Patents

Literature

70results about "Tubing catchers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

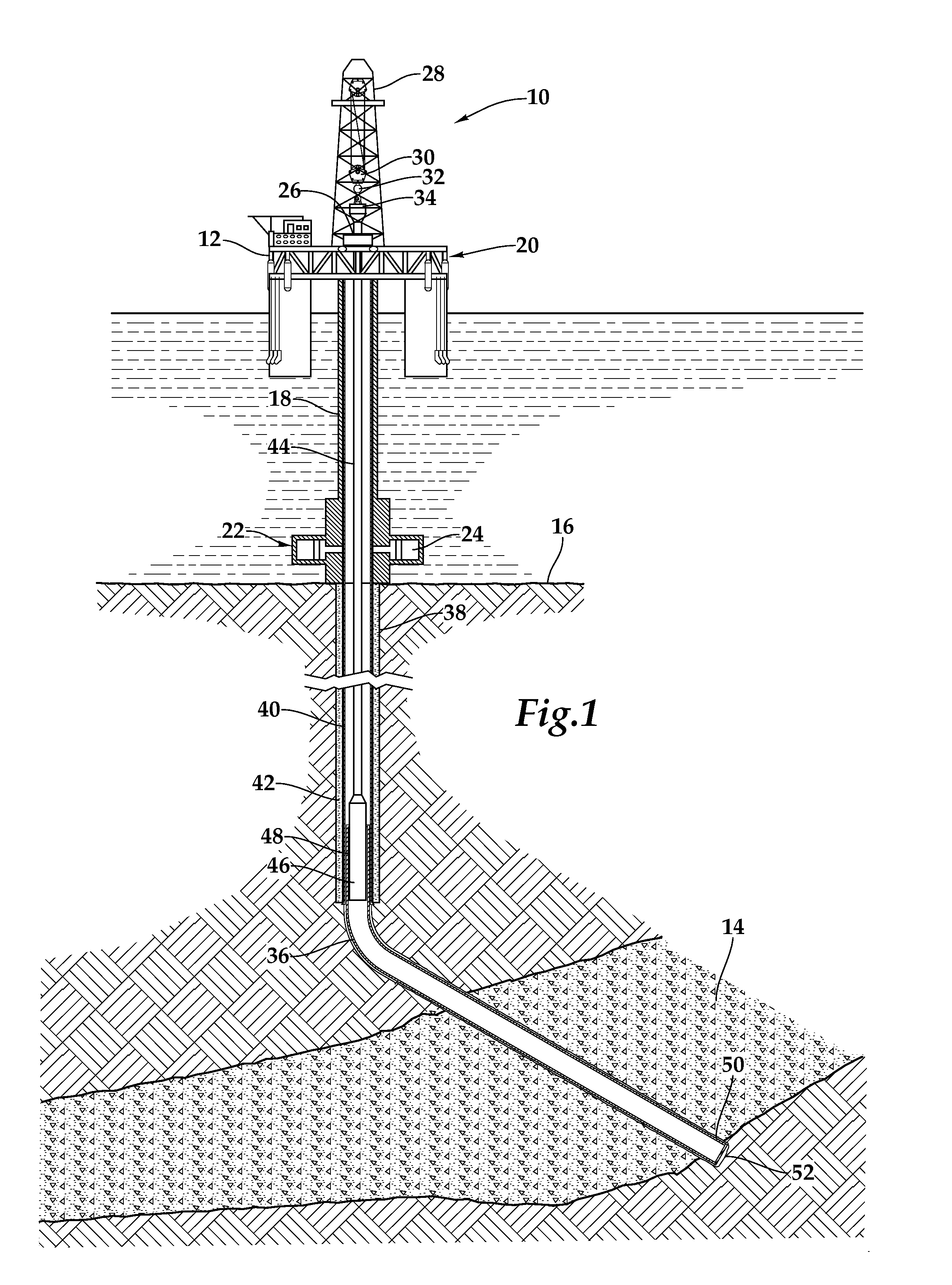

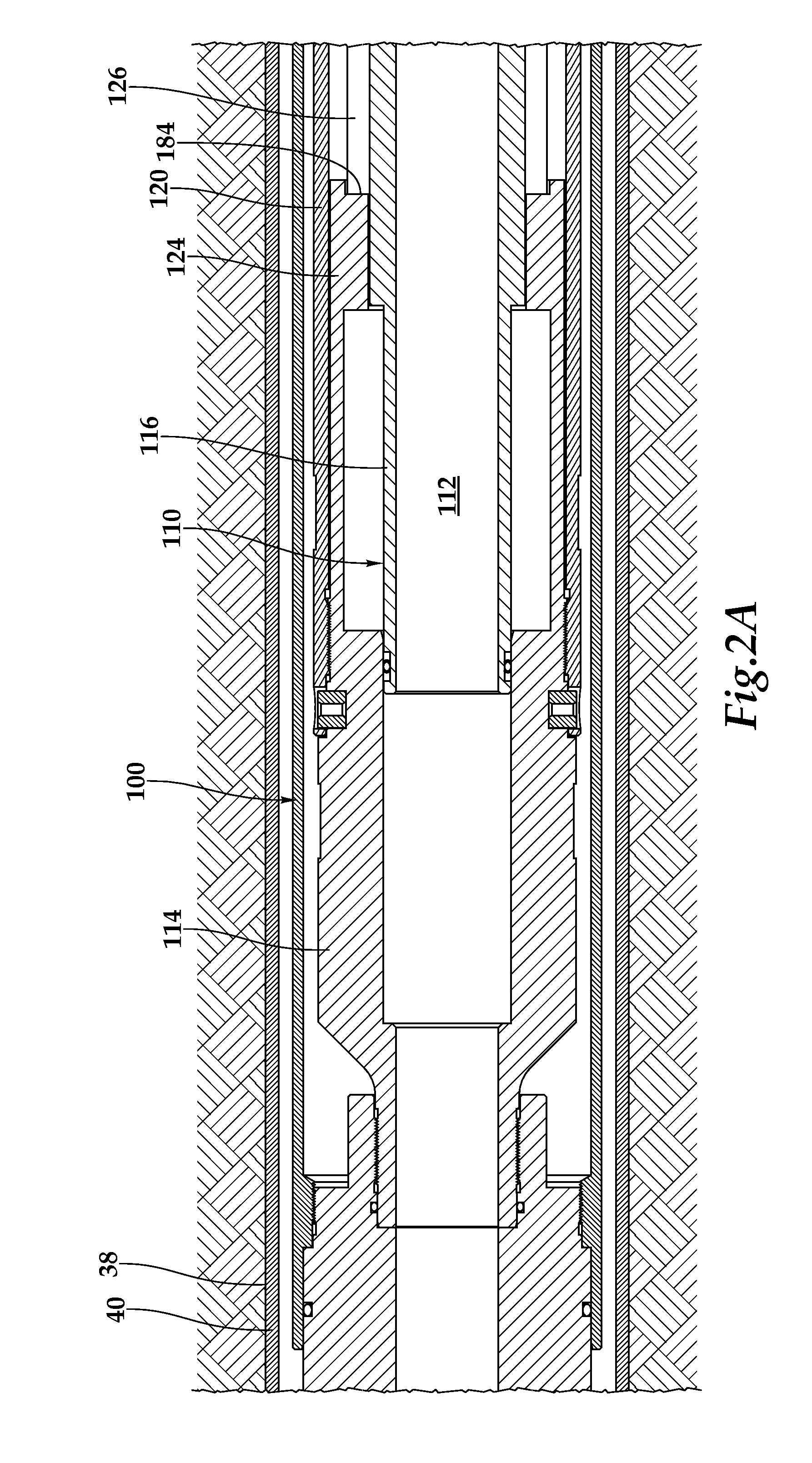

Apparatus and methods for utilizing a downhole deployment valve

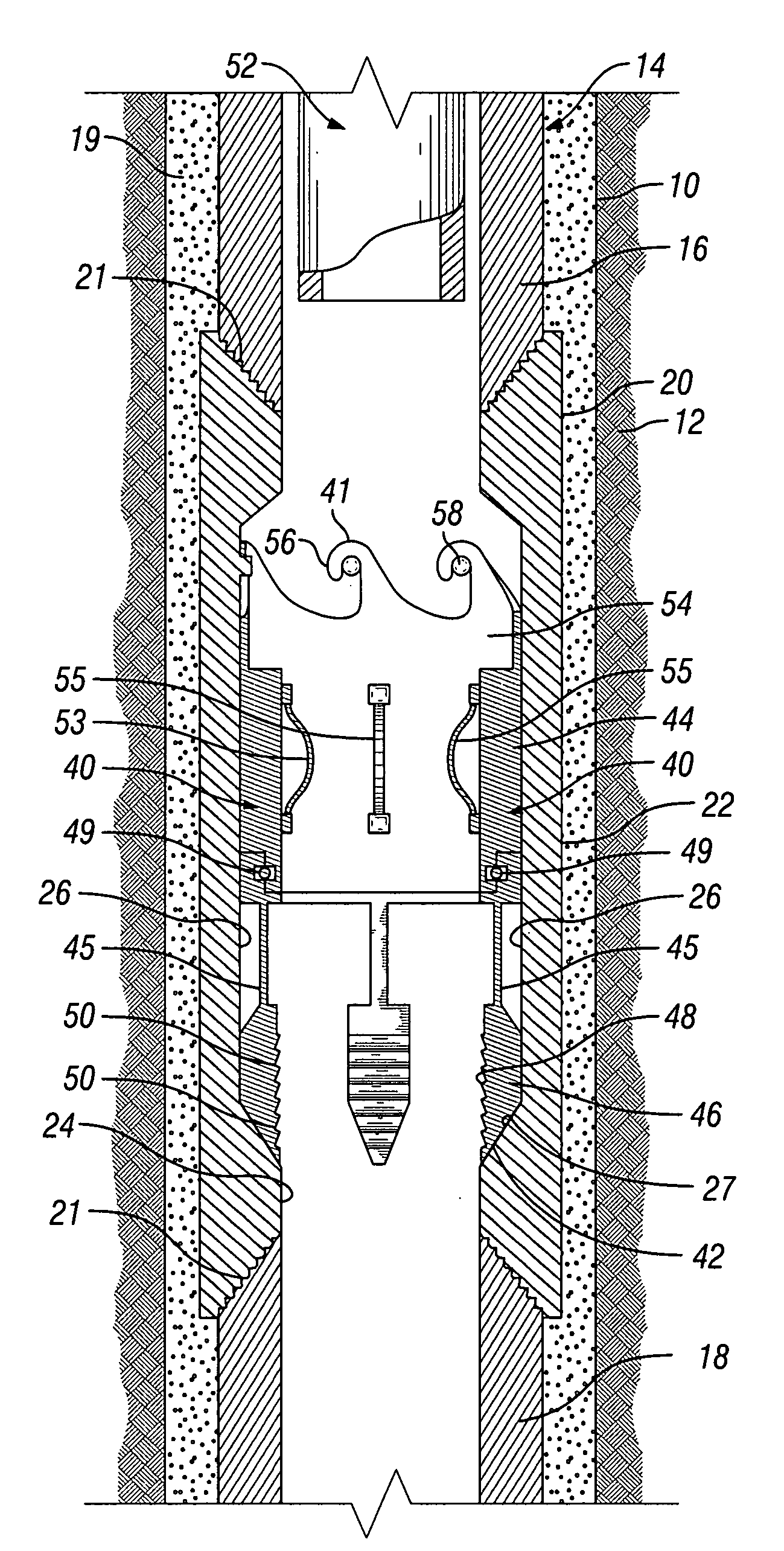

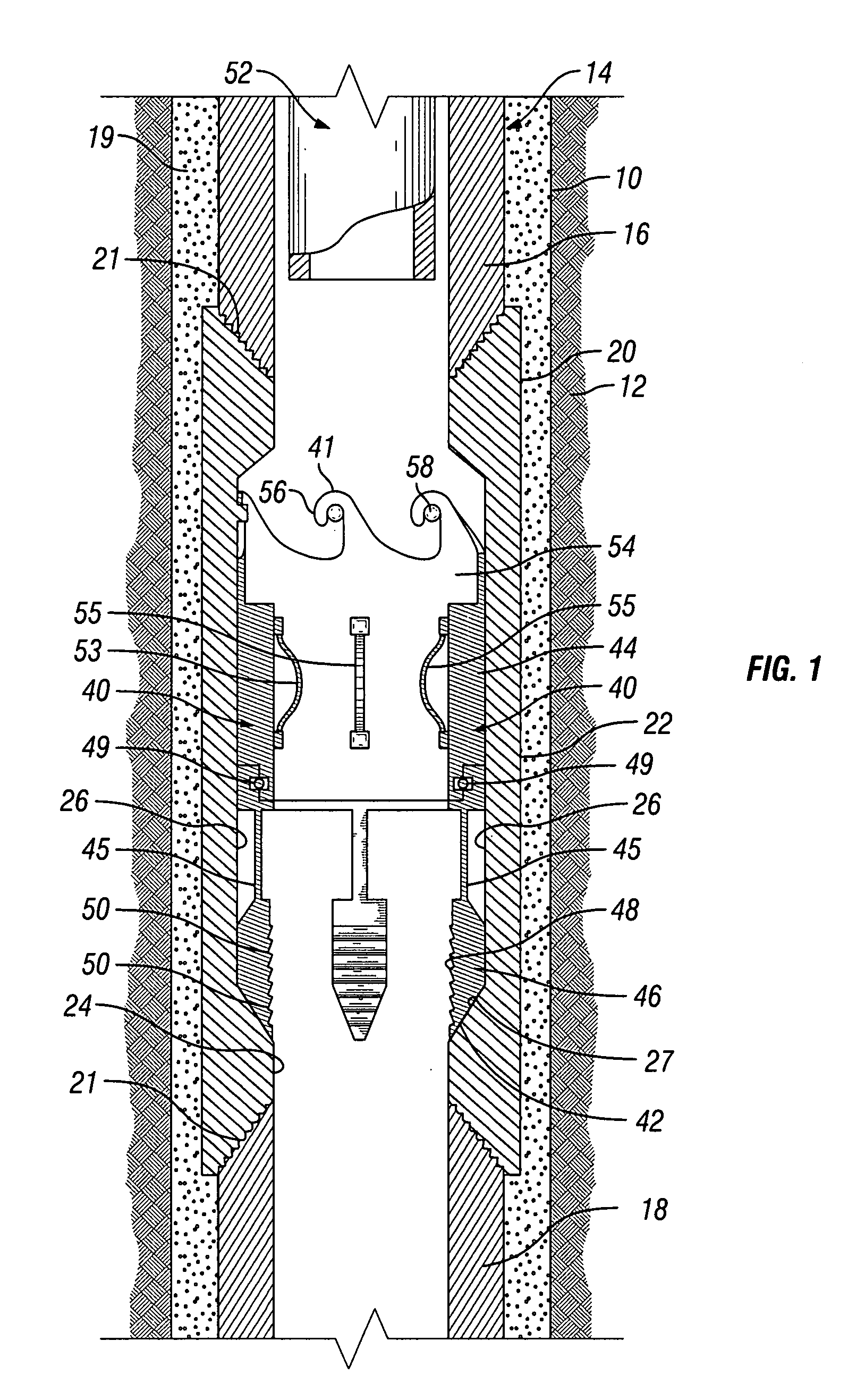

Methods and apparatus for utilizing a downhole deployment valve (DDV) to isolate a pressure in a portion of a bore are disclosed. Any combination of fail safe features may be used with or incorporated into the DDV such as redundant valve members, an upward opening flapper valve or a metering flapper below a sealing valve. In one aspect, a barrier or diverter located in the bore above a valve member of the DDV permits passage through the bore when the valve member is open and actuates when the valve member is closed. Once actuated, the barrier or diverter either stops or diverts any dropped objects prior to the dropped object reaching and potentially damaging the valve member. In another aspect, the tool string tripped in above the DDV includes an acceleration actuated brake that anchors the tool string to a surrounding tubular if the tool string is dropped.

Owner:WEATHERFORD TECH HLDG LLC

Method of Preventing Dropped Casing String with Axial Load Sensor

A method of running casing into a well utilizes a load sensor to avoid dropping the casing string accidentally. The rig has a spider at the rig floor that suspends a casing string in the well when in a gripping position. A casing lifting mechanism will place a new joint of casing on the casing string suspended in the spider. The new joint of casing is rotated to make up with the casing string. After makeup, the casing lifting mechanism lifts the new joint of casing and the casing string. The operator releases the spider to allow the casing string to be lowered further into the well. Before releasing the spider, a load sensor will send a signal indicating that the casing lifting mechanism is supporting a minimum amount of weight.

Owner:NABORS DRILLING TECH USA INC

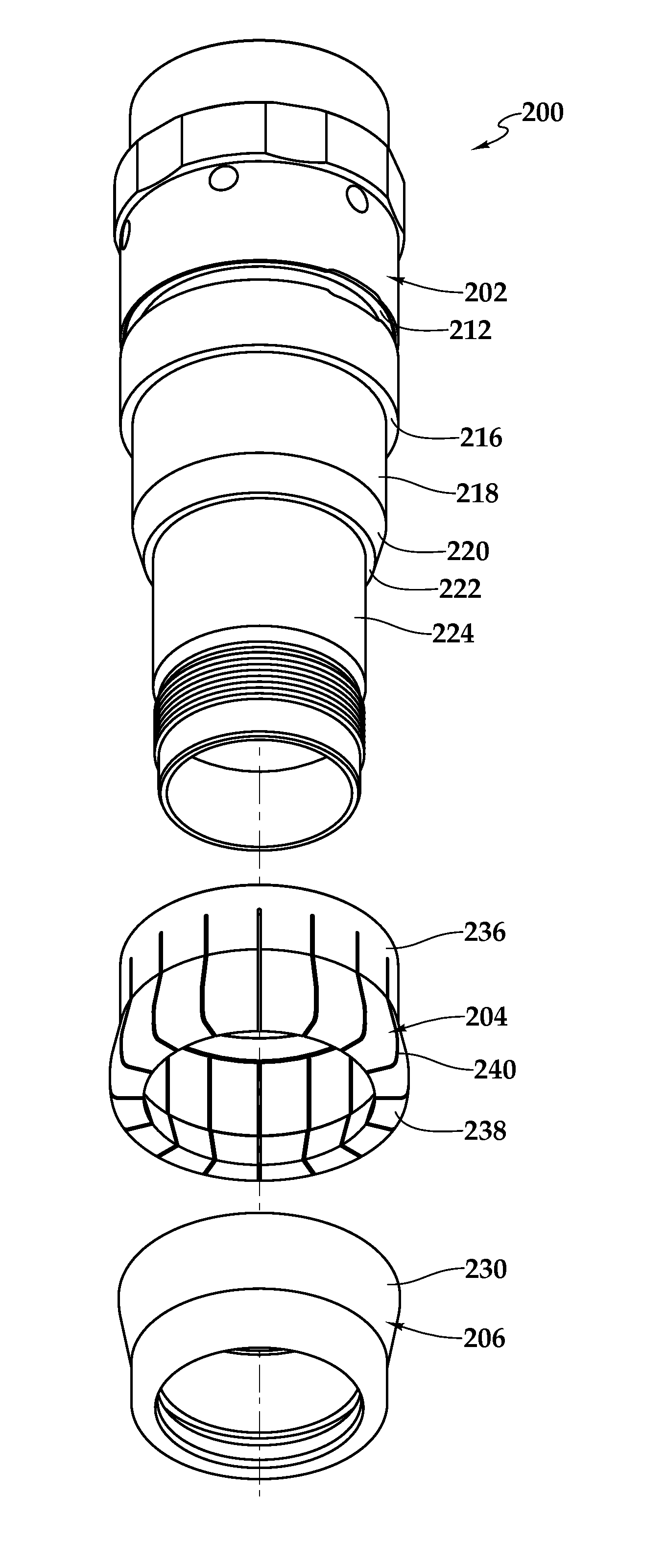

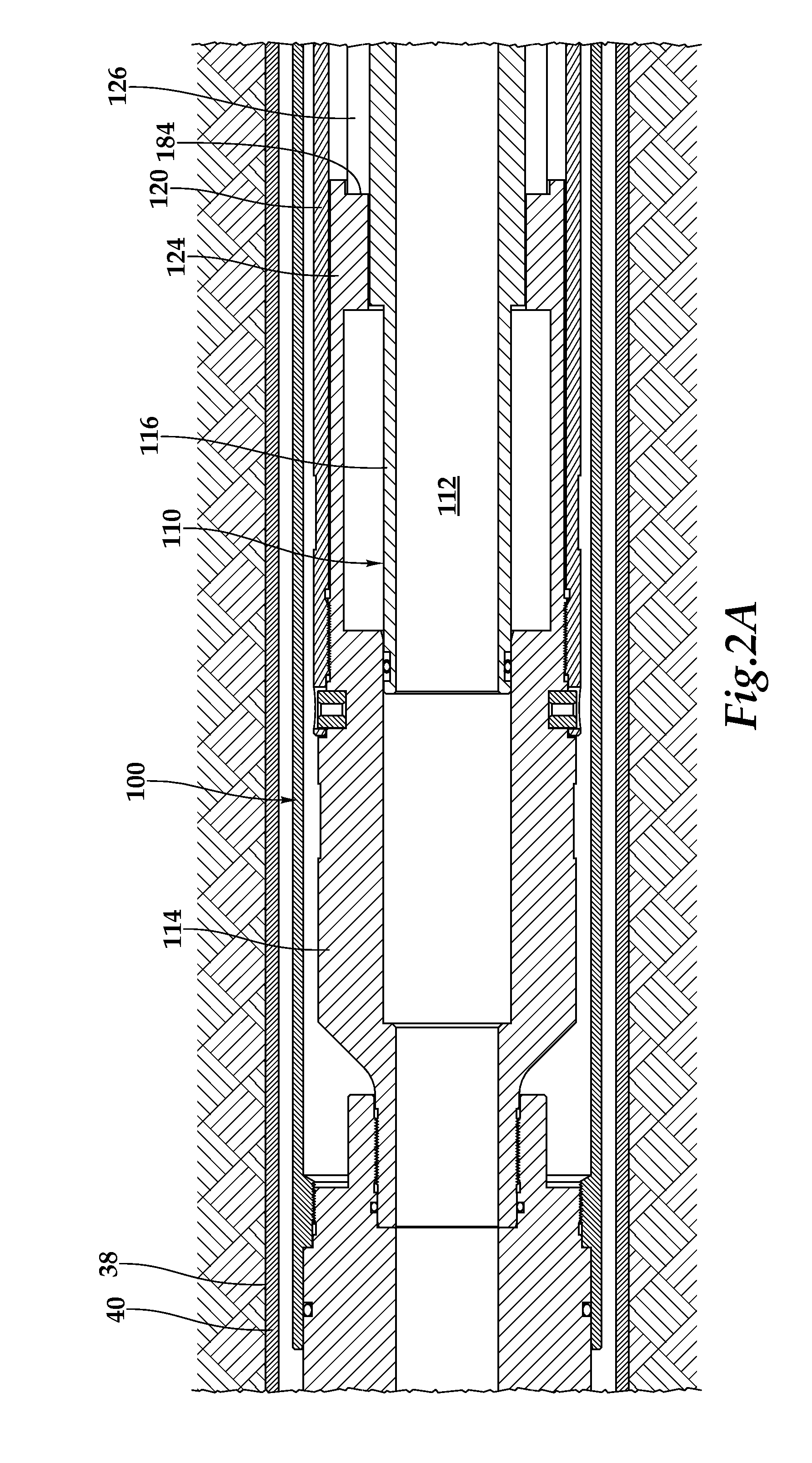

Expansion Cone Assembly for Setting a Liner Hanger in a Wellbore Casing

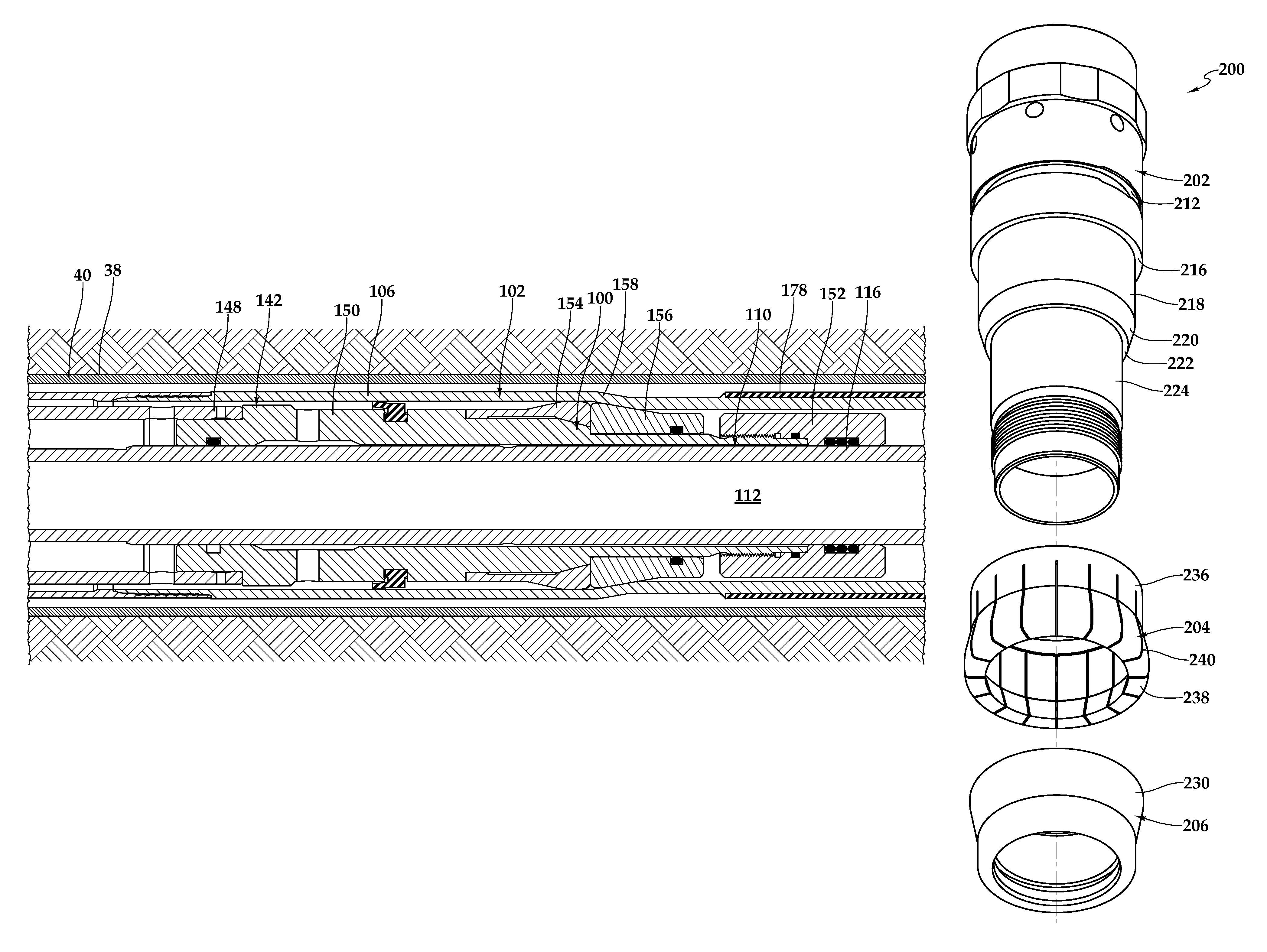

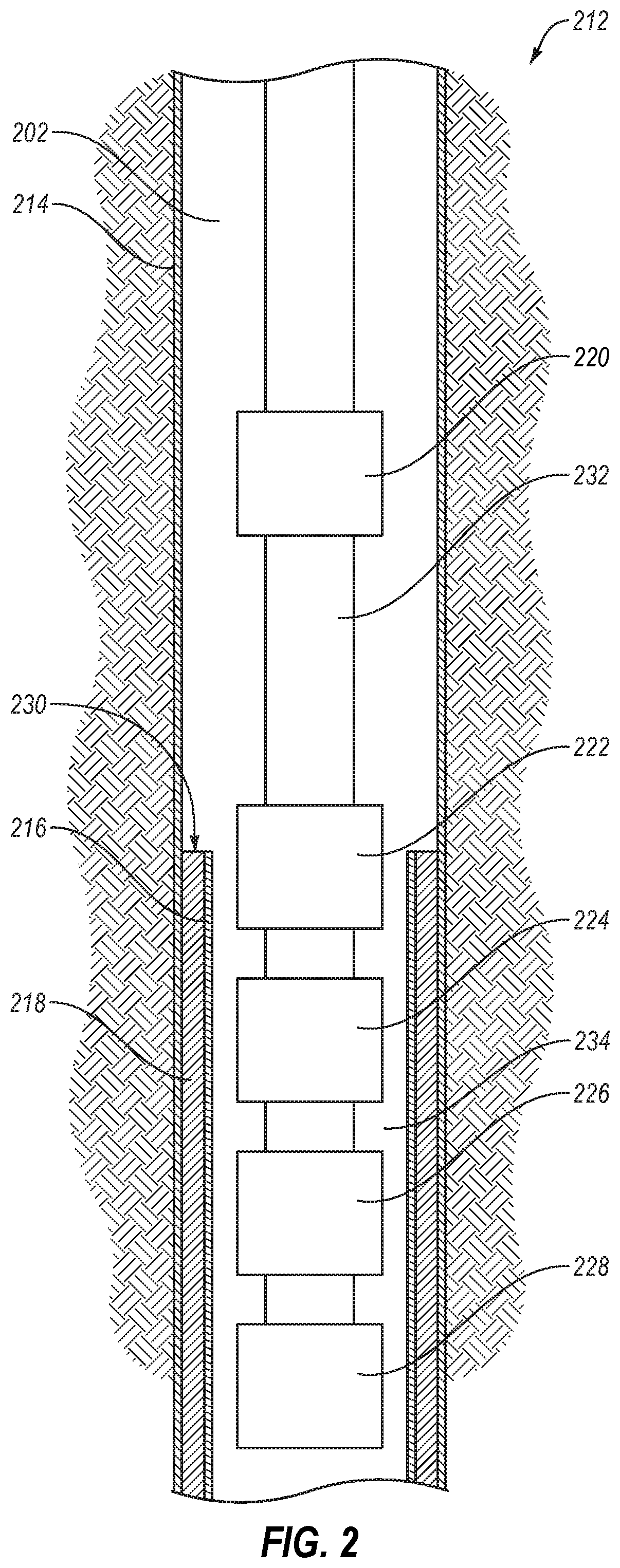

An expansion cone assembly (200) for setting a liner hanger. The expansion cone assembly (200) includes a cone mandrel (202) having an outer frustoconical surface (220), a lead cone (206) slidably disposed around the cone mandrel (200) having a frustoconical surface (228) with a maximum outer diameter (230) and a collapsible cone (204) slidably disposed at least partially around the outer frustoconical surface (220) of the cone mandrel (202). In an expansion configuration, the outer frustoconical surface (220) radially props the collapsible cone (204) such that it has a first maximum outer diameter (232) that is greater than the maximum outer diameter (230) of the lead cone (206). In a retrieval configuration, the collapsible cone (204) axially shifts relative to the outer frustoconical surface (220) such that it has a second maximum outer diameter (234) that is no more than the maximum outer diameter (230) of the lead cone (206).

Owner:HALLIBURTON ENERGY SERVICES INC

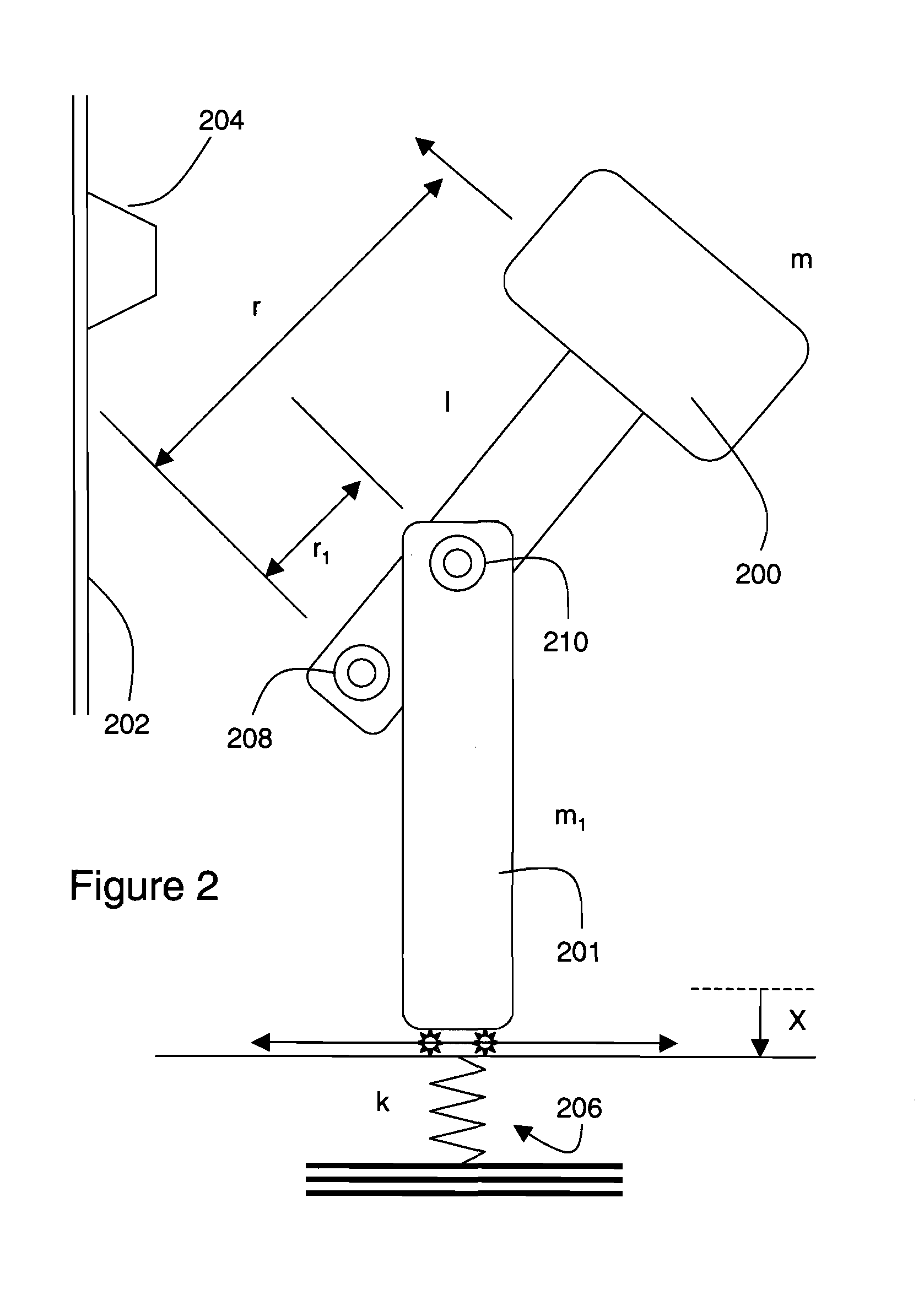

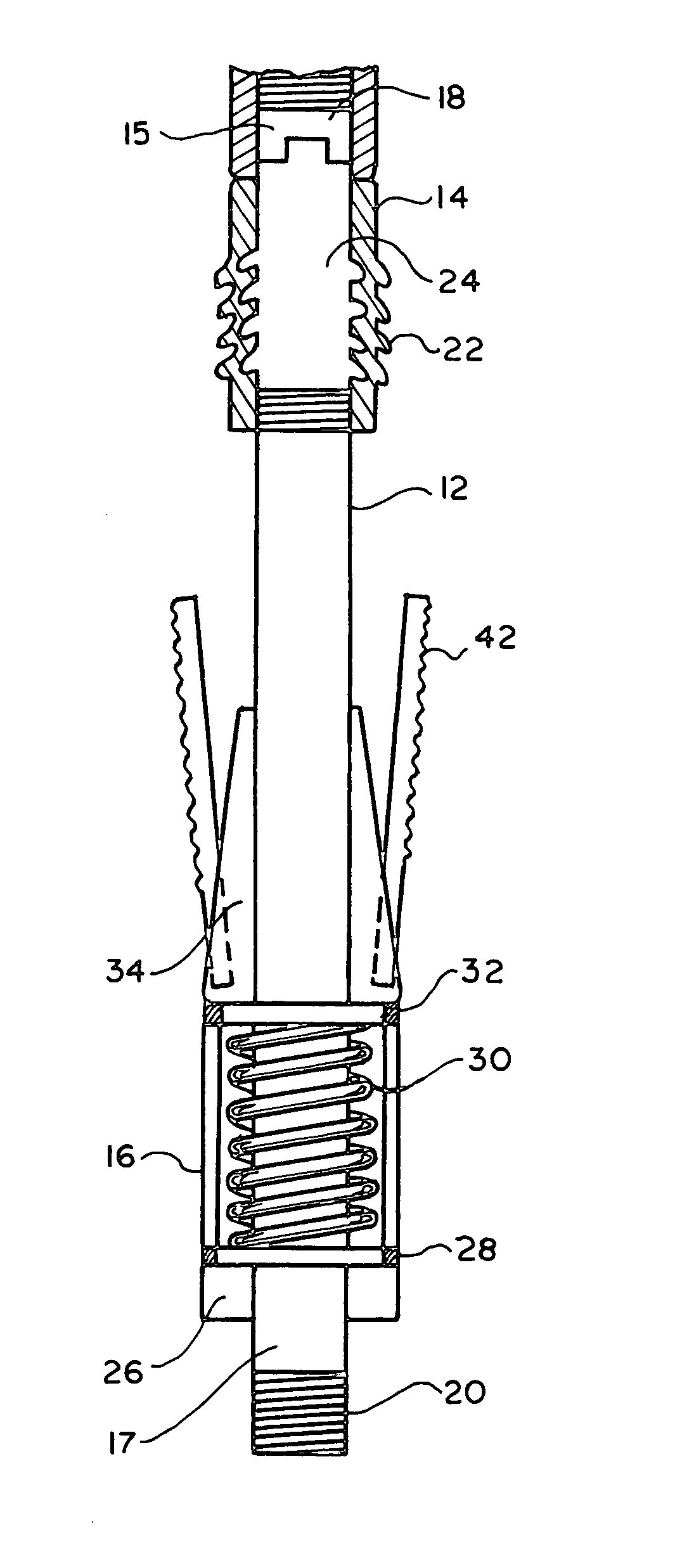

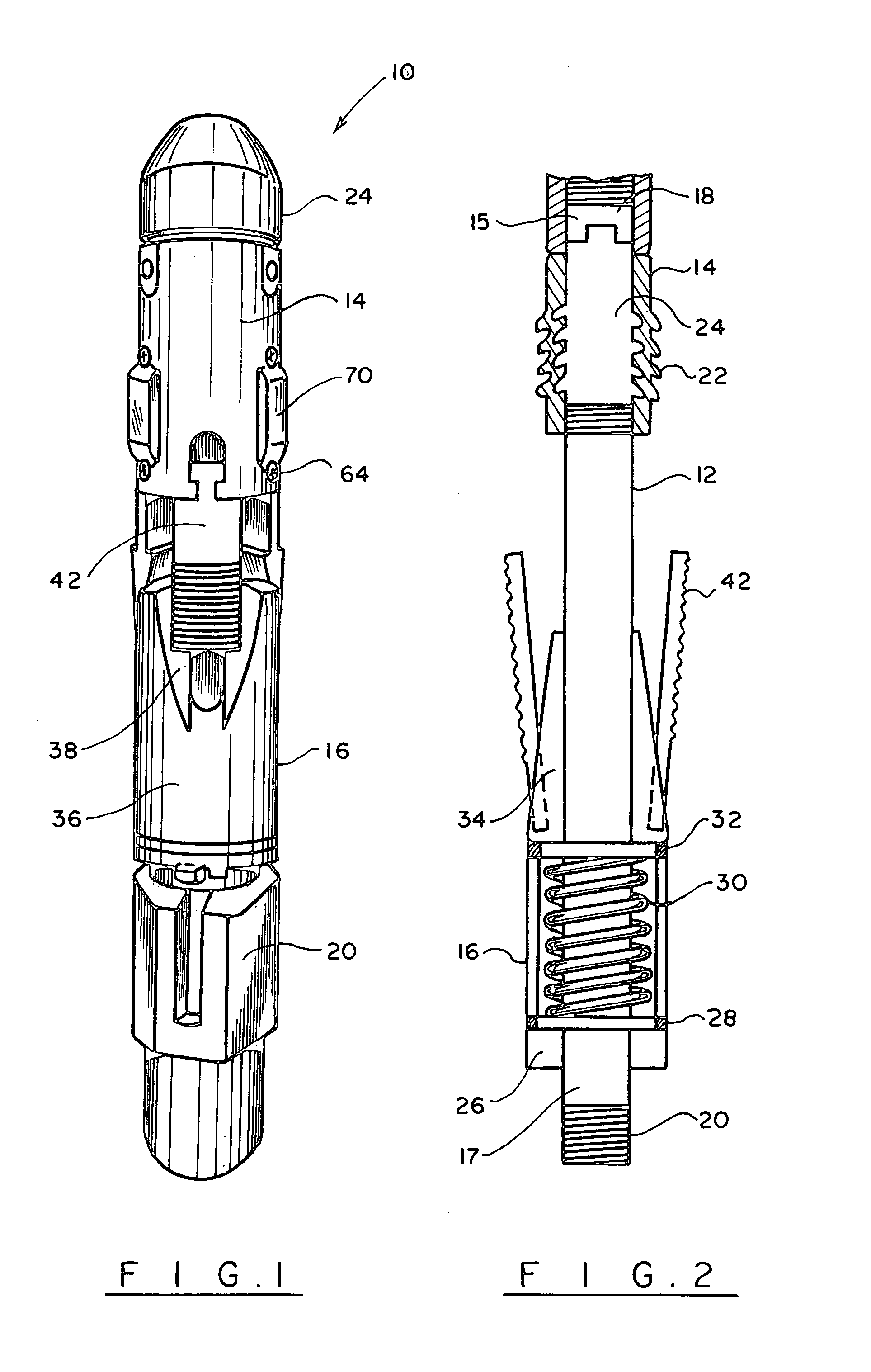

Downhole seismic source

Elastodynamic waves are generated by a tool having a hammer rotatably connected with a housing by a first hinge and an actuator arm rotatably connected with the hammer by a second hinge. An axial force applied to the actuator arm by a drive shaft and spring is translated and amplified to a radial impact force by rotation of the hammer around the first hinge. The tool may also include a stabilizer arm connected to the actuator arm by a third hinge, and connected to the housing by a fourth hinge. The housing may be an acoustic wireline tool cylinder having an opening that permits the hammer mass to extend outside the housing when rotated in a first direction. The housing may also include a second opening that permits the hammer mass to extend outside the housing when rotated in a second direction, and a third opening that permits the hammer mass to extend outside the housing when rotated between the first and second openings.

