Patents

Literature

770 results about "Radial motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

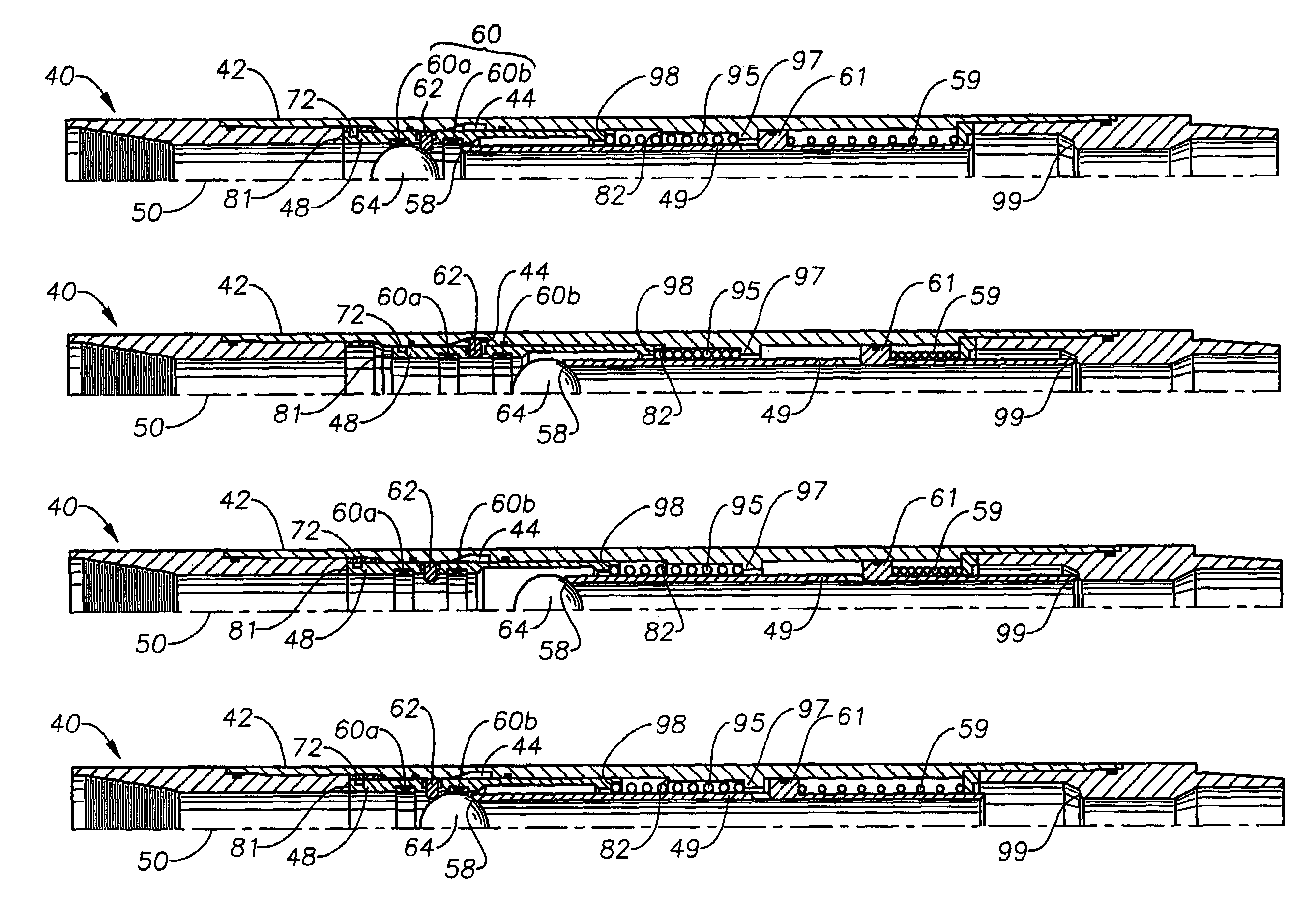

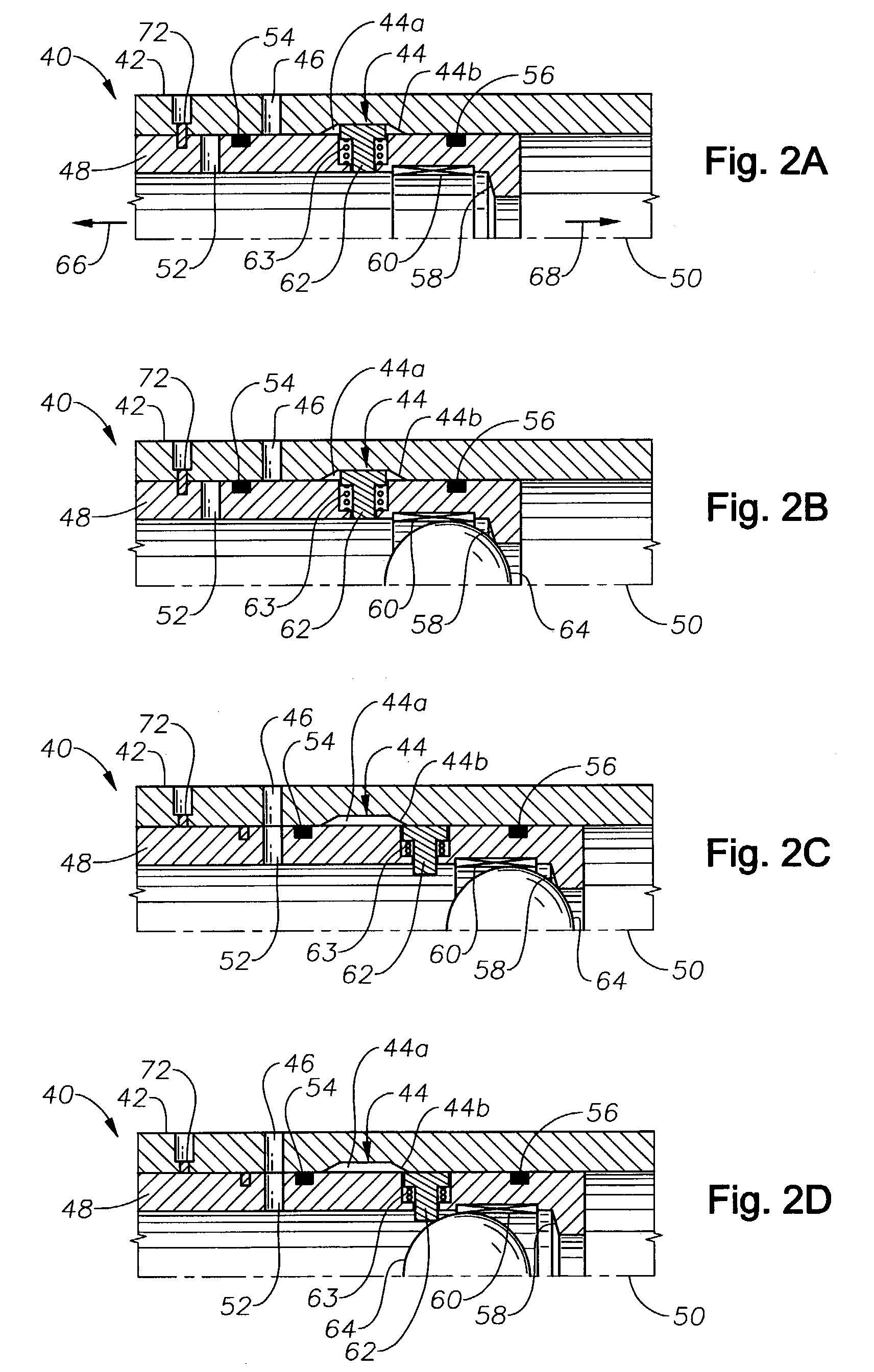

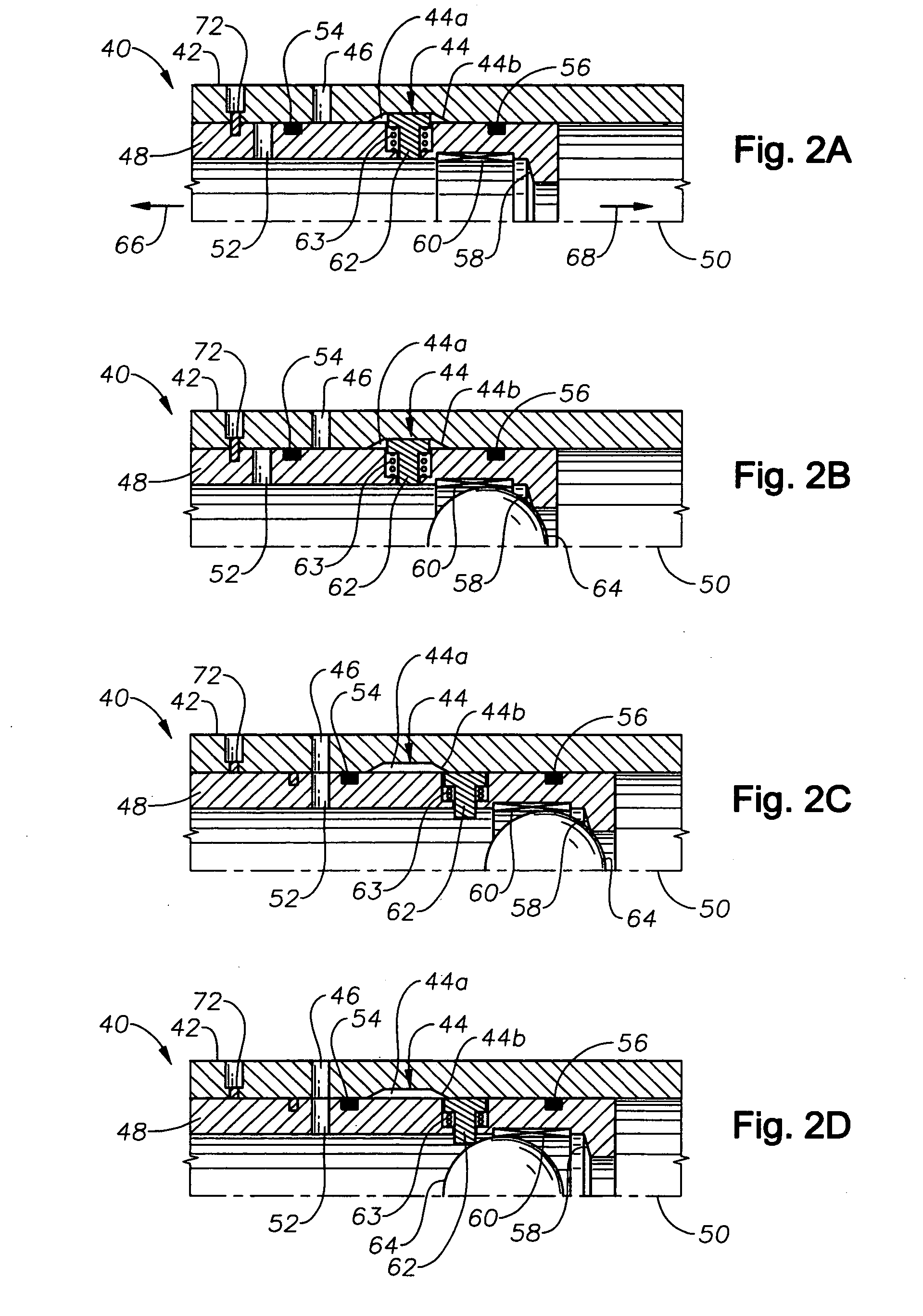

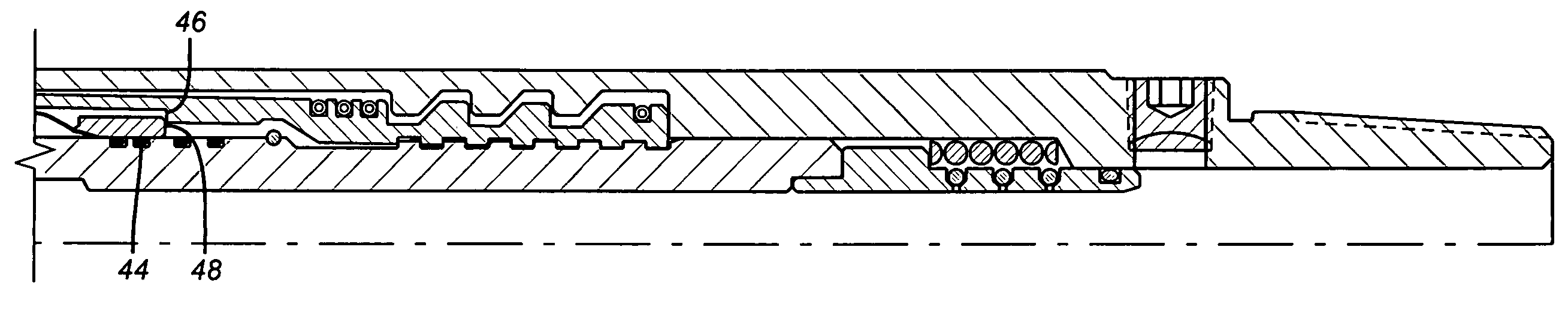

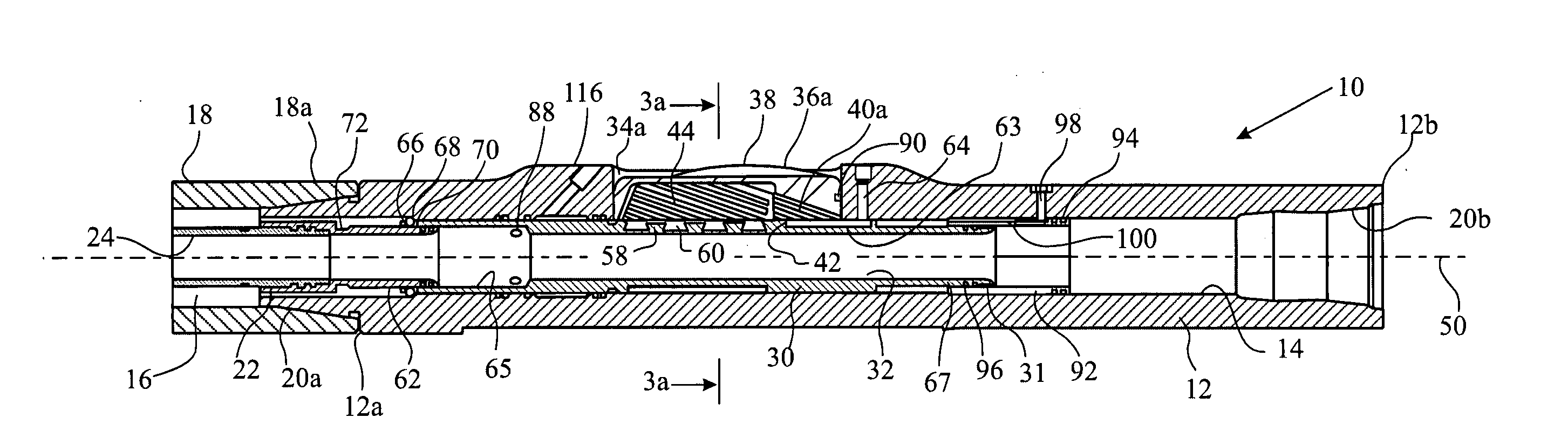

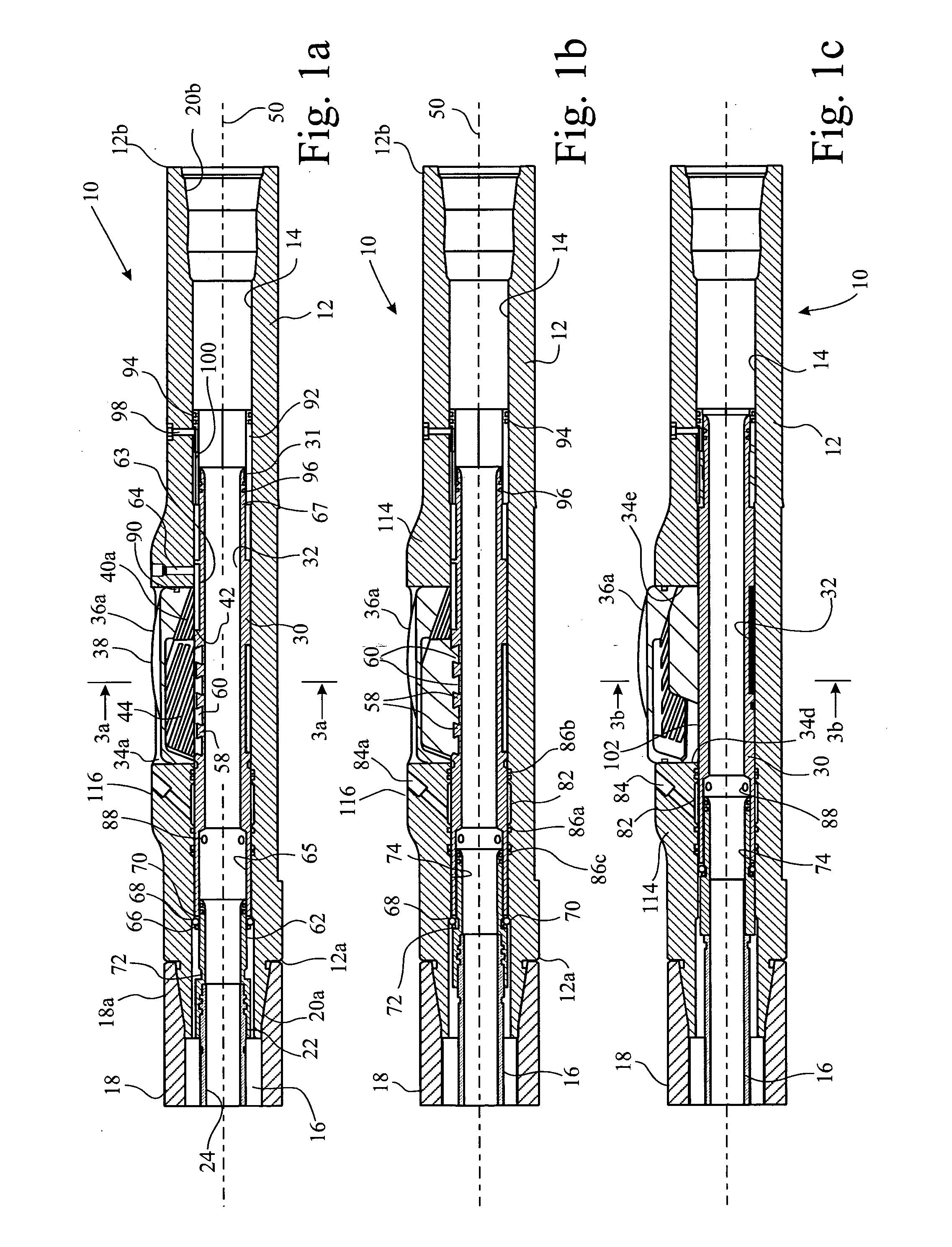

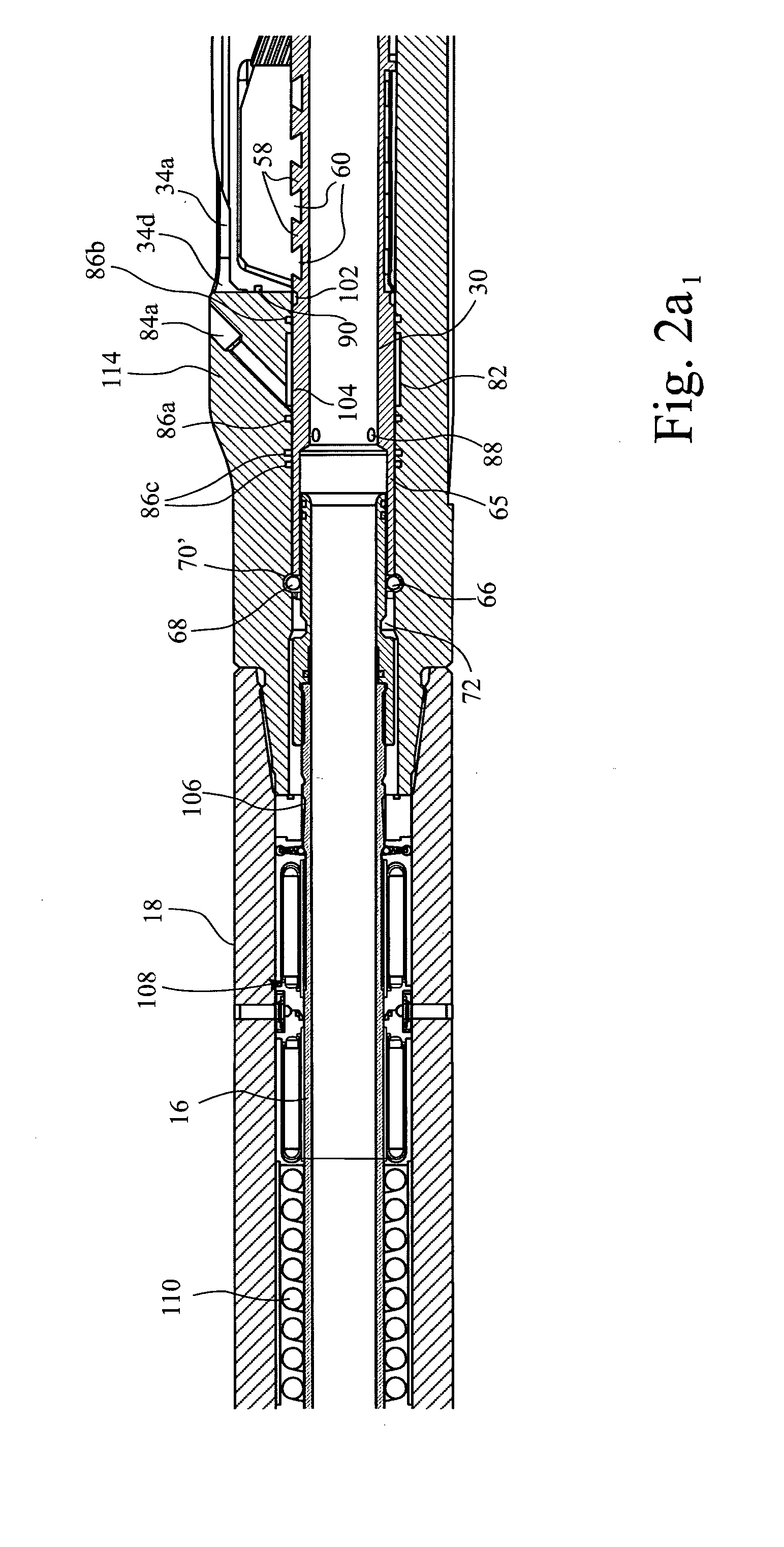

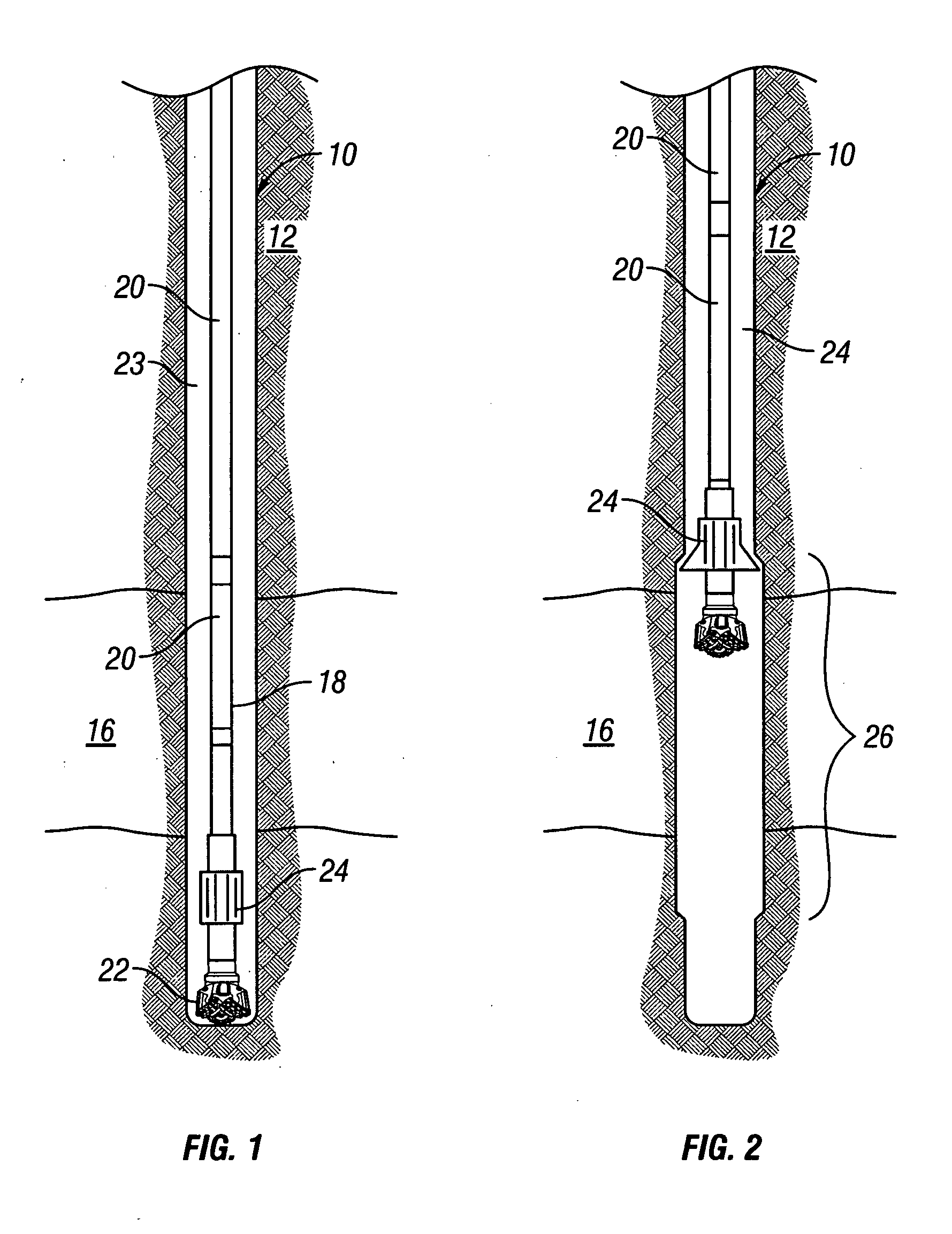

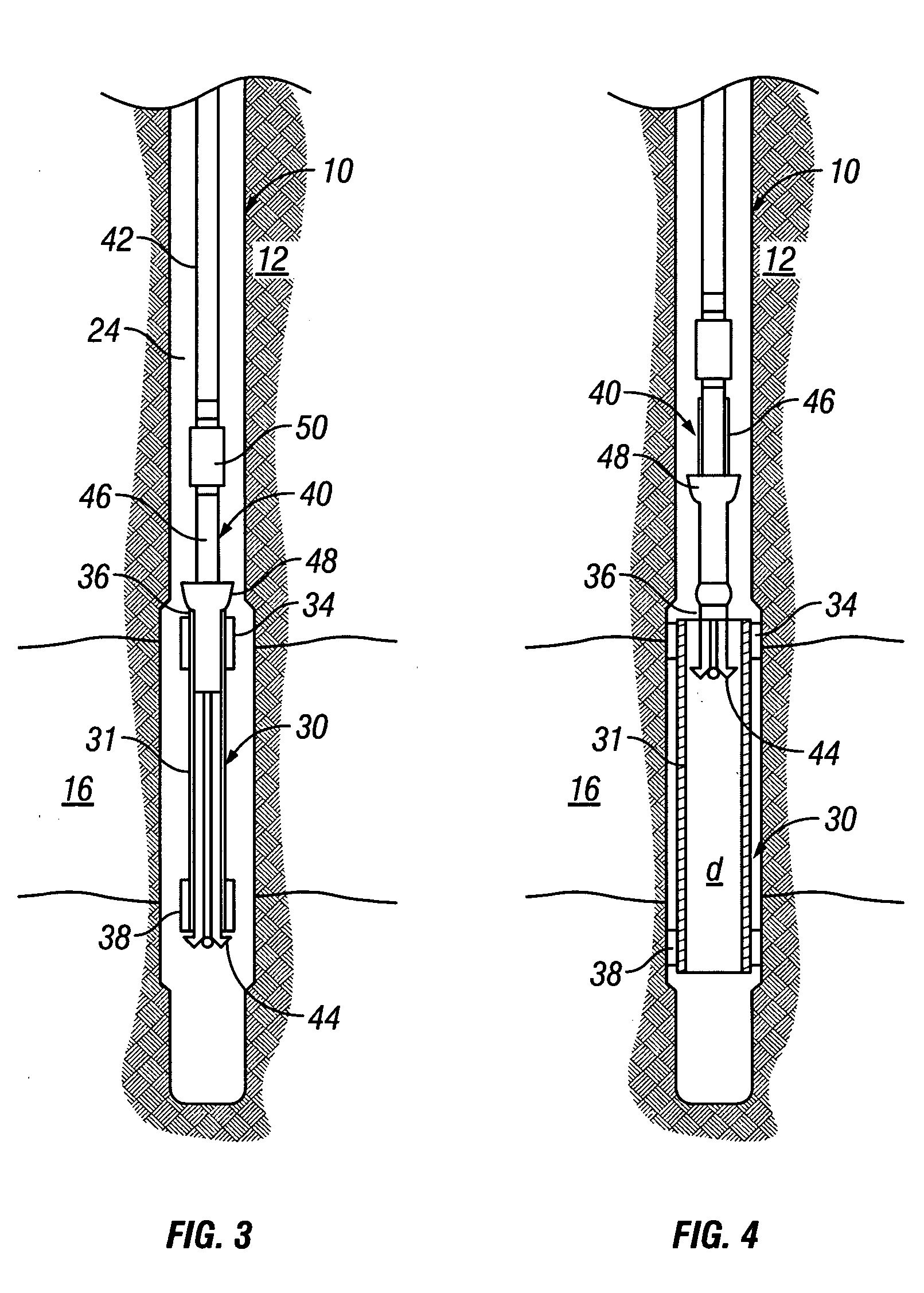

Bi-directional ball seat system and method

The present invention provides a bi-directional ball seat and method of use. In at least one embodiment, the present invention provides a fluid control system that includes a radial protrusion that can be selectively engaged and disengaged upstream and / or from a ball seat. For example, a ball can be placed in a passageway, engaged with a downstream ball seat, and the radial protrusion radially extended into the passageway distally from the seat relative to the ball. A reverse movement of the ball is restricted by the active radial movement of the radial protrusion into the passageway. The control system can be used to control a variety of tools associated with the well. Without limitation, the tools can include crossover tools, sleeves, packers, safety valves, separators, gravel packers, perforating guns, decoupling tools, valves, and other tools know to those with ordinary skills in the art.

