Patents

Literature

59results about How to "Meet particle size requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel core material capsule, paint prepared from same and preparation method of paint

InactiveCN105363396AAvoid destructionHigh surface area for strong adsorptionCoatingsMicroballoon preparationThermal insulationFilm-forming agent

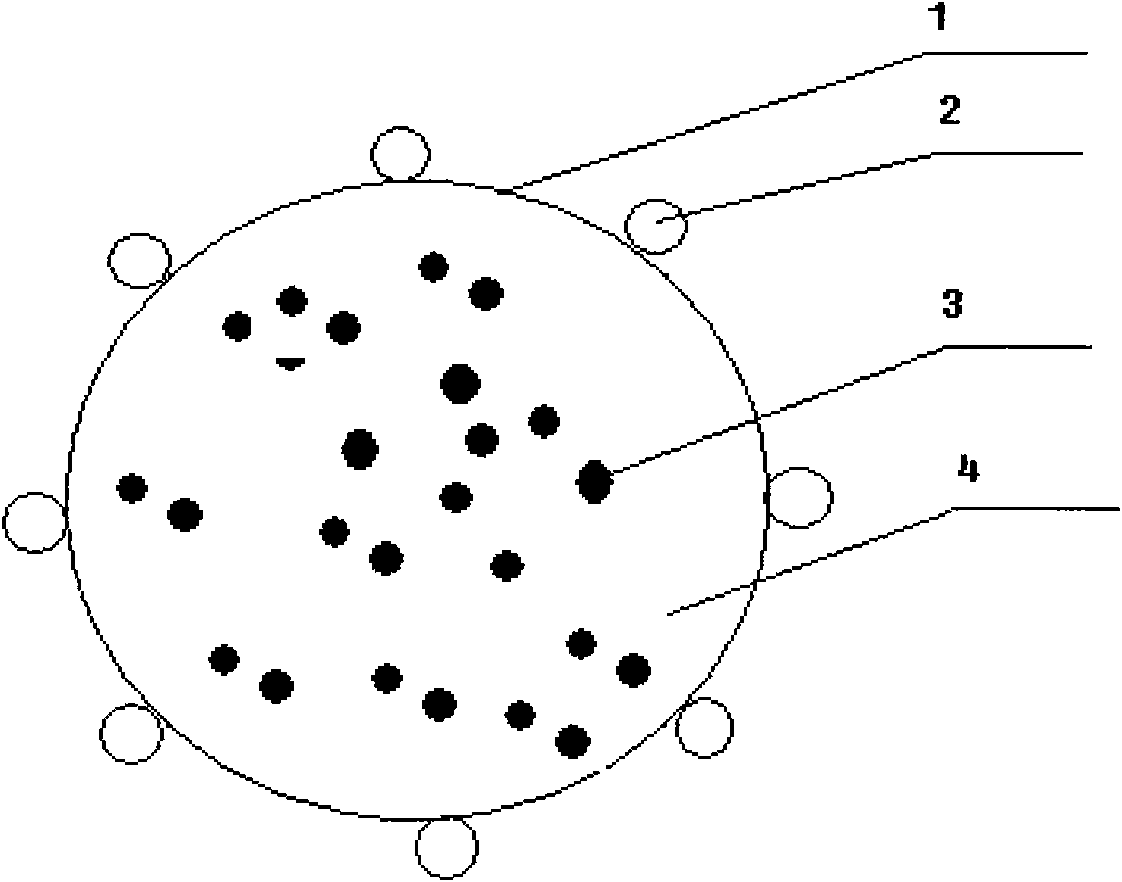

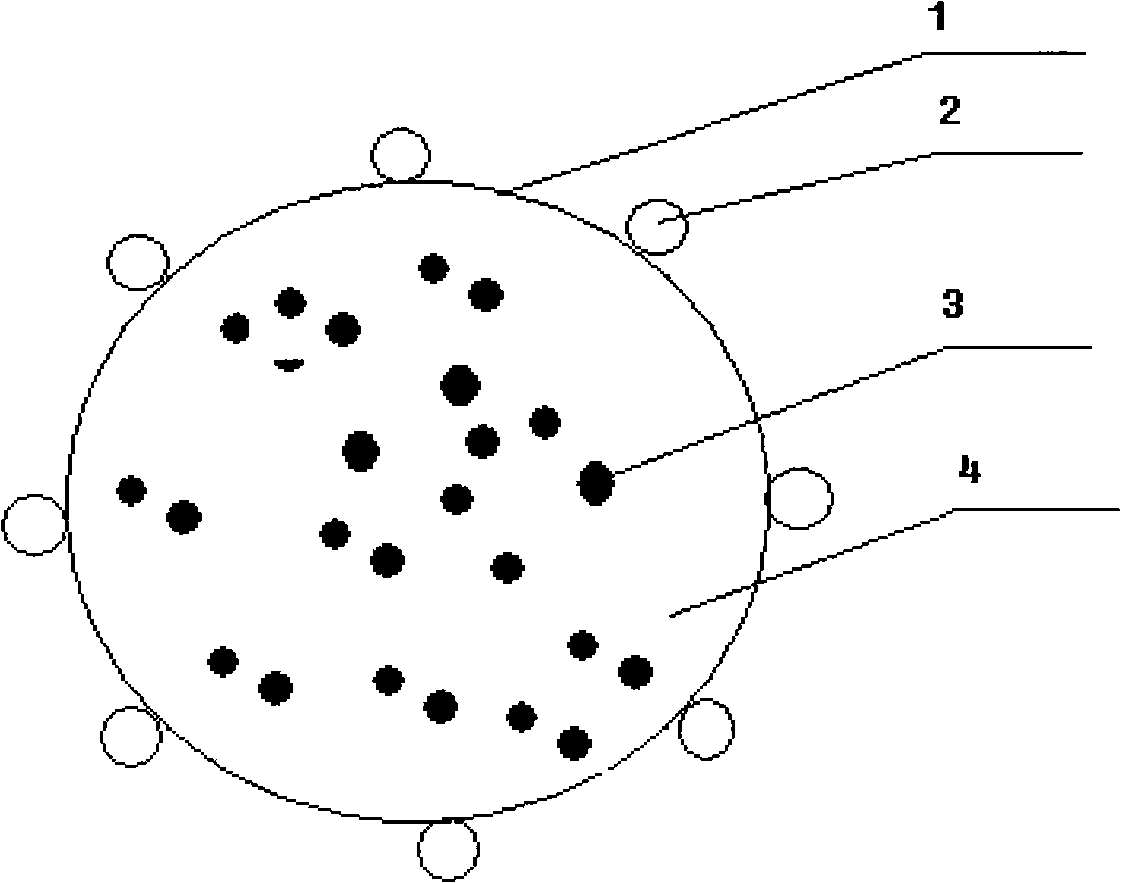

The invention relates to an aerogel core material capsule, paint prepared from the same and a preparation method of the paint, in particular to the paint which is prepared by conducting encapsulation on aerogel particles through a suspension coating method and adding a film forming agent, reinforcement powder, function powder and an additive with the capsule, with aerogel particles as the core material, as the main thermal insulation component, and has the nanometer porous structure. Encapsulation is conducted on aerogel particles through the suspension coating method, it is avoided that water or other reagents permeate aerogel nano-pore particles to generate capillary force and damage porous structures, and therefore the paint of the complete nano-pore structure is prepared. The prepared paint has excellent thermal insulation performance and is easy to operate, low in production cost, green, environmentally friendly, safe, capable of being applied to thermal insulation and corrosion prevention of devices such as hearths, pipelines, valves and storage tanks in the fields of aviation and military, metallurgy forging, petroleum refining, electric power, ships and the like, and also capable of being used for heat preservation and thermal insulation in the field of construction.

