Patents

Literature

77results about How to "Ensure welding reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

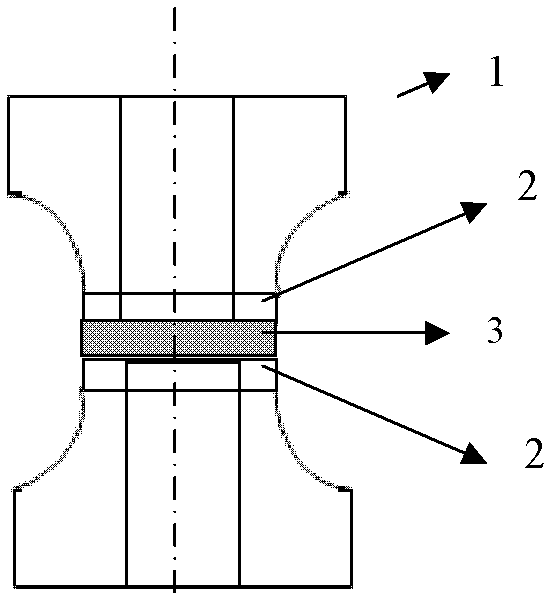

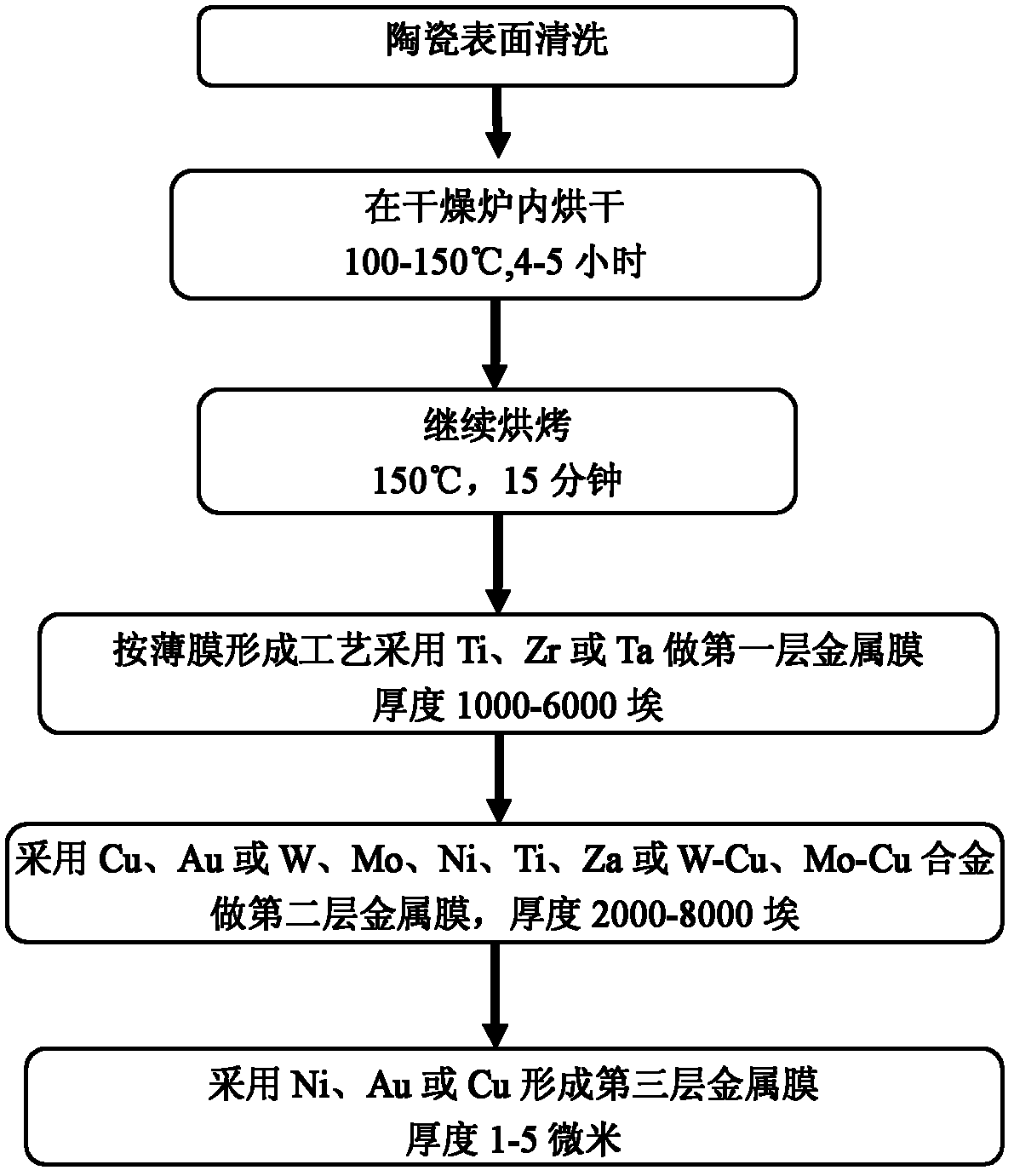

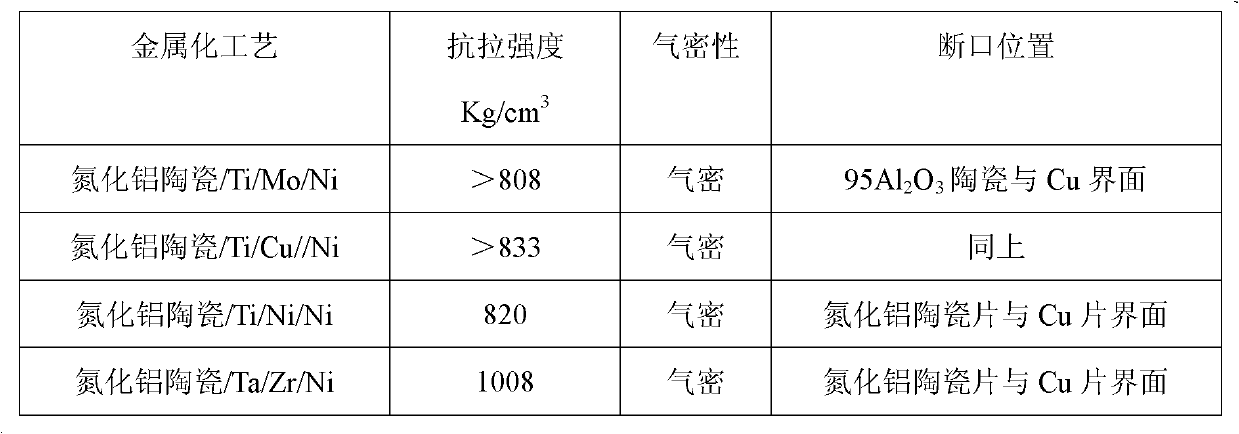

Method for metalizing surface of aluminum nitride ceramic

The invention discloses a method for metalizing the surface of aluminum nitride ceramic, and belongs to the technical field of ceramic materials. The method comprises the following steps of: cleaning the surface of ceramic; baking at the temperature of between 100 and 150 DEG C in a drying furnace for 4 to 4.5 hours; continuously baking, namely baking at the temperature of 150 DEG C for 15 minutes; and forming a first metal film layer by a film forming process by using Ti, Zr or Ta, forming a second metal film by using Cu, Au, W, Mo, Ni, Ta, Zr, W-Cu alloy, or Mo-Cu alloy, and forming a third metal film layer by using Ni, Au or Cu, wherein the thickness of the third metal film layer is 1 to 5 mu m. According to the method for metalizing the surface of the aluminum nitride ceramic, the first film layer and the second film layer are formed by optimally adopting a magneto-controlled sputter coating method, and the third film layer is formed by optimally adopting an electroplating or chemical plating method. Strong adhesion with ceramic matrix can be obtained, and the welding intensity and reliability on a ceramic seal component can be ensured by the method for metalizing multiple layers of metal films.

Owner:NO 12 RES INST OF CETC

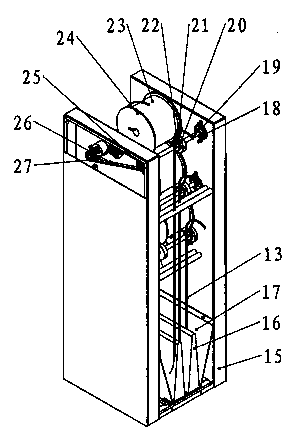

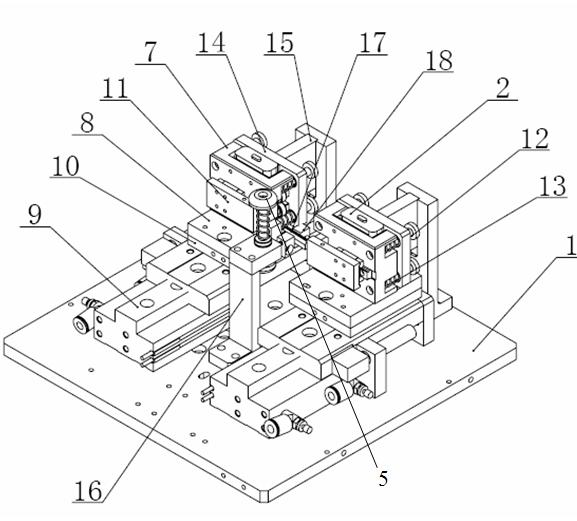

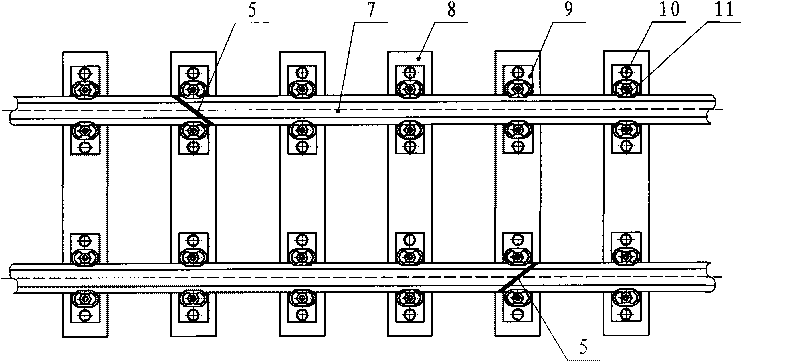

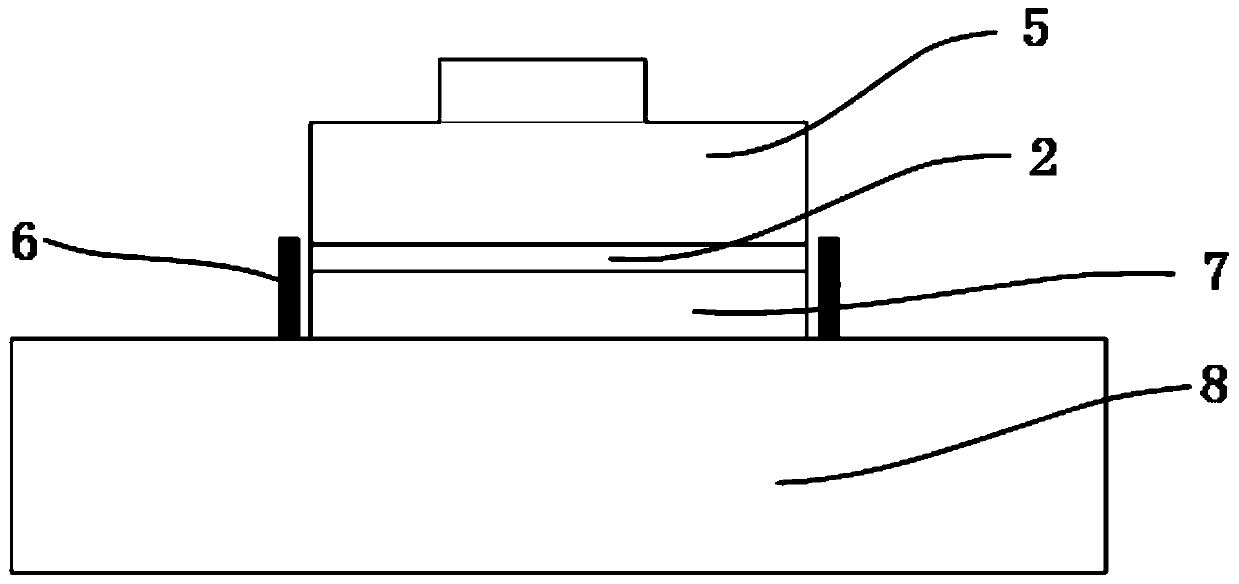

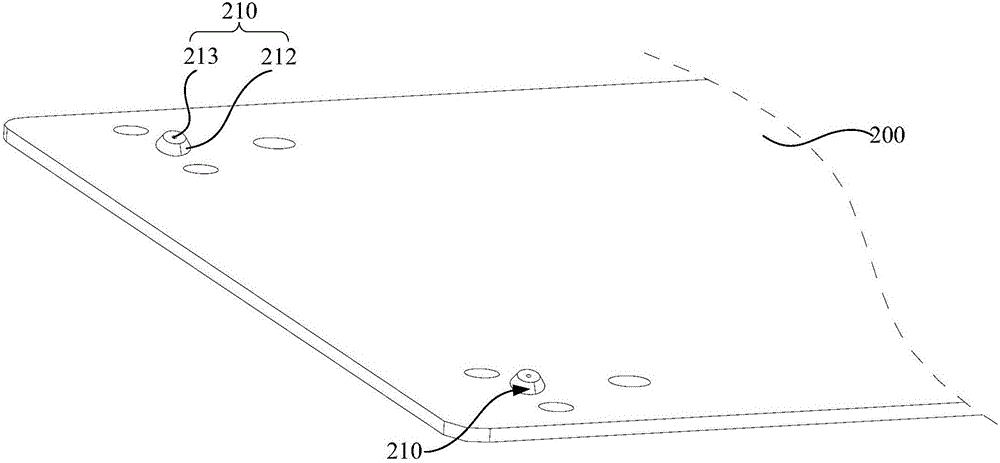

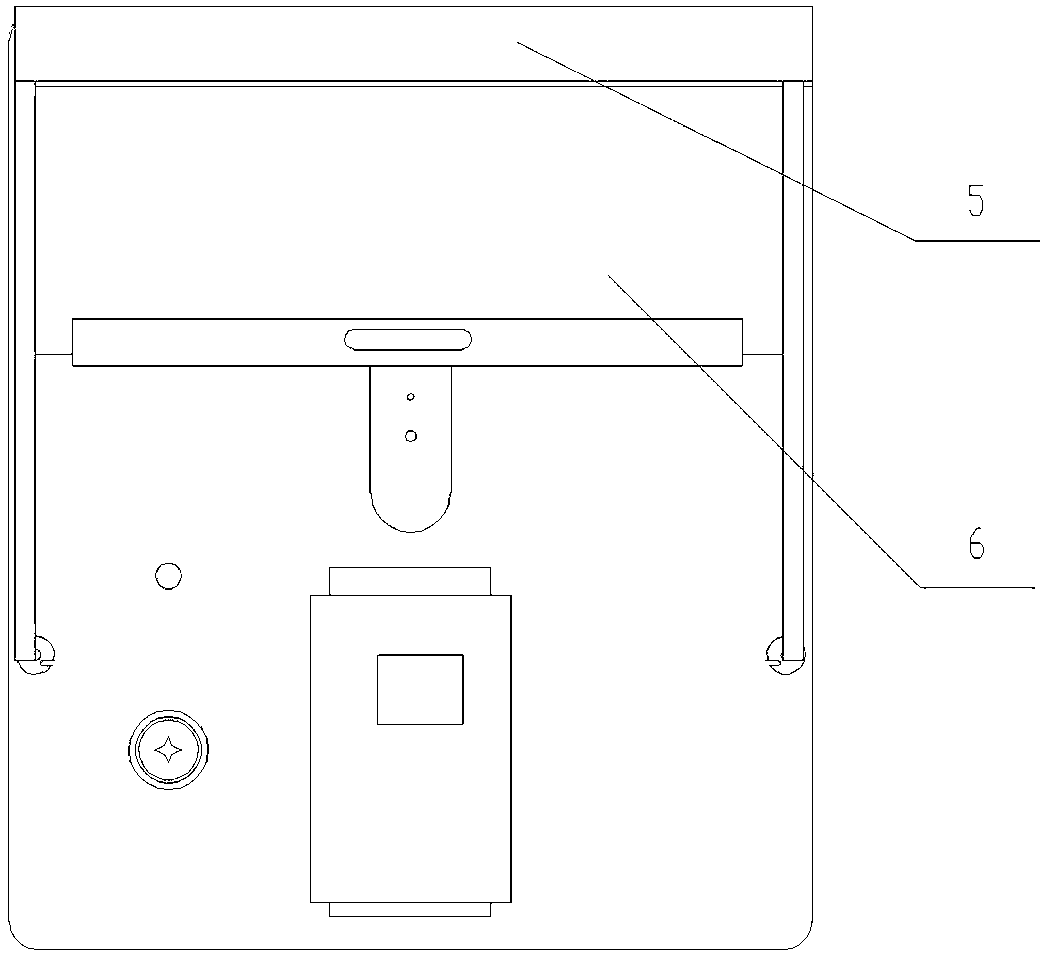

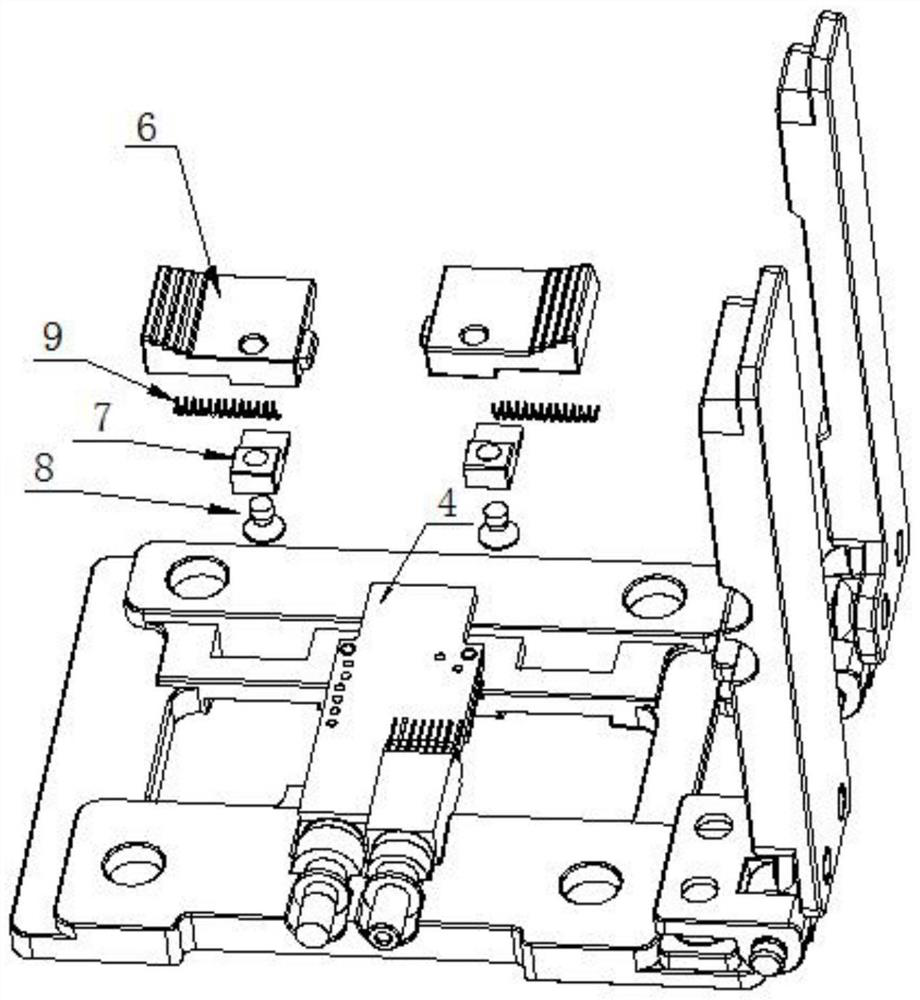

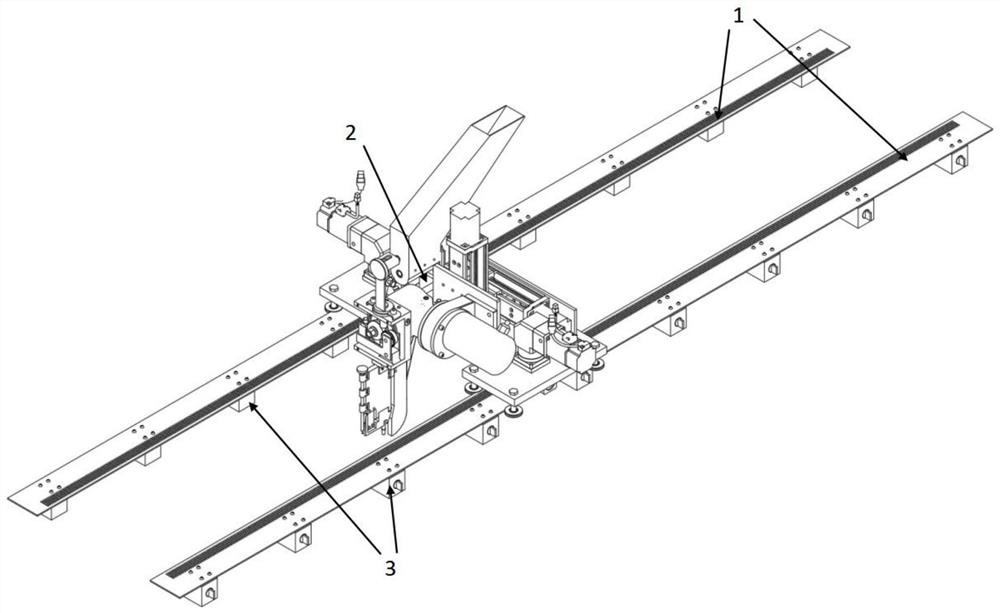

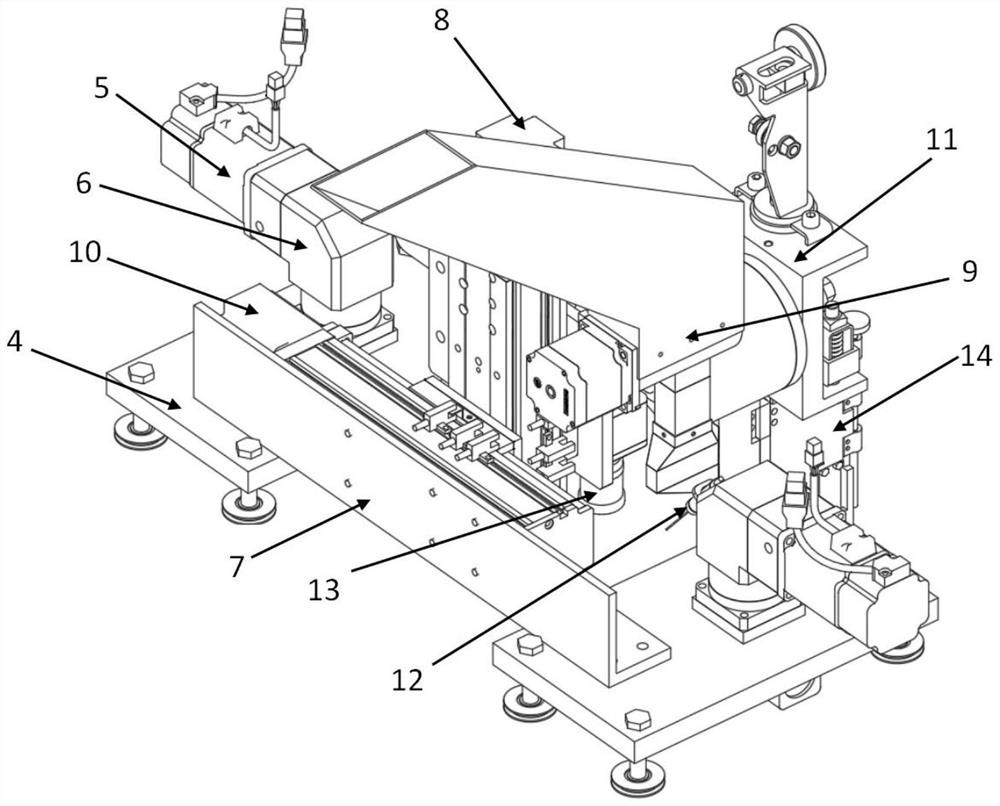

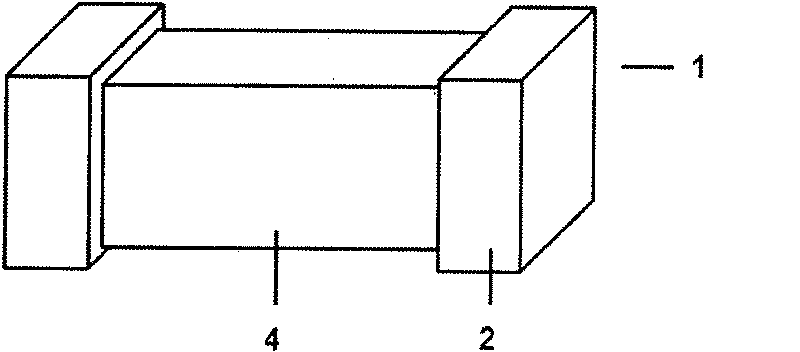

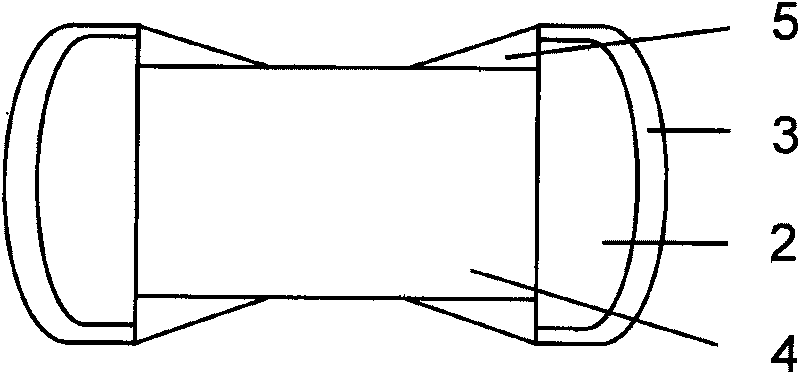

Automatic transferring welding carrying platform for solar cell piece series welding machine

