Patents

Literature

455results about How to "High polymerization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing article having been subjected to low reflection treatment, solution for forming low reflection layer and article having been subjected to low reflection treatment

InactiveUS20060204655A1High polymerization efficiencyIncrease resistanceGroup 4/14 element organic compoundsOptical filtersDecompositionRoom temperature

A low reflection treated article manufacturing method wherein a low reflection layer solution, obtained by mixing and reacting (1) silica microparticles, comprising at least one type of silica microparticles selected from the group consisting of non-aggregated silica microparticles with an average particle diameter of 40 to 1000 nm, hollow non-aggregated silica microparticles with an average particle diameter of 10 to 100 nm, and chain-like aggregated silica microparticles with an average primary particle diameter of 10 to 100 nm, (2) a hydrolyzable silicon compound, water, and a binder solution, containing a solvent and a hydrolysis catalyst for the above-mentioned silicon compound, to hydrolyze the above-mentioned silicon compound and (3) adding a curing catalyst, which promotes the condensation of silanol groups, is coated onto a resin base material and reacted and cured at room temperature or within a range of room temperature to “a temperature at which the base material will not be damaged” (the deformation temperature or less in the case of a thermoplastic resin or the decomposition temperature or less in the case of a hardening resin) to form a low reflection layer, containing silica microparticles and a binder at a solids weight ratio of 30:70 to 95:5.

Owner:SDC TECH ASIA

Cationic polymerization initiation system and cationic polymerization method

The invention discloses a cationic polymerization initiation system and a cationic polymerization method. The cationic polymerization initiation system comprises at least one initiator, at least one Lewis acid and at least one additive. The initiator is a compound capable of providing protons or carbocations, wherein a mole ratio of the initiator to monomers is (5.0*10<-5> to 1.2*10<-2>): 1. The Lewis acid is a metal halide or an organic metal halide, wherein a mole ratio of the Lewis acid to the monomers is (5.0*10<-4> to 4.0*10<-1>): 1. The at least one additive is selected from sulfur-containing organic compounds, phosphorus-containing organic compounds and organic compounds containing sulfur and phosphorus, wherein a mole ratio of the at least one additive to the monomers is (1.0*10<-3> to 5.0*10<-2>): 1. The cationic polymerization initiation system has high activity, a low price and stable properties, is convenient for use, has high polymerization efficiency, and can greatly improve polymerization product molecular weight, wherein weight-average molecular weight of polymerization products obtained at a temperature of -60 DEG C is 1*10<6>.

Owner:CHINA PETROLEUM & CHEM CORP +1

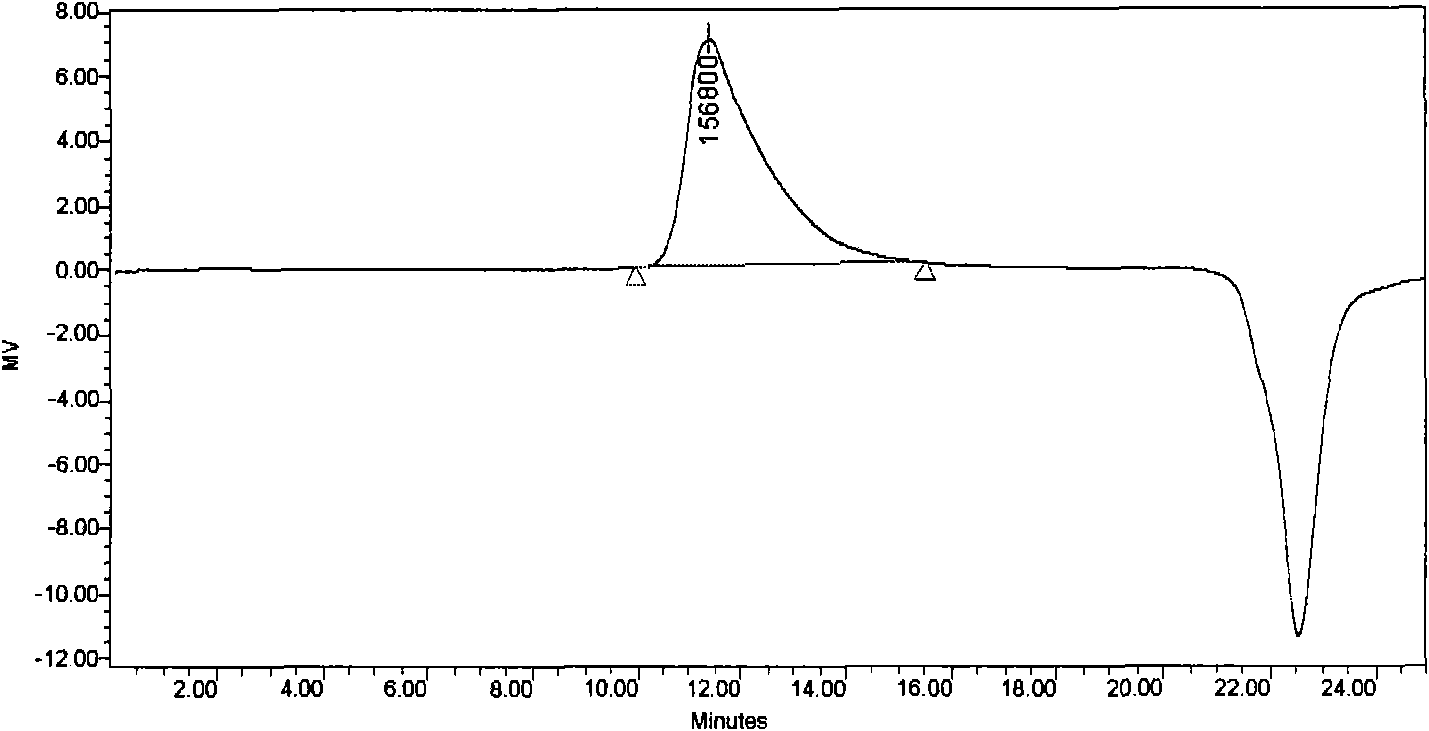

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

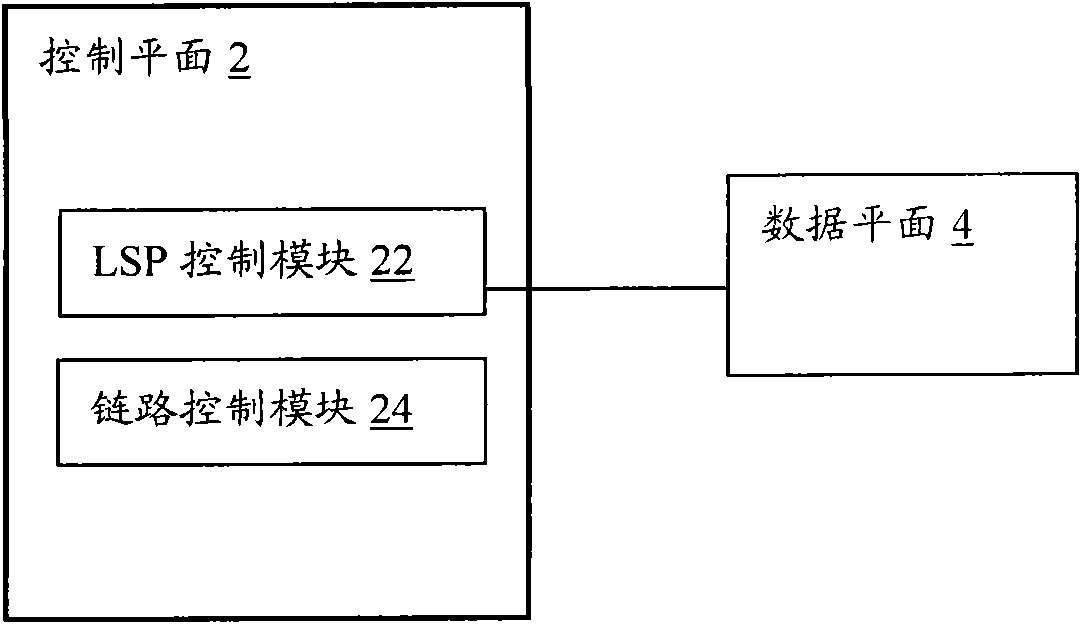

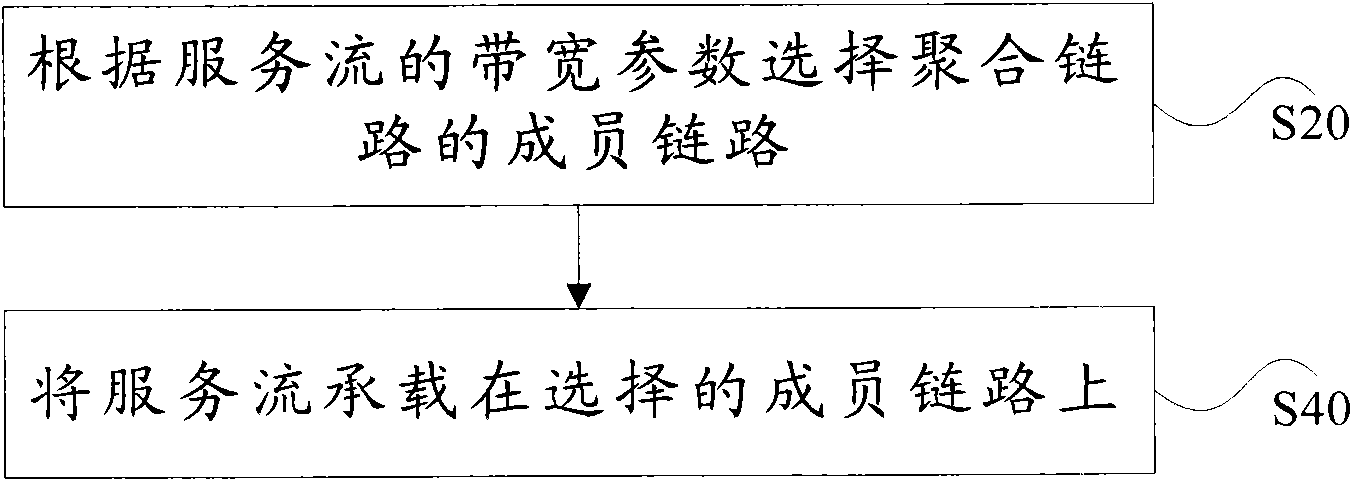

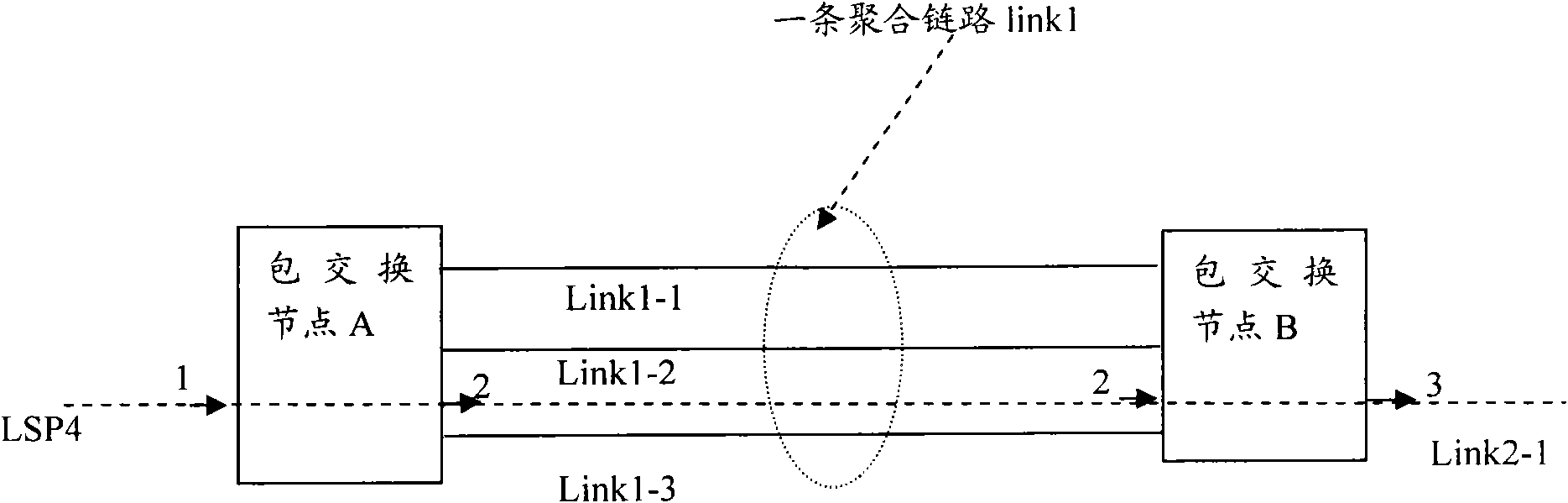

Configuration method for aggregating link service flow and packet switching device

InactiveCN101841487AGuaranteed service qualityHigh polymerization efficiencyData switching networksService flowQuality of service

The invention discloses a configuration method for aggregating link service flow and a packet switching device. The method includes: a member link for aggregating link is selected according to bandwidth parameter of service flow; and service flow is carried onto the selected member link. By adopting the invention, the problem that repetitious adjusting from service flow to the member link is caused by jamming of member link or overloading in link aggregation is solved, thus the effects of ensuring service quality of service flow and improving link aggregating efficiency are achieved.

Owner:ZTE CORP

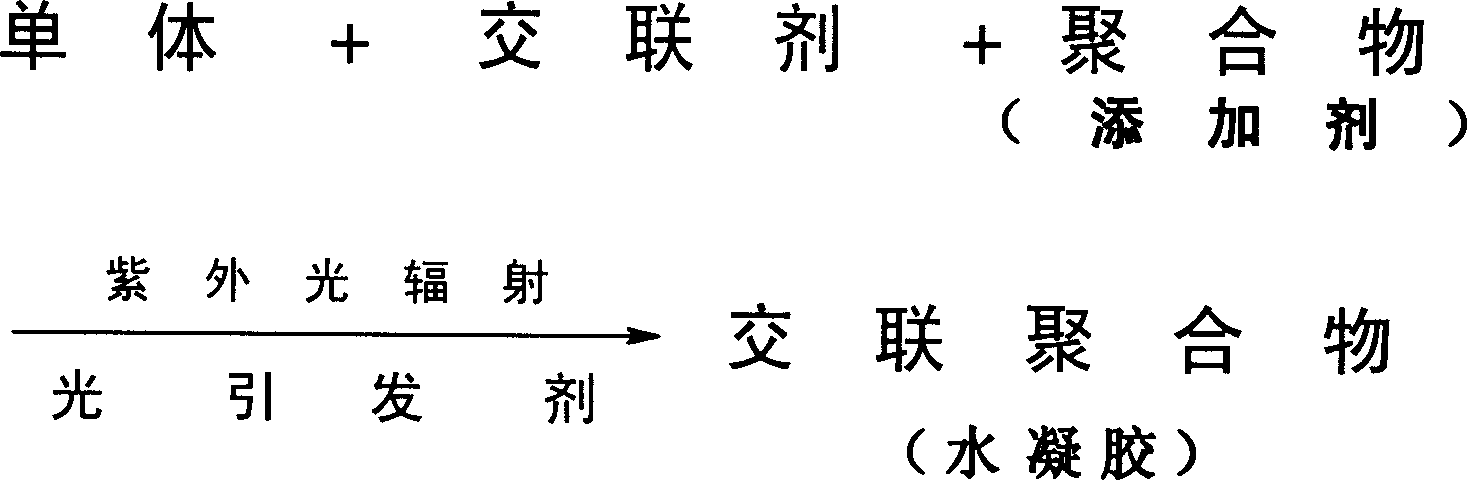

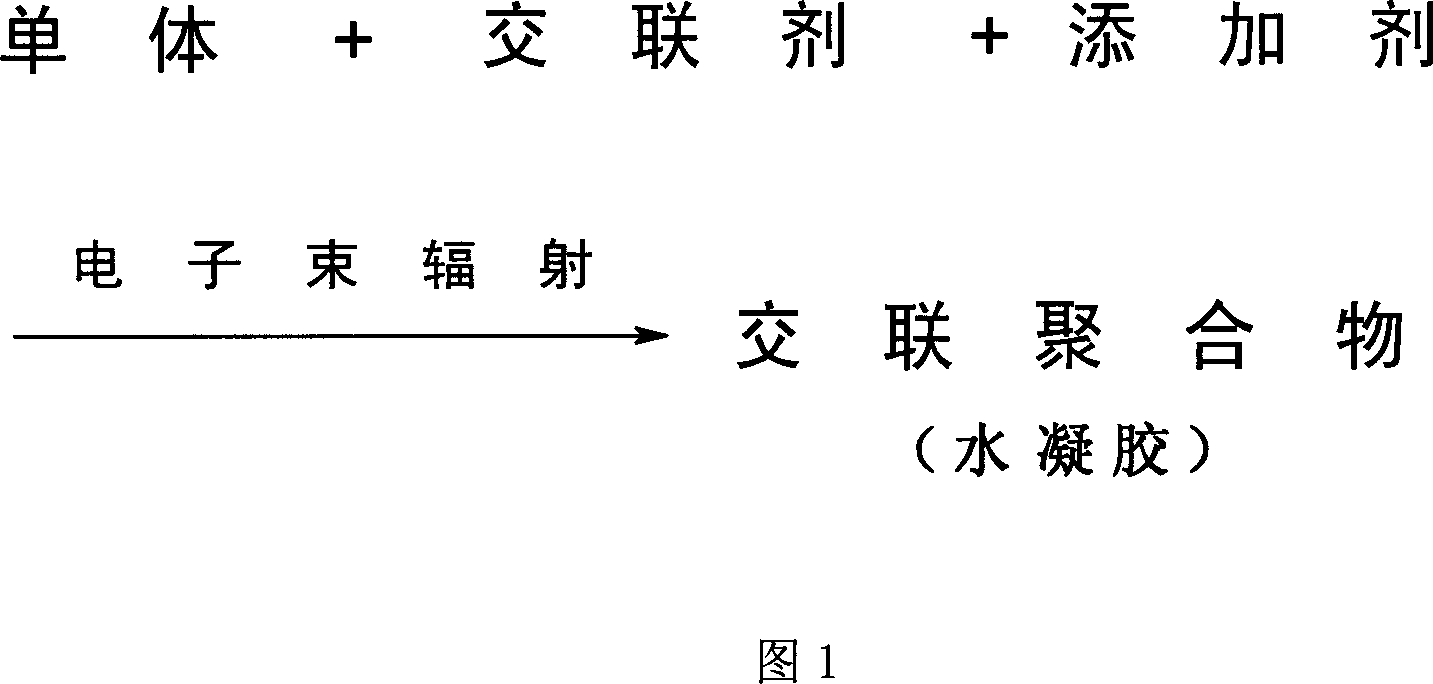

Direct synthesis of temperate sensitive aquogel by ultraviolet radiant polymerization

Synthesis of warm sensitive aquagel from ultraviolet light radiation polymerization is carried out by adding reacting raw materials into deionized water to prepare preformed solution, laying aside under ultraviolet light radiation, exposing, polymerizing directly to prepare cross-linking polymer, putting the polymer into sorbitic extractor, extracting from boiled deionized water for 24hrs, taking it out, and drying in vacuum drier to obtain warm sensitive aquagel. Its low critical temperature varies between 30-40 Deg C. with raw material formula. It can be used for various aquagels, medicine control-releasing system, memory element switch, artificial muscle and chemical industrial separation. It achieves low cost, simple process, high efficiency and normal-temperature operation.