Owner:浙江圣润纳米科技有限公司

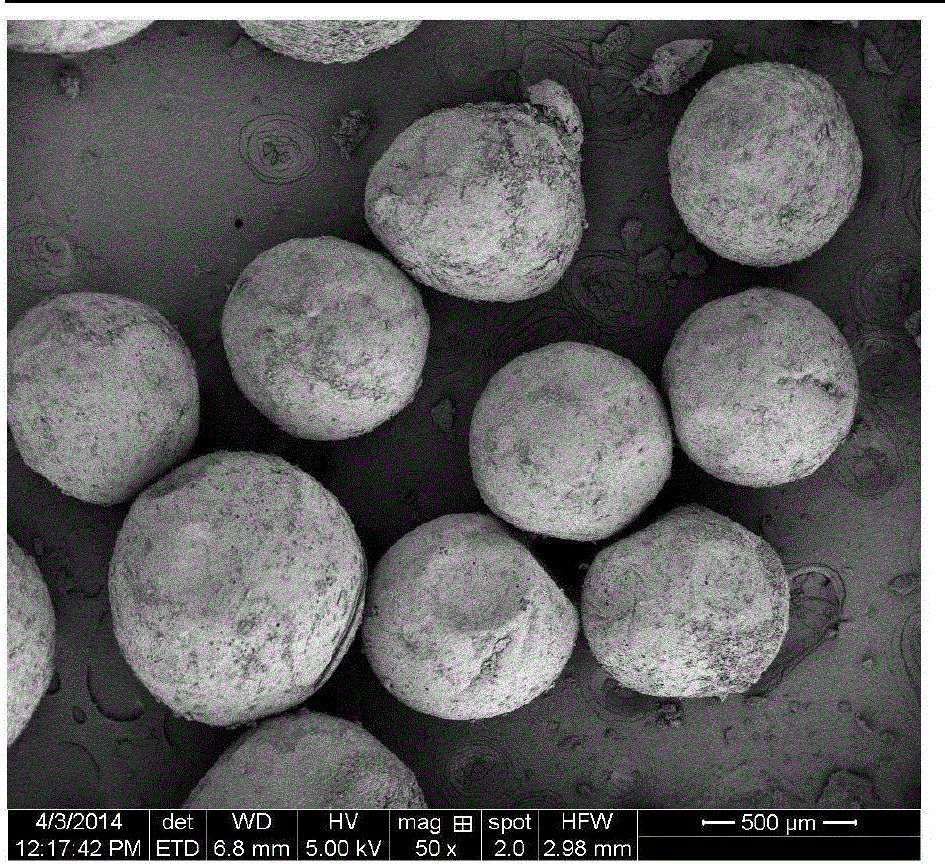

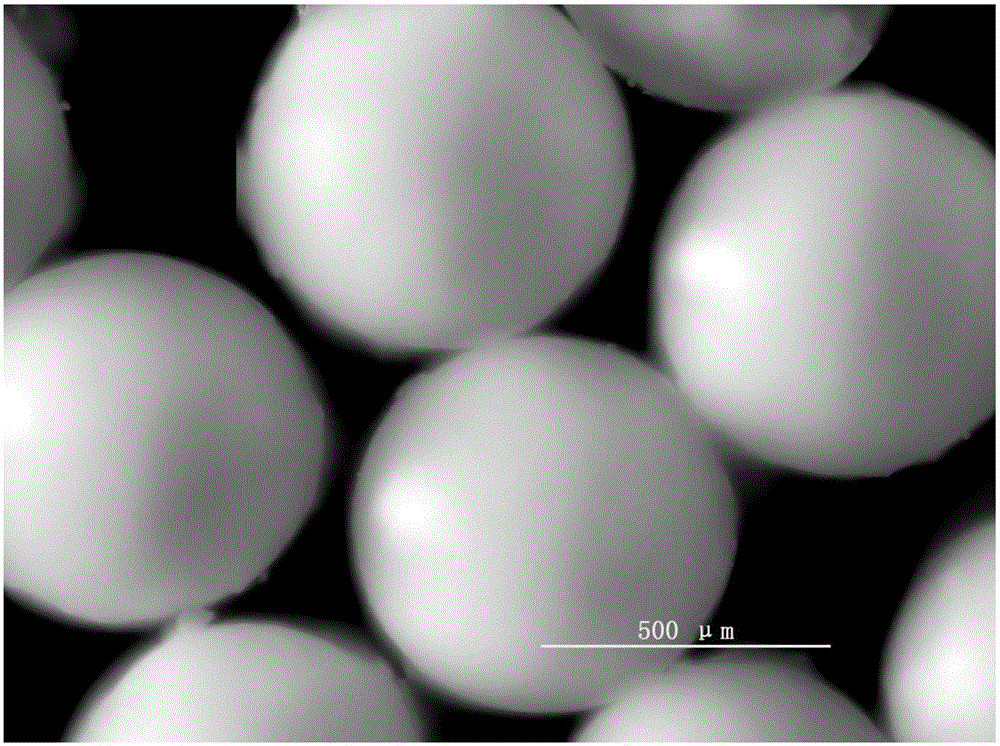

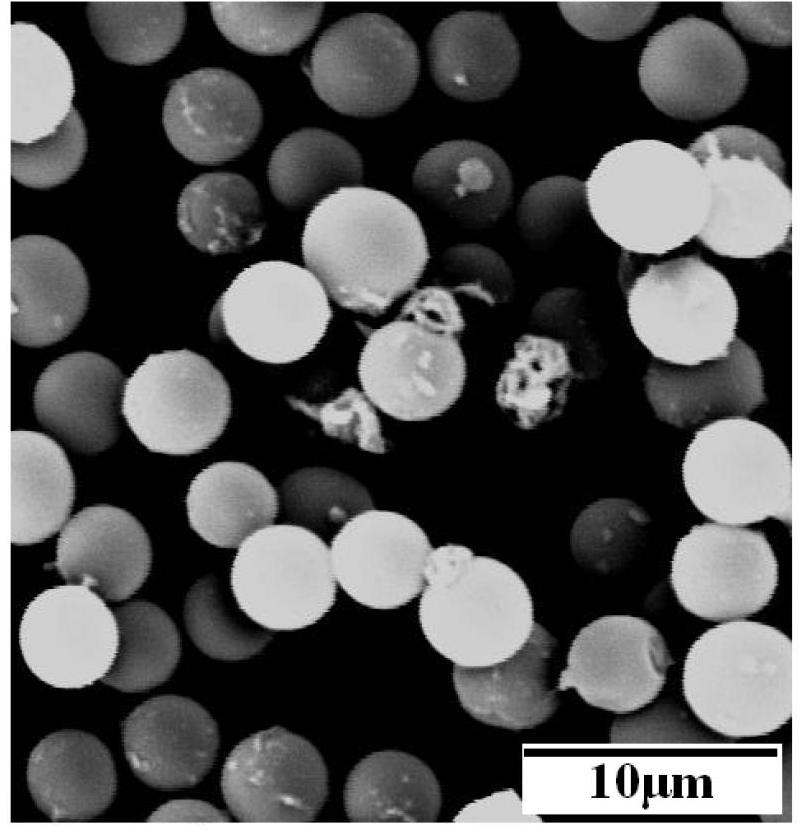

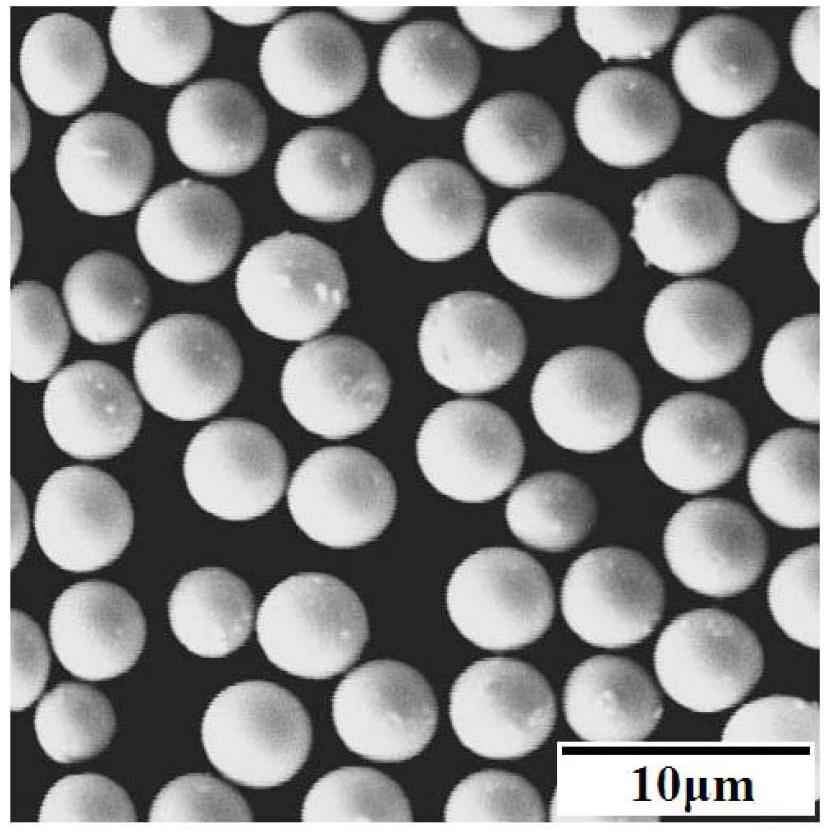

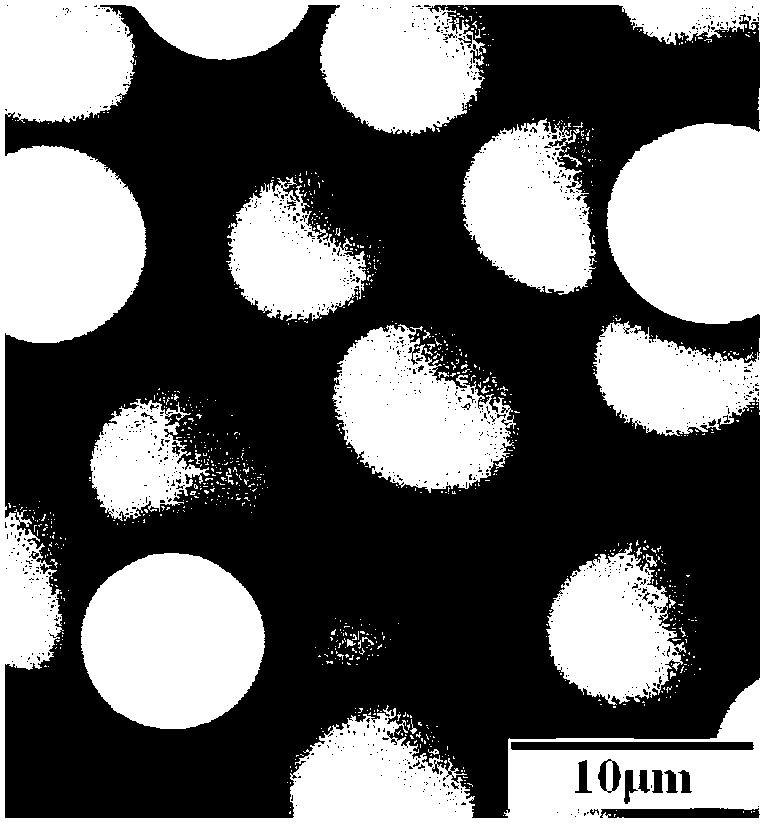

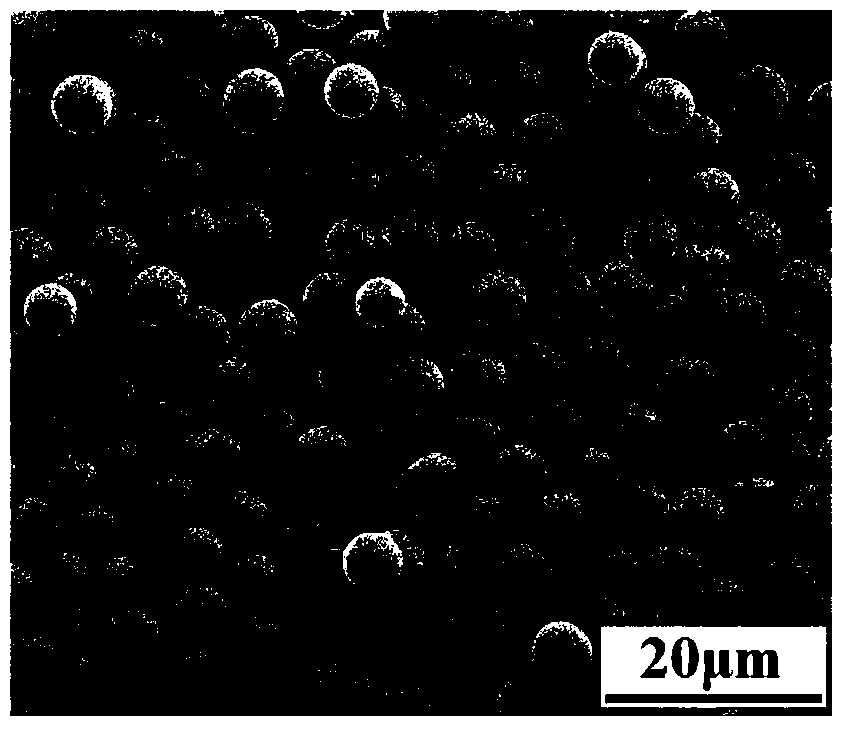

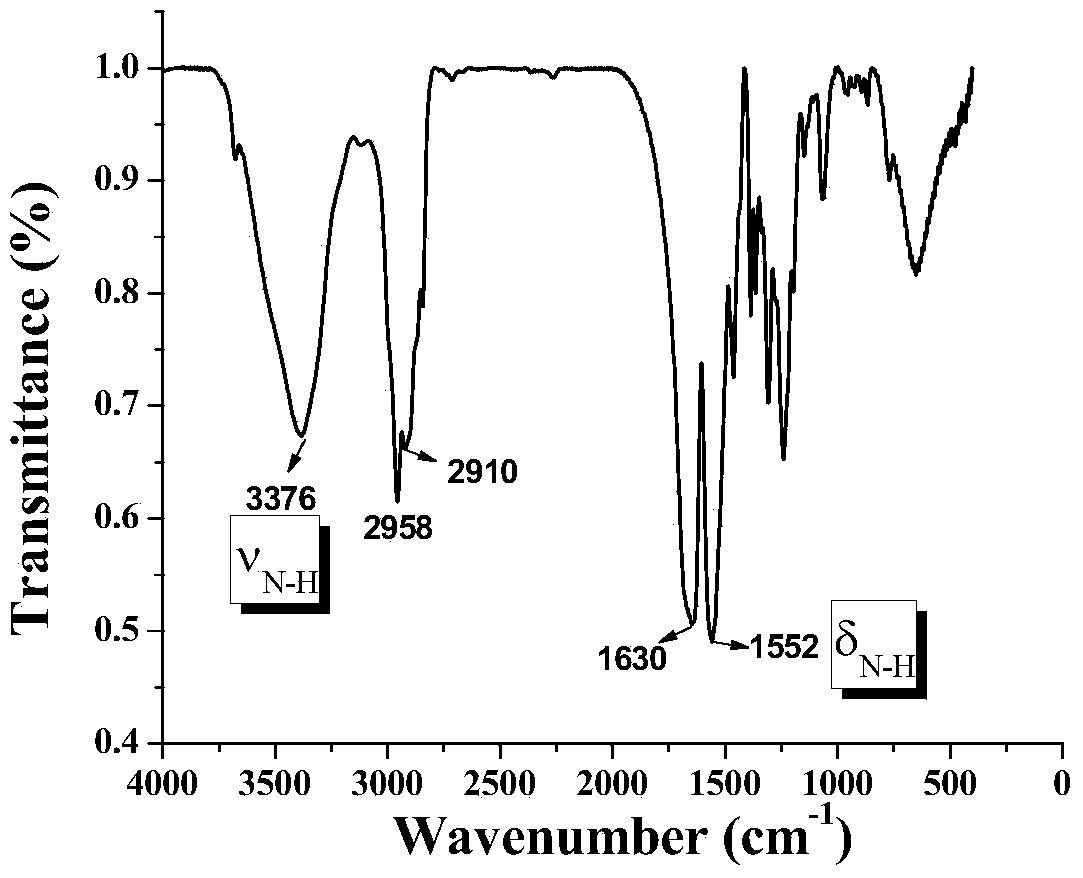

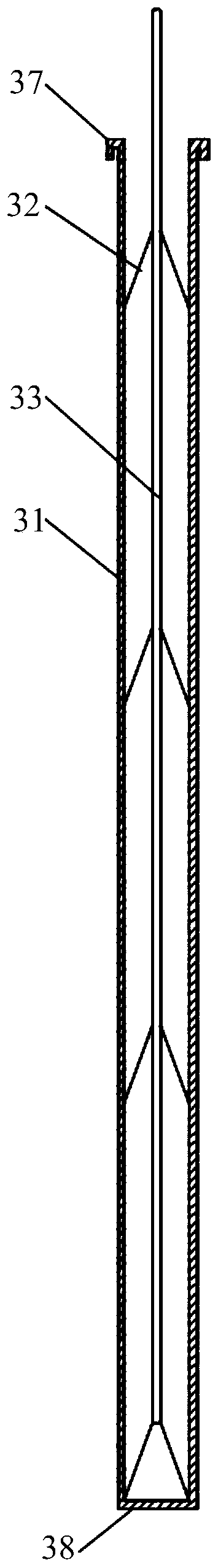

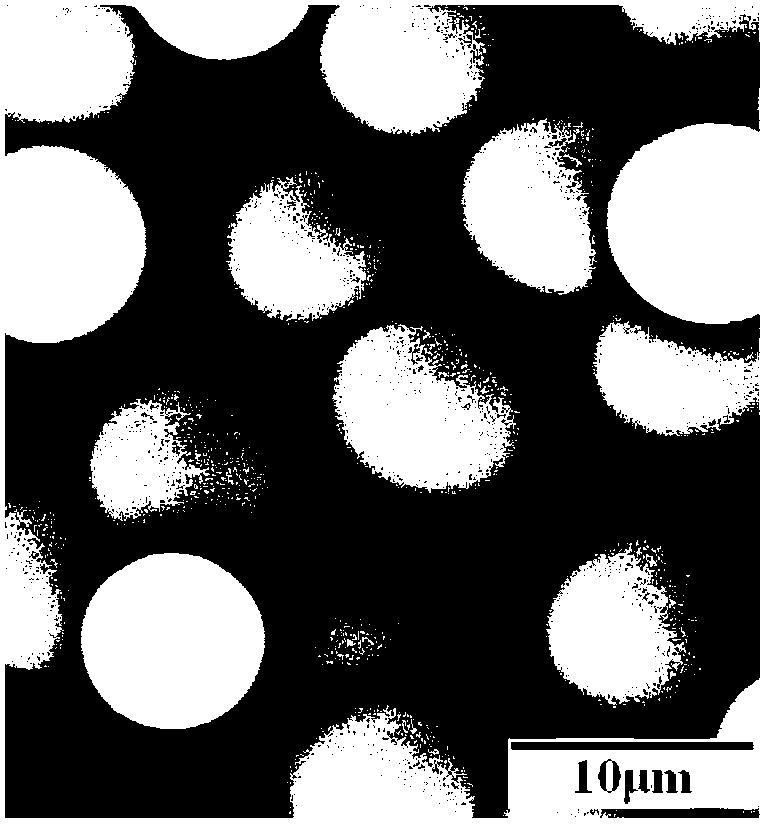

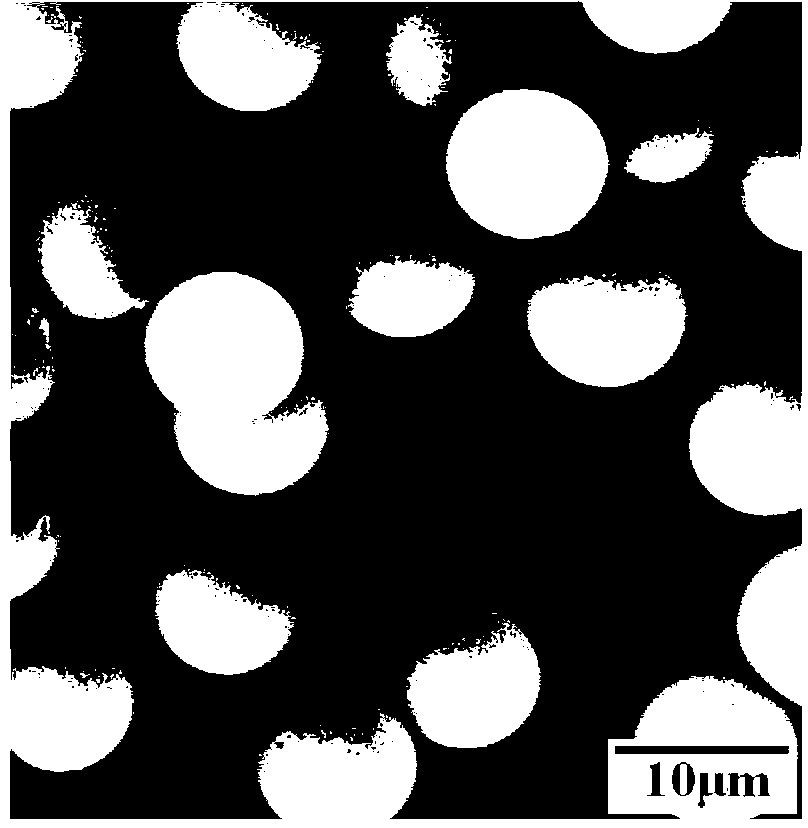

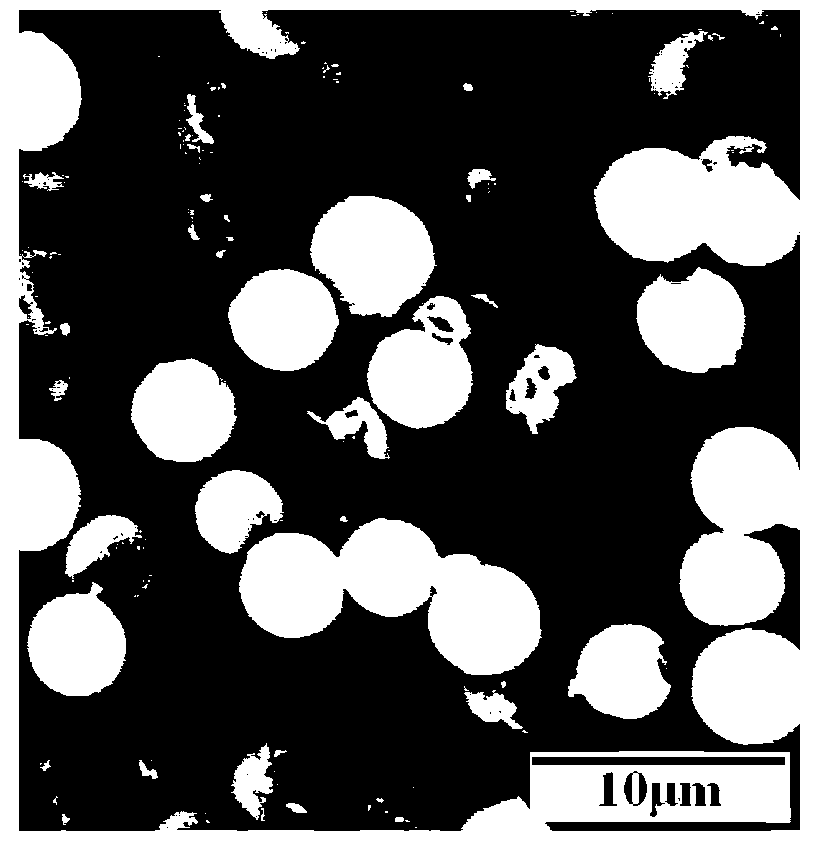

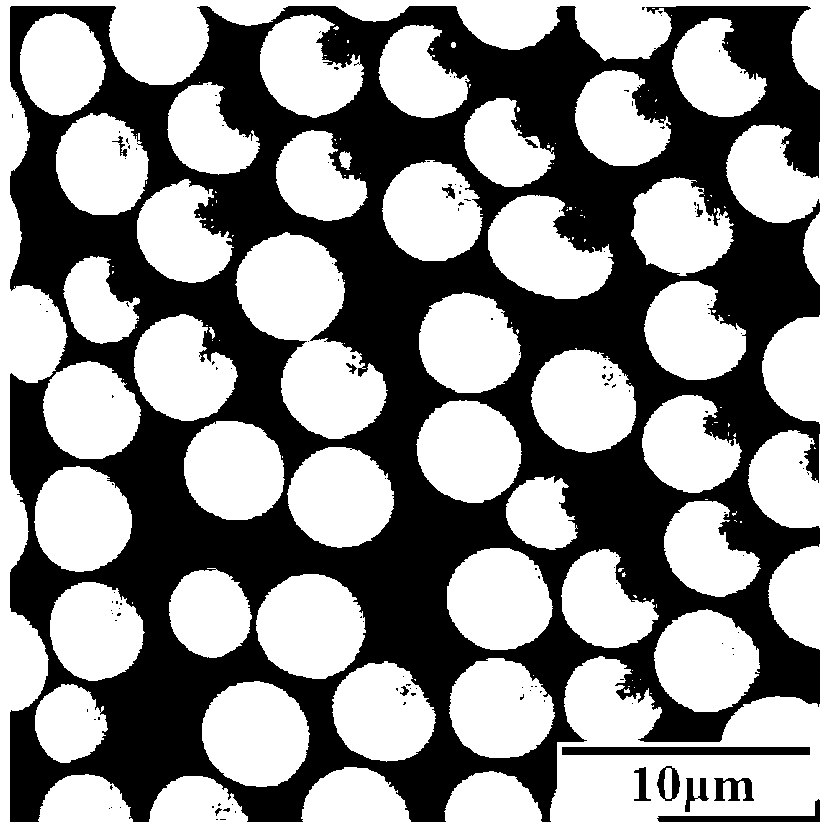

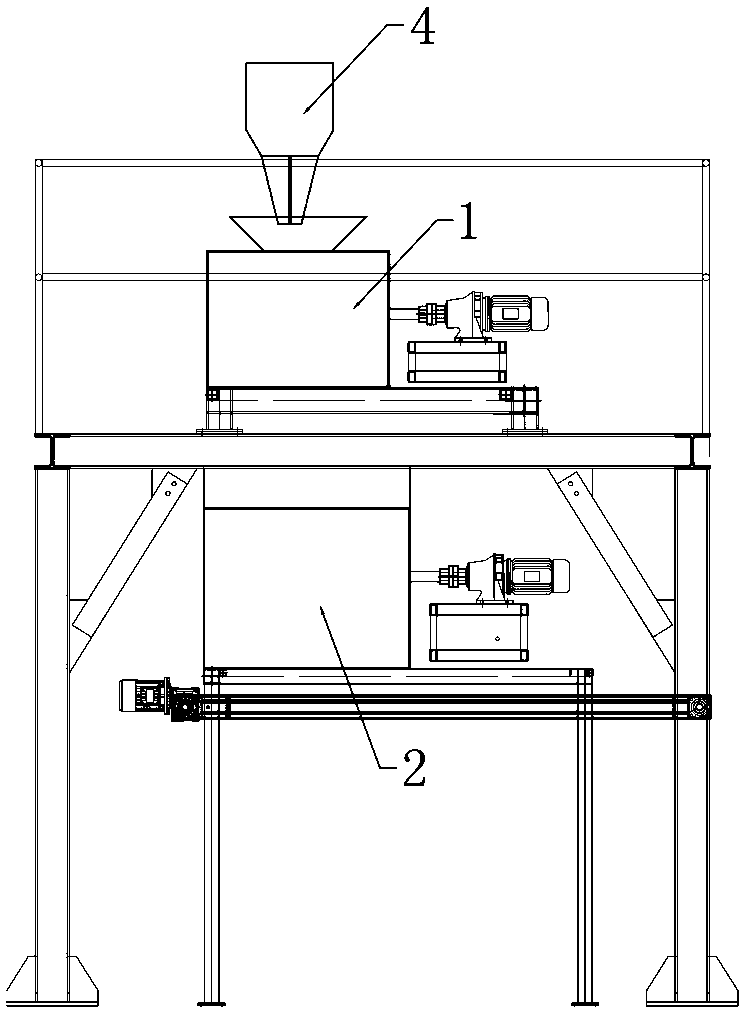

Preparation method for particle diameter controllable millimeter-scale polyurea monodisperse microsphere

InactiveCN104151516AMeet particle size requirementsNo pollutionMicroballoon preparationMicrocapsule preparationMicrospherePollution

The invention relates to a preparation method for a particle diameter controllable millimeter-scale polyurea monodisperse microsphere. The preparation method comprises the following steps: isocyanate compound is adopted as a monomer and is squeezed through syringe needles or capillary tubes to form liquid drops and the liquid drops are added into water or a polyamine aqueous solution for sedimentation and polymerization; during the settlement process of the liquid drops, the monomers on the surfaces of the liquid drops react with the water or the polyamine aqueous solution rapidly to form a gelatin layer or callus and the stability of particles is maintained. According to the method, as water is adopted as the dispersion medium, no pollution is generated; the polymerization reaction can be conducted under lower temperature, the equipment is simple and the manufacturing cost is low; the obtained microsphere is free from residual monomer and the post-processing is simple; no surface modified agent or pore-foaming agent is needed, porous polyurea microsphere with rich amino on the surface is prepared in one step; the method can be used in the fields of enzyme immobilization, chemocatalysis, dye, adsorption and separation of heavy metal ions and the like.

Owner:UNIV OF JINAN

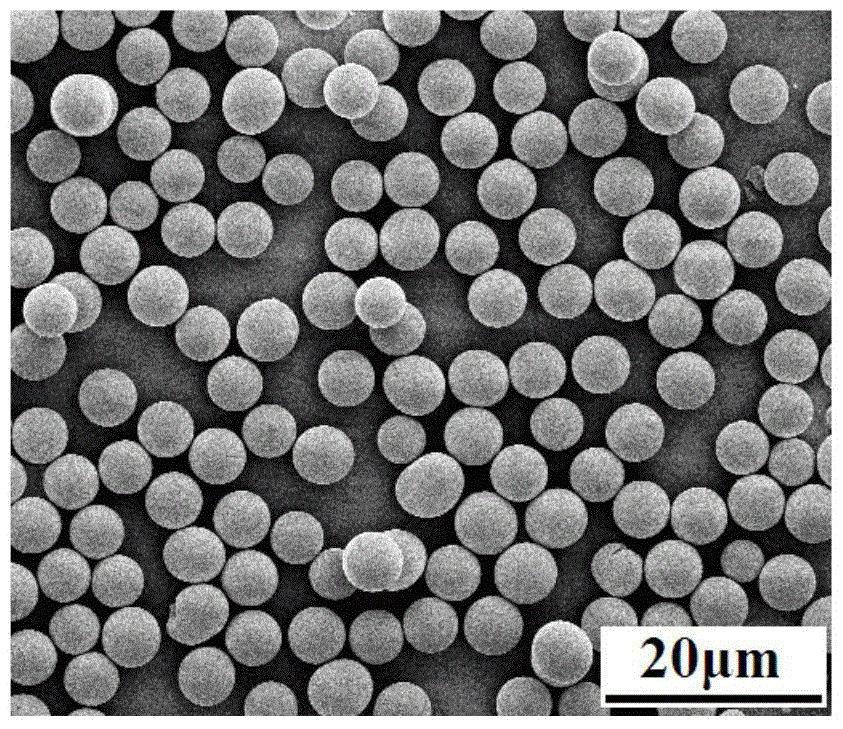

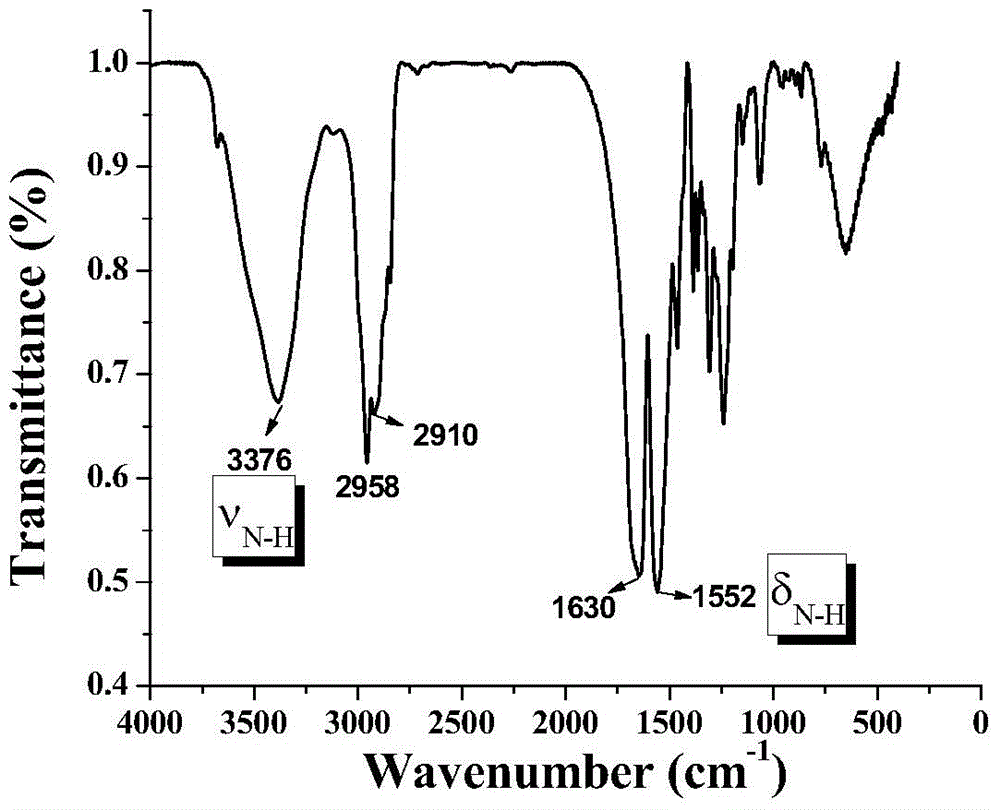

Method for preparing micro-sized monodisperse polyuria microspheres

The invention relates to a method for preparing micro-sized monodisperse polyuria microspheres. The method comprises the following steps of: adding a mixed solvent of water and acetone and a diisocyanate compound monomer to a reaction flask at room temperature, wherein the weight ratio of the water to the acetone is 2 / 8-6 / 4, and the diisocyanate compound monomer accounts for 0.5-10.0 percent of the total weight of a mixed system; hermetically shaking up; putting in a constant-temperature water-bath vibrator; performing a polymerization reaction under the conditions that the vibration frequency is 70-150 times per minute and the temperature is 20-80 DEG C; and performing centrifugal separation and drying on a product after polymerization is ended to obtain the micro-sized monodisperse polyuria microspheres. According to the method for preparing the micro-sized monodisperse polyuria microspheres, precipitation polymerization is performed under the vibration condition by using only one monomer, thereby, the process is simple, the raw materials are single, the consumed reaction time is short, the monomer can be completely converted, and the yield of the microspheres can reach at least86 percent. All the microspheres are clean in surface and contain a large amount of amido and can be used for the field of protein adsorption and separation, enzyme immobilization and chromatographicanalysis.

Owner:UNIV OF JINAN

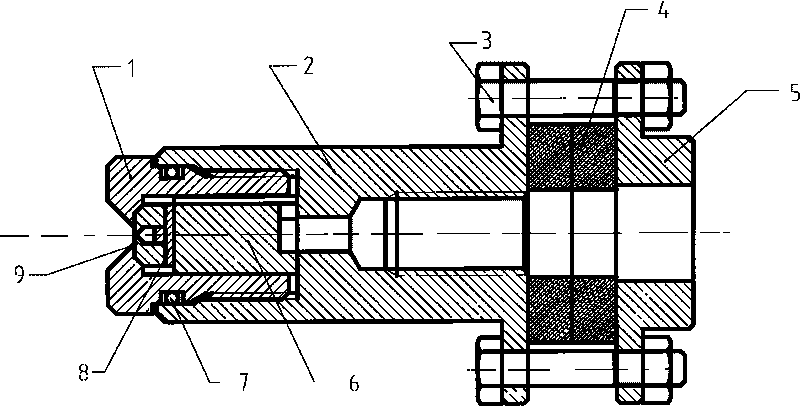

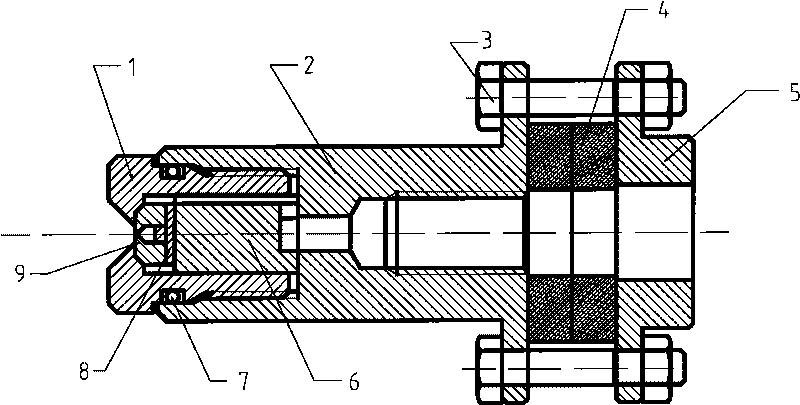

Ultrasonic wave and pressure rotary atomizer

InactiveCN101703980AOvercoming pressure bottlenecksStrong disturbanceLiquid spraying apparatusUltrasonic sensorEngineering

The invention provides an ultrasonic wave and pressure rotary atomizer, comprising an ultrasonic wave energy converter and a pressure rotating liquid nozzle, wherein the ultrasonic wave energy converter comprises an energy converter back cover plate, a pretightening bolt and a pretightening nut, piezoelectric crystal and a nozzle front cover; the pressure rotating liquid nozzle comprises a drainage member, a gasket, a swirl member and a nozzle head; the piezoelectric crystal is clamped between the nozzle front cover and the energy converter back cover plate by the pretightening bolt and the pretightening nut; the nozzle head is installed on the drainage member and arranged at the front end of the nozzle front cover; the drainage member and the swirl member are arranged in the nozzle head; the gasket is clamped between the drainage member and the swirl member; an O-shaped seal ring is arranged between the nozzle head and the nozzle front head; and a swirl chamber is arranged in the middle of the swirl member. The atomizer can further generate liquid drops the Sauter diameters of which are several microns to one micron on the basis of the pressure rotating nozzle, thereby overcoming the pressure bottleneck of the pressure rotating nozzle after the size of the liquid drop is decreased to a certain degree.

Owner:HARBIN ENG UNIV

Target-oriented sustained-release microsphere containing paclitaxel and albumin and preparation process thereof

InactiveCN1994291AMeet particle size requirementsImprove bioavailabilityOrganic active ingredientsInorganic non-active ingredientsOrganic solventMicrosphere

The invention relates to a method for preparing magnetic nanometer Paclitaxel albumin target slow-release agent, wherein its production comprises that: dissolving Paclitaxel into organic solvent; adding nanometer magnetic flow, to be emulsified and mixed; adding albumin with higher combination with Paclitaxel as carrier, to be heated and solidified. The average diameter of product is 50-500nm; via magnetic function, it can directionally move with slow-release property, to target slowly release. The invention has low cost and high effect.