InactiveCN104084716AMeet precise positioningSatisfy positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention discloses an automatic transferring welding carrying platform for a solar cell piece series welding machine. The automatic transferring and welding carrying platform solves the problems that an existing welding carrying platform is inaccurate for welding alignment of a plurality of grid lines of cell pieces and is poor in welding quality. A welding zone (4) is arranged at the left end of a welding transferring platform (3), a transferring zone (5) is arranged at the right end of the welding transferring platform (3), welding zone welding strip negative-pressure suction holes (6) are formed in the welding zone, transferring zone welding strip negative-pressure suction holes (7) are formed in the transferring zone, a solar cell piece negative-pressure suction groove (8) is formed in the welding transferring platform (3), a negative-pressure cylinder bracket (9) is arranged on a welding carrying platform substrate (2), and a welding strip negative-pressure cylinder (10) and a cell piece negative-pressure cylinder (11) are respectively arranged on the negative-pressure cylinder bracket. The automatic transferring welding carrying platform is a mechanism integrated with machinery, air and electricity, and meets the requirements that welding strips are accurately positioned and constantly heated during the series welding process and the cell pieces are quickly adsorbed in a crossed manner.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

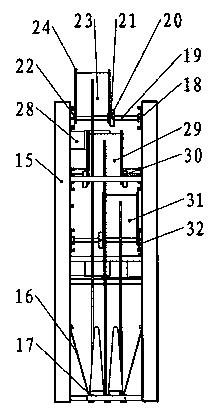

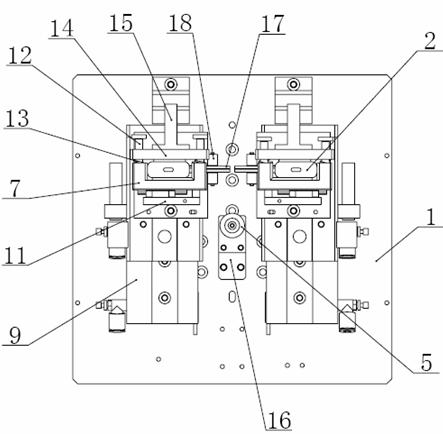

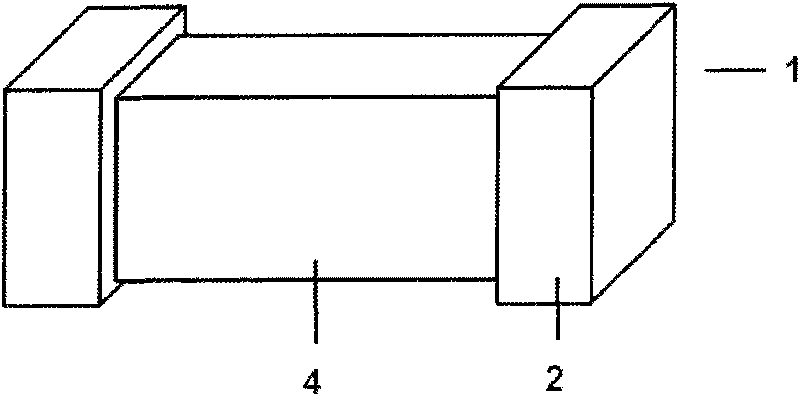

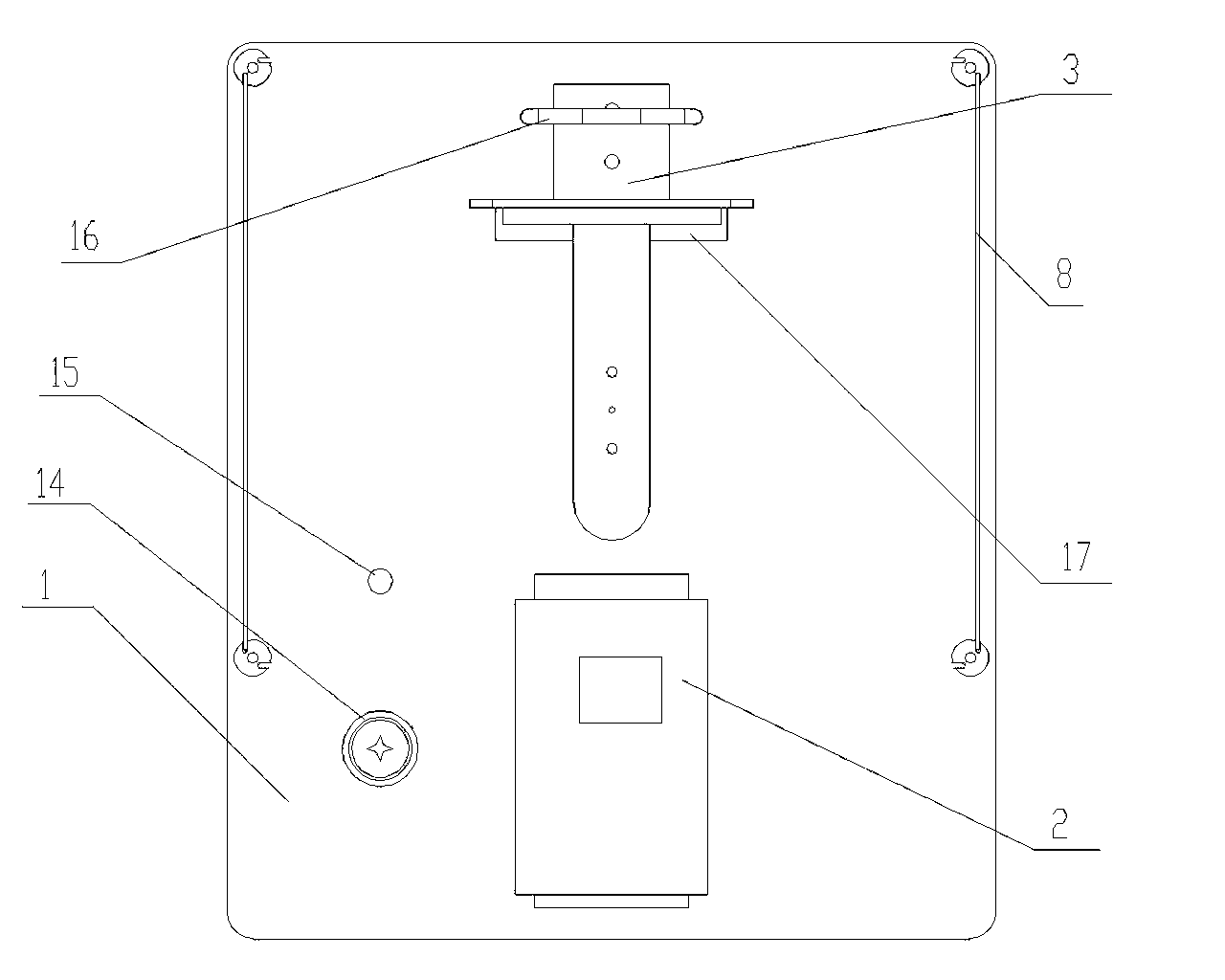

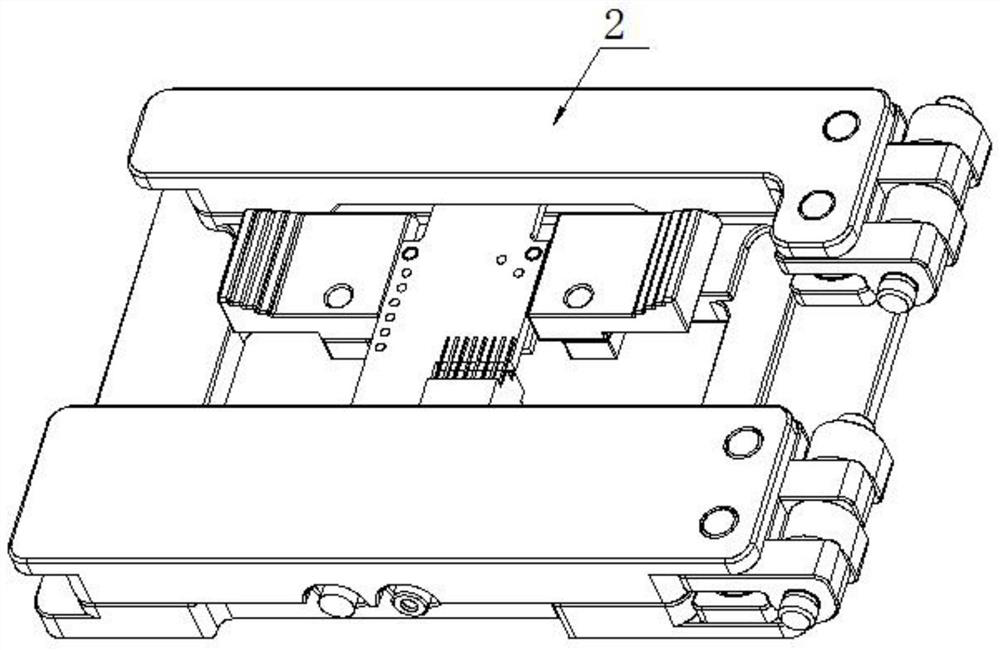

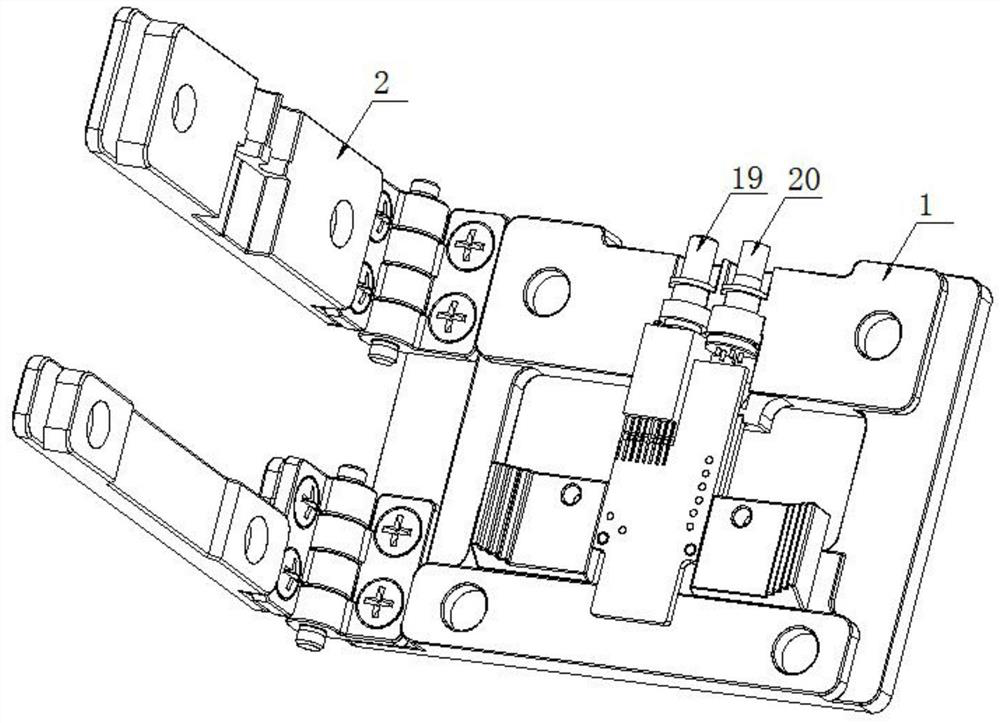

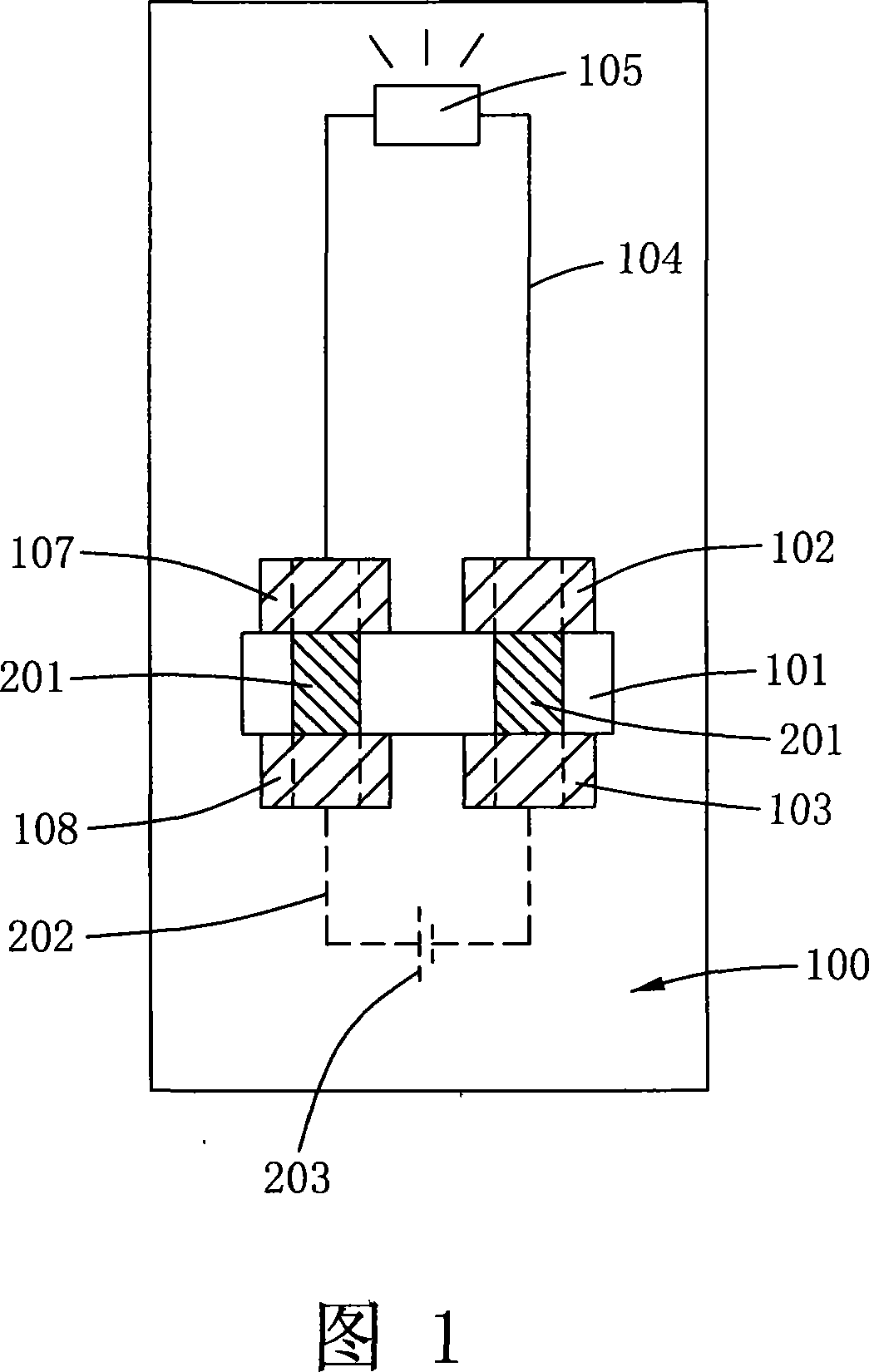

Laser welding fixture for power batteries

ActiveCN102000919AMaintain stabilityImprove quality pass rateWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryPower battery

The invention discloses a laser welding fixture for power batteries. The fixture comprises a bottom plate (1), wherein two limiting plates (15) used for welding are arranged at the rear end of the bottom plate (1) at an interval; a sliding table cylinder (9) is respectively arranged right ahead each limiting plate (15) used for welding; a battery fixture positioning plate (7) and a mobile limiting plate (14) are respectively arranged on the upper surface of each sliding table cylinder (9) in tandem; at least one battery fixture guide shaft (12) is respectively fixed to the left end and the right end of each battery fixture positioning plate (7); each mobile limiting plate (14) is connected with each battery fixture positioning plate (7) through the battery fixture guide shaft (12); and a groove is reserved in the middle of each battery fixture positioning plate (7). The laser welding fixture for the power batteries disclosed by the invention can maintain the stability of battery clamping, ensures the welding reliability of the power batteries in various welding fields, and improves the quality passing rate of the power batteries.

