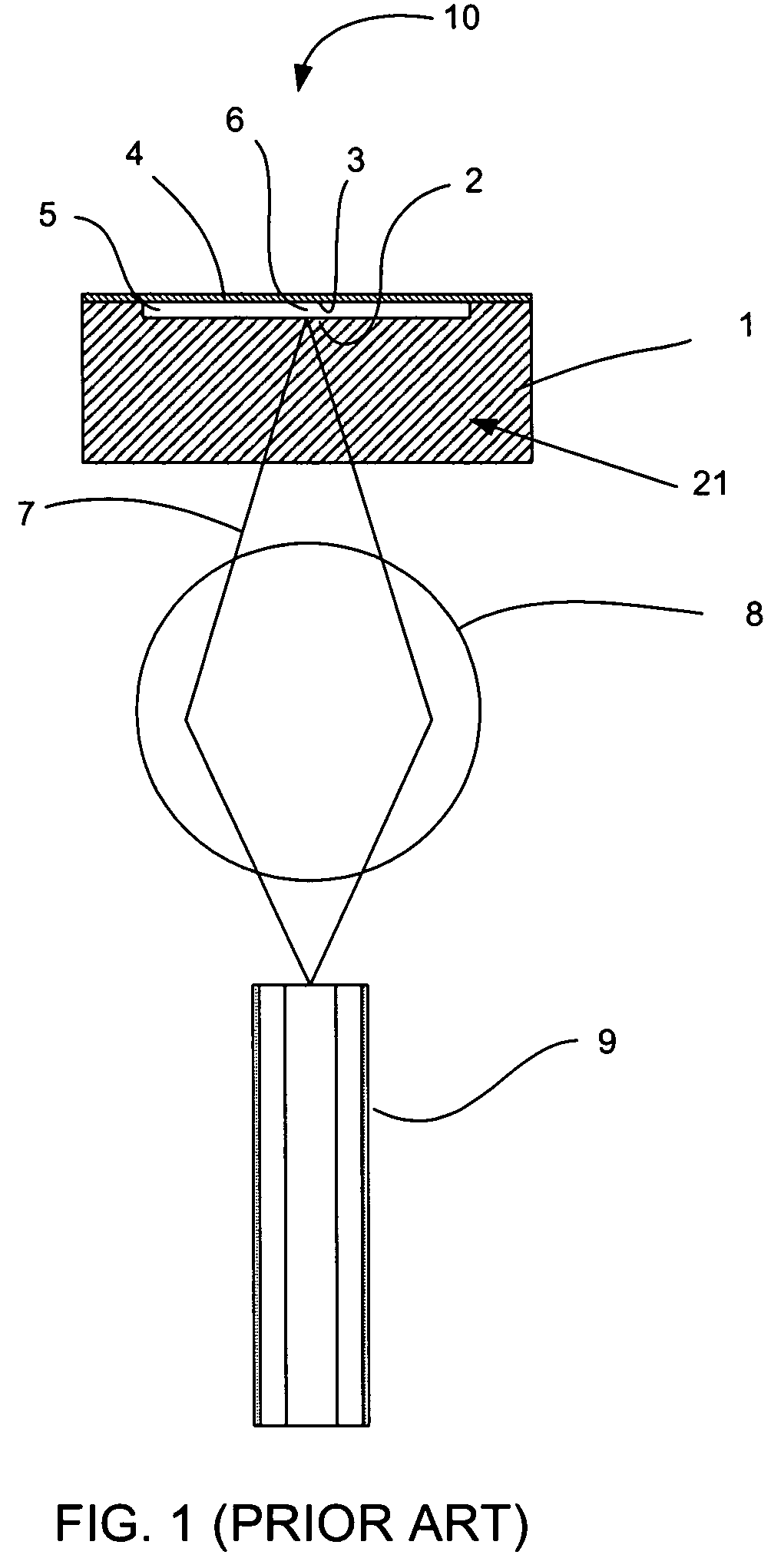

Fiber optic pressure sensor for catheter use

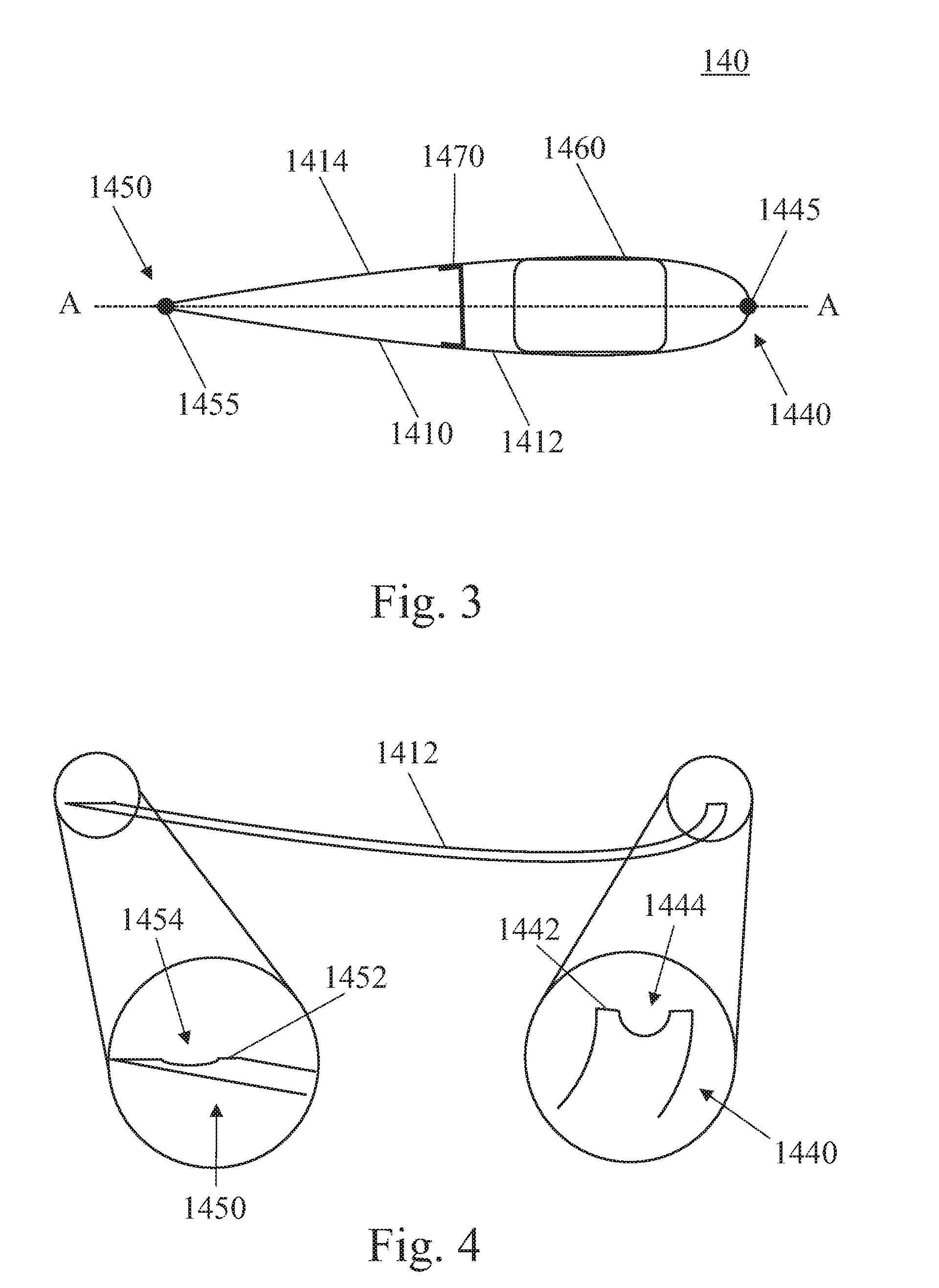

ActiveUS20060133715A1Low costHigh fidelity measurementFluid pressure measurement by electric/magnetic elementsCatheterAdhesiveEngineering

The invention provides a miniature robust fiber optic pressure sensor. The miniature fiber optic sensor comprises a Fabry-Perot chip bonded to an optical fiber. The invention provides a new sensor design that reduces the amount of adhesive required to bond the optical fiber to the Fabry-Perot sensor such that the sensor is less sensitive to moisture. The invention also provides manufacturing methods of the sensor comprising a method based on etching and a method based on using an excimer laser. The invention also provides a chip design that renders the chip less sensitive to thermal changes. The invention also provides a chip design in which a sensor diaphragm has a well-defined thickness. The invention also provides a chip design that protects the chip from etching.

Owner:OPSENS

Fiber optic pressure sensor for catheter use

ActiveUS7689071B2Low costHigh fidelity measurementFluid pressure measurement by electric/magnetic elementsCatheterAdhesiveMoisture

The invention provides a miniature robust fiber optic pressure sensor. The miniature fiber optic sensor comprises a Fabry-Perot chip bonded to an optical fiber. The invention provides a new sensor design that reduces the amount of adhesive required to bond the optical fiber to the Fabry-Perot sensor such that the sensor is less sensitive to moisture. The invention also provides manufacturing methods of the sensor comprising a method based on etching and a method based on using an excimer laser. The invention also provides a chip design that renders the chip less sensitive to thermal changes. The invention also provides a chip design in which a sensor diaphragm has a well-defined thickness. The invention also provides a chip design that protects the chip from etching.

Owner:OPSENS

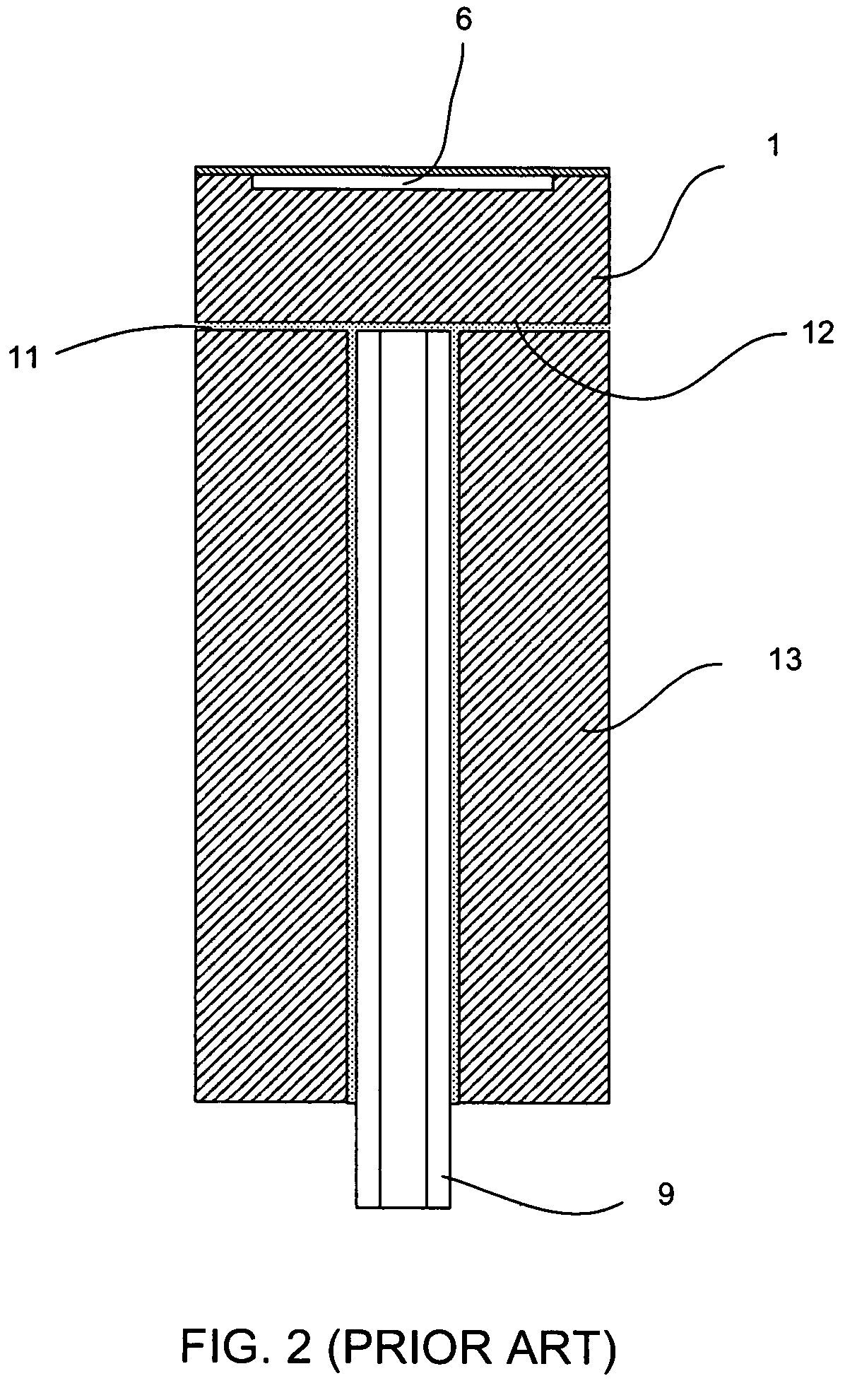

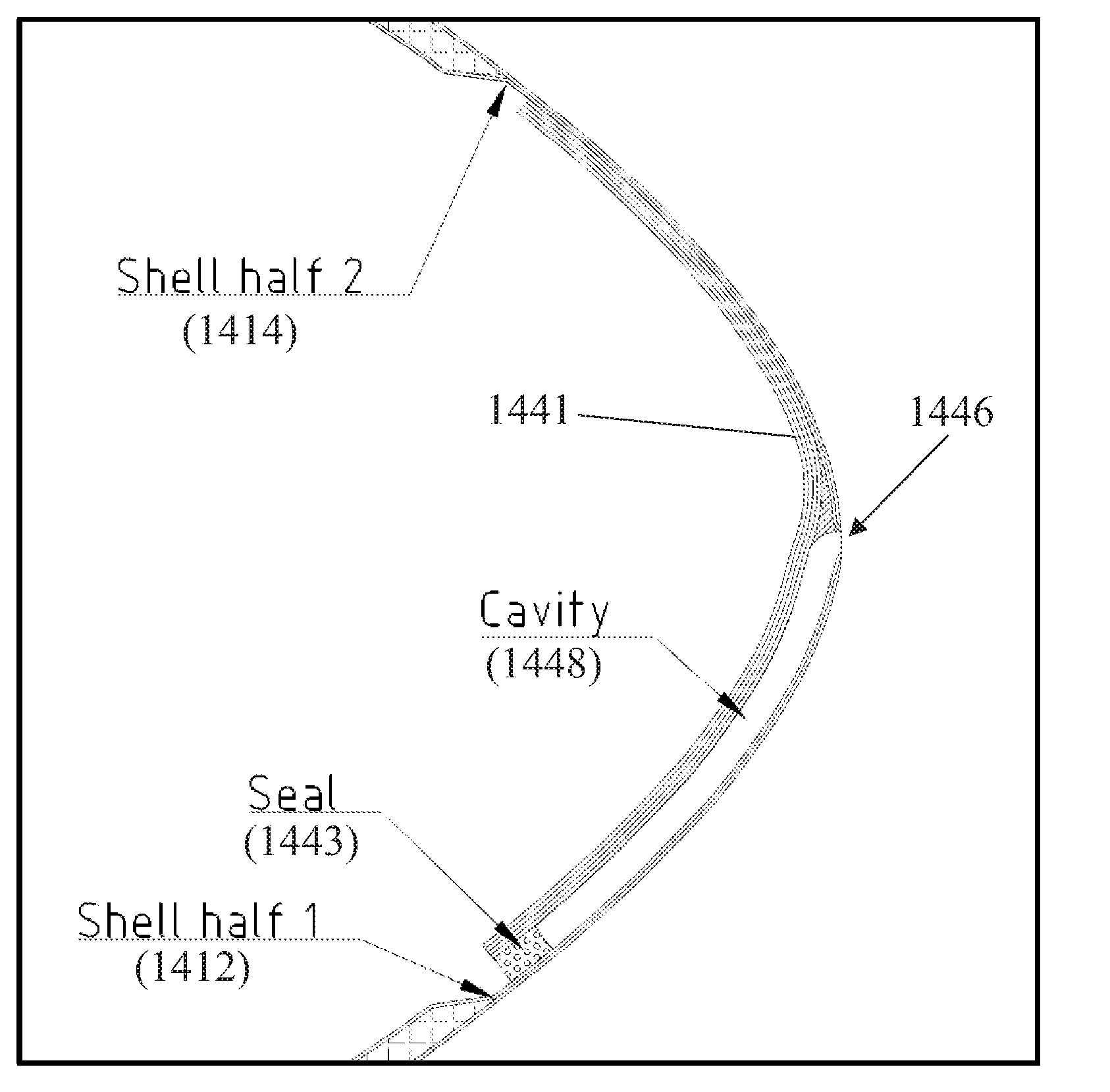

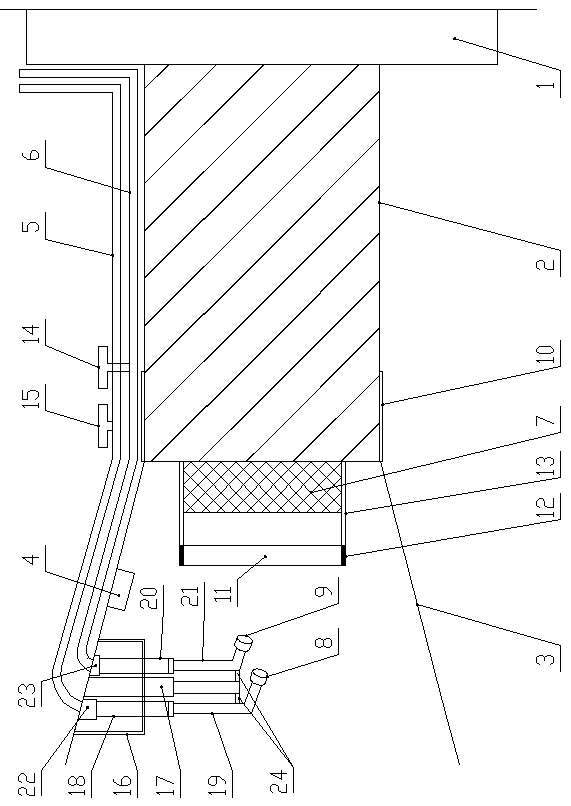

Bond line forming method

ActiveUS20080075603A1Easy to controlReduce the amount of adhesionPropellersEngine manufactureEngineeringMechanical engineering

