Patents

Literature

84results about How to "Realize fully automatic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-position welding method for pipeline by full-automatic external welding machine

ActiveCN102009251AImprove efficiencyReduce weld metal fillerArc welding apparatusWeld seamProcess engineering

The invention discloses a full-position welding method for a pipeline by a full-automatic external welding machine, which comprises the following steps of: pretreating a pipe orifice end face of the pipeline; conventionally checking a welded pipeline, and performing environmental protection and equipment debugging; inputting and saving welding technical parameters into a tractor controller of an automatic external welding machine; machining the pipe orifice end face of the pipeline to be welded to form the needed groove by using a groove processing machine, and clearing and assembling the pipe orifice end face with the machined groove; checking welding rails and loading a welding tractor; and performing pre-welding preheating on the pipeline to be welded according to regulation requirement in welding technology, and welding according to the specified welding technical parameters. The method realizes real full-automatic pipeline welding, guarantees stable control of the welding process, ensures effective protection on electric arcs and molten baths, guarantees impact toughness of welded joints and welding quality, solves the bottleneck problems which restrict semi-automatic welding flow construction work, and improves the working efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

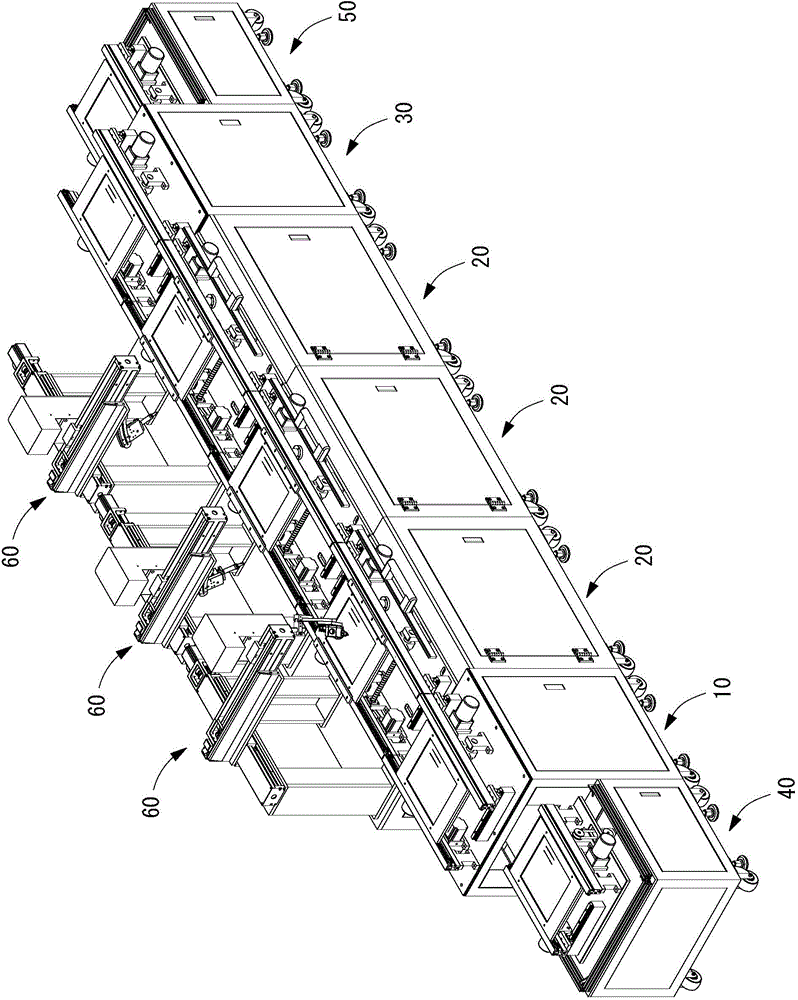

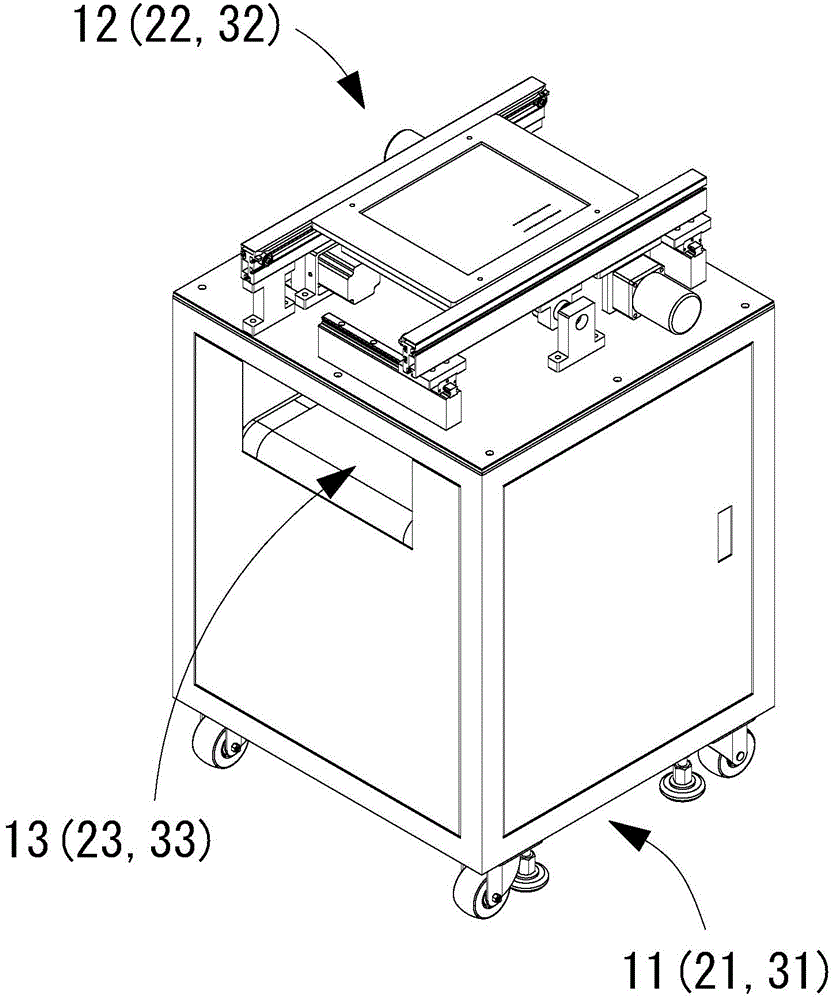

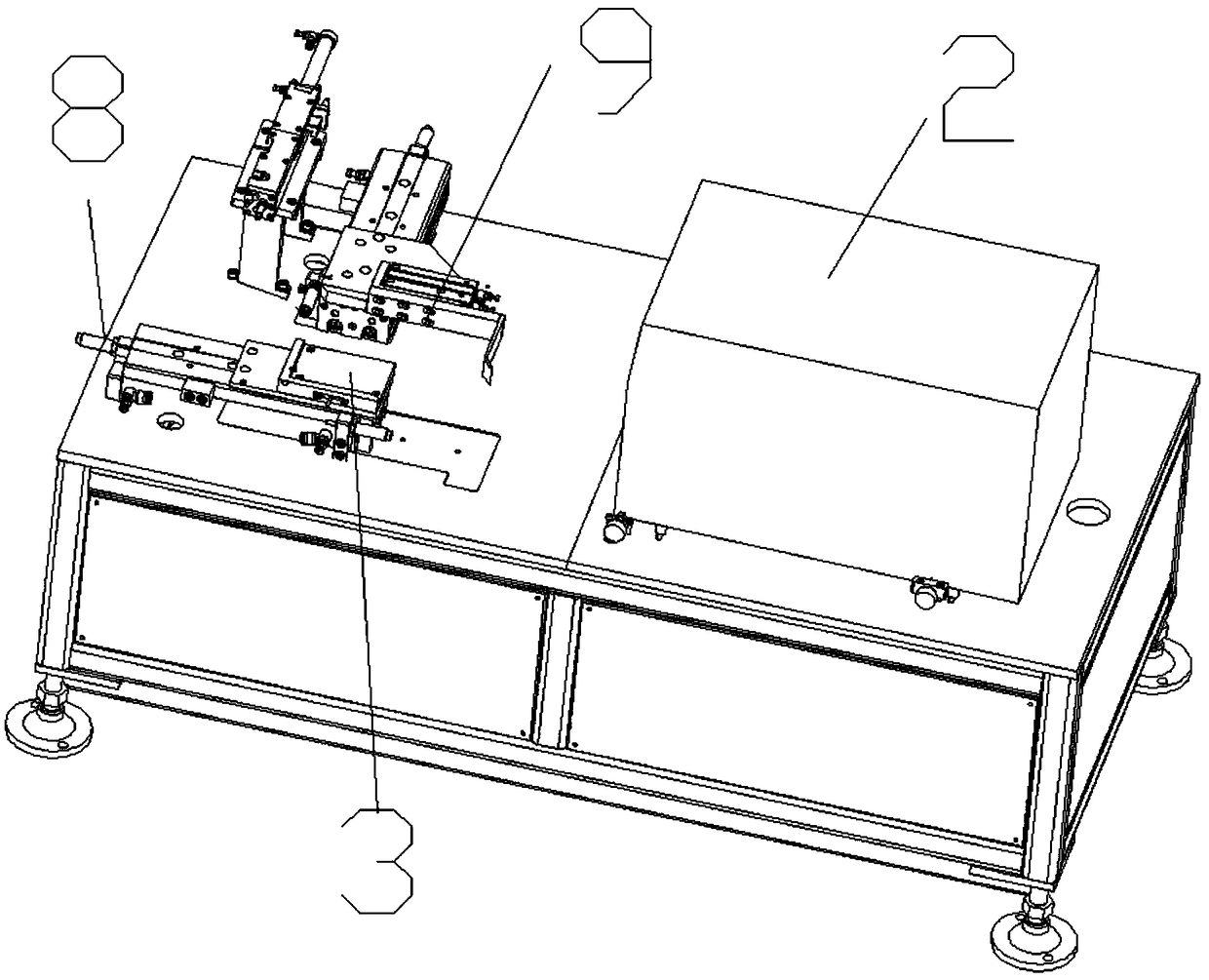

Online tin soldering machine

ActiveCN104551303ARealize fully automatic weldingRealize automatic reflowPrinted circuitsMetal working apparatusEngineeringManipulator

The invention relates to an online tin soldering machine comprising a first conveying platform, second conveying platforms, a third conveying platform, tin soldering manipulators, a first lifting platform and a second lifting platform. Each of the first, second and third conveying platforms comprises a table rack, a forward conveying mechanism mounted on the table rack and a return conveying mechanism mounted on the table rack and located under the forward conveying mechanism. The first lifting platform is mounted on one side of the first conveying platform, and the second lifting platform is mounted on one side of the third conveying platform. According to the online tin soldering machine, jigs can be conveyed forward among the first lifting platform, the first conveying platform, the second conveying platforms, the third conveying platform and the second lifting platform, and full-automatic soldering can be realized. Meanwhile, empty jigs can be conveyed backward to realize automatic return of the jigs, the whole soldering process is operated fully automatically, and working efficiency is higher.

Owner:深圳市联合创新实业有限公司

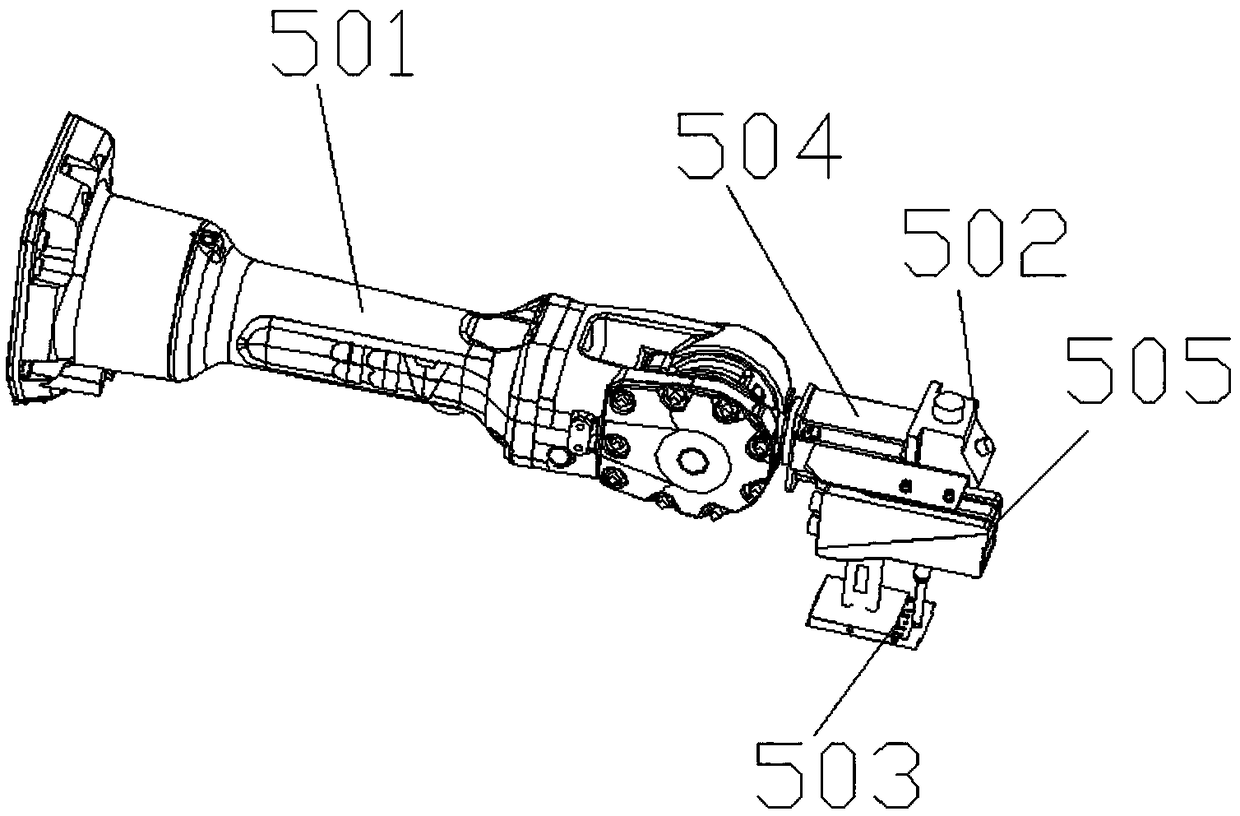

Welding manipulator

InactiveCN102909471ARealize fully automatic weldingLow costResistance electrode holdersGear transmissionBody in white

The invention relates to a welding manipulator which comprises a feeding device and welding pliers connected with the feeding device. The feeding device comprises a linear module and a rotating module which are connected with the welding pliers; the rotating module comprises a gear bank rotating module connected with the feeding device by a slewing bearing; the welding pliers are fixed on the gear bank rotating module; the welding manipulator replaces a robot to move so as to carry out feeding by the linear module and the rotating module and is low in cost; by the linear motion of the linear module and the rotation motion of the rotating module, the high-accuracy positioning of a random space trace can be implemented in a mechanical stroke; the rotating module adopts the gear bank rotating module to carry out high accuracy rotation; the linear module implements high-accuracy linear transmission; when the linear module is linked with the rotating module in a multi-axis manner, the full-automatic welding of a resistance spot welding point on an automobile body in white can be implemented; the welding pliers are fixed and driven to rotate by a gear of the gear bank rotating module; the structure setting is ingenious; an additional connecting mechanism is simplified; and the high-accuracy feeding is implemented by gear transmission.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

