Patents

Literature

1000 results about "Poly methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

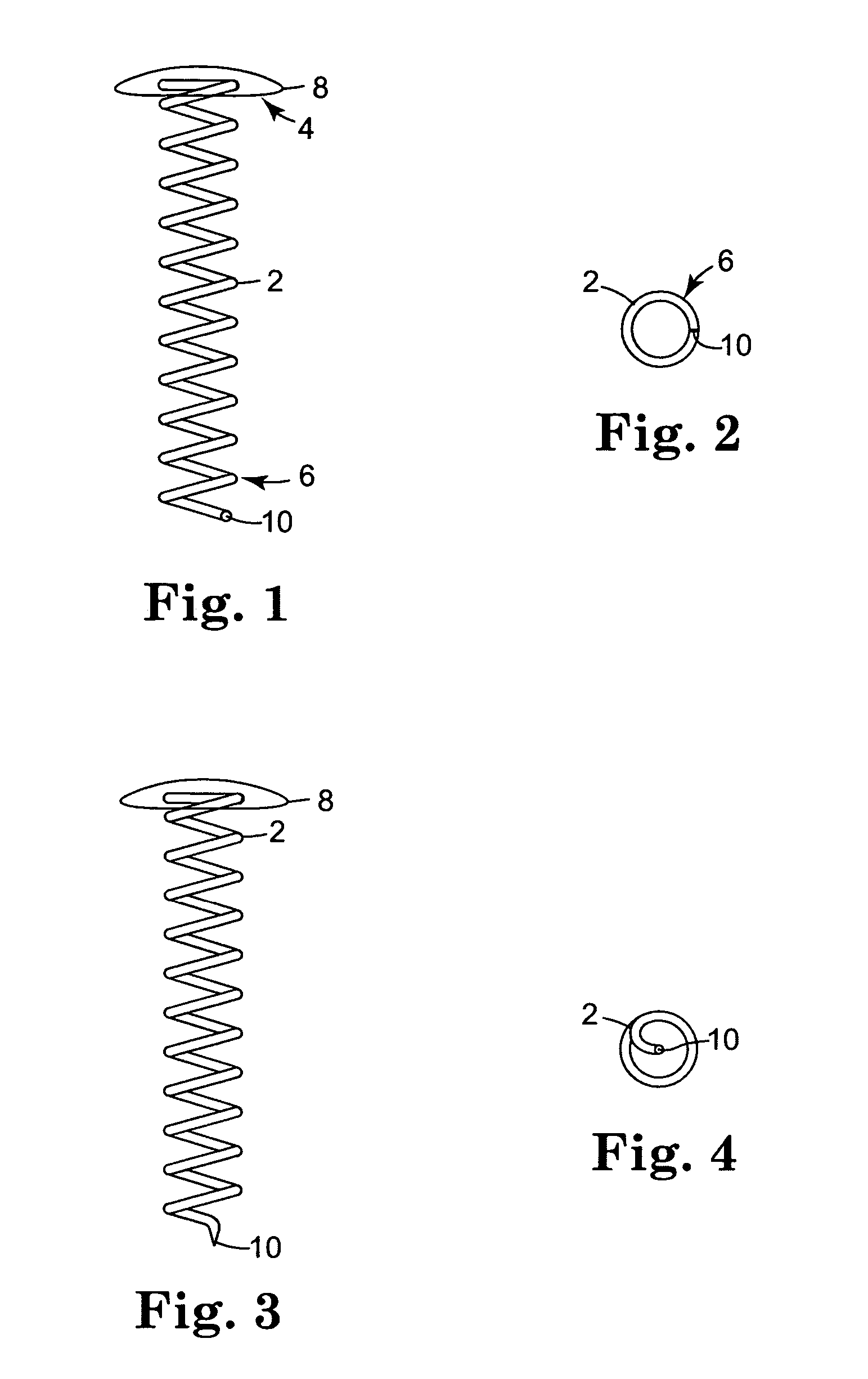

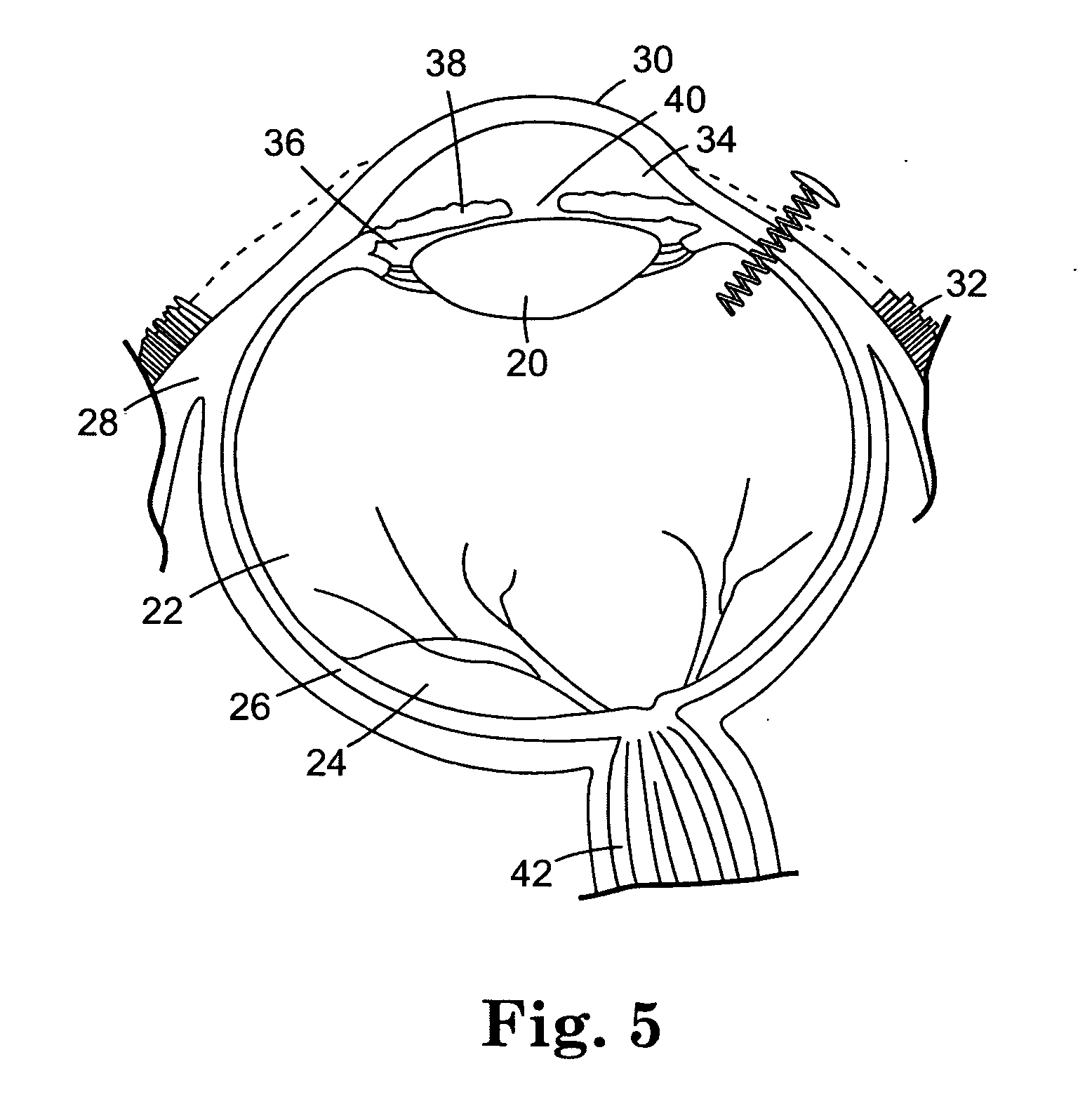

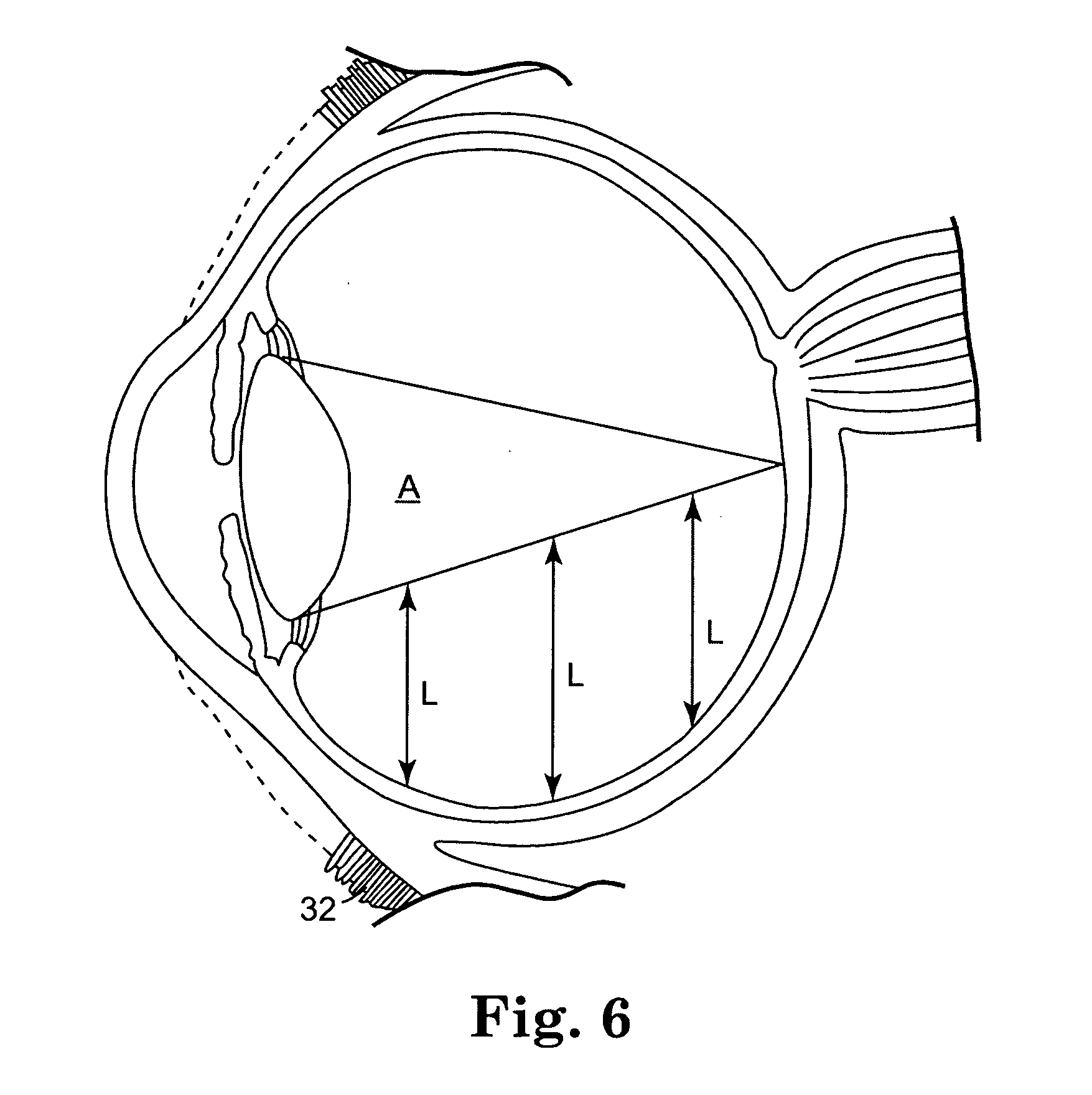

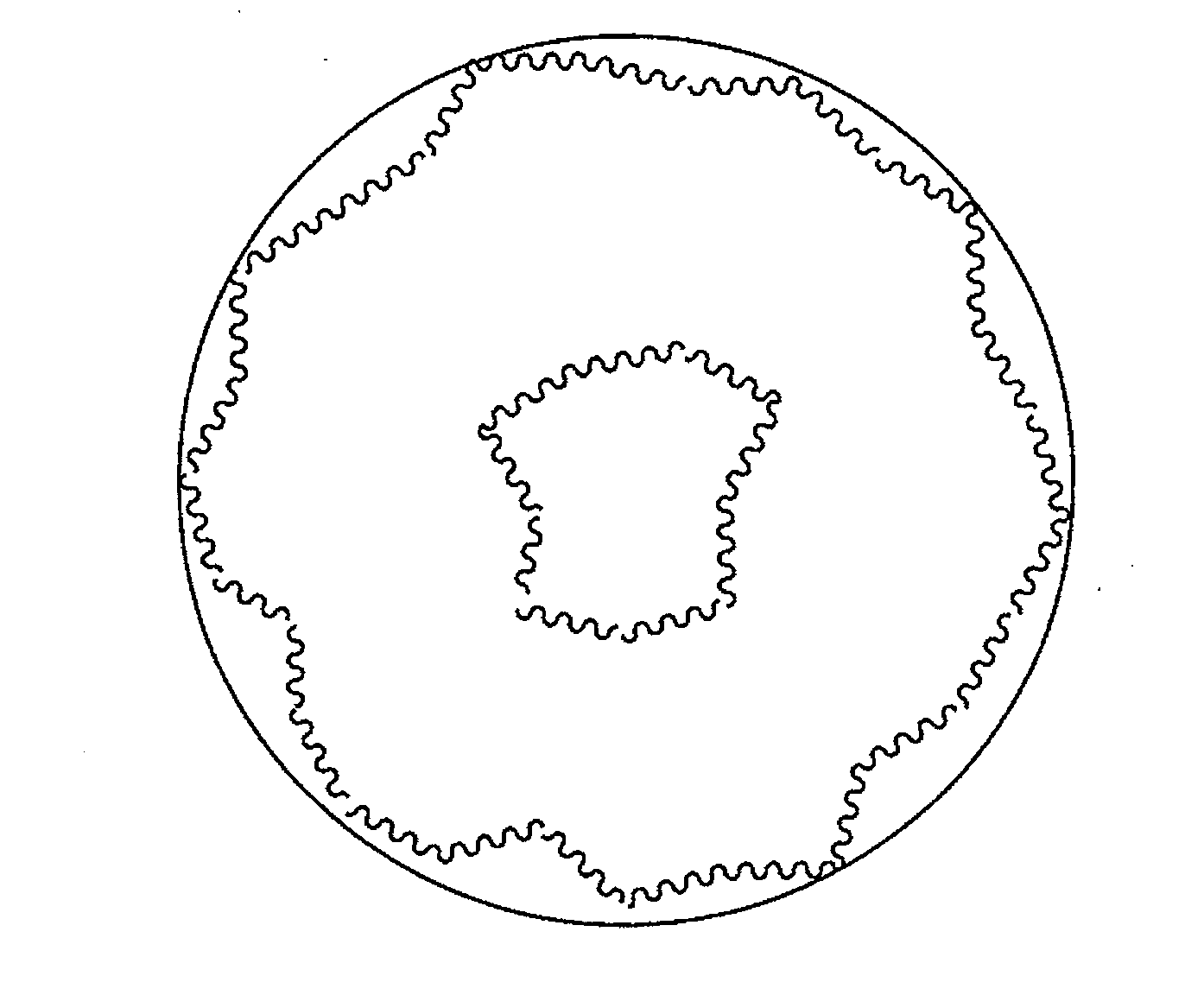

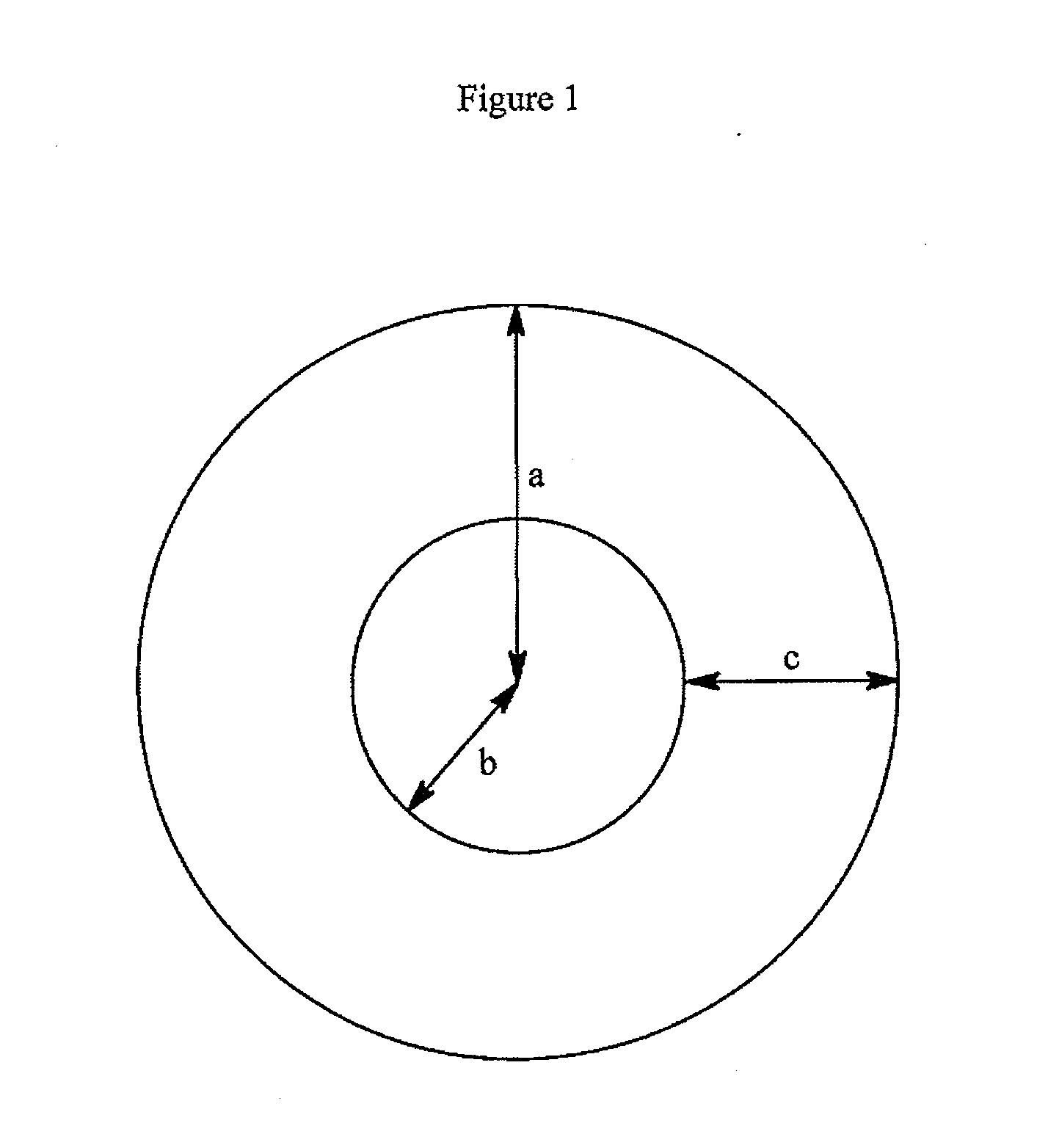

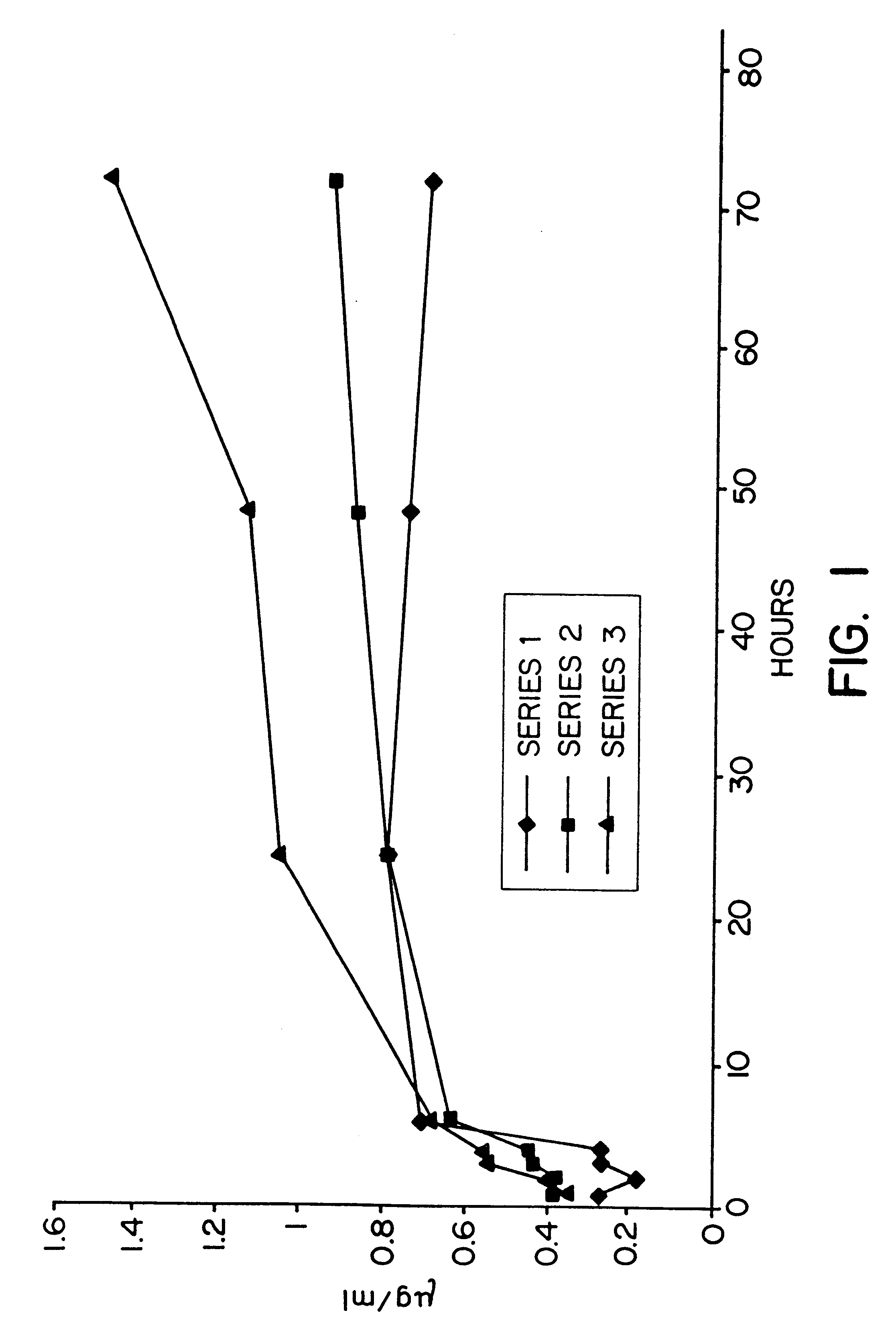

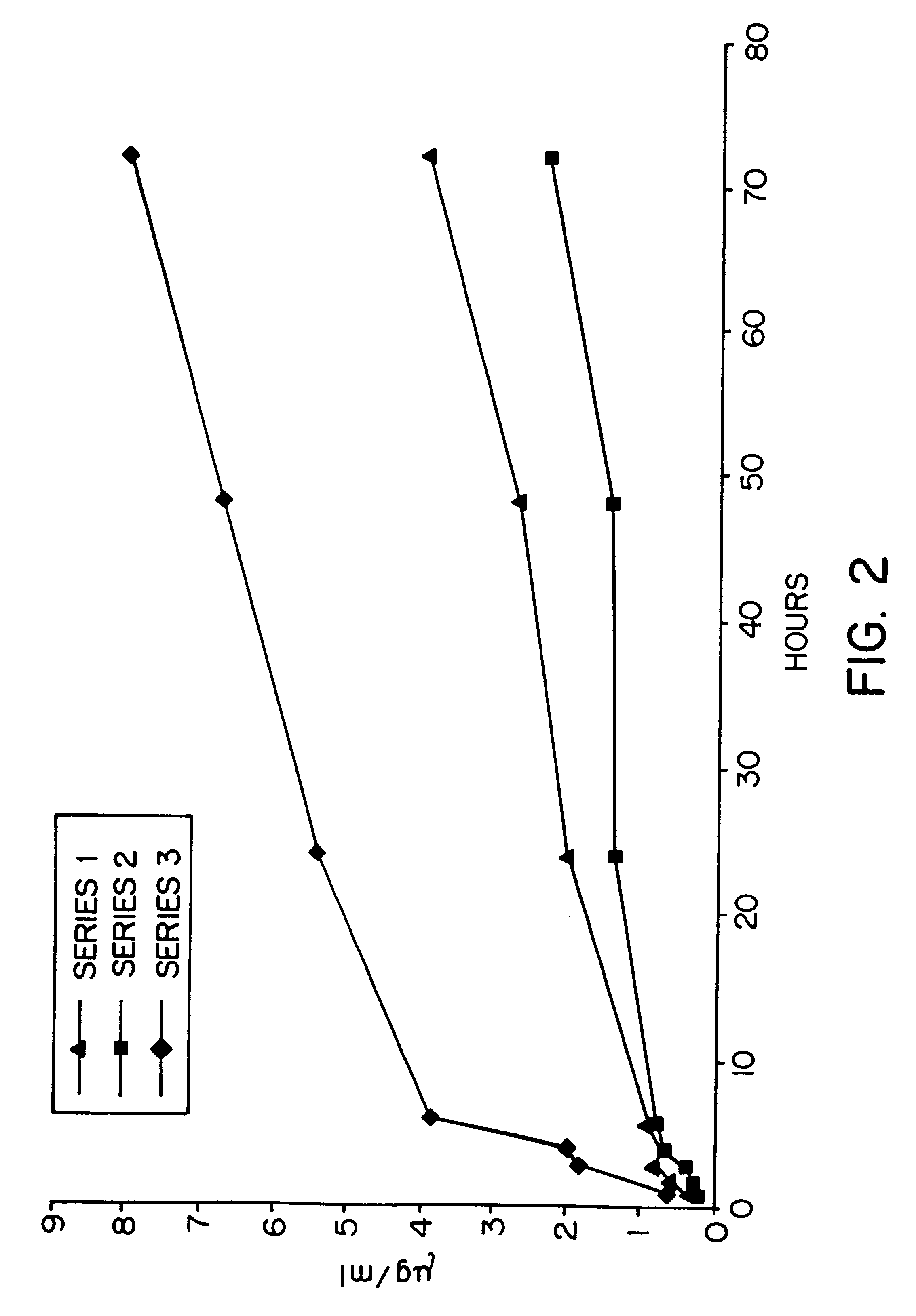

Controlled release bioactive agent delivery device

InactiveUS20050019371A1Minimize damageInterference minimizationOrganic active ingredientsSenses disorderControlled releaseMeth-

