Patents

Literature

236results about How to "Avoid phase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrically conductive thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20020177027A1Good compatibilityImprove adhesionElectrode carriers/collectorsConductive materialFuel cellsHeat resistance

A conductive thermosetting composition comprises a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a conductive agent. After curing, the composition exhibits good stiffness, toughness, heat resistance, and conductivity, and it is useful in the fabrication of a variety of conductive components, including the bipolar plates of fuel cells.

Owner:SABIC GLOBAL TECH BV

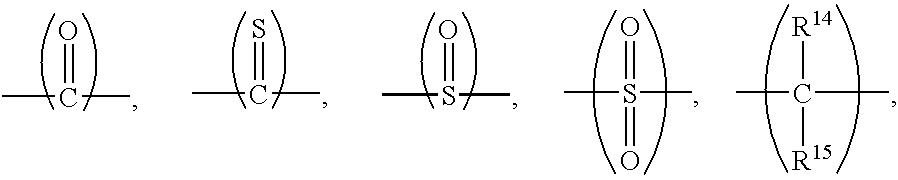

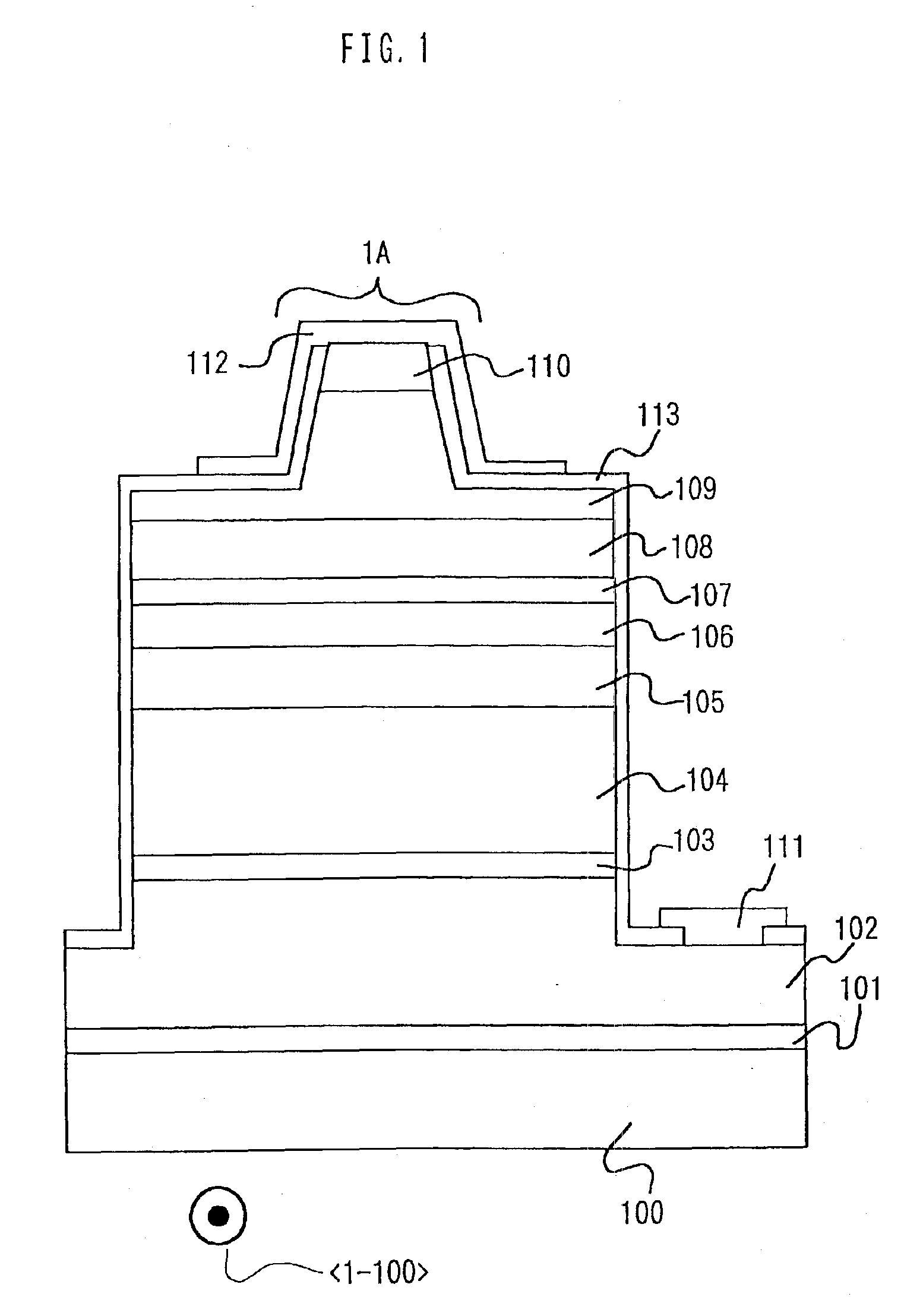

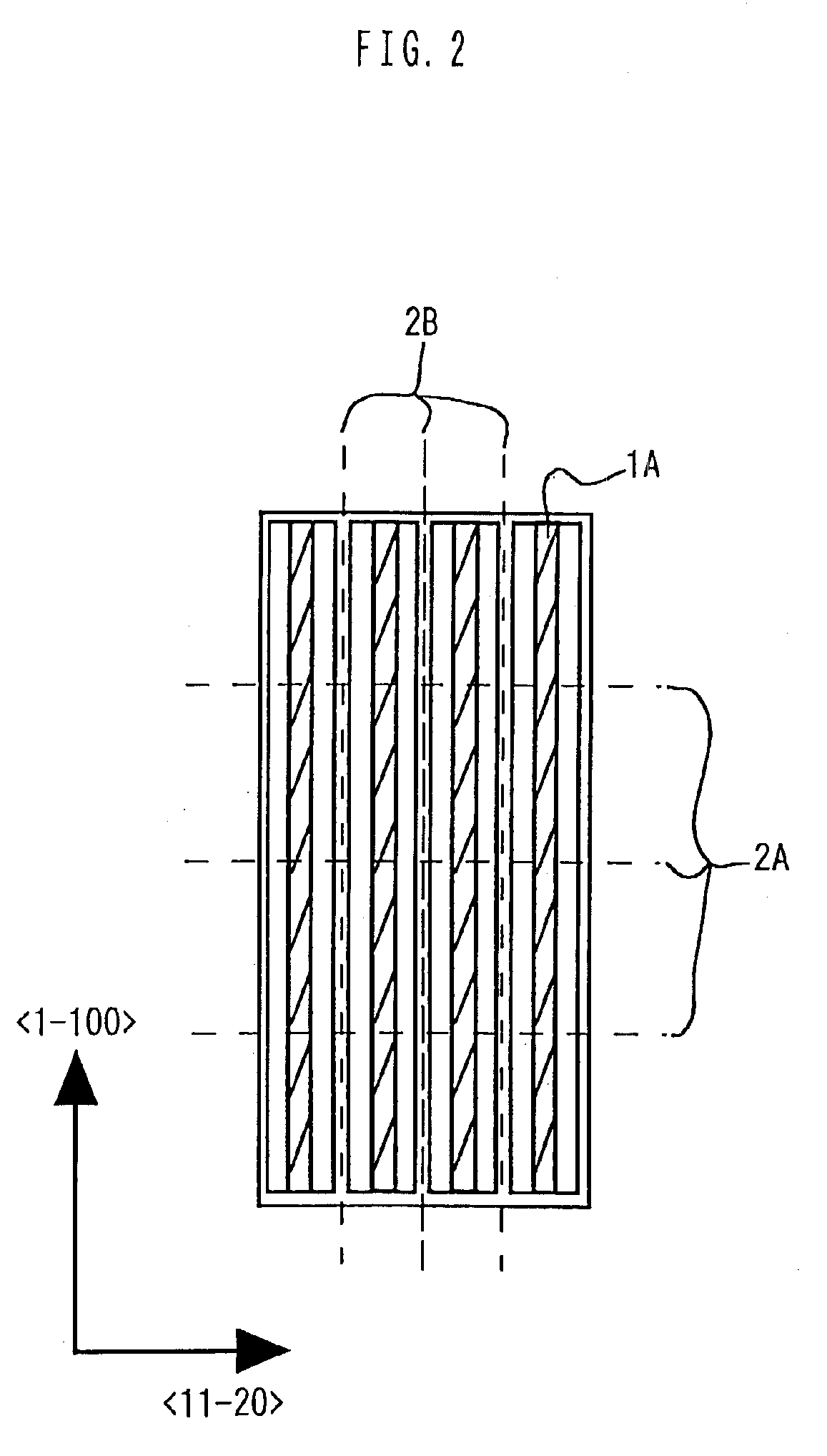

Nitride semiconductor light-emitting device and optical apparatus including the same

InactiveUS6924512B2Improve luminous efficiencyHigh crystallinityOptical wave guidanceLaser detailsLight emitting deviceQuantum

A nitride semiconductor light emitting device includes an emission layer (106) having a multiple quantum well structure where a plurality of quantum well layers and a plurality of barrier layers are alternately stacked. The quantum well layer is formed of XN1-x-y-zAsxPySbz (0≦x≦0.15, 0≦y≦0.2, 0≦z≦0.05, x+y+z>0) where X represents one or more kinds of group III elements. The barrier layer is formed of a nitride semiconductor layer containing at least Al.

Owner:SHARP KK

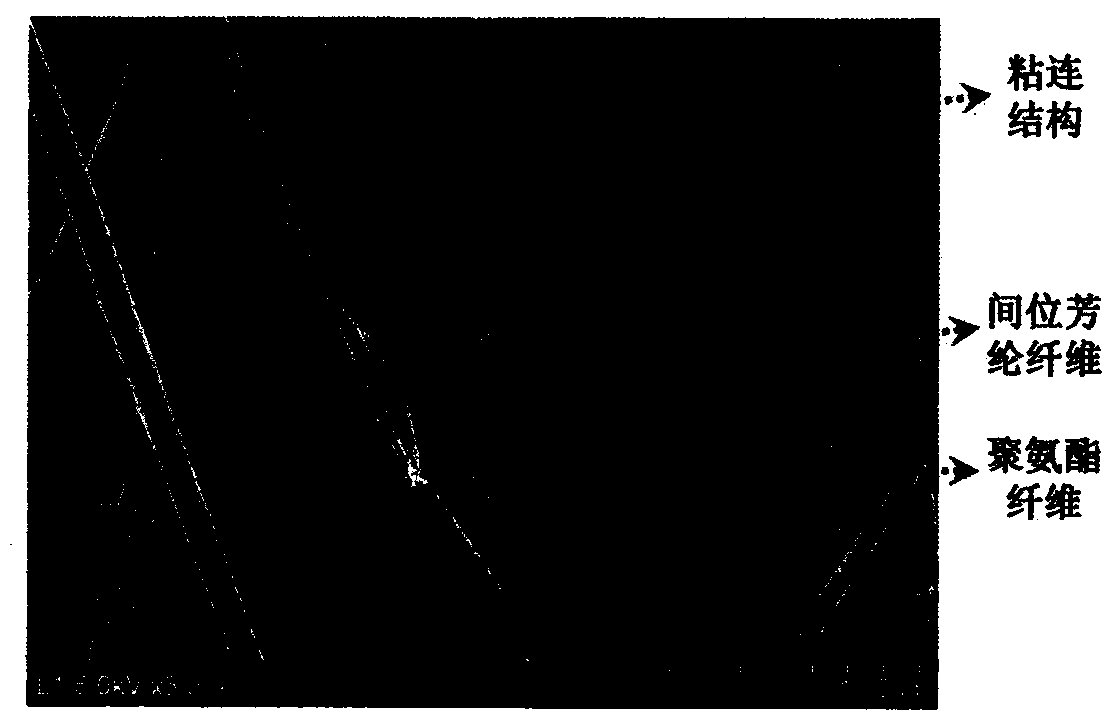

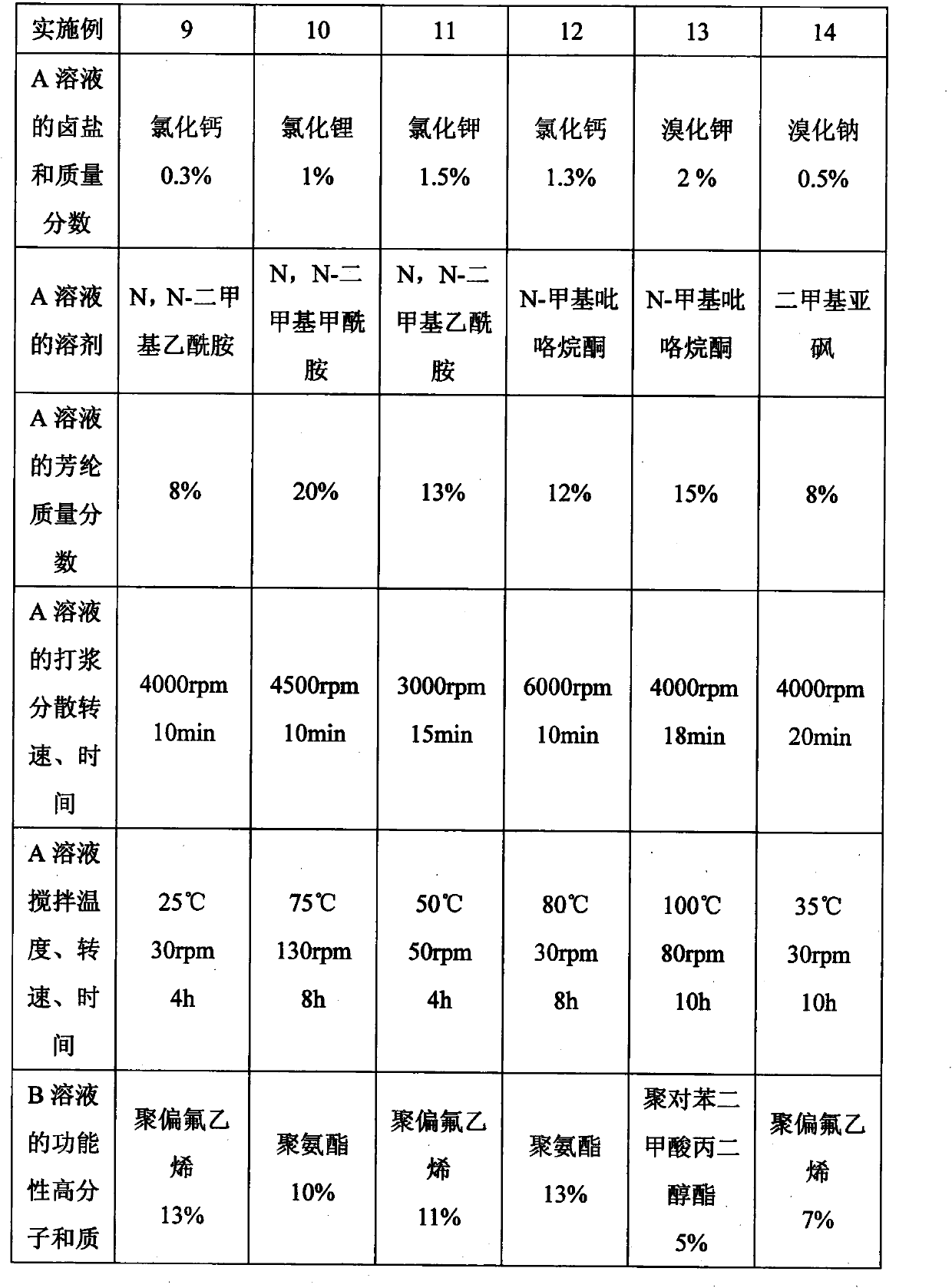

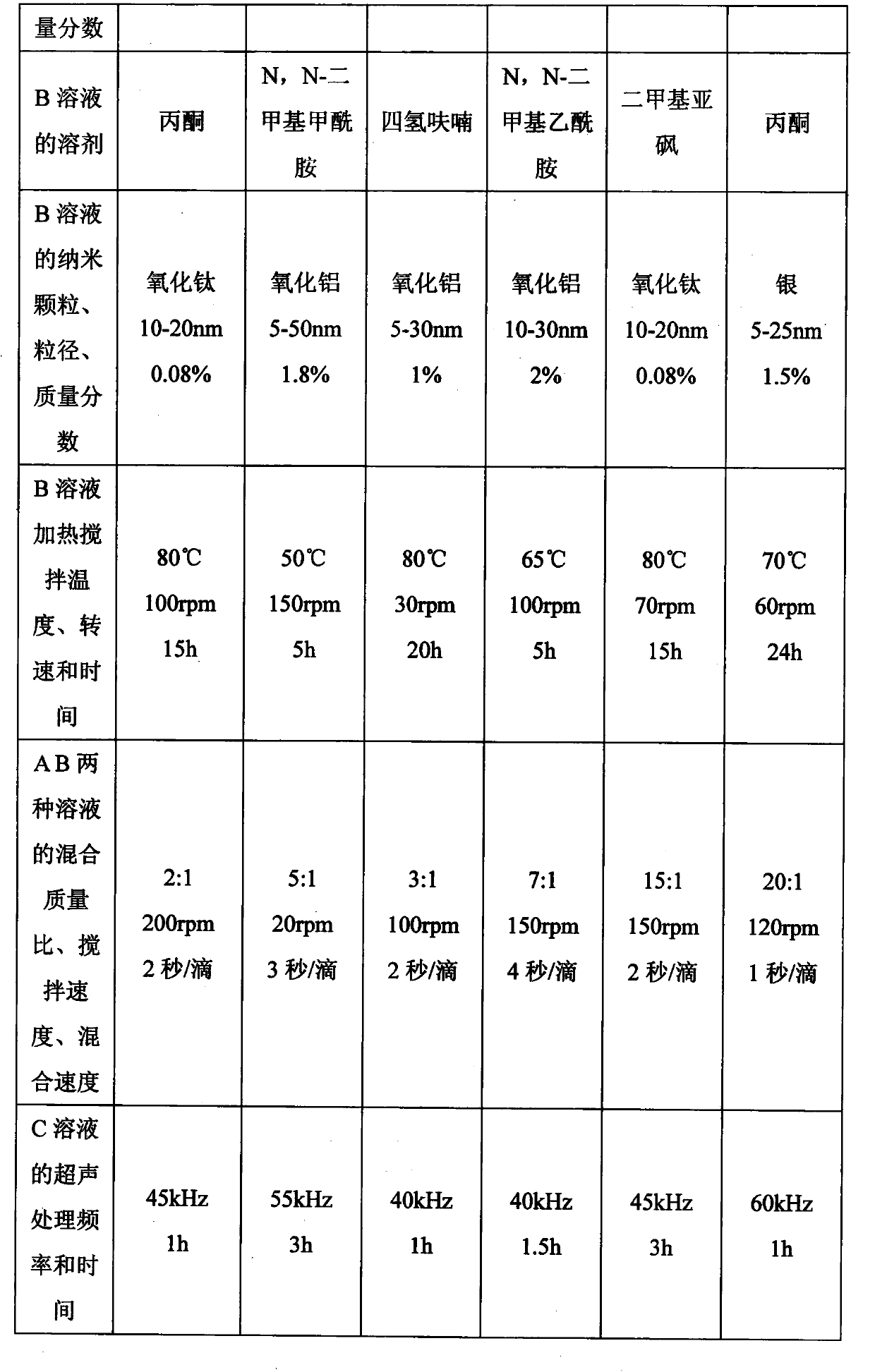

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

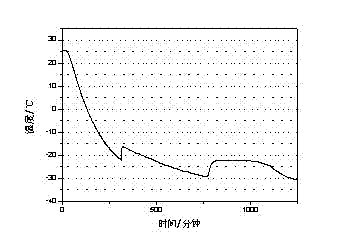

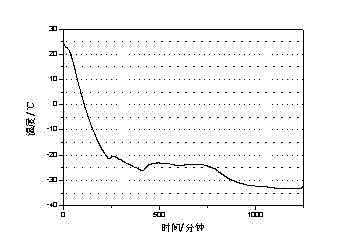

Inorganic salt phase-change cold accumulation material

ActiveCN103242806AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsHigh energyCold storage

The invention discloses an inorganic salt phase-change cold accumulation material which is prepared from the following raw materials in parts by weight: 100 parts of a 15-25% inorganic salt solution, 1-7 parts of a nucleation agent and 2-15 parts of a thickening agent. Inorganic salt is used as an inorganic phase-change material. The inorganic salt phase-change cold accumulation material has the advantages that the phase-change latent heat is high (can reach 200-400J / g); the heat conductivity coefficient is good (when being compared with an organic phase-change energy accumulation material); no toxin exists and a pH (Potential of Hydrogen) value is neutral; and the price is low. According to the inorganic salt phase-change cold storage material disclosed by the invention, compared with the prior art (the phase-change latent heat is in a range of 100-200J / g), the inorganic salt phase-change cold accumulation material has the advantages of high energy storage density, small condensate depression and good circulatory stability.