Owner:BAKER HUGHES INC

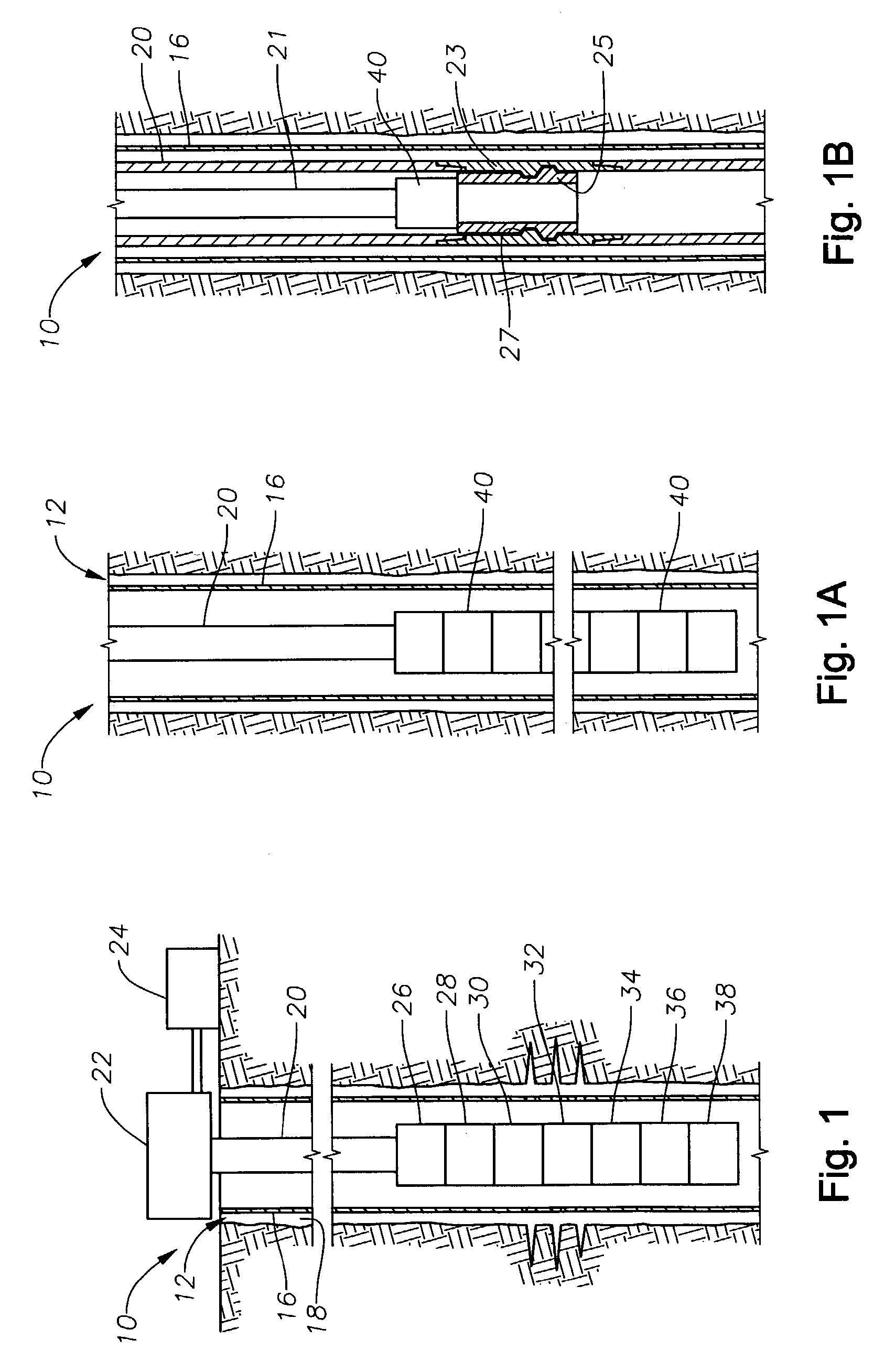

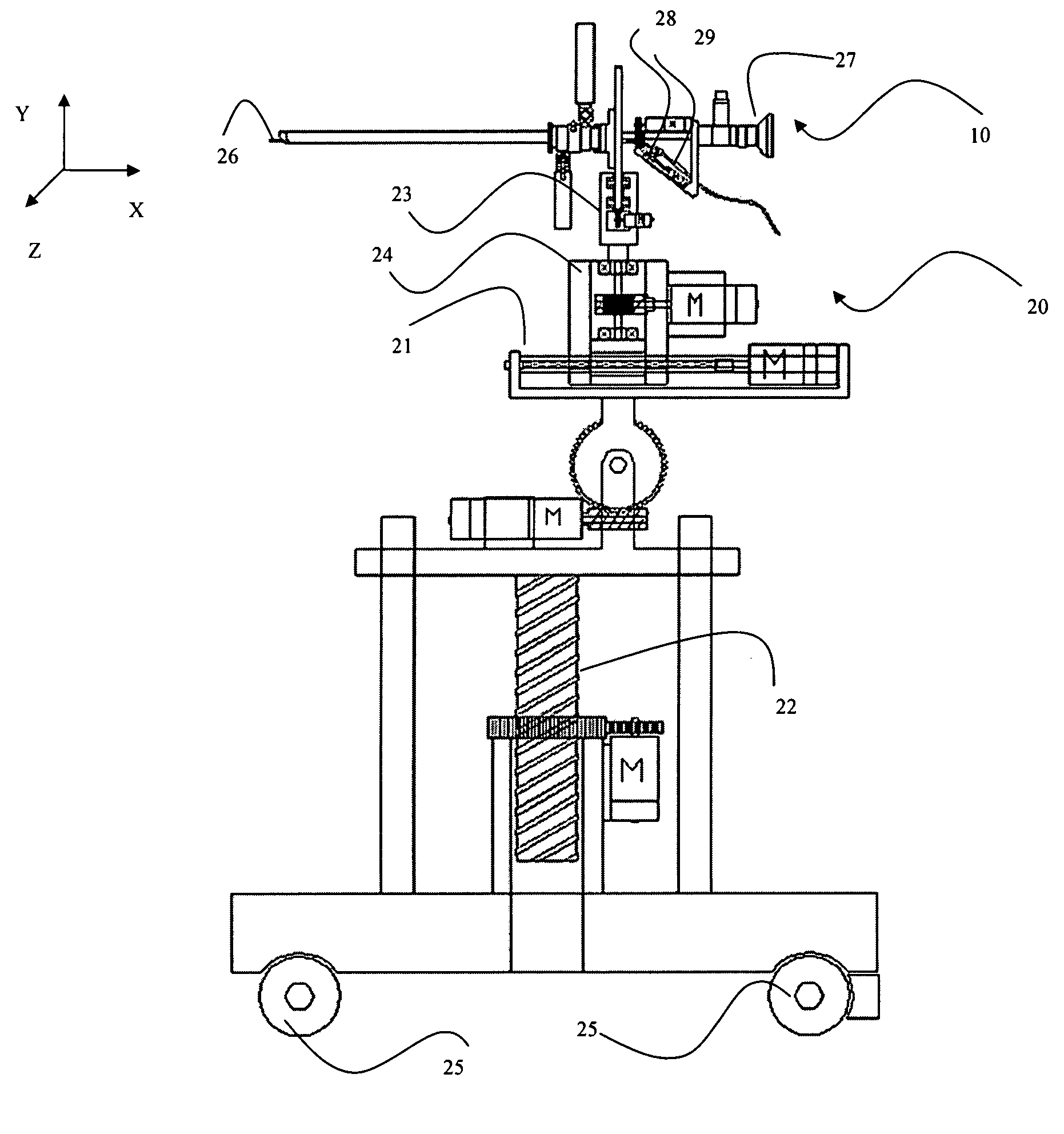

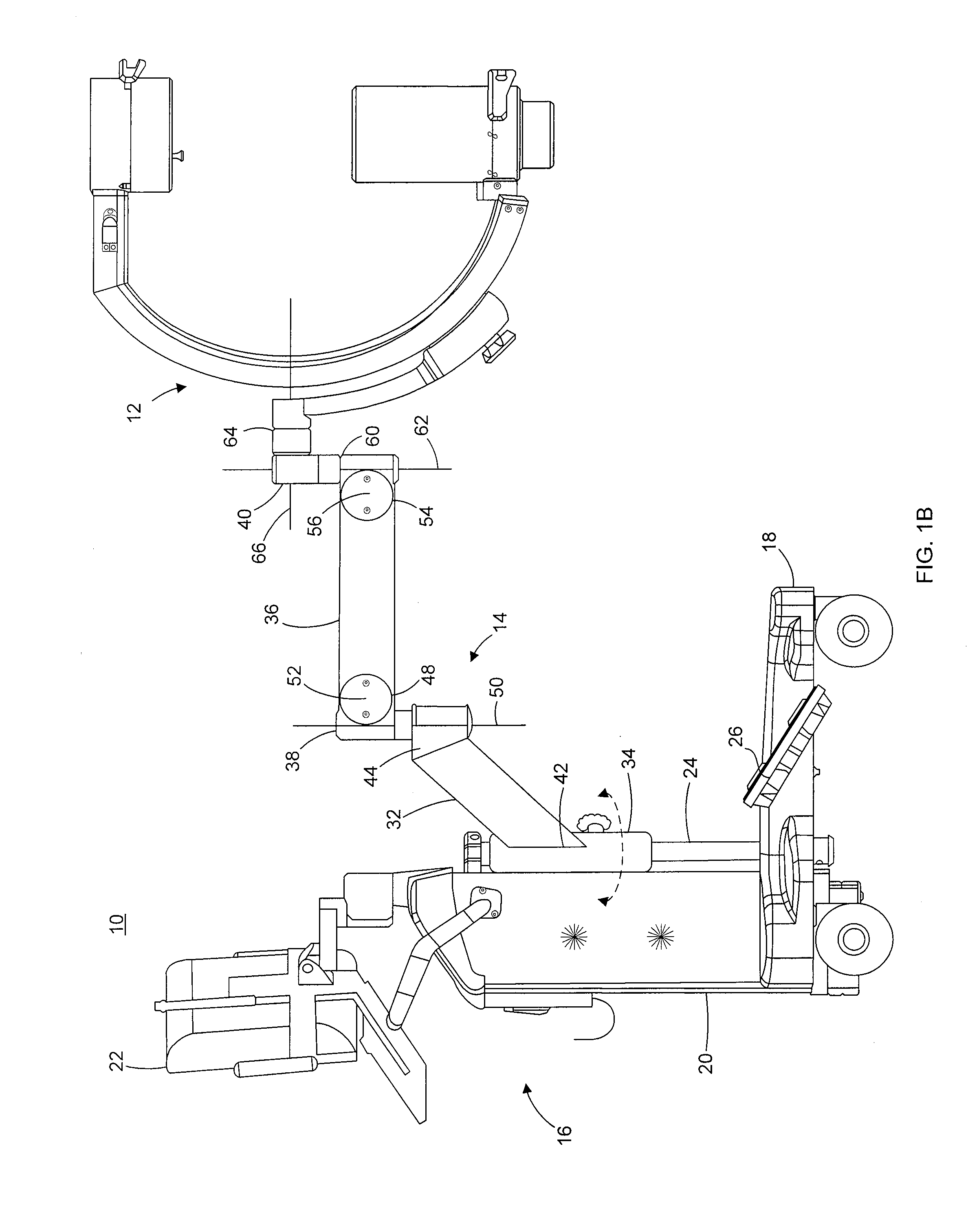

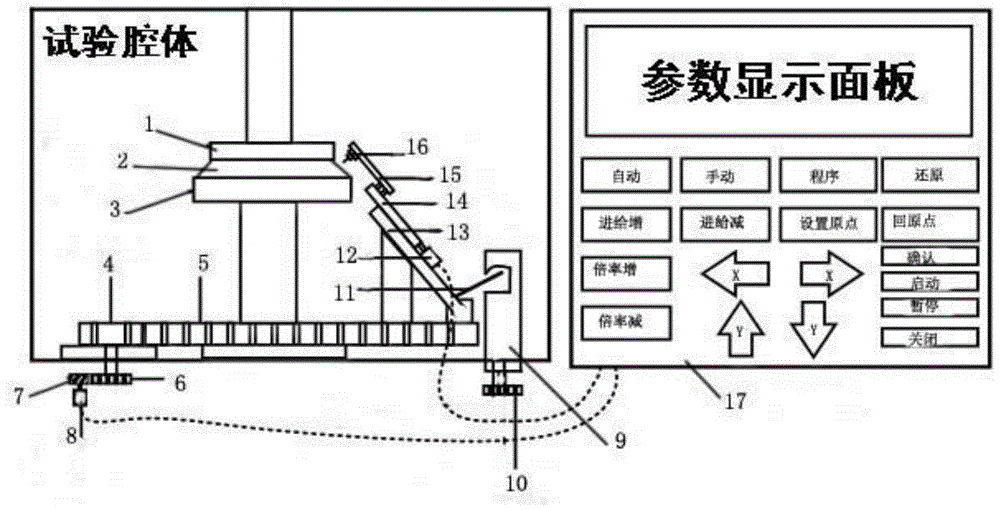

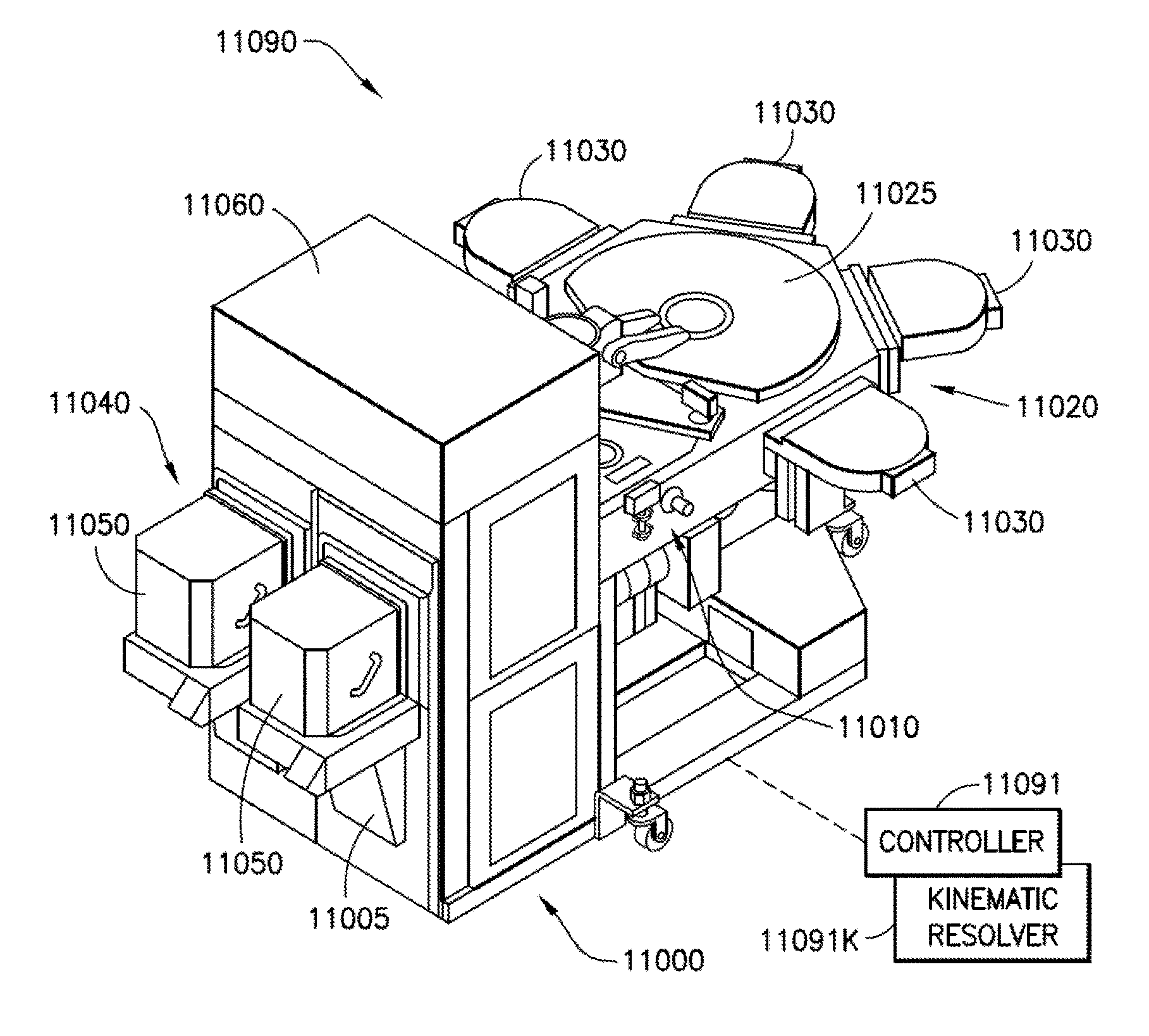

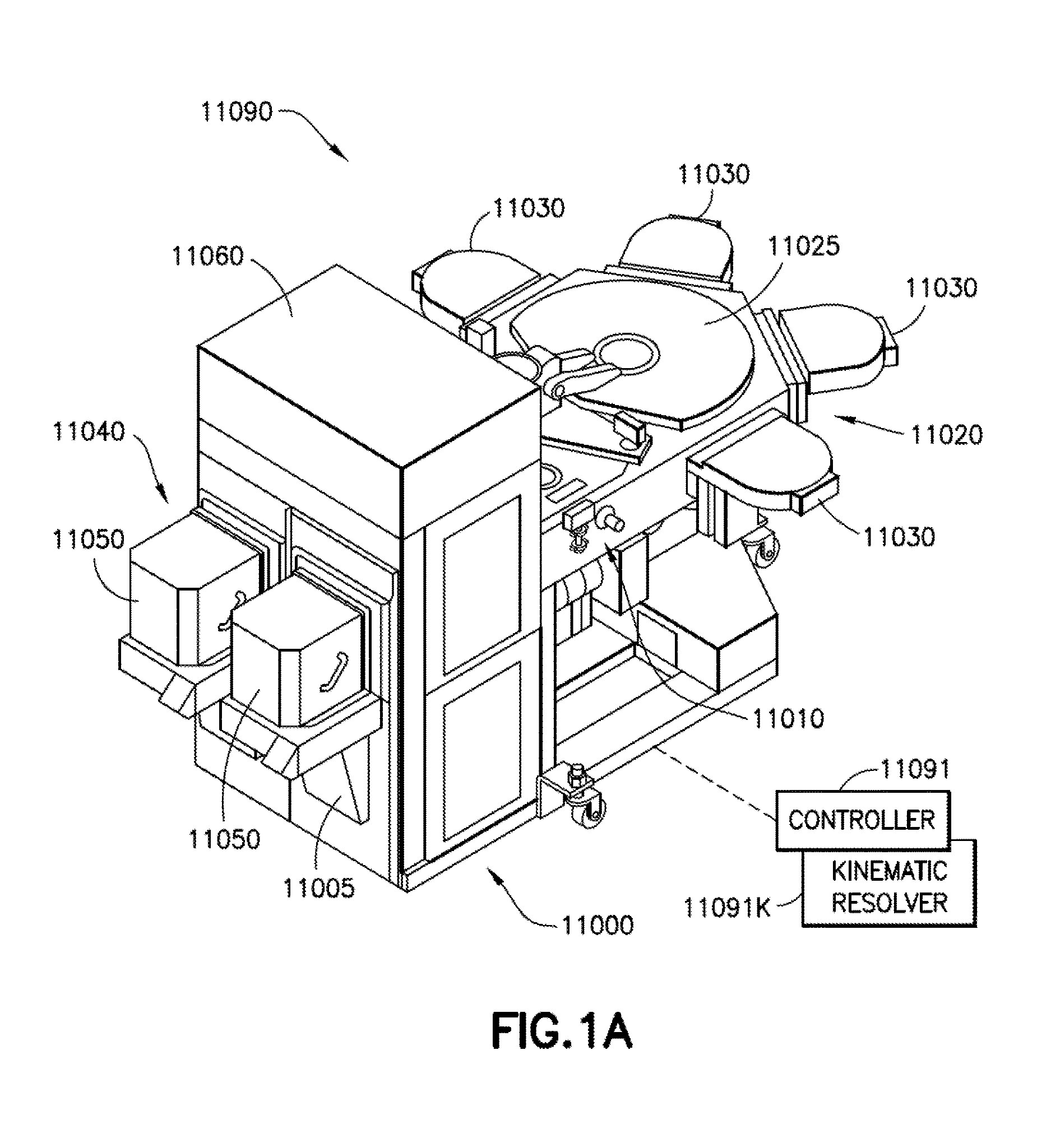

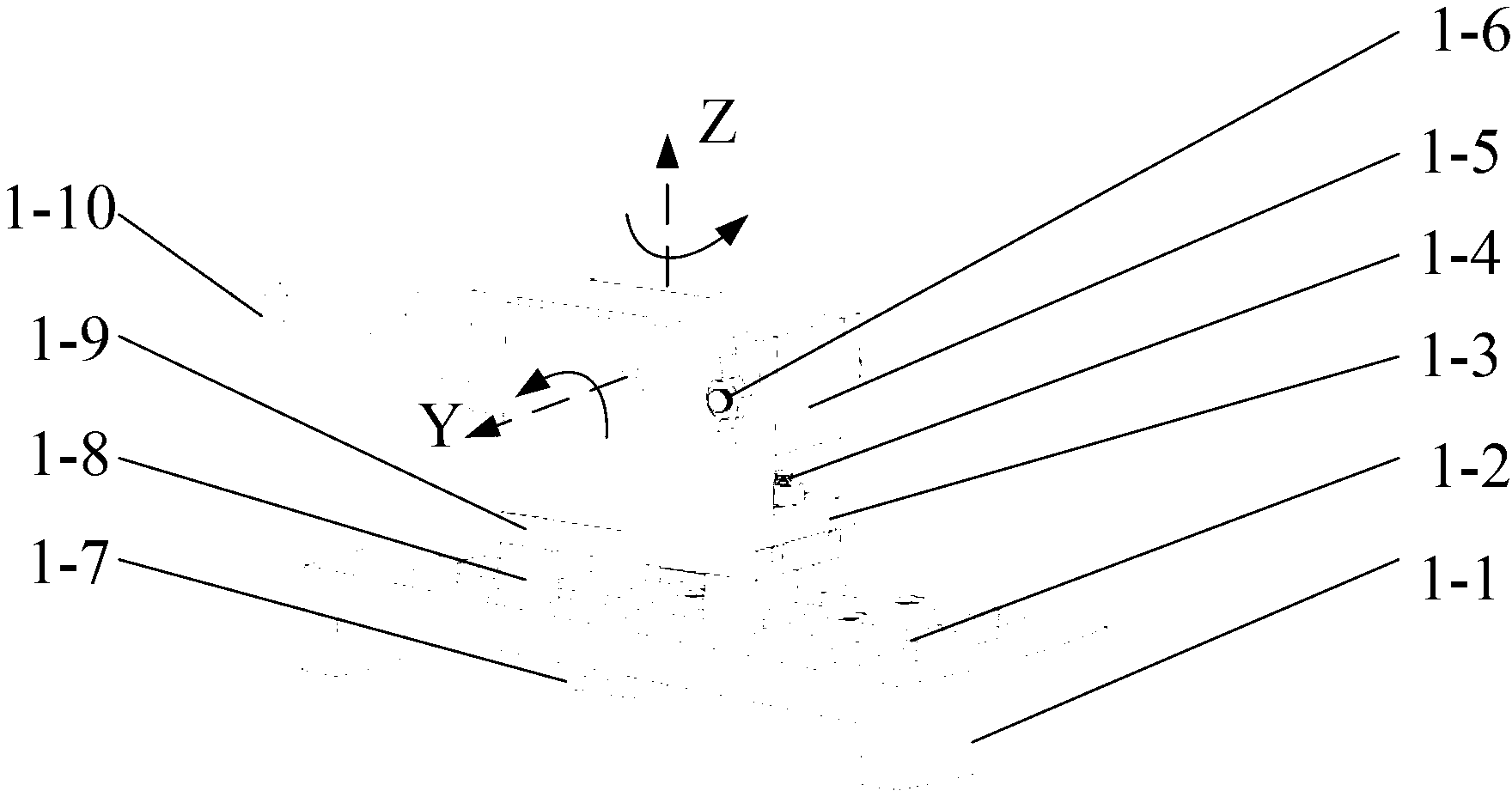

Robotic surgical system

InactiveUS20090228019A1Quicker procedureDiagnosticsSurgical instrument detailsSurgical operationEngineering

It is an object of the present invention to provide an automated, a semi-automated, a surgeon-guided quasi-automated and / or a fully surgeon's controlled surgical system surgical system useful for performing a fully automated medical procedure within a body cavity such that faultless and quick medical procedure is obtained. Each of the surgical systems comprises: (a) at least one effecter for performing the medical procedure; (b) at least one maneuverable platform reversibly coupled with the effecter; the platform provides the effecter with a scheduled set of independent displacements selected from a group consisting of up to six (degrees of freedom) DOFs, namely linear movement along the X,Y,Z-coordinates, and radial movement around the X,Y,Z coordinates, such that the time-resolved spatial position of the effecter is defined by the up to six coordinates (three-dimensional spatial position, 3DSP); and (c) sensing and processing means.

Owner:GROSS YOSEF +4

Bi-directional ball seat system and method

The present invention provides a bi-directional ball seat and method of use. In at least one embodiment, the present invention provides a fluid control system that includes a radial protrusion that can be selectively engaged and disengaged upstream and / or from a ball seat. For example, a ball can be placed in a passageway, engaged with a downstream ball seat, and the radial protrusion radially extended into the passageway distally from the seat relative to the ball. A reverse movement of the ball is restricted by the active radial movement of the radial protrusion into the passageway. The control system can be used to control a variety of tools associated with the well. Without limitation, the tools can include crossover tools, sleeves, packers, safety valves, separators, gravel packers, perforating guns, decoupling tools, valves, and other tools know to those with ordinary skills in the art.

Owner:BAKER HUGHES HLDG LLC

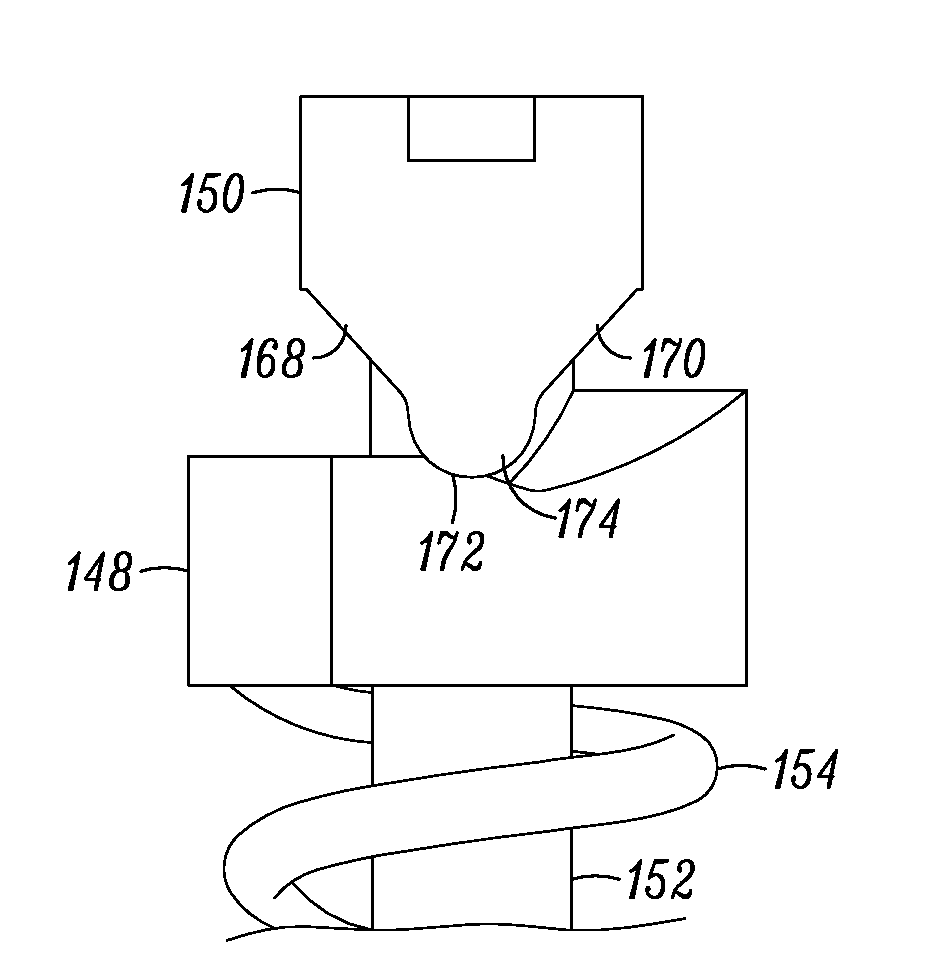

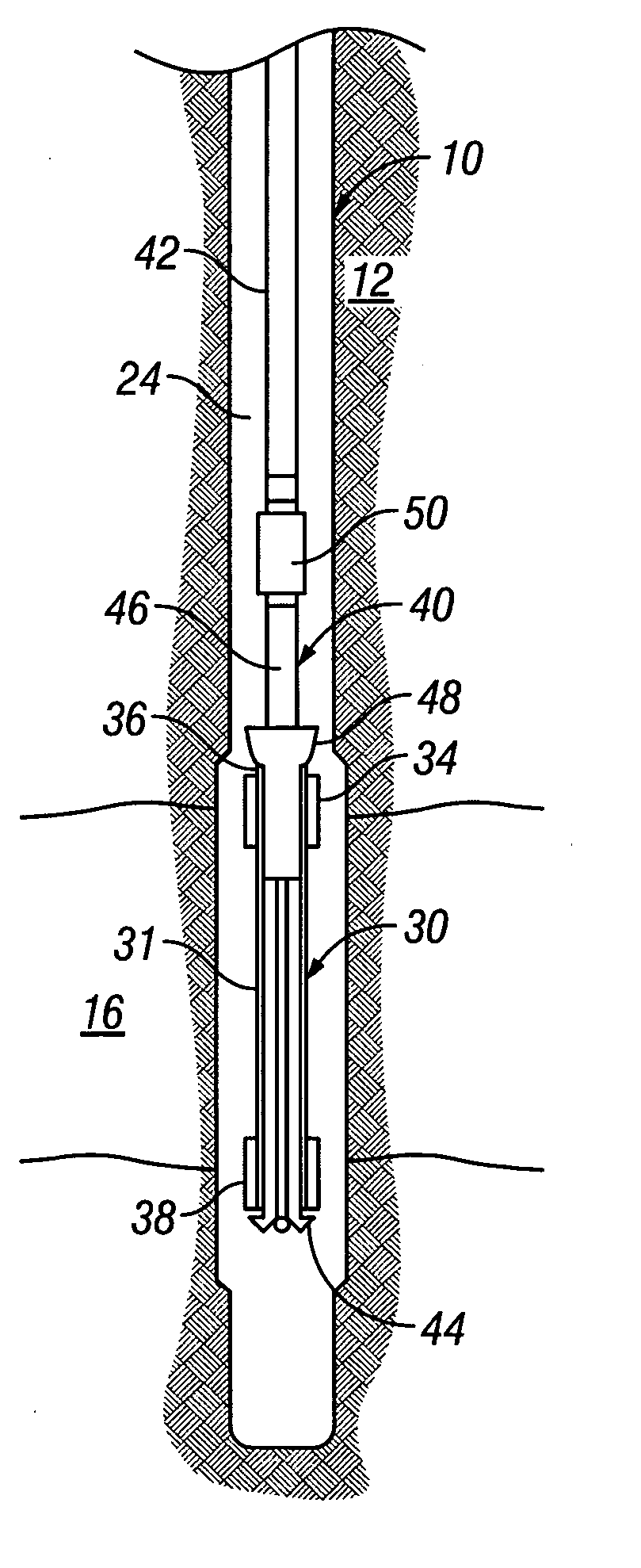

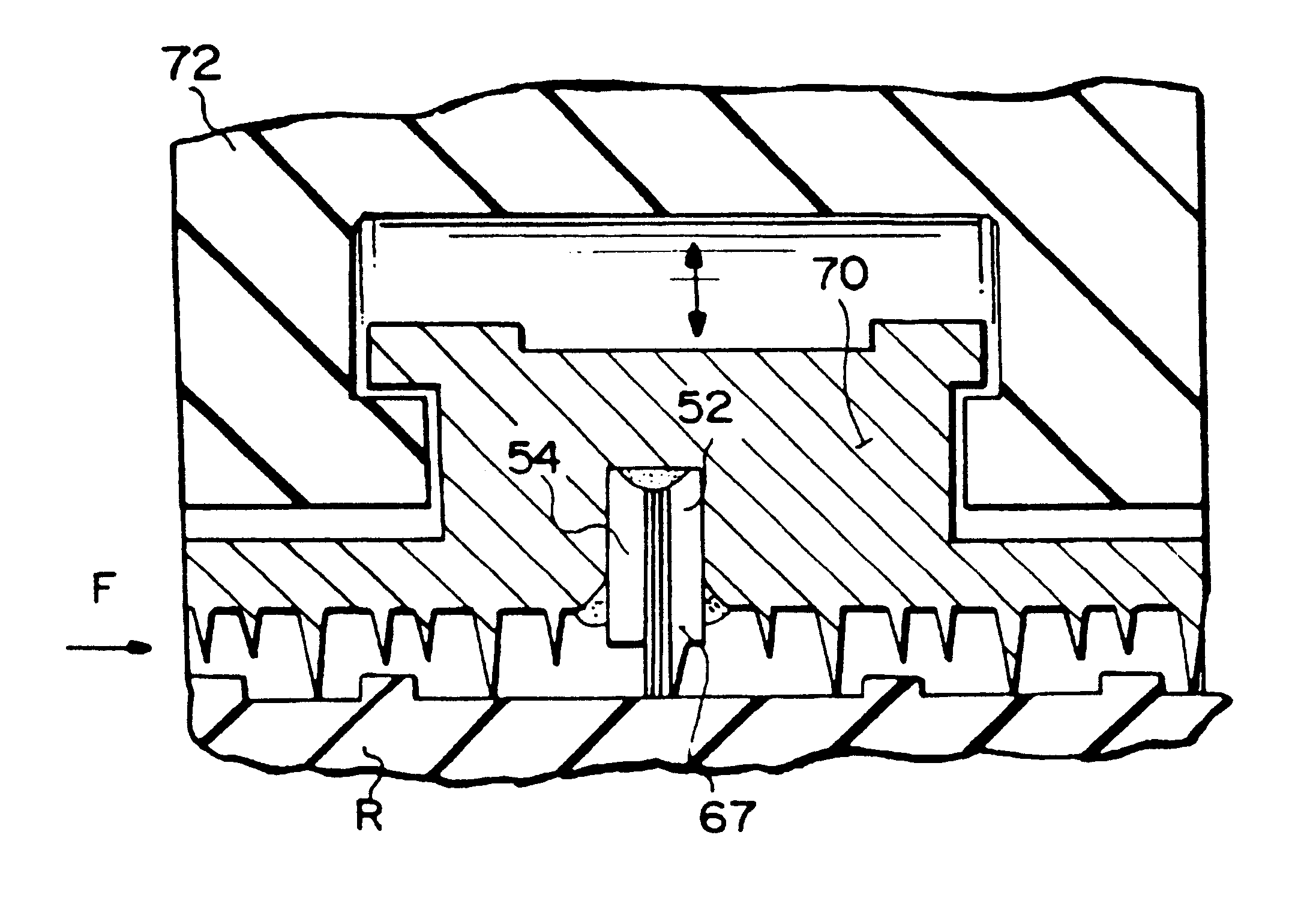

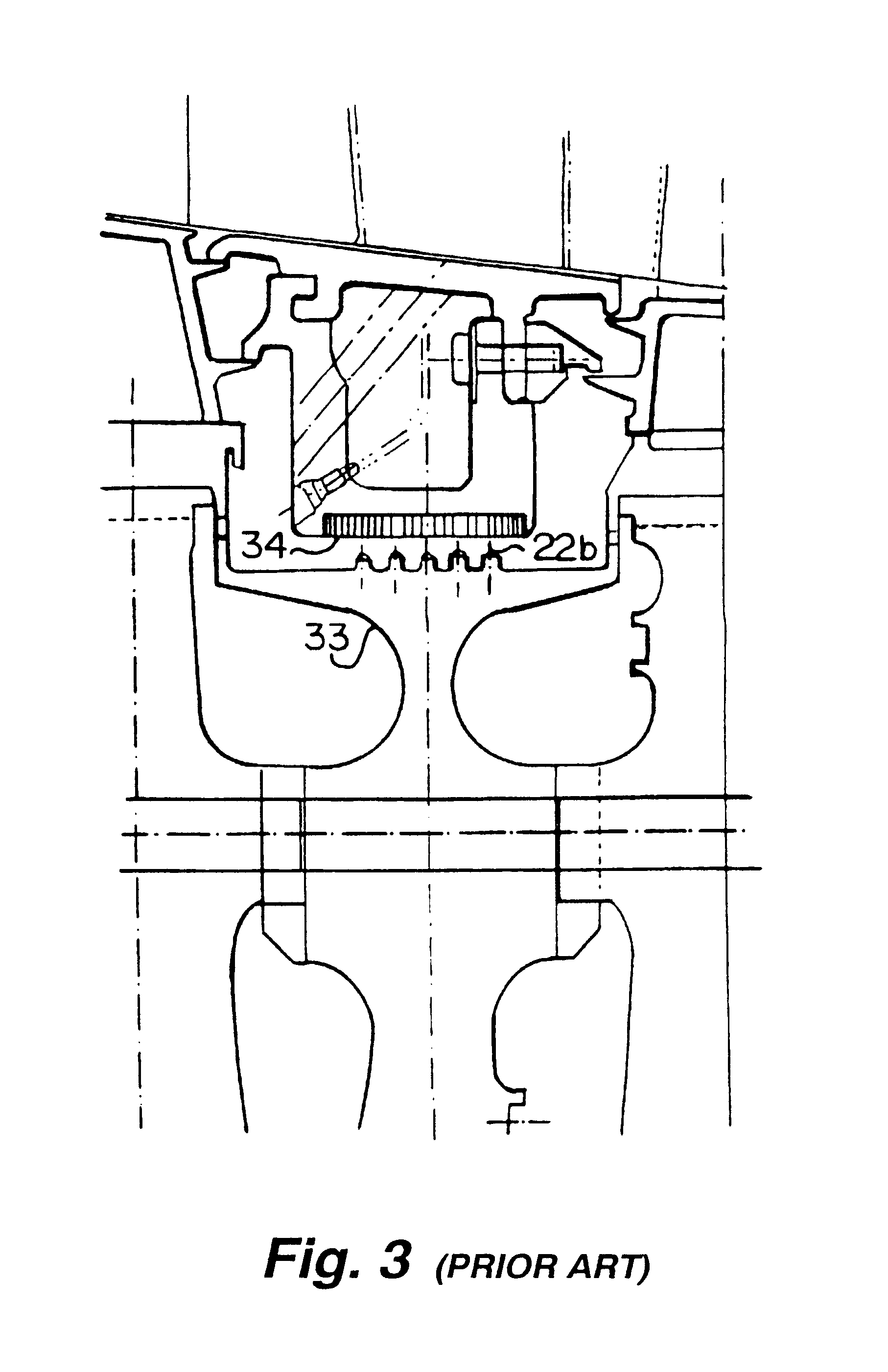

Release mechanism for downhole tool

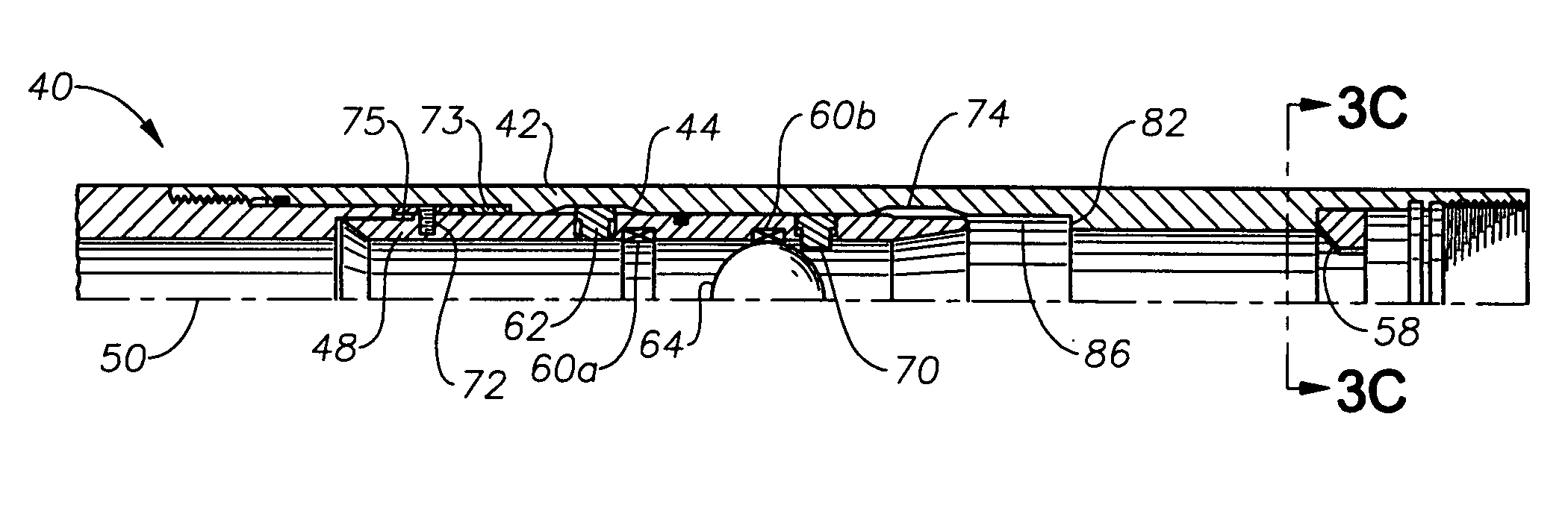

A release mechanism for a downhole tool is actuated by radial movement of a locking member. The locking member provided as much as full circumferential support in the locked position and once released can be prevented from re-gripping the previously connected elements. Illustrative examples of the mechanism for radial movement for release comprise sleeves that expand and radially oriented pistons. Shear pins or collets are not used to hold the components together in the preferred embodiment. Internal pressure fluctuations before initiating the release sequence will not cause unwanted release. The mechanism is applicable to a variety of downhole tools and is illustrated in the context of a hydraulic release.