Owner:TIANJIN LISHEN BATTERY

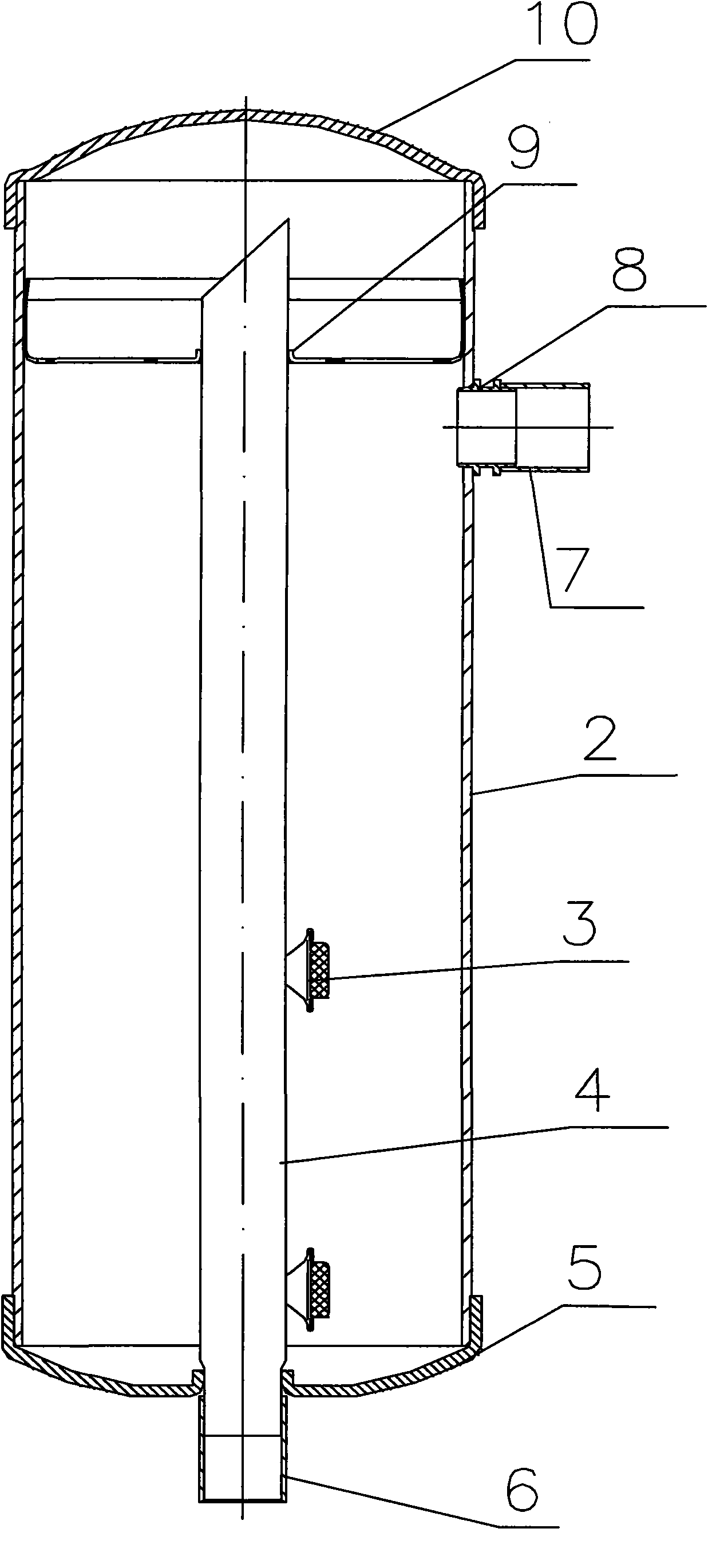

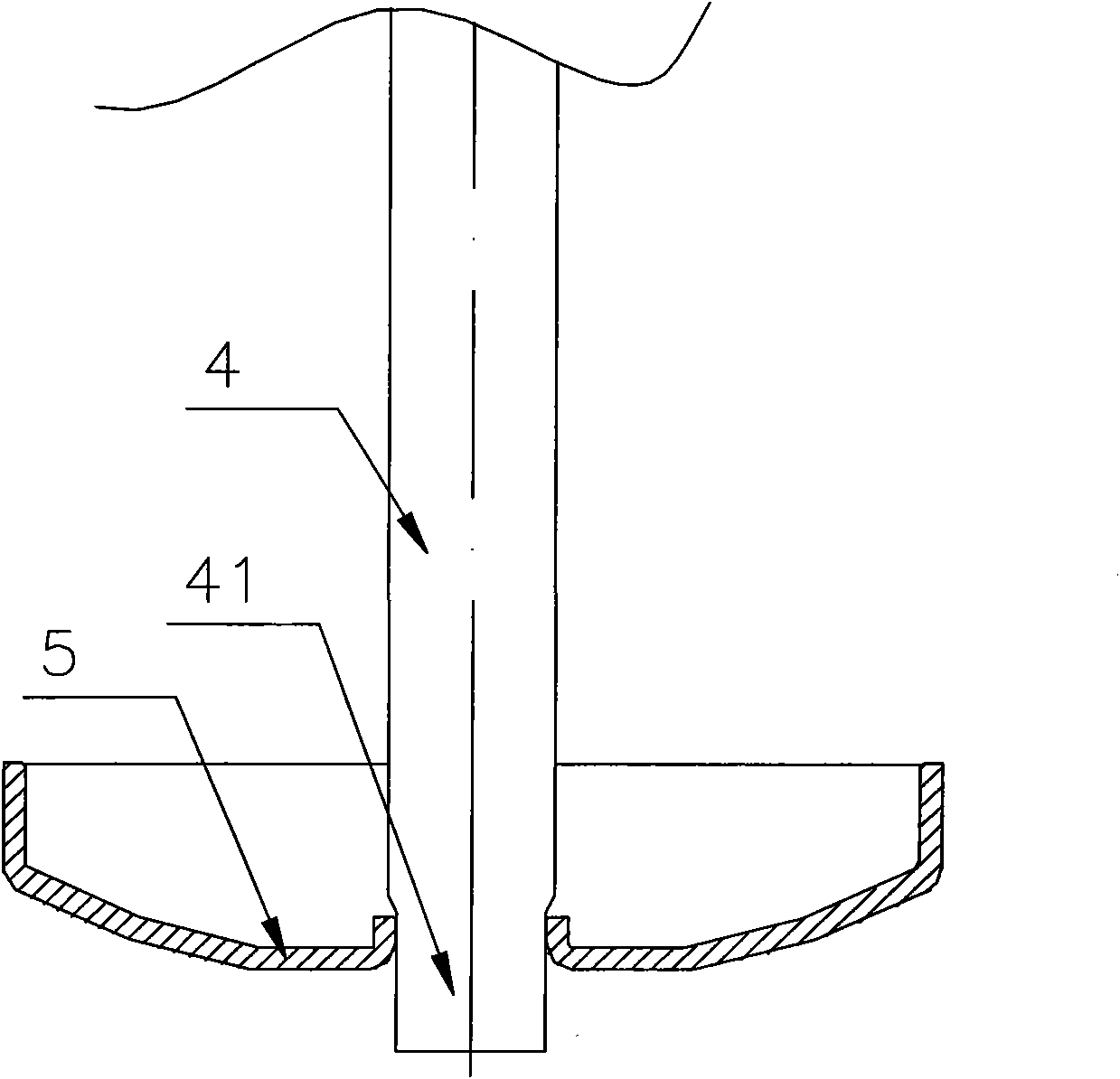

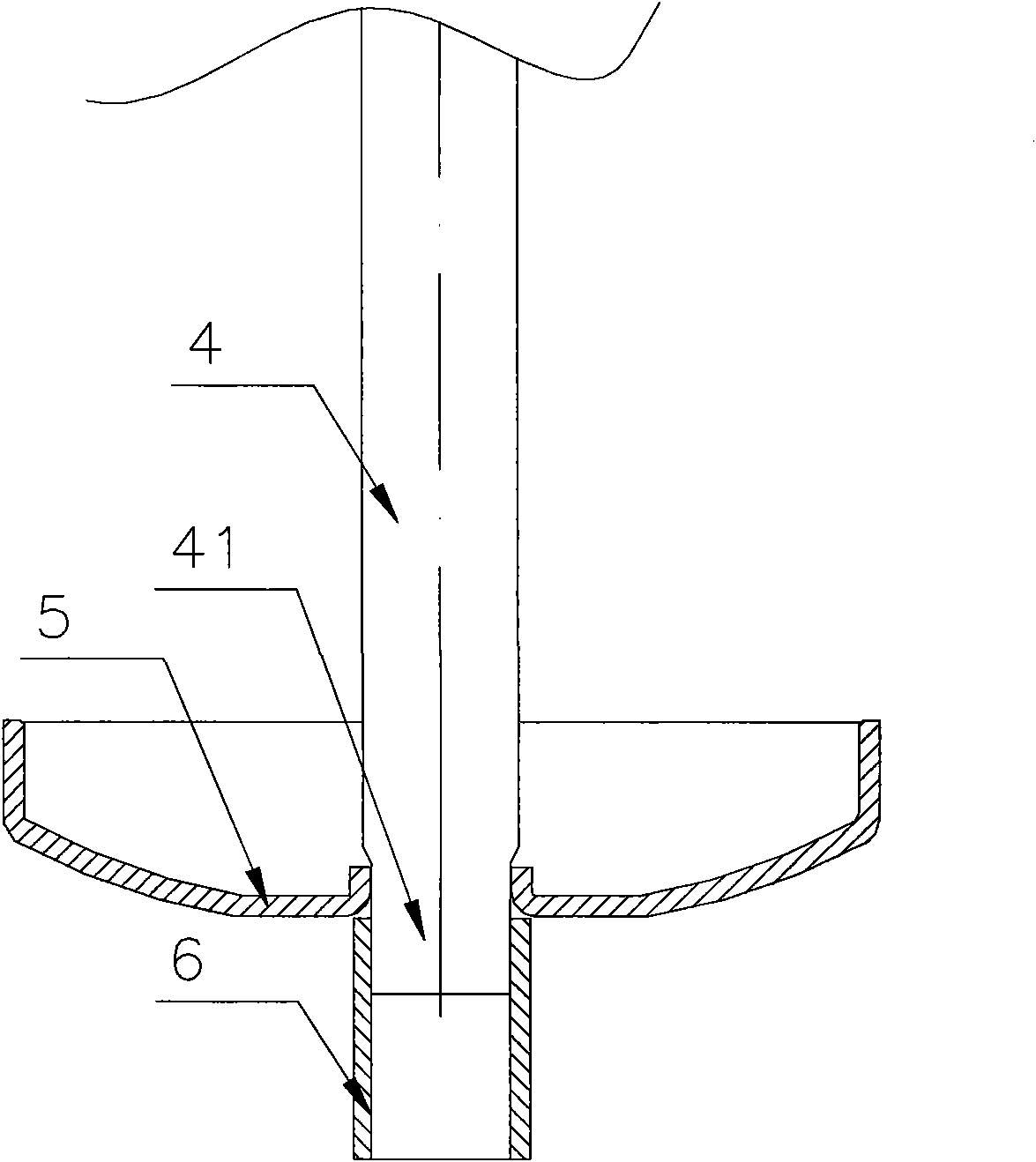

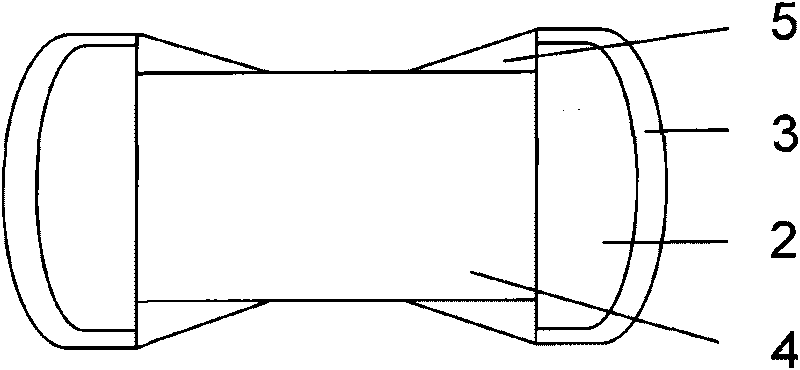

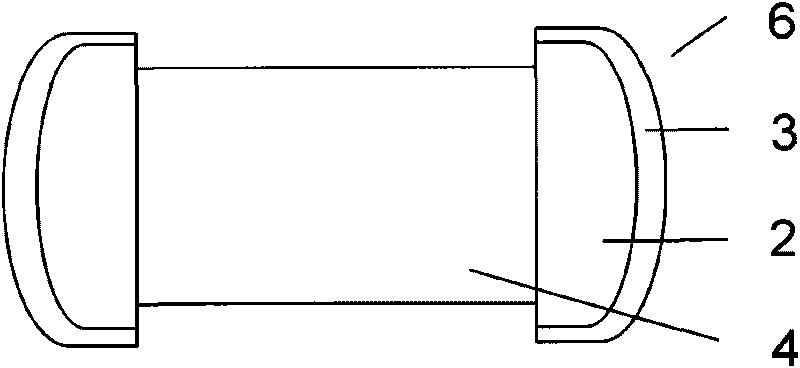

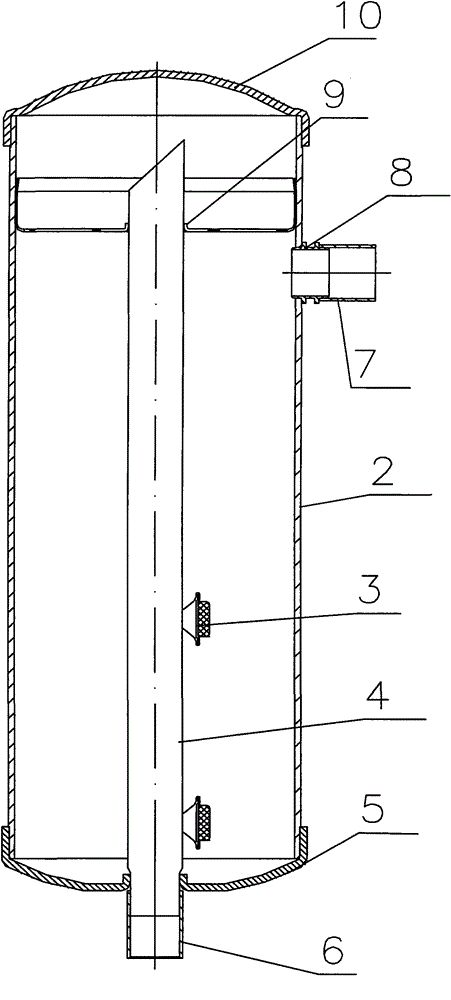

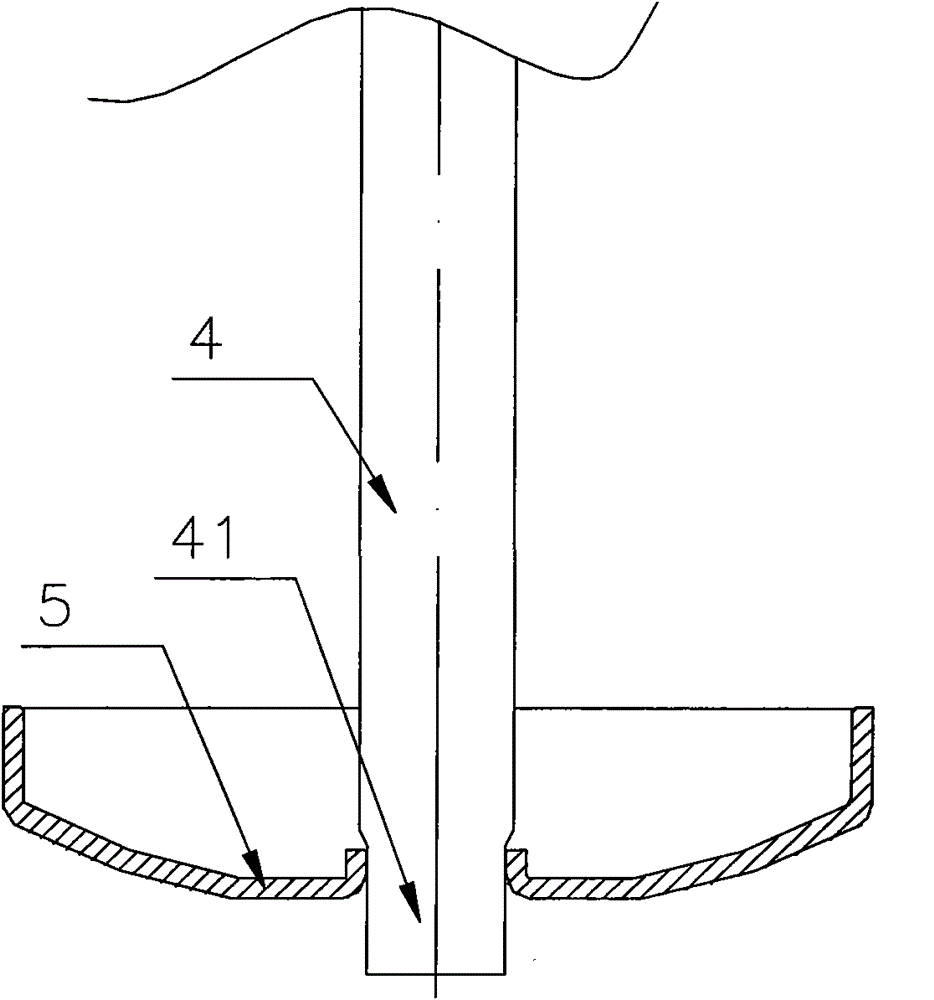

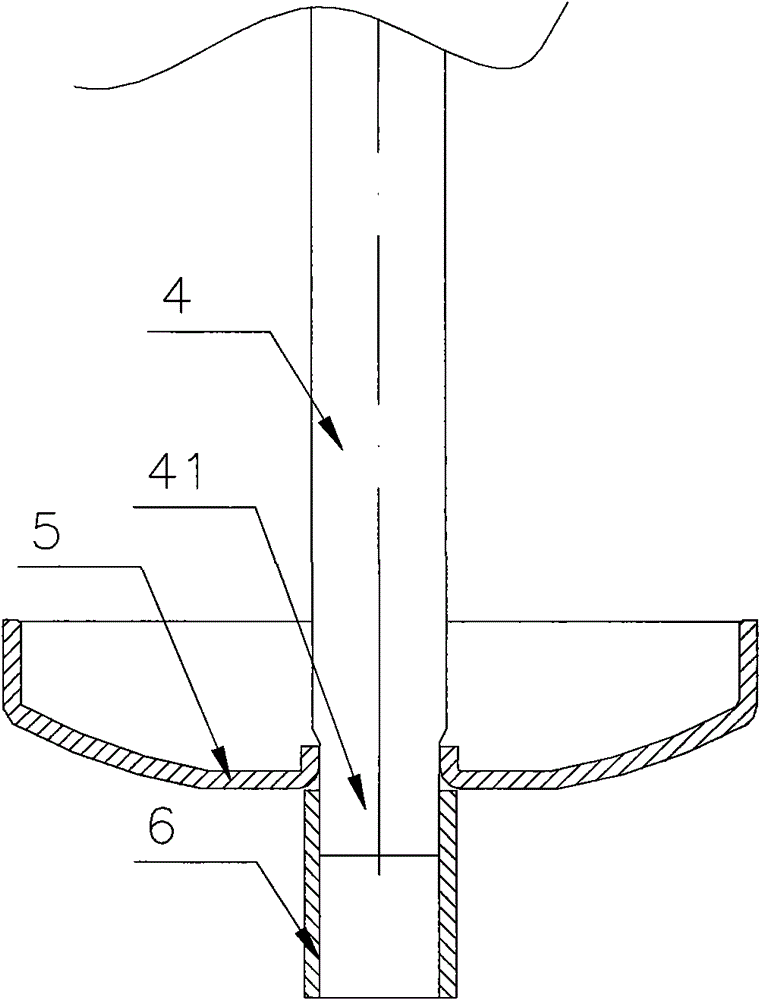

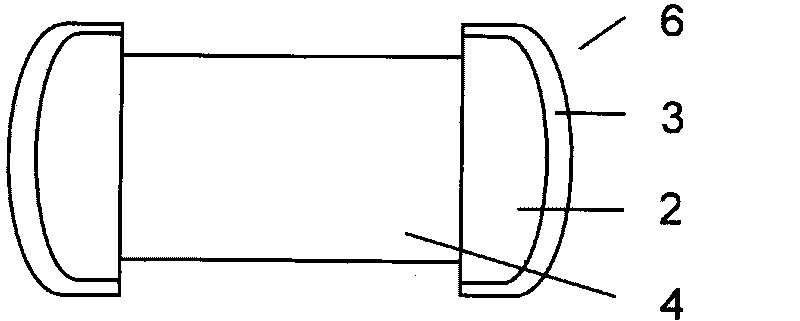

Gas-liquid separator

ActiveCN101852522AWelding fit distance is stableGuarantee welding qualityRefrigeration componentsWelding apparatusEngineering

The invention discloses a gas-liquid separator, which comprises a cylinder, an upper end cover, a lower end cover, an outlet adapter and an iron pipe. The iron pipe is positioned in the gas-liquid separator body; the outlet adapter is connected with the iron pipe through the lower end cover; the lower end cover is provided with an outward turnover edge part; the iron pipe is fixed with the inner wall of the outward turnover edge part of the lower end cover; and the outlet adopter is matched and fixed with the outer wall of the outward turnover edge part of the lower end cover by welding. Structural and technical improvements are made, so a welding fitting distance between the iron pipe and the lower end cover is stable, a galling phenomenon between welded contact surfaces is avoided and a welding fitting distance between the outlet adapter and the lower end cover is stable. Therefore, the quality, reliability and consistency among the lower end cover, the iron pipe and the outlet adapter are ensured.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

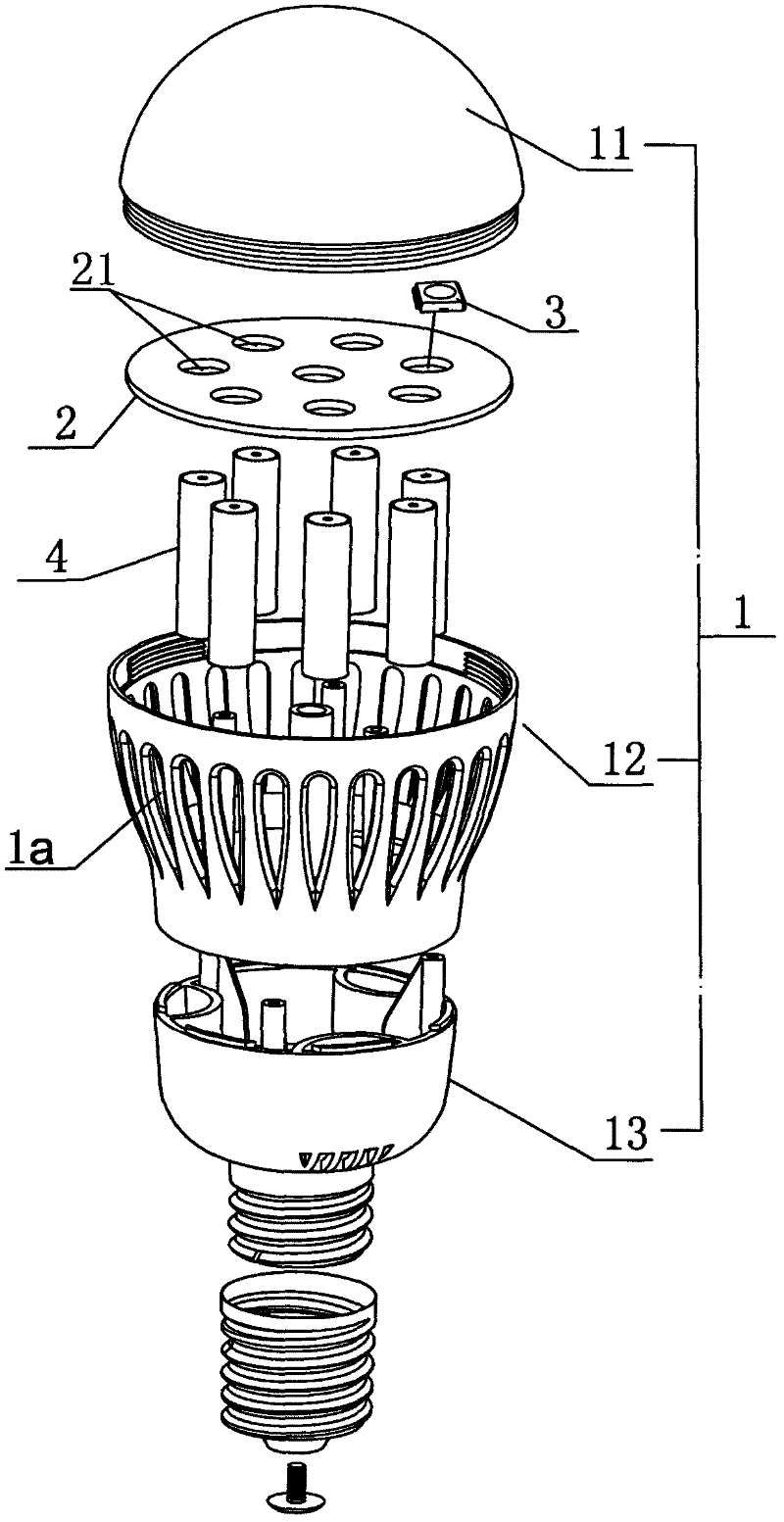

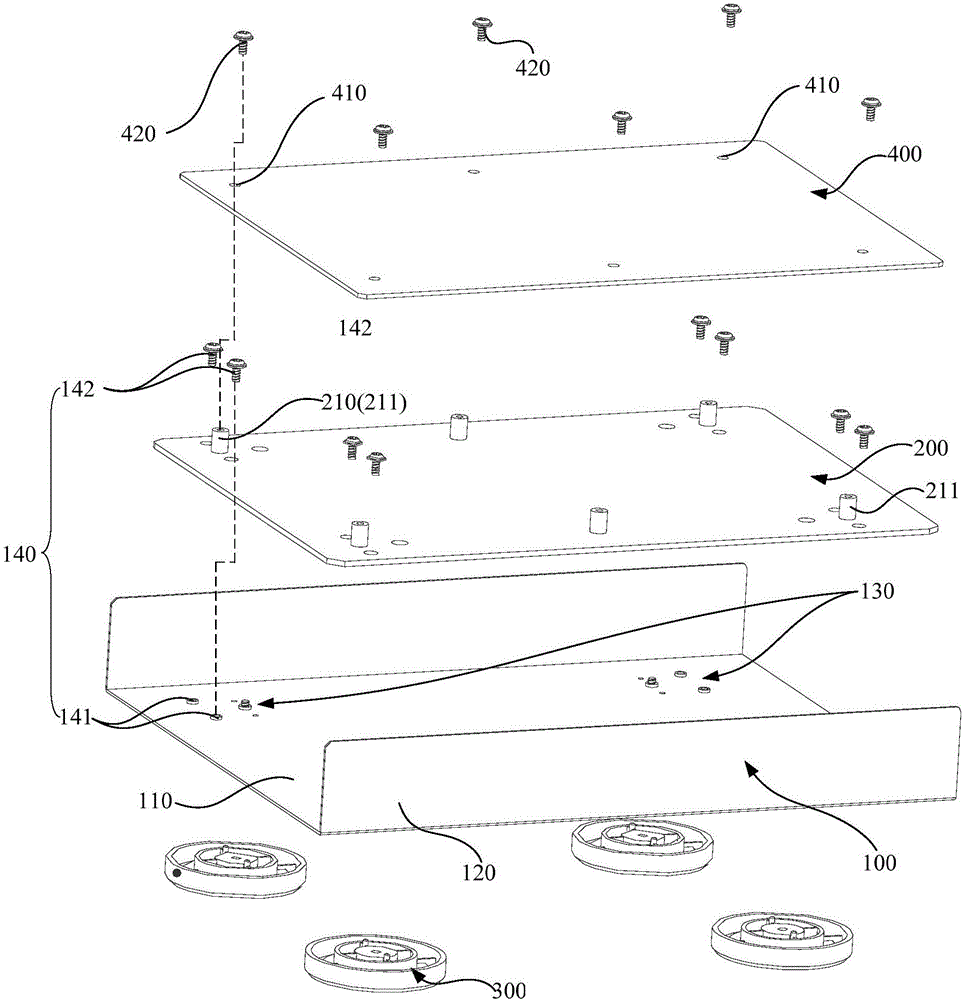

Thermoelectric separation power type light-emitting diode bulb with high integration and high lighting effect

InactiveCN102644867ASimple assembly structureEasy to assemble and disassemblePoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The invention relates to a thermoelectric separation power type light-emitting diode bulb with high integration and high lighting effect, comprising a case, a circuit board and light-emitting diodes, wherein the circuit board is arranged in the case, the light-emitting diode is arranged on the circuit board, the case is a non-metal hollow case, air holes are arranged on a lower side, the lower side of the circuit board is provided with radiation pillars which are fixed the light-emitting diodes in one-to-one correspondence, heat is radiated by virtue of the radiation pillars which are independently corresponding to the light-emitting diodes, independent heat radiation technical effect realized by a heat radiation pillar body with large heat radiation area to a corresponding light-emitting diode is effectively enhanced, heat produced when an LED (light-emitting diode) lamp gives out light is better transferred to the air and radiated, so as to solve problems of heat transfer and heat radiation in a using process, and service life of the LED lamp is guaranteed.

