Preparation method of nickel-cobalt layered bimetallic hydroxide/graphene electrocatalyst

A layered bimetallic and hydroxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. Simple chemistry and synthesis method, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

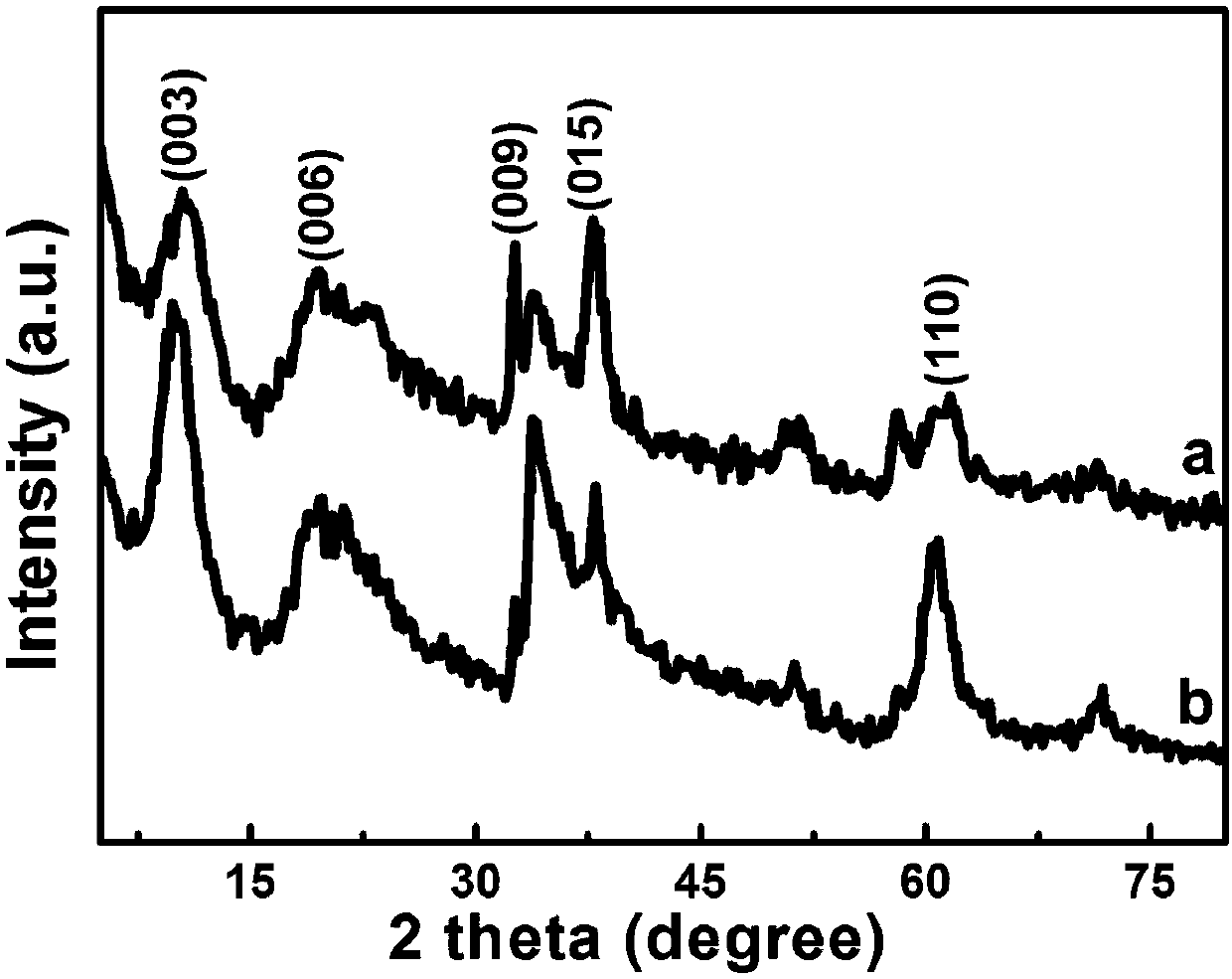

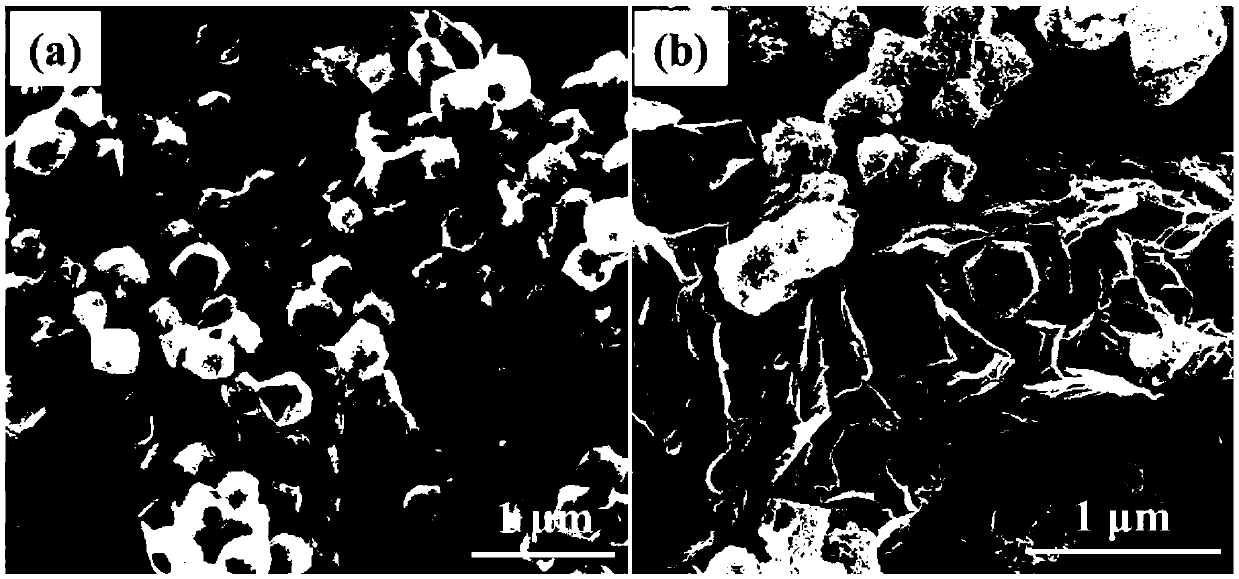

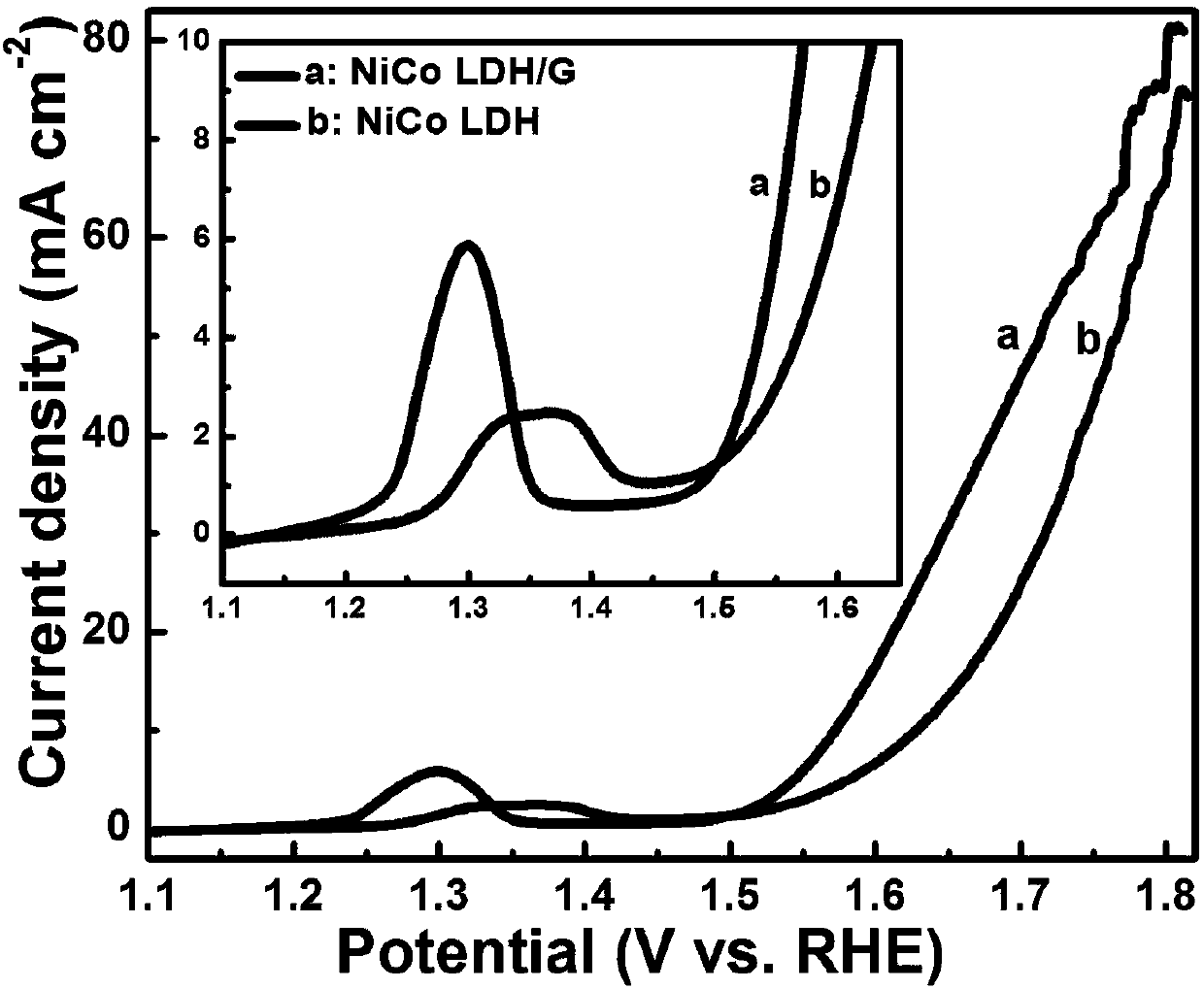

[0028] Embodiment 1 (according to cobalt nitrate: graphene weight ratio is 174:1; The mol ratio of cobalt nitrate and dimethylimidazole is 1:2, and ZIF-67 / G composite material and nickel nitrate mass ratio are 3:1)

[0029] The preparation method of nickel-cobalt layered double metal hydroxide / graphene electrocatalyst uses imidazole metal organic framework ZIF-67 as a precursor, comprising the following steps:

[0030] 1) Weigh 0.01g graphene and 1.74g cobalt nitrate, and disperse the above two substances evenly in 100ml of anhydrous methanol by ultrasonic wave, the power of ultrasonic wave is 150W, and the ultrasonic time is 12 hours to obtain solution A;

