Patents

Literature

495 results about "Particle board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle board – also known as particleboard, low-density fibreboard (LDF), and chipboard – is an engineered wood product manufactured from wood chips, sawmill shavings, or even sawdust, and a synthetic resin or other suitable binder, which is pressed and extruded. Oriented strand board, also known as flakeboard, waferboard, or chipboard is similar, but uses machined wood flakes offering more strength. All of these are composite materials that belong to the spectrum of fiberboard products.

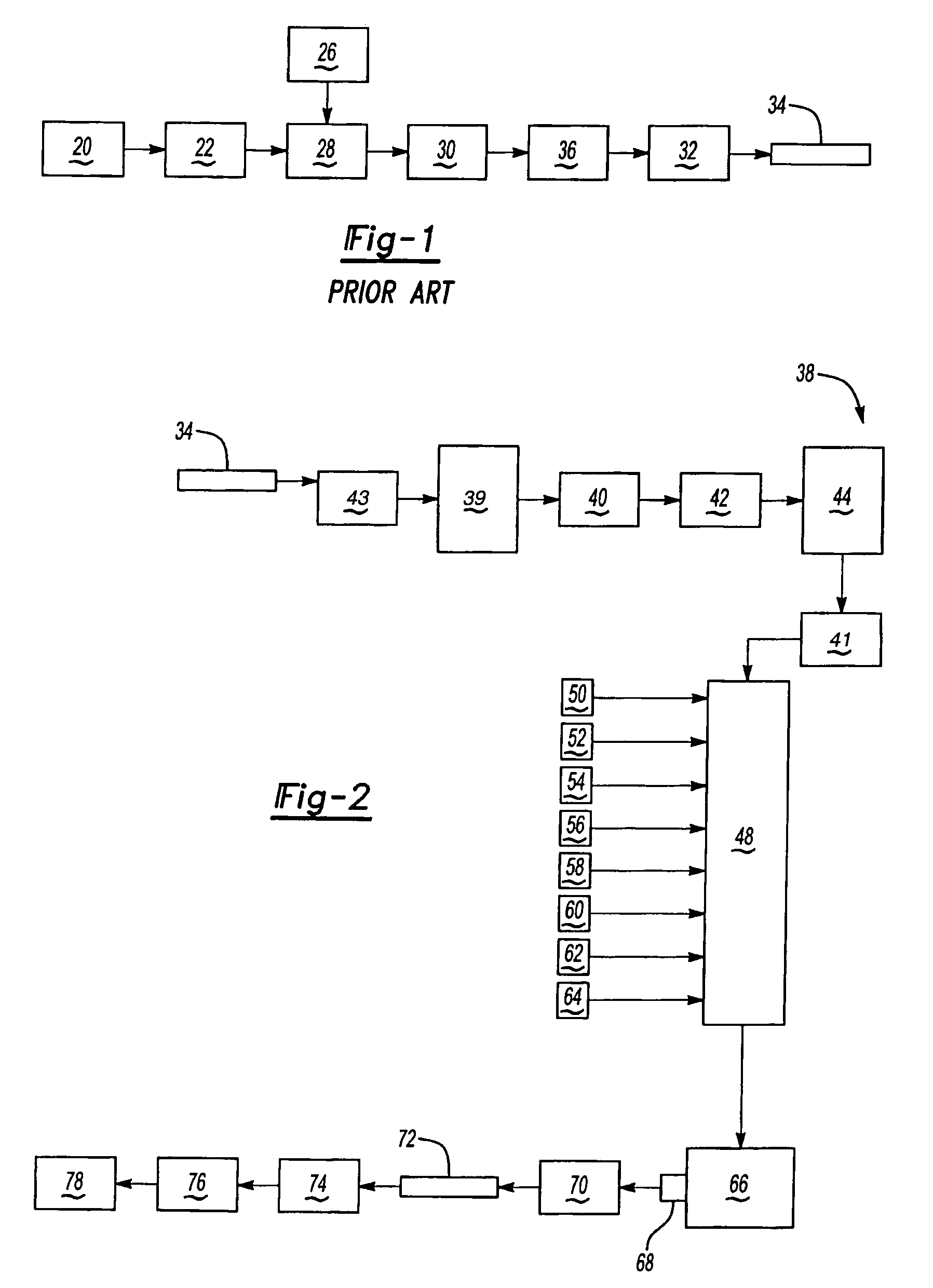

Method of manufacturing composite board

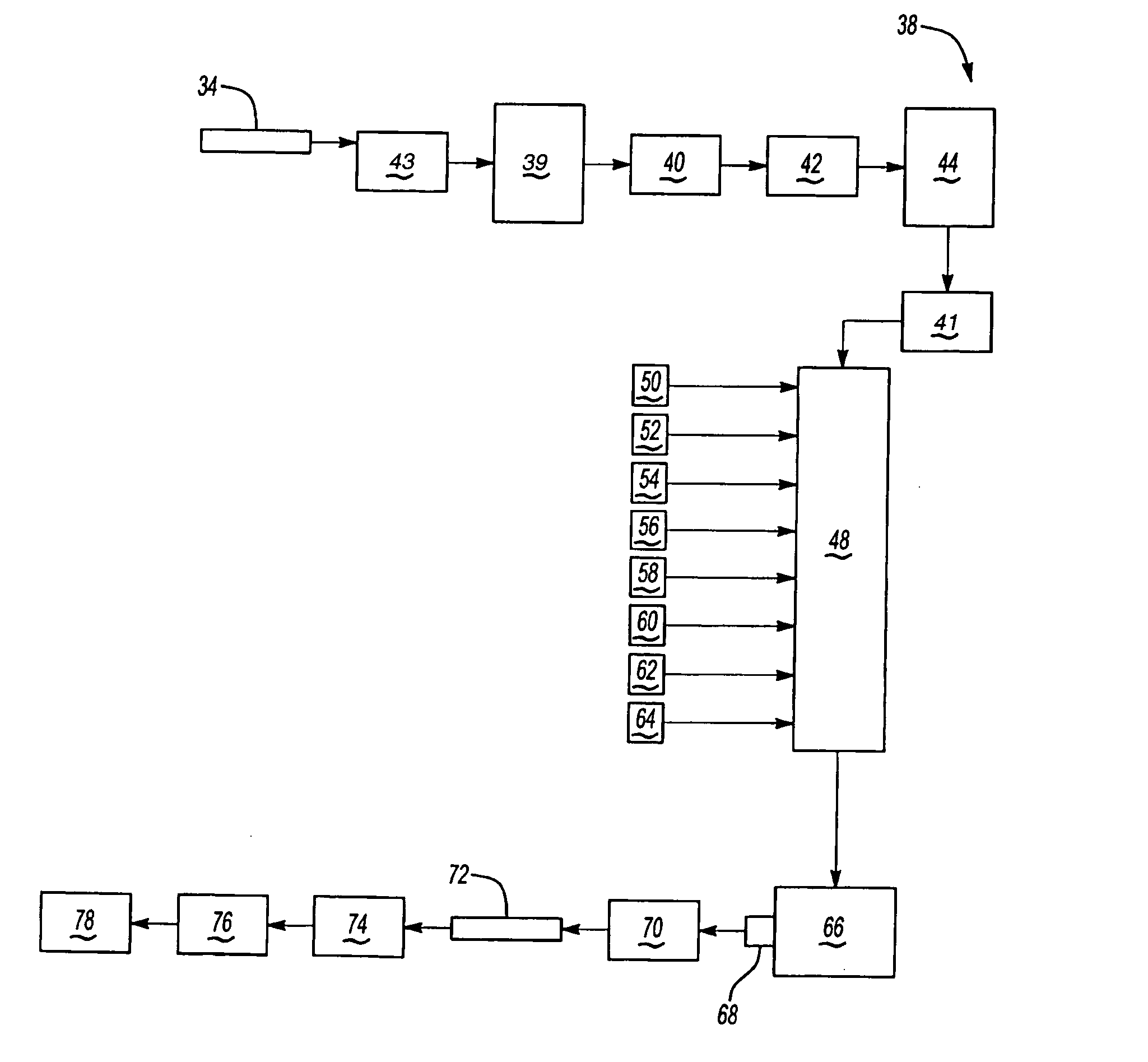

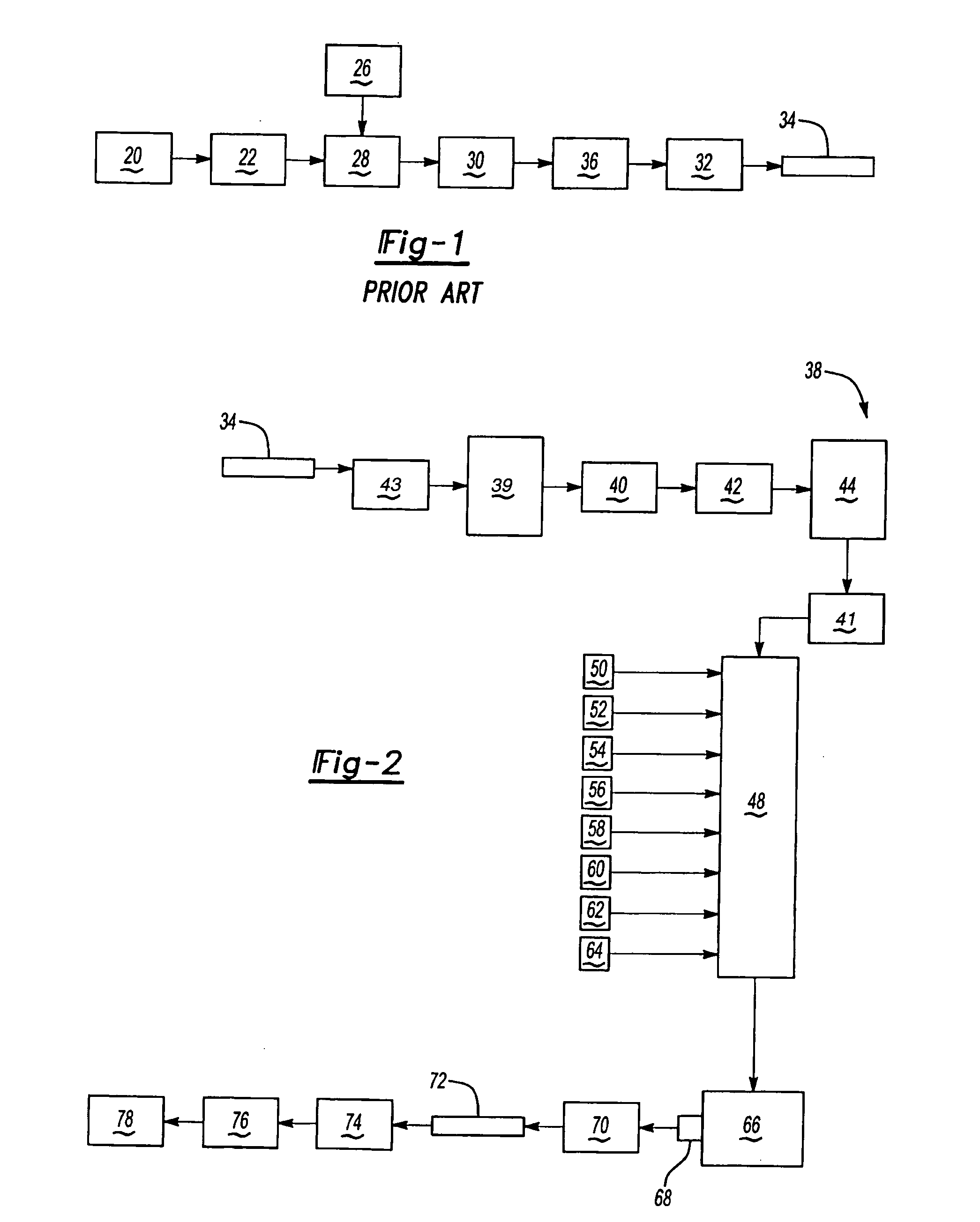

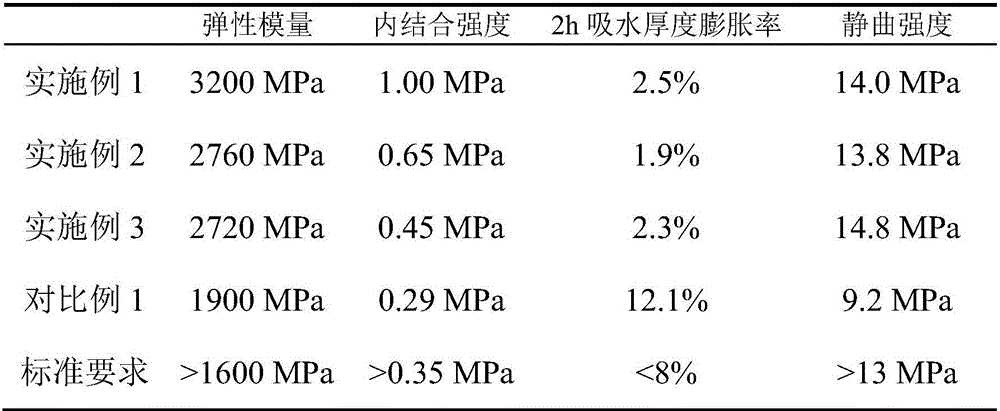

InactiveUS7022756B2Improve flow characteristicsIncreased flexural modulusSynthetic resin layered productsWood working apparatusThermoplasticFiber

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO RETAIL CABINET GROUP

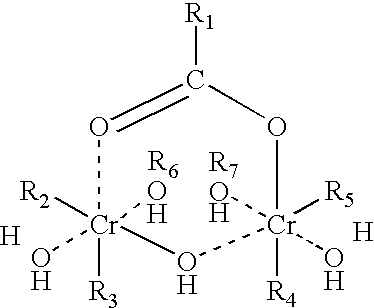

Wood surface inkjet receptor medium and method of making and using same

Wood surfaces treated to be inkjet receptive media are disclosed, where the wood surface is treated in a manner that can control the spread of an ink droplet reaching the wood surface to provide a superior image graphic. The treatment uses an image fixing agent comprising an aqueous solution of containing an organo-metallic complex of a hydrophobic fatty acid coordinated with a halogenated trivalent chromium. Veneers, plywoods, and particle boards having faces of lesser value woods can be digitally imaged to give the appearance of higher value woods or other customized inkjet images. Environmental and economic considerations benefit from the use of commonly available wood surfaces to simulate exotic and threatened wood species.

Owner:BROOKER DENNIS B

Durable thermoset binder compositions from 5-carbon reducing sugars and use as wood binders

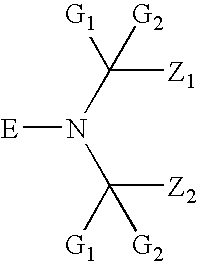

ActiveUS20110263757A1Minimize formaldehyde contentWeaken energyCosmetic preparationsOrganic detergent compounding agentsTris(2-aminoethyl)amineParticle board

The present invention provides thermosetting aqueous binder compositions of (i) one or more diprimary diamine, e.g. lysine, or poly(primary amine), e.g. polyethylenimine and tris(2-aminoethyl)amine, and (ii) one or more 5-carbon reducing sugar, such as xylose. The binders are at least substantially formaldehyde free and cure rapidly at temperatures sufficiently low and with sufficiently little swelling to enable one to provide wood or woody material containing articles, such as particle board, oriented strand board and bamboo boards or articles.

Owner:ROHM & HAAS CO

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

Flame retardant coatings

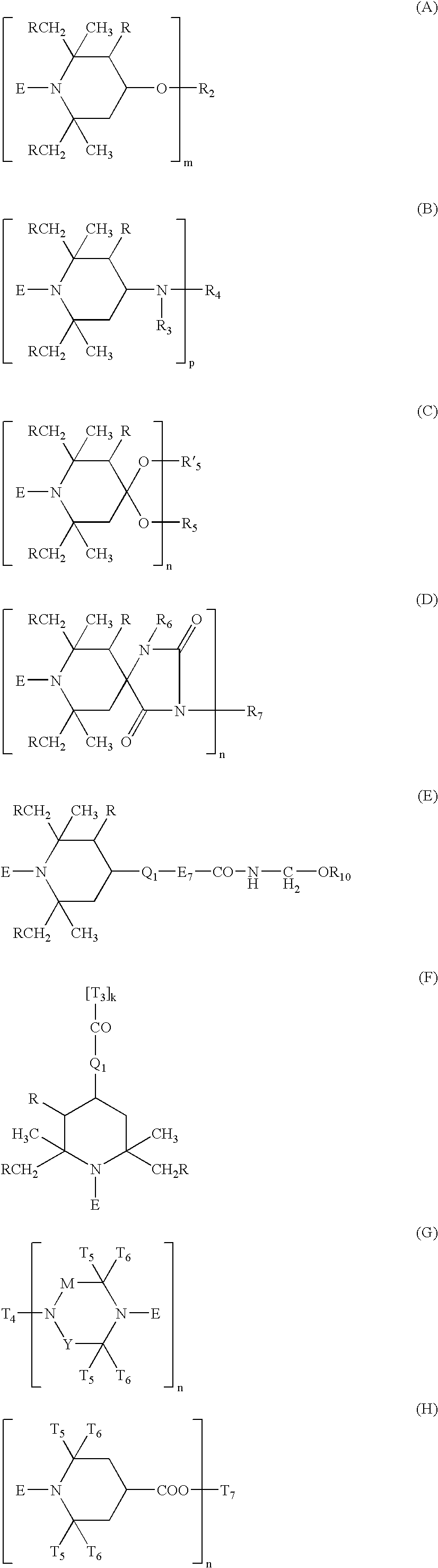

Provided are flame retardant coating compositions and articles coated therewith, which compositions comprise (A) a coating and (B) an effective flame retarding amount of a mixture of (i) at least one compound selected from the group consisting of the (a) sterically hindered nitroxyl stabilizers, (b) sterically hindered hydroxylamine stabilizers and (c) sterically hindered alkoxyamine stabilizers and (ii) at least one conventional flame retardant selected from the group consisting of (d) organohalogen flame retardants, (e) organophosphorus flame retardants, (f) isocyanurate flame retardants and (g) melamine based flame retardants. The coated articles are for example iron, steel, stainless steel, aluminum and other non-ferrous metals, wood, plywood, paper, cardboard, chip board, particle board, plastics, thermoplastics, epoxies, neoprene, rubber, composites, fiberglass reinforced composites, polyesters, polymeric foam, masonry, fabric or textiles, wire and cable constructions and circuit boards.