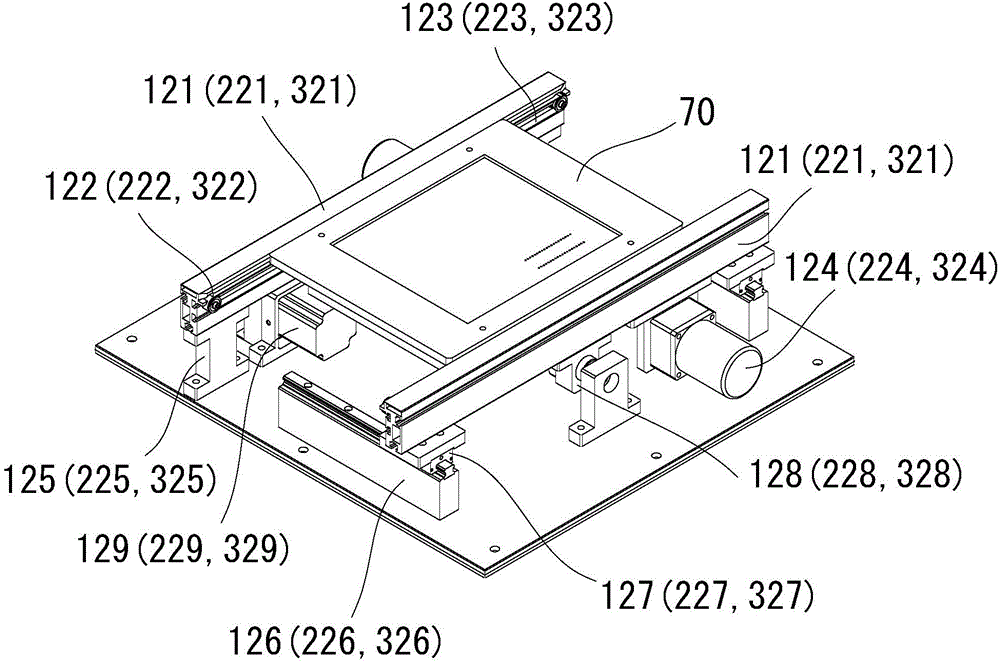

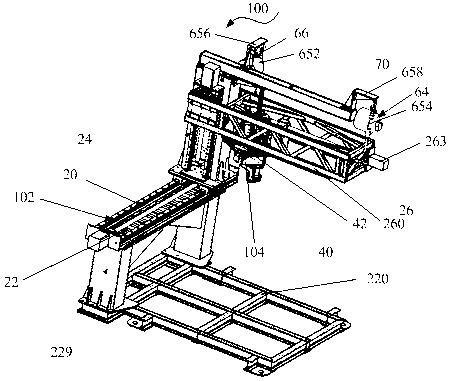

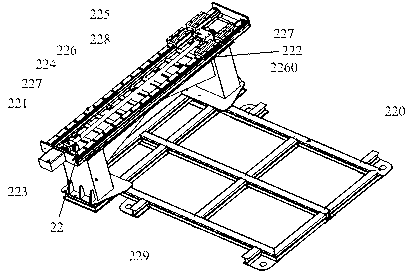

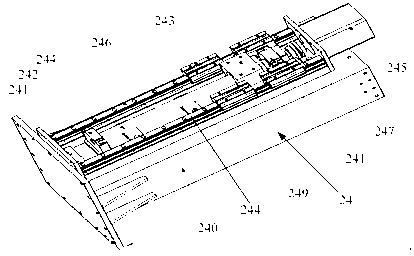

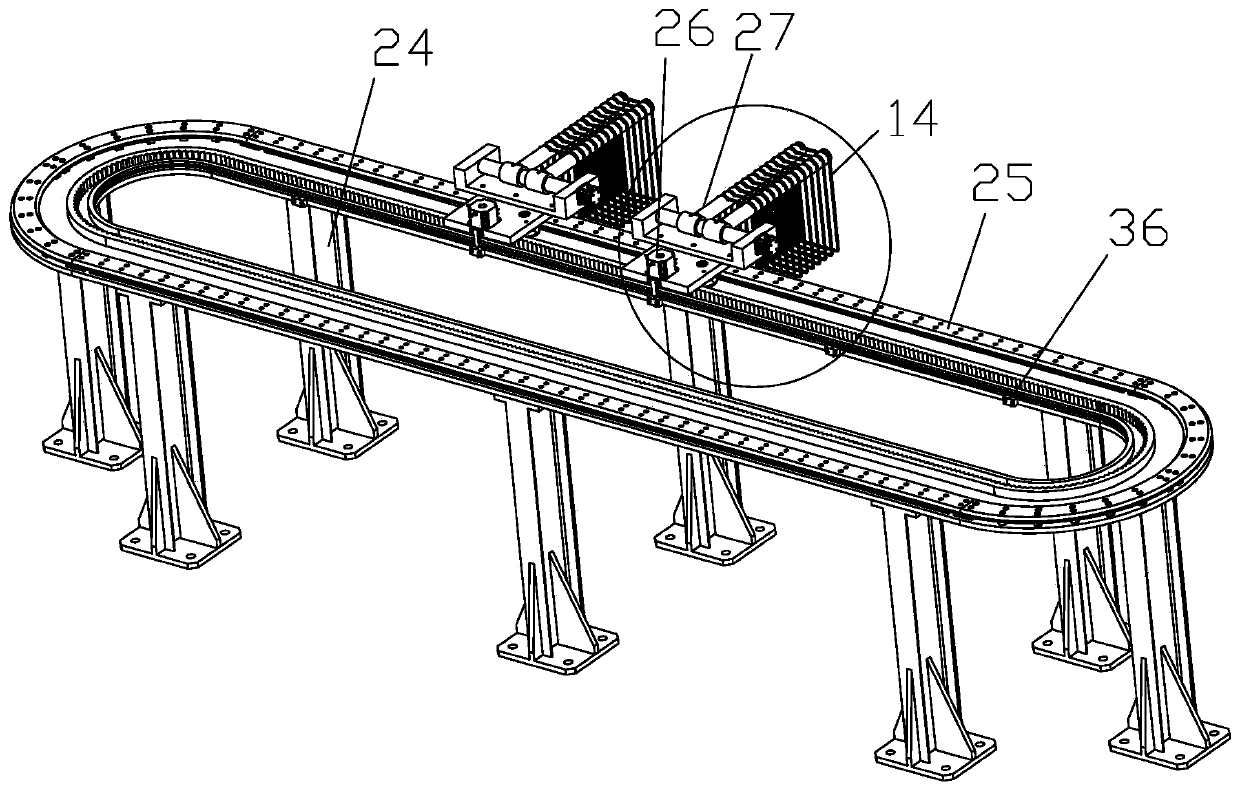

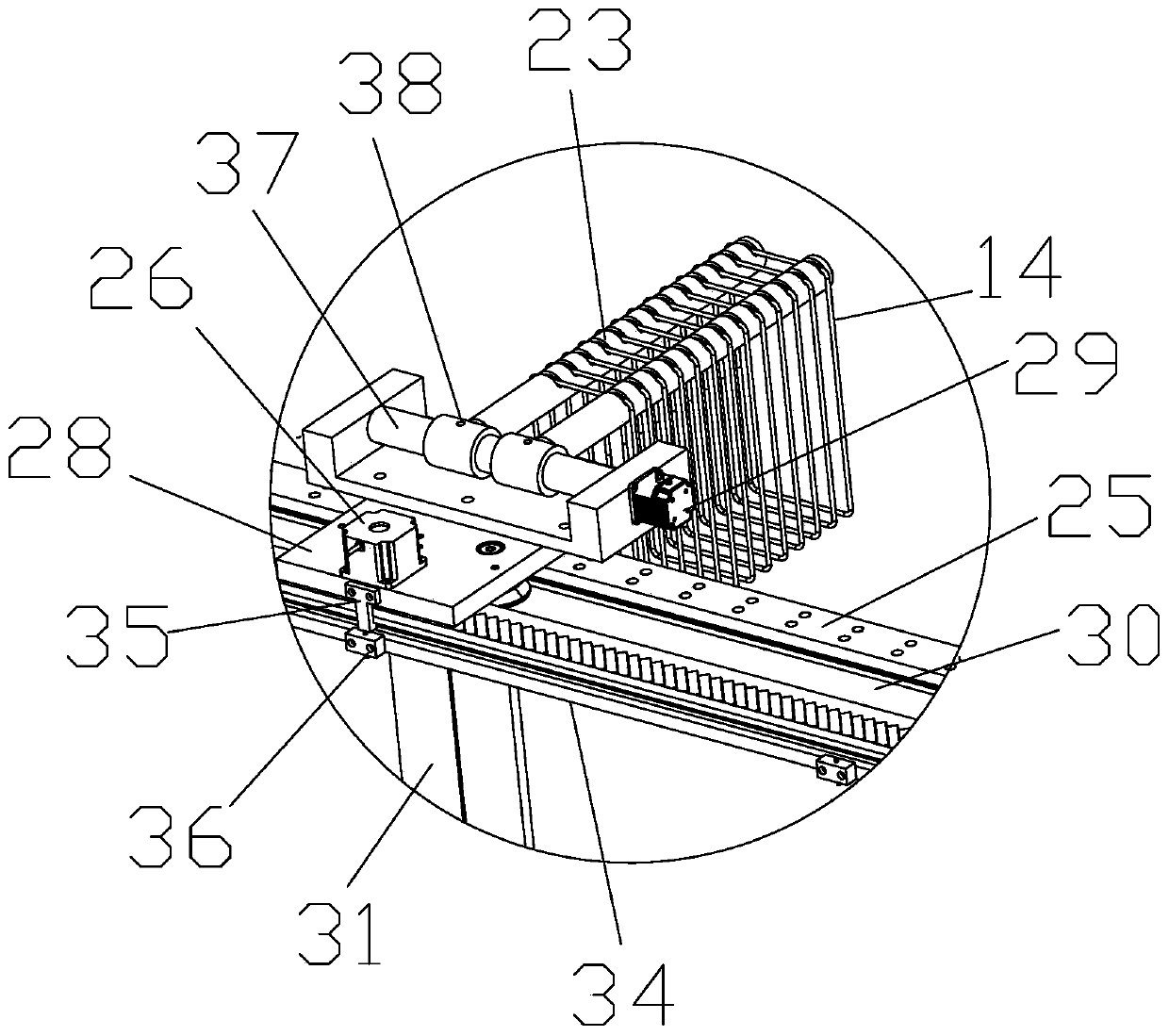

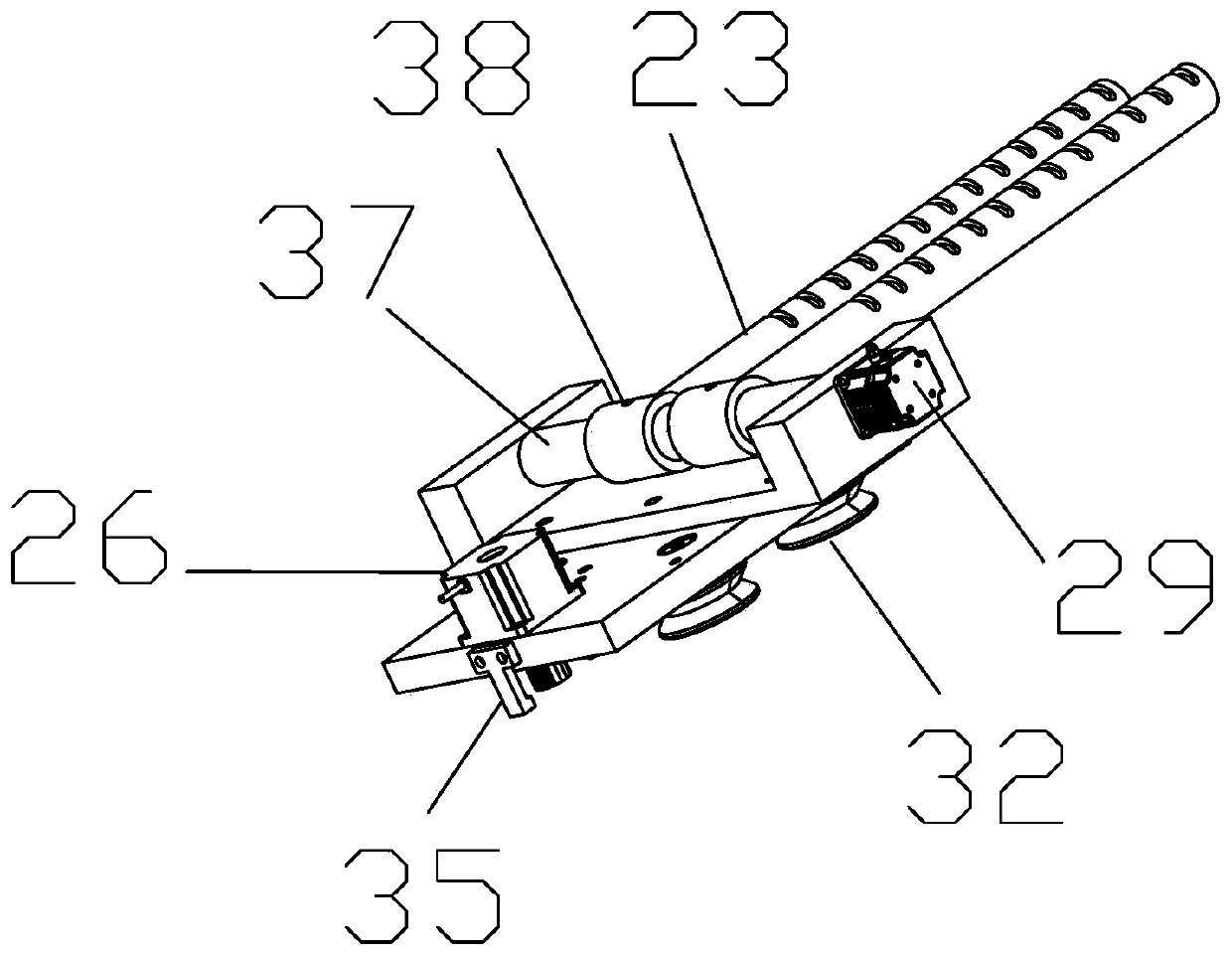

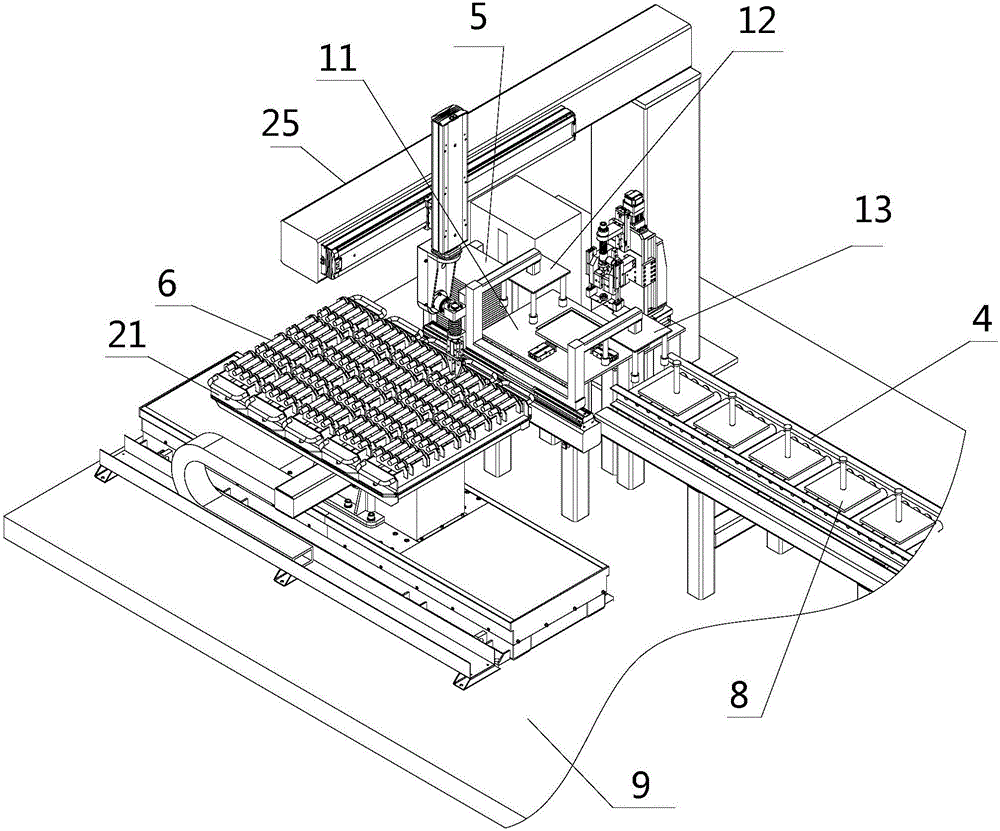

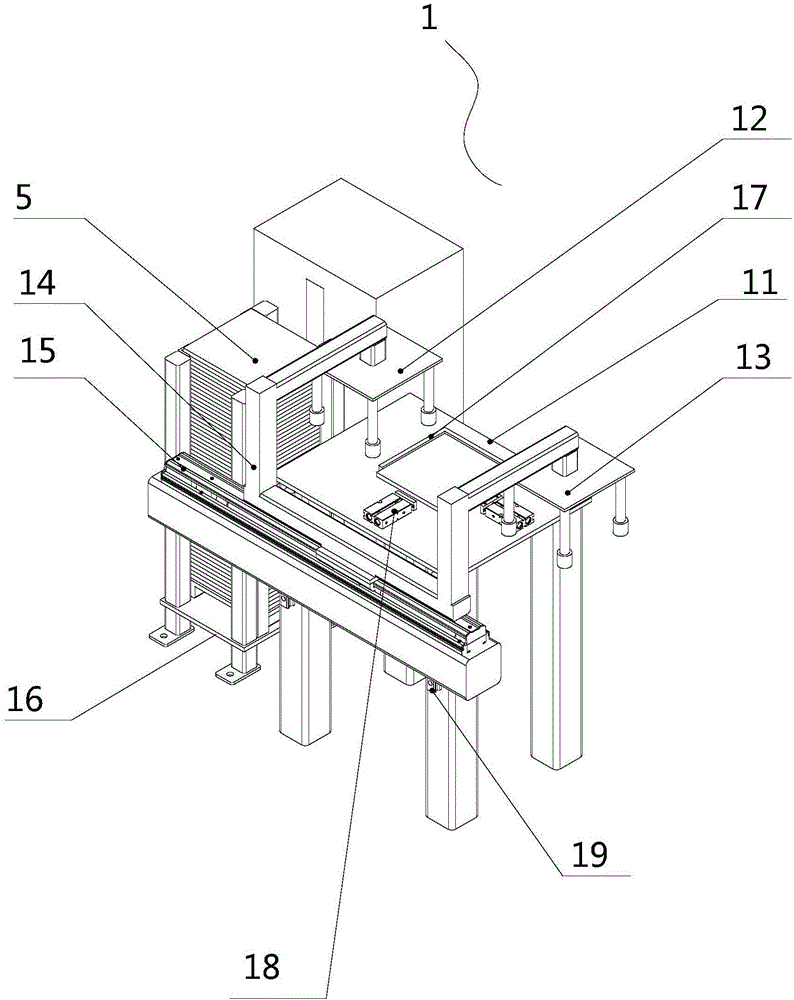

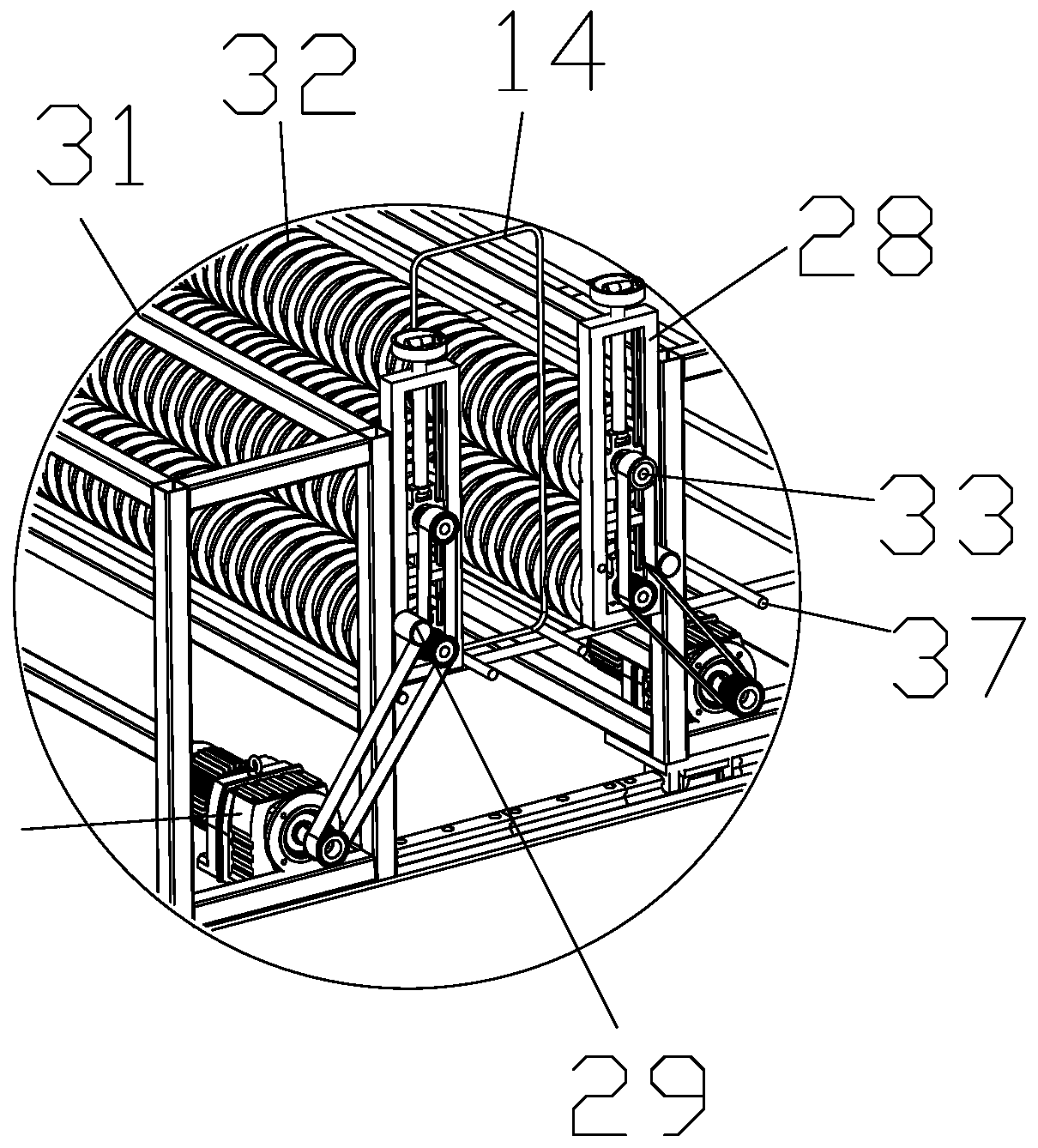

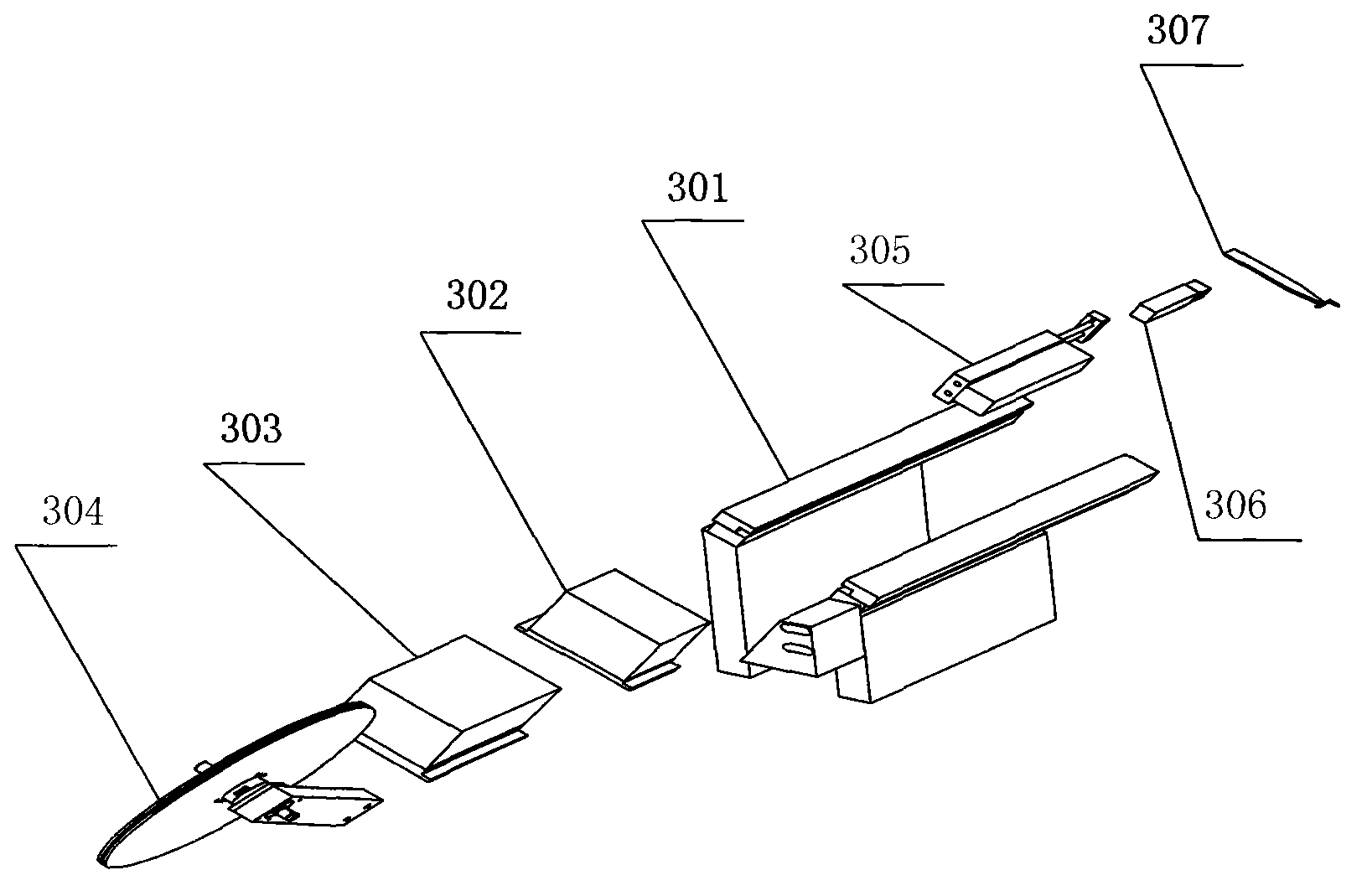

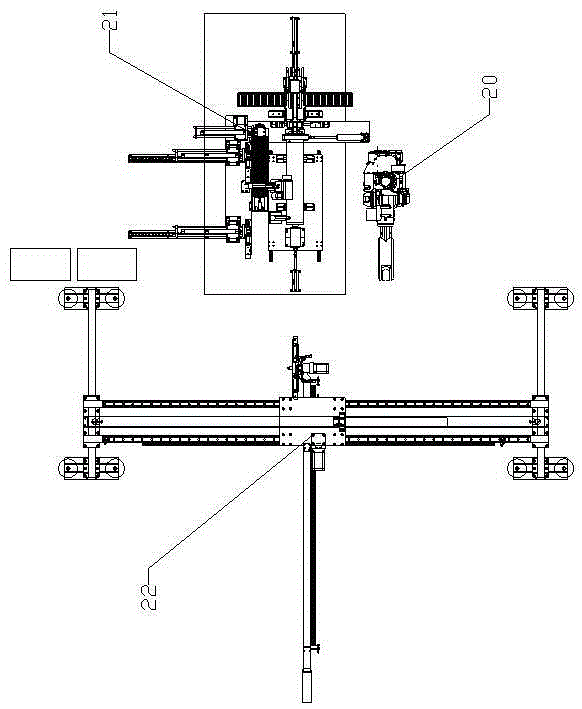

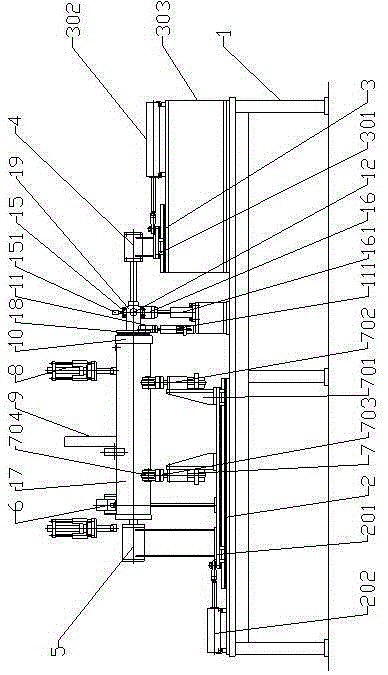

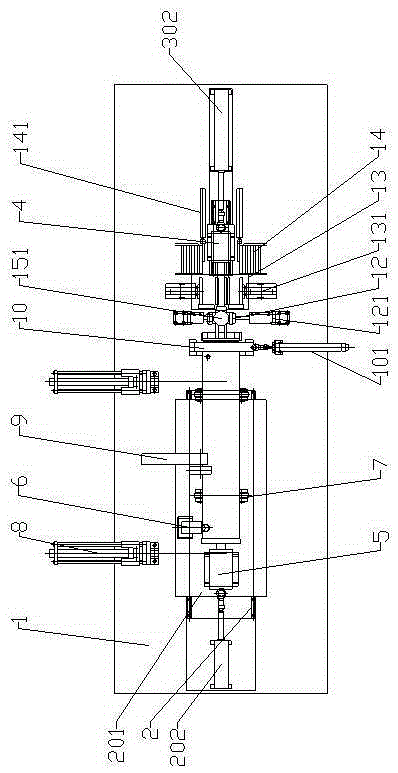

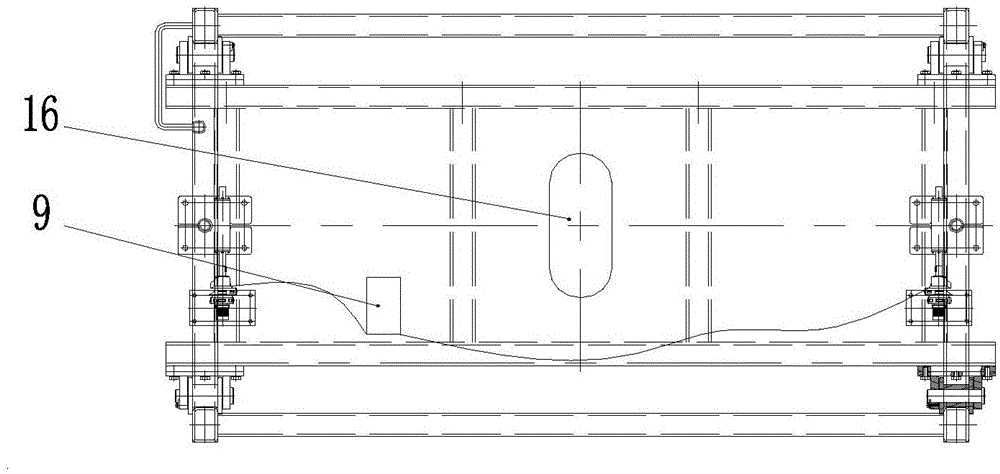

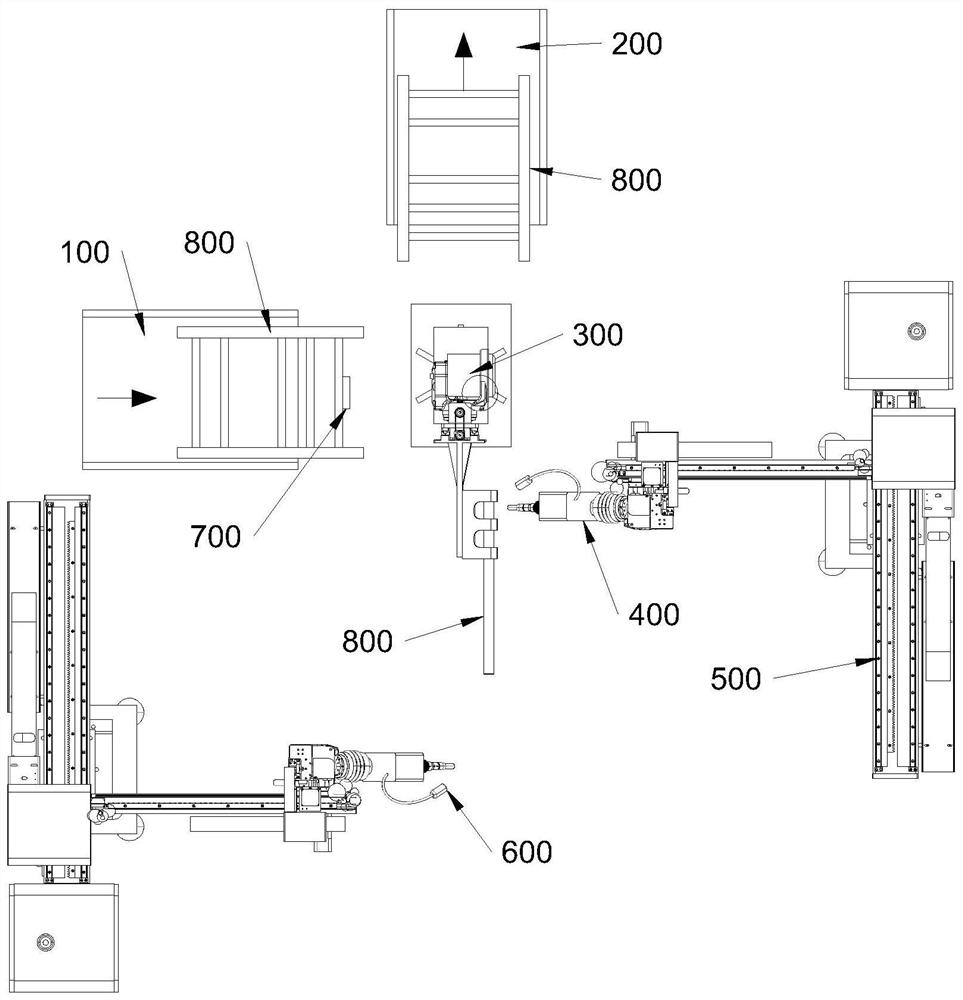

Full-automatic welding production equipment for beam or column steel reinforcement cage

PendingCN109894764ARealize automatic deliveryImplement cachingWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringRebar

The invention provides full-automatic welding production equipment for a beam or column steel reinforcement cage. The full-automatic welding production equipment for the beam or column steel reinforcement cage comprises a guide rail type automatic stirrup conveying device, a longitudinal bar feeding device and a welding device which are arranged in sequence according to a production process; the guide rail type automatic stirrup conveying device is used for transporting a stirrup to a welding position; the longitudinal bar feeding device is used for transporting a longitudinal bar to the welding position and enabling the longitudinal bar to penetrate through the stirrup; the welding device is used for welding the stirrup to a plurality of longitudinal bars to form a steel reinforcement cage; and the welding device comprises a base and a welding arm. According to the full-automatic welding production equipment for the steel reinforcement cage provided by the invention, automatic feedingof the stirrup and the longitudinal bars and automatic welding of the steel reinforcement cage can be realized; the mechanization degree and the automation degree are high; and the work efficiency ishigh.

Owner:CHINA MINSHENG ZHUYOU

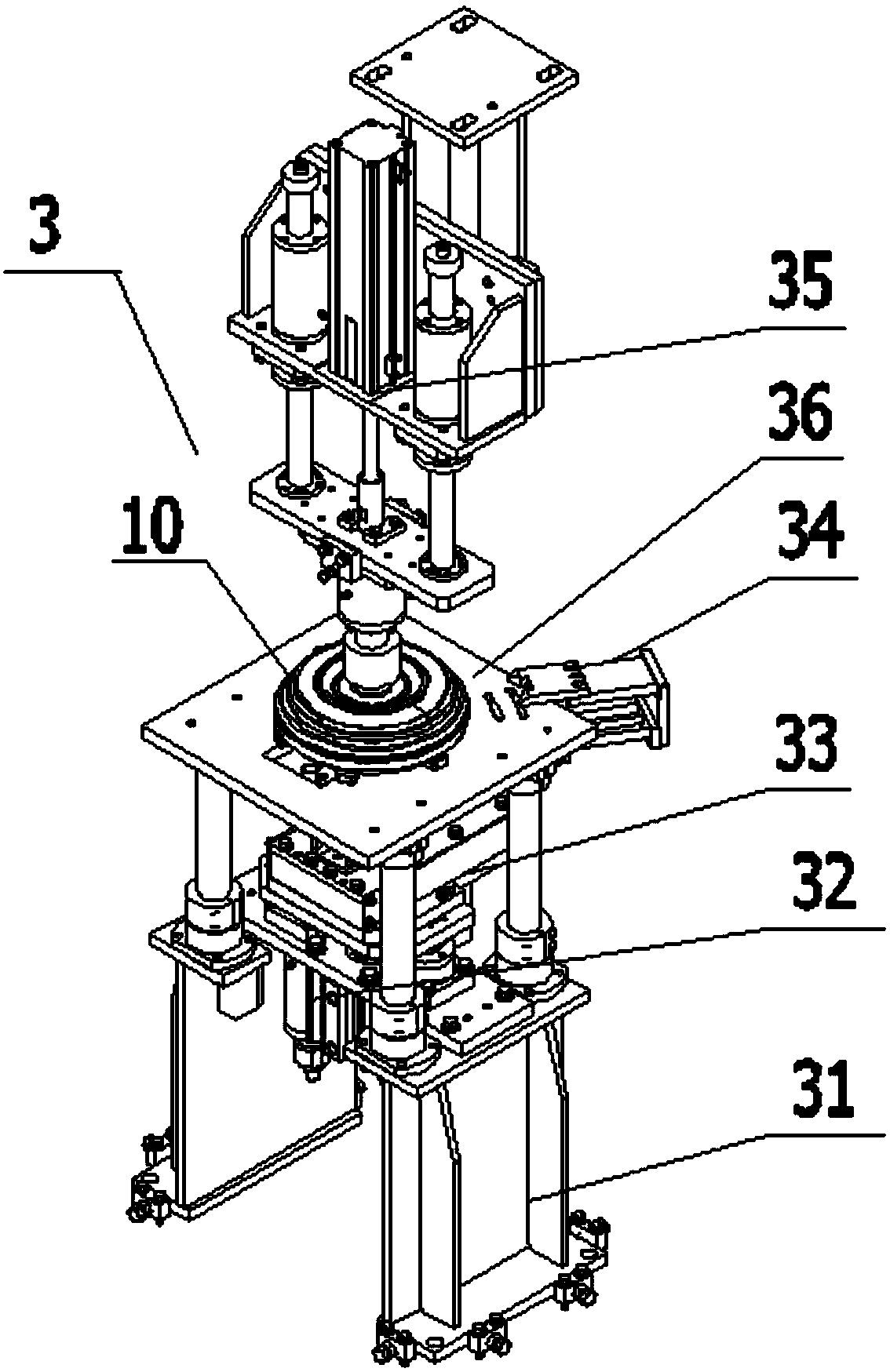

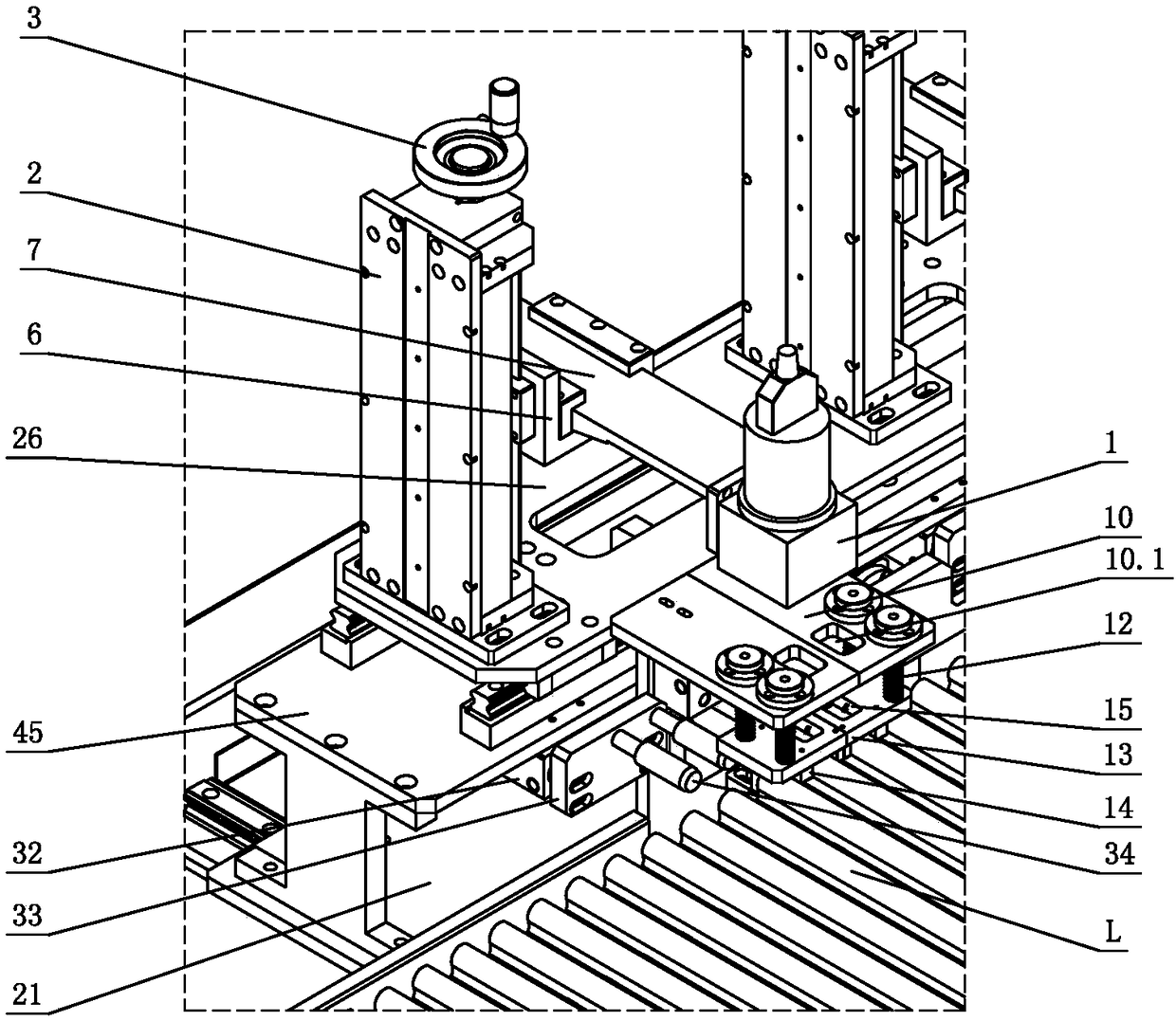

Full-automatic box plate and screw welding device for anchoring box

ActiveCN106425051AIngenious structural designCompact layoutWelding accessoriesStud weldingEngineering

The invention discloses a full-automatic box plate and screw welding device for an anchoring box. The full-automatic box plate and screw welding device comprises a box plate and finished product synchronous-transfer mechanism, a screw feeding mechanism, a stud welding mechanism and a finished product delivery mechanism, wherein the box plate and finished product synchronous-transfer mechanism comprises a material tray positioning rack, a sucking disc material-taking device and a box plate storage plate, the sucking disc material-taking device comprises left and right electromagnetic sucking discs arranged side by side, and the two electromagnetic sucking discs are connected together through a sucking disc supporting frame. The screw feeding mechanism comprises a screw storage pallet and a screw taking manipulator. The stud welding mechanism comprises a base, a welding bearing frame, a welding bearing plate, a metal chuck, a stud welding machine and a ceramic ring compression piece. Compared with the prior art, the full-automatic box plate and screw welding device has the following advantages that automatic feeding, automatic welding and automatic delivery are integrated, the welding quality and production efficiency are greatly improved, and the welding device is ingenious in structural design, compact in layout and suitable for popularization and usage.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

