Patents

Literature

98 results about "Micro damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

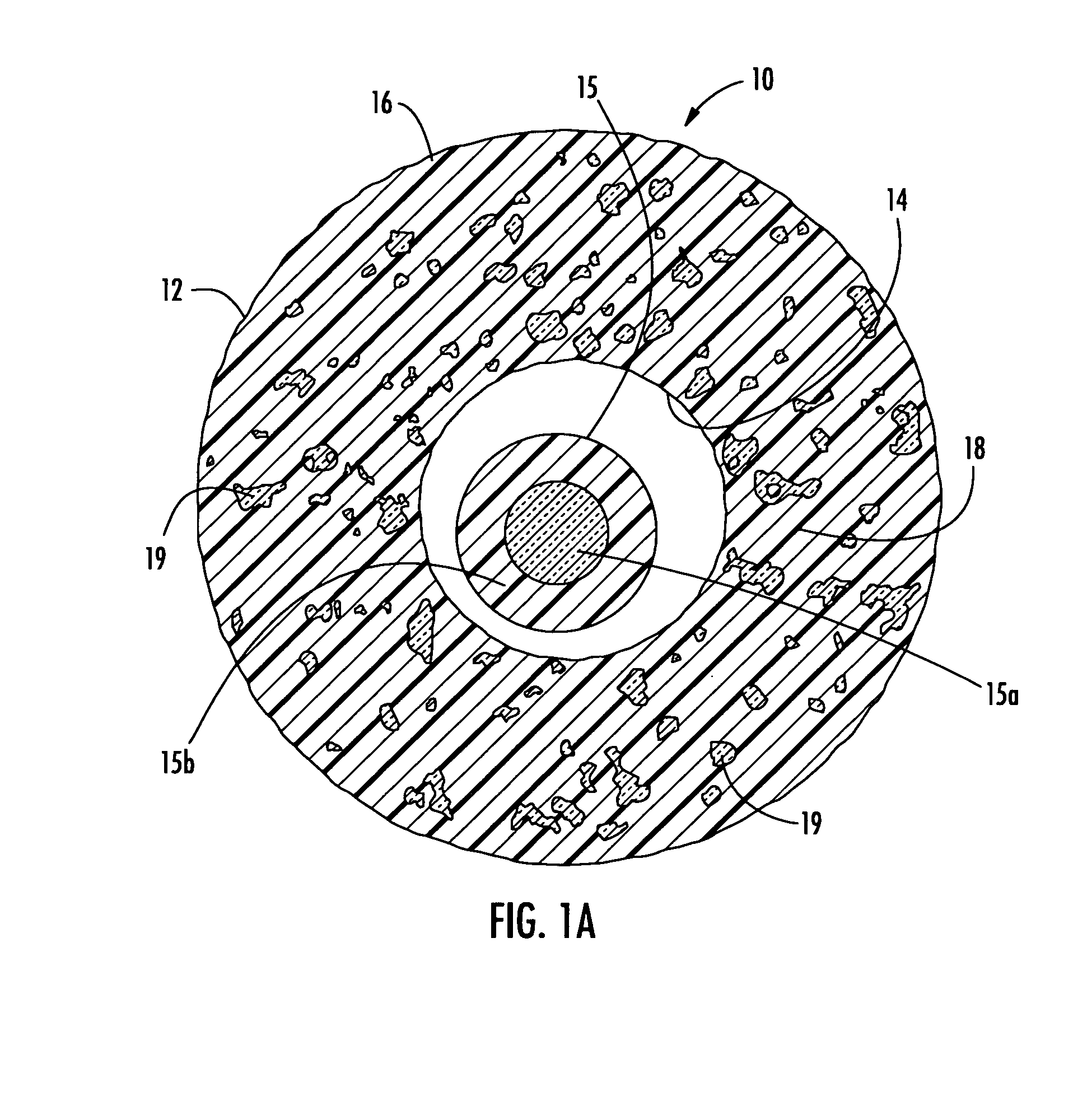

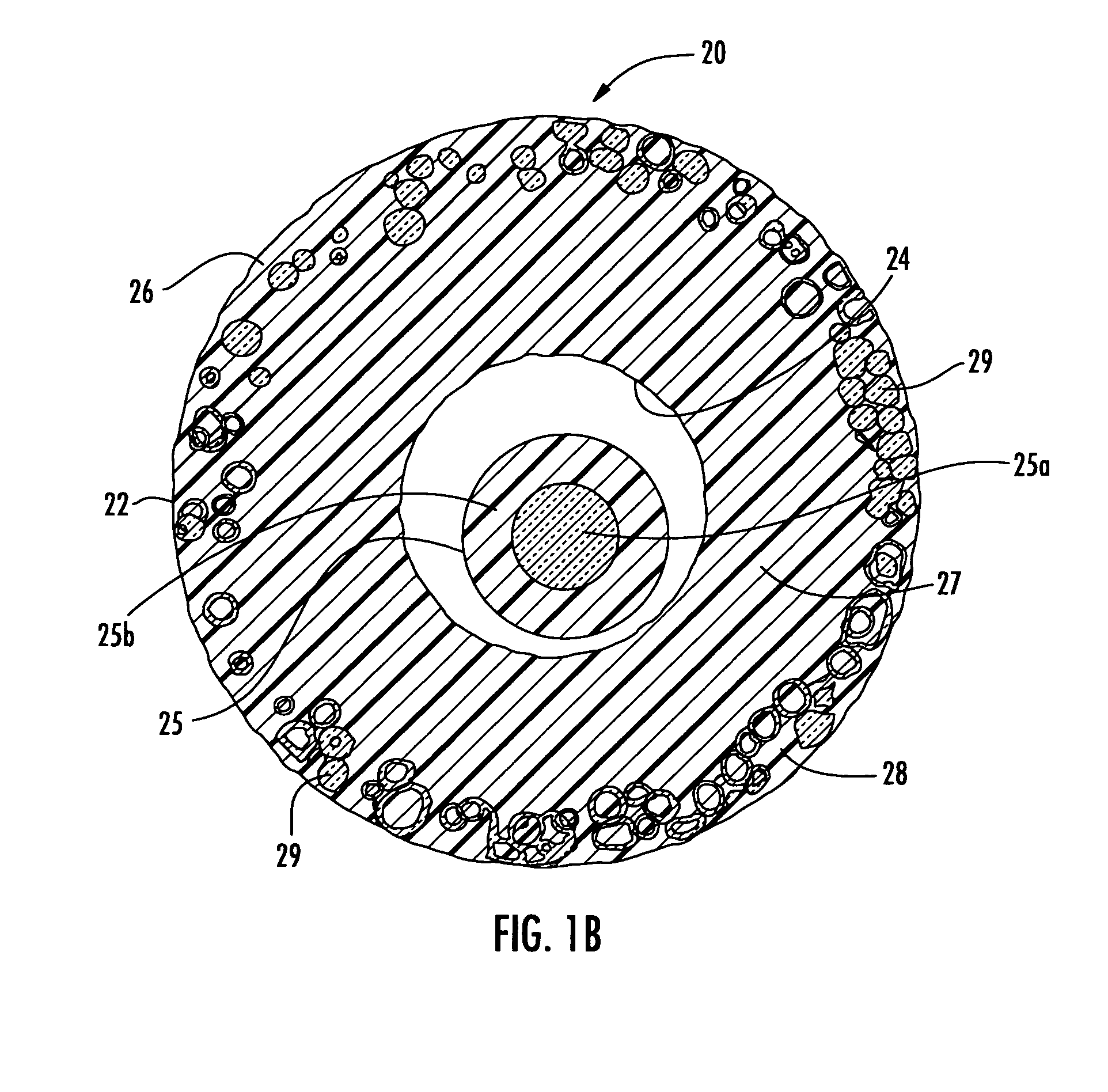

Microdamage in bone. Microdamage in bone can be caused by the various loads to which bones are subjected during normal daily activity. It occurs in two different types mainly depending on the load: diffuse damage and microcracks.

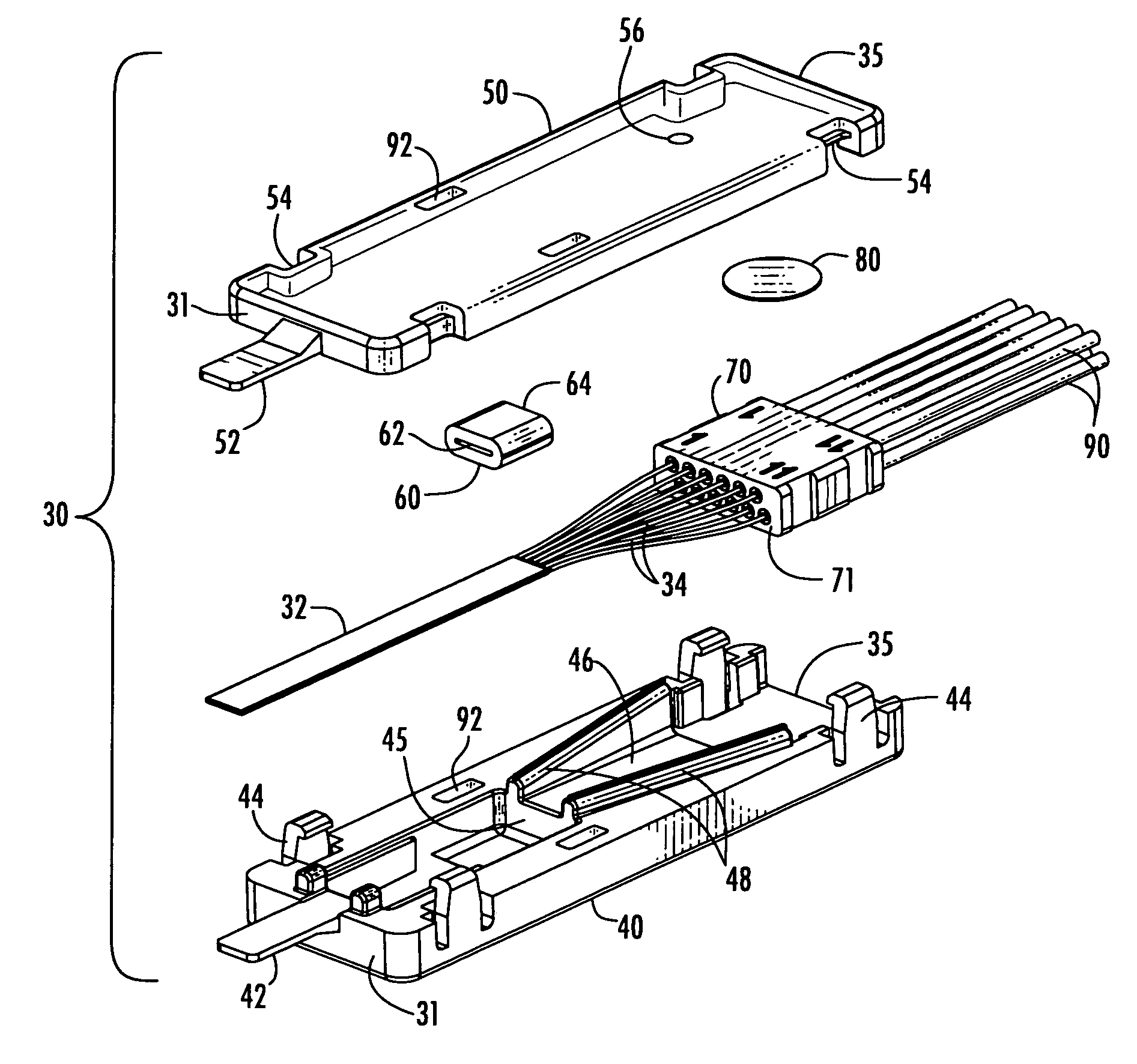

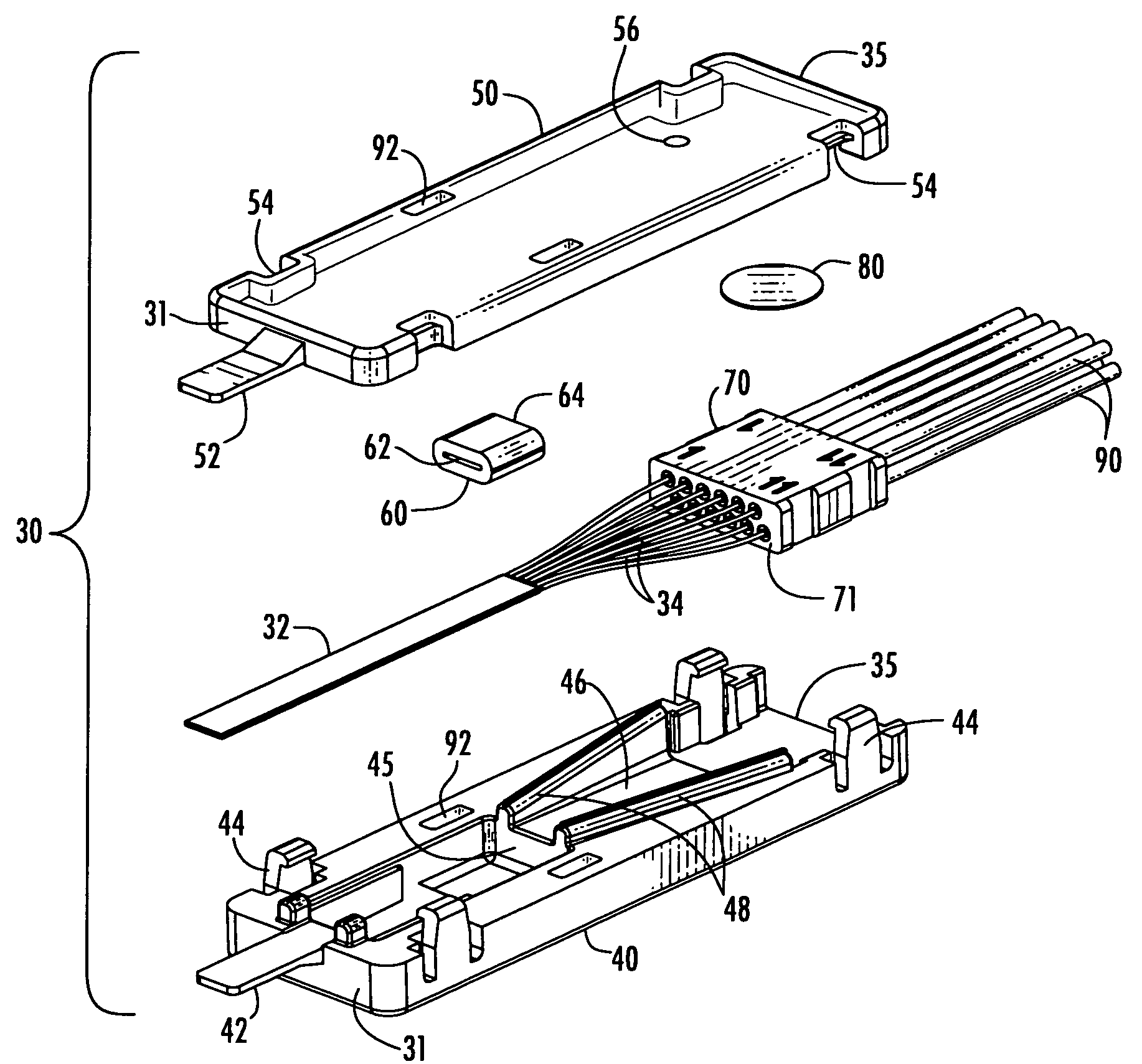

Furcation tubing and fanout furcation kit

ActiveUS20080138026A1Reduced longitudinal shrinkageIncreased tensile bond strengthCoupling light guidesOptical light guidesFiberUltrasound attenuation

Furcation tubing is made of glass-filled Teflon (PTFE) that provides reduced longitudinal shrinkage and increased tensile bond strength in the standard colors utilized for fiber identification. The furcation tubing experiences no more longitudinal shrinkage than furcation tubing made of polyvinylidene fluoride (PVDF) and has a tensile bond strength no less than furcation tubing made of clear, etched Teflon (PTFE). A fanout furcation kit prevents movement of the separated optical fibers in a funnel area of a lower furcation body. The funnel area is bathtub shaped with an increasing depth in the direction of an insert block having at least two rows of passageways in a staggered array. Guide walls defining the funnel area form a seal with an upper furcation body. Use of the furcation tubing and fanout furcation kit significantly reduces unacceptable attenuation and micro-damage to optical fibers deployed in an outdoor fiber optic network.

Owner:CORNING OPTICAL COMM LLC

Furcation tubing and fanout furcation kit

ActiveUS7461981B2Reduced longitudinal shrinkageIncreased tensile bond strengthCoupling light guidesFiberUltrasound attenuation

Furcation tubing is made of glass-filled Teflon (PTFE) that provides reduced longitudinal shrinkage and increased tensile bond strength in the standard colors utilized for fiber identification. The furcation tubing experiences no more longitudinal shrinkage than furcation tubing made of polyvinylidene fluoride (PVDF) and has a tensile bond strength no less than furcation tubing made of clear, etched Teflon (PTFE). A fanout furcation kit prevents movement of the separated optical fibers in a funnel area of a lower furcation body. The funnel area is bathtub shaped with an increasing depth in the direction of an insert block having at least two rows of passageways in a staggered array. Guide walls defining the funnel area form a seal with an upper furcation body. Use of the furcation tubing and fanout furcation kit significantly reduces unacceptable attenuation and micro-damage to optical fibers deployed in an outdoor fiber optic network.

Owner:CORNING OPTICAL COMM LLC

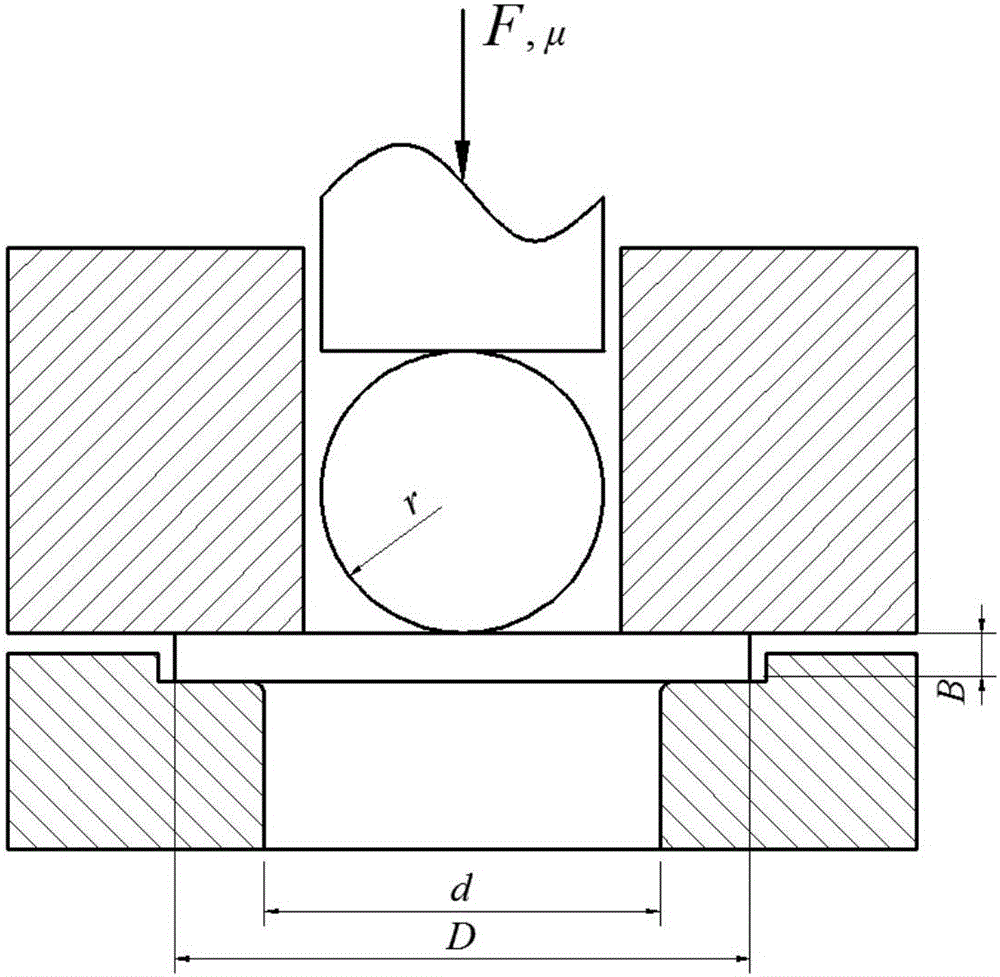

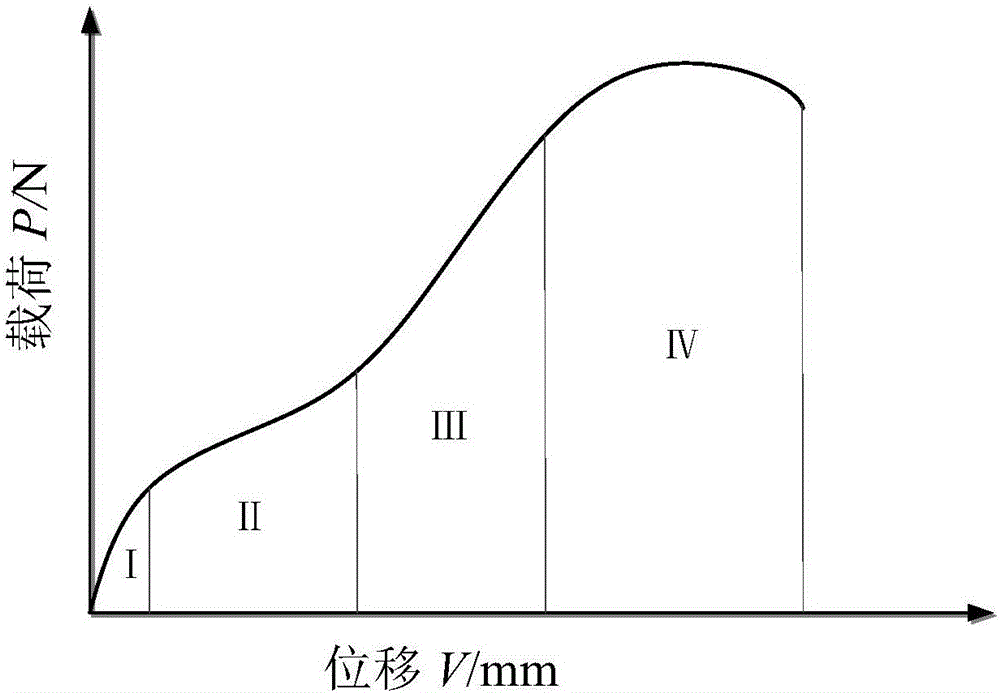

Method for obtaining uniaxial stress-strain relation of material through small punch test

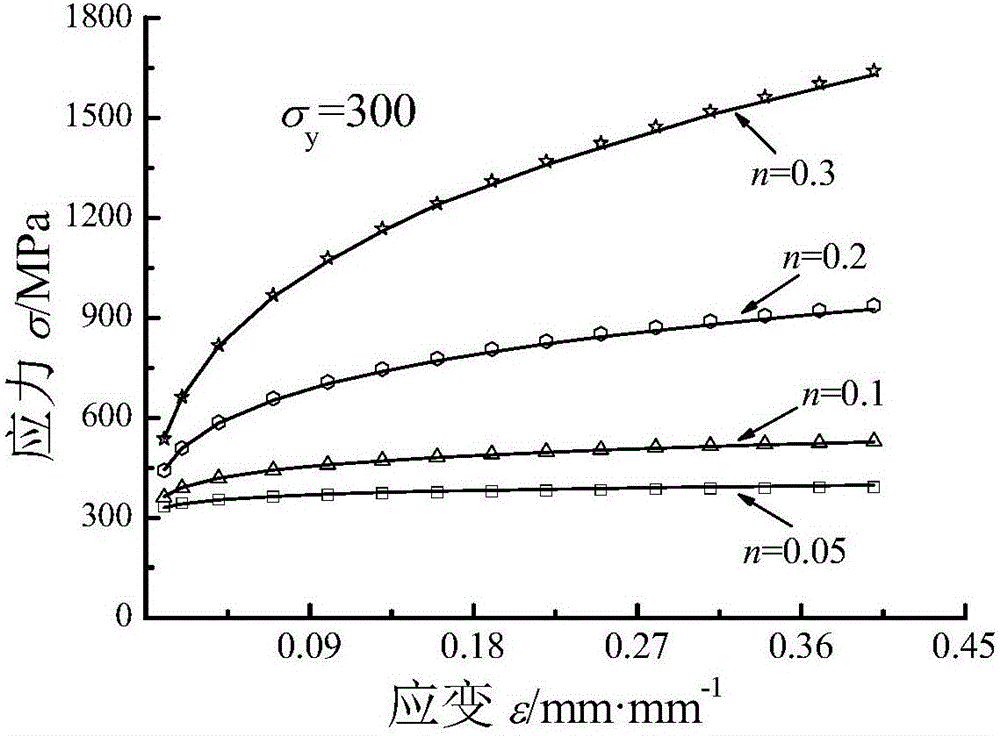

ActiveCN106124293AQuantitative evaluation of degradation performanceTo overcome the shortcomings such as large size restrictionsStrength propertiesSmall sampleMaterials testing

The invention discloses a method for obtaining uniaxial stress-strain relation of a material through a small punch test. After a continuous load-displacement curve of a stamped wafer sample is obtained, power-law fitting is conducted on the stage III of the P-V curve, obtained load characteristics and displacement indexes are introduced to a Hollomon equation so as to obtain the uniaxial stress-strain relation of the material. The method is suitable for ductile and power-law isotropic hardening materials, the uniaxial stress-strain relation of the material can be obtained only by cutting out a small wafer sample from an existing member in special circumstances such as high temperature and irradiation, and accordingly the degradation properties of the material are assessed. The method has weaker destructiveness on the existing member, achieves the micro-damage detection, sample processing and testing principles are simpler, obtained results have higher accuracy, the shortcoming that a traditional uniaxial drawing test is largely limited by material size and the like is overcome, and the cost lower. The method has the greater advantages in testing of precious-metal servicing micro-force materials establishing constitutive relation of minimally invasive wafers and other small samples.

