Patents

Literature

308 results about "Stickies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

When recycling post-consumer paper, stickies are tacky substances contained in the paper pulp and process water systems of paper machines. Stickies have the potential to contaminate the components either within or around the equipment necessary in the Stages of Manufacturing that a Paper Mill follows in its Developed Process, but would have otherwise excluded it in its routine cleaning and maintenance procedures. Contaminations of paper that are classified as tacky are also called stickies. The main sources for stickies are recycled paper, waxes, and soft adhesives.

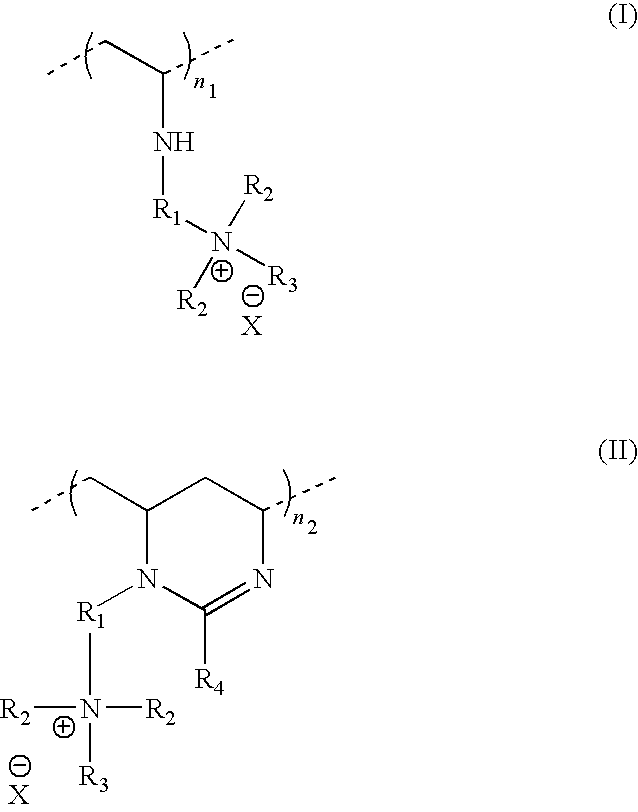

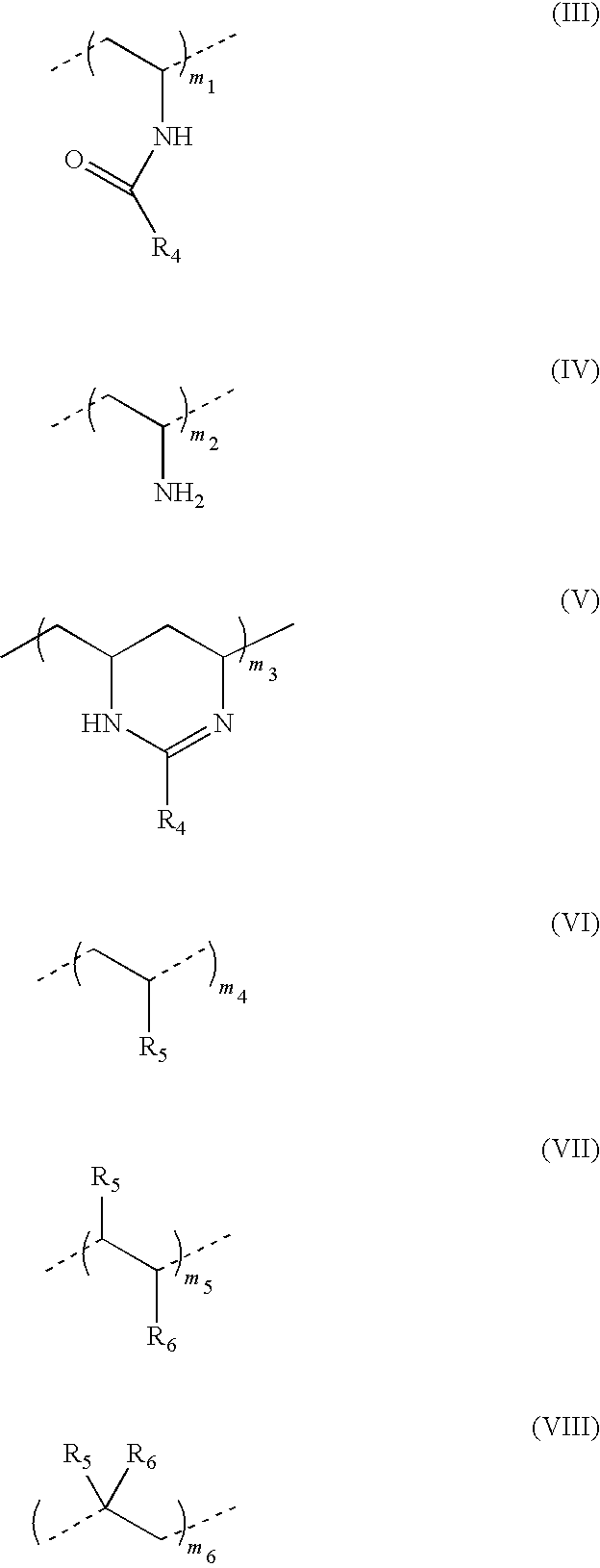

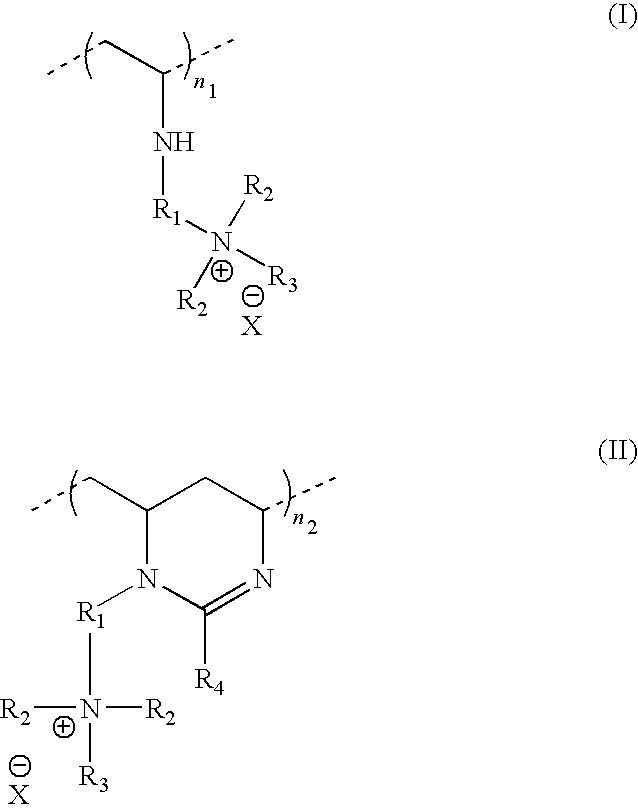

Quaternary Vinylamine-Containing Polymers as Additives in Papermaking

ActiveUS20100193148A1Improve propertiesHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperPolymerPolymer science

Vinylamine-containing polymers are disclosed where the amine groups are substituted with cationic functional groups. Processes for preparing such polymers, as well as compositions comprising such polymers are also disclosed. Among other applications, these polymers can be used in papermaking applications as dry strength additives, wet strength additives, retention aids, drainage aids, and pitch and stickies control agents.

Owner:SOLENIS TECH CAYMAN

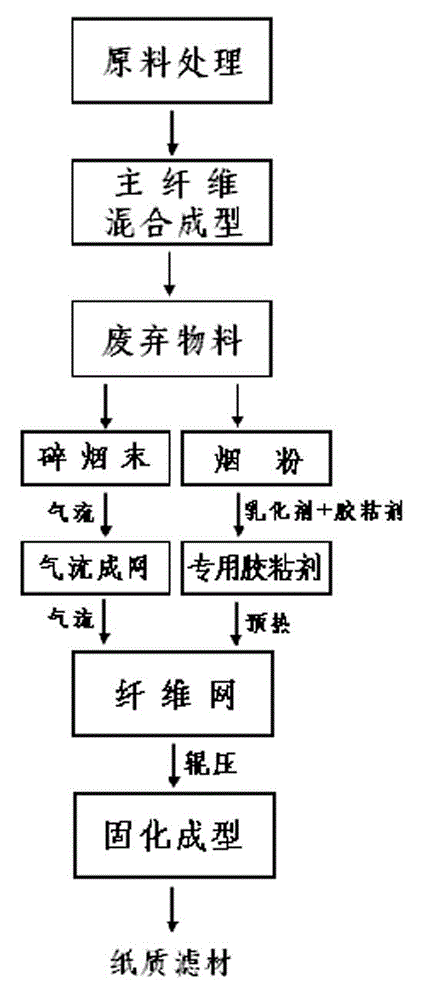

Paper cigarette filter rod filter media and processing method thereof

ActiveCN102747647AImprove sensory qualityEvenly distributedTobacco smoke filtersTextiles and paperFiberFilter media