Owner:BAKER HUGHES INC

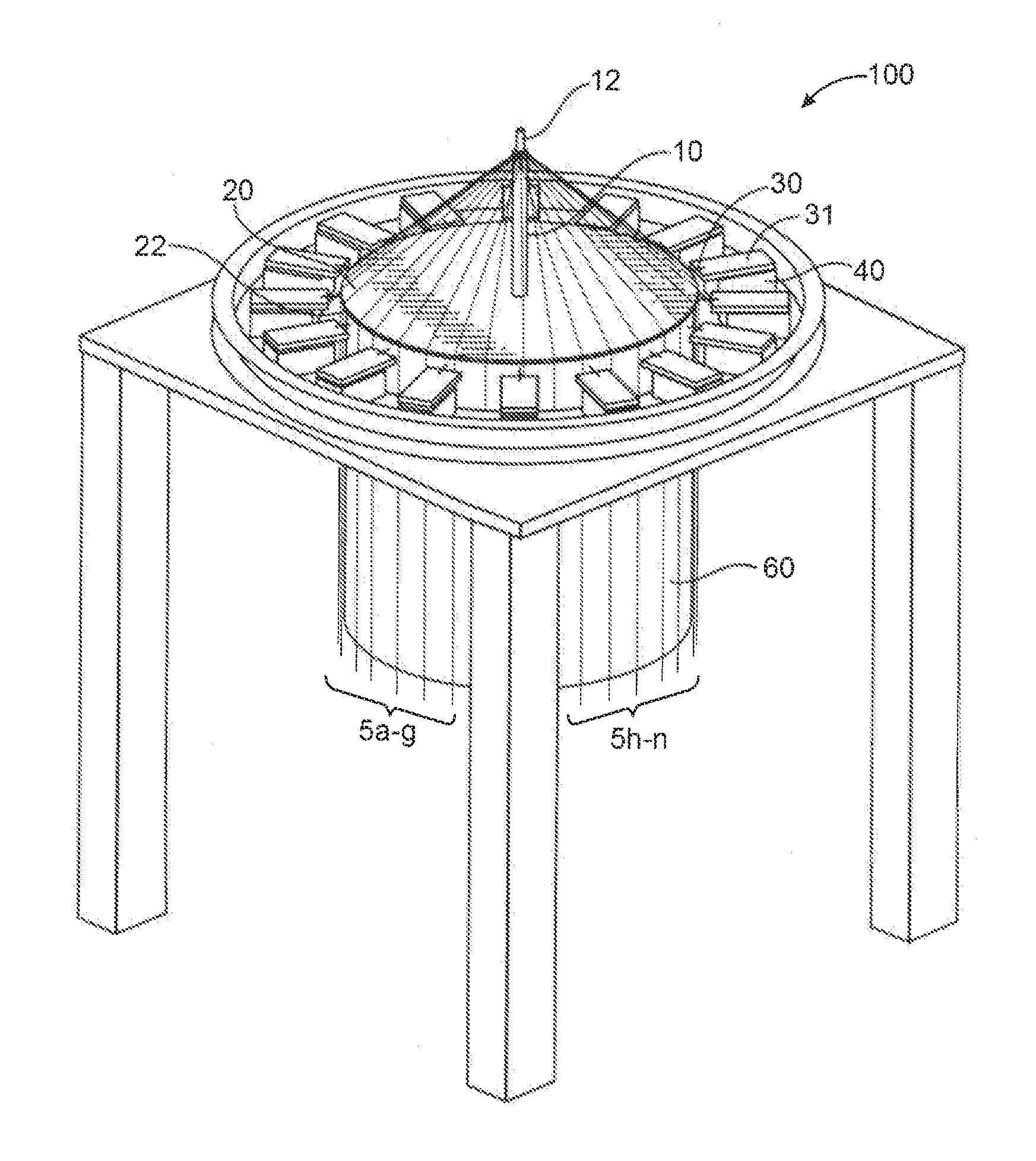

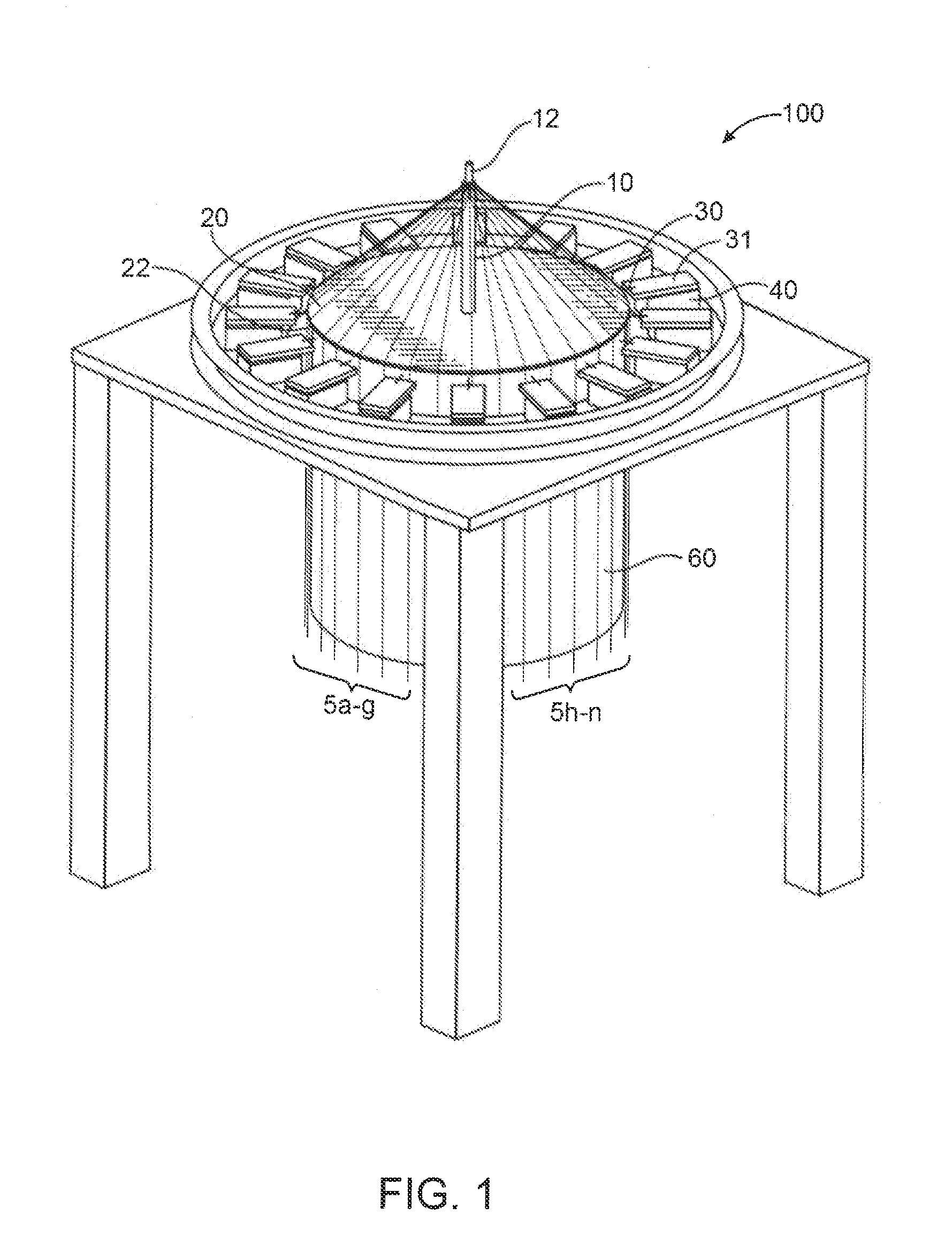

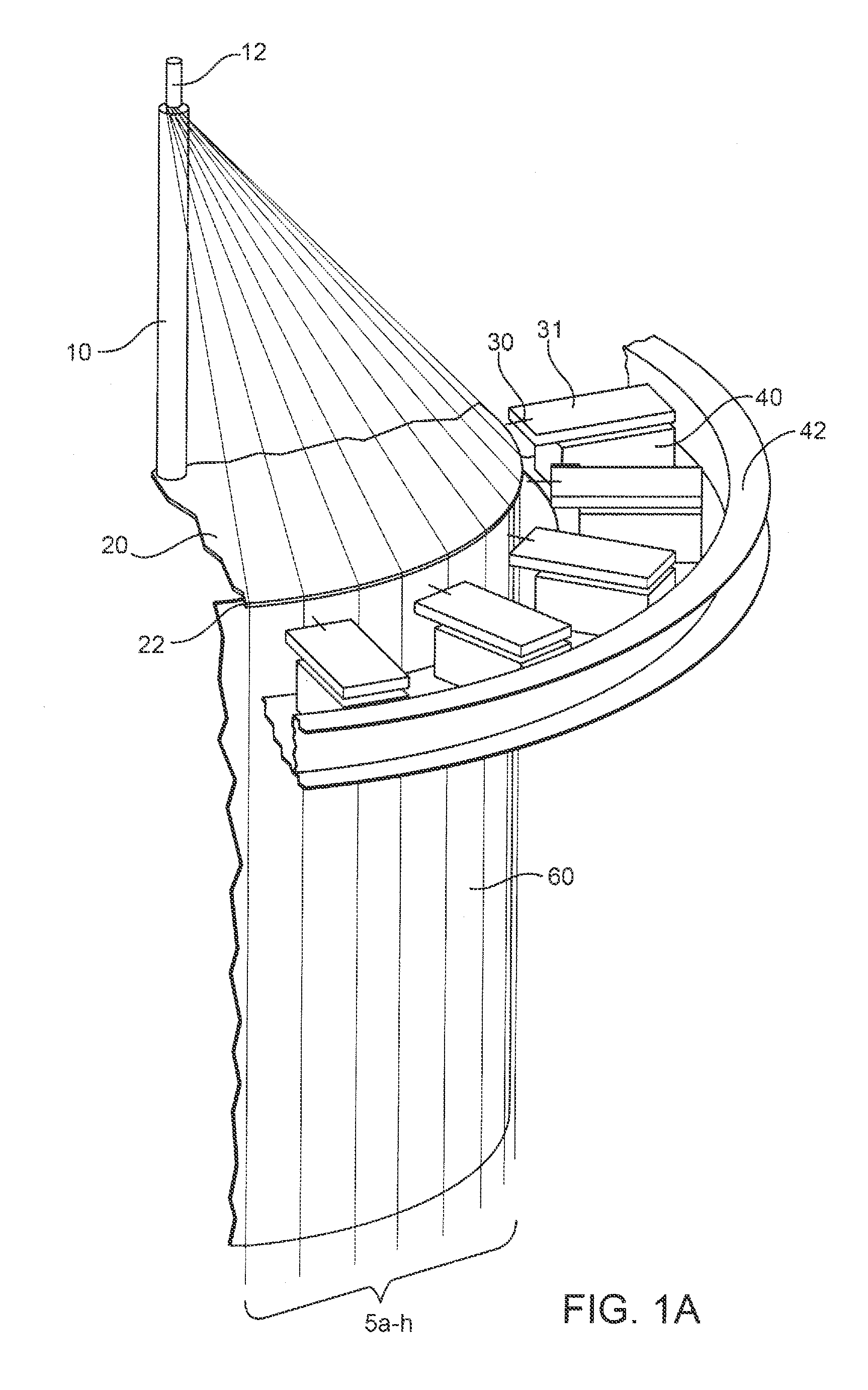

Braiding mechanism and methods of use

Devices and methods for forming a tubular braid comprising a plurality of filaments. The braiding machine includes a circular array of filament guiding members defining a plane; a mandrel defining an axis and adapted to carry one or more filaments extending from the mandrel to the circular array; a plurality of filaments extending from the mandrel in a radial array; a plurality of actuator mechanisms disposed operably about the disc; and a rotating mechanism adapted to rotate one or more filaments. The actuator mechanisms and rotating mechanism are configured to move each of the one or more filaments about the mandrel axis in a path comprising a series of arcs and radial movements. The braiding machine may alternately first and second annular members, a mandrel, first and second plurality of tubular wire guides, and a plurality of wires extending from the mandrel.

Owner:MICROVENTION INC

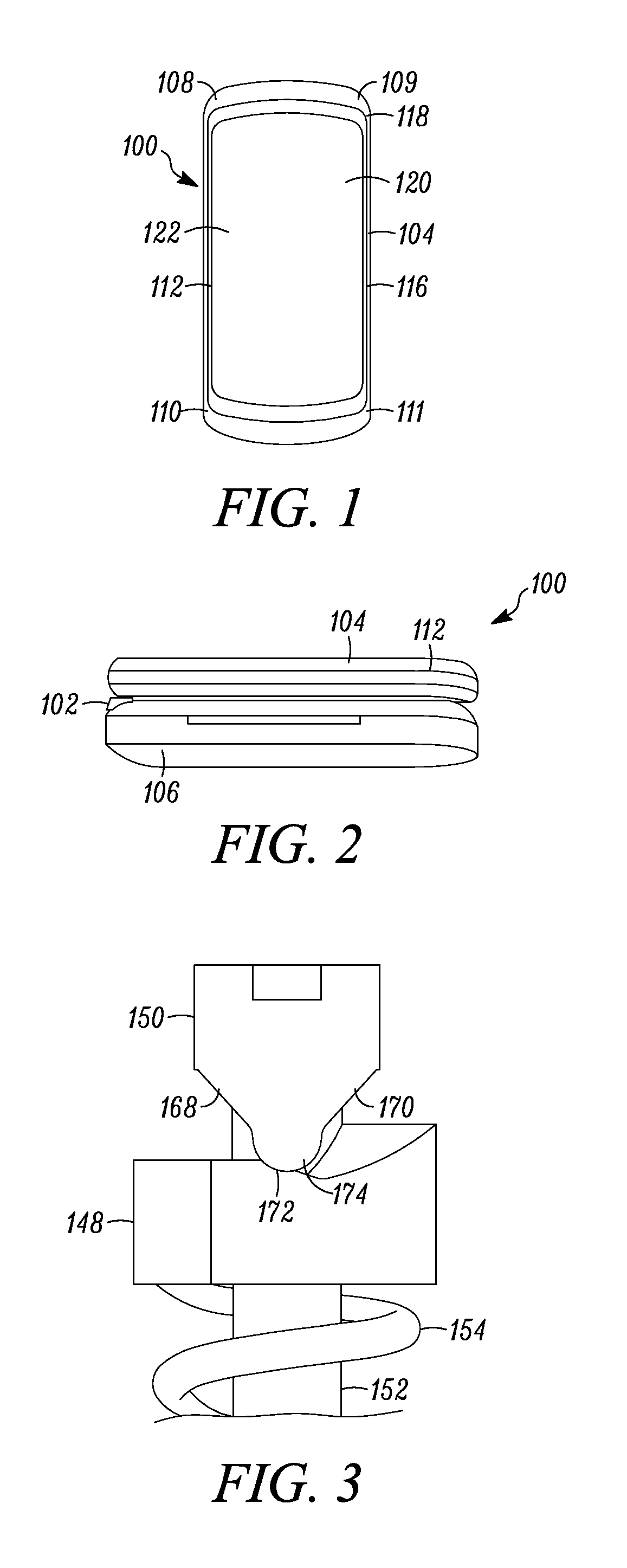

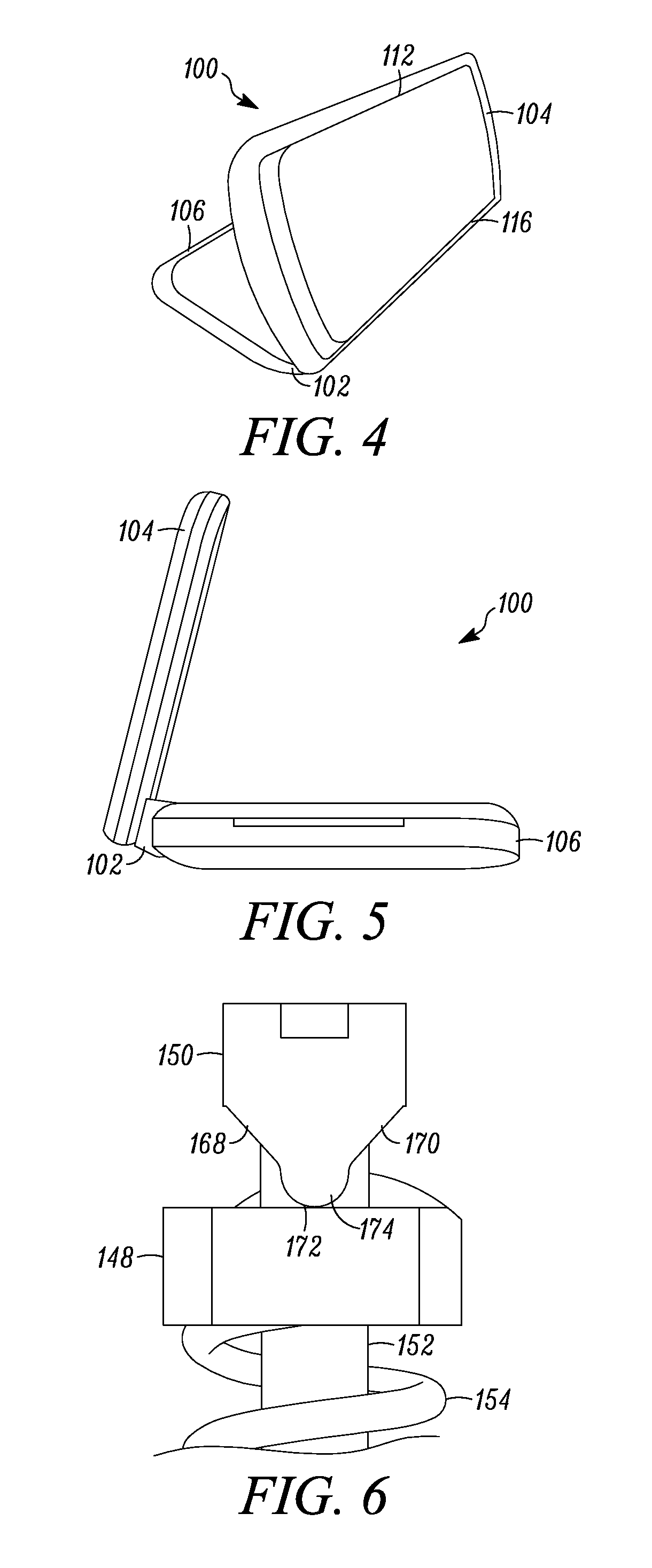

Design and Implementation of Friction Hinge with a Range of Motion and Detent Separation Greater than 180 Degrees

InactiveUS20100154171A1Easy to useEasy to manufactureWing fastenersHingesRadial motionRadial position

A mobile phone or other electronic device is provided with an improved friction hinge with a radial range of motion greater than 180 degrees and with detents at both ends of travel. The friction hinge can include an asymmetrical cam in conjunction with a single tab on a follower. Advantageously, the electronic device with the improved friction hinge can allows a full 360 degree range of motion with any number of detents at any radial position.

Owner:GOOGLE TECH HLDG LLC

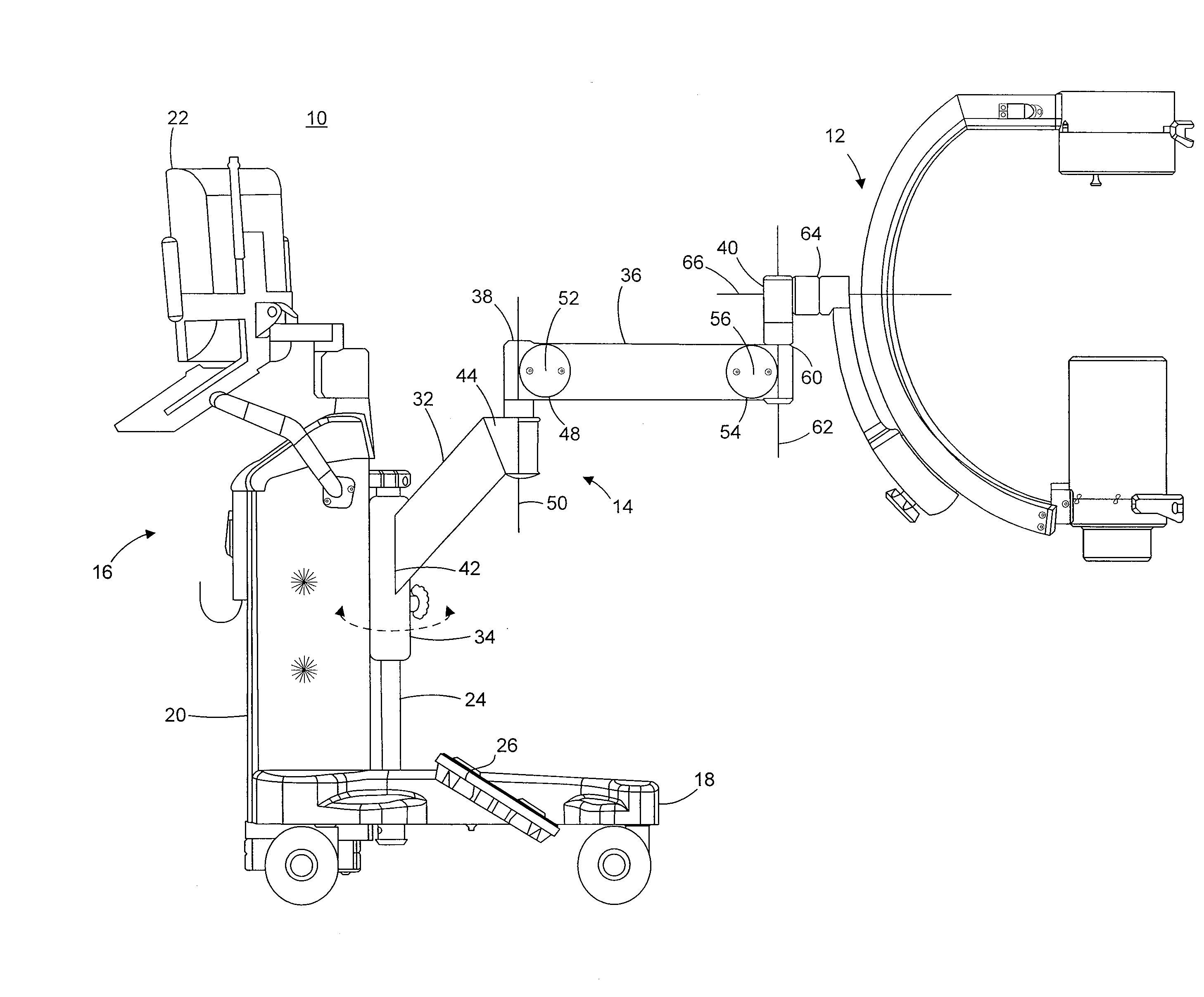

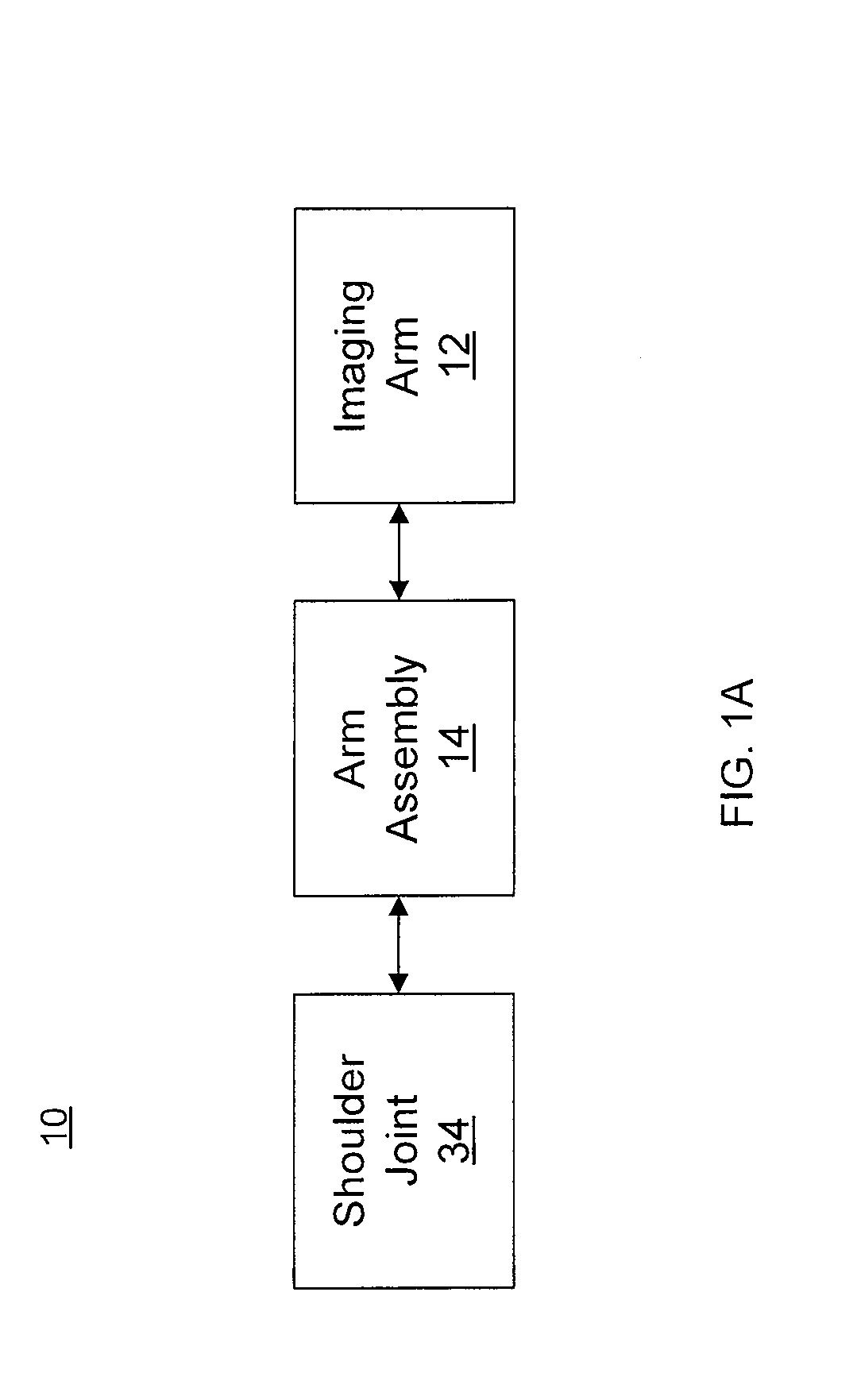

Mobile imaging apparatus

In an exemplary embodiment, an imaging apparatus comprises an arm assembly coupled to an imaging arm. The arm assembly includes a shoulder joint, an elbow joint, and an articulation assembly. The shoulder joint is configured to travel a vertical distance in a substantially linear fashion and provide rotational movement. The imaging arm comprises a first end and a second end. As such, the imaging apparatus is configured to provide radial motion along a path equal to the length of the arm assembly and the imaging arm along the vertical distance and the horizontal distance of the shoulder joint. The imaging apparatus may also comprise a movable cabinet, a monitor, and a control, with the arm assembly coupled to the movable cabinet. Furthermore, the imaging arm may comprise an x-ray source and a sensor, with the monitor displaying data detected by the sensor.

Owner:ORTHOSCAN INC

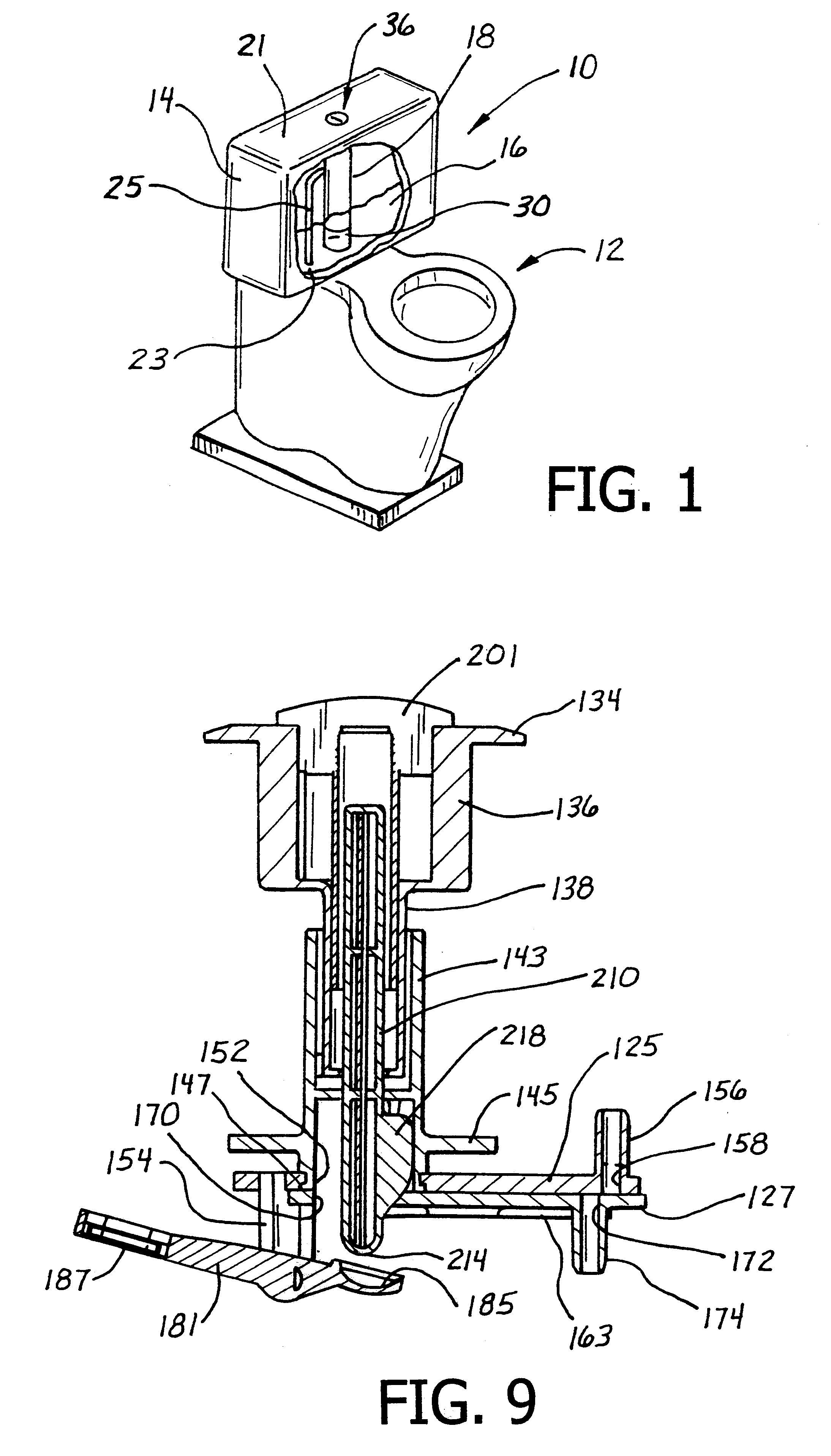

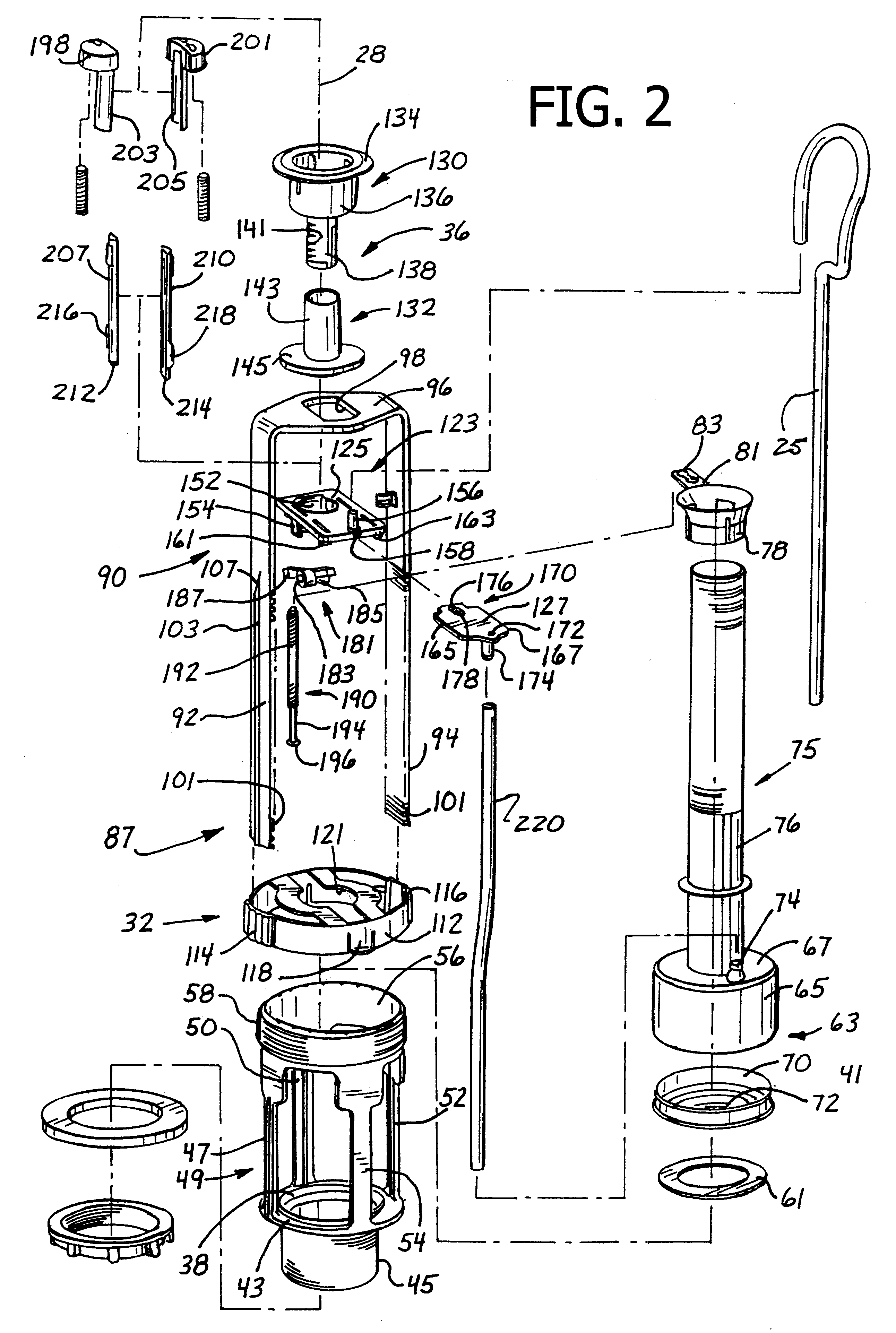

Downhole Tool

A downhole tool (10′) comprises a body (12′) having a longitudinal axis and a body through-bore (14′), a slot (34′) communicating the outside of the body with the body through-bore. A sleeve actuator (30′) mandrel also has a bore and is selectively axially slidable in the body through-bore. A hollow bar (36′) is slidable with a radial component in the slot. At least two levers (210), each pivoted to the mandrel (about a first axis perpendicular the longitudinal axis) extend into the hollow bar and are pivoted thereto (about a second axis parallel the first axis). The levers lie in an actuation plane perpendicular the first and second axes and containing the slot. The levers are disposed at an inclined angle with respect to the longitudinal axis so that longitudinal motion of the mandrel translates into radial movement of the bar.

