Process for removing stickies in waste paper pulping process

A technology of pulping process and stickies, which is applied in the field of papermaking, can solve the problems of dust spots, affecting production costs, high cost of biological enzyme treatment, etc., and achieve the effect of reducing the content and solving the obstacles of stickies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

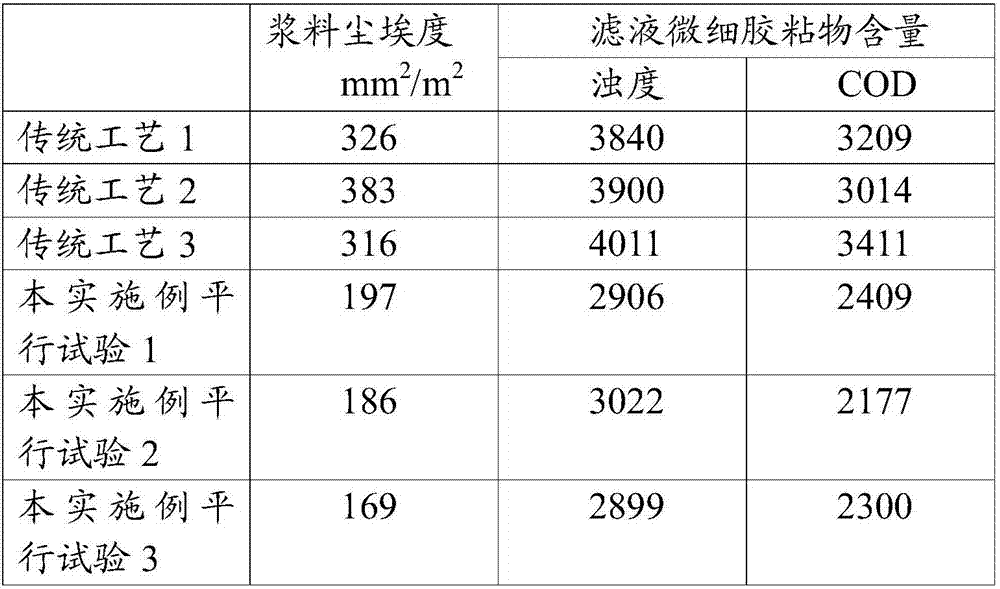

Embodiment 1

[0024] A process for removing stickies in waste paper pulping process, the specific process is as follows:

[0025] Pre-treatment process: the waste paper enters the drum to disintegrate, passes through the coarse screen, enters the unloading tower, and then enters the heat dispersion after passing through the flotation tank; at the same time, the pH value is controlled at 7.5-8.5;

[0026] Heat Dispersion:

[0027] The thermal dispersion temperature is 85°C, the power is 2000-2200KW; the passing rate of the slurry during thermal dispersion is 0.6 tons / min;

[0028] Cationic modified calcium carbonate is dispersed into a suspension with a solid content of 40% in warm water at 40°C;

[0029] Add the prepared cation-modified calcium carbonate suspension in the proportion of 15% of the absolute dry pulp to the forward slurry pump of the second-stage flotation,

[0030] The air intake of the flotation tank is controlled at 15m 3 / s, the overflow liquid level is 24%, and after 0...