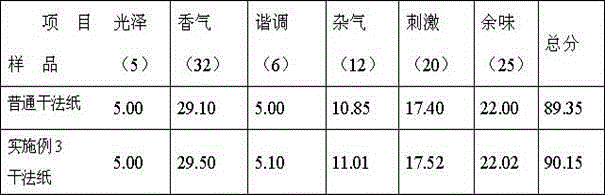

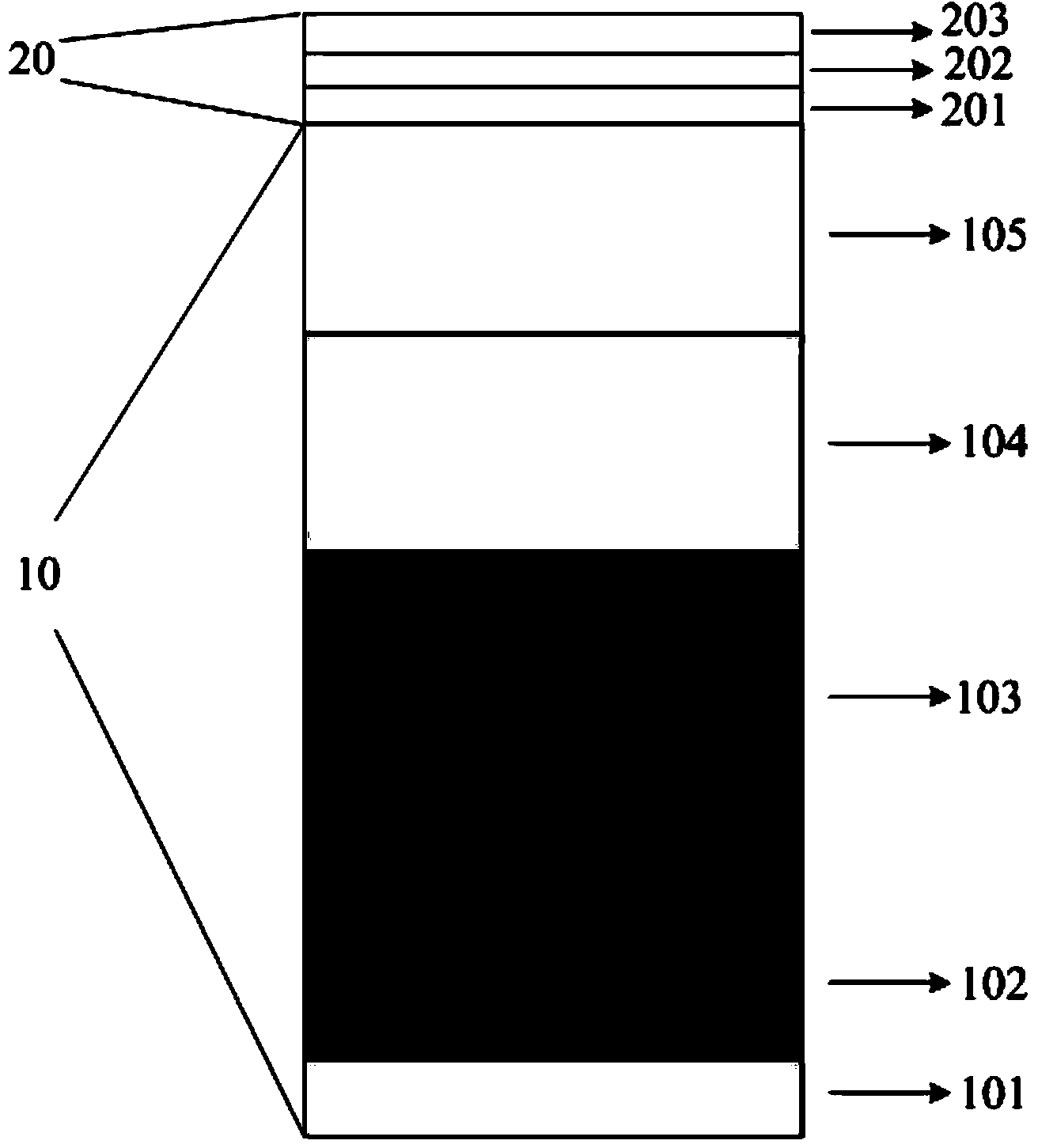

The present invention discloses a paper cigarette filter rod filter media and a processing method thereof, wherein the paper filter media is obtained through performing a dry process on the following components: 40-74% of natural cigarette fiber, 4-40% of bast fiber, 1-12% of natural tobacco waste raw material, and 4-20% of adhesive. The method comprises the following steps: raw material processing, main fiber mixing shaping, waste material adding and prepared paper shaping process. After the natural tobacco fiber is mixed with the bast fiber, discongestion is performed. After sufficient dispersion, the mixed material is conveyed to a shaping section through a blower for being laid on a net and shaped. A fluffy and uniform fiber net is formed on a shaping net belt. The cigarette filter media paper is obtained through adhesive applying, preheating, roller pressing, solidifying and shaping. As the cigarette fiber is used as the main fiber raw material, the paper cigarette filter rod filter media according to the invention has reduced foreign gas of wood and settles a problem that the fragrance quality is reduced by the foreign gas of wood in the prior-art paper filter rod. The natural tobacco waste raw material is added in the paper shaping process. Not only is whole aesthetic quality of the cigarette improved, but also the tobacco raw material is uniformly distributed in the dry process paper and does not easily drop off. The quality of the filter rod is more stable.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Low glue consumption method for making medium density fiberboard

InactiveCN102514071AGuaranteed mechanical propertiesReduce the amount of sizingWood working apparatusFlat articlesFiberFiberboard

The invention relates to a low glue consumption method for making a medium density fiberboard, which comprises the following steps of: material preparation, i.e. processing the raw materials of small dimension wood, brush wood and the like into wood chips by adopting a drum chipper; fiber preparation, i.e. sending qualified wood chips to a wood chip cooking pot through a belt conveyor, introducing papermaking waste liquid into a boiler to carry out cooking softening treatment after filtering the papermaking waste liquid, sending the wood chips which are cooked and preheated into a thermofiner to carry out mechanical separation through a feeding screw, and filling molten wax before the wood chips enter a grinding chamber body of the thermofiner, so that after the wood chips are separated into the fibers, the wax is uniformly distributed on the surfaces of the fibers; sizing and drying of the fibers, wherein a production process of firstly sizing and then drying is adopted; pavement and formation of a board blank; hot-press forming, i.e. sending the single board blank into a hot press to carry out hot pressing through a loader, so that under the combined action of heat and pressure, moisture in the board blank is gasified and evaporated, the density of the board blank is improved, glue is cured and a waterproof agent is redistributed; and post-processing, i.e. finally, sending the obtained product into a sanding machine to carry out surface processing. The low glue consumption method for making the medium density fiberboard is simple and convenient.

Owner:广西新凯骅实业集团股份有限公司

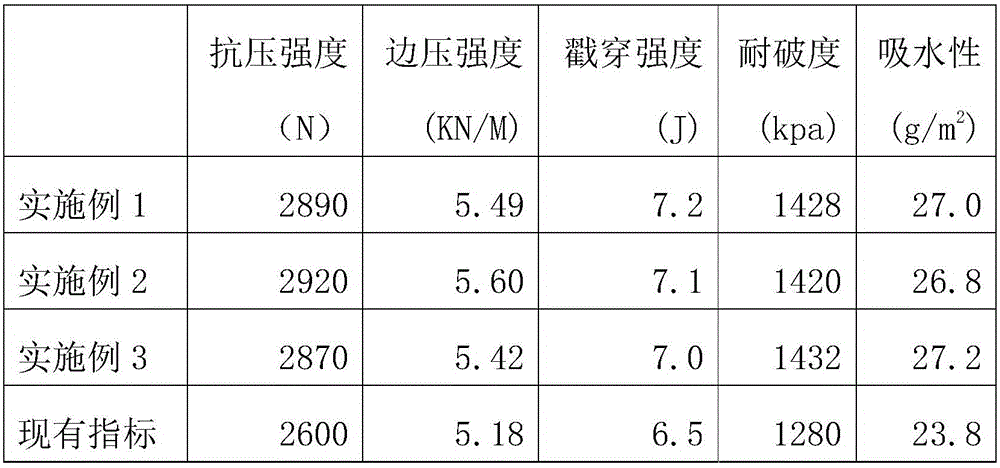

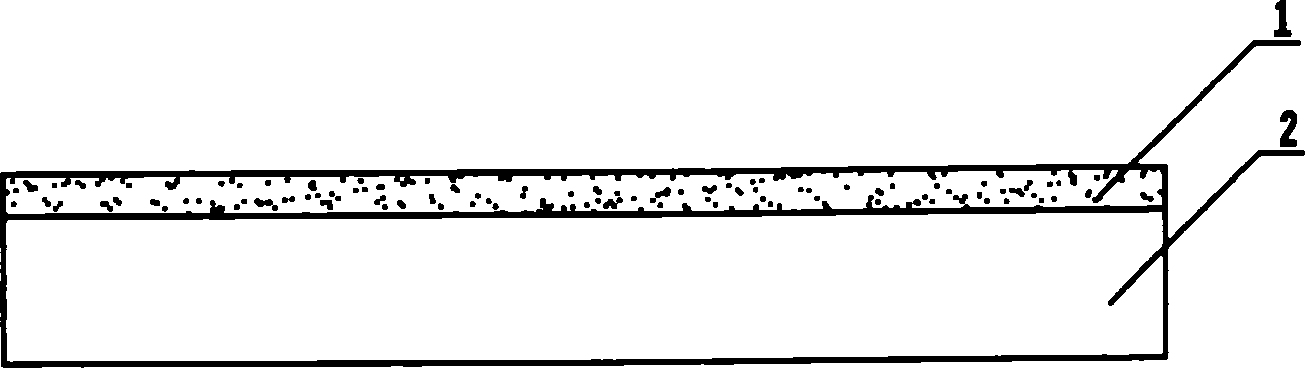

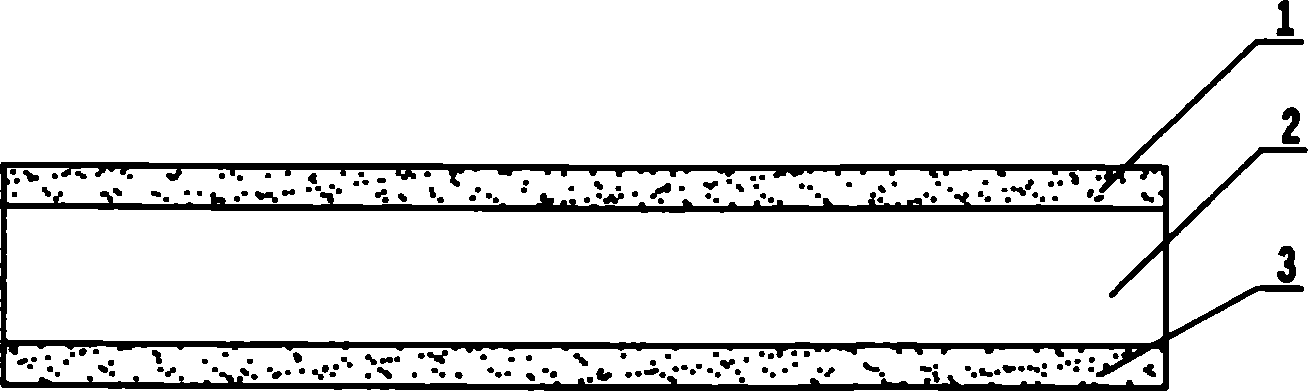

Low-quantification and high-strength coating white board paper and preparation process thereof

InactiveCN104389235AGuaranteed low quantitative high strengthPaper banner uniformCoatings with pigmentsCalendersSizingCalcium carbonate

Embodiments of the present invention disclose low-quantification and high-strength coating white board paper and a preparation process thereof. The low-quantification and high-strength coating white board paper comprises raw paper and a surface coating layer, wherein the surface coating layer further comprises a pre-coating, a middle coating and a surface coating, the coating materials of the pre-coating and the middle coating comprise 70-90% of calcium carbonate, 10-30% of kaolin, 0.1-0.3% of a dispersant, 8-12% of an adhesive, 0.3-0.7% of a water resistant agent, and 0-0.5% of a lubricant, and the coating materials of the surface coating comprise 50-70% of calcium carbonate, 20-50% of kaolin, 0-10% of a plastic pigment, 0.1-0.3% of a dispersant, 10-14% of an adhesive, 0.4-1.0% of a water resistant agent, and 0.4-1.0% of a lubricant. According to the present invention, with the optimized design of the pulps in each layer of the coating white board paper, the core pulp ratio is preferably selected, the coating material formula and the filler adding process are improved, the reliable film transfer type surface sizing is adopted, and the low-quantification and the high-strength of the paper board are ensured.

