Patents

Literature

35results about How to "Increase the number of lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

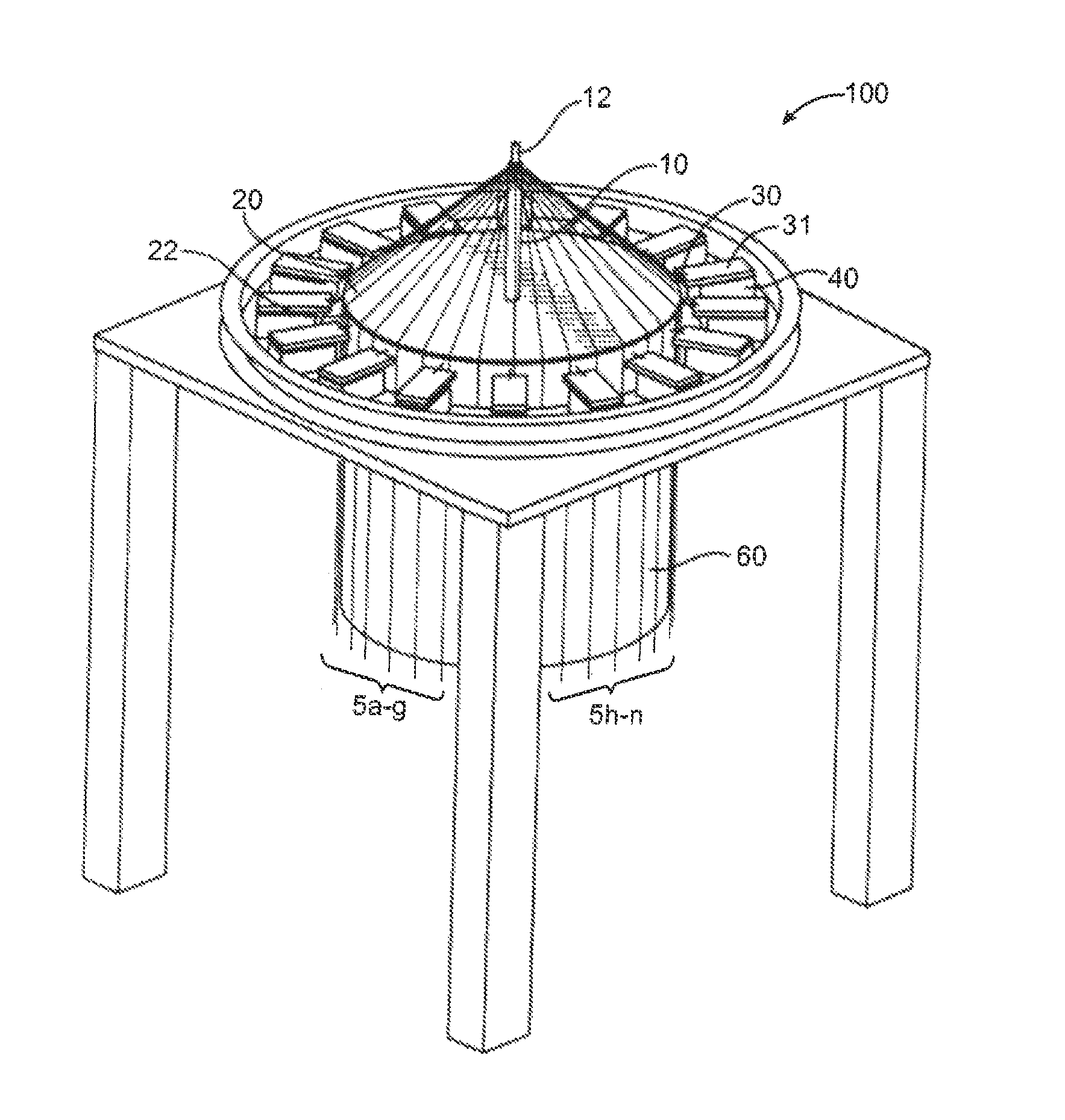

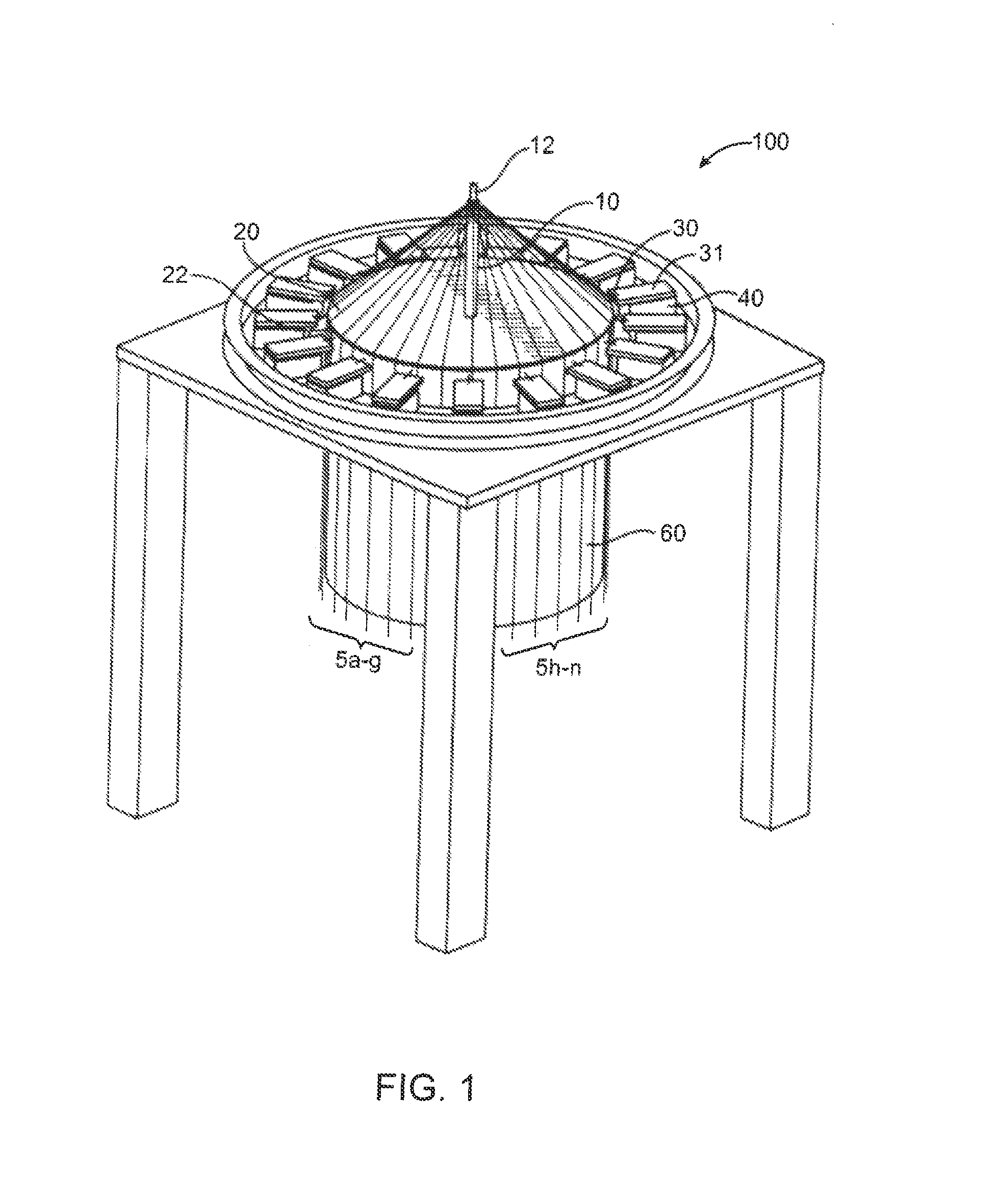

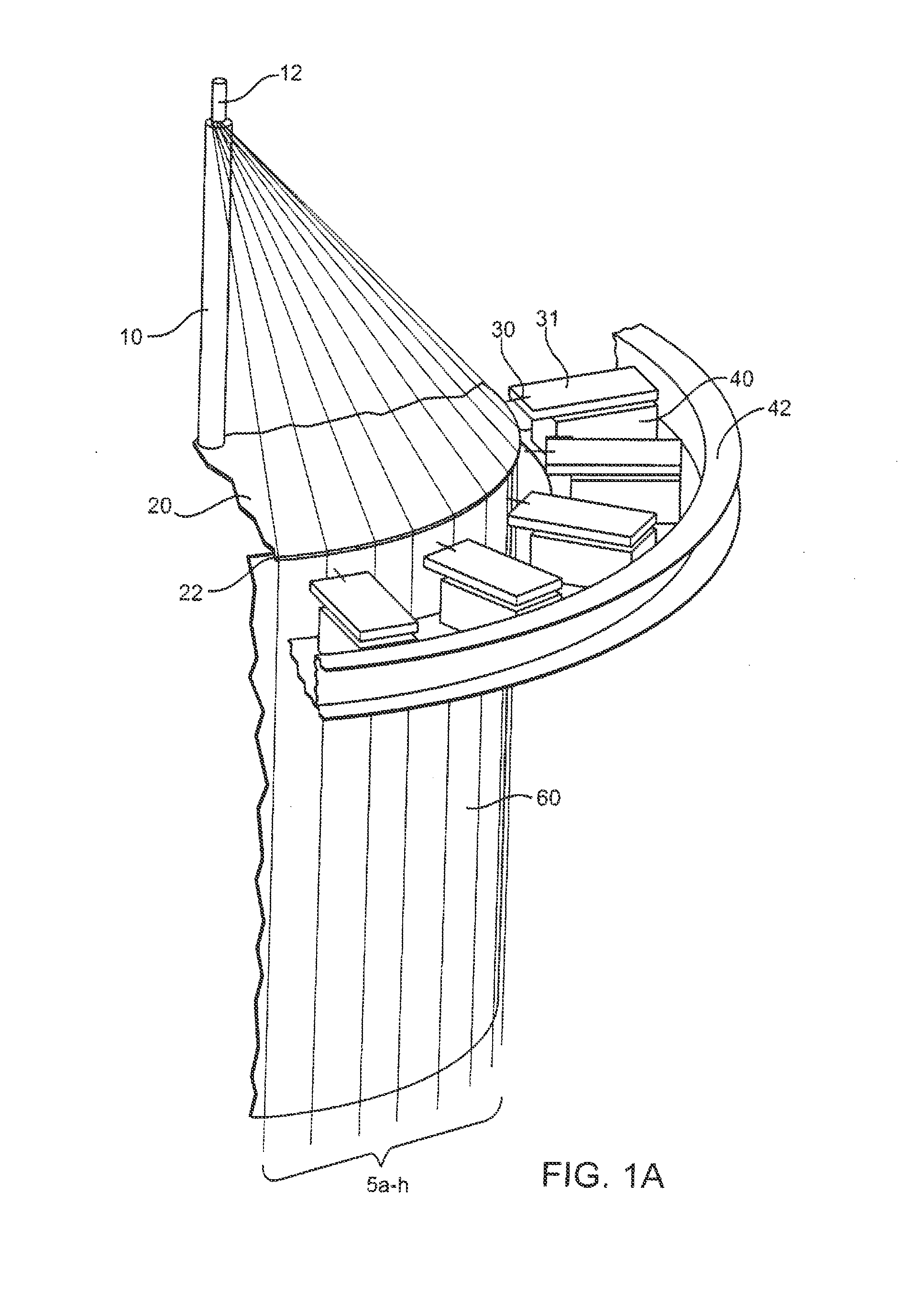

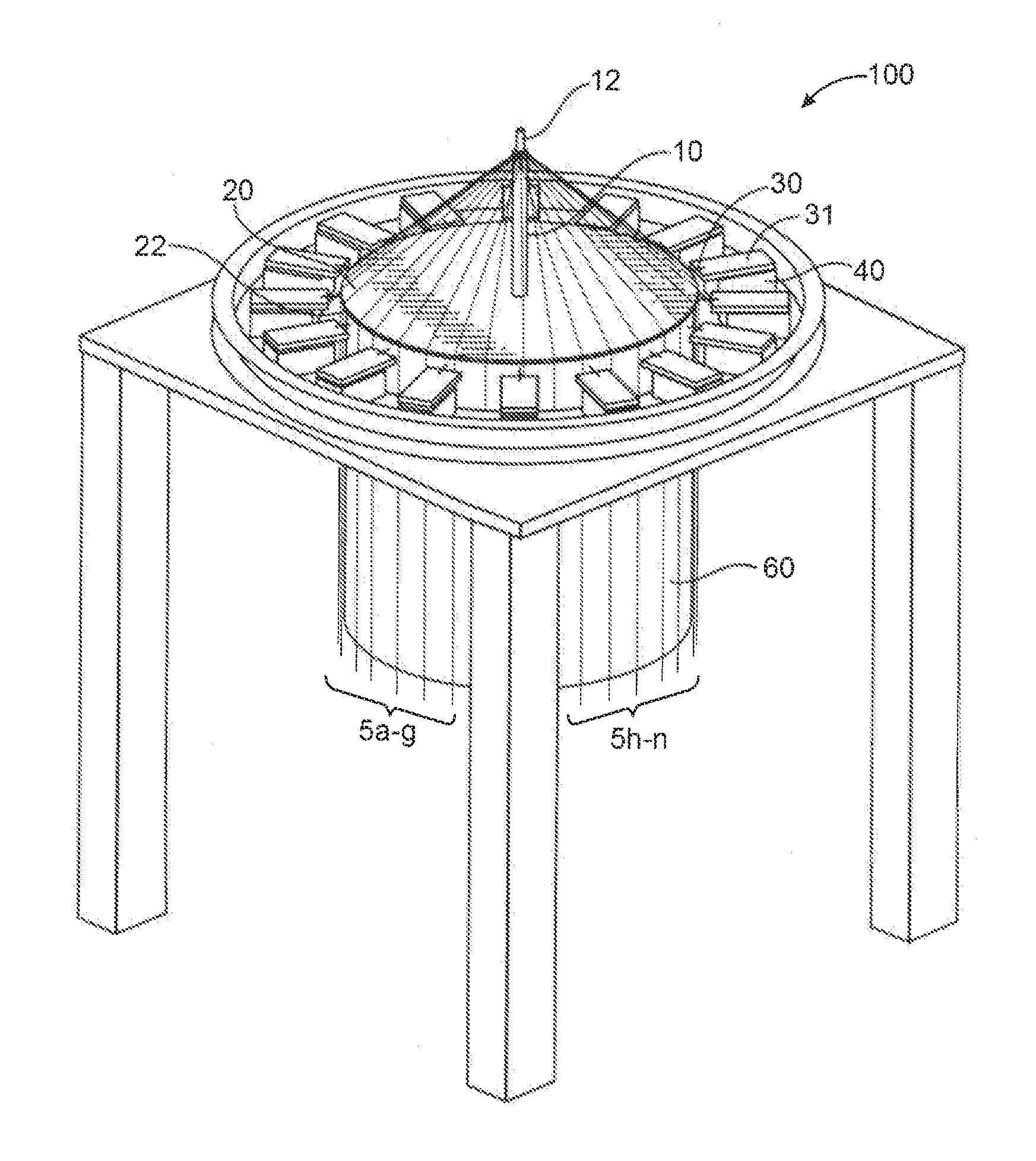

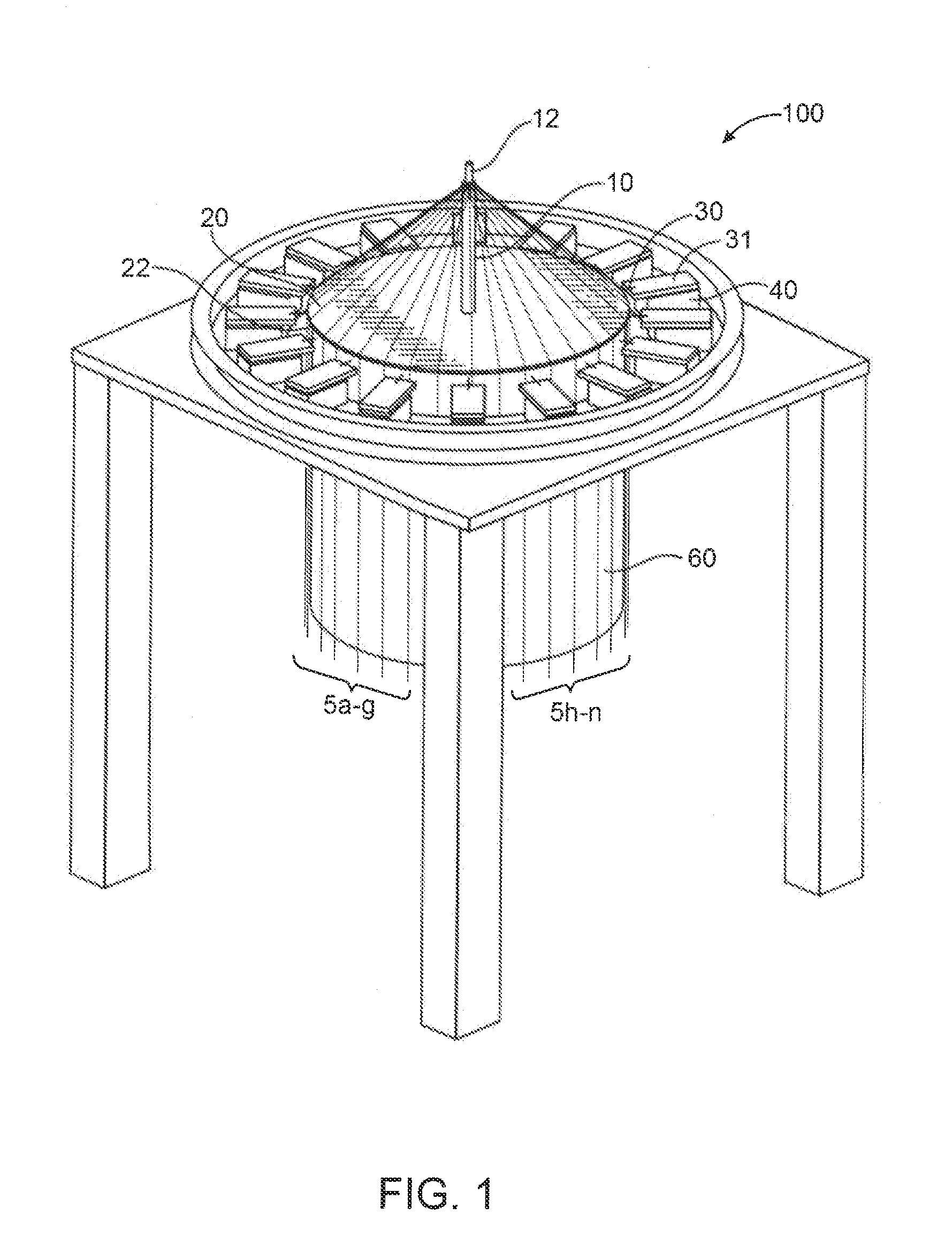

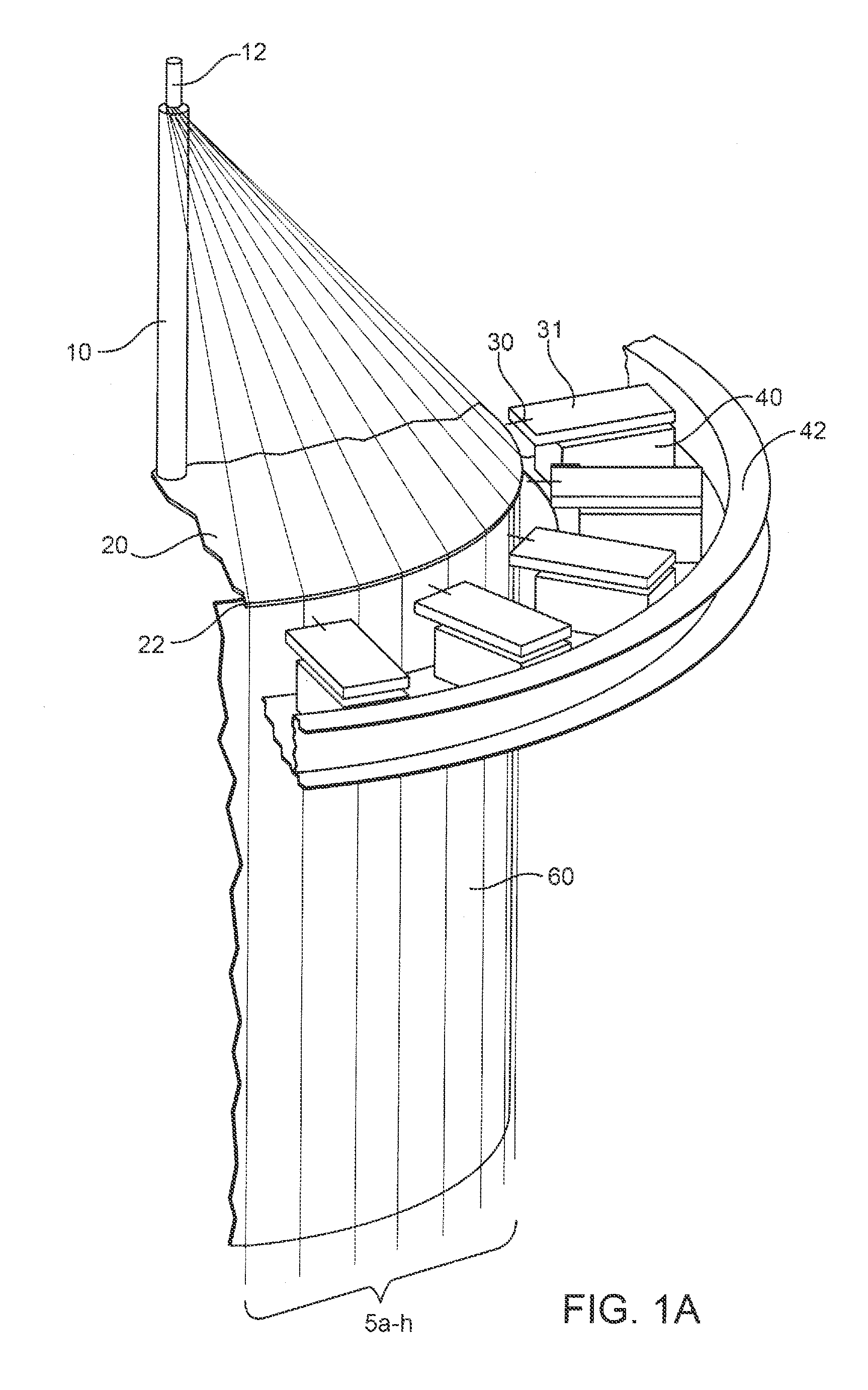

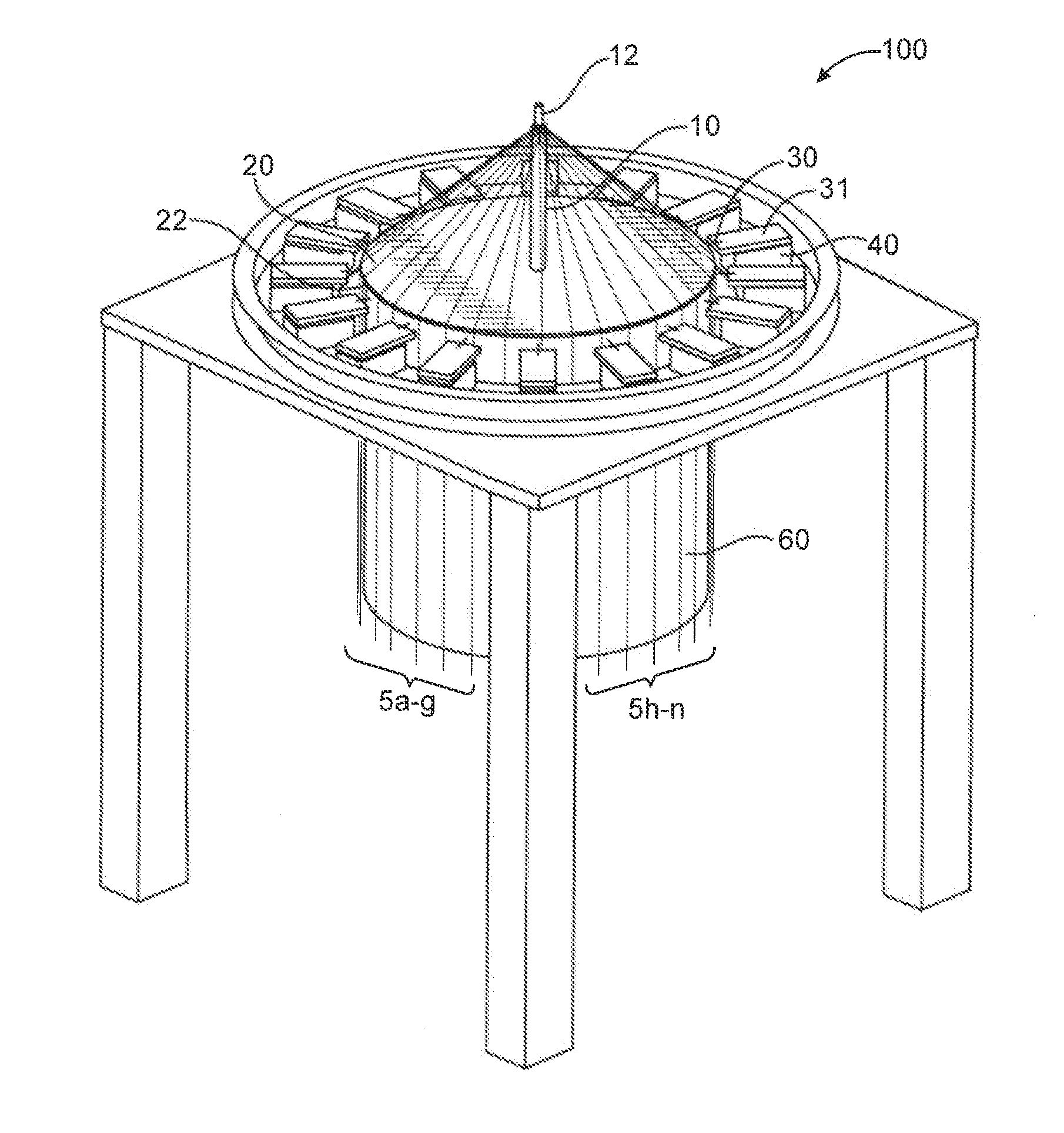

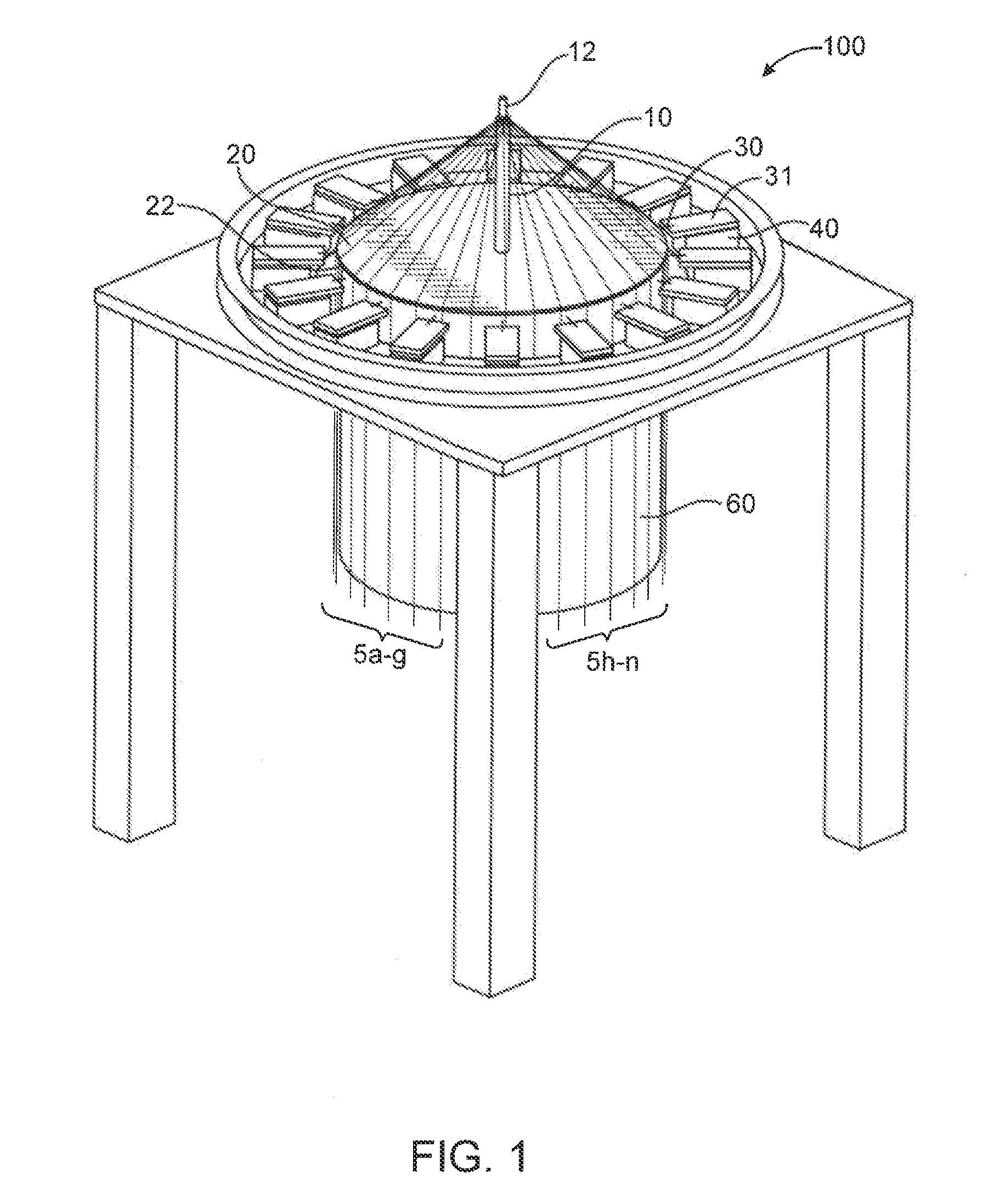

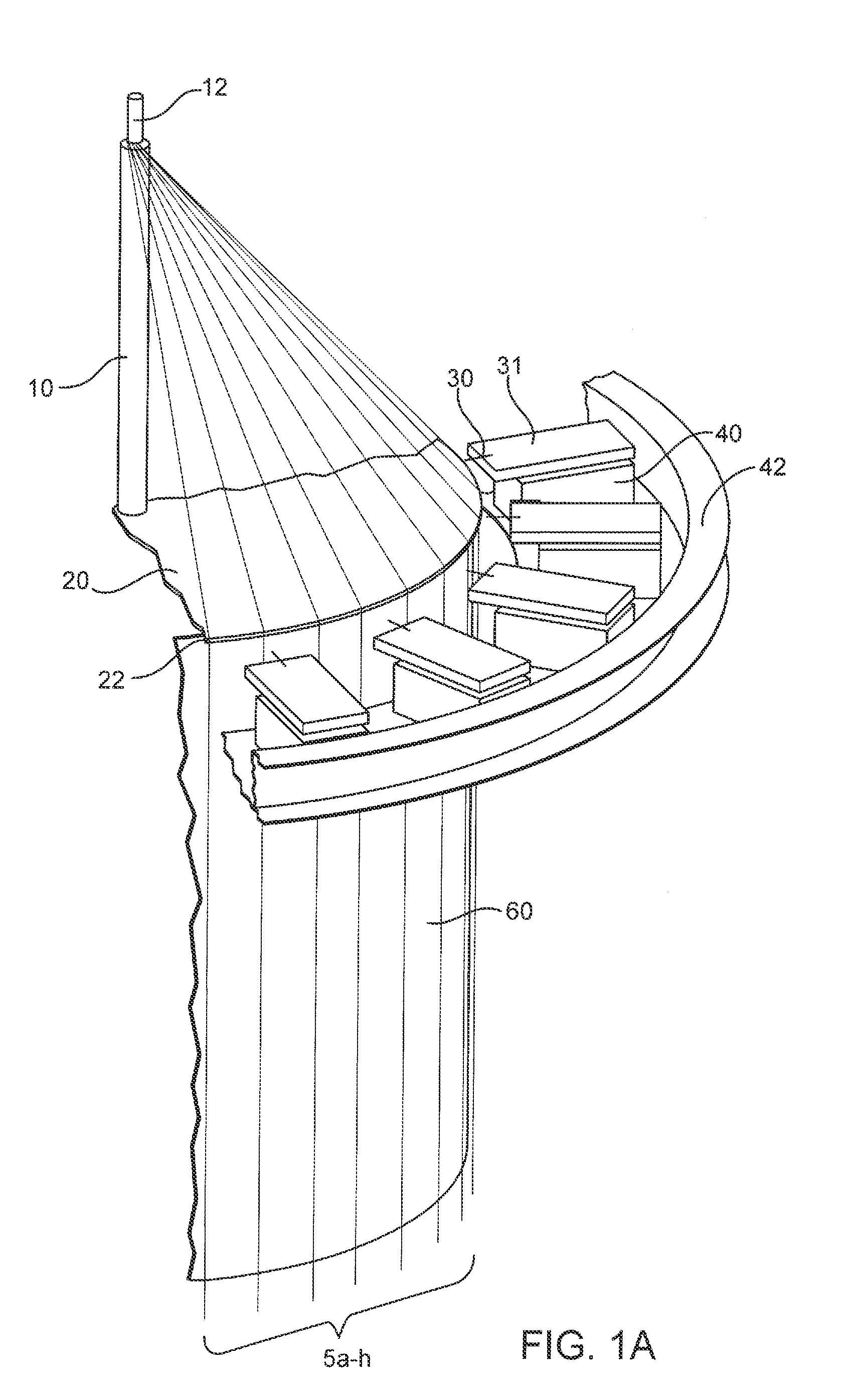

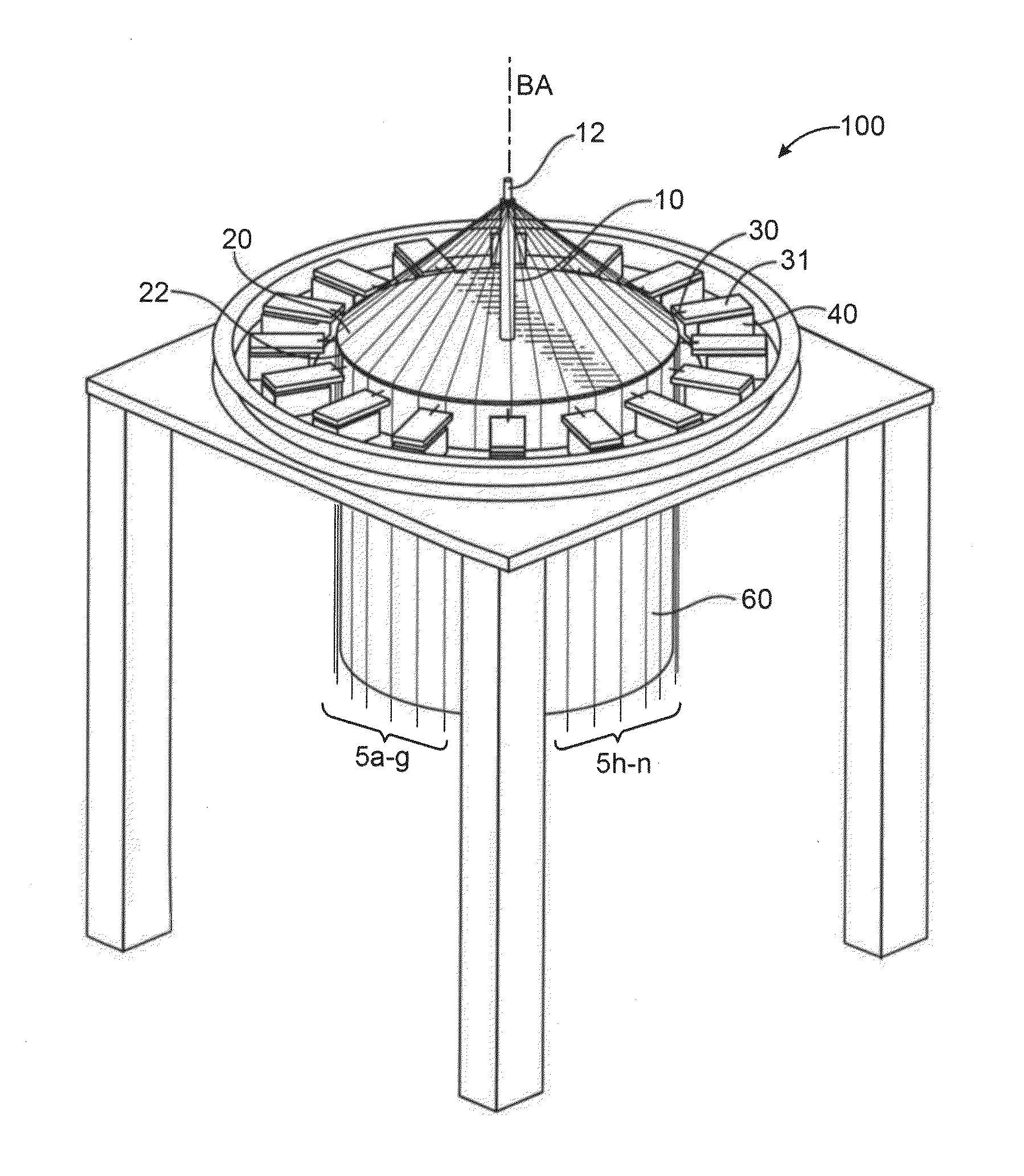

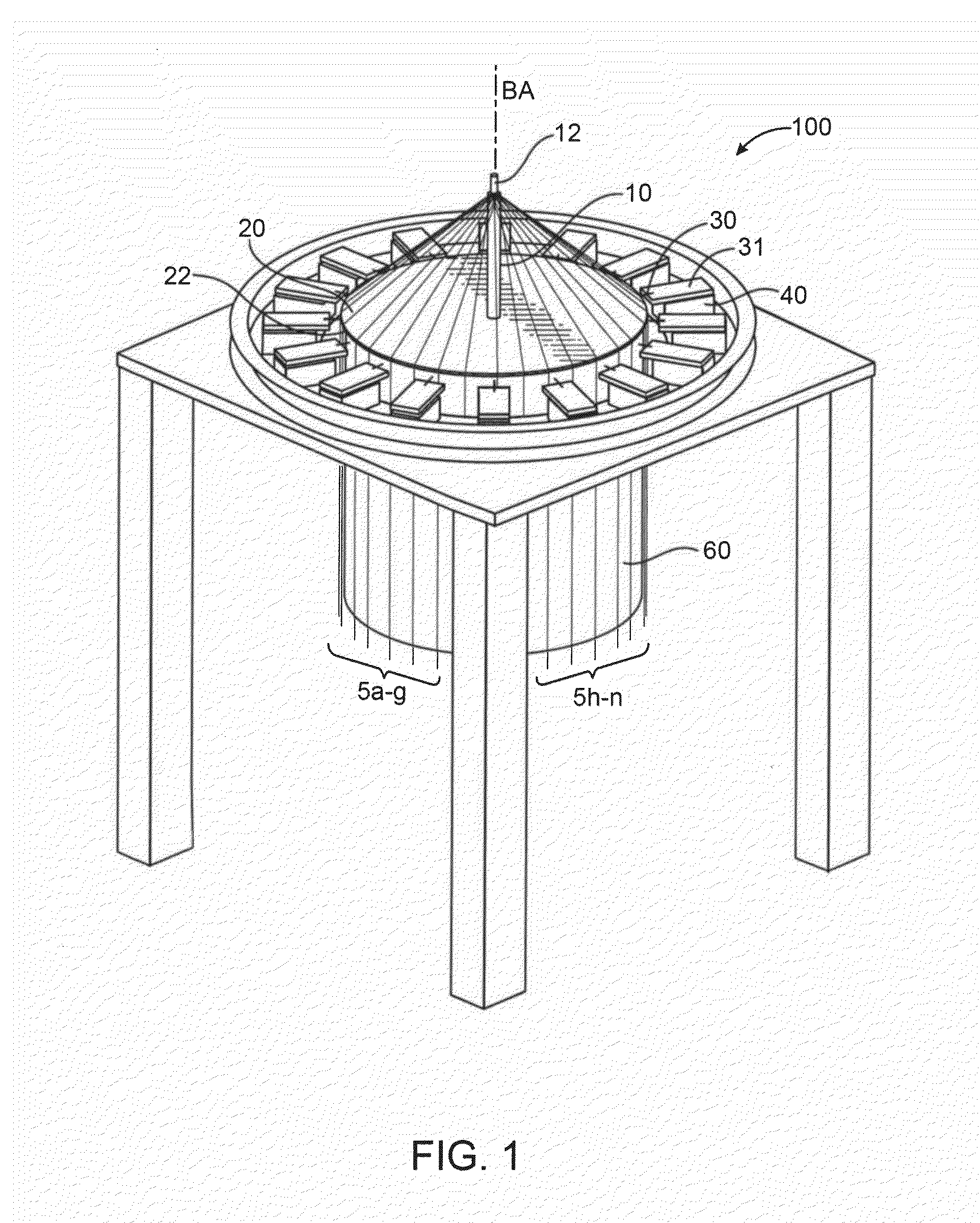

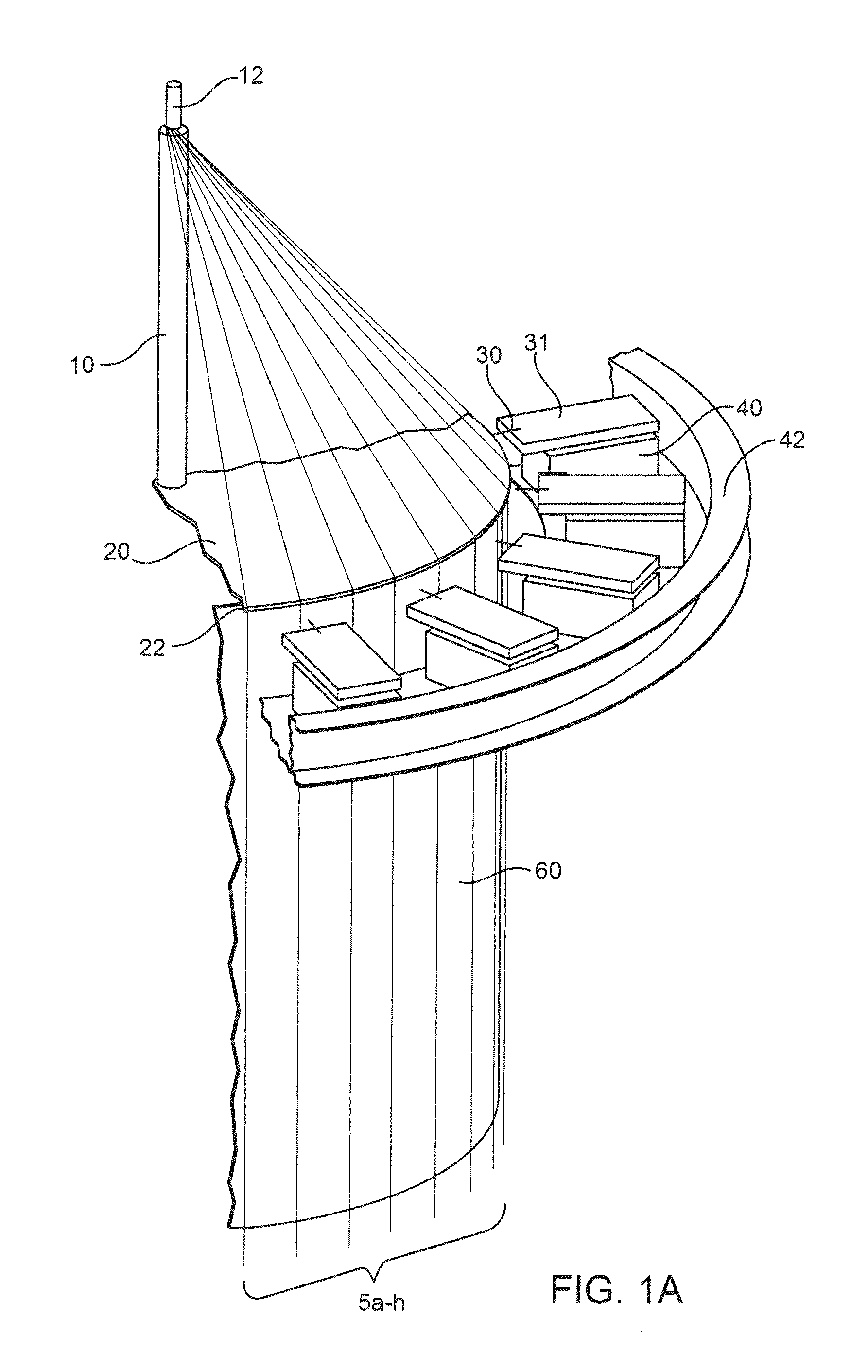

Braiding mechanism and methods of use

A device and method for forming a tubular braid comprising a plurality of filaments. The braiding machine comprises a disc with a mandrel extending from the center in a perpendicular direction and a plurality of catch mechanisms arranged circumferentially around the edge of the disc. A plurality of filaments are temporarily affixed to the mandrel, each filament extending from the mandrel toward the edge of the disc and engaging the edge of the disc at a discrete point of engagement The plurality of catch mechanisms are attached to actuators adapted to move the catch mechanisms in a generally radial direction relative to the edge of the disc to allow the catch mechanism to engage a subset of the filaments and move the engaged filaments beyond the circumferential edge of the disc.

Owner:MICROVENTION INC

Braiding mechanism and methods of use

Devices and methods for forming a tubular braid comprising a plurality of filaments. The braiding machine includes a circular array of filament guiding members defining a plane; a mandrel defining an axis and adapted to carry one or more filaments extending from the mandrel to the circular array; a plurality of filaments extending from the mandrel in a radial array; a plurality of actuator mechanisms disposed operably about the disc; and a rotating mechanism adapted to rotate one or more filaments. The actuator mechanisms and rotating mechanism are configured to move each of the one or more filaments about the mandrel axis in a path comprising a series of arcs and radial movements. The braiding machine may alternately first and second annular members, a mandrel, first and second plurality of tubular wire guides, and a plurality of wires extending from the mandrel.

