Patents

Literature

219results about How to "Improve particle size uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for inhibiting bone resorption

InactiveUS20050261250A1Reduce moisture contentPreventing and reducing and inhibiting and treating metabolic bone diseaseBiocidePhosphorous compound active ingredientsDiseaseNormal bone

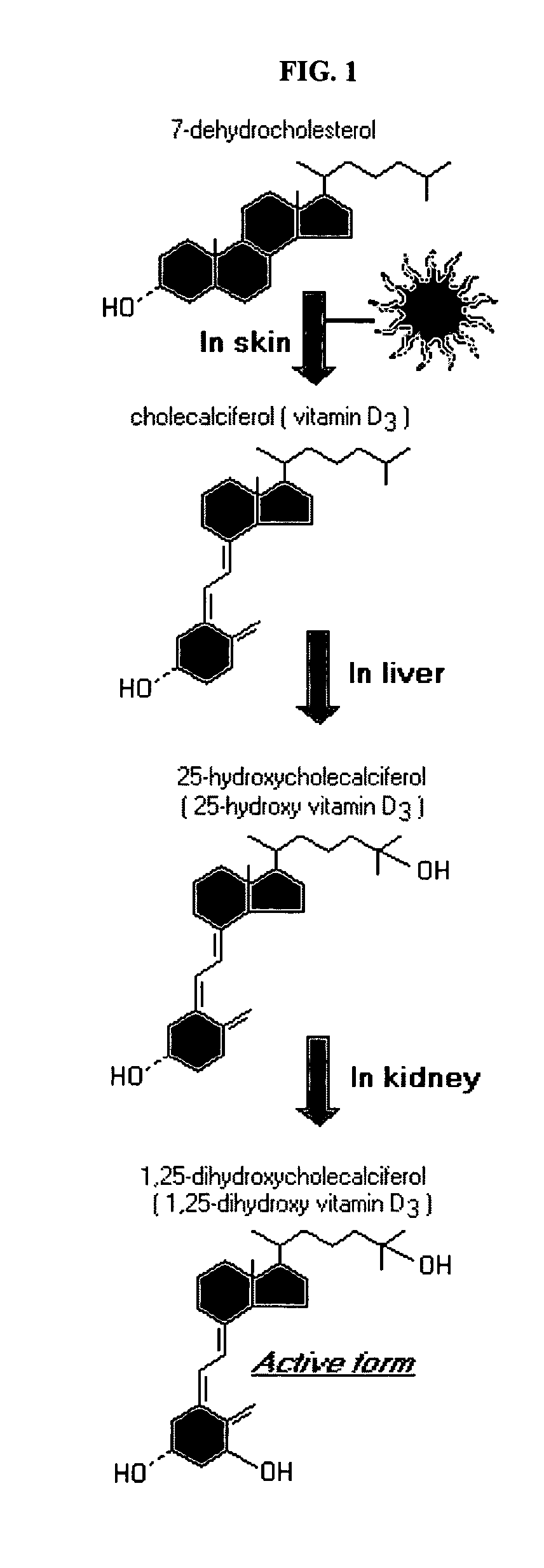

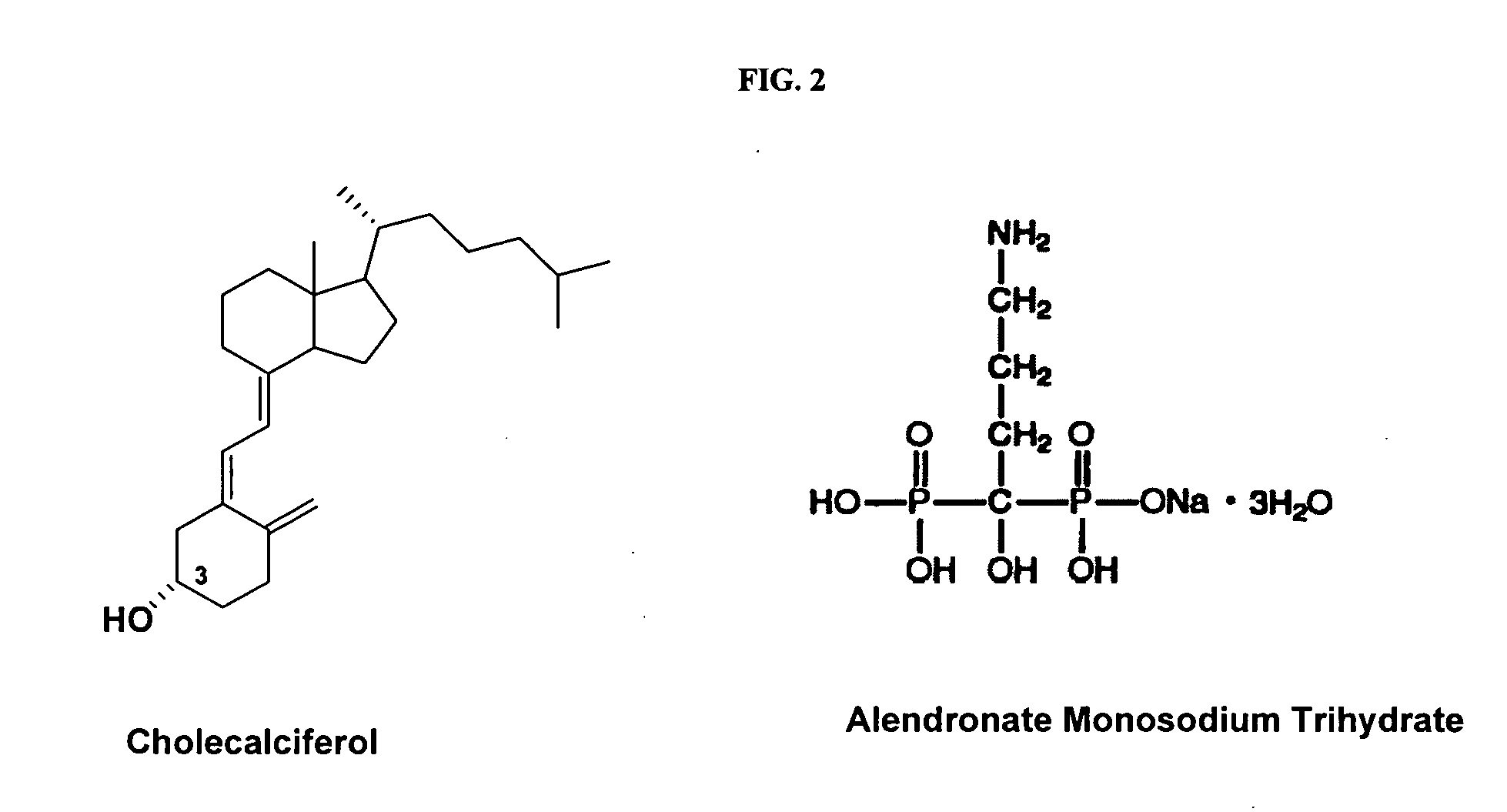

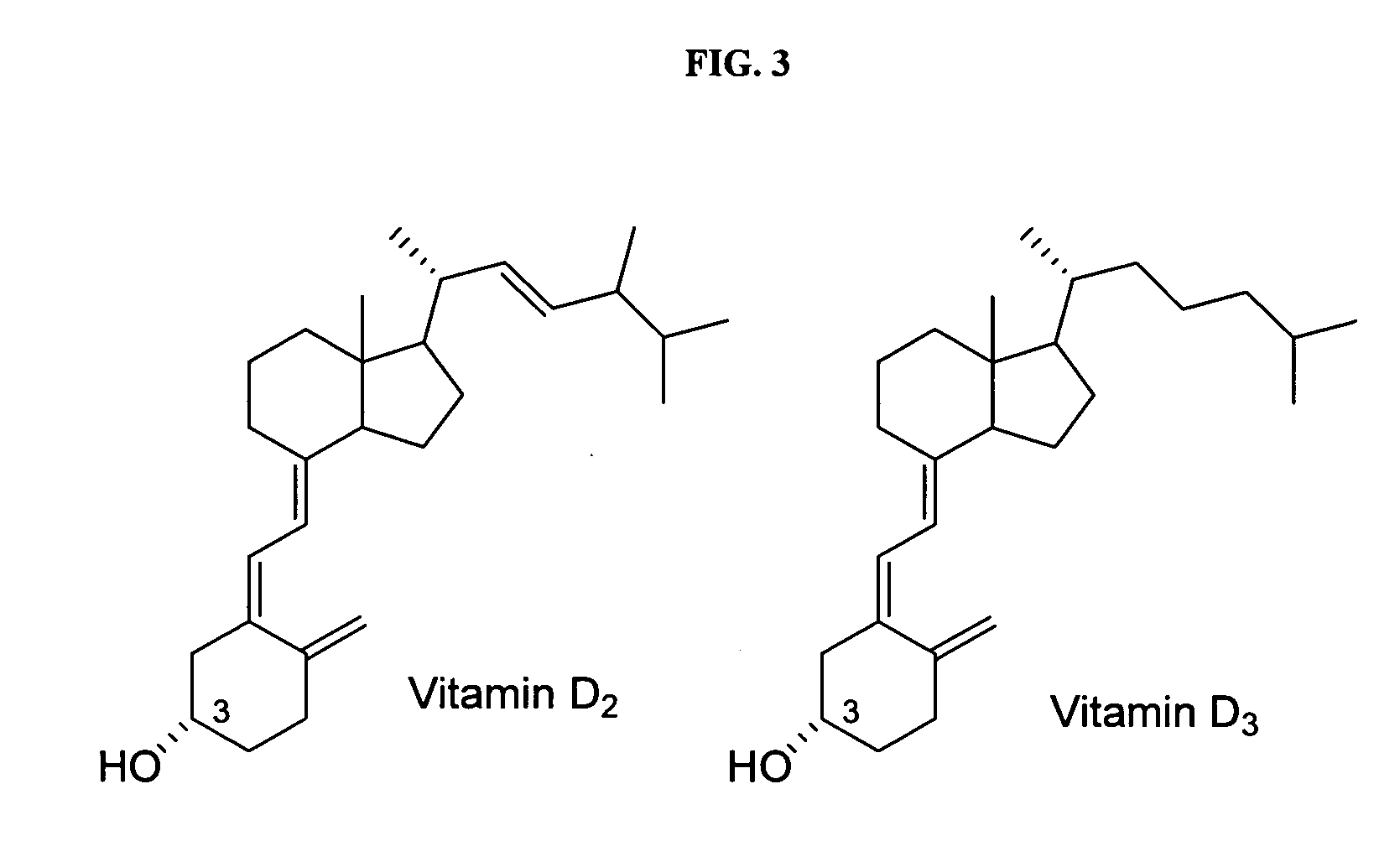

Disclosed are compositions and methods for preventing, inhibiting, reducing and treating conditions and diseases associated with abnormal bone resorption in mammals, including for example osteoporosis. Embodiments of compositions of the invention comprise a pharmaceutically effective amount of alendronate and vitamin D3 suitable for once-weekly dosing. Compositions and methods of the invention provide vitamin D nutrition during bisphosphonate treatment to facilitate normal bone formation and mineralization while minimizing the occurrence of or potential for the complications associated with vitamin D insufficiency, such as hypocalcaemia and osteomalacia. Also disclosed are methods for manufacturing compositions of the present invention, for measuring stability and degradation of those compositions, and for measuring blood plasma levels of vitamin D.