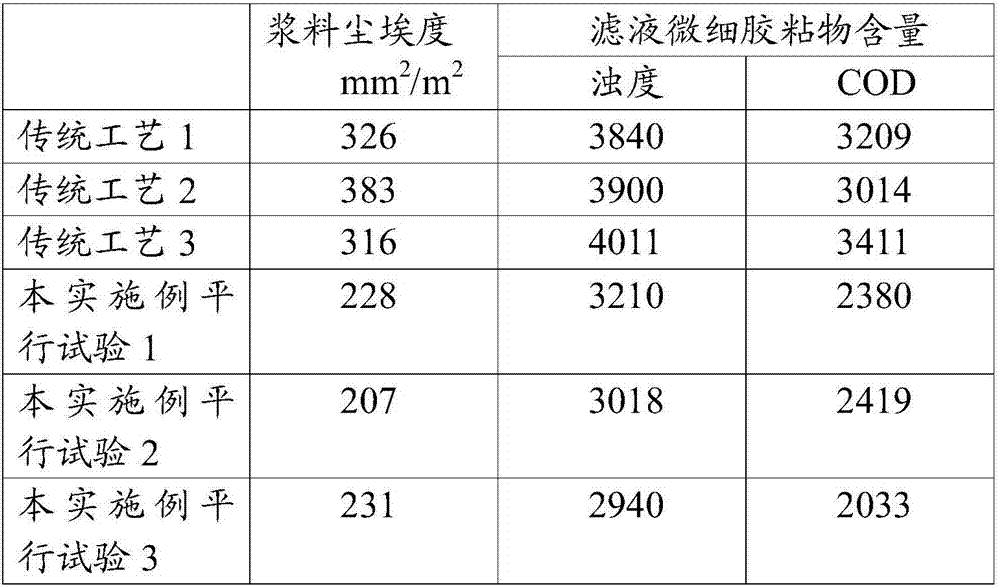

Embodiment 2

[0036] A process for removing stickies in waste paper pulping process, the specific process is as follows:

[0037] Pre-treatment process: the waste paper enters the drum to disintegrate, passes through the coarse screen, enters the unloading tower, and then enters the heat dispersion after passing through the flotation tank; at the same time, the pH value is controlled at 7.5-8.5;

[0038] Heat Dispersion:

[0039] The thermal dispersion temperature is 82-86°C, the power is 1800-2000KW; the passing rate of the slurry during thermal dispersion is 0.7 tons / min;

[0040] Cationic modified calcium carbonate is dispersed into a suspension with a solid content of 40% in warm water at 45-50°C;

[0041] Add the prepared cation-modified calcium carbonate suspension to the slurry pump in the second-stage flotation at a ratio of 10% of the dry pulp;

[0042] The air intake of the flotation tank is controlled at 16m 3 / s, the overflow level is 20%, and after 0.5-1 hour of circular flo...

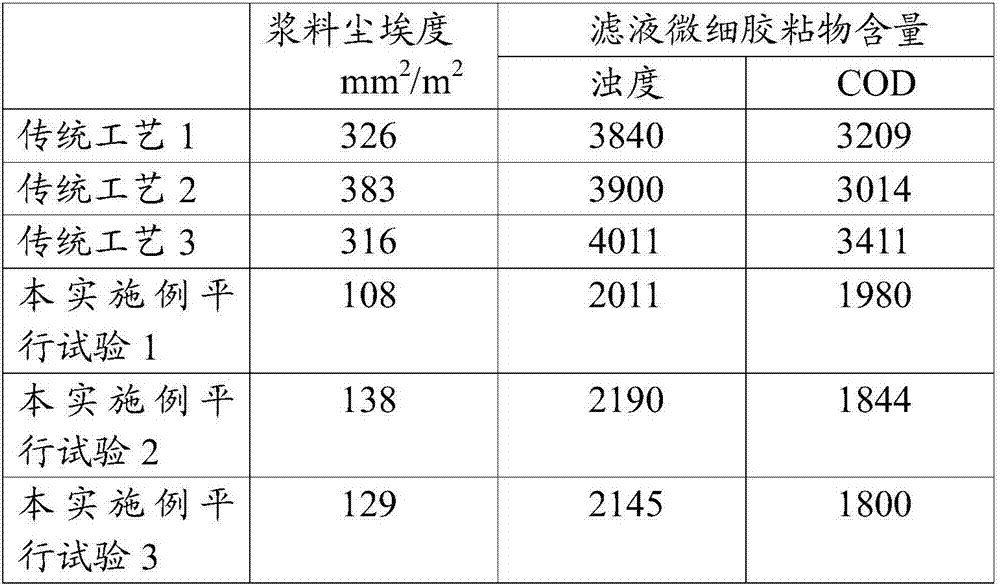

Embodiment 3

[0047] A process for removing stickies in waste paper pulping process, the specific process is as follows:

[0048] Pre-treatment process: the waste paper enters the drum to disintegrate, passes through the coarse screen, enters the unloading tower, and then enters the heat dispersion after passing through the flotation tank; at the same time, the pH value is controlled at 7.5-8.5;

[0049] Heat Dispersion:

[0050]The thermal dispersion temperature is 85-88°C, the power is 1800-2100KW; the passing rate of the slurry during thermal dispersion is 0.8 tons / min;

[0051] Cationic modified attapulgite is dispersed into a suspension with a solid content of 20% in warm water at 45-50°C;

[0052] Add the prepared cation-modified attapulgite suspension to the slurry pump for the second-stage flotation at a rate of 5% of the dry slurry;

[0053] The air intake of the flotation tank is controlled at 13m 3 / s, the overflow liquid level is 22%, and after 0.5-1 hour of circular flotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com