Patents

Literature

40results about How to "Does not drop powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional environmental protection putty

InactiveCN101265375AHard wallNo rapid drying of the surfaceFilling pastesCarboxymethyl celluloseEmulsion

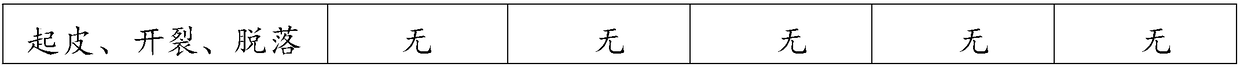

The invention discloses multifunctional environment-friendly lacquer putty, which primarily comprises ground chalk powder accounting for 50 to 60 percent by weight; light calcium carbonate powder accounting for 10 to 20 percent by weight; ash-calcium-powder accounting for 30 to 40 percent by weight, carboxymethyl cellulose accounting for 3 to 5 percent by weight; water-soluble dispersible emulsion powder accounting for 5 to 8 percent by weight; and an anion additive accounting for 1 to 3 percent by weight. The multifunctional environment-friendly lacquer putty powder has the advantages of high water-resistance, no peeling, no crackle and so on, and can facilitate construction and release anions.

Owner:何林道

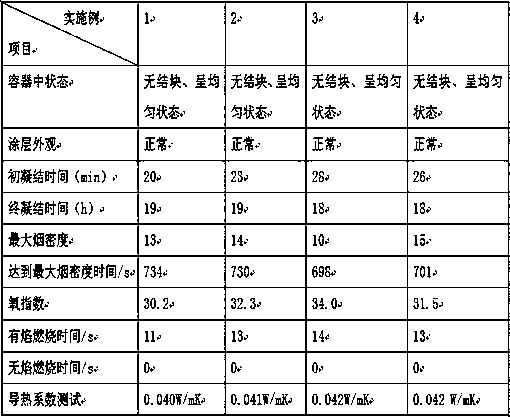

Inner wall heat-preservation flame-retardant diatom ooze and preparation method

InactiveCN107778929AHighlight substantive featuresSignificant progressFireproof paintsBuilding material handlingFiberEpoxy

The invention discloses inner wall heat-preservation flame-retardant diatom ooze and a preparation method. The diatom ooze comprises raw materials, namely kieselguhr, ramie fibers, epoxy resin, a composite coupling agent, vermiculite powder, barium sulfate, chlorinated paraffin, a pigment, a flame retardant, a defoaming agent, a thickening agent, a dispersant, a moistening agent and water. The diatom ooze disclosed by the invention has the advantages of good heat preservation effect, good flame retardancy, good adhesive property, no powder off, no cracking, high strength, a remarkable indoor air humidity adjustment effect, reduction of influence caused by wet air, and improvement of the comprehensive properties of the diatom ooze.

Owner:GUANGXI JISHUN ENERGY TECH

Method for manufacturing calcined type fireproof mica tape

InactiveCN104319029ADoes not fall offDoes not drop powderCable/conductor manufactureProcess engineeringToluene

The invention provides a method for manufacturing calcined type fireproof mica tape. The method includes the steps of preparing tackiness agents, preparing tackiness agent solutions, coating glass fabric with the tackiness agent solutions, gluing mica paper and the glass fabric, and carrying out baking in a dryer. The method is characterized in that baking is carried out within three periods at different temperatures. The mica tape produced with the method is free of falling, powder falling, foam generating and reverse gluing and good in breathability, the mica paper is not separated from the glass fabric after the mica tape is soaked by methylbenzene for seventy-two hours, and the temperature resistant level and the voltage withstand level of the mica tape are higher; in addition, the rate of finished products is quite high, flexibility is excellent, and various properties are more stable.

Owner:TONGCHENG ZHONGTIAN MICA PROD

High-temperature-resistant paper for steel sign

ActiveCN103966906AGood printabilityDoes not change colorNon-fibrous pulp additionCoatings with pigmentsPolyesterVegetable fibers

The invention specifically relates to high-temperature-resistant paper for a steel sign, which belongs to the field of specialty paper. The high-temperature-resistant paper is prepared by subjecting a vegetable fiber, a filling material with a high proportion and a high retention rate, an additive and the like to paper making so as to obtain high-temperature-resistant raw paper, then preparing a high-temperature-resistant coating from a pigment with good spreadability, high-temperature-resistant latex, a PAPU water resisting agent, CMC, a lubricant and the like and coating a single surface of the raw paper with the high-temperature-resistant coating. The high-temperature-resistant paper provided by the invention can be used for preparation of signs and labels for high temperature industries like the steel metallurgy industry; specifically speaking, a layer of a polyester film is compounded between uncoated surfaces of two pieces of high-temperature-resistant paper to prepare a high-temperature-resistant sign which has a good printing effect, does not have fading and powder-falling when put in an environment with a temperature of about 300 DEG C for 2 to 3 min, can resist acid and endure the sun and rain and has lower cost and environment friendliness compared with a traditional aluminum sign.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD +1

Environmental protection type water resisting putty powder in use for inner wall

InactiveCN1260313CNo pollution in the processNot easy to mildewFilling pastesCarboxymethyl celluloseMethyl cellulose

The invention discloses an environment-friendly water-resistant interior wall putty powder, which mainly comprises the following components by weight: heavy calcium carbonate powder 70-75, light calcium calcium powder 20-35, gray matter calcium powder 40-55, Alpha starch 15-20, carboxymethyl cellulose 18-25, water-soluble rubber powder 14-18. This environmentally friendly water-resistant interior wall putty powder has the advantages of strong water resistance, no slag, no peeling, and no cracks. The construction surface is smooth, easy to calender, not easy to mildew, and it is convenient for construction and low in cost.

Owner:赵炜

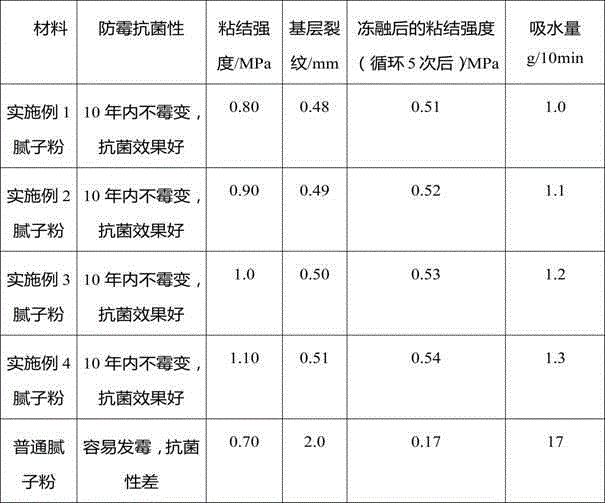

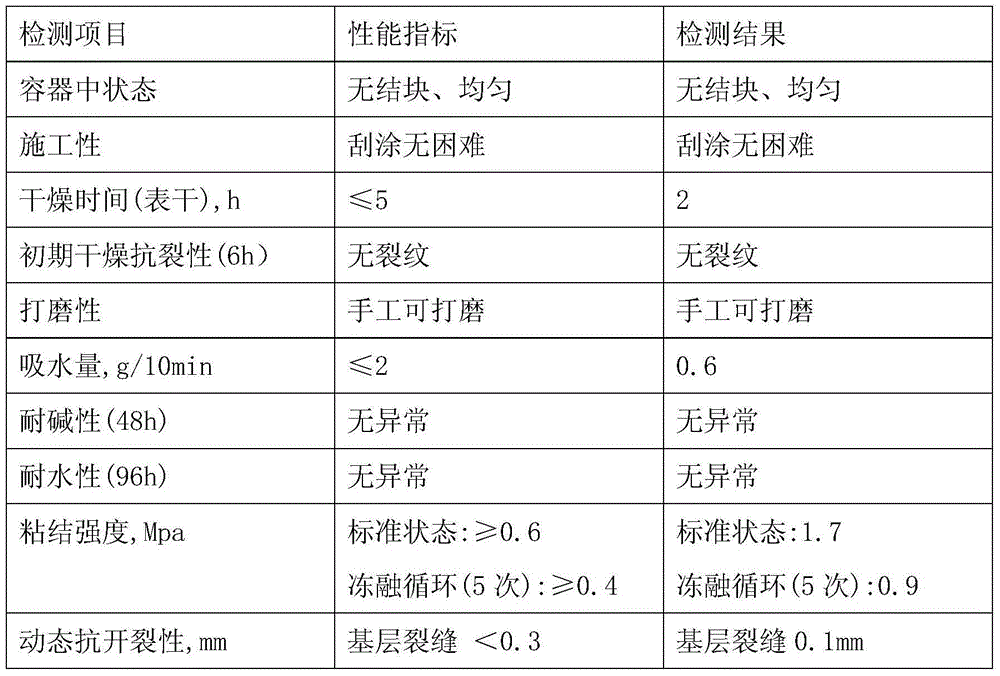

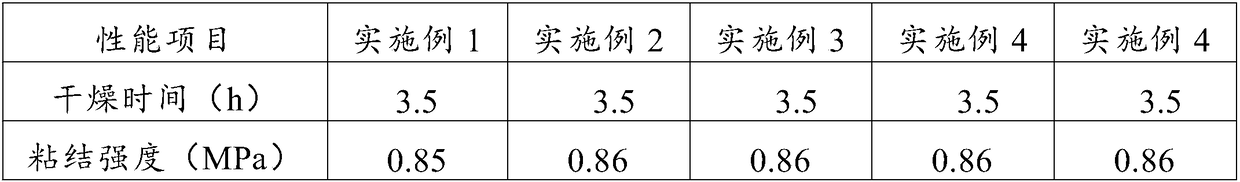

Mildew-proof antibacterial putty powder and using method

InactiveCN105273474AImprove water resistanceHigh bonding strengthFilling pastesFreeze thawingPolymer science