Owner:浙江光明纸业有限公司

Manufacturing method for environmental-friendly fire-retardant fiber board

InactiveCN101879739ASolve pollutionSolve problems that endanger human healthWood working apparatusFlat articlesWaxWood waste

The invention relates to an environmental-friendly fire-retardant fiber board and a manufacturing method thereof. In the technical scheme of the invention, forest residues and wood wastes are used as main raw materials to output with wood fiber, filling materials such as lignin ammonium sulphonate, industrial urea and wax emulsion recycled from paper-making waste liquid in raw materials after the raw materials are dried and treated, appropriate amount of ammonium dihydrogen phosphate flame retardant is added, and the processing technology of heat treatment setting under high pressure is adopted to manufacture the middle and high density fiber board with functions of high strength ratio, environment-friendly characteristic, fire retardant property and the like. On one side, the manufacture process solves the practical problem of low resource utilization ratio in spite of rich biomass resources in China. On the other side, the manufacture process abandons the traditional processing method of direct glue sizing, breaking away from depending on formaldehyde adhesives. Therefore, the process is a novel, environmental-friendly technology with functions such as fire retardant property for fiber board manufacture.

Owner:郭明辉 +2

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

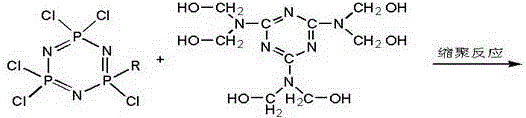

Melamine-urea-methyl aldehyde copolycondensation resin lumber adhesive and preparation thereof

ActiveCN101302412AStable storageImprove performanceAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceMethyl aldehyde

The invention relates to melamine-urea-formaldehyde copolycondensation resin (MUF) wood adhesives and a method for preparing the same, belonging to the wood processing and production technical field. The adhesives are formed by copolycondensation of melamine (M), urea (U) and formaldehydes (F) and are characterized in that: the formaldehydes are added at a time and the urea and the melamine are added for a plurality of times, and the amount of the formaldehydes is over 40 percent of the total amount of the urea and the melamine, wherein, the formaldehydes are added at a time during the initial reaction stage, and urea for the first time and melamine for the first time are added during the initial reaction stage; after the urea for the first time is added, the mole ratio of the formaldehydes and the urea is controlled to be over 2.9; melamine for the second time is added during the intermediate reaction stage; and urea for the second time is added during the late reaction stage. The melamine-urea-formaldehyde copolycondensation resin (MUF) wood adhesives have the advantages of good stability, excellent performance and so on, are used for producing hard boards and particularly high-performance hard boards, laminwood and so on, and also can be used for producing impregnated paper.

Owner:SOUTHWEST FORESTRY UNIVERSITY

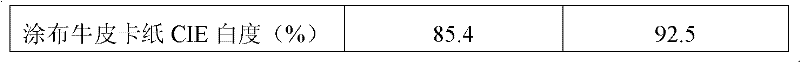

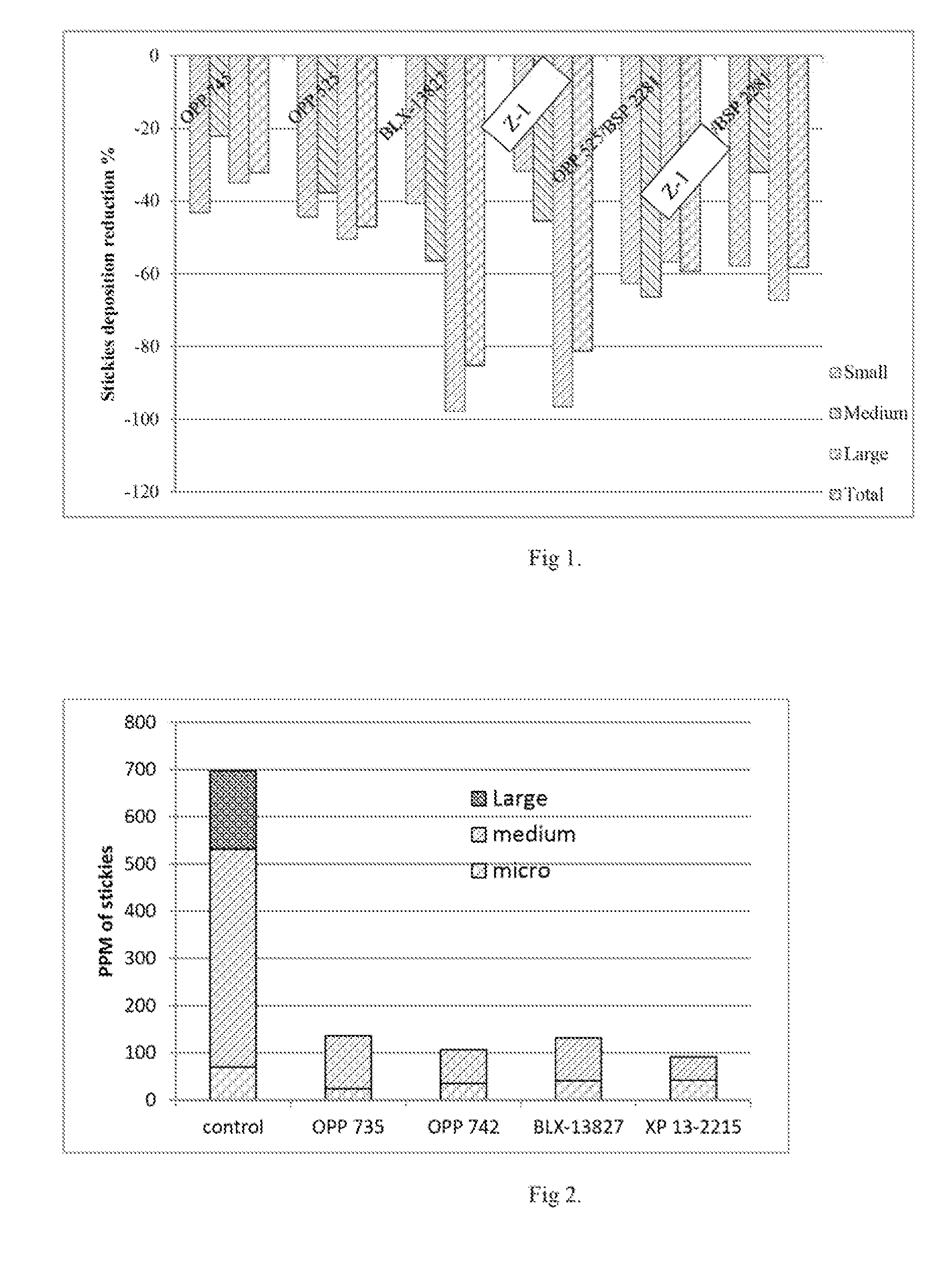

Pitch and stickies control in pulp and papermaking processes

InactiveUS20080169073A1Avoid depositionCellulosic pulp after-treatmentMicroorganism/enzyme additionProcess equipmentPapermaking

Methods for inhibiting the depositions of organic contaminants from pulp in pulp and papermaking systems are disclosed. A combination of an enzyme and a nonionic polymeric detackifier are added to the pulp or applied to deposition-prone process equipment surfaces of a pulp and papermaking system.

Owner:HERCULES INC

High density fibrous filter plate and manufacturing method

InactiveCN1562442AHigh filtration precisionFiltration accuracy is higher than or excellentFibreboardStationary filtering element filtersPorosityEpoxy

A high-density filtering fibreboard is prepared from sepiolite wool, paper pulp fibre, adhesive (polyvinyl alcohol or epoxy resin), wet strengthening agent (polyvinylimine, polyamide epoxy resin, or cyanuramide), and dry strengthening agent (carboxymethyl cellulose or polyacrylamide) through preparing pulp, mixing shaping, baking, and shearing by needed sizes. It has high porosity and filtering throughput.

Owner:HEBEI UNIV OF TECH

Fast drying paper product adhesive with high strength and low cost and its prepn

InactiveCN101020806AImprove toughnessImprove adhesionGraft polymer adhesivesPolyvinyl alcoholAdhesive

The present invention provides one kind of paper product adhesive with low cost, high strength and fast drying and its preparation process. The present invention features that the paper product adhesive is produced with PVA, starch, acrylic acid, urea, glyoxal and other materials in certain weight proportion, and through certain reaction. The paper product adhesive features its fast drying speed, low cost and high strength, possesses certain water resistance and moisture-proof performance. It has the advantages of acrylate adhesive, white latex adhesive and starch glue, and is used in producing honeycomb card board, paper pipe, paper box, paper box and other paper products.