Owner:NANJING UNIV OF TECH

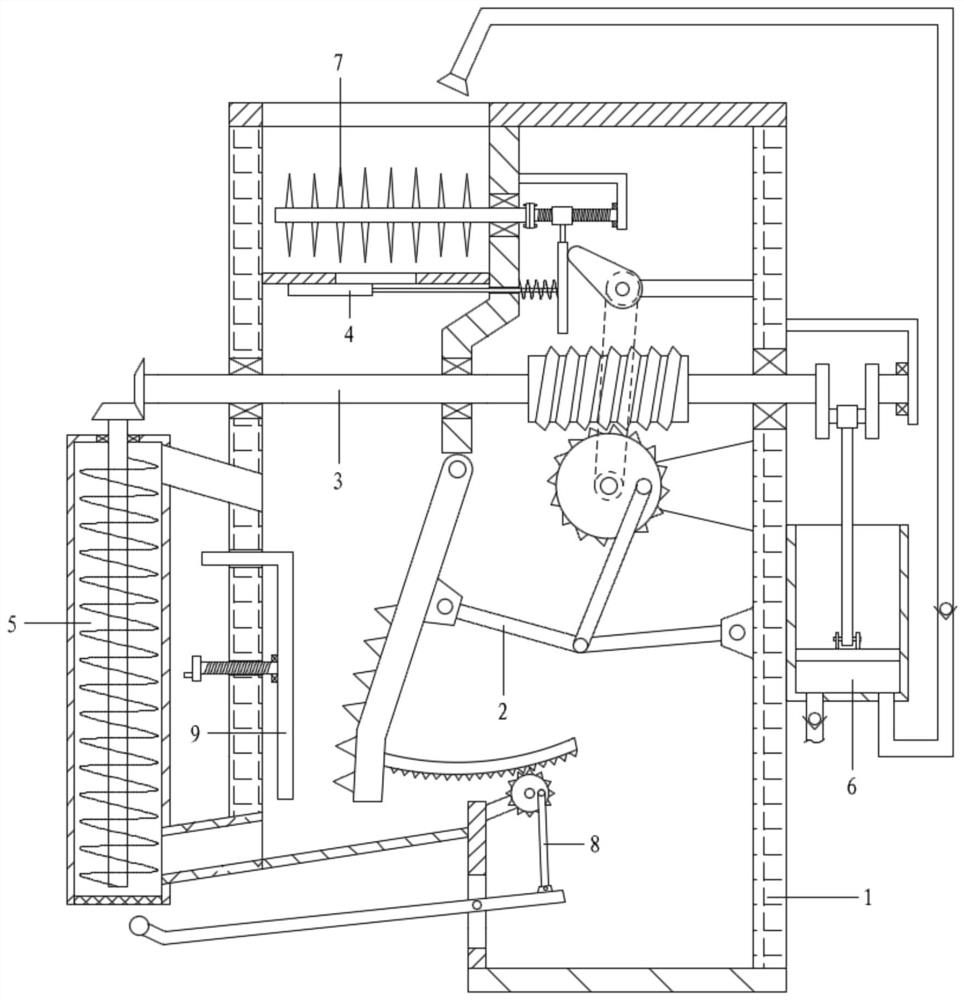

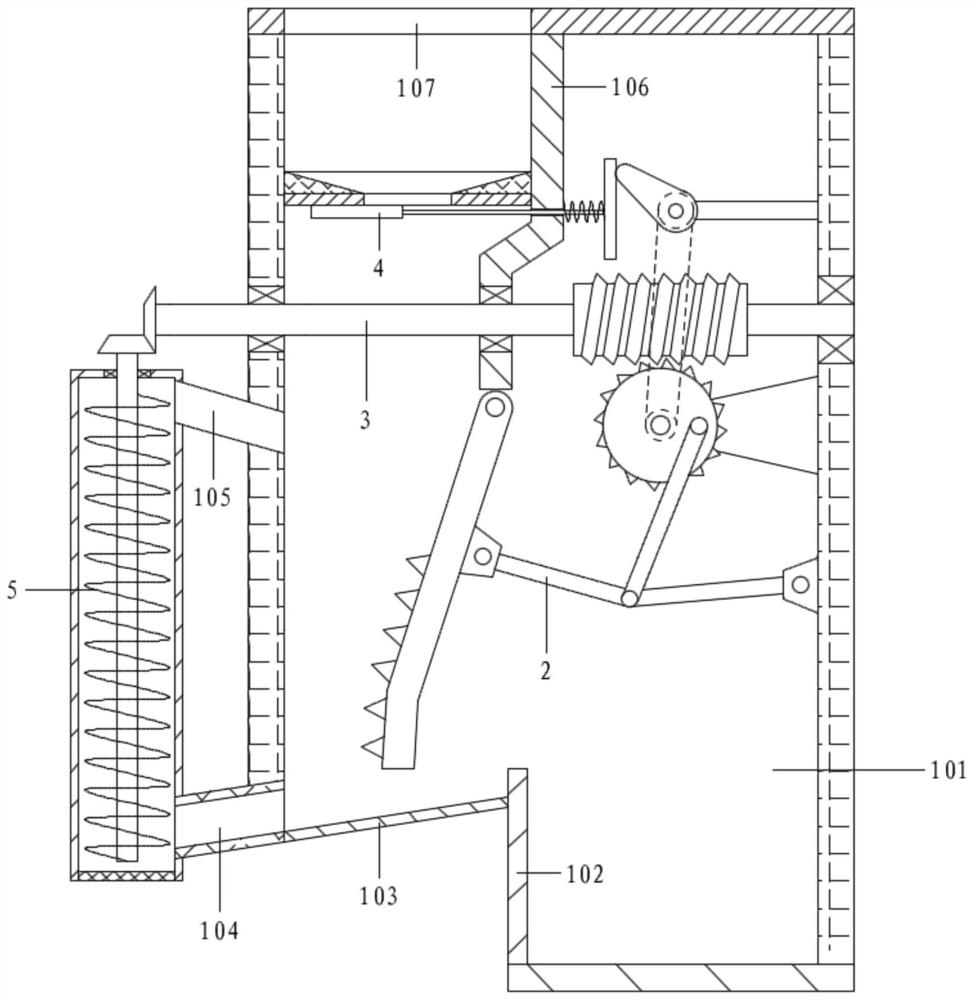

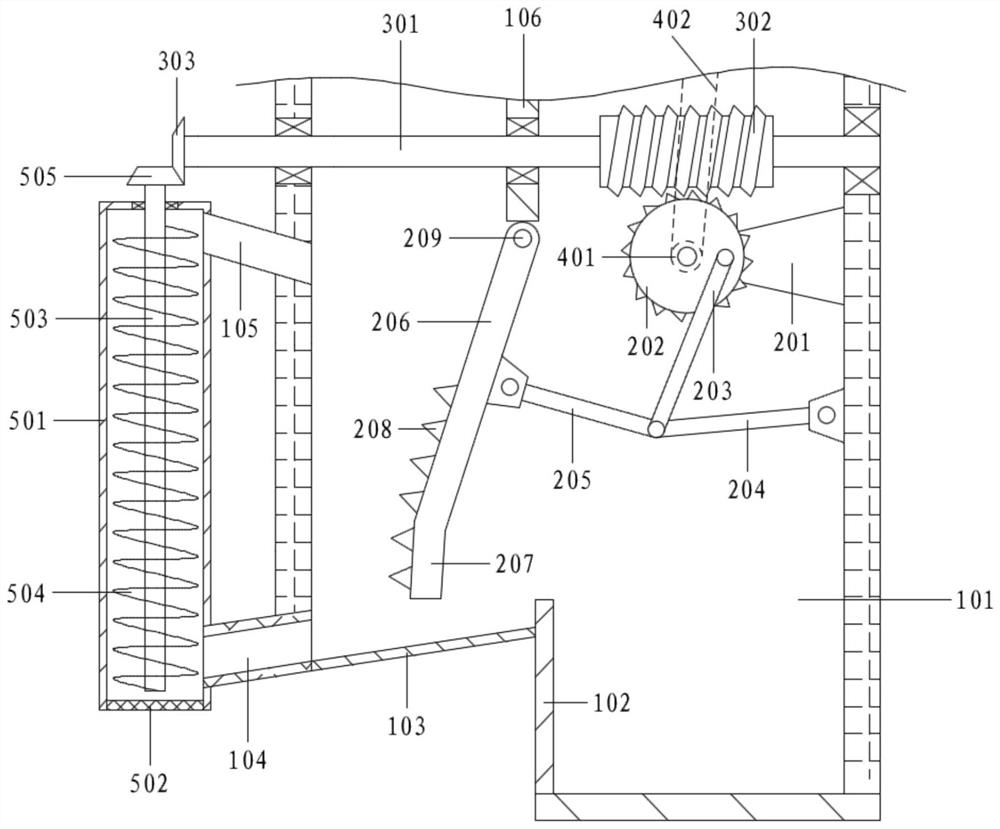

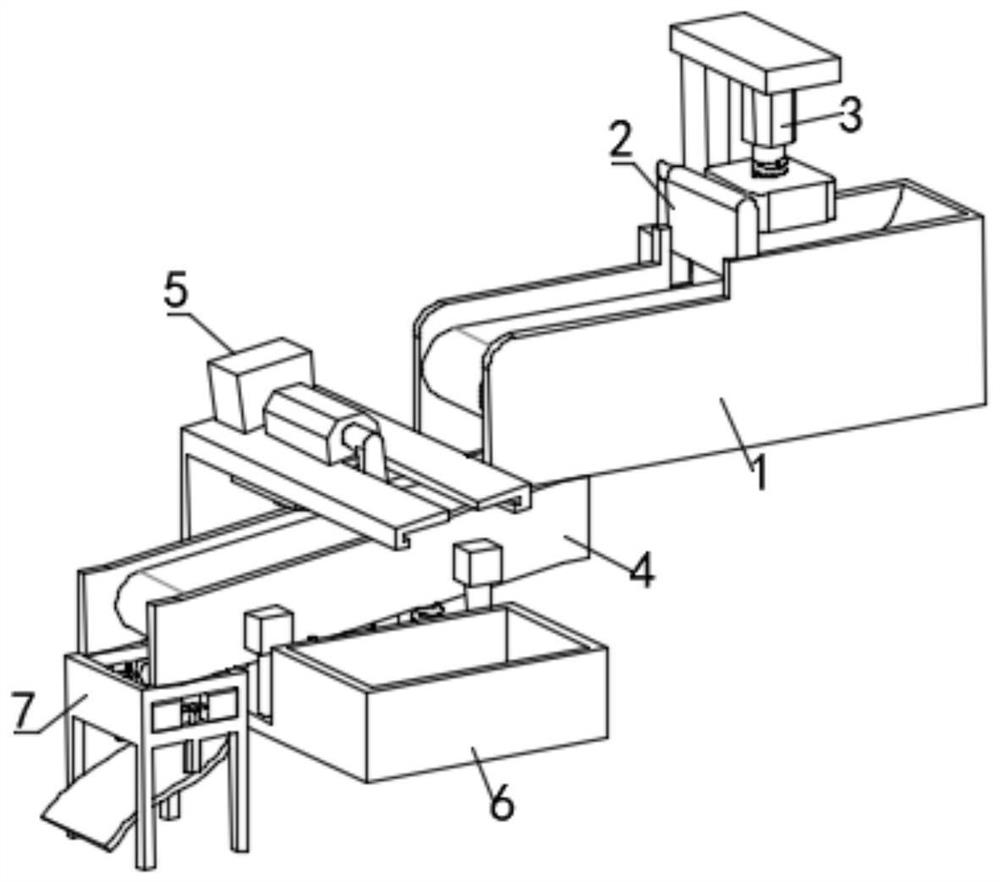

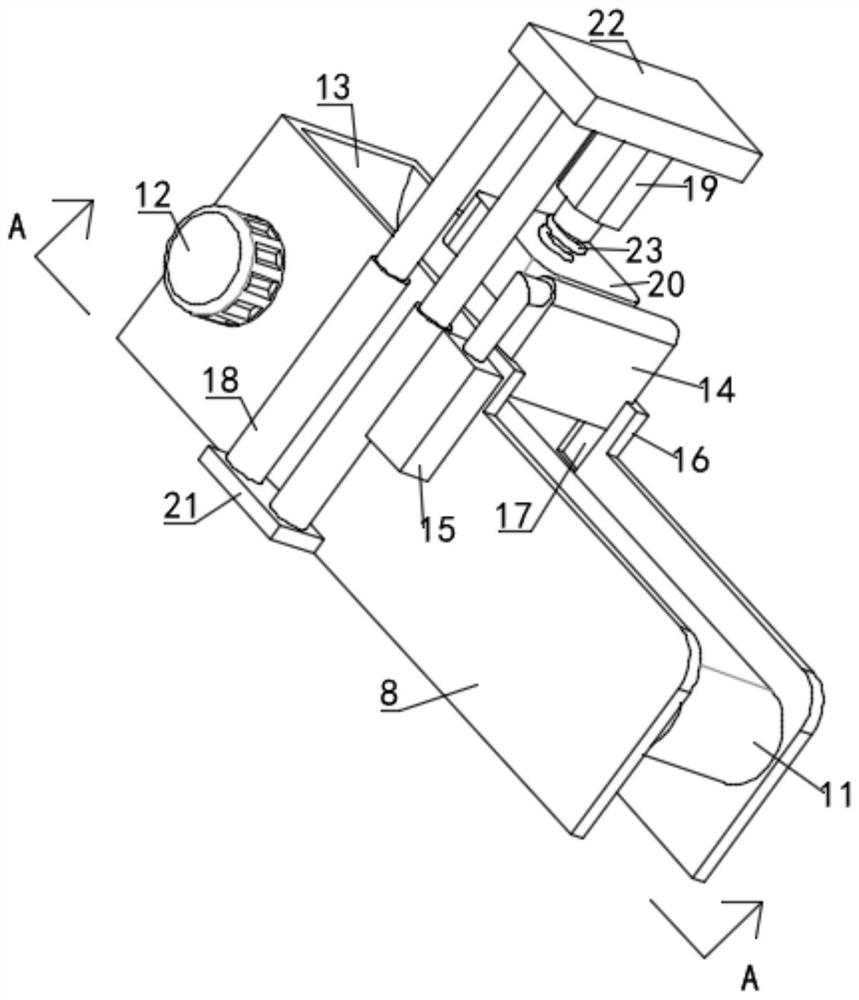

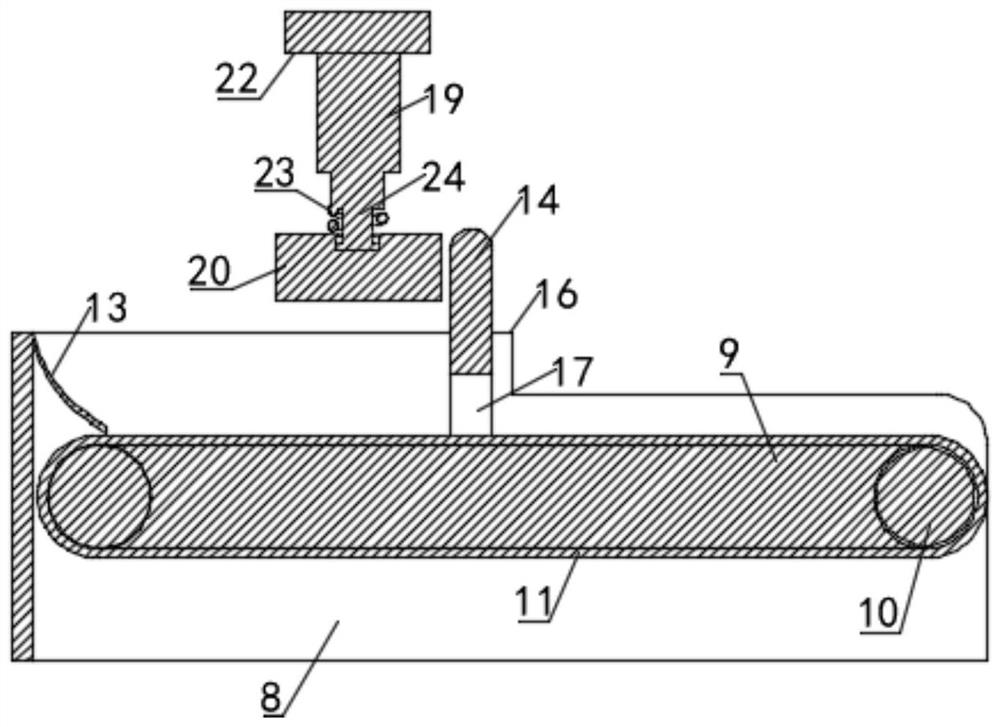

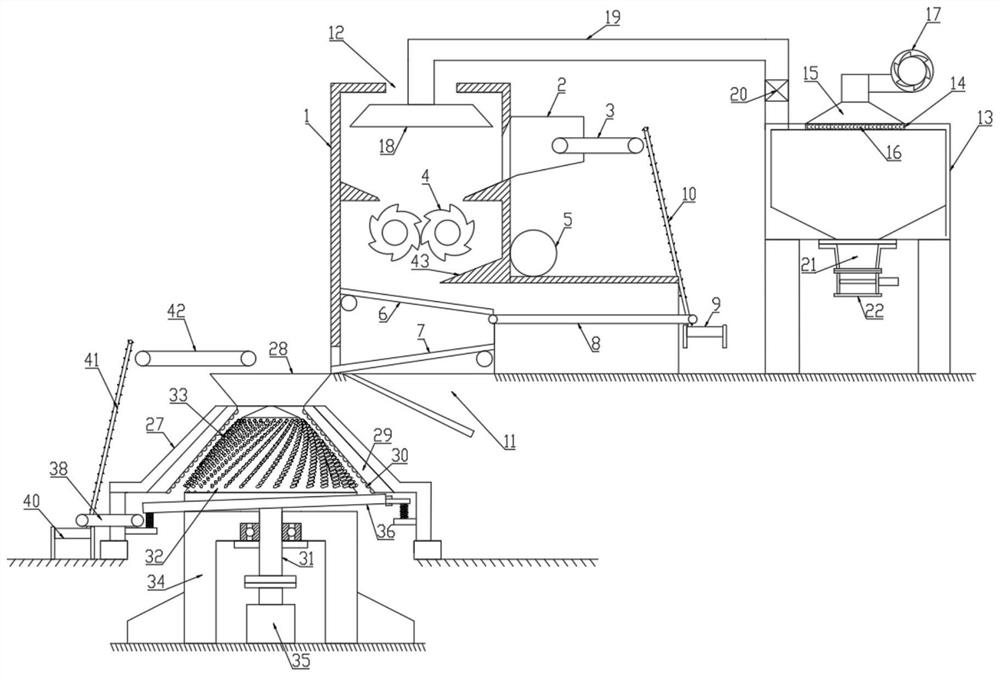

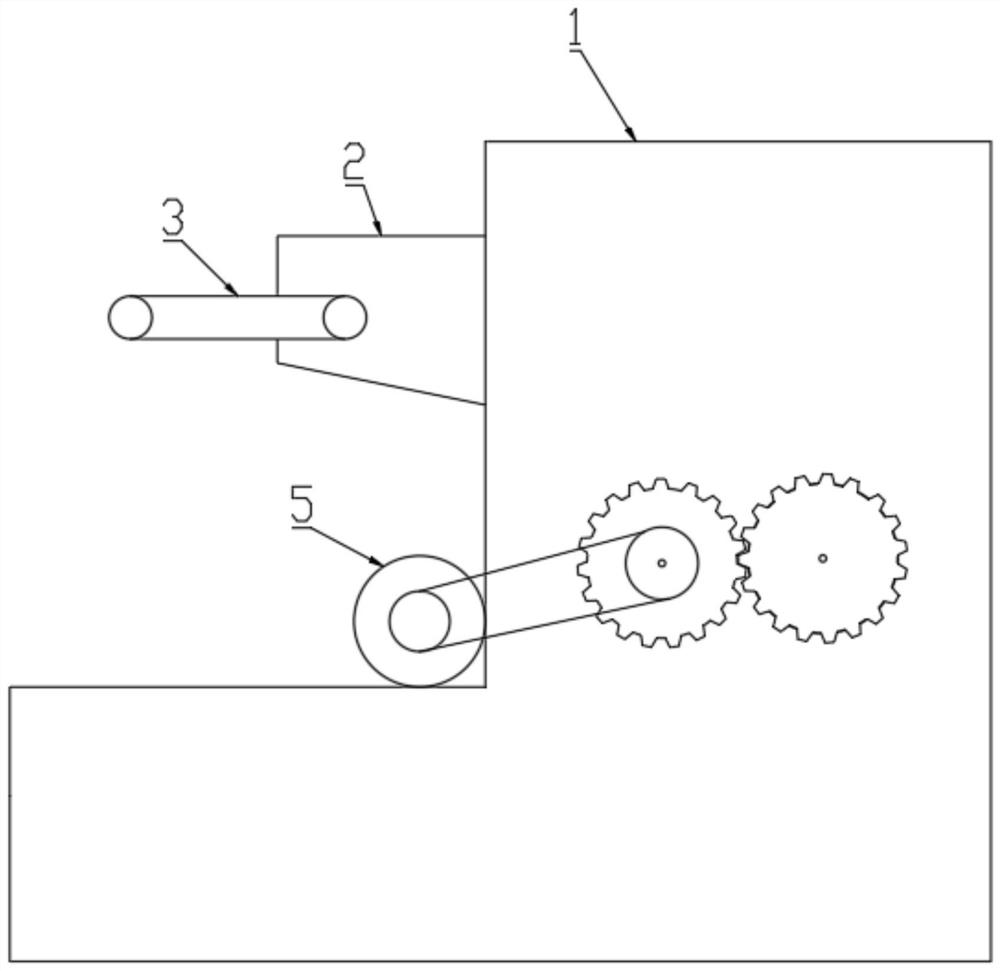

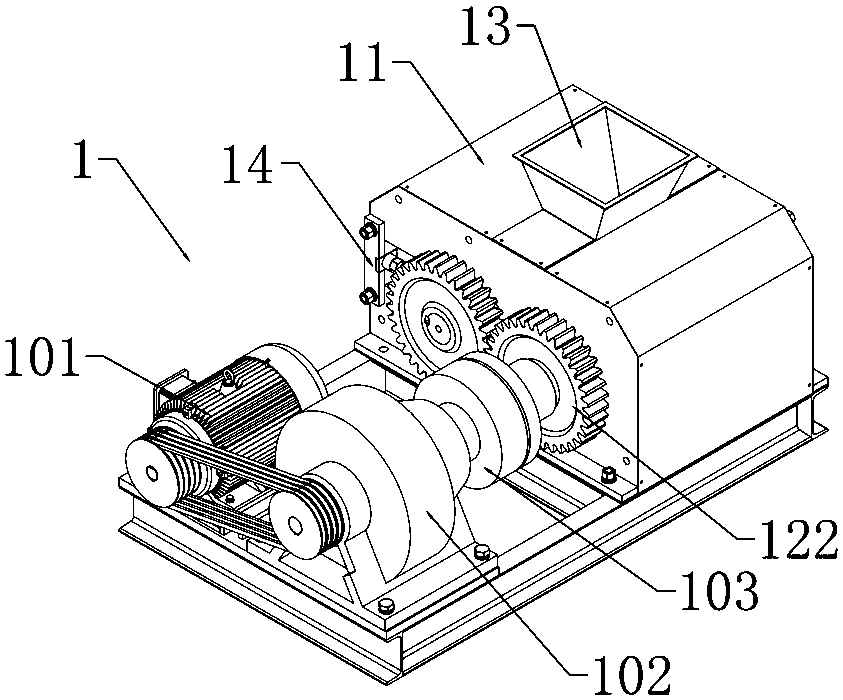

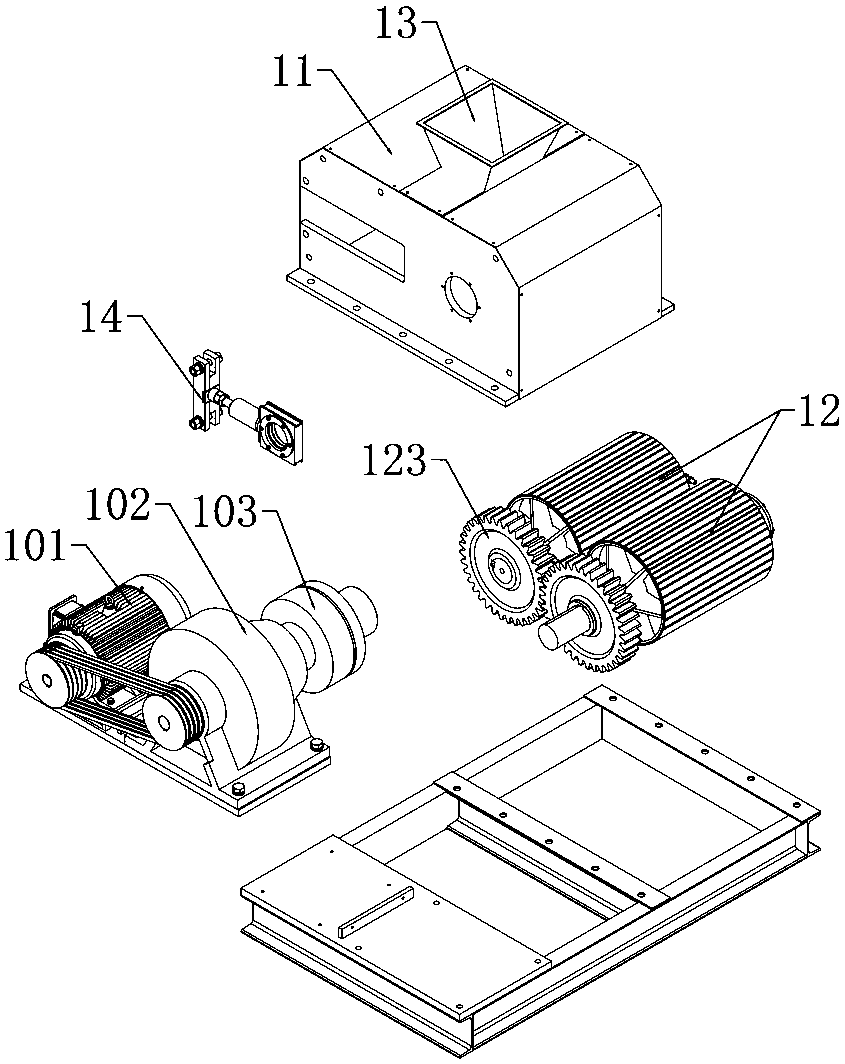

Recycling and crushing treatment machine for plastic products and method of use

The invention relates to the technical field of crushing treatment for hard plastic waste products, in particular to a recycling and crushing treatment machine for plastic products and a method of use. A No.1 transmission wheel is driven to rotate by a servo motor, and a No.2 transmission wheel is rotated by a transmission belt; the coaxial cam of the No.2 transmission wheel rotates along there-with and acts on a right pressure plate, a No.4 rod drives a blocking plate to move left and right with a spring to intermittently block a feeding opening to realize intermittent blanking, which is convenient for subsequent swing crushing action; the servo motor also drives a worm wheel to rotate, and the worm wheel rotates a No.1 rod to make No.2 and No.3 rods swing, thereby driving a rocking plateto swing left and right; the falling plastic products are crushed in cooperation with a left plate, the broken plastic products fall into a loading barrel through the guide of a guide plate and a guide tube, and are filtered through a screen, and plastic products that meet the requirements of particle size can be obtained by collection at the bottom of the screen.