Owner:GENERAL ELECTRIC CO

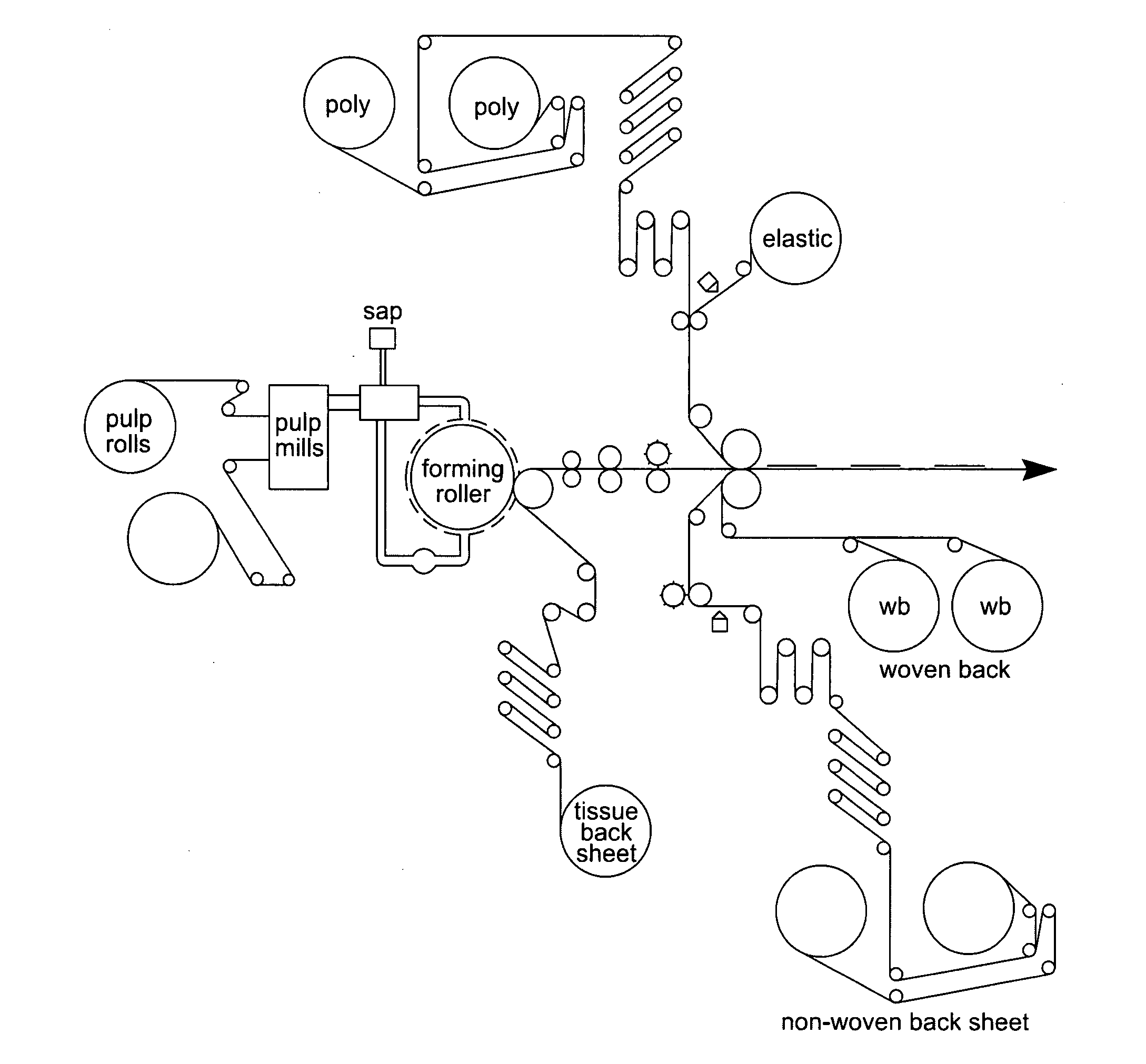

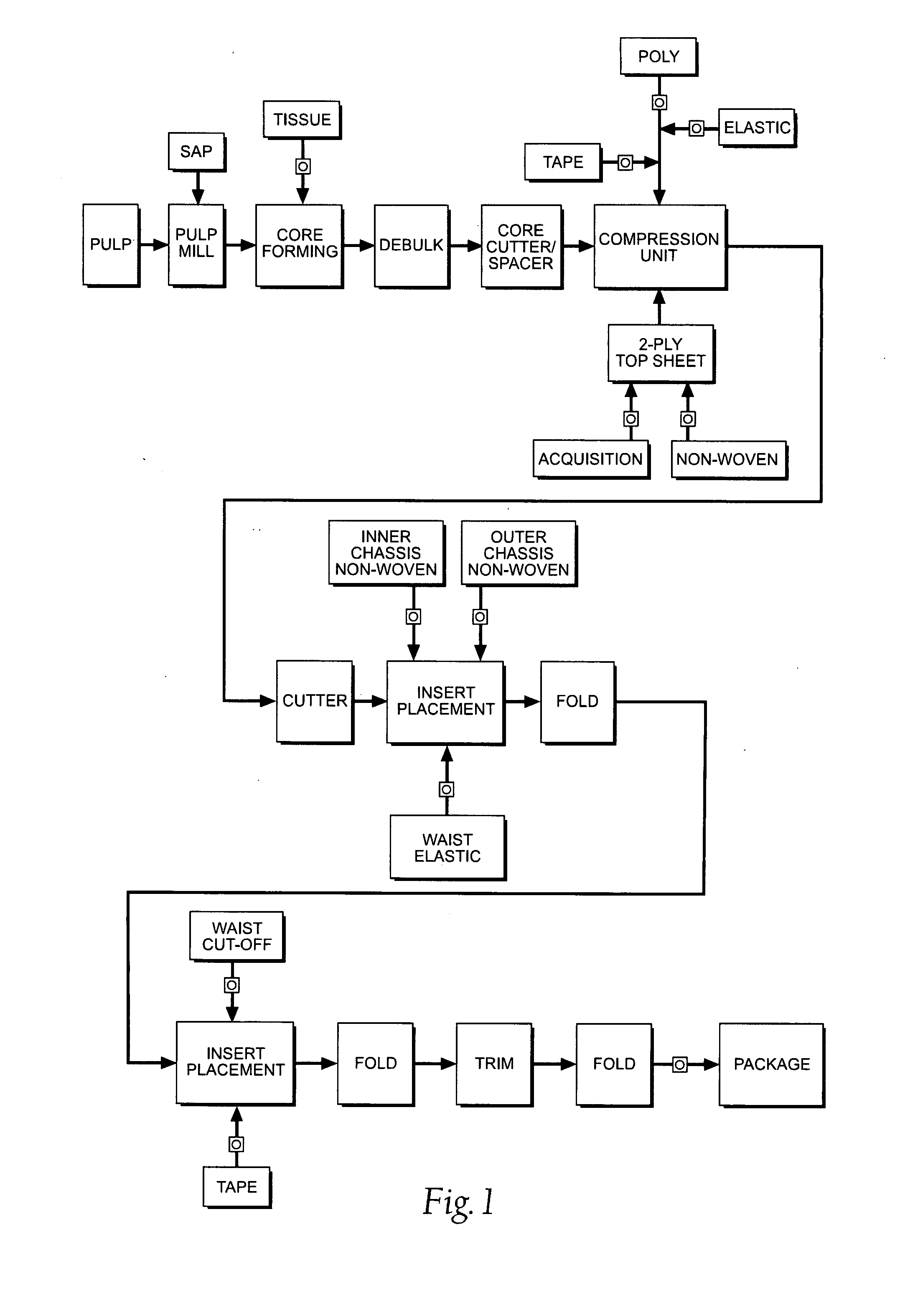

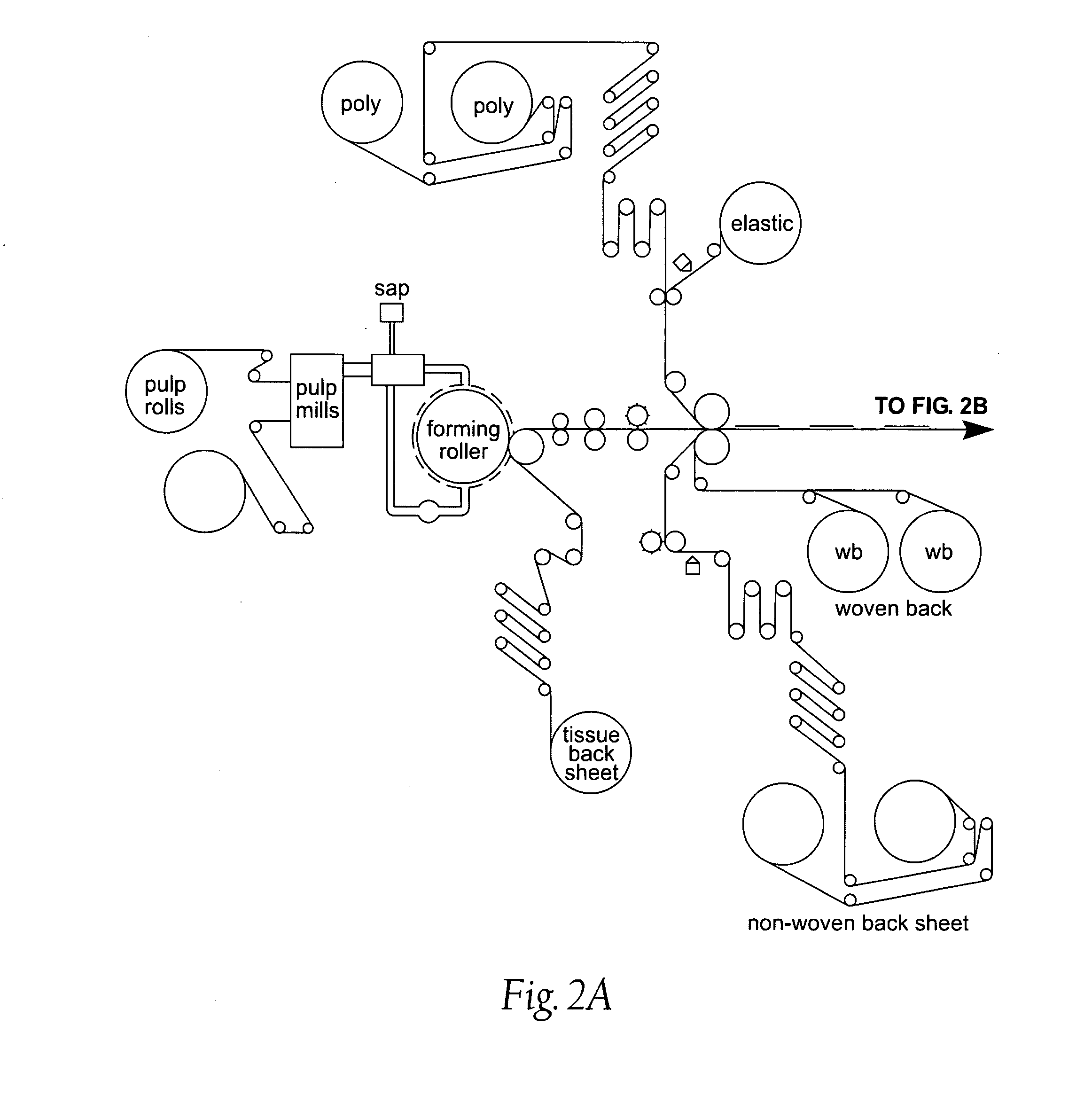

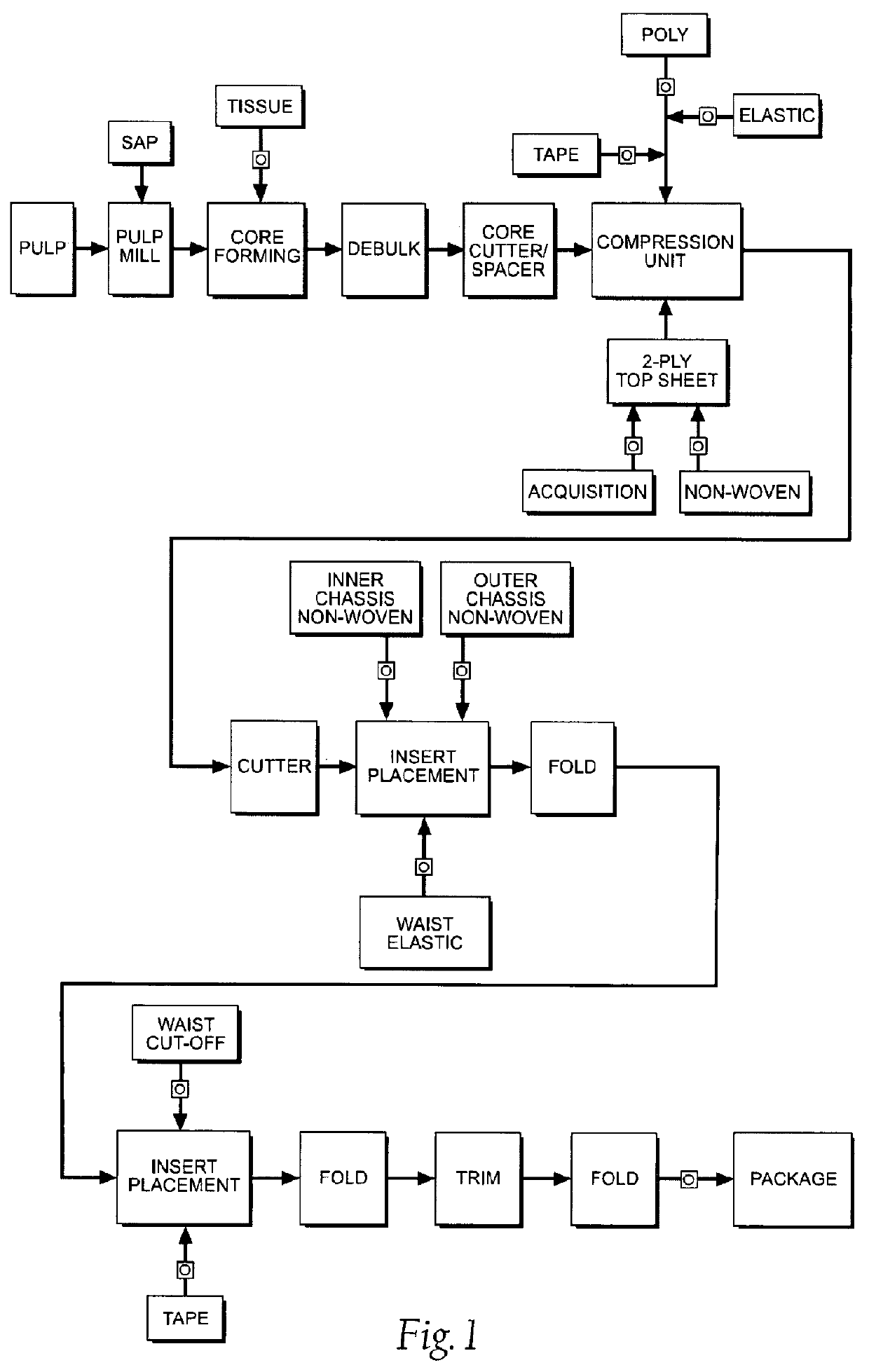

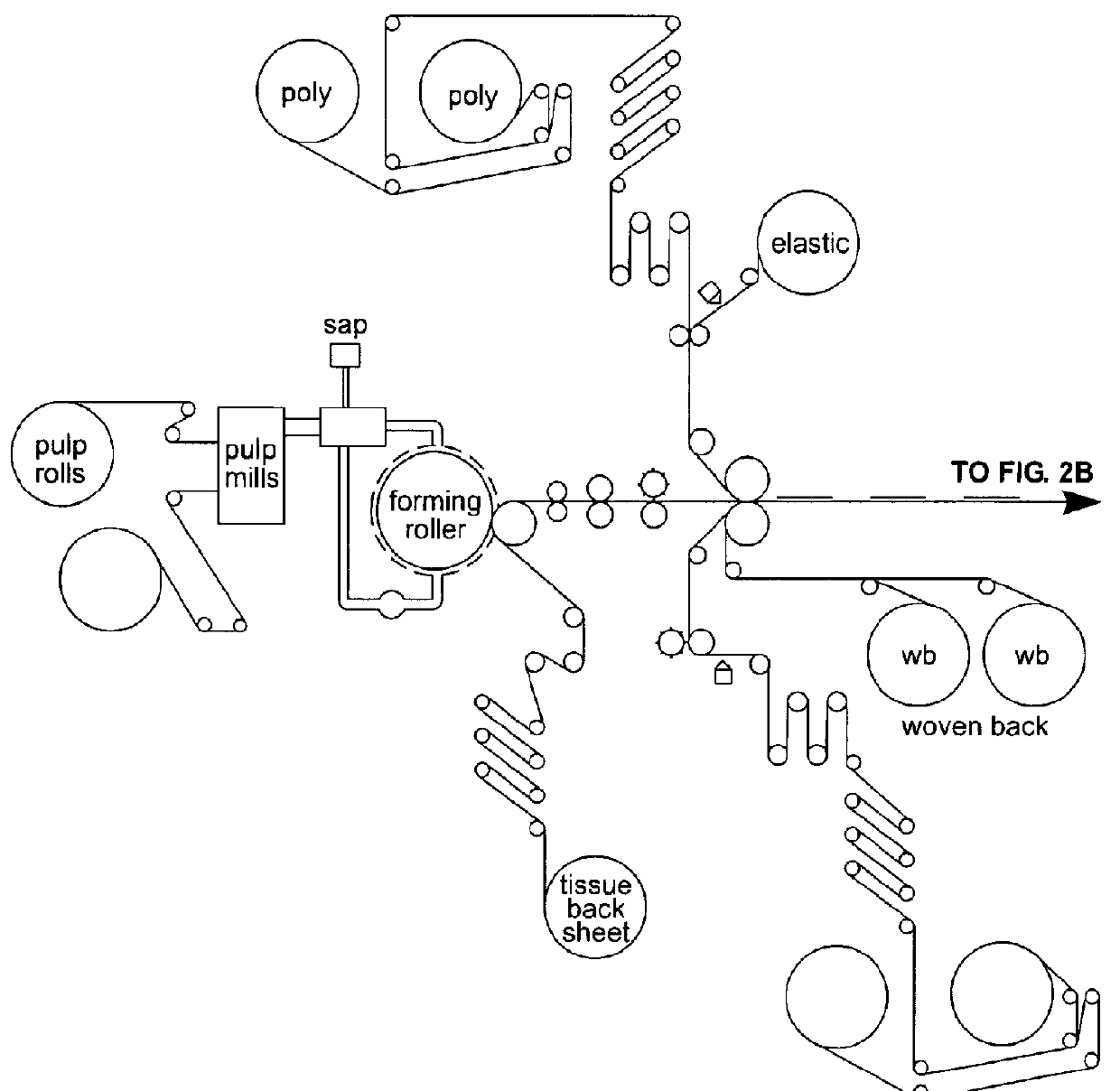

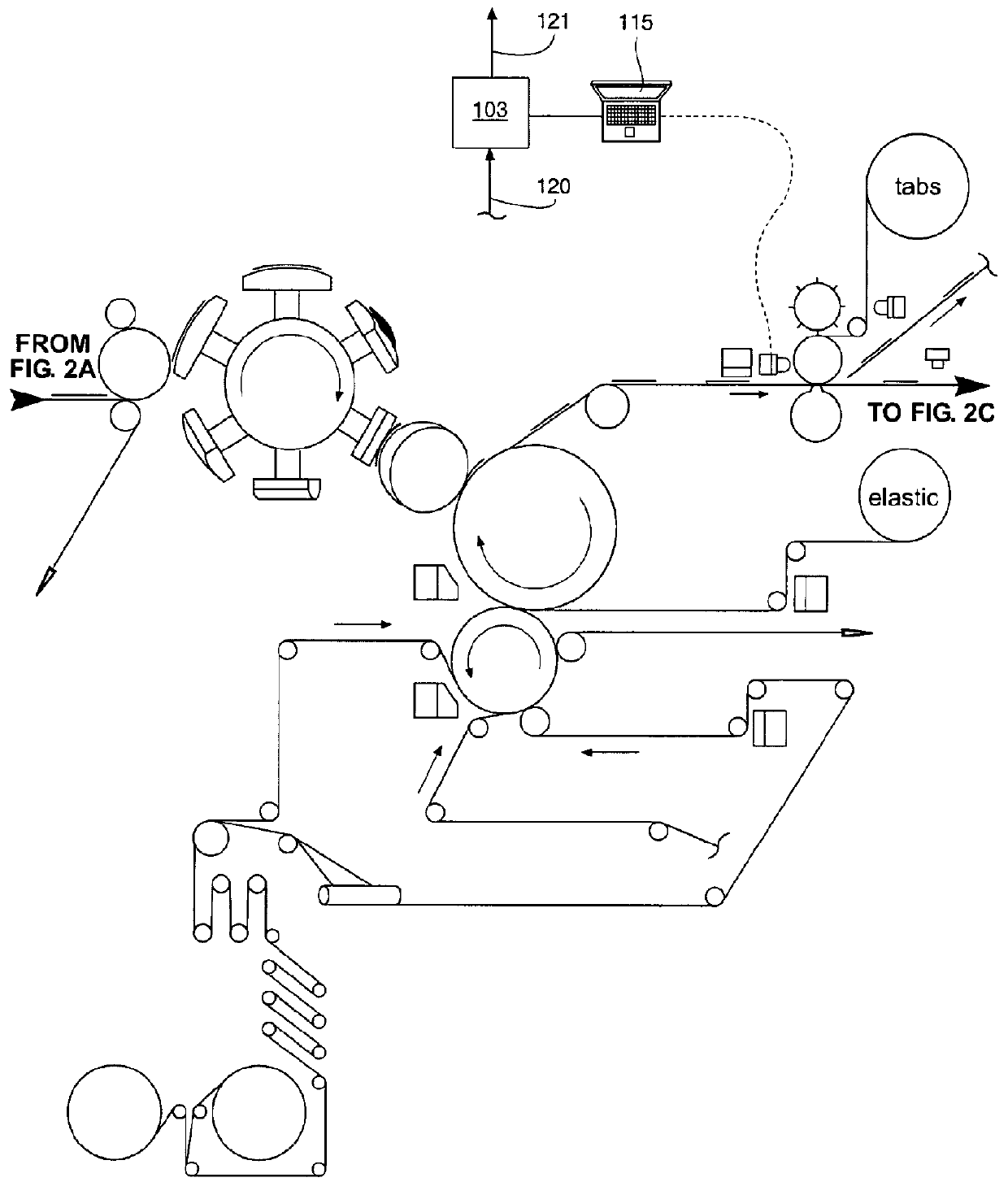

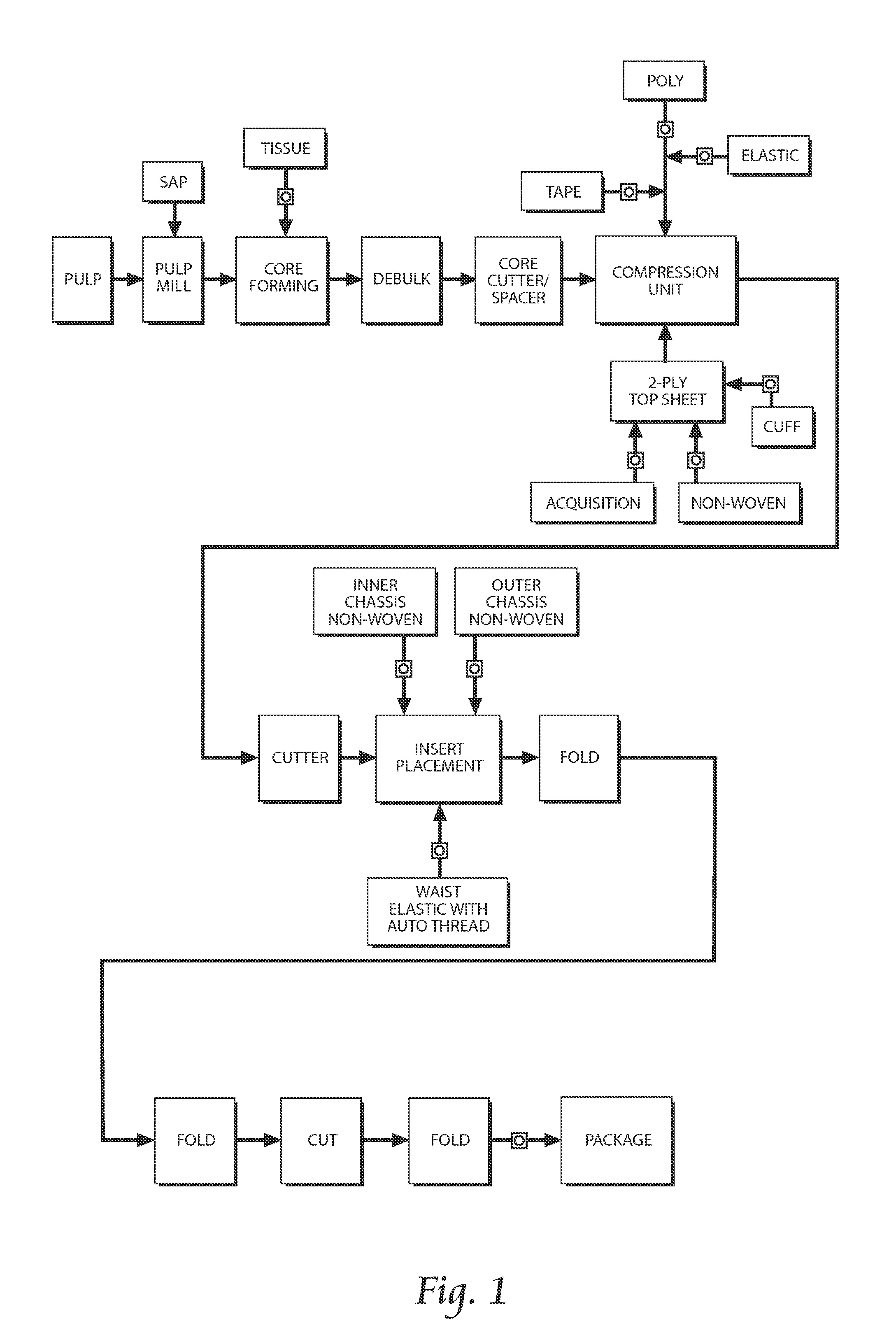

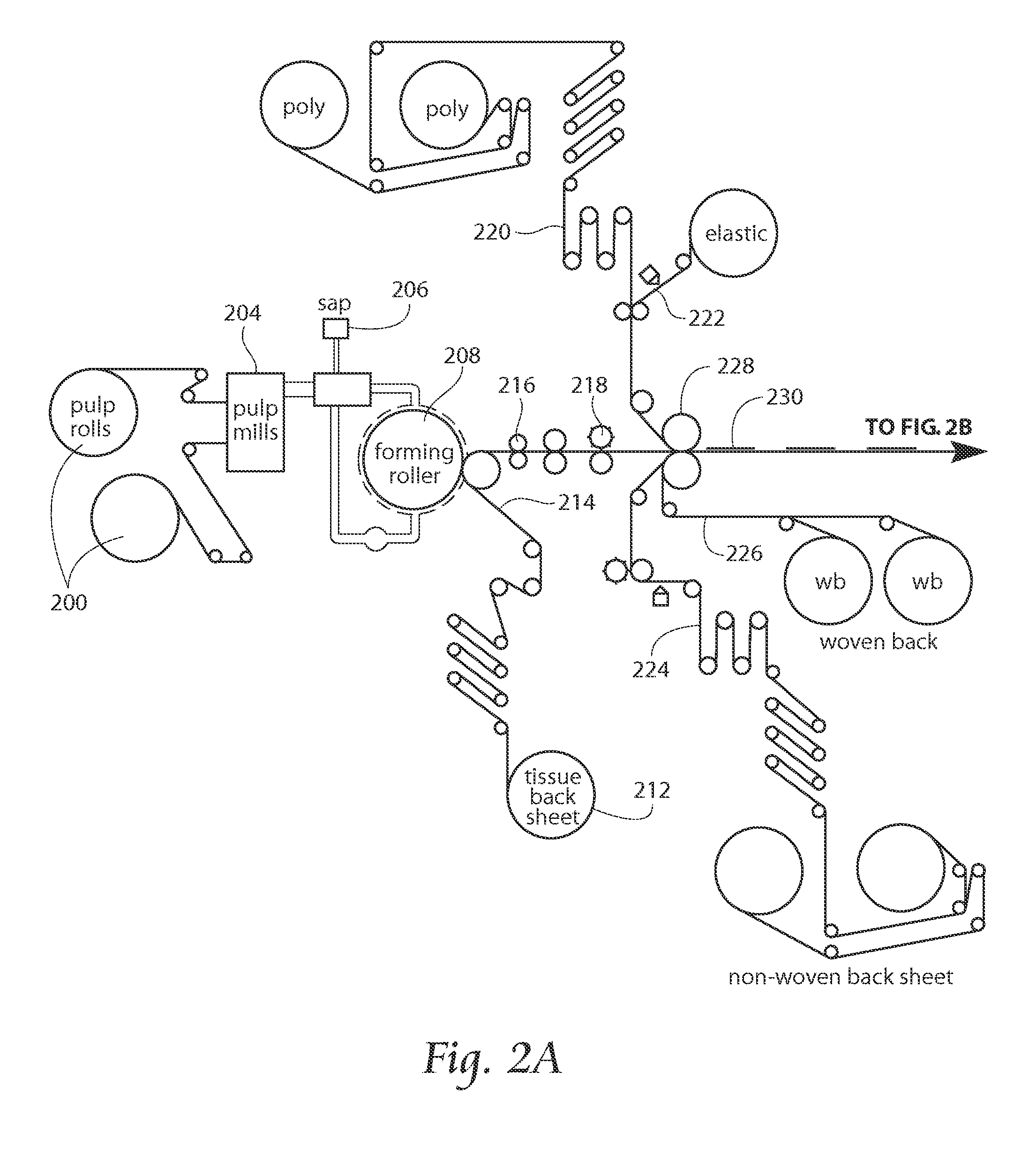

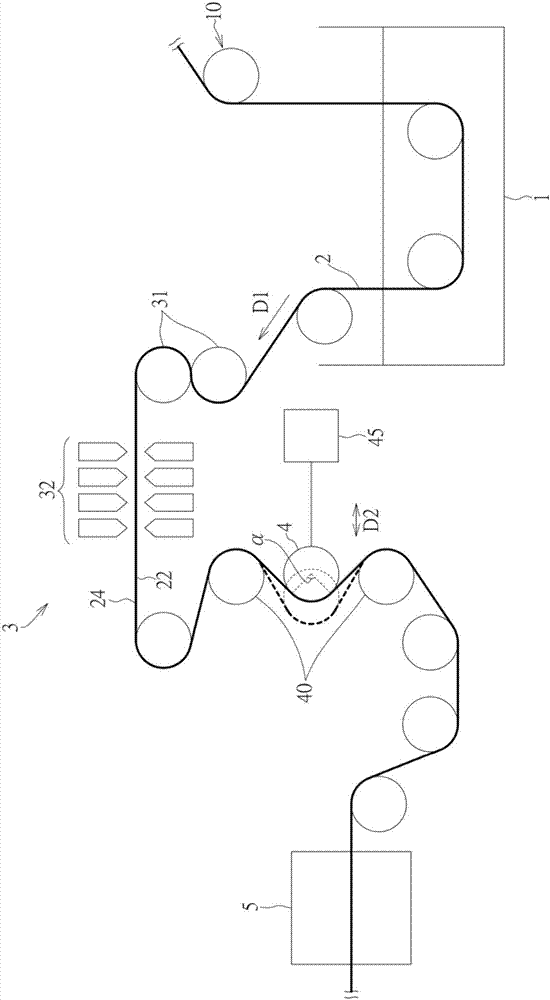

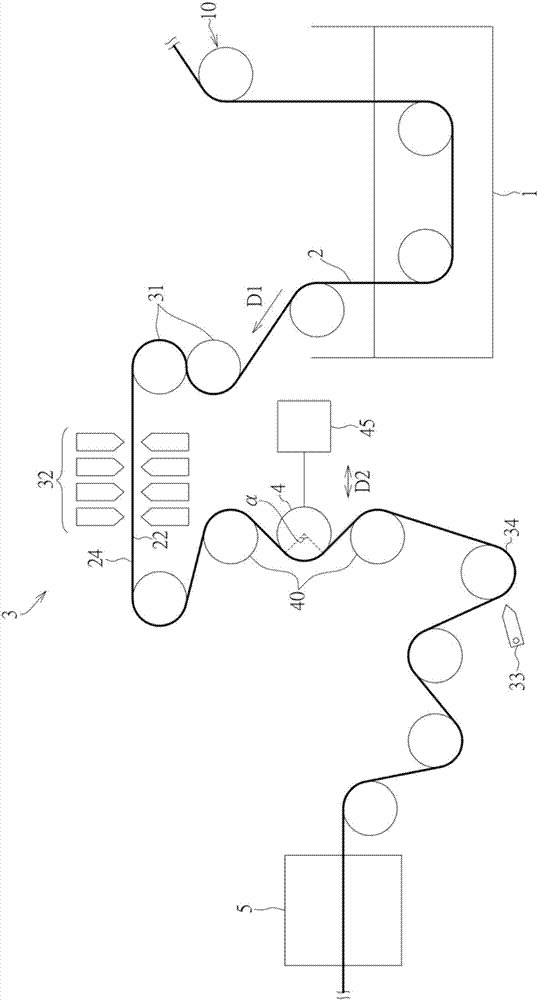

Apparatus and method for minimizing waste and improving quality and production in web processing operations

InactiveUS20090020211A1Reduce wasteQuality improvementLamination ancillary operationsControlling laminationProximateVisual inspection

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection both before and after application of component patches to a traveling web to create a product. Web defect detection may be provided by way of at least one visual inspection station located upstream from the patch applicator. Patch defect detection may be accomplished by way of a visual inspection station located proximate the patch applicator. If defects are detected in either the traveling web or the component patch prior to patch application, patch application may be prevented until both a satisfactory web and patch are provided. If defects are detected after patch application, the resulting product may be culled. Furthermore, the apparatus may be provided with diagnostic software to warn against extant or imminent machine complications.