Owner:MICROVENTION INC

Braiding mechanism and methods of use

ActiveUS20130239790A1Increase the number of linesSuture equipmentsStentsEngineeringStructural engineering

Devices and methods for forming a tubular braid comprising a plurality of filaments. The method for braiding includes the step of loading a plurality of filaments on a mandrel and extending the filaments radially from the mandrel, the plurality of filaments have a first subset and a second subset. Tension is applied to the plurality of filaments using a weight attached to each filament. The first subset of the plurality of filaments is engaged, moved circumferentially relative to the second subset, and then released. The second subset of filaments is then engaged and moved circumferentially relative to the first subset of filaments, such that a tubular braid of filaments is formed.

Owner:MICROVENTION INC

Braiding mechanism and methods of use

A device and method for forming a tubular braid comprising a plurality of filaments. The braiding machine comprises a disc with a mandrel extending from the center in a perpendicular direction and a plurality of catch mechanisms arranged circumferentially around the edge of the disc. A plurality of filaments are temporarily affixed to the mandrel, each filament extending from the mandrel toward the edge of the disc and engaging the edge of the disc at a discrete point of engagement. The plurality of catch mechanisms are attached to actuators adapted to move the catch mechanisms in a generally radial direction relative to the edge of the disc to allow the catch mechanism to engage a subset of the filaments and move the engaged filaments beyond the circumferential edge of the disc.

Owner:MICROVENTION INC

Method for cultivating spring corn in hilly region

The invention discloses a method for cultivating spring corn in hilly region wherein breeds, seeding date, density, mulch film blanketing and mulch film nursery sock grow transplanting, fertilizer application are considered for increasing maize production, experimental investigation and demonstration application are conducted to spread the fine breeds suitable for the Wuling Mountains which have the advantages of late ripening, medium late ripening, big ear, medium-sized to large ear.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

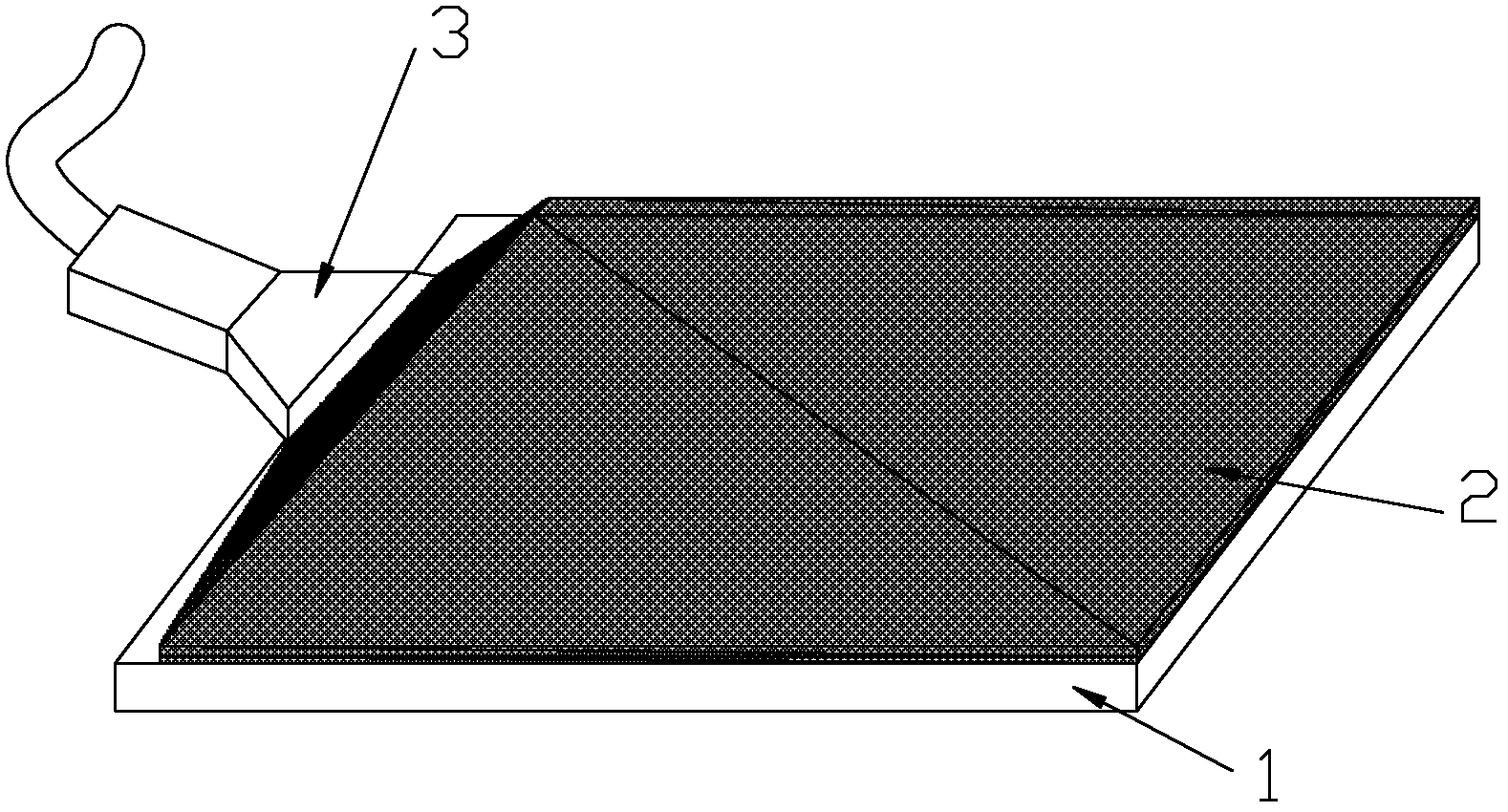

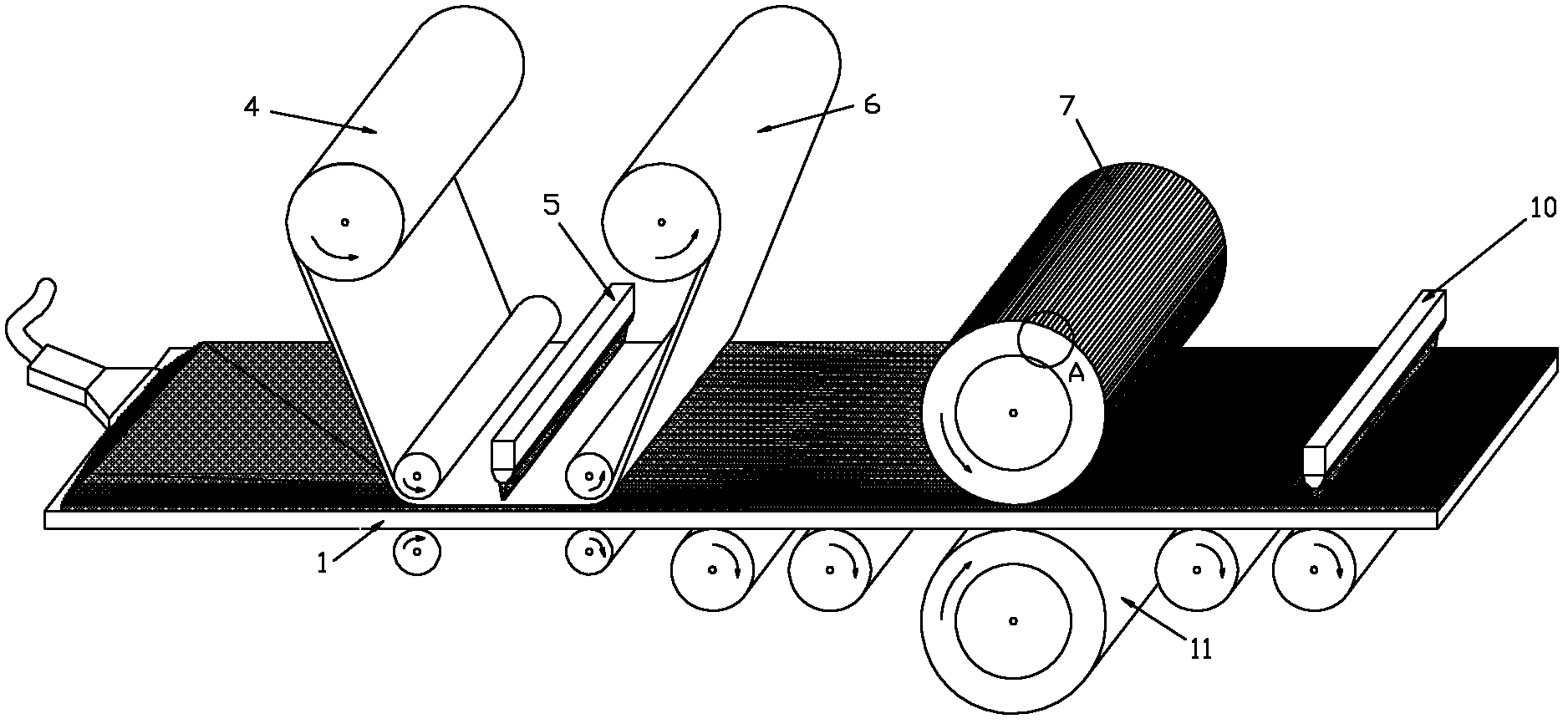

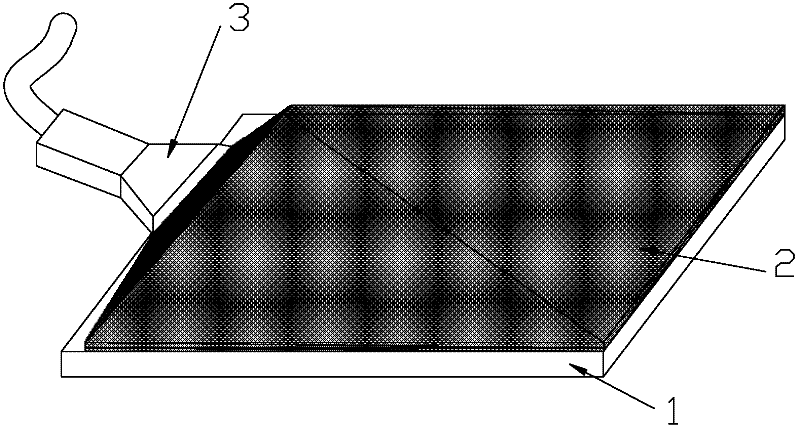

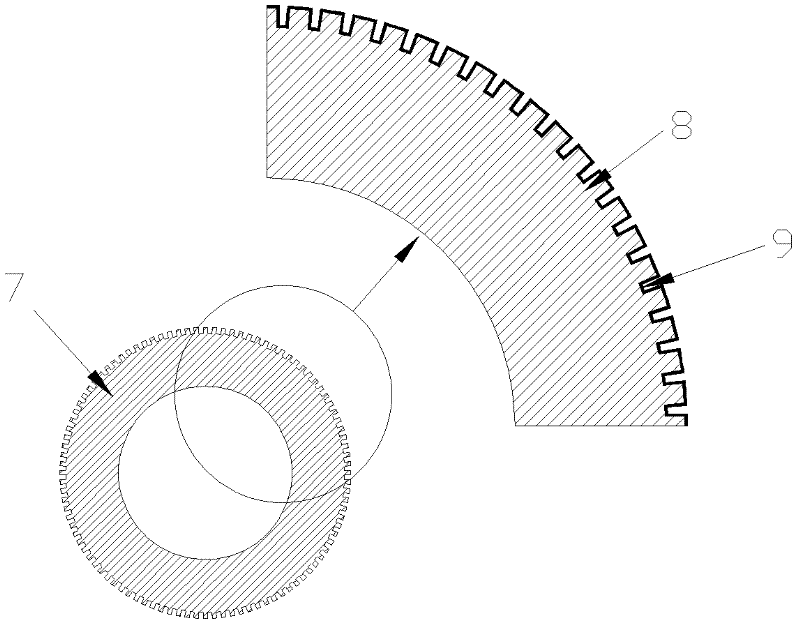

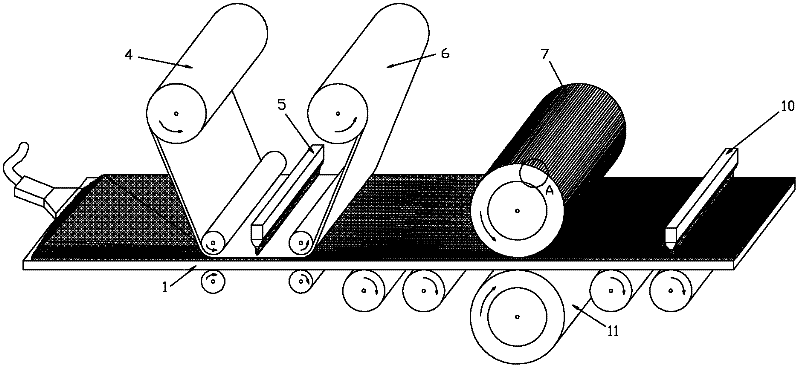

Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

ActiveCN102193310ALow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

The invention relates to a method for forming a grating for machine tool measurement in a two-step solidifying rolling pressing forming manner, which comprises the following steps: 1) coating an ultraviolet light solidifying adhesive layer on a grating blank substrate; 2) manufacturing a rolling mould having a prototype grating structure on the surface of a cylindrical mould, making an alignment mark, and polishing and performing low surface energy treatment on the surface of the rolling mould; 3) coating a flexible film on the adhesive layer on the grating blank substrate, carrying out primary exposure and peeling the film; 4) comparing the alignment mark on the grating blank substrate with an acquired alignment mark image on the surface of the rolling mould, adjusting and calibrating; 5) gluing the rolling mould with the grating, applying a pressing force, and compounding the prototype grating structure on the surface of rolling mould on the adhesive layer on the surface of the substrate; 6) carrying out exposure on the compounded ultraviolet light solidifying adhesive layer; and 7) collecting and packaging the grating. According to the method, the required pressing force is small, and thus, the substrate deformation and stress concentration are avoided. The method has high production efficiency and can be used for realizing the mass production of the grating for large-area and altitude machine tool measurement.