Owner:杭州鲁尔新材料科技有限公司

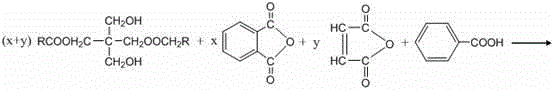

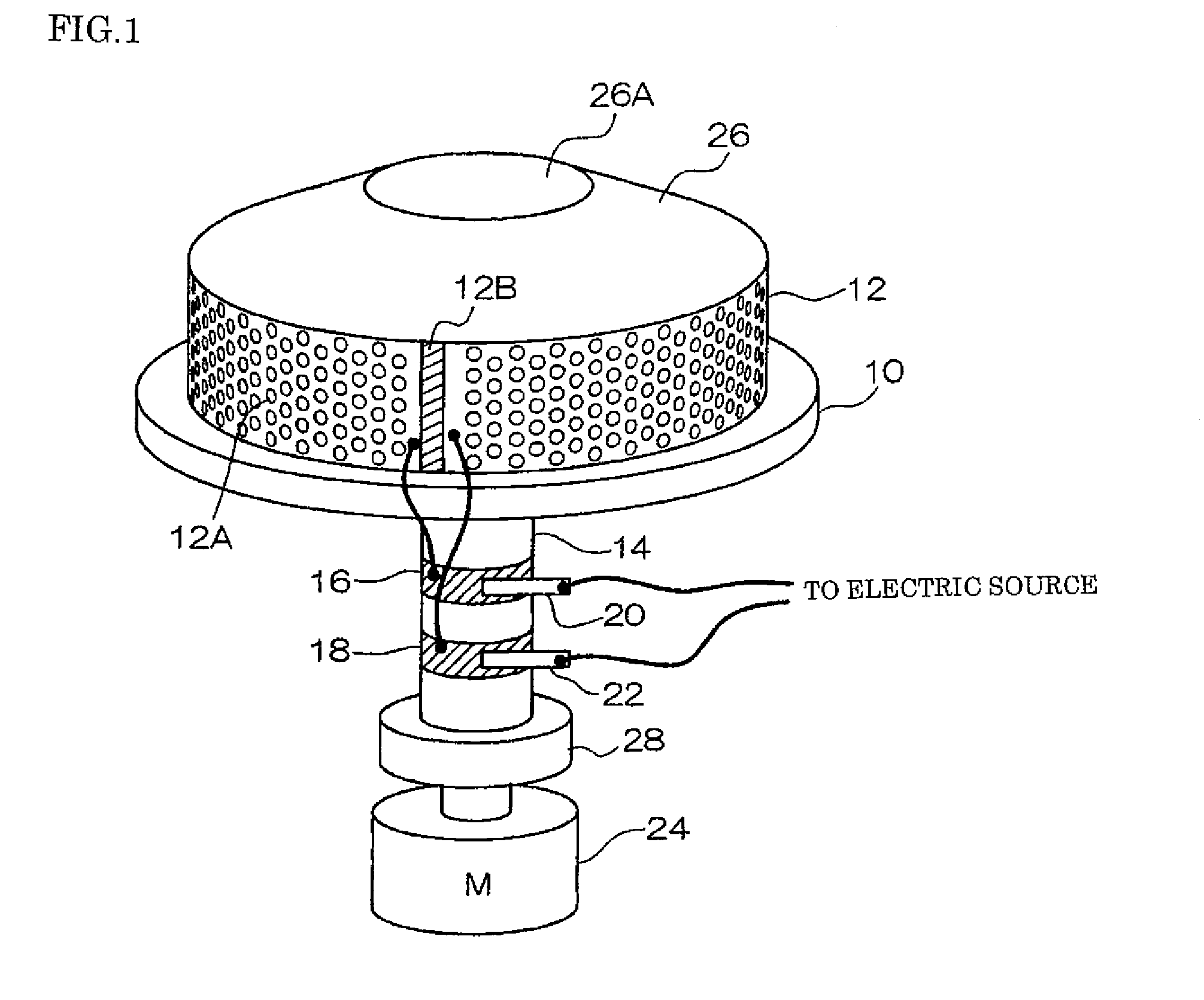

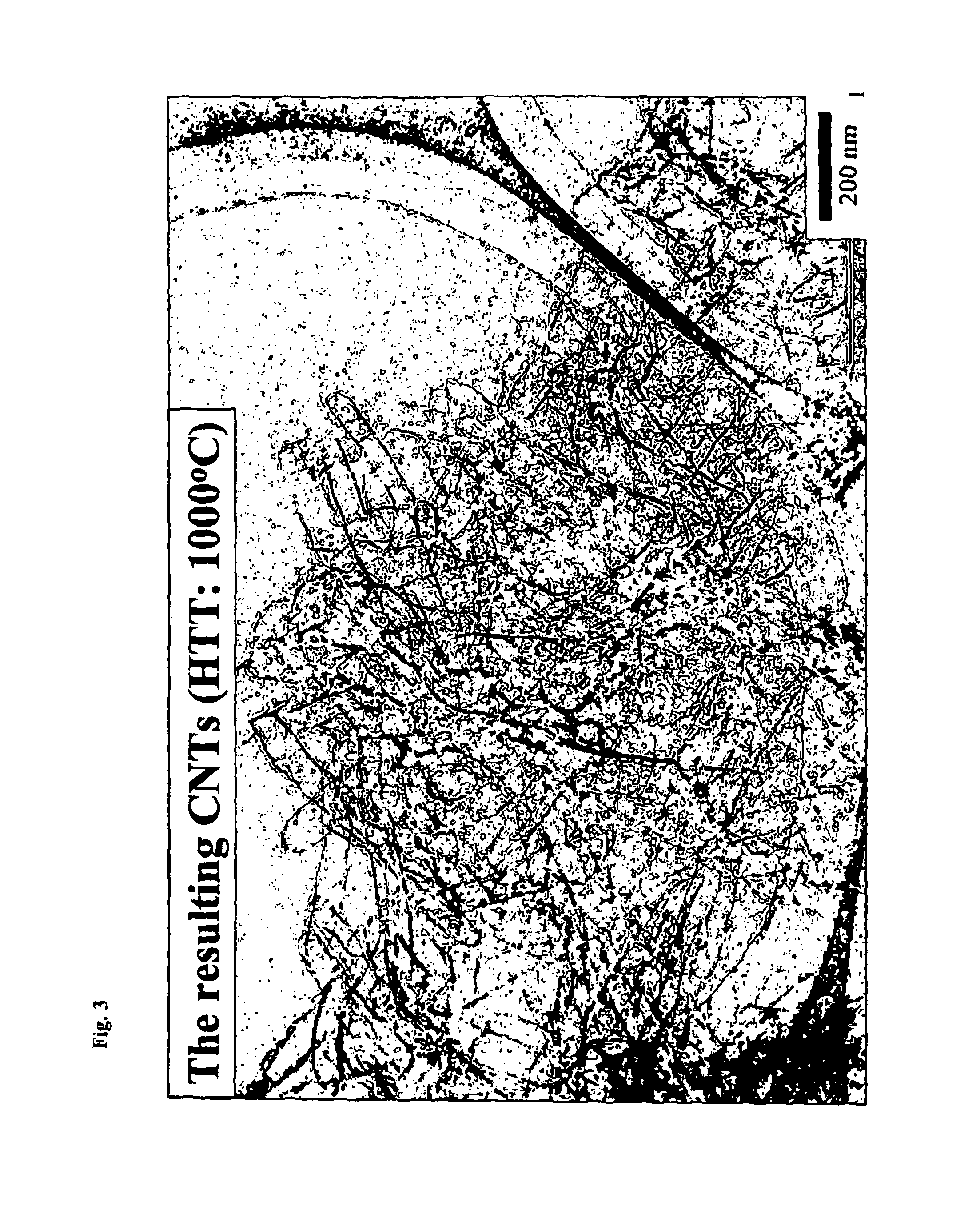

Method of Producing Carbon Nanomaterials and Centrifugal Melt Spinning Apparatus

InactiveUS20080050304A1Producing a carbon nanomaterialImprove efficiencyMaterial nanotechnologyFilament/thread formingPolymer scienceCarbonization

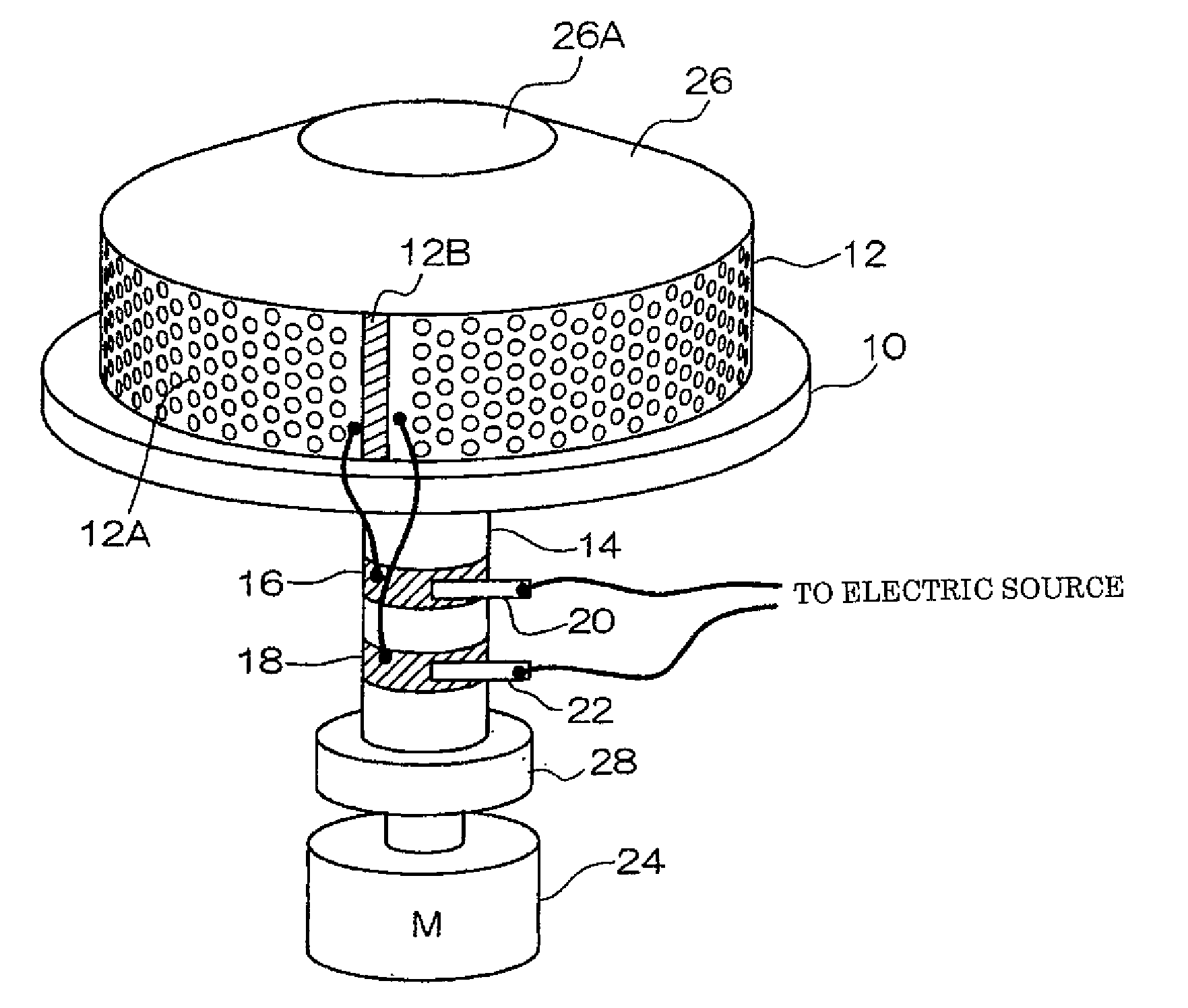

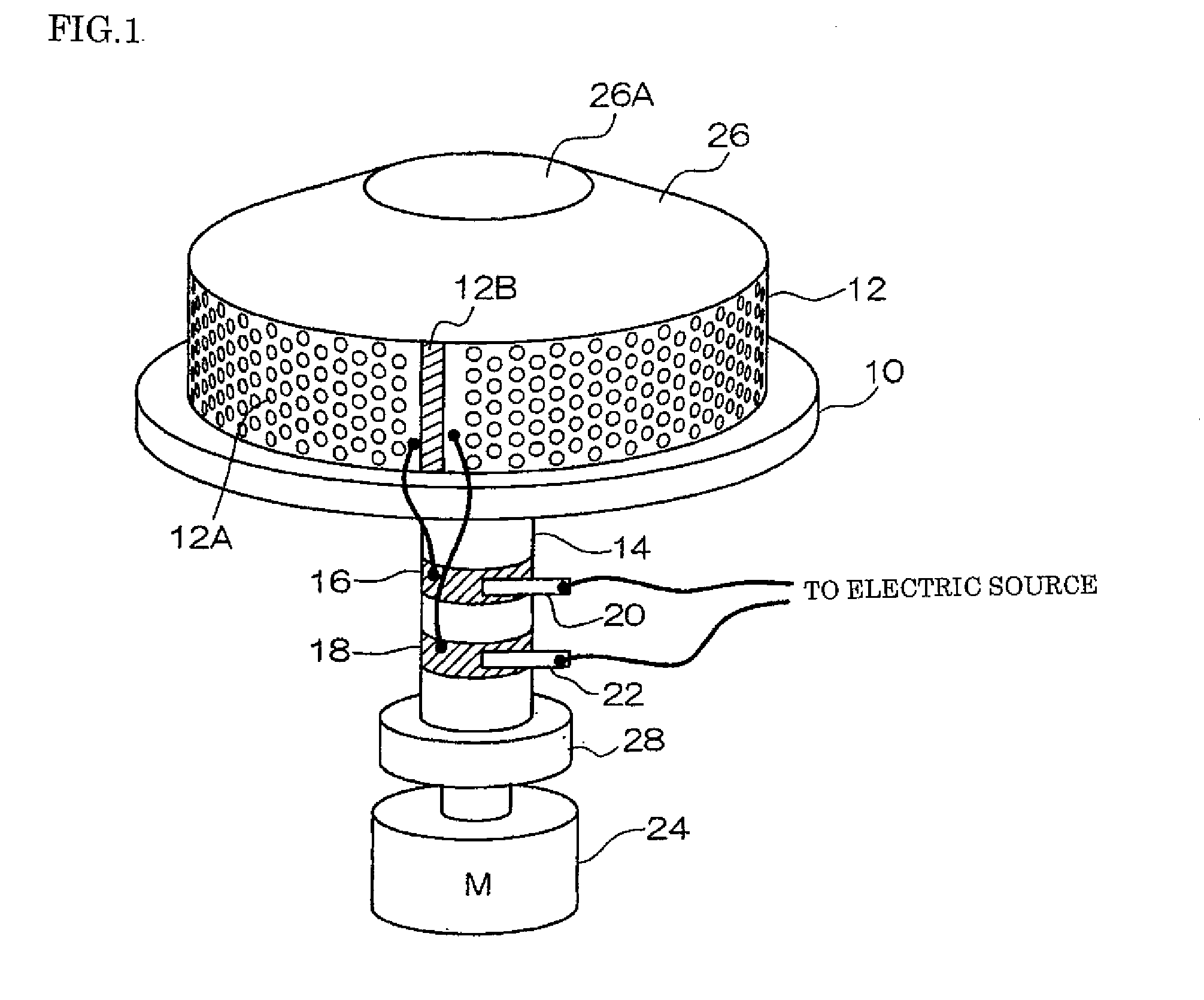

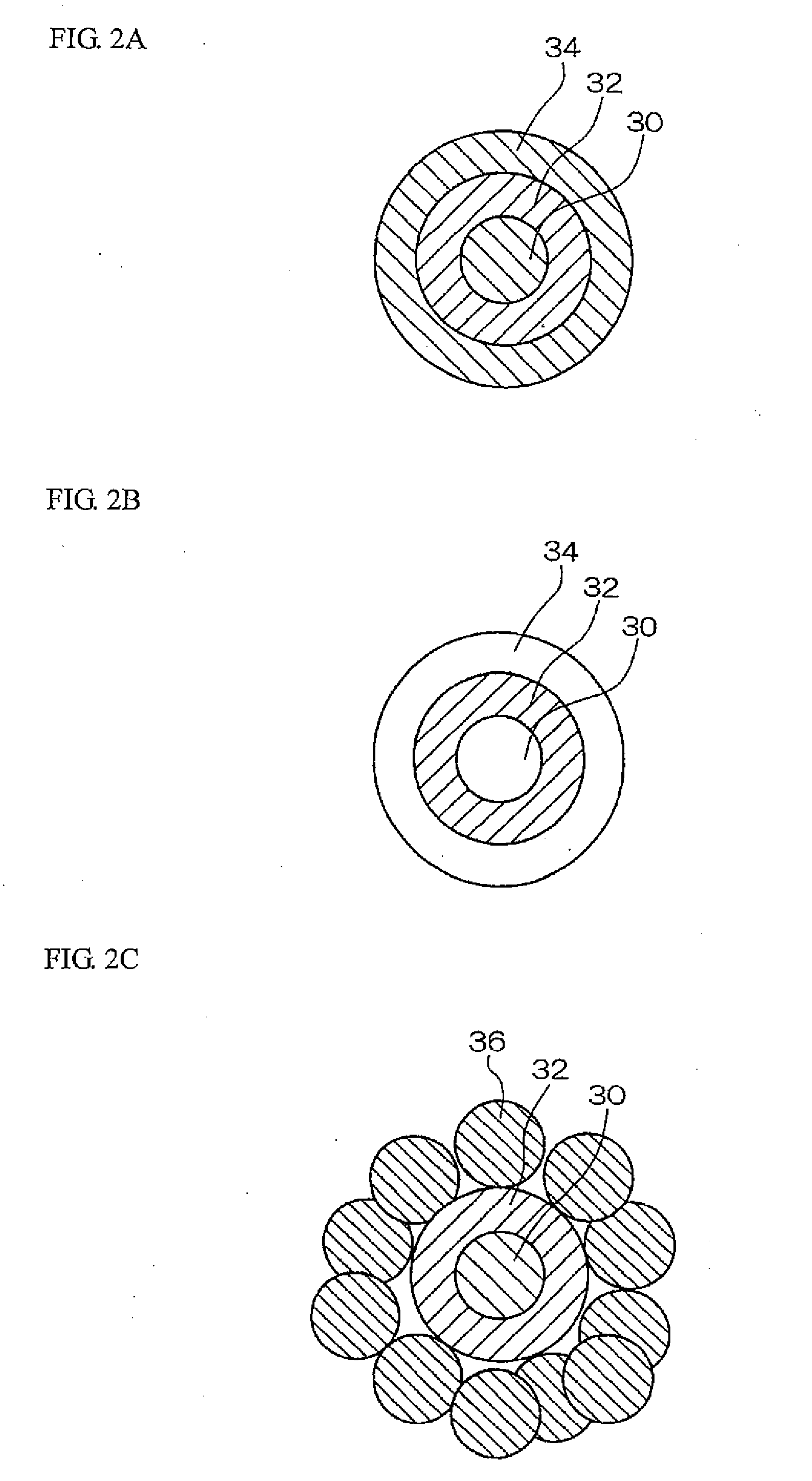

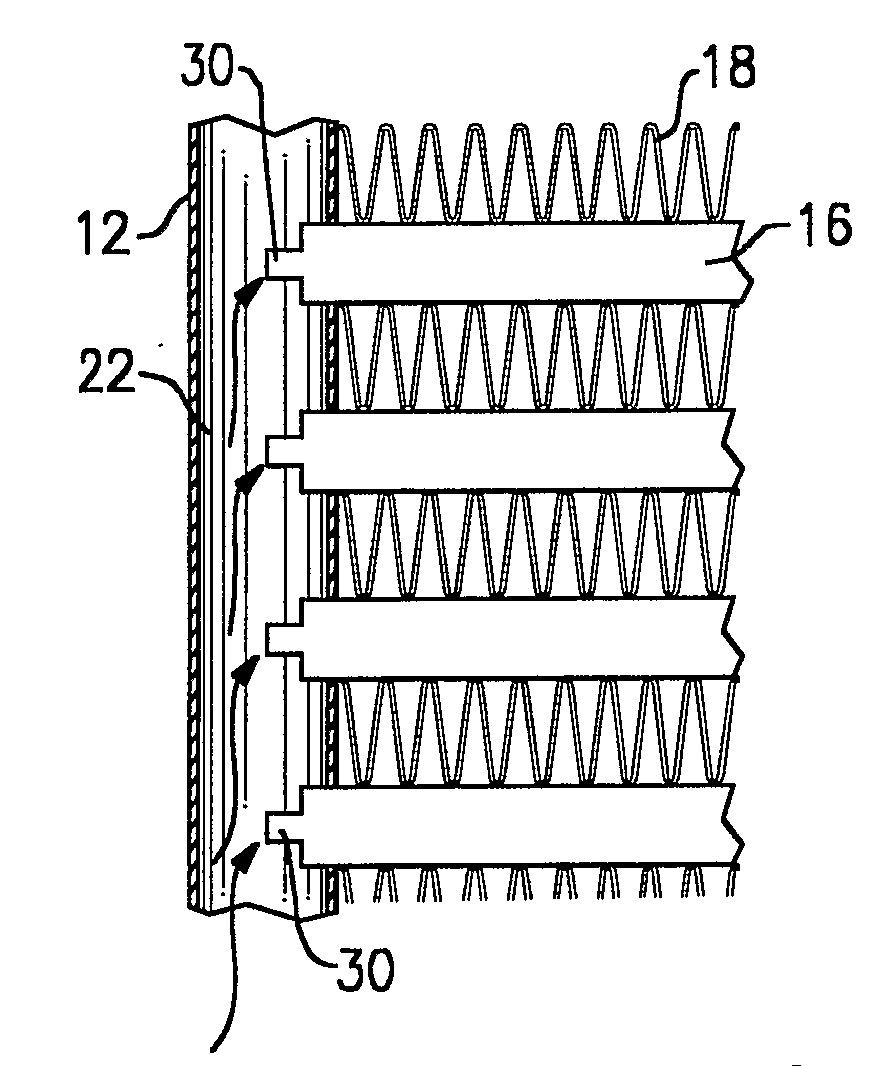

A carbon nanomaterial produced by: performing centrifugal melt spinning of core-shell particles that are prepared by using fine particles containing a carbon precursor polymer and a thermally decomposable polymer that disappears as a result of heat treatment, wherein the core-shell particles are heated up to a temperature at which phase separation thereof is not caused, and pressed against a plate-like heater 12 having a large number of pores 12A that penetrate therethrough in a thickness direction of the plate-like heater using centrifugal force; making the fiber obtained by the centrifugal melt spinning infusible; and performing carbonization thereof. According to this method, a carbon nanomaterial such as a carbon nanotube or a carbon nanofiber can be produced with high efficiency.