Owner:TROUTMAN MALISA +3

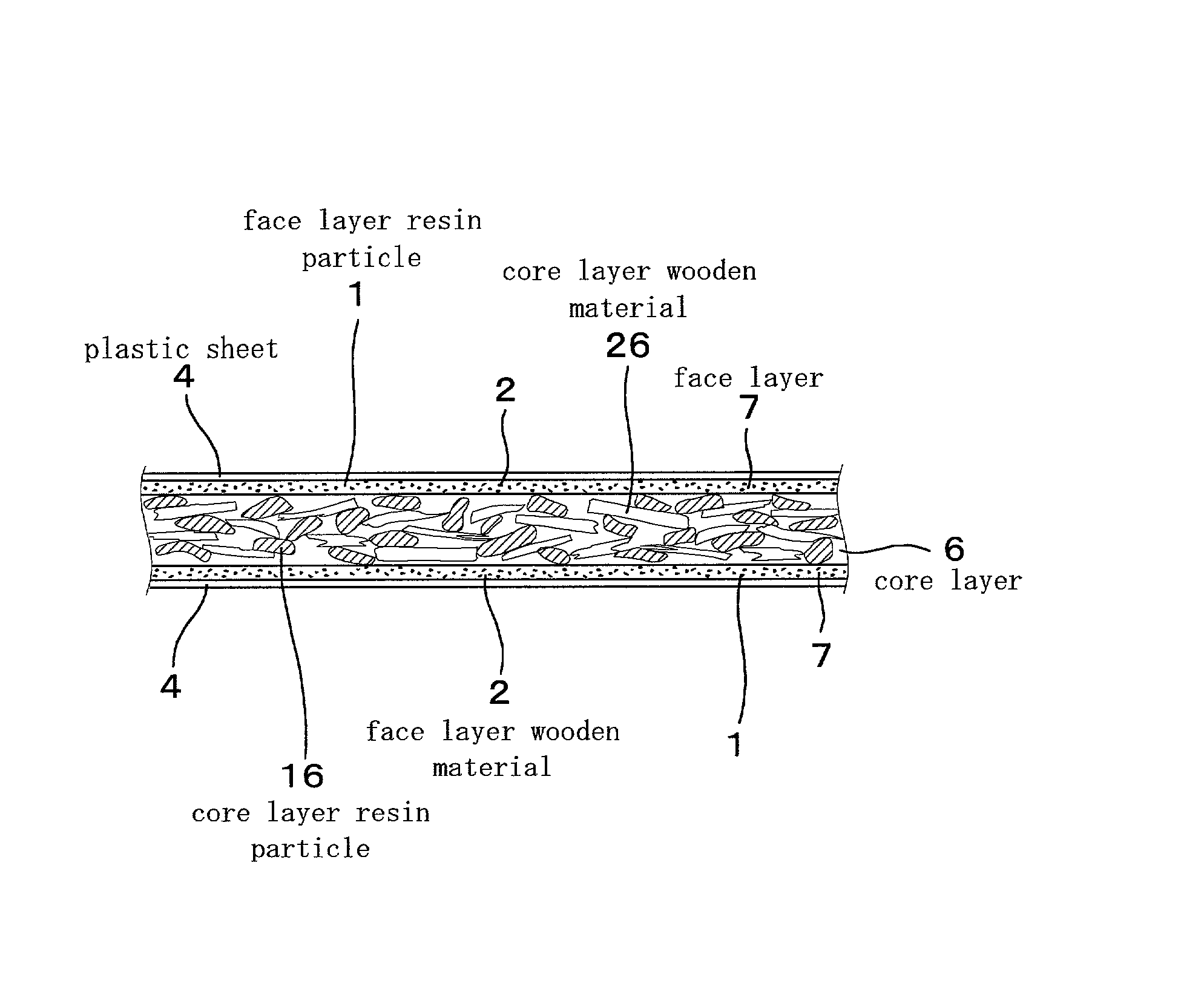

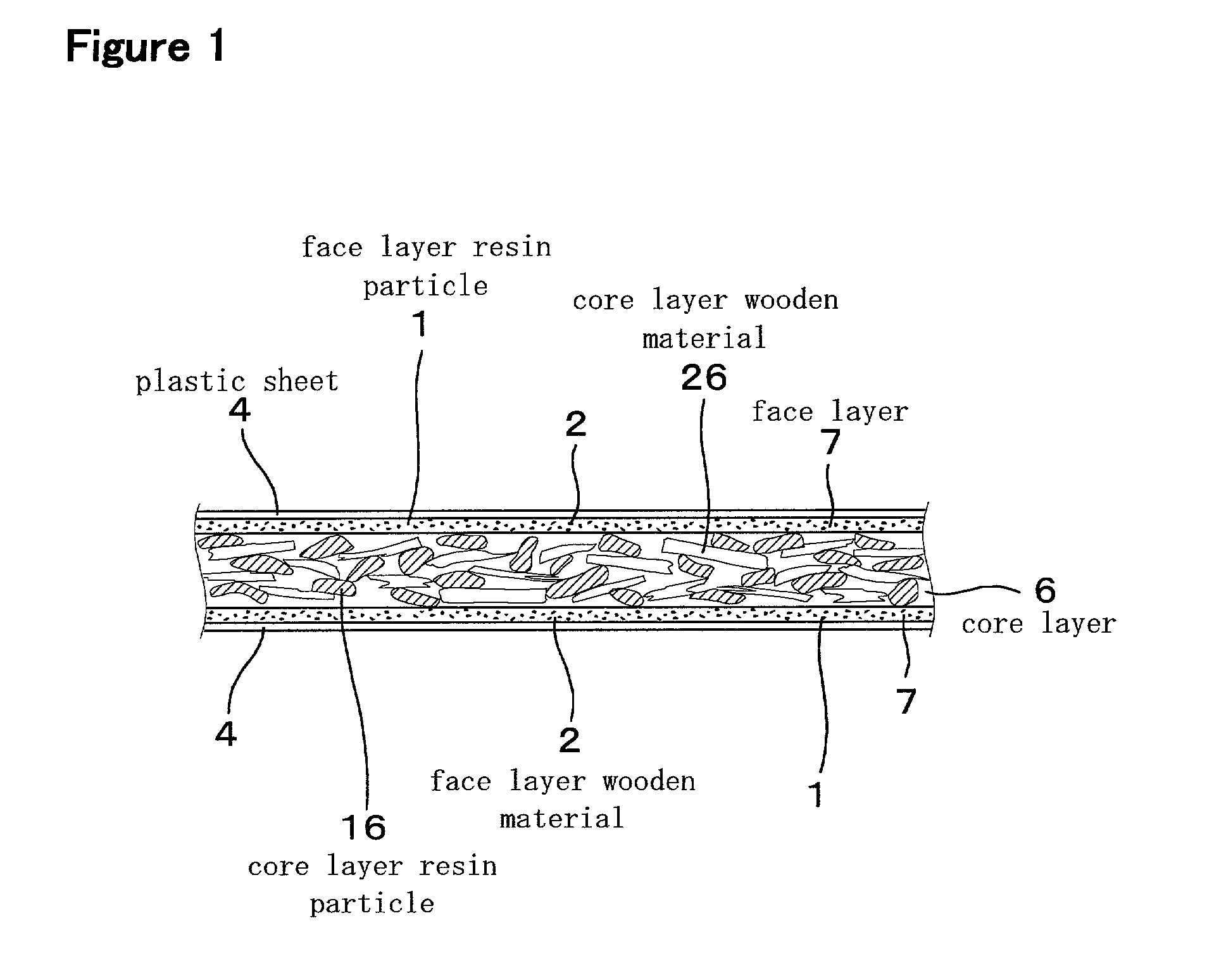

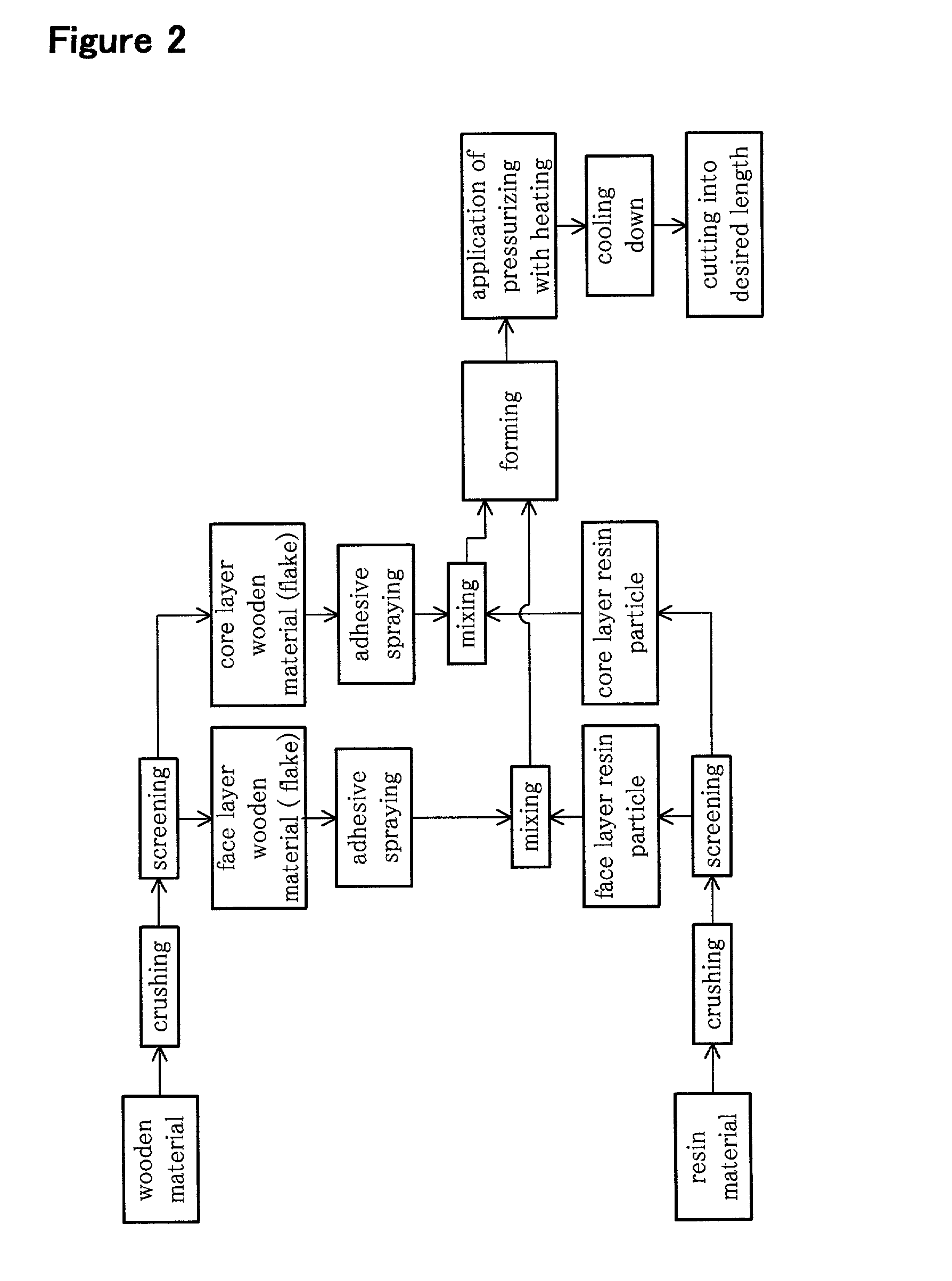

Particle board and method of making the same

InactiveUS20030008130A1Improve water resistanceHigh levelSynthetic resin layered productsCellulosic plastic layered productsAdhesiveParticle board

The object of the present invention is to provide a particle board which is improved at its entirety in the resistance to water without impairing its performance as a bearing board member and provide a method of making the particle board. A particle board of the invention having wooden materials coated with an adhesive of a thermosetting resin and pressurized with being heated, the particle board comprising: a core layer and face layers provided on both, front and back, sides of the core layer, wherein the wooden materials of the face layer are smaller in the average particle diameter than the wooden material of the core layer; and voids between the adjacent wooden materials in the face layer and the core layer are filled with resin particles of a thermoplastic resin by being pressurized with being heated.

