Film coating plywood for bottom plate of container and its production process

A container bottom plate and plywood technology, which is applied in the jointing of wooden veneers, layered products, manufacturing tools, etc., can solve the problems of impact resistance, wear resistance and pollution resistance, and high-quality wood, etc., to achieve wear resistance Good performance and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

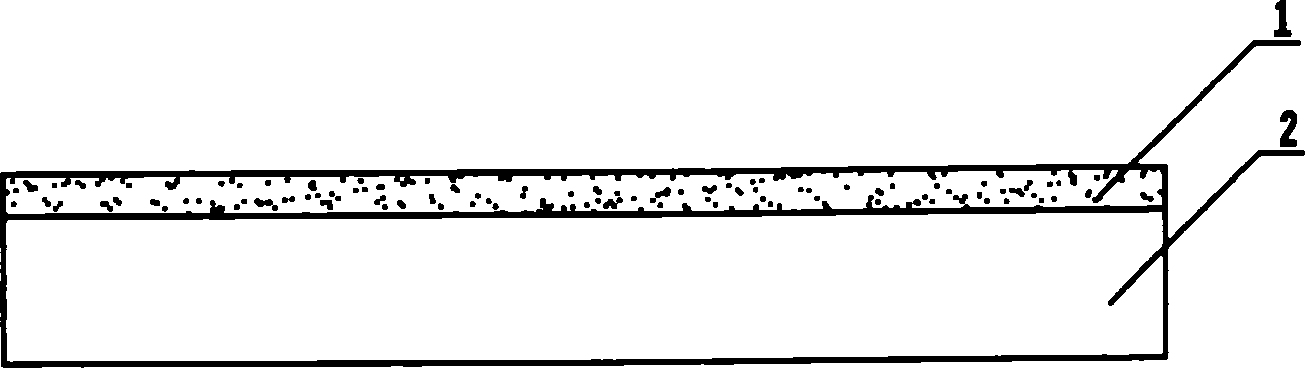

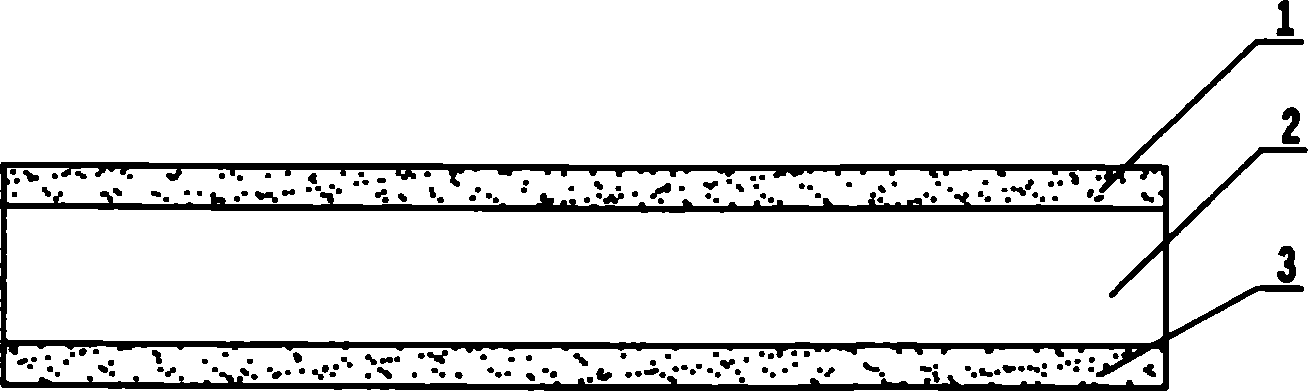

[0010] like figure 1 As shown, the film-coated plywood for the bottom plate of the container according to the present invention is formed by laminating and pressing veneers, and one side of the plywood is covered with an impregnated film paper 1 . The impregnated film paper 1 is the paper that is properly dried after being impregnated with phenolic resin or melamine formaldehyde resin.

[0011] The impregnated adhesive film paper 1 can also be the paper that has added Al2O3 powder in phenolic resin or melamine formaldehyde resin, and is properly dried after impregnation.

[0012] The impregnated adhesive film paper 1 can also be the paper that is sprayed with Al2O3 powder on the paper that is properly dried after being impregnated with phenolic resin or melamine formaldehyde resin.

[0013] The production process of the film-coated plywood for the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com