Owner:陈宝元

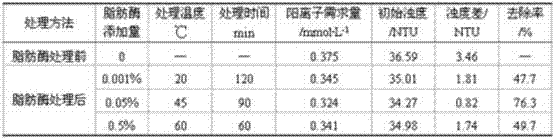

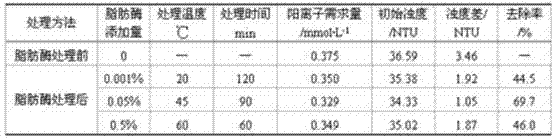

Method for controlling secondary stickies through lipase

ActiveCN103074795AEliminate hazardsQuality improvementFats/resins/pitch/waxes removal in pulpTransesterificationPulp treatment

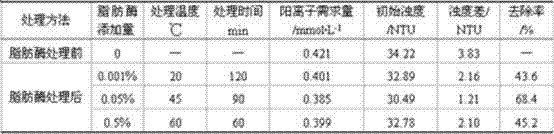

The invention discloses a method for controlling secondary stickies in paper pulp and white water during waste paper papermaking process through lipase. According to the invention, the pH (potential of hydrogen) value of lipase ranges from 7.5 to 9.0, the enzyme activity is larger than 100 U / mL, the hydrolysis rate for triglyceride is not lower than 95%, and transesterification and lipid synthesis rate of alkaline lipase is lower than 3%; a paper pulp processing method comprises the steps that lipase which is 0.001-0.5% of paper pulp dry weight is added into paper pulp with the pulp concentration which is adjusted in a range from 2% to 5%, and then the processed pulp is filtered, centrifuged and detected; and a white water processing method comprises the steps that lipase which is 0.001-0.5% of white water weight is added into papermaking white water for processing, and then the processed white water is filtered, centrifuged and detected. The method utilizes lipase to degrade the stickies thoroughly and reduce the deposition trend of the stickies, so that the removal purpose is achieved, and the problem of secondary sticky pollution is thoroughly solved; and the operation is simple, the removing effect is remarkable, the waste paper papermaking quality is improved, and the production cost is reduced.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Production process for high-strength carton

PendingCN105711149AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesLamination ancillary operationsCartonPaperboard

The invention discloses a production process for a high-strength carton. The production process comprises the following steps: 1) manufacturing a cardboard: selecting two pieces of kraft paper, and bonding the two pieces of kraft paper through a tackifier, thereby manufacturing the cardboard; 2) printing an image: selecting an image printing forme, transfer-printing printing ink onto the cardboard by use of an offset press, and nearly drying the printing ink by utilizing ultraviolet irradiation for later use, wherein a printing temperature ranges from 20 DEG C to 26 DEG C; 3) cutting the cardboard, and cutting the mounted kraft paper according to geometric figures of the kraft paper by use of a die-cutting blade on a die cutter; and 4) bonding the cardboard: bonding the die-cut kraft paper through a carton bonding machine, thereby forming a carton finished product. The production process is easy to realize, and the prepared carton is high in anti-pressure ability.

Owner:WUHU CIGARETTE MATERIAL FACTORY

Single-ingredient solvent-free type polyurethane bonding agent, and preparation method and application thereof

InactiveCN106883807ARaw materials are easy to getSimple compositionPolyureas/polyurethane adhesivesHydrogenAlcohol

The invention relates to the technical field of a polyurethane bonding agent, in particular to a single-ingredient solvent-free type polyurethane bonding agent, and a preparation method and application thereof. The single-ingredient solvent-free type polyurethane bonding agent is prepared from isocyanate terminated polyurethane prepolymers and optional additives; the isocyanate terminated polyurethane prepolymers are prepared from alcohol compounds containing reactive hydrogen and isocyanate through chain expansion reaction. The single-ingredient solvent-free type polyurethane bonding agent provided by the invention has the advantages that the raw materials can be easily obtained; the composition is simple; the production process is safe and controllable; good transparency, primary stickiness and bonding intensity are realized; the single-ingredient solvent-free type polyurethane bonding agent can be widely used in paper / plastic and paper / aluminum compounding.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

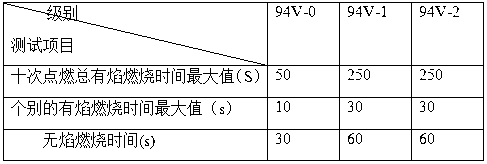

Flame-retardant nonwoven wallpaper and preparation method thereof

ActiveCN103343489AGood flexibilityReduce manufacturing costCovering/liningsSpecial paperFiberPolymer science

The invention relates to flame-retardant nonwoven wallpaper and a preparation method of the flame-retardant nonwoven wallpaper. The wallpaper comprises body paper of nonwoven wallpaper, wherein the body paper of nonwoven wallpaper is prepared by mixing functional fiber, wood pulp fiber and adhesive and papermaking or coating in a machine through adhesive; one or a plurality layers of a flame-retardant coating are coated on the body paper of nonwoven wallpaper, the coating dosage accounts for 15-60% of the fixed paper quantity, the flame-retardant coating comprises a flame retardant, the flameretardant is a halogen-free flame retardant and is selected from one or a combination of a plurality of phosphorus-nitrogen synergistic flame retardants, and the flame retardant accounts for 50-100% of the flame-retardant coating. By adopting the technical scheme provided by the invention, the flame retardant grade of the produced nonwoven wallpaper flame is V-1 level, the production cost of the flame-retardant wallpaper is reduced, the wallpaper product is free of shrinkage in the processing process and is free of moist feeling, the discovered paper is integral, and the toughness of the paperis very good.

Owner:浙江凯恩新材料有限公司 +1

Non-formaldehyde-release consolidated composite floor and production method thereof

InactiveCN105599414AReduce releaseEnvironmental protection is goodSynthetic resin layered productsPaper/cardboard layered productsWear resistantAdhesive

A non-formaldehyde-release consolidated composite floor and a production method thereof are disclosed, the non-formaldehyde-release consolidated composite floor from the surface to the bottom sequentially comprises an impregnated wear-resistant paper layer; an impregnated decorative paper layer; a high-density fiberboard substrate layer prepared from a MDI ecological adhesive; and an impregnated balance paper layer; and the production process is as follows: using 37wt% formaldehyde, melamine, urea, hexanolactam and diethylene glycol for preparation of melamine formaldehyde resin; mixing 1.4 to 1.6 parts by weight of cetyl trimethyl ammonium bromide and 55 to 57 parts by weight of deionized water, stirring evenly, adding 18 to 20 parts by weight of a tea extract and 23 to 24 parts by weight of carbonyldiimidazole for preparation of a formaldehyde catcher; using the obtained melamine formaldehyde resin and formaldehyde catcher, and urine phthalic acid and triethanolamine for preparation of impregnation resin; using the obtained impregnation resin for preparation of impregnated wear-resistant paper, impregnated decorative paper and impregnated balance paper; and using a high-density fiberboard prepared by the MDI ecological adhesive, and the prepared impregnated wear-resistant paper, impregnated decorative paper and impregnated balance paper for preparation of the consolidated composite floor.

Owner:圣保罗家居科技有限公司

Formula for sludge corrugated base paper, production process and produced corrugated board

ActiveCN102561100AImprove waterproof performanceHigh strengthWaste product additionSpecial paperAdhesiveSludge

The invention discloses a formula for sludge corrugated base paper, which consists of major ingredient and accessory, wherein the major ingredient is papermaking waste water sludge; and the accessory is mixing superfine padding formed by mixing inorganic superfine padding and organic superfine padding. The invention further provides a production process for producing corrugated base paper by the formula for sludge corrugated base paper, as well asprovides sludge corrugated base paper and case board paper prepared by the invention and a corrugated board made of adhesives. The papermaking waste water sludge is directly used as papermaking raw materials to be recycled and manufactured into recycled paper, so that the invention can solve the problem of secondary environment pollution caused by papermaking sludge; the solid wastes of the papermaking waste water sludge can be recycled; and the produced corrugated board has better strength and waterproof property.

Owner:浙江上峰包装新材料有限公司

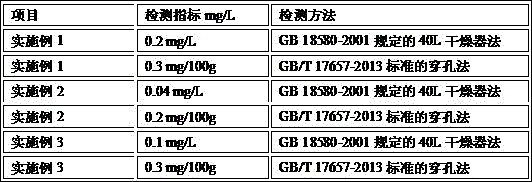

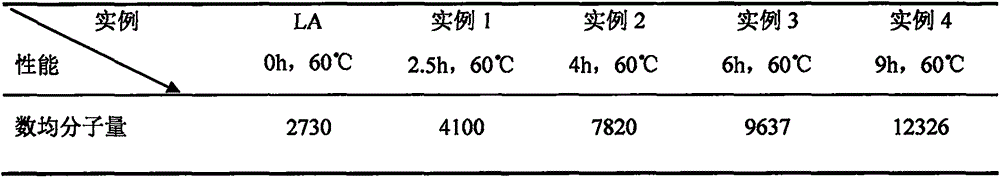

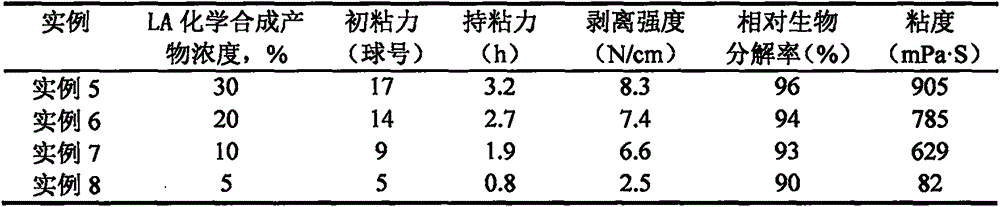

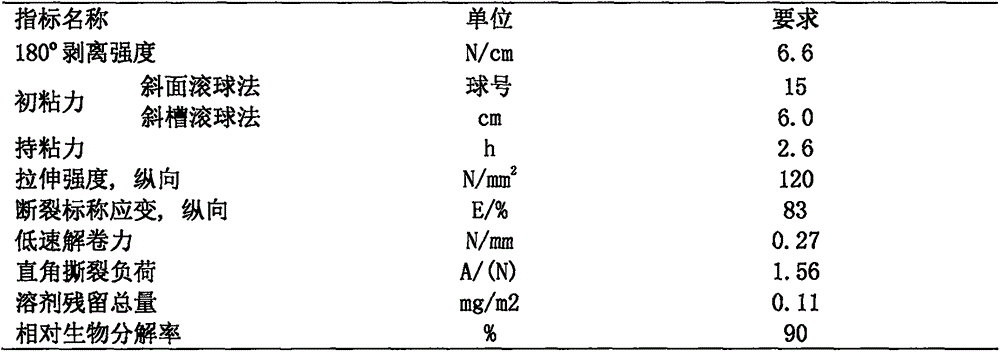

Biodegradable LA (lactide) oligomer bonding agent, and preparation method and purpose thereof