Owner:NICHIHA CORP

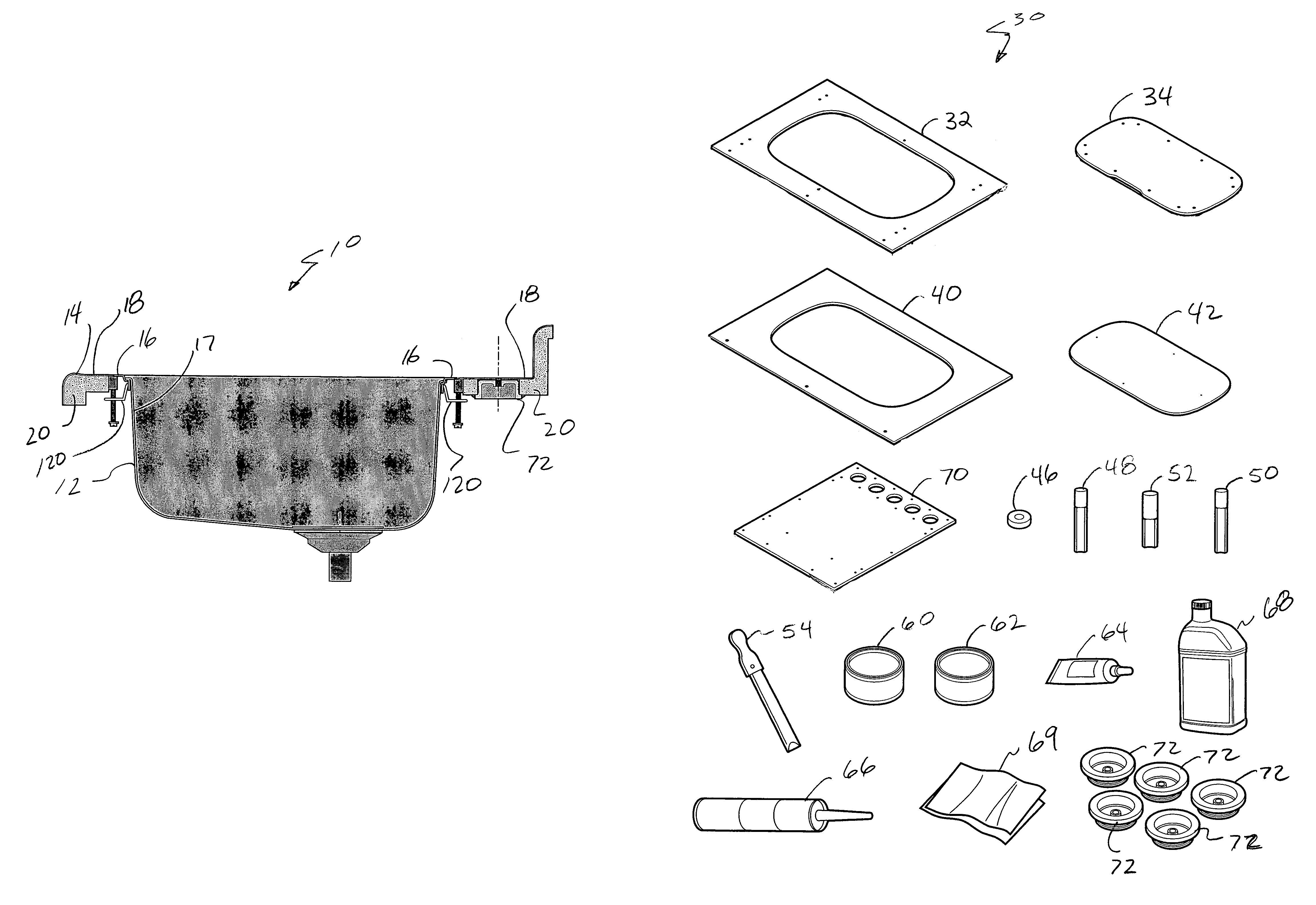

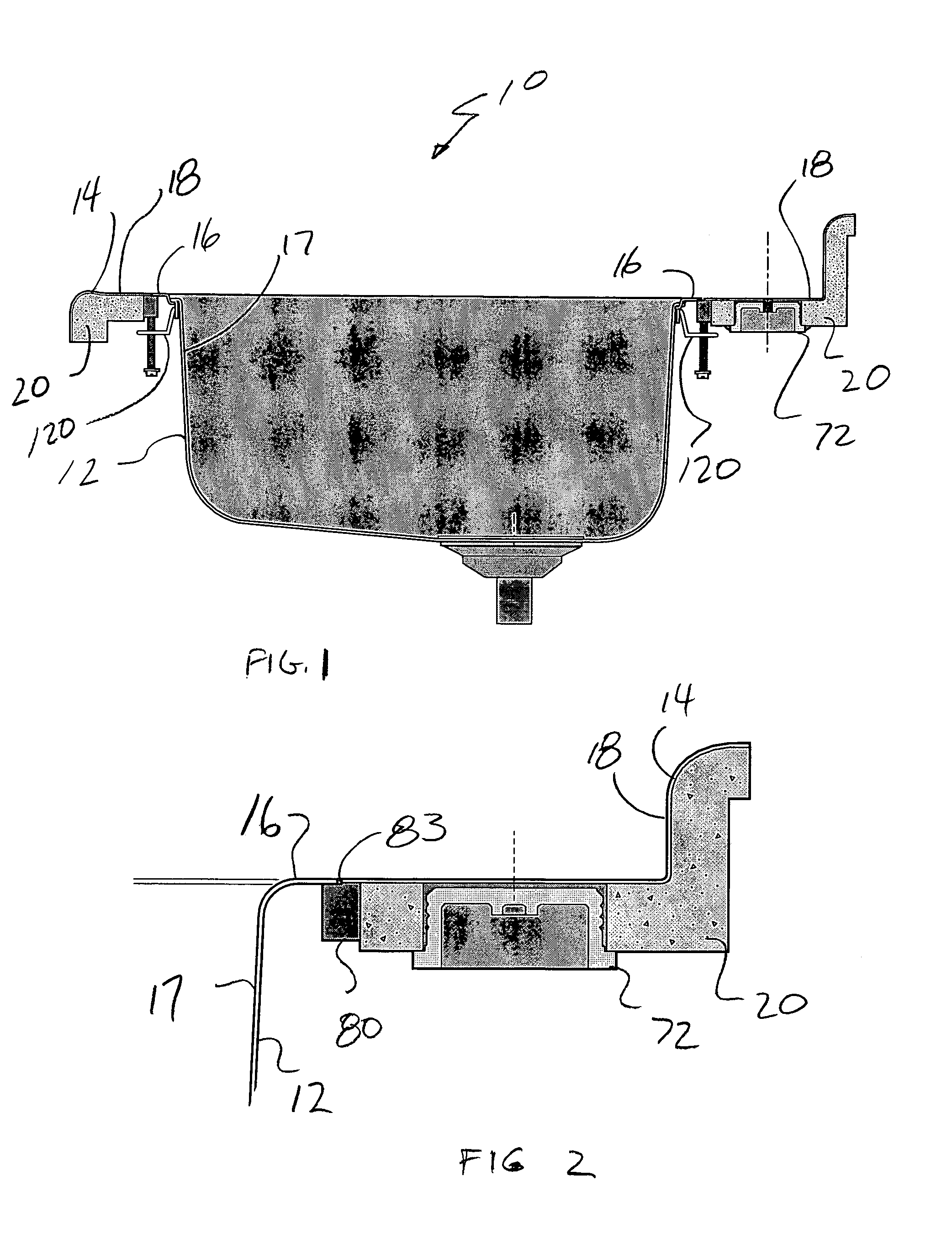

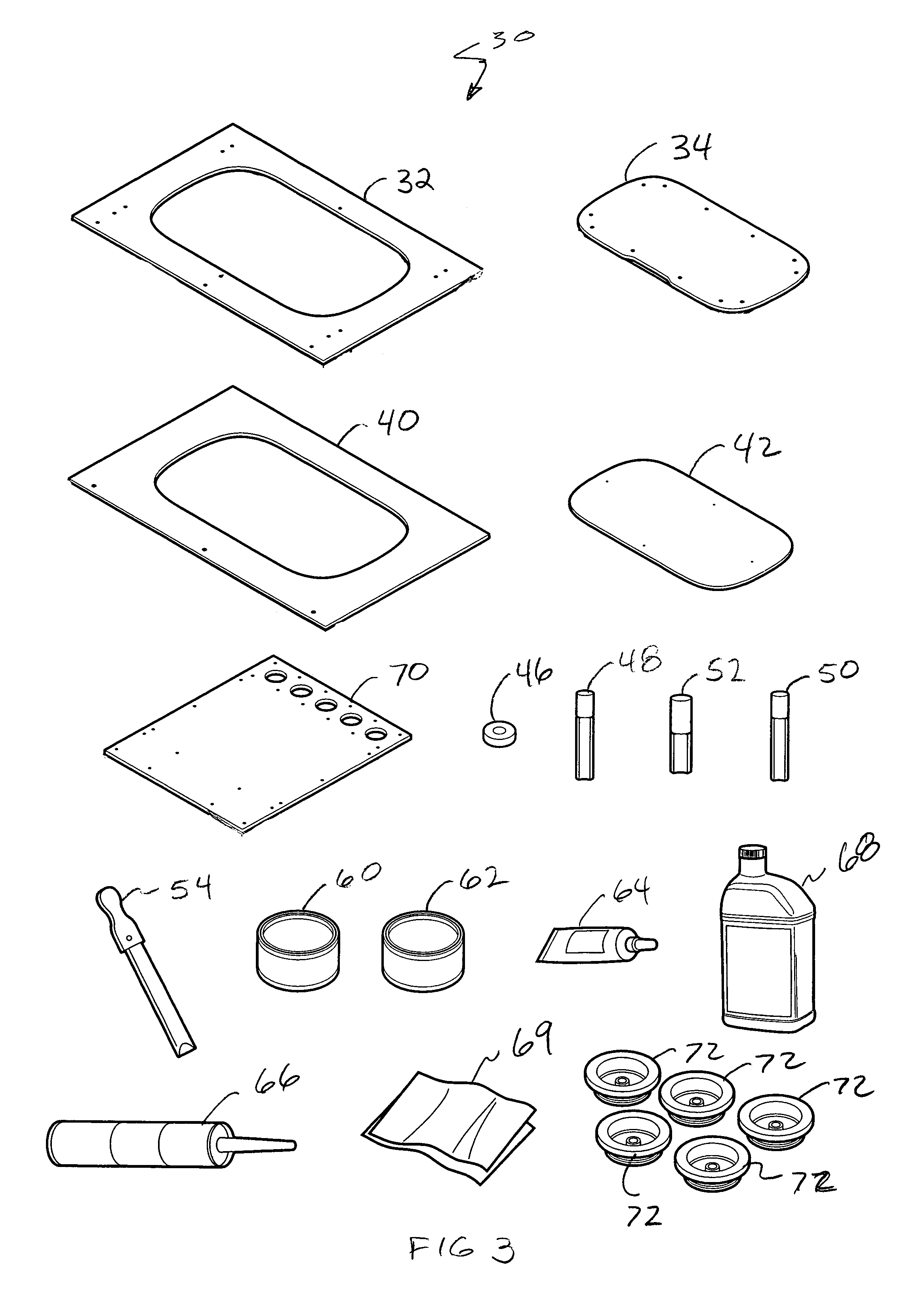

Sink/faucet flush mounting system

This invention deals with a sink having a flange can be flush mounted in a countertop where the countertop is made of a laminate upper layer supported by a wood based body such as particle board. The countertop is readied for sink mounting by ploughing out a sink channel in the supporting body of the countertop. The sink channel is filled with a hardenable plastic such as an epoxy. The upper surface of the epoxy and the laminate is machined such as by a router to create a rabbet to accommodate the flange of the sink. The sink channel is arranged so that the hardened epoxy extends under the laminate so that any water which passes under the flange of the sink will contact the epoxy and not the wood based structure. A faucet having holes to accommodate hot water, cold water, spigot and faucet accessories can be mounted using the same channel and epoxy system.

Owner:FRANKE TECH & TRADEMARK LTD

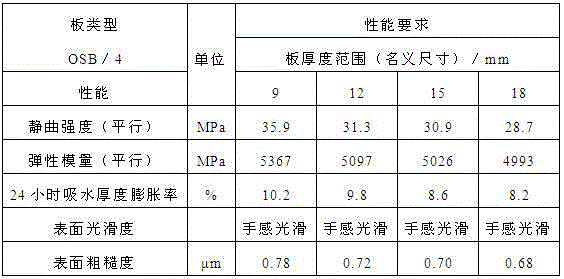

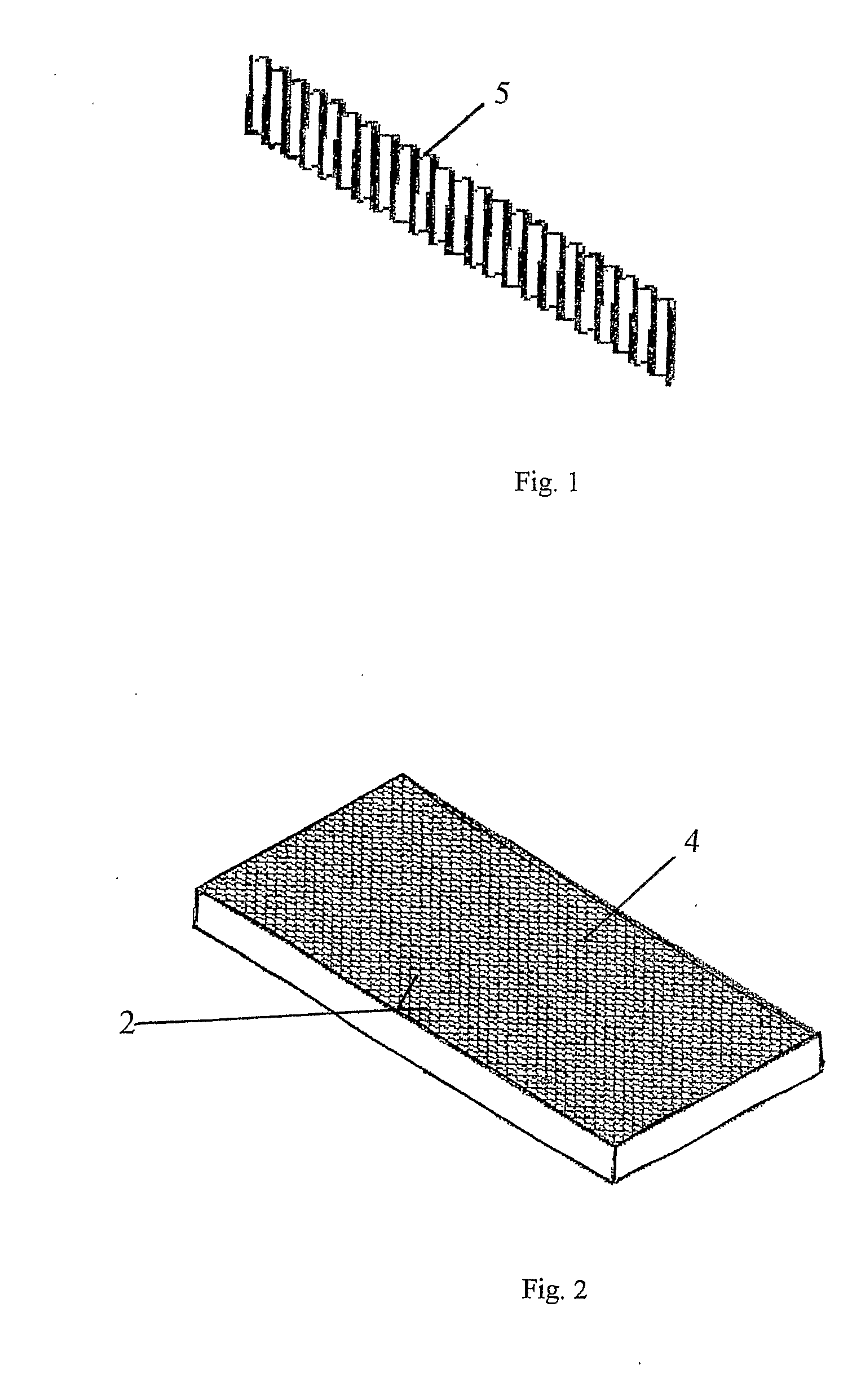

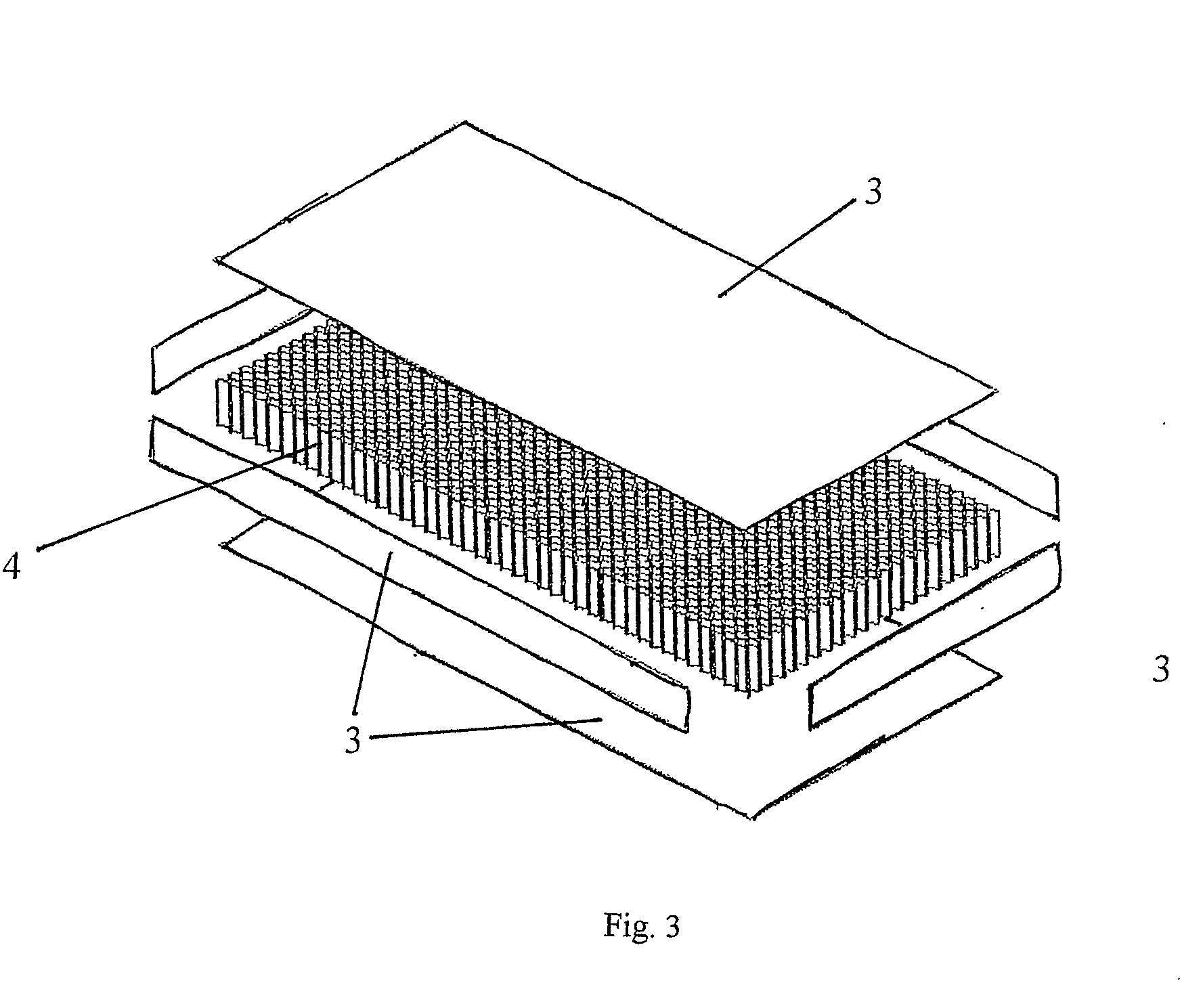

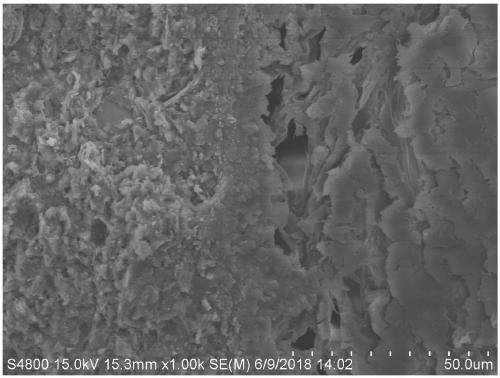

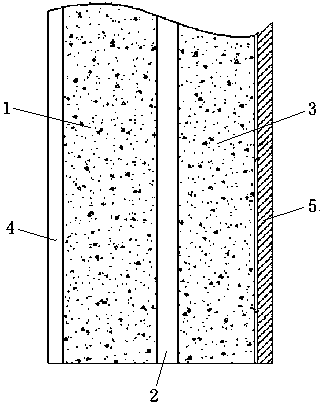

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

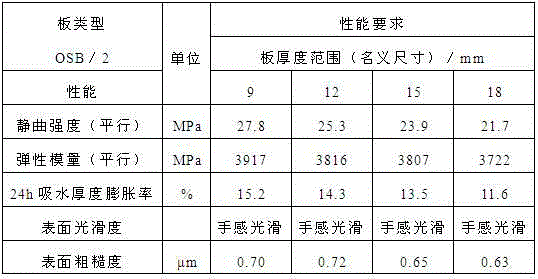

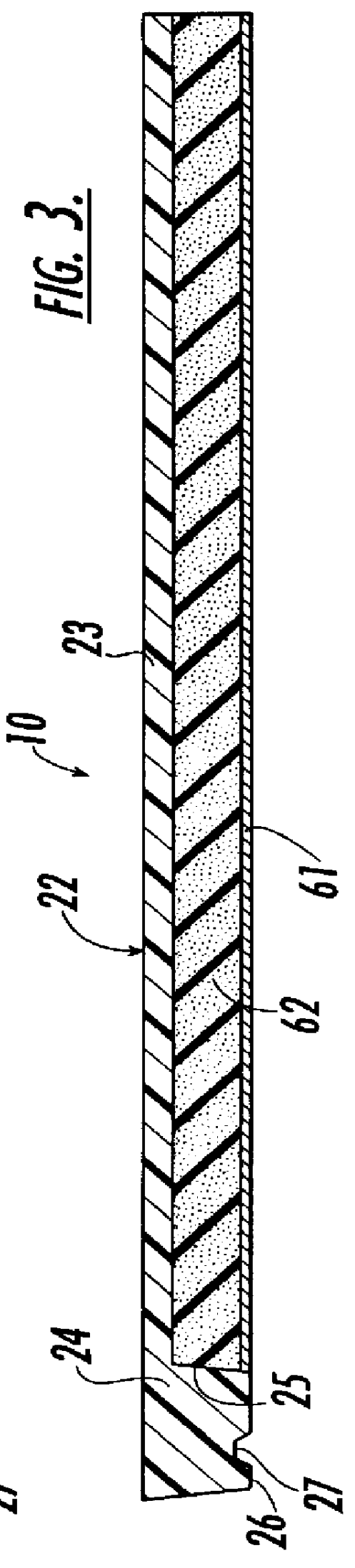

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

Laboratory countertop

InactiveUS6113199AHigh level of hardnessHigh level of smoothnessBuilding componentsLike countersEngineeringParticle board