Owner:GUNMA UNIVERSITY

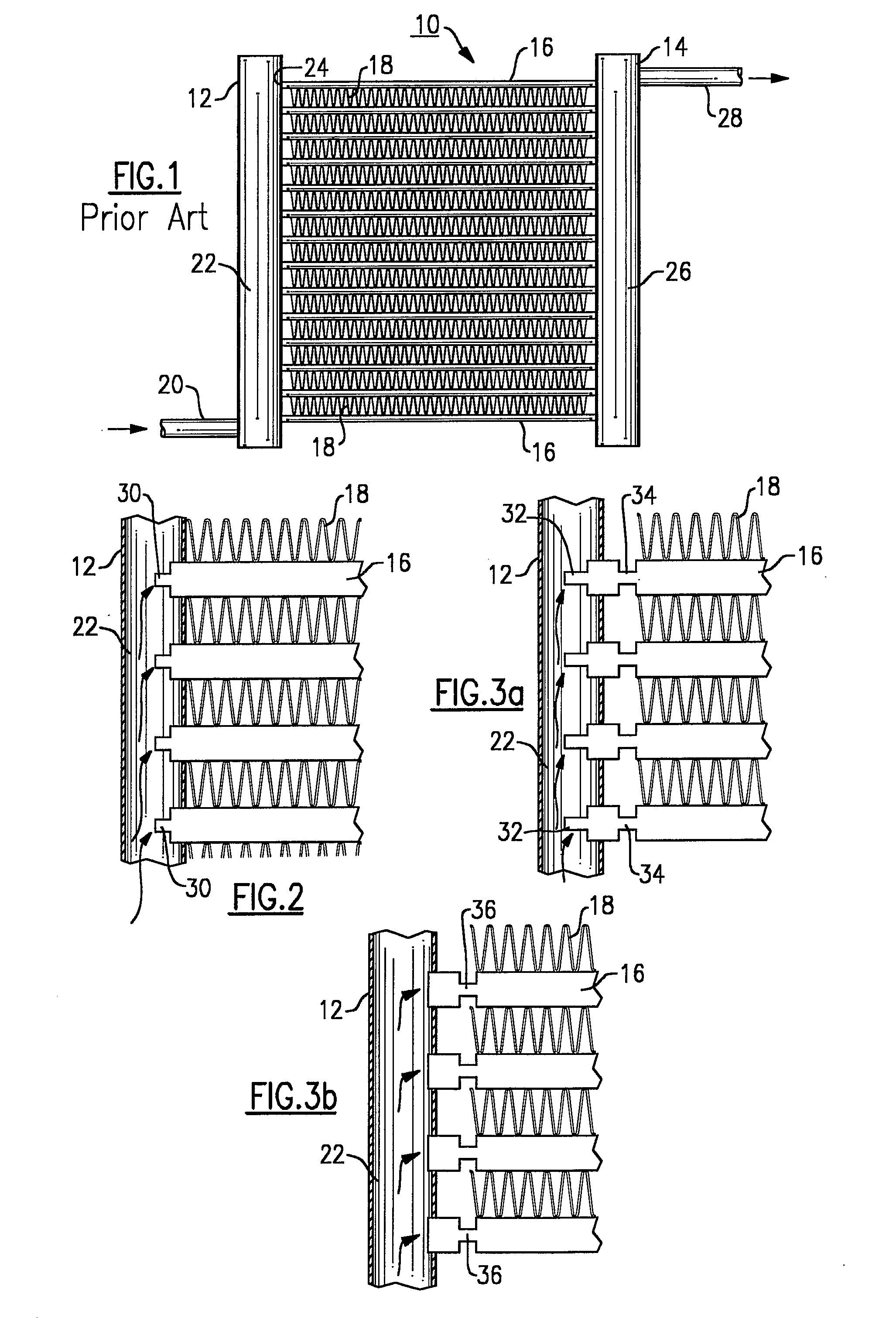

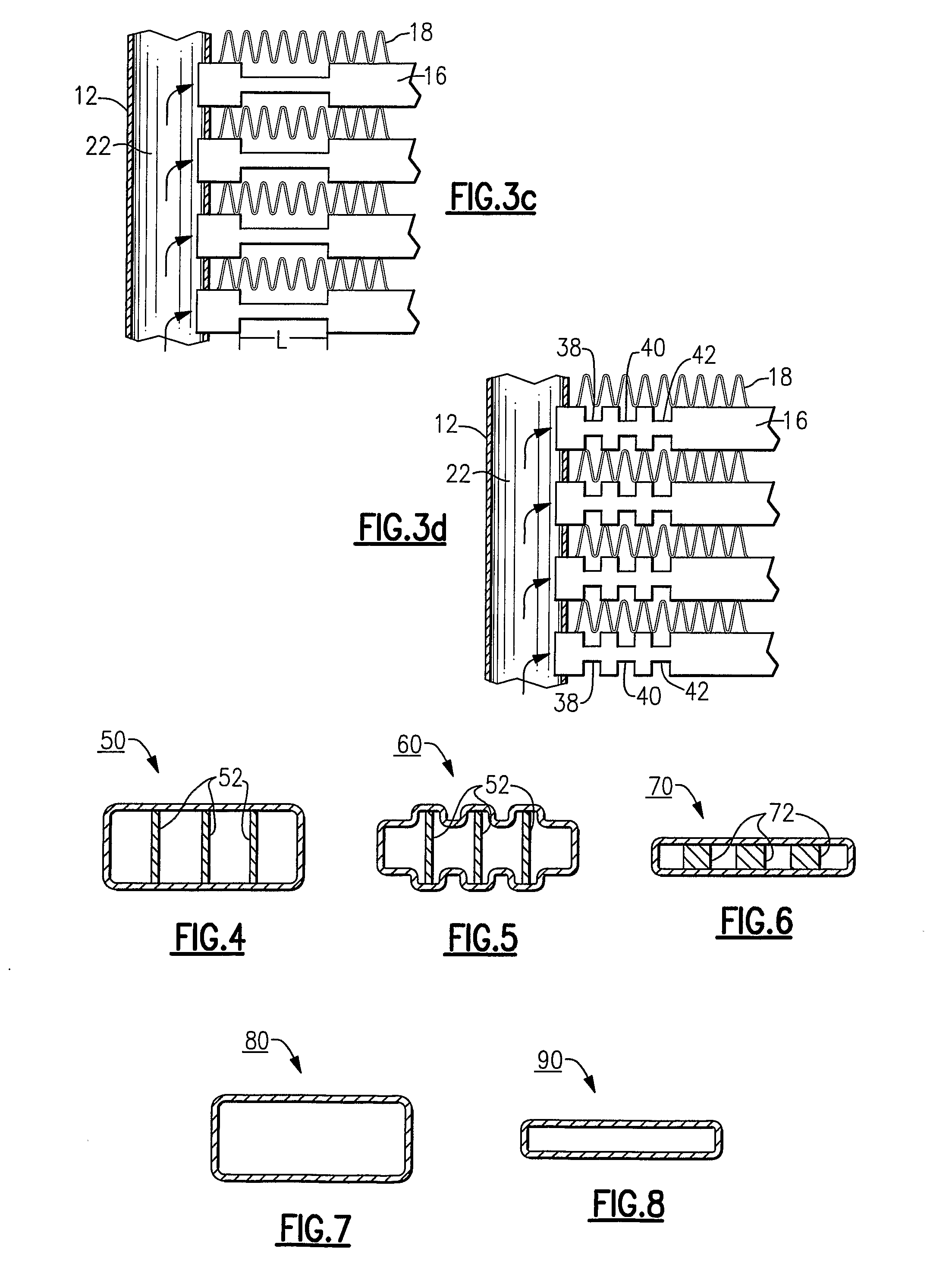

Parallel Flow Heat Exchanger With Crimped Channel Entrance

InactiveUS20080105420A1Improve system performanceAvoid inhalationMechanical apparatusEvaporators/condensersRefrigerant distributionEngineering

A parallel flow (minichannel or microchannel) evaporator includes channels which are crimped at or adjacent to their entrance location which provides for a refrigerant expansion and pressure drop control resulting in the elimination of refrigerant maldistribution in the evaporator and prevention of potential compressor flooding. Progressive crimping to counter-balance factors effecting refrigerant distribution is also disclosed.

Owner:CARRIER CORP

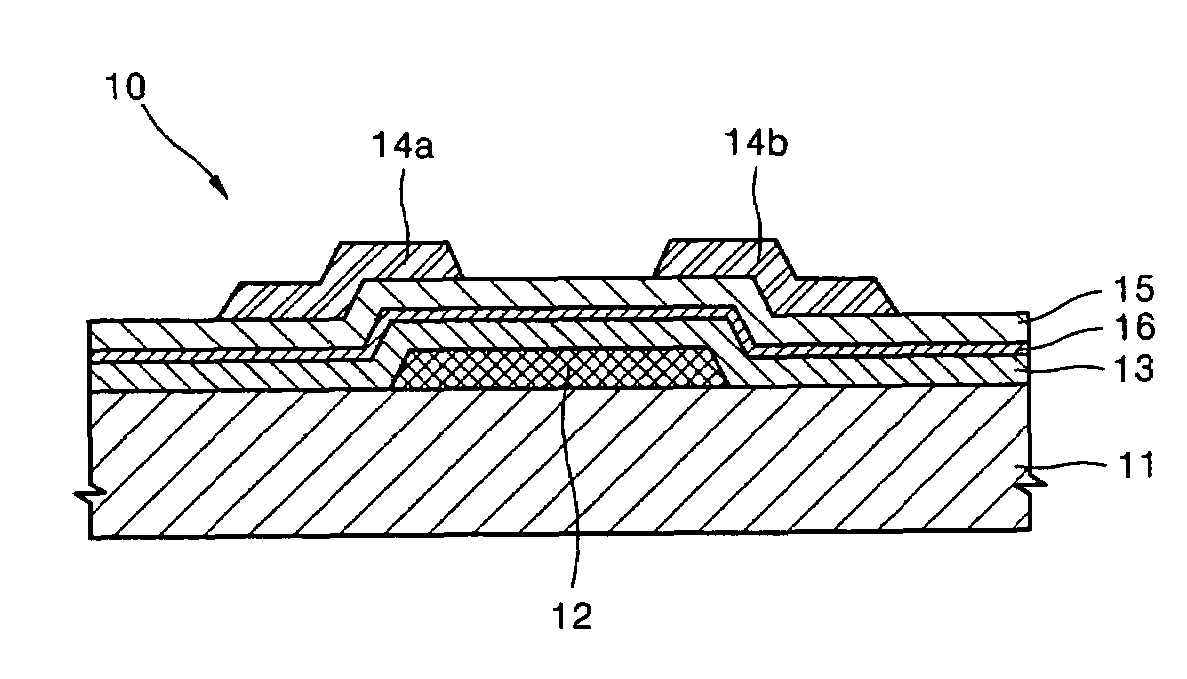

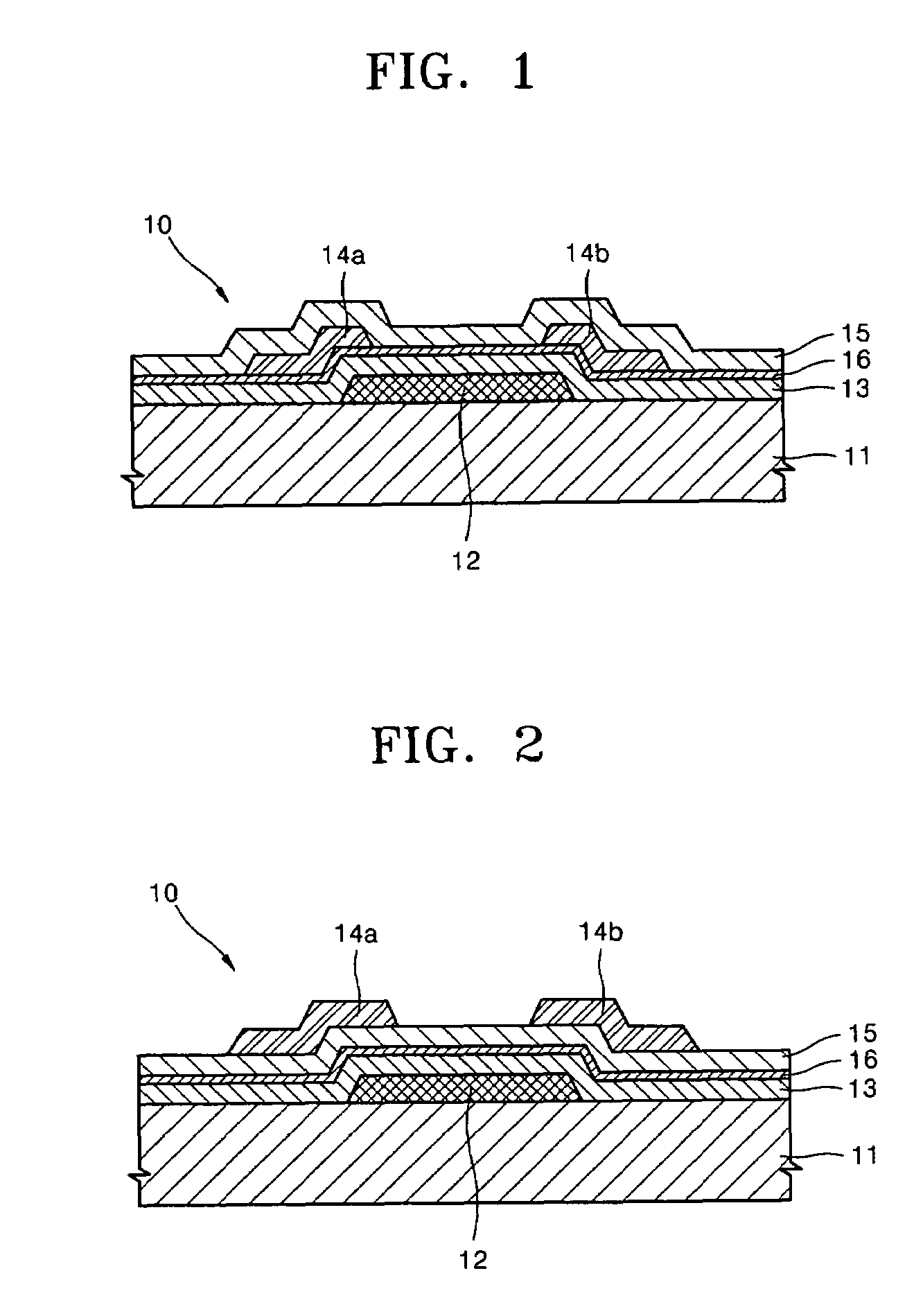

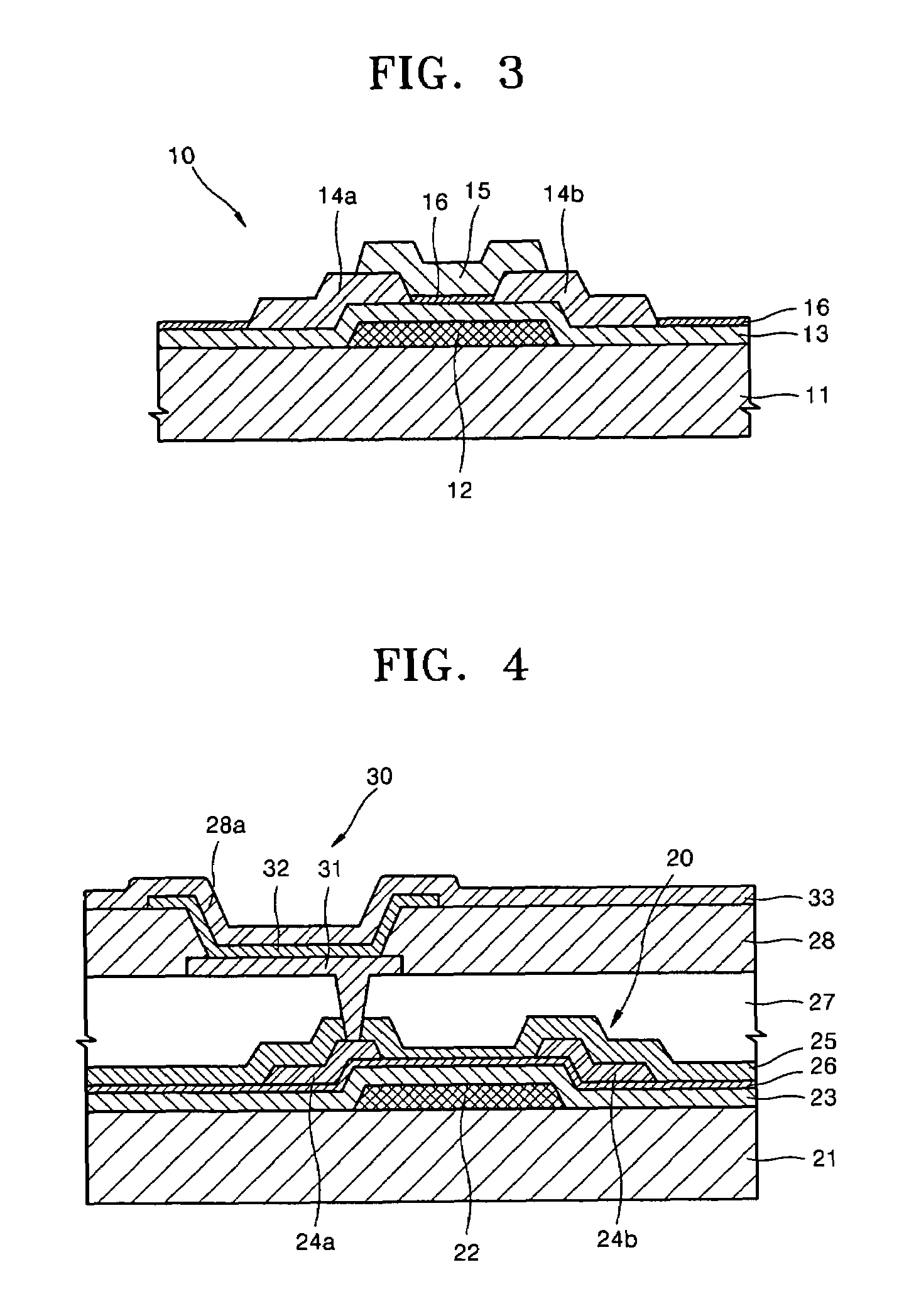

Organic thin film transistor including a self-assembly monolayer between an insulating layer and an organic semiconductor layer and flat panel display comprising the same