Owner:MERCK & CO INC

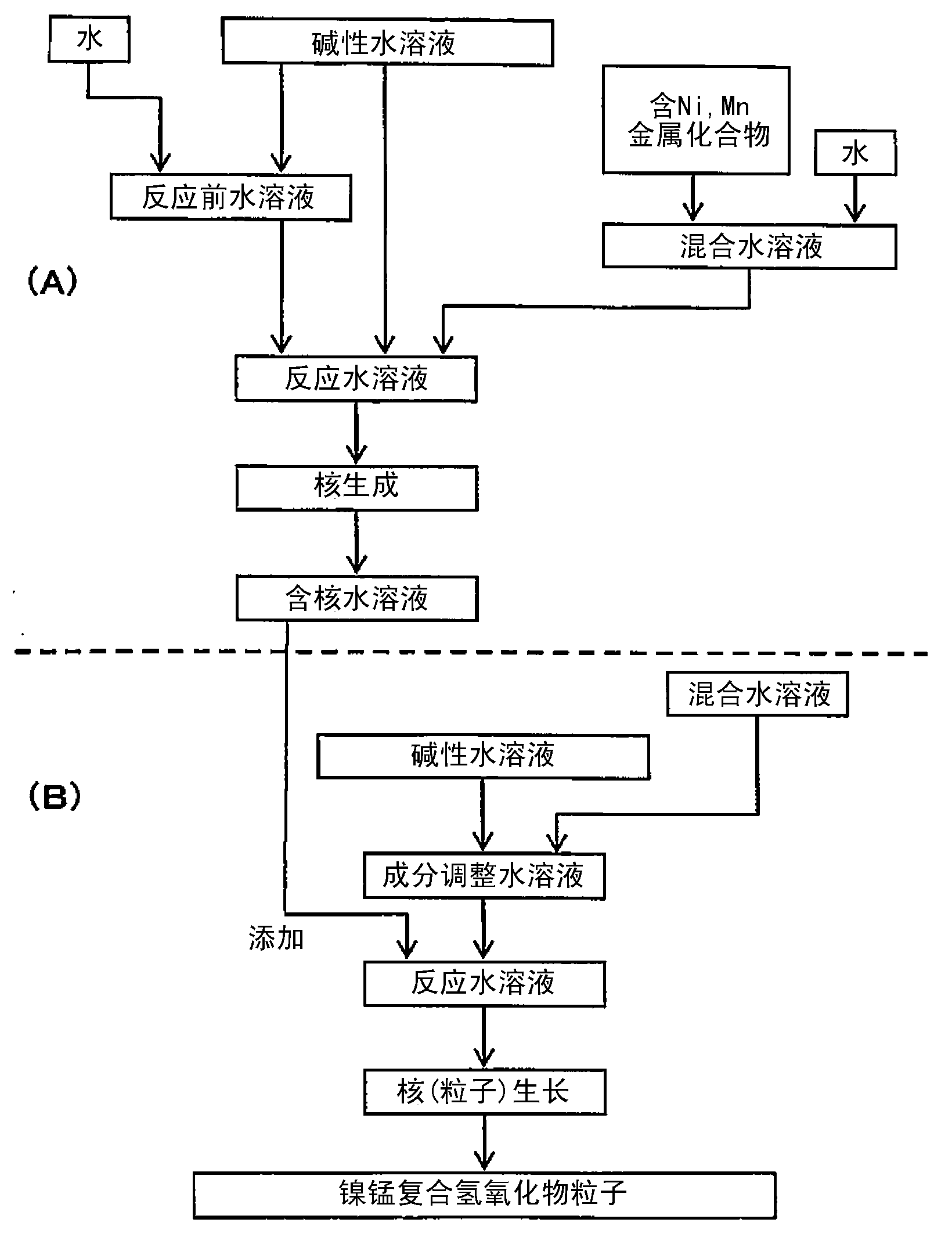

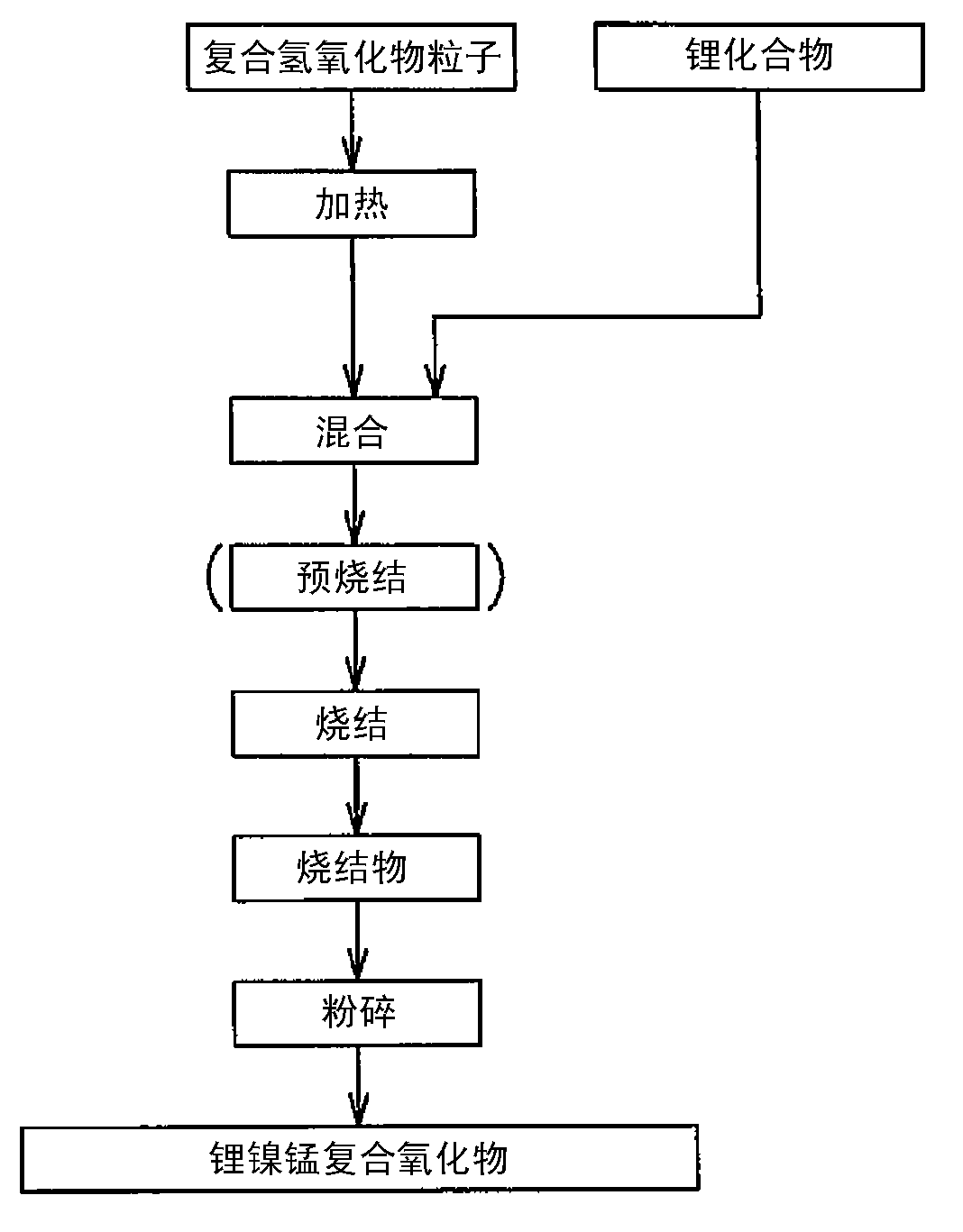

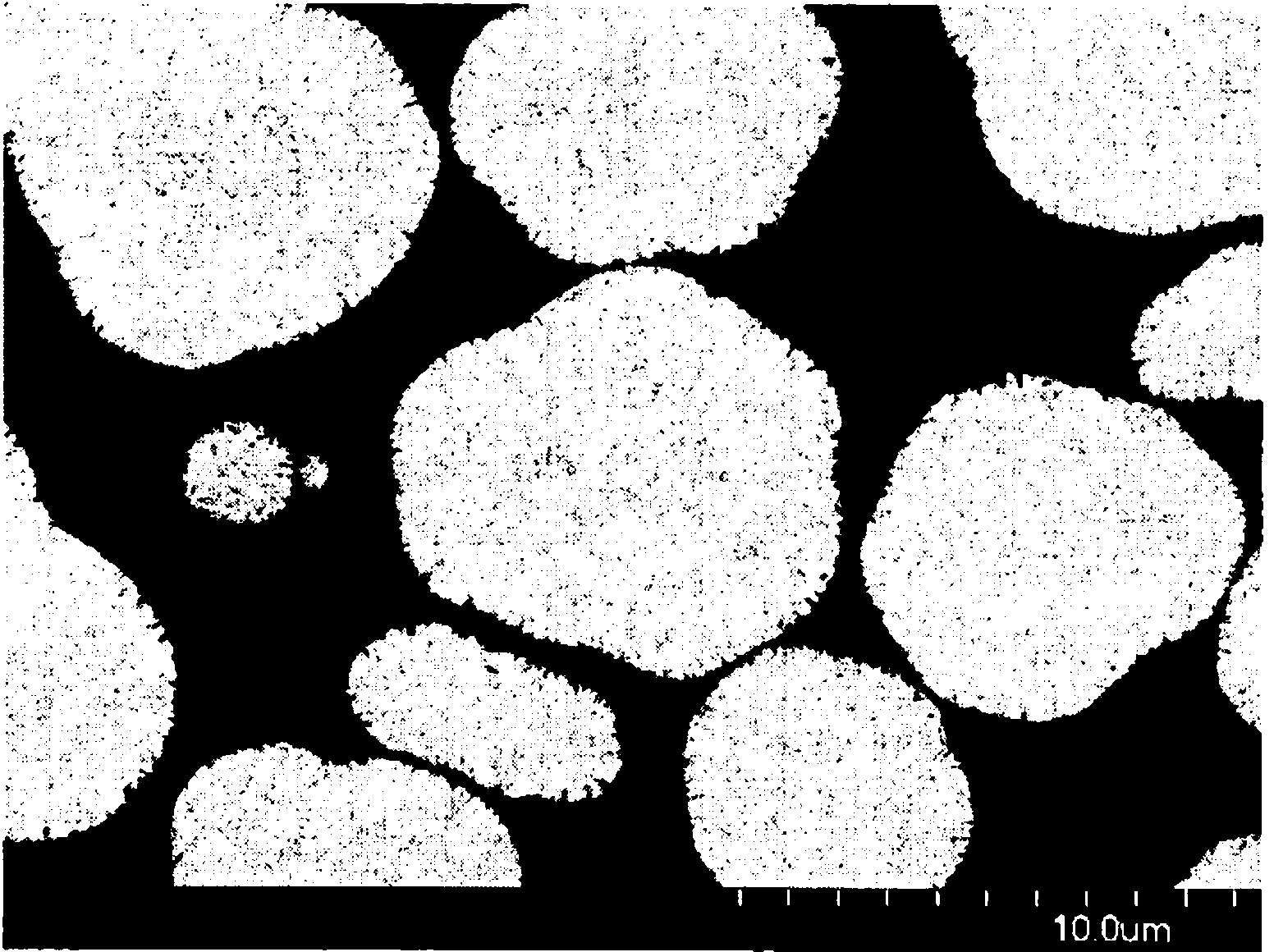

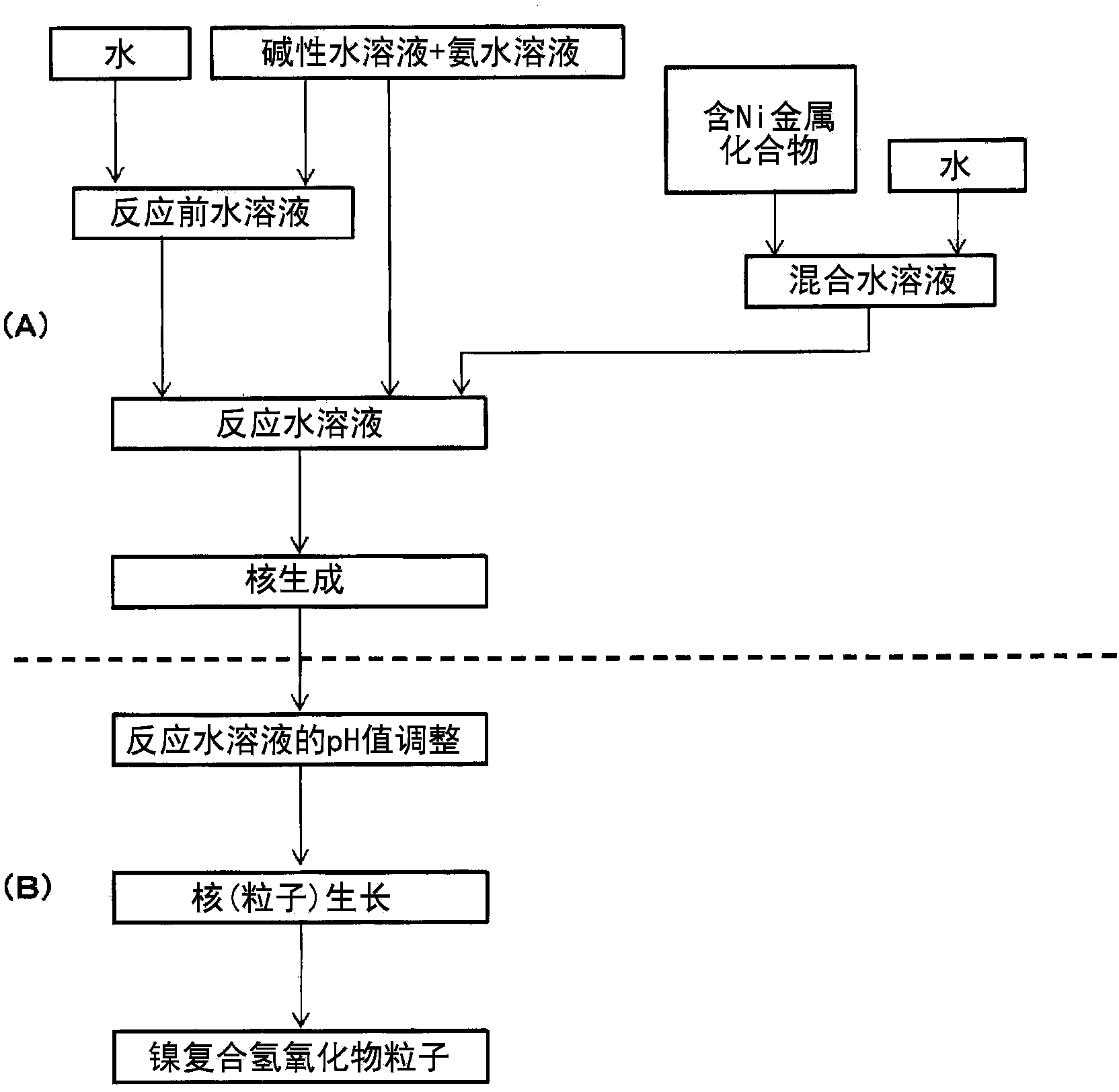

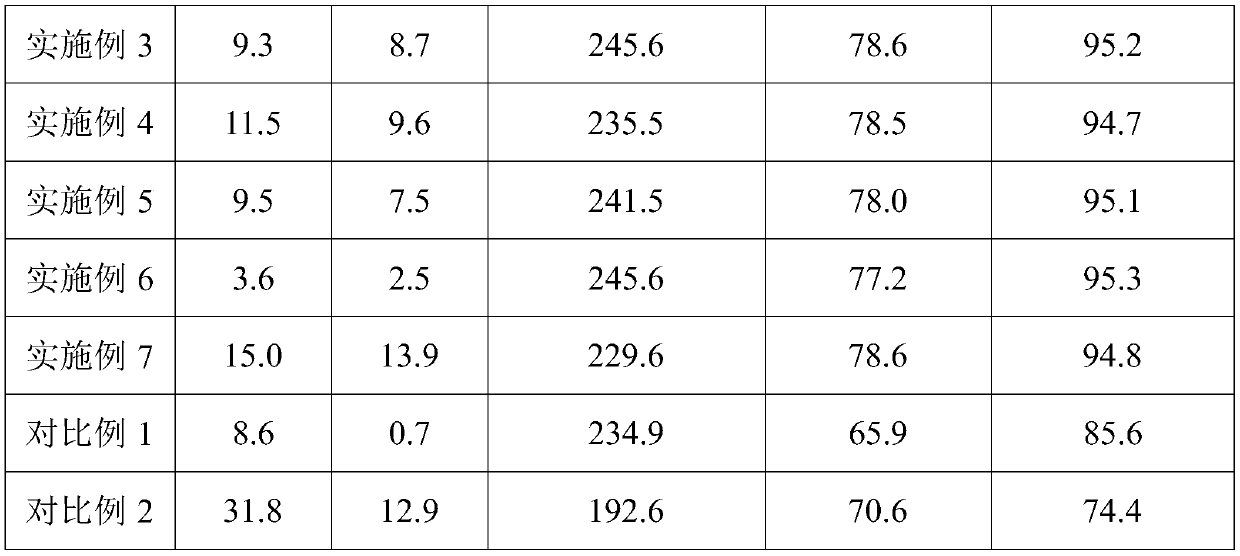

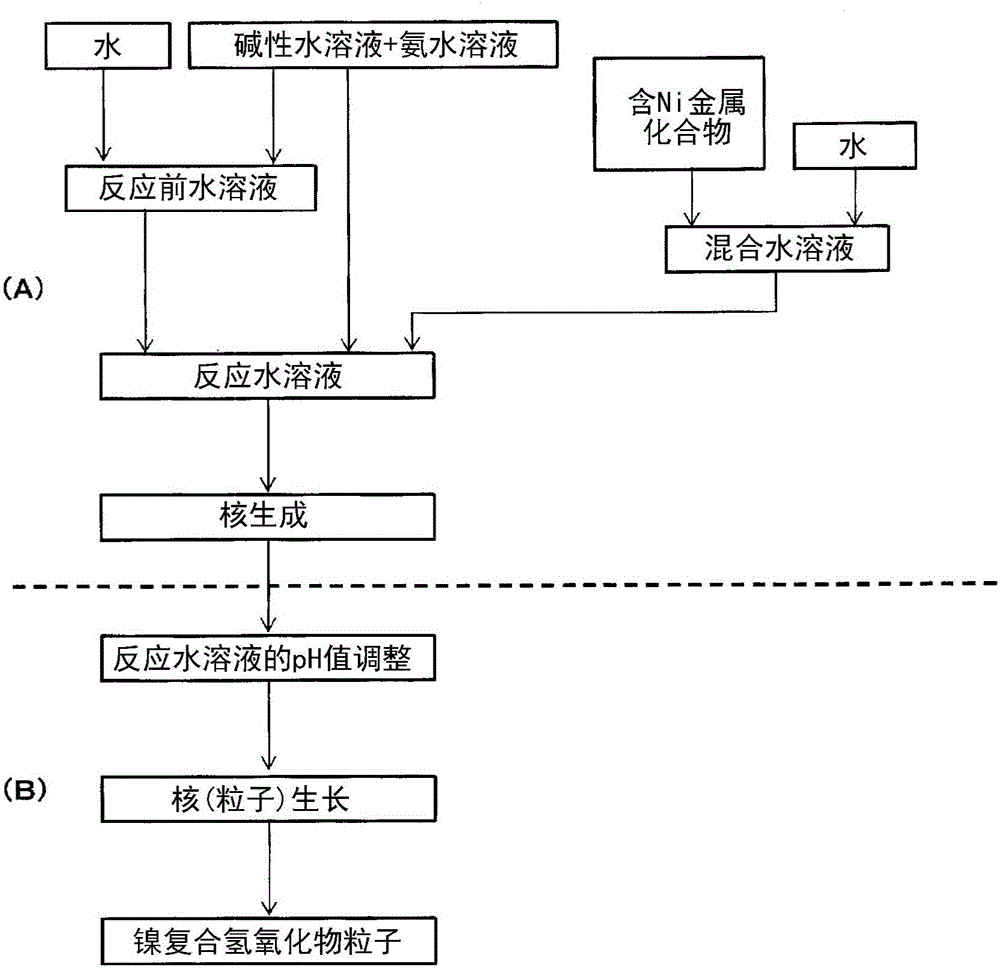

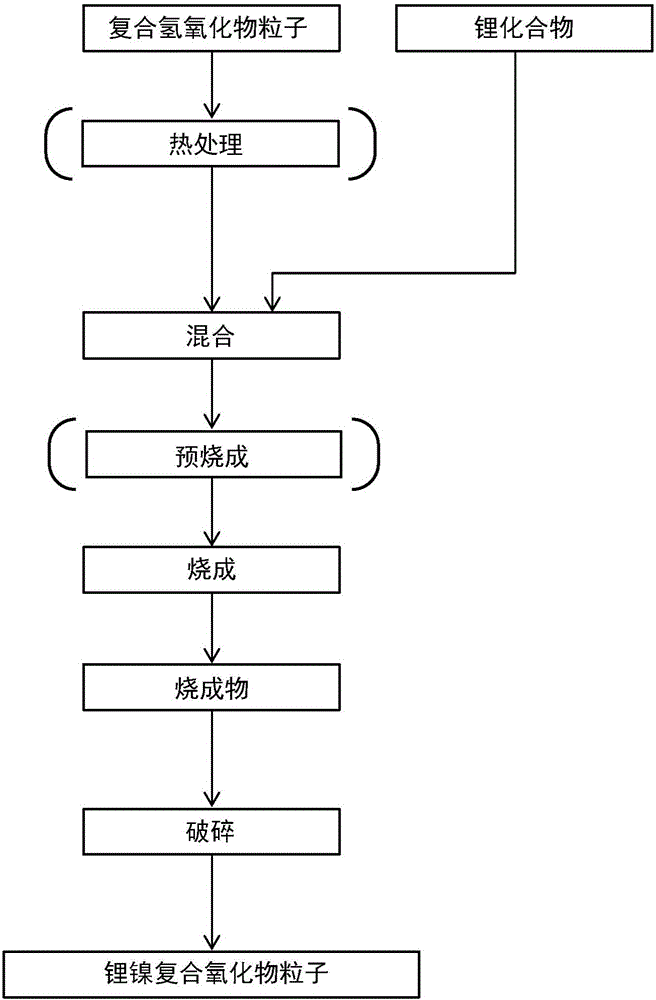

Nickel-manganese composite hydroxide particles, method for producing same, positive electrode active material for nonaqueous electrolyte secondary batteries, method for producing said positive electrode active material, and nonaqueous electrolyte secondary battery

ActiveCN102884659ASmall particle sizeImprove particle size uniformityFinal product manufactureCylindrical casing cells/batteryComplex ionsComposite oxide

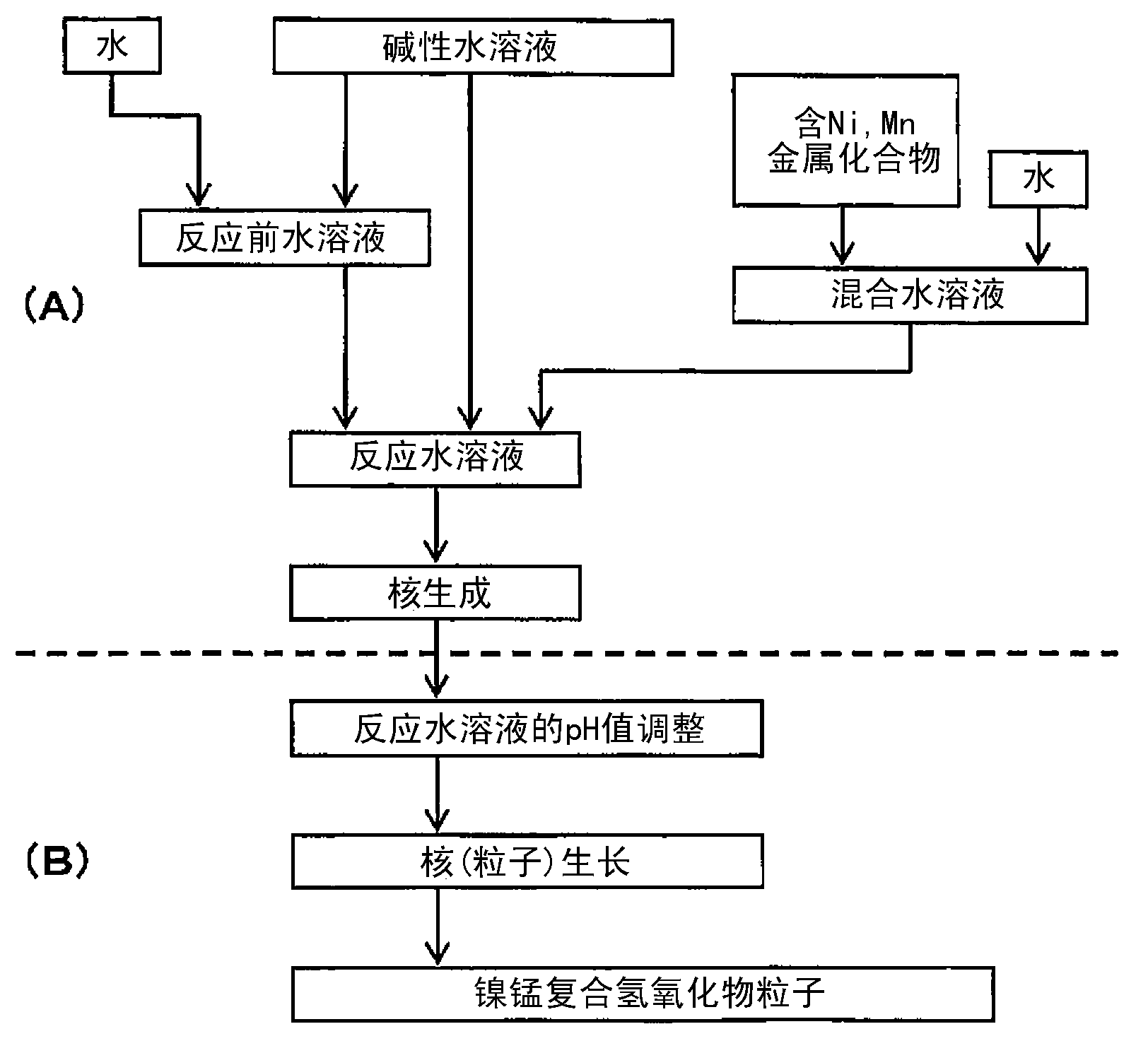

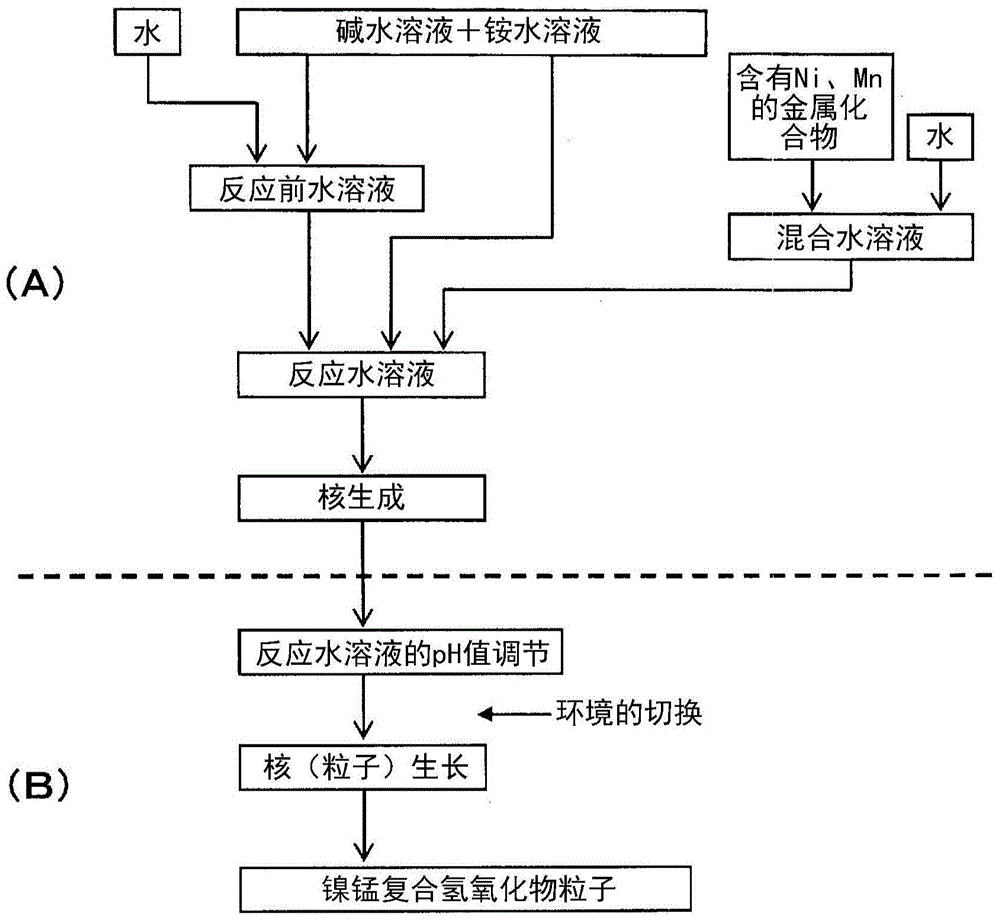

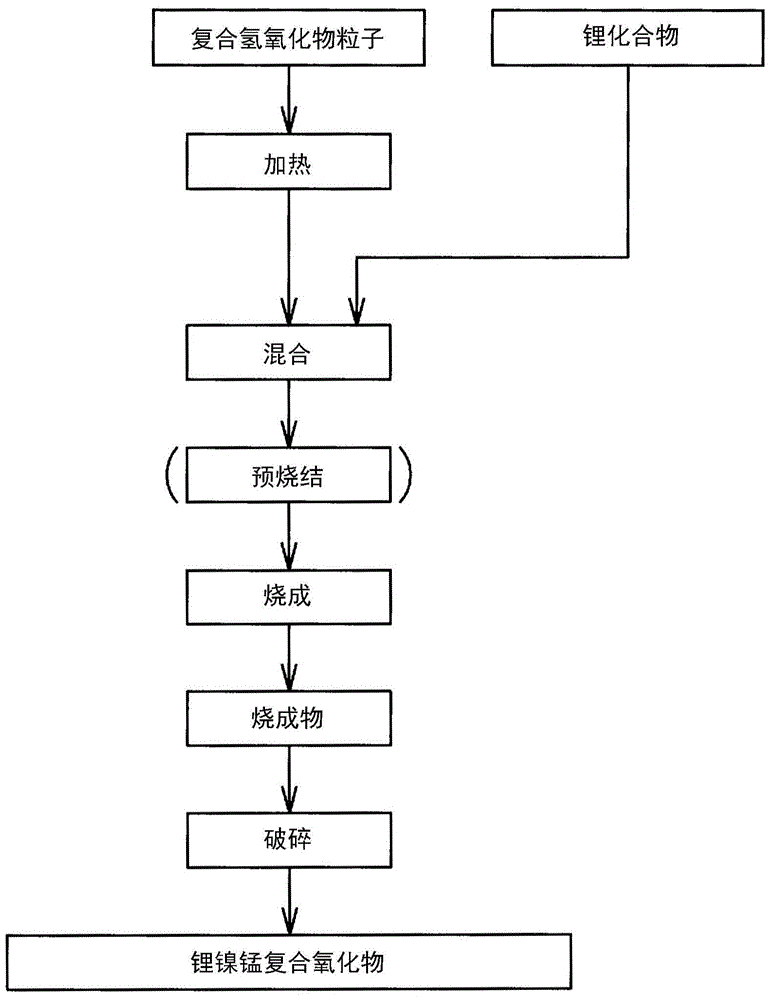

Provided are nickel manganese composite hydroxide particles that are a precursor for forming cathode active material comprising lithium nickel manganese composite oxide having hollow structure of particles having a small and uniform particle size for obtaining a non-aqueous electrolyte secondary battery having high capacity, high output and good cyclability. When obtaining the nickel manganese composite hydroxide particles from a crystallization reaction, an aqueous solution for nucleation, which includes at least a metallic compound that contains nickel and a metallic compound that contains manganese, and does not include a complex ion formation agent that forms complex ions with nickel, manganese and cobalt, is controlled so that the temperature of the solution is 60 DEG C or greater, and so that the pH value that is measured at a standard solution temperature of 25 DEG C is 11.5 to 13.5, and after nucleation is performed, an aqueous solution for particle growth, which includes the nuclei that were formed in the nucleation step and does not substantially include a complex ion formation agent that forms complex ions with nickel, manganese and cobalt, is controlled so that the temperature of the solution is 60 DEG C or greater, and so that the pH value that is measured at a standard solution temperature of 25 DEG C is 9.5 to 11.5, and is less than the pH value in the nucleation step.