The laboratory countertop of the present invention utilizes a thin chemical and heat resistant surfacing panel in the form of a thin planar sheet made of a cured thermoset resin composition. In accordance with one broad aspect of the present invention, the thin chemical and heat resistant surfacing panel is mounted overlying a backing panel of a less expensive and lighter material such as particle board or plywood. The surfacing panel is of a cast, monolithic construction and has a width at least 50 times its thickness and a length at least 100 times its thickness. The surfacing panel can additionally include an edge flange integrally formed with the thin planar sheet. The edge flange hides the underlying backing panel from view and gives the countertop the appearance of a unitary thick slab.

Owner:KEWAUNEE SCI

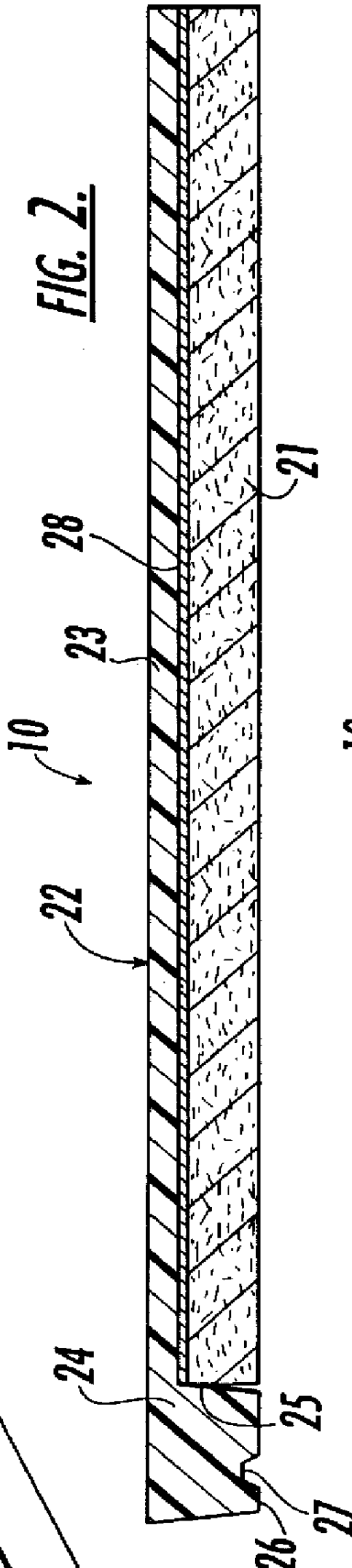

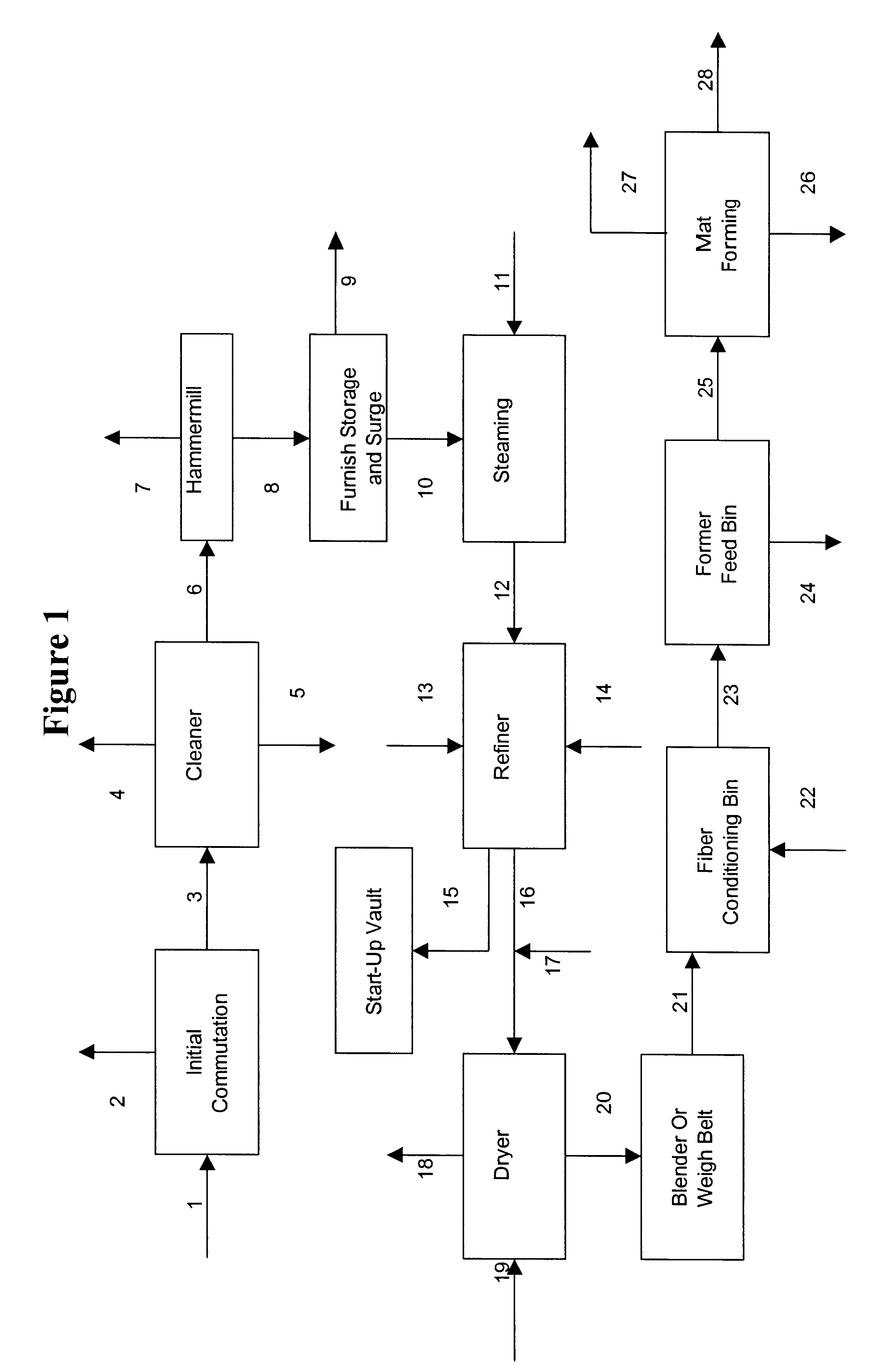

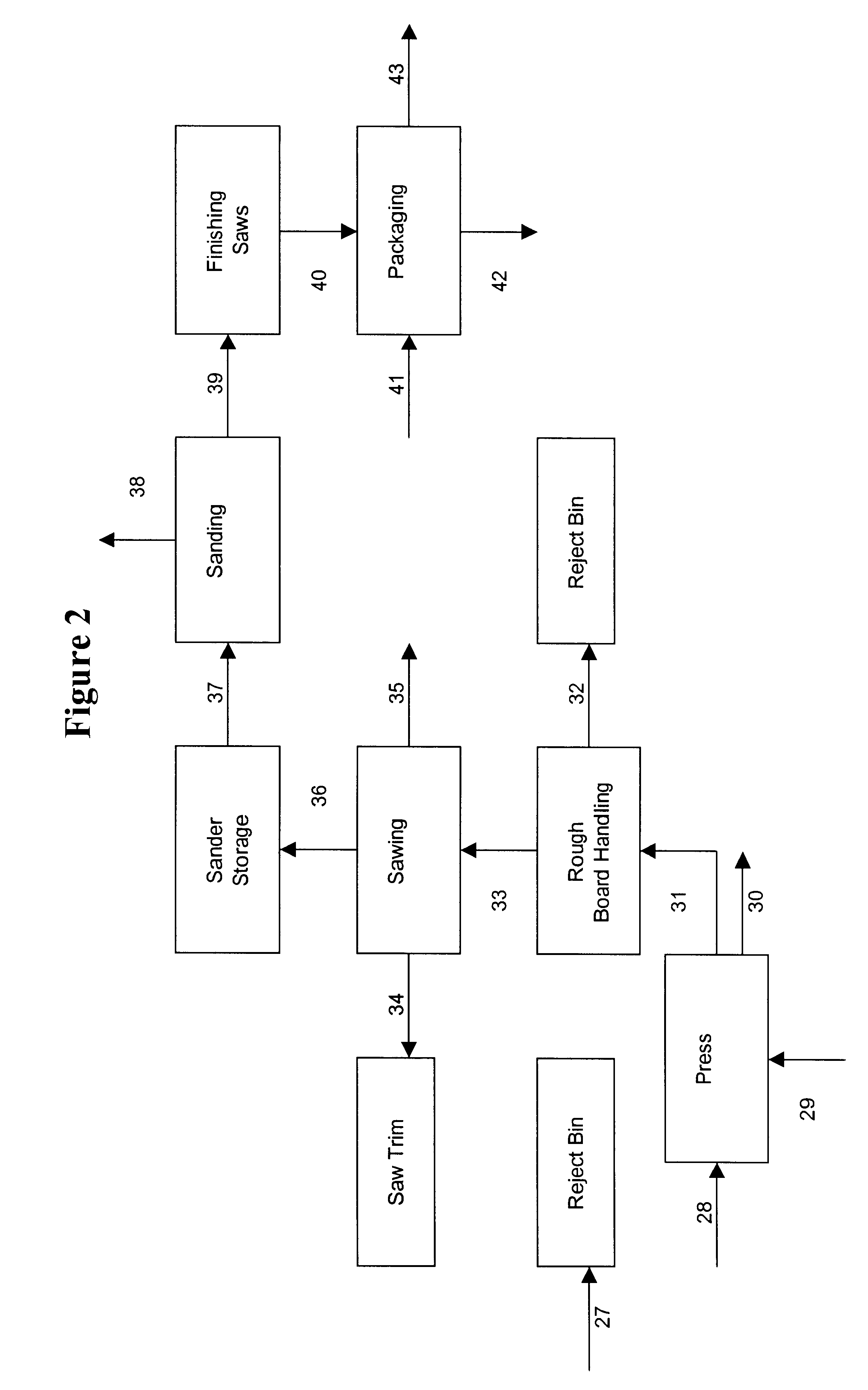

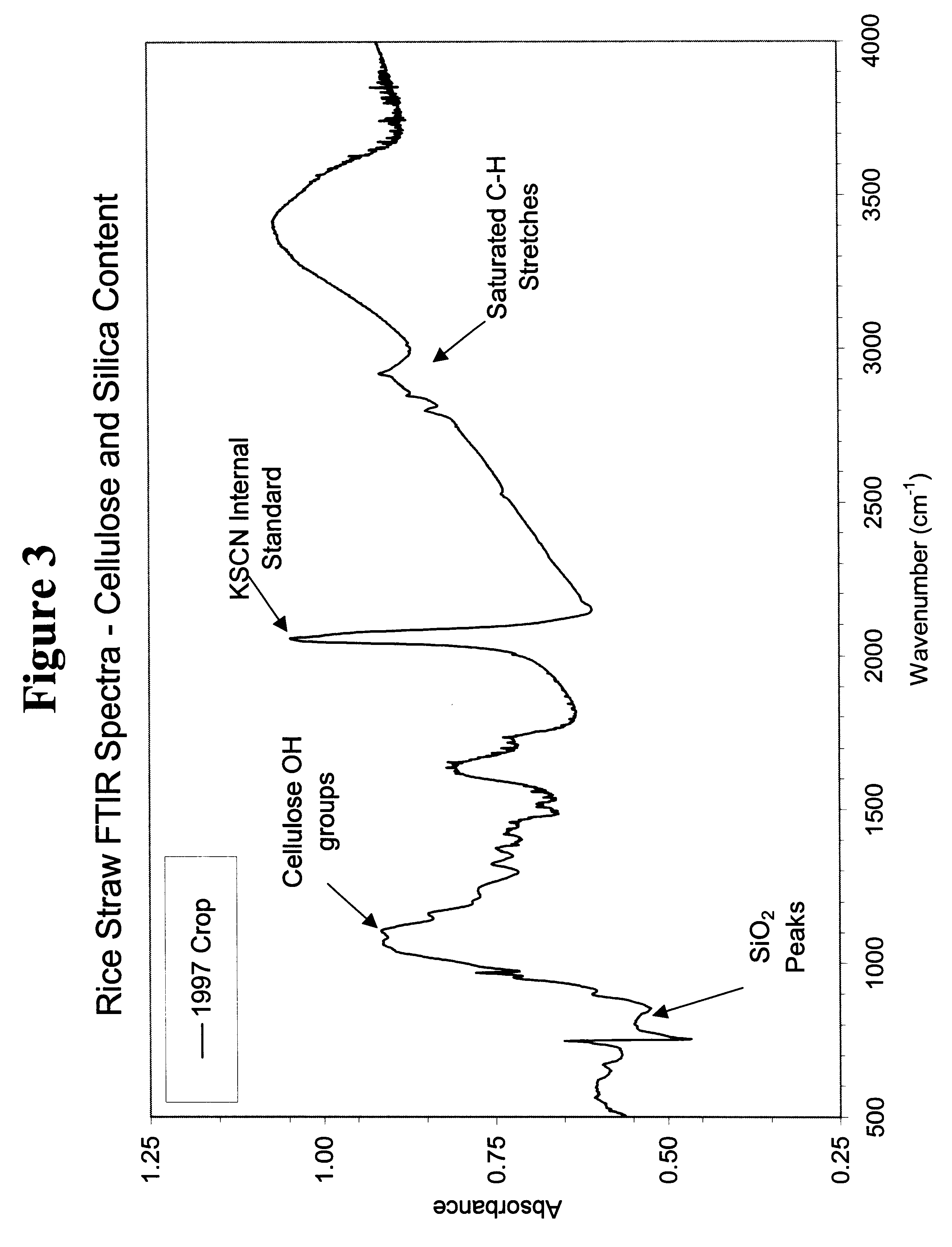

Production of particle board from agricultural waste

The present invention describes a process of using agricultural biomass to make particle or fiberboards. The preferred biomass is selected with high cellulose and hemicellulose concentration and low silica content. The process utilizes short refining time and low steam pressure.