Owner:CURT G JOA

Ultra thick bamboo-wood composite panel, ultra thick solid wood composite panel and manufacturing methods thereof

InactiveUS20110274872A1Improve technologyLess amountWood veneer joiningPlant material mechanical workingLine segmentSolid wood

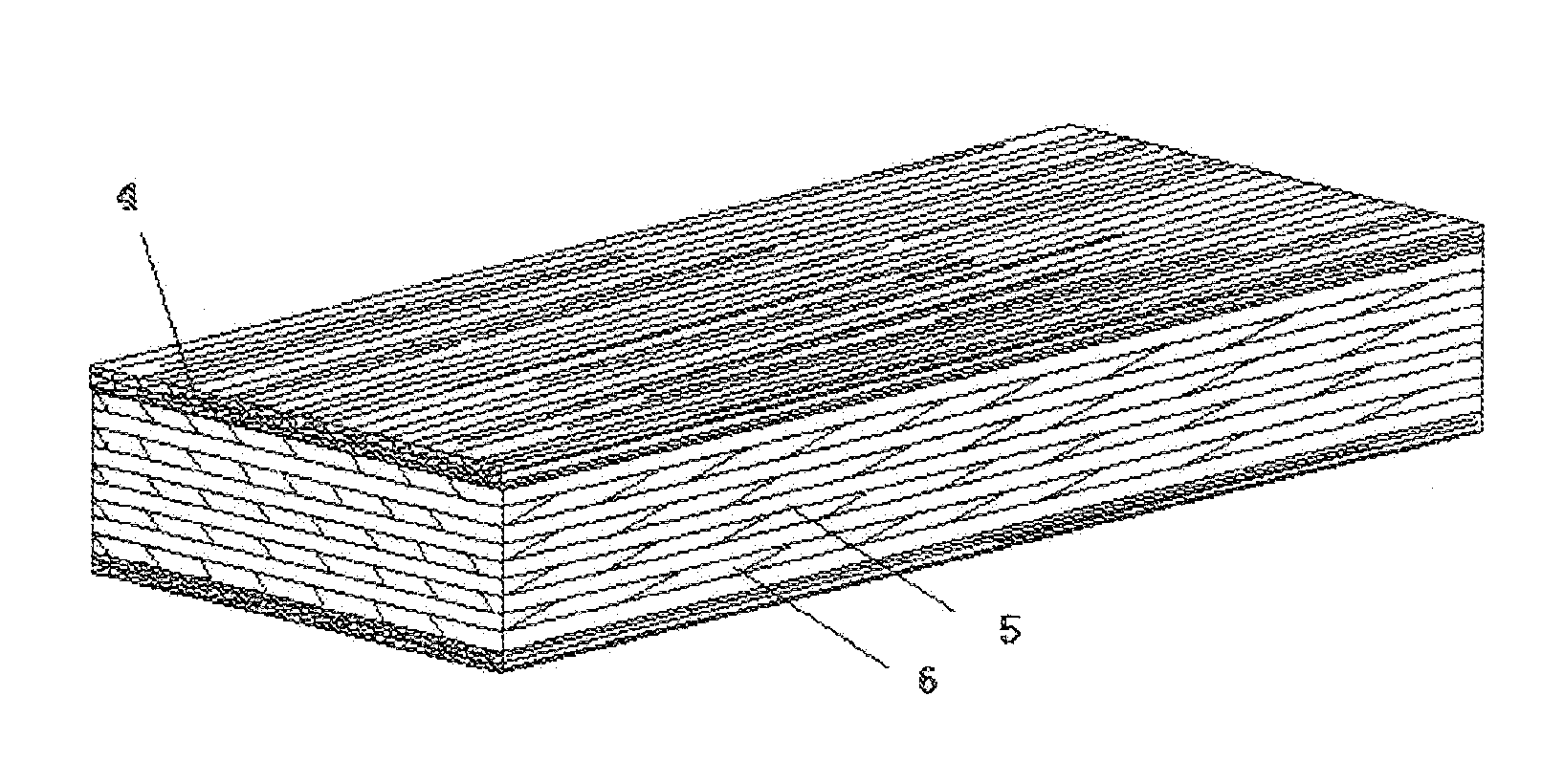

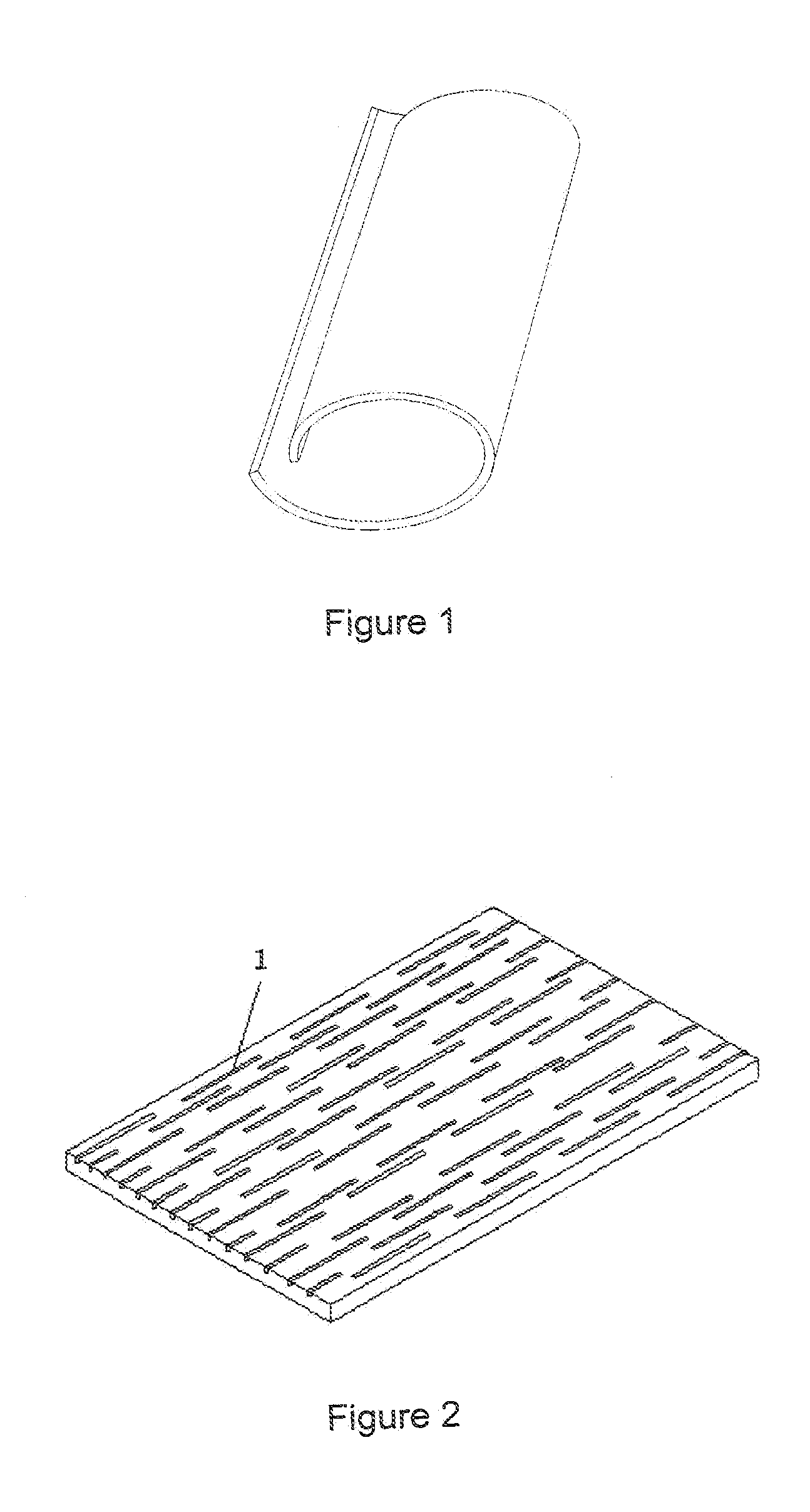

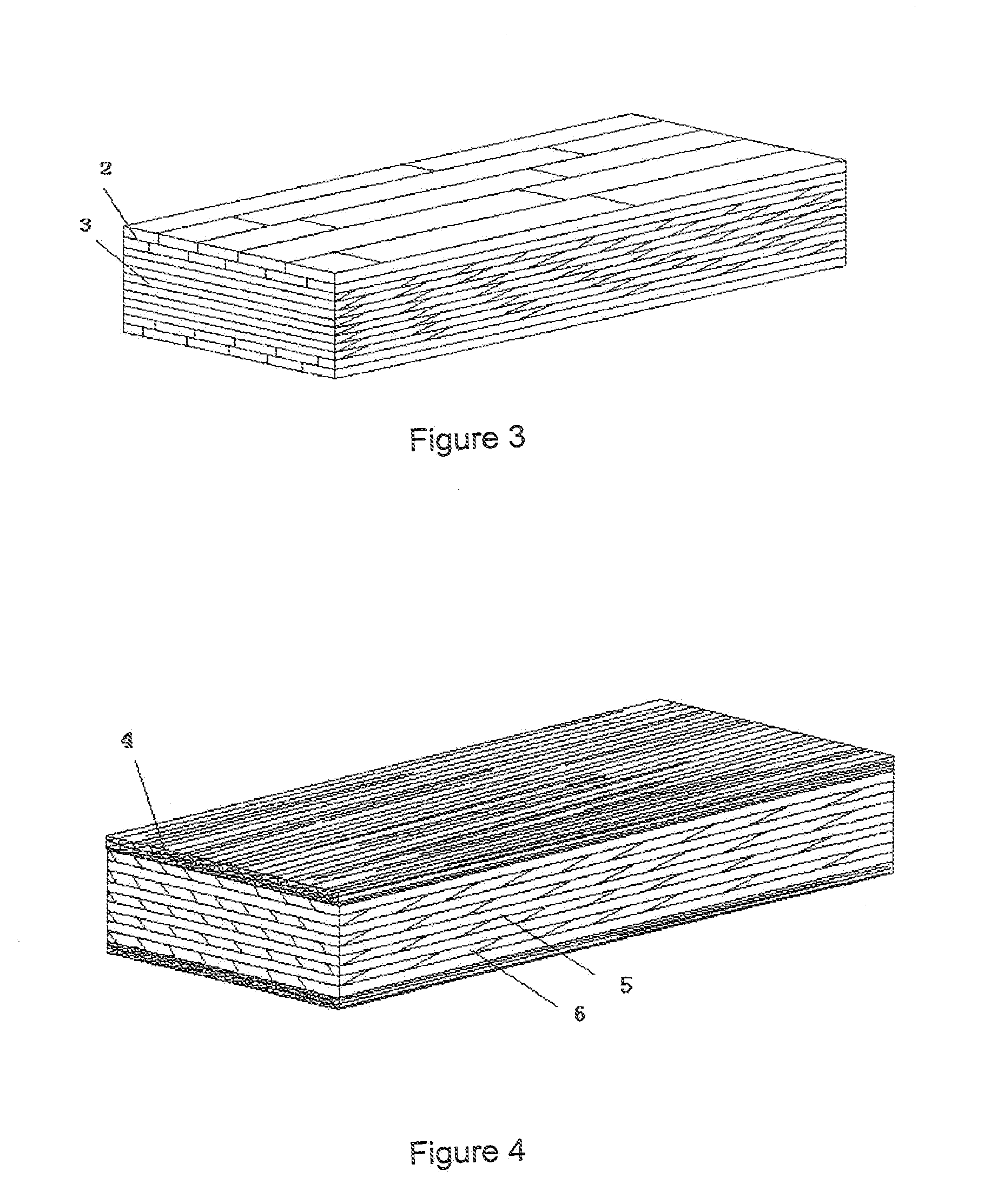

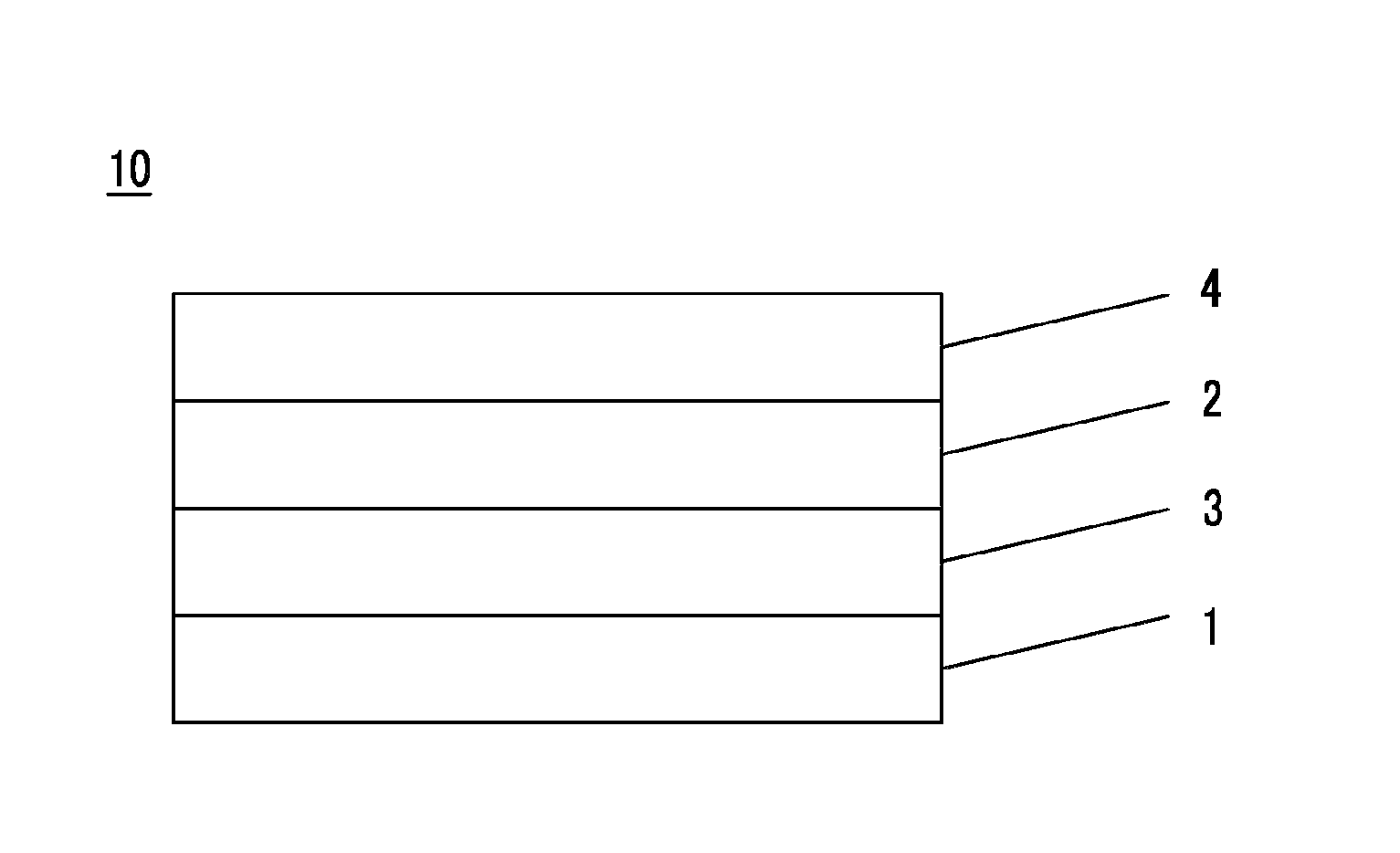

The present invention provides ultra-thick bamboo / wood and solid wood composite panels, comprising core board, surface board and back board; said core board is composed of ultra-thick peeling veneers with the thickness of 6 to 12 mm, both said surface board and back board are made of bamboo or wood; said core board comprises several layers of said ultra-thick veneers, and the veneers of contiguous layer are assembled with parallel structure; glue layer is arranged between contiguous said veneers, the adhesive in the glue layer is the aqueous macromolecule isocyanate adhesive; said ultra-thick veneers of the core layer are the veneers with stress degradation treatment, i.e., punctate or line segment cracks are formed along the grain of said veneer loose side in each layer. The glue spread amounts of said composite panels are obviously less than that of the existing composite panels with the same thickness, and the composite panels are without warping or deformation. The present invention also provides the manufacturing method of the above composite panels.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

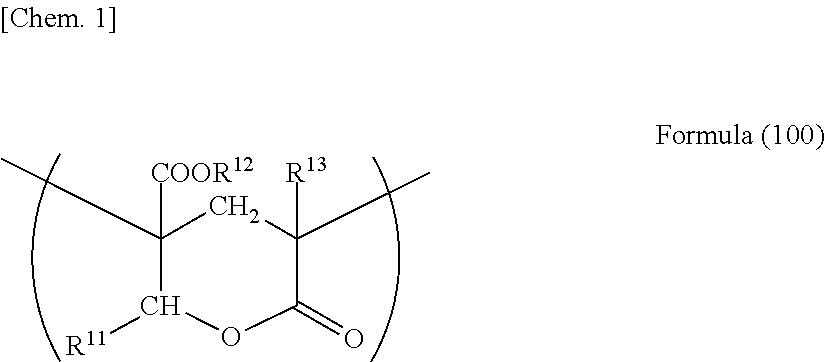

Polarizing plate and liquid crystal display

ActiveUS20140098331A1Suppress light leakageLow moisture permeabilityPolarising elementsNon-linear opticsCelluloseTectorial membrane

A polarizing plate according to the invention includes a first protective film; a polarizer; a second protective film; and an adhesive layer in this order, in which a moisture vapor permeability of the first protective film is less than or equal to 200 g / m2 / 24 hours, the second protective film contains cellulose acylate as a major component, a creep amount of the adhesive layer is less than 100 μm, and a shrinkage force of the polarizing plate in an absorption axis direction thereof which is represented by the following expression (A) is lower than or equal to 2000 N / m. Expression (A) is the Shrinkage Force (N / m) of Polarizing Plate in Absorption Axis Direction=Elastic Modulus (GPa) of Polarizing Plate in Absorption Axis Direction×|Humidity Dimensional Change Rate (%) of Polarizing Plate in Absorption Axis Direction|×Thickness (μm) of Polarizing Plate×10.