Owner:SUMITOMO METAL MINING CO LTD

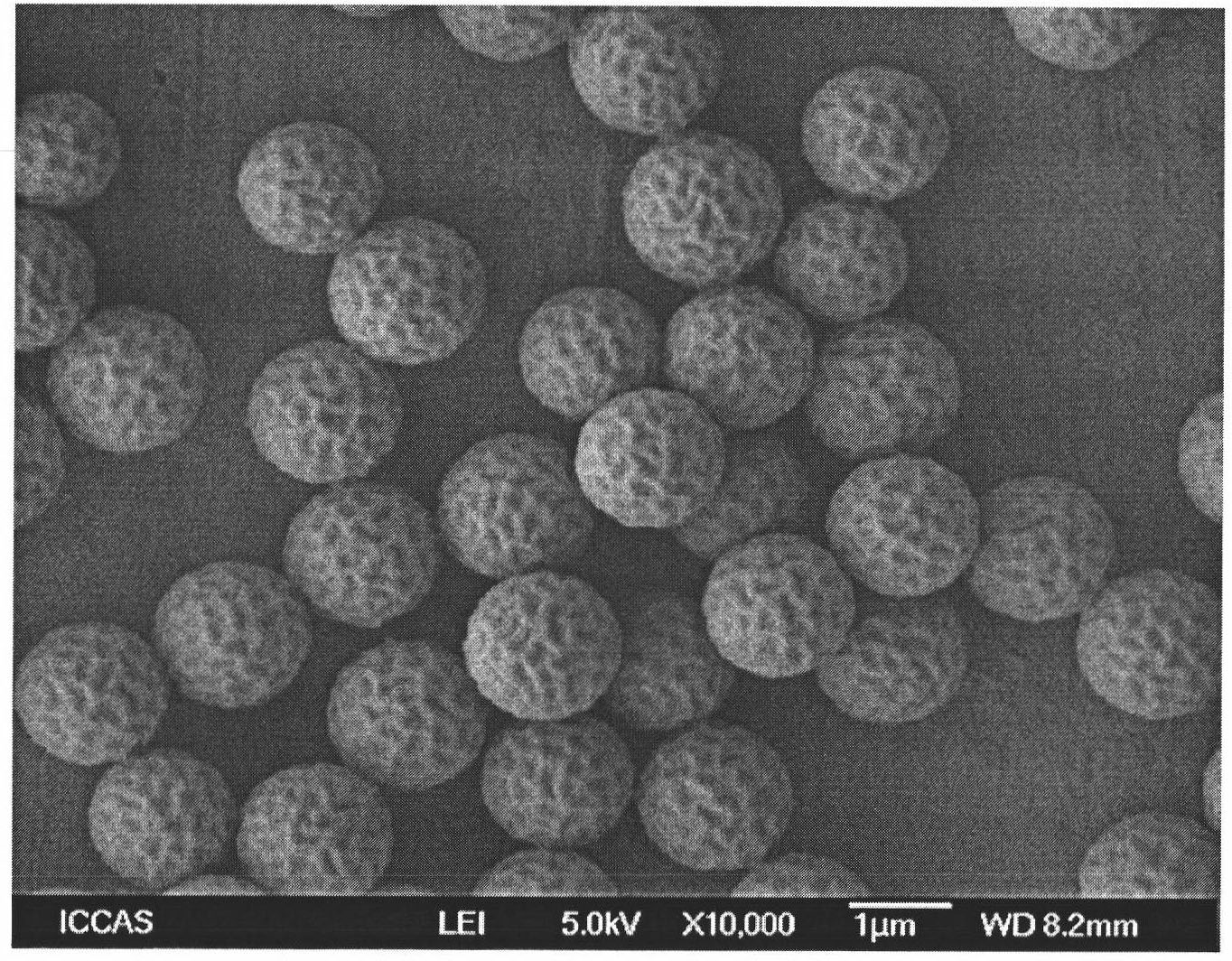

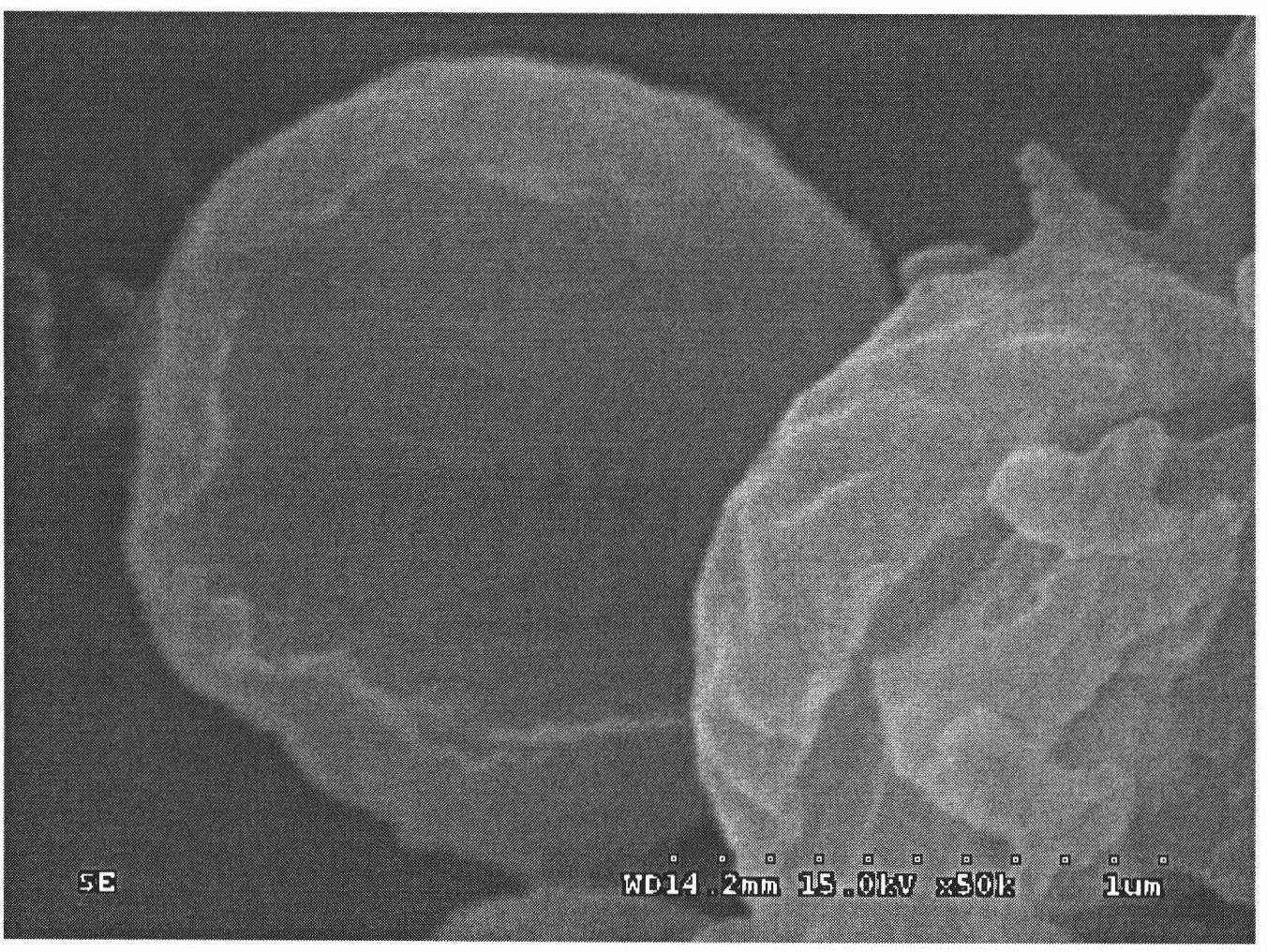

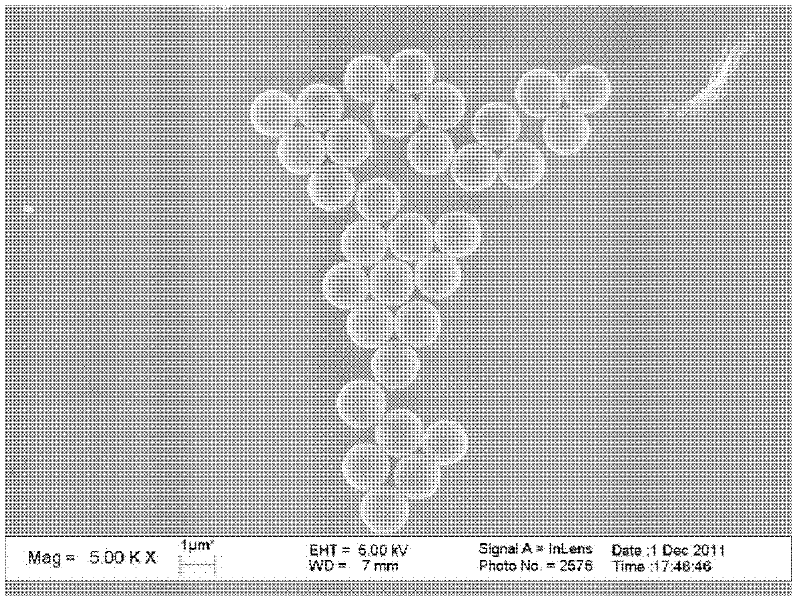

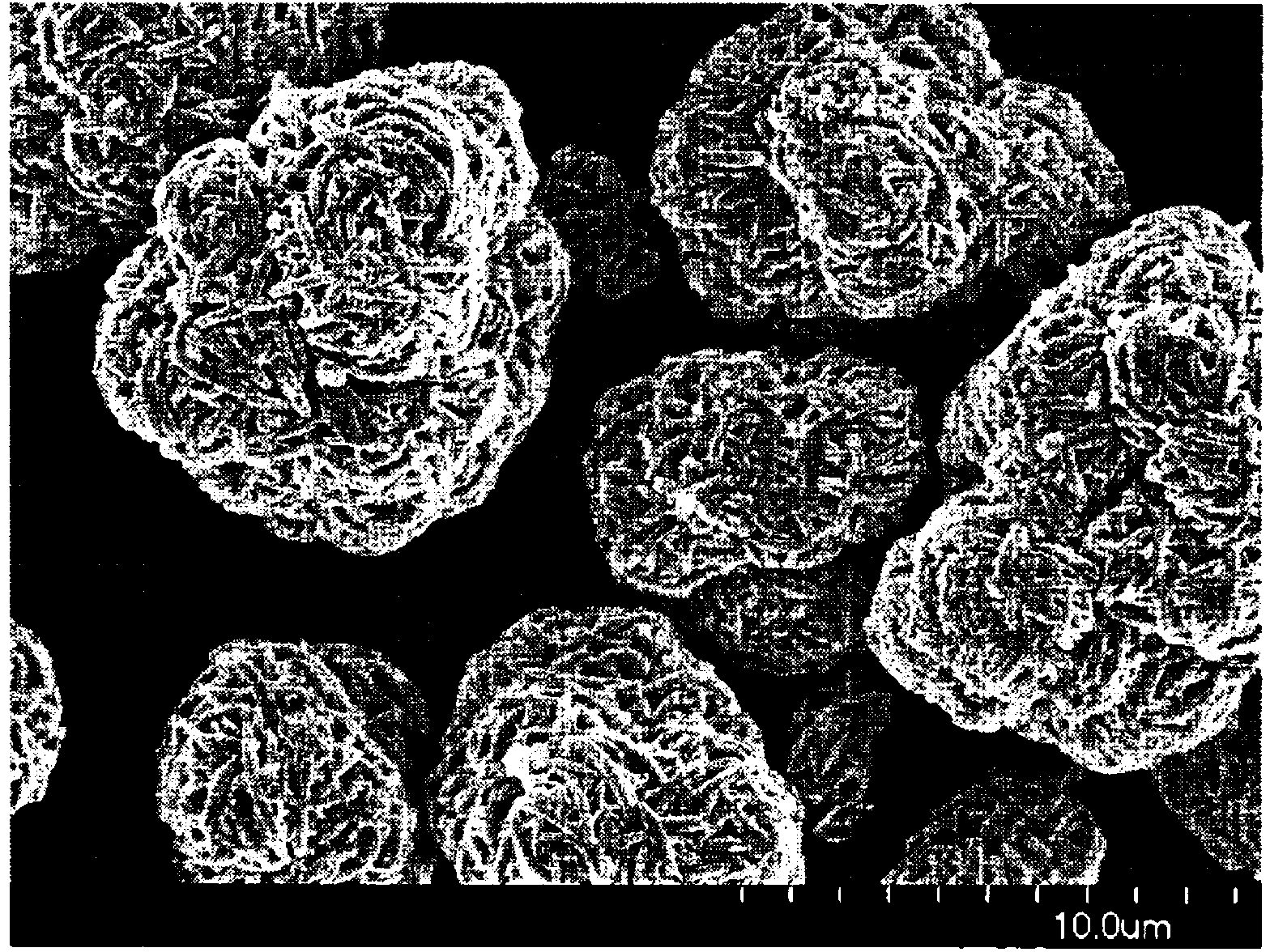

Hollow organosilane microsphere with rough surface structure and preparation method thereof

ActiveCN102140250AImprove particle size uniformitySolve the problem that the size uniformity is not easy to controlMicroballoon preparationMicrocapsule preparationCrystallographyRough surface

The invention provides a hollow organosilane microsphere with a rough surface structure and a preparation method thereof. The hollow organosilane microsphere with the rough surface structure is characterized by being prepared by the following steps of: providing an alkaline solution with the pH value of between 10 and 13; mixing at least two types of organosilane to obtain an organosilane mixture; adding the organosilane mixture into the alkaline solution; undergoing a hydrolytic polycondensation reaction; and standing and ageing. Organosilane microsphere particles are provided with folds on the surface and are hollow inside, and the particle sizes of the particles have high uniformity. The method provided by the invention is simple and feasible. By adopting the method, the problems of non-uniform particle size and breakage of a large number of sphere bodies caused by the conventional hollow microsphere preparation method can be solved.

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

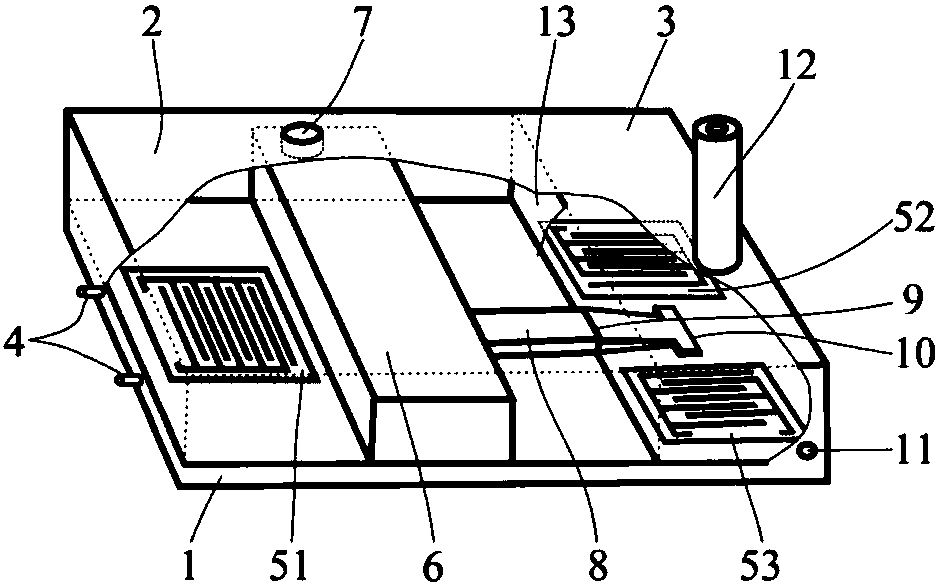

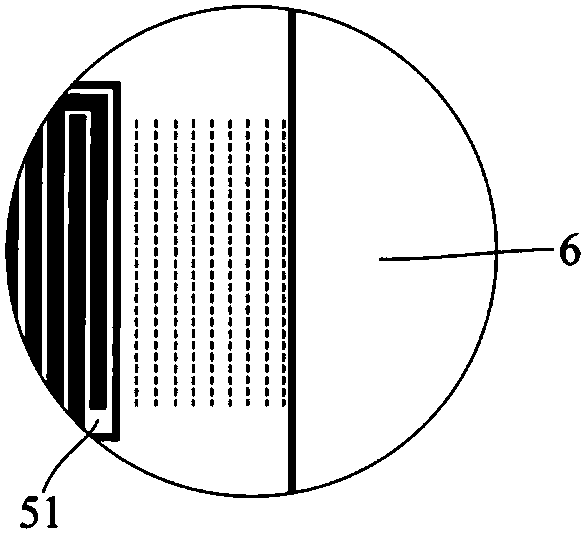

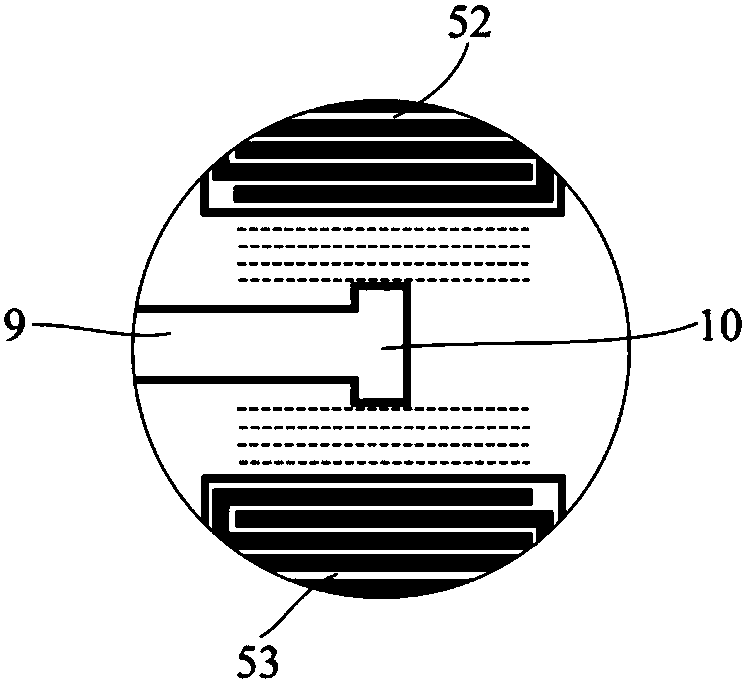

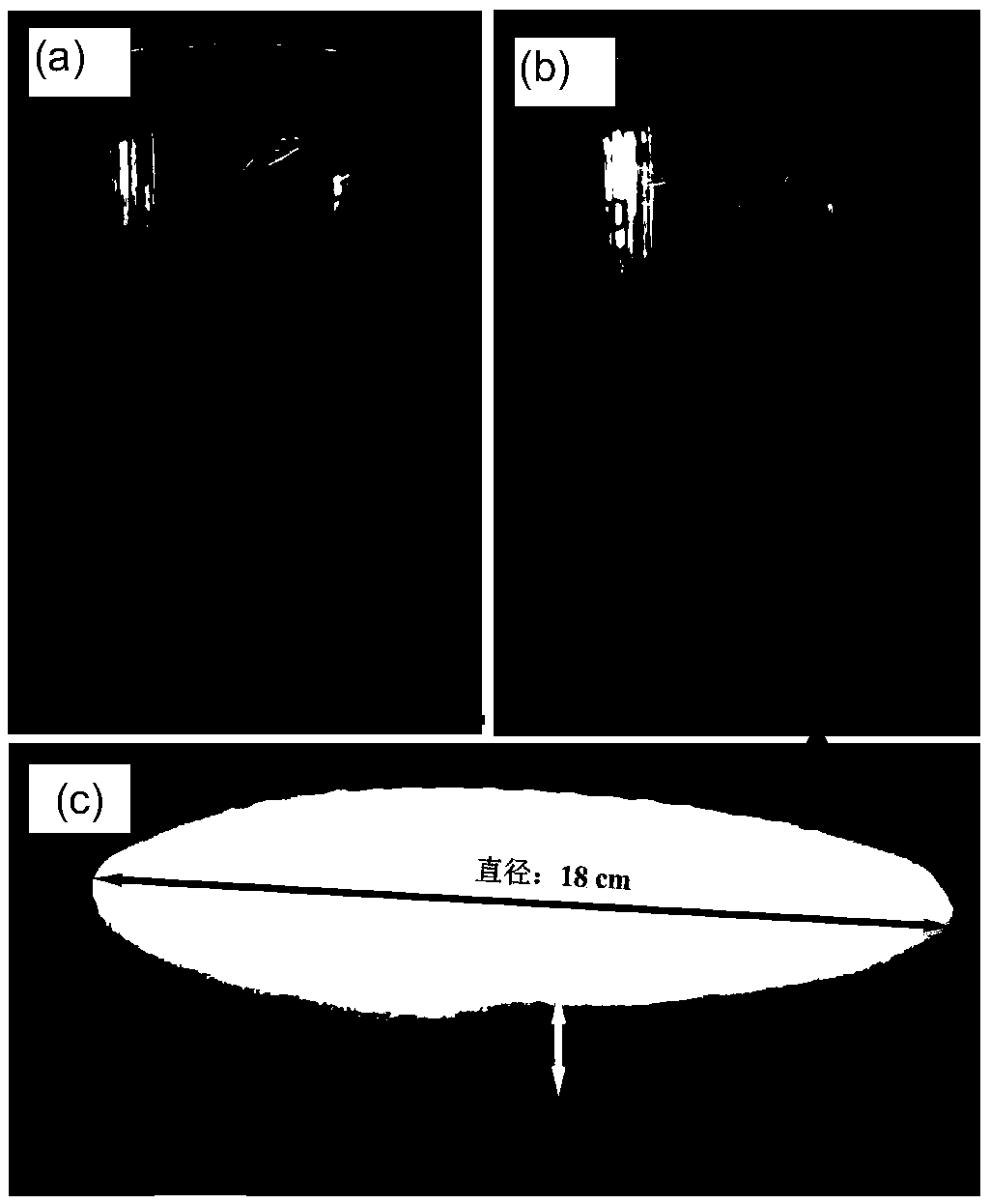

Acoustic surface wave electronic cigarette system

ActiveCN108030153AContinuous and stable pumpingFully atomizedMaterial analysis using sonic/ultrasonic/infrasonic wavesTobacco treatmentElectricityElectronic cigarette

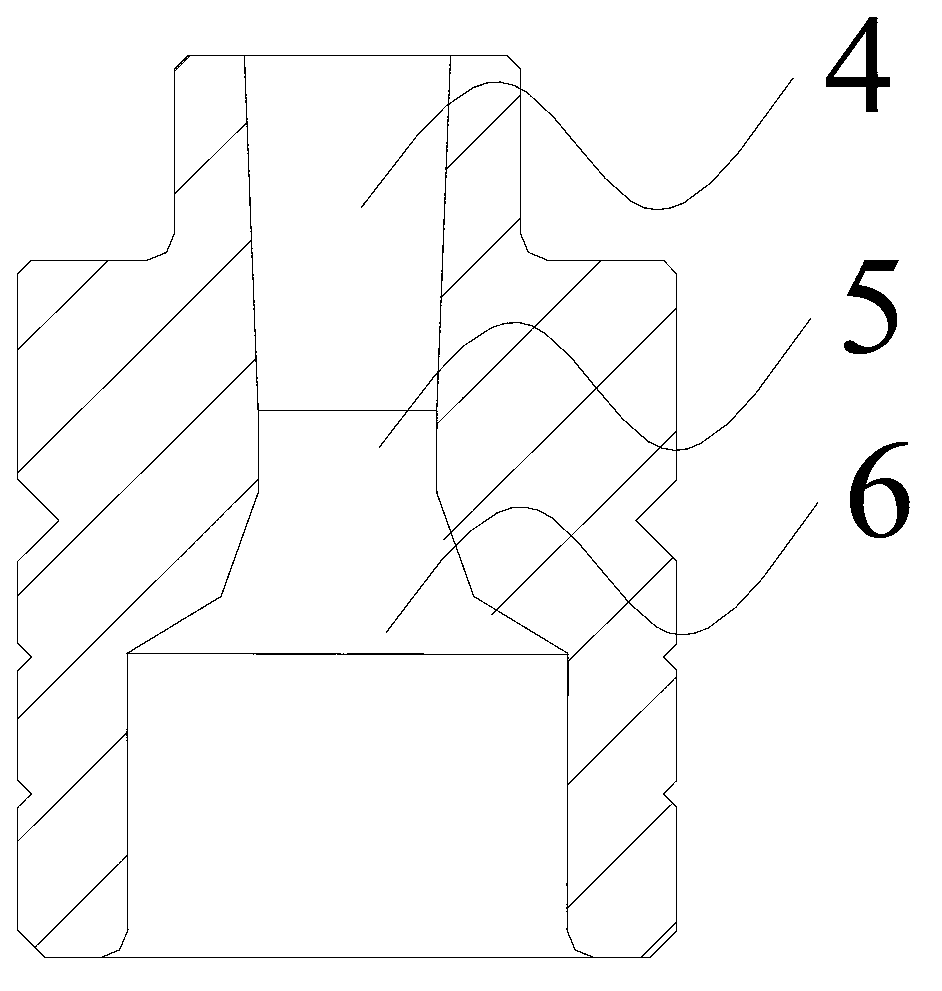

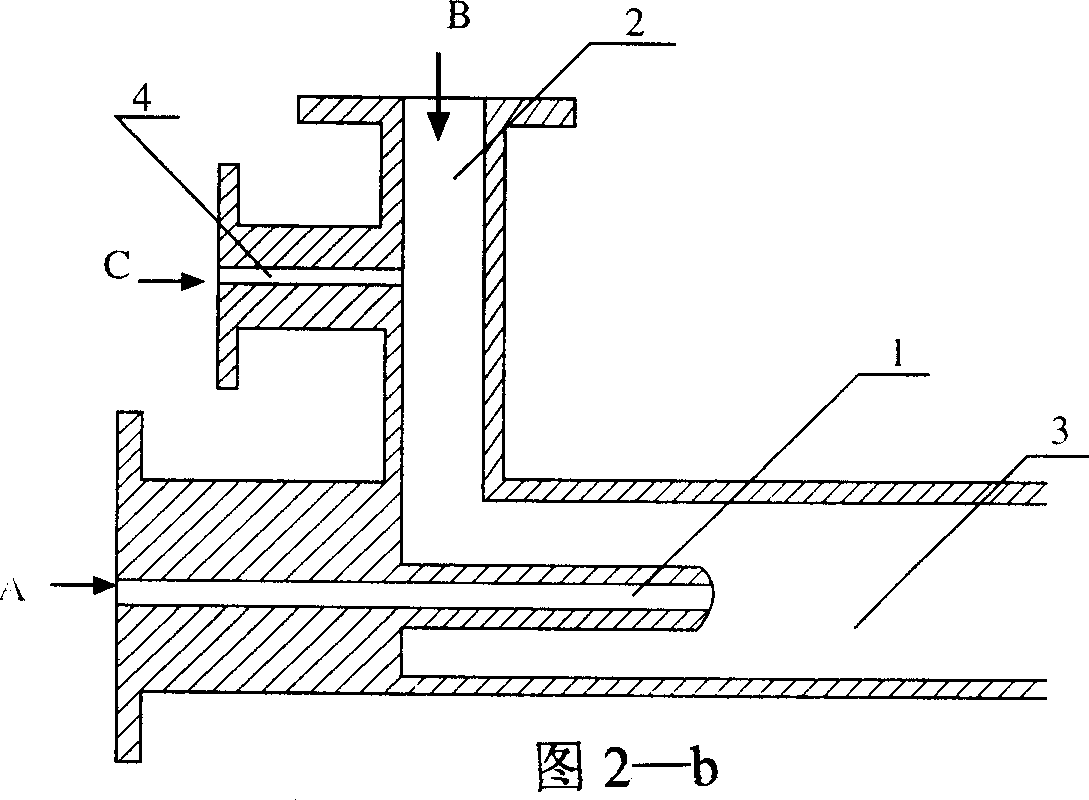

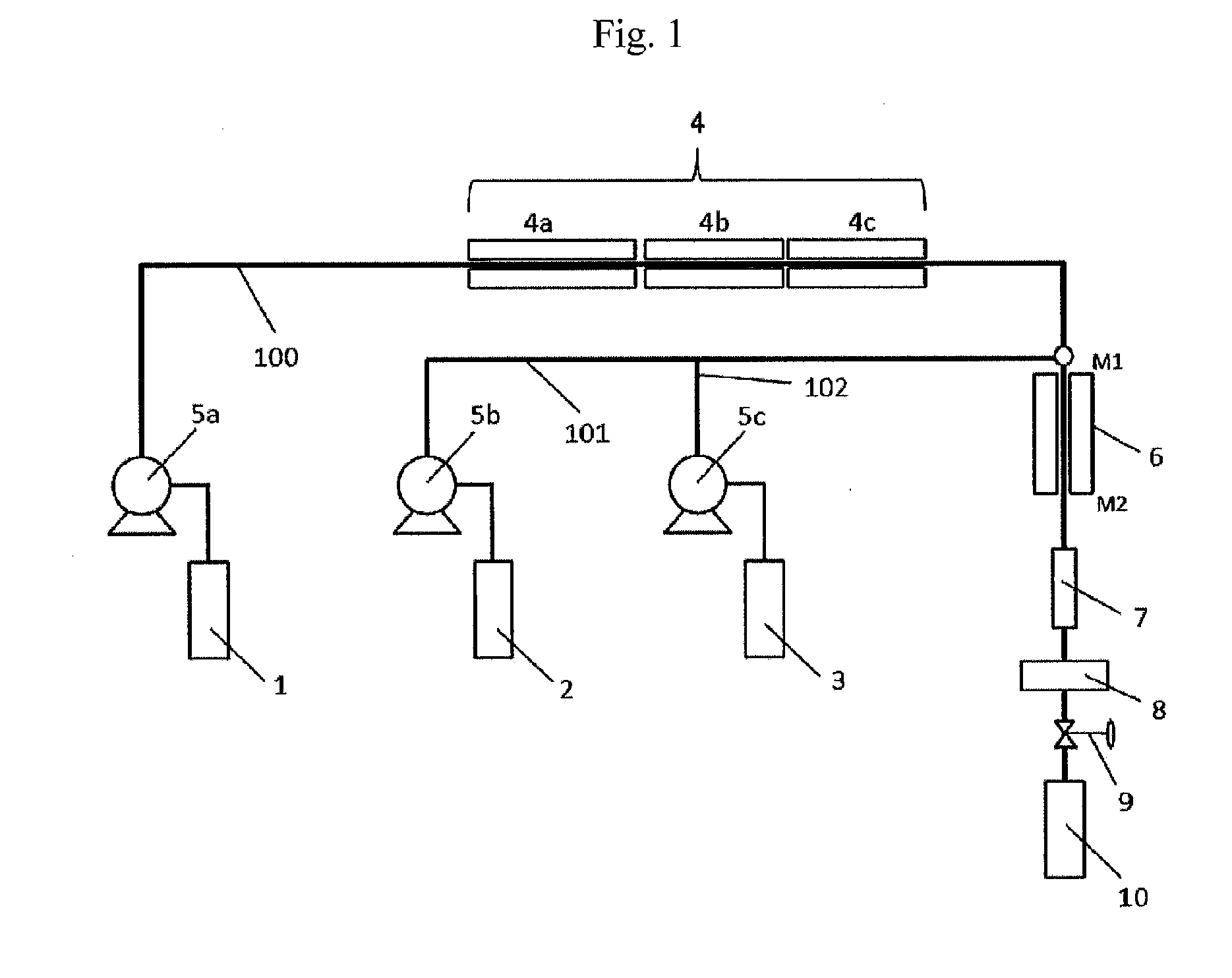

The invention discloses an acoustic surface wave electronic cigarette system which comprises a piezoelectric substrate (1), a liquid guide cavity (2), an atomization cavity (3) and feed ports (4). Thefeed ports (4) are used for loading high-frequency signals. The liquid guide cavity (2) and the atomization cavity (3) are arranged on the upper side of the piezoelectric substrate (1); an isolationplate (13) is arranged between the liquid guide cavity (2) and the atomization cavity (3); the feed ports (4) are arranged on the outer side of the piezoelectric substrate (1). The acoustic surface wave electronic cigarette system has the advantages that aerosol generated by the acoustic surface wave electronic cigarette system by means of atomization has small particle sizes, accordingly, the acoustic surface wave electronic cigarette system is high in smoking comfort, and aroma is mellow and exquisite.