Owner:SCHLUMBERGER TECH CORP

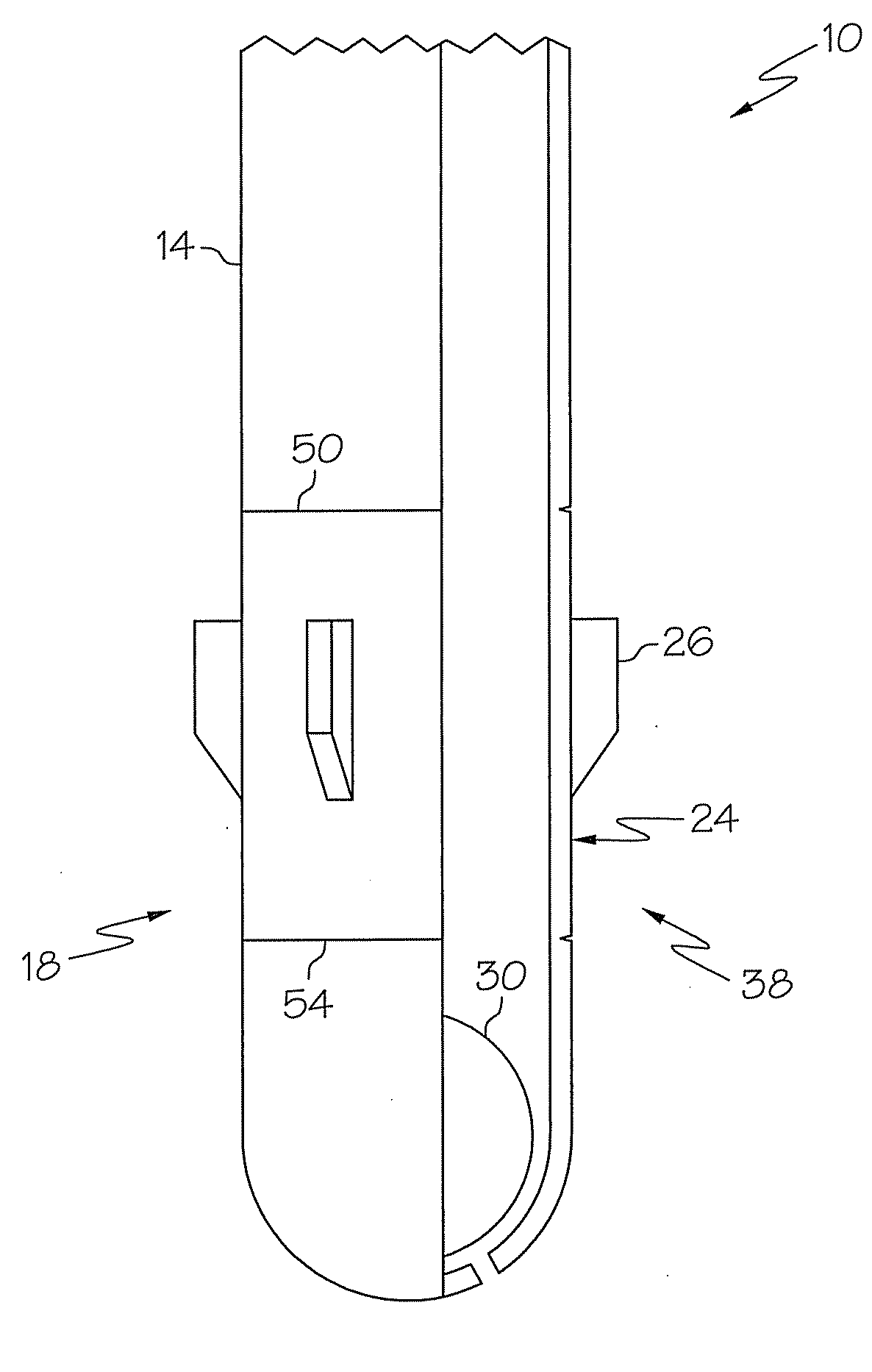

Well abandonment plug

A method and apparatus of plugging and abandoning a well includes using a plug apparatus and installing bentonite elements in an oil well production casing having a bore. The plug apparatus is lowered into the production casing bore to a selected elevation using a slick line or the like. The apparatus has a tool body and slip dies that are movably mounted upon the tool body to move between extended and retracted positions. Afer the tool body is positioned at a selected location within the casing bore, tension is applied to the slick line to move the slip dies to an extended position wherein the slip dies engage the casing and secure the tool body in a desired location. The casing bore is then displaced with water above the tool body. Bentonite elements are then dumped into the water filled wellbore. The bentonite elements are allowed to swell to form a plug. The tool body can be retrieved from the casing bore if desired.

Owner:GARRETT JONATHAN +2

System and method for providing a downhole mechanical energy absorber

InactiveUS20100132939A1Maximizes limit loadMinimizing shock loadingPortable framesDrilling rodsMechanical energyEngineering

A system and a method are disclosed for providing a downhole mechanical energy absorber that protects downhole tools from impact loads and shock loads that occur during run-in contacts, tool drops, perforating blasts, and other impact events. A continuous localized inelastic deformation of a tube is a primary energy absorber in a load limiting design of the downhole mechanical energy absorber.

Owner:STARBOARD INNOVATIONS

Method of preventing dropped casing string with axial load sensor

A method of running casing into a well utilizes a load sensor to avoid dropping the casing string accidentally. The rig has a spider at the rig floor that suspends a casing string in the well when in a gripping position. A casing lifting mechanism will place a new joint of casing on the casing string suspended in the spider. The new joint of casing is rotated to make up with the casing string. After makeup, the casing lifting mechanism lifts the new joint of casing and the casing string. The operator releases the spider to allow the casing string to be lowered further into the well. Before releasing the spider, a load sensor will send a signal indicating that the casing lifting mechanism is supporting a minimum amount of weight.

Owner:NABORS DRILLING TECH USA INC

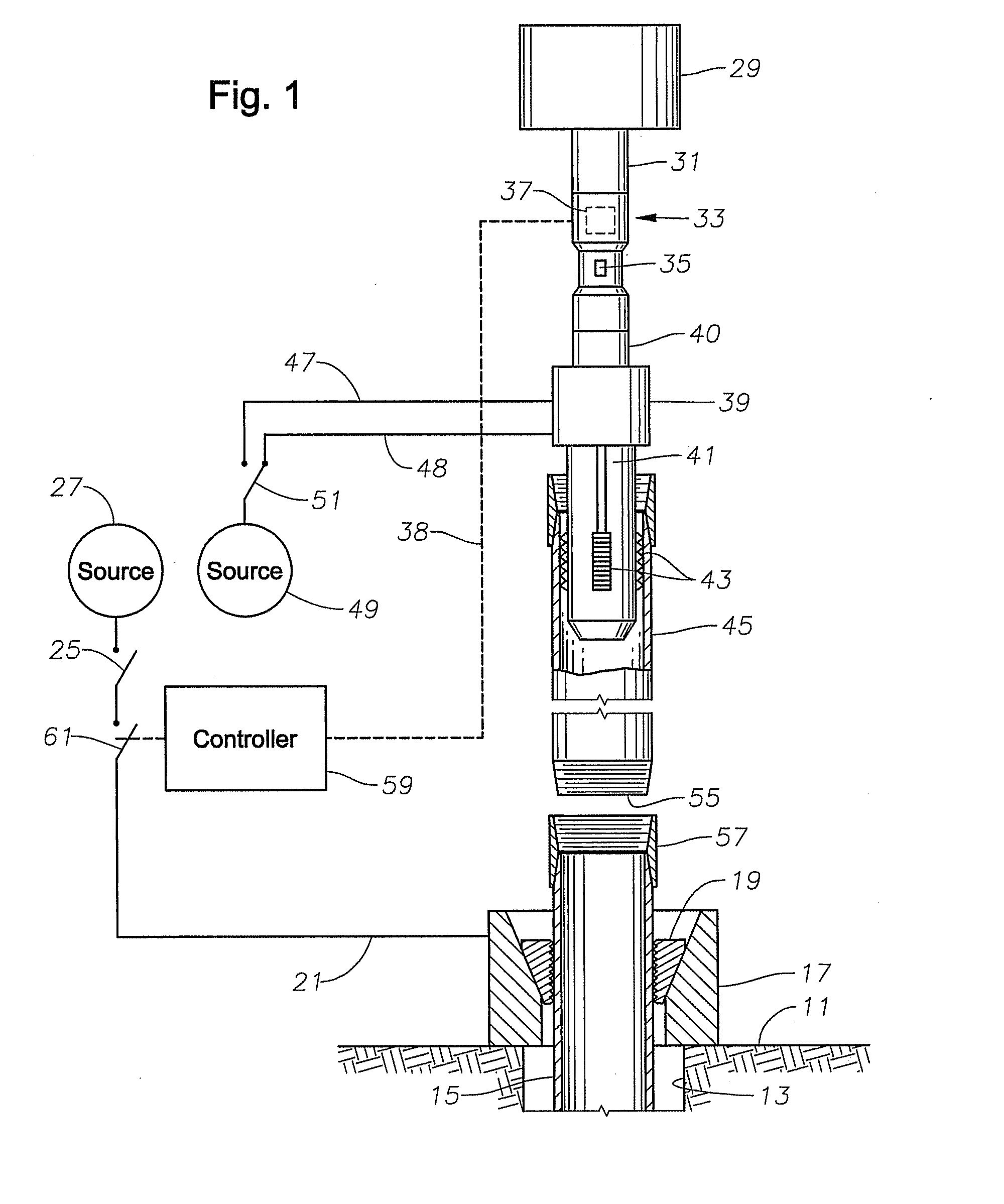

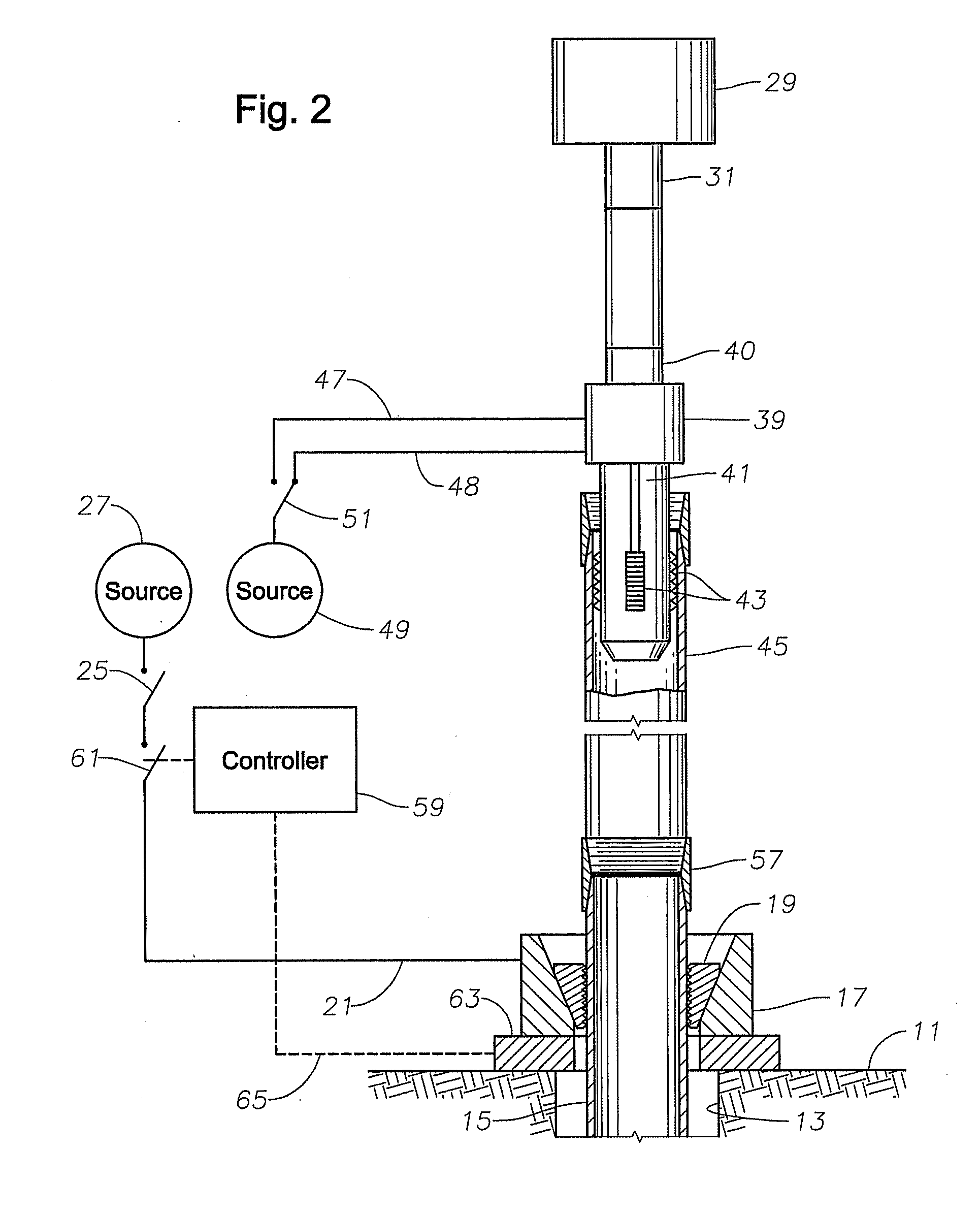

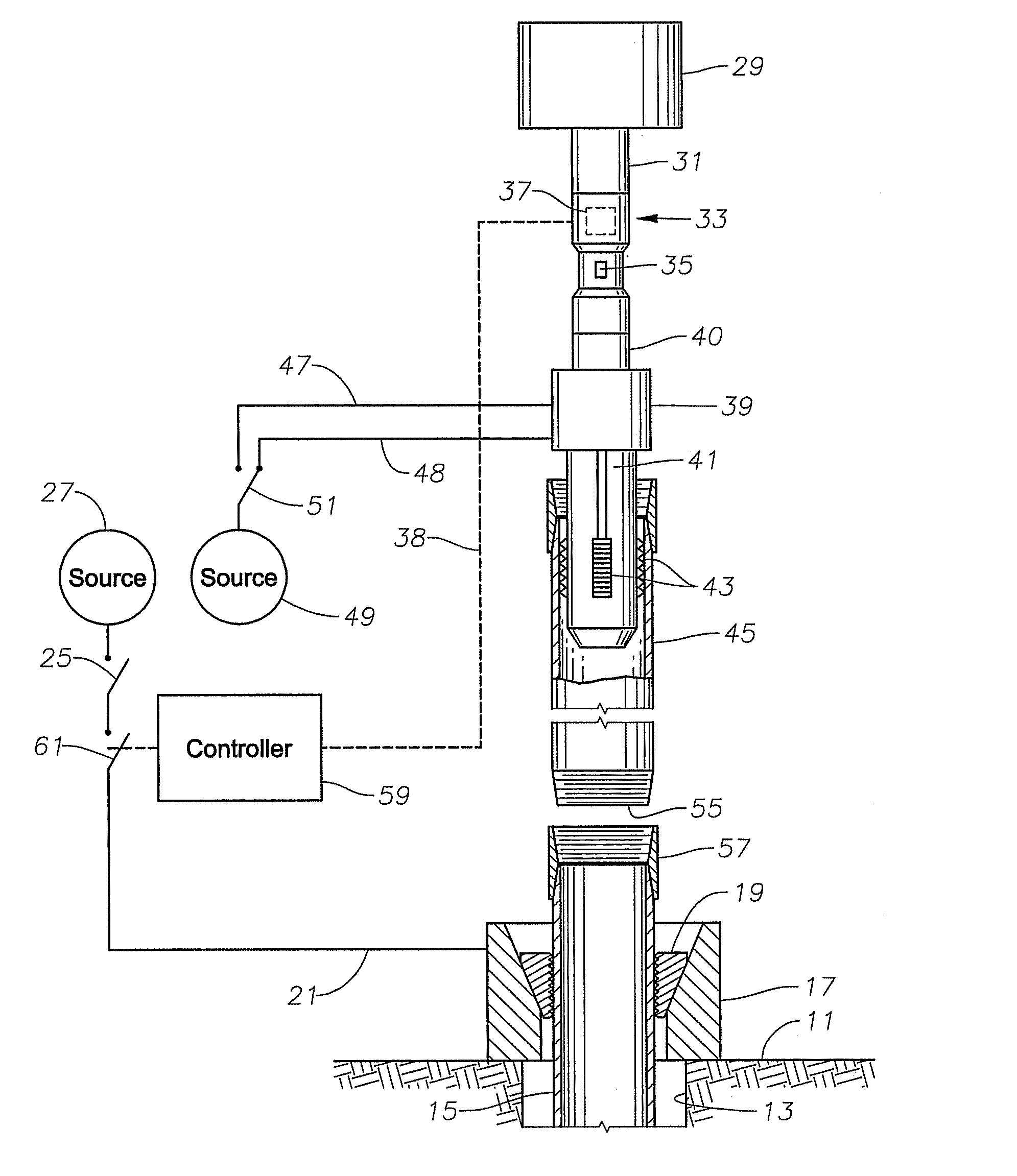

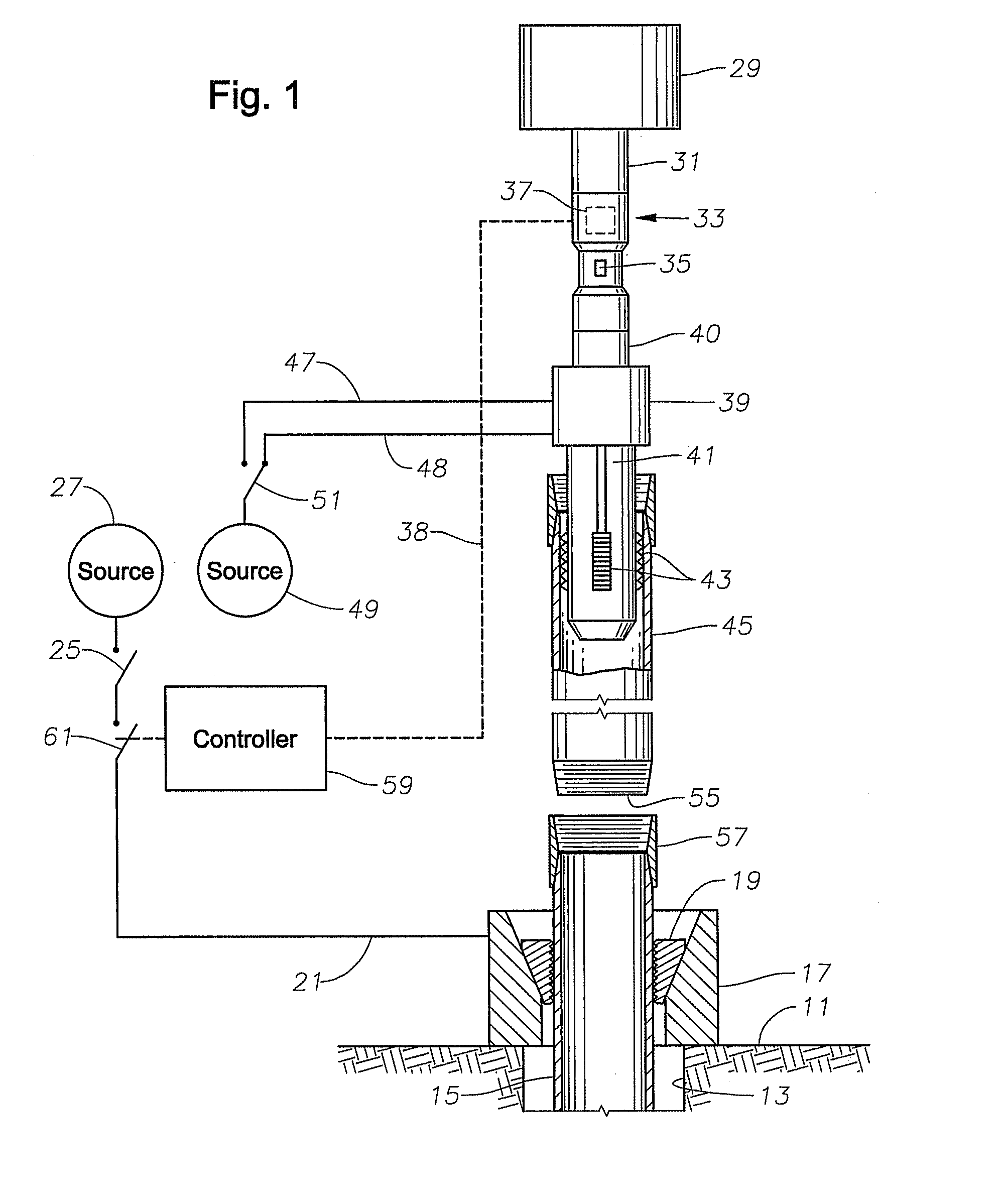

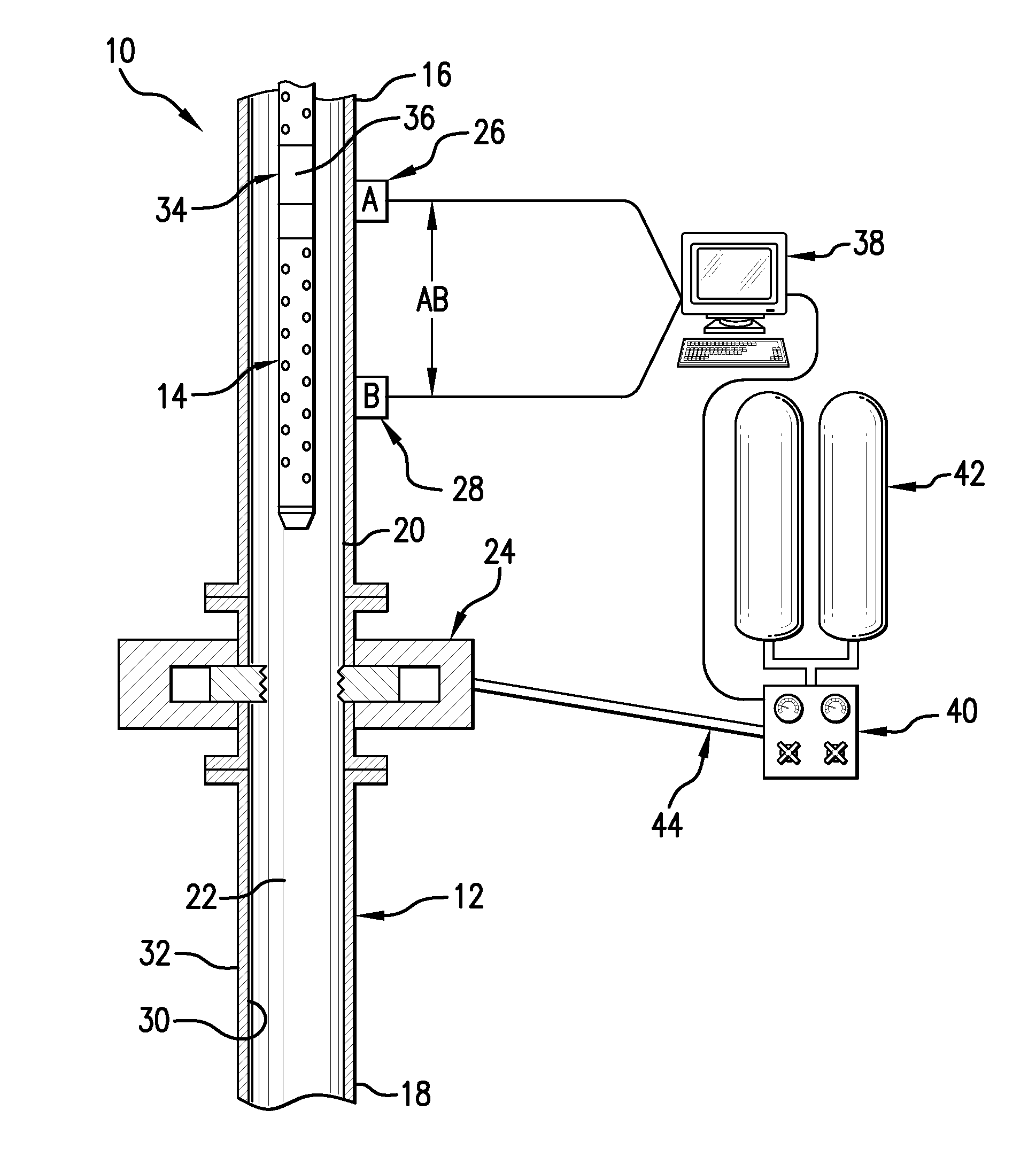

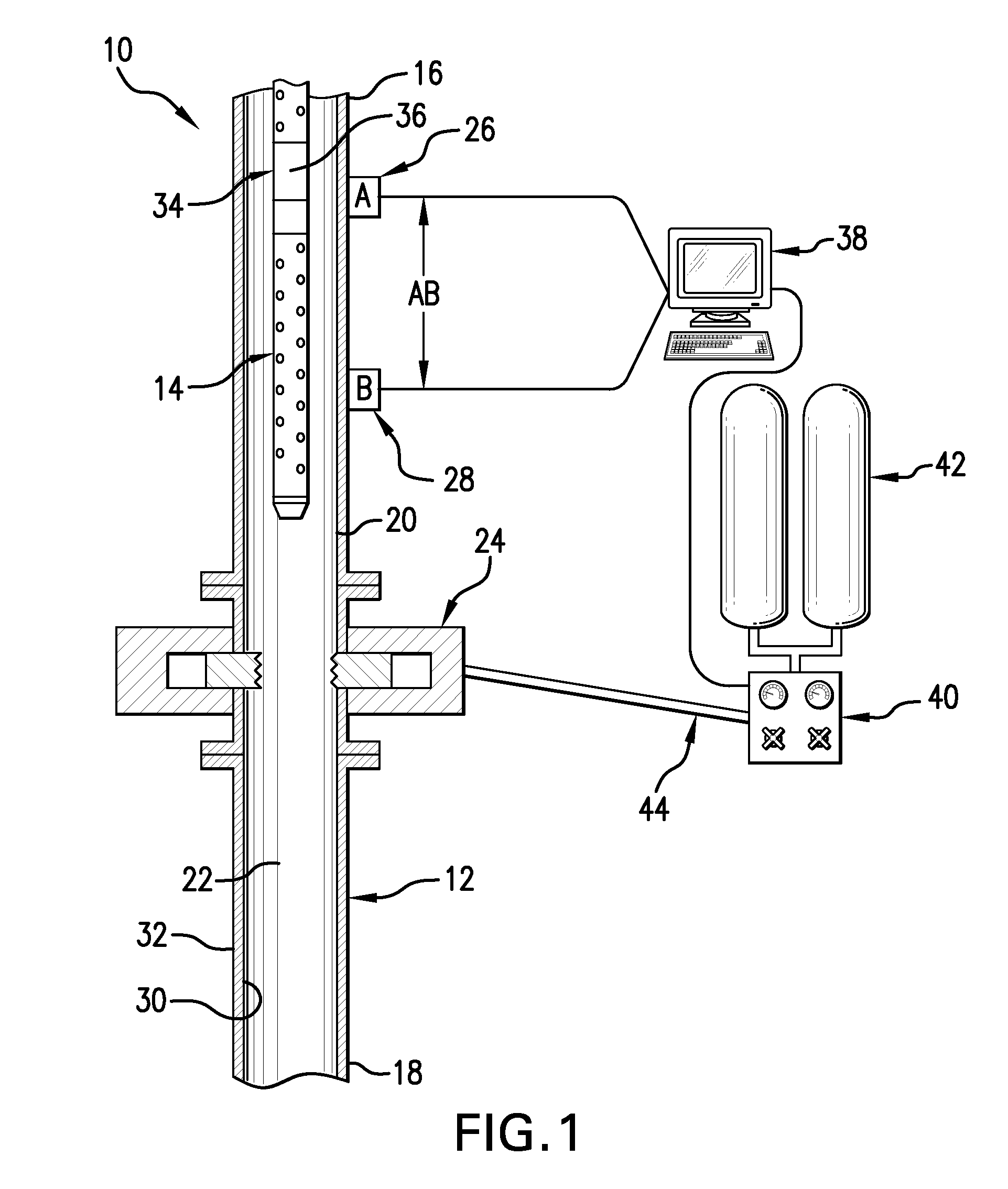

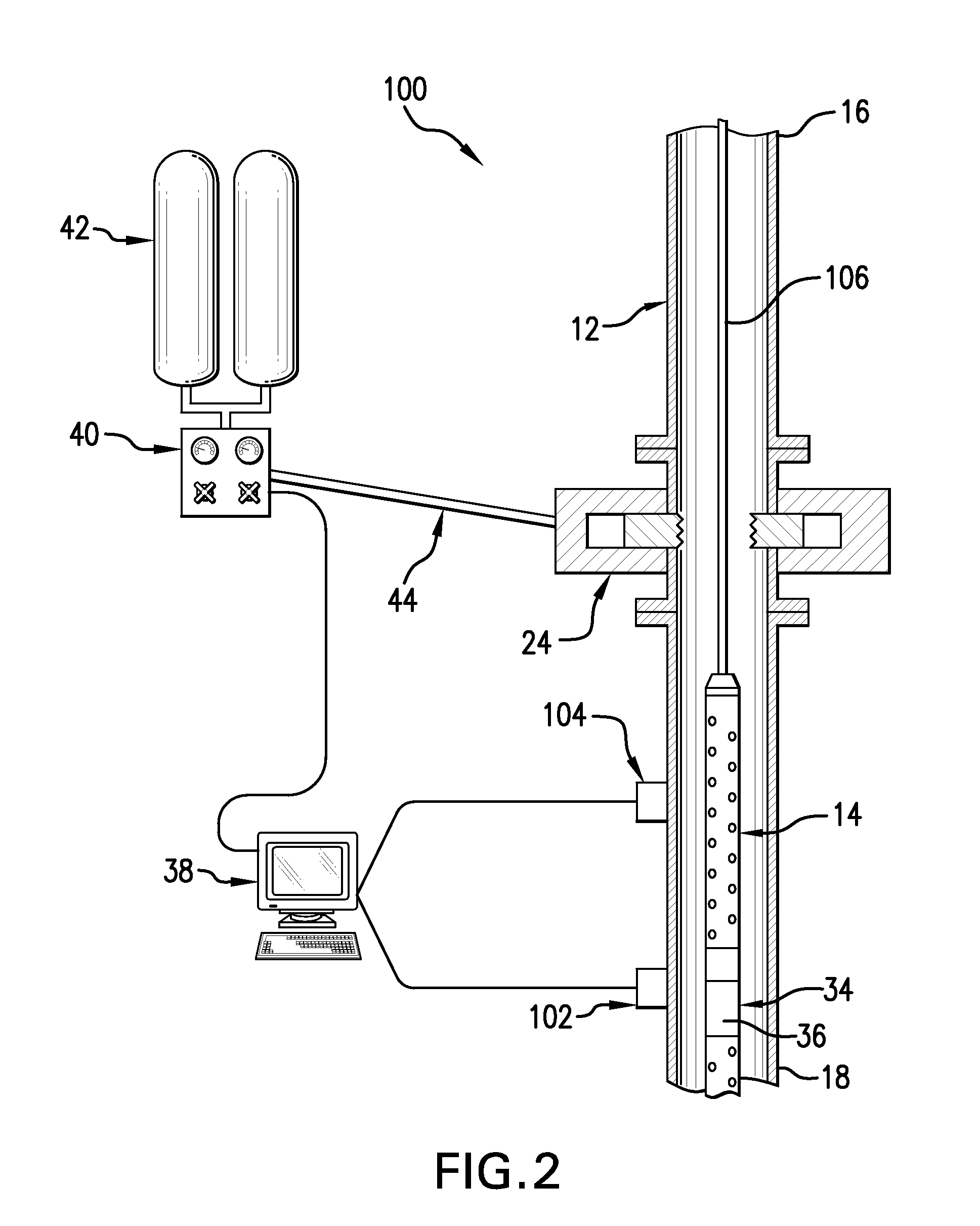

Speed activated closure assembly in a tubular and method thereof

A tubular closure assembly responsive to speed or velocity of an object. The tubular closure assembly includes at least one sensor in operable communication with an interior of a tubular. The at least one sensor sensing an object passing a first point and then a second point within the tubular. A processor receiving an output from the at least one sensor and calculating speed of the object from the first point to the second point. A control panel receiving information from the processor and a closure system movable between an open condition and a closed condition. Activatable to the closed condition by the control panel in response to the object moving from the first point to the second point at speed faster than a preset value or at a velocity outside a preset range. Also included is a method of closing a tubular of a borehole.

Owner:BAKER HUGHES INC

Elevator grip assurance

According to one or more aspects of the invention an interlock device is adapted for connection within a load path of a tubular support device to lock the tubular support device in a closed position in response to detecting a load suspended from the tubular support device. The interlock device includes a first member moveably connected to a second member and a biasing mechanism operationally connected to the first member and the second member providing a load setting resisting movement of the first member and the second member relative to one another. The first and the second member may be rotationally locked with one another to transmit rotation across the interlock device to the elevator.

Owner:FRANKS INT

Anchor device to relieve tension from the rope socket prior to perforating a well

An anchoring sub used in combination with hydrocarbon exploration and production tools, such as perforating guns and logging devices, within a wellbore. The anchor sub is reversible and includes a mandrel, a slip assembly and a slip cone, where the slip assembly selectively travels up and down the mandrel and is able to mate with the slip cone. The anchor sub secures itself to the inner circumference of a wellbore when the slip assembly is mated with the slip cone. Mating and de-mating of the slip assembly with the slip cone is accomplished by selective up and down movement of the anchor sub.