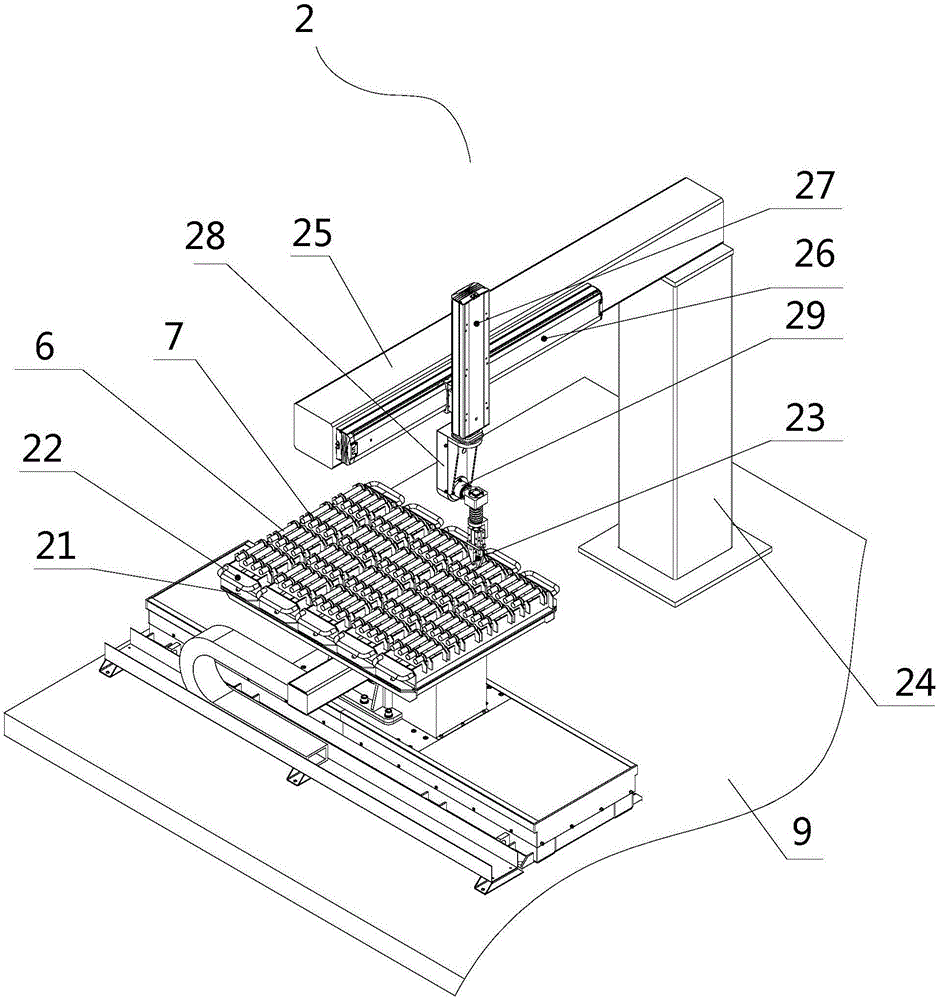

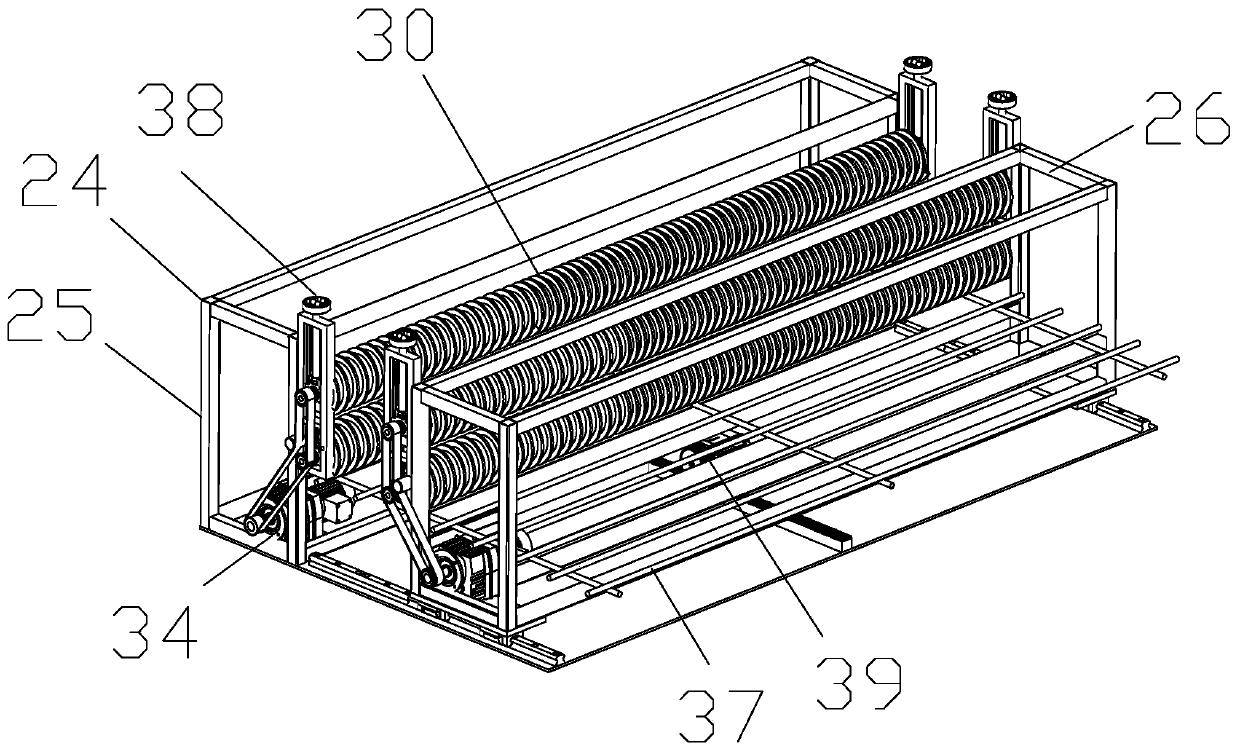

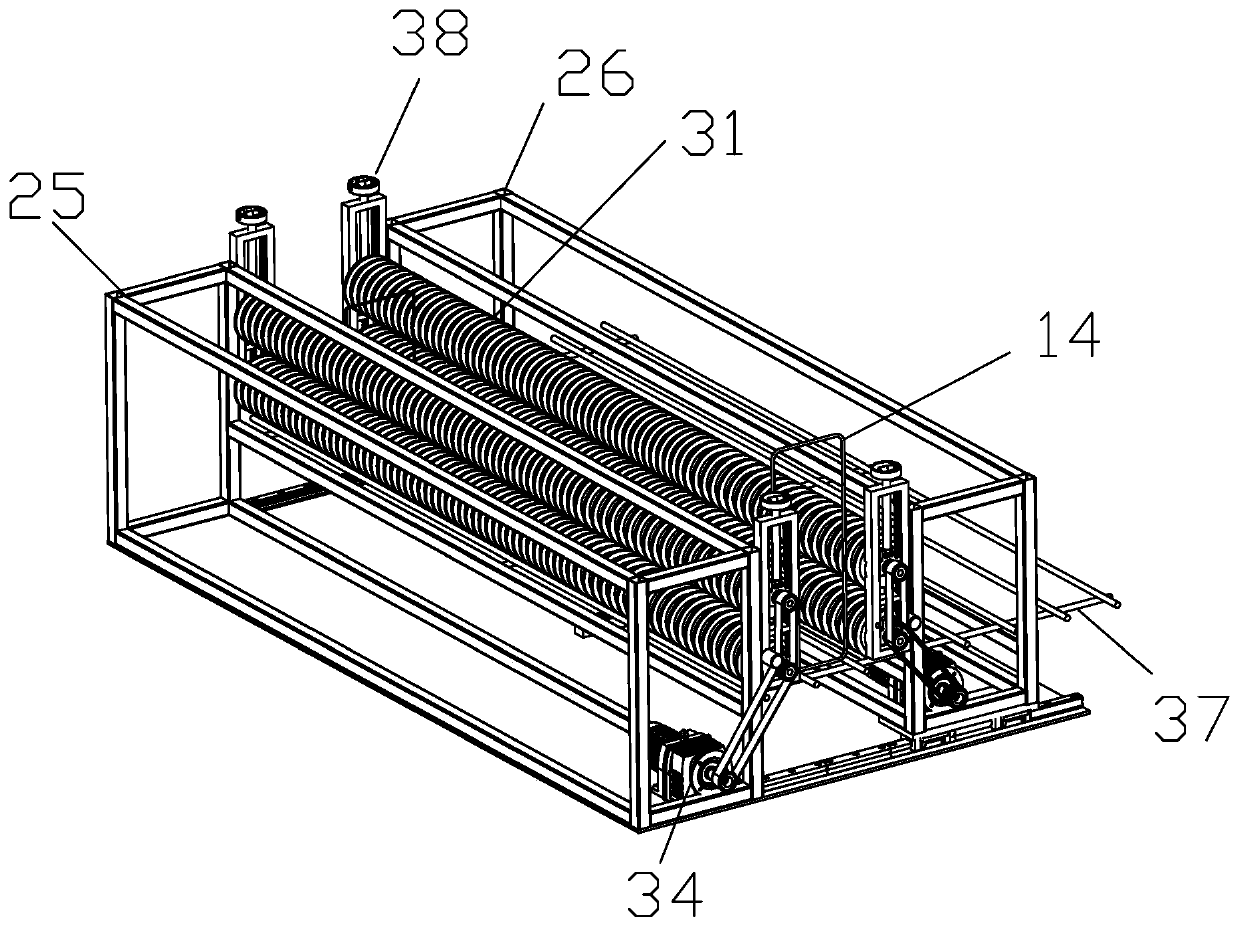

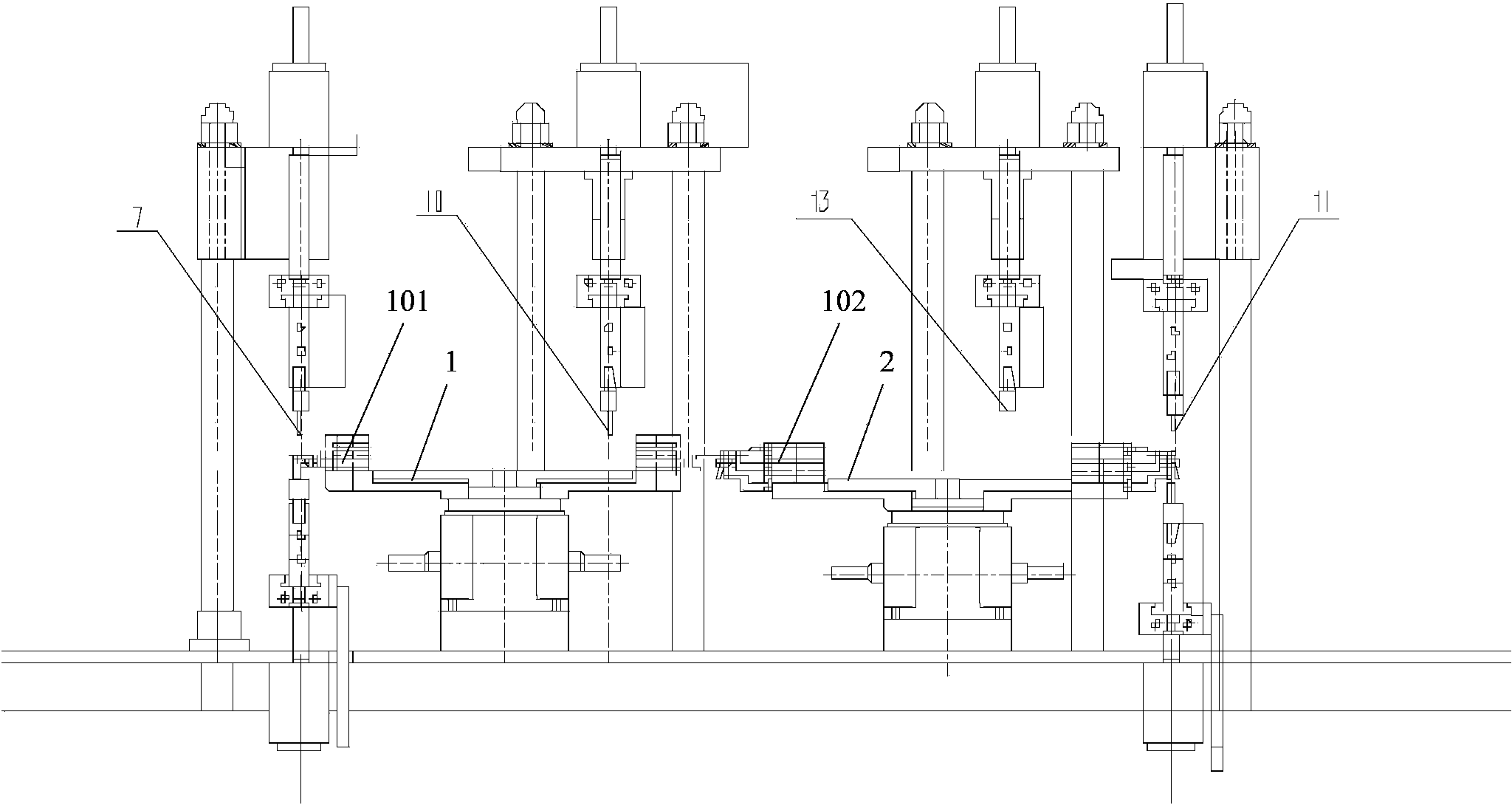

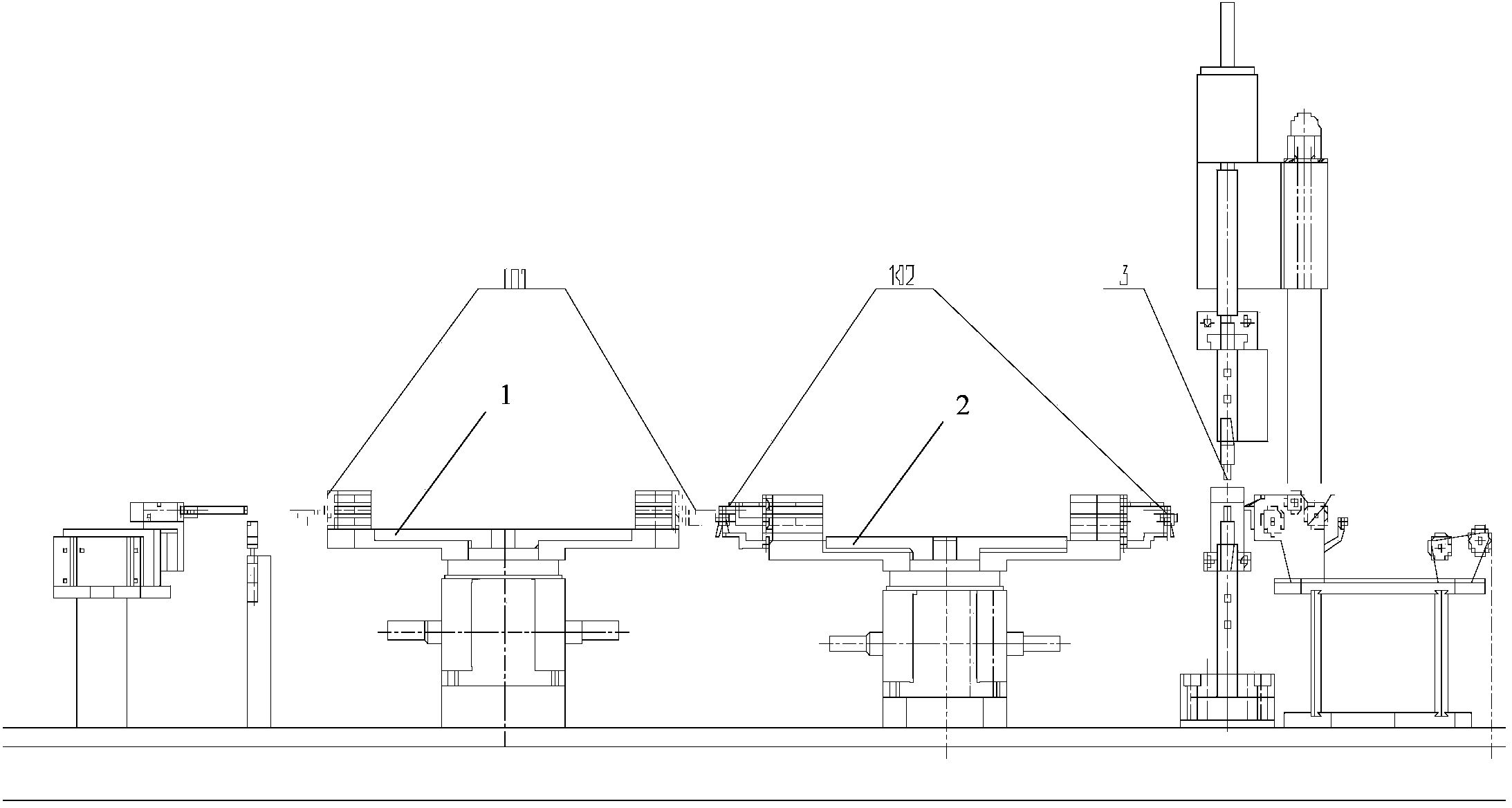

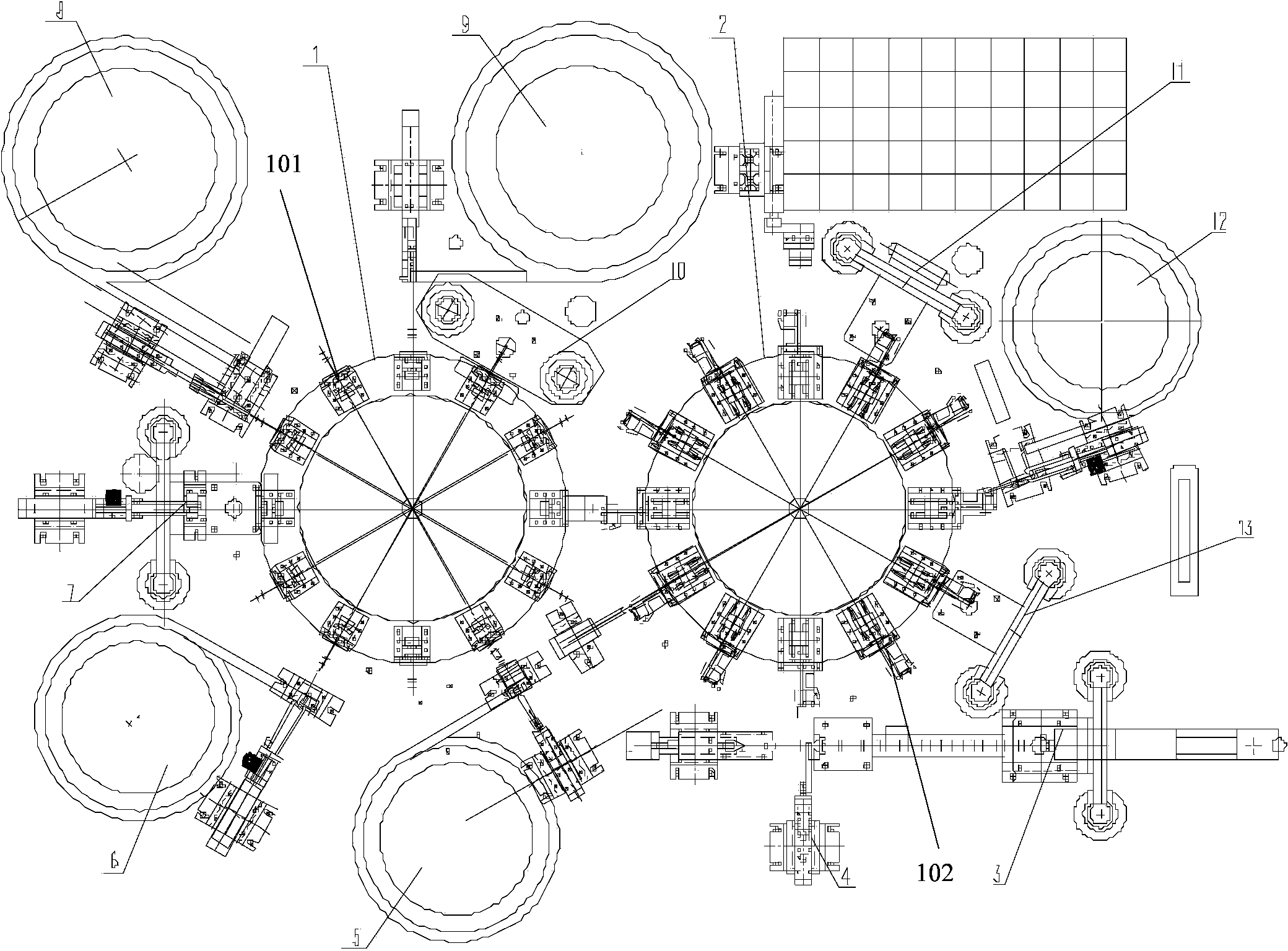

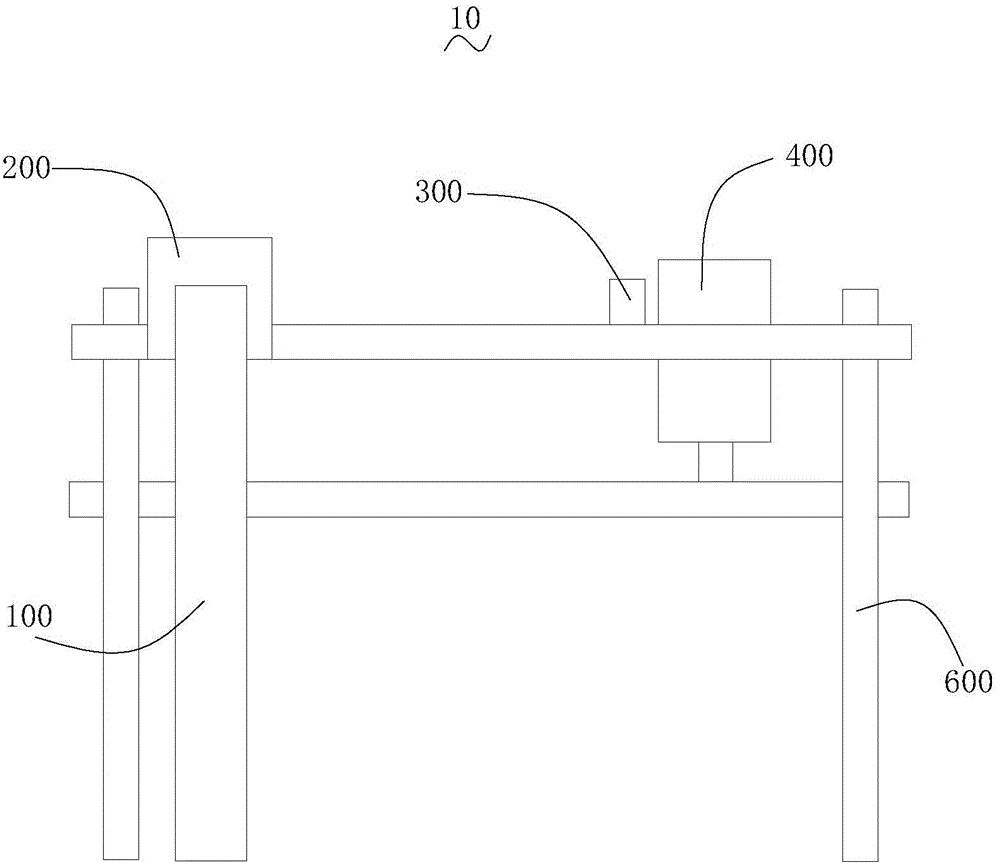

Complete equipment for welding beam or column reinforcement cage

PendingCN109877481ARealize automatic transportationRealize feedingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention provides complete equipment for welding a beam or column reinforcement cage. The equipment comprises a spiral hooping rib feeding device, a longitudinal rib feeding device and a weldingdevice, wherein the spiral hooping rib feeding device, the longitudinal rib feeding device and the welding device are sequentially arranged according to the production process, the spiral hooping ribfeeding device is used for conveying hooping ribs to the welding device, the longitudinal bar feeding device is used for conveying the longitudinal bars to the welding device, the tail ends of the longitudinal bars are inserted into the hooping ribs, and the welding device is used for welding the hooping ribs on the peripheries of the plurality of longitudinal ribs to form the reinforcement cage.According to the equipment, automatic feeding of the hooping ribs and the longitudinal ribs and automatic welding of the reinforcement cage can be realized, manual participation is reduced, the working efficiency is improved, and the automatic and intelligent degree is high.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

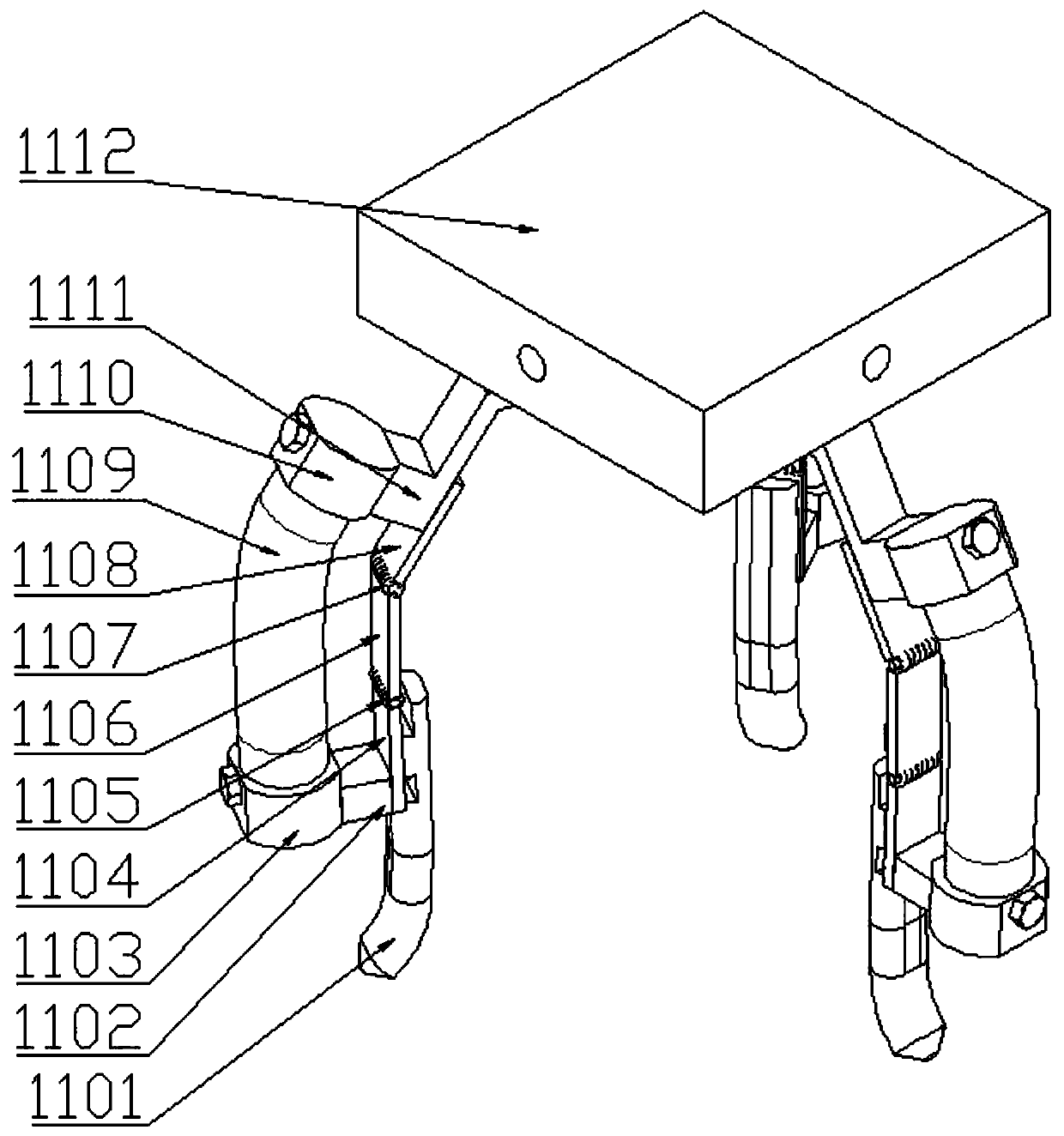

Flexible joint clamp, multi-layer mechanical arm with same and full-automatic welding system

ActiveCN103521958APrecise positioningGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesPerformance indexEngineering

The invention discloses a flexible joint clamp, a multi-layer mechanical arm with the flexible joint clamp and a full-automatic welding system provided with the multi-layer mechanical arm. The flexible joint clamp comprises a first flexible joint clamping board and a second flexible joint claming board, wherein the first flexible joint clamping board and the second flexible joint clamping board are arranged oppositely. The middle portion of the second flexible joint clamping board is installed on the first flexible joint clamping board in a pivoting mode. The upper portion of the first flexible joint clamping board and the upper portion of the second flexible joint clamping board are respectively provided with a flexible joint clamping portion. The lower portion of the second flexible joint clamping board is an inclined pressing board. The second flexible joint clamping board presses and abuts against the first flexible joint clamping board through a flexible joint spring. The flexible joint clamp can be matched with other hard elements so that the multi-level mechanical arm can be installed and formed, the multi-level mechanical arm with the flexible joint clamp can be applied to the welding system, and therefore full automatic welding between flexible joint and the hard elements is achieved. An accurate welding point and the good welding uniformity can be kept and the performance index of the welded product is good.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

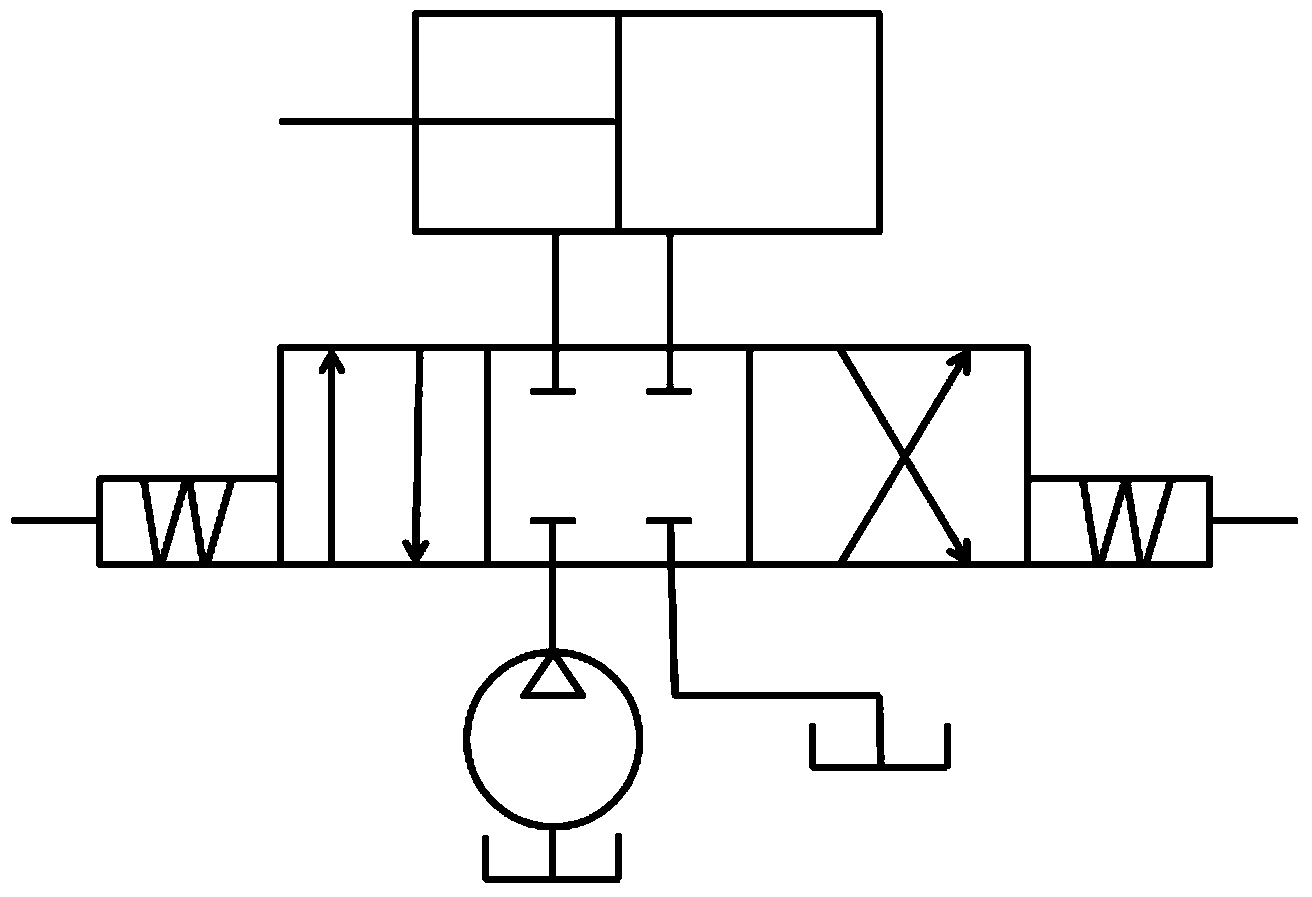

Semi-automatic welding device for circumferential welds

InactiveCN103521979AAvoid deformationUniform feedWelding/cutting auxillary devicesAuxillary welding devicesWeld seamAir pump

The invention relates to a semi-automatic welding device for circumferential welds. The semi-automatic welding device comprises a motor controller, an electromagnetic speed adjusting motor, a locating mechanism, a clamping mechanism, a first air cylinder, a first electromagnetic control valve, an air pump, a travel switch, a control mechanism, a second air cylinder, a second electromagnetic control valve and the like. The control mechanism controls the amount of air pumped to the first air cylinder through the first electromagnetic control valve, the first air cylinder pushes the clamping mechanism to move in the direction towards the locating mechanism through a rotary disc mechanism, and after signals for triggering the travel switch are detected, the clamping mechanism stops moving towards the locating mechanism. The motor controller controls the rotation speed of the electromagnetic speed adjusting motor, the locating mechanism and the clamping mechanism synchronously rotate, the control mechanism controls the amount of air pumped to the second air cylinder through the second electromagnetic control valve, the second air cylinder pushes a welding gun to move, and when the welding gun moves to a limiting block, the travel switch is triggered, and the welding gun stops moving. The semi-automatic welding device is prone to guaranteeing the welding quality, high in welding efficiency, low in cost and simple in structure.

