Microcapsules for self-repairing of asphalt micro-damage and preparation method of microcapsules

A self-healing microcapsule and micro-damage technology, applied in the field of building materials, can solve problems such as limited self-healing ability, and achieve the effect of enhancing self-healing ability and improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

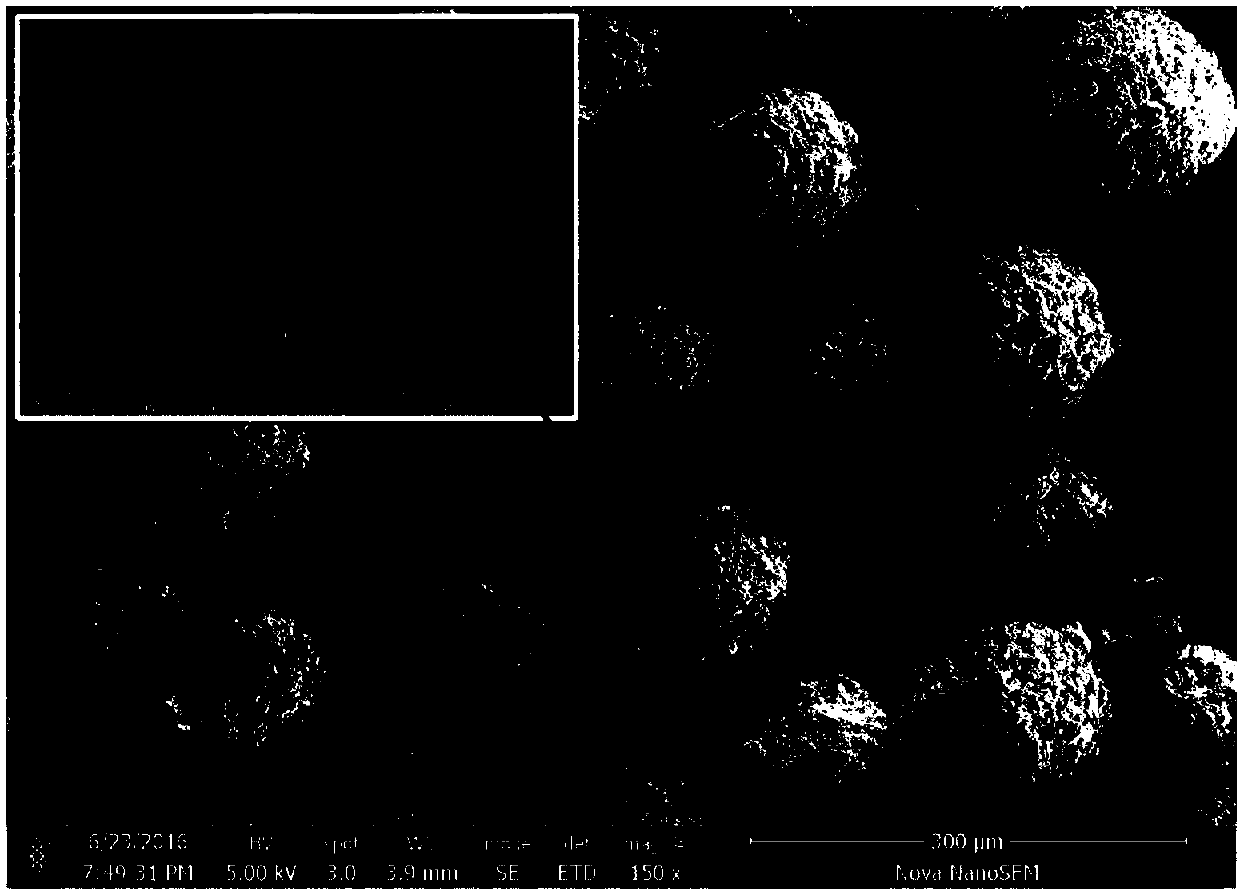

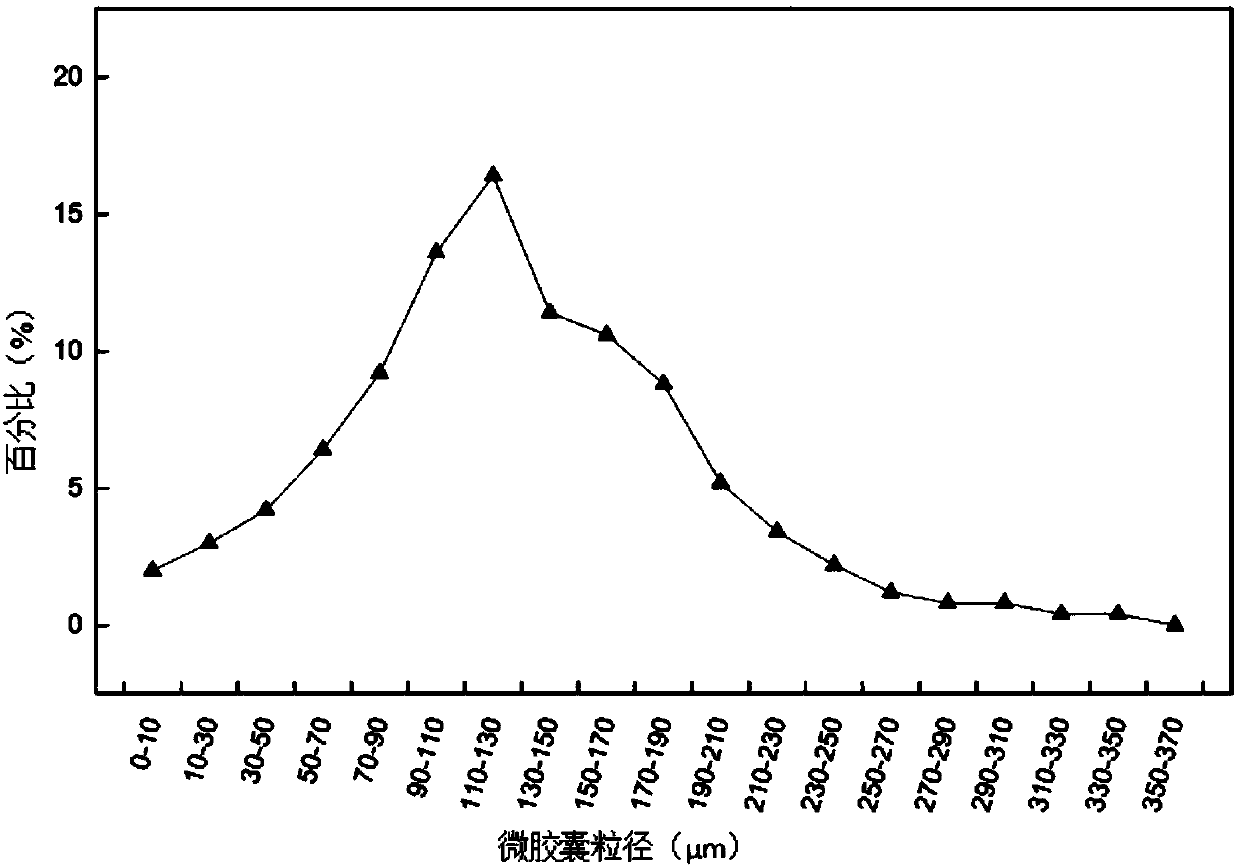

[0028] This example is about asphalt micro-damage self-healing microcapsules (core material is asphalt regenerant, wall material is melamine-urea-formaldehyde resin) and its preparation method and performance.

[0029] (1) The raw materials and instruments required for preparation are shown in Table 1 and Table 2.

[0030] Table 1 Raw materials

[0031]

[0032] Table 2 Instruments

[0033]

[0034]

[0035] (2) Melamine, urea, formaldehyde (molar ratio, urea: melamine: formaldehyde = 1:1.9:7.2) were added to 25ml deionized water altogether 5g, and stirred to make the mixture mix evenly, after the urea powder was completely dissolved and disappeared, use The pH value of the mixed solution is adjusted to 8-9 with a 10% NaOH solution, and then the temperature of the mixed solution is slowly raised to 70-80° C. under the condition of 300-500 r / min mechanical stirring and maintained at this temperature for 1 h. After 1 h, the reaction was finished, and the temperature o...

Embodiment 2

[0054] This embodiment is that the core material of the present invention is asphalt rejuvenator, the wall material is melamine-urea-formaldehyde (MUF) resin asphalt micro-damage self-repairing microcapsules and the traditional core material is asphalt rejuvenator, and the wall material is melamine-urea-formaldehyde (MUF) resin. Performance comparison of formaldehyde (MF) resin microcapsules.