Owner:OUTRACE TECH

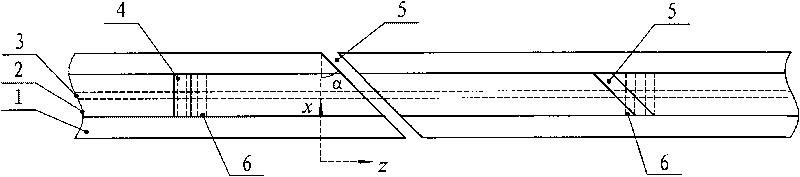

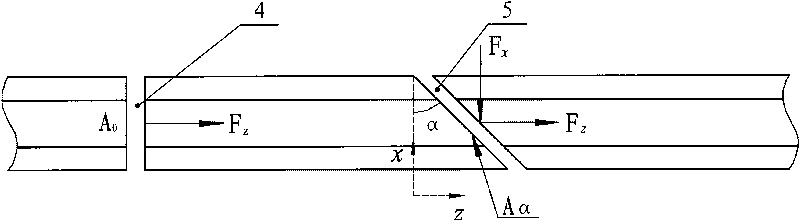

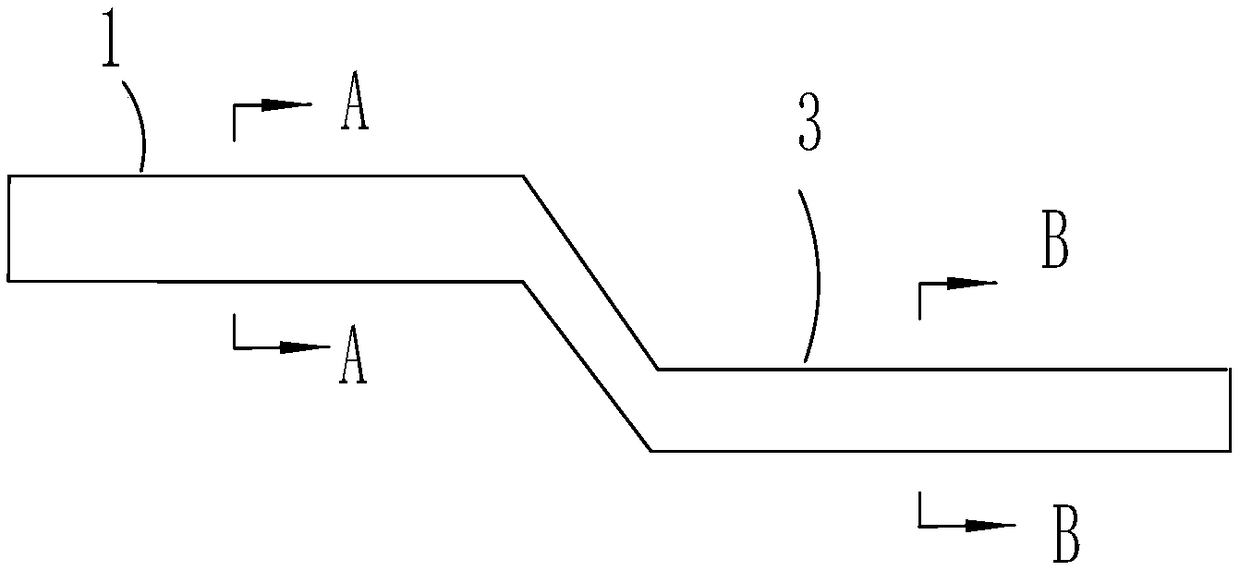

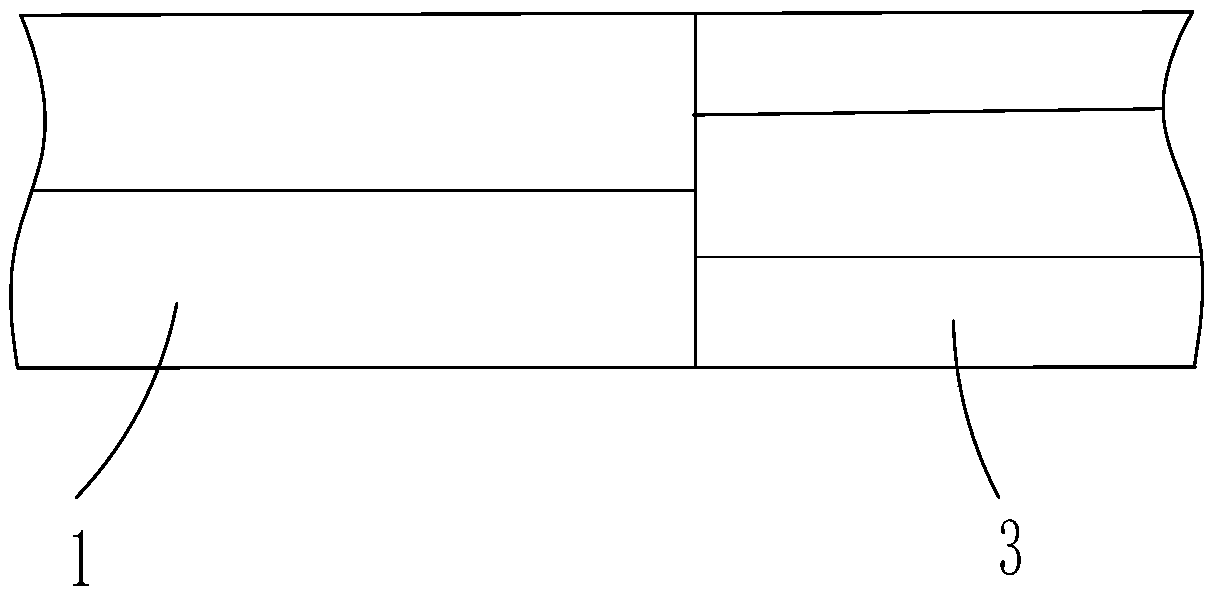

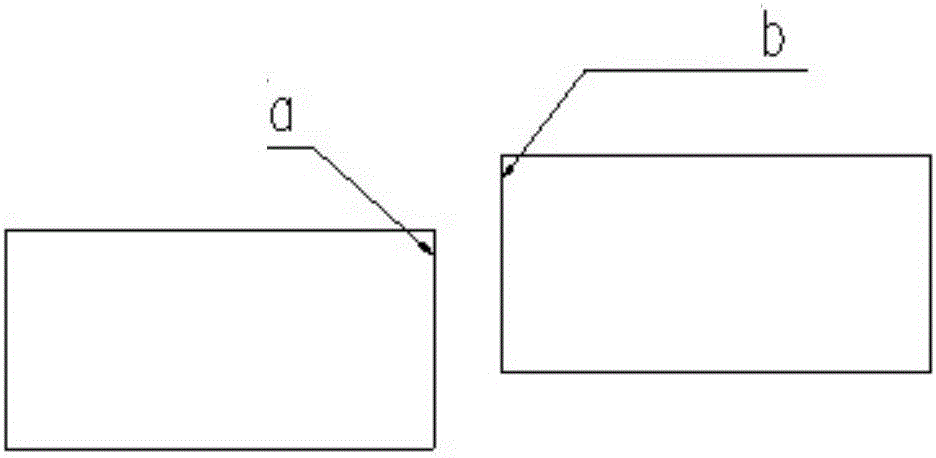

Welding structure of seamless steel rails with smooth operation up and down and large carrying capacity of welding seams

The invention relates to a welding structure of seamless steel rails with smooth operation up and down and large carrying capacity of welding seams. The reinforced welding structure of the seamless steel rails with smooth operation up and down belongs to the technical field of welding of steel rails of trains. The welding structure of the invention comprises steel rails and welding seams, wherein the connecting parts of the steel rails are in inclined surfaces which are connected in a welding way; the inclined surfaces at the connecting parts of two parallel steel rails are asymmetrically arranged in a staggered way; the staggered length is larger than the length of a section of carriage; and each inclined surface is determined by being parallel with the y axis and forming 45 degree or 60 degree angle with the x axis. The inclined welding surfaces of the invention can prevent wheels from bumping up and down when the wheels pass through the welding seams; compared with straight welding surfaces, the inclined welding surfaces can increase the welding area, reduce pure positive tension stress and pure shearing stress, and can increase the carrying capacity of the steel rails to the wheels; and even the aluminothermic welding is adopted, the welding strength and welding reliability can also be ensured, and the aluminothermic welding can improve the welding efficiency, simplify the welding technology and save the welding cost and can be operated in an on-line way. The invention is especially suitable for welding seamless long rails of heavy load trains and high-speed CRH, and can also be used for welding seamless steel rails of urban rail trains.

Owner:宋玉泉

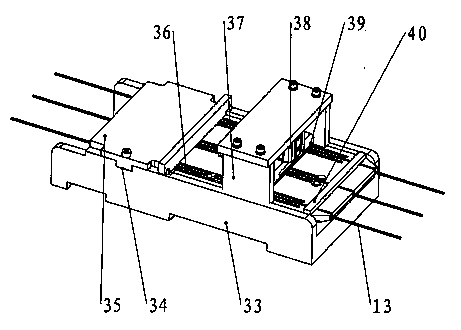

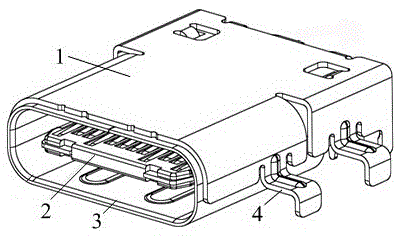

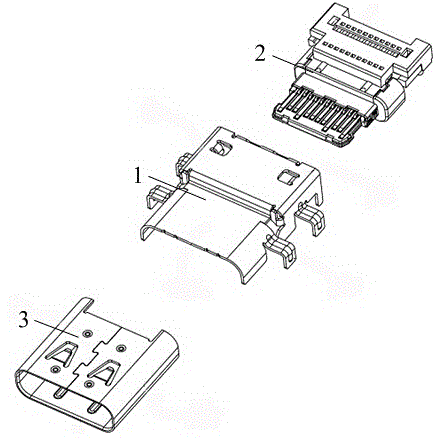

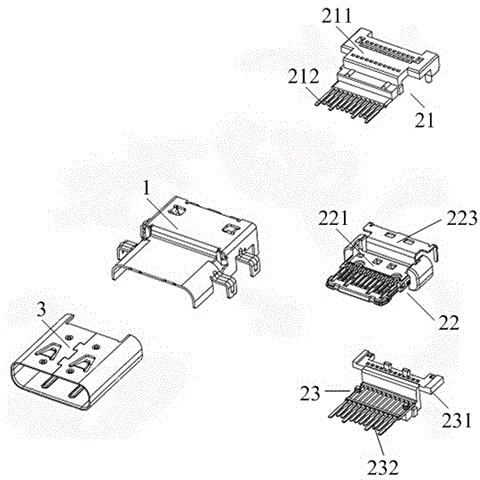

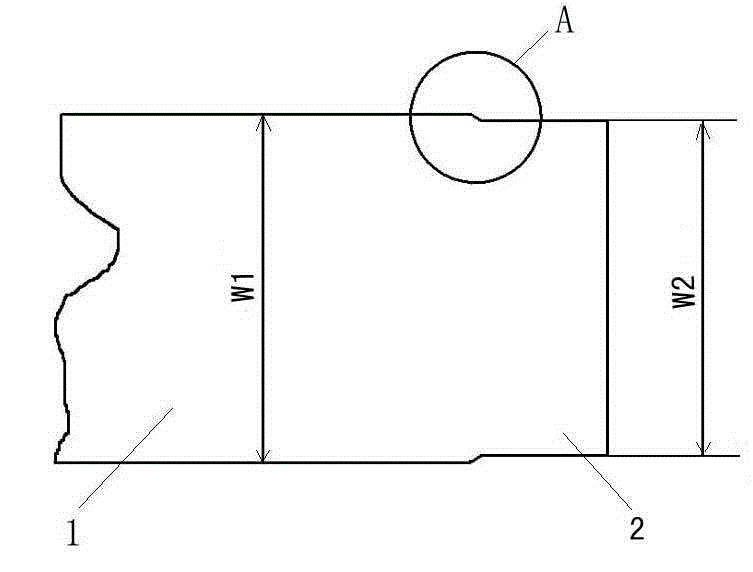

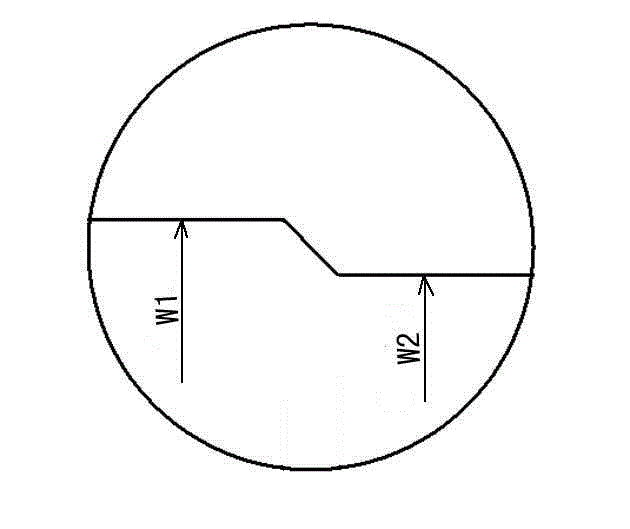

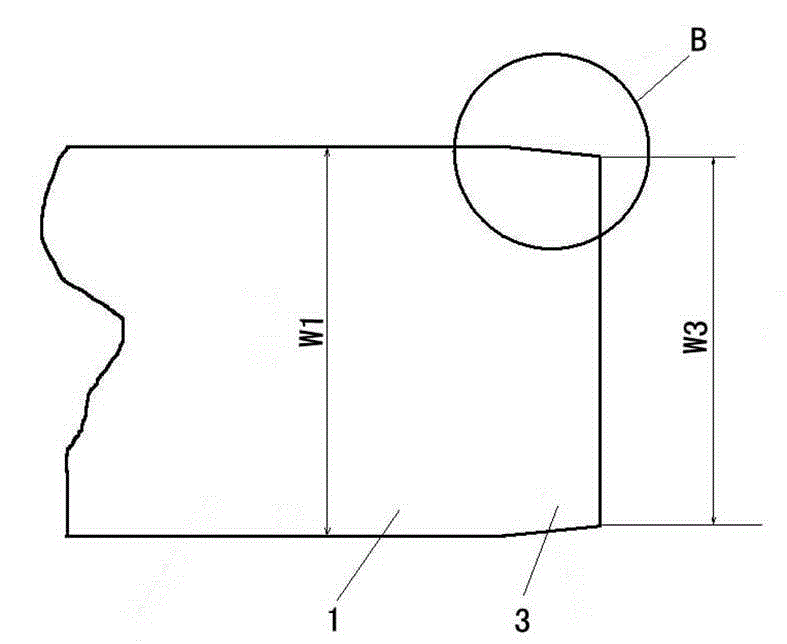

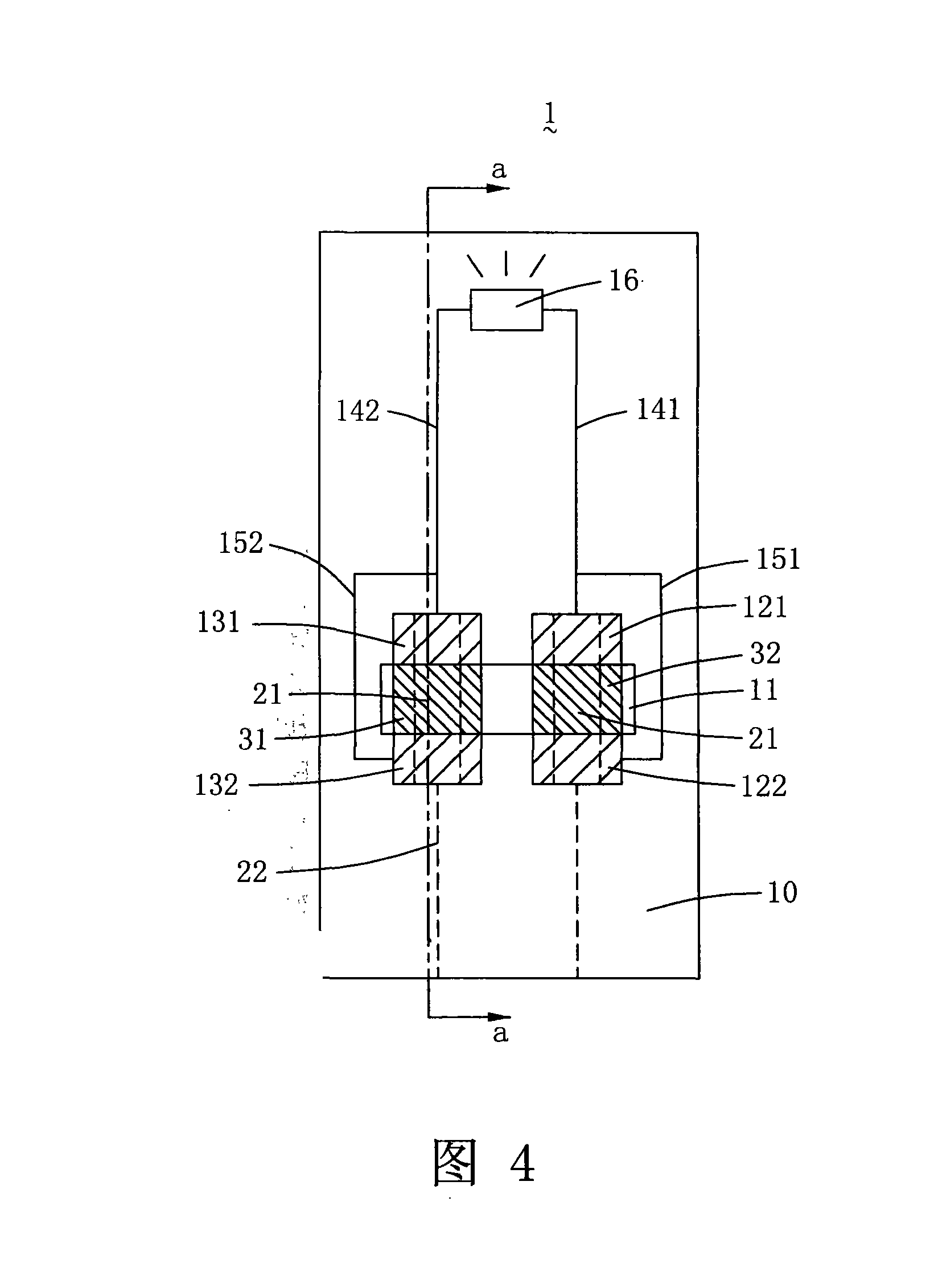

USB Type-C socket connector convenient for firm welding

ActiveCN104810683AEnsure welding reliabilityImprove reliabilityLine/current collector detailsCoupling device detailsHeight differenceUSB

The invention discloses a USB Type-C socket connector convenient for firm welding. The USB Type-C socket connector convenient for the firm welding comprises a metallic shield shell and an inserting component; the metallic shield shell is provided with more than two pairs of welding leg sets; and the rear row of the welding leg set is higher than the front row of the welding leg set. The USB Type-C socket connector convenient for the firm welding is used for, only if the actual deviation value of the welding leg set is not greater than the preset height difference value between the rear row of the welding leg set and the front row of the welding leg set, ensuring the welding reliability of the front row of the welding leg set and the substrate. The producer only detects the rear row of the welding leg set convenient for the detection under the usual situation, and the welding firmness of the USB Type-C socket connector can be determined directly. The product reliability is improved, and the production difficulty and production cost are reduced.

Owner:ALL BEST ELECTRONICS TECH CO LTD

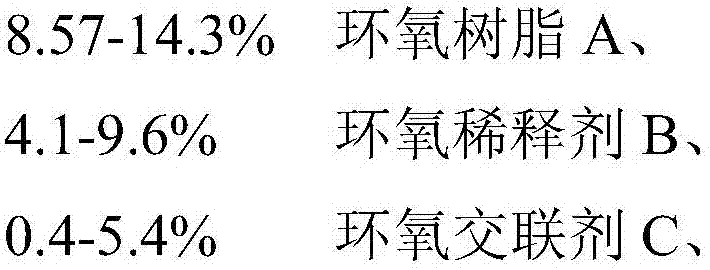

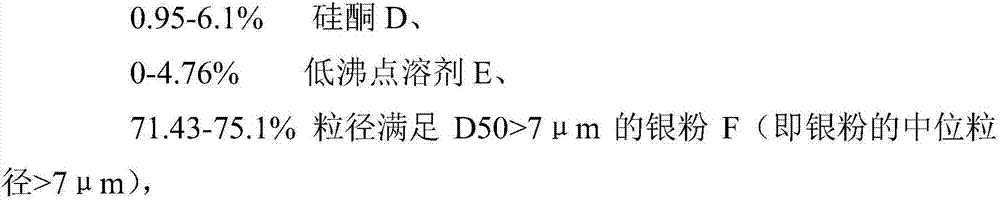

Normal-temperature cured conductive adhesive and process method thereof for connecting rechargeable battery pack

ActiveCN107446520AClose contactAvoid circuit breakingNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyElectrical battery

The invention discloses a normal-temperature cured conductive adhesive and a process method thereof for connecting rechargeable battery packs. The conductive adhesive is used for communicating rechargeable battery pack electrodes and reinforcing battery packs, and then the rechargeable battery pack electrodes and the battery packs can endure vibration and impact under use conditions. The normal-temperature cured conductive adhesive comprises an epoxy resin, an epoxy diluent, an epoxy curing agent, silicone aids and 30-90% by mass of silver powder of which D50 is greater than 7mu m. When being applied to connection and reinforcement of battery cathodes, the normal-temperature cured conductive adhesive disclosed by the invention can be called as a 'cathode cold welding' process, both the welding reliability of hot welding is maintained, and no external heat is needed in the welding process, direct damage or hidden damage of battery structures is avoided, and thus the properties of conductors are not affected by external heat.

Owner:晶丰电子封装材料(武汉)有限公司 +1

Preliminary treatment method for electroplating of chip ferrite product

The invention discloses a preliminary treatment method for electroplating of a chip ferrite product, comprising the following steps: I. the chip ferrite semi-finished product after silver ink firing is carried out is arranged in ferrum complex saturated aqueous solution, and then is soaked at normal temperature, and the chip ferrite semi-finished product is taken out after complexing is carried out to ferric ions on the surface of a magnet completely; II. The chip ferrite semi-finished product is cleaned for 3-5 times by pure water with 55-100 DEG C, so as to clean the ferrum complex left on the silver end, and then the chip ferrite semi-finished product can be directly electroplated after being arranged in a basket; the design principle is that: the ferrum complex aqueous solution is utilized to remove the ferric ions left on the surface of the magnet of the chip ferrite semi-finished product after the silver ink firing is carried out to the chip ferrite, no ferric ions are deoxidized when in electroplating, so as not to form an overplating substrate. The preliminary treatment method for electroplating of the chip ferrite product has convenient operation, good effect and short time; the method not only can prevent the chip ferrite semi-finished product from generating the overplating phenomenon in the electroplating procedure, but also can not cause poor plating layer; in addition, the welding reliability of the chip ferrite after being electroplated is ensured.

Owner:SUNLORD (SHANGHAI) ELECTRONICS CO

Tool-free fixed welding method for high-power IGBT module

ActiveCN110142475AAchieving Soldering ReliabilityEnsure welding reliabilitySoldering auxillary devicesEngineeringSilica gel

The invention discloses a tool-free fixed welding method for a high-power IGBT module. The method comprises the following steps that a polymer binder is sprayed on the back surface of a first weldinglug, and the first welding lug is placed on the surface of the copper-clad ceramic lining plate; the polymer binder is sprayed on the back surface of a chip, the chip is placed on the surface of the first welding lug, the chip and the first welding lug are assembled into a lining plate subunit, and the lining plate subunit is put into a welding furnace, thus finishing the first welding; an organicsilica gel is coated on the surface of the lining plate, the coating shape is a rectangular frame, and the size of the rectangular frame is larger than that of a secondary welding lug; the secondarywelding lug is placed in the rectangular frame of the organic silica gel; the polymer binder is sprayed on the back surface of the lining plate subunit, and the lining plate subunit is placed on the surface of the secondary welding lug, and then the lining plate subunit and the secondary welding lug are assembled together and put into the welding furnace, thus finishing the secondary welding. According to the method, a tool is not required for fixing, so that the welding reliability can be ensured; the cleaning is not needed; and the organic silica gel in the secondary welding can not only beused for fixing the welding lug, but also avoid the phenomena of overflow of welding flux on the surface of a base plate due to the fact that the large-size welding lug is melted, short circuit and the like.