Owner:XUZHOU BAISHILI ELECTRIC VEHICLE +1

Automatic welding device and method achieving low deformation for circular seam of thin-wall aluminum alloy oil tank

ActiveCN112453654ASpeed up coolingEfficient weldingWelding/cutting auxillary devicesAuxillary welding devicesCooling effectRobot welding

The invention relates to an automatic welding device achieving low deformation for a circular seam of a thin-wall aluminum alloy oil tank. The automatic welding device is used for annularly welding tank body end plates and a tank body plate into a whole. The peripheral areas of the weld joint before and after welding are cooled at the same time, the cooling speed of base metal around the weld joint is increased, and deformation before and after welding is reduced. A robot cooperative control mode is adopted, the accessibility of the welding position is guaranteed while the cooling effect is guaranteed, and full-automatic welding of peripheral weld joints can be achieved. When the device is used for welding the thin-wall aluminum alloy oil tank, the tack welding procedure can be omitted, and the welding efficiency is improved by 20%-40%. By means of the automatic welding device, welding manufacturing of thin-wall aluminum alloy oil tanks of different sizes can be achieved, automatic high-precision welding of circular seams of various aluminum alloy oil tanks is achieved, and therefore welding stability is improved, and robot welding of thin-wall components can be efficiently and rapidly achieved.

Owner:内蒙古第一机械集团股份有限公司

Welding robot for lidless box

ActiveCN107877060AImprove welding quality and welding efficiencyRealize fully automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingMotor shaft

A welding robot for a hexagonal prism lidless box comprises a base, a base plate fixing portion, an external welding portion, an internal welding portion and four walking portions. The welding robot for the hexagonal prism lidless box is characterized in that the lower side bottom board of the base plate fixing portion is fixedly installed on a motor shaft of a first stepping motor, a second circular ring groove is installed on 15 second balls in a sliding manner, a first circular ring groove is installed on 30 first balls in a sliding manner, and a rotating shaft of the internal welding portion is rotationally installed in a round hole. Two sixth hydraulic cylinders, a second steering machine and two seventh hydraulic cylinders cooperatively work to enable a first welding head to weld theouter portion of the box, and a fourth stepping motor drives a third gear so as to drive a sliding plate to drive a second welding head to complete side seam welding; the welding robot can achieve welding of the bottom of the outer side and side seams, the welding efficiency is improved, and automatic welding is achieved.

Owner:华粹智能装备有限公司

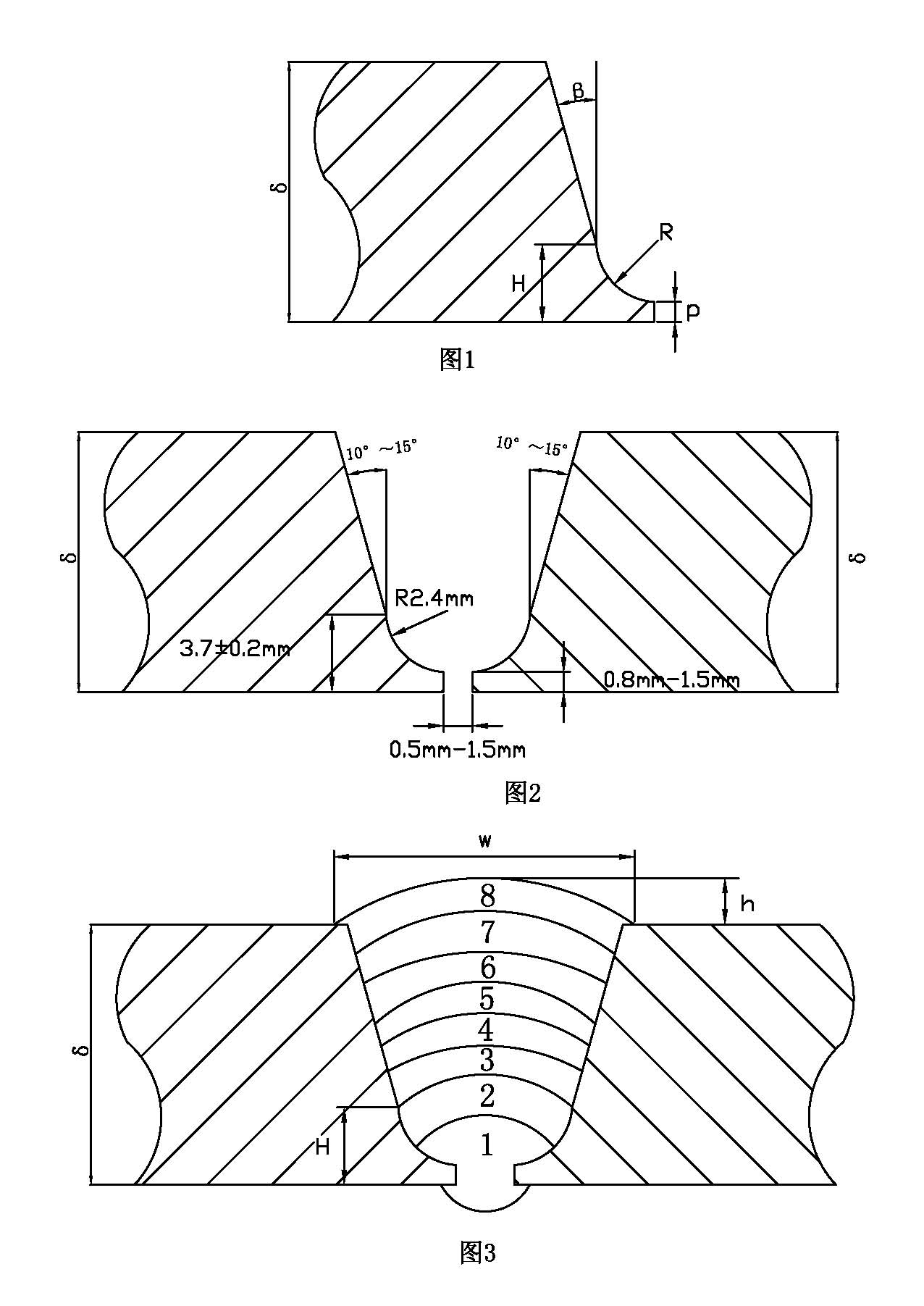

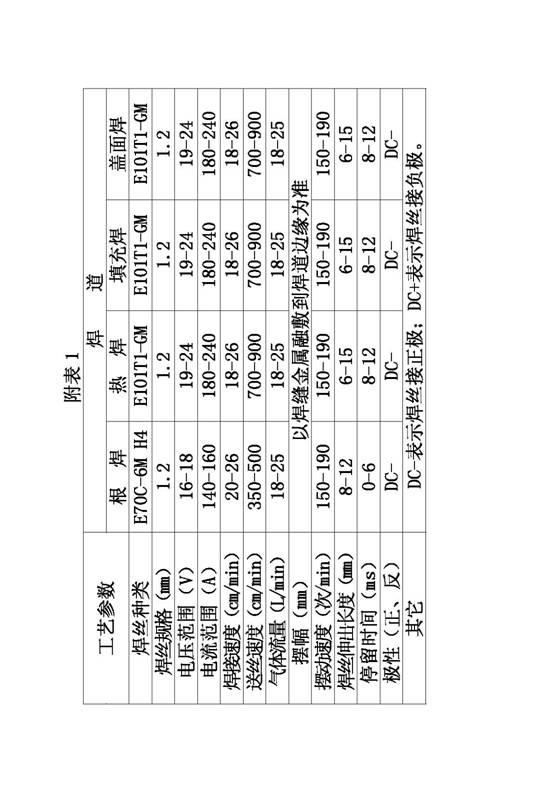

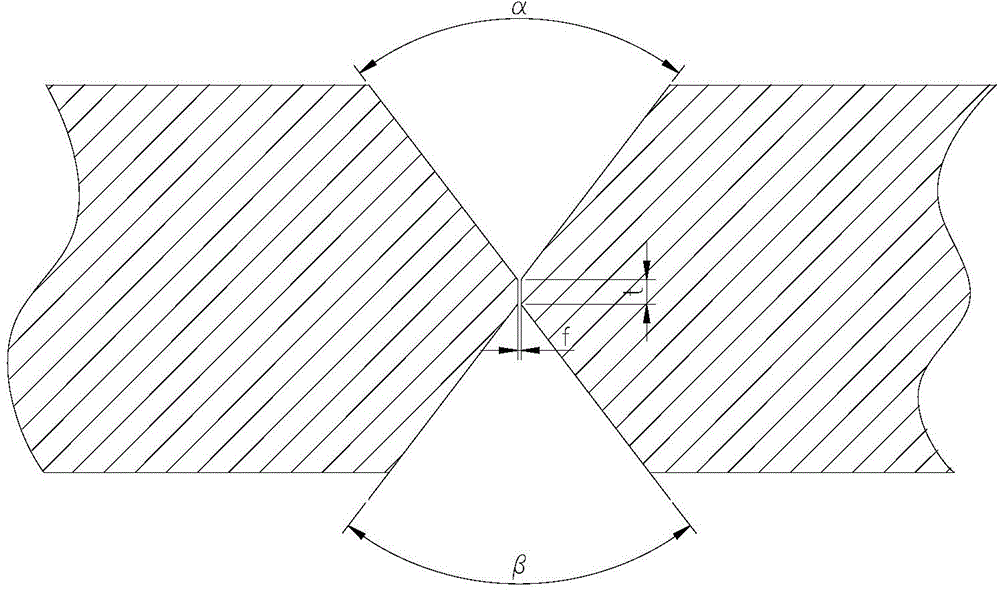

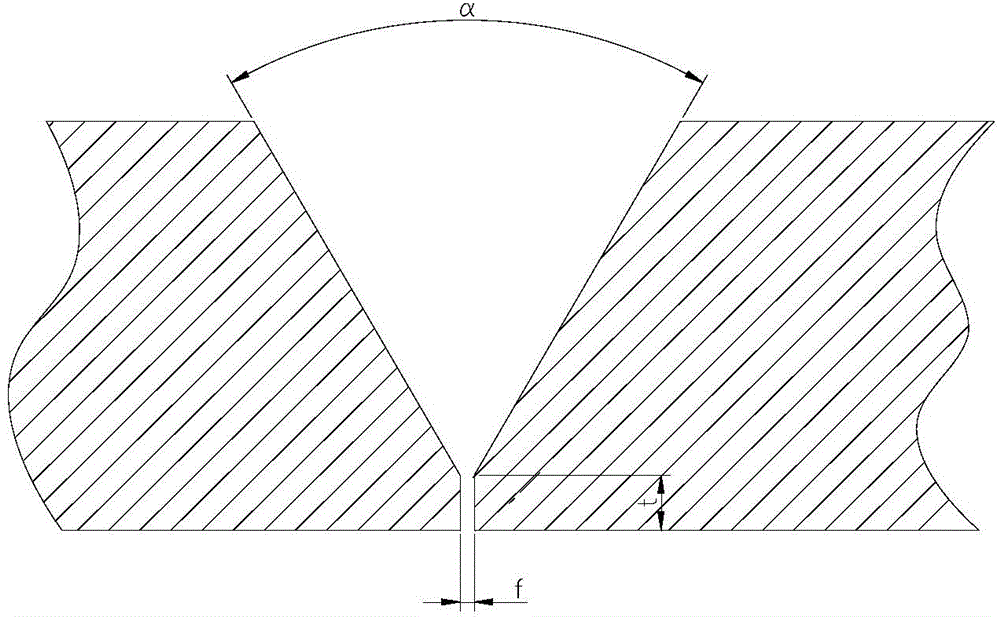

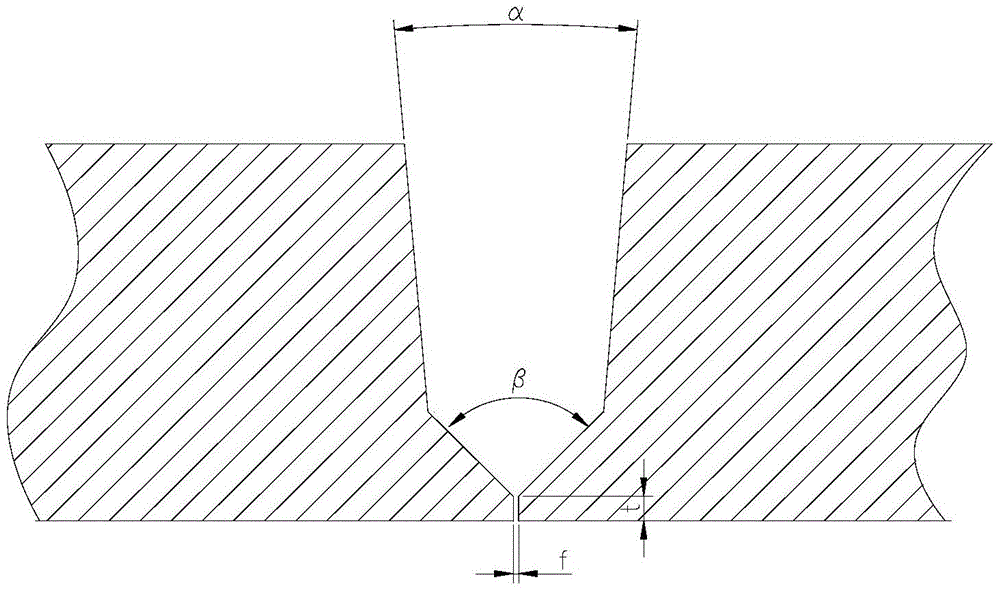

Full-automatic welding method for metal powder-cored wire pipeline girth welding joints

InactiveCN105583499ASolve defects such as uneven welding thickness and even unwelded weldingIncreased weld thicknessArc welding apparatusTubular articlesEngineeringMetal powder

The invention discloses a full-automatic welding method for metal powder-cored wire pipeline girth welding joints. The full-automatic welding method is characterized by comprising the following steps: S1, grooves are machined; S2, pipe openings are pretreated; S3, root welding layer welding, hot welding layer welding, packing layer welding and cover surface welding are performed by adopting metal powder-cored wires, wherein the method M1 for root welding layer welding comprises the step of welding according to root welding layer welding parameters; the method M2 for hot welding layer welding comprises the step of welding according to hot welding layer welding parameters; the method M3 for packing layer welding comprises the step of welding according to packing layer welding parameters; and the method M4 for cover surface welding comprises the step of welding according to cover surface welding parameters. By adopting the full-automatic welding method for metal powder-cored wire pipeline girth welding joints, during welding of pipelines, the detect that side walls are not fused is not easily caused; and the method is high-efficient and environment-friendly.

Owner:廊坊市管道人机械设备有限公司

MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and welding process of MIG welding solid-core welding wire

PendingCN114289929AReduce surface tensionRealize all position weldingArc welding apparatusWelding/cutting media/materialsManganeseUltimate tensile strength

The invention relates to an MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and a welding process of the MIG welding solid-core welding wire. According to the technical scheme, the MIG welding solid-core welding wire for the high-manganese austenite low-temperature steel comprises the following chemical components: 0.20-0.60 wt% of C; si is less than or equal to 0.05 wt%; the content of Mn is 20-32 wt%; the content of Ni is 0.1 to 2 weight percent; the content of Cr is 0.1 to 1.8 wt%; the content of Cu is 0.55 to 1.00 wt%; the content of W is 0.5 to 1.9 weight percent; the content of Mo is 1.3 to 3.0 wt%; the content of Al is 0.5 to 2 weight percent; nb + V + Ti + B + RE < = 0.5 wt%; p < = 0.002 wt%; s < = 0.001 wt%; and the balance of Fe and inevitable impurities. Full-automatic and all-position welding can be achieved, the welding efficiency is high, forming is good, and the mechanical property is excellent; the strength of weld metal formed through inert gas protection is matched with that of high-manganese austenite low-temperature steel, the forming performance is good, the low-temperature toughness is excellent, and the technical requirements for the strength and ultralow-temperature toughness of the LNG storage tank at the working temperature of-196 DEG C can be met.

Owner:WUHAN UNIV OF SCI & TECH

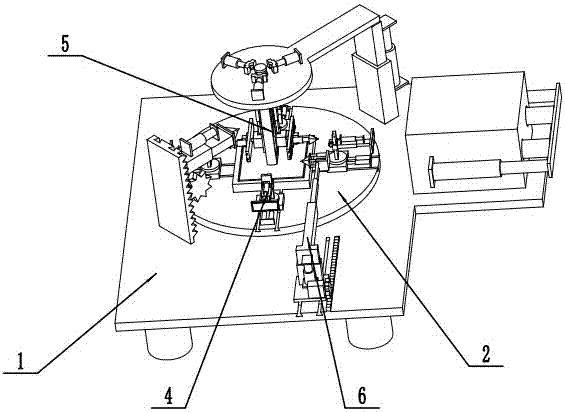

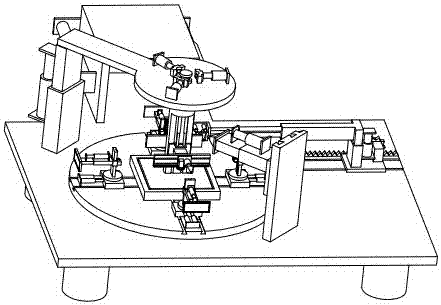

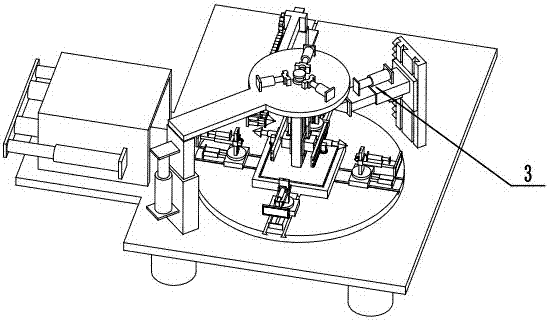

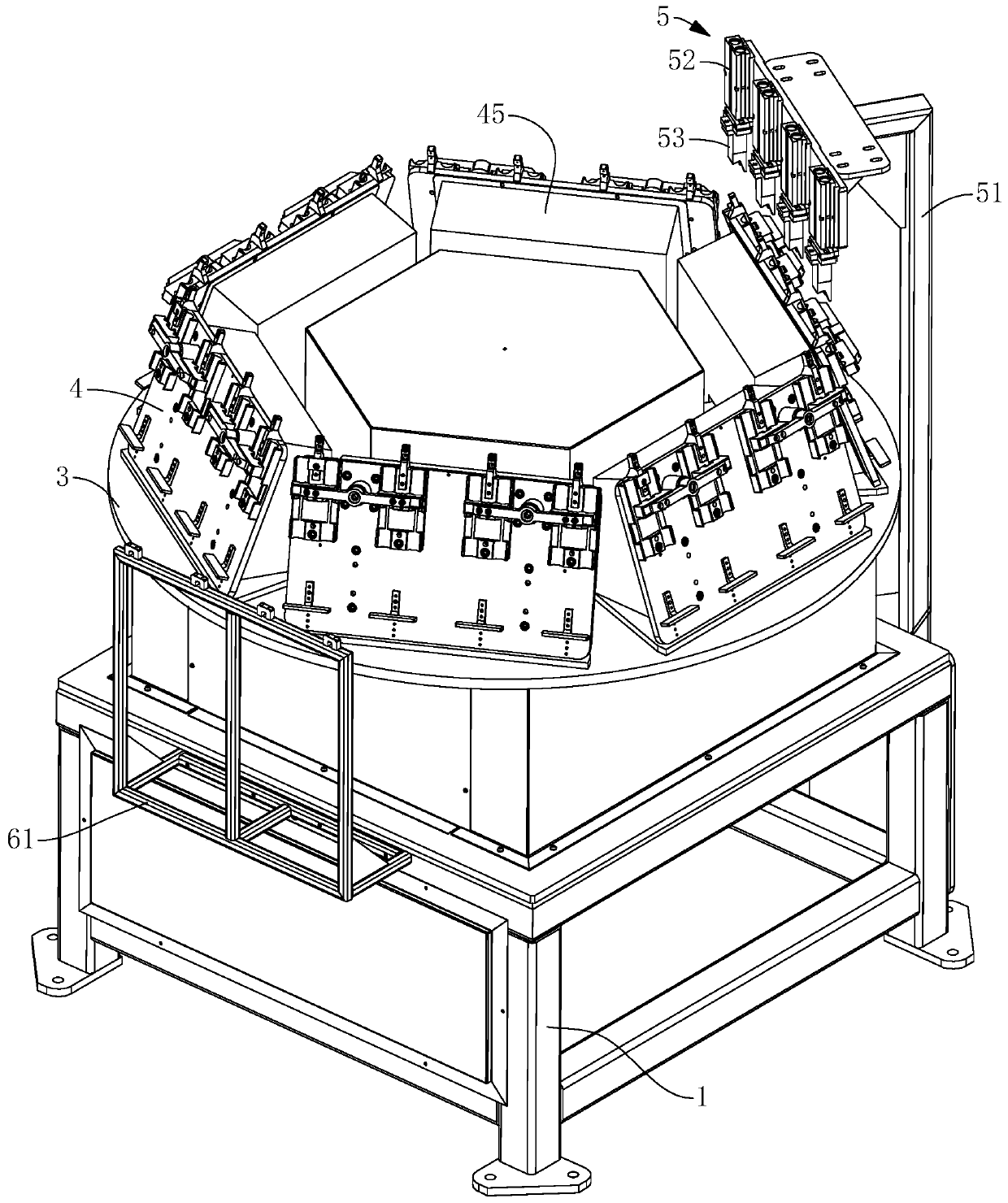

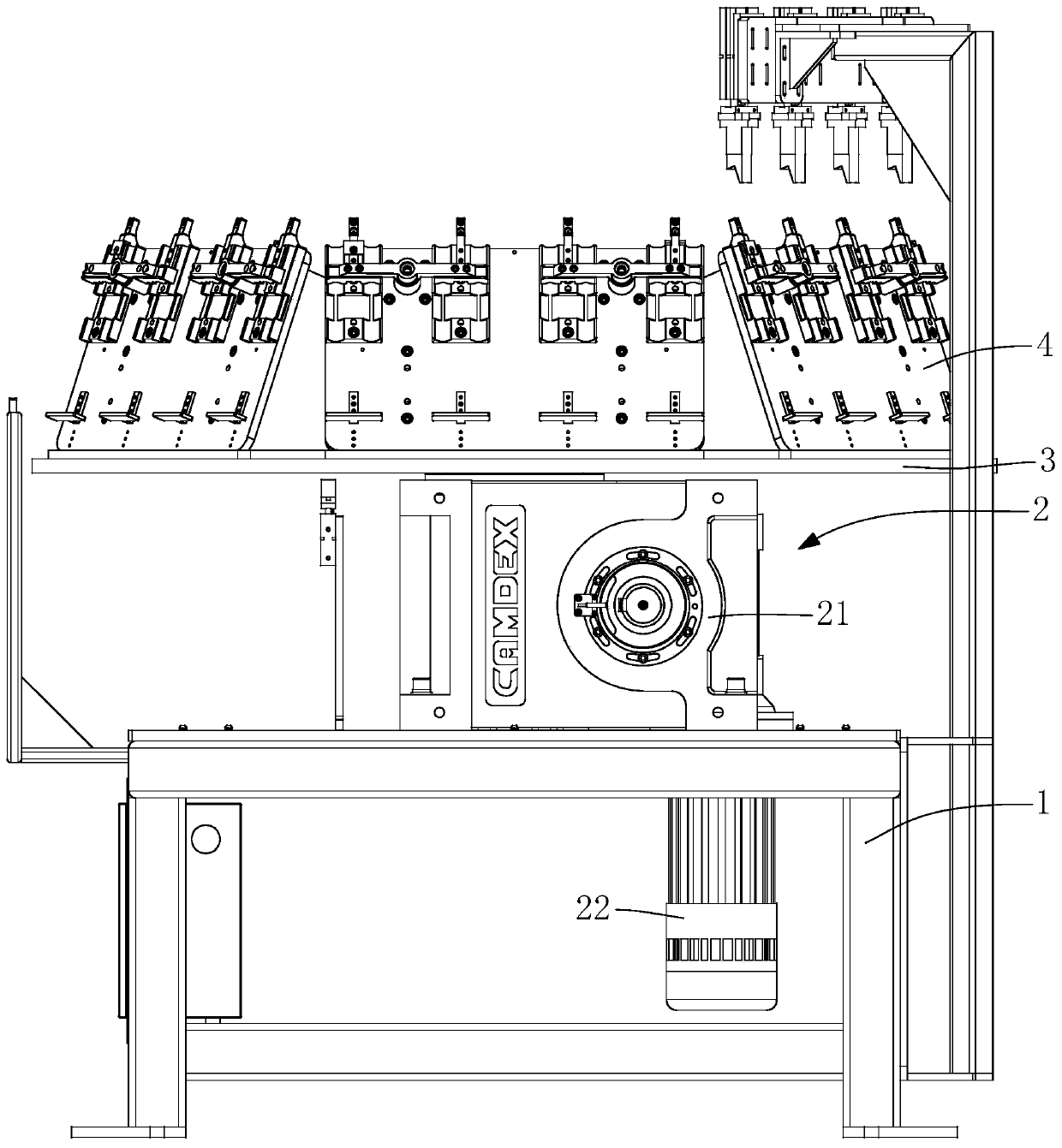

Automatic welding device with multi-station rotary disc, and welding method

PendingCN110142527ARealize fully automatic weldingImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManipulator

The invention provides an automatic welding device with a multi-station rotary disc, and a welding method. The automatic welding device comprises a base, a drive device, a rotary disc and a pluralityof workpiece location devices, wherein the drive device is fixed to the base; the rotary shaft is fixed to an output shaft of the drive device; the drive device drives the rotary disc to intermittently rotate; the plurality of workpiece location devices are fixed to the rotary disc in the form of an annular array; a loading station, a welding station and an unloading station which corresponding tothe workpiece location devices are sequentially arranged in the rotation direction of the rotary disc; a loading manipulator is arranged at the loading station and used for conveying a workpiece to the workpiece location device at the loading station; a welding robot is arranged at the welding station and used for welding the workpiece; an unloading manipulator is arranged at the unloading station and used for taking down the welded workpiece; and the rotary disc drives the plurality of workpiece location devices to rotate by a predetermined angle and then stops for a predetermined time, forcyclic loading, welding and unloading. The automatic welding device is capable of realizing fully-automatic welding, improving the welding quality and increasing the welding efficiency.

Owner:广东网纳智能装备有限公司

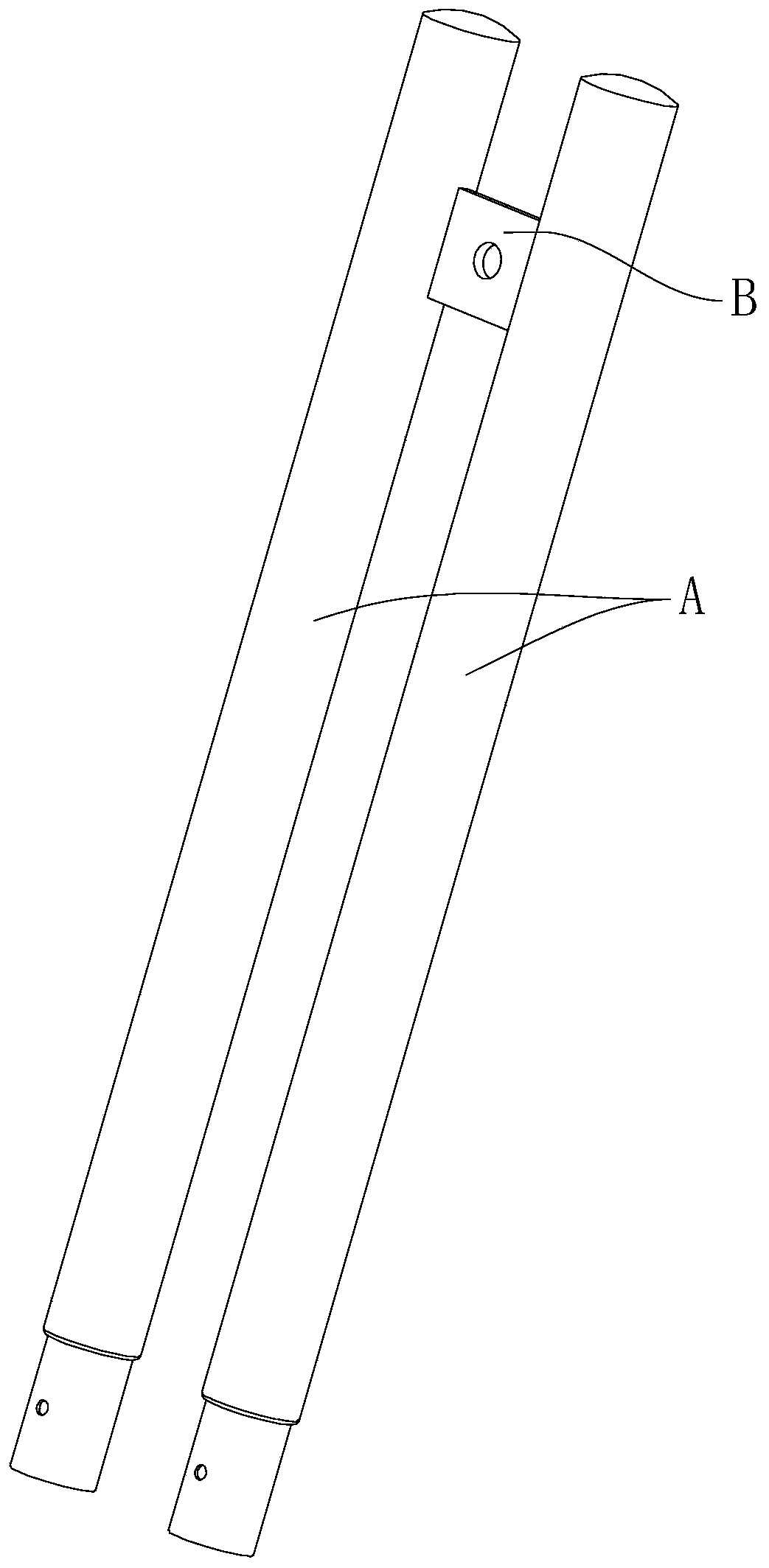

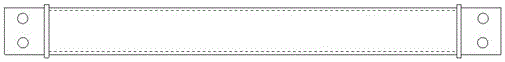

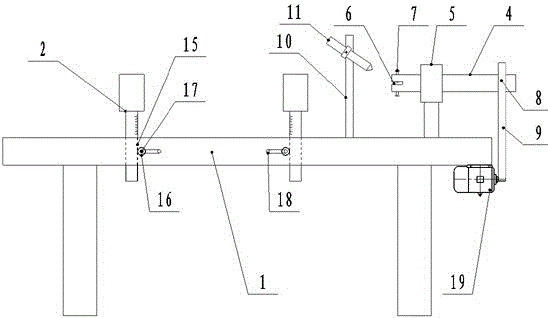

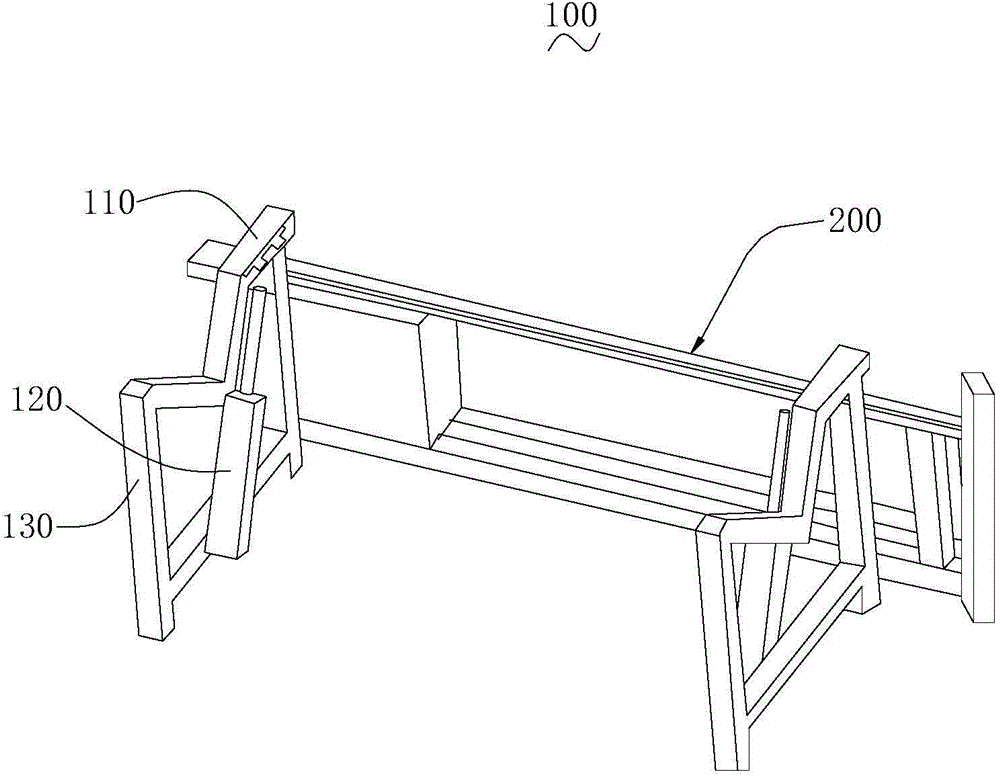

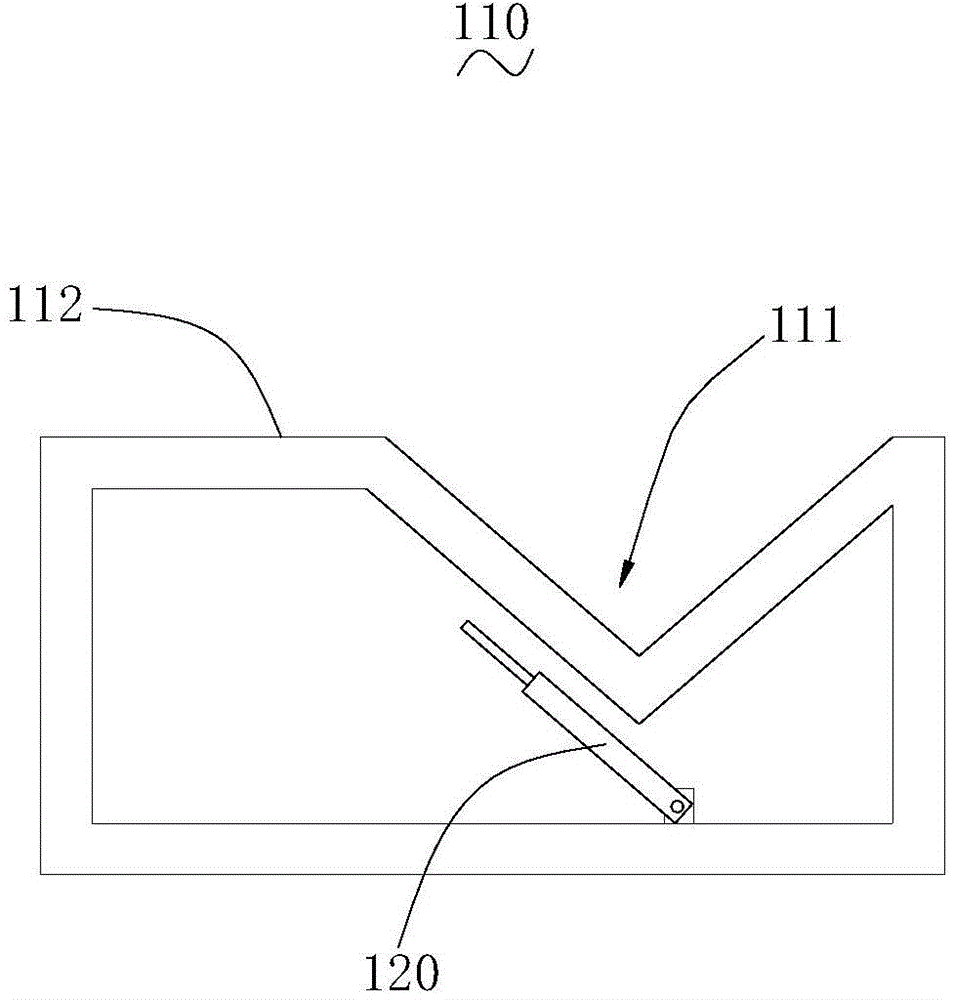

Device for manufacturing rigid tie bar structural member

InactiveCN105666019APrecise dockingPrevent deviationWelding/cutting auxillary devicesAuxillary welding devicesRotational axisEngineering