Owner:SOUTHWEST JIAOTONG UNIV

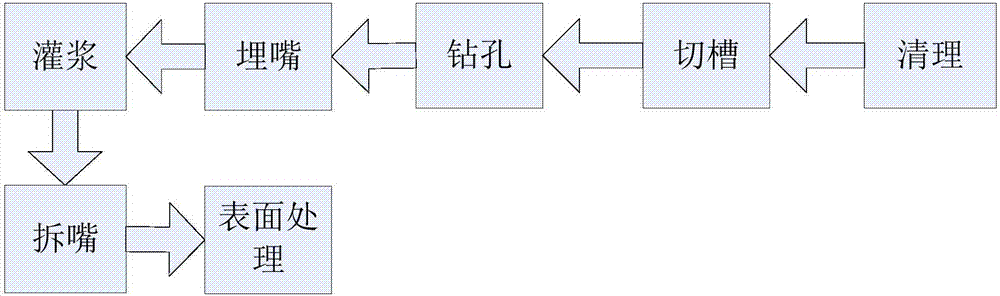

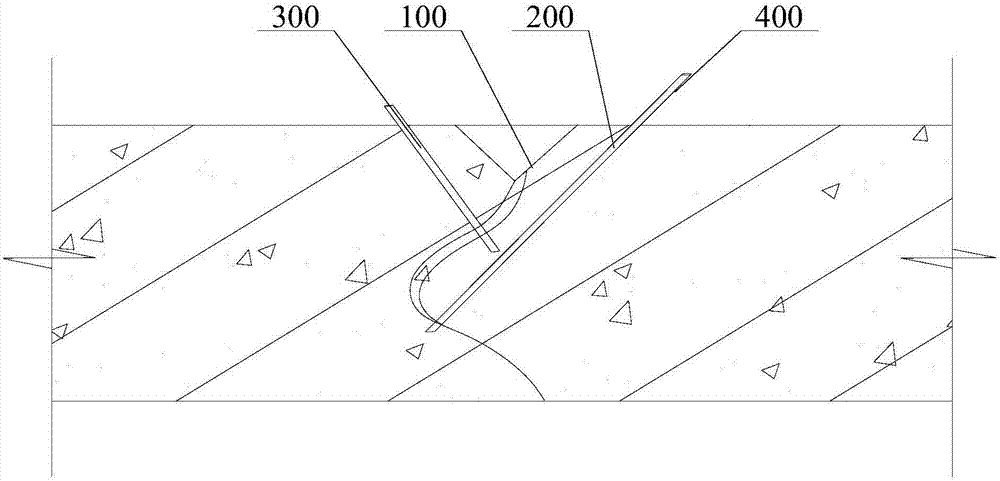

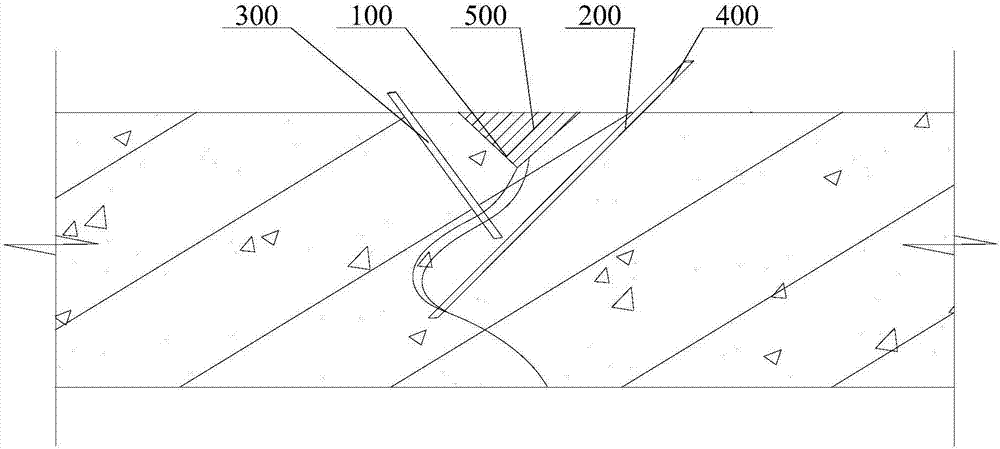

Leaking stoppage and reinforcement method for traffic tunnel cracks in vibration and disturbance environments

InactiveCN107201910ARecovery strengthPrevent leakageUnderground chambersTunnel liningWhole bodySlurry

The invention provides a traffic tunnel crack plugging and reinforcement method used in a vibration-disturbed environment, and relates to the technical field of crack repair in traffic tunnels. The grouting material is poured by using the method of minimal damage and adopting the pinhole oblique side drilling method. , Reinforcing while plugging. The specific method is to use a cutting machine to cut grooves along the seam first, clean them up and fill them with special cement for sealing, then make grouting holes along both sides of the seam to 1 / 3 to 1 / 2 of the seam. The grouting nozzle is installed in the hole, the grouting material is injected, and through the sealing effect of the cutting groove, and through the cross grouting, the grout is injected into the depth of the crack, so that the lining concrete at the crack is restored to form a whole, which solves the existing problems in the prior art. The technical problem that underground engineering cannot effectively plug leaks in the vibration-disturbed environment prevents leakage and cracking due to vibration-disturbed deformation and damage, and restores the compactness and structural integrity of the lining concrete.

Owner:南京康泰建筑灌浆科技有限公司

A method and apparatus for construct a new rock mass damage constitutive model

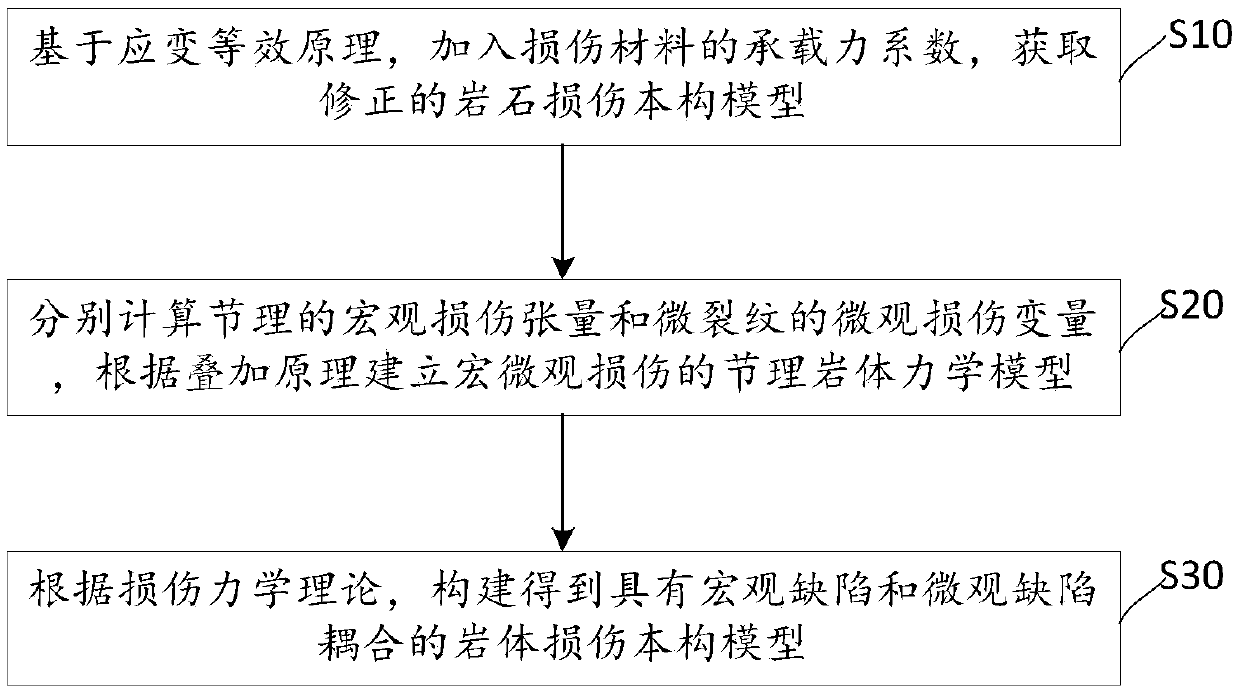

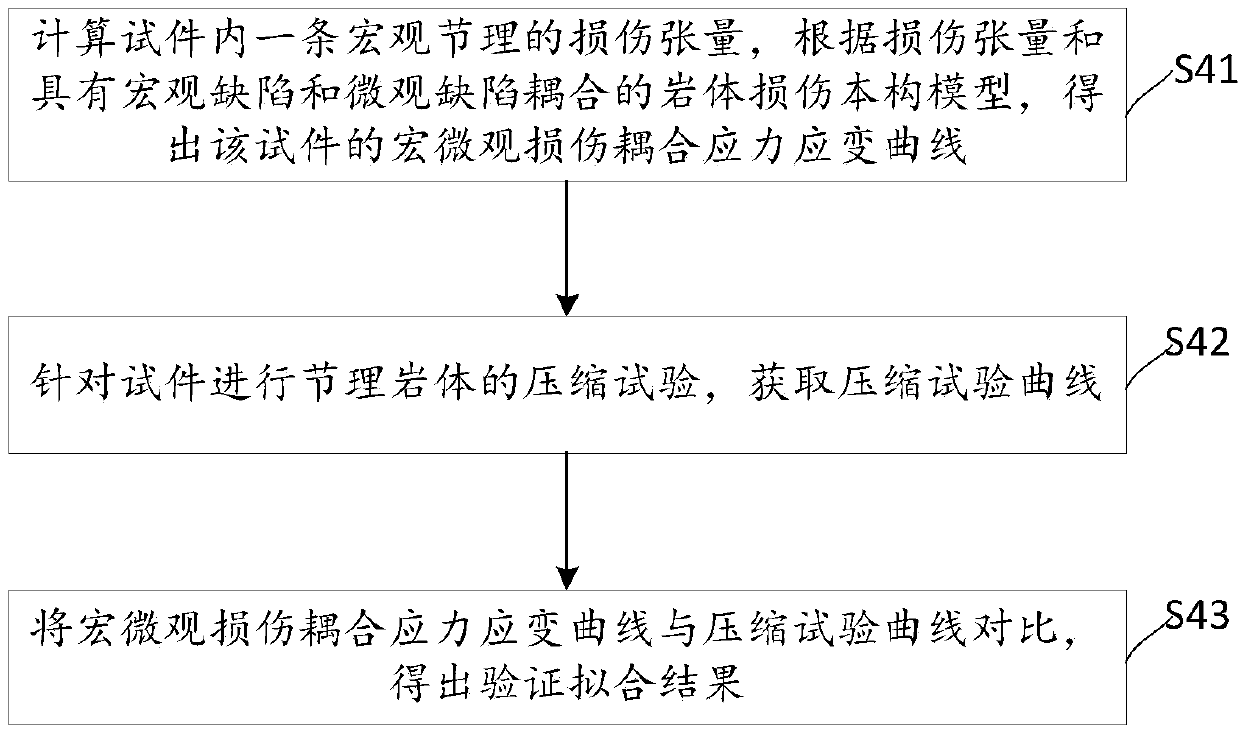

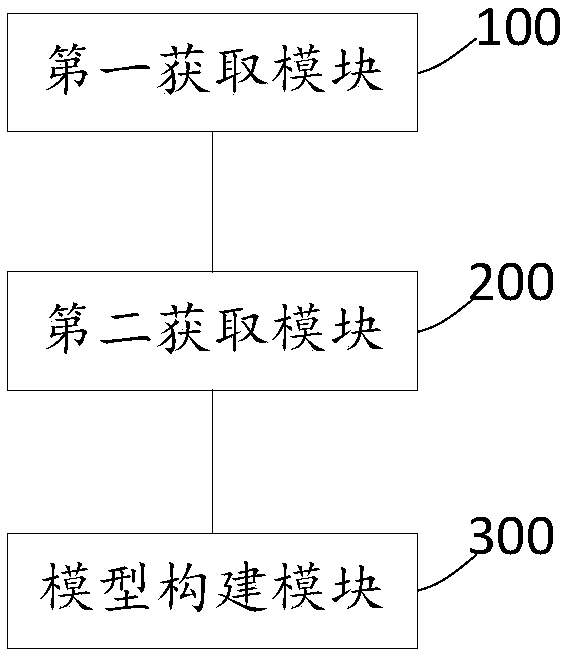

PendingCN109522611AThe principle is simpleReasonable and reliable resultsGeometric CADDesign optimisation/simulationMacroscopic scaleMechanical models

The invention relates to a new rock mass damage constitutive model construction method, comprising the following steps: step S10: based on strain equivalence principle, adding a bearing capacity coefficient of a damaged material to obtain a modified rock damage constitutive model; Step S20, respectively calculating a macro damage tensor of the joint and a micro damage variable of the micro crack,and establishing a mechanical model of the macro damage and the micro damage of the joint rock according to the superposition principle; Step S30: According to the damage mechanics theory, constructinga rock mass damage constitutive model with coupling of macroscopic defects and microscopic defects. The novel rock mass damage constitutive model construction method and device provided by the invention provide a simple principle, The damage constitutive model of rock mass, which is easy to operate and low in cost, is reasonable and reliable considering the coupling of macroscopic and microscopicdefects. The mining range can be delineated accurately and reasonably by using the damage constitutive model in the design of excavation slope engineering.