Owner:AGFIBER IP LLC

Tea stem particle board and production process thereof

InactiveCN102152369ASave resourcesReasonable structureWood working apparatusDomestic articlesAdhesiveBuilding renovation

The invention relates to a tea stem particle board and a production process thereof. The production process comprises the following steps of: 1) drying tea stems, and crushing the tea stems into tea stem particles; 2) mixing the crushed tea stem particles with an adhesive uniformly to form a mixture; and 3) paving the mixture which is obtained in the step 2) to make the mixture formed, and pressing to form the particle board. By the process, residuals of tea leaves can be utilized efficiently, timber resources are saved effectively, and the particle board which is manufactured by raw materials of the tea stems can be applied to the fields of building renovation, interior decoration, furniture manufacture, transportation and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

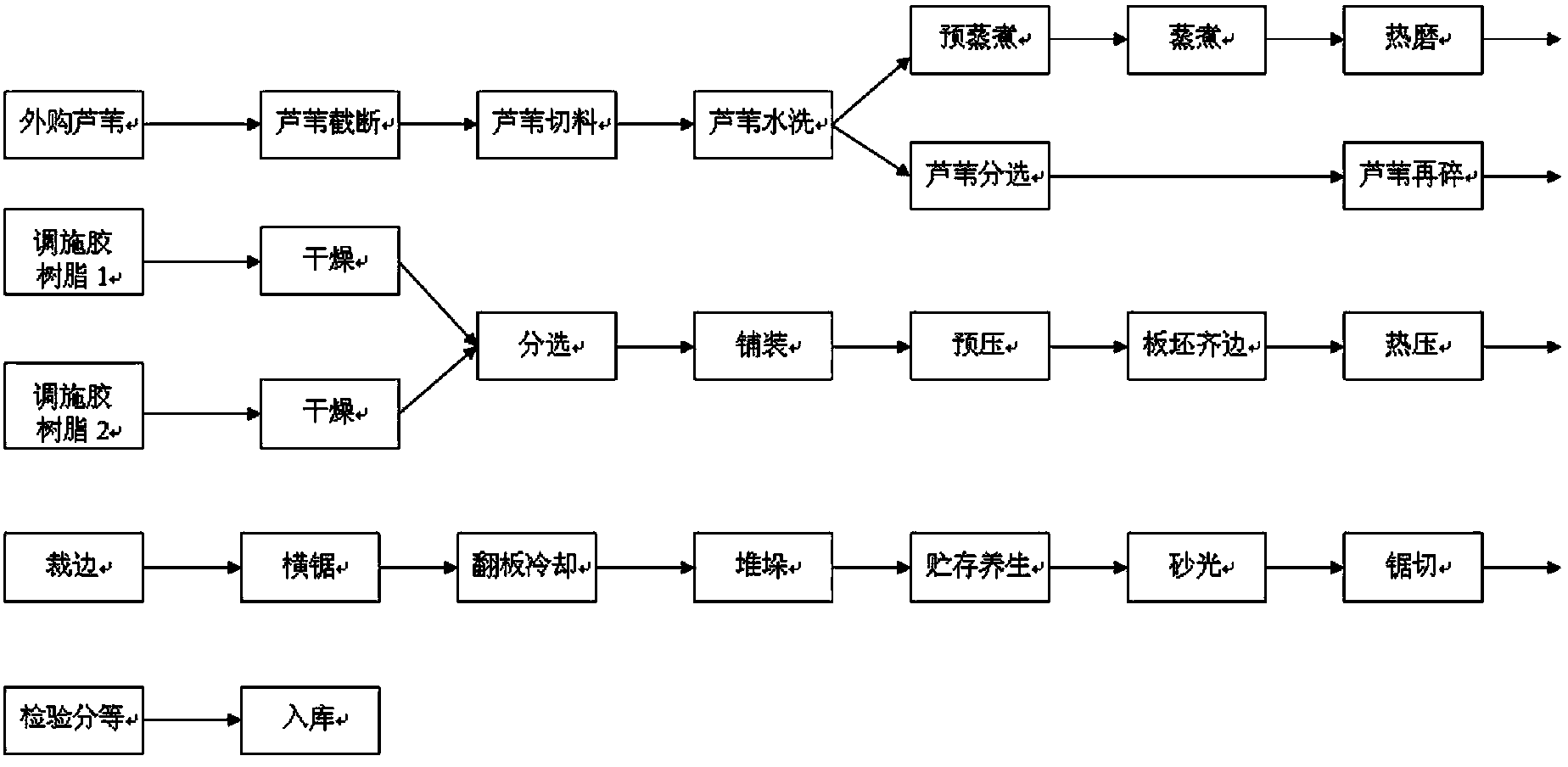

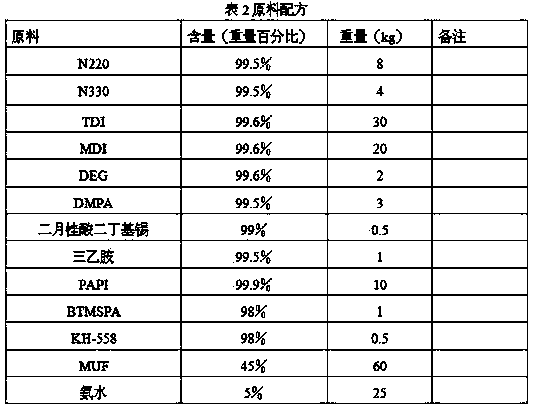

Preparation method for reed fiber particle board

ActiveCN104227819AReduce the effects of gluingReduce releaseLaminationLamination apparatusFiberWood shavings

The invention discloses a preparation method for reed fiber particle board. The preparation method comprises the following steps: cutting a reed raw material by using a circular sawing machine to prepare stem-shaped reeds with certain sizes; cutting the material by using a reed cutting machine, wherein one part of the cut material is cooked and softened to obtain the reed fibers, and the other part of the cut material crushed again to obtain fine reed shavings; respectively applying different resin adhesives to the reed fibers and the shavings, and drying, air-sorting and paving to form three-layer or multi-layer structural board blank; pre-pressing the three-layer or multi-layer structural board blank into a continuous flat-pressing hot press to press and produce the environment-friendly reed fiber particle board. The preparation method has the advantages that the influence of a wax layer on the surface of a reed on gluing performance is reduced to the greatest extent by graded pavement treatment; the production cost of the reed fiber particle board prepared by the process is moderate; both the physical and chemical properties of the reed fiber particle board meet related national standard requirements; the free formaldehyde release amount reaches the level-E1 standard requirement. According to the preparation method, reed resources of a wet land are fully utilized; the source of production raw materials of artificial boards is enlarged; the requirements on building resource-saving and environment-friendly society of China are met.