Owner:FUJIFILM CORP

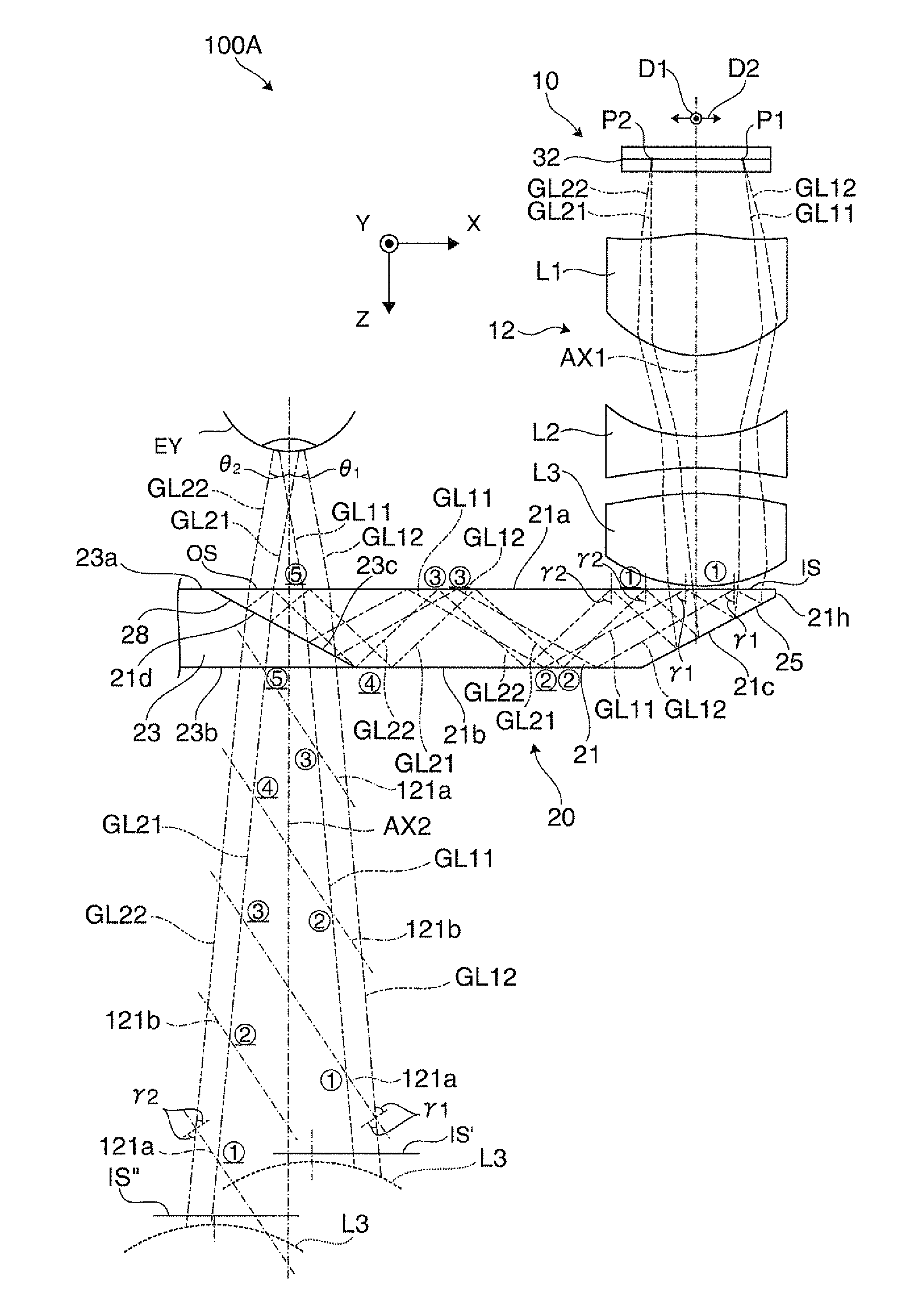

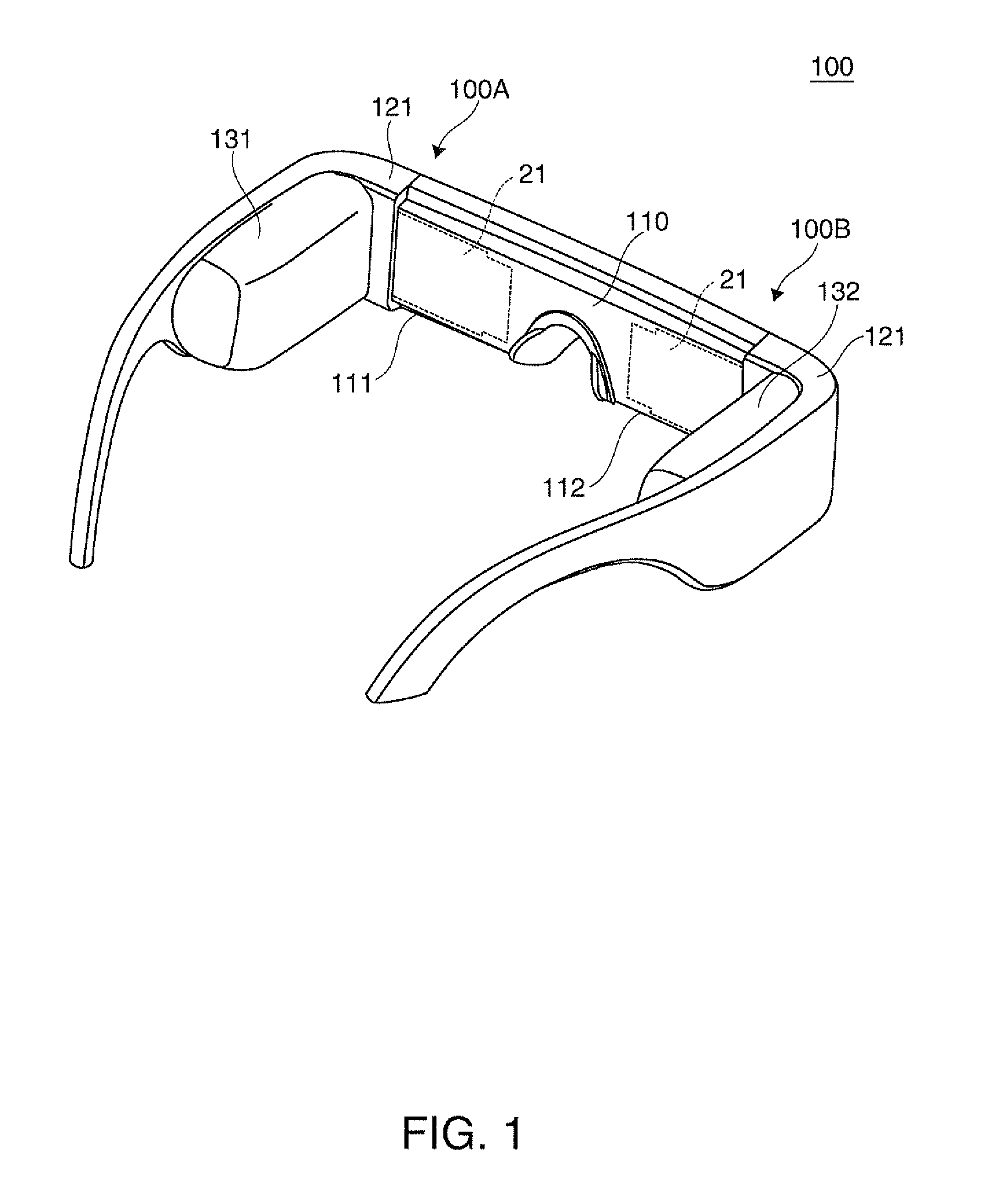

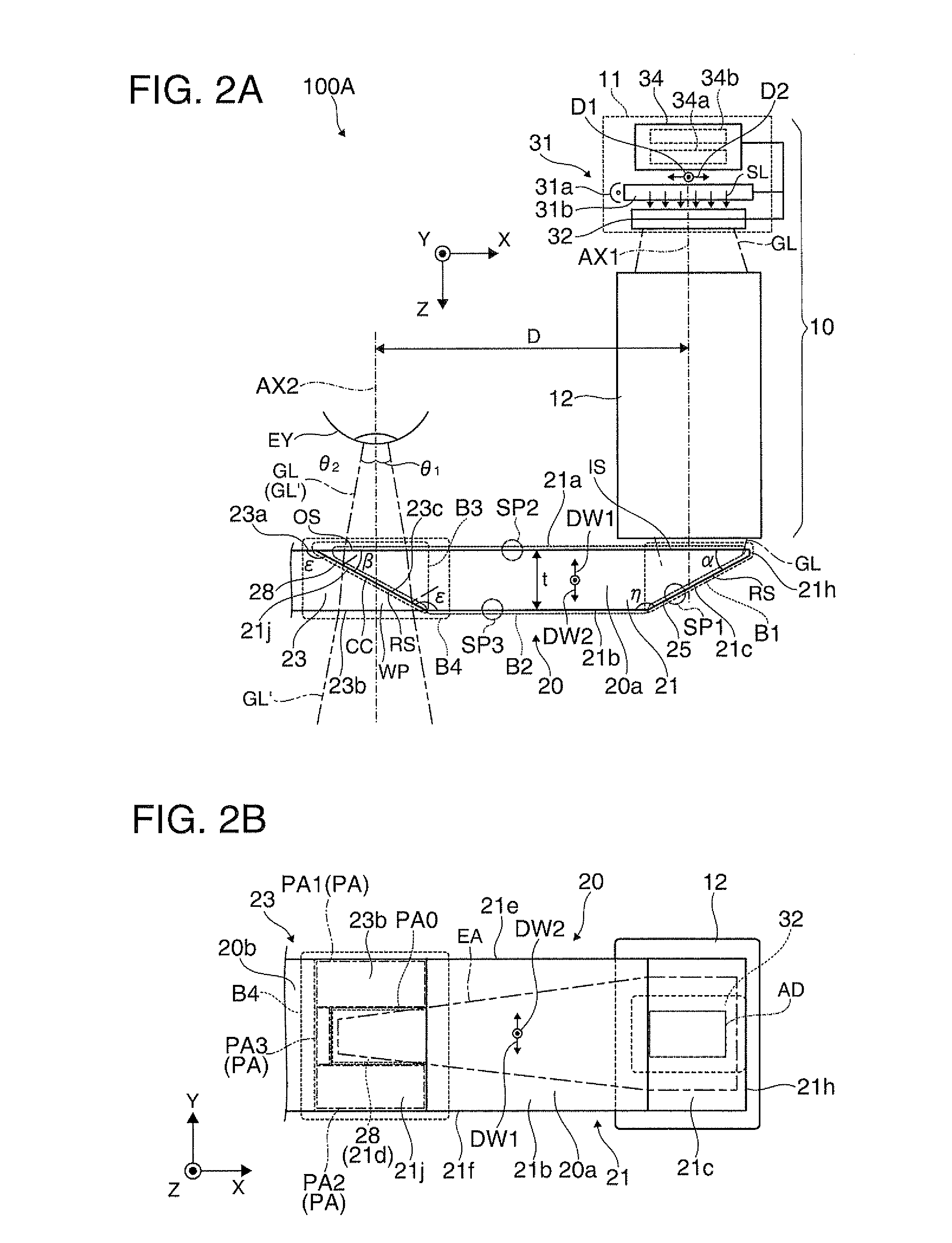

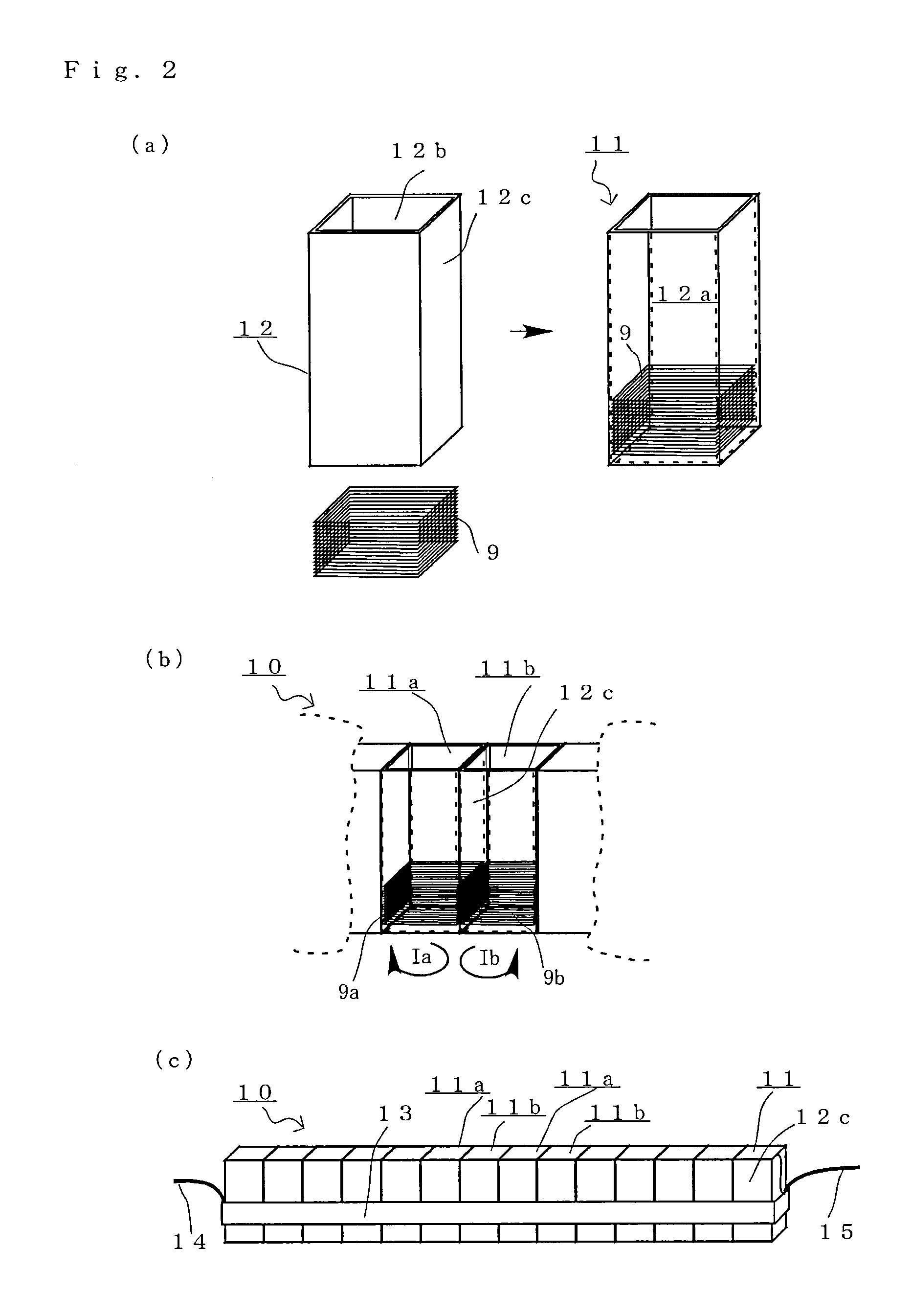

Virtual image display device

ActiveUS20130083404A1High strengthBonding strengthBundled fibre light guideLight guideDisplay device

A virtual image display device has a light guide device in which the half mirror layer (the semi-transmissive reflecting film) of the light guide member is formed on the partial area of the first junction surface, and the second junction surface of the light transmitting member is bonded to the first junction surface in at least the exceptional area. Therefore, it is possible to increase the bonding strength of the first junction surface and the second junction surface, namely the strength of the light guide device composed of the light guide member and the light transmitting member combined with each other even in the case in which the attachment force of the half mirror layer (the semi-transmissive reflecting film) with respect to the first junction surface is not sufficiently strong.

Owner:SEIKO EPSON CORP

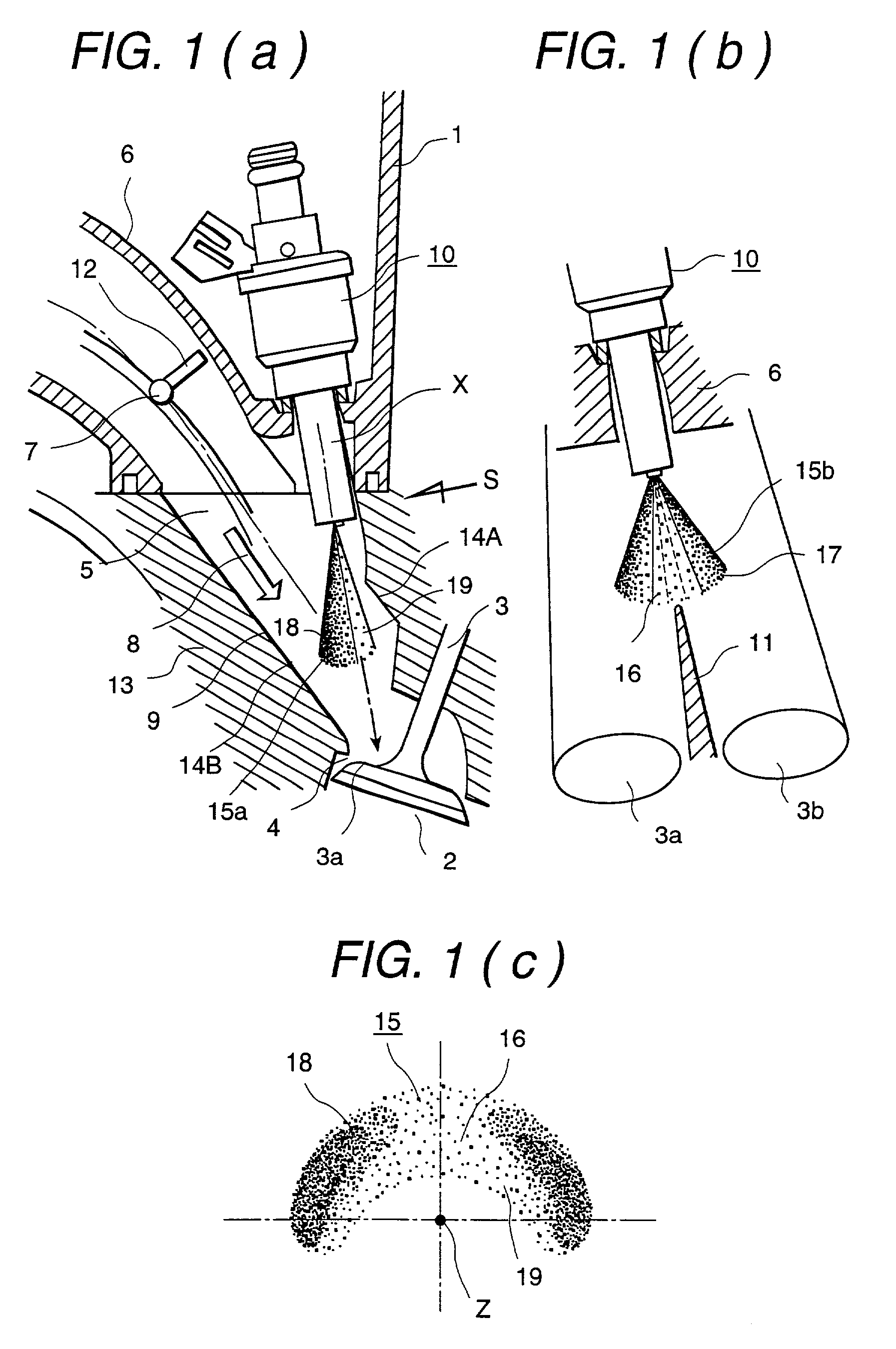

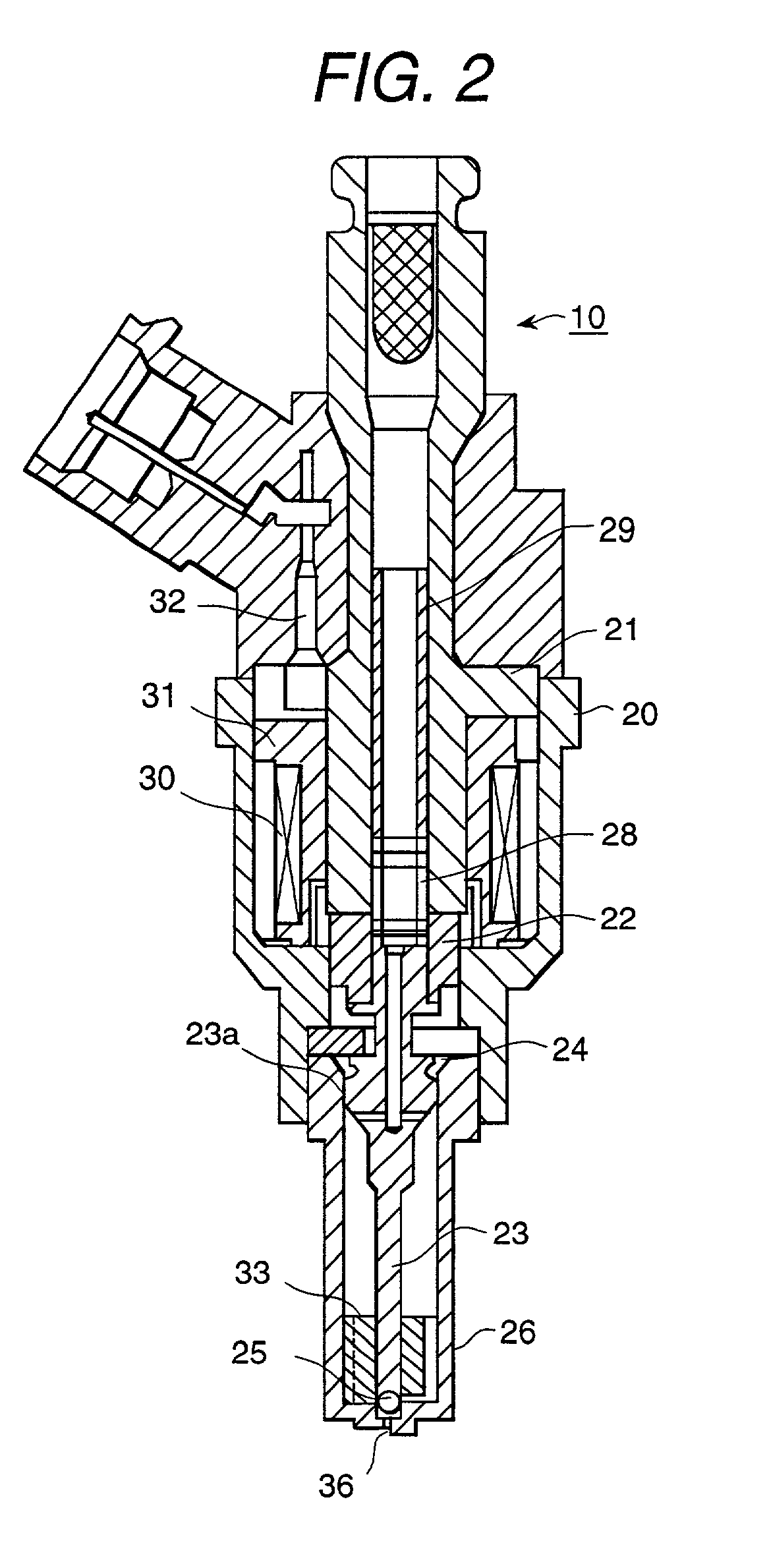

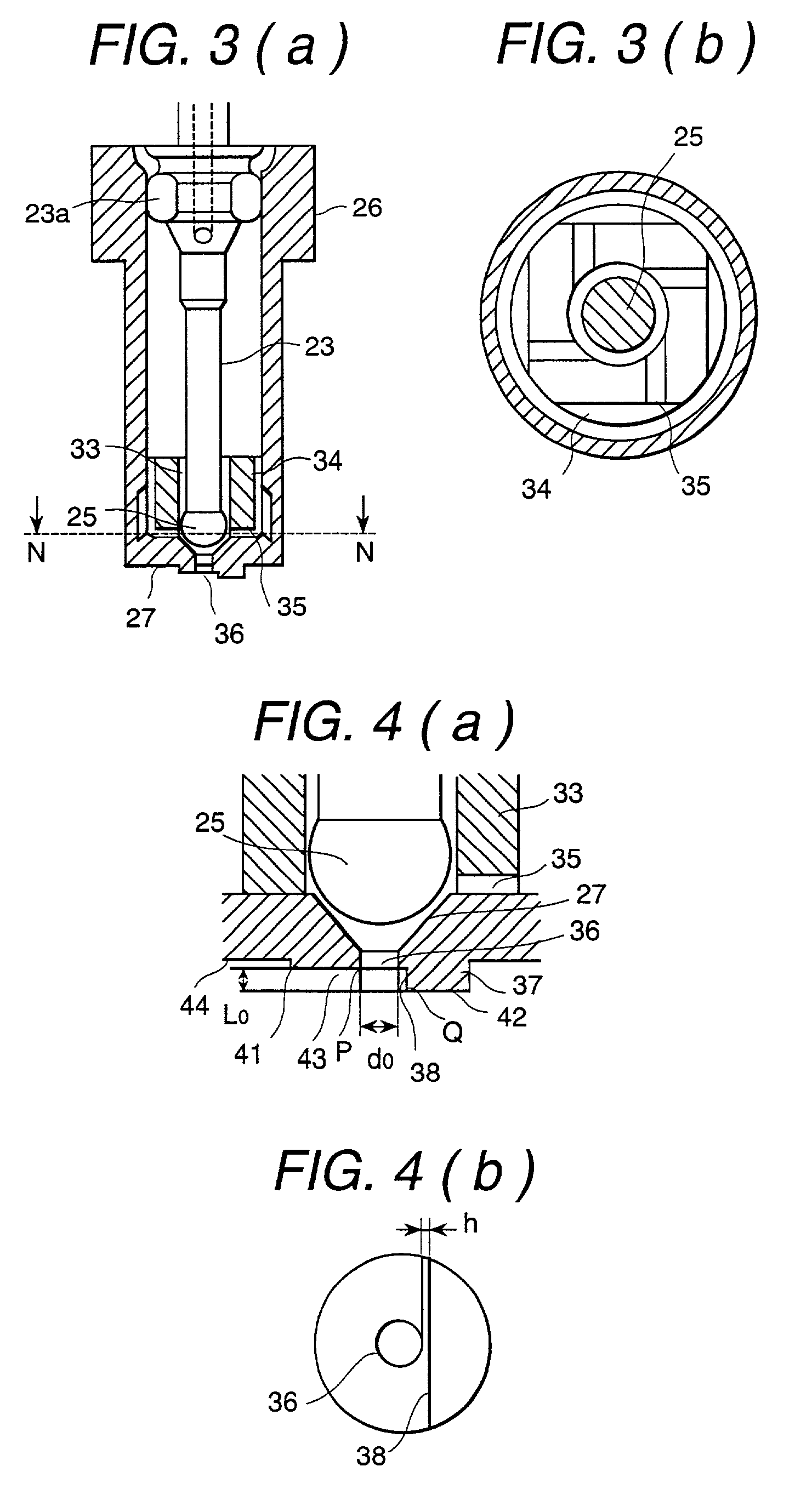

Fuel injection method of internal combustion engine and fuel injection apparatus of internal combustion engine

InactiveUS20010022170A1High degreeQuality improvementEngine testingCombustion enginesExternal combustion engineCylinder head

In a fuel injection apparatus of an internal combustion engine comprising a fuel injector, an intake valve device for opening and closing an intake port, and an intake air flow control device arranged in an upstream side of the intake valve device, a fuel injection is synchronized with an intake stroke of the engine. A fuel spray is oriented to an inner wall face which is positioned in an opposite side to an inner wall face of a cylinder heads in a fuel injector side and the fuel spray is transported by an air flow having a strong fluidization which is entered from the intake air control device. In a port injection lean burn engine, an adhesion to the wall face according to the fuel spray can be reduced, and a quality and a formation state of an air-fuel mixture in a cylinder can be improved.

Owner:HITACHI LTD +1

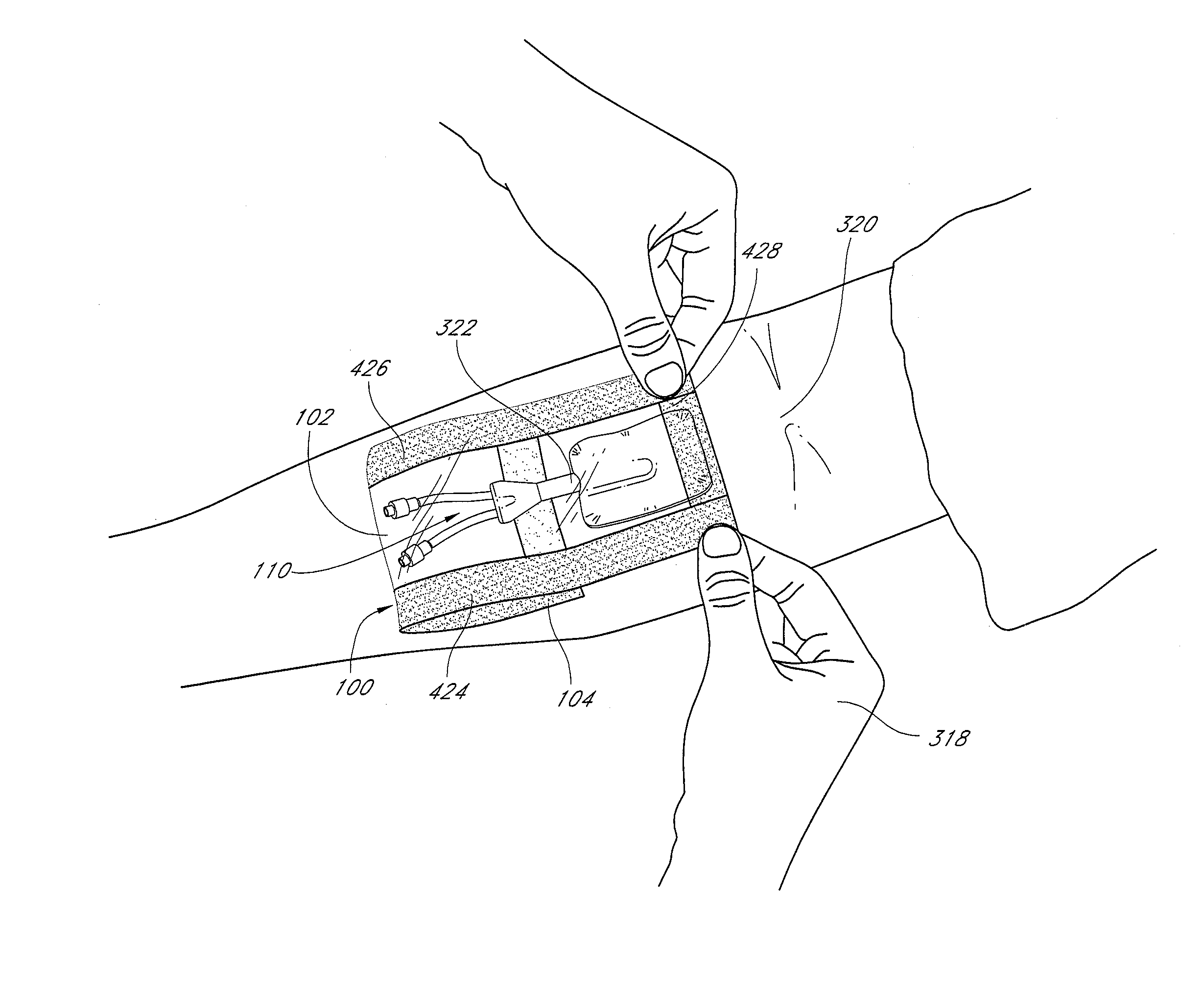

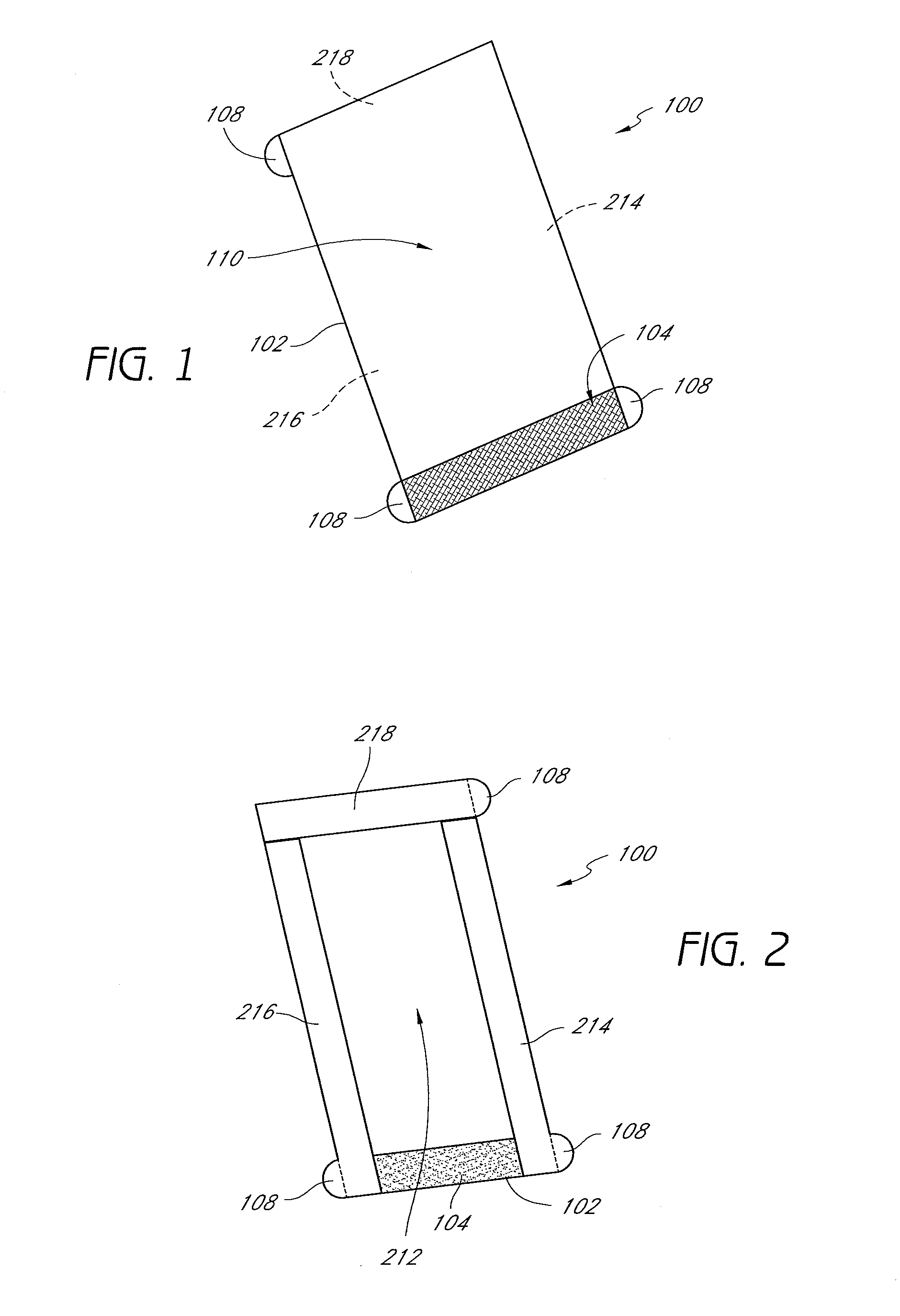

Flexible and leakproof and leak-resistant medical barriers and systems and methods of use thereof

InactiveUS20100294286A1Reduced adhesion areaImprove sealingSurgeryCatheterBiomedical engineeringRelease liner

A leak-resistant medical barrier is disclosed as having a sheet with a first side and a second side. The first side has an adhesive portion adapted to be disposed on a patient's skin and a release liner disposed on the adhesive portion. The second side also has an adhesive portion adapted to be disposed either on a patient's skin, on itself, or on a patient's skin and on itself and a release liner disposed on its adhesive portion. The second side adhesive portion is adapted such that when it is disposed on itself, it joins portions of surfaces of the medical barrier to form a leak-resistant seal between the surfaces, thereby providing for a medical barrier of adjustable volume and patient-adhesive contact area.