Owner:NARI TECH CO LTD +1

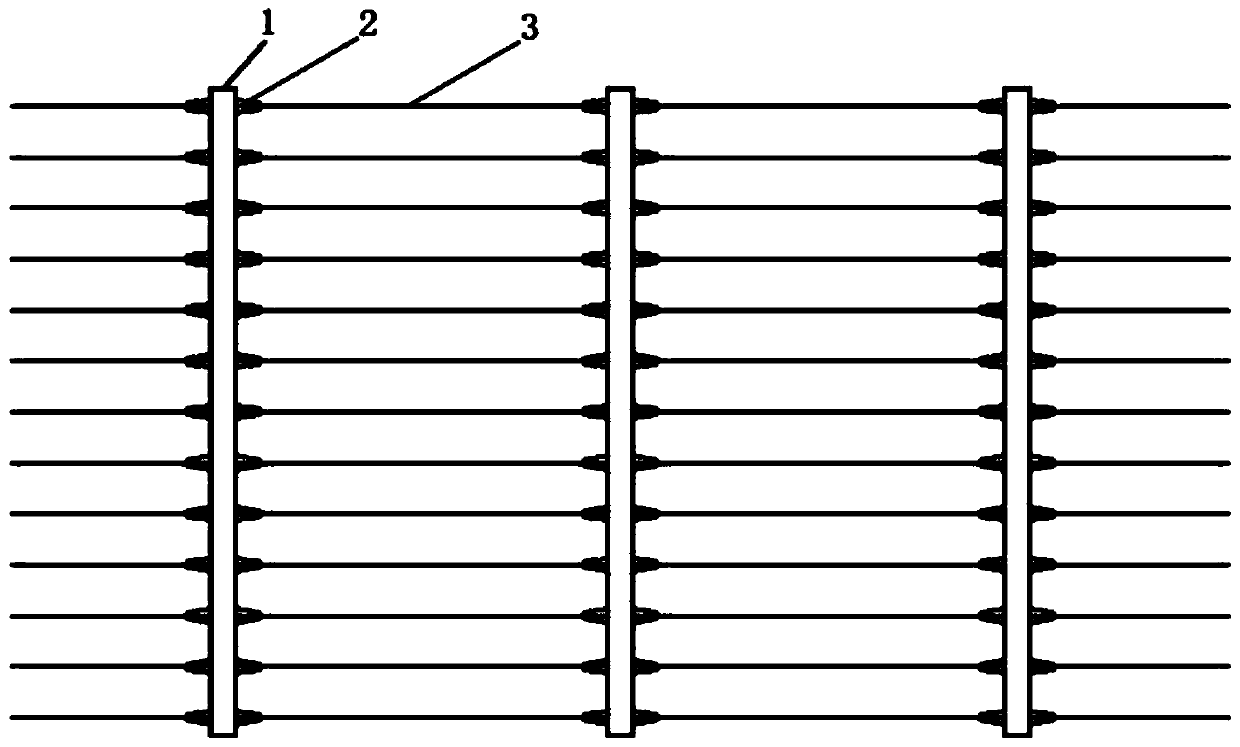

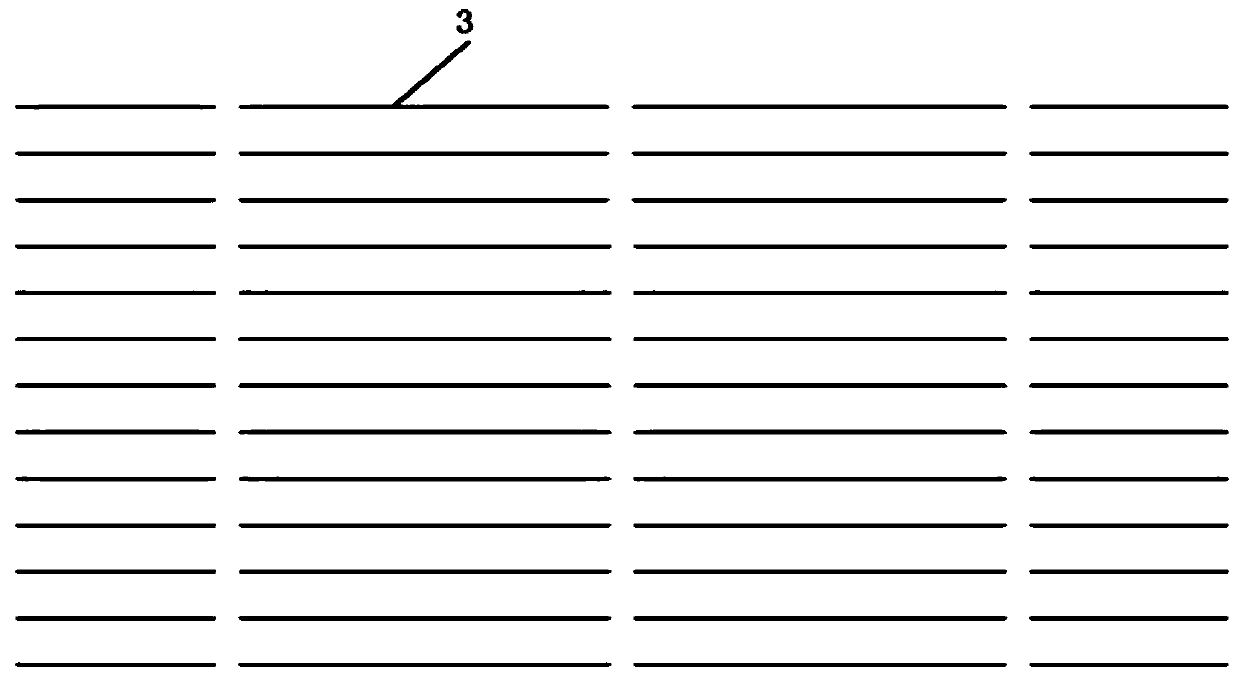

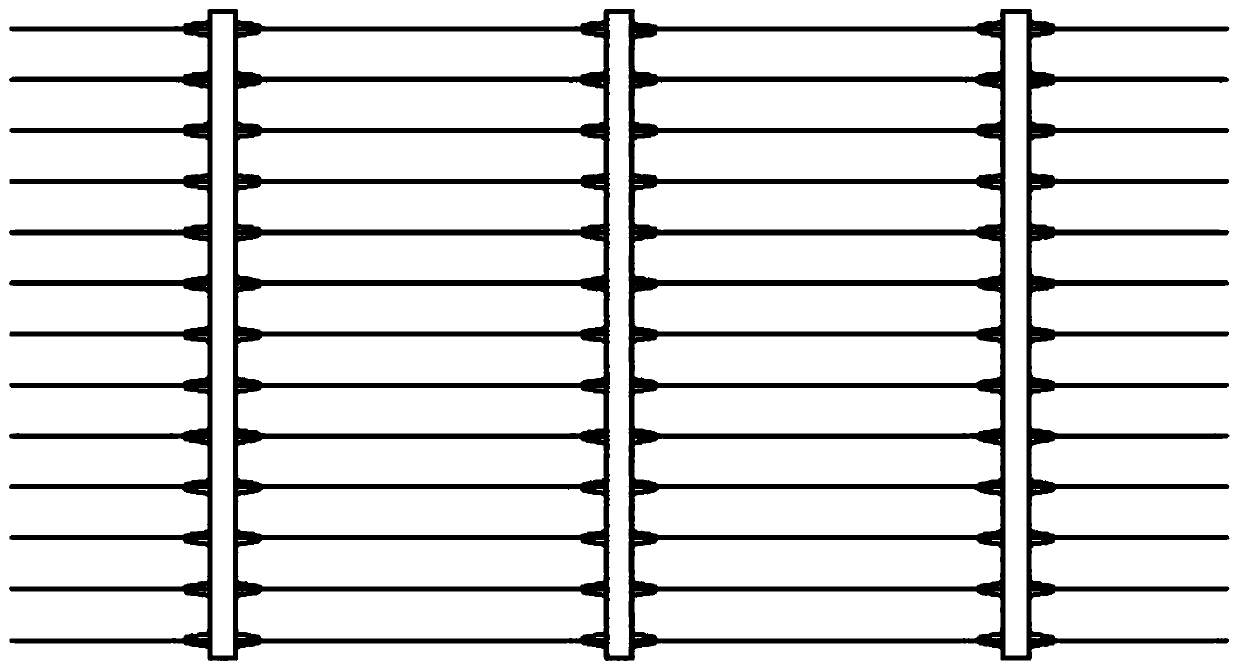

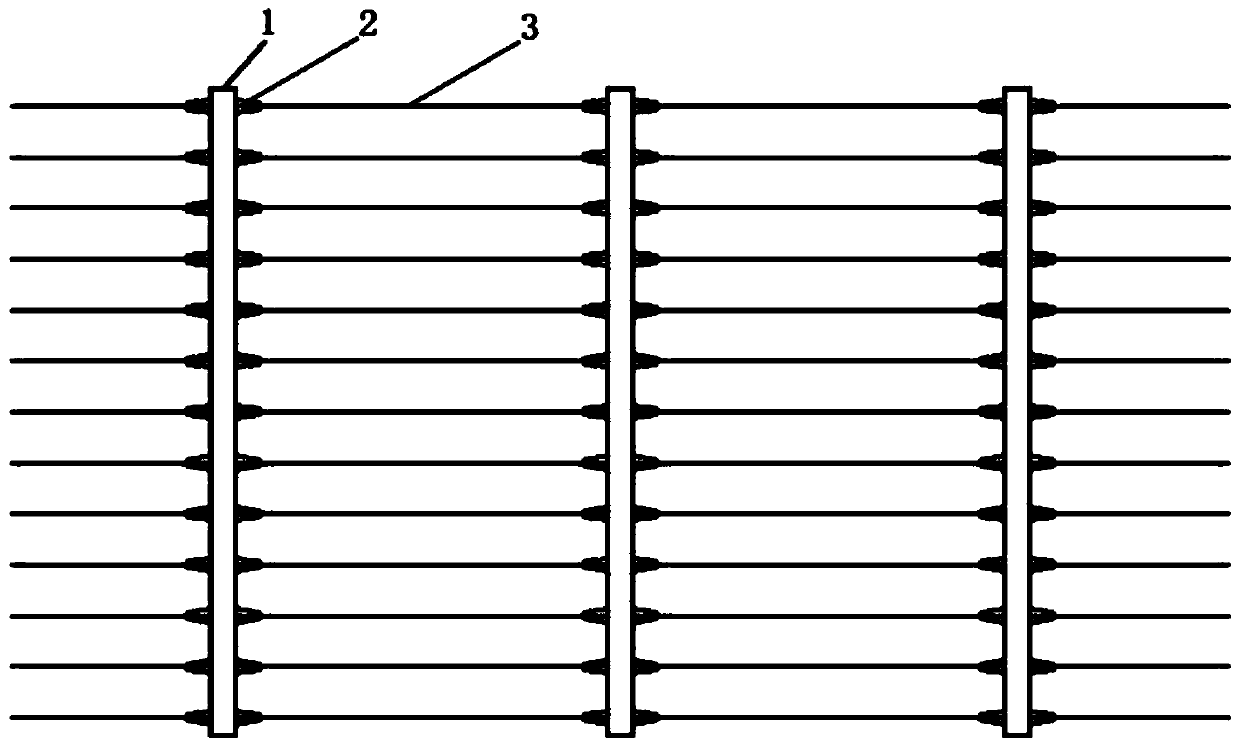

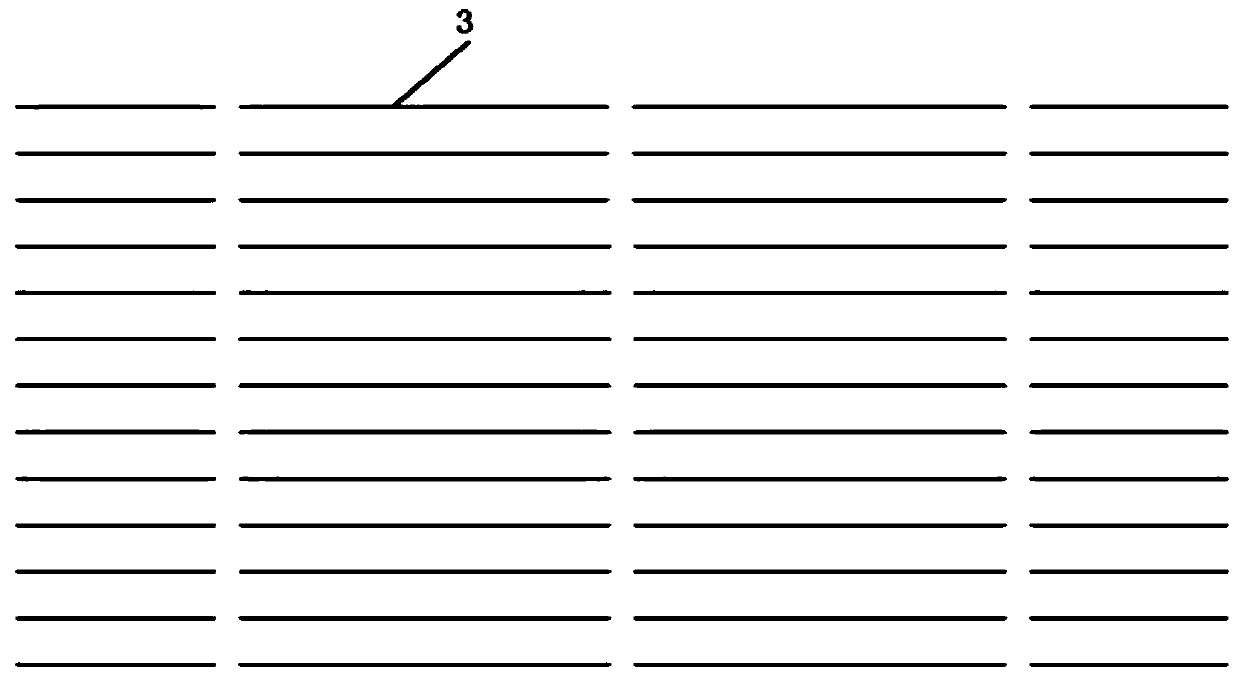

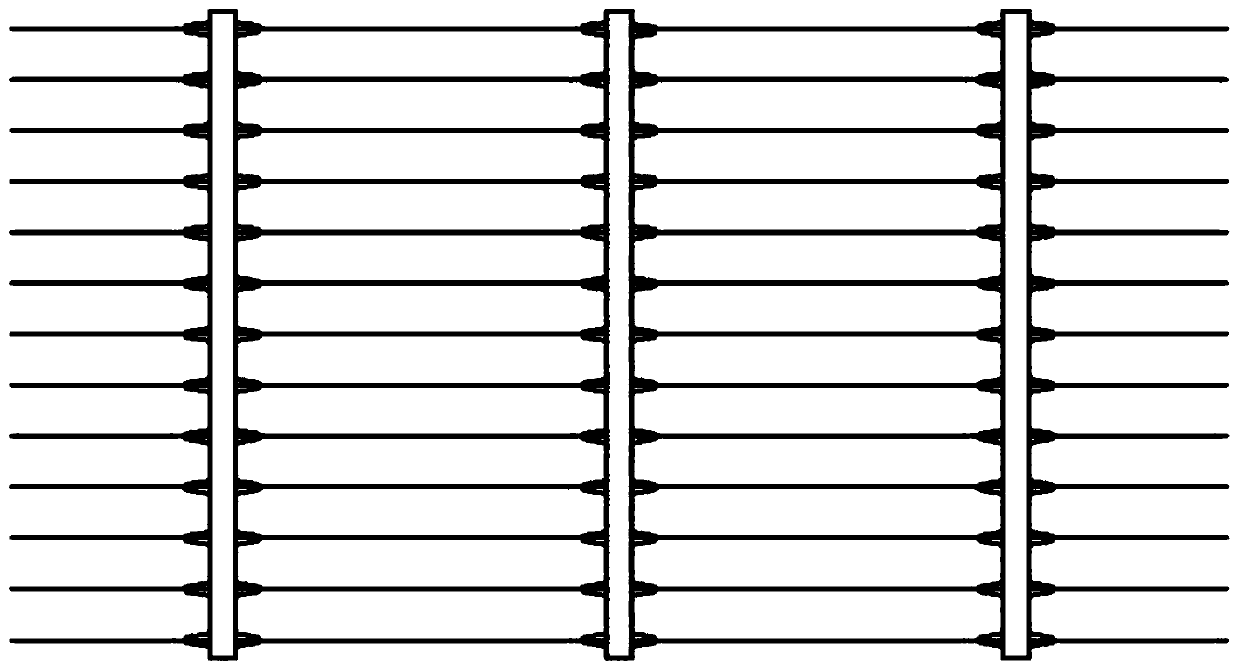

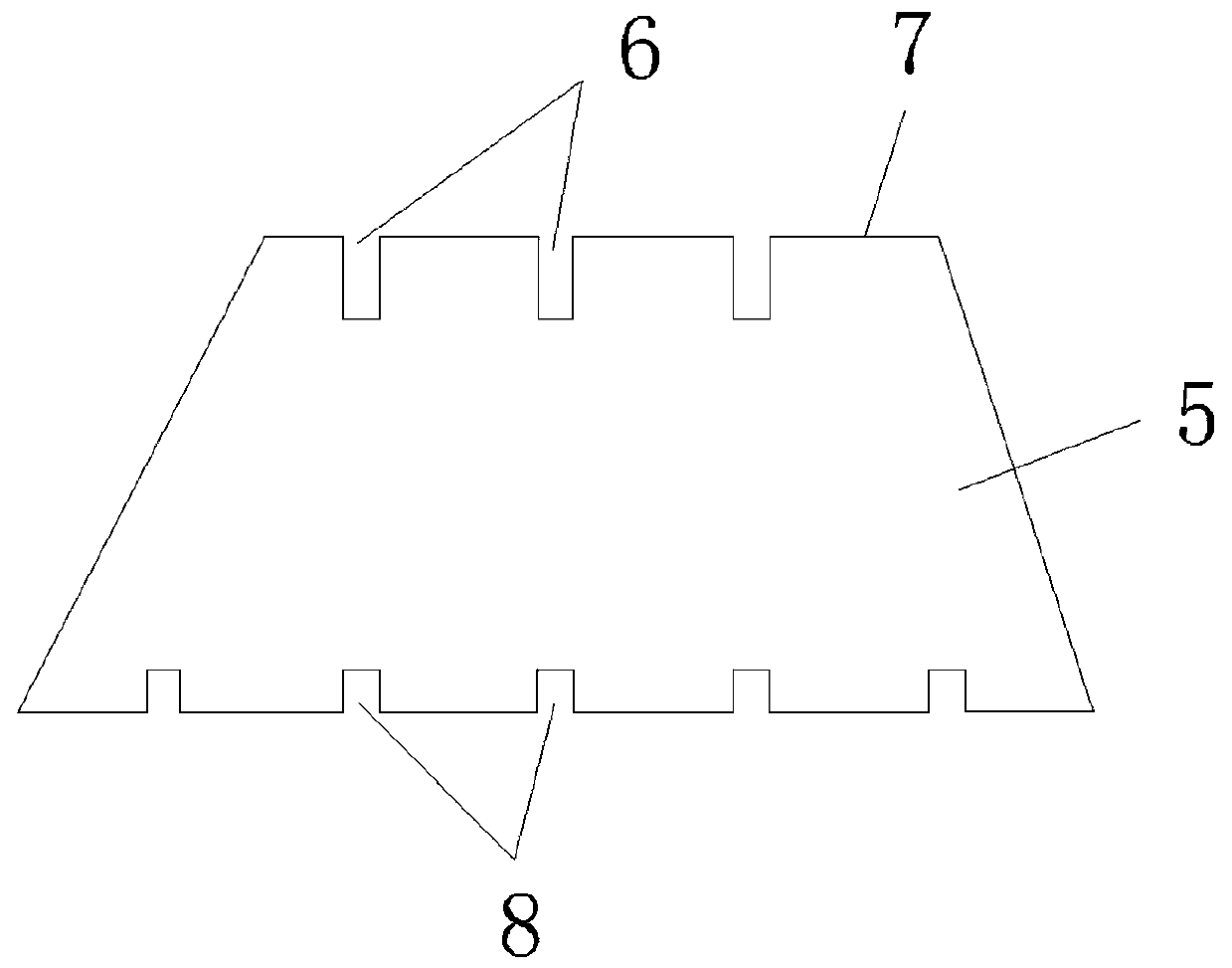

Electrode structure of high-efficiency solar cell suitable for step-by-step printing

PendingCN110957387AGood lap reliabilityHigh precision error tolerancePhotovoltaic energy generationSemiconductor devicesElectrical batterySolar cell

The invention discloses an electrode structure of a high-efficiency solar cell suitable for step-by-step printing. The structure comprises main grids and fine grids which are connected with each other, wherein each main grid comprises a welding area main grid line and a main grid lap joint structure; each fine grid comprises a fine grid line and a fine grid lap joint structure for connecting everytwo adjacent fine grid lines; the distance between every two adjacent main grids is the distance between the main grid lap joint structures, the distance between the main grid lap joint structures ismatched with the length of the thin grid lines, the main grid lap joint structures and the thin grid lap joint structures are intersected and overprinted, and at least two intersected and overprintedintersection points are formed on the two sides of each main grid and the two sides of each thin grid line respectively. By adopting the method, the problems of poor appearance and EL caused by step-by-step printing alignment offset and poor printing caused by parallel overprinting at the lap joint position are effectively avoided, and the problem of assembly end welding caused by poor lap jointof the main grids and the fine grids of the battery is avoided.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