Owner:TSINGHUA UNIV

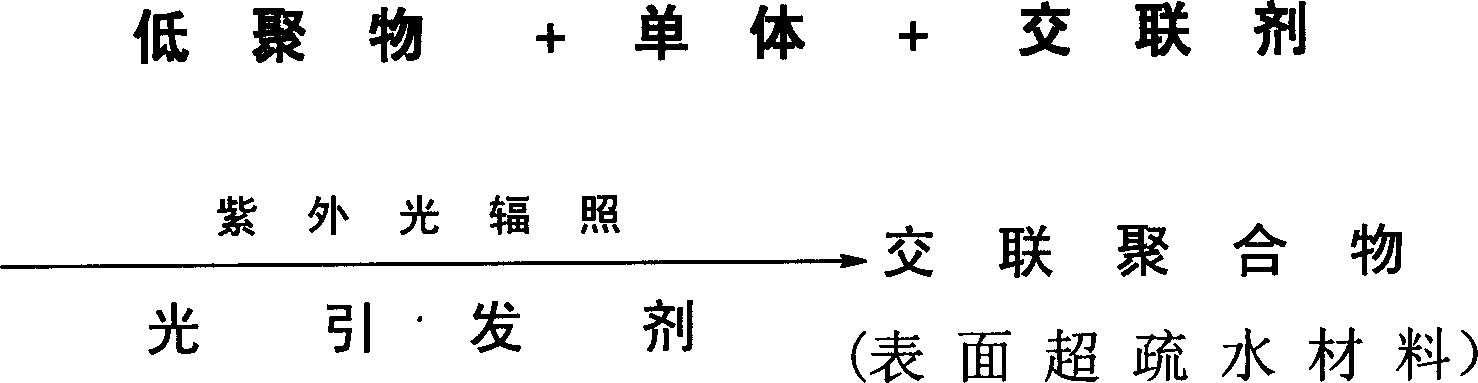

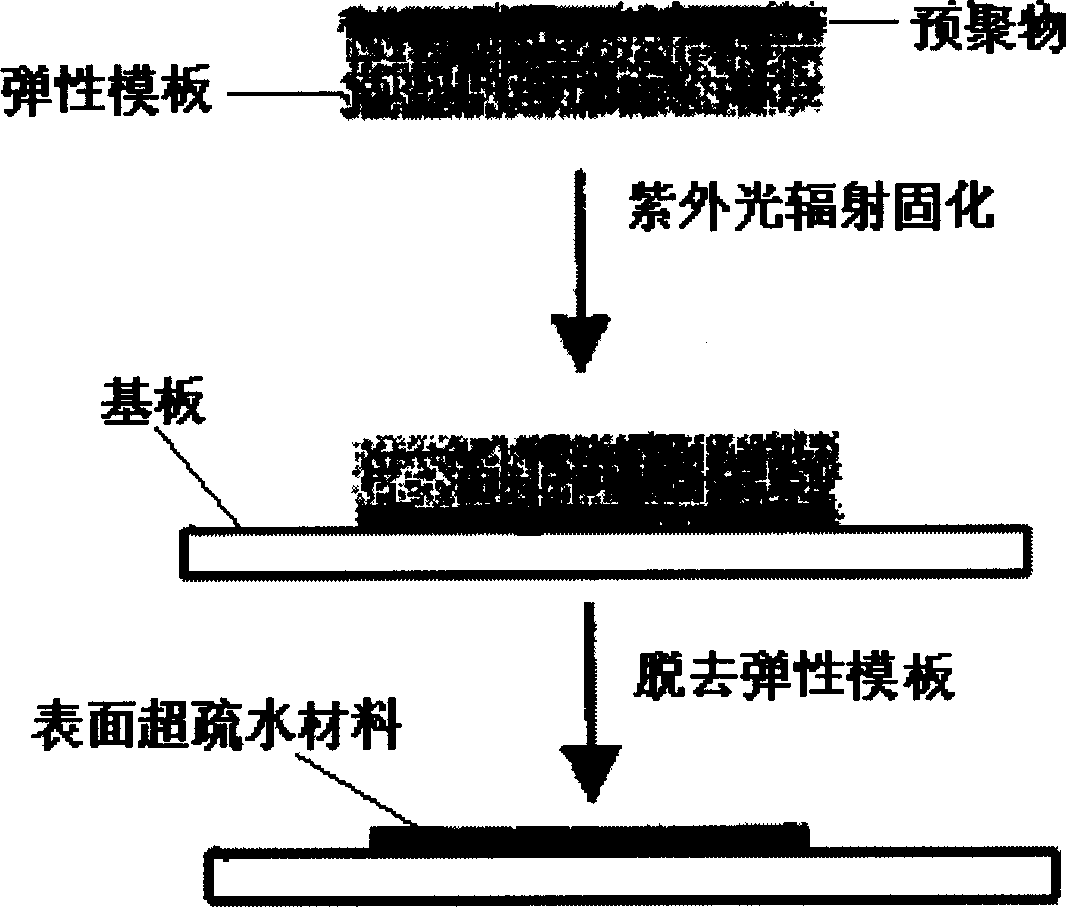

Soft template and ultraviolet curing process to prepare surface super hydrophobic material

InactiveCN1810912AExcellent superhydrophobic propertiesStrong adhesionOther chemical processesCross-linkRoom temperature

The present invention is soft template an ultraviolet curing process to prepare surface super hydrophobic material, and belongs to the field of solid material surface modifying technology. The surface super hydrophobic material is prepared through preparation of elastic soft template, setting the pre-polymer between the elastic template and the base board, ultraviolet irradiation to cure and eliminate the elastic template to obtain surface super hydrophobic material. The surface super hydrophobic material of cross-linked polymer is adhered onto the base board and is easy to separate from the elastic template. The surface super hydrophobic material has pattern copied from the elastic template, excellent super hydrophobic performance and surface water contact angle at room temperature greater than 150 deg. The surface super hydrophobic material has simple preparation process, high polymerization efficiency, less pollution, low cost and environment friendship.

Owner:TSINGHUA UNIV

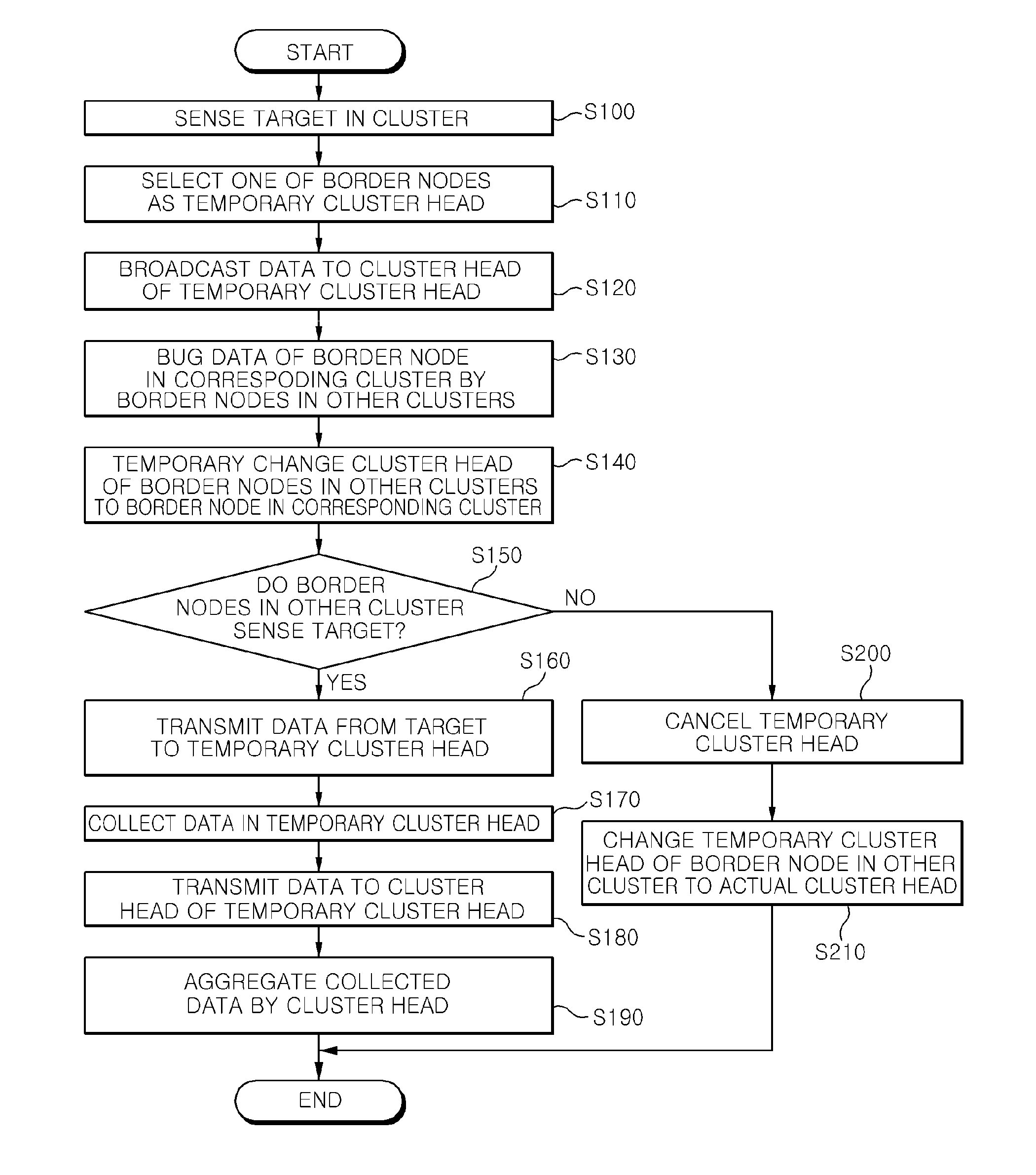

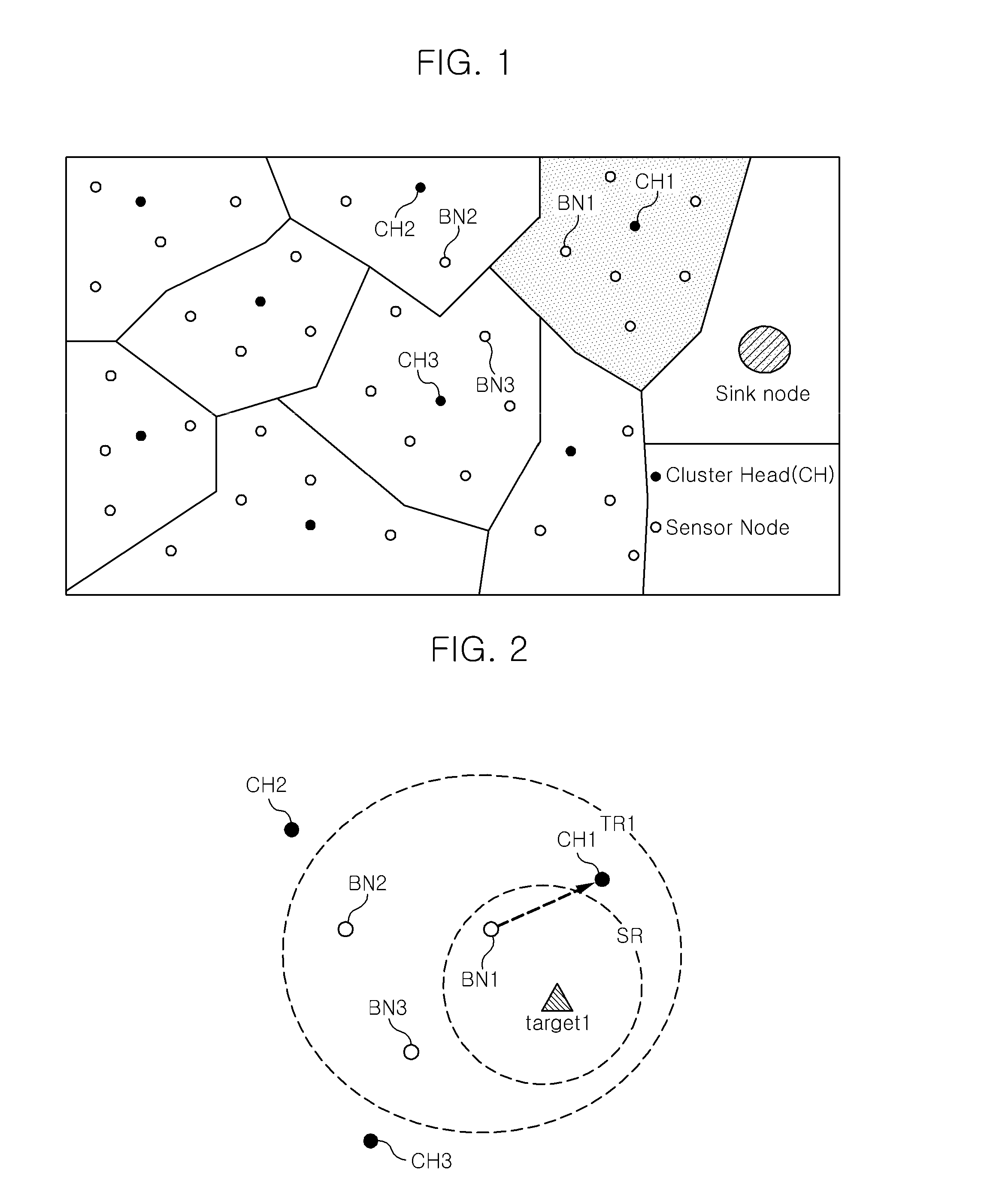

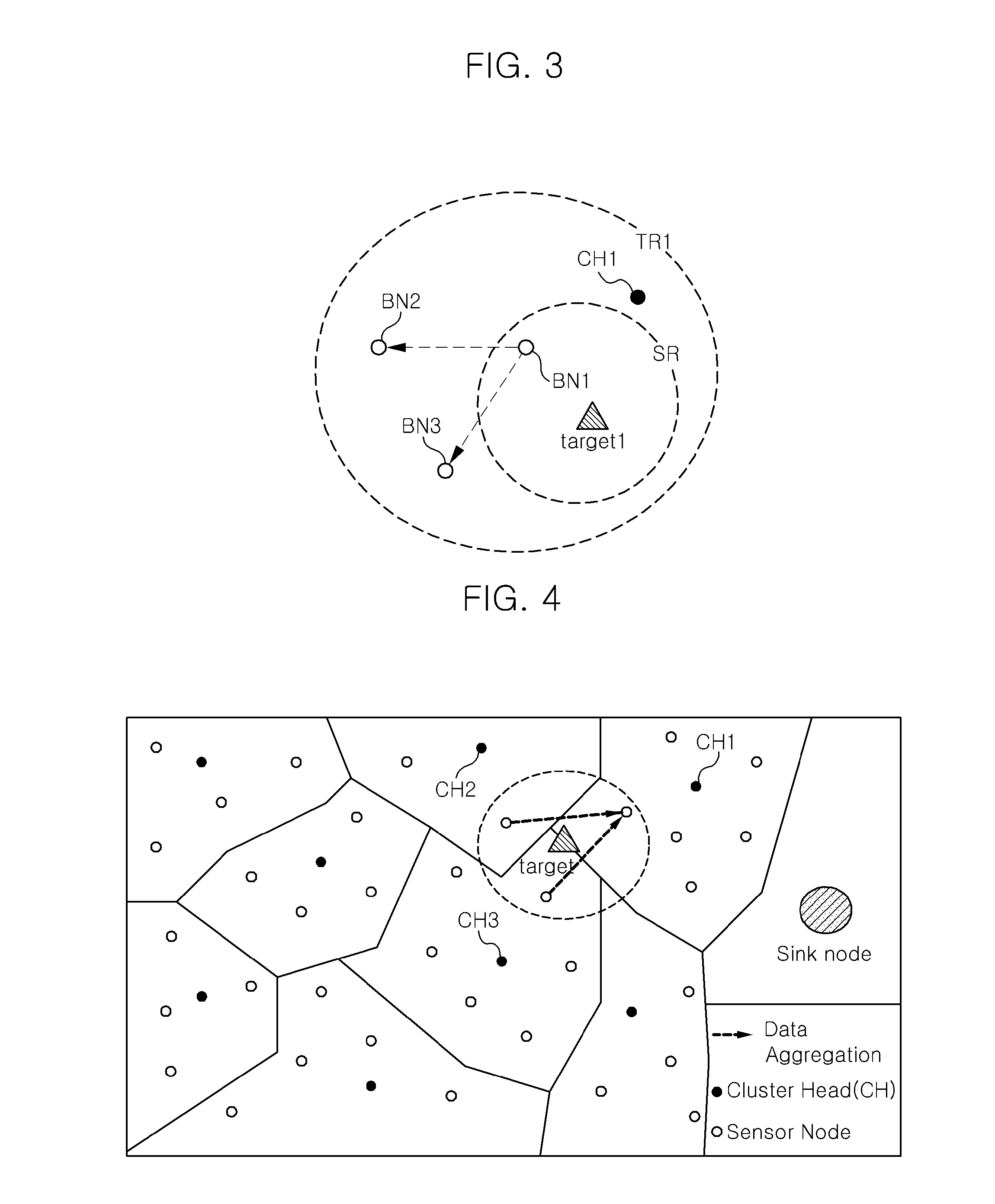

Method for cluster based data transmission in wireless sensor networks

ActiveUS20110130162A1High data efficiencyImprove energy efficiencyNetwork traffic/resource managementAssess restrictionWireless mesh networkWireless sensor networking

The present invention relates to a method for cluster based data in wireless sensor networks. The method includes: selecting any one of border nodes positioned at the edge of a cluster as a temporary cluster head as a temporary cluster head when a target is sensed in the cluster; bugging data of the temporary cluster head by border nodes in other adjacent cluster which do not sense the target to temporarily change the border node selected as the temporary cluster head to a cluster head of each of the border nodes; when the target is sensed by at least one of the border nodes, collecting data from each of the border nodes by the temporary cluster head to transferring the collected data to an actual cluster head of the temporary cluster head; and aggregating the collected data by actual cluster head of the temporary cluster head.

Owner:ELECTRONICS & TELECOMM RES INST

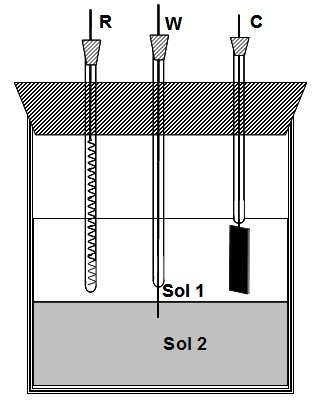

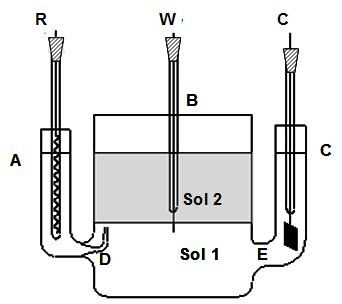

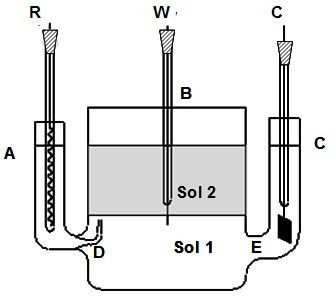

Preparation method of conductive polypyrrole

InactiveCN101979438ARegulate polymerization speedHigh polymerization efficiencyElectrolysis componentsElectrolytic organic productionSupporting electrolytePolypyrrole

The invention discloses a preparation method of conductive polypyrrole. The method comprises the following steps of: dissolving a pyrrole monomer in an organic solvent and dissolving a supporting electrolyte in water so as to prepare solutions respectively; transferring the solutions into a reactor in two steps so as to form a liquid-liquid interface; directly inserting a working electrode into the liquid-liquid interface; putting an auxiliary electrode and a reference electrode into solution of supporting electrolyte; and performing electrochemical polymerization by an electrochemical measure. A prepared conductive polypyrrole film is a polymer of pyrrole, which has the thickness of between 1 and 500mu m, the tensile strength of more than or equal to 0.5MPa and high electrical conductivity, and can be used in the aspects of super capacitors, anode and cathode materials of batteries, electromagnetic shielding and the like.

