Friction material without asbestos layer and manufacturing method

A technology of friction materials and manufacturing methods, applied in chemical instruments and methods, textiles and papermaking, and other chemical processes, can solve problems such as poor molding and poor tooth strength, achieve uniform distribution, reduce production costs, and integrate as a whole good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Use liquid phenolic resin (or modified phenolic resin) as the adhesive. Friction modifiers may or may not be used. Reinforcement materials are: glass fiber, aramid fiber, copper wire and friction spinning. Friction spinning is made by blending viscose fiber, glass fiber and acrylic fiber in a ratio of 1:1:1. Its formula is as follows:

[0025]

[0026] The manufacturing method is as follows:

[0027] The glass fiber, the aramid fiber, the 0.2mm copper wire and the friction spinning yarn are plied according to the above ratio, and the plied twist is 9-10 / 10CM.

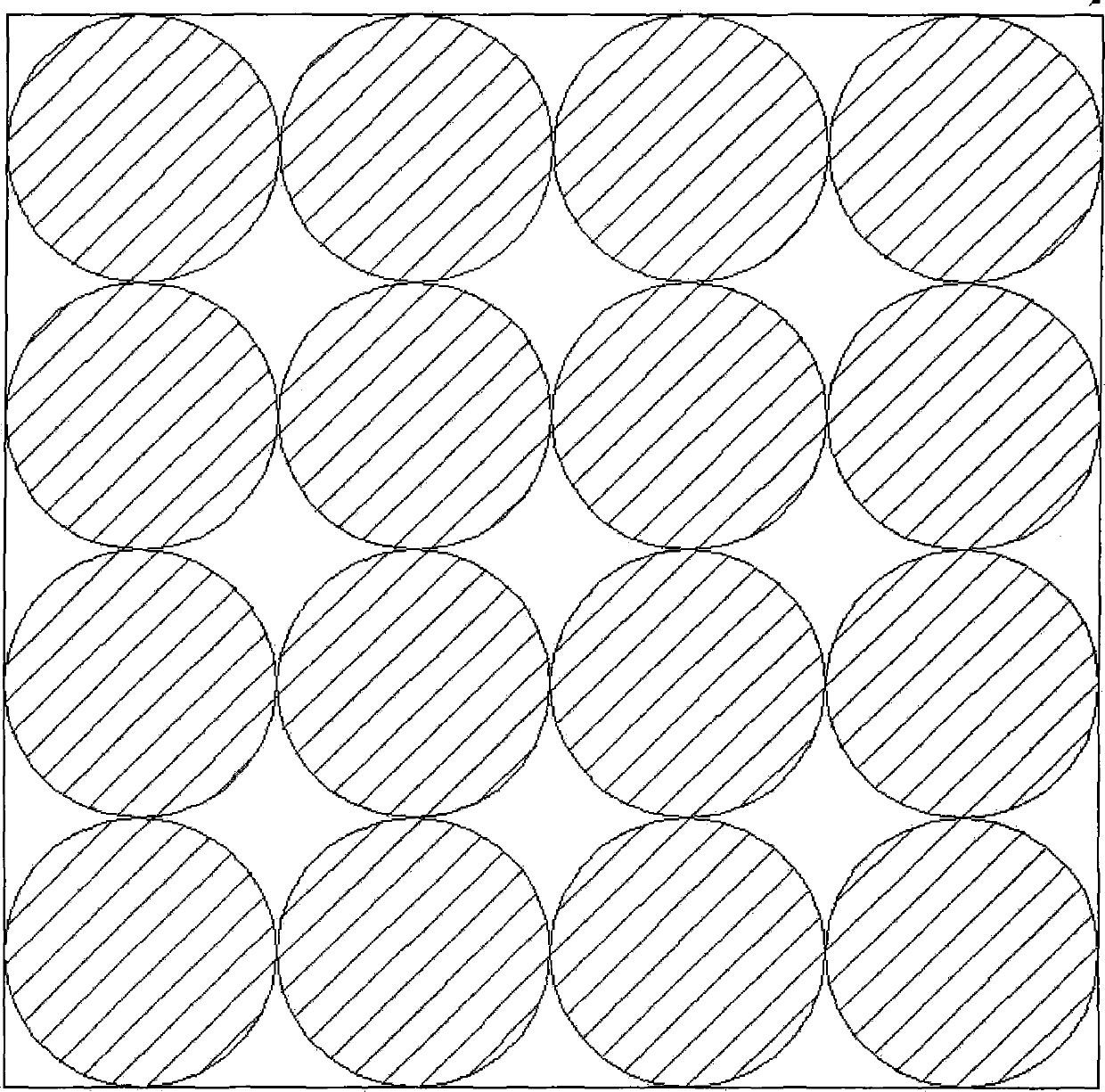

[0028] Then the twisted on-line knitting machine is woven into a grid cloth with a width of 900 mm, a warp density of 38 / CM, and a weft density of 30 / CM.

[0029] Put the grid cloth into a dipping tank filled with liquid phenolic resin to fully impregnate it, remove it and drip it dry, bake it in an oven at 100°C for 1 hour, and then take it out.

[0030] Then cut according to the size of the desired fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com