Patents

Literature

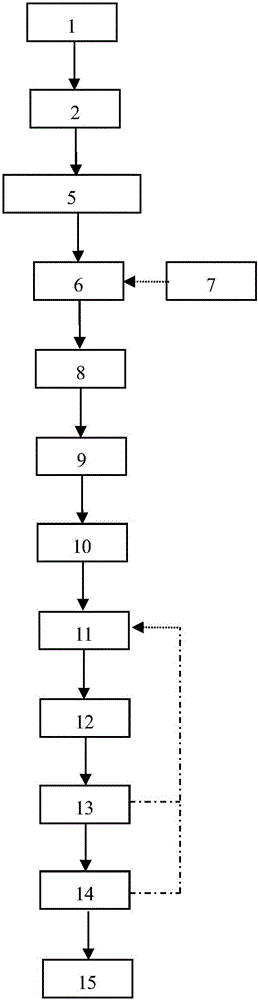

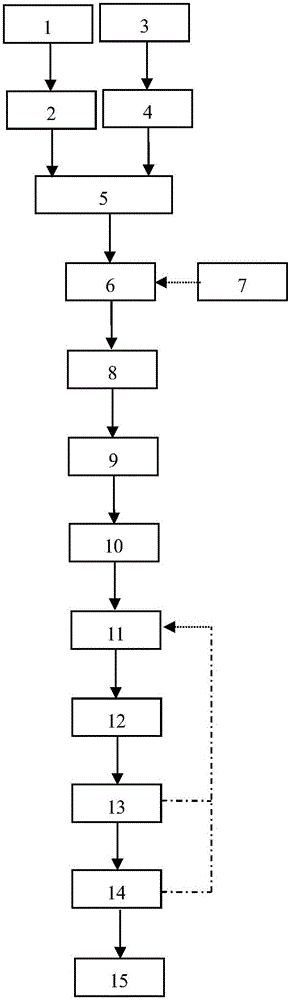

482results about How to "Have mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

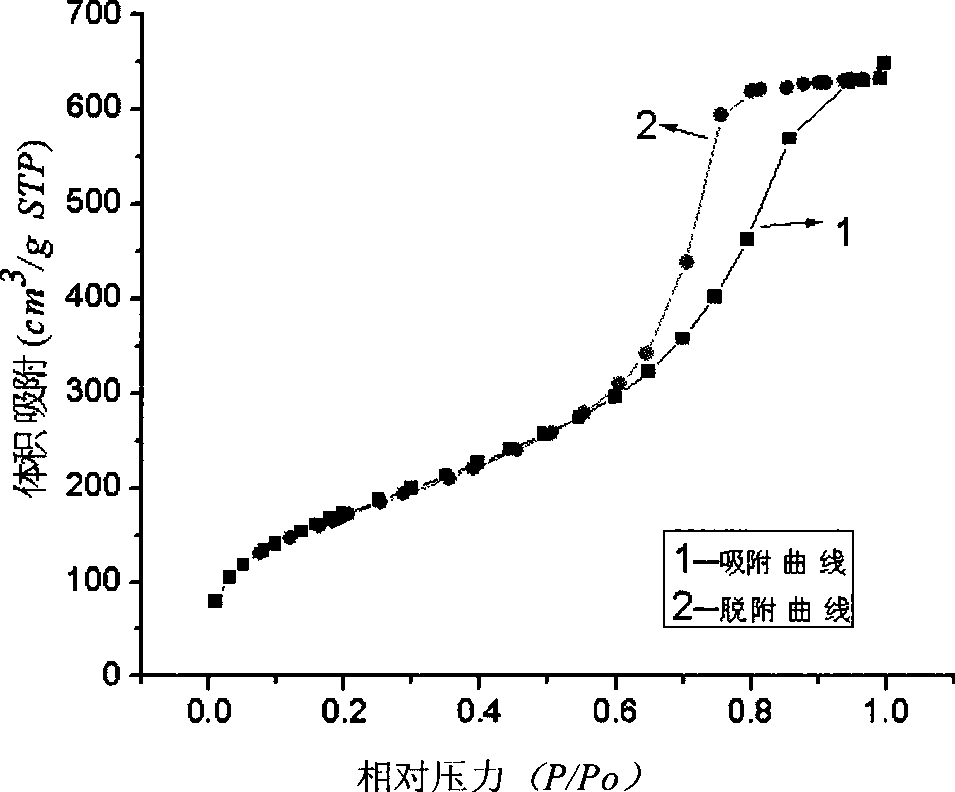

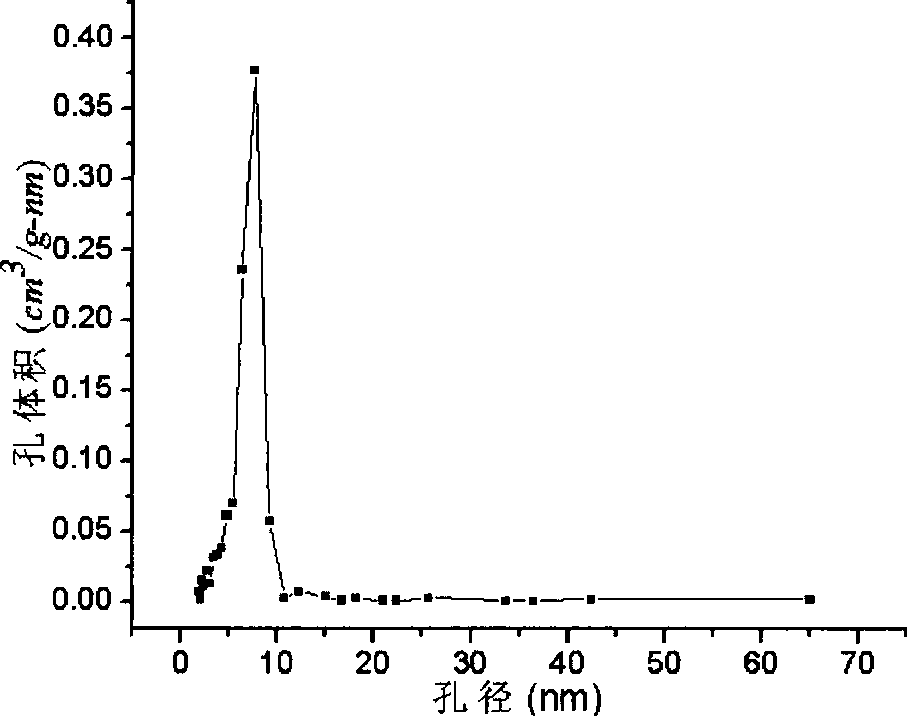

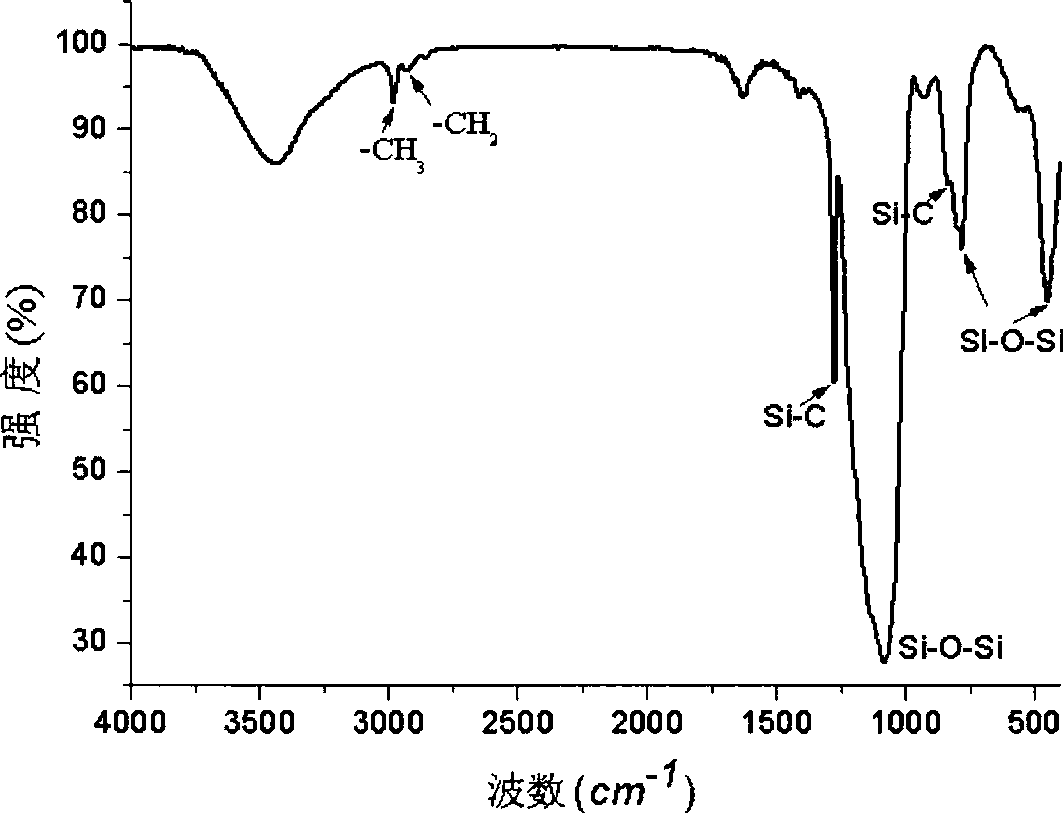

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Chitosan medical nerve and productive method thereof

The present invention discloses a kind of chitosan medical nerve, including chitosan bio-catheter and chitosan fibre scaffold inserted into the chitosan bio-cathether. Its production method includes the preparation of the above-mentioned materials and their combination steps. It is a pure natural bio-degradable material, so that it possesses good bio-compatibility, has no any adverse reaction. Itthe course of preparation is does not add any foaming agent, cross-linking agent and surfactant, therefore said product contains no any exogeneous toxic substances capable of producing said effect.

Owner:NANTONG UNIVERSITY

Cigarette water capsule with water and hydrotropic substance as core materials and manufacturing method of cigarette water capsule with water and hydrotropic substance as core materials

ActiveCN104305521AValid packageHave mechanical strengthTobacco smoke filtersEssential-oils/perfumesFood gradeWater soluble

The invention relates to a water capsule with water and hydrotropic substance as core materials and a manufacturing method of the water capsule. The water capsule is composed of a certain number of water capsule wall materials and the core materials, wherein the water capsule wall materials are compositions of long-chain ester materials and food-grade coagulant aids in specific proportion; the core materials are compositions of pure water, water-soluble substance and the hydrotropic substance. The water capsule is not used as an existing capsule capable of containing oil-soluble flavor substance only, the water and water substance can be included in the water capsule, and meanwhile the single-layer wrapped water capsule is achieved due to the fact that the wall materials are made of the long-chain ester materials and the specific coagulant aids. The water capsule is relatively simple in process; multi-layer wrapping is not needed; the commercial production is easily achieved; raw materials are easily obtained; the water capsule is easy to operate.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Composite material based on nanometer, preparation method of composite material and application in flexible energy storage device