Owner:WUHAN UNIV

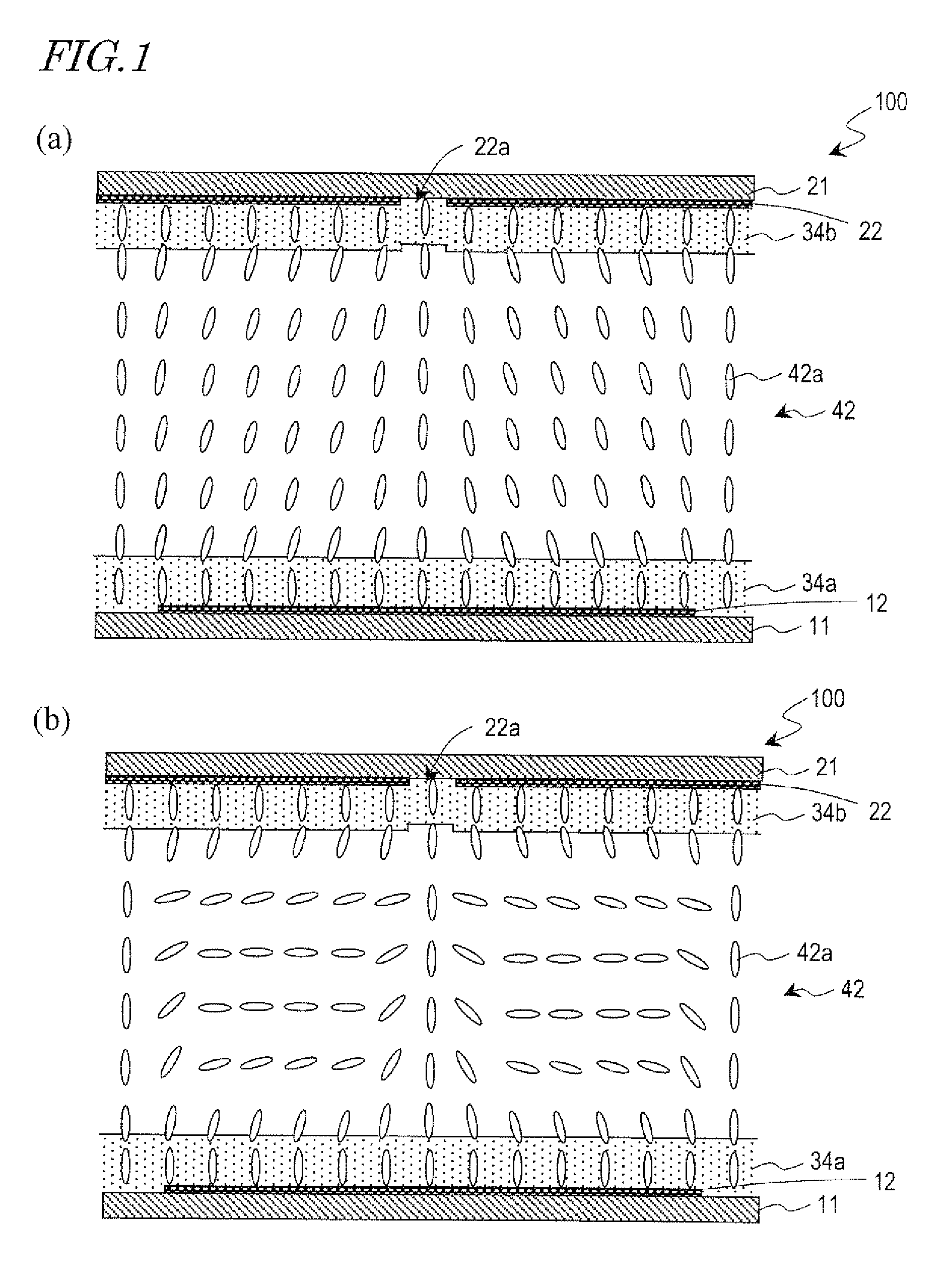

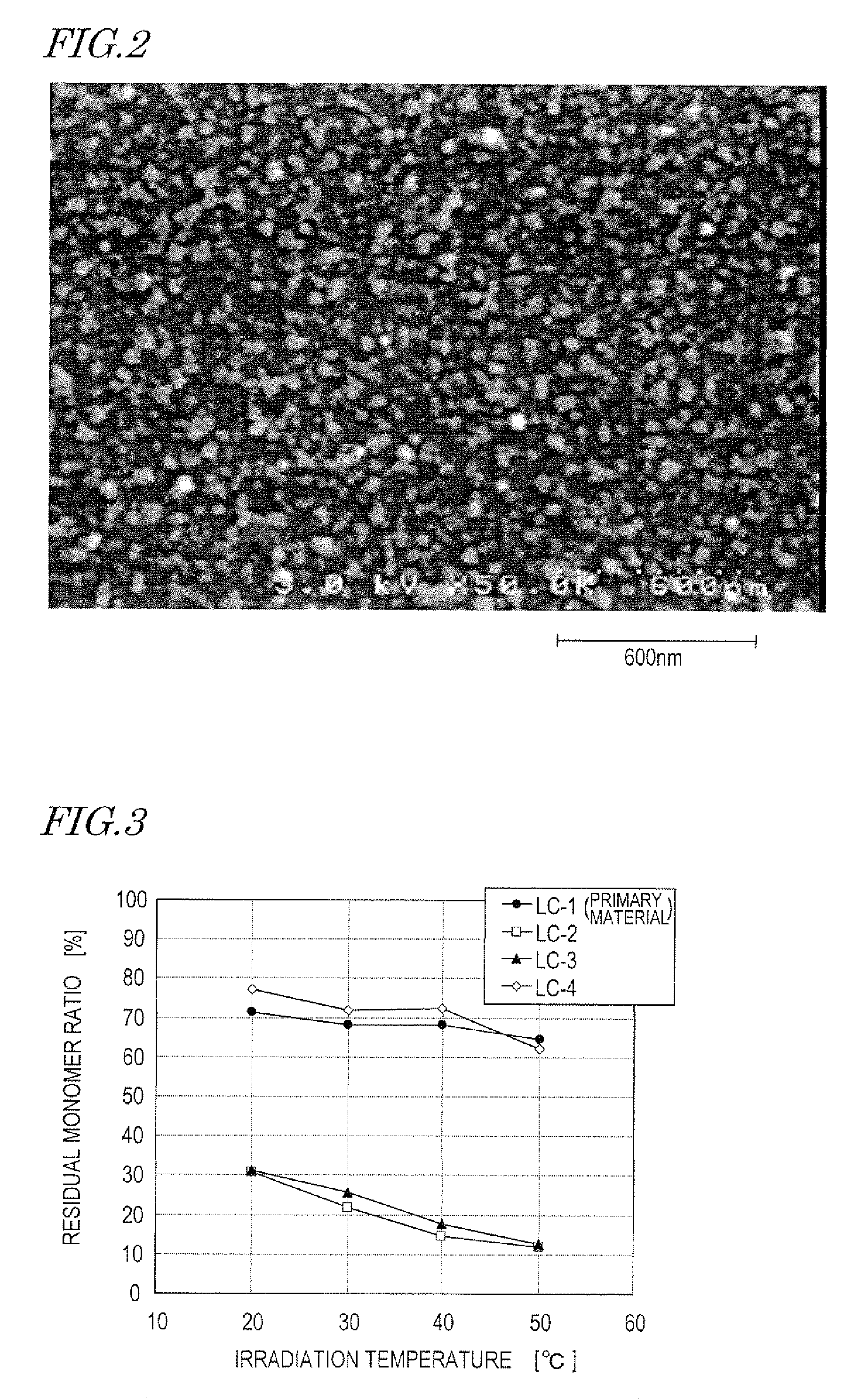

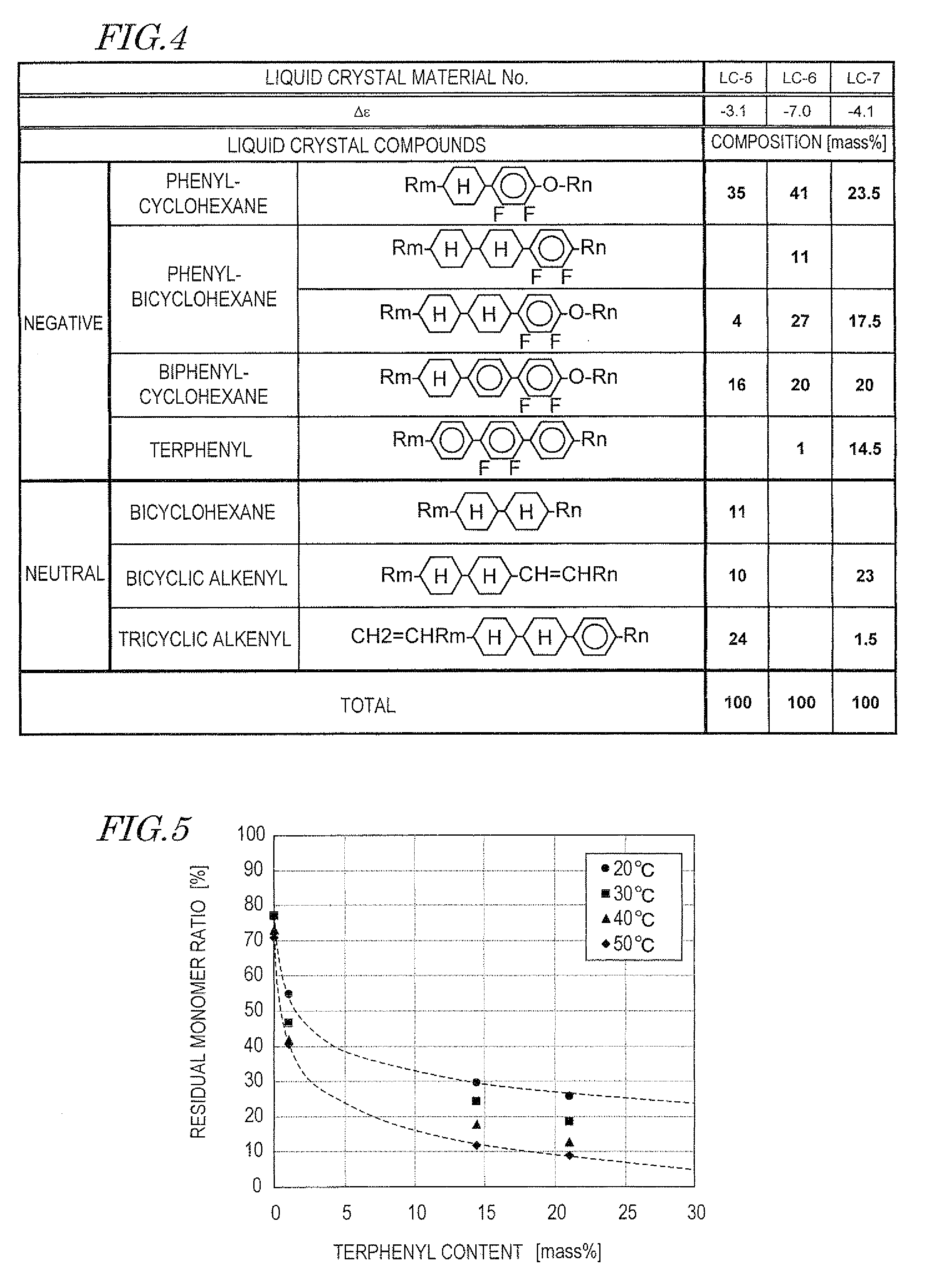

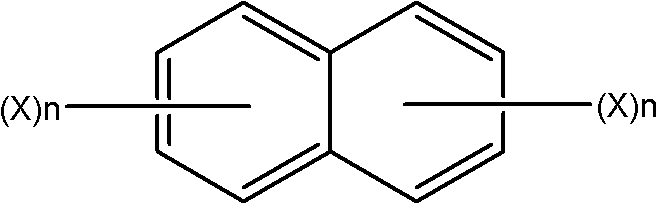

Liquid crystal display device

ActiveUS8092871B2High polymerization efficiencyReduce doseLiquid crystal compositionsThin material handlingSource materialEngineering

A liquid crystal display device of the present invention includes: a liquid crystal layer containing a nematic liquid crystal material; a pair of electrodes opposing each other via the liquid crystal layer; a pair of alignment films respectively provided between the pair of electrodes and the liquid crystal layer; and an alignment sustaining layer formed of a photopolymerized material on each of surfaces of the pair of alignment films which are closer to the liquid crystal layer, the alignment sustaining layer being configured to regulate a pretilt azimuth of a liquid crystal molecule of the liquid crystal layer during the absence of an applied voltage across the liquid crystal layer, wherein the pretilt azimuth of the liquid crystal molecule of the liquid crystal layer is regulated by the alignment sustaining layer during the absence of an applied voltage across the liquid crystal layer. The nematic liquid crystal material contains a liquid crystal compound having a terphenyl ring system as an indispensable component, and the liquid crystal layer further contains part of a photopolymerizable compound which is a source material of the photopolymerized material, a content of the photopolymerizable compound relative to the nematic liquid crystal material being less than 0.015 mol %.

Owner:MERCK PATENT GMBH

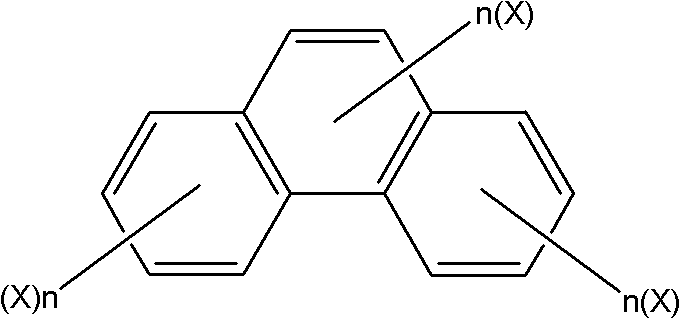

Liquid crystal medium composite as well as liquid crystal display using same and manufacturing method of liquid crystal medium composite

ActiveCN102660300AImprove uniformityImprove efficiencyLiquid crystal compositionsNon-linear opticsPolycyclic aromatic hydrocarbonLiquid-crystal display

The invention provides a liquid crystal medium composite as well as a liquid crystal display using the liquid crystal medium composite and a manufacturing method of the liquid crystal medium composite. The liquid crystal medium composite comprises the following components: a liquid crystal material, a polymerizable monomer, a stabilizing agent and a sensitizing agent, wherein the sensitizing agent has strong absorption on ultraviolet light with the wavelength in a range of 300-380 nm; and the structure is formed by connecting a polycyclic aromatic hydrocarbon formed by connecting a plurality of benzene rings, with an aromatic ring. The liquid crystal display comprises an upper substrate, a lower substrate and the liquid crystal medium composite, wherein the upper substrate and the lower substrate are arranged in parallel; and the liquid crystal medium composite is arranged between the upper substrate and the lower substrate. According to the invention, the stabilizing agent which has the strong absorption on the ultraviolet light with the wavelength in the range of 300-380 nm is used so that a reaction wavelength of the polymerizable monomer can be moved towards a long wavelength; the ultraviolet light with the wavelength in the range of 300-380 nm is used for irradiating to keep away from the absorption wave section of a liquid crystal material, so that the damage effect on the liquid crystal material and an alignment material PI (Polyimide) by the ultraviolet light is reduced, and the polymerization reaction efficiency and the uniformity of the polymerizable monomer can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