Owner:SURMODICS INC

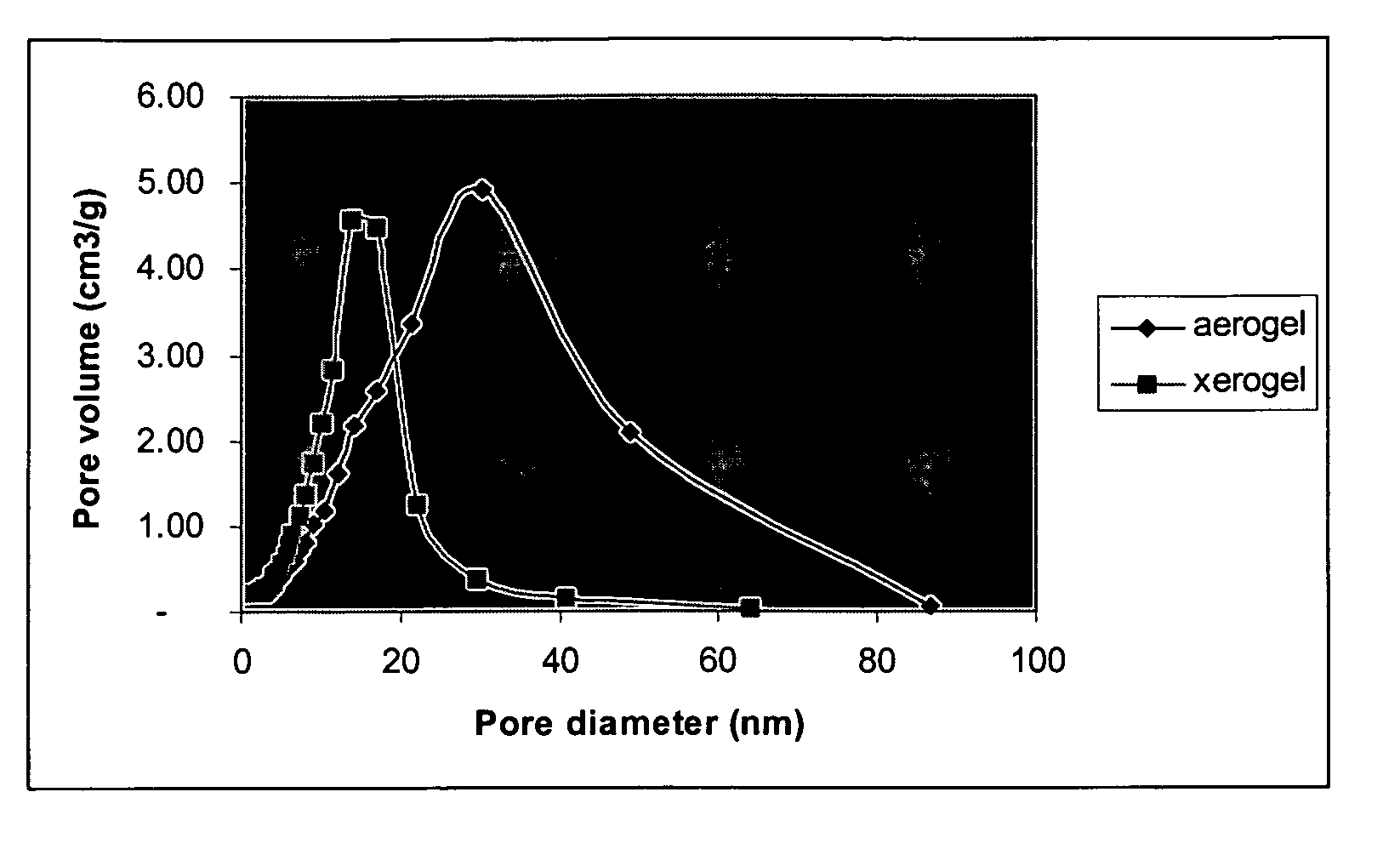

Ormosil aerogels containing silicon bonded polymethacrylate

InactiveUS20050192366A1Reduce uniformityAvoid phase separationMechanical clocksSilicon compoundsFiber-reinforced compositePoly methacrylate

Owner:ASPEN AEROGELS INC

Fluorochemical sulfonamide surfactants

InactiveUS6852781B2High yieldLow costNon-macromolecular adhesive additivesPhotosensitive materialsSide chainSulfonyl fluoride