Owner:REAMERCO

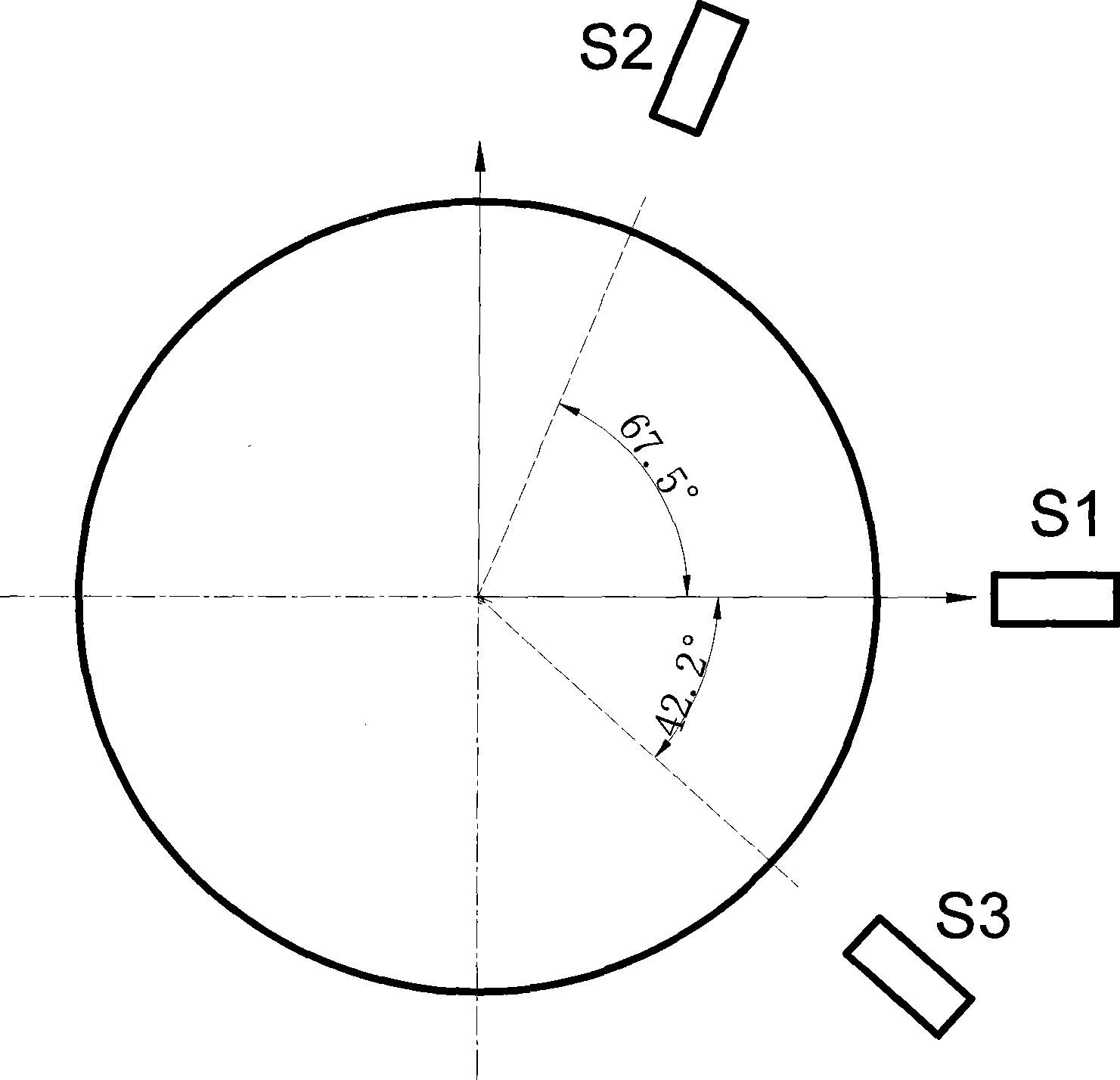

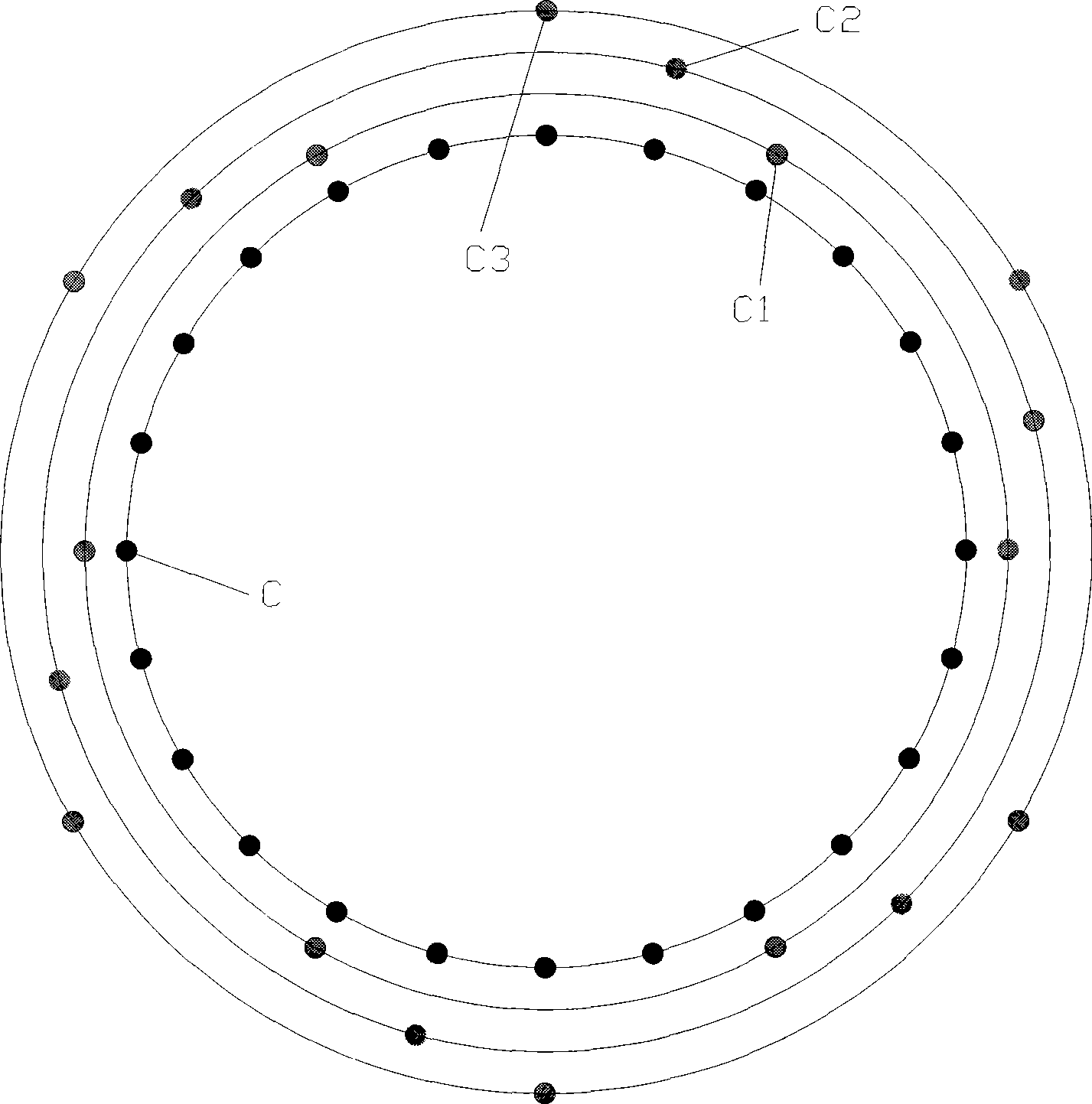

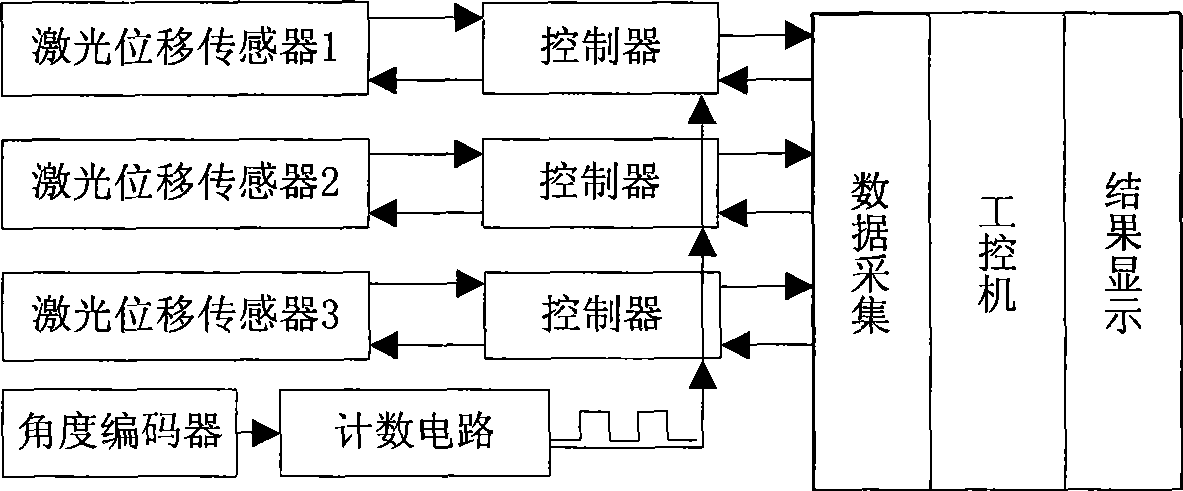

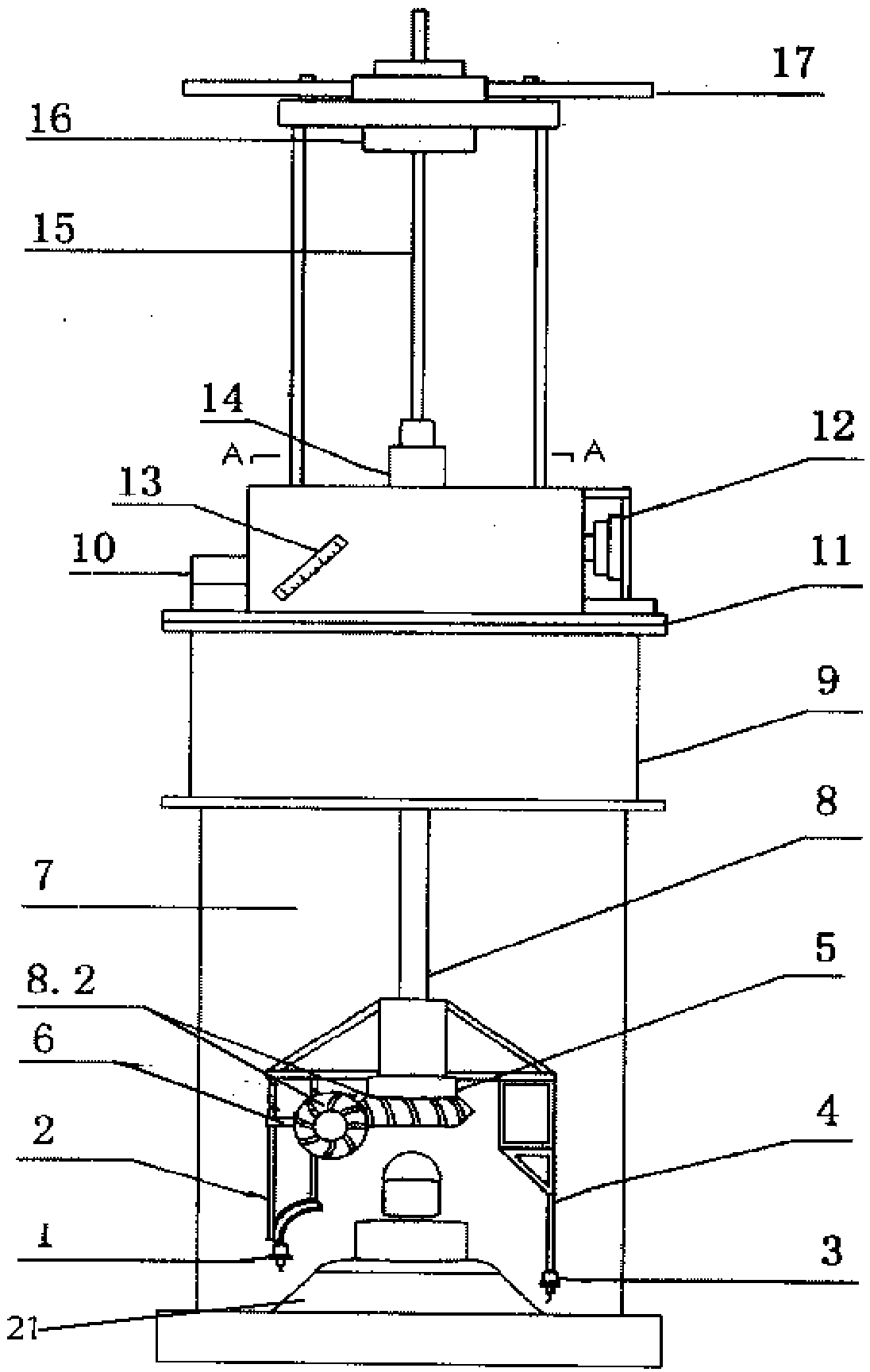

Method for detecting radial motion error of high speed principal axis by multi-ring coincidence three-point method

InactiveCN101424512ALower resolution requirementsMeasurement/indication equipmentsUsing optical meansRadial motionUSB

The invention discloses a method for detecting radial motion error of a high-speed principal axis by adopting a multi-circle superposition three-point method. Three laser displacement sensors are distributed around the high-speed principal axis which is provided with an angle encoder that has N lines and is connected with a scaling circuit; when the scaling circuit counts for Z times in an accumulating way and Z can not be divided exactly by N, the scaling circuit outputs sampled signals, and a trigger sensor implements sampling once; by repeating in this way, the principal axis is evenly distributed with n points for sampling by rotating the principal axis for a plurality of times to complete a sampling period; after every time of sampling, the sampling value is transmitted to an industrial computer through a USB interface and is then recorded; according to the requirements of detection accuracy, the sampling work having a plurality of sampling periods is carried out, the average sampling value of n points of every laser displacement sensor is calculated, and the deviation from circular form, the eccentric error and radial turning error of the principal axis which are obtained by separation are calculated. The method is not sensitive to the performance of the laser displacement sensor and is suitable for detecting radial motion error of the high-speed principal axis.

Owner:ZHEJIANG UNIV

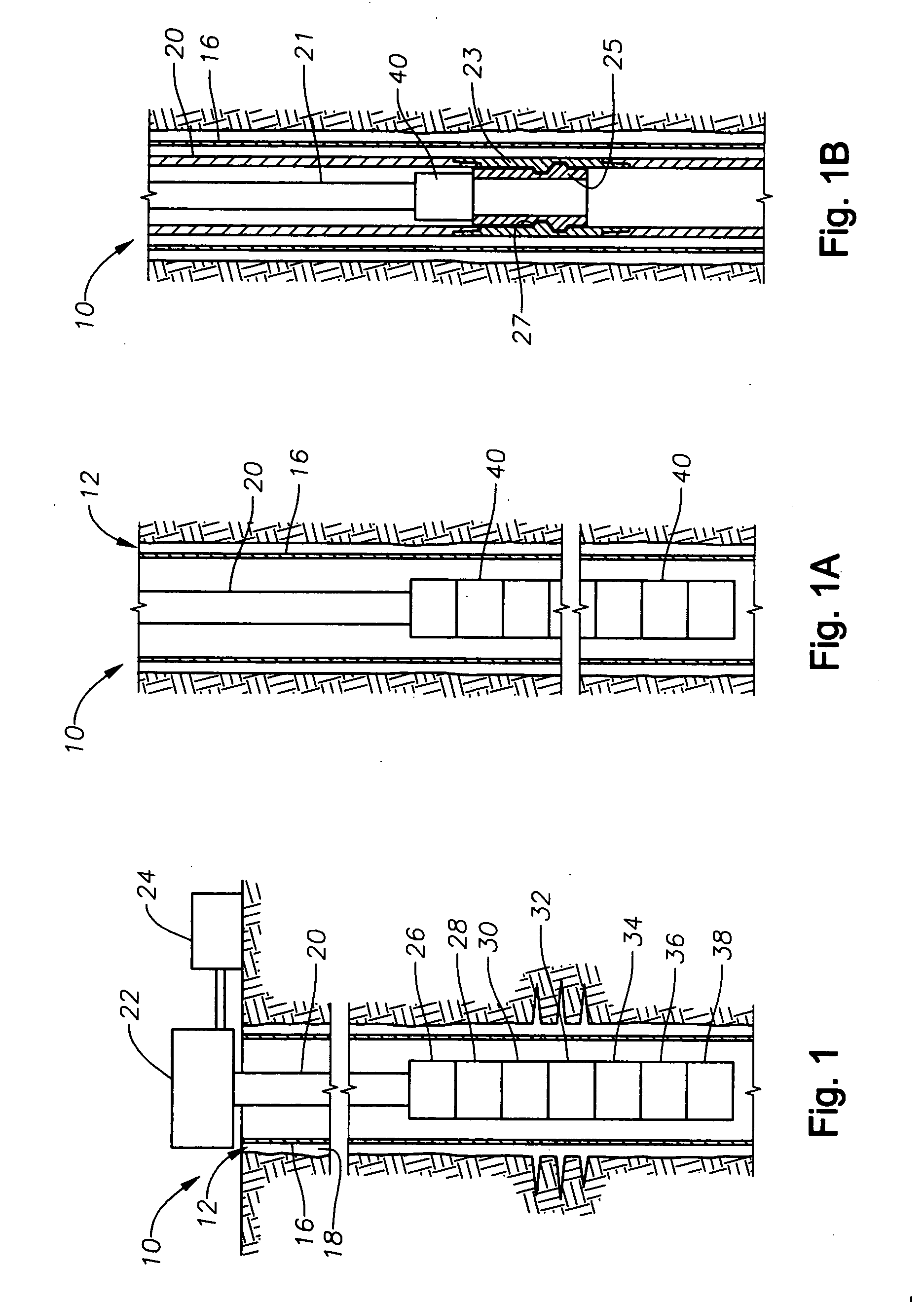

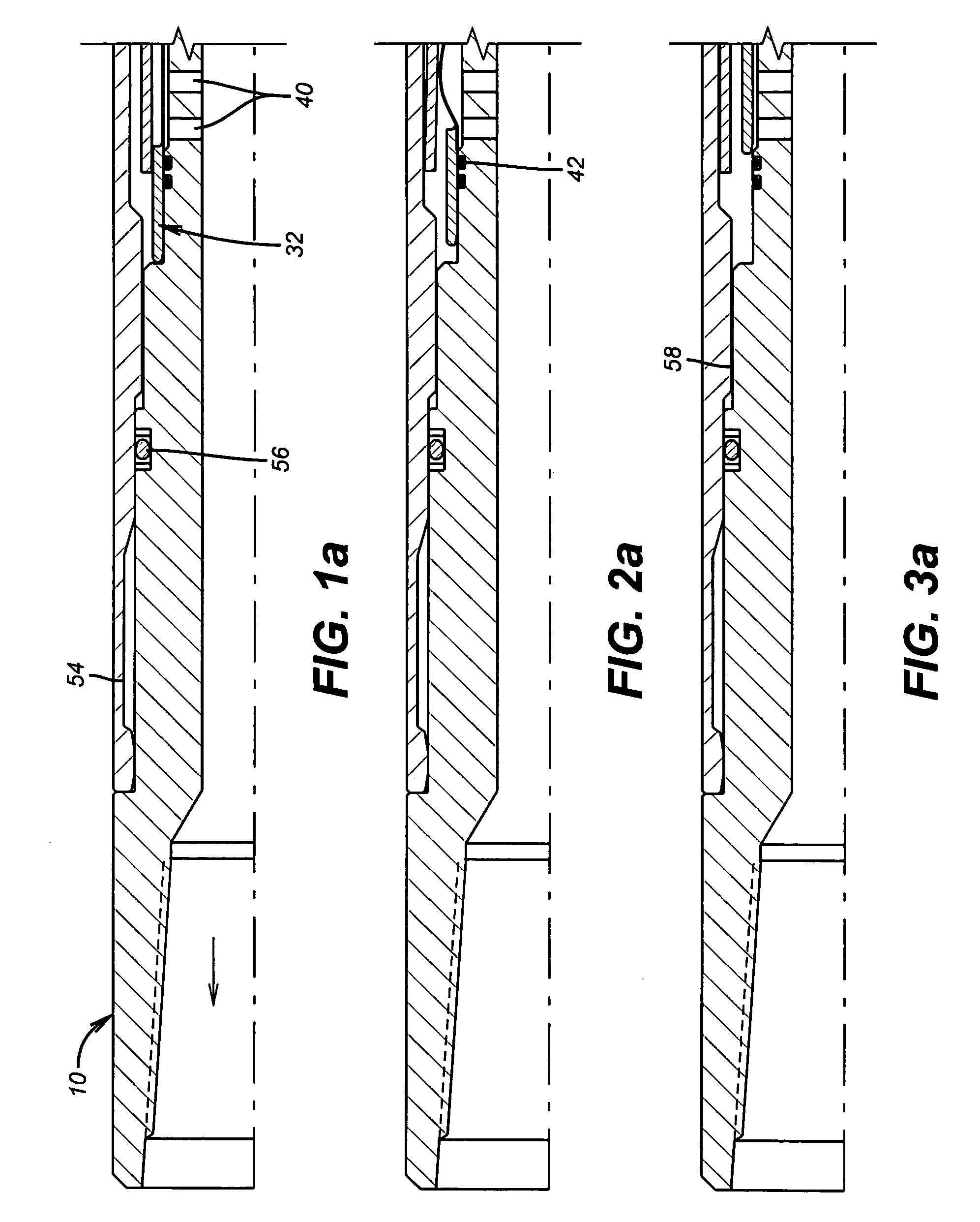

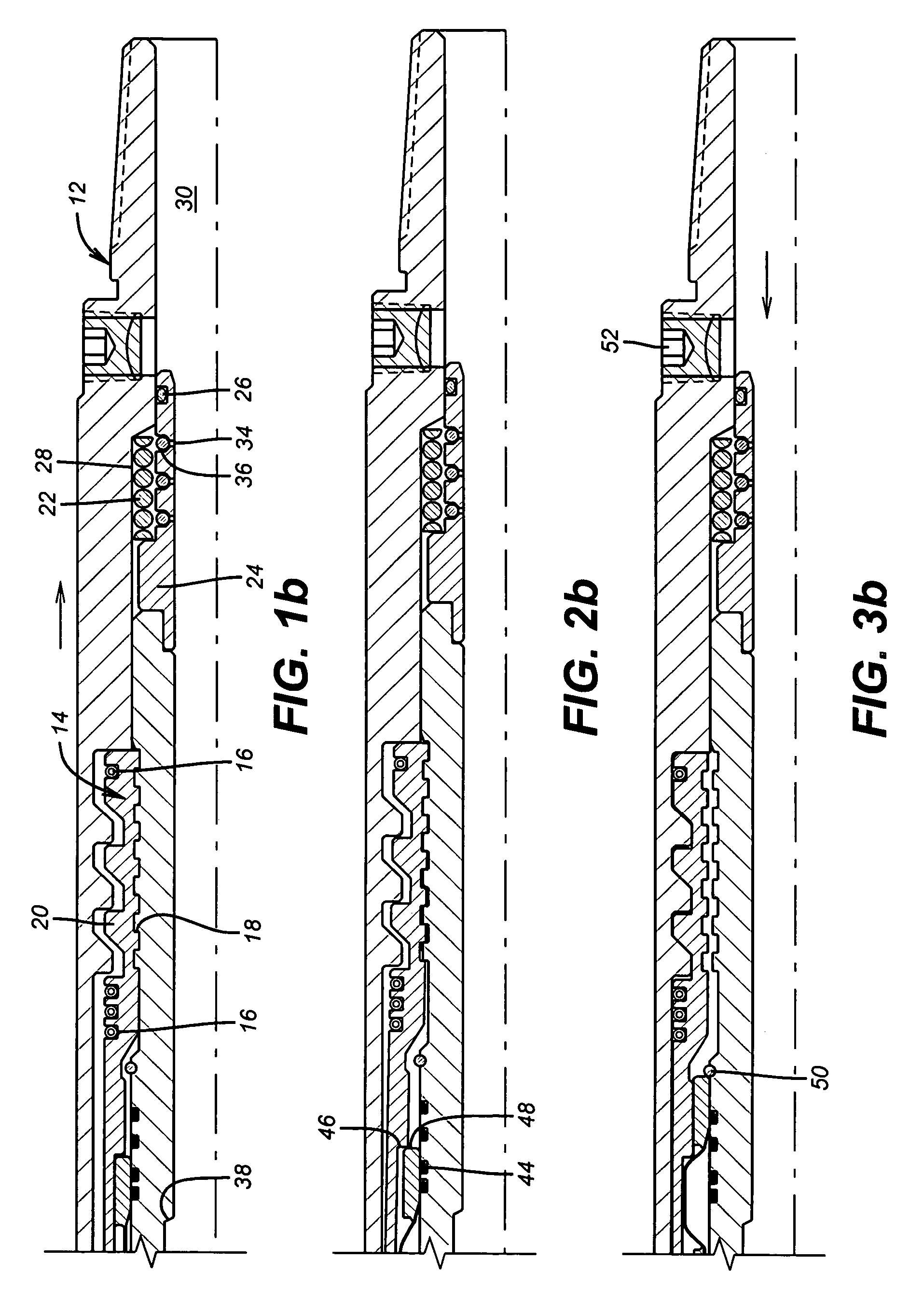

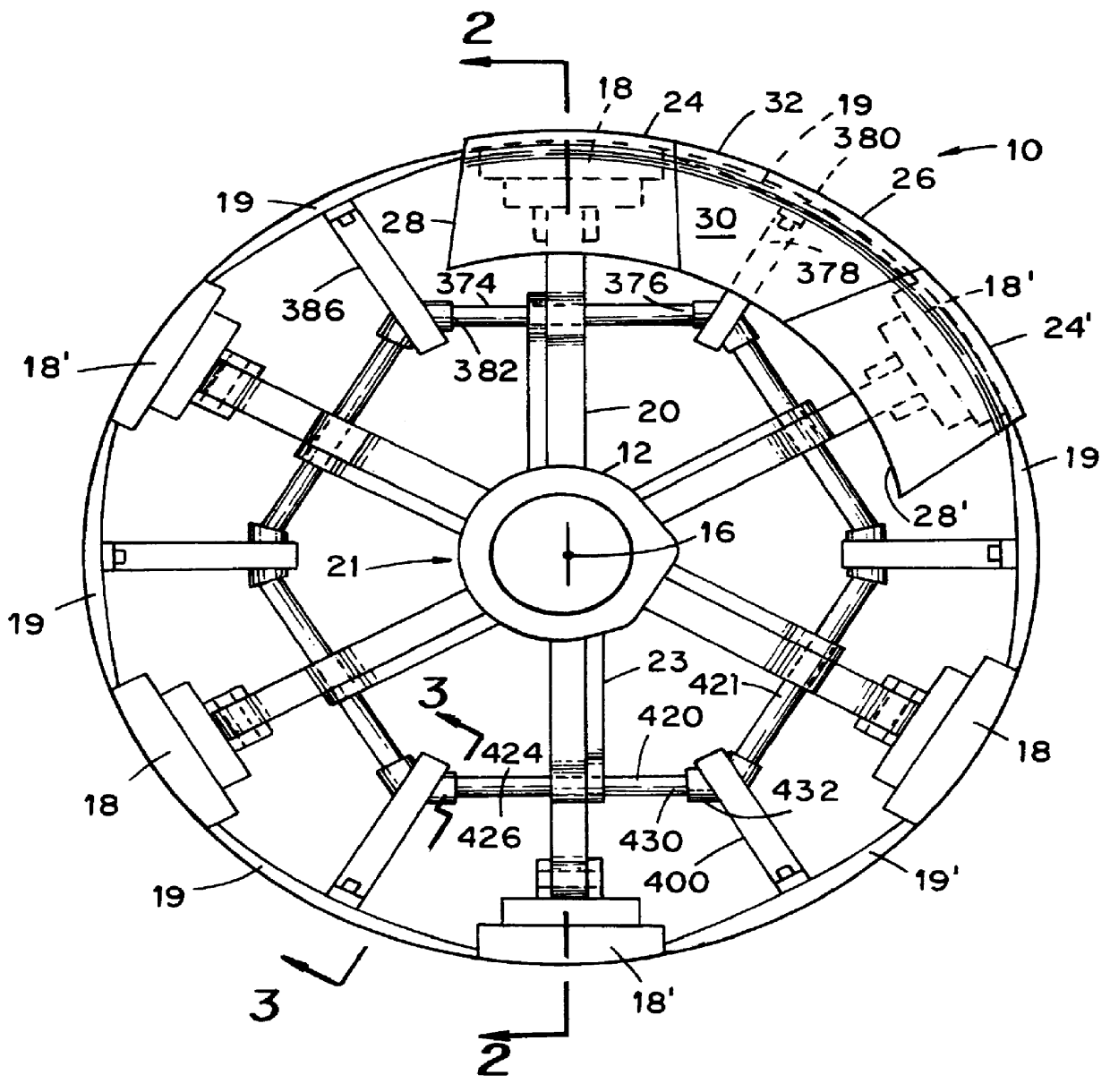

Tire manufacturing drum having simultaneous axial and radial adjustability

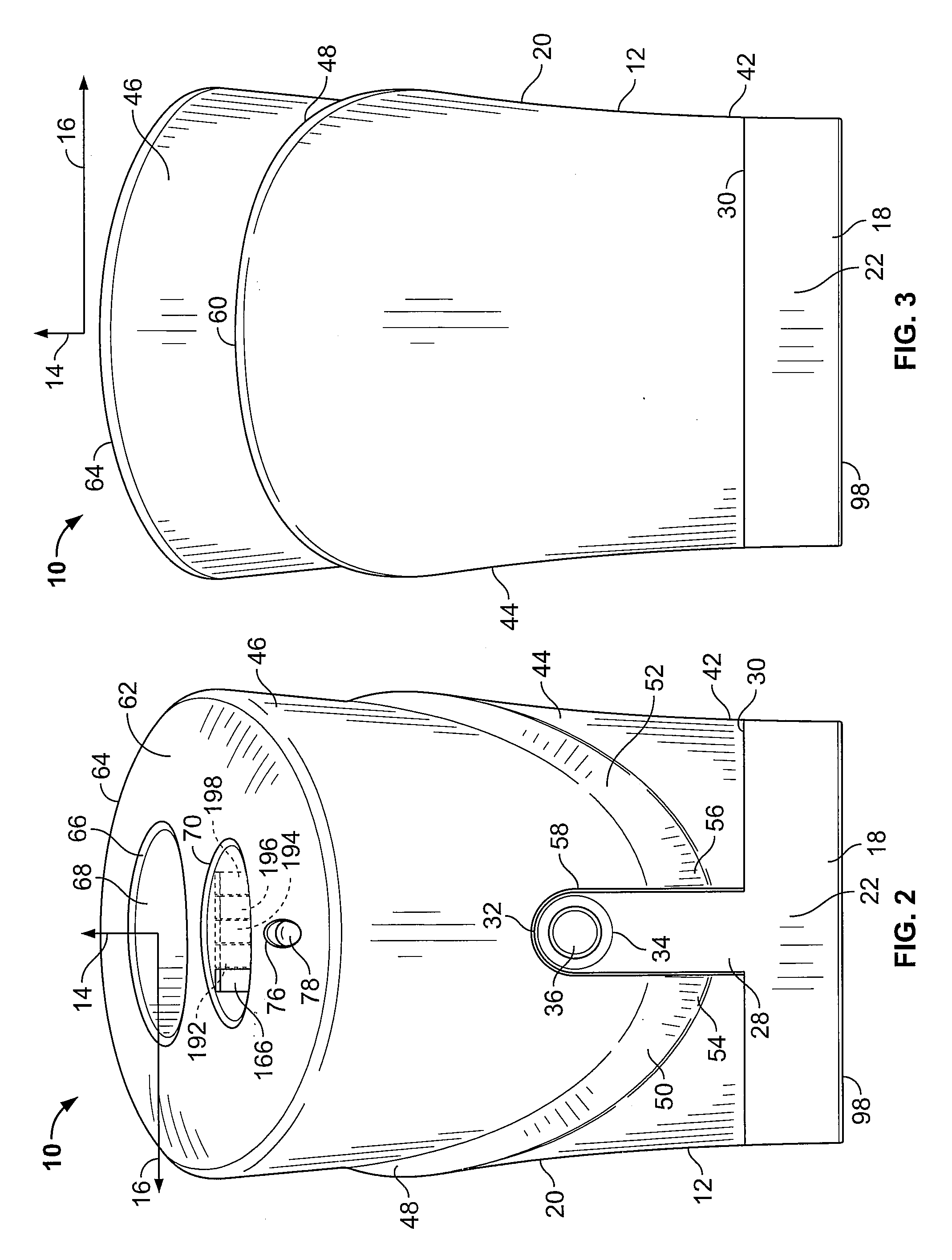

A rotatable drum (10) for use in the manufacture of vehicle tires, the drum including a plurality of segments which collectively define an outer circumference (32) of the drum. The segments are divided into first and second end portions (15,17) which are individually mounted for axial and radial movement between expanded and retracted positions relative to the rotational axis (16) of the drum. Each end portion of segments is further divided into first and second groupings (23,25), the segments (18,18') of the first and second groupings (23,25) being disposed in alternating juxtaposition with respect to the segments of the second grouping (18') and with the segments of the first grouping being movable axially further and radially faster than the segments of the second grouping as the segments are moved between their expanded and retracted positions so that the segments of the second grouping are received in overlying relationship to the segments of the first grouping as the segments of the first and second groupings are simultaneously moved radially inward toward the rotational axis of the drum. A third grouping 23 of the segments of each end portion of segments is provided for, with these segments (19,19') being received in overlying relationship to the segments of the first and second groupings. Further, in a preferred embodiment, each segment is provided with a shell member (24,26), with the shell members collectively defining the outer cylindrical surface (32) of the drum. A method for the production of a rotatable cylindrical drum (10) and a method for the manufacture of an OTR vehicle tire are disclosed.