Owner:DONGYING ZHENGHE WOOD IND

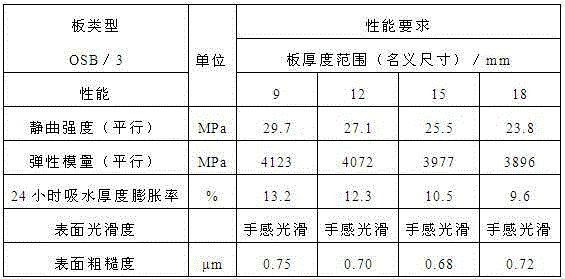

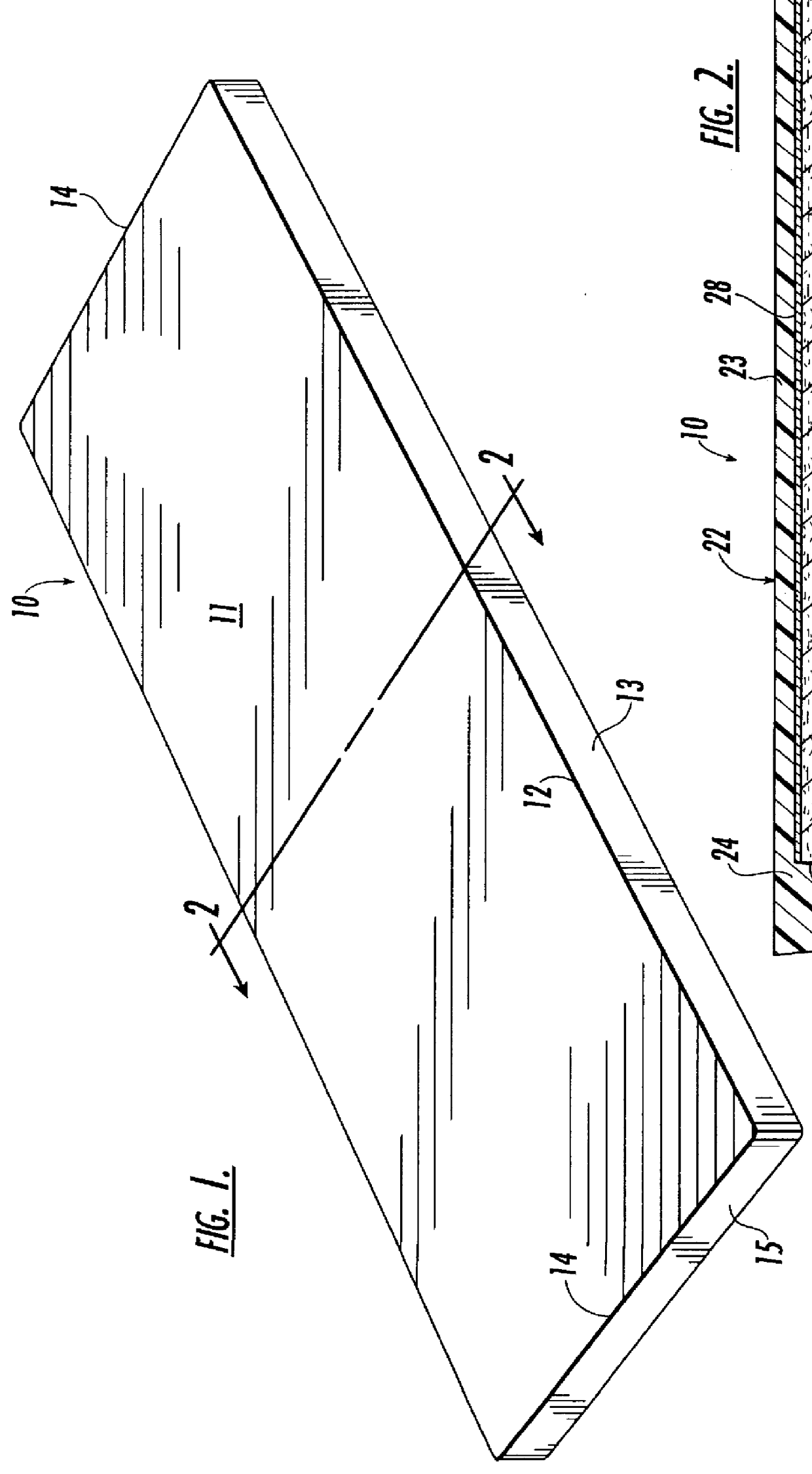

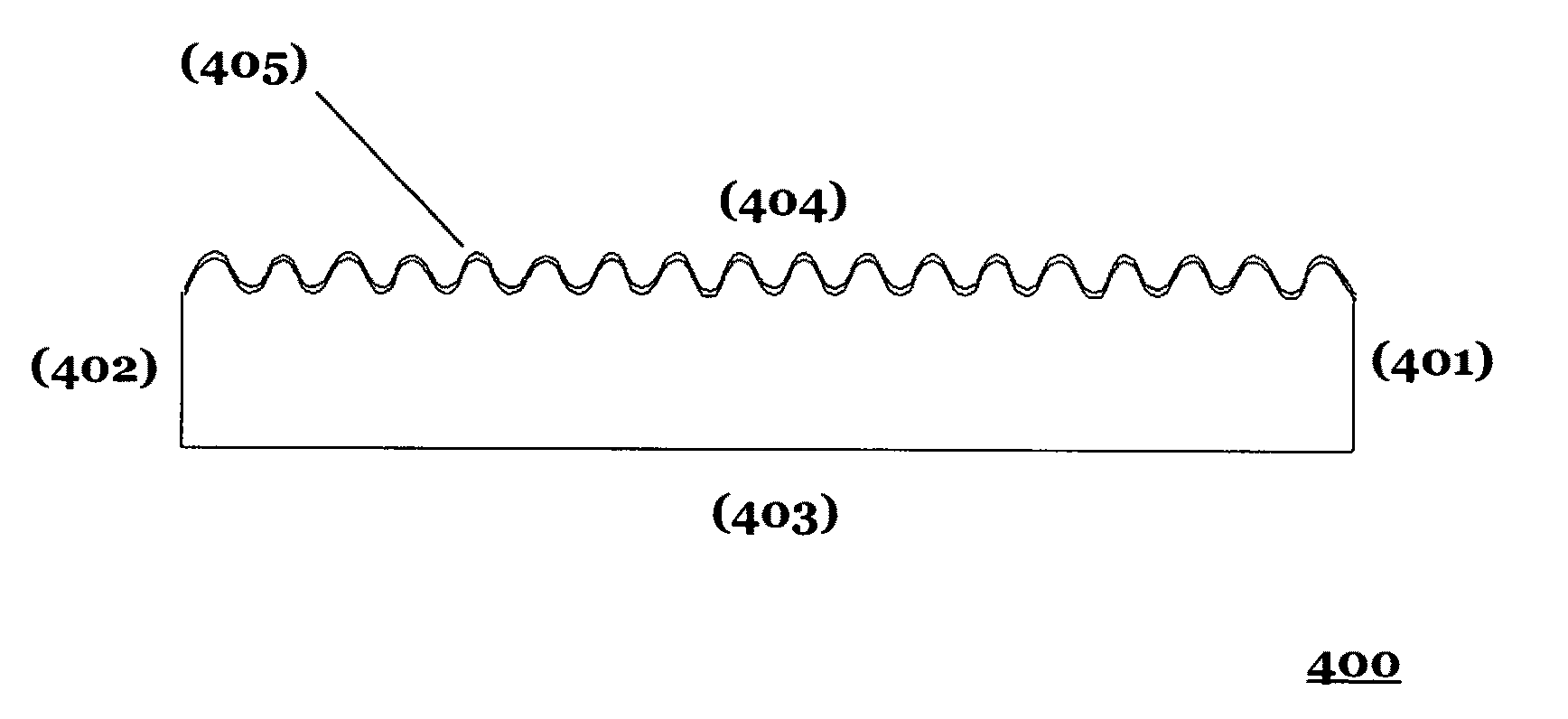

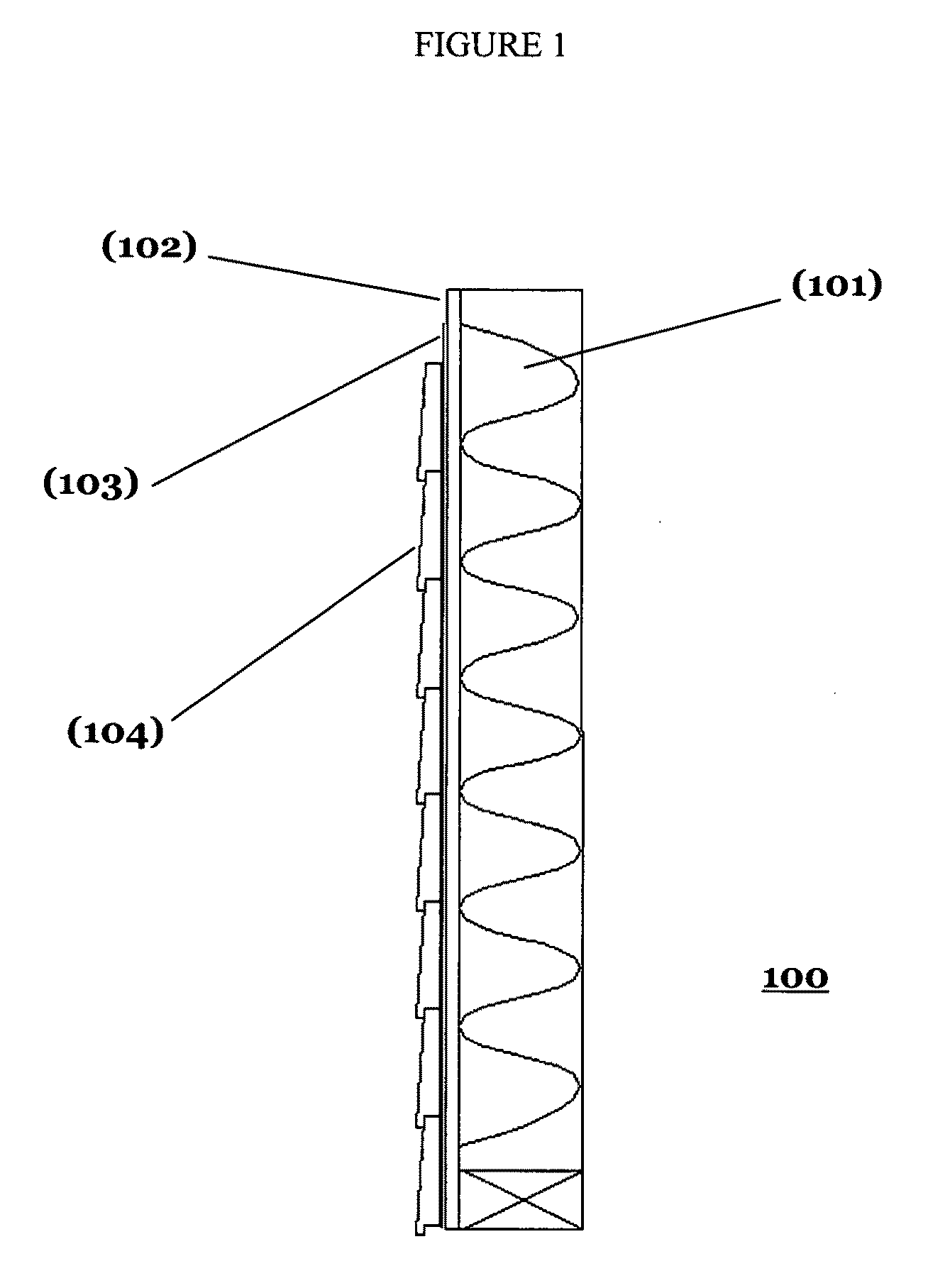

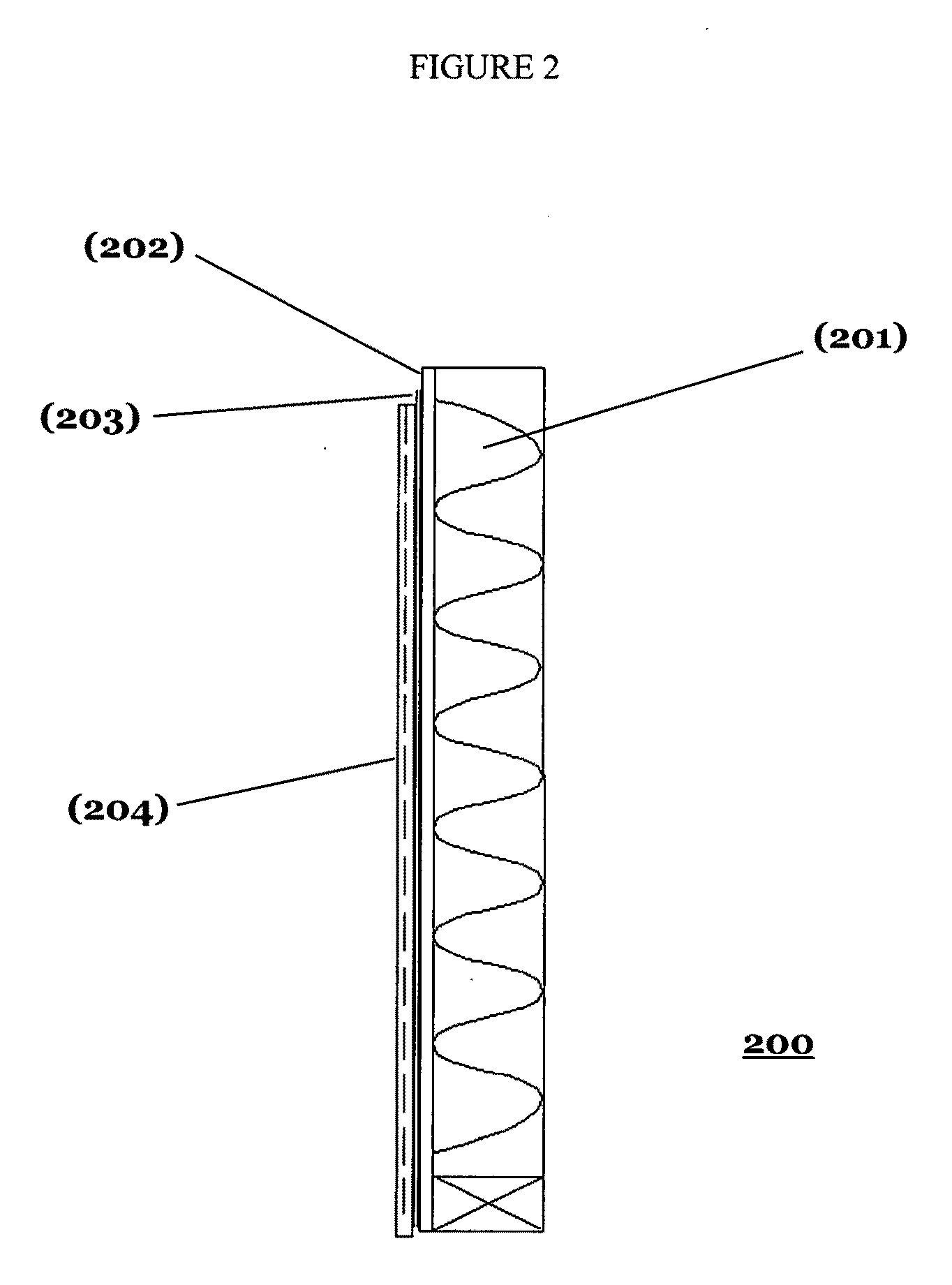

Structural boards having integrated water drainage channels

InactiveUS20090113838A1Improve waterproof performanceCost time be reducedWallsDecorative surface effectsWater trapEngineering

A water resistant structural board suitable for use in a wall system is disclosed. The structural board has water drainage channels on at least one of its surfaces to drain any water trapped behind the sealed wall system. The water drainage channels may be imparted into the structural board during or applied subsequent to a board production process, and the produced board is shipped to the construction site for a wall installation. When desired, the channeled surface of the structural board may be laminated, coated, or sprayed with a water resistant layer to further enhance the water resistant property of the board. A wall system including the disclosed structural board does not require a layer-by-layer installation of a component having water resistant property and a component having water drainage channel structure at a work site; therefore, labor cost and installation time may be reduced significantly. Examples of structural boards are oriented strand board, plywood, particle board, oriented strand lumber, dimensional lumber, fiberboard, wafer board, chipboard, laminated veneer lumber, and any substantially equivalent wood composite board known in art.

Owner:PAULSEN FRITZ G +1

Non-formaldehyde adhesive particle board and preparation method thereof

InactiveCN106313199ASolve the problem of hot pressing sticky boardSolve the problem of poor initial viscosityProtein adhesivesLaminationSurface layerAdhesive

The invention discloses a non-formaldehyde adhesive particle board and a preparation method thereof. The non-formaldehyde adhesive particle board comprises a surface layer and a core layer; the surface layer adopts non-formaldehyde soy bean glue as adhesive of surface layer shavings; the use level of the non-formaldehyde soy bean glue is 15-50% of the weight of the surface layer shavings; the core layer adopts isocyanate glue as adhesive of core layer shavings; and the use level of isocyanate glue is 2-8% of the weight of the core layer shavings. The non-formaldehyde adhesive particle board solves the problems of hot-pressed board bonding and weak primary bonding performance of isocyanate glue; the preparation method is the same with a preparation process of a traditional formaldehyde-contained particle board; production equipment has no need to transform; all performances reach the standard requirements; and no formaldehyde is used, so that the non-formaldehyde adhesive particle board is a real green environmental protecting product.

Owner:宁波中科朝露新材料有限公司

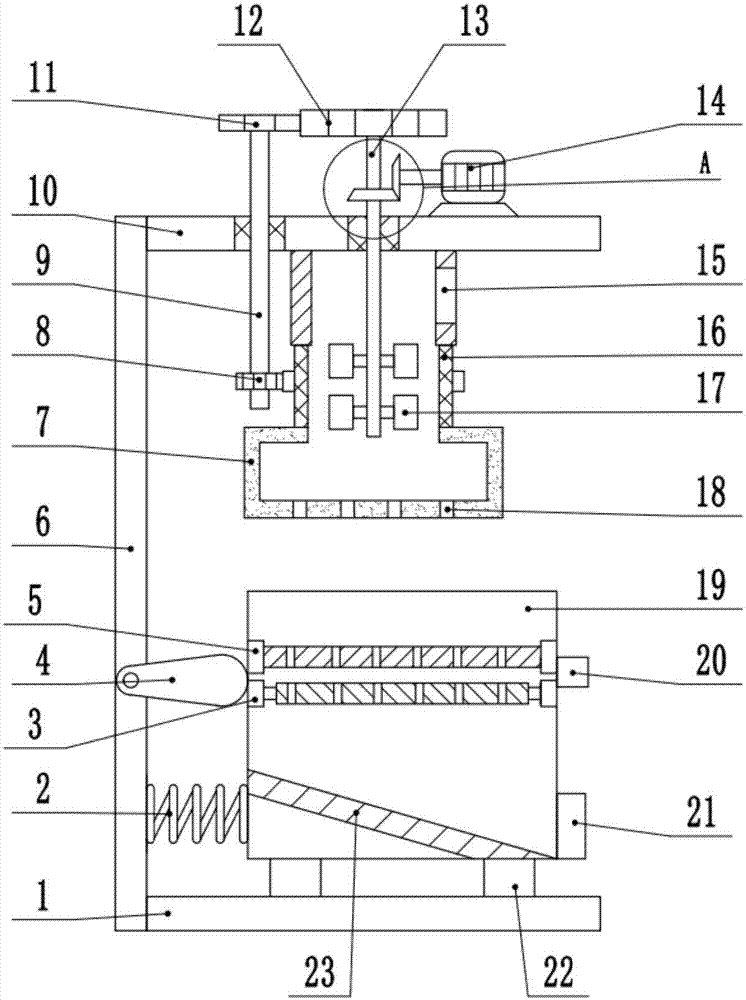

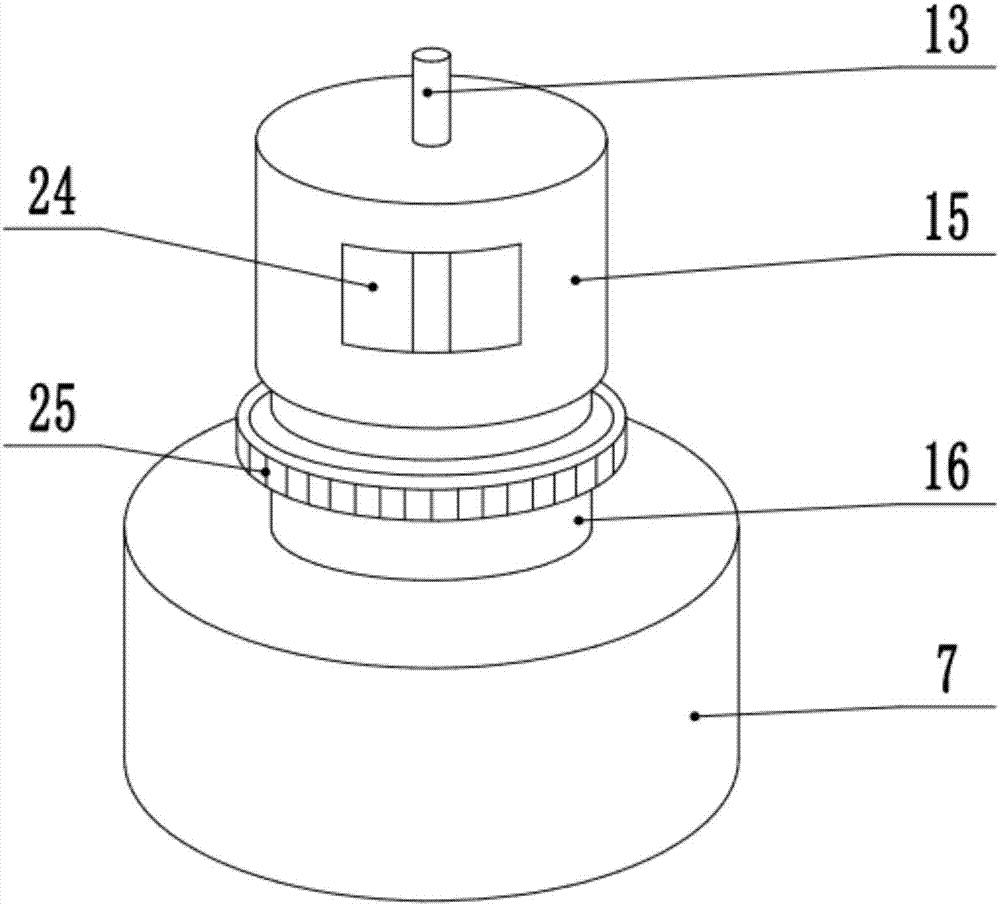

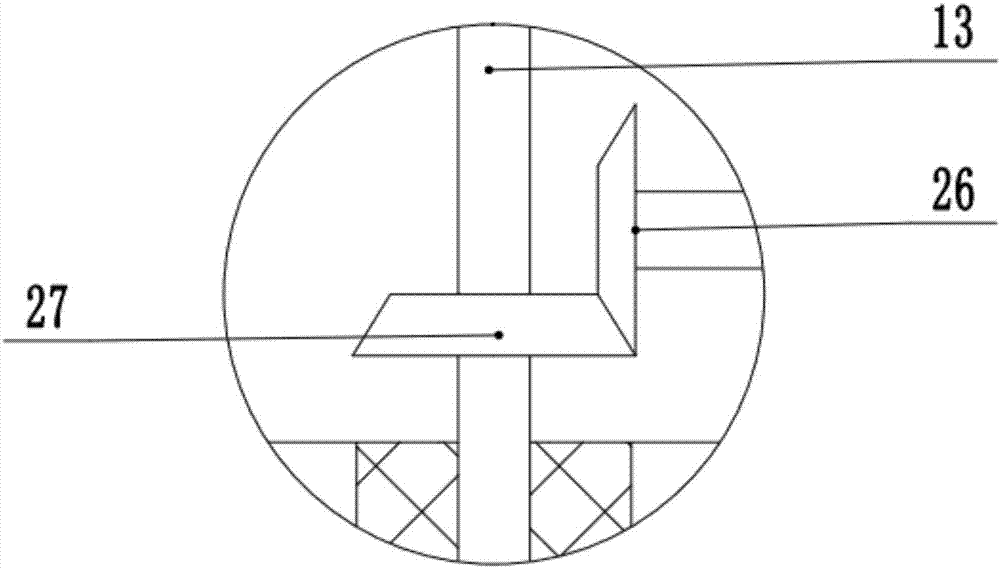

Blocky coarse sand screening device used in construction sites

InactiveCN107297266AImprove screening efficiencyImprove sand screening effectSievingScreeningEngineeringParticle board

The invention discloses a block coarse sand screening device for a construction site, which comprises a base, a material spreader, a top plate, a first rotating shaft, a second rotating shaft, a feeding barrel and a sand screening barrel; the upper side of the feeding barrel Fixedly installed on the lower side of the top plate, the lower end of the feeding barrel is rotated and installed with a rotating cylinder; the lower end of the rotating cylinder is fixedly connected with a material spreading plate; the feeding barrel is provided with a feeding port; the bottom plate of the material spreading plate A number of discharge holes are evenly opened on the top; the sand screening box is a circular structure with an upper end opening, and the sand screening box is located below the material spreading tray; the inside of the sand screening box is sequentially provided with fixed sieve plates and movable screens from top to bottom. sieve plate. The invention is provided with a particle board, a rotating cylinder and a material spreading plate, and a heating wire is arranged on the inner wall of the rotating cylinder, which can effectively improve the screening efficiency of massive coarse sand and improve the sand screening effect; it is also provided with a fixed sieve plate and a movable The sieve plate can not only control the particle size of the discharged fine sand, but also facilitate the discharge of coarse sand.

Owner:苏天平

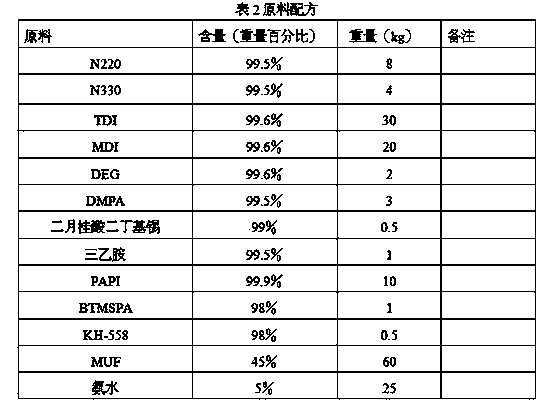

Starch-based aqueous macromolecule-isocyanate wood adhesive and preparation method thereof

InactiveCN101157833AImprove stabilityImprove the defects of dehydration and drynessGraft polymer adhesivesWater basedAdhesive cement

A wood adhesive made from isocyanate which is starch base water based polymer is made into main agent consisting of 40 portions to 65 portions of composite modified corn starch emulsion, 8 portions to15 portions of dibasic acid esterifying agent, and 10 portions to 30 portions of polyvinyl alcohol; polymerization isocyanate that is not closed is used for curing agent. The type I and II nonformadehyde with different compression-shear strength are adhesive. The type I repeatedly boiling, type II impregnation in hot water and type II normal state, etc., can be made when being used. The adhesive can be widely applied to wood or bamboo adhesive products such as multi-layer plywood, three-layer wood or bamboo parquet floor, a multi-layer wood parquet floor, a block board, bending wood furniture, a particle board and so on, characterized by inimitable design, low making cost, a long activity period, low apparent viscosity, an easily available equipment, good prepressing performance, easy operation, and no environment pollution. Ecological environmental benefits social and economic benefits come into being after the application and popularization of the product.

