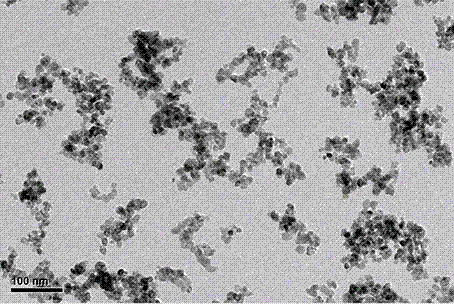

Production method of nanoscale high-purity zirconium dioxide composite powder

A technology of zirconia and composite powder, which is applied in the field of material engineering, can solve the problems of defect diffusion, no strengthening effect, affecting the mechanical strength of ceramic materials, insulation, corrosion resistance and chemical reaction performance, and achieves good particle size uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below, but the present invention is not limited to this embodiment.

[0037] According to this embodiment, the nanoscale high-purity zirconia composite powder is prepared through the following steps.

[0038] (1) Put industrial-grade zirconium tetrachloride into a drying oven at 80°C and dry it for 8 hours.

[0039] (2) Put the zirconium tetrachloride crystals dried in step (1) into an evaporative condensation crystallizer, heat them to 380°C, keep them warm for 3 hours, and carry out preliminary physical purification by evaporative condensation crystallization.

[0040] (3) Put the crystallized zirconium tetrachloride crystal obtained in step (2) into the evaporative condensation crystallizer again and heat it to 320°C. The temperature control accuracy is -0.5~+0.5°C, and the molten salt is heated by high-power ultrasonic waves. Vibrated for 6 hours, and the evaporating product was collected by condensation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com