Owner:CENORIN

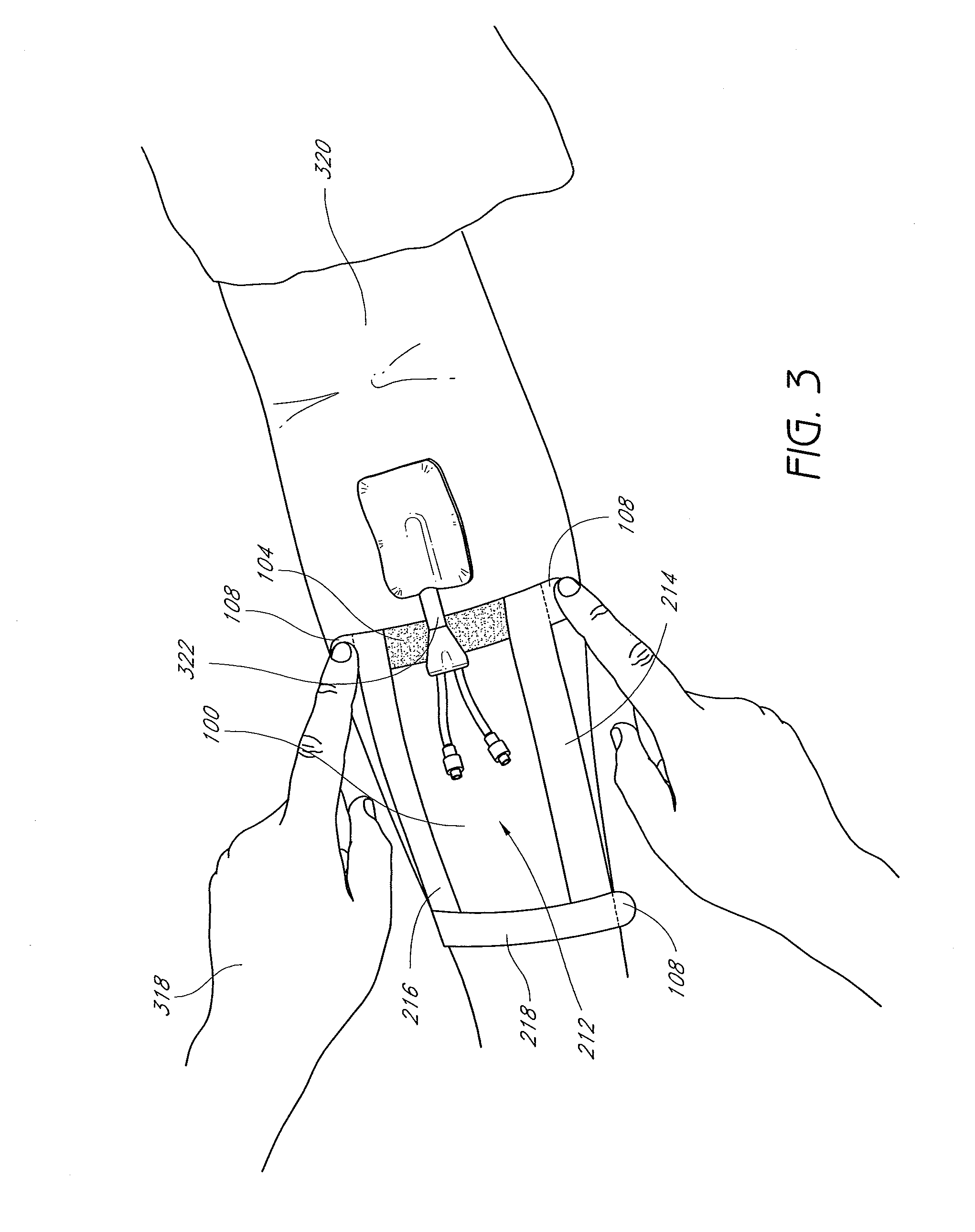

Voice coil assembly, loudspeaker using the same, and method for producing the same

InactiveUS20090116681A1Reduced divided vibrationIncrease bobbin rigidityTransducer detailsElectromagnetsBobbinEngineering

A voice coil assembly capable of realizing a flat thin loudspeaker having a high efficiency, reduced divided vibrations, a flat frequency response, and reduced operation defects. The voice coil assembly includes a plurality of internal-winding voice coils, each including a rectangular bobbin having a rectangular cross section and defining a rectangular space therein and an internal rectangular coil fixed to an inner wall surface of the rectangular bobbin defining the rectangular space, wherein an outer wall surface of the rectangular bobbin of one internal-winding voice coil is adhered and fixed to an outer wall surface of the rectangular bobbin of another internal-winding voice coil.

Owner:ONKYO KK

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

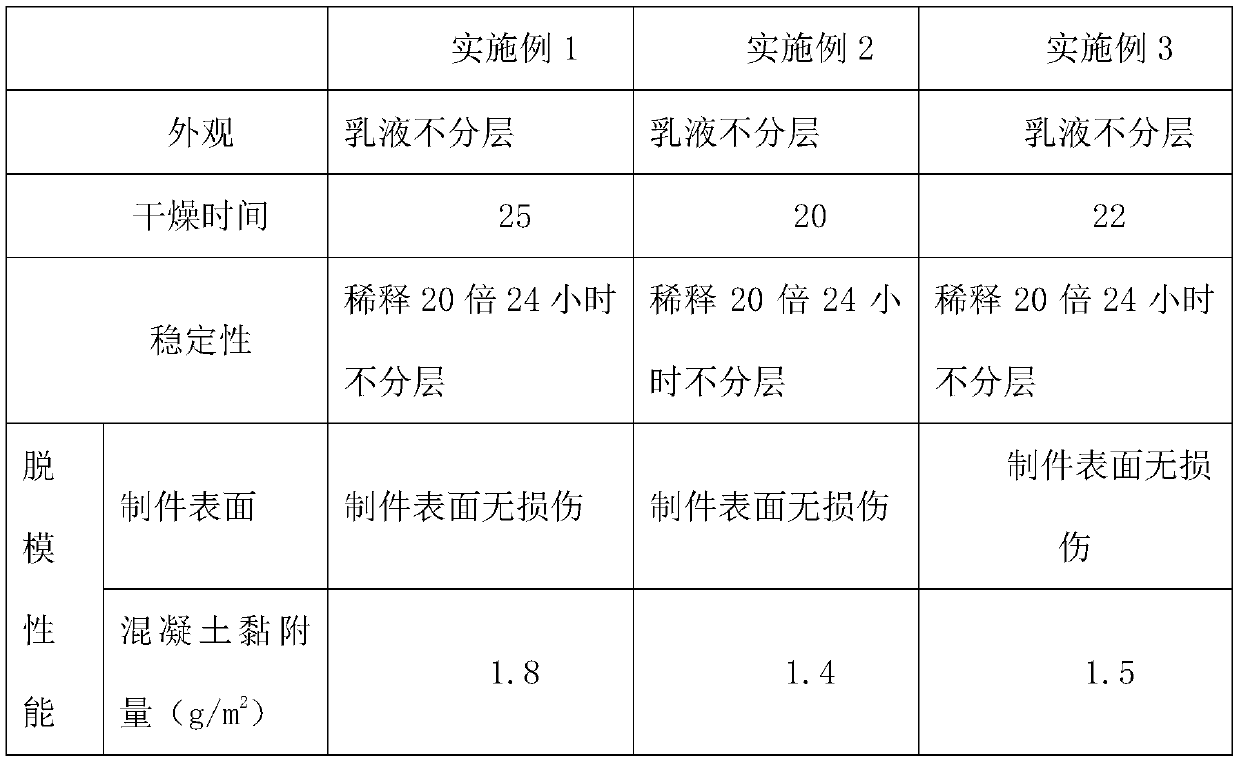

Aqueous demolding agent and preparation method thereof

InactiveCN110029010AEasy to demouldImprove stabilityCeramic shaping apparatusLubricant compositionPreservativeRoom temperature

The invention discloses an aqueous demolding agent and a preparation method thereof. The aqueous demolding agent comprises the following raw materials in parts by weight: 30-50 parts of oil, 5-15 parts of filming substances, 5-12 parts of an emulsifier, 1-20 parts of aids, 0.1-0.5 part of a stabilizer, 0.5-1 part of an anti-rusting agent, 0.1-0.5 part of a corrosion resistant agent and 60-200 parts of water. The demolding agent can be prepared at an increased temperature or a room temperature, and has the characteristics of being good in stability, easy to demold, small in amount, small in concrete adhesion amount, small in pollution, and the like.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

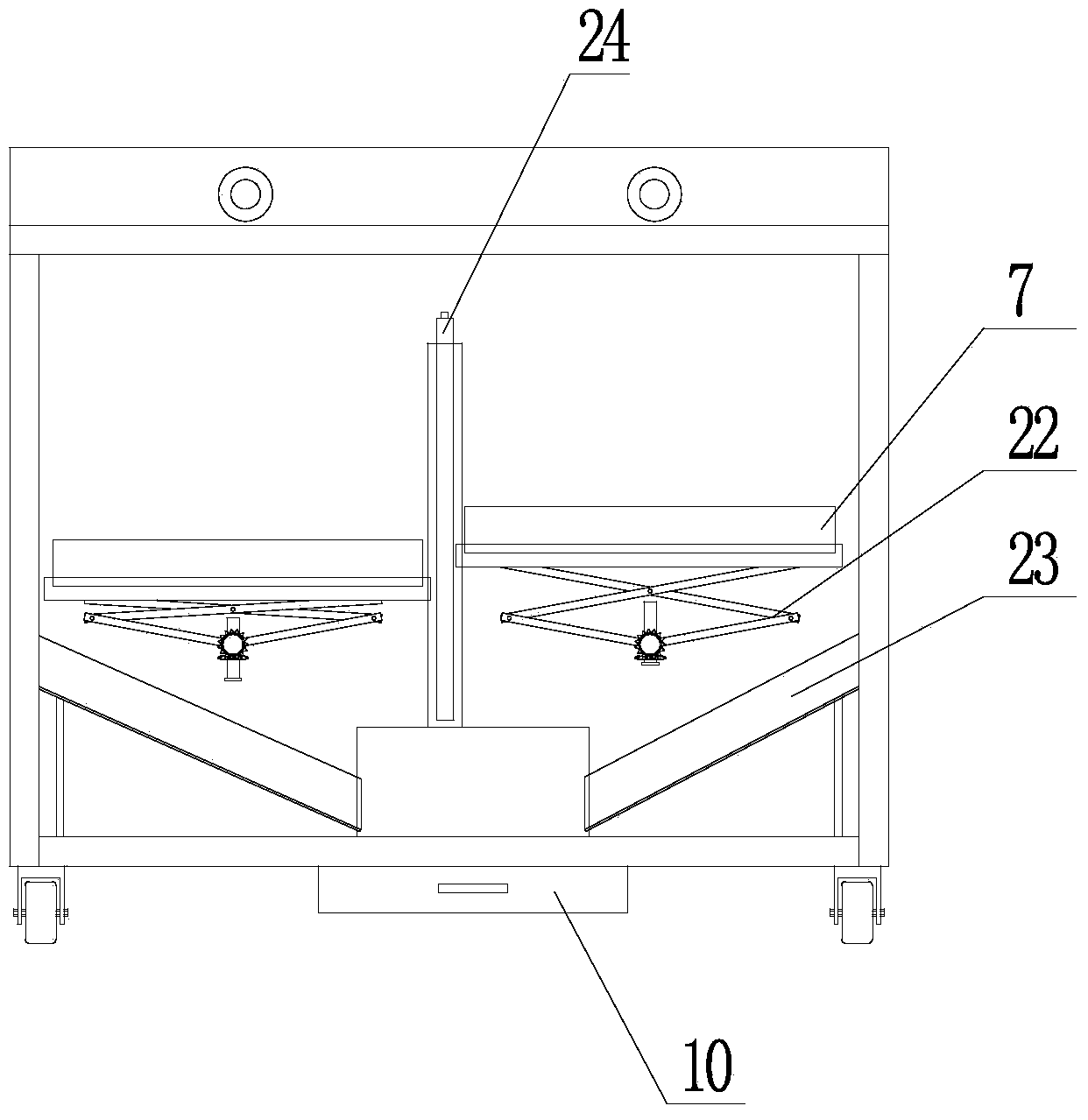

Apparatus and method for minimizing waste and improving quality and production in web processing operations

InactiveUS8398793B2Reduce wasteIncrease productionLamination ancillary operationsControlling laminationProximateVisual inspection

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection both before and after application of component patches to a traveling web to create a product. Web defect detection may be provided by way of at least one visual inspection station located upstream from the patch applicator. Patch defect detection may be accomplished by way of a visual inspection station located proximate the patch applicator. If defects are detected in either the traveling web or the component patch prior to patch application, patch application may be prevented until both a satisfactory web and patch are provided. If defects are detected after patch application, the resulting product may be culled. Furthermore, the apparatus may be provided with diagnostic software to warn against extant or imminent machine complications.

Owner:CURT G JOA

Environment-friendly concrete-dedicated aqueous demoulding agent and preparation method thereof

ActiveCN104152225AImprove film formationGood release effectCeramic shaping apparatusLubricant compositionAlcoholFatty acid

The invention discloses an environment-friendly concrete-dedicated aqueous demoulding agent and a preparation method thereof. The preparation method comprises the following steps: making aliphatic acid carry out reactions with C3-C5 alkyl alcohol to obtain alkyl aliphatic ester, then mixing the alkyl aliphatic ester with modified polyether, an emulsifier, and an isolating agent to carry out reactions, carrying out high-speed emulsification, adding a penetrating agent, an antirust agent, and a stabilizing agent at the same time, and finally evenly mixing so as to obtain the environment-friendly concrete-dedicated aqueous demoulding agent. The preparation method has a simple technology, the obtained environment-friendly concrete-dedicated aqueous demoulding agent has a very good demoulding ability, the concrete surface is smooth, flat, and flawless after the demoulding, little concrete is adhered on the mould, and the demoulding agent does not corrode the mould and has the advantages of environment-friendliness, economy, and harmlessness.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Ferrite particles and production method thereof

InactiveUS20090246526A1Reduce the amount of adhesionImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsReducing atmosphereSlurry

A method for producing ferrite particles by weighing, mixing, then crushing ferrite raw materials, and granulating the resultant slurry, and then sintering the resultant granulated material using a rotary furnace, wherein the sintering is carried out under a positive pressure reducing atmosphere.

Owner:POWDERTECH

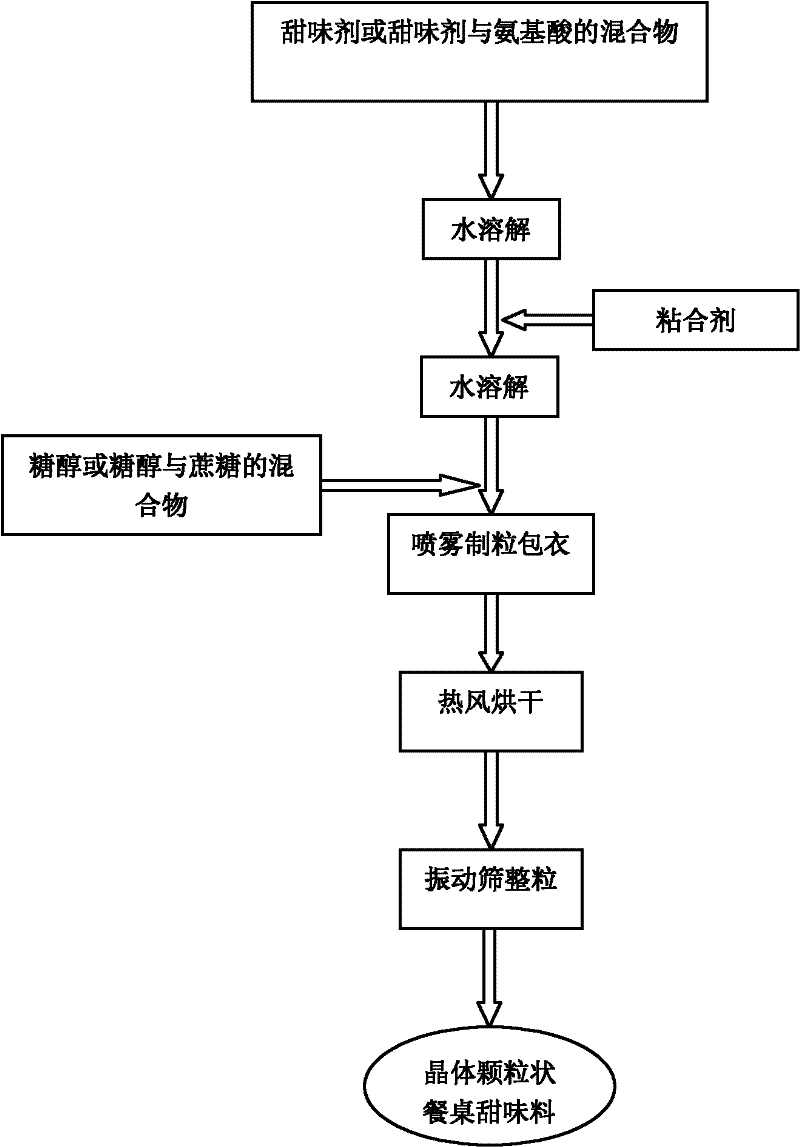

Crystal-granular sweetener for dining, and preparation method thereof

ActiveCN102228175AAdjustable sweetnessAchieve sweetness modificationFood preparationSucroseFluidized bed

The invention provides a crystal-granular sweetener for dining, and a preparation method thereof. The sweetener is prepared from the materials of, by weight: 82.5 to 99.89% of alditol, or a mixture of alditol and sucrose; 0.1 to 10% of a sweetening agent; 0 to 5% of amino acid; and 0.01 to 2.5% of a binder. The particle size of alditol is 10 to 80 meshes. The sweetener is prepared with a fluidized bed coating technology. The specific steps of the method are that: the sweetening agent, or a mixture of the sweetening agent and amino acid is dissolved, the binder is added to the dissolved material, the material is uniformly coated on alditol granules or alditol and sucrose mixed granules by spraying, and the coated granules are dried by baking, such that the crystal-granular sweetener for dining is obtained. The crystal-granular sweetener provided by the present invention has a crystal form similar to sucrose crystals. The crystal grains have advantages of well-distributed sizes, good stability, high fluidity, and low calorie or no calorie. The sweetener is non-hygroscopic, and is a healthy edible sweetener for dining. The production technology of the sweetener is simple and feasible, and the method is suitable for industrialized productions.