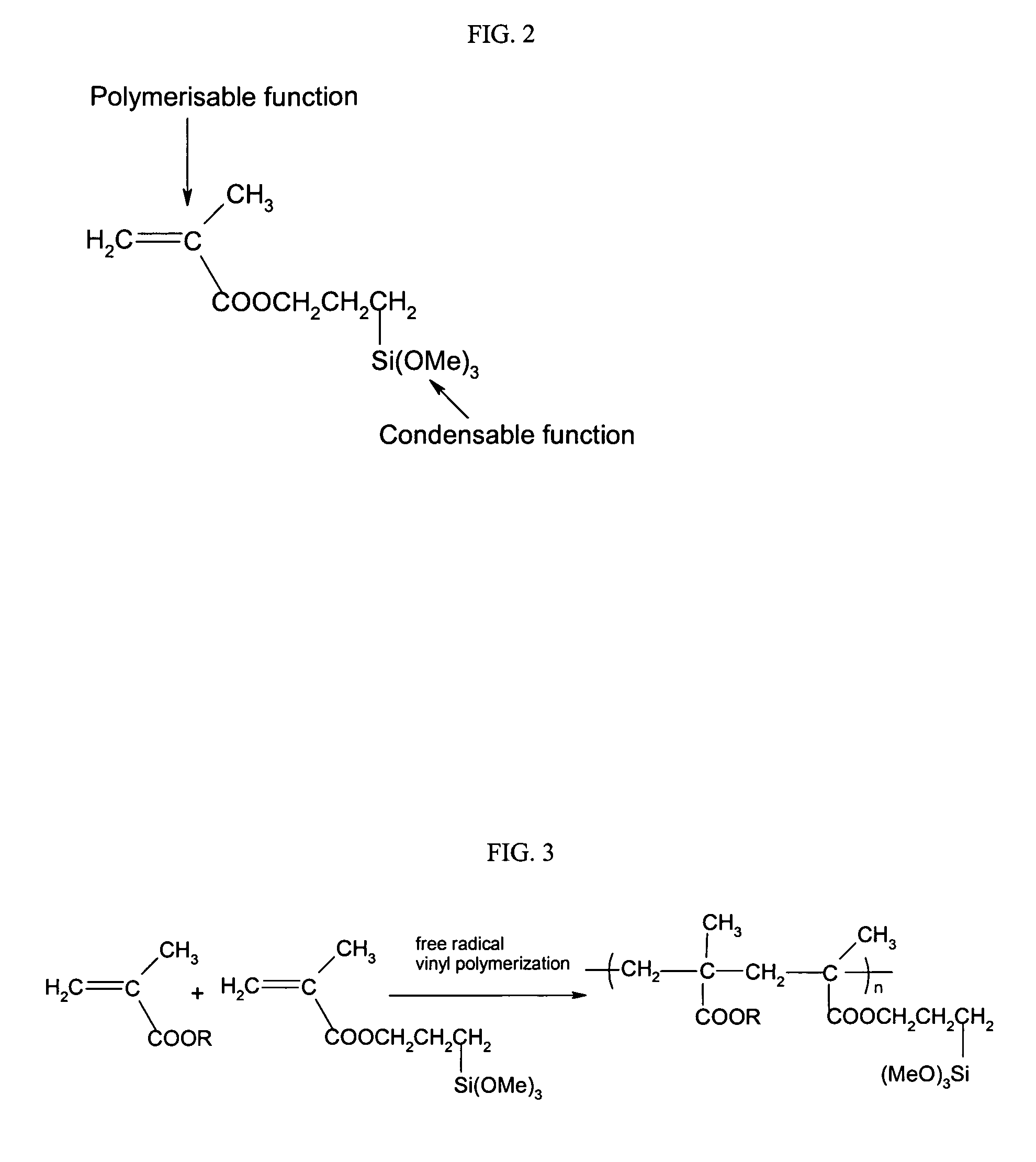

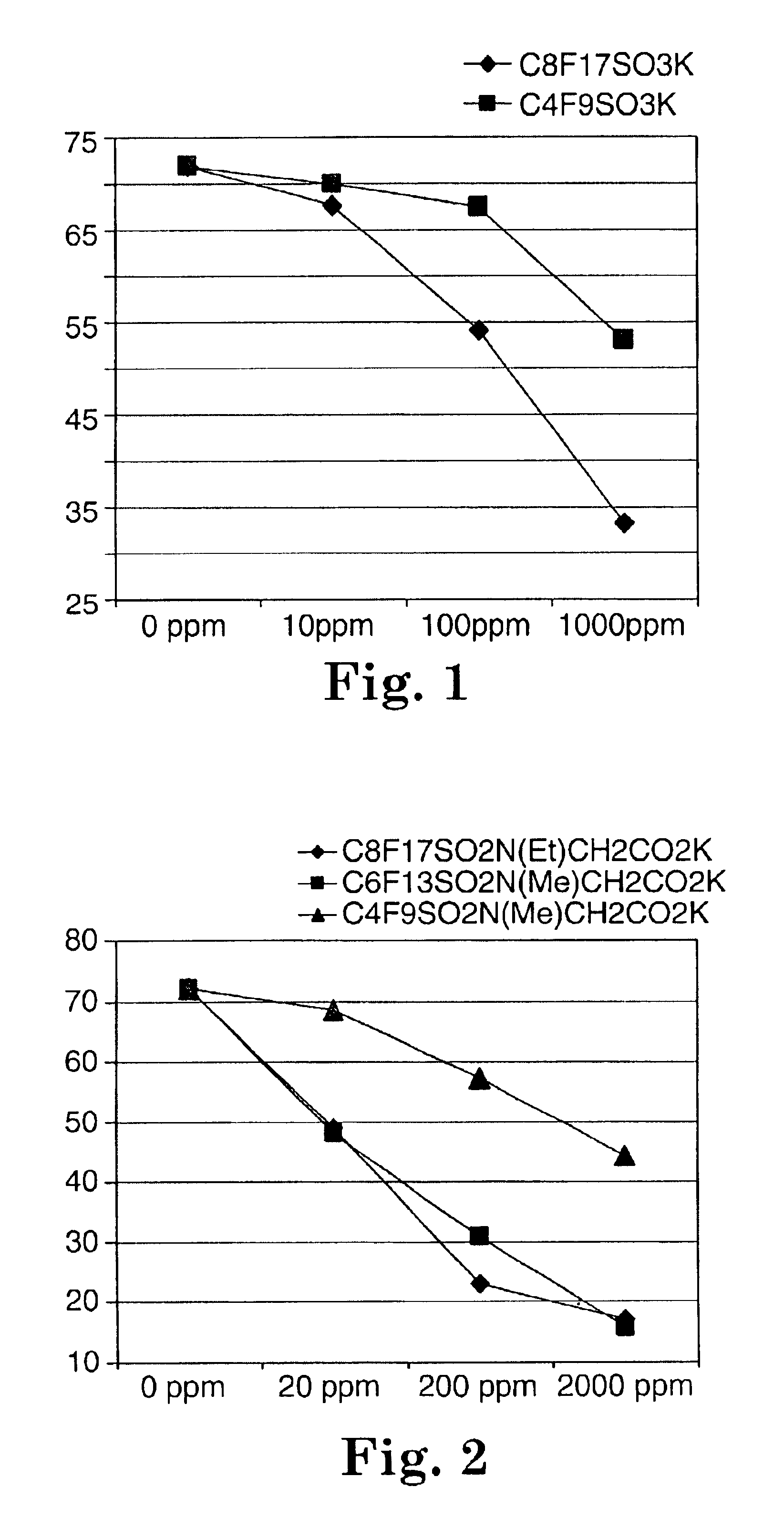

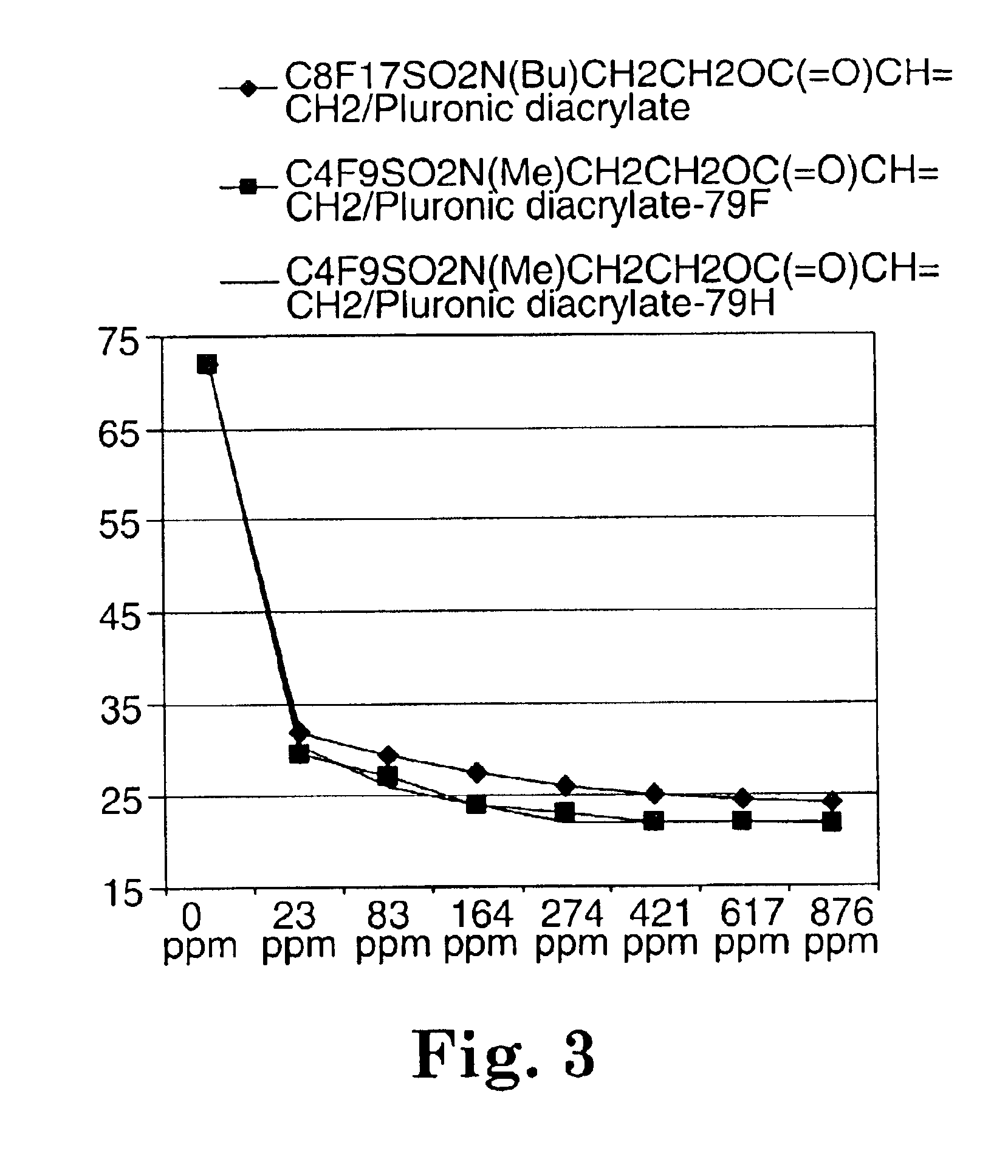

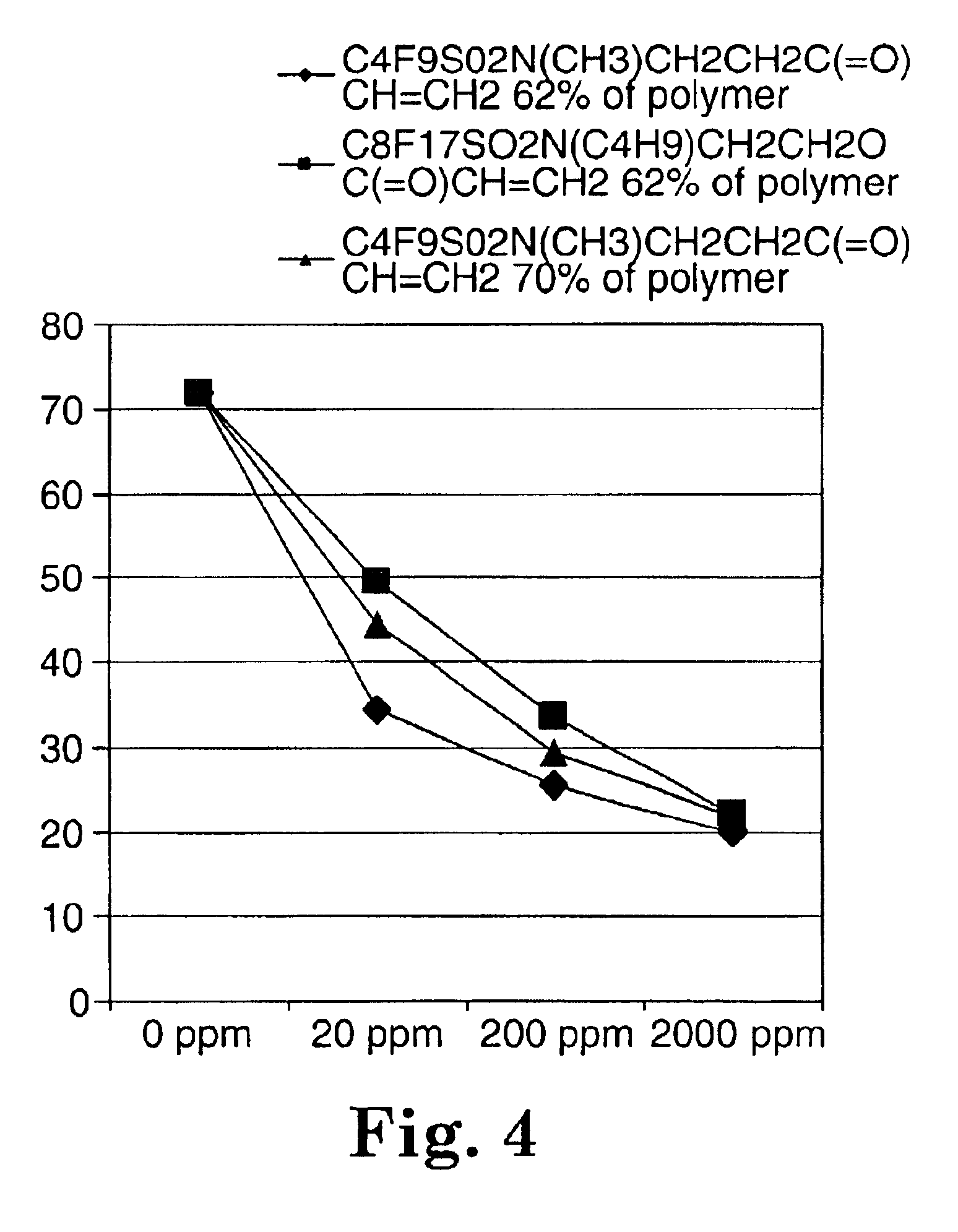

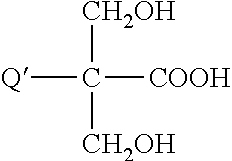

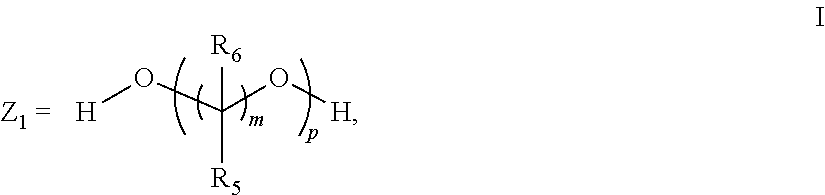

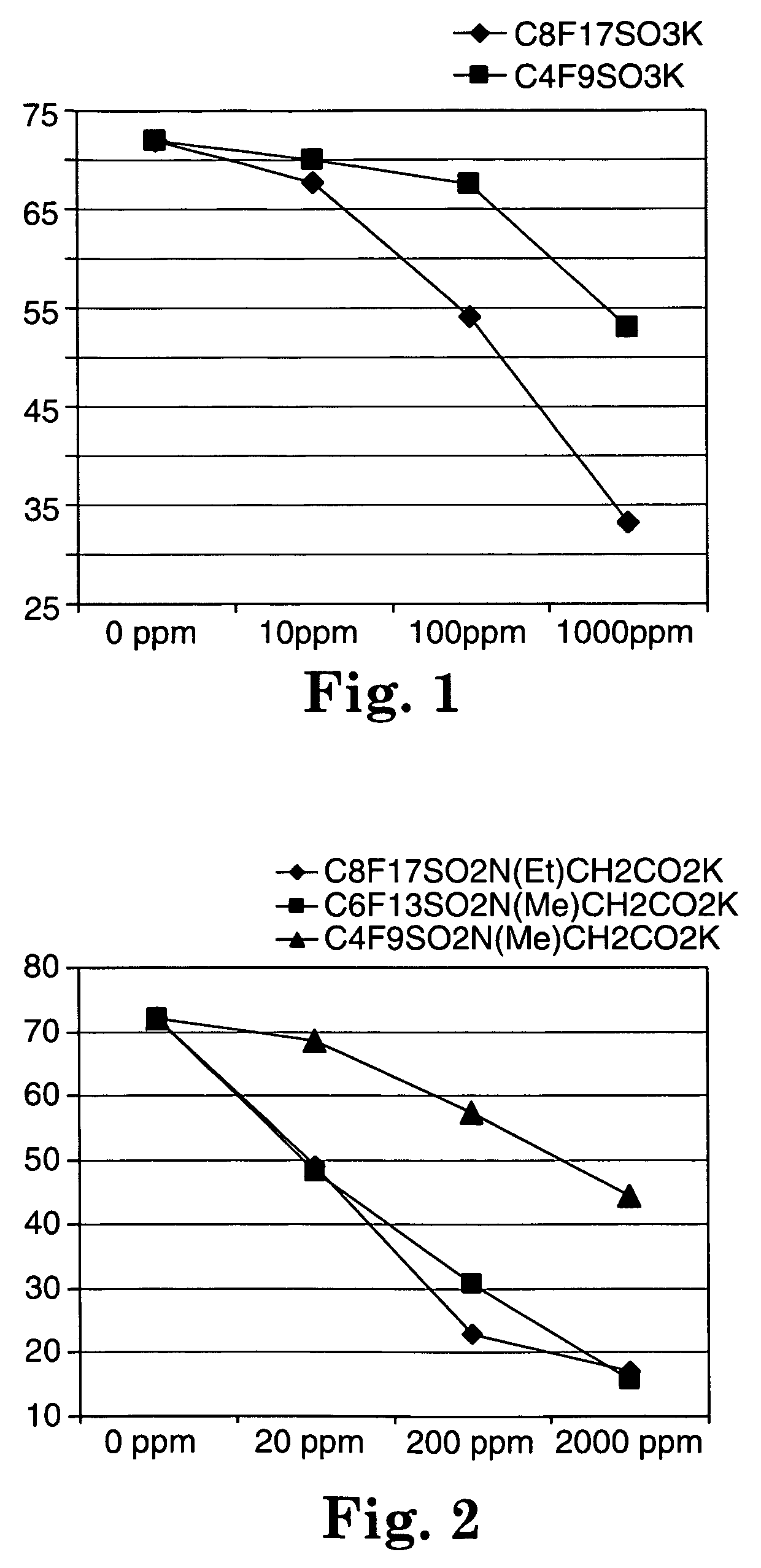

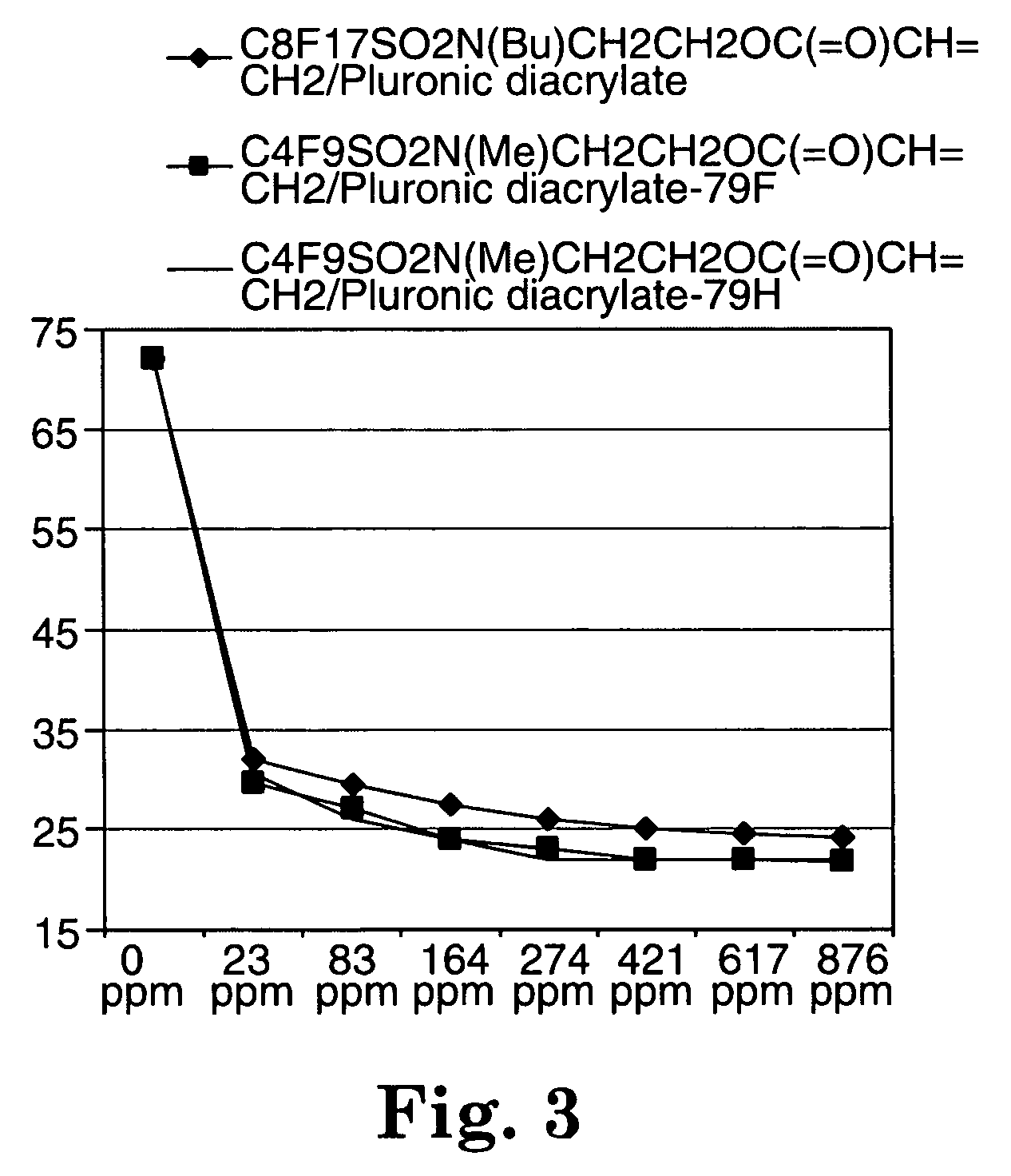

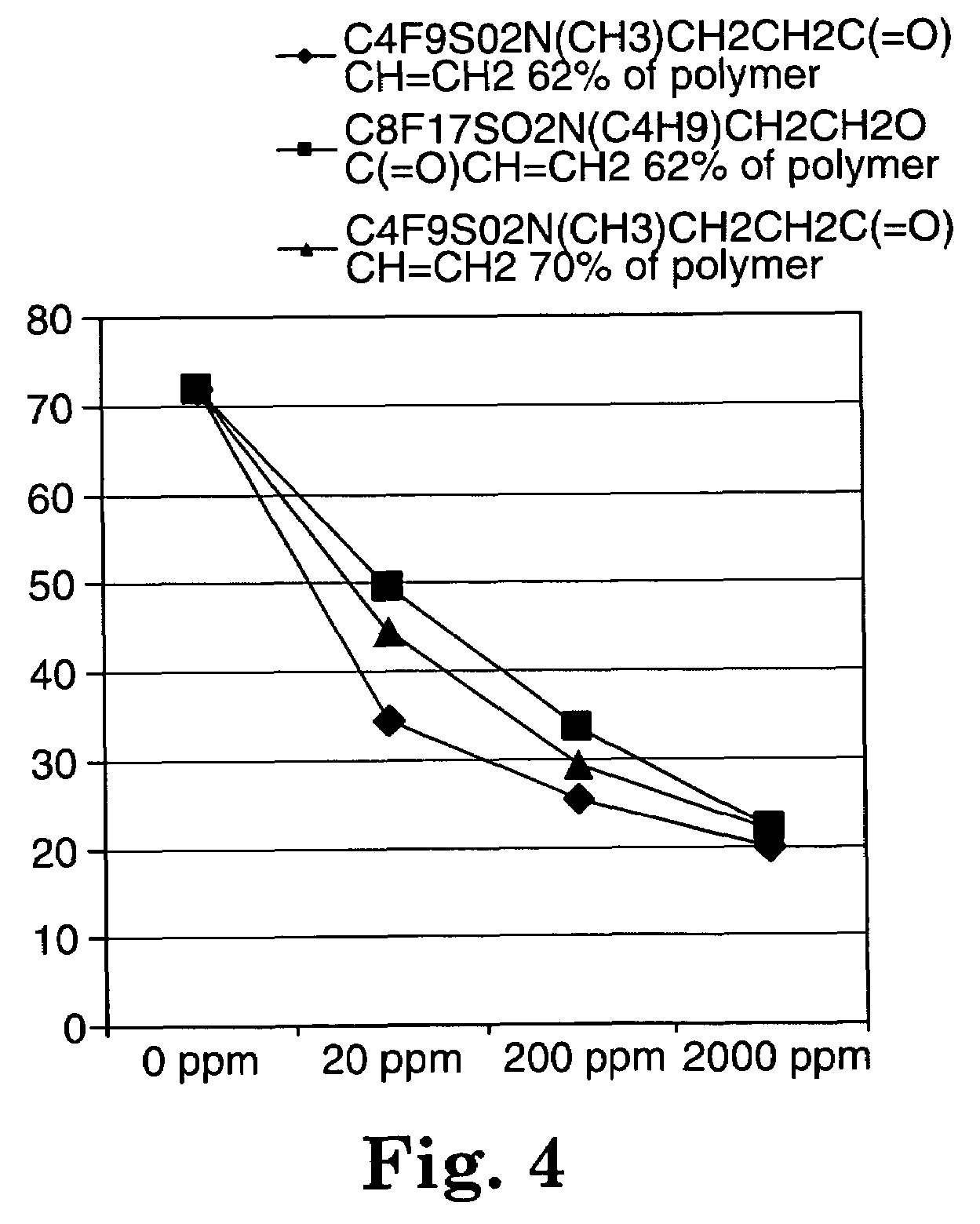

Described are fluorochemical surfactants derived from nonafluorobutanesulfonyl fluoride that contain polyalkyleneoxy side chains and may be copolymerized with acrylic acid or methacrylic acid to form polyacrylates or polymethacrylates. The surfactants surprisingly lower the surface tension of water and other liquids in the same or similar low values achieved by premier surfactants such as those derived from perfluorooctane sulfonyl fluoride.