ActiveUS7800102B2Phase separation of the organic semiconductor materialImprove reliabilityTransistorMaterial nanotechnologyArylSelf-assembled monolayer

Owner:SAMSUNG DISPLAY CO LTD

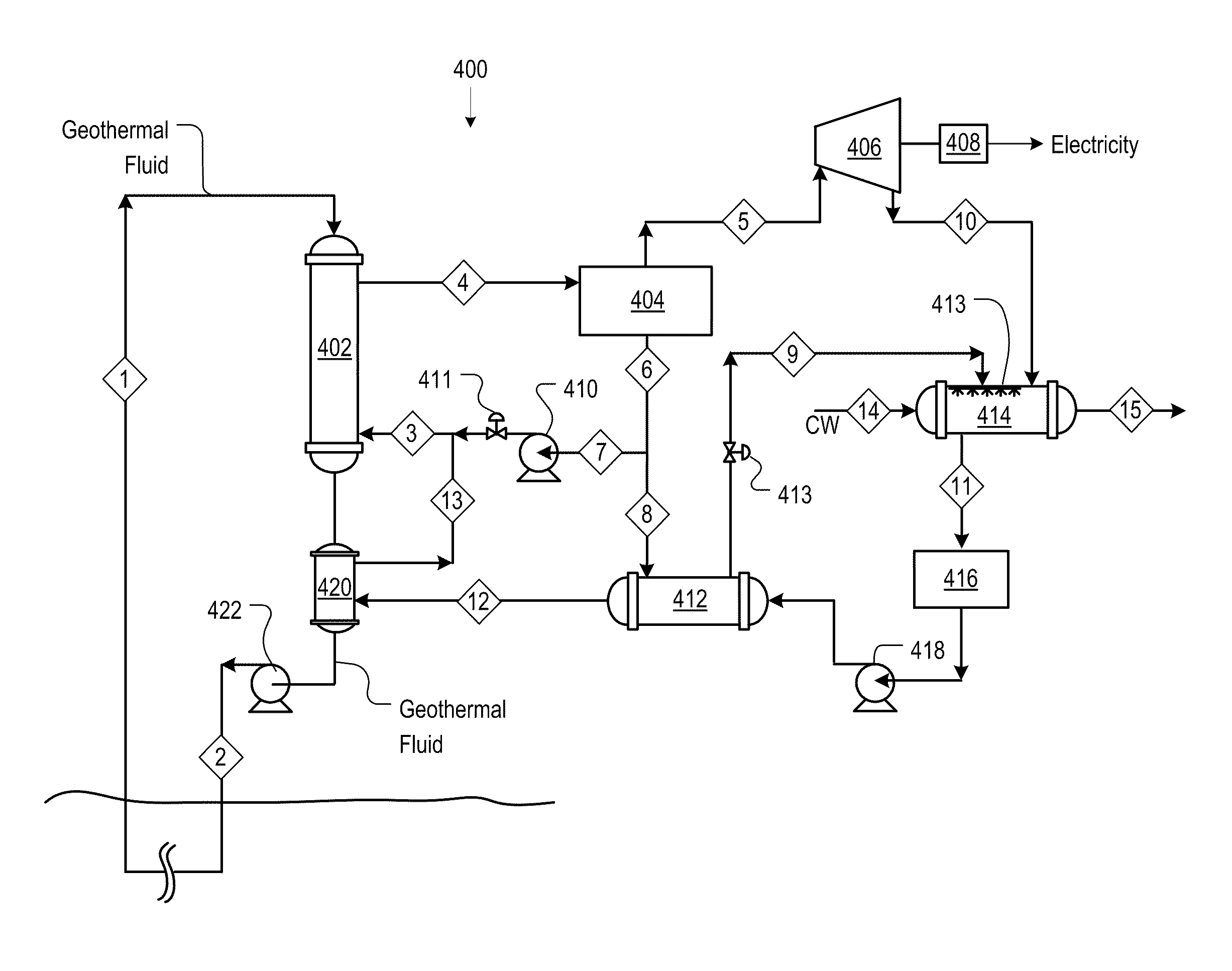

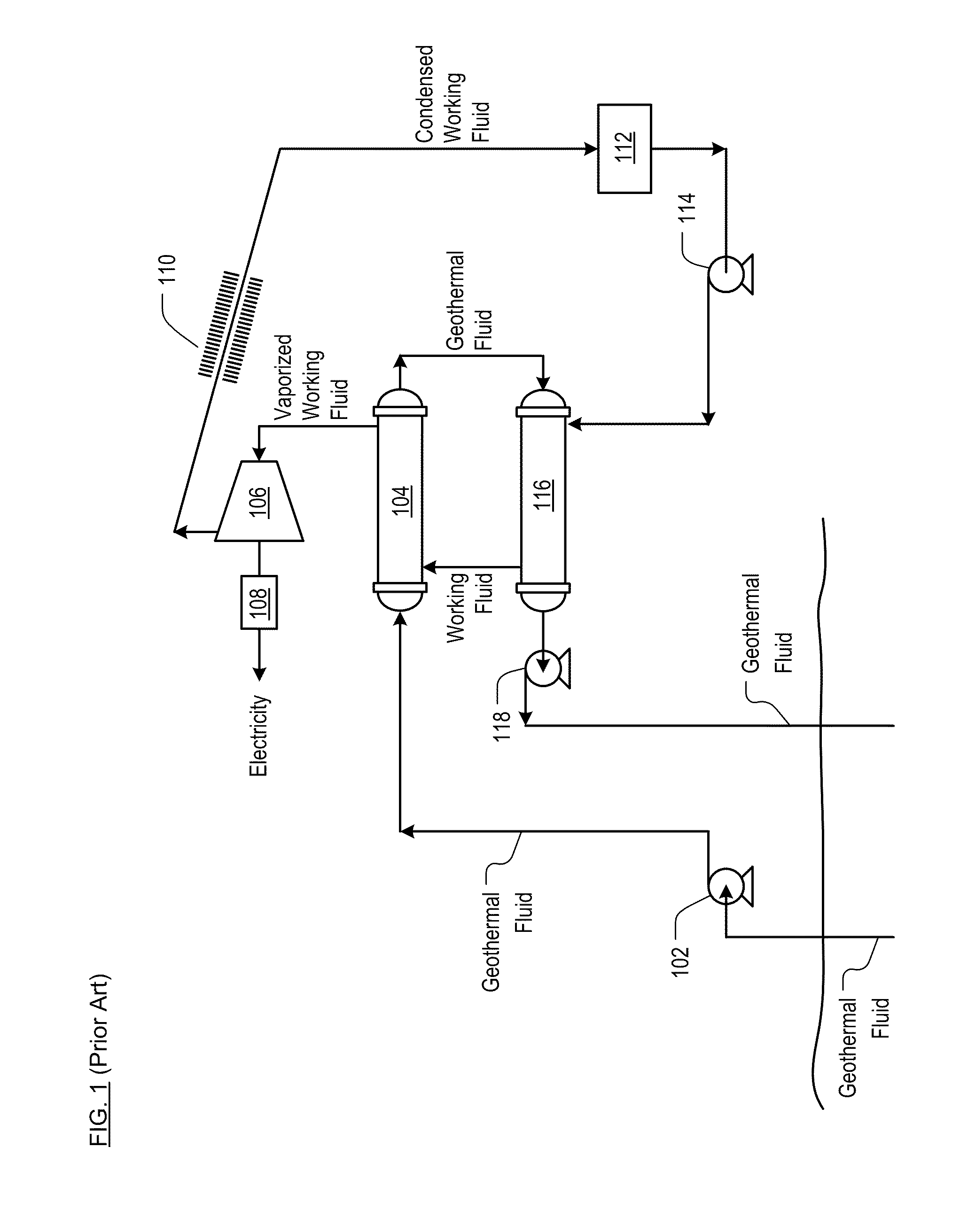

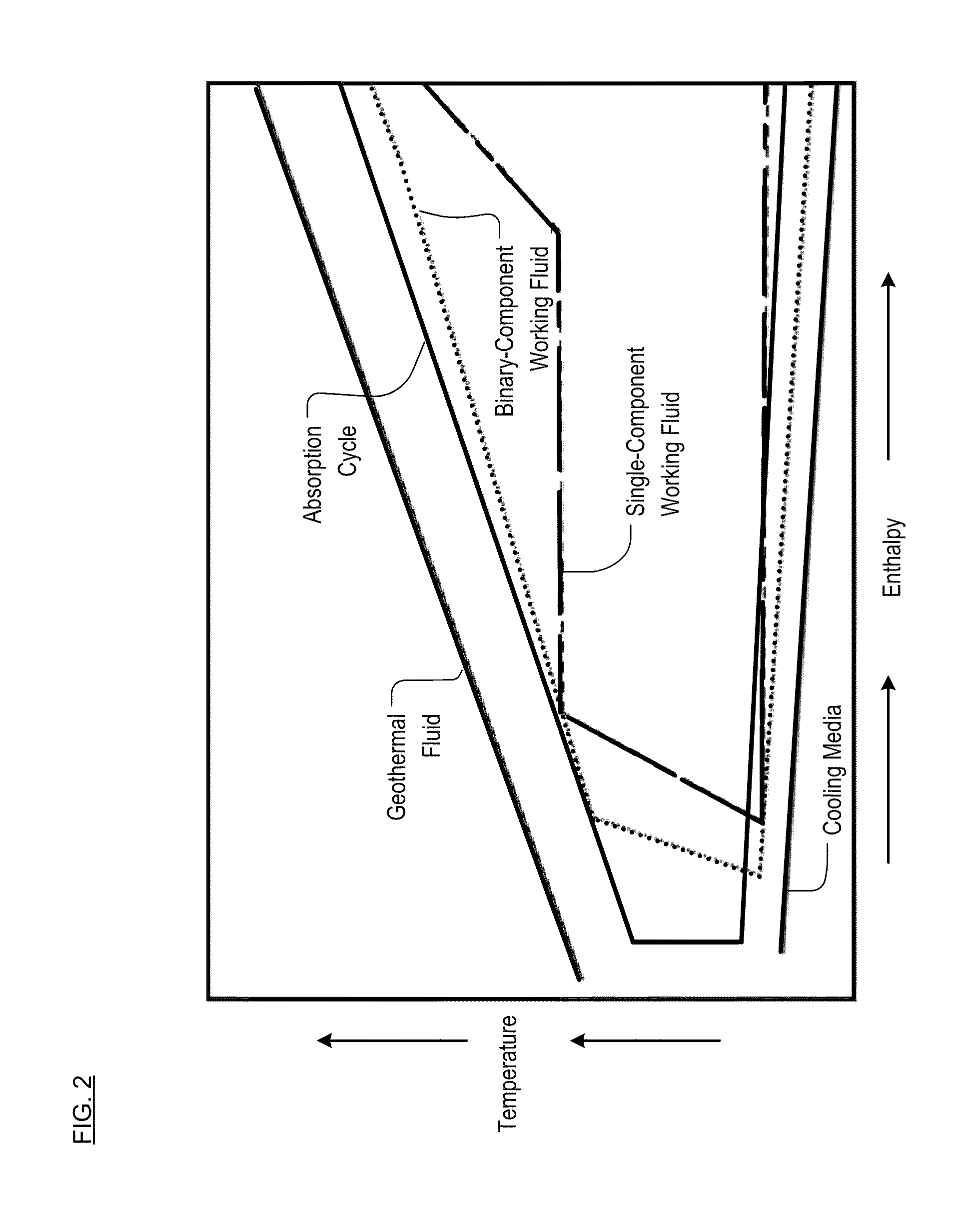

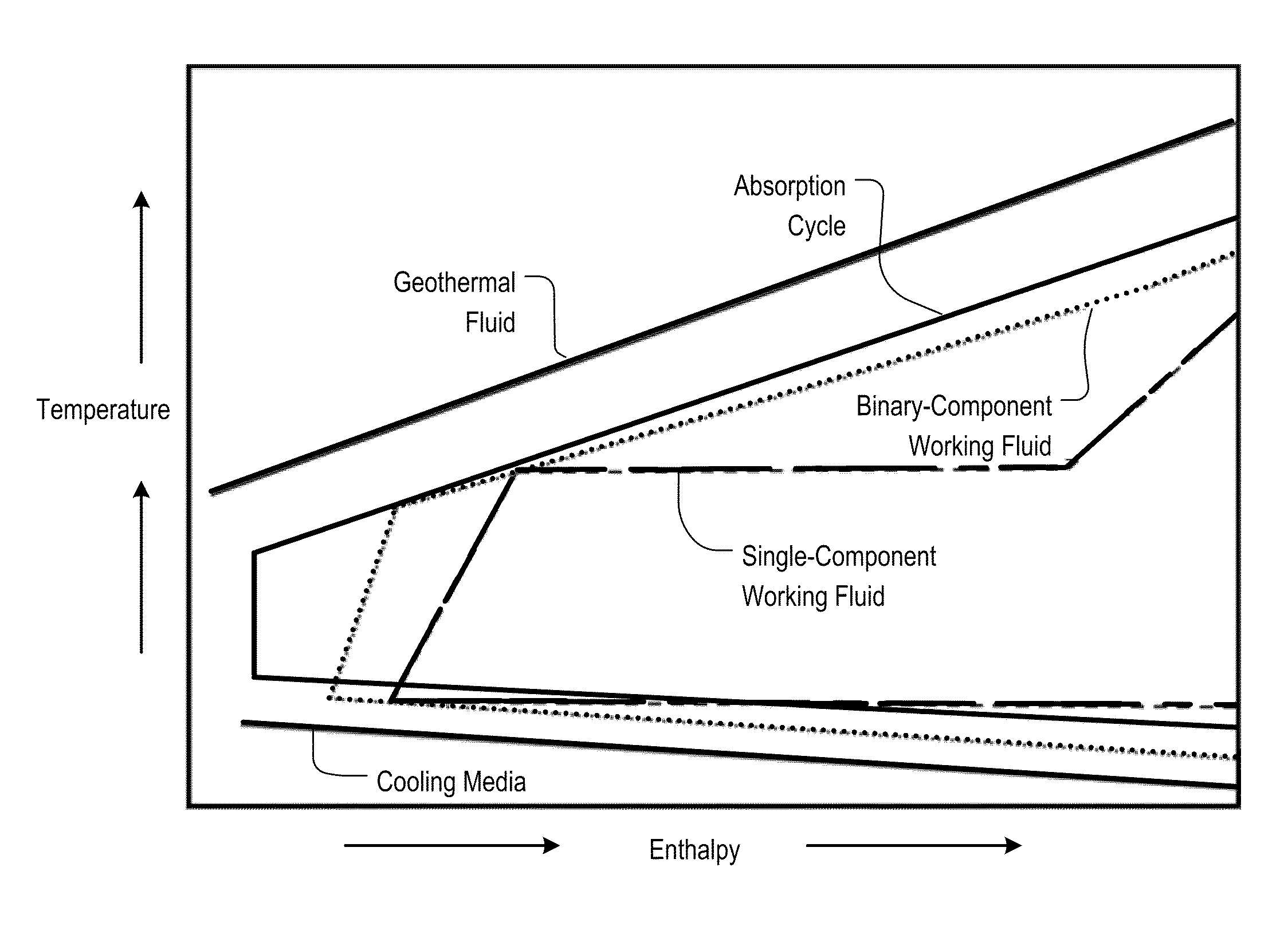

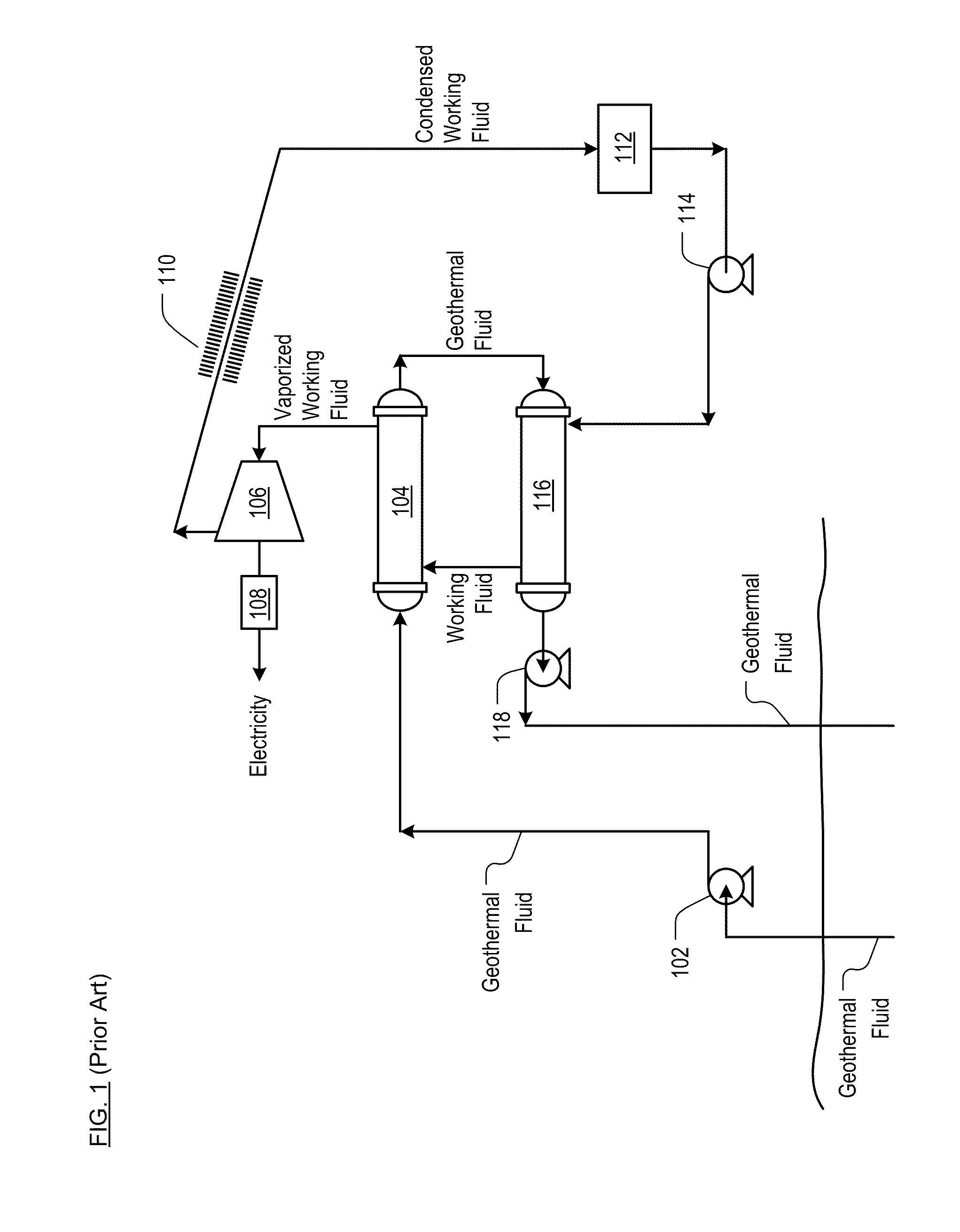

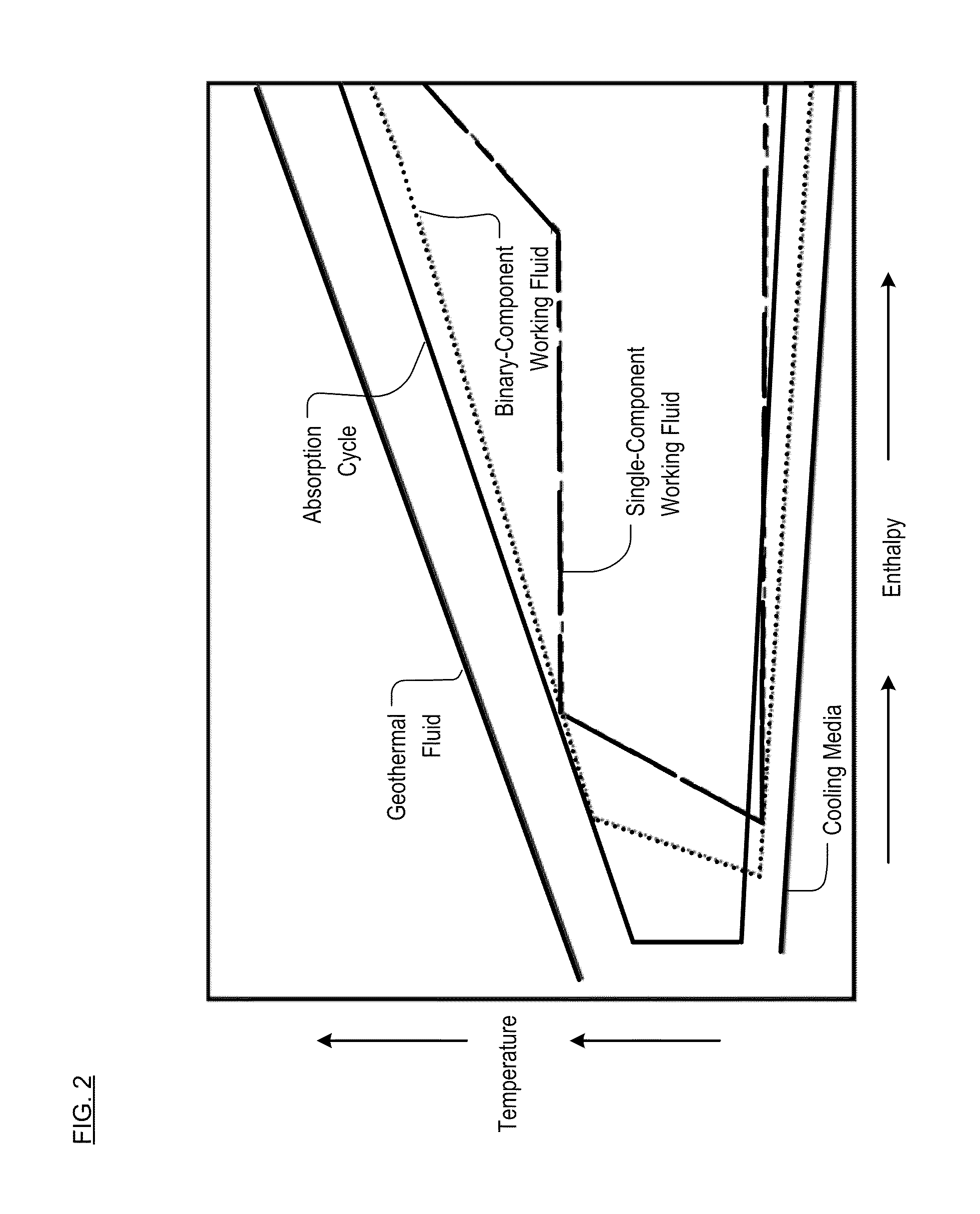

Working-fluid power system for low-temperature rankine cycles

ActiveUS8578714B2Avoid disadvantagesIncrease heatSteam engine plantsMechanical power devicesWorking fluidPower cycle

A power system based on a binary power cycle and utilizing a multi-component working fluid is disclosed. The working fluid is partially vaporized and a split recirculation approach is used to control the enthalpy-temperature profiles to match the heat source. A portion of the unvaporized working fluid is sprayed into the condenser.