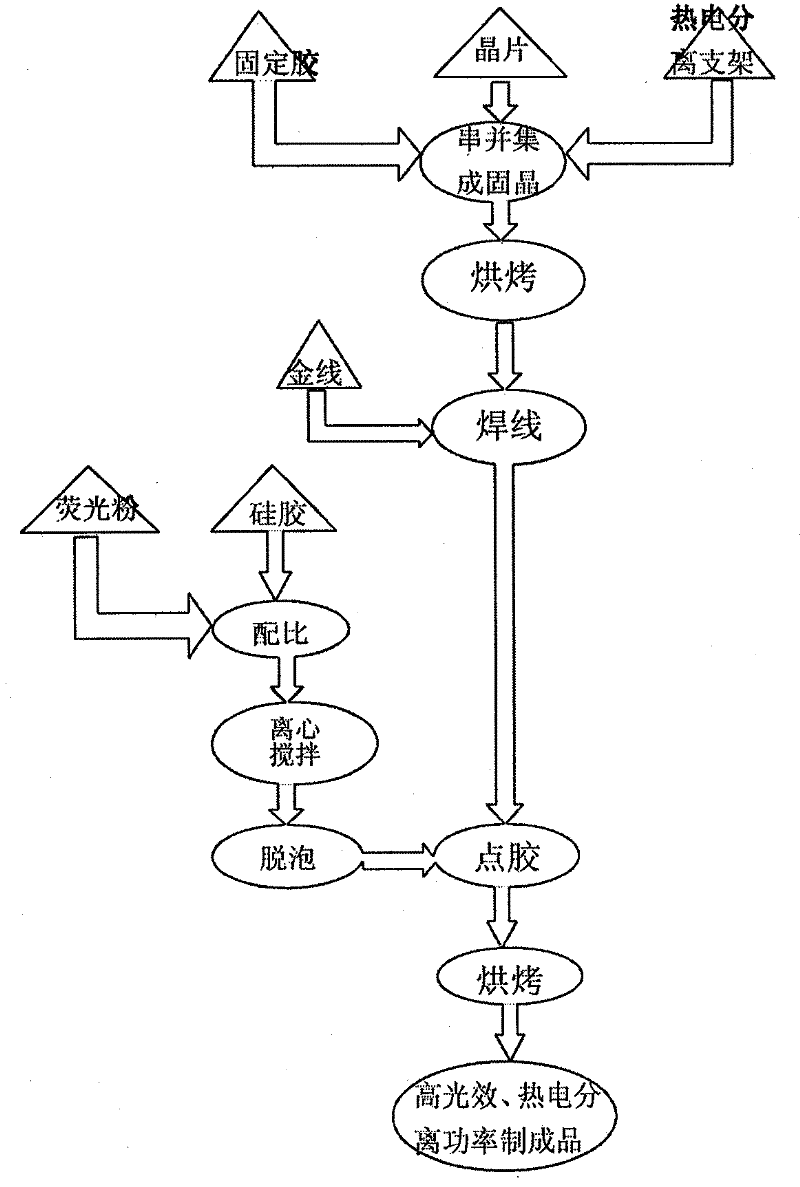

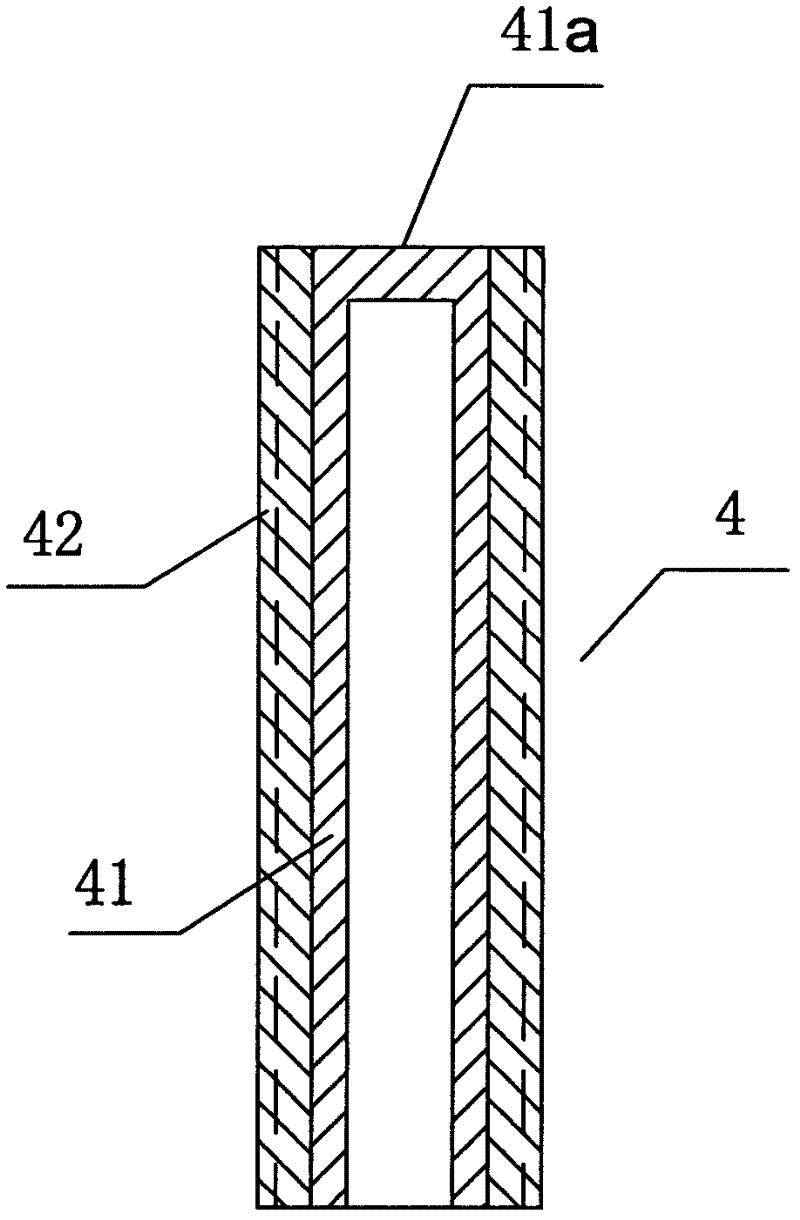

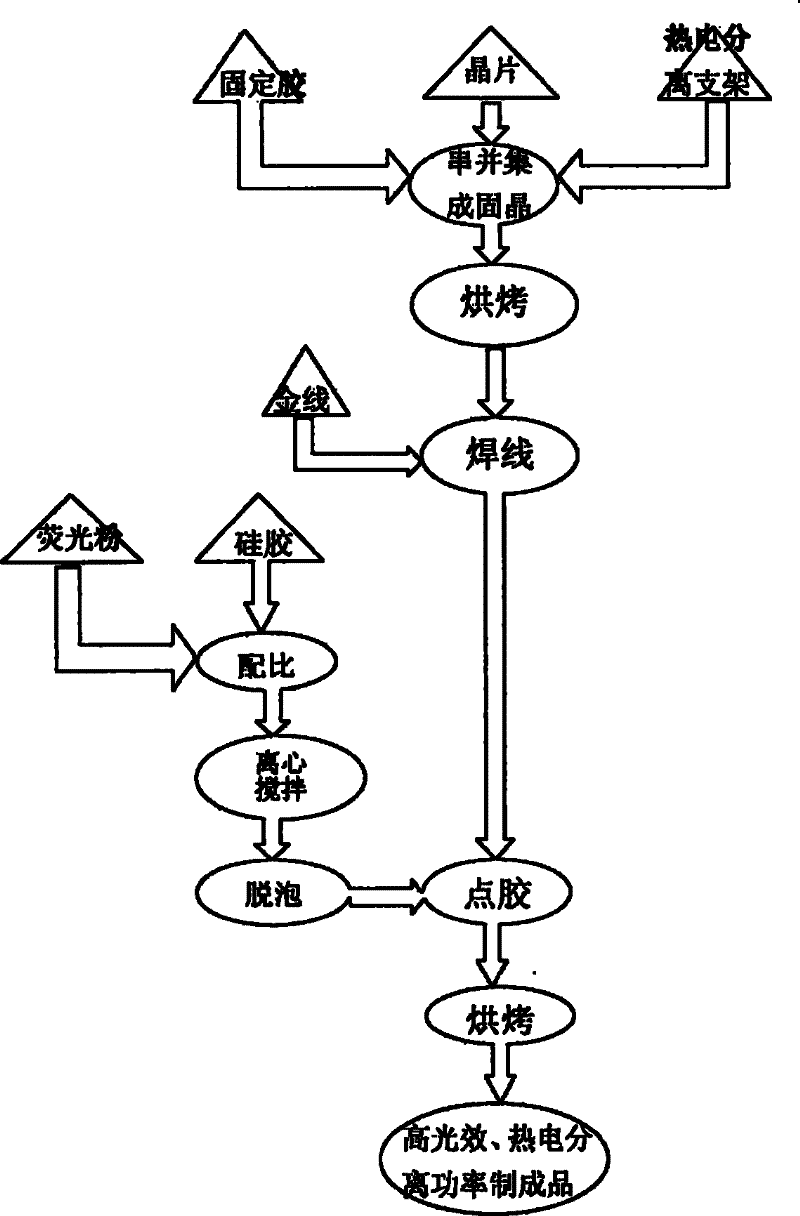

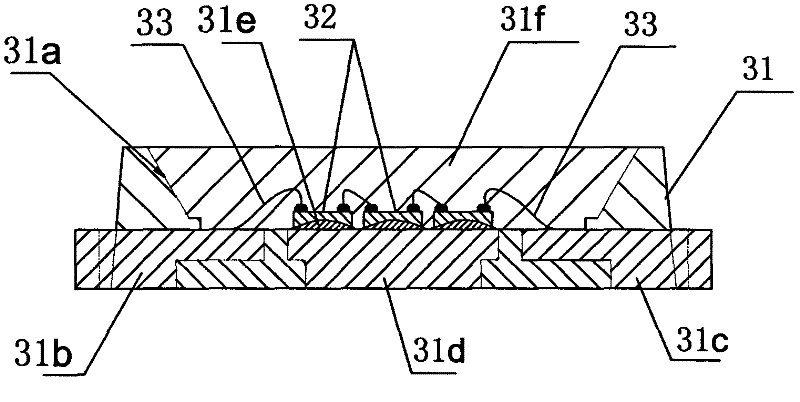

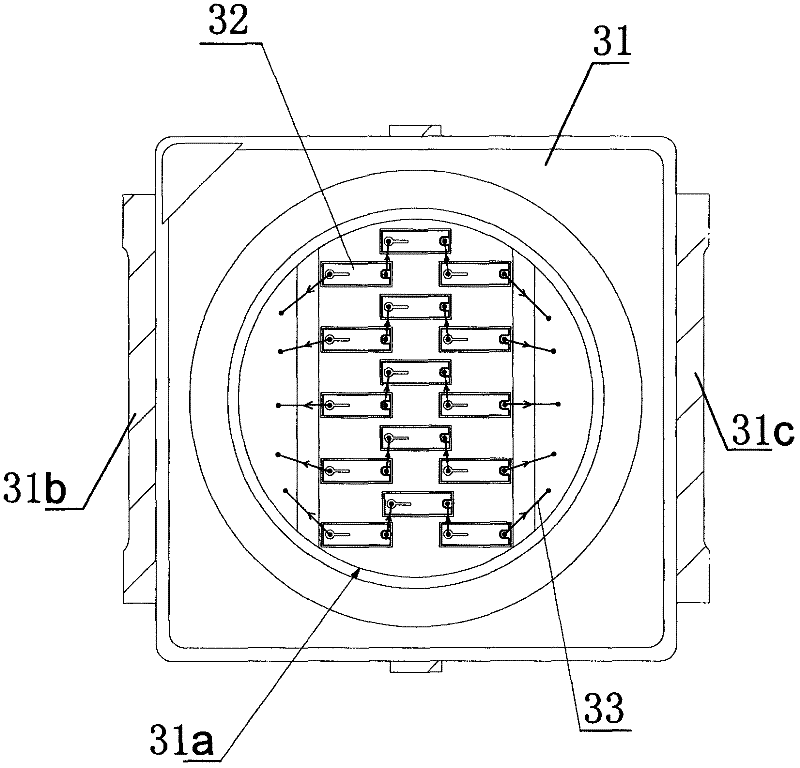

Highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED) and encapsulating method thereof

InactiveCN102646673ASolve the problem of generally low light efficiencyHigh light efficiencySolid-state devicesSemiconductor devicesElectricityHeat conducting

The invention discloses a highly integrated high light efficiency thermoelectric separation power type light emitting diode (LED). The LED comprises a paster type bracket, an LED chip and gold threads, wherein a concave cup is formed on the upper surface of the bracket, electric conducting channels which are independently communicated into two sides of the concave cup are arranged at left and right sides of the bracket, the bottom surface of the bracket is provided with a heat conducting channel of which the middle part is communicated to the middle part of the concave cup, the LED chip is stuck with the heat conducting channel through heat conducting insulation paste, two poles of the LED chip are respectively electrically connected with the electric conducting channel through the gold threads, and a fluorescent colloid which is formed by mixing silica gel and fluorescent powder is filled and sealed in the concave cup. Because of the design of thermoelectric separation, heat dissipated when the LED chip works can be independently conducted to a heat dissipating pillar in time, and the impacts of heat on the reliability of second spot welding and the service life of the chip are reduced. With the design of polycrystal serial and parallel integration and thermoelectric separation, the LED disclosed by the invention has the technical effects of high light efficiency, independent heat and electric channels, simple structure, good heat dissipation effect and the like.

Owner:OUTRACE TECH

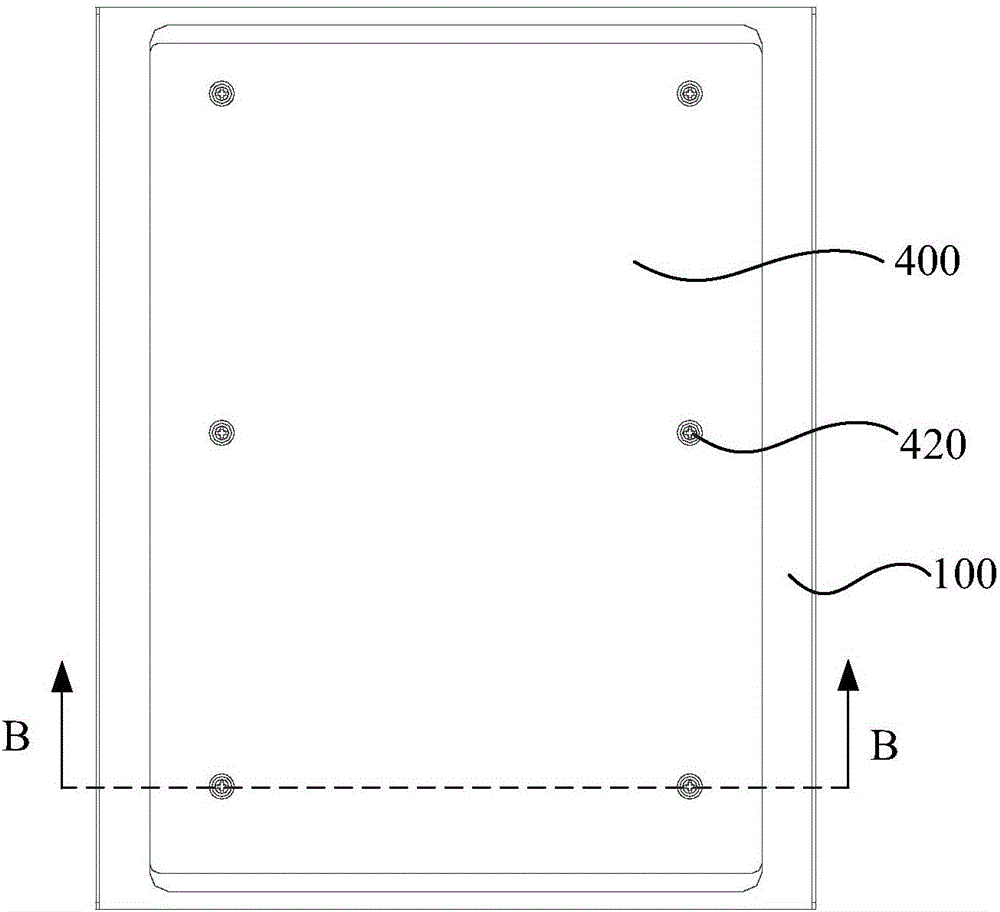

PCB fixing device

InactiveCN106455403ASmall amount of deformationEnsure welding reliabilityMounting boards securingVertical projectionElectronic component

The invention relates to a PCB fixing device used for fixing the PCB. The fixing device comprises a shell body, a support body and a machine leg. The shell body is provided with an installation location and a first connecting piece is arranged in the installation location; the support body is used for installing the PCB and is fixedly connected to the shell body through the first connecting piece; the machine leg is used for supporting the shell body and is arranged in the installation location of the shell body, corresponding to the first connecting piece. A vertical projection of the machine leg on the shell body completely covers a vertical projection of the first connecting piece on the shell body. The PCB is directly installed on the support body and deformation of the support body is small, therefore, the PCB can not be driven to deform and the welding reliability of electronic components on the PCB can be ensured. At the same time, the vertical projection of the machine leg on the shell body completely covers the vertical projection of the first connecting piece on the shell body, the first connecting piece is concealed by the machine leg which is also arranged at the installation location, so that the surface of the shell body is more smooth and the appearance quality of the fixing device is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Electrode step-by-step printing method of high-efficiency solar cell

InactiveCN111146297AGood lap reliabilityHigh precision error toleranceFinal product manufacturePhotovoltaic energy generationGrid patternElectrical battery

The invention discloses an electrode step-by-step printing method for a high-efficiency solar cell, and the method comprises the steps: firstly printing a main grid according to a main grid pattern, enabling the main grid to comprise a welding region main grid line and a main grid lap joint structure, and enabling the main grid lap joint structure to be connected with the welding region main gridline; then printing a fine grid according to the fine grid pattern, wherein the fine grid comprises fine grid lines and a fine grid lap joint structure for connecting two adjacent fine grid lines, thedistance between every two adjacent main grids is the distance between the main grid lap joint structures, the distance between the main grid lap joint structures is matched with the length of the thin grid lines, and the main grid lap joint structures and the thin grid lap joint structures are intersected and overprinted, so that at least two intersected and overprinted intersection points are formed on the two sides of each main grid and the two sides of each thin grid line respectively. By adopting the method, the problems of poor appearance and EL caused by step-by-step printing alignmentoffset and poor printing caused by parallel overprinting at the lap joint position are effectively avoided, and meanwhile, the problem of assembly end welding caused by poor lap joint of the main grid and the fine grid of the battery is avoided.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Cable splicing operation platform

InactiveCN103293601AEnsure cutover safetyImproved cutover securityCoupling light guidesTerrainCircular disc

The invention discloses a cable splicing operation platform comprising a platform body with support legs. Two ends, in the horizontal direction, of the top of the platform body are provided with a groove for accommodating a splicer and a U-shaped clamping board for fixing a cable joint box. A rectangular fixing groove is formed at the inner top of the U-shaped clamping board and matches with a disc part of the cable joint box. Wind boards are arranged at a cable inlet of the platform body and on adjacent two sides. By the aid of the cable splicing operation platform, splicing workers can set up and place splicing equipment conveniently under various conditions, the cable splicer, an OPGW (optical fiber composite overhead ground wire) cable and the joint box can be fixed, cable breakage or core breakage due being mistakenly hit by external forces can be avoided, safe cutting and splicing of the cables can be guaranteed, the reliability rate, quality and efficiency of cable splicing can be increased, and quality and efficiency of cable splicing can be improved. The cable splicing operation platform can be assembled rapidly, and is adaptable to terrains, convenient to operate and carry, reasonable in structure, light in weight, durable and consistent to splicing specifications.

Owner:STATE GRID CORP OF CHINA +1

Closing structure for flat tube of condenser of automobile air-conditioner

InactiveCN103557644AEnsure welding reliabilityImprove appearance qualityEvaporators/condensersHeat exchanger casingsEngineeringWedge shape

The invention provides a closing structure for a flat tube of a condenser of an automobile air-conditioner, in order to solve the problems of a present flat tube structure that the inserting and positioning are difficult, the correcting for the center distance of collecting mains is required before brazing, the invariableness cannot be ensured during a brazing process after the correcting, the appearance effect is inferior, and the like, during a core manufacturing process. A joint of an end of the flat tube and the collecting main is arranged in a wedge form, namely, the size of an outer edge on one side of the port of the end of the flat tube is smaller than the size of an inner edge of an assembling hole of the collecting main, and then, is linearly increased to be consistent with the size of the outer edge of a tube body, so that a wedge-shaped transitional zone is formed between the tube body of the flat tube and the port. The closing structure provided by the invention has the beneficial effects that the flat tube can be conveniently inserted into the assembling hole on the collecting main and can be accurately positioned, the center distance between the collecting mains at two ends meets a design demand, and meanwhile, the welding reliability (zero leakage) is ensured. Besides, after the welding is finished, no closing trace of the flat tube can be seen and the appearance quality is increased.

Owner:CHONGQING CHAOLI HI TECH

Double-layer PCB welding device, clamp and method and welding clamp for PCB and connecting pin

ActiveCN112548433AGuaranteed parallelEnsure welding reliabilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention relates to a double-layer PCB welding device, clamp and method and a welding clamp for a PCB and a connecting pin. The double-layer PCB welding device comprises the welding clamp for thePCB and connecting pin and the double-layer PCB welding clamp, wherein the connecting pin is welded and fixed to an auxiliary plate through the welding clamp for the PCB and connecting pin, two sliding blocks of the double-layer PCB welding clamp are pushed aside, then the auxiliary plate is placed on the lower layer of the clamp, a main plate is placed in the upper layer of the clamp through limiting and clamping of the sliding blocks, the clamp is provided with a limiting protrusion, the limiting protrusion is matched with pressing of a first cover plate for fixation, then welding is conducted, and therefore two welded plates are parallel, and high-precision welding and positioning of the connecting pin are achieved. According to the double-layer PCB welding device, clamp and method andthe welding clamp for the PCB and the connecting pin, the structural design is reasonable, use and operation are easy and convenient, the positioning and fixing precision is high, the cost is low, the implementation time is short, and the double-layer PCB welding device, clamp and method and the welding clamp for the PCB and the connecting pin are capable of being applied to the connecting, welding and assembling process of double-layer PCBs of the same size, in the same space and of different types.

Owner:LINKTEL TECH CO LTD

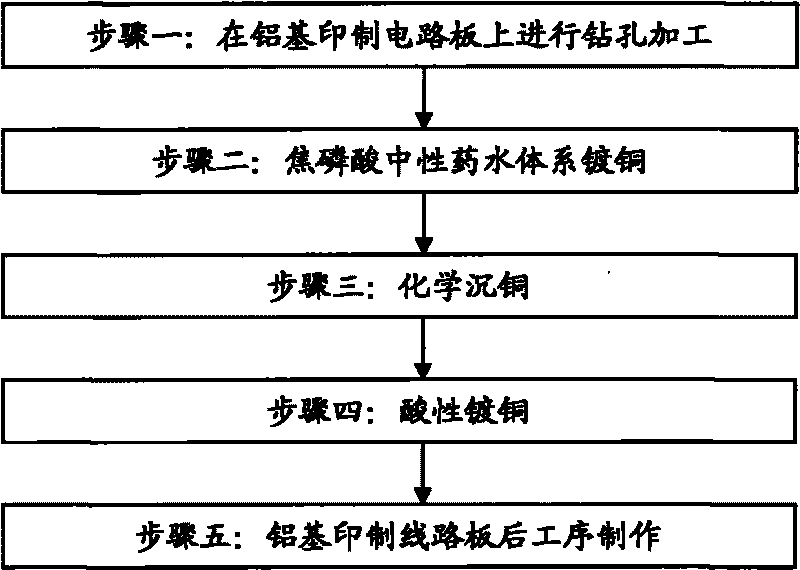

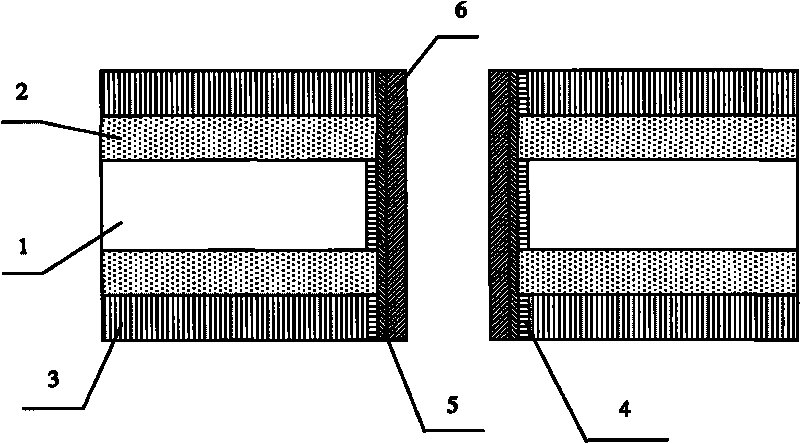

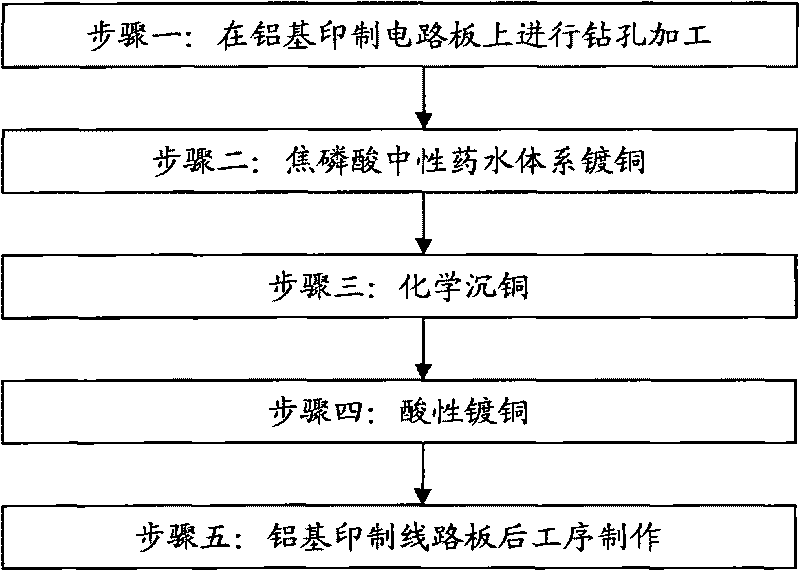

Manufacturing method of aluminum-substrate printed circuit board in-hole metallization

InactiveCN101765342AIsolated contactAchieve in-hole metallizationPrinted element electric connection formationHigh concentrationCopper plating

The invention relates to a manufacturing method of aluminum-substrate printed circuit board in-hole metallization, which comprises the following steps: 1, drilling holes on an aluminum-substrate printed circuit board; 2, placing the aluminum-substrate printed circuit board in a neutral medicinal liquid system of pyrophosphoric acid to plate copper, namely, to form a layer of copper protective layer on an aluminum substrate; 3, performing electroless copper deposition to form a copper layer at non-metal positions; 4, performing acidic copper plating; and 5, performing post aluminum-substrate printed circuit board manufacturing process. In the invention, the aluminum substrate is effectively prevented from contacting medium-strong acidic and alkaline medicinal liquid in the processes of electroless copper deposition and acidic copper plating, which ensures the smooth operation of the subsequent processing steps of the aluminum-substrate printed circuit board. The process guarantees the welding reliability and high heat conductivity of the product after subsequent surface mounting, sets a high-concentration and high-power consumption trend for the development of the design of circuit boards, greatly reduces crosstalk between signals, reduces electric noises and further optimizes signal transmission. The method has a simple process and low cost and makes large-scale industrial production convenient.

Owner:GCI SCI & TECH

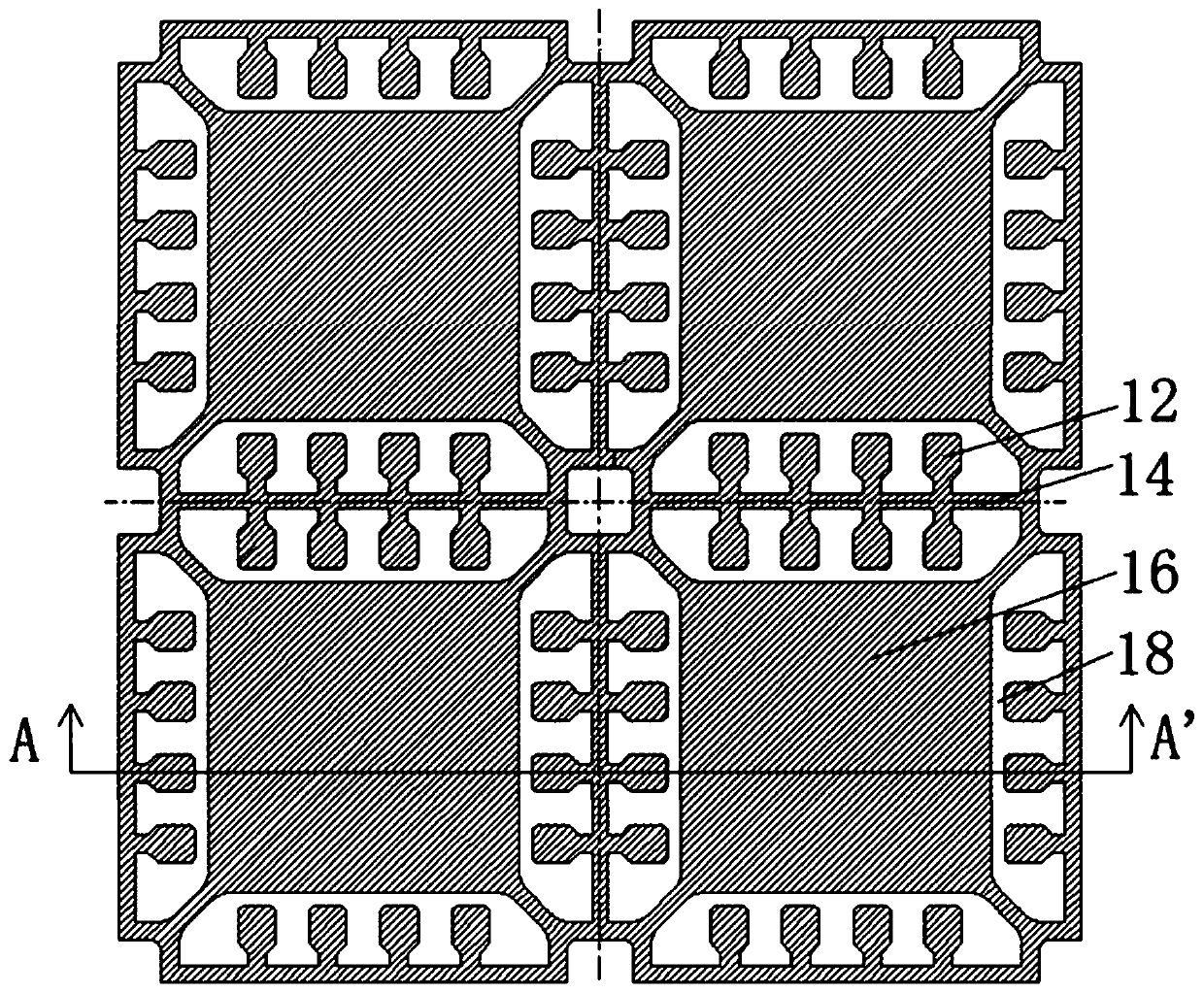

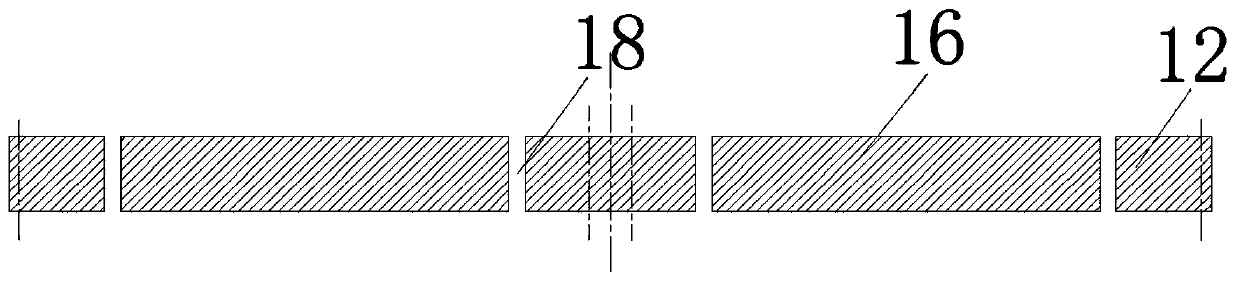

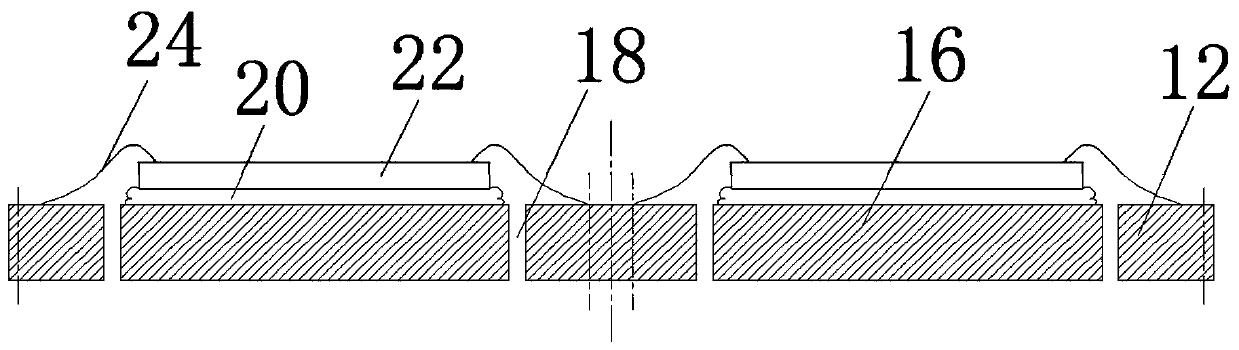

Semiconductor packaging method

InactiveCN109950159AEliminate short circuit problemsEnsure welding reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingMetal substrateEngineering

The invention discloses a semiconductor packaging method comprising the steps of: providing a metal substrate, wherein the metal substrate has opposite front and back sides, the metal substrate comprises a plurality of operating units, each operating unit comprises pins, and the pins of two adjacent operating units are connected through a scribe line connecting strip; pasting and electrically connecting a semiconductor chip; fixing the semiconductor chip to the front side of the metal substrate, and electrically connecting the pins to the semiconductor chip; performing plastic package; forminga plastic package layer on the front side of the metal substrate, wherein the plastic package layer completely covers the semiconductor chip and the front side of the metal substrate; performing halfcutting; cutting the scribe line connecting strip on the back side of the metal substrate to form a groove, wherein the adjacent operating units are still in a conductive interconnection state afterthe half cutting, and the scribe line connecting strip generates metal burrs in the half cutting process; removing the metal burrs; forming a first protective layer; and performing full cutting. The semiconductor packaging method provided by the application can remove metal debris or wire residues formed in the cutting step.