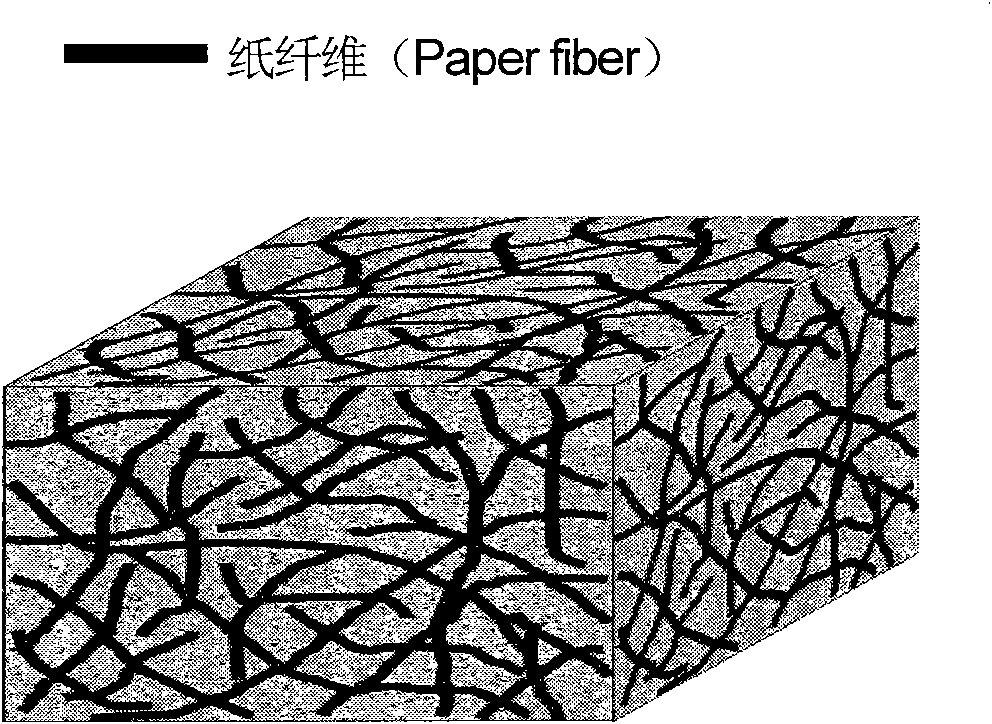

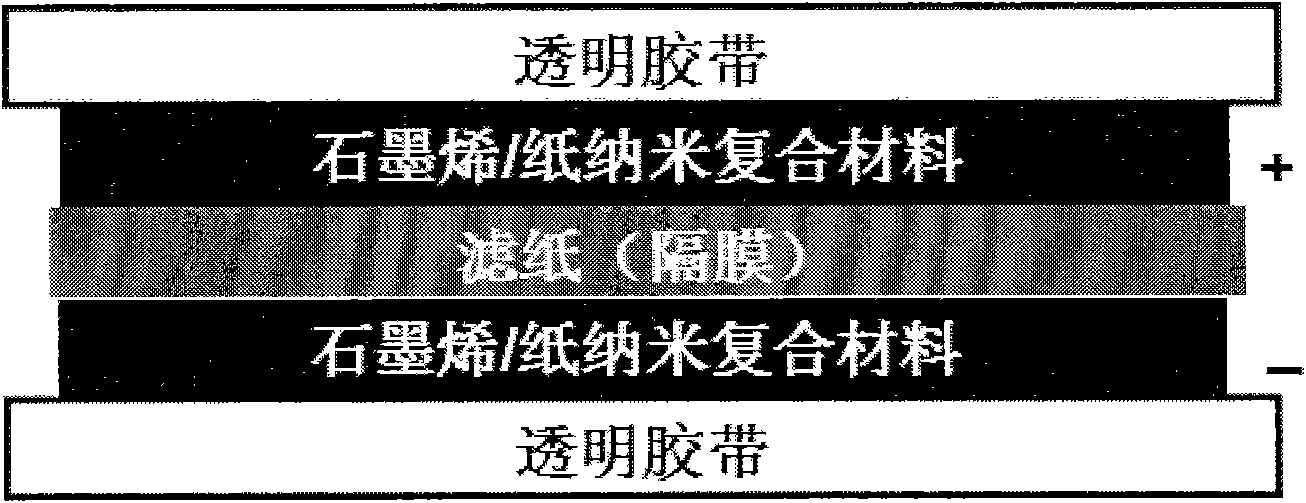

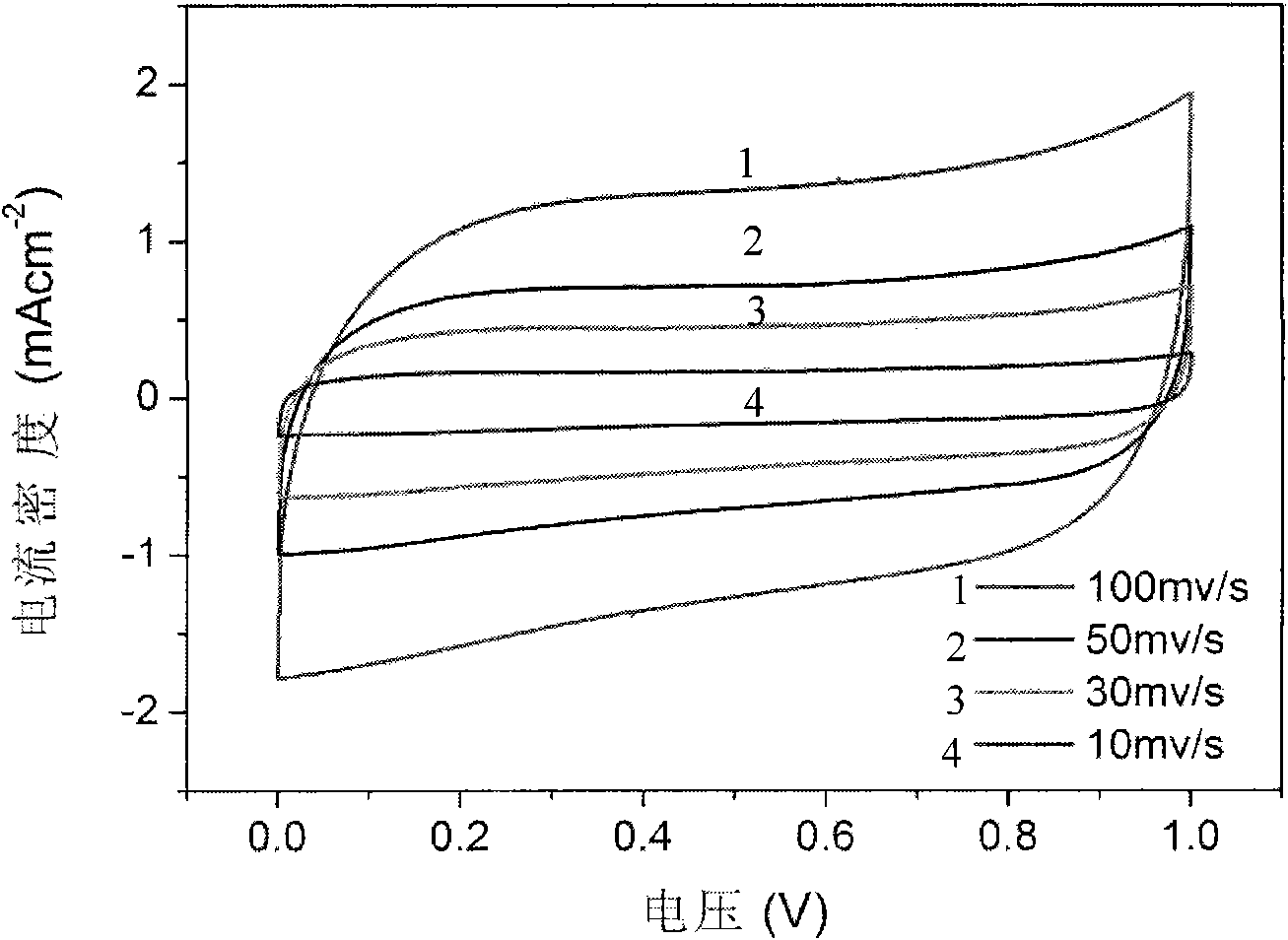

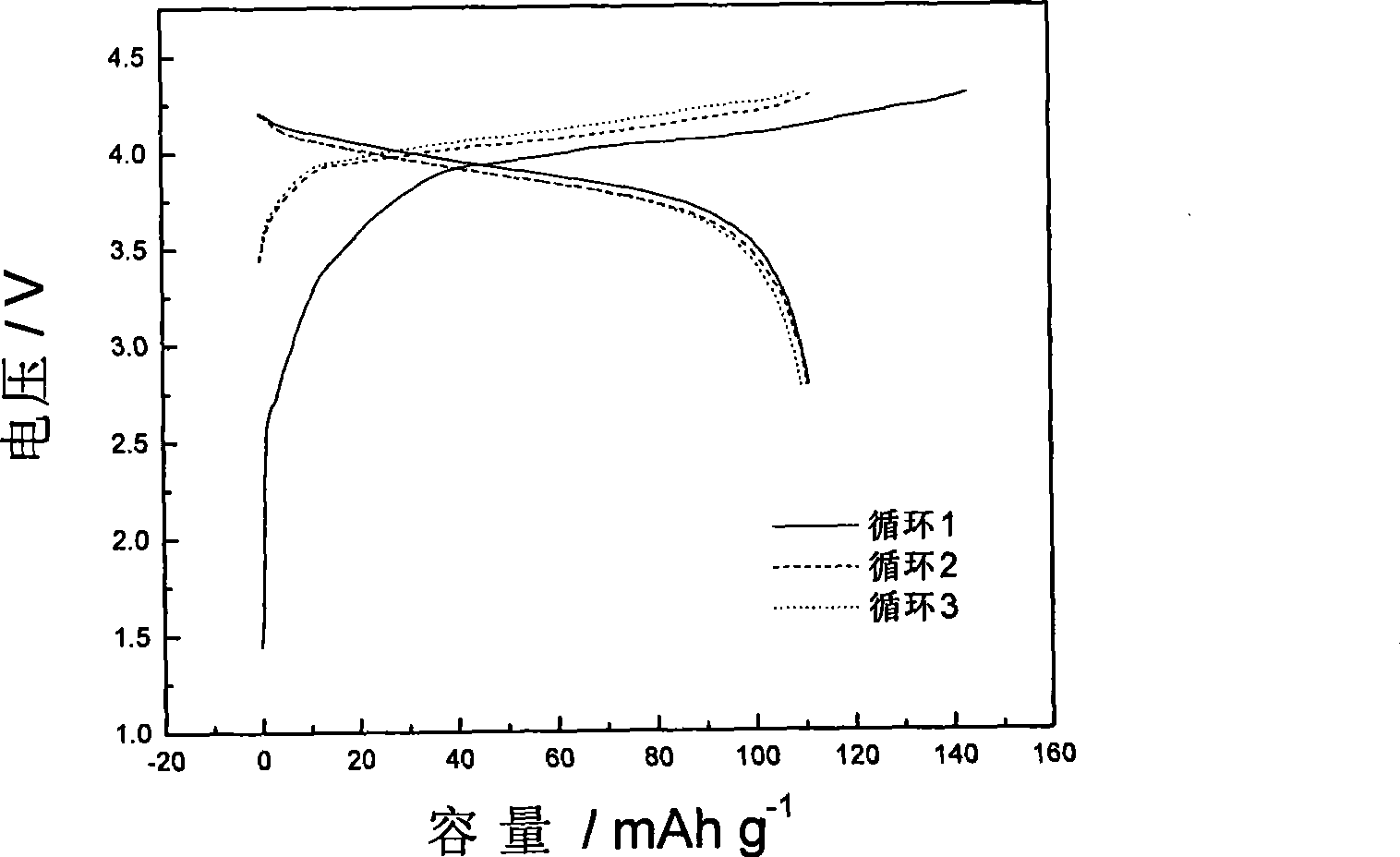

InactiveCN102403050AImprove energy storage characteristicsImprove mechanical propertiesElectrolytic capacitorsElectrode carriers/collectorsHigh energyNetwork structure

The invention relates to the field of chemical energy storage devices such as super capacitors, batteries and the like, and particularly discloses a composite material based on nanometer, a preparation method of the composite material and application in a flexible energy storage device, which solve the problem that common energy storage devices are difficult to be bent and deform. Nanometer active materials are compounded with flexible fibers, high-energy-storage characteristics of the nanometer active materials and excellent flexibility of flexible fiber materials are integrated, the quality percentage of the nanometer active materials ranges from 0.1% to 40%, the rest components of the composite material are the flexible fibers, the flexible nanometer composite material in a three-dimensional communication network structure is formed, furthermore, the composite material can be used as an electrode active material and a current collector simultaneously so as to be assembled to form the bendable flexible energy storage device, higher specific capacity can be realized under a bending condition and is equivalent to that when the flexible energy storage device is not bent, and the composite material can be expected to be applied to the field of flexible devices in the future.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

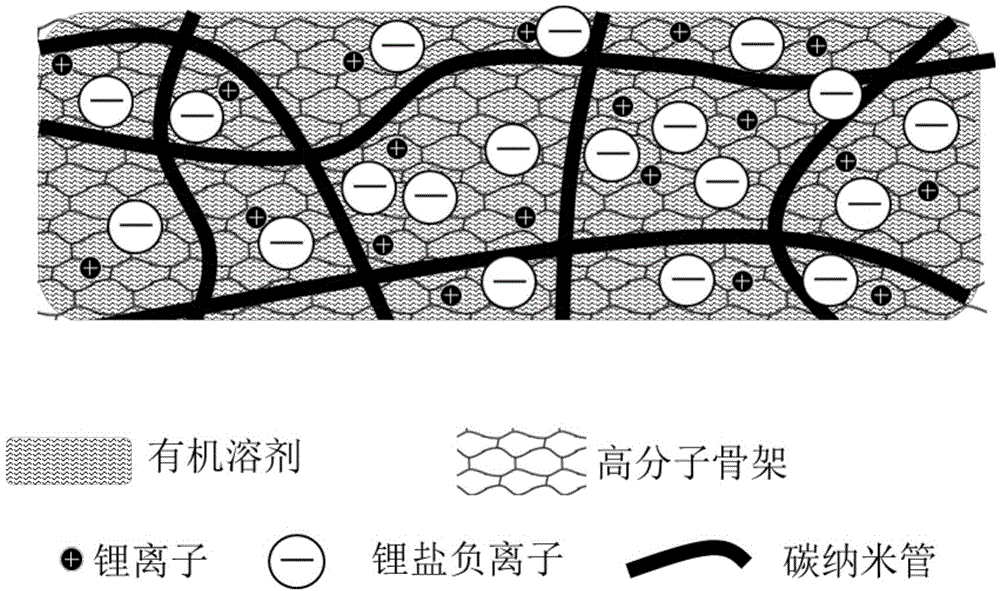

Electrolyte film and porous substrate and preparation thereof, lithium ion secondary battery