Owner:BAKER HUGHES INC

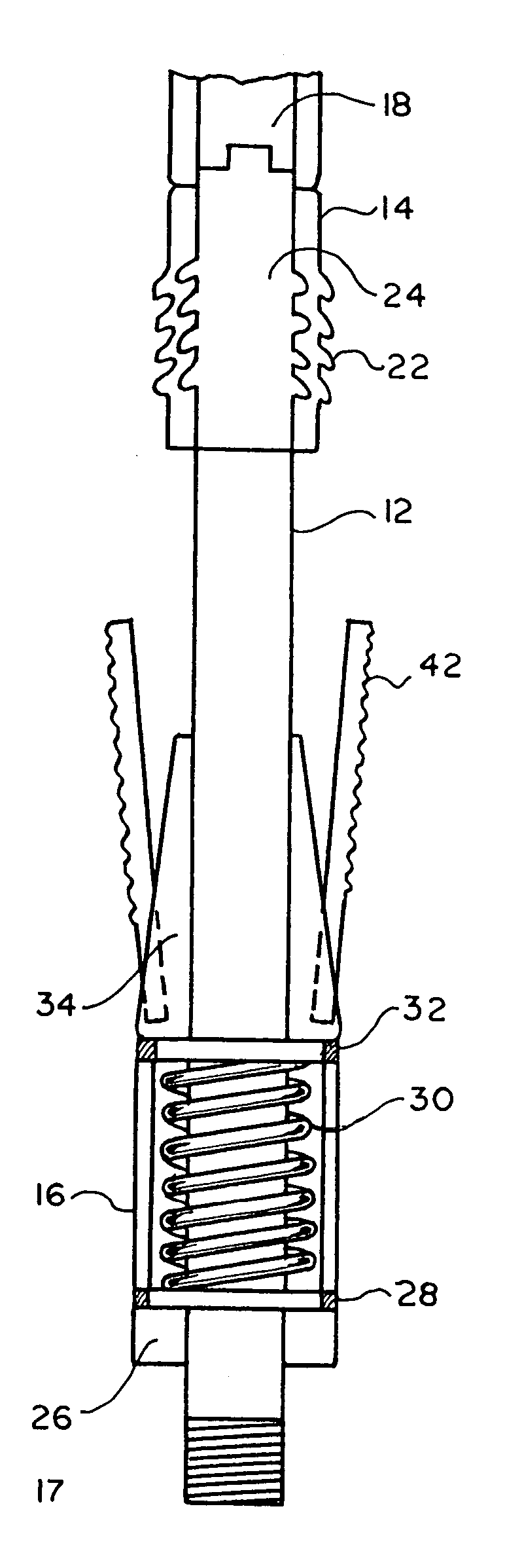

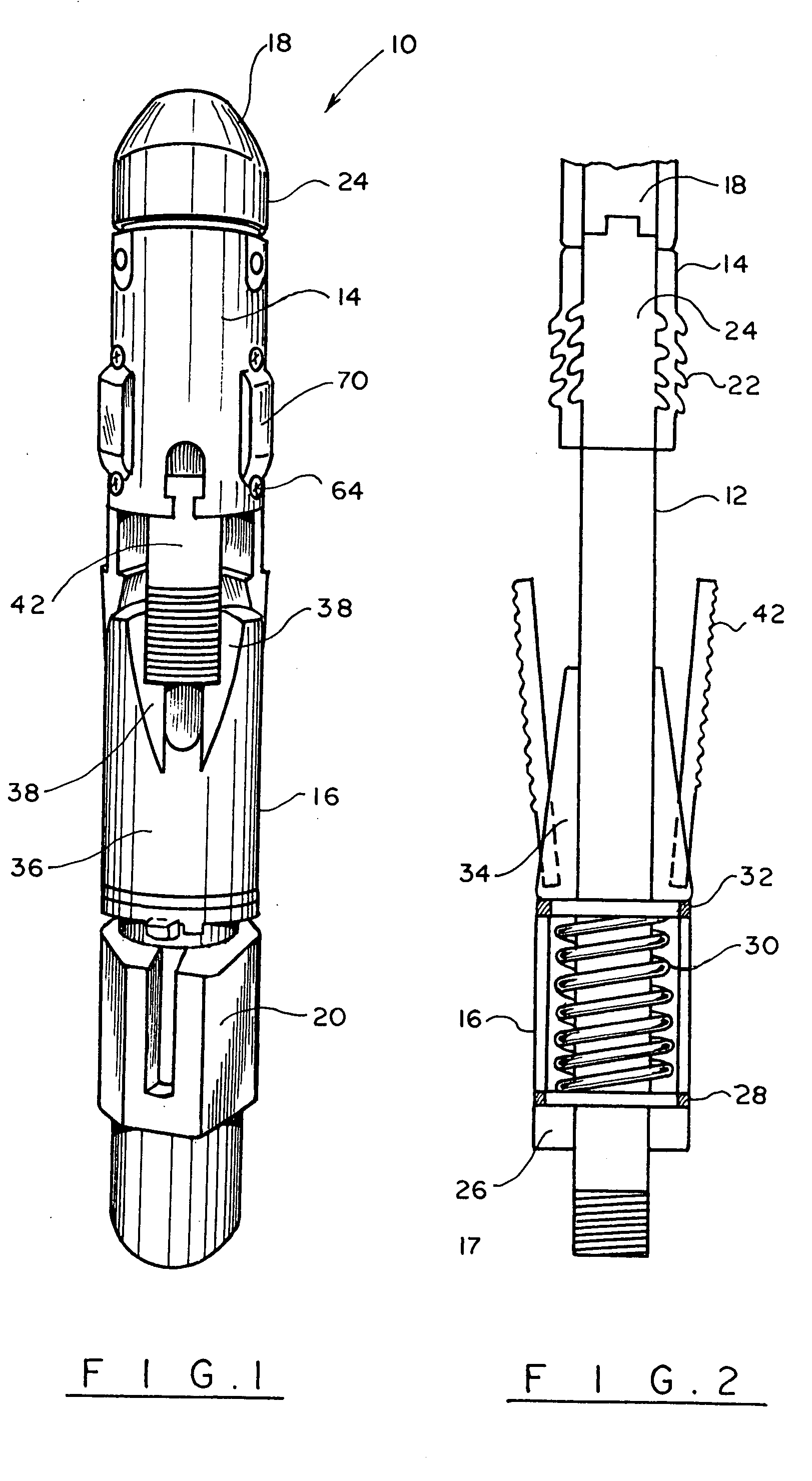

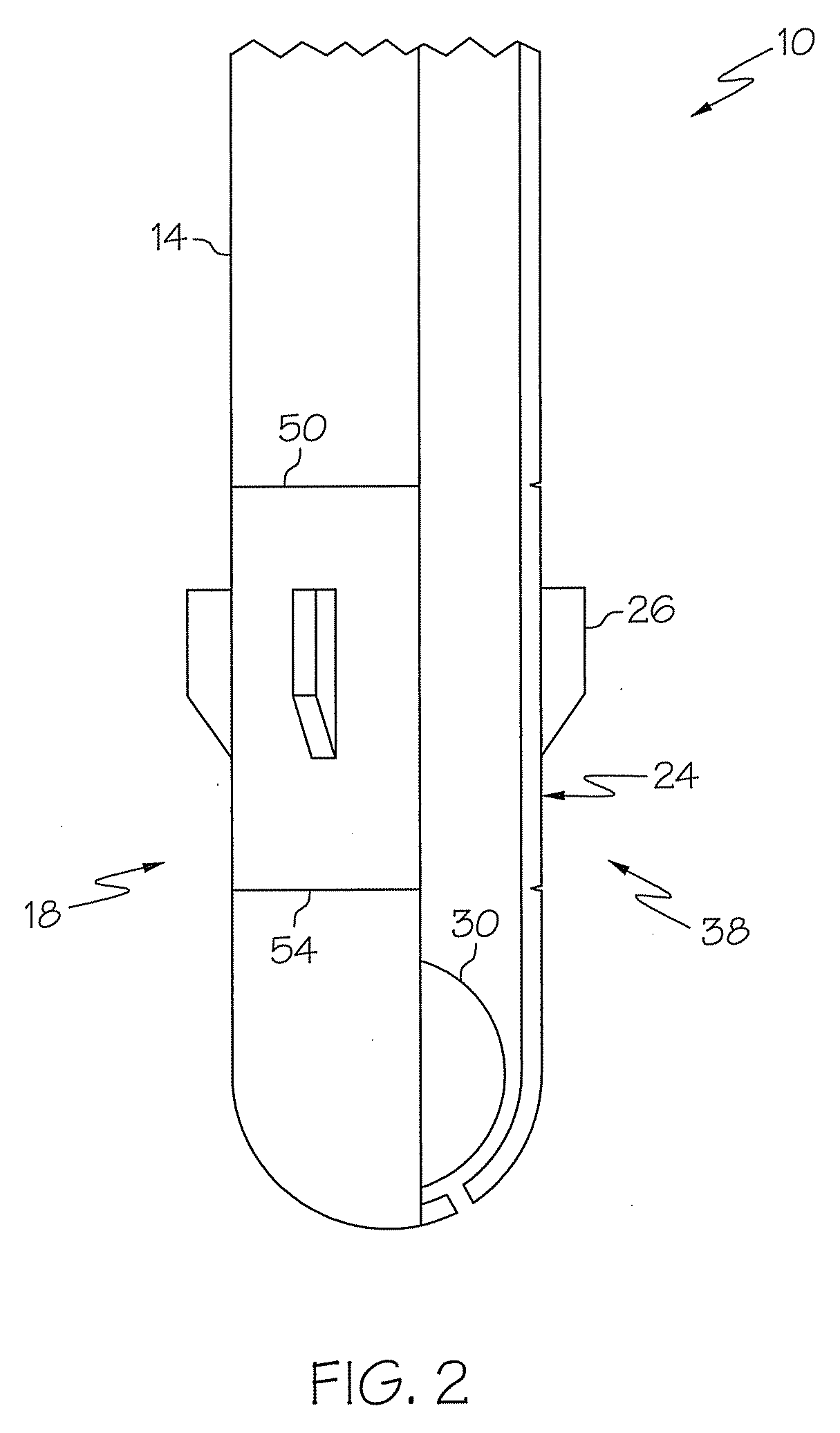

Wellbore anchor tool

An anchor assembly for a downhole tool has upper and lower frictional engagement member for engaging with an inner wall of the casing. The upper frictional members are spring-tensioned, while the lower frictional engagement members slide, to certain degrees, in relation to a longitudinal axis of the anchor assembly. At the same time conical engagement between the lower frictional members and the supporting surface causes the lower frictional members to extend outwardly and engage the inner surface of the casing. As a result, the working tool, for instance a sand cutter secured to the anchor assembly is stabilized in the casing, and an even cut may be performed.

Owner:ABRADO

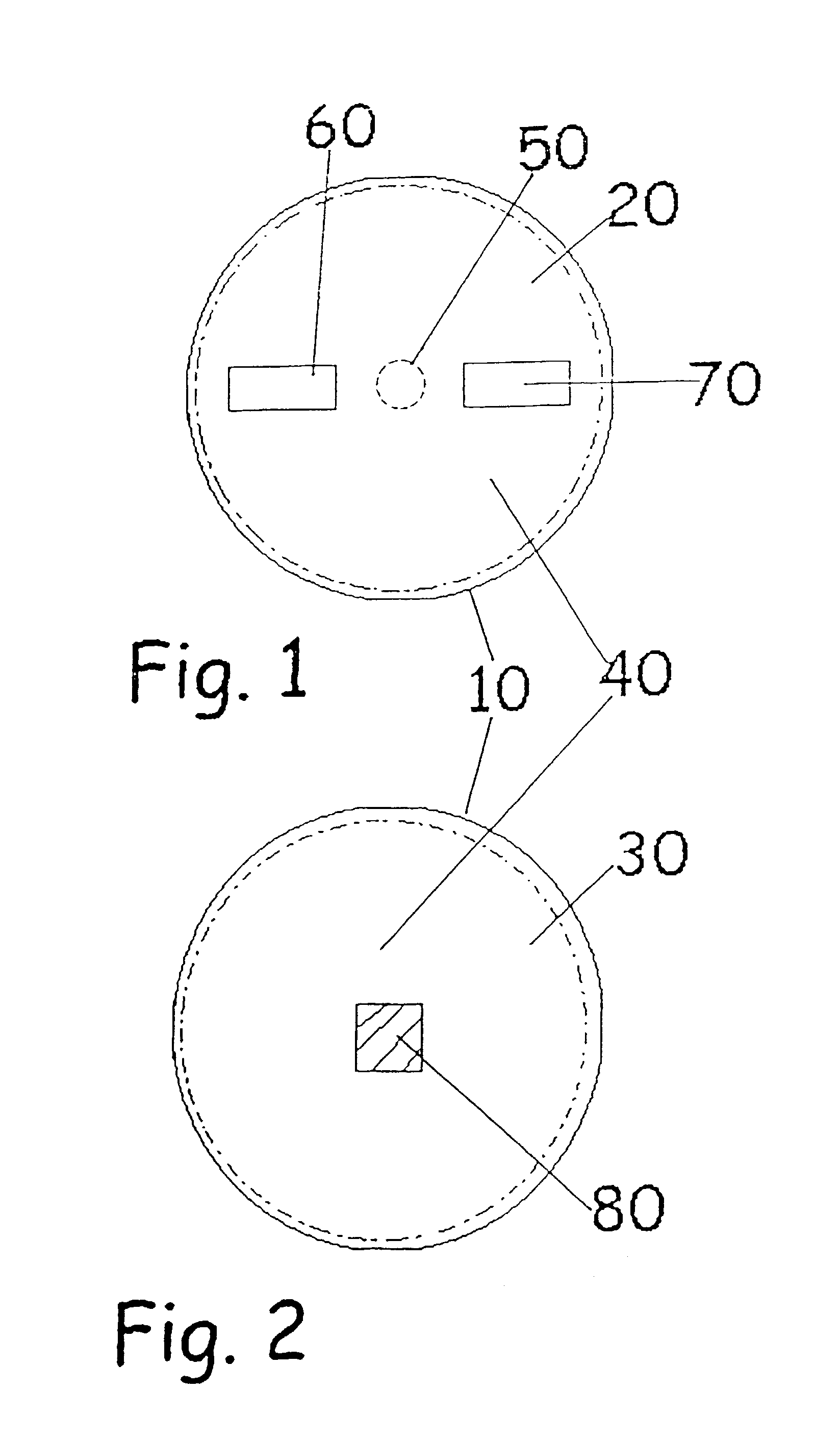

Debris collection device and method

InactiveUS6997653B2Simple yet effective constructionEasy to mass produceThread cutting feeding devicesCleaning machinesAdhesiveBiomedical engineering

A collection device for use with a drill to capture debris ejected from drilling into a surface includes a body formed of flexible material having a first, substantially flat, configuration and a second erect configuration defining a cavity. The body includes a hole for receiving a drill bit into the cavity when the body is erect and adhesive means for adhering the body to the surface.

Owner:DUSTLESS DEPOT

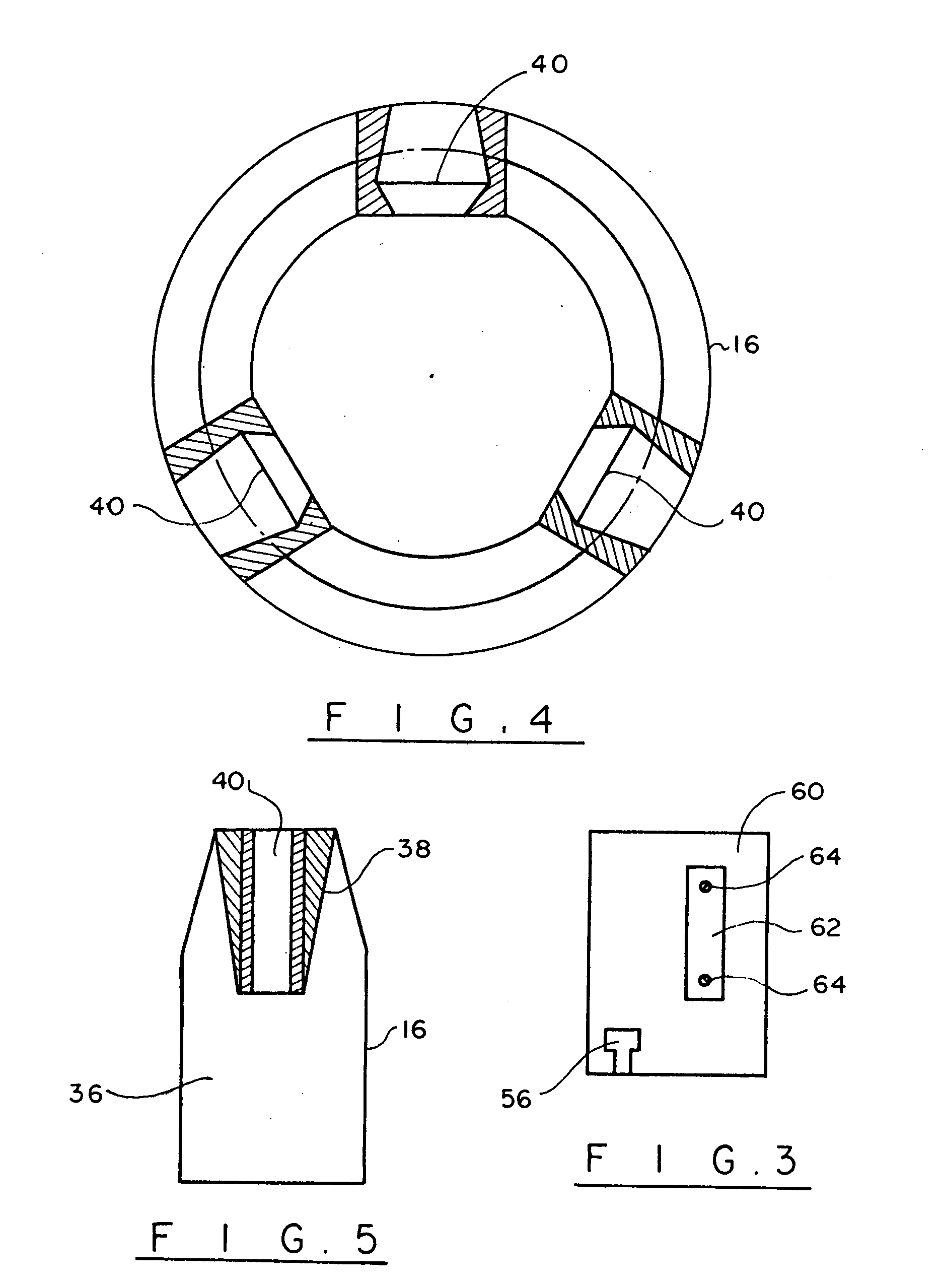

Torque anchor

InactiveUS7121350B2Repeat usagePrevent further rotationFluid removalTubing catchersEngineeringMechanical engineering