Owner:XI AN JIAOTONG UNIV

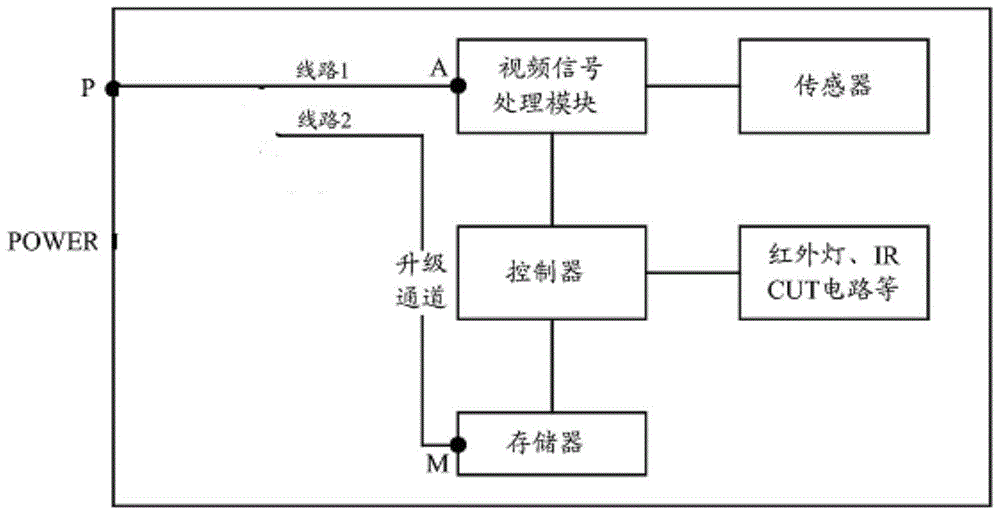

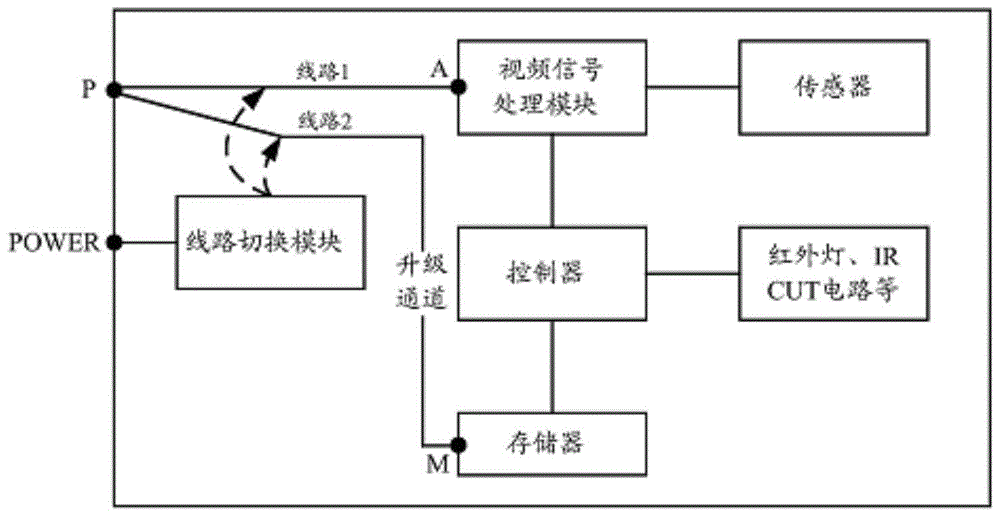

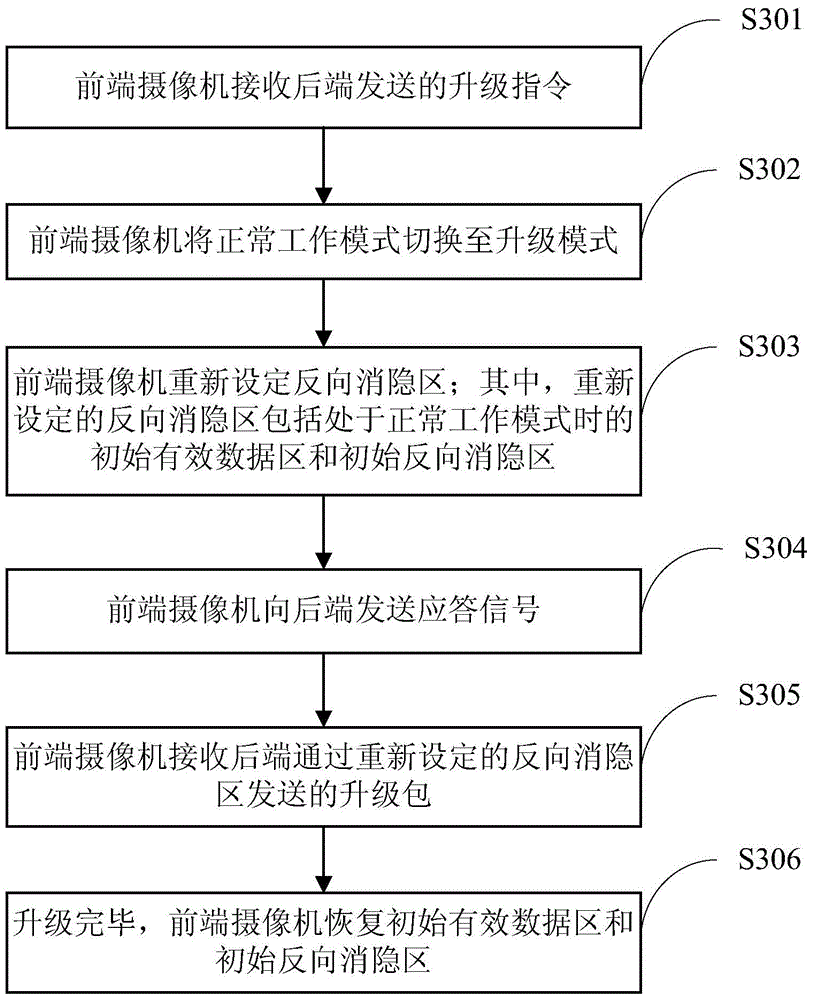

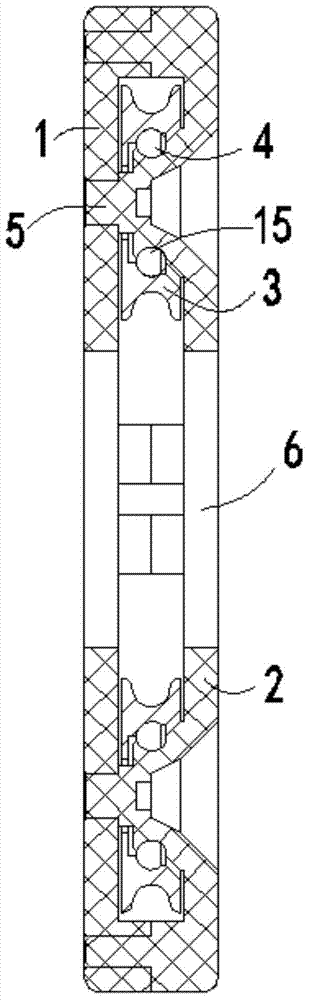

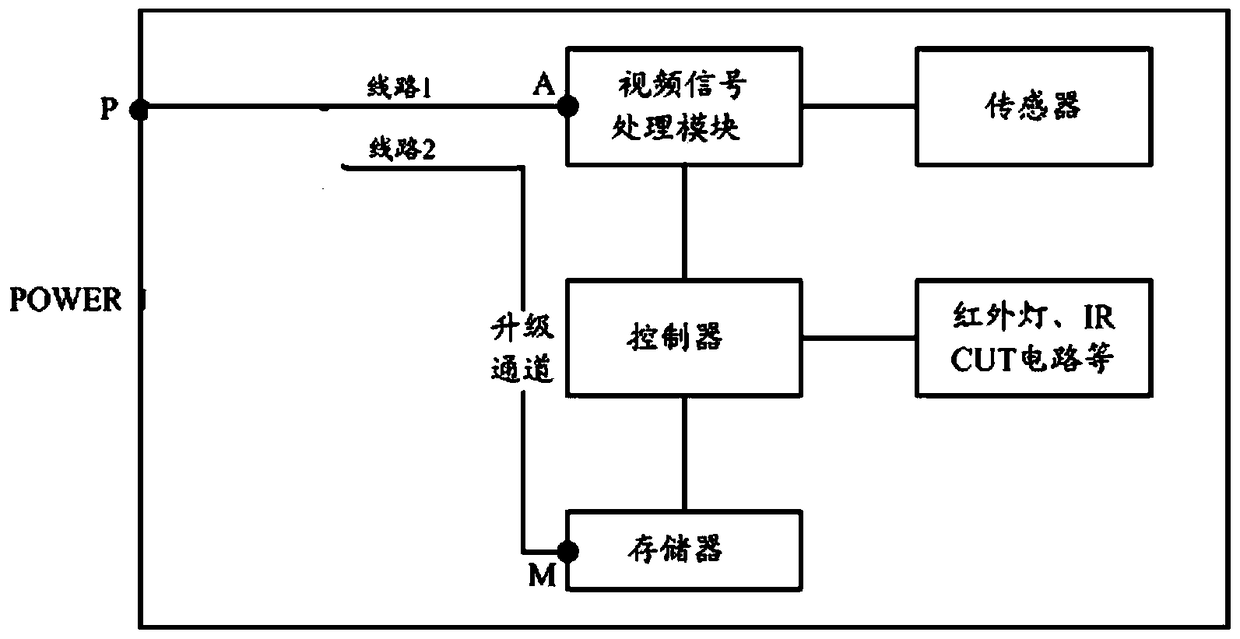

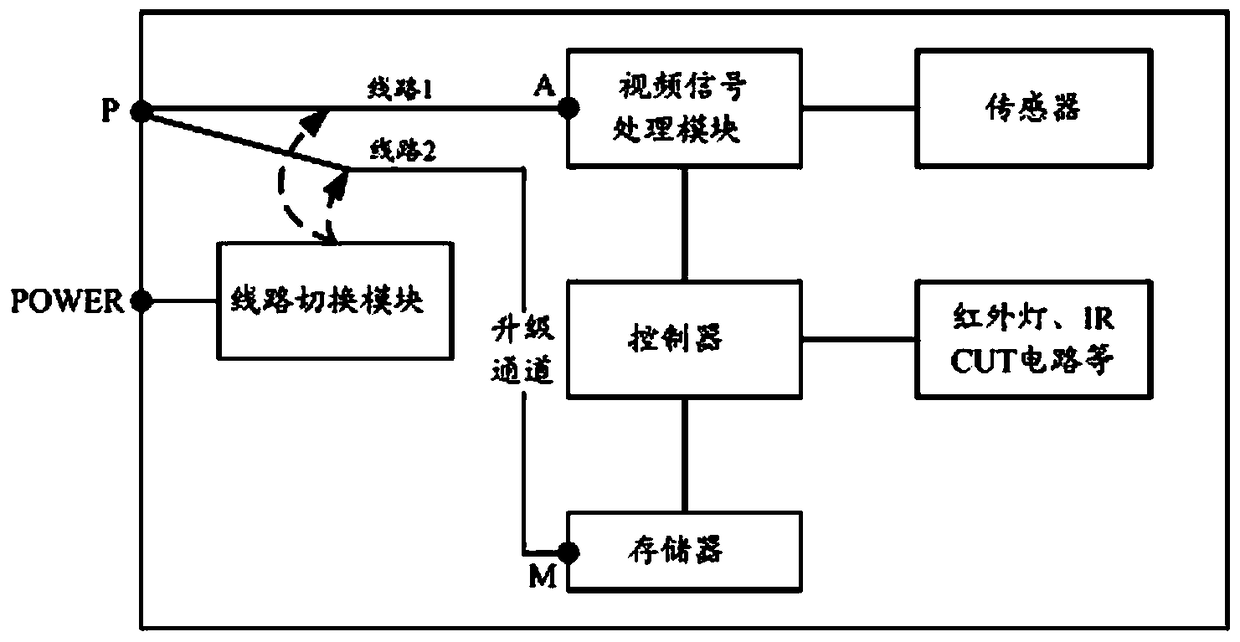

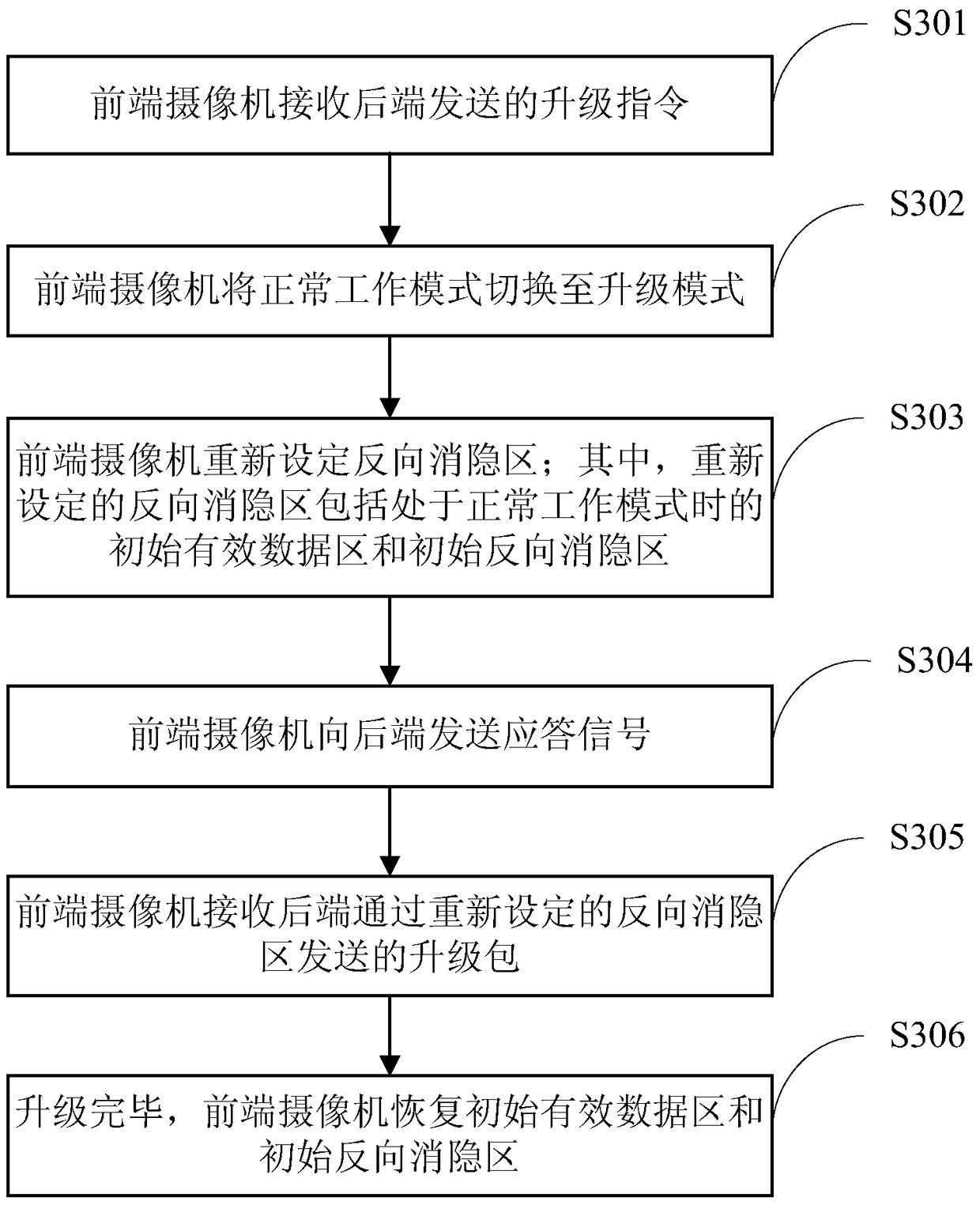

Method for upgrading video camera

ActiveCN105704445AImprove transmission performanceIncrease transfer speedTelevision system detailsColor television detailsComputer hardwareUpgrade

The invention discloses a method for upgrading a video camera. The method upgrades the video camera by using a transmission upgrade packet of a reverse blanking zone, prevents disassembly, and achieves simple operation and low upgrade cost. After receiving a upgrading instruction sent from a rear end and switches a normal operating mode to a upgrading mode but before transmitting a response signal to the rear end, a front-end video camera sets an initial valid data zone and an initial reverse blanking zone in the normal operating mode as reverse blanking zones, namely increases the number of rows of the reverse blanking zone. Thus, when receiving the upgrading packet sent from the rear end via the reset reverse blanking zone, the front-end video camera may increase the transmission capability and speed of the reverse blanking zone so as to increase the upgrading speed of the video camera. Additionally, after upgrading is completed, the front-end video camera restores the initial valid data zone and the initial reverse blanking zone in order not to influence the normal operation of the front-end video camera after the upgrading.

Owner:ZHEJIANG DAHUA TECH CO LTD

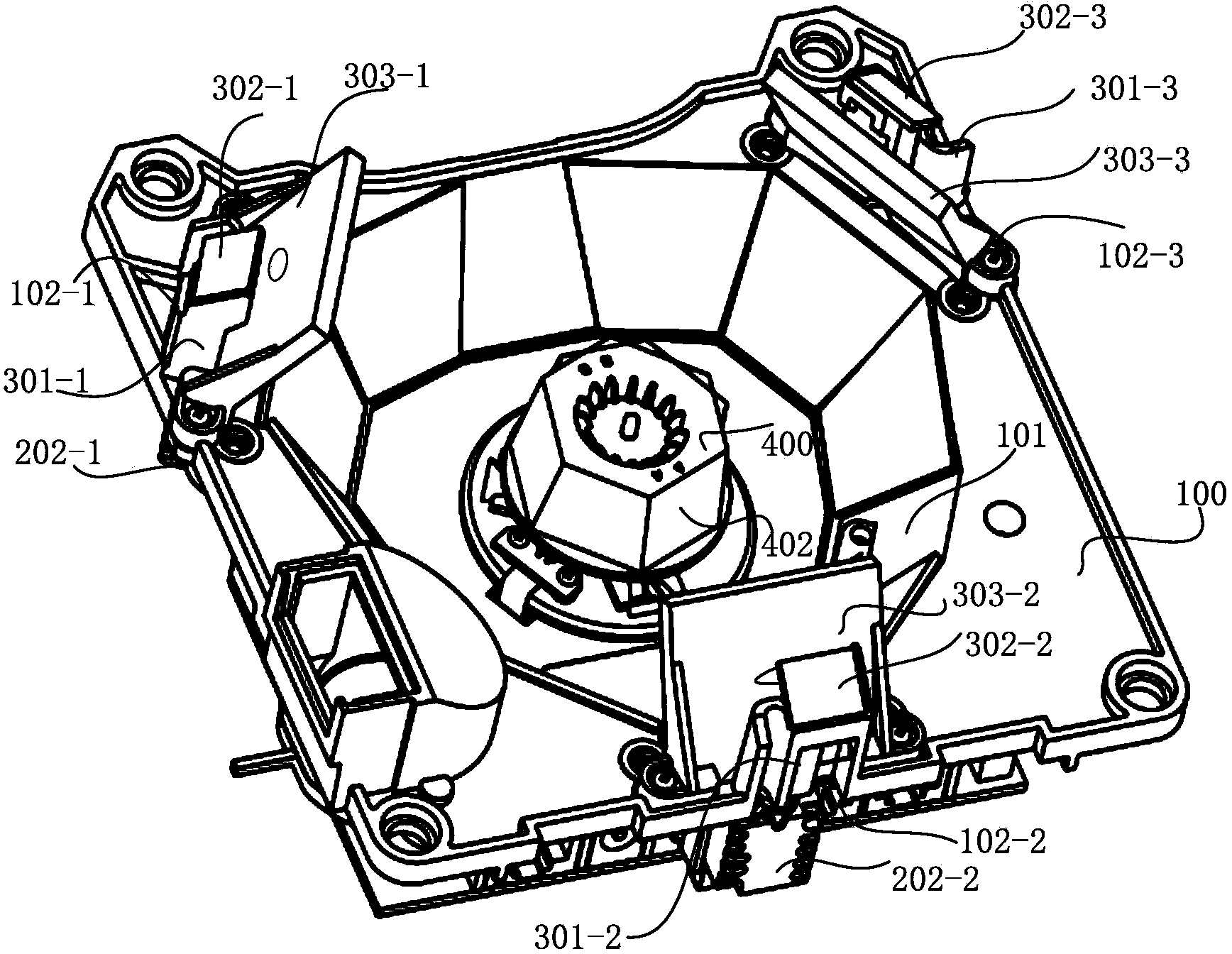

All-directional high-speed laser bar code scanning device

ActiveCN103745189AFast scanningLarge scanning rangeSensing by electromagnetic radiationOptical elementsPhysicsLight source

The invention discloses an all-directional high-speed laser bar code scanning device. The device comprises a base shell, wherein a groove is formed in the middle of the base shell; three light source open grooves are formed in the periphery of the base shell; the included angle between every two adjacent light source open grooves is 120 degrees; three laser diodes are correspondingly fixed in the light source open grooves; three reflecting mirror brackets are in one-to-one correspondence to the light source open grooves; each reflecting mirror bracket is provided with an emitted light reflecting mirror and a received light reflecting mirror; an opening is formed in the middle of the received light reflecting mirror; a rotary reflecting mirror group is arranged at the central position of the groove; the rotary reflecting mirror group comprises a rotary motor and a plurality of reflecting mirrors arranged on the side surfaces of the rotary motor; an annular column reflecting mirror group is arranged on the side surface of the boundary of the groove; three light receiving open grooves are formed below the rotary reflecting mirror group, wherein the included angle between every two adjacent light receiving open grooves is 120 degrees; a photosensitive receiving tube is arranged on each light receiving open groove. The all-directional high-speed laser bar code scanning device provided by the invention has the advantages of wide scanning range, high scanning speed, large line number, good bar code identification effect and the like.

Owner:SUNLUX IOT TECH GUANGDONG

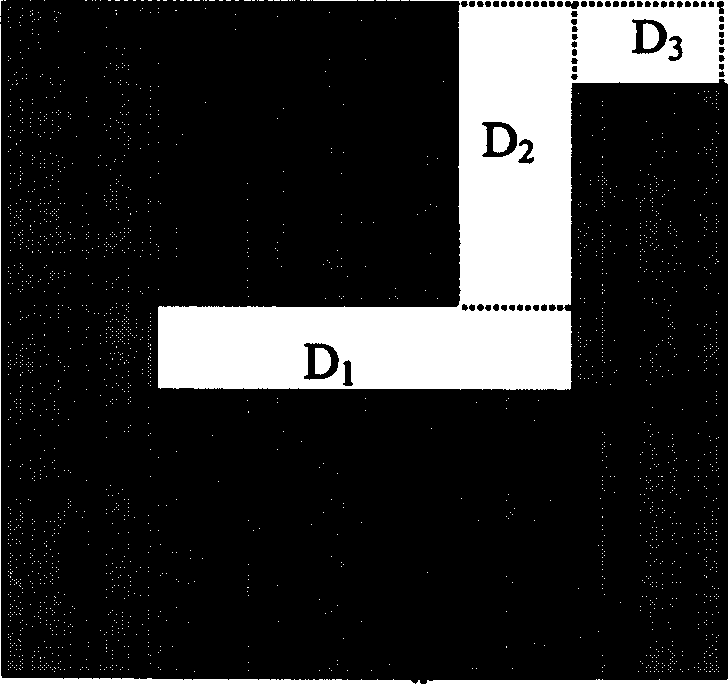

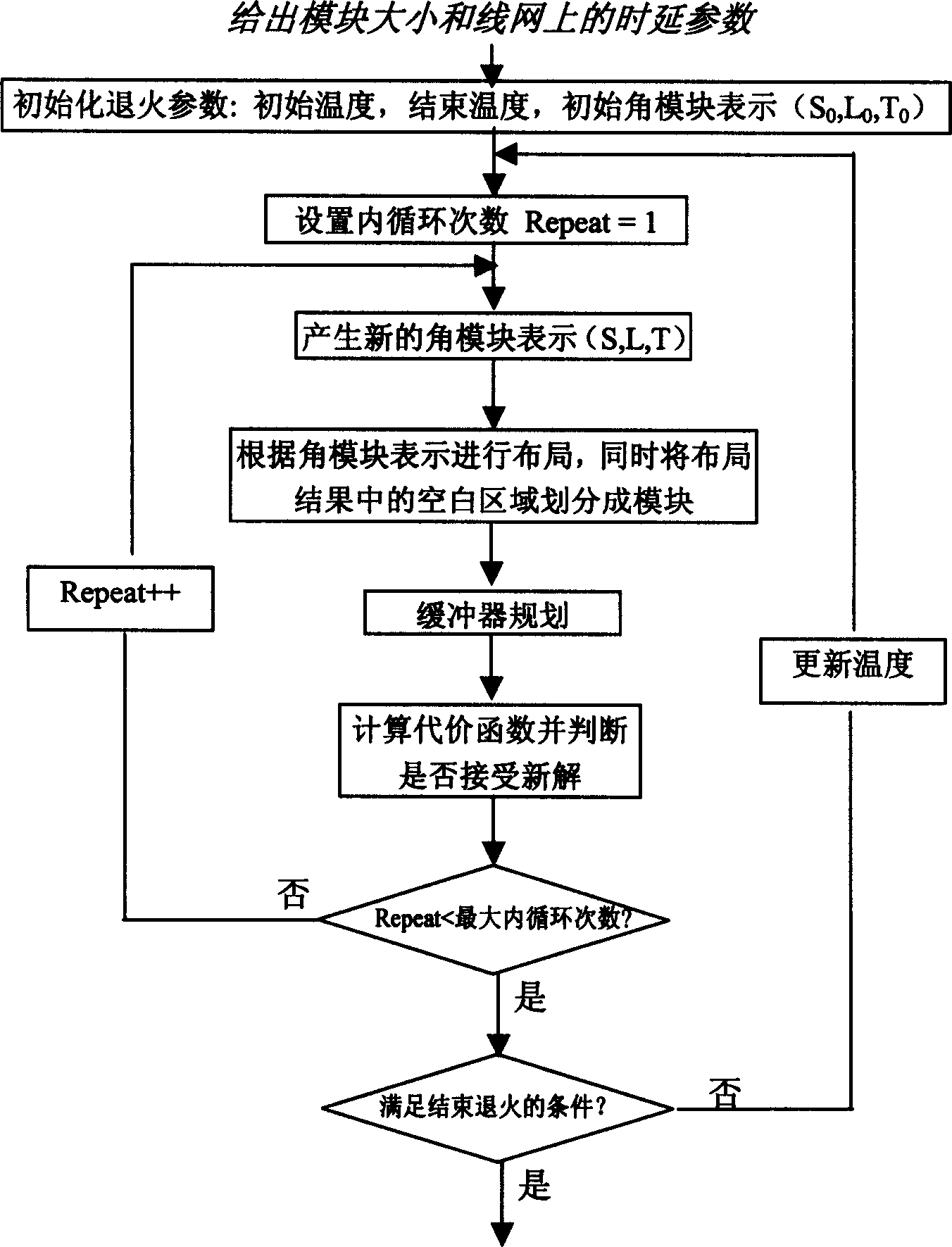

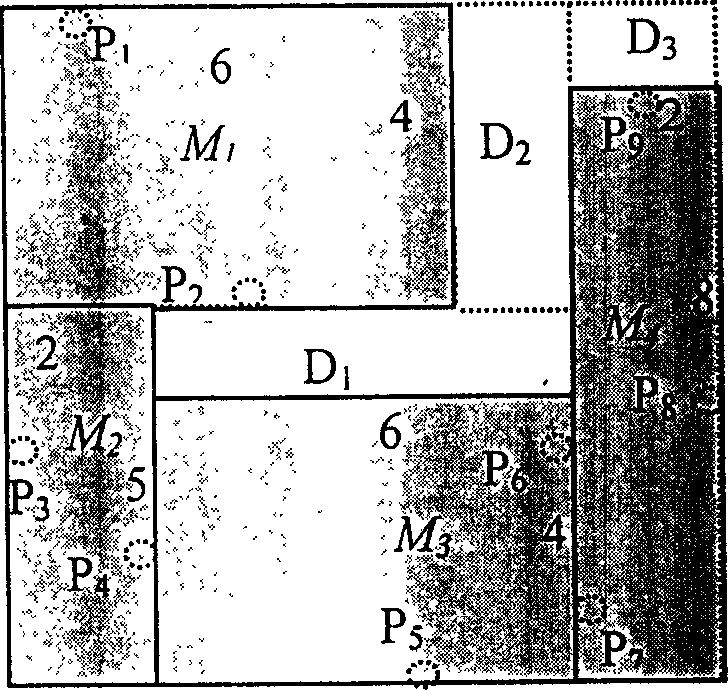

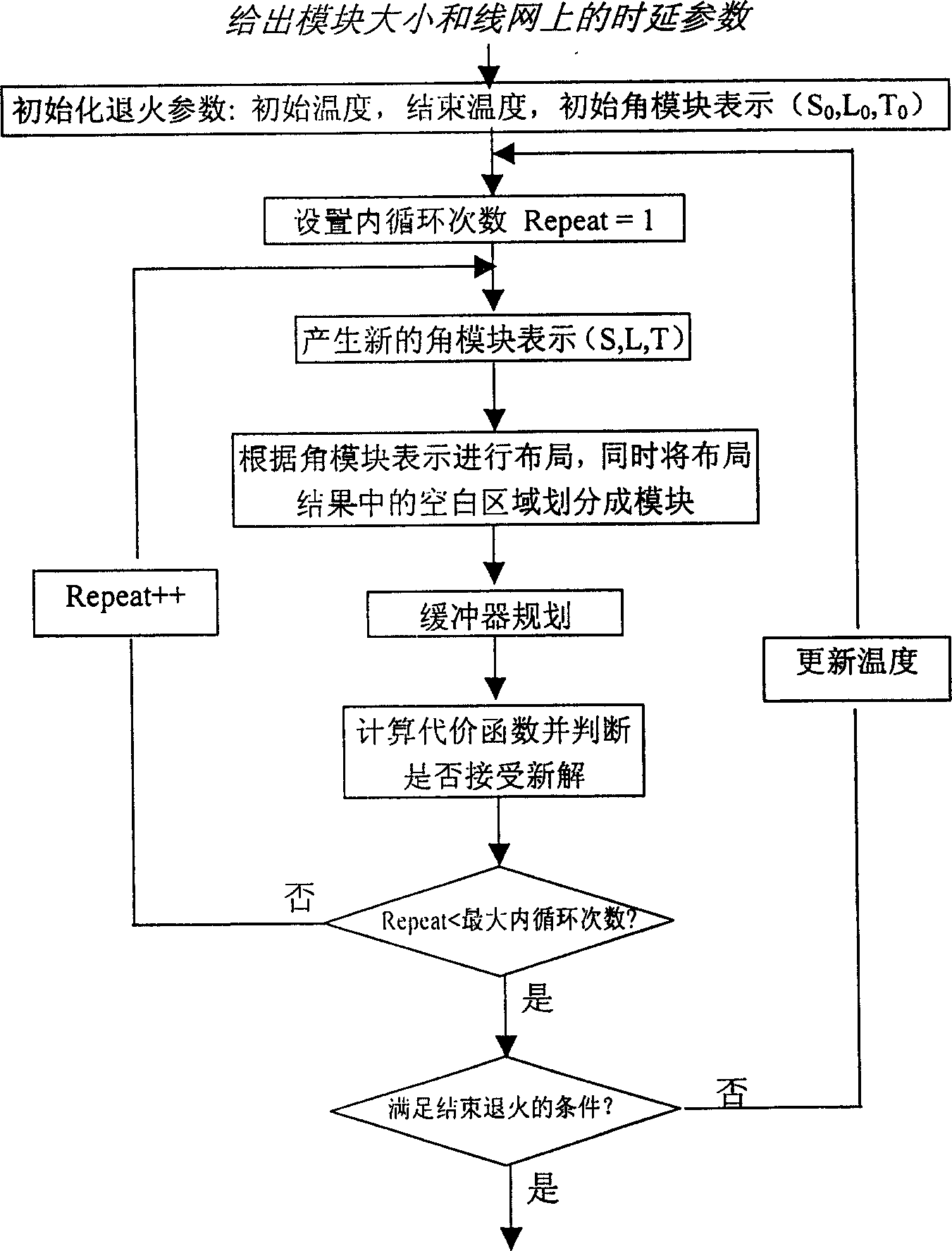

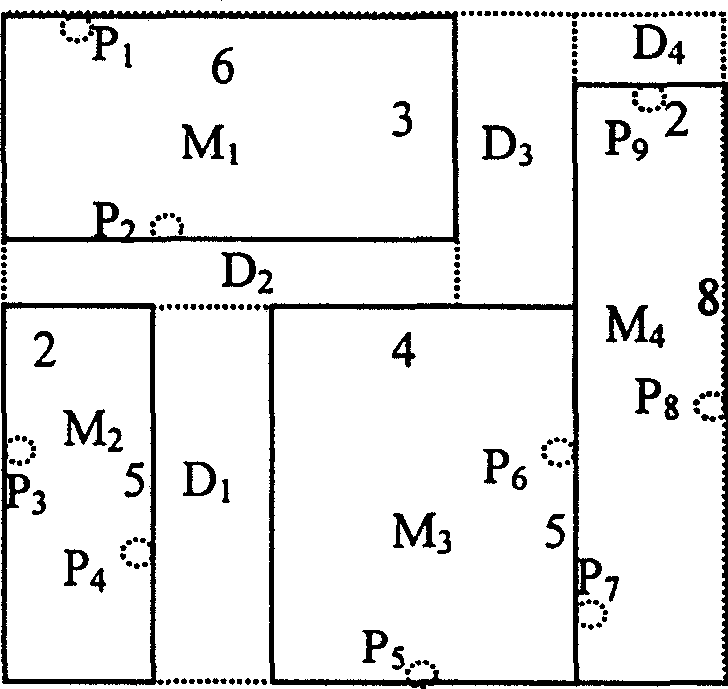

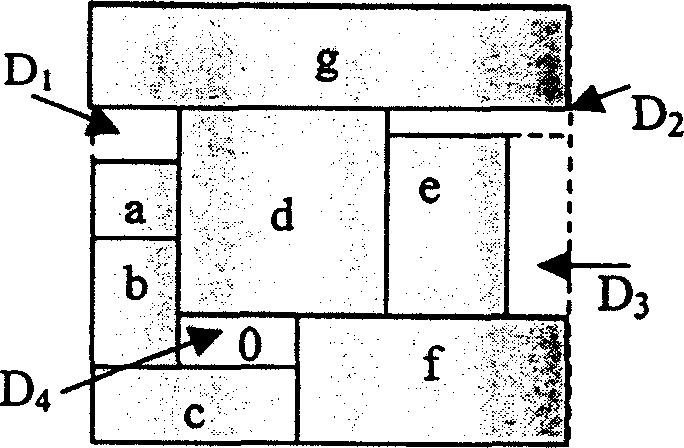

Integrated circuit layout plan and buffer plan integrated layout method

InactiveCN1547252AHigh insertion rateImprove delay characteristicsSemiconductor/solid-state device manufacturingSpecial data processing applicationsComputer Aided DesignDistribution method

The invention is a distribution method integrating the integrated circuit distribution plan and the buffer plan, the invention belongs to computer aided design for integrated circuit field. The character lies in: it introduces the feasible area calculation when the buffer is inserted in, and simplifies the complexity of the buffer distribution through distribution of the blank area in the plan result, the design is carried on pointing to the solution procedure to the simulated quenching by the buffer distribution, the distribution of the buffer is integrated in the solution of the distribution plan. The buffer distribution is leaded in the optimization process of the wiring plan, realizes the optimization to the delay performance.