Owner:安徽苿莱信息技术有限公司

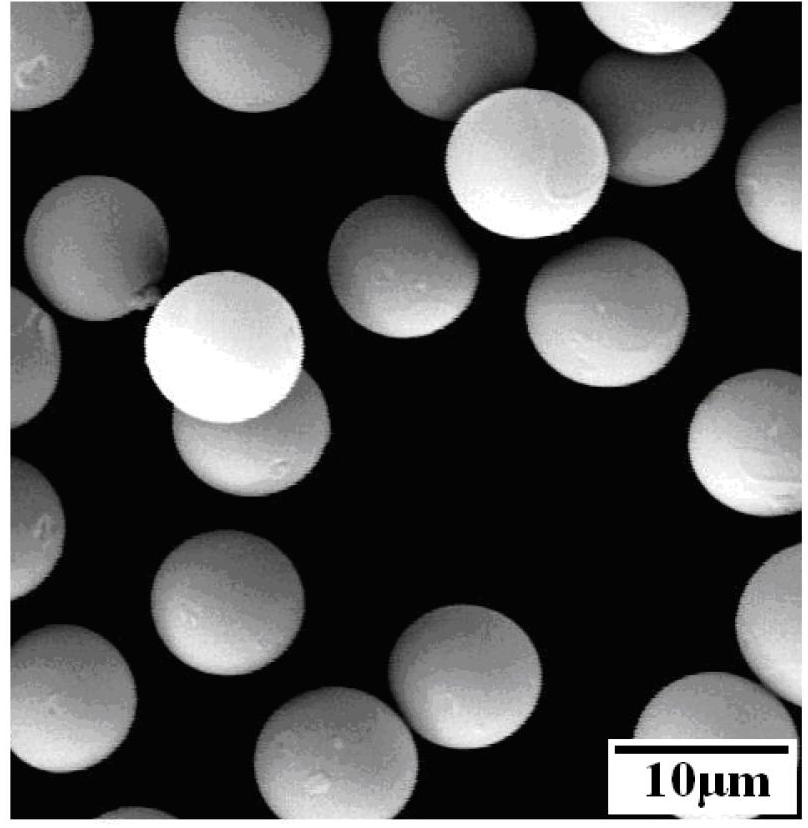

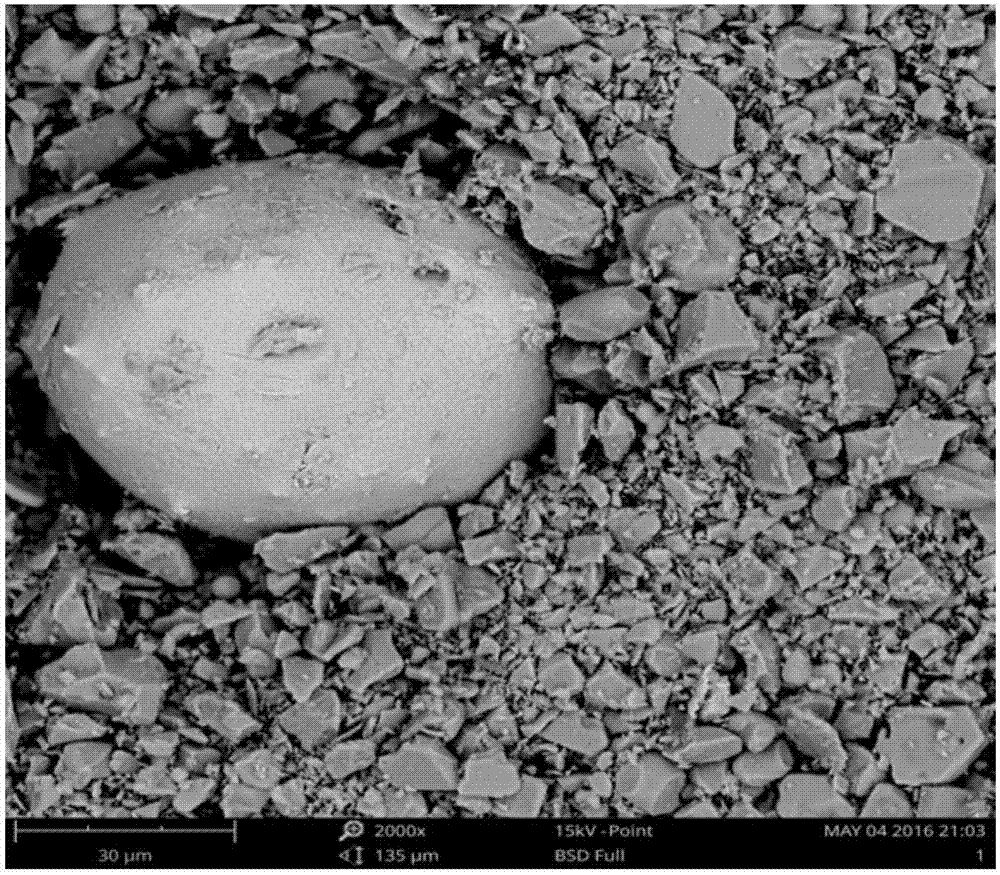

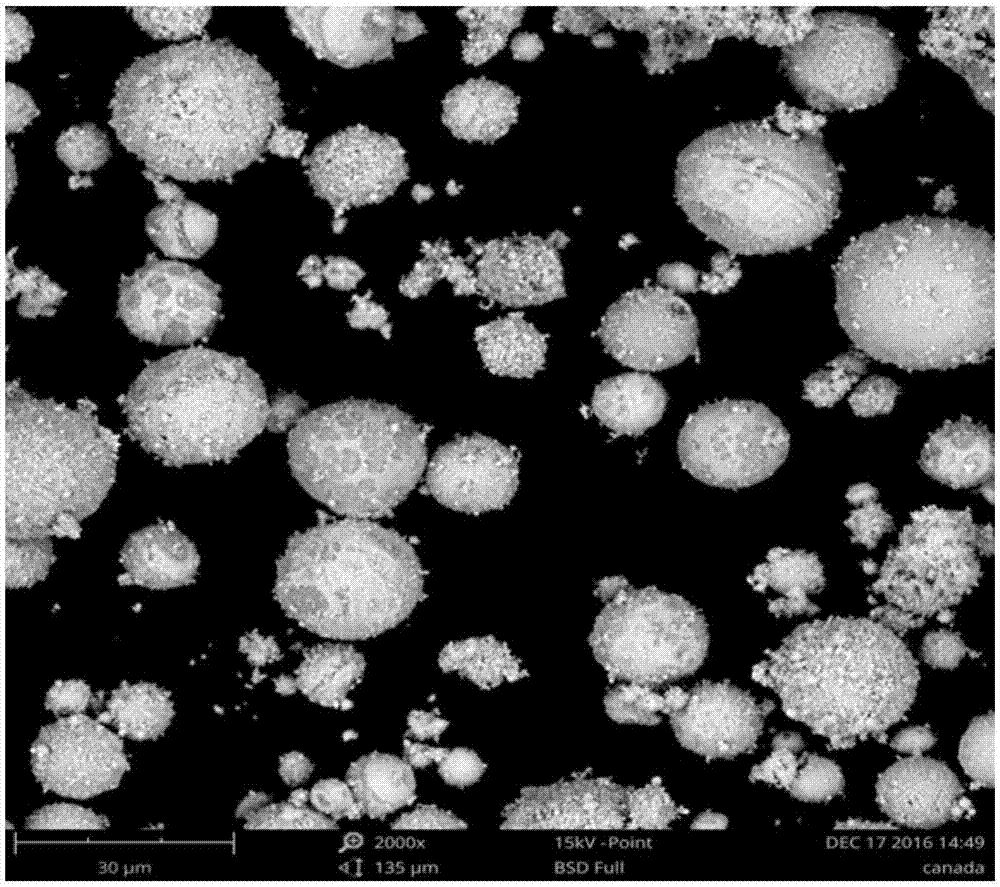

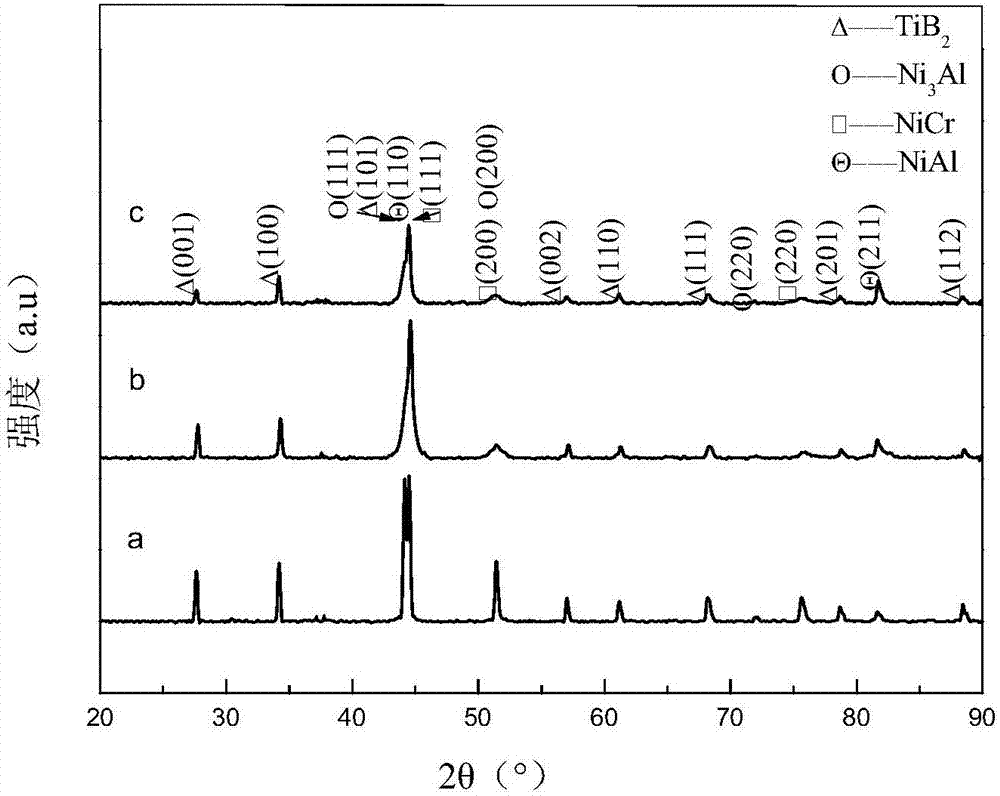

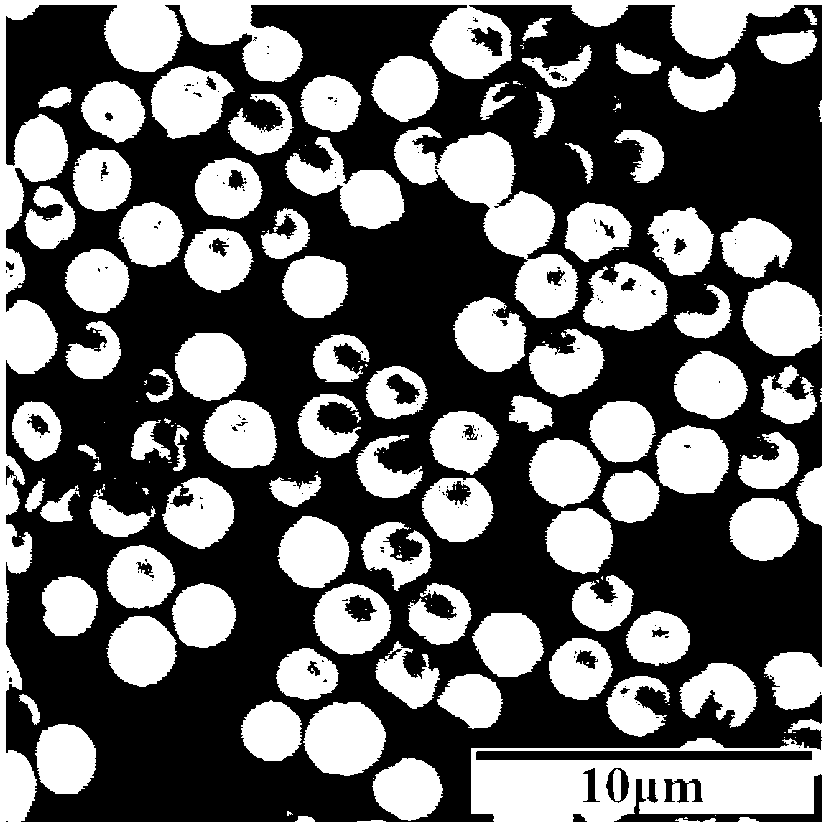

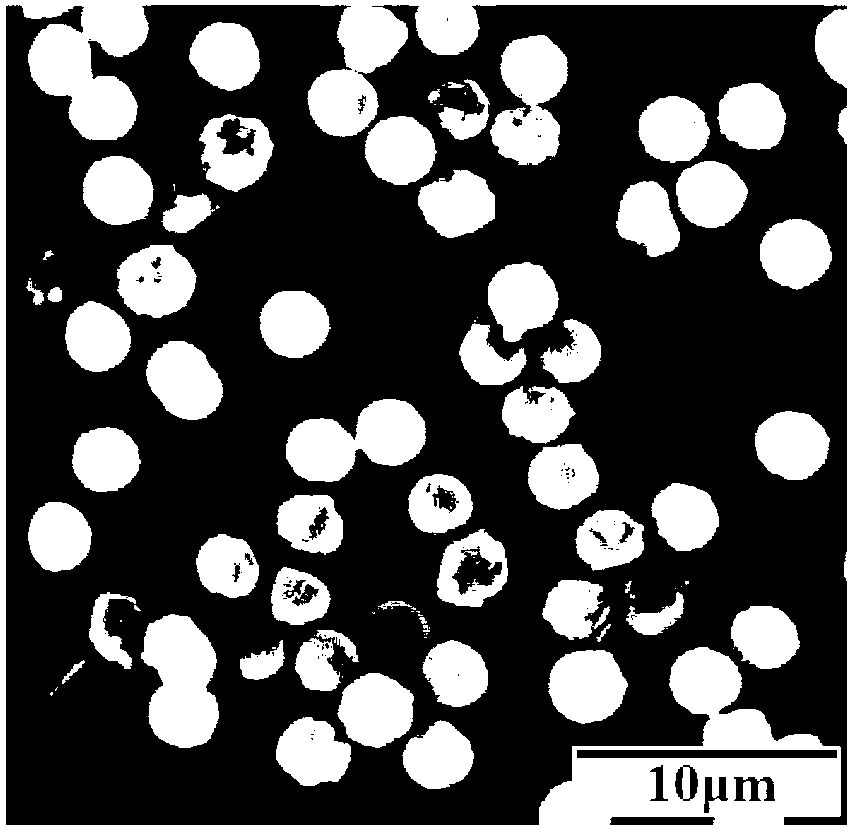

High-performance metal and ceramic composite powder used for feeding of thermal spraying structure and preparation method for high-performance metal and ceramic composite powder

InactiveCN107243640AIncrease profitImprove performanceMolten spray coatingTransportation and packagingCeramic compositeThermal spraying

The invention belongs to the technical field of nanocomposite materials, and discloses high-performance metal and ceramic composite powder used for feeding of a thermal spraying structure and a preparation method for the high-performance metal and ceramic composite powder. The method comprises the steps that (1) 20-40wt% of TiB2 powder and 60-80wt% of NiCrCoAlY powder are uniformly mixed so as to obtain NiCrCoAlY-TiB2 mixed powder; (2) the NiCrCoAlY-TiB2 mixed powder and a process control agent are put into a ball mill, are subjected to wet milling in an inert gas atmosphere, are dried and are cooled so as to obtain composite powder; and (3) ball milling treatment is carried out on the composite powder under the inert gas atmosphere, and plasma spheroidization is carried out so as to obtain the high-performance metal and ceramic nano composite powder. The composite powder has the advantages of being resistant to high temperature, wear, thermal fatigue, corrosion and high-temperature oxidation, the fluidity and density are good, and the particle size is mainly concentrated at 5-50 microns. The preparation method has the advantages of being simple and easy to operate and environment-friendly.

Owner:SOUTH CHINA UNIV OF TECH

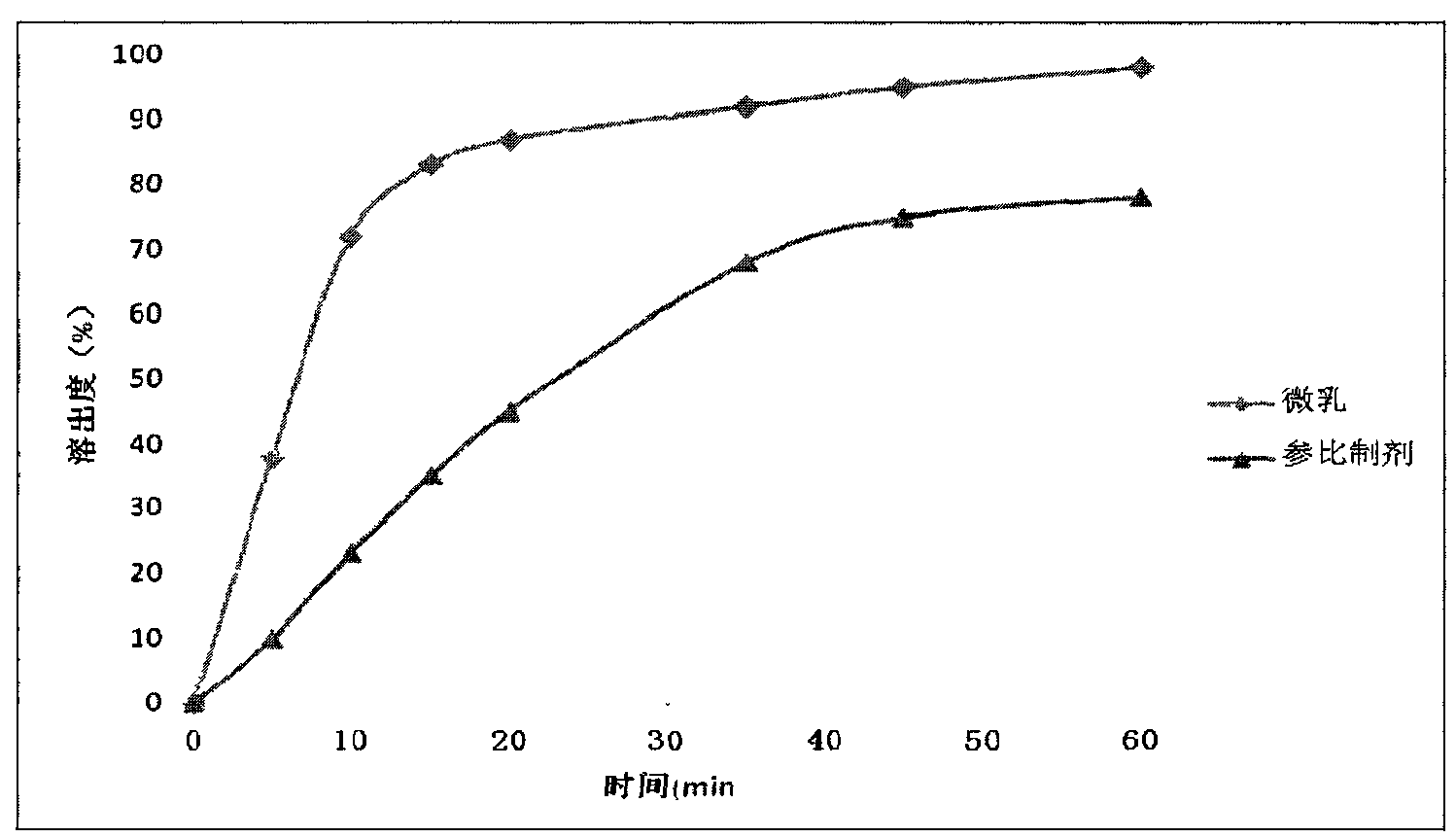

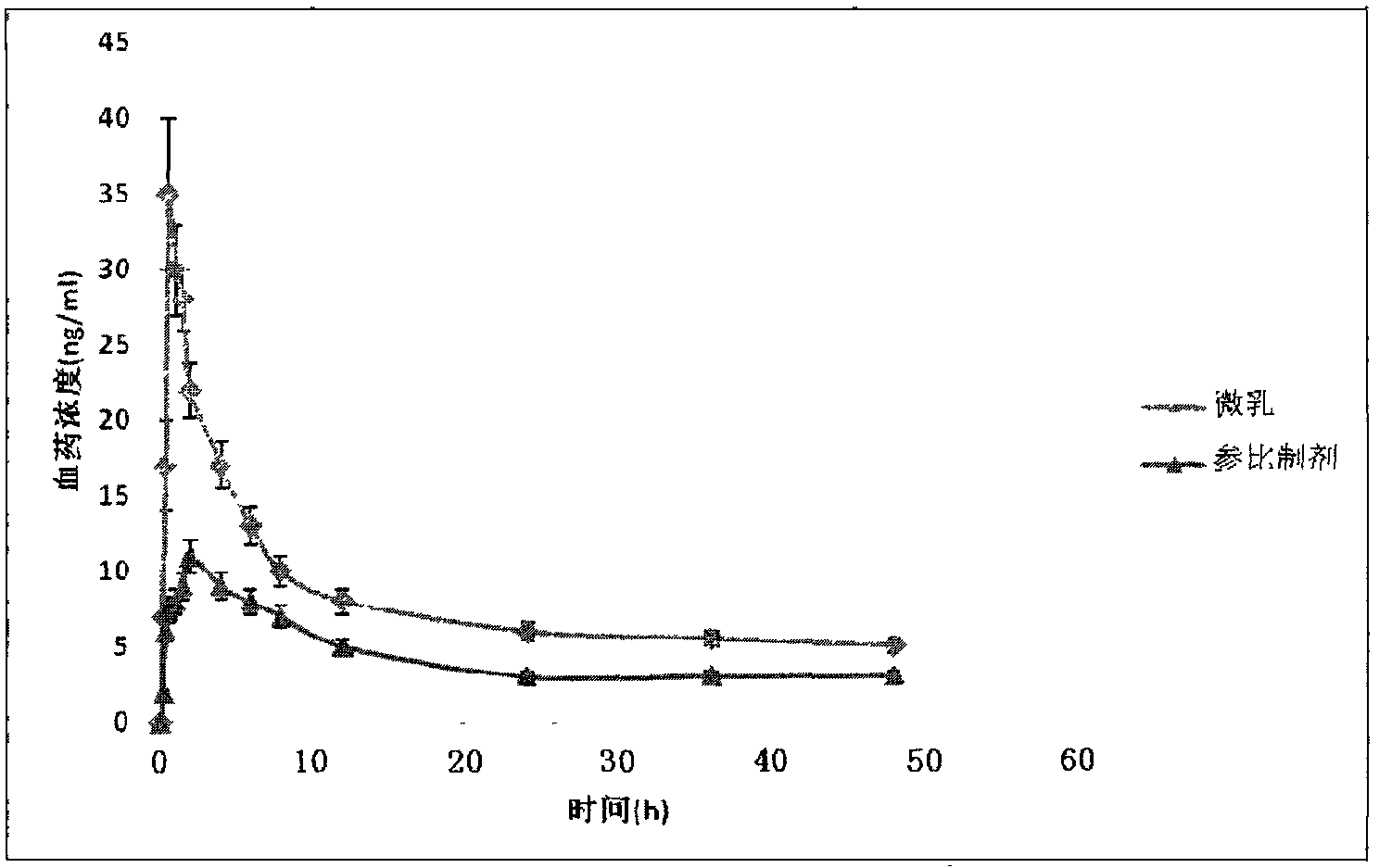

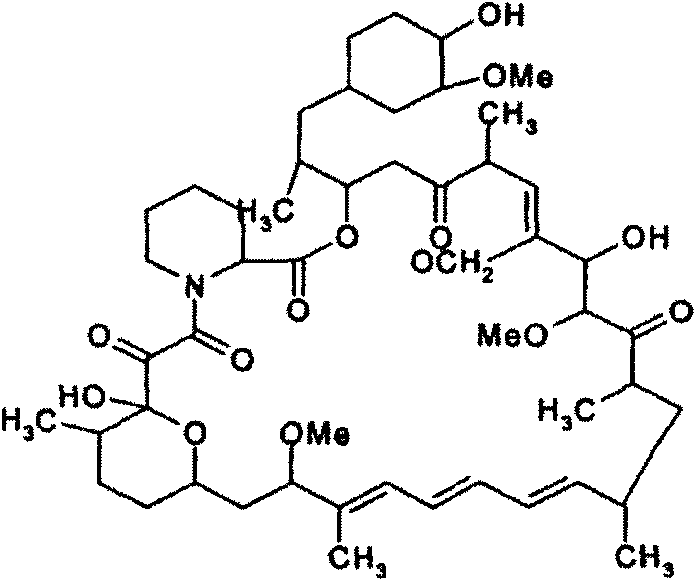

Sirolimus micro-emulsion particles and preparation method and application thereof

ActiveCN103655486AReduce usageAvoid emulsificationOrganic active ingredientsPharmaceutical non-active ingredientsMolten stateEmulsion

The invention provides sirolimus micro-emulsion particles and a preparation method and an application thereof. The sirolimus micro-emulsion preparation and sirolimus micro-emulsion particles are prepared from the following steps: mixing an emulsifier, a co-emulsifier and water; adding sirolimus into the mixture obtained, and heating up to a melting state at a temperature ranging from 70 DEG C to 90 DEG C; shearing and stirring the mixture in the melting state by adopting a high speed tissue stamping machine, wherein the shearing and stirring rotating speed is 8000-12000r / m, and the shearing and stirring time is 10-30 minutes to obtain an initial micro-emulsion; circularly emulsifying the initial micro-emulsion to obtain a micro-emulsion; and drying the micro-emulsion to obtain the sirolimus micro-emulsion particles. The stability of the sirolimus preparation provided by the invention is improved, the dissolution rate of the preparation is improved, and the bioavailability is increased.