Owner:SAMPWELL TESTING SERVICES COBA PROGRESSIVE TECH

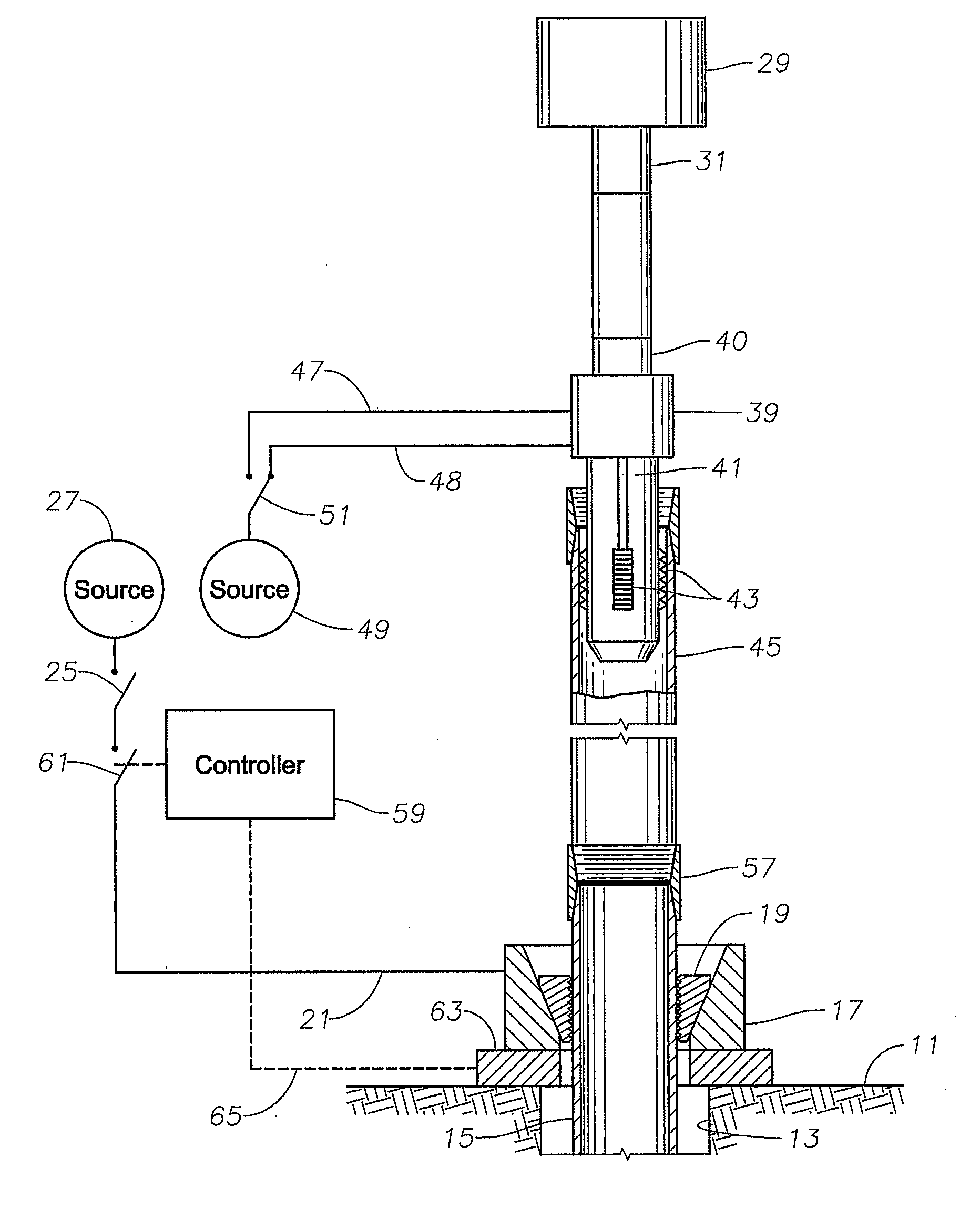

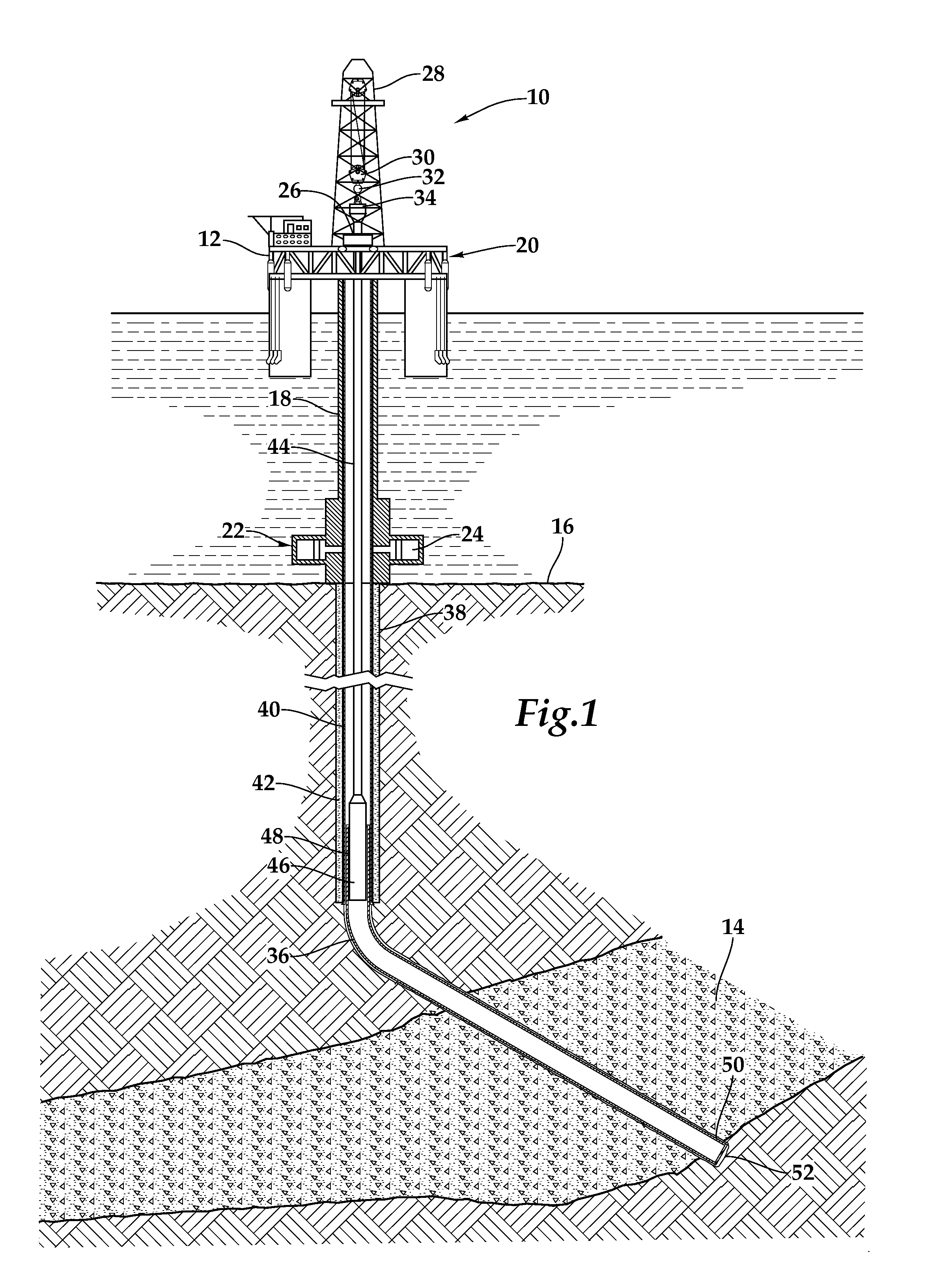

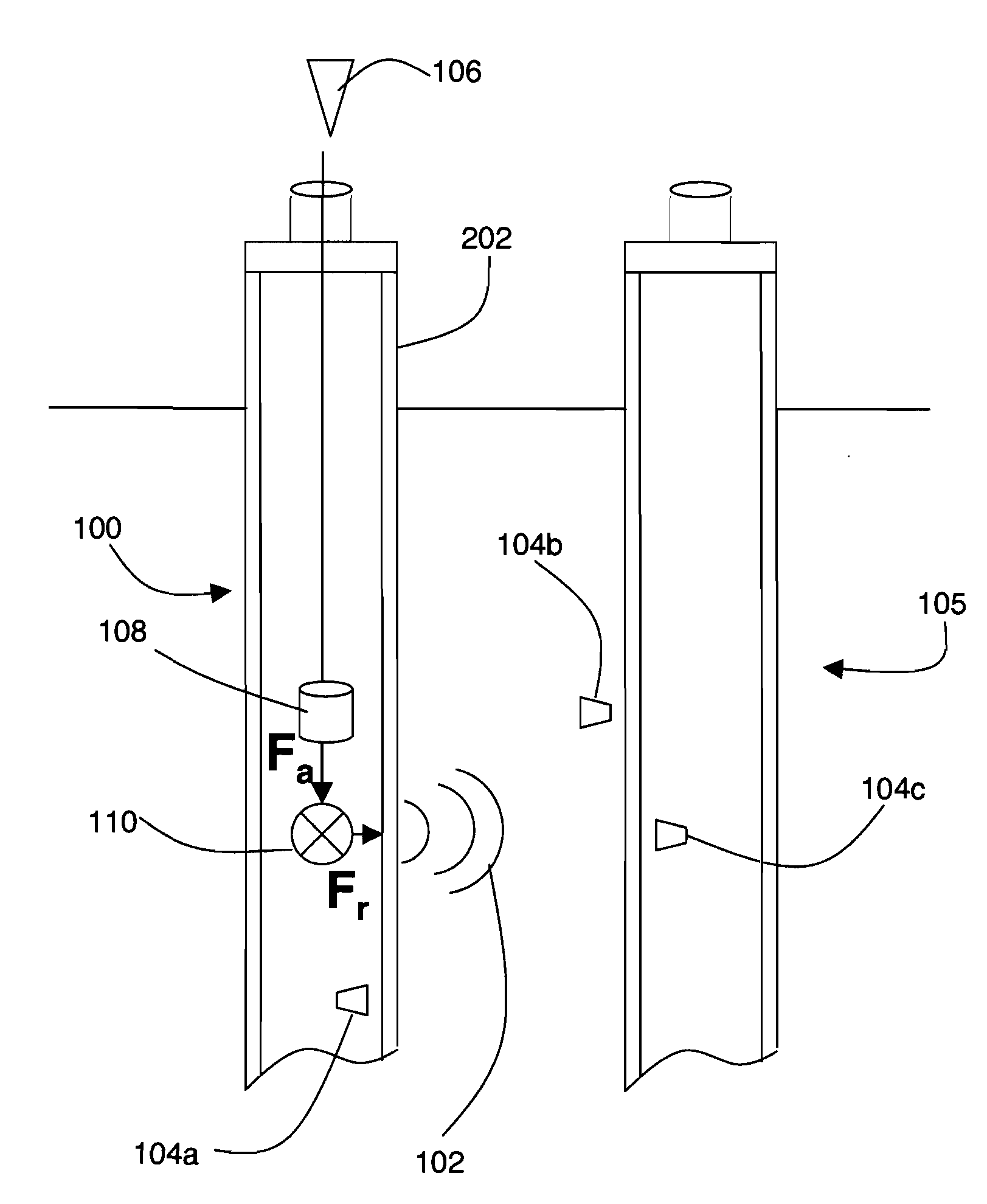

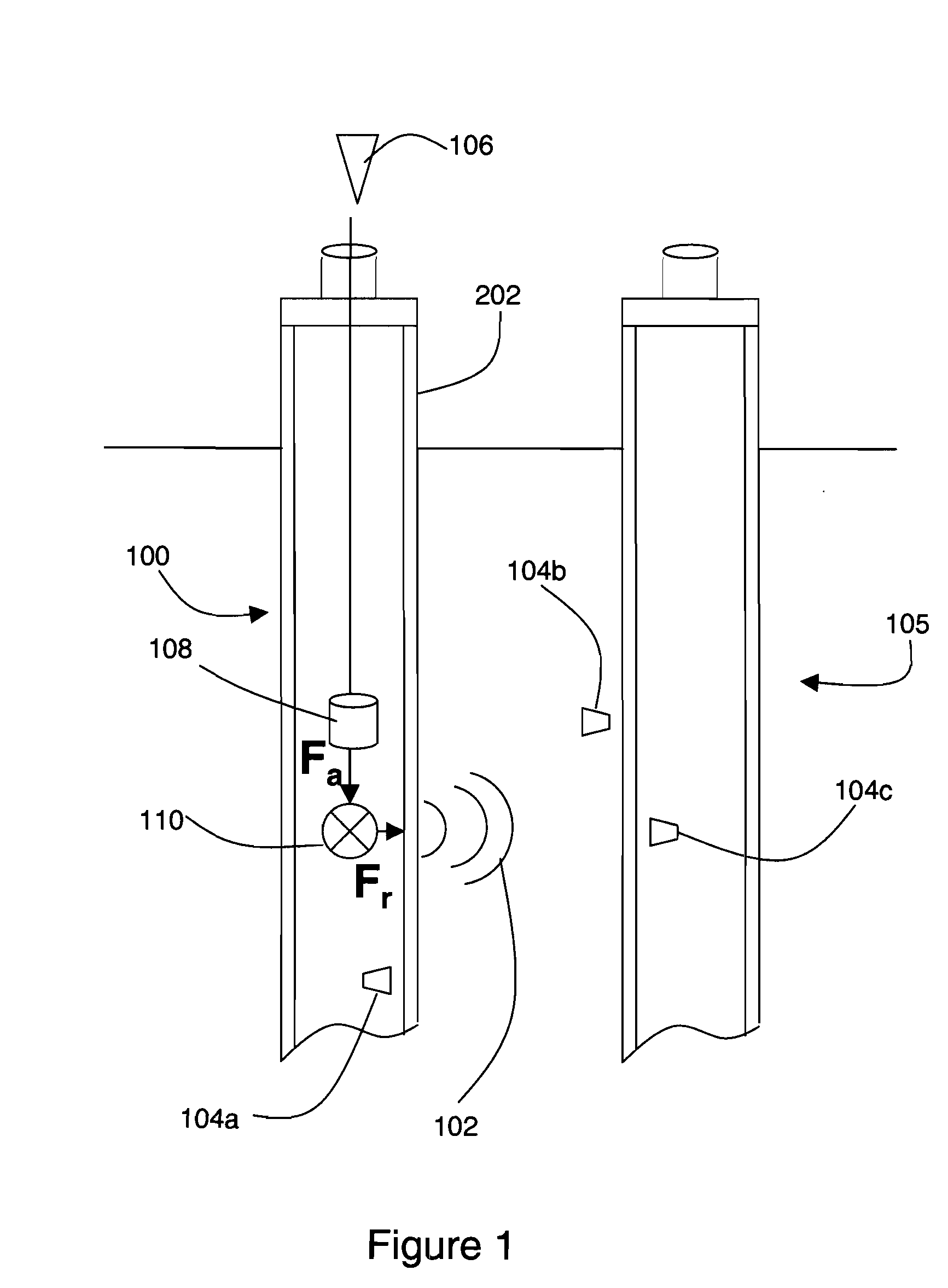

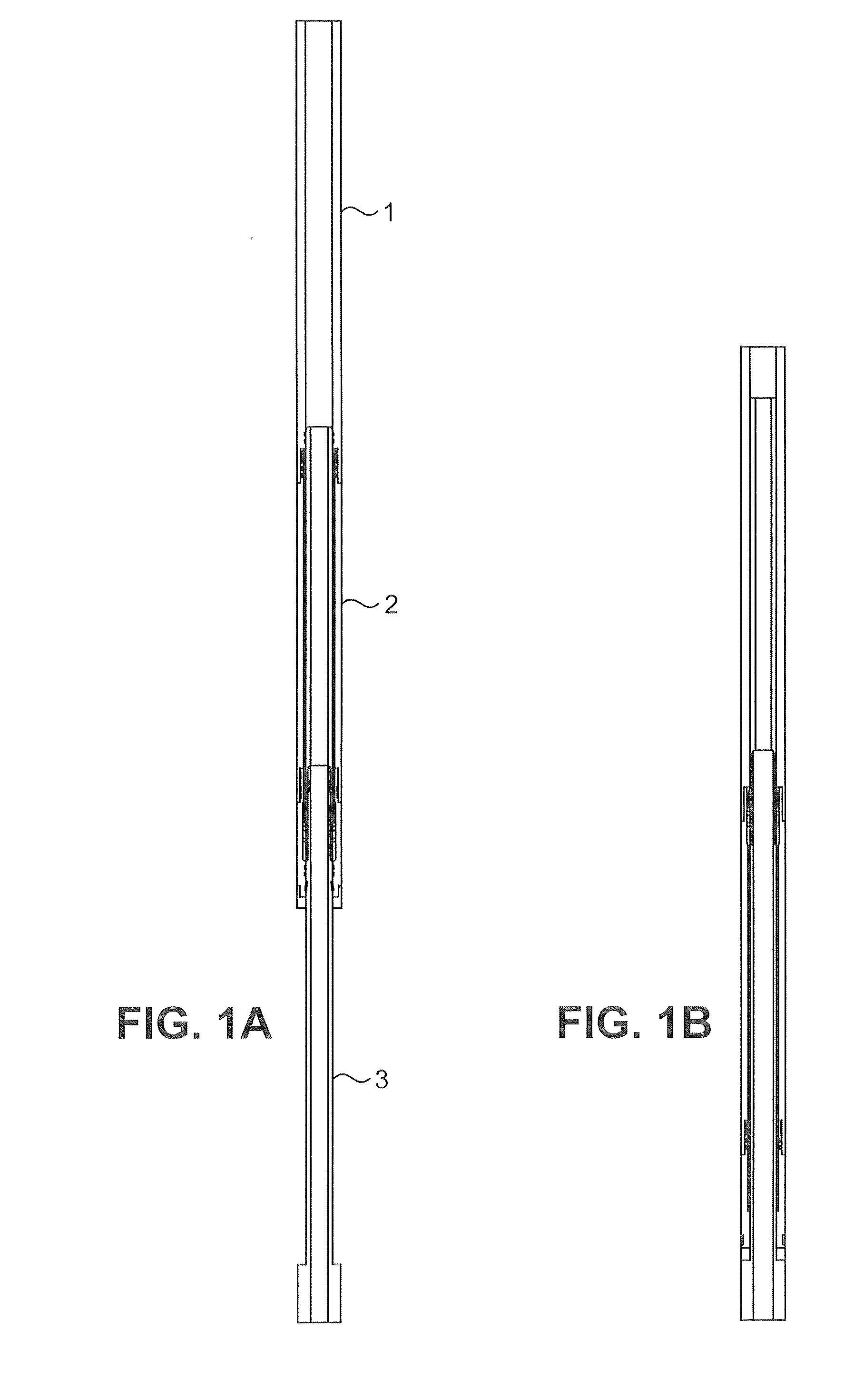

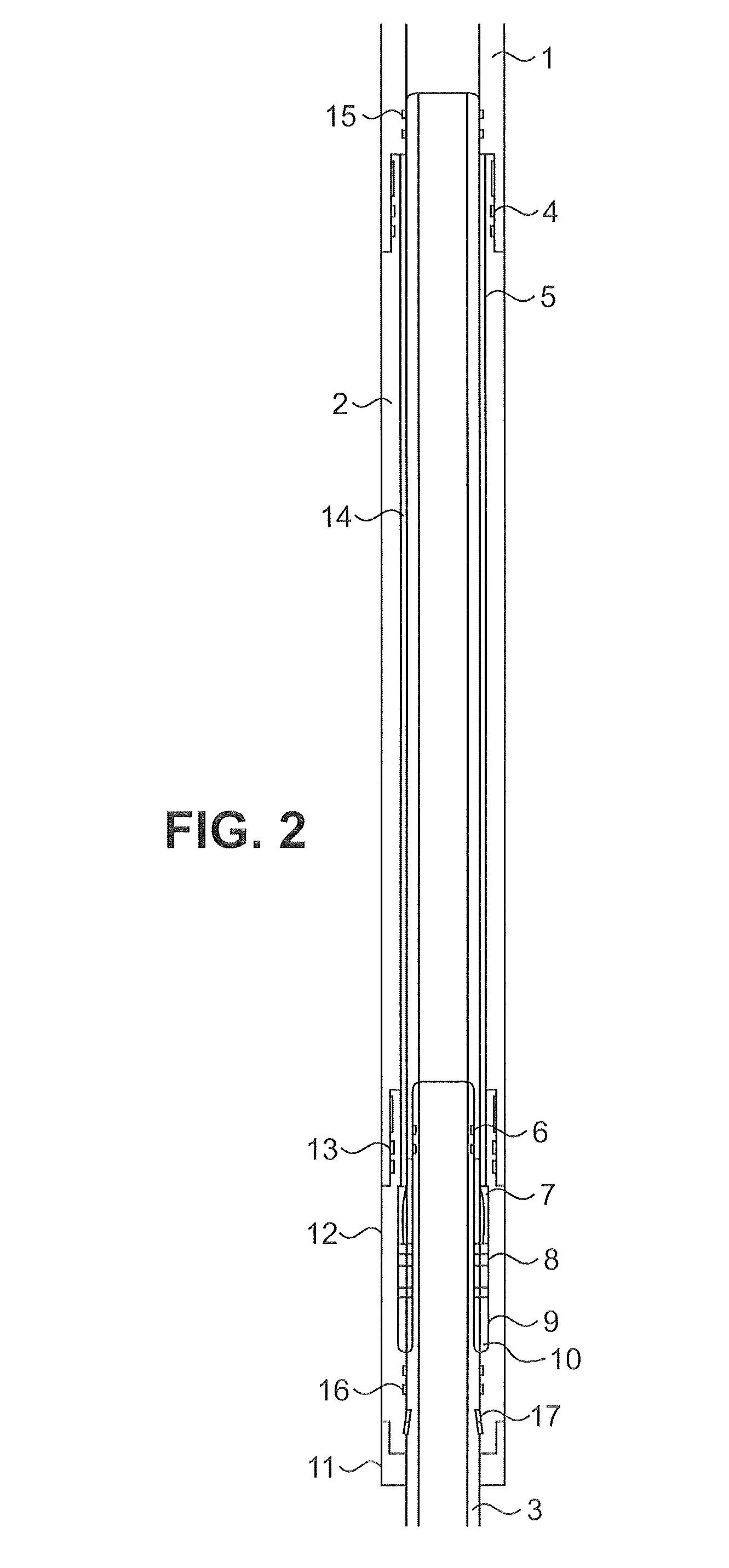

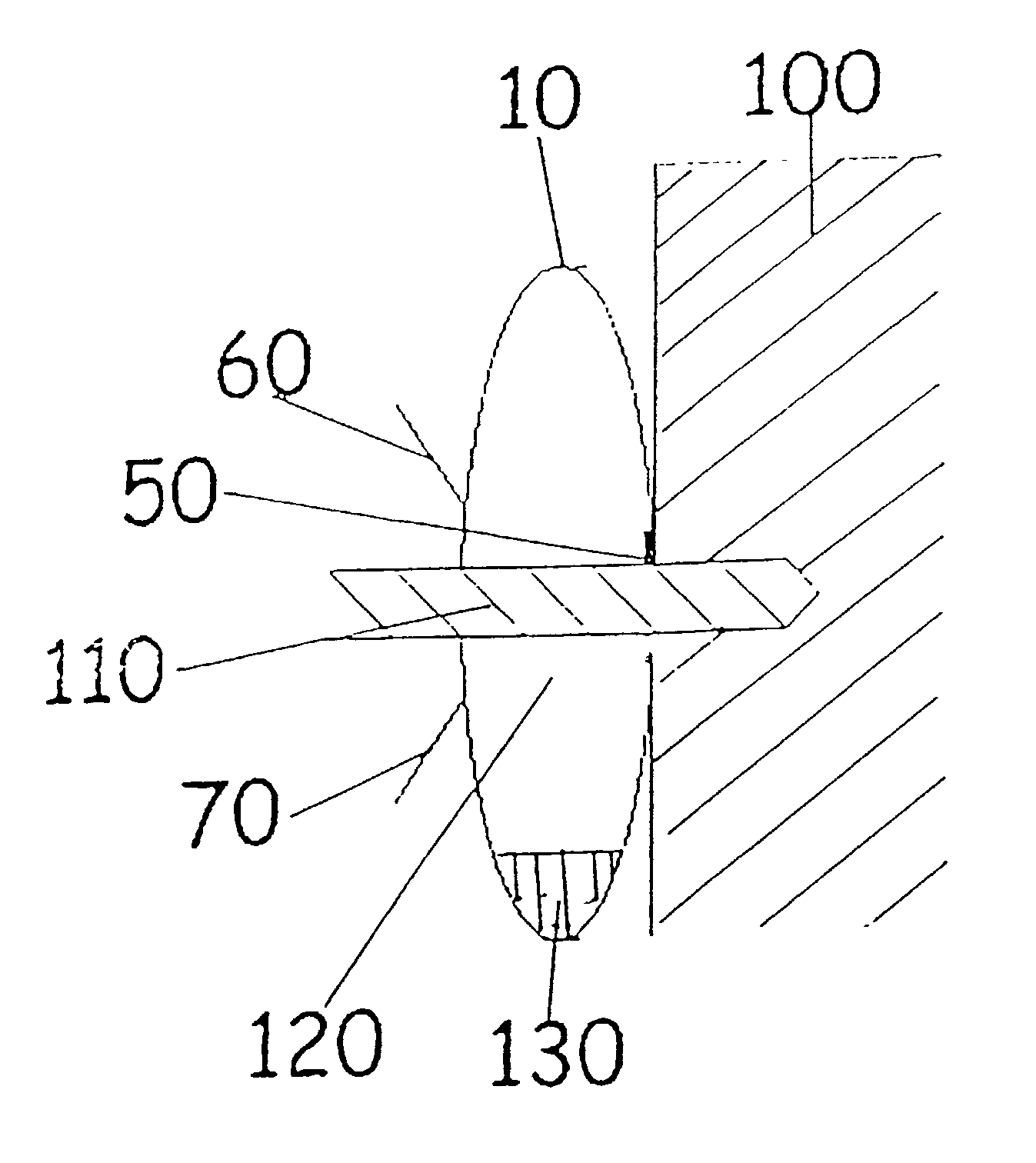

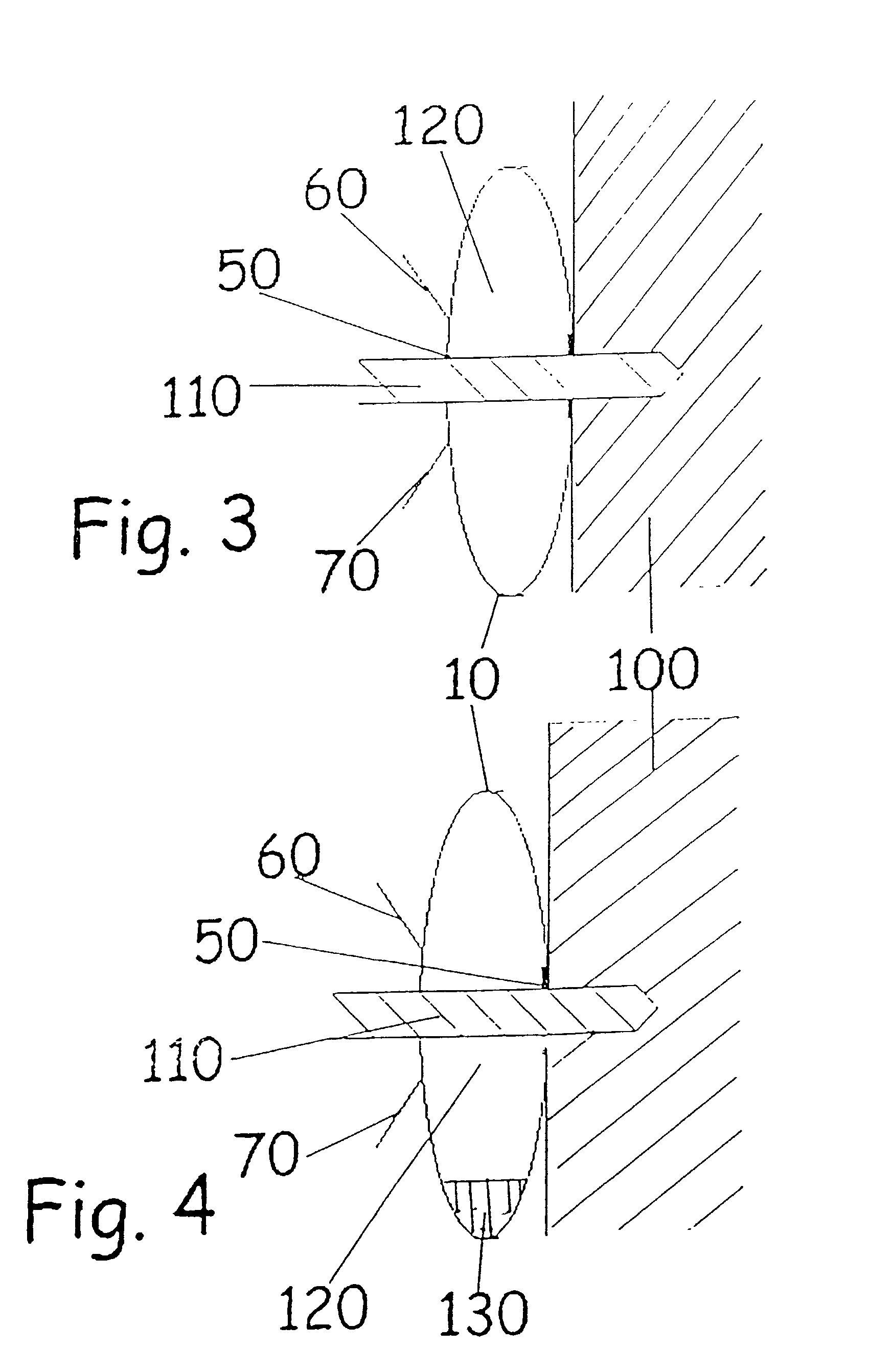

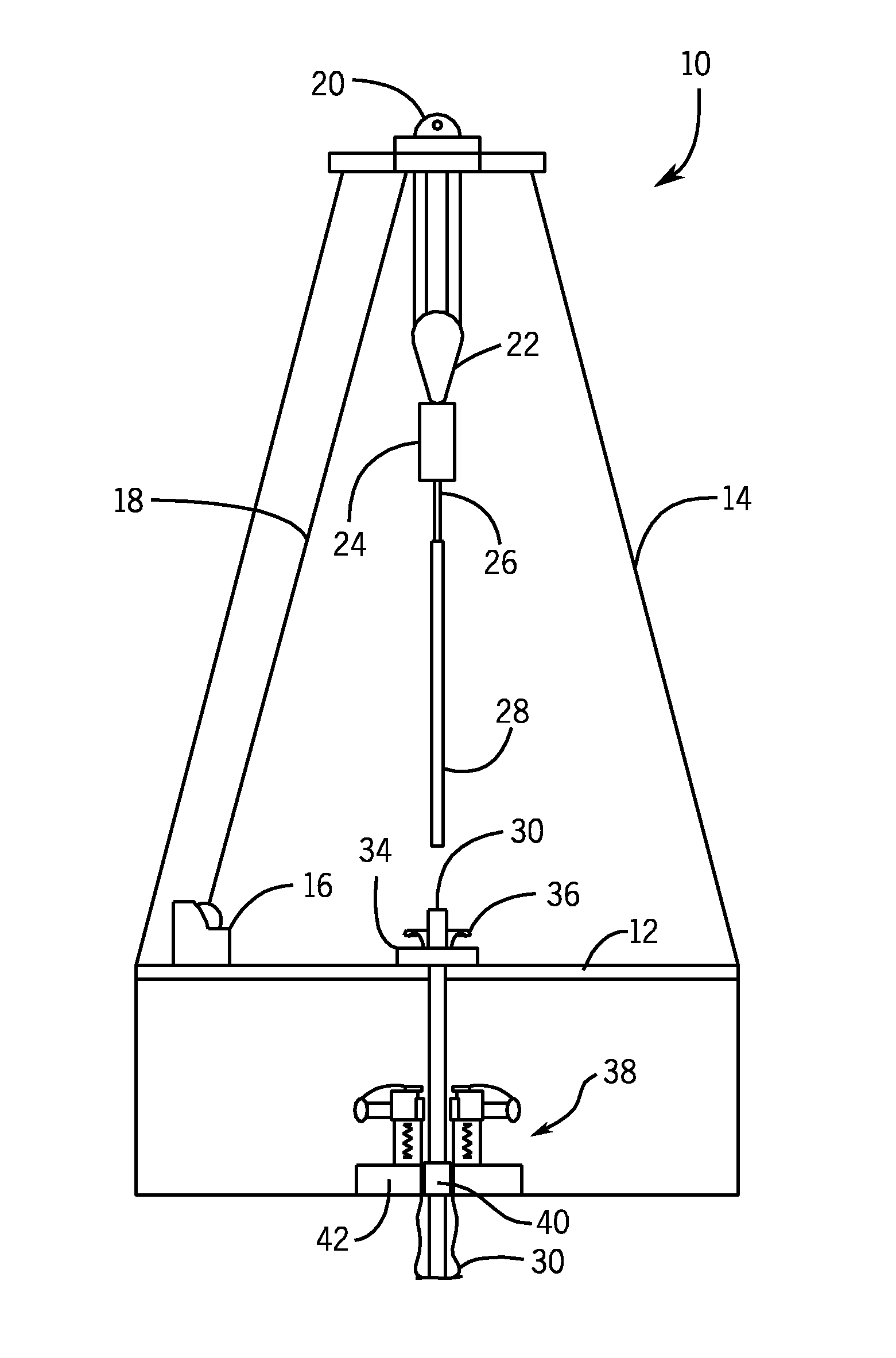

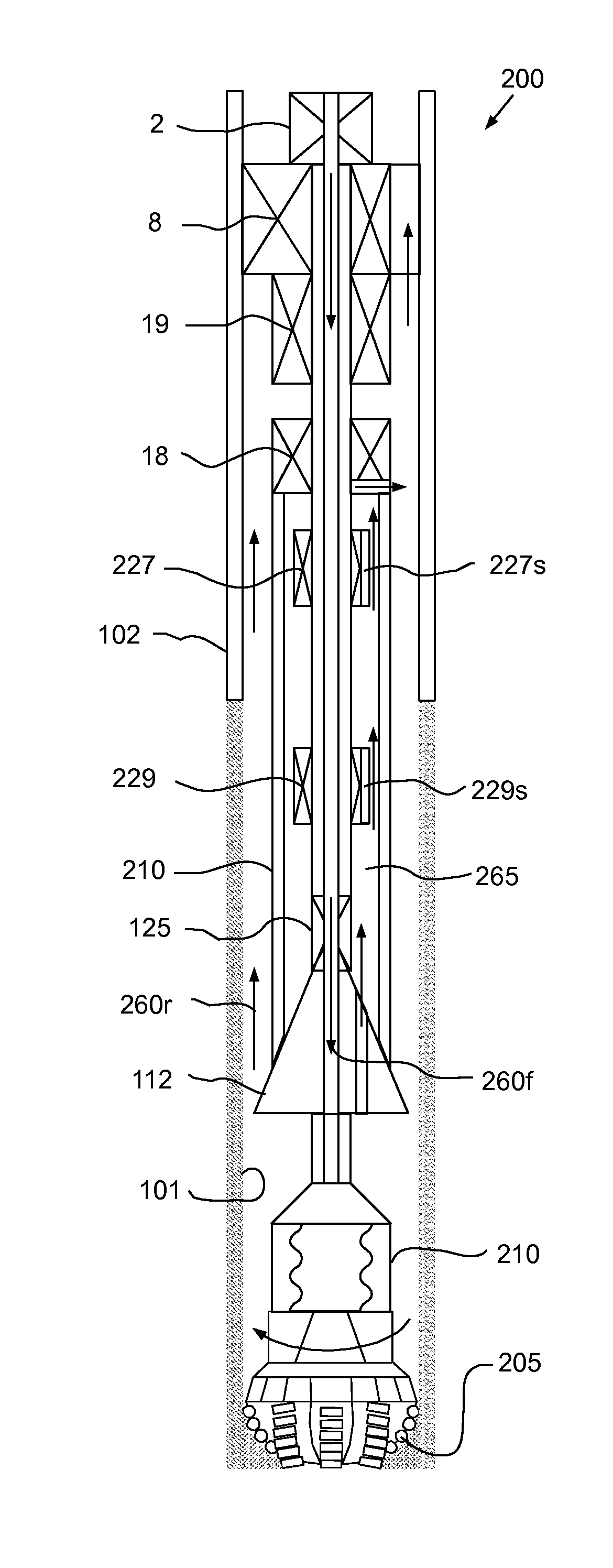

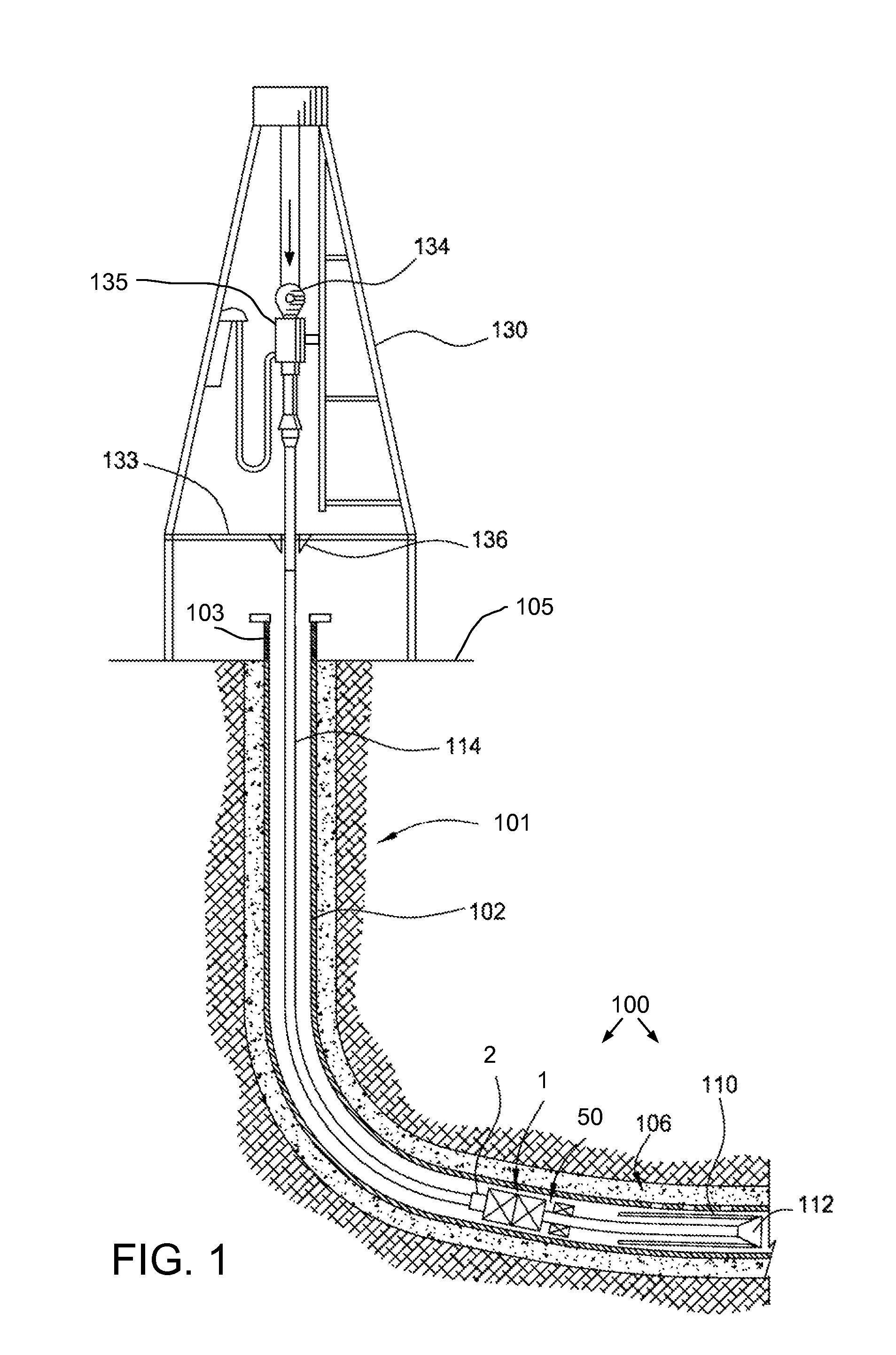

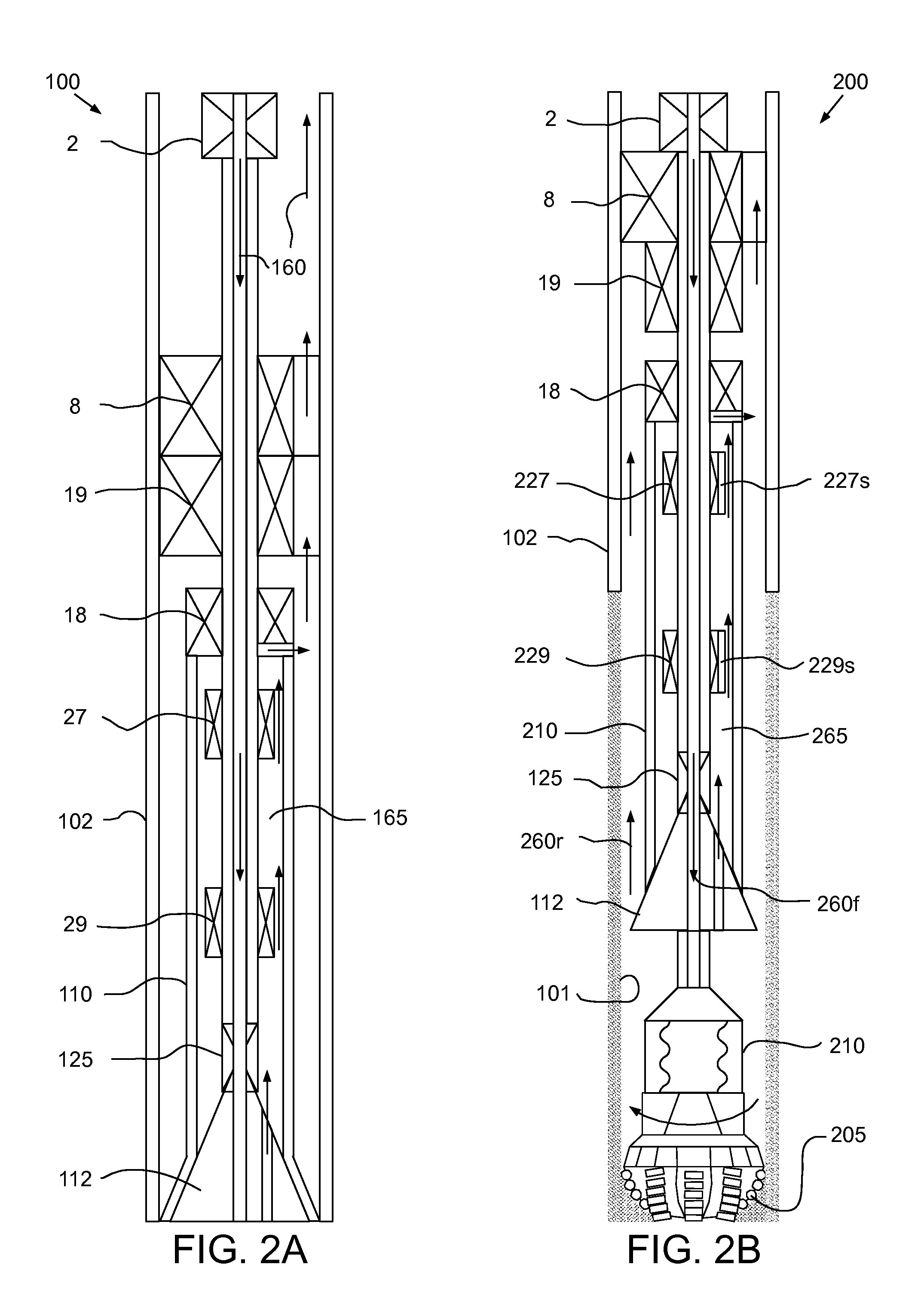

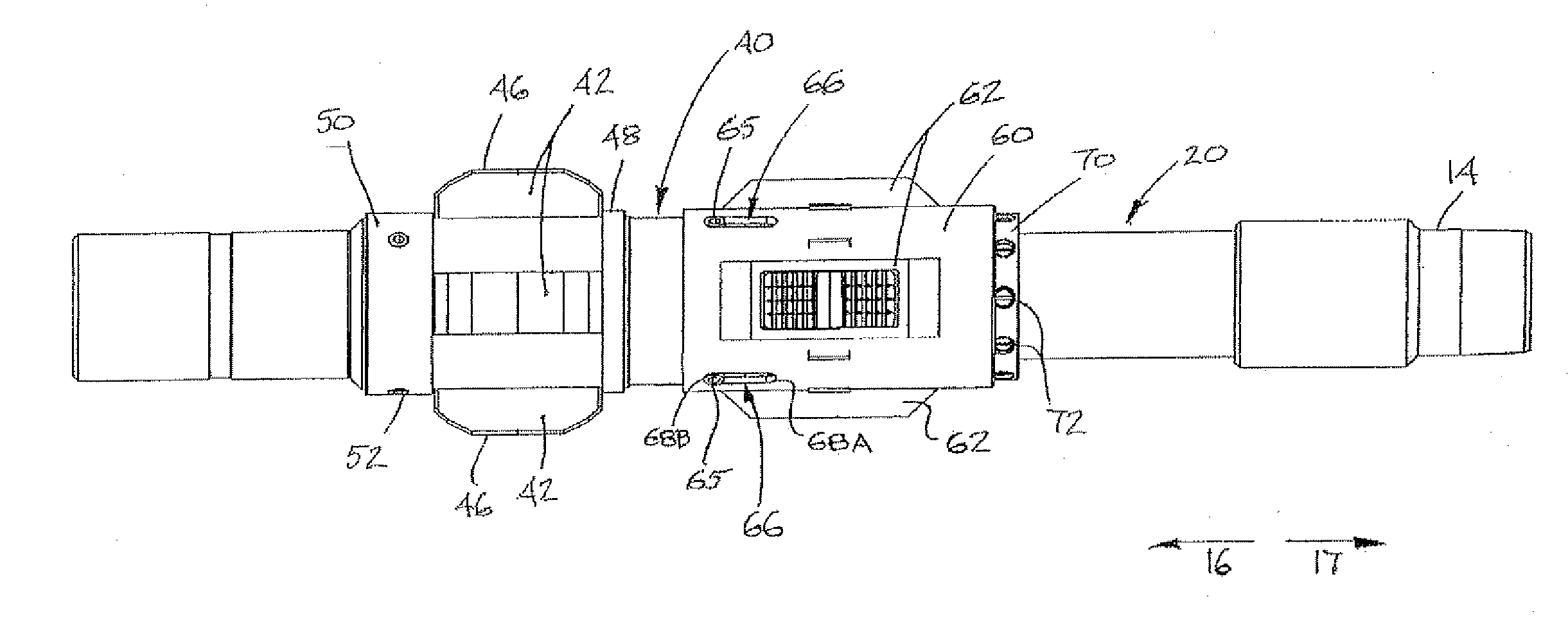

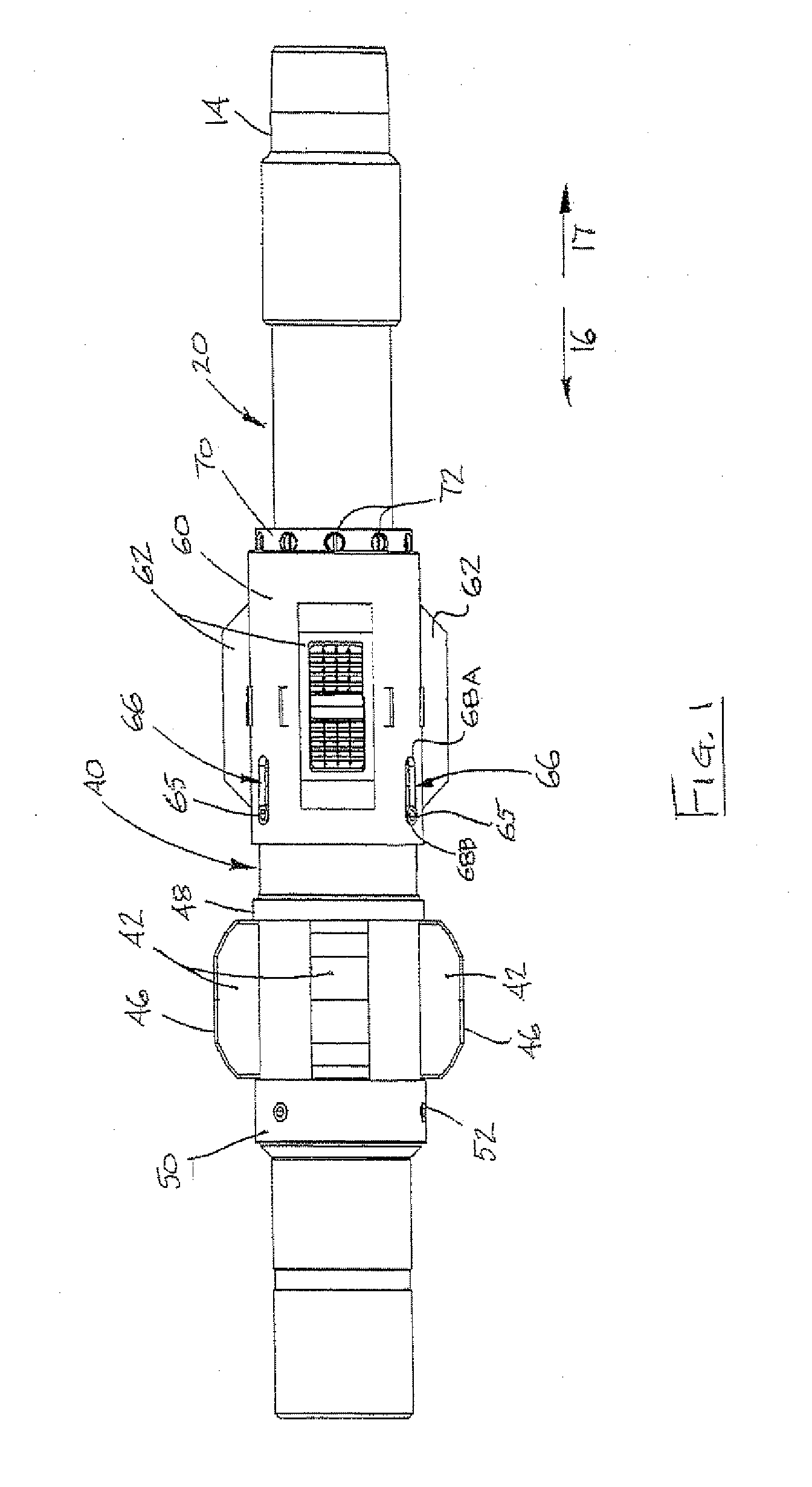

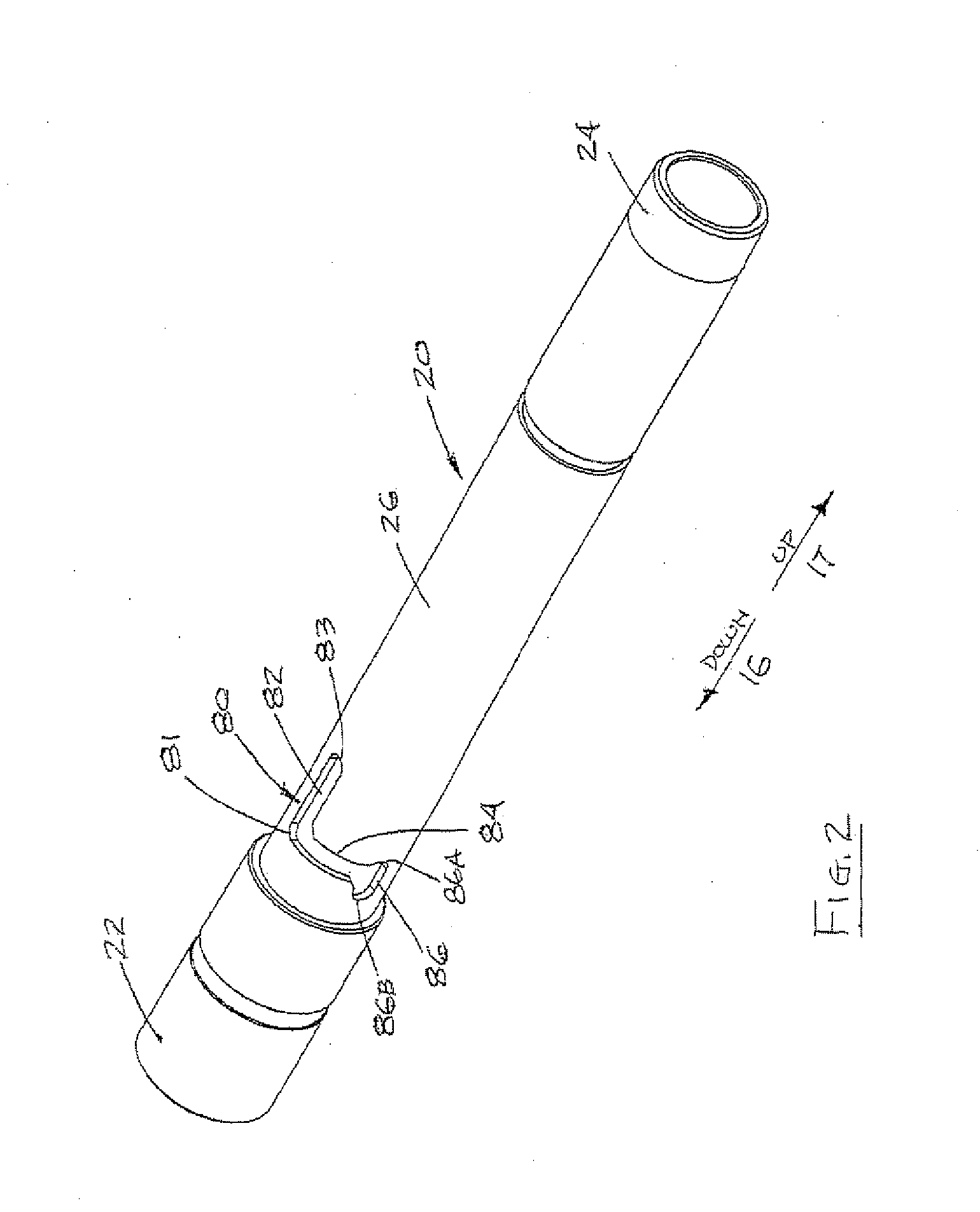

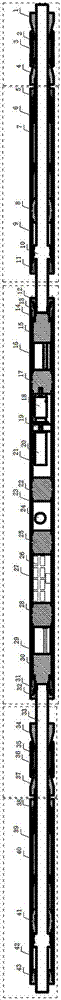

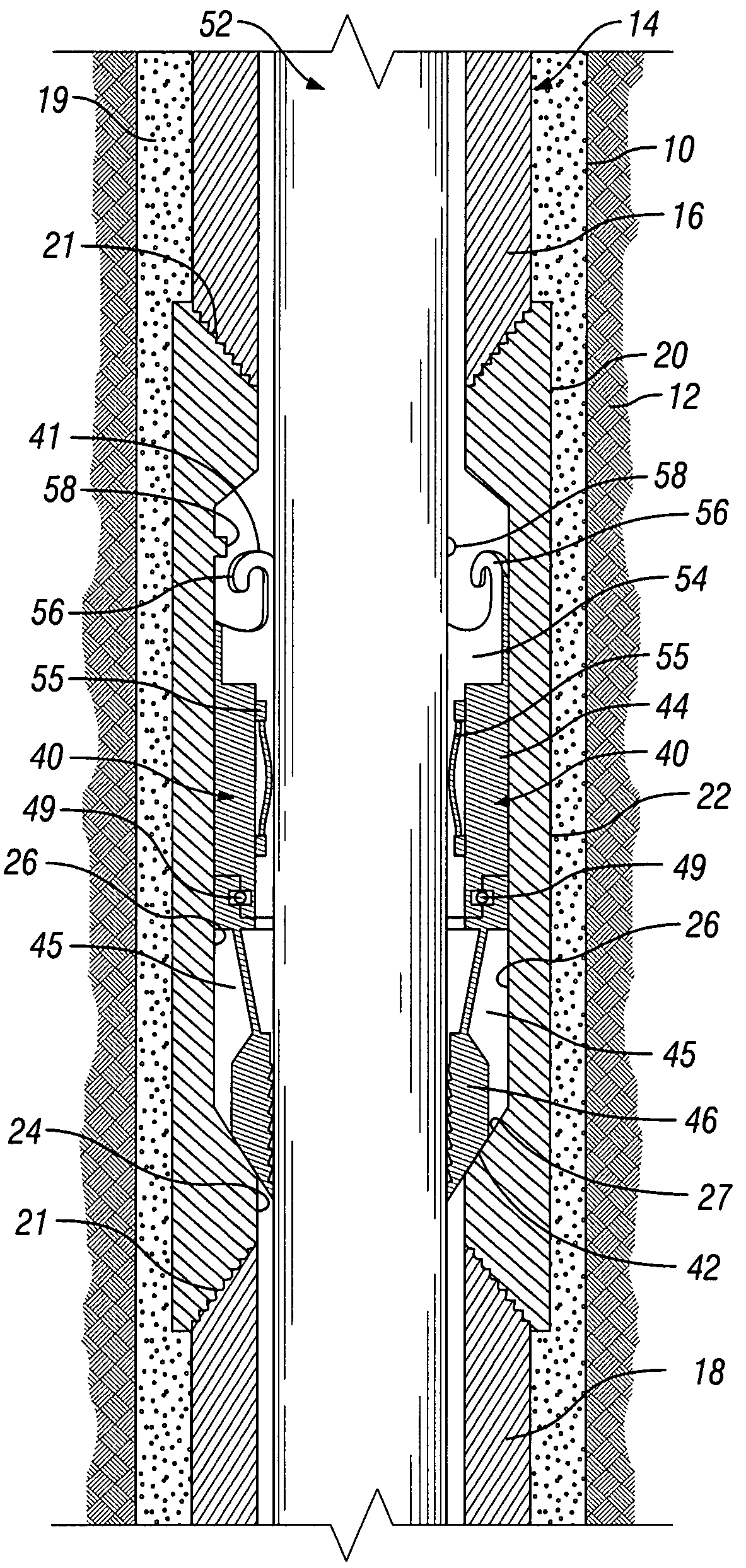

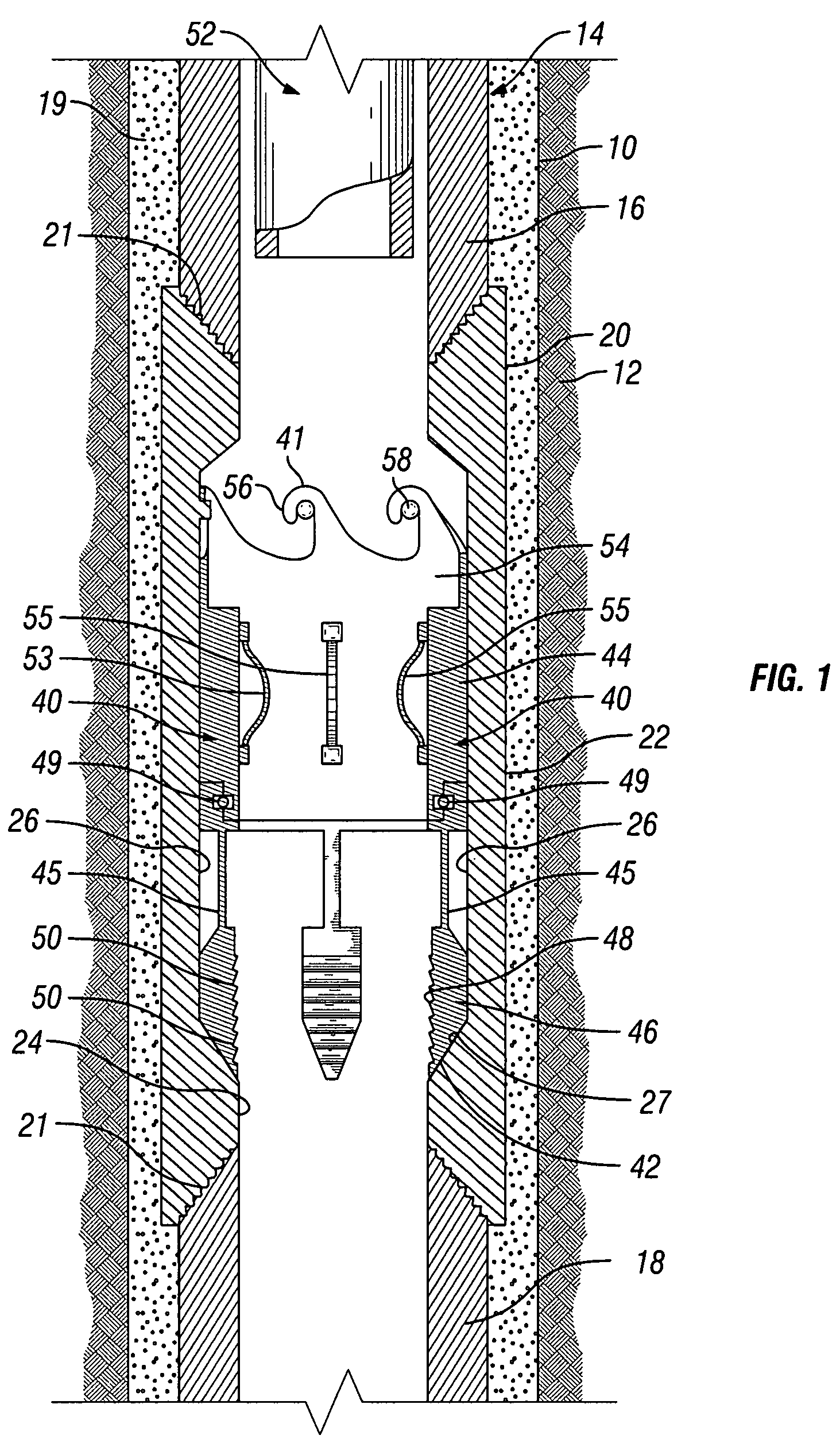

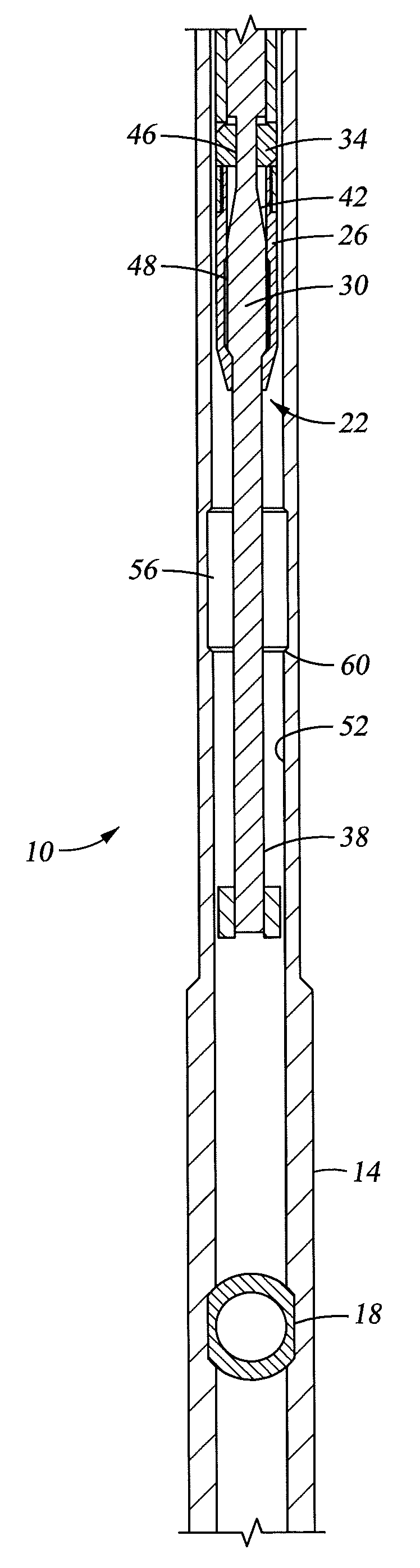

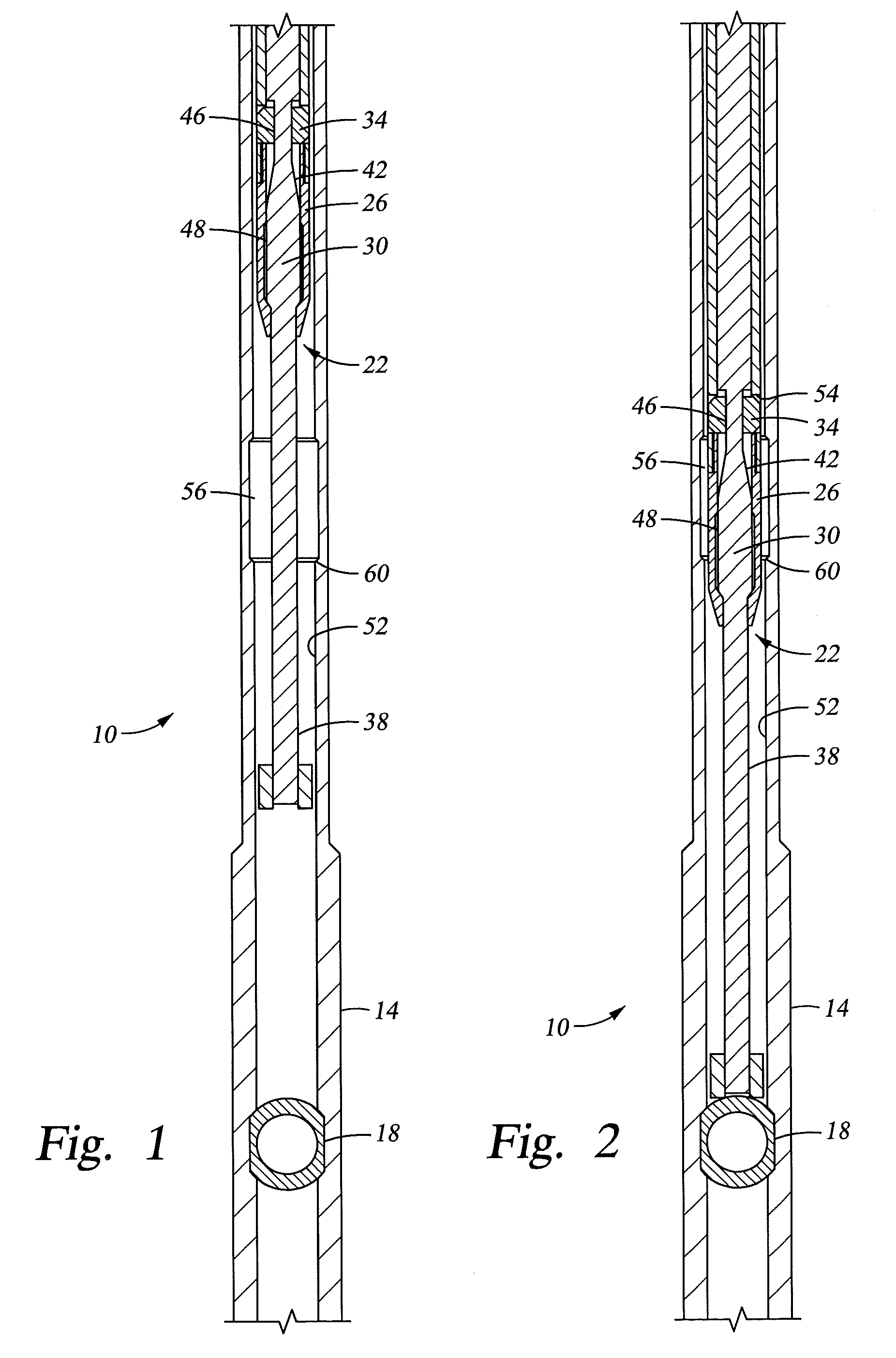

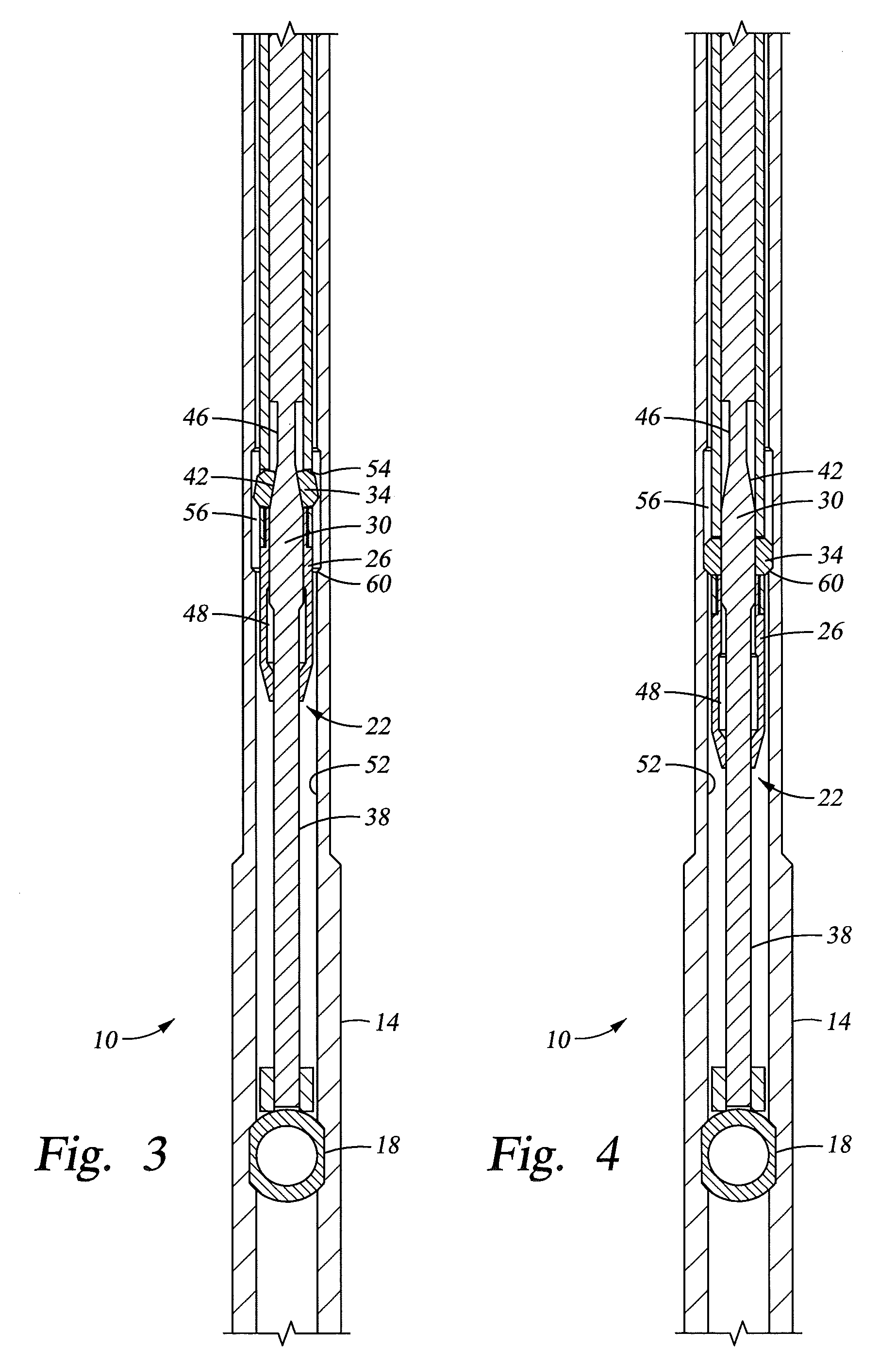

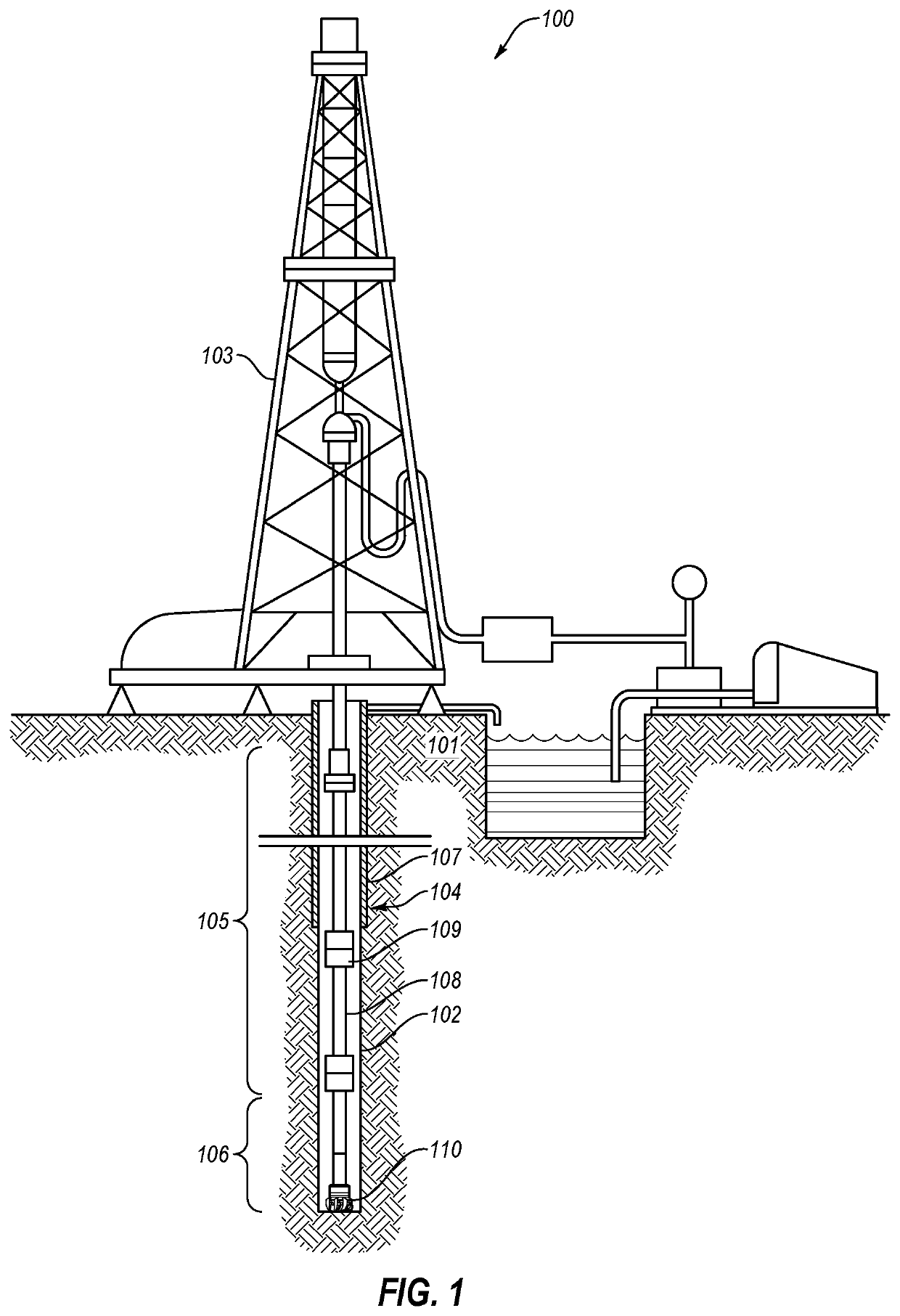