Owner:NEWTREND TECHNOLOGY CO LTD

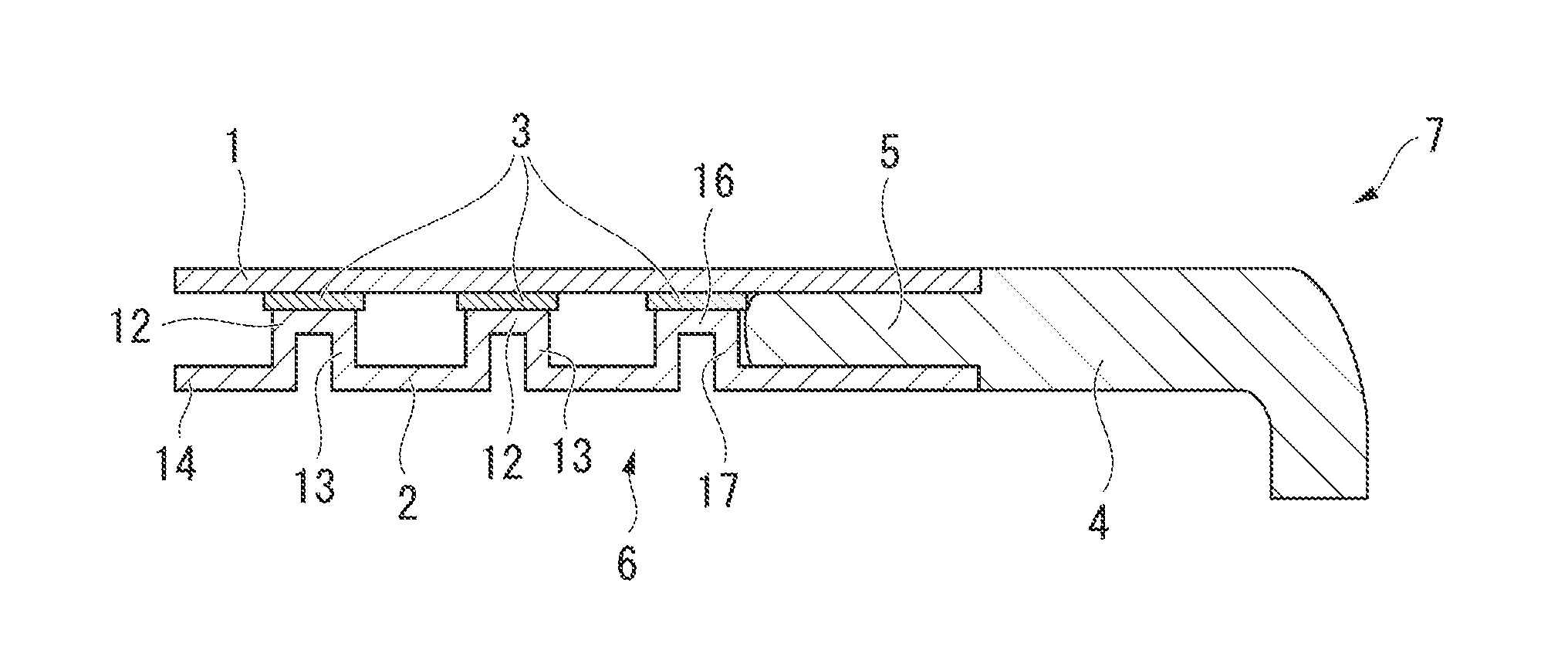

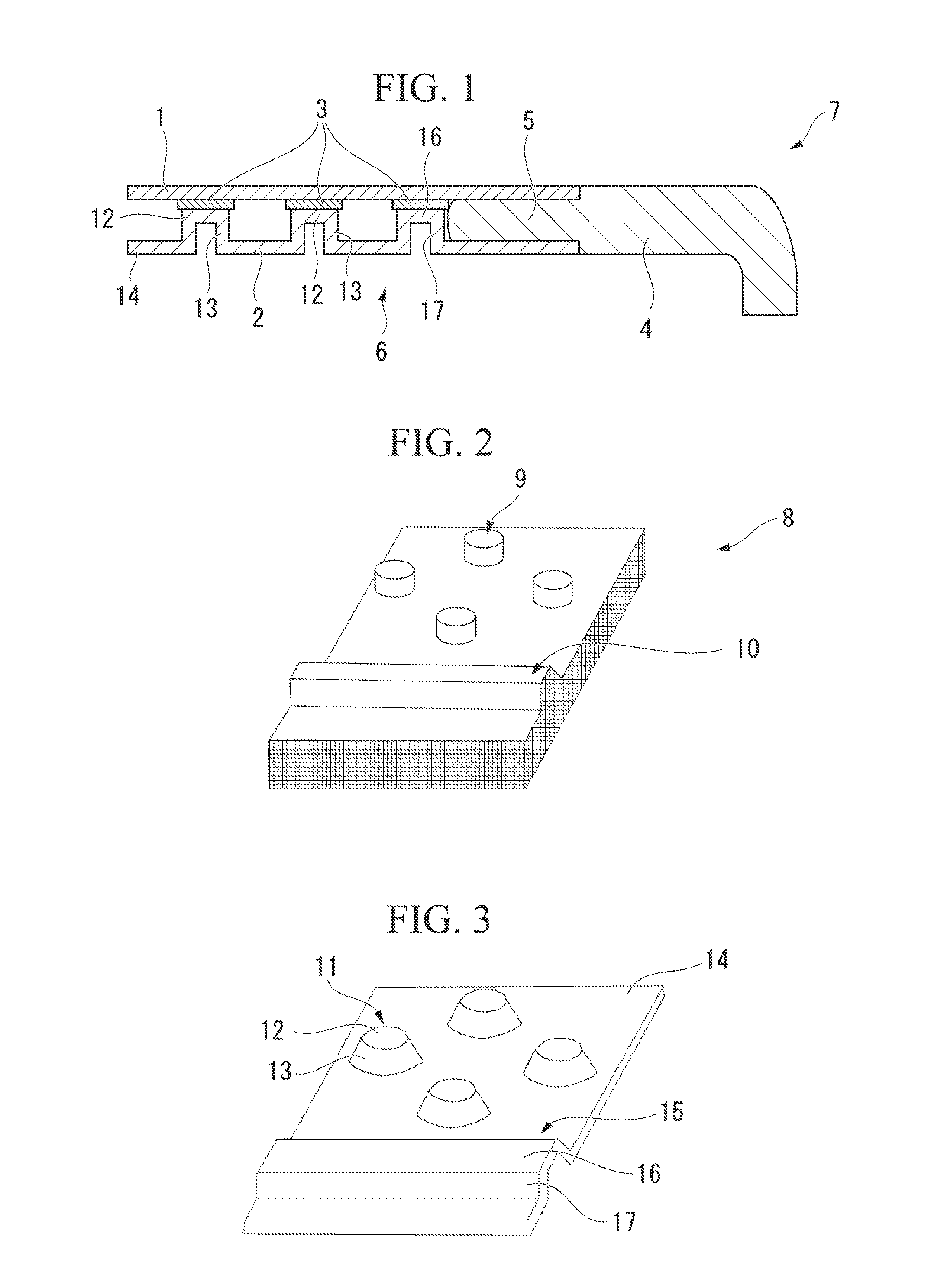

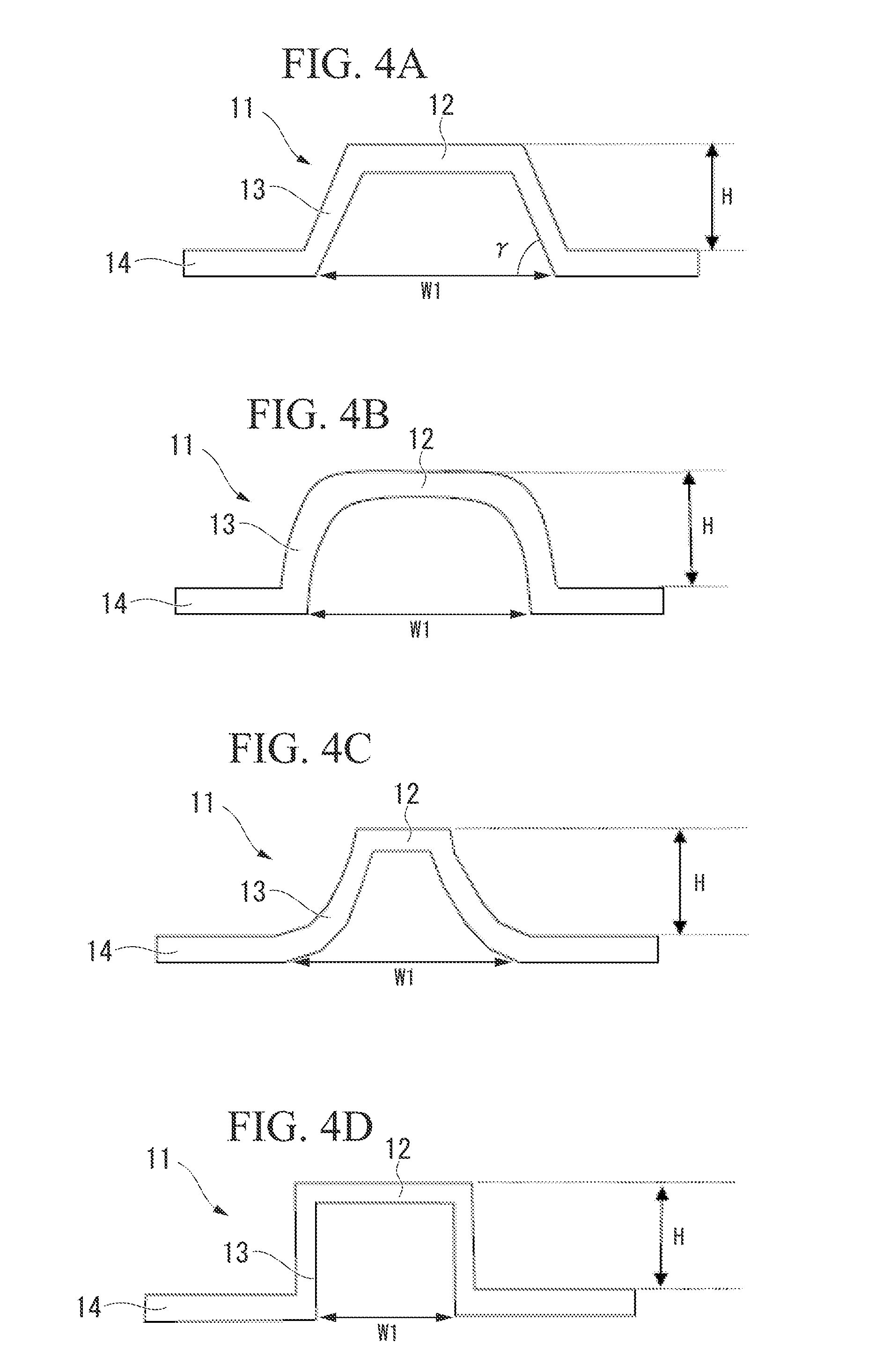

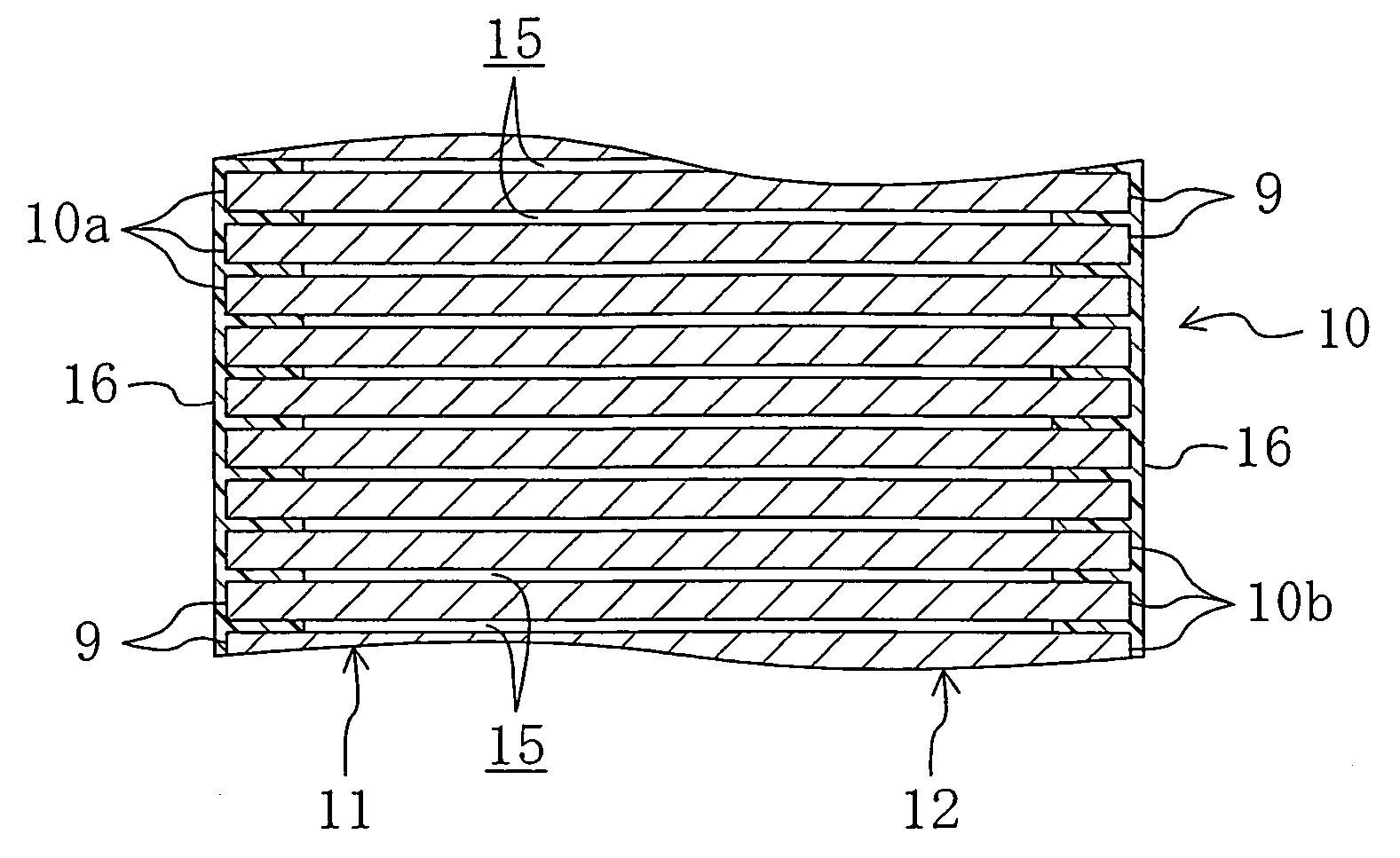

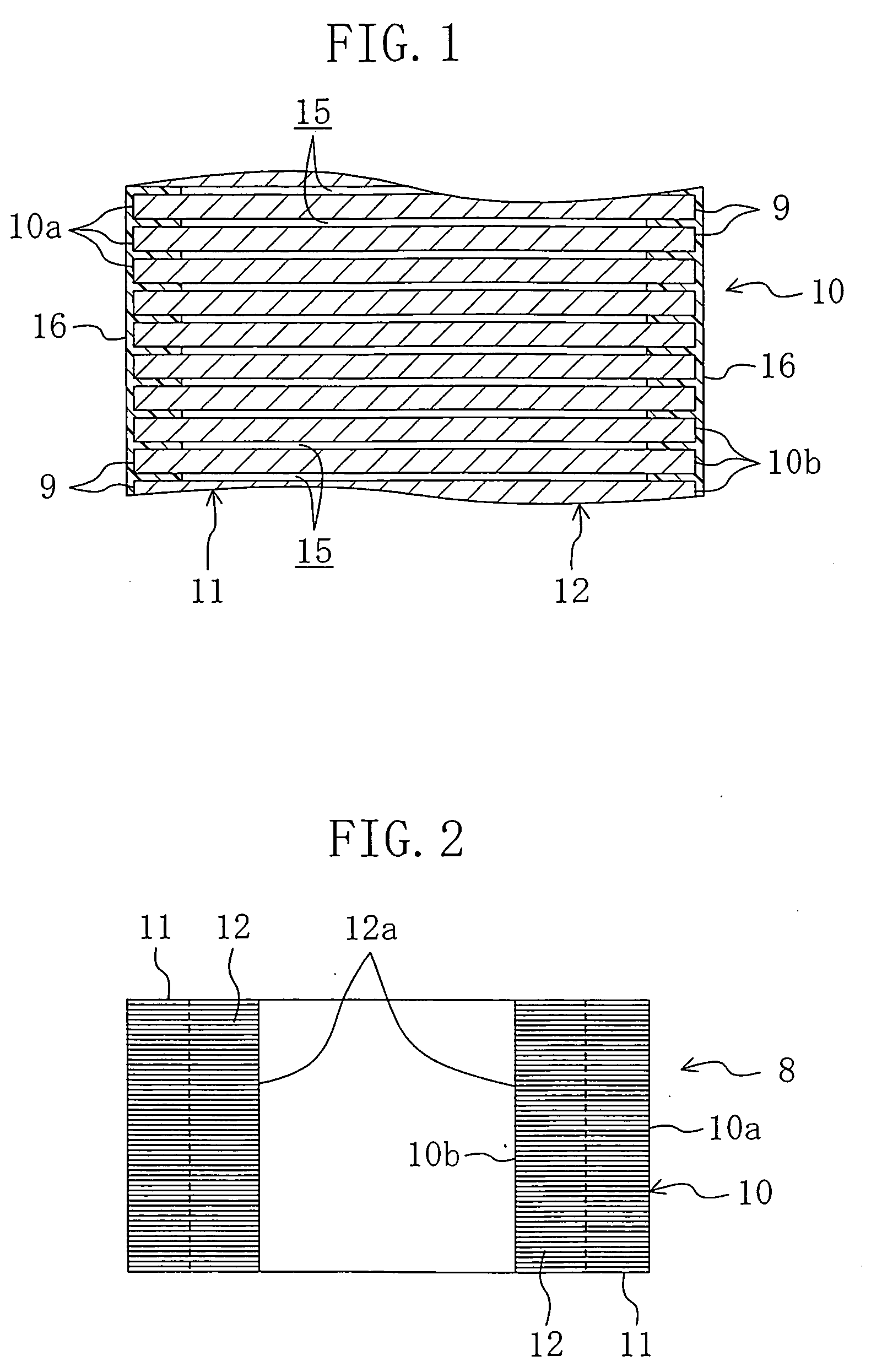

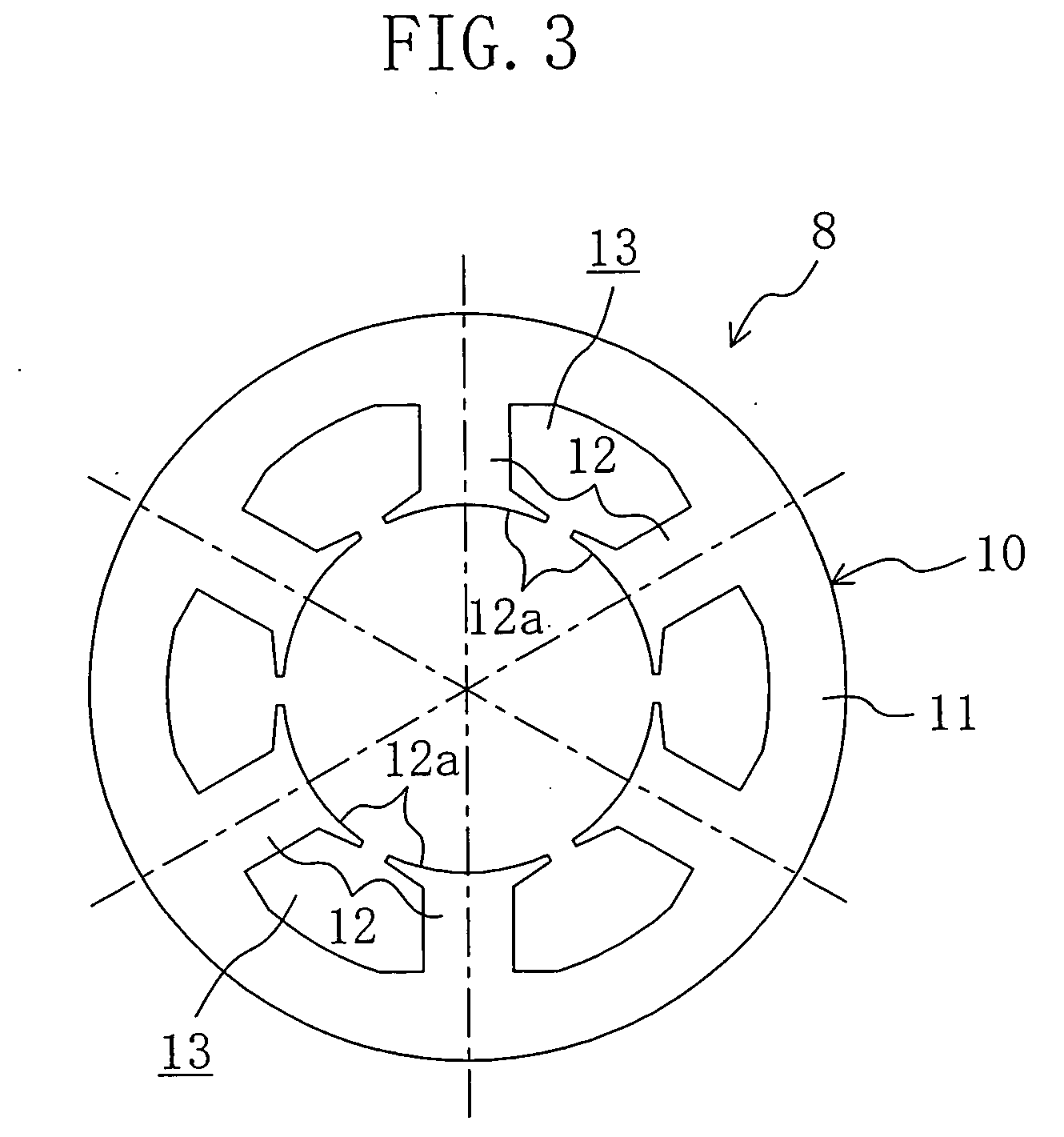

Fiber reinforced composite material structure, composite material molded body using the same, and manufacturing method therefor

ActiveUS20150183183A1Reduce thicknessRigid enoughLayered productsWood working apparatusFiber-reinforced compositeMaterials science

A fiber reinforced composite material structure comprises a thin sheet that includes a first surface and a plurality of convex portions which protrude and are regularly arranged on the first surface and each of which includes a top face; and a surface material that includes a second surface and is bonded to the top faces on the second surface.

Owner:MITSUBISHI CHEM CORP

Method for preparing pollution-proof surface material suitably applied in marine environment

InactiveCN101531865AEvenly distributedGood control effectAntifouling/underwater paintsPaints with biocidesPolymer scienceBiofouling

The invention relates to a method for preparing a pollution-proof surface material suitably applied in the marine environment. The method comprises that: vinyl end capped dimethyl silicone polymer, hydrogen contained silicone oil, a platinum catalyst and polyacrylamide microcapsules are evenly mixed and stirred and sulfated at normal temperature to prepare the pollution-proof surface material of which hydrophilic surfaces and hydrophobic surfaces are distributed at intervals; the hydrophilic polyacrylamide microcapsules are evenly distributed on the material surfaces, and after the surface material is soaked in water, a local hydrophilic area with even distribution is formed, and the local hydrophilic area and the hydrophobic organic silicon surfaces are regularly distributed at intervals; polluted marine lives are not easy or not tight to be attached to the hydrophilic-hydrophobic surface, thereby preventing pollution; the pollution-proof surface material can strongly inhibit the attachment of marine lives such as diatom, mussels, and the like, and the attached quantity of mussel byssus is reduced by more than 50 percent; moreover, the surface material is environment friendly, nontoxic and unharmful.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

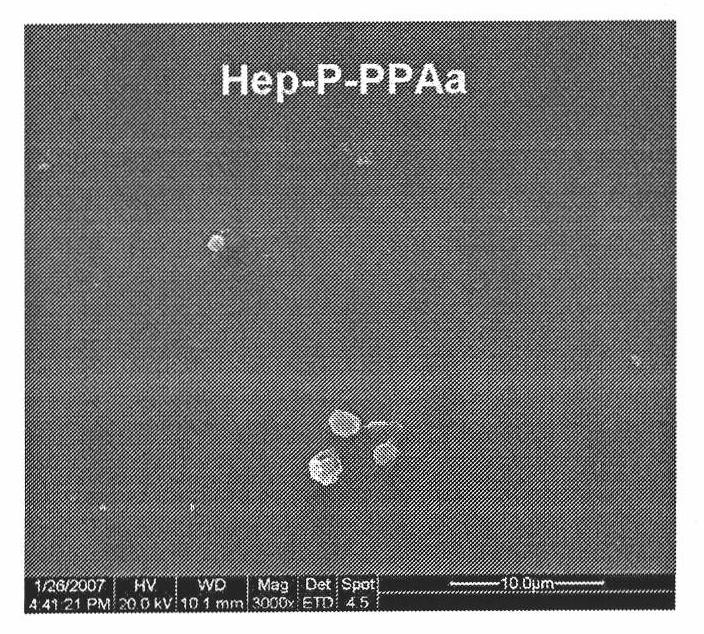

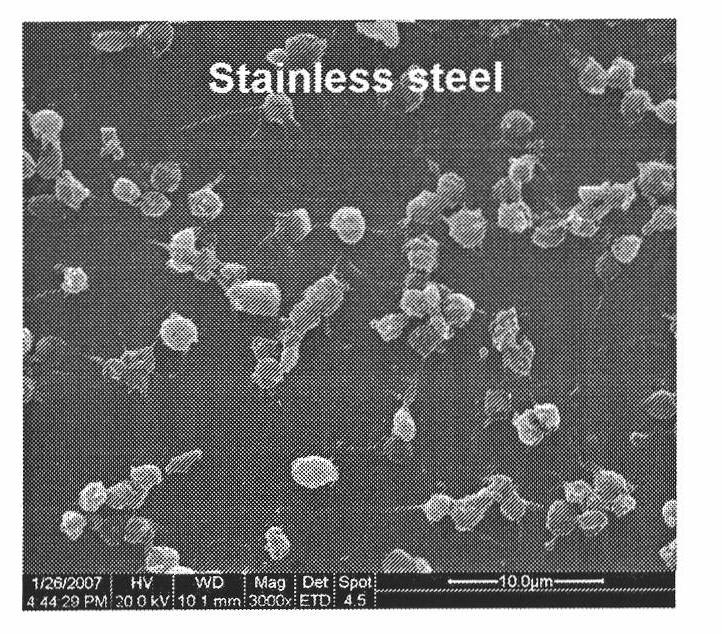

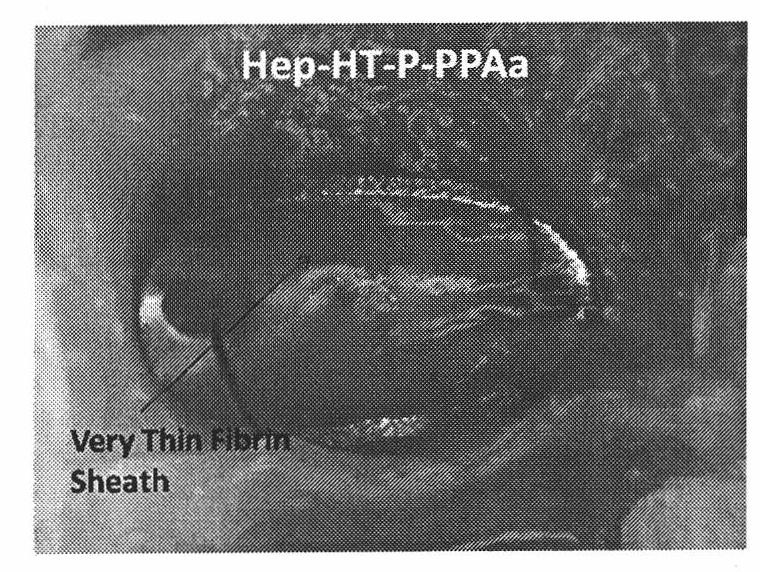

Method for preparing anticoagulant vascular stent

InactiveCN101927037AImprove bindingNot easy to fall offPharmaceutical containersMedical packagingMedicineDistilled water

The invention discloses a method for preparing an anticoagulant vascular stent, which comprises the following steps of: A, depositing a plasma-polymerized allyl amine functional film on the surface of the vascular stent by using a pulse plasma polymerization method; B, preparing heparin sodium mixed solution; and C, precipitating heparin sodium, namely soaking the vascular stent on which the plasma-polymerized allyl amine functional film is deposited prepared in the step A into the heparin sodium mixed solution prepared in the step B, reacting at the temperature of between 4 and 20 DEG C for 12 to 48 hours, and after the reaction, fully rinsing by using distilled water, and drying to obtain the anticoagulant vascular stent. The vascular stent prepared by the method has the advantages of high binding force between an anticoagulant film layer on the surface of the vascular stent and the vascular stent, and excellent tissue compatibility and blood compatibility.

Owner:CHENGDU SOUTHWEST JIAOTONG UNIV SCI & TECH GARDEN MANAGEMENT

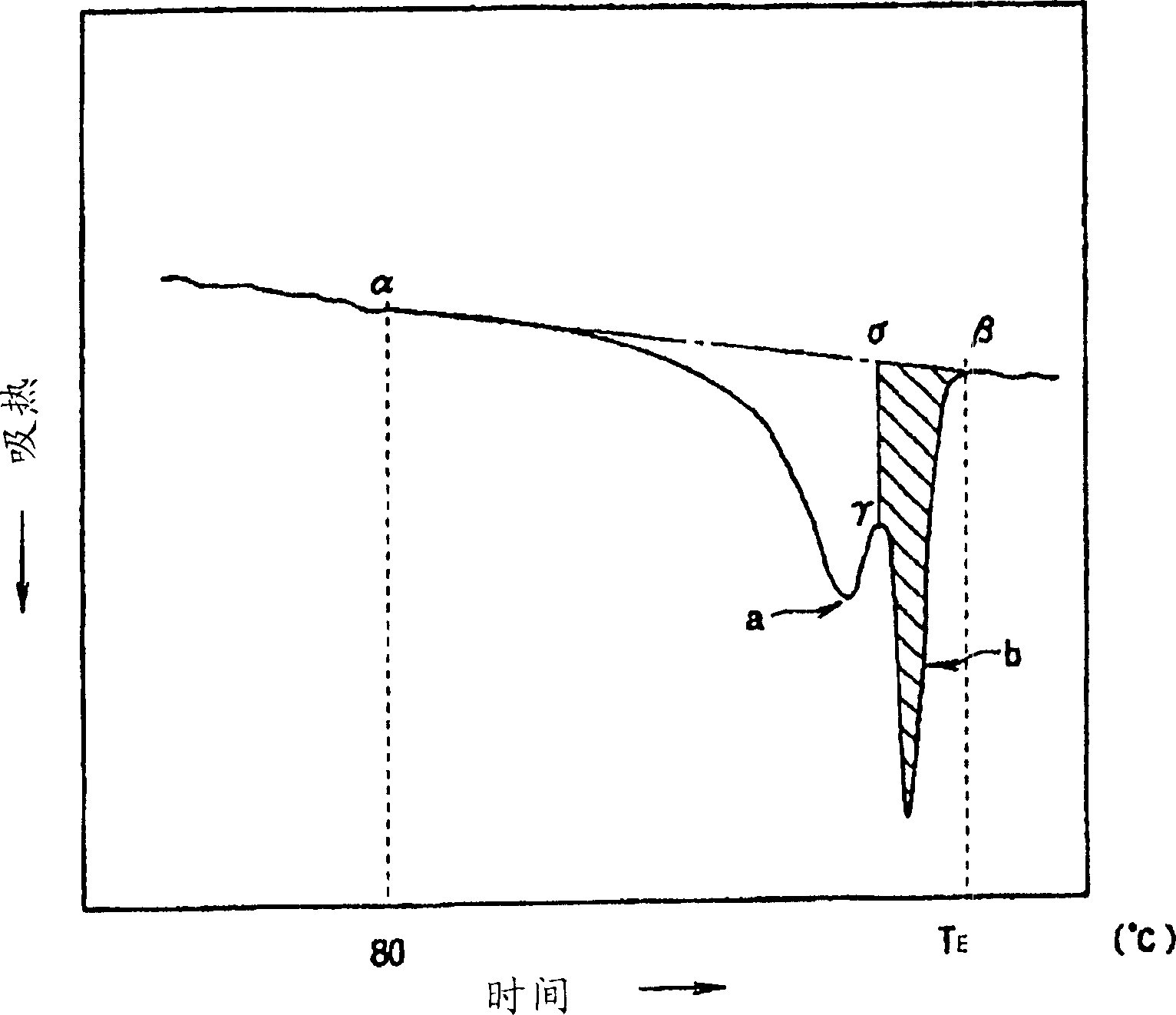

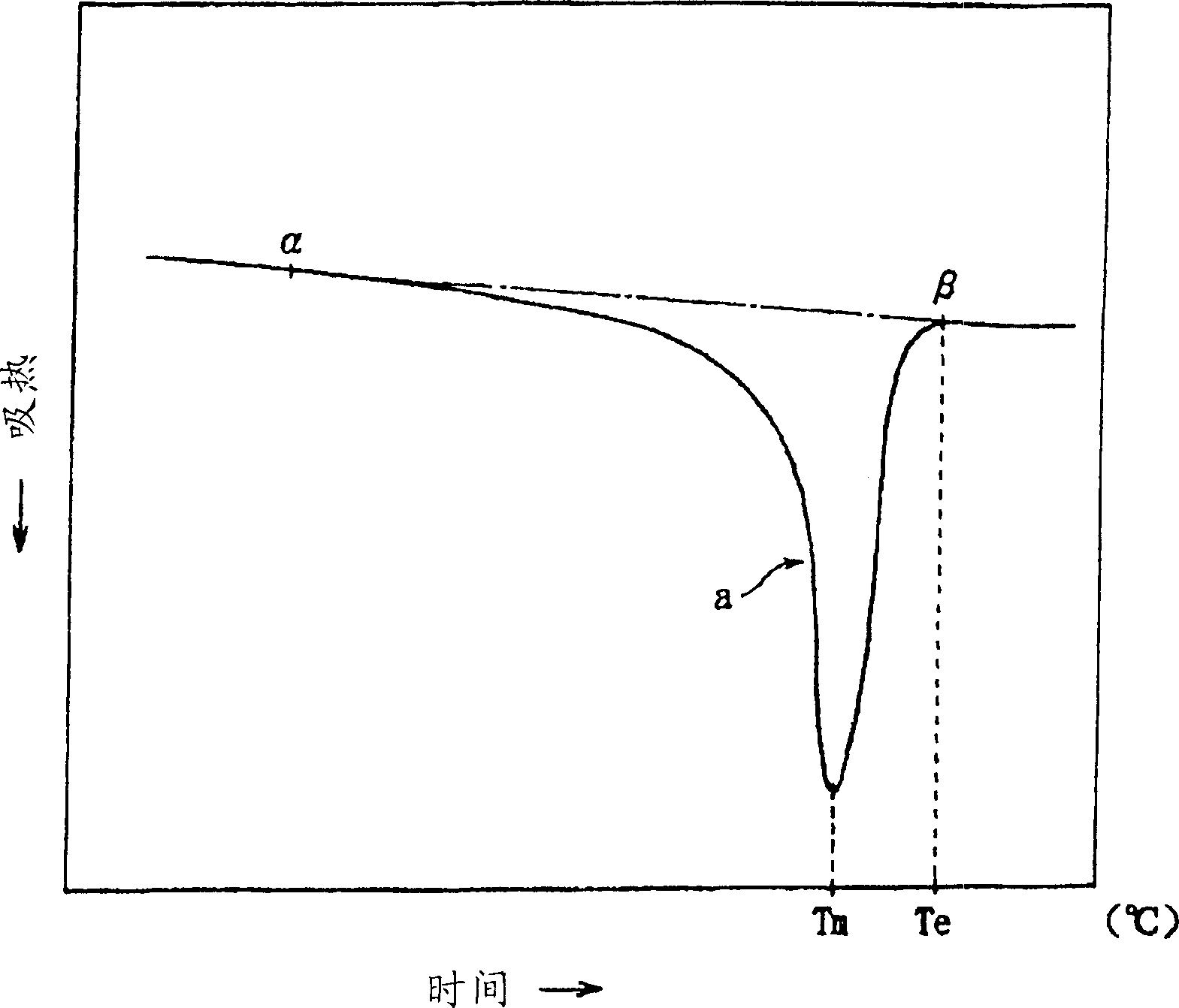

Method for producing polypropylene type resin foamed particle

The present invention relates to a method for producing expanded polypropylene resin particles, wherein favorable expanded particles that are not fused together can be obtained without inconsistencies caused by differences in the amount of dispersant adhering to the expanded particles that are obtained or the amount of dispersant which is added to prevent the resin particles from fusing together during a heat treatment step for ensuring the blowing agent impregnation of resin particles dispersed in an aqueous medium in a pressure tight vessel during the production of expanded polyolefin resin particles using a physical blowing agent, and it is also possible to more consistently produce expanded polyolefin resin particles which fuse together better when such expanded particles are molded, giving moldings with better mechanical strength. The method of the present invention is a method for obtaining expanded particles by allowing polypropylene resin particles impregnated with a physical blowing agent, which have been heated along with an aqueous medium and a dispersant, to be released and expanded at reduced pressure from the interior of a pressure-tight vessel, wherein the aforementioned aqueous medium has an electrical conductivity of from not less than 0.00 mS / m to not more than 20.00 mS / m.

