Perpendicularly-lifting tail plate capable of carrying out loading and unloading automatically

A vertical lifting, self-loading and unloading technology, applied to vehicles with elevated loading platforms, vehicles with inclined bearing motion, etc., can solve the problems of efficient loading and unloading, inability to achieve, hidden dangers, etc., and achieve the effect of high degree of automation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described as follows:

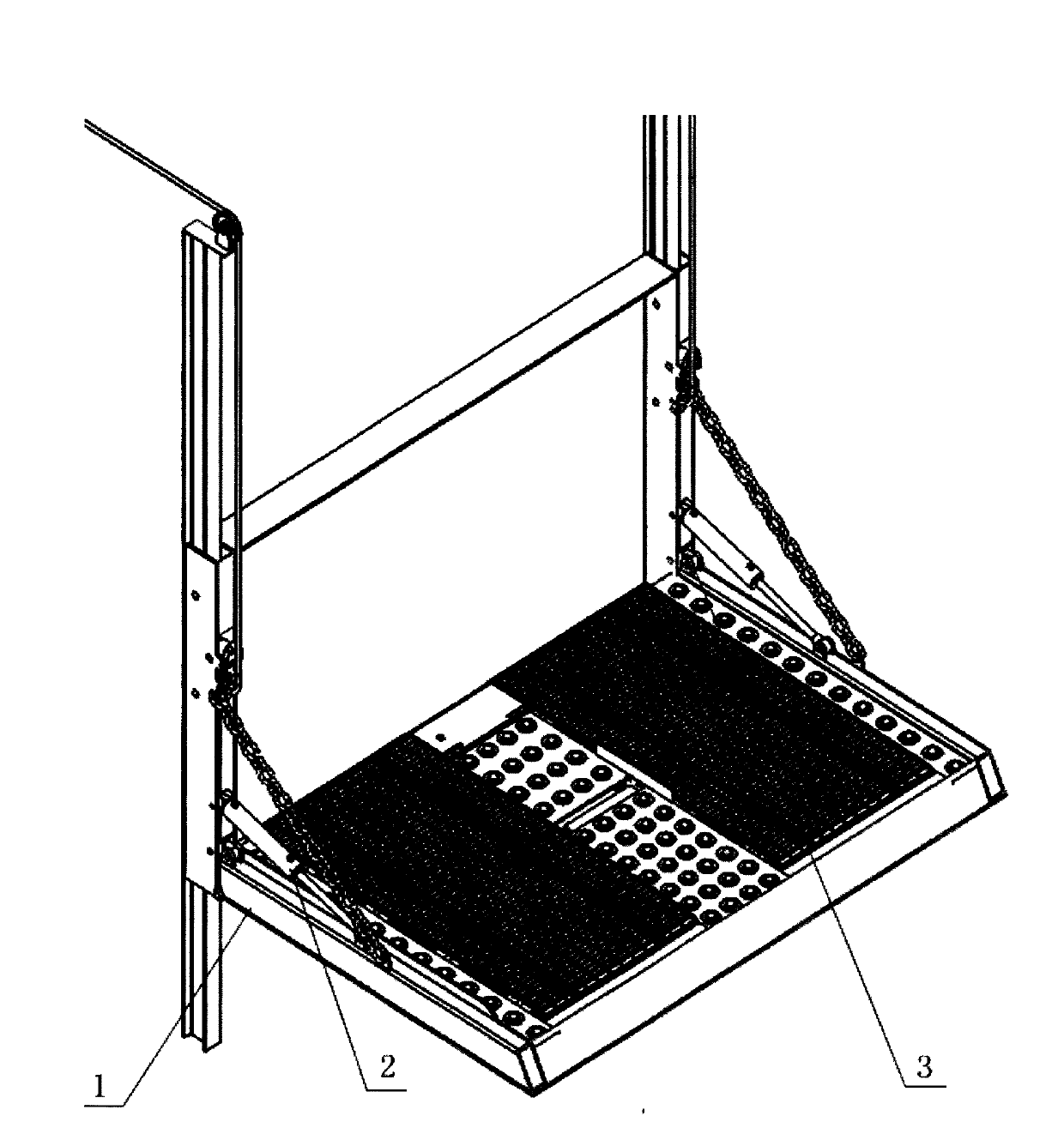