[0031] 2) Weigh 3.9398g of dimethylimidazole and dissolve it in 100mL of anhydrous methanol, solution B, according to the molar ratio of cobalt nitrate in solution A and dimethylimidazole in solution B is 1:2, add solution A to solution B After stirring evenly, let it stand for 20 hours, then centrifuge, wash and dry to ob...

Embodiment 2

[0033] Embodiment 2 (according to cobalt nitrate: graphene weight ratio is 174:2; The mol ratio of cobalt nitrate and dimethylimidazole is 1:16, and ZIF-67 / G composite material and nickel nitrate mass ratio are 1:3)

[0034] The preparation method of nickel-cobalt layered double metal hydroxide / graphene electrocatalyst uses imidazole metal organic framework ZIF-67 as a precursor, comprising the following steps:

[0035] 1) Weigh 0.02g of graphene and 1.74g of cobalt nitrate, and uniformly disperse the above two substances in 100ml of anhydrous methanol by ultrasonic waves. The power of the ultrasonic waves is 300W, and the ultrasonic time is 10 hours to obtain solution A;

[0036] 2) Weigh 7.8796g of dimethylimidazole and dissolve it in 100mL of anhydrous methanol, solution B, according to the molar ratio of cobalt nitrate in solution A and dimethylimidazole in solution B is 1:16, add solution A to solution B After stirring evenly, let it stand for 32 hours, then centrifuge, w...

Embodiment 3

[0038] Embodiment 3: (according to cobalt nitrate: graphene weight ratio is 43.5:1; The mol ratio of cobalt nitrate and dimethylimidazole is 1:8, and ZIF-67 / G composite material and nickel nitrate mass ratio are 2:1)

[0039] The preparation method of nickel-cobalt layered double metal hydroxide / graphene electrocatalyst uses imidazole metal organic framework ZIF-67 as a precursor, comprising the following steps:

[0040] 1) Weigh 0.04g graphene and 1.74g cobalt nitrate, and disperse the above two substances evenly in 100ml of anhydrous methanol by ultrasonic wave, the power of ultrasonic wave is 300W, and the ultrasonic time is 8 hours to obtain solution A;

[0041] 2) Weigh 3.9398g of dimethylimidazole and dissolve it in 100mL of anhydrous methanol, solution B, according to the molar ratio of cobalt nitrate in solution A and dimethylimidazole in solution B is 1:8, add solution A to solution B After stirring evenly, let stand for 30 hours, then centrifuge, wash and dry to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com