Owner:嘉盛半导体(苏州)有限公司

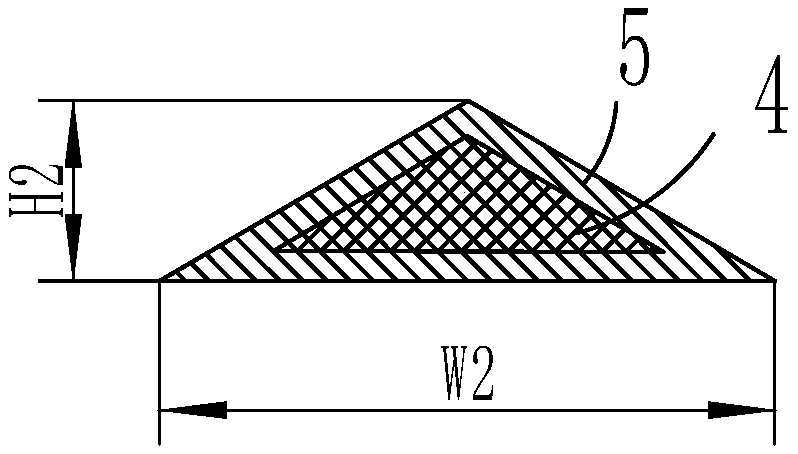

Solder strip used for photovoltaic module, and photovoltaic module

InactiveCN109346548AGuaranteed reliabilityIncrease profitPhotovoltaic energy generationSemiconductor devicesStructural engineeringEngineering

The invention provides a solder strip used for a photovoltaic module, and a photovoltaic module, and belongs to the technical field of solar cell manufacture. The solder strip comprises a front side main grid solder strip and a back side main grid solder strip, wherein the cross section of the front side main grid solder strip is of a triangular structure and is used for the front side welding front side main grid of a photovoltaic cell, and a plane where one edge of the triangle is positioned is welded with the front side main grid; and the cross section of the back side main grid solder strip is of a trapezoidal structure and is used for the back side welding back side main grid of the adjacent photovoltaic cell, and a plane where one bottom edge of the trapezoid is positioned is weldedwith the back side main grid. By use of the solder strip used for the photovoltaic module, the triangular solder strip welded to the front side of a cell effectively improves the use ratio of incidentlight, the trapezoidal solder strip is welded to the back side main grid of the cell so as to increase the welding area with the back side main grid of the cell, and welding reliability and the reliability of the photovoltaic module in a use process are guaranteed.

Owner:YINGLI ENERGY CHINA

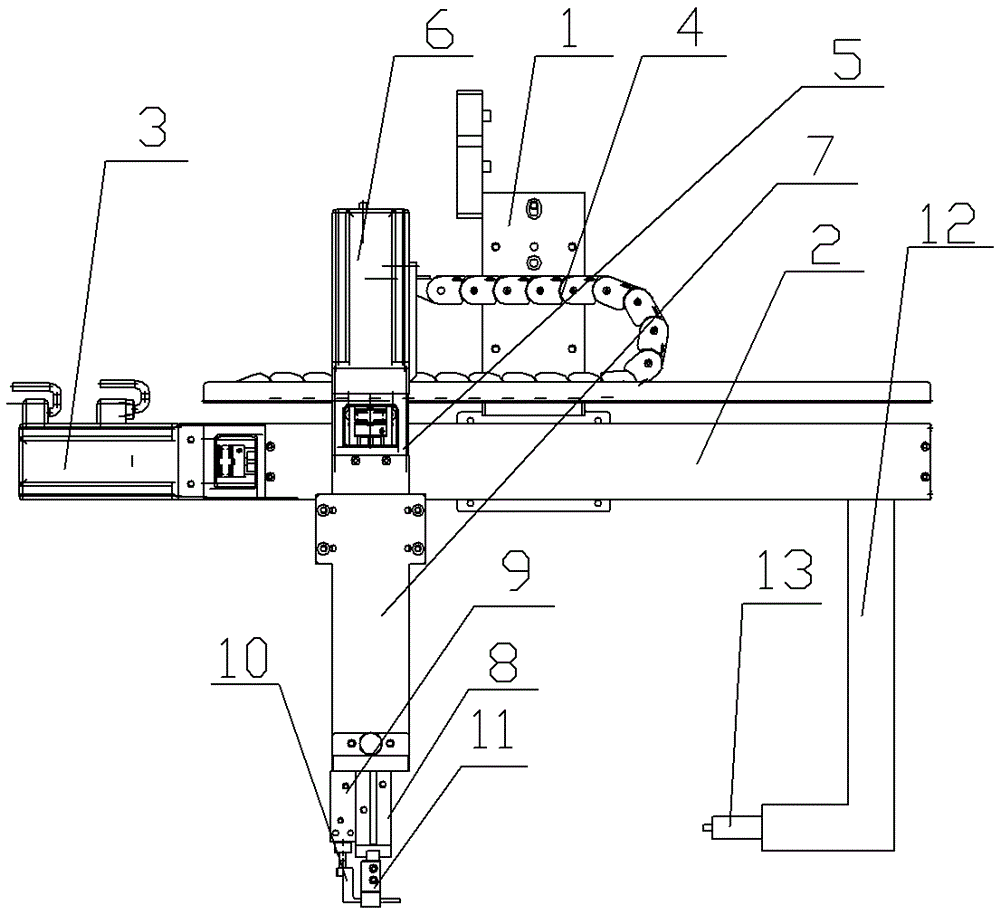

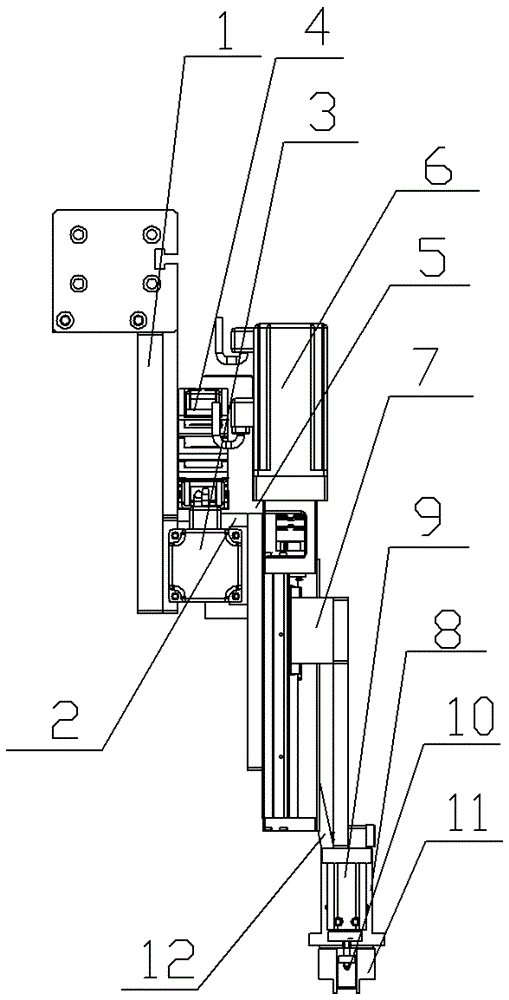

Rapid welding device

InactiveCN106695185AEnsure welding safetyEnsure welding reliabilityWelding/cutting auxillary devicesAuxillary welding devicesControl theoryLinear actuator

The invention relates to the technical field of welding equipment, in particular to a rapid welding device which can effectively ensure welding safe reliability. The rapid welding device comprises a suspension bracket, and a transverse linear actuator mechanism is installed on the suspension bracket through a transverse supporting base; the transverse linear actuator mechanism comprises a transverse driving servo motor, a transverse lead screw and a transverse sliding block connected with the transverse lead screw, and a longitudinal linear actuator mechanism is installed on the transverse sliding block; the longitudinal linear actuator mechanism comprises a longitudinal servo motor, a longitudinal lead screw and a longitudinal sliding block connected with the longitudinal lead screw, a clamping jaw cylinder and a limiting cylinder are installed at the bottom of the longitudinal sliding block, an L-shaped limiting block is installed on a piston rod of the limiting cylinder, and the L-shaped limiting block is arranged between two clamping jaws of the clamping jaw cylinder; and an L-shaped supporting base is installed at the end of the transverse supporting base, and a welding gun corresponding to the L-shaped limiting block is installed on the L-shaped supporting base.

Owner:WUXI MINGZHU TURBOCHARGER MFG

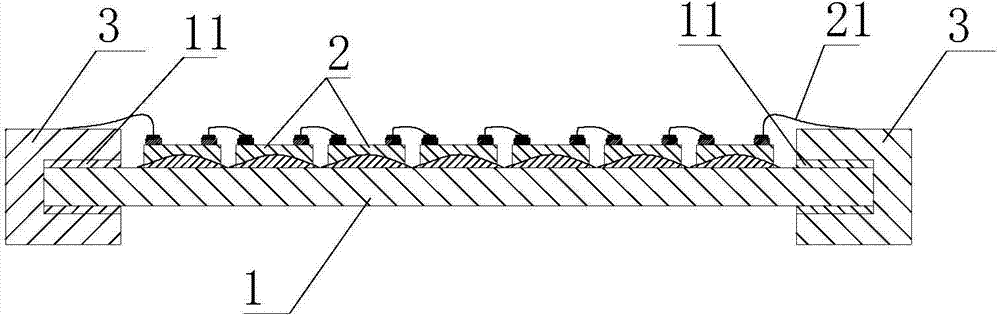

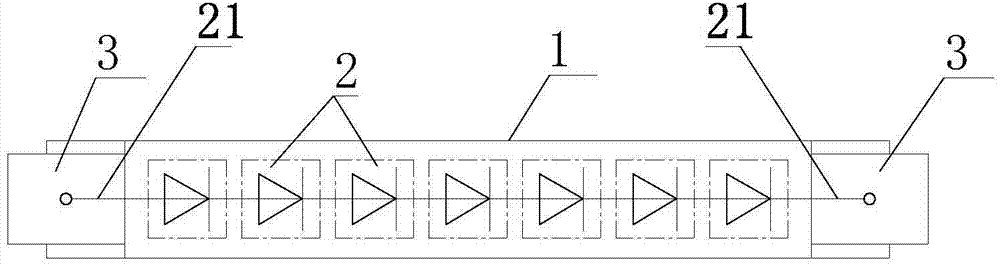

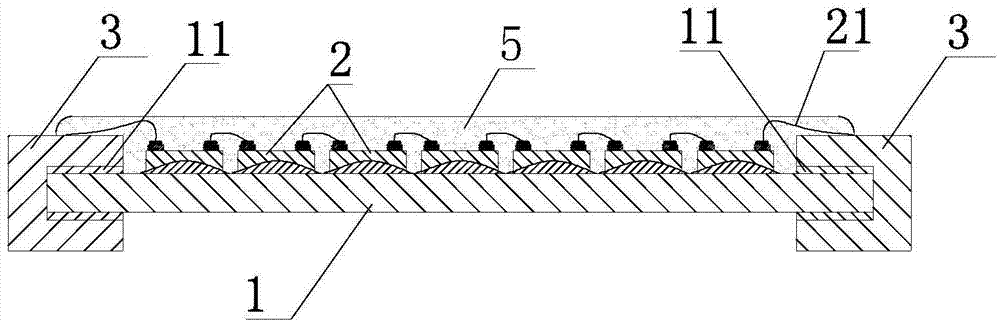

Three-dimensional LED (light emitting diode) luminous body and processing method thereof

InactiveCN103872032AEasy to separateConvenient production operation and fixedSolid-state devicesSemiconductor devicesAdhesiveEngineering

The invention relates to a three-dimensional LED (light emitting diode) luminous body and a processing method of the three-dimensional LED luminous body. The three-dimensional LED luminous body comprises a strip-shaped transparent base plate and a plurality of LED wafers in tandem connection, wherein the LED wafers are positioned on the transparent base plate through transparent silica gel, and two ends of the LED wafers are provided with leads, wherein two ends of the transparent base plate are respectively provided with metal connecting elements, the metal connecting elements are provided with U-shaped clamp openings and are clamped and buckled at two ends of the transparent base plate, adhesives are adopted between the metal connecting elements and the transparent base plate for fixation, and the leads are electrically connected with the metal connecting elements. The invention aims at providing the three-dimensional LED luminous body with simple structure and stable connection, and the processing method of the three-dimensional LED luminous body.

Owner:东莞市昱鸿光电有限公司

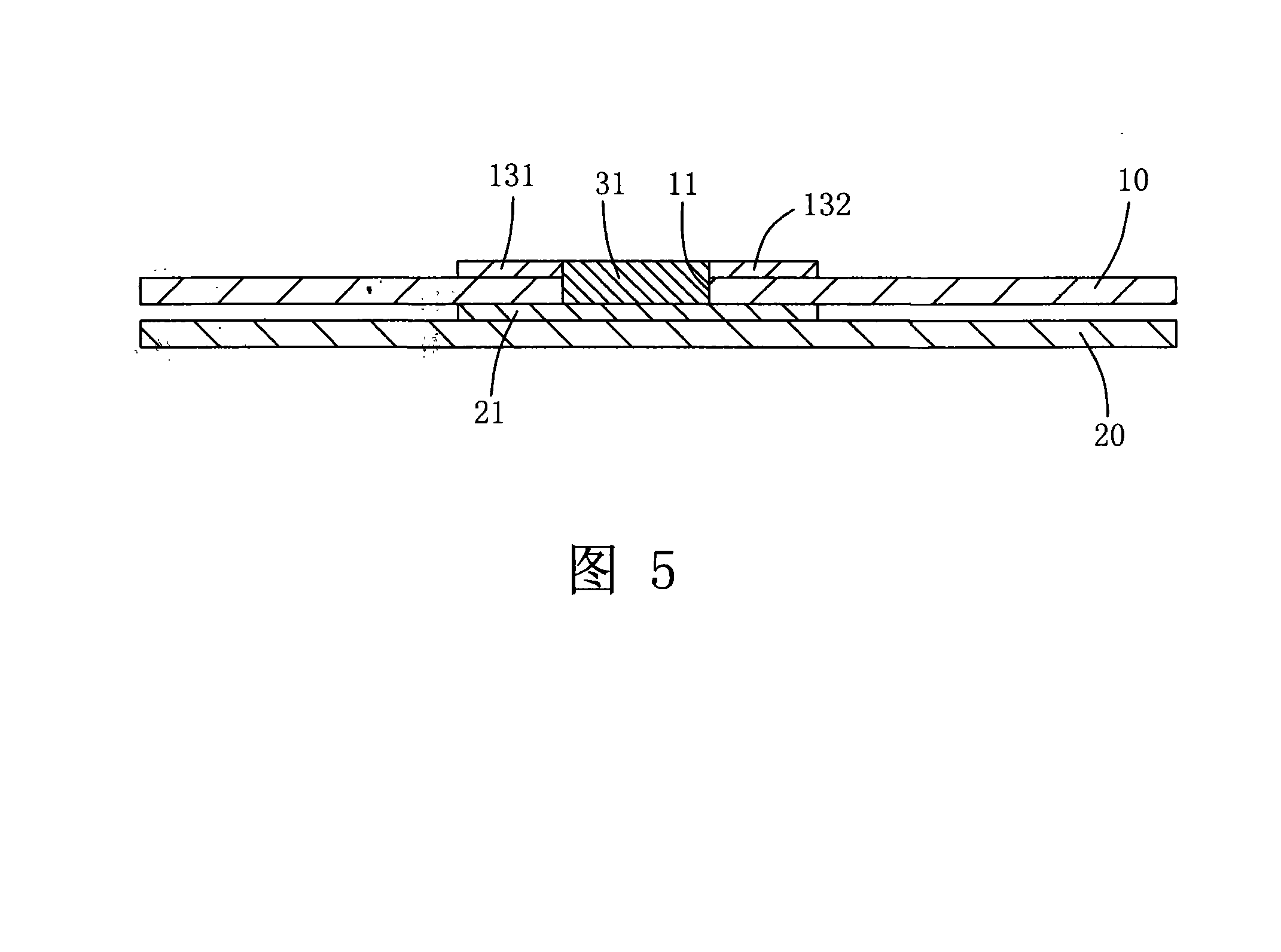

Soldering circuit plate and soldering method thereof

InactiveCN101252808AEnsure welding reliabilityImprove flexural strengthPrinted circuit assemblingPrinted circuit detailsEngineeringSoldering

The invention relates to a weldable circuit board and the welding method thereof. The weldable circuit board is used for being electrically connected to an electronic element and comprises at least a circuit board and at least a pair of welding pads. The circuit board is provided with at least an opening, and the pair of welding pads is respectively arranged at two opposite sides of the opening. One of the welding pads is electrically connected to the electronic element through a conducting line, and the other welding pad is electrically connected to the conducting line through an external conducting line, thus, the reliability of the electric connection between the circuit board and the electronic element can be enhanced.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

Laser welding system and method

ActiveCN106271043AIncrease productivityRealize fully automatic weldingLaser beam welding apparatusEngineeringLaser

The invention provides a laser welding system which comprises a laser device, a workpiece positioning device and a servo mechanism. The laser device is used for welding a first workpiece and a second workpiece. The workpiece positioning device comprises a positioning block used for conducting rough positioning on the positions of the first workpiece and the second workpiece, and a pressing assembly used for pressing the first workpiece and the second workpiece. The servo mechanism is used for conducting precise positioning on the first workpiece and the second workpiece and controlling the laser device and the workpiece positioning device to act. The invention further provides a corresponding laser welding method on the other hand. By means of the above laser welding system and method, the production efficiency can be obviously improved, full-automatic welding is achieved, the laser welding system and method are suitable for various large-scale application, and meanwhile the welding reliability can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

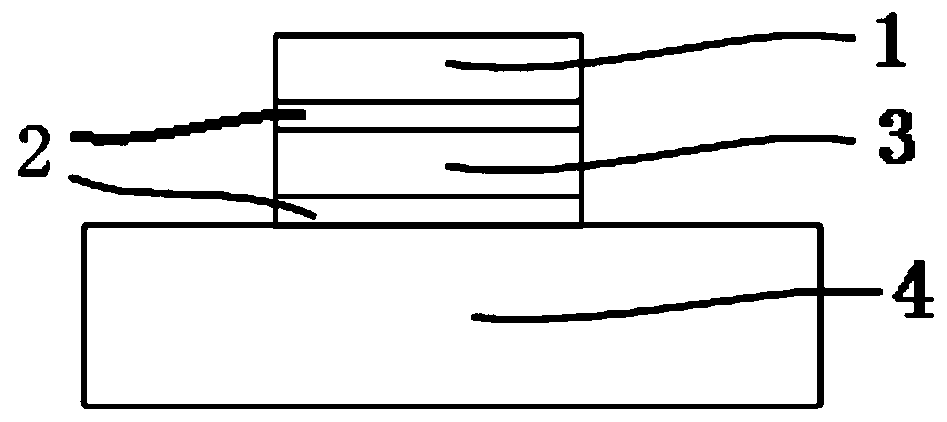

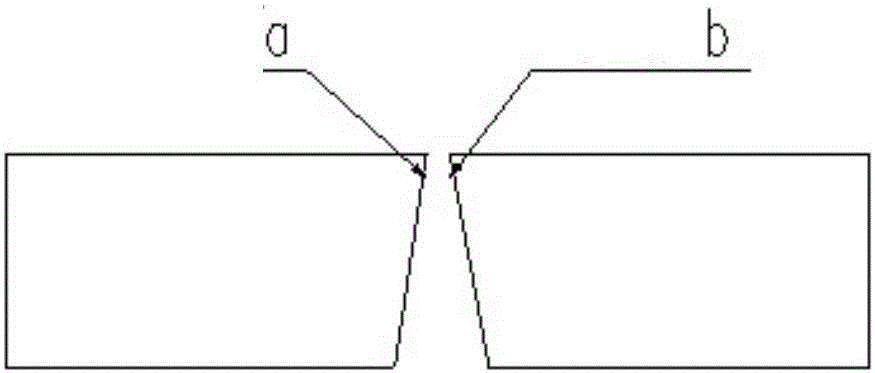

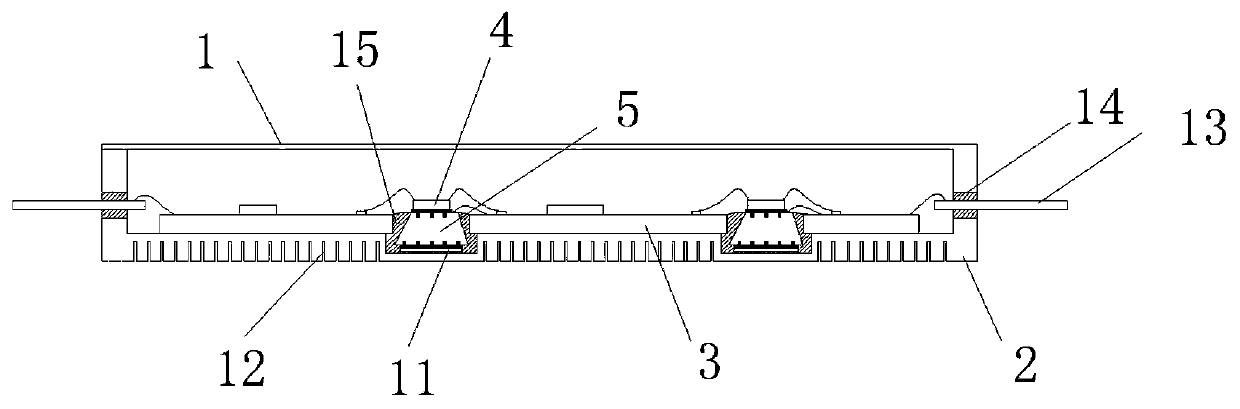

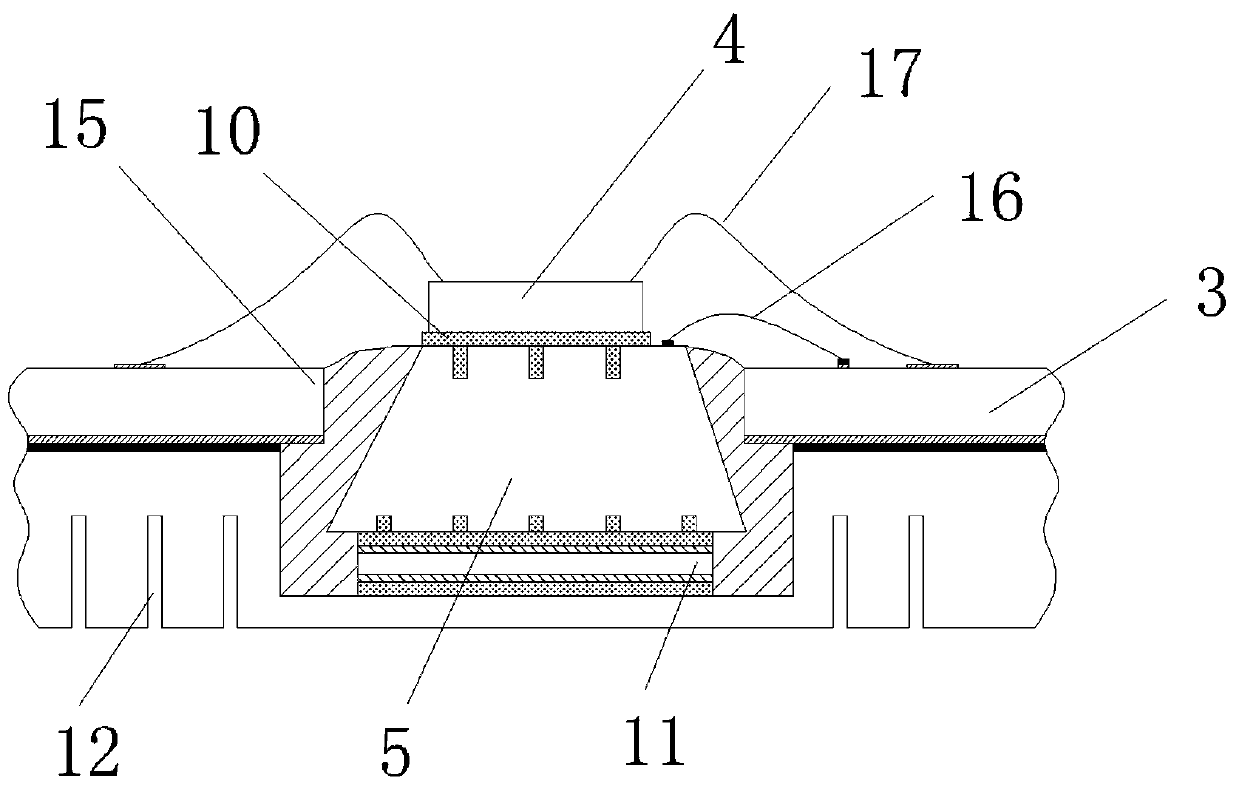

Thick film power hybrid integrated circuit

ActiveCN110676236AIncrease heating capacityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