InactiveCN101388441AHave mechanical strengthGood flexibilitySecondary cellsCell component detailsPorous substratePolymer electrolytes

The invention relates to a gel-type polymer electrolyte film for a lithium ion secondary battery and a process for preparation, and a lithium ion secondary battery which contains the electrolyte film. The gel-type polymer electrolyte film for the lithium ion secondary battery can be obtained through the following method: preparing polyvinylidene fluoride nonwoven through the electrostatic spinning method, making the surface of the polyvinylidene fluoride nonwoven activate through radiating electron beams for the obtained the polyvinylidene fluoride nonwoven in air, contacting a methyl methacrylate monomer and the polyvinylidene fluoride nonwoven after the surface activation, thereby obtaining the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate. Furthermore, the lithium ion battery electrolyte film can be obtained through making the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate absorbs a certain amount of electrolytic solution. The invention develops the respective advantages in the lithium ion battery owing to using the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate, compared with singly using polyvinylidene fluoride or polymethyl methacryate or the both simple composite, and eliminates the disadvantages caused by singly using one material or several materials. The electrolyte film has high ion electrical conductivity under ambient temperature after absorbing the electrolytic solution, and can manifest excellent heavy-current discharge performance and circulation stability after being assembled in the batteries.

Owner:PANASONIC CORP +1

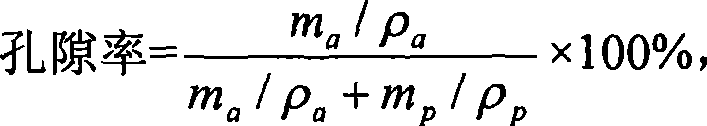

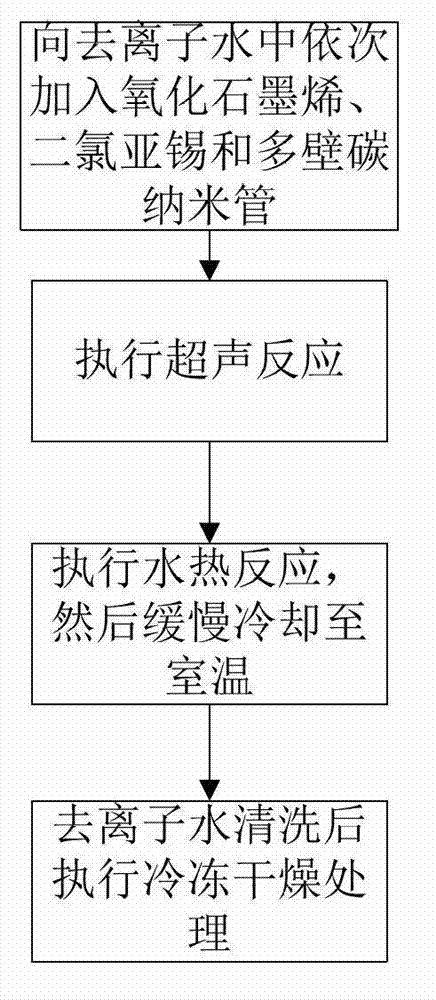

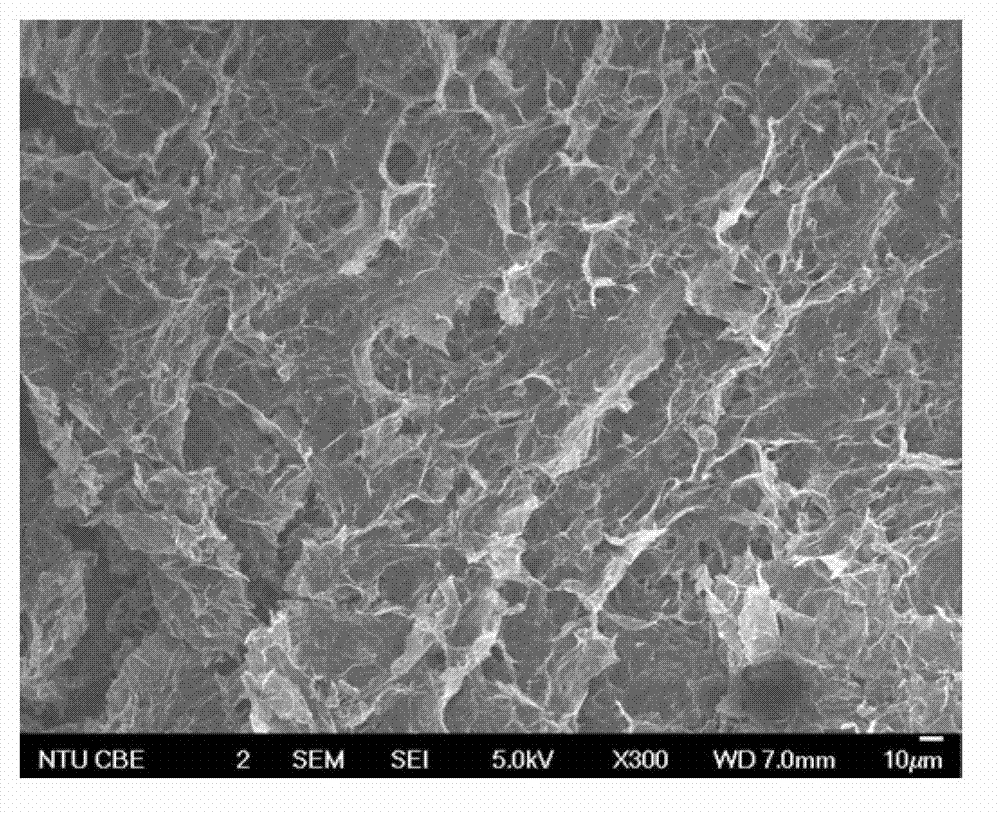

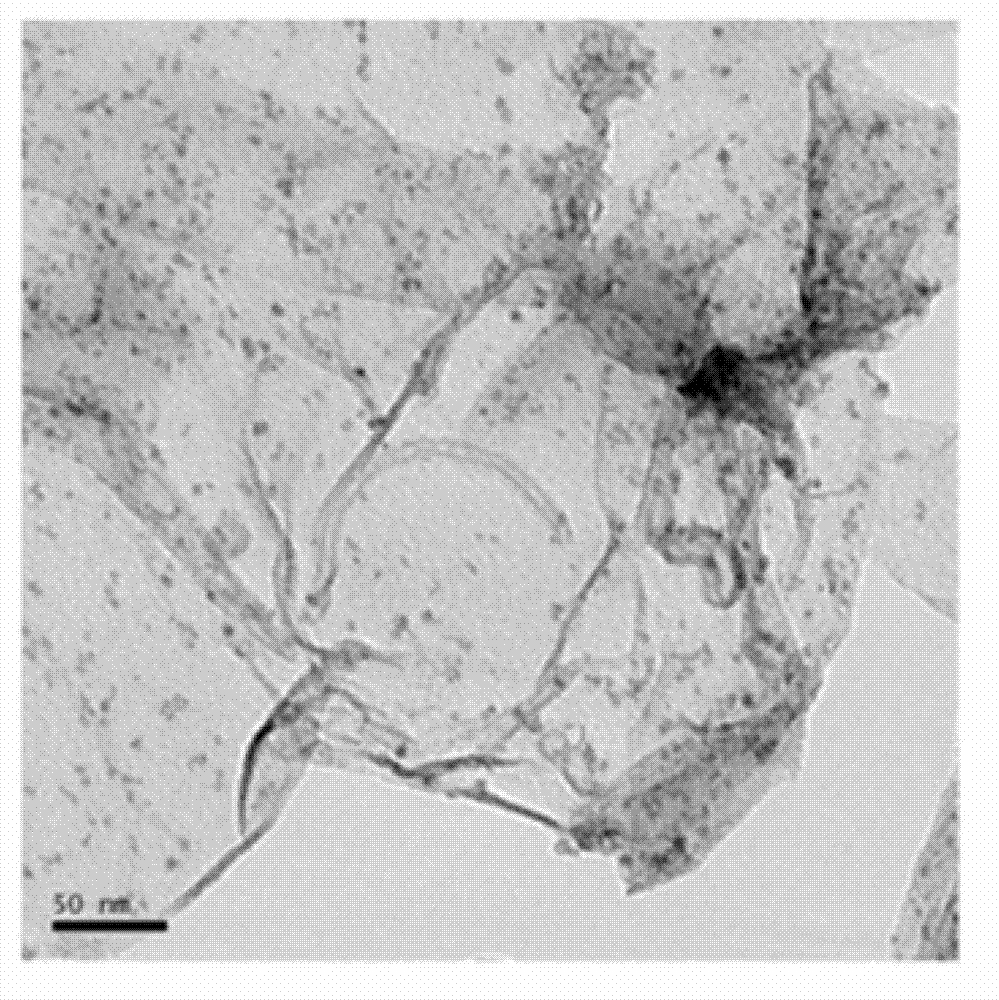

Preparation method of graphene-carbon nanotube-nano tin dioxide three-dimensional composite material and product thereof

InactiveCN103112846ALarge specific surface areaLight in massMaterial nanotechnologyCarbon compoundsTin dioxideCarbon nanotube

The invention discloses a preparation method of a graphene-carbon nanotube-nano tin dioxide three-dimensional composite material, which comprises the following steps: (a) by using deionized water as a solvent, sequentially adding graphene oxide, stannous dichloride and multiwall carbon nanotubes as solutes, and mixing; (b) performing ultrasonic reaction on the mixed solution at 25-40 DEG C under the ultrasonic power of 100-300W for 1-2 hours; and (c) transferring the solution subjected to ultrasonic reaction into a hydrothermal kettle, performing hydrothermal treatment at 120-300 DEG C for 6-72 hours, and slowly cooling to room temperature, thereby obtaining the three-dimensional-structure graphene-carbon nanotube-nano tin dioxide composite material product. The invention also discloses a corresponding product and application thereof. The method disclosed by the invention can be used for preparing the three-dimensional-structure graphene composite material in an economic environment-friendly and convenient-operation mode; and the graphene-carbon nanotube-nano tin dioxide three-dimensional composite material has the characteristics of high specific surface area, porousness, light weight, long cycle life and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

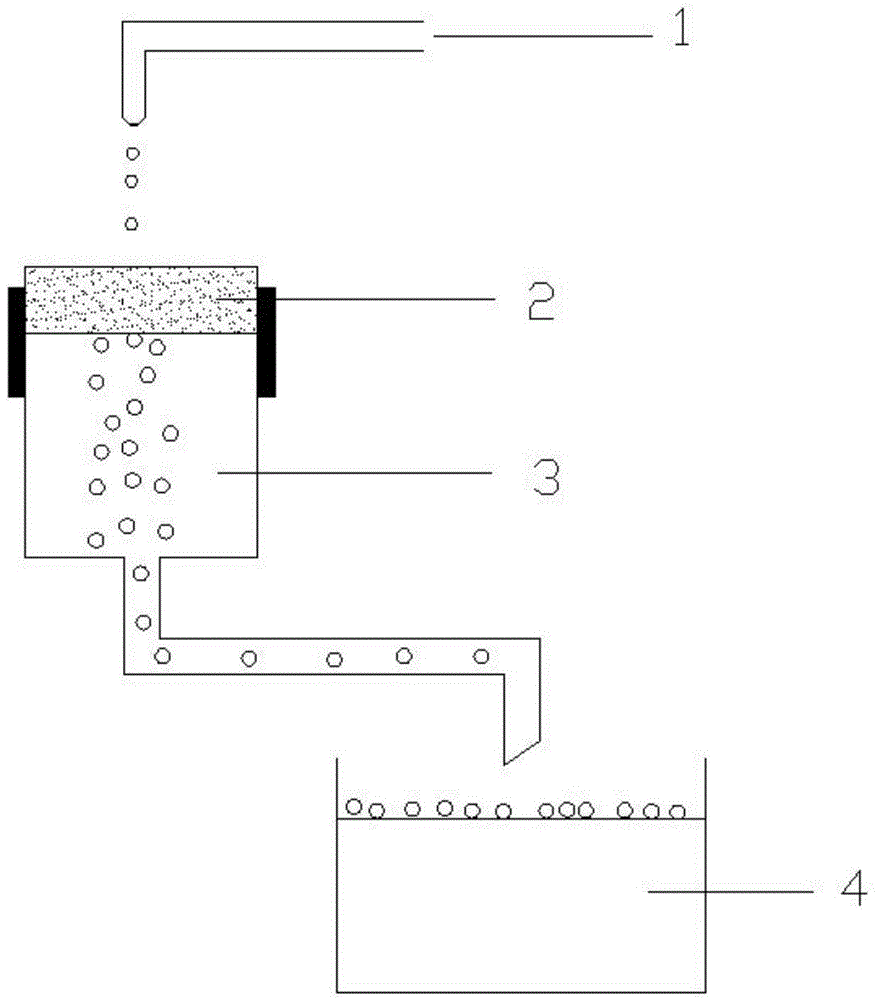

Method and device for preparing ceramsite from sludge pyrolytic biochar

ActiveCN106007776AAchieving mass utilizationEfficient curingCeramic materials productionCeramicwareSludgeBiochar