Tubular catcher system and method

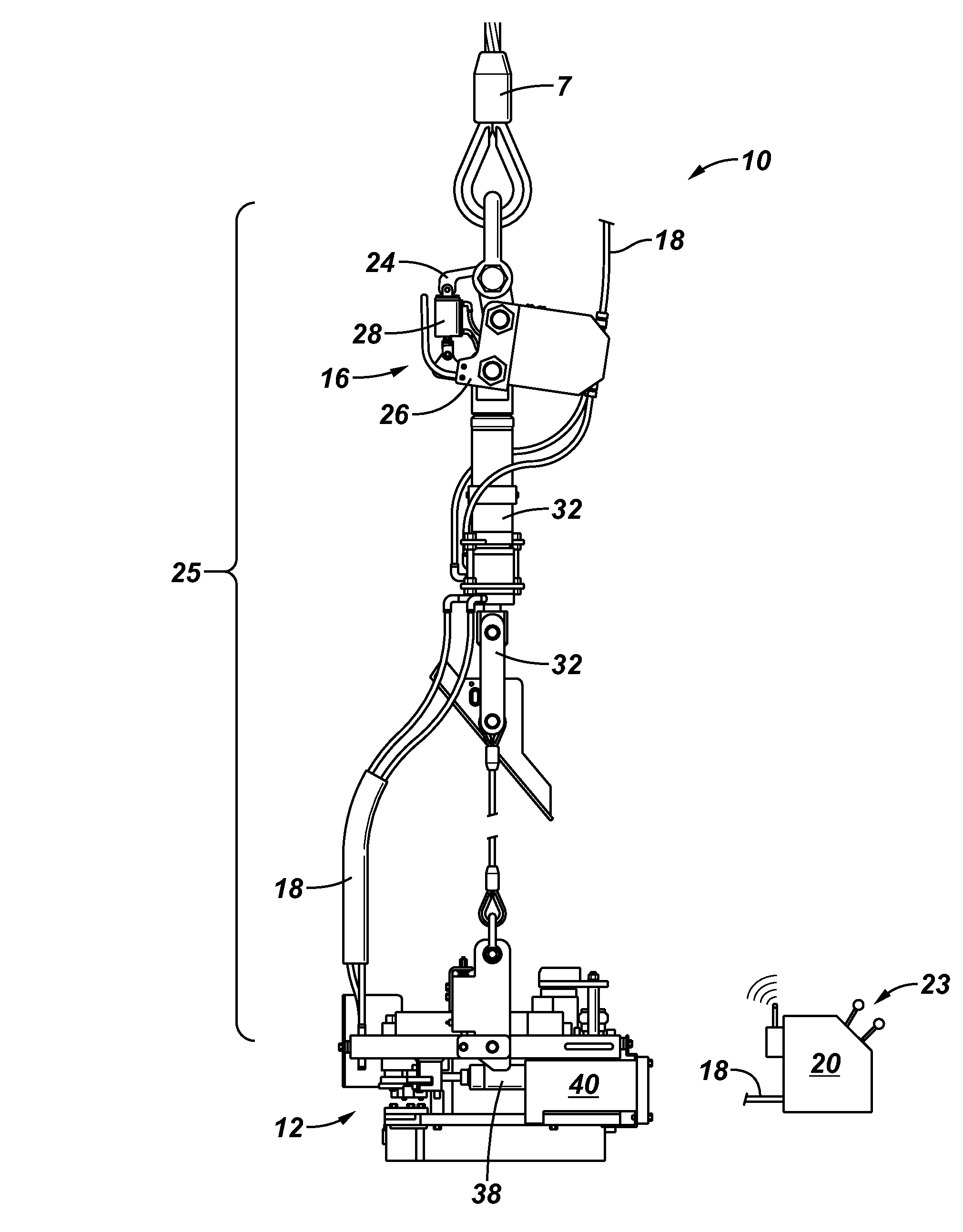

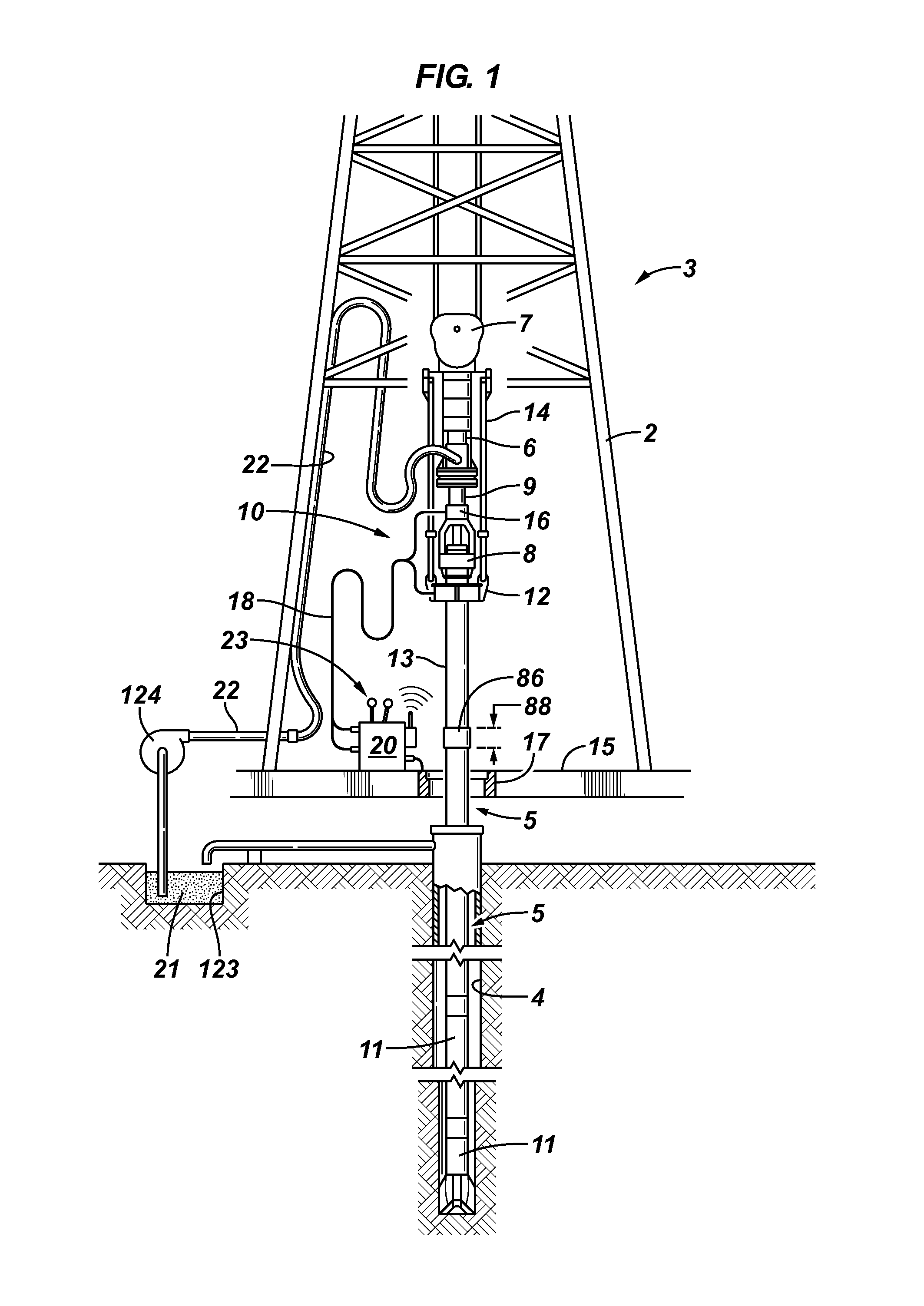

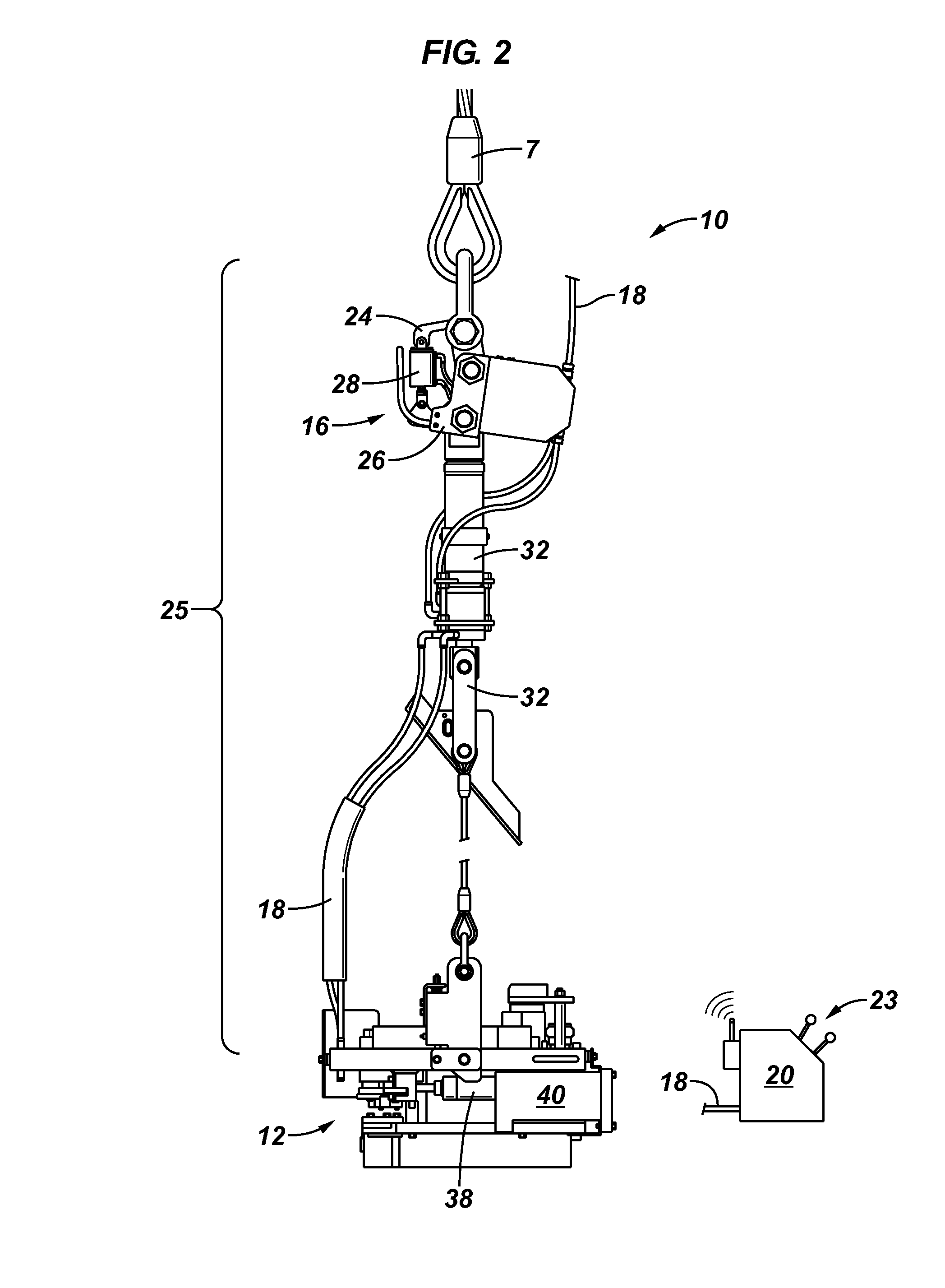

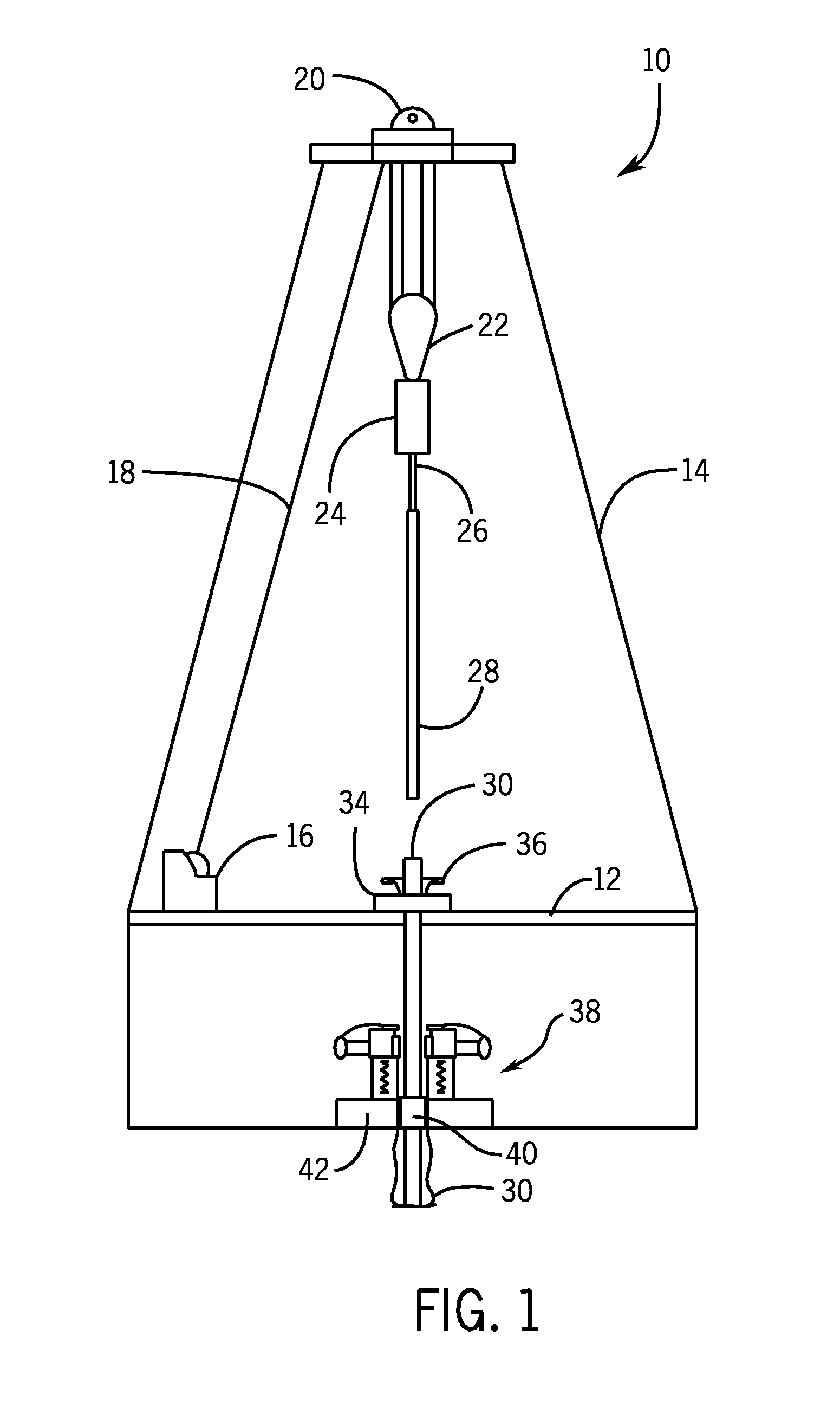

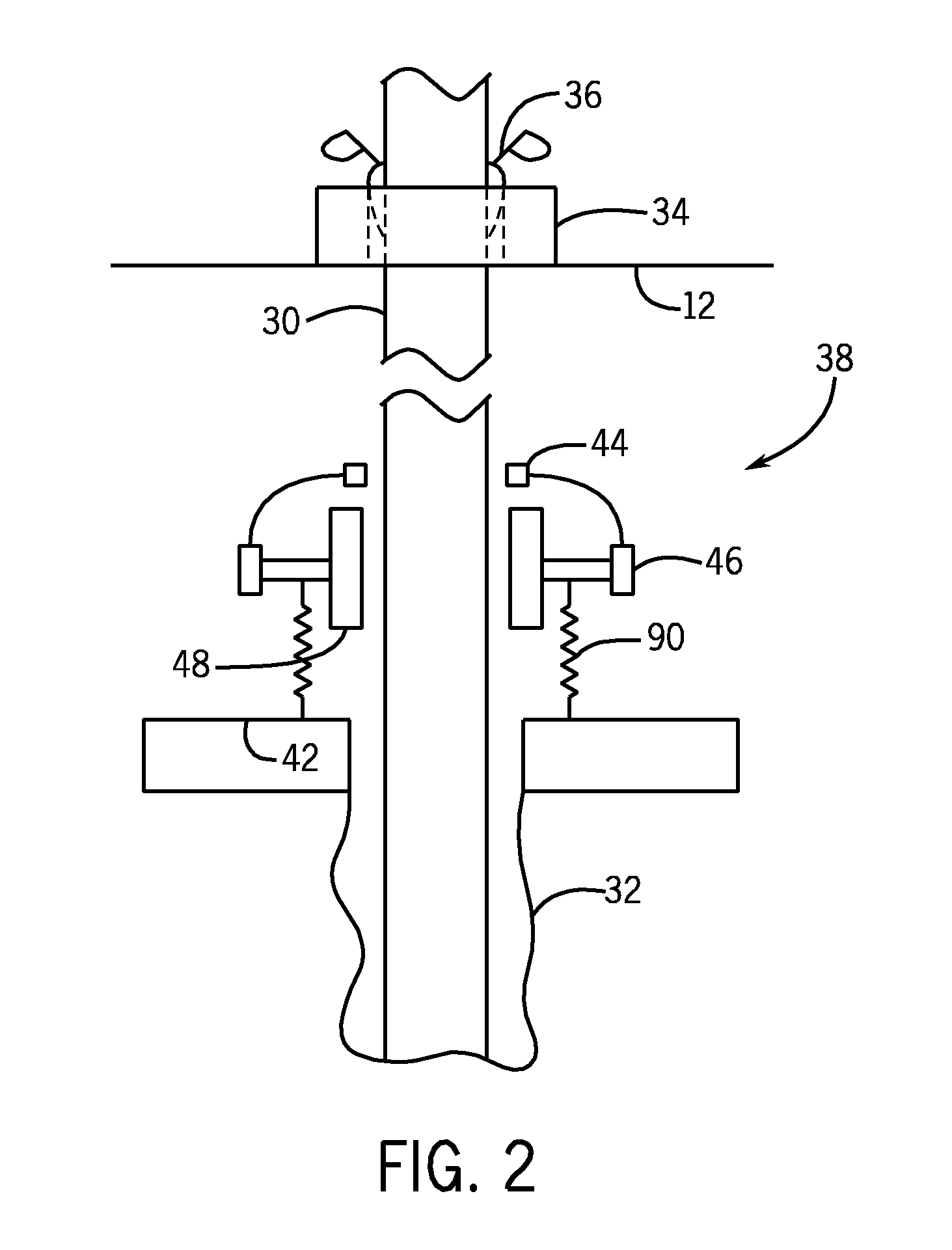

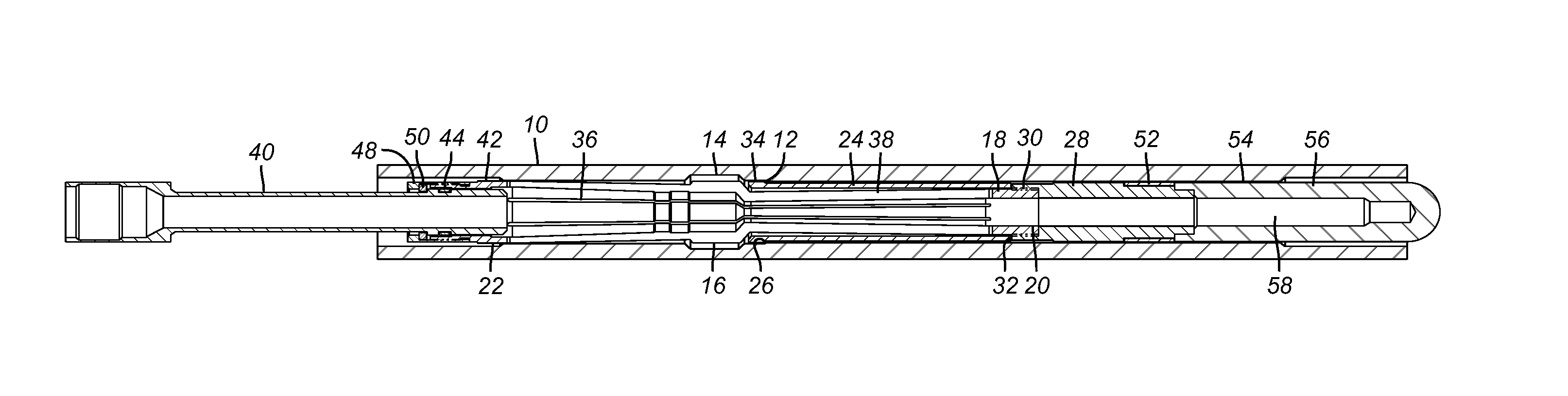

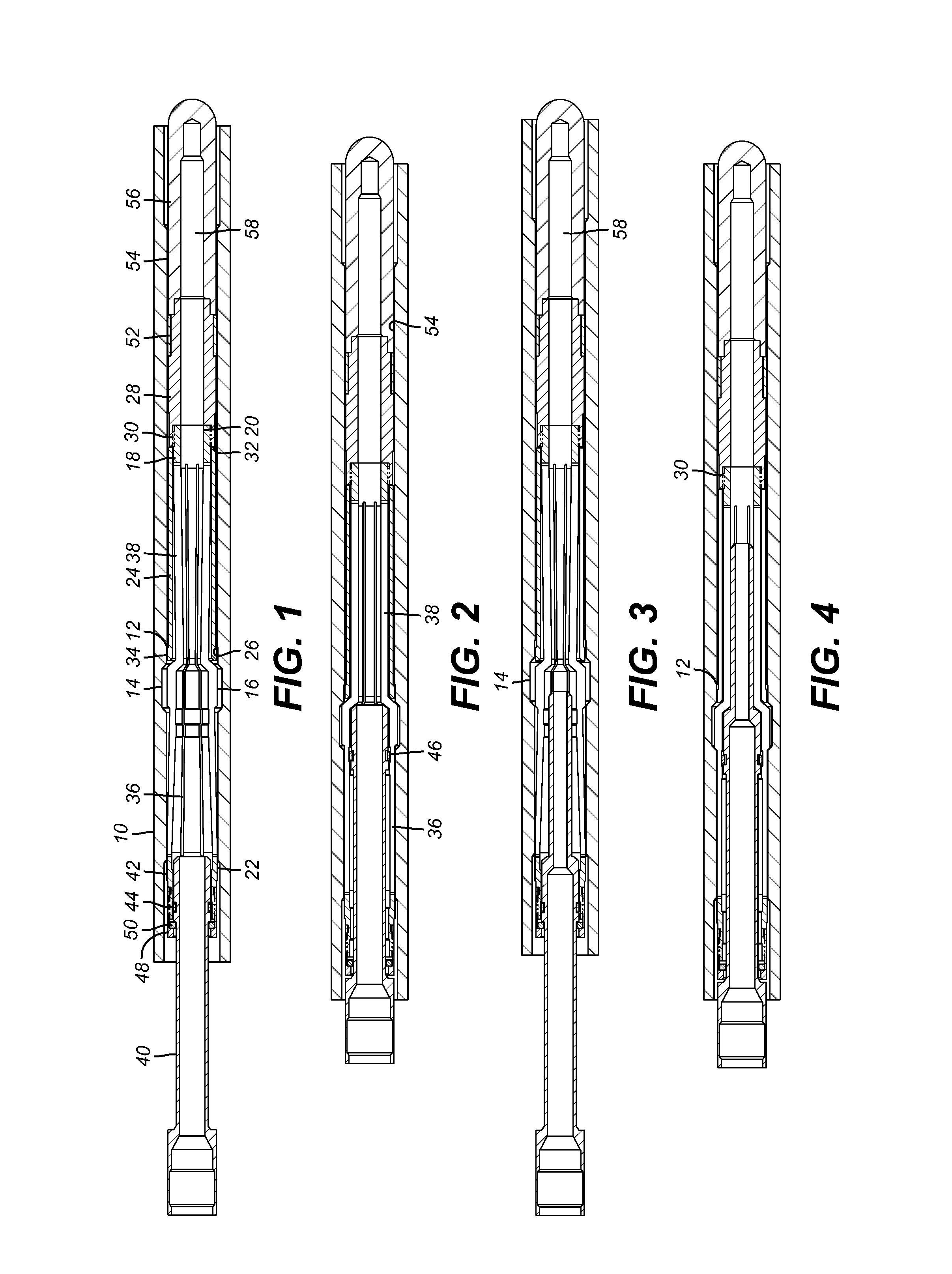

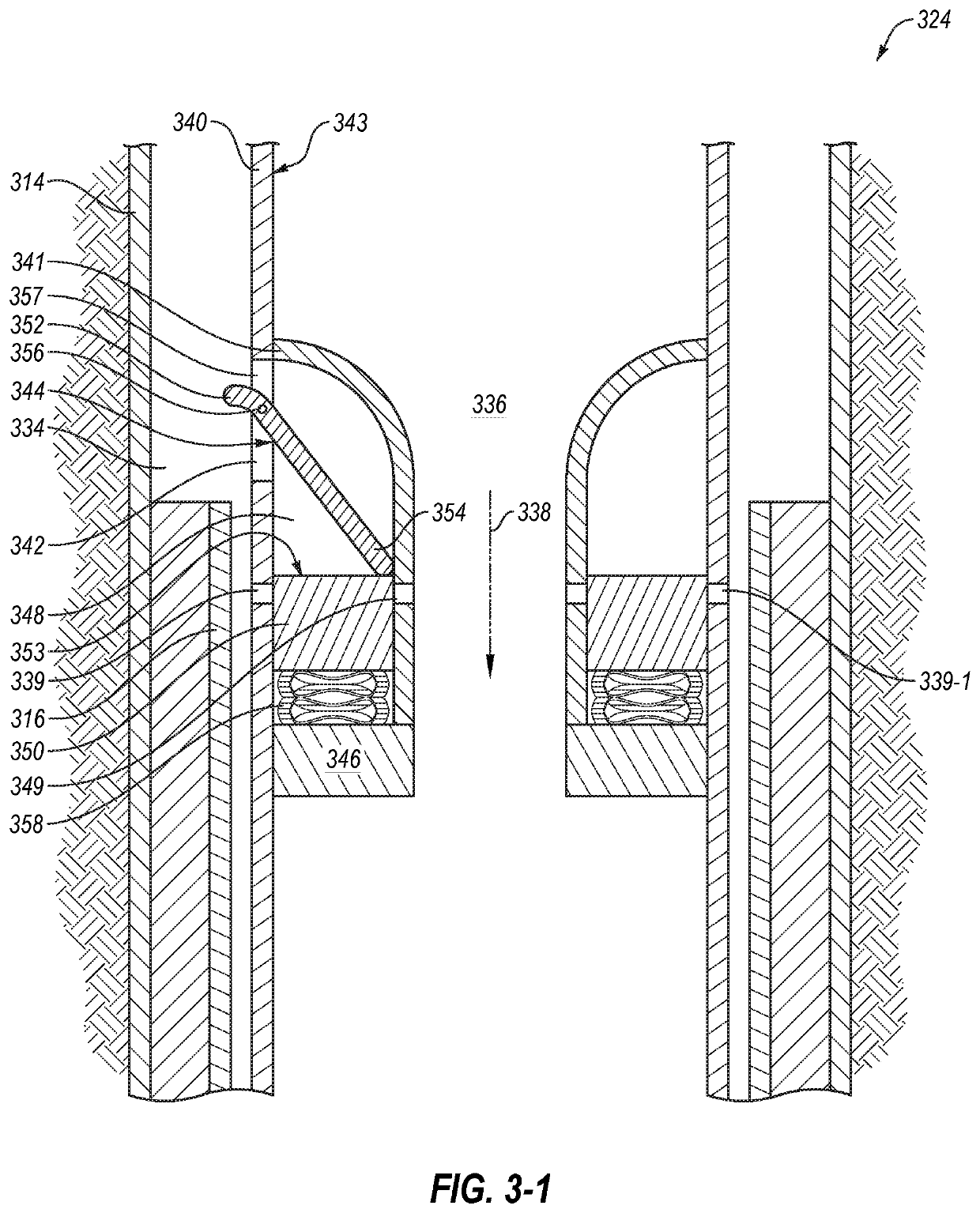

Present embodiments are directed to a tubular catcher system configured to detect a falling tubular through a drilling rig and grip the tubular before it drops into the wellbore. A sensor configured to detect the velocity or acceleration of the tubular activates an actuation mechanism when the velocity or acceleration exceeds a specific threshold, indicating a falling tubular. The actuation mechanism forces a gripping mechanism into contact with the tubular, catching the tubular and sending energy from the tubular to a hydropneumatic shock absorber coupled to the actuation mechanism and / or the gripping mechanism.