Owner:JSP CORP

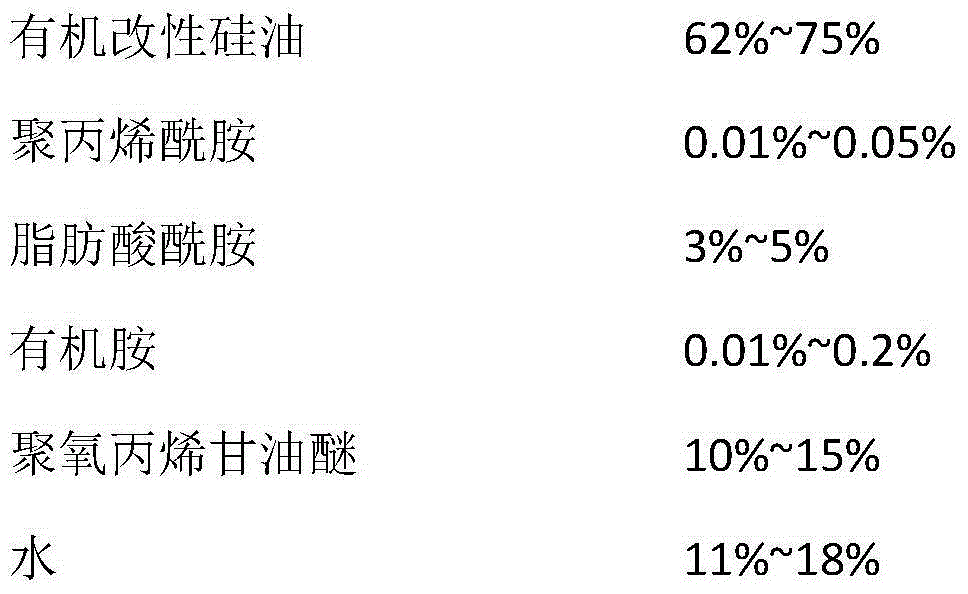

Releasing agent special for bare concrete and preparation method thereof

ActiveCN105001965AGood water solubilityEliminate Bubble ProblemsLubricant compositionSilicone oilPolyacrylamide

The invention relates to a releasing agent special for bare concrete and a preparation method thereof. The releasing agent special for the bare concrete is a water dispersion solution and comprises raw materials including organic modified silicone oil accounting for 62%-75% of the total mass of the raw materials, polyacrylamide accounting for 0.01%-0.05% of the total mass of the raw materials, fatty acid amide accounting for 3%-5% of the total mass of the raw materials, organic amine accounting for 0.01%-0.2% of the total mass of the raw materials, polyoxypropylene glycerol ether accounting for 10%-15% of the total mass of the raw materials and water accounting for 11%-18% of the total mass of the raw materials. The polyacrylamide is firstly solved in the water, the temperature is improved to be 35-55 DEG C, other components are added after even stirring, natural cooling is performed after re-stirring to obtain the releasing agent special for the bare concrete. The appearance effect of a bare concrete cement product can be improved, the surface of the bare concrete cement product can be smooth and free of air bubbles, the releasing agent special for the bare concrete is environmentally friendly, free of pollution and low in cost, 1-7.5 times of water can be added for dilution when the releasing agent is used, 3-4 times of continuous releasing can be performed through one-time spraying, and performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Electric motor and compressor

InactiveUS20050067915A1Improve rigidityReduce vibrationPositive displacement pump componentsMagnetic circuit stationary partsStatorVarnish

In an electric motor including a stator core having a plurality of layered steel thin plates, the rigidity of the stator core is maintained and the vibration during its operation is suppressed. Namely, at least parts of the thin plates of the stator core are adhered to each other by a varnish that is an insulating adhesive.

Owner:DAIKIN IND LTD

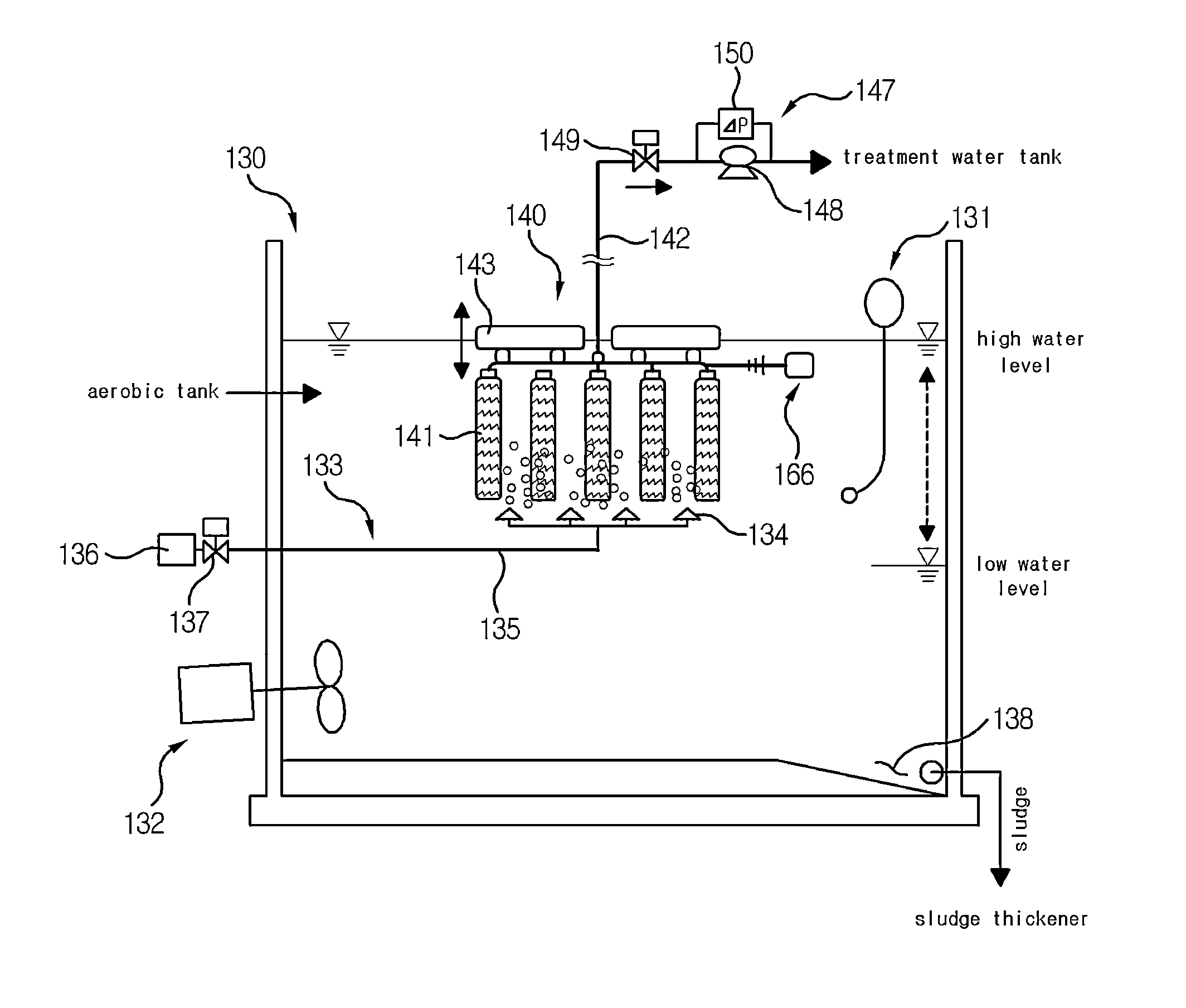

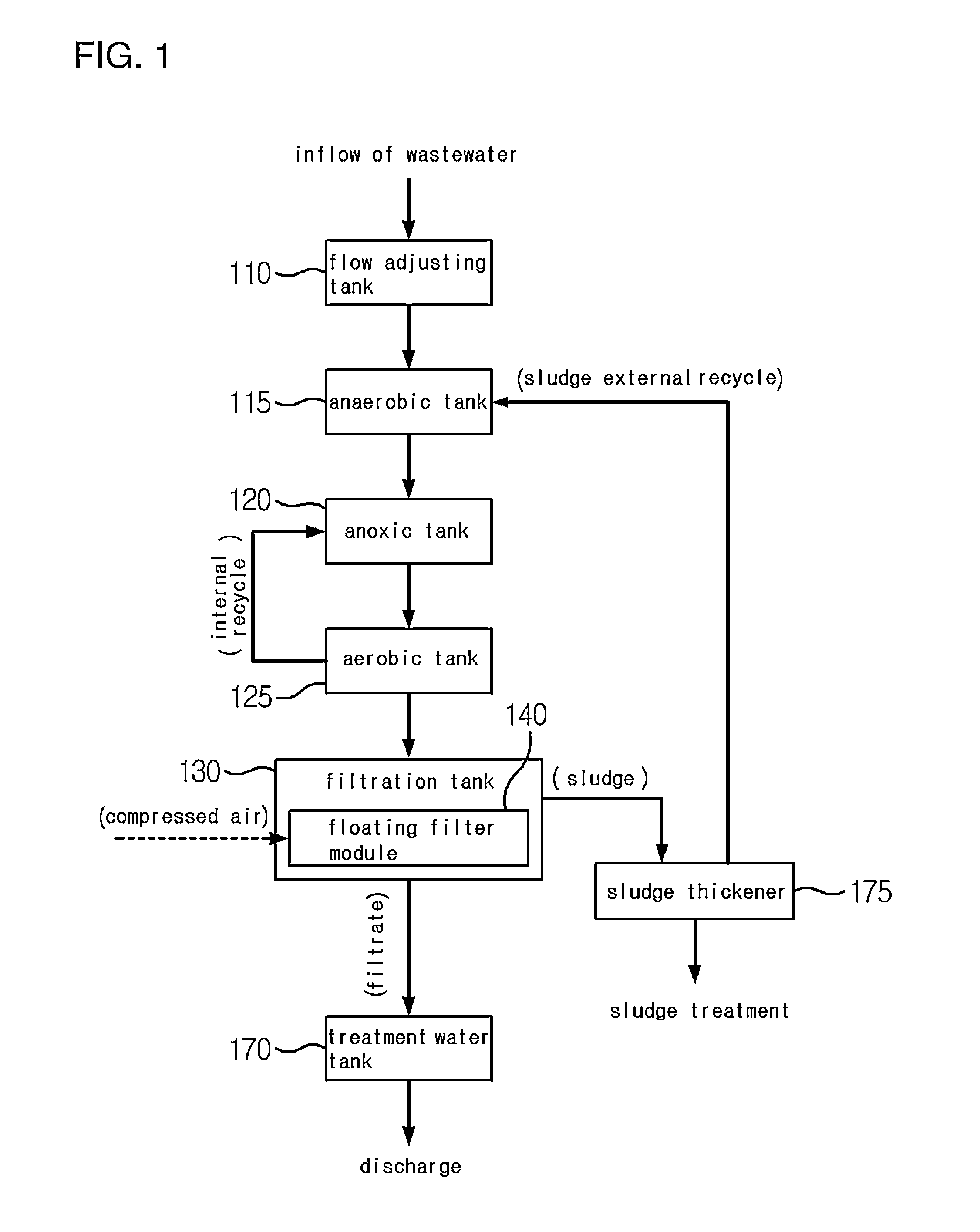

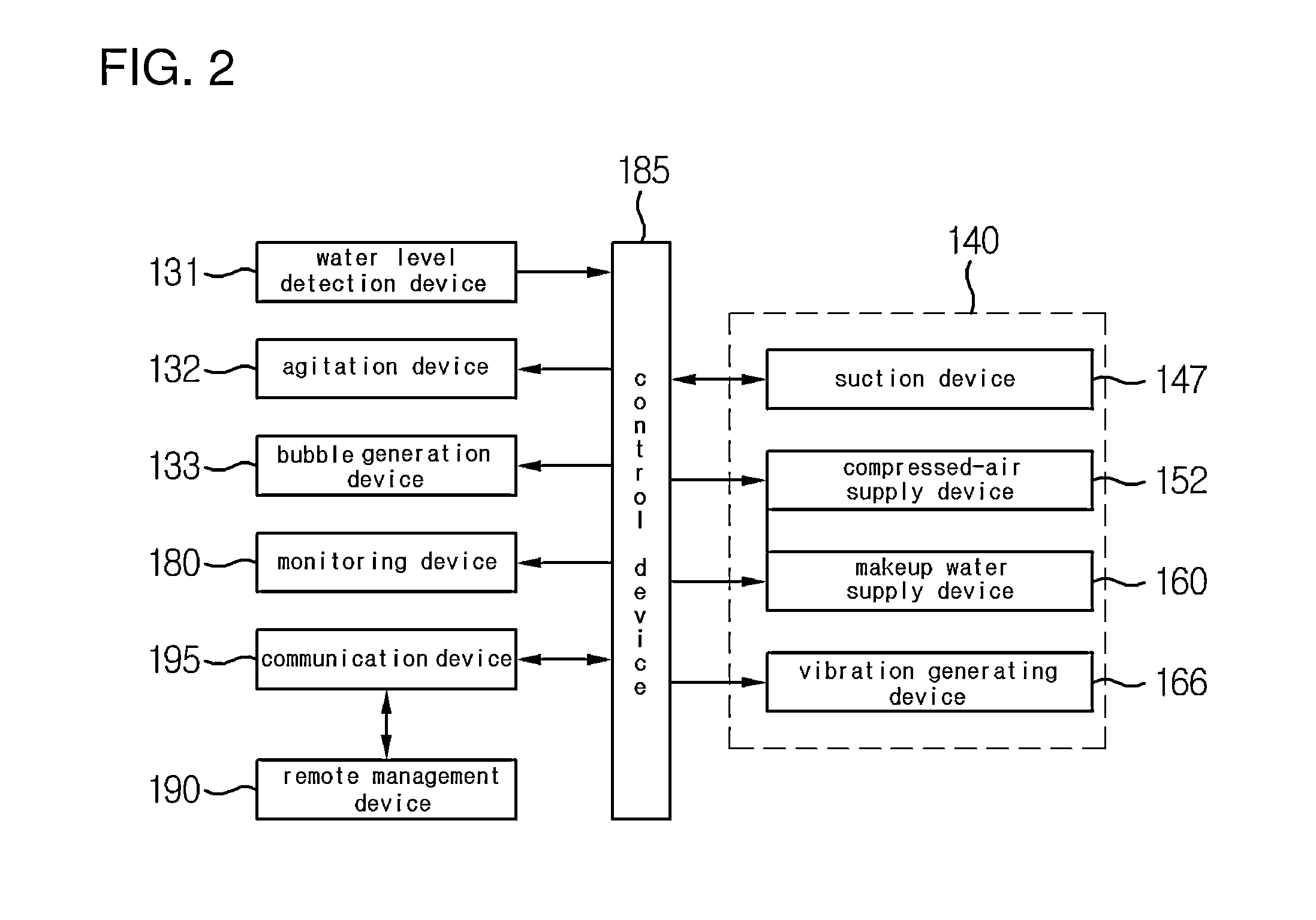

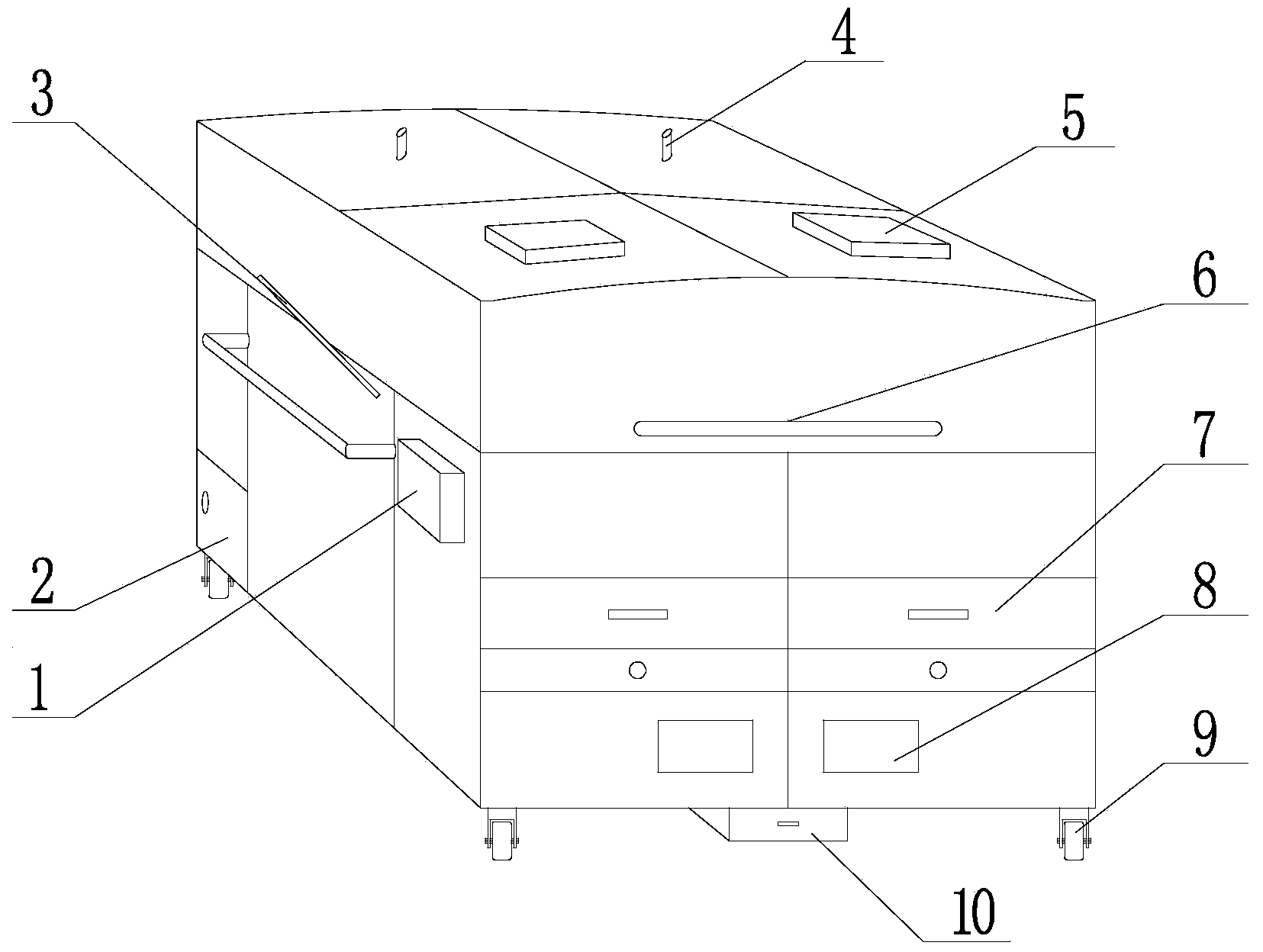

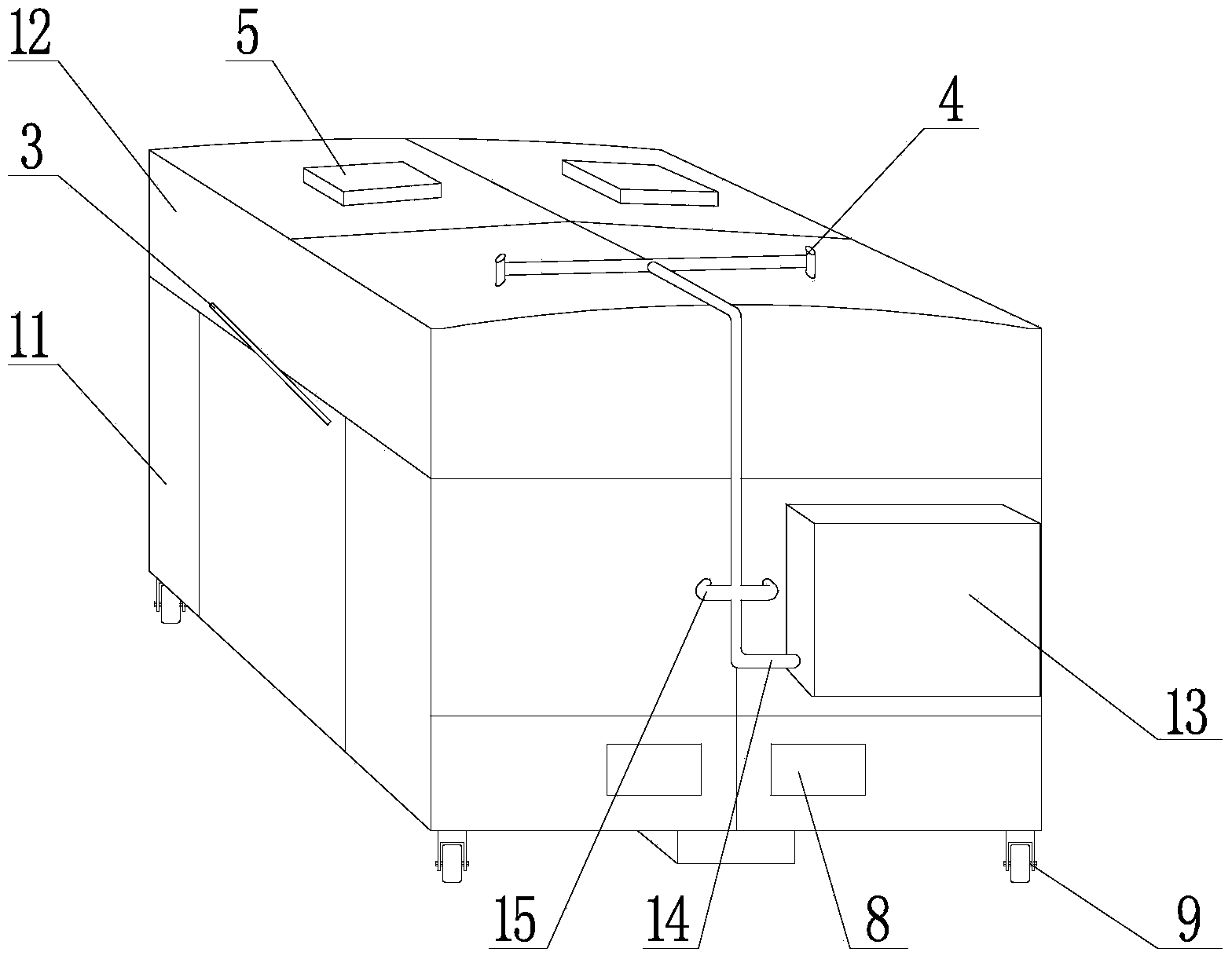

Floating filter module and water treatment apparatus and method using the same

InactiveUS20140116957A1Improve filtering effectIncrease ratingsGeneral water supply conservationBiological treatment regulationSuction forceSewage

The present invention relates to a floating filter module installed in a water treatment apparatus, such as in a public water treatment plant, a village water supply facility, a public sewage treatment plant, a wastewater treatment plant, or a village sewage treatment plant, in order to remove contamination particles. The floating filter module according to the present invention comprises: a hollow-type sintered filter having a plurality of fine pores which is arranged in wastewater within a water treatment tank in order to separate and filter the contamination particles from the wastewater introduced into the water treatment tank; a floating body connected to the sintered filter, and which floats to the surface of the wastewater within the water treatment tank so as to position the sintered filter at the upper portion of the wastewater in the water treatment tank; a main pipe communicating with an inner space of the sintered filter; a suction device coupled to the main pipe in order to provide a suction force to the sintered filter through the main pipe, thereby suctioning the wastewater in the water treatment tank through the plurality of fine pores and into the sintered filter; and a compressed-air supply apparatus having a compressed-air supply tube communicating with the inner space of the sintered filter through the main tube and an air compressor coupled to the compressed-air supply tube in order to supply compressed air into the inner space of the sintered filter, thereby releasing from the sintered filter the contamination particles that clog the fine pores of the sintered filter.

