Patents

Literature

31results about How to "Avoid direct destruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for restoring cadmium-contaminated farmland soil

InactiveCN105363769ASimple compositionHigh cadmium removal rateContaminated soil reclamationContaminated soilsHeavy metals

The invention discloses a method for restoring cadmium-contaminated farmland soil. The method comprises the specific steps that cadmium in the contaminated soil is transferred and removed through a chemical elution mode, a mixed water solution of ferric chloride and ammonium chloride is adopted as an eluting agent during chemical elution, the mass concentration of ferric chloride ranges from 0.8% to 2.0%, and the mass concentration of ammonium chloride ranges from 0.5% to 1.5%. Ferric chloride and ammonium chloride are compounded to serve as the eluting agent, the cadmium removal rate is high, and especially when the cadmium-contaminated farmland soil with the cadmium content smaller than or equal to 1.1 mg / kg is restored, the content of cadmium in the restored soil can conform to the secondary standard GB15618-1995. The environmental pollution risk of the cadmium-contaminated farmland soil is thoroughly eliminated, and safety production of agricultural products is ensured. In addition, the prepared eluting agent can effectively protect the integrity of the soil structure, and the probability that the restored soil can be used for farming is ensured.

Owner:中国有色桂林矿产地质研究院有限公司

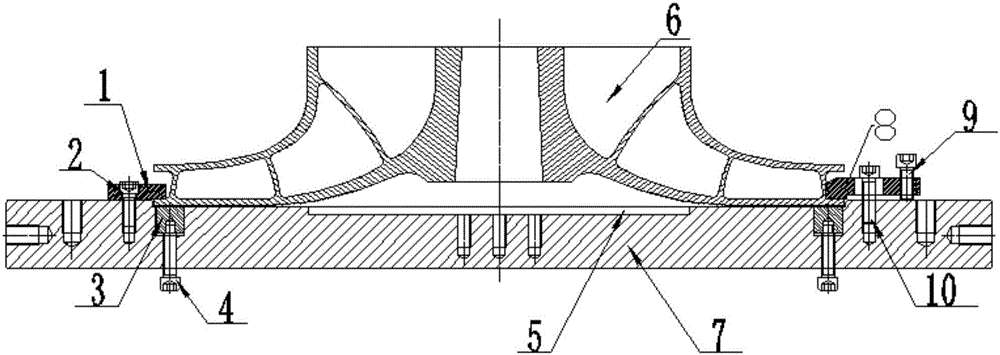

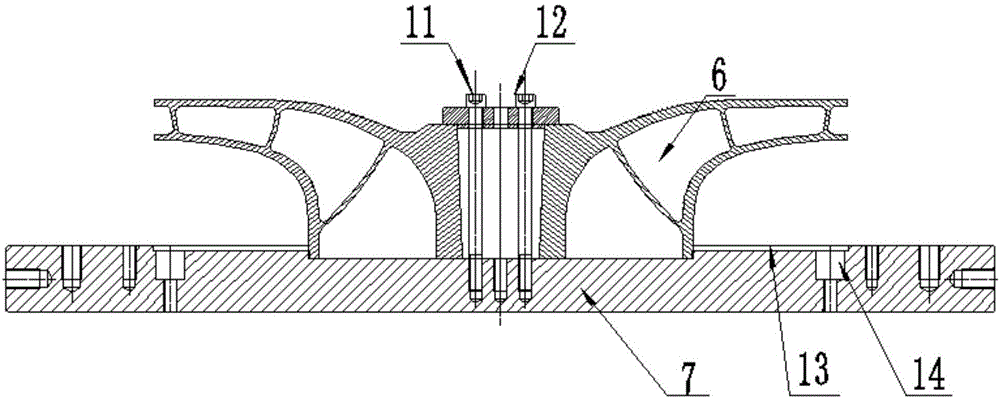

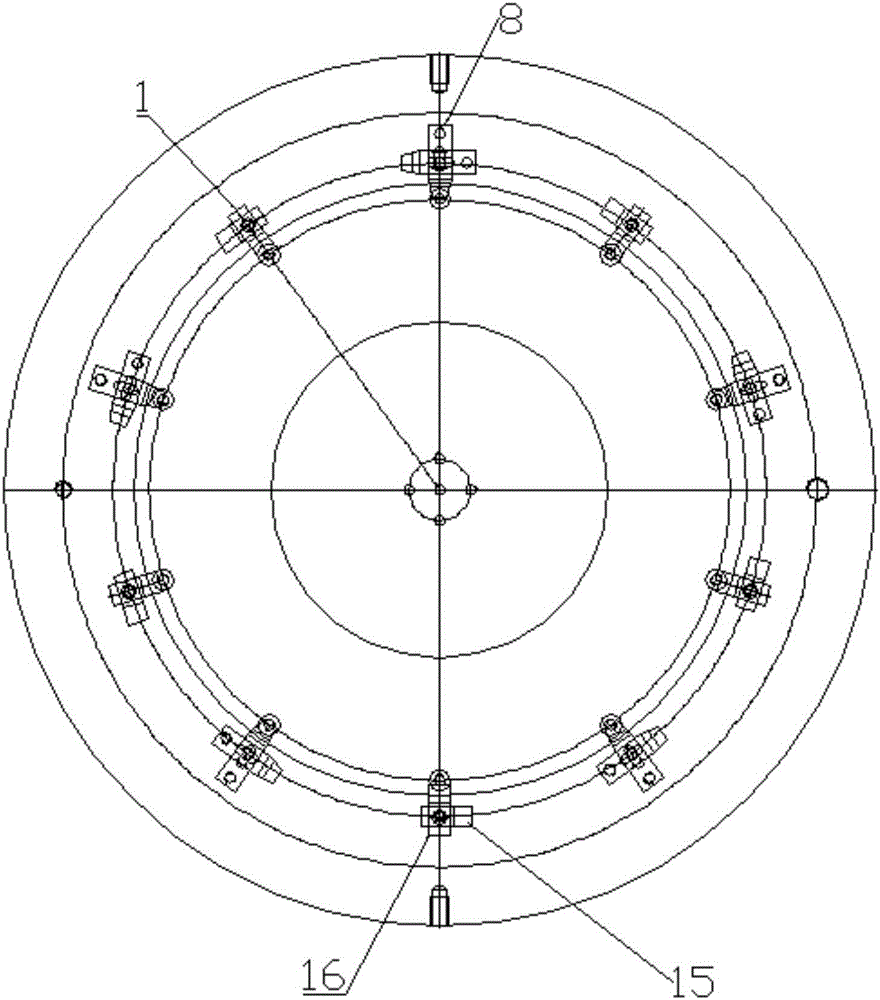

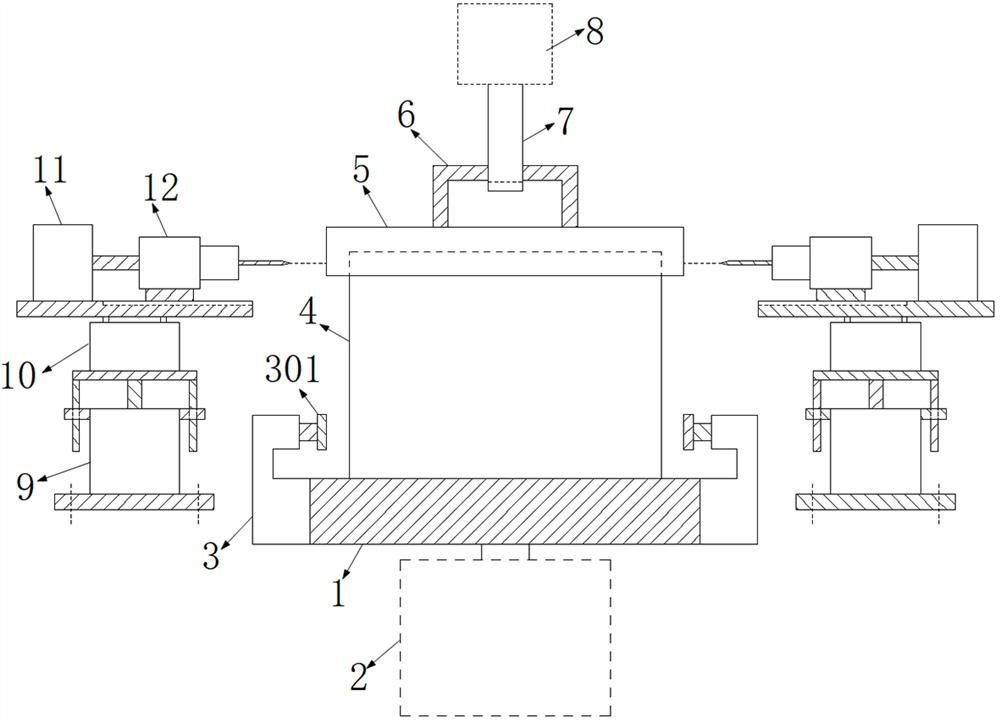

Clamp device for machining large-sized thin-walled impeller and finish machining method of large-sized thin-walled impeller

InactiveCN106041589AImprove surface accuracyEasy to fixWork clamping meansPositioning apparatusImpellerEngineering

The invention discloses a fixture device for machining large-scale thin-walled impellers and a finishing method for large-scale thin-walled impellers. The fixture device includes a bottom plate, and the working surface of the bottom plate is provided with a first recess and a second recess. The circular surface fits, and the second concave part cooperates with the second circular surface of the impeller end. The edge of the first concave part is provided with a first pressing part for pressing the impeller wall, and the center of the second concave part is detachably provided with a The second circular surface is locked to the second pressing part of the bottom plate. In the present invention, the first circular surface at the end of the impeller is positioned by setting the first recess, and the impeller is locked to the bottom plate through the first pressing part without welding. The fixing is convenient and fast. After the first round of machining of the impeller, the second concave part is set to position the second circular surface of the impeller, and the second pressing part is used to fasten the impeller to realize sequential machining of the impeller. Avoid the situation that some surfaces are not processed due to fixtures or other reasons, and improve the surface accuracy of the impeller.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

