Patents

Literature

468results about How to "Sticky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

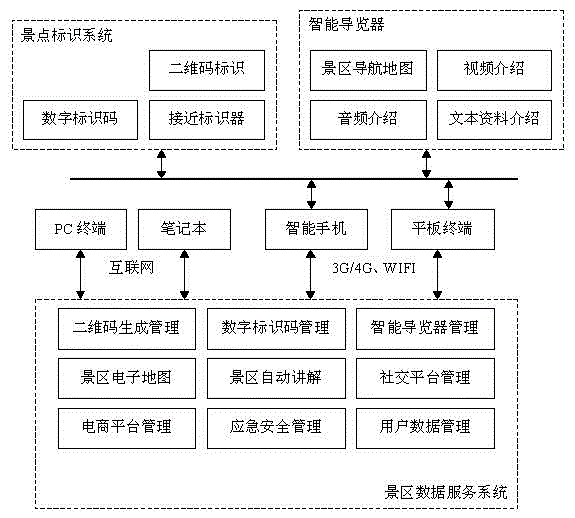

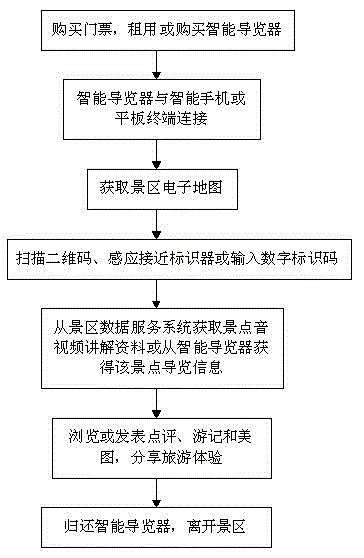

Scenic spot self-help tour system and scenic spot self-help tour method based on mobile Internet

InactiveCN104680440ASolve the needs of explanationEnable self-guided toursData processing applicationsSensing record carriersTablet computerGeolocation

The invention discloses a scenic spot self-help tour system and a scenic spot self-help tour method based on a mobile Internet. The system comprises a scenic spot identification system, a user terminal, a scenic spot data service system, and an intelligent navigator. A PC terminal and a notebook access the scenic spot data service system via the Internet. A smart phone or a tablet computer terminal identifies a two-dimension identification code, a proximity identification device or a digital identification code of the scenic spot identification system, and accesses video and audio explanation information in the scenic spot data service system via a wireless network. The smart phone or the tablet computer terminal is further connected with the intelligent navigator through a data line interface, and looks up navigation information of a scenic spot in the intelligent navigator. According to the invention, accurate location information of a scenic spot is judged by using the smart phone or the tablet computer terminal to scan the two-dimension identification code, sense a proximity identification device signal or input the digital identification code, and the video and audio explanation information of the scenic spot is acquired by accessing the scenic spot data service system or directly accessing a rented intelligent navigator, thus realizing self-help tour guide.

Owner:CHENGDU GUOHENG INFORMATION SECURITY TECH +1

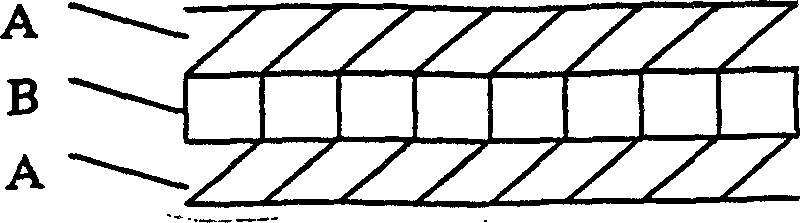

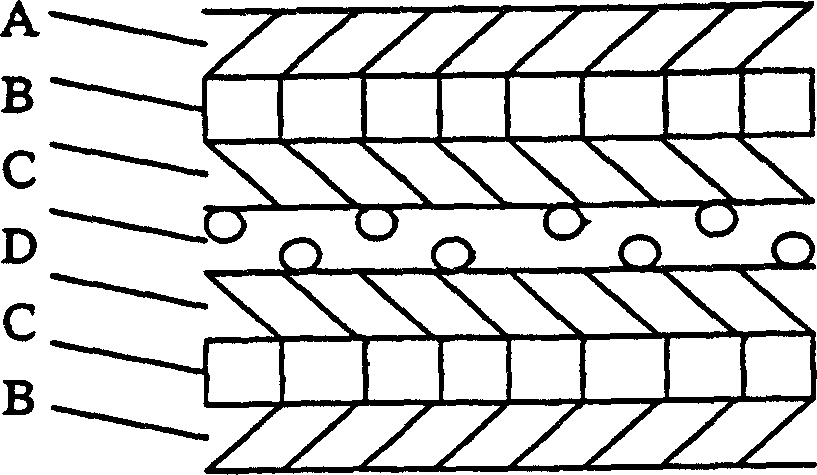

Foodstuff packaging membrane and its manufacturing method

InactiveCN1736813AHigh transparencyGood air resistanceFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a production of food packaging film and the method for preparation, specifically a degradable complex film prepared with degradable nanometer PA polymer as the obstruct material. Said complex film has a layer structure containing at least two outer layers and one interlayer, at least one layer among which is the obstruct layer, the obstruct layer being made up of degradable nanometer PA polymer, and others being made up of degradable polyolefin or polyolefin. Compared with the high-obstruct film prepared with PVDC, the invention overcomes the shortcomings that the manufacture is hard, the cost is high, environmental pollution is serious, and the recovery is hard. And the high-obstruct packaging film prepared mainly with nanometer PA has identical obstruct effect with PVDA film.