Owner:HUBEI BIO PHARMA IND TECHCAL INST

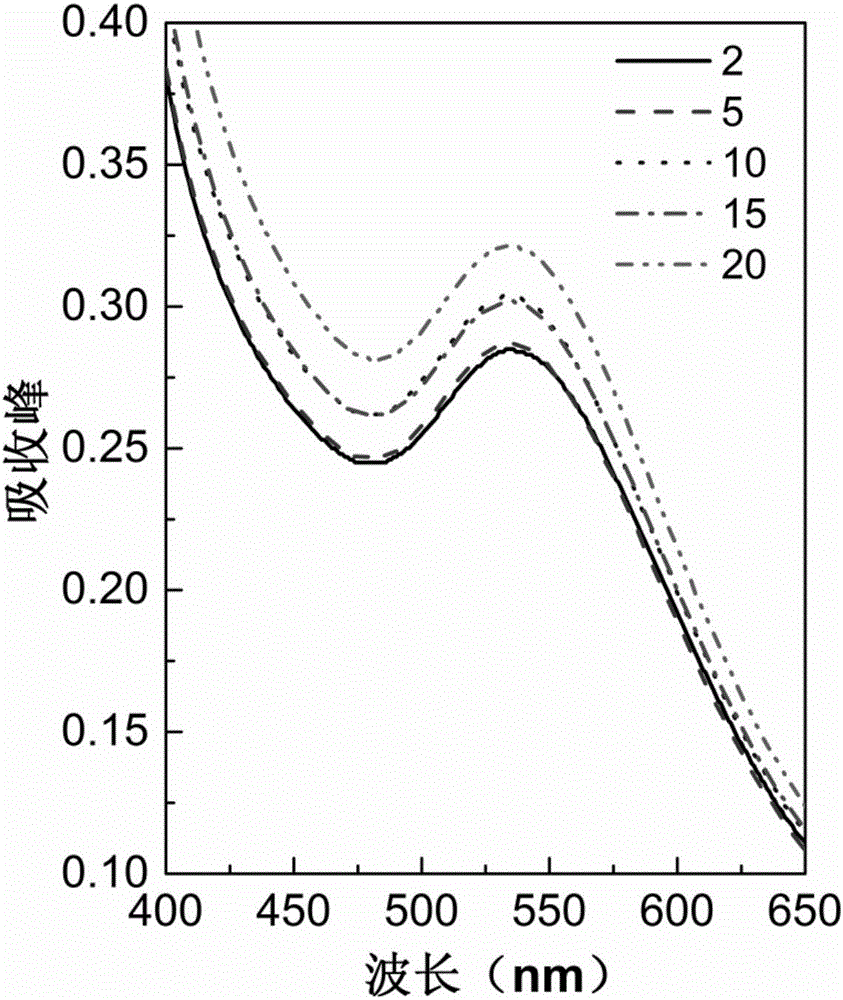

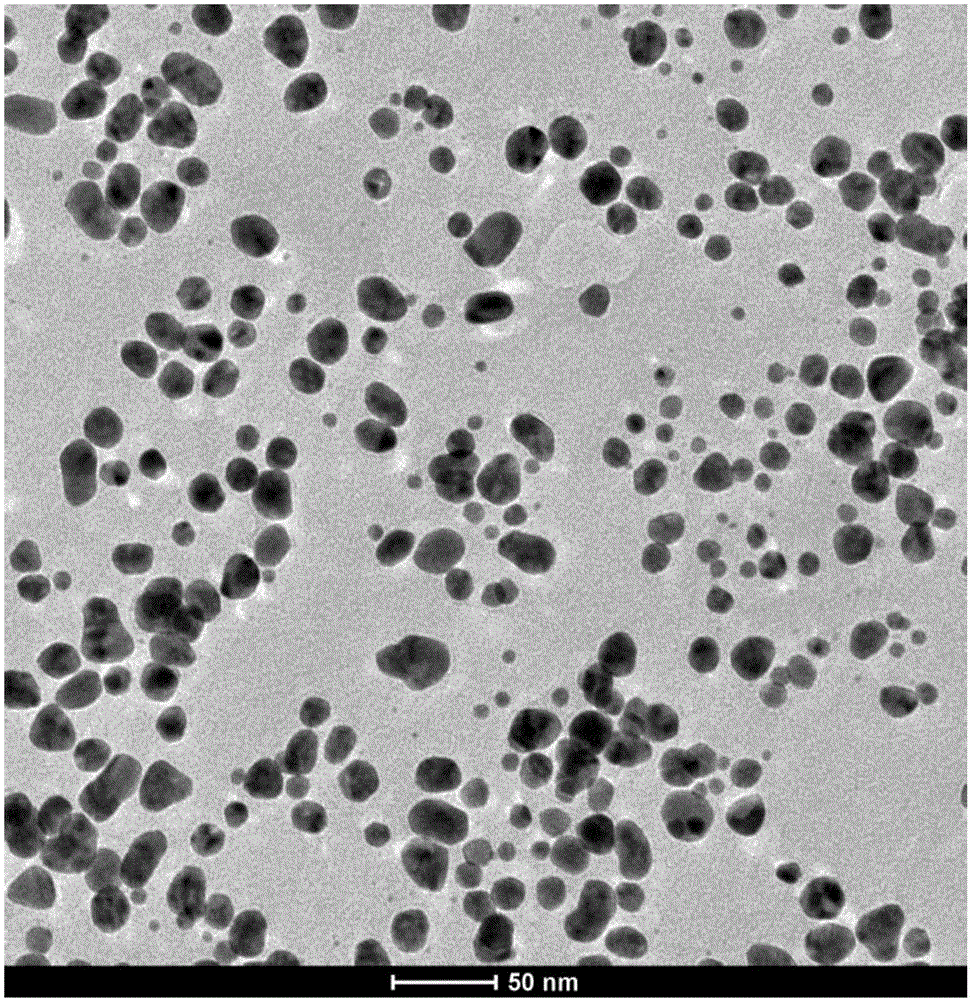

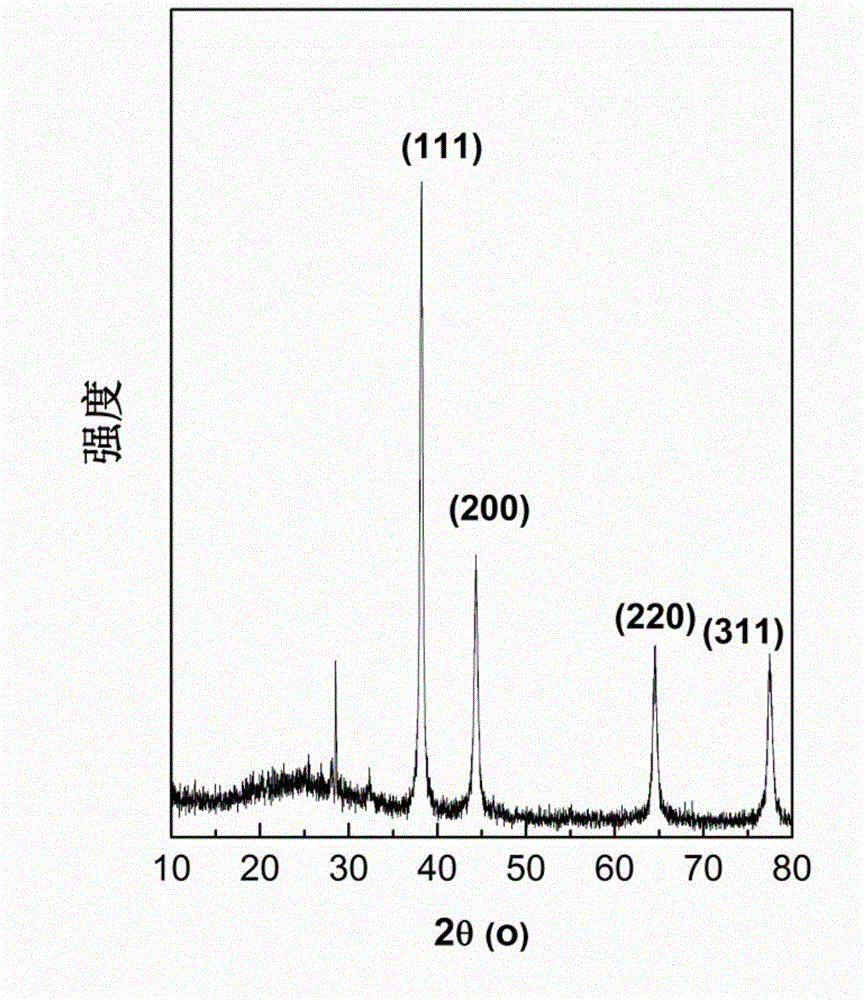

Method for preparing gold nanoparticles through fructus lycii extract liquid

ActiveCN105965031AAvoid residueNo pollutionTransportation and packagingMetal-working apparatusNanoparticleReaction system

The invention provides a method for preparing gold nanoparticles through fructus lycii extract liquid. The method comprises the following steps that firstly, fructus lycii is washed and then subjected to extraction through deionized water, and the fructus lycii extract liquid is obtained; secondly, the fructus lycii extract liquid obtained in the first step is heated to be boiled, and boiling is kept for a certain time, a chloroauric acid solution is added into the fructus lycii extract liquid to form a reaction system, the pH of the reaction system is adjusted to be 4.0-5.5 by regulating the addition amount of the chloroauric acid solution, the reaction system is kept in a boiling state, reaction is carried out for 2-60 minutes, and reaction liquid is obtained; thirdly, the reaction liquid obtained in the second step is subjected to centrifugal separation, precipitate is obtained and dried, and the gold nanoparticles are obtained. The particle sizes of the gold nanoparticles prepared through the method are smaller than 50 nm, and the gold nanoparticles do not contain chemical reagent residuals and are suitable for being applied to the field of biological medicines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

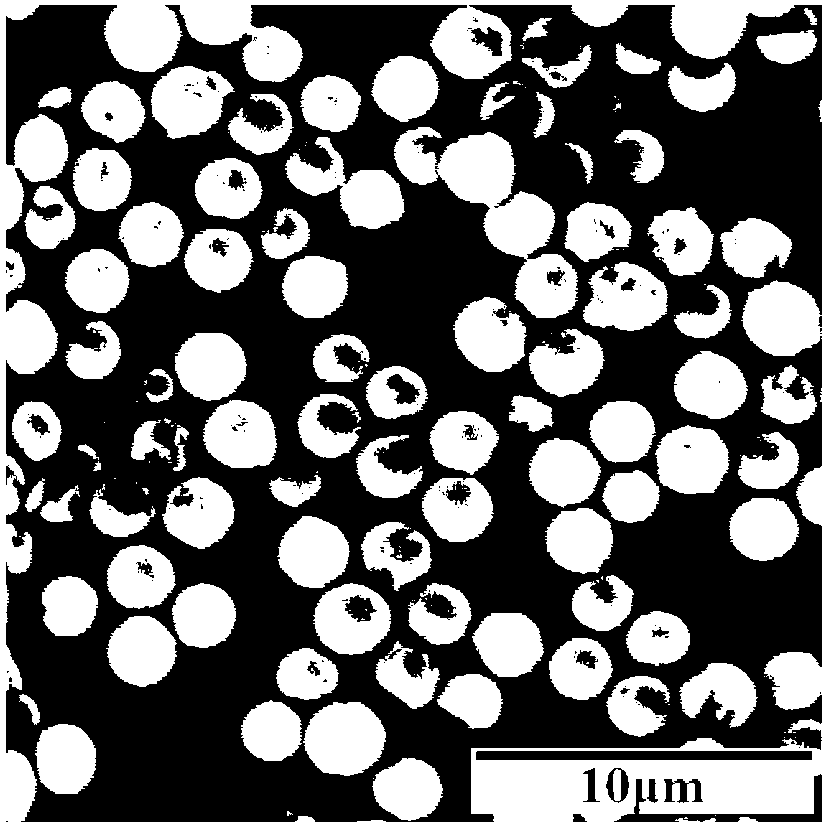

Method for preparing micro-sized monodisperse polyurea microsphere in static condition

The invention relates to a method for preparing micro-sized monodisperse polymer microspheres in static condition. The method comprises the steps that diisocyanate monomers and a water-acetone mixed solvent are added into a reaction bottle, wherein the mass ratio of water to acetone ranges from 20 / 80 to 60 / 40, and the diisocyanate compound accounts for 0.5-13.0% of the total mass of the polymerization system; after the reaction bottle is sealed and the mixed solvent is shaken up, the reaction bottle is placed in thermostatic waterbath of 20-80 DEG C for polymerization; after polymerization, the products are centrifugalized and dried to obtain the micro-sized monodisperse polyurea microspheres. The method for preparing micro-sized monodisperse polymer microspheres in static condition has the advantages that one monomer is used for precipitation polymerization completely in static condition without any stirring or oscillation, so that the reaction time is short, the monomer can be transformed completely, the yield of microspheres is high, and the operation is simple; the method is conducive to scale production of monodisperse microspheres; and the produced microspheres have clean surfaces and a large amount of amido, and can be used in various fields of protein adsorption and separation, enzyme immobilization, chromatographic analysis and the like..

Owner:UNIV OF JINAN

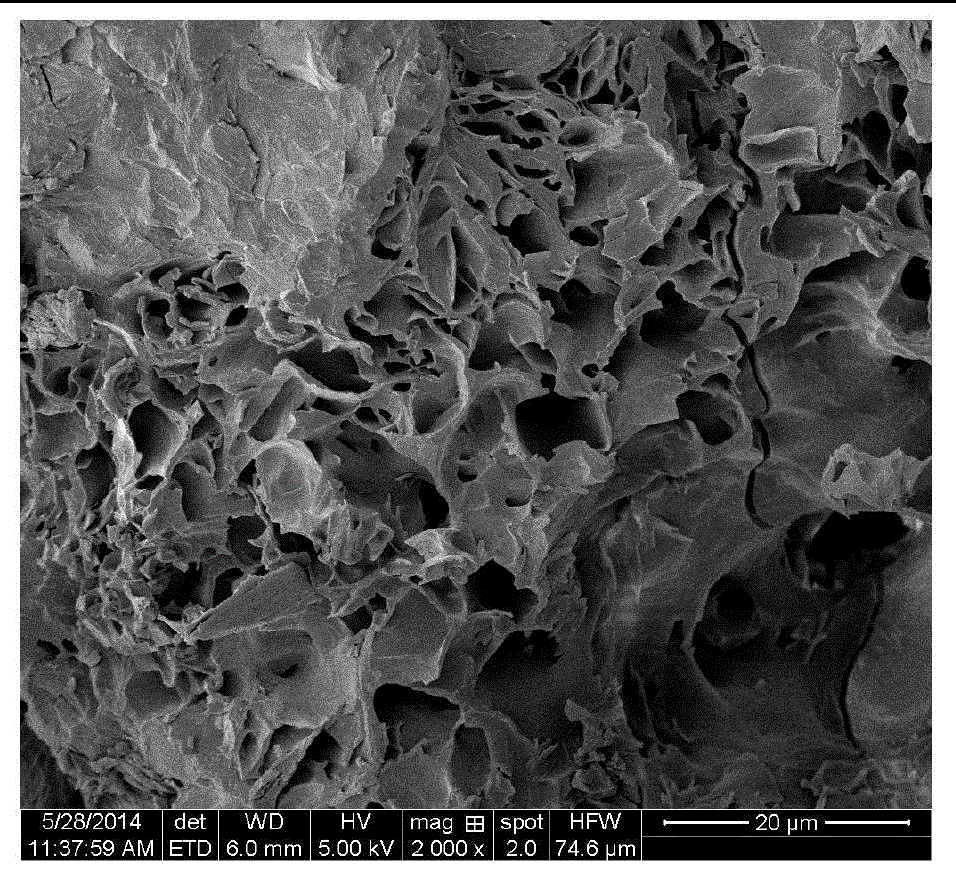

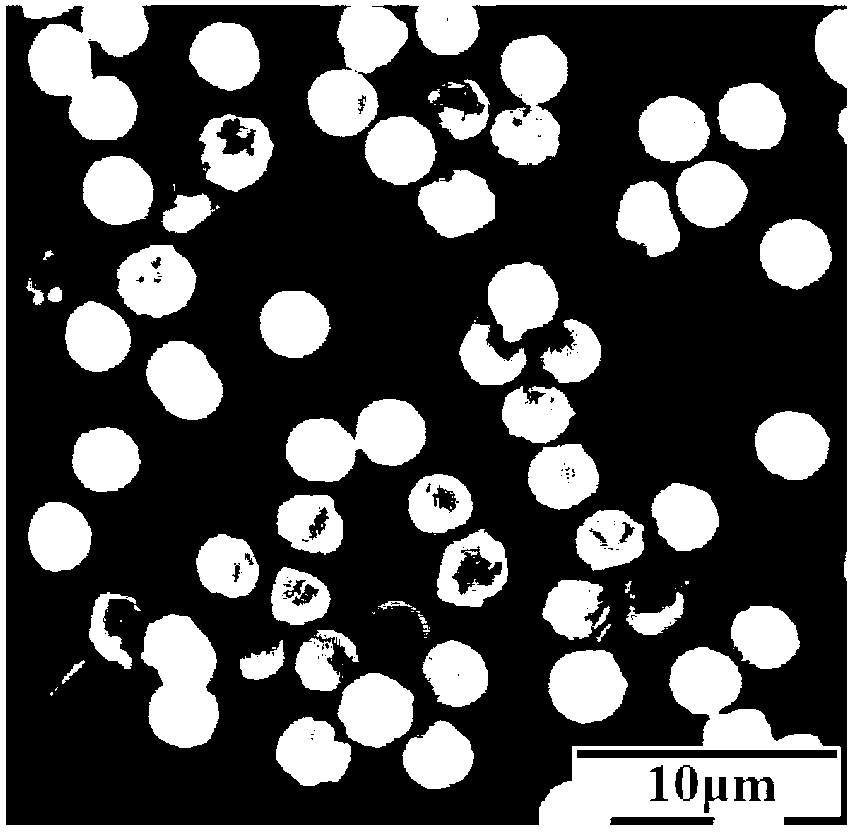

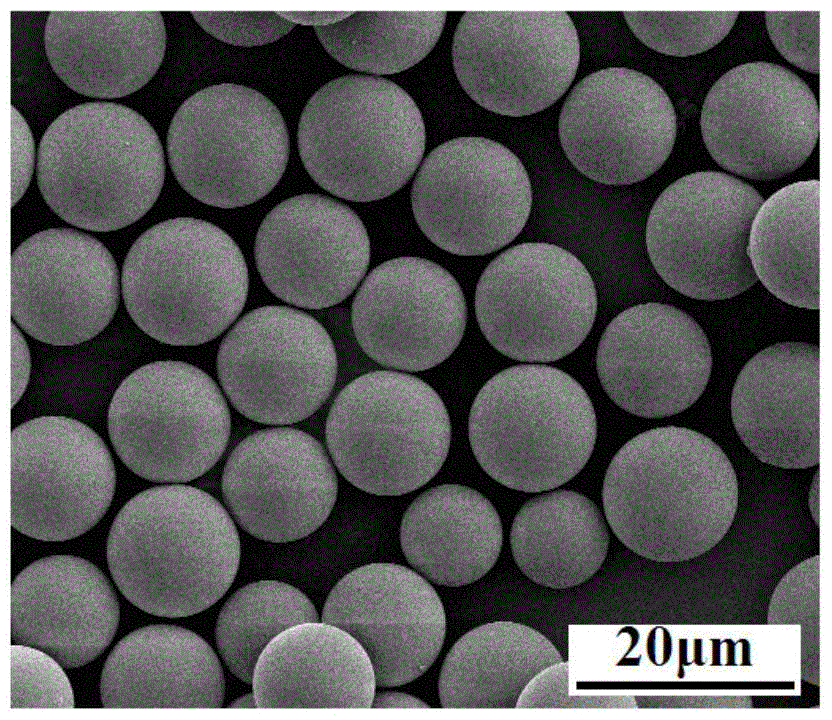

High-yield preparation method of functional monodisperse polyurea microspheres

The invention relates to a high-yield preparation method of functional monodisperse polyurea microspheres. The method adopts a precipitation polymerization process and comprises the following step: with water and acetonitrile as solvents and isophorone diisocyanate as monomers, reacting isocyanate with the water to prepare the monodisperse polyurea microspheres with rich amine groups on the surfaces. According to the method, single raw material is used, the reaction time is short, the monomers are completely converted, and the monomer content and the microsphere yield during preparation of the monodisperse microspheres are remarkably increased; the microsphere preparation process can be carried out in a complete standing condition, the functional polyurea microspheres can be obtained in one step without any surface modification, the process is simple, and the obtained microspheres can be used in the fields of enzyme immobilization, chemical catalysis, chromatographic analysis and the like.