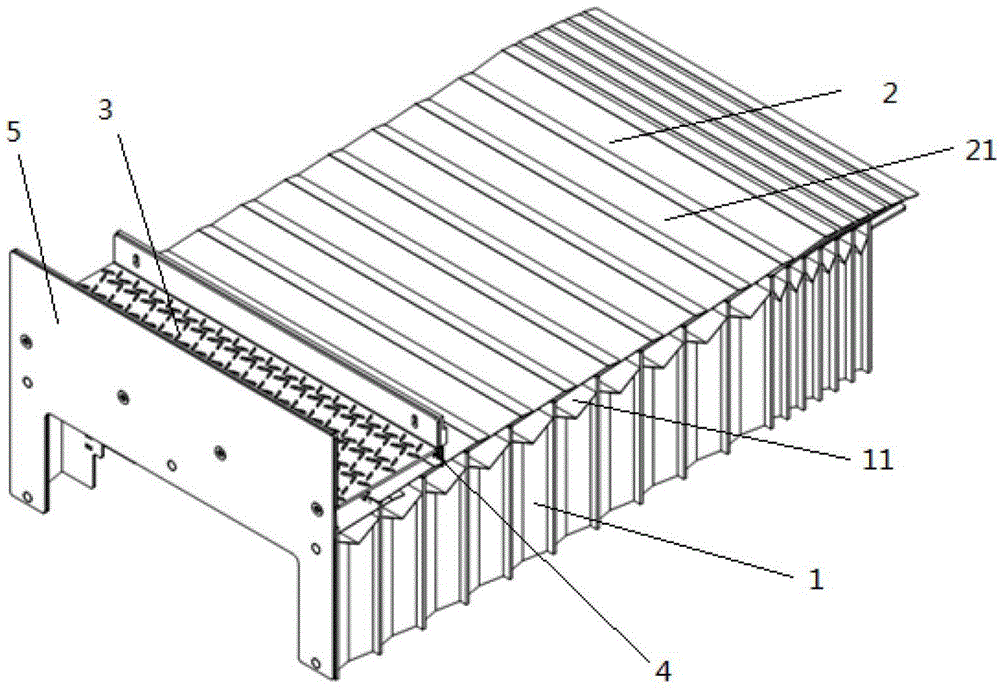

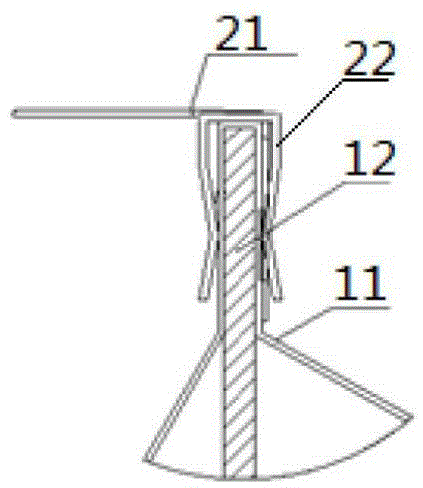

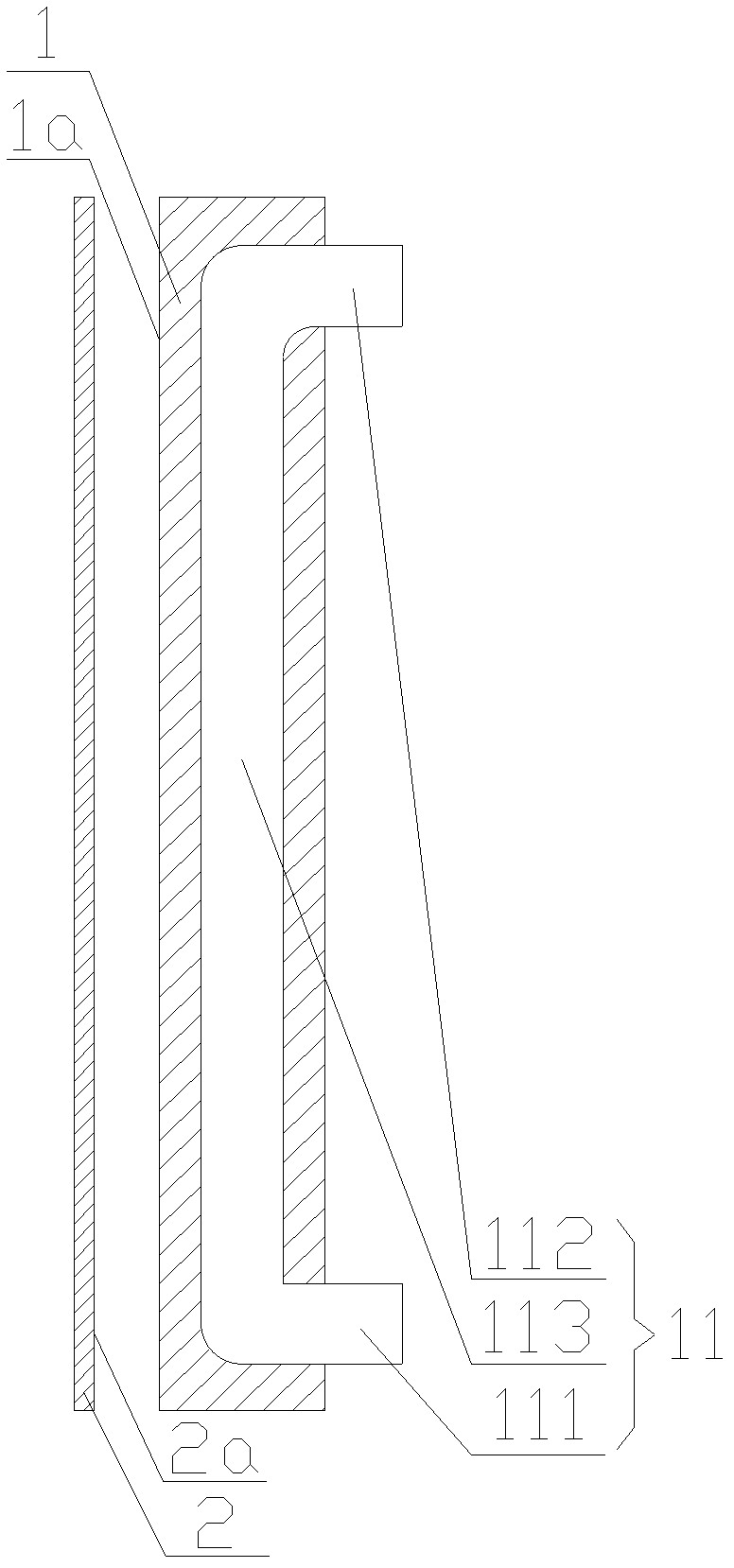

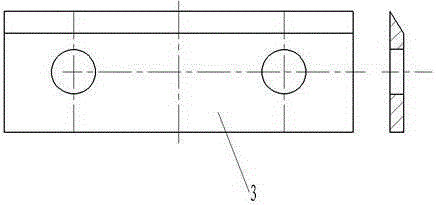

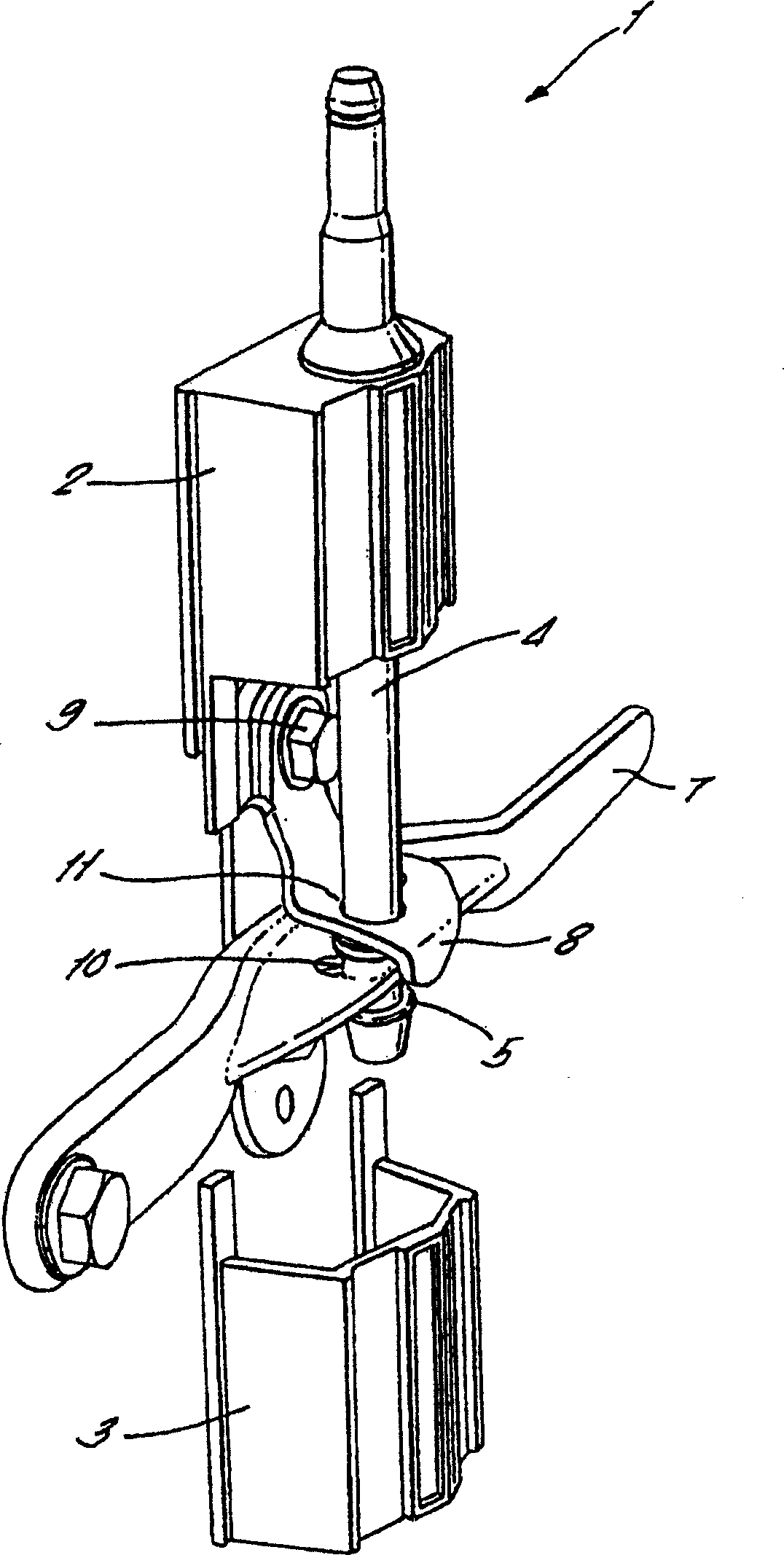

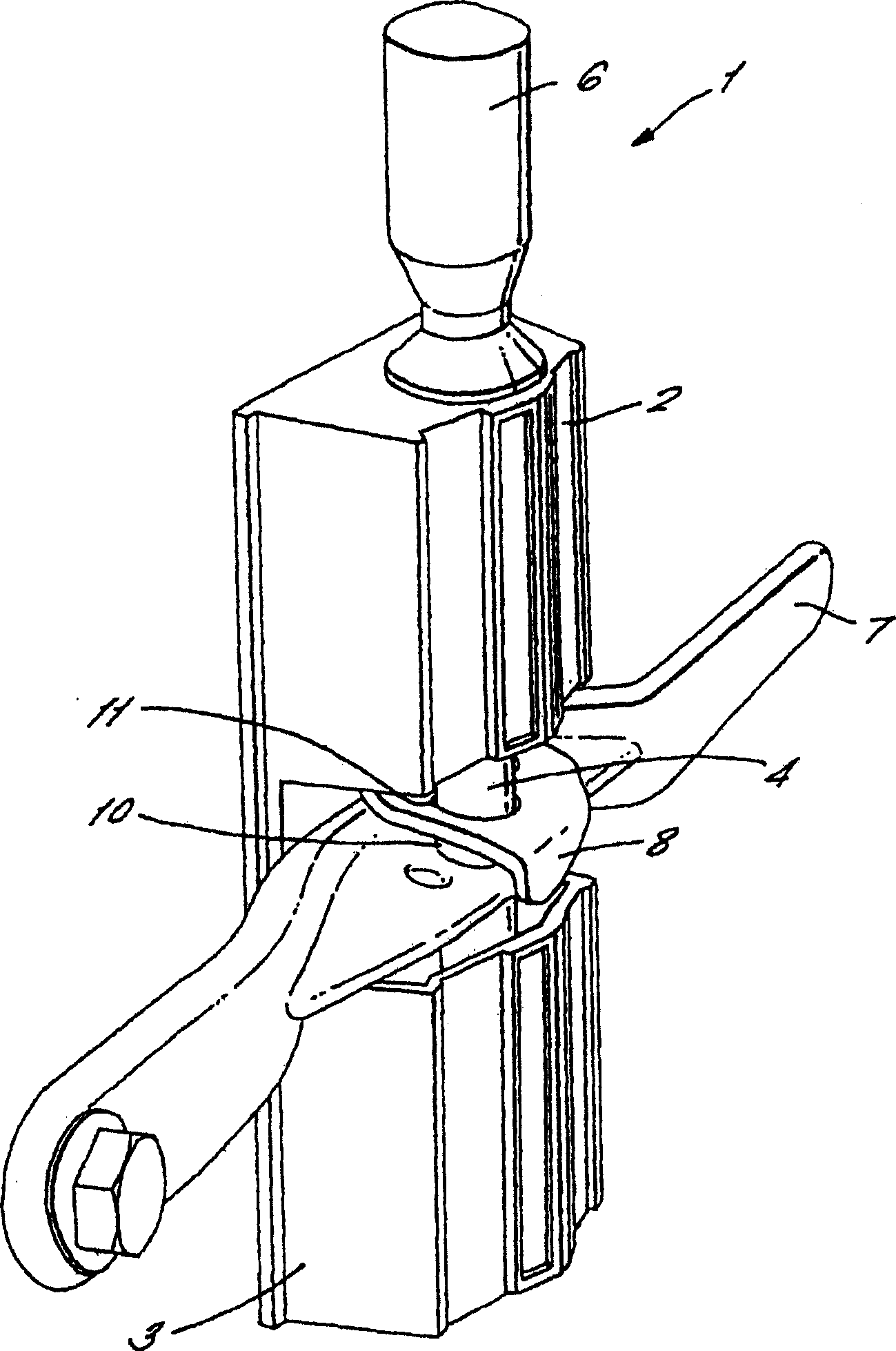

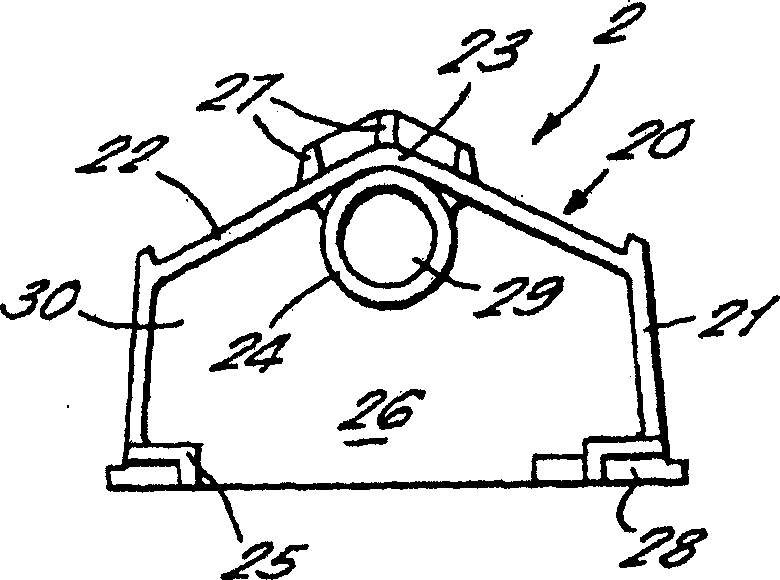

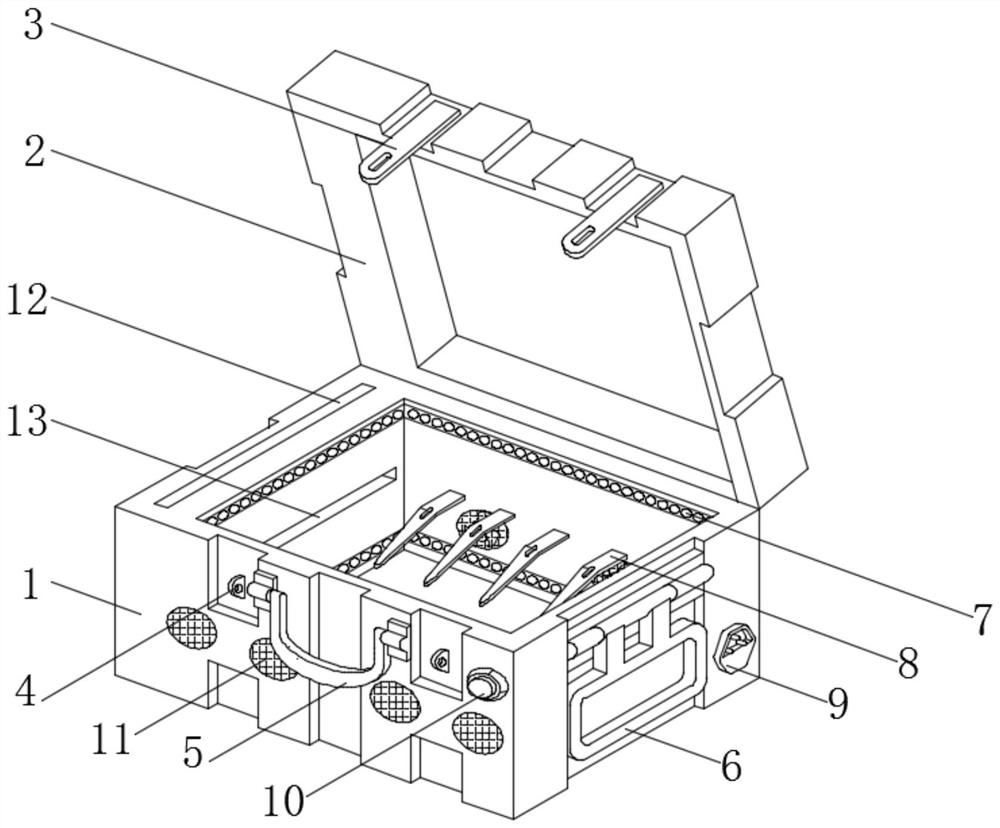

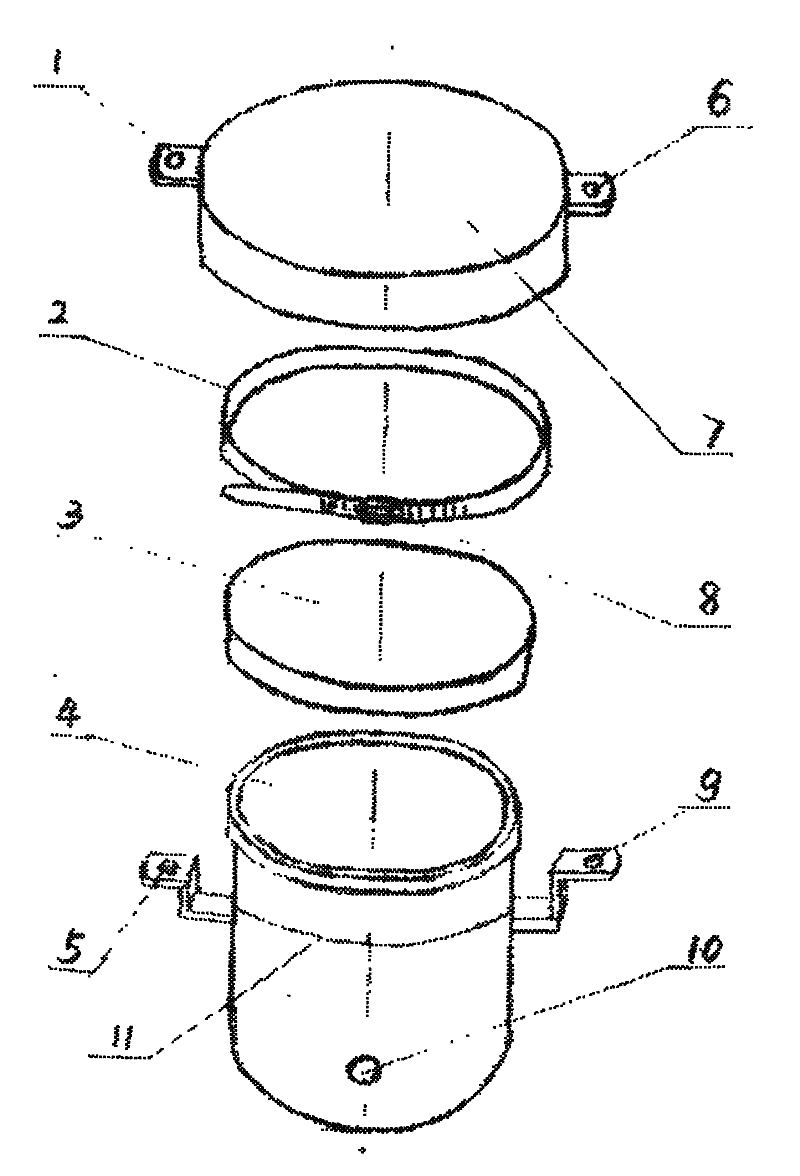

Armor type protective cover

InactiveCN105033746AAvoid destructionAvoid direct destructionMaintainance and safety accessoriesGrinding/polishing safety devicesMobile endMachine tool

The invention relates to an armor type protective cover comprising the following structures: a flexible organ shield comprising a folding, an inner side of the folding being supported by a plurality of support sheets, folding protrusions formed on fixedly connecting portions between the folding and the support sheets; an armor arranged on the top of the flexible organ shield and including a plurality of armor telescoping sheets, the armor telescoping sheets being mutually independent and respectively fixedly connected above an outer side of the folding from the folding protrusions; a mobile end plate fixing one end of the armor type protective cover on a mobile end of a machine tool guide rail; a fixed end plate fixing the other end of the armor type protective cover on a fixed end of the machine tool guide rail; at least one hairbrush fixedly connected with the mobile end plate of the armor type protective cover. The armor type protective cover can automatically clean the armor telescoping sheets in a protective cover telescoping process.

Owner:JIANGSU KRIUS MACHINE TOOL ACCESSORIES

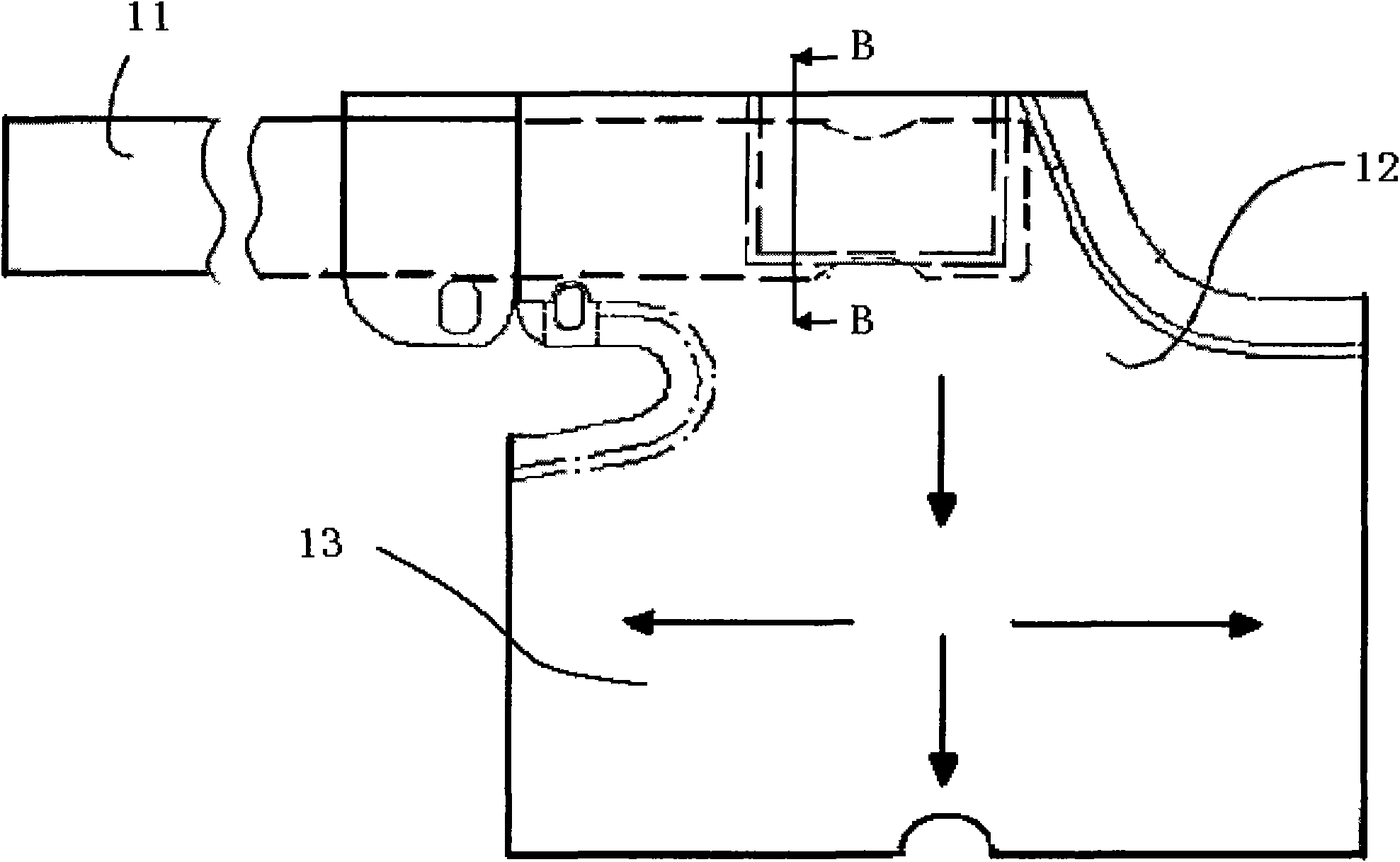

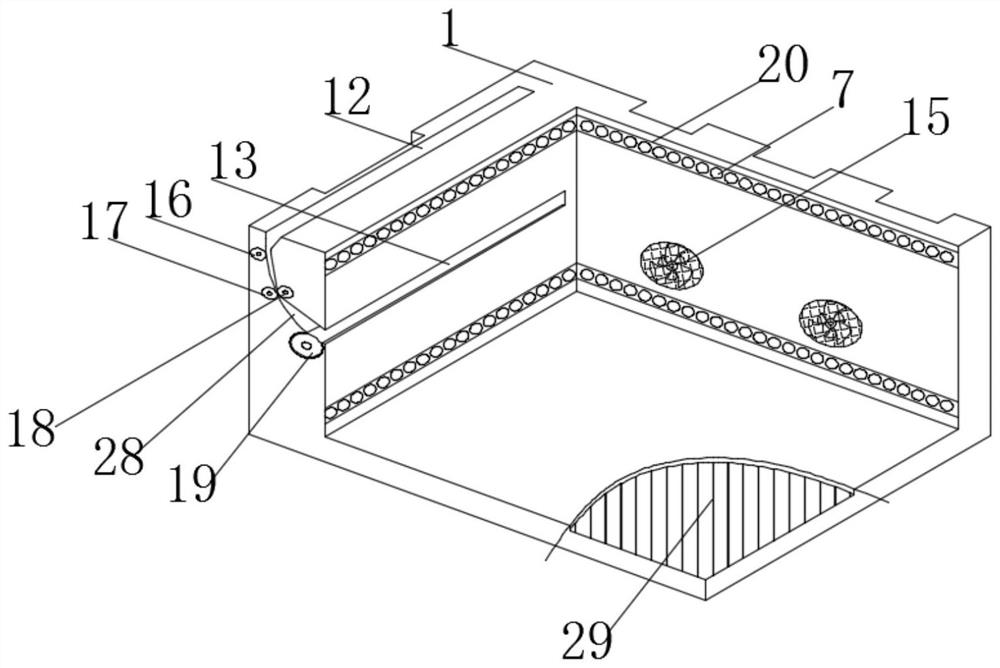

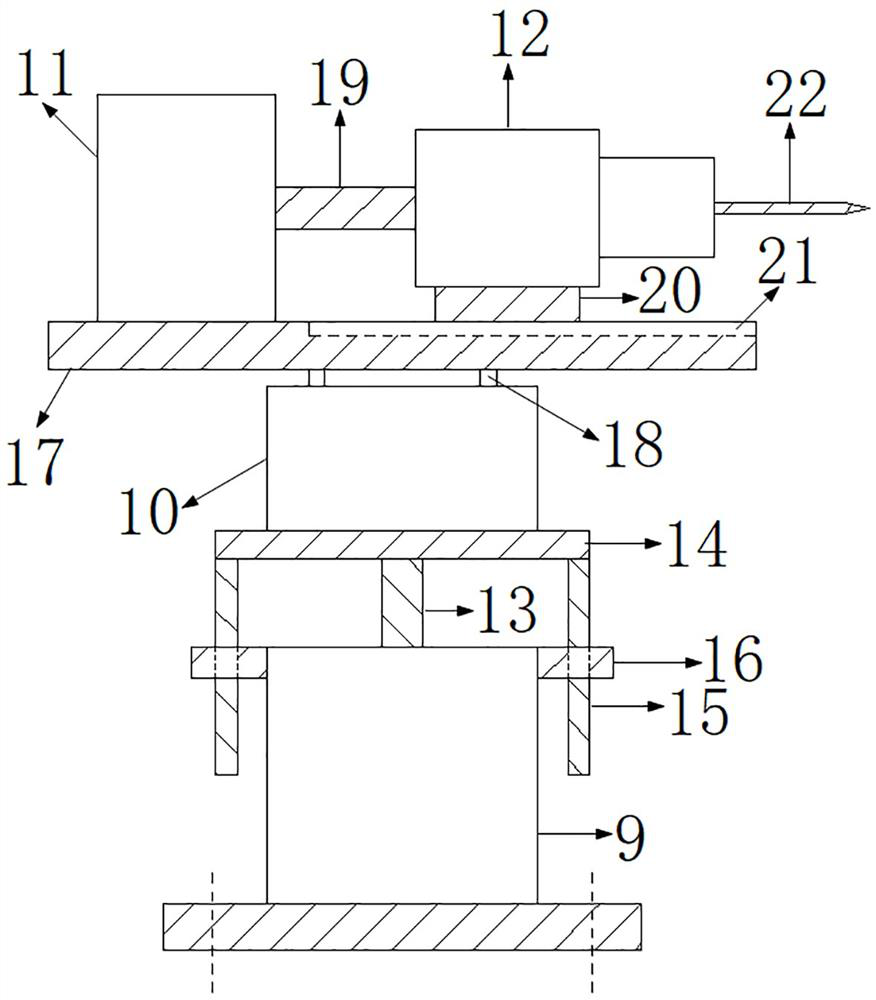

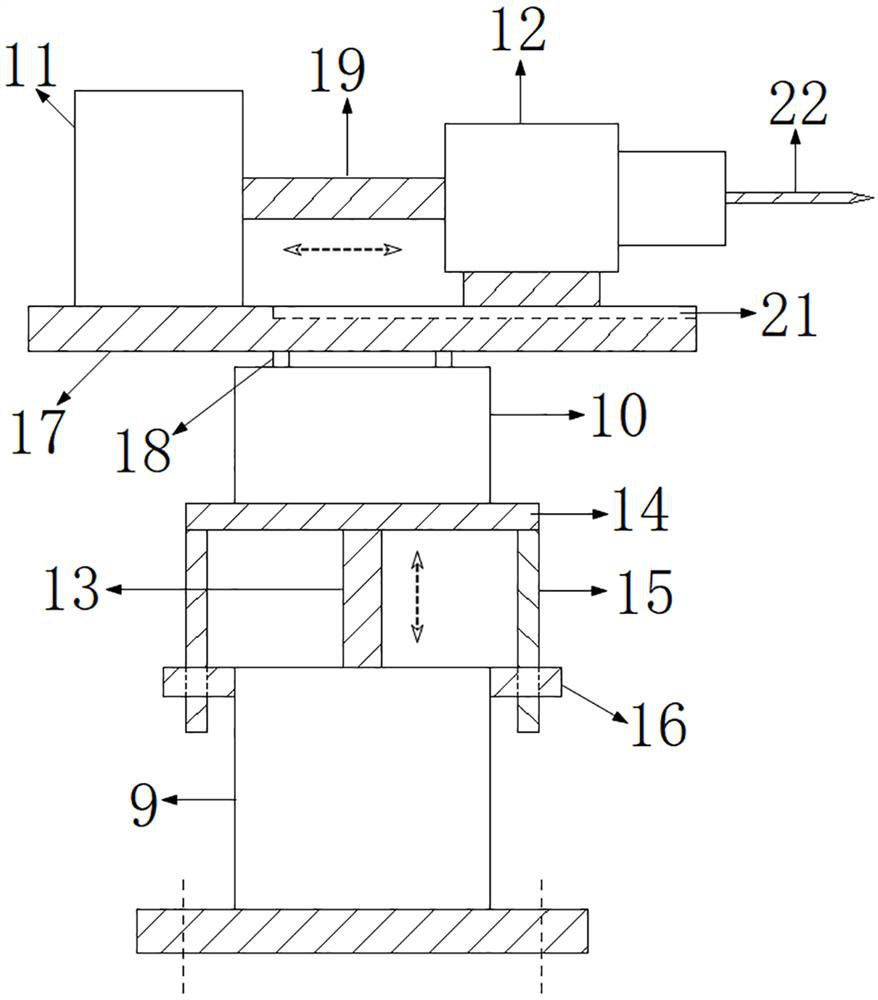

Mining automatic high-pressure flushing type camera device and monitoring method thereof

ActiveCN111327801AAvoid direct destructionImprove cleanlinessTelevision system detailsFouling preventionCamera lensSprayer

The invention discloses a mining automatic high-pressure flushing type camera device. The device comprises a base, a camera, a conical cover, a dust induction recognizer, a controller, a high-pressureairflow hose, a high-pressure water flow hose and a telescopic spray pipe mechanism, a camera lens on the left of the camera is positioned in the conical cover; a dustproof transparent assembly is arranged on the left of the camera lens. The dust induction recognizer is arranged in the conical cover and used for monitoring dust attached to the surface of the left side of the dustproof transparentassembly, the telescopic spray pipe mechanism is arranged at the top of the left side of the conical cover and can stretch out and draw back vertically, and the lower end of the telescopic spray pipemechanism is provided with an airflow sprayer and a water flow sprayer for spraying towards the dustproof transparent assembly. According to the invention, automatic induction is realized through thedust induction recognizer; cleaning is achieved by combining high-pressure water flow, air flow and other pressure intensities, the cleanliness of the dustproof glass can be effectively guaranteed, the high-pressure air flow can effectively achieve the effects of drying and water stain removing, and therefore the workload of manual wiping can be effectively reduced, damage to the camera lens is reduced, and the service life of the camera lens is prolonged.