Owner:LOCKHEED MARTIN CORP

Method for preparing protein modified cellulose fibre

InactiveCN101113535AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsYarnCellulose fiber

The invention relates to a preparation method of a protein modified cellulose fiber, comprising the steps that: (1) a protein and a cellulose are dissolved in ion solution to prepare homogeneous mixing spinning solution; (2) the spinning solution is deaerated, filtered, measured, and extruded out through spinning jet to form spinning rills, and the spinning rills pass through a wet air layer and enter into a solidification bath to be solidified and molded; (3) the yarn is extended, cleaned by water, dried and heat molded, and formed into fiber to prepare the protein modified cellulose fiber. The method has the advantages of environmental protective, low cost, fast spinning speed and high production efficiency, and the prepared fiber has the advantages of comfort and health care, etc.

Owner:DONGHUA UNIV

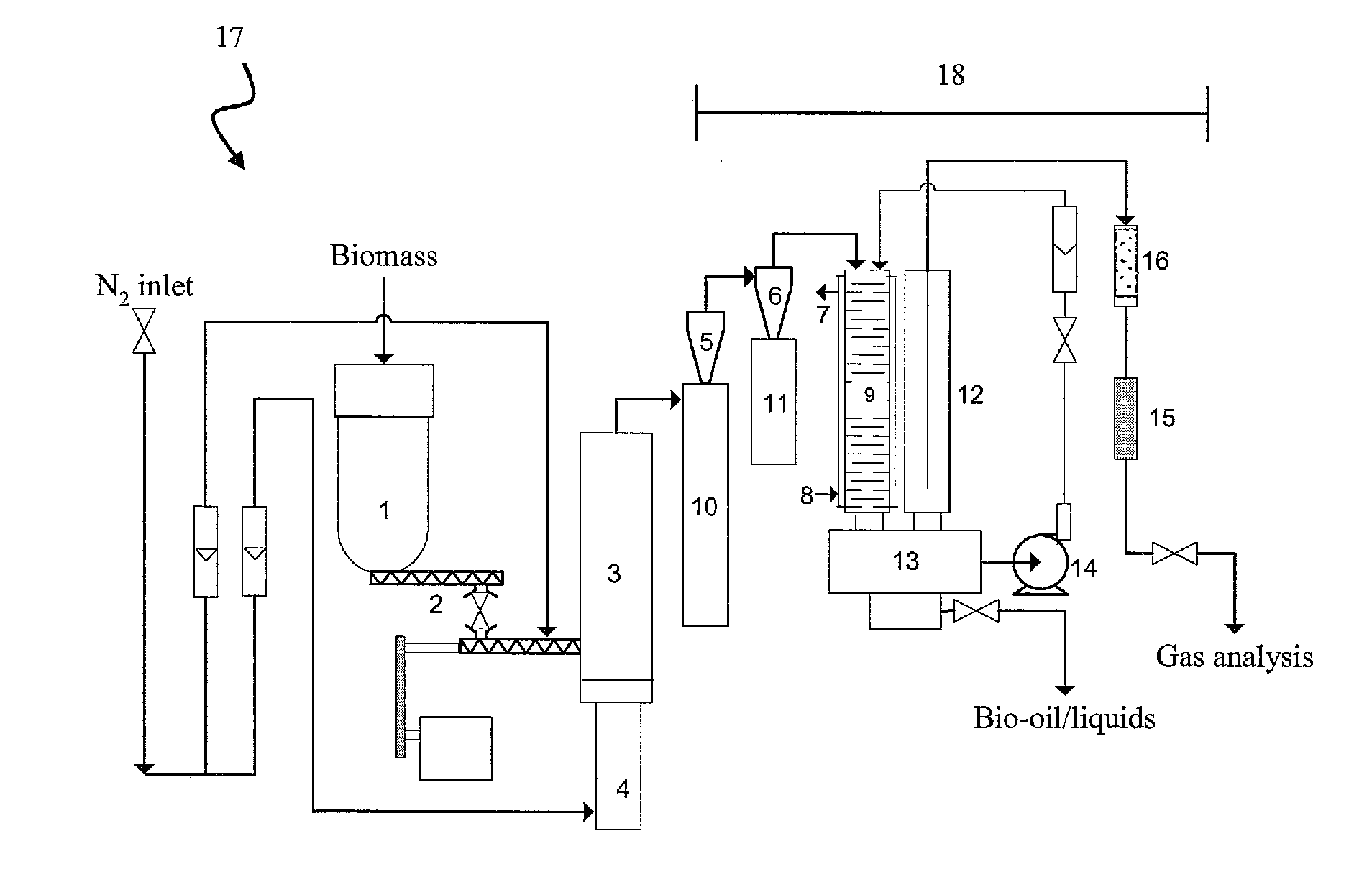

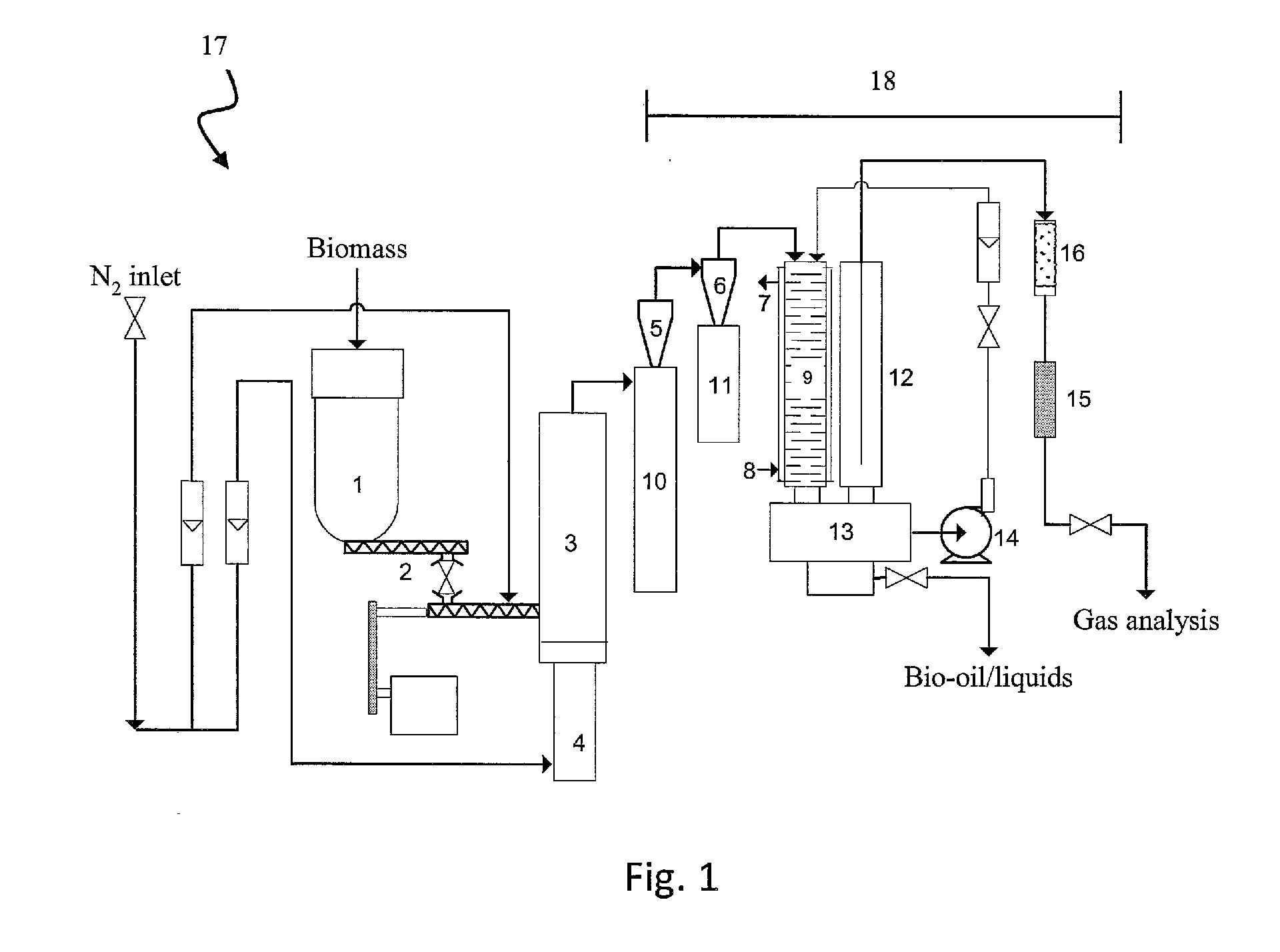

Biomass pyrolysis

InactiveUS20090227766A1Reduce concentrationReduce the probability of reactionCombustible gas coke oven heatingDirect heating destructive distillationBiomassChemistry

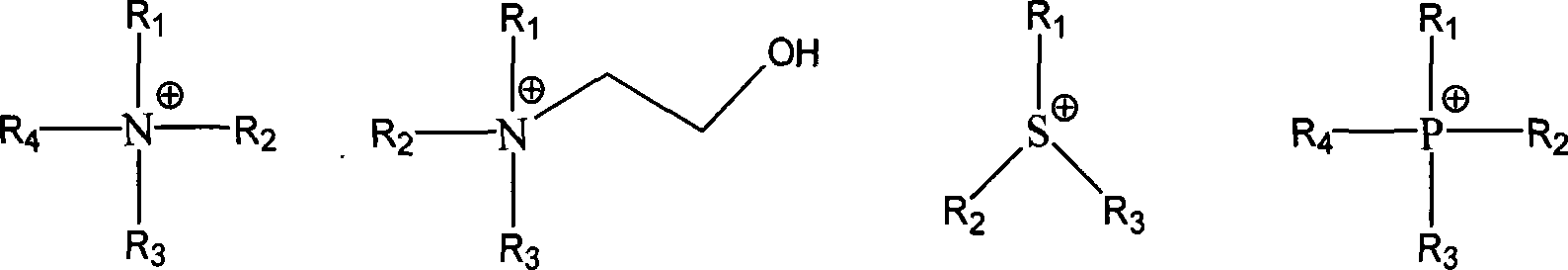

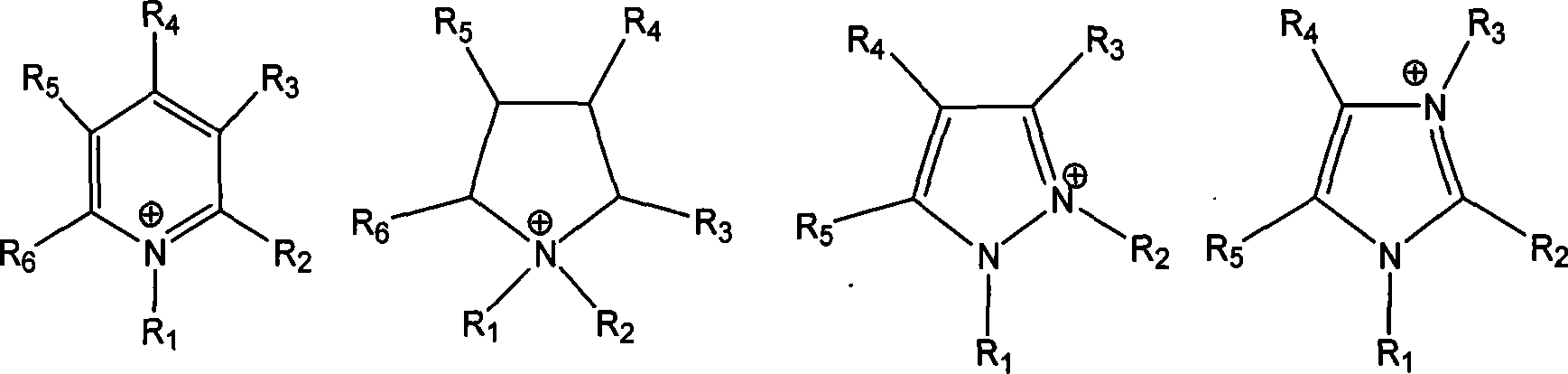

A process for pyrolysing biomass is provided. The process comprises providing biomass to a pyrolysis reactor to produce a vapour product and condensing said vapour product to produce a condensed product, wherein a phase separation suppression agent is added during said process so as to promote the formation of a single phase condensed product.

Owner:ASTON UNIV

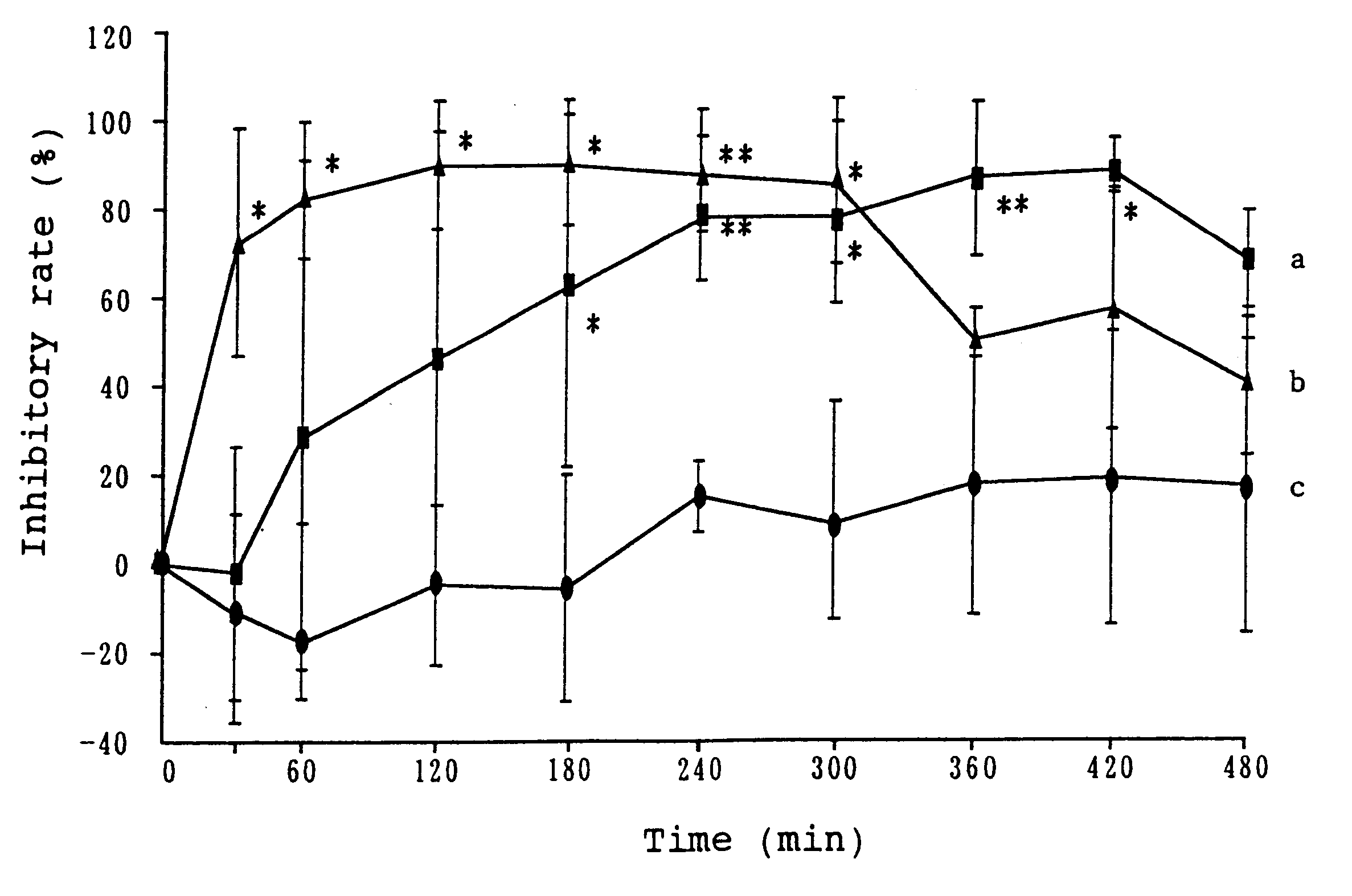

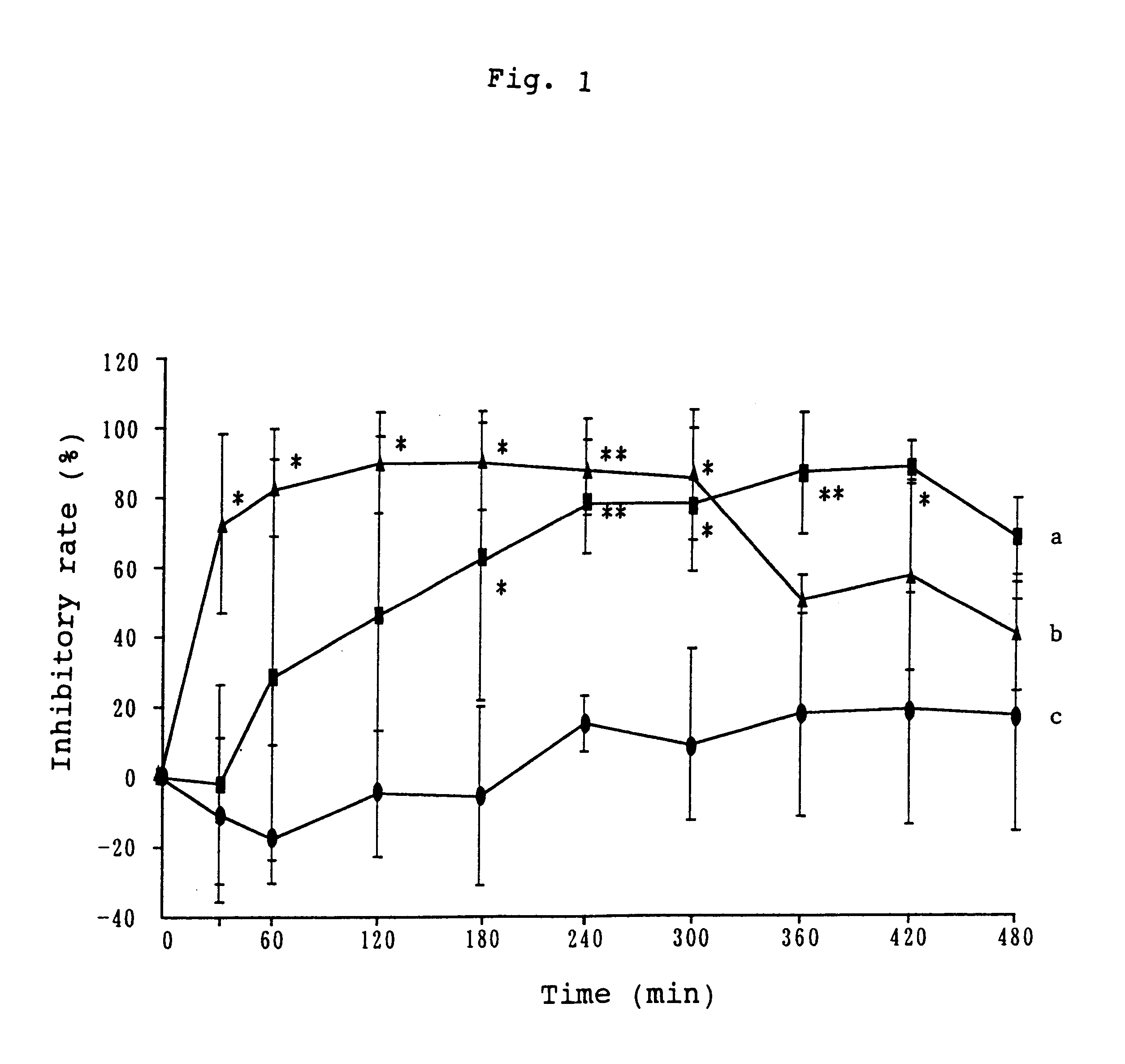

Patch

InactiveUS6211425B1Improve long-term stabilitySmooth releaseOrganic active ingredientsThin material handlingTransdermal patchDisease

A transdermal patch containing a drug comprising formoterol and / or a salt, a solvent for the drug, a pressure-sensitive adhesive comprising an ethylene / vinyl acetate copolymer resin and at least one of a filler and a plasticizer. The patch is substantially water-free. The patch serves to promote percutaneous absorption of the formoterol and / or a salt thereof and allow the efficacy of the drug to stably persist for a long period of time. The patch is thus effective for diseases such as asthma, which can be cured or prevented by exciting beta-receptors.