Owner:YANGTZE UNIVERSITY

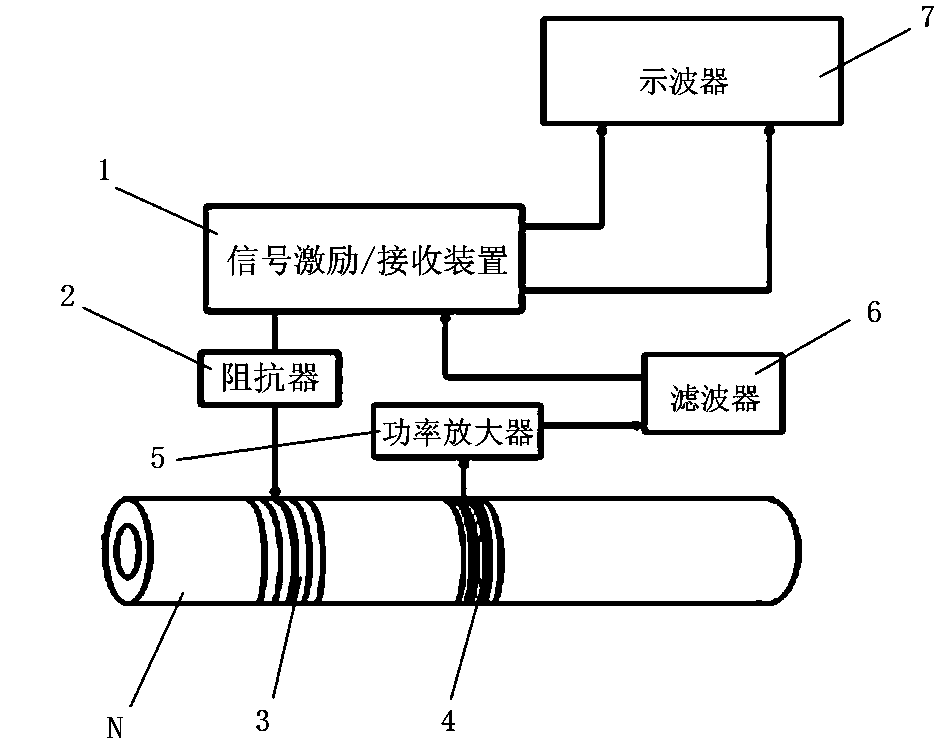

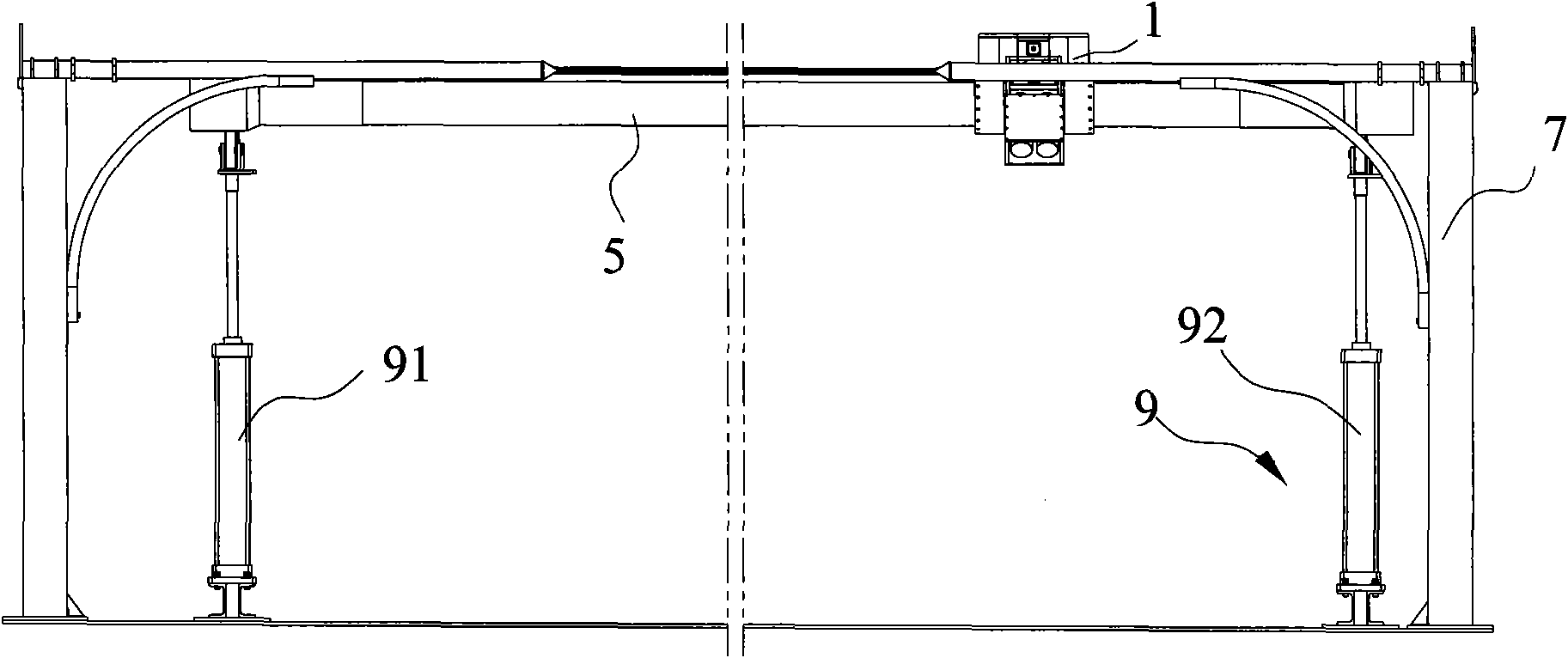

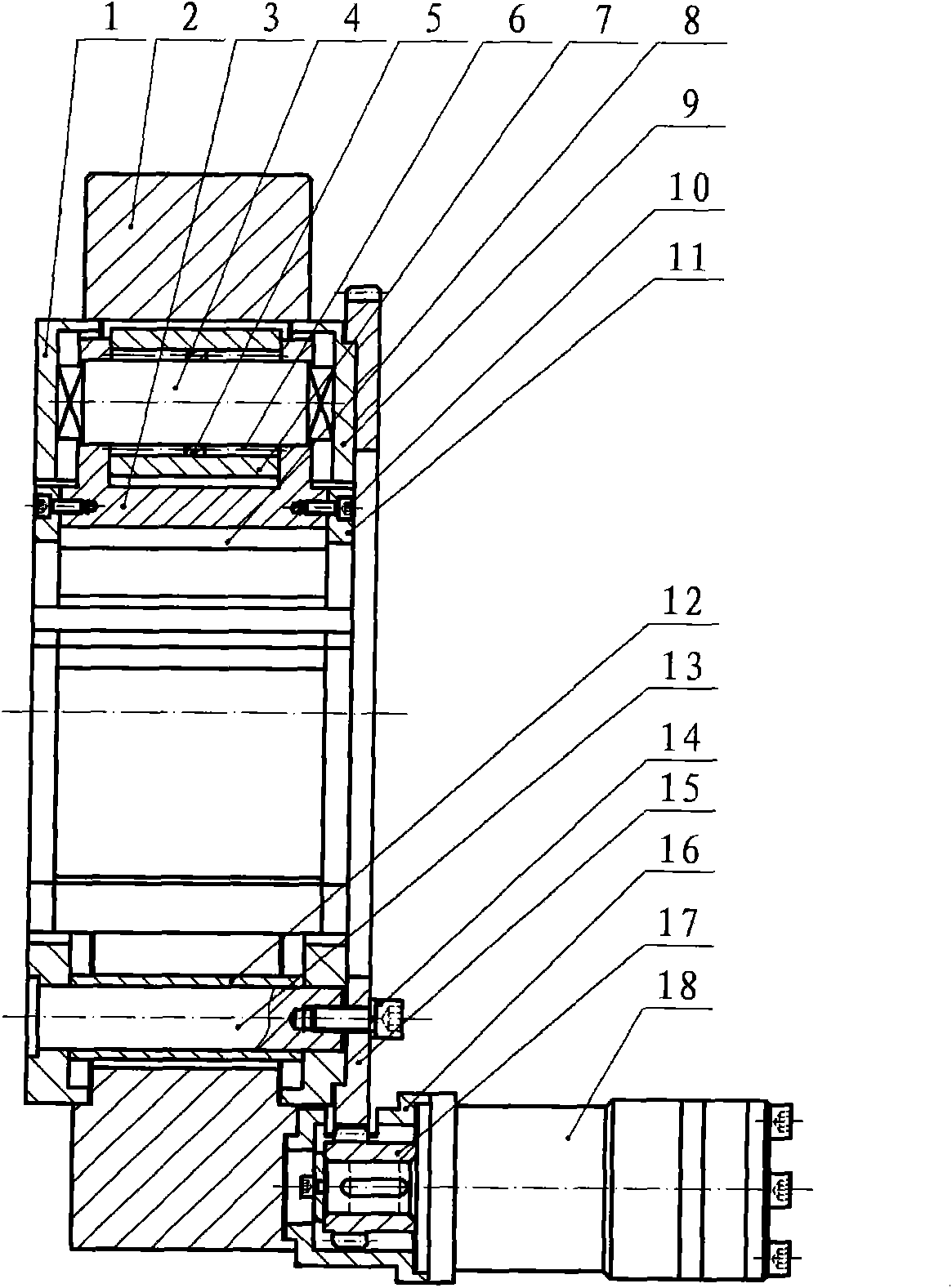

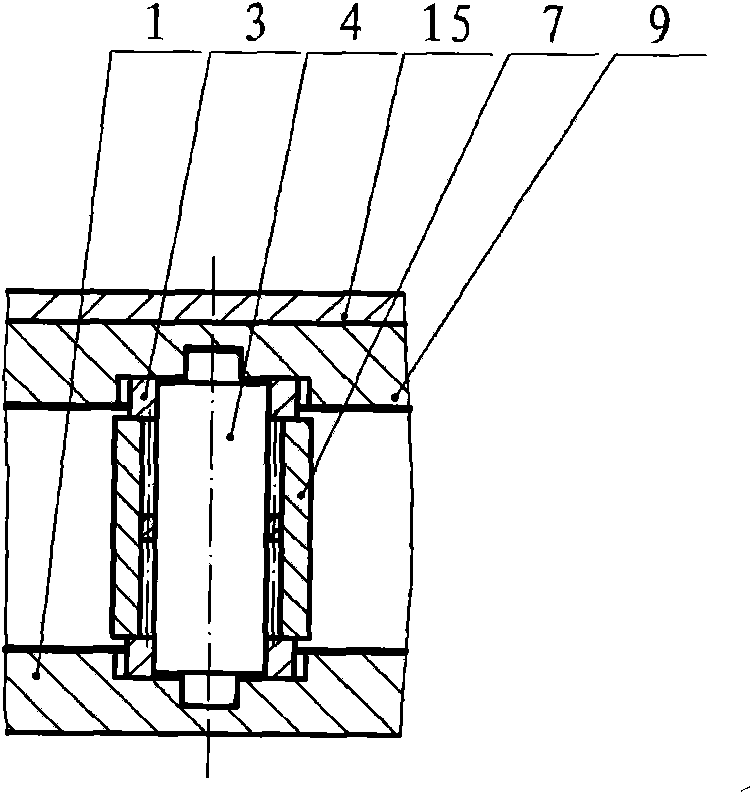

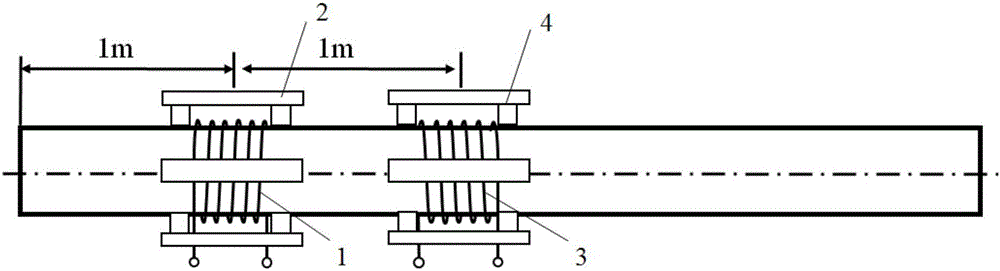

Nonlinear ultrasonic guided wave detection method and device for pipeline micro damage

InactiveCN103969339AEfficient receptionStable under pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

The invention discloses a nonlinear ultrasonic guided wave detection method and a nonlinear ultrasonic guided wave detection device for pipeline micro damage. An exciting transducer capable of exciting single guided wave modal state and a matched receiving transducer are adopted, the transducers can wind a pipeline to excite axisymmetric modal states, the receiving efficiency of a second order harmonic signal is improved by a matching and corresponding receiving probe, the detection capacity of the system on second order harmonic waves of the guided waves is improved. The nonlinear change of a material is characterized by detecting the ratio of nonlinear response to propagation distance, nonlinear interference of instruments is effectively reduced, nonlinear ultrasonic guided wave evaluation of the pipeline material is realized, and nonlinear ultrasonic high sensitivity can be used for early detection of the pipeline micro defects.

Owner:XIAMEN UNIV

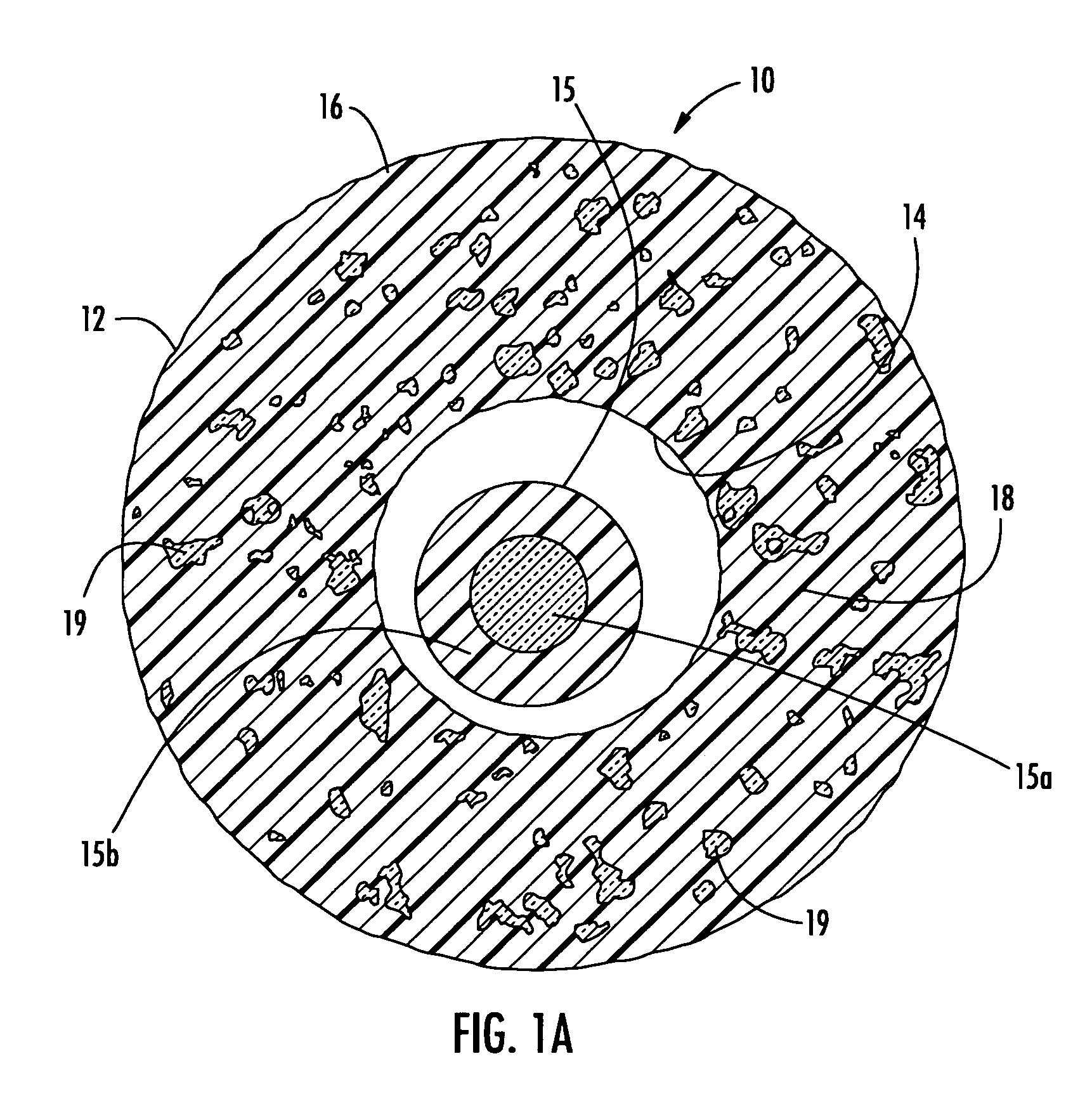

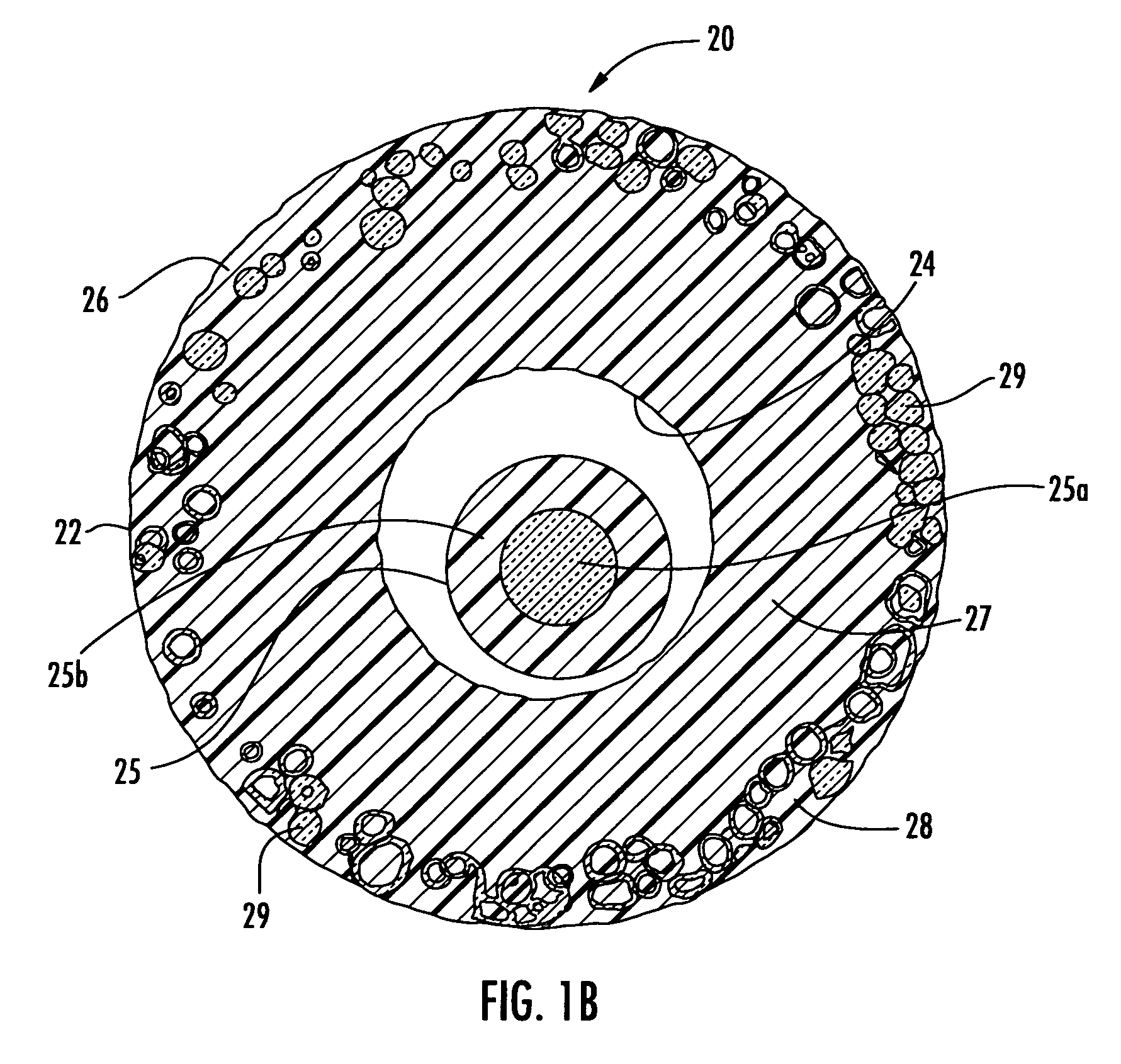

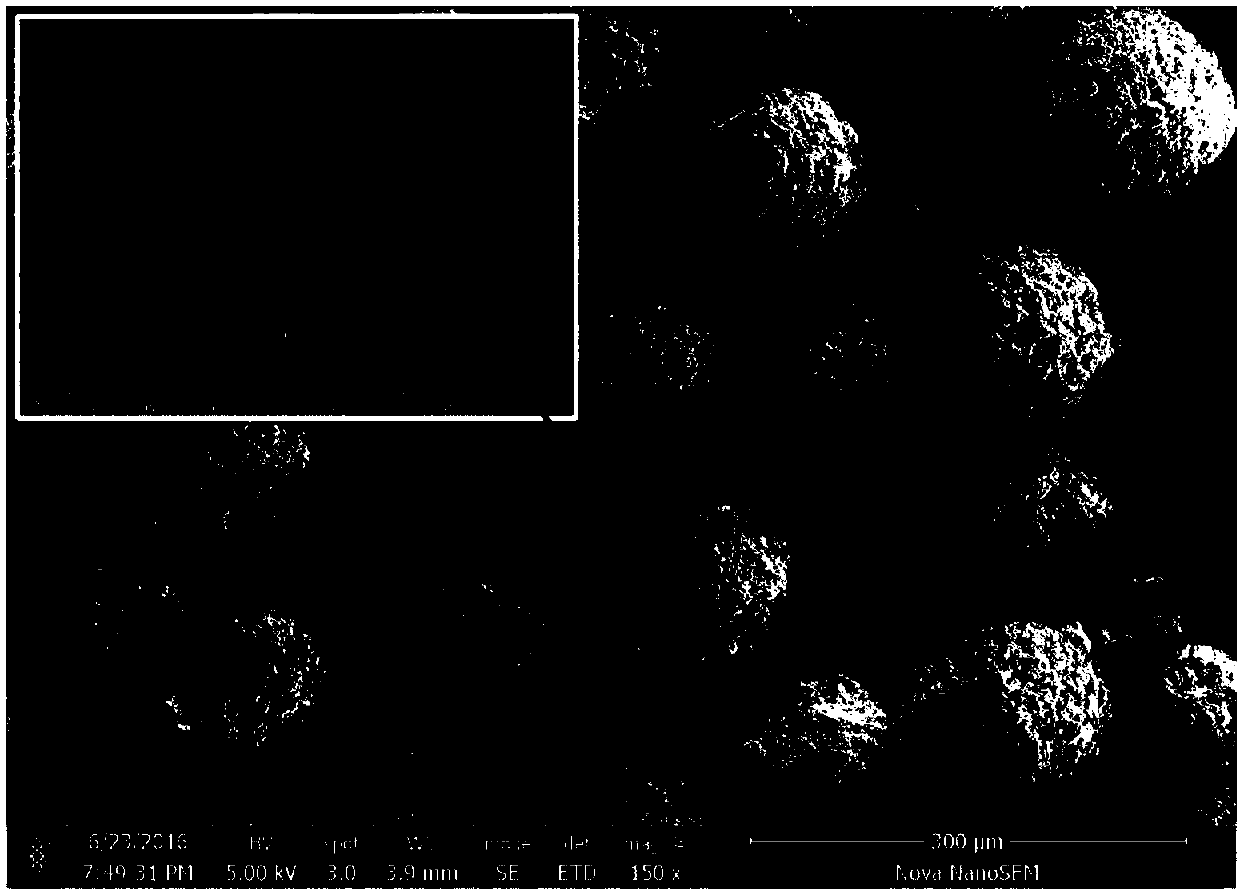

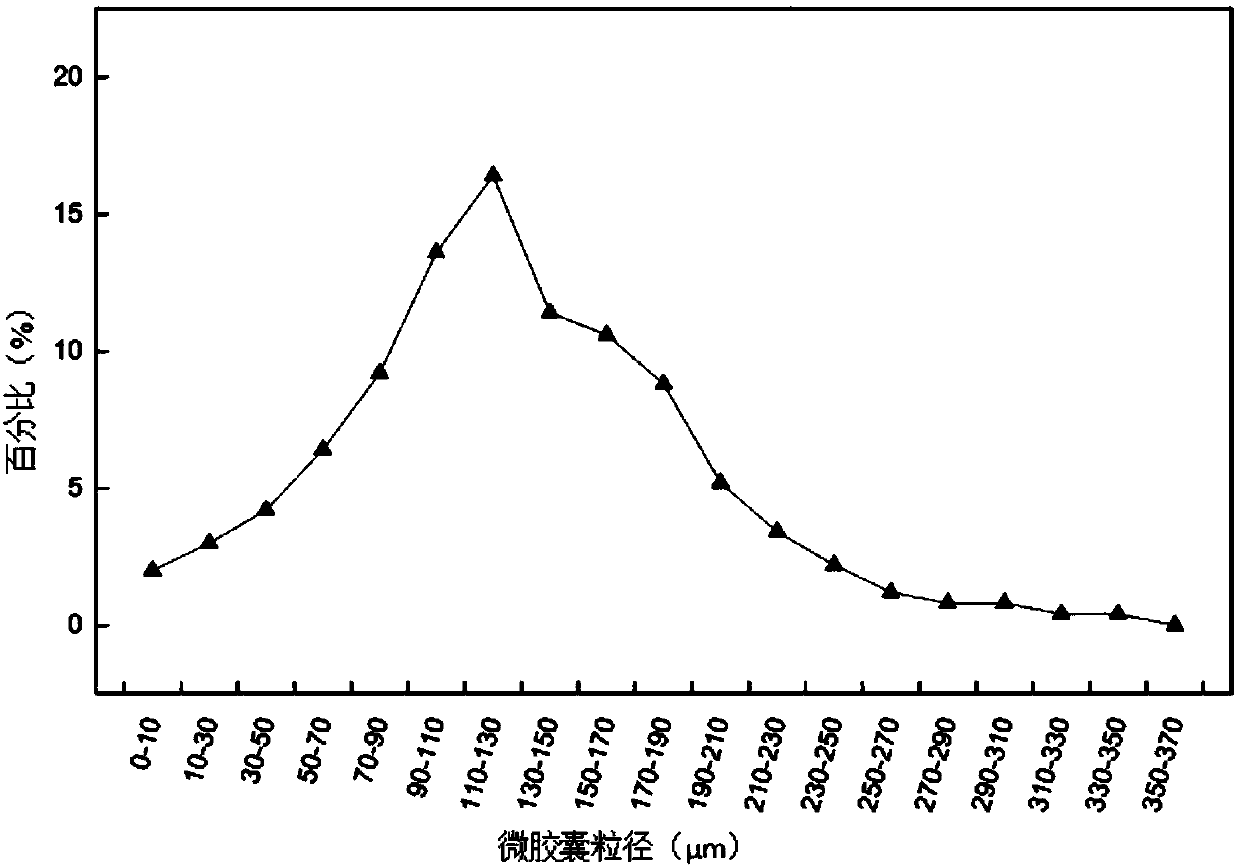

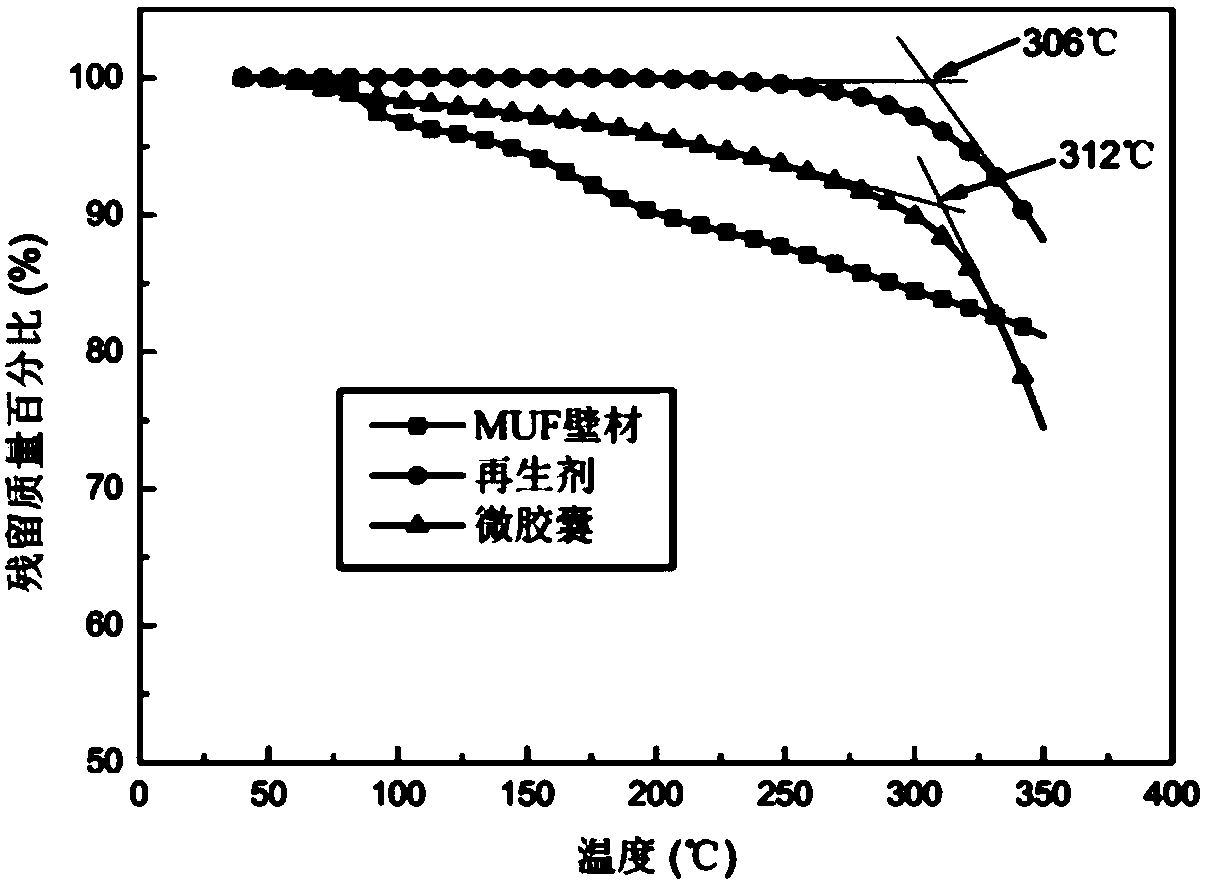

Microcapsules for self-repairing of asphalt micro-damage and preparation method of microcapsules

InactiveCN107617398AImprove self-healing abilityImprove high temperature stabilityBuilding insulationsMicroballoon preparationSelf-healingIn situ polymerization

The invention provides microcapsules for the self-repairing of asphalt micro-damage and a preparation method of the microcapsules and relates to the field of building materials. The core material of the microcapsules is an asphalt regenerating agent, and the wall material of the microcapsules is melamine-urea-formaldehyde resin. The preparation method includes: adding melamine, urea and formaldehyde into deionized water, stirring, and regulating pH until the solution is clear and transparent to obtain a prepolymer solution; adding sodium dodecyl sulfate into deionized water, stirring until thesodium dodecyl sulfate is dissolved completely, adding the regenerating agent, performing high-speed shearing and emulsification to obtain a core material emulsion; adding the prepolymer solution into the core material emulsion while stirring, heating at the same time, lowering pH, performing reaction for 4 hours, and increasing pH to end the reaction; allowing a microcapsule suspension to stand,cooling to room temperature, filtering, repeatedly washing with deionized water, and drying to obtain the microcapsules. The microcapsules and the preparation method have the advantages that the microcapsules prepared by an in-situ polymerization method is good in high-temperature stability and mechanical strength and capable of effectively enhancing the self-healing ability of asphalt.