The invention discloses a manufacturing device for a rigid tie rod structure, which comprises a tie rod welding table, a steel pipe bracket and a T-shaped plate clamping rotating assembly. The tie rod welding table is provided with two sets of steel pipe brackets. The T-shaped clamping rotating assembly includes a rotating shaft, a rotating shaft bracket and a motor, the rotating shaft bracket is arranged on the tie rod welding table, the rotating shaft is arranged on the rotating shaft bracket to rotate, and the inner end of the rotating shaft There is a T-shaped plate clamping groove in the middle of the head, and the fastening bolts for clamping the T-shaped plate are arranged on the T-shaped plate clamping groove. The outer end of the rotating shaft is provided with a pulley, and the pulley corresponds to A motor is arranged on the tie rod welding table, and the motor drives the pulley to rotate through a belt.

Owner:CHINA MCC5 GROUP CORP

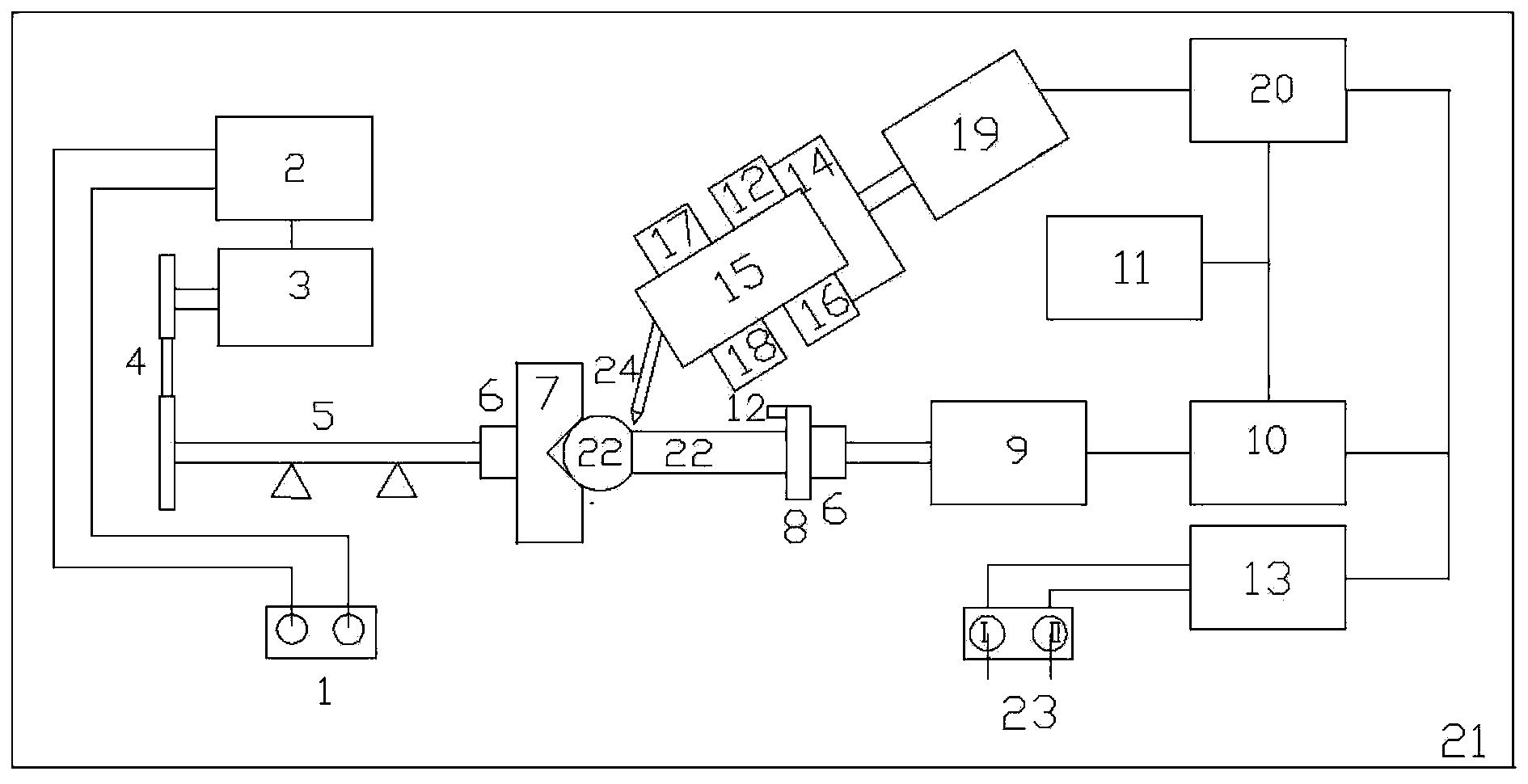

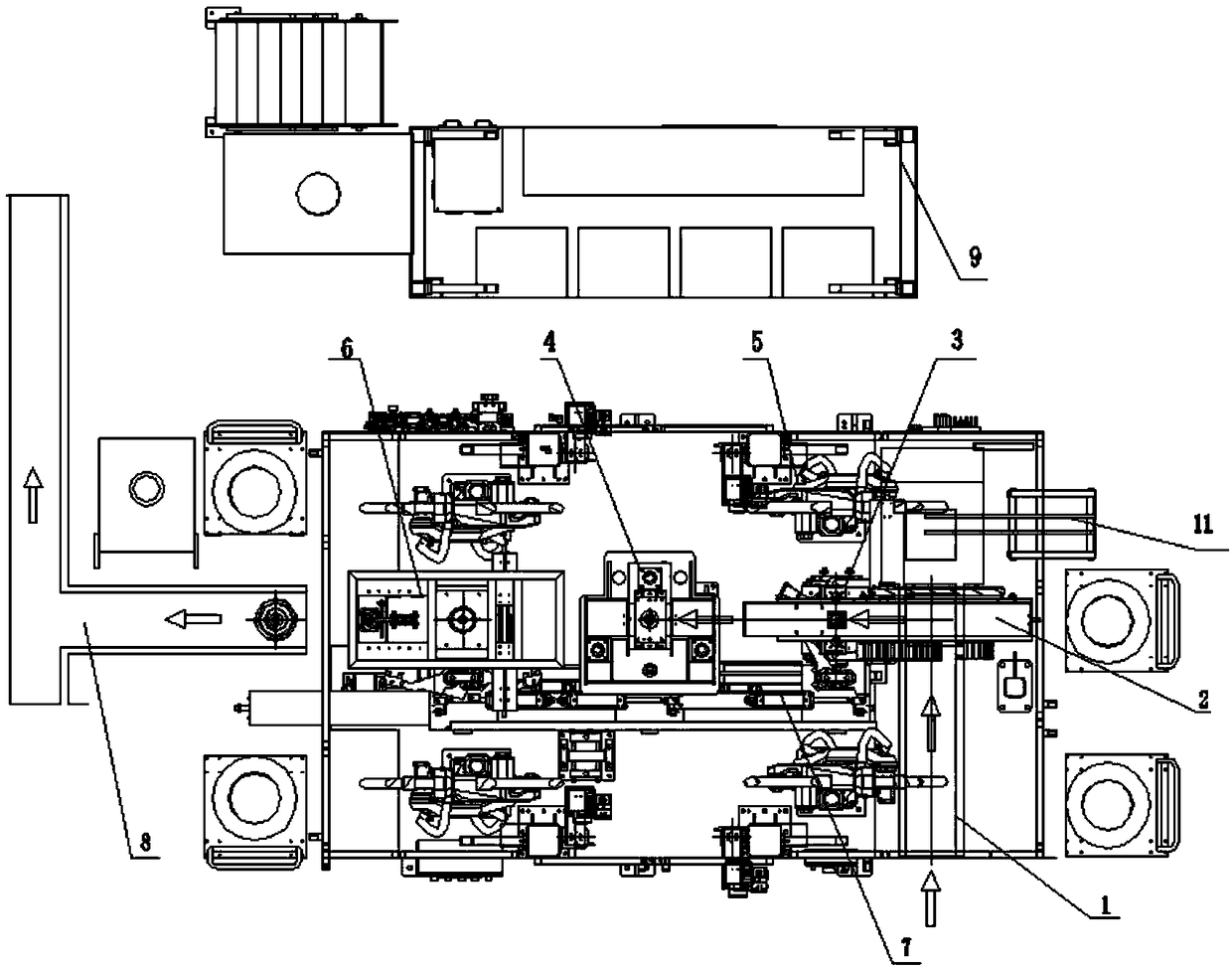

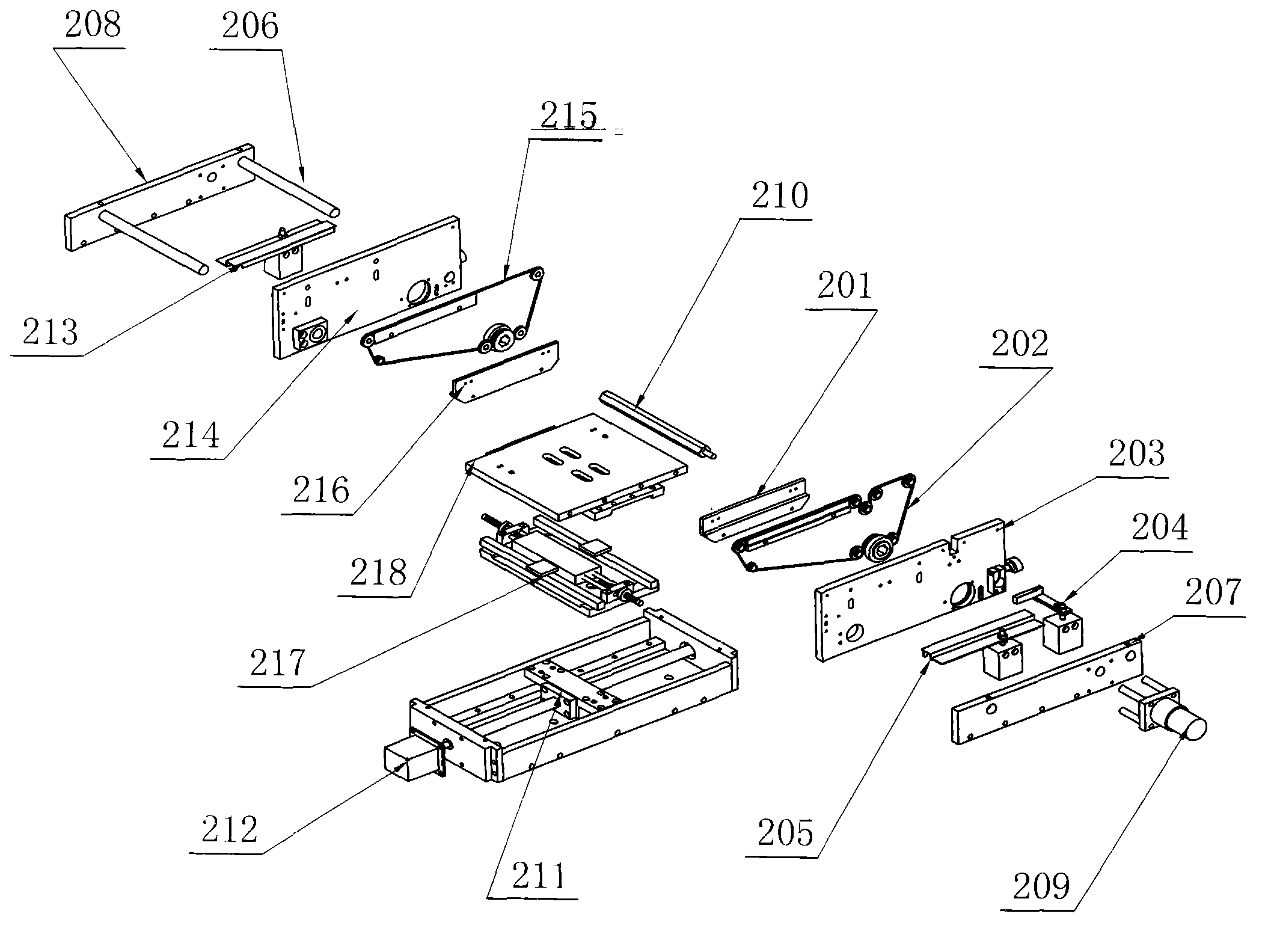

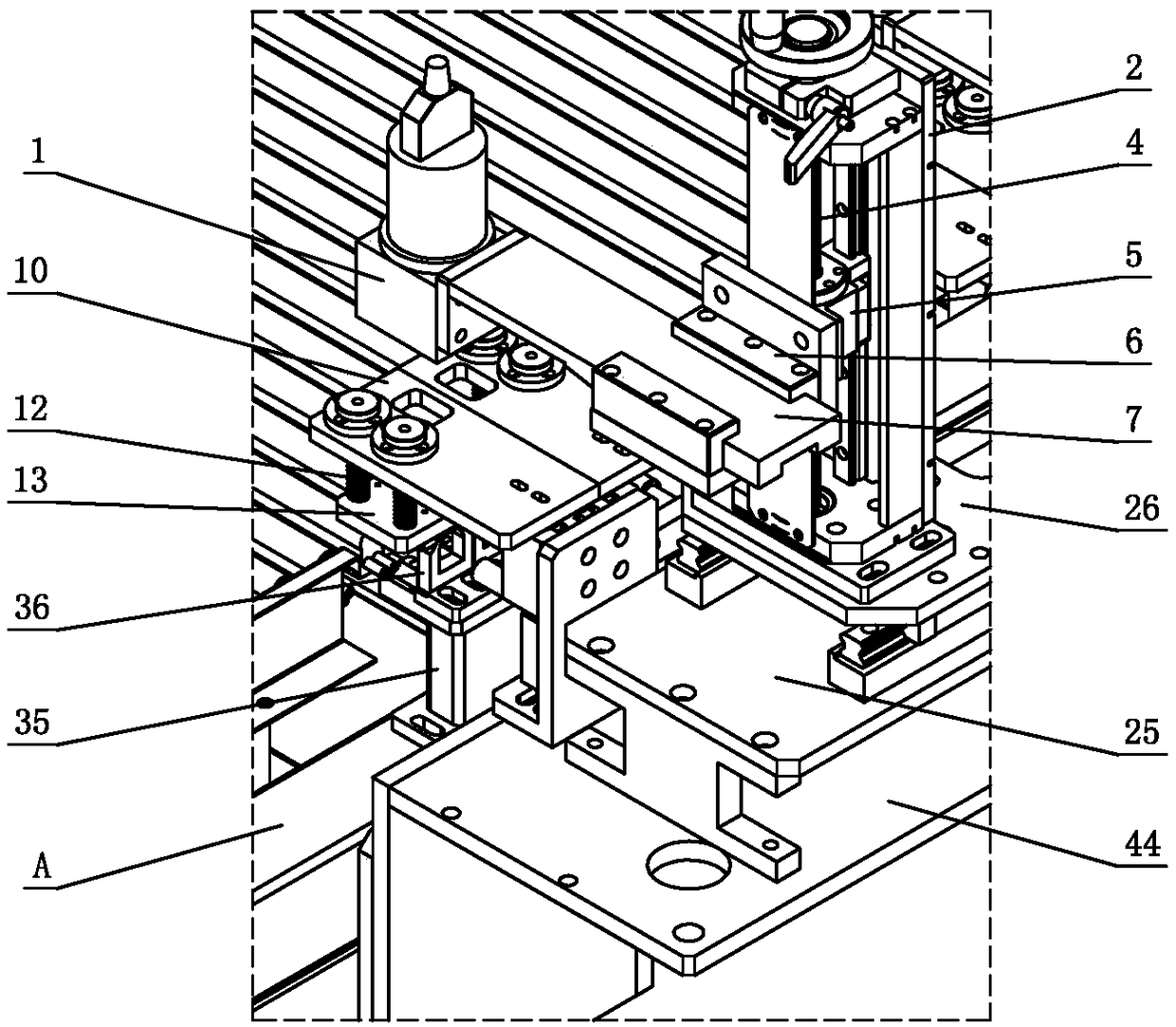

Hydraulic torque converter assembly welding equipment and welding method thereof

ActiveCN109434255ARealize fully automatic weldingImprove welding precisionOther manufacturing equipments/toolsWelding accessoriesElectrical controlEngineering

The invention discloses hydraulic torque converter assembly welding equipment and a welding method thereof. The hydraulic torque converter assembly welding equipment comprises a feeding conveying mechanism, a feeding transferring mechanism, a workpiece height detecting mechanism, an unqualified product storage frame, a welding station, robot welding systems, an automatic grinding station, a discharging conveying mechanism, a multi-station automatic transferring mechanism and an electrical control cabinet, wherein the multi-station automatic transferring mechanism is connected with the feedingtransferring mechanism, the workpiece height detecting mechanism, the welding station, the automatic grinding station and the discharging conveying mechanism. According to the hydraulic torque converter assembly welding equipment, the feeding conveying mechanism conducts conveying, the feeding transferring mechanism conducts feeding and transferring of unqualified products, the workpiece height detecting mechanism conducts product detecting and angle positioning, the welding station and the robot welding systems conduct automatic welding, the grinding station conducts automatic grinding, all mechanisms conduct workpiece carrying and connecting through the multi-station automatic transferring mechanism, thus workpieces are automatically welded, the size accuracy of the products is ensured,the limitation of the prior art is relieved, and the production efficiency is improved.

Owner:CHENGDU HANYAN TECH

Label welding system

InactiveCN108637516AReduce labor intensityRealize fully automatic weldingWelding/cutting auxillary devicesTypewritersEngineeringManipulator

The invention discloses a label welding system. The label welding system comprises a supporting frame, a printing mechanism, a tray, a nail conveying mechanism, a mechanical arm and a welding machine,wherein the printing mechanism is arranged on the supporting frame, and the printing mechanism is used for label printing; the tray is arranged below the printing mechanism in a sliding manner, and the tray is used for bearing and transmitting of printed labels; the nail conveying mechanism is arranged on the supporting frame and used for transmission of welding nails needed during label welding;the mechanical arm is arranged in the transmitting direction of the tray and the nail conveying mechanism, and the mechanical arm is used for grabbing and positioning the printed labels and the welding nails; and the welding machine is arranged at the side portion of the mechanical arm, and the welding machine is used for welding the labels to workpieces which are about to be subjected to label welding. According to the provided label welding system, through the structural design of the label welding system, full-automatic welding of the labels on a disc roll can be achieved, the phenomena ofmistaken hanging and omitted hanging are effectively avoided, and meanwhile the labor intensity of workers can be relieved.

Owner:HUNAN RAMON SCI & TECH

Automatic 7-shaped nickel sheet welding machine for protection board

ActiveCN103567618AAutomatic welding fastFast solderingResistance electrode holdersOther manufacturing equipments/toolsControl systemEngineering

The invention belongs to the technical field of welding equipment and provides an automatic 7-shaped nickel sheet welding machine for a protection board. The welding machine comprises a board feeding mechanism, a spot welding platform, two feeding mechanisms, a spot welding mechanism and a press wheel mechanism, wherein the board feeding mechanism comprises a driving device for feeding PCBs (printed circuit board) onto the spot welding platform in sequence; the spot welding platform comprises a transmission device capable of being jointed with the board feeding mechanism and a linear and left-right movable platform; the feeding mechanisms comprise a cutting die capable of punching straight strip-shaped nickel belts into the 7-shaped nickel sheets and a feeding device; the spot welding mechanism comprises a first spot welding needle, a second spot welding needle, a first spot welding cylinder, a second spot welding cylinder and a conductive copper bar; the press wheel mechanism comprises a press wheel device capable of flattening the well spot-welded 7-shaped nickel sheets. According to the automatic 7-shaped nickel sheet welding machine for the protection board, the board moving width of the board feeding mechanism and the spot welding platform, the material clamping and feeding position of the feeding mechanisms and the spot welding positions of the welding needles can be previously adjusted, and then the welding machine is matched with a spot welding machine and a control system for use, full-automatic welding can be realized, the 7-shaped nickel sheets can be fast welded on the protection board and high efficiency is realized.

Owner:刘辉国

Automatic welding line for LED tube

PendingCN108581205AImprove connection efficiencyGood connection qualityLaser beam welding apparatusChain conveyorWeld line

An automatic welding line for an LED tube comprises a tube transfer assembly and a laser welding assembly; the tube transfer assembly comprises a chain conveyor mechanism and locating transfer blocksarranged on a conveyor chain in the chain conveyor mechanism, and LED tubes are driven to convey by the conveyor chain through the locating transfer blocks; the laser welding assembly comprises laserwelding mechanisms arranged on one side or the both sides of the chain conveyor mechanism; each laser welding mechanism comprises a laser welding component and a welding locating component; the laserwelding component comprises a laser welding joint; the welding locating component comprises transparent pressing blocks and a pressing locating cylinder, and the LED tubes are located and pressed on the locating transfer blocks by the transparent pressing blocks in the pressed state at least; and in work, laser penetrates the transparent pressing blocks for welding the corresponding LED tubes. Theautomatic welding line has the characteristics of reliable performance, high automation degree, low labor cost, and high welding efficiency and welding quality; and connection of plastic cases of theLED tubes through a laser welding technology is pioneered in the industry.

Owner:广东顺德华焯机械科技有限公司

Automatic welding apparatus for hard weld wires of buzzers

ActiveCN109048108AAvoid misalignmentAvoid jitterWelding/cutting auxillary devicesAuxillary welding devicesEngineeringVertical axis

The invention relates to an automatic welding apparatus. The technical scheme of the invention is to provide an automatic welding apparatus for hard weld wires of buzzers, which is characterized in that: the apparatus comprises a bottom plate, a circular table fixed on the bottom plate, an annular rotating plate horizontally arranged and rotationally positioned on the circular table about a vertical axis, a stepping motor for driving the rotating plate to intermittently rotate, a plurality of fixtures radially fixed on the rotating plate for placing buzzers, and a feeding station, a first wirefeeding station, a first welding station, a second wire feeding station, a second welding station, and a discharging station that are sequentially arranged on the bottom plate along the rotating direction of the rotating plate. The first wire feeding station has the same structure as the second wire feeding station, and the first welding station has the same structure as the second welding station. According to the automatic welding apparatus for the hard weld wires of the buzzers, automatic feeding, automatic wire feeding, automatic welding, and automatic discharging can be carried out, so that the full automation of the wire welding of the buzzers is achieved, the wire welding efficiency of the buzzers is greatly improved, and the production cost is reduced.