Owner:UNIV OF JINAN

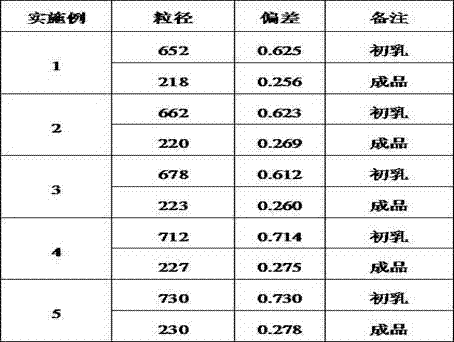

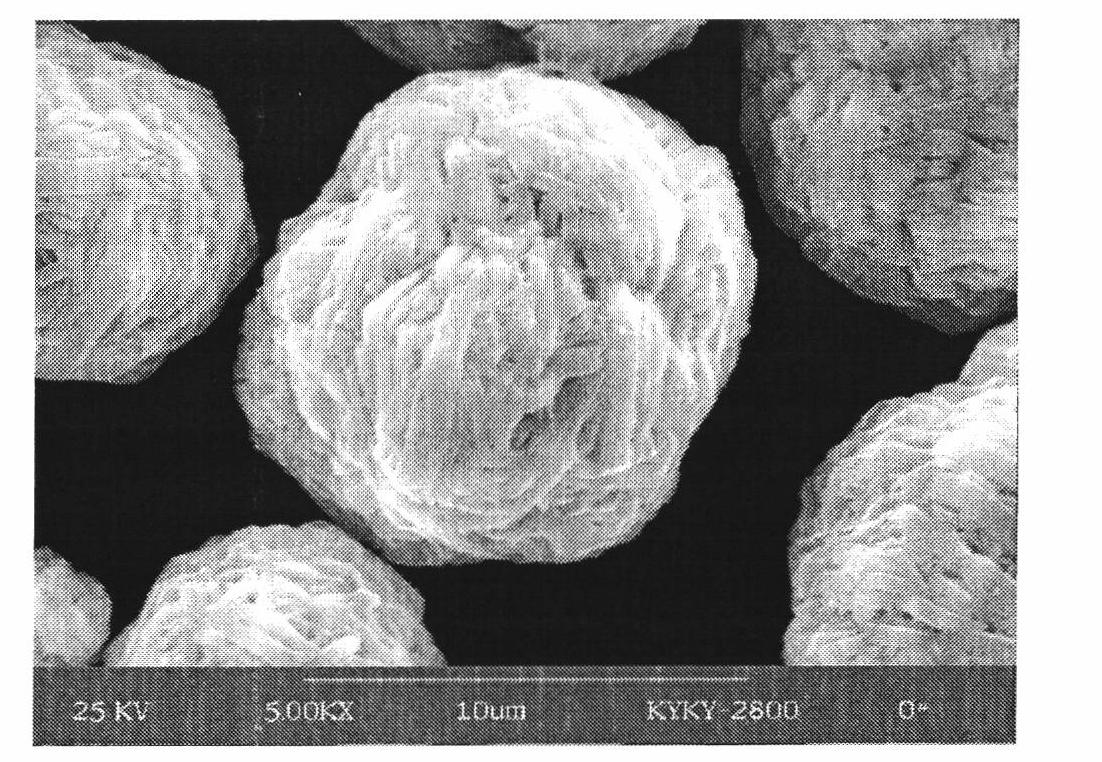

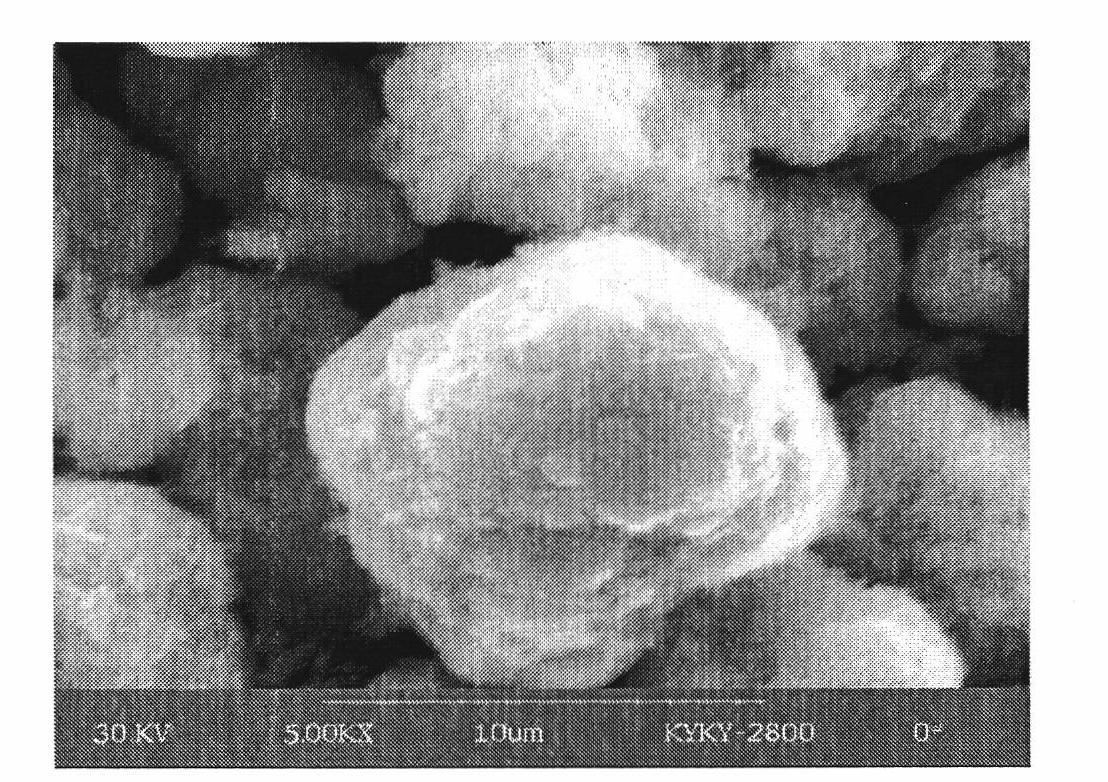

Preparation method of propofol fat emulsion injection

ActiveCN104490780AImprove the shortcomings of excessive particle size deviationMeet particle size requirementsHydroxy compound active ingredientsPharmaceutical product form changeSide effectOil phase

The invention discloses a preparation method of a propofol fat emulsion injection. The preparation method comprises the following steps: uniformly mixing soybean oil, lecithin and oleic acid and adding propofol; spraying an oil phase into a water phase under the protection of nitrogen gas to prepare emulsion; shearing the emulsion to obtain primary emulsion; homogenizing the primary emulsion under the pressure of 10000psi-20000psi to prepare an emulsion semi-finished product; and filtering, inflating nitrogen and sterilizing to prepare the propofol fat emulsion injection. According to the preparation method, the grain diameter uniformity is enhanced and the disadvantage that the grain diameter deviation of the primary emulsion is too great is improved; the stability of finished-product emulsion is improved; the average grain diameter of the detected emulsion is 210nm-230nm and the grain diameter deviation is 0.20-0.30; the requirements on the grain diameters by the fat emulsion injection are met; the emulsion grains with the size being more than 1 micron are not detected, and the grain diameters are obviously better than the standards that the content of the emulsion grains with the size being 1 micron in emulsion large grains of national drug standards is not more than 3%; the physicochemical properties are stable, the toxic side effect is low, the pains caused by injection are reduced, and the compliance of using drugs by patients is increased, so that the application prospect is very good.

Owner:HEBEI YIPIN PHARMA

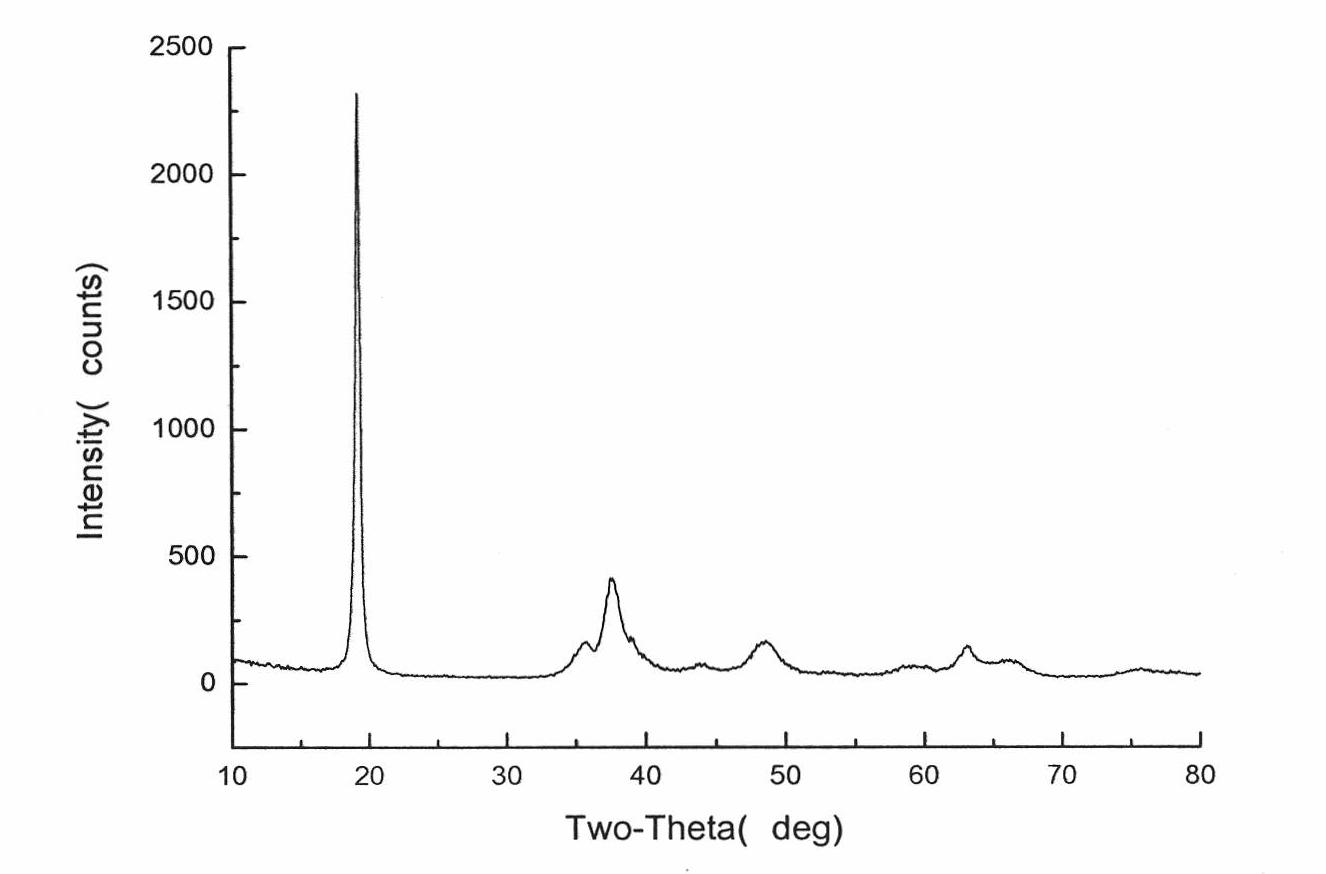

Method for preparing lithium battery anode material precursor

InactiveCN101777639AHigh tap densityLarge specific surface areaElectrode manufacturing processesNickel compoundsManganesePhysical chemistry

The invention discloses a method for preparing a lithium battery anode material precursor, which comprises the following steps of: adding a surfactant into a reaction cylinder; adding salt solution of nickel, salt solution of manganese or / and cobalt to carry out aging reaction with alkali solution; and dewatering and drying after the reaction is finished to obtain the lithium battery anode material precursor. The invention provides the method for preparing the lithium battery anode material precursor having regular topography, large specific surface area and high tap density.

Owner:深圳市天骄科技开发有限公司

Building waste treatment device for civil engineering

PendingCN112024564AConvenient recycling workMeet particle size requirementsConstruction waste recoverySolid waste disposalArchitectural engineeringWaste treatment

The embodiment of the invention discloses a building waste treatment device for civil engineering in the technical field of civil engineering. The building waste treatment device comprises a first conveying mechanism, a height limiting adjusting mechanism, an air hammer knocking mechanism and a second conveying mechanism; the first conveying mechanism is transversely arranged, the height limitingadjusting mechanism is used for filtering waste particles on the first conveying mechanism, the air hammer knocking mechanism is used for conducting waste crushing on the conveying starting end of thefirst conveying mechanism, and the second conveying mechanism is obliquely arranged on one side of the bottom of the conveying tail end of the first conveying mechanism for shaking and conveying waste materials. According to the building waste treatment device for civil engineering, through the three procedures of waste knocking treatment, metal part separation treatment and crushing treatment, the waste particles with different particle sizes can be fully knocked and crushed, so that the metal parts and the waste particles are thoroughly separated, and the metal parts and the waste particlesare conveyed through shaking, an electromagnet is used for better completing the recovery work of the metal parts, and meanwhile, the particle size requirements of the waste particles with differentrequirements can be met by adjusting crushing treatment.

Owner:刘凤翔

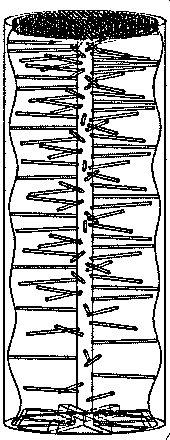

Oil-gas well slug flow combined type gas slug breaking device and method

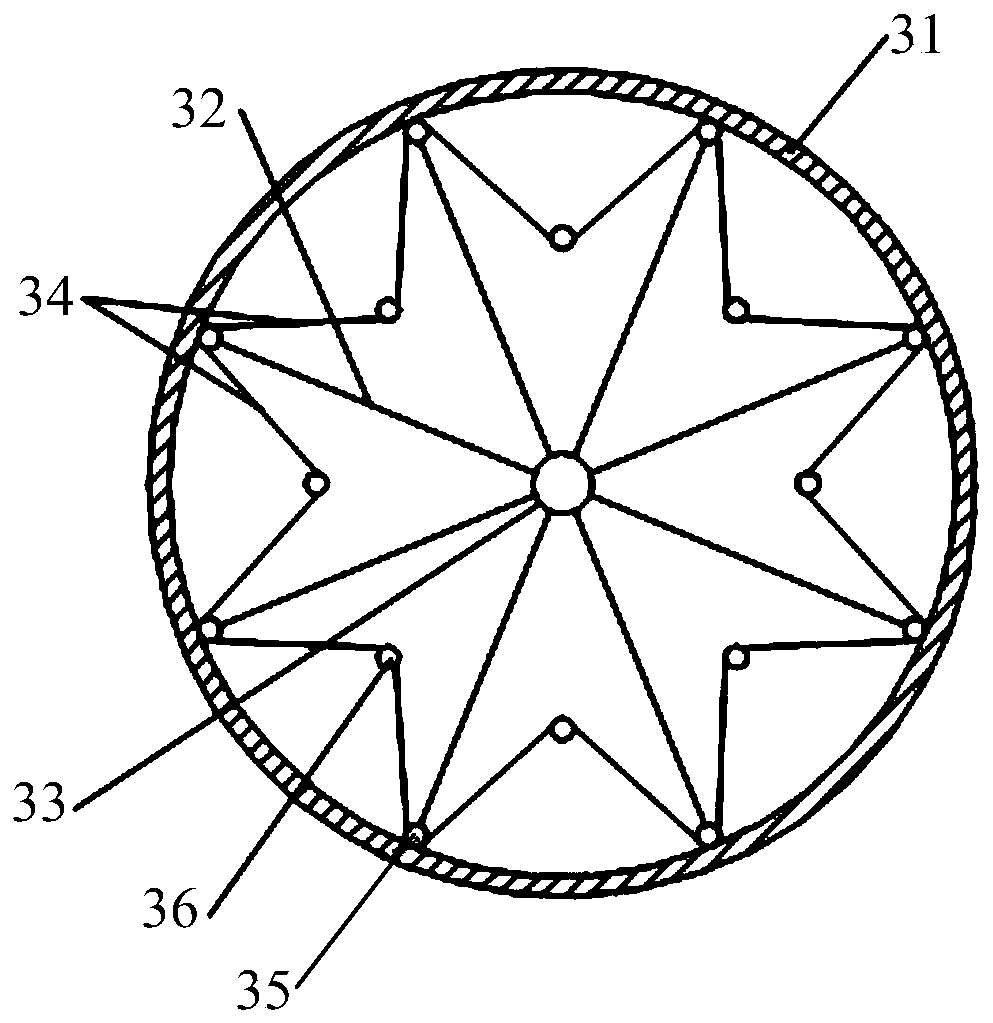

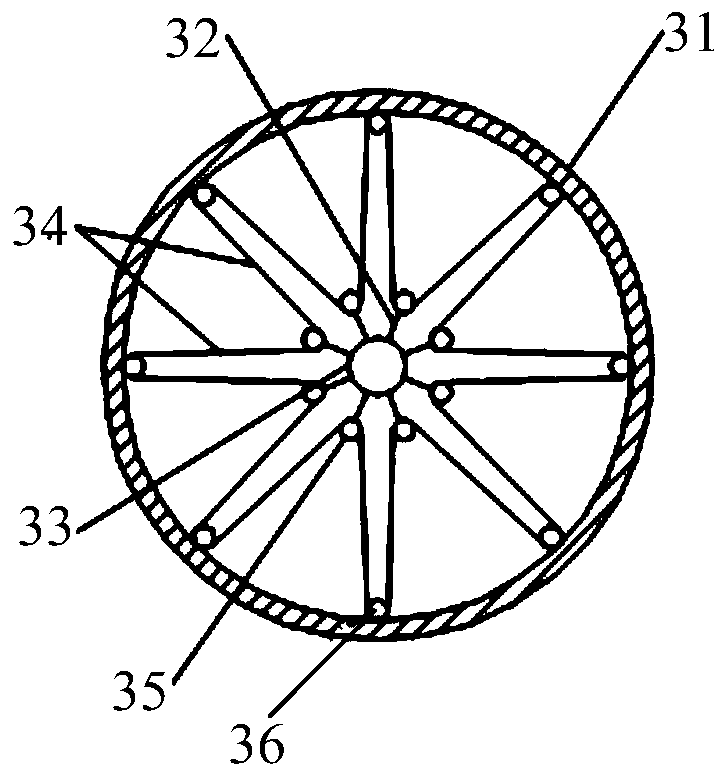

InactiveCN109630075AAvoid recollision coalescingSolve the accumulationFluid removalGas phaseEngineering

The invention provides an oil-gas well slug flow combined type gas slug breaking device and method, and relates to the field of slug flow bubble breaking. A bubble breaking device is composed of an entry cross-bar, a central column, vibratile metal wires, a corrugated tube wall and a perforated plate; the entry cross-bar supports the central column, and a slug is initially broken; the vibratile metal wires spirally rise along the central column and are arranged from thin to dense, and the problem that a fluid is stirred irregularly, and bubble braking is incomplete is solved; by means of the corrugated tube wall, turbulent fluctuation and fluid impact are improved, and a liquid film is dispersed into a gas phase; by means of the perforated plate, the bubbles are broken into small bubbles meeting the requirements; the residual liquid film on the tube wall flows out of a hole tangent to the liquid film to prevent liquid phase accumulation. Accordingly, by means of combined design, two kinds of bubble breaking methods are organically combined and improved, and the defect of the single method is overcome; the corrugated tube wall is adopted, the turbulence intensity is improved, gas-liquid distribution is improved, the pressure drop loss is reduced, the oil-gas well maintenance period is prolonged, and the oil-gas field development benefit is increased.

Owner:SOUTHWEST PETROLEUM UNIV

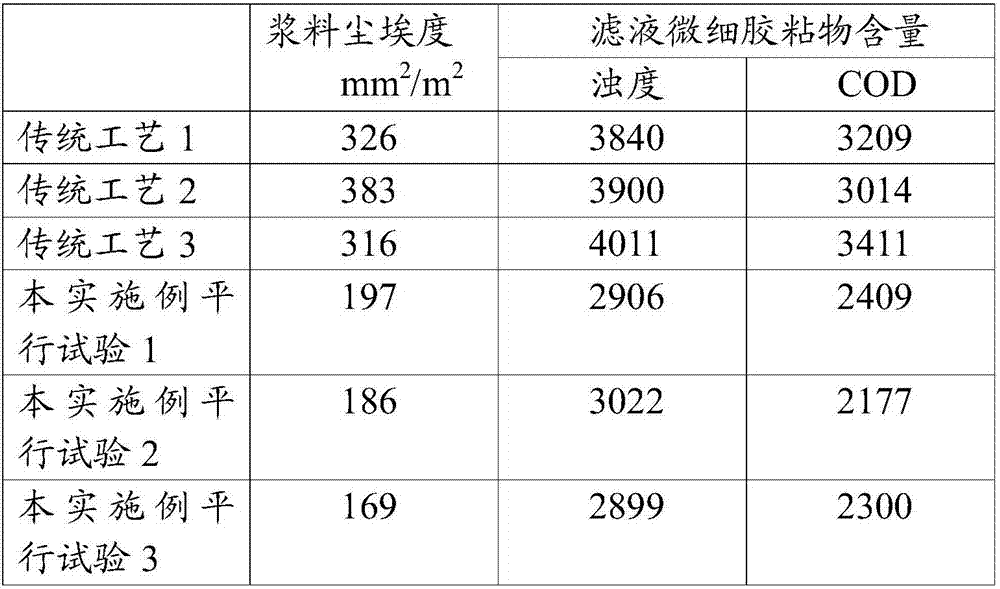

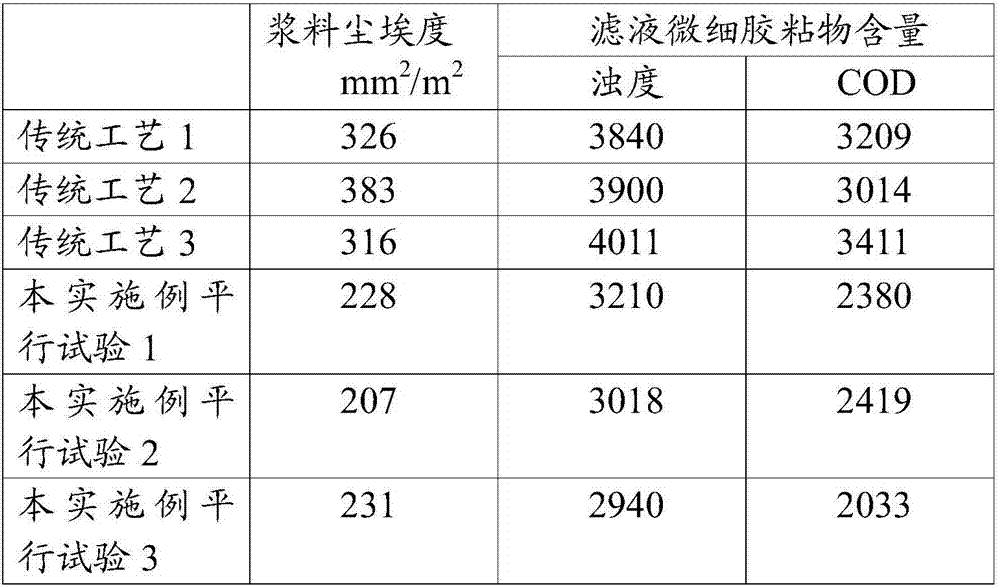

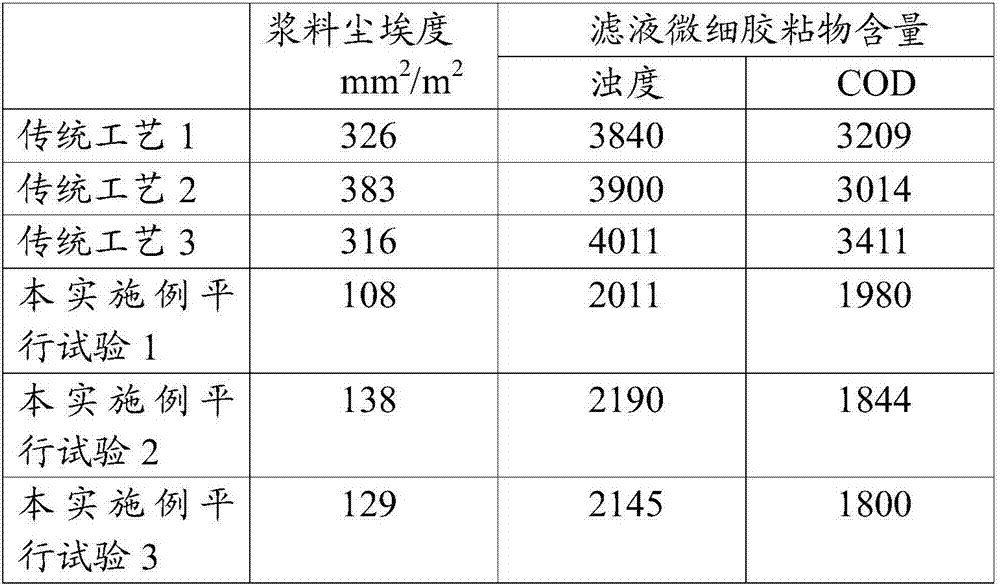

Process for removing stickies in waste paper pulping process

ActiveCN107476105AReduce contentAvoid obstaclesCellulosic pulp after-treatmentPaper recyclingSodium BentoniteSlurry

The invention relates to the fields of pulping and papermaking, and concretely relates to a process for removing stickies in a waste paper pulping process. According to the process, inorganic mineral matters such as cation modified talc powder, bentonite, attapulgite soil and calcium carbonate are added after heat dispersion and before secondary floatation in a waste paper pulping workshop section, cations of the inorganic mineral matters are used to adsorb the micro-fine stickies with negative charges, relatively large particle aggregate of the stickies is formed, a particle size requirement of floatation is achieved, the aggregate of the stickies is brought out from a liquid surface by utilizing floatation bubbles, the content of the stickeis in slurry is reduced, and the obstacle caused by the stickies in a papermaking workshop section is solved fundamentally.