Owner:TONGJI UNIV

Small punch testing device and method for deep sea hydrogen-induced stress cracking behavior

InactiveCN109813594AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringOxygen

The invention discloses a small punch testing device and method for the deep sea hydrogen-induced stress cracking behavior. A deep sea environment is simulated through a temperature control box and anitrogen charging oxygen removing reflux tank, and the flow state of deep sea water is simulated through the circulating flow of an electrolyte. Meanwhile, a deep sea hydrogen environment is simulatedby charging hydrogen online through an electrochemical workstation, and the deep sea static pressure is simulated by applying loads through a mechanical test machine and a small punch clamp. By changing the hydrogen charging current and the hydrogen charging time and investigating the mechanical properties of a metal sample in the deep sea simulation environment, the deterioration degree of a material in the deep sea environment is evaluated according to the fracture morphology, yield strength, strength limit and other information. The method can be used for studying the hydrogen-induced stress cracking behavior of the material during the service of a mechanical device in the deep sea environment and evaluating the degradation degree of the material in the deep sea environment, and can also provide an effective way for micro-damage detection of the service device in the deep sea environment.

Owner:CHINA UNIV OF MINING & TECH

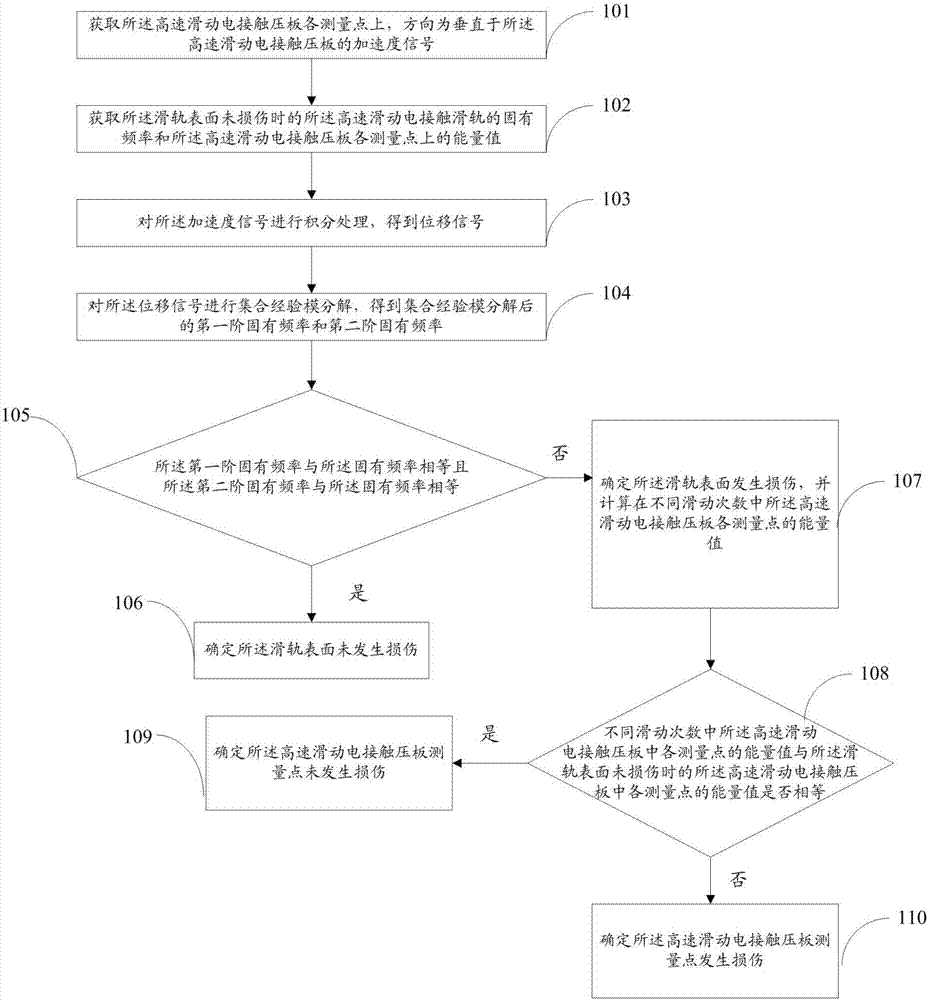

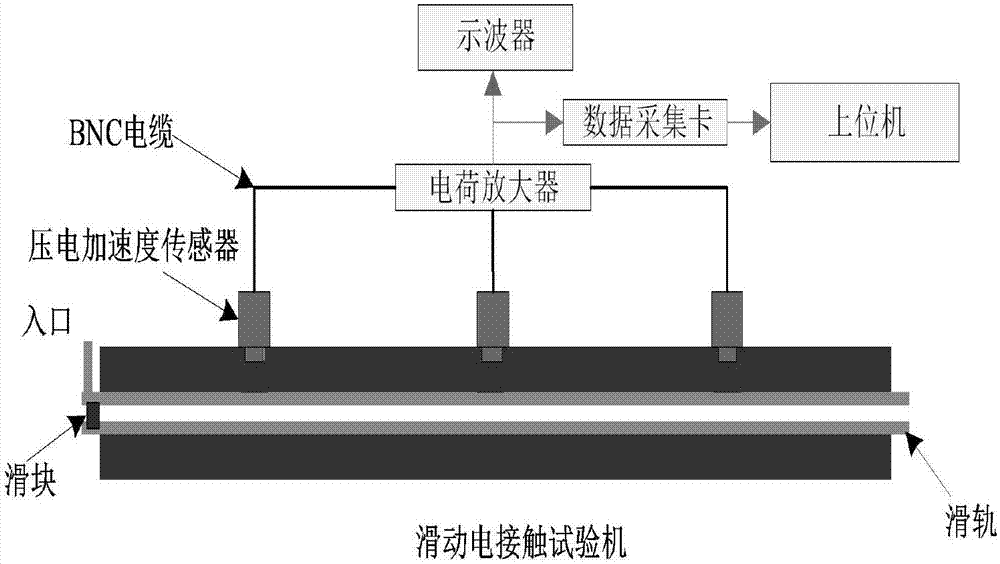

Online real-time monitoring method and system for structural damage

InactiveCN107505396AReal-time detection of transient micro-damagesAnalysing solids using sonic/ultrasonic/infrasonic wavesDecompositionMeasurement point

The invention discloses an online real-time monitoring method and system for structural damage. According to the method or the system, a set empirical mode decomposition algorithm is utilized on microvibration response signals in the direction perpendicular to a structure to obtain a first stage natural frequency and a second stage natural frequency, and whether the first stage natural frequency and the second stage natural frequency are equal to a natural frequency of an undamaged structure is judged; if so, that the surface of the structure is not damaged is determined; if not, that the surface of the structure is damaged is determined, and energy values of different measurement points of different slide times are calculated out; whether the energy value of some measurement point of different slide times is equal to that of a corresponding measurement point of the undamaged structure is compared; if so, that the measurement point is not damaged is determined; if not, that the measurement point is a damaged position is determined. Therefore, the method or the system disclosed by the invention can be used for detecting transient micro damage of the structure and determining the damaged position in real time under the high-frequency and high-speed background conditions.

Owner:YANSHAN UNIV

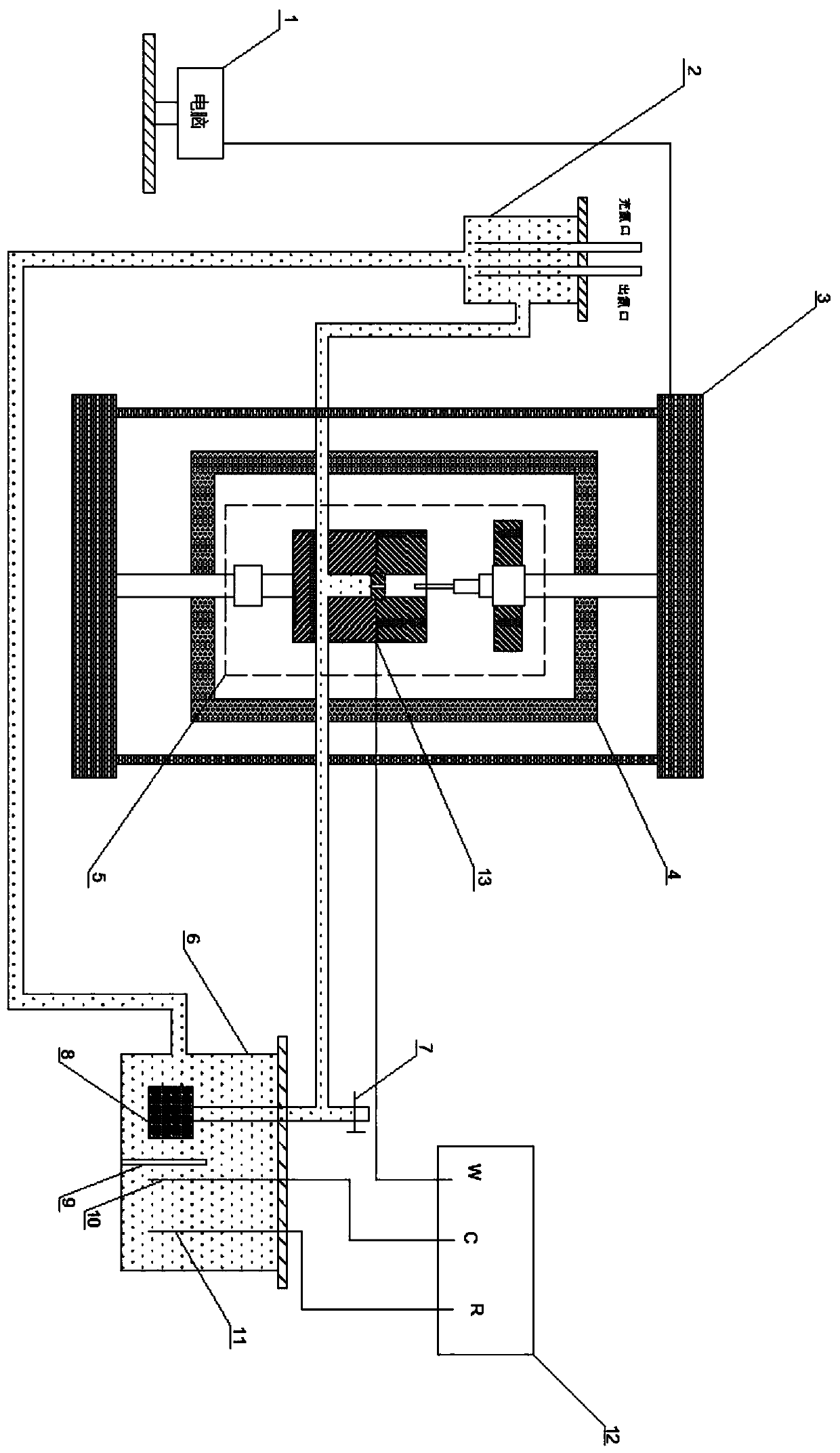

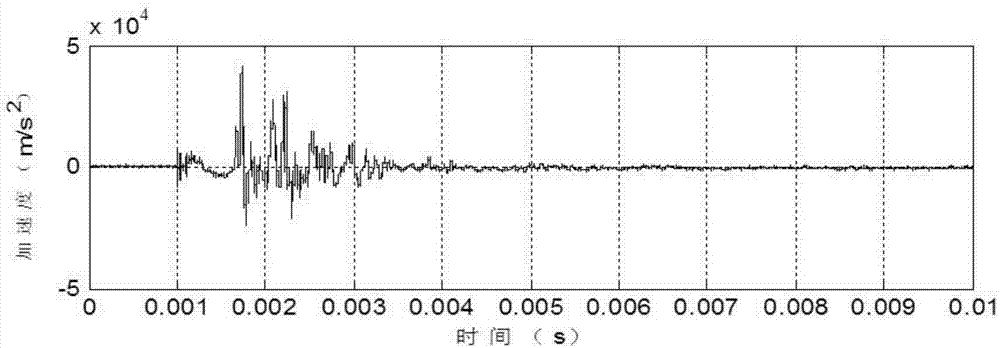

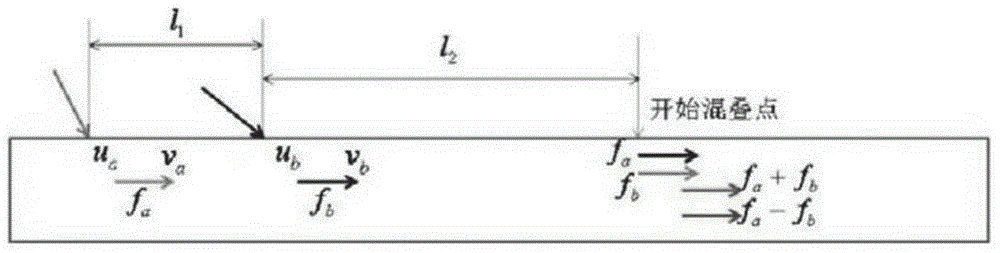

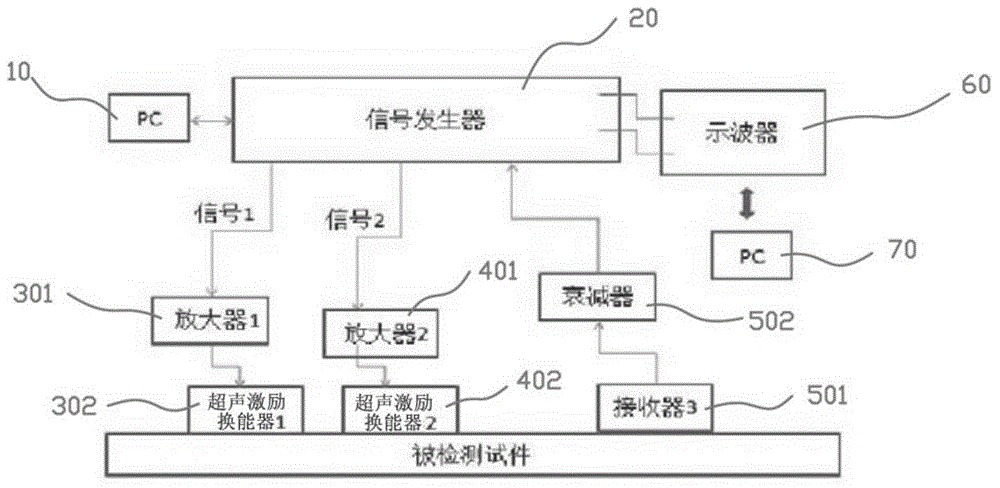

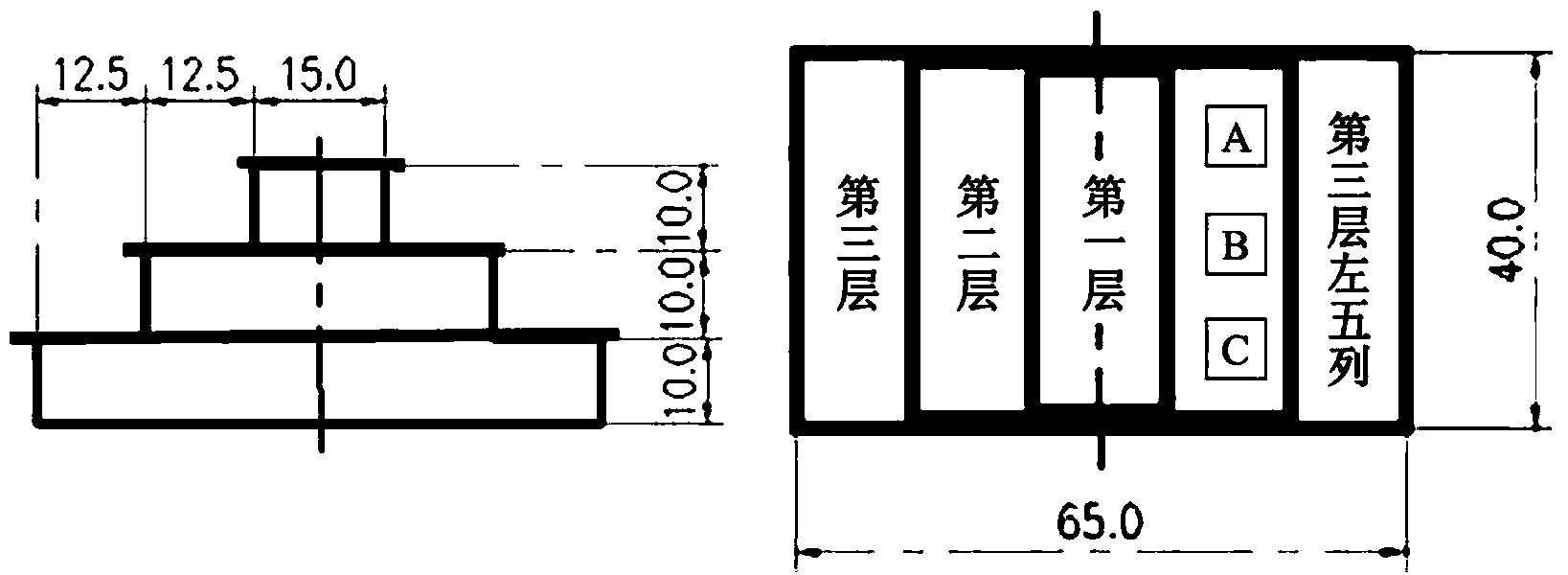

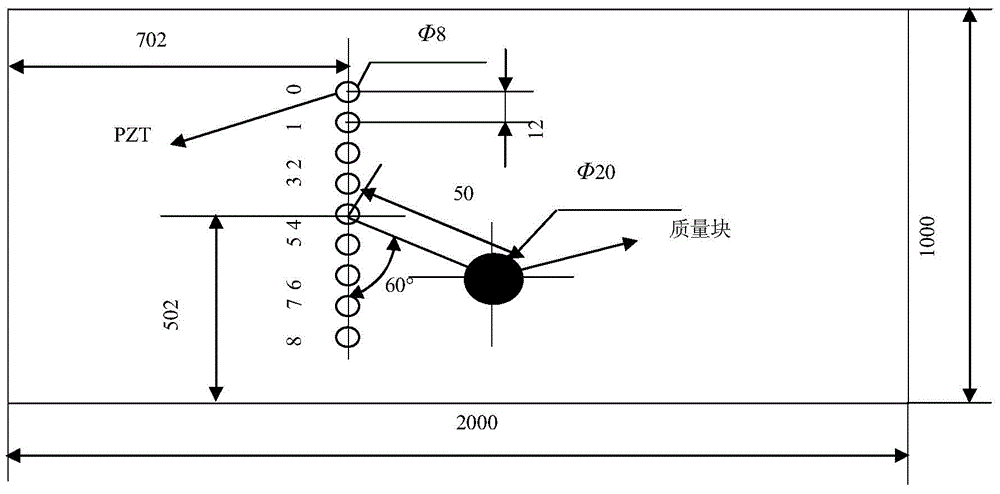

Ultrasonic micro-damage location detection method and device based on collinear aliasing of Lamb waves

InactiveCN104407054AHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesLocation detectionSonification

The invention relates to nondestructive testing, and provides an ultrasonic micro-damage location detection method based on collinear aliasing of Lamb waves. The method comprises the following steps: (A), a pair of Lamb wave mode combinations with different frequency and propagation modes is determined; (B), generated difference frequency harmonic waves of the Lamb waves are determined; (C), the pair of initial Lamb wave modes are excited by signal excitation units; (D), a signal receiving unit having corresponding frequency with the difference frequency harmonic waves is selected to receive the difference frequency harmonic waves; (E), an area where beams start for aliasing is confirmed; (F), positions of two initial excitation sources are changed; (G), scanning detection is performed on a tested object; and (H), the micro-damage location of the tested object is calculated and confirmed according to amplitude change of the difference frequency harmonic waves. The invention further provides an ultrasonic micro-damage location detection device based on the collinear aliasing of the Lamb waves. The device comprises a first computer, a signal generator, a first signal excitation unit, a second signal excitation unit, a signal receiving unit, an oscilloscope and a second computer. The ultrasonic micro-damage location detection method and device are applied to material detection.

Owner:XIAMEN UNIV

Method for measuring residual stress on surface of metal sample based on micro indentation

InactiveCN103969108AAccurate measurementThe operation process is simple and convenientMaterial strength using tensile/compressive forcesInvestigating material hardnessResidual strainMeasurement cost

The invention discloses a method for measuring residual stress on surface of a metal sample based on micro indentation. The method comprises the following steps: performing a micro indentation test on the surface of the sample by utilizing a Vickers microhardness tester, recording the indentation morphology by adopting a scanning electron microscope, and obtaining the nominal projection area and actual projection area of the indentation on the surface of the sample through calculation for diagonal length and side length of the micro indentation; obtaining a strength coefficient and strain hardening index of the material through a standard tensile test; and obtaining a theoretical formula for measuring the residual stress through an indentation method and containing the ratio of the actual projection area to the nominal projection area of the micro indentation, the strength coefficient and strain hardening index based on the hypothesis for the two-dimension isometric residual stress field on the surface of the sample, and further obtaining the residual strain and residual stress on the surface of the sample. The measurement method belongs to basically nondestructive or micro-damage measurement and has the advantages of low measurement cost, simplicity and convenience in operation and high measurement efficiency. If being combined with a portable high-power optical microscope with a distance measurement function, the method can be popularized and applied in the field of engineering.