Owner:HENAN POLYTECHNIC UNIV

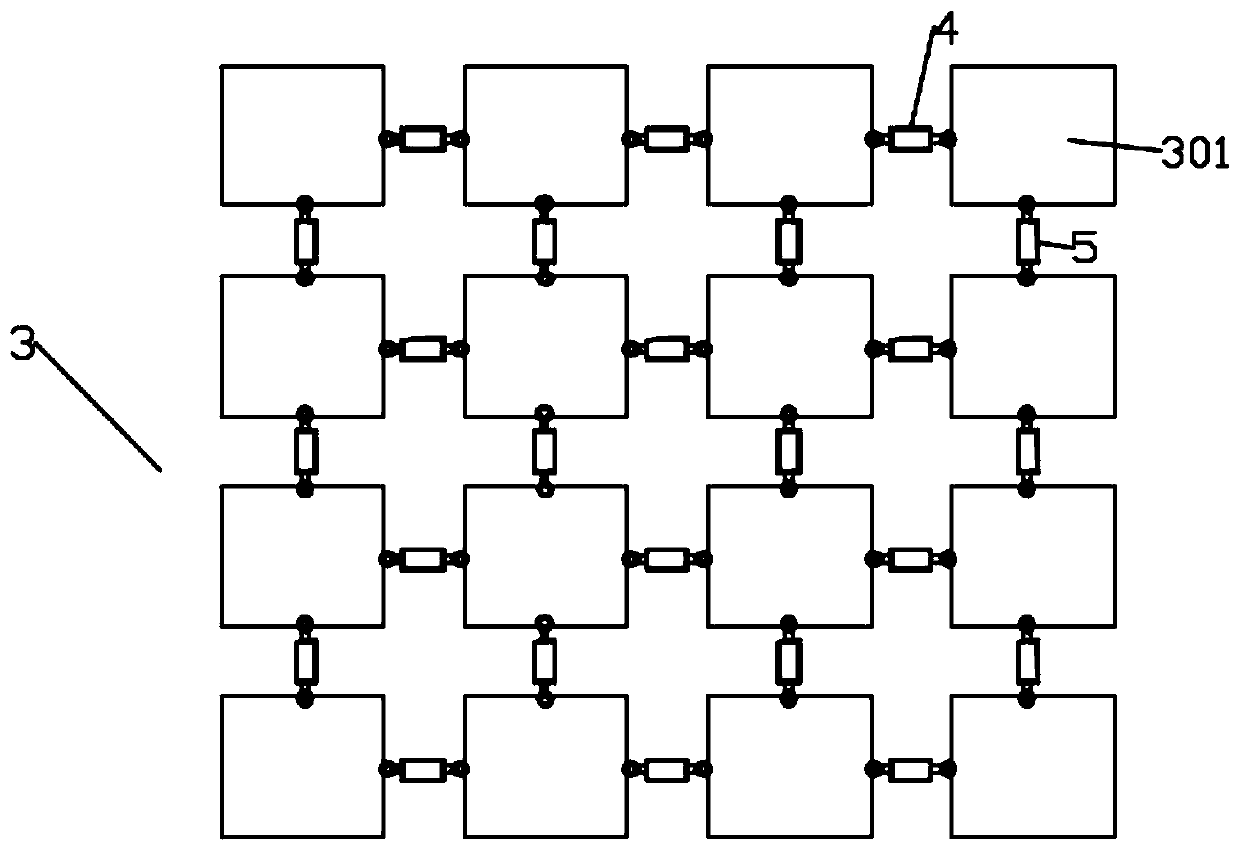

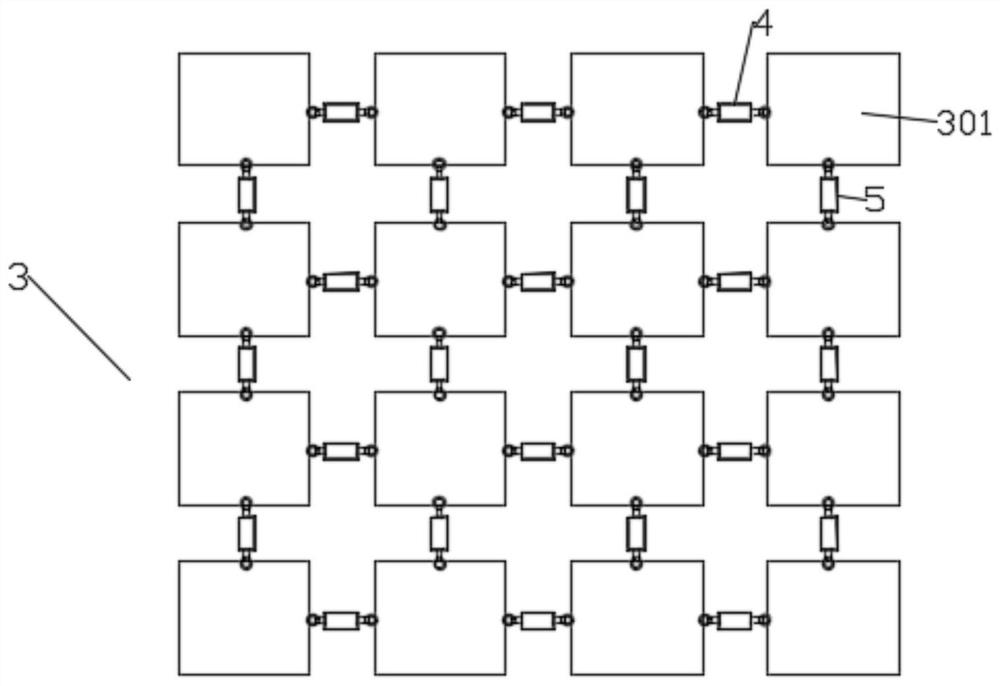

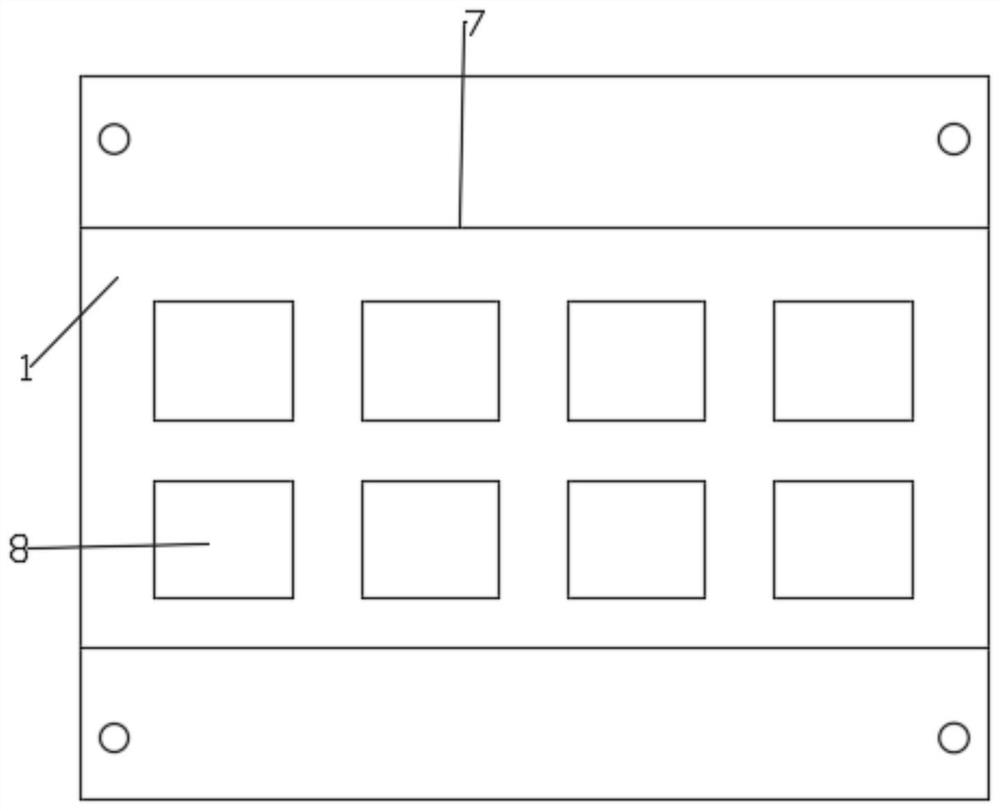

Fabricated building wall body

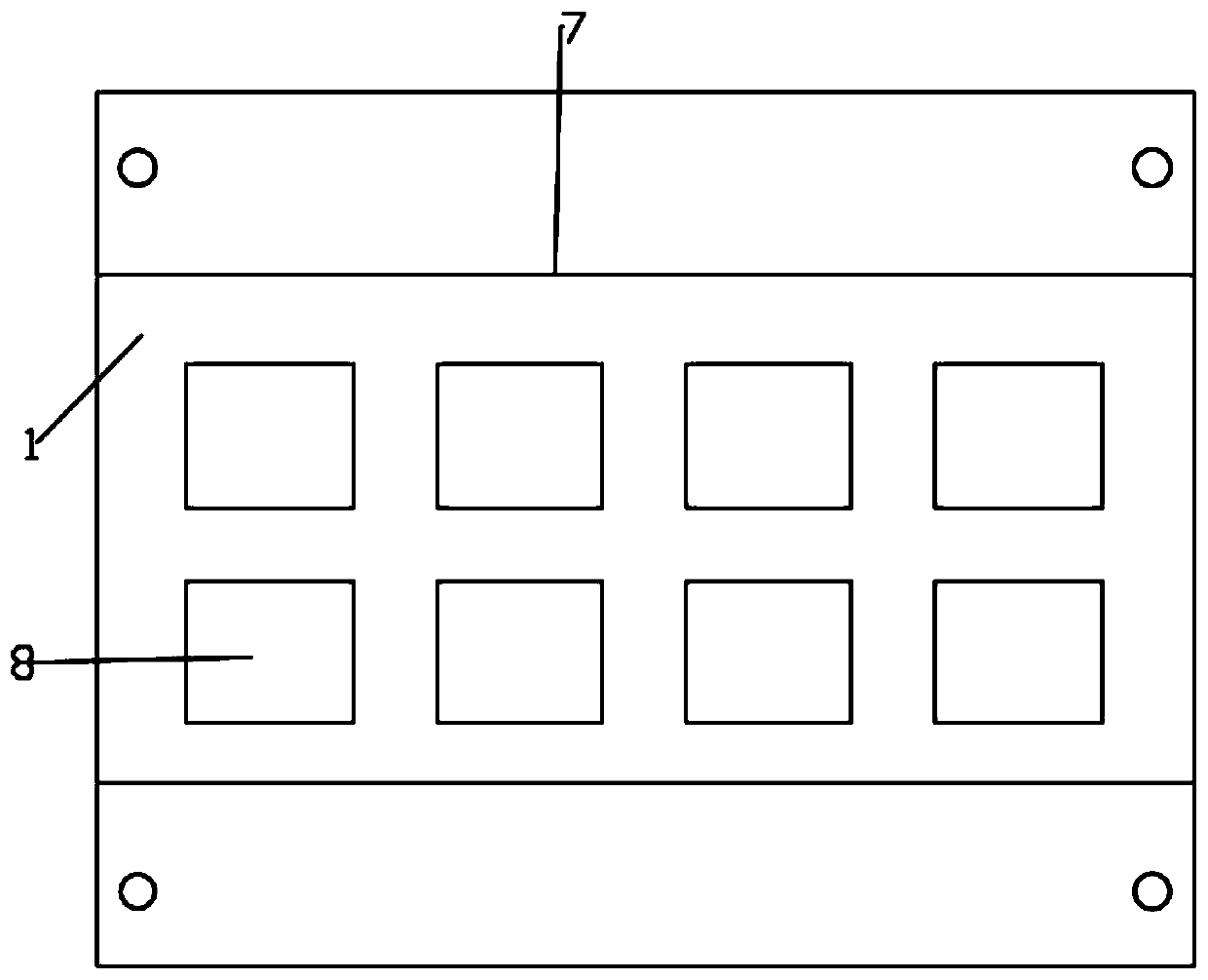

ActiveCN110258851AImprove stabilityImprove securityWallsProtective buildings/sheltersWall plateRectangular array

The invention discloses a fabricated building wall body, and belongs to the field of fabricated buildings.The wall body comprises an anti-seismic assembly, an outer wall panel, and an inner wall panel, the outer wall panel and the inner wall panel are arranged parallel to each other and connected through a connection assembly, a mounting part used for mounting the anti-seismic assembly is arranged on the side surface of the side of the outer wall panel or / and an opposite side of the inner wall panel, the anti-seismic assembly is pressed between the outer wall panel and the inner wall panel by the outer wall panel and the inner wall panel through the connecting assembly, and the anti-seismic assembly is assembled by a plurality of wall block units and damper devices, the wall block unitsare distributed in a rectangular array in the plane of the wall body, one or more damper devicesarearranged between the adjacent two wall block units, and the mounting part is used for mounting and fixing one or more wall block units. According to the fabricated building wall body,the main structure of the wall body can be protected from damage during the action of external forces such as earthquakes, thus the collapse of a house is prevented, and stability and safety of a building are improved.

Owner:ZHEJIANG TINSHINE ARCHITECTURAL DESING CO LTD

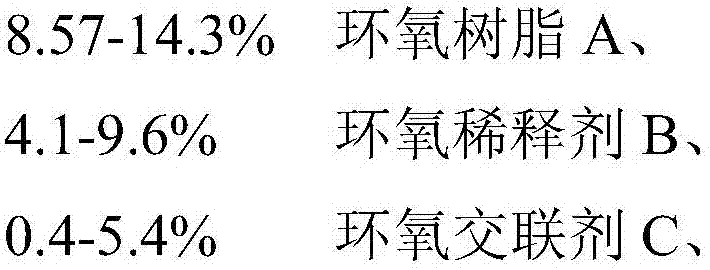

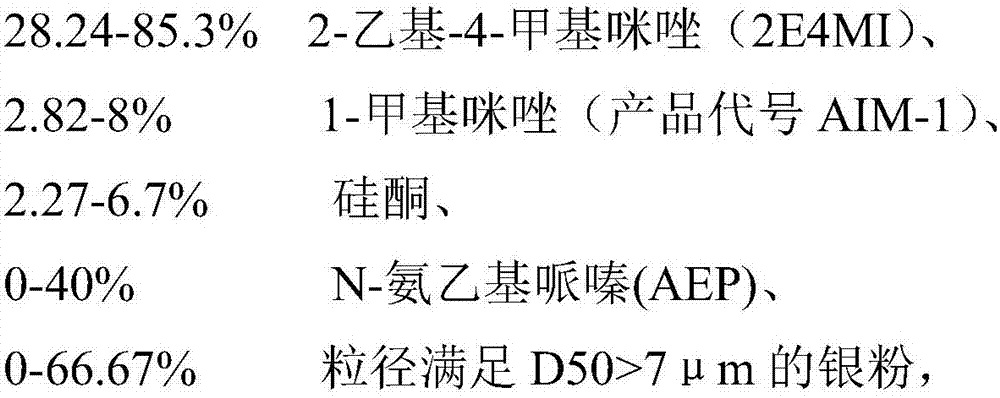

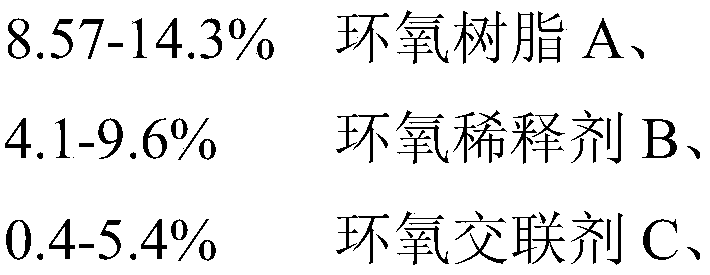

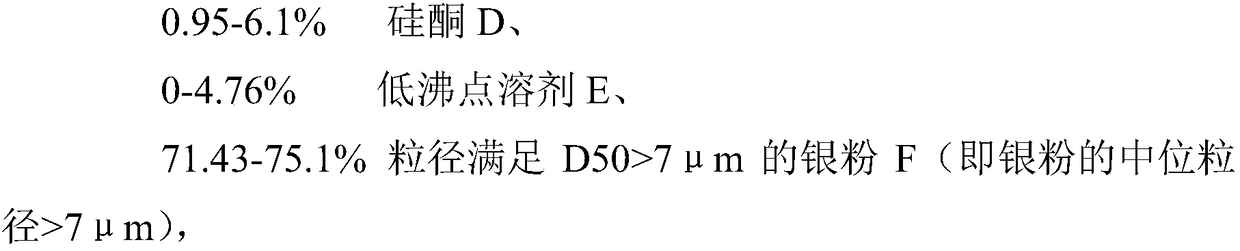

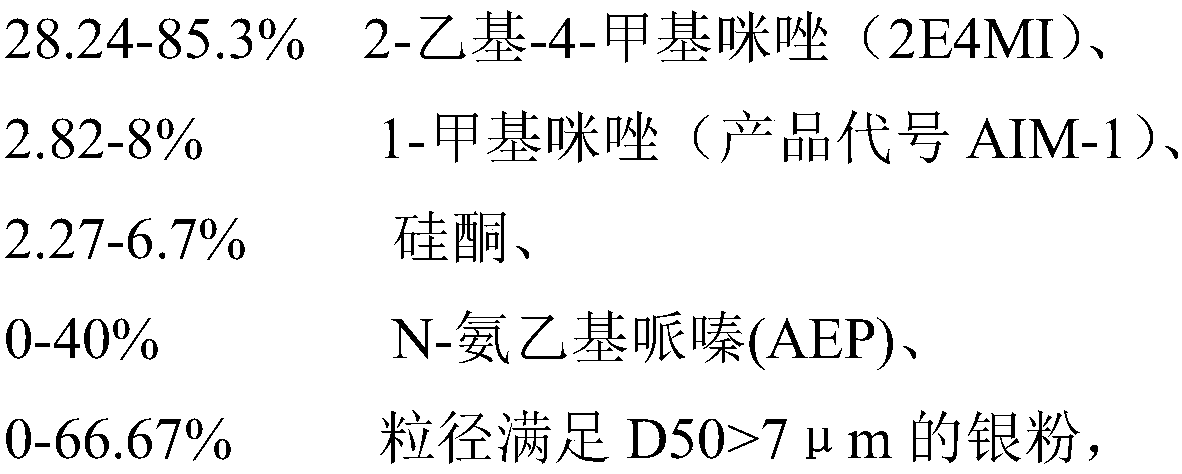

Normal-temperature cured conductive adhesive and process method thereof for connecting rechargeable battery pack

ActiveCN107446520AClose contactAvoid circuit breakingNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyElectrical battery

The invention discloses a normal-temperature cured conductive adhesive and a process method thereof for connecting rechargeable battery packs. The conductive adhesive is used for communicating rechargeable battery pack electrodes and reinforcing battery packs, and then the rechargeable battery pack electrodes and the battery packs can endure vibration and impact under use conditions. The normal-temperature cured conductive adhesive comprises an epoxy resin, an epoxy diluent, an epoxy curing agent, silicone aids and 30-90% by mass of silver powder of which D50 is greater than 7mu m. When being applied to connection and reinforcement of battery cathodes, the normal-temperature cured conductive adhesive disclosed by the invention can be called as a 'cathode cold welding' process, both the welding reliability of hot welding is maintained, and no external heat is needed in the welding process, direct damage or hidden damage of battery structures is avoided, and thus the properties of conductors are not affected by external heat.

Owner:晶丰电子封装材料(武汉)有限公司 +1

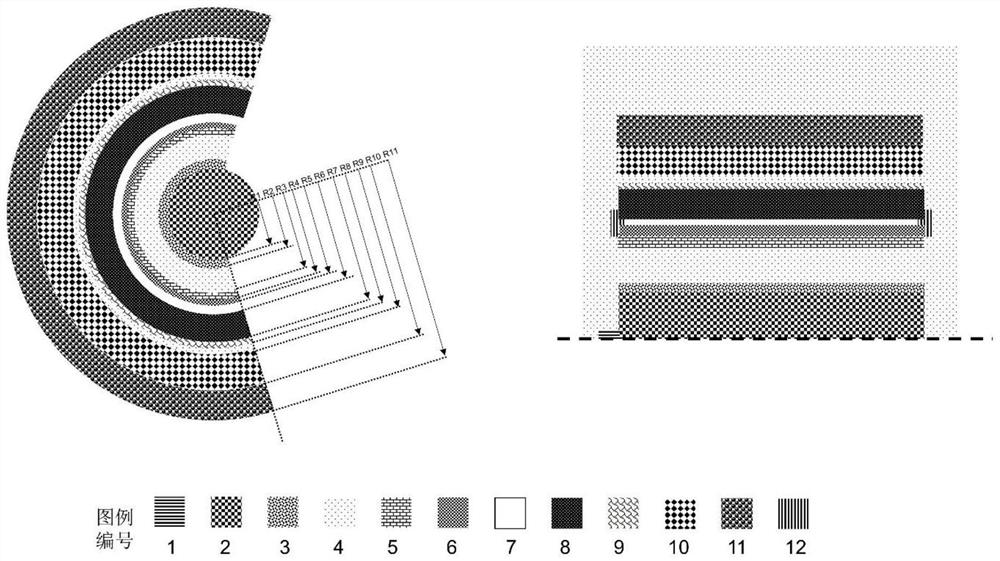

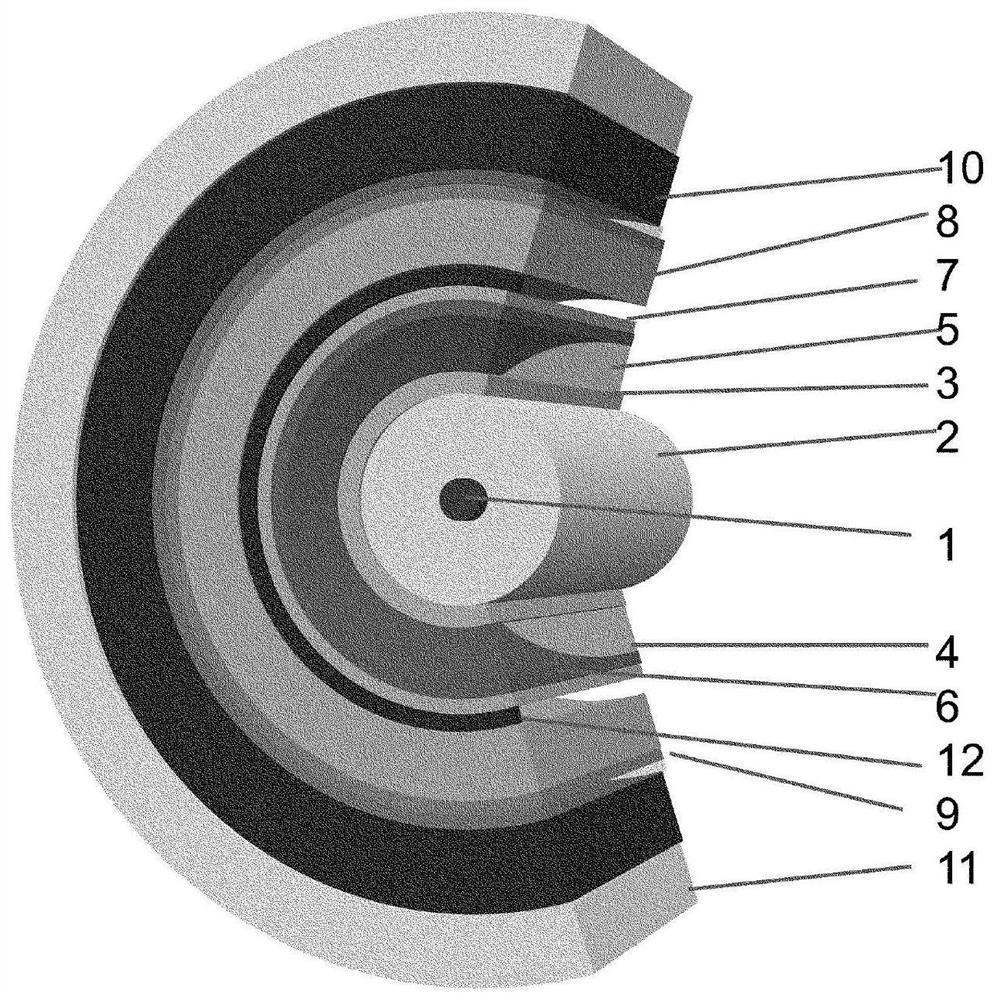

High-wave impedance self-restraint explosive welding method and device for dissimilar metal composite pipe

PendingCN114589389ASuppression of distortionSuppress irregular distortionNuclear energy generationMetal working apparatusDetonatorTEX-explosive

The invention discloses a high-wave impedance self-restraint explosive welding method and device for a dissimilar metal composite pipe. The device is sequentially and concentrically provided with selectable outer constraint explosive, an outer mold, a selectable outer constraint layer, an outer pipe, an inter-pipe gap, an inner pipe, a selectable protection pipe, a pressure transmitting medium, a charging pipe, explosive welding explosive and a detonator from outside to inside. In the inter-pipe gap between the outer pipe and the inner pipe, the supporting and sealing structures are fixed at the two ends of the inter-pipe gap, so that the gap is kept uniform and sealed; wherein the external base body structure comprises an outer mold, an outer restraint layer and an outer pipe; the internal coating structure comprises an inner tube and a protective tube; the explosive welding cartridge comprises a charging tube and explosive welding explosive. By means of the method and device, distortion of the explosive welding pipe can be restrained, the straightness of the composite pipe can be improved, collision damage between an outer pipe and an outer mold is reduced, the adjustable and controllable range of welding parameters is widened, the risk of crack generation is greatly reduced, and the gap distance between all structures is accurately limited.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

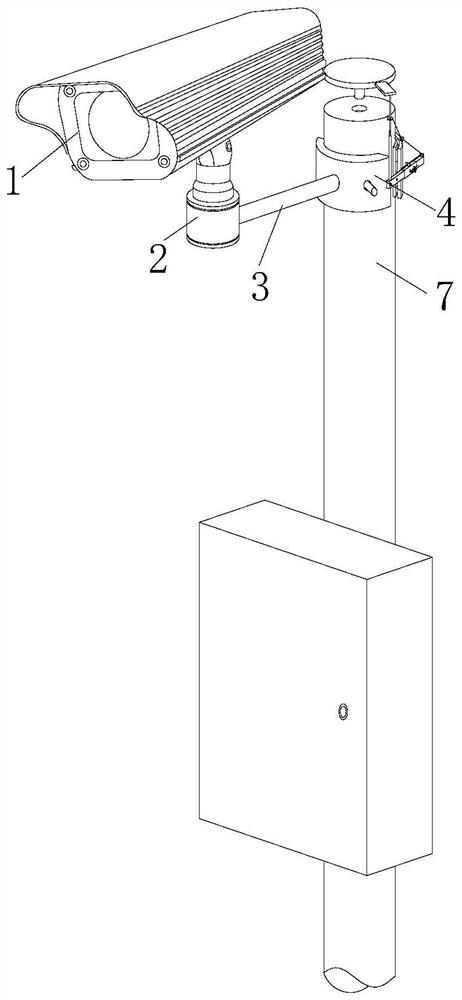

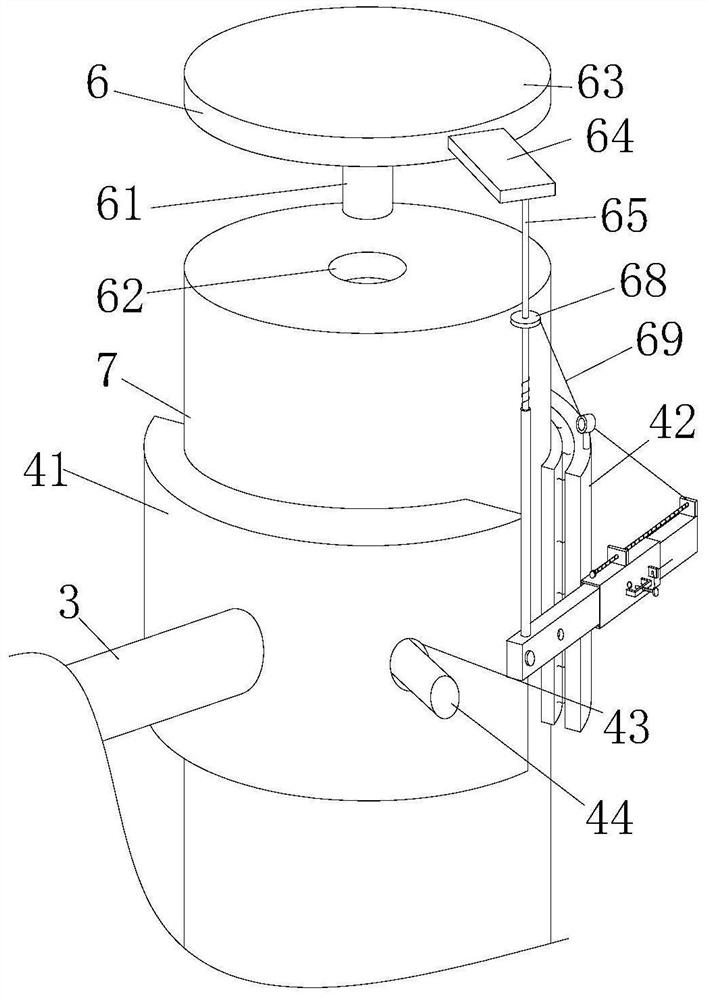

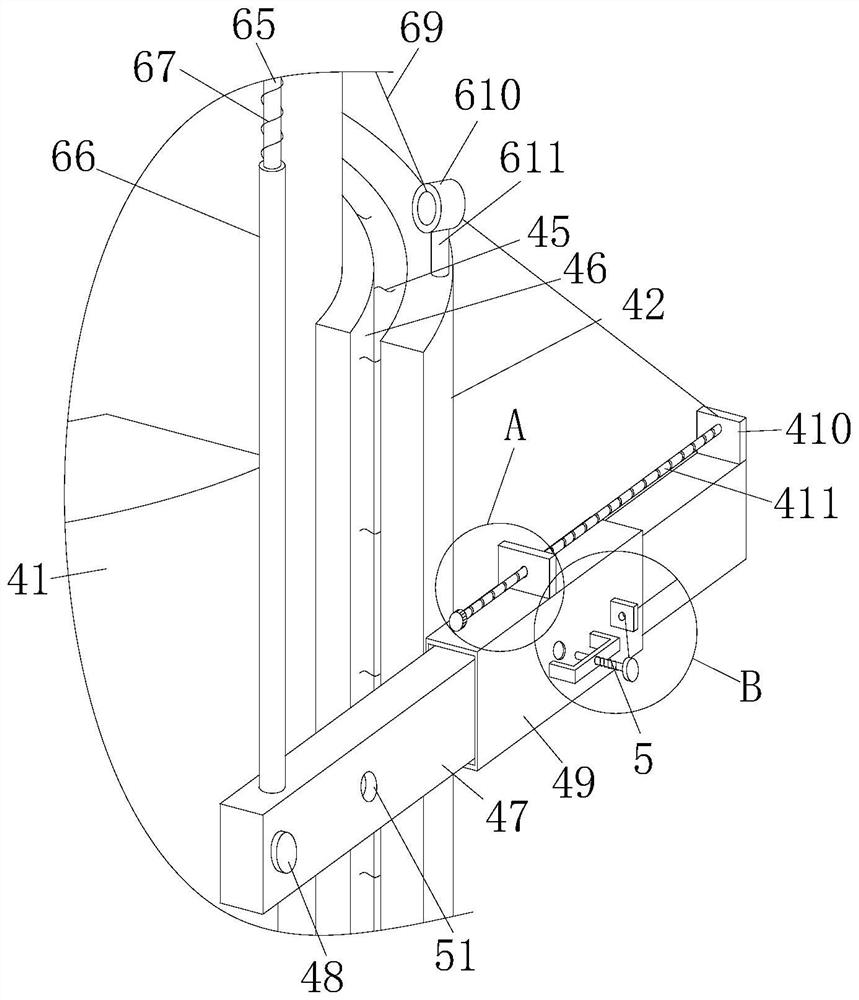

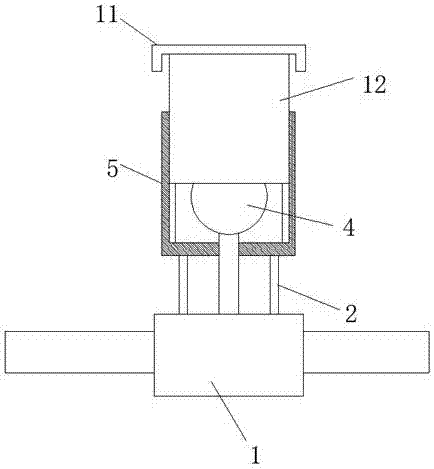

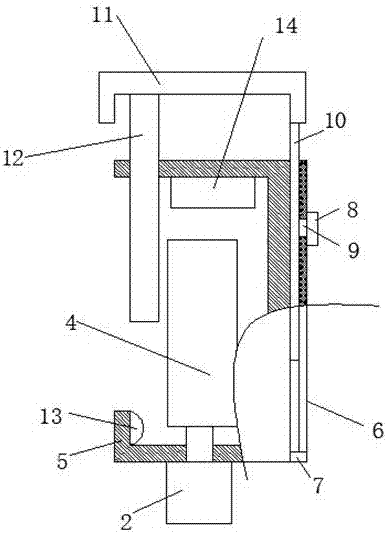

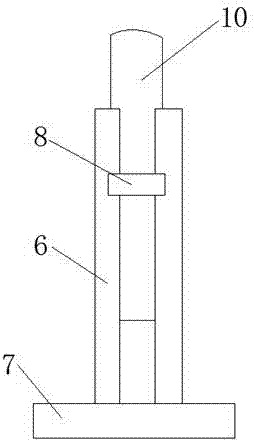

Monitoring camera mounting system

InactiveCN112944174AAvoid direct destructionExtend your lifeTelevision system detailsColor television detailsComputer hardwareSurveillance camera