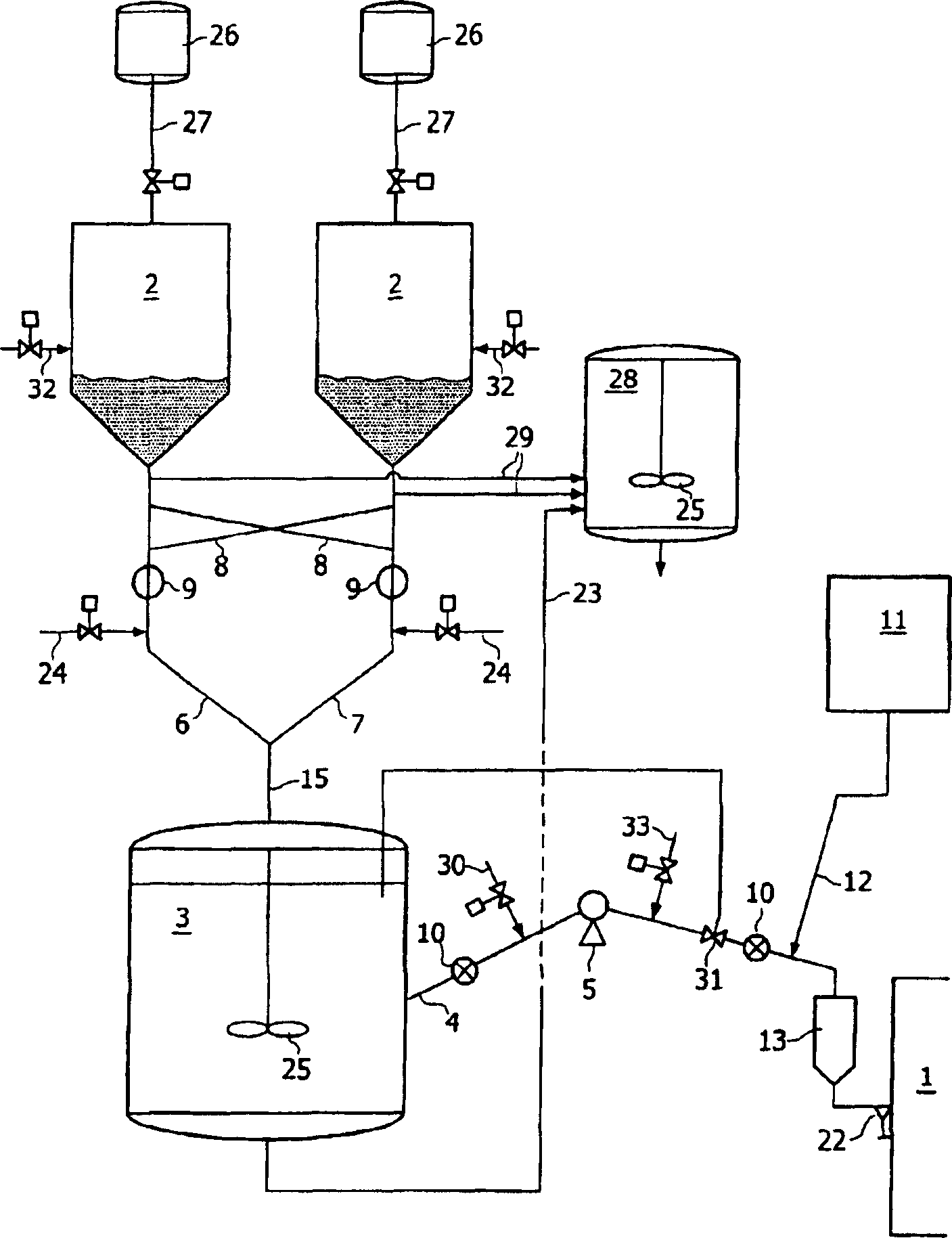

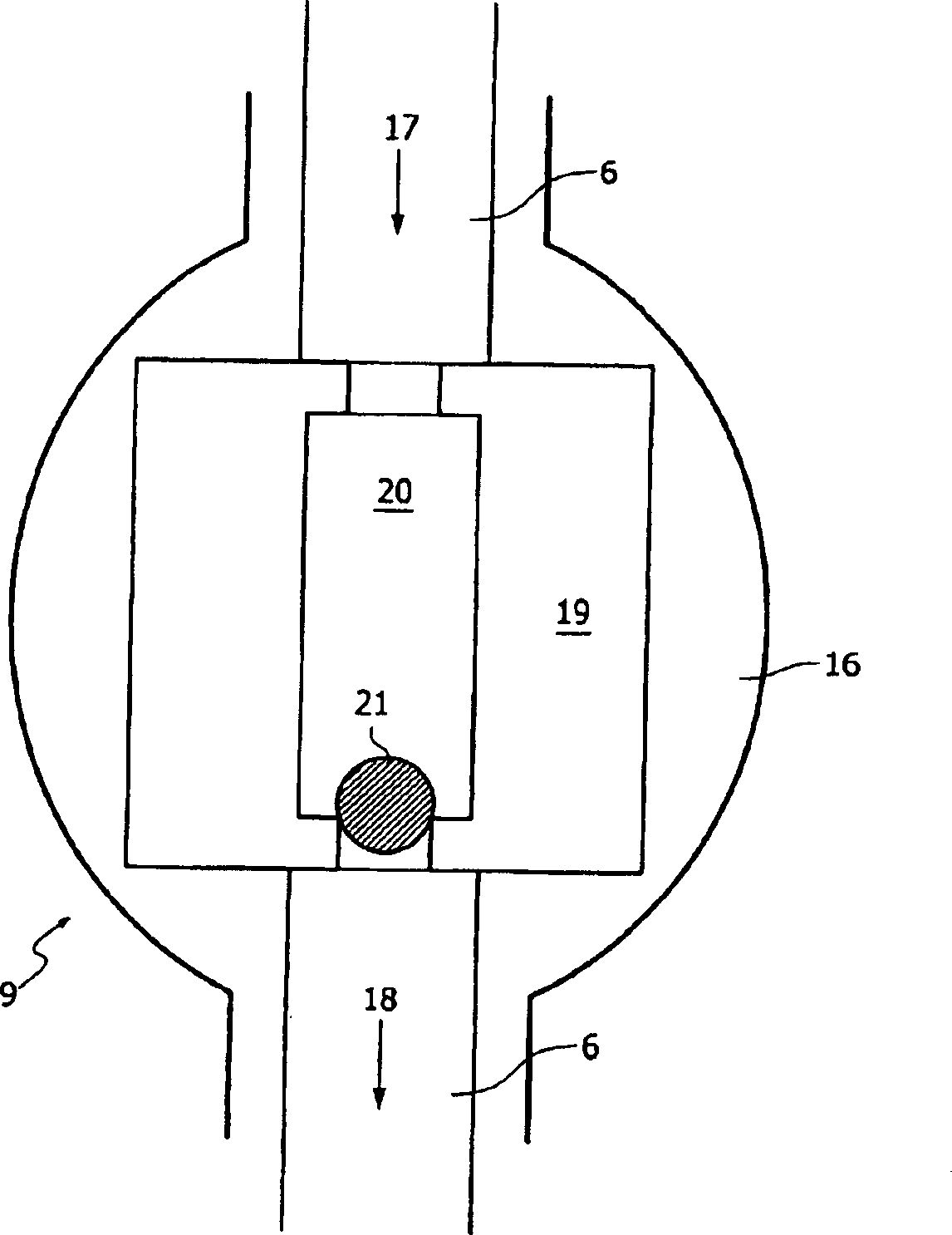

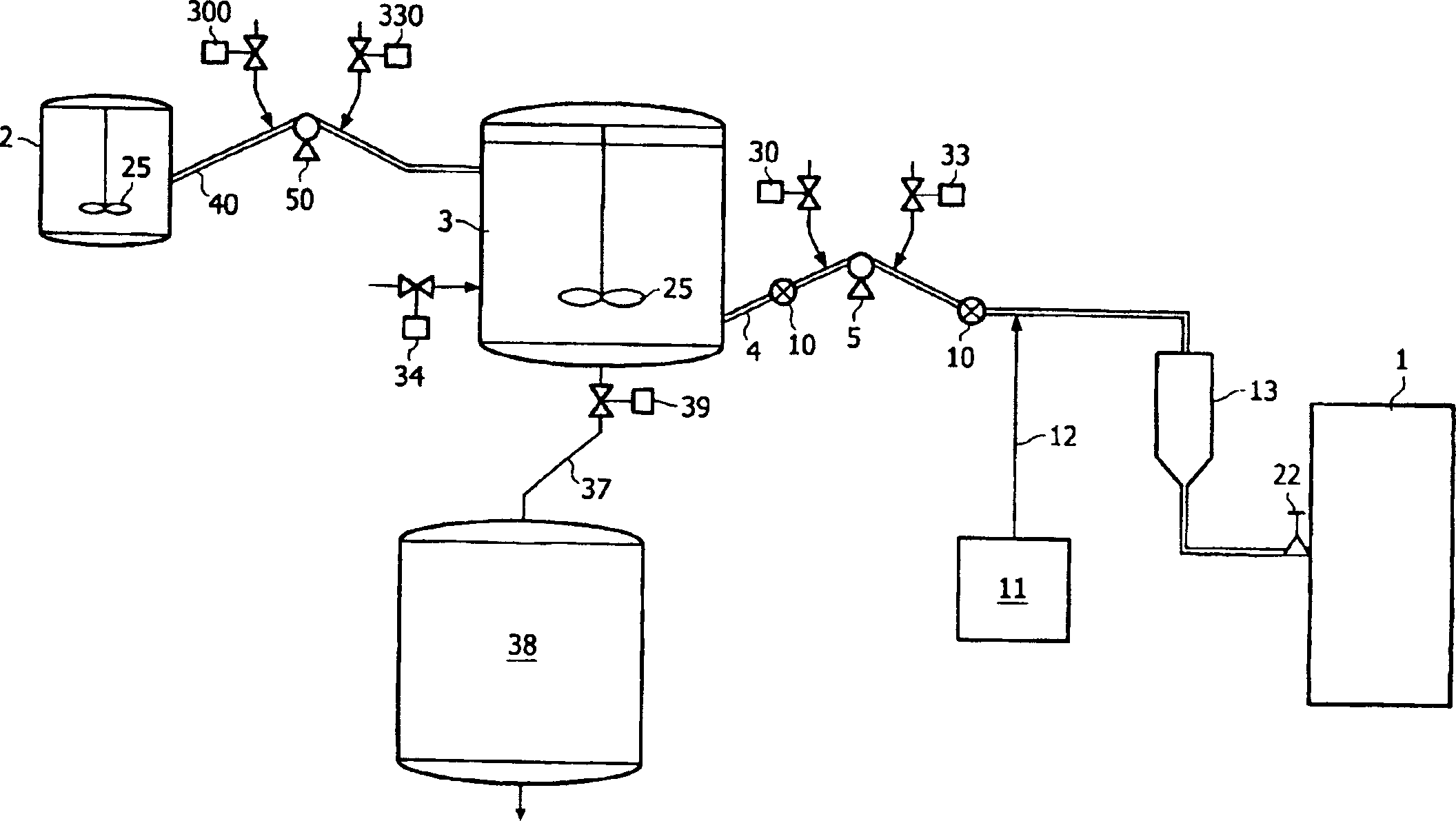

Method and apparatus for preparing and supplying catalyst slurry to a polymerisation reactor

InactiveCN1917949AImprove the yield of polymerization reactionsQuality improvementChemical/physical/physico-chemical stationary reactorsSlurryReagent

The present invention relates to an apparatus for preparing and supplying catalyst to an ethylene slurry loop polymerisation reactor and to an apparatus for controlling the injection of catalyst slurry in a polymerization reactor wherein polyethylene is prepared. The present invention a Iso relates to a method for optimising catalyst supply to a polymerisation reactor. The diluted catalyst is transferred to the reactor (1) using a membrane pump (5) controllable in function of the concentration of a reactant in said reactor (1).

Owner:TOTAL RES & TECH FELUY

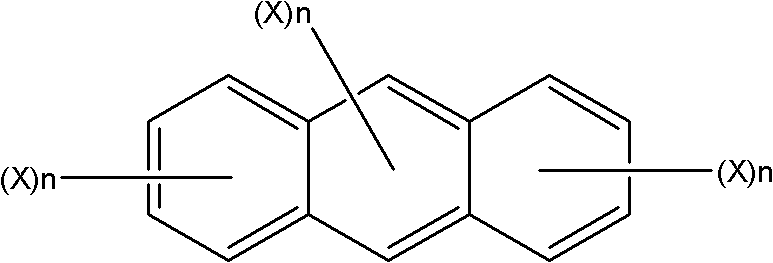

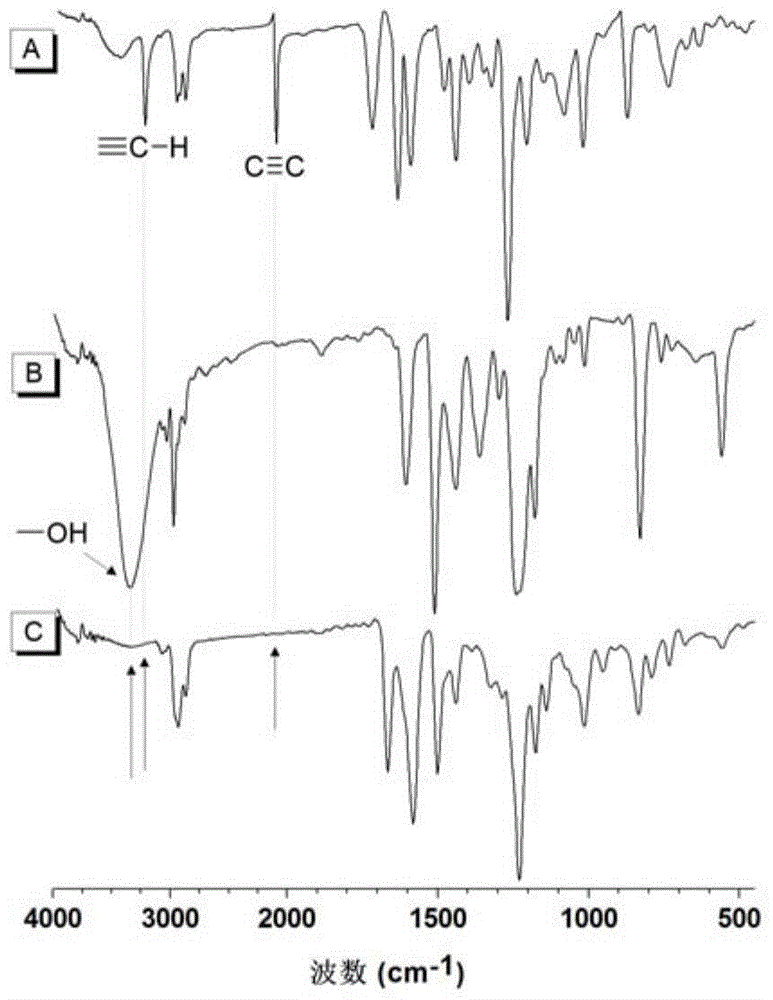

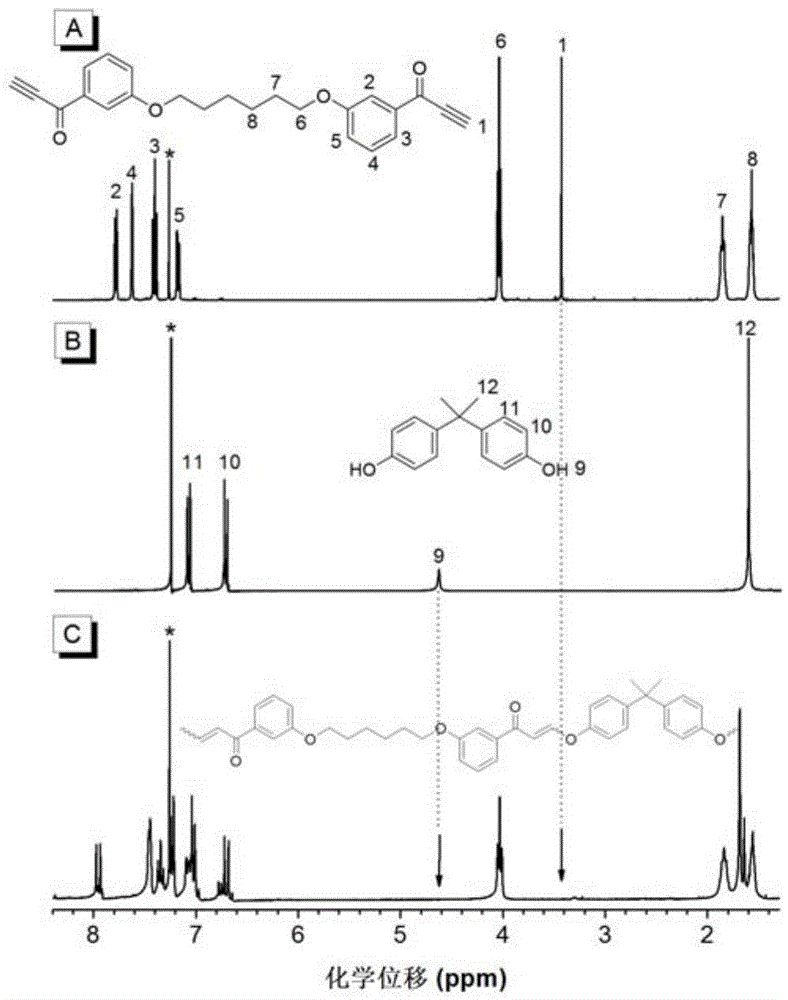

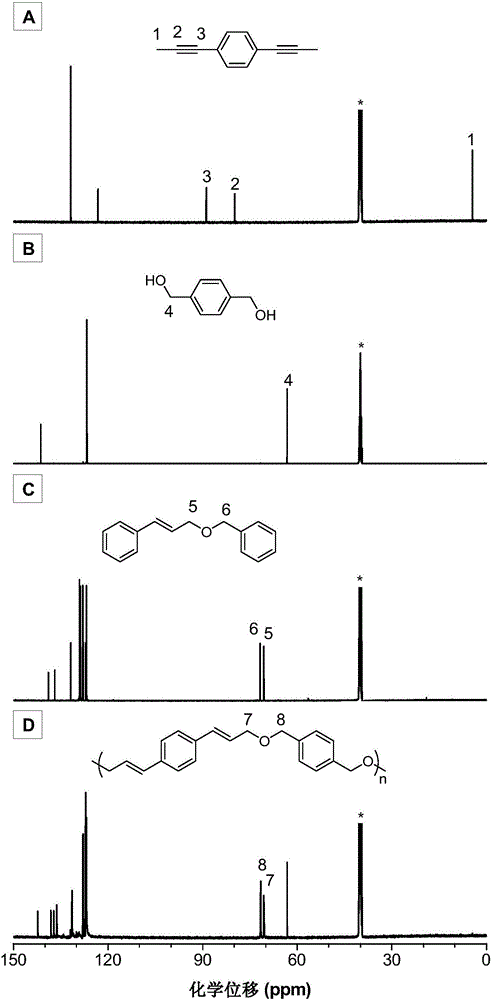

Polyene ether compounds and preparation method thereof

The invention discloses a preparation method of polyene ether compounds. The method includes: organic small-molecule 4-dimethylamino pyridine (DMAP) is used as the catalyst, binary alkynyl compounds and binary hydroxy compounds are mixed with organic solvent, and the polyene ether compounds are obtained by using the click polymerization reaction of alkynyl-hydroxy. The polyene ether compounds comprise an inner unit indicated by formula (I). The polymerization step is showed in the formula (V), wherein n is larger than 1, and R1 and R2 are selected from organic groups. The method has the advantages that water and oxygen do not need to be removed during reaction, polymerization temperature is low, polymerization efficiency is high, and no metal residues exist in products; the prepared polyene ether compounds are high in steric regularity, good in machinability, and high in heat stability, degradability and aggregation-induced emission performance.