The present invention discloses mildew-proof antibacterial putty powder including a main body material, an adhesive material and a mildew-proof antibacterial material, the main body material, the adhesive material and the mildew-proof antibacterial material are respectively individually packaged in a putty powder large package, before the package, the main body material, the adhesive material and the mildew-proof antibacterial material are respectively individually pulverized, the powder putty basic level crack is 0.48mm-0.51mm, the adhesive strength is 0.80MPa-1.1MPa, the bond strength after 5 times of freeze-thaw cycle is 0.51MPa-0.54MPa, the water absorbing amount is 1.0g / 10min-1.3g / 10min, and the fineness is 50mum-80mum. The putty powder prepared by the invention is not easy to mildew, good in water resistance, and high in bond strength, has the advantages of no dusting, no peeling, no cracking, no mildewing, easy construction, and good antibacterial effect.

Owner:苏锦忠

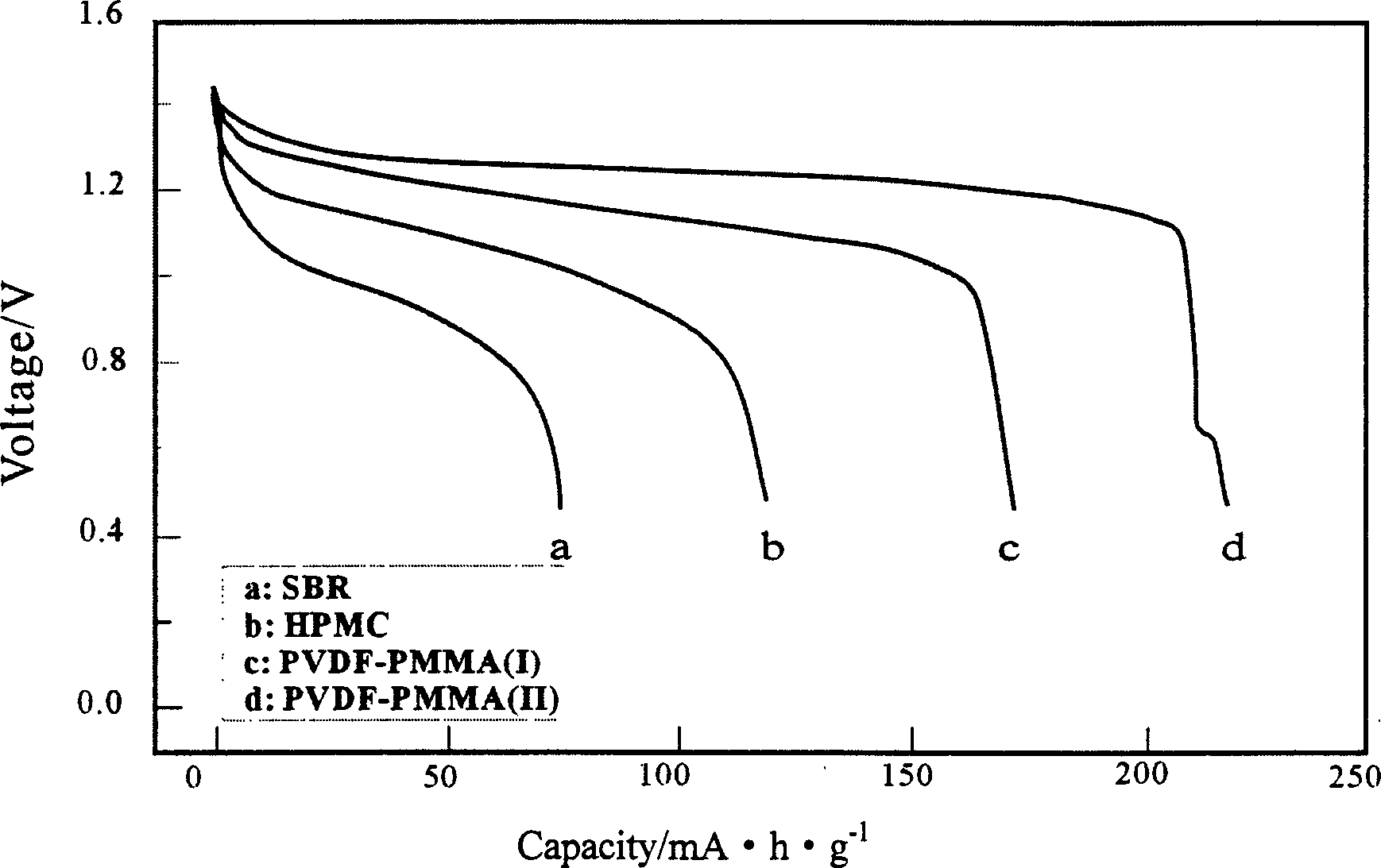

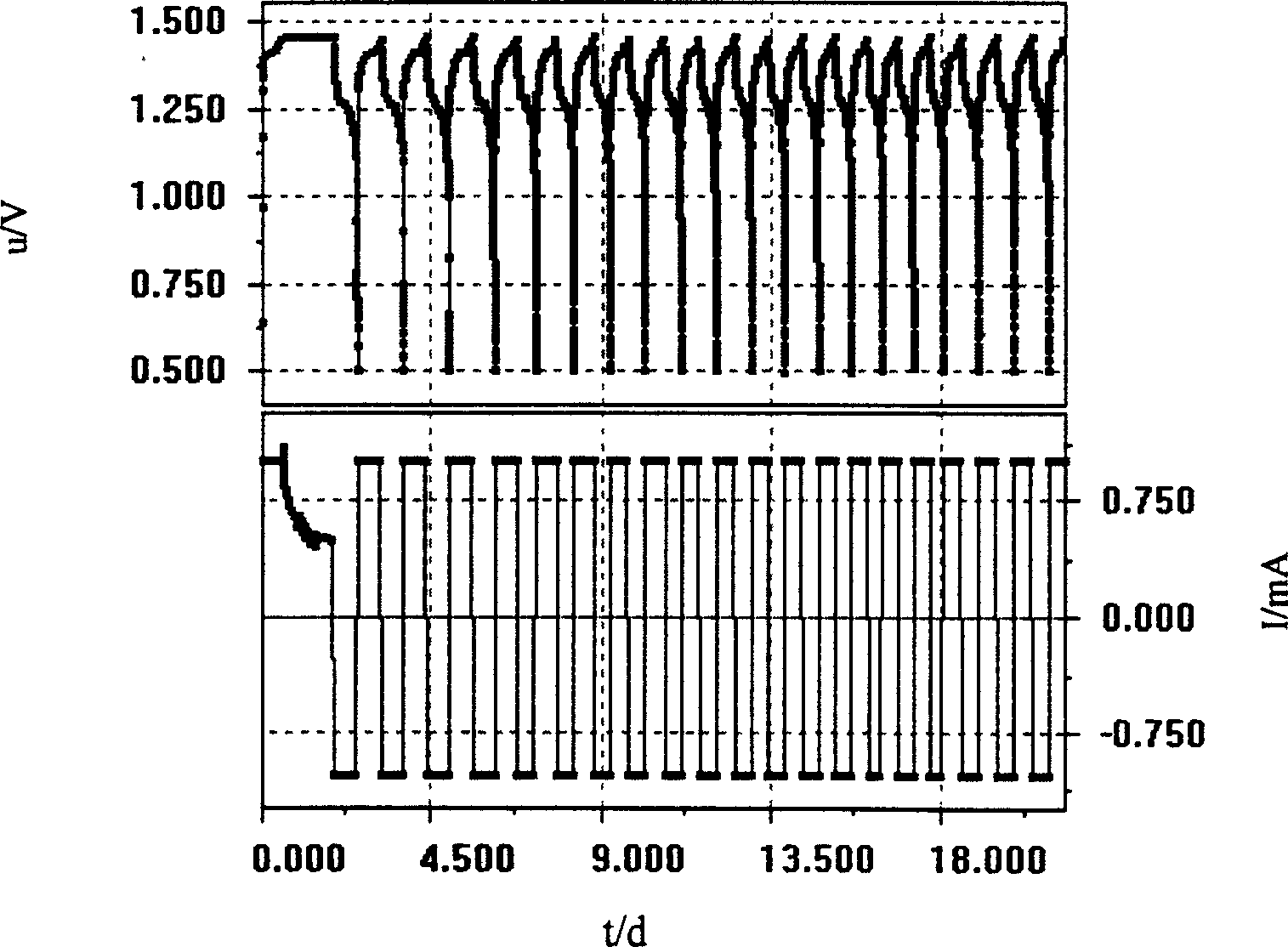

Nickel-hydrogen battery adhesive

InactiveCN1523073AImprove discharge capacityImprove cycle performanceEster polymer adhesivesNickel accumulatorsPolymer scienceAdhesive