Owner:朱春英

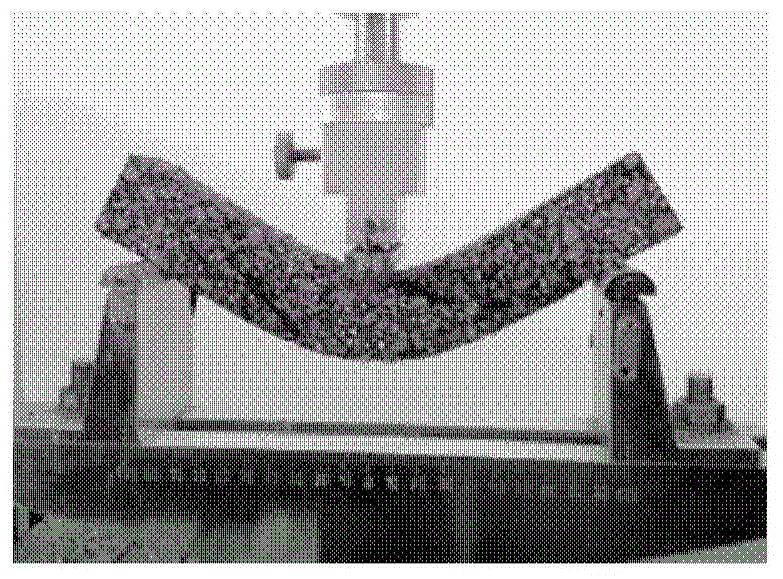

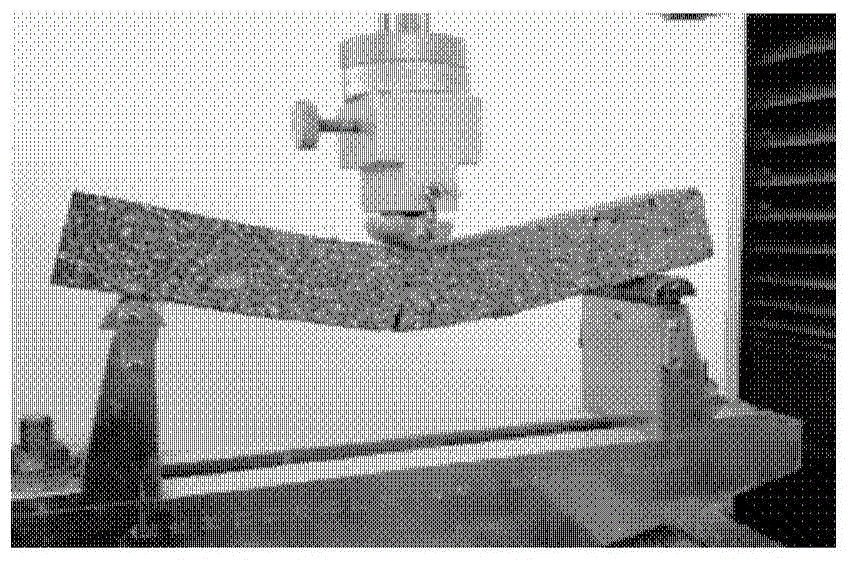

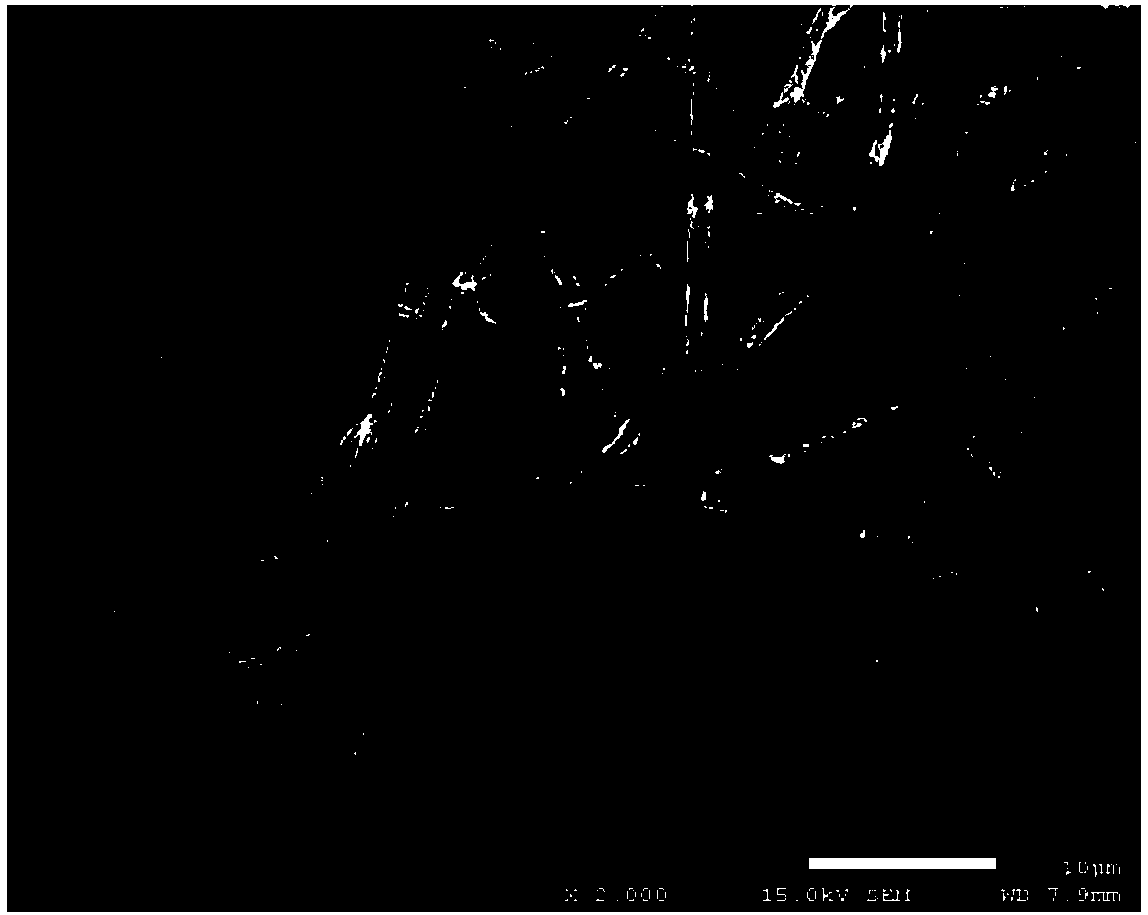

Bionic flexible dry electrode and manufacturing method thereof

The invention discloses a bionic flexible dry electrode which comprises a conductive bionic electrode sheet and an external interface. A bristle structure imitating a gecko is arranged on the surface of the conductive bionic electrode sheet. The bionic flexible dry electrode is of a structure of three levels. The first level and the second level of the electrode sheet are prepared through the micro-reversed mold technology. A mold of a two-level structure is prepared through a PDMS. A mixture CPDMS of the PDMS and a CNT is filled into the mold. After the CPDMS is solidified, a film provided with the two-level structure and prepared by the CPDMS is taken down. Then, the third level is formed on the second level of the film of the two-level structure through the inkin technology. The micro-machining process technology is adopted to manufacture the dry electrode, so that the dry electrode has viscidity and flexibility and can be directly adhered to the skin of a user without harm to the skin of the user. The dry electrode can be better in contact with the skin so that the stability of a signal and the comfort of the user can be improved. After the bionic flexible dry electrode is disinfected and cleaned, the viscidity of the bionic flexible dry electrode is not influenced, so that the bionic flexible dry electrode is reusable and has the advantages of environment friendliness. Compared with an existing dry electrode, the bionic flexible dry electrode is obvious in performance and ingenious in structure.

Owner:无锡交大联云科技有限公司

Self-adhering type chitosan haemostatic membrane and preparation thereof

InactiveCN101239199ANon-adhesiveKeep shapePharmaceutical delivery mechanismAbsorbent padsChemistryHemostatics

The present invention discloses a self-adhesive type chitosan hemostatic film, which is composed of components by weight percentage: 85-93% chitosan, 5-10% glycerin, 2-5% citric acid. The preparing steps includes: weighing chitosan, glycerin and citric acid, then adding chitosan into acetum with 1.5%-2% mass concentration, mixing to chitosan dissolved, adding glycerin and citric acid again, mixing to mixed solution; pouring said solution into glass mould and self-levelling, drying to form film, and cooling to room temperature; supporting the mould with film in closed container filling with absolute ethyl alcohol, and suffocating 2-3 hours, exposing film from mould. The film has no bacterium, and the self-adhesive surface absorbs moisture and forms gel instantly when contacts with blood or body fluid after is planted into body, the gel has adhesive and has effects of hemostasia and healing. Other side of the film has no adhesive and acts on isolation function with periphery.