Owner:3M INNOVATIVE PROPERTIES CO

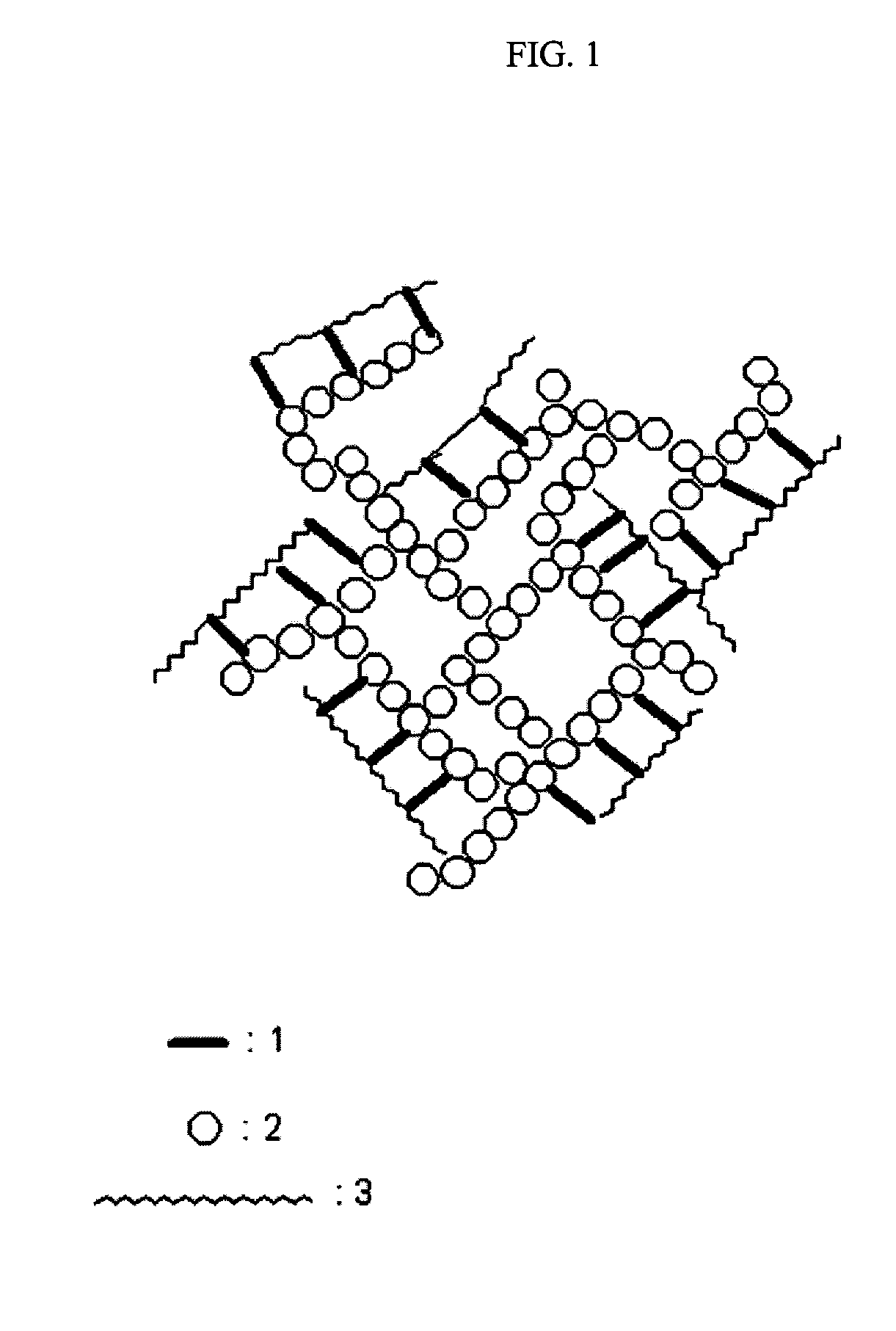

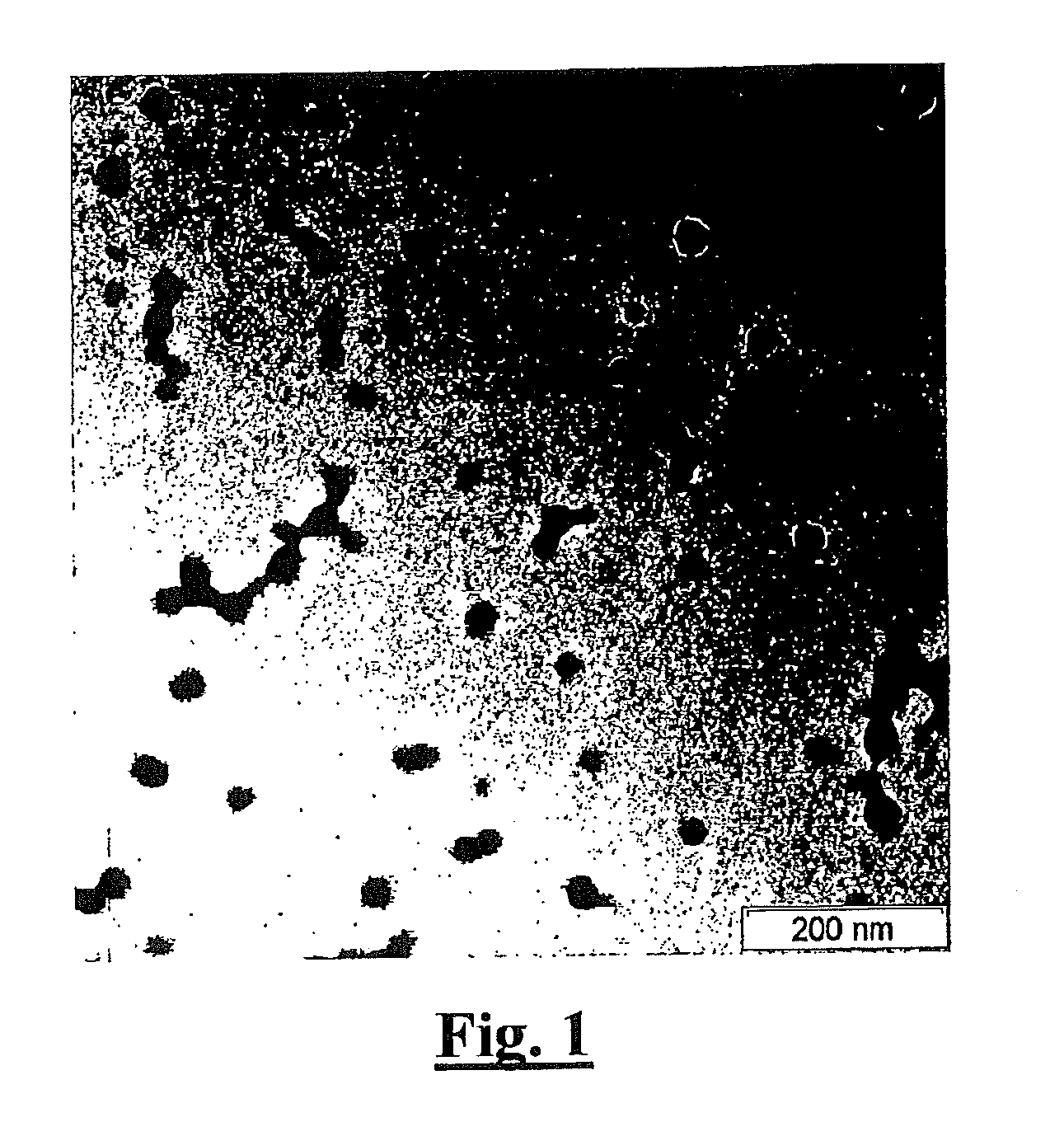

Functionalized vinyl polymer nanoparticles

Owner:MICHELIN RECH & TECH SA

Highly purified tocopheryl phosphate, process for producing the same, analytical method therefor and cosmetic

InactiveUS6046181AGood water solubilityNo skin irritationOrganic active ingredientsCosmetic preparationsSolubilityCosmetic ingredient

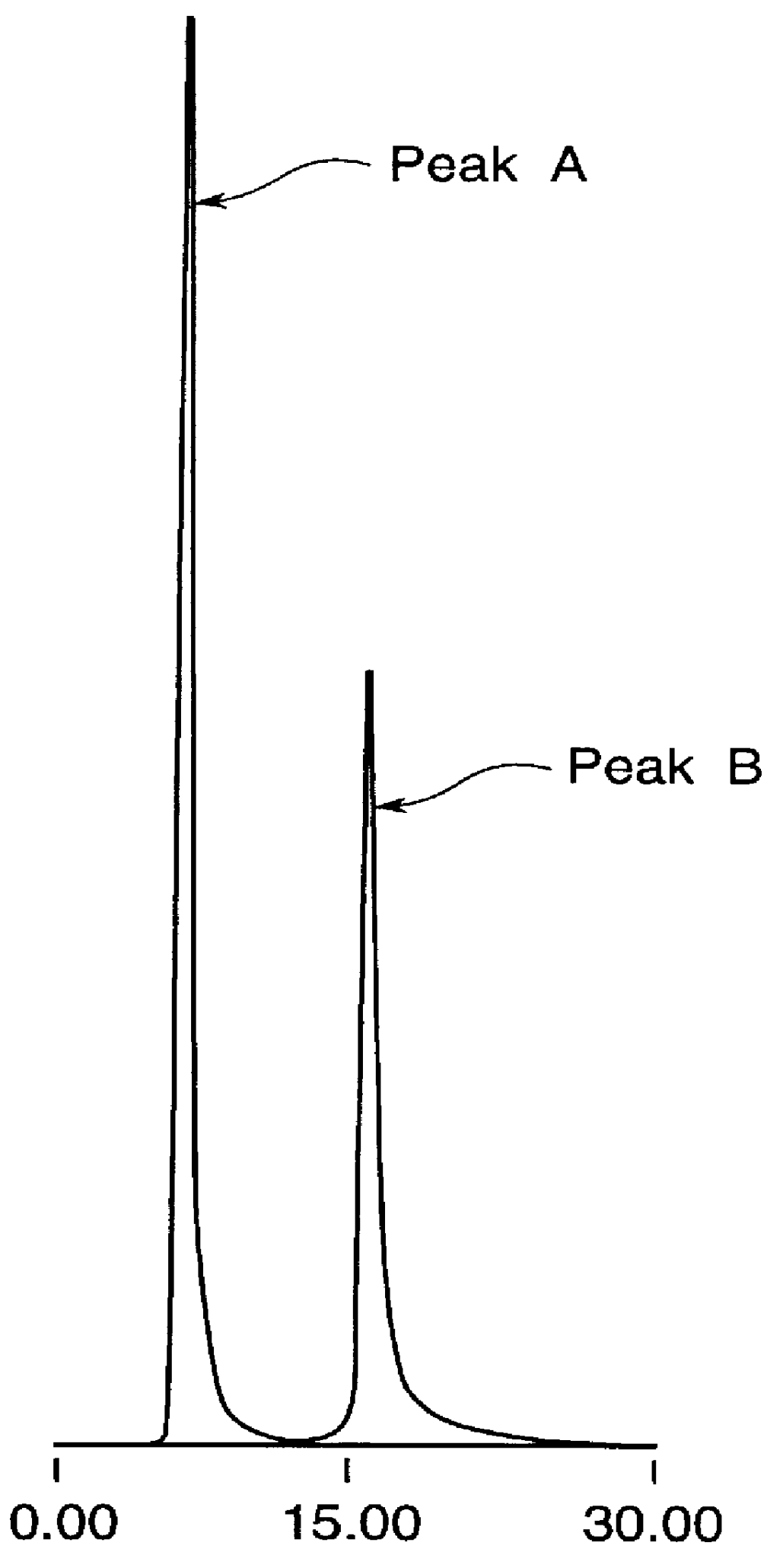

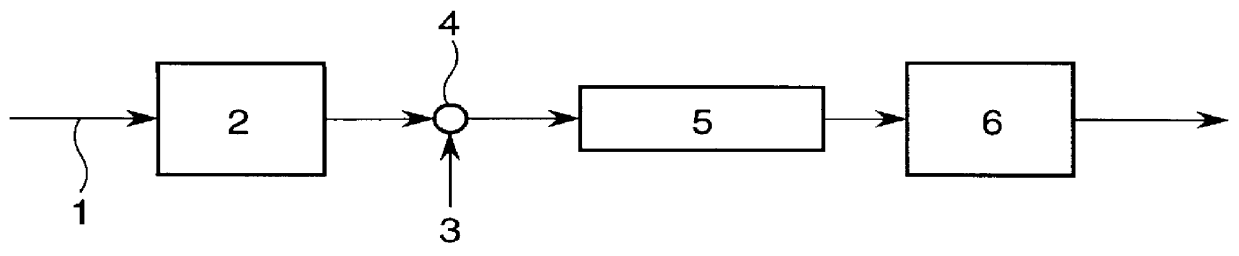

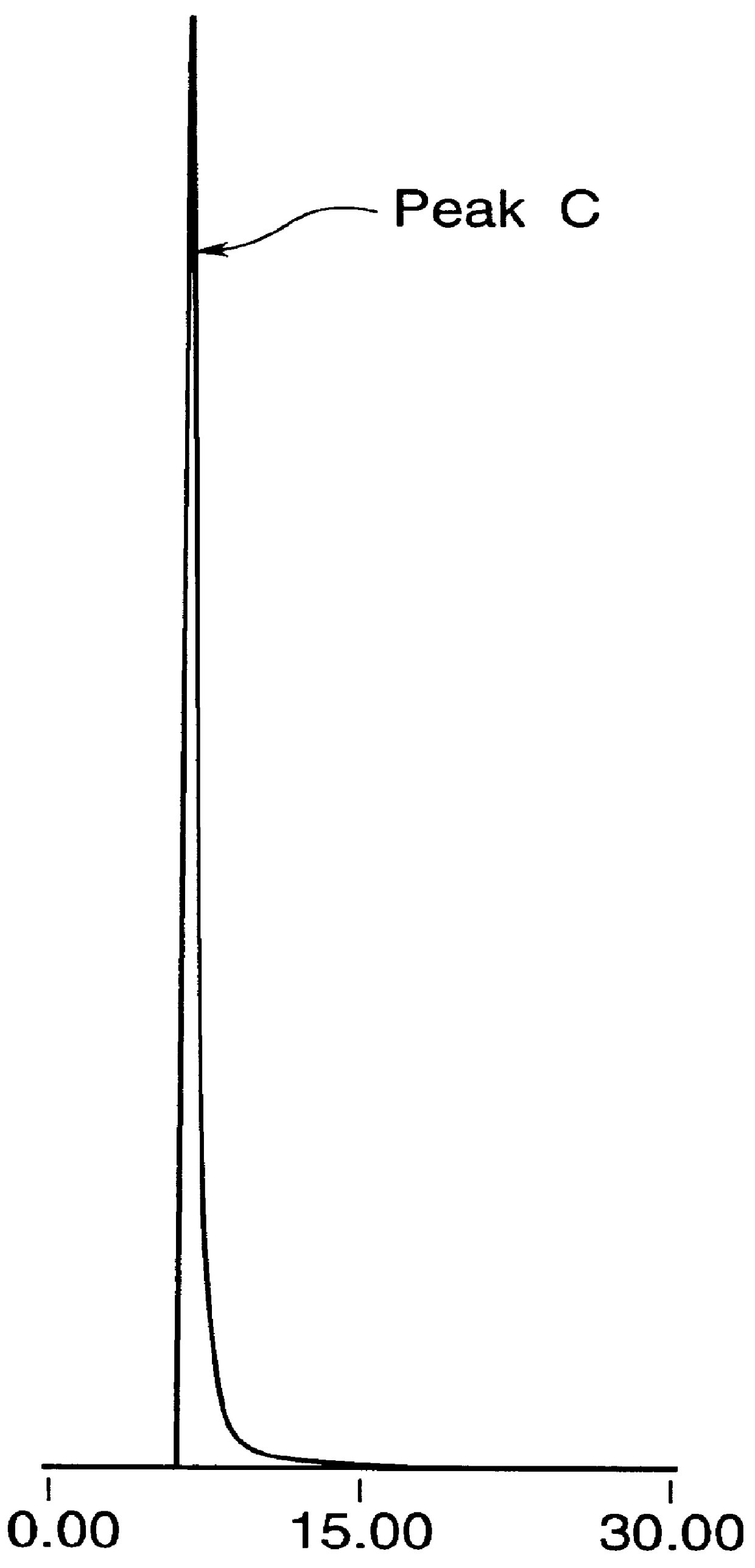

Disclosed herein are a highly purified tocopheryl phosphate and / or a salt thereof (tocopheryl phosphates) wherein a P,P'-bistocopheryl hypophosphate and / or a salt thereof (P,P'-bistocopheryl diphoshates) is contained in a proportion of not higher than 3% by weight; a process for producing a highly purified tocopheryl phosphate and / or a salt thereof, which comprises the steps of reacting a tocopherol with an oxyphosphorus trihalide followed by treating with an acid or basic aqueous solution to thereby form tocopheryl phosphates (i) in which P,P'-bistocopheryl diphoshates (ii) formed as by-products are contained, hydrolyzing the P,P'-bistocopheryl diphoshates (ii) under acid condition, and, optionally, rendering the hydrolyzate neutral or basic under basic condition; and a method of analyzing tocopheryl phosphates, comprising analyzing a sample containing components (i) and (ii) with the use of a high-performance liquid chromatograph column packed with a gel of a polymethacrylate having, bonded thereto, long-chain alkyl groups. None or only an extremely minute amount of P,P'-bistocopheryl diphoshates are contained in the highly purified tocopheryl phosphates, so that the highly purified tocopheryl phosphates exhibit antioxidant and blood circulation promoting effects, have excellent water solubility, are powdery so that the handling thereof is extremely easy, are free from cutaneous irritation and allergenecity and ensure dermal safety. Therefore, the highly purified tocopheryl phosphates are useful as cosmetic ingredients. The amounts of components (i) and (ii) can be simply measured with high accuracy by the above method.

Owner:SHOWA DENKO KK

Coating composition forming wear-resistant coat and article covered with the coat

A coating composition forming a abrasion resistant coating comprising (A) an ultraviolet-curable silicone prepared by chemically modifying particulate colloidal silica with a specific silane compound, (B) a monomer mixture comprising a (meth)acrylate having a specific isocyanate skeleton and a urethane poly(meth)acrylate having an alicyclic skeleton, and (C) a photo-polymerization initiator. By using a urethane poly(meth)acrylate having an alicyclic skeleton as part of the component (B) and the component (A) having an enhanced reactivity of chemical modification, the compatibility of the component (A) with the component (B) is improved to give a cured coating with excellent wear resistance, weather resistance and durability.