Owner:UNIV OF SCI & TECH BEIJING

Concrete anti-cracking reinforced self-repairing material and preparation method and application thereof

The invention discloses a concrete anti-cracking reinforced self-repairing material and a preparation method and application thereof, and relates to the technical field of building materials. The concrete anti-cracking reinforced self-repairing material is prepared from the following raw materials in parts by weight: 40 to 60 parts of dense component, 10 to 30 parts of water storing component, 10 to 20 parts of plastifying component, 2 to 8 parts of complexing component, and 4 to 20 parts of thickening and reinforcing component. By adopting the concrete anti-cracking reinforced self-repairing material, the crack resistance of a substrate can be improved, micro-cracks or micro-damages which are not greater than 0.4mm in a concrete hardened body due to various causes can be repaired continuously, and continuous increase in the strength of the substrate after repairing of the cracks can be facilitated.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

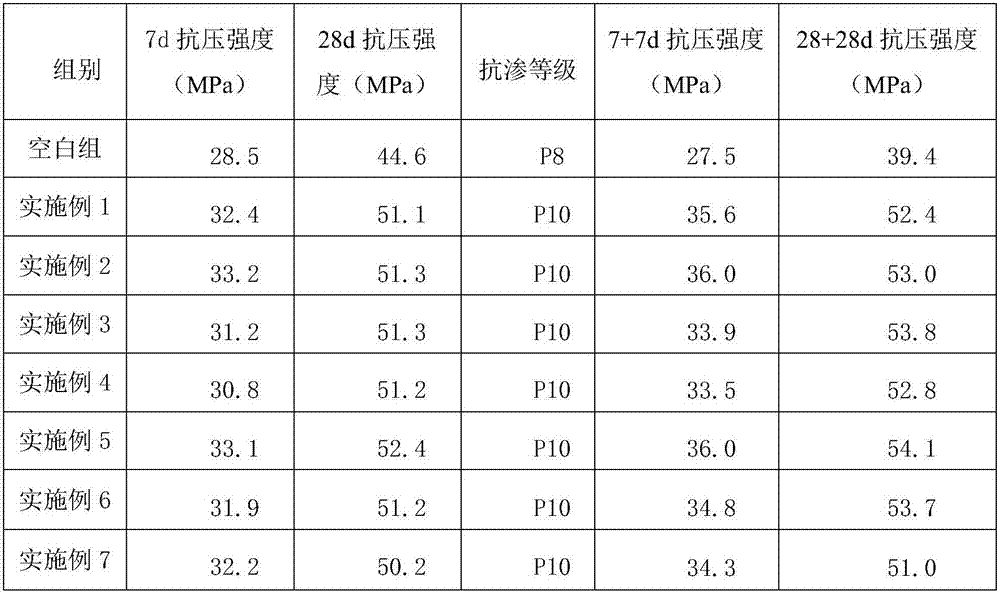

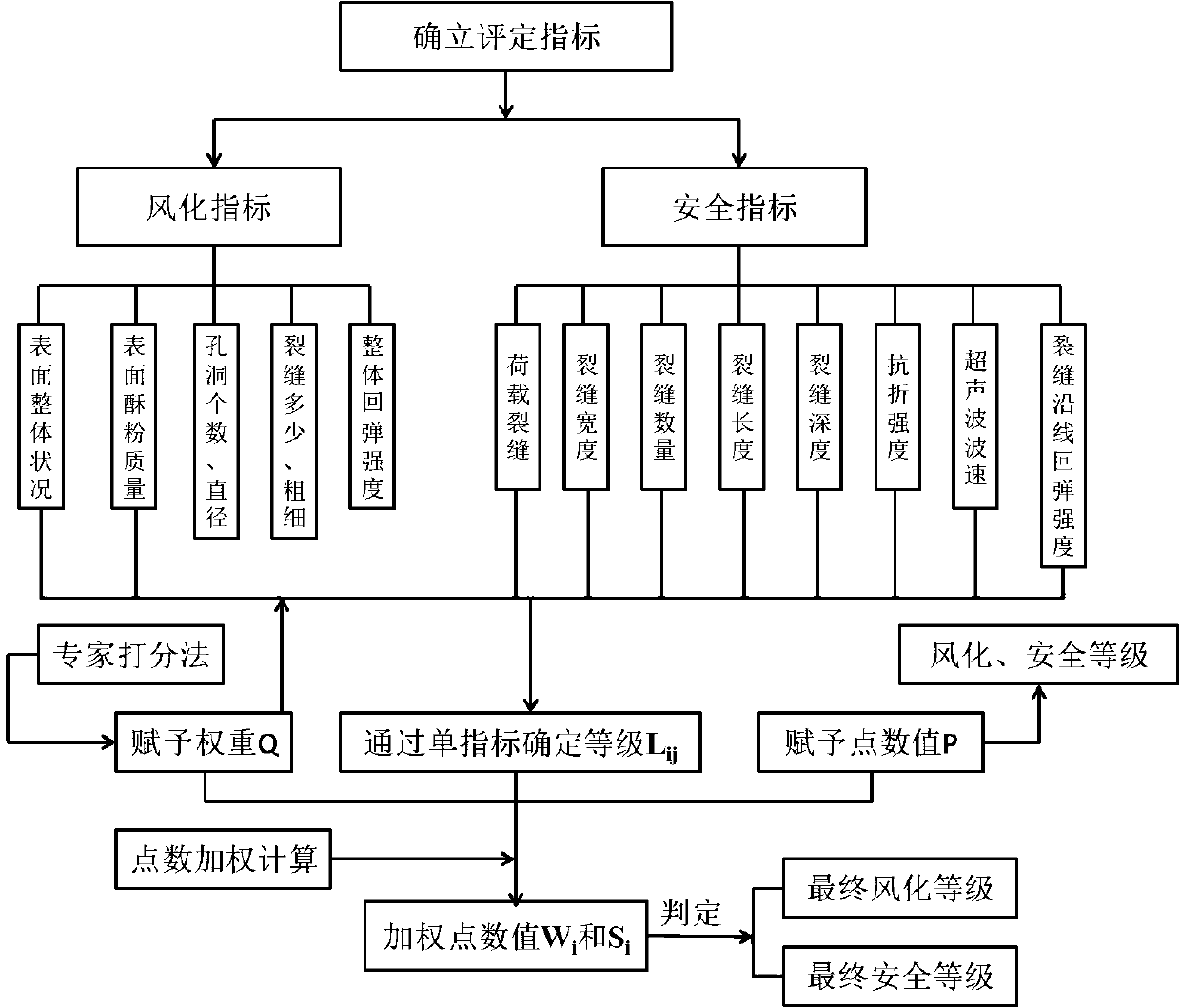

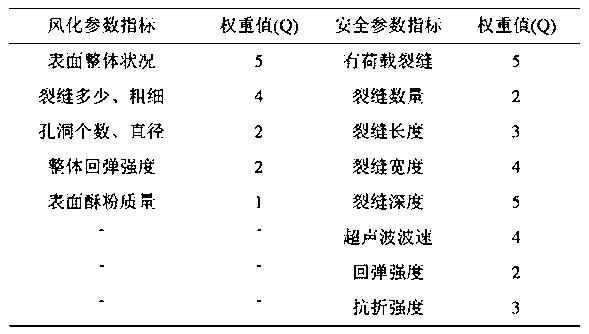

Quantitative assessment method for stone cultural relic component weathering and security degree

A quantitative assessment method for stone cultural relic component weathering and security degree includes the following steps: selecting physical properties which can be achieved through lossless or micro-damaged detecting and capable of reflecting features of rock weathering and security as evaluation indexes according to protective principles of cultural relics, distributing corresponding weighted values to all the evaluation indexes through an expert scoring method to reflect degree of impact of different indexes to the component weathering and the security degree, dividing weathering degree into five levels and the security degree into four levels and formulating point values for all levels, preliminarily determining the weathering degree and the security degree according to a single evaluation index, and adopting a point weighting method to calculate final weathering points and security points of all the components to achieve the weathering degree and the security degree of the component visually and accurately.

Owner:BEIJING UNIV OF CHEM TECH +1

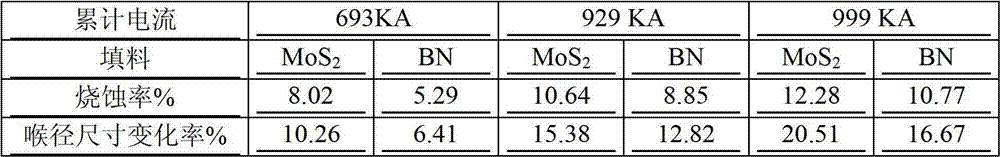

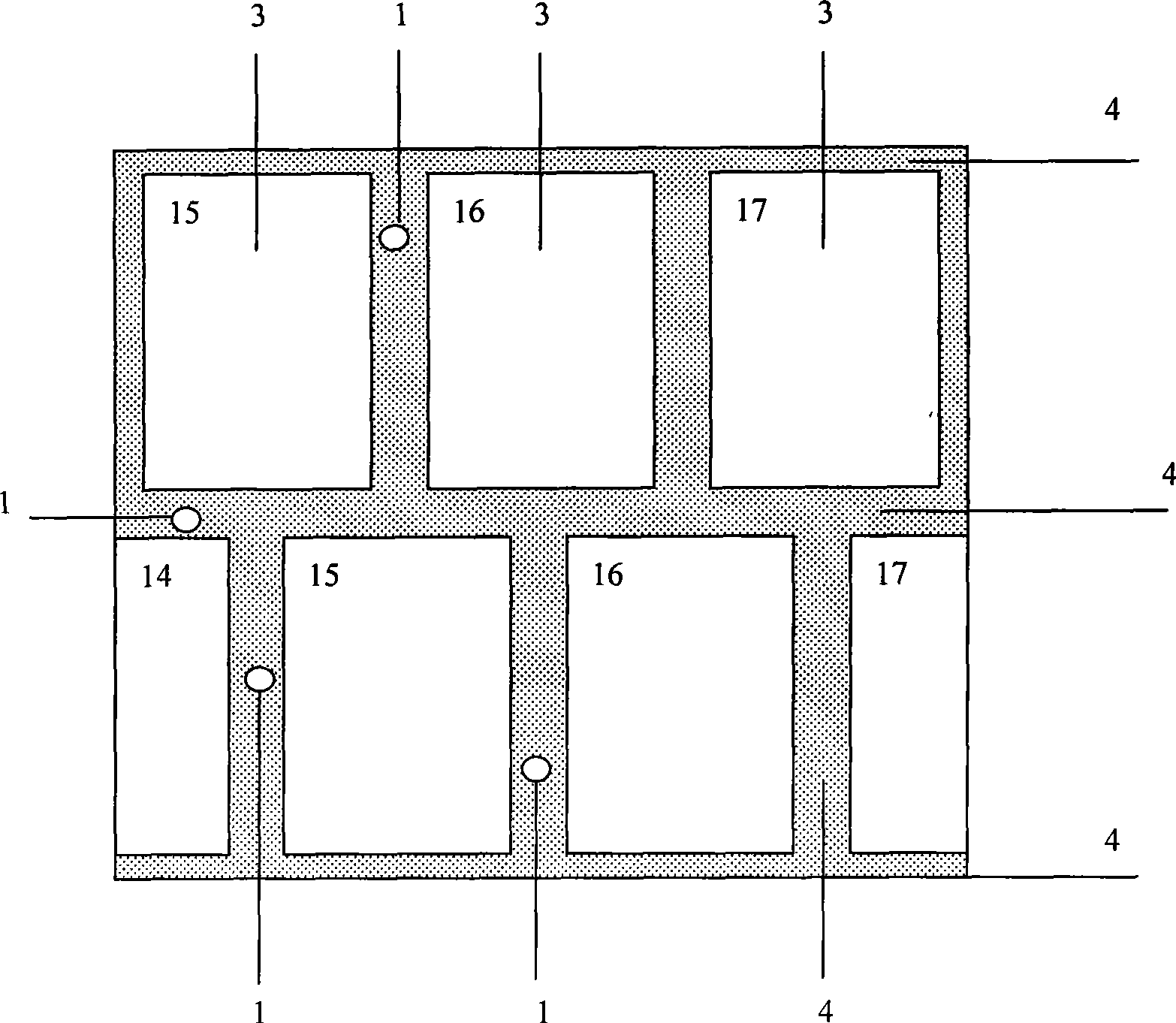

SF6 high-voltage circuit breaker polytetrafluoroethylene composite material nozzle and preparation method thereof

The invention provides an SF6 high-voltage circuit breaker polytetrafluoroethylene composite material nozzle which is composed of the components of, by mass, 1-8% of boron nitride (BN), 0.1-0.4% of molybdenum disulfide (MoS2), and balance of polytetrafluoroethylene (PTFE). According to the invention, MoS2, BN, and PTFE are compounded for preparing a nozzle which can resist high voltage and large current arc ablation. When the nozzle composed of the composition is in use, during a thermal cracking process controlled by heat, the BN component can reduce the decomposition speed of PTFE. When PTFE is decomposed due to arc ultraviolet light, the filling material containing MoS2, short-wave ultraviolet can be blocked and absorbed, such that the ablation of the composite material and local micro-damage on the surface of a nozzle throat can be retarded. The nozzle is suitable to be used in extra-high-voltage circuit breaker products and ultra-high-voltage circuit breaker products. With the material, the service life of the nozzle, which is a core component, can be prolonged.

Owner:CHINA XD ELECTRIC CO LTD

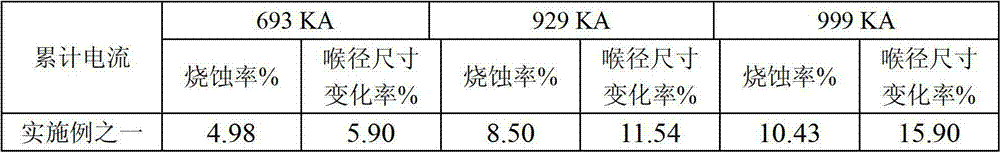

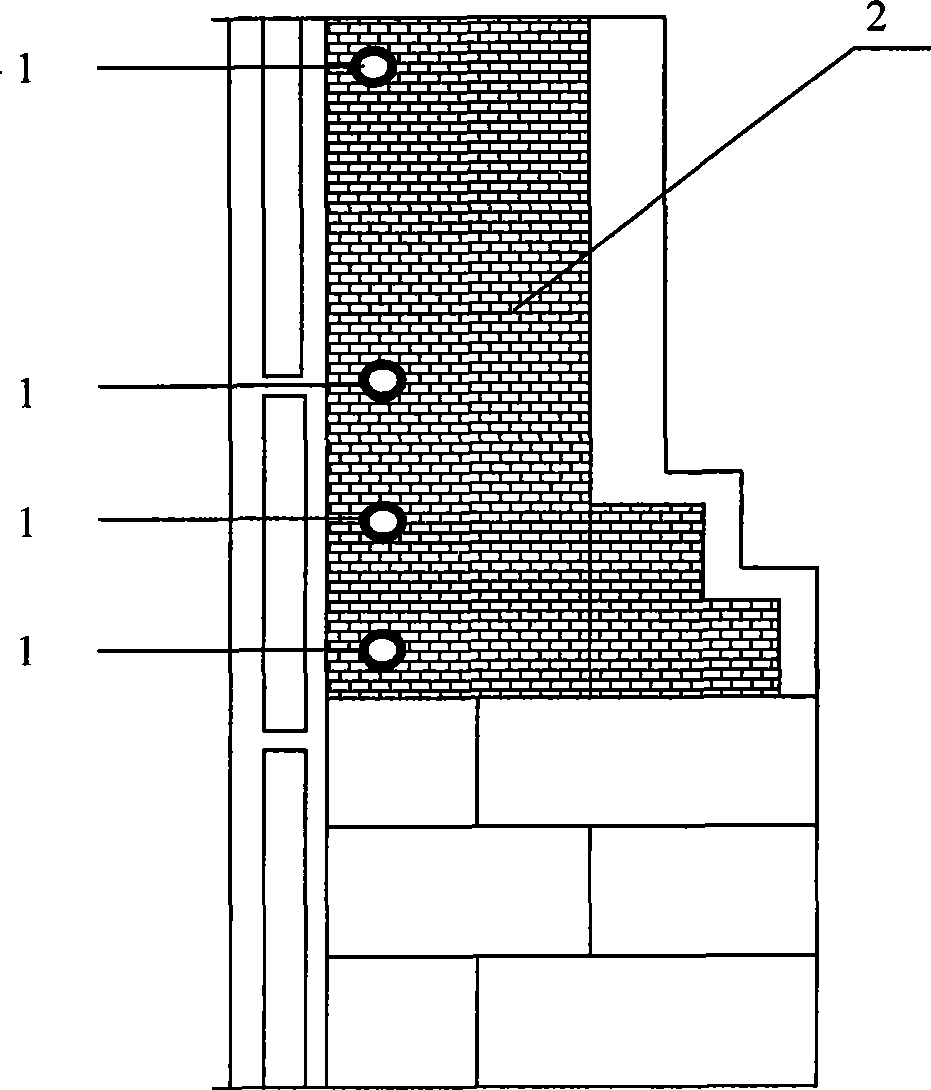

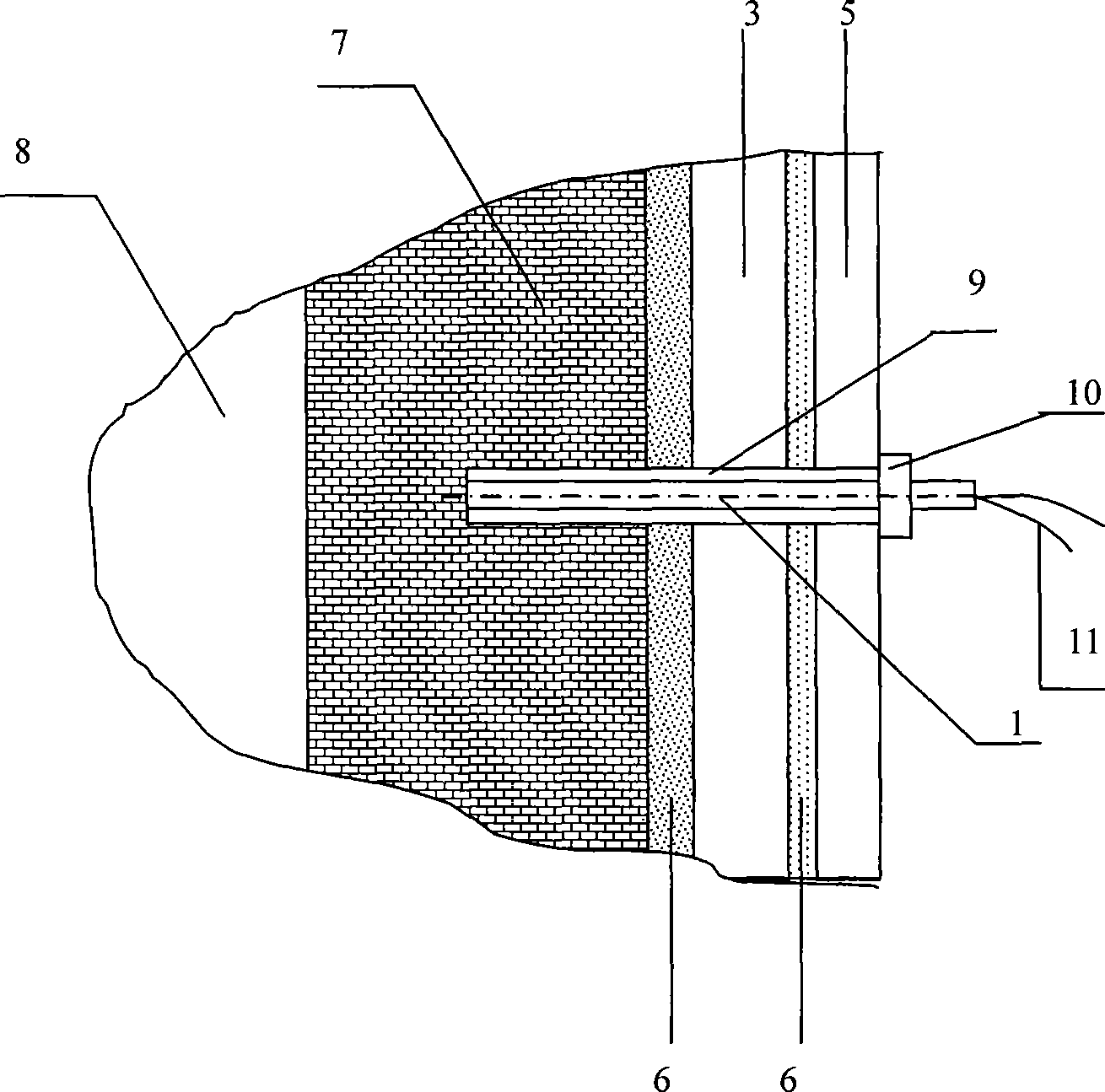

Blast furnace online small-bore micro-damage furnace hearth side wall temperature detection method

InactiveCN101504319AEasy to measureAccurate measurementThermometers using electric/magnetic elementsUsing electrical meansBrickCrucible

The invention provides a method for detecting temperature of the side wall of a small-bore micro-damage crucible of a blast furnace on line, and belongs to the technical field of blast furnace smelting crucible detection. The detecting method comprises the following steps that: 1) a blast furnace to be detected comprises a furnace shell, a cooling wall and carbon bricks, and padding is filled between the furnace shell and the cooling wall and between the cooling wall and the carbon bricks respectively; 2) detecting points and depths of the detecting points are determined, the detecting points are respectively distributed in clearances of the cooling wall on the side wall of the crucible, and the depths of the detecting points are determined according to a medium to be detected and the thickness of the medium; 3) the surface of the furnace shell of the crucible to be detected is provided with horizontal holes according to the detecting points and the depths of the detecting points determined in the step 2); 4) a thermocouple with a sheath is placed in a horizontal hole, a sealing element is fixed on the furnace shell, and the thermocouple with the sheath is fixed on the crucible to be detected; and 5) the thermocouple and PLC are connected through a thermocouple lead wire to realize real-time detection and acquire solid temperature variation gradient. The method has the characteristics of simpleness, convenience, reliability, less investment, less maintenance and installation without blast furnace overhaul.