The invention relates to a monitoring camera mounting system. The system comprises a monitoring camera body, a support rotating base and a fixed connecting rod, the monitoring camera body is arranged on the support rotating base, the side wall of the support rotating base is fixedly connected with the fixed connecting rod, a free end of the fixed connecting rod is fixedly connected to a fixing mechanism, and the fixing mechanism is detachably arranged outside a fixed supporting column. According to the system, a fixing mode of an existing monitoring camera body is optimized, specifically, the monitoring camera body is fixedly arranged on the fixed supporting column in a punching-free mode, in this way, direct damage to the fixed supporting column can be effectively avoided, the service life of a device is prolonged, and the optimized fixing structure is simple in structure, reasonable in design and easy to operate, can achieve the effects of saving time and labor and facilitating operation in the actual operation process, and meanwhile can prolong the service life of the device, thereby having higher practical value in actual application.

Owner:苏州市佳信美智能装备有限公司

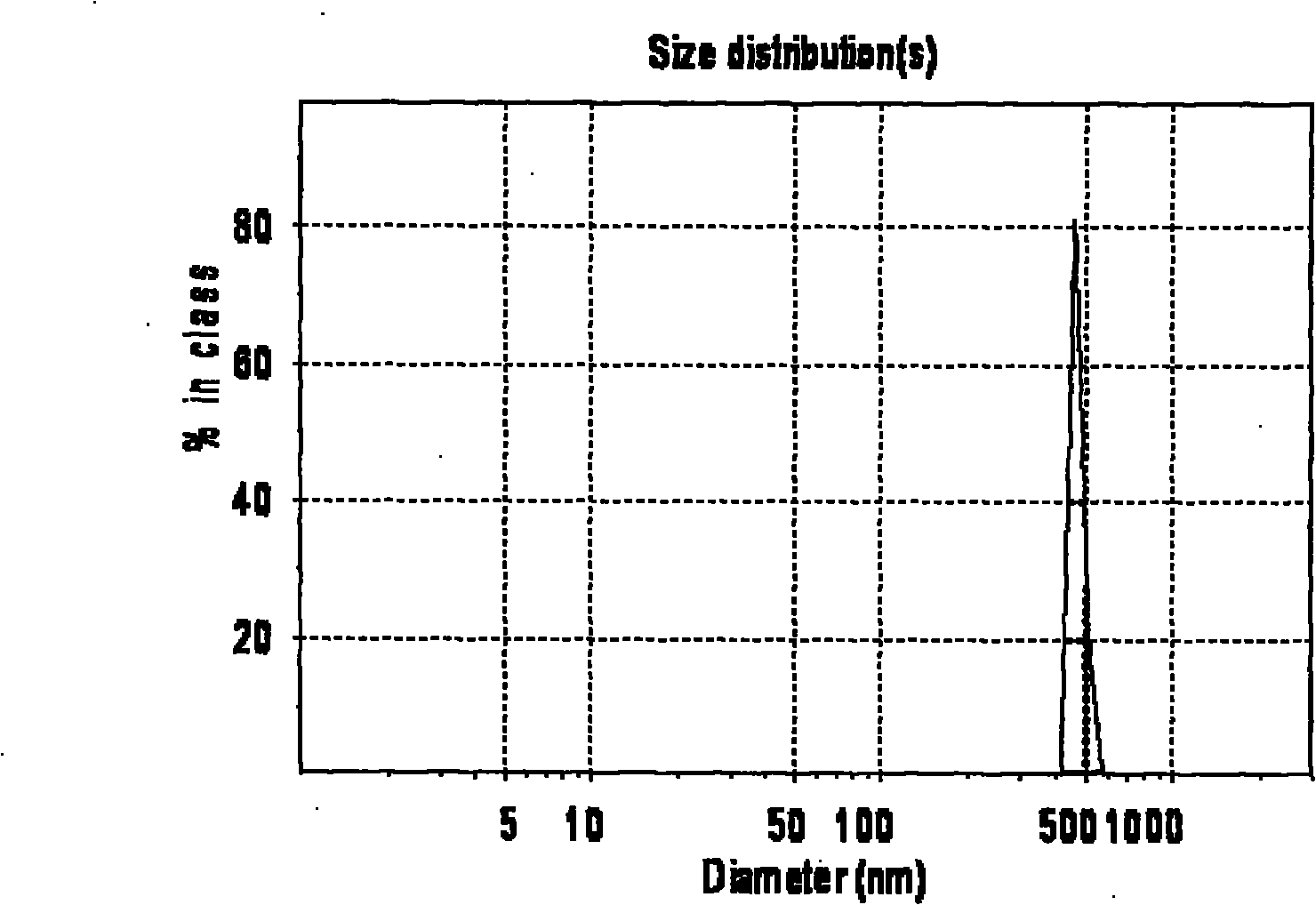

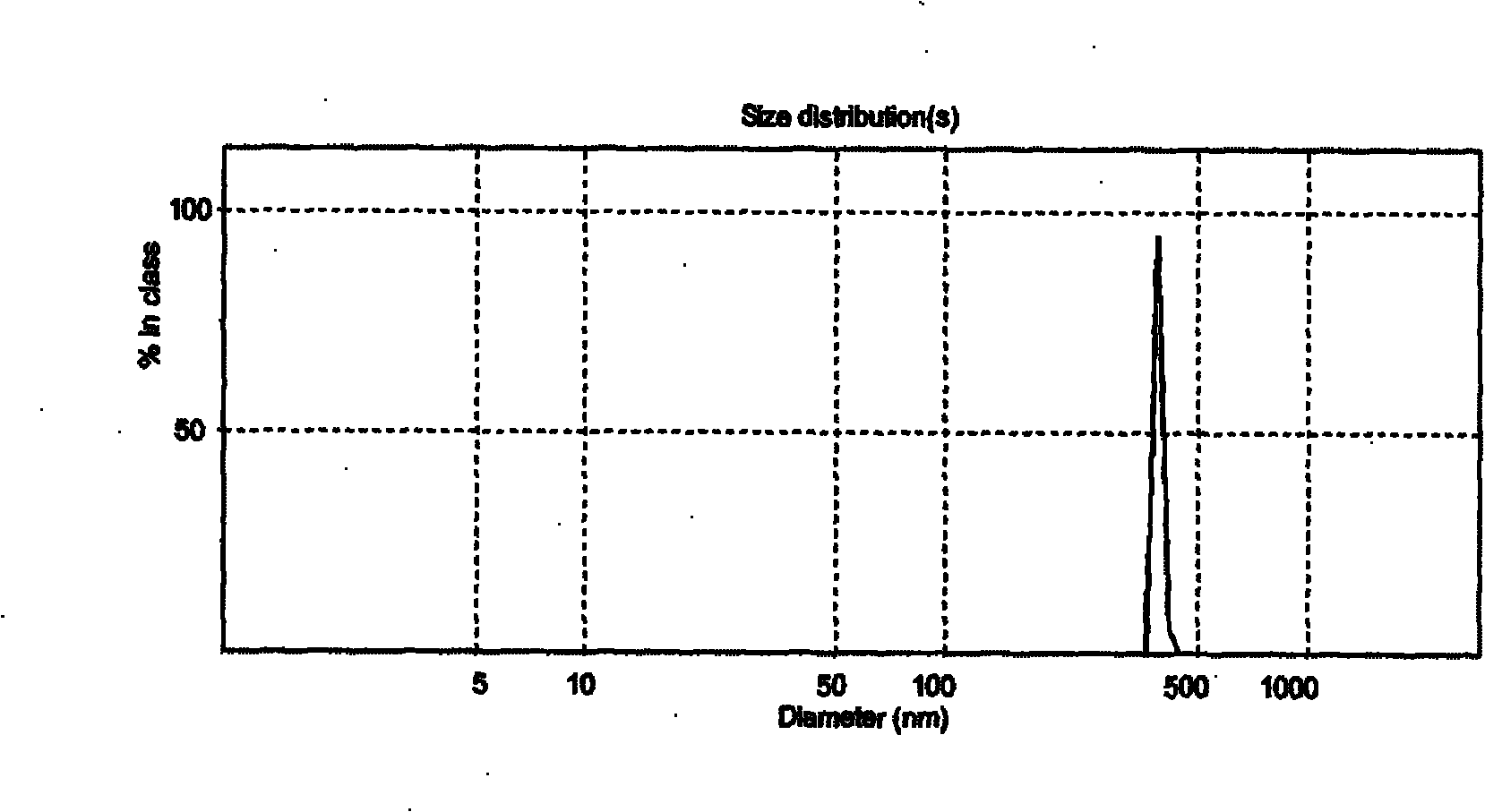

Self-assembling proliposome soft capsule and preparation method thereof

InactiveCN101780056AAvoid safety hazardsImprove complianceOrganic active ingredientsCapsule deliveryOral medicationPolyethylene glycol

The invention relates to the field of pharmaceutical preparations, in particular to a nimodipine self-assembling proliposome soft capsule and a preparation method thereof. The invention is characterized in that self-assembling proliposome liquid medicine which is composed by medicine, phospholipids, dispersion medium and polyethylene glycol modifier is wrapped by a soft capsule. The invention fills the self-assembling proliposome liquid medicine into the soft capsule, then self-assembling proliposome is completely wrapped by a capsule shell, and thereby the soft capsule not only can play the role of isolating oxygen, moisture and the like, but also can cover up bad taste and bring convenience to oral administration. After being disintegrated by gastric juice, the soft capsule can quickly hydrate and self-assemble to form liposome with high entrapment rate and uniform particle size.

Owner:CHINA PHARM UNIV

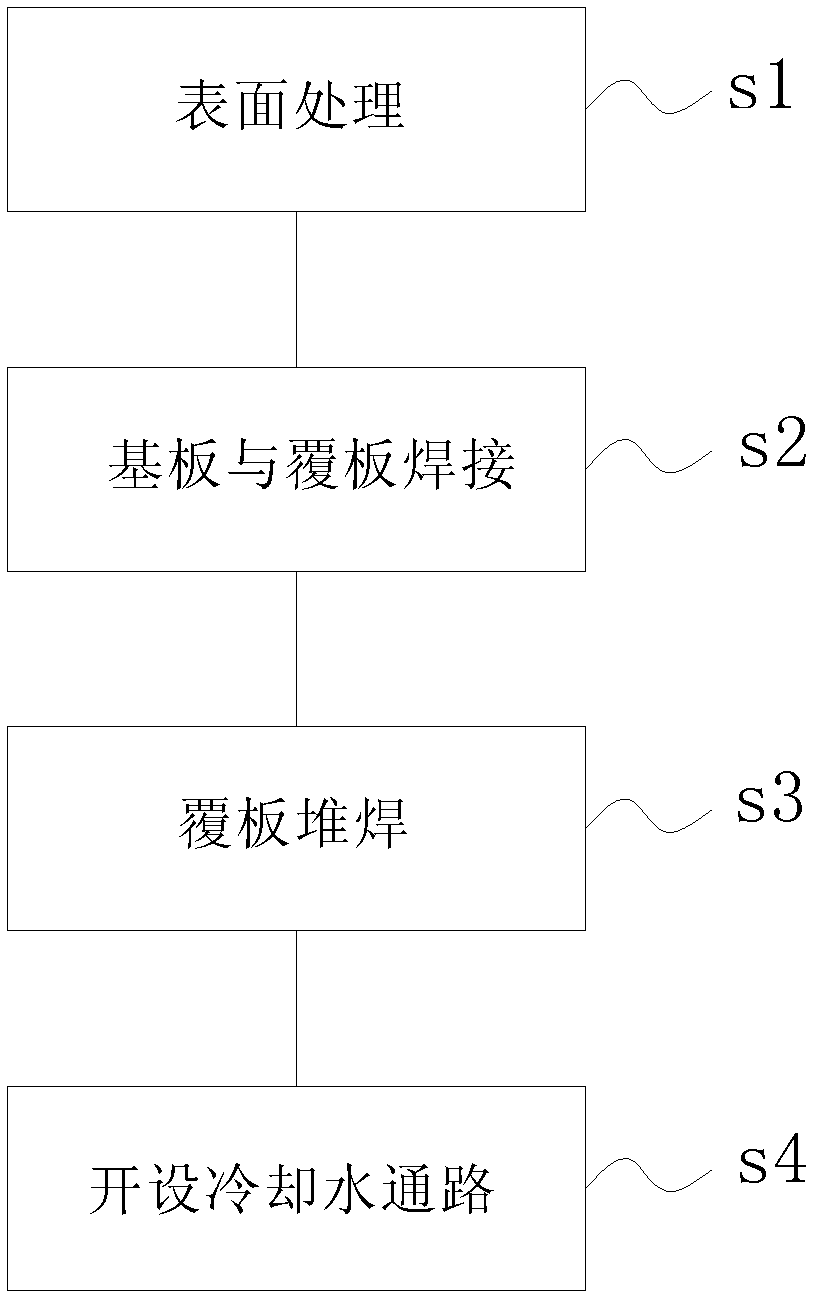

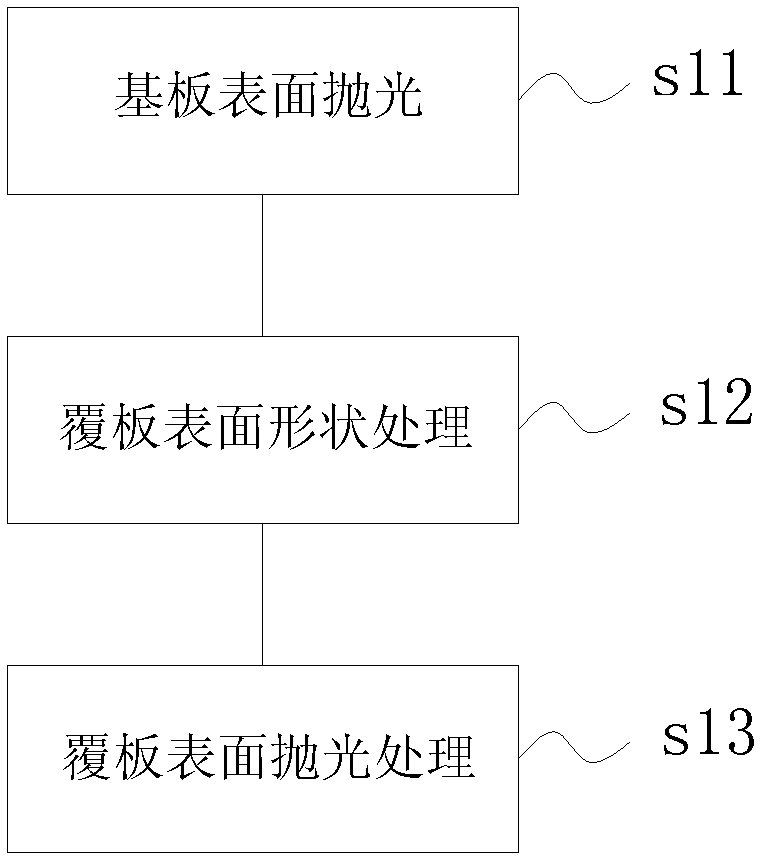

Method for manufacturing cooling element and cooling element

The invention discloses a method for manufacturing a cooling element. A copper substrate is welded with a stainless steel shroud plate by an explosive welding method, so that the cleaning degree of the welding surface on a welding piece can be improved; and the heating time of the welding piece during welding is short, so that the degree of heated oxidation of the welding surface is reduced, and the reliability of welding is improved. The invention also provides the cooling element manufactured by the method. Due to the adoption of the explosive welding method, the degree of oxidation of the surface of the welding piece is reduced, and the generation of oxides on the copper substrate is avoided, so that the welding quality of the cooling element is improved, and the operating reliability of the cooling element is improved. In addition, the cooling element is welded with the stainless steel shroud plate and an overlaying layer, and the stainless steel shroud plate and the overlaying layer can prevent a metallurgical furnace from damaging the copper substrate directly, so that the damage resistance of the cooling element is improved.

Owner:YANGGU XIANGGUANG COPPER

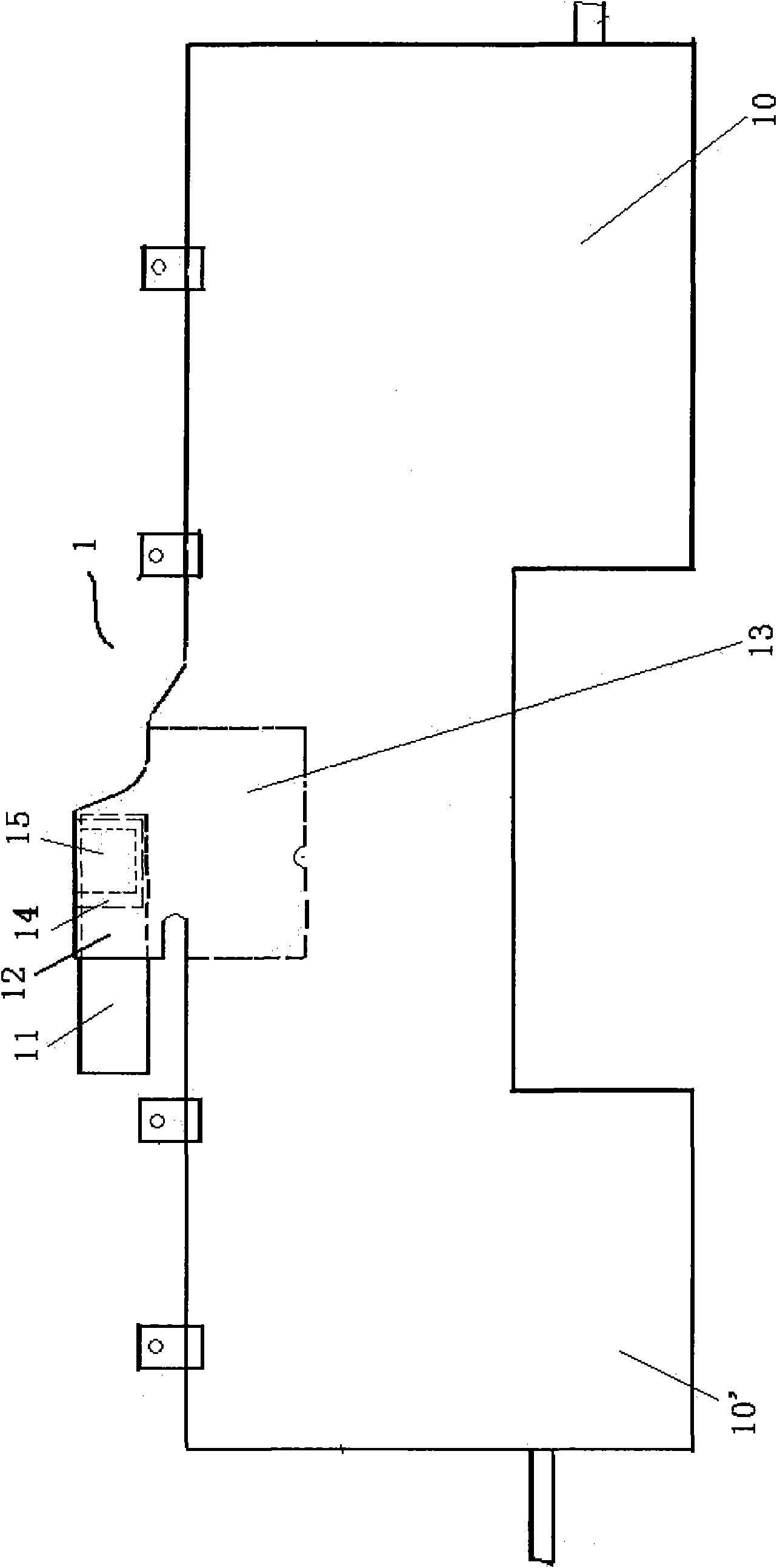

Gas-closed electrical box

InactiveCN101552449AAvoid direct destructionNot easy to destroy directlyCable junctionsCushioningElectric power system

The present invention relates to a box which is used in field and is used for installing cable joint of electrical power system or electrical equipment, wherein the box comprises a box body, an inner rubber cover, a throat fixer and an outer cover. The box provided by the invention can resist crushing and cutting. Furthermore a special structure neatly uses a principle of atmospheric pressure so that the closeness can be kept for a long time. Because the main supporting force of cover body comes from the cement floor, the cover body can bear a large pressure. Even when the cover body is damaged, the box is not damaged because of the cushioning of inner rubber cover. The repairing and maintenance are easy.

Owner:蔺新衔

Protecting device for instrument of instrument valve

InactiveCN107191654AExtended service lifeEasy to readLighting elementsMeasurement apparatus housingsSlide plateEngineering

The invention discloses a protecting device for an instrument of an instrument valve. The protecting device for the instrument of the instrument valve comprises an instrument valve body and the instrument connected with the instrument valve body. The instrument is located above the top of the instrument valve body. Fixing rods are arranged on the two sides of the instrument. One end of each fixing rod is fixed to the top of the instrument valve body, and the other ends of the fixing rods are fixedly provided with a protective shell with one open side. The instrument is located in the protective shell. The side, far away from the open side, of the protective shell is fixedly provided with a fixing block. The top of the fixing block is fixedly provided with a limiting rod. A connection rod is arranged between the limiting rod and the protective shell. One side of the connection rod is fixedly provided with a connection column. The protecting device for the instrument of the instrument valve can prevent dust from covering the instrument, protect the instrument, prevent external factors from directly damaging the instrument and prolong the service life of the instrument through cooperative use of the arranged structures of a push button, the connection column, the connection rod, a connection cover, a sliding plate, the protective shell and the like.

