Patents

Literature

262results about How to "High degree of curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

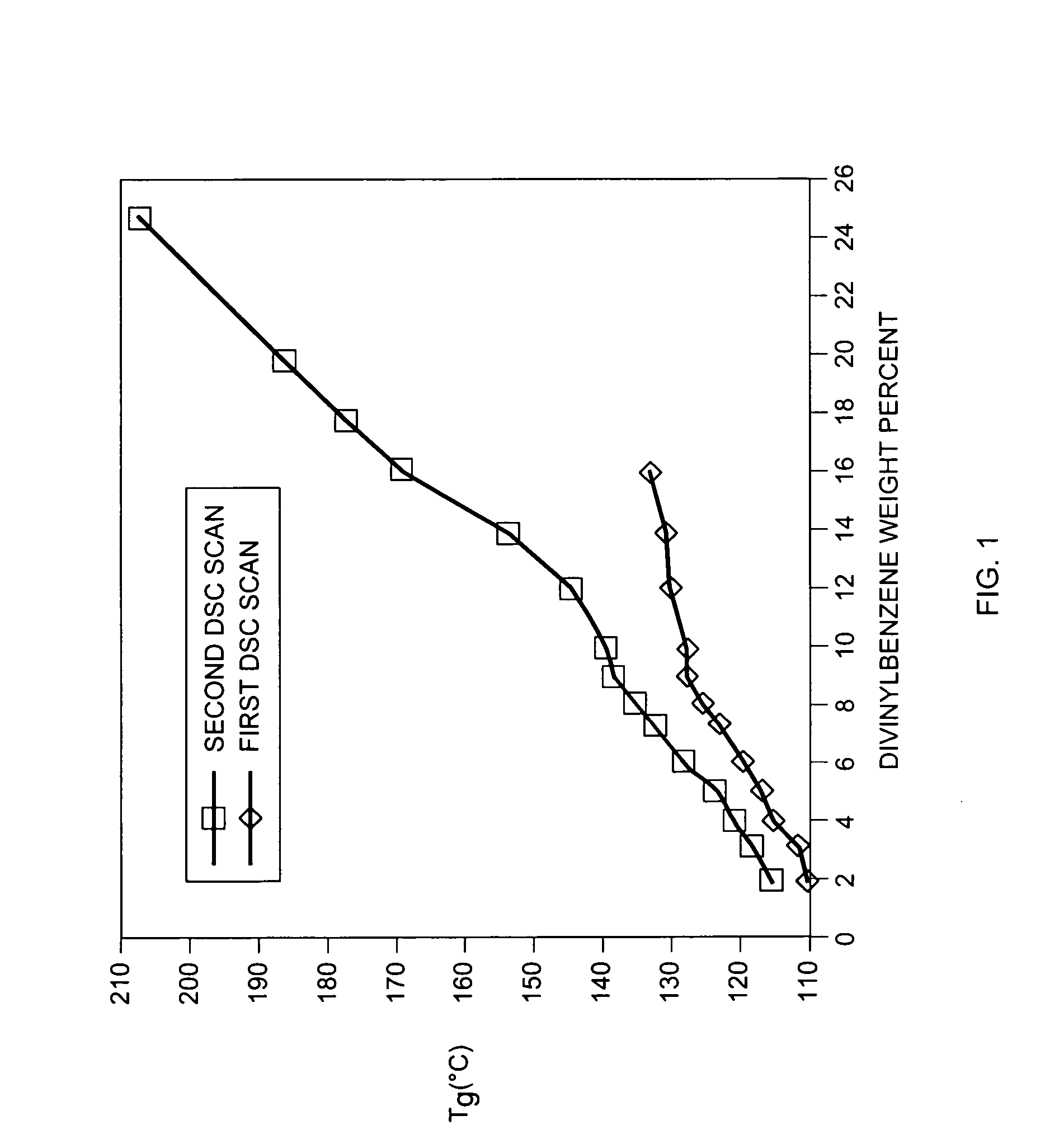

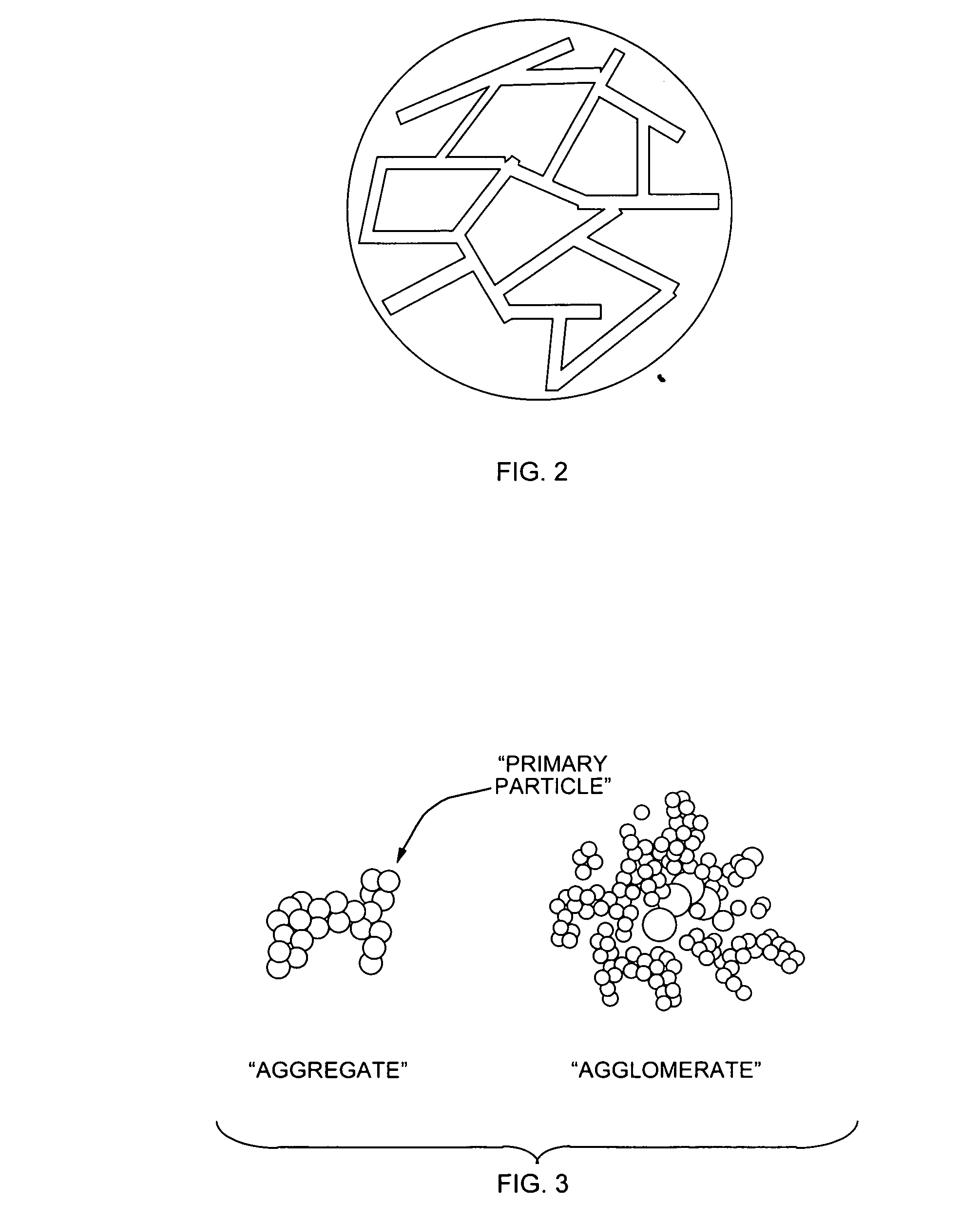

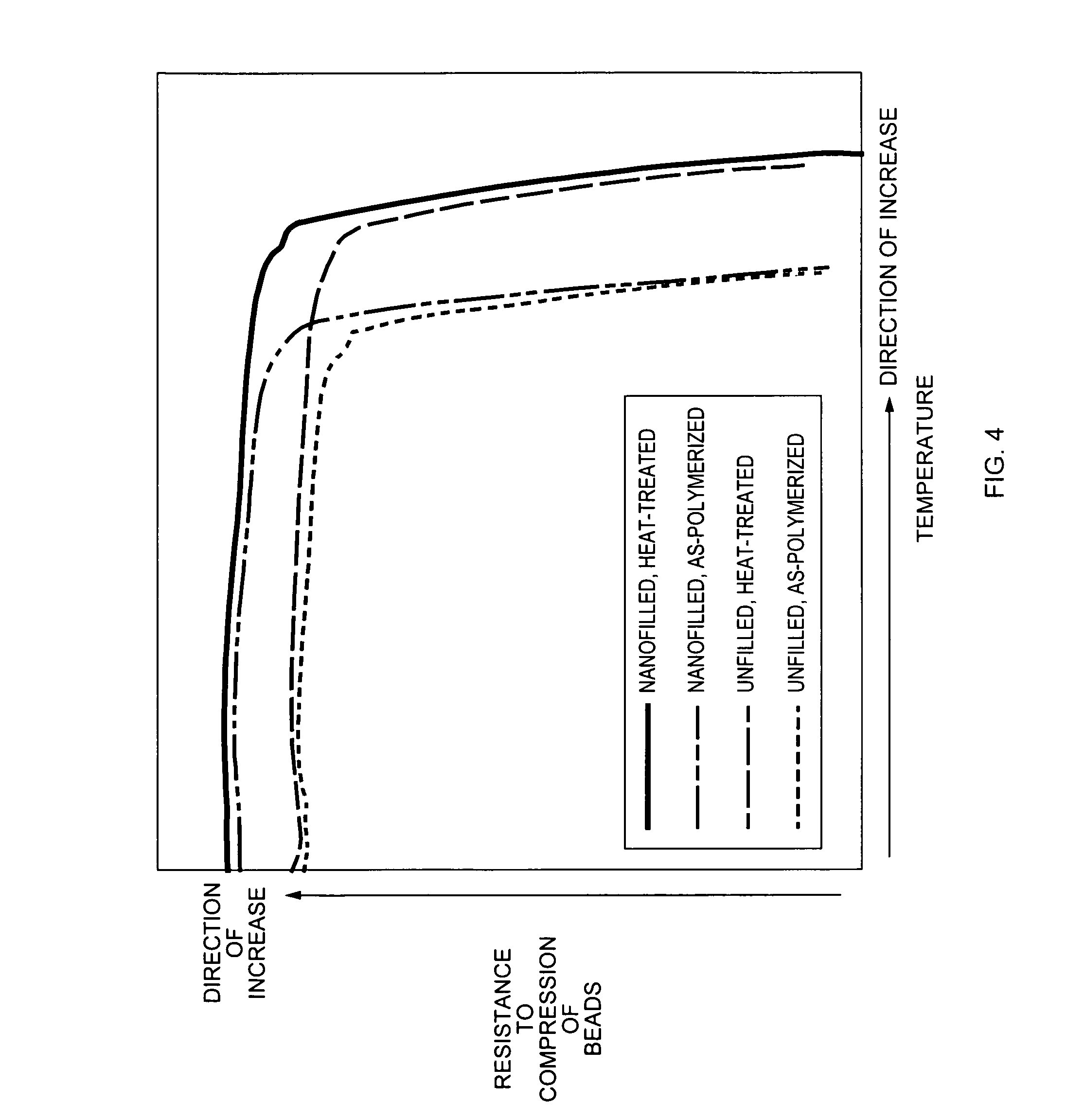

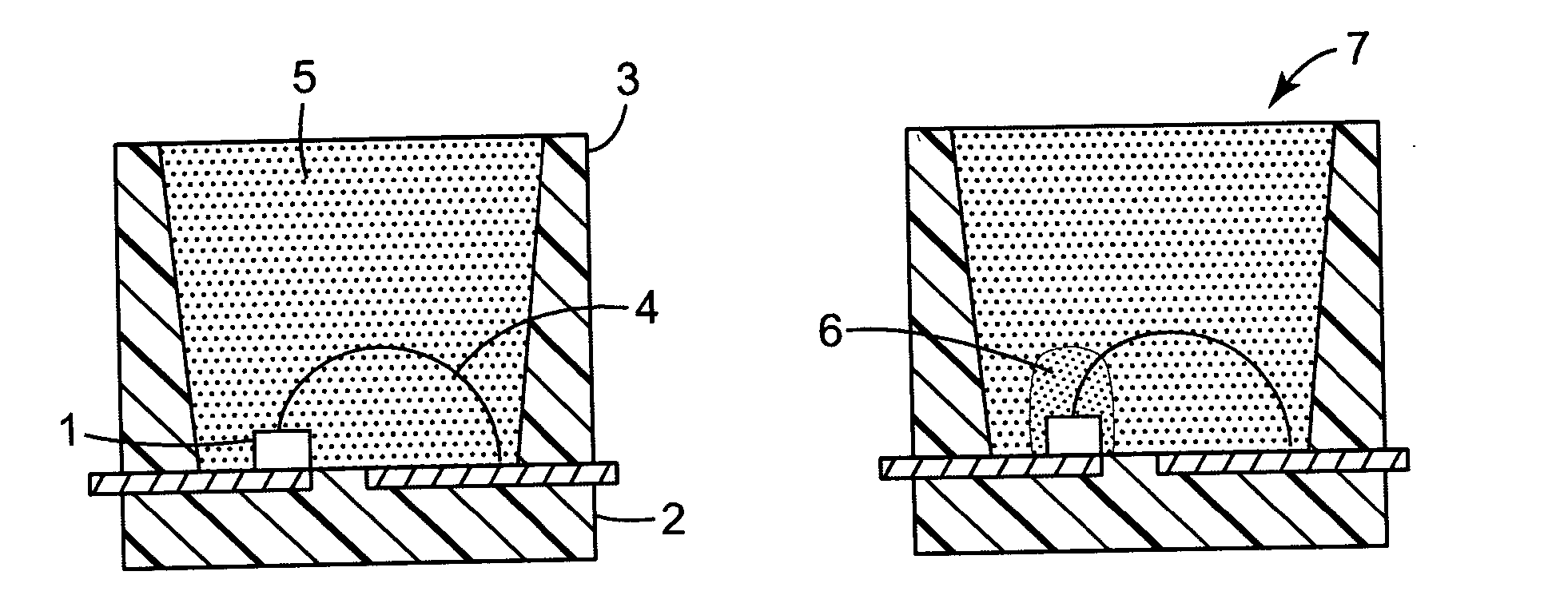

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

Encapsulated light emitting diodes and methods of making

InactiveUS20060105483A1Reduce and limit mechanically generated stressDiffuse more easilySolid-state devicesSemiconductor/solid-state device manufacturingSealantLight-emitting diode

Owner:3M INNOVATIVE PROPERTIES CO

Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

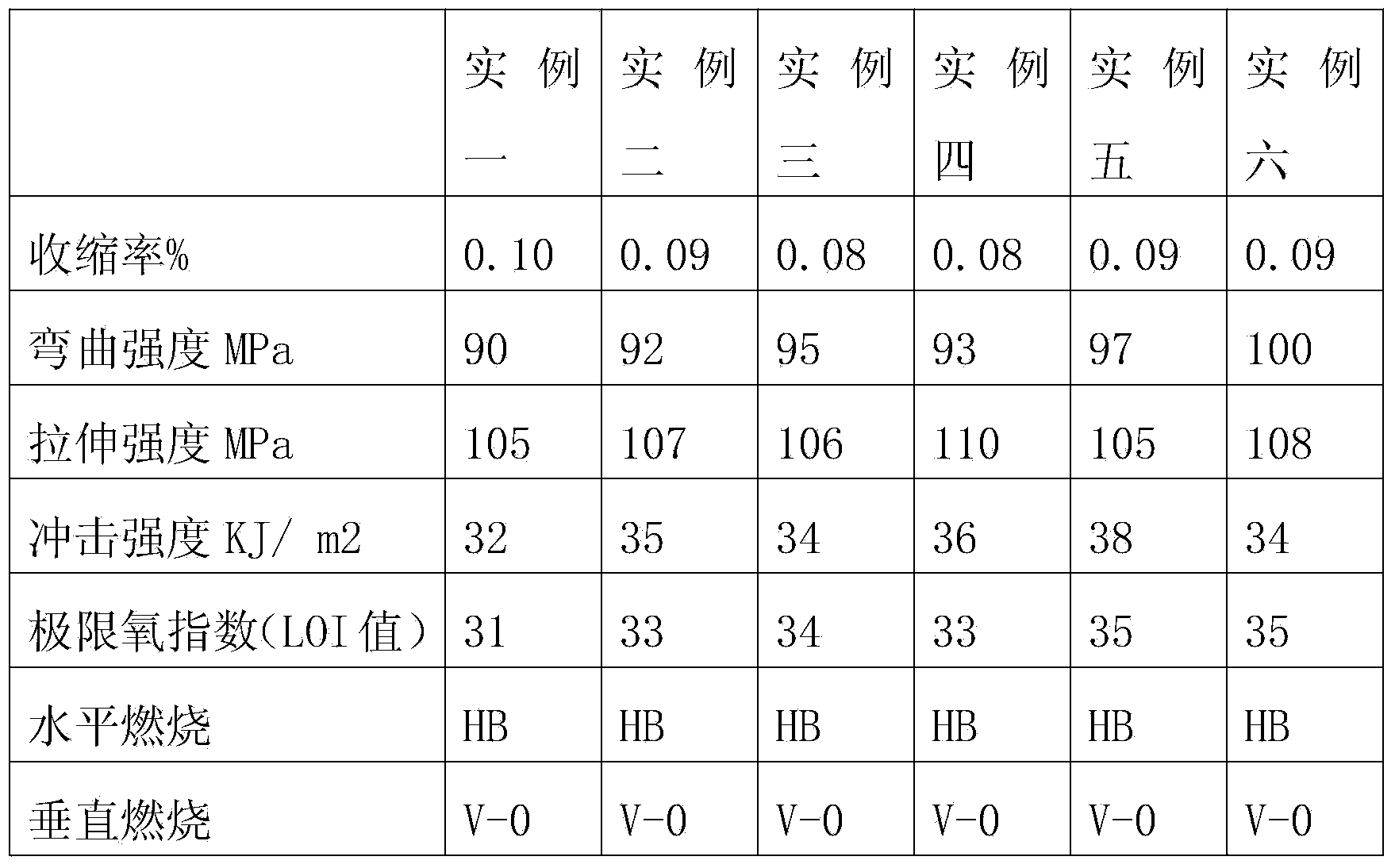

The invention discloses a low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and a preparation method thereof. The low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board is prepared from the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 20-30 parts of a low-shrinkage additive, 1-3 parts of an accelerant, 0.5-2 parts of an initiator, 2-5 parts of a medium-temperature curing agent, 0.1-0.5 part of a thickening agent, 8-15 parts of a novel halogen-free flame retardant, 100-130 parts of inorganic filler, 2-3 parts of a release agent and 100-150 parts of fiberglass. The curing degree, the bending strength and the flexibility of the low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board can be improved; residual styrene in the fiberglass reinforced plastic board is reduced.