Owner:MITSUBISHI RAYON CO LTD

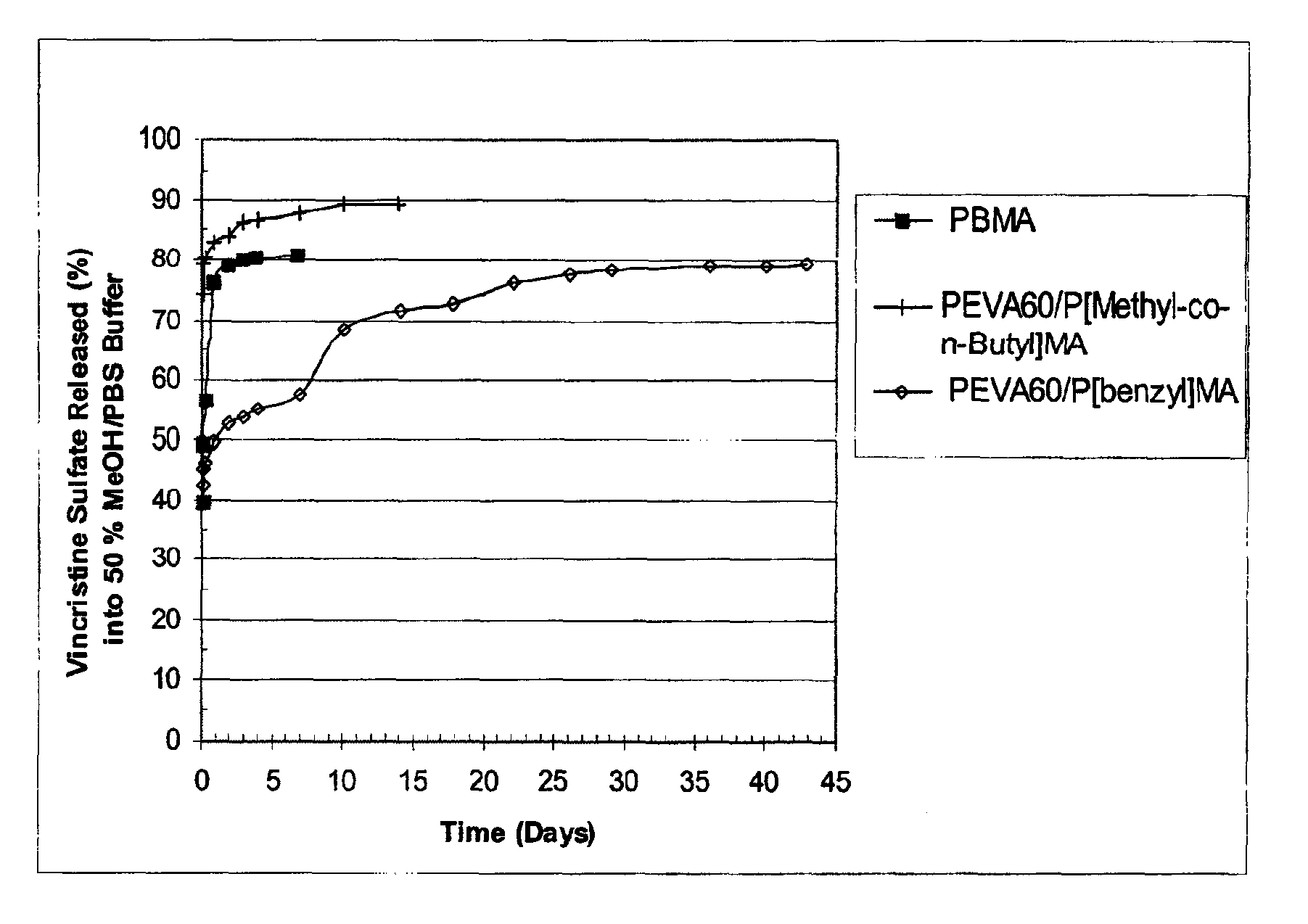

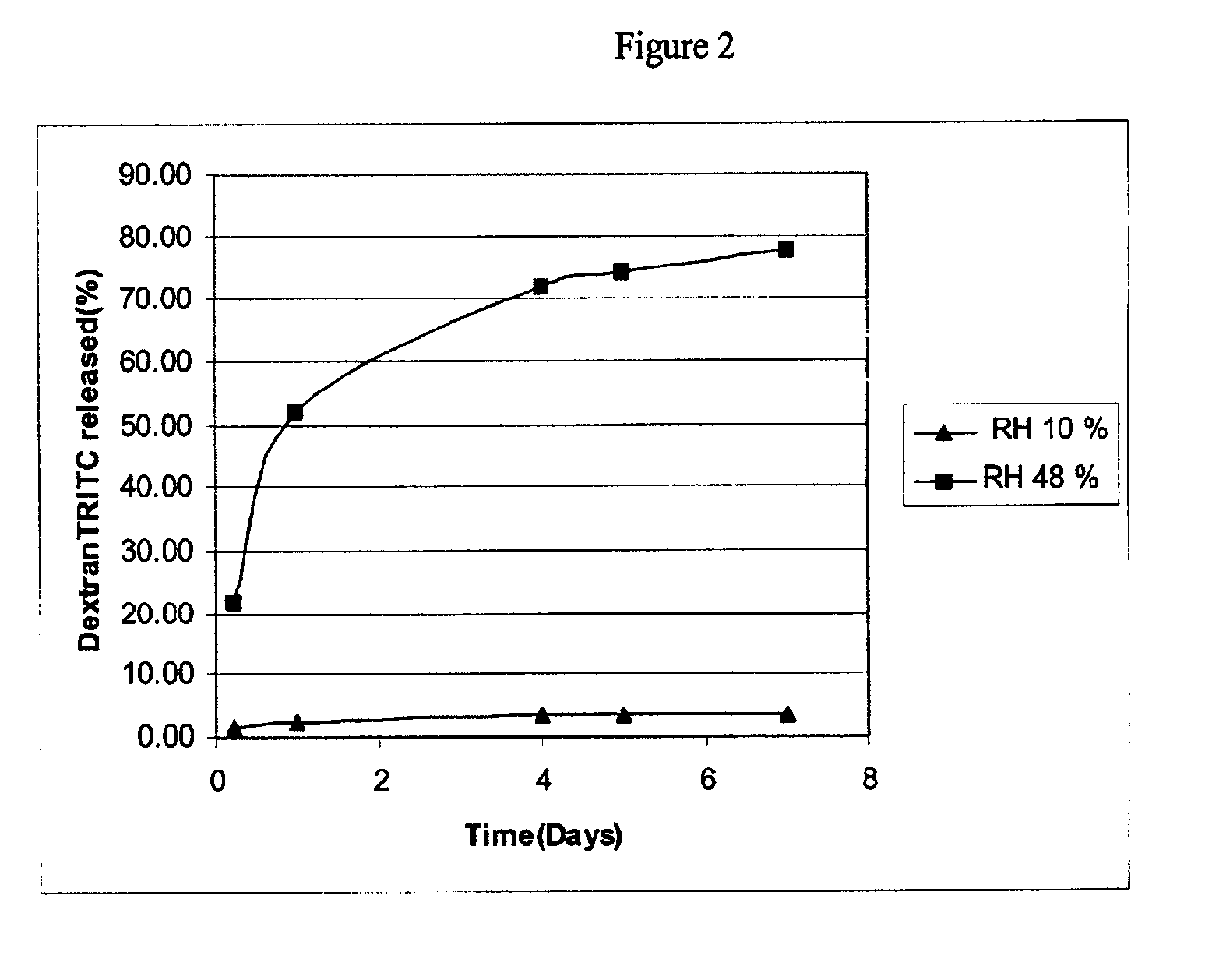

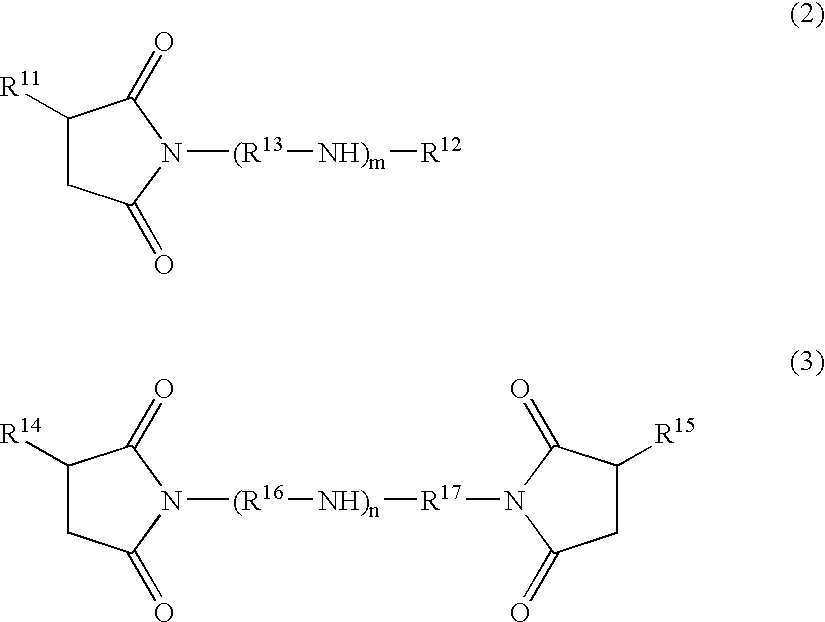

Bioactive agent release coating and controlled humidity method

A coating composition in the form of a one or multi-part system, and method of applying such a composition under conditions of controlled humidity, for use in coating device surfaces to control and / or improve their ability to release bioactive agents in aqueous systems. The coating composition is particularly adapted for use with medical devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a first polymer component such as polyalkyl(meth)acrylate, polyaryl(meth)acrylate, polyaralkyl(meth)acrylate, or polyaryloxyalkyl(meth)acrylate and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

Single phase whitening dentifrice

The invention provides a single phase whitening dentifrice that includes (i) a whitening agent selected from the group consisting of hydrogen peroxide, a bound peroxide and a solid peroxide (ii) an abrasive and (iii) a substantially anhydrous orally acceptable carrier, for example, polyethylene glycol. The bound peroxide may be hydrogen peroxide and a polymer and / or any peroxide compound and a porous cross-linked polymer, such as polymers of polyvinyl pyrrolidone, polyacrylates, a polymethacrylates, and a polyitaconates. The solid peroxide may be sodium perborate or urea peroxide. The invention also provides methods of whitening the tooth surfaces by contacting the surface with the composition.

Owner:COLGATE PALMOLIVE CO

Plastic body provided with a microstructured surface

InactiveUS20060121248A1Lamination ancillary operationsSynthetic resin layered productsThermoplasticPoly methacrylate

The invention relates to a process for the production of a plastics article with a microstructured surface via production of a composite composed of a backing layer composed of a thermoplastic or thermoelastic with one or more structure layers, characterized in that the structure layer(s) is / are composed of from 1 to 100% by weight of a polymethacrylate moulding composition which comprises from 80 to 100% by weight of free-radical-polymerized methyl methacrylate units and from 0 to 20% by weight of other comonomers capable of free-radical polymerization, and which has an average (weight-average) molar mass Mw of from 30 000 g / mol to 70 000 g / mol and, where appropriate, is present in a. mixture with up to 99% by weight of a polymethacrylate moulding composition which is composed of from 80 to 100% by weight of free-radical-polymerized methyl methacrylate units and from 0 to 20% by weight of other comonomers capable of free-radical polymerization, and which has an average (weight-average) molar mass Mw of from 90 000 g / mol to 200 000 g / mol and the structure layer(s) obtain microstructuring via known structuring processes, after production of the composite. The invention further relates to the plastics articles themselves which are capable of production according to the invention, and also to their uses.

Owner:ROEHM GMBH & CO KG

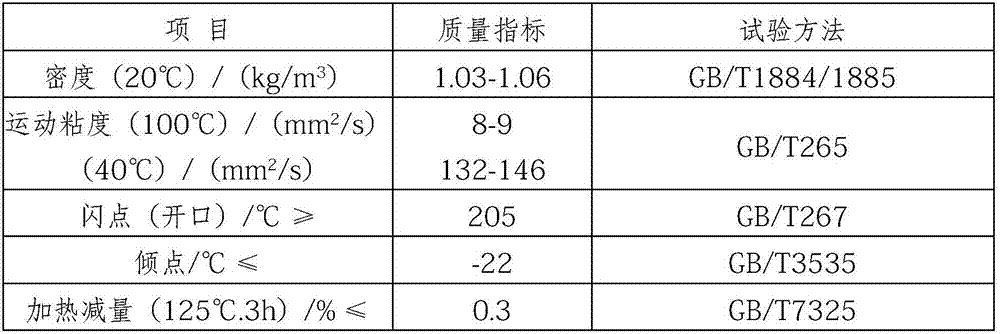

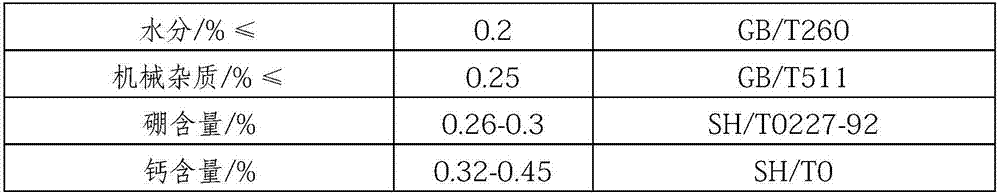

Lubricating oil composition for transmission

ActiveUS20070191239A1Improve fatigue lifeExcellent Low Temperature ViscosityOrganic chemistryAdditivesMeth-Viscosity index

Lubricating oil compositions for transmissions comprises (A) a lubricating base oil with a kinematic viscosity at 100° C. adjusted to 1.5 to 6 mm2 / s, composed of (A1) a lubricating base oil with a kinematic viscosity at 100° C. of 1.5 mm2 / s or higher and lower than 7 mm2 / s or (Al) the lubricating oil and (A2) a lubricating base oil with a kinematic viscosity at 100° C of 7 to 50 mm2 / s, blended with (B) a poly(meth)acrylate-based additive, so that the composition has a kinematic viscosity at 100° C. of 3 to 8 mm2 / s and a viscosity index of 95 to 200, (A) and (B) fulfill a specific requirement. The compositions achieve long fatigue life though having low viscosity.

Owner:NIPPON OIL CORP

Inkjet recording ink, process for producing the inkjet recording ink, inkjet cartridge, inkjet recording apparatus, and inkjet recorded image

InactiveUS20110318551A1Good storage stabilityReduce eliminateMaterial nanotechnologyLayered productsMeth-Organic solvent

Provided is an inkjet recording ink including: a resin nanoparticle having a core-shell structure containing a core and a shell; a pigment; a water-soluble organic solvent; and water, wherein the core is composed of a poly(meth)acrylate resin, and wherein the shell is composed of a polycarbonate-polyurethane copolymer. Also provided is a process for producing the inkjet recording ink, an inkjet cartridge containing the inkjet recording ink, an inkjet recording apparatus containing the inkjet cartridge, and an inkjet recorded image including the inkjet recording ink located on a recording medium.

Owner:RICOH KK

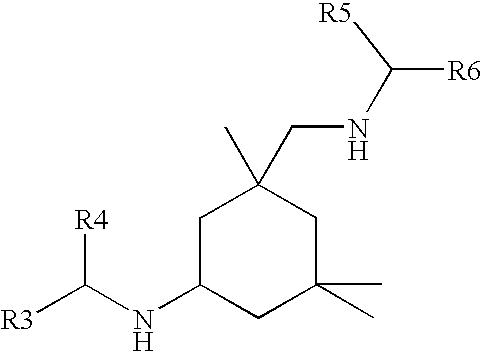

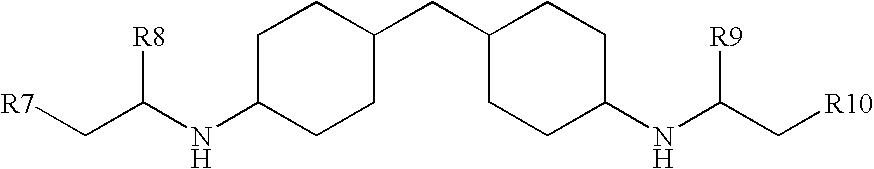

Polyurea coating comprising an amine/(METH)acrylate oligomeric reaction product

InactiveUS20070160851A1Liquid surface applicatorsSynthetic resin layered productsPoly methacrylatePolyurea

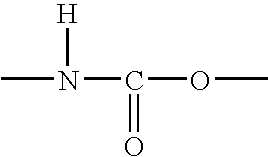

Coating compositions comprising a polyurea formed from a reaction mixture comprising isocyanate and an acrylated amine are disclosed. The (meth)acrylated amine is the reaction product of a polyamine and a (meth)acrylate; when the (meth)acrylate comprises a poly(meth)acrylate, the reaction product further comprises a mono(meth)acrylate and / or a monoamine. Methods for using the coatings, and substrates coated therewith, are also disclosed.

Owner:PPG IND OHIO INC

Pmma/pvdf film with particularly high weathering stability and high UV protective action

InactiveUS20100189983A1Improve the immunityImprove stabilitySynthetic resin layered productsCoatingsPolymer scienceMeth-

The invention describes a transparent foil composed of plastic with improved weathering resistance and increased intrinsic stability where the foil encompassesa) poly(meth)acrylate and polyvinylidene fluoride in a ratio of from 1:0.01 to 1:1 (w / w); andb) a mixture composed of UV stabilizers and of UV absorbers.PMMA matrix plastics with high molecular weights and with a certain selected coacrylate proportion are preferably used in order to achieve excellent weathering resistance, and also improved intrinsic stability of the surface-protection foils.

Owner:EVONIK ROEHM GMBH

Polylactic acid resin composition, process for producing the same, biaxially stretched polylactic acid film, and molded articles thereof

The invention provides a resin composition containing poly(lactic acid) and a cellulosic ester, which are biomass type materials; a resin composition excellent in transparency, mechanical properties, and thermostability; a biaxially drawn film containing poly(lactic acid) and at least one compound selected from cellulosic esters, poly(meth)acrylates, and polyvinyl compounds having a glass transition temperature of 60° C. or higher; and a biaxially drawn film excellent in transparency, mechanical properties, and thermostability. The aims of the invention can be achieved by a resin composition obtained by melt-kneading a poly(lactic acid) polymer with a weight average molecular weight of 50,000 or higher and a cellulosic ester; a resin composition excellent in transparency and having luminous transmittance of 40% or higher for visible light with 400 nm; its production method; a molded article and a film made of the resin composition; a poly(lactic acid) biaxially drawn film containing a poly(lactic acid) polymer with a weight average molecular weight of 50,000 or higher and at least one compound selected from cellulosic esters, poly(meth)acrylates, and polyvinyl compounds having a glass transition temperature of 60° C. or higher; a poly(lactic acid) biaxially drawn film excellent in transparency and having film haze of 10% or lower; and a molded article made of the film.

Owner:TORAY IND INC

Inkjet inks for textiles containing crosslinked polyurethanes and further containing additional reactive components

InactiveUS20110124799A1Increase ratingsIncreased durabilityInksDyeing processTextile printerPolymer science

Owner:EI DU PONT DE NEMOURS & CO

Fluorochemical sulfonamide surfactants

InactiveUS7417099B2High yieldLow costNon-macromolecular adhesive additivesPhotosensitive materialsSide chainSulfonyl fluoride

Described are fluorochemical surfactants derived from nonafluorobutanesulfonyl fluoride that contain polyalkyleneoxy side chains and may be copolymerized with acrylic acid or methacrylic acid to form polyacrylates or polymethacrylates. The surfactants surprisingly lower the surface tension of water and other liquids in the same or similar low values achieved by premier surfactants such as those derived from perfluorooctane sulfonyl fluoride.

Owner:3M INNOVATIVE PROPERTIES CO

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

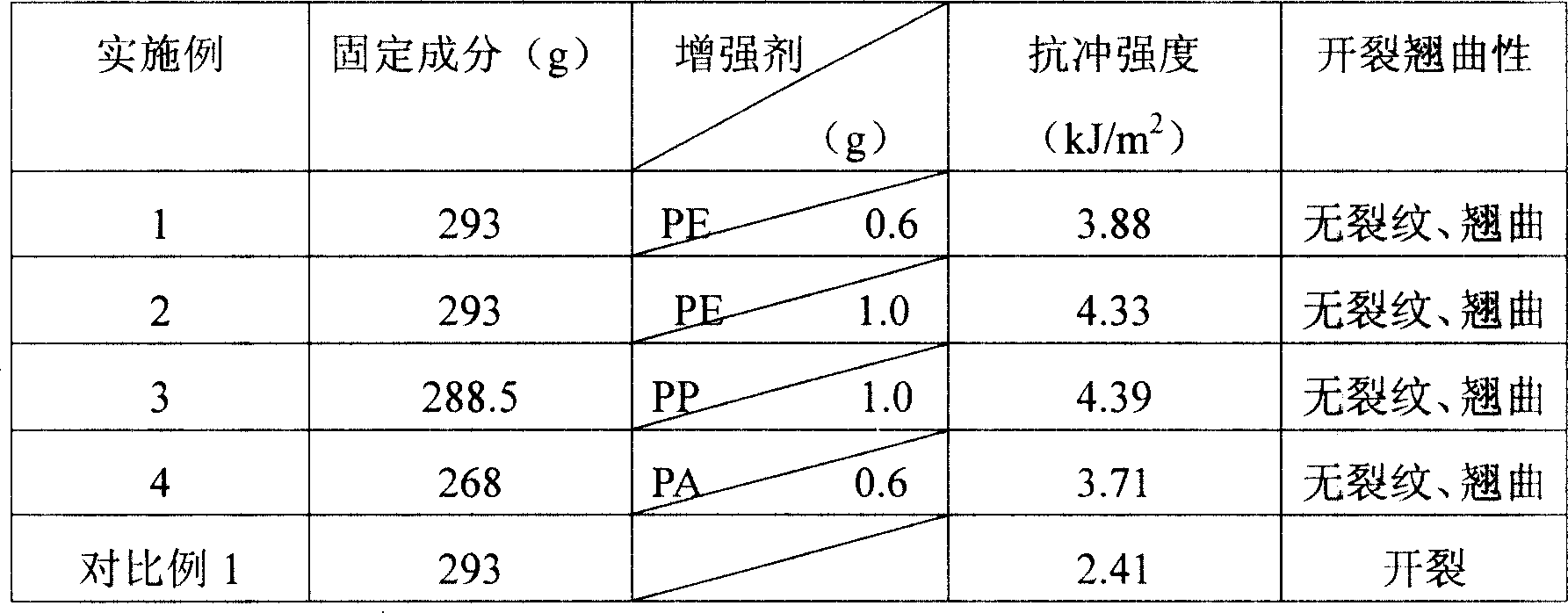

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

Anaesthetic bone cement

InactiveUS6355705B1Deaden and block painAvoid painPowder deliveryCosmetic preparationsPoly methacrylateAnalgesic effect

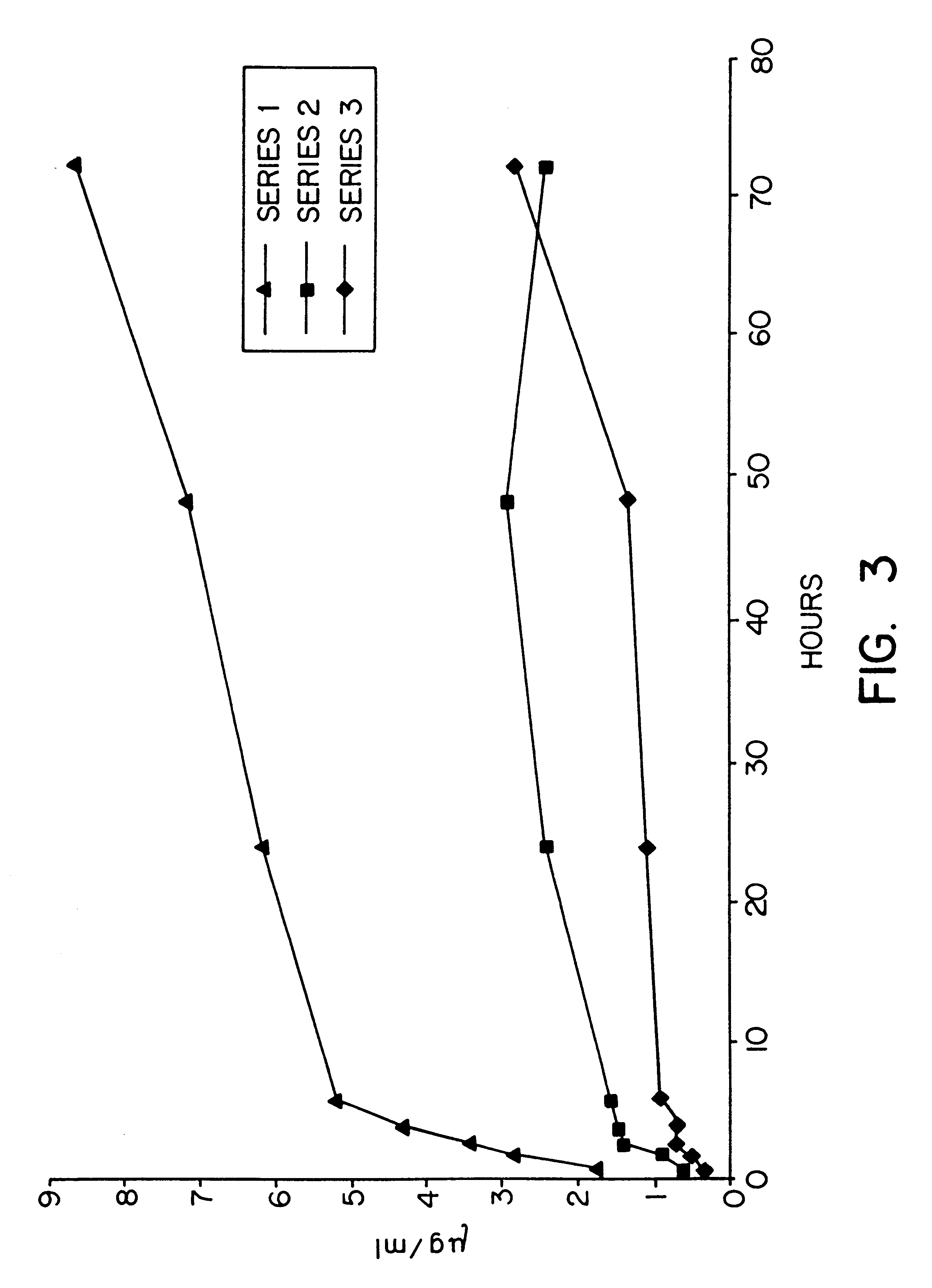

A polymethacrylate or other bone cement composition having analgesic properties is described. Bone cements containing up to 5% by weight of a local anaesthetic agent, such as lidocaine, have been demonstrated to elute sufficient lidocaine to provide an analgesic effect in vivo.