Owner:ZHEJIANG UNIV

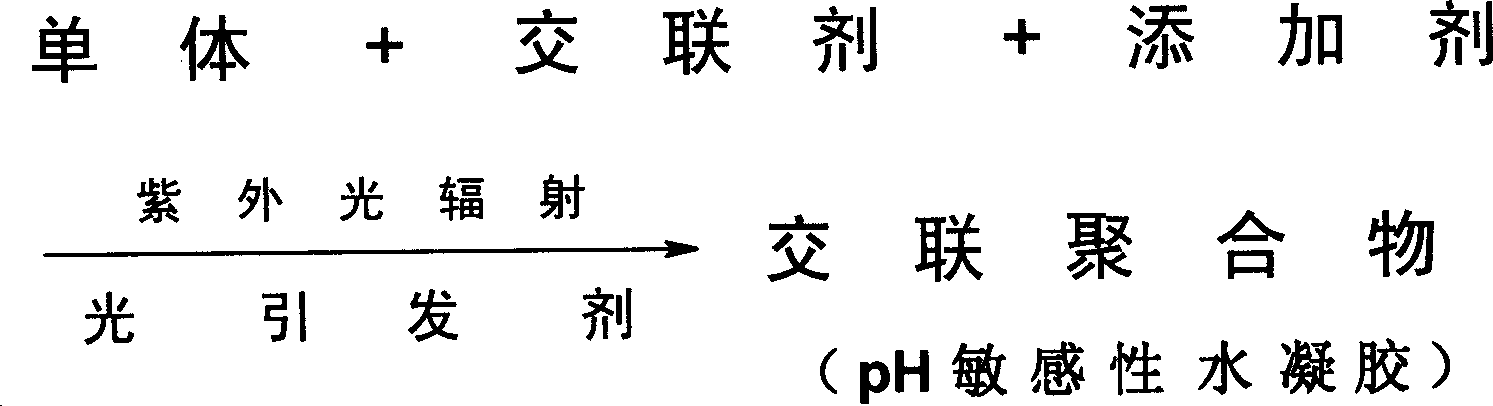

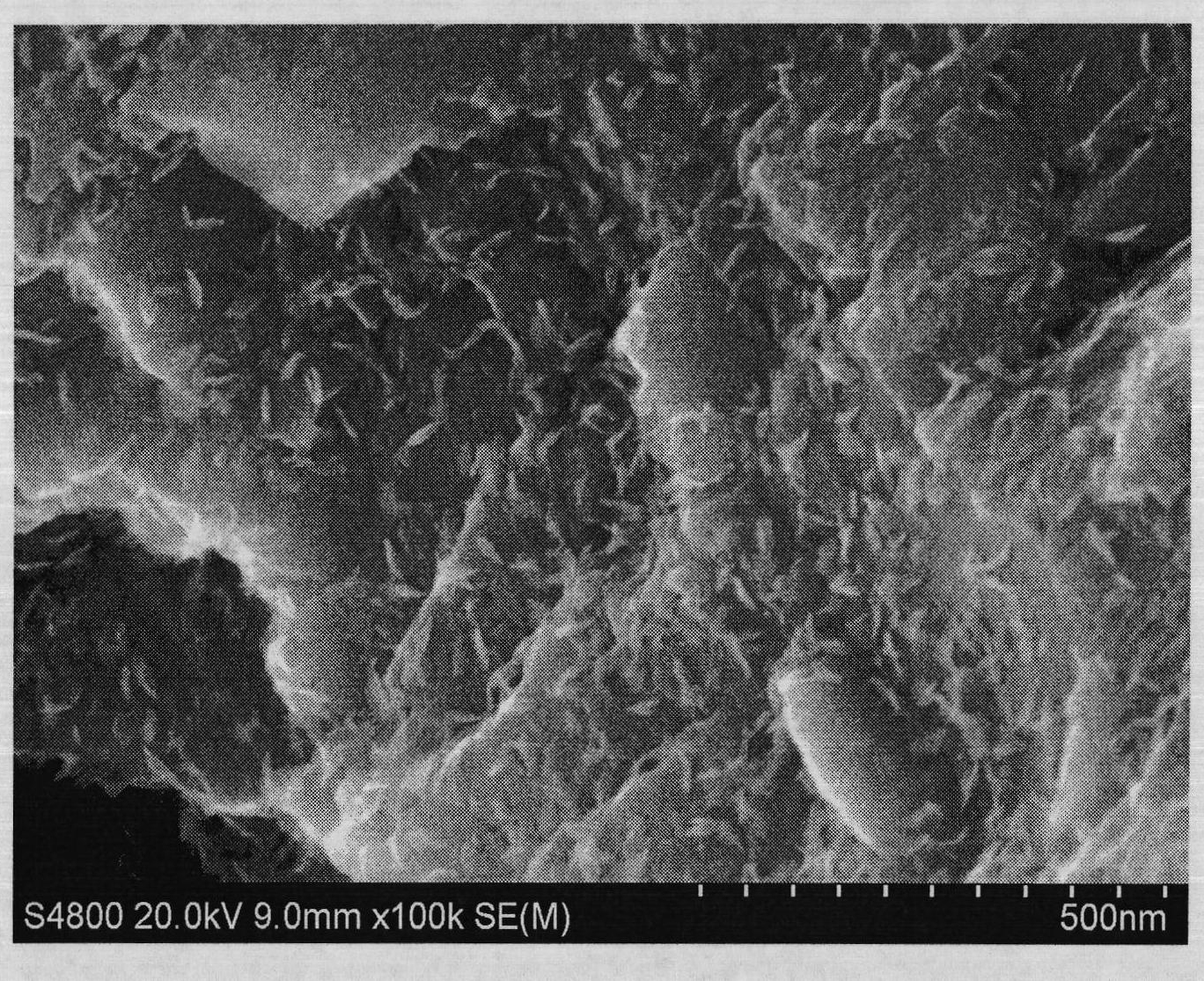

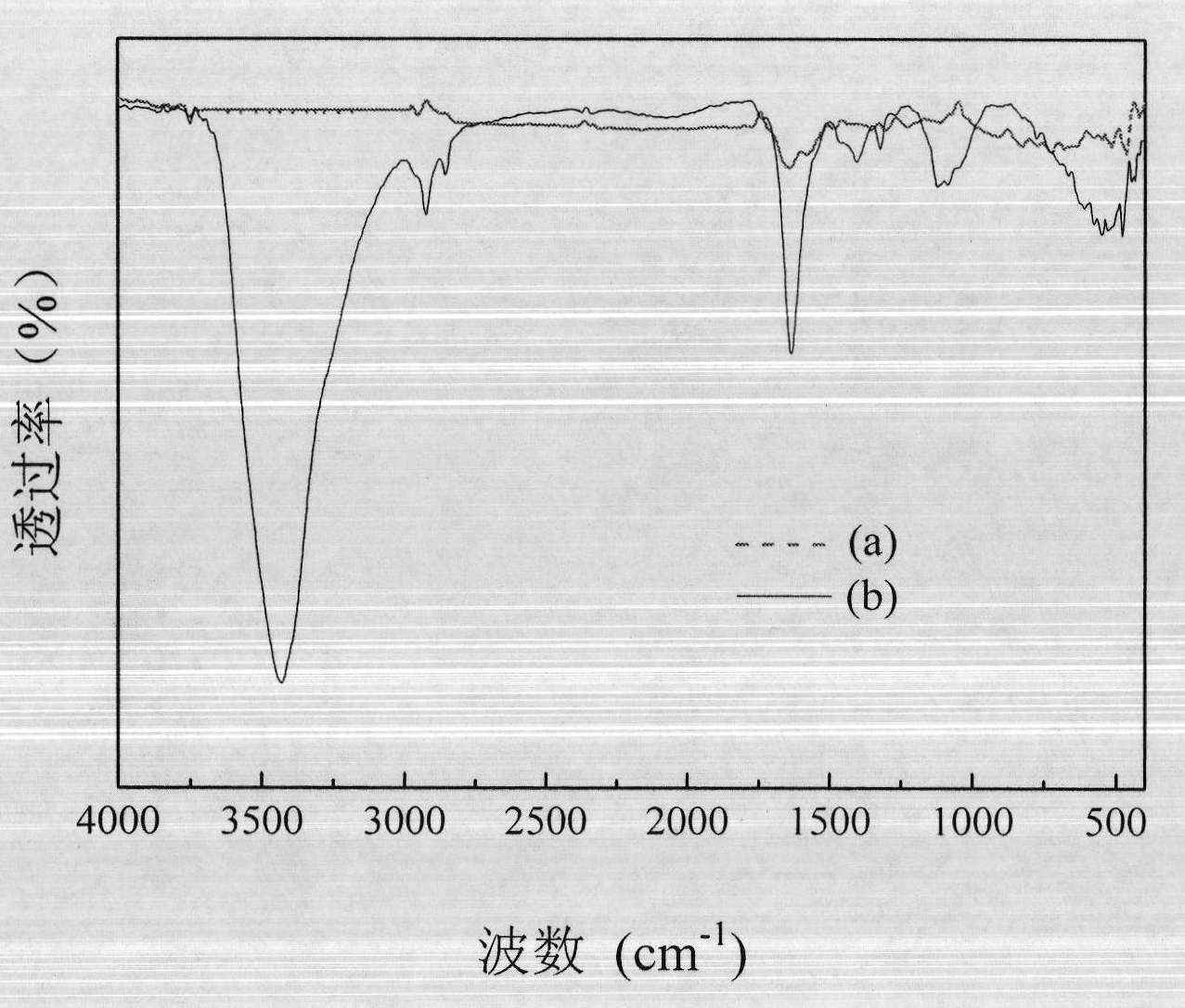

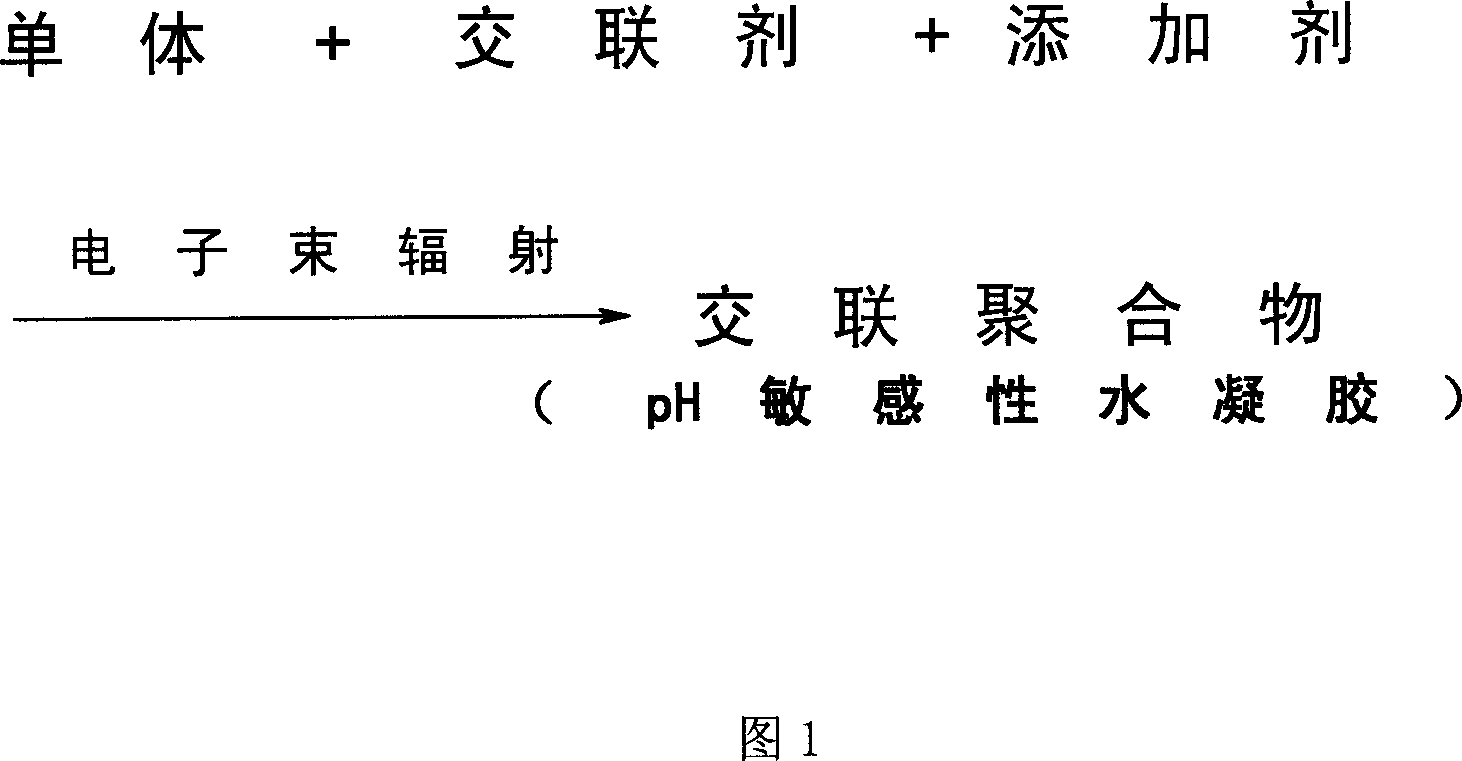

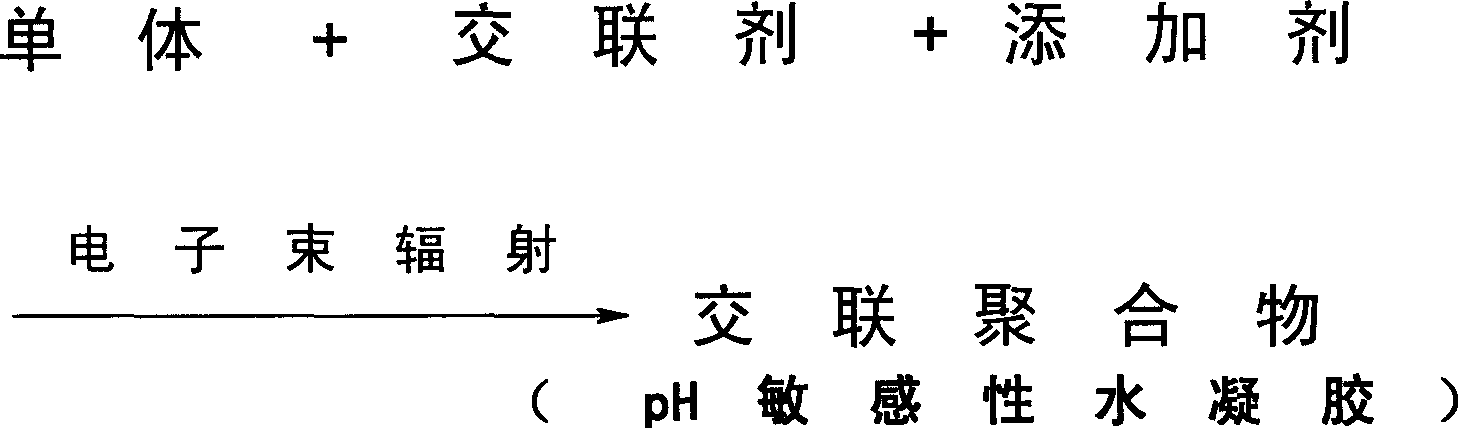

Process of directly synthetizing pH sensitive aquagel polymerized by UV radiation

This invention relates to a method to directly synthesize pH sensitive hydrogel by ultraviolet irradiation polymerization, which is attributed to the technology of preparing pH sensitive hydrogel materials. Monomers, cross-linking reagent, additives and photoinitiators are dissolved in deionized water together at certain mass fractions and the solution is irradiated in ultraviolet light for direct cross-linking polymerization into a cross-linking polymer. The cross-linking polymer is dried and pH sensitive hydrogel is obtained. The swelling ability of the hydrogel in aqueous solution changes with pH value and reaches a maximum at the pH value range of 6~8. By varying the species and content of the additives in raw materials, equilibrium swelling coefficient and mechanical strength of the hydrogel can be adjusted for different applications. This invention has the advantages of simple technique, high polymerization efficiency, open operation at room temperature and ambient pressure, no waste liquid pollution and low cost.

Owner:TSINGHUA UNIV

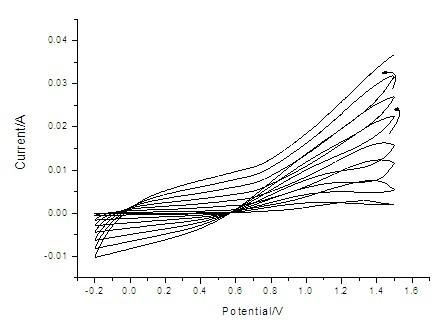

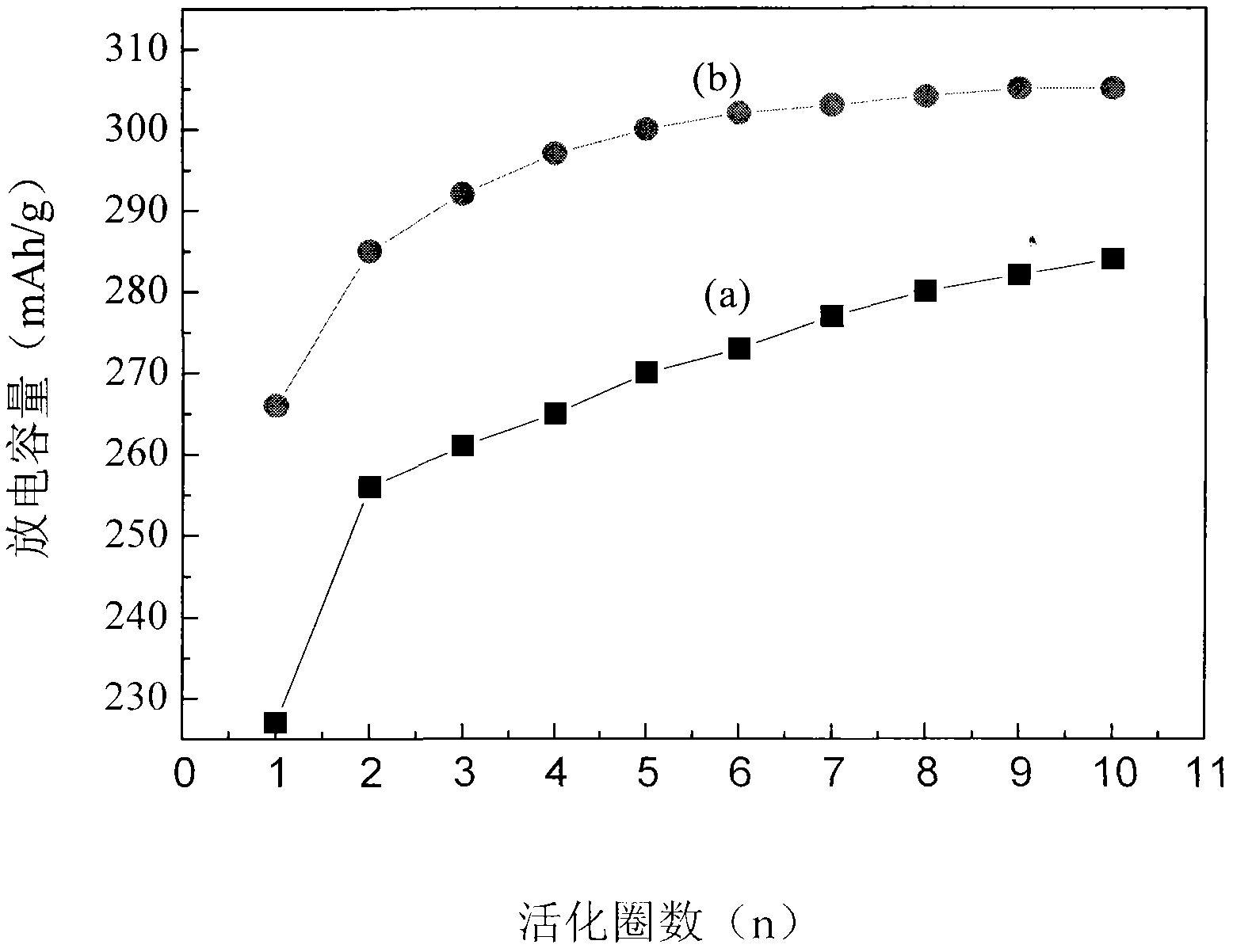

Method for Improving the Electrochemical Performance of Hydrogen Storage Alloy Powder Using Electropolymerized Polyaniline

ActiveCN102274965AEasy to operateReduce manufacturing costCell electrodesElectrophoretic coatingsElectrochemistryCorrosion

The invention relates to a method for improving the electrochemical performance of hydrogen storage alloy powder by utilizing electropolymerization polyaniline, and belongs to the technical field of the surface treatment of hydrogen storage alloy. The method comprises the following steps of: putting hydrogen storage alloy powder of which the granularity is between 100 and 400 meshes into mixed solution containing phenylamine and protonic acid in a certain ratio, and stirring uniformly at a speed of between 50 and 100 revolutions / minute, wherein the mass ratio of the hydrogen storage alloy powder to the mixed solution is 10 / 100-100 / 100; and applying direct-current voltage of between 1 and 2 V for 0.5 to 5 minutes by taking the hydrogen storage alloy powder as an anode and graphite as a cathode, so that the phenylamine performs electro-deposition polymerization reaction on the surface of the hydrogen storage alloy powder to form a polyaniline membrane layer. In the method, a polyanilinewrapped membrane with electrical conductivity and corrosion resistance is formed on surfaces of hydrogen storage alloy powder particles to improve the hydrogen storage capacity, high-multiplying power discharging performance and cyclic stability of the hydrogen storage alloy. The method has the characteristics of simplicity of operation, low production cost, obvious improvement effect and the like.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD +1