Owner:ZHEJIANG UNIV

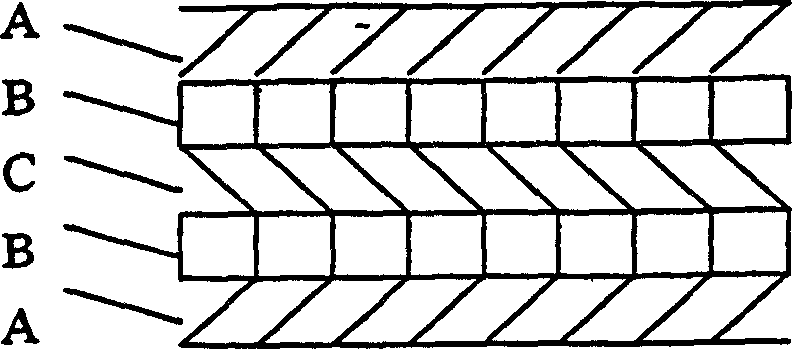

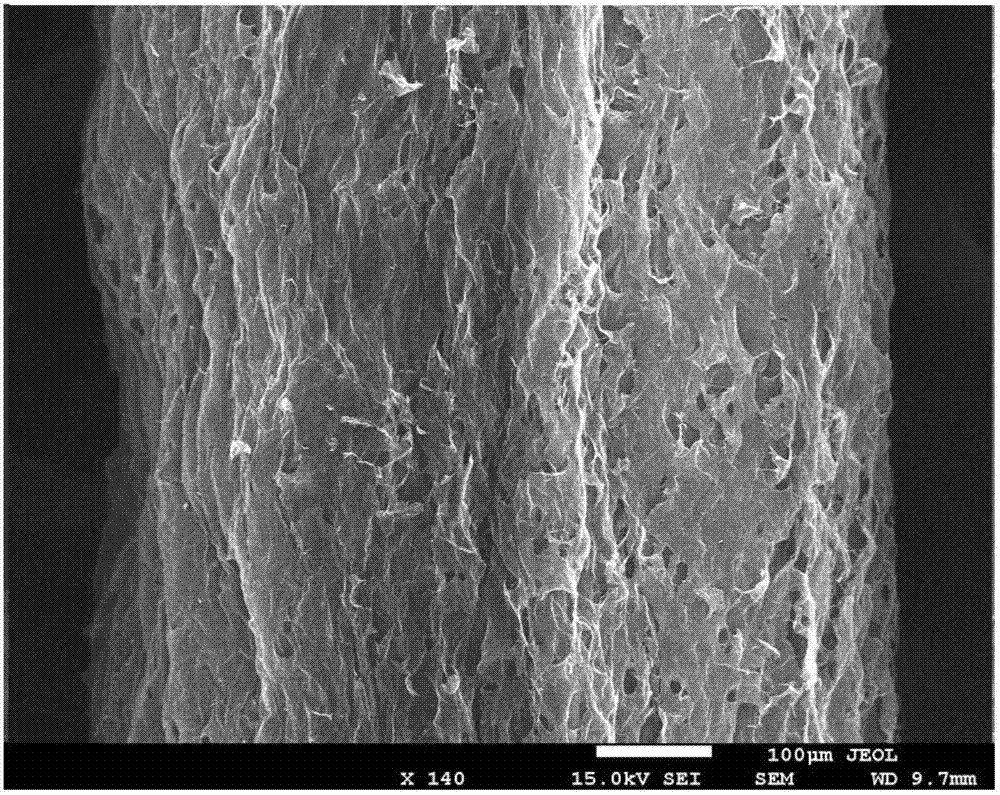

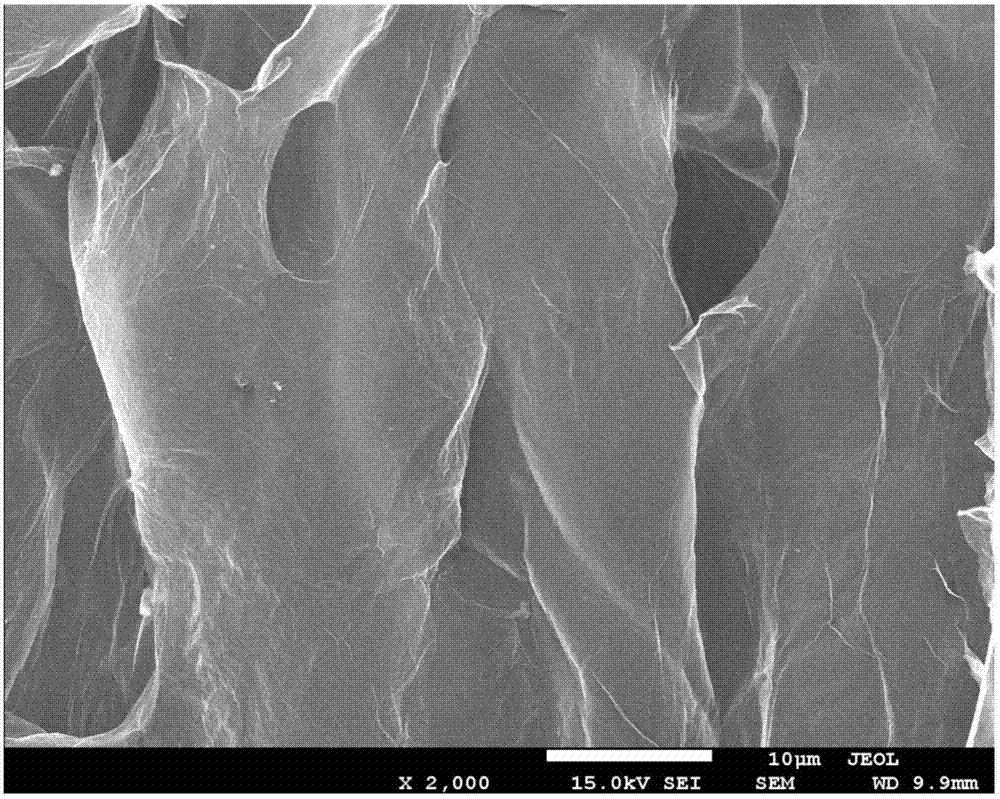

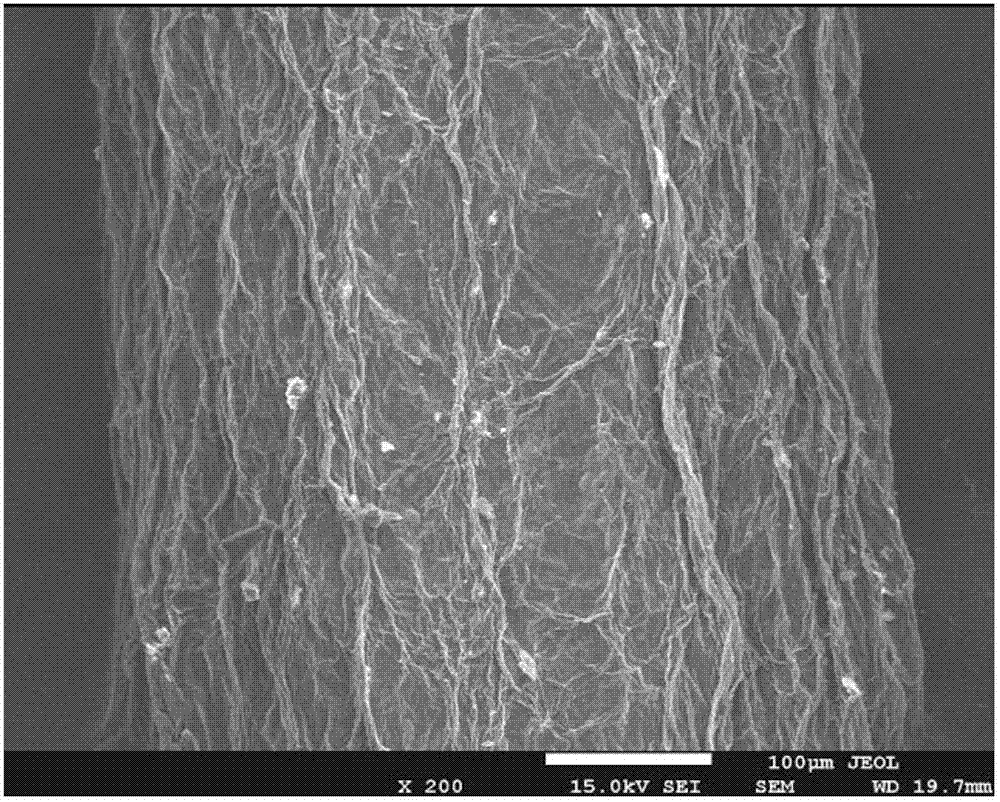

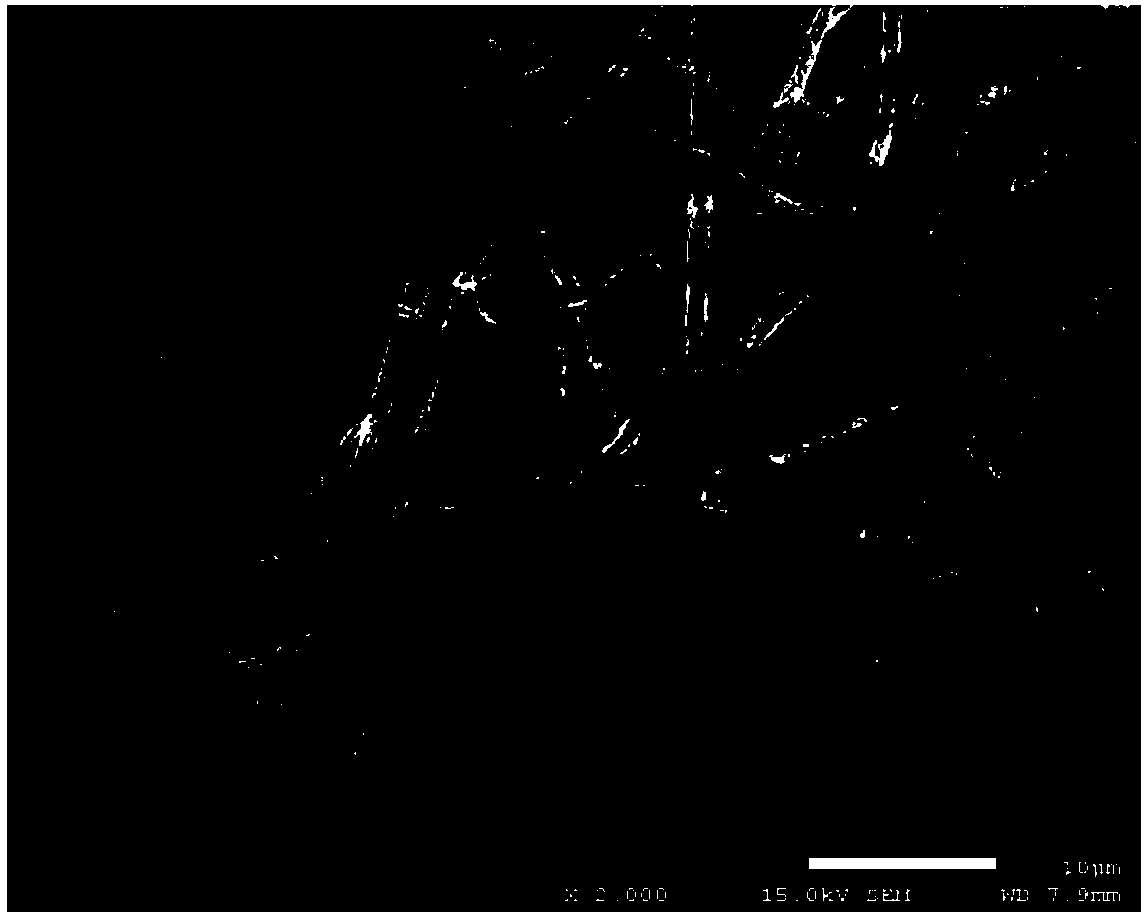

Preparation method of graphene oxide hollow fiber and graphene hollow fiber

ActiveCN103031618AEvenly dispersedStickyInorganic material artificial filamentsHollow filament manufactureMaterials preparationFiber

The invention relates to a preparation method of a graphene oxide hollow fiber and a graphene hollow fiber, and belongs to the technical field of graphene oxide and graphene material preparation. The method comprises the following steps that an outer layer solution and an inner layer solution are respectively input into an outer layer and an inner layer of a coaxial needle head; the outer layer solution is injected into a receiving solution to form an aqueous graphene oxide hollow fiber, and then dried to form a graphene oxide hollow fiber; and the graphene oxide hollow fiber is reduced to a graphene hollow fiber. The outer layer solution is a 20-25mg.mL<-1> graphene oxide solution; the inner layer solution and the receiving solution are methanol solutions of KCL with a mass concentration greater than or equal to 3mol / L; the flow velocity of the inner layer solution is 0.6ml / min; and the flow velocity of the outer layer solution is greater than or equal to 0.1ml / s. According to the preparation method, the graphene oxide hollow fiber and the graphene hollow fiber can be prepared respectively in different steps of one method, the operation is easy and simple, aftertreatment and edulcoration are not required, the cost is low, and mass continuous production can be conducted.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

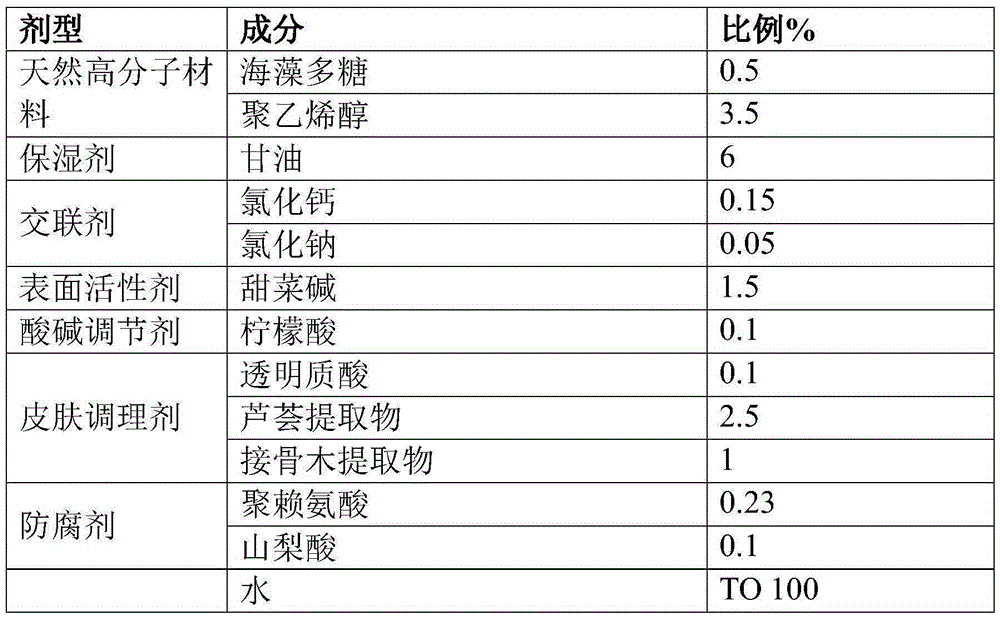

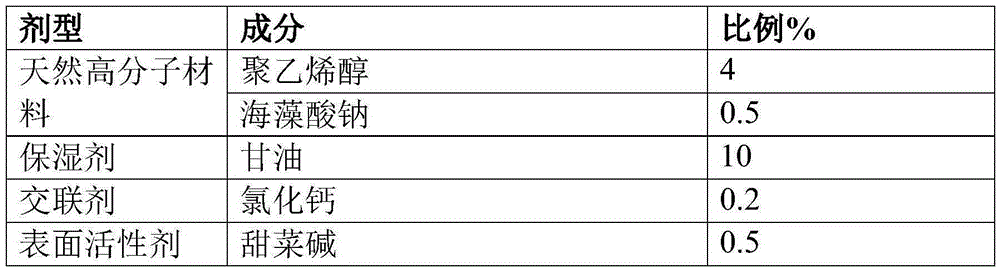

Biology-breathable cosmetic mask and preparation method thereof

ActiveCN105232354AOvercome inherent flawsImprove breathabilityCosmetic preparationsToilet preparationsMedicinePreservative