The invention discloses a method and device for preparing ceramsite from sludge pyrolytic biochar. The method includes the steps that powder grinding, humidifying, pelleting, low-temperature drying, middle-temperature presintering, high-temperature sintering and cooling are carried out on the sludge pyrolytic biochar to obtain the ceramsite. The device comprises a quantitative feeding device, a water adding device, a humidifying device, a forming and pelleting device, a drying device, a middle-temperature presintering device, a high-temperature sintering device and a cooling device. The sludge pyrolytic biochar is used for preparing the ceramsite, large-scale utilization of the sludge pyrolytic biochar is achieved, heavy metal element in the sludge pyrolytic biochar is further efficiently solidified and passivated, potential heavy metal accumulated pollution of the sludge pyrolytic biochar in the land using process is avoided, and the method and device are particularly suitable for resource utilization of sludge pyrolytic biochar with heavy metal content exceeding standard. The method is simple, practical, low in equipment investment and low in cost and has good economic benefits and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

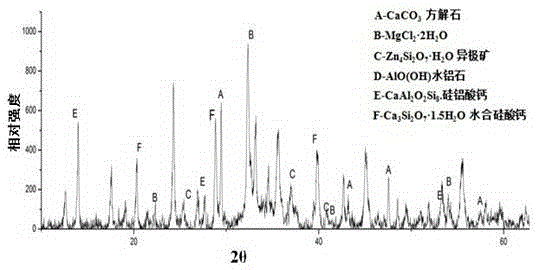

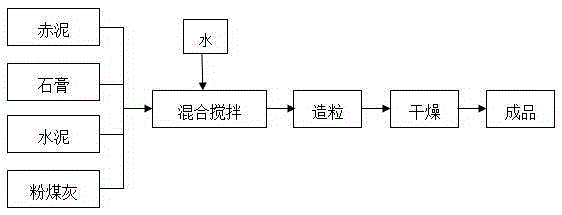

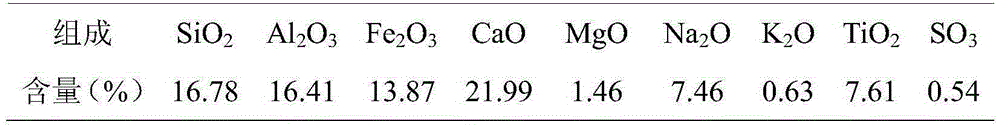

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

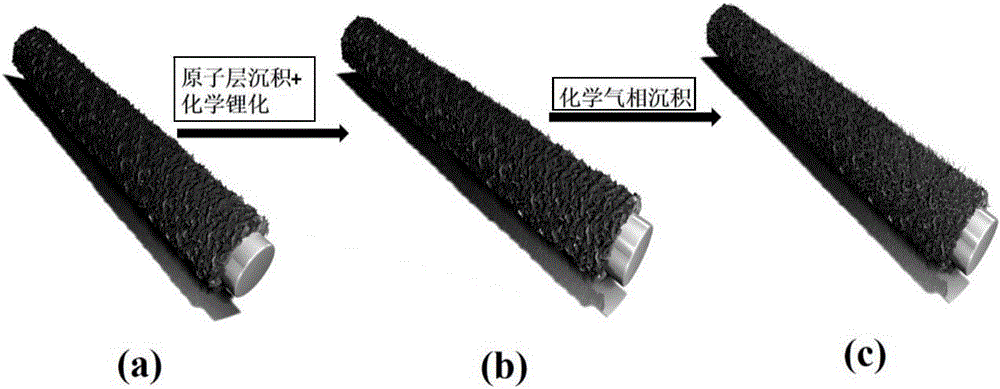

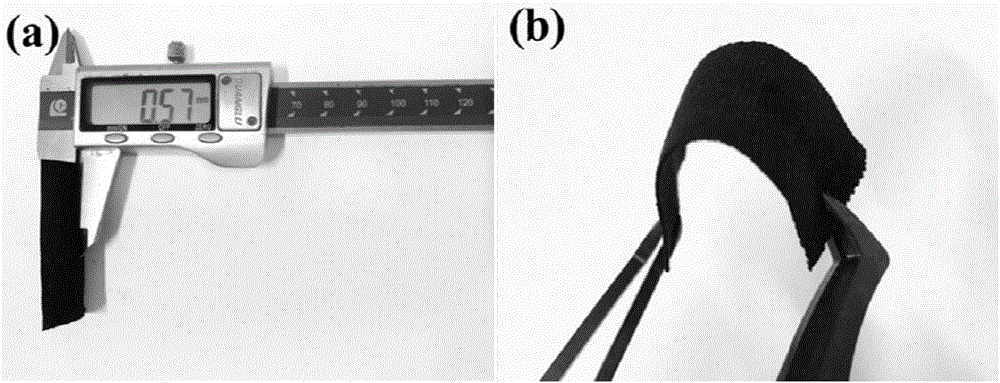

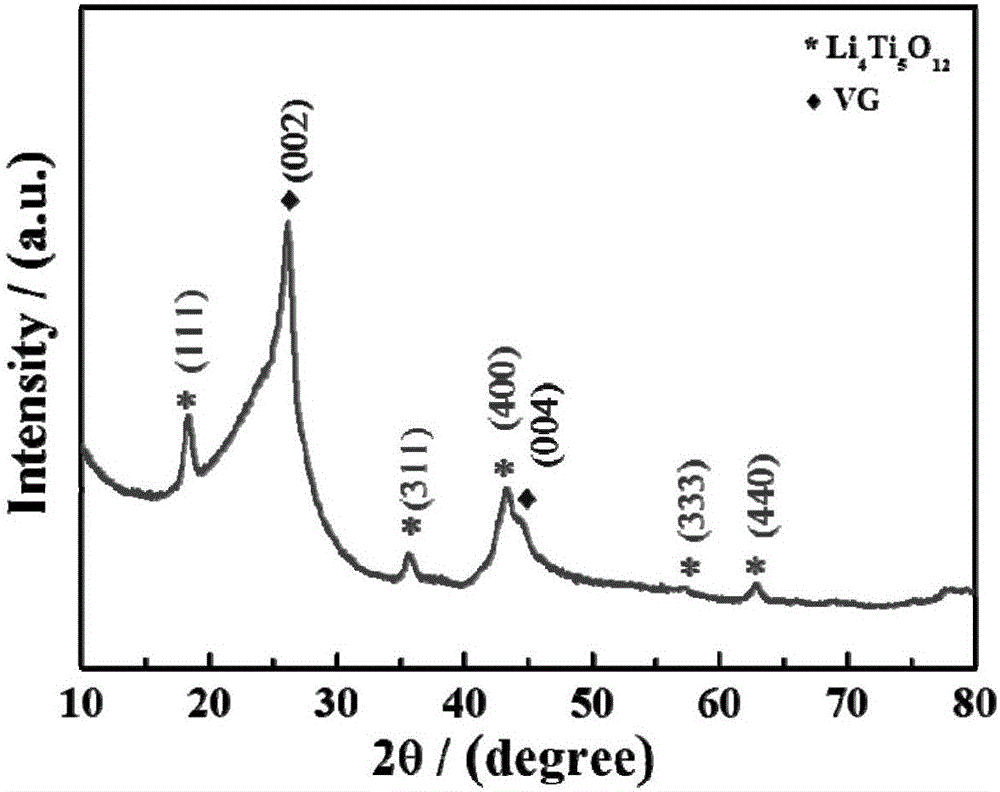

Graphene array-loaded lithium titanate/carbon nanotube composite array electrode and preparation method and application thereof

ActiveCN106784692AUniform coverageImprove performanceSecondary cellsVapour deposition manufacturingHigh rateGas phase

The invention discloses a graphene array-loaded lithium titanate / carbon nanotube composite array electrode and a preparation method and application thereof. The preparation method comprises the following steps of utilizing a microwave plasma enhanced chemical vapor phase deposition technique to vertically grow a graphene array on a carbon cloth; utilizing an atom layer deposition technique to grow TiO2 (titanium dioxide) on the obtained graphene array; dissolving lithium hydroxide into water to form a solution A; putting the vertical graphene-loaded TiO2 composite electrode material into the solution A, performing hydrothermal reaction, washing, drying and calcining; utilizing a chemical vapor phase deposition technique, using acetylene as a carbon source, and growing a carbon nanotube on the graphene array-loaded lithium titanate composite array electrode under the hydrogen and argon atmospheres, so as to obtain the graphene array-loaded lithium titanate / carbon nanotube composite array electrode. When the graphene array-loaded lithium titanate / carbon nanotube composite array electrode is used as the negative electrode material of lithium ion batteries, the high-rate property and circulating stability are excellent.

Owner:ZHEJIANG UNIV

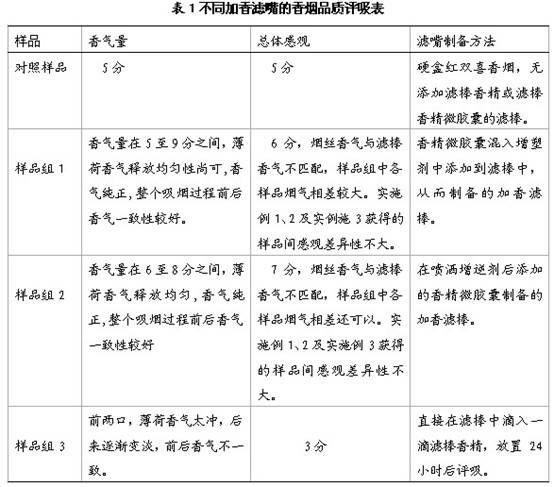

Slowly-released filter stick essence microcapsule and preparation method thereof

InactiveCN101972038AHave mechanical strengthImprove particle size uniformityTobacco preparationEssential-oils/perfumesPolymer sciencePolymer chemistry

The invention discloses a slowly-released filter stick essence microcapsule and a preparation method thereof. The slowly-released filter stick essence microcapsule is prepared from the following raw materials in parts by weight: 12-18 parts of sodium alginate, 6-12 parts of Arabic gum, 15-25 parts of emulsifier and 10-15 parts of filter stick essence. The preparation method comprises the following steps: firstly, respectively preparing an Arabic gum solution and a sodium alginate solution; then, injecting the sodium alginate solution into the Arabic gum solution proportionally to obtain a mixed wall material solution; in the stirring process, successively adding the emulsifier and the filter stick essence to obtain emulsion; standing; and carrying out high-voltage electrostatic treatment after foam is eliminated to obtain the microcapsule. The slowly-released filter stick essence microcapsule prepared by the invention has the advantages that the embedding rate is more than 80%, the particle diameter uniformity is good, the essence retention rate is more than 85% after the microcapsule is stored for 6 months at 20 DEG C, and the release rate of the essence microcapsule at 40 DEG C is about 6 times of the release rate of the essence microcapsule at 20 DEG C.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