Owner:扬州万盛实业有限公司

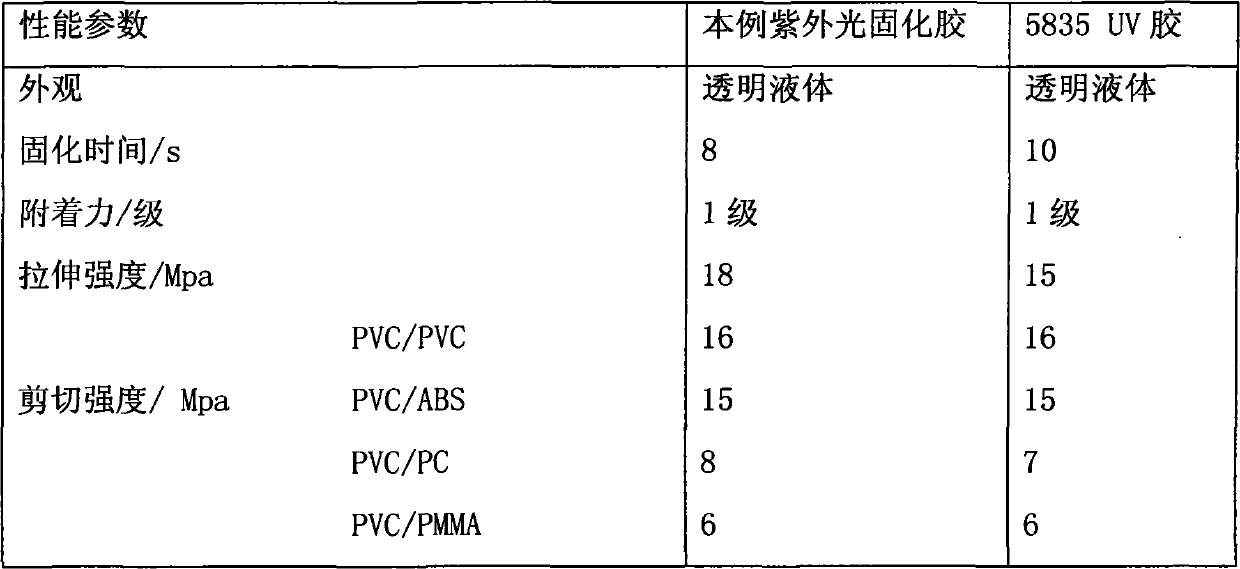

UV-cured adhesive for plastic and preparation method thereof

InactiveCN101906284AImprove flexibilityImprove curing speedPolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesiveDiluent

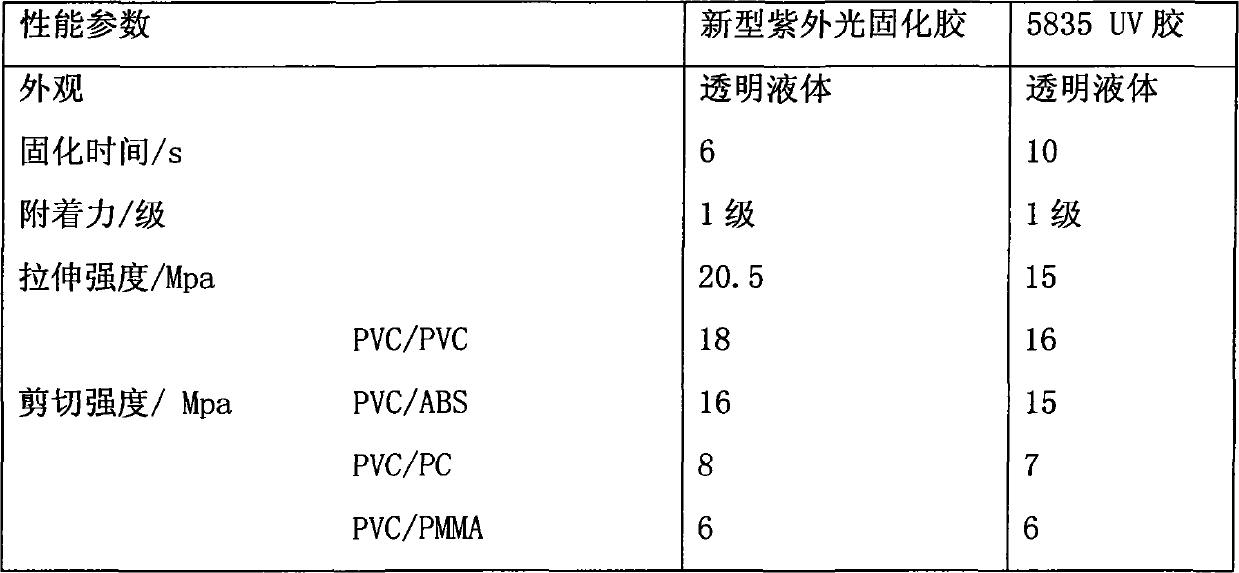

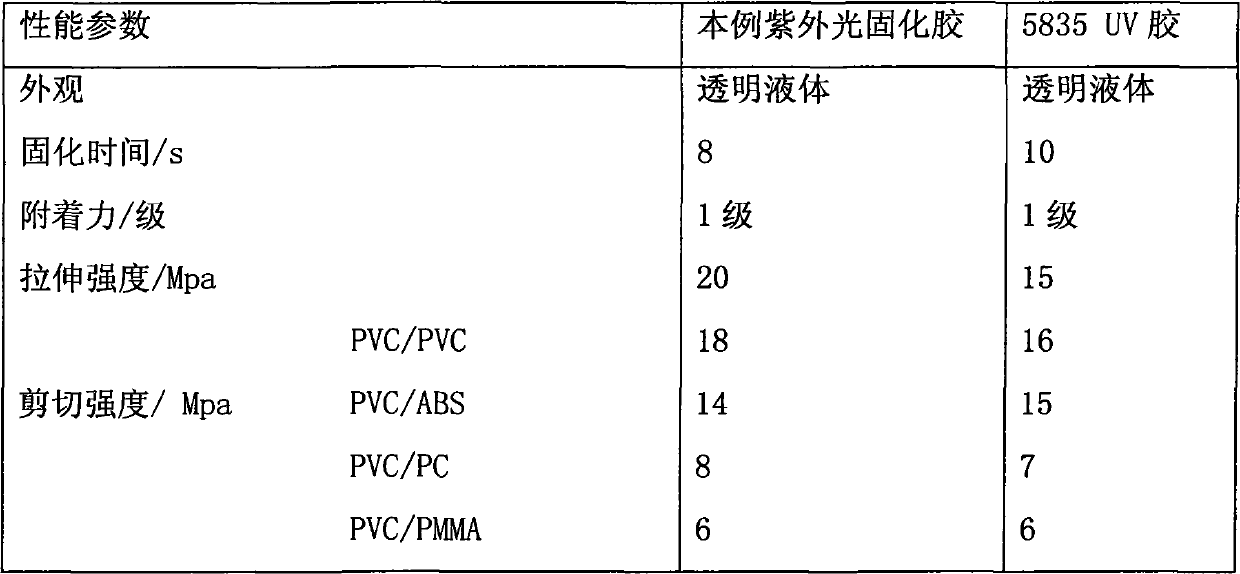

The invention discloses a novel UV-cured adhesive for plastic and a preparation method thereof. The UV-cured adhesive is prepared by the following steps of: adding polyurethane acrylate and a monomer diluent into an epoxy acrylate resin, stirring at the constant temperature of between 50 and 55 DEG C for 3 to 4 hours, and adding a photoinitiator, an accelerating agent and a polymerization inhibitor; and regulating the temperature to between 60 and 70 DEG C, stirring at the constant temperature for 1 to 2 hours and discharging to prepare the novel UV-cured adhesive. The UV-cured adhesive comprises the following components in percentage by weight: 30 to 60 percent of polyurethane acrylate, 10 to 30 percent of epoxy acrylate resin, 4 to 5 percent of photoinitiator, 25 to 65 percent of monomer diluent, 0.1 to 0.9 percent of accelerating agent and 0 to 0.2 percent of polymerization inhibitor. The product is mainly applied to adhesion of PVC, ABS, PC, PMMA and other plastics, and has the advantages of no solvent, simple and easy operation and suitability for mass production.