Owner:贵州大通电子科技有限公司

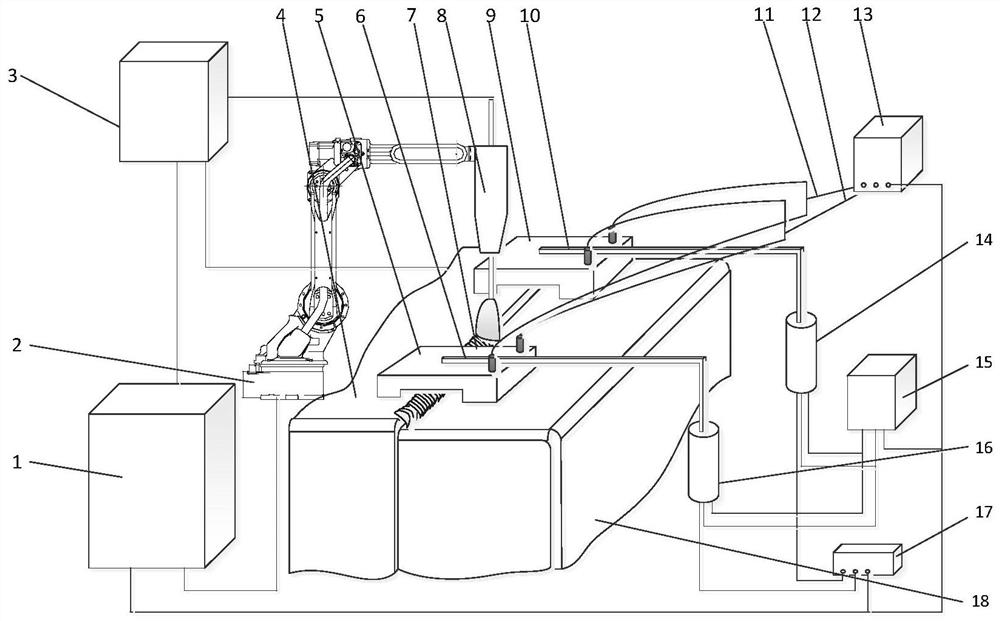

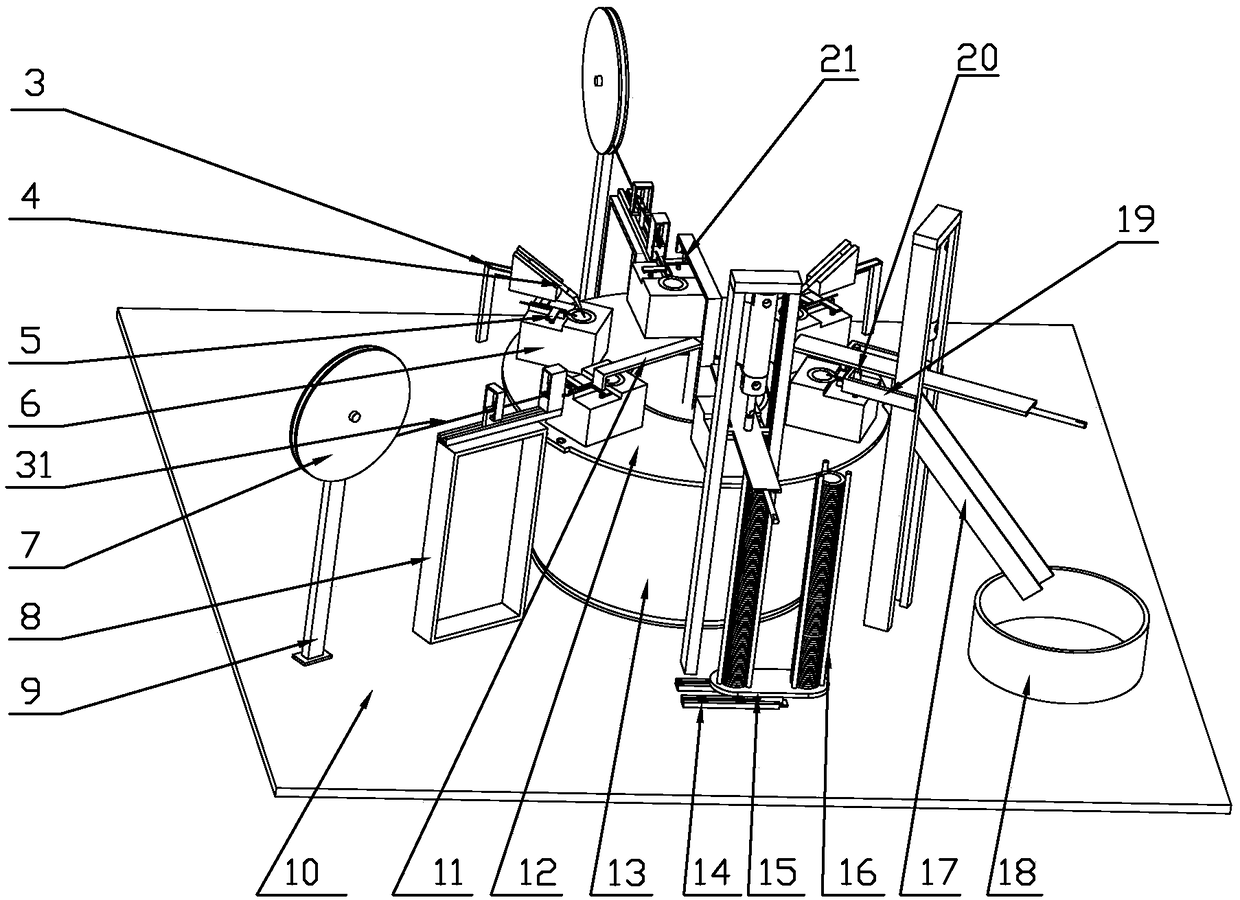

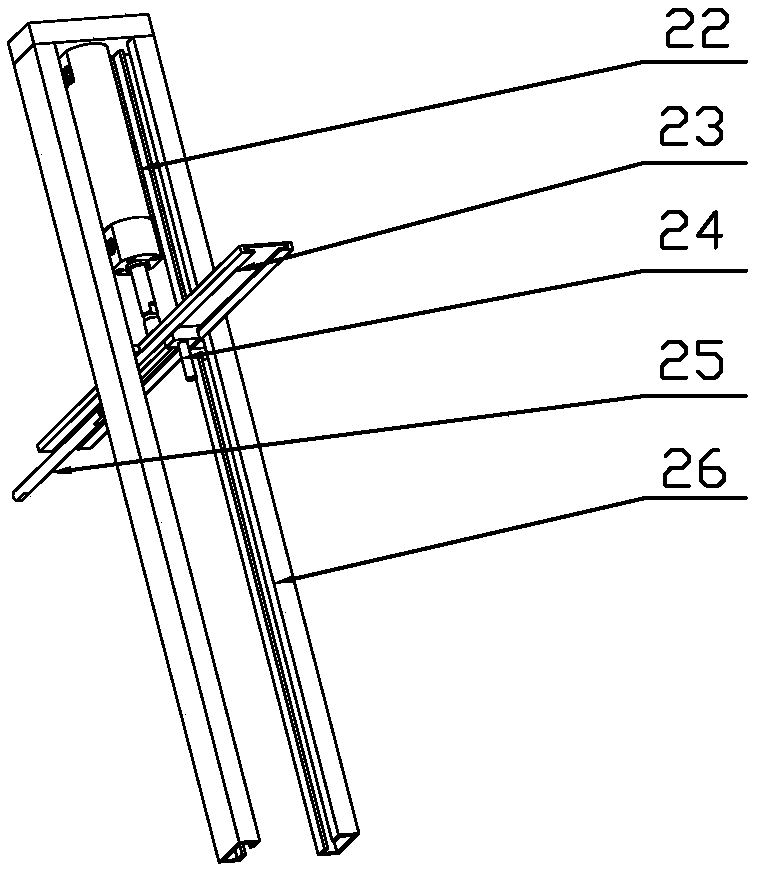

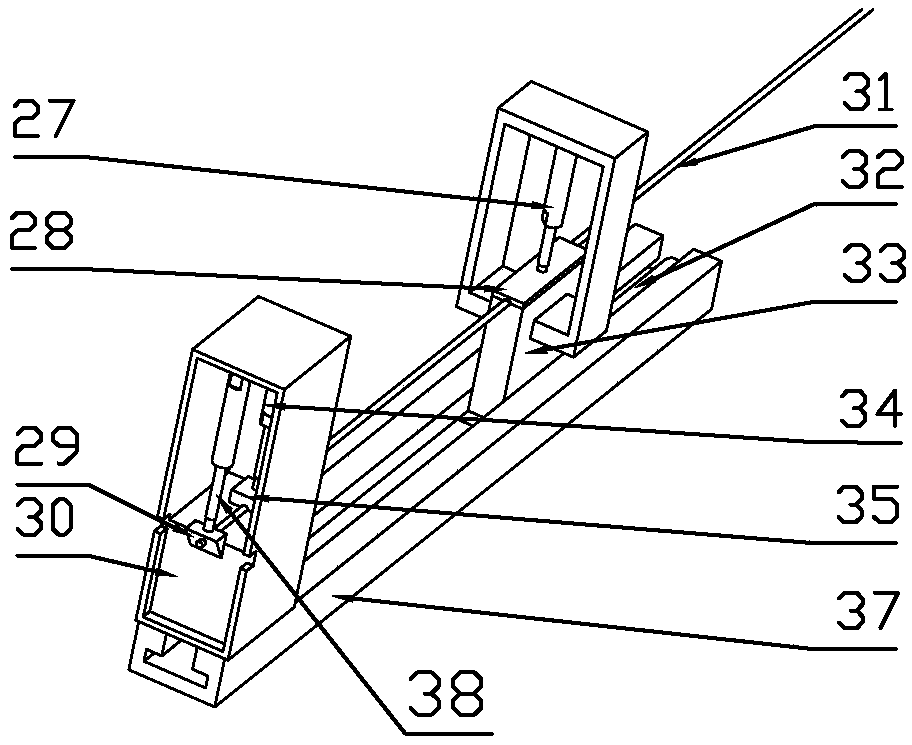

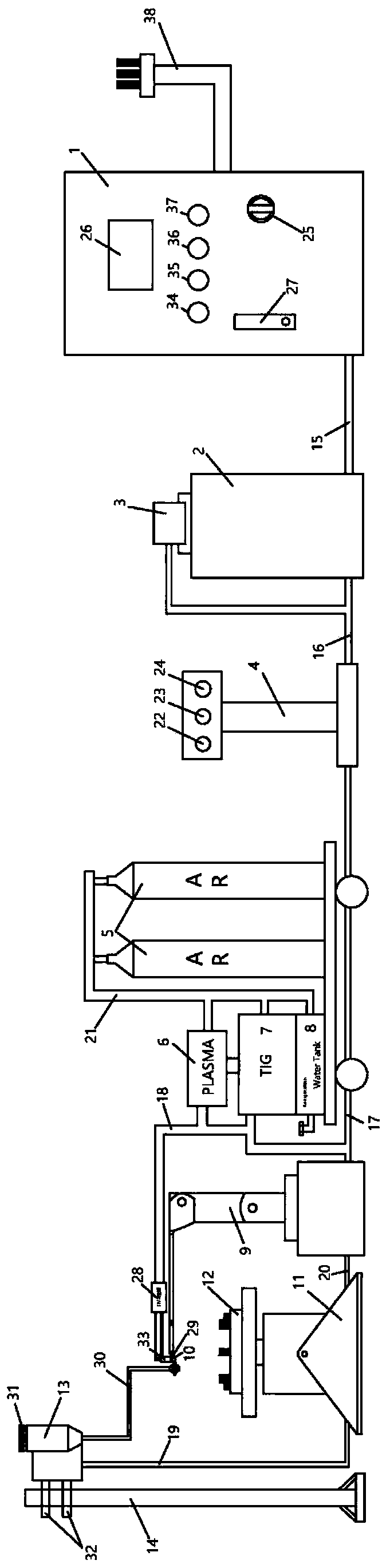

Robot automatic welding system for PTA process and using method thereof

PendingCN110270743AReduce the difficulty of operationWith fully automatic weldingShielding gas supply/evacuation devicesManipulatorControl systemPlasma generator

The invention discloses a robot automatic welding system for a PTA process. The system comprises a control system, a welding system and a travelling system; the control system involves a cabinet and a control box; the welding system involves a gas bottle, a plasma generator, an alternating-current and direct-current TIG welding machine, a refrigerating water tank, a welding gun, a powder feeding device, a powder feeding device frame and a transferring box; the travelling system involves a robot control cabinet, a demonstrator, a robot, an external shaft and a tool clamping disc. The invention further discloses a using method of the welding system. According to the system and the method, the dependence of welding on people can be effectively reduced, the operation difficulty is reduced, the use is convenient, the welding efficiency is high, and the welding quality is good.

Owner:福尼斯(南京)表面工程技术有限公司

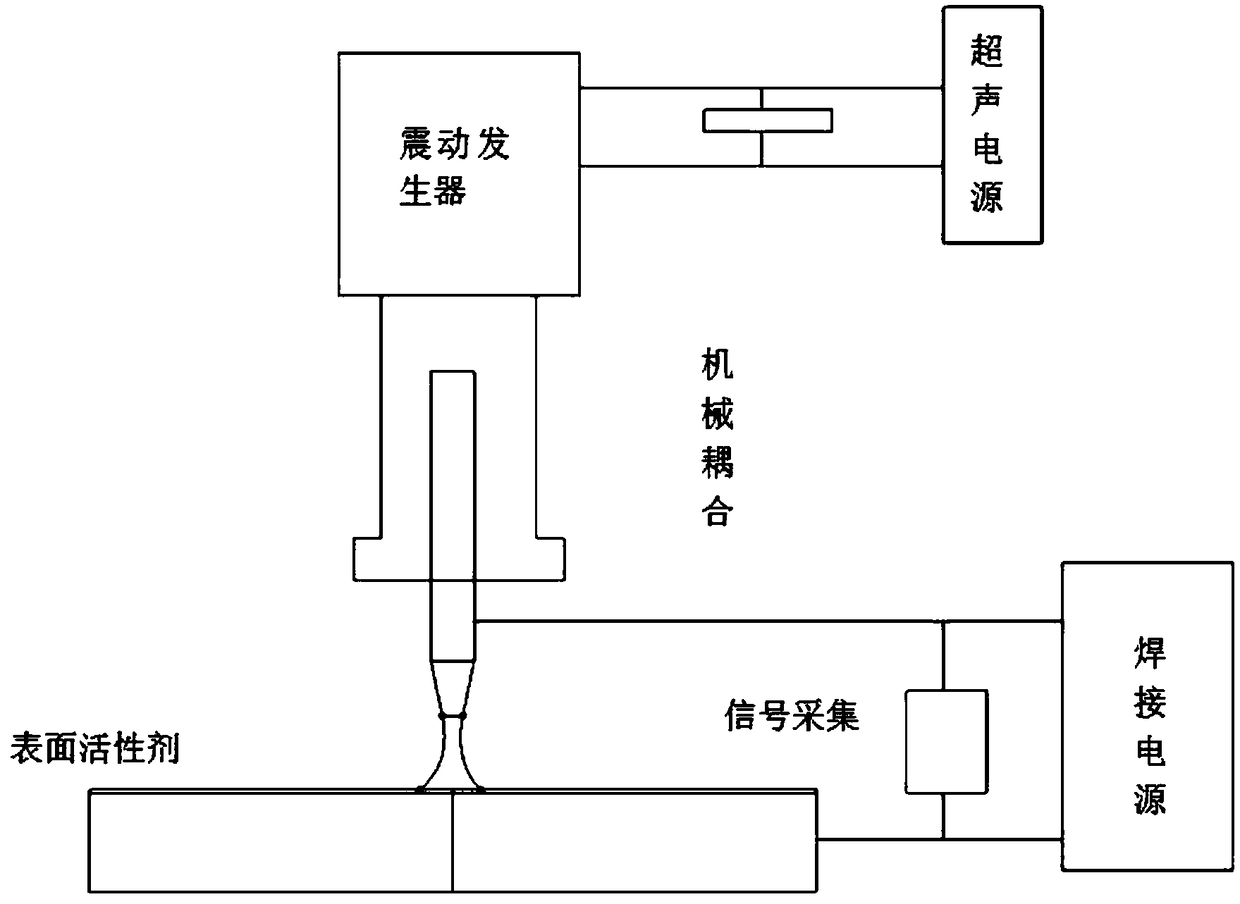

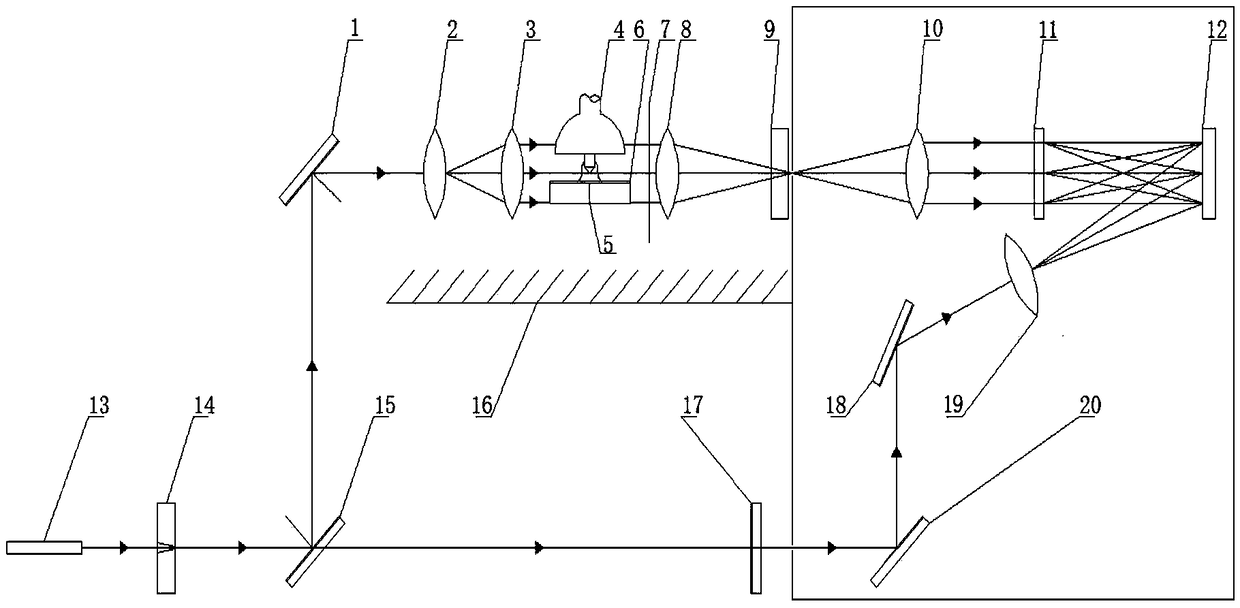

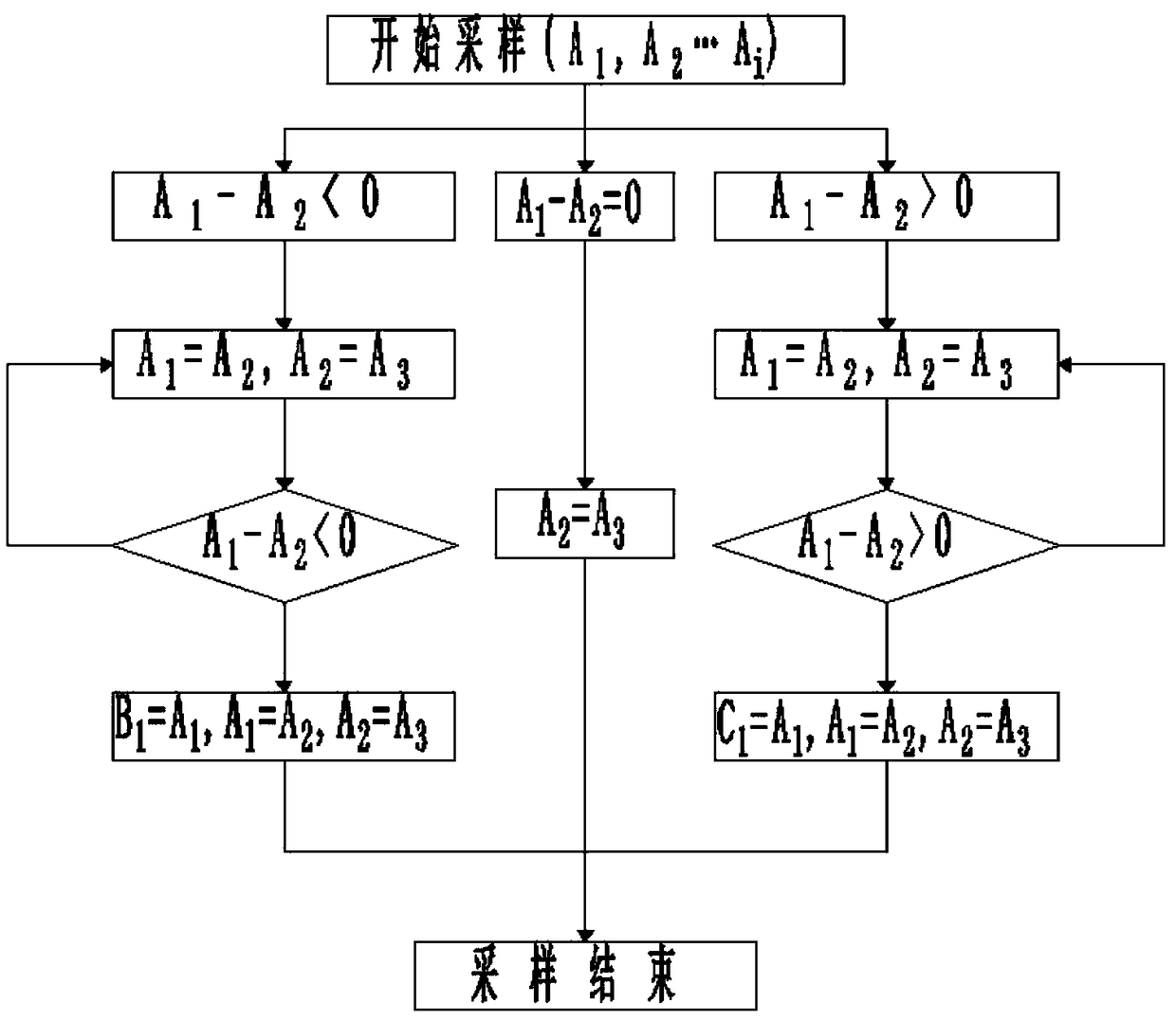

Aluminum alloy TIG tracking method based on ultrasonic electric arc

InactiveCN109128440AReal-time trackingImprove welding efficiencyWelding/soldering/cutting articlesWelding accessoriesWeld seamActive agent

The invention relates to an aluminum alloy TIG tracking method based on an ultrasonic electric arc. The aluminum alloy TIG tracking method is used for overcoming the defects that aluminum alloy TIG single-pass welding is small in weld penetration depth, low in welding efficiency and poor in manual welding weld seam quality. According to the method, a small-angle double-exposure holographic interference method is designed; by means of the method, influences of an oxide active agent, a chloride active agent, a fluoride active agent and a mixed active agent formed by the oxide active agent, the chloride active agent and the fluoride active agent on arc plasmas are confirmed, and the active agent with the best arc gathering effect is selected as an experiment material; the selected active agent is sprayed, and ultrasound is loaded in the coaxial direction of the TIG electric arc; after welding starts, the waveform of welding current is extracted, the envelope curve value of semiconservative filtering is designed, tracking is conducted, and feasibility of the method is verified through the small-angle double-exposure holographic interference method. The method has the beneficial effectthat ordinary ultrasound and electric arc compound welding is achieved, and the ultrasonic electric arc and the surface active agent are fused.