Owner:QUEENS UNIV OF KINGSTON

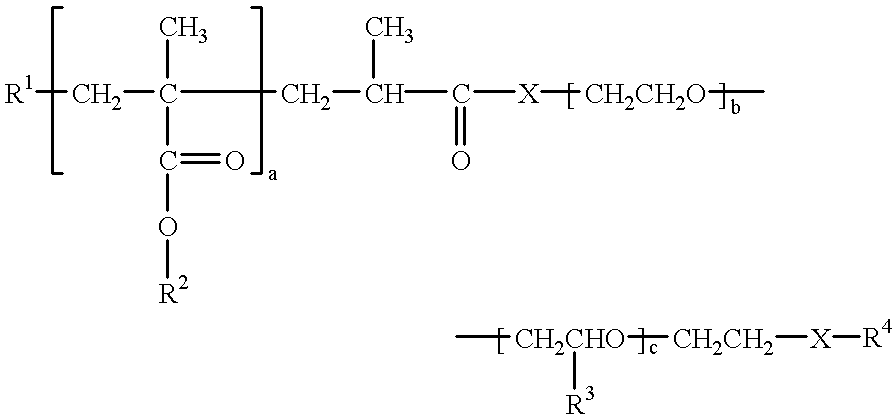

Radiation-sensitive resin composition for optical waveguides, optical waveguide, and method for manufacturing optical waveguide

InactiveUS20070081782A1High dimensional accuracyImprove transmission characteristicsPhotomechanical apparatusOptical light guidesPolyesterMeth-

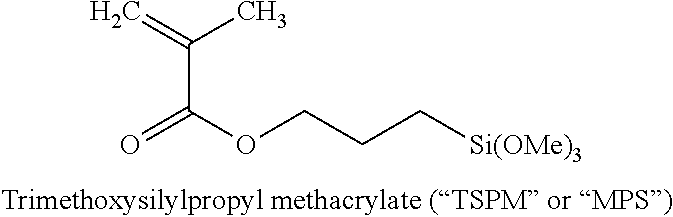

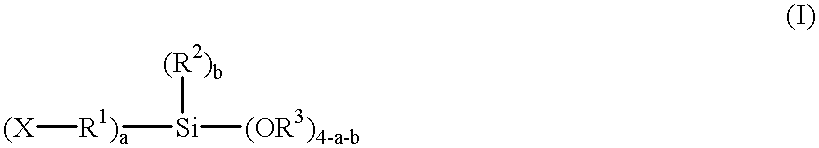

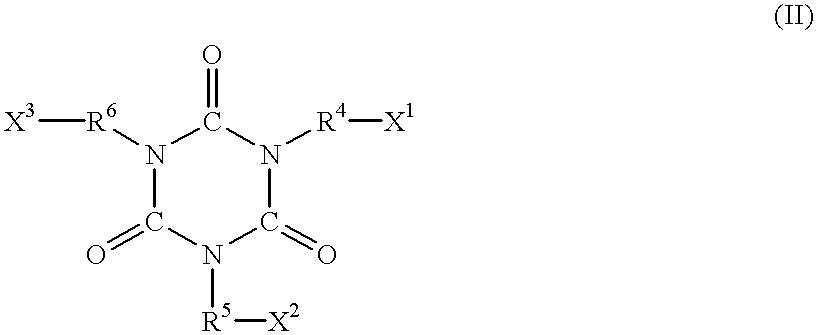

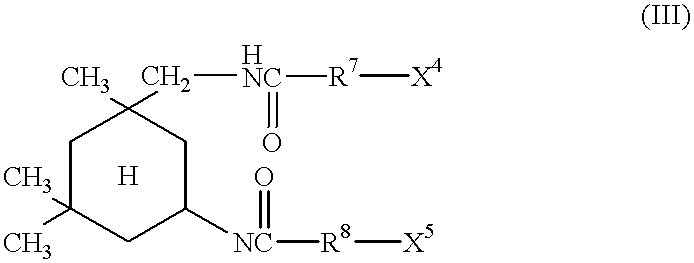

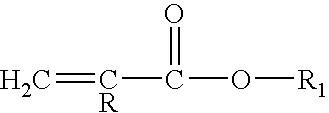

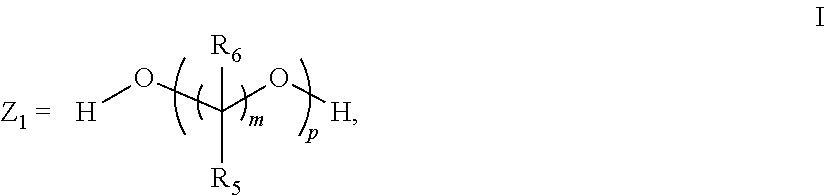

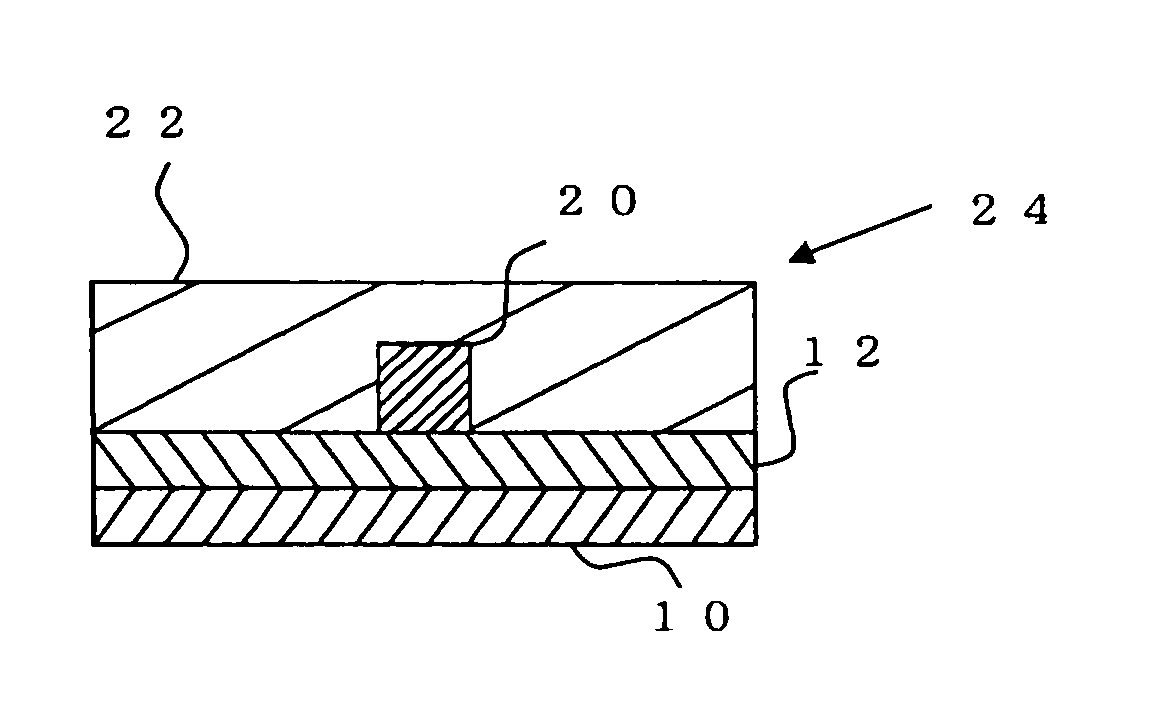

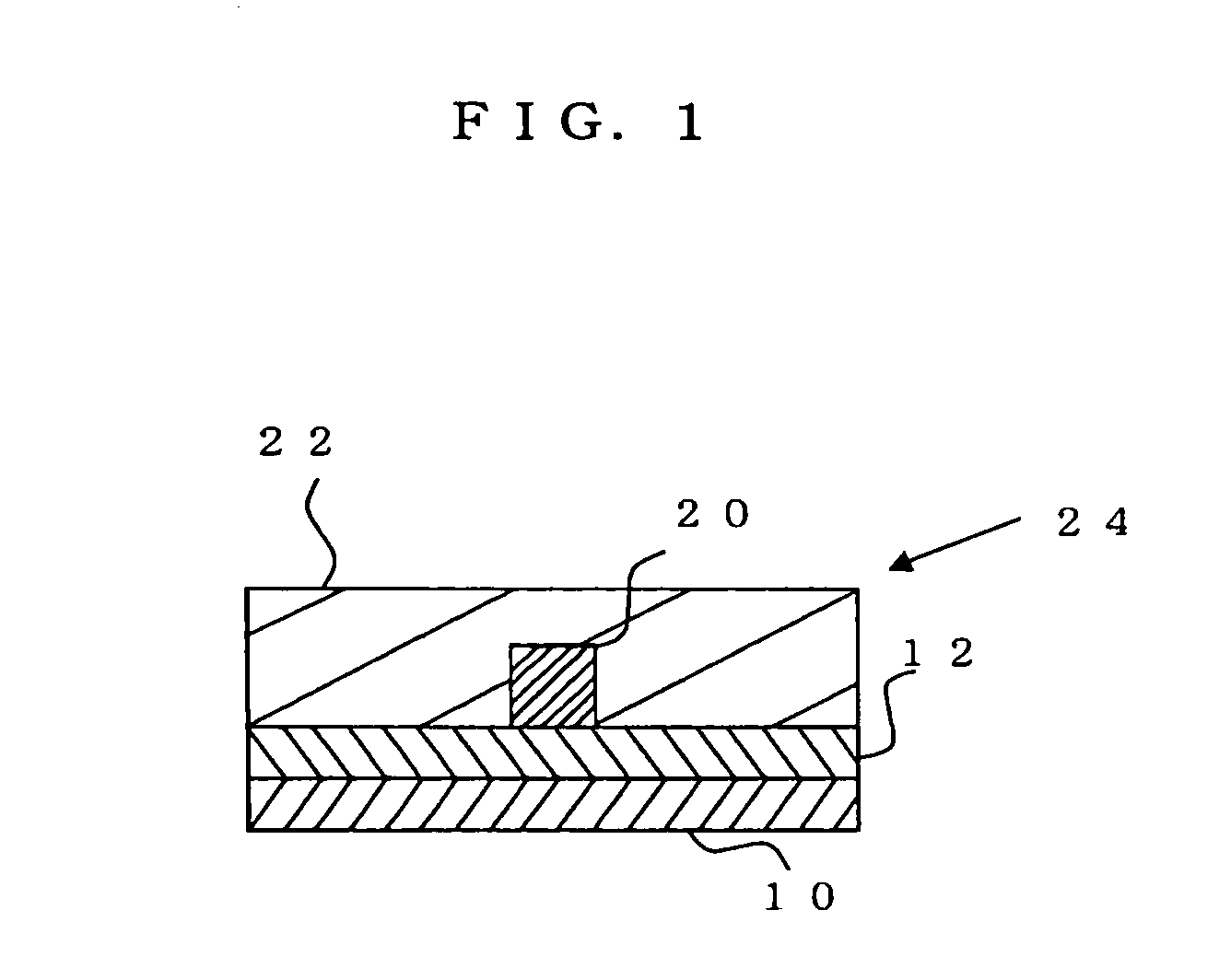

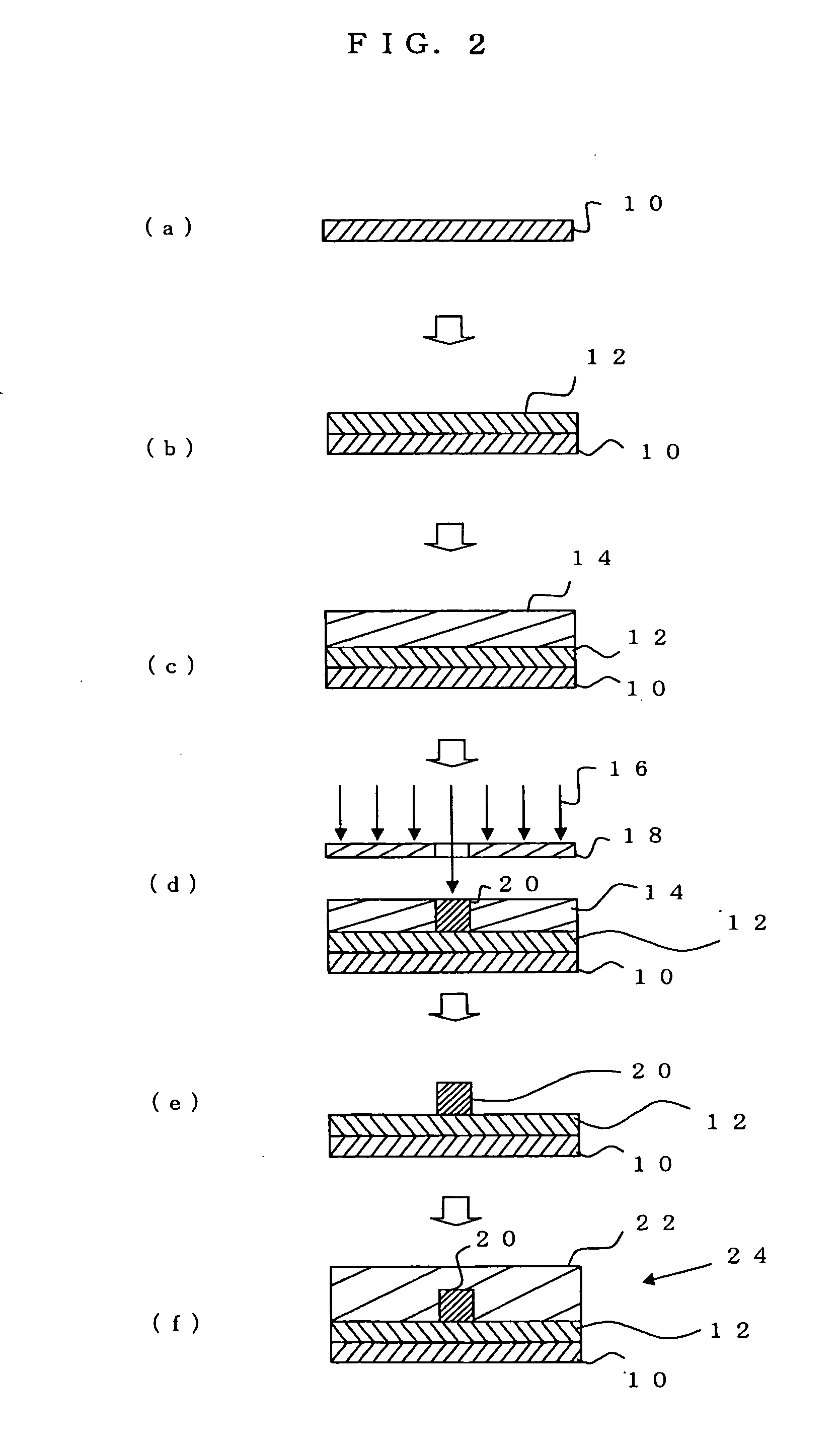

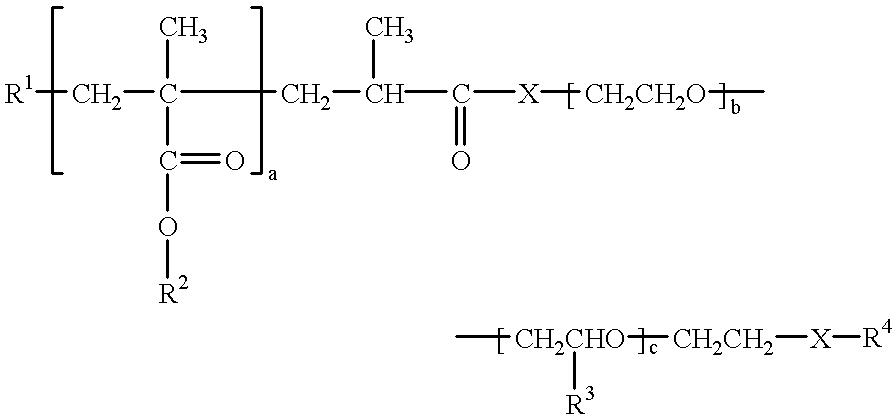

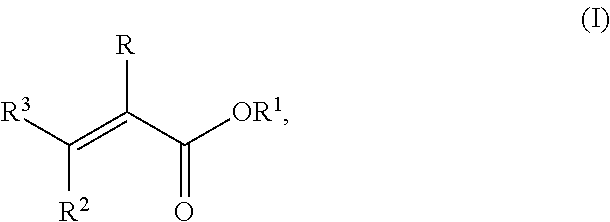

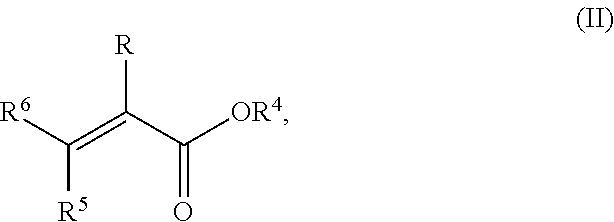

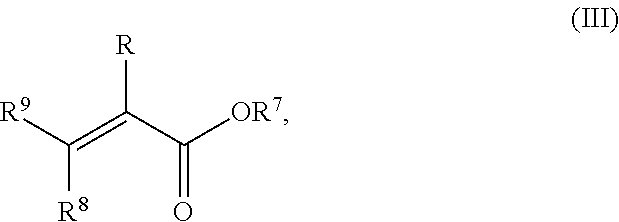

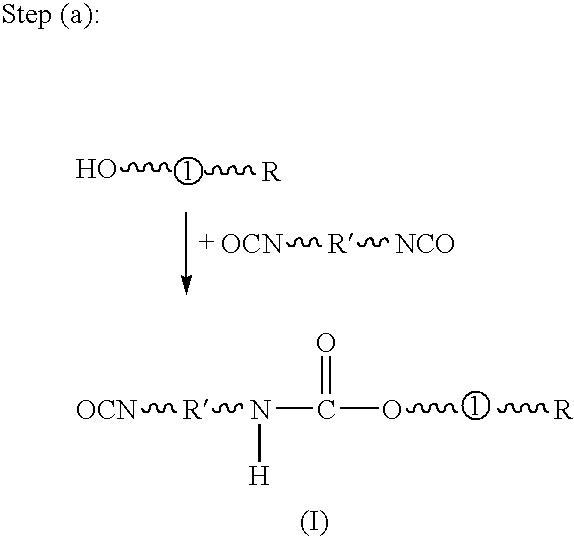

A radiation-sensitive resin composition for optical waveguides having high dimensional accuracy, good transmission characteristics, and excellent bending resistance is provided. The composition comprises: (A) a poly(meth)acrylate having a repeating unit represented by the following general formula (1) (in the formula, R1 is a hydrogen atom or a methyl group, R3 is a (meth)acryloyl group, X is a bivalent organic group); (B) an urethane (meth)acrylate compound which is a reaction product of a polyester polyol compound, a polyisocyanate compound, and a (meth) acrylate having a hydroxyl group; (C) a compound having at least one ethylenically unsaturated group and having a boiling point of 130 degree C. or higher under 0.1 MPa other than components (A) and (B); and (D) a photo-radical polymerization initiator. The composition was used as the material for the lower clad layer 12 of the optical waveguide 24, and the like.