Owner:BEIHUA UNIV

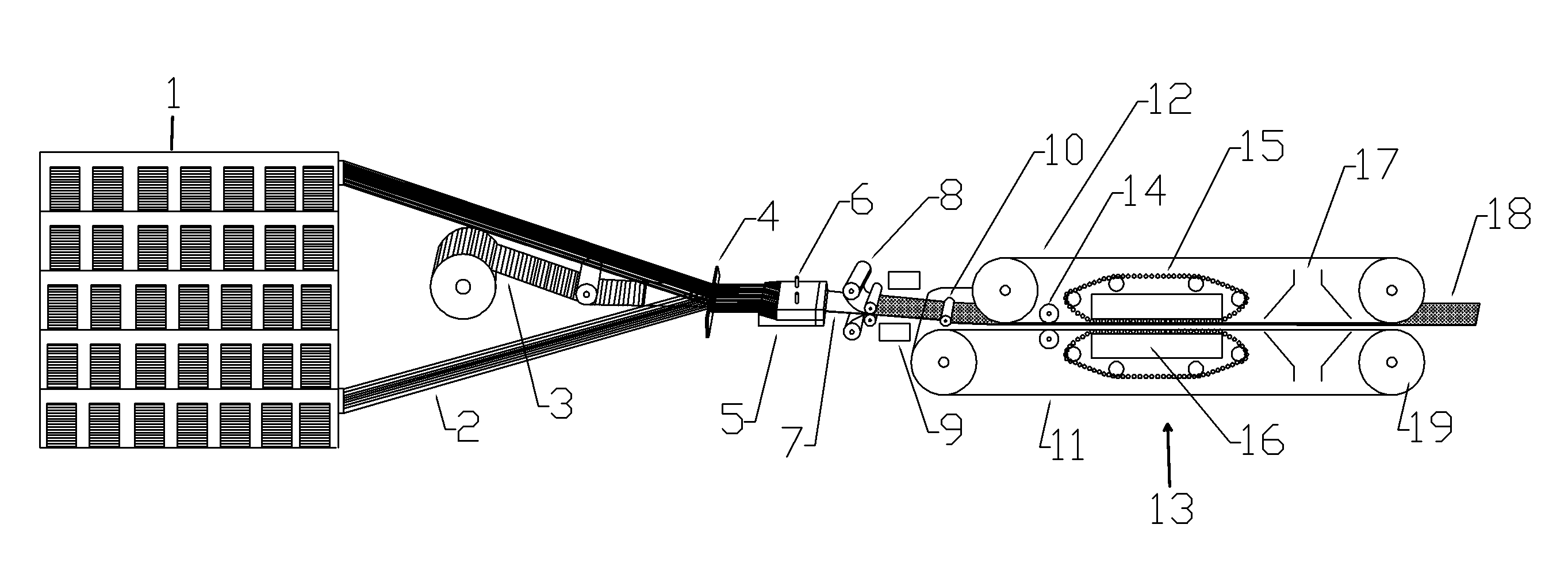

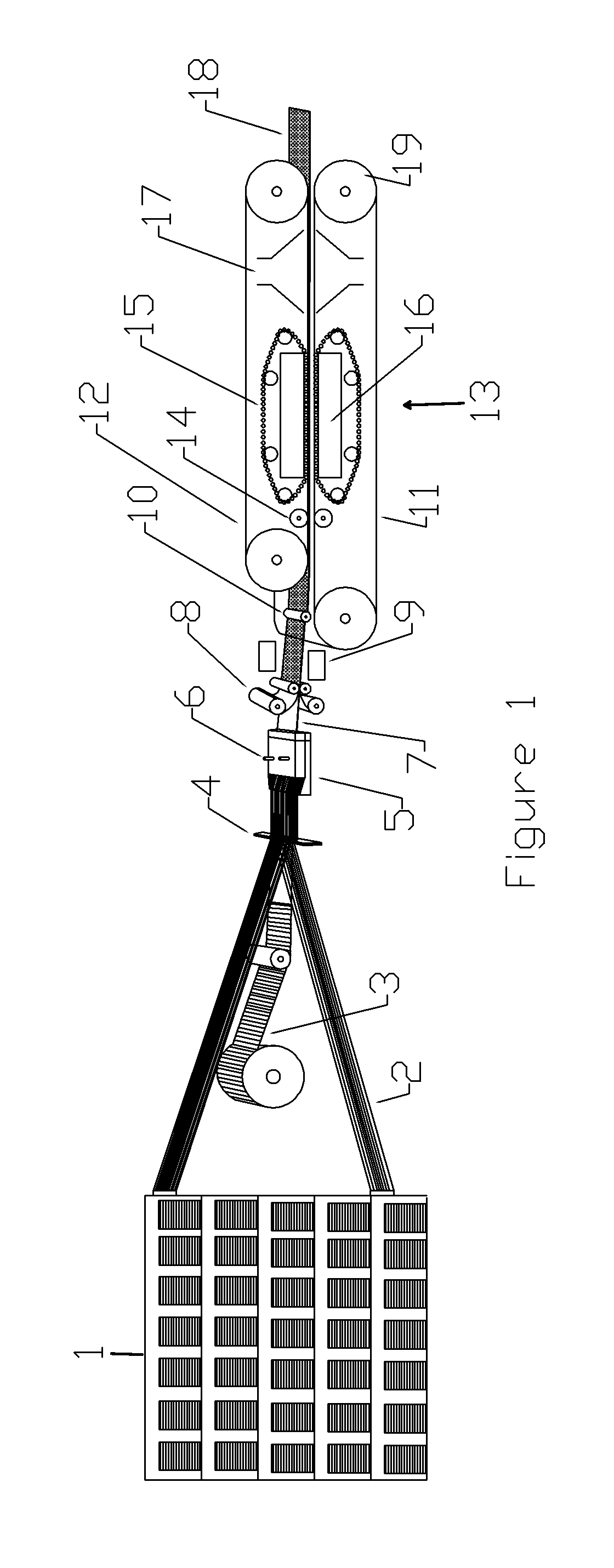

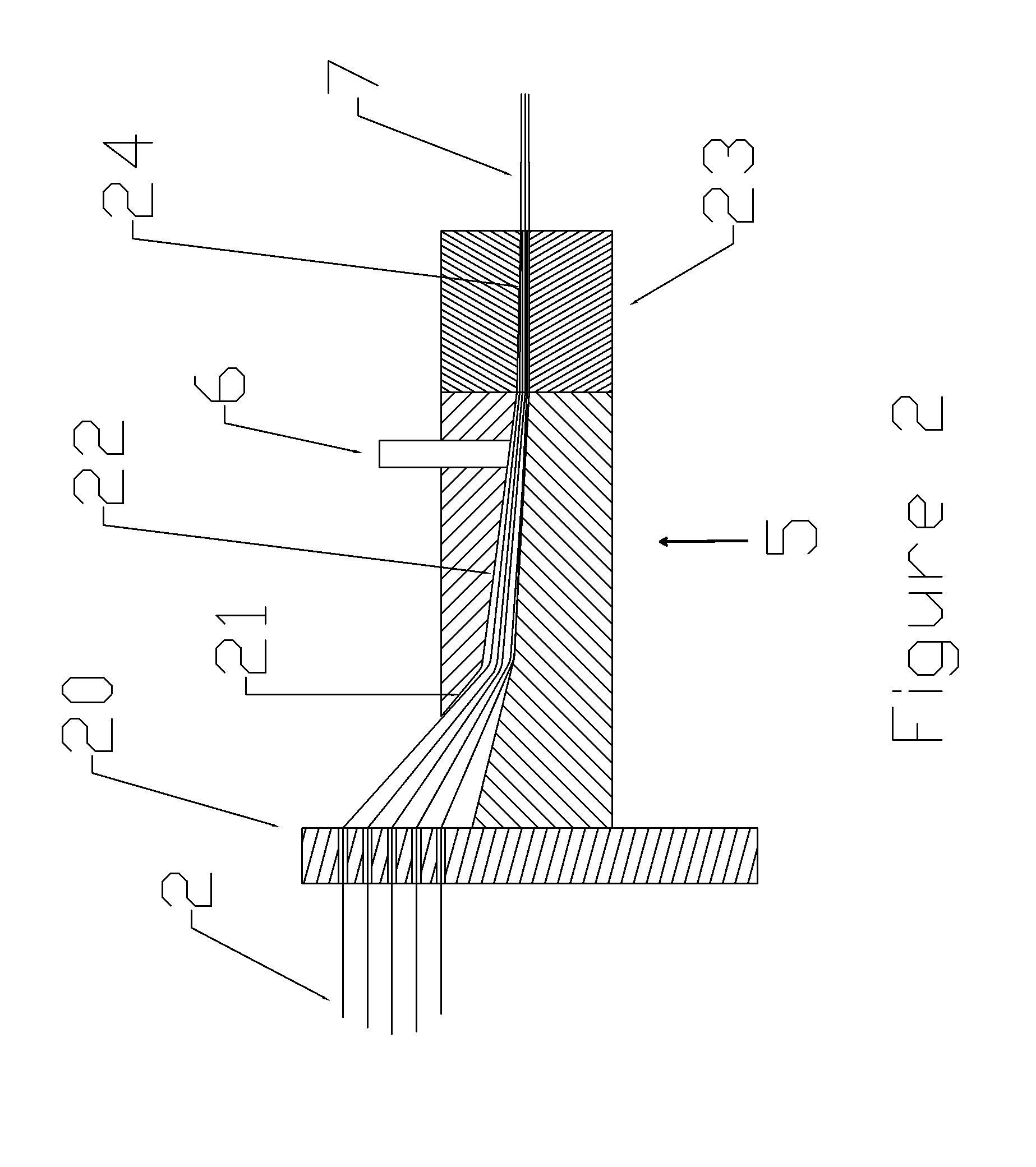

Method for producing environment-friendly particle board through continuous hot pressing of total eucalypt wood leftover material

ActiveCN106363714ASolve insufficient resourcesSave raw materialsLaminationLamination apparatusNational standardParticle board

The invention discloses a method for producing an environment-friendly particle board through continuous hot pressing of a total eucalypt wood leftover material. The method comprises the procedures like chipping, flaking, drying, two-time screening (veneer removing and grit removing), sorting and polishing, mixing glue, hot press molding, aftertreatment, sanding and board selecting. According to the method, the eucalypt wood leftover material is fully utilized, and the wood waste is reduced; the produced particle board reaches the national standard and meets the GB / T4897-2015 requirement in Particle Board and the GB18570-2001 requirement in Indoor Decorating and Refurbishing Materials Limit of Formaldehyde Emission of Wood-based Panels and Finishing Products; melamine impregnated paper can be pasted on the surface of a produced panel; and the particle board is manufactured into high-end desk panels, wardrobe and cabinet panels, partitions, wood floors, ceilings, and other panels.

Owner:广西华晟木业有限公司

Polyurethane laminates made with a double belt press

InactiveUS20130115412A1Excellent Adhesive PropertiesFine surfaceSynthetic resin layered productsPaper/cardboard layered productsComposite laminatesResin matrix

A fiber reinforced composite laminate with fibers generally oriented along two major axes and having a polyurethane resin matrix suitable for reinforcing wood based substrates such as trailer / container flooring, glulams, plywood, particle boards, laminated veneer lumber, and oriented strand board, is provided. The laminate is produced by pulling the fibers through a resin injection box, where a polyurethane resin is injected into the box to wet the fibers. The polyurethane resin wetted fiber layer is then covered with a release media on the top and bottom sides of the layer. The sandwich of fiber, resin and release media is fed to a double belt press capable of applying pressure and heat to consolidate and cure the laminate. The laminate thus made can be thinner than 0.080 inch and provides excellent flatness compared to pultruded thin laminates.

Owner:HAVCO WOOD PRODS

Straw particle board employing bark powder modified phenolic resins as adhesives

ActiveCN101693380ALow costImprove performanceFlat articlesDomestic articlesWood shavingsWood machining

A straw particle board employing bark powder modified phenolic resins as adhesives adopts straws as main raw materials and woodworking fragment wood shavings as secondary materials. The particle board is characterized in that the adhesives of the pressed straw particle board employ the bark powder modified phenolic resins, a large amount of renewable wood processing remained bark powders are adopted to replace parts of petrochemical phenols, the phenols are employed to directly activate the bark powders, the bark powders are applied to preparation of phenolic resin adhesives, and operation is simple. In a gluing process, CH3Si (OH) 3 organic silicon liquor with low cost is adopted to modify the adhesives so as to enable the adhesives to easily moisten, penetrate and diffuse on the surfaces of the straws, thereby being favorable for glue joint of the straws. Simultaneously, interfaces of the straws are modified so as to enable the bark powder adhesives to be applied to production of the straw particle board. The straw particle board produced by adopting the adhesives has the advantages of attaching importance to effective usage of biological materials, having low product manufacturing cost, fine performance, strong operability and bringing remarkable ecological benefits and environmental benefits after being popularized.

Owner:BEIHUA UNIV

Cement flakeboard and production process thereof

InactiveCN101117005AEasy to useLow costSolid waste managementCeramic shaping apparatusWood shavingsChloride

The present invention provides a cement particle board and the manufacturing method thereof; the cement particle board comprises the weight percentage compositions of raw materials: 15 to 35 percent of wood wool (absolute dry wood wool), 15 to 45 percent of high-calcium fly ash, 30 to 55 percent of cement, 1 to 3 percent of sodium silicate, 0.3 to 1.8 percent of calcium chloride and 0.1 to 2 percent of addition agent. The method of the present invention uses high-calcium fly ash of industrial wastes, frutex or lops wood shavings for manufacture of hard board, thereby reaching the 'Cement Xylolite Slab (JC / T411-1991)' standard and saving production cost, reducing environmental pollution, expanding, at the same time, the range of wood raw materials for particle board production and creating higher economic value.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

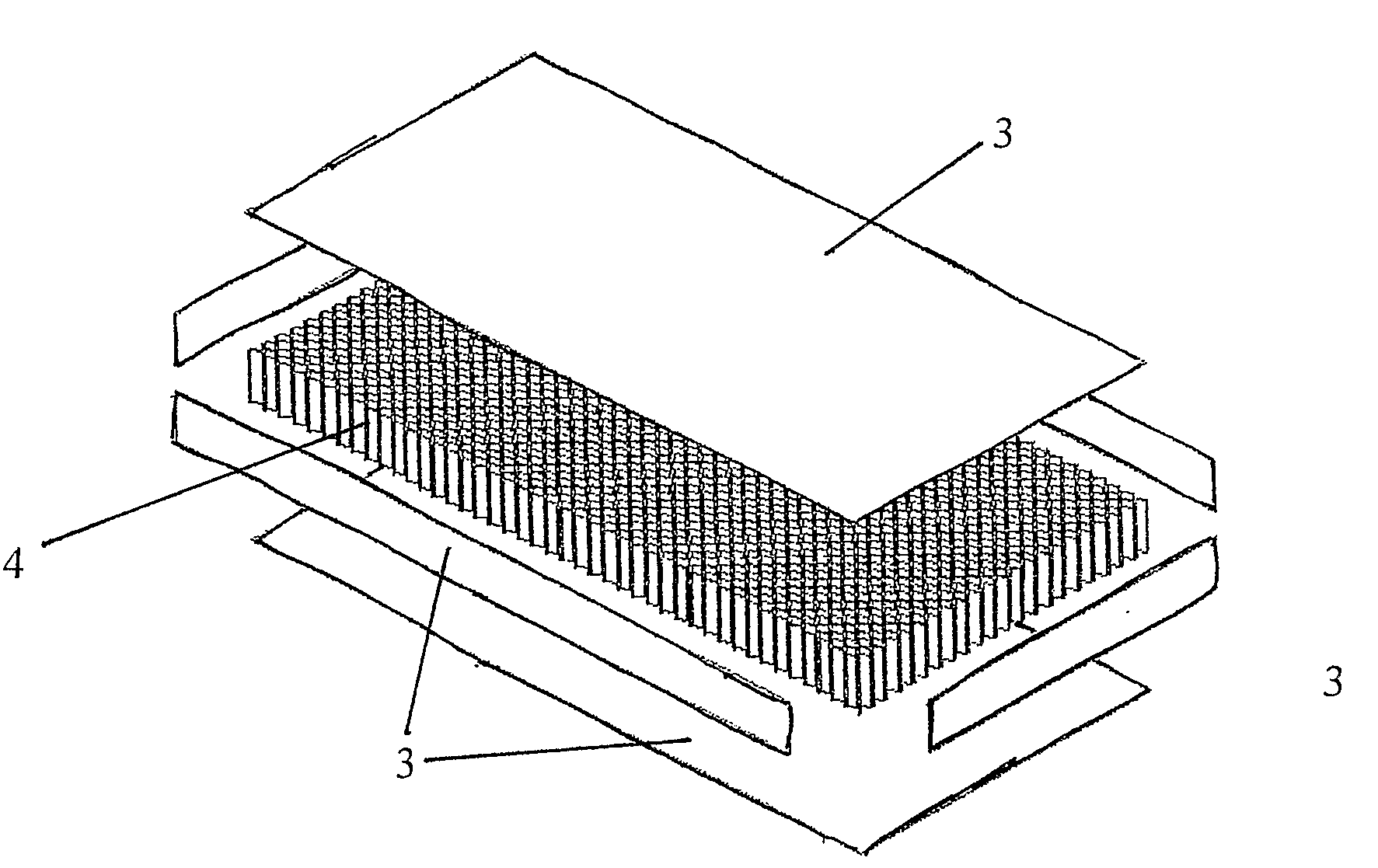

Lightweight Structural Composite for Load Bearing Application

ActiveUS20090123687A1High strengthLow costSynthetic resin layered productsLaminationAdhesiveEngineering

The present invention relates to a lightweight structural composite, which comprises an inner core of lightweight panel encapsulated by outer layers of polymer material. Specifically, the lightweight panel consists of multiple laminations of corrugated thin metal or fibre reinforced plastic sheets kept in position by polymeric foam and / or adhesive, and enclosed in a casing of the same material. The outer layer is made up of a blend of thermosetting and thermoplastic polymers. The method of forming the composite comprises of stacking the corrugated sheets, filling the interstitial spaces with the foam, constructing the casing, the surface treatment of the panel for good adhesion to the outer polymer layer and the high temperature / pressure encapsulation of the panel with the polymer blend containing curing agents. The composite has application as replacement to wood, concrete or particle board panels used in ship docking, panels for wall, door and windows, blast-proof panels, rail sleepers and shipping pallets.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

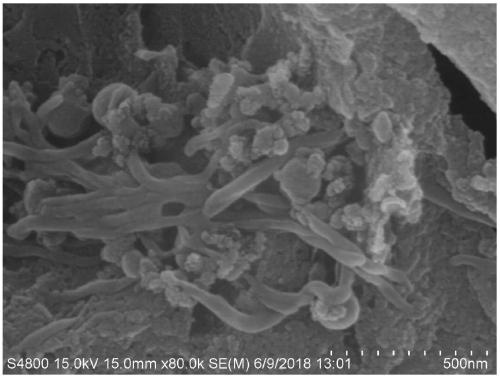

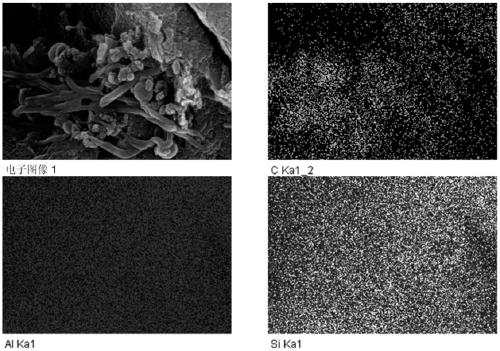

Geopolymer-based wood adhesive and preparation method and application thereof

ActiveCN109251682AWide variety of sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesDopantAdhesive

The invention relates to an environmentally-friendly high-performance geopolymer-based wood adhesive and a preparation method and application thereof. The geopolymer-based wood adhesive is prepared from the following raw materials (by weight): 100 parts of a base material, 1-20 parts of an organic dopant, 87.5-280 parts of an alkali activator, 0.3-1 part of an initiator, 1-2.4 parts of a couplingagent, 1-2.4 parts of an emulsifier, 0.4-1.6 parts of an antifoaming agent and 50-200 parts of water. After the organic dopant is solidified, a chain or net structure can be formed. Thus, the chain ornet structure and the geopolymer form interpenetrating networks to achieve the toughening modification effect, and a mechanical locking effect with the wood material can also be achieved. The geopolymer-based wood adhesive is green and environmentally friendly; the sources of raw materials are wide; production cost is low; and the process is simple. The geopolymer-based wood adhesive is non-flammable, has no release of formaldehyde and has good bonding performance. The geopolymer-based wood adhesive is instant to use when prepared and the formula can be adjusted flexibly. The geopolymer-basedwood adhesive can be used to glue wooden raw materials such as wood, bamboo, straw and the like and to prepare wooden composite materials such as particle boards, fiberboards, plywoods, reconstitutedwood / bamboo and the like, and has industrial application value.