The present invention relates to a new-type cell adhesive, in particular, it is a new type adhesive which is suitable for hydrophobicity of Ni / MH cell system and adopts composite material. Its main composition includes polyvinylidene fluoride and polymethacrylate, in which the content of polymethacrylate in the mixed body of said two polymers is 1%-20%. The described polymer mixed body is made into the mixing form. As compared with hydrophilic adhesive used in current industry the obtained cell has high capacity of discharge and good circulation property, and has the advantage of no falling powder and having no dendrite phenomenon.

Owner:XIAMEN UNIV

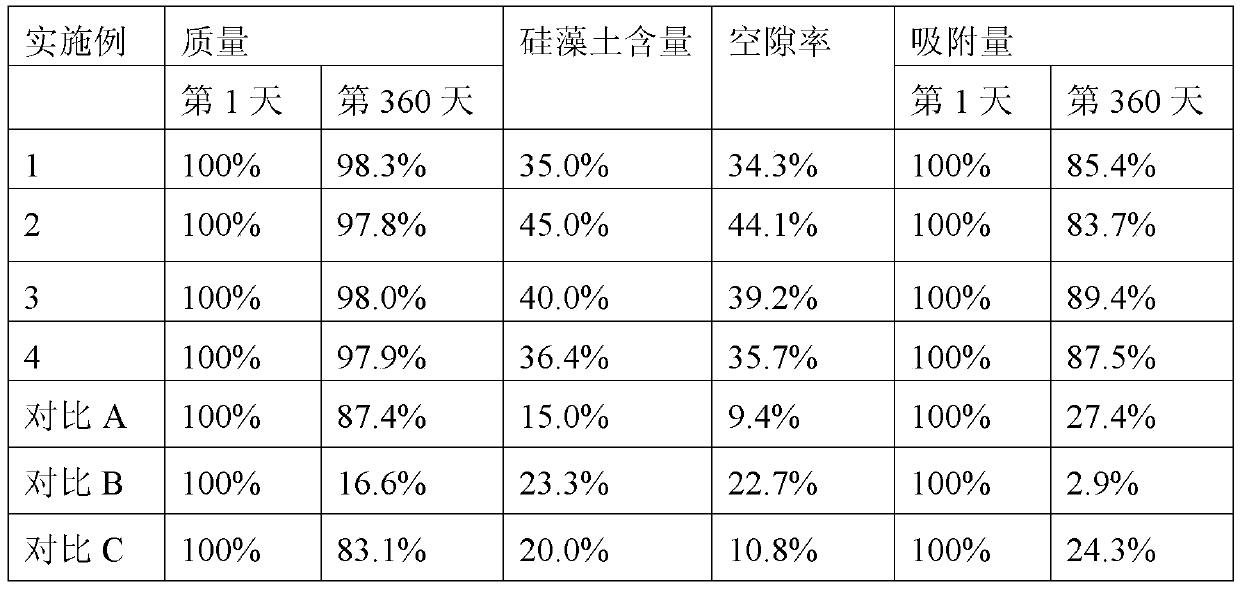

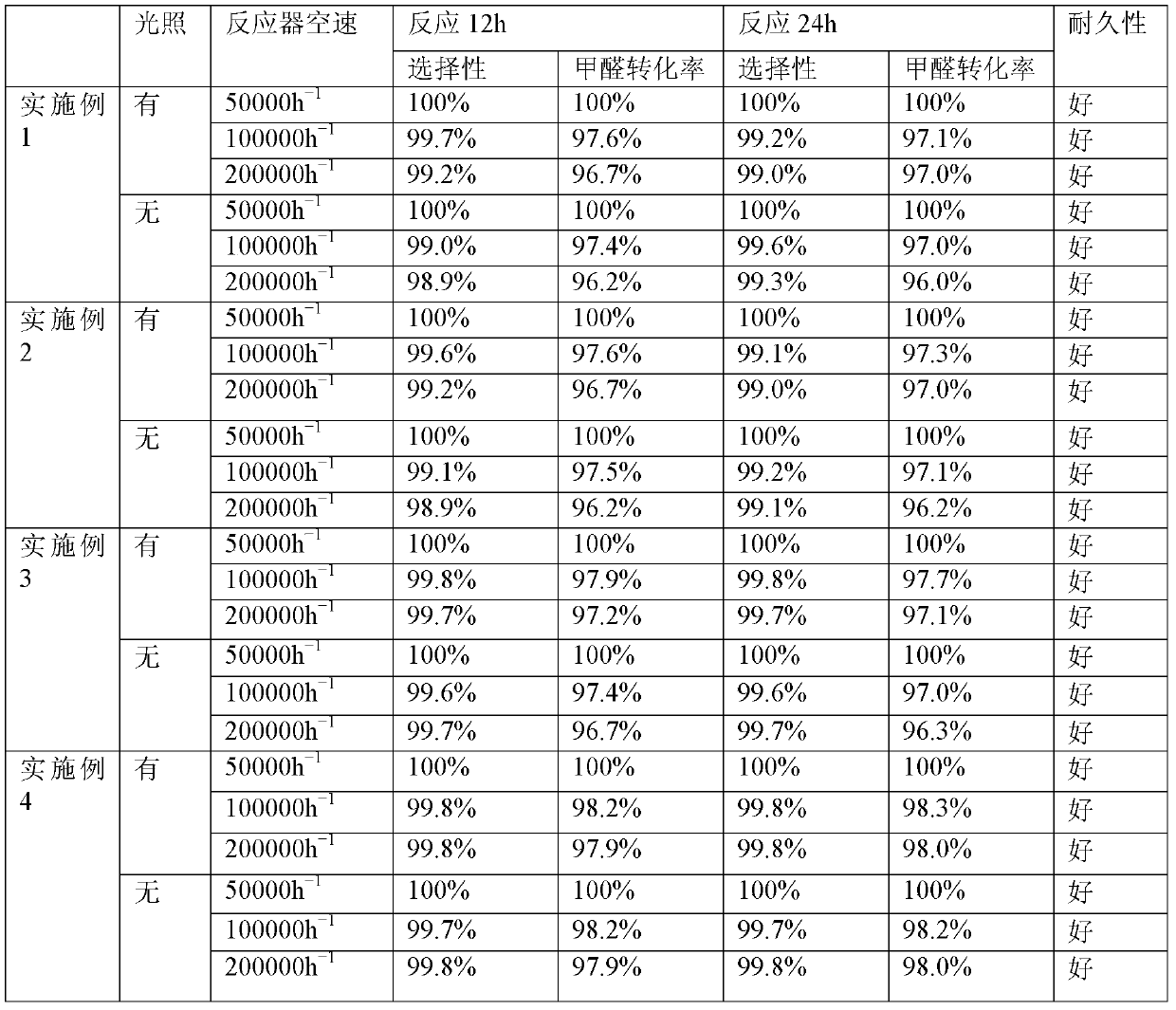

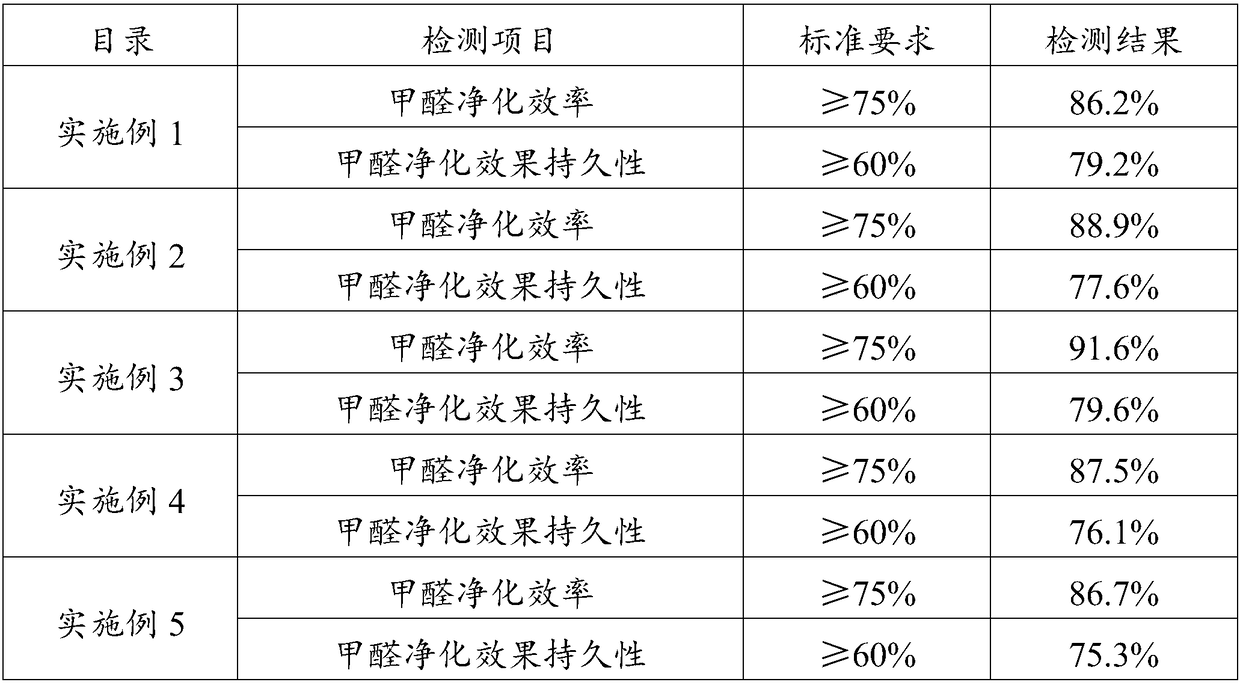

A non-glue-type non-photocatalytic diatom mud material for purifying formaldehyde in the air

The invention provides an adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air and relates to a diatomite wall material capable of purifying air. The existing problems that a diatomite coating added with a chemical adhesive is hardened and solidified and loses original filtration and absorption functions and that chemical adhesive-free diatomite is poor in adhesiveness and has such serious problems as dusting and peeling off after moisturizing are solved. The diatomite wall material is mainly prepared from diatomite, starch, lanthanide oxide and opal in parts by weight. The adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air in the invention is chemical adhesive-free and thus harmless to human body, and achieves true green and environmental protection.

Owner:HARBIN AOBAO DIATOM NEW MATERIALS CO LTD

Exterior wall surface dry powder coating and preparation method thereof

The invention belongs to the technical field of coating, and particularly relates to exterior wall surface dry powder coating and a preparation method thereof. The exterior wall surface dry powder coating is mainly prepared from the following raw materials in parts by weight: 45-50 parts of heave calcium, 10-20 parts of grey calcium, 10-20 parts of quartz sand, 5-12 parts of porous quartz powder,1-15 parts of cellulose ether and 1-5 parts of a moisturizing lubricant HS-2. The exterior wall surface dry powder coating has the advantages that the comprehensive use performance is good, and the raw materials are easy to obtain.

Owner:河南方众环保科技有限公司

Heavy plastering gypsum and preparation method thereof