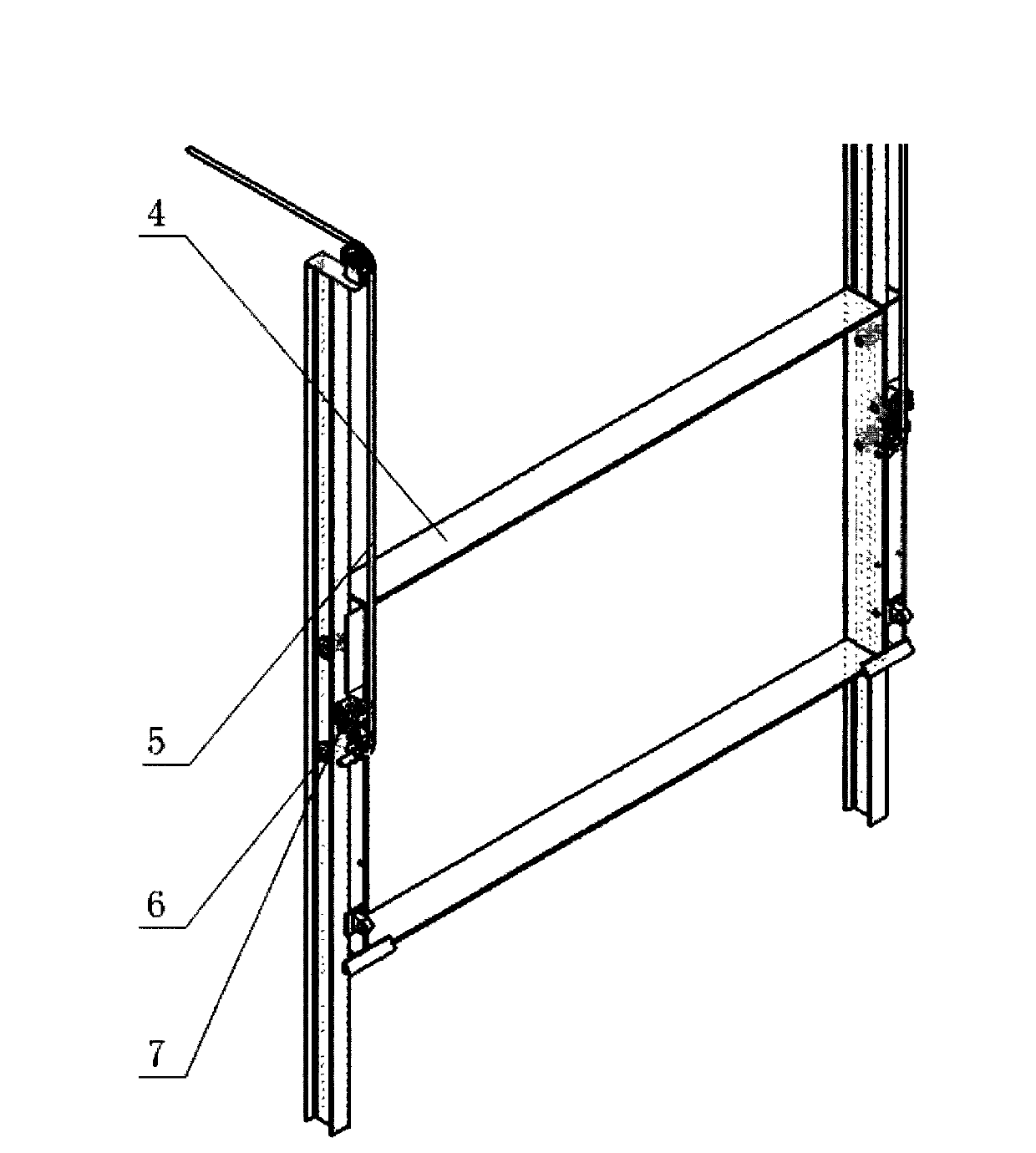

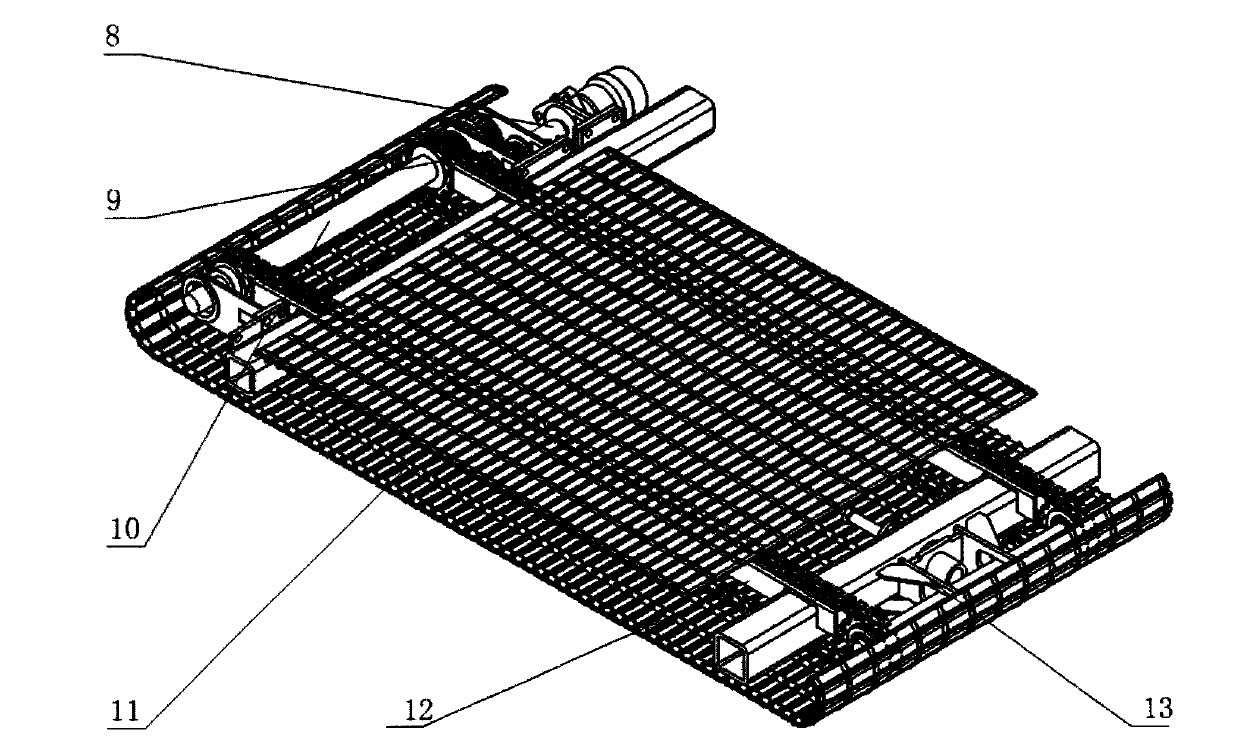

[0014] A kind of self-loading and unloading vertical lifting tailboard that embodiment relates to, its structure is as follows Figure 1-Figure 5 As shown, the self-loading vertical lifting tailgate is mainly composed of a tailgate system, a vertical lifting system, an automatic conveying system, an automatic positioning device, a protection device and a hydraulic control system. Among them, the tailgate system is composed of the tailgate frame 1, the turning cylinder 2 and the hinge 3; the vertical lifting system is composed of the guide rail frame 4, the steel wire rope 5, the rear roller 6, the front roller 7 and the lifting drive device; the automatic conveying device consists of hydraulic Motor 8, reducer 9, chain drive shaft 10, chain plate 11 track 12 and chain tensioning device 13; automatic positioning device consists of universal ball 14, chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com