Owner:NABORS DRILLING TECH USA INC

Flexible collet anchor assembly with compressive load transfer feature

A collet assembly has a housing and the collets disposed on flexible fingers connected to the housing at their opposed ends. A surrounding landing sleeve stops the assembly so that collets are aligned with a recess in a landing collar that is part of a surrounding tubing string. Once set the landing sleeve transmits compressive loads so that compressive stress essentially bypasses the finger structure supporting the collets. The fingers are initially tapered toward a longitudinal axis so that when internally supported they assume an aligned orientation to the housing axis to allow greater tensile loading and to provide a retraction force when the housing is to be removed after the collet support is removed.

Owner:BAKER HUGHES INC

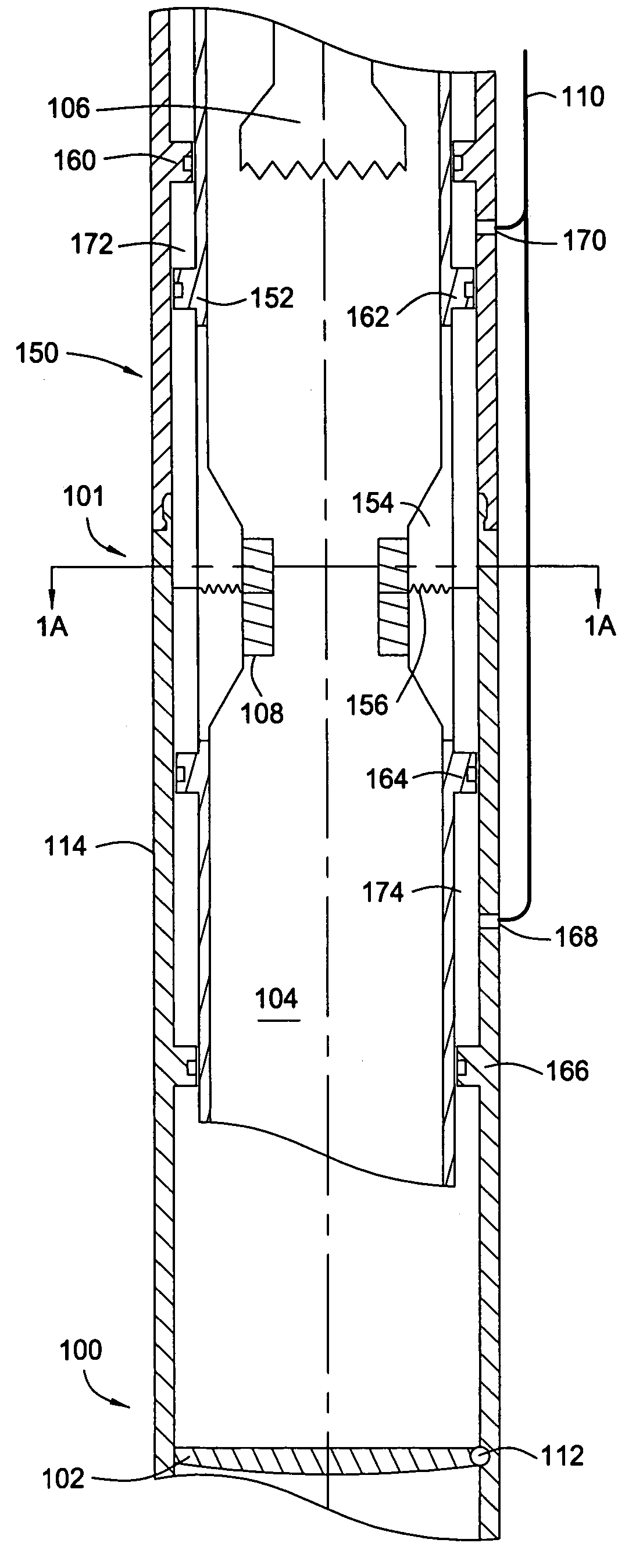

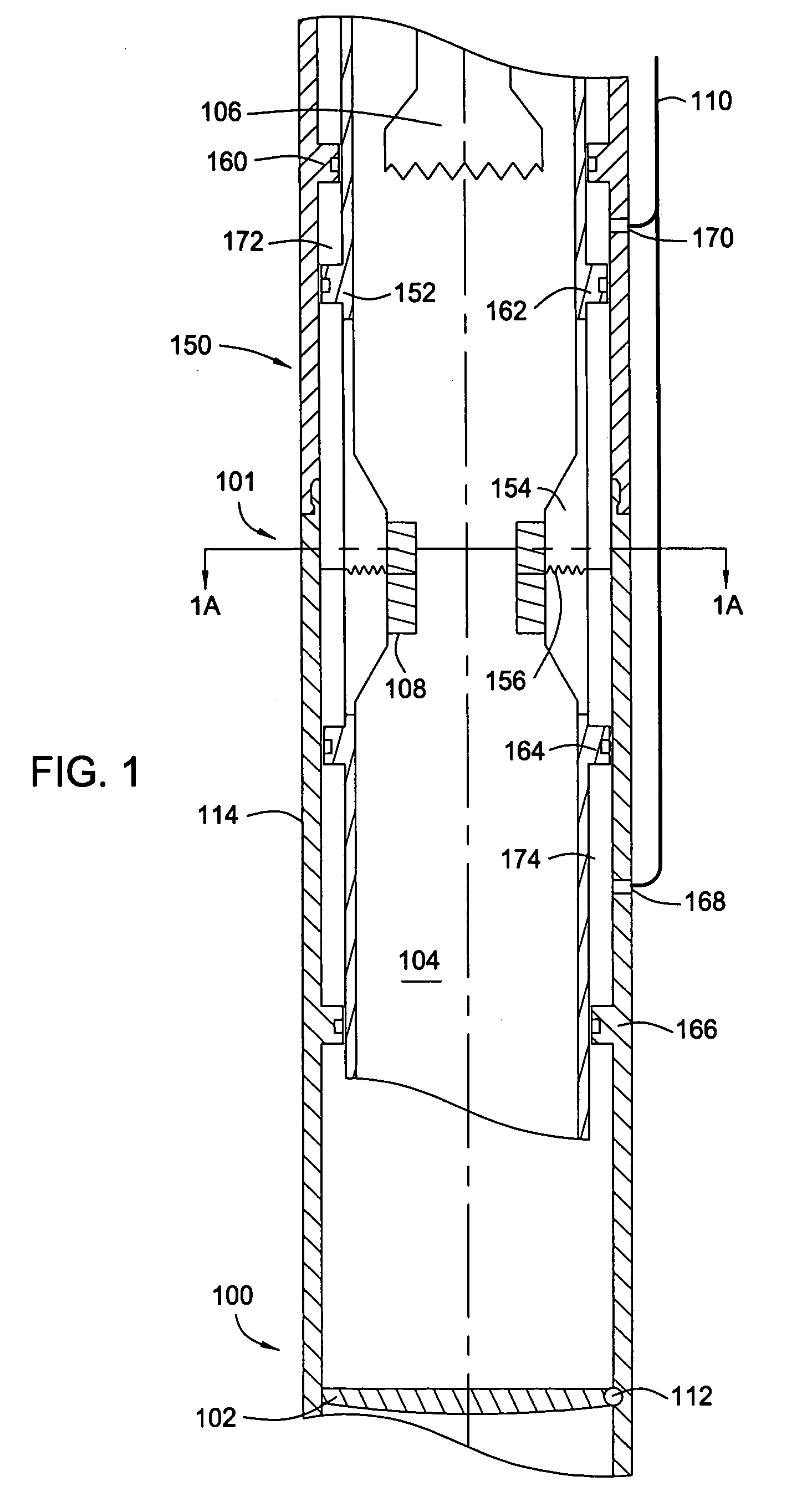

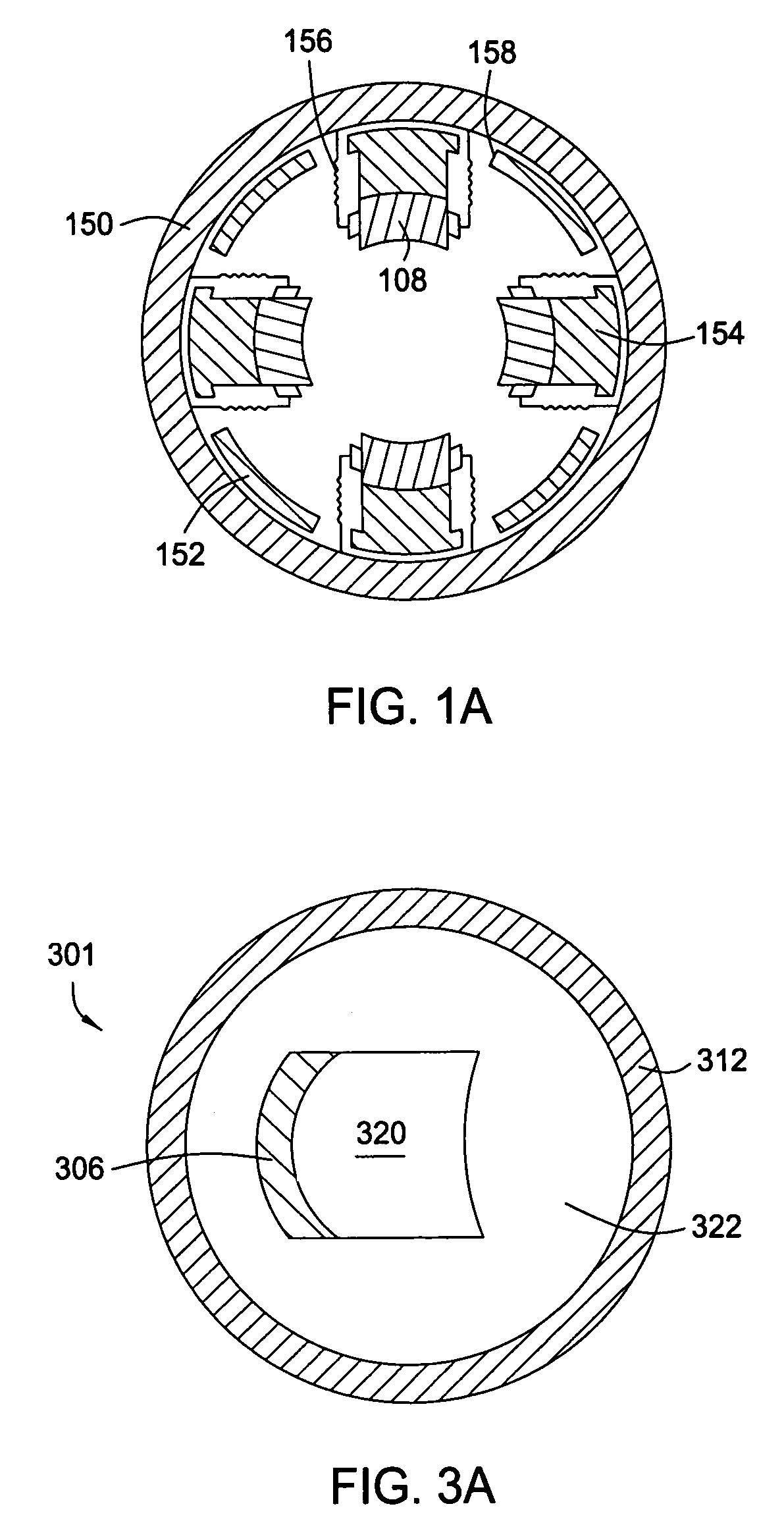

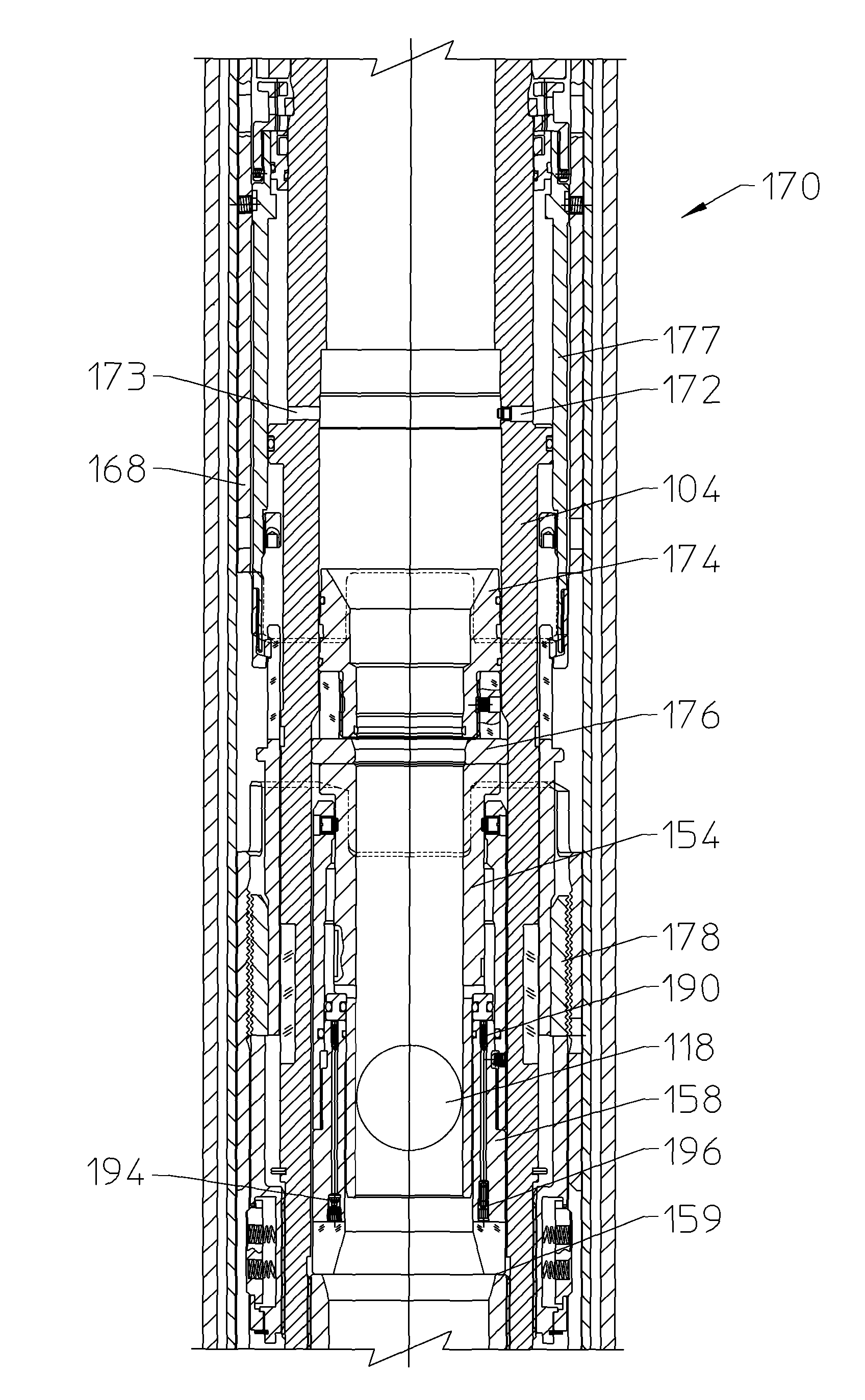

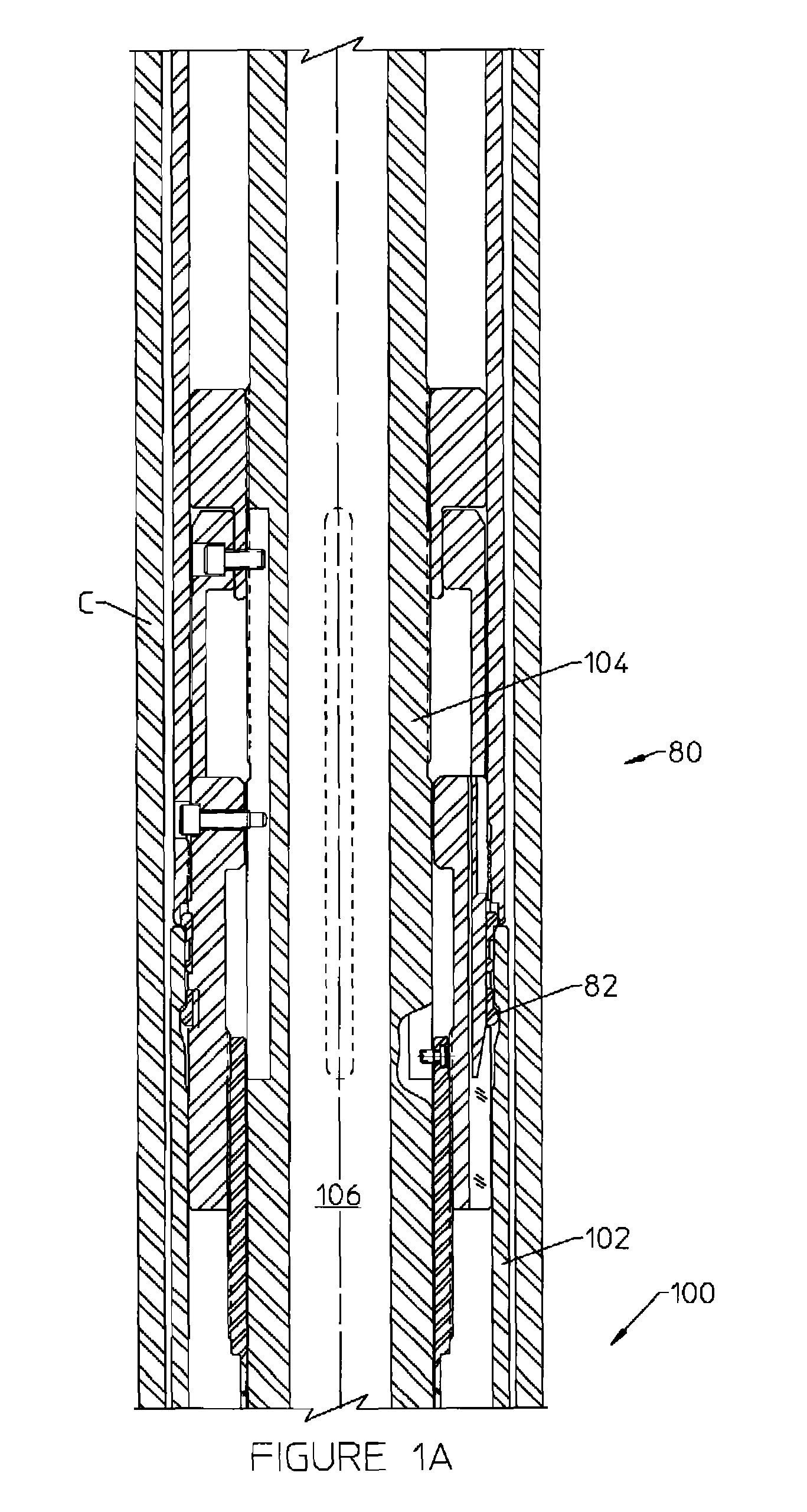

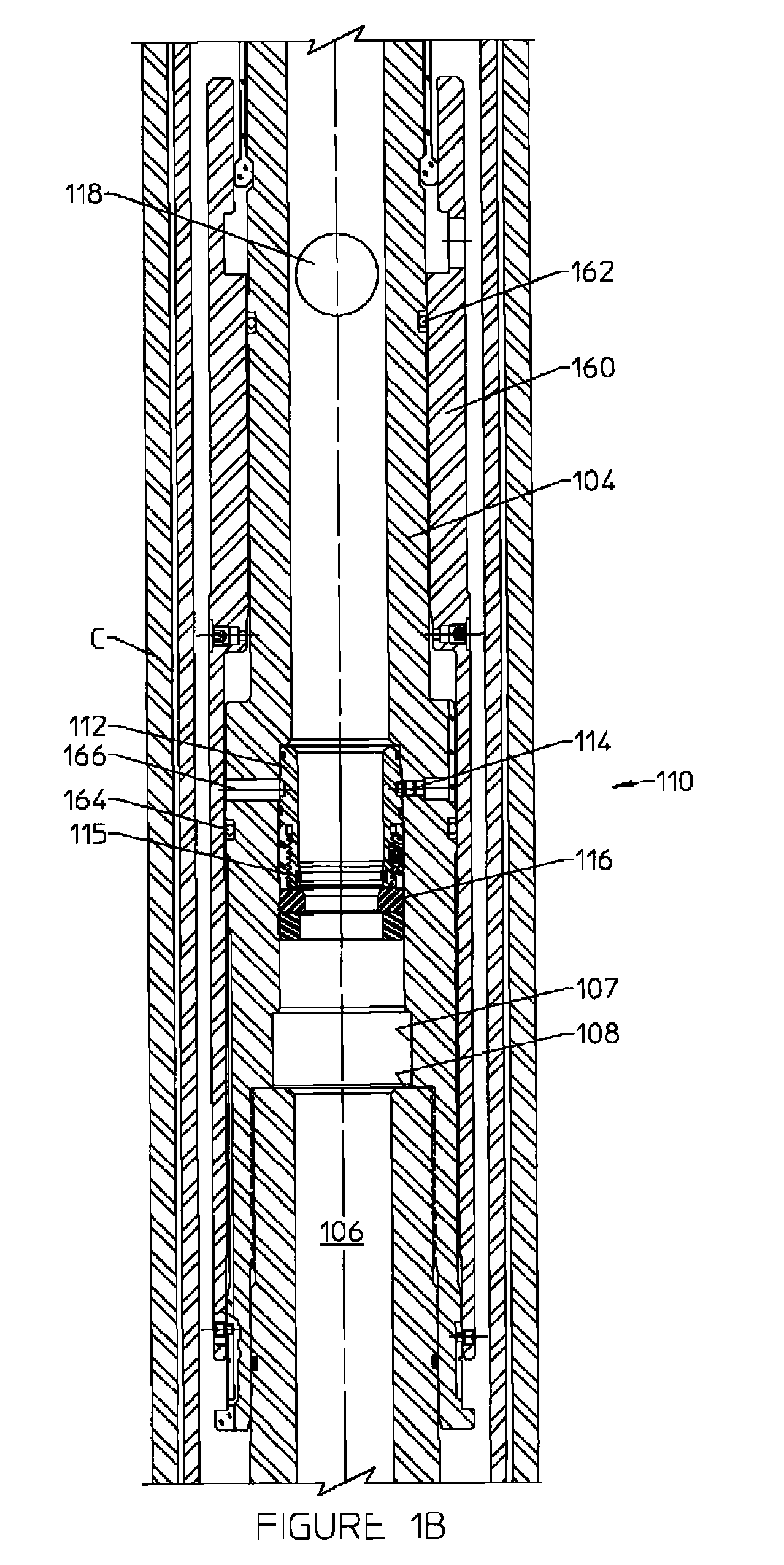

Downhole tool with hydraulic closure seat

A downhole tool 100 includes closure seats 116, 176 for seating with a closure, such as a ball. Shear pins or other connectors temporarily limit axial movement of each closure seat which is initially housed within a restricted diameter portion of the central throughbore in the tool body. A piston axially moves in response to fluid pressure to pressurize fluid in a chamber and controllably release fluid through one or more restrictions. The closure seat may be lowered to engage a stop 108, 159, such that the seat may move axially to an enlarged diameter bore portion of the tool, thereby allowing radial expansion of a closure seat to release the ball.

Owner:DRIL QUIP

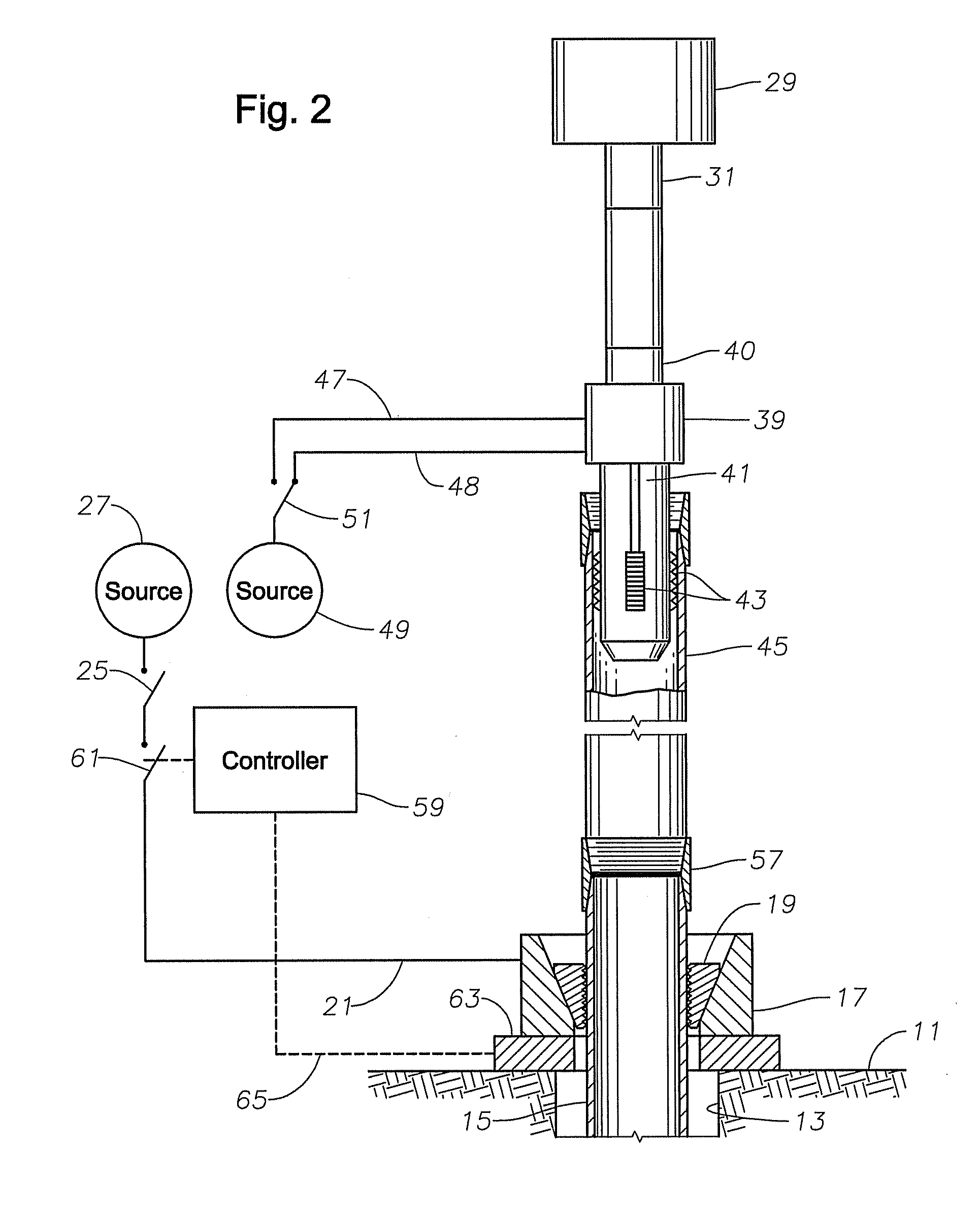

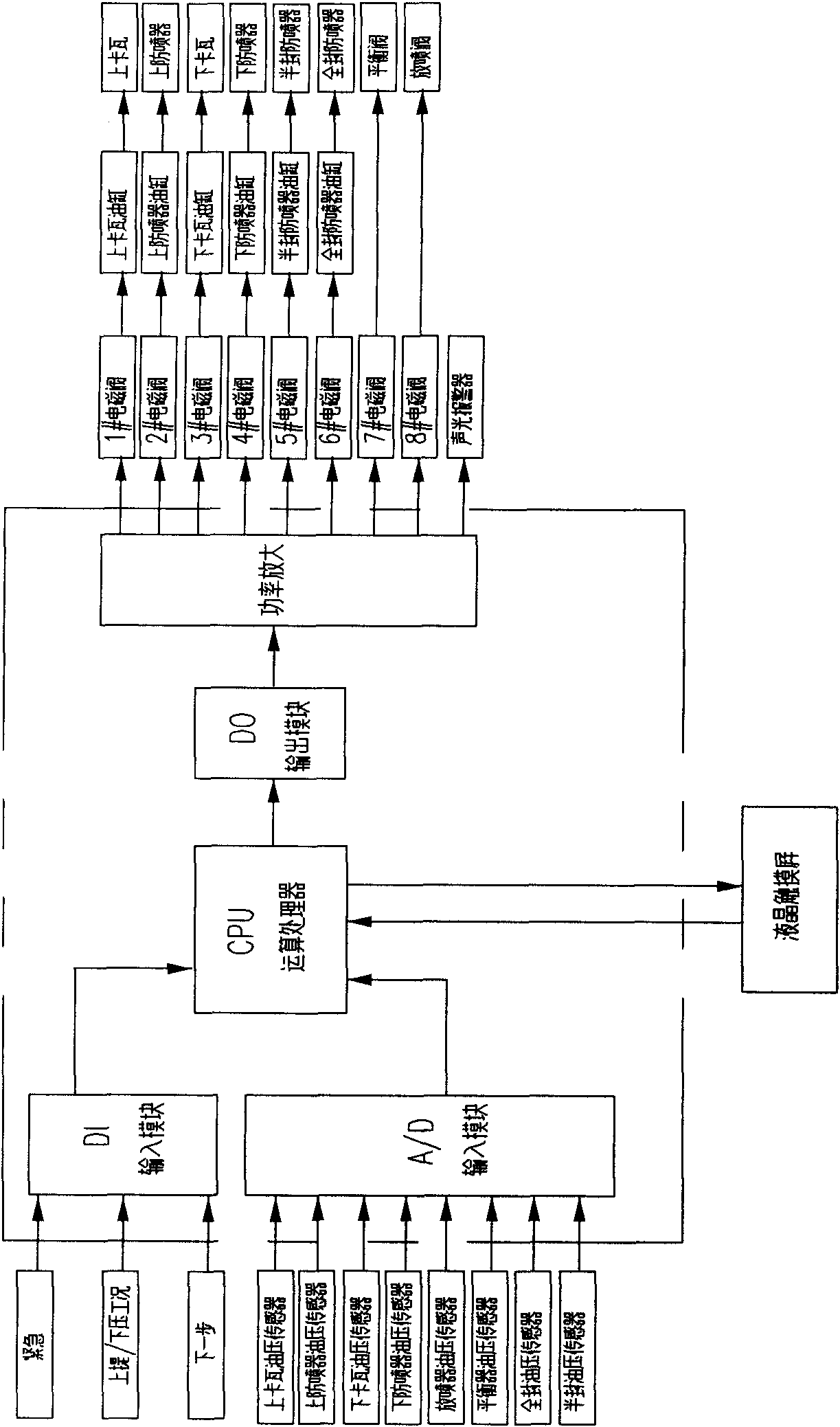

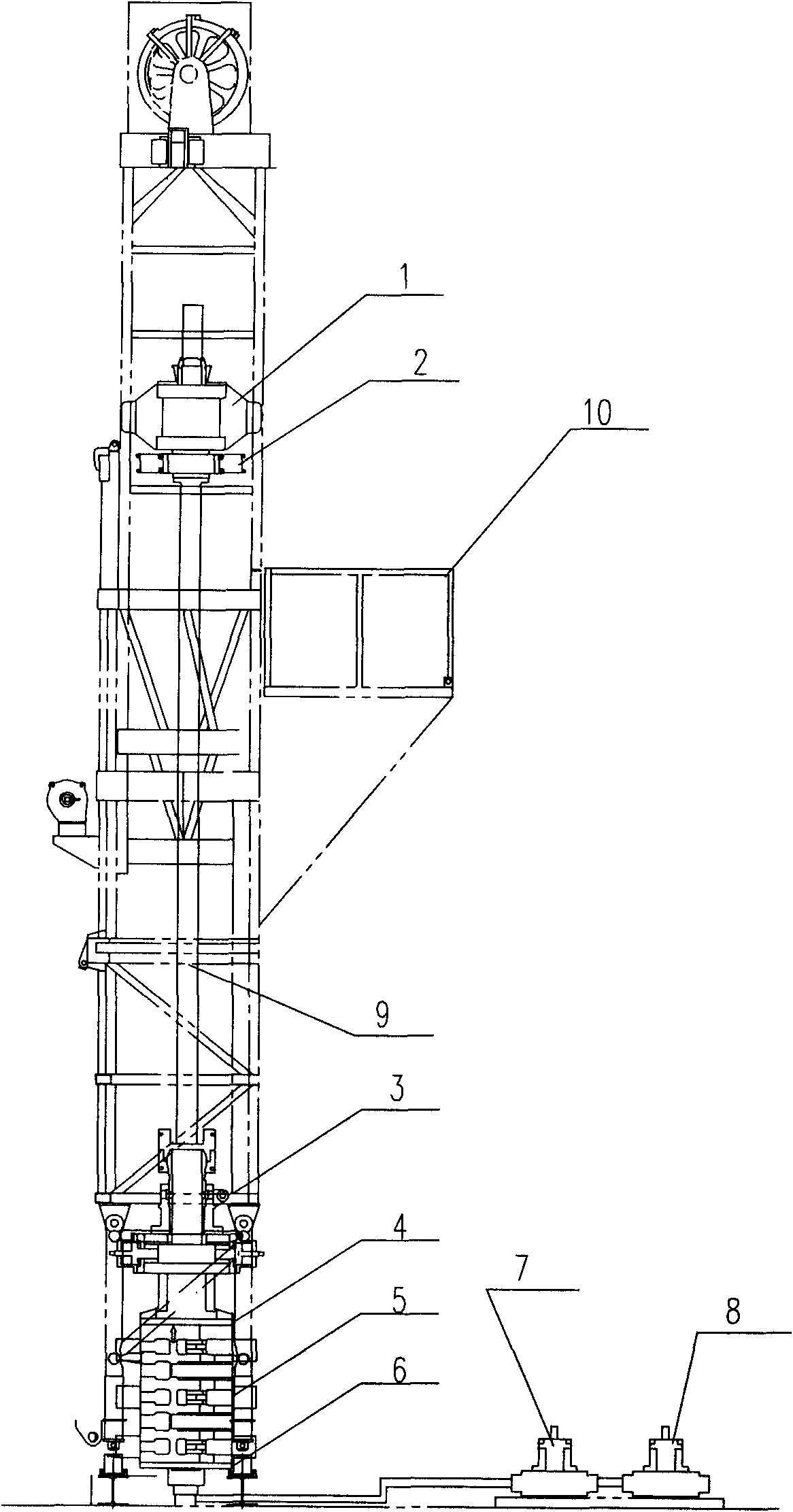

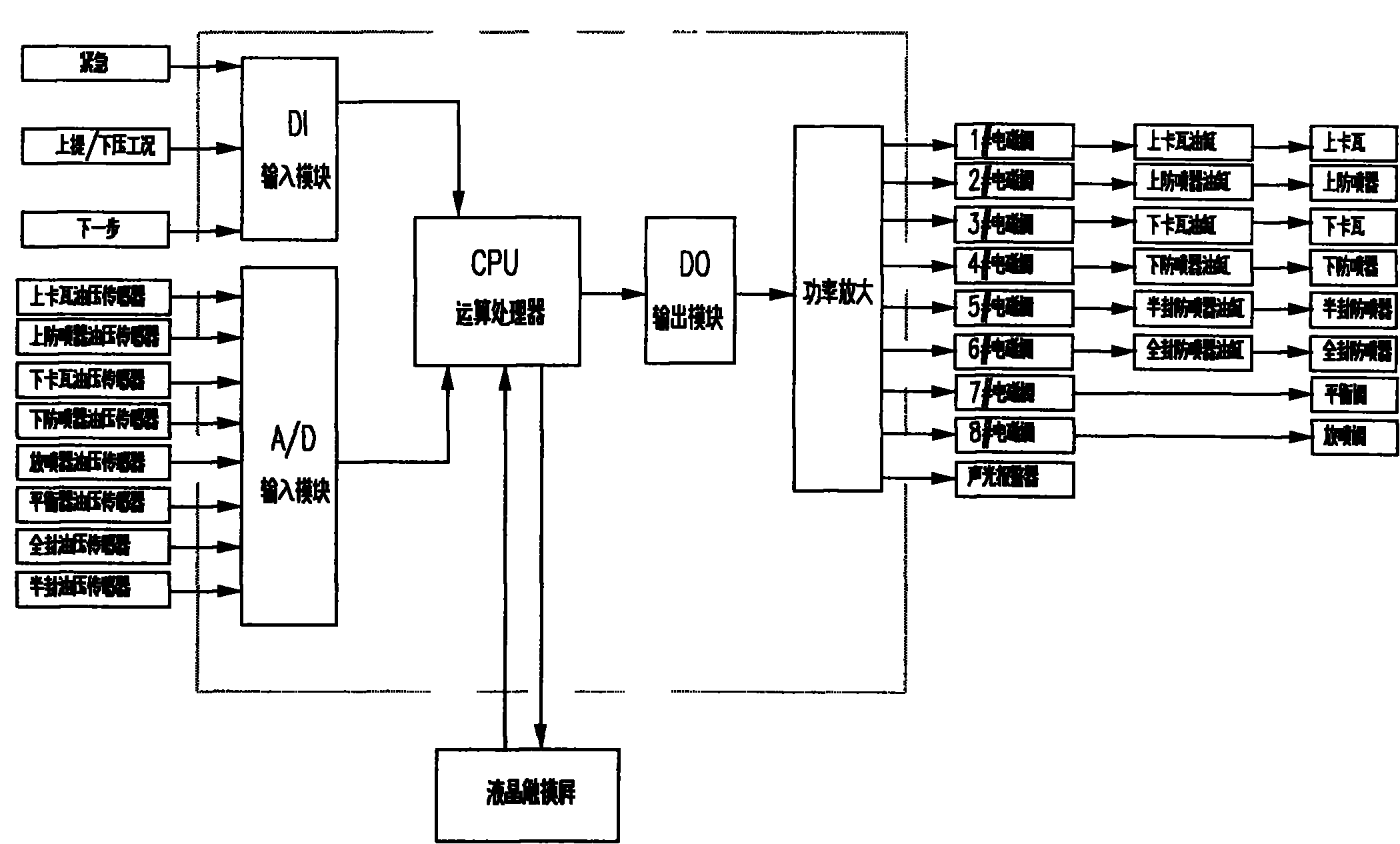

Automatic control device of oil pipe clamping mechanism of non-well killing workover rig

ActiveCN101818639ARealize automatic controlImprove securityTubing catchersAutomatic control for drillingWell killAutomatic control

The invention relates to an automatic control device of an oil pipe clamping mechanism of a non-well killing workover rig, belonging to the field of non-well killing workover operation equipment. The automatic control device is used for the non-well killing workover operation equipment and comprises a control device, a plurality of electromagnetic valves, oil pressure sensors and hydraulic oil cylinders, wherein the control device takes a controller loading self-authoring software as a core; the oil pressure sensors are the same as the electromagnetic valves in number; and the hydraulic oil cylinders are the same as the electromagnetic valves in number. The automatic control device is characterized in that a data processing device comprises a DI (Data Input) module, a CPU operation processor, a DO (Data Output) module, a power amplifier, an A / D (Analog / Digital) input modules and a CPU, wherein the DI module, the CPU operation processor, the DO module and the power amplifier are sequentially connected, and the A / D input module is connected with the CPU; an executive device comprises eight electromagnetic valves, six hydraulic oil cylinders, two hydraulic valves and a clamping mechanism; and the input end of the A / D input module is also connected with eight oil pressure sensors, and the oil pressure sensors are connected with oil inlet pipelines of the hydraulic oil cylinders orthe hydraulic valves one by one. The invention solves the problem of equipment safety caused by the complexity and the easy error of the manual operation of the oil pipe clamping mechanism and reduces the labor intensity of operators.