The invention provides a biology-breathable cosmetic mask. The biology-breathable cosmetic mask is prepared from, 1%-5% of natural polymer material, 1%-10% of wetting agent, 0.12%-0.25% of cross-linking agent, 0.1%-5% of surface active agent, 0.1%-2% of preservative, 0.01%-1% of acid-base modifier, 0.01%-30% of medicine carrying functional component and the balance distilled water. The pH value of the biology-breathable cosmetic mask is 5.5-8.0. The invention further provides a preparation method of the biology-breathable cosmetic mask. The biology-breathable cosmetic mask can be dissolved quickly and completely in hot water of above 50 DEG C and is swelled only without being dissolved after being placed in normal temperature water; however, the mask can be dissolved gradually after several hours, complete biodegradation is achieved, and no pollution to the environment is caused. The biology-breathable cosmetic mask can be either a transparent thin film or a translucent or opaque thin film.

Owner:赵勤

Method for producing all-hydrogel stretchable supercapacitor and capacitor

ActiveCN108586664AGood electrochemical propertiesGood stabilityHybrid capacitor electrolytesHybrid capacitor electrodesCarbon nanotubePolyacrylamide

The invention belongs to the field of supercapacitor production and specifically discloses a method for producing an all-hydrogel stretchable supercapacitor and the capacitor. The stretchable supercapacitor is assembled in a traditional sandwich structure by taking sodium alginate / polyacrylamide / carbon nanotube / poly(3,4-ethylendioxythiophene)-polystyrolsulfon acid composite hydrogel with high stretchability as an electrode material and sodium alginate / polyacrylamide / sodium sulfate / redox couple composite hydrogel with high stretchability as electrolyte. Each of the electrode material and electrolyte provided in the method is based on a stretchable hydrogel material, and strong adhesion exists between the electrode material and the electrolyte, so that the constraint that an existing assembling technology needs the help of a stretchable base can be avoided. The all-hydrogel stretchable supercapacitor is suitable for a traditional application field of the supercapacitor and high-end application fields such as wearable electronic equipment, stretchable electronic equipment, electronic skins and portable integrated devices.

Owner:HUAZHONG UNIV OF SCI & TECH

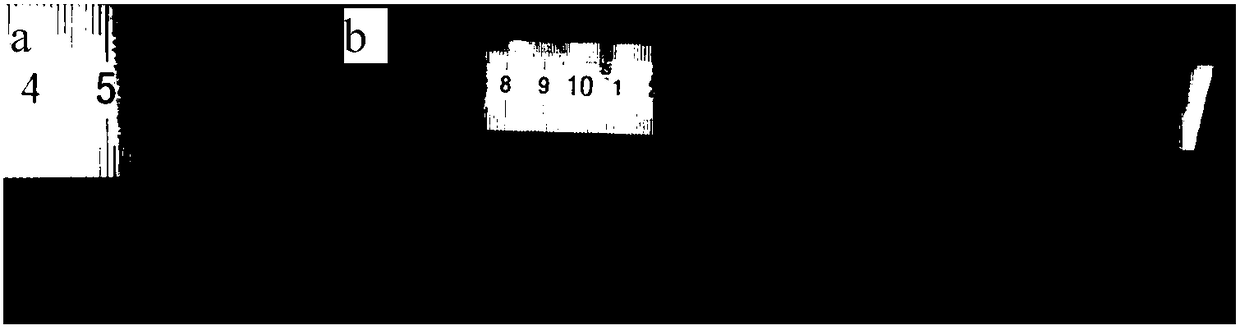

Heat conduction insulating material, heat conduction insulating strip and preparation method thereof

ActiveCN102372925AImprove insulation performanceStickyHeat-exchange elementsModifications by conduction heat transferElectricityElectronic component

The invention provides a heat conduction insulating material, a heat conduction insulating strip and a method for preparing the heat conduction insulating material and the heat conduction insulating strip. The heat conduction insulating material comprises the following components by weight part: 4-40 parts of high-molecular base material; 1-20 parts of tackifying additive, wherein the tackifying additive contains a reaction group which is identical or analogous with at least one solidified active group in the high-molecular base material; and 40-85 parts of heat conduction insulating particles. The heat conduction insulating material of the present invention has good heat conduction insulating property and viscosity, and can adhere between a radiator and an electronic component without using a double faced adhesive tape or corona treatment.

Owner:TIANJIN LAIRD TECH LTD

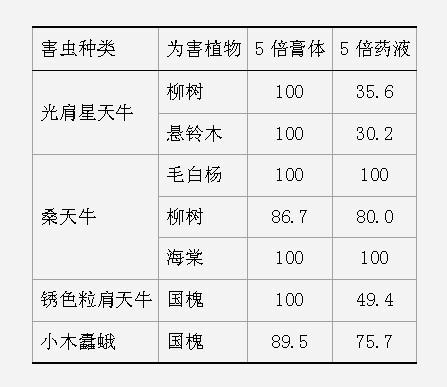

Paste for preventing and curing stem borer

The invention relates to a paste for preventing and curing stem borers, which is prepared by mixing the following raw materials based on the weigh ratio: 0.1-4 parts of botanical pesticide, 4-6 parts of kaolin, 0.5-1.5 parts of glycerol, 0.3-1 part of thickening agent and 10-13 parts of water. The paste has the advantages of certain stickiness, moderate mobility and long moisturizing period and pesticide effect period and has small possibility of drying and volatilizing. The paste is neutral and nontoxic, is safe to plants and does not pollute environment. The prevention and cure effect of the paste on Anoplophora glabripennis is improved by 64.4-69.8%, the prevention and cure effect on the Apriona swainsoni is improved by 50.6%, and the prevention and cure effect on small carpenter moths is improved by 13.8%. Meanwhile, the use amount and the loss amount of pesticides are lowered, thereby lightening environmental pollution.

Owner:乔建国

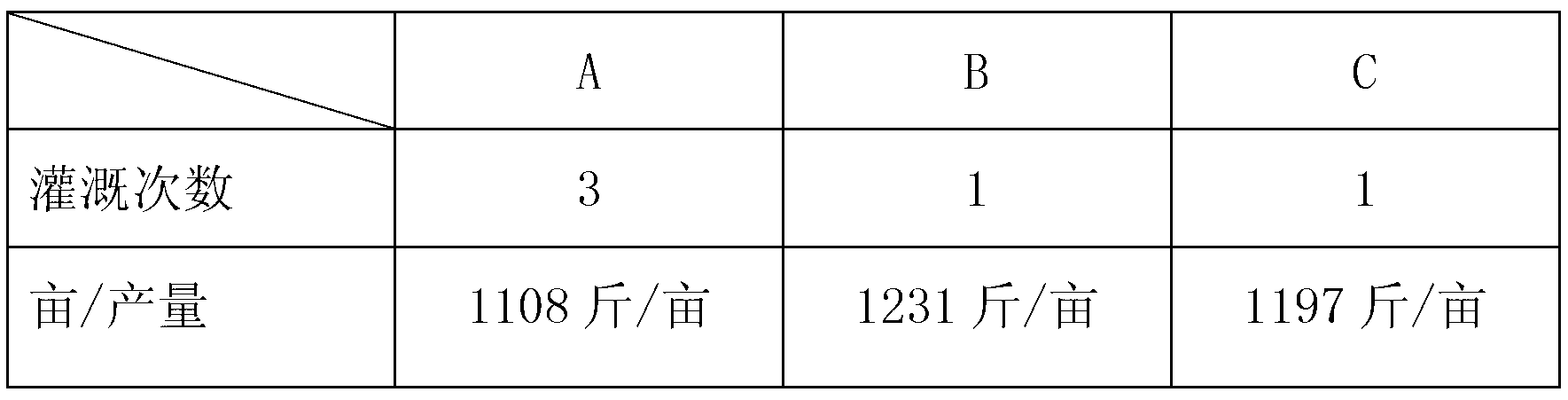

Complex water-retaining synergistic chemical fertilizer

The invention discloses a complex water-retaining synergistic chemical fertilizer which is composed of the following constituents by weight proportion: 88%-92% of nitrogenous fertilizer, 1%-2% of laurinol oxethyl ammonium sulfate, 1%-2% of water-retaining agent, 2%-3% of complex biological bacteria, 1%-2% of humic acid, 1%-2% of zeolite powder and 1%-2% of bentonite. The complex water-retaining synergistic chemical fertilizer provided by the invention can be used for effectively improving the soil aggregate structure, eliminating the soil hardening and enhancing the soil permeability, thereby enhancing the fertilizer utilization rate, increasing the soil water-retaining ability, improving the soil structure, promoting the crop growth and improving the crop quality.