Owner:DAEWOONG ECOSYST & SOLUTION

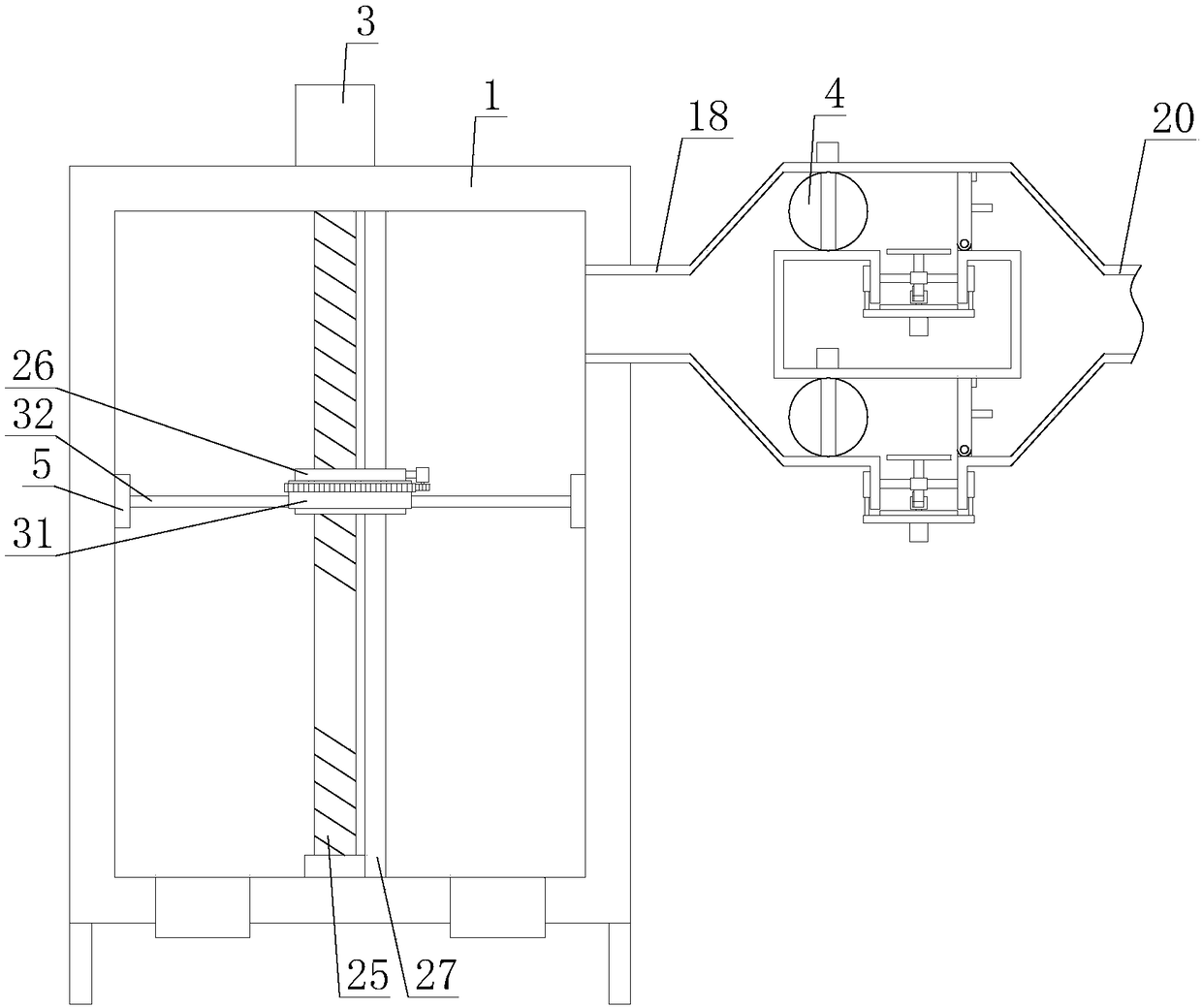

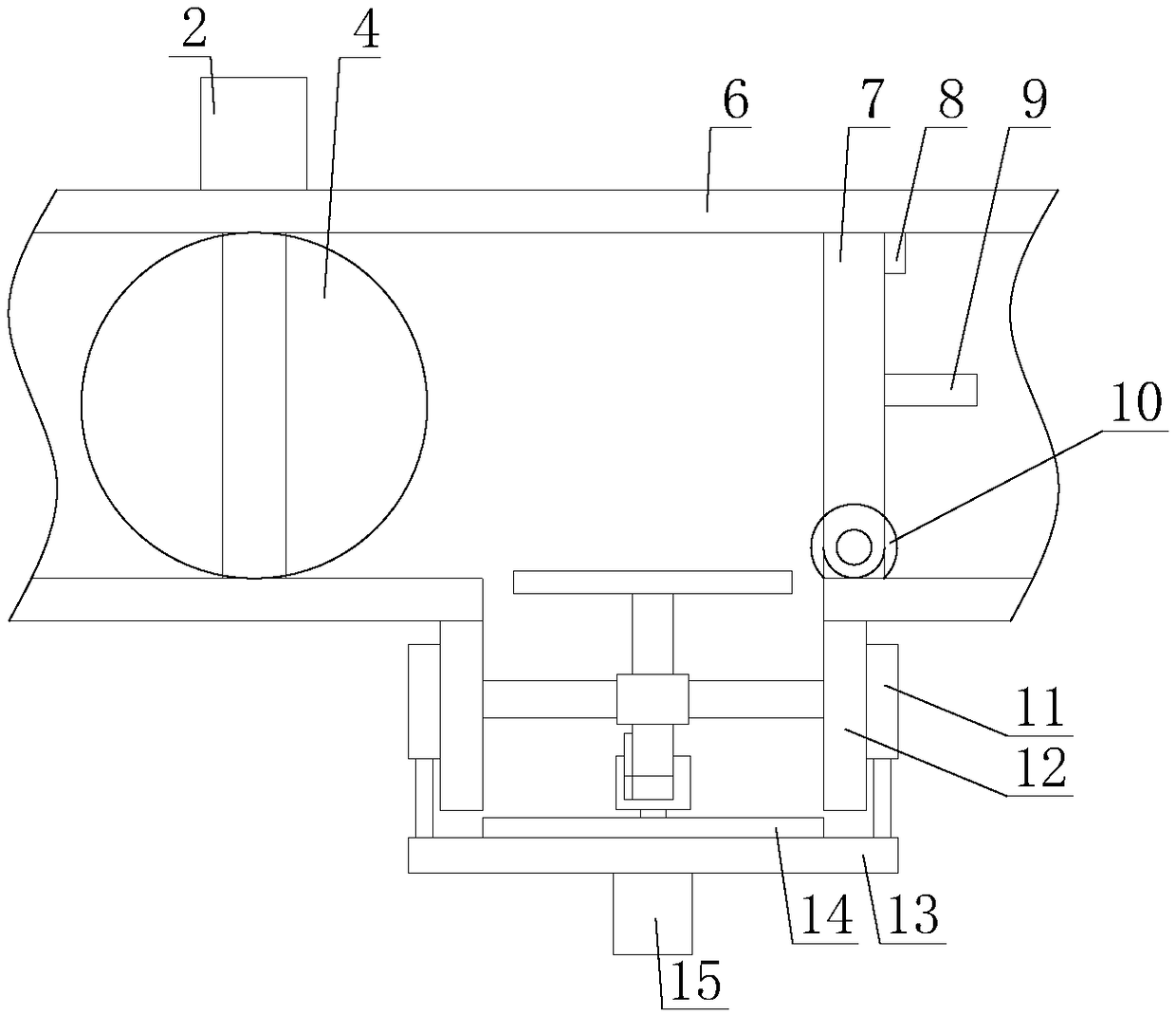

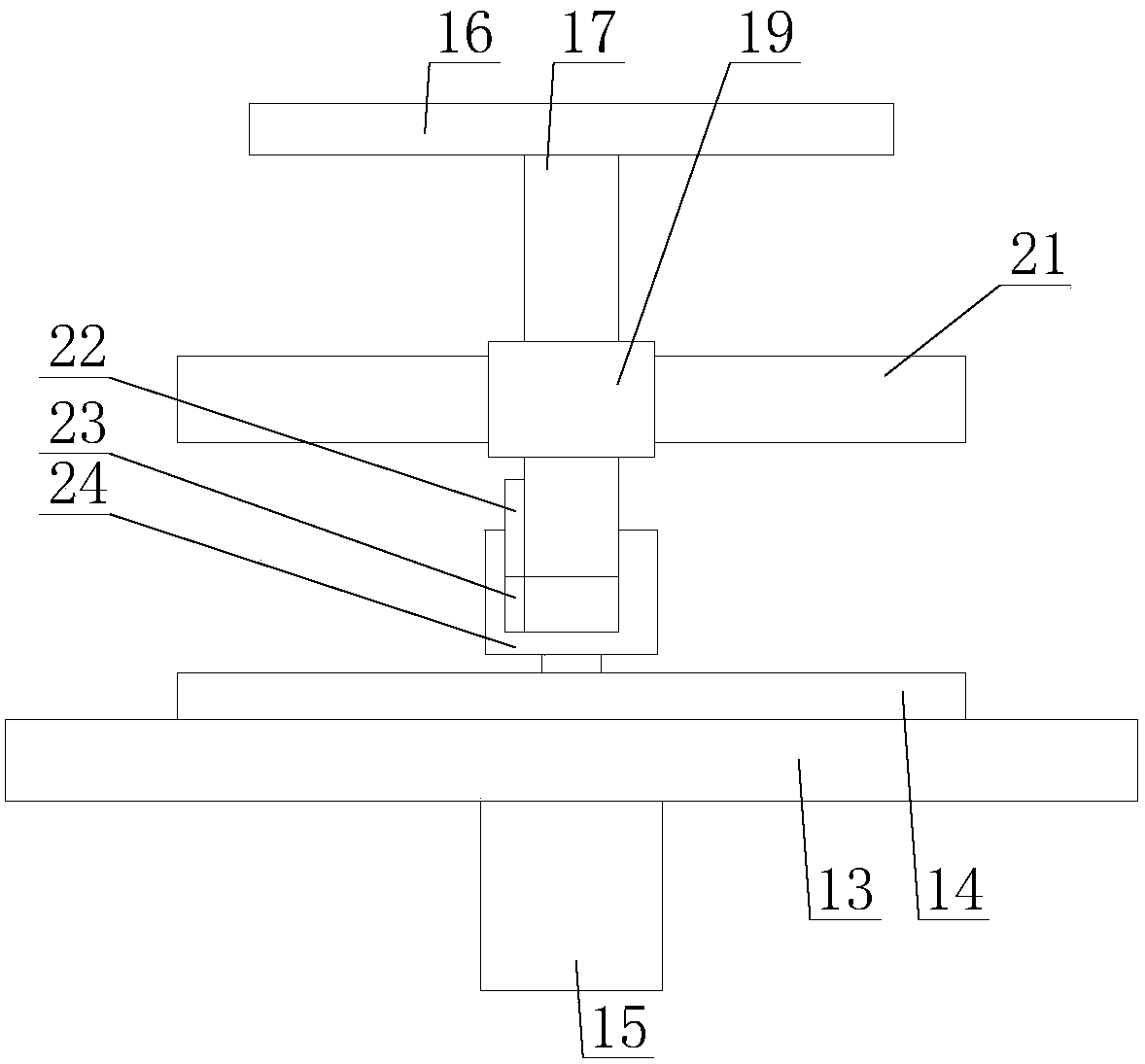

Automatic charcoal-fire sheep roasting machine

InactiveCN103651646AGuaranteed tasteKeep fresh tasteSpecial goods bakingAutomatic controlComputer module

The invention provides an automatic charcoal-fire sheep roasting machine. The automatic charcoal-fire sheep roasting machine comprises an oven, a grill, charcoal fire chambers and a control unit; the oven comprises a box body, and coaxial shaft sleeves are arranged at the upper end of the box body in pairs; a rotary shaft is arranged on the grill, the shaft head at one end of the rotary shaft is fixedly connected with a transmission device which is connected with a driving device, and the driving device is connected with the control unit; air holes are formed in the bottoms of the charcoal fire chambers which are arranged inside the box body and below the grill, and ventilation openings are formed in the positions, below the charcoal fire chambers, of the box body; the control unit comprises a rotary-shaft forward and reverse rotation motion control module, a forward and reverse rotation number control module and a master switch. The automatic charcoal-fire sheep roasting machine achieves uniform roasting heating, saves manpower, is capable of automatically controlling roasting time and short in roasting time, achieves good mouthfeel, is capable of being used for roasting multiple sheep, achieves batch roasting, saves energy, is beneficial to environmental protection, improves efficiency, reduces the number of carcinogenic substances adhering to the surfaces of the roasted sheep, guarantees cleanliness of waste gas, and has the advantages of being simple in structure, convenient to operate and low in cost.

Owner:刘文山

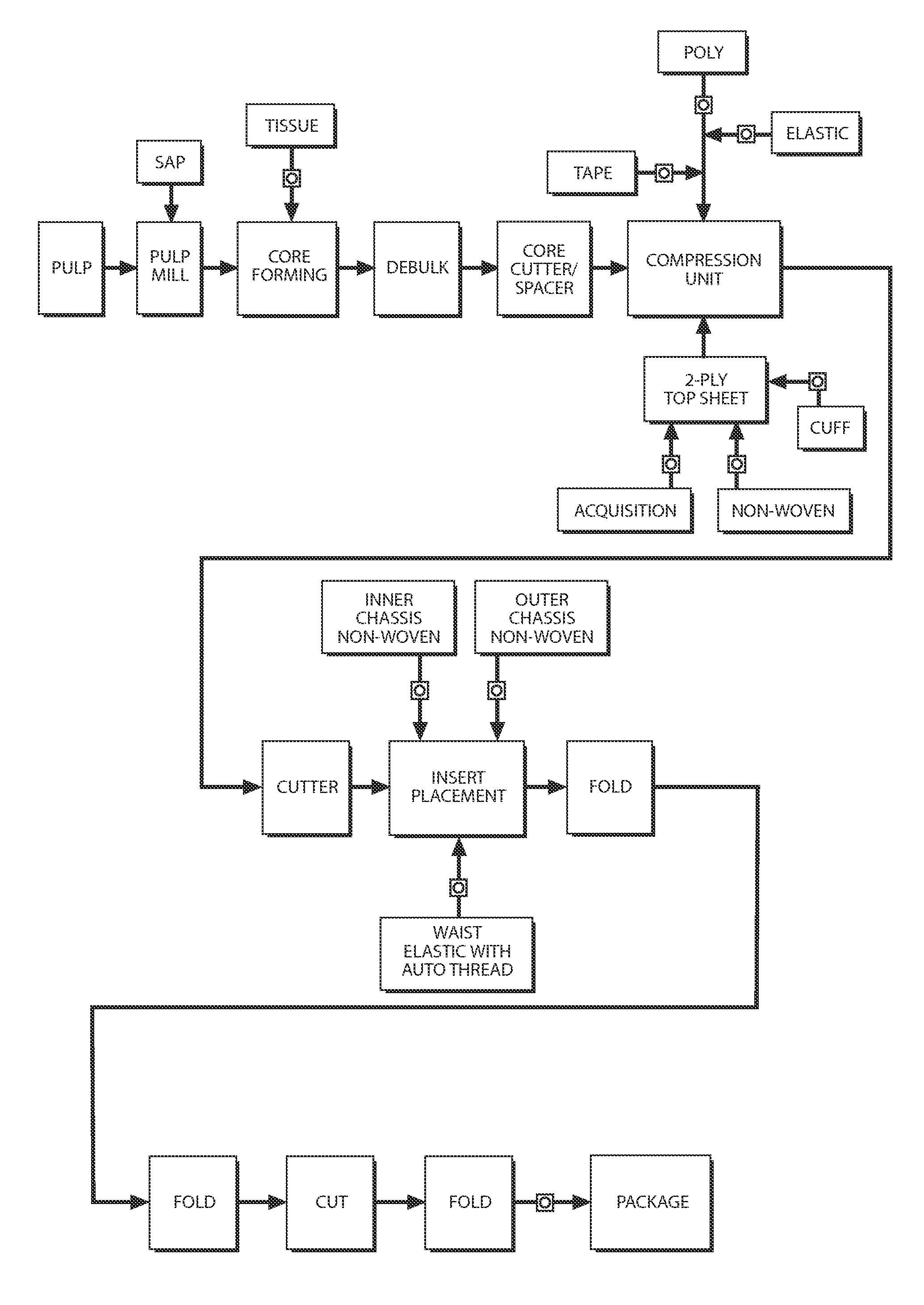

Apparatus and method for minimizing waste and improving quality and production in web processing operations by automatic cuff defect correction

ActiveUS20120202664A1Reduce wasteQuality improvementBox making operationsPaper-makingVisual inspectionCuff

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection both before and after application of component patches to a traveling web to create a product. Web defect detection may be provided by way of at least one visual inspection station located upstream from the patch applicator. Patch defect detection may be accomplished by way of a visual inspection station located proximate the patch applicator. If defects are detected in either the traveling web or the component patch prior to patch application, patch application may be prevented until both a satisfactory web and patch are provided. If defects are detected after patch application, the resulting product may be culled. Furthermore, the apparatus may be provided with diagnostic software to warn against extant or imminent machine complications.

Owner:CURT G JOA

Coating system for achieving excellent MVSS adhesion

ActiveUS8906507B2High bonding strengthMinimizing detrimental effectLiquid surface applicatorsSynthetic resin layered productsCarbamateCoating system

A coating system includes a clear coat layer and a sealant. The clear coat layer is formed from a clear coat composition that comprises a crosslinkable carbamate-functional resin and an aminoplast. Optionally, the coating system further includes a sub-clear coat layer. The sealant is bonded to the clear coat layer opposite the sub-clear coat layer. Optionally, the coating system further includes a tie coat layer and that is disposed between the sealant and the clear coat layer. An adhesion promoter is present in the clear coat composition in an amount of less than or equal to about 3% by weight based on the total weight of resin solids of the clear coat composition. Further, the adhesion promoter is present in at least one of the sub-clear coat composition and the tie coat composition in an amount sufficient to increase adhesion between the clear coat layer and the sealant.

Owner:BASF CORP

Boiler with pipeline impurity cleaning function based on Internet of Things

InactiveCN108548170AImprove filtering effectImprove heat transfer efficiencyBoiler cleaning apparatusCleaning using toolsThe InternetHearth

The invention relates to a boiler with a pipeline impurity cleaning function based on the Internet of Things. The boiler comprises a hearth, a first air outlet pipe, a second air outlet pipe, a descaling mechanism, a filter mechanism and a center control mechanism. The descaling mechanism comprises a first drive assembly, a lifting assembly, at least two drive rods and at least two scraper blades;the filter mechanism comprises two filter assemblies; and each filter assembly comprises a second motor, a cleaning port, a steam pipe, a baffle plate, a filter screen, a limiting block, a torsion spring, an anti-wind plate, a cleaning unit and two air cylinders. In the boiler with the pipeline impurity cleaning function based on the Internet of Things, through the descaling mechanism, water scale on an inner wall of the hearth can be effectively scraped, so that the adhesion amount of the water scale on the inner wall of the hearth is reduced, the heat conduction efficiency of the boiler isimproved, and the practicability of the boiler is improved; and through the filter mechanism, the impurities in the steam pipelines in the boiler can be filtered, so that the steam quality is improved, and the practicability of the boiler is further improved.

Owner:SHENZHEN LEILING GUANGTONG TECH DEV CO LTD

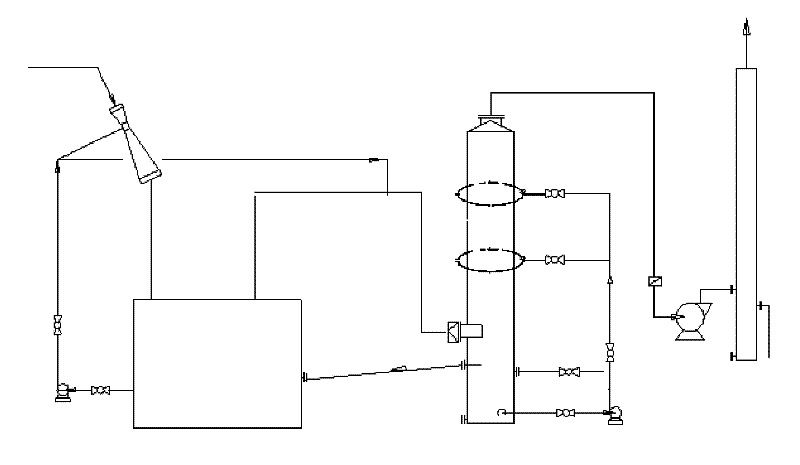

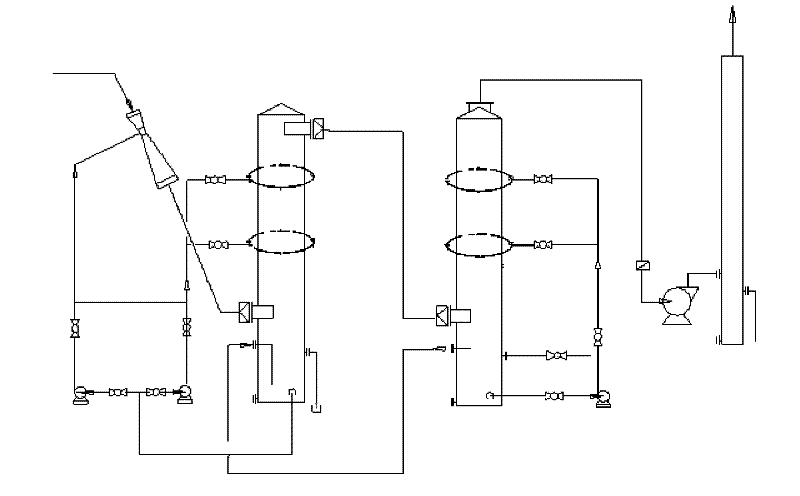

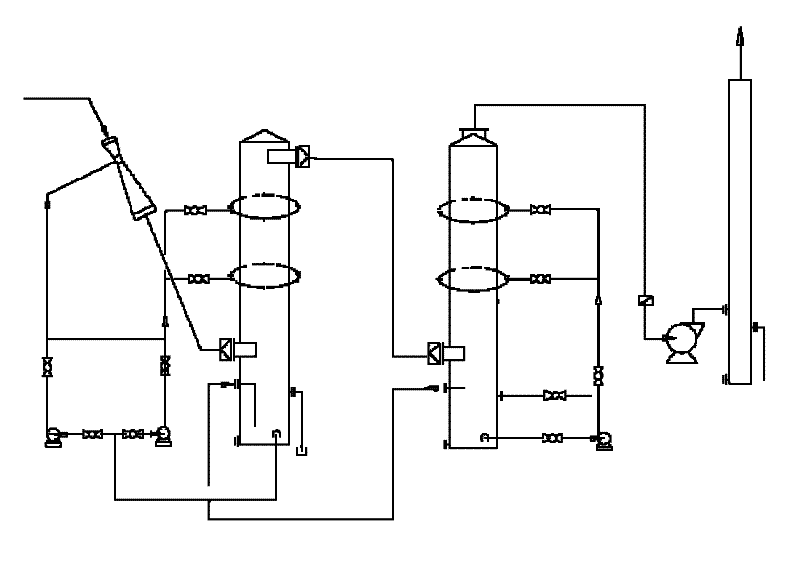

Phosphoric acid production tail gas recovery method

InactiveCN102258929AIncrease flow rateThe beneficial effect of increasing the first-level scrubber is: 1) reduce the flow rateDispersed particle separationPhosphoric acidRecovery methodPhosphoric acid

The invention relates to a method for recovering tail gas from phosphoric acid production. The process flow is as follows: the fluorine-containing gas enters the Venturi scrubber through the tail gas duct, and performs first-stage downstream spray washing with the washing liquid from the first washing pump, and the washed gas enters the first washing tower and the first washing tower. The washing liquid sent by the washing pump is subjected to the first-stage countercurrent two-layer spray washing again, and the gas after washing enters the second washing tower and the washing liquid sent by the second washing pump is subjected to the second-stage countercurrent two-layer spray washing. After being pumped by the tail gas fan, it enters the defoaming tower for defoaming, and finally discharges into the atmosphere through the chimney; the process water for washing first enters the second washing tower and is preheated and sprayed by the second washing pump, and then overflows from the second washing tower into The first washing tower is sent to the Venturi scrubber and the spraying device of the first washing tower by the first washing pump for spray washing and absorption. The beneficial effects of the present invention are: 1) reduce the gas flow rate, increase the washing and absorption efficiency; 2) preheat the washing liquid through the second washing tower, accelerate the formation of H2SiF6, and further strengthen the washing and absorption effect; 3) reduce the adhesion of the fan impeller, Reduce fan failures and corrosion of related equipment; 4) Strengthen the stability of operating indicators and increase the operating rate.

Owner:WUHAN ZHONGDONG PHOSPHATE TECH

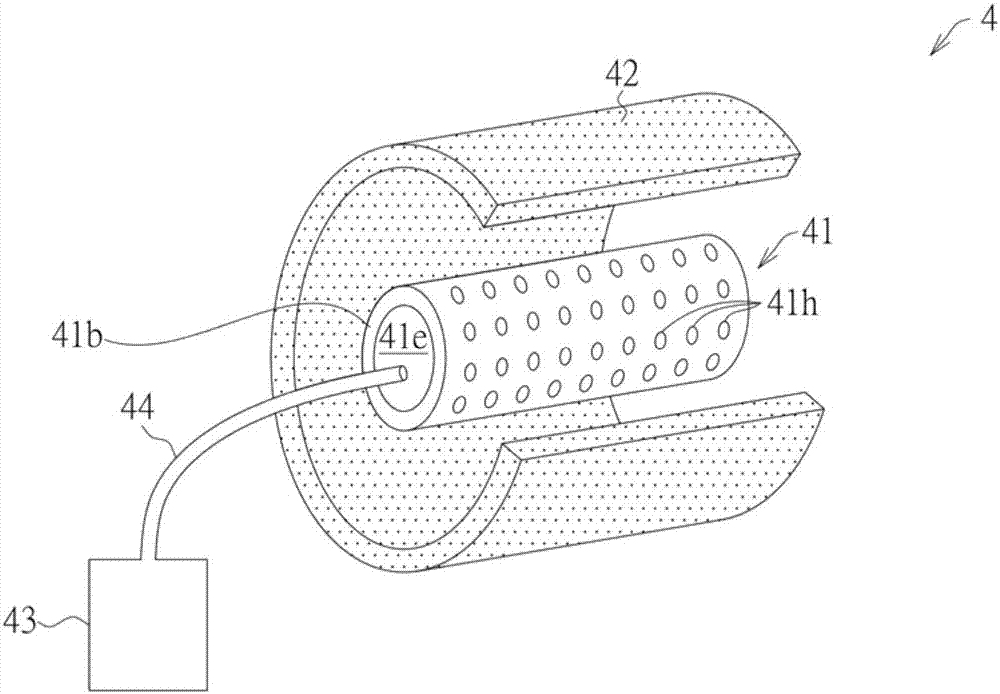

Liquid removing equipment and liquid removing method

ActiveCN106945209AImprove yieldImprove production yieldOptical articlesFlat articlesEngineeringOptical film

The invention relates to liquid removing equipment and a liquid removing method. The liquid removing equipment comprises a liquid absorption roller which is used for contacting with an optical film material and absorbing the liquid on the surface of the optical film material. The liquid absorption roller comprises a core body and a water absorption material. The core body comprises a solid body portion and a hollow portion, the solid body portion comprises a plurality of through holes, and the water absorption material wraps the core body and covers the through holes.

Owner:SUMIKA TECH

Mining automatic high-pressure flushing type camera device and monitoring method thereof

ActiveCN111327801AAvoid direct destructionImprove cleanlinessTelevision system detailsFouling preventionCamera lensSprayer

The invention discloses a mining automatic high-pressure flushing type camera device. The device comprises a base, a camera, a conical cover, a dust induction recognizer, a controller, a high-pressureairflow hose, a high-pressure water flow hose and a telescopic spray pipe mechanism, a camera lens on the left of the camera is positioned in the conical cover; a dustproof transparent assembly is arranged on the left of the camera lens. The dust induction recognizer is arranged in the conical cover and used for monitoring dust attached to the surface of the left side of the dustproof transparentassembly, the telescopic spray pipe mechanism is arranged at the top of the left side of the conical cover and can stretch out and draw back vertically, and the lower end of the telescopic spray pipemechanism is provided with an airflow sprayer and a water flow sprayer for spraying towards the dustproof transparent assembly. According to the invention, automatic induction is realized through thedust induction recognizer; cleaning is achieved by combining high-pressure water flow, air flow and other pressure intensities, the cleanliness of the dustproof glass can be effectively guaranteed, the high-pressure air flow can effectively achieve the effects of drying and water stain removing, and therefore the workload of manual wiping can be effectively reduced, damage to the camera lens is reduced, and the service life of the camera lens is prolonged.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com