Atomizing formation apparatus for producing spherical casting WC powder

A tungsten carbide powder and spherical technology is applied in the field of equipment for producing cemented carbide powder, which can solve the problems of short process flow, low spheroidization rate, poor uniformity of product particle size, etc., and achieves simple device structure design and stable product quality. , Good particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

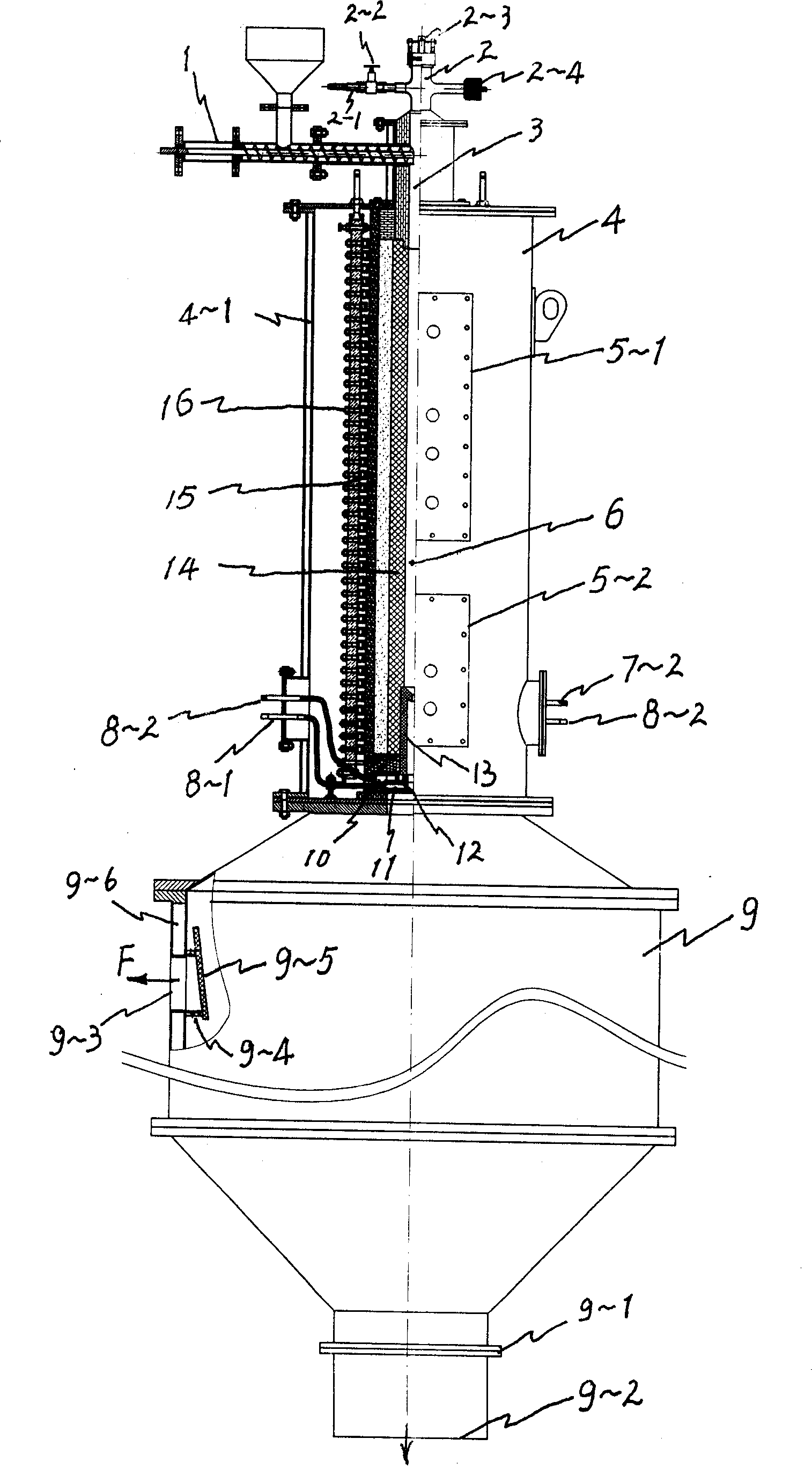

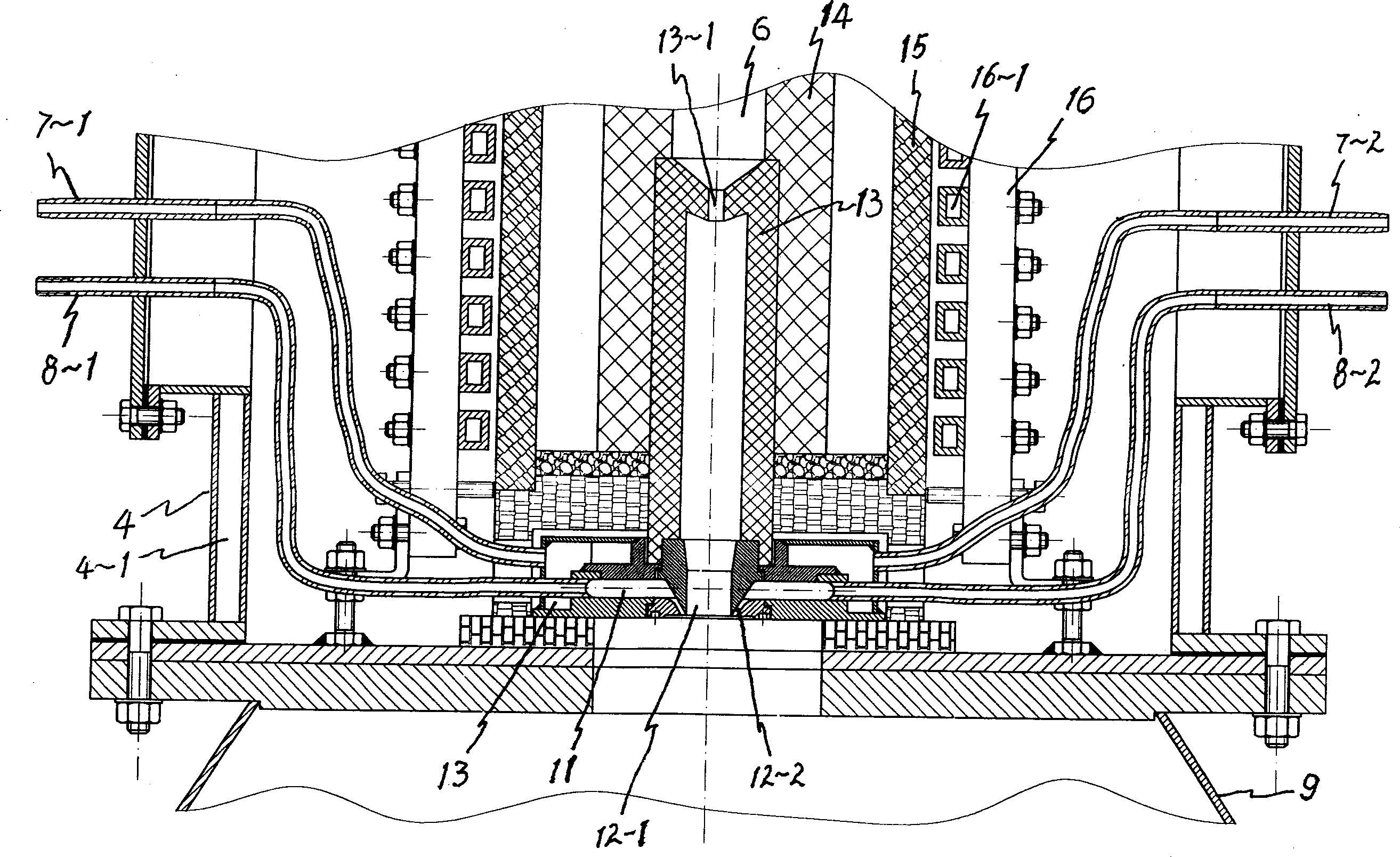

