Nickel-hydrogen battery adhesive

A nickel-metal hydride battery and adhesive technology, which is applied in the direction of nickel battery, adhesive type, ester copolymer adhesive, etc., can solve the problems of hydrogen escape, battery internal pressure rise, increase battery internal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

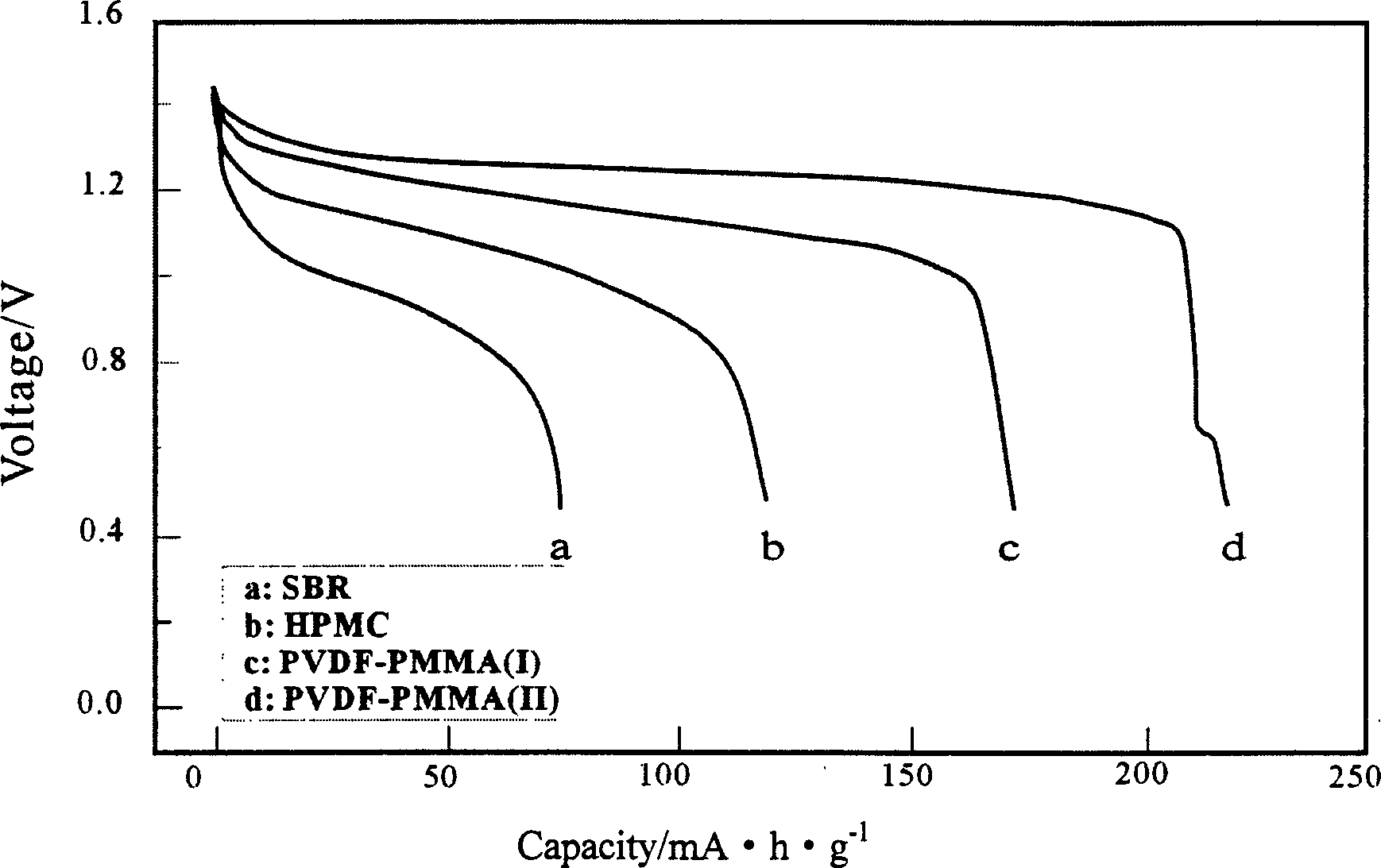

[0018] Embodiment 1: PVDF90g, PMMA10g are mixed, rubber mixing. The polymer mixture after rubber mixing was dissolved in 900g DMF to form a polymer solution with a concentration of 10%. Add 90g of electrode active material, 1g of additive, and 4g of conductive agent to 50g of 10% polymer solution and stir to make a slurry, and coat the prepared slurry on current collectors such as nickel foam or perforated steel strip After drying and rolling, the positive and negative plates are obtained. The resulting product (see figure 1 The influence of curve b) and other different binders on the battery discharge capacity is determined by figure 1 It can be seen that the order of discharge capacity is PVDF(d)>HPMC(c)>PVDF+PMMA(b)>SBR(a), indicating that PVDF has the highest discharge capacity under the same discharge conditions.