Owner:XIANGTAN UNIV

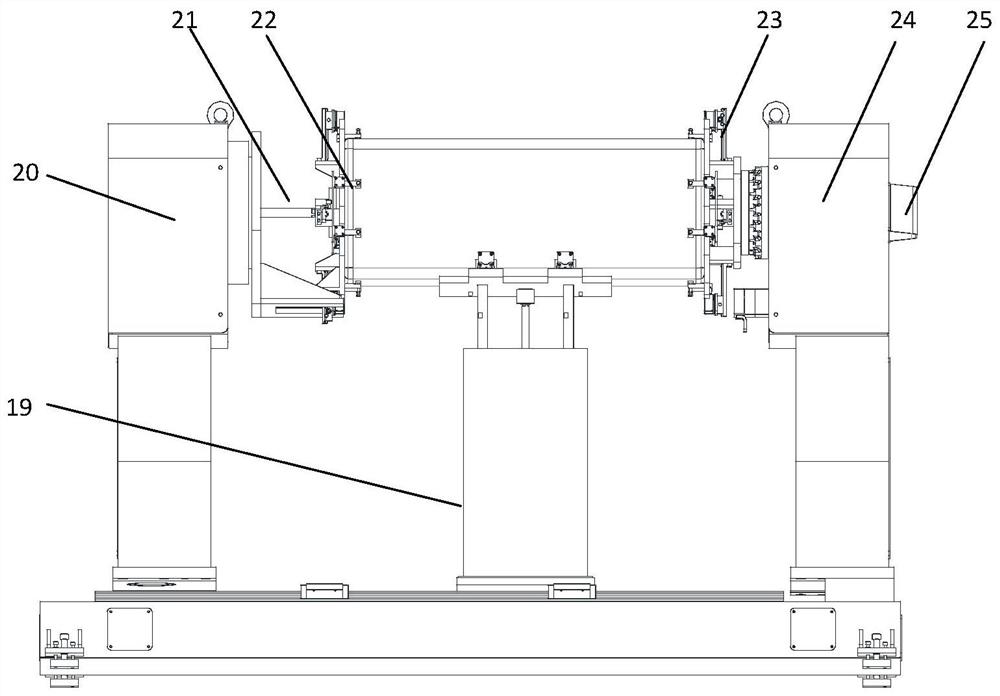

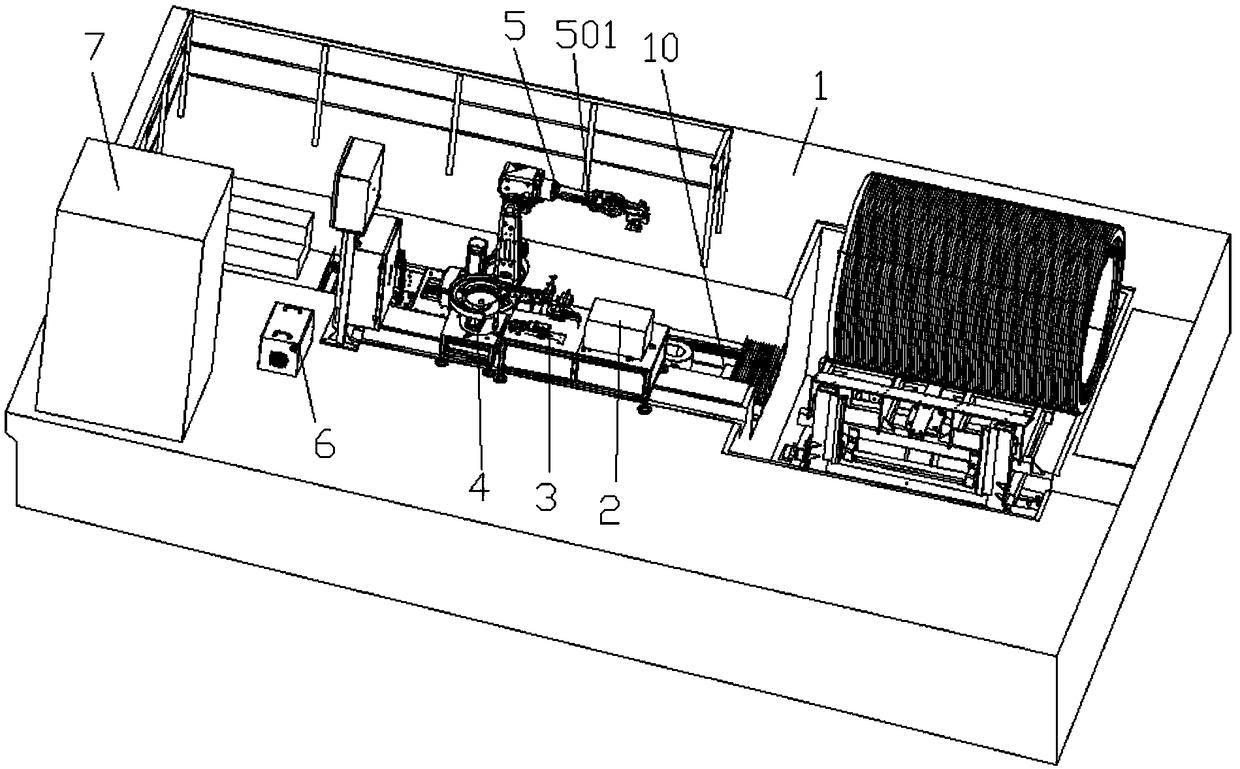

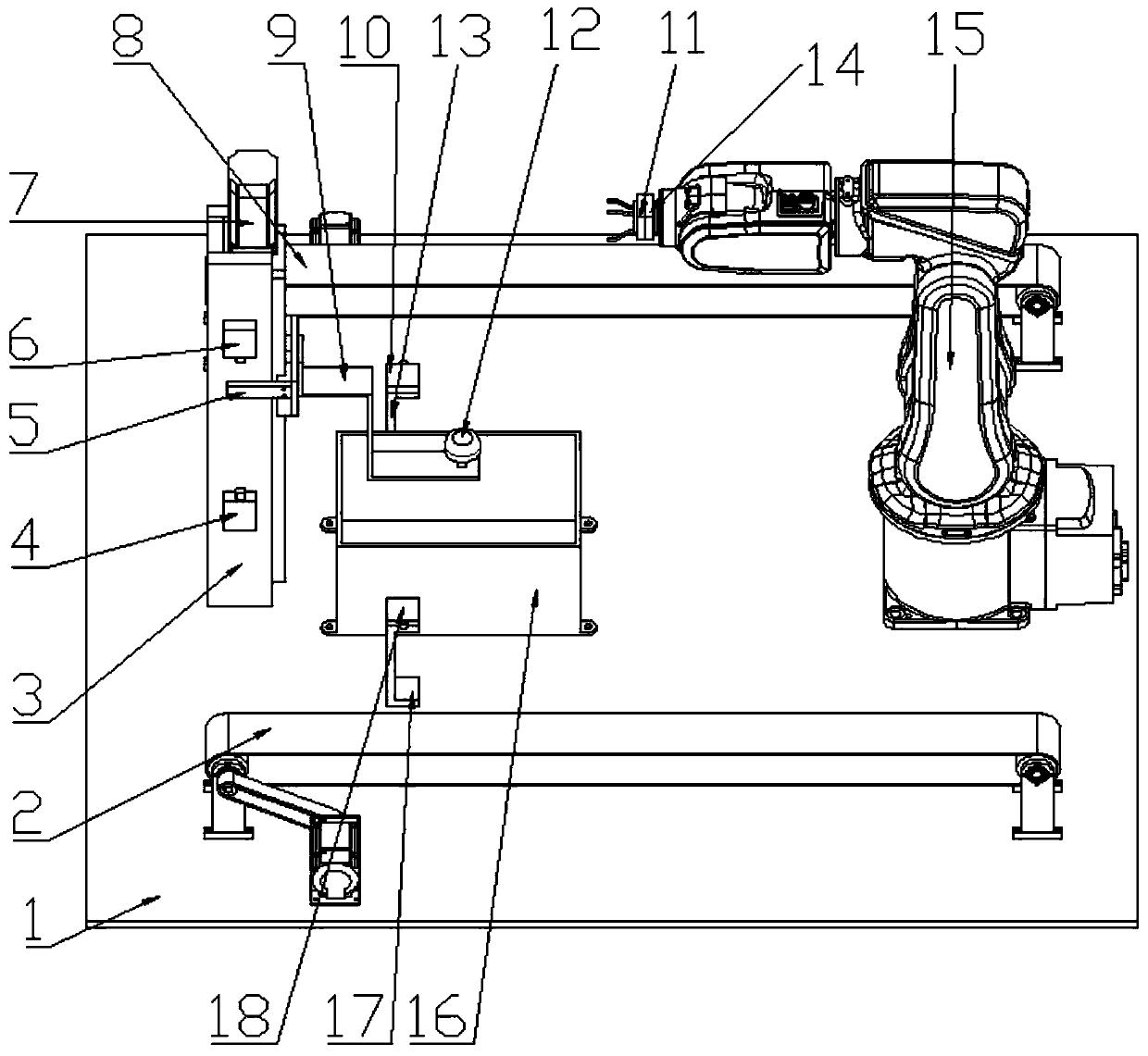

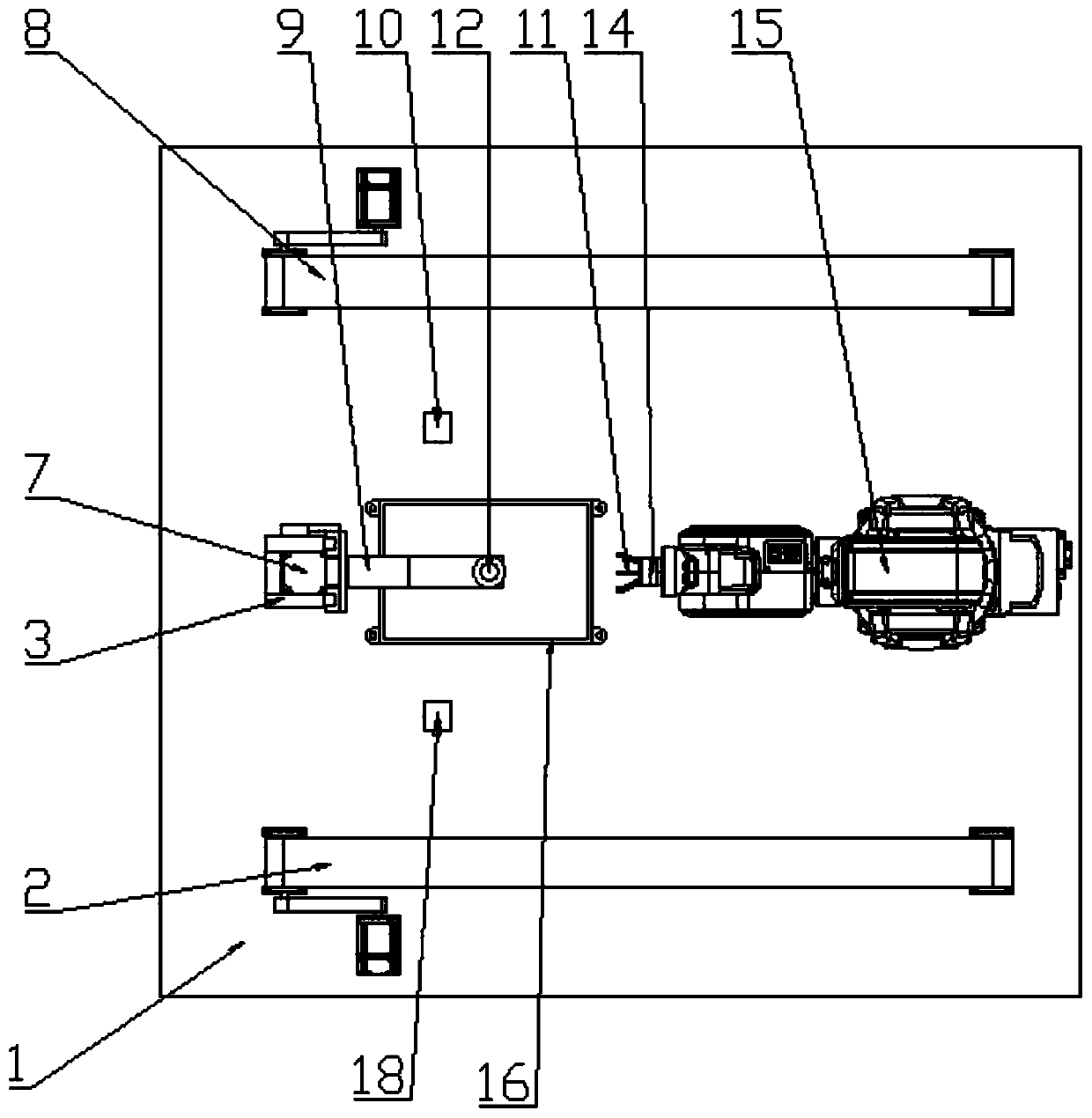

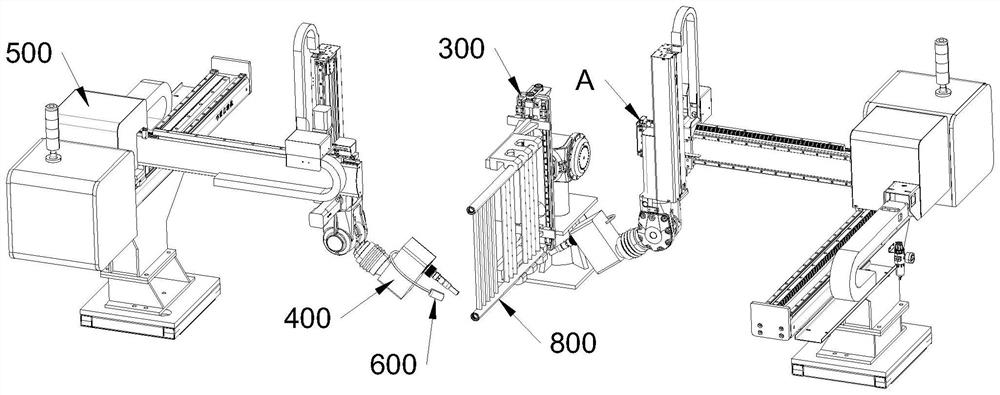

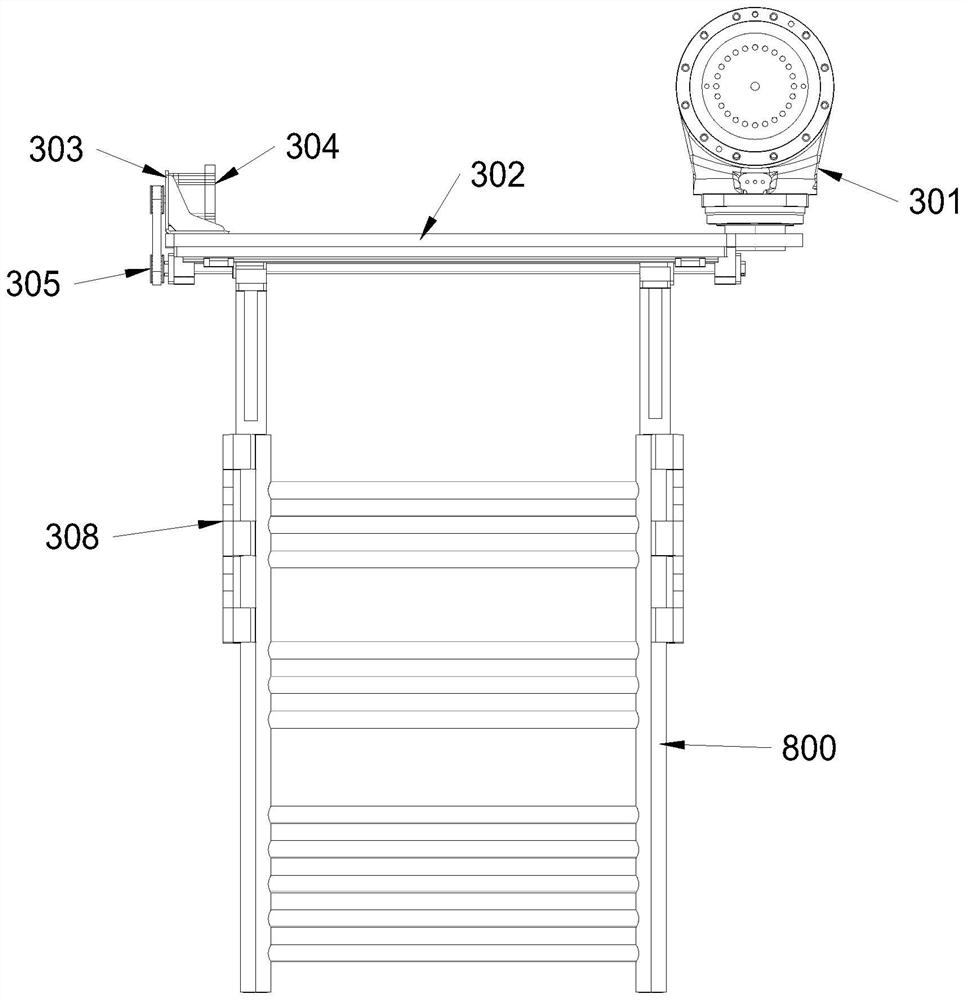

A cylinder robot welding workstation

ActiveCN104551464BRealize fully automatic weldingEnable mobilityWelding/cutting auxillary devicesAuxillary welding devicesThree degrees of freedomRectangular coordinates

The invention relates to the technical field of welding equipment, and particularly discloses a robot welding work station for an oil cylinder. The robot welding work station comprises a six-degree-of-freedom welding robot, a cylinder barrel support positioning table and a three-degree-of-freedom rectangular coordinate servo-cylinder loading and unloading manipulator, wherein the cylinder barrel support positioning table comprises a left sliding plate and a right sliding plate on a rack; the left sliding plate is provided with a positioning device; the rear side of the left sliding plate is provided with pneumatic manipulators and a cylinder barrel rotating drive roller mechanism; a reference positioning plate, a V-shaped support block, a centering shaft, two transverse feeding plates and axial feeding hoppers are arranged between the left sliding plate and the right sliding plate; a centering sleeve is arranged above the centering shaft; a positioning block is arranged below the centering sleeve; the right sliding plate is provided with a cylinder bottom welding block axial positioning barrel. According to the work station, full-automatic welding of various components of the oil cylinder can be achieved; automatic movement and welding of the components are achieved in the welding process; the work station is simple in structure; time and labor are saved; the labor efficiency can be greatly improved; the labor intensity of a worker is alleviated.

Owner:LAIZHOU XINGDA HYDRAULIC MACHINERY TECH

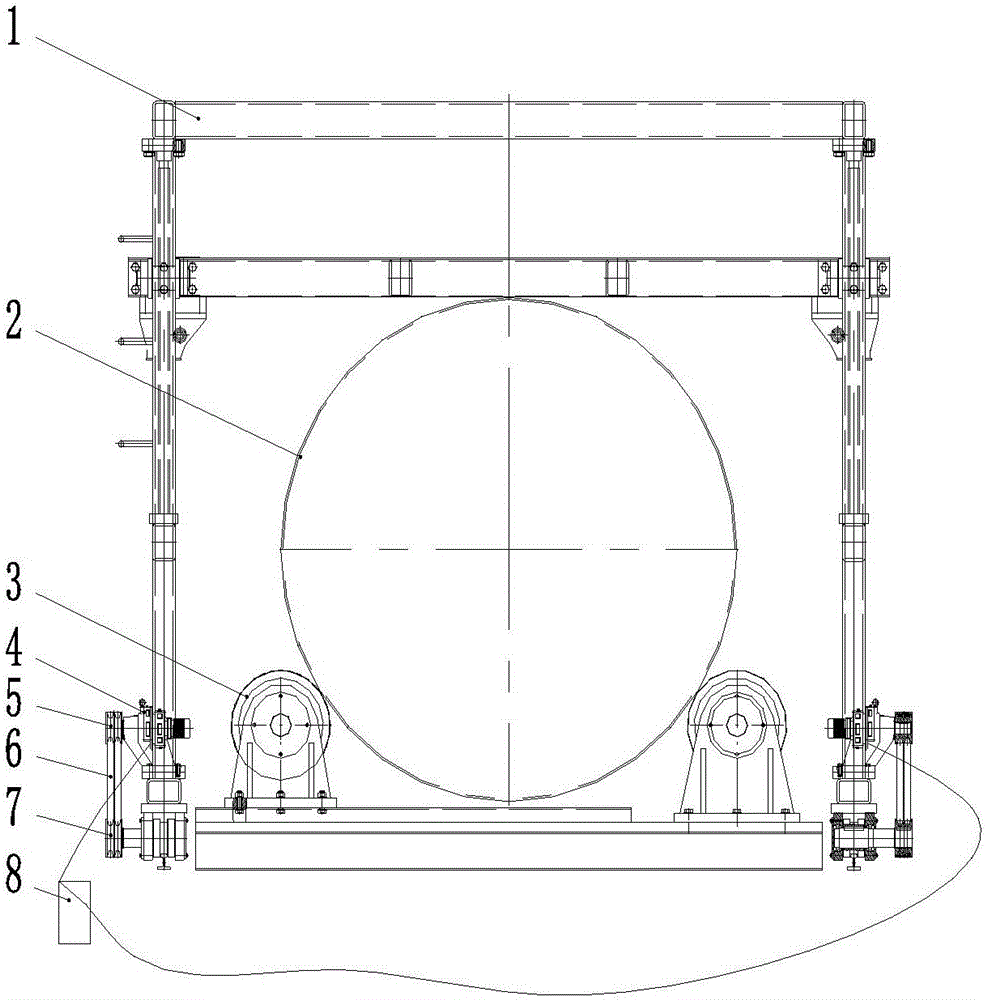

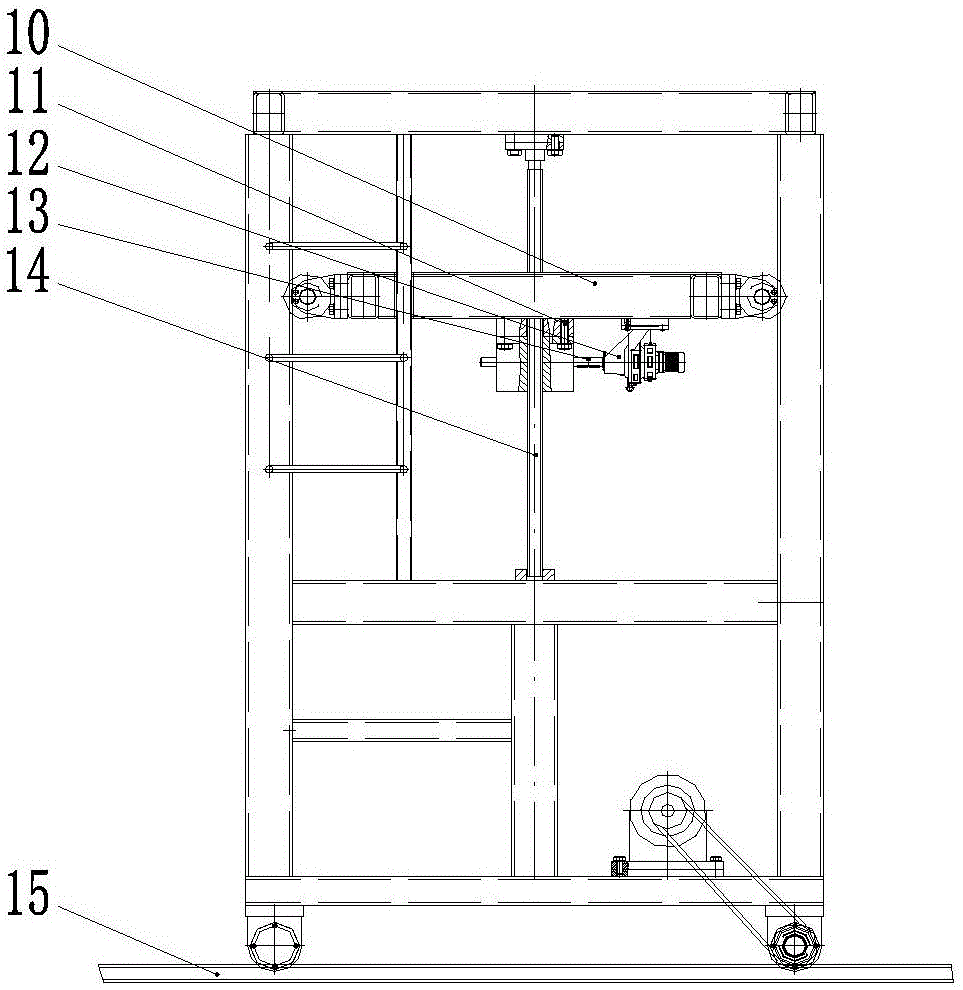

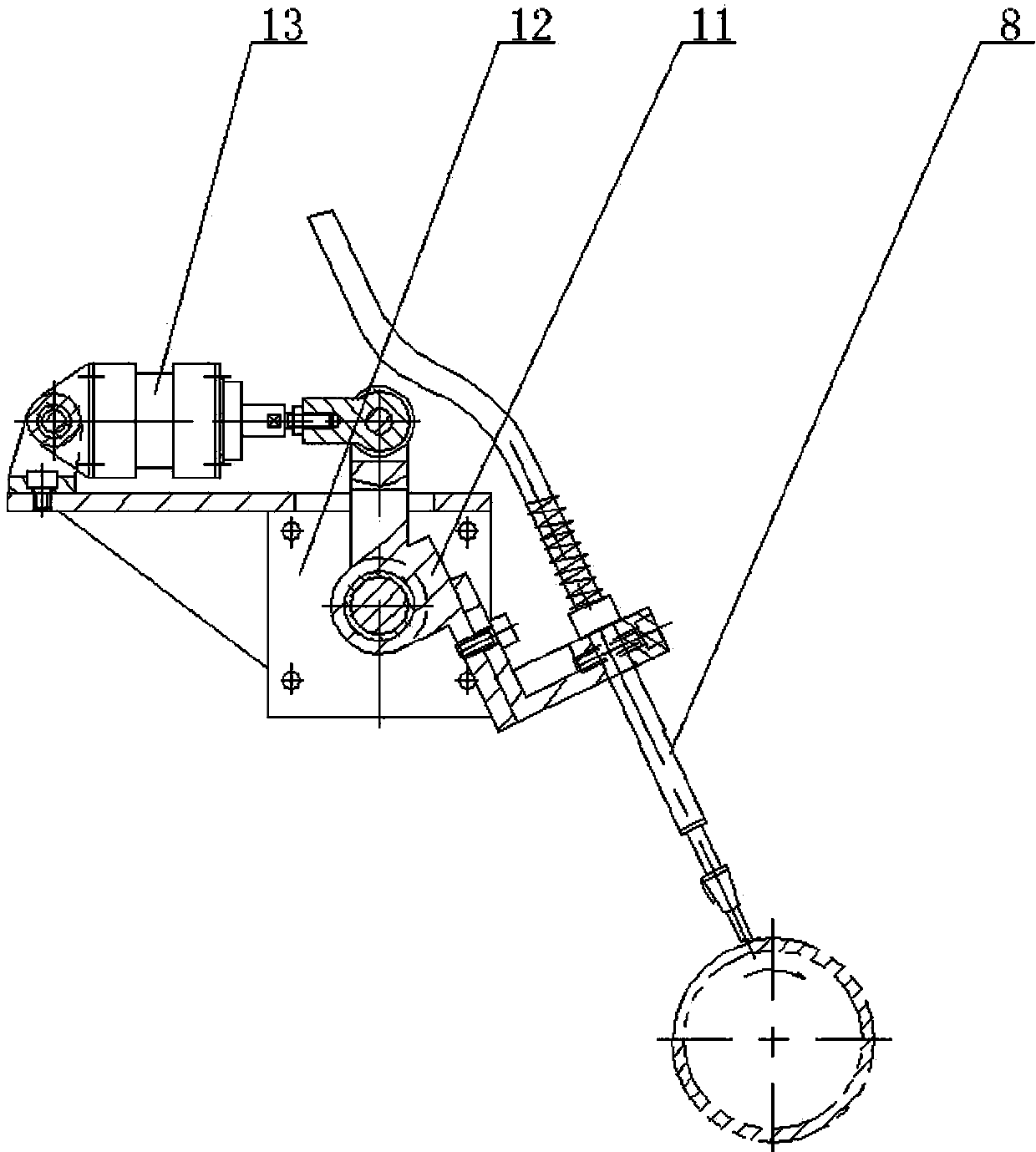

Automatic cylinder welding device

InactiveCN106271170ARealize fully automatic weldingCircumferential welds are beautifulWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPulley

The invention relates to an automatic cylinder welding device. The automatic cylinder welding device comprises a traveling mechanism, overturning mechanisms, a base platform, tracks, a frequency converter and an electric cabinet, wherein the traveling mechanism comprises an operation platform, an operation platform lifting motor, belts, small belt pulleys, large belt pulleys, traveling wheels, a rack, a worm gear and a lead screw; two columns of tracks are parallelly arranged at the lower ends of the two sides of the rack; each overturning mechanism comprises rollers, the base platform and an overturning mechanism motor; a group of rollers are movably arranged at each of two ends of the cylinder in the length direction; the center distance between each fixed roller and the corresponding adjustable roller is adjustable; the length distance between the two groups of rollers is adjustable; each overturning mechanism motor is connected with the electric cabinet through the frequency converter; the electric cabinet is arranged on the operation platform. The diameter range of cylinders applicable to welding by the device is large; full-automatic welding can be performed by an operator on the operation platform; straight welds and circumferential welds welded by the device are uniform, attractive and defect-free, the welding time is saved greatly, and the welding efficiency and quality are improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

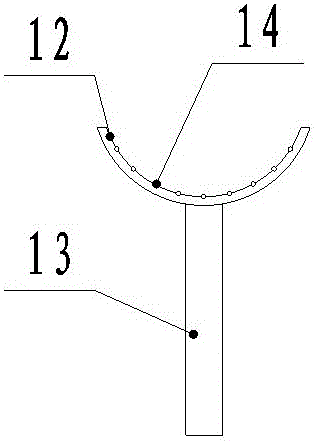

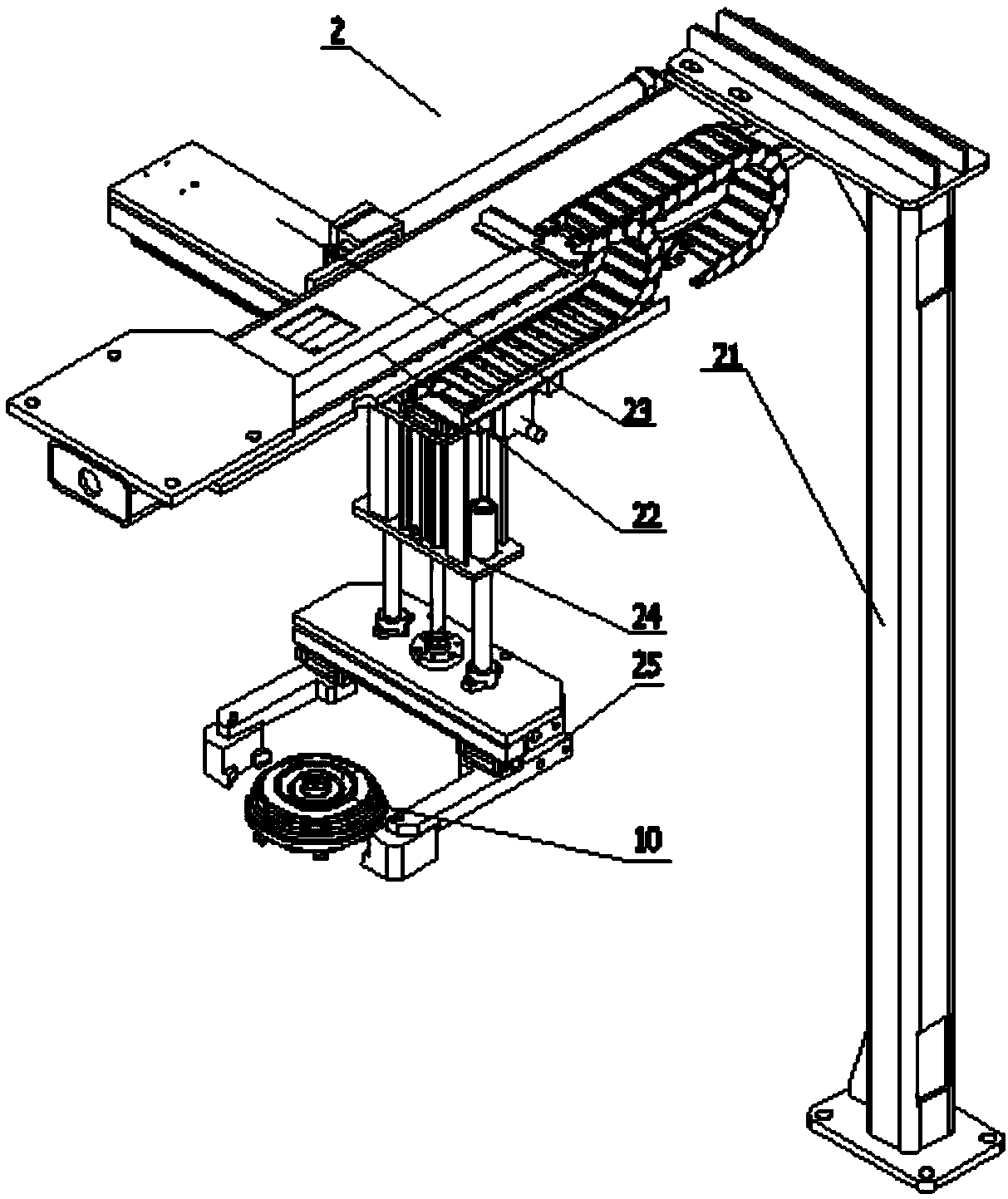

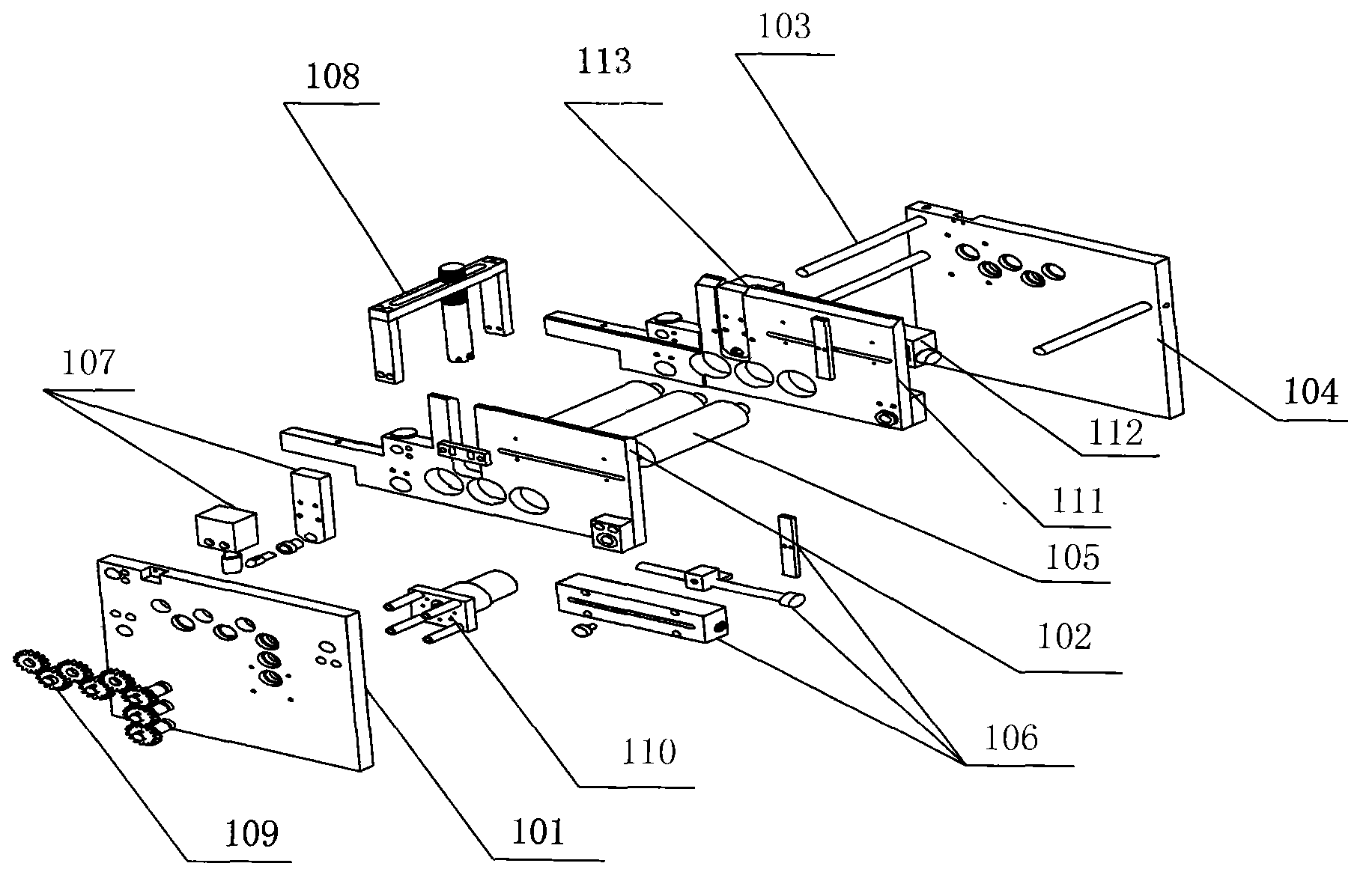

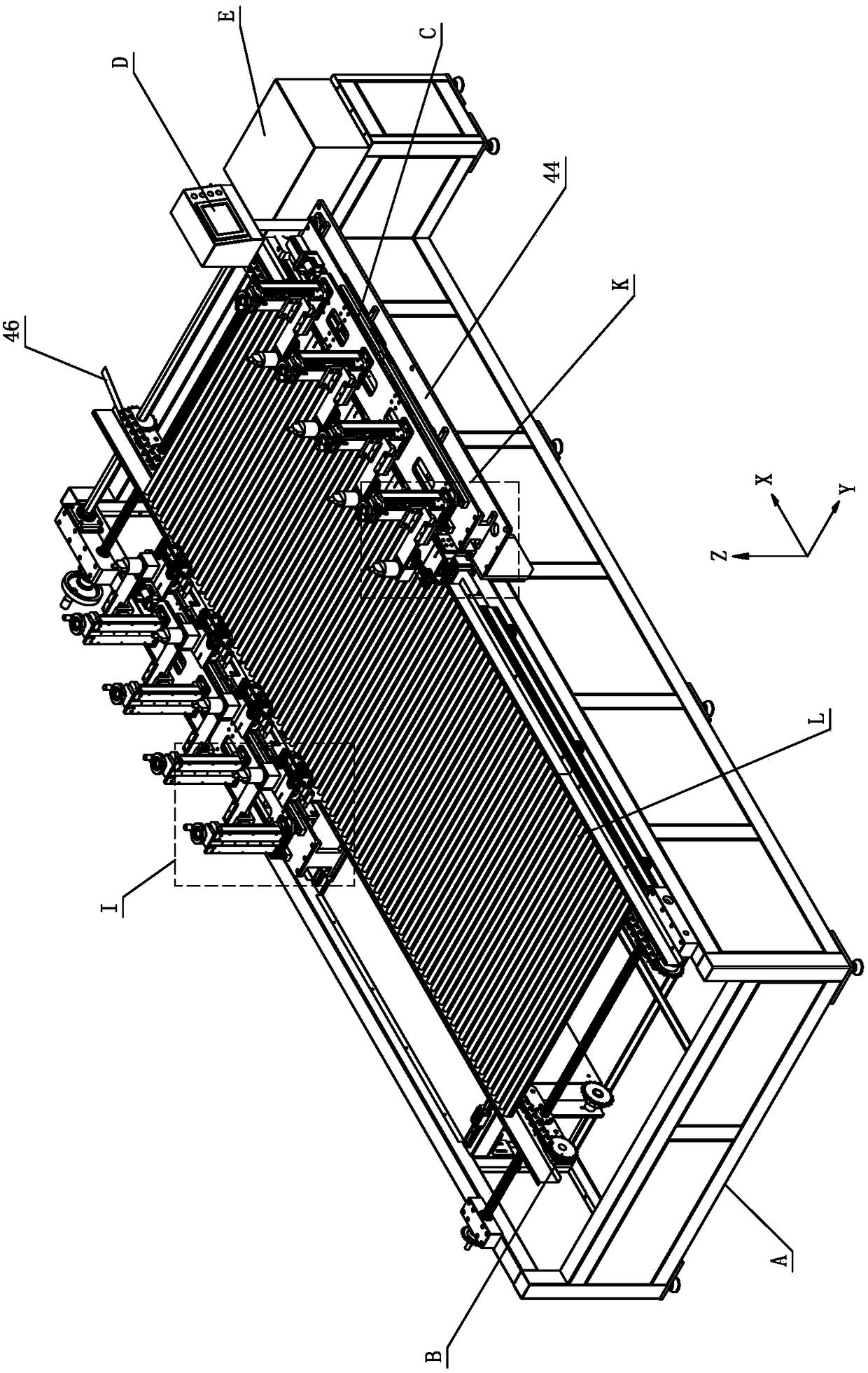

Full automatic welding system and device for fishbone type cathode wire

ActiveCN104858558ARealize fully automatic weldingGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCathode

The invention relates to a full automatic welding system and device for a fishbone type cathode wire, and the full automatic welding system and device for the fishbone type cathode wire is applied to welding of tubing and spray points. The full automatic welding system and device for the fishbone type cathode wire comprises a loading assembly, a feeding assembly, a clamping and centering assembly and a welding assembly, the loading assembly is connected with the feeding assembly, and the loading assembly is used for conveying the tubing to the feeding assembly; the feeding assembly is connected with the clamping and centering assembly, the feeding assembly is used for conveying the tubing to the welding assembly, the clamping and centering assembly is used for clamping and automatically centering the tubing coming from the feeding assembly, the welding assembly is connected with the feeding assembly, and the welding assembly is used for welding the spray points to the tubing. According to the full automatic welding system and device for the fishbone type cathode wire, by means of the loading assembly, the feeding assembly, the clamping and centering assembly and the welding assembly, the full automatic welding of the spray points and the tubing is achieved, and the normal operation of the automatic welding system is effectively guaranteed.

Owner:YONKER ENVIRONMENTAL PROTECTION

Automatic double-screw bolt driving machine for water outlet plate

InactiveCN107498153ARealize fully automatic weldingImprove work efficiencyArc welding apparatusEngineeringWelding

The invention discloses an automatic double-screw bolt driving machine for a water outlet plate, and relates to the technical field of water outlet plate production. The automatic double-screw bolt driving machine comprises a welding platform and a welding mechanism which is erected on the welding platform and used for conducting automatic welding; the welding platform comprises a rack and positioning platforms slidably installed on the rack, and a left fixture and a right fixture which are used for clamping a workpiece are symmetrically installed on each positioning platform; the left fixtures and the right fixtures each comprise a hinge base, a clamping arm which is arranged on the hinge base and faces one end of the workpiece and a driving air cylinder arranged at the other end of the hinge base, and the driving air cylinders are used for controlling the clamping arms to position the workpiece. According to the automatic double-screw bolt driving machine for the water outlet plate, the purpose of full-automatically welding double-screw bolts of the water outlet plate can be achieved, the working efficiency is high, the labor cost is low, positioning is precise, and the welding precision is high.

