Preparation method of formaldehyde-free soybean meal-based wood adhesive for artificial boards

A wood adhesive and soybean meal-based technology, which is applied in the field of preparation of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, can solve the problem of unsatisfactory wet bonding strength of plywood, uneven particle size of protein adhesive raw materials, and crosslinking. Uneven structural distribution and other problems, to achieve the effect of easy spraying and sizing, improving physical and chemical properties, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

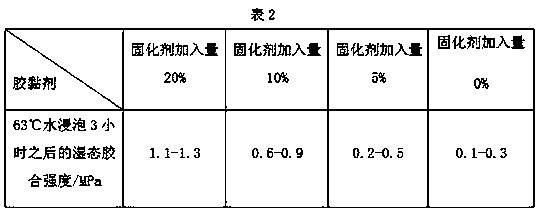

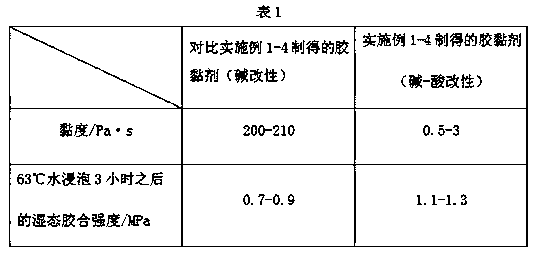

Examples

Embodiment 1

[0027] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0028] (1) Put the soybean meal into the water and mix it for 10 minutes according to the weight ratio of water: soybean meal = 75:25; use the alkaline substance sodium hydroxide to adjust the pH value of the mixture to 10.0, and continue stirring for 30 minutes.

[0029] (2) Adjust the pH value to 4.0 with acidic hydrochloric acid and stir for 25 minutes to obtain mixture A;

[0030] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 50°C for 35min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0031] (4) According to the weight ratio of mixture A:soybean gum high-efficiency composite curing agent of 5:1, mix mixture A...

Embodiment 2

[0033] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0034](1) Put the soybean meal into the water and mix and stir for 15 minutes according to the ratio of water:soybean meal=80:30 by weight; adjust the pH value of the mixture to 11.0 with alkaline substance potassium hydroxide, and continue stirring for 25 minutes.

[0035] (2) Adjust the pH value to 5.0 with acidic hydrochloric acid and stir for 30 minutes to obtain mixture A;

[0036] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 53°C for 33min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0037] (4) According to the weight ratio of mixture A: soybean gum high-efficiency composite curing agent of 5:1, mix mixtur...

Embodiment 3

[0039] A preparation method of formaldehyde-free soybean meal-based wood adhesive for wood-based panels, comprising the following steps:

[0040] (1) Put the soybean meal into the water and mix it for 20 minutes according to the weight ratio of water: soybean meal = 95:35; use the alkaline substance sodium hydroxide to adjust the pH value of the mixture to 13.0, and continue stirring for 20 minutes.

[0041] (2) Adjust the pH value to 6.0 with acidic substance phosphoric acid and stir for 33 minutes to obtain mixture A;

[0042] (3) According to the weight ratio of epoxy resin: dicyandiamide: low molecular weight polyamide is 8:1:1, mix epoxy resin, dicyandiamide and low molecular weight polyamide, and stir at 55°C for 30min to obtain Soybean gum high-efficiency composite curing agent; the molecular weight of the low molecular weight polyamide is 1000-1500;

[0043] (4) According to the weight ratio of mixture A:soybean gum high-efficiency composite curing agent of 5:1, mix m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com