Owner:DAVIAN ENTERPRISES LLC

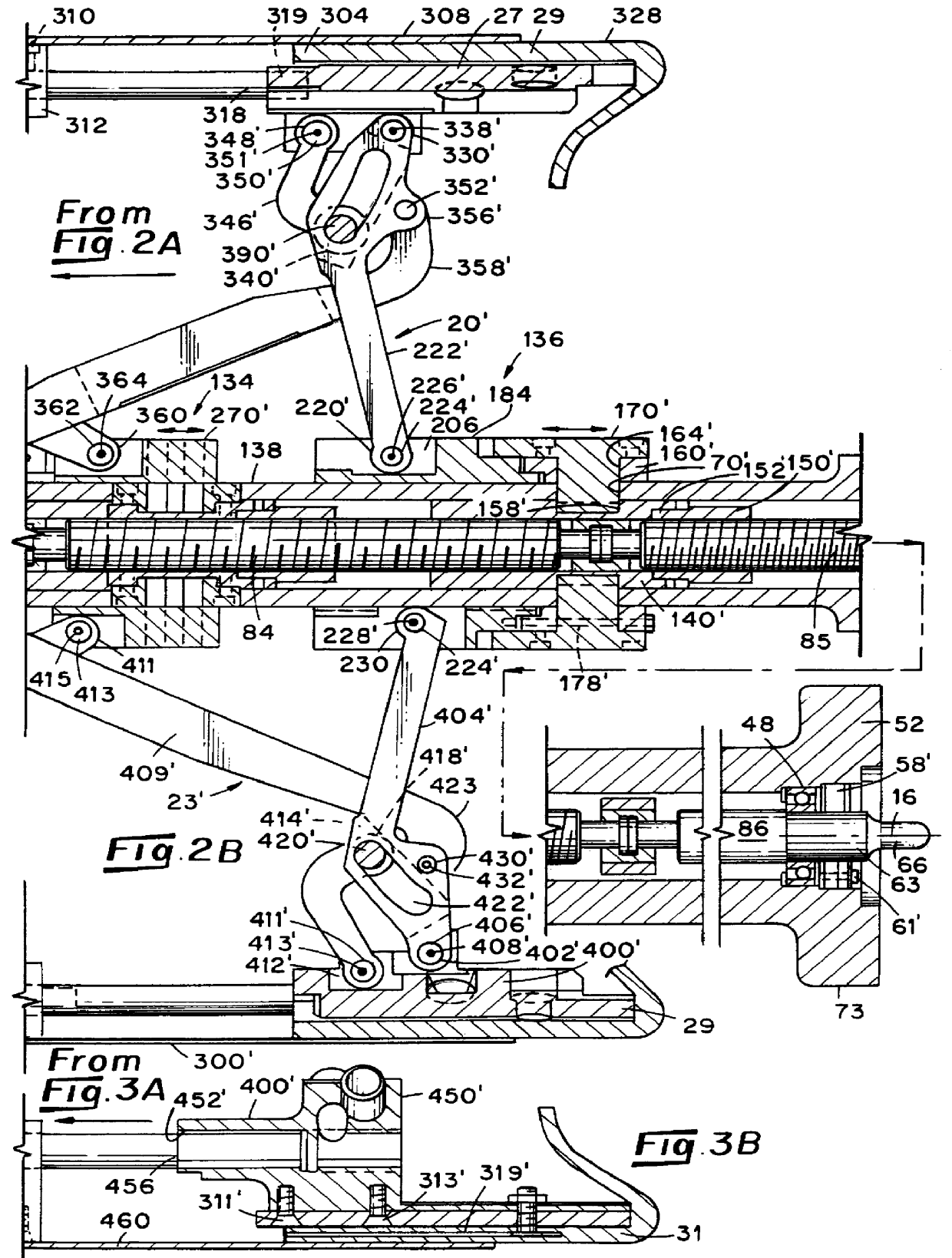

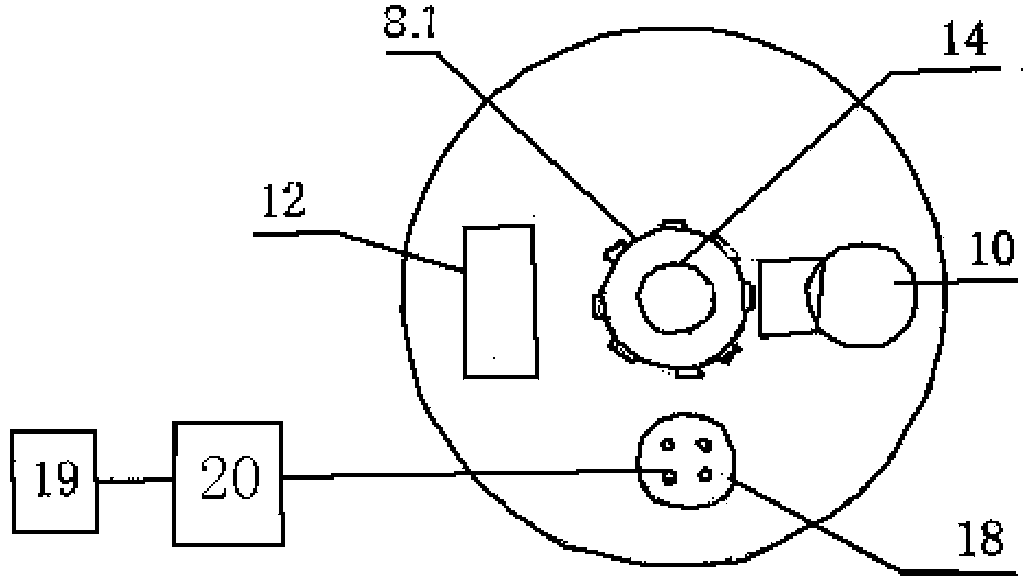

Vacuum insulator surface charge three-dimensional measurement apparatus

ActiveCN104991129AKeep awayGuaranteed air tightnessElectrical measurementsRadial motionImage resolution

The invention discloses a vacuum insulator surface charge three-dimensional measurement apparatus, belonging to the insulation measurement and charge measurement technical field under the vacuum environment. The measurement apparatus is composed of an insulator to be measured, a test electrode, a static probe, a probe support, a probe radial motion mechanism, a probe rotation control mechanism, a probe rotary motion control mechanism, a stepping motor and a probe motion control panel, wherein a high voltage electrode is fixed to the top panel of a vacuum test cavity, a ground electrode is fixed to the central section of a probe rotary table, the insulator to be measured is placed between a high voltage electrode and a ground electrode, and the probe rotary table is supported on the bottom panel of the vacuum test cavity. The invention provides the vacuum insulator surface charge three-dimensional measurement apparatus, which can realize insulator surface charge three-dimensional measurement in all radial directions and all angles through the radial control mechanism and the rotary control mechanism, meanwhile guarantee that a probe is far from the surface of the insulator to be measured in compression or not measuring charges, and possess higher charge resolution and spatial resolution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

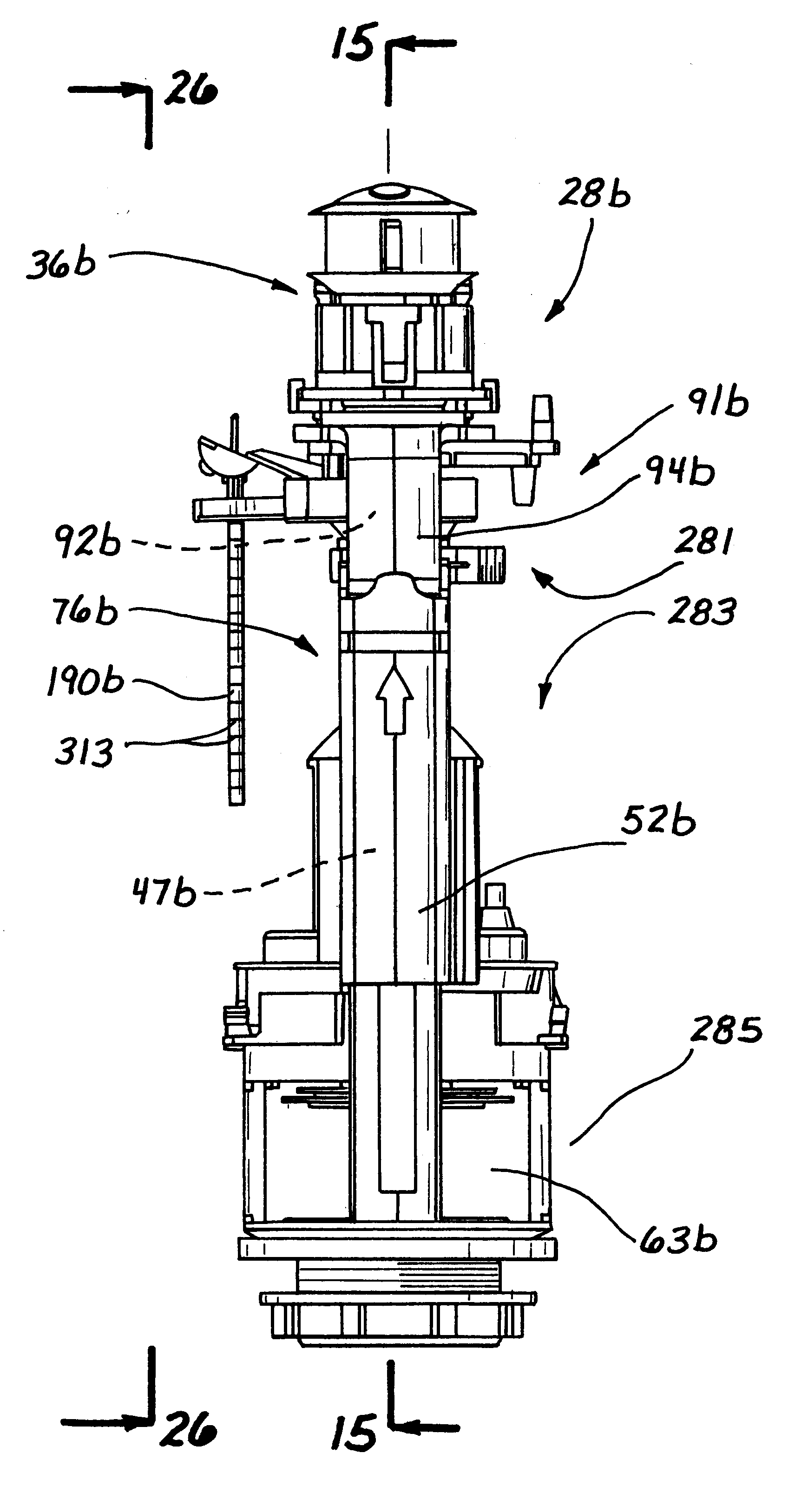

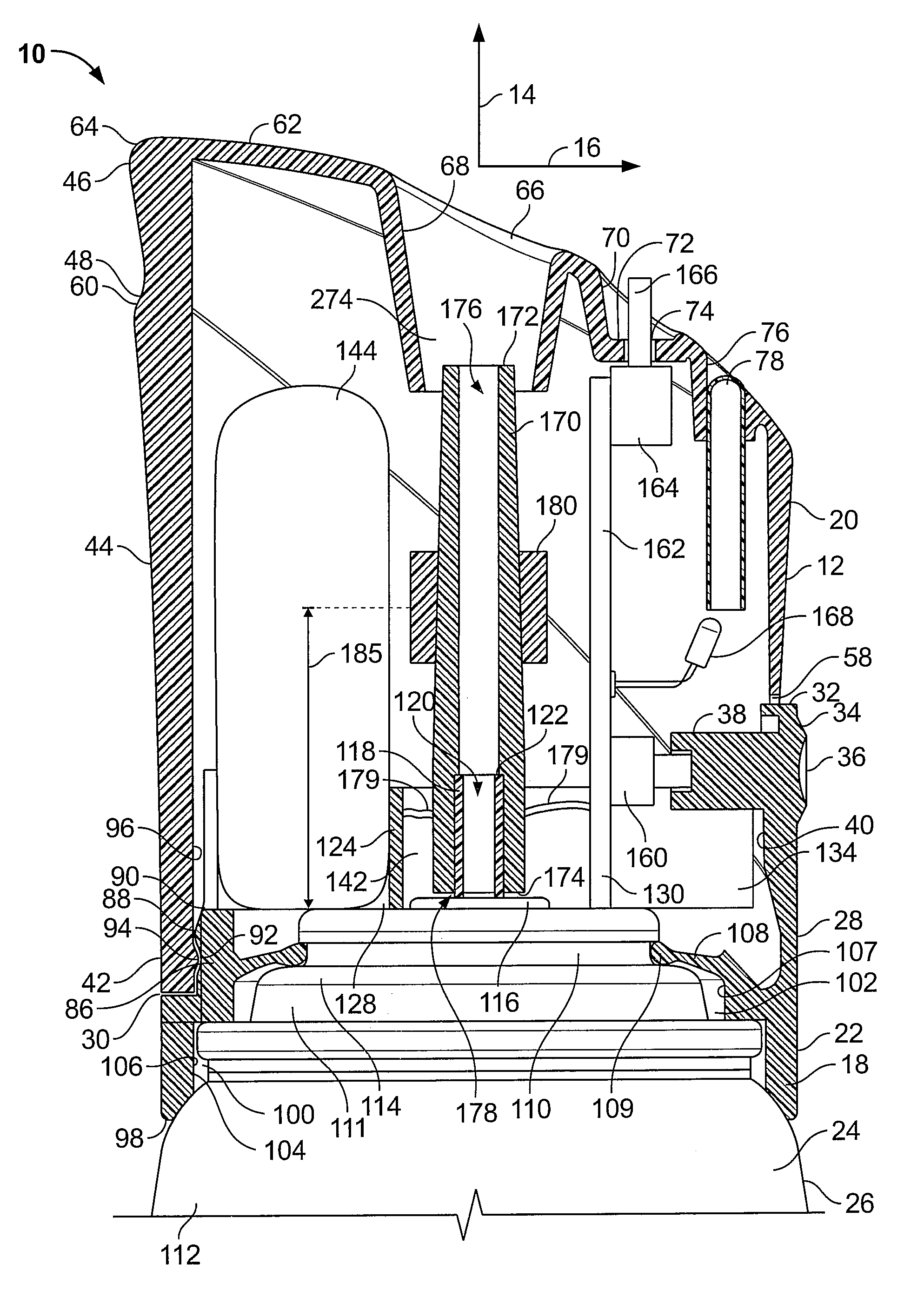

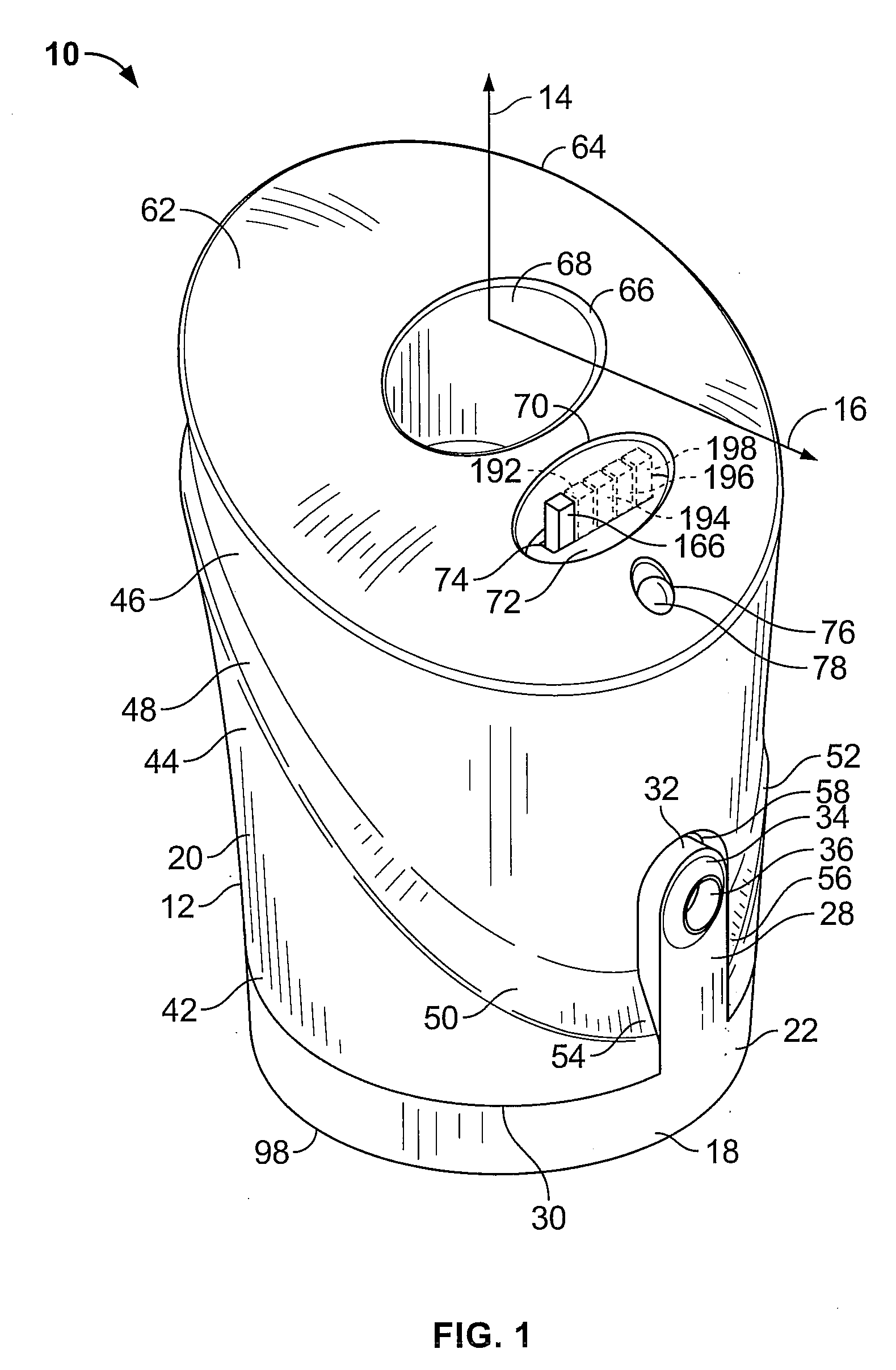

Advanced dual-flush valve

InactiveUS6442772B2Operating means/releasing devices for valvesFlushing devicesRadial motionRinse water

A flush valve is adapted to be mounted in the tank of a toilet and includes a selector assembly and a flush valve. The selector assembly is accessible from outside the toilet and provides for initiation of the flushing operation and an alternative choice between a larger flush water volume and a smaller flush water volume. A support structure provides for both axial and radial movement of the selector assembly relative to the flush valve in order to facilitate mounting and aligning of the flush valve assembly. A slide mechanism provides for variation of at least the smaller flush water volume.

Owner:FLUIDMASTER

Overcap for a spray device

A dispensing system includes a tilt-activated valve stem operably connected to a valve on a container and a vibe motor in communication with the valve stem. The vibe motor is adapted to impart radial motion to the valve stem upon activation.

Owner:SC JOHNSON & SON INC

Open hole expandable patch

ActiveUS20060016597A1Block fluid flowAvoid flowDrilling rodsFluid removalRadial motionClassical mechanics

The invention discloses a patch for placement in a wellbore and associated methods. The patch has a longitudinal member and an anchor that is radially expanded to engage the wall of the borehole to secure the patch against axial and radial movement. The anchor is set using a running tool that radially expands the anchor and the longitudinal body. The anchor may include one or more elements that can be securely engaged within the wellbore. The longitudinal member and / or the anchor may include a sealing element to provide a seal between the wellbore inside and the earth formation surrounding the wellbore.

Owner:BAKER HUGHES INC

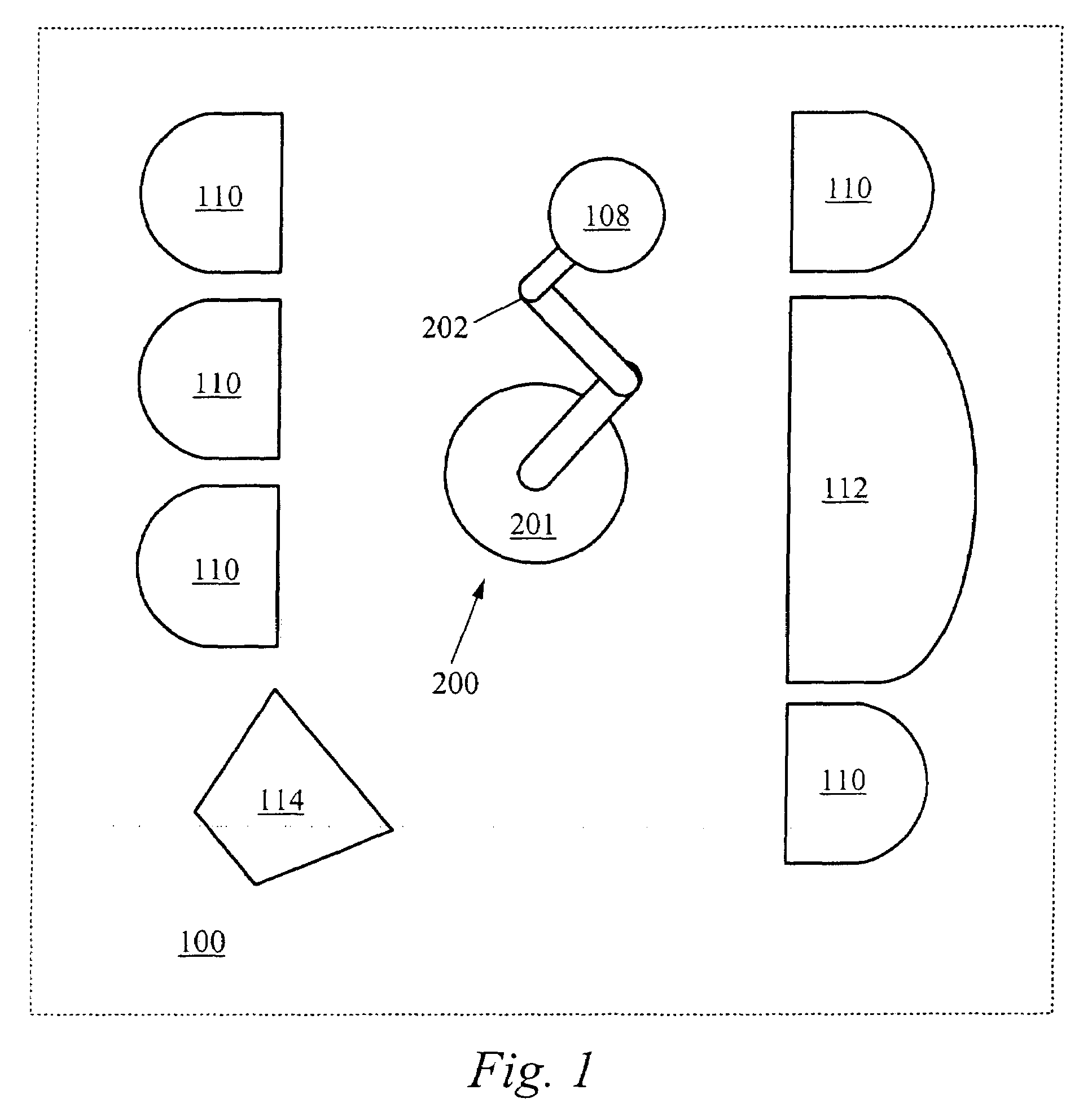

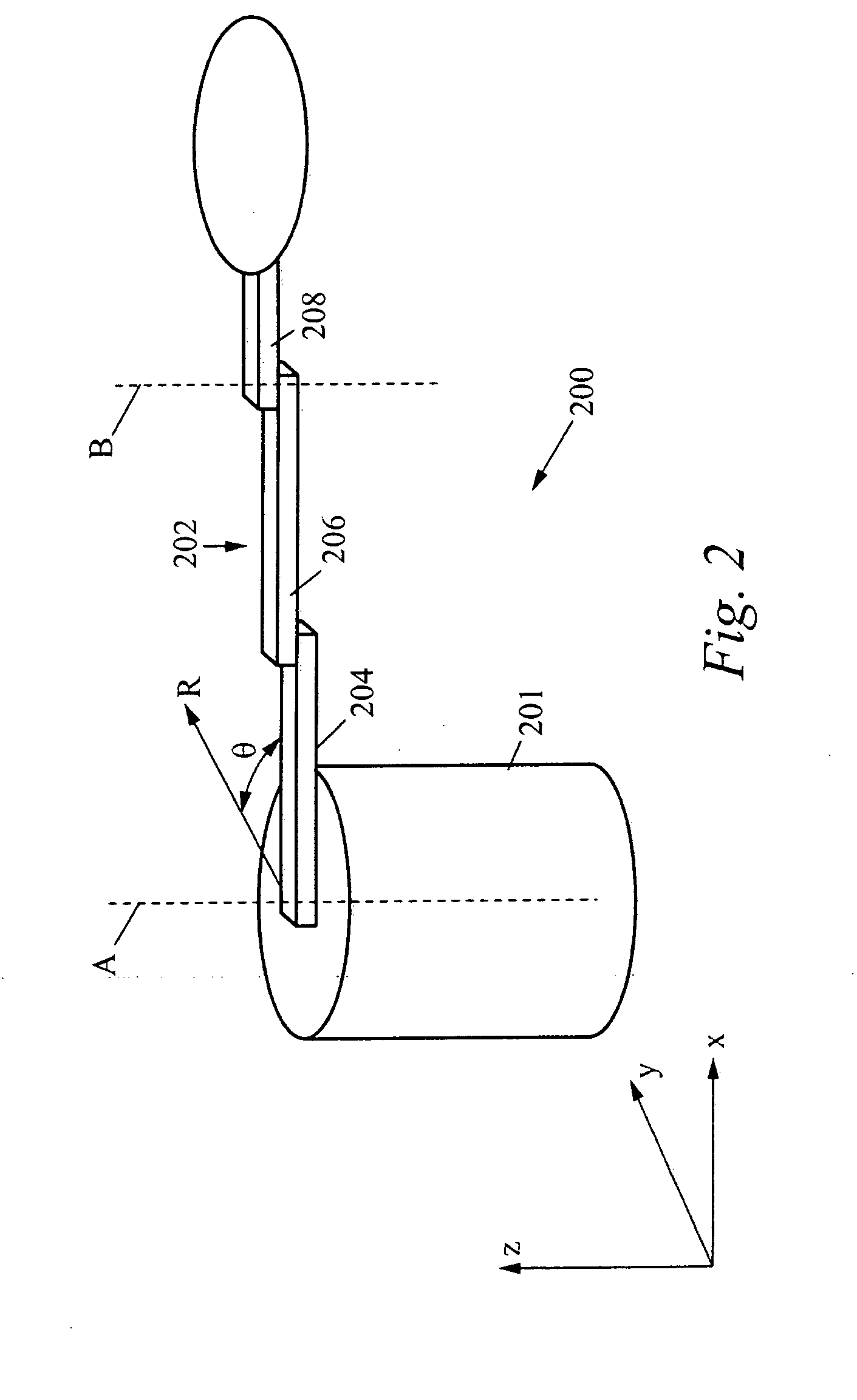

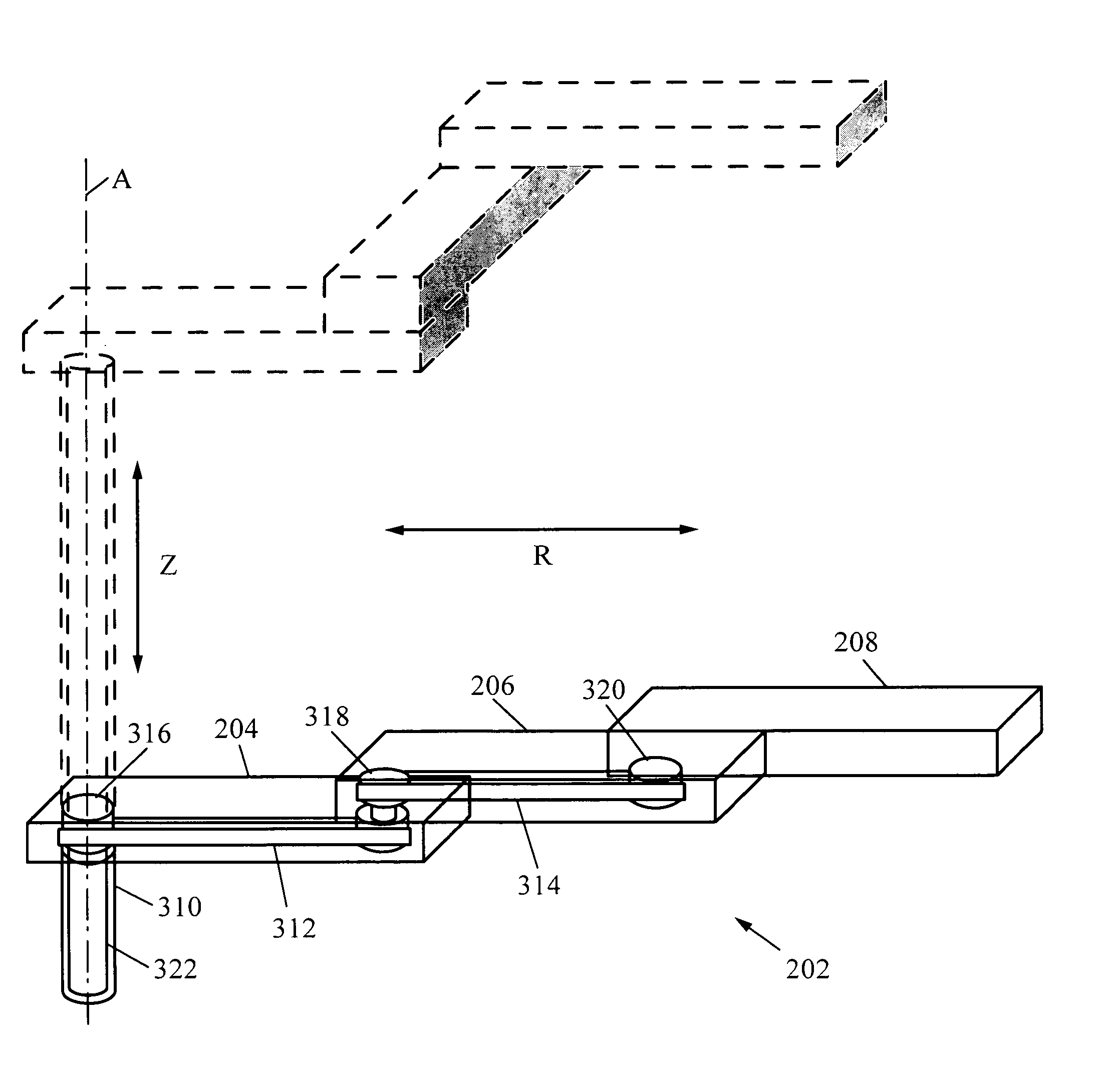

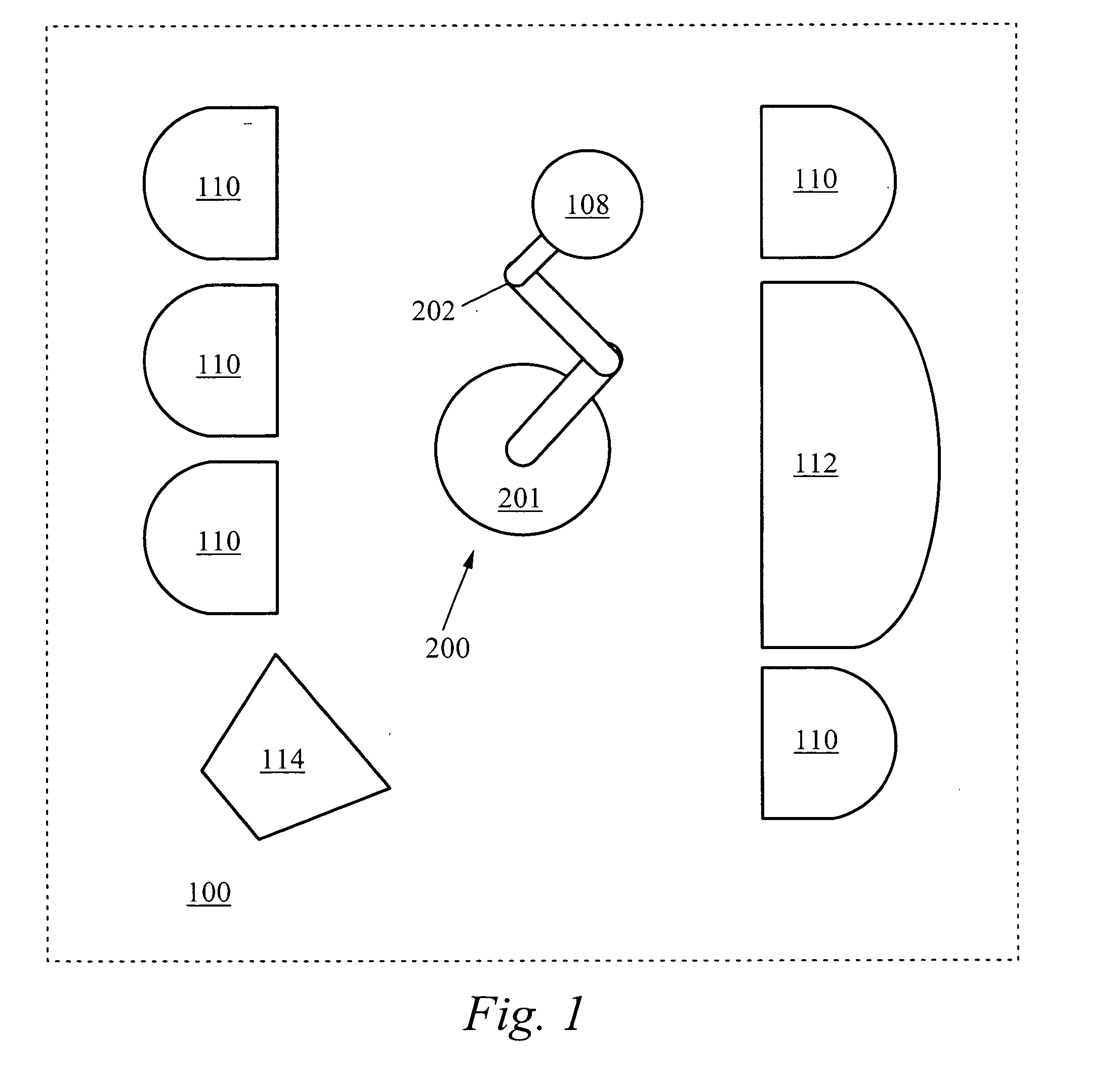

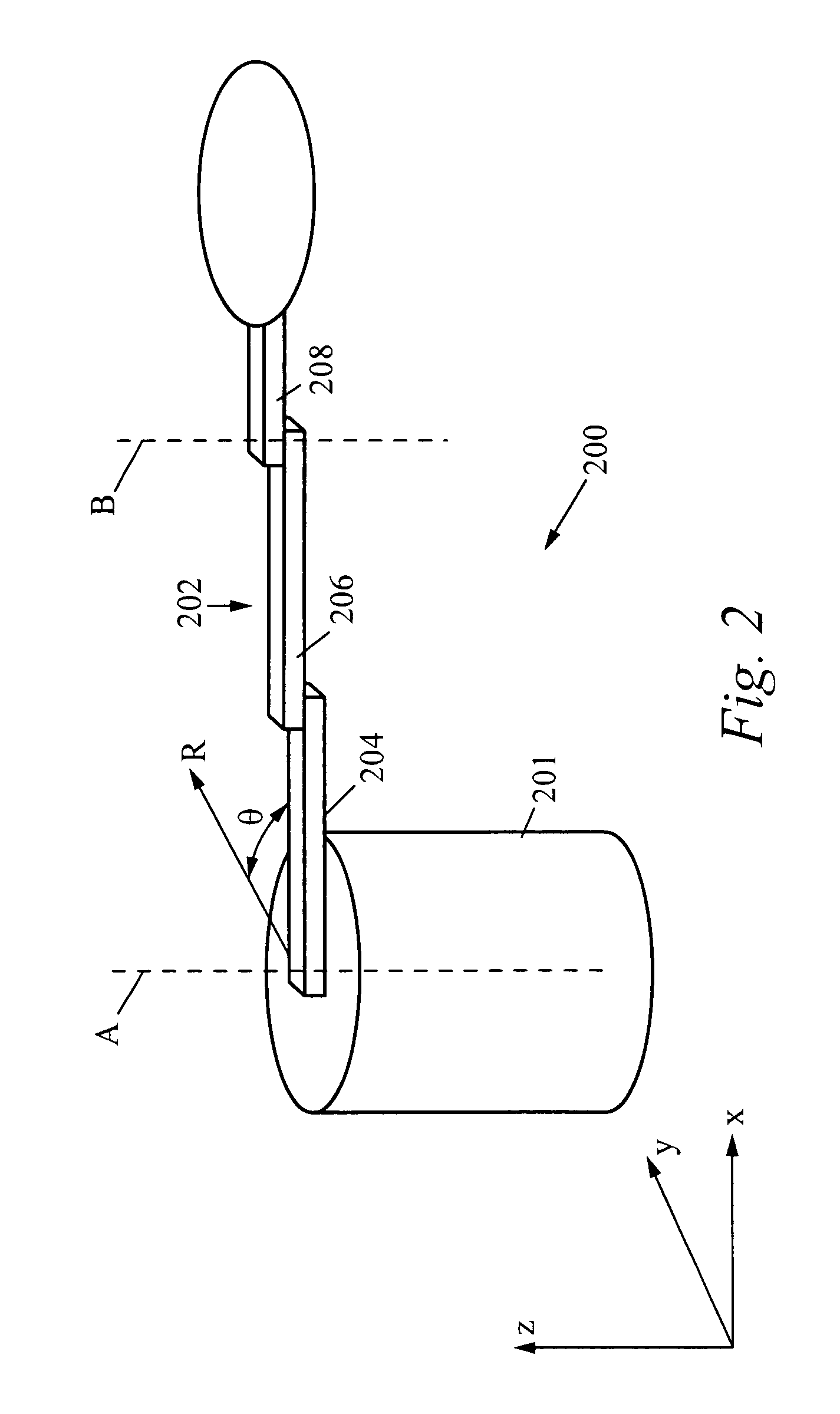

Robot with belt-drive system

ActiveUS20080121064A1Minimizes robot weightReduces component inertiaProgramme-controlled manipulatorMechanical apparatusRadial motionRelative motion

A substrate handling robot having a robot body and a robot arm with an end effector is configured to exhibit angular (θ), radial (R) and Z motion. A pair of coaxial shafts link the robot arm to respective motors dedicated to angular (θ) and radial (R) motions. The motors are stationarily mounted with respect to the robot body. The shafts are rotatably supported by a floating platform which is motivated in the Z direction by a third motor also stationarily mounted with respect to the robot body. The third motor is coupled to the platform by a Z motion linkage. The first and second motors are coupled to the coaxial shafts by angular and radial motion linkages each of which includes primary and secondary timing belts whose relative motions are synchronized with the Z motion linkage to achieve controllable independent angular (θ), radial (R) and Z motions in a simple, light-weight package.