Owner:SHANDONG HUATAI PAPER

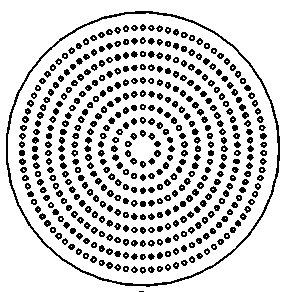

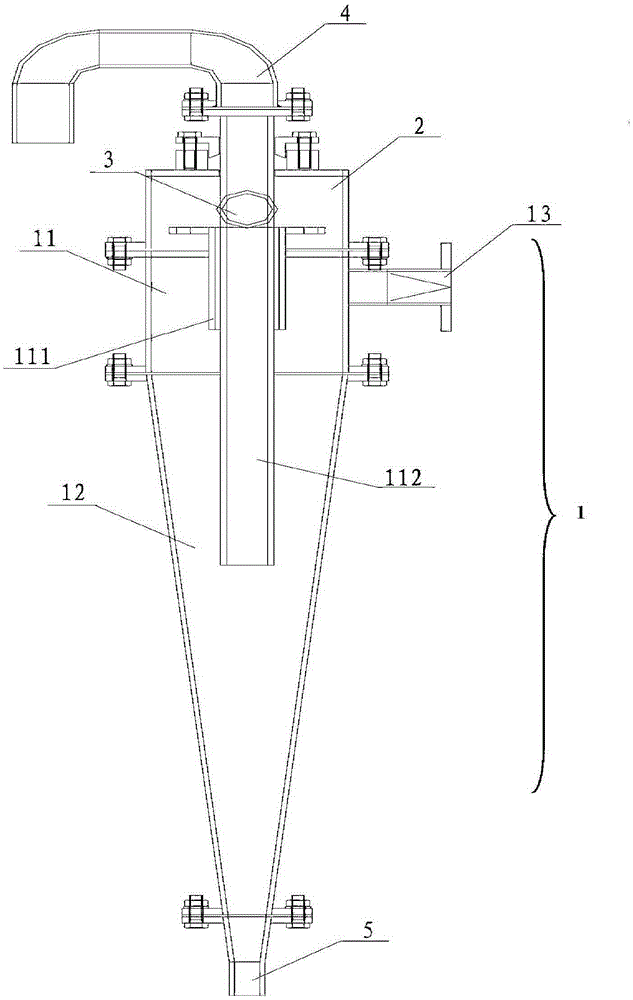

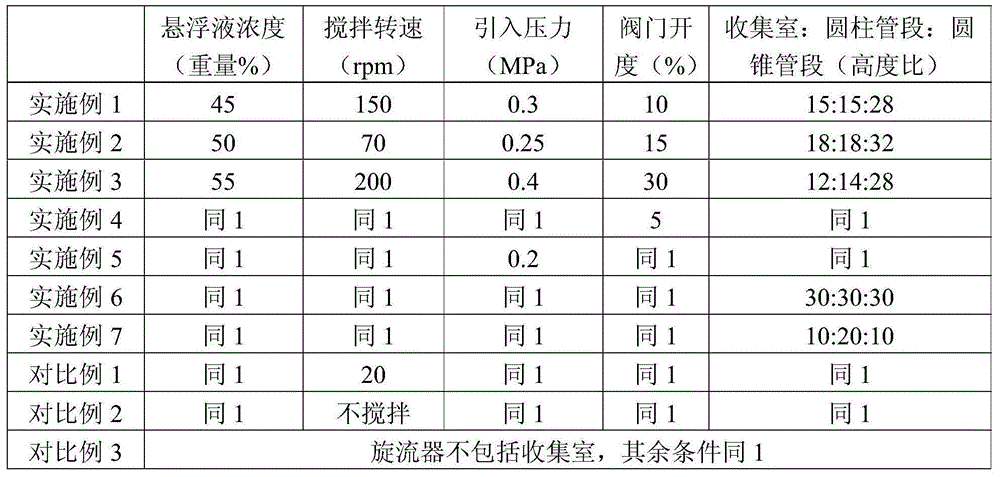

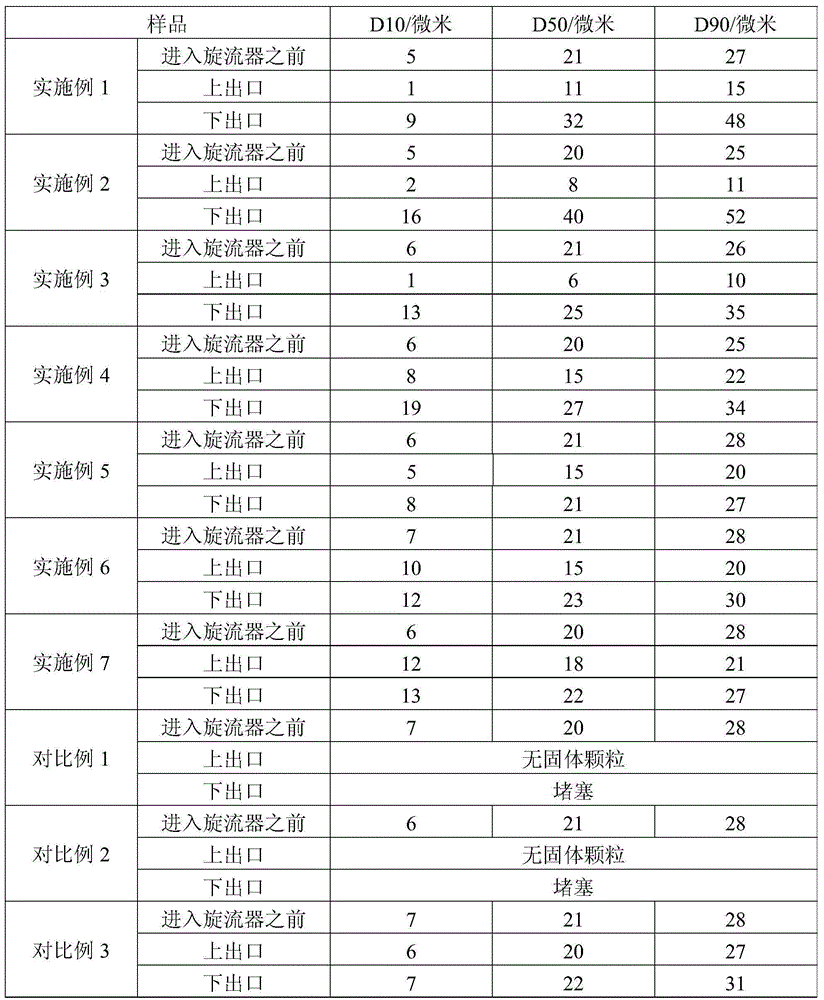

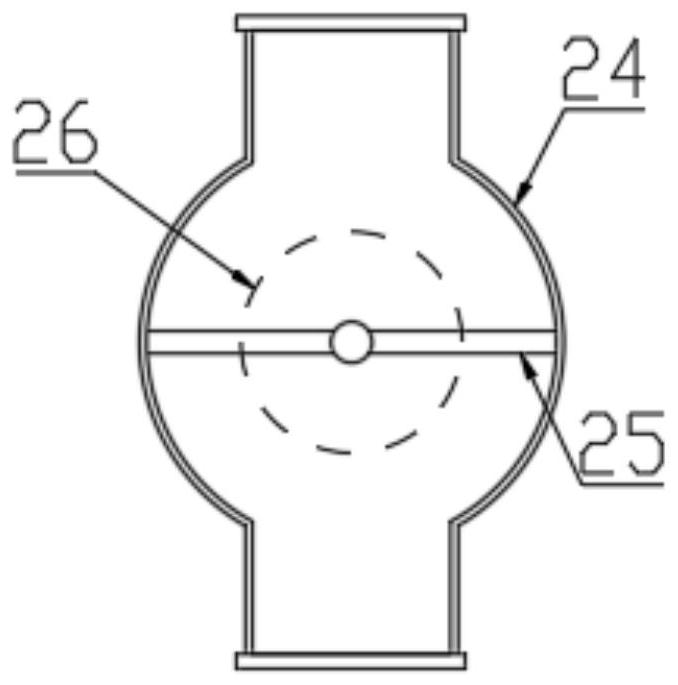

Grading method for olefin polymerization catalyst suspension liquid

The invention relates to the field of olefin polymerization catalysts and discloses a grading method for an olefin polymerization catalyst suspension liquid. Grading is conducted in a cyclone; the cyclone comprises a cyclone body and a collecting chamber; the cyclone body comprises a cylindrical pipe section and a conical pipe section from top to bottom; a first overflow pipe in airtight connection with the collecting chamber is arranged inside the cylindrical pipe section; and the cyclone body communicates with the collecting chamber through the first overflow pipe only. The method comprises steps as follows: the olefin polymerization catalyst suspension liquid is introduced into the cyclone body via a feeding port and rotates in the cyclone body; large particles are discharged via an outlet in the lower part of the conical pipe section; and small particles enter the collecting chamber through the first overflow pipe and are discharged via an outlet in the collecting chamber. The olefin polymerization catalyst suspension liquid is graded with the cyclone, the product particle sizes at the upper outlet and the lower outlet of the cyclone can be effectively controlled, and requirements of different olefin production technologies for the particle sizes of olefin polymerization catalyst particles can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dissociation agent for water wetting type oil sand slurrying

InactiveCN107267184AEasy to cleanEasy extractionLiquid hydrocarbon mixture productionMineral oilOil sands

The invention discloses a dissociation agent for water wetting type oil sand slurrying. The dissociation agent is prepared from a penetrating agent, mineral oil, an asphalt emulsifier, a stripping agent, a PH value regulator and water, wherein the penetrating agent and the mineral oil constitute a mixture A, the penetrating agent accounts for 0.020%-0.025% of the mixture A in percentage by mass and is prepared from Oep-70 and Aep-98, and a mass ratio of Oep-70 to Aep-98 is (10:13)-(1:1); the asphalt emulsifier, the stripping agent, the PH value regulator and water constitute a mixture B, the asphalt emulsifier accounts for 0.2%-0.4% of the mixture B in percentage by mass, the asphalt emulsifier is prepared from Span-80 and Tween-80, a mass ratio of Span-80 to Tween-80 is (1:12)-(1:8), the stripping agent accounts for 0.005%-0.010% of the mixture B in percentage by mass, and the PH value regulator accounts for 0.3%-0.5% of the mixture B in percentage by mass. The dissociation agent is higher in physicochemical stability, and not only can meet the requirement of follow-up thermochemical washing for grain size of water wetting type oil sand grains, but also can improve the oil-sand separation effect.

Owner:XINJIANG KELI NEW TECH DEV +1

Method for preparing fluorescence-encoded micro-beads and product thereof

InactiveCN101906184AAvoid churnAvoid inactivationFluorescence/phosphorescenceLuminescent compositionsMicrosphereHigh flux

The invention discloses a method for preparing fluorescence-encoded micro-beads, which comprises the following steps of: cleaning styrene with alkali, and cleaning with pure water; adding azodiisobutyronitrile, a fluorescent material and a stabilizer; performing polymerization; performing functionalization modification and the like. The fluorescence-encoded micro-beads comprise beads and functional groups modified on the beads. The main components of the beads comprise the fluorescent material and styrene polymer, and the fluorescent material is dispersed in the styrene polymer. The method overcomes the defects that the conventional fluorescent material is easy to lose, and the prepared micro-beads have single fluorescent color, does not meet the high-flux analysis requirement of biological samples and the like.

Owner:吕军

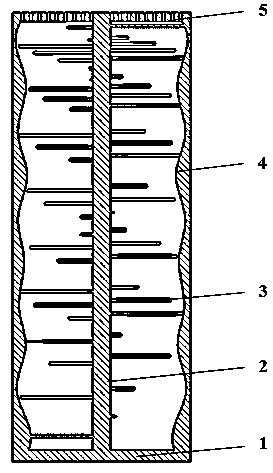

Filter bag device and dust remover

ActiveCN111389118AImprove versatilityMeet particle size requirementsDispersed particle filtrationElectrostatic separationProcess engineeringMechanical engineering

The invention discloses a filter bag device and a dust remover. The filter bag device comprises an elastic filter bag and a bag cage arranged in the elastic filter bag, wherein the bag cage can adjustthe size of filter holes of the elastic filter bag. According to the filter bag device, by adopting the elastic filter bag, the elastic filter bag can deform, and the bag cage capable of adjusting the size of the filter holes of the elastic filter bag is adopted, when the size of dust needing to be filtered is changed, the size of the filter holes of the elastic filter bag can be adjusted throughthe bag cage to meet the filtering requirement, the universality of the elastic filter bag is effectively improved, the requirements of different dust particle sizes can be met, namely the requirements of different smoke and different coal types are met, and the dust removing effect of the dust remover is improved; meanwhile, when the elastic filter bag is deformed, a dust layer on the elastic filter bag can fall off, and the service life of the elastic filter bag is prolonged; by adjusting the pore size of the filter holes of the elastic filter bag, the filtering resistance of the elastic filter bag is reduced, the energy consumption of a fan is reduced, and the service life of the elastic filter bag is prolonged.

Owner:FUJIAN LONGKING

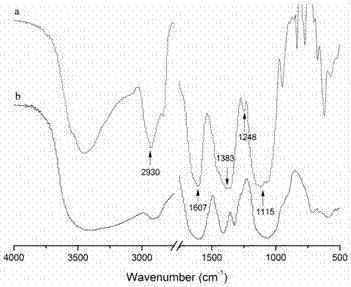

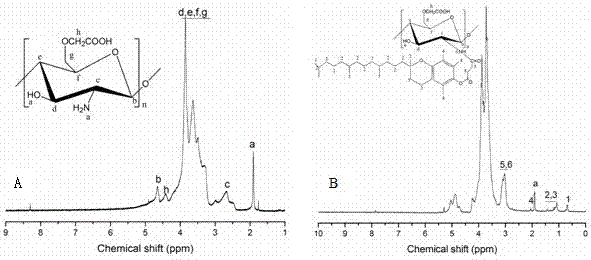

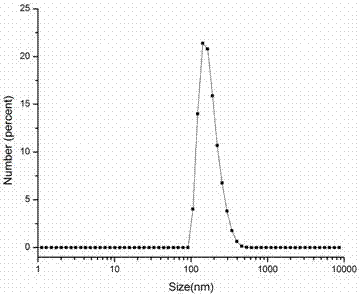

Novel carboxymethyl chitosan derivative, and preparation method and application thereof

ActiveCN107501440AEvenly dispersedMeet particle size requirementsPowder deliveryOrganic active ingredientsZeta potentialO carboxymethyl chitosan

The invention provides a novel carboxymethyl chitosan derivative and a preparation method and application thereof. The preparation method comprises the following steps: firstly synthesizing a novel material O-carboxymethyl chitosan-vitamin E succinate (O-CMCTS-VES), and grafting some of free amino groups of the O-carboxymethyl chitosan with the vitamin E succinate, wherein covalent bonds are formed between the O-carboxymethyl chitosan and the vitamin E succinate in a way of forming amide bonds and the degree of VES substitution is 3-5%. The O-CMCTS-VES is self-assembled in water to form nanoparticles, and the nanoparticles have the particle size of 100-200 nanometers, the Zeta potential of -29mV, the highest model drug doxorubicin (DOX) encapsulating rate of 74.5% and the highest drug loading capacity of 13%. The drug-loaded nanoparticles prepared by using the preparation method provided by the invention have the particle size of 100-200 nanometers, have uniform shapes and sizes and are uniformly dispersed, which indicate that the O-CMCTS-VES / DOX prepared by using the preparation method provided by the invention can effectively coat a hydrophobic drug and is a good drug carrier.

Owner:OCEAN UNIV OF CHINA

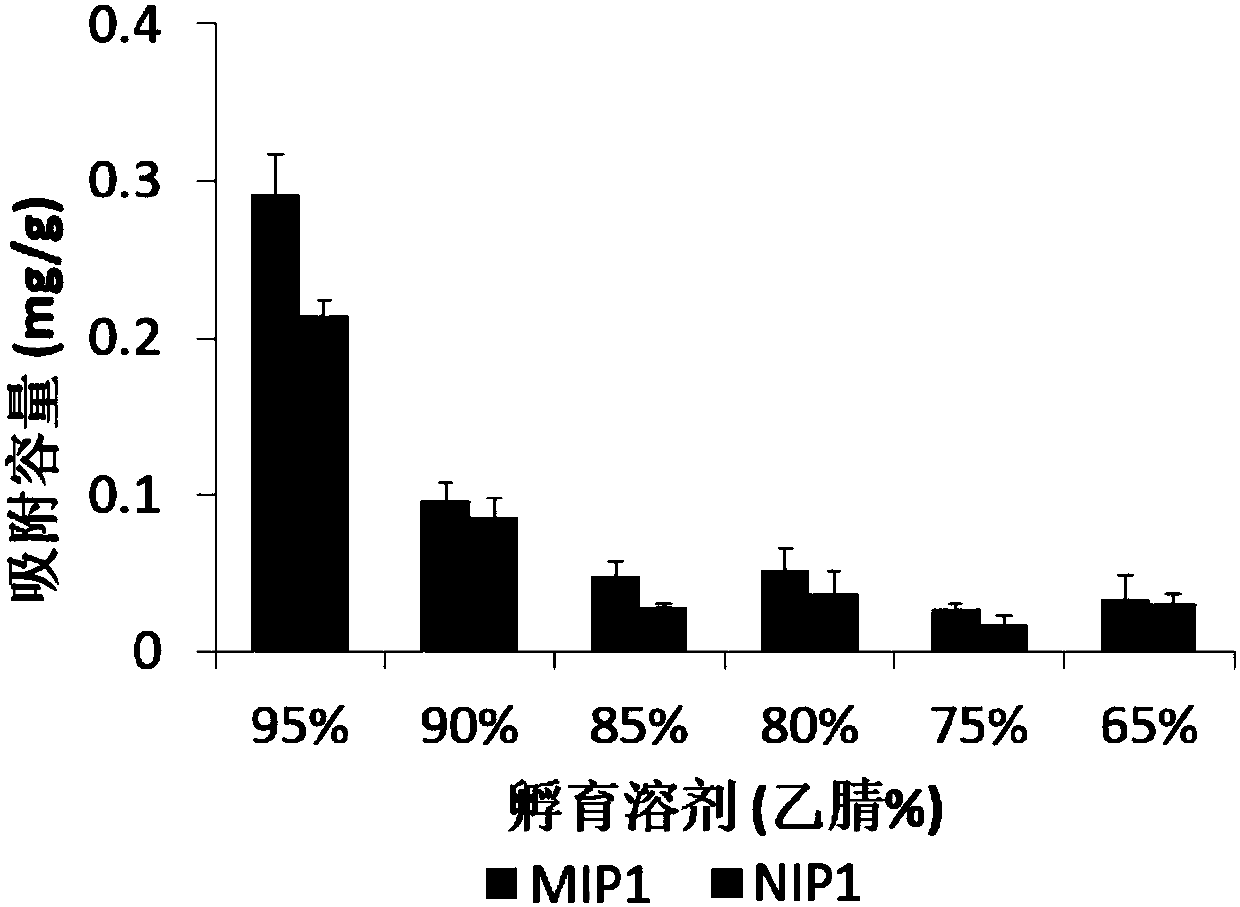

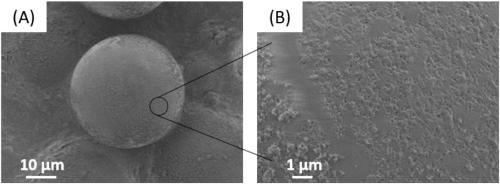

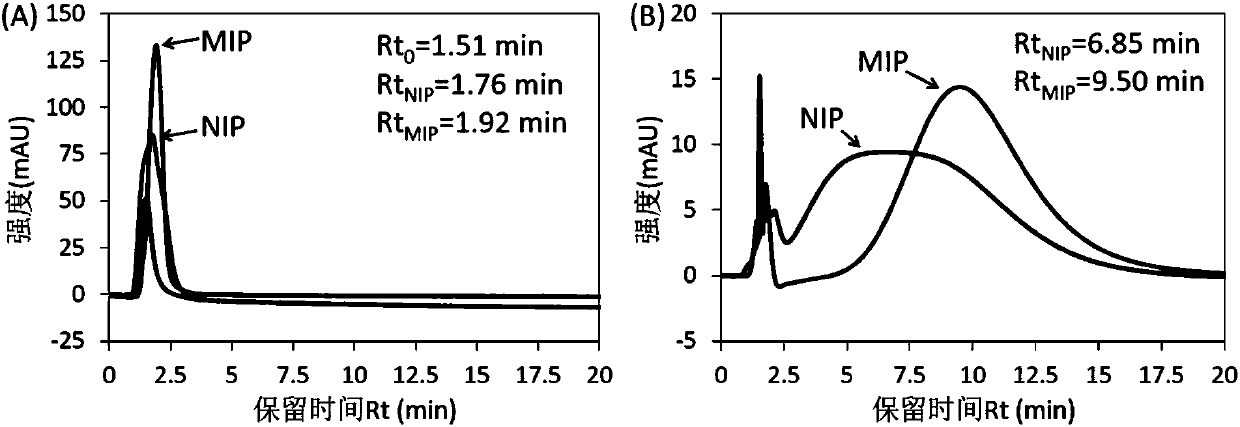

Acetylglucosamine imprinting material and applications of acetylglucosamine imprinting material in recognition of acetylglucosamine and acetylglucosamine modified peptides

ActiveCN109721759ALow priceEasy to buyOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The present invention relates to an acetylglucosamine (N-GlcNAc) imprinting material and applications of the acetylglucosamine (N-GlcNAc) imprinting material in recognition of acetylglucosamine and acetylglucosamine modified peptides, wherein acetylglucosamine as a template molecule is polymerized with a functional monomer and a cross-linking agent to obtain the imprinting material, and the imprinting material is used in the recognition of acetylglucosamine and acetylglucosamine modified peptides.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Device for producing superfine sand from waste bricks and tiles

PendingCN112756094AMeet particle size requirementsImprove crushing efficiencySolid waste managementDirt cleaningBrickStructural engineering

The invention belongs to the technical field of constructional engineering, and particularly relates to a device for producing superfine sand from waste bricks and tiles. The device for producing superfine sand from waste bricks and tiles comprises a crushing box, a feeding belt, a crushing roller, a crushing motor, a first vibrating screen, a second vibrating screen, a coarse material guiding and conveying belt, a material returning belt, a scraper type lifting belt I and a grinding machine. The two-stage crushing structure is arranged to circularly crush waste bricks and tiles, the first-stage crushing adopts a double-roller mode to mainly crush large materials into small materials, and the second-stage crushing adopts a grinding mode to grind the small materials, so that the crushing efficiency is high, the crushed materials can basically meet the particle size requirement of superfine sand, and the crushing effect is good.

Owner:北京惠地智能技术研究院有限公司 +1

Method for preparing micro-sized monodisperse polyurea microsphere in static condition

Owner:UNIV OF JINAN

Method for preparing micro-sized monodisperse polyuria microspheres

The invention relates to a method for preparing micro-sized monodisperse polyuria microspheres. The method comprises the following steps of: adding a mixed solvent of water and acetone and a diisocyanate compound monomer to a reaction flask at room temperature, wherein the weight ratio of the water to the acetone is 2 / 8-6 / 4, and the diisocyanate compound monomer accounts for 0.5-10.0 percent of the total weight of a mixed system; hermetically shaking up; putting in a constant-temperature water-bath vibrator; performing a polymerization reaction under the conditions that the vibration frequency is 70-150 times per minute and the temperature is 20-80 DEG C; and performing centrifugal separation and drying on a product after polymerization is ended to obtain the micro-sized monodisperse polyuria microspheres. According to the method for preparing the micro-sized monodisperse polyuria microspheres, precipitation polymerization is performed under the vibration condition by using only one monomer, thereby, the process is simple, the raw materials are single, the consumed reaction time is short, the monomer can be completely converted, and the yield of the microspheres can reach at least 86 percent. All the microspheres are clean in surface and contain a large amount of amido and can be used for the field of protein adsorption and separation, enzyme immobilization and chromatographic analysis.