The invention discloses a thick film power hybrid integrated circuit, which comprises an upper cover, a shell base, a ceramic substrate and a power chip, wherein the ceramic substrate and the power chip are located in the shell base, and the bottom surface of the ceramic substrate is welded to the inner bottom surface of the shell base; the shell base is further internally provided with a copper heat sink block in a trapezoidal table shape, and the copper heat sink block is vertically embedded in the ceramic substrate and the inner bottom surface of the shell base; the upper surface of the copper heat sink block is provided with an upper Chinese character 'tian'-shaped groove, one side of the upper Chinese character 'tian'-shaped groove is a chip back electrode leading-out end welding area, and the lower surface of the copper heat sink block is provided with a lower Chinese character 'tian'-shaped groove; the power chip is welded on the upper surface of the copper heat sink block; andan aluminum nitride transition sheet is welded between the lower surface of the copper heat sink block and the inner surface of the shell base. The copper heat sink block is arranged as a heat dissipation medium, so that the heat capacity and the heat dissipation performance of a high-power chip can be effectively improved; the copper heat sink block is arranged to be the shape of a trapezoidal table, so that the radial heat dissipation requirement of the power chip is met, and the heat dissipation capacity of the heat sink can be effectively improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Deep and narrow gap submerged arc welding device with melon petal welding track self-recognition and welding method

ActiveCN112276312AImprove welding efficiencyGuaranteed welding occasionsElectrode accessoriesWelding accessoriesButt weldingVehicle frame

The invention provides a deep and narrow gap submerged arc welding device with melon petal welding track self-recognition and a welding method which are more suitable for circular curve and ellipsoidal curve space butt welding seams. The deep and narrow gap submerged arc welding device comprises a flexible rail, a laser vision sensor located above a gap, two vehicle frames movably connected to theflexible rail and connected into a whole through a base plate, a guide mechanism located above a to-be-welded deep and narrow gap, an automatic welding flux conveying mechanism and an automatic wirefeeding mechanism, wherein the automatic welding flux conveying mechanism and the automatic wire feeding mechanism are connected with a z-axis guide rail sliding block of the guide mechanism, a deep narrow gap welding gun is fixedly connected to the lower part of the automatic wire feeding mechanism, the automatic welding flux conveying mechanism is fixedly connected with the deep narrow gap welding gun, a y-axis guide rail of the guide mechanism is fixedly connected to the base plate, and a z-axis guide rail of the guide mechanism is fixedly connected to a sliding block of the y-axis guide rail. The deep and narrow gap submerged arc welding device is suitable for welding occasions of flat welding, vertical upward welding and transition from vertical upward welding to flat welding, good weld joint forming quality can be guaranteed, and welding efficiency is improved.

Owner:JILIN UNIV

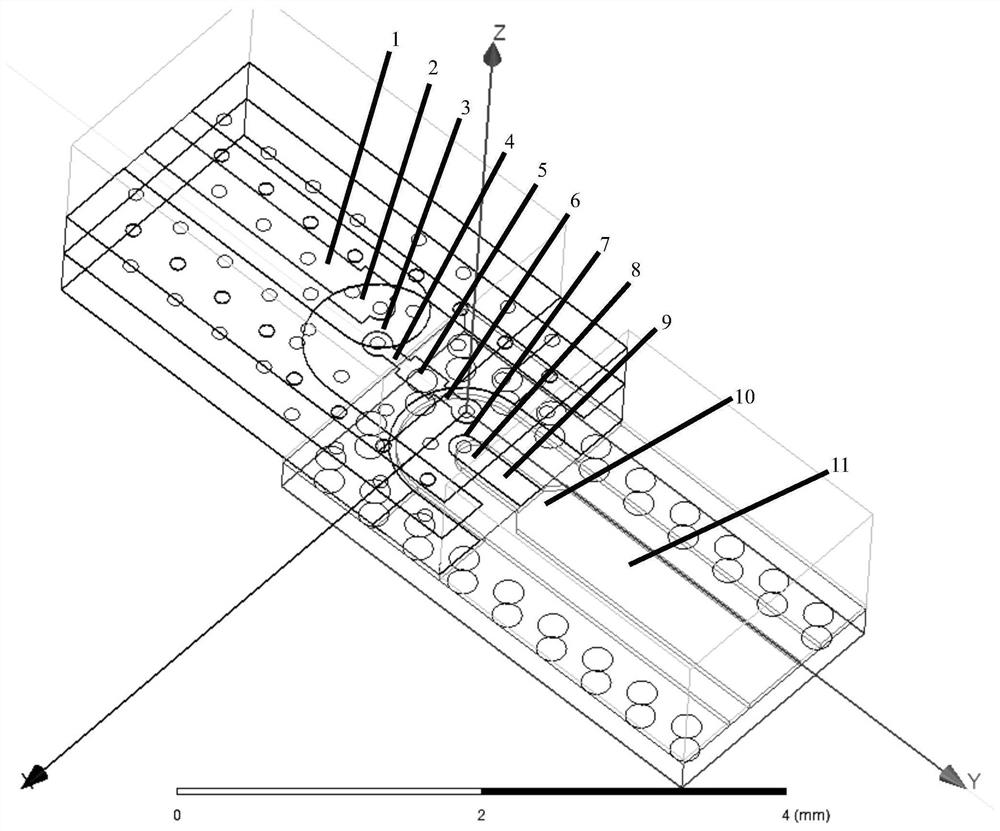

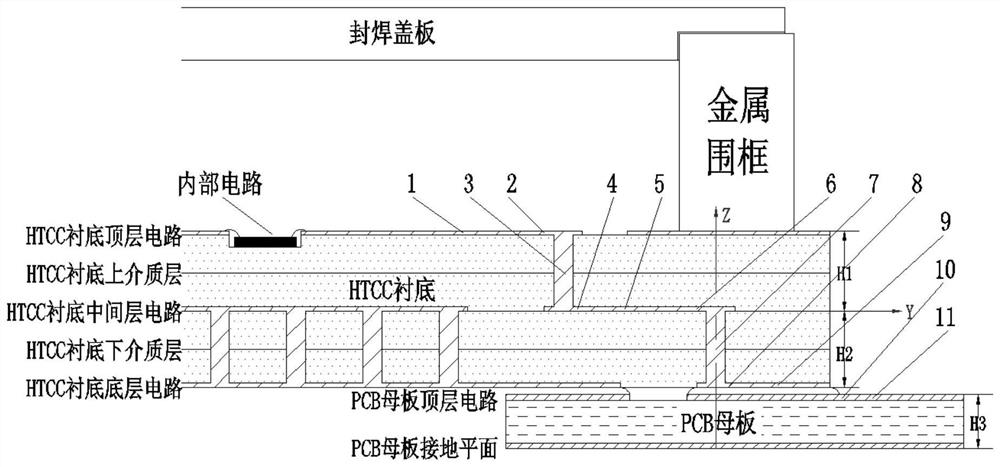

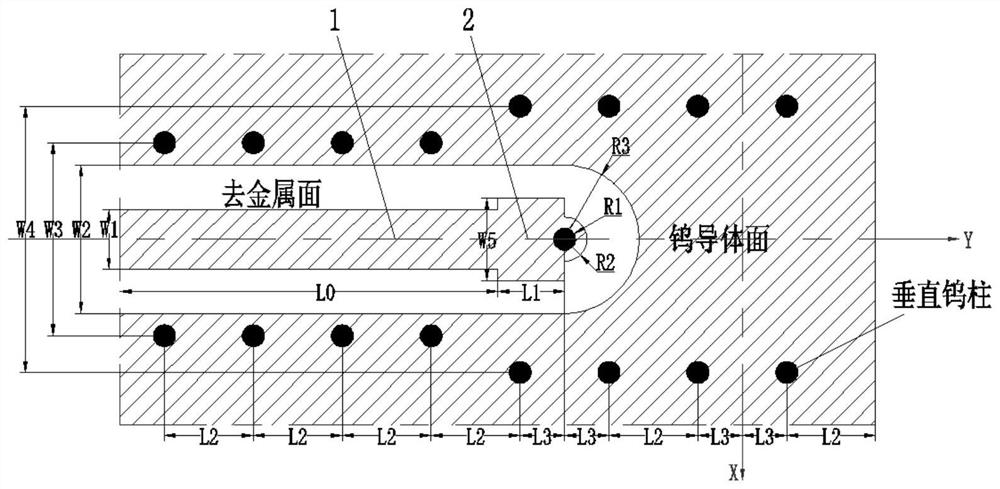

Ultra wide band millimeter wave vertical interconnection structure based on HTCC

ActiveCN114006139AIncrease working frequencyImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesUltra-widebandCoplanar waveguide

The invention provides an ultra wide band millimeter wave vertical interconnection structure based on an HTCC, and belongs to the technical field of radio frequency interconnection. The vertical interconnection structure comprises an HTCC substrate and a PCB mother board. The HTCC substrate and the PCB mother board are sequentially connected in series with a transmission sub-structure which is formed by a first coplanar waveguide, a first class coaxial, a first strip line, a second class coaxial, a second strip line and a second coplanar waveguide. The invention provides the ultra wide band millimeter wave vertical interconnection structure based on a mature HTCC process technology for SIP adopting the HTCC as a substrate material, and the radio frequency vertical interconnection structure realizes excellent electrical characteristics of high working frequency, wide working frequency band, low insertion loss and the like, and has the characteristics of easiness in processing, high reliability and the like.

Owner:CHENGDU SEEKCON MICROWAVE COMM

A vapor-liquid separator

ActiveCN101852522BWelding fit distance is stableGuarantee welding qualityRefrigeration componentsWelding apparatusEngineering

The invention discloses a gas-liquid separator, which comprises a cylinder, an upper end cover, a lower end cover, an outlet adapter and an iron pipe. The iron pipe is positioned in the gas-liquid separator body; the outlet adapter is connected with the iron pipe through the lower end cover; the lower end cover is provided with an outward turnover edge part; the iron pipe is fixed with the inner wall of the outward turnover edge part of the lower end cover; and the outlet adopter is matched and fixed with the outer wall of the outward turnover edge part of the lower end cover by welding. Structural and technical improvements are made, so a welding fitting distance between the iron pipe and the lower end cover is stable, a galling phenomenon between welded contact surfaces is avoided and a welding fitting distance between the outlet adapter and the lower end cover is stable. Therefore, the quality, reliability and consistency among the lower end cover, the iron pipe and the outlet adapter are ensured.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Chip ferrite product electro-plating pre-treatment method

The invention discloses a chip ferrite product electro-plating pre-treatment method, including the following processes: semi-finished product of chip ferrite after silver ink firing is placed into 0.1-3% solution composed of ferric dispersant and propyl acetate solvent for soaking for 10-24 hours and then is taken out when the surface of magnet is covered with a protective film; pure water at 55-100 DEG C is used for washing for 3-5 times, residual ferric dispersant on silver tip is cleaned, and then electro-plating can be carried out after product is placed into basket. The principle includes that the characteristic that ferric dispersant has strong affinity effect on ferric ion and weak affinity effect on silver is utilized to form a protective film on the surface of the magnet of semi-finished product of chip ferrite after silver ink firing. The invention has the beneficial technical effects that the chip ferrite product electro-plating pre-treatment process is convenient in operation, effect is good, and time is short. The invention not only can prevent climbing plating from being produced by semi-finished products of the chip ferrite after silver ink firing in electro-plating process, but also defect plating can not be caused, and welding reliability of electroplated chip ferrite product is ensured.

Owner:SHENZHEN SUNLORD ELECTRONICS

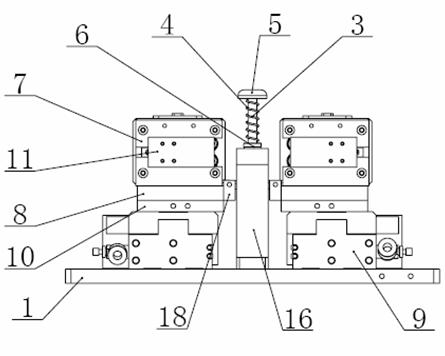

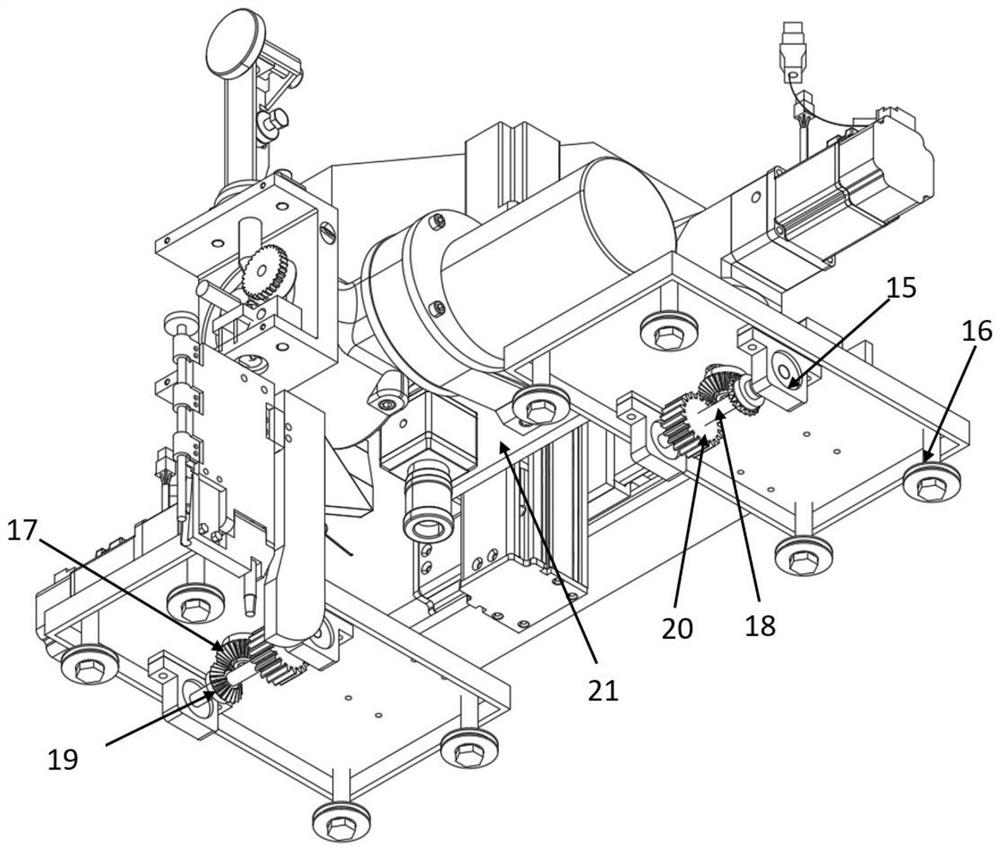

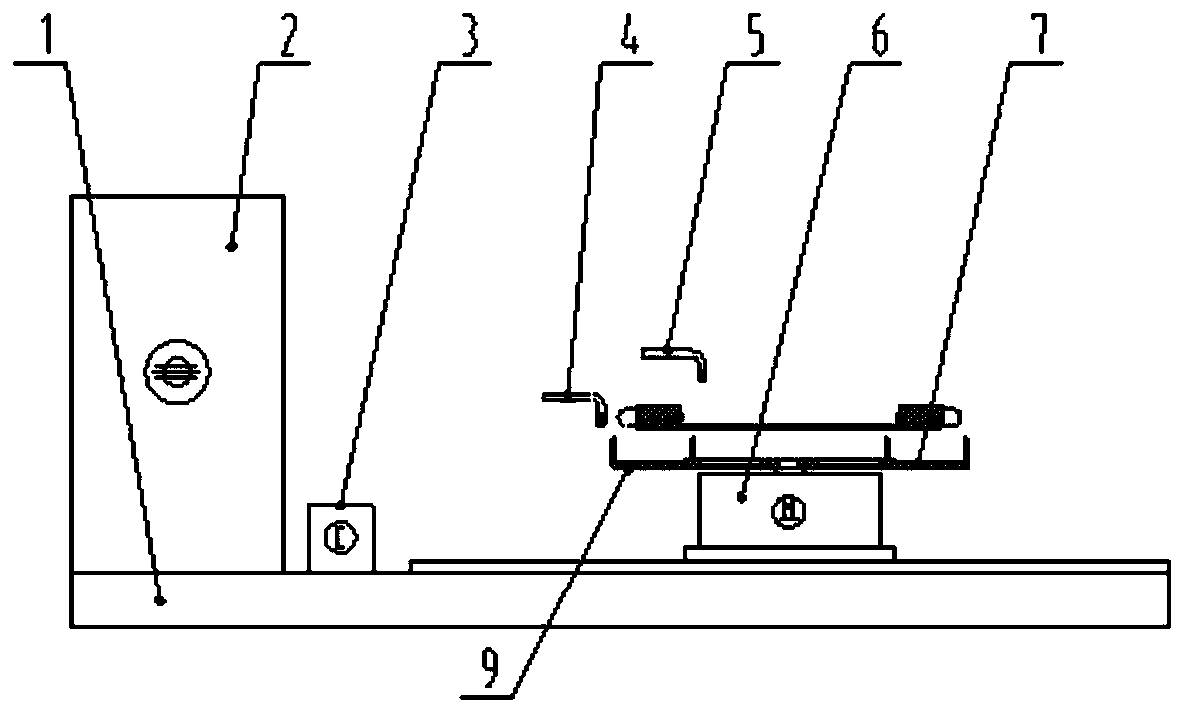

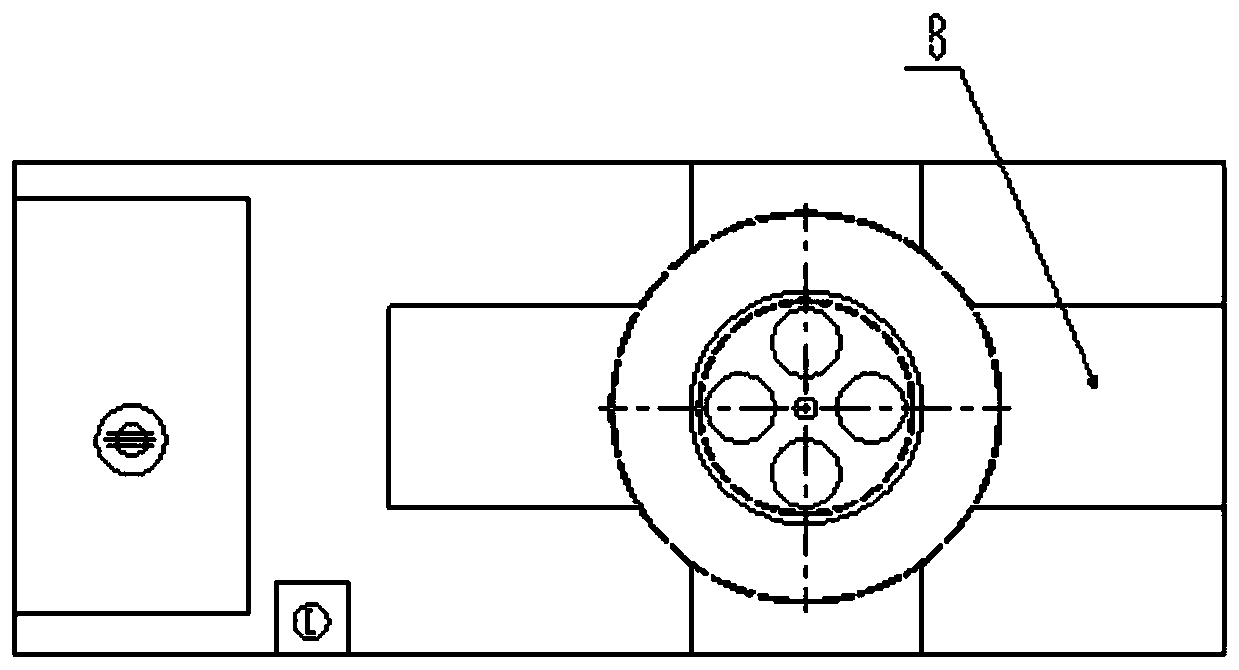

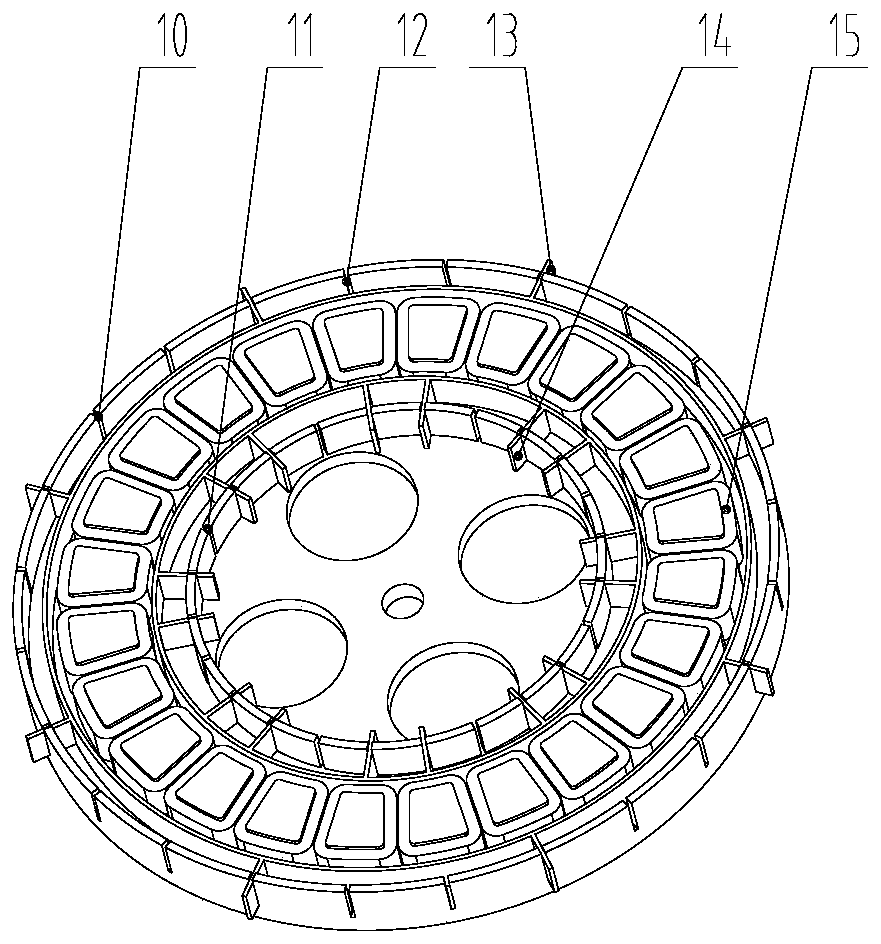

Disc type motor stator winding welding device and use method thereof

PendingCN110640382ARealize simultaneous weldingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesElectric machineEngineering

The invention discloses a disc type motor stator winding welding device. The device comprises a hot melting welder and an XY axis moving platform which are assembled on a base, wherein a tray is rotationally arranged on the XY axis moving platform, an outer-circle wire clamping groove and an inner-circle wire clamping groove are formed in the tray, the outer-circle wire clamping groove is locatedon the outer side of the inner-circle wire clamping groove, an outer-circle welding spot and an inner-circle welding spot are arranged on the outer-circle wire clamping groove and the inner-circle wire clamping groove respectively, and the hot melting welder is provided with a welding head I corresponding to the outer-circle welding spot and a welding head II corresponding to the inner-circle welding spot. The device is simple in structure and convenient to use, by utilizing the regularity of the disc type motor stator winding welding spots, the inner-circle and outer-circle wire ends of a stator winding are simultaneously welded, the welding reliability is ensured, and meanwhile, the welding efficiency is improved.

Owner:深圳小象鸿业机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com