Owner:GENMARK AUTOMATION

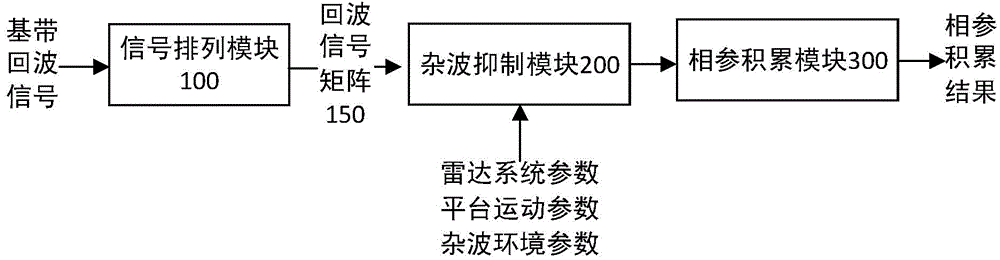

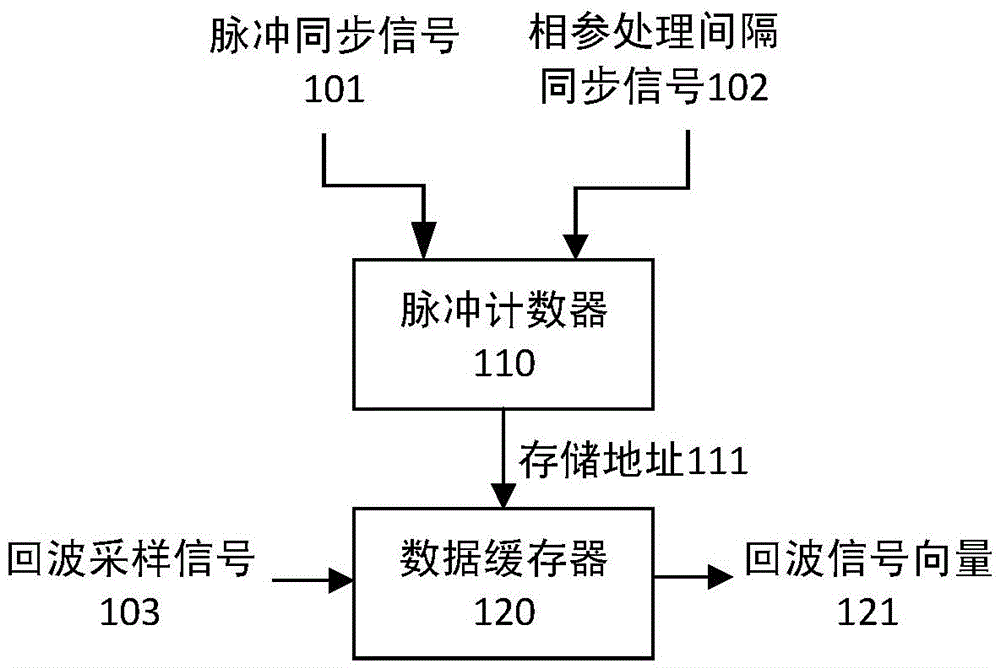

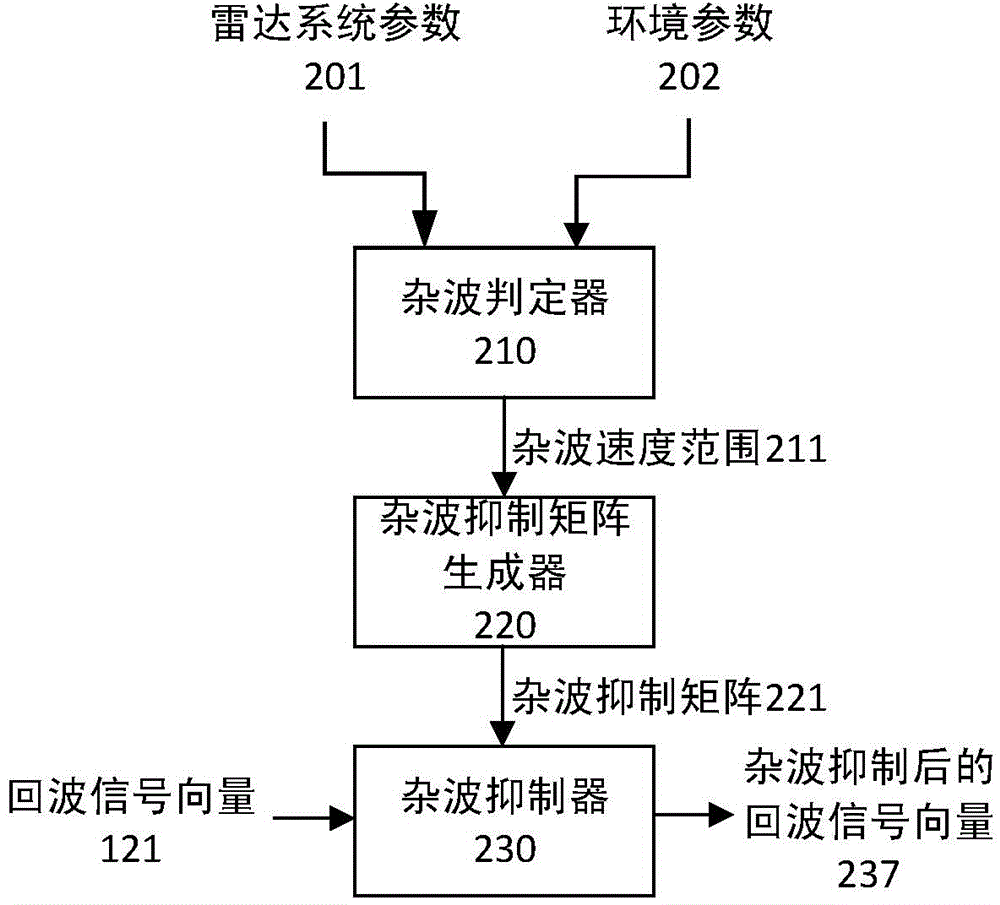

Coherent agile frequency radar clutter inhibition method and system

ActiveCN104931938AHigh speedAvoid missing targetsWave based measurement systemsRadial motionSignal-to-noise ratio (imaging)

The invention discloses a coherent agile frequency radar clutter inhibition algorithm, comprising: arranging radar base-band echo signals to perform clutter inhibition and coherent integration in an echo signal matrix; calculating the matrix to inhibit clutter components in the echo signals and reserve signal components in a movable target; and performing coherent integration on the echo signals after clutter inhabitation. The invention also discloses a coherent agile frequency radar clutter inhibition system corresponding with the algorithm, comprising a signal arrangement module, a clutter inhibition module and a coherent integration module. The algorithm can effectively inhibit clutter energy, obtain radial motion speed information of a target at the same time of detecting a movable target, and meanwhile obtain a high resolution range profile of the target so as to realize simultaneous high resolution detection of speed and range of the target; the algorithm has lower calculated amount, and can inhibit clutter components in signals, increase a signal to noise ratio of the target, and obtain speed information and high resolution images of the target.

Owner:TSINGHUA UNIV

On the fly automatic wafer centering method and apparatus

ActiveUS20170018446A1Semiconductor/solid-state device manufacturingConveyor partsRadial motionThermal expansion

Substrate processing apparatus including a wafer transport apparatus with a transport arm including an end effector, an arm pose deterministic feature integral to the substrate transport apparatus and disposed so that a static detection sensor of the substrate processing apparatus detects at least one edge of the at least one arm pose deterministic feature on the fly with radial motion of the transport arm, and a controller configured so that detection of the edge effects a determination of a proportion factor identifying at least a thermal expansion variance of the transport arm on the fly and includes a kinematic effects resolver configured to determine, from the detection of the edge on the fly, a discrete relation between the determined proportion factor and each different discrete variance respective to each different link of the transport arm determining at least the thermal expansion variance of the transport arm on the fly.

Owner:BOOKS AUTOMATION US LLC

Three-dimensional measuring device and method of charges on surface of basin-type insulator

ActiveCN104020363AGuaranteed air tightnessDoes not affect field strength distributionElectrical measurementsMeasurement deviceThree dimensional measurement

The invention belongs to the technical field of high-voltage equipment and electrostatic measuring, and discloses a three-dimensional measuring device and method of charges on the surface of a basin-type insulator. The device comprises an arc surface and inclined surface measuring probe, a probe support guide rail, a probe radial motion control mechanism, a link mechanism, a 360-degree rotation control disk, a reading mechanism, a lifting control lead screw, a control mechanism, a sealed through-connection cavity, a main shaft for controlling motion, a coupler and an operation platform base. The whole set of mechanisms is in sealed connection with a GIS testing cavity. The three-dimensional measuring device can realize three-dimensional control over charge measuring on the surface of the actual basin-type insulator; air impermeability of a testing device is guaranteed, therefore, the purpose that all-direction and totally-radial three-dimensional measuring is conducted on the charges on the surface of the basin-type insulator in voltage equipment or high-air-pressure environment is realized, and high charge resolution and spatial resolution is achieved in measuring the surfaces of various basin-type insulators. Meanwhile, the three-dimensional measuring device and method can be used for environments with high requirements for air impermeability and the measuring process can be observed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

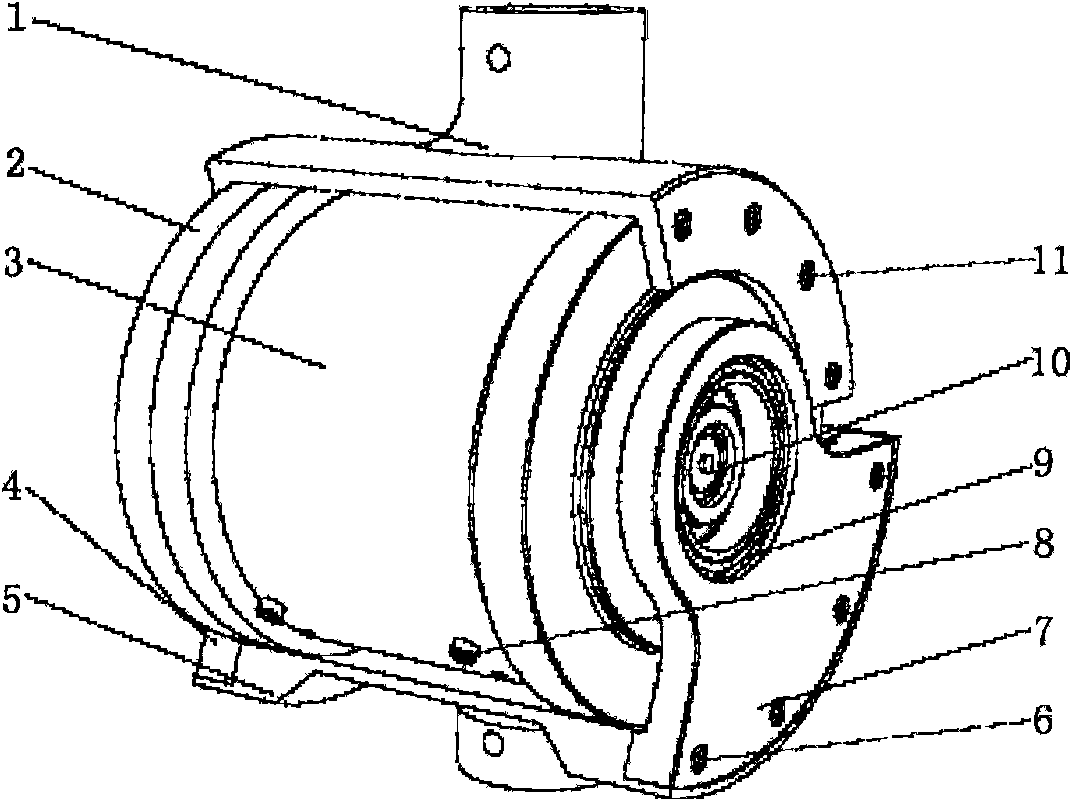

Passive robot joint with adjustable rigidity elasticity

InactiveCN101973037AImprove exercise energy efficiencyRealize dynamic high-speed movementJointsThighRadial motion

The invention discloses a passive robot joint with adjustable rigidity elasticity, comprising a spring reel and a joint rigidity elasticity adjustment device arranged inside the spring reel, wherein the spring reel is connected with thigh support seats; an extended end of the joint rigidity elasticity adjustment device is connected with crus support seats by crus support plates; the joint rigidity elasticity adjustment device comprises a non-contact plane volute spring of which the inner end is connected with a spring scroll and the outer end is connected with the spring reel; the middle of the spring scroll is hollow and is internally provided with a rigidity adjustment motor; one end of the spring scroll is connected with the rigidity adjustment motor; and the middle of the non-contact plane volute spring pitch is supported by a bracing piece which is connected with a rigidity adjustment reducer by a transmission gear. The bracing piece and the transmission gear perform radial motion, thus improving motion energy efficiency of the robot, realizing dynamically high-speed motion, and having good performance, compact structure and reliable operation.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Special fixture for processing outer circle of long-cylinder part

The invention relates to a machining fixture, and discloses a special fixture for processing an outer circle of a long-cylinder part. Guide sleeves, taper sleeves and lock nuts are mounted at the two ends of a central spindle of the special fixture symmetrically and sequentially from inside to outside; the guide sleeves are in large-small end structures; the small ends of the guide sleeves are fixed with the central spindle by set screws; through holes are formed in casings at the large ends of the guide sleeves; ejection blocks are arranged in the through holes; cambered surfaces and grooves are arranged and formed at the outer ends of the ejection blocks; taper surfaces are arranged at the inner ends of the ejection blocks; cones of the taper sleeves eject the taper surfaces of the ejection blocks; and annular springs are mounted around the grooves of the ejection blocks. According to the special fixture, radial ejection block ejecting workpieces are added on the basis of axial clamping; radial motion during the processing of the outer circles of the workpieces is avoided; the centering precision is high; with the adoption of the matched design of the guide sleeves and the taper sleeves, and added shaft sleeves, centering clamping can be adjusted conveniently according to the length and an inner hole of the long-cylinder part; and the generality of the tool fixture for processing the outer circle of the long-cylinder part is improved.

Owner:XINYU IRON & STEEL CO LTD

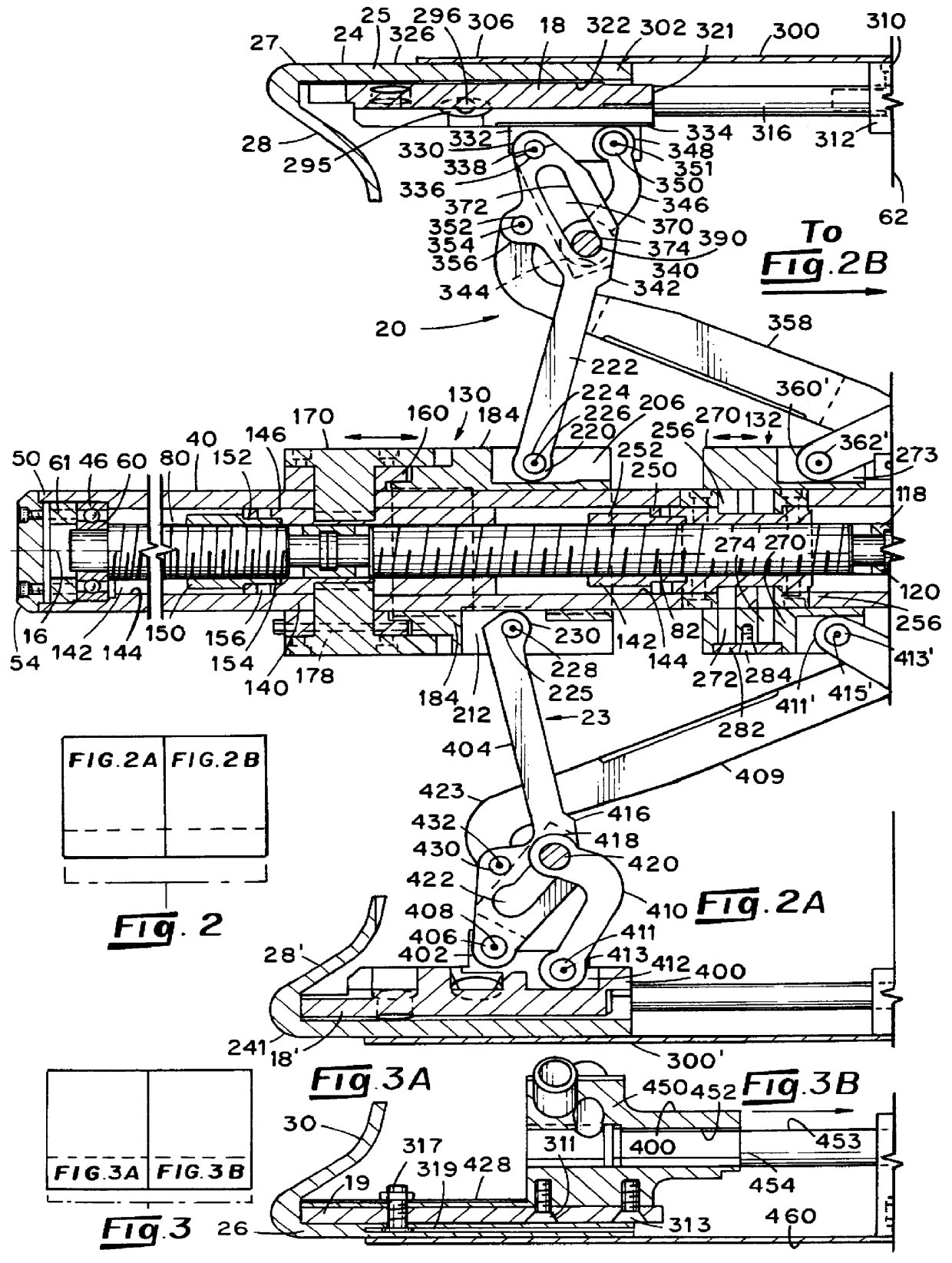

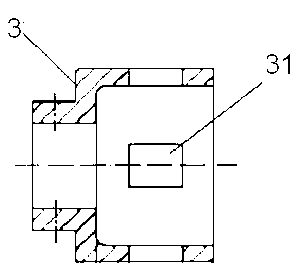

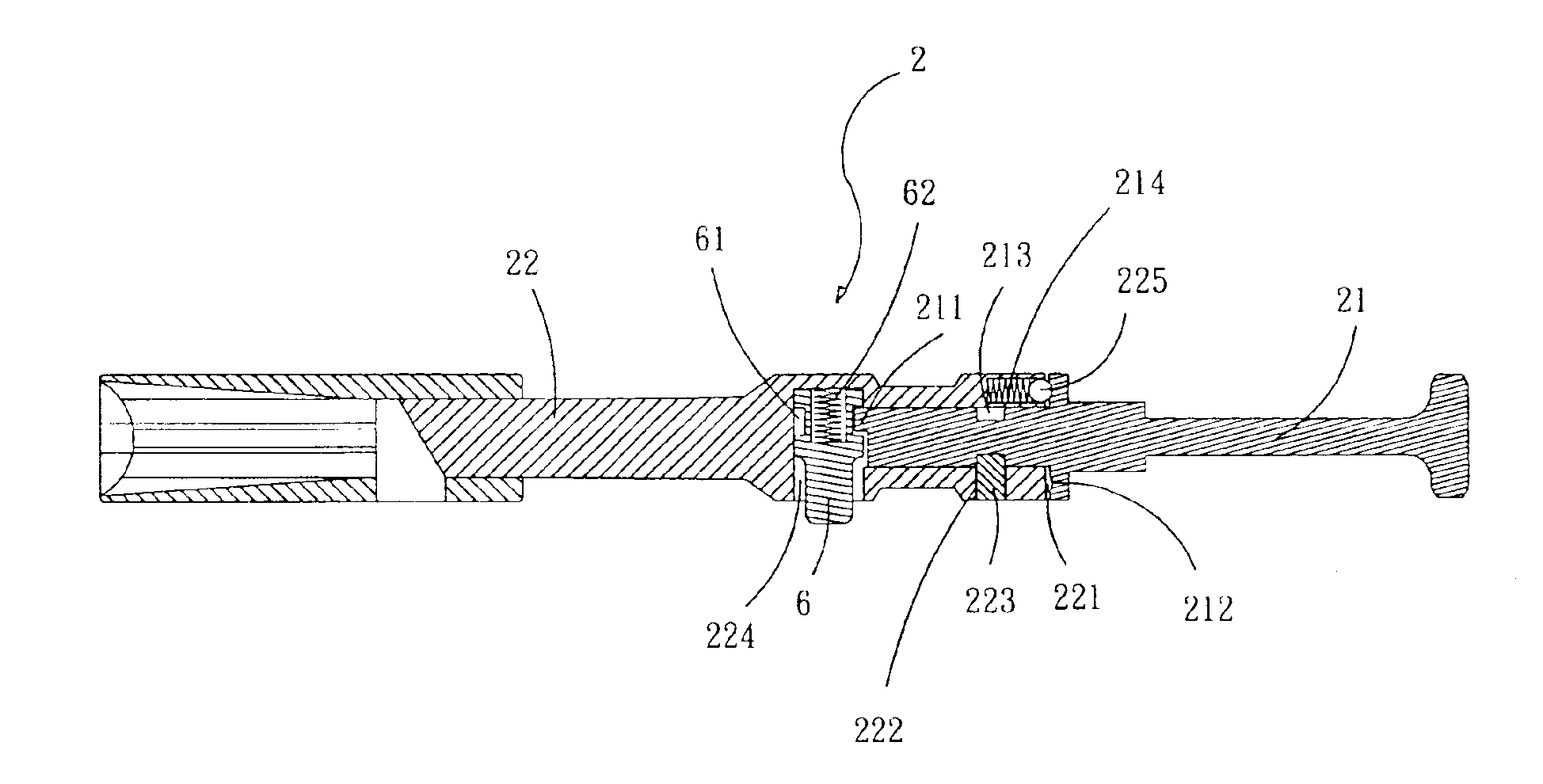

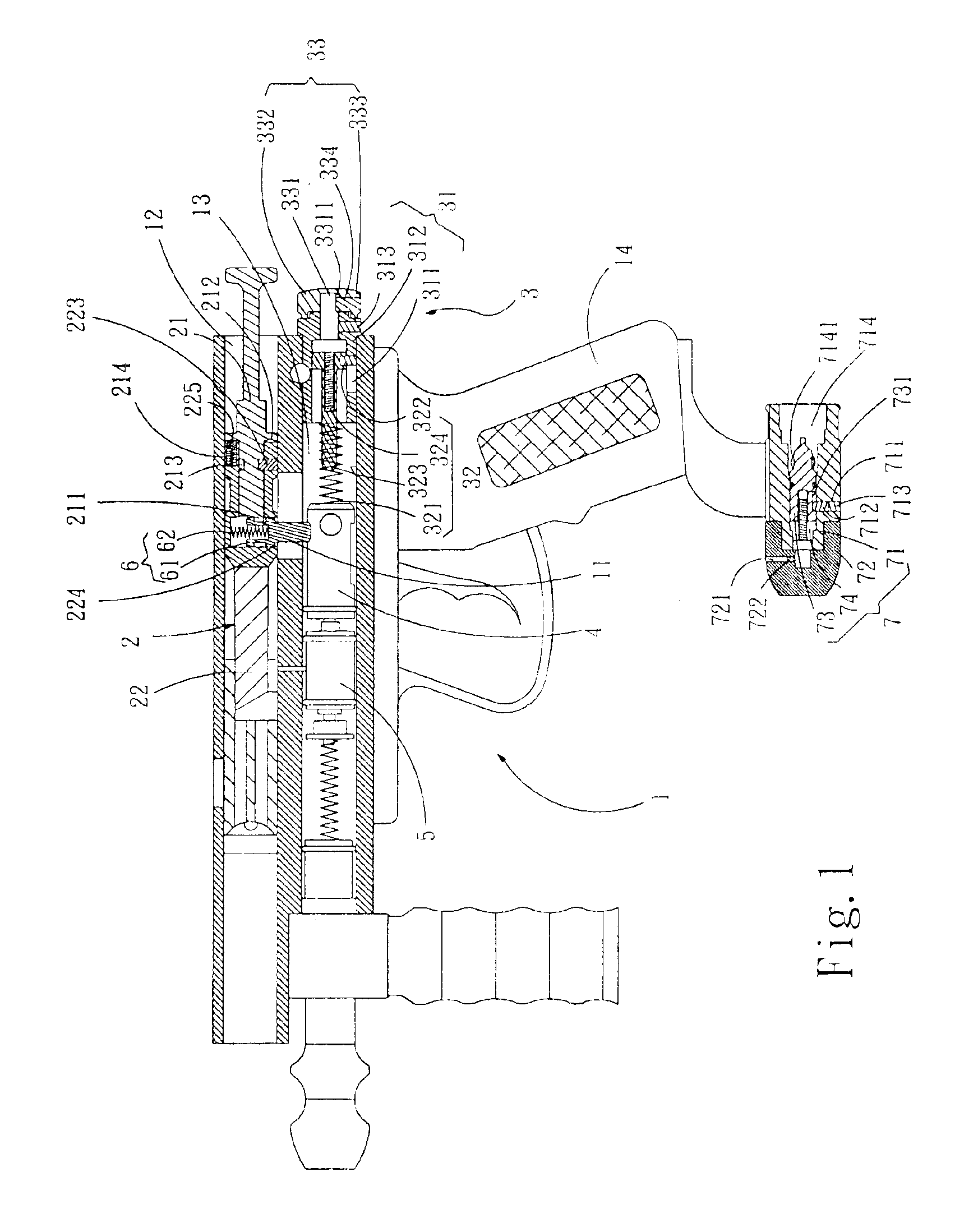

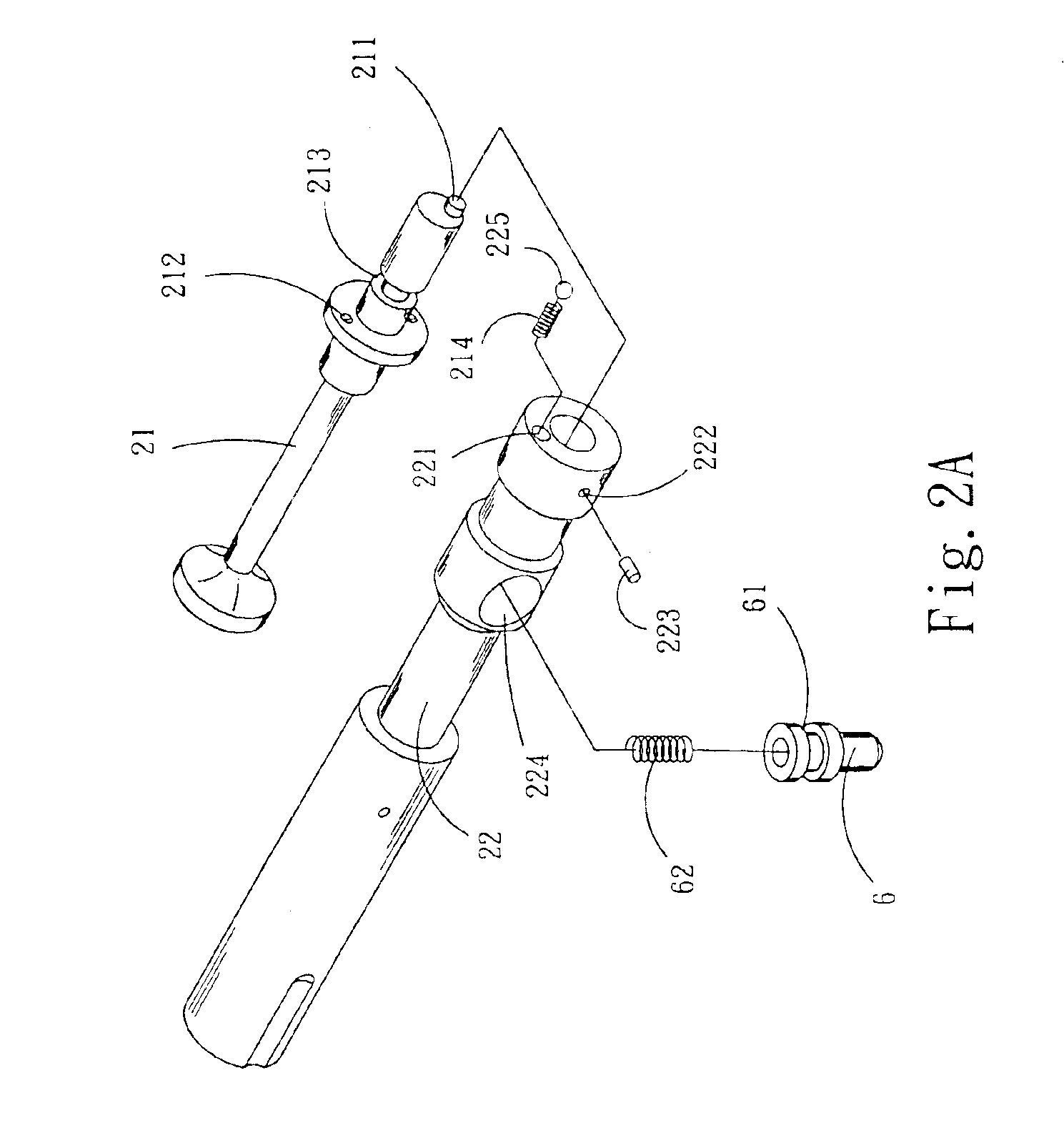

Structure for a toy gun

The present invention discloses an improved structure for a toy gun comprises a body, which includes an upper moving trough and a lower moving trough, both are parallel to each other and connected via a connecting trough; inside the upper moving trough is an extruder and inside the lower moving trough is arranged a rear portion, a mechanical component connecting to the rear portion and a valve controller connecting to the mechanical component in series from a rear end of the lower moving trough. Wherein, for the design of the extruder, the connecting piece is driven by the pulling portion, thus to rotate the pulling portion is to generate relative and radial motions among the connecting piece in the connecting trough, the injection portion and the mechanical component; further that, the connecting piece is taken off from the mechanical component to terminate the connecting stage of the extruder and the mechanical component. To turn the knob of the rear portion is to simultaneously move the leading rod of the rear portion in the rear piece back and forth, and the knob may not have an axial movement from original position thereof. Further, to utilize the rotation of the rotating piece of the gas-control portion is capable of controlling the adjusting rod; hence the thimble of the gas-control portion being driven is to handle the combining body.

Owner:JZN AMY

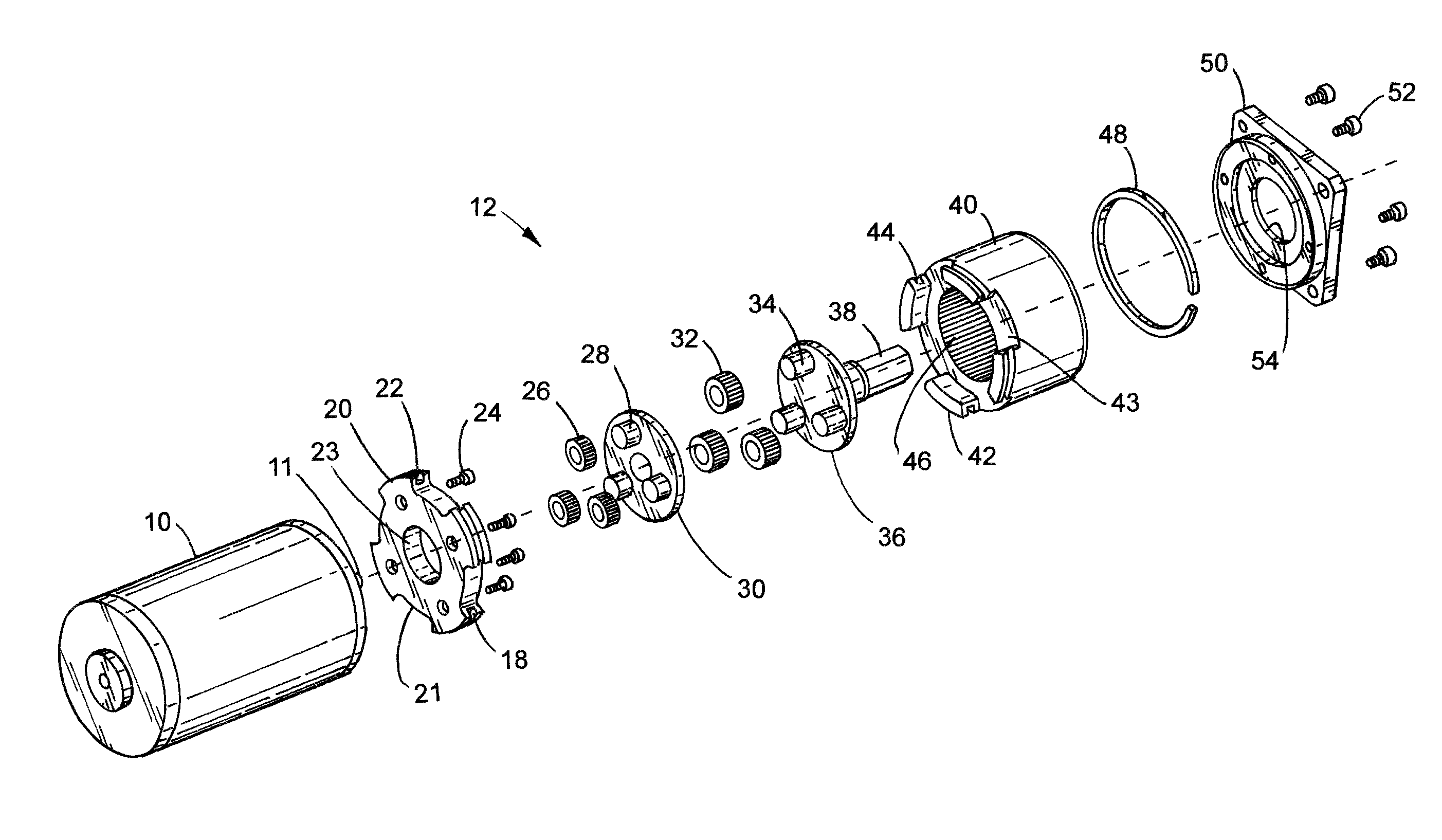

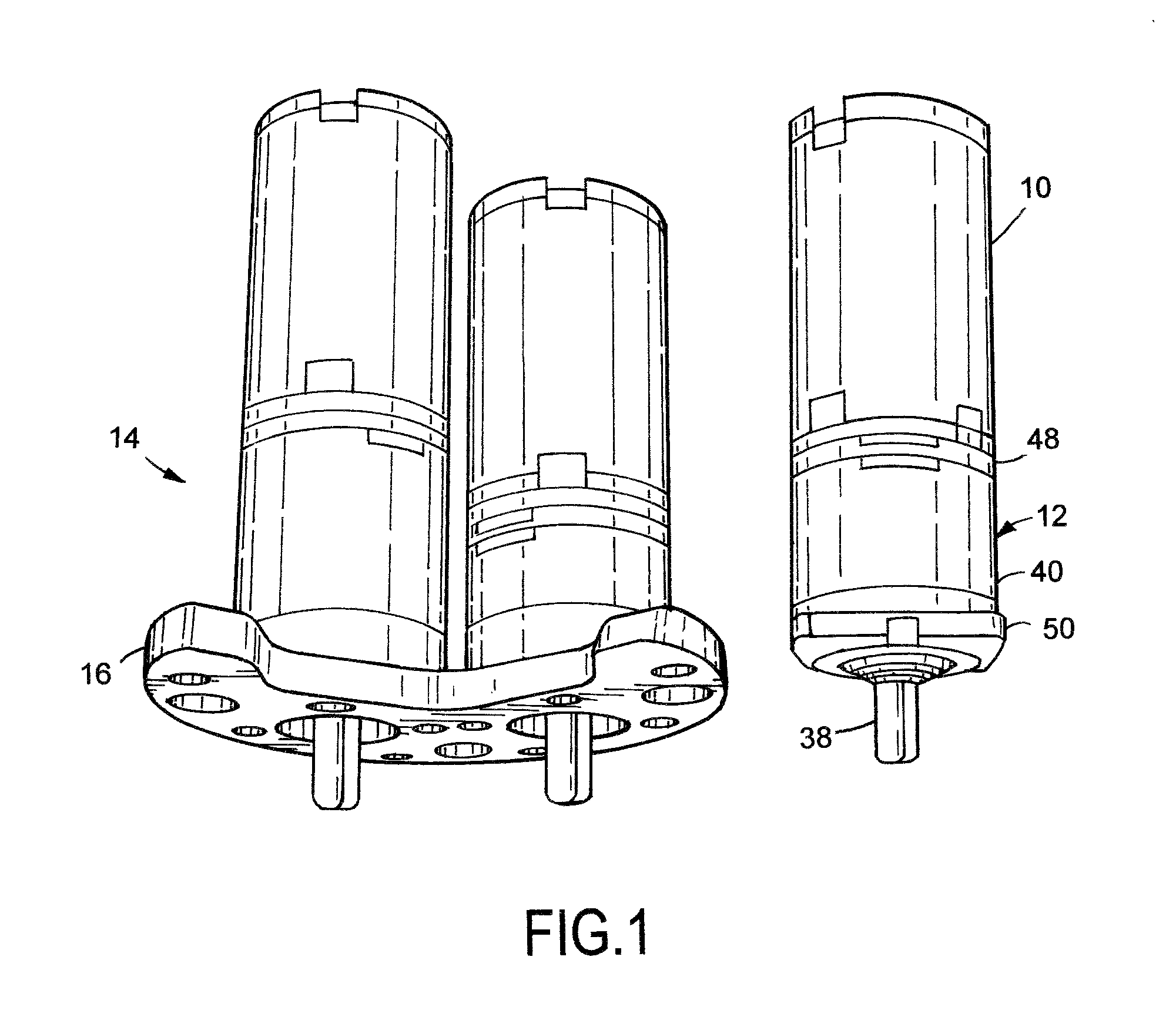

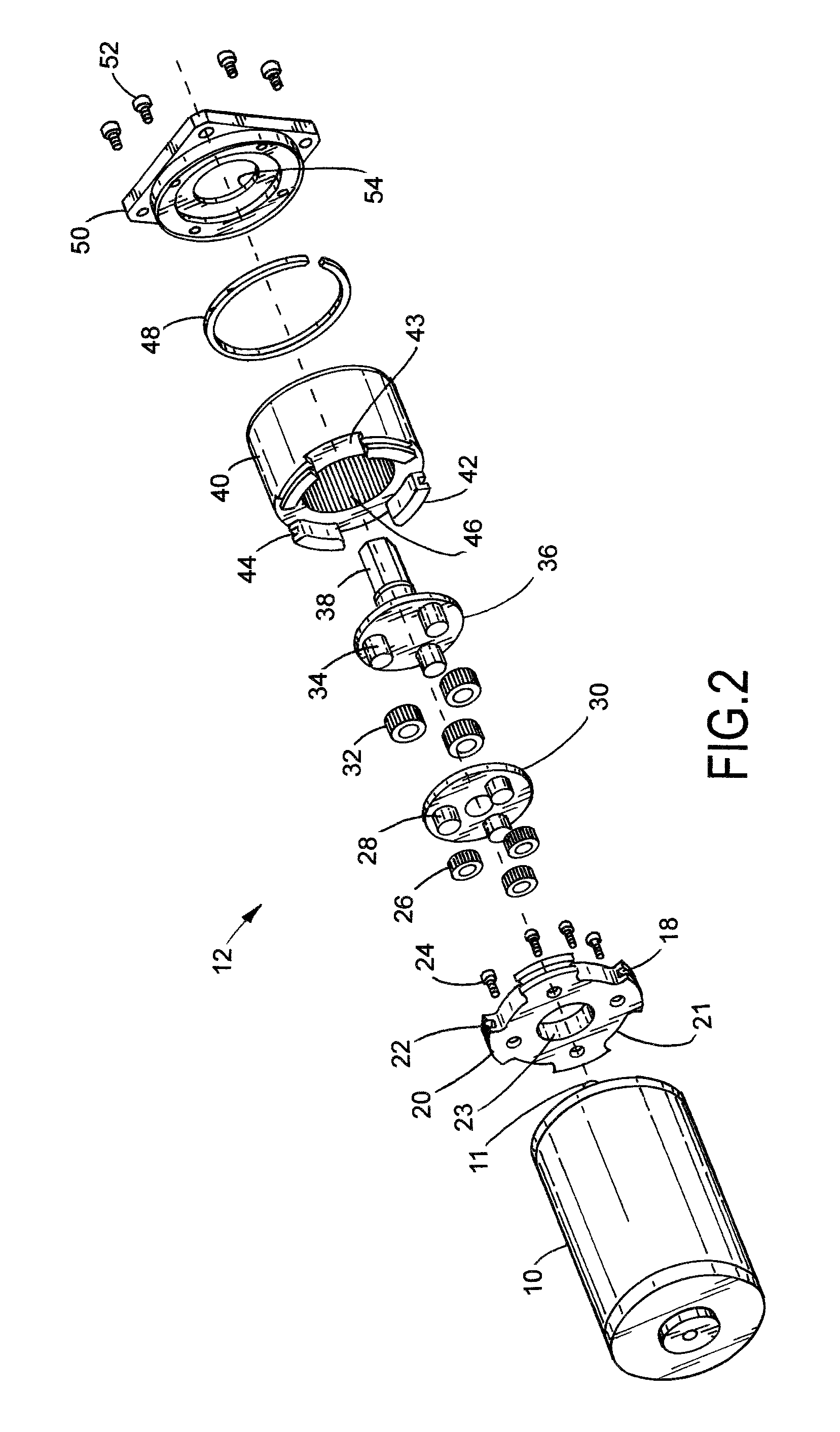

Floating ring gear epicyclic gear system

InactiveUS8584359B1Binding between the gears is reduced or eliminatedReduce adverse outcomesMetal-working apparatusToothed gearingsRadial motionGear wheel

A small size epicyclic gear system in which the mating between gear housings is purposefully made with some play to allow a certain degree of relative movement to accommodate machining runout errors in the manufacture of the gears. A castellated cap fastened to the motor engages with a castellated gear reduction body. The tolerances built into the cap and gear reduction body allow relative radial movement therebetween to reduce binding of the gears during rotational positions in which the gear component runout tolerances are additive.