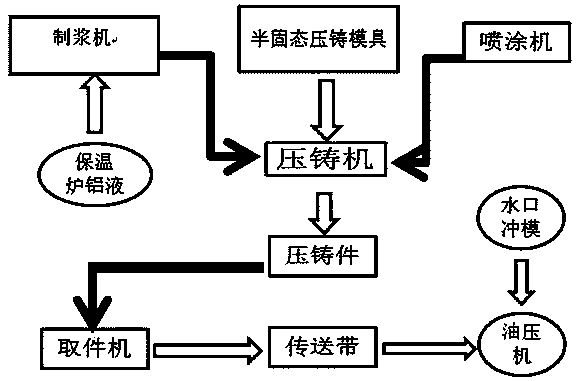

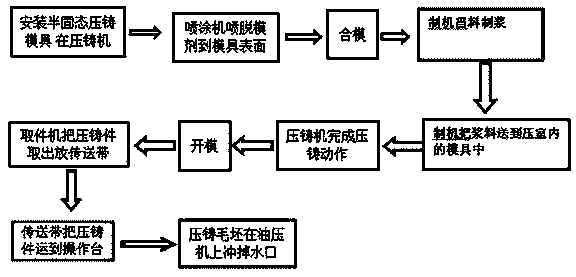

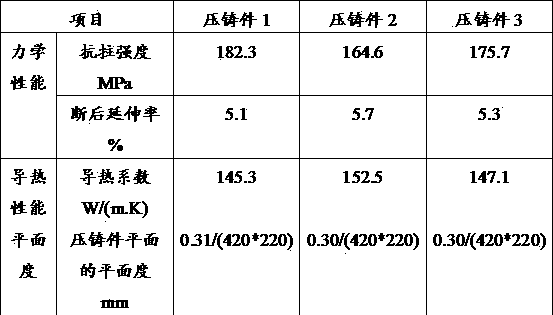

Die-casting process method for semi-solid state metal die-cast formation

The invention discloses a die-casting process method for semi-solid state metal die-cast formation. The die-casting process method includes using a semi-solid state die-casting machine as a processing device and using a pulper as a device for preparing and delivering a semi-solid state slurry; adding a metal modificator to a liquid metal raw material during preparation of the semi-solid state slurry so that the liquid metal raw material generates more crystal nucleuses, and die-cast member products have better mechanical properties. According to the die-casting process method, by means of a die-cast manner of the semi-solid state slurry, the die-cast member products are compact interiorly or do not produce air holes during a die-casting process, the best interior structure and mechanical properties of the die-cast member products and product qualities are guaranteed; by means of semi-solid state slurry die-casting, compared with traditional high-speed high-pressure injection formation processes, the die-casting process method has the advantages that during mold stripping, die-cast members are low in temperature and extremely small in deformation amount and need not complicated surface processing, and the best shapes and surface smoothness of products can be guaranteed.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

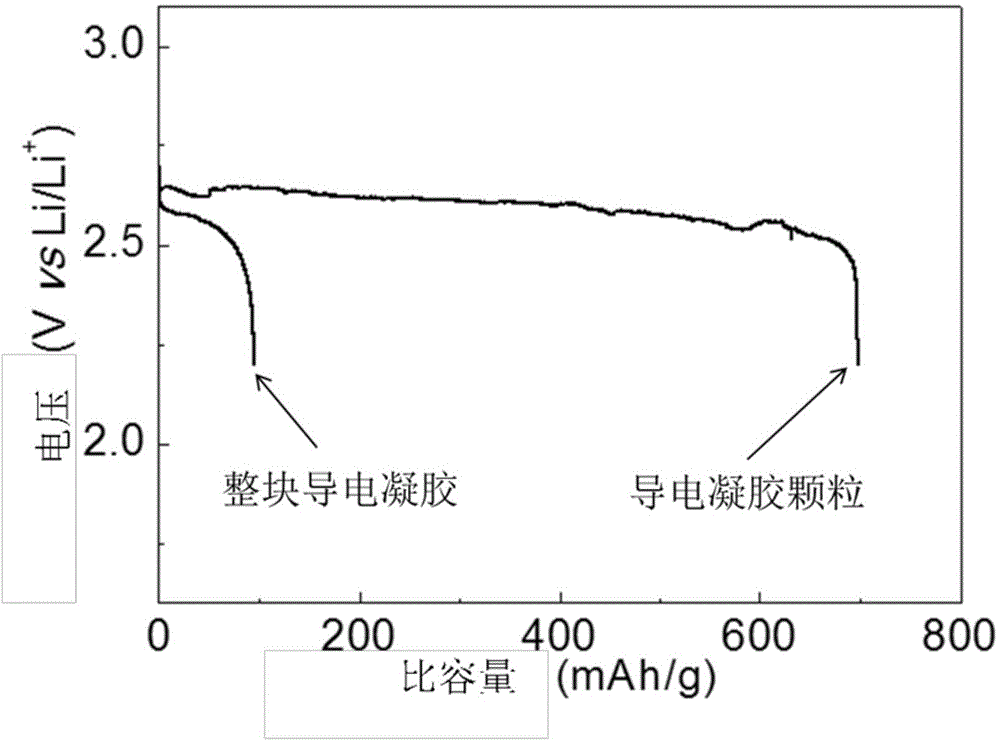

Air positive electrode constructed by conductive gel particles and lithium air battery

ActiveCN104659375AEasy and quick passFast deliveryFuel and primary cellsCell electrodesSolid structureLithium–air battery

The invention discloses an air positive electrode constructed by conductive gel particles and a lithium air battery. The air positive electrode is characterized by being of a full-solid structure and comprising particles with arbitrary shapes, wherein the particles are prepared from conductive gel, gaps are formed among the particles, electrons and ions can be simultaneously conducted by conductive gel, and the size range of the particle sizes of the particles is 10-500 microns; the particles are stacked to form a laminated structure, and the thickness of the laminated structure is 50 microns to 5 millimeters. A battery cell of the lithium air battery is of a multi-layer winding type structure or a multi-layer laminating type structure and is formed by winding and laminating a plurality of repetitive units, and each repetitive unit comprises the air positive electrode. A rapid gas dispersion channel is formed in the air positive electrode and can be prepared to be relatively thick, so that the problem that oxygen is difficult to diffuse is effectively solved, and the air positive electrode can be truly input into actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing inorganic particle/epoxy resin super hydrophobic film

The invention discloses a method for preparing an inorganic particle / epoxy resin super hydrophobic film. The method is characterized by comprising the following steps: (1) preparing amination nano silica and nano titanium dioxide particle; (2) preparing coating sol; (3) coating the sol on a substrate material; (4) performing post-treatment on substrate material, and finally preparing the inorganic particle / epoxy resin super hydrophobic film. The method is simple in process and good in repeatability, and the prepared coating has excellent super hydrophobicity and self-cleaning property and is suitable for industrial production of super hydrophobic paint.

Owner:QILU UNIV OF TECH

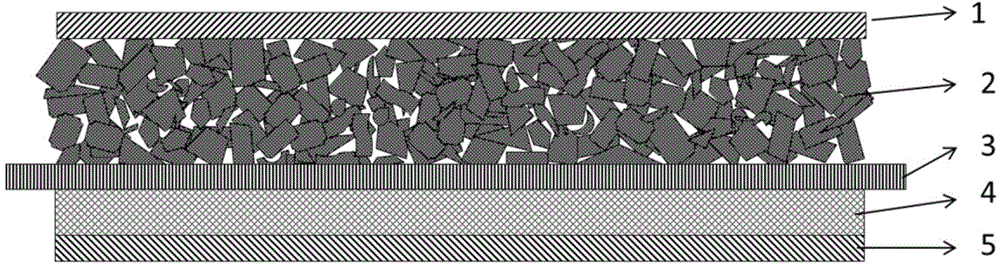

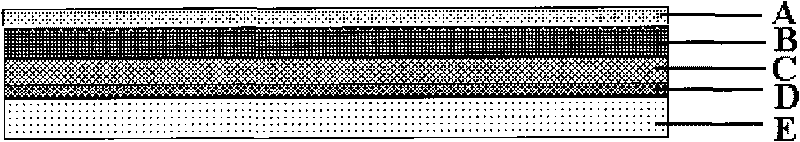

Back film for solar module

ActiveCN101764163AHigh gas barrierGood mechanical strengthSynthetic resin layered productsPhotovoltaic energy generationChemistryWater vapor

The invention discloses a back film for a solar module; the back film comprises an outer surface fluoride containing layer, a middle layer and an inner surface ethylene- vinyl acetate copolymer layer; the middle layer comprises a polyester layer, an ethylene-vinyl alcohol copolymer layer and a bonding layer; the middle layer is prepared by co-extruding the polyester material layer, the ethylene-vinyl alcohol copolymer layer and the bonding layer; the outer surface fluoride containing layer is a fluoride containing film compounded on the polyester layer of the middle layer or the fluoride containing coating coated on the polyester layer of the middle layer; and the inner surface ethylene- vinyl acetate copolymer layer is applied on the bonding layer of the middle layer by curtain coating. The back film of the solar module provided by the invention has the advantages of low water vapor transmission rate and high insulation performance, not only has excellent barrier and insulation performance, but also has the packaging performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

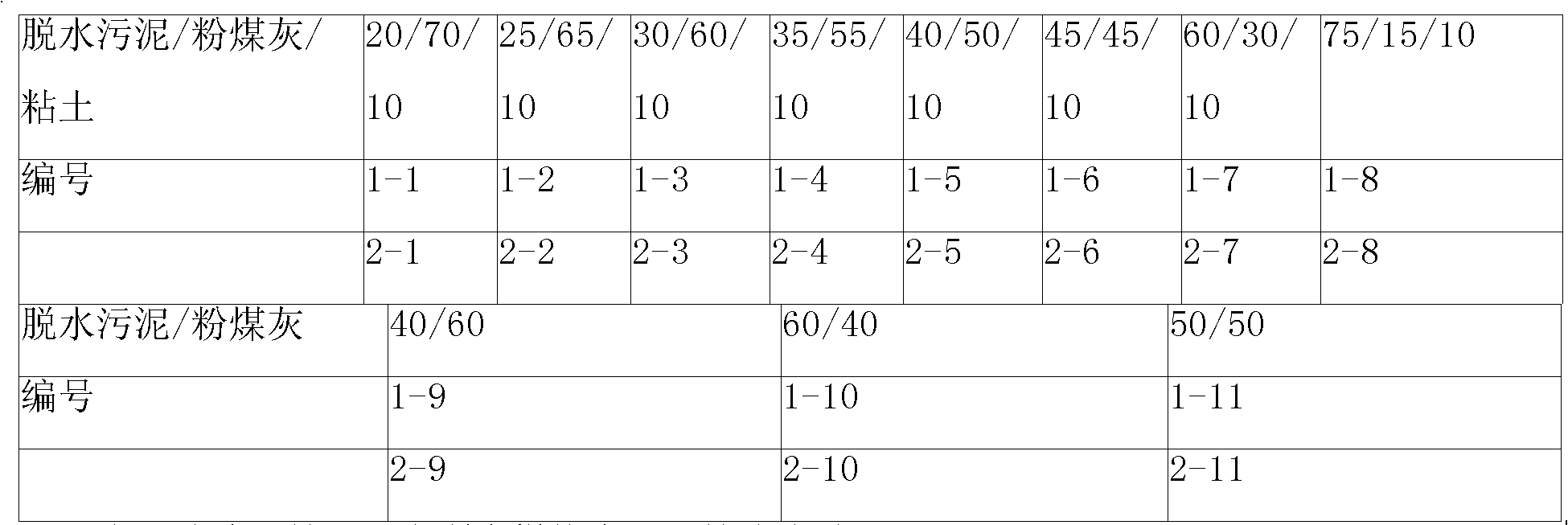

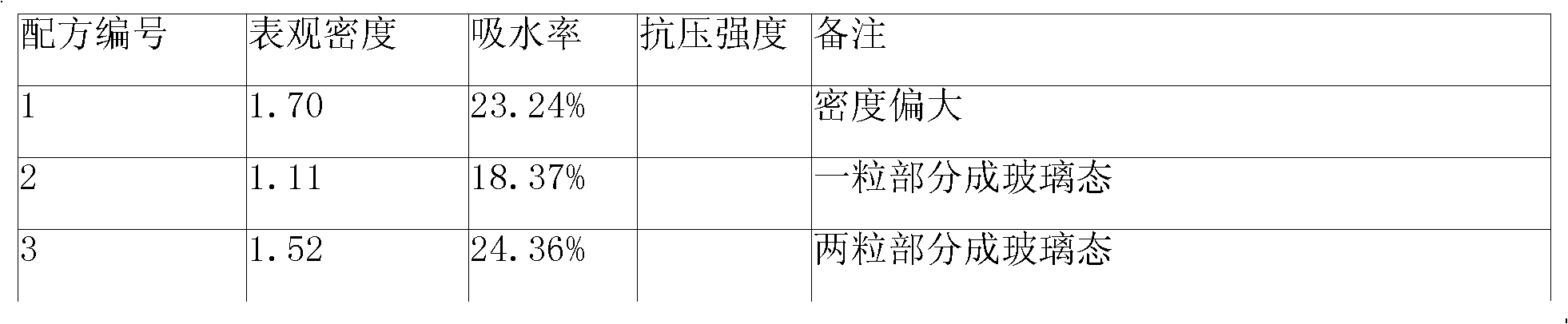

Ceramic aggregate biological filler and preparation method thereof

InactiveCN101514112ALight weightHave mechanical strengthSustainable biological treatmentCeramic materials productionSludgeExpanded clay aggregate