Owner:中石化四机石油机械有限公司 +1

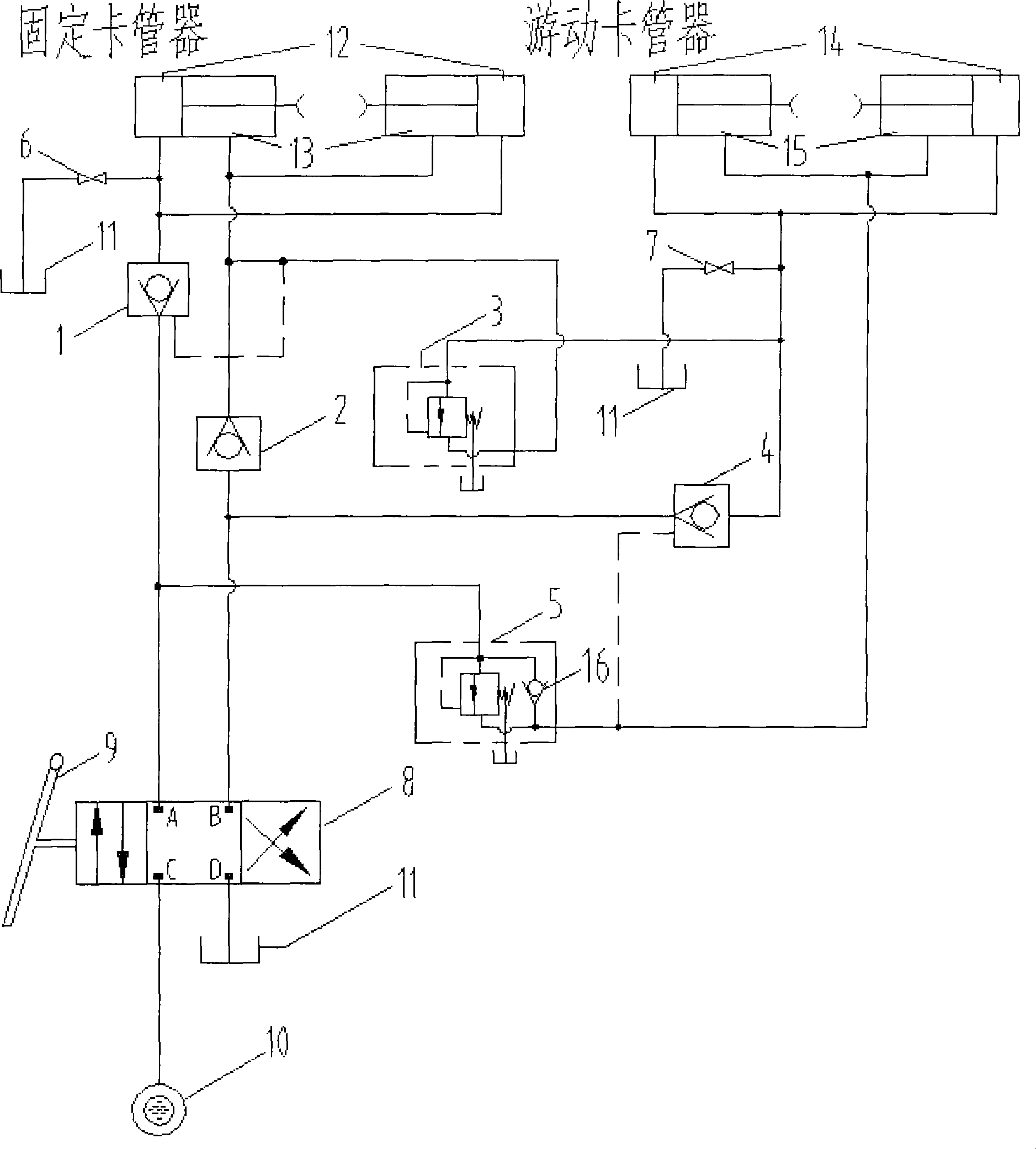

Hydraulic control method and hydraulic control loop for down-hole column clamping device

InactiveCN101476453APrevent flying outSimplify operation contentTubing catchersAutomatic control for drillingDevice formEngineering

The invention discloses a hydraulic control method and a hydraulic control loop for a pipe clamping device of an underground pipe column used in the petroleum industry, which is used for operation of an oil-water well under the pressure condition, effectively controls the action of the pipe clamping device, and ensures the safe production. The control method of the invention is to use a reversing valve to simultaneously control the oil inlet and the oil outlet of the hydraulic control loop of a fixed pipe clamping device and a floating pipe clamping device, and ensure that one pipe clamping device is clamped tightly first, and then the other pipe clamping device is loosened. The hydraulic control loop comprises a hydraulic source, a reversing valve, large and small cavities of an oil cylinder of the fixed pipe clamping device and large and small cavities of an oil cylinder of the floating pipe clamping device; the reversing valve and the fixed pipe clamping device and the floating pipe clamping device form a clamping loop and a loosening loop of two pipe clamping devices respectively; a direct control sequence valve is communicated with an oil inlet path of the loosening loop of the fixed pipe clamping device and an oil inlet path of the clamping loop of the floating pipe clamping device; and a direct control unidirectional sequence valve is communicated with an oil inlet path of the clamping loop of the fixed pipe clamping device and an oil inlet path of the loosening loop of the floating pipe clamping device.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

Torque anchor

An anchor to inhibit rotation of a device relative to an oil well casing, comprising a tubular mandrel adapted for direct or indirect connection to the device; a cylindrical housing to receive at least a portion of the mandrel concentrically therethrough, the housing being rotatable relative to the mandrel and having a plurality of circumferentially spaced apart apertures formed in an outer surface thereof; a plurality of spaced apart anchoring slips disposed between the housing and the mandrel in registry with respective ones of the apertures in the housing's outer surface; first biassing means associated with the mandrel for rotation therewith in the clockwise or counterclockwise directions to engage and then move respective ones of the anchoring slips radially towards and then into temporarily anchoring contact with the casing to prevent further rotation of the mandrel and the device connected thereto in either of the clockwise or counterclockwise directions; and one or more drag blocks disposed in the housing in registry with respective ones of the apertures in the housing's outer surface to extend radially outwardly therefrom, each of the drag blocks being normally biassed into frictional contact with the casing to inhibit rotation of the housing relative to the casing.

Owner:SAMPWELL TESTING SERVICES COBA PROGRESSIVE TECH

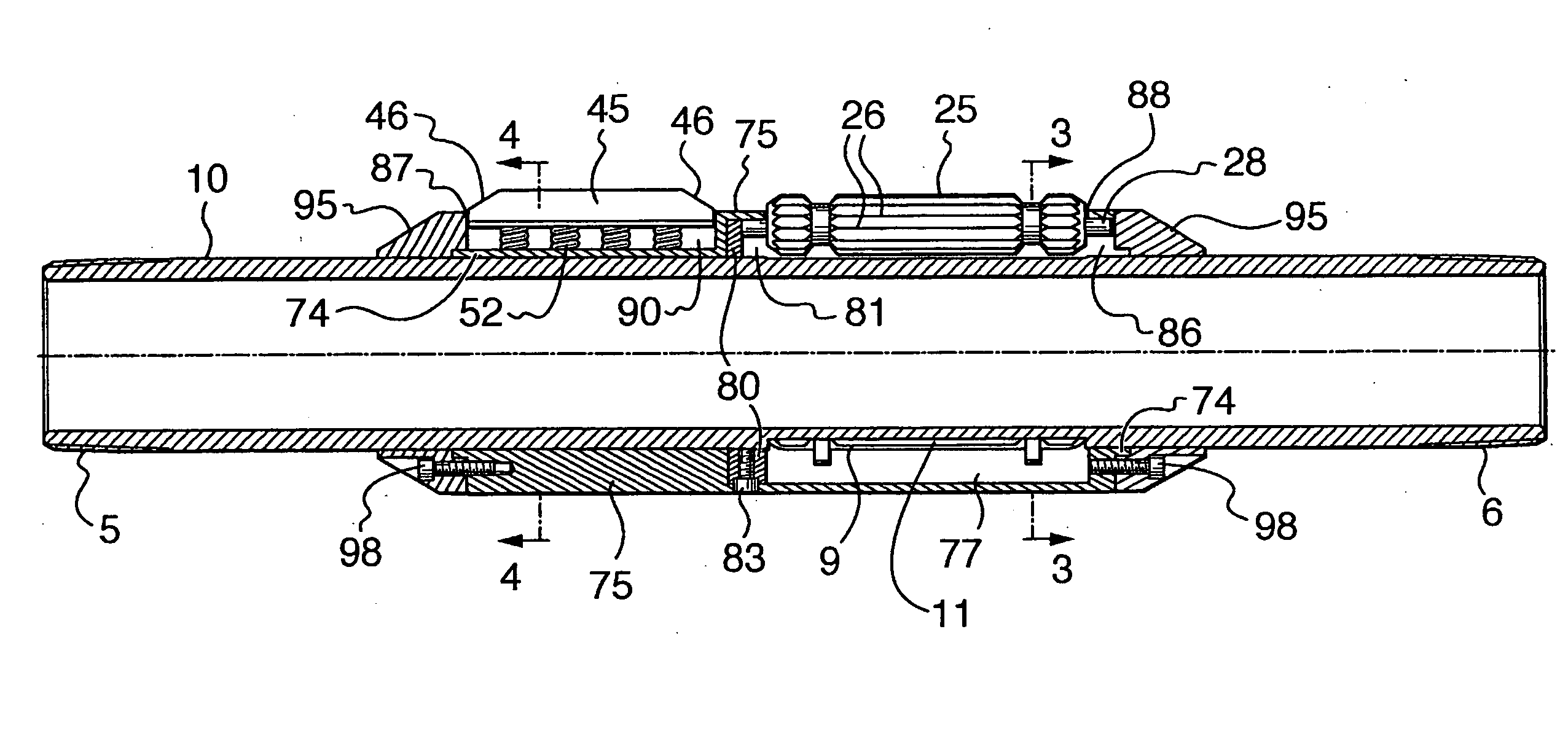

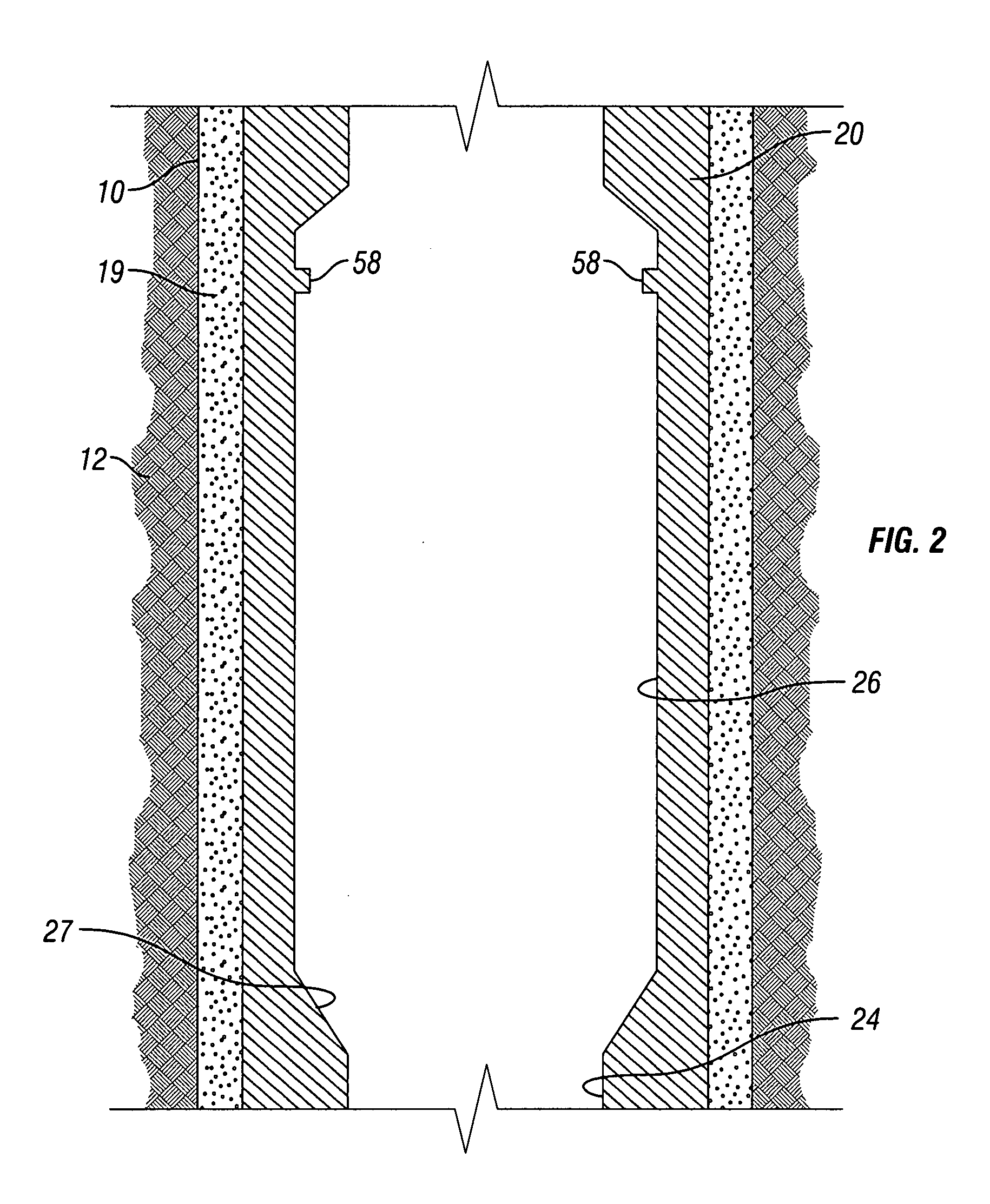

Casing coupler liner hanger mechanism

InactiveUS20080257561A1Easy to disassembleLittle appreciable reduction in useable areaFluid removalTubing catchersEngineeringMechanical engineering

Owner:BAKER HUGHES INC

Anchor for use with expandable tubular

A method of lining a wellbore includes deploying a BHA into the wellbore using a conveyance. The BHA includes setting tool, an anchor, and an expandable tubular. The method further includes pressurizing a bore of the setting tool, thereby releasing the anchor from the setting tool. The method further includes pulling the conveyance, thereby: extending the anchor into engagement with a casing of the wellbore, pulling an expander of the setting tool through the expandable tubular, and expanding the tubular into engagement with an open and / or cased portion of the wellbore and retracting the anchor.