Embodiment 2

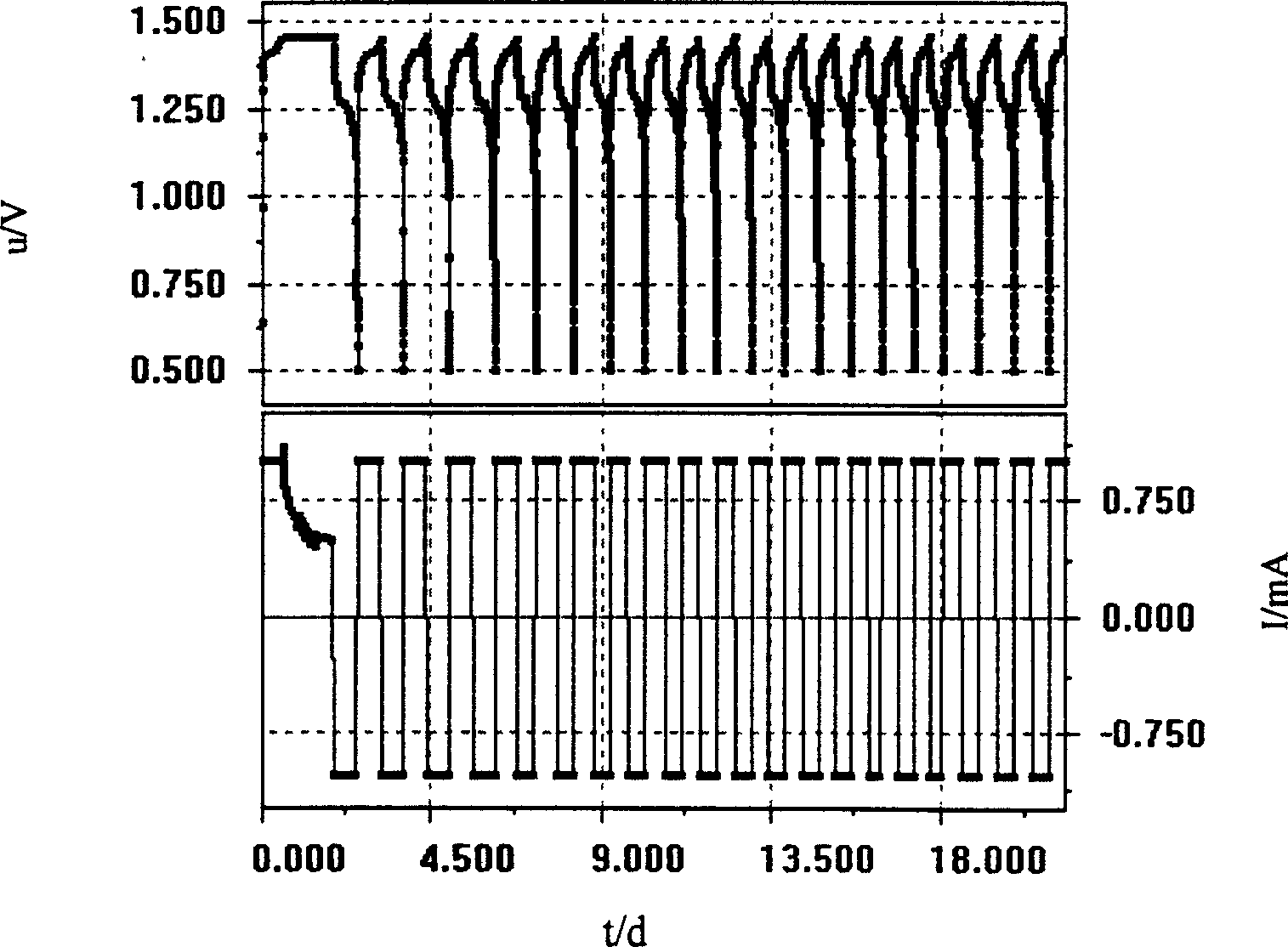

[0019] Embodiment 2: PVDF 85g and PMMA 15g are mixed, and the polymer mixture after rubber mixing is dissolved in 900g DMF to form a polymer solution with a concentration of 10%. Similar to Example 1, add 90 g of electrode active material, 1 g of additive, and 4 g of conductive agent to 50 g of a 10% polymer solution and stir to form a slurry, and coat the prepared slurry on foamed nickel or perforated steel On the belt and other current collectors, the positive and negative plates are obtained after drying and rolling. see figure 2 The battery cycle performance of the given PVDF-PMMA binder. The results indicate that the highest discharge capacity can reach 251mAh / g, and when the battery is cycled for 15 weeks and then cycled for 20 weeks, its capacity efficiency is still around 90%. It shows that the battery with PVDF-PMMA as binder has quite good cycle performance.