The invention discloses heavy plastering gypsum. The heavy plastering gypsum comprises the following raw materials by weight: 480 to 520 kg of phosphogypsum, 80 to 120 kg of triple superphosphate powder, 380 to 450 kg of mechanical sand, 0.2 to 0.4 kg of a PE gypsum retarder, 1 to 3 kg of cellulose H620, 0.2 to 0.4 kg of starch ether and 3 to 5 kg black iron. The heavy plastering gypsum has the advantages of firm bonding with a base layer, no hollowing, no falling, no dusting, hydration micro-expansion, no cracking, convenient construction, early strength, rapid hardening, environmental protection, etc., is ensured in service life, satisfies the requirements of normal use of the construction industry and has high promotion and application value.

Owner:贵州砂浆博士科技有限公司

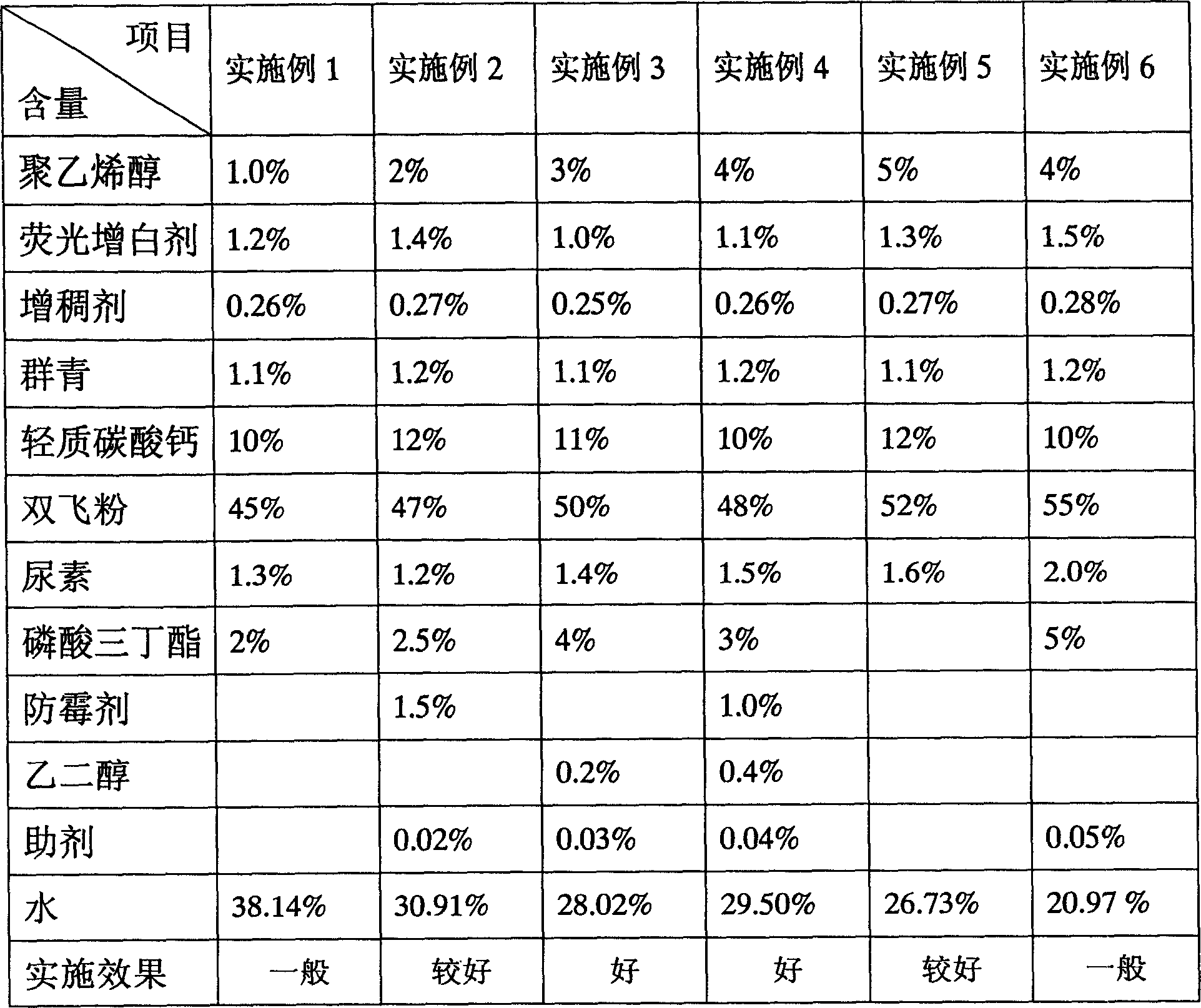

Low-cost internal-external wall porcelain-imitated coating

A low-cost enamel-like paint for internal and external walls is prepared from polyvinyl alcohol fluorescent whitening agent, thickening agent, ultramarine, light calcium carbonate, urea, heavy calcium carbonate and water. Its advantages are smooth surface, high film hardness, high adhesion, high resistance to acid and alkali corrosions, and low cost.

Owner:周华海

Thread-shaped evapotranspiration type tantalum-titanium alloy getter

InactiveCN101433816AImprove reliabilityReduce volumeOther chemical processesVacuum obtaining/maintenanceVacuum pressureVoltage

The invention discloses a wire-shaped evaporable tantalum-titanium alloy getter, which comprises raw materials in percentage by weight: 68 to 80 percent of tantalum, 20 to 32 percent of titanium, and unavoidable impurities, wherein impurity elements, namely Si, Fe, Pb, Sb, Na and K are all less than or equal to 50ppm. The getter has the characteristics of small volume, small outgassing amount during the evapotranspiration, low vapor voltage, steady chemistry, and no drop of powder during the evapotranspiration, and has strengthened mechanical property and absorption property; the getter is of a wire shape with the diameter of between 0.20 and 0.30 millimeters, and the room temperature strength of an alloy wire is more than or equal to 1,100 Mpa. When the temperature is more than or equal to 800 DEG C and the vacuum pressure is less than or equal to 10<-6>, the uniform evaporation of titanium element generates on the alloy wire of the getter to form a titanium film on the wall of a container for air suction, and no sudden rupture of the wire generates during the evapotranspiration and air suction; and during the evapotranspiration, the maximum degassing amount is less than or equal to 10Pa.cm<3> / cm, and no power drops during the evapotranspiration, thereby ensuring the cleanliness of an used instrument.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Internal wall paint capable of resisting organic corrosion

InactiveCN1618902AImprove the decorative effectDoes not drop powderAnti-corrosive paintsEpoxyHigh resistance

An organic corrosion resistant paint for internal wall is composed of matrix A and inert material B. Its advantages are high decorative effect, smooth surface of wall, no poison and radioactivity, and high resistance to acid, alkali and organic solvent.