Owner:TSINGHUA UNIV

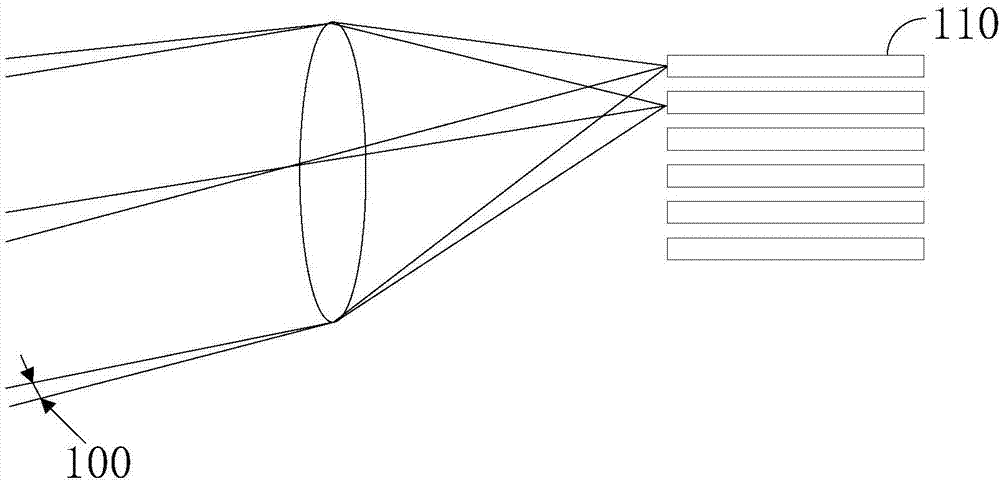

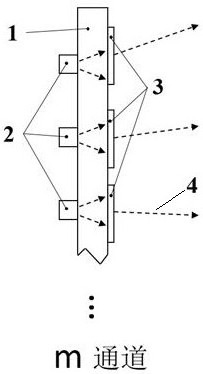

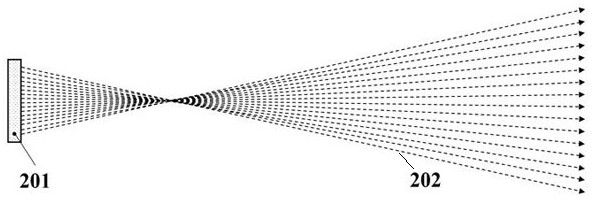

Laser radar and laser radar control method

PendingCN107153198AIncrease vertical resolutionIncrease the number of linesElectromagnetic wave reradiationImage resolutionMechanical engineering

The embodiment of the invention discloses a laser radar and a laser radar control method. The laser radar comprises a plurality of laser emitting plates for emitting emergent laser; and preset angles are formed between the plurality of laser emitting plates and a horizontal plane. Two or more than two laser emission units are arranged at each laser emitting plate. Therefore, the vertical resolution of the laser radar can be improved.

Owner:SUTENG INNOVATION TECH CO LTD

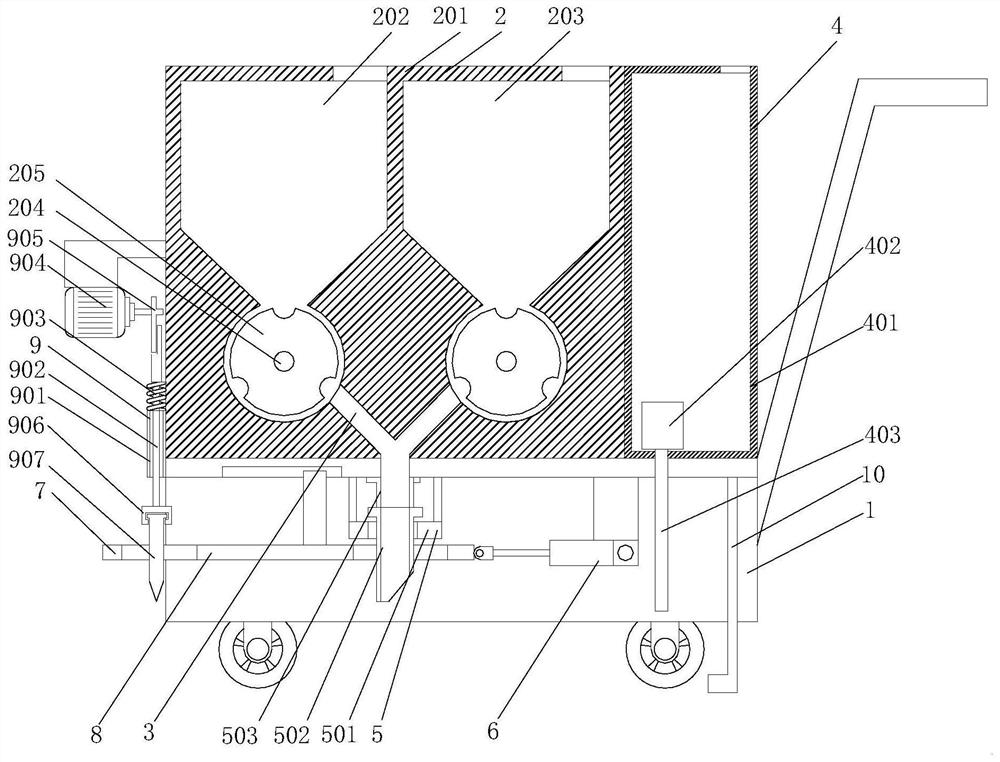

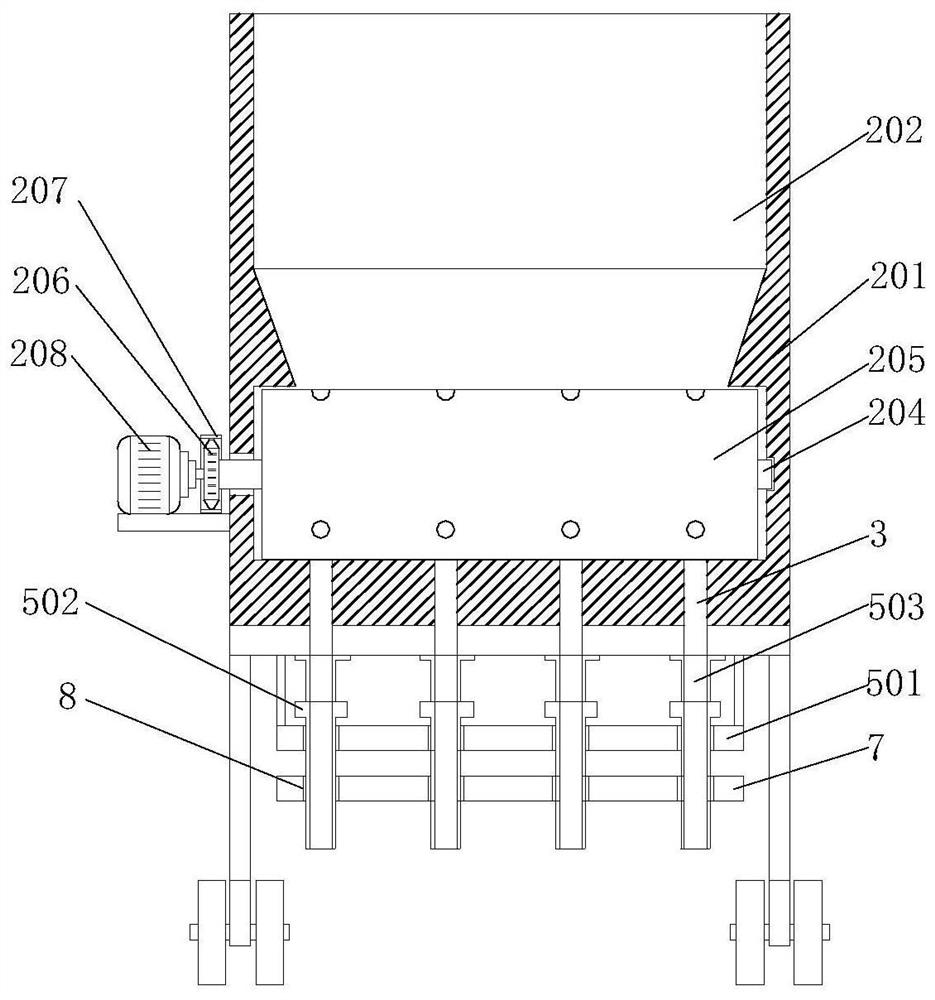

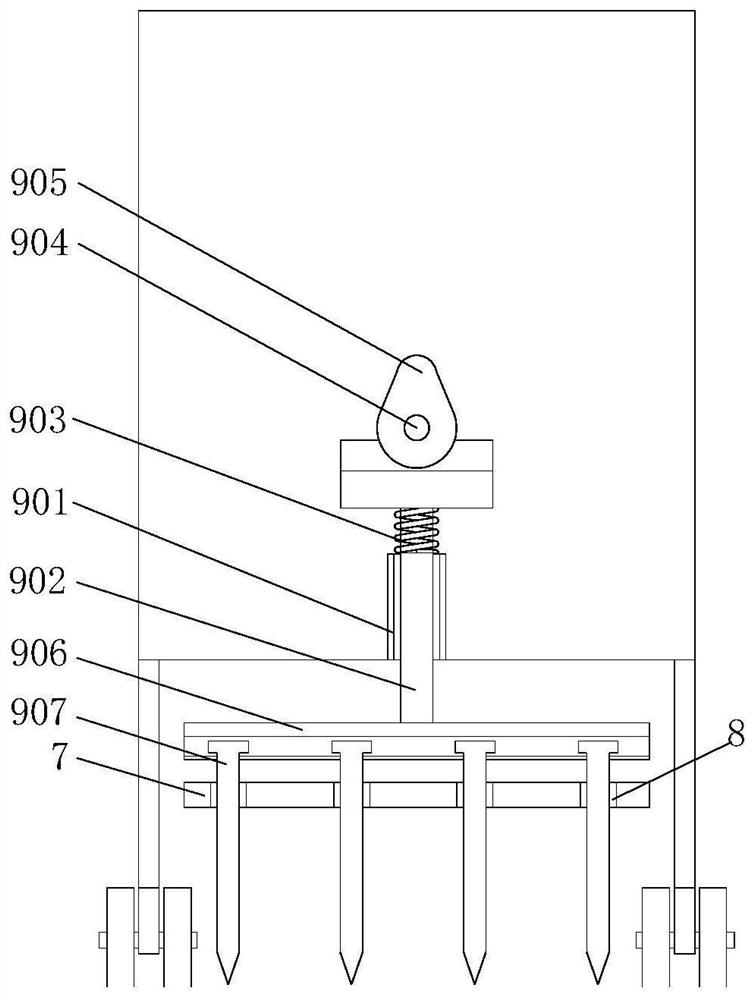

Agricultural fertilizing and seeding device with soil covering function

InactiveCN111937540AImprove growing conditionsEasy sowingPlantingDibble seedersAgricultural engineeringSoil cover

The invention relates to the technical field of agricultural fertilization and seeding, in particular to an agricultural fertilizing and seeding device with a soil covering function. In order to solvethe technical problems that an existing seeding device cannot conduct punching and fertilization at the same time, the seeding efficiency is low, and the seeding interval cannot be changed, the agricultural fertilizing and seeding device with the soil covering function is provided and comprises a cart, wherein the top of the cart is fixedly connected with a seeding device, and four material guidepipes are embedded in the bottom of the seeding device; and an irrigation device is fixedly connected to the right side of the seeding device, a soil covering plate is installed at the right side ofa watering pipe of the irrigation device, and a perforating device is fixedly connected to the left side of the seeding device. Seeds and fertilizer are mixed for use or separately used through the seeding device, seeding, fertilization, watering, pit filling and burying can be conveniently conducted on the seeds and the fertilizer at the same time, and the seeding efficiency is improved.

Owner:杨先文

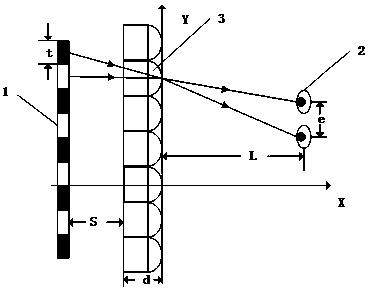

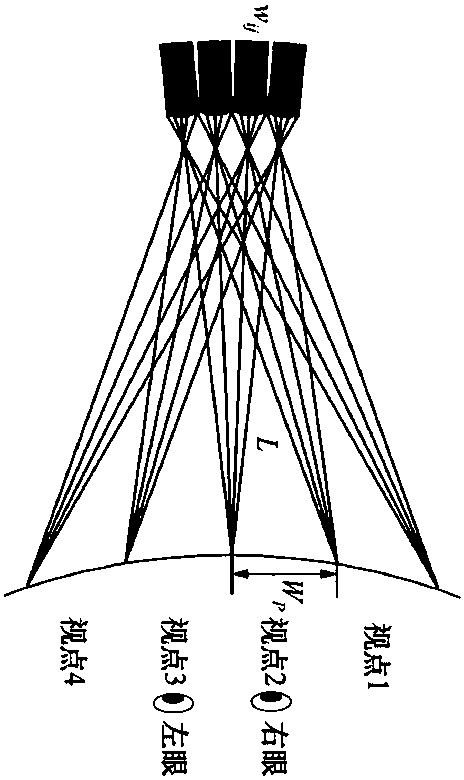

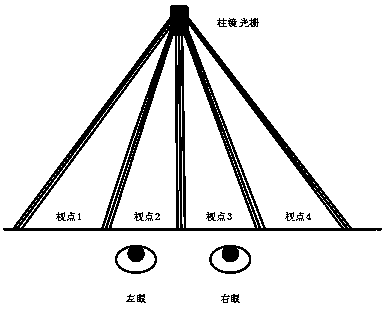

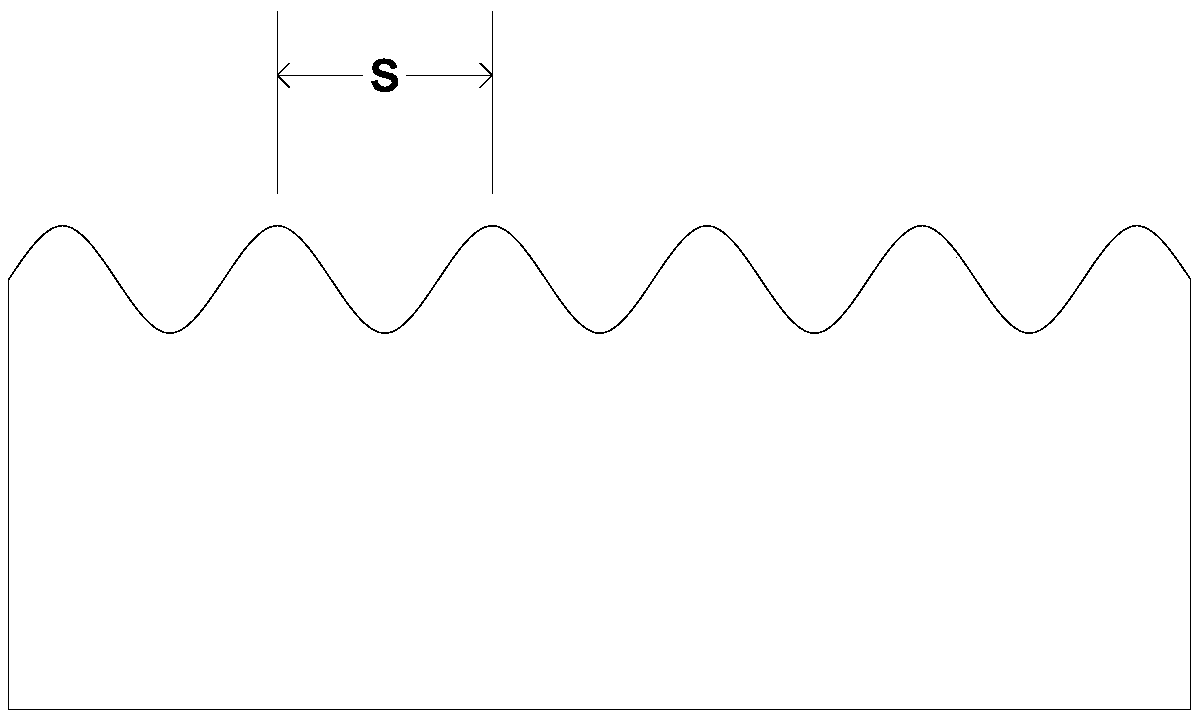

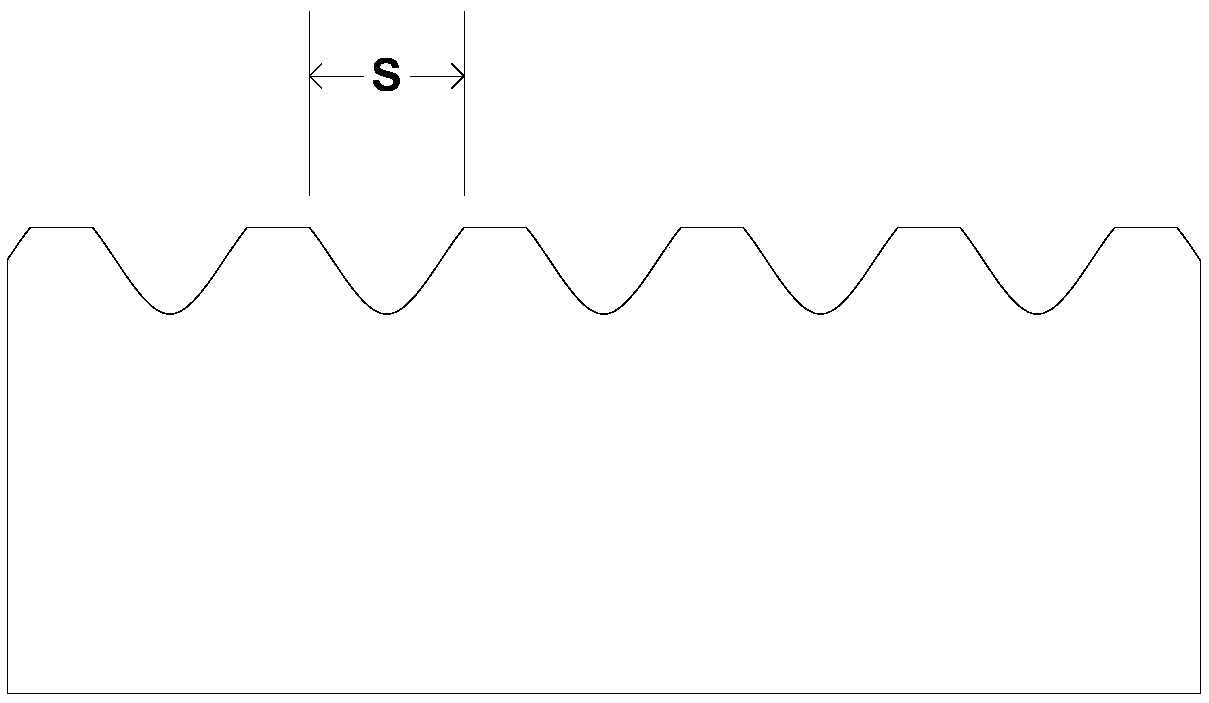

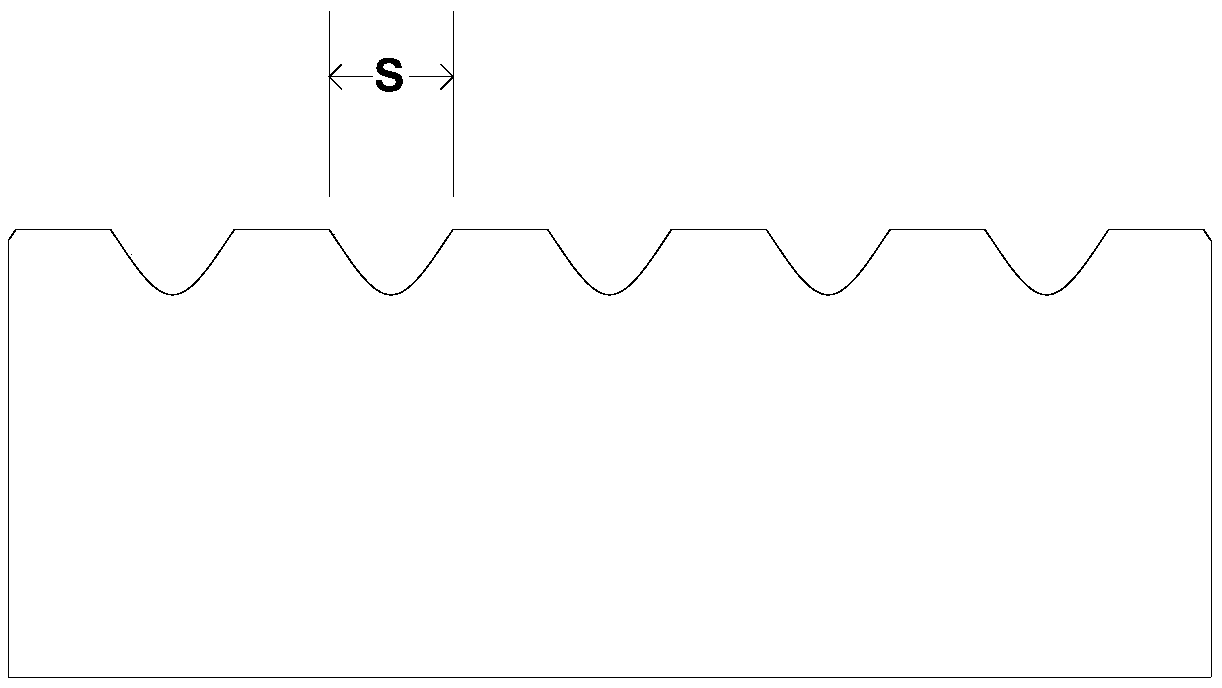

Lenticular grating based LED stereoscopic display screen device with great many of viewpoints