Embodiment 3

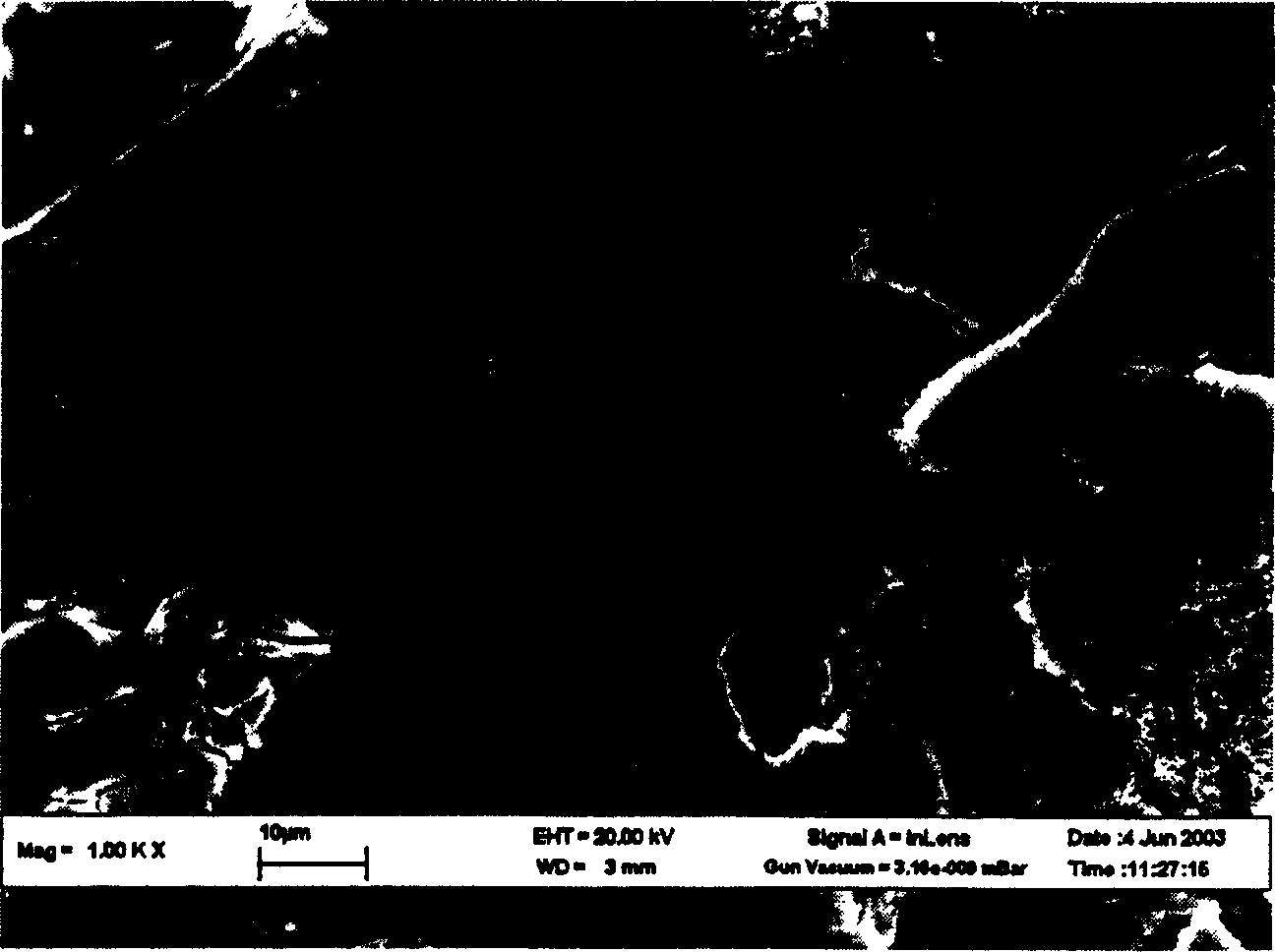

[0020] Embodiment 3: 95g of PVDF and 5g of PMMA were mixed, and the rubber was mixed, and the polymer mixture after rubber mixing was dissolved in 900g of DMF to form a polymer solution with a concentration of 10%. Add 90g of electrode active material, 1g of additive, and 4g of conductive agent to 50g of 10% polymer solution and stir to make a slurry, and coat the prepared slurry on current collectors such as nickel foam or perforated steel strip After drying and rolling, the positive and negative plates are obtained. Such as Figure 3 to Figure 6 As shown, when the battery with HPMC as the binder was cycled for 4 weeks, from image 3 You can clearly see the signs of electrode powder falling, which will reduce the battery cycle and reduce the service life of the battery. Similarly, dendrites can be observed in the negative electrode with HPMC as the binder, resulting in a short circuit of the battery. When PVDF-PMMA is used as the binder, although the positive electrode has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com