Owner:SHANDONG IRON & STEEL CO LTD

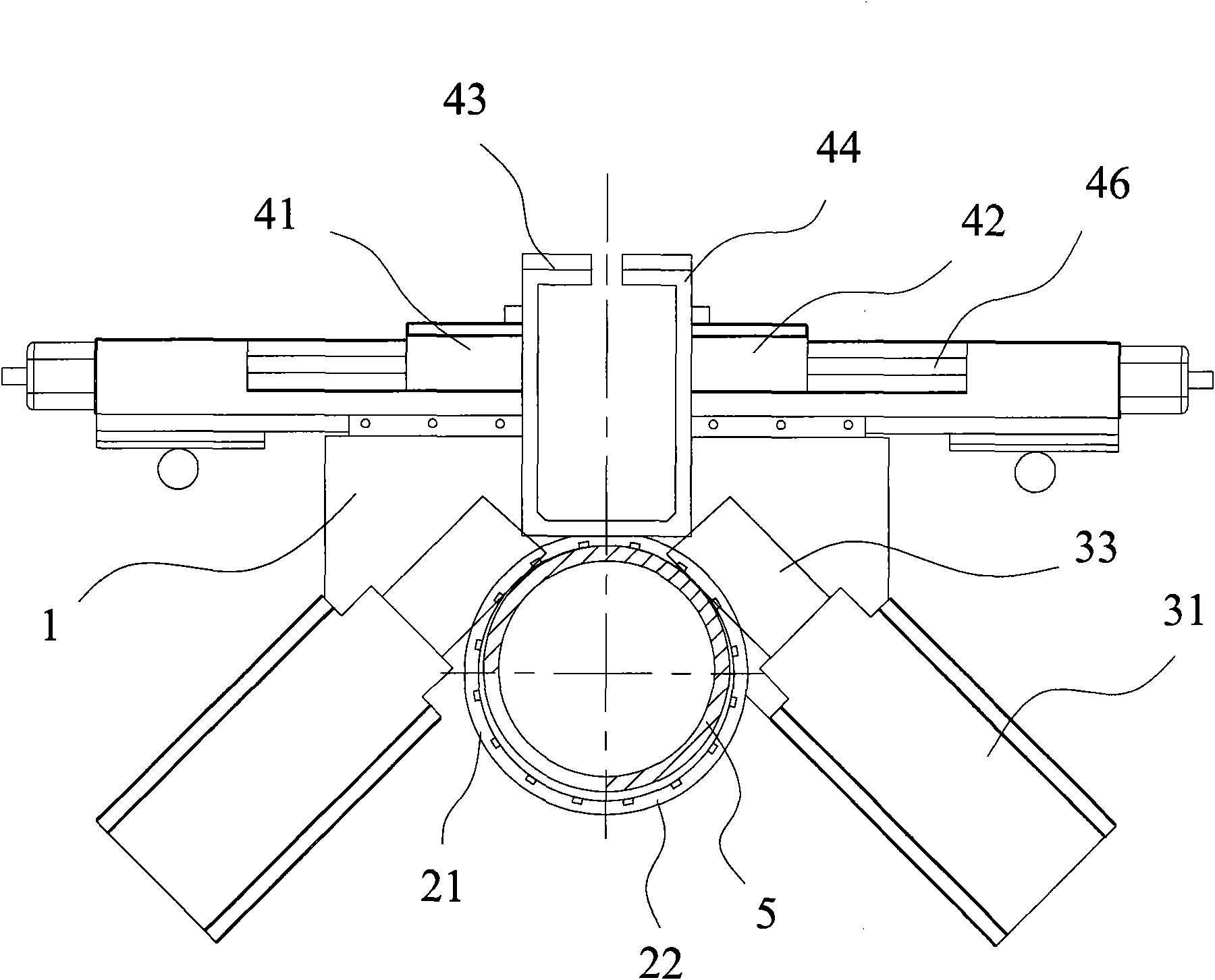

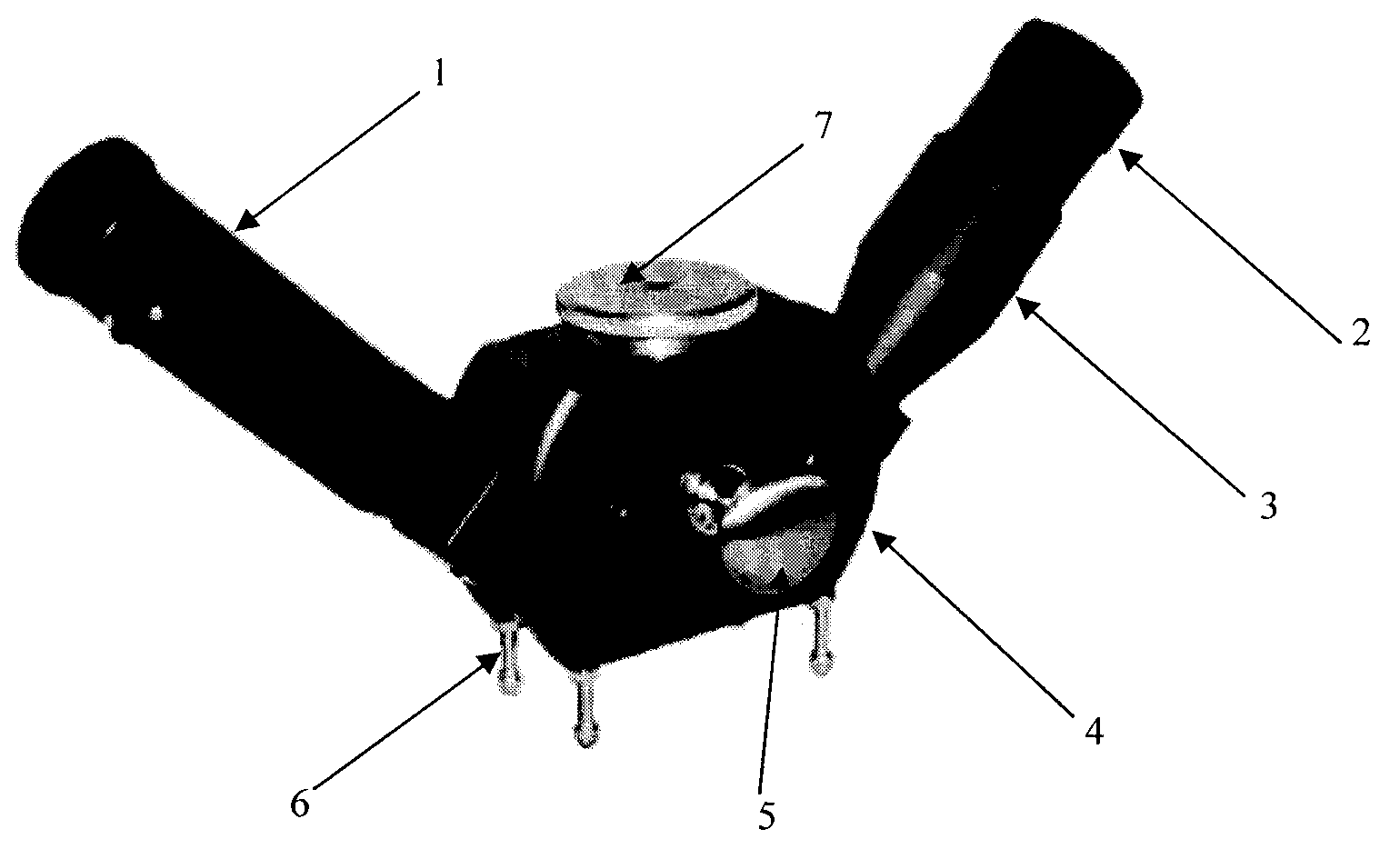

A magnetic memory detection device of oil drill rod micro-crack

ActiveCN101551360ARealize non-contact non-destructive testingReduce volumeMaterial magnetic variablesStress concentrationNon destructive

The invention discloses a magnetic memory detection device of oil drill rod micro-crack including: rack and testing ring. The testing ring is set up on the rack and can be installed on the drill rod. The testing ring has the magnetic memory sensor used for testing the described drill rod; the rack has the first driving device used to drive the rack move along the axial direction of the drill rod on the rack. The invention can achieve the non-contact non-destructive test on the micro-damage and stress concentration of oil drill rod in order to provide a basis for drill rod classification management. It mainly features: no special magnetic device, small size and light weight.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Manufacturing method for two-layer silicon epitaxial wafer used for bipolar transistor

ActiveCN103367252AKeep surfaces cleanGuaranteed uniformitySemiconductor/solid-state device manufacturingHydrogenRepeatability

The invention discloses a manufacturing method for a two-layer silicon epitaxial wafer used for a bipolar transistor. Compared with a manufacturing method for a conventional two-layer silicon epitaxial wafer, the manufacturing method for the two-layer silicon epitaxial wafer used for the bipolar transistor is characterized by comprising the following steps of removing micro damages of the surface of a silicon wafer by using a hydrogen chloride (HCl) polishing process before a first layer silicon epitaxial wafer is grown; taking out the silicon wafer after the first layer silicon epitaxial wafer is grown to perform etching treatment on a system; and cleaning the silicon wafer before a second layer is grown to ensure the surface to be clean, removing the micro damages of the surface by using the HCl polishing process, and removing impurities by using hydrogen (H2) after polishing. According to the manufacturing method, a reaction chamber etching step is inserted, and therefore, the uniformity and the repeatability of the electrical resistivity of an epitaxial layer are ensured, and the performance and the finished product rate of a device are ensured.

Owner:HEBEI POSHING ELECTRONICS TECH

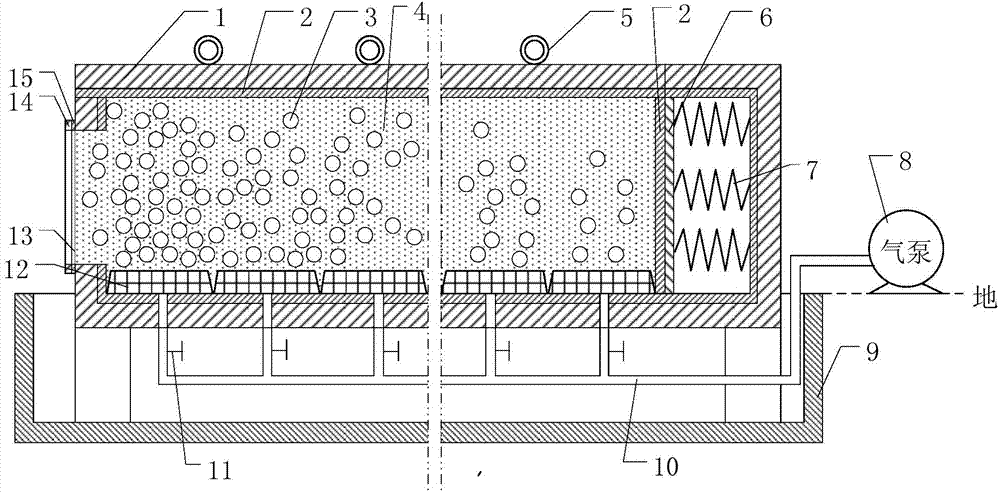

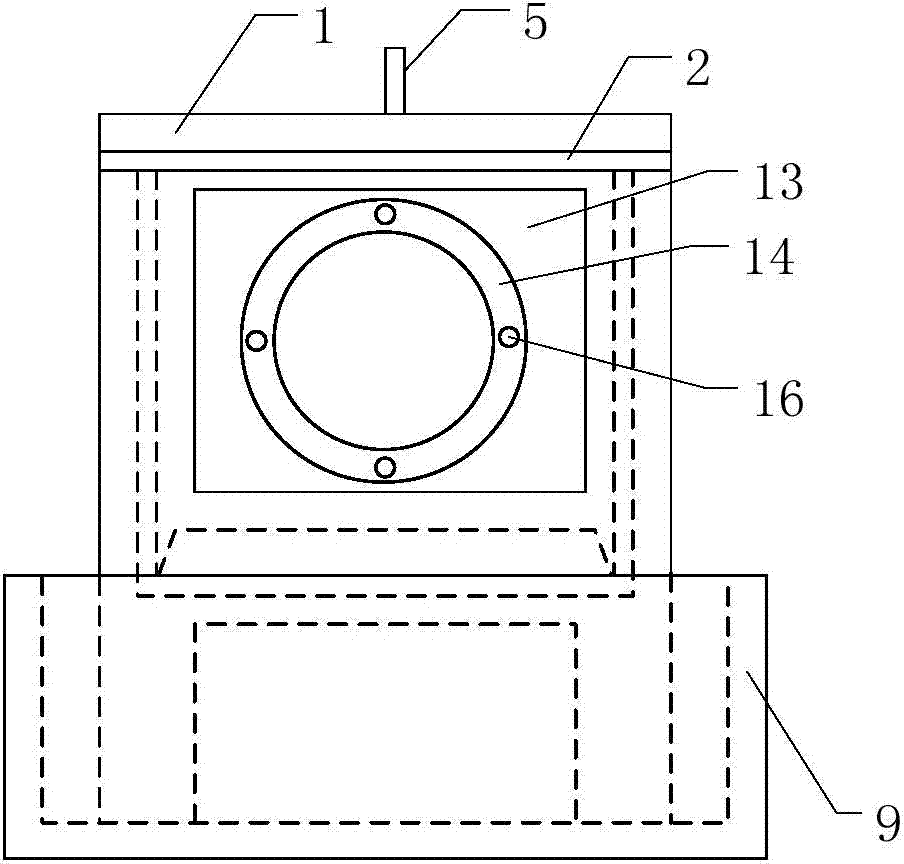

Speed reducing device for retrieving high-speed flight body with slight damage

The invention discloses a speed reducing device for retrieving a high-speed flight body with slight damage, and belongs to the technical field of buffer protection. The speed reducing device is a speed reducing device for retrieving the high-speed flight body with slight damage through non-isopycnic air and water mixtures, and the flying speed of the high-speed flight body ranges from 50 m / s to 500 m / s. The speed reducing device is composed of a retrieval box, water, bubbles, a bubble generator, a felt pad, rubber, springs, a water pool and the like, wherein the water, the bubbles, the bubble generator, the felt pad, the rubber and the springs are arranged in the retrieval box, the retrieval box is placed into the water pool, the bubbles are generated by the bubble generator, a buffer and speed-reducing mechanism is formed by non-isopycnic air and water mixture space in the forwarding direction of the flight body from the edge of the front wall of the interior of the retrieval box, a retrieval protection mechanism is formed by the felt pad on the rear portion of the retrieval box, the rubber and the springs, and the water pool is used for recycling water which overflows after the high-speed flight body penetrates through film on an inlet of the retrieval box. The speed reducing device has the advantages that the non-isopycnic air and water mixtures are used for effectively buffering the high-speed flight body, the structure of the flight body is slightly damaged, it can be ensured that the speed of a high-speed flying object is evenly reduced under the condition of small acceleration, the speed reducing device has the advantages of being simple in structure, convenient to use and reliable in retrieval, and the speed reducing device for retrieving the high-speed flight body with slight damage is worthy of application and popularization.

Owner:ZHONGBEI UNIV

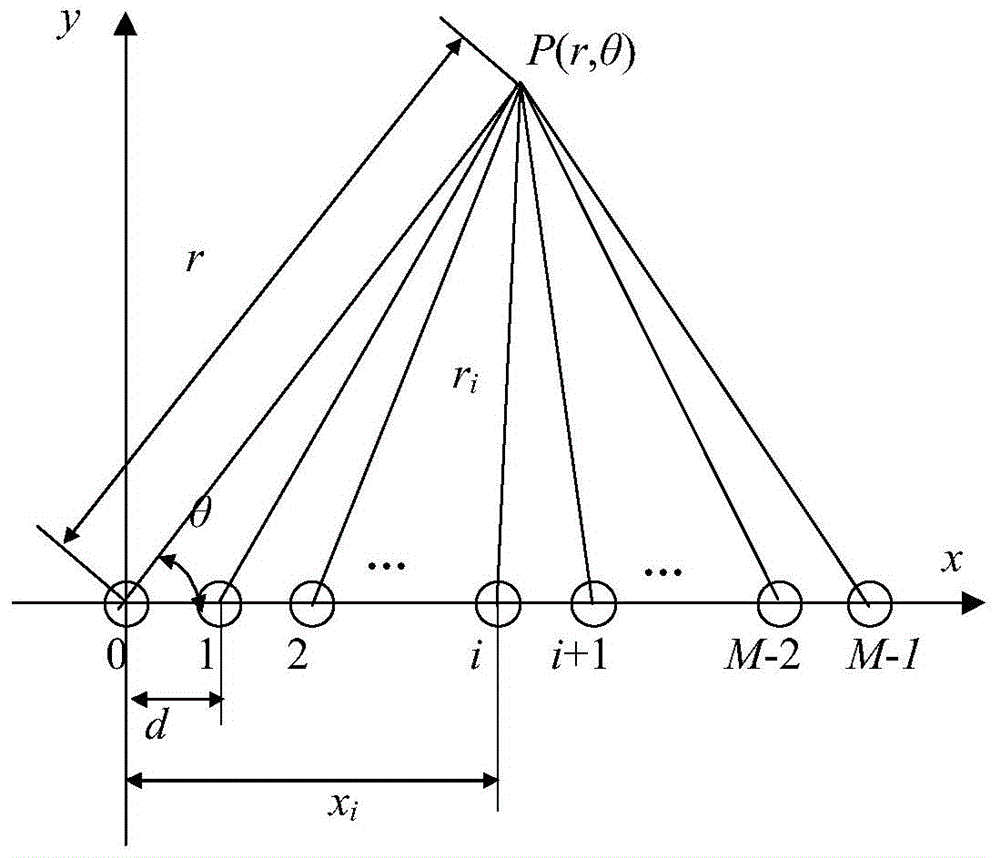

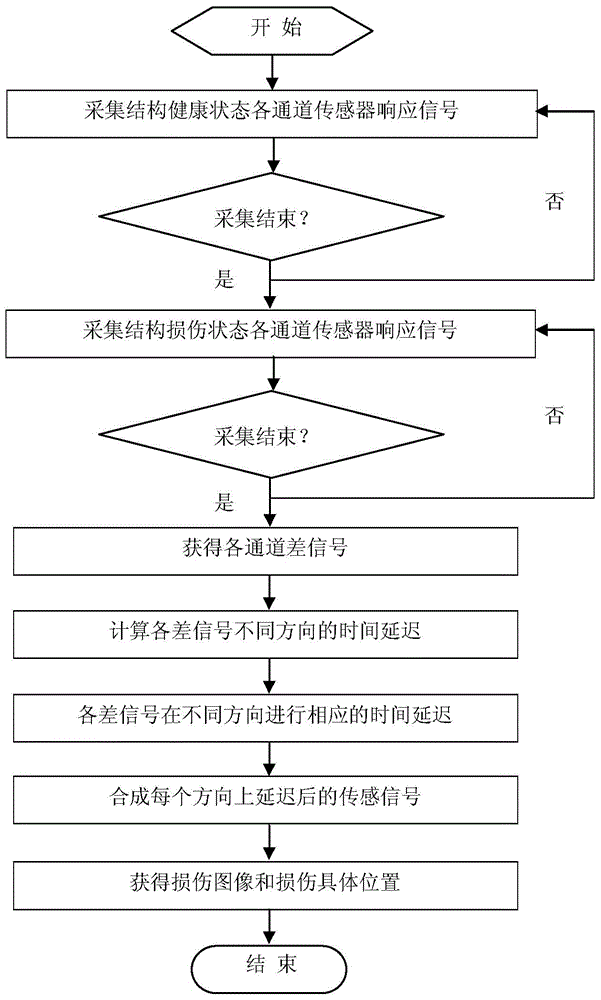

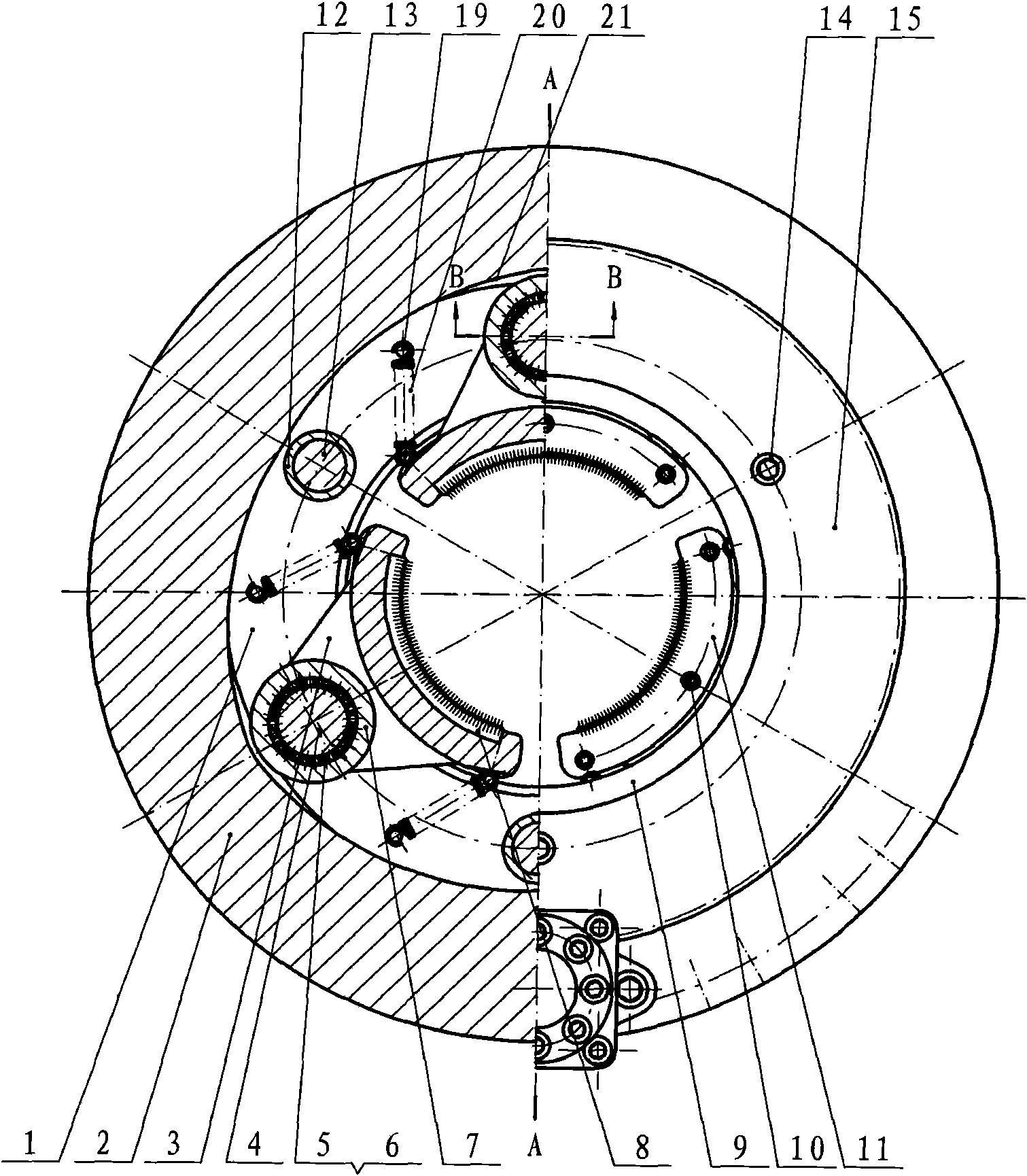

Near field phased array structure health monitoring method based on piezoelectric array

InactiveCN104374830AOvercome limitationsImprove practicalityAnalysing solids using sonic/ultrasonic/infrasonic wavesStructure health monitoringTime delays

The invention discloses a near field phased array structure health monitoring method based on a piezoelectric array. The method comprises the following steps: arranging a piezoelectric linear array on a monitoring structure so as to obtain a damage scattering signal of each excitation-sensing channel, adding time delay to a damage signal, and determining the damage direction; and finally, determining the damage position according to a signal arrival moment t. With the adoption of the near field phased array structure monitoring method disclosed by the invention, micro damage in a complex structure can be identified, and the limitation of a far field phased array on the monitoring distance is overcome.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Non-distortion repairing method for micro-damage of casting alloy part

InactiveCN101444869ALow heat inputInstant high temperatureArc welding apparatusCrazingElectric discharge

The invention discloses a non-distortion repairing method for micro-damage of casting alloy part. In the method, a revolving solid anode bar made from CoCrW alloy is clamped on a rotary collet of an electric discharge machine, and spare parts to be repaired are connected with the cathode of the electric discharge machine; the power of the electric discharge machine is adjusted between 1000W and 1800W, and the frequency is adjusted into low frequency; shield argon is adjusted between 8L / min and 35L / min, and argon in an argon bottle is guided to a coating part by a copper pipe; a dipped finish of the copper pipe aims damage parts of the spare parts; after the power is turned on, the rotary cathode bar and the damage surfaces of the spare parts are contacted with degrees between 55 degrees and 75 degrees, and reciprocating coating is carried out at repairing parts. The method uses the characters of high transient temperature and short endurance time of electric spark micro-arc aggradation to reduce heat input in the repairing of spare parts, thereby avoiding the defects of great heat input amount of argon-arc welding, long acting time, much deformation of spare parts and easy generation of cracks in the prior art. The method overcomes the problems of border effect of plasma spraying, great investment cost of devices, low bonding strength of coating, easy plunger separation and chip off-falling for hot spraying in the prior art.