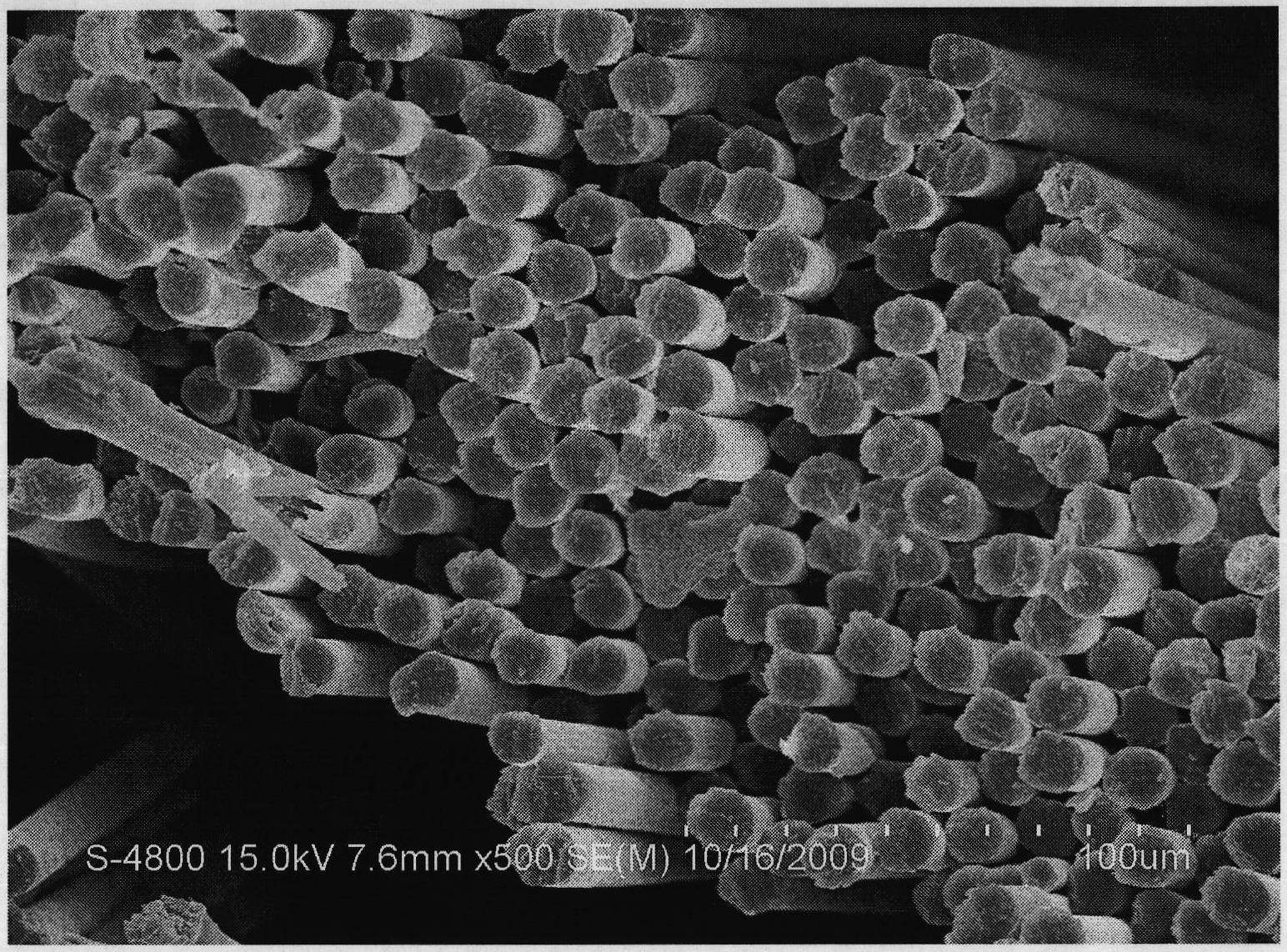

Preparation of nano composite gel with organic/inorganic hybrid microspheres as crosslinking points

ActiveCN101524630AGood mechanical propertiesEvenly arrangedMicroballoon preparationMicrocapsule preparationMicrosphereAqueous electrolyte

The invention relates to a preparation of nano composite gel with organic / inorganic hybrid microspheres as cross linking points. The preparation comprises the following steps: (1) dissolving clay in 0-0.5mol / L aqueous electrolyte solution, ultrasonically treating after fully stirring, dropwise adding to the clay solution during the ultrasound process, heating to 70-80 DEG C after further ultrasonic treatment for a period, polymerizing in nitrogen atmosphere for 6-8 hours to obtain crosslinking point hybrid microsphere emulsion; and (2) mixing 20g of the crosslinking point hybrid microsphere emulsion with 5-10g of a water soluble monomer, 0.01-0.05g of a water soluble initiator and 8-24mul of a catalyst to obtain prepolymerized solution, polymerizing the prepolymerized solution at the room temperature of 20-30 DEG C for 30-50 hours to obtain the nano composite gel. The preparation has the advantages of simple process and high polymerization rate, the obtained macromolecular microsphere composite gel has excellent mechanical properties, and the method has large raw material range and great application value.

Owner:DONGHUA UNIV

Electronic beam radiopolymerization process of directly synthesizing temperature sensitive hydrogel

The present invention is electronic beam radiopolymerization process of synthesizing temperature sensitive hydrogel directly, and belongs to the field of temperature sensitive hydrogel preparing technology. Material monomer, cross-linking agent and additive in the weight ratio of 75-98.5 to 0.1-1 to 1-10 are dissolved in deionized water and polymerized through electron radiation to form cross-linked polymer. The cross-linked polymer is then extracted in a Soxhlet extractor with boiled deionized water for 24 hr and dried in a vacuum oven to obtain the temperature sensitive hydrogel. The temperature sensitive hydrogel may be used in medicine controlled releasing system, memory element switch, artificial muscle, chemical separation and other field. The present invention has the features of simple technological process, high polymerization efficiency, less pollution, low cost, normal temperature operation, etc.

Owner:TSINGHUA UNIV

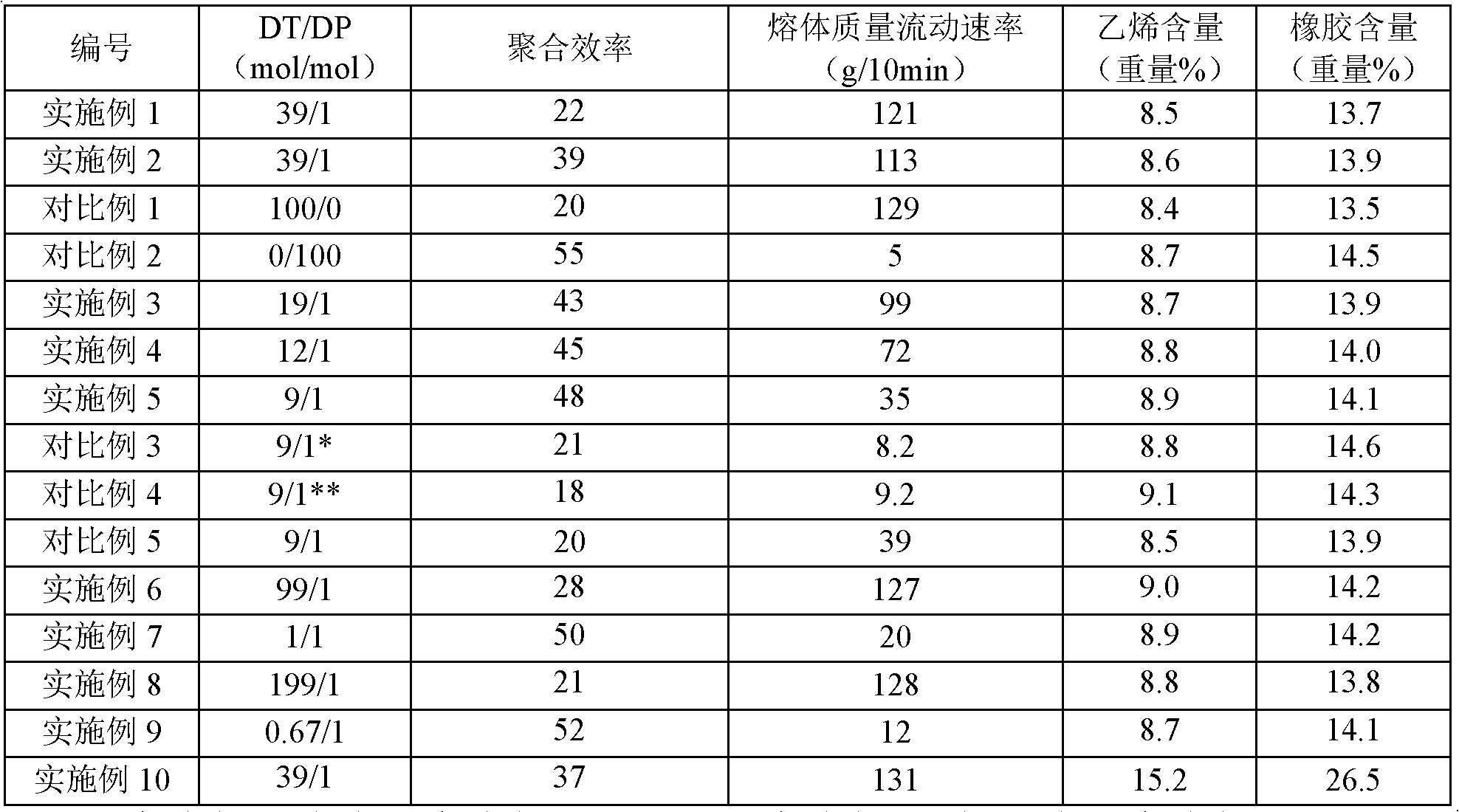

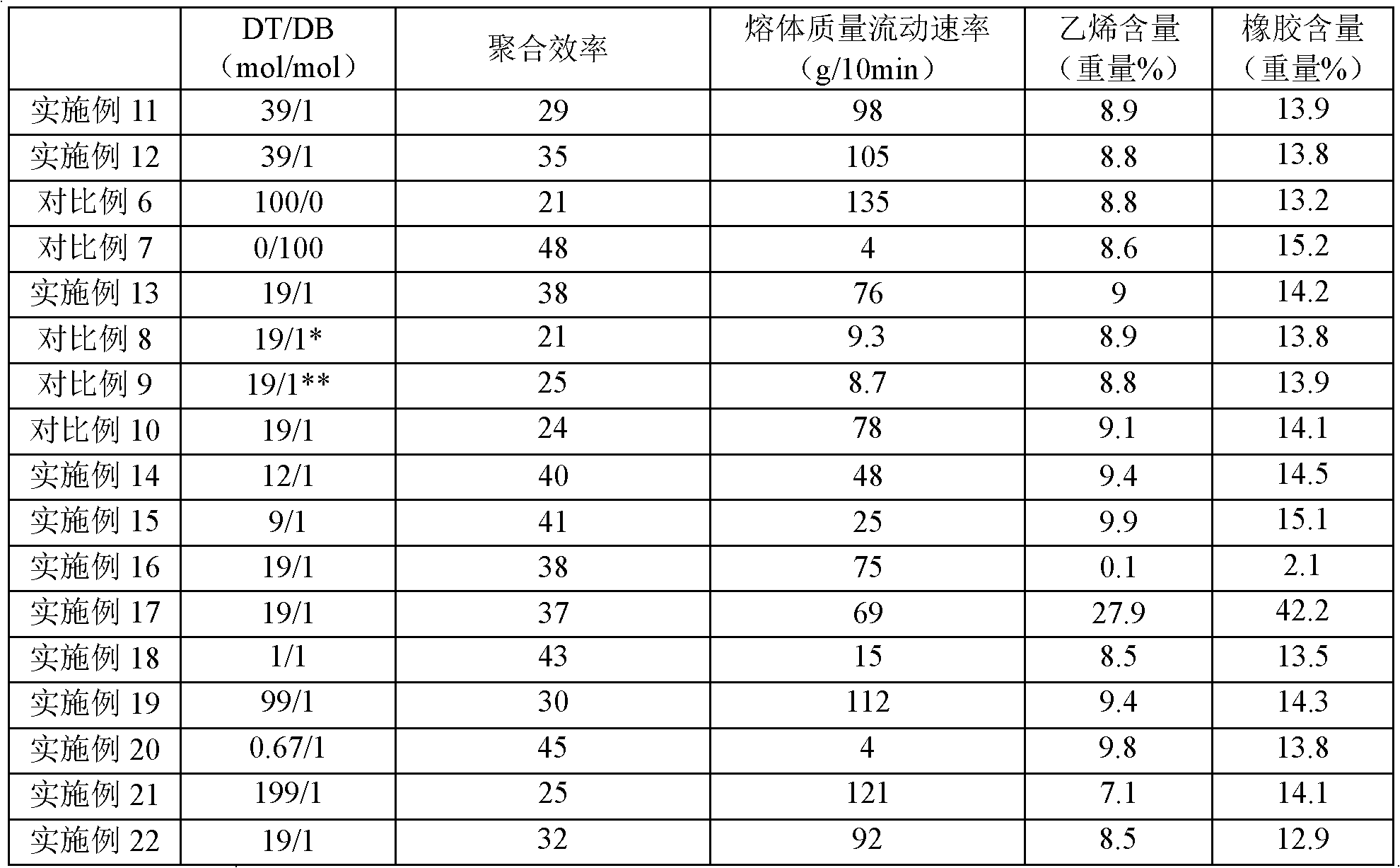

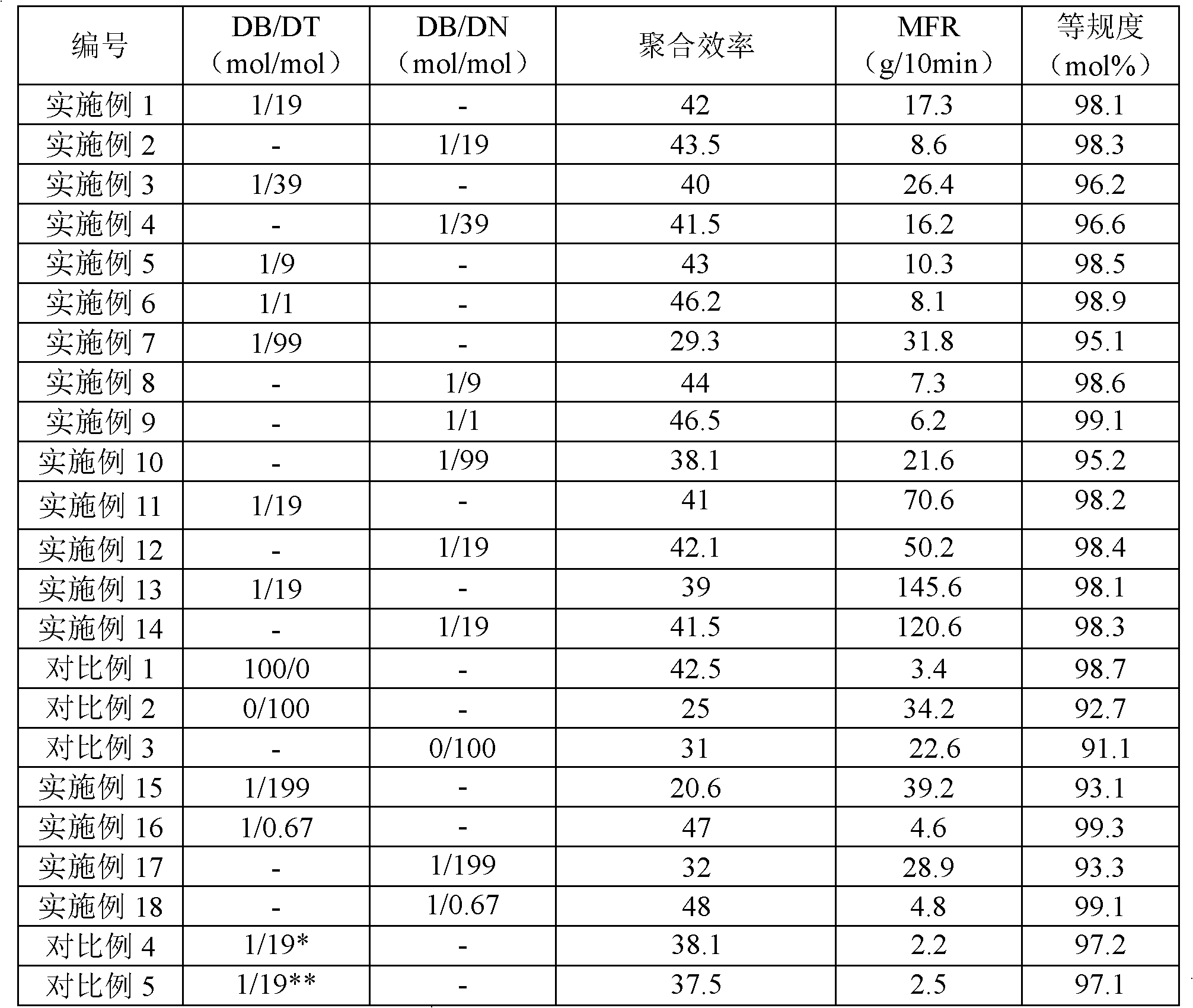

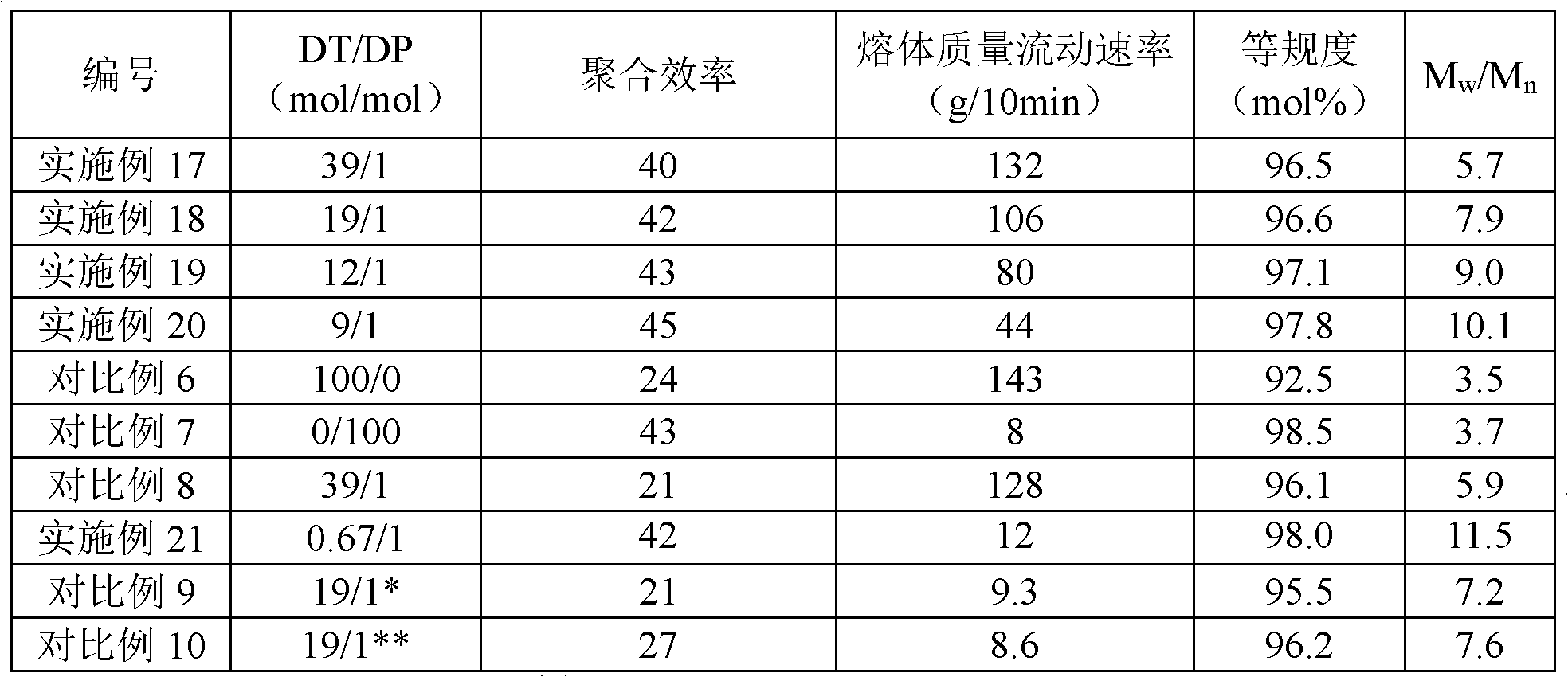

Propylene polymer and preparation method thereof

The invention provides a propylene polymer and a preparation method thereof. The method provided by the invention comprises the following steps: under first olefin gas-phase polymerization conditions, performing first contact reaction on a first part of propylene and a first part of hydrogen gas, and removing unreacted monomers and hydrogen gas from the mixture obtained through the first contact reaction, thus obtaining a first contact reaction product; and under second olefin gas-phase polymerization conditions, performing second contact reaction on the first contact reaction product, a second part of propylene, a second part of hydrogen gas and a comonomer, thus obtaining the propylene polymer, wherein an olefinic polymerization catalyst system contains an external electron donor compound, the external electron donor compound contains a first external electron donor compound selected from tetraethoxy silane and n-propyl trimethoxy silane and a second external electron donor compound selected from diisopropyl dimethoxy silane and diisobutyl dimethoxy silane. The method provided by the invention has favorable hydrogen regulation sensitivity and high polymerization efficiency.