Owner:焦楠

High fracture toughness and elasticity modified asphalt, preparing method and application thereof

Provided is high fracture toughness and elasticity modified asphalt. The needle penetration of the high fracture toughness and elasticity modified asphalt is larger than 301 / 10 mm, the ductility is larger than 40 cm under the temperature of 5 DEG C, and the softening point is larger than 90 DEG C. The high fracture toughness and elasticity modified asphalt comprises, by mass, 70%-85% of matrix asphalt, 5%-20% of thermoplastic elastomer, 2%-5% of reinforcing agent, 1%-5% of compatilizer, 5%-20% of a softening agent, 0.01%-0.1% of a dispersing agent, 0.2%-0.5% of a cross-linking agent and 0.5%-2% of viscosity reducer. According to the modified asphalt, the mixing amount of a modifying agent is high, the stability is good, the high and low temperature performances are good, using for construction is convenient, curl pavements and other functional pavements can be prepared, and the high fracture toughness and elasticity modified asphalt is used for paving of roads and bridge faces.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Drilling fluid and preparation method thereof

The invention provides a drilling fluid and a preparation method thereof. The drilling fluid comprises base slurry and additives, wherein the additives include a high-softening point asphalt composition particle, a performance regulator, a stable dispersant and a stable dispersing aid, the addition amount of the high-softening point asphalt composition particle is 2% to 5% of the total mass of the drilling fluid, and the average particle size of the high-softening asphalt composition particle is 10 to 120 mm. The preparation method comprises the following steps: (1) preparing the high-softening point asphalt composition particle; and (2) adding the high-softening point asphalt composition particle into the drilling fluid and then adding proper additives like the performance regulator, a surfactant and a film-forming additive so as to allow the high-softening point asphalt particle to be uniformly and stably dispersed into the drilling fluid. The drilling fluid provided by the invention overcomes the problem that high-softening point asphalt is hard to be crushed into fine particles and has difficulty in stable dispersion in a water-based drilling fluid, and the drilling fluid can be widely used in the process of drilling operation for deep oil and gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

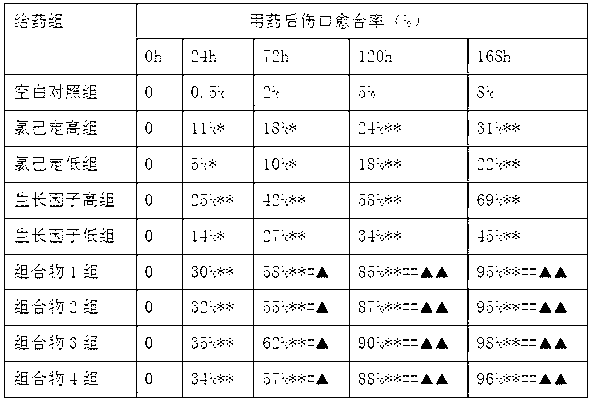

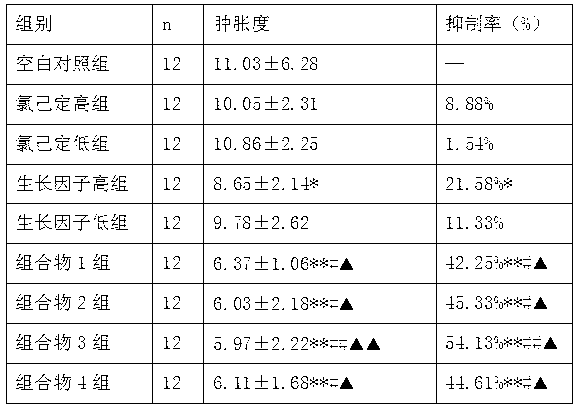

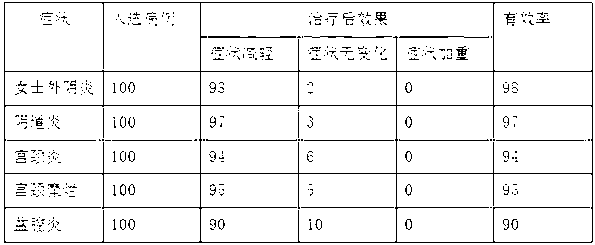

External composition, and preparation and application thereof

ActiveCN103182070AStickyAvoid secondary cross-infectionPeptide/protein ingredientsAerosol deliveryOfficinalChlorhexidine

The invention relates to an external composition, and a preparation and an application thereof and belongs to the field of medicines. The external composition provided by the invention is a medicine composition which contains chlorhexidine or officinal salt thereof, or benzalkonium bromide or officinal salt thereof and a recombinant human epidermal growth factor or a recombinant cattle alkali fibroblast growth factor. According to the invention, the medicine composition is also further prepared into gel, liniment, ointment or paste, and the gel further comprises chitosan or officinal salt thereof and hyaluronic acid or officinal salt thereof. When being used for treating vagina inflammation, the external composition disclosed by the invention can improve a vagina microenvironment, promote growth of granulation tissue and repair vagina micro damage; and when being used for skin wound atraumatic restorative treatment, the external composition also can speed up restoration and regeneration of a wound tissue, promote healing and reduce scar formation, so that the external composition has a wide medical application prospect.

Owner:JIANGSU DIWO BIOLOGICAL PROD

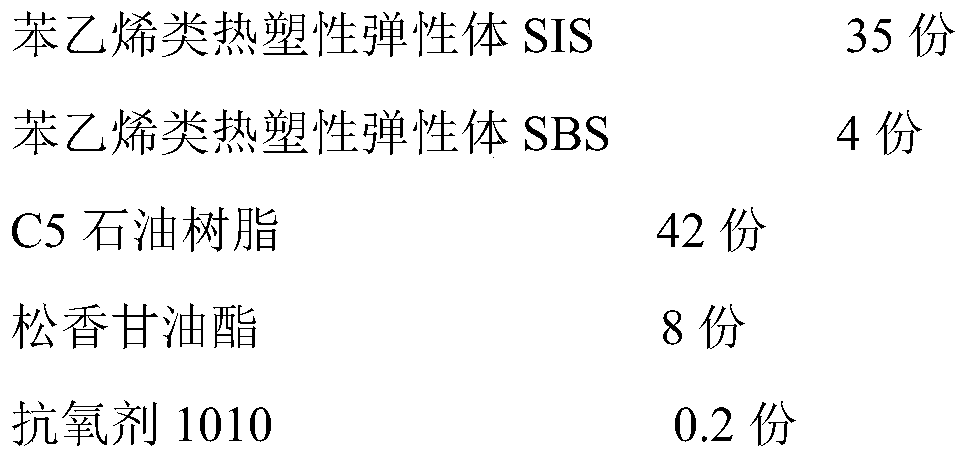

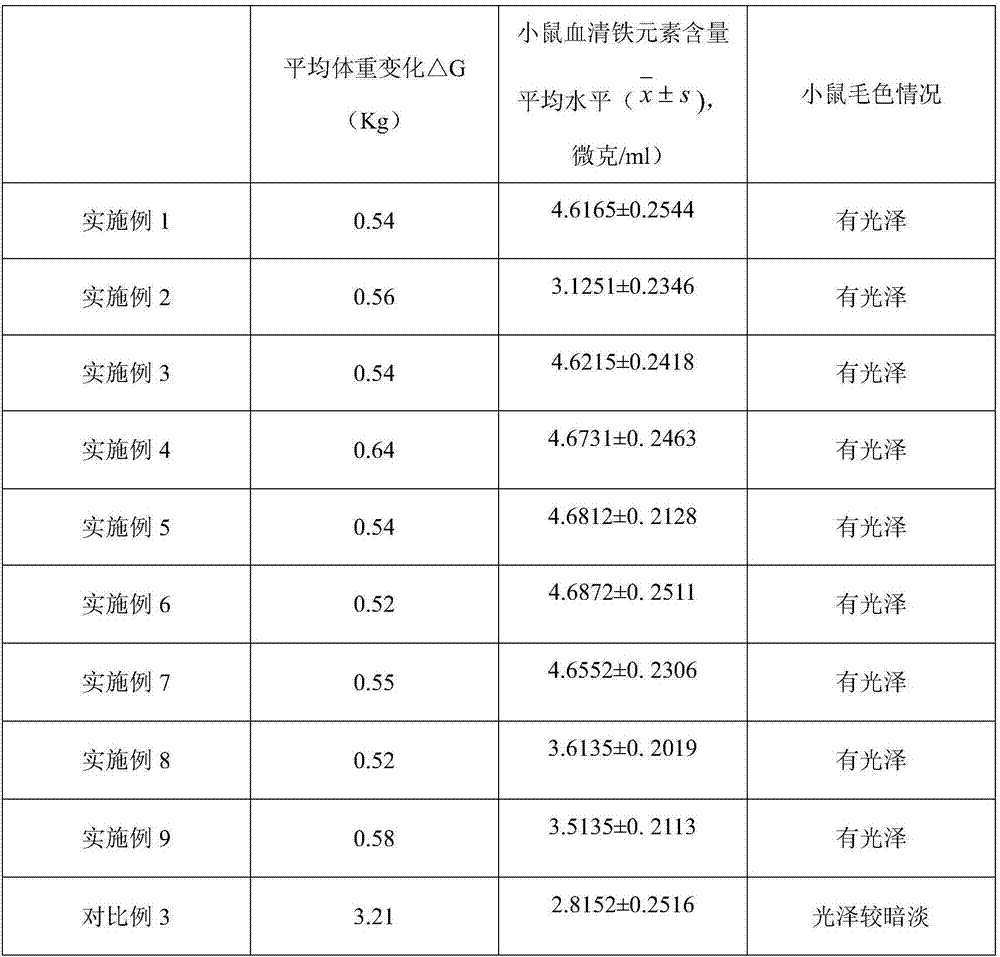

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Nutritional quinoa composition, and quinoa product

The invention discloses a nutritional quinoa composition. The composition contains quinoa flour, Ficus tikoua powder and vegetable and fruit plant enzyme powder. The nutritional quinoa composition has no influences on normal diet, allows the body weight to be successfully controlled and the health to be kept while enjoying delicious foods, and makes people keep a good spirit state and a good working efficiency.

Owner:成都南野食品有限公司

Polymer composite membrane as well as preparation method and lithium ion battery with same

InactiveCN107785519AImprove high temperature resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufacturePolymer sciencePolymer composites

The invention relates to the field of lithium ion batteries, discloses a polymer composite membrane as well as a preparation method thereof, and further discloses a lithium ion battery with the polymer composite membrane. The polymer composite membrane comprises a porous base membrane and a thermal-resistant fiber layer, wherein the surface of at least one side of the porous base membrane is covered with the thermal-resistant fiber layer; the thermal-resistant fiber layer is made of a material containing a first high polymer material and a second high polymer material simultaneously; the firsthigh polymer material is a thermal-resistant high polymer material of which the melting point is 180 DEG C or greater; the melting point of the second high polymer material is lower than that of thefirst high polymer material; the liquid absorption capacity of the second high polymer material in electrolyte of 25 DEG C is 40% or greater, with the error of + / -5%. Due to adoption of the first highpolymer material and the second high polymer material, the high temperature stability and the mechanical properties of the polymer composite membrane under high temperature conditions can be improved.