Owner:DONGYANG BUILDING DECORATION JILIN PROV

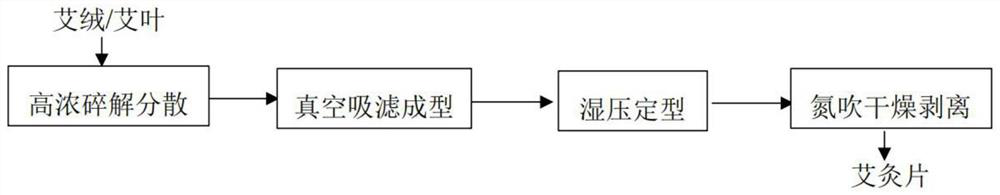

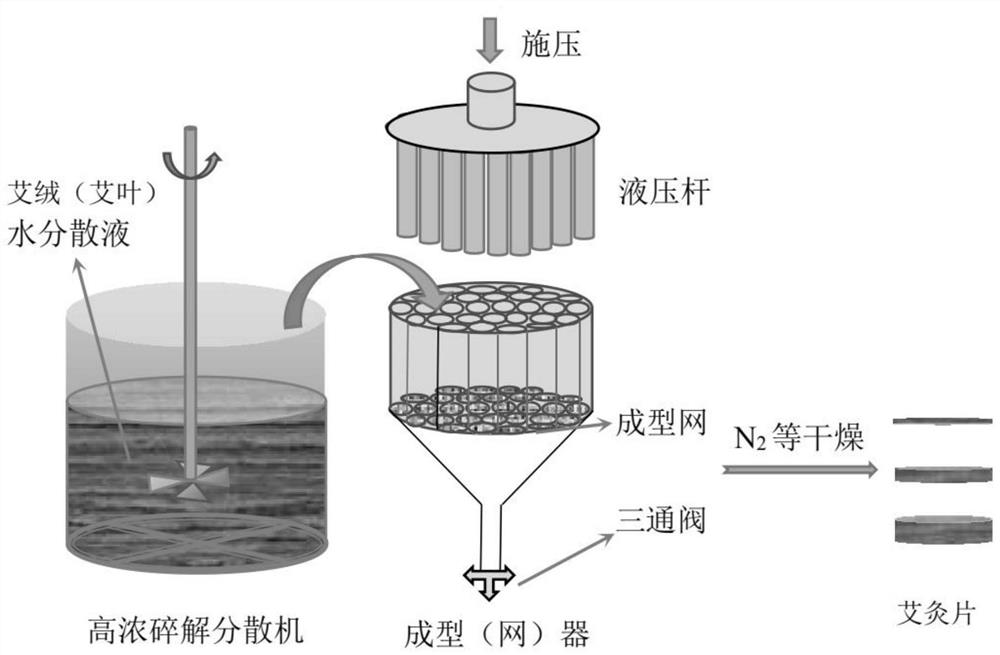

Functional moxibustion sheet and preparation method thereof

PendingCN114272117AImprove compactnessHigh strengthDevices for heating/cooling reflex pointsPharmaceutical product form changeFiberBiomedical engineering

The invention relates to the technical field of moxibustion medicines, in particular to a preparation method of a moxibustion sheet, a functional moxibustion sheet and a preparation method of the functional moxibustion sheet. The preparation method provided by the invention comprises the following steps: crushing and dispersing a wormwood raw material in water to obtain a wormwood fiber aqueous dispersion, the wormwood raw material comprising folium artemisiae argyi and / or moxa floss; dehydrating and forming the wormwood fiber aqueous dispersion to obtain a wormwood fiber wet substrate; the wormwood fiber wet substrate is pressed and shaped through a wet method, and the moxibustion sheet is obtained. The prepared moxibustion piece is easy to control in thickness, uniform and stable in quality, easy to produce on a large scale and high in efficiency, and the problems that accurate metering is difficult, the product uniformity and stability are poor and the production efficiency is low in dry-method punch forming are solved.

Owner:SOUTH CHINA UNIV OF TECH +1

Wall surface toughened paint

InactiveCN102336537AStrong water resistance and water washing resistanceImprove adhesionPOWDERED CELLULOSECalcium carbonate

The invention discloses wall surface toughened paint, which comprises the following ingredients in part by weight: 6 to 8 parts of polyvinyl alcohol, 15 to 25 parts of light calcium carbonate, 15 to 23 parts of sierozem powder, 10 to 20 parts of talcum, 20 to 35 parts of bentonite powder, 10 to 20 parts of cellulose fiber, 0.1 to 0.5 part of silicate, 1 to 3 parts of ethanediol and 30 to 45 parts of water and is prepared through mixing, heating, stirring and filtering. The wall surface toughened paint has the advantages that the whiteness and the brightness are high, the acid and alkali resistance is realized, the hardness is high, the abrasion resistance is realized, and the adhesive force is strong. In addition, the direct washing by water can be realized, the peeling is avoided, the adhesion force is high, the wrinkling, the decoloration, the discoloration and the powder falling are avoided under the condition of being exposed to the wind, the rain and the sun, the preparation process is simple, the cost is low, and the wall surface toughened paint is suitable for being widely popularized and applied.

Owner:王琴

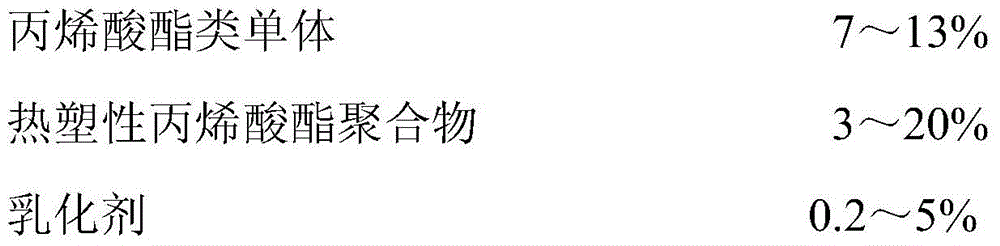

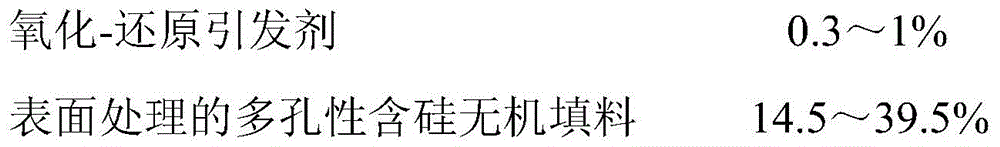

Silicon-containing Acrylate Polymer Composite Porous Respiratory Coating and Its Application

ActiveCN104212208BFull respirationHigh breathing capacityCoatingsPigment treatment with organosilicon compoundsPolymer scienceAir cleaning

Owner:国科广化(南雄)新材料研究院有限公司

Environment-friendly type decoration paste

The invention relates to an environment-friendly type decoration paste, wherein the raw materials include (by weight percentage): pentaerythritol 10-20, polyvinyl alcohol 25-30, ash calcium 2-3, heavy calcium carbonate 40-60, light calcium carbonate 3-10. The invention can be applied for interior wall painting of various wall coverings.

Owner:刘玉生

Production method of multifunctional water-washing and filling putty paste

InactiveCN105348894ANovel ideaSimple production processFilling pastesEmulsionUltimate tensile strength

The invention provides a production method of multifunctional water-washing and filling putty paste. The technological process includes the steps of picking calcium carbonate powder and white emulsion, conducting mixing and stirring, conducting spiral stirring and squeezing and obtaining a finished product. According to the production method, a formula is simple, the formed product is environmentally friendly, batched scrapping is achieved, filling is simple, and the putty paste can be used after a package is opened. In the preparation process, a spiral blender is adopted to conduct stirring and extrusion forming, the formed product is uniform in fusion and low in moisture content, the product is easy to store and not prone to curing as long as moisturizing is well conducted; meanwhile, in the application process, the affinity with wood is good, bonding is firm, strength is high, and dryness is high in speed. Within 72 hours, the protruding and uneven positions obtained after filling can be washed with water and wiped away, and no professional grinding machine is needed to conduct grinding and sorting; besides, the production cost is low, the filling property is good, harness is good, the sealing property is high, adhesion is stable, and the putty paste is suitable for any wood. The putty paste further has the advantages of being free of falling, cracking, collapse and powder falling, easy to color and the like after repairing, and the market prospect is wide.