Owner:CHINA TOBACCO YUNNAN IND

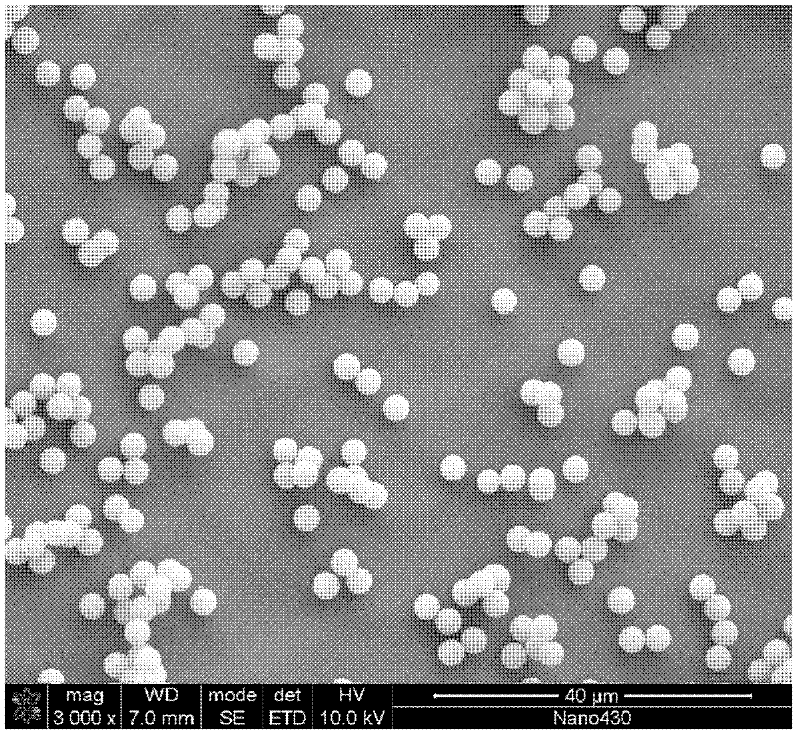

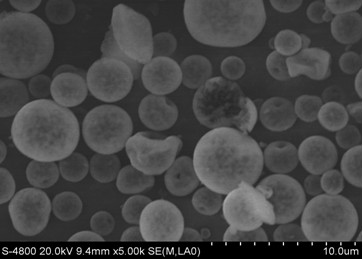

Preparation method of monodispersity micron-sized polysilicon microspheres

The invention discloses a preparation method of monodispersity micron-sized polysilicon microspheres which comprises the following steps: (1) adding deionized water and a basic catalyst in trialkoxysilane, and stirring in a nitrogen condition for hydrolysis; (2) centrifugally separating and filtering a mixed system in step (1) to remove unreacted monomers; and (3) adding the basic catalyst in a reaction system obtained from the step (2) for polycondensation, filtering, washing and drying to obtain the monodispersity micron-sized polysilicon microspheres. According to the method, the reaction temperature is low, the reaction can be conducted at room temperature, the synthesis steps are simple; the method does not use organic solvents which pollute the environment or emulsifiers in the reaction process, is simple in post treatment, less in types of raw materials, high in yield, and low in preparation cost, and can effectively adjust the grain size range of the microspheres to realize controllable sizes; and the obtained silicon microspheres are good in grain size uniformity and high in monodispersity, and has extremely good sphericity.

Owner:SOUTH CHINA UNIV OF TECH

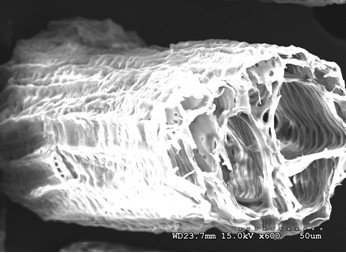

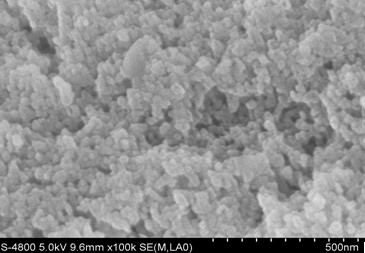

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

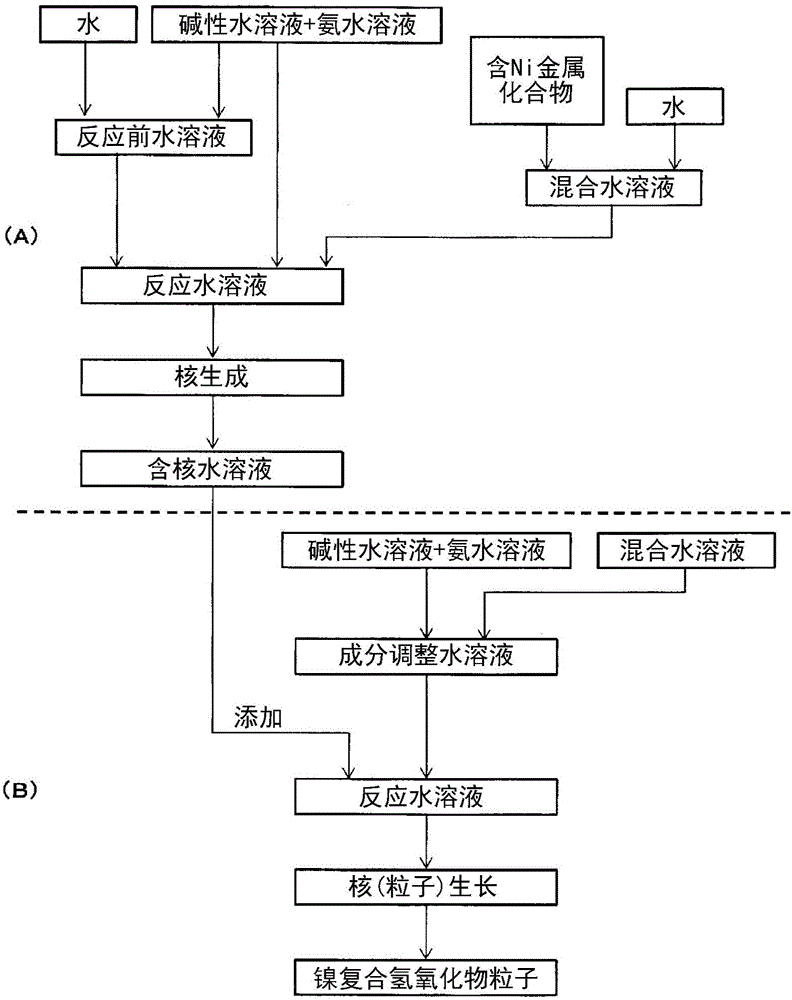

Nickel composite hydroxide and process for producing same, positive active material for nonaqueous-electrolyte secondary battery and process for producing same, and nonaqueous-electrolyte secondary battery

ActiveCN103797623AImprove particle size uniformityLarge specific surface areaPositive electrodesLi-accumulatorsOxygenElectrolyte

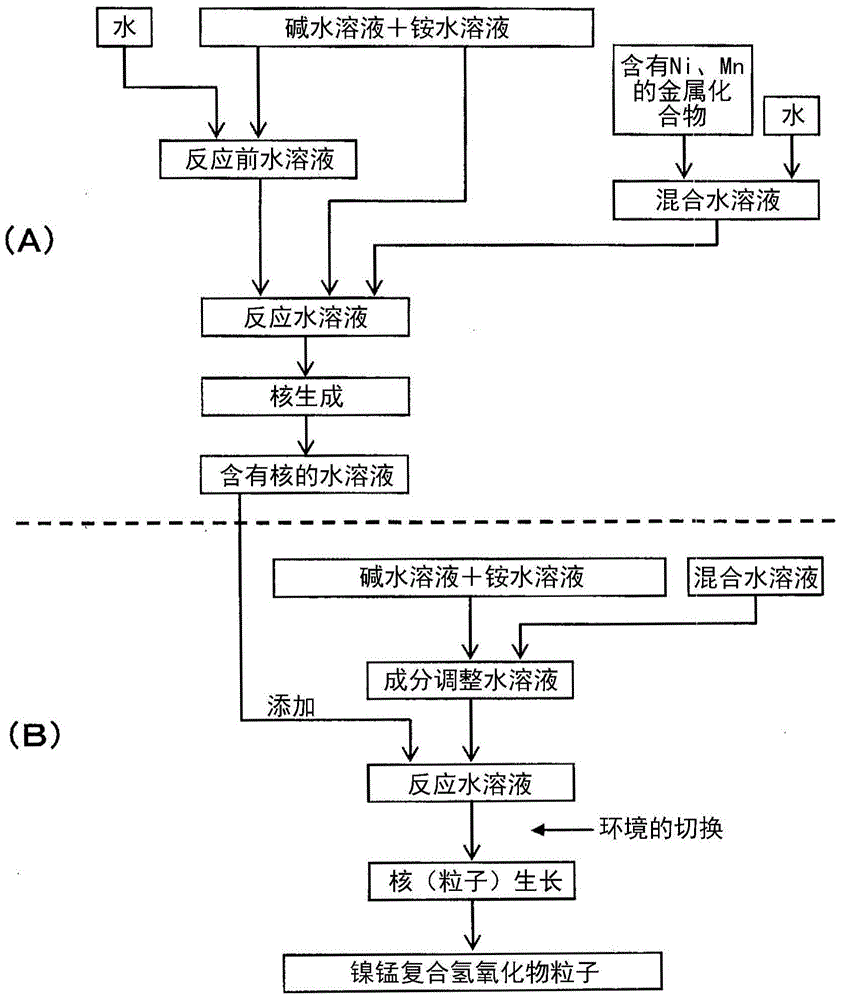

To provide a positive active material which has a moderate particle diameter and has high evenness in particle diameter and a nickel composite hydroxide which is for use as a precursor for the positive active material. When a nickel composite hydroxide is obtained through a crystallization reaction, an aqueous solution for nucleation which contains both a metal compound at least containing nickel and an ammonium ion source is used to conduct nucleation after having been regulated so as to have a pH of 12.0-14.0 at a solution temperature of 25 degree centigrade, and thereafter the resultant aqueous solution, which is for particle growth and which contains formed nuclei, is regulated so as to have a pH that, at a solution temperature of 25 degree centigrade, is 10.5-12.0 and lower than in the nucleation step, thereby growing the particles. This particle growth is conducted in a non-oxidizing atmosphere having an oxygen concentration of 1 vol.% or lower, over a period which ranges from initiation of the particle growth step and which accounts for more than 40% of the whole period of the particle growth step. Furthermore, the stirring power per unit volume in at least the nucleation step is regulated to 0.5-4 kW / m3.

Owner:SUMITOMO METAL MINING CO LTD

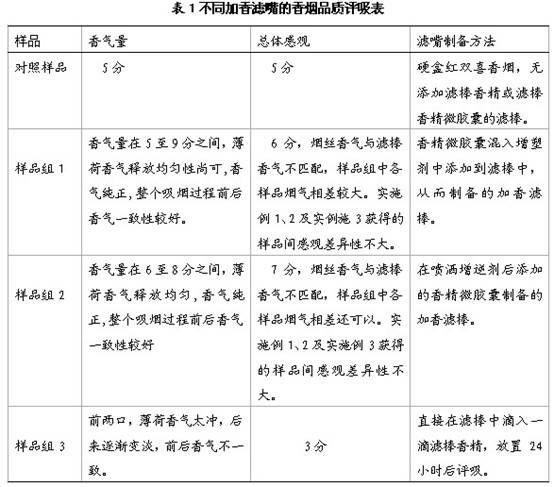

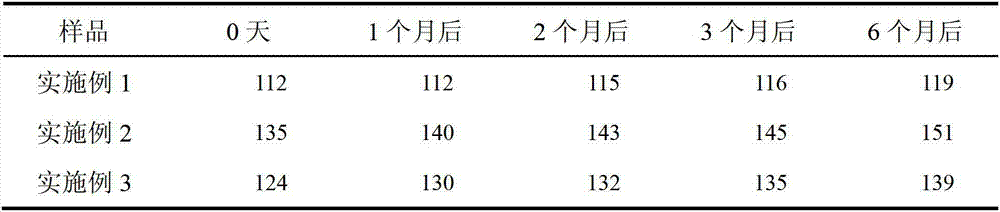

Slowly-released filter stick essence microcapsule and preparation method thereof

InactiveCN101972038AHave mechanical strengthImprove particle size uniformityTobacco preparationEssential-oils/perfumesPolymer sciencePolymer chemistry

The invention discloses a slowly-released filter stick essence microcapsule and a preparation method thereof. The slowly-released filter stick essence microcapsule is prepared from the following raw materials in parts by weight: 12-18 parts of sodium alginate, 6-12 parts of Arabic gum, 15-25 parts of emulsifier and 10-15 parts of filter stick essence. The preparation method comprises the following steps: firstly, respectively preparing an Arabic gum solution and a sodium alginate solution; then, injecting the sodium alginate solution into the Arabic gum solution proportionally to obtain a mixed wall material solution; in the stirring process, successively adding the emulsifier and the filter stick essence to obtain emulsion; standing; and carrying out high-voltage electrostatic treatment after foam is eliminated to obtain the microcapsule. The slowly-released filter stick essence microcapsule prepared by the invention has the advantages that the embedding rate is more than 80%, the particle diameter uniformity is good, the essence retention rate is more than 85% after the microcapsule is stored for 6 months at 20 DEG C, and the release rate of the essence microcapsule at 40 DEG C is about 6 times of the release rate of the essence microcapsule at 20 DEG C.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

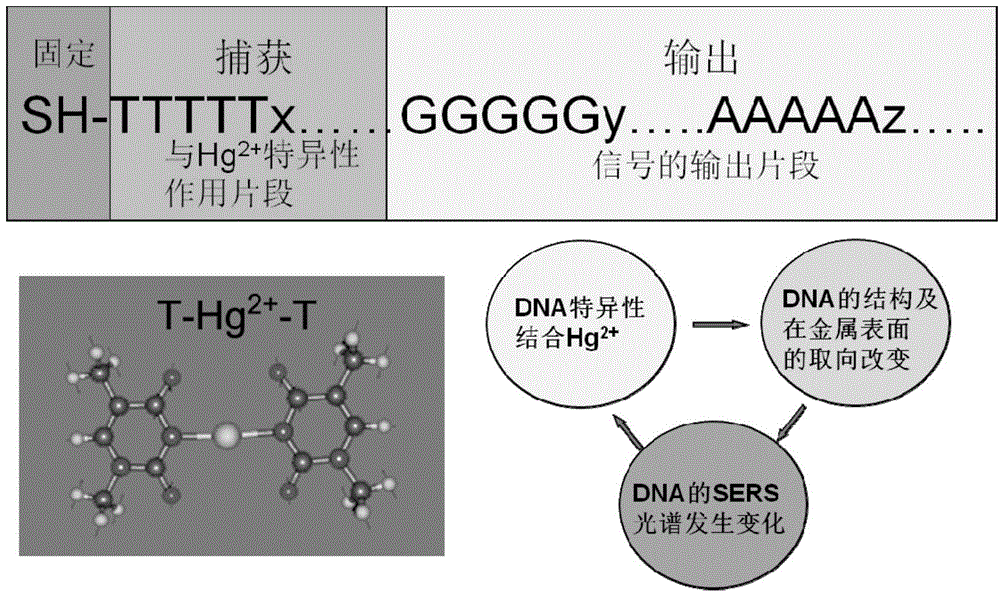

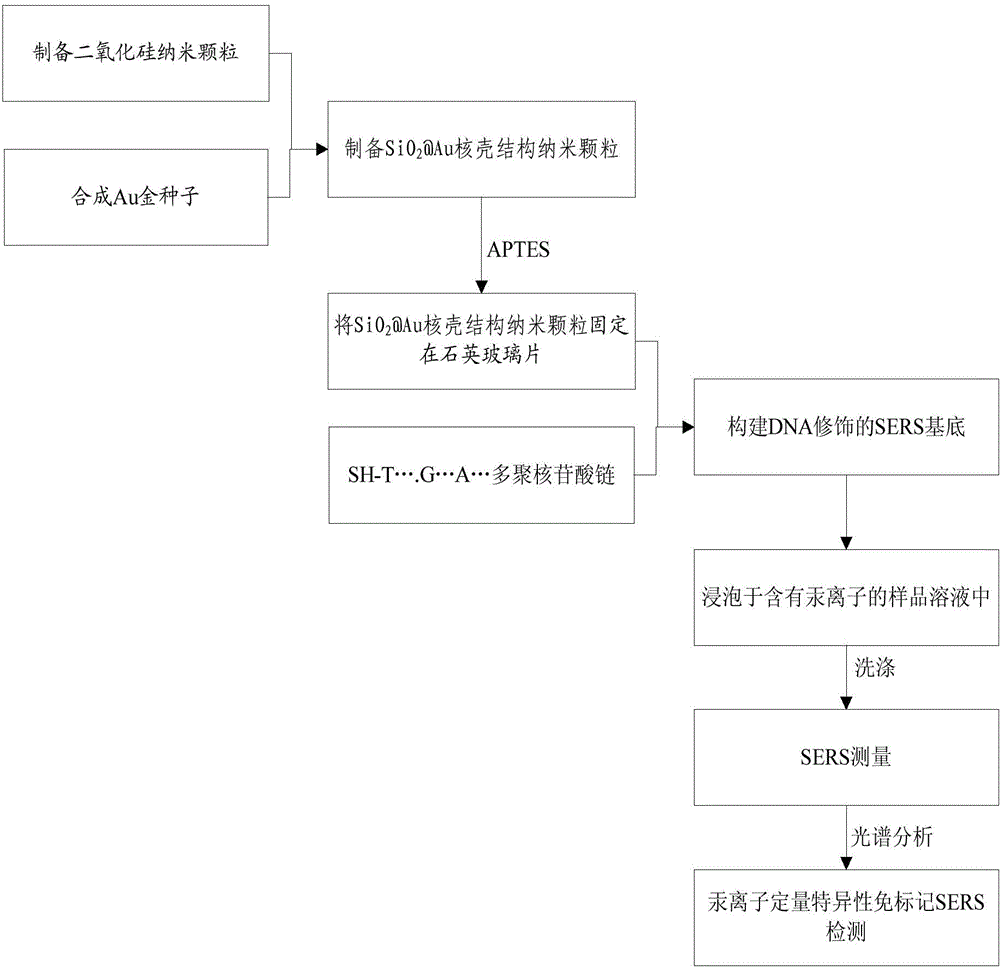

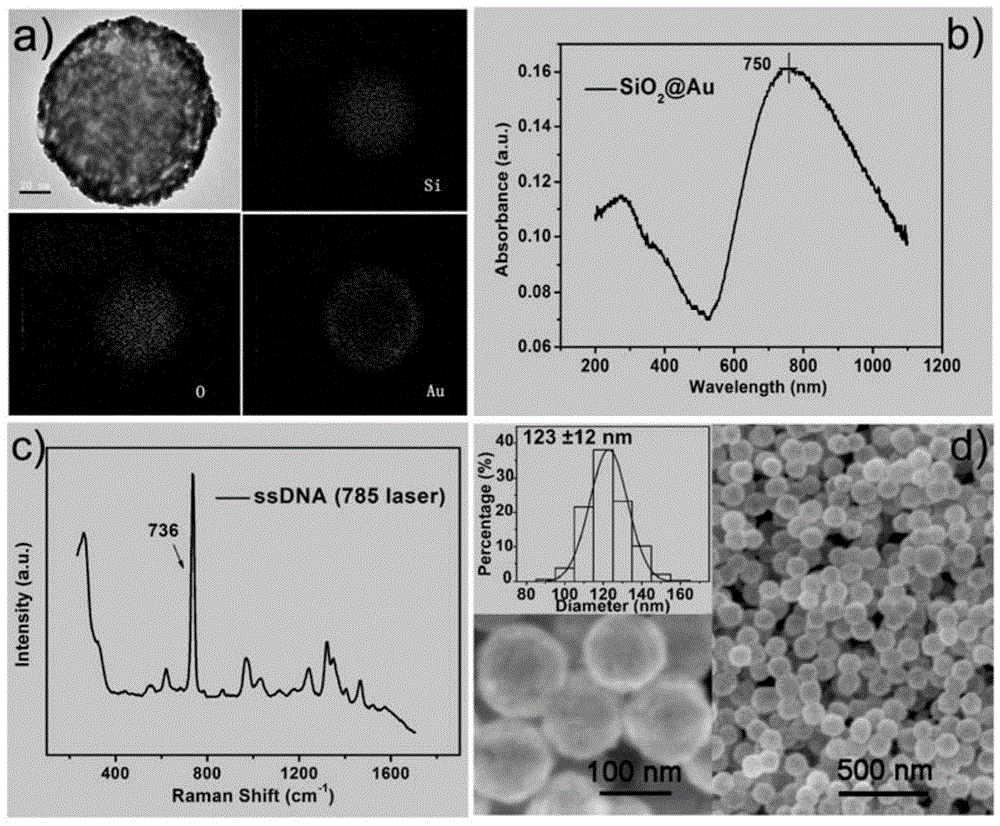

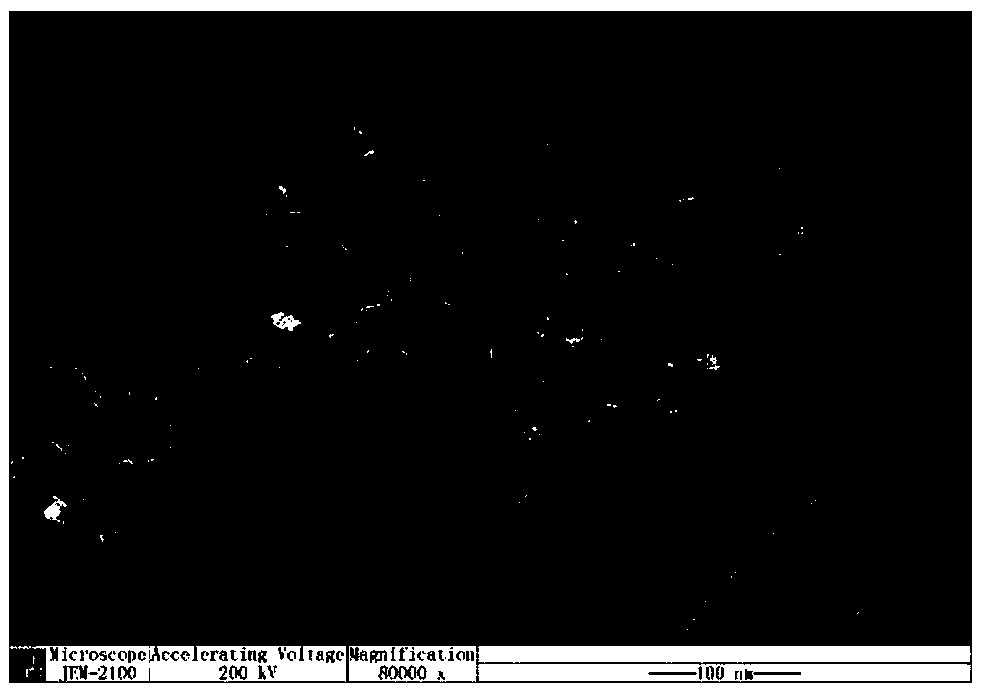

Method for detecting low-concentration mercury ions based on DNA modified SERS substrate

ActiveCN104458704AStrong specificityHigh sensitivityPreparing sample for investigationRaman scatteringDNA AptamersSilicon dioxide

The invention discloses a method for detecting low-concentration mercury ions based on a DNA modified SERS substrate. The method comprises the following steps: preparing uniform gold-covered silicon dioxide nano particles by a fractional step method and fixing nano particles with a core-shell structure on a quartz glass sheet by a coupling agent to construct an SERS substrate; modifying single-chain DNA molecules on the surfaces of gold shell layers of the gold-covered silicon dioxide nano particles through sulfydryls; immersing the prepared DNA aptamer modified SERS substrate into a solution containing the mercury ions; washing with de-ionized water; by taking an SERS signal specific value of a G basic group and an A basic group as spectrum standard measurement of DNA at a metal surface state, realizing quantitative and specific detection on the mercury ions by analyzing a characteristic Raman peak and the change of the specific value. Compared with the prior art, the method has the following advantages that the sensitivity of the method is high, the detection lower limit is about 50nM, the measurement operation is simple, the cost is low, and the real-time and rapid measurement can be realized.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method of improving coercivity of sintering Nd-Fe-B magnetic material

ActiveCN103056370AImprove crushing efficiencyImprove particle size uniformityMagnetic materialsHydrogenShielding gas

The invention discloses a method of improving the coercivity of sintering Nd-Fe-B magnetic materials. The method includes the following steps of using hydrogen to crush Nd-Fe-B alloy, powder processing, compression moulding, sintering and tempering under the protection of vacuum or protective gases. The sintering condition consists of heating to 300 to 600 DEG C, keeping the temperature for 5 to 6 hours to dehydrogenize, heating once again to 1060 to 1120 DEG C, sintering for 1 to 60 minutes under high temperature, finally decreasing the temperature to 1000 to 1050 DEG C, keeping sintering for 1 to 4 hours under the temperature and cooling. The method adopts the steps of sintering for a short period under high temperature to precipitate the liquid phase and then sintering under lower temperature. The liquid phase is rapidly precipitated under high temperature, thereby improving the sintering process of the magnetic materials, promoting the performance of sintering process, controlling the grain size through sintering under lower temperature, inhabiting grain growth and benefiting obtaining an excellent coercivity of magnetic materials.