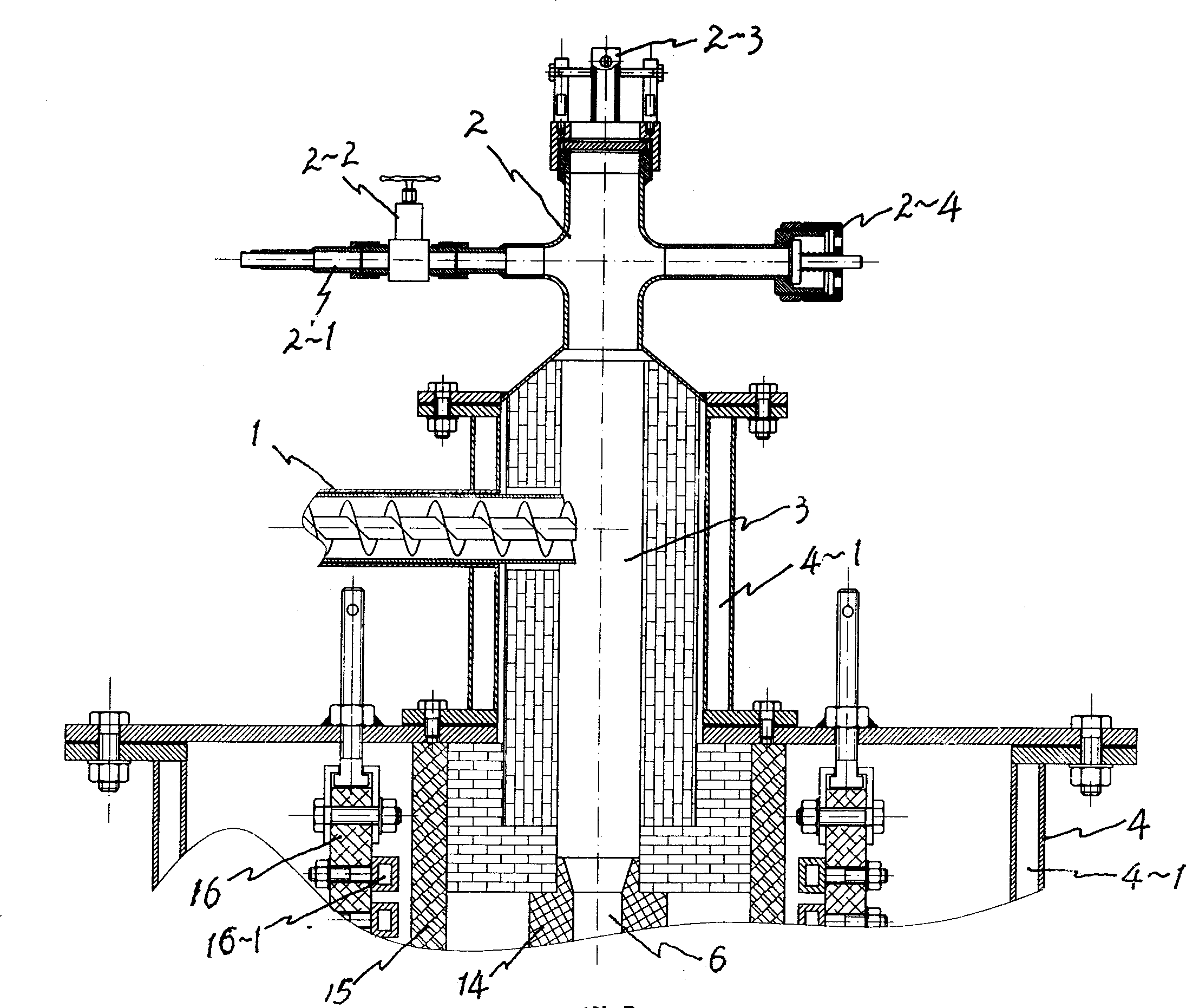

[0014] In this embodiment, the device with a production capacity of 350kg / h spherical cast tungsten carbide powder is taken as an example: the total height is 6710mm, of which: the furnace body is 1957mm high; the atomization forming barrel 9 is 4430mm high and 1400mm in diameter.

[0015] The feeding mechanism 1 is a screw feeder with a diameter of φ45; the low-pressure inert gas inlet pipe 2-1 has a diameter of φ14mm, the gas valve 2-2 is a DN15 needle valve, and the argon pressure is 0.10MPa; the thermometer 2-3 adopts optical measurement Thermometer; shell 4 is an interlayer with a height of 1715mm and a diameter of φ648mm, and 4 to 1 in the middle of the interlayer are cooling water chambers; the length (height) of the graphite furnace tube 14 is 1548mm, and the diameter of the melting chamber 6 is φ35mm; the lower beam tube 13 is 250mm long and the inner diameter φ40mm, beam hole 13~1 diameter φ10mm, hole length 30mm; heater 16 is a double intermediate frequency induction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com