Owner:SAITAMA DAIICHI SEIYAKU

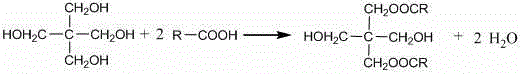

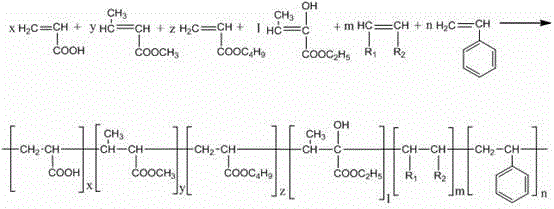

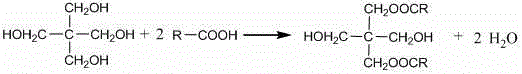

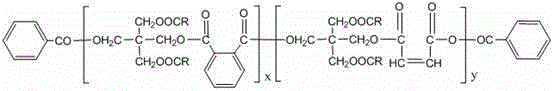

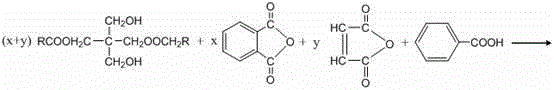

Aqueous alkyd acrylic resin paint and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin paint and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin paint is obtained. The aqueous alkyd acrylic resin paint comprises the components of: aqueous alkyd acrylic resin 65%-80%, the pigment 3%-4%, the filling material 6-10%, deionized water 10%-20%, the dispersing agent 0.05%-0.5%, the antifoaming agent 0.10%-0.30%, and the siccative 0.9%-3.5%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method of producing carbon nanomaterials and centrifugal melt spinning apparatus

InactiveUS7763228B2Producing a carbon nanomaterialImprove efficiencyMaterial nanotechnologyFilament/thread formingPolymer scienceCarbonization

A carbon nanomaterial produced by: performing centrifugal melt spinning of core-shell particles that are prepared by using fine particles containing a carbon precursor polymer and a thermally decomposable polymer that disappears as a result of heat treatment, wherein the core-shell particles are heated up to a temperature at which phase separation thereof is not caused, and pressed against a plate-like heater 12 having a large number of pores 12A that penetrate therethrough in a thickness direction of the plate-like heater using centrifugal force; making the fiber obtained by the centrifugal melt spinning infusible; and performing carbonization thereof. According to this method, a carbon nanomaterial such as a carbon nanotube or a carbon nanofiber can be produced with high efficiency.

Owner:GUNMA UNIVERSITY

Working-Fluid Power System for Low-Temperature Rankine Cycles

ActiveUS20110011089A1Avoid disadvantagesIncrease heatSteam engine plantsMechanical power devicesWorking fluidPower cycle

A power system based on a binary power cycle and utilizing a multi-component working fluid is disclosed. The working fluid is partially vaporized and a split recirculation approach is used to control the enthalpy-temperature profiles to match the heat source. A portion of the unvaporized working fluid is sprayed into the condenser.

Owner:LOCKHEED MARTIN CORP

Method of preparing protein modified polyacrylonitrile fibre

InactiveCN101109115AImprove protectionGood for healthConjugated cellulose/protein artificial filamentsWet spinning methodsIonic liquidHigh productivity

The invention relates to a preparing method for a protein modified polyacrylonitrile fiber, which comprises the following procedures: (1) some protein and polyacrylonitrile are solved in some ion liquid to prepare some equal-phase mixed crude liquid for spinning; (2) the spinning liquid is de-bubbled, filtered, dosed, then extruded by a spinning jet to form a fine spinning flow, which passes a wet air layer and enters into a condensing bath to condense and form; (3) fiber is spun after pre-tensioning, tensioning, water washing, drying and thermal forming, so protein modified polyacrylonitrile fiber is prepared. The method is environmental friendly, easy to recycle, of low production cost and high productivity; the clothing from the product made by the method is highly comfortable and healthy, and is of high fiber property.

Owner:DONGHUA UNIV

Stabilized pharmaceutical solid compositions of low-solubility drugs and poloxamers, and stabilizing polymers

InactiveUS20070148232A1Improve concentrationHigh dissolution rateBiocidePowder deliverySolubilityPhysical stability

Solid compositions with improved physical stability comprise an amorphous, low-solubility drug, a poloxamer, and a stabilizing polymer. The compositions provide good physical stability during storage and concentration enhancement of dissolved drug when administered to an aqueous environment of use.

Owner:BEND RES

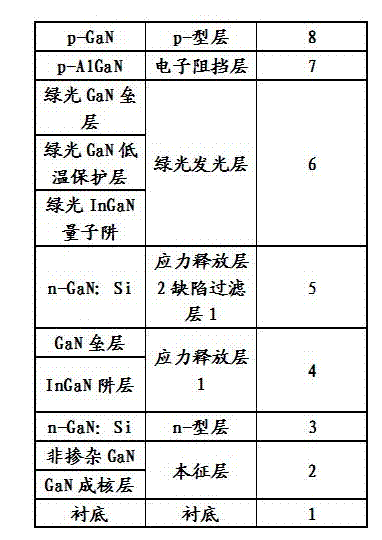

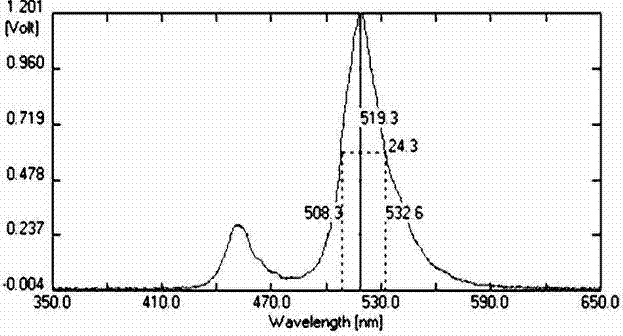

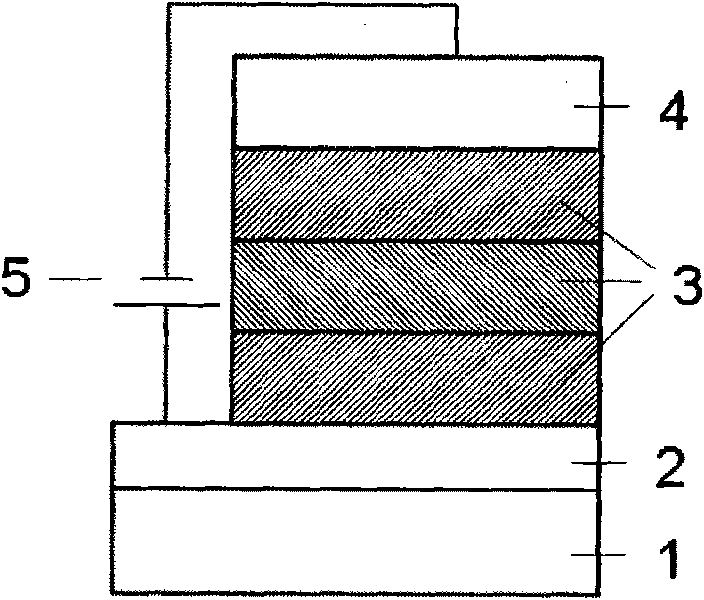

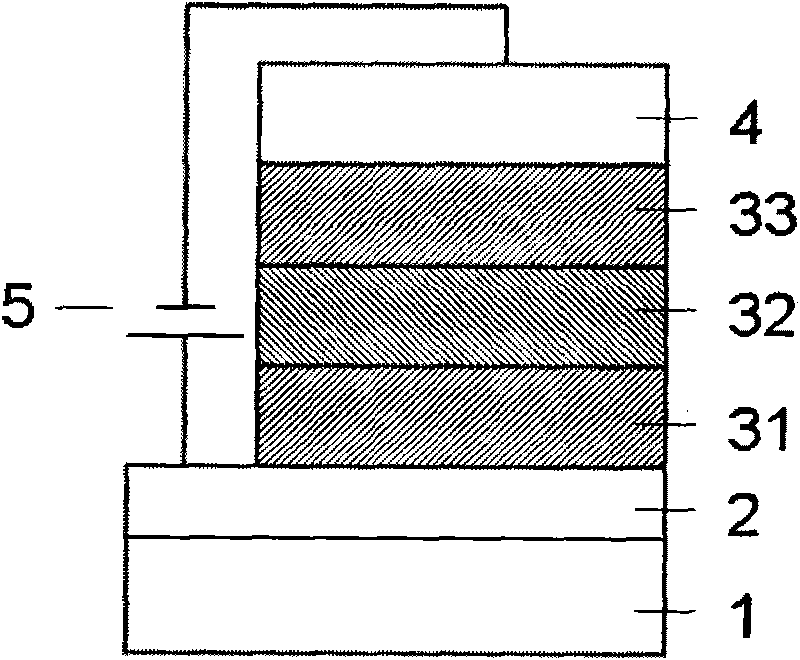

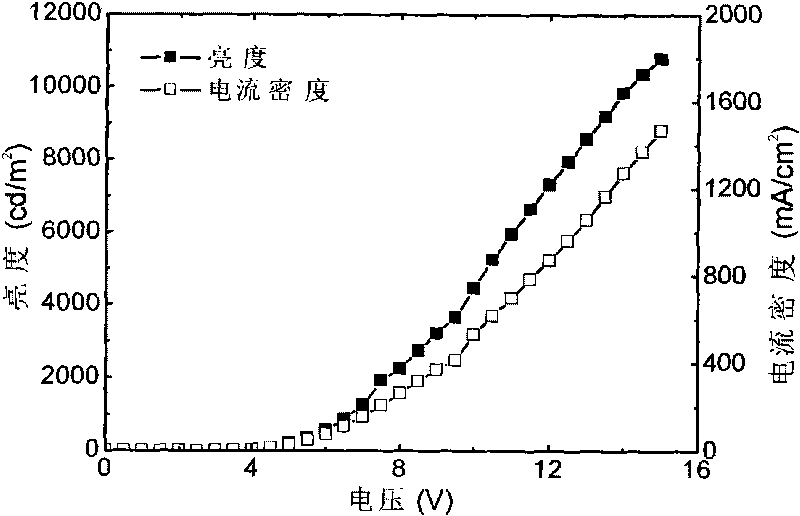

Green light emitting diode and manufacturing method thereof

InactiveCN102738333AImprove luminous efficiencyAvoid phase separationSemiconductor devicesQuantum efficiencyStress relieving

The invention discloses a green light emitting diode and a manufacturing method thereof. The green light emitting diode is characterized in that a low-temperature protective layer is introduced during epitaxial growth of an InGaN (Indium Gallium Nitride) / GaN (Gallium Nitride) quantum well; the quantum well structure changes from InGaN / GaN to an InGan / Gan low-temperature protective layer 1 / GaN structure; thereby protecting In in the InGaN / GaN, and avoiding damage to the In in high-temperature growth, and thus effectively avoiding phase separation of an In component in the InGaN, and improving the internal quantum efficiency; and in addition, two different stress relieving layers are located between an n-type layer and a green light emitting layer, and thus the stress of the green light emitting diode is decreased.

Owner:江苏汉莱科技有限公司

Organic electroluminescent device and preparation method thereof

InactiveCN101740724AImprove luminous efficiencyIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingEnergy transferFluorescence

The invention discloses an organic electroluminescent device, comprising a substrate, an anode layer and a cathode layer, wherein the anode layer or the cathode layer is positioned on the surface of the substrate. The organic electroluminescent device also comprises organic functional layers between the anode layer and the cathode layer. The organic functional layers at least include a luminescent layer which emits light by being driven by an applied power source. The luminescent material combines the organic fluorescent dye with the matrix molecules by chemical bonds by way of chemical crosslinking, so that energy transfer of the luminescent material is improved, thus not only avoiding the complex process caused by doping, but also avoiding the dye from being separated in the matrix molecules, optimizing the device structure and improving the luminescent efficiency, brightness and stability of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Single fluid acidizing treatment

An acidizing formulation for use in the stimulation of hydrocarbon production is stable when packaged and stored as a single fluid for periods exceeding one year. The formulation contains a miscibility solvent which substantially prevents any phase separation between the constituents and lack of dispersion of the additives in the fluid.

Owner:THE LUBRIZOL CORP

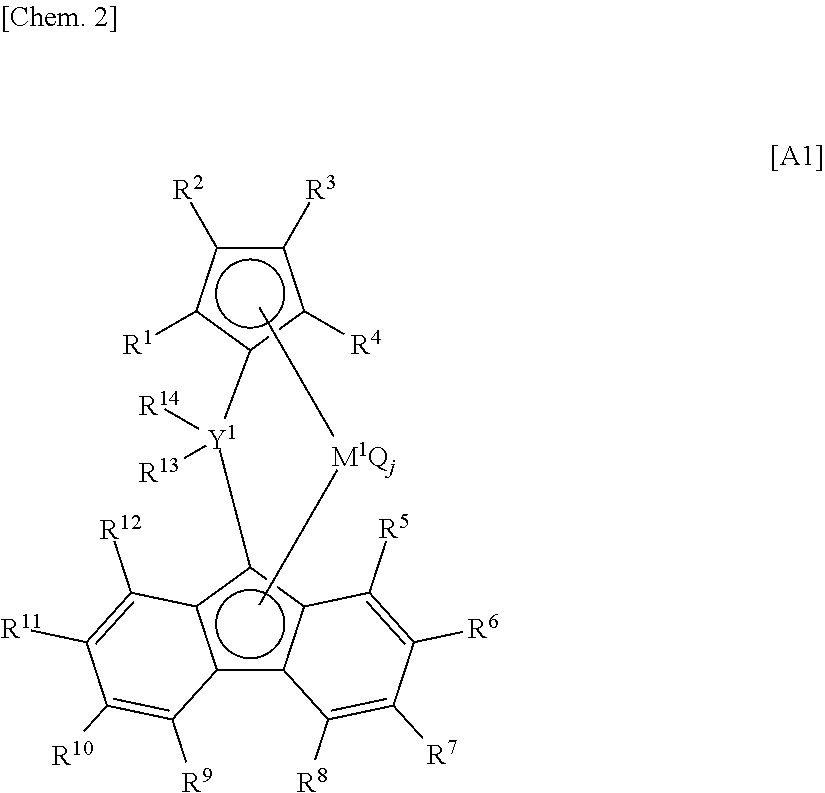

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

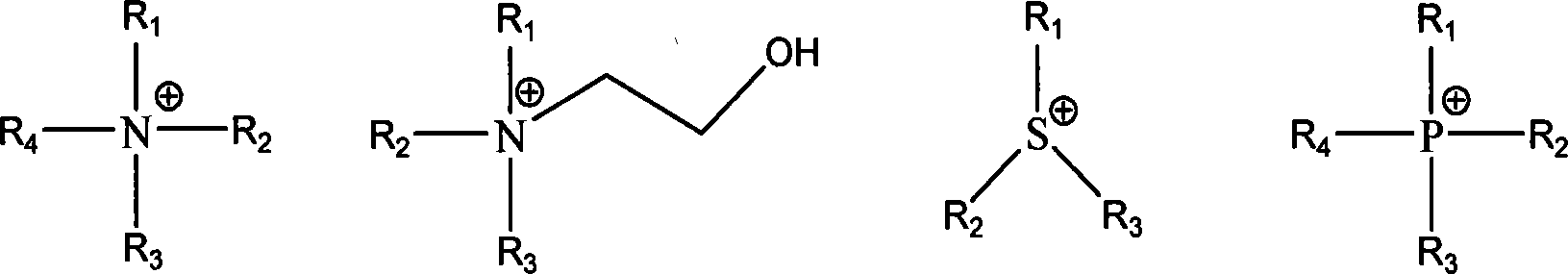

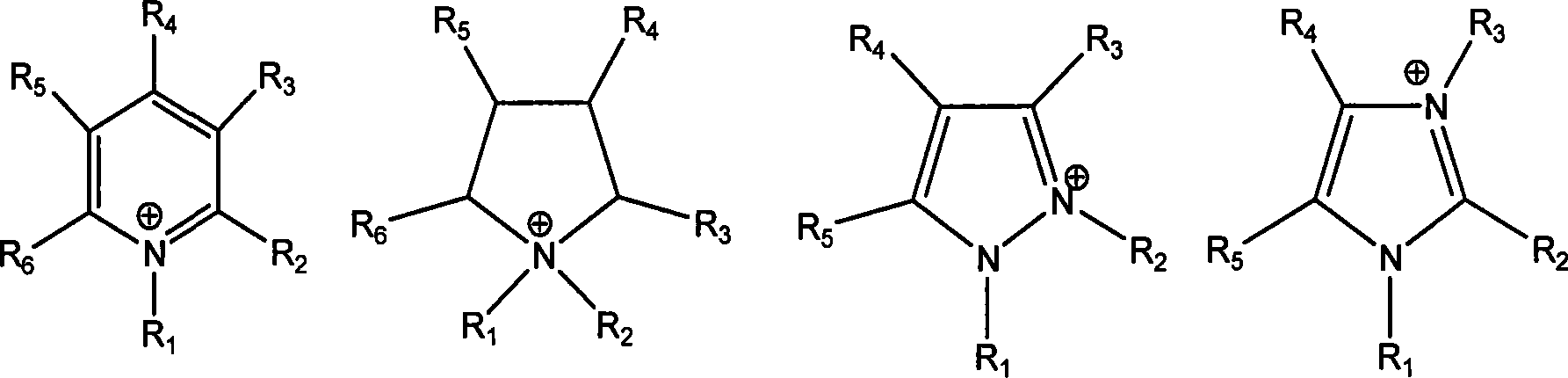

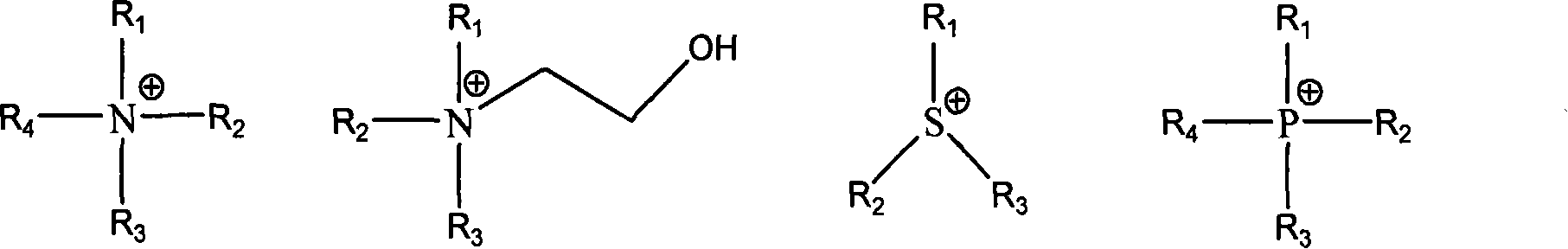

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

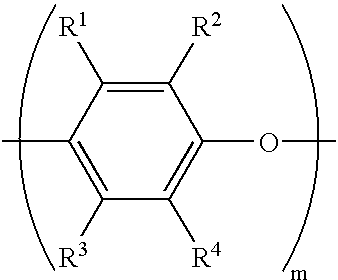

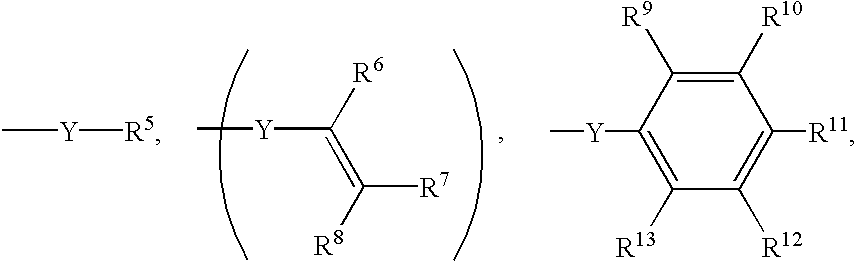

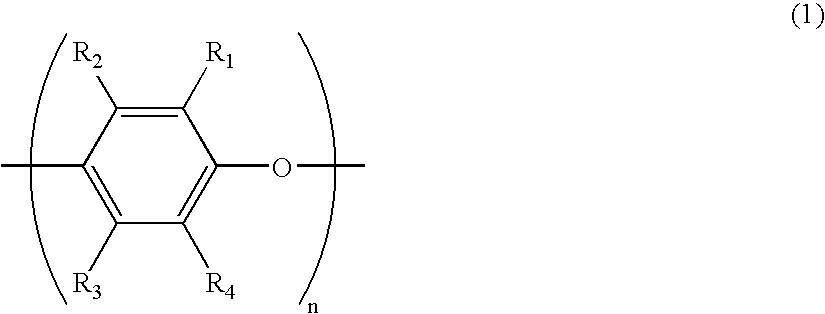

Epoxy resin composition

InactiveUS20070093614A1Improve featuresSatisfied with stabilityPlastic/resin/waxes insulatorsSkin careEpoxyEther