Owner:ZHEJIANG ZHONGHANG NEW MATERIAL

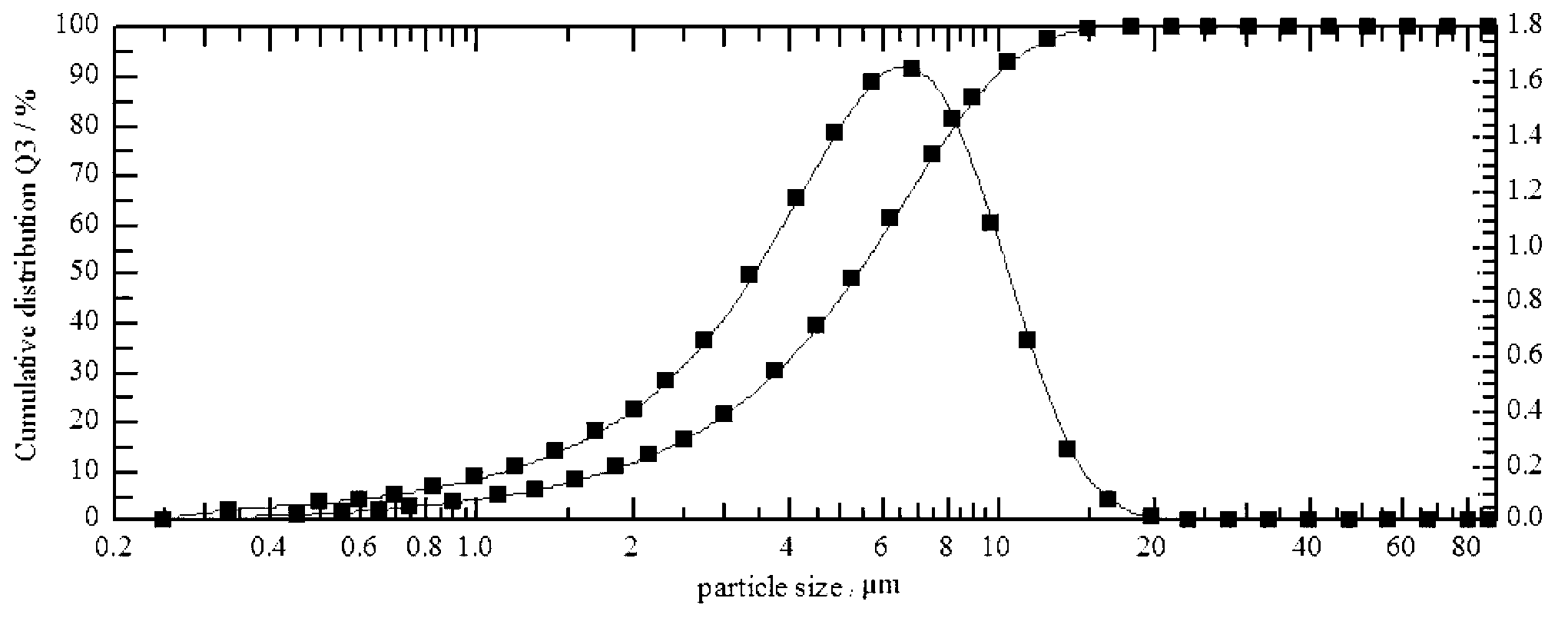

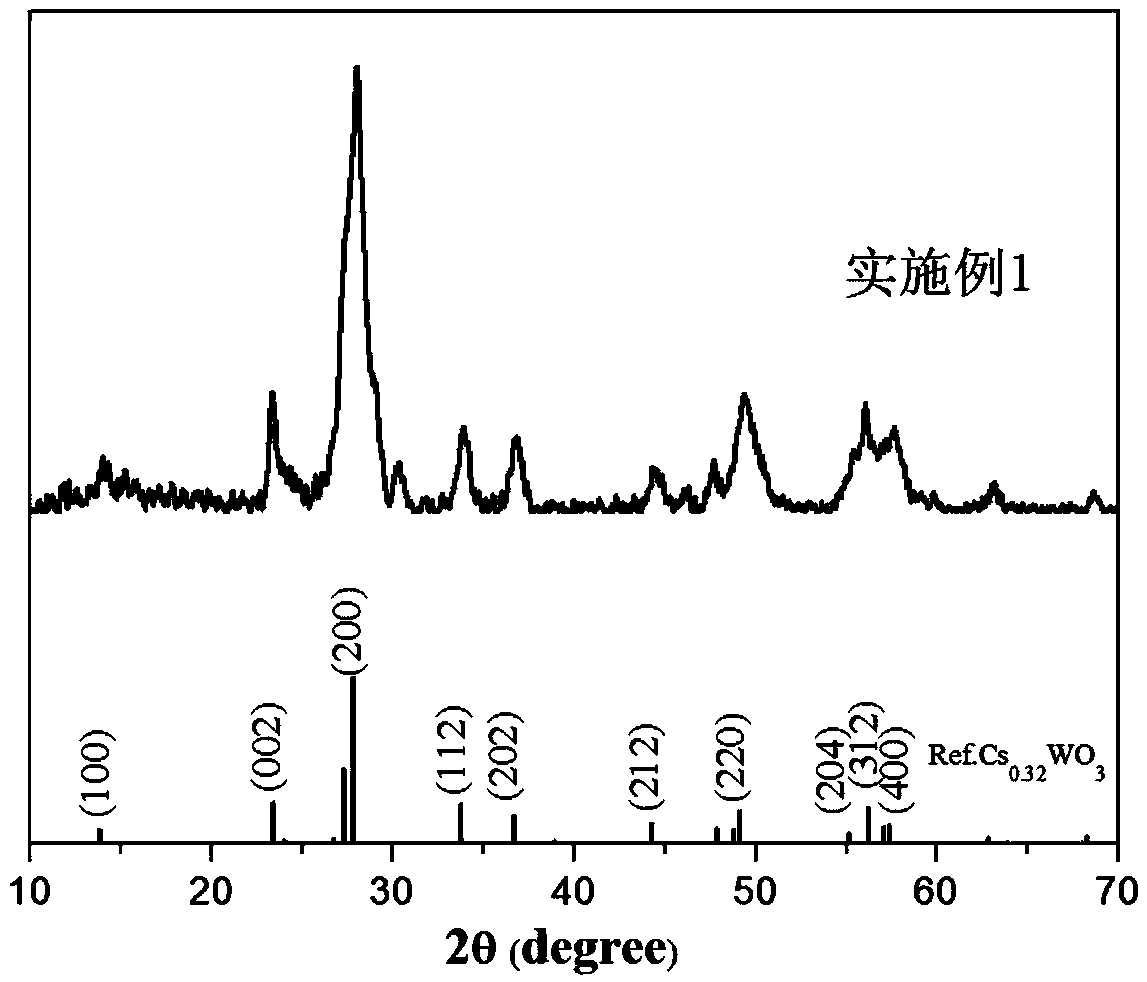

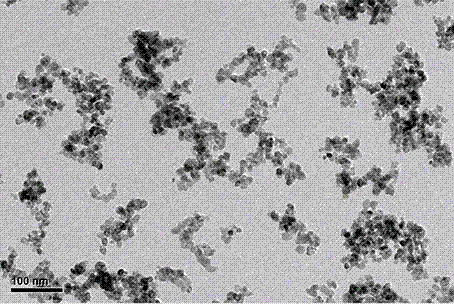

Hexagonal crystal tungsten bronze short rod nanoparticles and preparation method thereof

ActiveCN105502503AFast suspensionGood suspensionMaterial nanotechnologyTungsten compoundsFiberTungstate

The invention discloses a preparation method for preparing hexagonal tungsten bronze short rod nanoparticles MxWO3 with tungstate as the raw material, and belongs to the field of the nanometer technology and the field of energy conservation and environment protection. The method includes the steps of preparing high-specific-surface-area solid colloidal wolframic acid through a cation exchange method or a rapid acidification method, and synthesizing the hexagonal tungsten bronze short rod nanoparticles MxWO3 through a thermal reaction with the solid colloidal wolframic acid as the tungsten source, wherein the synthesized short rod nanoparticles are small in size and high in granularity uniformity, are in a short rod nanometer shape, have the advantages of being quite good in dispersibility and the like, and are particularly suitable for preparing a transparent thermal insulating coating and a thin film of the transparent thermal insulating coating. The visible light permeability and near infrared shielding / thermal insulating performance of the prepared powder can be further improved through nitrogen thermal treatment or reduction thermal treatment. The method is suitable for preparing the glass transparent thermal insulating coating and thermal insulating and heating compounds such as a thermal insulating thin film, a thermal insulating curtain, a solar thermal collector, a solar water heater coating, heating fiber, a thermal insulating and heat preservation plate and photothermal therapy.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Propofol fat emulsion injection and preparation method thereof

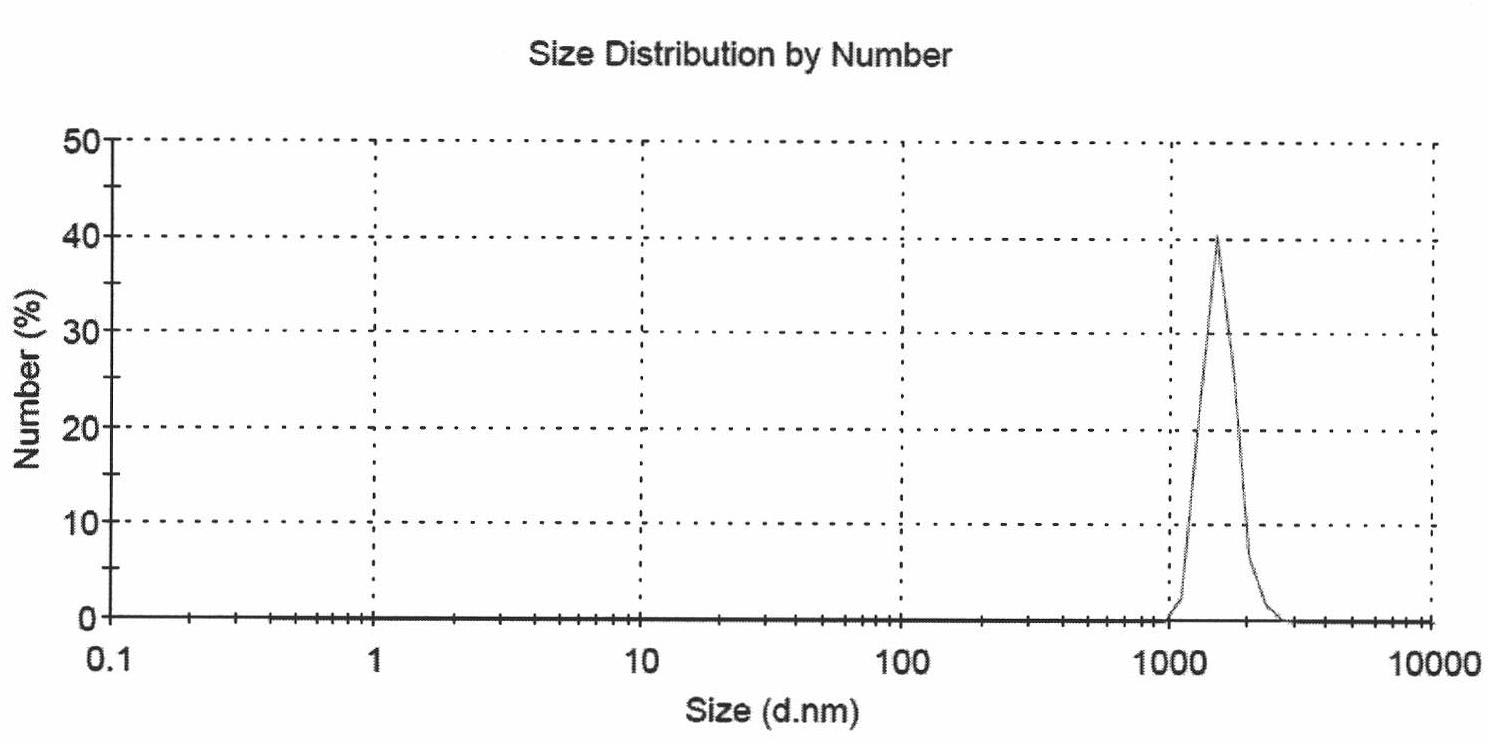

ActiveCN102805728AImprove physical stabilityImprove stabilityNervous disorderHydroxy compound active ingredientsO-Phosphoric AcidMass-Volume Percentage

The invention discloses propofol fat emulsion injection and a preparation method thereof. The propofol fat emulsion injection comprises, by weight percent, 1% of propofol, 6-8% of soybean oil, 1.5-2.0% of soybean lecithin, 3-5% of glycerol, 0.1-0.8% of tween-80, 0.05-0.1% of phosphoric acid, appropriate amount of pH regulator and the balance of water for injection, wherein the amount of the pH regulator is enough to regulate pH of the water for injection to 7.5-8.0. The propofol fat emulsion injection improves drug delivery, decreases particle size, and improves uniformity of particle size, and accordingly stability of the injection is improved, pain during injection is lowered, and drug dependency of patients is increased.

Owner:NANJING CHIA TAI TIANQING PHARMA

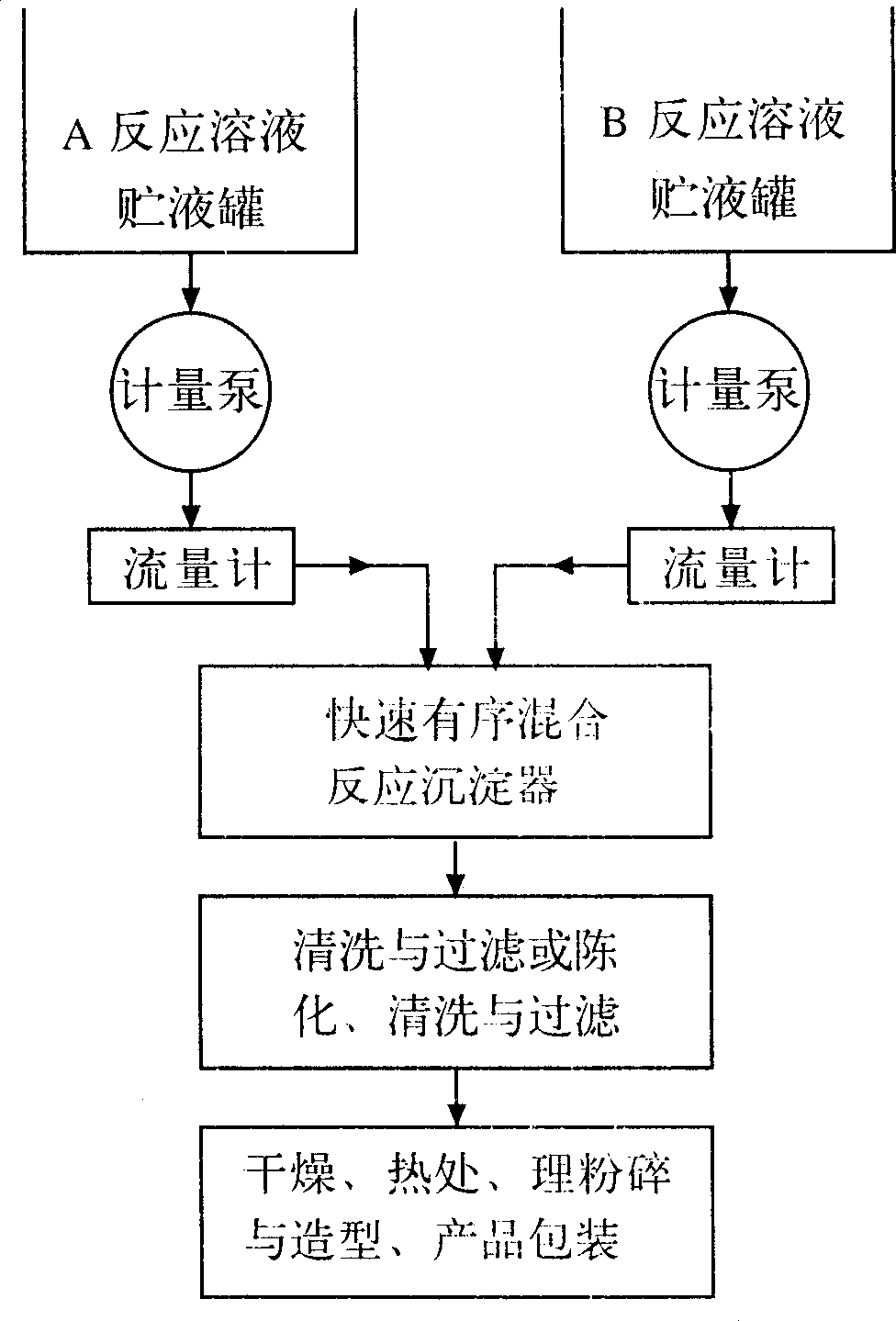

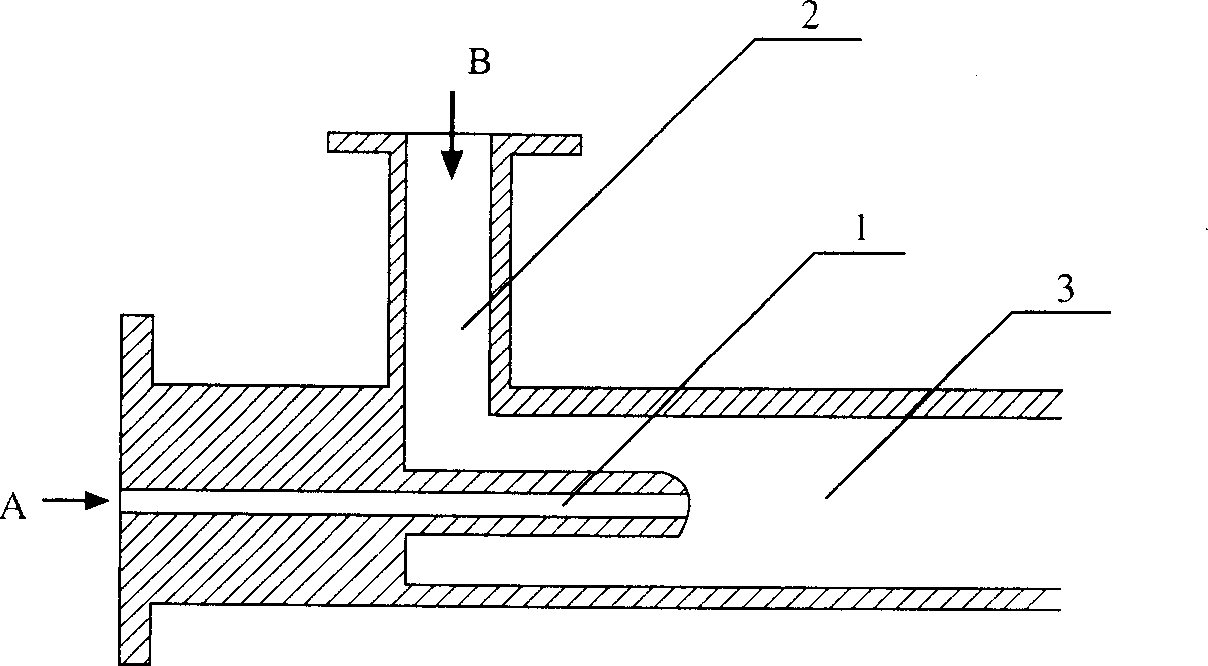

Liquid phase nano powder body and preparation method of nano particle agglutinative structure material

InactiveCN1400044ASmall particle sizeSmall and uniform particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologySlurryChalcoides

The present invention discloses a nano powder body and nano particle aggregative structure material preparation method. Said method can regulate and control grain size of nano particle, can make saidmaterial possess uniform grain size, good dispersion property and high yield. Its equipment is simple, and consumption is less. Said method mainly includes the following steps: continuously feeding reactant solution into quickly-mixing reaction precipitation equipment, and continuously discharging the precipitate-contained slurry material from said equipment, then making the slurry material undergo the processes of cleaning, filtering or ageing, cleaning and filtering, drying, heat treatment, pulverizing and packaging. Said method can be used for producing various nano powder body and nano particle aggregative structure materials.

Owner:UNIV OF SCI & TECH LIAONING

Spherical polyphenylene sulfide powdery material for 3D printing and preparation method of spherical polyphenylene sulfide powdery material

The invention provides a spherical polyphenylene sulfide powdery material for 3D printing. According to the material, nano mica powder is dispersed in polyphenylene sulfide and has quick meltbility and flowability. The invention further provides a preparation method of the spherical polyphenylene sulfide powdery material for 3D printing. The spherical polyphenylene sulfide powdery material with high sphericity is obtained through crushing and spheroidizing. Powdery polyphenylene sulfide is subjected to surface softening and pelletizing through high-temperature air flow under the action of a crosslinking agent, and the spherical polyphenylene sulfide powdery material with high sphericity is obtained. With the introduction of nano mica powder, the spherical polyphenylene sulfide material can be quickly and uniformly heated and melted and is suitable for the field of quick forming during 3D printing.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Nickel-manganese composite hydroxide particle and manufacturing method thereof, positive electrode active material and manufacturing method thereof and non-water-system electrolyte secondary battery

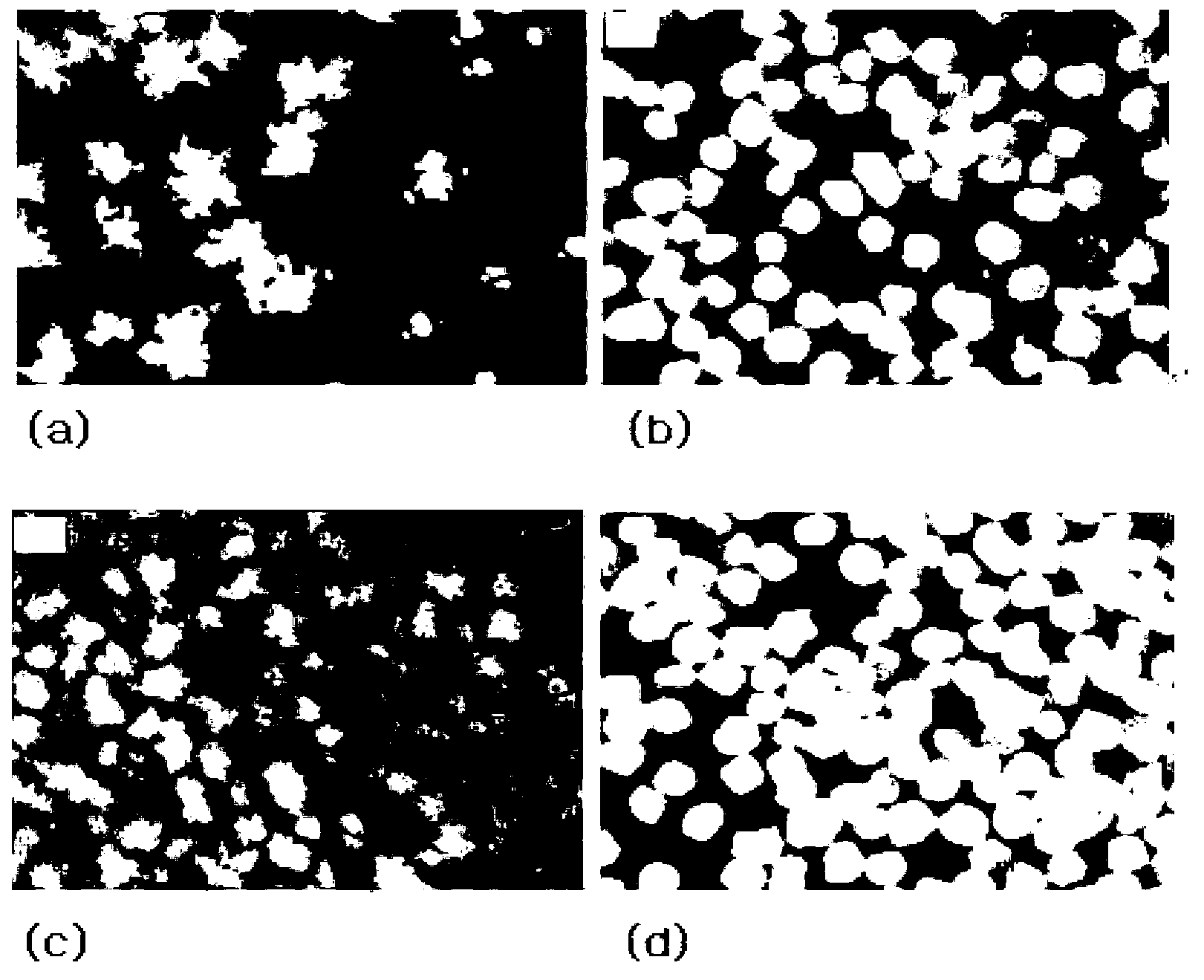

InactiveCN104953111ASmall particle sizeImprove particle size uniformitySecondary cellsPositive electrodesDevitrificationManganese

The invention provides a nickel-manganese composite hydroxide particle and a manufacturing method thereof. The nickel-manganese composite hydroxide particle has the small and uniform particle size and is of a hollow structure. According to the solution, when nickel-manganese composite hydroxide is obtained through a devitrification reaction, a nickelic metallic compound, a manganeses metallic compound and a water solution for nucleus formation of an ammonium ion donator are controlled so that the pH value of the water solution can be controlled to range from 12.0 to 13.4 with the solution temperature being 25 DEG C as the reference, nucleus formation is performed in the oxidability environment, then, a water solution for growth of the particle with the formed nucleus so that the pH value of the water solution can be controlled to range from 10.5 to 12.0 with the solution temperature being 25 DEG C as the reference, and the oxidability environment with the oxygen concentration being larger than 1% is switched into the oxygen and non-active gas mixture environment with the oxygen concentration being smaller than 1% so that the nucleus can grow.