Owner:YANCHENG XINGHUO VALVE IND MFG CO LTD

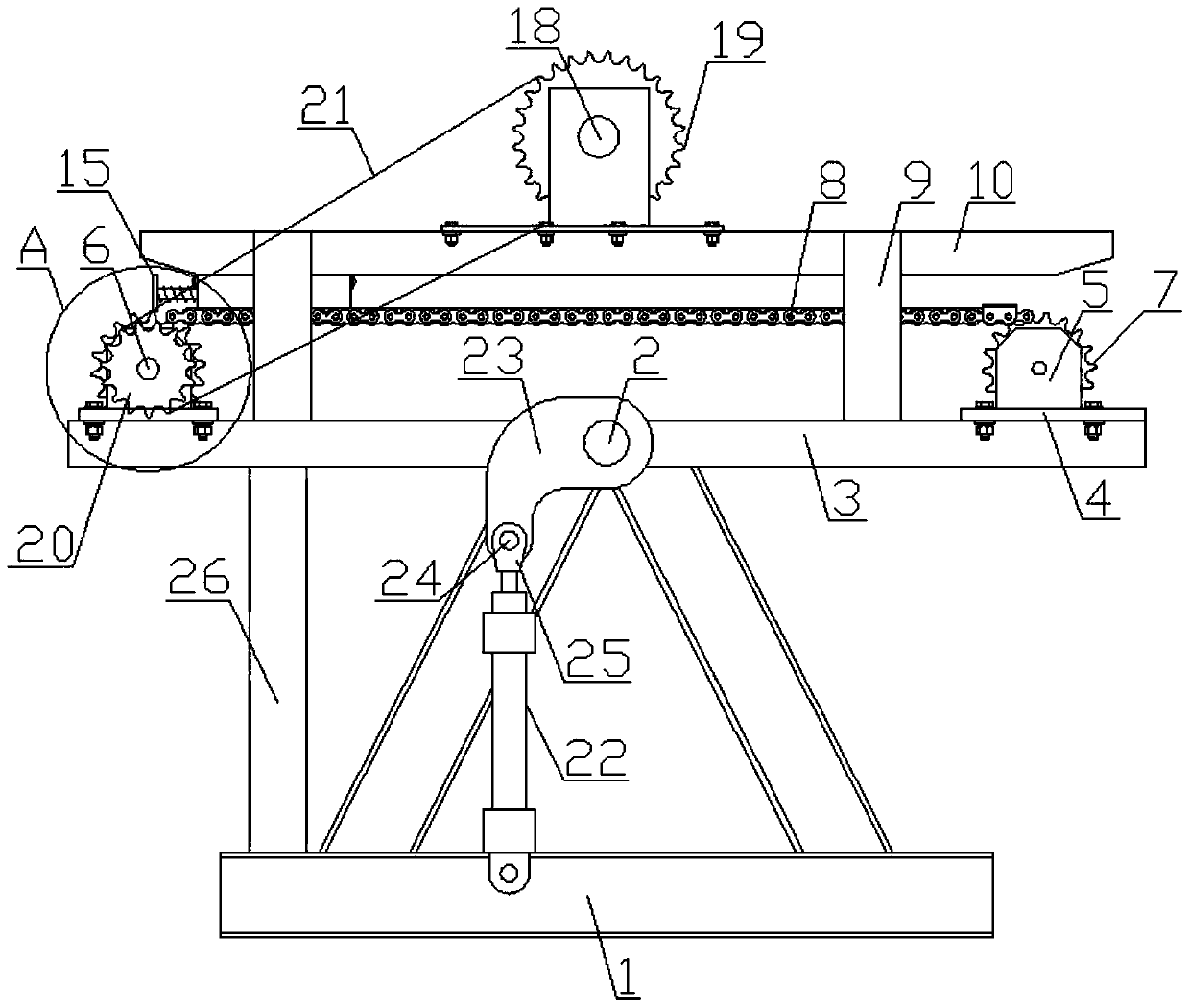

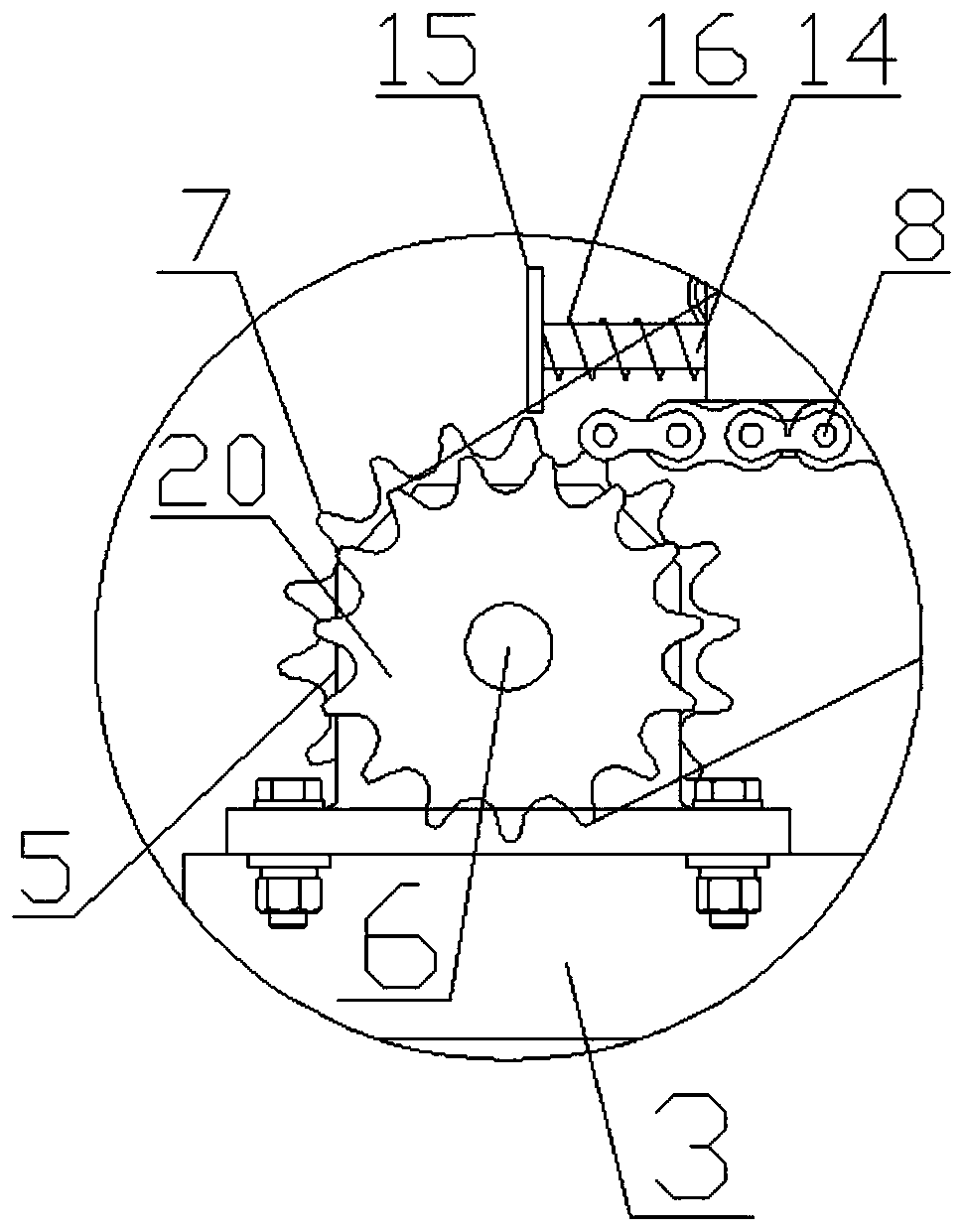

A stubble cutting and digging straw root stubble cleaning and crushing device

InactiveCN102771211BEasy to replaceAvoid direct destructionGatherer machinesEngineeringEarth surface

Owner:SHANDONG UNIV OF TECH

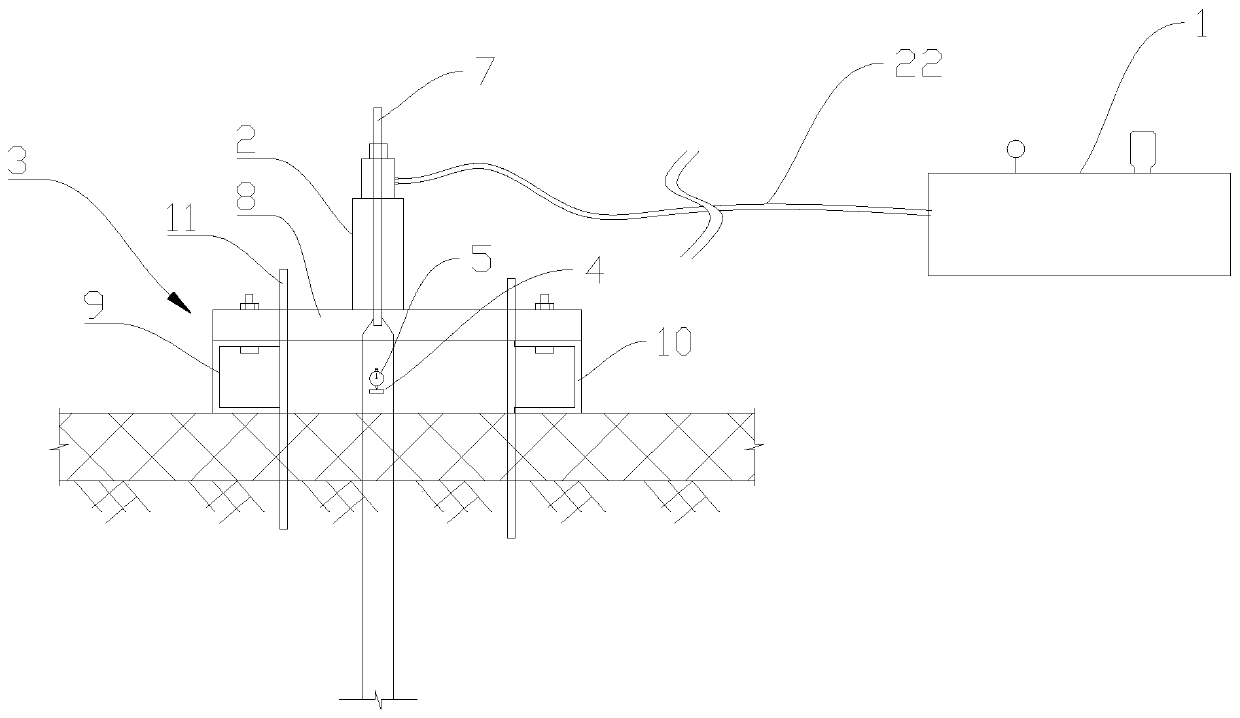

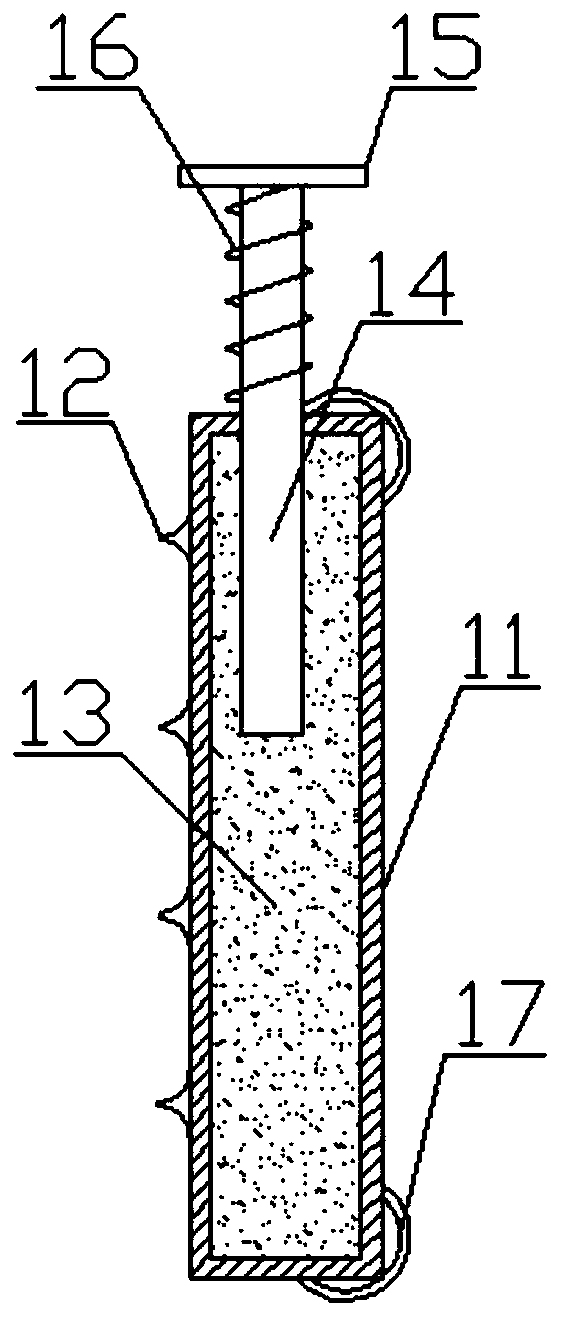

Perforated soil nail pull-out test device and test method thereof

The invention relates to the technical field of civil engineering, and particularly discloses a perforated soil nail pull-out test device and a test method thereof. The perforated soil nail pull-out test device comprises an oil pressure pump pressurization system, a jack, a support component, a first extension piece and a first dialgage. The perforated soil nail pull-out test method includes the following steps that the perforated soil nail pull-out test device is assembled and is subjected to debugging and checking firstly, and normal operation of the test device is ensured; a small amount ofload is put, and then test pulling is conducted; a pull-out test is conducted according to designed grading load, and readings of a oil pressure gauge, the first dialgage and a second dialgage are recorded when operation is conducted; and data analysis and treatment is conducted according to recorded data. According to the test device, the structure is simple, use is convenient, and the test canbe carried out fast and easily; and the operation method is easy, and accuracy of results is high.

Owner:张亮

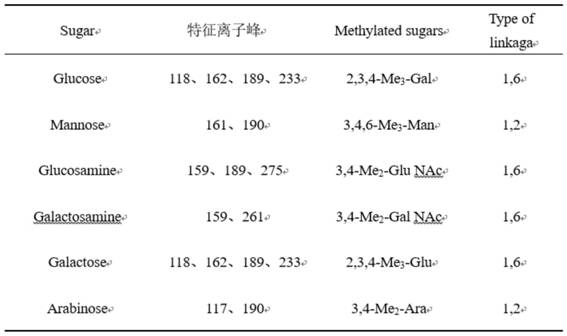

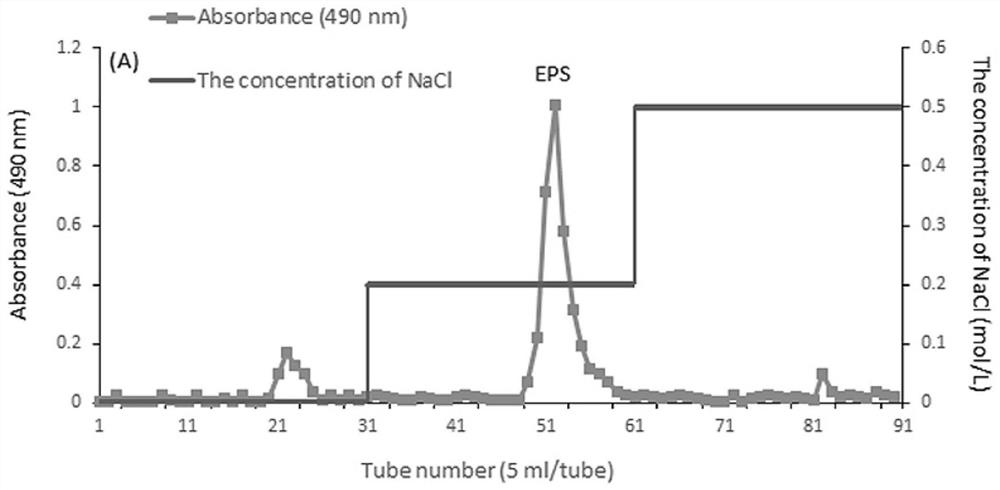

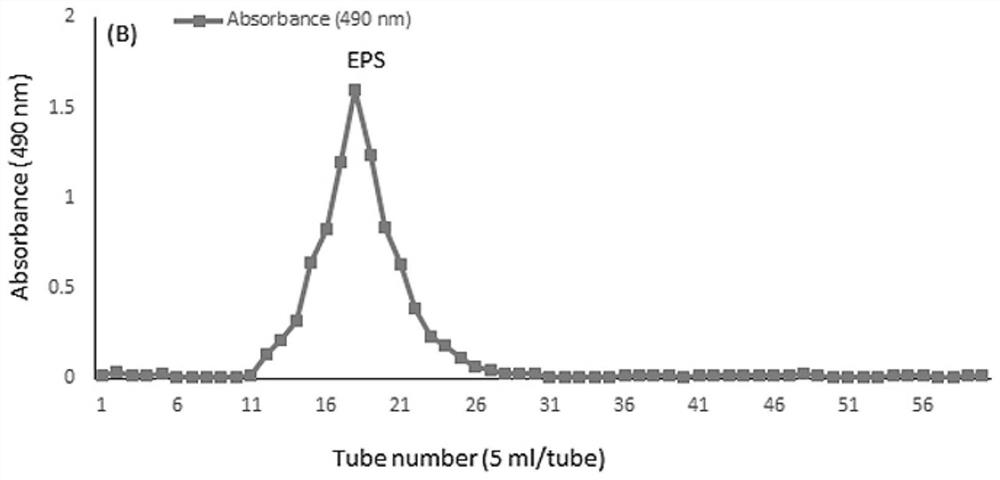

A kind of exopolysaccharide and its application

ActiveCN109517752BHigh ability to scavenge free radicalsImprove protectionBacteriaMicroorganism based processesBio engineeringClostridium organisms

Owner:湖南大泽农生物科技有限公司

A kind of normal temperature curing conductive adhesive and its process method for connecting rechargeable battery pack

ActiveCN107446520BClose contactAvoid circuit breakingNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyElectrical battery

The invention discloses a normal temperature curing conductive adhesive and a process method for connecting a rechargeable battery pack. The conductive adhesive is used for the connection of the electrodes of the rechargeable battery pack and the reinforcement of the battery pack, so that it can adapt to vibration and impact under use conditions , the room temperature curing conductive adhesive contains epoxy resin, epoxy diluent, epoxy curing agent, silicone auxiliary agent, and silver powder with a mass fraction of 30-90% and D50>7 μm. The present invention adopts room temperature curing conductive adhesive as the connection and reinforcement of the negative electrode of the battery, which can be called the "negative electrode cold welding" process, which can not only maintain the welding reliability of heat welding, but also not apply external heat during the welding process, and avoid damage to the battery structure. Direct damage or invisible internal damage, so as to avoid the influence of external heat on the conductor properties.

Owner:晶丰电子封装材料(武汉)有限公司 +1

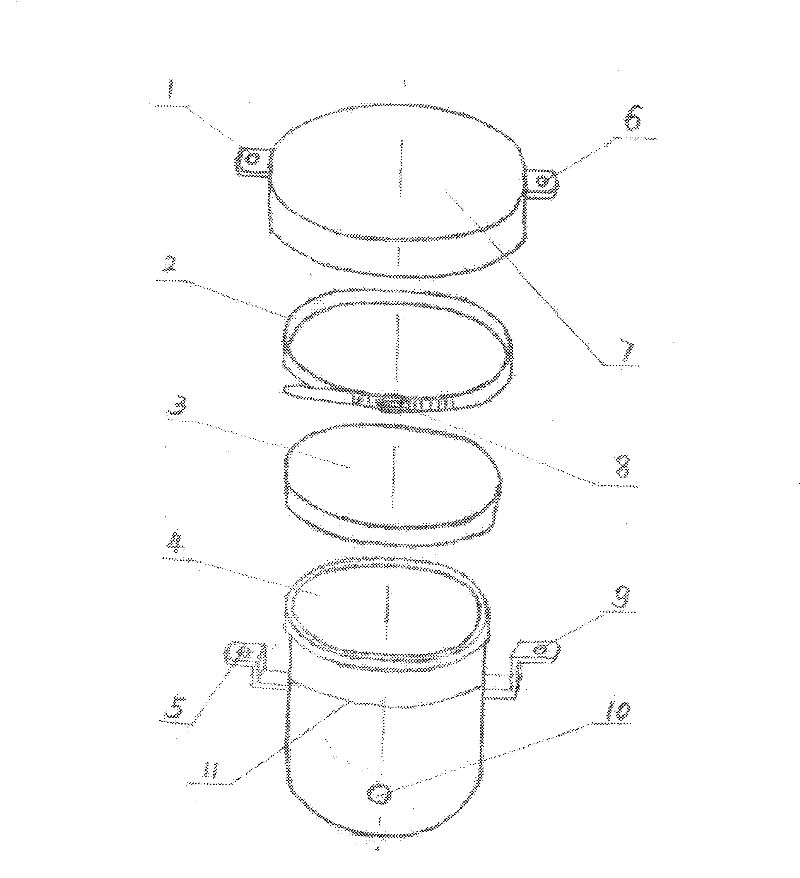

Ultraviolet disinfection money box

ActiveCN111588869AUniform radiationAvoid incomplete disinfectionLavatory sanitoryHeatEngineeringMechanical engineering

The invention discloses an ultraviolet disinfection money box which comprises a box body, a box cover and lock catches and is characterized in that the box cover is hinged to the upper portion of thebox body, the lock catches are installed on the left side and the right side of the front side wall of the box cover, and lock pieces matched with the lock catches are installed at the positions, corresponding to the lock catches, of the front side wall of the box body. Through conveying rollers and grinding rollers in a communicated groove, a single paper money enters an inlet groove along with the rotation of a first conveying roller and then subjected to high-temperature grinding treatment through a first grinding roller and a second grinding roller, the paper money is subjected to high-temperature disinfection during ironing, the initial speed is given through the speed regulation of the second conveying roller, so that the paper money moves to the lower side of a certain money clip, in the moving process of the paper money, the upper and lower groups of ultraviolet lamp strips in the inner cavity of the box body disinfect the upper and lower surfaces of the paper money, ultraviolet rays have no irradiation shadows, are uniformly radiated on the paper money, cooperate with the grinding rollers for high-temperature disinfection, avoid incomplete disinfection, improve the disinfection effect, and are suitable for wide popularization and application.

Owner:PINGYANG SILVER NEW FINANCIAL PROD CO LTD

Automotive safety air curtain

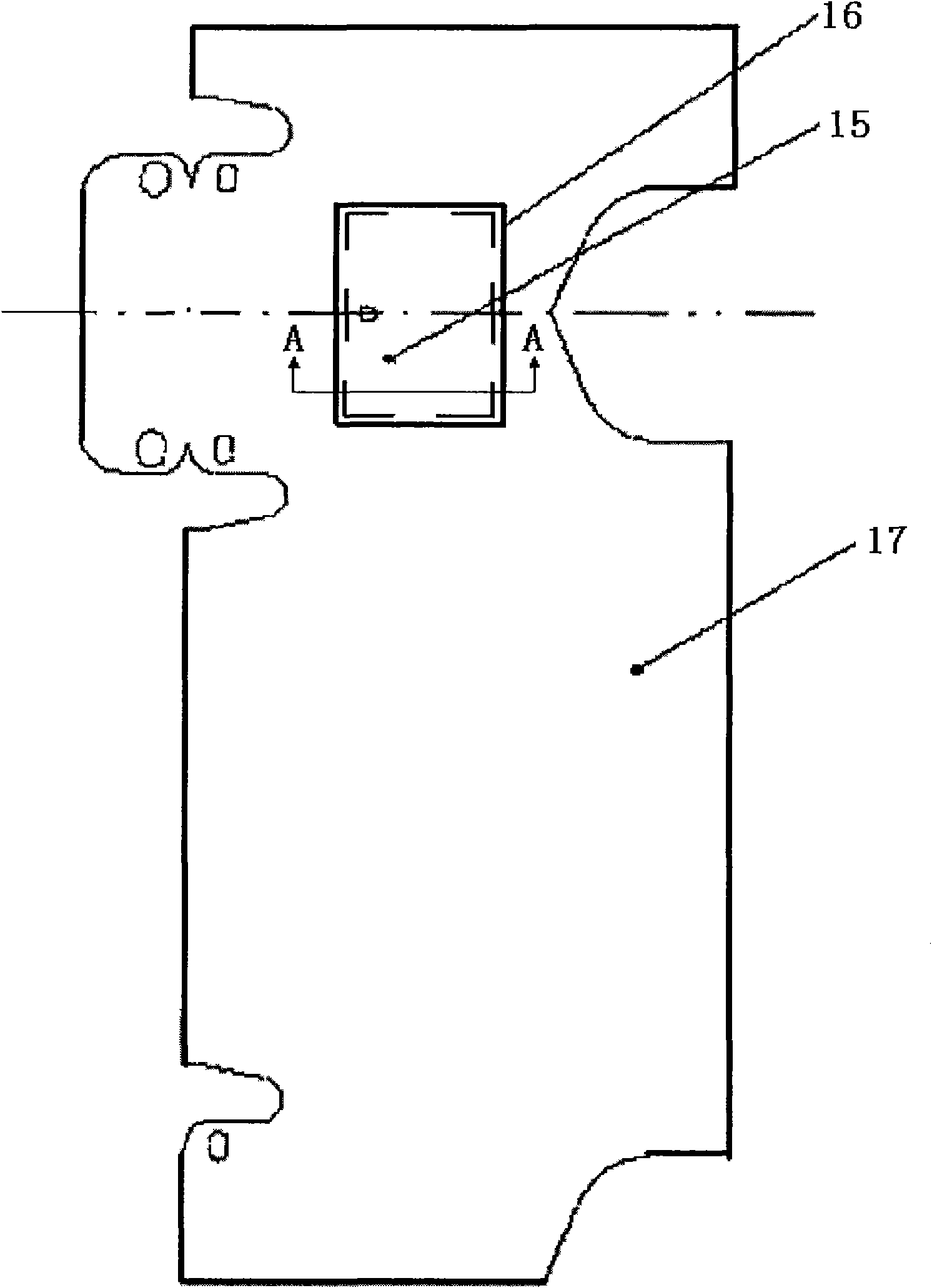

InactiveCN102398563AAvoid direct destructionInflated in time and smoothlyPedestrian/occupant safety arrangementProcess engineeringAirbag

The invention discloses an automotive safety air curtain, which comprises an inflatable airbag for providing lateral protection and a gas generating device for inflating the airbag; the airbag is provided with an inflating part axially connected with the gas generating device; the inflating part comprises an outer layer made of textile material and fixed on the airbag by sewing, and a gas guide part which is in gas communication with the inflating part and guides the inflating gas into the airbag in the longitudinal direction; and the gas generating device is a firework type gas generating device. The inflating part of the air curtain is also provided with an inner layer which encircles the gas outlet of the gas generating device, the inner layer encircles the gas outlet at the upper middle part of the gas generating device, and a gas passage communicated with the gas guide part is formed at the lower gas outlet. The air curtain has the characteristics of light weight, short corresponding time and convenience for installation and fixation.