Owner:BYD CO LTD

Sticky protein hydrogel and preparation method thereof

The invention discloses sticky protein hydrogel and a preparation method thereof and belongs to the technical field of high polymer hydrogel. According to the method, casein protein (casein) in a milk protein serves as a raw material. The preparation method comprises the following steps: firstly, regulating an aqueous solution of casein protein by a sodium hydroxide solution, and fully dispersing in a dispersion device to enable the casein protein to be completely dissolved in water; then adding the casein protein solution, a hydrophilic monomer acrylamide, a chemical cross-linking agent N,N-methylenebisacrylamide and an initiator potassium persulfate into deionized water, stirring at a room temperature to be completely dissolved; adding an aid tetramethylethylenediamine to be uniformly mixed, and directly pouring the prepared solution into a mold; finally, putting the mold into a drying oven to carry out a redox reaction, and enabling the casein protein and the hydrophilic monomer to perform free radical polymerization, thereby obtaining the high polymer hydrogel. The casein protein is the main protein in milk of mammals including cows, sheep and humans, has excellent biocompatibility, does not have any toxicity and is readily available in raw material and low in cost. The hydrogel has toughness and stickiness and can be applied to the fields of drug controlled release, drug dressings and the like.

Owner:CHANGCHUN UNIV OF TECH

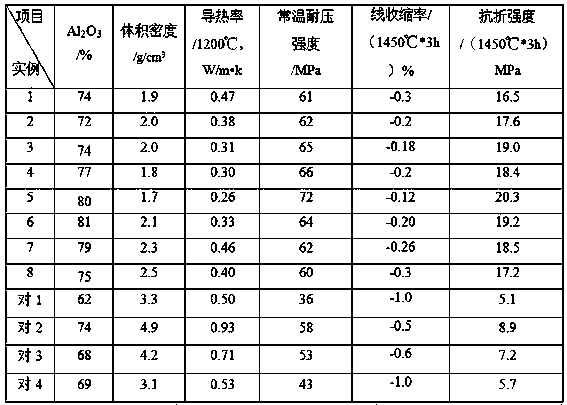

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

Extraction and separation method of anthocyanin

ActiveCN110643196AImprove drying methodOvercoming inefficiencyOrganic chemistryNatural dyesProcess engineeringFruit juice

The invention discloses an extraction and separation method of anthocyanin, and belongs to the technical field of natural pigment extraction and separation. According to the method, the drying mode isimproved, the anthocyanin in pomace is extracted with a deep-crystal eutectic solvent by combining microwave extraction and ultrasonic assistance, the effective and systematic anthocyanin extraction,separation and purification process is established, and the defects of low efficiency, residual organic solvent in product and low safety of the traditional natural anthocyanin extraction method areovercome; and the new way is provided for high-valued utilization of pomace waste, the pomace is turned into wealth, the by-product treatment burden of fruit juice processing enterprises is relieved,and great economic benefits, social benefits and ecological benefits are achieved.

Owner:JINAN UNIVERSITY

Golden camellia cutting nursery method

InactiveCN103548526ASimple processEasy to implementCultivating equipmentsHorticultureCamellia chrysanthaShoot

A golden camellia cutting nursery method particularly includes the steps: selecting a nursery site as needed; building seedling beds on the nursery site; selecting robust golden camellia trees without disease and pest injury as female parents; shearing golden camellia branches into in-vitro materials with more than two shoots and within four shoots; soaking cuttings in ABT rooting liquor and then planting the cuttings into substrates of the seedling beds; spraying disinfectants made of carbendazim to the seedling beds and the cuttings to perform disinfection; finally, building a small shed on each seedling bed, sealing each whole seedling bed by a plastic film, managing the cuttings until rooting and removing the cuttings from the seedling beds. Each seedling bed is structurally characterized in that a layer of river sand is spread on the seedling bed, and then a layer of red subsoil is laid on the seedling bed. By implementing the golden camellia cutting nursery method, various specifications of branches on the golden camellia female parents are optionally picked to serve as breeding cutting slips, stock plants, particularly, wild plants of the golden camellia female parents do not need to be excavated, wild golden camellia resources can be effectively protected and developed, and the method is far-reaching.

Owner:凌爱秋

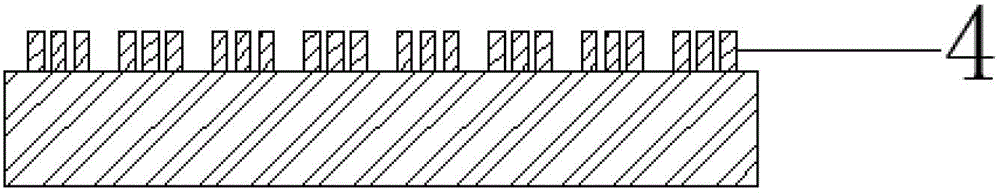

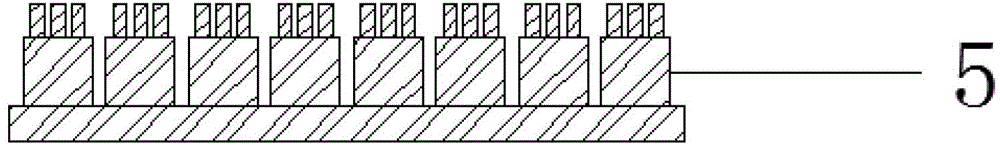

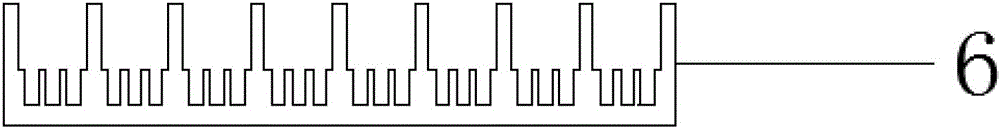

Method for manufacturing half-dry mold-pressed honeycomb carboards

InactiveCN102108655AReduce weightStress resistantSpecial paperPaper/cardboardZero emissionMachinability

The invention discloses a method for manufacturing half-dry mold-pressed honeycomb carboards, which comprises the following steps of: (1) preparing starch glue; (2) preparing mixed pulp; and (3) processing honeycomb carboards. In the method for manufacturing the half-dry mold-pressed honeycomb carboards, waste carboard paper, agricultural stalks, waste textiles and the like can be recycled. In the manufacturing method, the total solid content in the mixed pulp is about 50 percent; compared with a wet processing method, the method has the characteristics of energy conservation and water conservation; and compared with a thermosetting processing method, the method has the characteristics of no aldehydes, zero emission, no toxin, no pollution and the like. The honeycomb carboards processed by the method have the characteristics of light weight, strong compressive resistance, waterproofness, moistureproofness, rot resistance, anti-mildew, anti-moth, and fumigation-free moth removal, have excellent processability such as capacity of being sawed, nailed and glued and the like, and can be widely applied to products such as heavy duty pallets, heavy duty packing boxes, light walls, decorative boards, furniture and the like.