The invention relates to a biodegradable bonding agent material prepared from LA (lactide) chemical synthesis products. The LA materials are poured into a reaction container containing solvents according to the proportion of 5 to 50 percent of the mass of the solvents; a reactor has a stirring and control function; the reactor is controlled under the nitrogen gas protection condition; a certain reaction temperature is controlled; meanwhile, the stirring is performed; after the LA is completely fused, catalysts are added; after reacting for a period of time, stirring is stopped; after the materials are taken out, extraction and centrifugation are performed, so that the LA chemical synthesis products are obtained; then, the LA chemical synthesis products are dissolved by acetic ester, so that the biodegradable bonding agent is obtained. The bonding agent has the characteristics that the preparation is simple; the relative molecular weight and the viscosity are controllable; the biodegradable performance is realized. The biodegradable bonding agent material can be used in the fields of adhesive tapes, leather, sticking paper, stationery, office, electronics, automobile edge trimming fixation, shoe industry, handwork ornament pasting and fixation and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

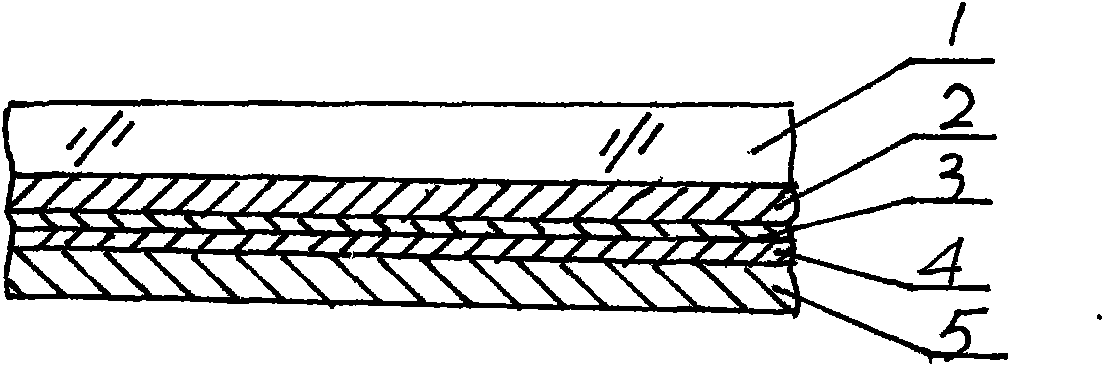

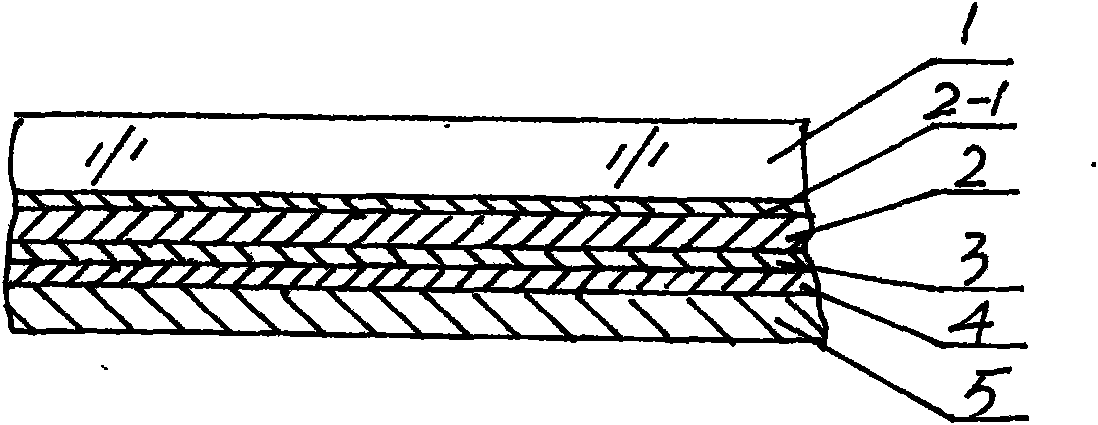

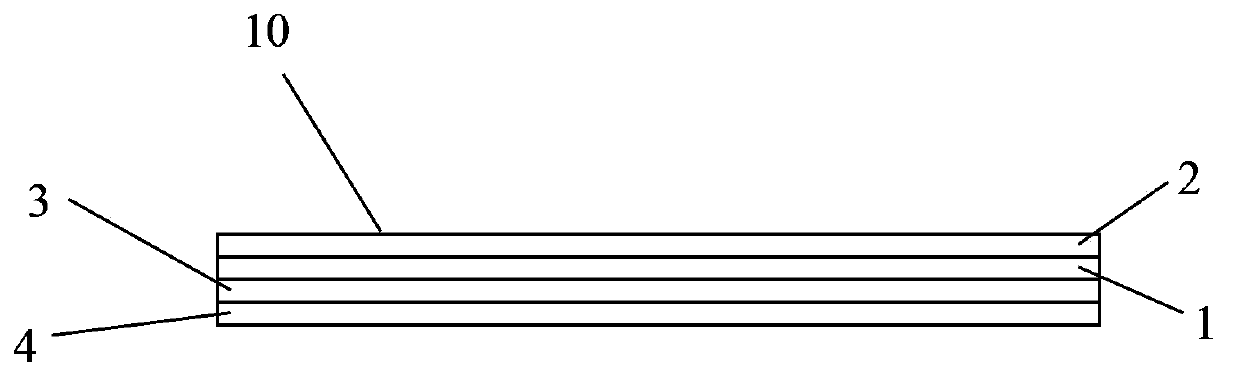

Film coating plywood for bottom plate of container and its production process

InactiveCN1887540AImprove impact resistanceImprove wear resistanceWood veneer joiningWood layered productsHigh resistanceSingle plate

The film coating plywood for bottom plate of container consists of laminated and pressed single plates and has soaked coating paper on its one or two surfaces. Its production process includes the following steps: laminating and gluing dry single plates painted with phenolic resin as adhesive to certain thickness, polishing, sawing edges, repairing to form the base material, adhering soaked coating paper on its one or two surfaces, milling edges and sealing edges. The present invention has the features of high impact strength, high wear resistance, and high fouling resistance, and may be used directly without further coating.