Owner:AUTOLIV DEV AB

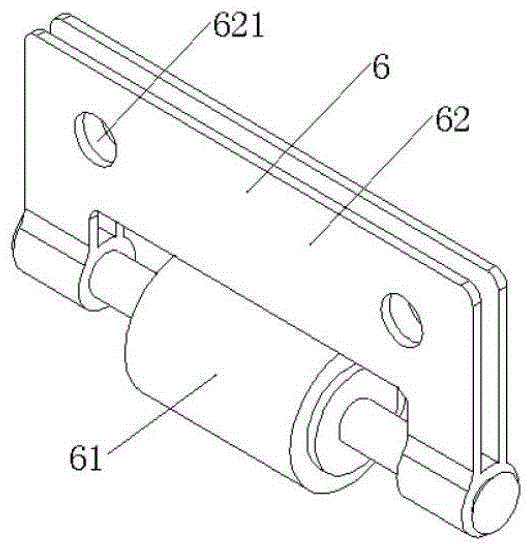

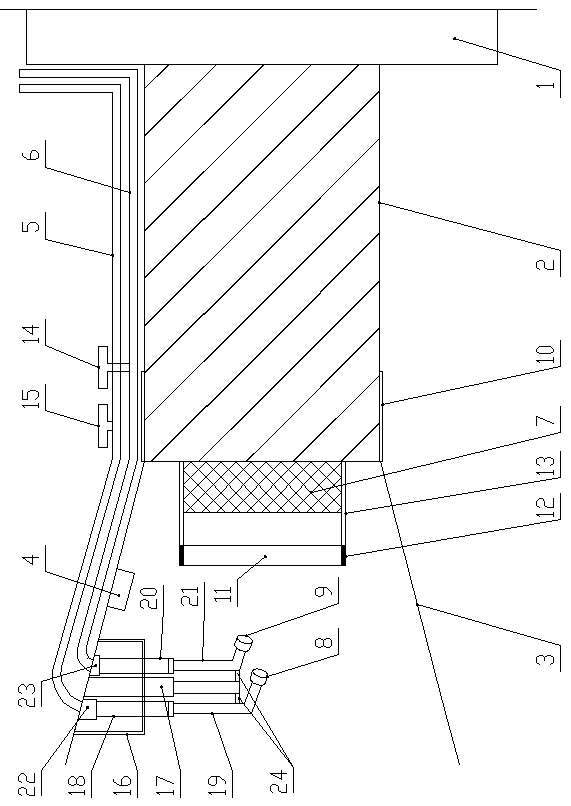

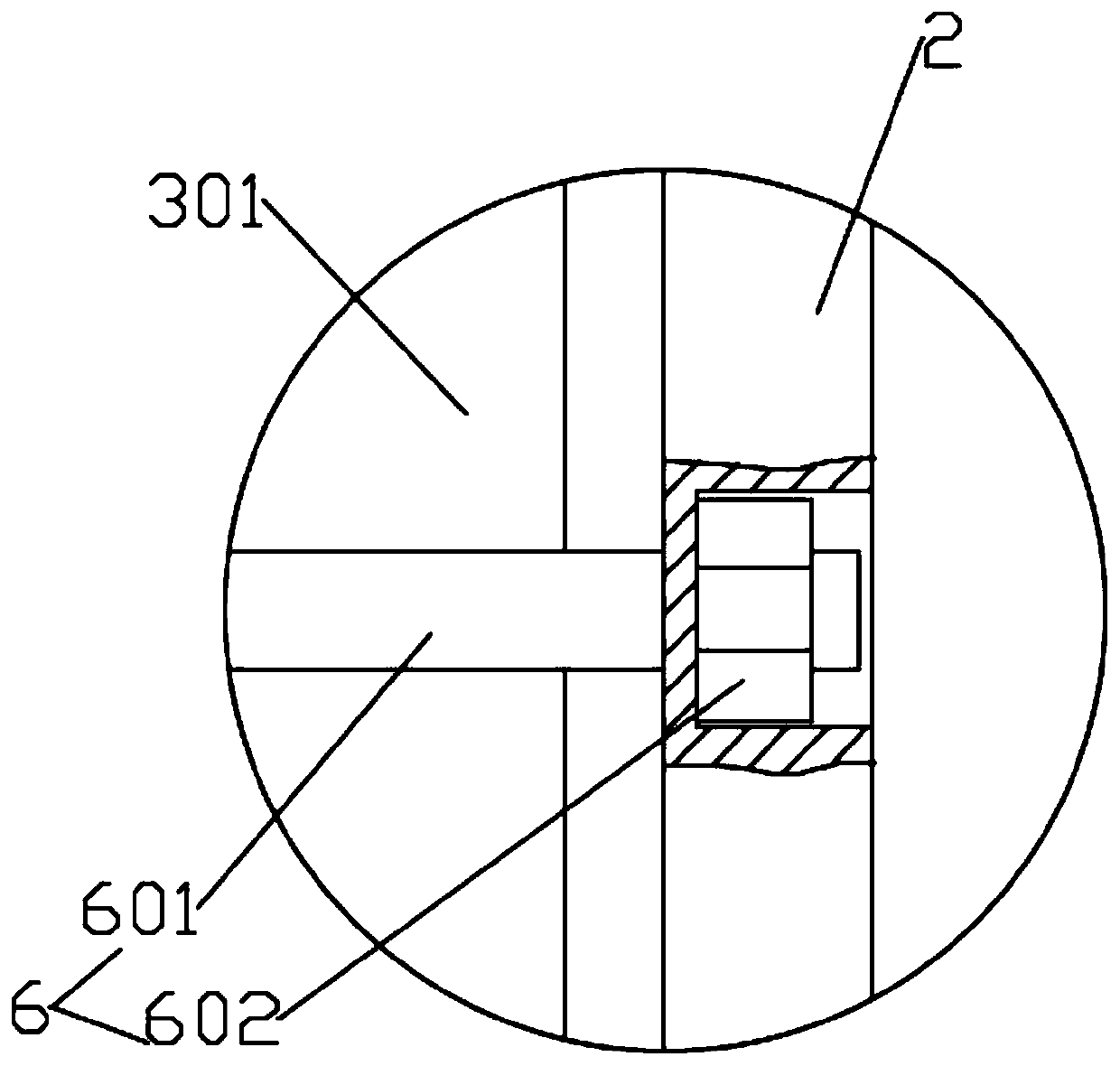

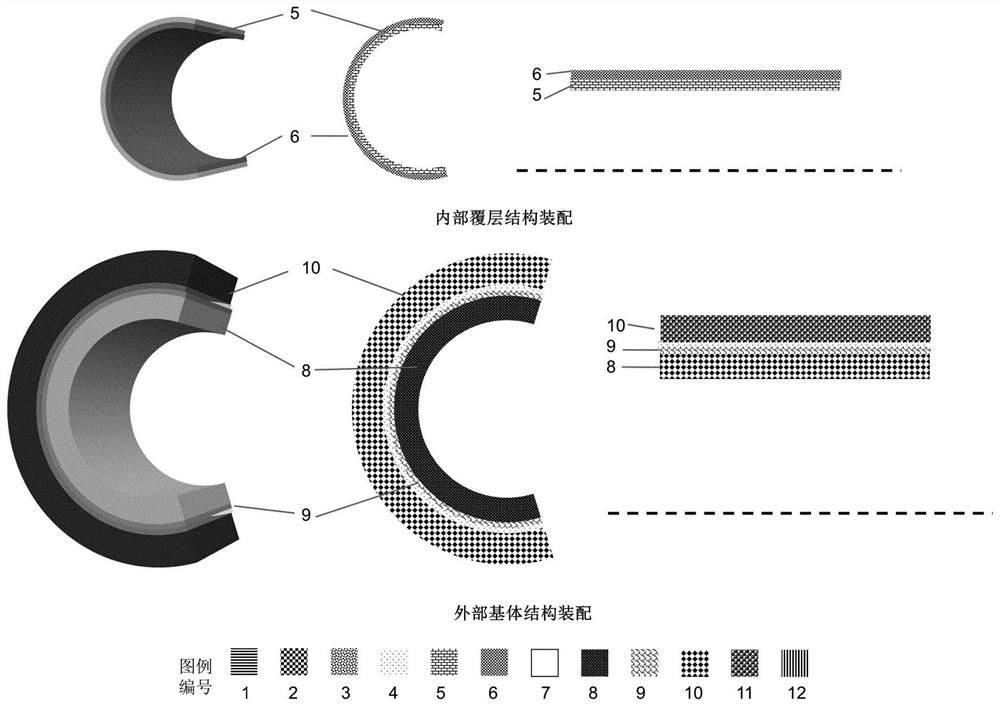

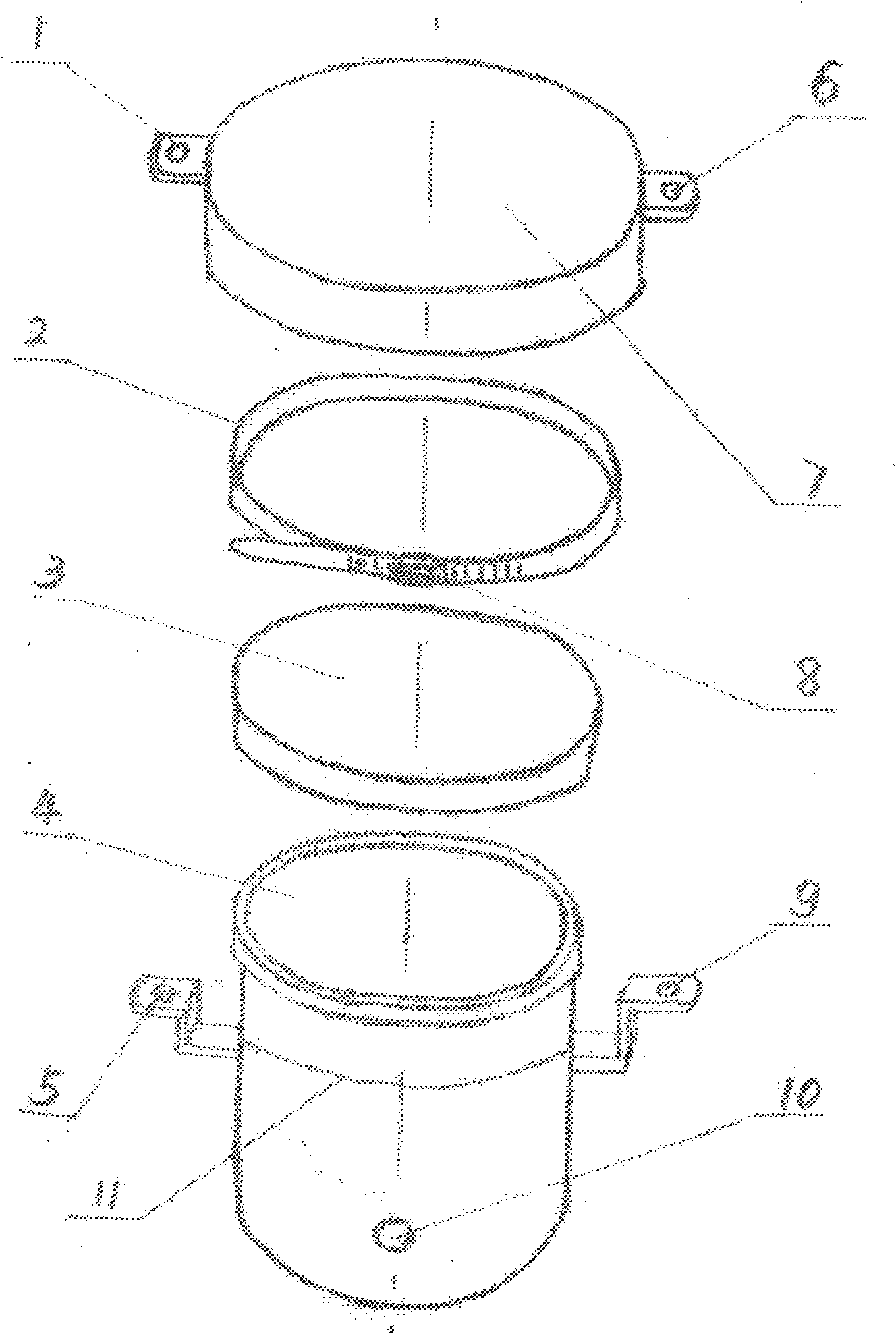

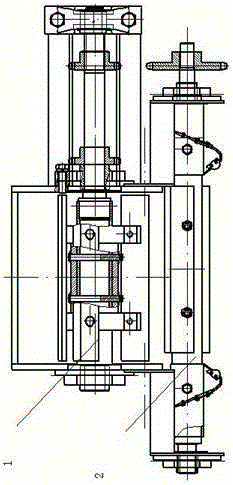

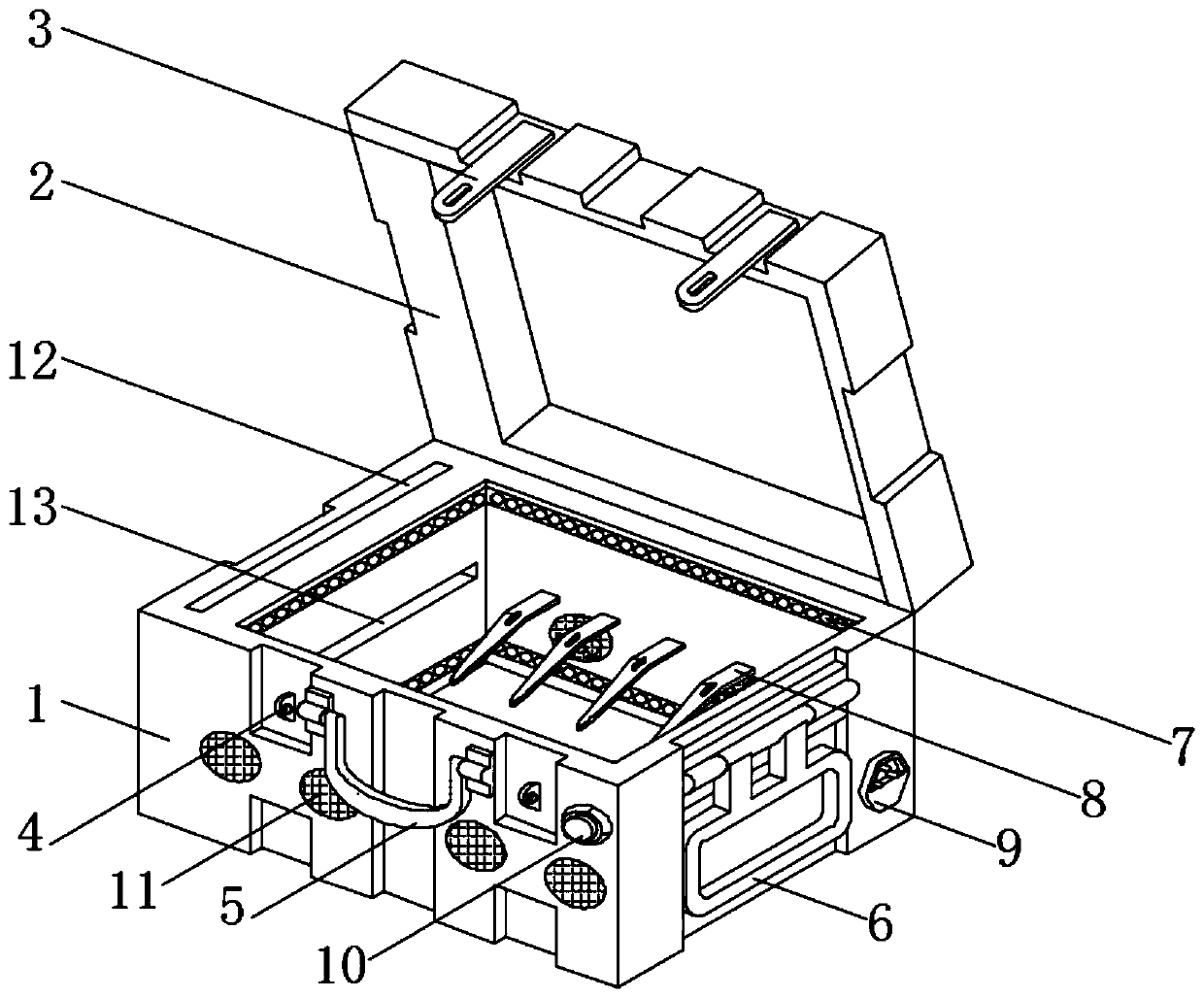

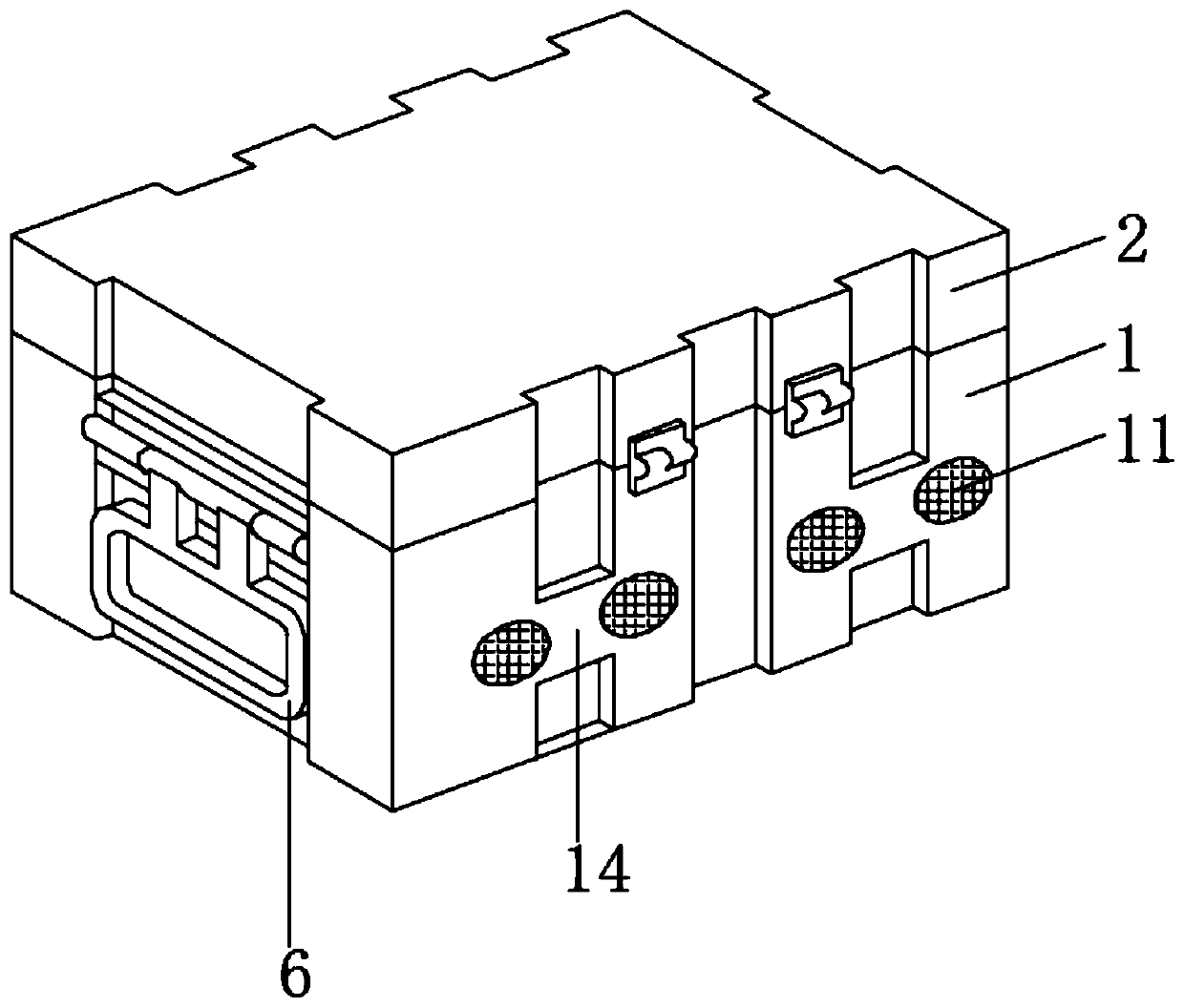

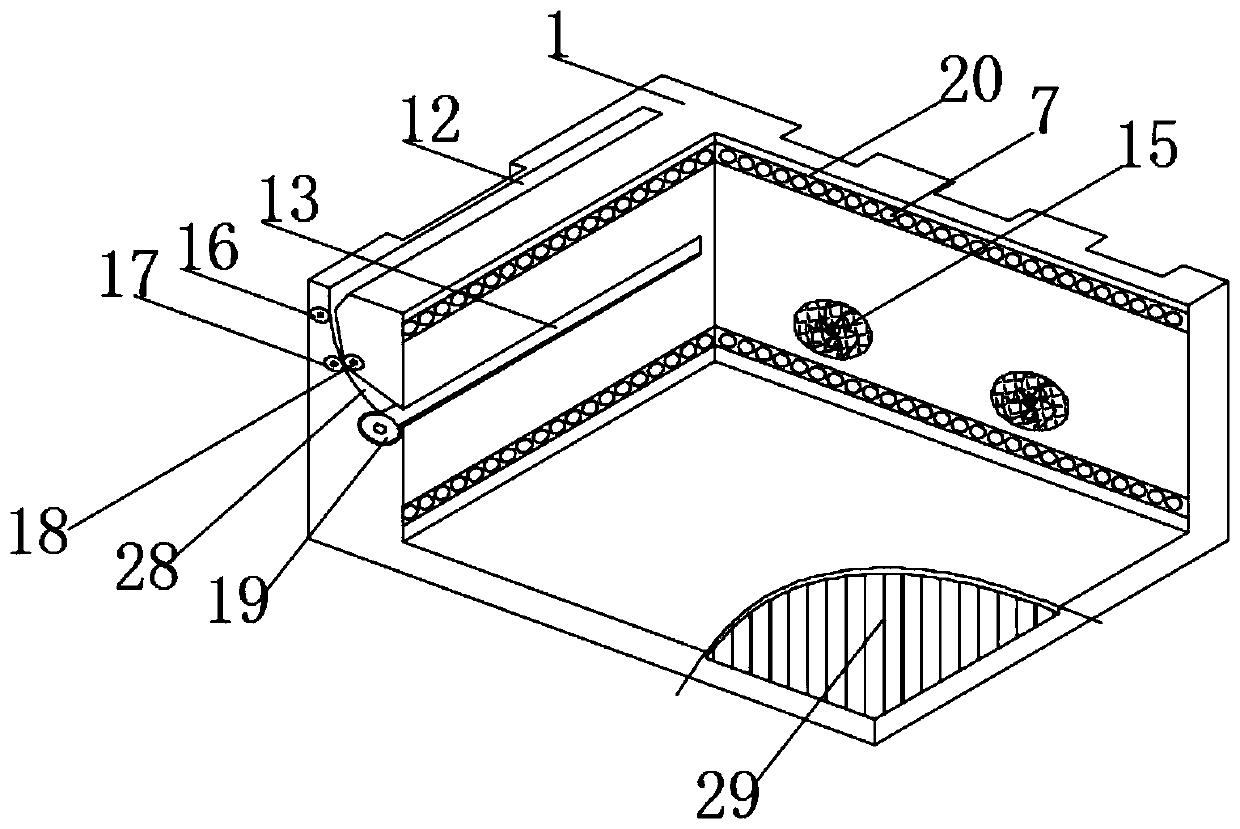

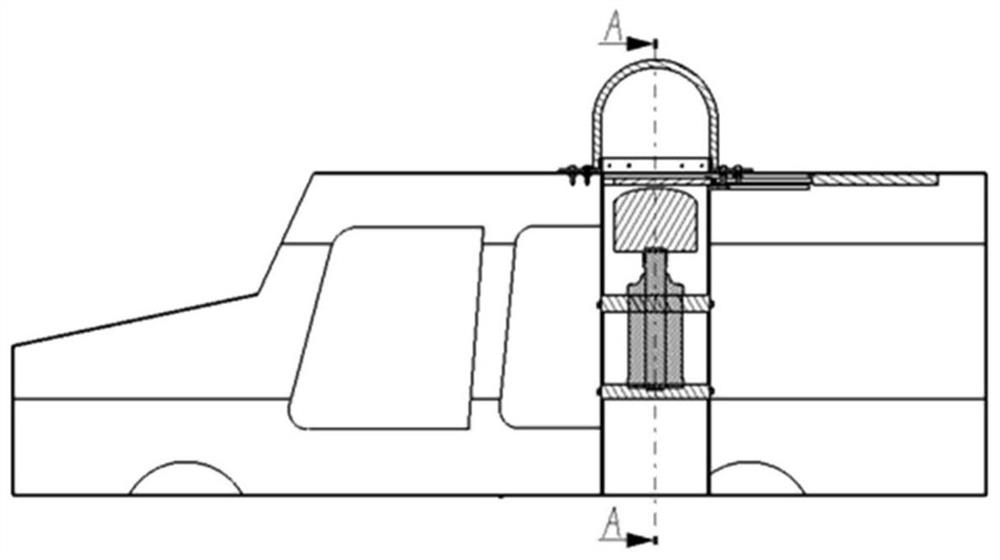

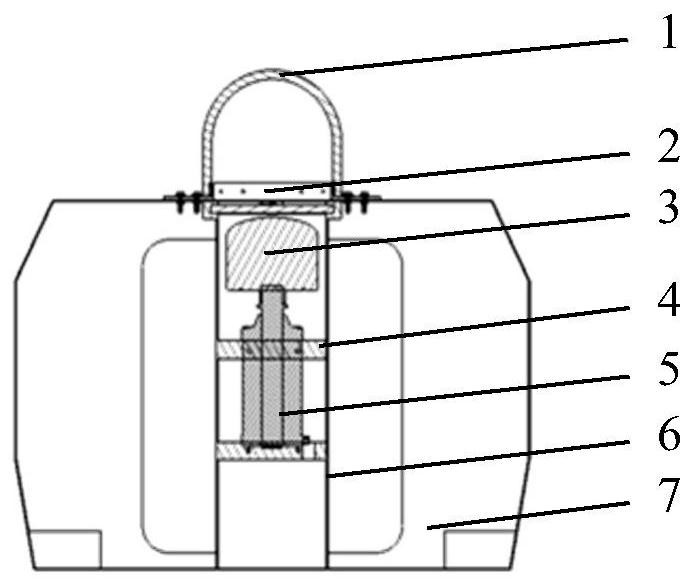

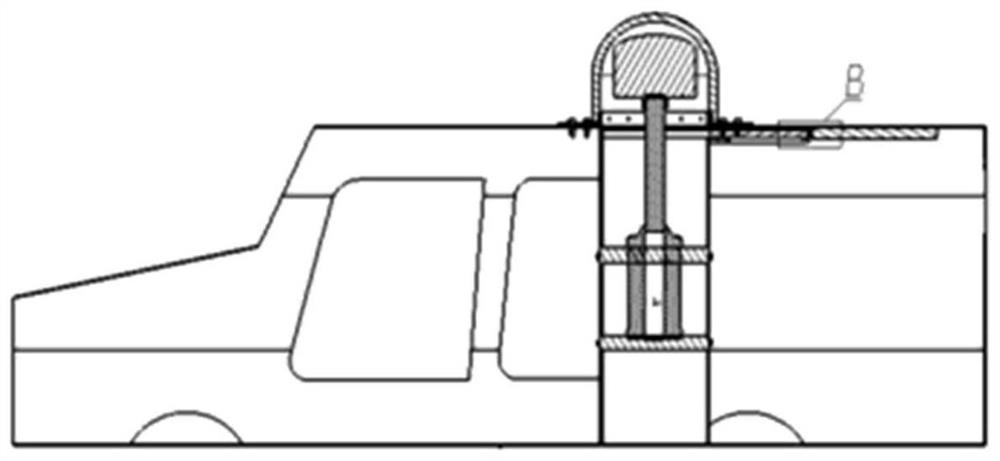

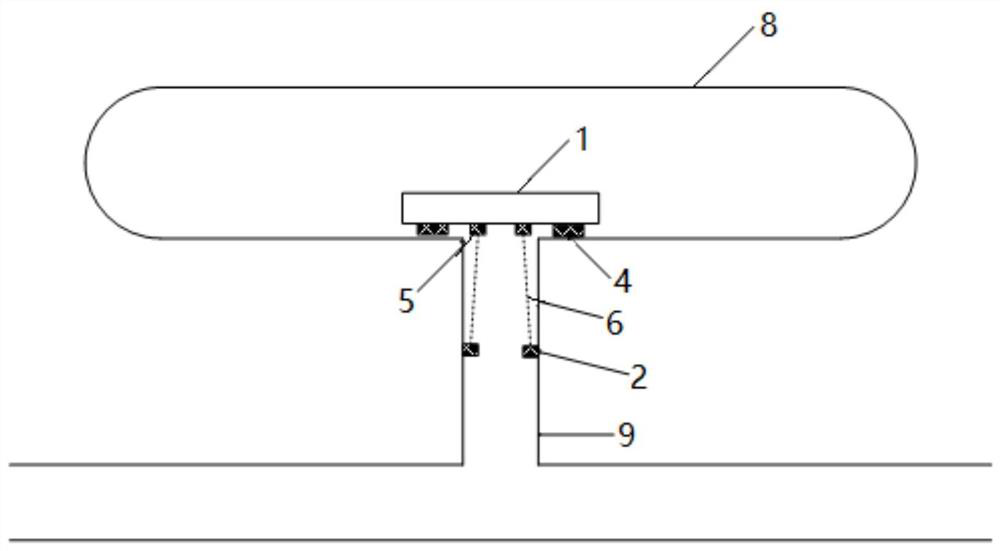

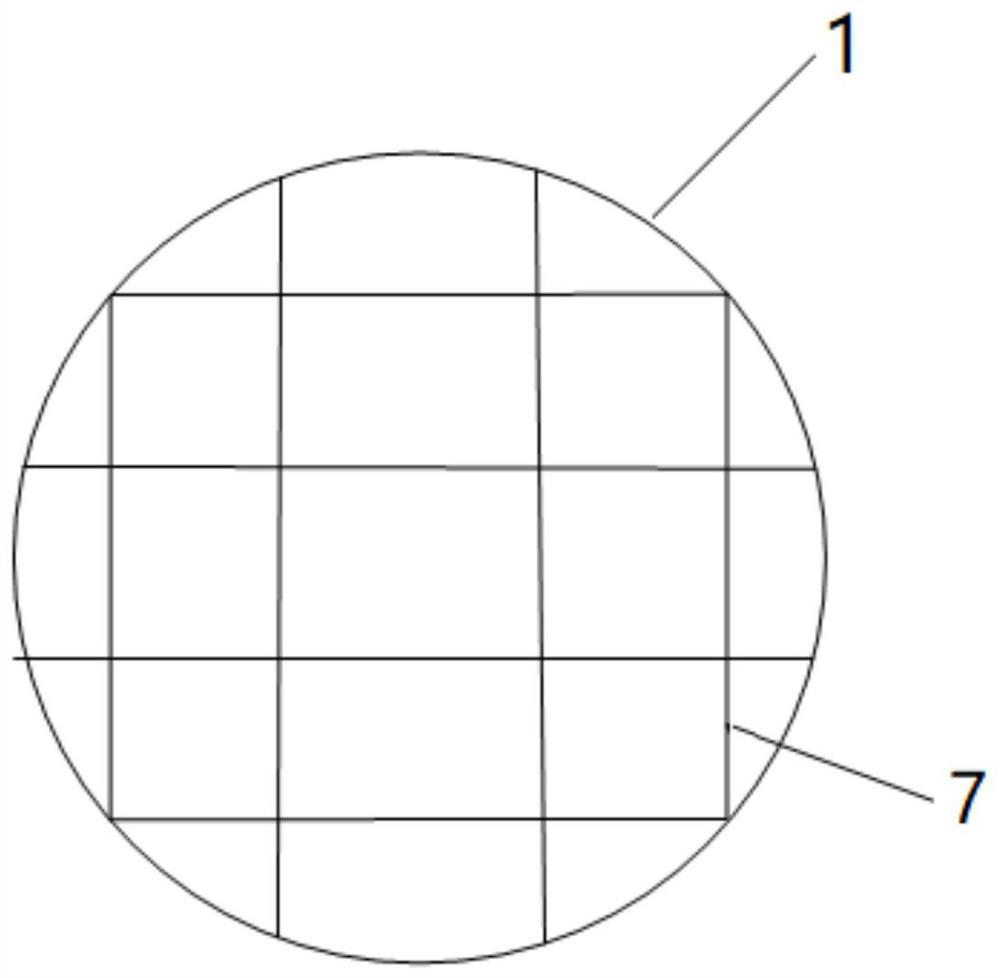

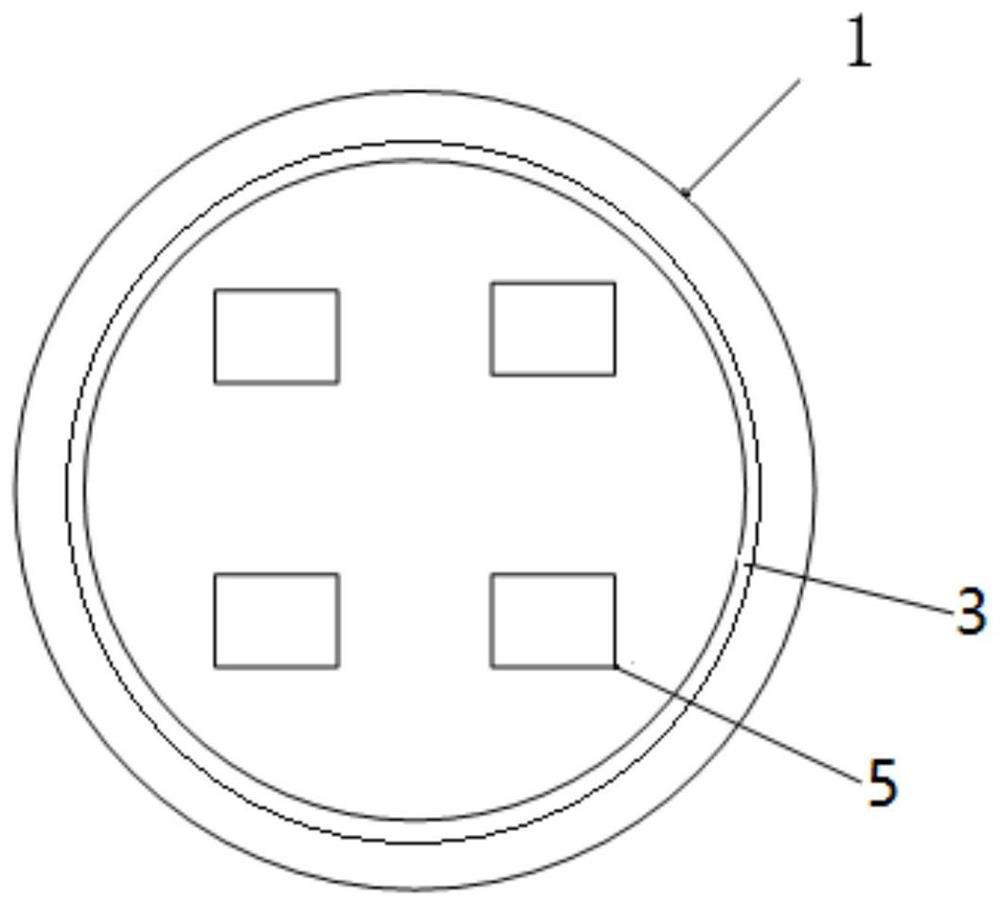

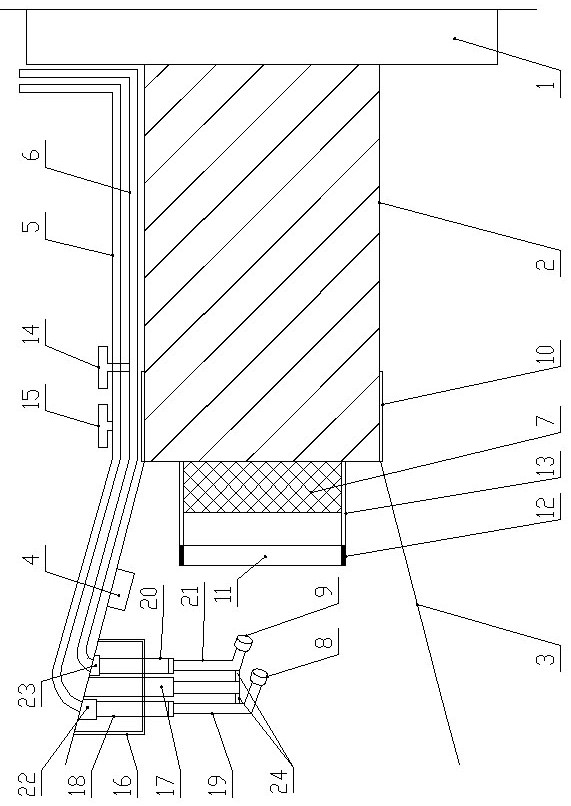

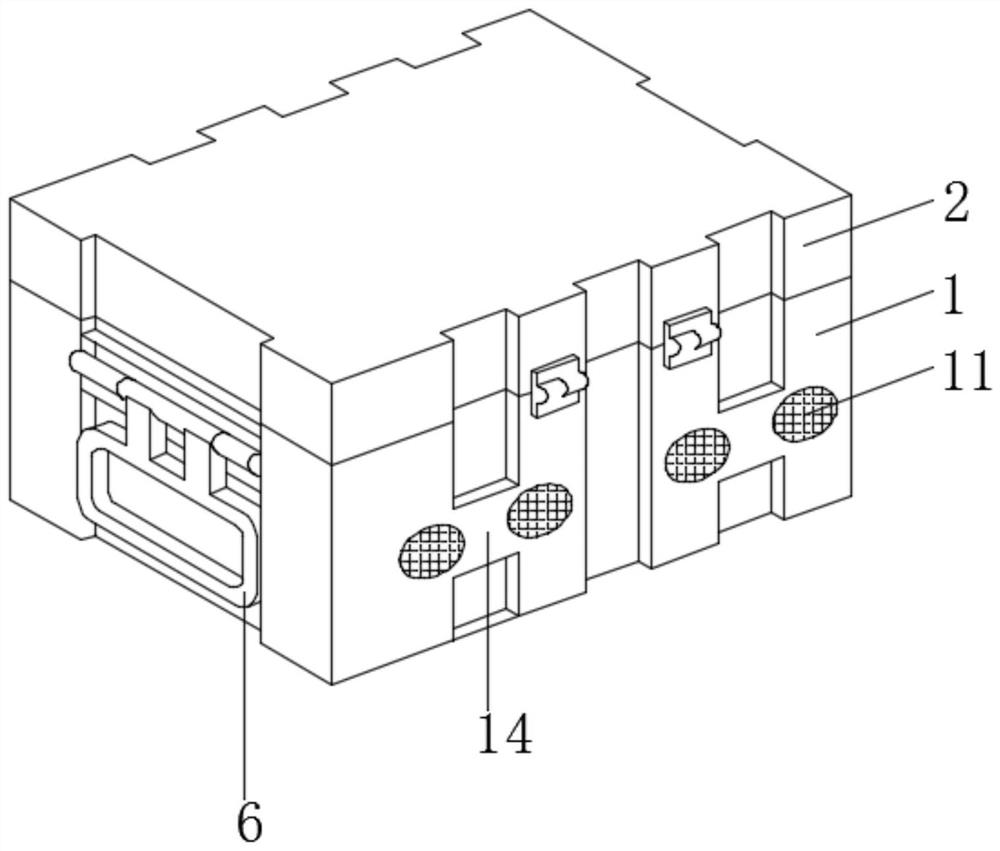

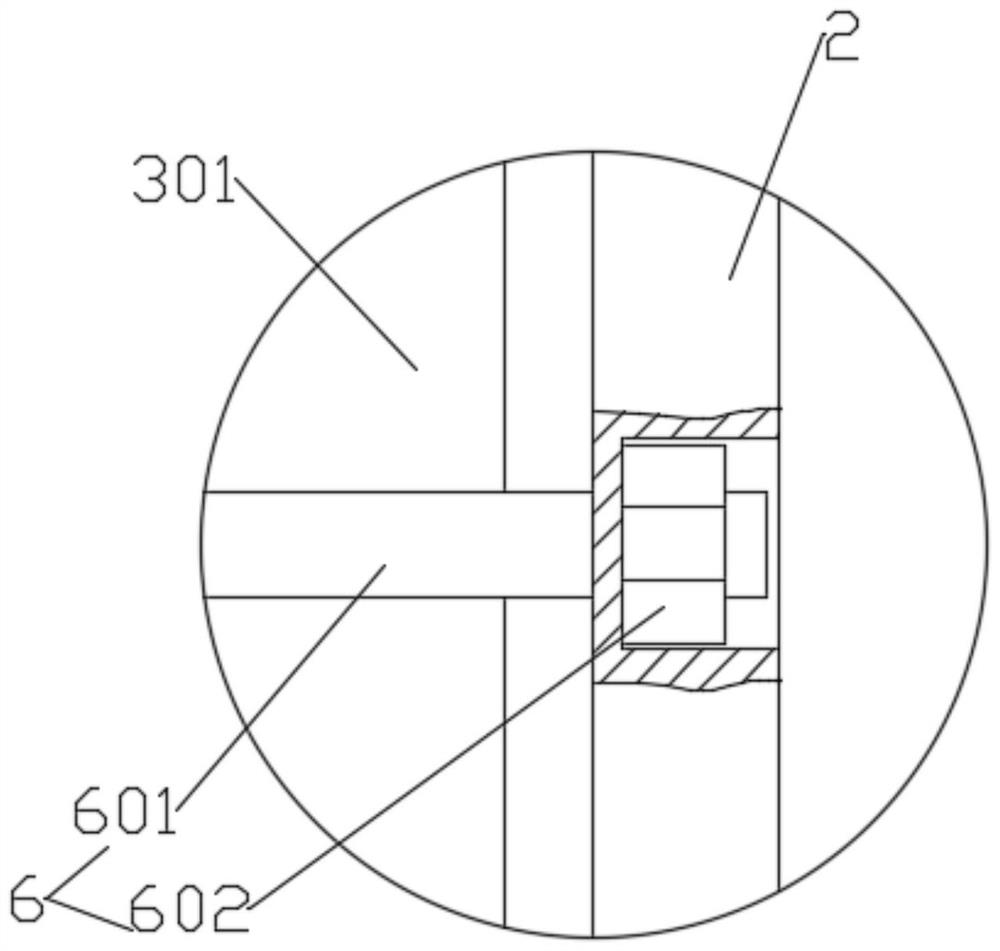

Vehicle Radar Antenna Protection System

ActiveCN111755817BAvoid direct destructionAvoid destructionAntenna adaptation in movable bodiesRadiating element housingsRadar antennasRadar systems

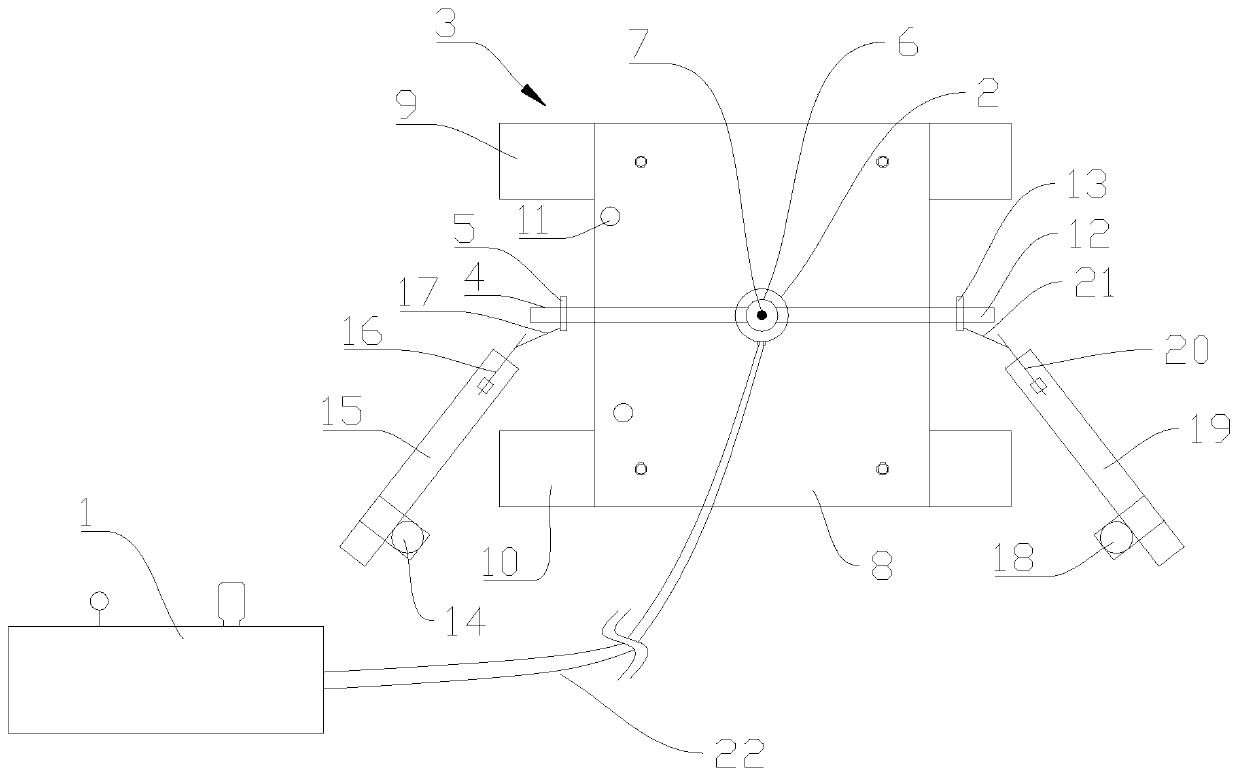

The invention discloses a vehicle-mounted radar antenna protection system, which comprises a protective cover (1) outside the vehicle body, a protective cover installation plate (2) inside the protective cover (1), and a radar antenna module installed in the protective cover (1) (3), linear drive device fixed installation plate (4), first linear drive device (5), car body inner protective box (6), protective plate (8), clamping plate (9), second linear drive device (10), ceramic fixed layer (11), ceramic layer (12), film layer (13), protective box casing, box door and slideway, the present invention can be applied in military product protection armored vehicle to improve radar system in the harsh environment of war self-defense ability.

Owner:63963 TROOP OF THE PLA

Hydropower station surge chamber non-welding sealing tool and installation method thereof

PendingCN112178351AImprove the sealing effectGood sealEngine sealsWater-power plantsPhysicsHydrostatic test

