Method for manufacturing anti-counterfeiting photoetching film tape

A manufacturing method and lithography technology, which are applied in the photoengraving process, optics and optomechanical equipment of the pattern surface, can solve the problems such as copying and counterfeiting of photolithographic films, and achieve the effect of preventing forgery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

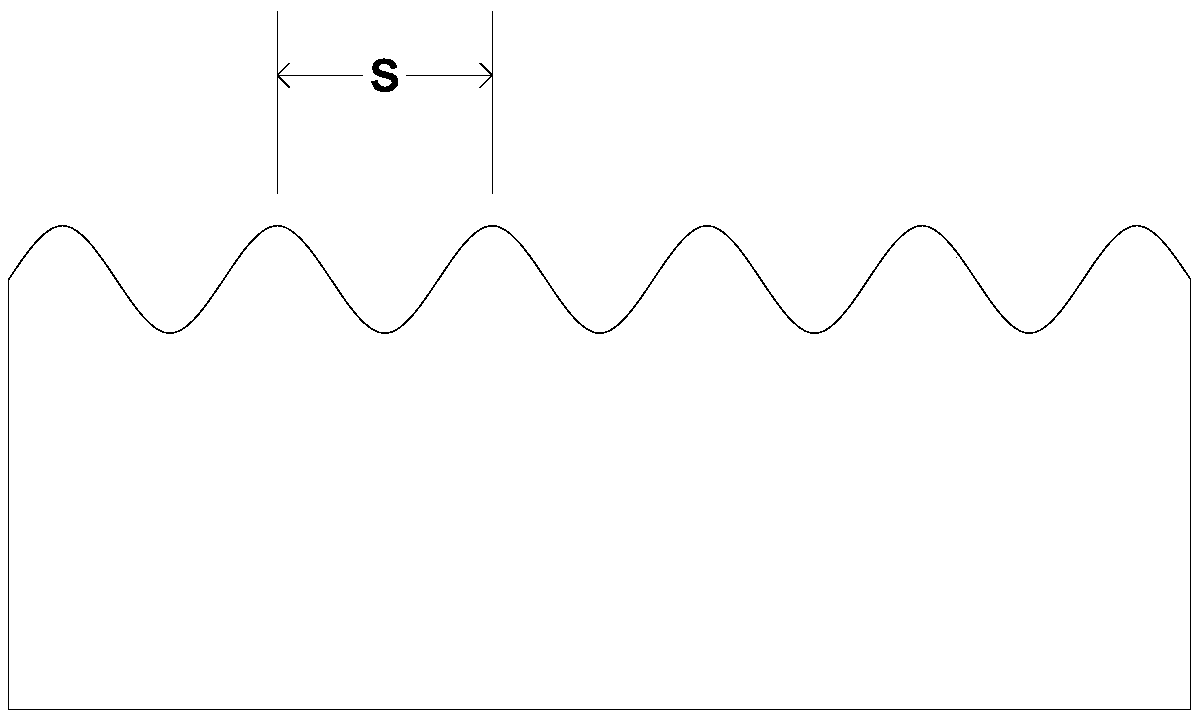

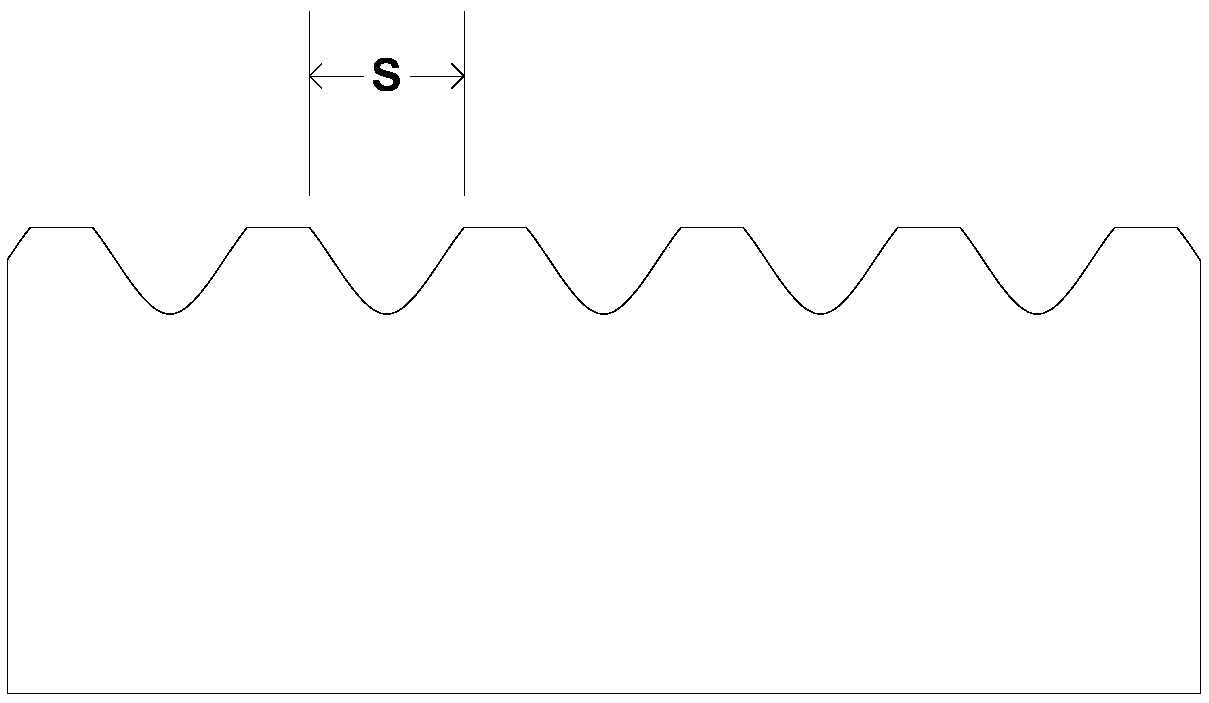

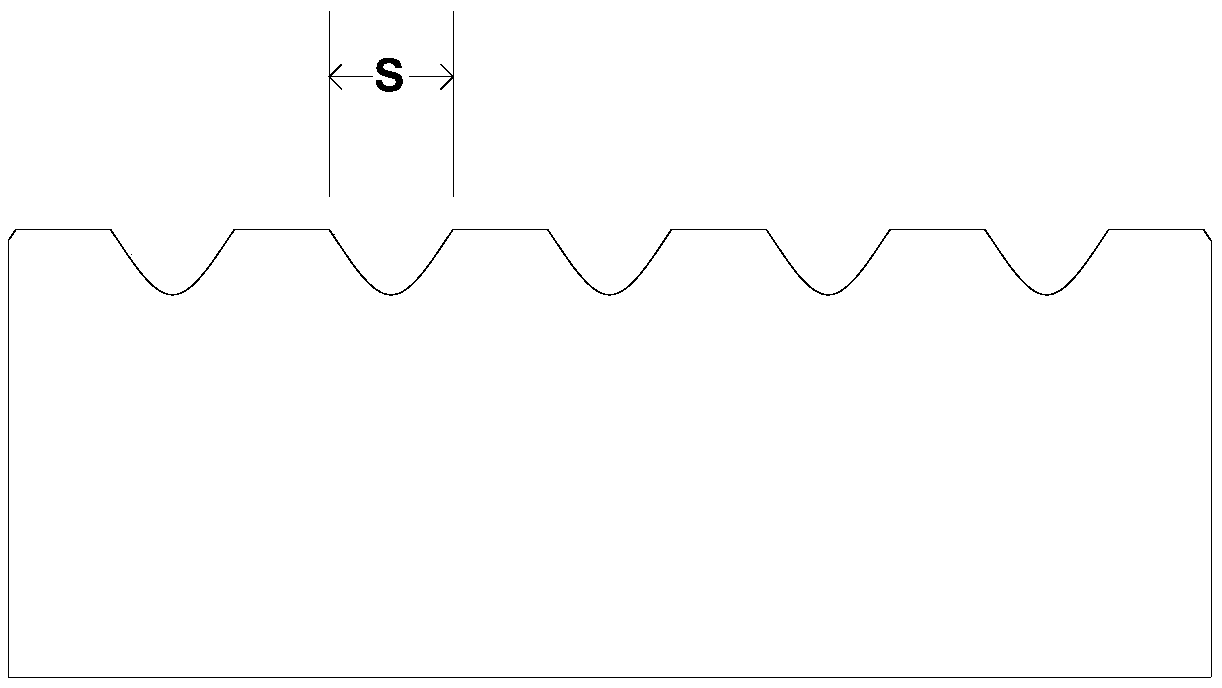

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0019] A kind of manufacture method of anti-counterfeit photoresist film belt provided by the invention comprises the following steps:

[0020] S1. Use professional drawing software on the computer to draw design drawings.

[0021] S2. Select a diffractive lithography machine, and set the number of alignments of the lithography machine to 2200-2600. Preferably, the inventor has found that the anti-counterfeiting effect is the best when the number of alignments is 2400-2500 through multiple tests. Then the design drawing is photoetched on the glass plate, the photoresisted surface of the glass plate is flat, and a layer of photoresist is evenly coated on it.

[0022] S3. Spraying silver on the photoetched glass plate, and then electroforming a replica to obtain a metal nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com