A kind of normal temperature curing conductive adhesive and its process method for connecting rechargeable battery pack

A room temperature curing and process technology, applied in battery pack parts, conductive adhesives, circuits, etc., can solve the problems of loosening, increasing the weight of the battery pack, reducing reliability, etc., to avoid open circuit, increase heat dissipation function, maintain The effect of welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to Table 1, the specific composition of the room temperature curing conductive adhesive in Example 1 of the present invention can be obtained as follows: the conductive adhesive includes mixture I and mixture II with a mass ratio of 20:1;

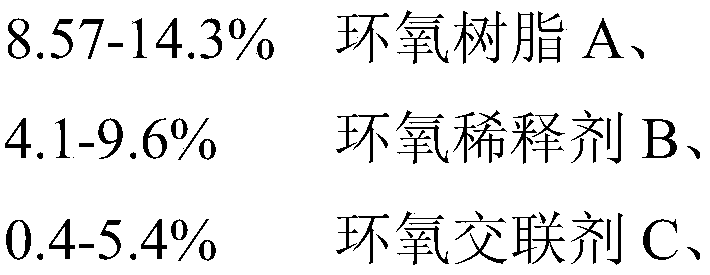

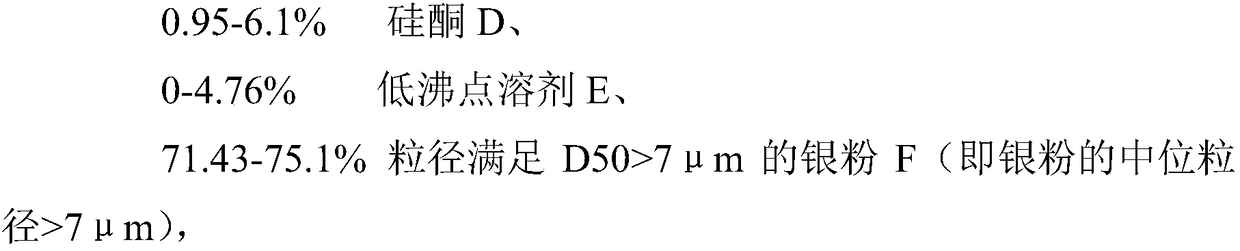

[0040] Mixture I includes the following components in mass percentage: 14.3% epoxy resin A, 4.1% epoxy diluent B, 0.4% epoxy crosslinking agent C, 6.1% silicone D, 75.1% silver powder with a particle size satisfying D50>7μm F; wherein: epoxy resin A is bisphenol A epoxy resin, epoxy diluent B is polyisopropylene glycol diglycidyl ether epoxy resin, and epoxy crosslinking agent C is pentaerythritol tetraglycidyl ether epoxy resin. Mix the above components uniformly to obtain mixture I.

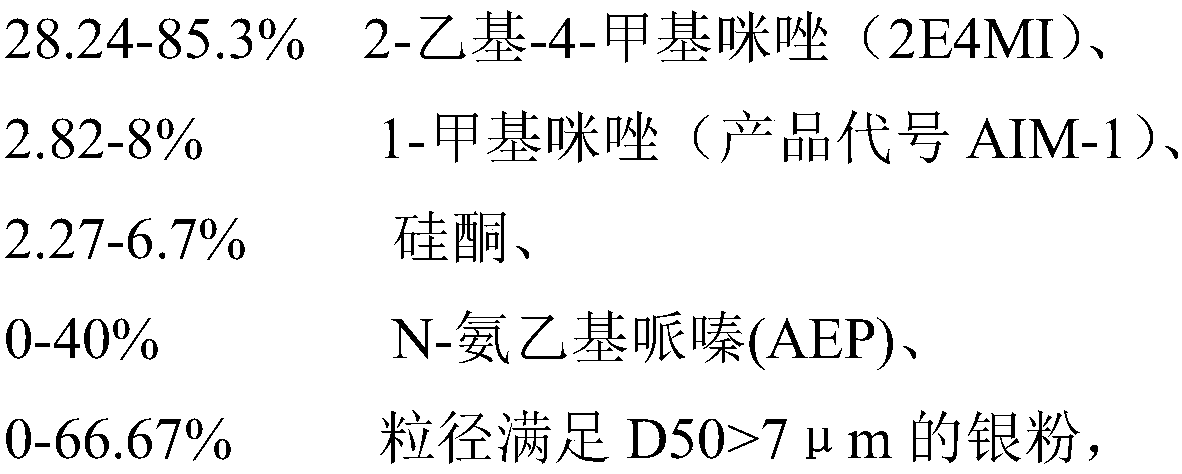

[0041] Mixture II includes the following components in mass percentage: 51.2% 2-ethyl-4-methylimidazole (2E4MI), 4.8% 1-methylimidazole (AIM-1), 4% silicone, 40% N-aminoethyl Alkylpiperazine (AEP). Mix the above components uniformly to obt...

Embodiment 2

[0044] According to Table 1, the specific composition of the room temperature curing conductive adhesive of Example 2 of the present invention can be obtained as follows: the conductive adhesive includes mixture I and mixture II with a mass ratio of 20:1;

[0045] Mixture I includes the following components in mass percentage: 14.3% epoxy resin A, 4.1% epoxy diluent B, 0.4% epoxy crosslinking agent C, 6.1% silicone D, 75.1% silver powder with a particle size satisfying D50>7μm F; wherein: epoxy resin A is bisphenol A epoxy resin, epoxy diluent B is polyisopropylene glycol diglycidyl ether epoxy resin, and epoxy crosslinking agent C is pentaerythritol tetraglycidyl ether epoxy resin. Mix the above components evenly to obtain mixture I

[0046] Mixture II includes the following components in mass percentage: 85.3% 2-ethyl-4-methylimidazole (2E4MI), 8% 1-methylimidazole (AIM-1), 6.7% silicone. Mix the above components uniformly to obtain mixture II.

[0047] Table 1 Composition...

Embodiment 3

[0050] According to Table 1, the specific composition of the room temperature curing conductive adhesive of Example 3 of the present invention can be obtained as follows: the conductive adhesive includes mixture I and mixture II with a mass ratio of 15:1;

[0051] Mixture I includes the following components in mass percentage: 14.3% epoxy resin A, 4.1% epoxy diluent B, 0.4% epoxy crosslinking agent C, 6.1% silicone D, 75.1% silver powder with a particle size satisfying D50>7μm F; wherein: epoxy resin A is bisphenol A epoxy resin, epoxy diluent B is polyisopropylene glycol diglycidyl ether epoxy resin, and epoxy crosslinking agent C is pentaerythritol tetraglycidyl ether epoxy resin. Mix the above components uniformly to obtain mixture I.

[0052]Mixture II includes the following components in mass percentage: 28.24% 2-ethyl-4-methylimidazole (2E4MI), 2.82% 1-methylimidazole (AIM-1), 2.27% silicone, 66.67% particle size meeting D50 >7μm silver powder. Mix the above components...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com