Owner:GUANGXI NANNING QIAOSHENG WOOD

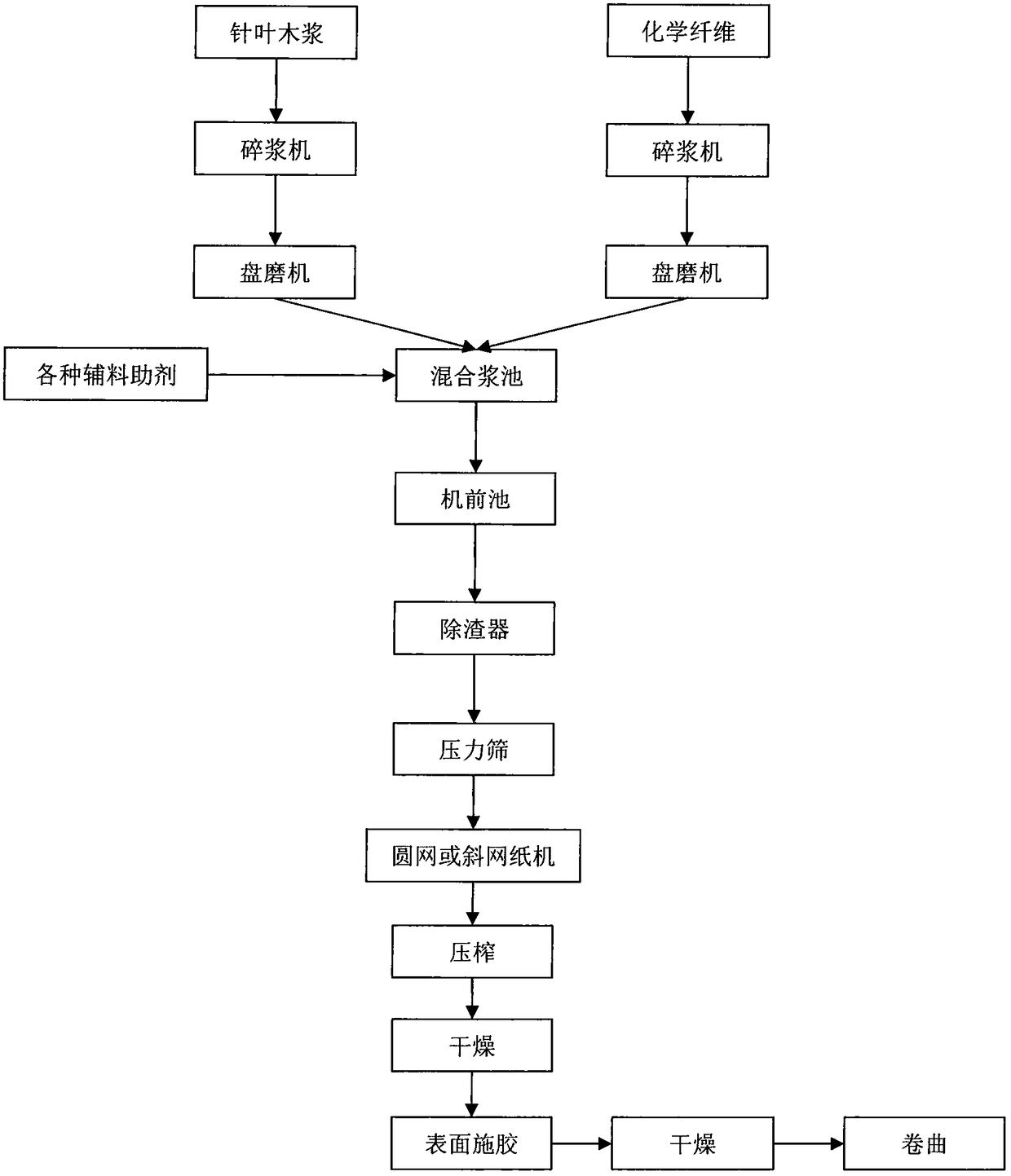

Manufacturing technology of efficient dust collecting sleeve paper for vacuum cleaners

InactiveCN109306637AHigh strengthImprove breathabilityPaper coatingReinforcing agents additionManufacturing technologyPulp and paper industry

The invention belongs to the field of specialty paper, and particularly relates to a manufacturing technology of efficient dust collecting sleeve paper for vacuum cleaners. The manufacturing technology includes the steps that dust collecting sleeve body paper with good permeability is manufactured with pulp by plant fibers, high-proportion chemical fibers, additives and the like, and then the dustcollecting sleeve paper is manufactured by engine sizing on the body paper with an enhanced glue solution which is prepared from enhanced natural polysaccharides substances and derivatives thereof, latex, CMC, an antiseptic and the like. The dust collecting sleeve paper can be used for manufacturing dust collecting sleeves in the cleaning industry such as dust collectors, specifically, dust collecting efficiency is greater than or equal to 99.9% under the pressure of 47 mu m Particle, lint and powder falling is avoided, and strength is high; and the dust collecting sleeve paper is suitable for manufacturing the efficient dust collecting sleeves of the vacuum cleaners, and compared with traditional non-woven fabric bags, the cost is low and the environment is protected.

Owner:中轻特种纤维材料有限公司 +1

Washable putty powder for interior wall latex paint

ActiveCN103497561BGood wash resistanceHigh bonding strengthFilling pastesMaterials scienceMilk paint

The invention discloses a water washing resistant putty powder for interior wall emulsion paint, and the water washing resistant putty powder comprises the following raw materials: by weight, 40-50 parts of calcium carbonate powder, 50-60 parts of modified talcum powder, 20-30 parts of ash calcium powder, 10-15 parts of white cement, 2.5-3.5 parts of hydroxypropyl methylcellulose, 3-5 parts of hydroxypropyl starch ether, 0.5-1 part of HS-2 moisturizing lubricant and 2-3 parts of NSJF-6 A emulsion powder. The putty powder has excellent water washing resistance and high bonding strength, when the putty powder meets water and is affected with damp, the putty powder may not fall off powder, pulverize, hollow and crack, is excellent in construction property, non-material-throwing and non curling, and has the advantages of being high in hardness, fast in film forming, moisturizing, mildew and damp proof, aging resistant, long in storage time, convenient to use, stable in performance and the like.

Owner:广东瓦科新材料有限公司

Electrode plate for alkaline storage battery and processing method thereof

InactiveCN1482697AImprove performanceIncrease capacityAlkaline accumulator electrodesHydrogenNickel cadmium

An alkaline accumulator electrode piece and processing method thereof, wherein the positive electrode sheet and the negative electrode sheet are composed of pole piece conducting base and hybrid powder, the composition and percentage by weight for the positive electrode sheets are, nickel oxyhydrogen 85.0-92.5%, Cobalt oxyhydrogen powder 7-13%, bonding agent 0.5-2.0%, the composition and percentage by weight for the negtive electrode sheets are, hydrogen storing alloy powder 97.5-99.5%, bonding agent 0.5-2.5%, the invention realizes easy availability of raw material, simple formula, stable performance, high capacitance and small resistance. íí

Owner:何策衡

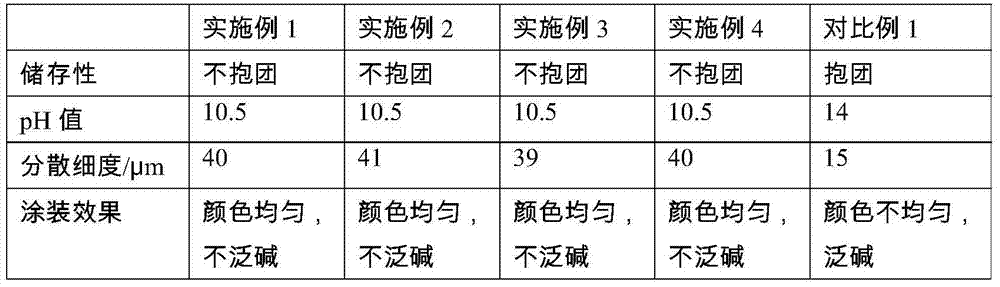

A kind of weak alkaline inorganic multifunctional diatom mud dry powder coating and preparation method thereof

The invention relates to a weakly alkaline inorganic multifunctional diatom ooze dry powder paint. The invention is characterized in that the paint is composed of the following components in parts by weight: 10-15 parts of diatom ooze, 5-30 parts of titanium white, 8-10 parts of 2000-mesh nano calcium carbonate, 25-40 parts of 600-mesh calcium carbonate, 3-5 parts of kaolin, 5-15 parts of talcum powder, 5-10 parts of zeolite powder, 1-2 parts of nano titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of tourmaline powder, 2 parts of powder defoaming agent, 2 parts of powder dispersing and wetting agent, 10 parts of dispersible latex powder, 2-4 parts of inorganic bentonite, 1-2 parts of cellulose ether, 2-4 parts of silicon dioxide, 5-8 parts of potassium methane-silicate powder, 5-8 parts of sodium methane-silicate powder, 0.3-0.5 part of silane coupling agent and 0-3 parts of inorganic pigment. The paint has the advantages of long storage time, stable performance, bright color, easy color matching, favorable weather resistance, high covering rate, stable color and delicate hand feeling.