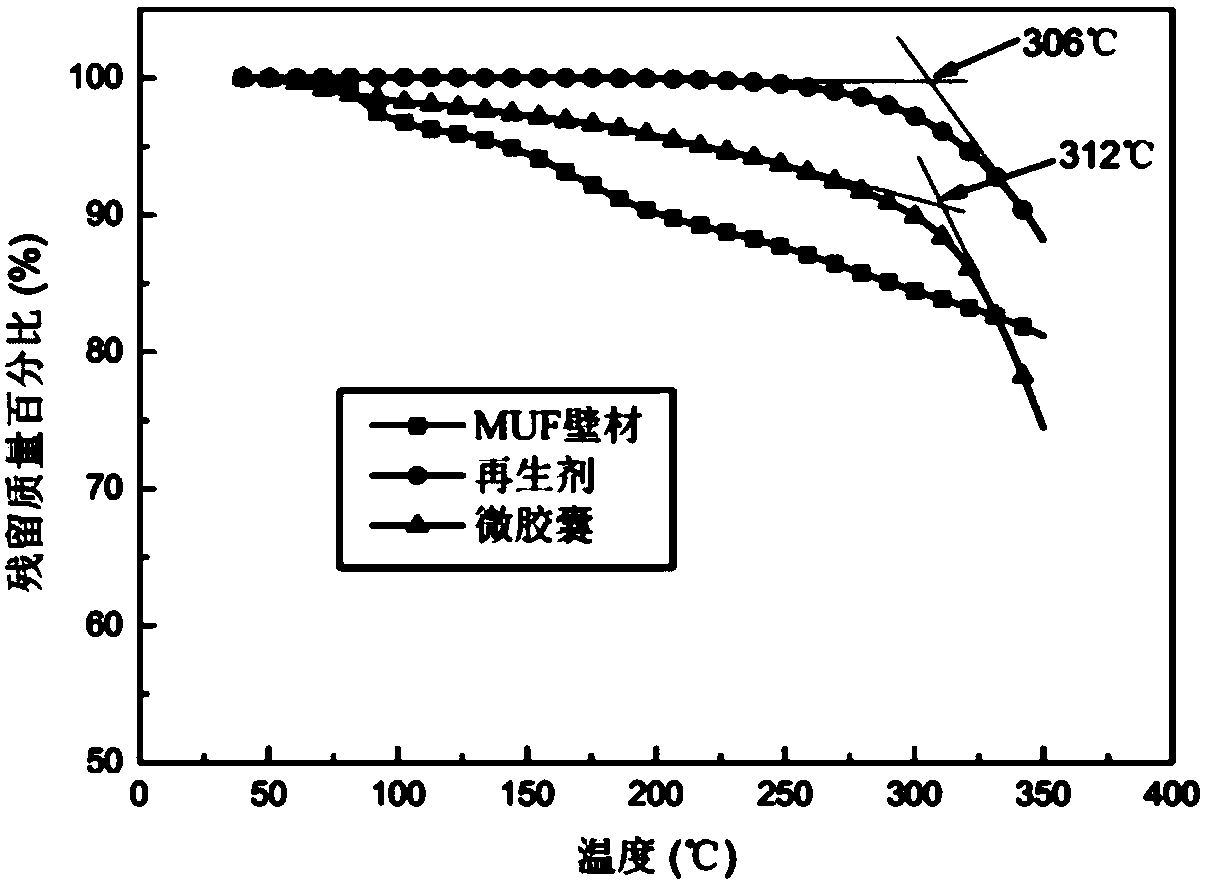

[0055] (1) Comparison of thermal stability

[0056] Figure 4 It is a thermogravimetric analysis comparison chart of the microcapsules of the present invention and the MF microcapsules.

[0057] The mixing temperature of hot mix asphalt mixture is close to 180°C. In this high temperature environment, if Figure 4 As shown, the mass loss of microcapsules with melamine-urea-formaldehyde (MUF) resin as wall material is about 4%, and the mass loss of microcapsules with melamine-formaldehyde (MF) resin as wall material is close to 15%. It can be seen that the microcapsules of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com