Owner:JSR CORPORATIOON

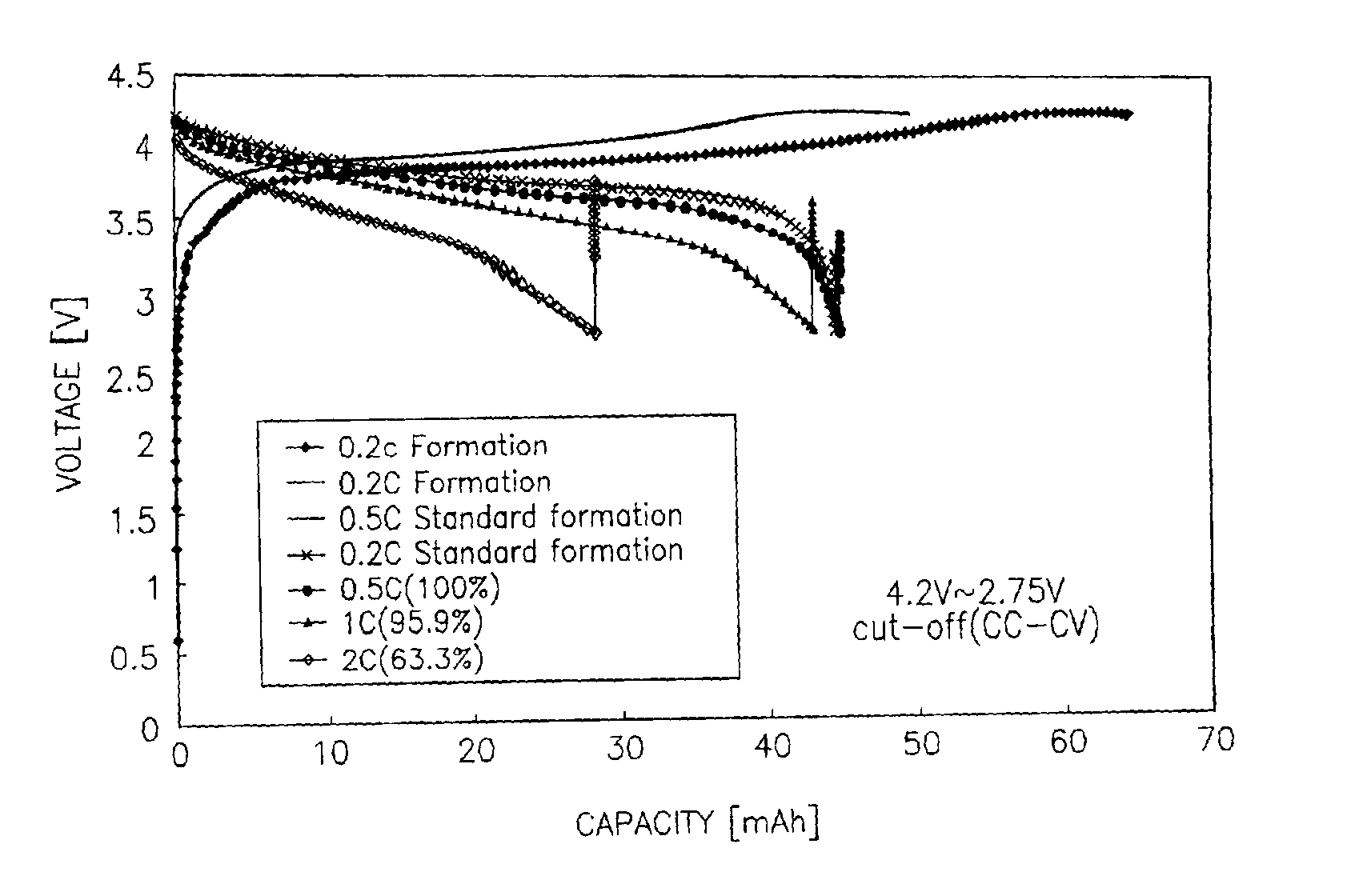

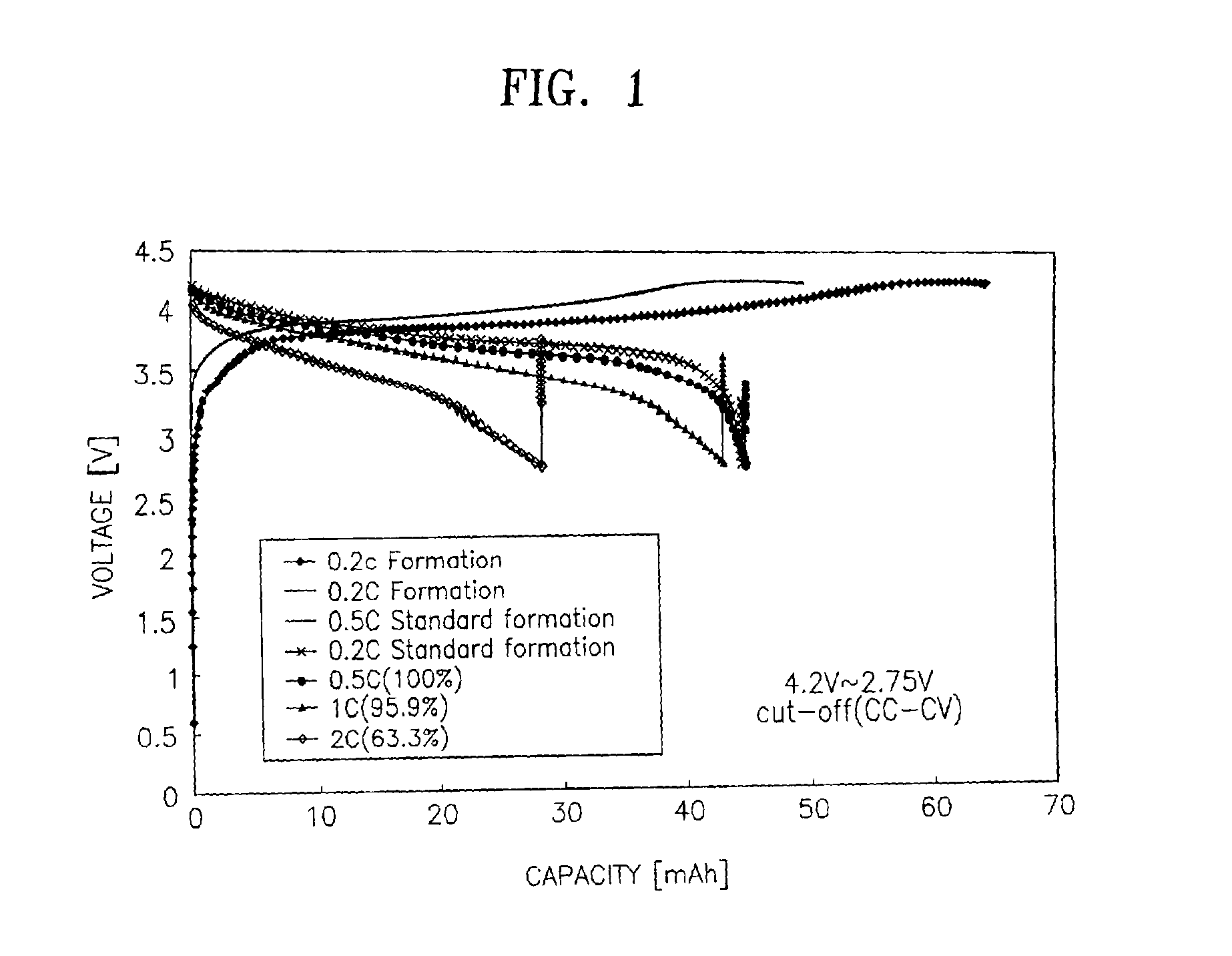

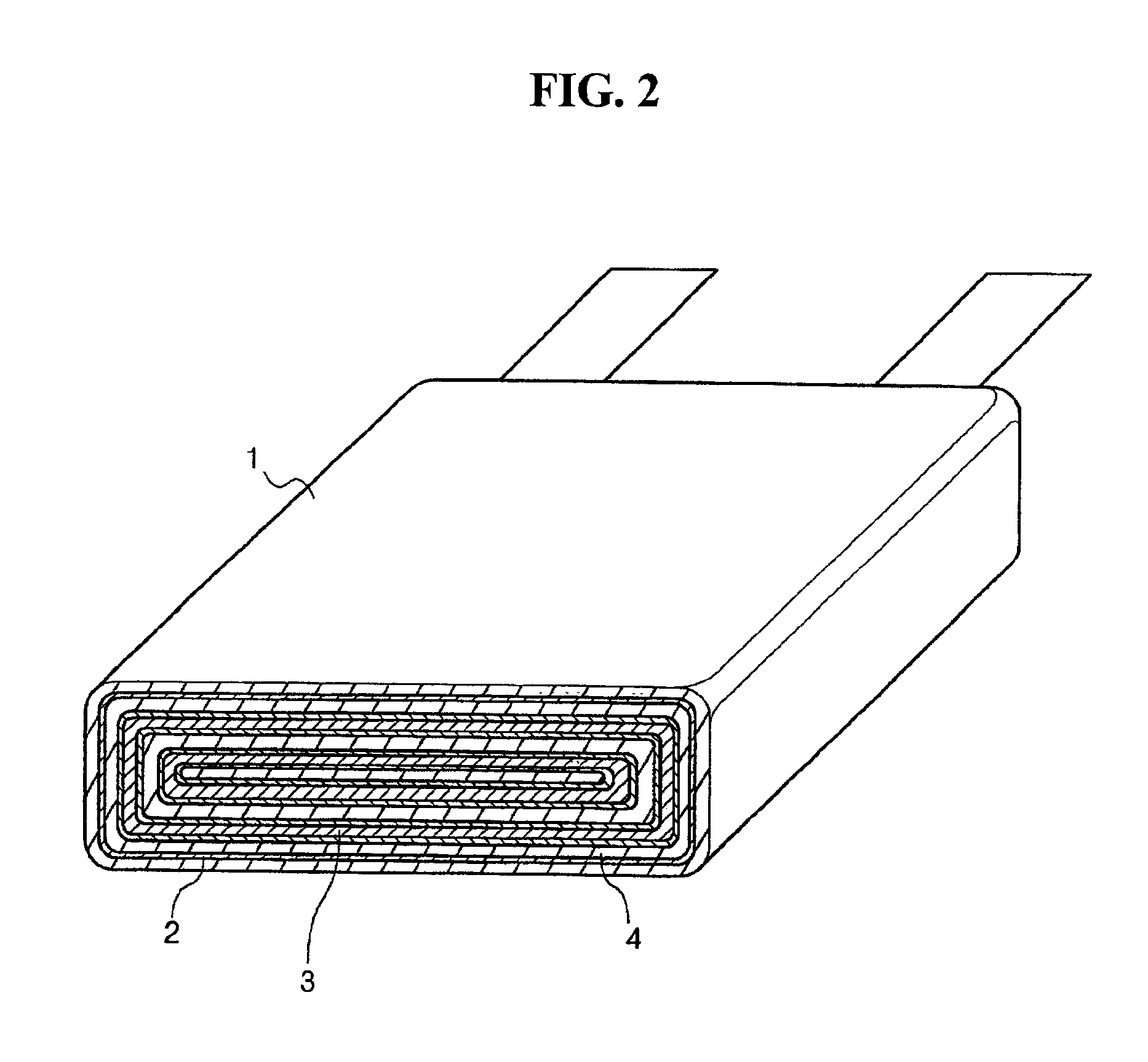

Separators for winding-type lithium secondary batteries having gel-type polymer electrolytes and manufacturing method for the same

InactiveUS6924065B2Improve ionic conductivityHigh mechanical strengthFinal product manufactureLi-accumulatorsLithiumPolymer science

A porous separator for a winding-type lithium secondary battery having a gel-type polymer electrolyte includes a matrix made of polyvinyl chloride, or a matrix made of mixtures of polyvinylchloride and at least one polymer selected from the group consisting of polyvinylidenefluoride, a vinylidenefluoride / hexafluoropropylene copolymer, polymethacrylate, polyacrylonitrileand polyethyleneoxide.

Owner:SAMSUNG SDI CO LTD

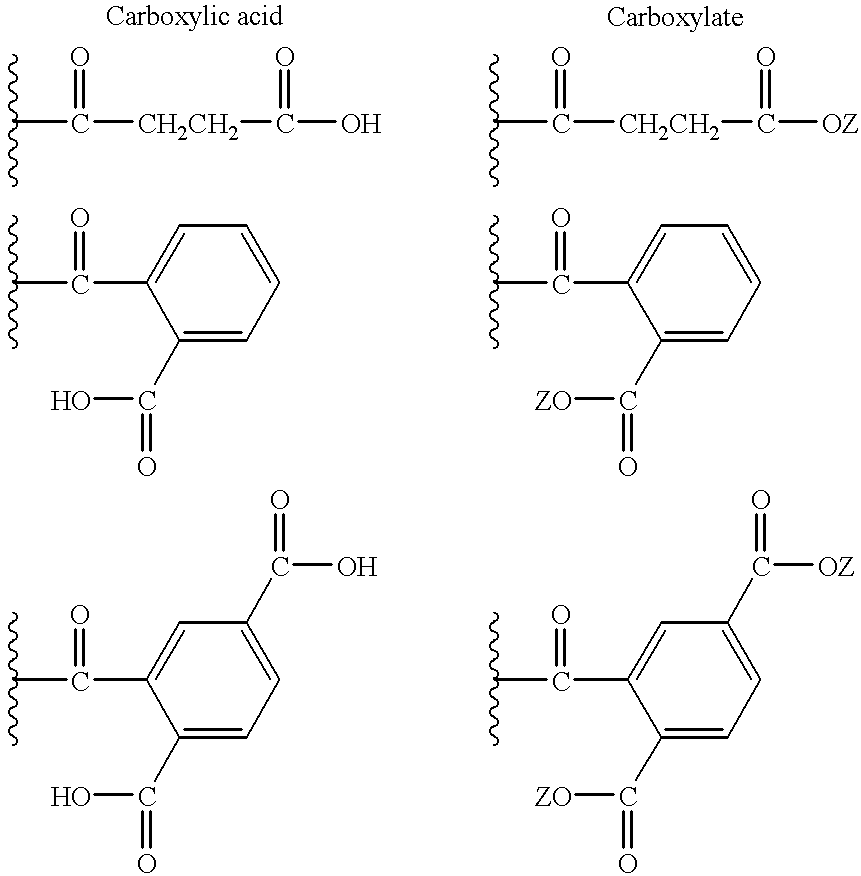

Dispersants for preparing aqueous pigment pastes

InactiveUS6235813B1Substantial of aggregationSubstantial of flocculationOrganic dyesPigment pastesCarboxylic acidPoly methacrylate

Owner:EVONIK GOLDSCHMIDT GMBH

High gloss, scratch-resistant, halogen-free and flame-retardant polycarbonate resin composition

The invention relates to the technical field of polymer materials, in particular to a halogen-free flame retardant polycarbonate resin composition material. The halogen-free flame retardant polycarbonate resin composition material comprises polycarbonate resin, styrene-based resin, polymethacrylate, flame retardants and antioxidants, and is characterized in that the composite material also comprises efficient compatibilizer; and the efficient compatibilizer is 4 to 13 percent of the total weight, and is a graft copolymer. The composite material has high-efficiency flame-retardant performance, excellent comprehensive mechanical properties and dimensional stability, particularly ensures scratch resistance and good surface gloss, simultaneously ensures good processing mobility, and is suitable for injection molding of various electrical and electronic equipment and household electrical products with environment-friendly and flame-retardant requirements.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

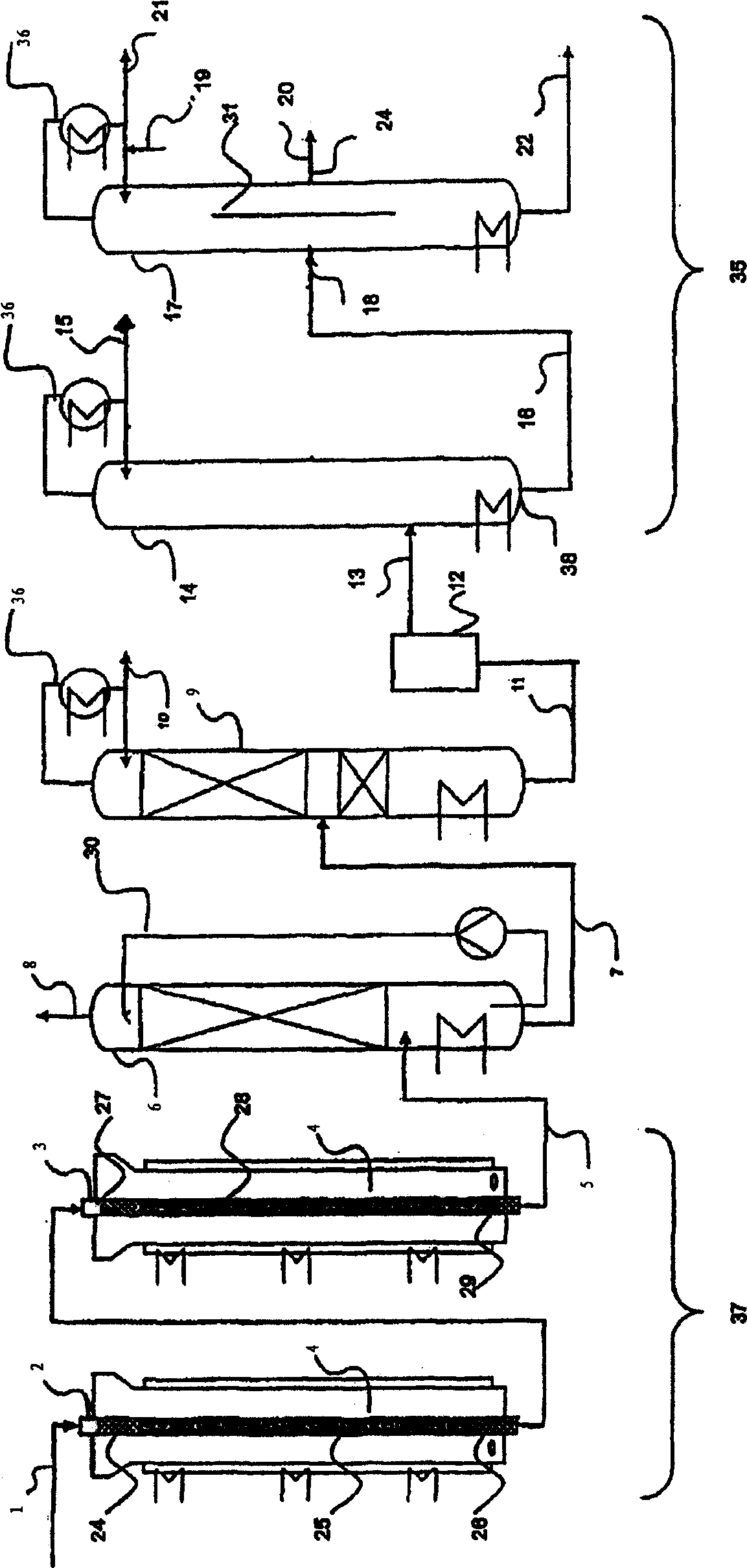

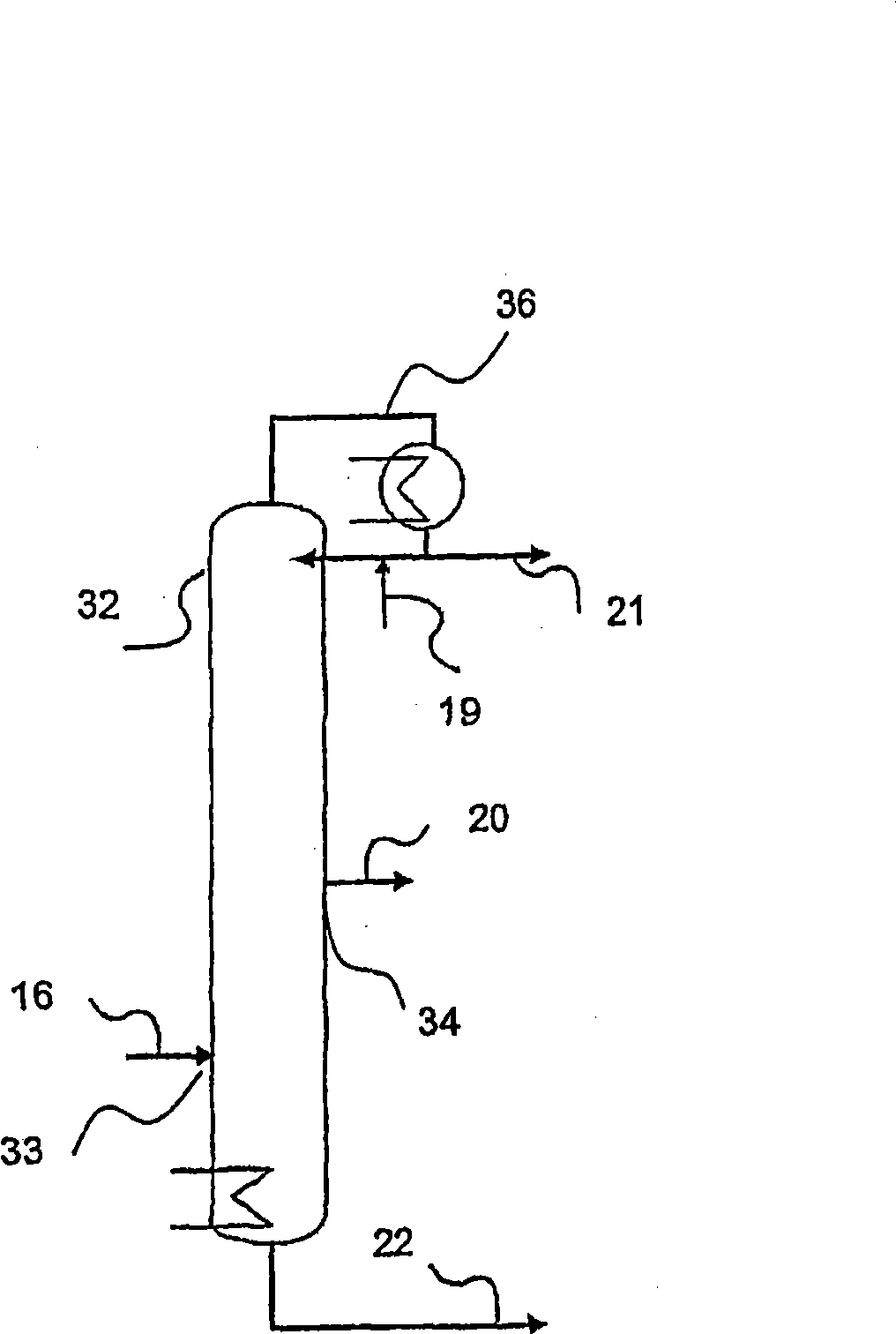

Process for preparation of high purity methacrylic acid

ActiveCN101497563AOrganic compound preparationCarboxylic acid esters preparationPoly methacrylateVarnish

The present invention relates to a process for preparation of pure methacrylic acid, at least comprising the process steps: a) gas phase oxidation of a C4 compound to obtain a methacrylic acid-comprising gas phase, b) condensation of the methacrylic acid- comprising gas phase to obtain an aqueous methacrylic acid solution, c) separation of at least a part of the methacrylic acid from the aqueous methacrylic acid solution to obtain at least one crude methacrylic acid- comprising product; d) separation of at least a part of the methacrylic acid from the at least one crude methacrylic acid -comprising product by means of a thermal separa tion process to obtain a pure methacrylic acid. The invention also relates to method for preparing metacrylic acid ester by the high-purity methacrylic acid obtained by the process, metacrylic acid ester that can be obtained by the method, a method for preparing polymethacrylic acid analogue and polymethacrylic acid analogue obtained by the method, a method for preparing polymethacrylate and polymethacrylate obtained by the method, pure methacrylic acid that can be obtained by the inventive method and the use of the metacrylic acid ester obtained by the inventive method, as well as fibers, films, varnishes, coatings, molding materials, formed bodies, paper additives, leather additives, flocculants and drilling additives.