The invention discloses ceramic aggregate biological filler and a preparation method thereof. The filler uses coal ash and sludge as main raw materials, clay as binder, and aluminum sulfate octadeca hydrate or hydrogen peroxide solution as foaming agent, and is prepared by mixing the raw materials, the binder, the foaming agent and water, granulating and sintering at high temperature. Compared with the prior art, the main raw materials of the invention are solid waste materials, thereby reducing pollution of coal ash and sludge to environment and treating waste materials by waste materials; the coal ash can be directly used without complicated pretreatment; organic substance and inorganic substance in the sludge are used to reduce resource waste; hole structure of sludge ceramic aggregate is improved, the ceramic aggregate has loose and porous structure for enriching a great amount of microorganism in sewage, thereby being suitable for biological filler can realizing sewage treatment with high efficiency and low cost; the invention has simple manufacturing process, low cost, strong adaptability, and good economic benefit and social benefit.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU

Thermosetting resin composition and preparation method and using method thereof

InactiveCN101985514AHas elastic strengthHave mechanical strengthBallastwayRailway track constructionRevolutions per minuteChemistry

The invention discloses a thermosetting resin composition and a preparation method and a using method thereof. The composition comprises a substance A and a substance B in a mass ratio of 100:1-100, wherein the substance B is a curing agent; the substance A consists of the following components in part by weight: 100 parts of thermosetting resin, 10 to 600 parts of filler, 1 to 10 parts of pigment, 0 to 100 parts of activated or non-activated thinner, 0 to 5 parts of ultraviolet absorbent, 0 to 5 parts of antioxidant, 0 to 2 parts of antifoaming agent and 0 to 5 parts of coupling agent; all the components of the substance A are stirred at the temperature of between 5 and 180 DEG C and the stirring rate of 10 to 3,000 revolutions per minute and mixed in vacuum for 0.1 to 10 hours and the substance A is obtained by packaging the mixture; and the substance B is obtained by packaging the curing agent. The composition is used as an elastic filling connection material among ballastless trackslabs of a railway and has high adhesion, ultraviolet irradiation resistance, wet and heat ageing resistance and chemical corrosion resistance, and certain elasticity and mechanical strength.

Owner:CHANGSHU JIAFA CHEM

Fully degradable biomaterial and product thereof

InactiveCN102702696AGood technical effectSave storage spaceFlexible coversWrappersLow-density polyethyleneMasterbatch

The invention relates to a fully degradable biomaterial and a thin film product thereof, and discloses the fully degradable biomaterial which consists of 75-90 percent by weight of PBAT (Poly (Butylene Adipate-co-Terephthalate)) and the balance of PLA (Poly Lactic Acid) and a thin film product prepared by taking the fully degradable biomaterial as a master batch. The fully degradable biomaterial and the thin film product thereof have the advantages of full degradability, water resistance, oil resistance, high tensile strength, high flexibility, physical and chemical properties similar to those of an LDPE (Low-Density Polyethylene) plastic thin film, single component, simple process, low energy consumption required for production and being a superior alternative for the LDPE plastic thin film.

Owner:ZHEJIANG HUAXIA PACKING CO LTD

Spherical forming Cu base metal organic skeleton-graphene oxide composite material and preparation method of spherical forming Cu base metal organic skeleton-graphene oxide composite material

ActiveCN104226256AShort reaction timeNo solvent requiredOther chemical processesAlkali metal oxides/hydroxidesMetal-organic frameworkOxide composite

The invention belongs to the technical field of metal organic skeleton material forming and discloses a preparation method of the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The method comprises the following specific steps: proportionally mixing water, methyl hydroxypropyl cellulose and silicate resin with Cu base organic skeleton-graphene oxide composite porous material powder which is synthesized by using a mechanical ball milling method so as to obtain a mixture, adding the mixture into a pelletizer, pelleting, and drying, so as to obtain the spherical forming Cu base metal organic skeleton-graphene oxide composite material. The spherical forming Cu base metal organic skeleton-graphene oxide composite material prepared by using the preparation method has the advantages of relatively large surface area, open pore structure and the like and has the special appearance, volume, mechanical strength, toughness and water resistance which are necessary for an actual industrial application.

Owner:SOUTH CHINA UNIV OF TECH

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method, and using method of the same used as filling material of railway plate type dreg-free track convex block. The polyurethane resin composition is mainly used as filling material of railway plate type dreg-free track convex block, and mainly includes: polyether or polyester polyol, isocyanate or prepolymer of the same, pigment, filling and other auxiliary agent. Advantages of the prepared polyurethane resin are: construction manufacturability is better, bonding to cement of cured resin is good; the polyurethane resin is resistant of ultraviolet ray irradiation, moisture, heat, ageing and fatigue, and owns appropriate elasticity and integrated mechanical capability.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

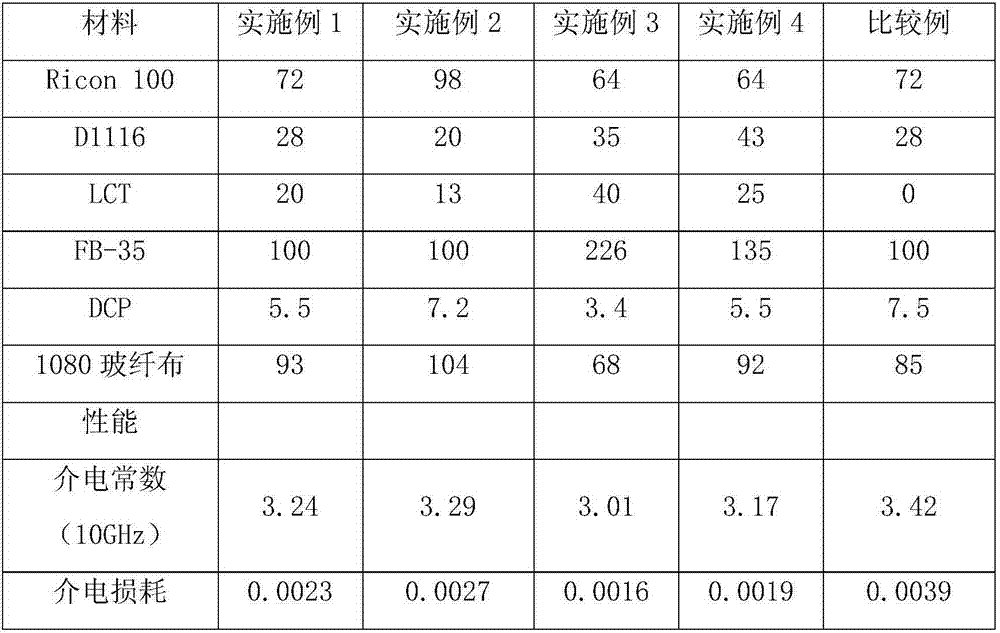

Prepreg composition with low dielectric constant, copper-clad plate and method for manufacturing same

ActiveCN107964203AImprove heat resistanceLow dielectric constantLamination ancillary operationsLaminationFiberDielectric loss

The invention provides a prepreg composition with a low dielectric constant, a copper-clad plate and a method for manufacturing the same. The prepreg composition with the low dielectric constant for the copper-clad plate comprises thermoset resin, fillers, curing agents and reinforcement fibers. The copper-clad plate which is a copper-clad laminated plate made of the prepreg composition comprisesa plurality of stacked prepregs and copper foils. The corresponding copper foils cover the single surface or double surfaces of each prepreg by means of compression. The prepreg composition, the copper-clad plate and the method have the advantage that the copper-clad plate has a low dielectric constant and a low thermal expansion coefficient and is low in dielectric loss.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Lithium silicon alloy material with surface modification layer, preparation method thereof, electrode and electrochemical energy storage device and negative electrode lithium-supplementing method

ActiveCN108565414AProcess stabilityImprove the first charge and discharge efficiencyFuel and secondary cellsCell electrodesSilicon alloyHigh energy

The invention discloses a lithium silicon alloy material with a surface modification layer, a preparation method thereof, an electrode and an electrochemical energy storage device and a negative electrode lithium-supplementing method. The lithium-silicon alloy material is in the form of particles, the particle size of the particles is 0.1 to 50 micrometers, and the lithium-silicon alloy material comprises lithium-silicon alloy particles and a surface modification layer which covers the exposed surfaces of the lithium-silicon alloy particles. The outer layer of the surface modification layer isused for preventing the lithium-silicon alloy from coming into contact with the external environment, so that the lithium-silicon alloy can be stably stored and used in the dry air, and the reactionbetween the material and the electrolyte during the electrochemical cycle can be effectively prevented, and the cycle stability is improved; in addition, the lithium silicon alloy with the surface modification layer can be used as the negative electrode alone, the first efficiency of the battery can be improved, and can also be used as an additive in other negative electrodes without lithium element to supplement lithium and reduce the loss of effective lithium, and a lithium ion battery with high energy density is prepared.

Owner:CHINA ENERGY LITHIUM

Preparation method of titanium dioxide-silicon dioxide-epoxy resin composite super-hydrophobic coating

InactiveCN102702931AImprove self-cleaning effectPhotocatalyticEpoxy resin coatingsEpoxyPolymer science

The invention discloses a preparation method of a titanium dioxide-silicon dioxide-epoxy resin composite super-hydrophobic coating. The preparation method is characterized by comprising following steps of (1) preparing epoxy modified nano titanium dioxide sol; (2) preparing a vinyl decorated nano silicon dioxide ball; (3) preparing a polymer grafted nano silicon dioxide ball; (4) preparing coating sol; and (5) coating on a substrate material, and solidifying and cross-linking the substrate material to obtain the titanium dioxide-silicon dioxide-epoxy resin composite super-hydrophobic coating. The process utilized by the method is simple, and is good in repeatability; and the prepared coating has excellent super-hydrophobic performance and excellent self-cleaning performance and is suitable for the industrialized production of the super-hydrophobic paint.