Owner:WEATHERFORD TECH HLDG LLC

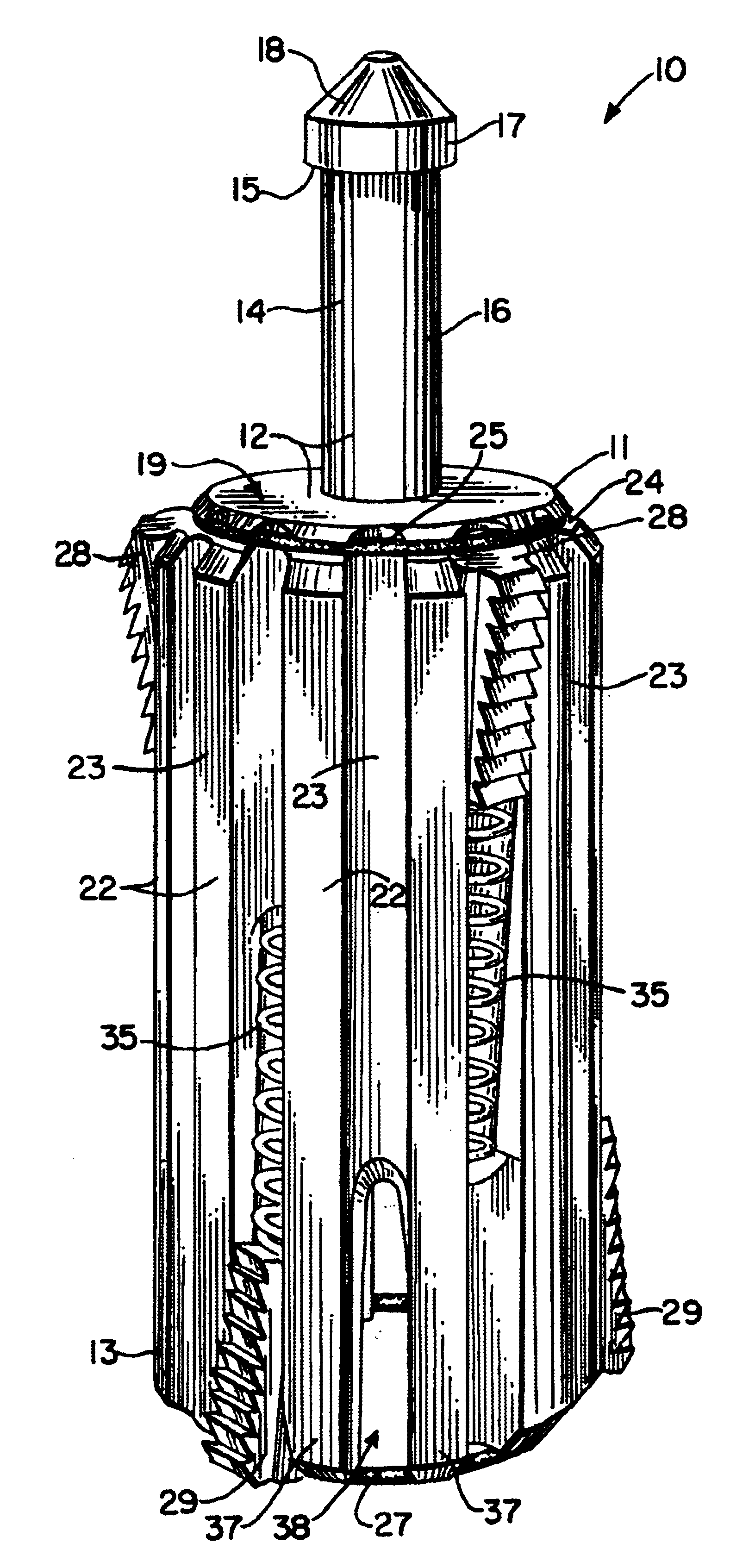

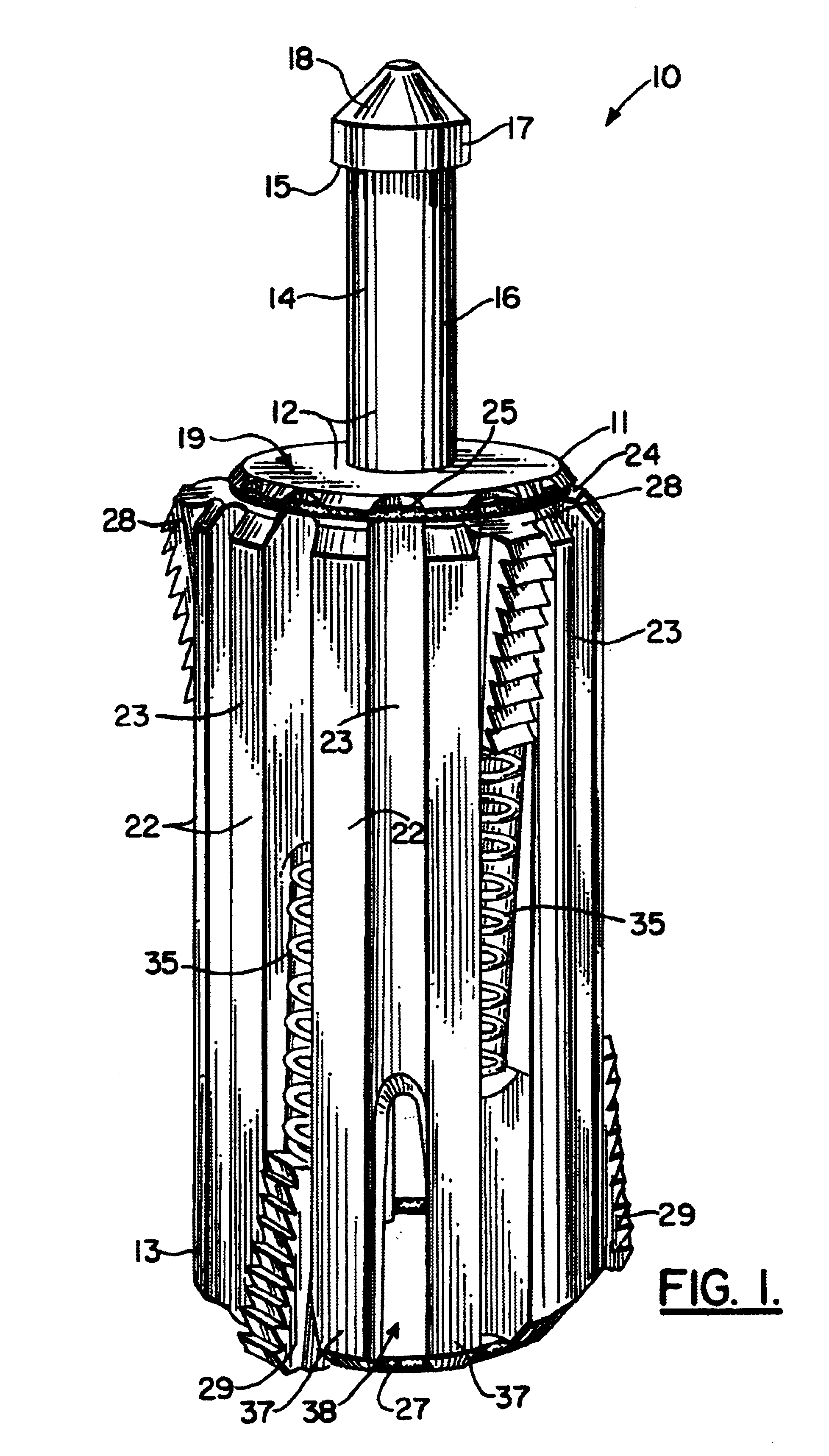

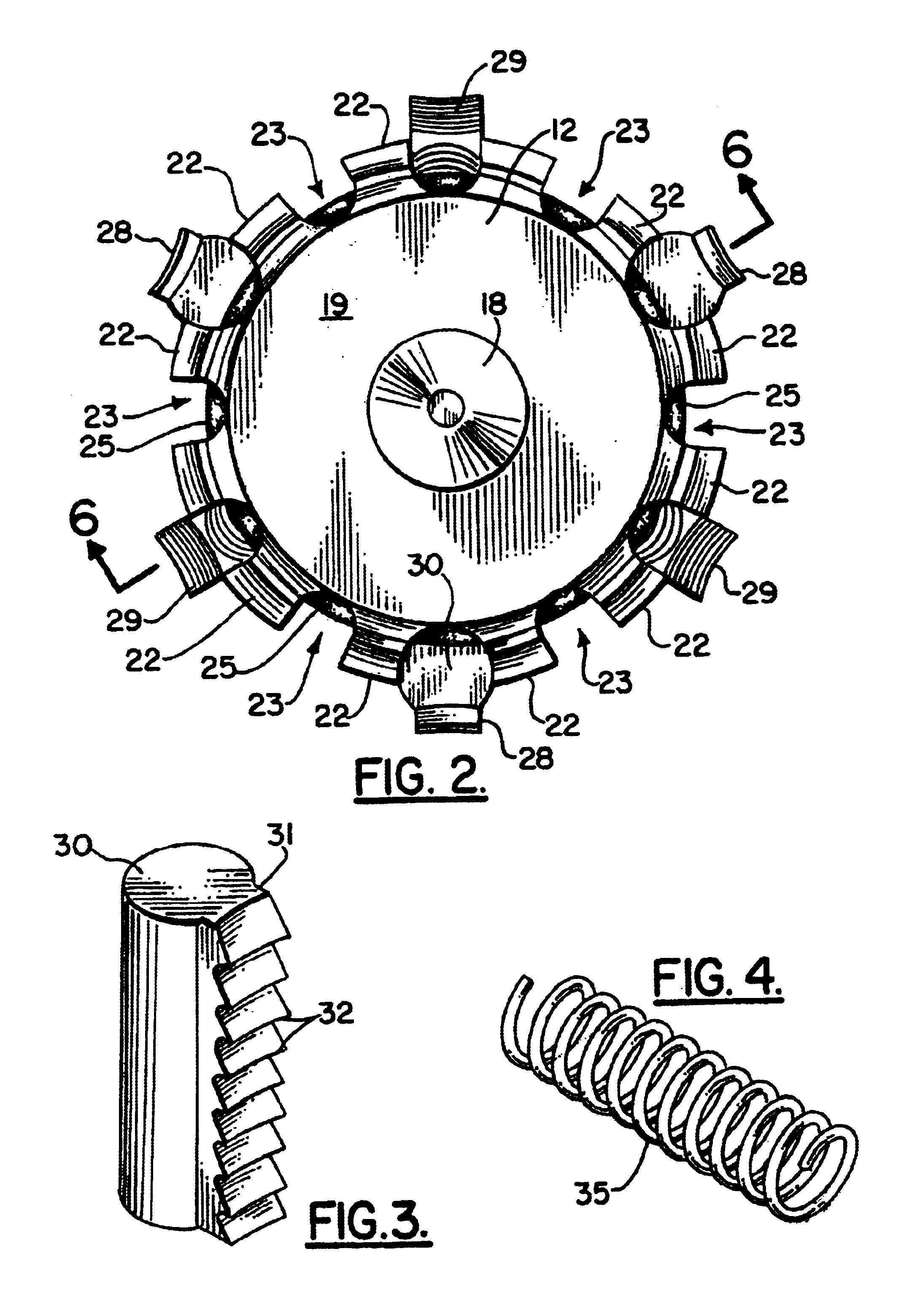

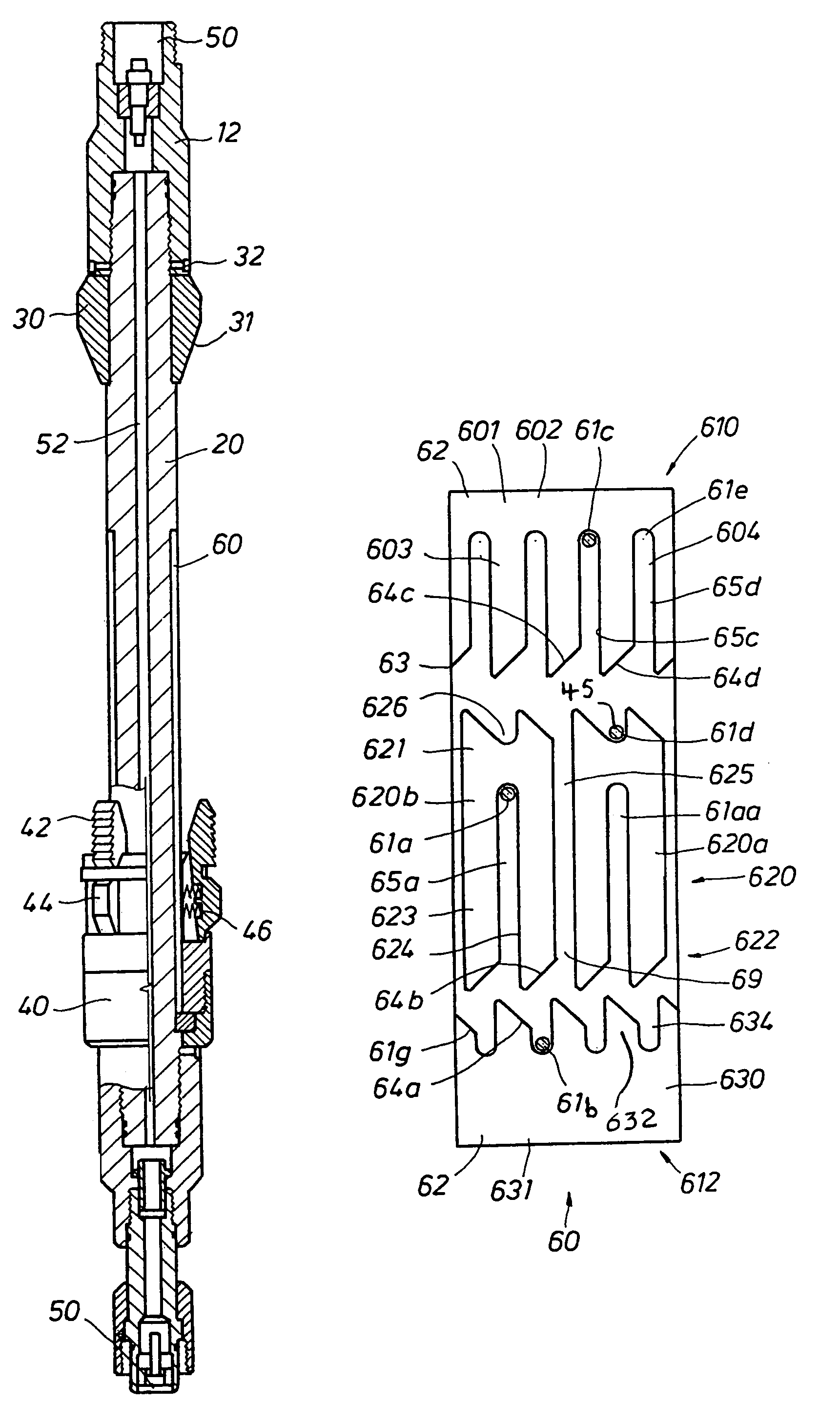

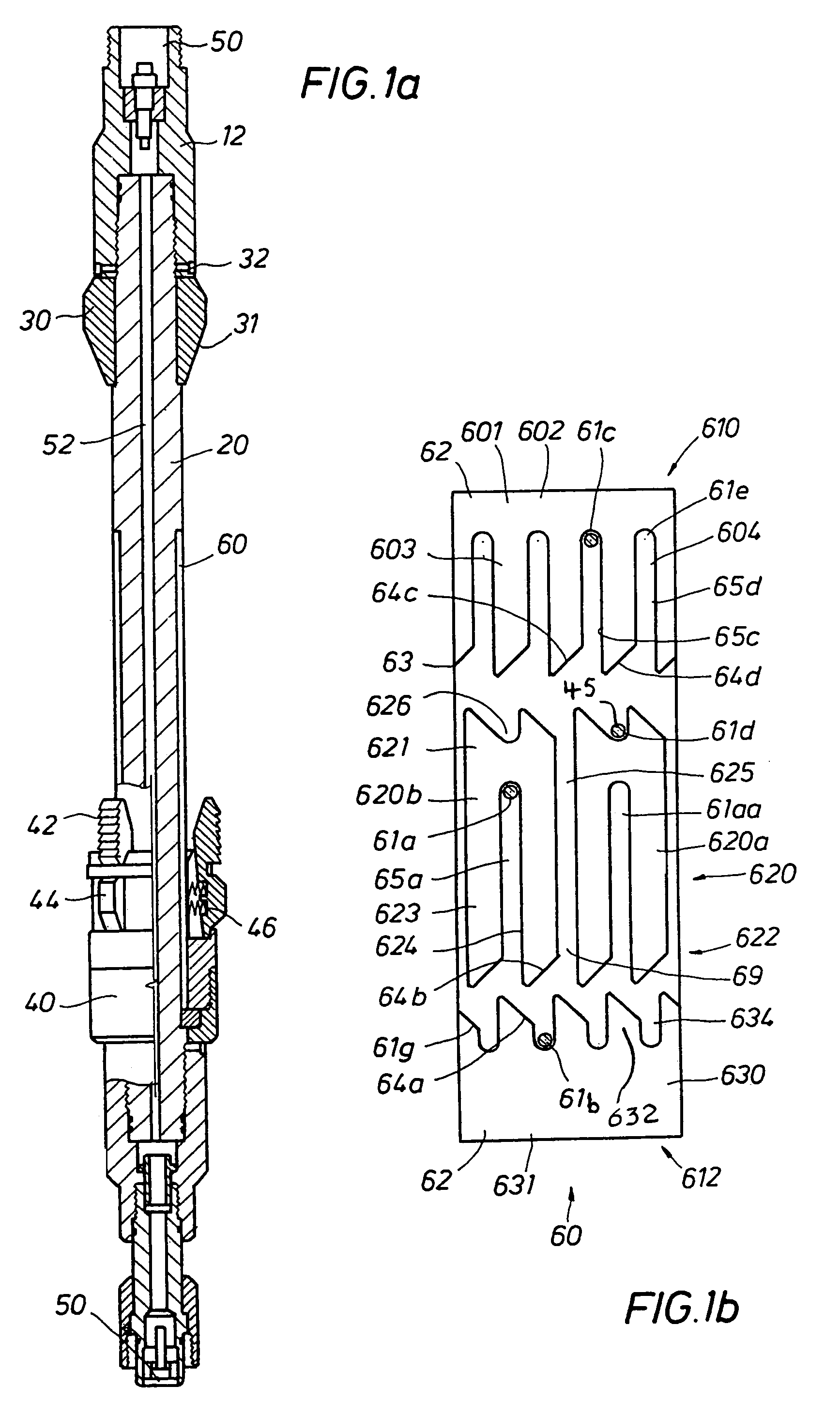

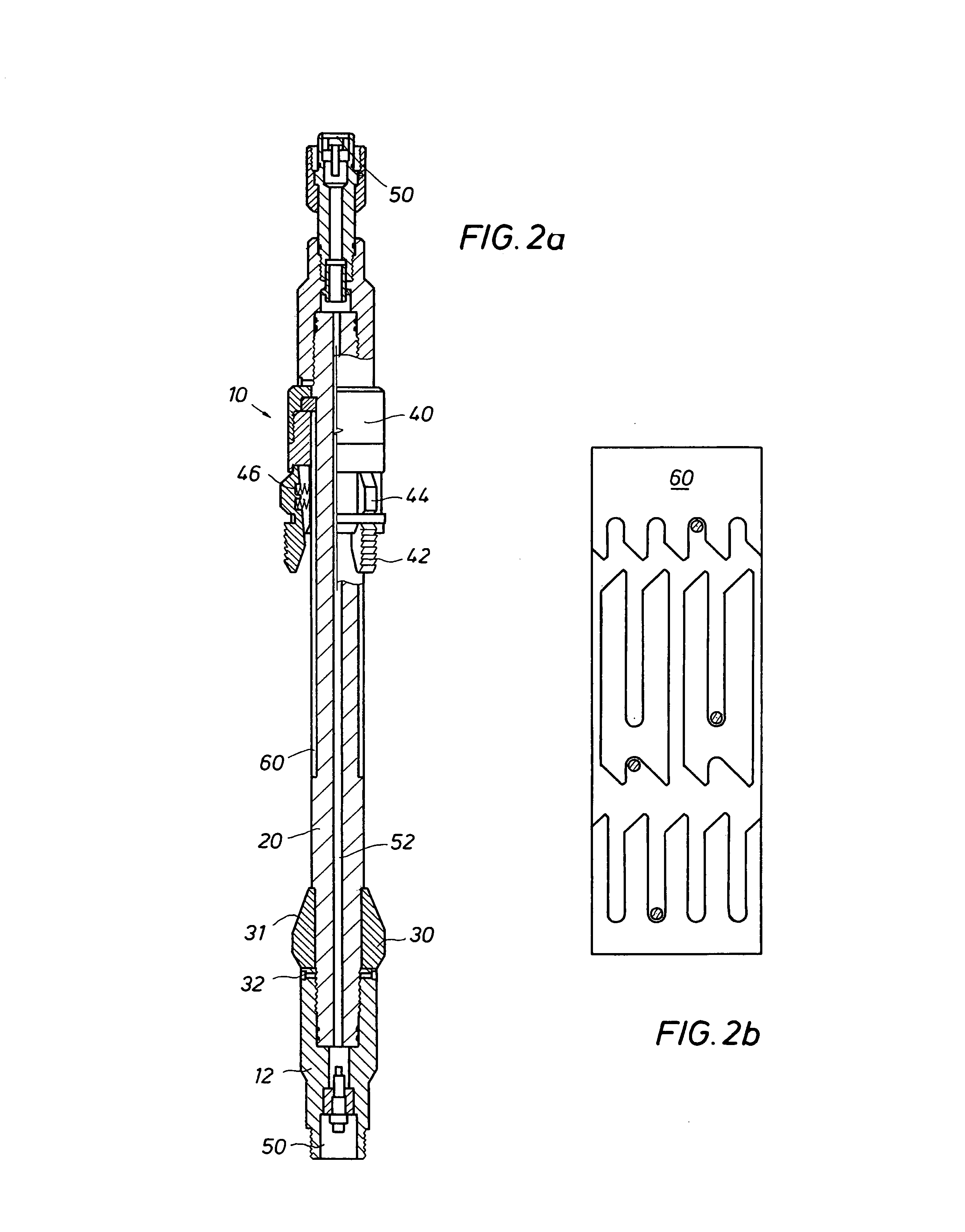

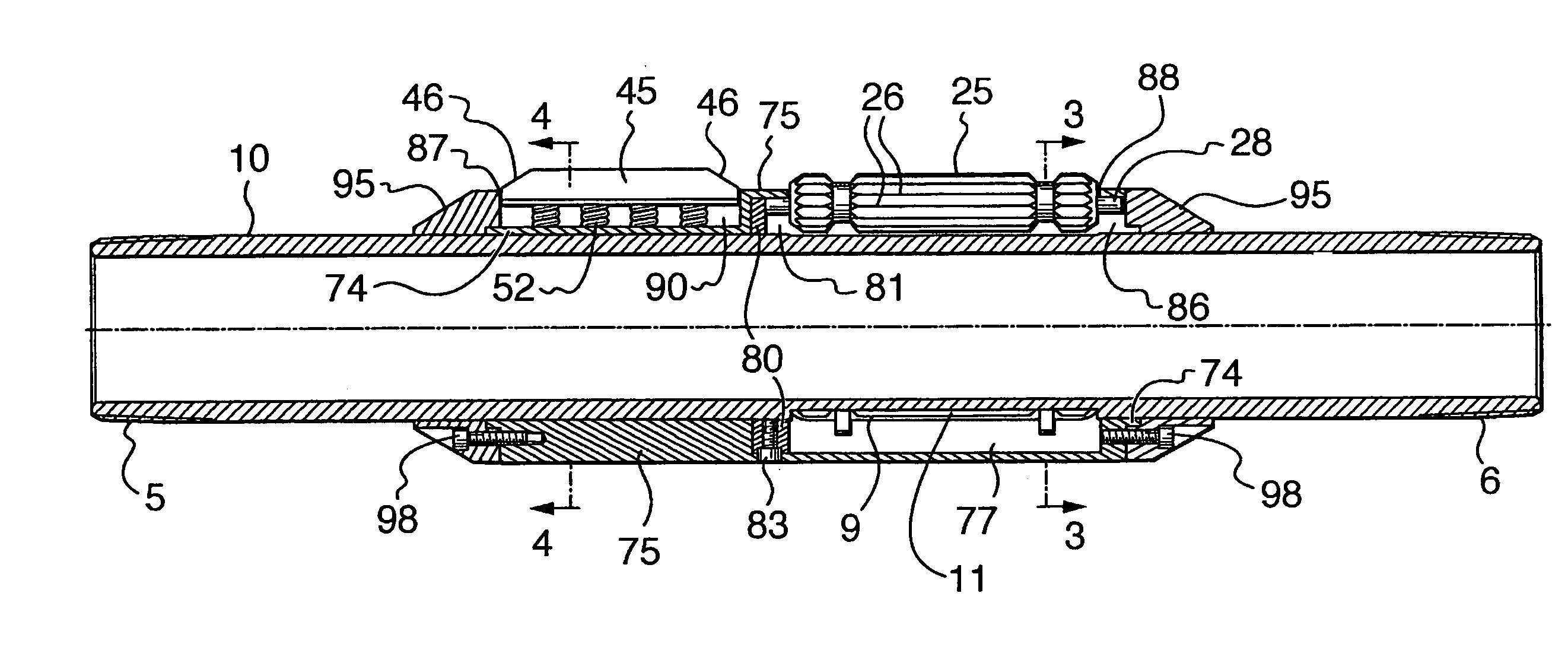

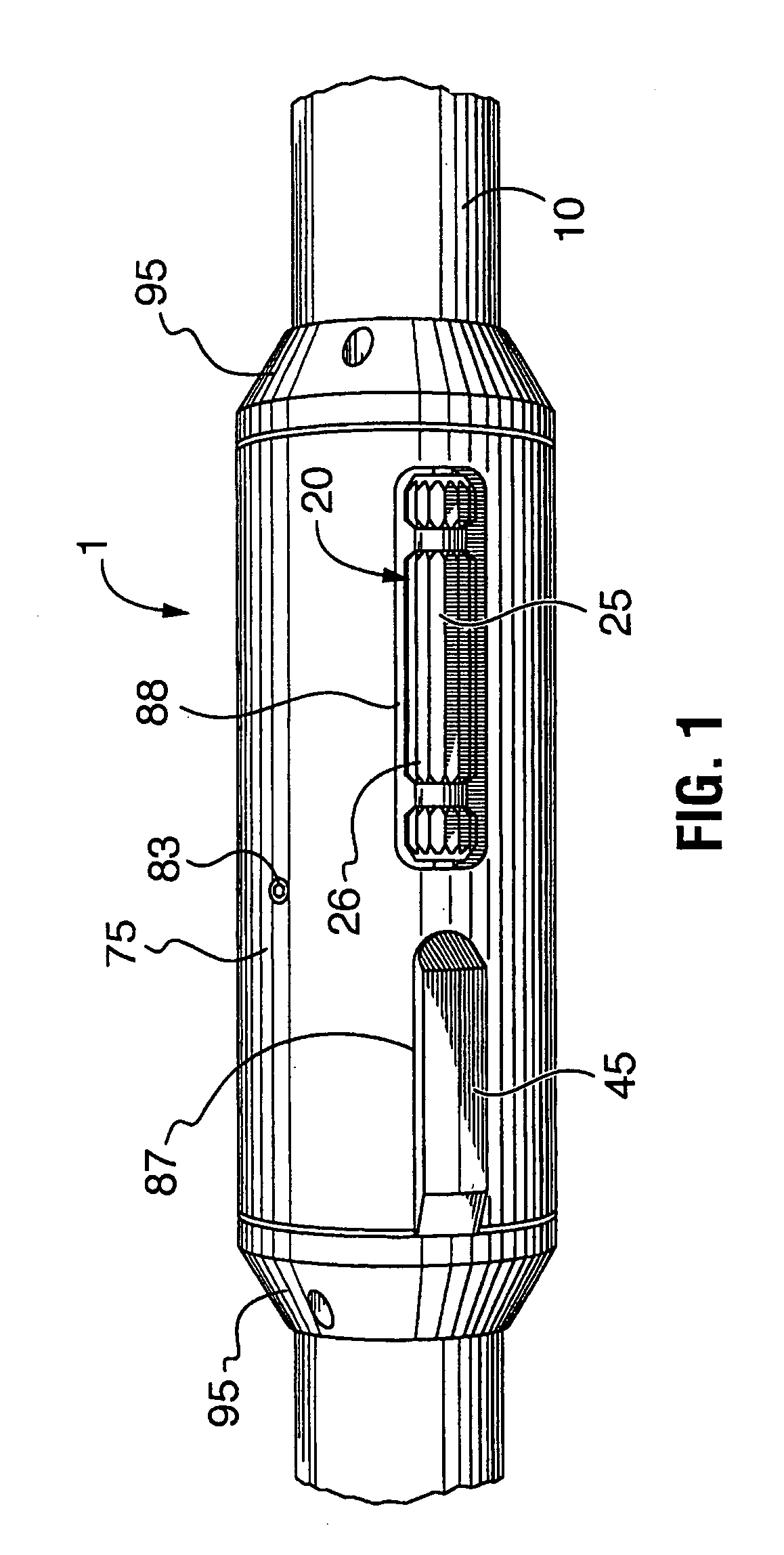

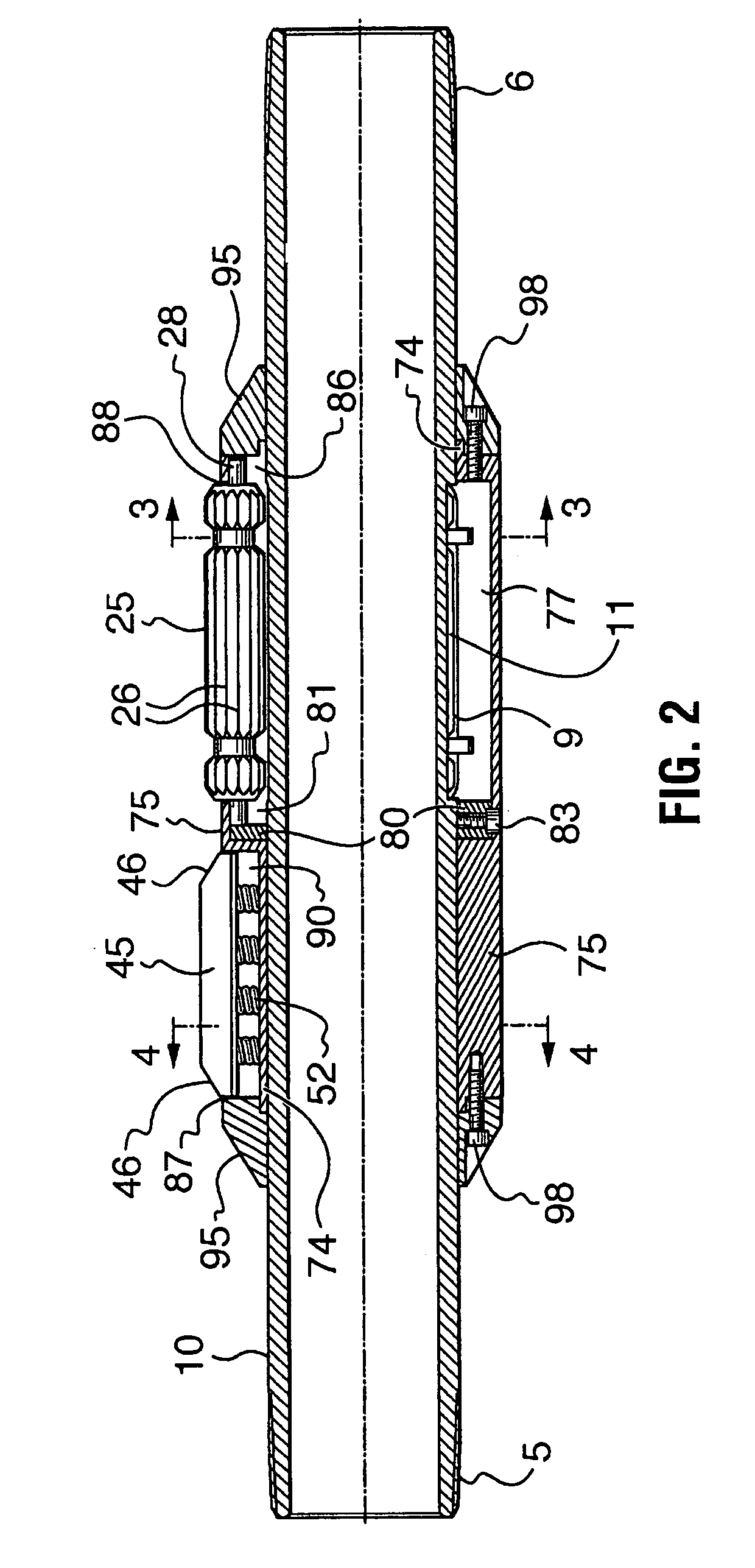

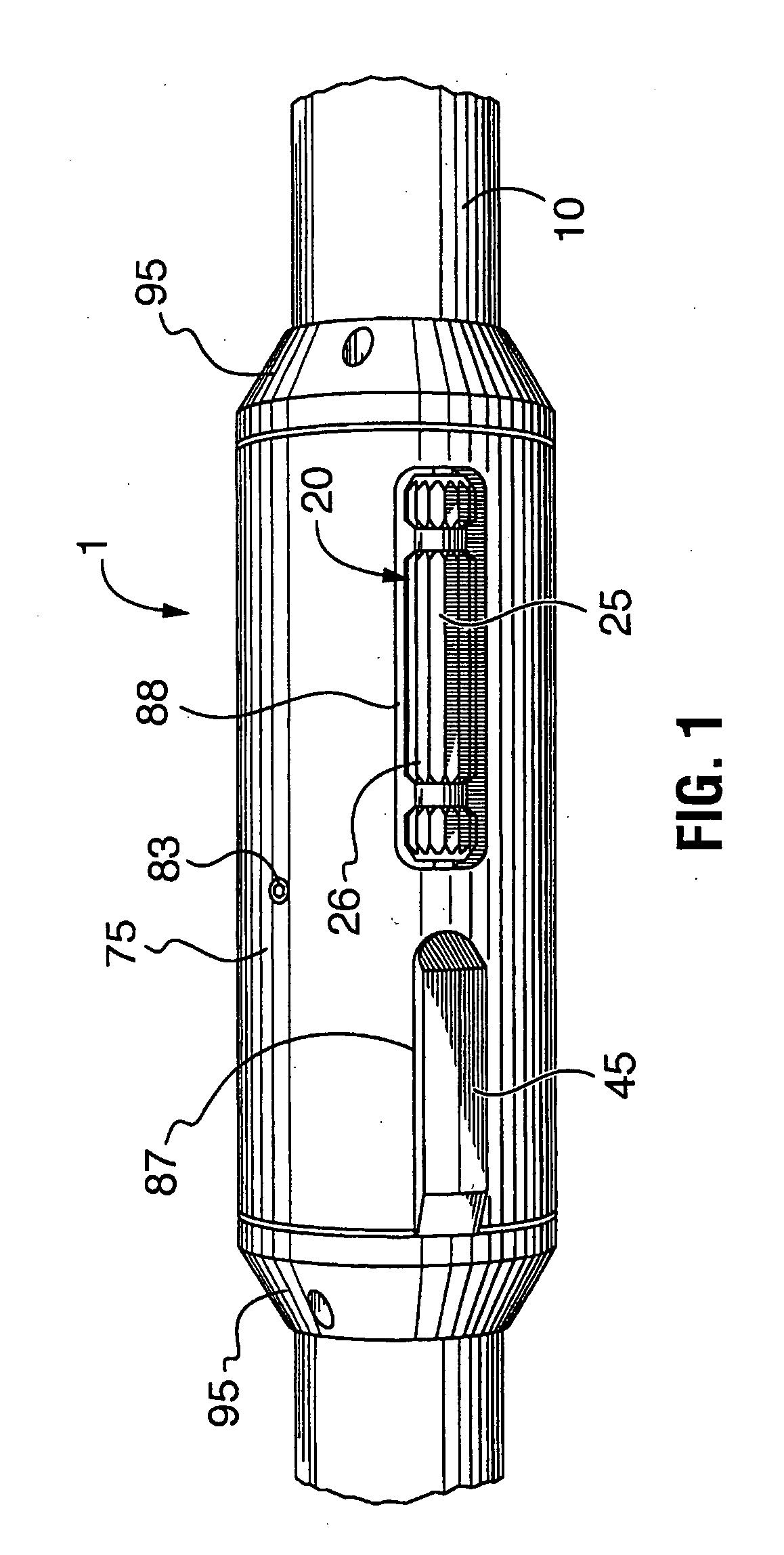

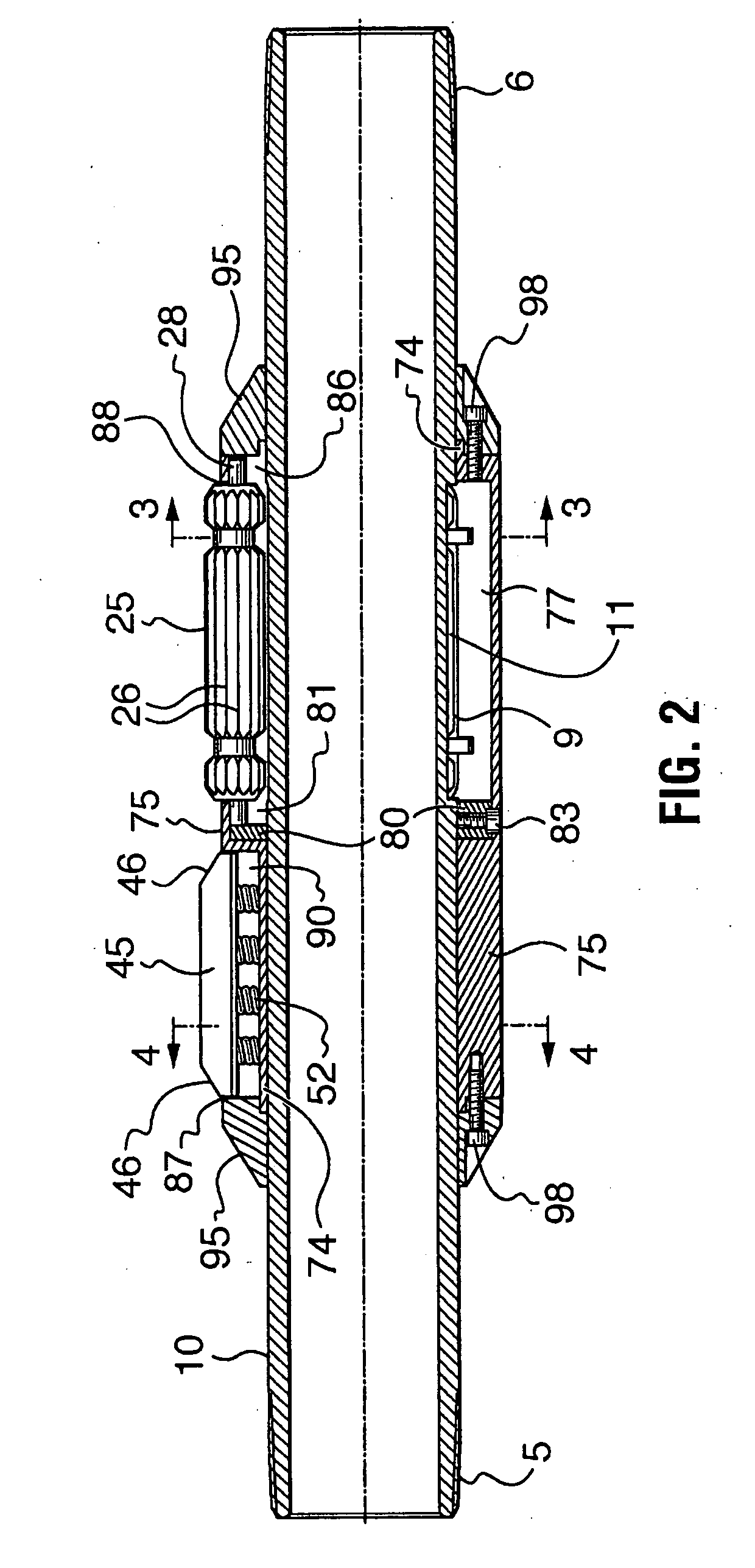

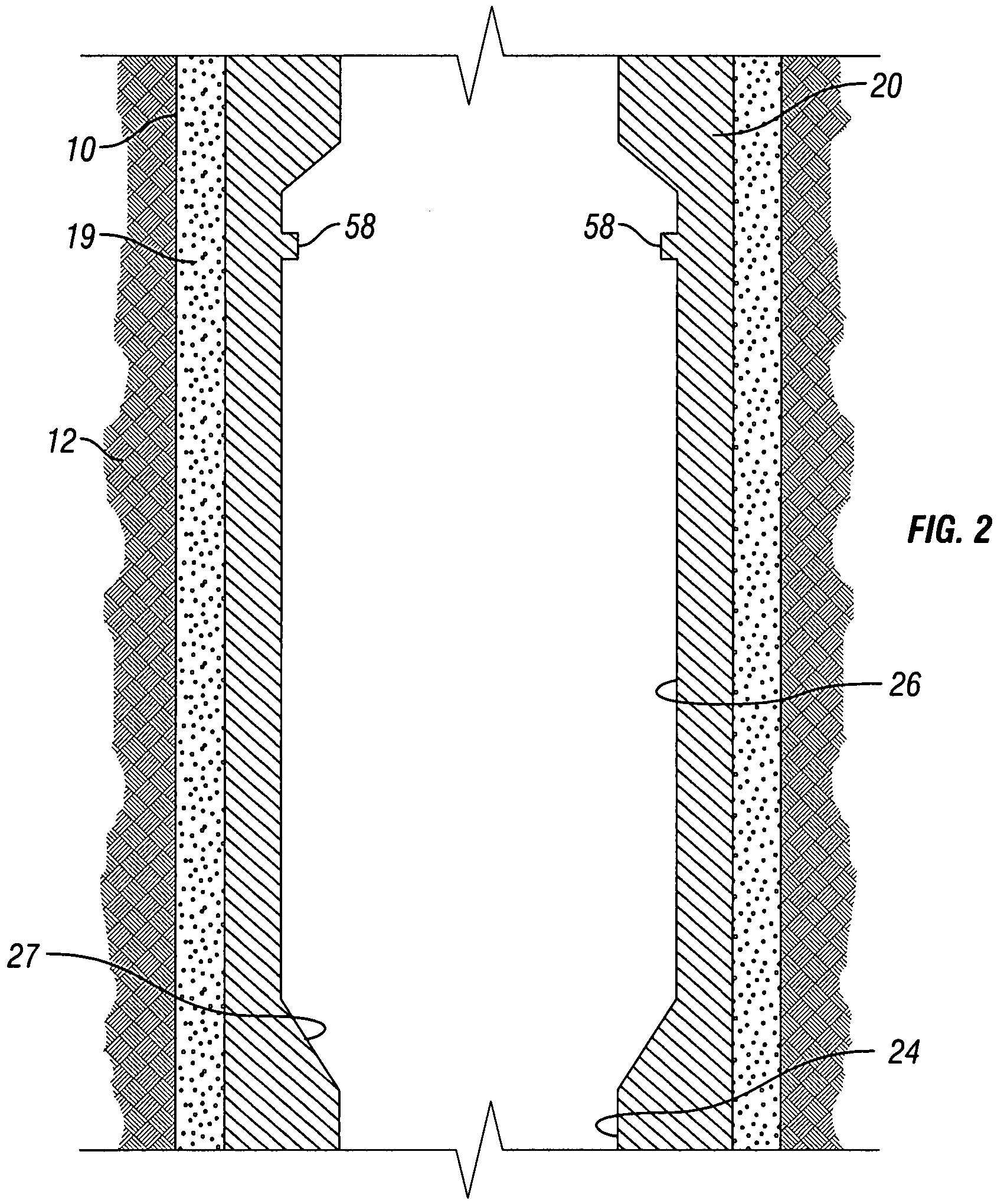

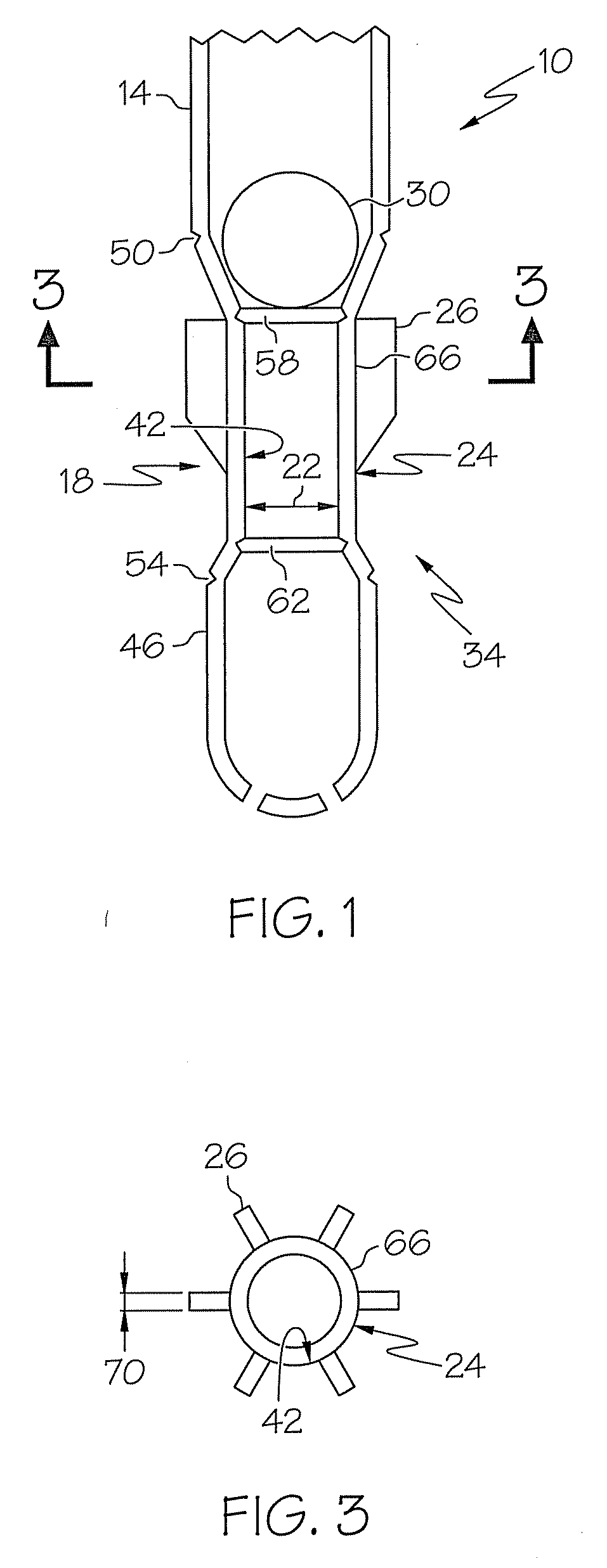

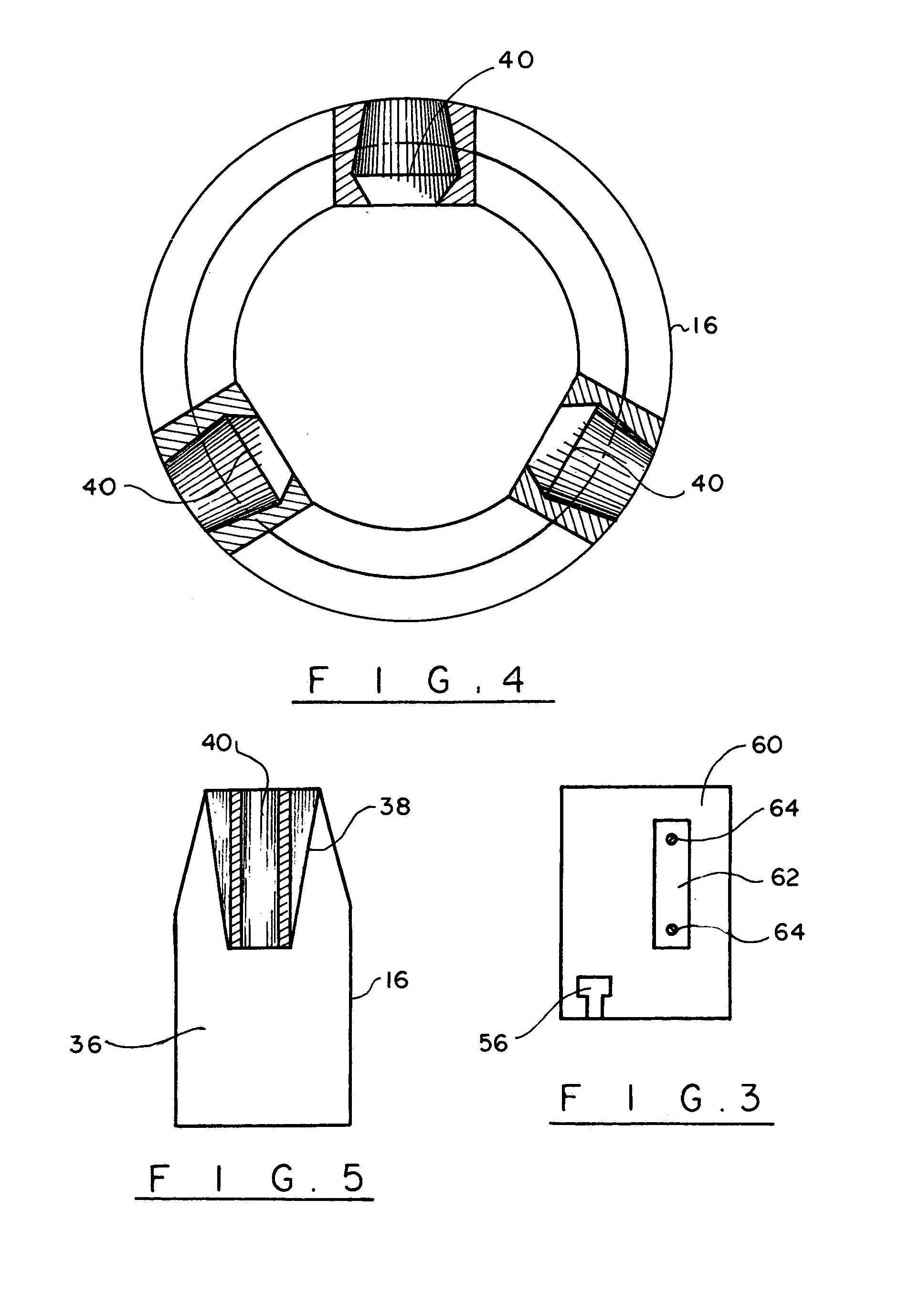

Quarter turn torque anchor and catcher

A tubing anchor for anchoring and catching well equipment in a well conduit to arrest movement in both longitudinal directions and rotation in a first direction. A mandrel connected to the equipment has in one embodiment C or reverse C-shaped grooves when viewed in front elevation for slideably receiving respective pins from a drag body on the mandrel. A slip retainer on the mandrel houses slips for selectively engaging and disengaging the conduit. An initial pull of the mandrel causes the pins to move the drag body toward the slip retainer driving the slips outward to grip the conduit. Rotation of the mandrel in the first direction sets the anchor to arrest movement. Further pulling and a reversed turn of the mandrel maintains the set position. A spring biases the slips outward to maintain their set to catch the well equipment in the event of a break in the string above the anchor.

Owner:TAZCO HLDG

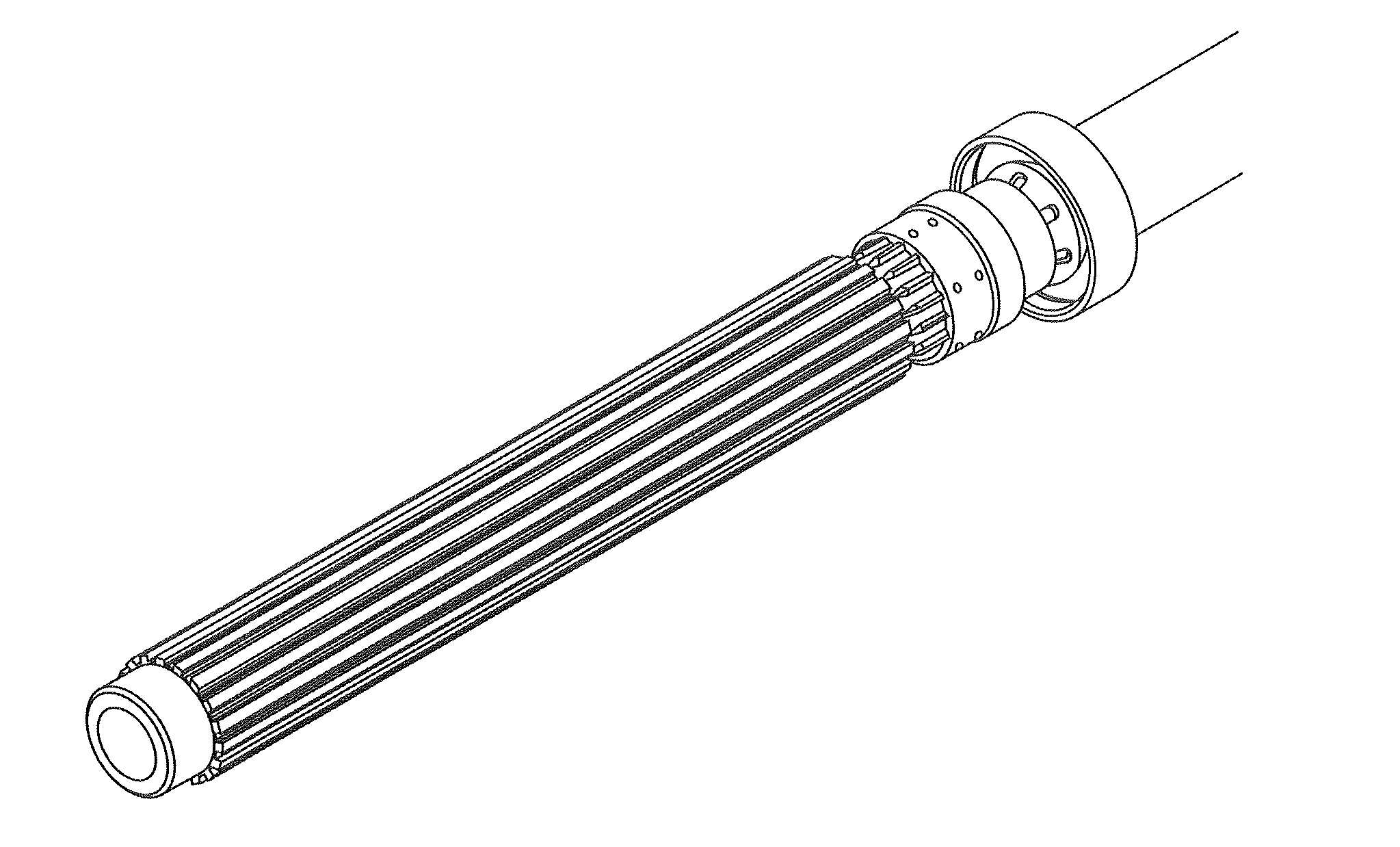

Coiled tubing traction robot

ActiveCN107366523AGuaranteed to pass throughCompact structureTubing catchersCoiled tubingAgricultural engineering

The invention discloses a coiled tubing traction robot, comprising a first segment, a second segment, a third segment, a fourth segment and a fifth segment arranged sequentially from right to left; both the front segment and the rear segment sleeve a front center shaft, both the fourth segment and the fifth segment sleeve a rear center shaft, and the left and right ends of the third segment sleeve the ends of the rear and front center shafts respectively. The coiled tubing traction robot has the advantages of high integrity level, high safety, high tractive capacity, and high success rate.

Owner:SOUTHWEST PETROLEUM UNIV

Casing coupler liner hanger mechanism

InactiveUS7540329B2Easy to disassembleReduce areaFluid removalTubing catchersMechanical engineeringEngineering

Owner:BAKER HUGHES INC

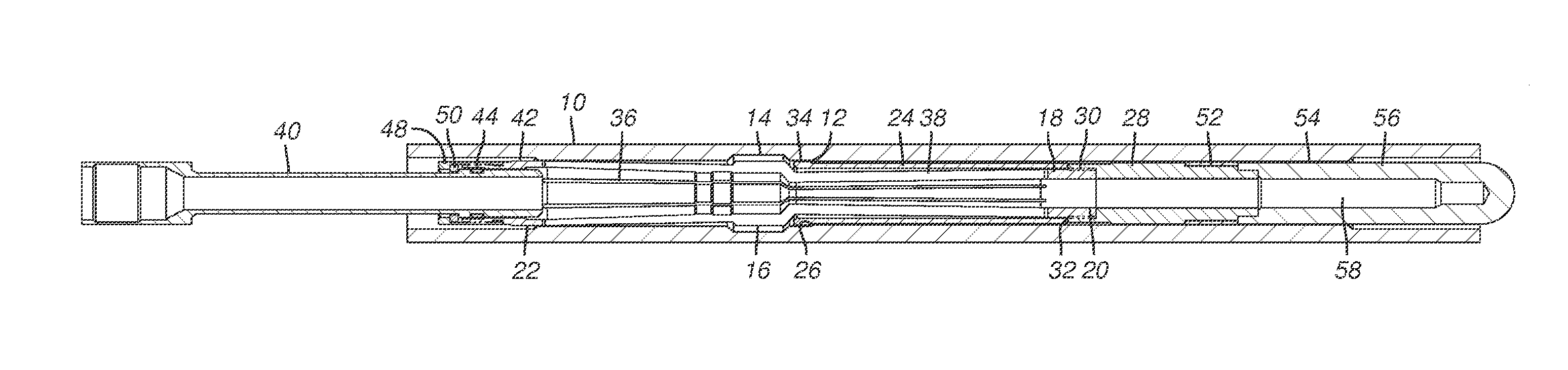

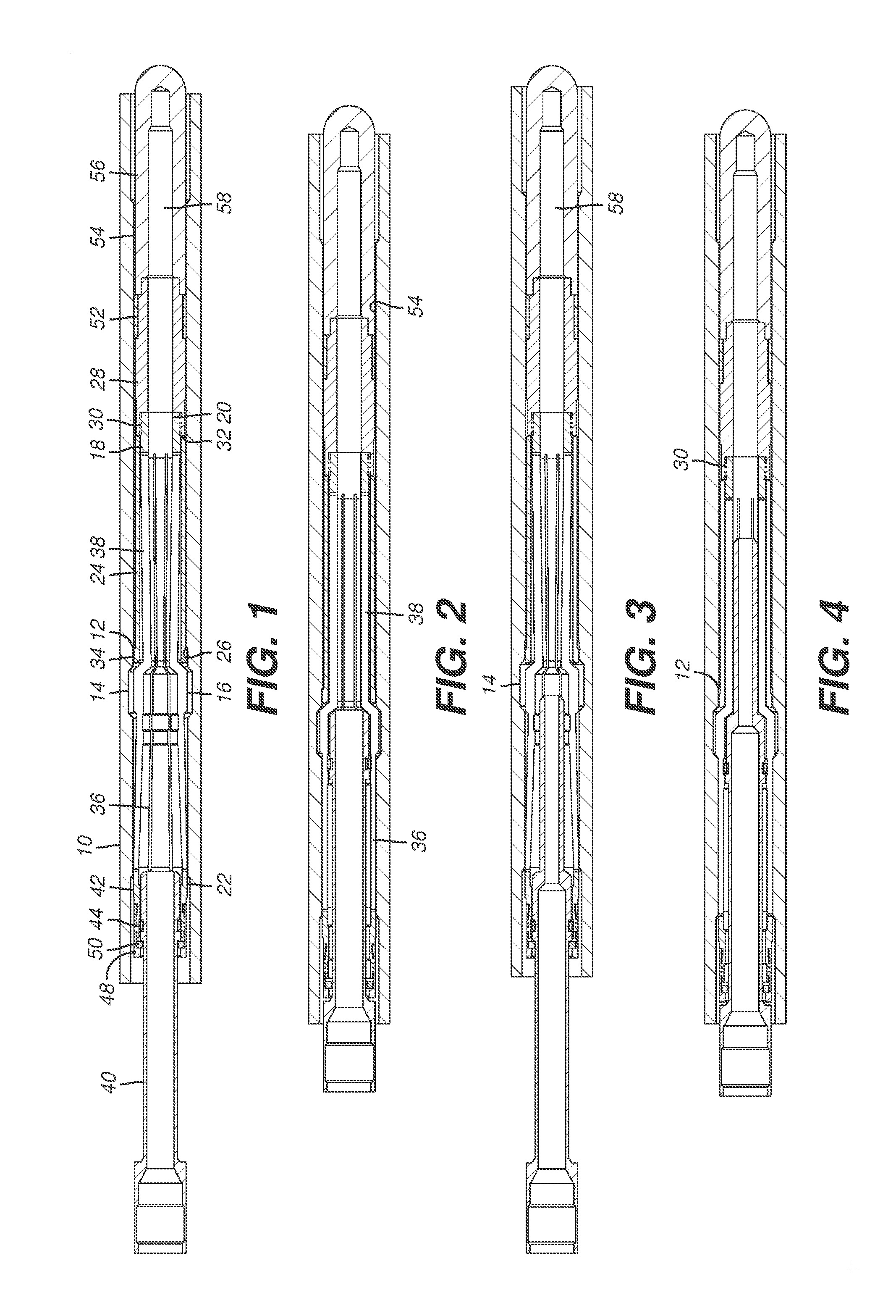

Downhole decelerating device, system and method

Owner:BAKER HUGHES INC

Expansion cone assembly for setting a liner hanger in a wellbore casing

Owner:HALLIBURTON ENERGY SERVICES INC

Downhole retrieving tool and method

ActiveUS20080223584A1Increases internal dimensionReduce internal sizeDrilling rodsFluid removalEngineeringInternal dimension

Disclosed herein is a downhole retrieving tool. The tool includes, a tubular member with a deformable portion having a reduced internal dimension, and a swage member engagable with the reduced internal dimension such that movement of the swage member through the deformable portion radially increases the internal dimension and the outer surface of the deformable portion causing the deformable portion to move radially outwardly.

Owner:BAKER HUGHES INC

Wellbore anchor tool

An anchor assembly for a downhole tool has upper and lower frictional engagement member for engaging with an inner wall of the casing. The upper frictional members are spring-tensioned, while the lower frictional engagement members slide, to certain degrees, in relation to a longitudinal axis of the anchor assembly. At the same time conical engagement between the lower frictional members and the supporting surface causes the lower frictional members to extend outwardly and engage the inner surface of the casing. As a result, the working tool, for instance a sand cutter secured to the anchor assembly is stabilized in the casing, and an even cut may be performed.

Owner:ABRADO INC

Flexible Collet Anchor Assembly with Compressive Load Transfer Feature

A collet assembly has a housing and the collets disposed on flexible fingers connected to the housing at their opposed ends. A surrounding landing sleeve stops the assembly so that collets are aligned with a recess in a landing collar that is part of a surrounding tubing string. Once set the landing sleeve transmits compressive loads so that compressive stress essentially bypasses the finger structure supporting the collets. The fingers are initially tapered toward a longitudinal axis so that when internally supported they assume an aligned orientation to the housing axis to allow greater tensile loading and to provide a retraction force when the housing is to be removed after the collet support is removed.

Owner:BAKER HUGHES INC

Flow Diversion Valve for Downhole Tool Assembly

InactiveUS20210115747A1Rate to changeReduce fluid flow rateTubing catchersFlushingStream flowMud motor

A casing removal system includes a flow diversion valve. The flow diversion valve includes a flow switch that engages an upper end of an inner casing. When the flow switch engages the upper end of the inner casing, the flow diversion valve opens and at least a portion of the fluid flow through the casing removal system exhausts to the annulus. The remaining fluid flow below the flow diversion valve is insufficient to operate a mud motor that drives a casing cutter. In other embodiments, when the flow switch is not engaged with the inner wall of casing, the flow diversion valve prevents fluid flow to components that are downhole of the valve and when the flow switch is engaged with the inner wall of casing, the flow diversion valve allows for fluid flow to components that are downhole of the valve.

Owner:STOKES DAVID A +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com