Owner:CHINA PETROLEUM & CHEM CORP

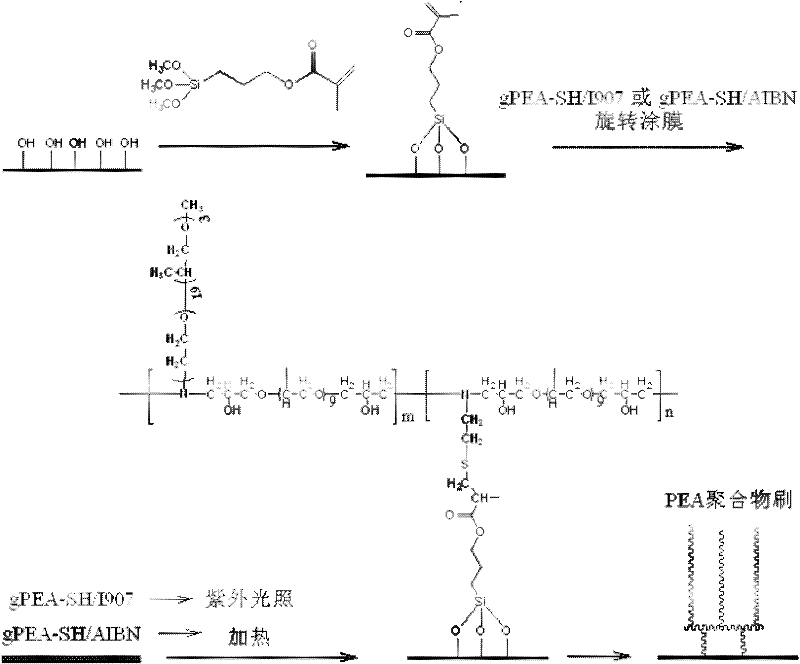

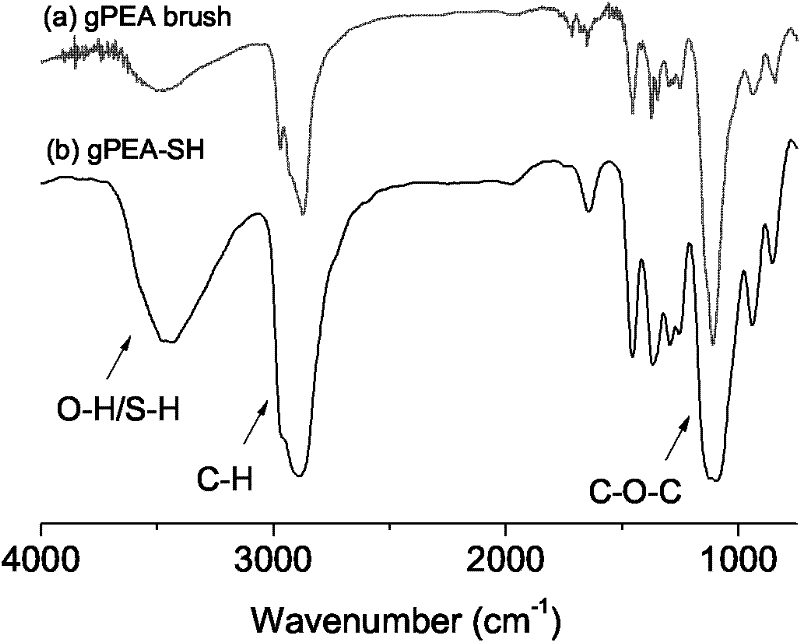

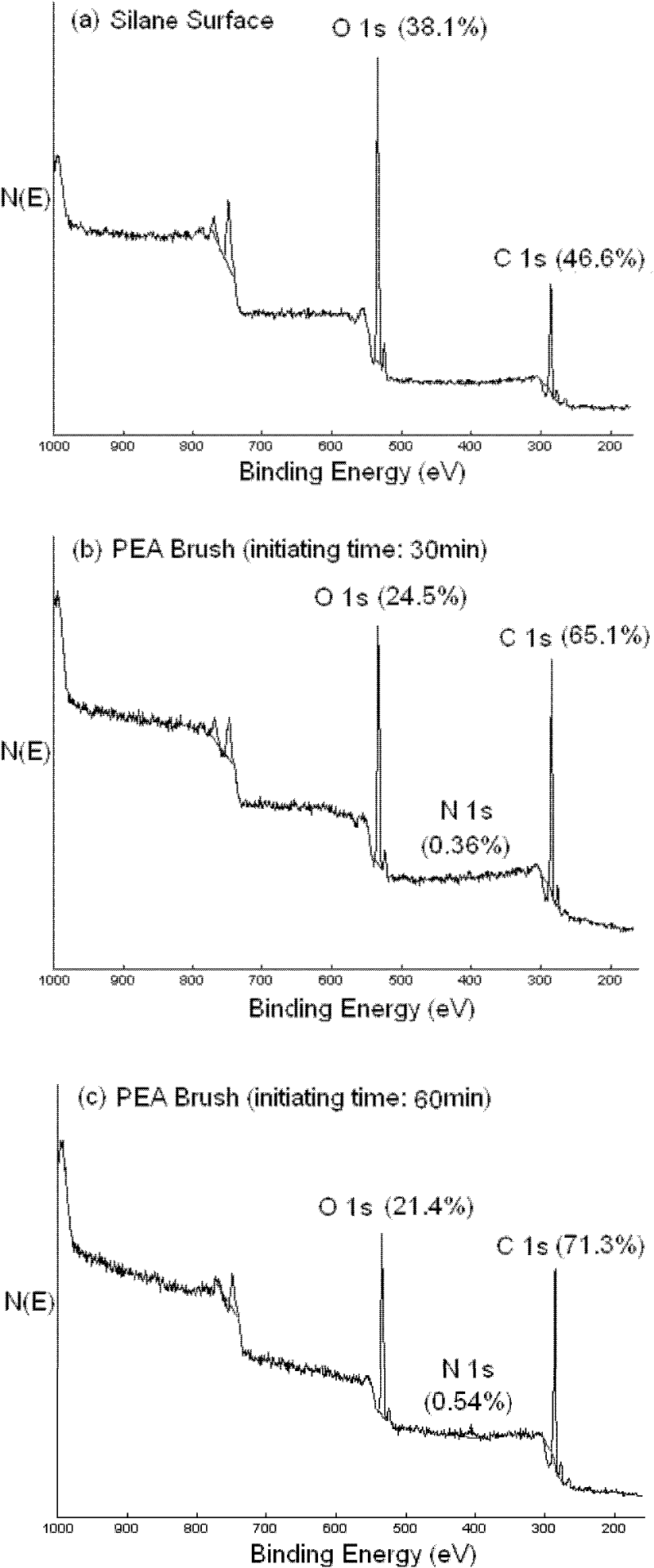

Sulfur-alkene click chemistry-based method for preparing stimulation responsive polyether amine macromolecular brush

The invention discloses a sulfur-alkene click chemistry-based method for preparing a stimulation responsive polyether amine macromolecular brush in the technical field of macromolecular chemistry. The method comprises the following steps of: reacting single side amino-terminated L100, polyoxypropylene and mercaptoethylamine to prepare a mercapto-containing stimulation responsive graft polyether amine gPEA-SH macromolecular polymer, initiating sulfur-alkene click chemistry reaction of double bonds and mercapto through an initiator, and fixing the stimulation responsive graft polyether amine gPEA-SH macromolecular polymer on an alkenyl silane coupler self-assembled substrate containing double bonds to realize the preparation of the stimulation responsive polyether amine macromolecular brush. The method is simple in operation, the polyether amine macromolecular brush with double response of pH and temperature can be effectively prepared in large scale, and the potential application of the stimulation responsive polymer brush is expanded.

Owner:SHANGHAI JIAO TONG UNIV

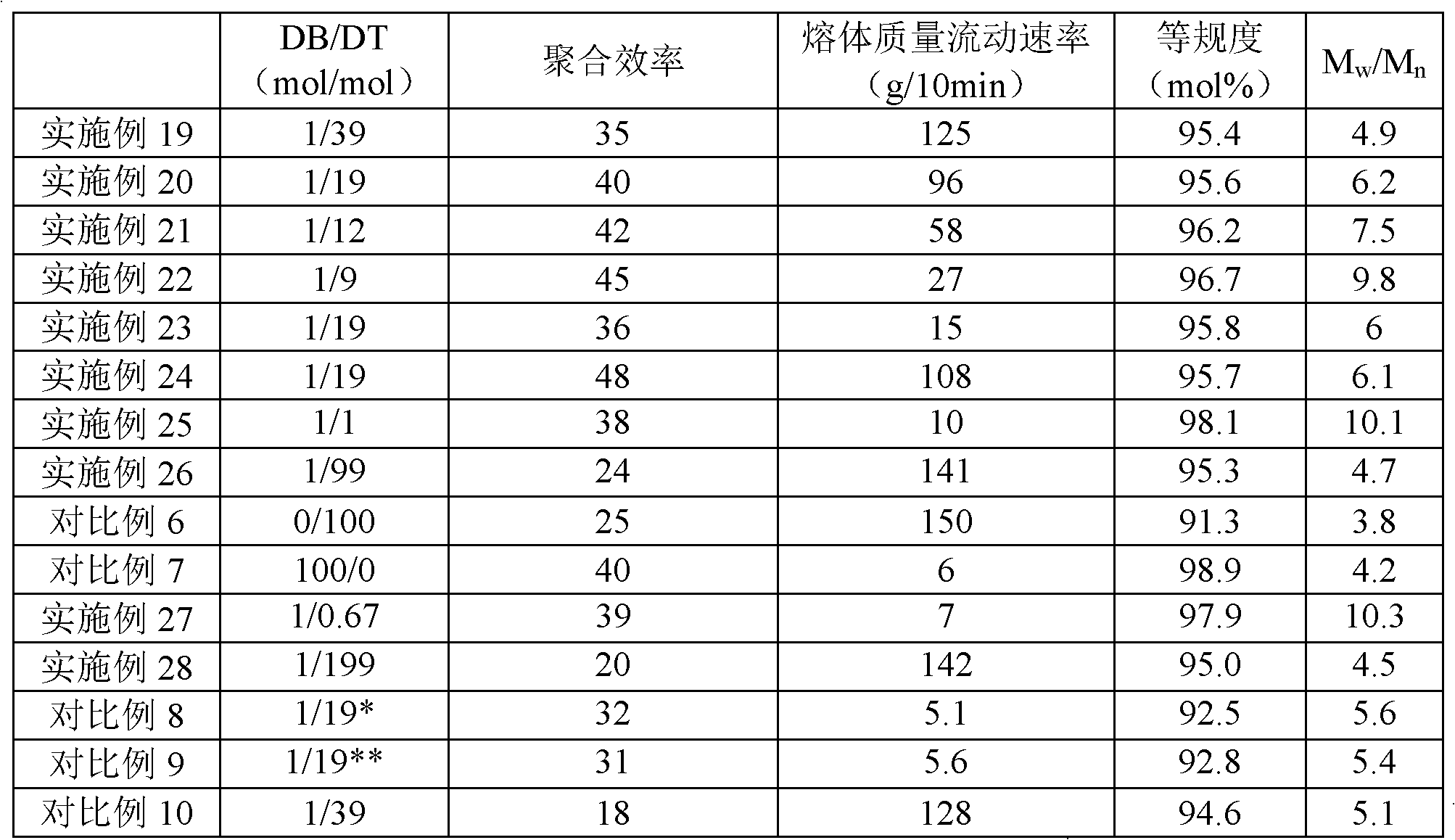

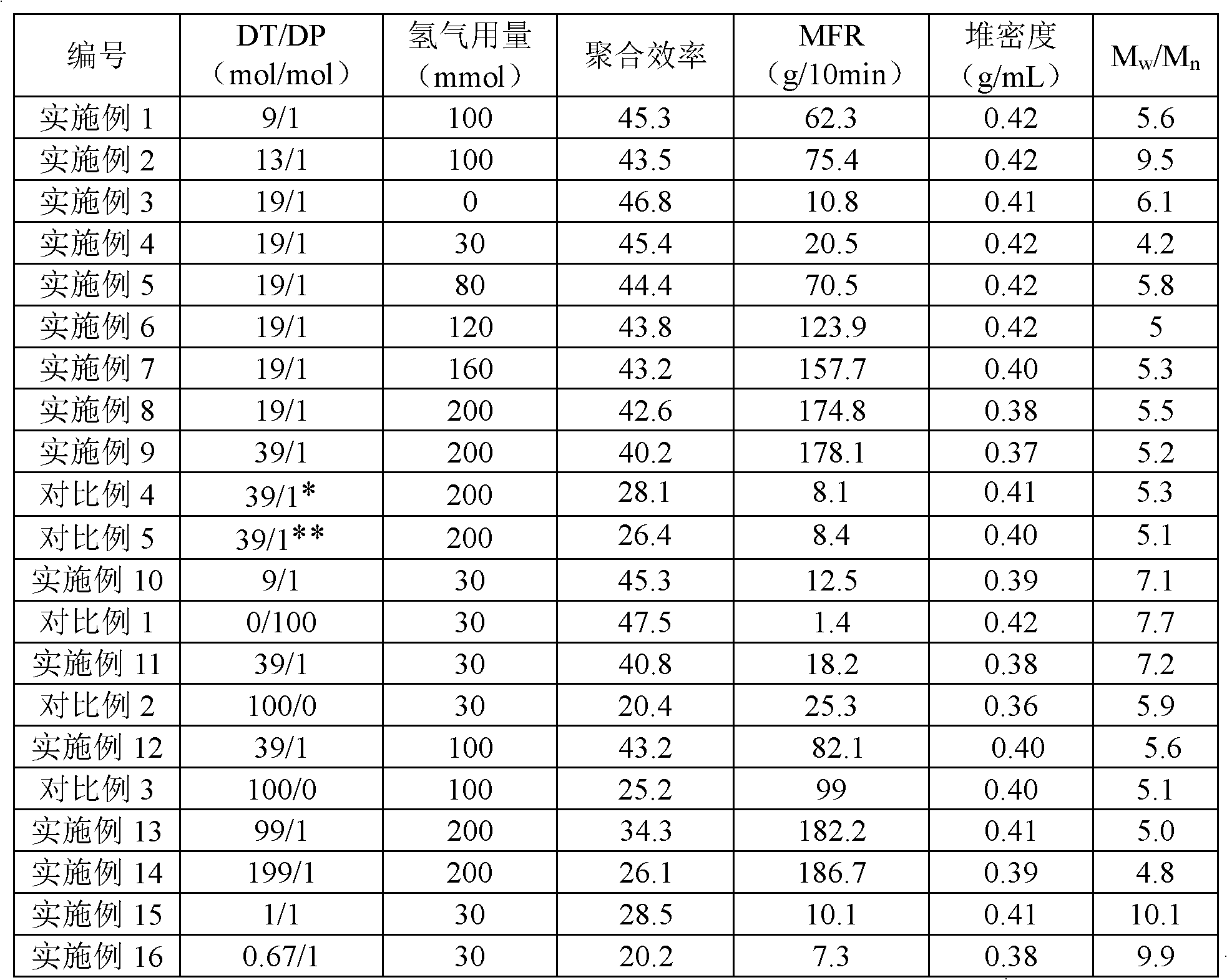

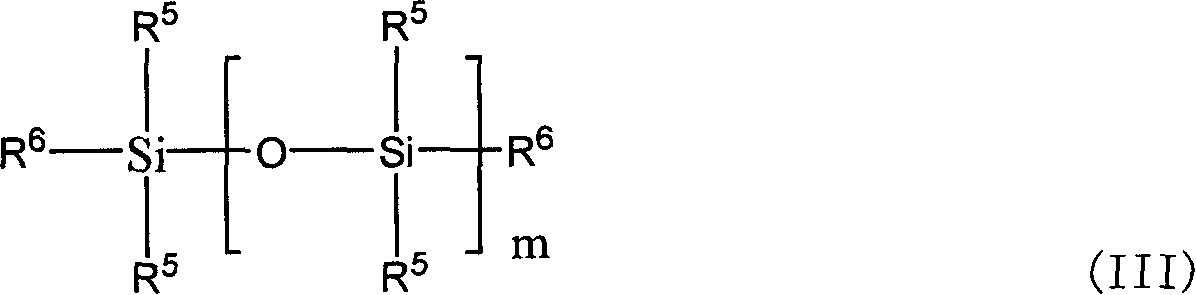

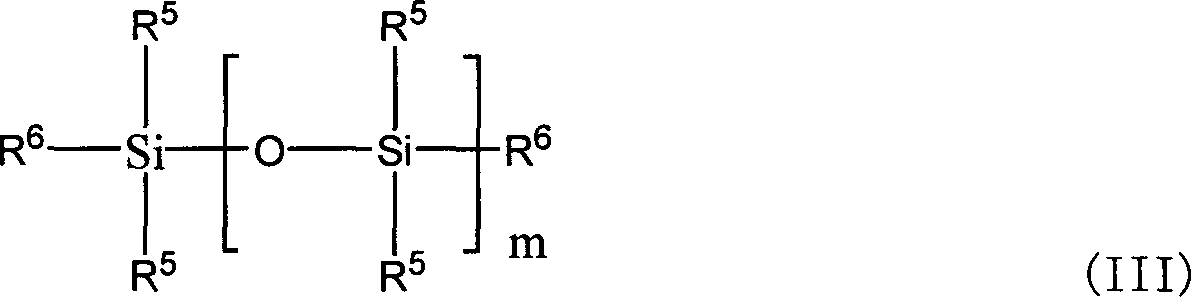

Olefin polymer and preparation method thereof

The invention relates to an olefin polymer and a preparation method thereof. According to the method, an olefin polymerization catalyst system comes into contact with one or more olefins under the condition of olefin polymerization, wherein the olefin polymerization catalyst system contains a solid component, an external electron donor compound and an organic aluminum compound, the solid component contains titanium, magnesium and an internal electron donor compound, the external electron donor compound contains a first external electron donor compound and a second external electron donor compound, the first external electron donor compound is diisobutyldimethoxysilane and the second external electron donor compound is n-propyl trimethoxysilane and / or tetraethoxy-silicone. The olefin polymerization method provided by the invention has excellent hydrogen regulation sensibility and high polymerization efficiency and is applicable to occasions of preparation of propene polymers in a gaseous polymerization way.

Owner:CHINA PETROLEUM & CHEM CORP

Olefin polymer and preparation method thereof

The invention relates to an olefin polymer and a preparation method thereof. The method comprises the following steps of contacting the olefin polymerization catalyst system with one or more olefin under olefin polymerization condition, wherein the olefin polymerization catalyst system comprises solid component, external electron donor compound and organo-aluminum compound, the solid component comprises titanium, magnesium and internal electron donor compound, and the external electron donor compound is diisopropyl dimethoxy silane and tetraethoxysilane. The olefin polymerization method not only has good hydrogen regulation sensibility, but also has high polymerization efficiency, and is especially suitable for preparing propene polymer through a vapor phase polymerization manner.

