Packing box casing machine

A box packing machine and box body technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems that affect the boxing speed, the packaging box cannot be accurately placed in the carton, and the packaging box is easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below:

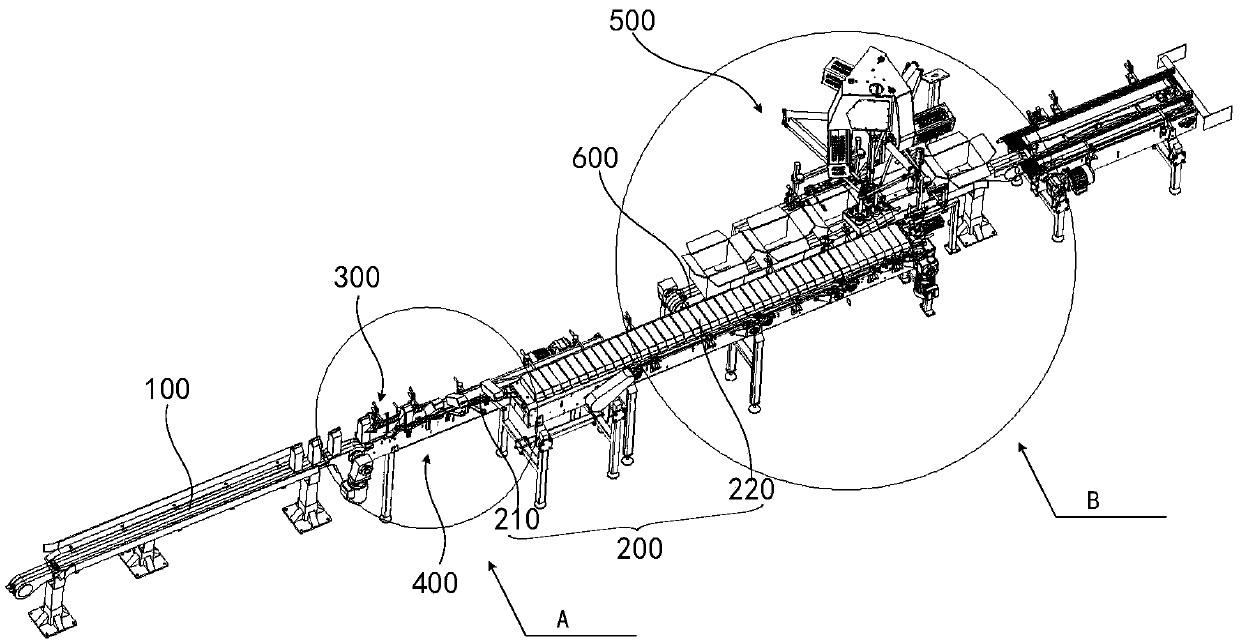

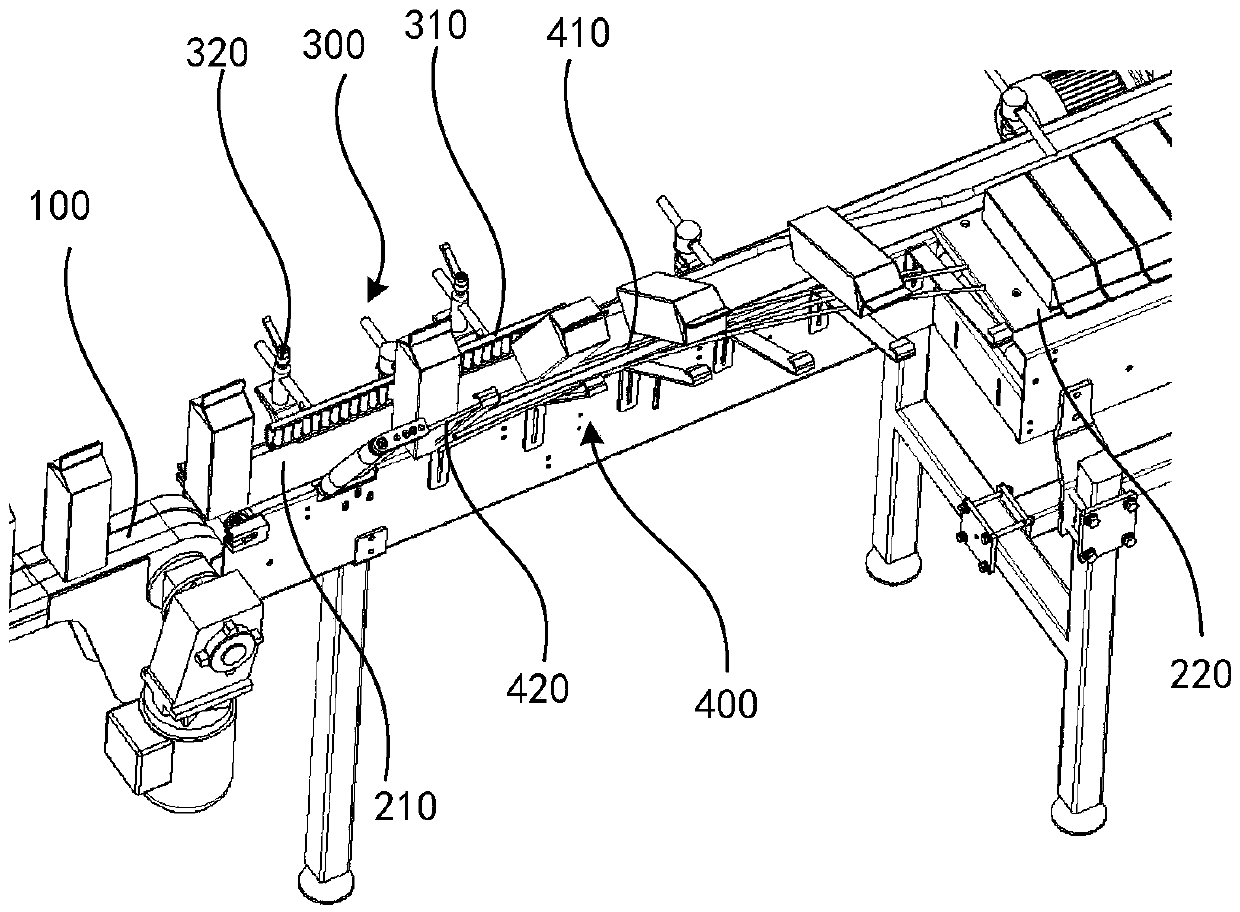

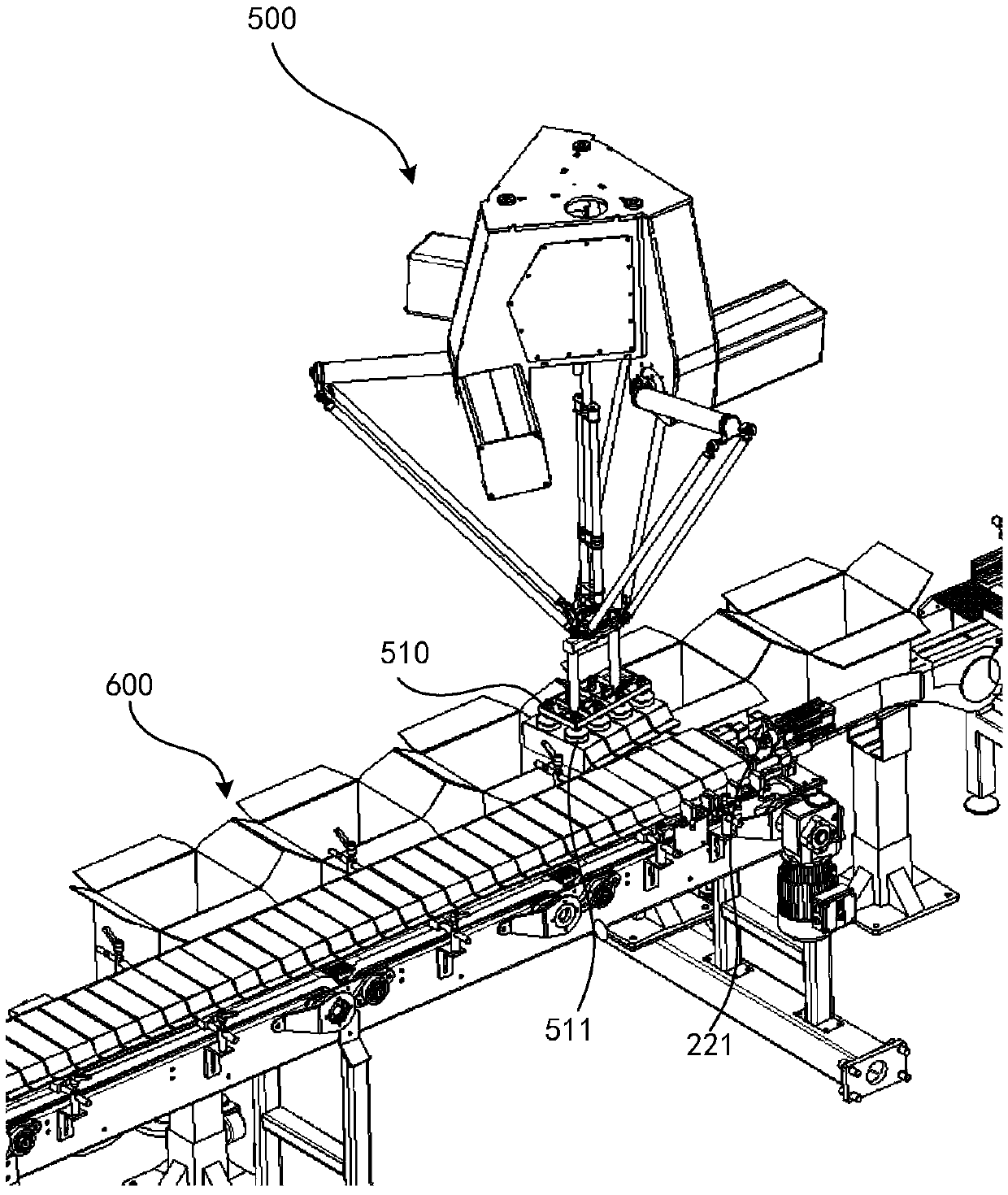

[0032] Such as figure 1 As shown, a box packing machine includes a retrieving mechanism 500 , a knockdown mechanism 300 and a first product conveyor belt 100 and a second product conveyor belt 200 connected in sequence. The first product conveyor belt 100 is used for conveying upright packaging boxes, and the second product conveyor belt 200 is used for conveying horizontal packaging boxes. The knockdown mechanism 300 is located above the end of the second product conveyor belt 200 close to the first product conveyor belt 100 . The retrieving mechanism 500 is associated with the output end of the second product conveyor belt 200 . When the packing box is conveyed upright on the first product conveyor belt 100 and enters the second conveying line, the overturning mechanism 300 switches the packing box from an upright state to a lying state, and then the picking mechanism 500 picks up the packing box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com