Owner:SOUTH CHINA UNIV OF TECH

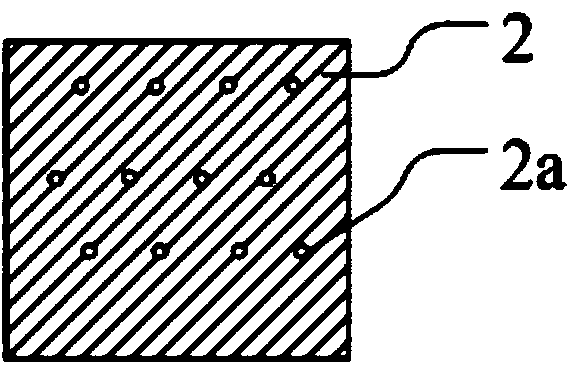

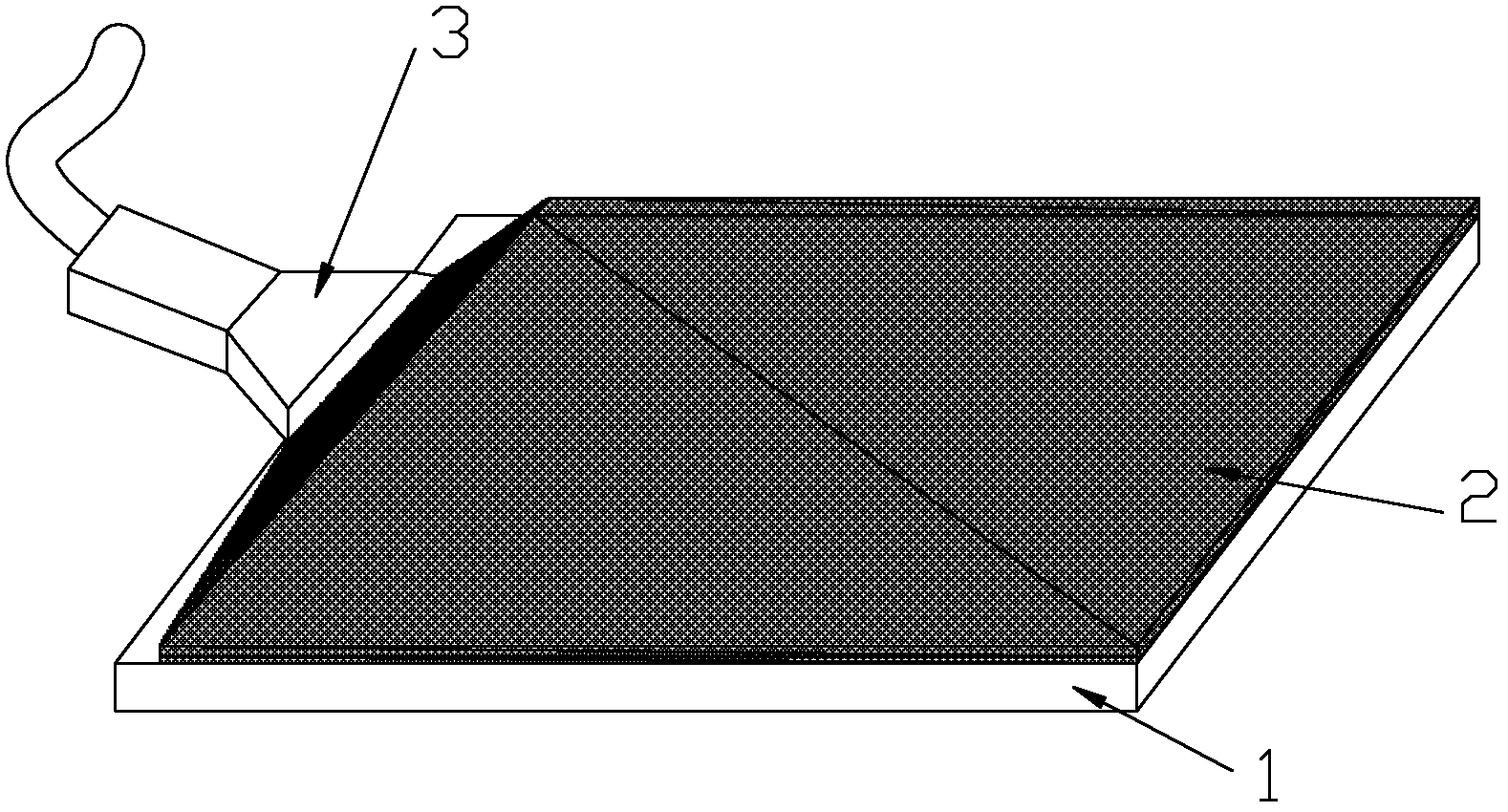

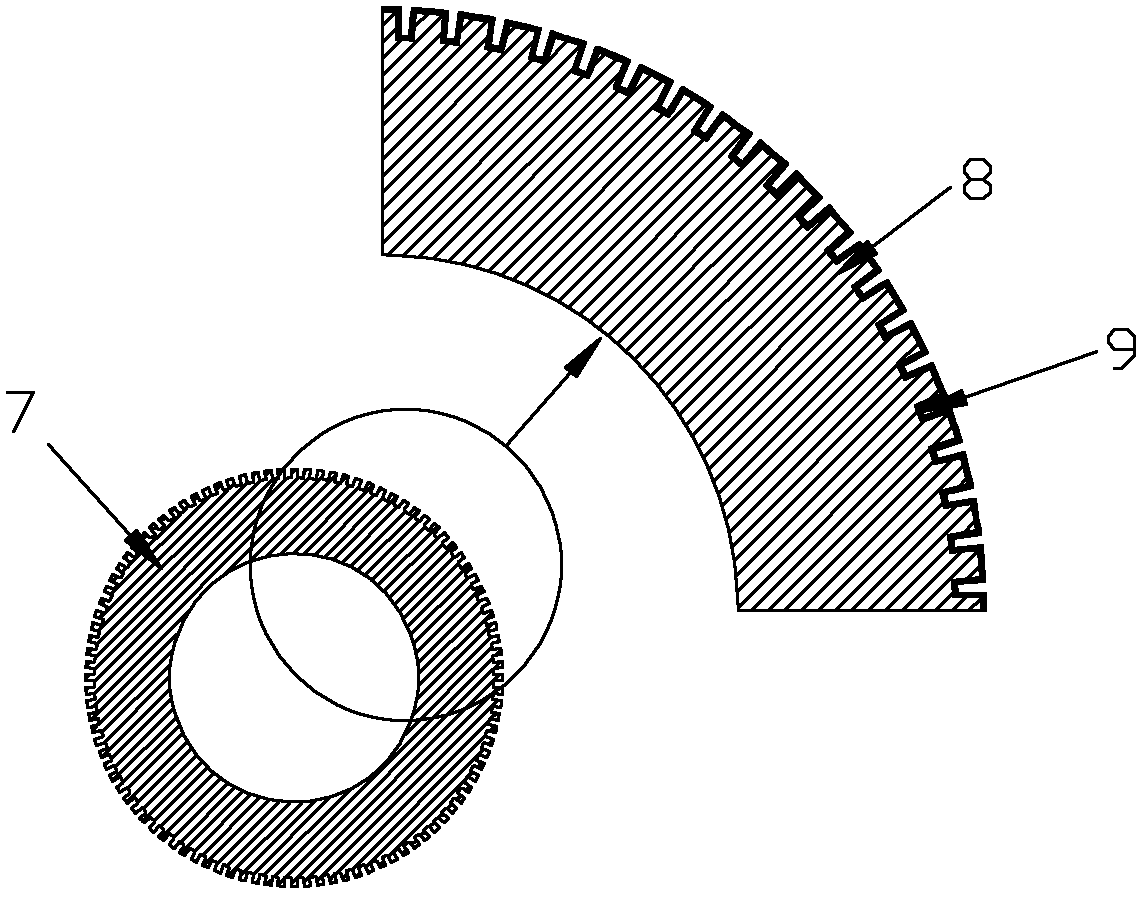

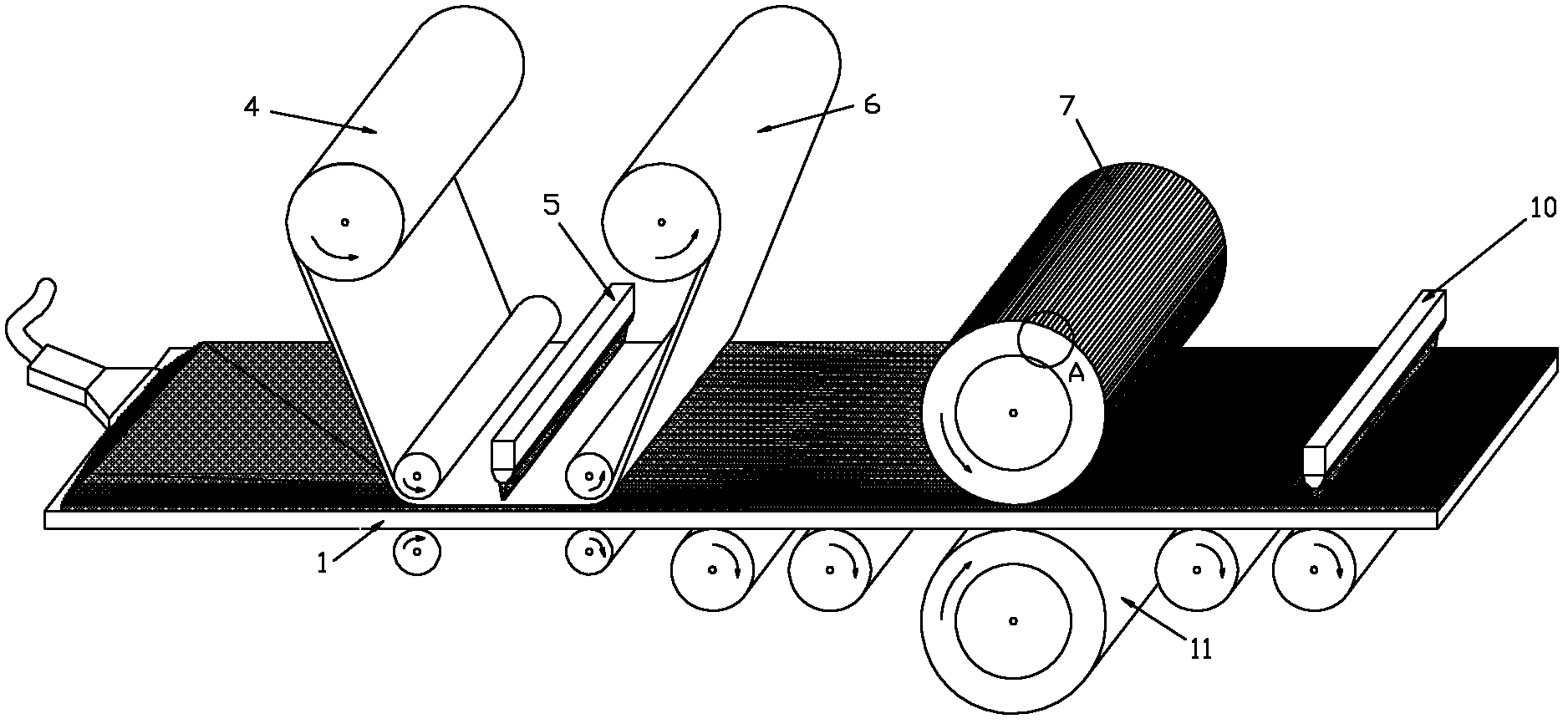

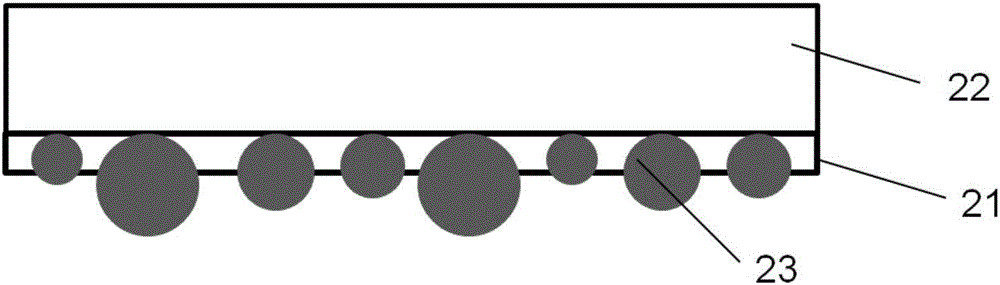

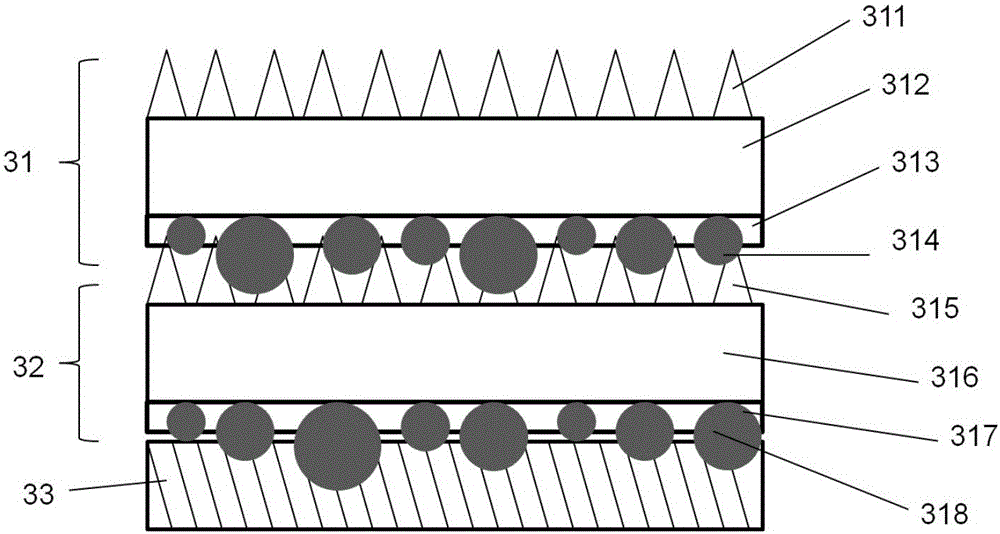

Grinding and polishing pad for cured grinding material based on thermal initiation curing and preparation method thereof

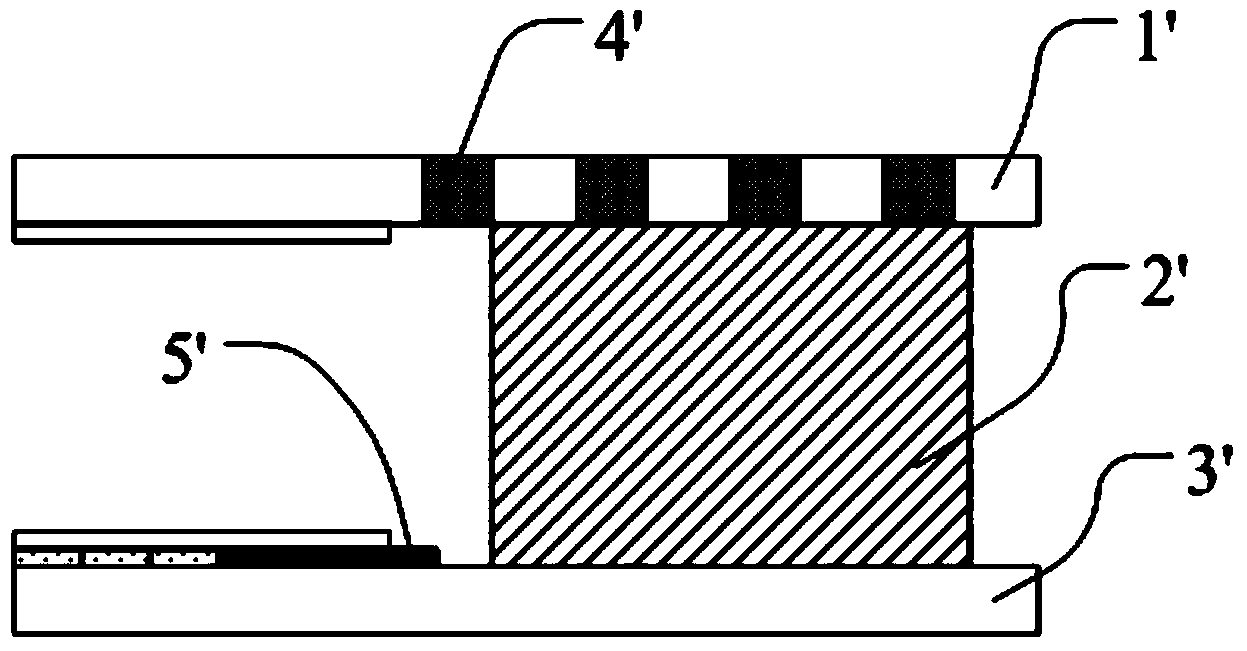

ActiveCN101817172AEliminates light transmission limitationsReduce usageAbrasion apparatusGrinding devicesMicrometerGranularity

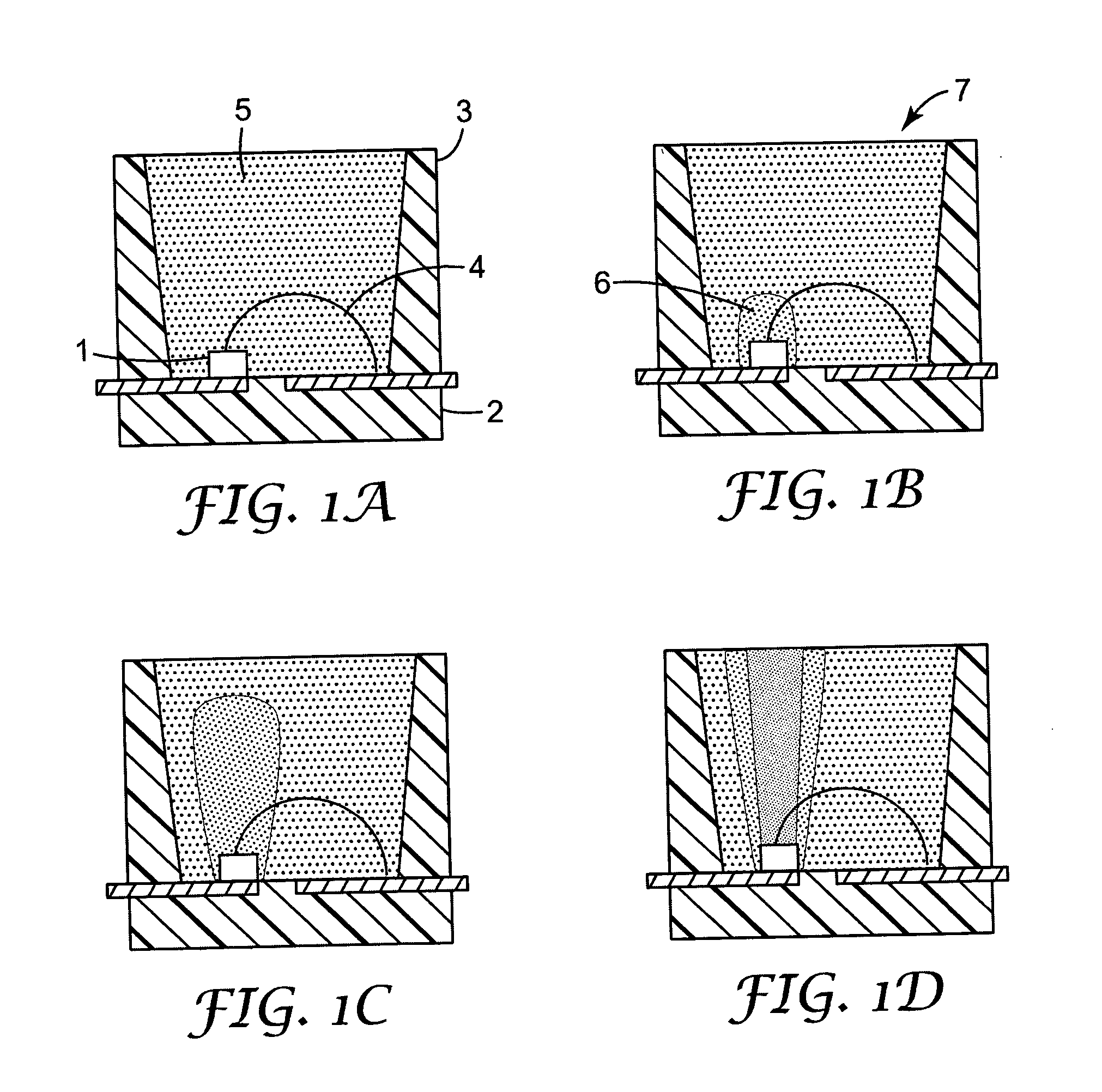

The invention discloses a grinding and polishing pad for a cured grinding material based on thermal initiation curing and a preparation method thereof, applied to the fields of precise and super precise grinding and polishing processing. The grinding and polishing pad is characterized in that a grinding material layer (1) contains the following components in percent by mass: 1-40 percent of grinding material with the granularity of 50 nanometers to 40 micrometers, 10-60 percent of prepolymer of polyacrylic ester, 0.5-7 percent of free radical / anions / oxidation-deoxidation thermal initiating agent, 0-2 percent of grinding material surface modifying and dispersing agent, 0-5 percent of accelerator, 0-20 percent of performance tuning additive and 5-40 percent of activated thinner of esterified acrylic acid. The preparation method of the grinding and polishing pad comprises the following steps of: (1) sufficiently and uniformly mixing raw materials; (2) preparing a polishing pad mould and preparing an abrasive particle layer by mould pouring, heating and curing; and (3) bonding the grinding material layer with an elastic or (and) rigid layer by using a bonding agent according to requirements to obtain the grinding and polishing pad required by the invention. The grinding and polishing pad prepared by adopting a thermal initiation curing method has stable processing performance, high processing efficiency and functions of hydrophily and self-correction and is suitable for precise and super precise processing.

Owner:ECO POWER WUXI

Active energy ray curable aqueous ink, and ink-jet recording process, ink cartridge, recording unit and ink-jet recording apparatus using the same

ActiveUS7285310B2High degree of curingImprove adhesionLiquid surface applicatorsOrganic chemistryWater solubleViscosity

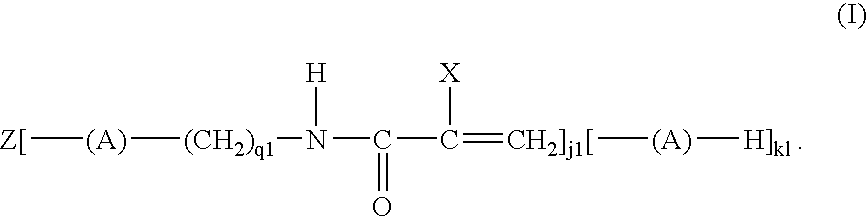

An active energy ray curable ink which is quickly polymerized by an active energy ray, high in crosslinking degree of a cured material formed, excellent in adhesive property, low in viscosity, excellent in long-term storability and also excellent in ejection stability, and an ink-jet recording process, an ink cartridge, a recording unit and an ink-jet recording apparatus using such an ink are provided. In the active energy ray curable aqueous ink comprising at least water and a polymerizable material which is radically polymerized by an active energy ray, the polymerizable material is a water-soluble polymerizable material represented by the following general formula (I). An ink-jet recording process, an ink cartridge, a recording unit and an ink-jet recording apparatus using such an ink

Owner:CANON KK

Seal agent and display device

InactiveCN103525316AHigh degree of curingNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyDisplay device

The invention relates to the display field, in particular to a seal agent and a display device. The seal agent comprises an epoxy resin, acrylic ester and scatterers. According to the seal agent and the display device, the scatterers are added in the seal agent, when ultraviolet light radiates the seal agent, the scatterers in the seal agent scatter the incident ultraviolet light irregularly in all directions, the scattered and incident ultraviolet light radiates on the surfaces of scatterers in other positions, and further scattering occurs, so that areas which cannot be directly radiated by the ultraviolet light in the seal agent can be radiated by the ultraviolet light, and the curing degree of the seal agent is increased.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

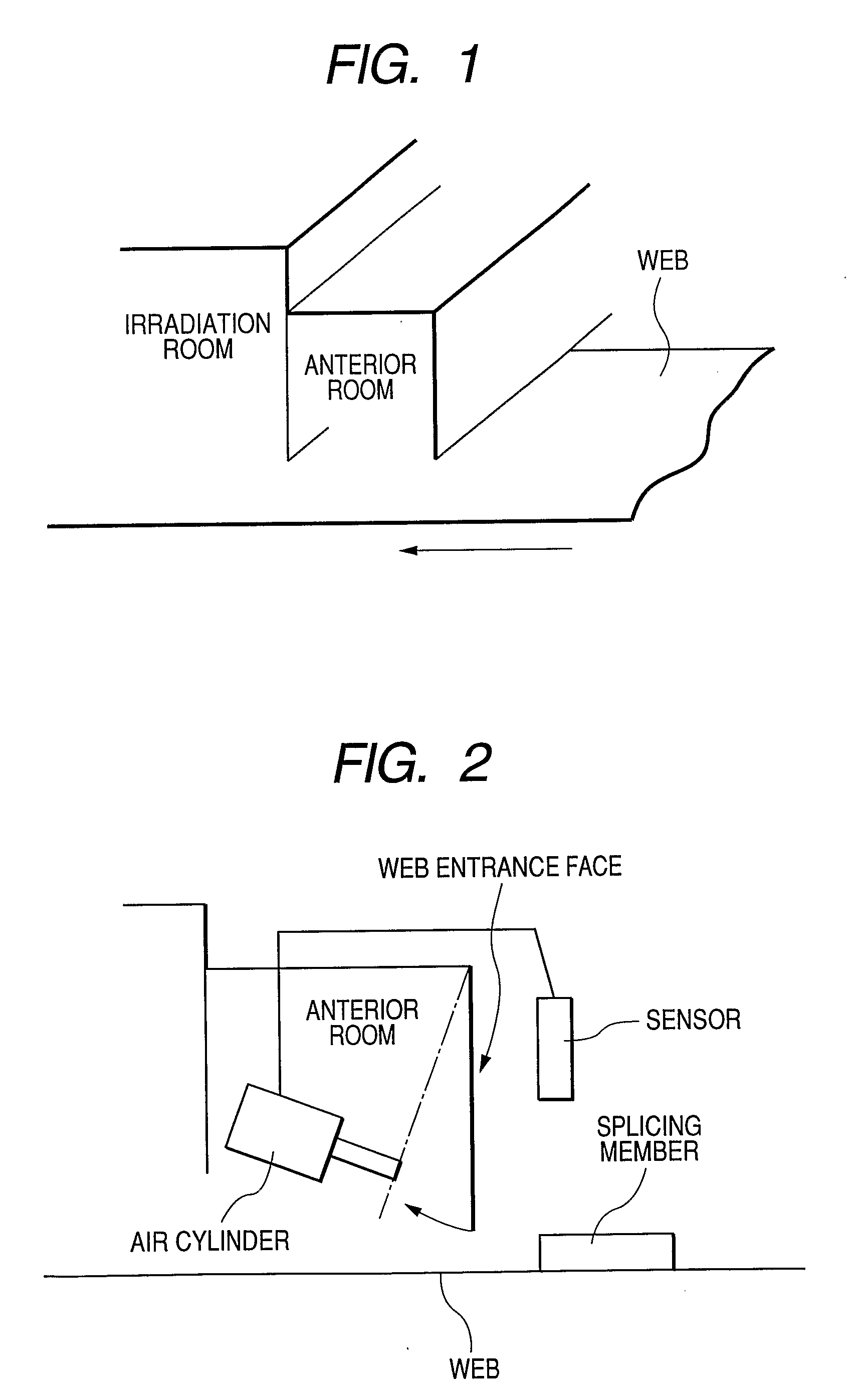

Method for forming grating for machine tool measurement in two-step solidifying rolling pressing forming manner

ActiveCN102193310ALow costIncrease productivityDiffraction gratingsPhotomechanical exposure apparatusStress concentrationGrating

The invention relates to a method for forming a grating for machine tool measurement in a two-step solidifying rolling pressing forming manner, which comprises the following steps: 1) coating an ultraviolet light solidifying adhesive layer on a grating blank substrate; 2) manufacturing a rolling mould having a prototype grating structure on the surface of a cylindrical mould, making an alignment mark, and polishing and performing low surface energy treatment on the surface of the rolling mould; 3) coating a flexible film on the adhesive layer on the grating blank substrate, carrying out primary exposure and peeling the film; 4) comparing the alignment mark on the grating blank substrate with an acquired alignment mark image on the surface of the rolling mould, adjusting and calibrating; 5) gluing the rolling mould with the grating, applying a pressing force, and compounding the prototype grating structure on the surface of rolling mould on the adhesive layer on the surface of the substrate; 6) carrying out exposure on the compounded ultraviolet light solidifying adhesive layer; and 7) collecting and packaging the grating. According to the method, the required pressing force is small, and thus, the substrate deformation and stress concentration are avoided. The method has high production efficiency and can be used for realizing the mass production of the grating for large-area and altitude machine tool measurement.