Owner:QILU UNIV OF TECH

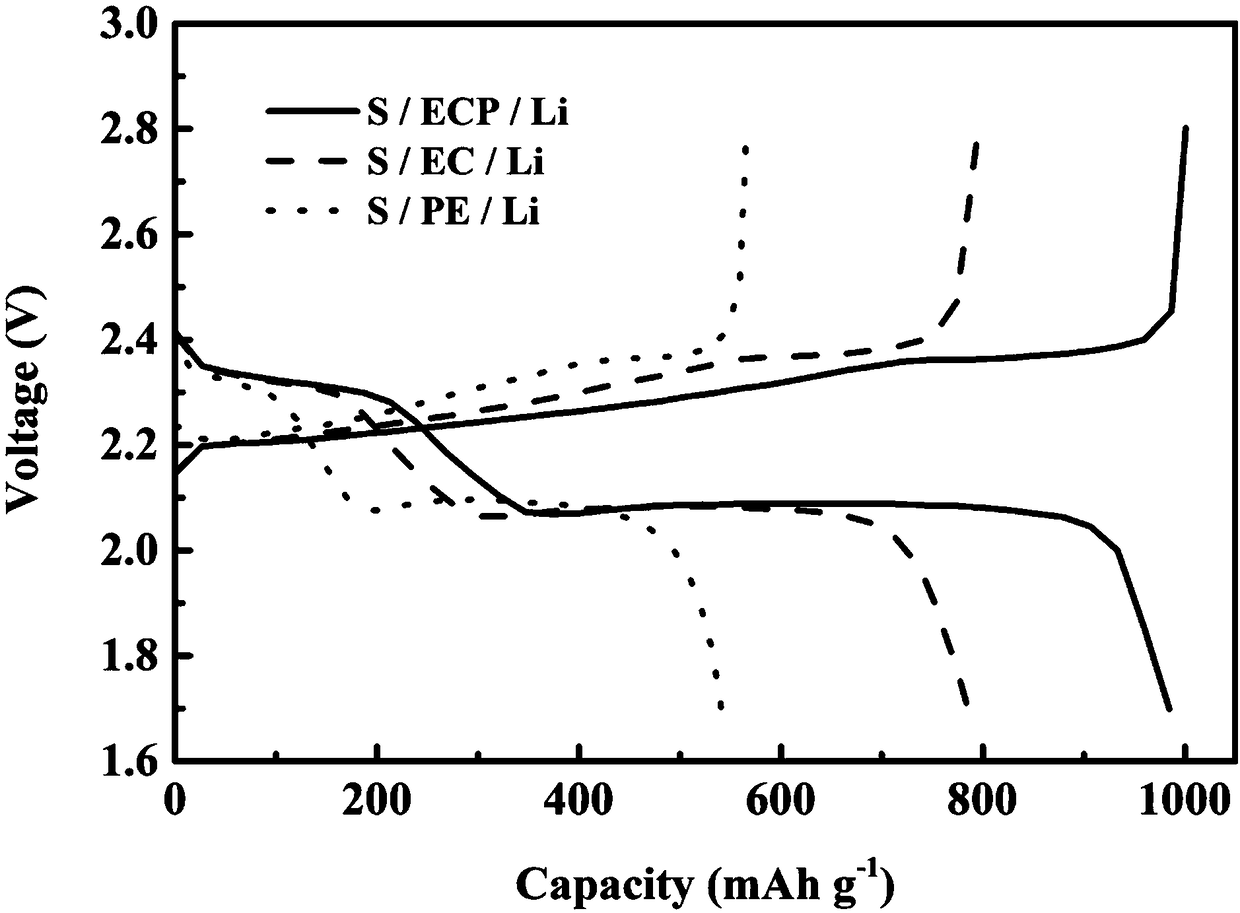

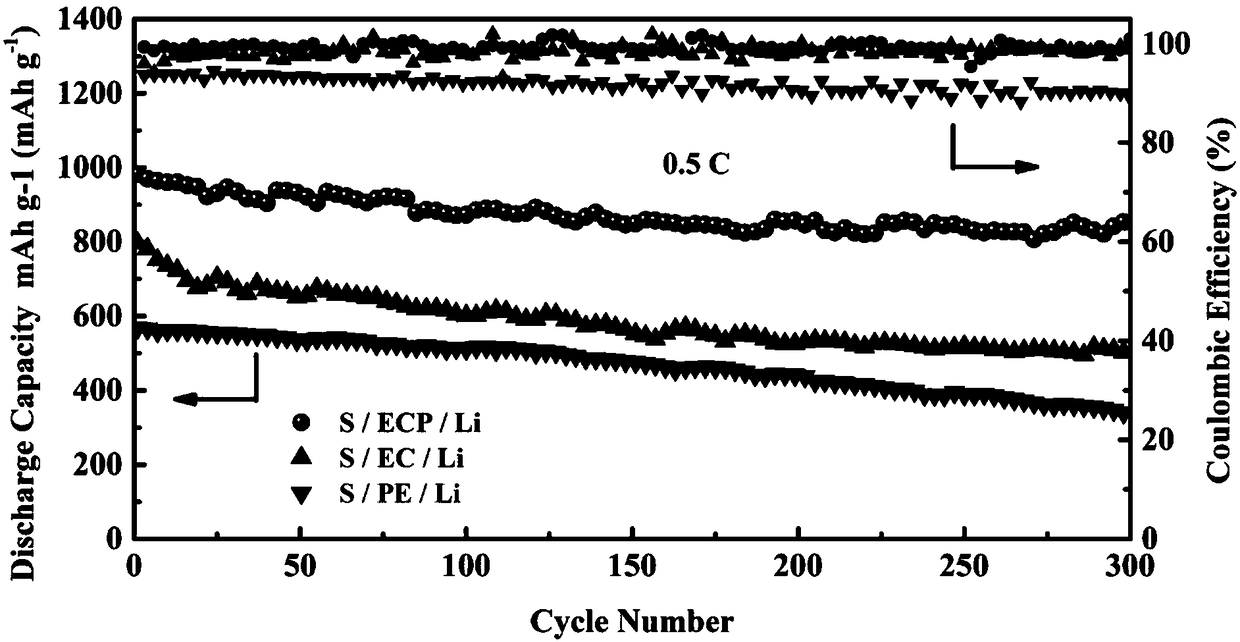

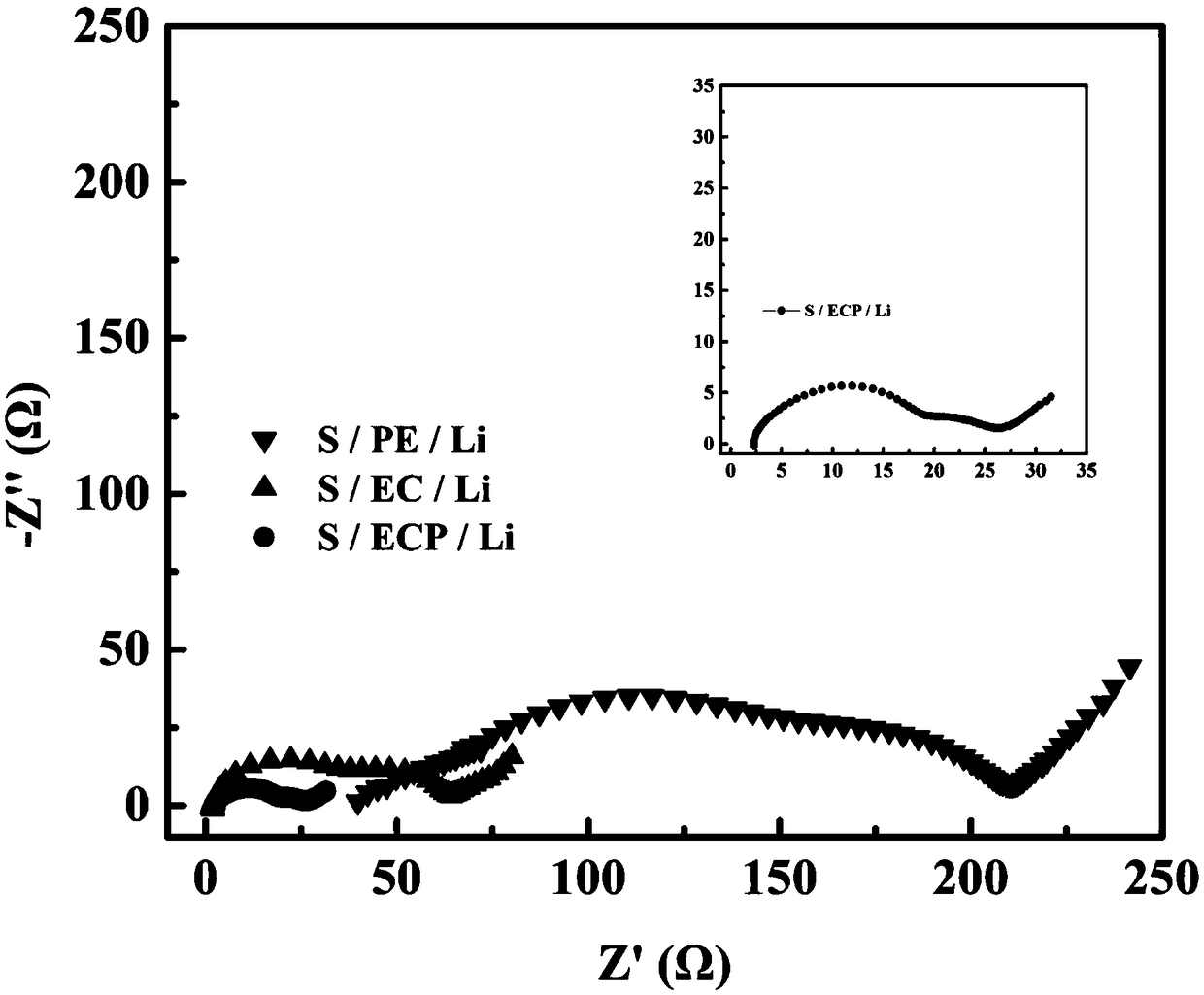

A functional separator for a lithium-sulfur battery, a preparation method thereof and an application thereof in lithium-sulfur battery

ActiveCN109103399AImprove adhesionImprove stabilitySecondary cellsCell component detailsCyclic processAdhesive

The invention relates to a functional separator for a lithium sulfur battery, and a preparation method and application thereof, belonging to the technical field of electrochemistry. The functional separator of the invention is composed of a polymer separator matrix and a functional modification layer applied one side surface of the polymer separator matrix, wherein the functional modification layer comprises a binder, a conductive carbon material and a dendritic branched macromolecule. The adhesive of the invention has good adhesion and high stability. The conductive carbon material has a veryhigh electron conduction rate, can improve the utilization rate of the active substance and greatly reduce the internal impedance of the battery. The dendritic branch macromolecule contains more organic functional groups, the dendritic branched macromolecule has chemisorption to the polysulfide generated in the sulfur positive electrode region during the cycle, and the carbon material has physical adsorption to the dissolve polysulfide, thereby effectively inhibiting the shuttle effect in the lithium-sulfur battery. Therefore, the lithium sulfur battery prepared using the functional separatordescribed in the present invention exhibits excellent cycle performance and rate performance.

Owner:WUHAN UNIV

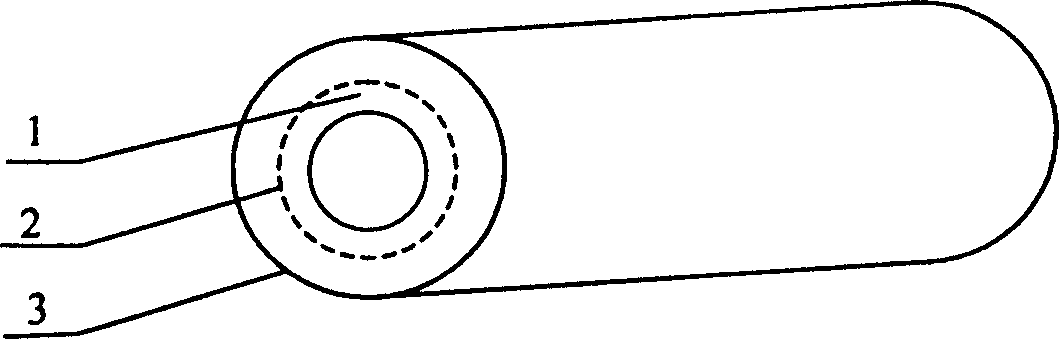

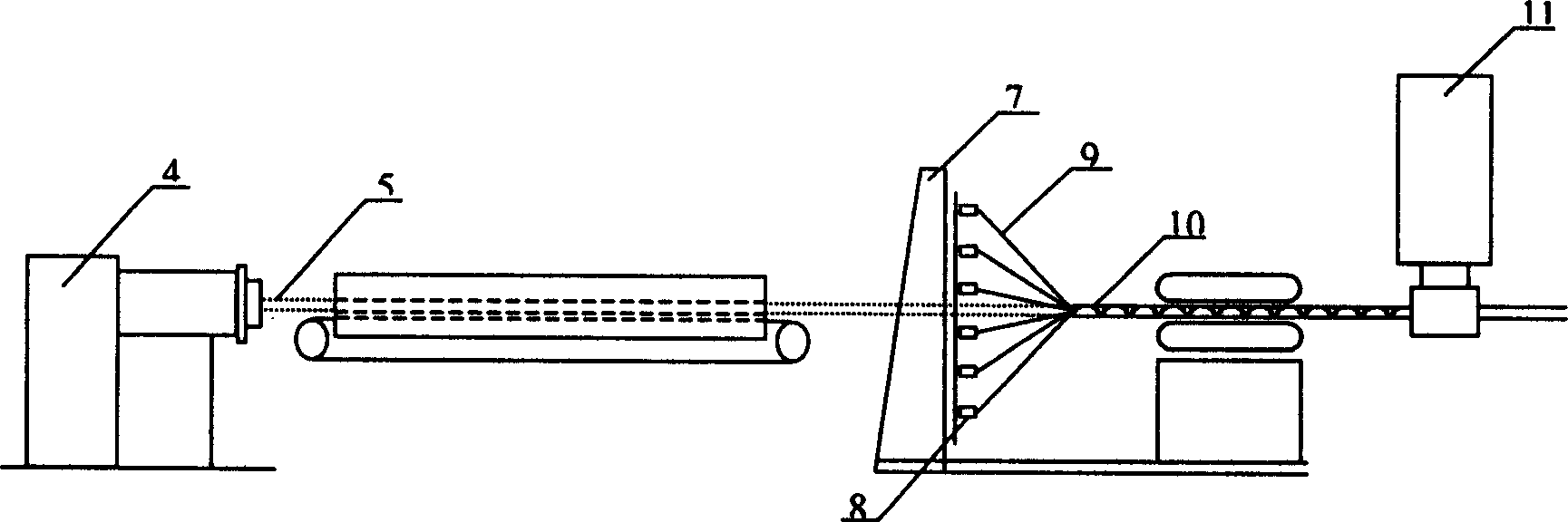

Pressure resisting Silicon rubber hose and its mfg. method

A pressure silicon rubber hose and its manufacture method adapted for use in food and pharmaceutical industries comprises an inner rubber layer, a fibre-braided reinforcement and an outer rubber layer. The main material of the inner and outer layers is silicon rubber. The inside diameter of the inner rubber layer after prevulcanizing process is phi 8~25 mm and the thickness is 2~4 mm. The prevulcanizing can carry out in a hot-air drying tunnel or in a water bath vulcanizing bank.