Owner:SUMITOMO METAL MINING CO LTD

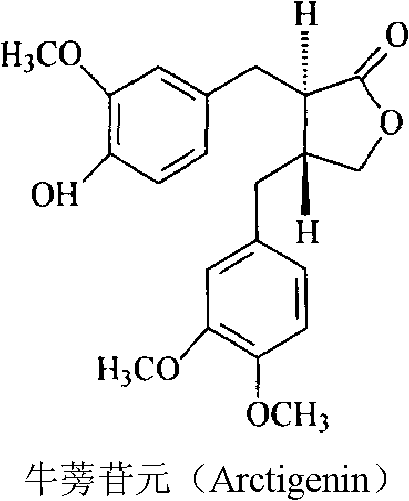

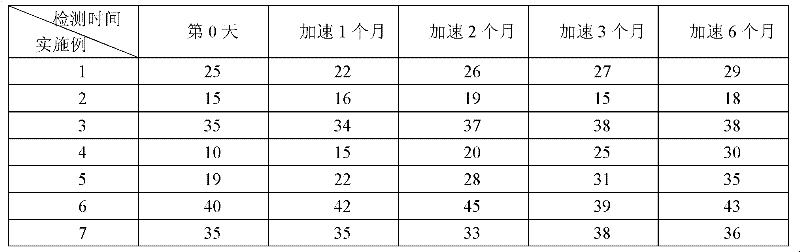

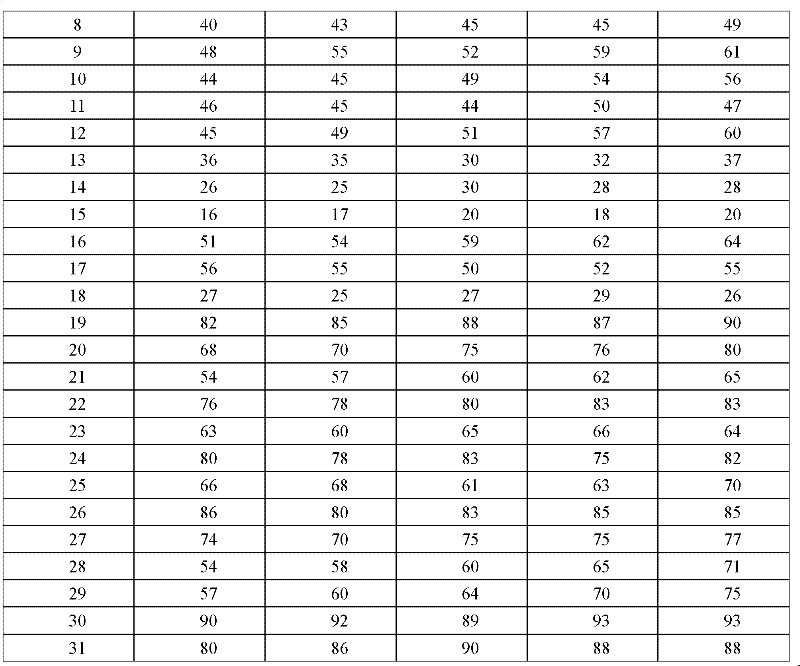

Burdock aglycone microemulsion

ActiveCN102210653AEasy to passIncrease capacityAntibacterial agentsOrganic active ingredientsOral medicationMedicine

The invention belongs to the field of medicines and relates to microemulsion. Particularly, the invention relates to microemulsion containing burdock aglycone and a microemulsion carrier, wherein the microemulsion carrier contains an oil phase and an emulsifier; and the average particle size of the microemulsion is 10 to 90 nanometers. The burdock aglycone microemulsion can improve the oral administration bioavailability and tumor suppressing effect of the burdock aglycone obviously.

Owner:LUNAN PHARMA GROUP CORPORATION

Lithium-rich manganese-based precursor, preparation method thereof and lithium-rich manganese-based positive electrode material

InactiveCN109704415AParticle size controllableImprove particle size uniformityCell electrodesSecondary cellsNickel saltManganese

The invention relates to a lithium-rich manganese-based precursor, a preparation method thereof and a lithium-rich manganese-based positive electrode material. The preparation method of the lithium-rich manganese-based precursor comprises the following steps: (1) dissolving nickel salt, cobalt salt, manganese salt and doping ion salt in water to obtain a mixed salt solution; (2) adding a precipitant and a complexing agent into the mixed salt solution, and adjusting the pH value to obtain a reaction precursor; and (3) carrying out intermittent ultrasonic vibration on the reaction precursor to obtain a lithium-rich manganese-based precursor crude product. According to the invention, the pH value of the reaction system is adjusted, so that the particle size of the material is in an increasingstage; the particle size in the reaction system is controlled by adopting intermittent ultrasonic concussion; when the particle size exceeds a control index, the ultrasonic oscillator is started, sothat nucleation of the reaction system is rapidly carried out, and the particle size is reduced; and when the particle size is reduced to a qualified standard range, the ultrasonic oscillator is turned off, so that the particle size of the lithium-rich manganese-based precursor is controllable.

Owner:EVE ENERGY CO LTD

Production method of nanoscale high-purity zirconium dioxide composite powder

InactiveCN106866142AImprove particle size uniformityEfficient removalMaterial nanotechnologyZirconium halidesDistillationIon exchange

The invention relates to a production method of nanoscale high-purity zirconium dioxide composite powder. The method comprises the following steps: taking zirconium tetrachloride as the raw material, drying the raw material, then removing impurity with boiling point being lower than that of zirconium tetrachloride and impurity with boiling point being higher than that of zirconium tetrachloride through a two-step distillation crystallization method, dissolving zirconium tetrachloride by using a mixed solution of deionized water and alcohol, carrying out separation of zirconium and hafnium in the solution through an MIBK extraction-elution resin filled extraction chromatographic column, then further purifying zirconium tetrachloride through an ion exchange mode, adding chloride into a high-purity zirconium tetrachloride solution to form a zirconium tetrachloride compound solution, then obtaining zirconium hydroxide gel through an ammonia water spraying co-precipitation manner, carrying out hydrothermal reaction of the zirconium hydroxide gel in a high-pressure reactor, and finally filtering, washing and drying to obtain the nanoscale high-purity zirconium dioxide composite powder. The nanoscale high-purity zirconium dioxide composite powder prepared by the method has the advantages of high purity, uniform particle size, high dispersibility and the like and is applicable to industrial production.