Owner:TIANJIN MINGTANG ENVIRONMENTAL PROTECTION TECH

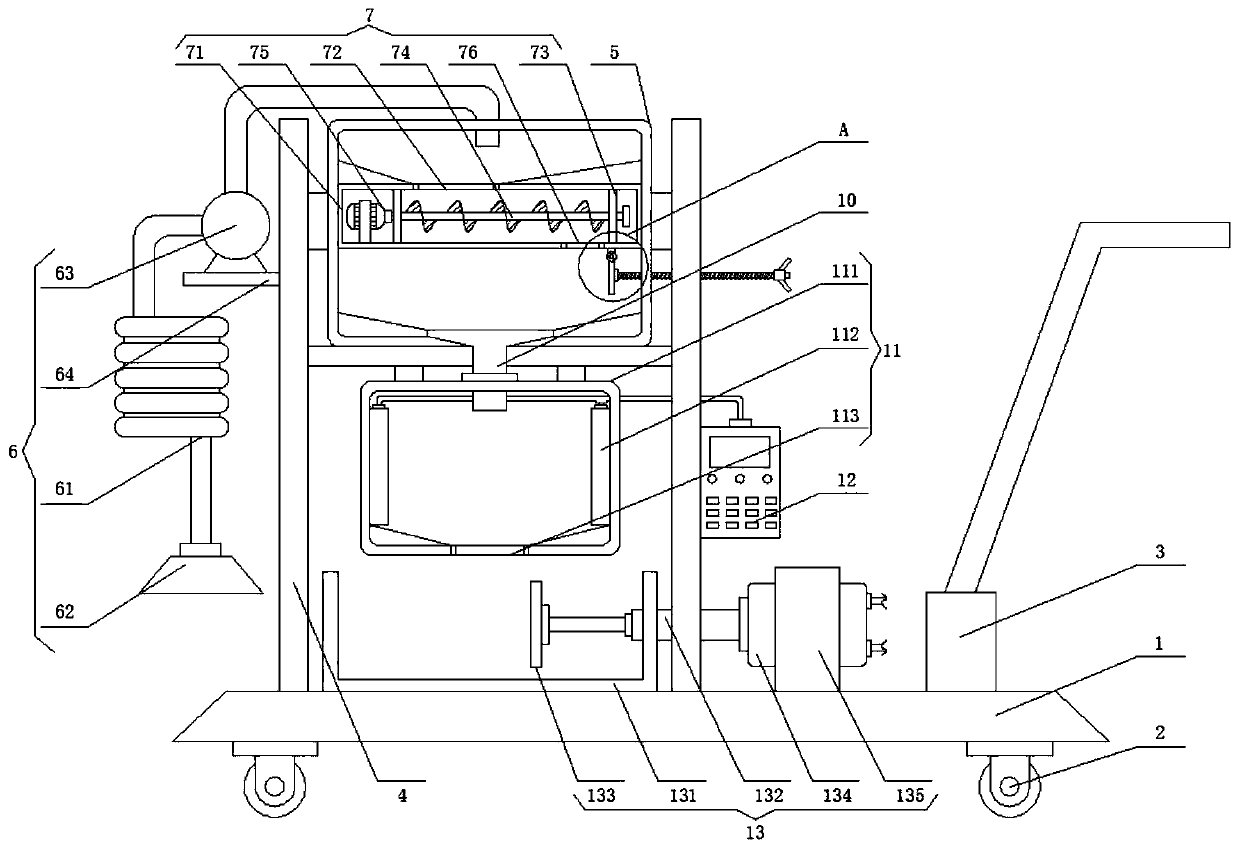

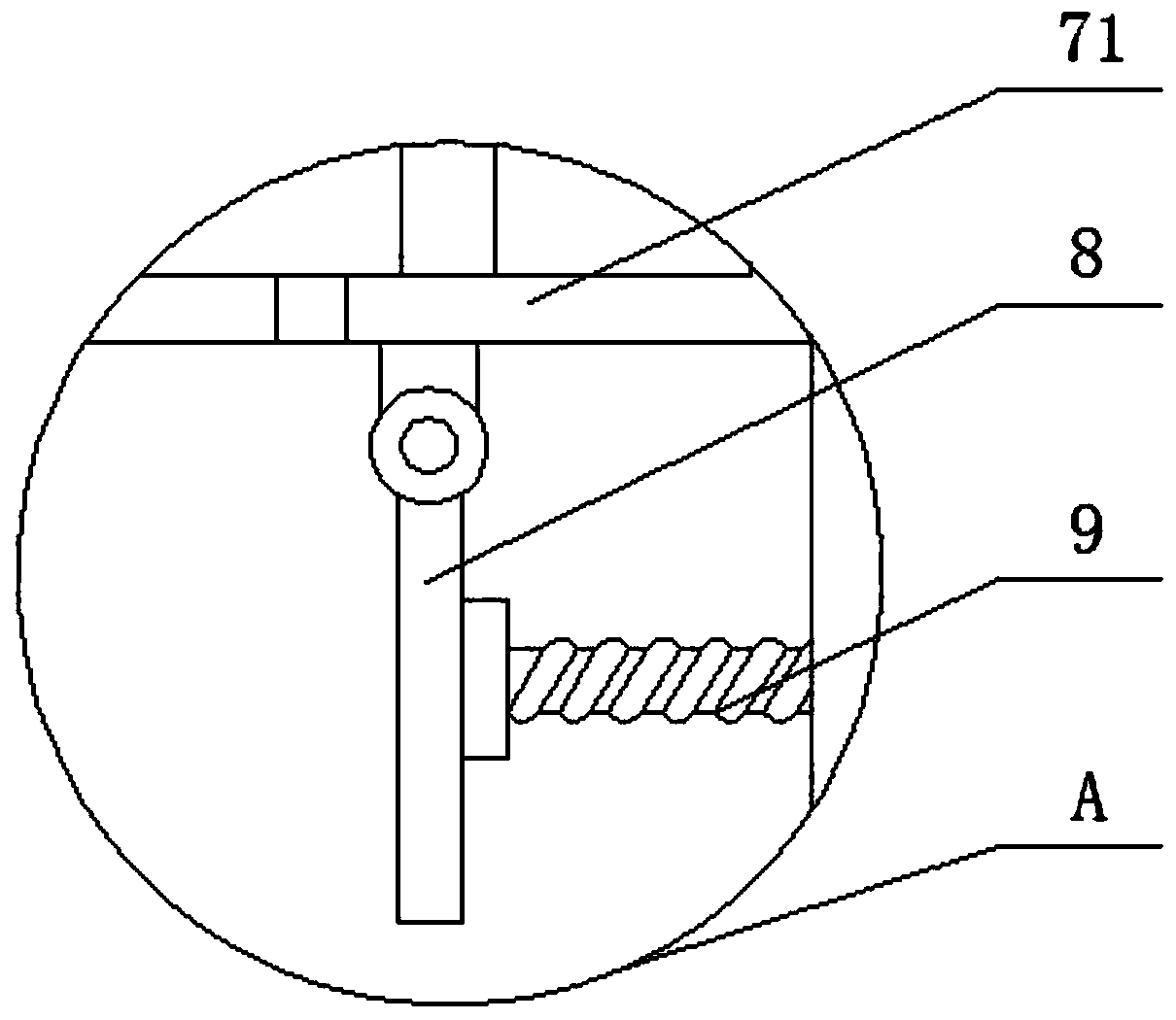

Waste recycling device and method for plastic product production

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

Cervical mucosa inducing gel

InactiveCN101690802ASuspension is effectiveNo side effectsOrganic active ingredientsPeptide/protein ingredientsTriclosanAfter treatment

The invention relates to a gel which can improve vaginal microenvironment and restore vaginal microdamage and is suitable for treatment on various kinds of vaginitis and cervicitis caused by vaginal microecological disturbance and vaginal microdamage, auxiliary treatment on vaginitis and cervicitis after clinical treatment, and treatment on cervical erosion, in particular to a cervical mucosa inducing gel which comprises carbomer, triclosan and human epidermal growth factors, wherein the concentration of the carbomer is 3%-5%, the concentration of the triclosan is 0.1%-0.6%, and the concentration of the human epidermal growth factors is 1 / 100000-1 / 10000. The cervical mucosa inducing gel can effectively improve the vaginal cleanness and increase the lactobacillus quantity to further reduce the vaginal pH value, has obvious effect on restoring cervical erosion, and can be used for auxiliary treatment on vaginitis and cervicitis after treatment.

Owner:杨霞

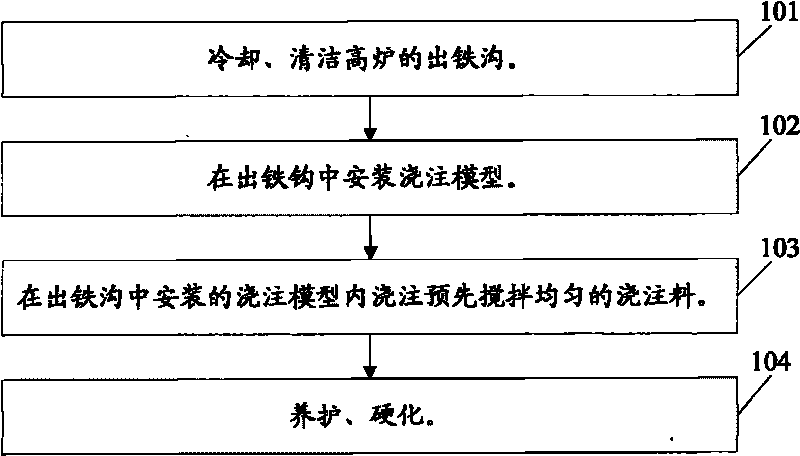

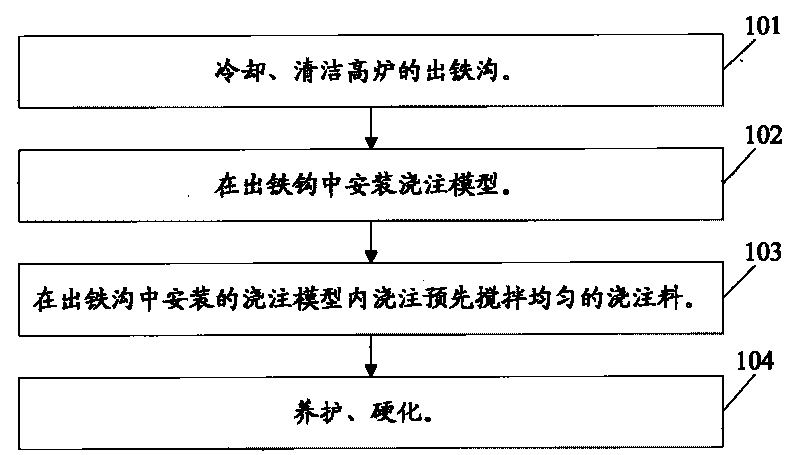

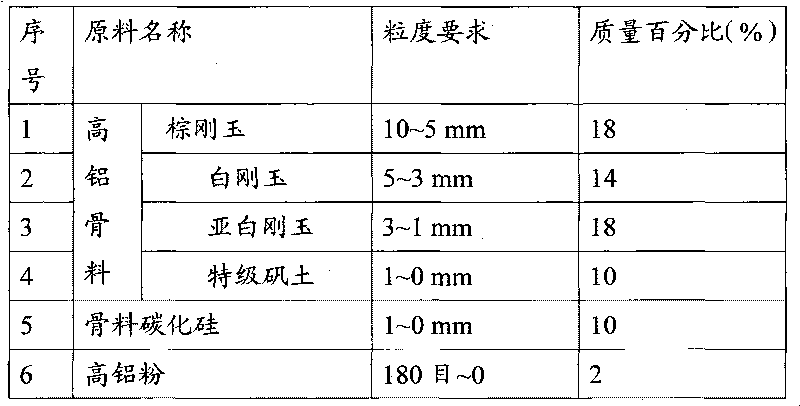

Baking -free castable and method for making tapping hole by using same

InactiveCN101723689AReduce the cost per ton of ironReduce or eliminate the use of ramming materialsSlagGranularity

The invention relates to the field of refractory materials and discloses a baking -free castable and a method for making a tapping hole by using the same. The baking -free castable is prepared from a skeletal material, powder and a binding agent, wherein the skeletal material is prepared from one or a mixture of several of white corundum, sub-white corundum, brown aluminium oxide, super alumina, silicon carbide and high-temperature ball asphalt; the powder is prepared from one or a mixture of several of silicon carbide, calcined alpha-alumina micro powder, micro silicon powder, silicon metal and high-alumina fly ash; the granularity of the skeletal material is no more than 10 millimeters and no less than 0 millimeter; and the granularity of the powder is no less than 0 mesh and no more than 180 meshes. The prepared tapping hole has excellent molten iron resistance, slag corrosion resistance and impermeability.