Owner:XI AN JIAOTONG UNIV

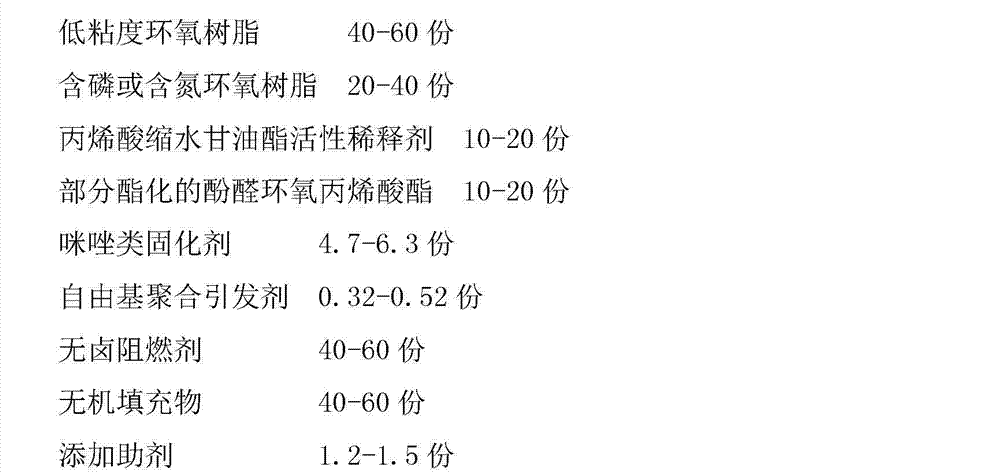

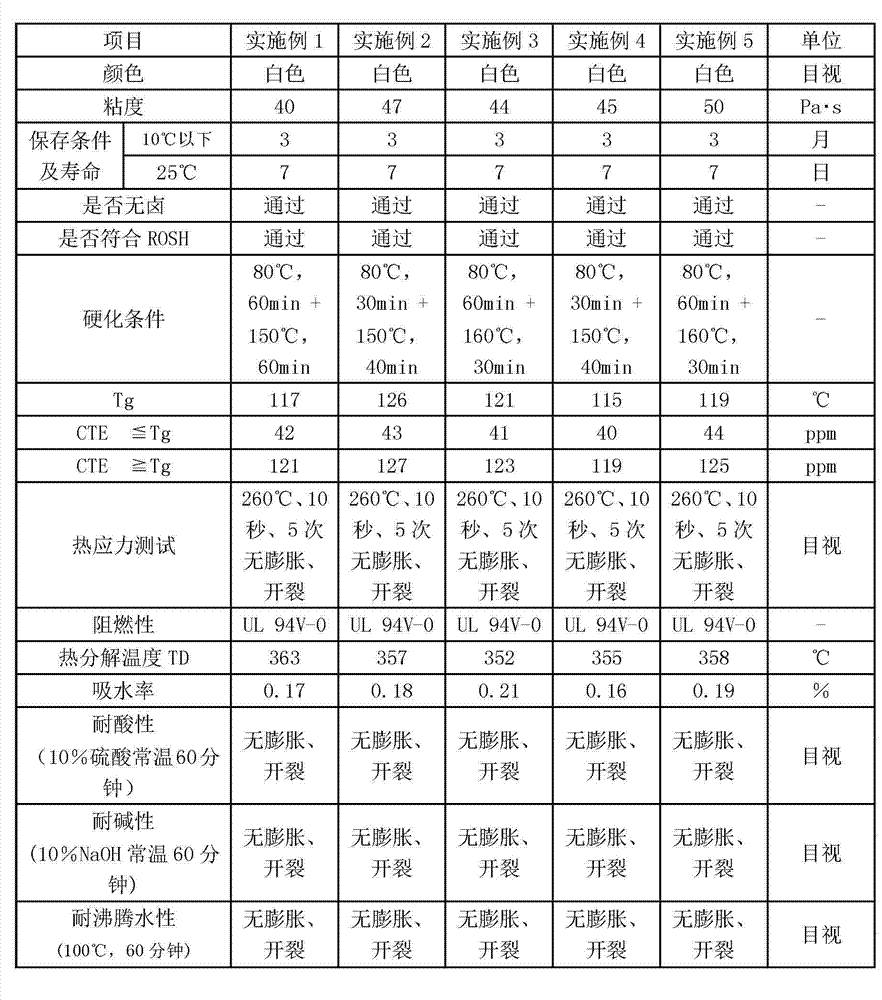

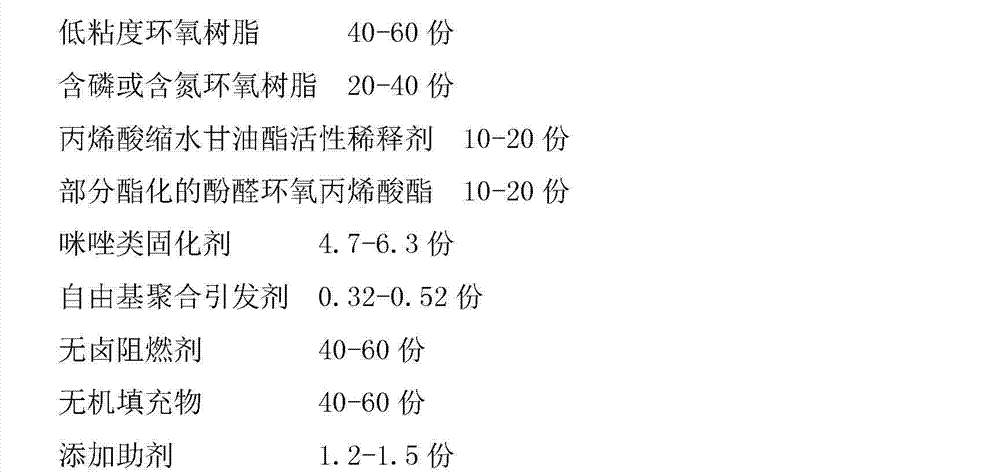

Halogen-free flame-retardant solvent-free double-curing ink composition and preparation method thereof

ActiveCN102732096ASmall coefficient of thermal expansionGuaranteed thermal stabilityInksSolvent freeThermal deformation

The invention relates to electronic materials and preparation, and aims to provide a halogen-free flame-retardant solvent-free double-curing ink composition and a preparation method thereof. The composition comprises the following components: low-viscosity epoxy resin, epoxy resin containing phosphorus or nitrogen, glycidyl acrylate reactive diluent, partially-esterified phenolic epoxy acrylate, imidazole curing agent, free radical polymerizing initiator, halogen-free flame retardant, inorganic filler and additives. The preparation method comprises the following steps of: mixing, dispersing and grinding the raw materials until the viscosity reaches 40 to 50 Pa.s per 25 DEG C, dispersing and uniformly agitating the raw materials after the grinding is stopped, and finally filtering, filling and packaging the raw materials. The halogen-free flame-retardant solvent-free double-curing ink composition has the advantages that the possibility of fire hazards caused by ink introduction when a hole is blocked can be reduced by virtue of halogen-free and flame-retardant performance; with adoption of a double-curing technology with free radical polymerizing and epoxide ring-opening addition polymerization, the halogen-free flame-retardant solvent-free double-curing ink composition has a high curing degree, a high temperature in thermal deformation, a low expansion coefficient, low water absorption and high heat resistance; the viscosity of the ink is easy to adjust, and thus the requirements on the use of the ink in different seasons can be ensured; and the curing material is moderate in rigidity and has the characteristic of grindability.

Owner:ELEK & ELTEK ELECTRONICS KUNSHAN

Visible-light-curing vinyl ester resin composite prepreg, and preparation method and application method thereof

The invention particularly provides a visible-light-quick-curing vinyl ester resin composite prepreg, and a preparation method and application method thereof, belonging to the field of repair of a fiber-reinforced resin-base structure with certain thickness. A special vinyl ester resin is used as a matrix; the proper visible light initiator, thermal initiator and other aids are selected to constitute the light-thermal composite initiation system; magnesium oxide is used as a thickener; different types of fabrics are selected as fiber-reinforcing materials according to performance requirements; and a proper composite technique is utilized to prepare the composite prepreg with certain thickness. The visible-light-curing prepreg material can be cured within 5 minutes under the single-side irradiation of visible light, and the once-time photocuring thickness can reach 10mm or above, thereby basically solving the problems of poor operability, poor safety and insufficient film thickness under ultraviolet light. The visible-light-curing prepreg can be subjected to mass application in the field of structure repair.

Owner:四川远鸣科技有限公司

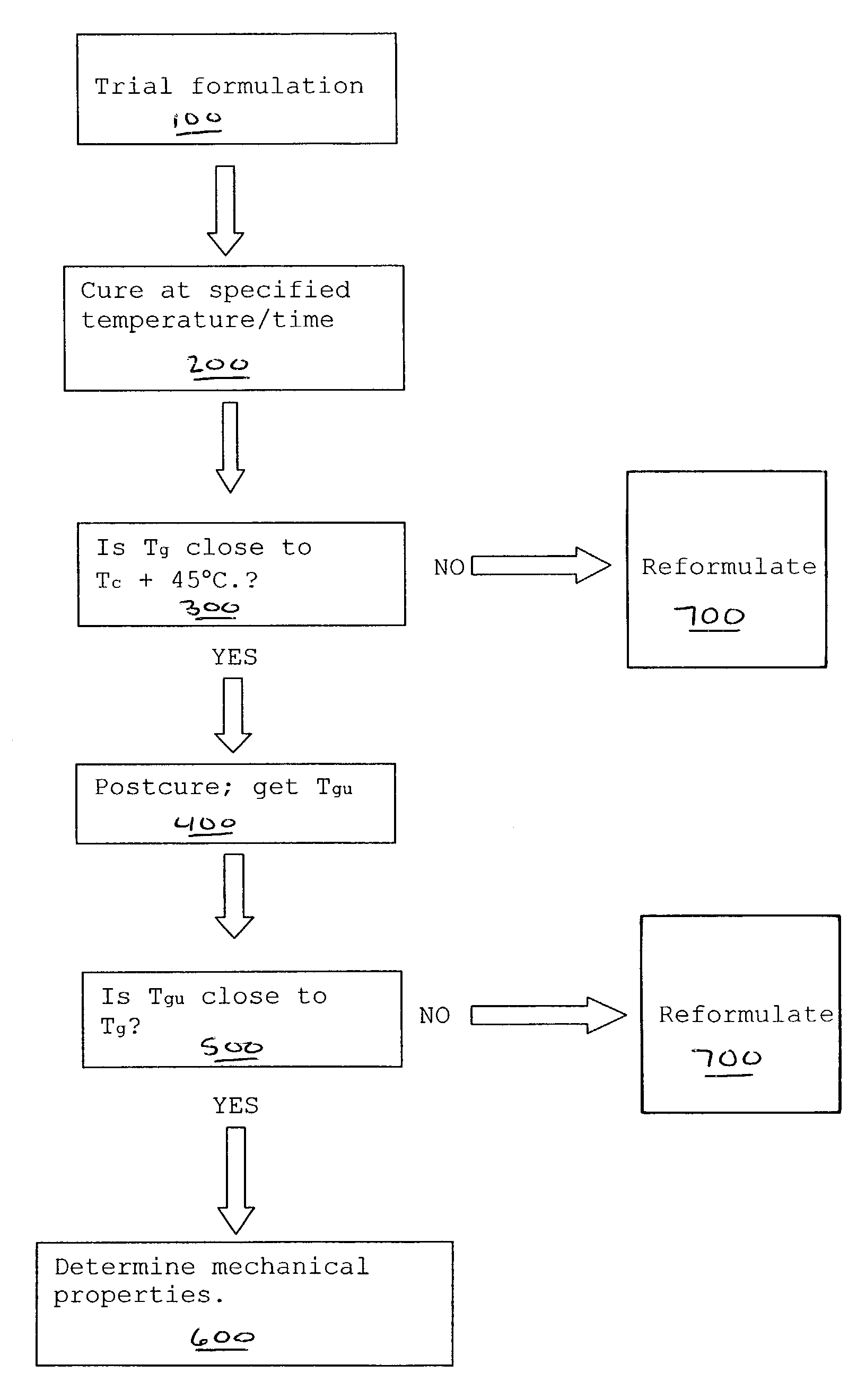

Epoxy hardeners for low temperature curing

Hardeners are provided for curing epoxies at lower temperatures than currently available hardeners while retaining superior mechanical and thermal properties. A first component is selected from imidazole, dicyandiamide, or a mixture of polyamines and tertiary amines. A poiyol mixture is then selected. The first component is combined with the polyol mixture to form a hardener. The hardener is combined with epoxy resin and is cured. A method for selecting a hardener to yield an epoxy-hardener system with good properties after curing at a specified temperature and time includes selecting components for the hardener so the glass transition temperature of the cured epoxy-hardener system is not significantly lower than 45° C. above the cure temperature. The method includes steps for adjusting and controlling the ultimate glass transition temperature to maximize the mechanical properties of the epoxy-hardener system. The method regularly produces hardened epoxy systems having about 90% or more epoxy groups reactect.

Owner:ARDES ENTERPRISES

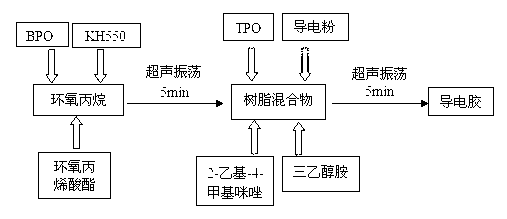

Photo-thermal double-curing conductive adhesive and preparation method thereof

InactiveCN103194166ASuitable for photothermal dual curing technologyShort curing timeNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer scienceUltraviolet lights

The invention provides a photo-thermal double-curing conductive adhesive and a preparation method thereof, which relates to conductive adhesives and preparation methods thereof. In order to solve the problems that when a compound type conductive adhesive is only subjected to thermal curing, the curing temperature is high, the curing time is long, and when the compound type conductive adhesive is only subjected to light curing, the curing is incomplete, thus resulting in restriction on volume production. The photo-thermal double-curing conductive adhesive is prepared from an epoxy acrylate prepolymer, a diluent, a thermal initiator, a silane coupling agent, a light initiator, a heat curing agent, a promoter and conductive powder which are different in esterification rate. According to the photo-thermal double-curing conductive adhesive, a photo-thermal double-curing technology is adopted, the light initiator, the thermal initiator and the heat curing agent are simultaneously used, the light initiator in conductive adhesive system is triggered by using the irradiation of ultraviolet lights, the thermal initiator in conductive adhesive system is triggered by simultaneously using heat generated by ultraviolet light irradiation and ultraviolet crosslinking reaction, and the hot polymerization reaction is triggered to achieve an ideal deep curing effect. The preparation method has the characteristics of high efficiency, rapidness, simple process and no pollution to the environment.