Owner:佛山市南海万磊建筑涂料有限公司

A kind of strong and anti-gray diatom mud wall material and its preparation method

The invention belongs to the field of indoor decoration coatings, and particularly relates to a strengthening and dust falling preventing diatom ooze wall material and a preparation method thereof. The diatom ooze wall material is prepared from diatomite, a water-soluble wrapping agent, calcium hydroxide, calcined gypsum, vital gluten, carbon fibers, silica sol and inorganic pigments. The kieselguhr is adopted as a main raw material, the surface of the kieselguhr is wrapped by the water-soluble wrapping agent, a water-soluble protection layer of a network structure is formed on the surface of the kieselguhr, and holes of the kieselguhr are prevented from being blocked by other additives and adhesives; a small quantity of calcium hydroxide, calcined gypsum and carbon fibers is added, the flexibility and strength of the kieselguhr are improved, the kieselguhr is prevented from cracking or falling in the use process, and the technological problems that a diatom ooze coating is prone to dust falling and cracking and low in strength are solved. The diatom ooze coating has the advantages of being high in strength, not prone to dust falling and free of fading, cracking and falling, the preparation process is simple, the price is low, and popularization is easy.

Owner:广东华矿新材料有限公司

Low-cost internal-external wall porcelain-imitated coating

The invention relates to a wall paint, in particular to a formula and a production method of a toughened interior wall paint with high hardness, high smoothness, high adhesion, and low cost. The formula of the present invention is: polyvinyl alcohol 6.0% ~ 8.0%, fluorescent whitening agent 0.5% ~ 1.0%, titanium dioxide 16% ~ 20%, gray calcium 10% ~ 16%, urea 1% ~ 2%, the rest is water. The invention has a product with a hardness of 6H after film formation, a bonding strength of >0.5MPa, a wall surface as smooth as porcelain, water-resistant, and high adhesion. It does not wrinkle, fade, discolor, or It has the characteristics of powder shedding, acid and alkali corrosion resistance, convenient construction and low cost. It is suitable for a variety of interior wall substrates and can achieve satisfactory decorative effects.

Owner:周华海

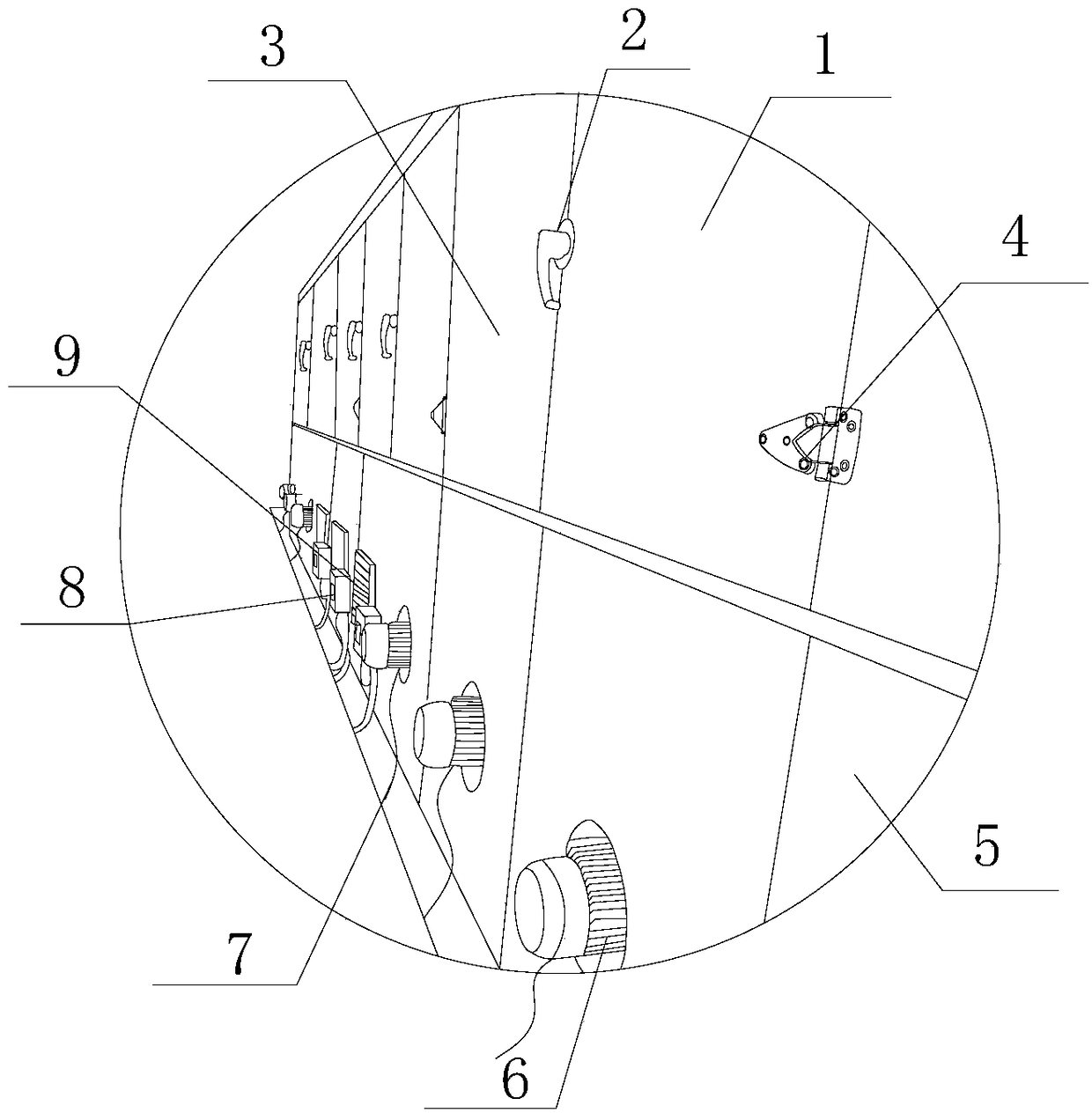

Segmented control of oven

InactiveCN109162050AAll the same sizeImprove product qualityLiquid/gas/vapor removalState of artRough surface

The invention discloses segmented control of an oven. An oven, a handle, hinges, a switch door, a cabinet, a motor, a power line, an alarm and a heat dissipation window are arranged. The oven is arranged and segmented control of the oven is performed. Three drying layers are arranged at the inner side of the oven. The entrance temperature of the yarn into the oven is controlled and thus the reaction speed is reduced from the low temperature to the high temperature when a yarn tape water-blocking solution enters the oven, so that the yarn surface becomes fine and smooth and is coated completelywithout power falling. Therefore, phenomenon that the water-blocking yarn has problems of rough surface, loose wrapping, and powder falling in production and thus inconvenience is caused in the priorart is avoided.

Owner:张家港保税区鸿卓光电材料科技有限公司

Anti-falling internal and external wall basaltic mud coating and preparing method thereof

The invention discloses an anti-falling internal and external wall basaltic mud coating which solves the technical problems that an existing coating is not high in strength and prone to cracking and falling, and belongs to the technical field of coating preparation. The coating is prepared from, by weight, 20-30 parts of basalt powder, 8-12 parts of shell powder, 4-8 parts of kieselguhr, 2-5 partsof sodium carboxymethylcellulose, 1-5 parts of quartz stone powder, 0.1-0.3 part of graphene and 6-10 parts of activated carbon. The invention further provides a preparing method of the anti-fallinginternal and external wall basaltic mud coating. The method includes the steps of raw material mixing, stirring, drying and the like. The anti-falling internal and external wall basaltic mud coating has the advantages of being high in wall surface adhesiveness, high in durability, free of chalking, free of color fading and free of cracking and falling and is suitable for indoor decoration of various types of buildings. The preparing method is easy to implement and suitable for large-scale production.

Owner:白山大金谷新型材料科技股份有限公司

Environment-friendly type decoration plaster

InactiveCN1524907AImprove water resistanceImprove heat resistanceCoatingsPolyvinyl alcoholAdditive ingredient

An environment-friendly type decoration plaster characterized in that, its raw material and ingredients are (percentage by weight) light calcium carbonate 8-15%, ash calcium 4-8%, ceramic powder 25-50%, polyvinyl alcohol 38-55%, wherein polyvinyl alcohol is a liquid prepared by adding 17kg water into each 1kg polyvinyl alcohol for hydrating. The plaster has strong adhesive force, good water resistance, nontoxicness and innocuousness.

