Self-healing environmental barrier coating on member surface and preparation method thereof

A coating and capability technology, applied in the field of environmental barrier coatings and preparations with self-healing ability on the surface of components, can solve the problems of corrosion of CMC-SiC parts, loss of EBC protection of CMC-SiC, etc., to improve crack resistance, The effect of prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

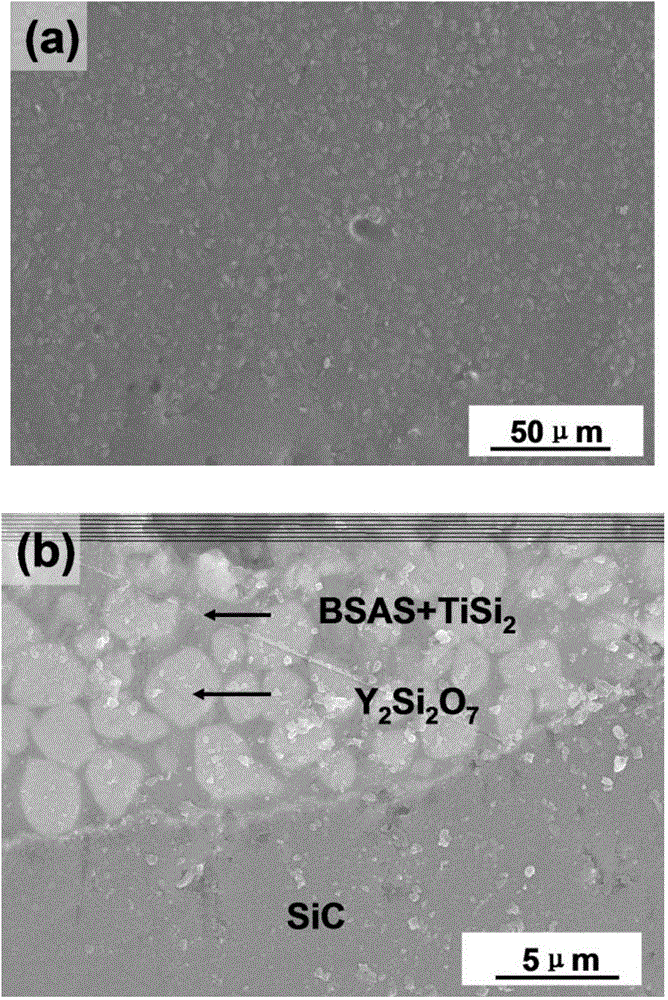

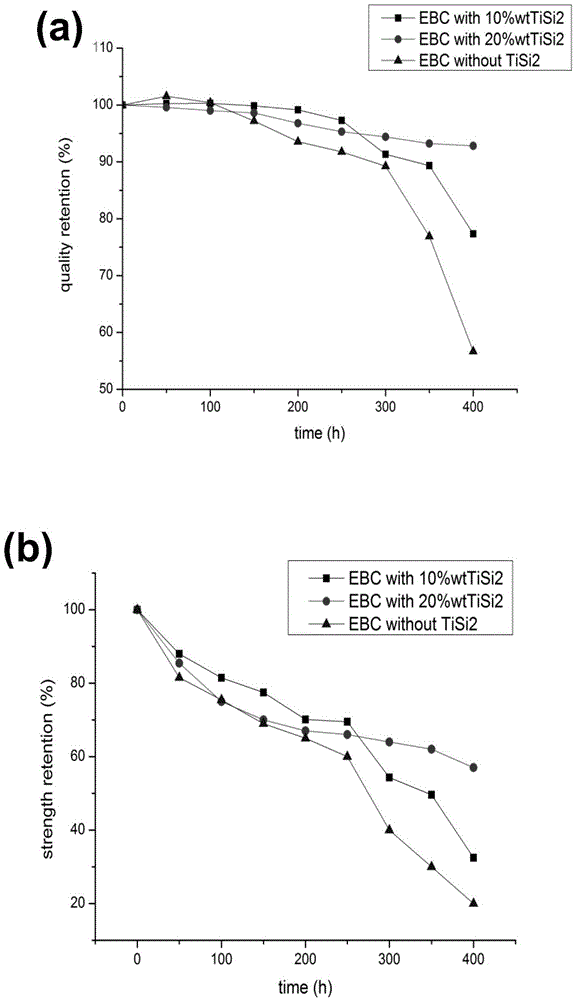

[0031] Embodiment 1: prepare BSAS+Y with brushing sintering method 2 Si 2 o 7 -Self-healing EBC of titanium silicide

[0032] Concrete preparation steps are as follows:

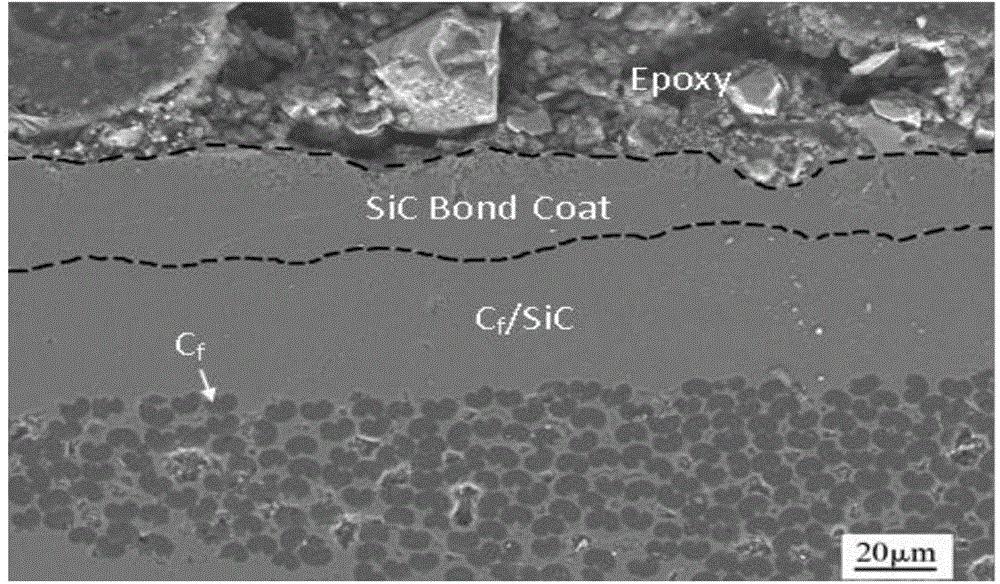

[0033] 1. Preparation of silicon carbide bonding layer: select continuous carbon fiber reinforced silicon carbide ceramic matrix composite (C f / SiC) as the matrix, the C f / SiC is made into a strip sample with a size of 40×5×3.5mm, which is cleaned by ultrasonic waves. A dense silicon carbide bonding layer was prepared on the surface of the sample by chemical vapor deposition (CVD). Using a scanning electron microscope (SEM), measure the thickness of the bonding layer, as figure 1 shown. In this embodiment, the adhesive layer has a thickness of 30 μm.

[0034] 2. Preparation of BSAS+Y 2 Si 2 o 7 -Self-healing EBC of titanium silicide and EBC of the same system without additives:

[0035] 1) The BSAS (Ba 0.5 Sr 0.5 al 2 Si 2 o 8 ) powder and Y 2 Si2 o 7 Powder, add 1.5-2 times the mass of a...

Embodiment 2

[0045] Example 2: Preparation of BSAS-molybdenum disilicide self-healing EBC by pulling method

[0046] Concrete preparation steps are as follows:

[0047] 1. Preparation of silicon carbide bonding layer: select continuous carbon fiber reinforced silicon carbide ceramic matrix composite (C f / SiC), the C f / SiC is made into a strip sample with a size of 40×5×3.5mm, which is cleaned by ultrasonic waves. A dense silicon carbide bonding layer was prepared on the surface of the sample by chemical vapor deposition (CVD). Using a scanning electron microscope (SEM), the thickness of the adhesive layer was measured. In this example, the thickness of the adhesive layer was 30 μm.

[0048] 2. Preparation of BSAS-molybdenum disilicide self-healing EBC and EBC of the same system without additives:

[0049] 1) The BSAS (Ba 0.5 Sr 0.5 al 2 Si 2 o 8 ) powder is added to 1.5-2 times the mass of alcohol solution, and 10%-20% mass ratio of molybdenum disilicide (MoSi 2 ) powder, addin...

Embodiment 3

[0059] Embodiment 3: adopt plasma spraying method to prepare Y 2 Si 2 o 7 - Chromium Disilicide Self-healing EBC

[0060] The preparation process and performance assessment methods are the same as in Examples 1 and 2. In this example, C f / SiC uses silicon carbide (thickness 30μm) as the bonding layer; at the same time, Y 2 Si 2 o 7 - The thickness of the self-healing EBC of chromium disilicide and the EBC of the same system without additives are both 50 μm. This method is to prepare the coating by plasma spraying method. What is different from Examples 1 and 2 is that this preparation method is a one-time preparation coating. layer. Pass the test to get Y 2 Si 2 o 7 -The self-healing EBC of chromium disilicide and the EBC strength and mass retention rate of the same system without additives vary with the time of water and oxygen, and the surface and cross-sectional morphology of the coating are obtained under the scanning electron microscope. 2 Si 2 o 7 -The surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com