Owner:南京金鲤新材料有限公司

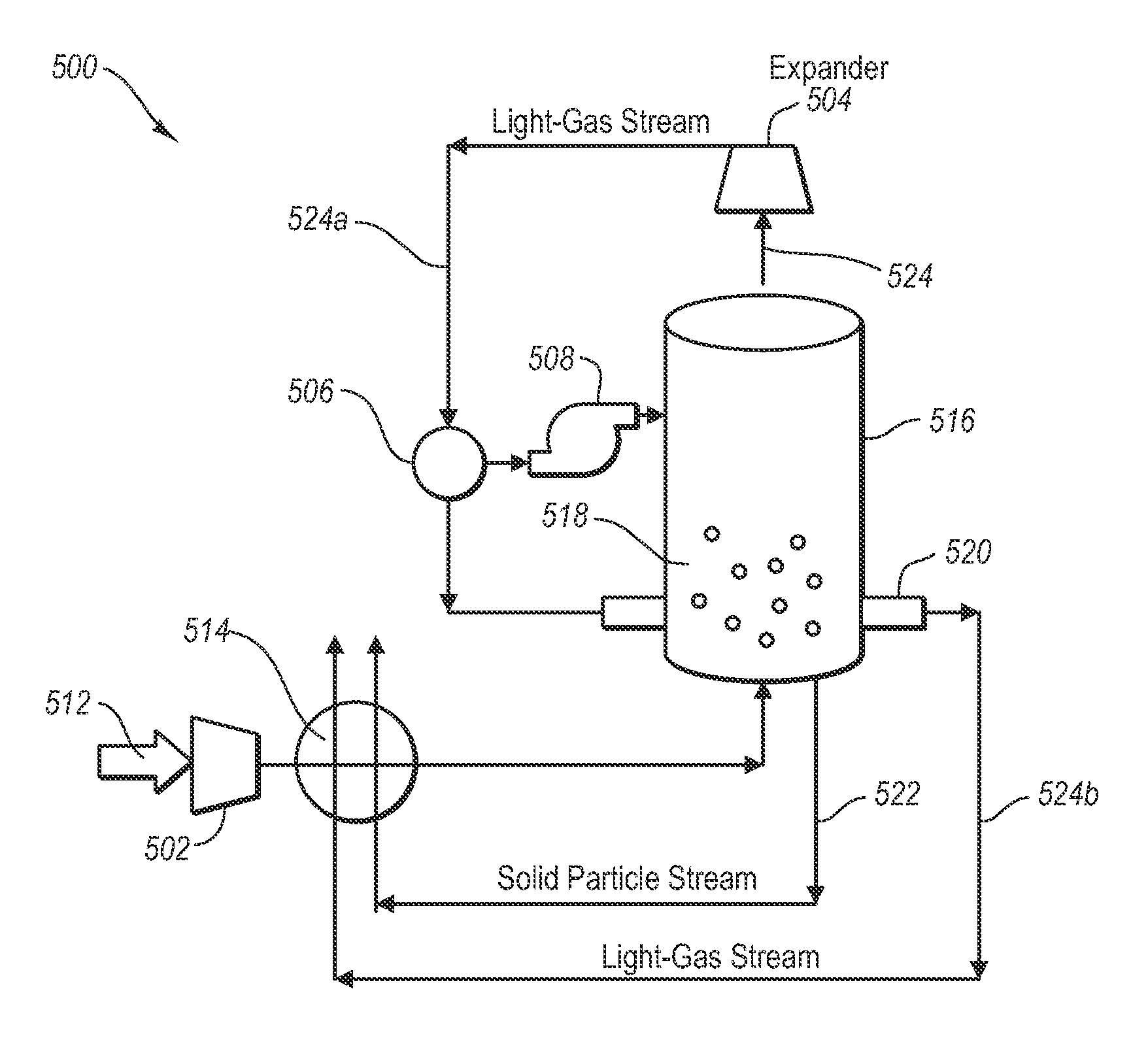

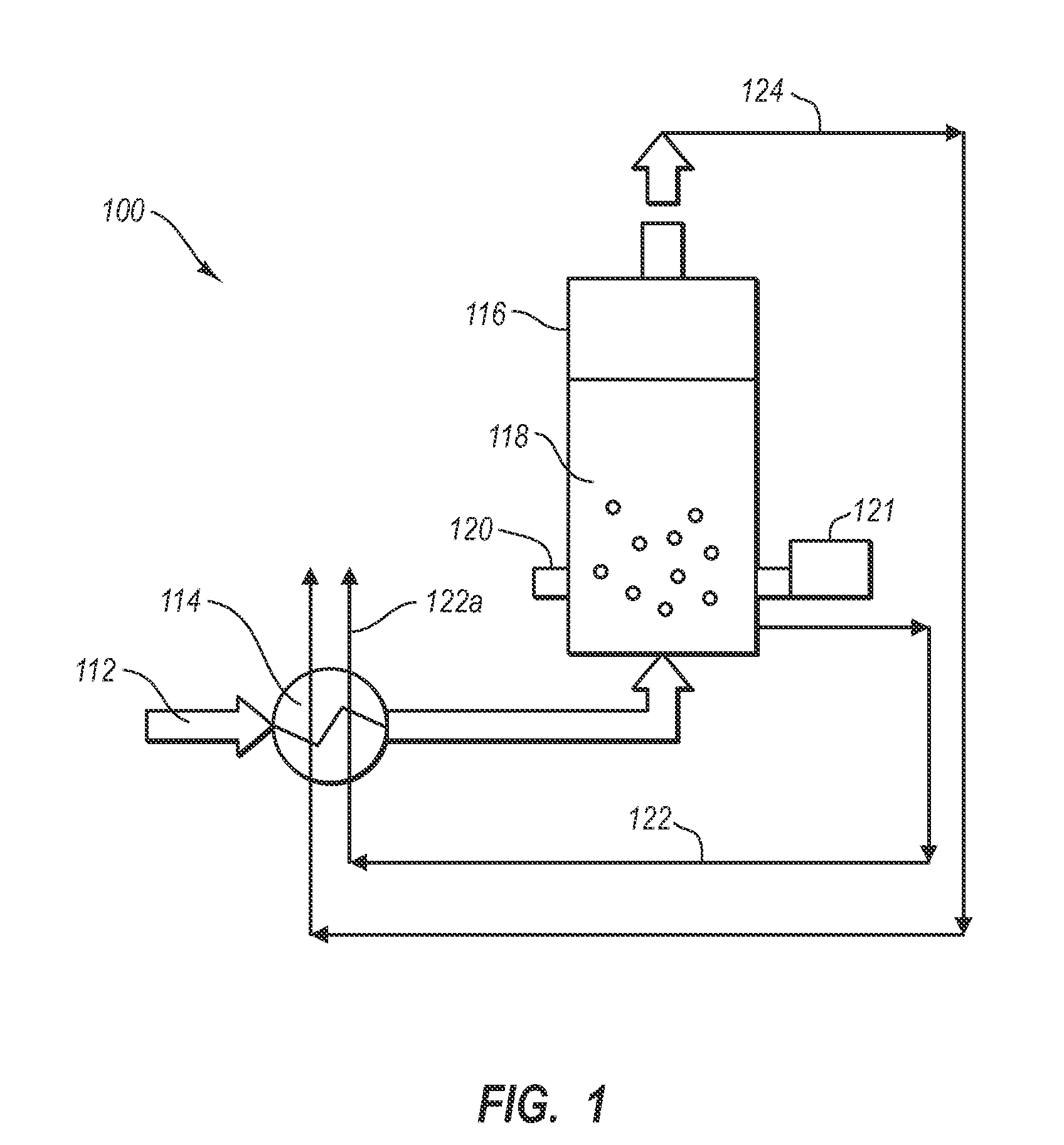

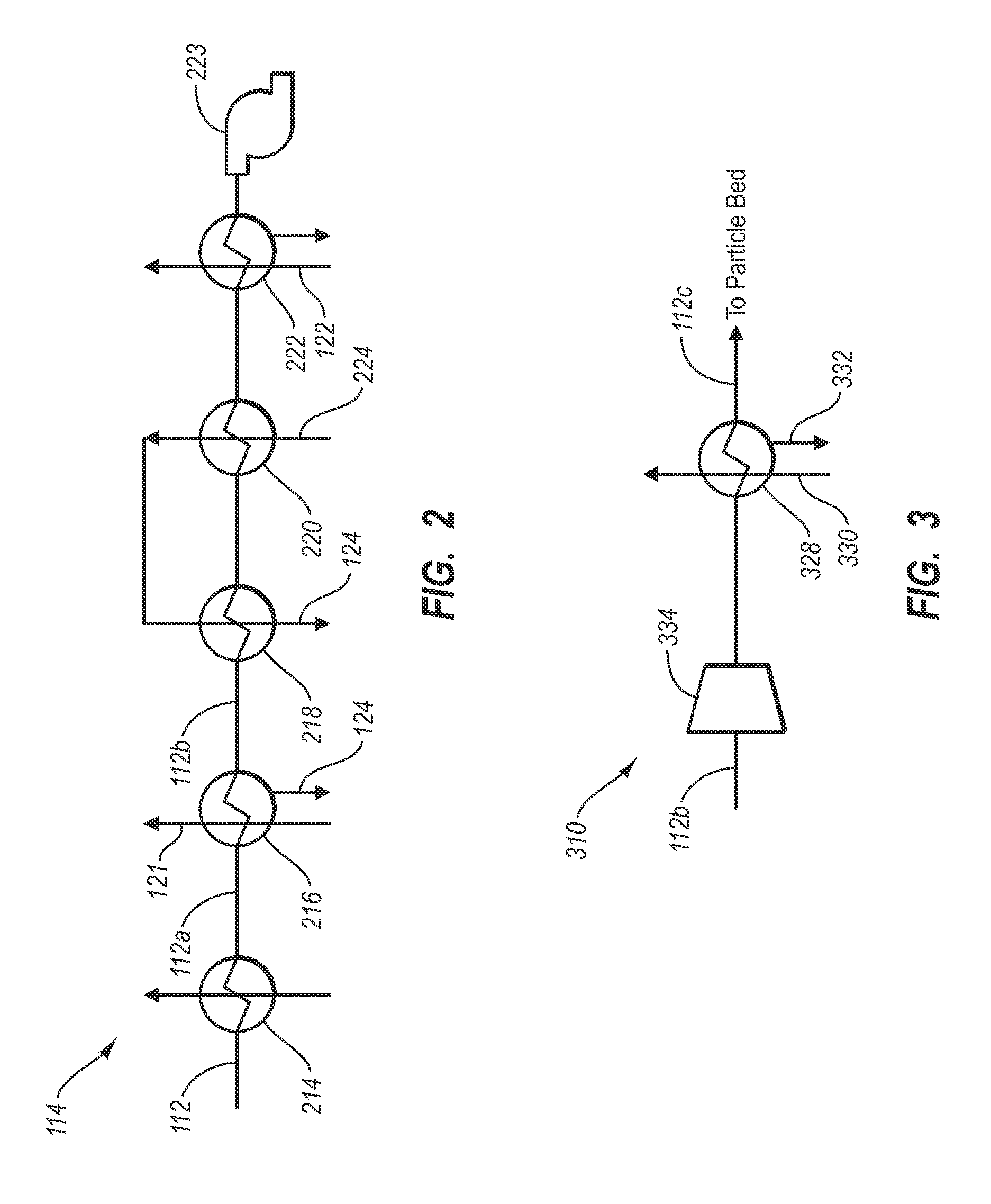

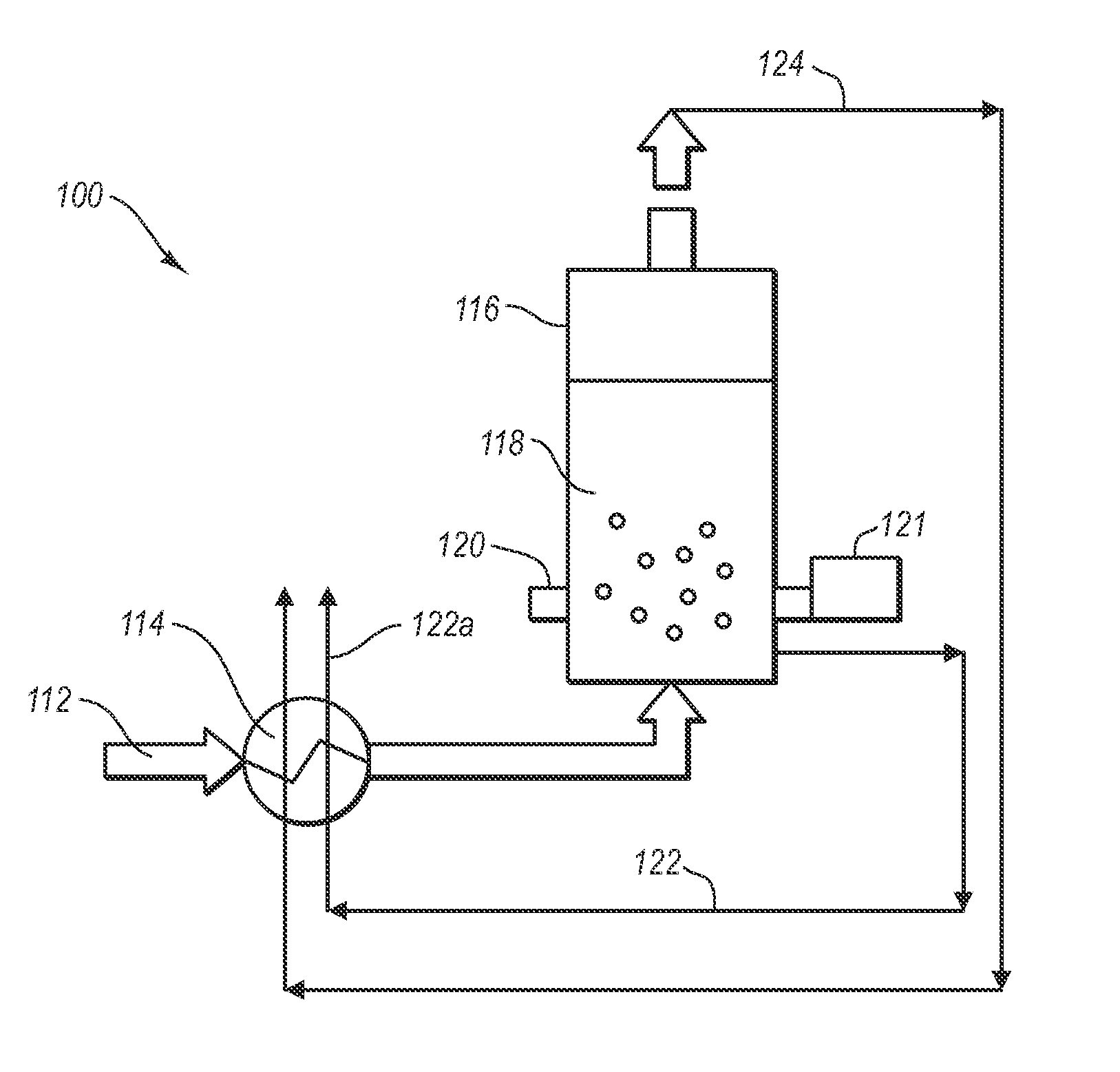

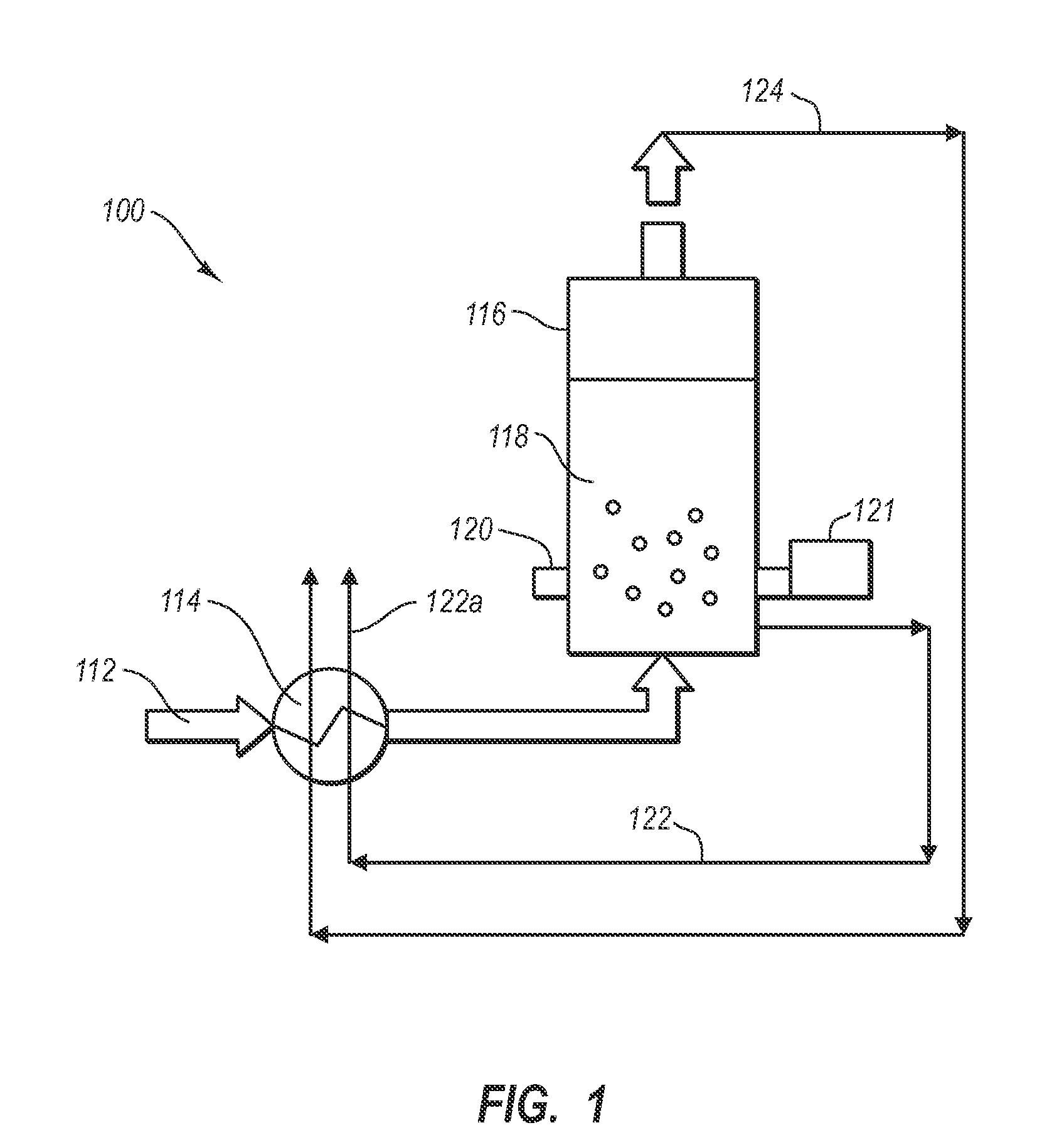

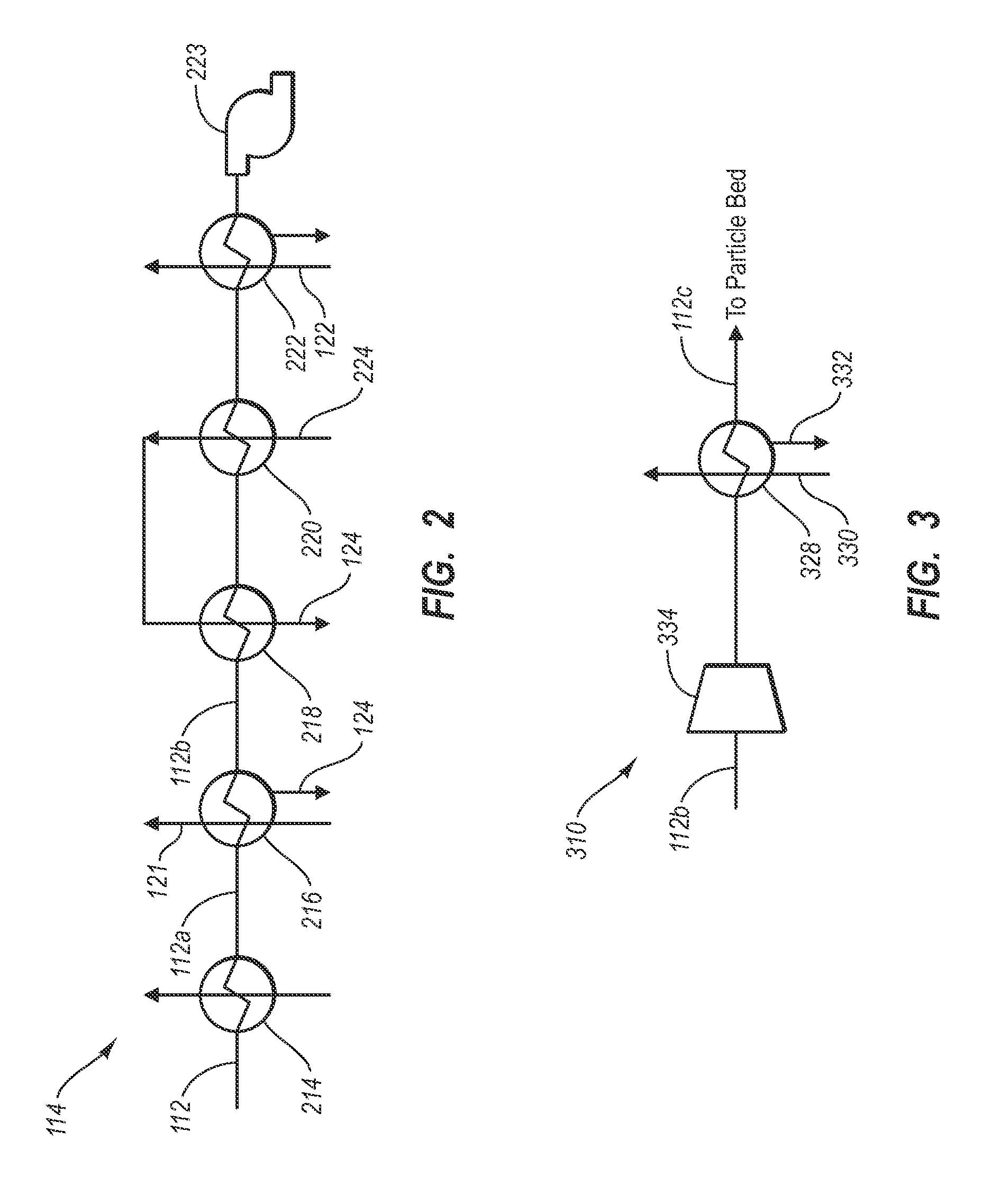

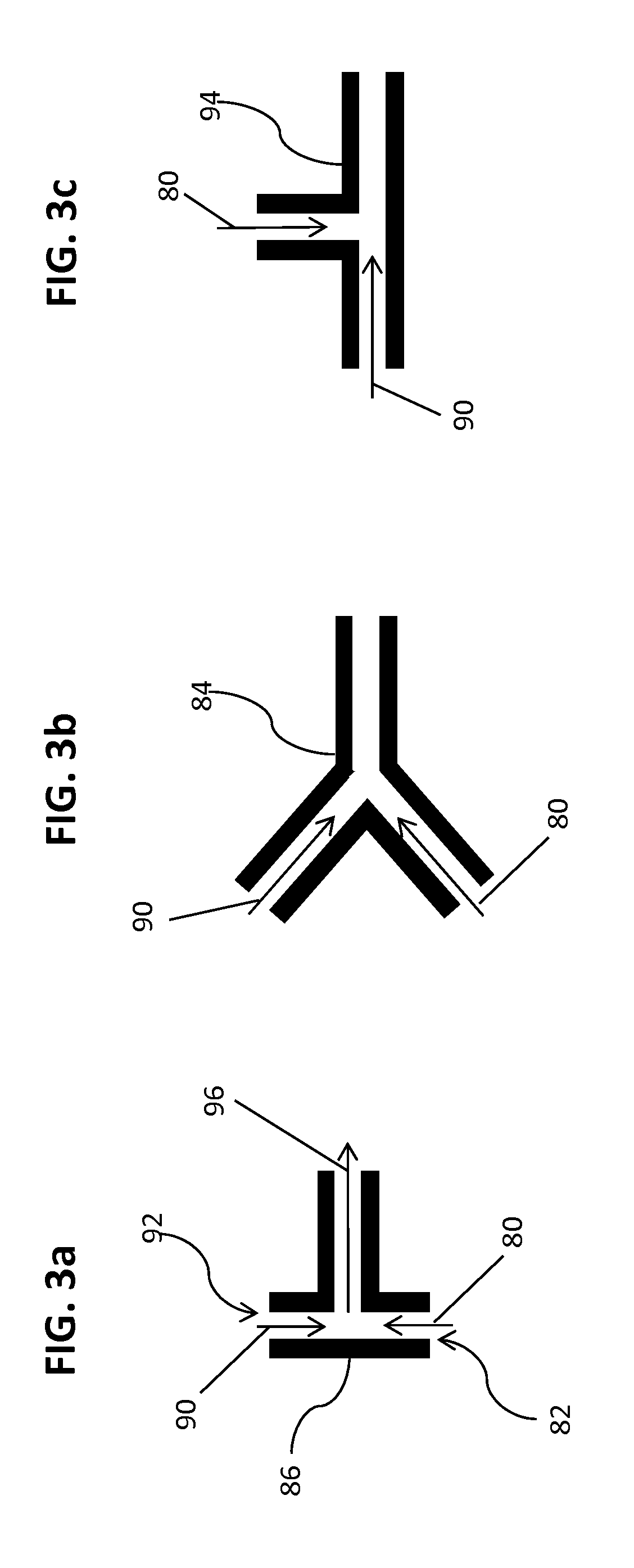

Methods and systems for separating condensable vapors from gases

ActiveUS20120132072A1Improve particle size uniformityFacilitate continuous operation of systemSolidificationLiquefactionCarbon dioxideEnvironmental chemistry

Condensable vapors such as carbon dioxide are separated from light gases in a process stream. The systems and methods employ a particle bed cooled by an in-bed heat exchanger to desublimate the condensable vapors from the process stream. The condensable vapors are condensed on the bed particles while the light gases from the process stream, which are not condensed, form a separated light-gas stream. The separated light-gas stream can be used in a recuperative heat exchanger to cool the process stream.

Owner:U S BANK TRUST CO NAT ASSOC

Nickel composite hydroxide and manufacturing method thereof, cathode active material for nonaqueous-electrolyte secondary battery and manufacturing method thereof, and nonaqueous-electrolyte secondary battery

ActiveCN106044871AImprove particle size uniformityLarge specific surface areaPositive electrodesLi-accumulatorsElectrical batteryParticle growth

Provided are a cathode active material having a suitable particle size and high uniformity, and a nickel composite hydroxide as a precursor of the cathode active material. When obtaining nickel composite hydroxide by a crystallization reaction, nucleation is performed by controlling a nucleation aqueous solution that includes a metal compound, which includes nickel, and an ammonium ion donor so that the pH value at a standard solution temperature of 25 DEG C. becomes 12.0 to 14.0, after which, particles are grown by controlling a particle growth aqueous solution that includes the formed nuclei so that the pH value at a standard solution temperature of 25 DEG C. becomes 10.5 to 12.0, and so that the pH value is lower than the pH value during nucleation. The crystallization reaction is performed in a non-oxidizing atmosphere at least in a range after the processing time exceeds at least 40% of the total time of the particle growth process from the start of the particle growth process where the oxygen concentration is 1 volume % or less, and with controlling an agitation power requirement per unit volume into a range of 0.5 kW / m3 to 4 kW / m3 at least during the nucleation process.

Owner:SUMITOMO METAL MINING CO LTD

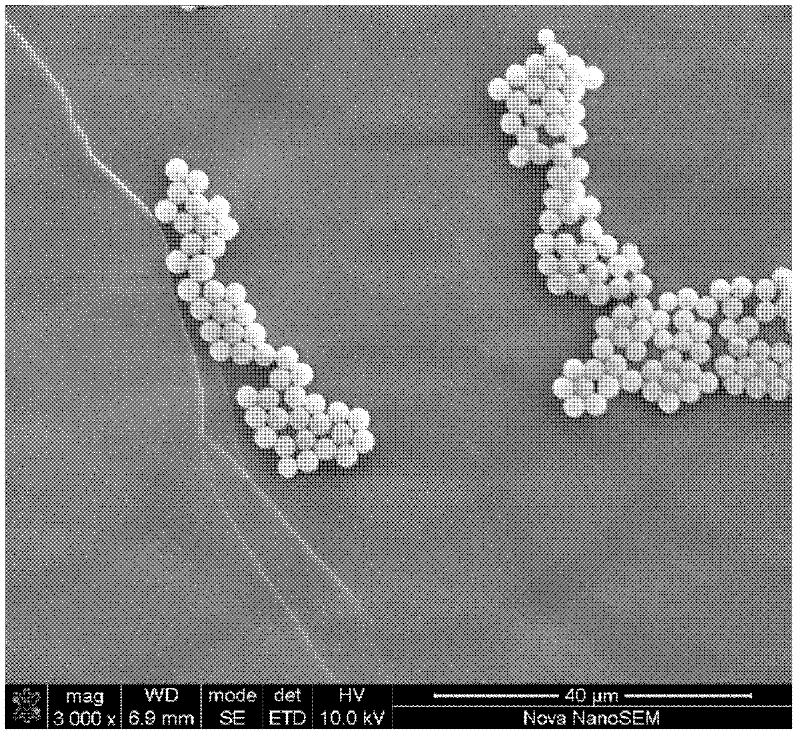

Microcapsule with silicon dioxide core-shell coating liquid and preparation method of microcapsule

ActiveCN103551093ASolve the problem that it cannot be coated into microcapsulesImprove thermal stabilityMicroballoon preparationMicrocapsule preparationMicrosphereHeat stability

The invention discloses a microcapsule with a silicon dioxide core-shell coating liquid and a preparation method of the microcapsule. The preparation method comprises the following steps of: selecting a polymer monomer A to prepare a polymer microsphere B with uniform grain size and having positive charge on the surface; absorbing a surface active agent onto the surface of the microsphere B to obtain a seed microsphere C; coating the seed microsphere C with tetraethoxysilane to obtain a microsphere D with porous silicon dioxide as a shell; calcining the microsphere D to obtain a hollow silicon dioxide microsphere E; soaking the hollow silicon dioxide microsphere E into liquid of a core material to obtain a microsphere F with the core material; coating the microsphere F with tetraethoxysilane to obtain the core-shell structured microcapsule G with dense silicon dioxide as the shell. The method is applicable to the preparation of the microcapsule coating low-polarity liquid, high-polarity liquid and dual-polarity liquid, solves the problem in the prior art that the dual-polarity liquid cannot be coated into the microcapsule, is simple in operation steps, and low in requirement for equipment, and the microcapsule is high in heat stability, good in corrosion resistance and uniformity of grain size.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Magnetic powder for magnetic recording, magnetic recording medium, and method of manufacturing magnetic powder for magnetic recording

ActiveUS20150187380A1Improve particle size uniformitySmall sizeMagnetic materials for record carriersRecord information storageStrontiumMaterials science

An aspect of the present invention relates to magnetic powder, which is magnetoplumbite hexagonal strontium ferrite magnetic powder comprising 1 atomic percent to 5 atomic percent of Ba per 100 atomic percent of Fe, the average particle size of which ranges from 10 nm to 25 nm, and which is magnetic powder for magnetic recording.

Owner:FUJIFILM CORP

Cuprous thiocyanate and production method

InactiveCN101428822AImprove particle size uniformityNarrow particle size rangeThiocyanic acidSulfateWhite powder

The invention relates to cuprous thiocyanate and a preparation method. Cuprous thiocyanate can be used as antifouling paint and paint used biological poisoning agents. The invention is characterized in that 35-50% thiocyanate water solution and 35-45% copper sulfate or hydrochloride water solution replacement-react under the protection of SO2 or CO, the mol ratio of the three is 1:1:(0.3-0.7), and white powder with grain diameter ranging from 5-25 Mum and white content being 70-80% is obtained. Compared with the prior art, the yield can be improved by 50%, and the yield and the purity can be improved to be above 99%; the output of waste water is small, and only 1-3 t waster water is generated per product; the obtained cuprous thiocyanate has good evenness and small grain diameter range reduced to be 5-25 Mum, the anti-corrosion effect is stable, and the white or off-white powder product greatly improves the commonality of color matching; and the integrated cost is reduced by 20%, thereby overcoming the defect of the prior art.