Owner:ROHM G M B H

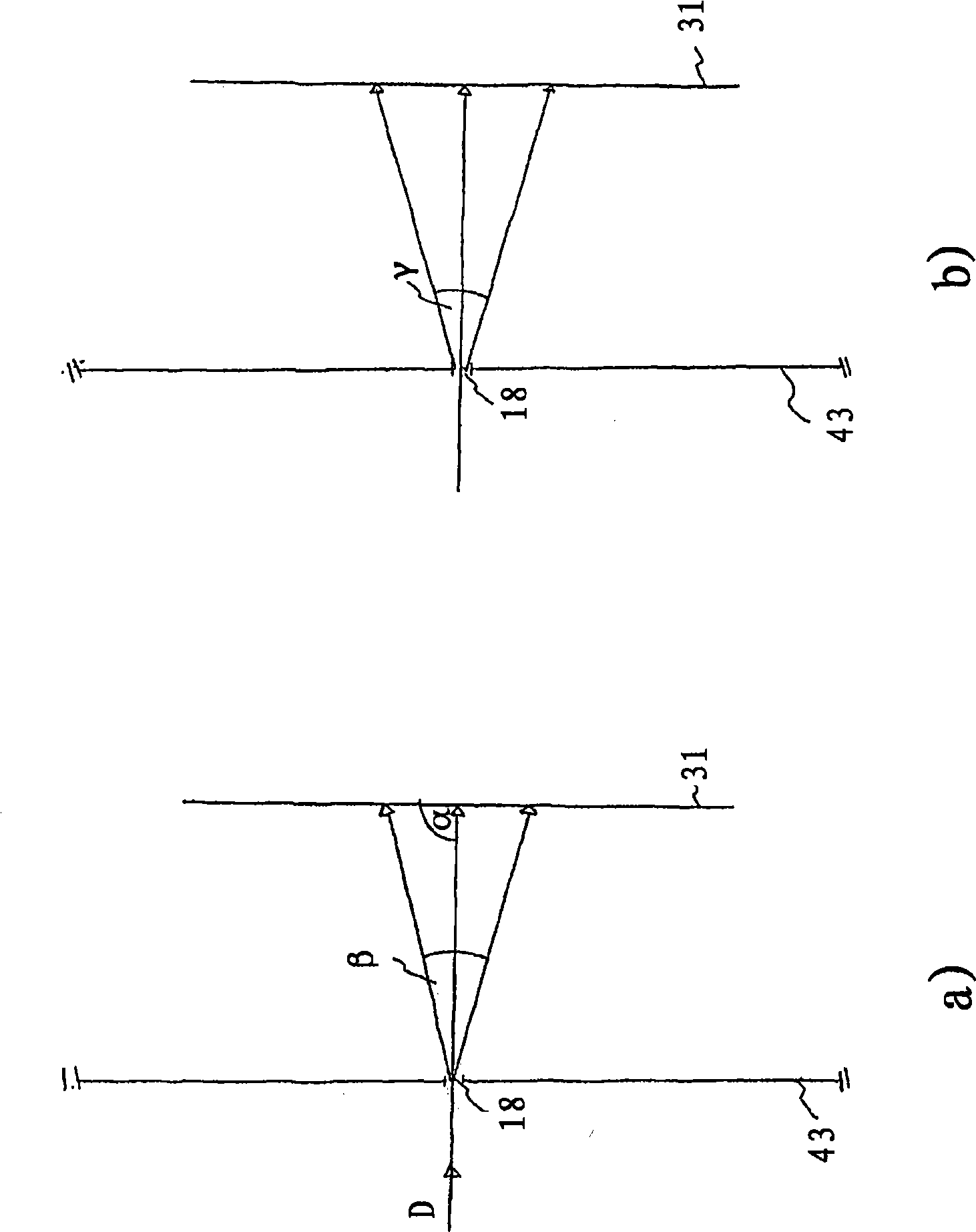

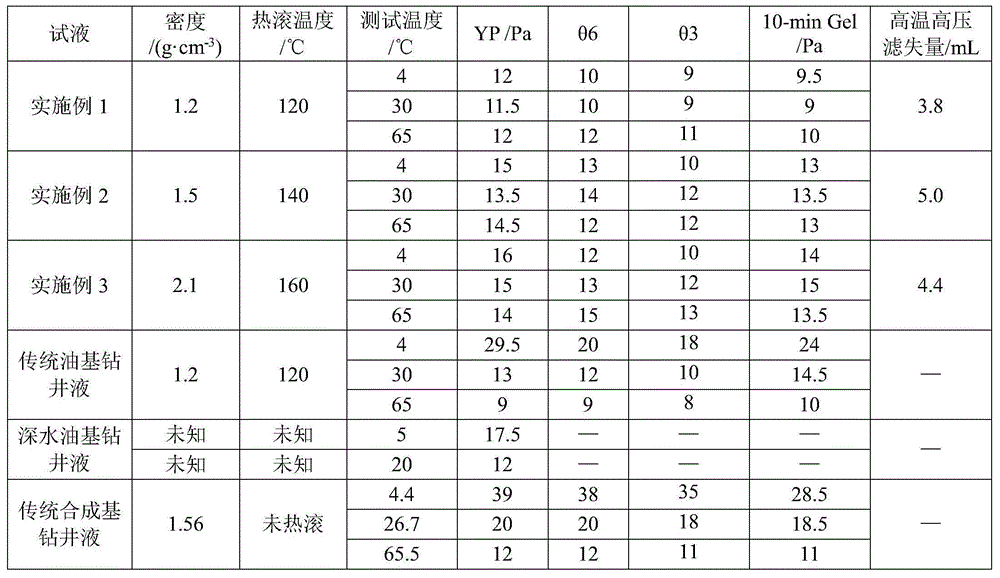

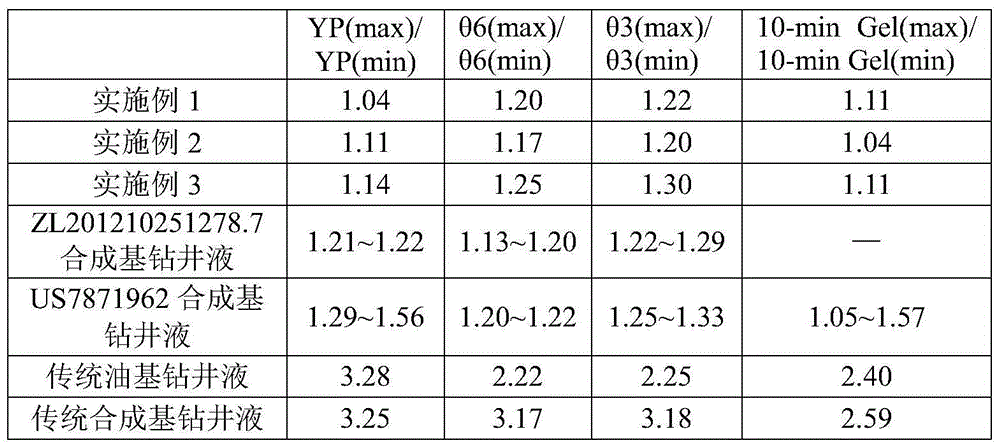

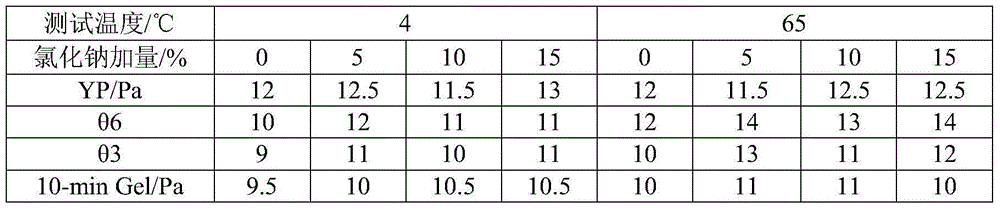

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fuel efficient lubricating oils

ActiveUS20150133352A1Reduce the amount requiredImprove fuel economyAdditivesBase-materialsMeth-Turbocharger

The present invention relates to an engine oil lubricant composition for use in internal combustion engines comprising one or more molybdenum containing compounds that deliver 1-1000 ppm molybdenum to the finished oil, one or more phosphorus containing compounds that deliver 25-650 ppm phosphorus to the finished oil, and one or more poly(meth)acrylate viscosity index improvers (VI improvers) that may or may not be functionalized, for improved fuel economy and turbocharger related deposits. In addition, the composition comprises an antioxidant system which is carefully balanced to provide improved fuel economy, comprising an aminic antioxidant, a phenolic antioxidant and an ashless dithiocarbamate. Additionally, the formulated oil may contain a dispersant poly(meth)acrylate, in addition to the PAMA VI improver, to reduce the amount of traditional succinimide dispersants.

Owner:VANDERBILT CHEM LLC

Radiation-curable, solvent-free and printable precursor of an adhesive

InactiveUS20050209360A1Easy to identifyPolyureas/polyurethane adhesivesOptical articlesMeth-Oligomer

The present invention relates to a free-radically radiation-curable, solvent-free and printable precursor of an adhesive, the precursor comprising (i) 15-60 wt. % of one or more mono(meth)acrylate functional oligomer compounds at least one of said oligomer compounds comprising at least one urethane bond, (ii) 5-8 5 wt. % of one or more poly(meth)acrylate functional oligomer compounds, (iii) 5-45 wt. % of one or more monomer compounds comprising one ethylenically unsaturated group, (iv) 0-10 wt. % of one or more monomer compounds comprising two or more ethylenically unsaturated groups, and (v) an effective amount of one or more free radical photoinitiators, wherein the percentages which are percentages by weight with respect to the mass of the precursor, are selected so that the precursor has a dynamic viscosity at 20° C. and at a shear rate of 100 s−1 of between 300 to 15,000 mPa·s.

Owner:3M INNOVATIVE PROPERTIES CO

Dispersant-viscosity improvers for lubricating oil compositions

A polyacrylate ester, and more particularly a polymethacrylate ester based dispersant-viscosity improver for lubricating oil compositions. Specifically, the dispersant viscosity improvers of this invention are nitrogen-containing copolymers comprising units derived from(A) from about 5% to about 75% by weight of alkyl acrylate ester monomers containing from 2 to 11 carbon atoms in the alkyl group;(B) from about 25% to about 95% by weight of alkyl acrylate ester monomers containing from 12 to about 24 carbon atoms in the alkyl group; and(C) From about 0.1% to about 20% by weight of at least one nitrogen containing monomer selected from the group consisting of vinyl substituted nitrogen heterocyclic monomers, N,N-dialkylaminoalkyl acrylate monomers, N,N-dialkylaminoalkyl acrylamide monomers and tertiary-alkyl acrylamides, provided that the total equals 100%. Processes for preparing the compositions, additive concentrates and lubricating oil compositions are described.

Owner:THE LUBRIZOL CORP

Combination of oil for pair of gear worm

A composite oil for worm gear set contains mineral lubricating oil, at least one pour depressor and / or viscosity index improver chosen from polymethylacrylate, poly-alpha-olefin, alkylnaphthalene, etc, at least one S-contained extreme pressure agent and / or P-contained extreme-pressure antiwear agent, at least one oil agent or friction improver, at least one phenol-type or amine-type antioxidizing agent, at least one phenyltriazole or thiabiazole type metallic deactivator, and at least one poly-alcohol-ether type antiemulsifying agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

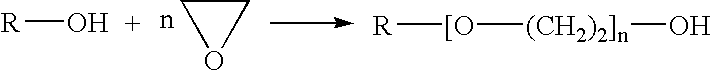

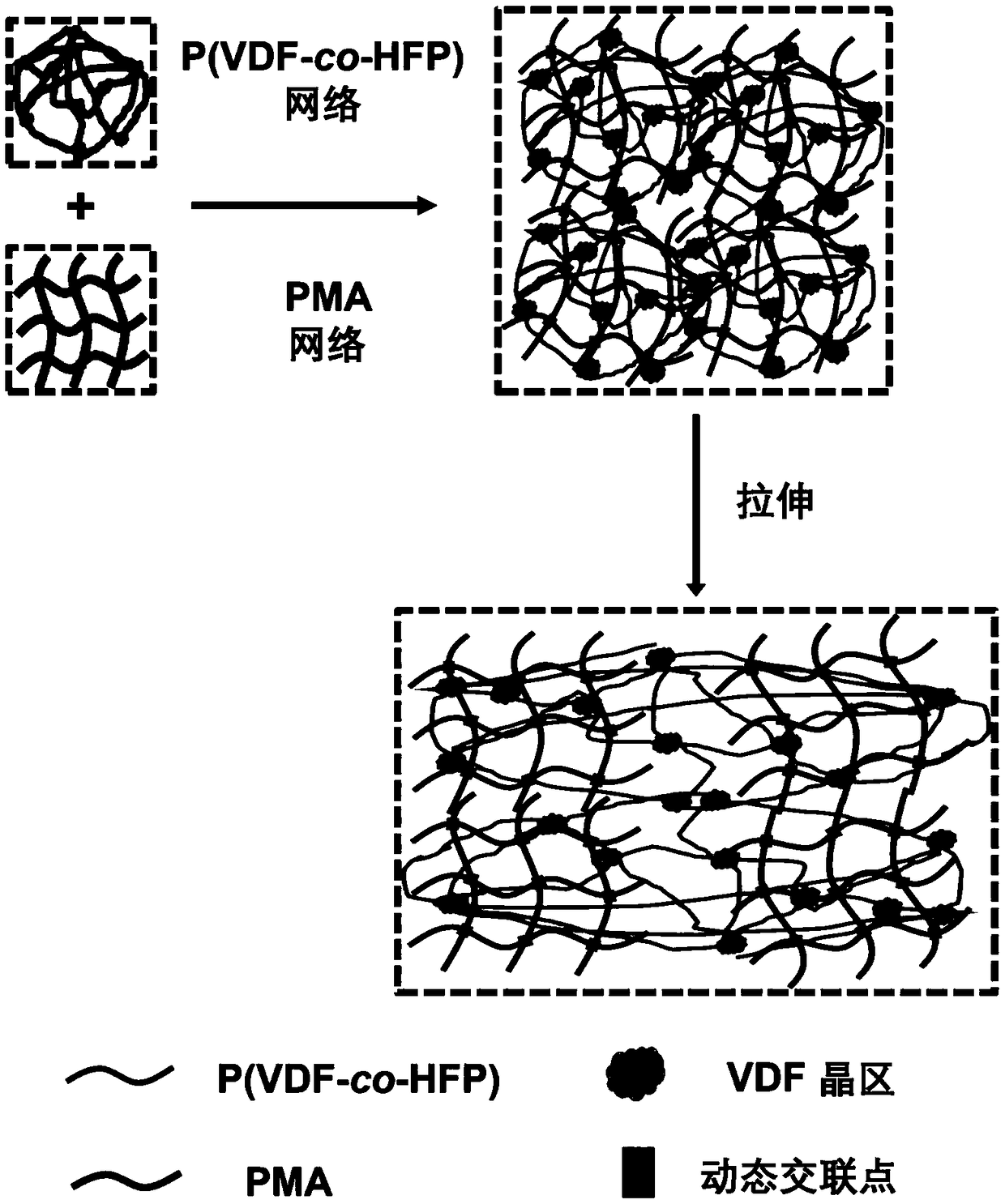

Double-network ionic gel with stimulation responsiveness and self repairability

ActiveCN108623826AImprove mechanical propertiesImprove thermal stabilitySecondary cellsCross-linkElectric devices

The invention discloses double-network ionic gel with stimulation responsiveness and self repairability. Ionic liquid serves as a substrate, P(VDF-co-HFP) is used as a physical cross-linking network,dynamic covalent bond cross-linked PMA (polymethacrylate) copolymer serves as a chemical cross-linking network, and the two polymer cross-linking networks penetrate mutually to form a double network.Under synergistic effects of the double network, the ionic gel is excellent in mechanical performance, thermal stability and ionic conductivity. In addition, due to containing of reversible dynamic covalent bonds, self repairability under stimulation of light, thermal and the like can be realized. The ionic gel can be widely applied to lithium ion battery solid-state polyelectrolyte materials, gasseparation membranes, flexible electric devices, electrochemical sensors and the like.

Owner:PEKING UNIV

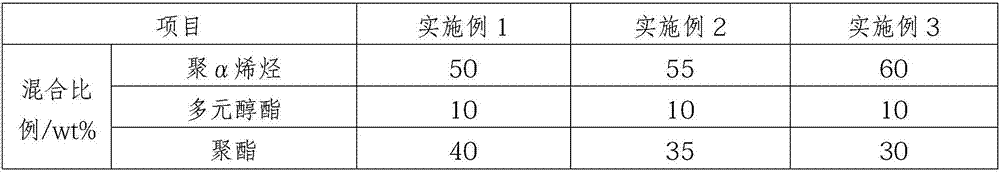

Low-temperature and over-loading synthetic gear oil

ActiveCN107312598AGood low temperatureGood thickening effectLubricant compositionViscosity indexBase oil

The invention relates to low-temperature and over-loading synthetic gear oil comprising at least the following components: an anti-wear reagent at extreme pressure, a friction modifier, a viscosity index improver, and base oil, wherein the anti-wear reagent at extreme pressure at least comprises an oil-soluble nano-borate, the viscosity index improver at least comprises a modified polymethacrylate tackifier, the friction modifier at least comprises organic molybdenum, the base oil is mixed base oil comprising polyalphaolefin and ester oil, the mass percentage of the mixed base oil is 78.4%, the mass percentage of the modified polymethacrylate tackifier is 7.5%, the mass percentage of the oil-soluble nano borate is 2%, and the mass percentage of organic molybdenum is 0.2-0.3%. The gear oil disclosed by the invention has excellent low temperature performance and can effectively prolong the life cycle of oil products, and a solid borate film formed by the borate has excellent extreme pressure resistance, can bear huge load and has excellent anti-wear and anti-friction performances.

Owner:北京雅士科莱恩石油化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com