Owner:MAOYOU WOOD

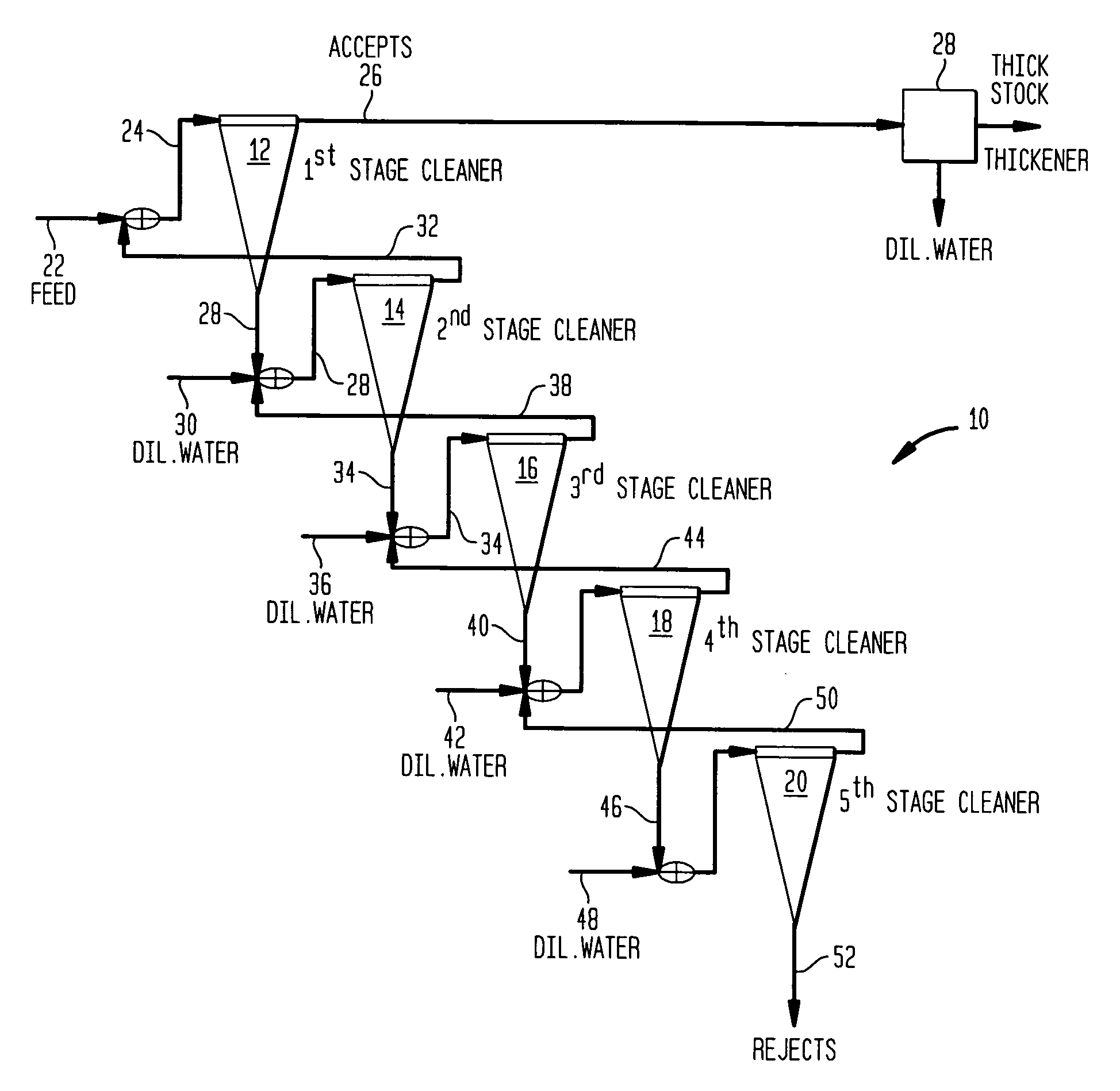

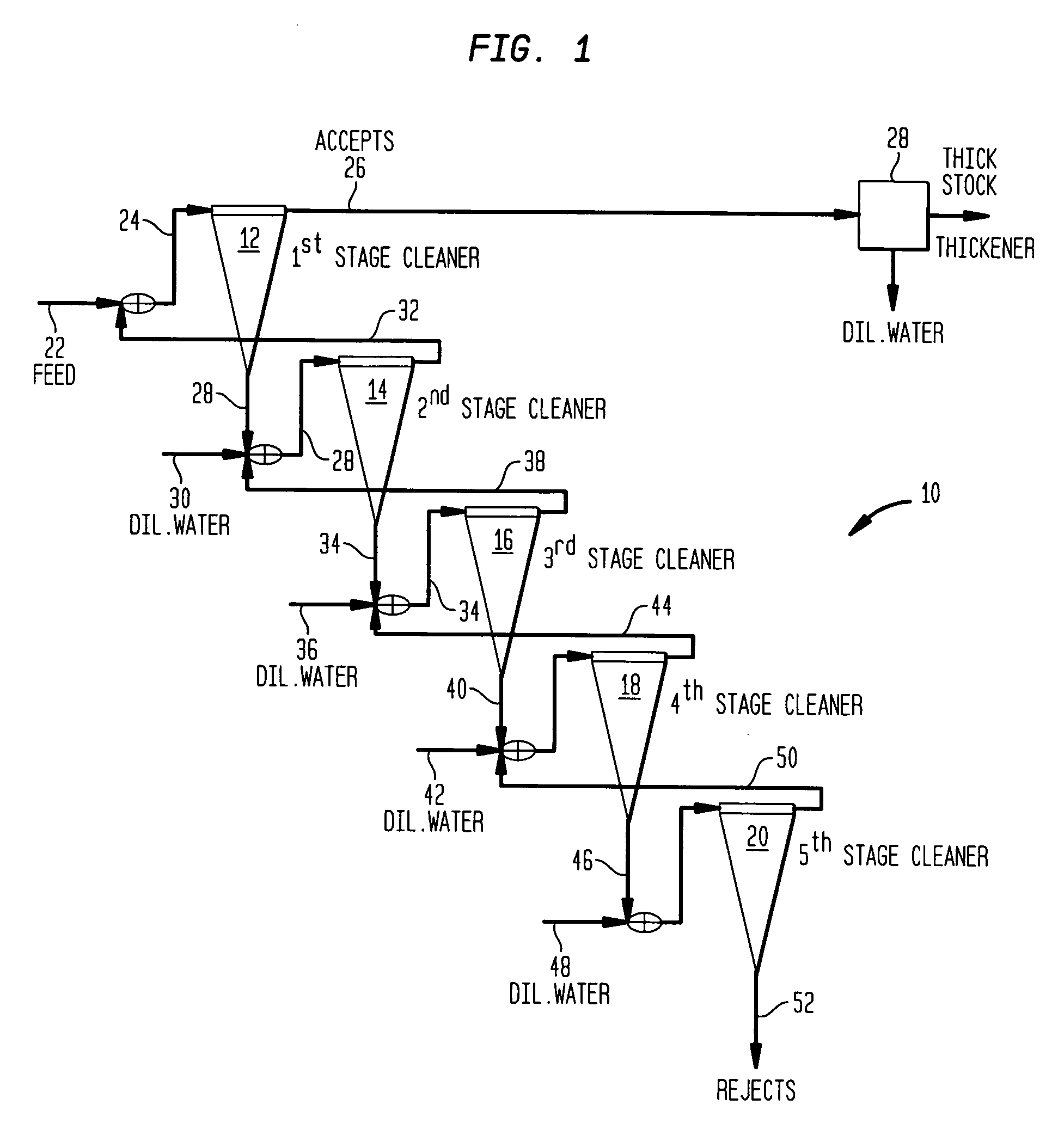

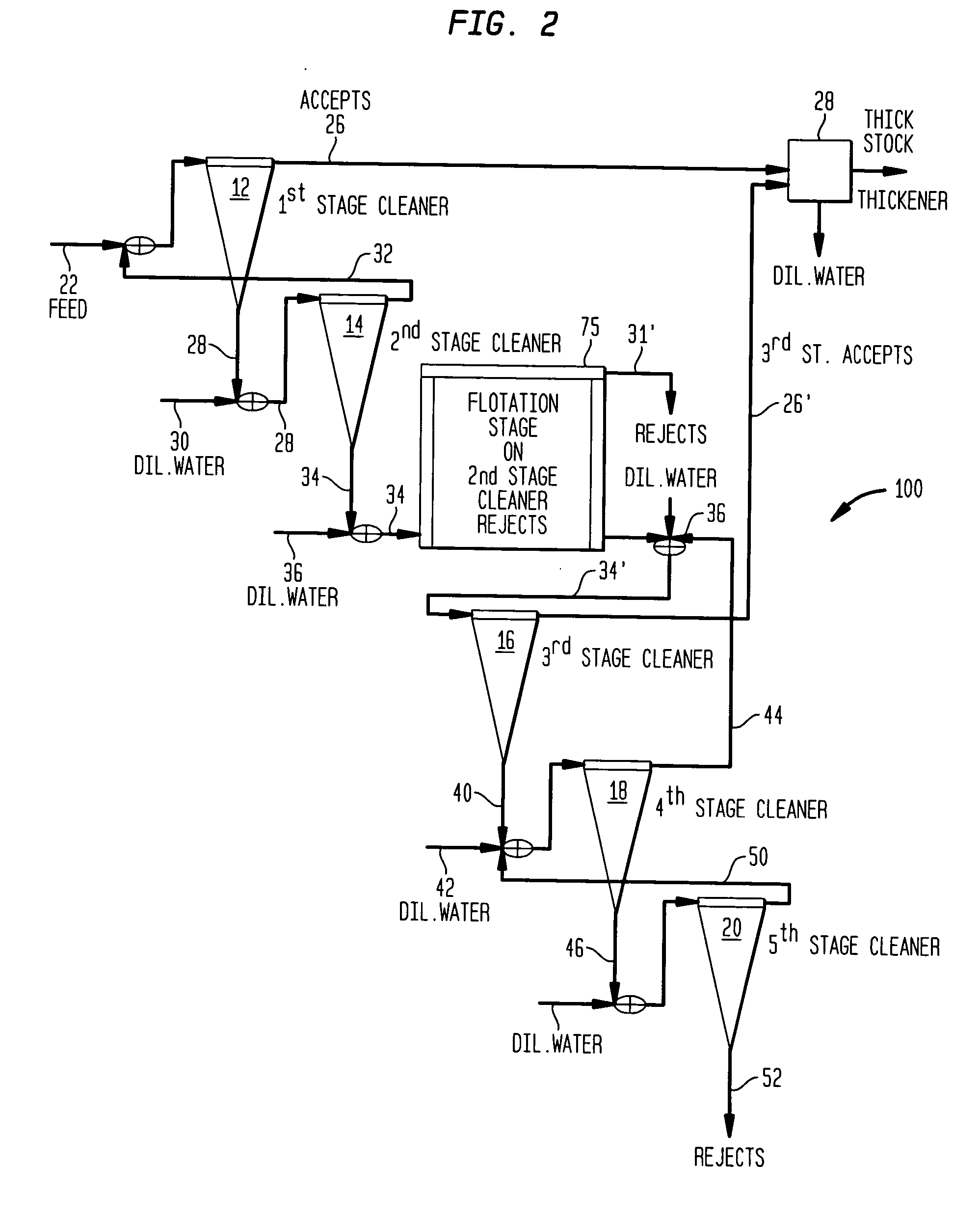

Method of removing high density stickies from secondary papermaking fibers

InactiveUS20060124256A1Reduce consistencyKeep costsReversed direction vortexFats/resins/pitch/waxes removal in pulpFiberHigh density

A hybrid method for processing papermaking fibers to remove high density stickies typically includes utilizing a multistage array of forward cleaners coupled with a flotation cell which increases overall efficiency of the system. In a preferred embodiment, a first rejects aqueous stream from a first stage bank of centrifugal cleaners is treated in a flotation cell before being fed to a second stage bank of centrifugal cleaners. With the improved technique, the accepts from the first stage bank of centrifugal cleaners may be combined with the accepts from the second stage bank of centrifugal cleaners and fed forward to a thickening device, for example. The technique is also suitably employed for removing stickies from material which has already been screened with a fine screen.

Owner:GPCP IP HLDG LLC

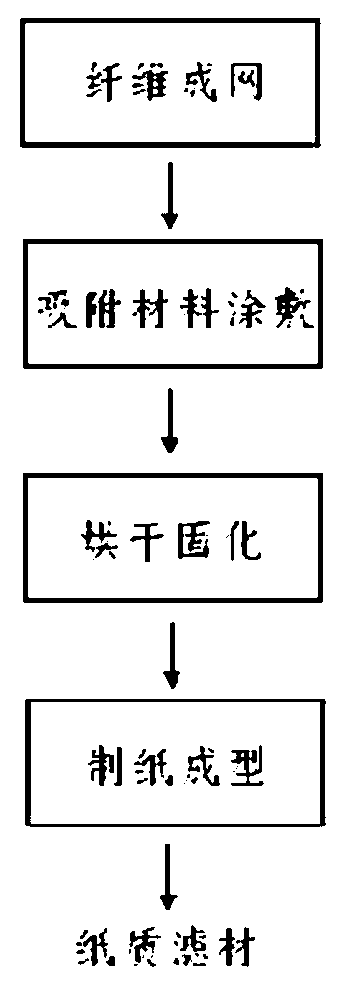

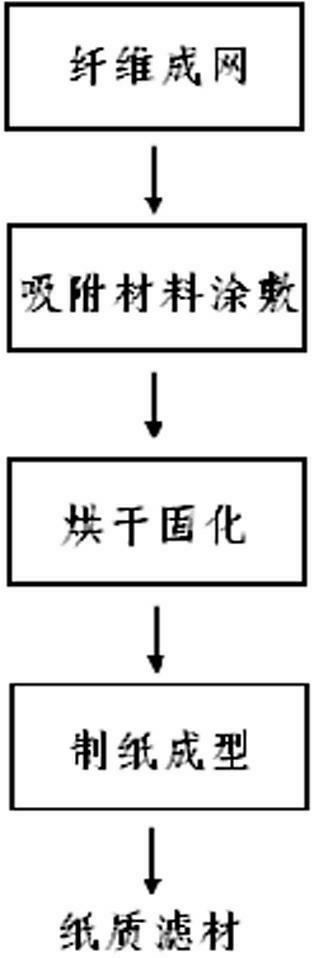

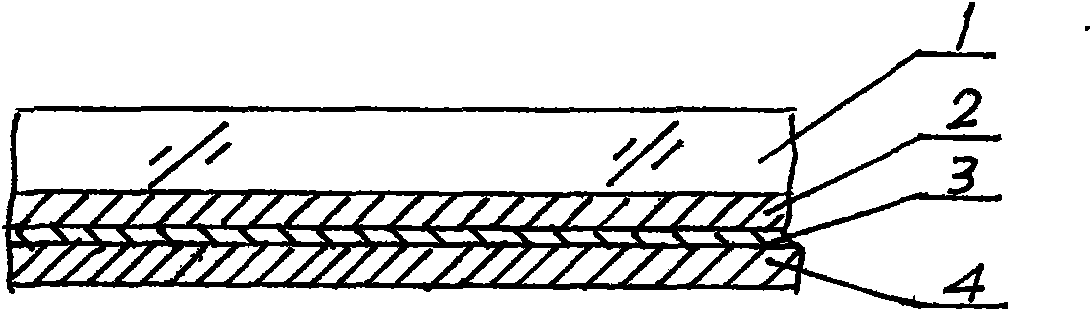

Selective absorbing dry method paper filter material for cigarette filter tip rod and preparation method thereof