Owner:巩义市教育化工助剂厂

Silicone oil release film with sticky surface and production process of silicone oil release film

InactiveCN104073185AWith release forceStickyLiquid surface applicatorsFilm/foil adhesivesCross-linkAlcohol

The invention discloses a silicone oil release film with a sticky surface and a production process of the silicone oil release film. The silicone oil release film comprises a substrate and a silicone oil face attached to the surface of the substrate, wherein the silicone oil face is prepared from the following components in parts by weight: 9240 parts of a solvent, 1000 parts of a releaser, 200 parts of a cross-linking agent, 13 parts of a curing agent, 300 parts of a releasing force adjustor and 3000 parts of an adhesive. The solvent comprises one or a mixture of more of a solvent TOL (Toluene), a solvent D-40, a solvent D-30, a solvent MEK (Methyl Ethyl Ketone) or a solvent IPA (Iso Propyle Alcohol). The releaser comprises a 7485 type releaser. The cross-linking agent comprises one or a mixture of more of a 297 type cross-linking agent, a 7672 type cross-linking agent or a 7028 type cross-linking agent. The adhesive is a 7652 type adhesive or a 7651 type adhesive. The release film disclosed by the invention has certain viscidity, can be stably attached to a hot melt adhesive without displacement, and is low in releasing force and convenient to be separated from the hot melt adhesive and free from residues on the surface of the hot melt adhesive separated.

Owner:佛山凯仁精密材料有限公司

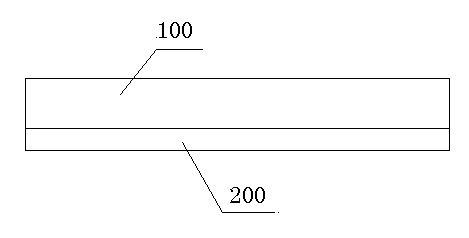

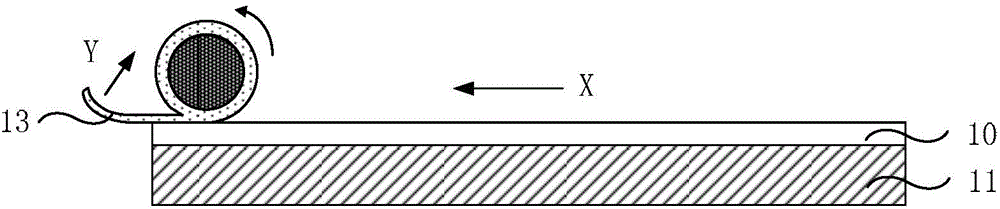

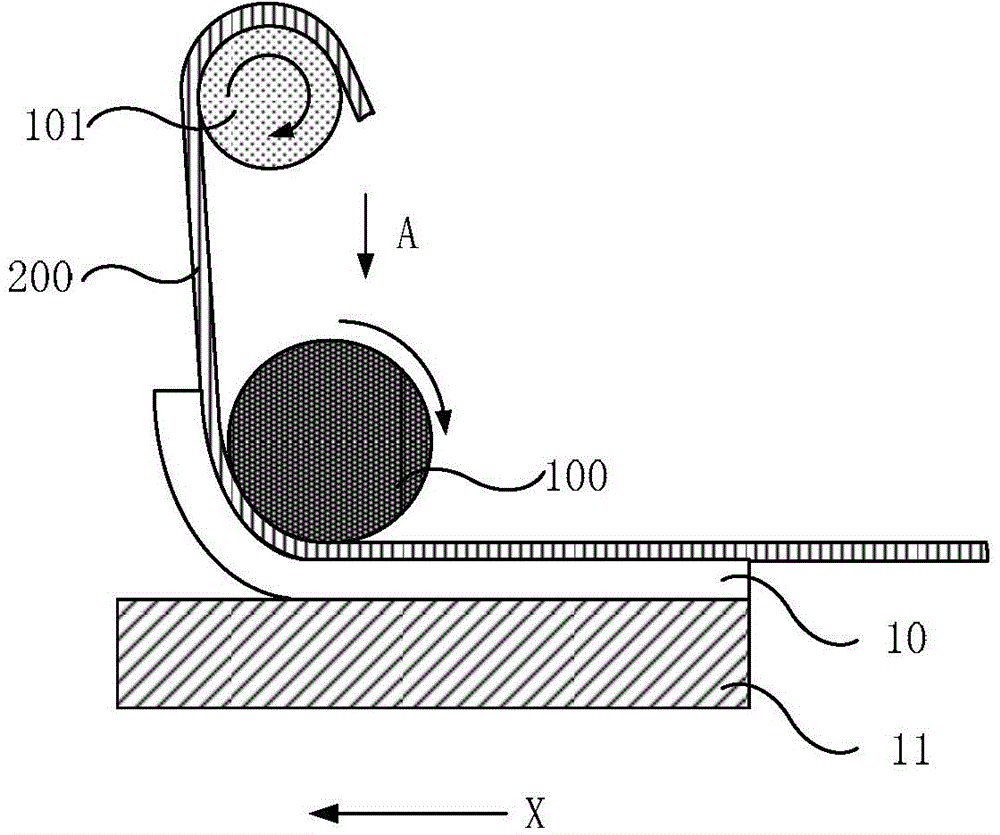

Film stripping device and film stripping method thereof

Owner:HEFEI BOE DISPLAY LIGHT +1

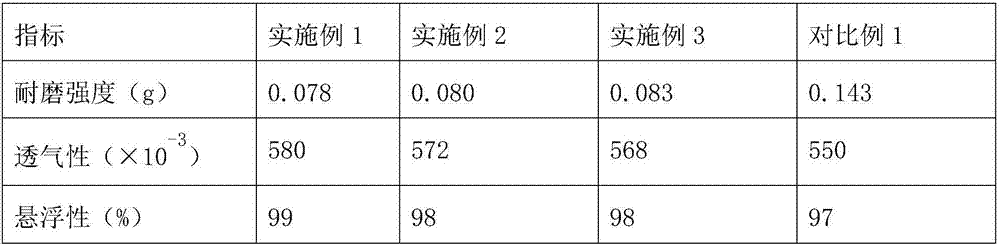

Full-mold casting paint and preparation method thereof

InactiveCN107052232ASolve the problem that cannot meet the production requirements of large castingsImprove wear resistanceFoundry mouldsFoundry coresPolyvinyl alcoholOlivine

The invention provides a full-shape casting coating and a preparation method thereof, relating to the field of casting. The full-shape casting coating includes the following raw materials in parts by weight: quartz powder, olivine powder, corundum powder, sodium bentonite, lignin sulfonic acid, and dextrin powder , sodium carboxymethyl cellulose, sodium benzoate, hollow glass microspheres, aluminum sulfate, polyvinyl alcohol, silica sol, iron oxide powder, n-octanol, graphite powder, zircon powder, attapulgite, water reducing agent and water The preparation method comprises the following steps: (1) weighing raw materials, (2) preparing each mixed solution in turn, and (3) adding to a reaction kettle and stirring in turn. The invention solves the problem that the existing solid casting coatings generally have strong wear resistance, high adhesion, excellent air permeability and quick drying under high temperature and low temperature environments, which makes them unable to meet the production requirements of large castings. question.

Owner:安徽华飞机械铸锻有限公司

Extracting method for curcumin

The invention discloses an extracting method for curcumin, comprising the following steps: pulverizing curcuma; pelleting the pulverized curcuma under the condition of introducing steam; and extracting particles obtained by pelleting with leach liquor. Since turmeric roots contain a large amount of starch which can be gelatinized in a manner of introducing steam for heating and has stickiness, thus the turmeric powder can be more compactly combined, has large rigidity, and is not easy to break; the prepared particles are provided with many micropores, and the solvent is easy to permeate, thus the extraction rate is high; and in addition, the gaps among the particles are larger than the gaps among the powdery materials, thus the solvent is more easy to permeate and the rate of filtration is high, thereby improving the extraction rate, the rate of filtration and the production efficiency.

Owner:HENAN ZHONGDA HENGYUAN BIOTECH CO LTD

Cleaning fluid composition for contact lens, its use and method

ActiveCN1818048APromote exchangeQuick washNon-ionic surface-active compoundsDetergent compounding agentsOphthalmologyActive agent

The invention provided a washing liquid compound for the contact lens. The batch formula is: at least one active agent, at least one antiseptic, the water, not or containing nonionic osmotic regulation agent, not or containing the non-ionic surface active agent, not or containing the non-ionic refrigerant. It can slake the disinfectant or the deproteinized agent of the contact lens, so it can avoid the illness of the eyes caused by the disinfectant or the deproteinized agent.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Polymer composite film and preparation method thereof, and lithium ion battery comprising polymer composite film

InactiveCN107799703AImprove high temperature resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberElectrolytic agent

The invention discloses a polymer composite film and a preparation method thereof, and a lithium ion battery comprising the polymer composite film. The polymer composite film comprises a polymer basefilm, which comprises a first surface and a second surface, wherein the first surface and the second surface are oppositely arranged, the polymer composite film further comprises a first ceramic layer, a first heat-resistant fiber layer and a first adhesion layer, the first ceramic layer, the first heat-resistant fiber layer and the first adhesion layer are sequentially arranged on the first surface of the polymer base film from inside to outside, the materials of the first heat-resistant fiber layer simultaneously contain a first macromolecule material and a second macromolecule material, thefirst macromolecule material is a heat-resistant macromolecule material with a melting point of more than 180 DEG C, the melting point of the second macromolecule material is lower than the melting point of the first macromolecule material, the liquid absorption rate of the second macromolecule material in a 25 DEG C electrolyte is more than 40%, and the error is + / -5%. According to the present invention, by simultaneously using the first macromolecule material and the second macromolecule material, the high temperature stability and the mechanical property under the high temperature condition can be easily improved.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com