The present invention relates to an epoxy resin composition comprising a polyphenylene ether having a number average molecular weight of 1,000, to 4,000 and containing components having a molecular weight of 20,000 or more in an amount of substantially 20% or less, and an epoxy resin. The present invention further relates to an epoxylated polyphenylene ether resin obtained by reacting a phenolic hydroxyl group of a polyphenylene ether having a number average molecular weight of 1,000 to 4,000 with an epoxy group of an epoxy compound or an epoxy resin.

Owner:ASAHI KASEI CHEM CORP

Pharmaceutical composition for parenteral administration of idebenone

InactiveUS20100130619A1Formula stableHigh shear mixingBiocideNervous disorderParenteral nutritionIdebenone

Owner:ALPHARX

Preparation method of polyacrylonitrile fibres by using protein as modifier

InactiveCN103397400AImprove protectionGood for healthArtificial thread manufacturing machinesArtificial filament washing/dryingTrickle flowHeat setting

The invention relates to a preparation method of polyacrylonitrile fibres by using protein as a modifier. The preparation method comprises the following steps of (1) dissolving protein and polyacrylonitrile in an ionic liquid, and preparing a homogeneous-phase mixed spinning solution; (2) defoaming, filtering and measuring the spinning solution, and then extruding via a spinning jet to form a spinning trickle flow, and passing the spinning trickle flow through a humid air layer and then entering into a coagulating bath, and performing coagulating forming; and (3) performing pre-drawing, drawing, water-washing, drying and heat-setting, and then performing spinning forming, so as to prepare protein-modified polyacrylonitrile filaments or short fibres.

Owner:SUZHOU LONGJIE SPECIAL FIBER

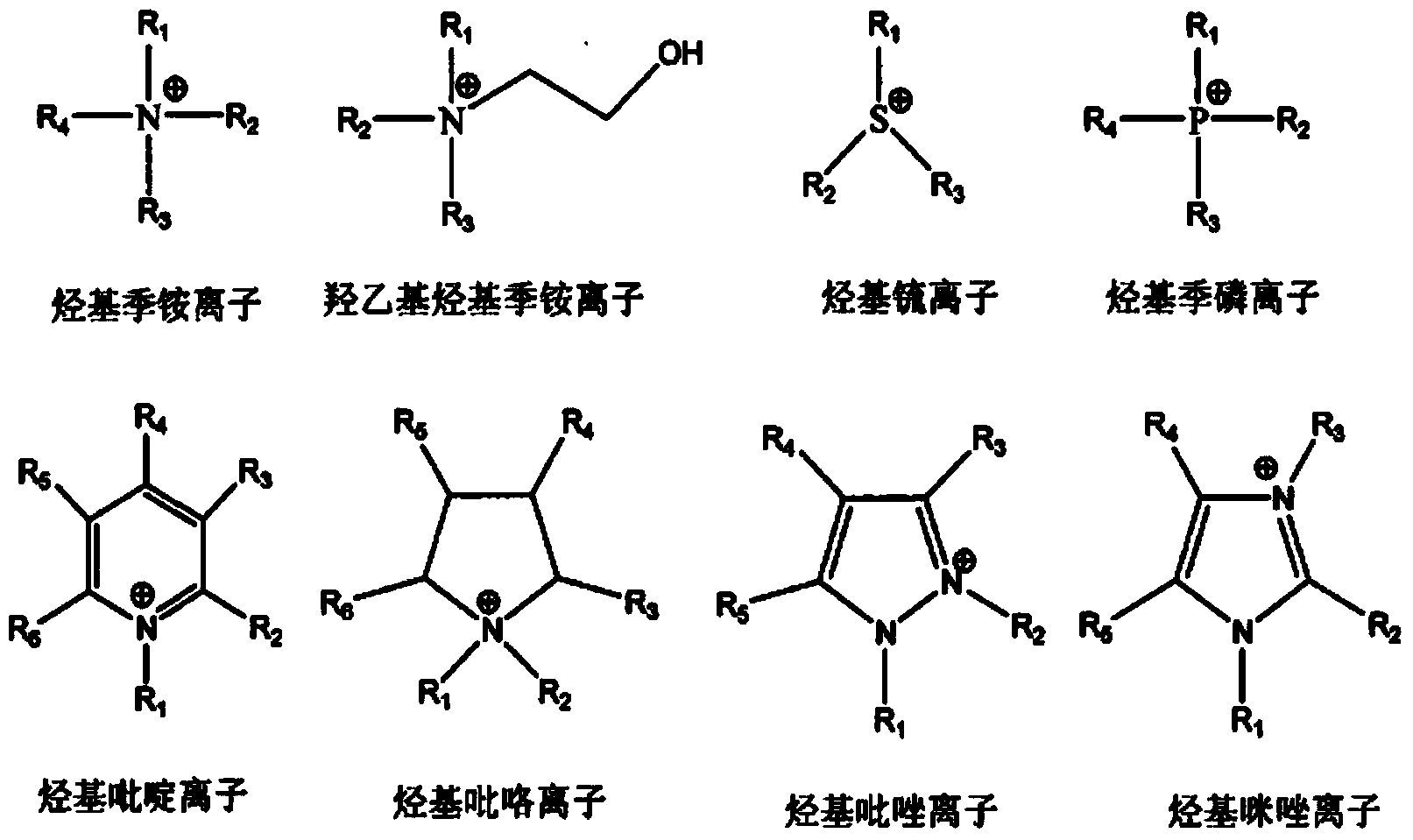

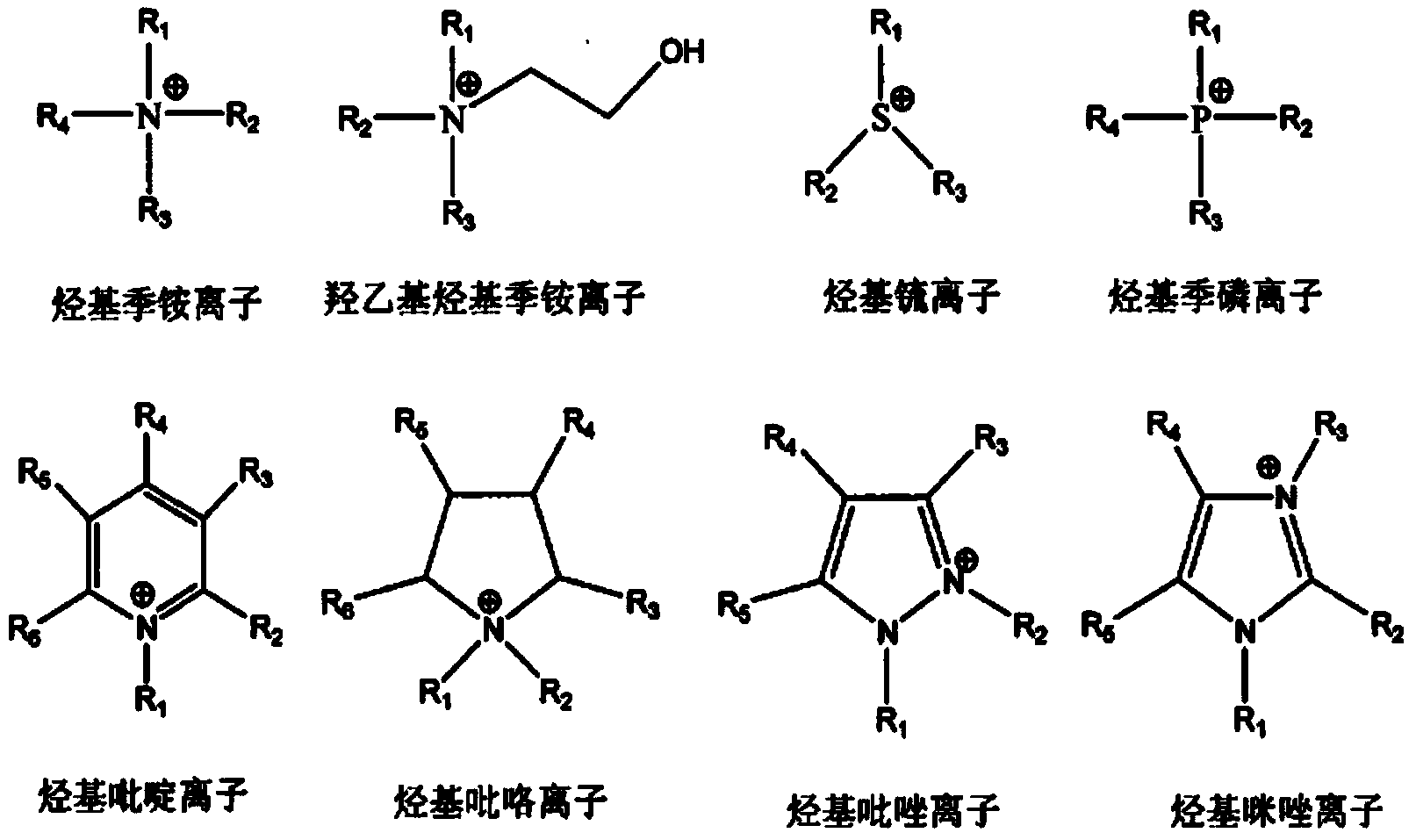

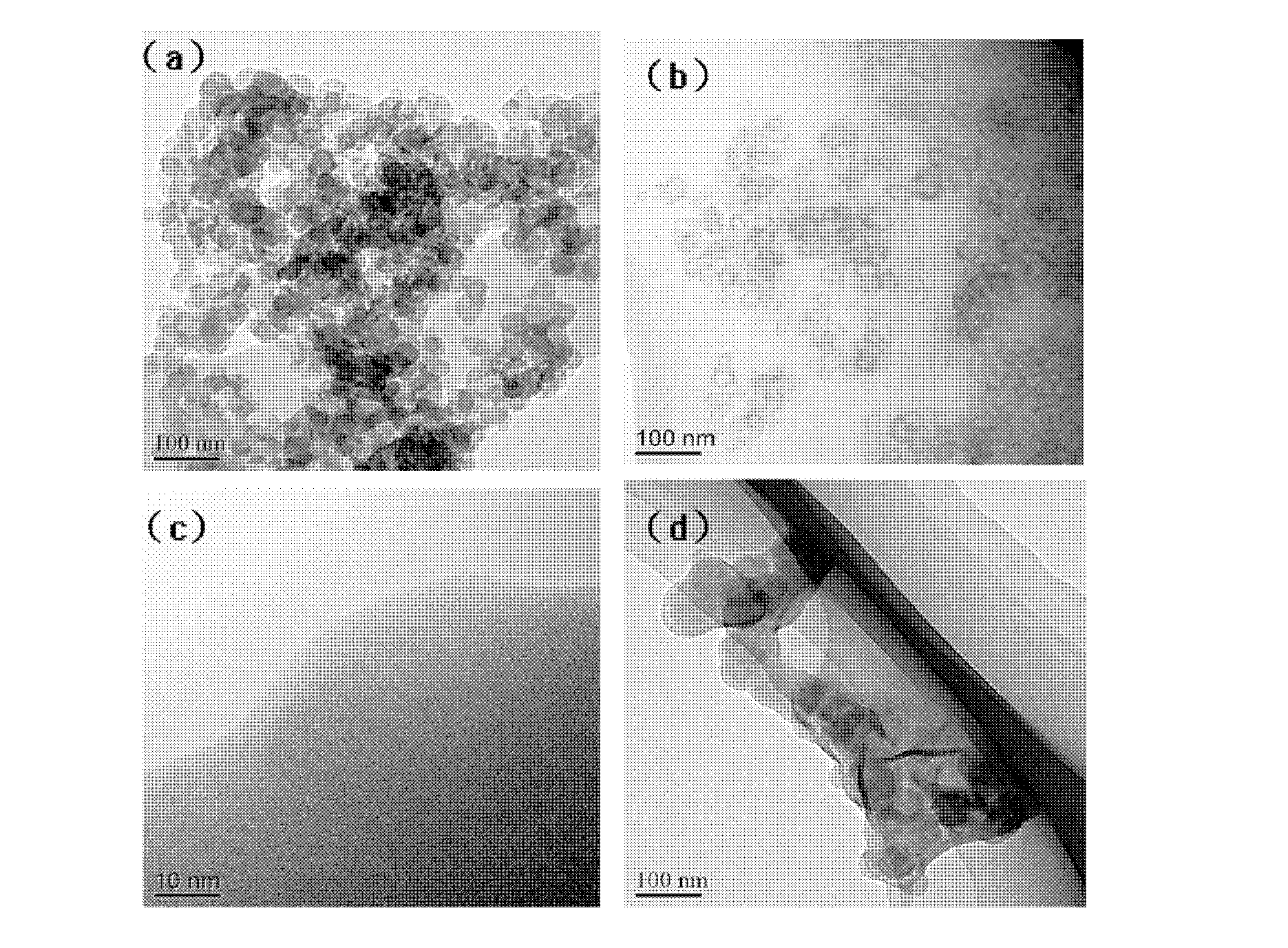

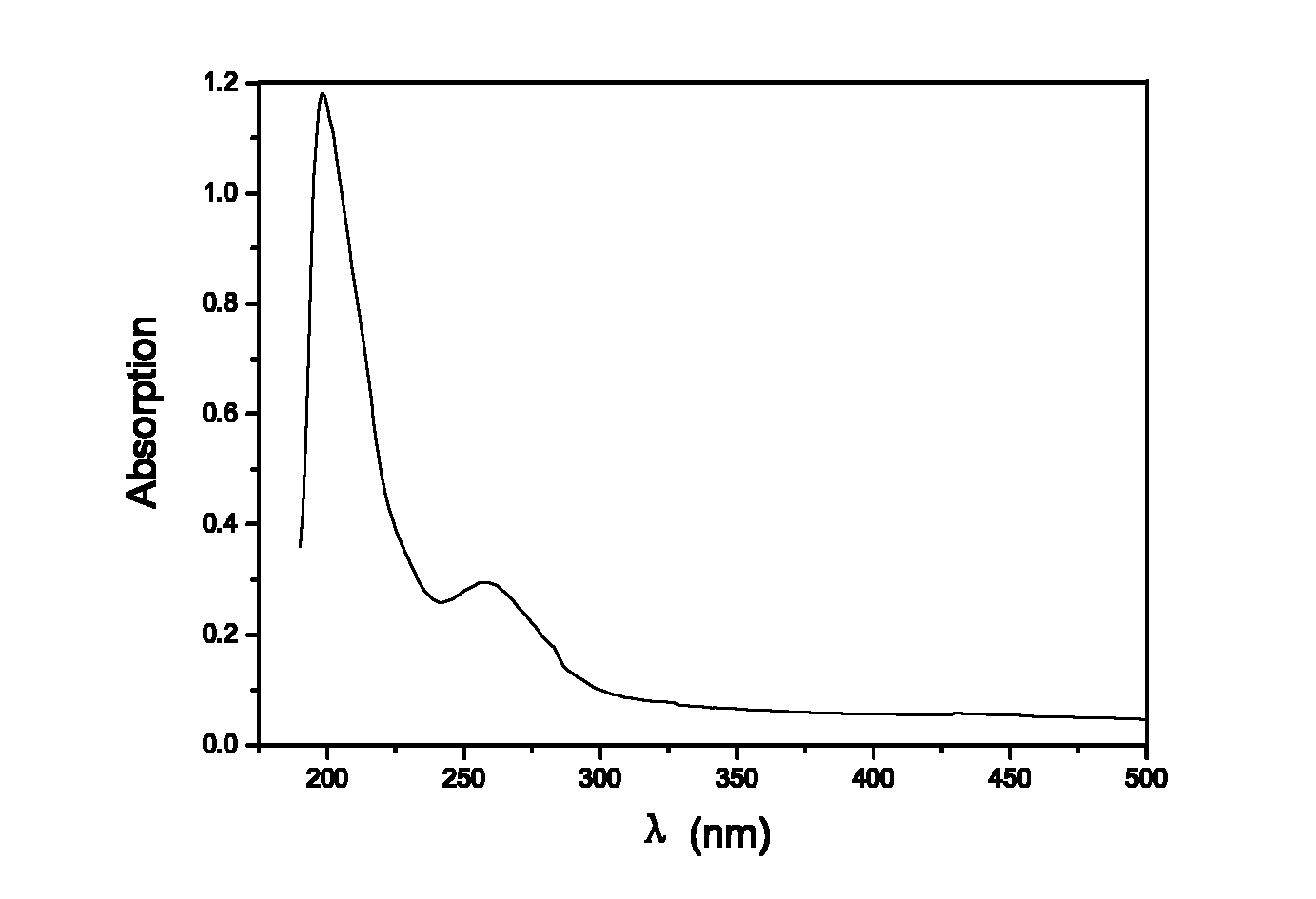

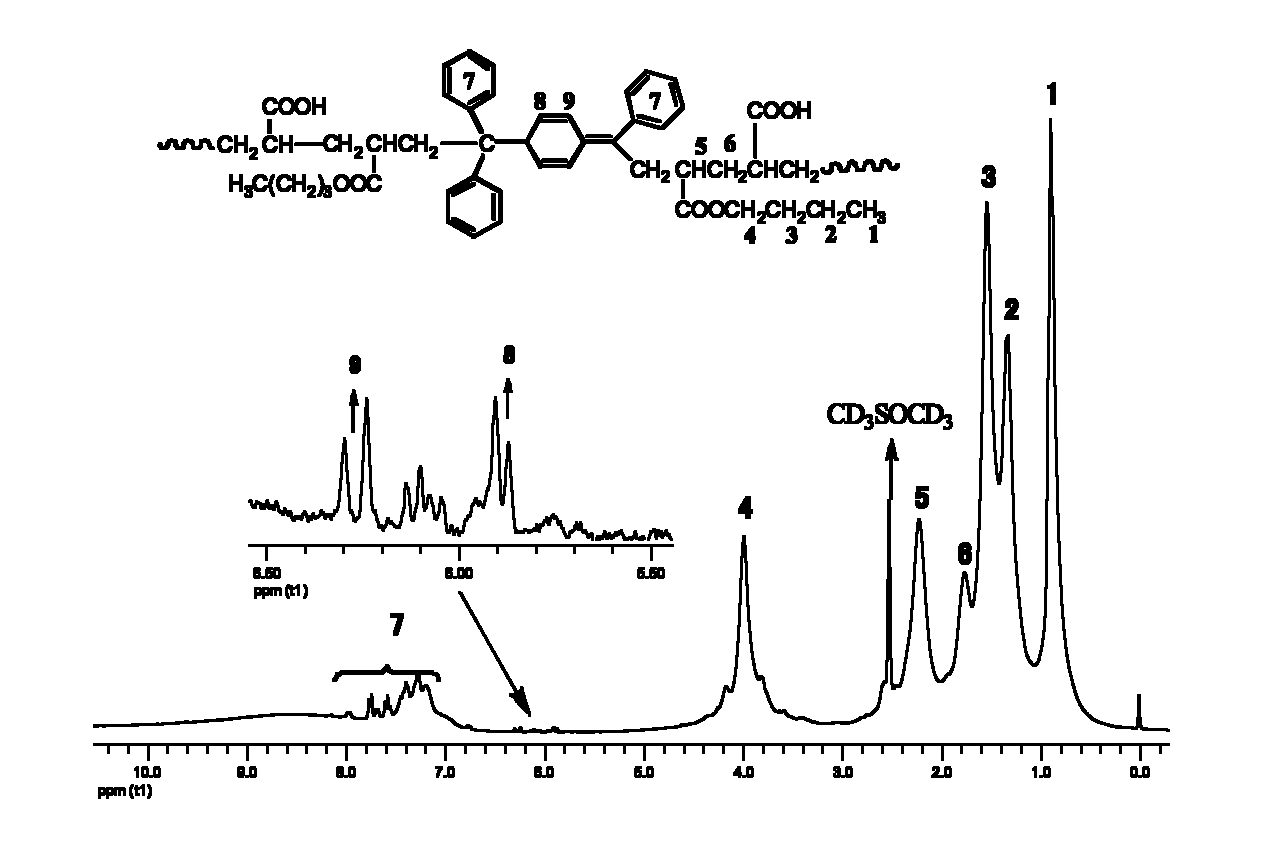

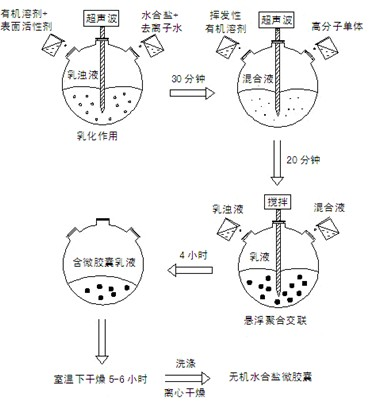

Method for preparing stable-dispersibility pigment/polymer core-shell structure composite granules by using by polymer-wrapped pigment particles