Owner:HARBIN INST OF TECH

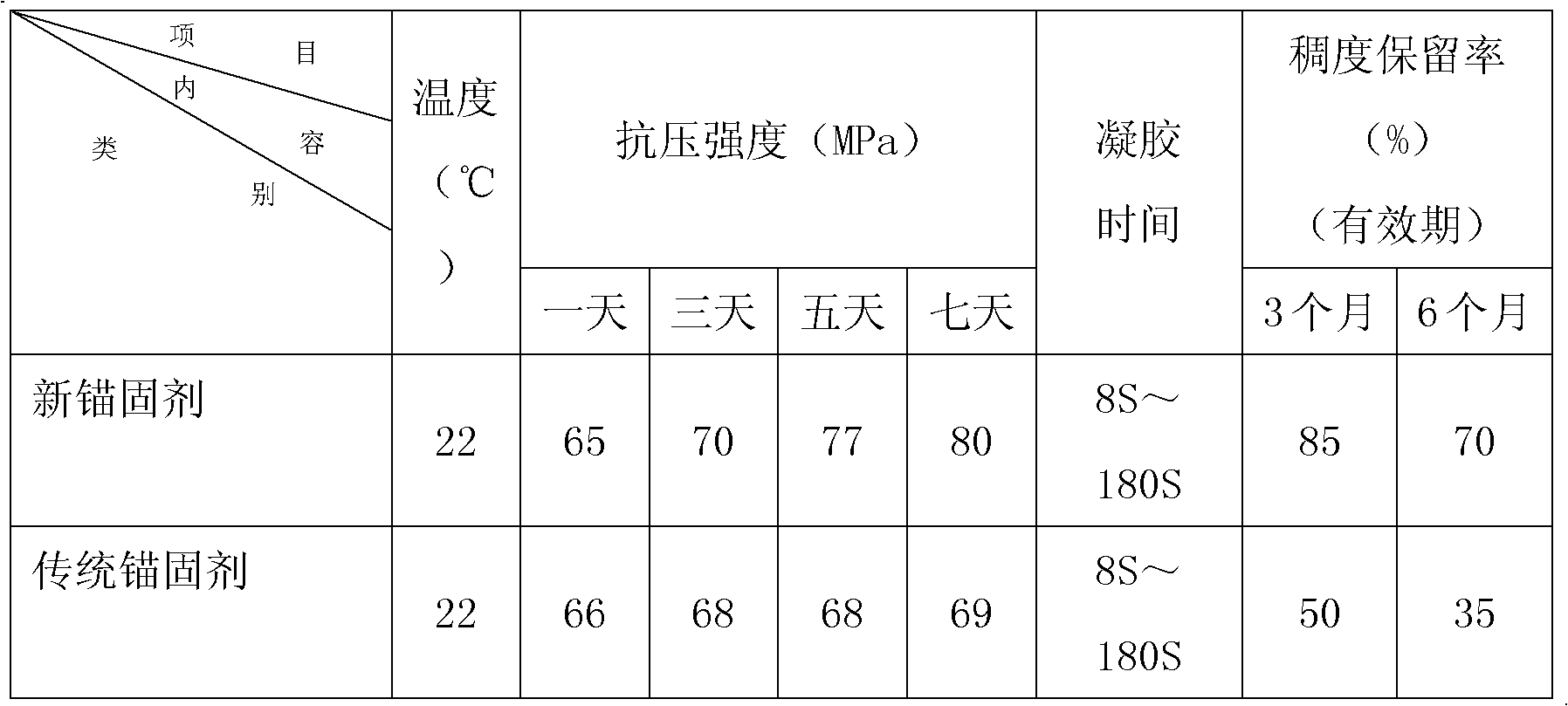

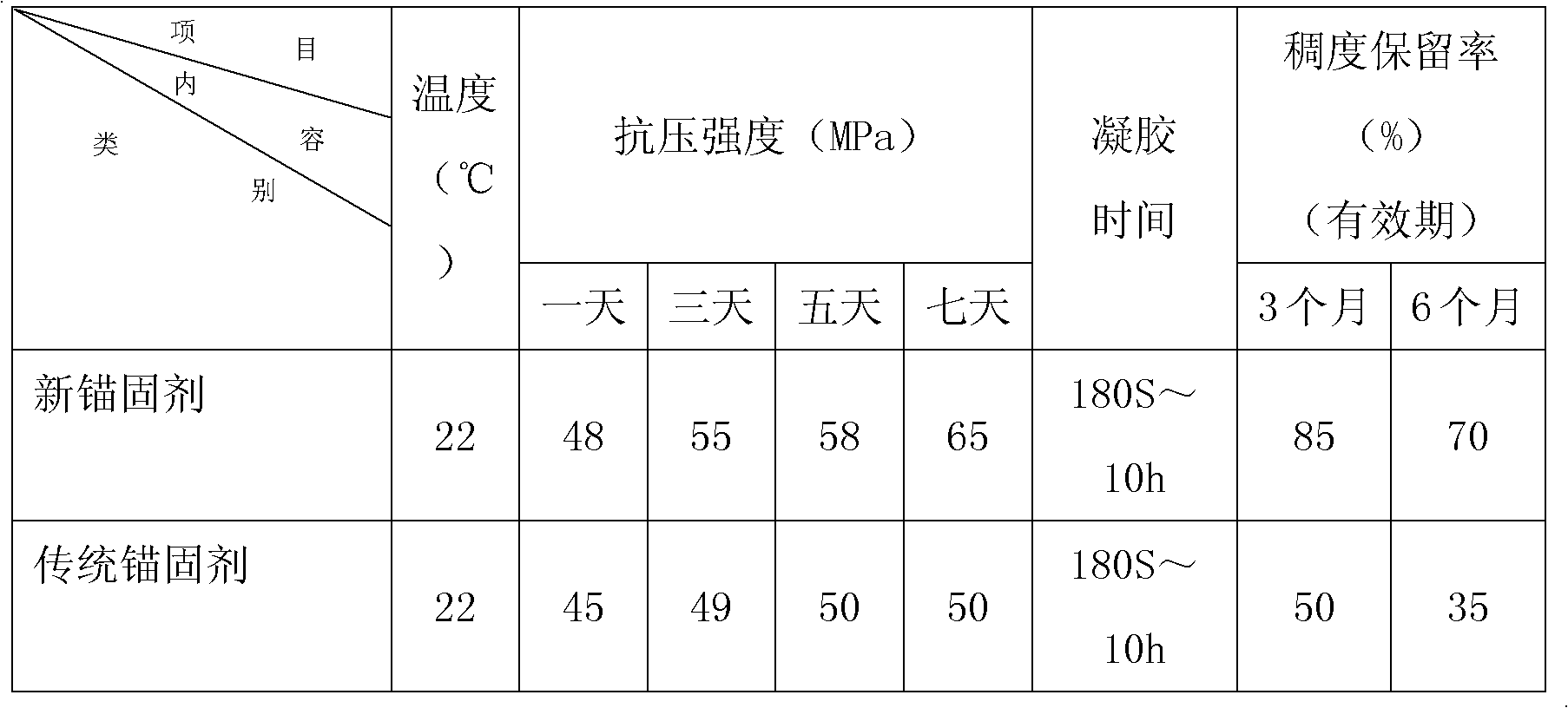

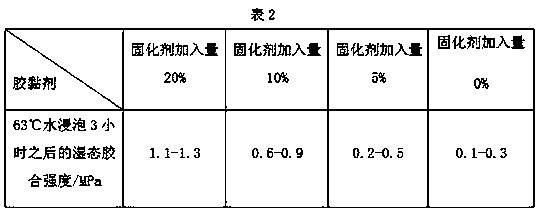

Resin anchoring agent for initiation system

The invention discloses a resin anchoring agent for an initiation system. In the invention, cobalt octoate or cobalt naphthenate is used as a promoter, or cobalt octoate or cobalt naphthenate and tertiary amine promoters are mixed to form a compound promoter. A novel initiator is hydroperoxides, particularly methyl ethyl ketone peroxide and cyclohexanone peroxide. In the invention, resin anchoring agent of all models can be designed and produced, the longest gelation time can be adjusted to 10 hours or even a longer time, the curing can be continued later on when the curing of a reaction is inadequate, the curing degree is high, and the final strength is high. Moreover, the period of validity of the resin anchoring agent can be prolonged for over 1 time.

Owner:美亚高新材料股份有限公司

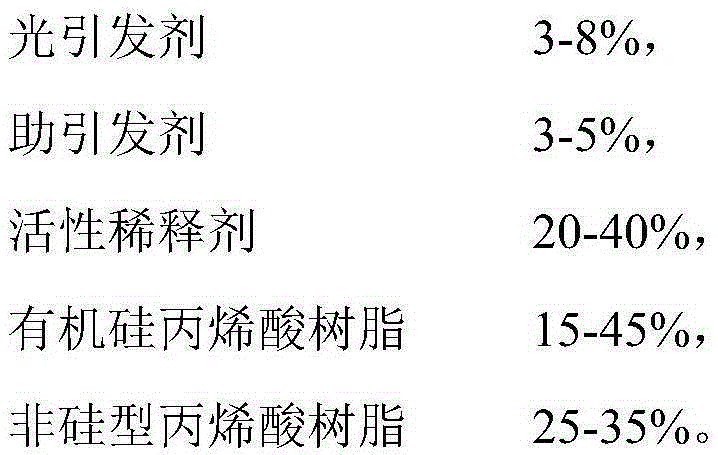

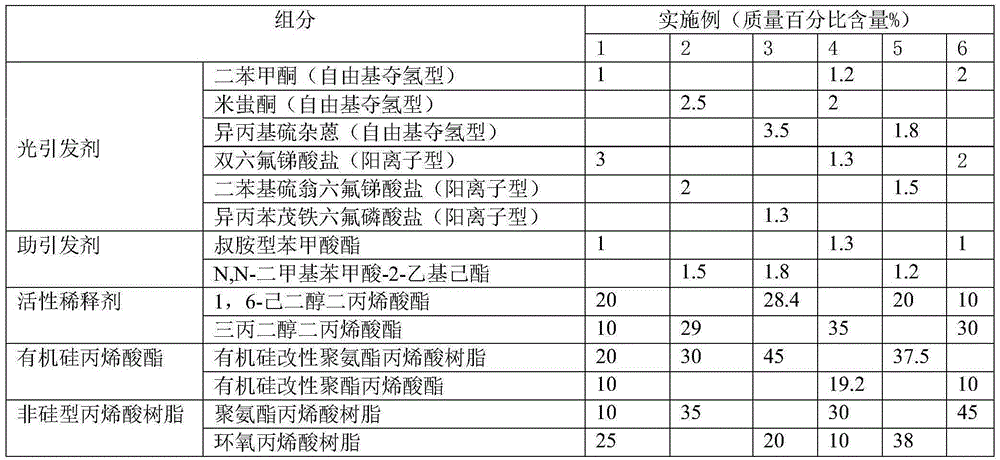

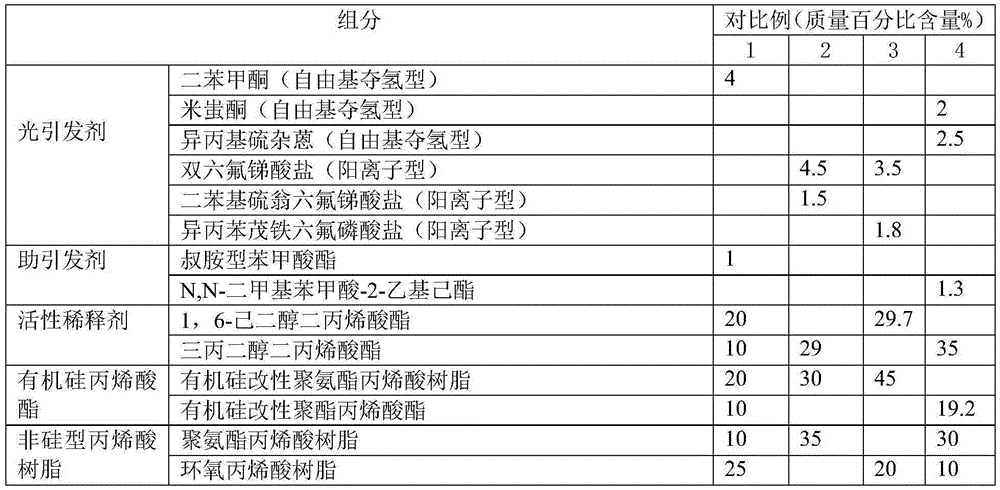

Efficient anti-sticking UV release paint applied to pressure-sensitive adhesive as well as preparation and application of efficient anti-sticking UV release paint

ActiveCN105315881ANo releaseOvercome polymerization inhibitionPolyurea/polyurethane coatingsEpoxy resin coatingsSolubilityAcrylic resin

The invention provides an efficient anti-sticking UV release paint applied to a pressure-sensitive adhesive as well as preparation and application of the efficient anti-sticking UV release paint. The paint comprises the following ingredients in percentage by weight: 3-8% of a photoinitiator, 3-5% of an auxiliary initiator, 20-40% of an active diluent, 15-45% of organic silicon-acrylic resin and 25-45% of non-silicon acrylic resin. The system of free radicals and the cationic composite initiator is adopted, a sensitization effect realized through the synergistic effect of the free radicals and the cationic composite initiator better solves the problems of oxygen inhibition and slow curing caused by the single initiator, meanwhile, the photo-curing speed is high, the solubility is good, the absorption wavelength reaches 390 nm and the paint is an efficient, energy-saving and environment-friendly photo-cured release paint.

Owner:SHANGHAI CHENGYING NEW MATERIALS

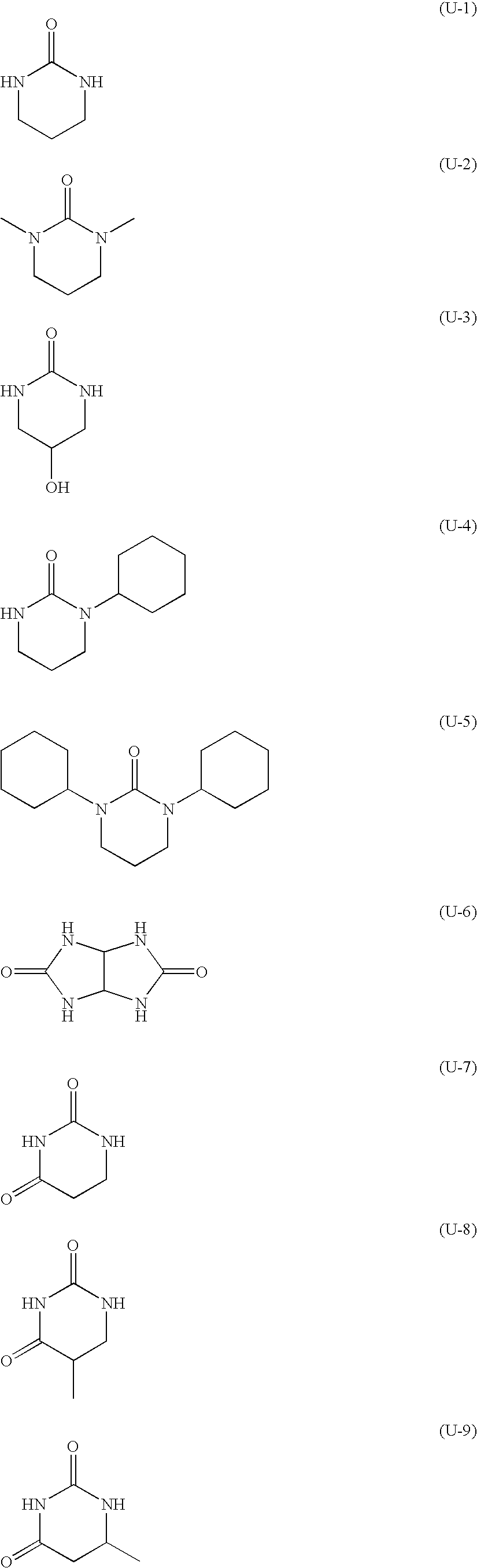

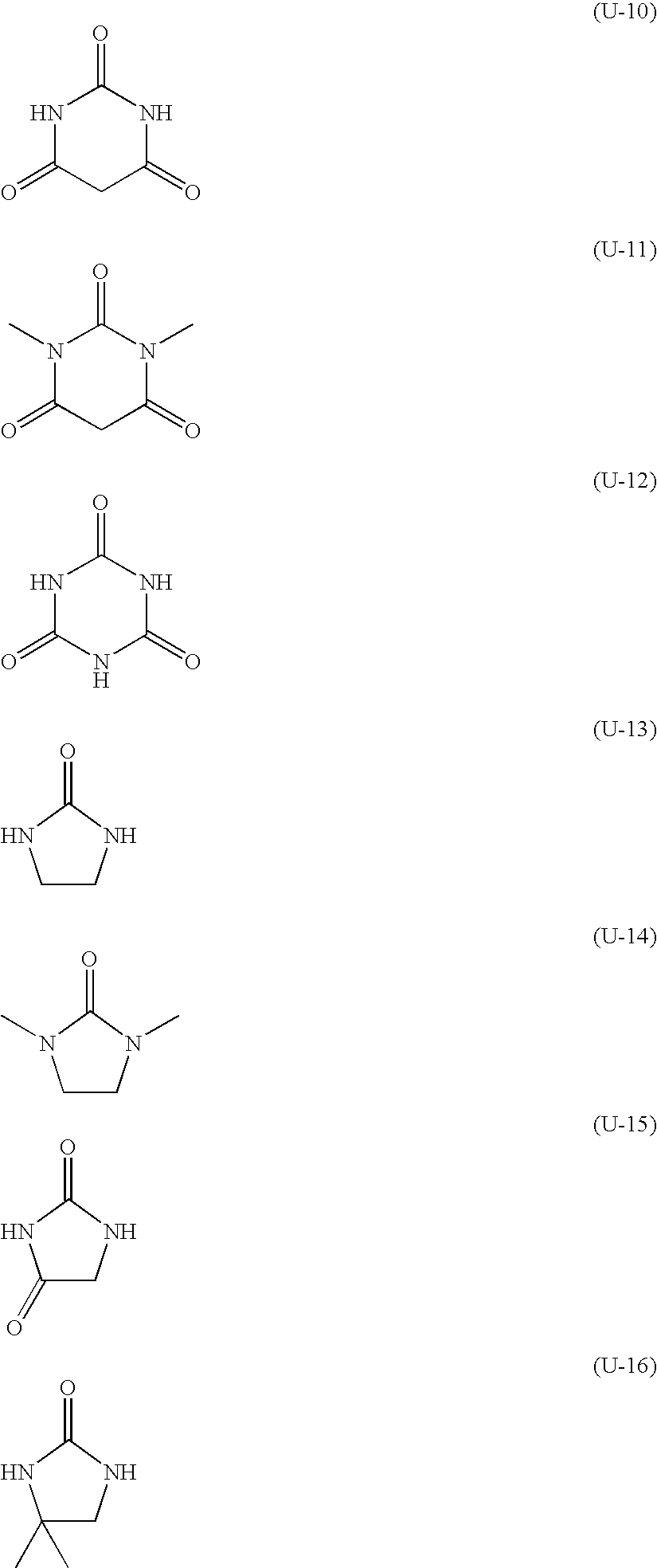

Curable composition, image forming material, and planographic printing plate precursor

InactiveUS20090075206A1High sensitivitySensitivity is suppressedPhotosensitive materialsRadiation applicationsUreaRadical polymerization

A curable composition, including: a polymerizable compound (a) including an ethylenically unsaturated bond; a binder polymer (b); a radical polymerization initiator (c); and an alicyclic compound (d) including a urea bond is provided.