Owner:PLA NO 5719 FACTORY

Enhanced anti-cracking self-repairing concrete and preparation method thereof

The invention discloses enhanced anti-cracking self-repairing concrete and a preparation method thereof, and relates to the technical field of building materials. The concrete is C30 concrete and comprises, by weight, 154-164 parts of cement, 36-44 parts of fly ash, 262-290 parts of fine aggregates, 613-677 parts of coarse aggregates, 41.8-46.2 parts of water, 1.6-2.2 parts of fibers, 7.6-16.8 parts of repairing agents and 18-20 parts of anti-cracking anti-seepage agents. The concrete improves crack resistance and can effectively restrain cracking and continuously and automatically repair micro-cracks or micro-damage of the concrete caused by various reasons, the mechanical property of the concrete before being damaged can be recovered, economy and durability of the concrete are improved,and the service life of the concrete is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

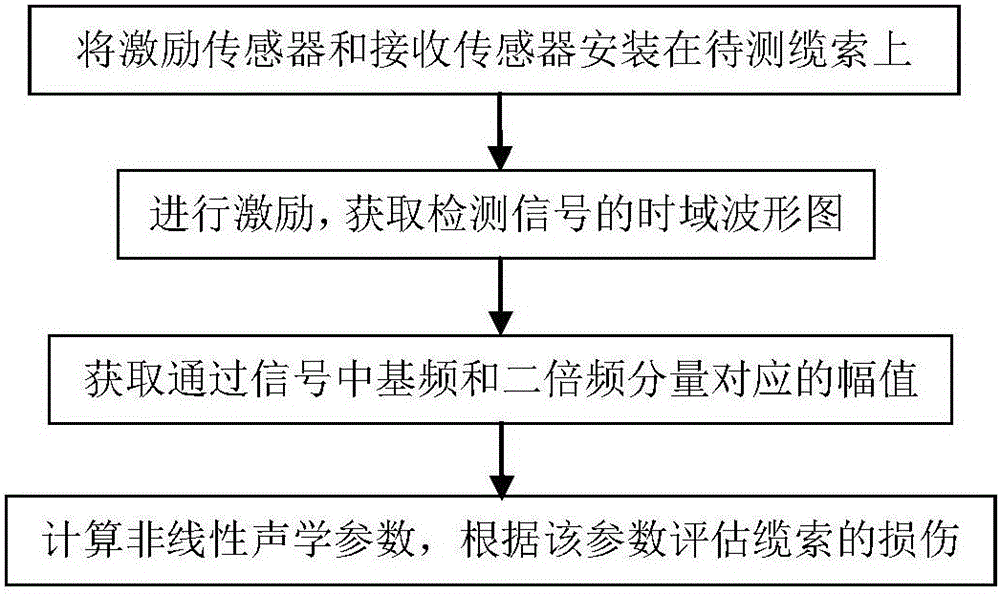

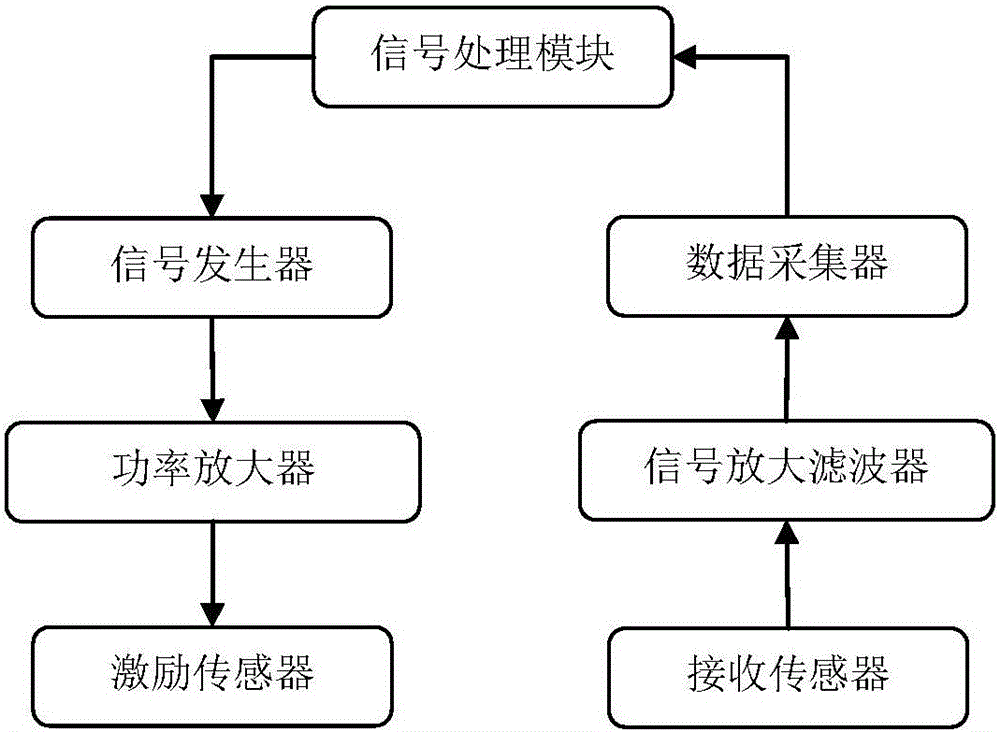

Method and device for detecting fatigue damage of cable

InactiveCN105806944ARealize detectionEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesFatigue damageBase frequency

The invention discloses a method and device for detecting fatigue damage of a cable.The method includes the steps that an excitation sensor and a receiving sensor are installed on the cable; the excitation sensor is controlled to generate excitation guide waves, and the receiving sensor acquires a time domain waveform graph of passing signals; according to the time domain waveform graph, amplitude values corresponding to base frequency and doubled frequency components in the passing signals are acquired; non-linear acoustic parameters are obtained according to the amplitude values, and the fatigue damage state of the cable is determined according to the non-linear acoustic parameters.The device is used for achieving the method and comprises a signal generation module, a signal receiving module and a signal processing module.Detection on micro-damage of the cable is achieved by acquiring the non-linear acoustic parameters caused by the micro-damage of the cable, and the advantages of being high in detection precision, facilitating detection and the like are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

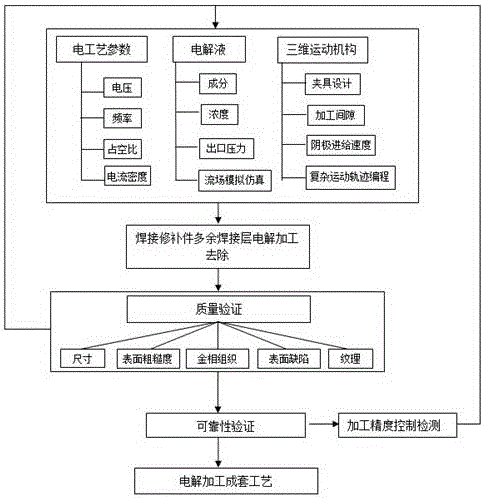

Electrolytic machining method for maintaining and remanufacturing of aeroengine

InactiveCN106695033AAvoid secondary damageNo overheatingMachining working mediaElectrolysisMachined surface

The invention discloses an electrolytic machining method for maintaining and remanufacturing of an aeroengine. The electrolytic machining method for maintaining and remanufacturing of the aeroengine comprises the first step of study on the electrolytic machining mechanism of titanium alloy, the second step of design and preparation of a cathode, the third step of preparation of a special electrolyte, the fourth step of acquisition of technological parameters in the electrolytic machining process, the fifth step of study on precision control of electrolytic machining, the sixth step of study on the influence of flow field distribution of the electrolyte, and the seventh step of establishment of an electrolytic machining quality evaluation system. According to the electrolytic machining method for maintaining and remanufacturing of the aeroengine, the electrolytic machining technique is used for replacing a traditional machining method to meet technical requirements for machining of molded surfaces of key components of the civil aeroengine, so that secondary damage such as micro-cracks, micro-scratches and generated mechanical stress, caused by the traditional machining method, to a machined surface is avoided. The electrolytic machining method is used as the machining basis for welded titanium alloy structural components, so that influences such as overheating, a cold working layer, mechanical stress and micro-damage to the surface can be avoided while a redundant surfacing layer is removed; and meanwhile, the influence of feeding limitation of the traditional machining method can be avoided, the machining time is greatly shortened, and economic cost is reduced.

Owner:江苏丰信航空设备制造有限公司

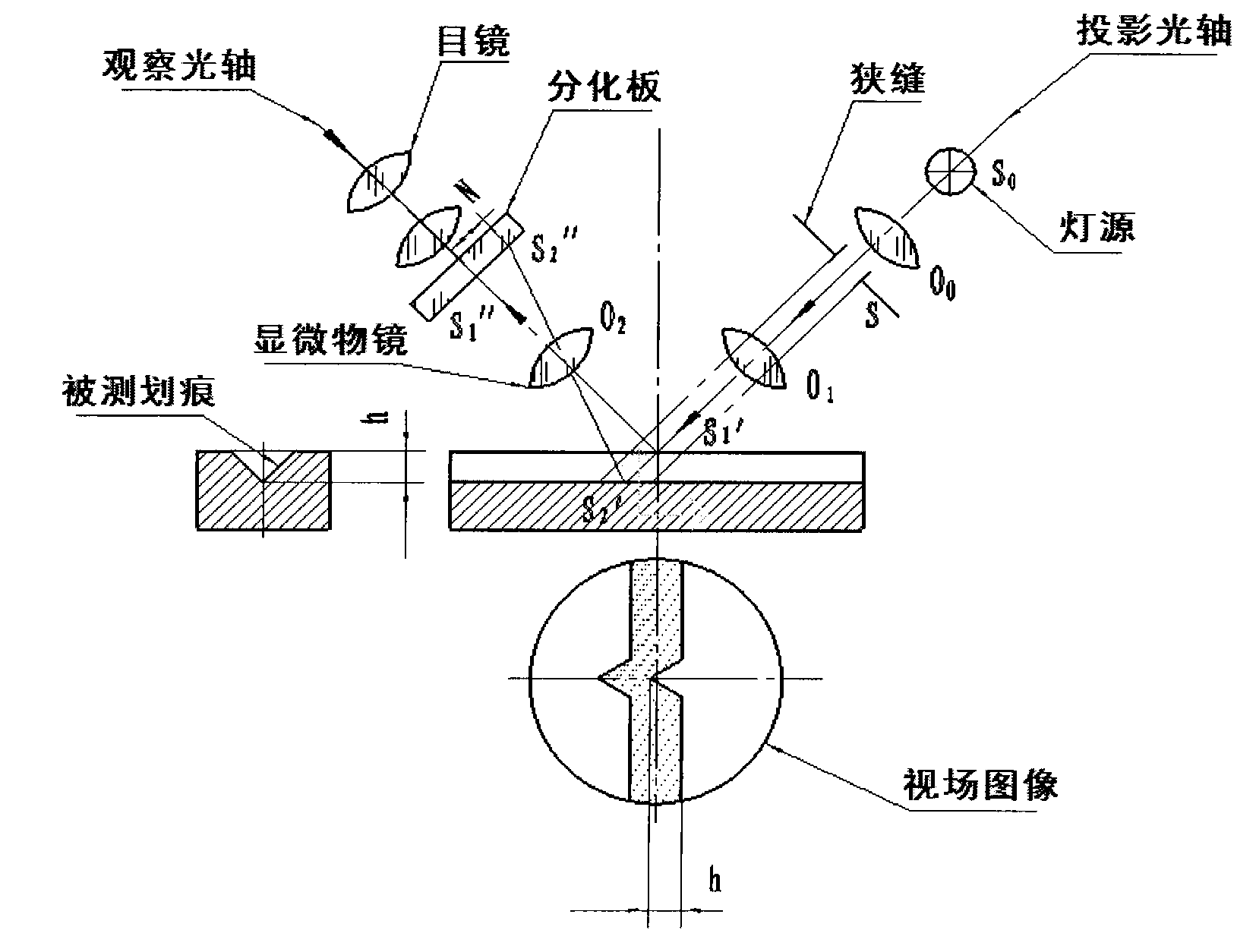

Device for detecting damage depth of object surface scratch

InactiveCN102937417AReduce volumeNo secondary damageUsing optical meansData processing systemData treatment

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

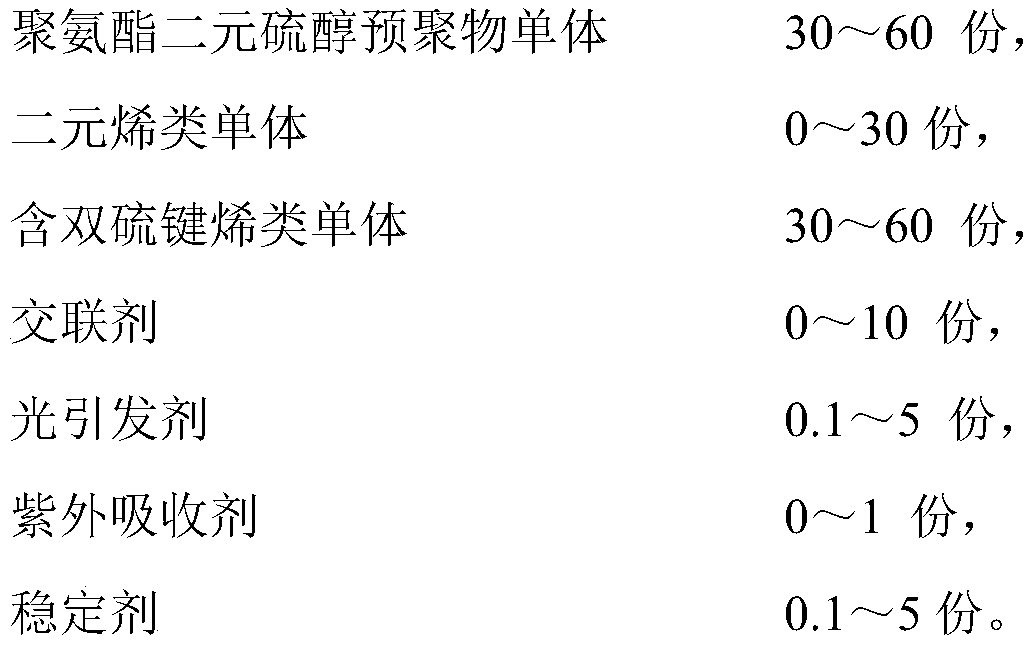

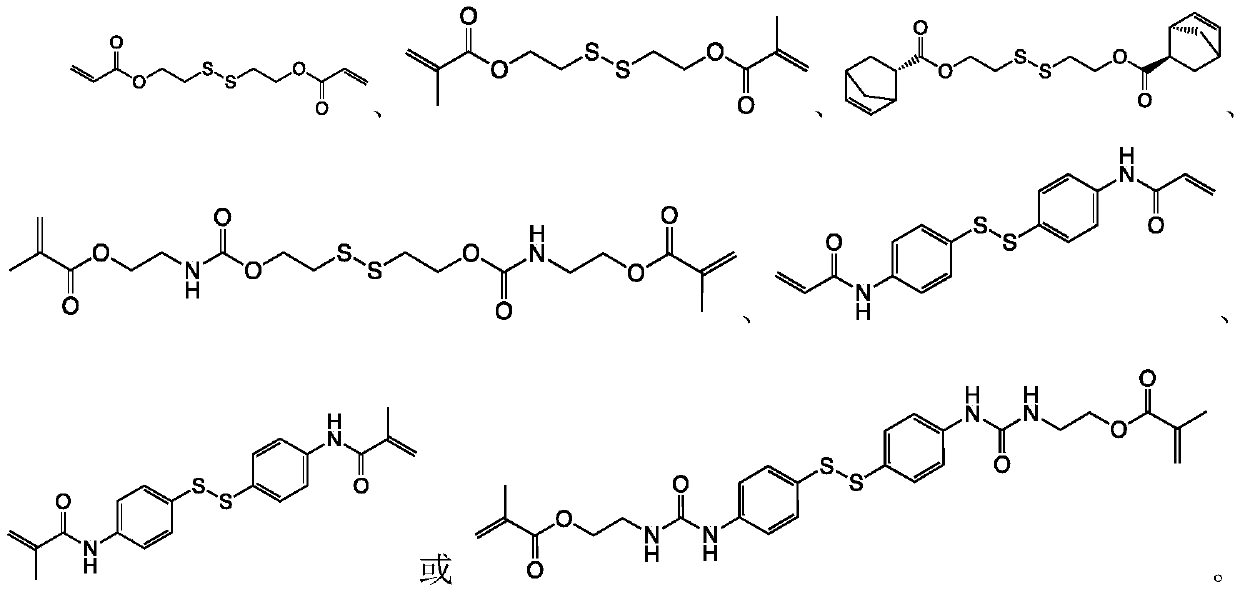

Self-repairing photosensitive resin composition based on mercaptan-alkene and application thereof

The invention discloses a composition for preparing photosensitive resin with self-repairing function, which comprises the following components in parts by weight: 30-60 parts of polyurethane dithiolmonomer, 0-30 parts of diene monomer, 30-60 parts of diene monomer containing disulfide bonds, 0-10 parts of crosslinking agent, 0.1-5 parts of photoinitiator, 0-1 part of ultraviolet absorbent and 0.1-5 parts of stabilizer. The photosensitive resin is prepare by using that composition for prepare the photosensitive resin with the self-repairing function obtained by the invention, so that the photosensitive resin has the self-repairing function, can repair micro damage in the material in time, has fast repair speed and good repair effect, meanwhile, the polymerization shrinkage is small, the tensile strength is large, and the service life of the material can be effectively prolonged.

Owner:LINGNAN NORMAL UNIV

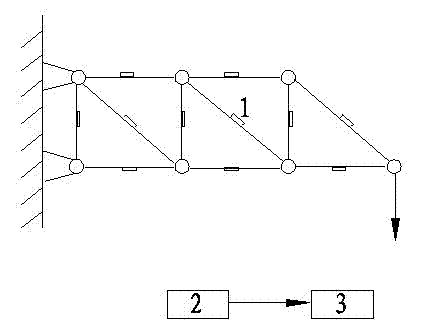

Damage diagnosis equipment for truss structure

InactiveCN102809632AHealth work status monitoringOvercome the defect of poor technical predictabilityMaterial analysisComputer moduleEngineering

The invention discloses damage diagnosis equipment for truss structure, which comprises wireless strain sensors, a wireless data acquisition instrument and a rod damage state diagnostor, wherein the wireless strain sensors are mounted at the middle parts of rods; the wireless data acquisition instrument can regularly acquire strain values of the rods under the same dynamic conditions of the truss structure and transmit the strain values to the rod damage state diagnostor; and the rod damage state diagnostor comprises a strain variance ratio module, a comparison and diagnosis output module and a voltage-stabilizing module. According to the method disclosed by the invention, only the one set of wireless data acquisition instrument and the plurality of wireless strain sensors are required, the operation is easy to implement, micro damage can be detected, and long-term monitoring of normal operation state of the truss structure is realized. The technical scheme provided by the invention is simple in structure, low in cost, easy to operate and implement, can detect the micro damage, and can monitor the normal operation state of the truss structure for a long term.

