Preparation method of nylon-6-based polyesteramide fiber

A technology based on polyesteramide and nylon, which is applied in the field of polymer fiber preparation, can solve problems such as molecular weight reduction, additive removal, and inability to form fibers, and achieve high polymerization completion, increased crystallinity, and superimposed effects of excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

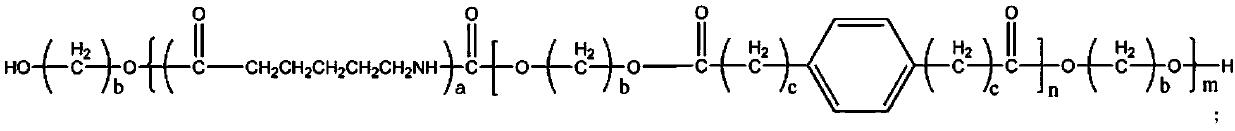

Image

Examples

Embodiment 1

[0058] A kind of preparation method of nylon 6 base polyamide ester fiber, the steps are as follows:

[0059] (1) prepare nylon 6 base polyamide ester polymer;

[0060] (1.1) At a temperature of 60°C, nylon 66 salt and NH 2 (CH 2 ) 4 A mixture of COOH (mass ratio 1:1), caprolactam, HOOC (CH 2 ) 2 COOH and deionized water were mixed with mechanical stirring to obtain a mixture, HOOC(CH 2 ) 2 The amount of COOH added is 11wt% of the amount of caprolactam added, the amount of deionized water added is 2wt% of the amount of caprolactam added, nylon 66 salt and NH 2 (CH 2 ) 4 The addition amount of the mixture of COOH is 0.2wt% of the addition amount of caprolactam, the rotating speed of mechanical stirring is 80r / min, and the time is 10min;

[0061] (1.2) The mixture is subjected to prepolymerization to obtain a dibasic acid-terminated nylon 6 prepolymer. The temperature of the prepolymerization is 220° C., the pressure is 0.5 MPa, the atmosphere is nitrogen, and the termi...

Embodiment 2

[0069] A kind of preparation method of nylon 6 base polyamide ester fiber, the steps are as follows:

[0070] (1) prepare nylon 6 base polyamide ester polymer;

[0071] (1.1) At a temperature of 100°C, mix nylon 66 salt with NH 2 (CH 2 ) 6 A mixture of COOH (mass ratio 1:1), caprolactam, HOOC (CH 2 ) 3 COOH and deionized water were mixed with mechanical stirring to obtain a mixture, HOOC(CH 2 ) 3 The amount of COOH added is 17wt% of the added amount of caprolactam, the amount of deionized water added is 2.5wt% of the added amount of caprolactam, nylon 66 salt and NH 2 (CH 2 ) 6 The addition amount of the mixture of COOH is 0.8wt% of the addition amount of caprolactam, the rotating speed of mechanical stirring is 150r / min, and the time is 30min;

[0072] (1.2) The mixture is subjected to a prepolymerization reaction to obtain a dibasic acid-terminated nylon 6 prepolymer. The temperature of the prepolymerization reaction is 280° C., the pressure is 1.3 MPa, the atmosphe...

Embodiment 3

[0080] A kind of preparation method of nylon 6 base polyamide ester fiber, the steps are as follows:

[0081] (1) prepare nylon 6 base polyamide ester polymer, concrete preparation steps are with embodiment 1;

[0082] (2) Nylon 6-based polyamide ester polymer is melt-spun to obtain nylon 6-based polyamide ester fiber. The melt-spinning process is FDY process, and the parameters are: spinning temperature 265°C, first godet speed 4000m / min, the speed of the second godet is 5000m / min, the draw ratio is 1.1 times, the cooling air temperature is 15°C, the cooling air speed is 0.8m / s, and the relative humidity of the cooling air is 60%.

[0083] The monofilament fineness of the finally prepared nylon 6-based polyamide fiber is 3 dtex, the breaking strength is 2.5 cN / dtex, and the stiffness of the fabric made from the nylon 6-based polyamide fiber is 4.5 mN*cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com