Owner:FUJIFILM CORP

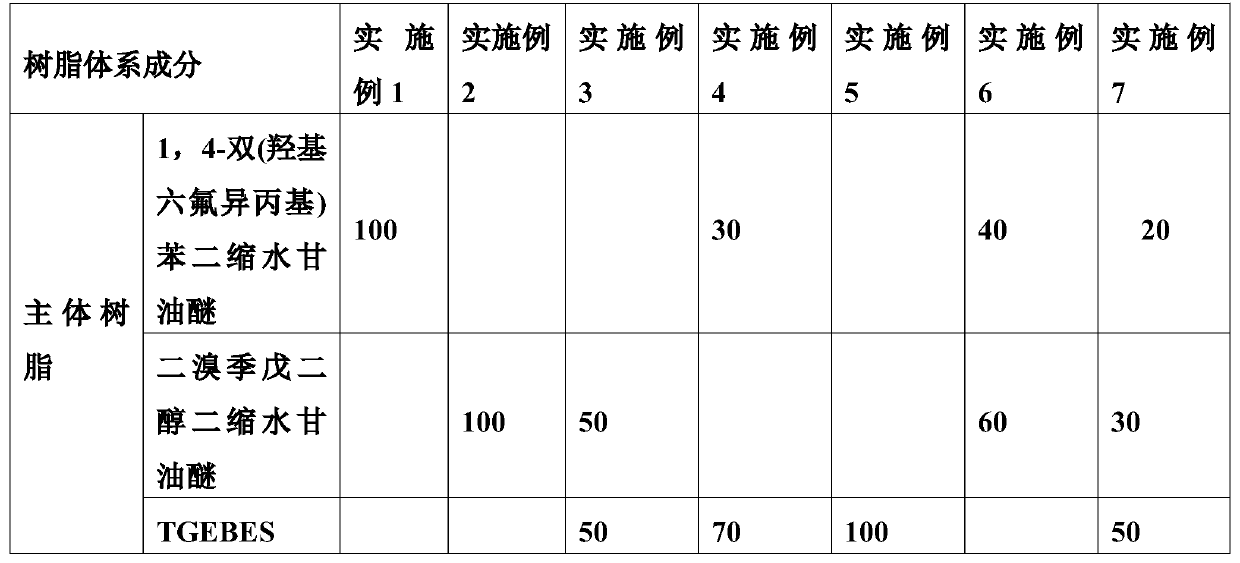

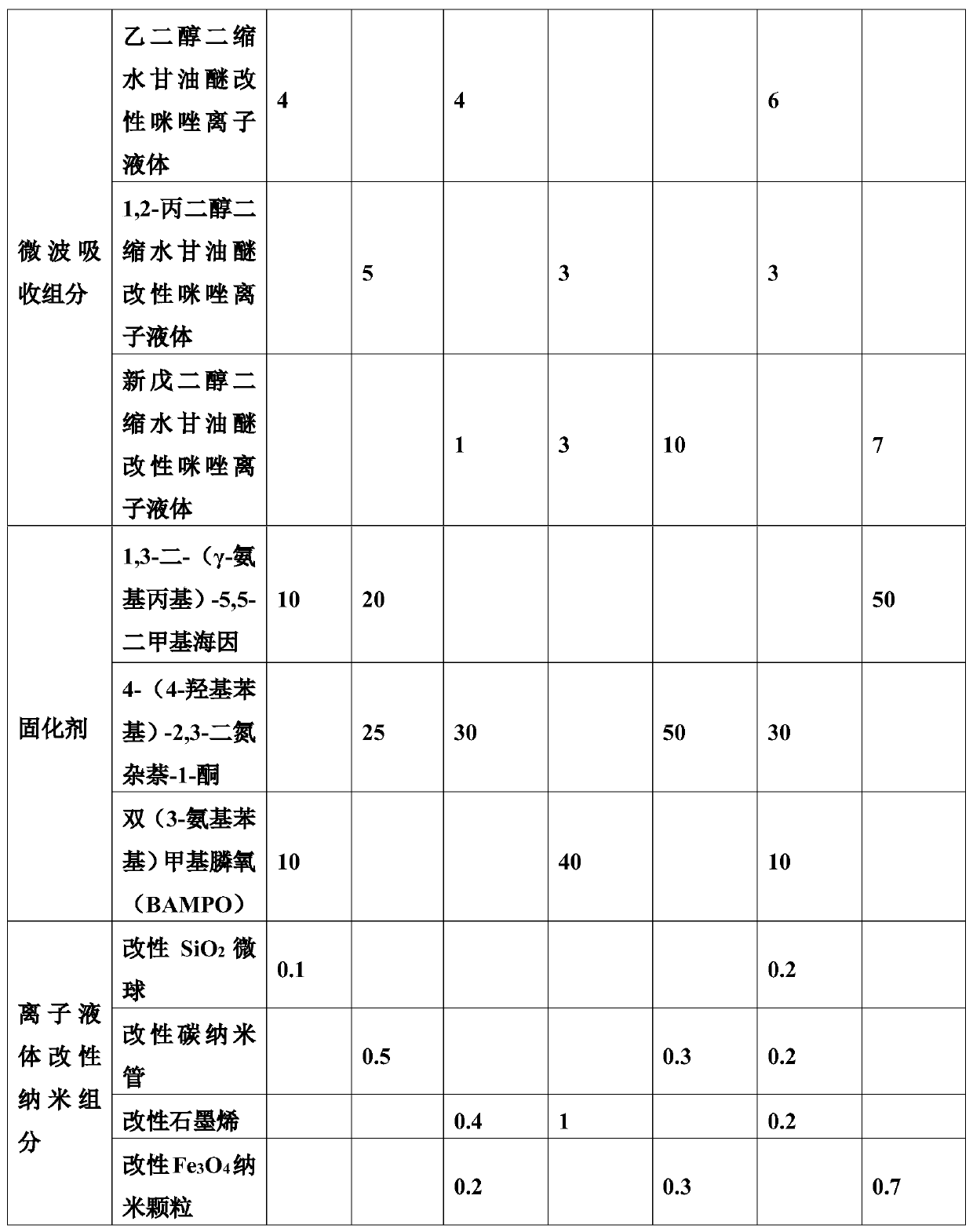

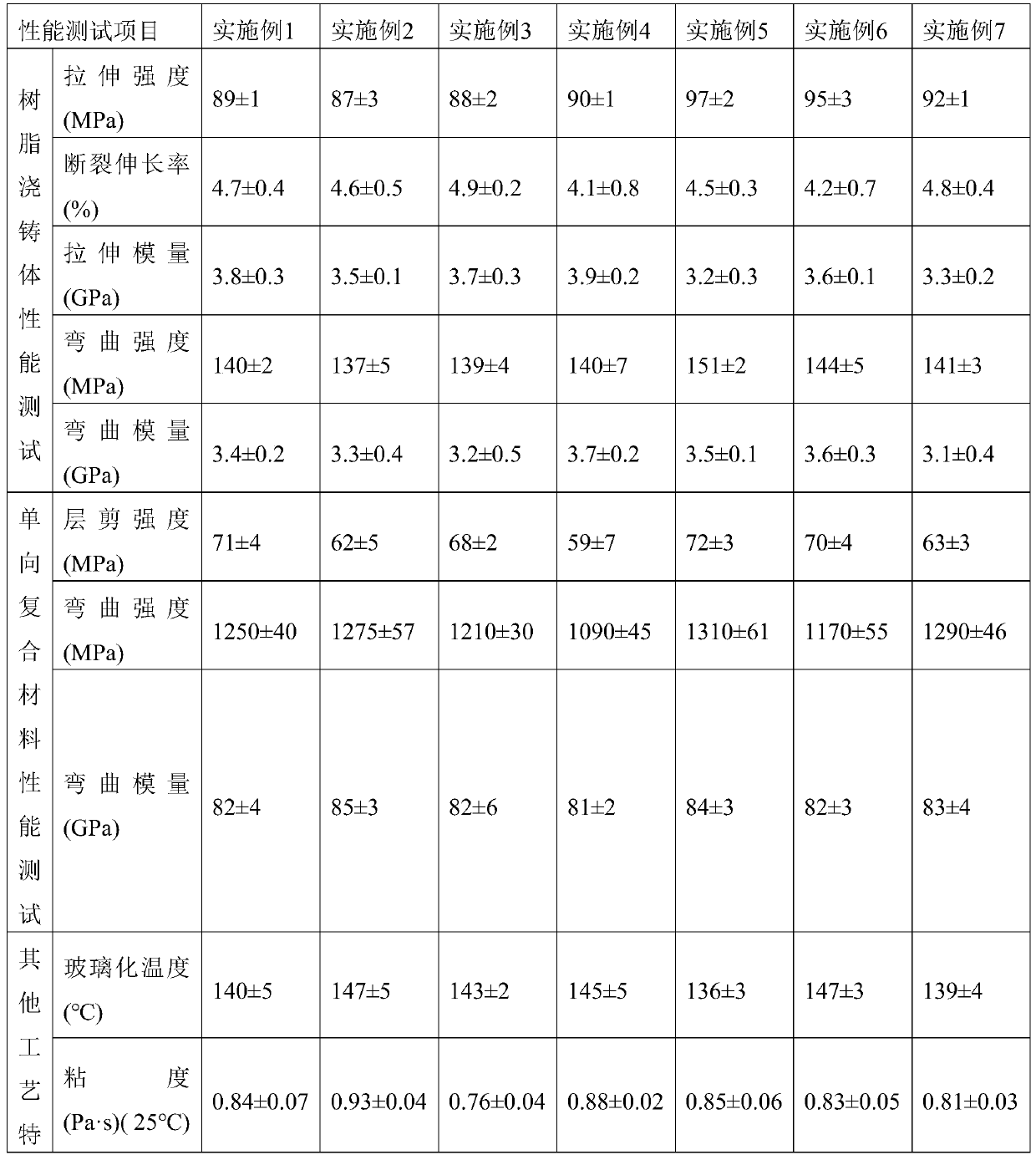

Resin matrix with strong microwave absorbability and preparation method thereof

Aresin matrix with strong microwave absorbability and a preparation method thereof belong to the field of composite materials. In the invention, high-performance epoxy resin with strong polarity is selected as matrix resin, a microwave absorptioncomponent is added for adjusting microwaveresponsiveness and viscosity of a resin system to adapt to liquid molding by winding and the like, a curing agent is selected for adjusting themicrowaveresponse activity of the resin system, and the mechanical property, the heat resistance and thedimensional stability of the resin matrix are achieved; on the basis, an ionic liquid modified nanometer component is adopted for further enhancing the microwaveresponsiveness of the resin matrix. By adjusting the component structure and thematch ratio of the matrix resin, the microwave absorption component, the curing agent,theionic liquid modified nanometer componentand the like, a microwave curing resin system with good microwave absorbability, good dispersity of the nanometer component, proper viscosity, uniform curing, excellent comprehensive mechanical property, good heat resistance and high dimensional stability is developed. The resin matrix has great guiding significance for preparation of fiber composite materials and can be widely applied to the fields of aerospace and the like.

Owner:BEIJING UNIV OF CHEM TECH

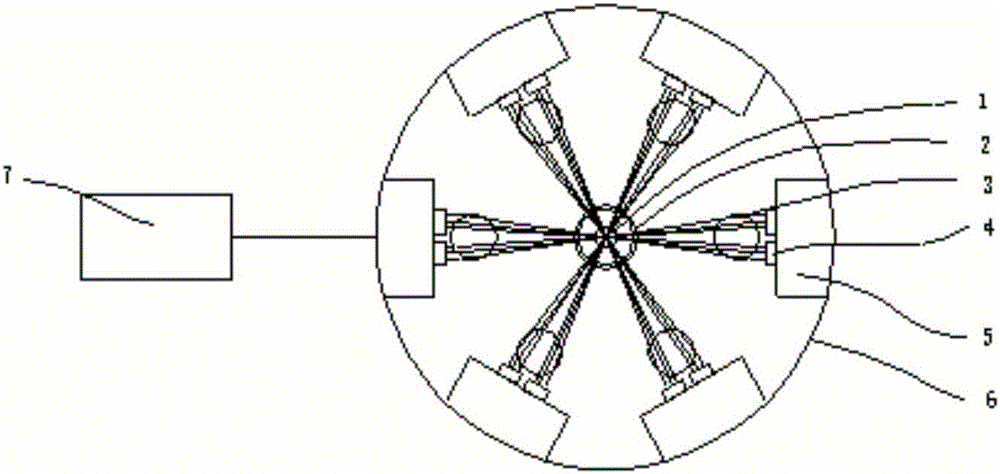

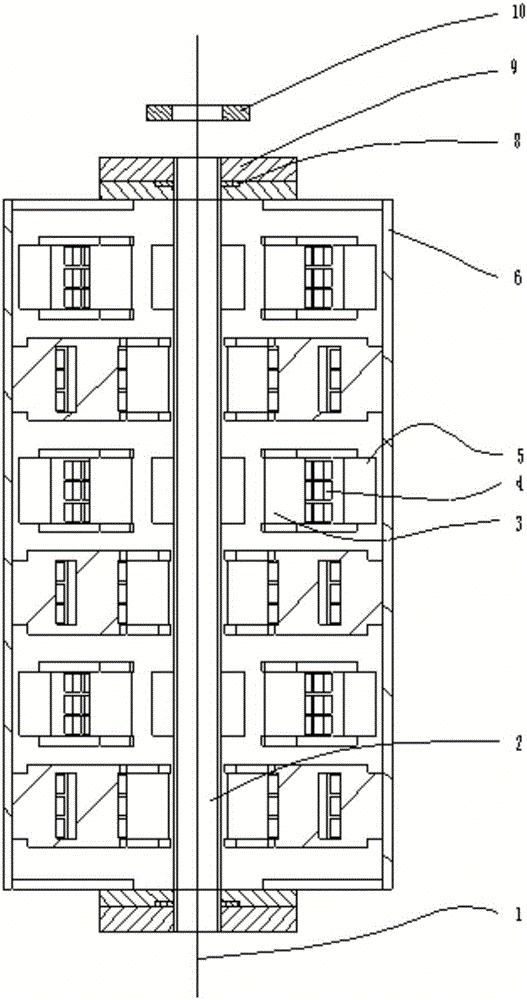

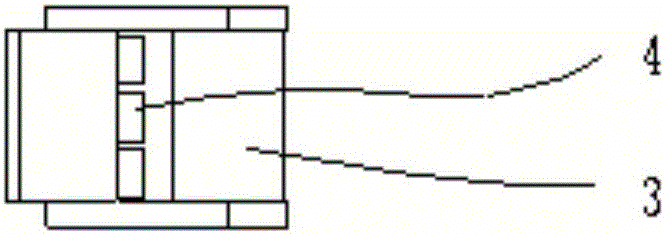

Optical fiber coloring and curing equipment

The invention discloses optical fiber coloring and curing equipment which comprises a cylindrical installing base. UVLED light source modules are installed in an inner cavity of the cylindrical installing base in the peripheral direction and the axial direction. Cylindrical surface focusing lenses are arranged in front of the light-emitting faces of the UVLED light source modules, and therefore ultraviolet light rays transmitted by the UVLED light source modules can be focused on a curing axis. The equipment is characterized in that the UVLED light source modules vertically arranged in the axial direction are arranged in a staggered mode in the peripheral direction, and one cylindrical surface focusing lens is correspondingly configured in front of each UVLED light source module. As the UVLED light source modules, arranged in the axial direction, of the adjacent sets are arranged in the staggered mode, light received by the surfaces of optical fibers is more uniform, the equipment has higher curing efficiency and better curing uniformity, curing time is shortened, and working efficiency and coating curing quality of optical fiber drawing are improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

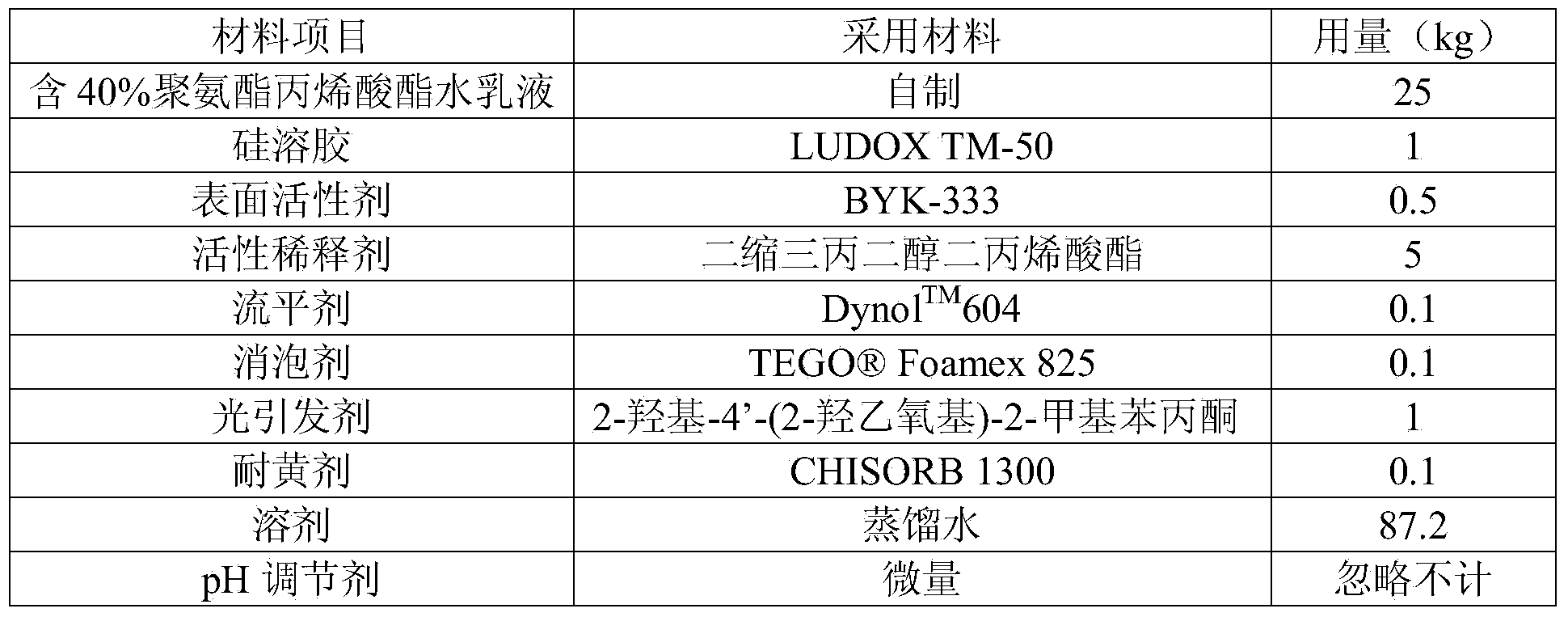

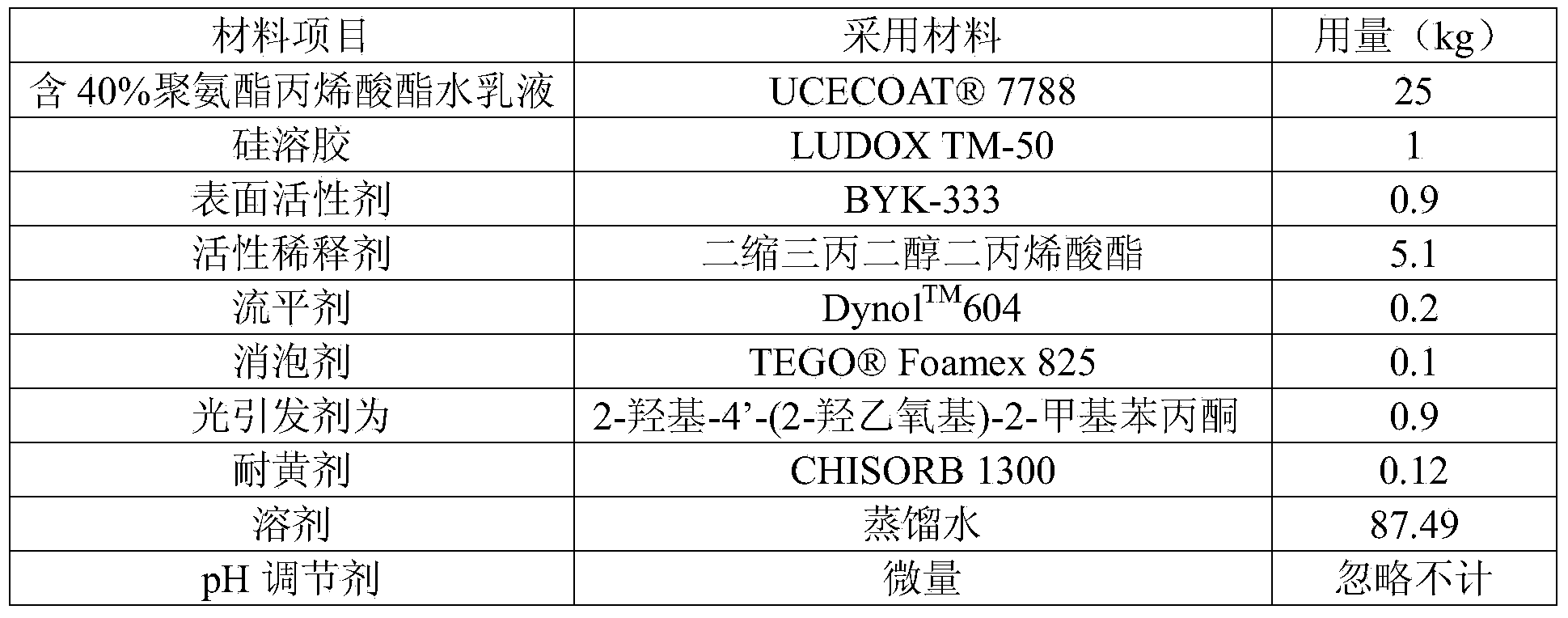

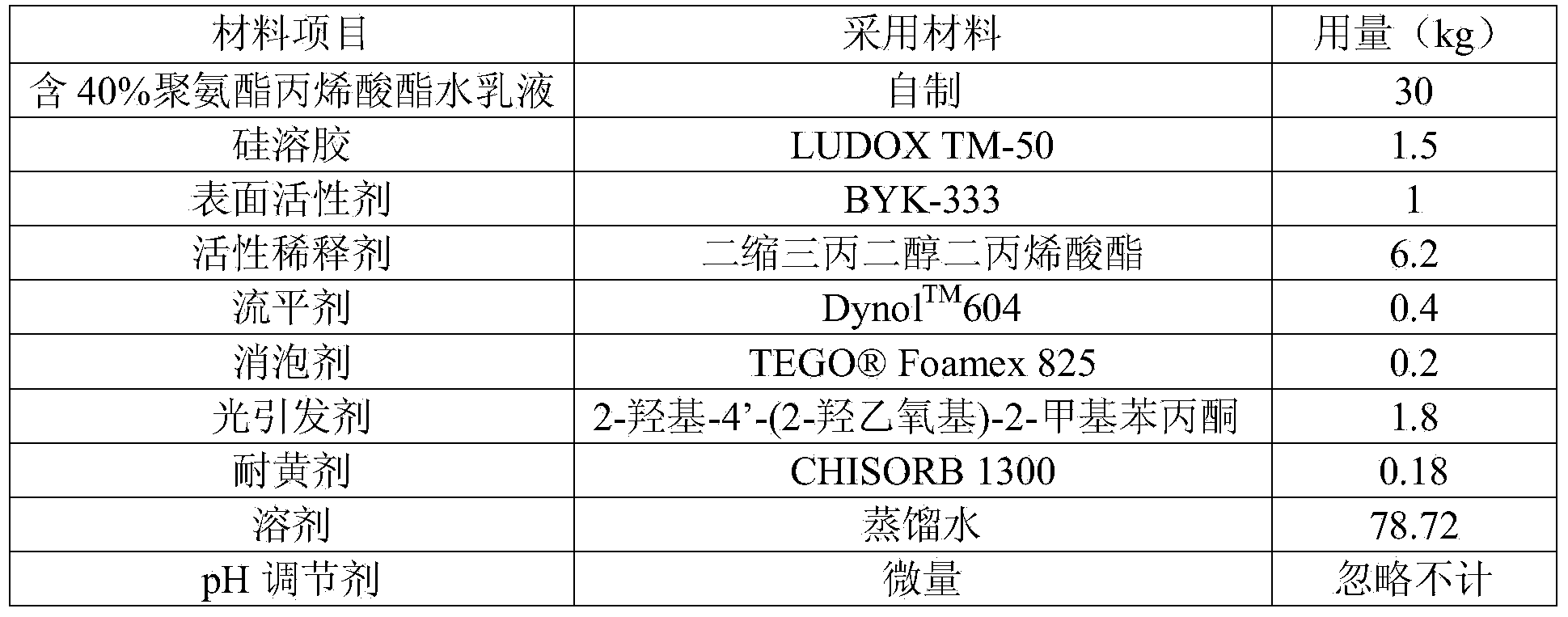

Single-sided or double-sided optical hardened polyester film and preparation method thereof