Owner:SHAOXING UNIVERSITY

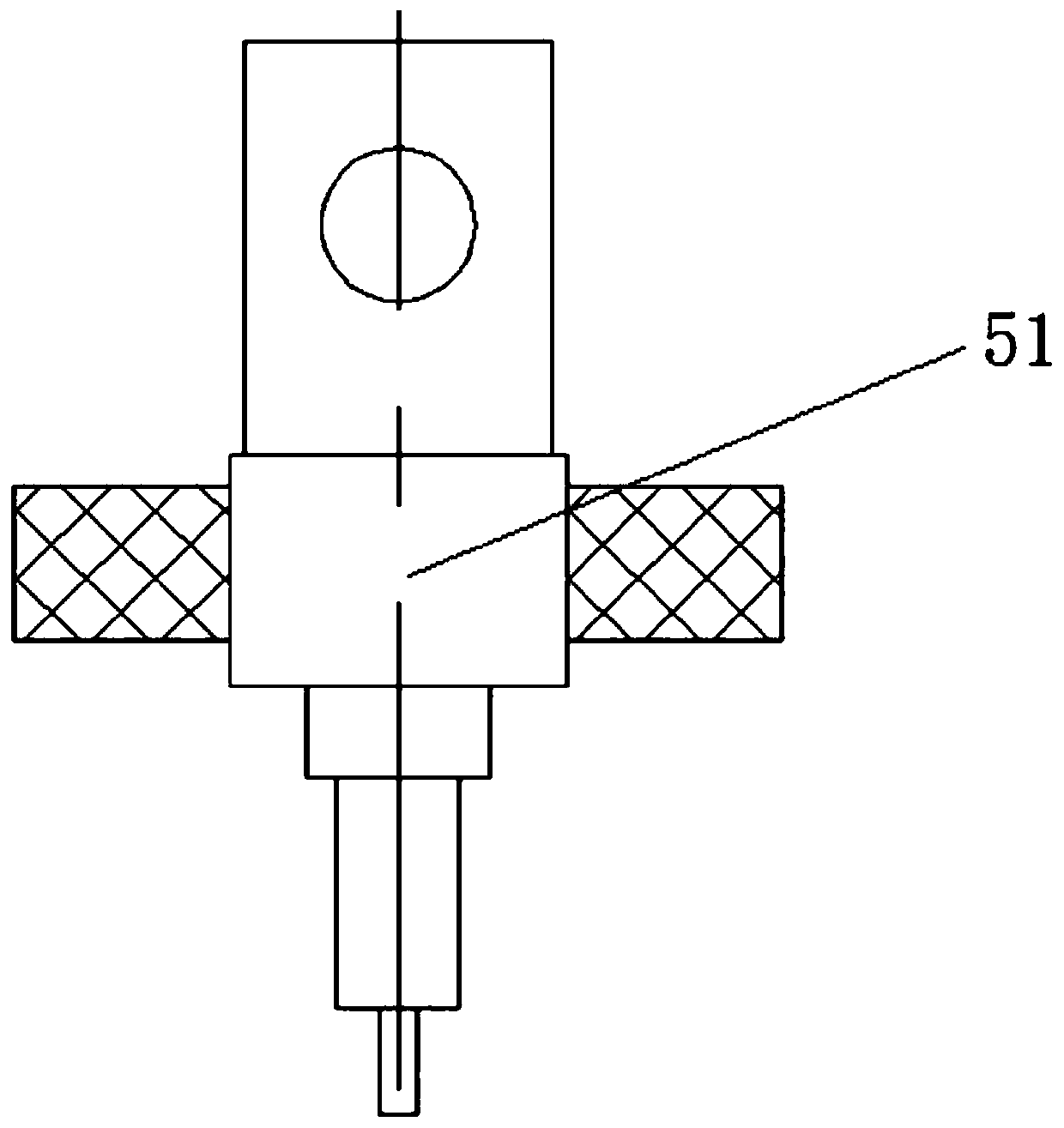

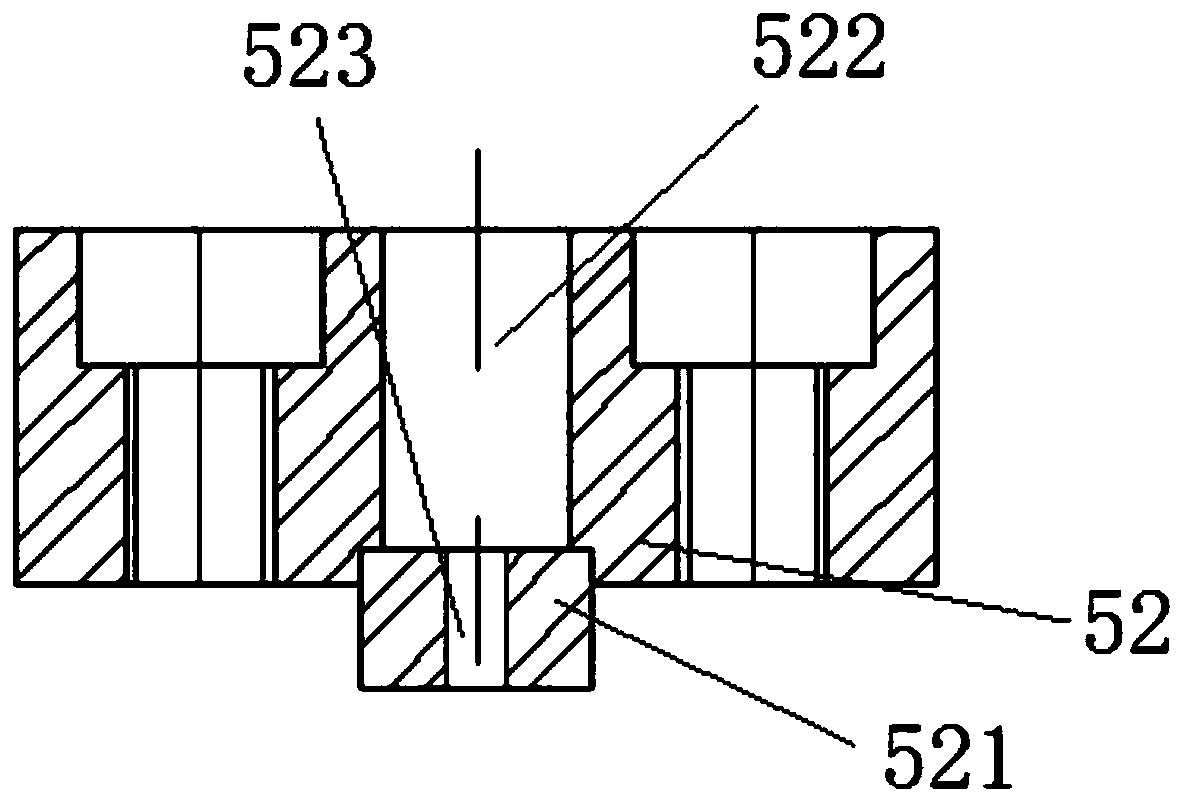

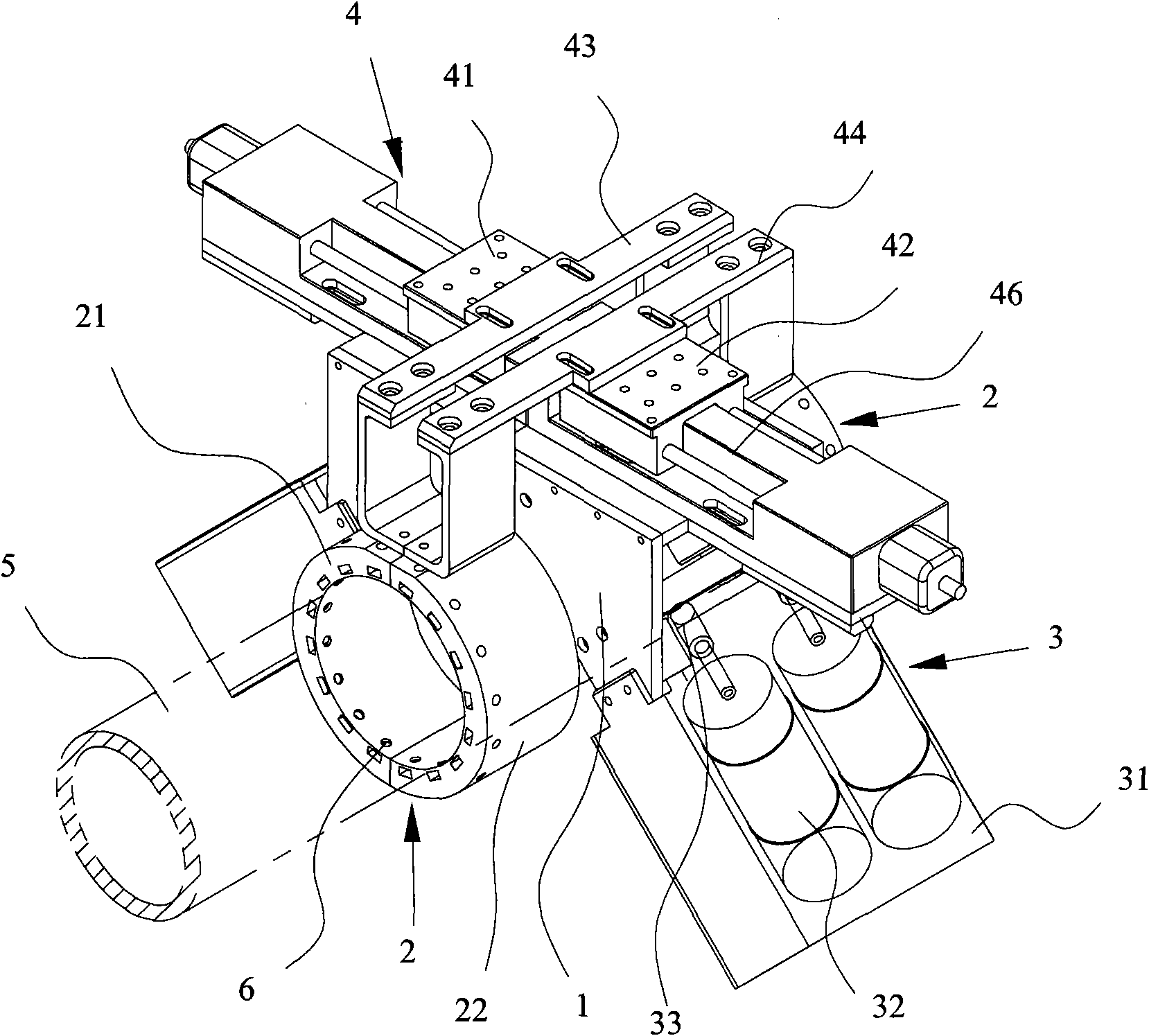

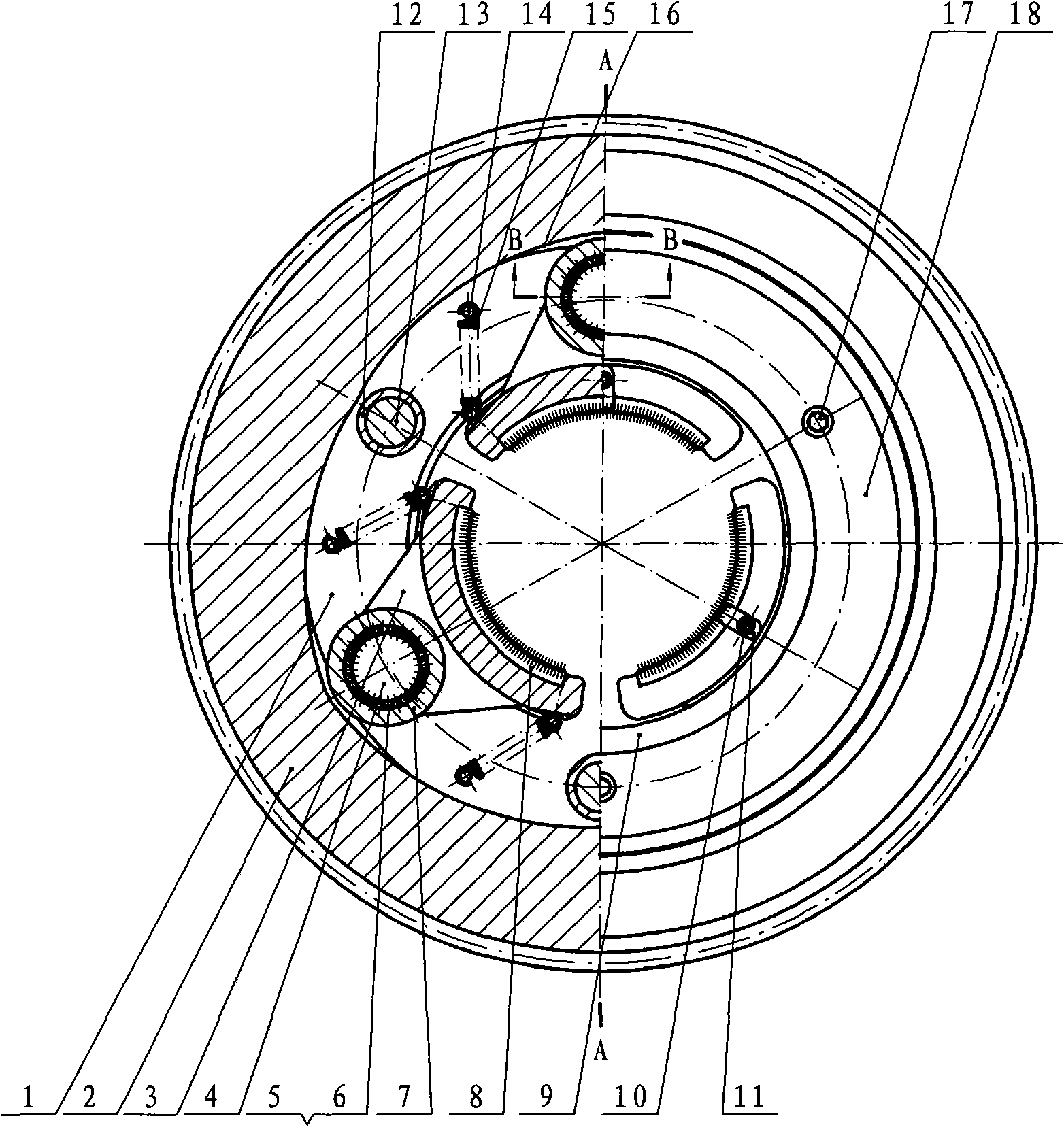

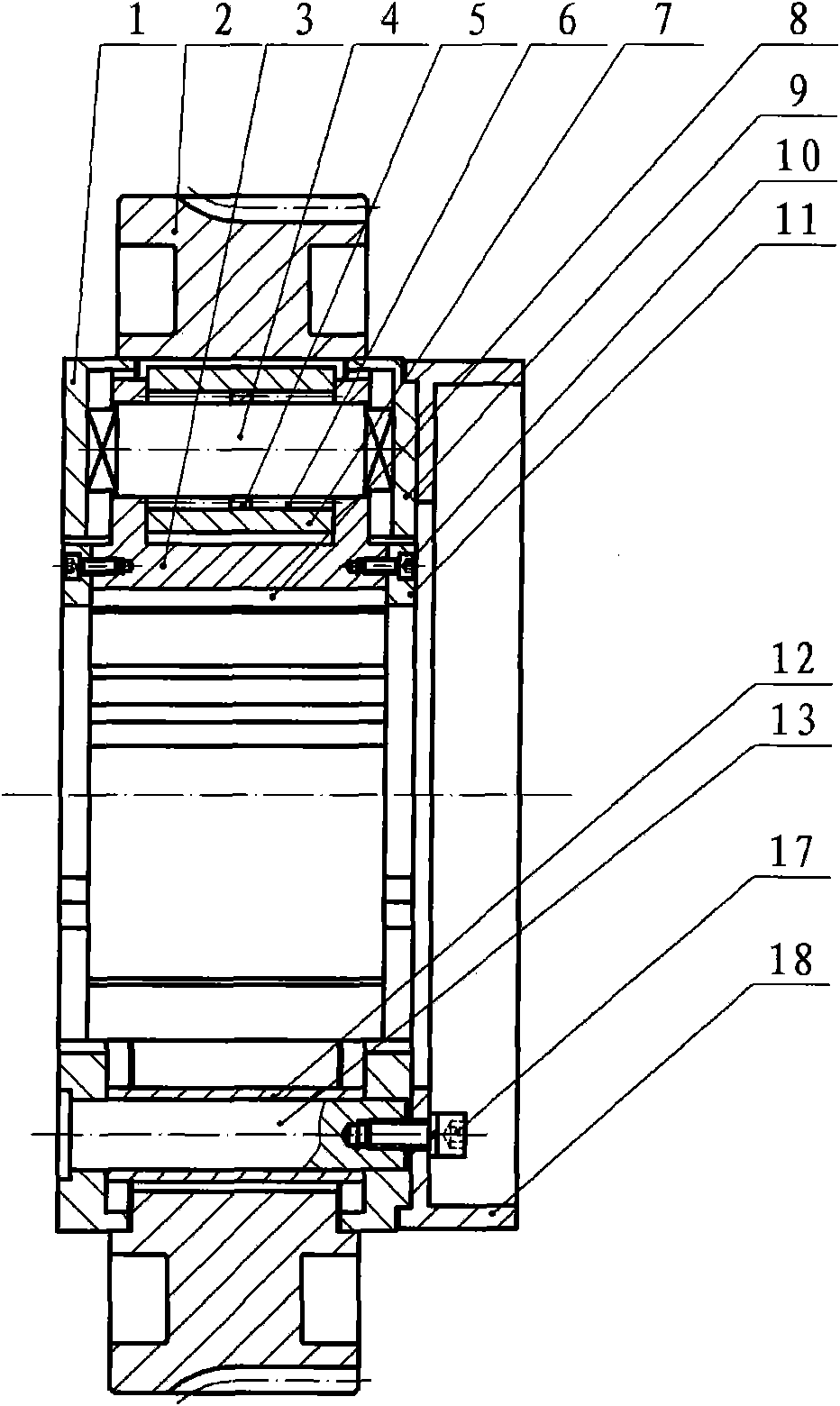

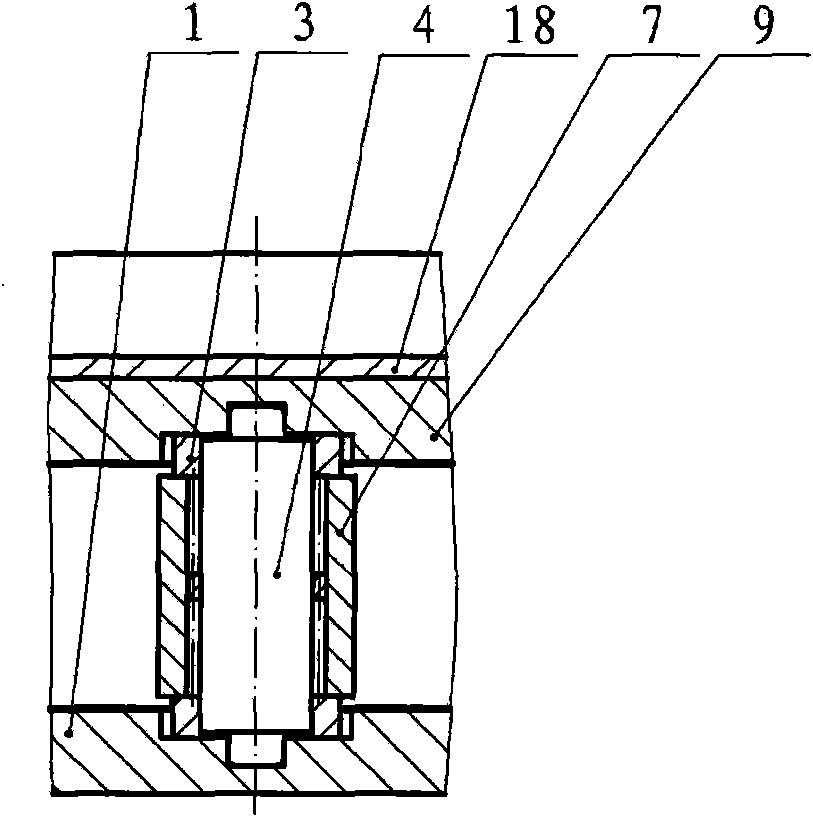

Main tong head clamping mechanism of micro-damage screwing machine

InactiveCN102061897AIncrease contact areaDrilling rodsDrilling casingsMechanical engineeringMicro damage

The invention discloses a main tong head clamping mechanism of a micro-damage screwing machine. The mechanism consists of a tong head gearwheel, a lower jaw plate rack, an upper jaw plate rack, jaw plates, tooth blocks, rollers, roller shafts, return springs, a fixed shaft, a fixed shaft sleeve, a brake disc and the like. The mechanism is structurally characterized in that: three or more jaw plates are arranged in the tong head gearwheel; the roller shafts, the rollers, the tooth blocks and the return springs are arranged on the jaw plates; the inner curved surface of the tong head gearwheel is provided with a working arc; and the lower jaw plate rack, the upper jaw plate rack and the brake disc are connected into a whole by the fixed shaft, the fixed shaft sleeve and screws. The mechanism is a simple and reliable inner curved surface roller climbing multi-jaw plate clamping mechanism, the tooth blocks are made of abrasion-resistant material, and the contact area of the tooth blocks and tubular columns is enlarged so that the tooth blocks play a role in clamping the tubular columns without damaging the tubular columns; and the system has considerable economic benefit.

Owner:吴立中

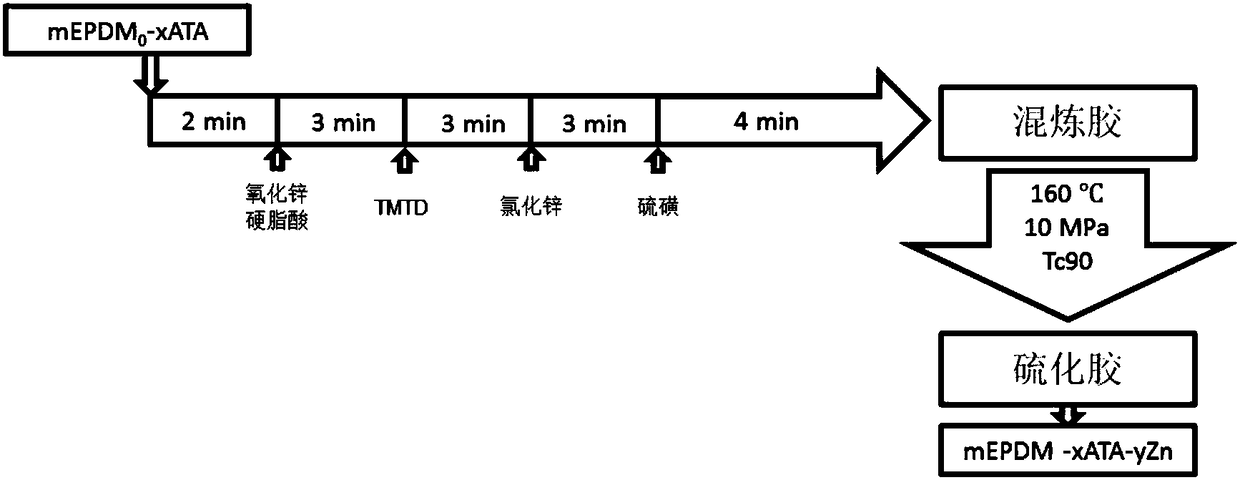

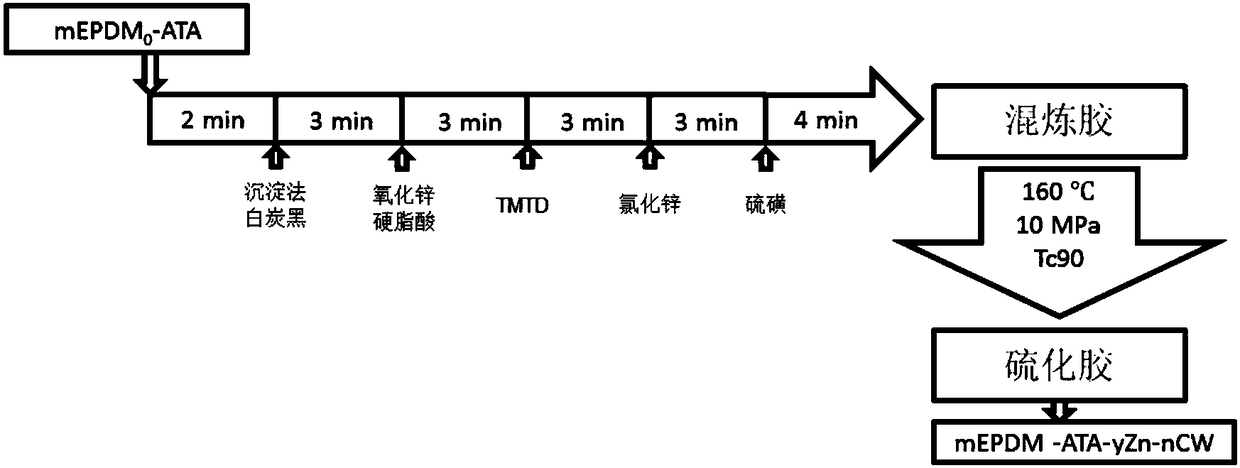

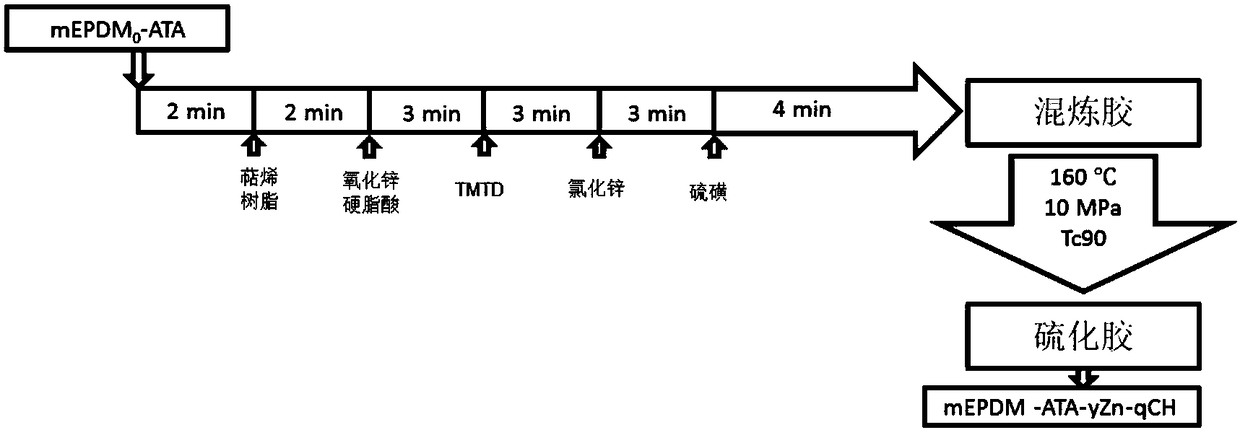

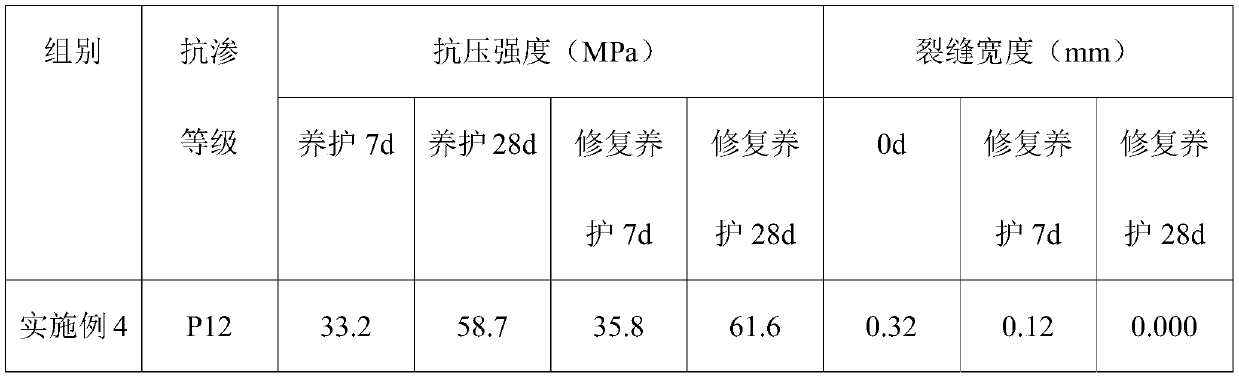

Ethylene-propylene-diene monomer composite elastomer and preparation method thereof

The invention belongs to the technical field of polymer materials, and discloses an ethylene-propylene-diene monomer composite elastomer and a preparation method thereof. The preparation method comprises the following steps: adding EPDM (ethylene-propylene-diene monomer), an initiator, MAH (maleic anhydride) and St (styrene) into a mixing device for carrying out mixing, so as to obtain MAH-g-EPDM;adding the MAH-g-EPDM, ATA (3-amino-1,2,4-triazole) ligands and an antioxidant into the mixing device for carrying out mixing to obtain ATA-functionalized EPDM; and carrying out uniform mixing on theATA-functionalized EPDM, a zinc chloride metal salt and a vulcanization system, and then carrying out vulcanization to obtain the ethylene-propylene-diene monomer composite elastomer. According to the invention, through the construction a dynamic cross-linking network structure with multiple hydrogen bonds and metal-ligand coordination and the synergy of a covalent bond chemical cross-linking network, the strength and toughness of the EPDM is enhanced, the rubber viscoelasticity is effectively adjusted, the damping performance of the EPDM is improved, a self-repairing property is provided tothe material, micro-damage can be repaired autonomously under a heat environment, and the service life is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

Bionic self-repairing concrete and preparation method thereof

ActiveCN110395884AHigh mechanical strengthSmall mechanical propertiesGlass shaping apparatusMicrosphereCarbon nanotube

The invention discloses bionic self-repairing concrete and a preparation method thereof. The bionic self-repairing concrete is characterized by being prepared from the following raw materials in partsby weight: 240 to 360 parts of cement, 180 to 250 parts of active admixture, 1300 to 1600 parts of aggregate, 60 to 90 parts of mesoporous bioactive glass composite microspheres, 20 to 30 parts of calcium peroxide microspheres, 20 to 30 parts of carbon nanotubes, 8 to 16 parts of polycarboxylate water reducing agent and 190 to 220 parts of water. The bionic self-repairing concrete provided by theinvention has a rapid self-repairing capability, can continuously and automatically repair micro-cracks or micro-damages of different deep layers in the concrete, promotes the continuous increase ofthe matrix strength after crack repairing, and improves the strength and durability of the concrete. The self-repairing concrete has the advantages of being wide in repairing range, rapid in repairingand lasting in repairing.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com