The invention provides a lenticular grating based LED stereoscopic display screen device with a great many of viewpoints. The display screen device comprises an LED planar display screen and human-eye watching viewpoints, an arc lenticular grating is arranged between the LED planar display screen and human-eye watching viewpoints, the LED planar display screen is arranged along the axis x and symmetric by taking the axis x as the center, the vertex of a cylindrical lens of the intermediate arc lenticular grating is positioned in the coordinate origin, an image side of the LED planar display screen is positioned in the focal plane of the cylindrical lens of the arc lenticular grating, the width of sub-pixel is t, the lenticular thickens of the arc lenticular grating is d, distance between the cylindrical lens of the arc lenticular grating and the LED planar display screen is s, the human-eye watching viewpoints are positioned in positions whose distance to the cylindrical lens of the arc lenticular grating is L, and the distance between the eyes is set as e. A 3D structure with a static effect as well as a 3D image with a dynamic effect can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

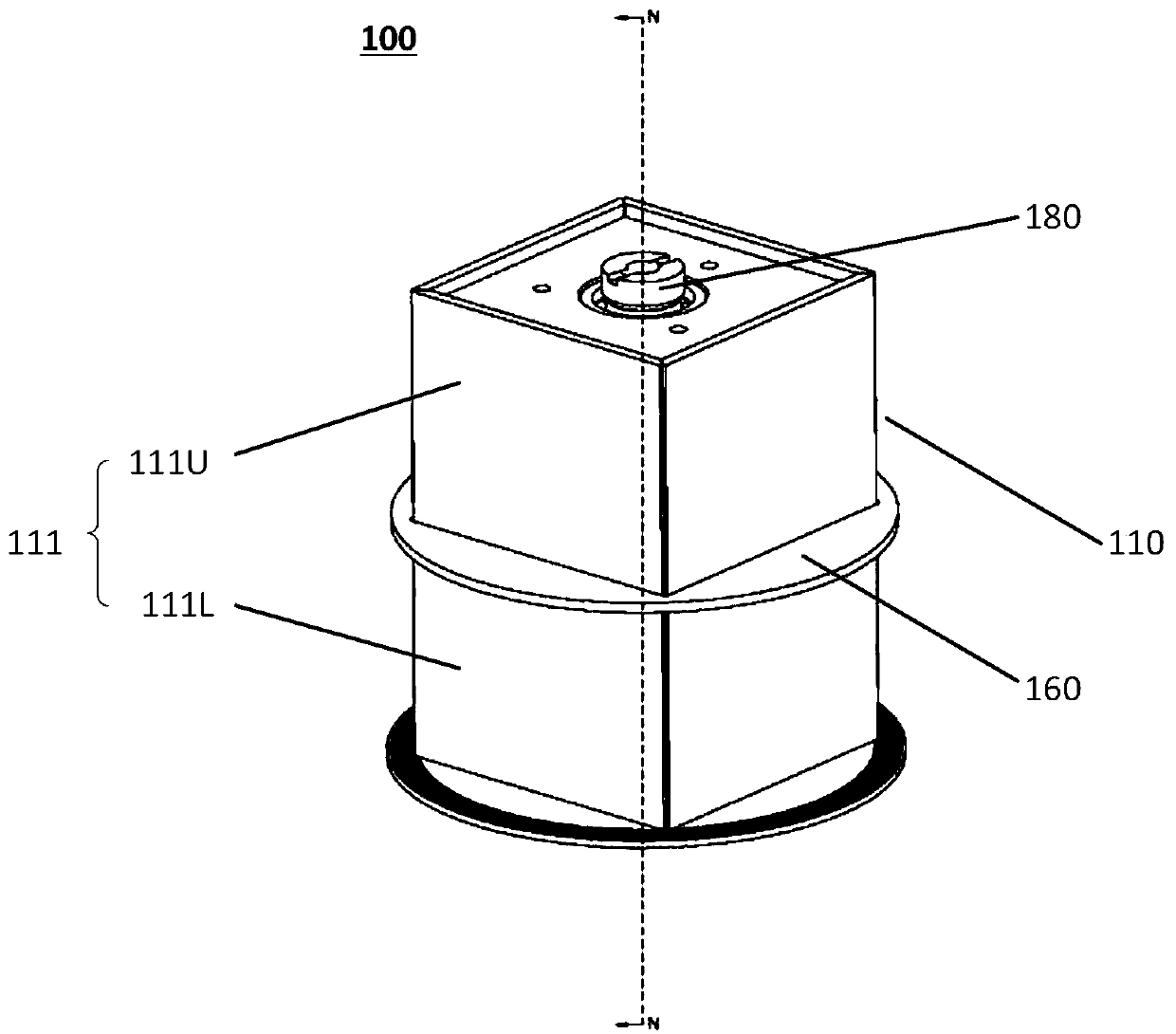

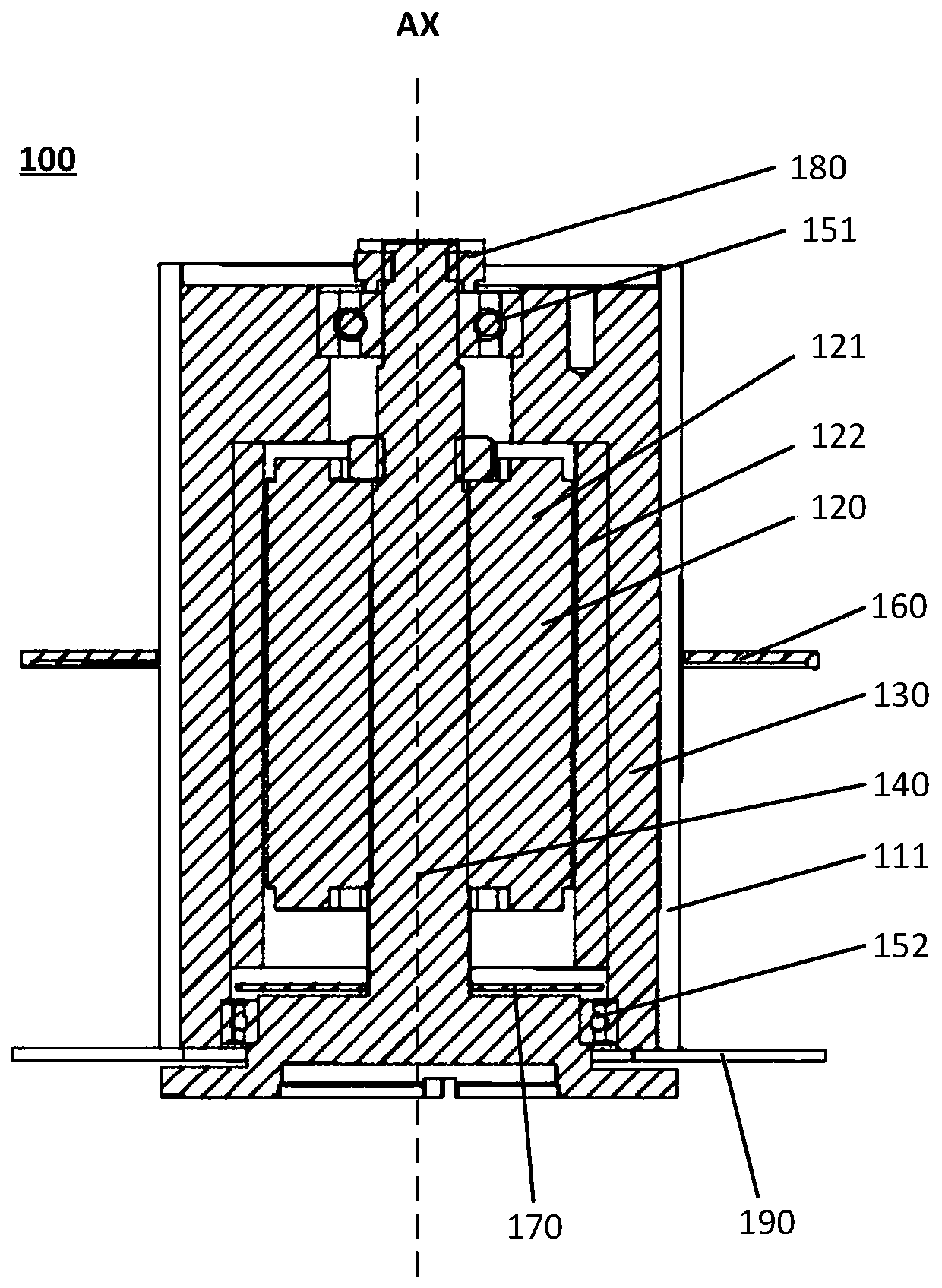

Rotating mirror unit for laser radar, corresponding laser radar and using method

PendingCN111580114ASolution volumeSolve quality problemsElectromagnetic wave reradiationLight beamEngineering

The invention discloses a rotating mirror unit suitable for a laser radar. The rotating mirror unit comprises a polyhedral rotating mirror part which is provided with an even number of reflecting surfaces forming a polygon in an enclosing manner, and is used for changing an angle of a light beam incident on the reflecting surfaces, a motor configured to drive the polyhedral rotating mirror part torotate around the axis of the polyhedral rotating mirror part, wherein each reflective surface includes an upper portion and a lower portion separated by a light blocking region. The rotating mirrorunit is advantaged in that the height of the rotating mirror type laser radar is reduced, the size of the laser radar is reduced, and scanning precision and the scanning quality of the laser radar areimproved.

Owner:HESAI TECH CO LTD

Multi-line laser radar system and a control method thereof

ActiveCN107153202AIncrease vertical resolutionIncrease the number of linesElectromagnetic wave reradiationRadar systemsOptoelectronics

The embodiment of the invention discloses a multi-line laser radar system and a control method thereof. The multi-line laser radar comprises at least two multi-line laser radars; and emitting angles of emitted laser of the at least two multi-line laser radars are staggered. In addition, the control method of the multi-line laser radar system includes: emitting angles of emitted laser of the at least two multi-line laser radars are staggered. Therefore, the vertical resolution during the scanning process of the multi-line laser radar system can be improved.

Owner:SUTENG INNOVATION TECH CO LTD

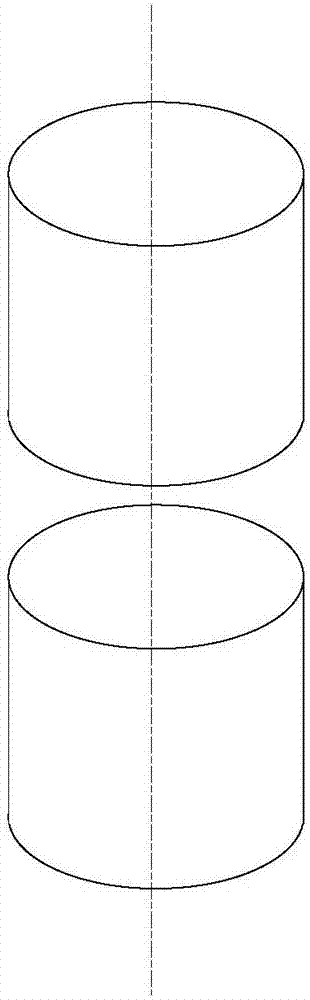

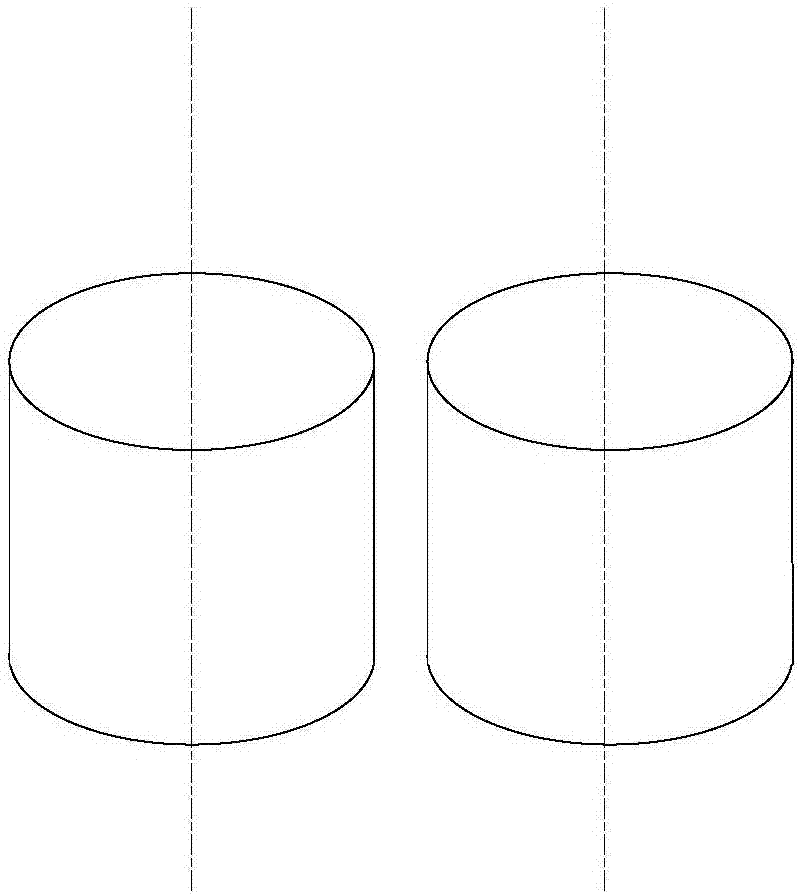

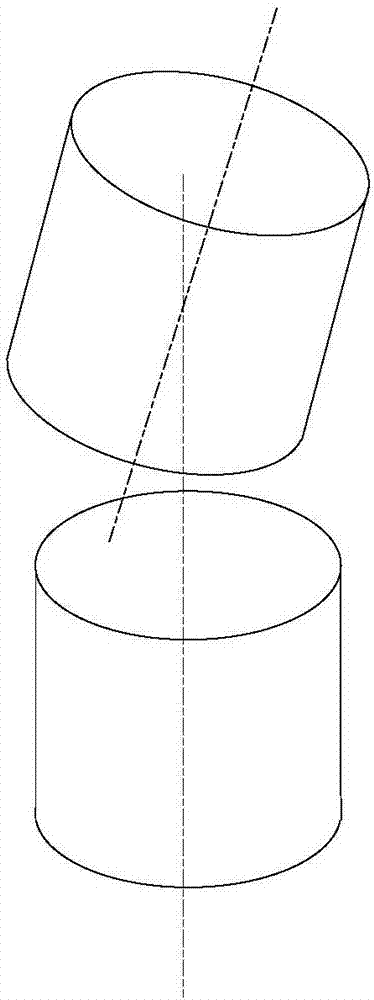

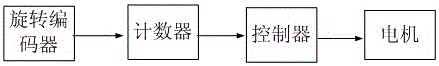

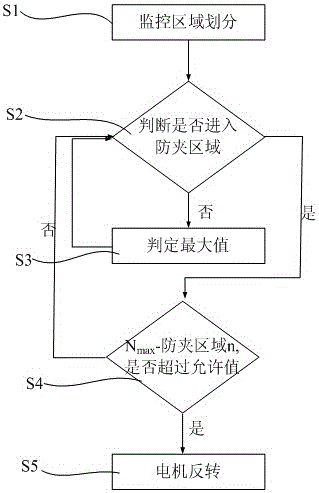

Automatic revolving door resistance stopping system and resistance stopping method

ActiveCN106761146AEasy to installIncrease the number of linesPower-operated mechanismBlind zonePower flow

The invention provides an automatic revolving door resistance stopping system and resistance stopping method. The automatic revolving door resistance stopping system comprises a motor for driving revolving door leaves to operate and a controller, a motor main shaft is provided with a revolving encoder for detecting the revolving speed of the revolving door leaves, the revolving encoder is connected with a counter, and the controller receives the pulse number of the counter and controls the motor to operate. When the revolving door leaves are hindered, the revolving encoder detects that the revolving speed is reduced, and the controller controls the motor to stop revolving or revolve reversely. The automatic revolving door resistance stopping system can be installed on a revolving door of any type, installation is simple, and extra equipment does not need to be added to the revolving door. In combination with the above resistance stopping method, the automatic revolving door resistance stopping system does not have a blind area, and recognition can be achieved as long as the revolving door leaves bear resistance. The system is good in flexibility and adjustable in sensitivity, a man-machine platform is utilized, the flexibility can be adjusted just by increasing the line number of the encoder, and the system is quite convenient to use. The resistance stopping method is sensitive in reaction and is high in recognition speed and reaction speed compared with an electric current detection method, and squeezing of pedestrians is eliminated timely.

Owner:青岛华昊自动化设备工程有限公司

Quinoa-sorghum mixed-band planting method

ActiveCN109247208AIncrease the number of linesPrevent lodgingSuperphosphatesBio-organic fraction processingSorghumThinning

The invention discloses a quinoa-sorghum mixed-band planting method. The method comprises the steps of field selection, field preparation, film covering, sowing, thinning, earth-up, fertilization, harvesting and the like. Quinoa and sorghum are high-pole easy-lodging crops, the strengths of stems of the two kinds of crops are different, quinoa and sorghum seeds are sowed according to the sequenceof internal strip sowing, and the situation is avoided that under severe weather such as high wind, the same kind of crops form the domino effect, and large-scale lodging is generated. According to the quinoa-sorghum mixed-band planting method, quinoa lodging is effectively prevented in the aspects such as field selection, sowing and earth-up. In addition, through cooperation application of base fertilizer and efficient composite fertilizer, the method is suitable for the whole growth period of quinoa and beneficial to lodging resistance of quinoa, the yield of quinoa is increased, and meanwhile the quality of quinoa is also effectively improved.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

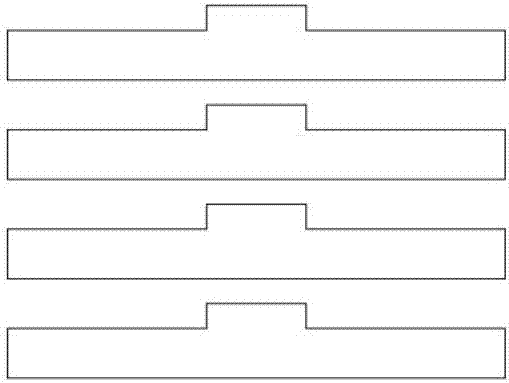

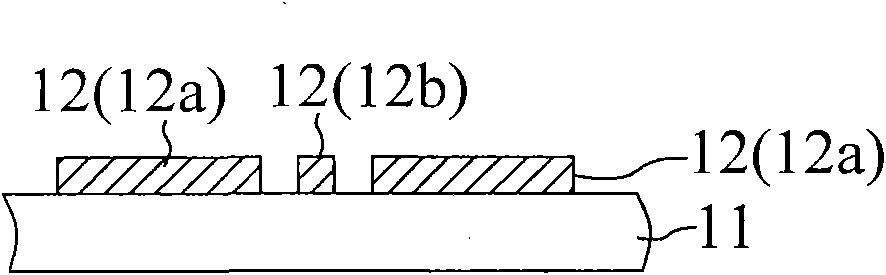

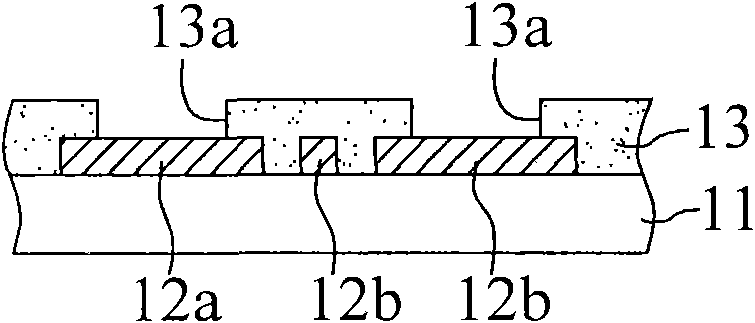

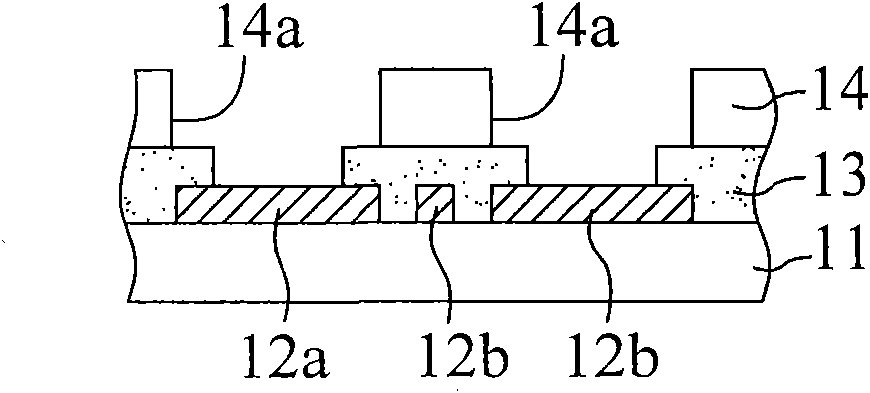

Structure and manufacturing method of packaged base plate

InactiveCN101587877AReduce the number of layers in the build-up structureImprove routing densitySemiconductor/solid-state device detailsSolid-state devicesDistributed circuitEngineering

The invention relates to a structure and a manufacturing method of a packaged base plate. The packaged base plate comprises a base plate body, a welding preventing layer and metal projections, wherein the base plate body is provided with a circuit layer on the surface, the circuit layer is provided with a plurality of electrically connected pads of which the planes are prolate so as to improve the flexibility of circuit distribution space; the welding preventing layer covers the base plate body and is provided with a plurality of open pores corresponding to the electrically connected pads, wherein the plane shapes of the open pores of the welding preventing layer are prolate; and the metal projections are matched with the open pores in the welding preventing layer and correspond to the electrically connected pads. When used for manufacturing the packaged base plate of a multilayer plate, the invention can reduce the layers of a circuit layer increasing structure of the multilayer plate because the distributed circuits can be increased in the space between two adjacent electrically connected pads, thereby lowering the manufacturing cost.