ActiveCN104228256ALow viscosityGood film formingLamination ancillary operationsSynthetic resin layered productsPolyesterUltraviolet lights

The invention discloses a single-sided or double-sided optical hardened polyester film and a preparation method thereof. The optical hardened polyester film is composed of a base film, and one or two hardened resin coatings, which are applied to and cured on the single surface or the double surfaces of the base film, wherein the base film thickness is 100-250 microns, and the surface coating thickness is 1-10 microns. The preparation method comprises the following steps: melting and casting a polyester chip through an extruder, longitudinally stretching the polyester chip to form a thin blank, coating the single or double surfaces of the thin blank with hardened resin coating liquid in an online coating mode, drying, horizontally stretching, and thermally forming to obtain the base film with the hardened resin coating liquid coatings, curing through ultraviolet light to obtain the single-sided or double-sided optical hardened polyester film, wherein the hardened resin coating liquid is composed of aqueous emulsion containing 40% of polyurethane acrylate, nanometer silicon sol, a surfactant, a flatting agent, a defoaming agent, photoinitiator and a yellow-resistant agent. The hardened polyester film prepared by the one-step method is suitable for the field of touch displays.

Owner:四川东方绝缘材料股份有限公司

Method for preparing phenolic resin fiber of high molecular weight

InactiveCN101289767AHigh degree of curingHigh tested mechanical strengthMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentCarbon fibersChemical reaction

The invention relates to a method for preparing high molecular weight phenolic resin fibers, comprising the following processing steps of: mixture making, chemical reaction, preparation of phenolic resins, preparation of nascent fibers, preparation of solidifying liquid, solidification reaction, and washing and drying. The method adopts phenol and aldehyde as raw materials which are prepared intothe high molecular weight phenolic resins under the condition of high temperature and high pressure; after melt-spinning, the solidification reaction is performed in the solidifying liquid and the high molecular weight phenolic resin fibers are prepared. The method has the advantages of short reaction time, high curing degree and so on; the high molecular weight phenolic resin fibers prepared by adoption of the method have high mechanical strength via test and are characterized by antiflamming, flame resistance, heat insulation, corrosion resistance and so on; the materials can be used as heat-insulating, insulating and corrosion resistant materials of an aerial aerocraft, as materials of fireproof and corrosion resistant clothes and also as materials of an acid and corrosion resistant filter, and are also raw materials of special fibers such as carbon fibers, graphite fibers, active carbon fibers, ion exchangers and so on.

Owner:SHAANXI NORMAL UNIV

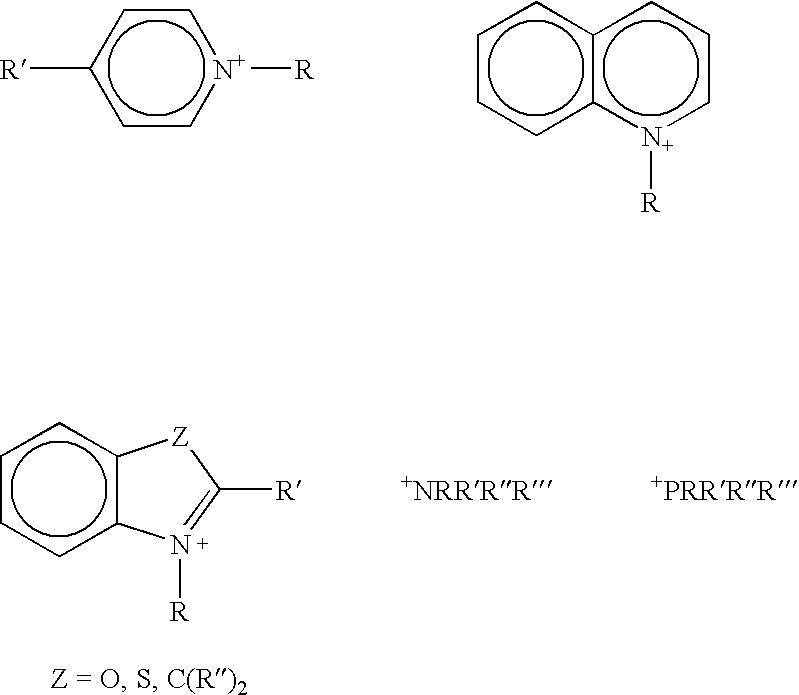

Curing agents for cationically curable compositions

Novel catalyst systems in cationically curable compositions provide colorless cationically cured compositions with improved degree of cure and thermal stability. The curable composition comprises at least one cationically curable monomer and a curing agent comprising Photocurative A or Photocurative B. Photocurative A comprises an effective amount of an accelerating photochemically active salt comprising a photochemically active cation and an accelerating anion, and an effective amount of an inhibiting non-photochemically active salt comprising a non-photochemically active cation and an inhibiting anion. Photocurative B comprises an effective amount of an inhibiting photochemically active salt comprising a photochemically active cation and an inhibiting anion, and an effective amount of an accelerating non-photochemically active salt comprising a non-photochemically active cation and an accelerating anion. The inhibiting and accelerating salts in photocuratives A and B are defined by photo differential scanning calorimetry (pDSC) and thermal differential scanning calorimetry (tDSC). The compositions are useful, for example, as optically colorless or low color coatings, adhesives, encapsulants, and sealants for optical and electronic applications.

Owner:3M INNOVATIVE PROPERTIES CO

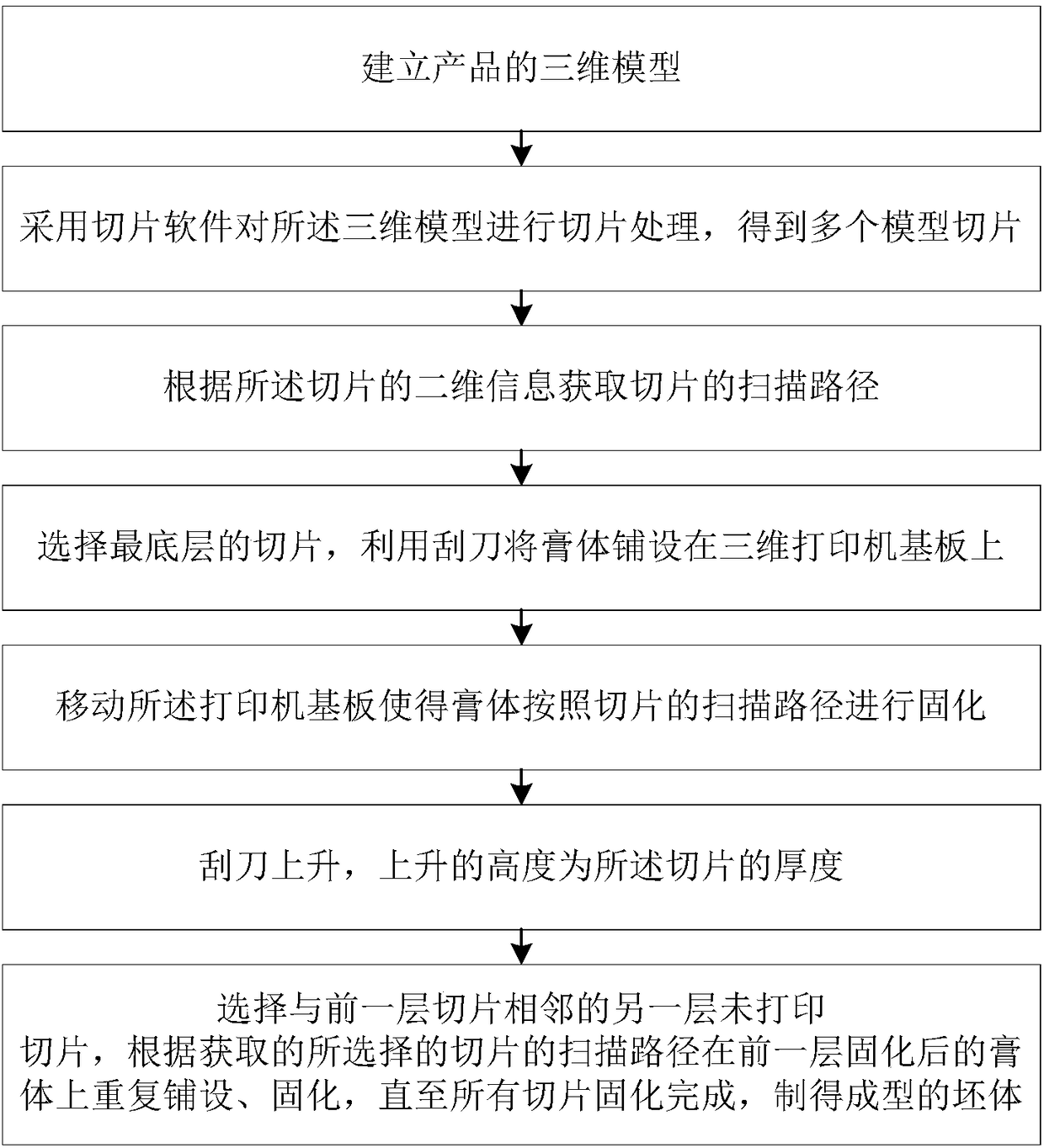

Rapid molding process method for ointment

InactiveCN108558372ACuring shrinkage is smallSmall shrinkageAdditive manufacturing apparatusRapid prototypingMaterials science

The invention relates to a rapid molding process method for an ointment. The ointment comprises 50-60% of an ointment powder, 0.5-2% of an initiator, 1-6% of a dispersant and the balance of a light-sensitive resin. The ointment provided by the invention has the characteristics of being small in curing shrinkage, rapid in curing speed, high in curing degree and small in shrinkage, and the 3D printing molding time of a product can be shortened. The ointment can be flattened by using a scraper, and in addition, the height that the scraper is raised each time is fixed, so that the precision of each layer of the product can be ensured, and the precision of the whole product can be ensured. By adopting the ointment provided by the invention, the product made by using a 3D printing molding process of the ointment has the advantages of being low in cost, high in efficiency and high in precision.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

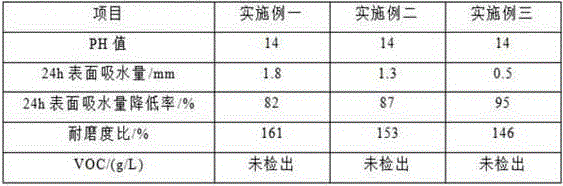

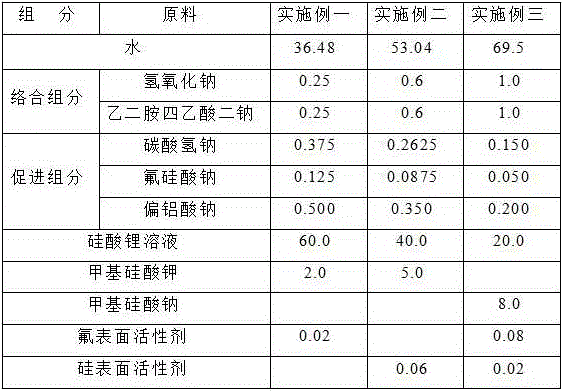

Penetrating type liquid hardening agent and preparation method thereof

The invention discloses a penetrating type liquid hardening agent and a preparation method thereof. The penetrating type liquid hardening agent comprises the following components in percentage by weight: 30 to 70 percent of water, 0.5 to 2.0 percent of complexing components, 0.4 to 1.0 percent of a promoting component, 20 to 60 percent of a lithium silicate solution, 2 to 8 percent of a penetration-resistant agent and 0.02 to 0.1 percent of a surfactant. According to the penetrating type liquid hardening agent, the gelatinization time of the hardening agent is prolonged by adopting an ionic complex method, so that the hardening agent can penetrate deeply into the surface of concrete and generate more thorough reaction with calcium ions. The penetrating type liquid hardening agent is a strongly alkaline solution and can greatly reduce the water absorption amount of the surface after being brushed on the surface of the concrete, thus enhancing the wear resistance of the surface of the concrete. The penetrating type liquid hardening agent does not contain VOC, belongs to an environment-friendly product and can be used for enhancing indoor and outdoor concrete surfaces.

Owner:苏州市姑苏新型建材有限公司

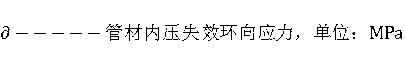

Anti-static flame-retardant steel skeleton fiber reinforced resin pipe and preparation technology thereof

ActiveCN103104754AGood mechanical propertiesReduce dosageRigid pipesTubular articlesEpoxyFine structure

The invention belongs to the technical field of mine conveying pipe bodies, and discloses an anti-static flame-retardant steel skeleton fiber reinforced resin pipe and a preparation technology of the anti-static flame-retardant steel skeleton fiber reinforced resin pipe. The anti-static flame-retardant steel skeleton fiber reinforced resin pipe is technically characterized in that the anti-static flame-retardant steel skeleton fiber reinforced resin pipe comprises a pipe body which comprises a seepage-proof flame-retardant conductive inner lining layer and a pressure-bearing flame-retardant conductive structural layer from inside to outside, wherein the seepage-proof flame-retardant conductive inner lining layer comprises glass fiber solidified on an inner base body, and the pressure-bearing flame-retardant conductive structural layer comprises an outer base body which is synchronously provided with a zinc-coated steel wire and glass fiber direct roving in a winding mode, wherein epoxy resin is coated on the outer surface of the zinc-coated steel wire. According to the anti-static flame-retardant steel skeleton fiber reinforced resin pipe, matching among all layers of fiber is reasonable, mechanical property is strengthened, meanwhile, weight of the tube body is lightened, multi-wall carbon nanotubes and nanometer aluminium hydroxide are filled, fine structures of all layers are changed, meanwhile, bending resistant strength and shock resistance capability are enhanced, wear-resisting property and conductivity are largely improved, service life is prolonged, and cost is reduced.

Owner:河北拓安管业有限公司

Antireflective Film, Method of Manufacturing Antireflective Film, Polarizing Plate and Image Display Device Using the Same

InactiveUS20080234461A1Improve scratch resistanceSufficient capabilityPretreated surfacesCoatingsPolarizerChemistry

An antireflective film comprising: a support; and at least one layer including an antireflective layer, wherein at least one of said at least one layer laminated on the support is a layer formed by ionizing radiation curing of a composition containing a combination of a radical polymerization initiator with at least one compound selected from two or more kinds of initiator assistants and further containing an ionizing radiation curable compound.

Owner:FUJIFILM CORP

Heat-resistant flame-retardant powder coating

InactiveCN105062303AAccelerated corrosionImprove water resistancePowdery paintsPolyamide coatingsEpoxyBenzoyl peroxide

The invention discloses heat-resistant flame-retardant powder coating. The coating comprises the following raw materials: epoxy resin, carboxyl-terminated unsaturated polyester resin, nitrogen-containing phenolic resin, polyamide resin, thermoplastic styrene-butadiene rubber, ammonium polyphosphate, pentaerythritol, melamine, expansible graphite, nano-zirconia, titanium dioxide, talcum powder, diphenyl silanediol, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, octadecendioic acid, tetrahydro-1,3,4,6-tetrakis(methoxymethyl)imidazo[4,5-d]imidazole-2,5(1H,3H)-dione, benzoyl peroxide and auxiliaries. The heat-resistant flame-retardant powder coating has good heat resistance and excellent flame retardant performance, can be used for coating surfaces of kitchen ware, instrument shells, display stands, electromechanical equipment, automobile components and parts and the like, and has the advantages of good comprehensive performance and long service life.

