Preparation method of multilayer composite film for backlight module set

A multi-layer composite film, backlight module technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems affecting the thermal shrinkage performance, flattening performance, cumbersome processes, and complicated preparation methods of the film, and reduce the production process. and UV energy consumption, the process is simple and efficient, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method comprises the following steps:

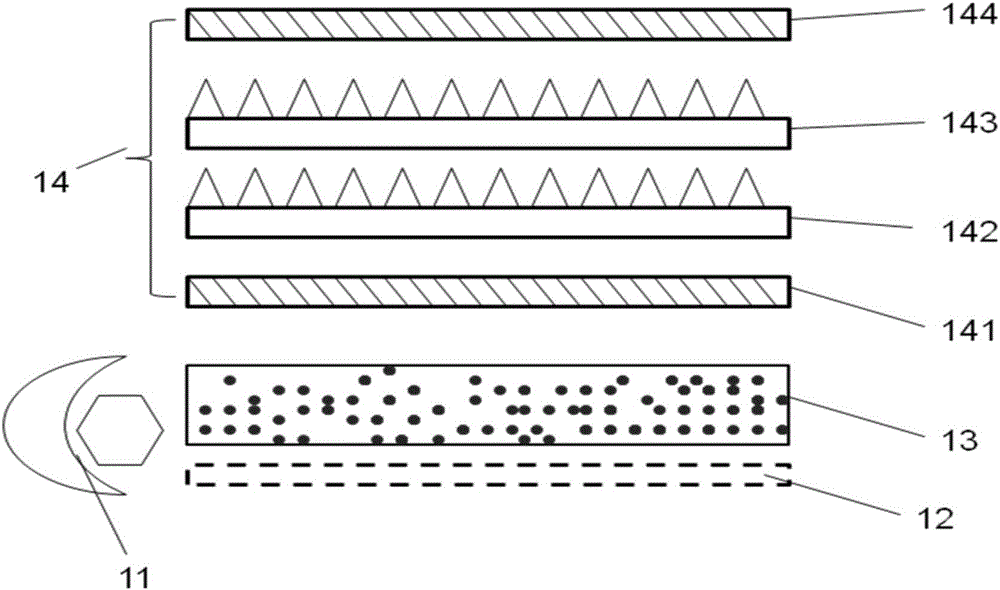

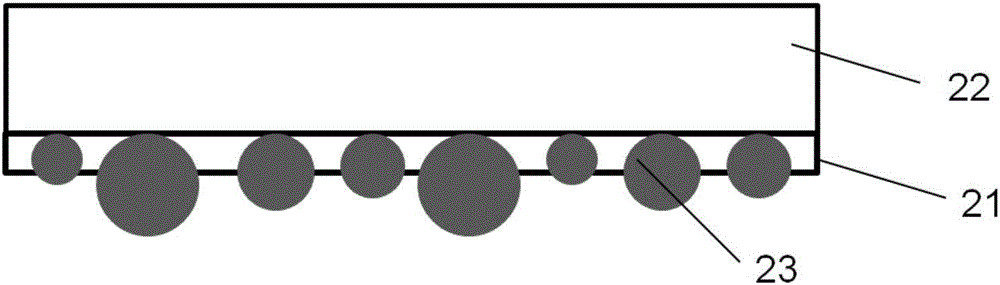

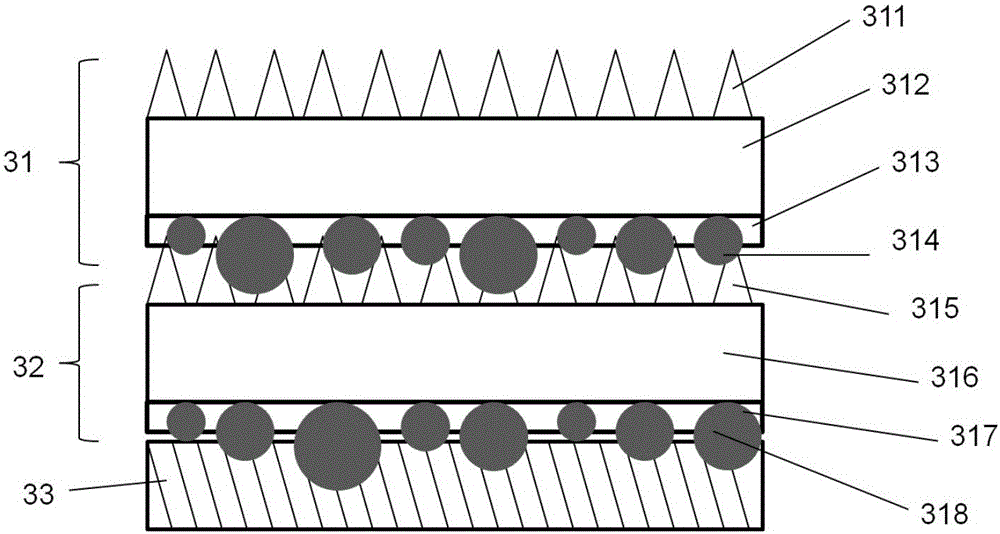

[0028] (1) Prepare the base material of the multilayer composite film for the backlight module: coat the diffuse reflection layer 21 on the PC film 22 (polycarbonate) of 125 μm, and the diffuse reflection layer is made of 20g ultraviolet light curing active monomer (trimethylolpropane Triacrylate, Changxing Chemical Materials Co., Ltd., trade name: EM231), 2g leveling aid (acrylic, BYK-350), 5g dispersion aid (Byk, BYK-111), 1g organic particles 23 (polystyrene PS, particle size is 4μm), 2g photoinitiator (1g photoinitiator 1 is 2-hydroxyl-2-methyl-1-phenyl-1-acetone, Beijing Yingli Technology Development Co., Ltd., commodity Name: IHT-PI 1173; 1g photoinitiator 2 is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, Beijing Yingli Technology Development Co., Ltd., trade name: IHT-PITPO), 70g The coating solution composed of ketone is cured; after the curing is completed, it is rolled up, and the diffuse reflection l...

Embodiment 2

[0033] The preparation of multilayer composite film comprises the following steps:

[0034] (1) Prepare the base material of the multilayer composite film for the backlight module: the diffuse reflection layer 21 is coated on the PET film 22 (polyethylene terephthalate) of 25 μm, and the diffuse reflection layer is made of 40g ultraviolet light curing active monomer ( Pentaerythritol triacrylate PET3A, Changxing Chemical Materials Co., Ltd., trade name: EM235), 0.5g leveling aid (acrylic acid, BYK-352), 0.5g dispersion aid (Byk, BYK-108), 0.05g organic particle (polymethyl acrylate PMMA, particle size is 6 μ m), 0.5g photoinitiator (0.42g photoinitiator 1 is 1-hydroxycyclohexyl phenyl ketone, Beijing Yingli Technology Development Co., Ltd., trade name : IHT-PI184; 0.08g photoinitiator 2 is ethyl 4-dimethylaminobenzoate, Beijing Yingli Science and Technology Development Co., Ltd., trade name: IHT-PI EDB), the coating solution that 58.45g ethyl acetate forms Cured; after the cu...

Embodiment 3

[0039] The preparation of multilayer composite film comprises the following steps:

[0040] (1) Prepare the base material of the multilayer composite film for the backlight module: the diffuse reflection layer 21 is coated on the PET film 22 (polyethylene terephthalate) of 50 μm, and the diffuse reflection layer is made of 40g ultraviolet light curing active monomer ( Two-trimethylolpropane tetraacrylate DiTMP4A, Changxing Chemical Materials Co., Ltd., trade name: EM242), 2g leveling aid (acrylic acid, BYK-354), 4g dispersion aid (ByK, BYK -2000), 2g organic particles (polybutylacrylate PBMA, particle size is 7μm), 2g photoinitiator (1.5g photoinitiator 1 is 2-hydroxyl-2-methyl-1-[4-(2-hydroxyl Ethoxy) phenyl]-1-acetone, Beijing Yingli Technology Development Co., Ltd., trade name: IHT-PI 659; 0.5g photoinitiator 2 is polyethylene glycol two (β-4-[to (2- Dimethylamine-2-benzyl) butyryl phenyl]-piperazine) propionate, Beijing Yingli Science and Technology Development Co., Ltd.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com