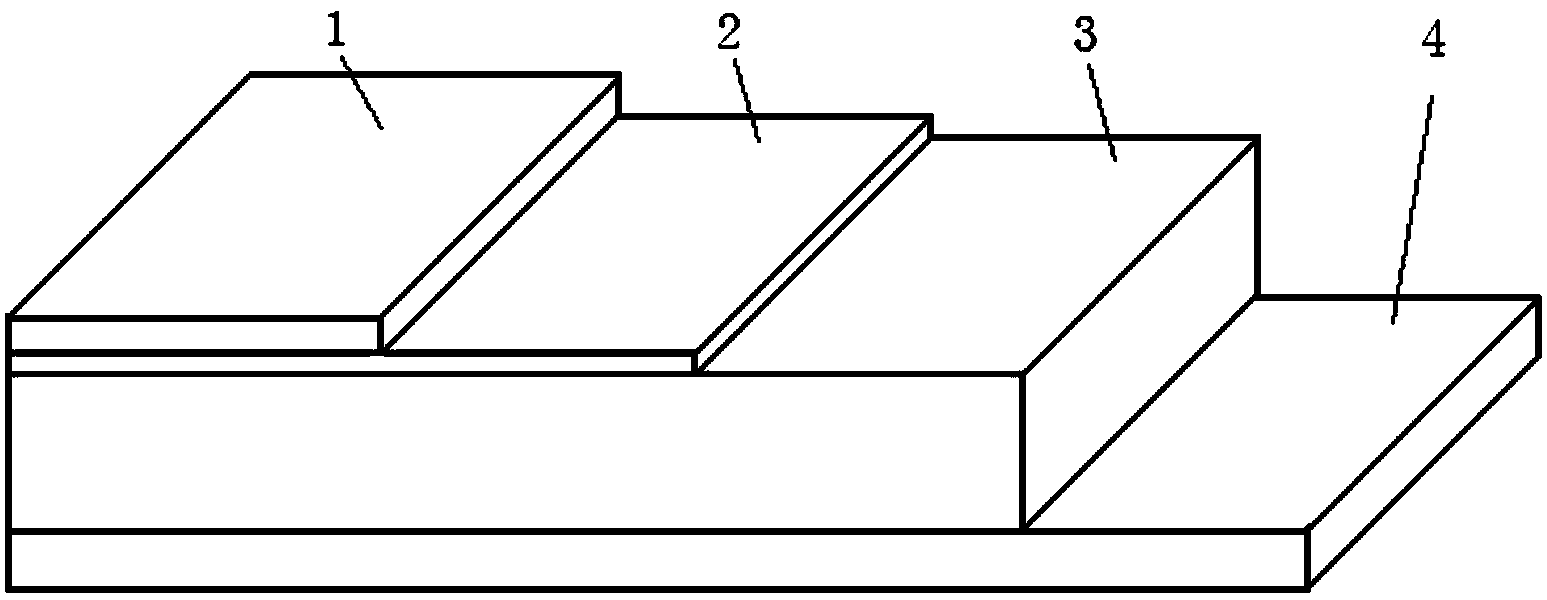

The invention discloses a selective absorbing dry method paper filter material for a cigarette filter tip rod and a preparation method thereof. The selective absorbing dry method paper filter material is formed by processing 80-100 parts of base material fibers, 0-20 parts of adhesive and adsorbing materials of which the weight is 0.5 percent to 10 percent of that of the base material fibers through a dry method papermaking technology. The preparation method comprises working procedures of fiber net formation, adsorbing material coating and paper making and formation, that is to say, after fiber nets are formed by fibrous raw materials containing hot melting fibers in an air-laid manner and are pre-pressed, the adsorbing materials are evenly sprayed into accumulated fiber net layers, or are sprayed and coated on the front surfaces of the fiber nets after being mixed with the adhesive, and the fiber nets are formed in a rolled manner; after the adsorbing materials are sprayed and coated on the back surfaces of the fiber nets, glue is applied to the fiber nets, the fiber nets are additionally formed in a rolled manner, and then the paper filter material is obtained. By adopting the selective absorbing dry method paper filter material, harmful ingredients such as solid particle matters, nicotine and nicotinamide in cigarette smoke can be effectively reduced, the tar content can be markedly reduced, the cigarette smoking quality can be improved and the cigarette safety can be enhanced. The preparation method of the selective absorbing dry method paper filter material has the advantages of simple and convenient technology, easiness in operation and high practicality.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Glass wall paper composite board and producing method thereof

InactiveCN101585287AImprove protectionReduced service lifeCovering/liningsSpecial ornamental structuresSurface patternPulp and paper industry

The present invention discloses a glass wall paper composite board and a producing method thereof, capable of prolonging a service lifetime of the wall paper greatly, improving a decorative effect andrigidity of the wall paper, especially being adapt to a fixed building, the plumbing installation of a toilet and a bathroom and facilities of a swimming pool. the glass wall paper composite board includes a glass layer and a wall paper surface pattern layer, wherein a transparent or semi-transparent adhesive layer is provided between the glass layer and the wall paper surface pattern layer, thebottom of the wall paper surface pattern layer is provided with a complementary color protective layer, so as to form a glass wall paper composite board with a four-layer structure. An optimum methodis that a thin complementary color protective layer is coated on a bottom face of the wall paper surface pattern layer, and a thick paint protective layer is coated on a bottom face of the complementary color protective layer.

Owner:何庭佳

Waterproof ink-jet printing engineering blueprinting paper

ActiveCN105803855AFine drawing informationGood ink absorptionCoatings with pigmentsSpecial paperEcological environmentAdhesive

The invention relates to a paper sheet and particularly relates to waterproof ink-jet printing engineering blueprinting paper. The waterproof ink-jet printing engineering blueprinting paper comprises a three-layered structure including a surface coating, a raw paper layer and a back coating, wherein paint of the surface coating comprises silicon dioxide, blue color paste, an adhesive, a color fixing agent and a water-resistant agent; and the back coating comprises polyvinyl alcohol. Aiming at abandoning a process in the prior art of dyeing papermaking raw materials or the paper sheet, a low-quantitative coating technology is applied, and low-quantitative coating and back coating processing can be carried out on the surface of the paper sheet, so that a blue color needed by the engineering blueprinting paper is given to the surface of the paper sheet, and printing drawing information needed by the ink-jet printing engineering blueprinting paper is fine and clear; the developing property and the color fixing performance are excellent, and the paper sheet has shape stability and is not curled and deformed; the waterproof ink-jet printing engineering blueprinting paper has an equivalent waterproof property and the drawing information on the blueprinting paper is not blurred and cannot lost when meeting water, and has the properties of folding resistance, no cracking and the like; and meanwhile, the technical scheme provided by the invention does not generate wastewater in a production and machining process, and the ecological environment can be effectively protected.