ActiveCN102659990AImprove dispersion stabilityAvoid phase separationOrganic dyesPigment treatment with macromolecular organic compoundsChemistryIn situ polymerization

The invention relates to a method for preparing stable-dispersibility pigment / polymer core-shell structure composite granules by using polymer-wrapped pigment particles. The method comprises the following steps of: preparing an amphipathic macromolecular dispersing agent by the soap-free emulsion polymerization in the presence of 1,1-diphenyl ethylene (DPE); adding pigment particle disperse liquid subjected to ultrasonic dispersion into a system; and heating the pigment particle disperse system to the temperature of 80 DEG C again, wherein the surface of the pigment particle disperse system is grafted, and an amphipathic macromolecular dispersing agent is adsorbed to the surface of the pigment particle disperse system, dripping a hard monomer into the system, grafting, and triggering the hard monomer added into the system to perform in-situ polymerization on the surfaces of the pigment particles to form a polymer shell layer by amphipathic macromolecules which are adsorbed to the surfaces of the pigment particles and contain DPE active structures. The appearance and the surface macromolecular shell layer of the pigment / polymer core-shell structure composite granules are subjected to characterization by using a transmission electron microscope, an ultraviolet absorption spectrum, nuclear magnetic resonance hydrogen, a carbon spectrum and a thermogravimetric analyzer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Aqueous alkyd acrylic resin printing ink and preparation method thereof

The invention relates to an aqueous alkyd acrylic resin printing ink and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin printing ink is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

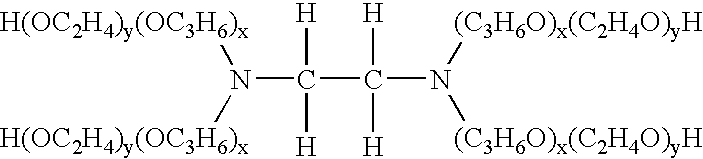

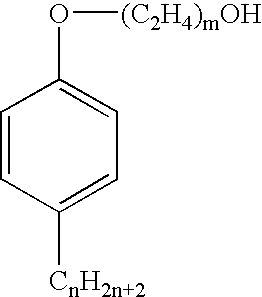

Resin composition

A resin composition includes a polyol and is used to form flexible foams. The resin composition also includes water and an alkoxylate of an active hydrogen containing species. The alkoxylate of the active hydrogen containing species acts in two separate ways. The alkoxylate acts as a blowing reaction modifier, thus maintaining slow-blow behavior of a foaming process that accompanies a reaction of the polyol with an isocyanate. The alkoxylate also acts as a compatibilizer. As the compatibilizer, the alkoxylate stabilizes the resin composition such that no phase separation occurs between the polyol, the water, and the alkoxylate. Stabilizing the resin composition allows for multiple day storage of the resin composition with no phase separation, thus extending useable shelf life and reducing production costs. Stabilizing the resin composition also allows for formation of flexible foams with consistent physical properties such as flexibility.

Owner:BASF CORP

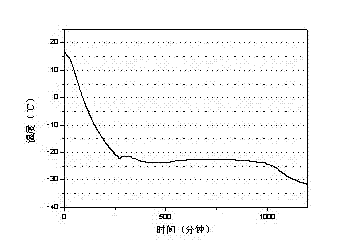

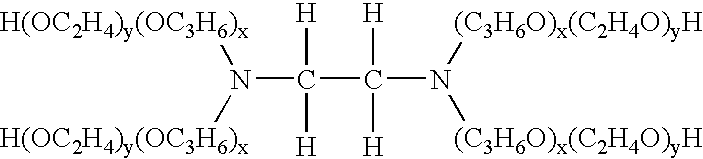

Inorganic hydrous salt phase change energy storage microcapsule and preparation method thereof

InactiveCN102676124AReduce subcoolingOvercoming phase separationEnergy storageHeat-exchange elementsActive agentSurface-active agents

The invention discloses an inorganic hydrous salt phase change energy storage microcapsule and a preparation method thereof. According to the microcapsule, an inorganic hydrous salt phase change material serves as a core material, and a high polymer serves as a capsule wall material. By means of a selection of an appropriate organic solvent, a surface active agent serves as a supplement, polymer monomer materials of the core material and the capsule wall material form an evenly dispersed mixed solution under the ultrasonication action, by means of an addition of functional additives of an initiating agent, a lubricating agent, a stabilizing agent, and a retarder and the like, under the reaction condition, the polymer monomers are subjected to suspension polymerization and solidification in the mixed solution, and then the core material is coated by the polymer monomers to form a phase change energy storage microcapsule. The preparation method is simple in operation and low in equipment requirements, the preparation method range of an inorganic core microcapsule is effectively widened, and by means of the sealing form of the microcapsule, the problems of the supercool and the phase separation of the hydrous salt phase change material are solved.

Owner:GUANGDONG UNIV OF TECH

Preparation method of nylon-6-based polyesteramide fiber

ActiveCN109706536ASuperposition of excellent characteristicsLarge irregularityMonocomponent copolyamides artificial filamentPolyesterPolymer science

The invention relates to a preparation method of a nylon-6-based polyesteramide fiber. The method comprises the steps of carrying out melt spinning on a nylon-6-based polyesteramide polymer to obtainthe nylon-6-based polyesteramide fiber. A preparation method of the nylon-6-based polyesteramide polymer comprises the steps of mixing nylon-6 prepolymer ester with a polyester prepolymer and then carrying out an ester exchange reaction to obtain the nylon-6-based polyesteramide polymer. The nylon-6 prepolymer ester is prepared by firstly synthesizing a dibasic-acid-terminated nylon-6 prepolymer and then adding dihydric alcohol to enable dihydric alcohol to react with carboxyl of terminal groups. According to the preparation method of the nylon-6-based polyesteramide fiber, the nylon-6-based polyesteramide polymer is obtained through a copolymerization approach, so that the uniformity of nylon-6 and polyester blocks is improved, and the phase domain is controllable; polyesteramide slices containing polyester chain segments at different ratios can be obtained by changing the addition quantity of the polyester prepolymer, so that the sequence structure is controllable, and the polymerization process is flexible. The prepared fiber has high spinnability and stiffness and can be applied to the fields of clothing, home textiles, automobile interior decoration and the like.

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

Single fluid acidizing treatment

An acidizing formulation for use in the stimulation of hydrocarbon production is stable when packaged and stored as a single fluid for periods exceeding one year. The formulation contains a miscibility solvent which substantially prevents any phase separation between the constituents and lack of dispersion of the additives in the fluid.

Owner:THE LUBRIZOL CORP

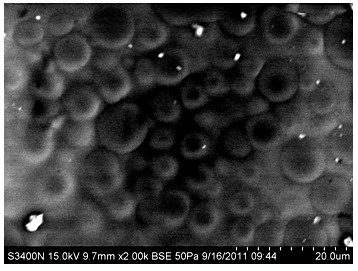

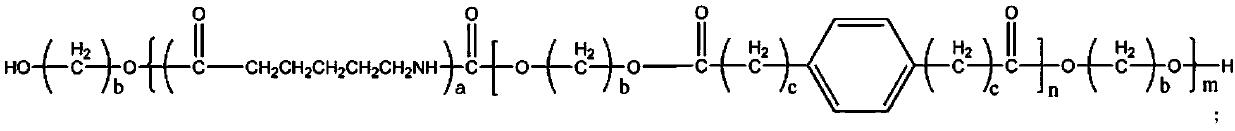

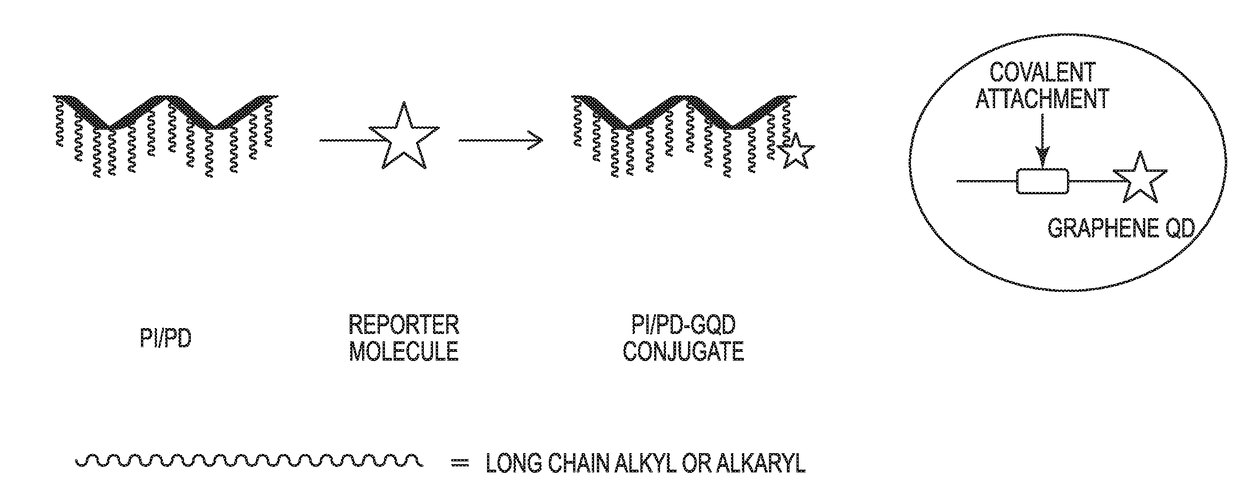

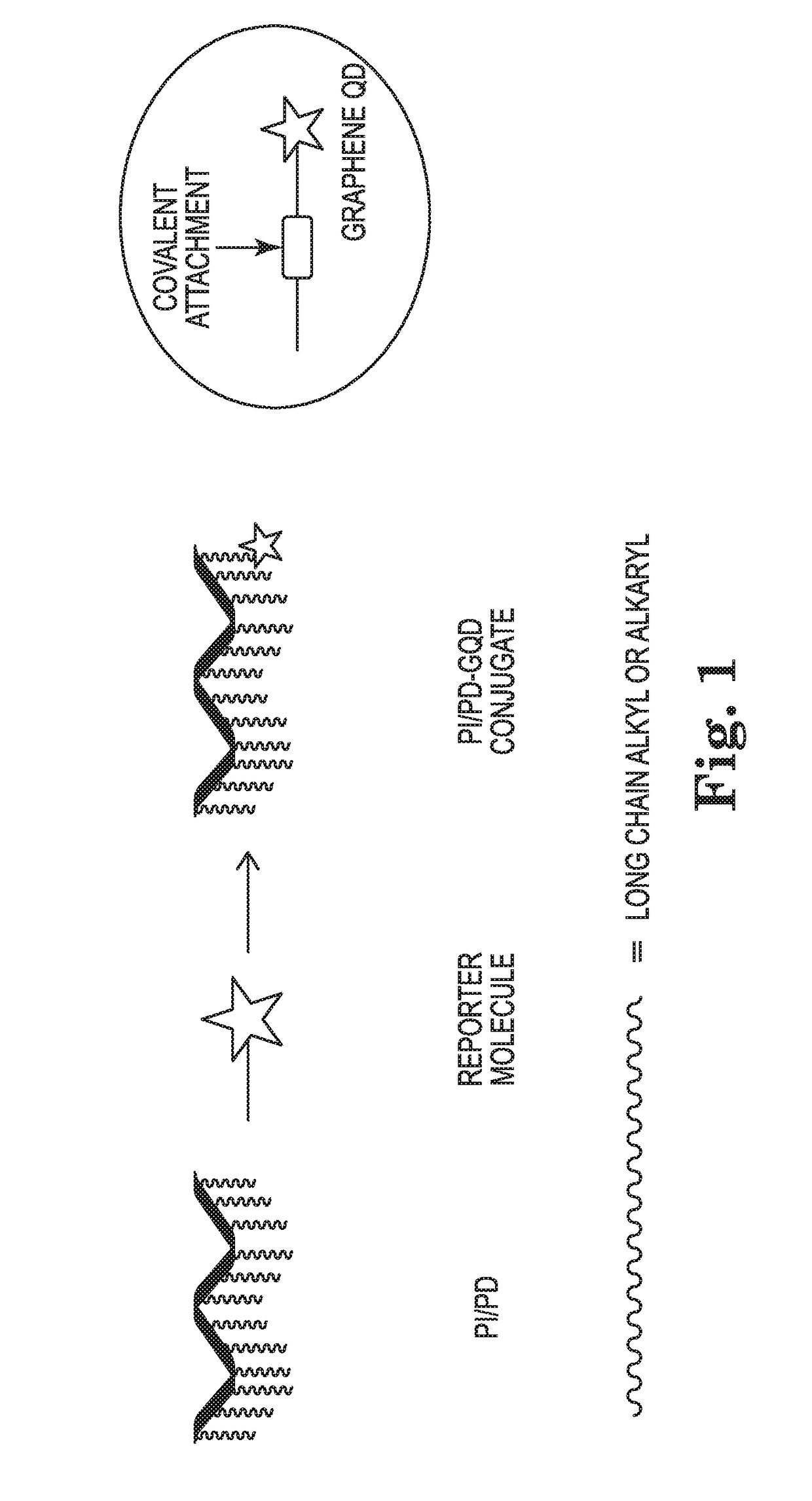

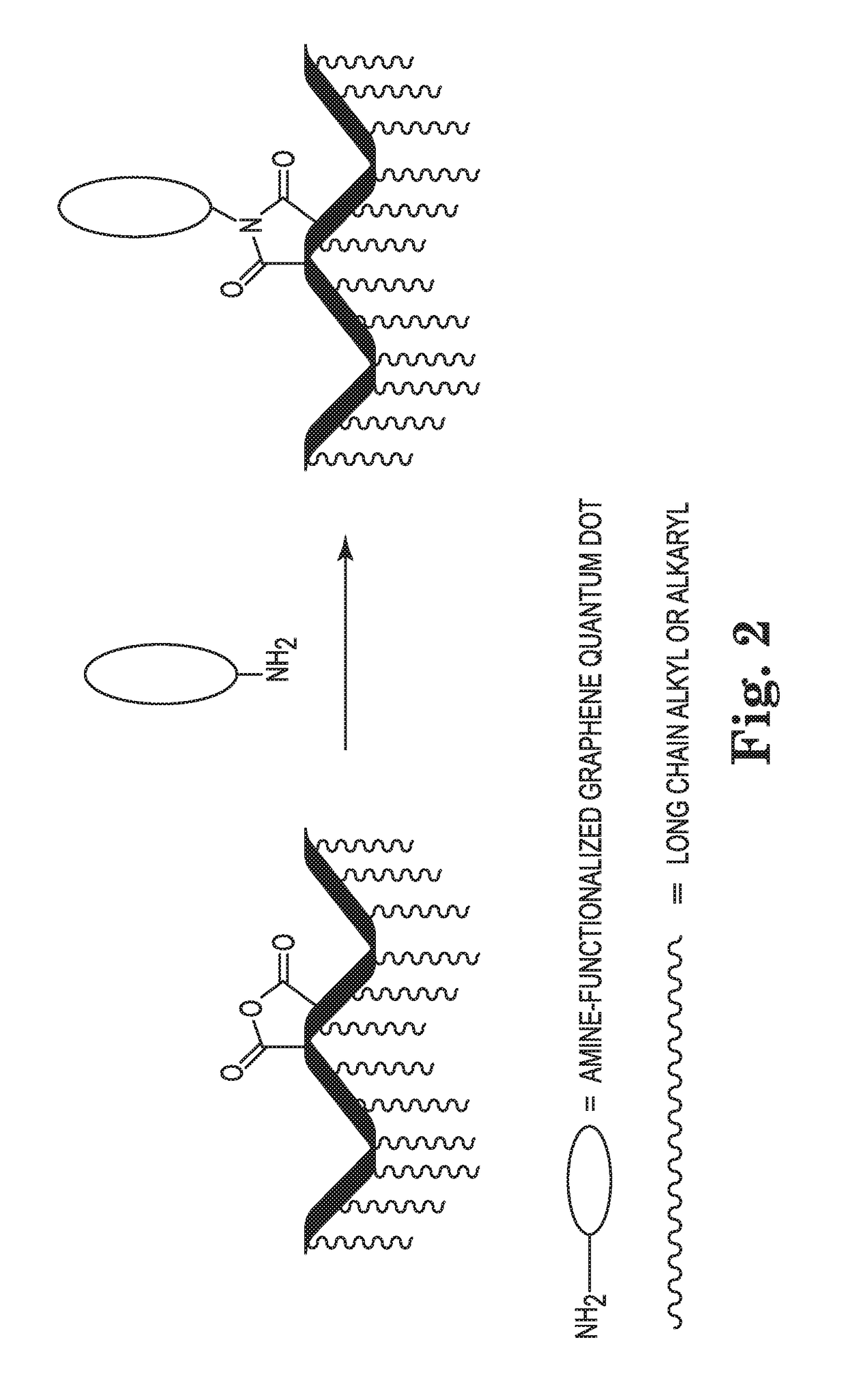

Paraffin suppressant compositions, and methods of making and using

ActiveUS20170355798A1Avoid phase separationCleaning apparatusMaterial testing goodsParaffin waxFluorescence

Disclosed herein are graphene quantum dot tagged paraffin suppressants such as graphene tagged paraffin inhibitors and paraffin dispersants and methods of making and using thereof. The graphene quantum dots are covalently bound to residues of paraffin inhibitors or dispersed with paraffin dispersants to form tagged paraffin suppressants active in inhibiting paraffin crystallization or dispersing crystalized paraffin wax in crude oils and compositions comprising crude oils. The dots can be tailored to fluoresce at wavelengths with minimized correspondence to the natural fluorescence of crude oils, enabling the measurement of the concentration of the paraffin suppressants in crude oils or compositions comprising crude oils. The tagged suppressants are used to trace the dispersion and disposition of the paraffin suppressants in oils and compositions comprising them, for example within crude-oil recovery, production, processing, or conveyance and transportation, by in situ sampling the oil or composition and measuring the fluorescence of the sampled material.

Owner:CHAMPIONX USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com