Owner:BEIJING FORESTRY UNIVERSITY

Method for producing formaldehyde-free low-density crop straw grain board

ActiveCN101037000ALow densityHave mechanical strengthClimate change adaptationDomestic articlesVolumetric Mass DensityParticle board

A making method of crop straw particle board of low density without formaldehyde includes crushing, taking materials and weighting by balance, paving, stirring of spray glue, prepressing and hot-pressing of the crop straw, characterized in that: the crop straw should crush to particle state of less than or equal to 4.75mm, after calculating weight of straw particle with density of 250-400kg / m3 based on thickness of board and once machining area of apparatus, taking materials by weight of following components, the hot-pressing temperature is 130-180 DEG C, through two times of increasing and reducing press hot set from high to low, at first time the press is increased to 90-110 bar during 10 seconds, keeping for 25 seconds, then the press is reduced to 40-60 bar, then second increasing press to 80-100 bar, keeping for 30 seconds, then three times of reducing press by speed of 1-3 bar / second, at last stabilizing the press in 10-20 bar, keeping for 10 seconds. The invention settles technological problem of hot-pressing mode and material compositions of artificial plate with production density less than 400kg / m3, secondly settles technological problem of spray glue.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Environment-friendly particle board for decoration

ActiveCN104339430AGood for healthFresh smellBiocideNon-macromolecular adhesive additivesHazardous substanceAdditive ingredient

The invention discloses an environment-friendly particle board for decoration. The environment-friendly particle board is characterized by comprising a first traditional Chinese medicinal board layer, a negative ion adhesive layer and a second traditional Chinese medicinal board layer, wherein the negative ion adhesive layer is prepared from a soy protein adhesive and negative ion natural mineral substance powder; the mass ratio of the soy protein adhesive to the negative ion natural mineral substance powder is 6:4; the negative ion natural mineral substance powder serves as a mixture comprising tourmaline, lanthanides and rare earths composite salts and titanium dioxide according to a weight ratio of 5:2:3; the tourmaline serves as a mixture comprising magnesium tourmaline and lithium tourmaline according to a weight ratio of 4:6. The environment-friendly particle board can sustainably release negative ions to remove formaldehyde and other hazardous substances and indoor peculiar smell, resist and inhibit bacteria and purify the indoor air, so as to achieve the health care effect; furthermore, the naturally traditional Chinese medicinal ingredients contained by the particle board can play roles of repelling mosquitoes and resisting and inhibiting bacteria, so that the environment-friendly particle board achieves multiple purposes, and is wide in application prospect.

Owner:佛山市联信高新材料股份有限公司

Bonding of solid lignocellulosic materials

InactiveUS6083623AOptimize allocationNot inhibit and reduce adhesive qualityWood veneer joiningBaby linensCelluloseParticulates

Consolidated or composite lignocellulosic products such as fiberboard, particle board, chipboard, waferboard, plywood, straw composites, etc. are formed by using a particulate binder or adhesive constituting particles of crude cellulose polysaccharide materials, e.g. wood flour or ground straw, coated with MDI or other isocyanate binder in a thickness preferably in the range of 1-7 mu m.

Owner:CARBOCOL SYST

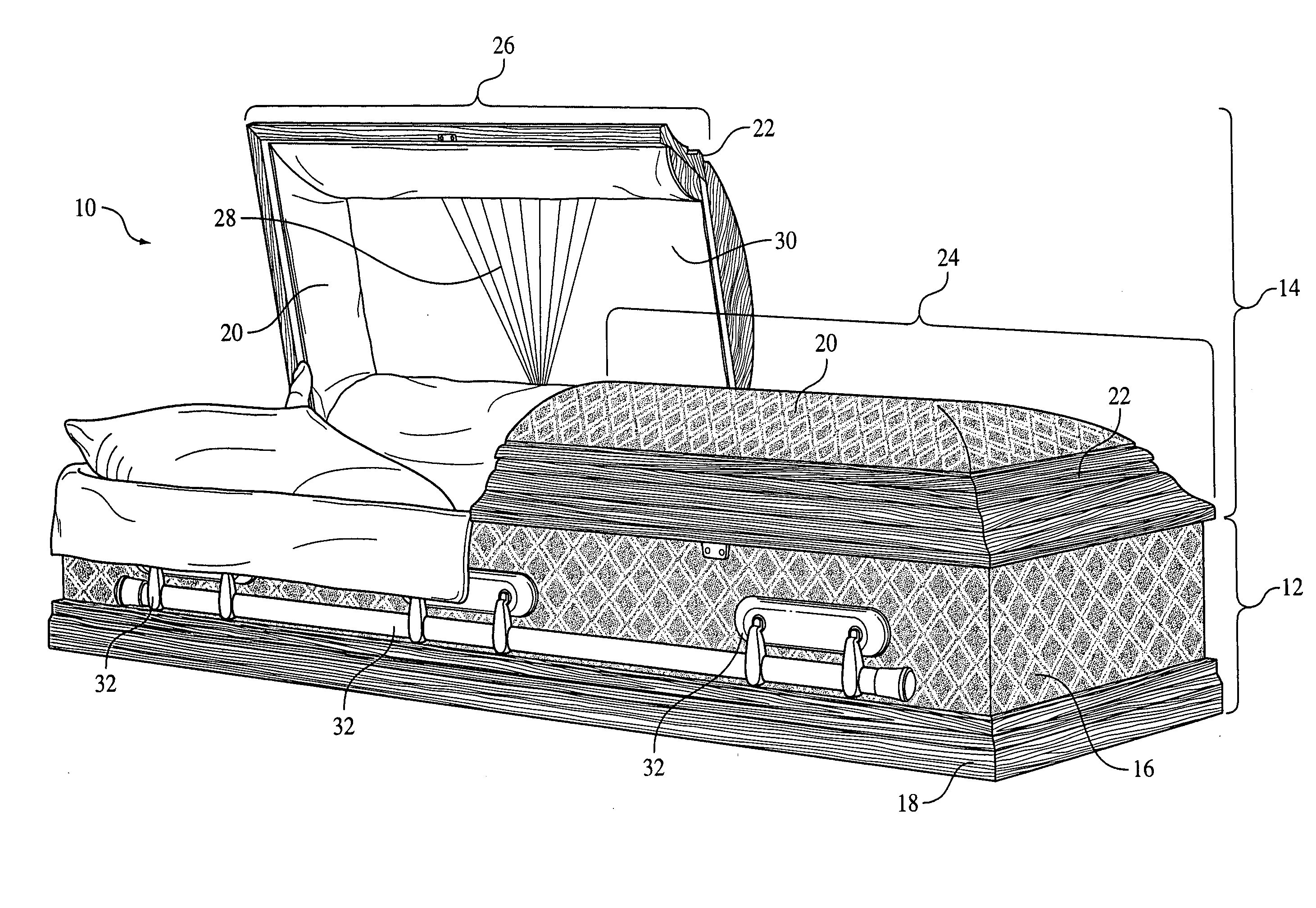

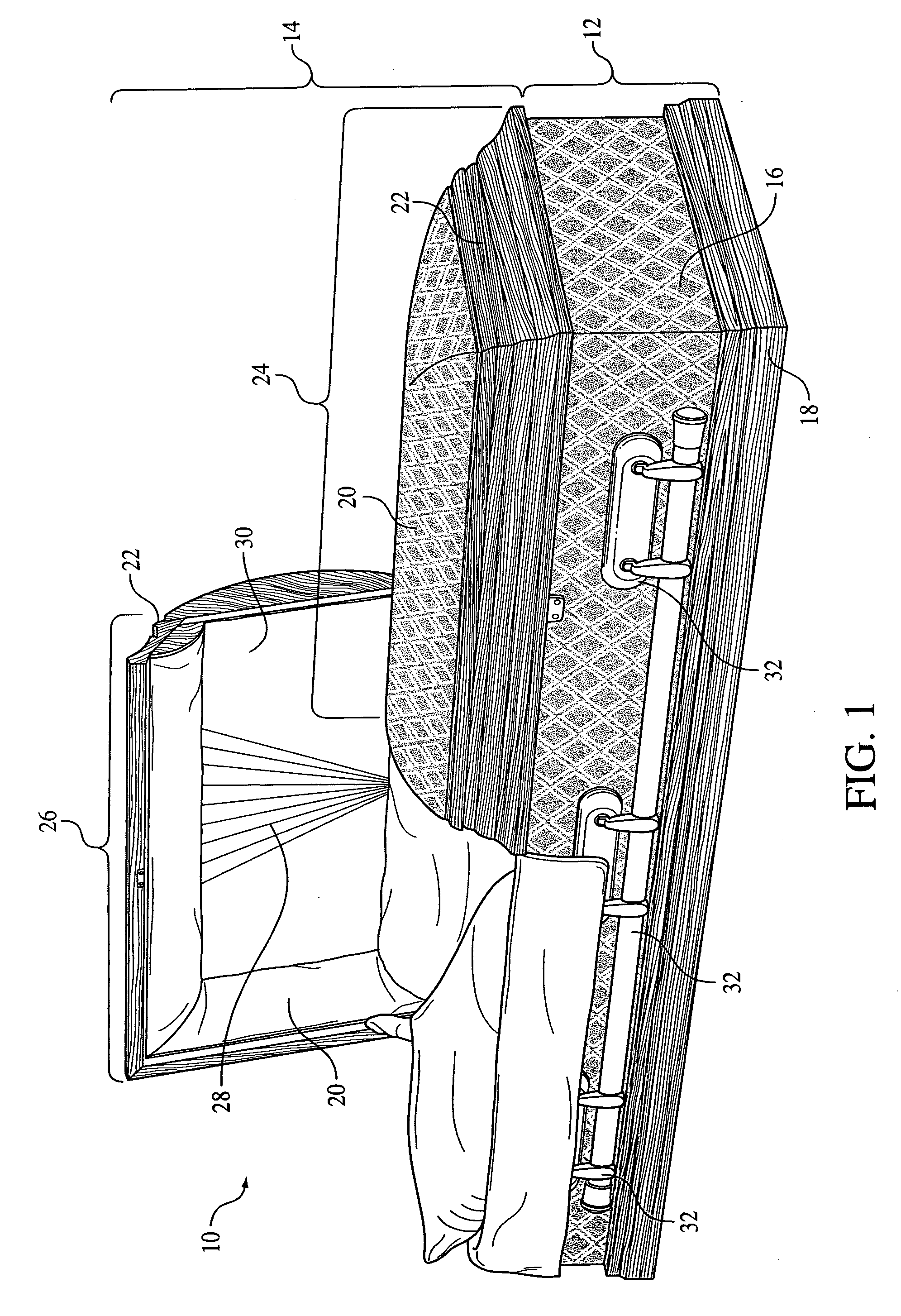

Burial casket

A particle board or corrugated casket is covered with cloth and trimmed with veneer. Specifically, the base portion of the lower shell of the casket and the rim portion of the cap of the casket are covered with veneer preferably having an ornamental molding. The remaining portions of lower shell and cap are covered with a decorative fabric, leather or cloth. In another embodiment, a domed casket is covered with a non-wood veneer.

Owner:MATTHEWS INT CORP

Self-cleaning environment-friendly bamboo particle board and method for manufacturing same

The invention discloses a self-cleaning environment-friendly bamboo particle board. The self-cleaning environment-friendly bamboo particle board comprises, by weight, 100 parts of bamboo particles, 10-15 parts of additives, 8-10 parts of activators, 0-5 parts of adhesive, 0.5-1.0 part of waterproof agents, 0.5-10 parts of adsorbents and 0.2-0.5 part of cleaning agents. The invention further discloses a method for manufacturing the bamboo particle board. The self-cleaning environment-friendly bamboo particle board and the method have the advantages that the particle board is made of waste ethanol residues of wood fuel, the absorbents, the cleaning agents, the waterproof agents and the like, the performance of the manufactured particle board can reach national standards, usage of the traditional adhesive can be prevented or reduced, and accordingly formaldehyde emission of the particle board can be greatly reduced; indoor pollution gas can be effectively absorbed by the manufactured particle board with the adsorbents, self-cleaning effects can be realized by the aid of the cleaning agents on the surfaces of the self-cleaning environment-friendly bamboo particle board, and accordingly the self-cleaning environment-friendly bamboo particle board is suitable for building decoration.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Production method of light particle board

InactiveCN107671979AReduce usageReduce Density EffectsFlat articlesDomestic articlesAdhesiveParticle board

The invention belongs to the technical field of artificial boards, and relates to production of particle boards, in particular to a production method of a light particle board. The production method of the light particle board comprises the steps of: shaving preparation, drying, glue stirring, pavement, prepressing and hot pressing; a surface layer adopts common wood fine shavings; core layer shavings are corn straw shavings and pennisetum alopecuroides straw shavings; and the hot pressing process is to hot press a prepressed board blank at a temperature of 170-190 DEG C under a pressure of 2.5-3.5 MPa for 3-6 min. Light materials are used as raw materials; and a production process is improved to produce the light particle board. Based on a traditional particle board production process, the core layer shavings are changed from common wood shavings to the corn straw shavings and the pennisetum alopecuroides straw shavings with lower density and bulk density; MDI resins are added in a core layer; and the use level of MUF resins is reduced to reduce influence on the board density by adhesive and to improve overall board physical performances. The light particle board, whose density iswithin 0.38-0.50 g / cm3 and physical and chemical indexes both meet national standard requirements, can be manufactured by the production method.

Owner:DARE WOOD BASED PANEL GRP

Three-layer particle board and manufacture method for same

InactiveCN105965658ASave resourcesNot releasedDomestic upholsteryWood veneer joiningWood shavingsFiber

The invention relates to a particle board with a three-layer structure and a manufacturing method, belonging to the field of artificial board manufacturing. The adhesive uses isocyanate, the upper and lower surface layers use wheat straw fiber, and the middle core layer uses wood shavings. When the proportion of wheat straw fiber is ≥ 35-45%, the performance indicators of the particleboard reach the best, fully meeting the requirements of GB / T 4897.3-2003 Require. The three-layer structure particle board produced by this method has no formaldehyde release, good environmental protection performance, uses part of crop straw to replace wood, saves wood resources, and has a positive guiding effect on the manufacture of three-layer structure particle board.

Owner:万华禾香生态科技股份有限公司

A method for preparing straw particle board

InactiveCN101157241AImprove wettabilityHigh bonding strengthDomestic articlesFlat articlesChemical treatmentMass ratio

The invention discloses a straw particle board manufacture method, which relates to a particle board manufacture method. The invention solves the problem that the straw surface includes a plurality of waxy layers and SiO2 substance, common urea formaldehyde resin glue and phenolic resin are hard to wet the straw surface to cause a plurality of gluing difficulty. The invention has the method that: the straw is cut into pieces and performed ash removal at first, and straw crushed aggregates which are performed with the pretreatment through the blending ratio of the 1:4 to 5.0 according to the mass ratio of the straw and alkali liquor is soaked in the alkali liquor of 1.4 to 1.6 wt percent (mass) for 10 to 15 hours, and the straw particle board can be manufactured after drying, glue applying, paving, pre-pressing, hot pressing, and cooling. The equipment performance request of the straw particle board manufacture through the invention is low, the method is simple, and the operation parameter is easy to control. The method of the invention for performing chemical treatment to the straw raw material surface improves the wetting property of the raw material, greatly enhances the inner combination intensity, enlarges the application scope of the straw, releases the lack of the timber resources, and the invention has great economic and social efficiency in the situation that the conflict between supply and demand becomes more prominent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com