Production method for a vinyl chloride-based resin having outstanding particle uniformity and heat stability

A technology of vinyl chloride resin and thermal stability, applied in the field of vinyl chloride resins, can solve the problem of no disclosure of particle size distribution effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0051] Preparation Example 1 (Preparation Example 1 of Inorganic Compound Surface-treated with Organic Modifier)

[0052] Based on 100 parts by weight of the inorganic compound, glycerol monostearate is added in an amount of 10 parts by weight to the 4 al 2 (OH) 12 CO 3 ·3H 2 O or Mg 4 Zn 2 al 2 (OH) 12 CO 3 ·3H 2 O structure and 0.5 μm (micrometer) or 10 μm (micrometer) particle size hydrotalcite, followed by heating at 180° C., thereby preparing an inorganic compound surface-treated with an organic modifier.

preparation example 2

[0053] Preparation Example 2 (Preparation Example 2 of Inorganic Compound Surface-treated with Organic Modifier)

[0054] Except that stearic acid is used in an amount of 1 part by weight based on 100 parts by weight of the inorganic compound instead of glycerol monostearate, the same method as Preparation Example 1 was used to prepare 4 al 2 (OH) 12 CO 3 ·3H 2 O or Mg 4 Zn 2 al 2 (OH) 12 CO 3 ·3H 2 Inorganic compounds with O structure and 0.5 μm (micrometer) or 10 μm (micrometer) particle size surface-treated with organic modifiers.

Embodiment 1

[0055] Example 1 (Inorganic compound 1 undergoing bulk polymerization and surface treatment with organic modifier)

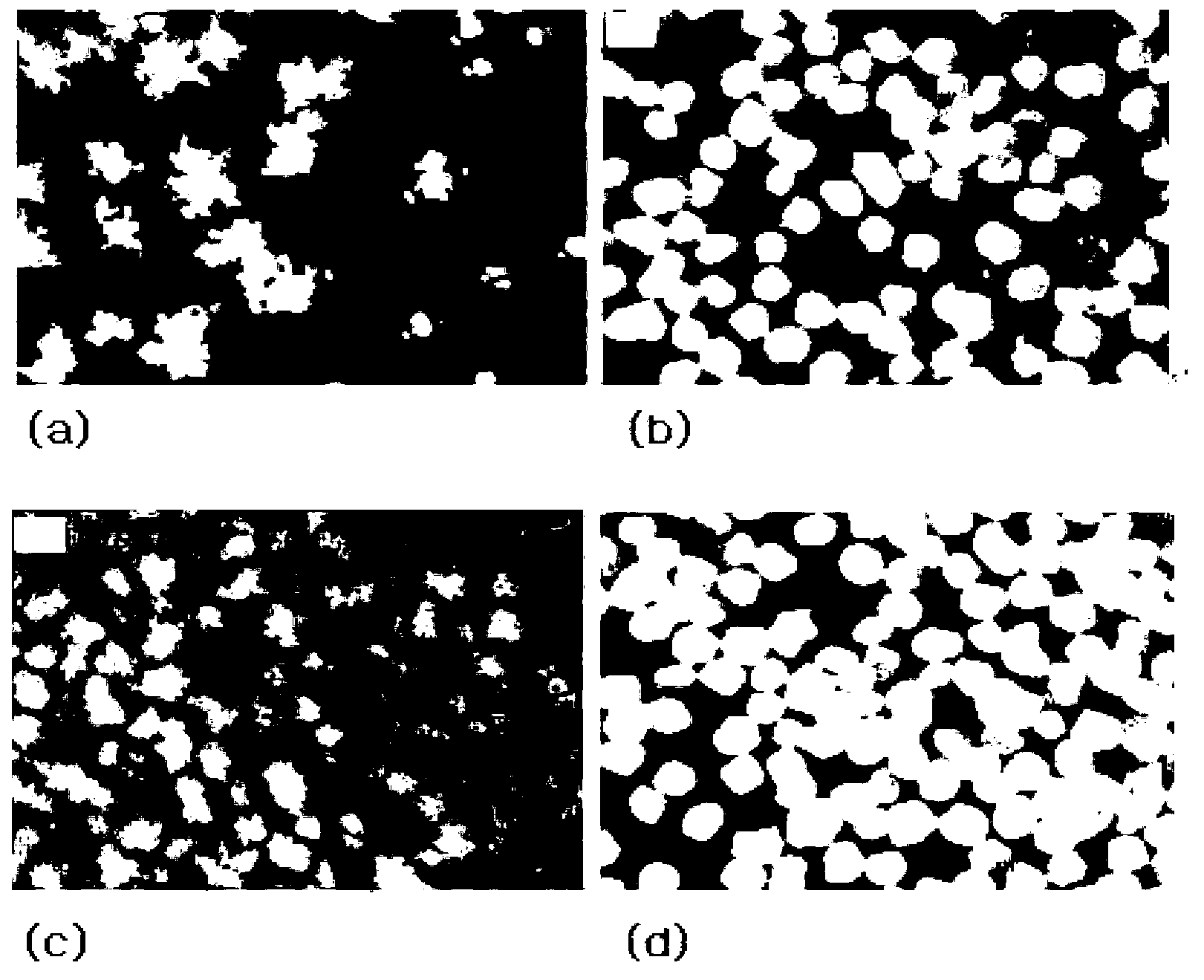

[0056] Except when the polymerization conversion rate is 10% or less than 10%, 0.01 parts by weight of the 0.5 μm (micrometer) particle size and Mg prepared in Preparation Example 1 are added. 4 Al 2 (OH) 12 CO 3 ·3H 2 Except for the hydrotalcite of the O structure surface-treated with an organic modifier, the same method as in Comparative Example 1 was repeated. Optical microscope images of the obtained seeds are shown in figure 1 Optical microscope images of neutralized final particles in c are shown in figure 1 d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com