Owner:ZHEJIANG JUNMA DIGITAL TECH

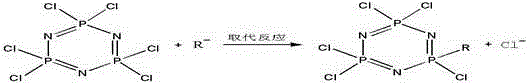

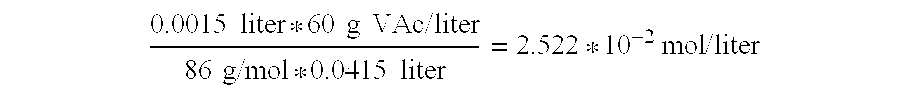

Enzymatic hydrolysis of a polymer comprising vinyl acetate monomer

Owner:NOVOZYMES AS

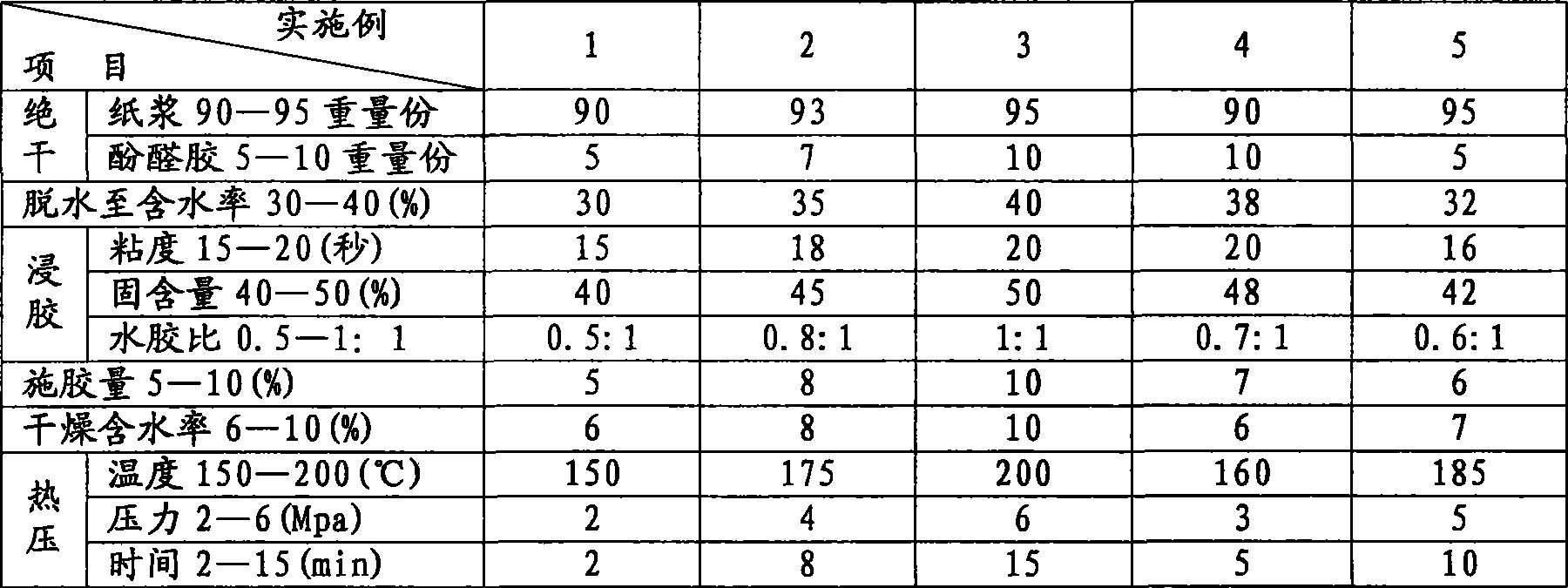

High strength fiberboard and production method thereof

The invention relates to a high strength fiber board which comprises 90-95 portions of paper pulp by weight and 5 to 10 portions of adhesive by weight. When the paper pulp which is raw paper pulp or deinked wastepaper paper pulp is taken as a raw material, a board body shows a maple color, and the density of the high strength fiber board is 1.3 to 1.5g / cm3. When the thickness of the high strength fiber board is 3mm, the static bening intensity of the high strength fiber board is 85 to 95MPa, the elasticity modulus of the high strength fiber board is 15000 to 17000MPa, and the inner bonding strength of the high strength fiber board is 2 to 5MPa. The production of the high strength fiber board comprises the following eight steps of: the pulping and the deinking of the paper pulp, squeezing for dehydration, gum dipping, squeezing for degumming, drying or refrigeration, crushing, mat formation and hot pressing. The high strength fiber board made according to the method has the advantages of single raw material, convenient collection, low cost, high strength of manufactured boards, and is especially suitable for being used as decorative boards and bottom boards on the high-level vehicles.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Structured wave-absorbing material and preparation method thereof

InactiveCN102523730AUniform structure distributionSimple preparation processMagnetic/electric field screeningFiberMicron scale

The invention discloses a structured wave-absorbing material and a preparation method thereof. The structured wave-absorbing material contains fiber with a micron-scale diameter and absorbent particles, wherein the fiber forms a three-dimensional network structure with adjustable and controllable porosity; and the absorbent particles are evenly covered in the three-dimensional network structure. The preparation method comprises the following steps of; mixing adhesives, fiber and the absorbent particles with water, and stirring at high speed to form uniform serous fluid; utilizing a wet papermaking process to make a precursor; and after drying the precursor, high-temperature sintering to form the structured wave-absorbing material with the absorbent particles covered by the paper-type micro fiber. The prepared structured wave-absorbing material has the characteristics of thinner thickness, high porosity, good flexibility, convenience in molding, strong absorbing capacity for electromagnetic wave; and the preparation process is simple and is low in cost. The structured wave-absorbing material can be applied to military and civil fields, the density and the weight of the wave-absorbing material are greatly reduced, the thermostable performance is good, the wave-absorbing efficiency can be improved, and the application prospect is broad.

Owner:SOUTH CHINA UNIV OF TECH

Production method for waterproof paper honeycomb compound sandwich board

ActiveCN102909899AMeet lightweight requirementsImprove waterproof performanceSynthetic resin layered productsLaminationPolymer scienceSandwich board

The invention relates to a production method for a waterproof paper honeycomb compound sandwich board. The production method comprises the following steps: 1) preparing a gum dipping solution, namely dissolving an adhesive agent in a diluting agent to prepare the gum dipping solution; 2) dipping gum, namely placing a paper honeycomb core into the gum dipping solution for gum dipping treatment; 3) standing, namely naturally drying the gum-dipped paper honeycomb core until the gum dipping solution does not drop, and placing the paper honeycomb core onto a film; 4) drying, namely placing the paper honeycomb core and the film for 10-30 minutes at the temperature of 60-80 DEG C, moving away the film, and placing the paper honeycomb core for 1-2 hours at the temperature of 150-170 DEG C; and 5) pressing, namely hot pressing the paper honeycomb core, upper and lower skins and a bonding layer. According to the production method, the paper honeycomb core is dipped with the gum and correspondingly processed, so that the compound sandwich board produced by the paper honeycomb core is good in waterproof performance, water is not accumulated in the paper honeycomb core due to moisture invasion in the process of long-term use so as to avoid increment of thermal conductivity and degumming, and the performance of a product is improved.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

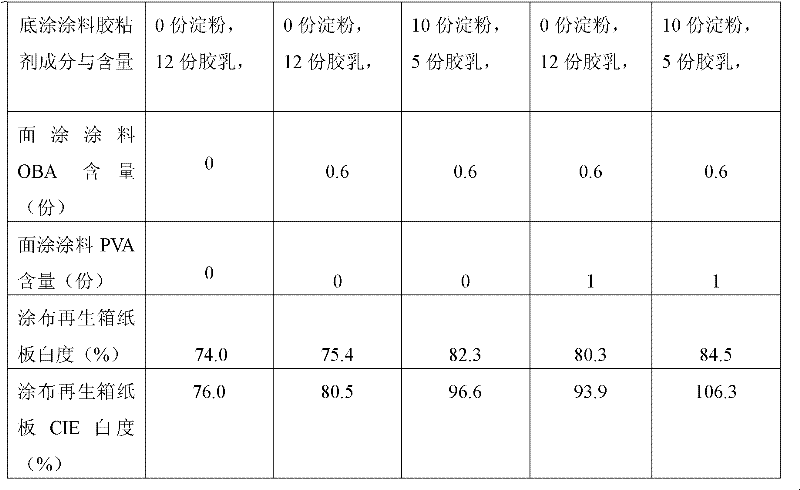

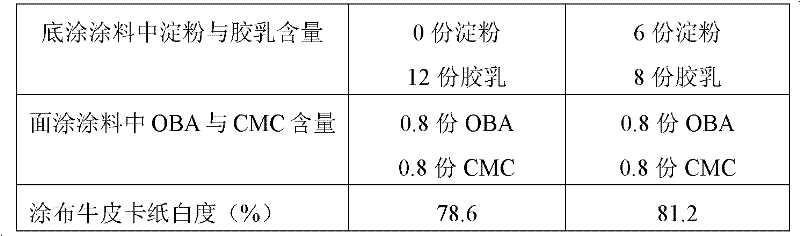

Method for enhancing whiteness of coated paper or coated paper board with starch

InactiveCN102230302AReduce dosageImprove protectionPaper coatingLuminescent/fluorescent substance additionCardboardWhiteboard

The invention relates to a method for enhancing whitening efficiency of an optical bleaching agent (OBA) in a double-coated / multi-coated paper or coated paper board with starch. In the method provided by the invention, starch is substituted for part or all of expensive synthetic latex adhesive in the paint by utilizing the characteristic that the cheap starch can retain the OBA on the surface of the coated paper, and meanwhile, the consumption of the expensive OBA carrier PVA (polyvinyl alcohol) or CMC (carboxymethyl cellulose) is lowered, thereby being beneficial to environmental protection and greatly lowering the production cost of the coated paper and coated paper board. The invention is suitable for factories for producing enamelled paper, coated ivory board, coated white board, coated box paper board, coated kraft cardboard, and other coated paper and coated paper boards by a double-coating or multi-coating technique.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Methods To Control Organic Contaminants In Fibers Using Zeolites

InactiveUS20150053358A1Easy to controlReduce viscosityFats/resins/pitch/waxes removal in pulpPulp bleachingFiberSufficient time

Methods to control organic contaminants in fibers are described. One method involves contacting the fibers with a) at least one zeolite and optionally b) detackifier, or an ester hydrolyzing enzyme, or both, for a sufficient time and in a sufficient amount to control the organic contaminants present in the fibers. This method is effective to reduce stickies in paper mill furnish formed with recycled fibers. A method for pitch control in paper mill furnish formed with virgin fibers is also provided. Resulting paper products formed from the processed fibers are also described as well as methods to make them.

Owner:BUCKMAN LAB INT INC

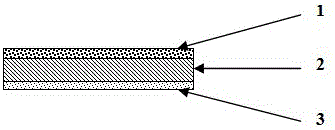

Method for manufacturing calcined type fireproof mica tape

InactiveCN104319029ADoes not fall offDoes not drop powderCable/conductor manufactureProcess engineeringToluene

The invention provides a method for manufacturing calcined type fireproof mica tape. The method includes the steps of preparing tackiness agents, preparing tackiness agent solutions, coating glass fabric with the tackiness agent solutions, gluing mica paper and the glass fabric, and carrying out baking in a dryer. The method is characterized in that baking is carried out within three periods at different temperatures. The mica tape produced with the method is free of falling, powder falling, foam generating and reverse gluing and good in breathability, the mica paper is not separated from the glass fabric after the mica tape is soaked by methylbenzene for seventy-two hours, and the temperature resistant level and the voltage withstand level of the mica tape are higher; in addition, the rate of finished products is quite high, flexibility is excellent, and various properties are more stable.

Owner:TONGCHENG ZHONGTIAN MICA PROD

Transferable double sided tape and production technology thereof

ActiveCN103666299ANo damageNo peelingFilm/foil adhesivesOther rubber adhesivesEngineeringMembranous layer

The invention provides a transferable double sided tape and a production technology thereof. The transferable double sided tape comprises a base material, film layers attached to two sides of the base material, and release paper attached to at least one film layer, wherein the film layer comprises a rubber pressure-sensitive adhesive, an acrylic acid pressure-sensitive adhesive and a silicone pressure-sensitive adhesive. When the transferable double sided tape is transferred, the base material is not damaged and is complete, and the adhesive is not peel off from the base material and is not torn off.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com