Owner:BOWMAN THOMAS W

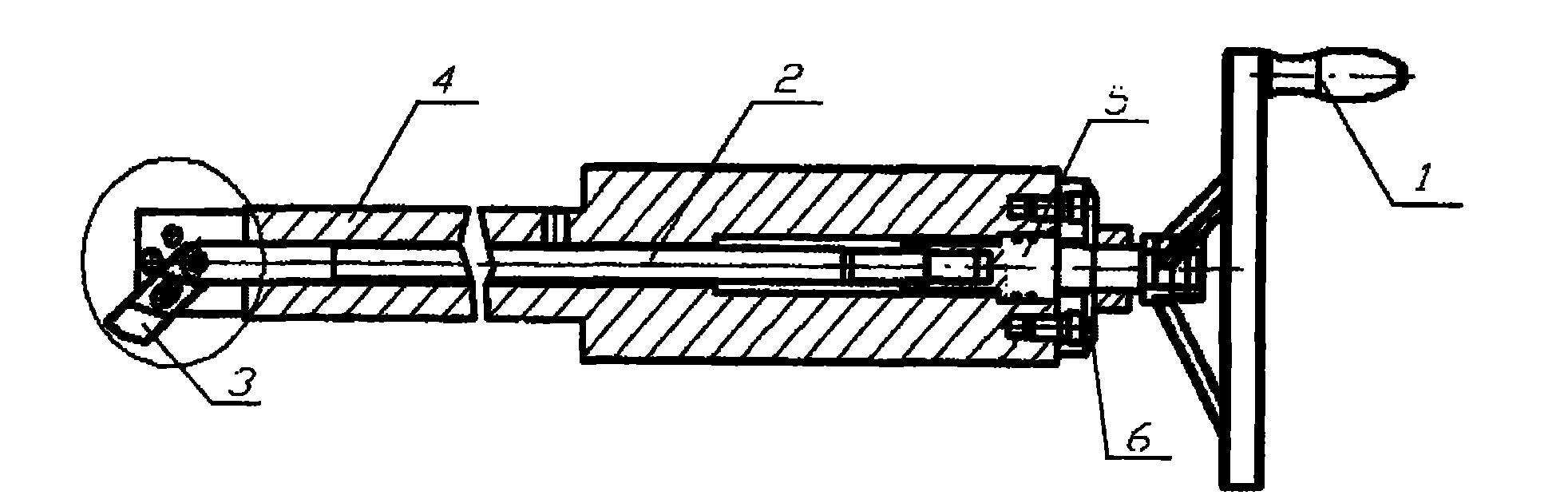

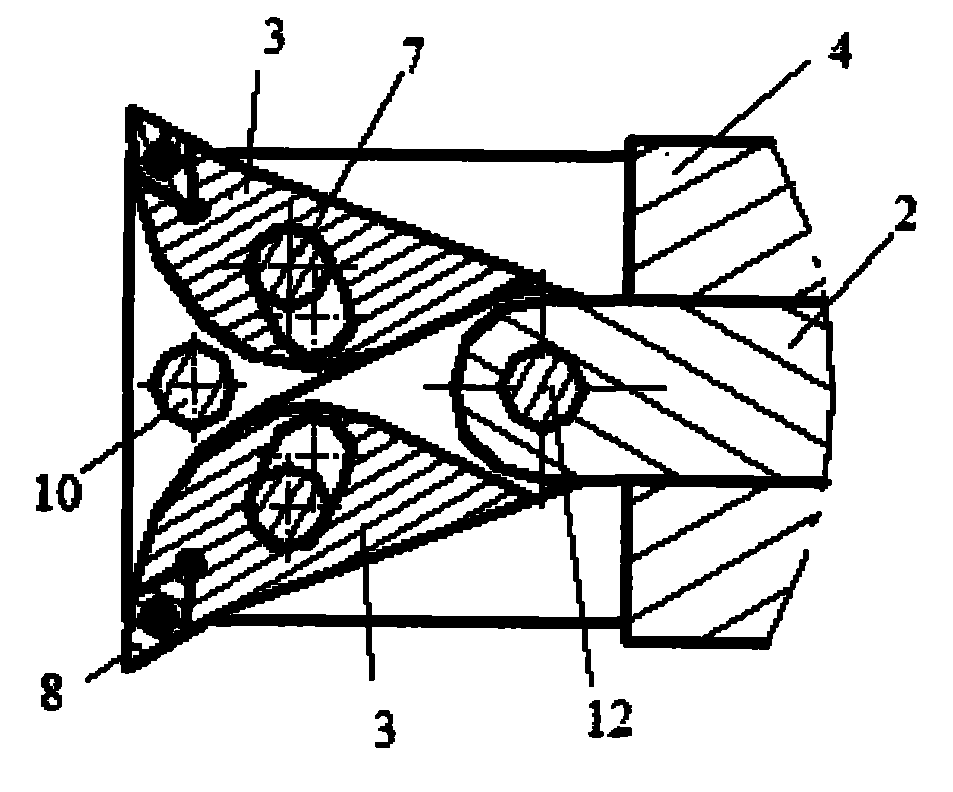

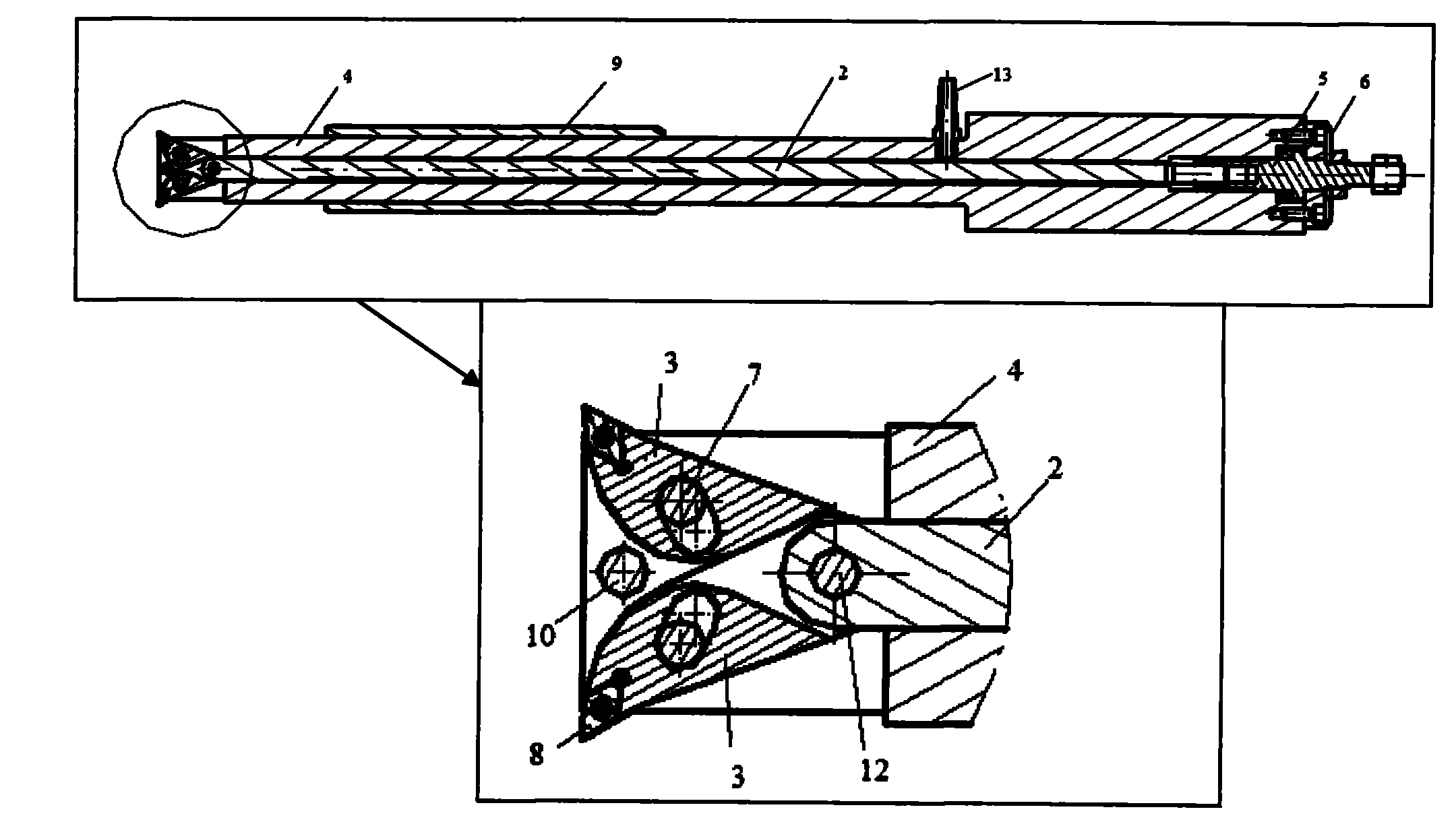

Telescopic double-edged deep-hole boring cutter

The invention provides a telescopic double-edged deep-hole boring cutter, aims to provide a deep-hole drilling boring cutter which has large length-diameter ratio, small self-excited vibration of a boring bar, reliable and stable feeding operation, no radial motion of a cutter arbor, and radial feeding of a cutting edge in a cutting process, and solves the problem that the deep-hole bottle cavity with large length-diameter ratio has large processing difficulty. The boring cutter comprises the boring bar which can extend to the deep-hole bottle cavity, wherein the central axis of the boring bar is provided with a through hole which runs through the central axis; a push rod (2) which is connected with a radial feeding device of the head of the boring bar is arranged in the through hole; the rear end of the push rod (2) is provided with a rotating handle; the rotating handle rotates a screw (5) and pushes the push rod (2) to do radial telescopic motion in the through hole of the boring bar; and the push rod (2) moves by way of pushing or pulling to drive the radial feeding device connected with the push rod and adjust the cutting edge of the double-edged boring cutter on a cutter block (3) to radically feed in the deep-hole bottle cavity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

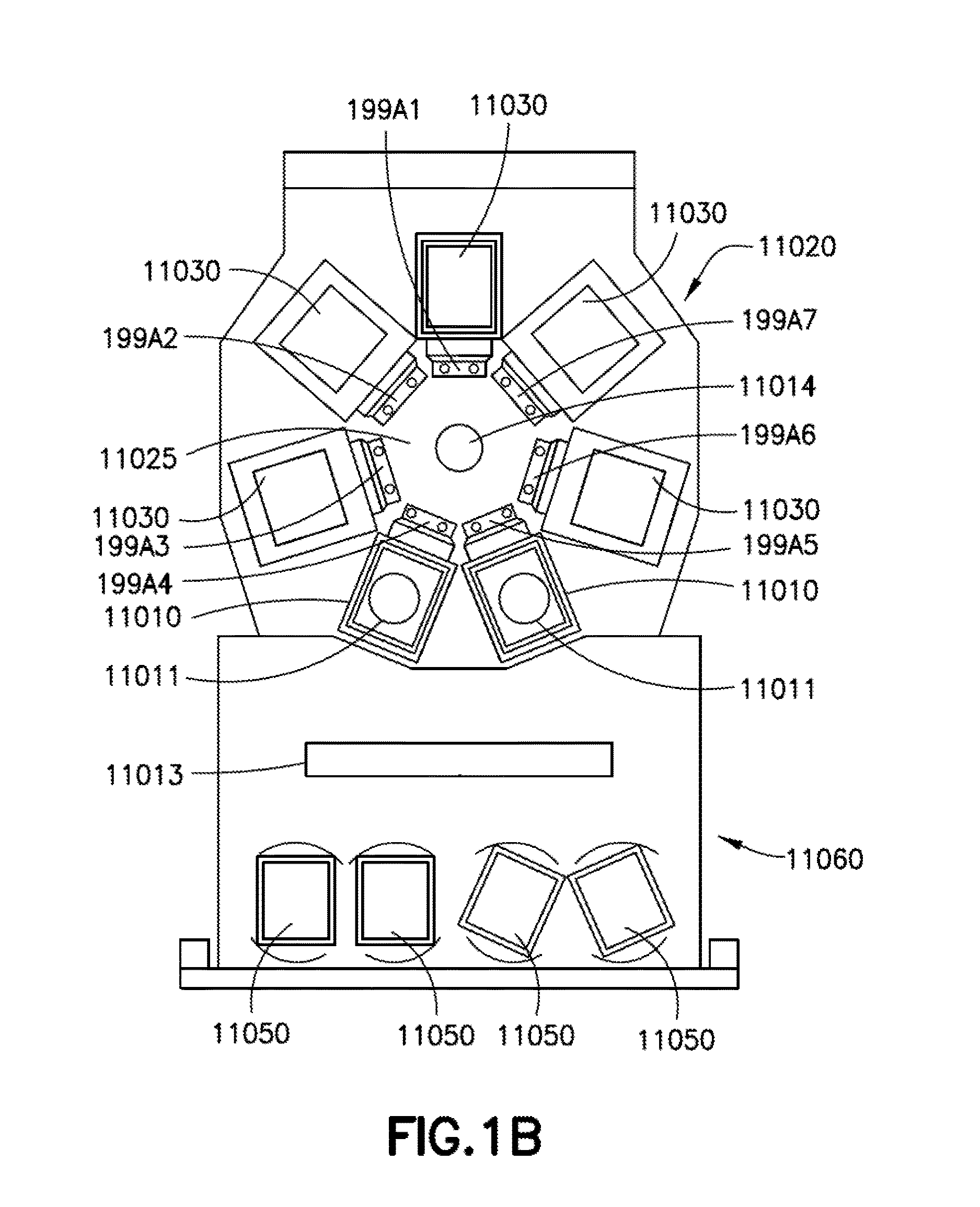

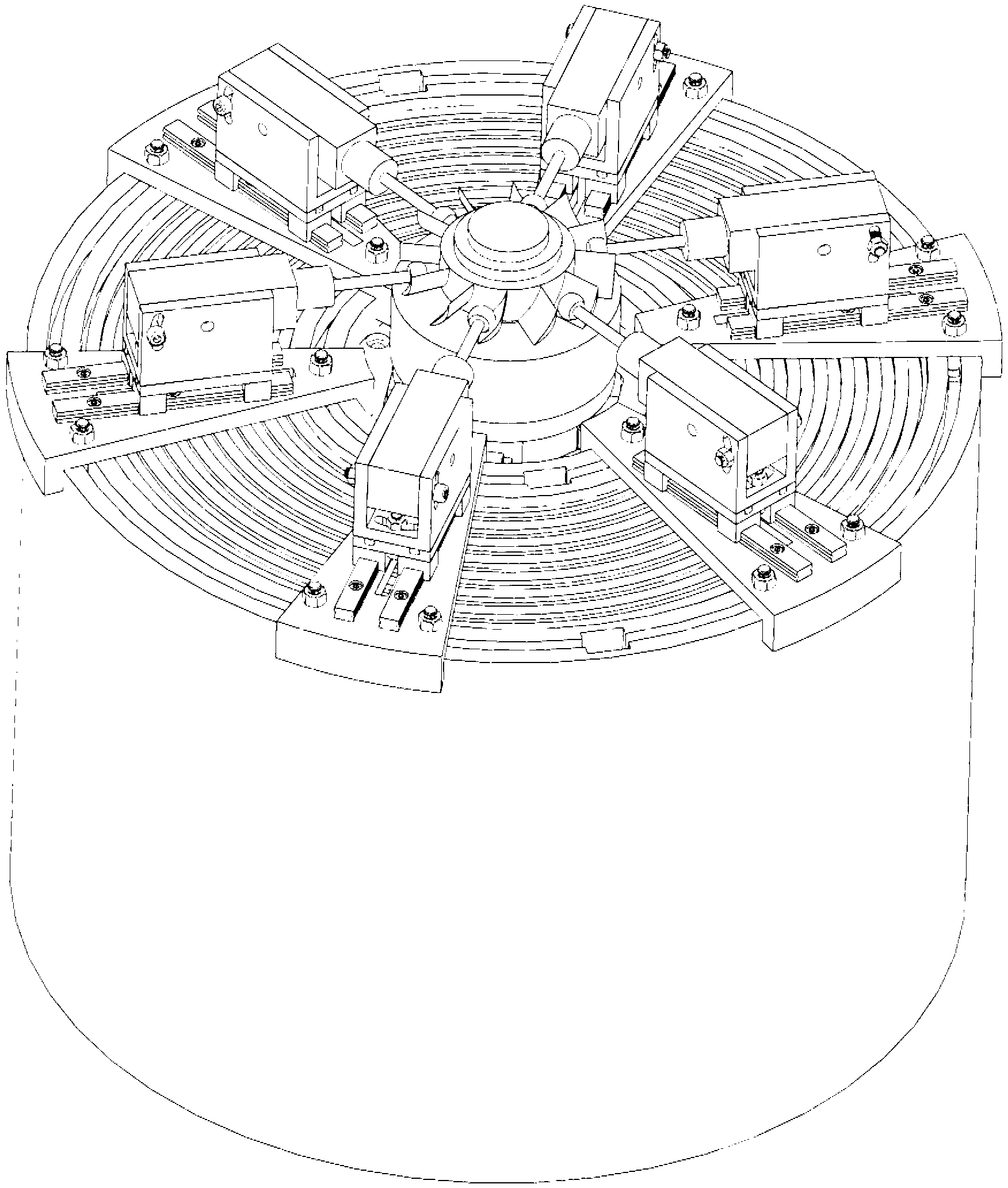

Synchronous processing device with circular array curve surface structure

ActiveCN103223634AImprove processing efficiencyGrinding carriagesGrinding drivesRadial motionImpeller

The invention discloses a synchronous processing device with a circular array curve surface structure. The synchronous processing device comprises main shaft processing units, radial motion units, a working table motion unit, dual-layer main shaft processing units and a gantry-type synchronous processing device with the circular array curve surface structure, wherein the main shaft processing units are mounted on the bases of the radial motion units, fixed through bolts, used for processing the curve surfaces of the blades of a workpiece impeller, and mounted in the circumferential direction; the central angle between every two main shaft processing units is an integral multiple of the included angle between the blades; the radial motion units are used for controlling the main shaft processing units on the radial motion units to move in the radial direction; the working table motion unit is mounted on the bases of the radial motion units and used for rotating and moving the blades up and down; the curve surfaces of the blades are processed through the three motions of the blades under the control of a digital control system; and the dual-layer main shaft processing units are mounted on the bases instead of the main shaft processing units and can be used for processing two layers of impellers at the same time, so that the processing efficiency of complex parts is improved.

Owner:北京宇同科技有限公司

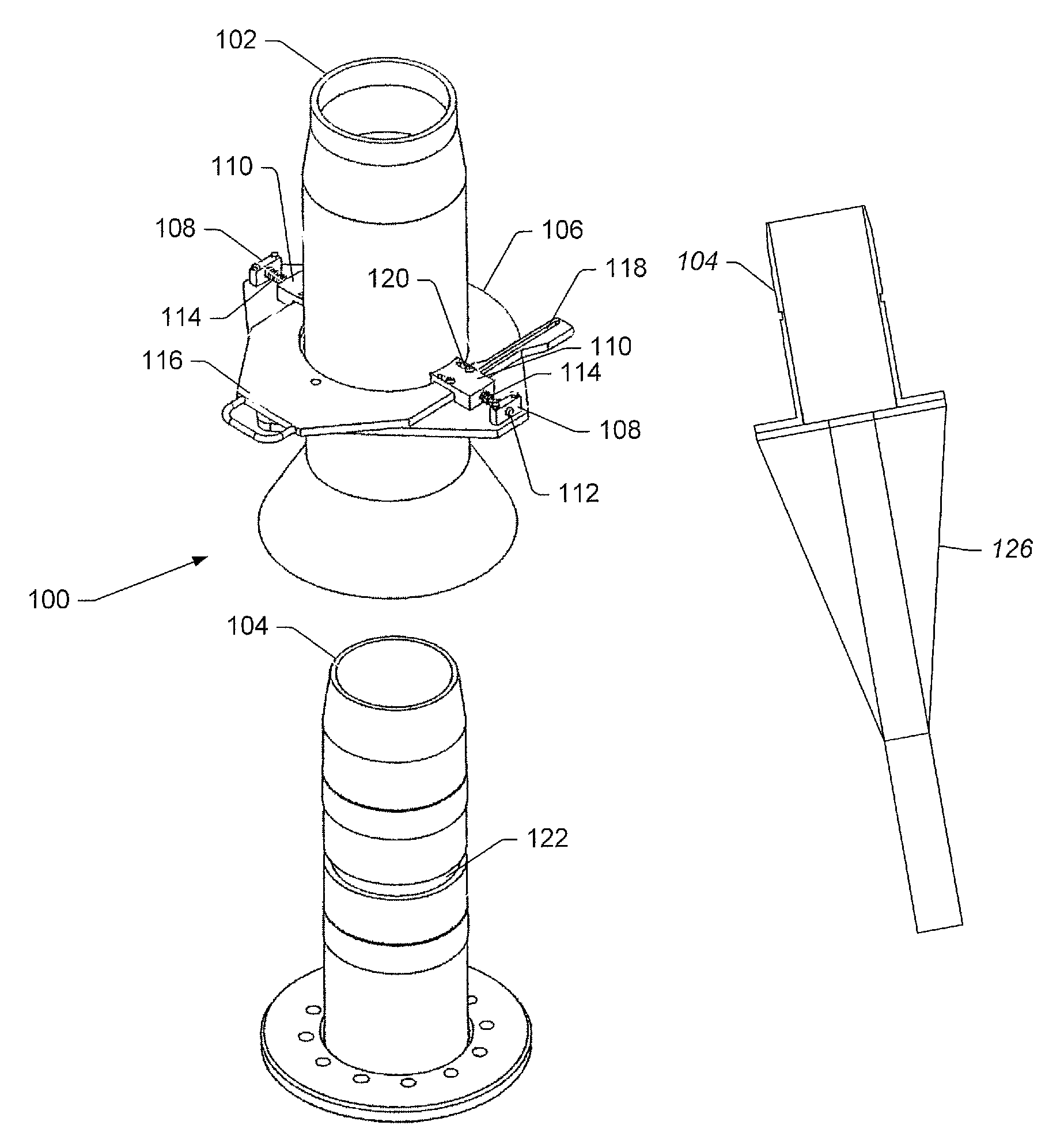

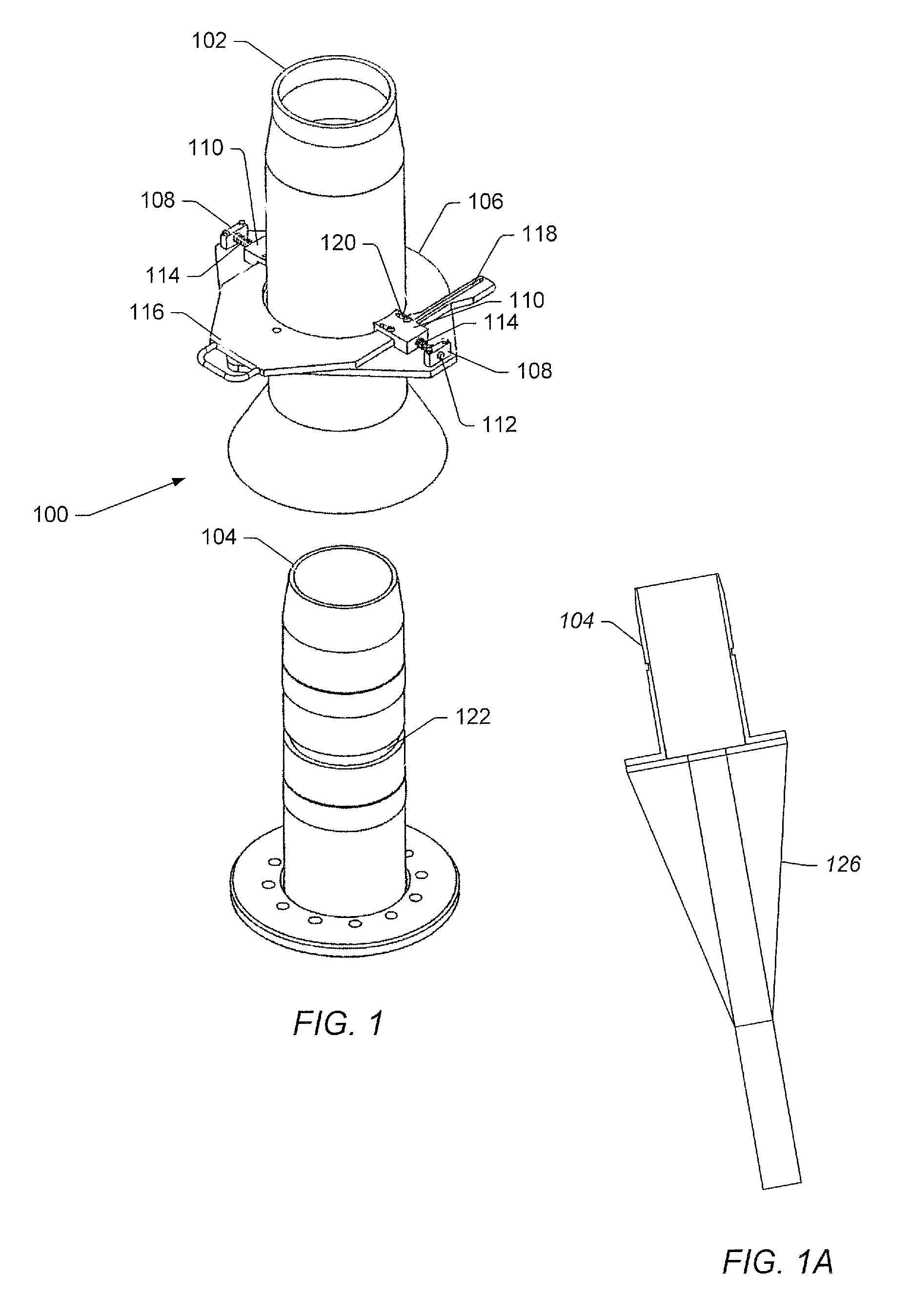

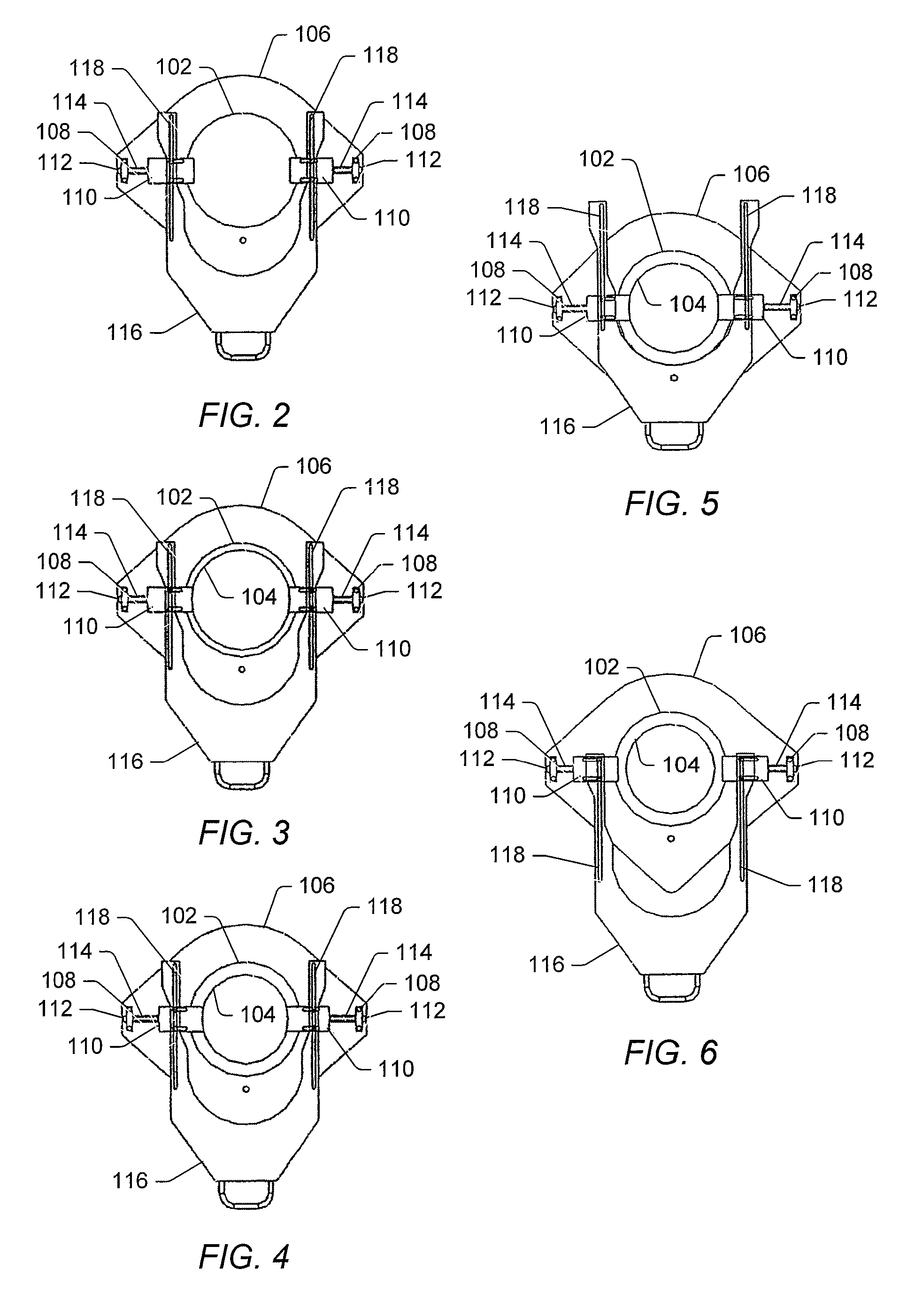

Diverless connector for bend restrictors and/or bend stiffeners

A subsea connector is disclosed. The connector includes a guide funnel assembly that may be coupled to a subsea structure. The guide funnel assembly may receive a shaft. The shaft may be coupled to a bend restrictor / limiter or a bend stiffener. The shaft may be received inside the guide funnel assembly. The shaft may include a recess. A latch assembly may be coupled to the guide funnel assembly. The latch assembly may include one or more dogs and a latch operating device. The dogs may be radially moveable in and out of the interior of the guide funnel assembly. The dogs may be inserted into the recess of the shaft to inhibit longitudinal axial movement between the shaft and the guide funnel assembly. The latch operating device may control the in and out radial movement of the dogs.

