Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

A technology of enclosure structure and steel frame, which is applied in the construction field of building components and the production and application of the building components to build buildings, achieving the effects of good thermal insulation and sound insulation, good toughness, and simple installation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

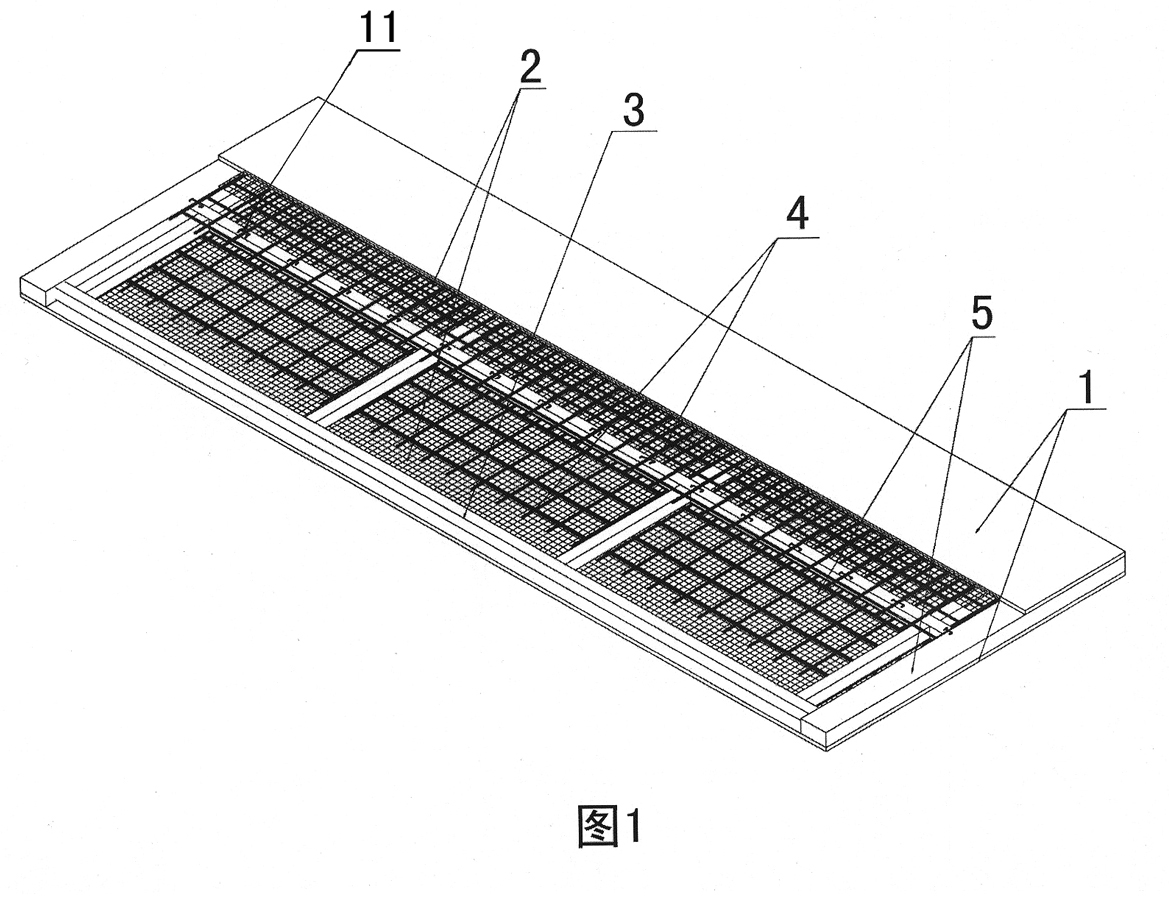

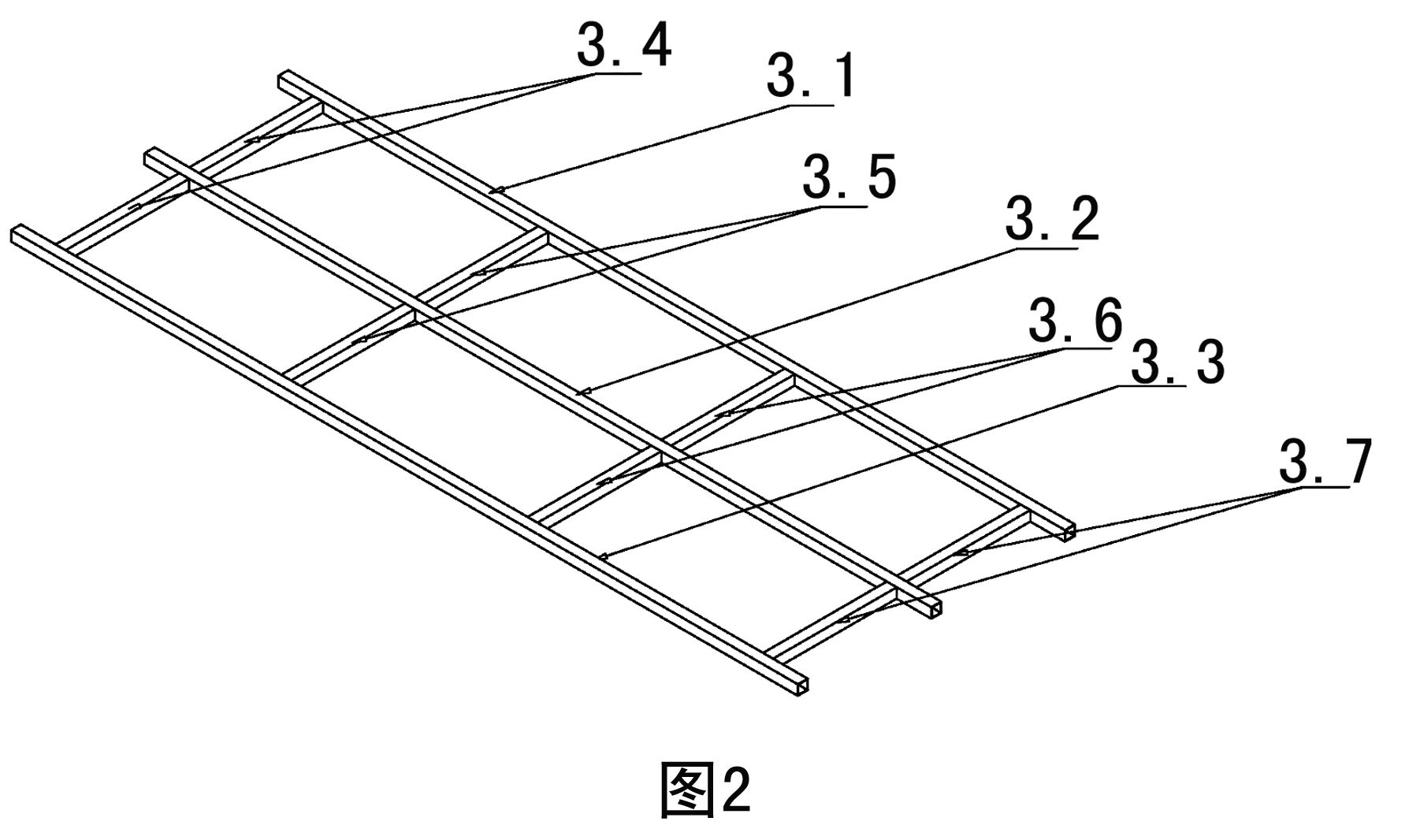

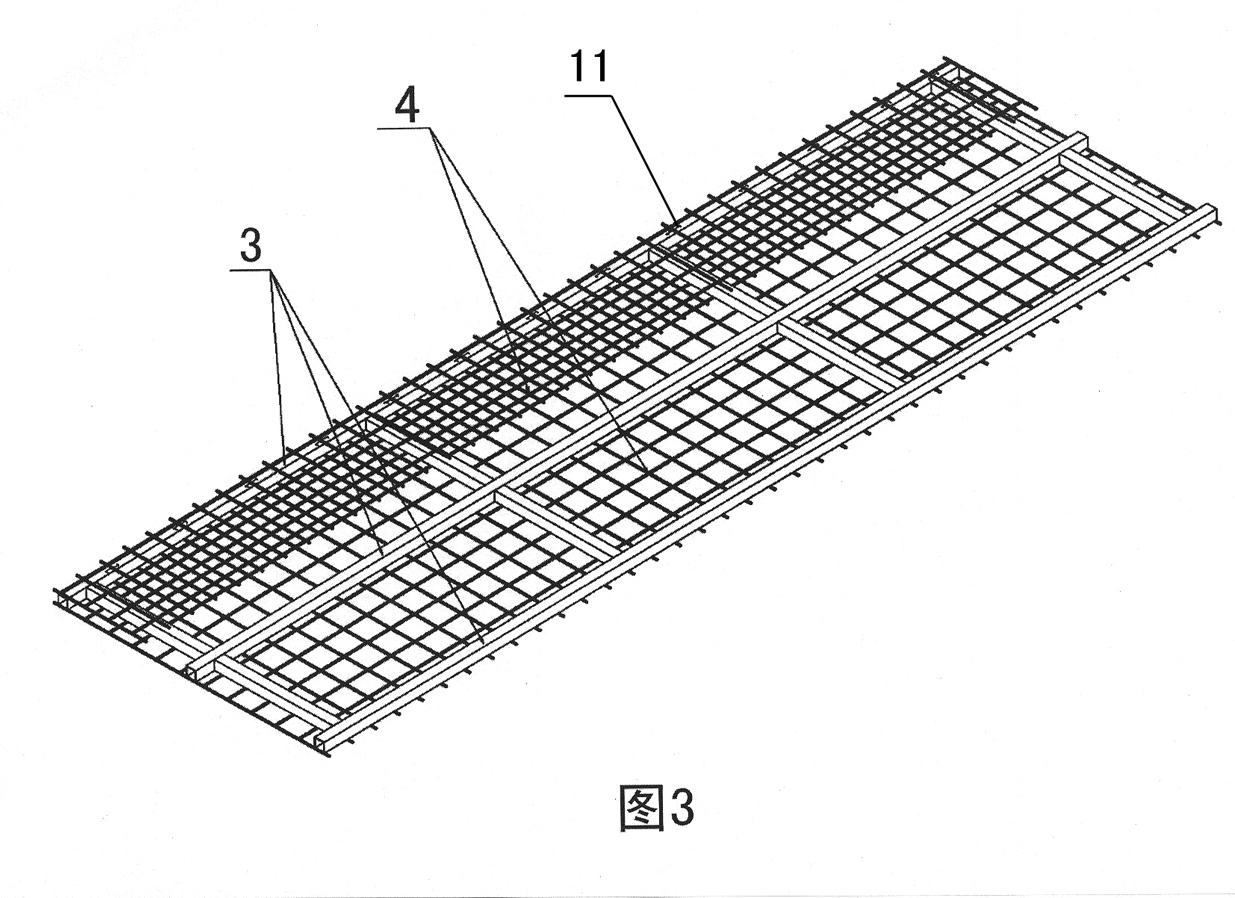

[0043] Examples see figure 1As shown, a built-in lattice steel frame enclosure structure board is a solid sandwich structure, the middle layer is a foamed cement filling layer 5, and the two sides of the middle layer are combined with a surface layer 1, and the foamed cement filling layer 5 There is a built-in lattice steel frame 3 inside, and one side of the built-in lattice steel frame 3 is covered with a steel wire mesh sheet 4, and the surface layer 1 is a high-strength anti-cracking mortar reinforcement surface that is mixed with fiber wire and covered with fiber mesh cloth 2 layer. The lattice steel frame is welded by square steel pipes distributed vertically and horizontally at intervals. The built-in lattice steel frame is connected with the steel wire mesh sheet through the connector 11 to form a lattice steel frame network. The built-in lattice steel frame 3 is biased to one side of the foamed cement filling layer 5 or is located in the middle of the foamed cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com