Owner:PHOENIX PRECISION TECH CORP

Method for cultivating spring corn in hilly region

InactiveCN100333635CExcellent agronomic traitsWide adaptabilityHorticulture methodsRipeningLarge ears

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Method for forming grating for machine tool measurement in two-step solidifying roll-pressing forming method

ActiveCN102193310BLow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

Owner:XI AN JIAOTONG UNIV

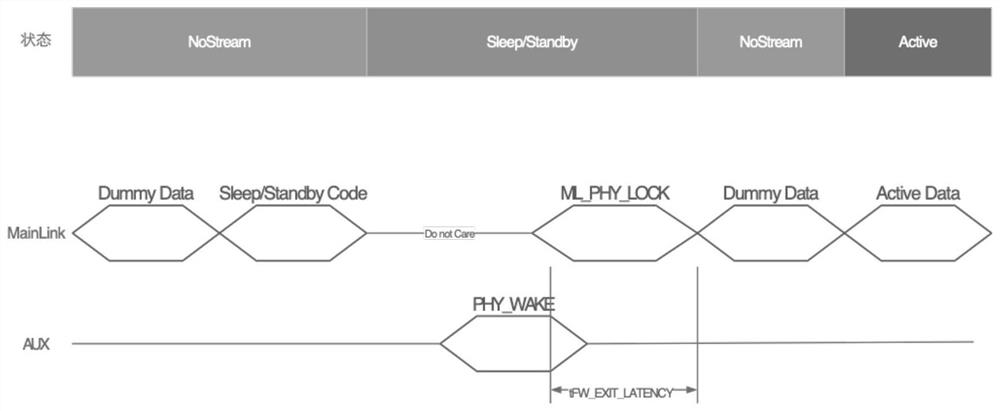

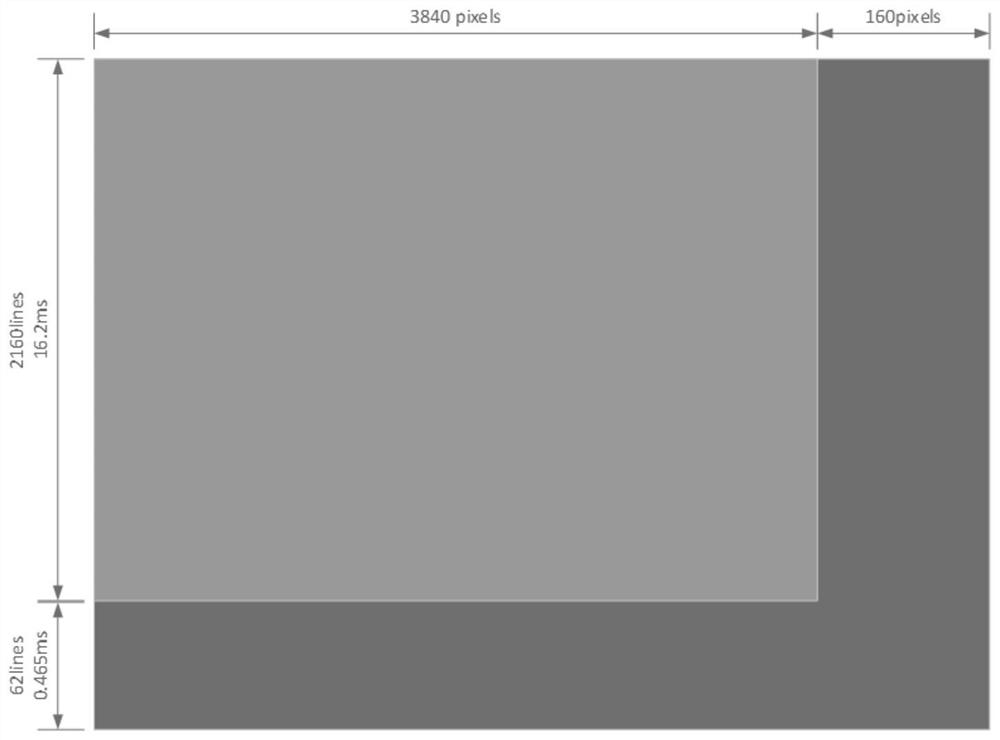

A method for reducing power consumption of edp signal chain

ActiveCN109830219BReduce transmission power consumptionReduce power consumptionCathode-ray tube indicatorsTelecommunicationsSignal source

The invention provides a method for reducing the power consumption of the eDP signal link, which reduces the refresh rate and at the same time reduces the transmission power consumption of the eDP link, which can be applied to both the working state and the idle state of the panel. The present invention provides a method for reducing the power consumption of eDP signal links, which includes the following steps: the signal source sending end outputs effective image data, and the signal source receiving end receives effective image data; the pixel clock of the image data remains unchanged, and the image data is increased. The number of lines in the vertical vanishing area of the data. When the transformed image data’s shadowing area starts to run, the signal source sending end outputs a dormancy command to the signal source receiving end; after the signal source receiving end receives the dormancy command, the signal source receives The main link between the end and the signal source sending end is closed; at the moment when the vanishing area of the transformed image data is about to end, the signal source sending end sends a wake-up signal and a lock signal; the signal source receiving end turns on after receiving the wake-up signal main link.

Owner:WUHAN JINGLI ELECTRONICS TECH

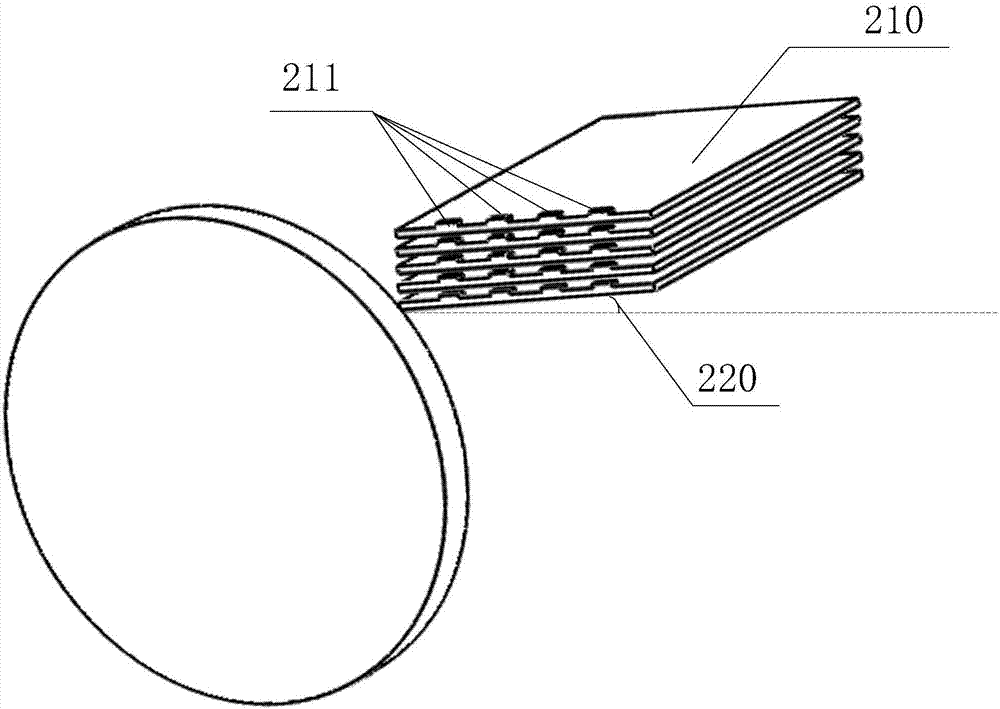

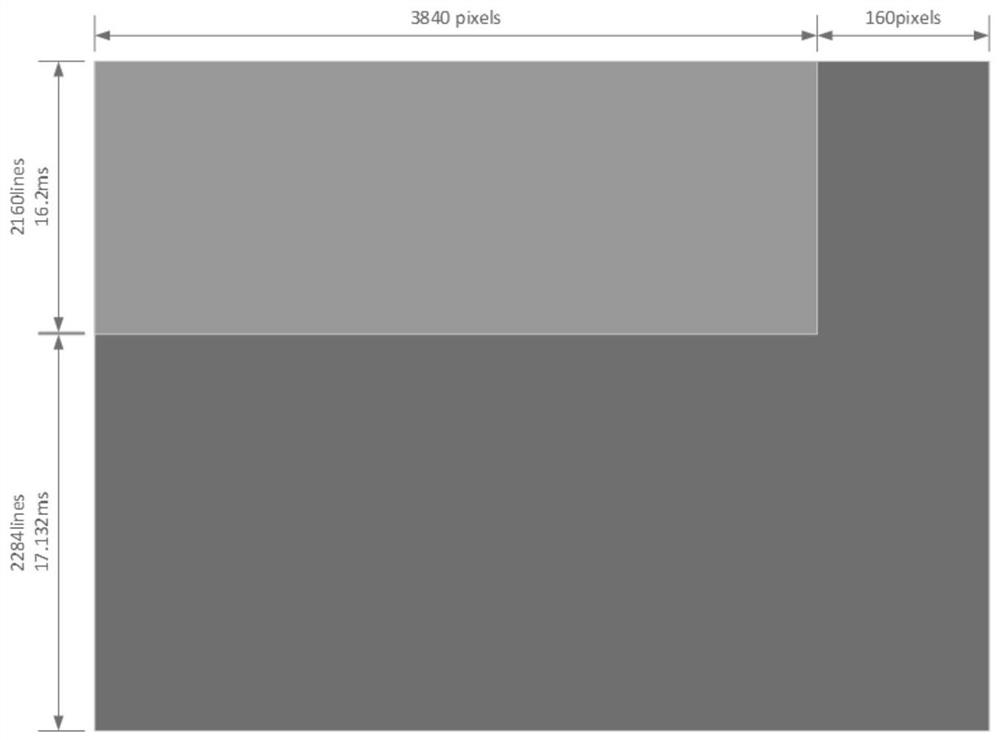

VCSEL linear array for multi-line laser radar

PendingCN113589322AIncrease the number of linesVertical scan range change and vertical resolution controlElectromagnetic wave reradiationVertical-cavity surface-emitting laserEngineering

The invention relates to the technical field of laser detection and semiconductor optoelectronic devices, and in particular, relates to a VCSEL linear array for a multi-line laser radar. The VCSEL linear array specifically comprises a semiconductor substrate, m-element vertical cavity surface emitting lasers (VCSEL) in a linear array and m-element optical microlenses, the m-element VCSELs in a linear array are prepared on the front surface of the semiconductor substrate, and the m-element optical microlenses are arranged on the back surface of the semiconductor substrate in an array; the m-element VCSELs are mutually independent and output m paths of mutually incoherent laser signals; and the VCSELs are in one-to-one correspondence with the optical microlenses, and the optical microlenses are used for collimating laser emitted by the VCSELs corresponding to the optical microlenses and regulating and controlling the light emitting direction to form multi-line laser beams. According to the invention, collimation and light beam direction regulation and control of a VCSEL output laser beam are realized; and the optical scanning structure of the laser radar can be simplified, and the cost of the laser radar is reduced.

Owner:TAIYUAN UNIV OF TECH

Integrated circuit layout plan and buffer plan integrated layout method

InactiveCN1275317CHigh insertion rateImprove delay characteristicsSemiconductor/solid-state device manufacturingSpecial data processing applicationsComputer Aided DesignDistribution method

The invention is a distribution method integrating the integrated circuit distribution plan and the buffer plan, the invention belongs to computer aided design for integrated circuit field. The character lies in: it introduces the feasible area calculation when the buffer is inserted in, and simplifies the complexity of the buffer distribution through distribution of the blank area in the plan result, the design is carried on pointing to the solution procedure to the simulated quenching by the buffer distribution, the distribution of the buffer is integrated in the solution of the distribution plan. The buffer distribution is leaded in the optimization process of the wiring plan, realizes the optimization to the delay performance.

Owner:TSINGHUA UNIV

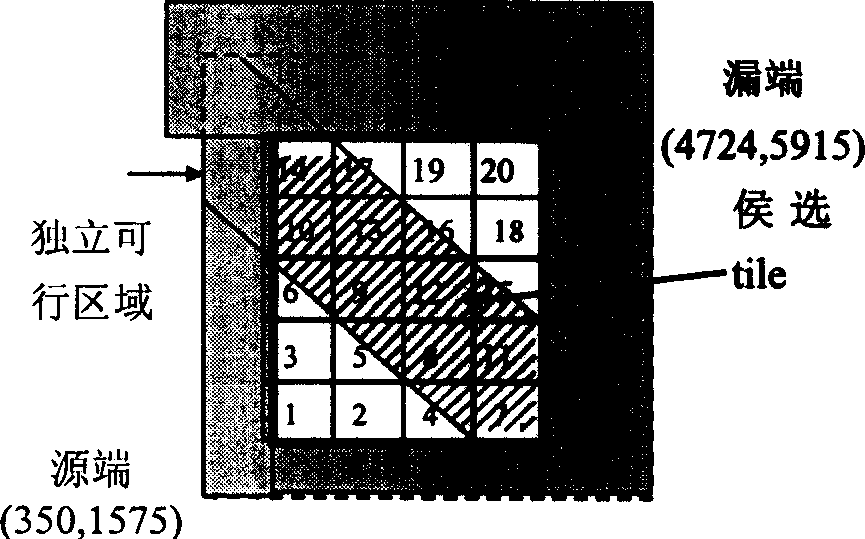

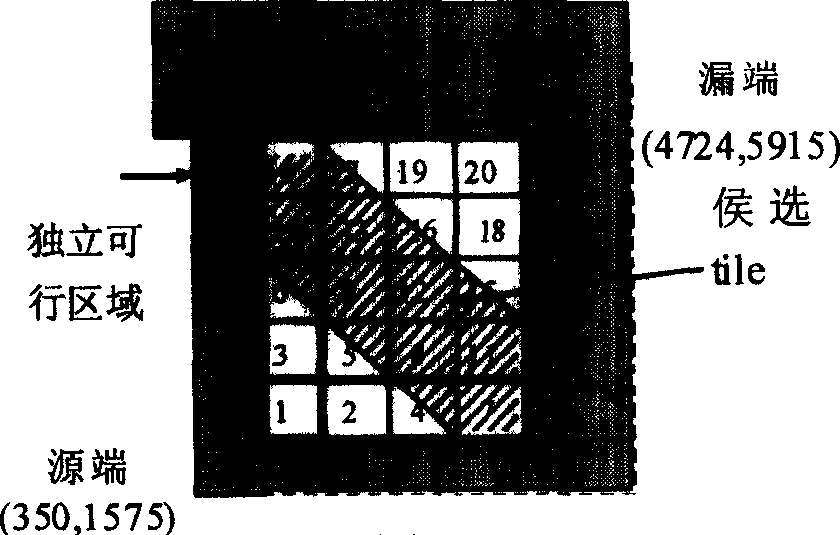

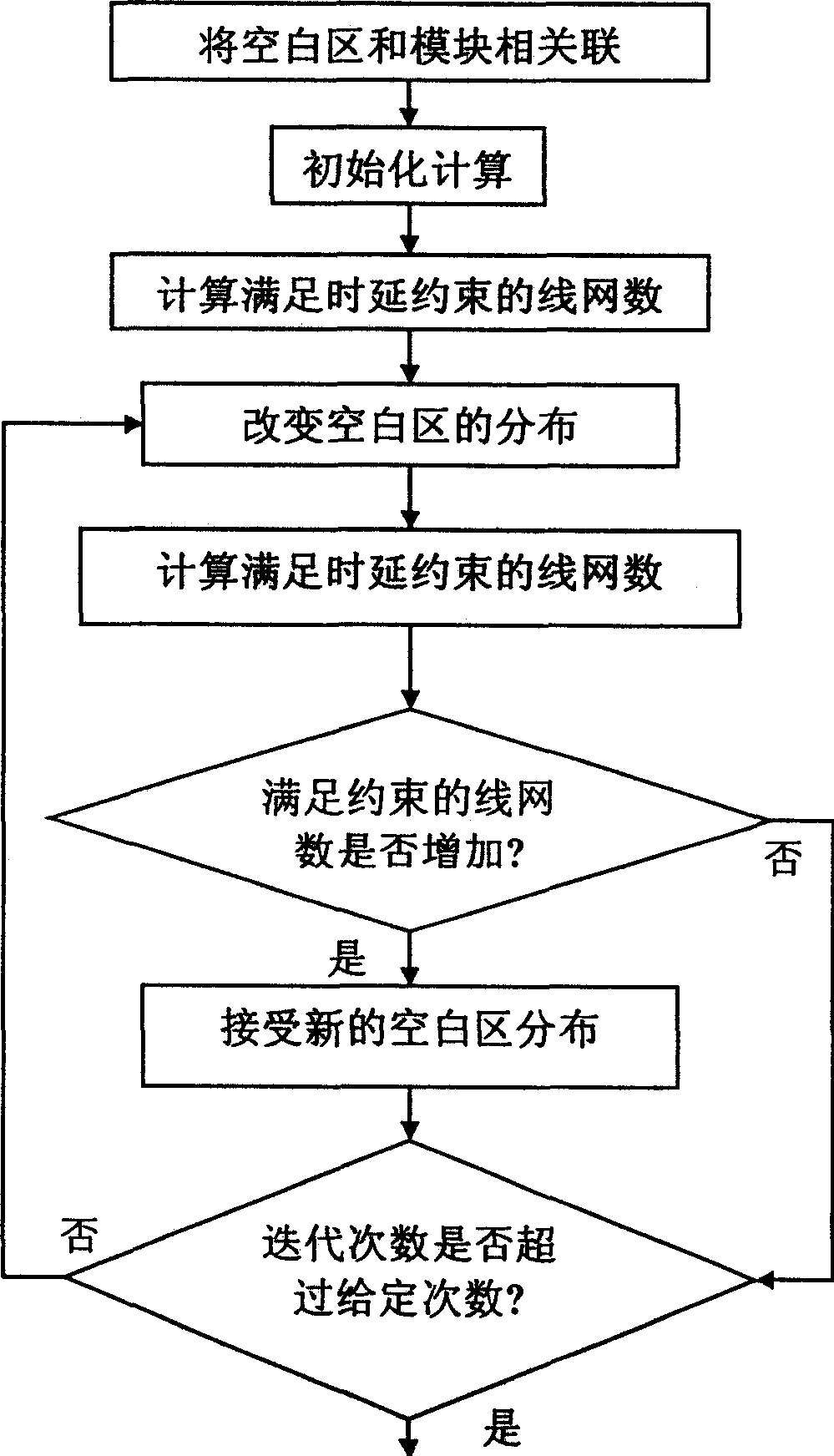

Buffer programming method based on blank region redistribution

InactiveCN1223955CIncrease profitImprove delay characteristicsSpecial data processing applicationsParallel computingPlanning method

A buffer planning method based on the relocation of empty areas includes finding out the relative number of buffers and the number of wire-meshes according to wire-mesh delay restriction, modifying the distribution of empty areas by iterating several times, updating the associated wire-mesh information, recalculating the number of wire mashes for meeting the delay restriction, and replacing original distribution of empty areas.