Owner:江苏燎原环保科技股份有限公司

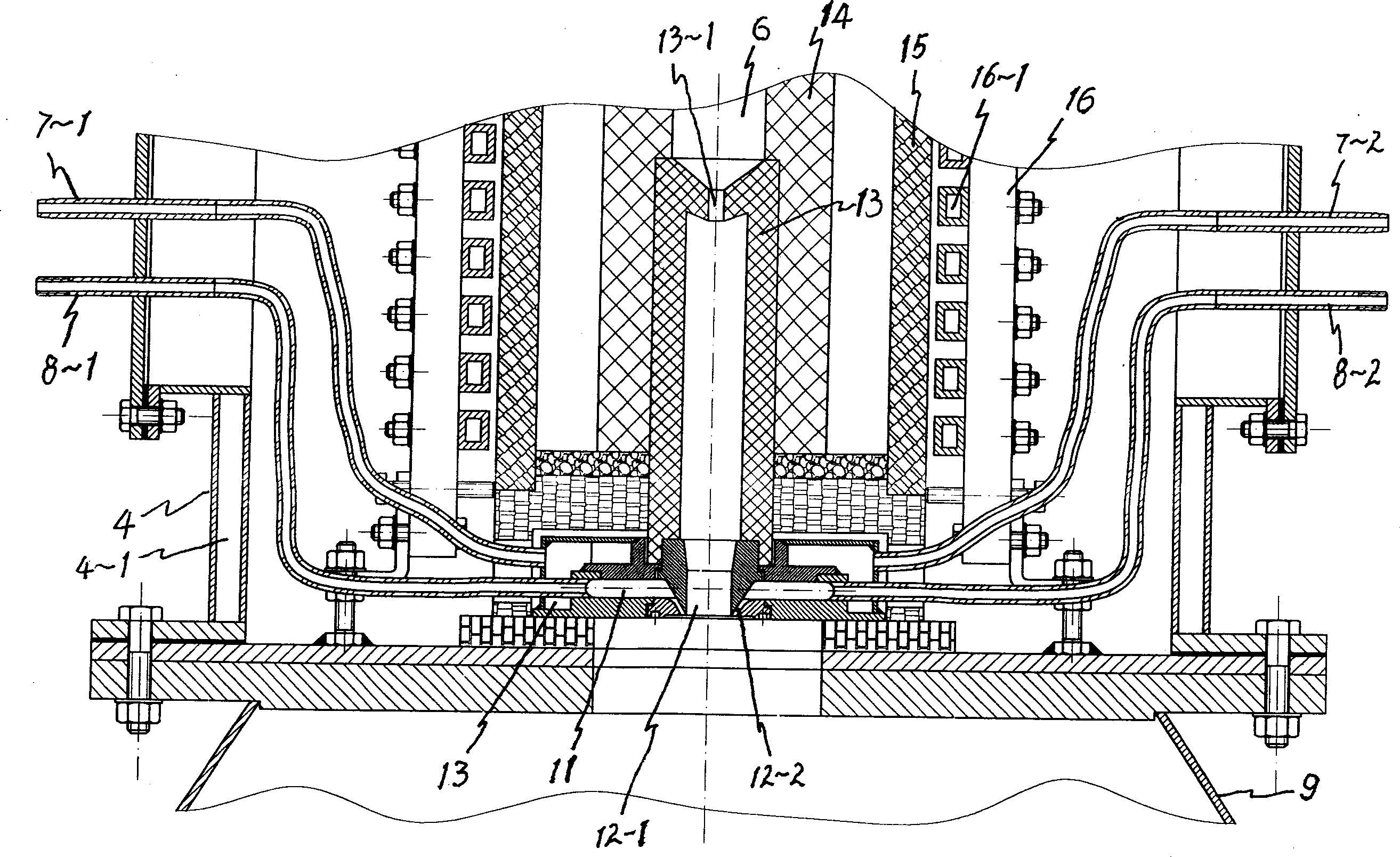

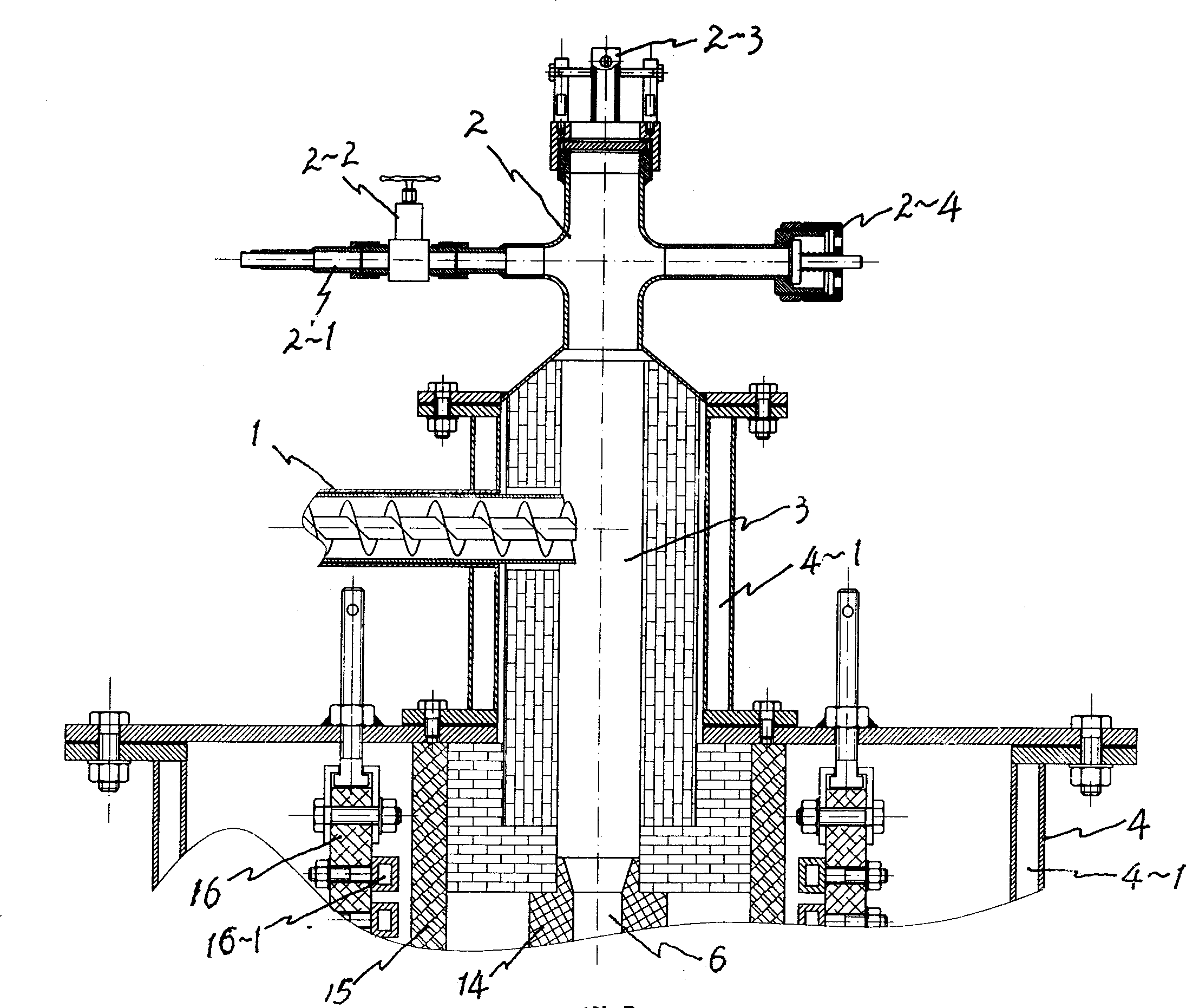

Fluid processing device with annular flow paths

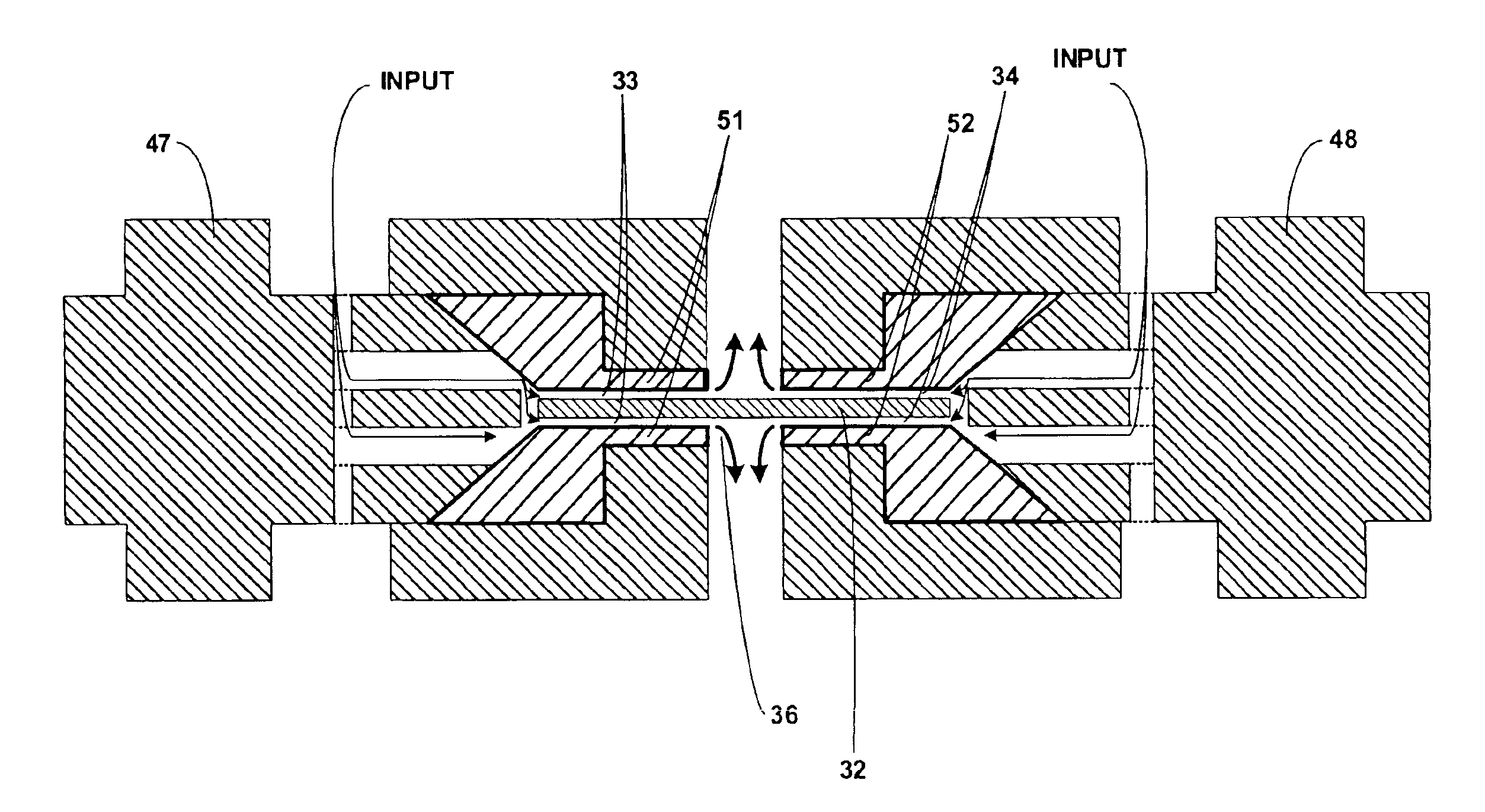

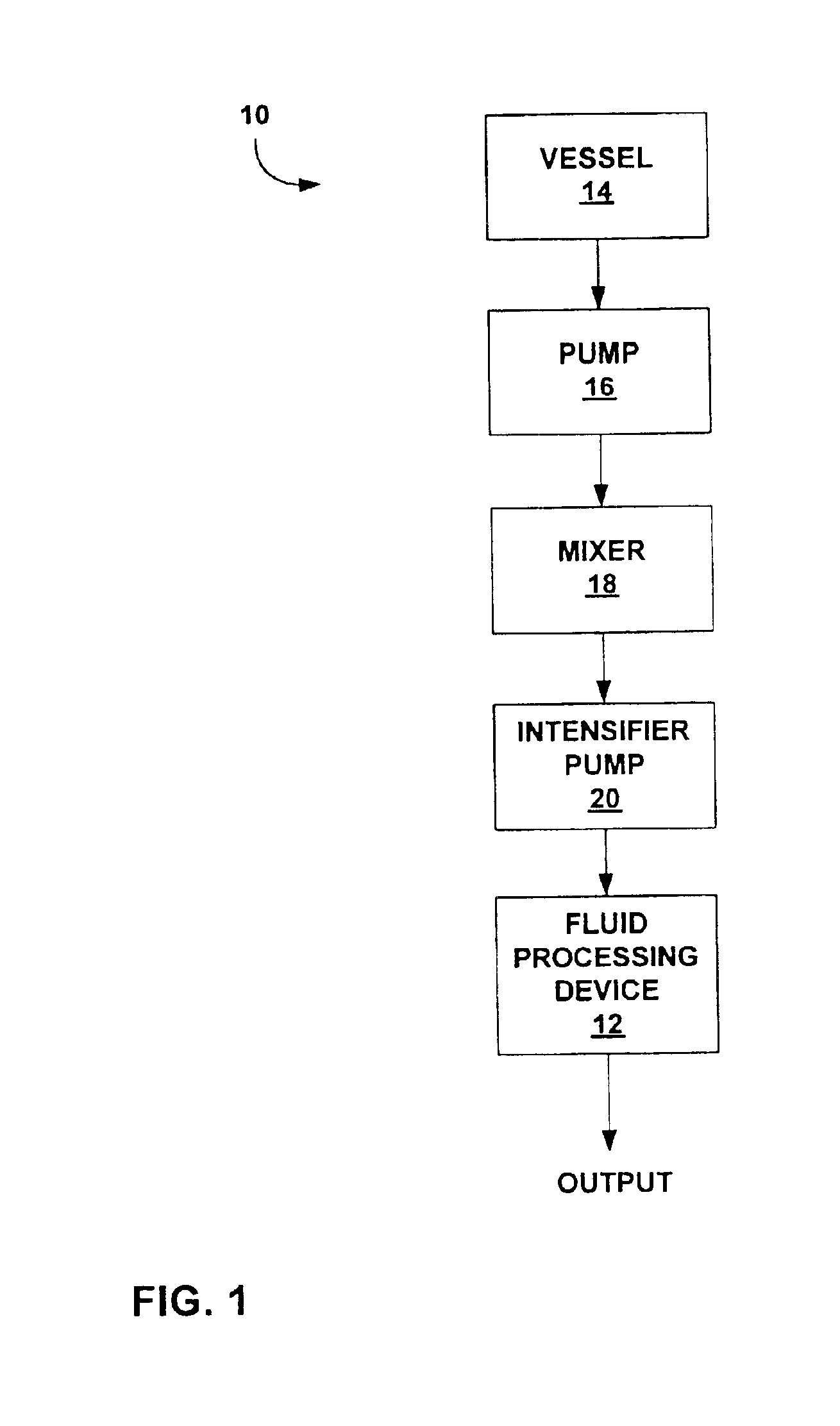

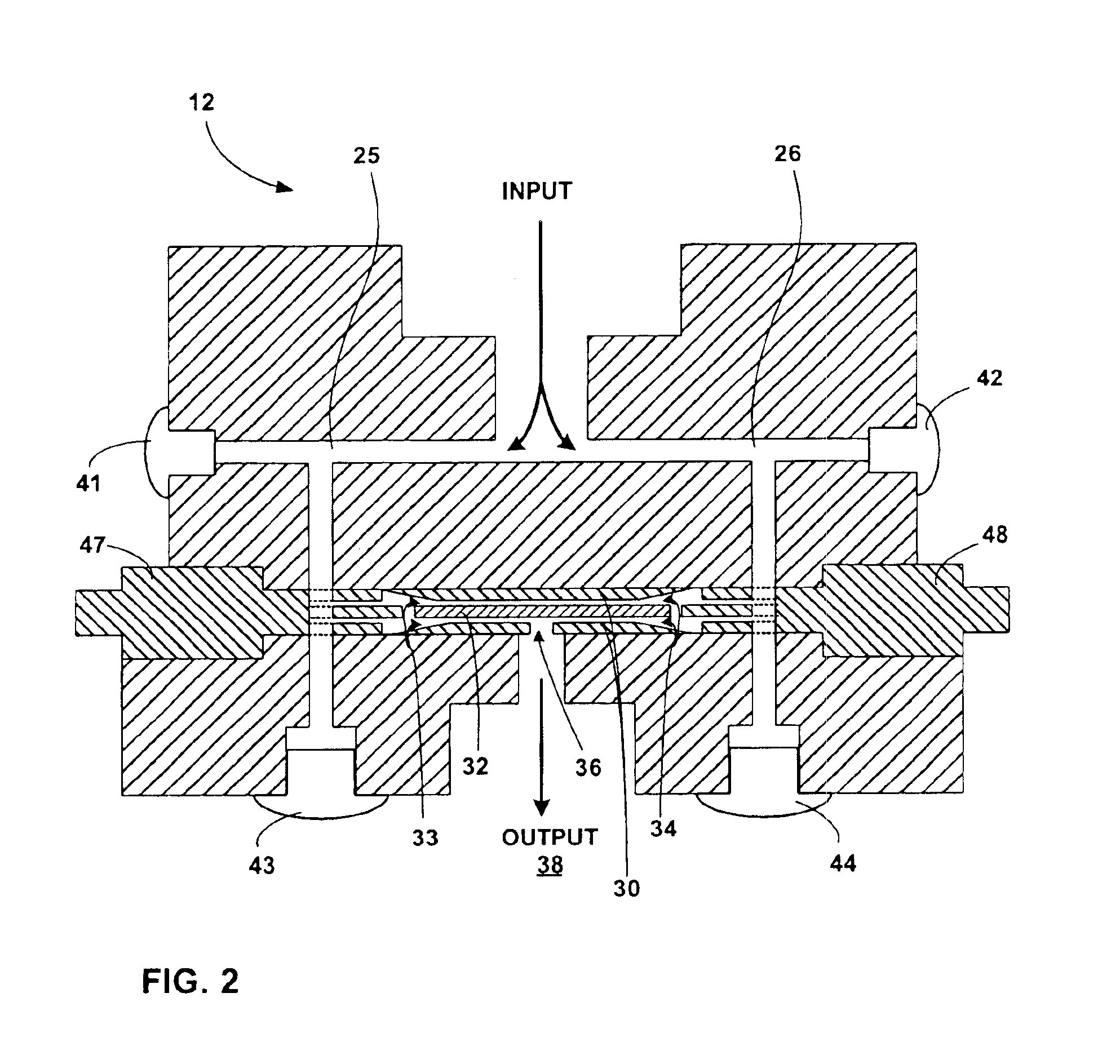

InactiveUS6923213B2Restore balanceEasy for industrial productionShaking/oscillating/vibrating mixersFlow mixersEngineeringHigh pressure

The invention is directed to a high pressure fluid processing device for shearing particles in a fluid mixture. The fluid processing device makes use of annular flow paths. For example, a fluid mixture can be separated into two flow paths which are introduced to first and second annular flow paths on opposite sides of a flow path cylinder. The two annular flow paths flow toward one another through the cylinder, and meet one another within the cylinder. An outlet extends through the cylinder where the two annular flow paths collide allowing the fluid mixture flowing down the annular flow paths to be expelled through the gap.

Owner:IMATION

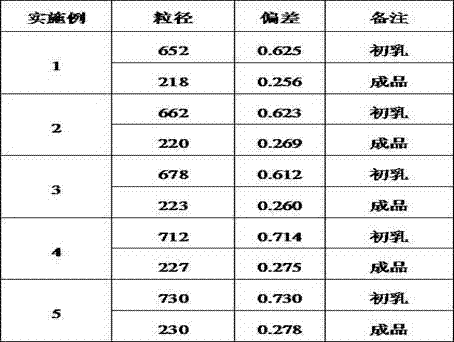

Preparation method of propofol fat emulsion injection

ActiveCN104490780AImprove the shortcomings of excessive particle size deviationMeet particle size requirementsHydroxy compound active ingredientsPharmaceutical product form changeSide effectOil phase

The invention discloses a preparation method of a propofol fat emulsion injection. The preparation method comprises the following steps: uniformly mixing soybean oil, lecithin and oleic acid and adding propofol; spraying an oil phase into a water phase under the protection of nitrogen gas to prepare emulsion; shearing the emulsion to obtain primary emulsion; homogenizing the primary emulsion under the pressure of 10000psi-20000psi to prepare an emulsion semi-finished product; and filtering, inflating nitrogen and sterilizing to prepare the propofol fat emulsion injection. According to the preparation method, the grain diameter uniformity is enhanced and the disadvantage that the grain diameter deviation of the primary emulsion is too great is improved; the stability of finished-product emulsion is improved; the average grain diameter of the detected emulsion is 210nm-230nm and the grain diameter deviation is 0.20-0.30; the requirements on the grain diameters by the fat emulsion injection are met; the emulsion grains with the size being more than 1 micron are not detected, and the grain diameters are obviously better than the standards that the content of the emulsion grains with the size being 1 micron in emulsion large grains of national drug standards is not more than 3%; the physicochemical properties are stable, the toxic side effect is low, the pains caused by injection are reduced, and the compliance of using drugs by patients is increased, so that the application prospect is very good.

Owner:HEBEI YIPIN PHARMA

Methods and systems for separating condensable vapors from gases

ActiveUS8715401B2Improve system efficiencyImprove efficiencySolidificationLiquefactionCarbon dioxideHeat exchanger

Owner:U S BANK TRUST CO NAT ASSOC

Production method for a vinyl chloride-based resin having outstanding particle uniformity and heat stability

ActiveCN103038262AImprove particle size uniformityImprove thermal stabilityCrystal structureHeat stability

The present invention relates to a production method for a vinyl chloride-based resin having outstanding particle uniformity and heat stability, which is advantageous in that, by using an inorganic dispersion that has a specific structure while also being able to eliminate hydrogen chloride in a step in which a vinyl chloride resin is produced, a vinyl chloride resin will be produced that has outstanding particle uniformity and heat stability and also the thermal decomposition temperature of the resin is increased such that it is possible to even improve the product whiteness and physical properties during processing.

Owner:LG CHEM LTD

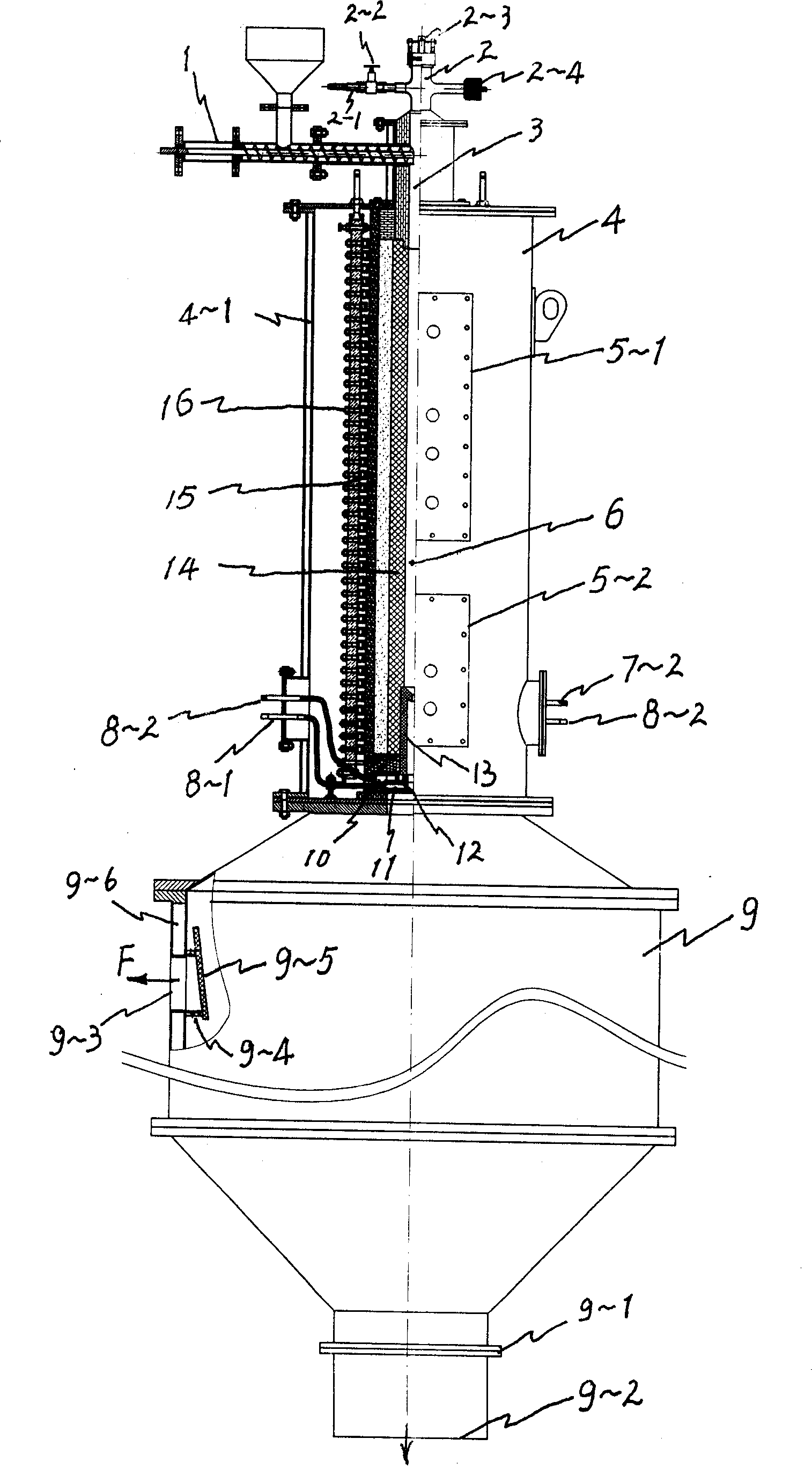

Atomizing formation apparatus for producing spherical casting WC powder

The atomizing formation apparatus for producing spherical casting WC powder includes low pressure inert gas intake assembly; furnace shaft containing the feeding mechanism, heater and graphite furnace tube; jetting and atomizing formation assembly containing beam current tube, inner and outer nozzles, high pressure inert gas supplying mechanism and atomizing formation barrel; and water cooling circulation mechanism. Owing to that the melt of the material in the protection of inert gas is acted by the high pressure inert gas flow to be jetted, atomized and formed into spherical powder, the produced spherical casting WC powder has compact structure and low cost. The technological process of the present invention is short, high in production efficiency, stable in product quality, low in power consumption and production cost and good in product using effect.

Owner:HUNAN DINGLI NEW MATERIAL ENG CENT +1

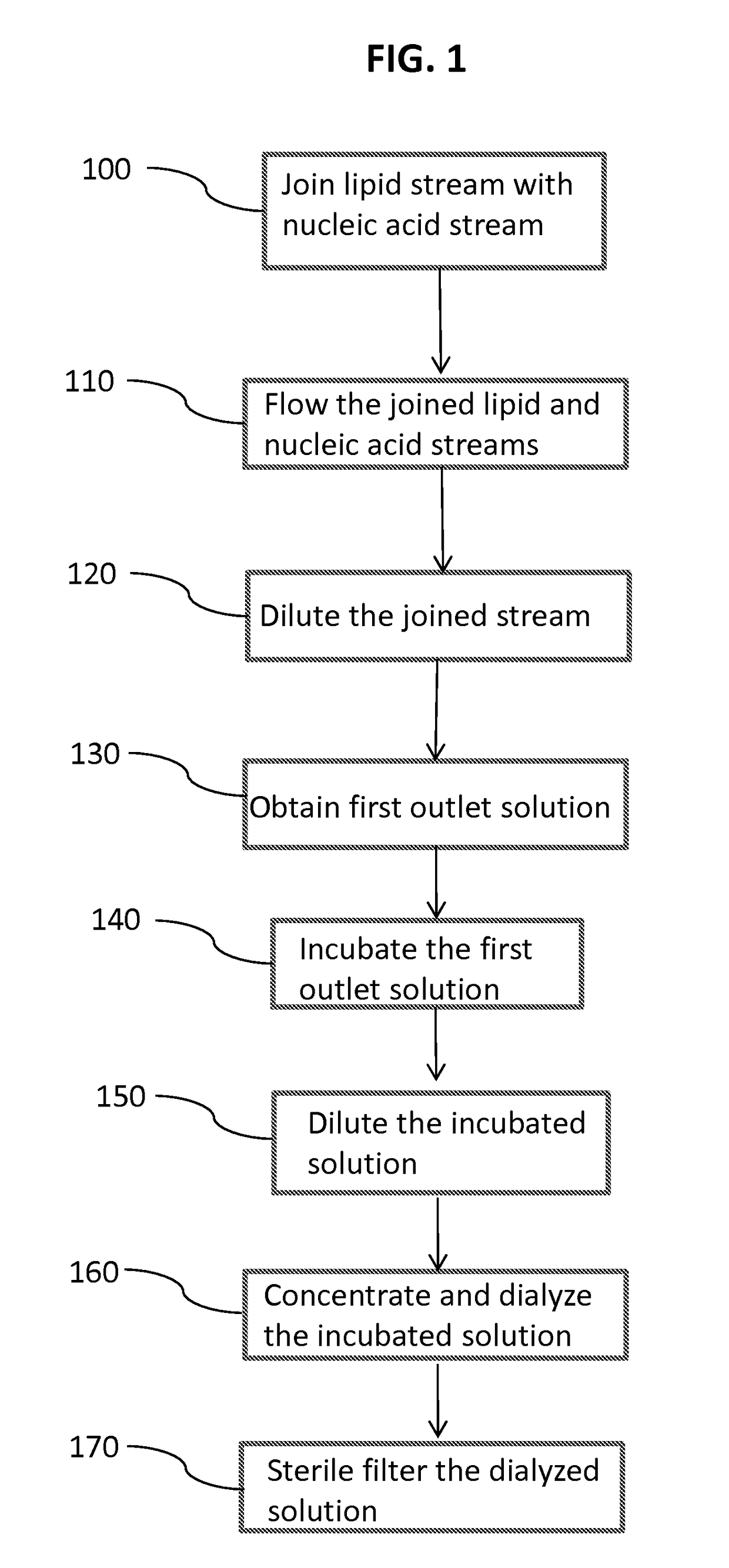

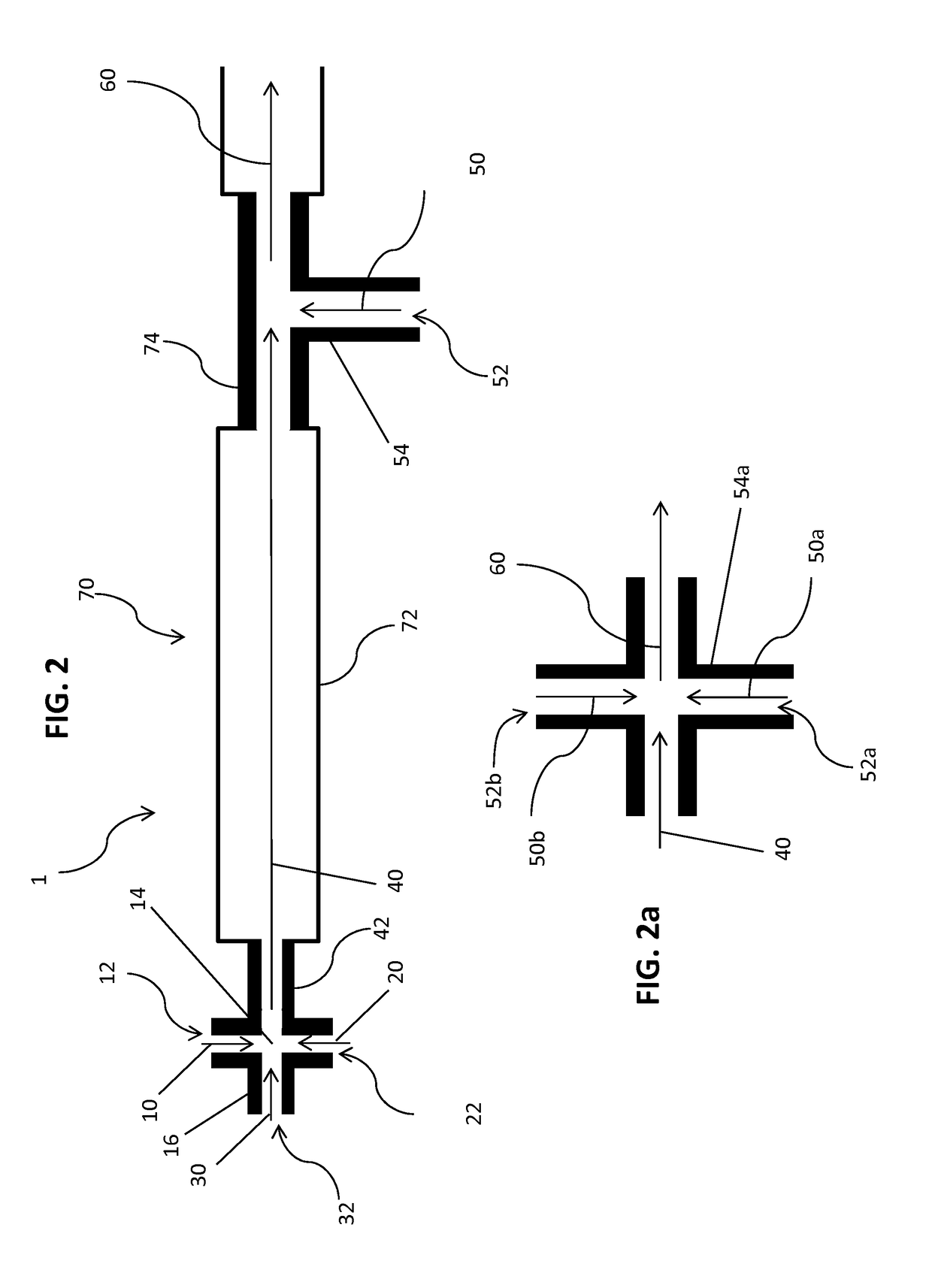

Method of encapsulating a nucleic acid in a lipid nanoparticle host

ActiveUS20170196809A1Long-term stabilityImprove particle size uniformityOrganic active ingredientsSpecial deliveryLipid formationOrganic solvent

Encapsulated nucleic acid nanoparticles of uniformly small particle size are produced by intersecting one or more nucleic acid streams with one or more lipid streams. The encapsulated nucleic acid nanoparticles include a nucleic acid encapsulated within a lipid nanoparticle host. Uniformly small particle sizes are obtained by intersecting an aqueous nucleic acid stream and a stream of lipids in organic solvent at high linear velocities and with total organic solvent concentrations less than 33%.

Owner:NOVARTIS AG

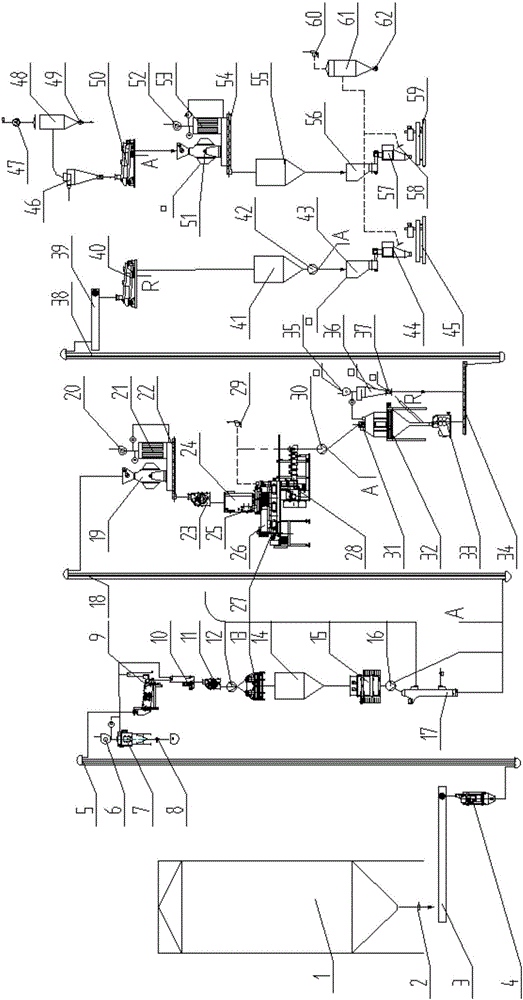

Full-fat extruded soybean production device and production technology

The invention discloses a full-fat extruded soybean production device and a production technology. The full-fat extruded soybean production device comprises a bulk bin, an impurity removal working section, a first crusher and a second tee, wherein a material outlet of the second tee is connected with a peel suction device for removing soybean peels, and another material outlet of the second tee is connected with the first crusher; an arch breaking feeding bin is connected with a tempering device; the material outlet end of the tempering device is connected with an extruding machine; the material outlet end of the extruding machine is connected with a cooler; the material outlet end of the cooler is connected with a second crusher; another material outlet of a third tee is connected with the first crusher; the material outlet end of the second crusher is connected with a first rotary vibration grading sieve; the first rotary vibration grading sieve is connected with a first packaging device. The full-fat extruded soybean production device has the advantages that soybeans are firstly broken and then crushed, so that the productivity of the first crusher is increased, the abrasion of a hammer blade is reduced, and the crushing effect is improved; the peel suction device is used for separating soybean peels from soybean halves, so that the quality of a finished extruded soybean product is mainly improved.

Owner:江苏丰尚油脂工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com