Owner:上海尚翔汽车胶管有限公司

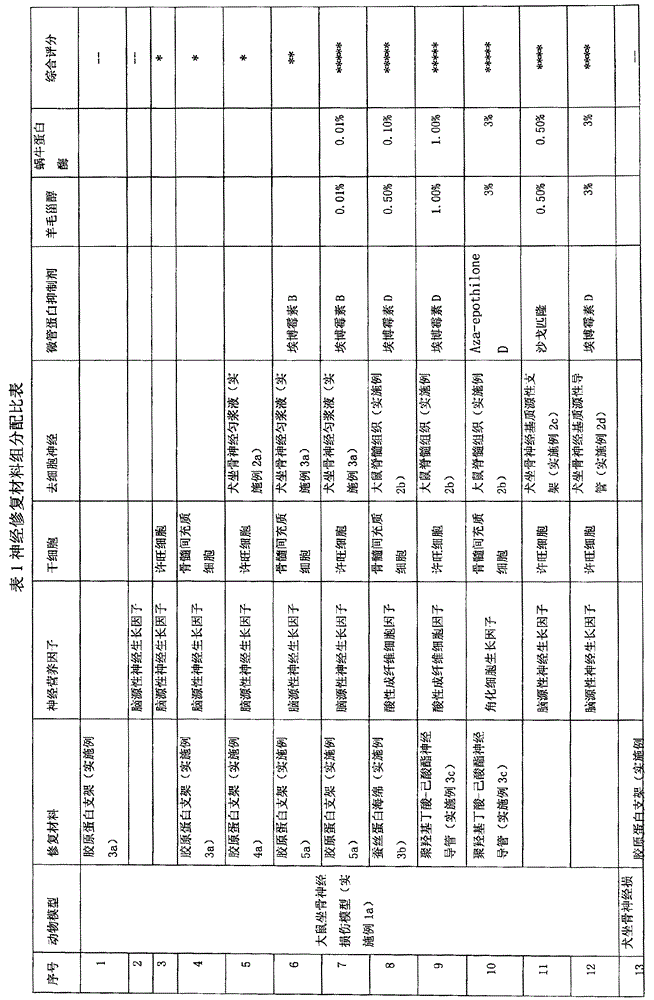

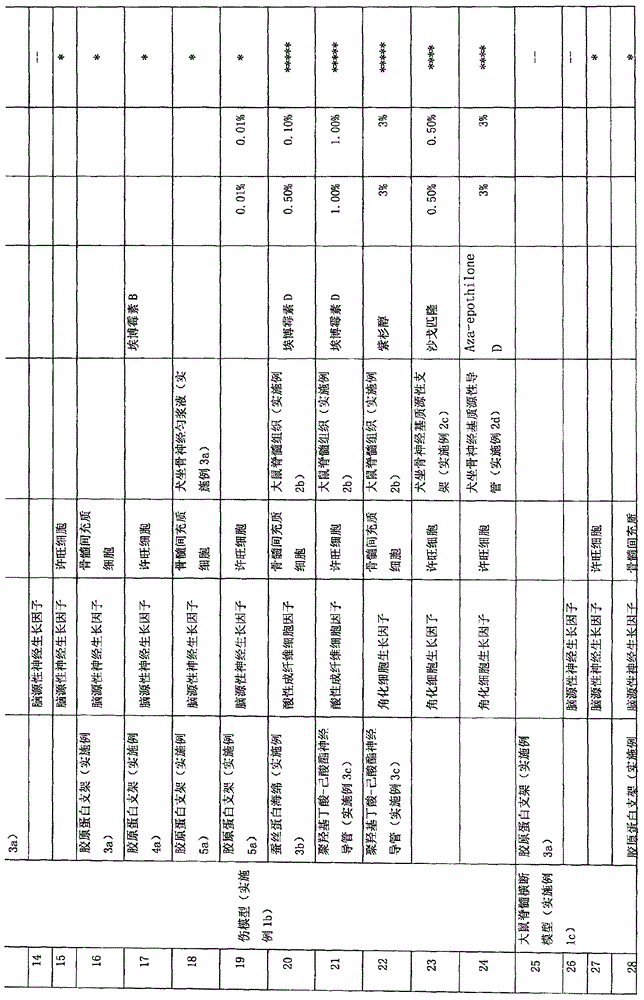

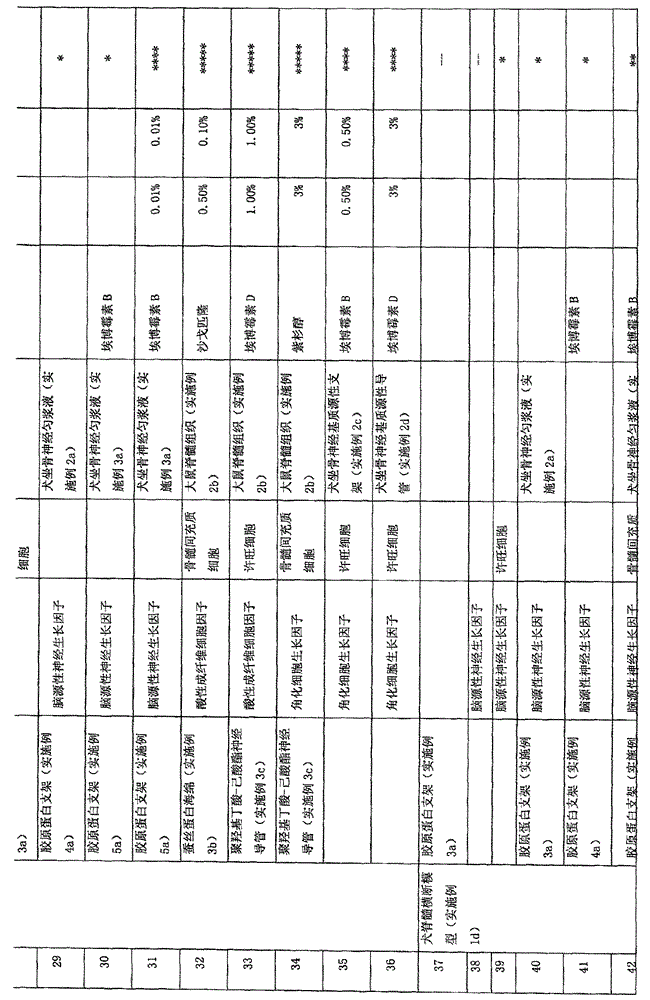

Neural restoration material combined with acellular nerve application

ActiveCN105169486AGood biocompatibilityNo toxicityProsthesisBiocompatibility TestingNeurotrophic factors

The invention aims to provide a neural restoration material combined with the acellular nerve application. The neural restoration material is prepared from nerves of an acellular allogene or acellular heterogeneous living organism, a restoration material, a microtubulin inhibitor, neurotrophic factors and stem cells. The neural restoration material disclosed by the invention has good biocompatibility, can provide nutrition supplies needed by nerve regeneration and restoration, is capable of maintaining an optimal physicochemical and biology microenvironment for nerve regeneration for a long time and has dual functions of preventing nerve tumor formation and promoting defect nerve restoration.

Owner:WENZHOU MEDICAL UNIV

Method for producing formaldehyde-free low-density crop straw grain board

ActiveCN101037000ALow densityHave mechanical strengthClimate change adaptationDomestic articlesVolumetric Mass DensityParticle board

A making method of crop straw particle board of low density without formaldehyde includes crushing, taking materials and weighting by balance, paving, stirring of spray glue, prepressing and hot-pressing of the crop straw, characterized in that: the crop straw should crush to particle state of less than or equal to 4.75mm, after calculating weight of straw particle with density of 250-400kg / m3 based on thickness of board and once machining area of apparatus, taking materials by weight of following components, the hot-pressing temperature is 130-180 DEG C, through two times of increasing and reducing press hot set from high to low, at first time the press is increased to 90-110 bar during 10 seconds, keeping for 25 seconds, then the press is reduced to 40-60 bar, then second increasing press to 80-100 bar, keeping for 30 seconds, then three times of reducing press by speed of 1-3 bar / second, at last stabilizing the press in 10-20 bar, keeping for 10 seconds. The invention settles technological problem of hot-pressing mode and material compositions of artificial plate with production density less than 400kg / m3, secondly settles technological problem of spray glue.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Preparation process of fuel cell electrode porous diffusion layer material carbon fiber paper

InactiveCN102936867AHave mechanical strengthChemically stableSpecial paperPaper/cardboardFiberCarbon fibers

The invention relates to the field of fuel cell electrode porous diffusion layer materials, in particular to a preparation process of basic material carbon fiber paper for manufacturing fuel cell electrode porous diffusion layers. The carbon fiber paper can be produced on common paper machine production lines in a batch mode and meets the requirement for manufacture of fuel cell electrode porous diffusion layer electrodes. The preparation process comprises the steps of (1) performing surface treatment to short carbon fiber; (2) performing surface treatment to conductive carbon black; (3) smashing raw wood pulp and placing the raw wood pulp into a pulping pond, wherein the ratio of the raw wood pulp to water is 5-15%; and the like. The carbon fiber paper produced by means of the preparation process can meet the requirement for manufacture of the fuel cell electrode porous diffusion materials, can evenly support catalyst layers in electrodes and stabilizing electrode structures, further has functions of providing gas channels, electronic channels and drainage channels for electrode reaction and the like, and has porous structures, excellent gas generating performance, high conductivity, certain mechanical strength, chemical stability and heat stability.

Owner:SHENYANG HUATIANXIN CARBON FIBER ELECTRIC HEATINGPROD

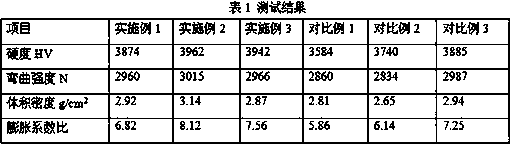

High-strength ice crack type ceramic product and preparation technology thereof

The invention relates to the technical field of preparation of ceramics, in particular to a high-strength ice crack type ceramic product and a preparation technology thereof. The high-strength ice crack type ceramic product comprises a blank and a glaze, wherein the blank comprises 58 parts of kaolin, 24 parts of potassium feldspar, 13 parts of quartz, 17 parts of clay, 2 parts of talcum, 15 partsof melting additive, 20 parts of wollastonite, 14 parts of brucite, 10 parts of sodium feldspar, 8 parts of calcium silicate, 8 parts of barium sulfate, and 6 parts of sepiolite; the glaze comprises45 parts of potassium feldspar, 16 parts of montmorillonite, 26 parts of quartz, 39 parts of sodium feldspar, 3 parts of color oxide, 2 parts of sodium hexametaphosphate, 5 parts of talcum, and 20 parts of calcium carbonate. The preparation technology comprises the following steps of S1, preparing of the materials; S2, drawing of the blank; S3, plain firing; S4, glaze applying; S5, firing. The high-strength ice crack type ceramic product prepared by the preparation technology has the advantages that the mechanical strength is high, the color is transparent and clear, and the cracks are fine and regular.

Owner:福建省泉州市契合工贸有限公司

Preparation method of isocyanate-based polyimide foam

ActiveCN104829835AImprove heat resistanceImprove thermal stabilityMaterials preparationHeat resistance

The invention provides a preparation method of isocyanate-based polyimide foam. The preparation method comprises that 1, polybasic aromatic anhydride is heated and dissolved in a polar solvent and undergoes a reaction with fatty alcohol to produce a polybasic aromatic anhydride derivative solution, 2, the polybasic aromatic anhydride derivative solution and a foam stabilizer are blended to form a white material, 3, polybasic aromatic anhydride and isocyanate undergo a reaction to produce a black material, 4, the foaming white material is immediately poured into the foaming black material at a room temperature under normal pressure, and the mixture is uniformly stirred, then is fast poured into a mold and is subjected to free foaming molding to form a foam intermediate and 5, the foam intermediate is heated and cured to form the isocyanate-based polyimide foam. The preparation method inhibits production of an amino group and an isocyanate group in foam material preparation, reduces a polyurea generation amount and improves isocyanate-based polyimide foam heat resistance, heat stability and flame resistance. The preparation method has the advantages of simple processes, excellent product comprehensive properties, and industrial production and wide application feasibility.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com