The invention discloses a hydropower station surge chamber non-welding sealing tool and an installation method thereof, and belongs to the technical field of hydropower station metal structures. The hydropower station surge chamber non-welding sealing tool comprises a sealing blocking plate and a plurality of first tensioning lifting lugs. An annular groove is formed in the lower surface of the sealing blocking plate, and a sealing water stop device is arranged in the annular groove. The lower surface of the sealing blocking plate is fixedly connected with a plurality of second tensioning lifting lugs, and the first tensioning lifting lugs and the second tensioning lifting lugs are connected with inhaul cable devices. When the hydropower station surge chamber non-welding sealing tool is inuse, the sealing water stop device is in close contact with a pipe orifice of a middle connecting pipe in a surge chamber in the circumferential direction, and the plurality of first tensioning lifting lugs are fixedly connected with the inner wall of a middle connecting pipe adjusting joint. Under the condition of no welding, the space between a main air chamber of the surge chamber and the connecting pipe is sealed, so that the surge chamber forms a closed space, and the hydrostatic test requirement of the air cushion type surge chamber is met.

Owner:XIAN THERMAL POWER RES INST CO LTD

Security device, use of a security device and a method of securing a handle

The present invention relates to a security device (1) for securing a handle (7) to a clasp (8) so as to prevent operation of said handle (2), the security device comprising a first housing having a bolt (4) extending therefrom and a second housing (3) comprising retaining means (5) for receiving and retaining a distal end of the bolt to secure the first and second housings together; in a first state the first and second housings being separate from each other and separate from said handle to which the security device is to be secured; the first and second housings being assemblable into a second state in which the first and second housings are secured together by means of engagement of the bolt with the retaining means, wherein, in use, in the second state the security device may enclose at least a portion of said handle within an interior of the security device and wherein the bolt may pass through an aperture in the handle and an aperture in the clasp; wherein, in use, in the second state the second housing shrouds the retaining means and wherein, in use, in the second state the first and second housings shroud the clasp.

