Full-automatic welding production equipment for beam or column steel reinforcement cage

A technology of fully automatic welding and production equipment, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to guarantee the precise position of longitudinal bars and stirrups, low degree of automation, etc., to achieve a high degree of automation and ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention are provided below to help further understanding of the present invention. Those skilled in the art should understand that the descriptions of the embodiments of the present invention are only exemplary, and are not intended to limit the solution of the present invention.

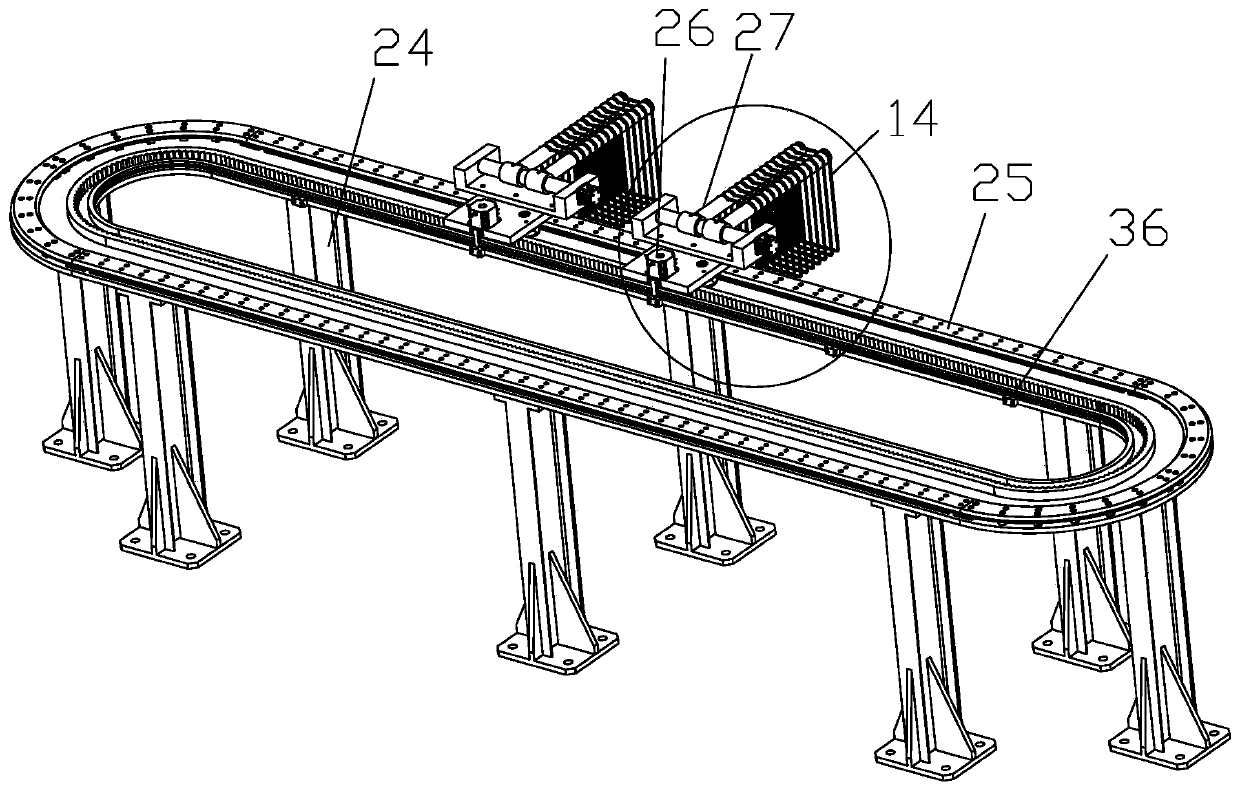

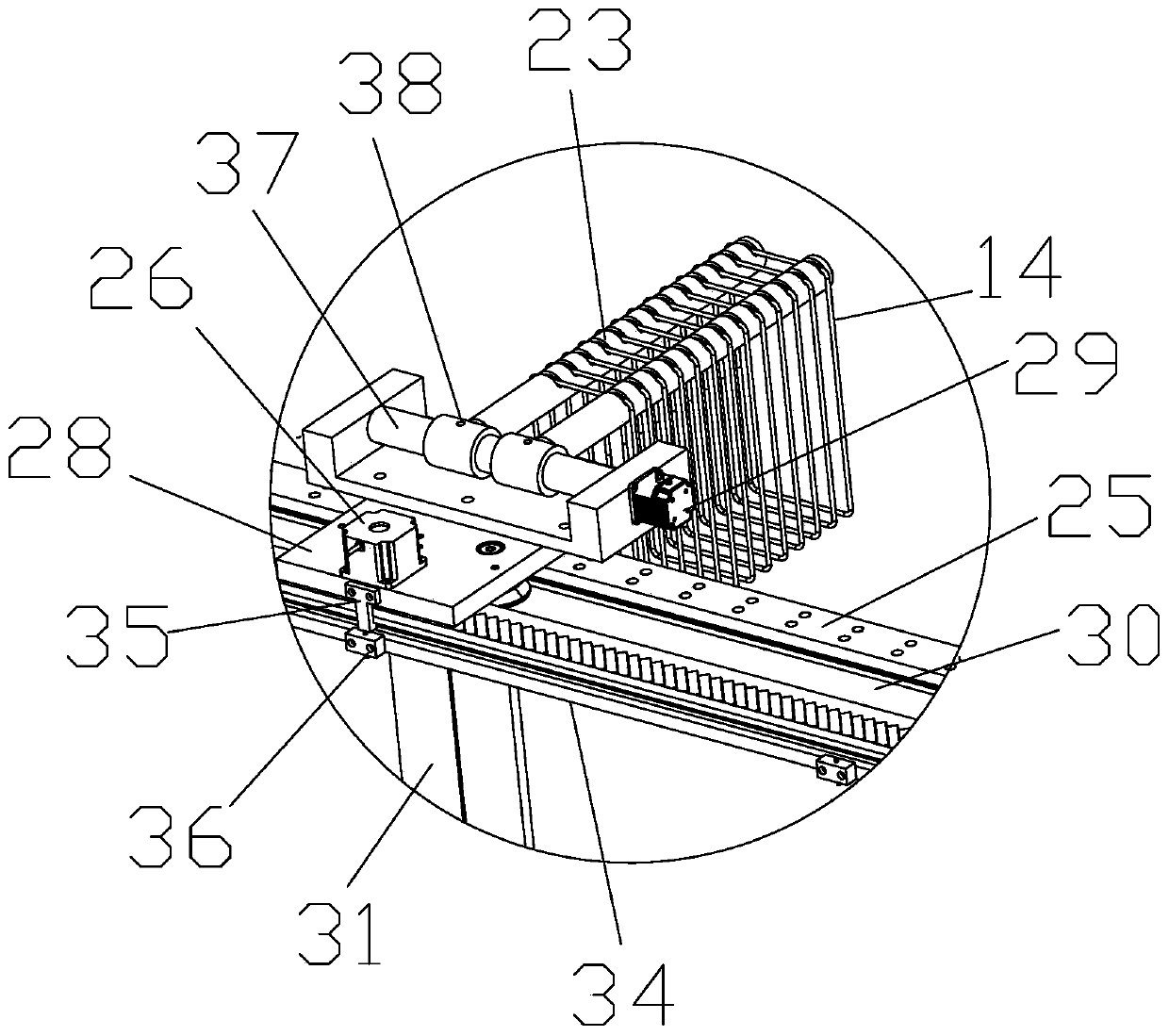

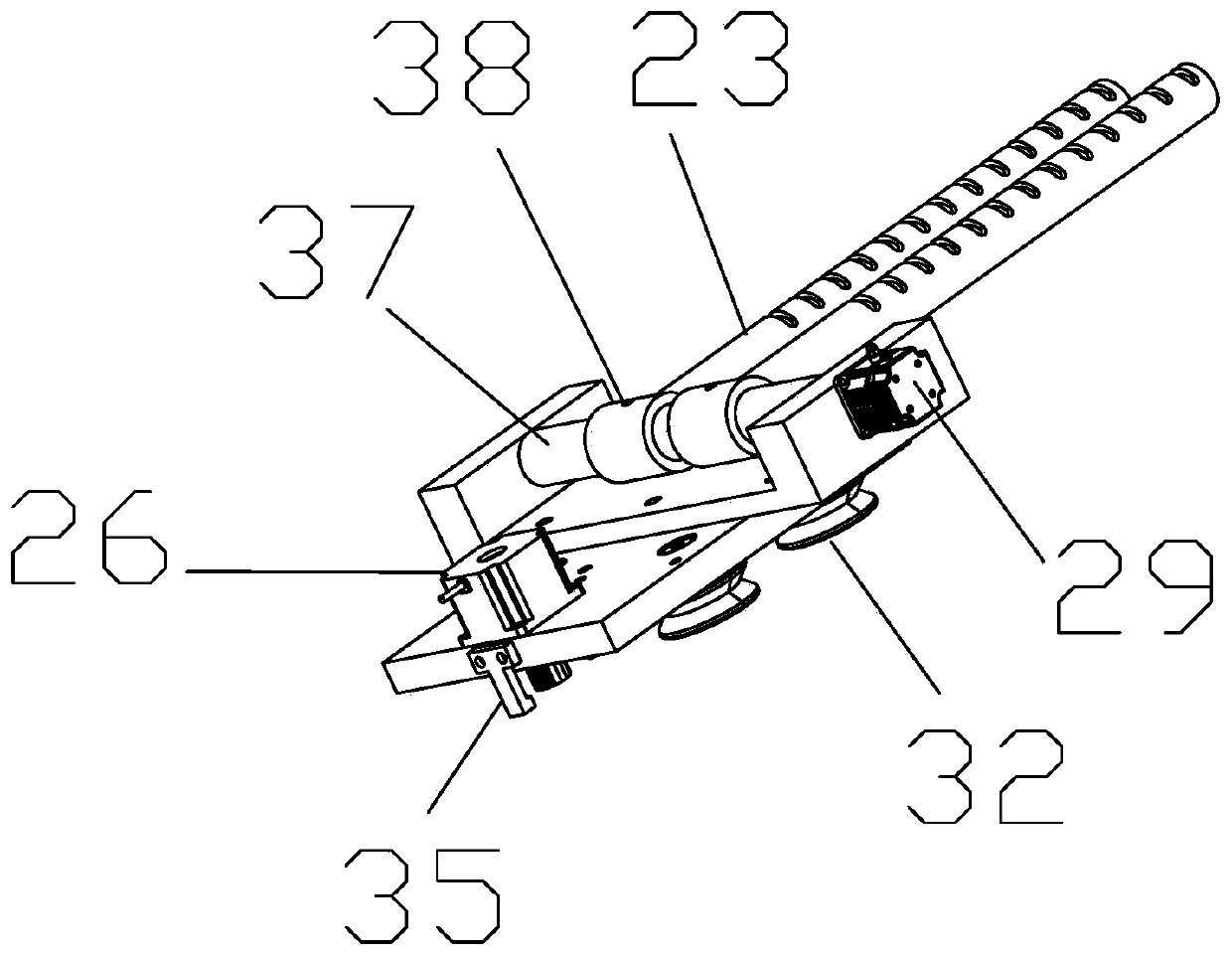

[0051] Reference Figure 12 The fully automatic welding production equipment for beam or column reinforcement cages in this embodiment includes a guide rail type stirrup automatic conveying device 01, a longitudinal reinforcement feeding device 02 and a welding device 04 connected in sequence according to the production process, and also includes a The stirrup unloading device 03 between the guide rail type stirrup automatic conveying device 01 and the welding device 04, and the balance material rack 21 arranged between the longitudinal bar feeding device and the welding device, the balance material rack 21 includes a connecting part 22 and a hanging 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com