Owner:UNIV OF JINAN

A method for preparing functional monodisperse polyurea microspheres with high yield

The invention relates to a high-yield preparation method of functional monodisperse polyurea microspheres. The method adopts a precipitation polymerization process and comprises the following step: with water and acetonitrile as solvents and isophorone diisocyanate as monomers, reacting isocyanate with the water to prepare the monodisperse polyurea microspheres with rich amine groups on the surfaces. According to the method, single raw material is used, the reaction time is short, the monomers are completely converted, and the monomer content and the microsphere yield during preparation of the monodisperse microspheres are remarkably increased; the microsphere preparation process can be carried out in a complete standing condition, the functional polyurea microspheres can be obtained in one step without any surface modification, the process is simple, and the obtained microspheres can be used in the fields of enzyme immobilization, chemical catalysis, chromatographic analysis and the like.

Owner:UNIV OF JINAN

Extruding and pelletizing device for ceramic powder

InactiveCN108673730AEfficient recyclingMeet particle size requirementsClay processing apparatusHardnessMechanical engineering

The invention discloses an extruding and pelletizing device for ceramic powder. The device comprises an extruding mechanism and a crushing mechanism, wherein the extruding mechanism comprises an extruding bin, and an extruding roller set which is arranged in the extruding bin; the extruding roller set comprises two extruding rollers which are arranged in parallel and oppositely rotated; fine powder conveyed to the surfaces of the two extruding rollers is extruded through the extruding bin to form blocky materials with proper hardness; the crushing mechanism comprises a crushing box, an arc-shaped friction sieving net which is arranged at the bottom part of the crushing box, and at least one crushing assembly which is arranged in the crushing box; the blocky materials conveyed into the crushing box can be collided and crushed through blades and a crushing hammer by circumferentially rotating along with a crushing shaft; in addition, the particles formed by colliding and crushing throughthe crushing hammer are extruded into a frictional clearance which is reserved between the crushing chamber and the arc-shaped frictional sieving net, and thus the particles formed by colliding and crushing can be pelletized by friction through the arc-shaped frictional sieving net.

Owner:佛山市铂灵科技有限公司 +1

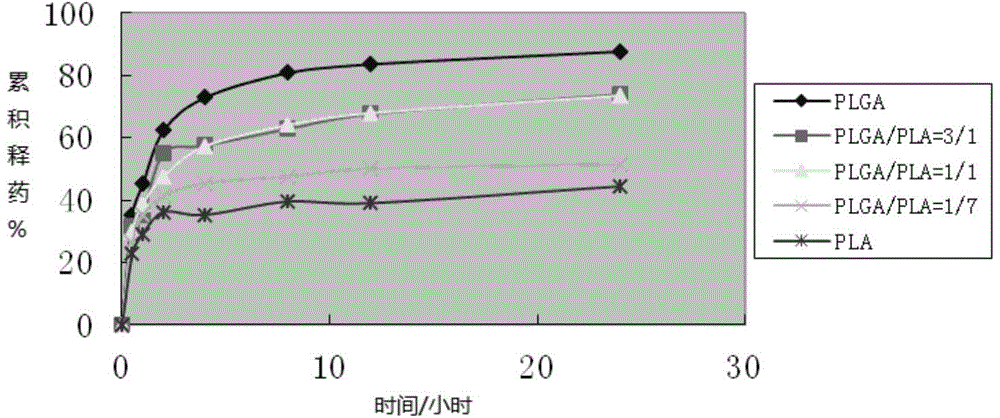

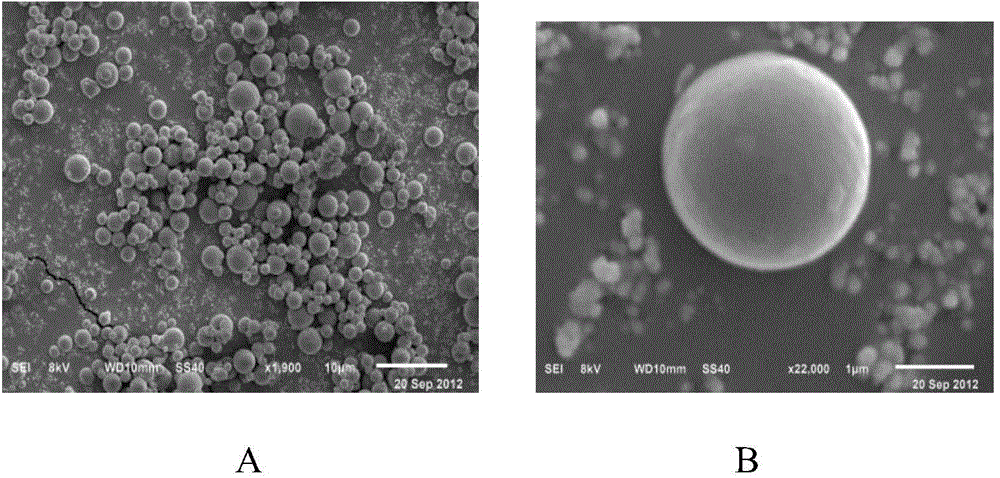

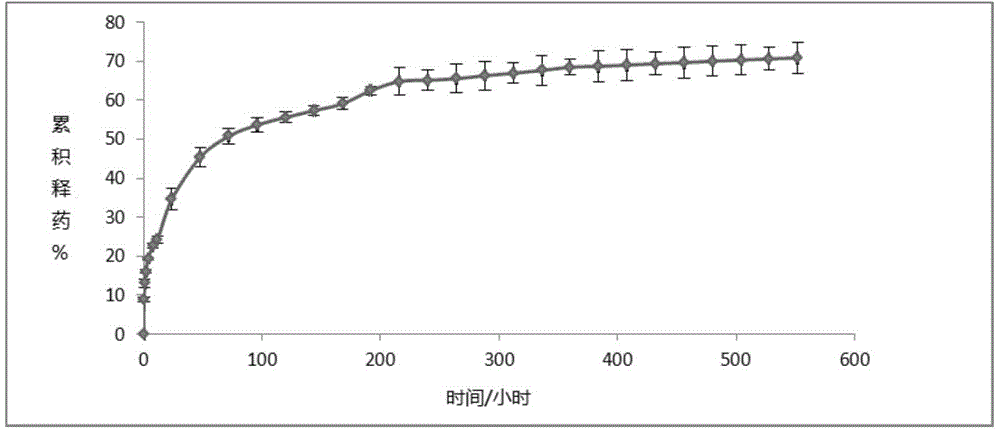

Preparation method of isoniazid slow release microspheres

InactiveCN104367554AHigh encapsulation efficiencyReduced burstAntibacterial agentsOrganic active ingredientsDrugChemistry

The invention provides a preparation method of isoniazid slow release microspheres. The method comprises the following steps: 1, uniformly mixing an isoniazid solid component (S) with an oil phase (O) and an organic solvent to form a solid-in-oil (S / O) suspension; and 2, carrying out spray drying on the suspension prepared in step 1 to prepare the slow release microspheres. The method adopting a solid-in-oil spray drying technology to prepare the isoniazid slow release microspheres overcomes the disadvantages of large particle size, burst release of drugs, low entrapment rate, complex preparation method and long preparation time of microspheres in the prior art. The method has the advantages of simple and controllable operation, suitable particle size, high entrapment rate, good slow release effect and no obvious burst release.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

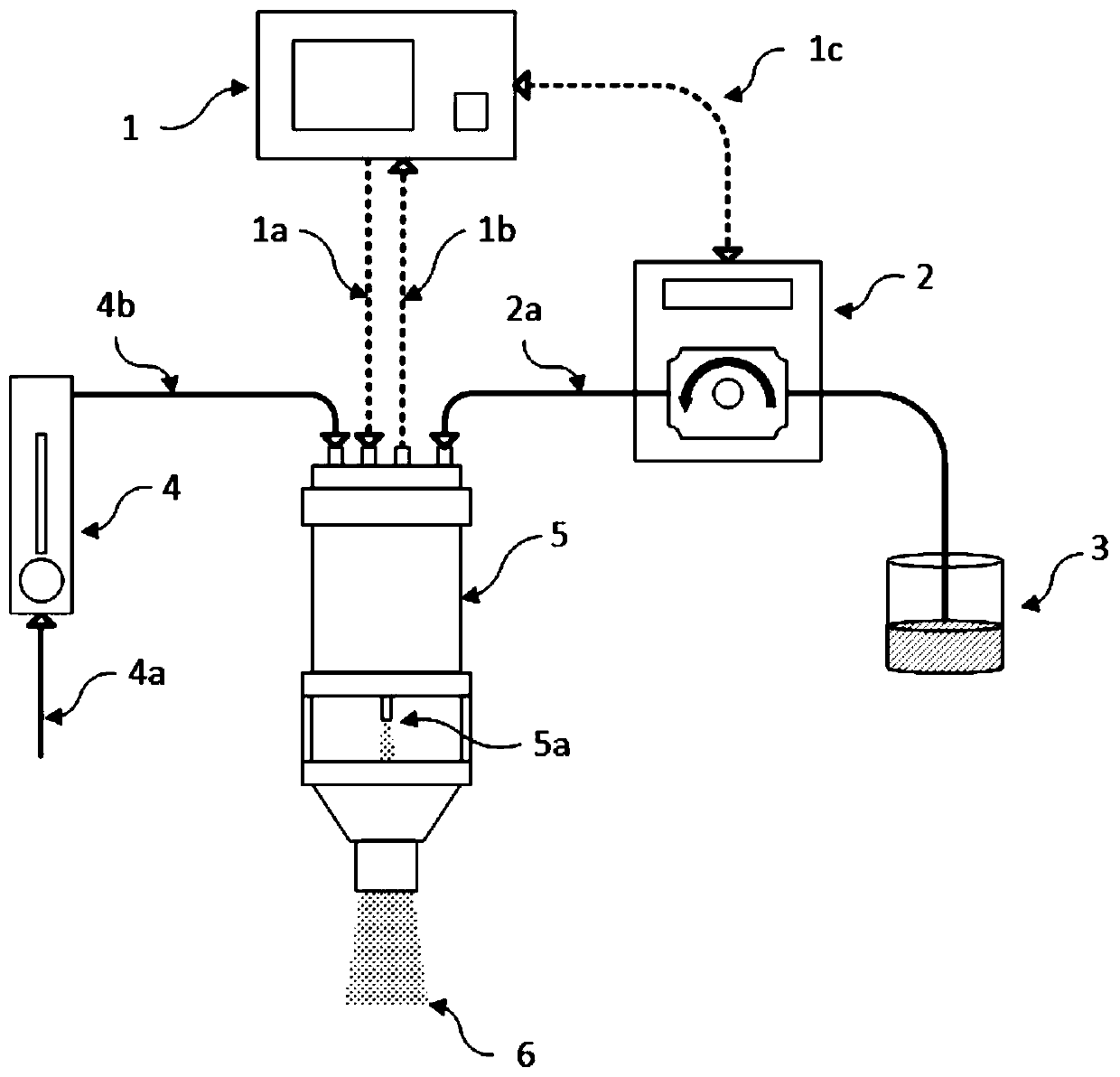

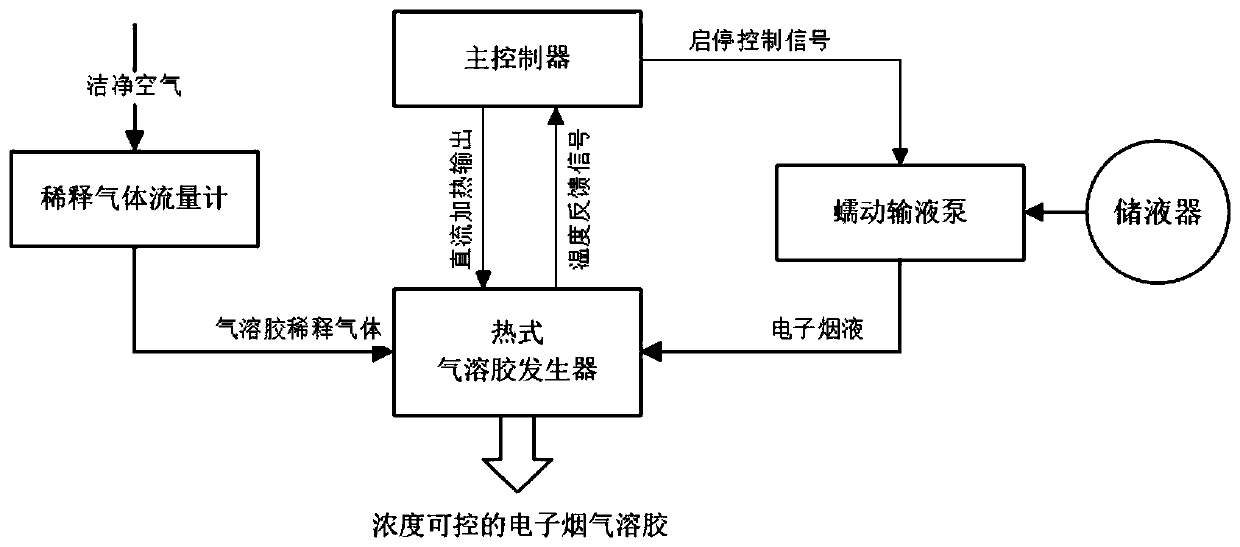

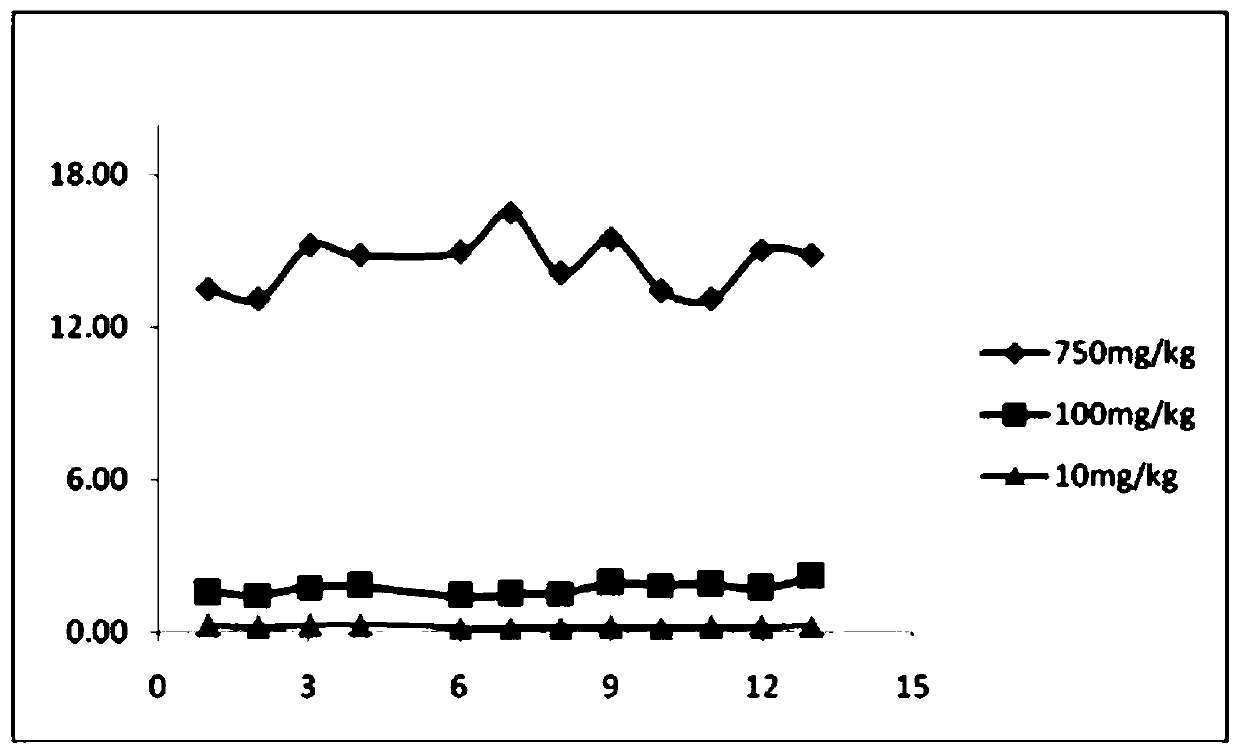

Aerosol supply and regulation system and application thereof in evaluation of electronic cigarette liquid inhalation exposure safety

PendingCN111077296AStable concentrationUniform concentrationBiological testingThermodynamicsInhalation exposure

The invention discloses an aerosol supply and regulation system. The aerosol supply and regulation system comprises a peristaltic infusion pump, a thermal aerosol generator, a main controller and a diluent gas flowmeter. A gas inlet of the thermal aerosol generator is connected with the diluent gas flowmeter through an aerosol diluent gas pipeline, and the amount of diluent gas entering the thermal aerosol generator can be adjusted. A liquid inlet of the thermal aerosol generator is connected with the peristaltic infusion pump through an electronic cigarette liquid conveying pipe. The main controller is electrically connected with the peristaltic infusion pump and a heating module in the thermal aerosol generator and controls starting, stopping and the transmission rate of the peristalticinfusion pump and the heating temperature of the heating module. The invention also discloses an application of the system in evaluation of electronic cigarette liquid inhalation exposure safety. Theaerosol supply and regulation system provided by the invention can meet the requirements of electronic cigarette liquid inhalation exposure safety evaluation, provides aerosol required by safety evaluation, is low in cost and stable and reliable in performance, and can be popularized on a large scale.

Owner:SHANGHAI INST FOR FOOD & DRUG CONTROL +1

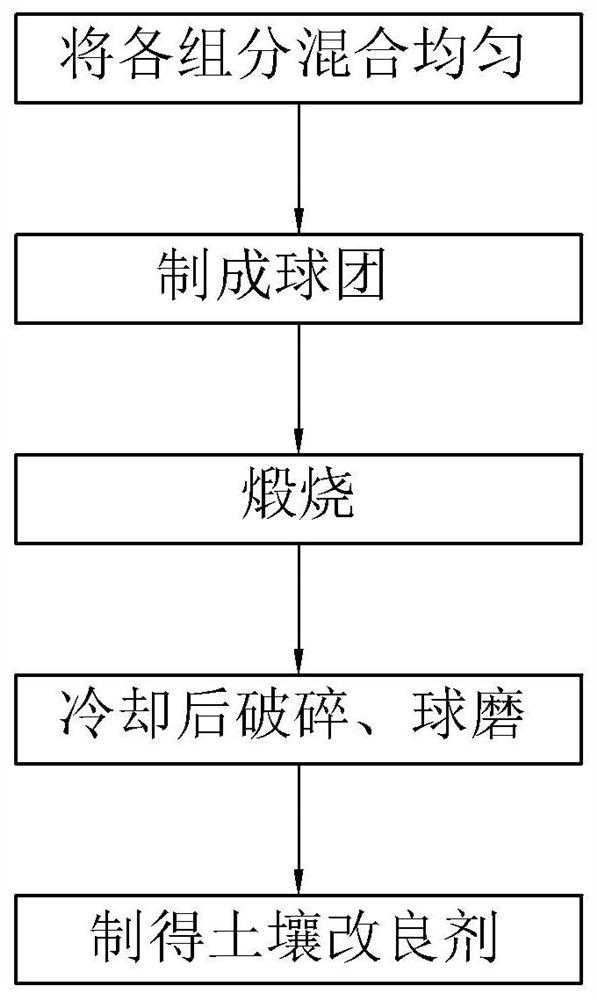

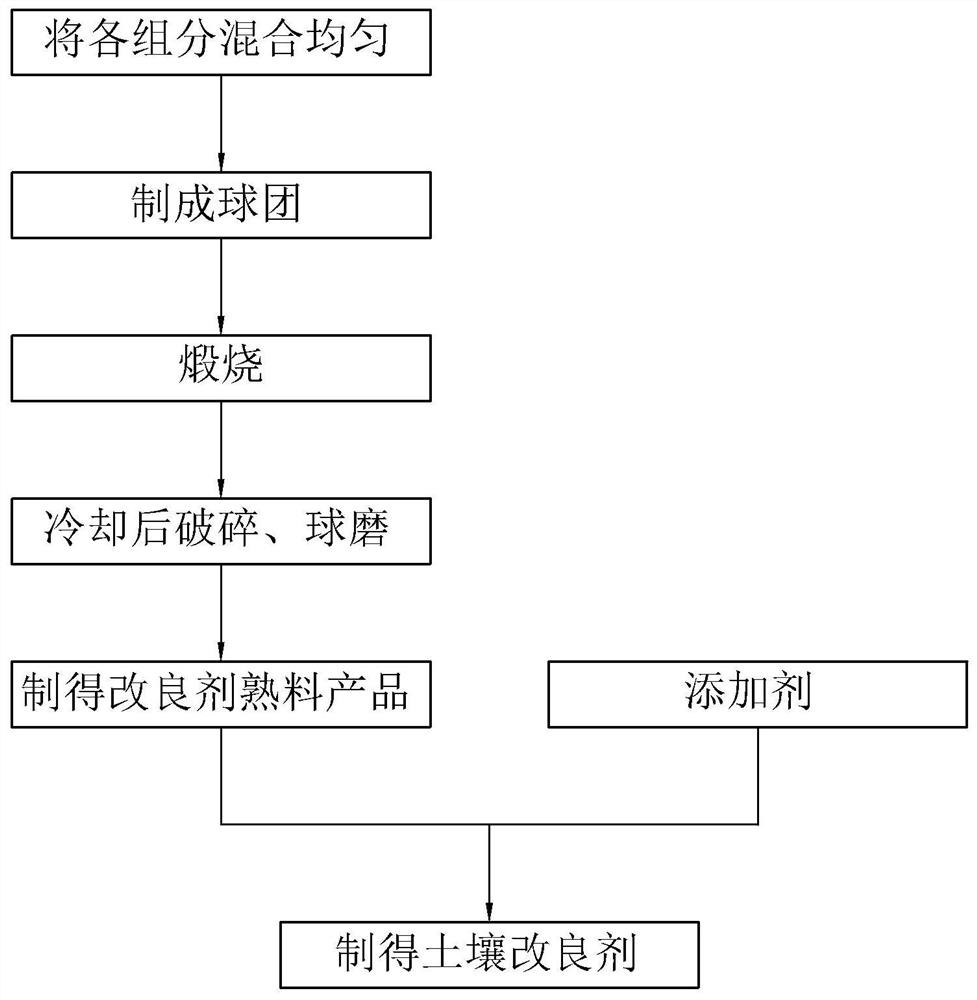

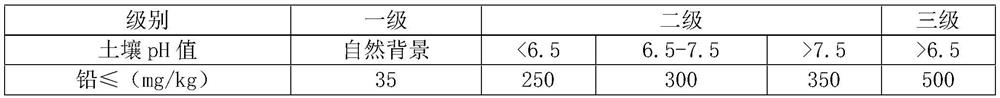

Soil conditioner and method for its preparation and use

ActiveCN110079332BReduced activityReduce the effect of conditioningCalcareous fertilisersAgriculture tools and machinesEngineeringDolomite

The invention relates to the technical field of soil restoration, in particular to a soil conditioner and its preparation method and application method. Soil conditioner contains the following components by weight percentage: copper tailings 40‑60%, fluorite tailings or limestone 20‑40%, talc or serpentine or dolomite 6‑20%, pellet curing agent 2 ‑5%, the sum of which is 100% by weight; the copper tailings contain quartz, alunite and dickite. The preparation method comprises the following steps: step 1, weighing and mixing each component; step 2, making the mixture obtained in step 1 into pellets; step 3, calcining the pellets at a temperature above 1000°C for 1.5 more than one hour; step 4, cooling and activating the pellets, and ball milling to obtain a soil conditioner. Contains non-ferrous metal minerals and non-metallic minerals, various large, medium and trace elements necessary for the growth of crops, fruit trees and seedlings, basically there is no need to add other large, medium and trace elements.

Owner:SHENZHEN MPD HITECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com