Owner:大卫卡特

Mine-used automatic high-pressure washing camera device and its monitoring method

ActiveCN111327801BAvoid direct destructionImprove cleanlinessTelevision system detailsFouling preventionCamera lensWater flow

Mine-used automatic high-pressure flushing camera device, including base, camera, cone cover, dust induction recognizer, controller, high-pressure air hose, high-pressure water flow hose and telescopic nozzle mechanism, the camera lens on the left side of the camera is located in the cone In the shaped cover, there is a dust-proof transparent component on the left side of the camera lens. The dust sensor recognizer is set inside the conical cover and is used to monitor the dust attached to the left surface of the dust-proof transparent component. The telescopic nozzle mechanism is set on the conical cover. The left top can be retracted up and down, and the lower end of the telescopic nozzle mechanism is provided with an airflow nozzle and a water nozzle for spraying toward the dustproof transparent component. The present invention realizes automatic induction through the dust induction recognizer, realizes cleaning in combination with high pressure water flow and air flow, and can effectively ensure the cleanliness of the dust-proof glass. The workload of manual wiping reduces the damage to the camera lens and prolongs the life of the camera lens.

Owner:HENAN POLYTECHNIC UNIV

An ultraviolet disinfection box

ActiveCN111588869BUniform radiationAvoid incomplete disinfectionLavatory sanitoryHeatUltraviolet lightsEngineering

The invention discloses an ultraviolet disinfection box, which comprises a box body, a box cover and a lock. , the front side wall of the box body is equipped with a corresponding lock at the position corresponding to the buckle. In the present invention, a single banknote enters the inlet trough with the rotation of the first conveying roller by connecting the conveying roller and the rolling roller in the groove, and undergoes high-temperature rolling treatment of the first rolling roller and the second rolling roller. While flattening the banknotes, the banknotes are sterilized at high temperature, and then the initial speed is given by the speed regulation of the second conveying roller, so that it moves to the bottom of a certain type of folder. The upper and lower surfaces are sterilized, the ultraviolet rays have no shadows, and the radiation is uniform on the banknotes. It cooperates with the high-temperature disinfection of the rolling rollers to avoid incomplete disinfection and improve the disinfection effect. It is suitable for widespread promotion and use.

Owner:PINGYANG SILVER NEW FINANCIAL PROD CO LTD

Gas-closed electrical box

InactiveCN101552449BAvoid direct destructionNot easy to destroy directlyCable junctionsCushioningElectric power system

The present invention relates to a box which is used in field and is used for installing cable joint of electrical power system or electrical equipment, wherein the box comprises a box body, an inner rubber cover, a throat fixer and an outer cover. The box provided by the invention can resist crushing and cutting. Furthermore a special structure neatly uses a principle of atmospheric pressure so that the closeness can be kept for a long time. Because the main supporting force of cover body comes from the cement floor, the cover body can bear a large pressure. Even when the cover body is damaged, the box is not damaged because of the cushioning of inner rubber cover. The repairing and maintenance are easy.

Owner:蔺新衔

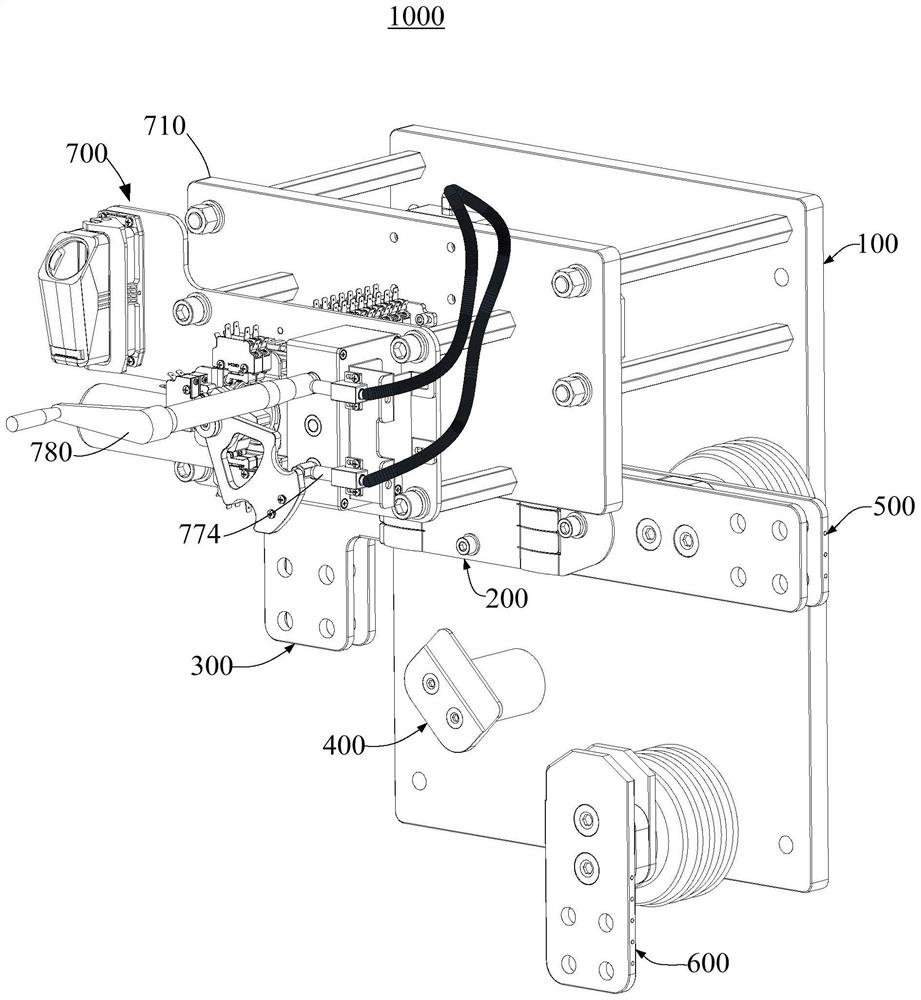

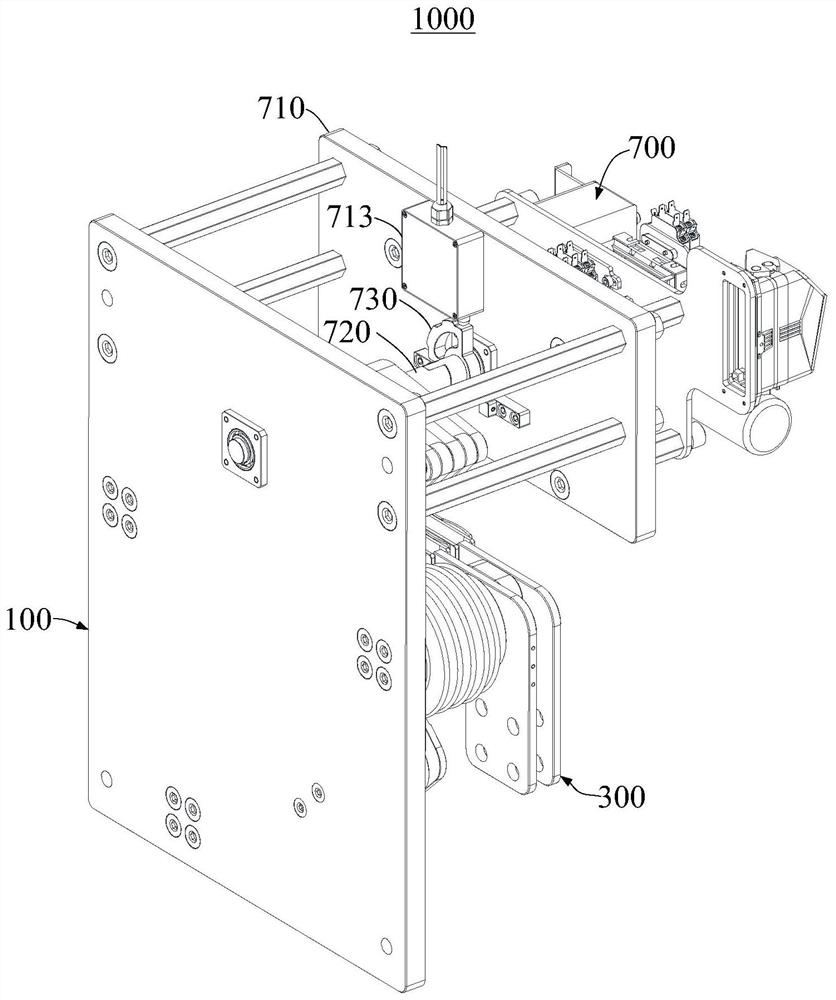

A lithium battery linear sensing detection primary disassembly device and method

ActiveCN114309766BAvoid direct destructionHigh recyclabilityShearing machinesBattery recyclingStructural engineeringControl theory

Owner:南京莱迪新能源科技有限公司

Natural mosquito repellent incense and preparation method thereof

ActiveCN103392748BGood mosquito repellentStrong repellent effectBiocidePest repellentsBiotechnologyRespiratory tract disease

Belonging to the technical field of articles for daily use, the invention relates to a natural mosquito repellent incense and a preparation method thereof. The natural mosquito repellent incense provided by the invention is characterized by comprising the following raw materials by weight: 40-50 parts of waste plant fiber, 30-60 parts of a bamboo charcoal powder, 2-10 parts of kaolin, 5-10 parts of wormwood, 2-5 parts of edgeworthia chrysantha, 3-7 parts of ginkgo, 2-5 parts of rhizoma atractylodis,3-6 parts of resveratrol and 1-2 parts of Codonopsis pilosula. The waste plant fiber is one or several selected from straw, rice husk, wood chips and nuts. The mosquito repellent incense provided by the invention employs natural Chinese herbal medicines as active ingredients, which are safe and non-toxic, and can emit smell during a combustion process to repel mosquitoes as well as inhibit bacteria, sterilize, prevent respiratory tract diseases and enhance the body's immune function. At the same time, the invention also uses a large amount of waste plant fibers to substitute wood powder, so as to save forest resources and reduce waste. In addition, the product is simple for preparation, and easy for popularization and application.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

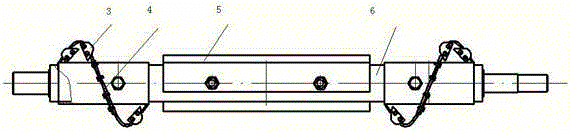

Multi-pole buffering receiving machine for anode vertical formworks

PendingCN111173885AImpact Dispersion ConsumptionAvoid direct destructionSpringsNon-rotating vibration suppressionHydraulic motorElectrolysis

The invention discloses a multi-pole buffering receiving machine for anode vertical formworks, and particularly relates to the technical field of lead electrolytic smelting equipment. The multi-pole buffering receiving machine for the anode vertical formworks comprises a rack; a supporting plate is rotationally connected onto the rack; two first chain wheels arranged in a spaced manner are rotationally connected onto the supporting plate; the two first chain wheels are coated with a first chain; a support is further arranged on the supporting plate; a baffle parallel with the supporting plateis arranged on the support; a buffering mechanism detachably connected with the first chain is arranged on the baffle; the buffering mechanism is glidingly connected onto the baffle; buffering force unloading can be performed on anode plates by the aid of the buffering mechanism; a second chain wheel is further rotationally connected onto the baffle; the second chain wheel and any first chain wheel are coated with a second chain; and a hydraulic motor is further arranged on the second chain wheel. With the adoption of the technical scheme, the problems that existing anode plate receiving buffering devices cause potential safety hazards easily and are disadvantageous to subsequent processing are solved, and the multi-pole buffering receiving machine can be applied to receiving and conveyingof the anode plates.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A prefabricated building wall

ActiveCN110258851BImprove stabilityImprove securityWallsProtective buildings/sheltersArchitectural engineeringWall plate

The invention discloses a prefabricated building wall, which belongs to the field of prefabricated buildings. The wall includes an anti-seismic component, an outer wall panel and an inner wall panel. The outer wall panel and the inner wall panel are arranged in parallel with each other and passed through a The connecting assembly is connected, and a mounting part for installing the anti-seismic assembly is provided on the side of the outer wall panel or / and the inner wall panel on the opposite side, and the outer wall panel and the inner wall panel are connected by the connecting assembly. The anti-seismic component is pressed between the outer wall panel and the inner wall panel. The anti-seismic component is assembled from a number of wall block units and shock absorbing devices. The wall block units are distributed in a rectangular array in the plane of the wall body. At least one shock absorbing device is arranged between two adjacent wall block units, and the installation part is used for installation and fixing of at least one wall block unit. The wall body of the invention can protect the main structure of the wall body from being damaged when it is subjected to external forces such as earthquakes, thereby preventing the house from collapsing and increasing the stability and safety of the building.

Owner:ZHEJIANG TINSHINE ARCHITECTURAL DESING CO LTD

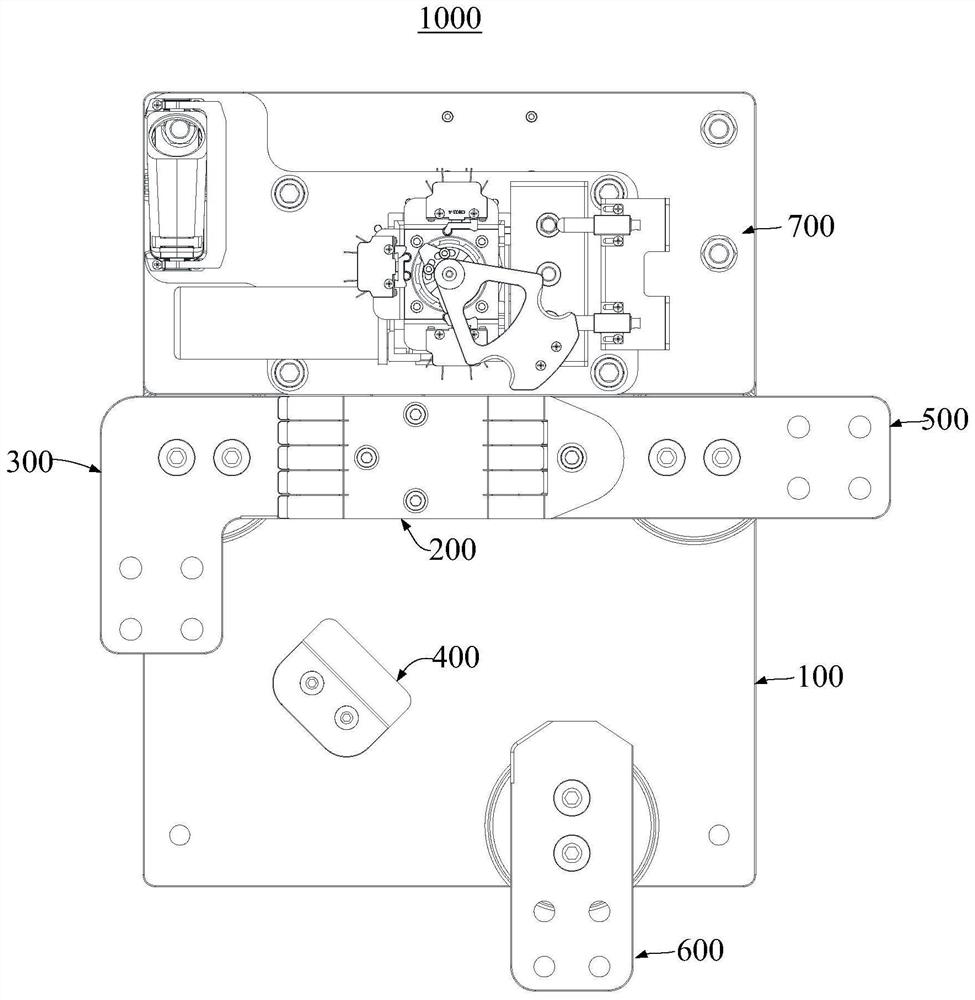

Operating device of three-station knife switch and three-station knife switch

ActiveCN114823207ASimple structureAvoid direct destructionElectrical apparatusDrive shaftControl theory

The invention discloses an operating device of a three-station knife switch and the three-station knife switch, and the operating device of the three-station knife switch comprises a mounting bracket, a driving shaft, a locking sheet, a locking shaft and a locking mechanism. The driving shaft is movably mounted on the mounting bracket; the locking piece is fixedly connected with the driving shaft, and the locking piece is correspondingly provided with a connection locking position, an isolation locking position and a grounding locking position; the locking shaft is mounted on the mounting bracket, moves relative to the mounting bracket and is provided with a first locking position for locking the connection locking position, the isolation locking position and the grounding locking position on the locking sheet and a first unlocking position for unlocking the connection locking position, the isolation locking position and the grounding locking position on the locking sheet; the locking mechanism is installed on the installation support, locks the locking shaft when the locking shaft is located at the first locking position, and unlocks the locking shaft, so that the locking shaft is driven by the locking piece to move to the first unlocking position. Through the arrangement, the locking piece can be prevented from being blocked by the locking mechanism.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

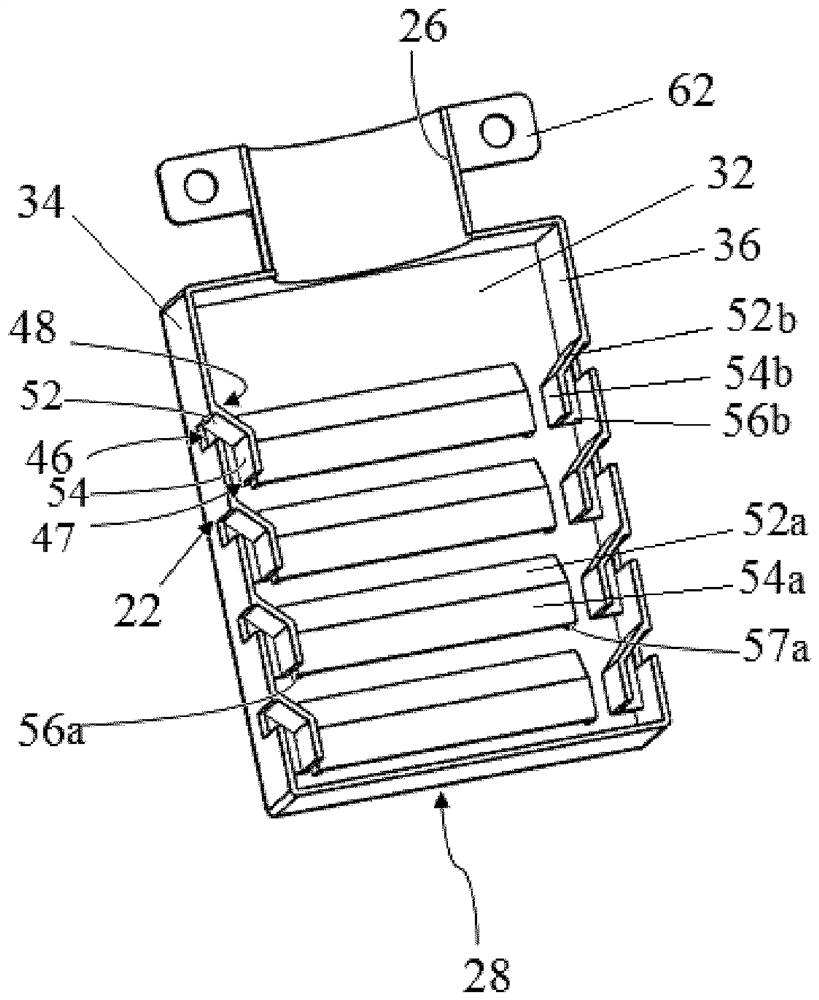

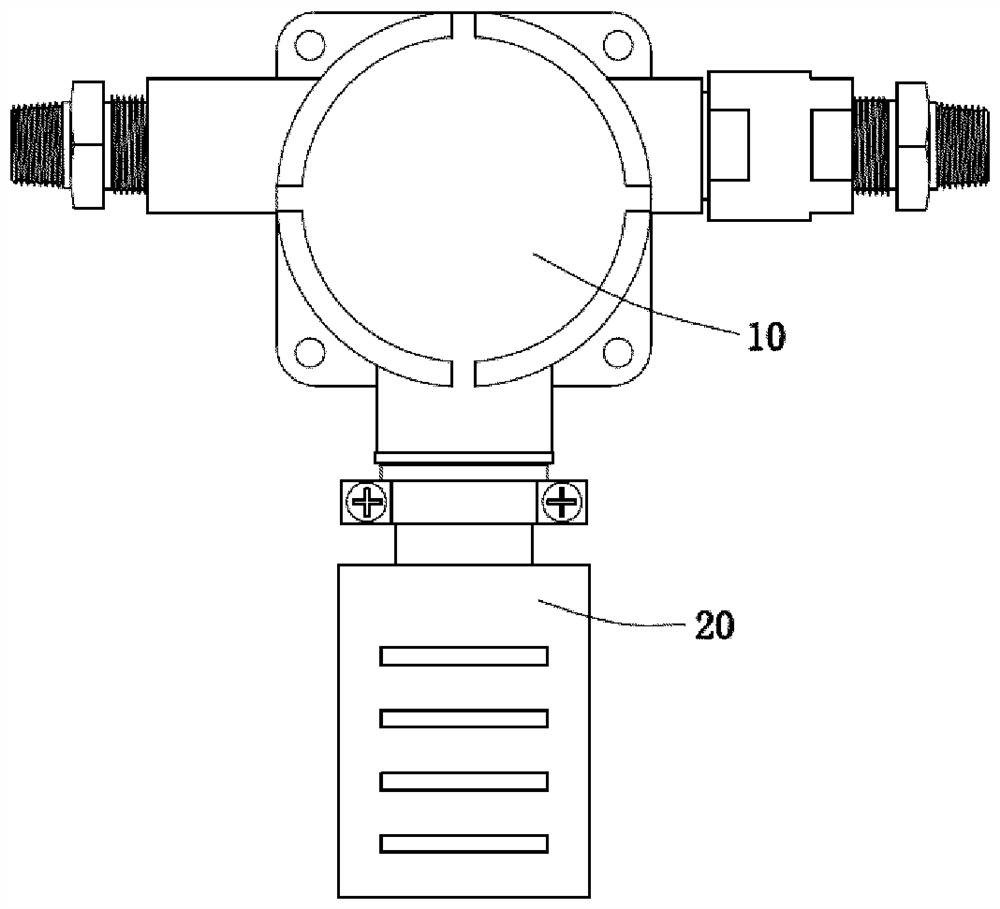

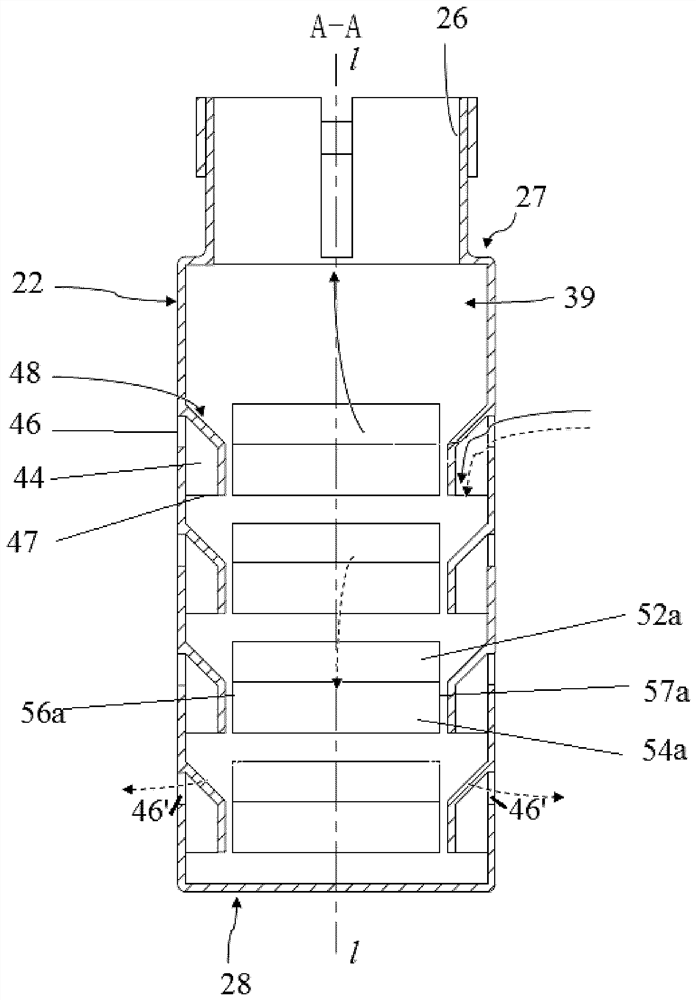

Waterproof gas detector

PendingCN112255366AShorten the path into the sensing elementImprove air intake efficiencyGas analyser construction detailsGas detectorGaseous detectors

The invention discloses a gas detector having a waterproof grade, which comprises a detector body and a cover, wherein the detector body comprises a mounting base in which a sensing element is disposed, the mounting base is provided an inlet for a gas to be detected, the inlet defines an axis direction; and the cover has a circumferential wall defines an enclosing space inside the cover, the enclosing space has a proximal end and a distal end in the axial direction, the cover is attached to the mounting base such that the proximal end of the enclosing space is located near the inlet, a plurality of shutter elements are attached to the circumferential wall, each of the plurality of shutter elements is configured to form a passage through which a water flow passes between an exterior of thecover and the enclosing space and extends toward the distal end.

Owner:GULF SECURITY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com