Owner:TSINGHUA UNIV

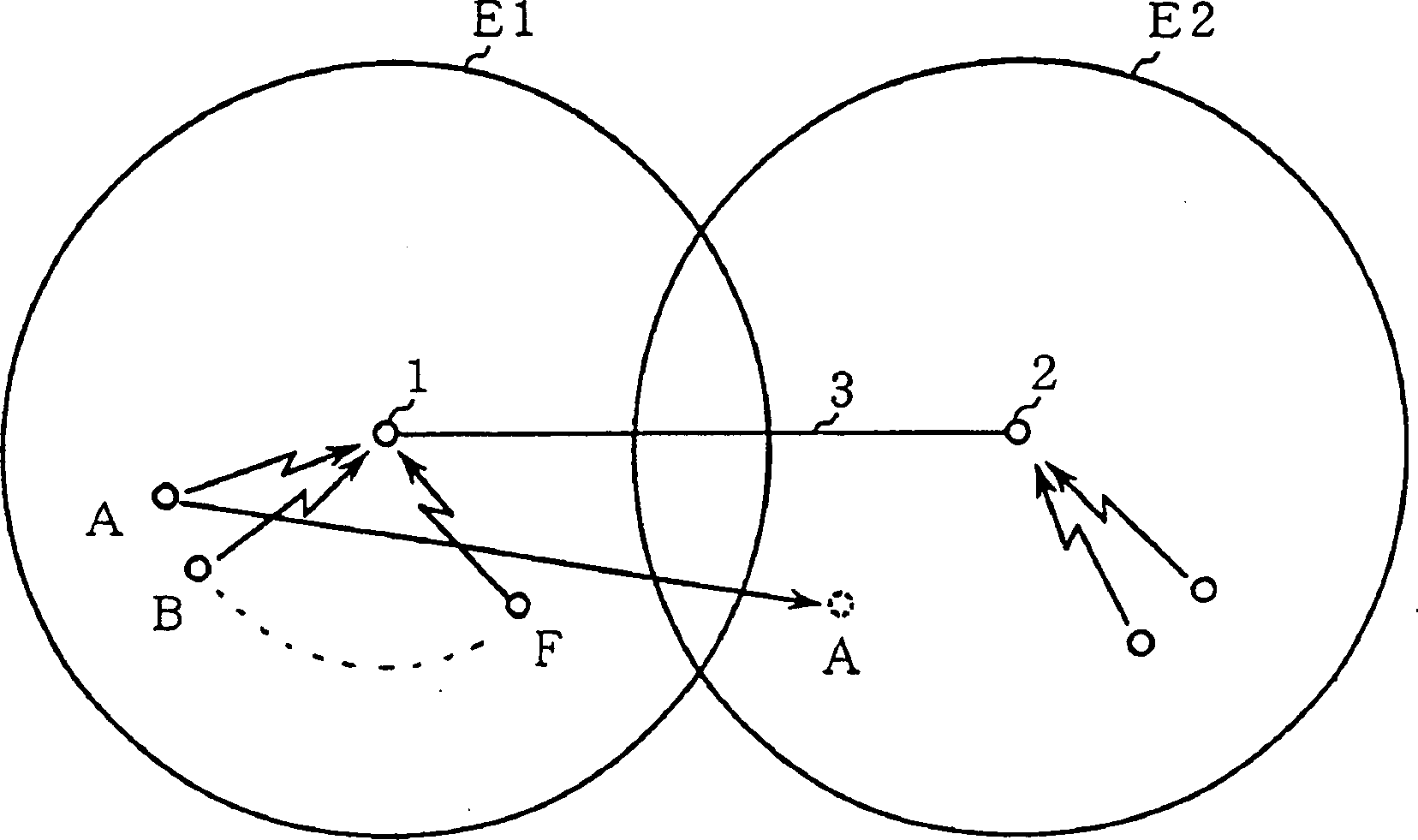

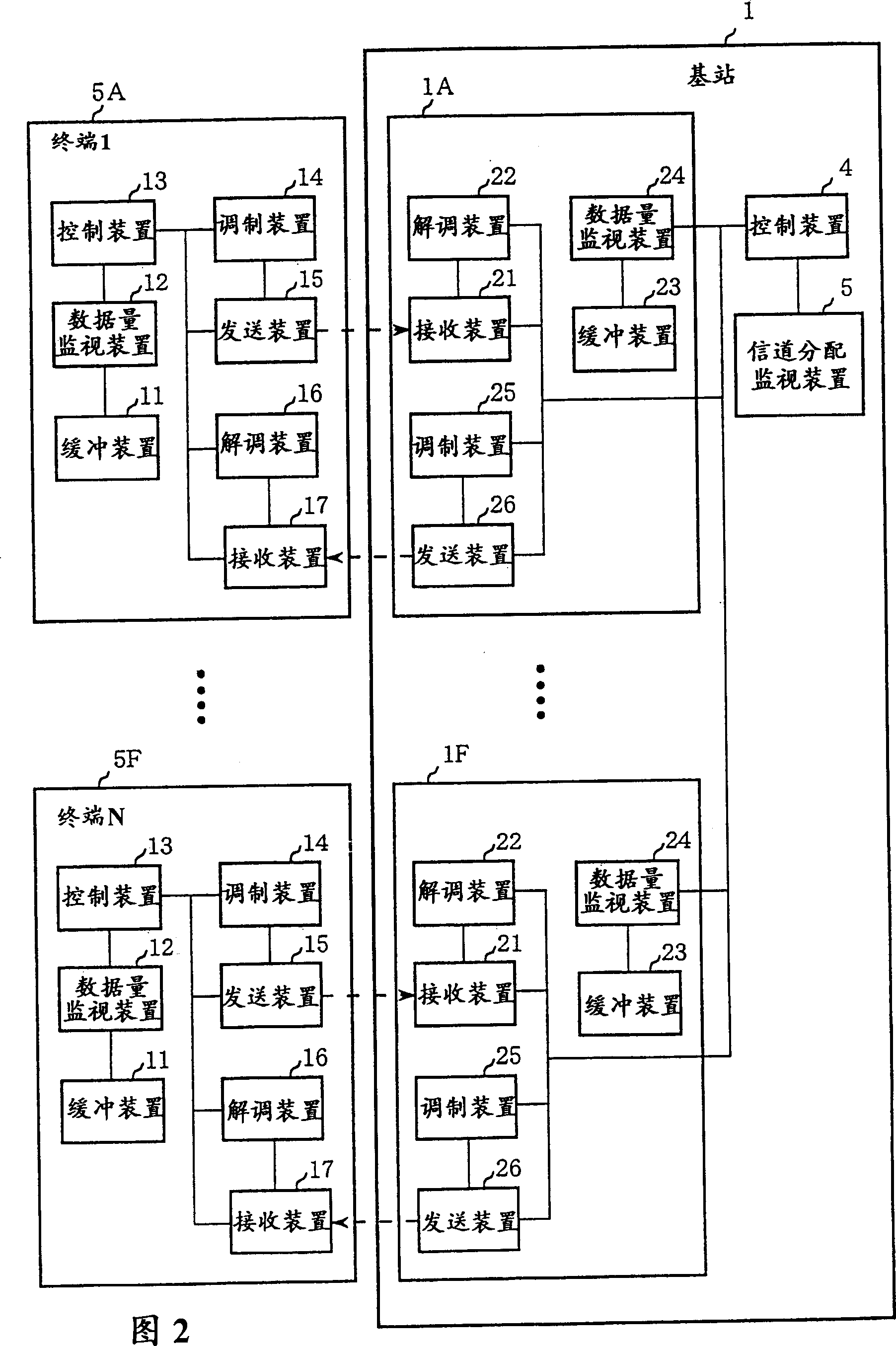

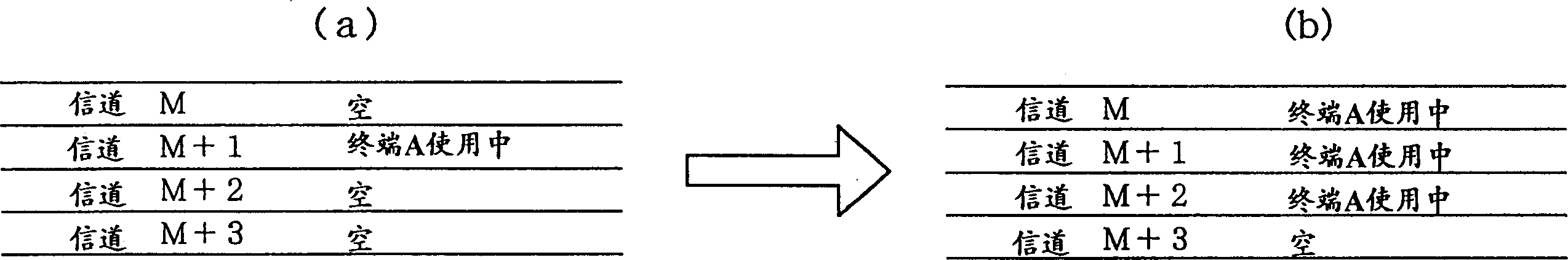

Method for allocating radio channel for radio communication

InactiveCN1161894CEasy to useReduce ineffective useRadio transmission for post communicationWireless communicationRadio channelChannel capacity

At the time of making radio communication between one base station and a plurality of radio terminals in the communication area of the base station, data communication is made at a higher speed and the wasteful use of the channel capacity is reduced by effectively using a limited channel capacity by changing the channel capacity, such as the number of channels, number of slots, frequency bandwidths, etc., in accordance with the rate of change of the quantity of communication data or quantity of communication data per unit time.

Owner:MITSUBISHI ELECTRIC CORP

A kind of quinoa-sorghum mixed strip planting method

ActiveCN109247208BIncrease the number of linesPrevent lodgingSuperphosphatesBio-organic fraction processingBiotechnologySorghum

The invention discloses a quinoa-sorghum mixed strip planting method, which comprises multiple steps such as site selection, site preparation, film covering, seeding, seedling thinning, soil cultivation, fertilization and harvesting. Since both quinoa and sorghum are high-stalked and easy to lodging crops, and the stalk strengths of the two crops are different, the quinoa and sorghum are sown in sequence at intervals to prevent the same type of crops from being exposed to severe weather such as strong winds. A domino effect is formed, resulting in large-scale lodging. The invention not only effectively prevents quinoa from lodging in the aspects of site selection, sowing, soil cultivation and the like. Moreover, the combined application of base fertilizer and high-efficiency compound fertilizer is suitable for the entire growth cycle of quinoa, which is beneficial to the lodging resistance of quinoa, increases the yield of quinoa, and effectively improves the quality of quinoa.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

Method for manufacturing anti-counterfeiting photoetching film tape

InactiveCN109671350AFunctions to prevent counterfeitingIncrease the number of linesStampsPhotomechanical apparatusHigh pressureGlass sheet

The embodiment of the invention discloses a method for manufacturing an anti-counterfeiting photoetching film tape, which comprises the following steps: S1, drawing a design drawing; S2, setting the number of alignment lines of the photoetching machine to be 2200-2600, and photoetching a design drawing on a glass plate; S3, spraying silver on the glass plate, electroforming and copying to obtain ametal nickel plate; S4, recopying the metal nickel plate to obtain a working plate unit, and splicing a plurality of working plate units to obtain a working plate; and S5, copying the pattern mirrorimage on the working plate onto the thin film material through high temperature and high pressure to obtain the anti-counterfeiting photoetching film tape. Compared with the prior art, the manufacturing method of the anti-counterfeiting photoetching film tape has the following beneficial effects that as the surface of the photoetching film tape is lost by about 20 percent in each copying, the manufacturing method of the anti-counterfeiting photoetching film tape improves the alignment number of the photoetching machine during photoetching, so that the manufactured original photoetching film strip reaches the imaging limit; and if the original photoetching film strip is copied again to forge the photoetching film strip, the pattern on the surface part of the original photoetching film stripis lost, and the function of preventing the photoetching film from being forged is realized.

Owner:武汉宇恩防伪技术有限公司

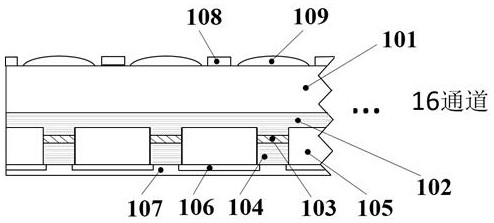

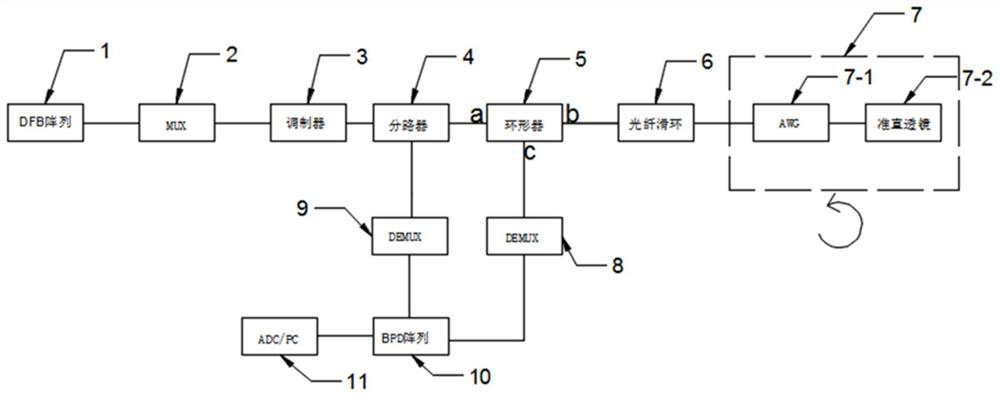

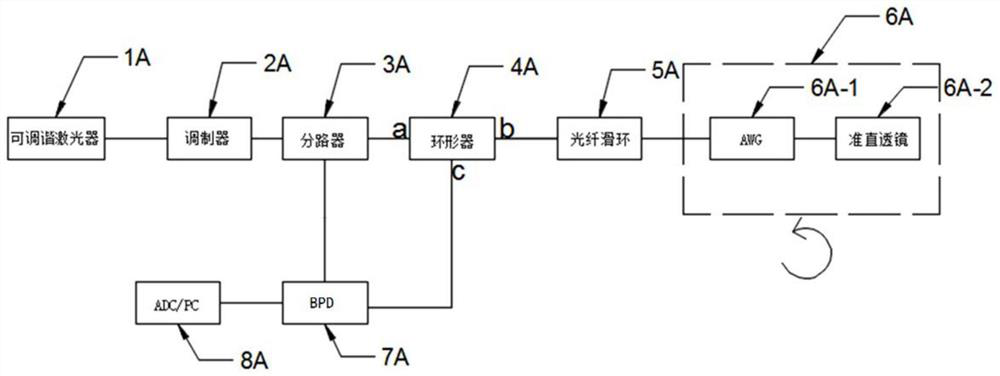

Laser radar scanning system based on AWG

PendingCN113376616ASmall sizeEasy to integrateElectromagnetic wave reradiationMultiplexingImage resolution

The invention discloses a laser radar scanning system based on AWG, wherein the system comprises a transverse rotating platform and a longitudinal scanning mechanism arranged on the transverse rotating platform; the longitudinal scanning mechanism comprises an AWG and a collimator, the AWG is a passive device, and the device is small in size, easy to integrate, light in weight and convenient to rotate; the transverse rotating platform is small in rotational inertia, high-speed rotation can be achieved conveniently, and the rotating service life is long; the transverse scanning of a laser radar is determined by mechanical rotation, the transverse resolution ratio is high, the longitudinal resolution ratio is determined by the AWG, and the resolution ratio can be further improved by adding optical switch multiplexing in front of or behind the AWG; the laser radar can realize cheap and large-scale deployment through component reuse; and the laser radar can increase the number of lines by increasing the number of DFB arrays or the number of tunable laser wavelengths.

Owner:HANGZHOU XIGHT SEMICON CO LTD

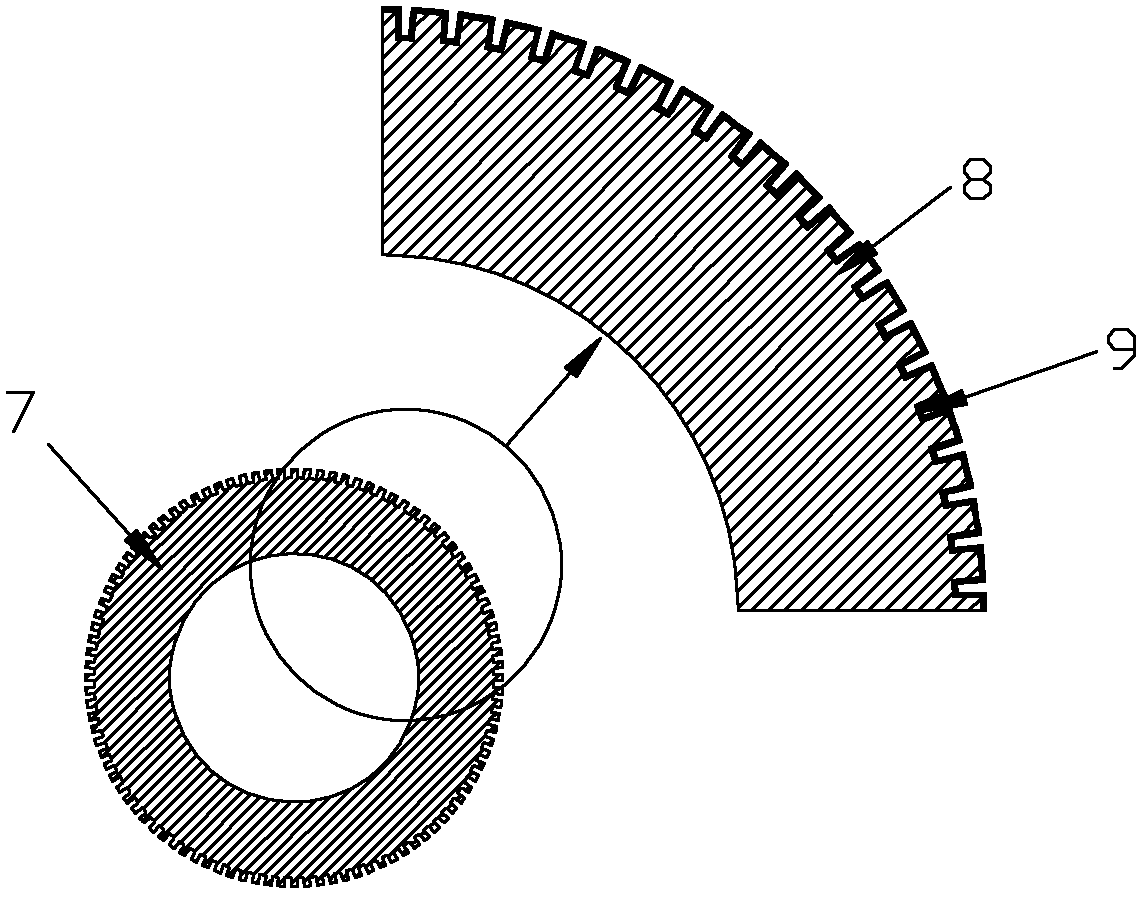

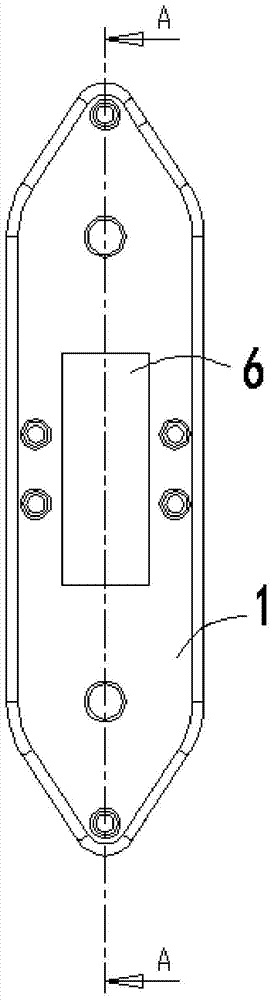

Jacquard pulley mechanism

The invention relates to a jacquard pulley mechanism. The jacquard pulley mechanism comprises an upper cover plate, a lower cover plate, a support and rollers, wherein the upper cover plate is matched with the lower cover plate, and the rollers are positioned between the lower cover plate and the support. Compared with the prior art, the jacquard pulley mechanism has the following advantages and effects that a large amount of space can be saved, more pulley mechanisms can be arranged in the same size, and more heddles can also be arranged, so that the wire number of a jacquard can be increased, and the economical benefit is increased; the whole pulley mechanism comprises four components, so that the integration degree is very high; the components are reduced, so that the space is saved, and the rollers of the large diameter can be selected; the rollers of the large diameter have the advantages that the rolling effect is good, stronger loads can be born, and a high-speed effect can be fitted.

Owner:浙江慧林智能设备有限公司

A camera upgrade method

ActiveCN105704445BImprove transmission performanceIncrease transfer speedTelevision system detailsColor television detailsComputer hardwareComputer science

The invention discloses a method for upgrading a camera, which uses a reverse blanking zone to transmit an upgrade package to upgrade the camera without dismantling, simple operation, and low upgrade cost; moreover, the front-end camera receives an upgrade instruction sent by the back-end , after the front-end camera switches the normal working mode to the upgrade mode, before the front-end camera sends a response signal to the back-end, the front-end camera will set the initial valid data area and the initial reverse blanking area when it is in the normal working mode to reverse Blanking area, that is, increasing the number of lines in the reverse blanking area, so that when the front-end camera receives the upgrade package sent by the rear end through the reset reverse blanking area, the transmission capacity of the reverse blanking area can be improved and transmission speed, so that the upgrade speed of the camera can be improved; in addition, after the upgrade is completed, the front-end camera restores the initial effective data area and the initial reverse blanking area, which will not affect the normal work of the front-end camera after the upgrade.

Owner:ZHEJIANG DAHUA TECH CO LTD

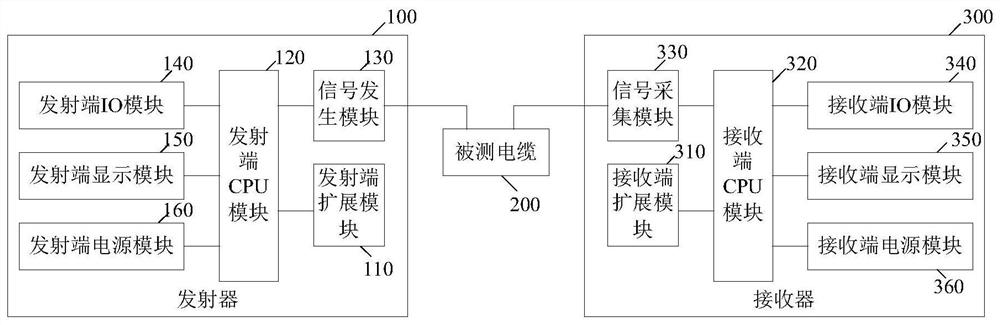

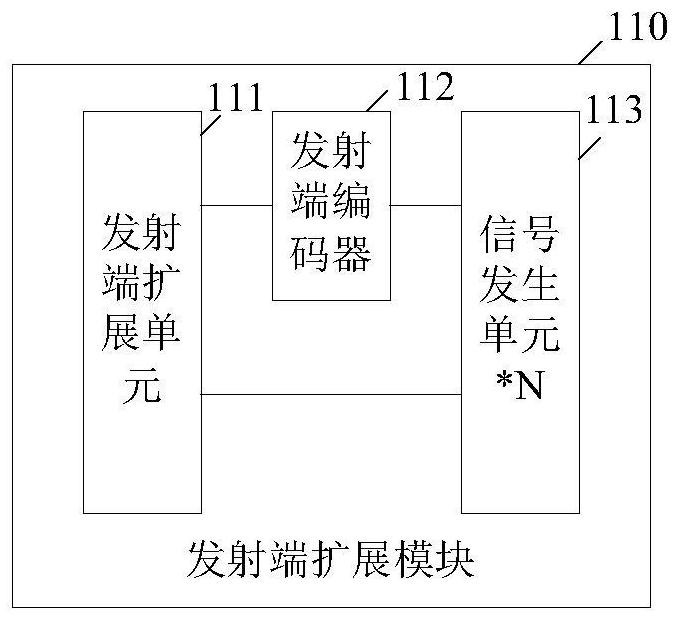

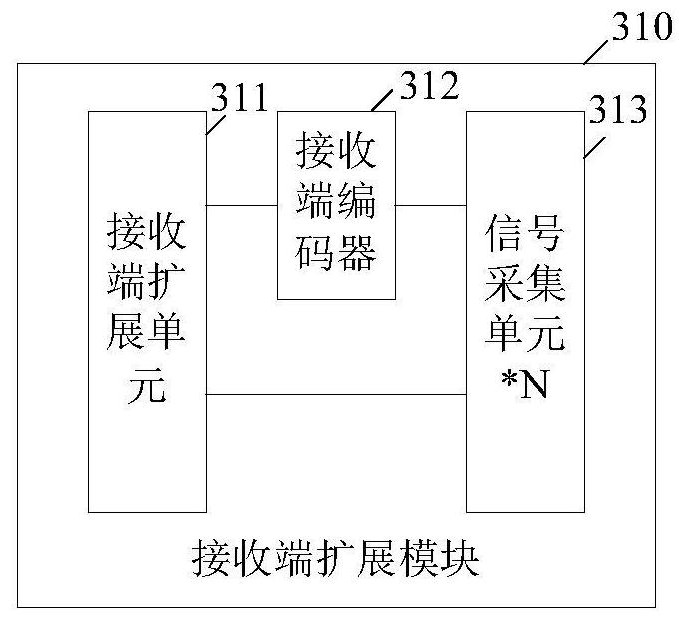

Cable alignment device

PendingCN113030788AImprove implementation efficiencyIncrease the number of linesElectrical testingSound waveElectric cables

The invention relates to the technical field of power systems, and particularly discloses a cable alignment device, which comprises: atransmitter which is connected with a tested cable and used for emitting a sound wave signal with a specific frequency to the tested cable; and a receiver which is connected with the tested cable, and is used for collecting the sound wave signal with the specific frequency transmitted by the tested cable, and analyzing the collected sound wave signal with the specific frequency to determine the line sequence relation between the transmitter and the receiver. The transmitter which comprises a transmitting end expansion module, the transmitting end expansion module is connected with the tested cables and used for providing expanded sound wave signals with specific frequency when the number of the tested cables is increased. The receiver comprises a receiving end expansion module, and the receiving end expansion module is connected with the tested cables and used for collecting the expanded sound wave signals of the specific frequency when the number of the tested cables is increased. According to the cable alignment device provided by the invention, the implementation efficiency of alignment is improved.

Owner:JIANGSU ELECTRIC POWER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com