Owner:刘玉生

A kind of red ceramic tile and its manufacturing method

InactiveCN104944914BHigh priceLow priceCeramic materials productionClaywaresAndraditeEnvironmental resistance

The invention discloses a red ceramic tile and a manufacturing method thereof. The ceramic tile is prepared from the following raw materials in parts by mass: 50-60 parts of red mud, 15-25 parts of kaolin, 15-25 parts of perlite, 10-15 parts of quartz sand, 5-10 parts of fly ash, 2-5 parts of andradite, 2-5 parts of gehlenite and 2-5 parts of diopside. The manufacturing technique comprises the following steps: material selection, powder preparation, compaction, drying, glazing and firing to obtain the finished product. The use proportion of the red mud is greater than one half of the total raw materials; and the consumption of the red mud is maximally increased, thereby relieving the abundant discharge of the red mud which has no place to arrange, changing wastes into valuable substances, utilizing the waste, lowering the production cost and reducing the environmental pollution. The red ceramic tile is corresponding to new product research, development and application in the whole ceramic brick industry around the environment-friendly problems of energy saving, emission reduction, waste slag utilization and the like.

Owner:绥阳县华夏陶瓷有限责任公司

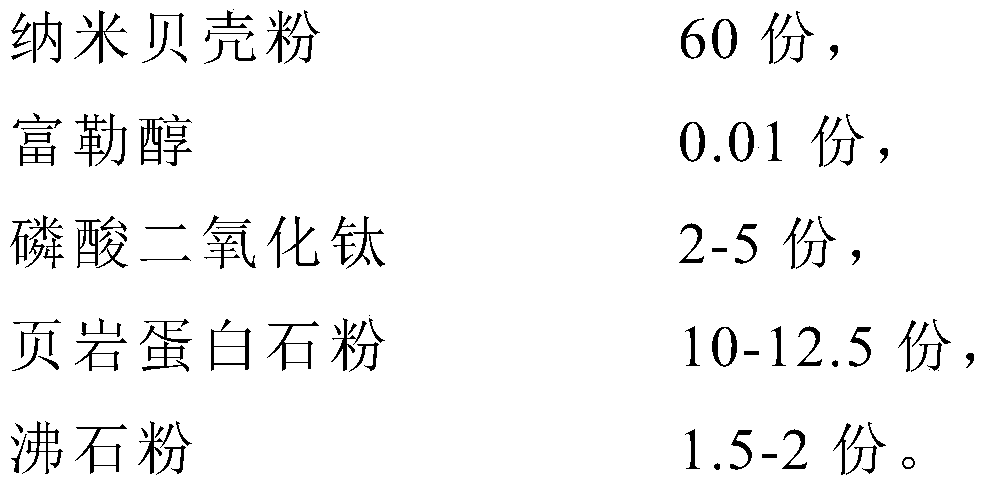

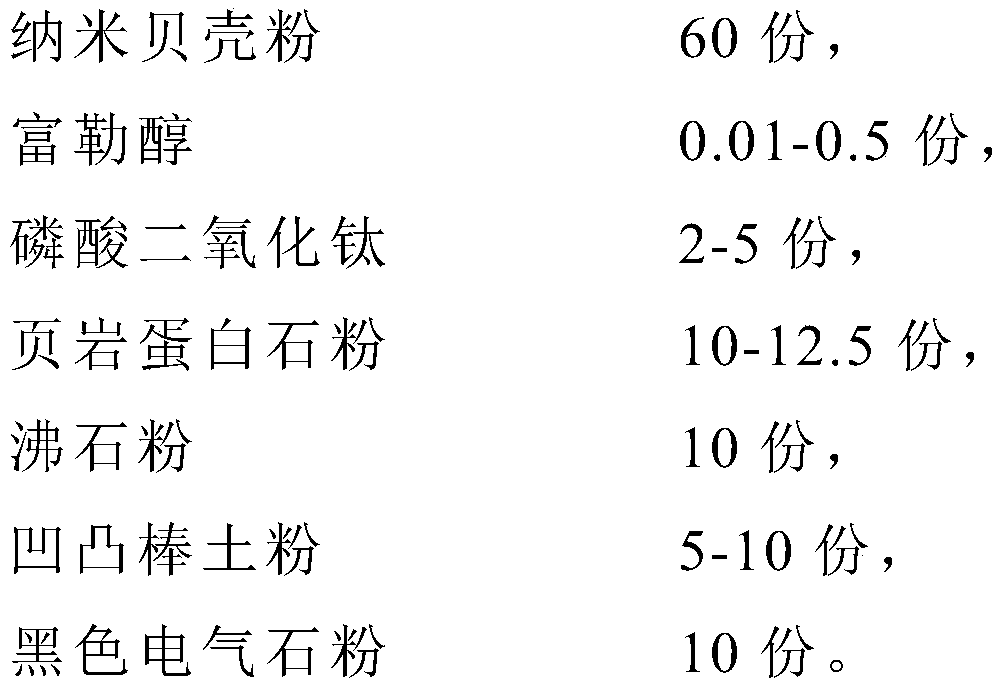

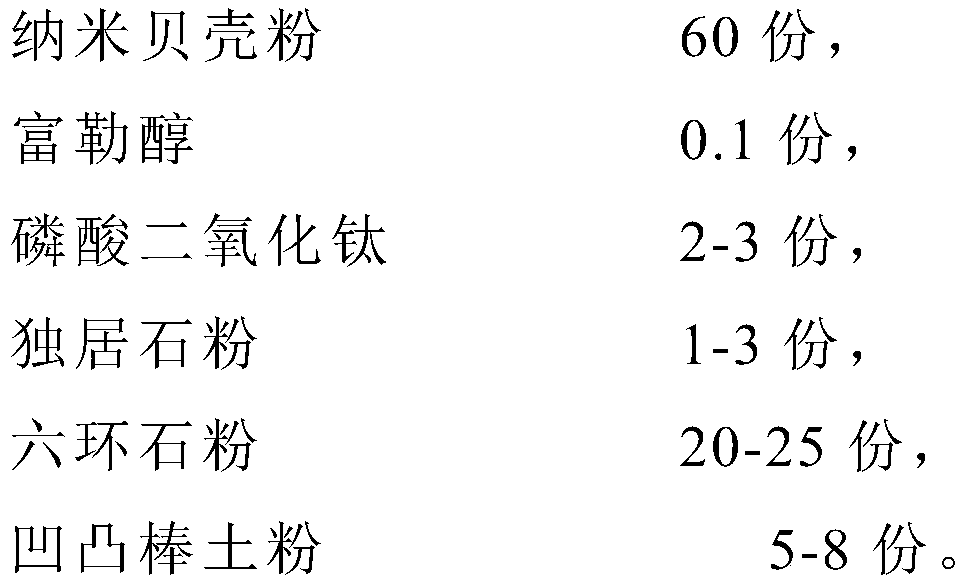

Fullerene negative ion dry powder coating and its application method

ActiveCN107418264BStrong concentrationPowerful killAntifouling/underwater paintsPaints with biocidesPhysical chemistryPerylene derivatives

The invention belongs to the technical field of dry powder coatings, and relates to a fullerene anion dry powder coating and a use method. The fullerene anion dry powder coating is prepared from the following components in parts by mass: 50 to 60 parts of a base material, 0.01 to 0.5 part of nano-fullerene and / or nano-fullerene derivative, 25 to 35 parts of a mineral powder additive, 1 to 2 parts of a binder, 1 to 2 parts of a thixotropic agent and 1 to 2 parts of a dispersing agent. The invention has the effects of releasing anions and inhibiting bacteria.

Owner:浙江纳巍健康科技有限公司

A modified starch for papermaking coating and sizing with high smoothness

The invention discloses high-smoothness modified starch for coating and gluing during papermaking. The modified starch is prepared according to the steps of 1, preparing starch suspension, wherein corn starch is fully ground and sieved with a 200-mesh sieve, added to purified water, and stirred with a stirrer constantly to form the suspension with mass fraction of 28-35%; 2, preparing an enzyme solution, wherein lupeose, lupeose, alkaline pectinase, amylase, cellulose and water are adopted to prepare the enzyme solution; 3, conducting modification, wherein temperature is maintained at 38 DEG C, the enzyme solution is added to the starch suspension dropwise according to the weight ratio of 1:50, stirring is conducted constantly with the stirrer for 35-45 min, and finally temperature is increased to 80 DEG C for treatment lasting 5 min; 4, conducting microwave radiation treatment, wherein 300w microwave is adopted for radiation lasting 10-12 min after enzyme modification; 5, conducting rinsing with clear water after microwave radiation treatment, and conducting drying at 80 DEG C.

Owner:长兴锦龙纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com