Owner:DEEP SEA TECH

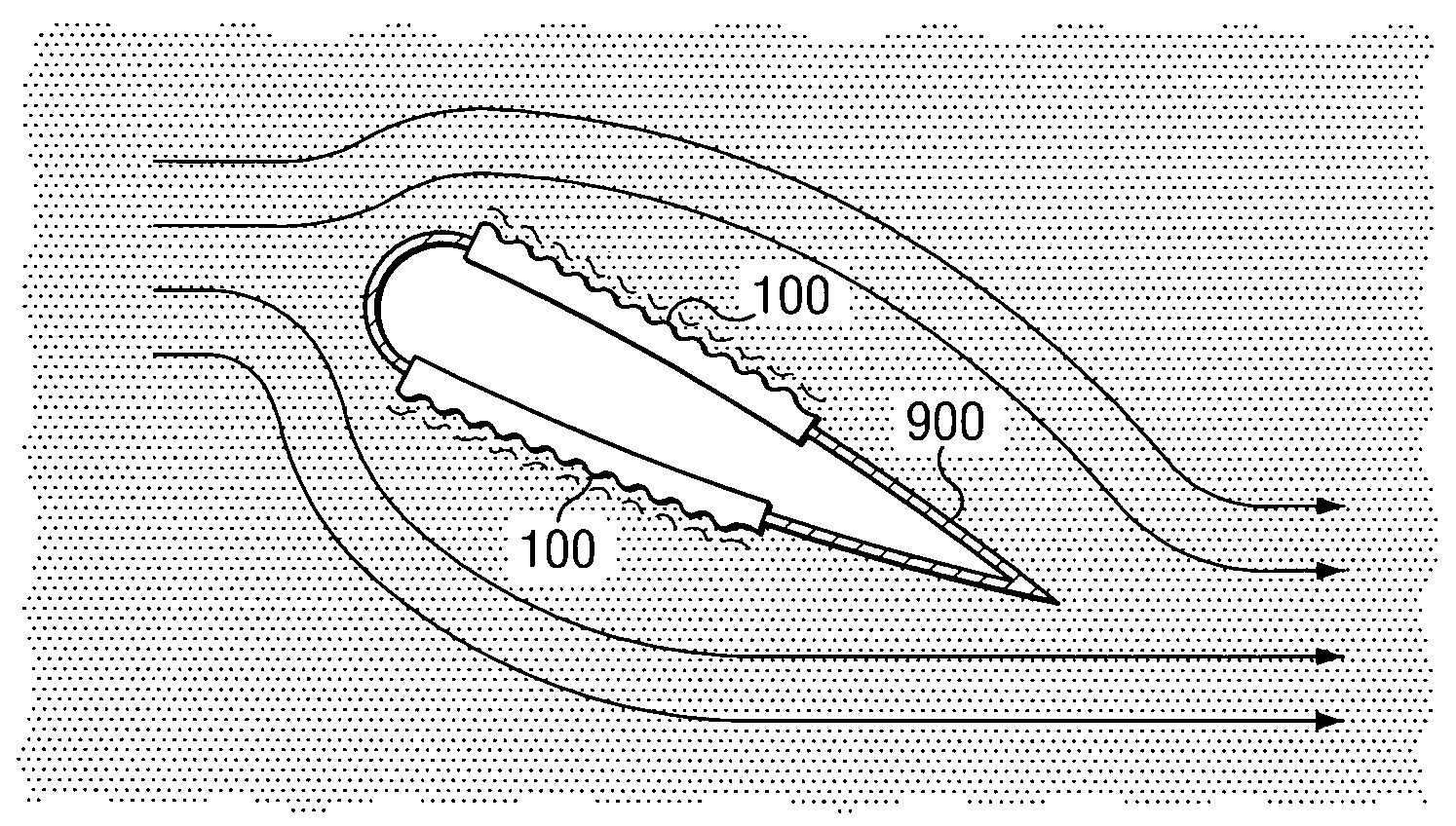

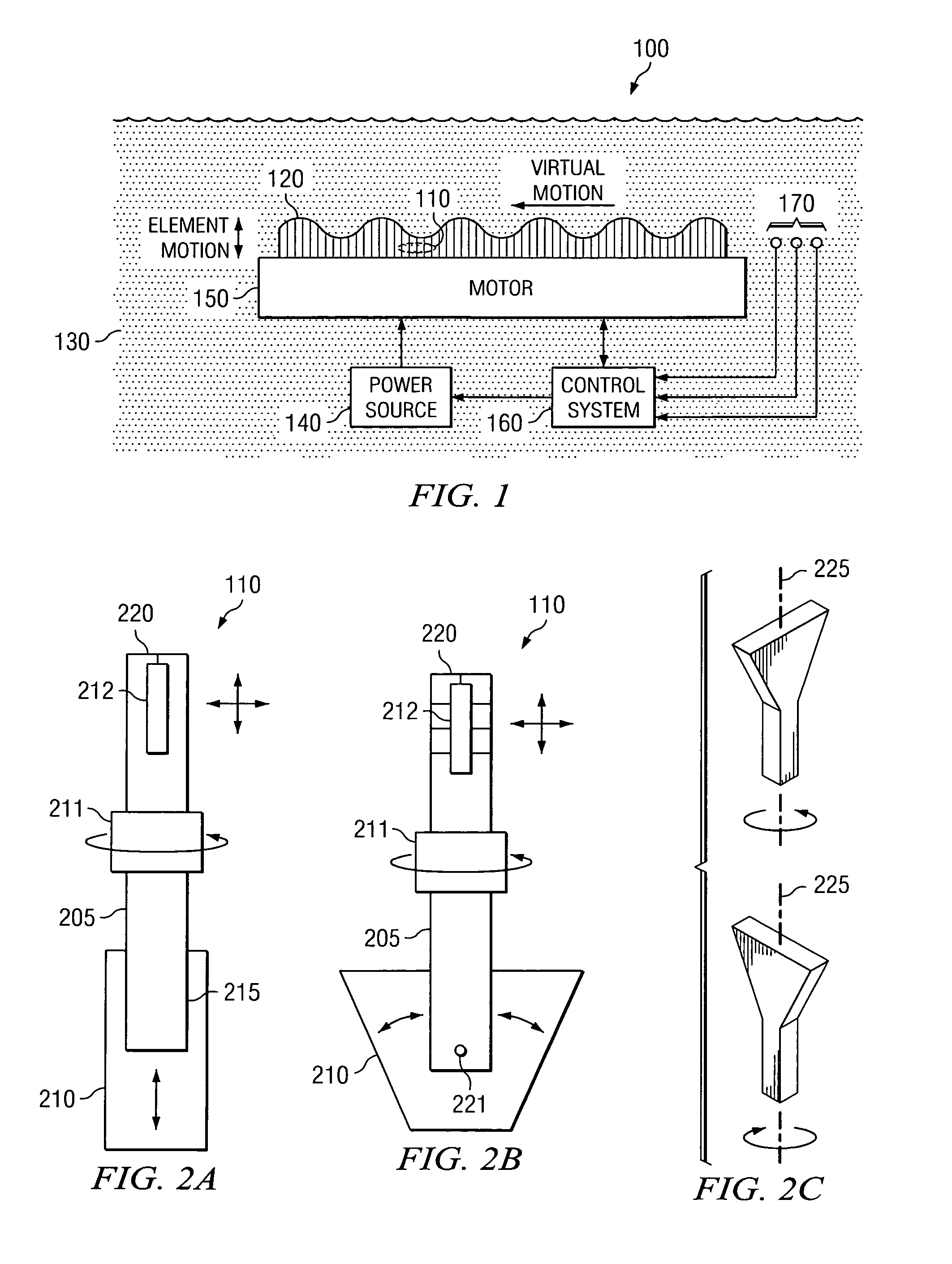

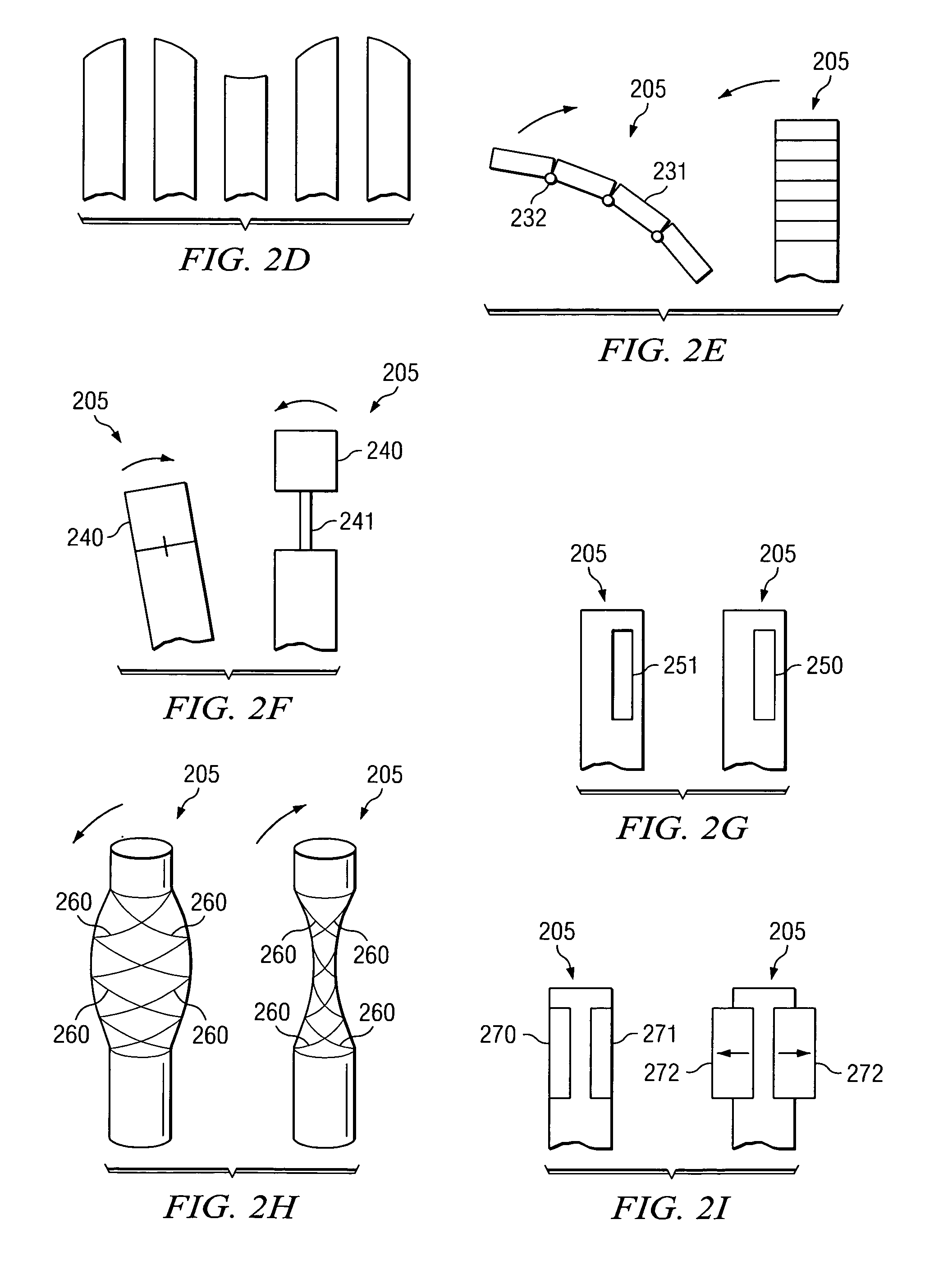

Linear propulsor with radial motion

The invention comprises a scalable, configurable “propulsor” system. A propulsor system is an assembly of individual propulsors that act in concert to form a substantially continuous control surface that undulates in a working fluid. Each propulsor is driven and configured by computer-controlled actuators so that the control surface undulates in various wave forms. Optional actuators that may refine the surface shape include an “orientation” actuator that drives rotation about the propulsor's longitudinal axis, and a “geometry” actuator that controls each propulsor's geometric configuration.

Owner:IBM CORP

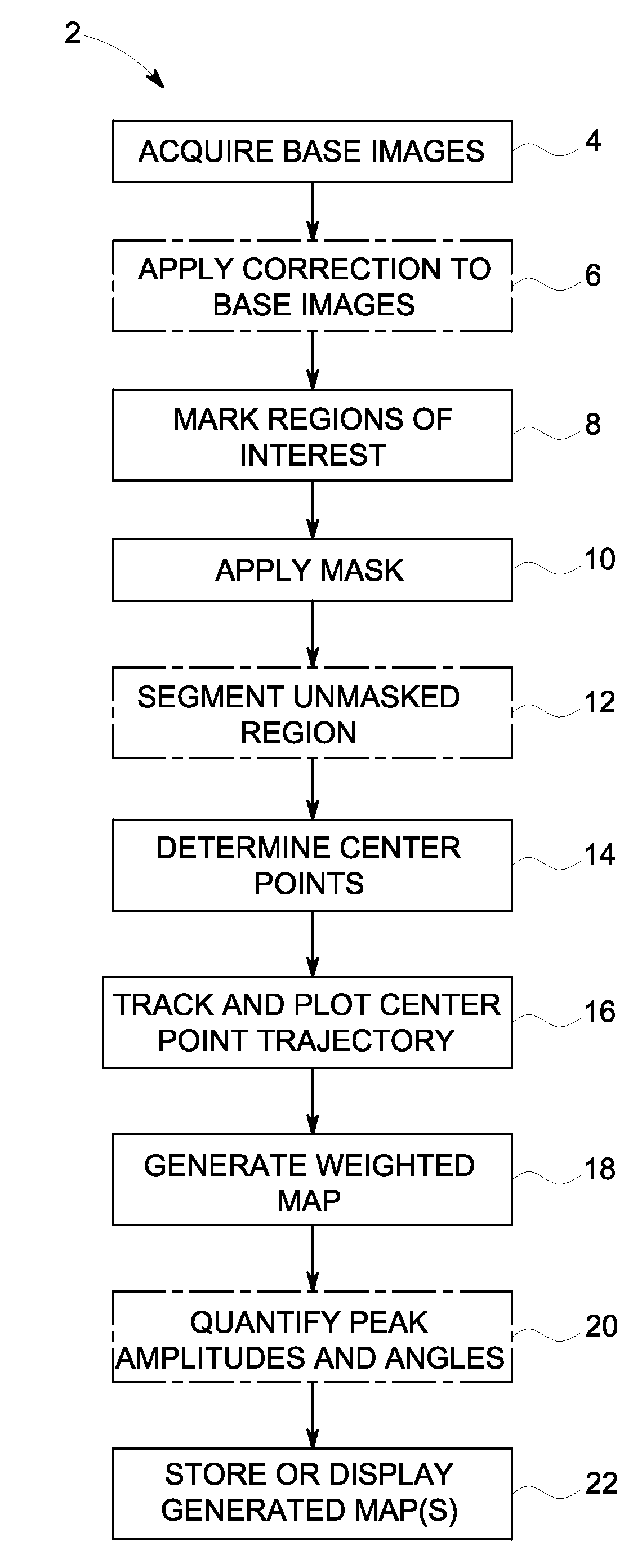

System and method for multi-segment center point trajectory mapping

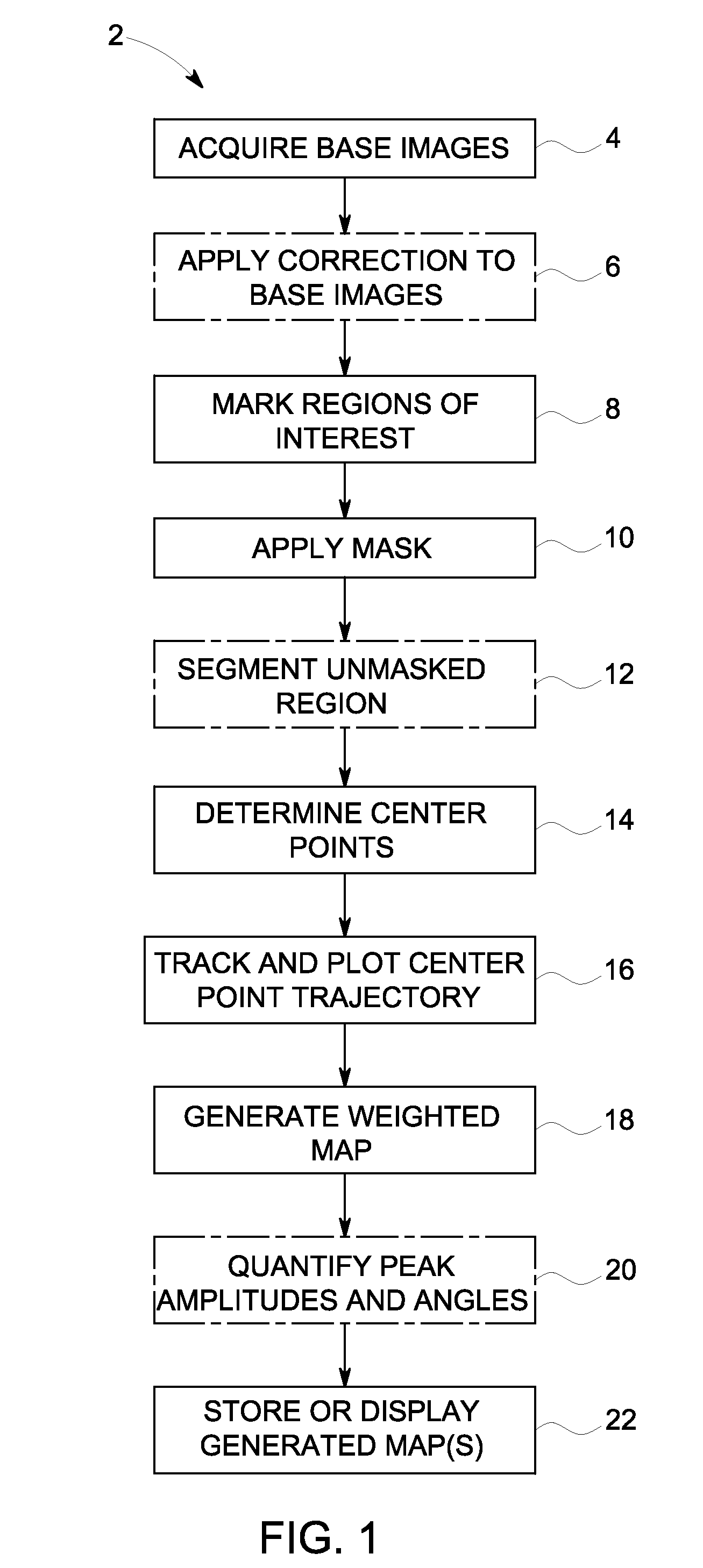

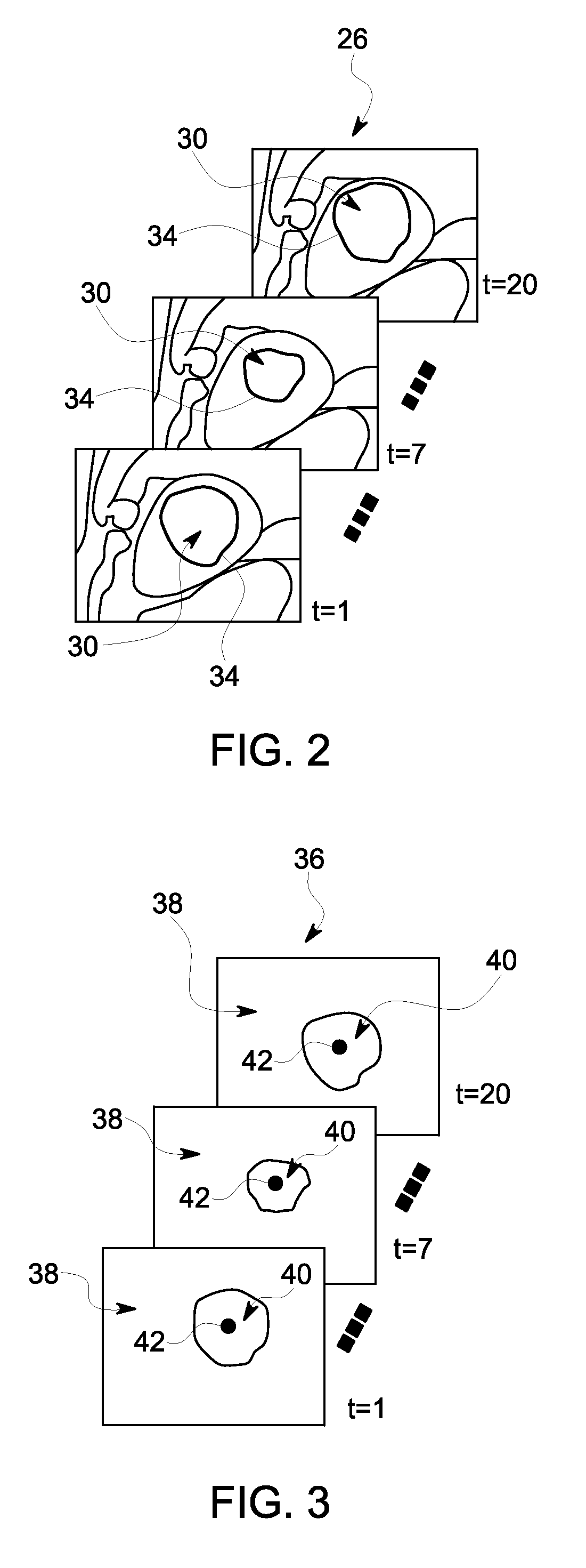

A computer implemented method of mapping of multiple regional center point trajectory movements of cavity walls is provided in which images are acquired and a region-of-interest is identified in each of the images. The region-of-interest is divided into a plurality of distinct regions and a regional center point for each of the regions is located in the images. For each regional center point, a center point trajectory is determined based on variances in position of the center points from each other in the images. The center point trajectory of each regional center point is decomposed into radial and circumferential components so as to isolate radial component of the center point trajectory for each regional center point in each of the images and radial motion versus time curves are displayed for each regional center point based on the determined radial component for each regional center point in each of the images.

Owner:THE HENRY M JACKSON FOUND FOR THE ADVANCEMENT OF MILITARY MEDICINE INC +1

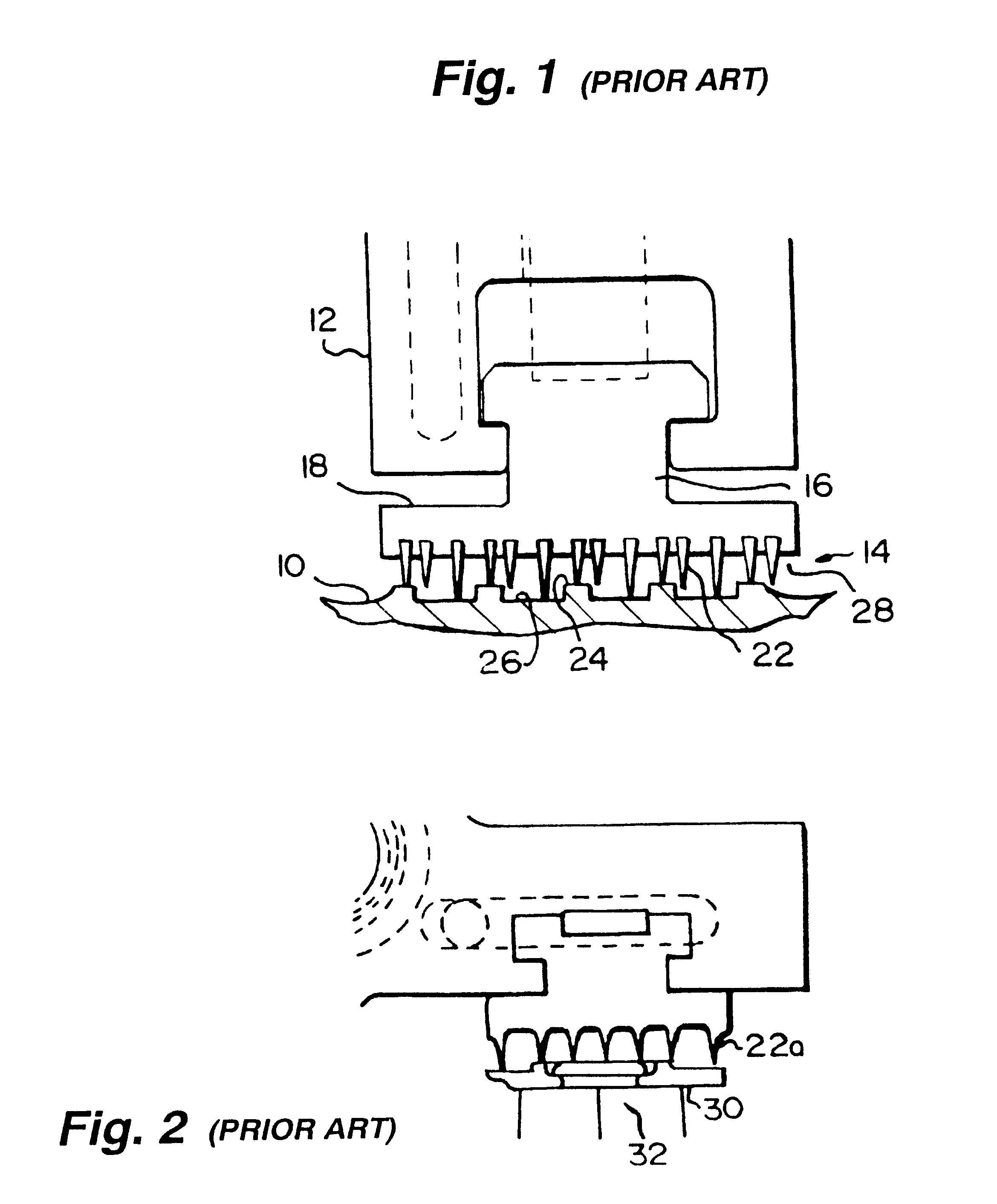

Combined brush seal and labyrinth seal segment for rotary machines

InactiveUS6435513B1Improve sealingImprove turbine efficiencyEngine sealsLeakage preventionRadial motionBristle

A brush seal is comprised of arcuate seal segments having ends cut in a radial direction with bristles "canted" at an approximate 45.degree. angle relative to radii of the segments, leaving triangular regions adjacent one end of each segment devoid of bristles at the segment interfaces. The brush seals are retrofit into conventional labyrinth seals with the backing plate for the bristles comprising a labyrinth tooth profile extending fully 360.degree. about the seal, including those areas where bristles are not present. The sealing capacity is not substantially degraded, while affording significant sealing improvements over conventional labyrinth seals. Additionally, when retrofit into labyrinth seals with radial movement, the individual labyrinth seal segments are free to move radially independently of one another during transients.

Owner:GENERAL ELECTRIC CO

Belt-driven robot having extended Z-axis motion

A robot has a robot arm, a support structure, and a movable platform. The platform includes a cantilevered member coupled to a guide of the support structure such that motion of the platform is directed along a first direction. The robot further includes first and second timing belts having portions that extend along the first direction and that are disposed on opposite sides of the cantilevered member, and first and second shafts movable with the movable platform. The shafts are coupled to the respective timing belts, to the robot arm such that rotation of the first shaft imparts angular motion to the robot arm and rotation of the second shaft imparts radial motion. The robot also includes a third timing belt to which the platform is coupled and by which it is moved. Motors are provided that impart movement to the timing belts.

Owner:GENMARK AUTOMATION

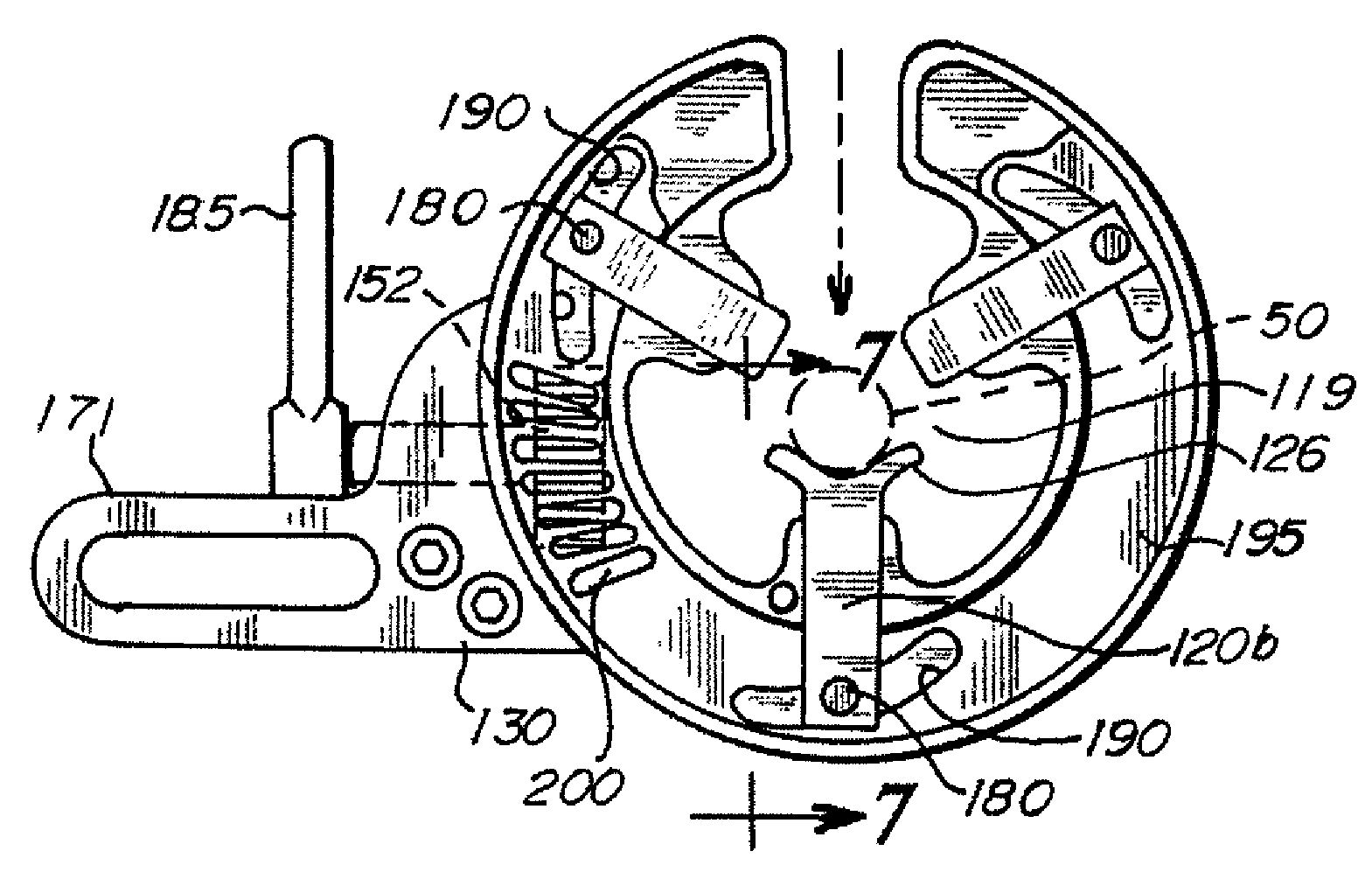

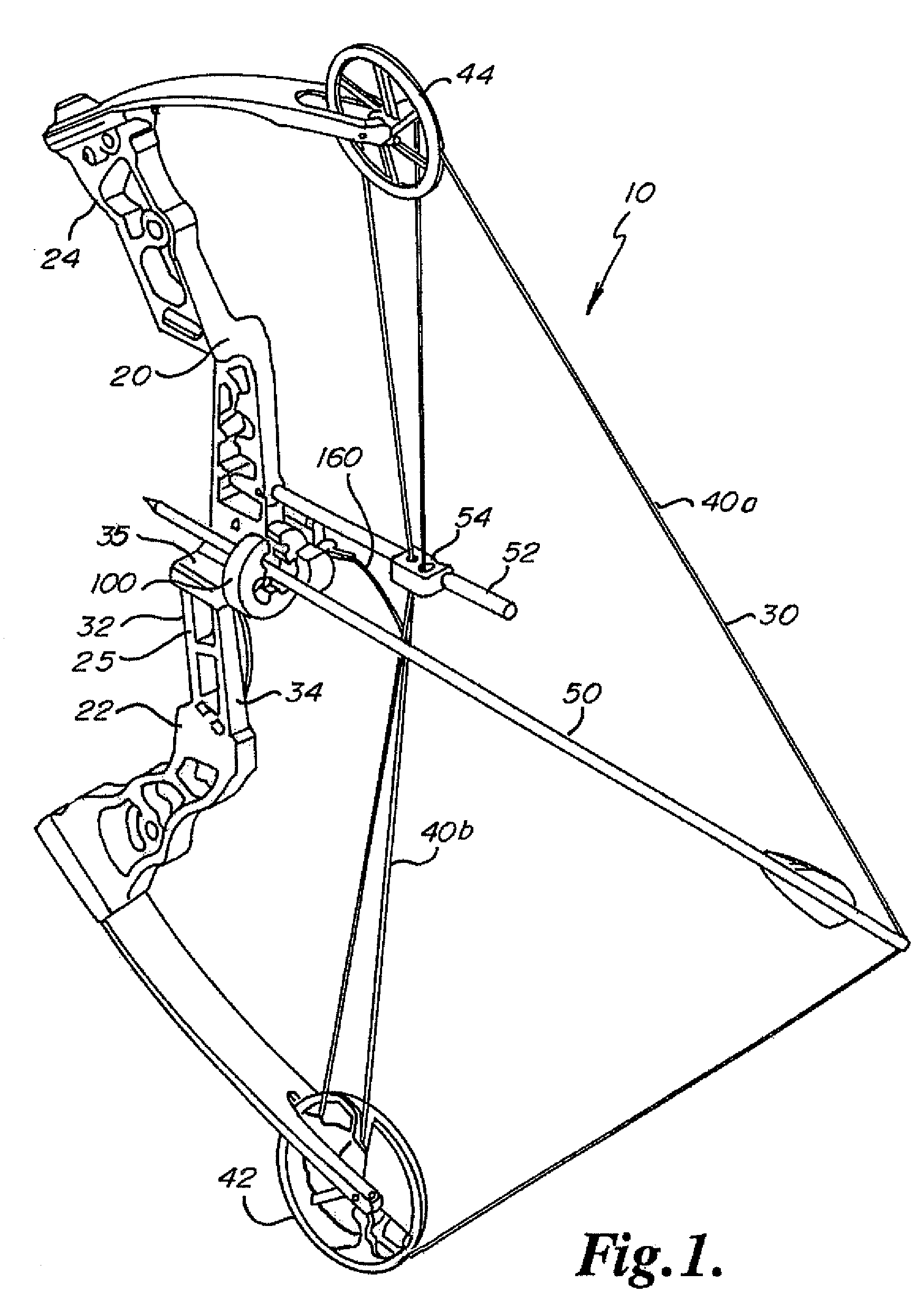

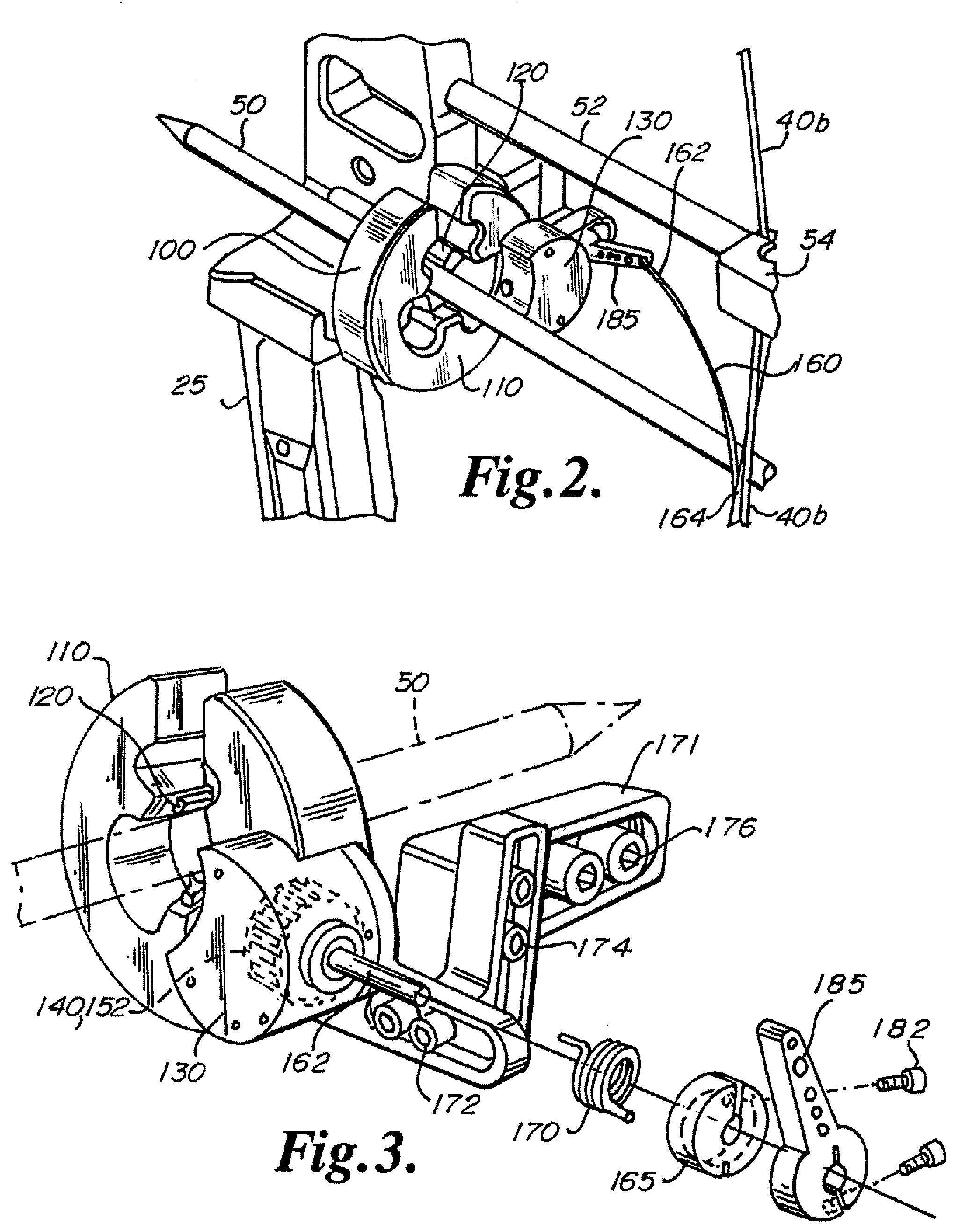

Retracting containment arrow rest

An arrow rest that contains the arrow shaft before, during, and after the shot. To give the archer a precise, accurate shot, pull-away support fingers 120 degrees apart move in a self centering radial motion towards the center of the arrow shaft when the archer draws the bow to full draw and simultaneously pull away from the arrow shaft in a simultaneous radial motion to give complete clearance to the arrow shaft and its vanes or fletching once released from full draw.

Owner:ATHENS OUTDOORS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com