Owner:江门市霈霖卫浴科技有限公司

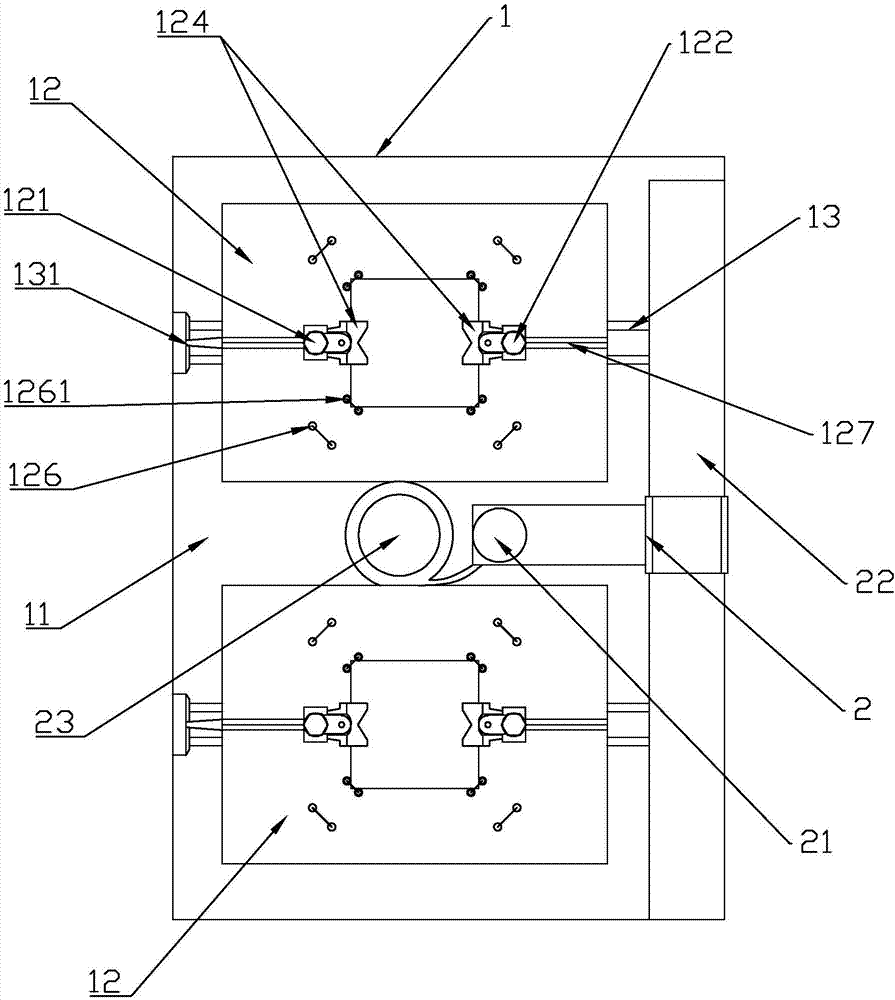

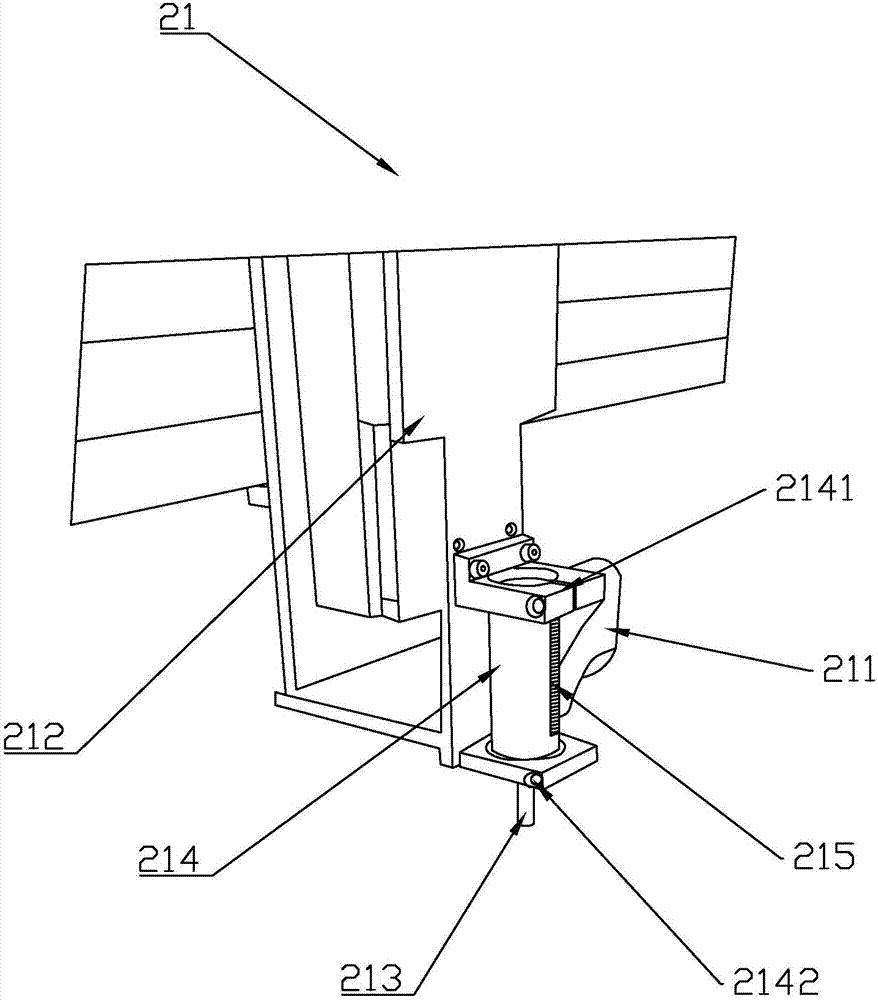

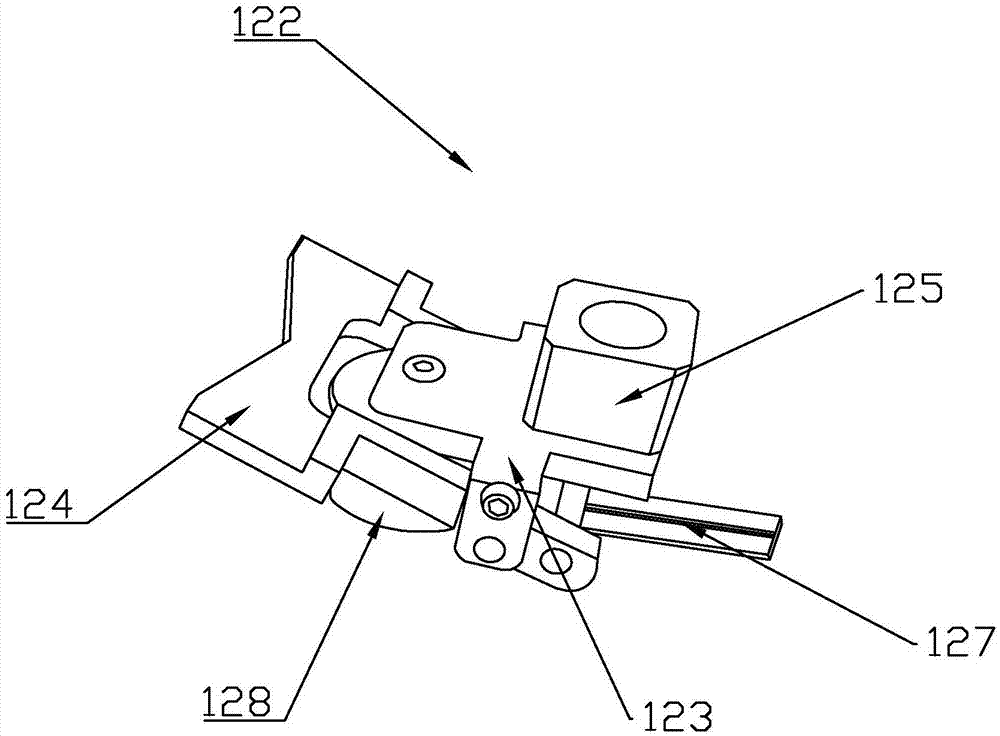

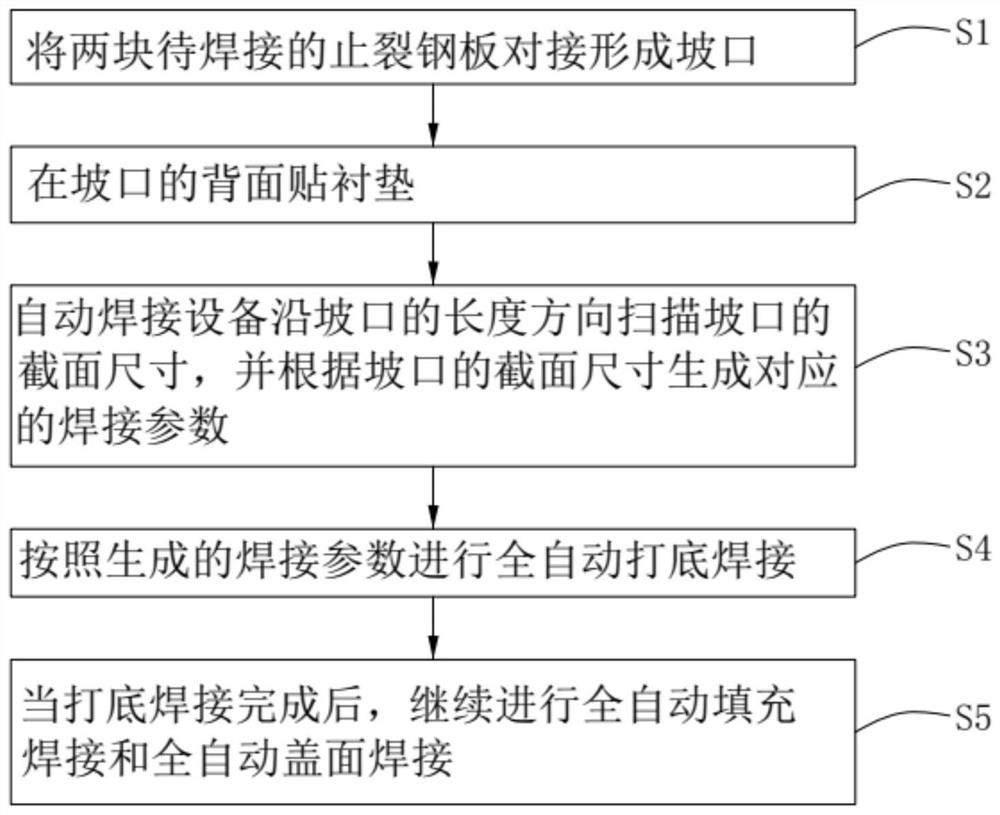

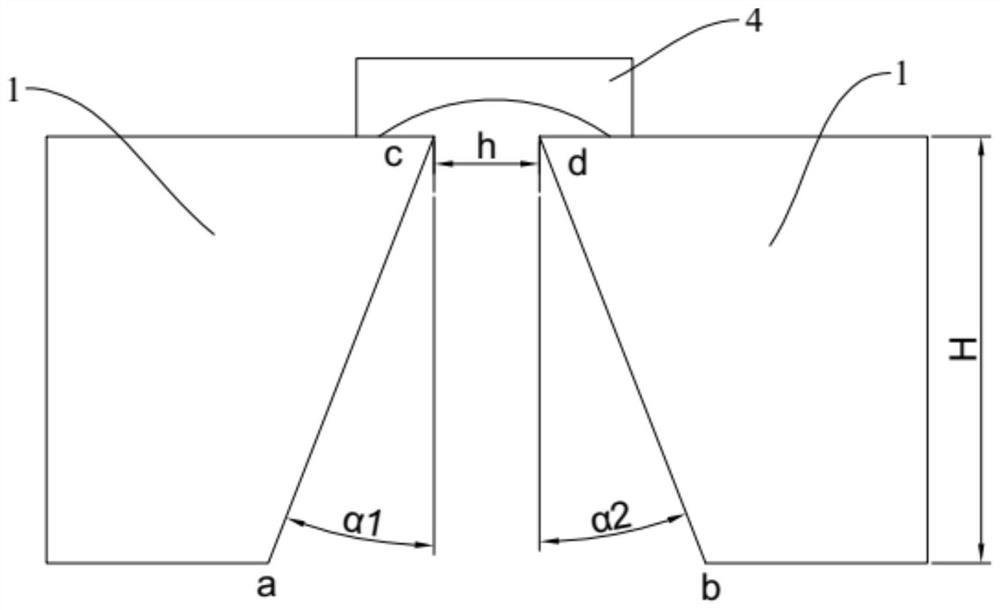

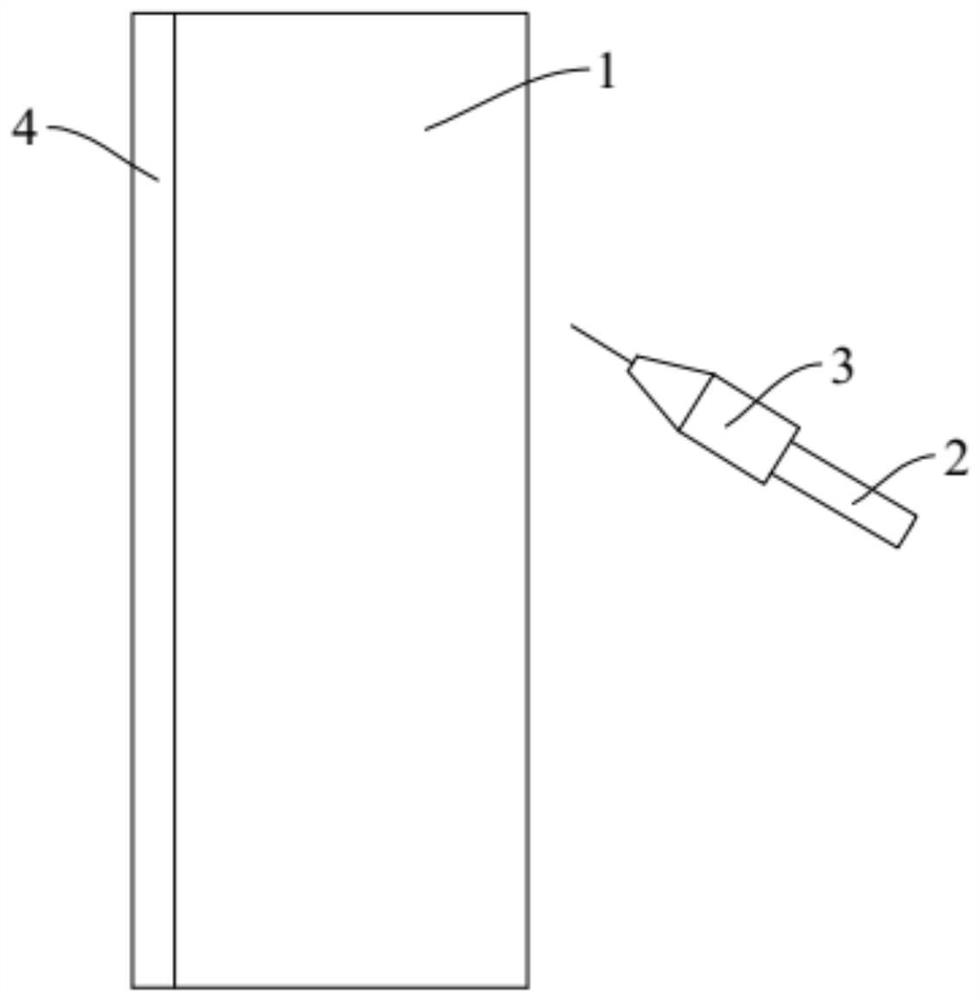

Full-automatic welding method for vertical butt joint of crack arrest steel plates

PendingCN114850624AImprove integrationImprove continuityNuclear energy generationArc welding apparatusButt jointWeld seam

The invention relates to the technical field of ship construction, in particular to a full-automatic welding method for vertical butt joint of crack arrest steel plates. The full-automatic welding method for vertical butt joint of the crack arrest steel plates comprises the following steps that S1, two to-be-welded crack arrest steel plates are in butt joint to form a groove; and S2, a liner is attached to the back face of the groove. And S3, the automatic welding equipment scans the section size of the groove in the length direction of the groove, and corresponding welding parameters are generated according to the section size of the groove. And S4, full-automatic backing welding is conducted according to the generated welding parameters. And S5, after bottoming welding is completed, full-automatic filling welding and full-automatic cosmetic welding continue to be conducted. According to the full-automatic welding method for vertical butt joint of the crack arrest steel plates, full-automatic backing welding is achieved, and the welding efficiency is improved. And meanwhile, a bottoming weld joint can be prevented from cracking, and the welding quality is improved. And moreover, the continuity of the bottoming welding seam is good, welding joints are avoided, carbon gouging repair is not needed, and the welding quality and the welding efficiency are further improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

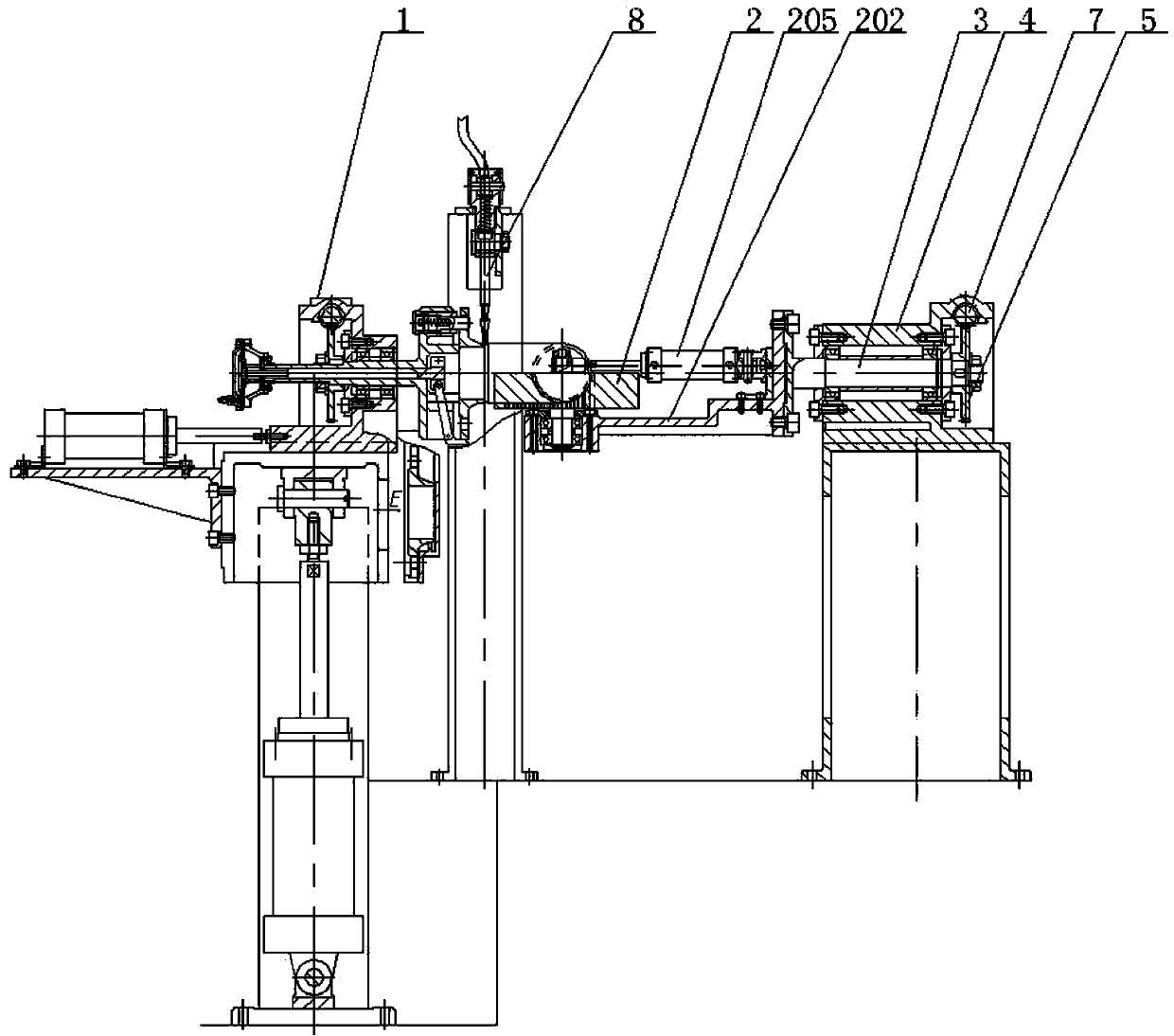

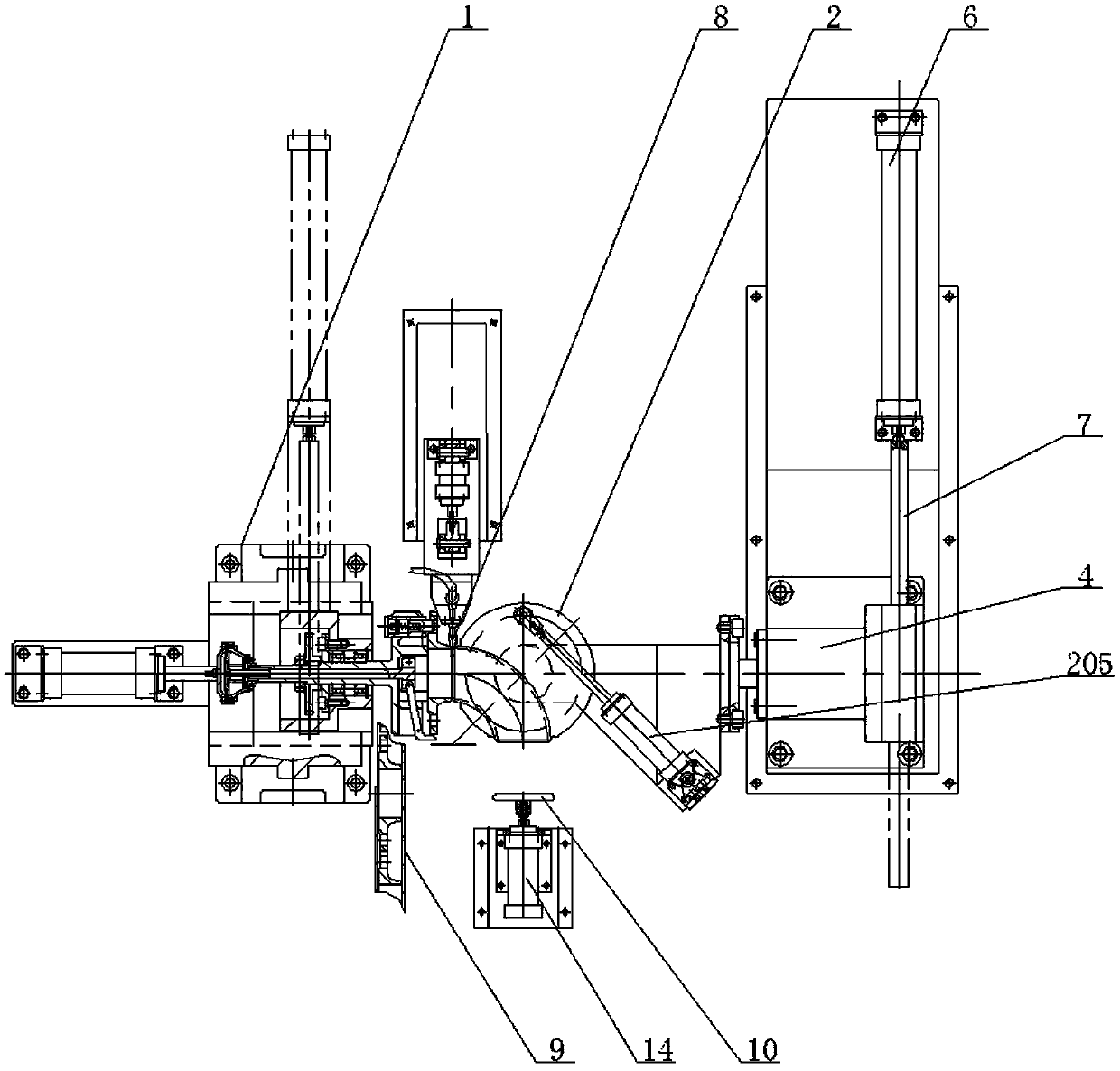

90-degree elbow and flange butt welding semi-automatic equipment

InactiveCN109531028AWith automated productionFully automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderButt welding

The invention relates to 90-degree elbow and flange butt welding semi-automatic equipment. The 90-degree elbow and flange butt welding semi-automatic equipment mainly solves the problems that when flanges are welded to a flange type 90-degree elbow in the prior art, the production efficiency is low, and the machining quality is difficult to guarantee. The 90-degree elbow and flange butt welding semi-automatic equipment is characterized in that an elbow rotary clamp (2) is arranged on one side of a clamp seat (105), an electromagnet (204) is arranged below a groove (203), an indexing air cylinder (205) is arranged on a supporting seat (202), and a flange rotary hydraulic cylinder (110) and an elbow rotary hydraulic cylinder (6) can synchronously run. According to the 90-degree elbow and flange butt welding semi-automatic equipment, a flange automatic alignment conveying device and the elbow rotary clamp are adopted to clamp the flanges and the elbow correspondingly and then enable the flanges and the elbow to correspond to each other, the flanges and the elbow can synchronously rotate, butt welding between the flanges and the elbow is realized by utilizing an automatic welding gun,the positions of bolt holes in all the flanges can be kept consistent through the flange automatic alignment conveying device, and the characteristics of high production efficiency and good welding quality are achieved.

Owner:WENZHOU POLYTECHNIC

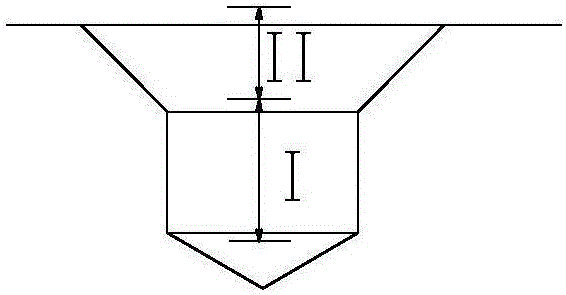

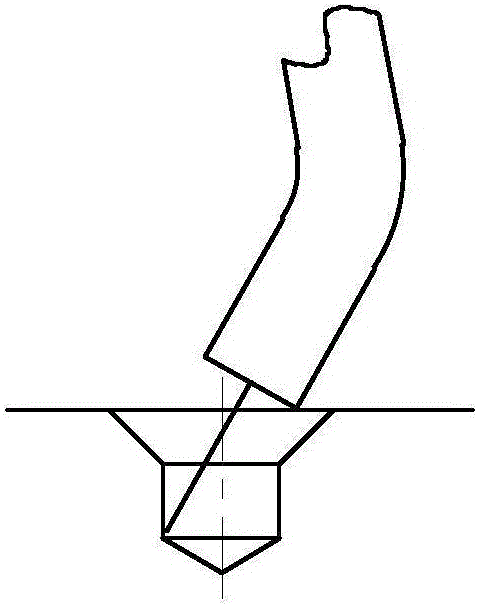

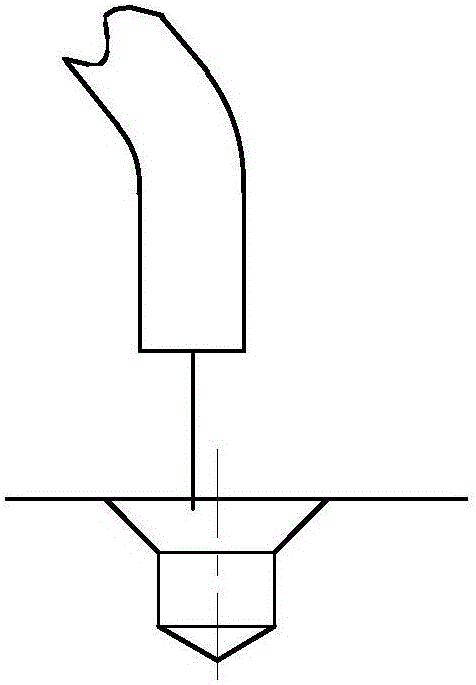

Air valve plate bottom of marine low-speed machine and welding process of air valve plate bottom

ActiveCN106077914AGuaranteed full weldingRealize fully automatic weldingArc welding apparatusEngineeringAlloy

The invention discloses an air valve plate bottom of a marine low-speed machine and a welding process of the air valve plate bottom. The air valve plate bottom is provided with a central hole; a base material of the central hole is a SNCrW material containing the following chemical components: C, Si, Mn, P, S, Ni, Cr, W, Nb, B, N and the balance of Fe. According to the shape of the central hole, the central hole of the air valve plate bottom is divided into two sections: a straight hole section and an inclined hole section; for different shapes of the central hole, a welding procedure is divided into a welding phase I and a welding phase II. According to the air valve plate bottom of the marine low-speed machine and the welding process of the air valve plate bottom, a welding gun is tilted to a certain angle, and then swung to make welding alloy well fused with the base material, to guarantee full welding of the central hole; furthermore, by the use of a six-axis industrial robot and an MIG welding machine, full-automatic welding is realized, the welding efficiency is high, and the quality is stable.

Owner:NANJING INT MARINE EQUIP & SPARES

Automatic wax pattern welding production line

PendingCN111085807AEliminate randomnessAvoid contactLiquid surface applicatorsWelding/cutting auxillary devicesPattern weldingProduction line

The invention discloses an automatic wax pattern welding production line. The production line comprises a base, an impeller mold conveyor belt, a lifting device, a lower stroke switch, a stroke switchtrigger plate, an upper stroke switch, a stepping motor, a guide shell mold conveyor belt, a brush head connecting plate, a guide shell mold photoelectric switch, a flexible mechanical gripper, a flexible gluing brush head, a guide shell mold photoelectric switch supporting plate, a gripper connecting plate, a six-degree of freedom robot, a glue pond, an impeller mold photoelectric switch supporting plate and an impeller mold photoelectric switch. The production line is composed of an automatic starting and stopping conveyor belt, an automatic lifting gluing industrial robot and a flexible mechanical gripper. Full-automatic welding is achieved, randomness of manual operation is eliminated, the production efficiency and the technological quality are improved, the production cost is lowered, and meanwhile contact between the human body and irritable glue is avoided. The flexible mechanical hand adopts the pneumatic mode, the gripping force of the gripper can be precisely controlled, waxpattern parts are gripped in a self-adaptive mode, and no damage is caused to a wax pattern.

Owner:HEBEI UNIV OF TECH

Towel rack laser welding device with double welding heads and welding method

PendingCN114769865AImprove solder plastic and qualityImprove welding efficiencyLaser beam welding apparatusPhysicsLaser soldering

A towel rack laser welding device with double welding heads comprises a material feeding belt, a rotary grabbing mechanism, a laser welding head and a laser welding head, and the discharging end of the material feeding belt faces the rotary grabbing mechanism; the feeding end of the material conveying belt faces the rotary grabbing mechanism; the rotary grabbing mechanism is arranged on the rotary platform and has three rotating positions including a material taking position, a welding position and a material placing position; the two sets of laser welding machines are arranged at the welding positions and located on the two sides of the towel rack; and the laser welding machine is movably arranged on the three-dimensional adjusting platform, and the laser welding machine is controlled to move according to a preset program. According to the structural characteristics of the towel rack, a welding track can be obtained according to a model, then a laser welding mode easy to control by a program is adopted, the two sets of laser welding machines located on the two sides of the towel rack during welding are arranged, laser welding is automatically carried out under the control of the three-dimensional adjusting platform according to a preset program, and full-automatic welding is achieved; the rotary grabbing mechanism grabs the towel rack and positions the towel rack in a vertical state at the same time, and the position randomness of the towel rack in the conveying process can be eliminated.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com