Transferable double sided tape and production technology thereof

A double-sided adhesive tape, production process technology, applied in the direction of adhesives, other rubber adhesives, adhesive types, etc., can solve problems such as non-environmental protection, human damage, poor transfer ability of double-sided adhesive tape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further elaborated below by way of specific embodiments:

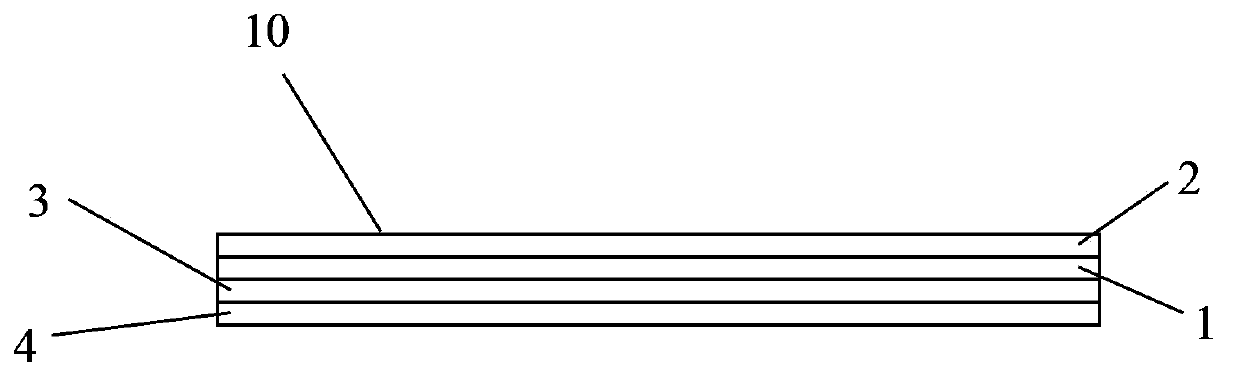

[0025] This embodiment provides a transferable double-sided adhesive tape 10, which includes a base material 1, adhesive film layers 2, 3 coated on both sides of the base material 1, and a release mold attached to at least one adhesive film layer 2, 3 Paper 4, the film layers 2 and 3 include rubber-based pressure-sensitive adhesives, acrylic pressure-sensitive adhesives, and silicone pressure-sensitive adhesives.

[0026] The release force ratio of the two sides of the release paper 4 ranges from 1:1.5 to 1:3.5. The base material 1 is non-woven fabric, tissue paper, polyethylene, polypropylene, PET or PVC. The adhesive film layers 2 and 3 are composite acrylic emulsions.

[0027] This embodiment also provides a production process for transferable double-sided adhesive tape, which specifically includes the following steps:

[0028] a. Select the substrate and release paper, first pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com