Owner:安徽圣德建材科技有限公司

Resin matrix applicable to microwave curing and preparation method of resin matrix

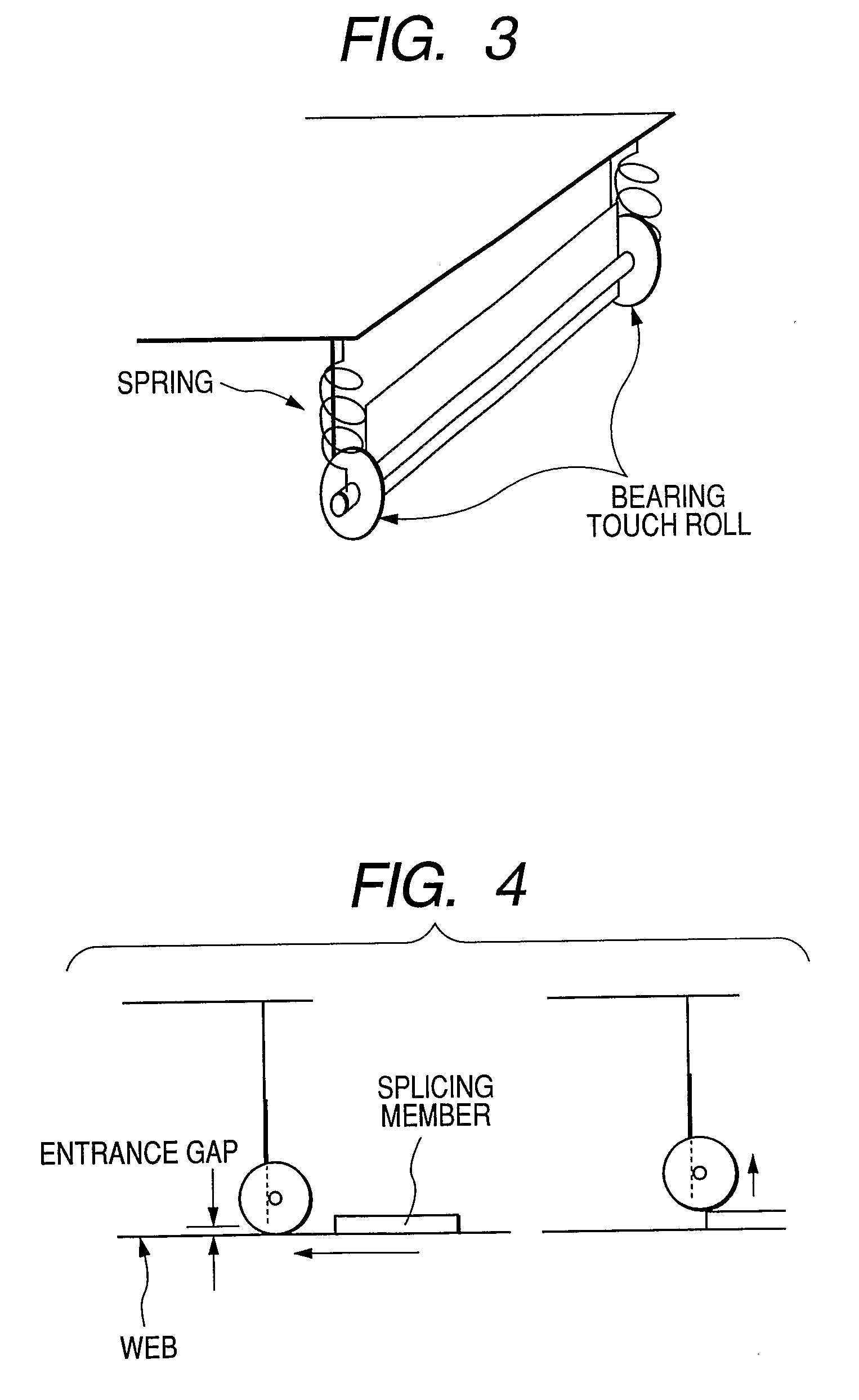

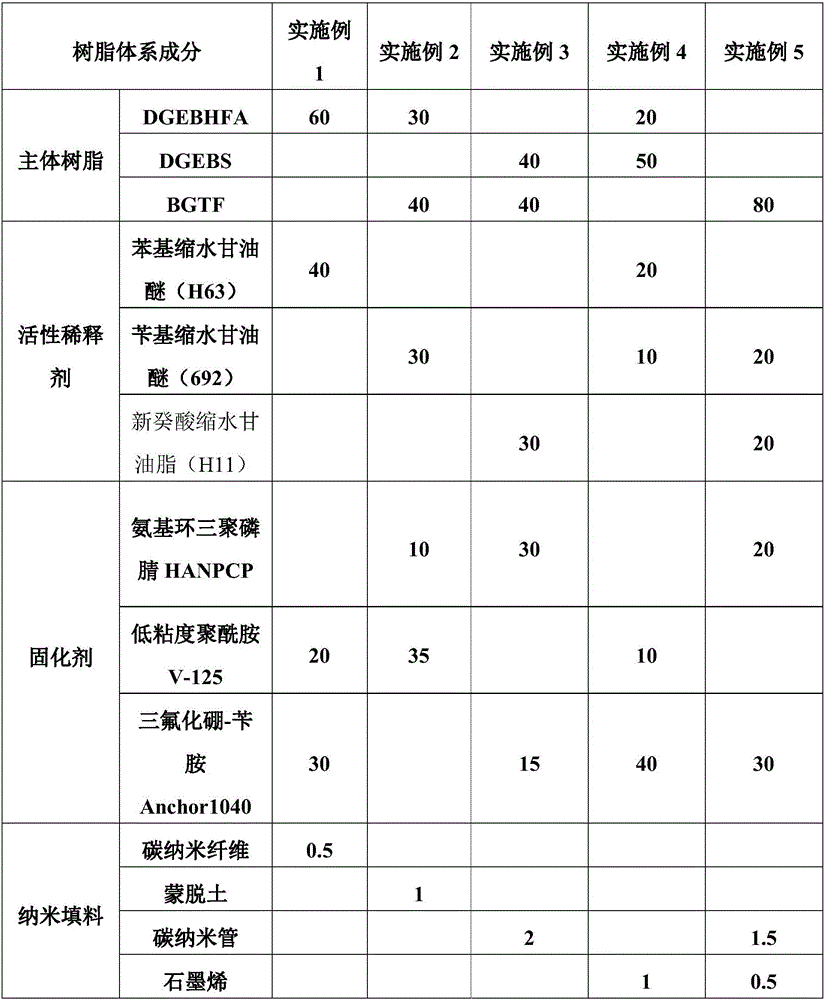

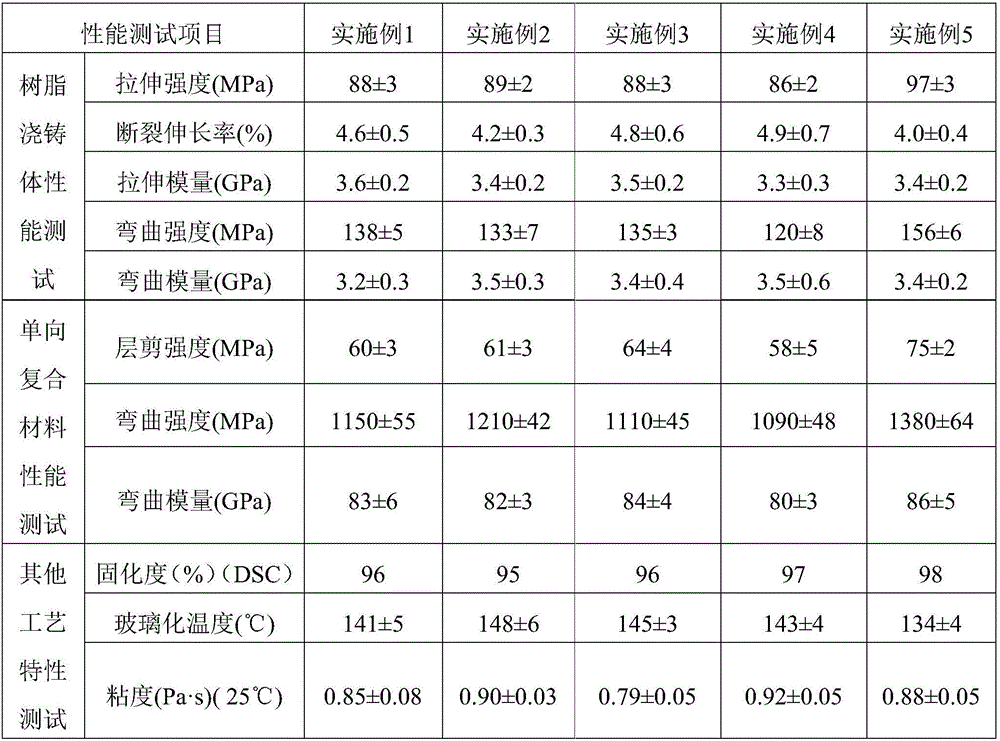

The invention discloses a resin matrix applicable to microwave curing and a preparation method of the resin matrix, and belongs to the field of preparation of composite materials. Polar mulfunctional high-performance epoxy resin is used as main body resin; an active diluent is added to adjust the viscosity of a resin system so as to enable the resin to adapt to liquid forming processes such as winding; a novel compound curing agent is selected to adjust the curing activity of the resin matrix, and nanofiller is added to improve the microwave responsiveness of the resin matrix and realize the mechanical property, the heat resistance and the size stability of the resin matrix; by the adjustment of the structures and the proportions of components such as the main body resin, the curing agent, the diluent and the nanofiller, the resin system which is proper in microwave responsiveness and curing activity, excellent in comprehensive mechanical property, high in heat resistance, high in size stability and low in viscosity and is applicable to microwave curing is developed, has a great guidance significance for preparation of a fiber composite material, and can be widely applied to the field of aerospaces and the like.

Owner:BEIJING UNIV OF CHEM TECH

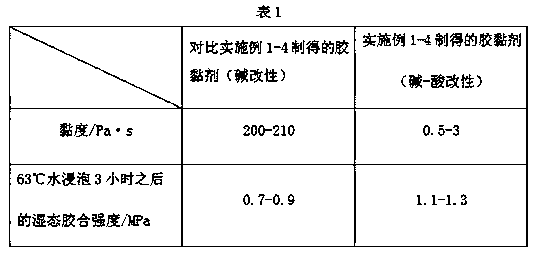

Preparation method of formaldehyde-free soybean meal-based wood adhesive for artificial boards

ActiveCN109880586ALow costLow priceNon-macromolecular adhesive additivesProtein adhesivesEpoxyChemical reaction

The invention relates to a preparation method of a formaldehyde-free soybean meal-based wood adhesive for artificial boards, and belongs to the technical field of adhesives. According to the invention, renewable resources, namely soybean meal, are used as raw materials, a water phase is selected as a solvent, and a process step of an alkali-acid two-step method is adopted. Epoxy resin, dicyandiamide, low-molecular-weight polyamide and soybean protein are combined for modification, a chemical reaction is carried out at the same time, and therefore the formaldehyde-free soybean meal-based wood adhesive with very high water resistance and bonding strength is prepared; the adhesive has the advantages of no formaldehyde, low viscosity, good cold pressing performance, low cost, high adhesive strength and the like; the adhesive does not volatilize formaldehyde, phenol or other harmful substances, has the characteristic of no formaldehyde, and is safe and environment-friendly, and the preparedsoybean meal-based wood adhesive is low in viscosity, convenient for applying, good in coating and pre-pressing performance, easy to spray and apply, convenient for repairing of plywood and capable of preventing a shaving board from being scattered, and the problems that a soybean adhesive is high in viscosity and difficult to spray are solved.

Owner:GUANGXI UNIV

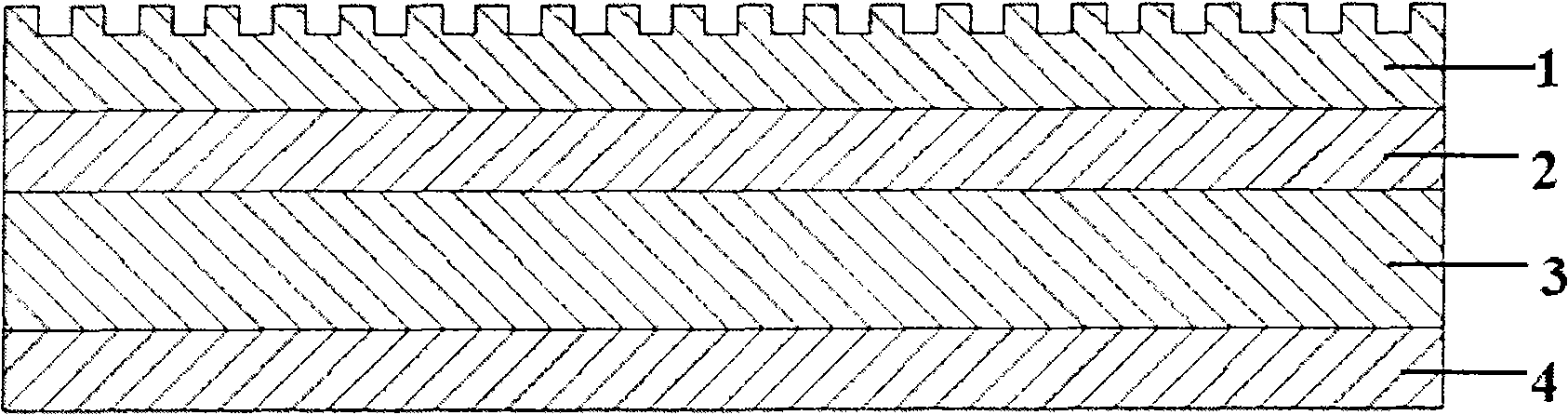

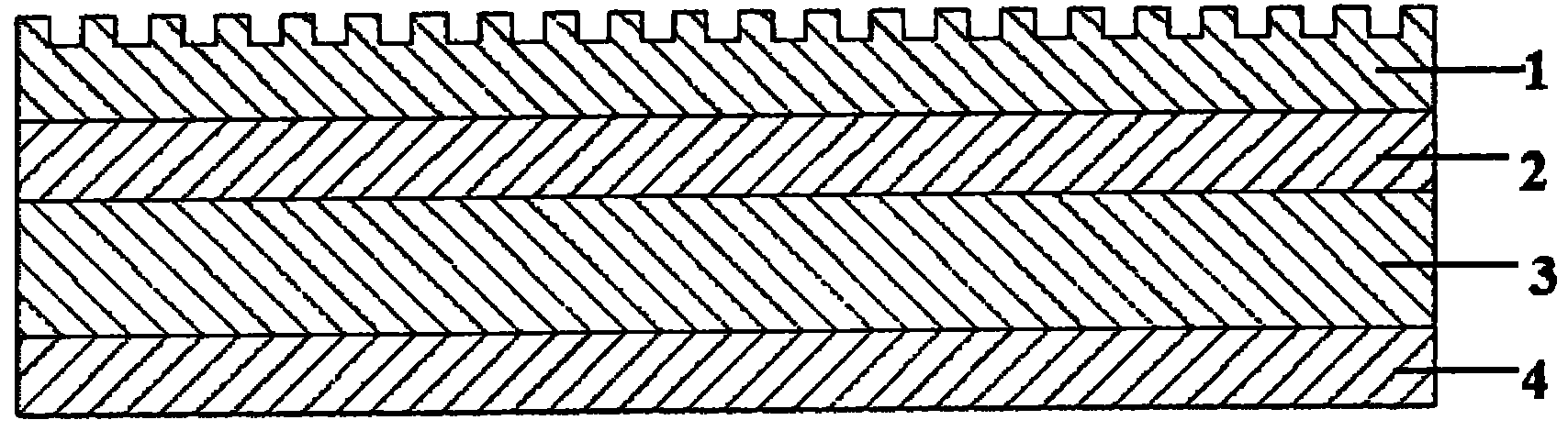

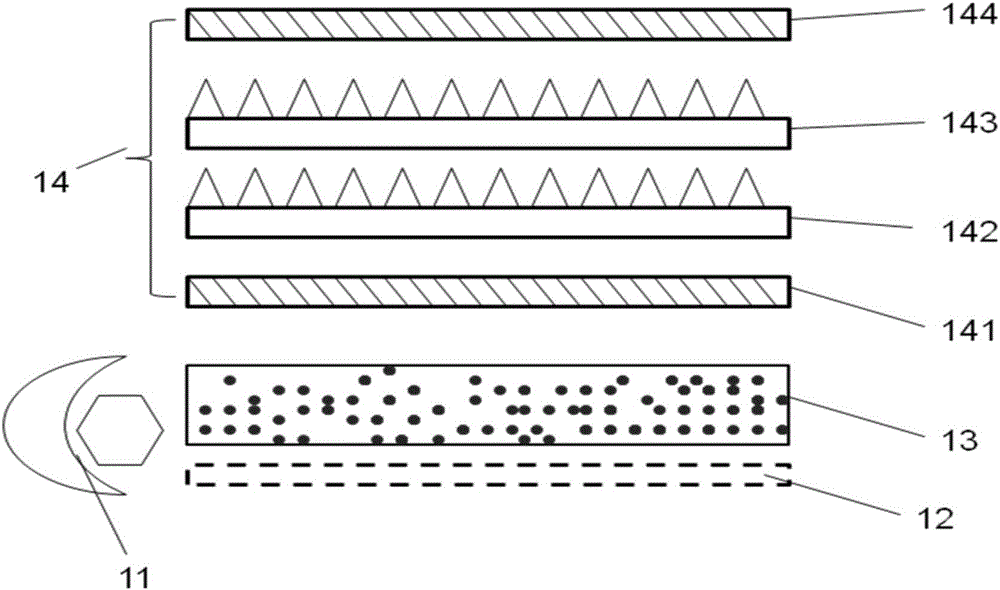

Preparation method of multilayer composite film for backlight module set

ActiveCN106707377AHigh degree of curingStickyNon-linear opticsOptical elementsDiffusionComposite film

The invention relates to a preparation method of a multilayer composite film for a backlight module set. The method includes the following steps that: (1) the base material of the multilayer composite film for the backlight module set is prepared; (2) a second prism film is prepared; and (3) a first prism is prepared. The preparation method of the invention is simple and efficient. With the preparation method of the invention adopted, the separate preparation of a diffusion film and prism films is avoided, and complicated steps such as winding, unwinding and cutting can be also avoided; production procedures are decreased; UV energy consumption is reduced; production costs are reduced; and production capacity is improved.

Owner:HEFEI LUCKY SCI & TECH IND +1

Friction material without asbestos layer and manufacturing method

InactiveCN103342985ALow costEasy dischargeOther chemical processesFibre treatmentCooking & bakingYarn

The invention relates to a friction material without an asbestos layer and a manufacturing method thereof. The friction material without the asbestos layer consists of an adhesive, reinforcing fibers and a friction performance regulating agent. The reinforcing fibers comprise glass fibers, aramid fibers, copper wires and friction spinning yarns. The manufacturing method of the friction material without the asbestos layer comprises the steps: acquiring the friction spinning yarns; twisting together for two times to obtain twisted threads; weaving the twisted threads to form a piece of mesh cloth; dipping the mesh cloth with the adhesive, and baking; clipping; carrying out press vulcanization after overlapping; and grinding the surface to obtain the finished product. The production cost of the friction material without the asbestos layer is low, the base material has better overall associativity, the metal wire distribution is more uniform, and the heat conductivity and the heat dissipation of the friction material are faster and better. The precision of the manufactured friction element size is higher than that of a friction element manufactured by a conventional method. Phenomena of blistering, swelling, stratifying and warping that often appear during the production of laminated products are completely avoided. The manufactured finished product has higher curing degree and more stable friction coefficient.

Owner:TALFRI BRAKES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com