Owner:CHINA PETROLEUM & CHEM CORP

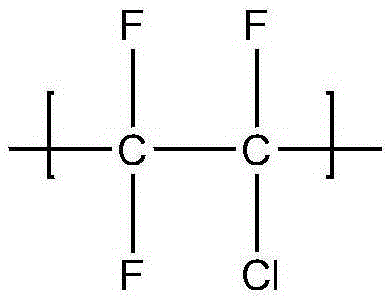

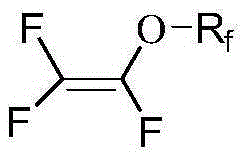

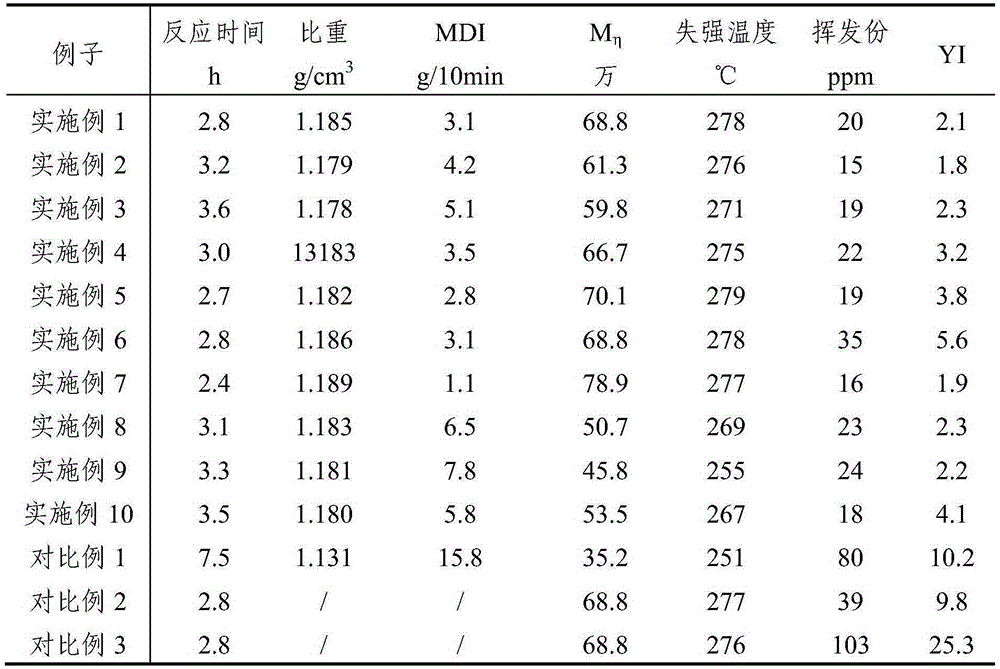

Polychlorotrifluoroethylene resin and preparation method thereof

ActiveCN106832072ALarge mass transfer areaQuick responseAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to a preparation method of polychlorotrifluoroethylene resin, which adopts a horizontal reactor with an aspect ratio ≥ 1.0 as polymerization equipment; uses chlorotrifluoroethylene monomer or chlorotrifluoroethylene monomer and other comonomers The polymerization reaction occurs under constant pressure conditions, which improves the reaction speed and polymerization efficiency; the semi-mechanical and semi-chemical coagulation method is used to effectively separate the impurities in the emulsion, and the residual unstable groups are removed through wet heat treatment, effectively reducing the volatilization of the product parts, greatly improving the appearance of the product. M can be obtained by the method of the present invention η PCTFE and its copolymerization products exceeding 500,000, volatile matter less than 0.01%, strength loss temperature higher than 260°C, yellowness index (YI) less than 10.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

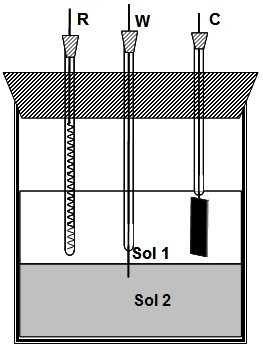

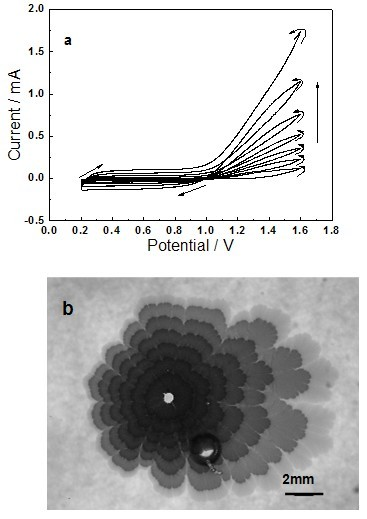

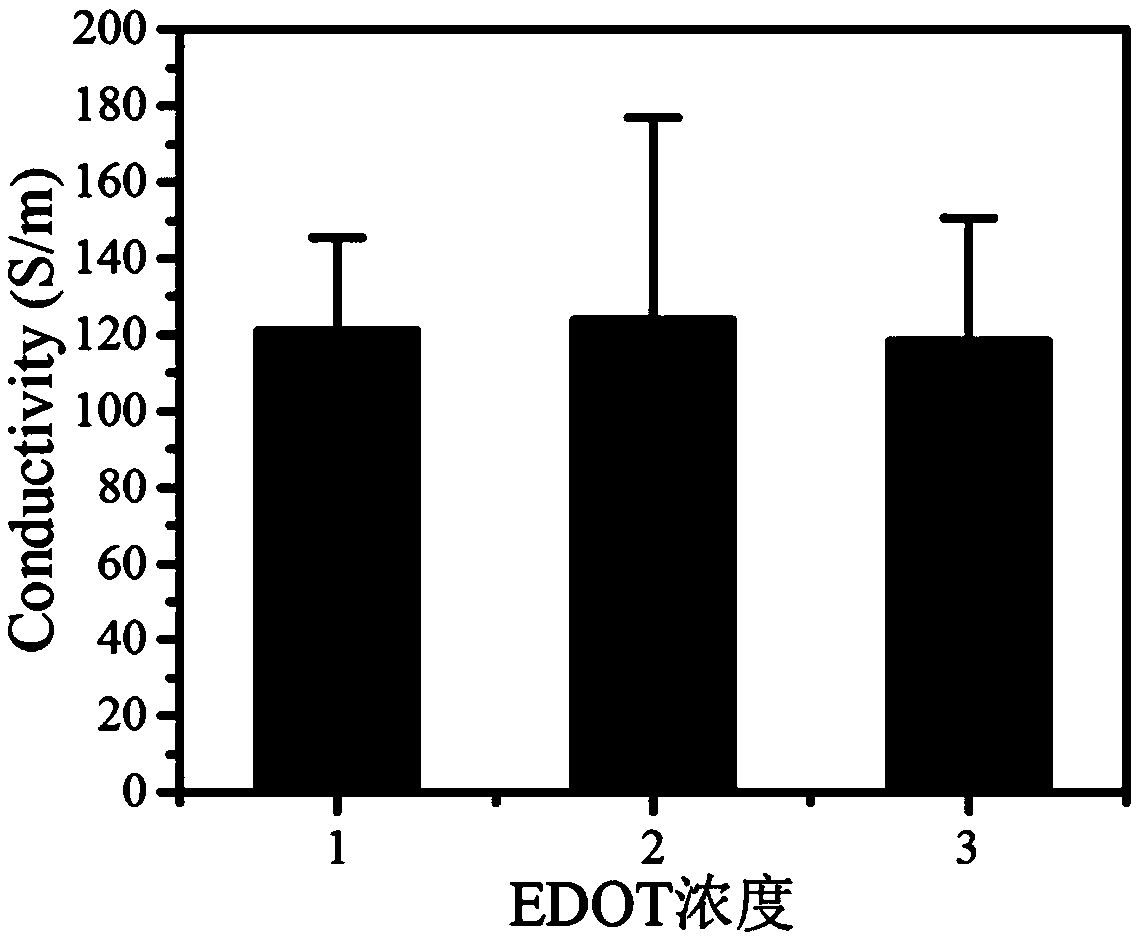

Conductive poly 3,4-ethylene dioxy thiophene film and preparation method thereof

InactiveCN102020832AGood electrical conductivityHigh polymerization efficiencyMaterial nanotechnologyElectrolysis componentsAuxiliary electrodeChemistry

The invention discloses a conductive poly 3,4-ethylene dioxy thiophene film and a preparation method thereof. The method is characterized by comprising the following steps: resolving a poly 3,4-ethylene dioxy thiophene monomer in an organic solvent, resolving supporting electrolyte into water, and preparing into solutions; transferring the two solutions stepwise into an reactor, thus forming a liquid-liquid interface; inserting a working electrode in the liquid-liquid interface; placing an auxiliary electrode and a reference electrode in the supporting electrolyte solution; and carrying out electrochemical polymerization by utilizing an electrochemistry means. The invention has the advantages that the prepared poly 3,4-ethylene dioxy thiophene film has good conductivity, and the topography has obvious dual character. One side, which is close to the water phase, of the conductive poly 3,4-ethylene dioxy thiophene film is a nano smooth film; the other side, which is close to the oil phase, of the conductive poly 3,4-ethylene dioxy thiophene film is a micrometer ordered cellular porous film; and a high reaction area is revealed, and the conductive poly 3,4-ethylene dioxy thiophene film can be used for positive electrode materials and negative electrode materials of super capacitors and batteries, electromagnetic shielding materials and the like.

Owner:WUHAN UNIV

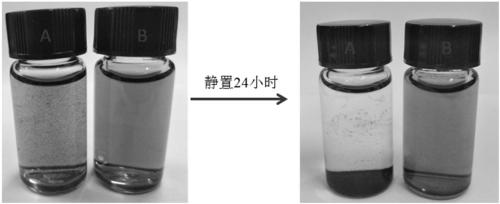

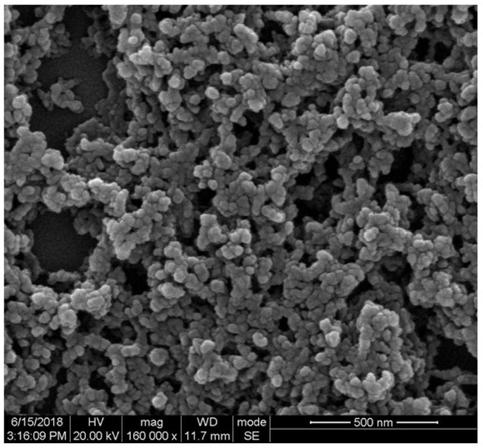

Preparation method of electric-conductive macromolecule polymer nanoparticles with good water phase dispersibility

InactiveCN109251326AImprove electrical conductivityEnhanced Nano ReinforcementElectrically conductivePolymer chemistry

The invention discloses a preparation method of electric-conductive macromolecule polymer nanoparticles with good water phase dispersibility. According to the method, an electric-conductive macromolecule monomer is dissolved in an organic solvent while a persulfate aqueous solution and a ferric salt are added to synergistically oxidize and polymerize the electric-conductive macromolecule monomer to obtain the electric-conductive macromolecule polymer nanoparticles. According to the present invention, the prepared electric-conductive macromolecule polymer nanoparticles can be uniformly and stably dispersed in an aqueous solution for a long time, and has excellent electrical conductivity.

Owner:SOUTHWEST JIAOTONG UNIV

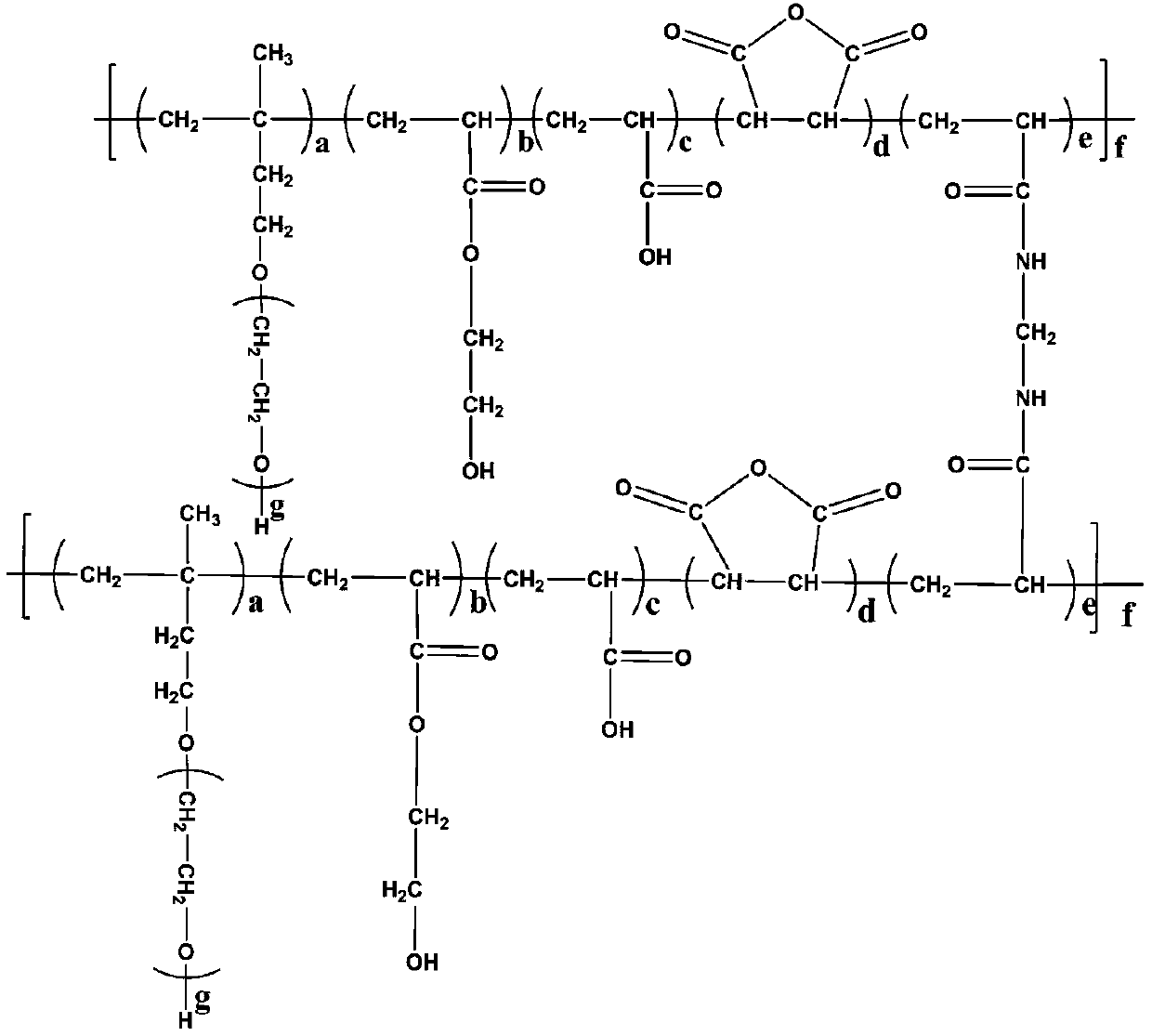

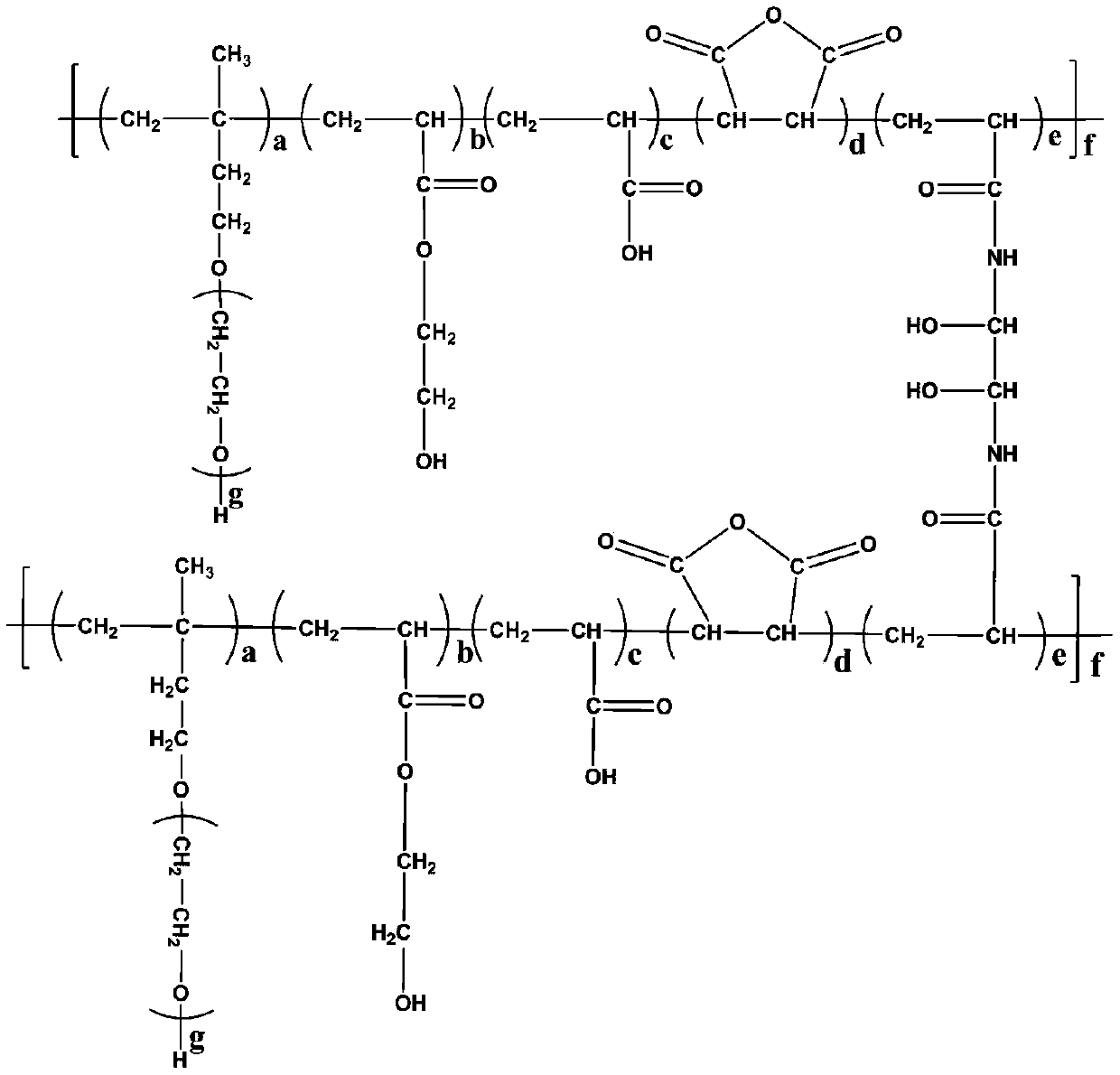

Electronic beam radiopolymerization process of directly synthesizing pH sensitive polymer hydrogel

The present invention is electronic beam radiopolymerization process of synthesizing pH sensitive hydrogel directly, and belongs to the field of pH sensitive hydrogel preparing technology. Material monomer, cross-linking agent and additive in the weight ratio of 75-99.7 to 0.1- 25 to 0.1-10 are dissolved in deionized water and polymerized through electron radiation to form cross-linked polymer. The cross-linked polymer is then extracted in a Soxhlet extractor with boiled deionized water for 24 hr and dried in a vacuum oven to obtain the pH sensitive hydrogel. The present invention has the features of low power consumption, simple technological process, high polymerization efficiency, no waste water pollution, low cost, normal temperature and normal pressure operation, etc.

Owner:TSINGHUA UNIV

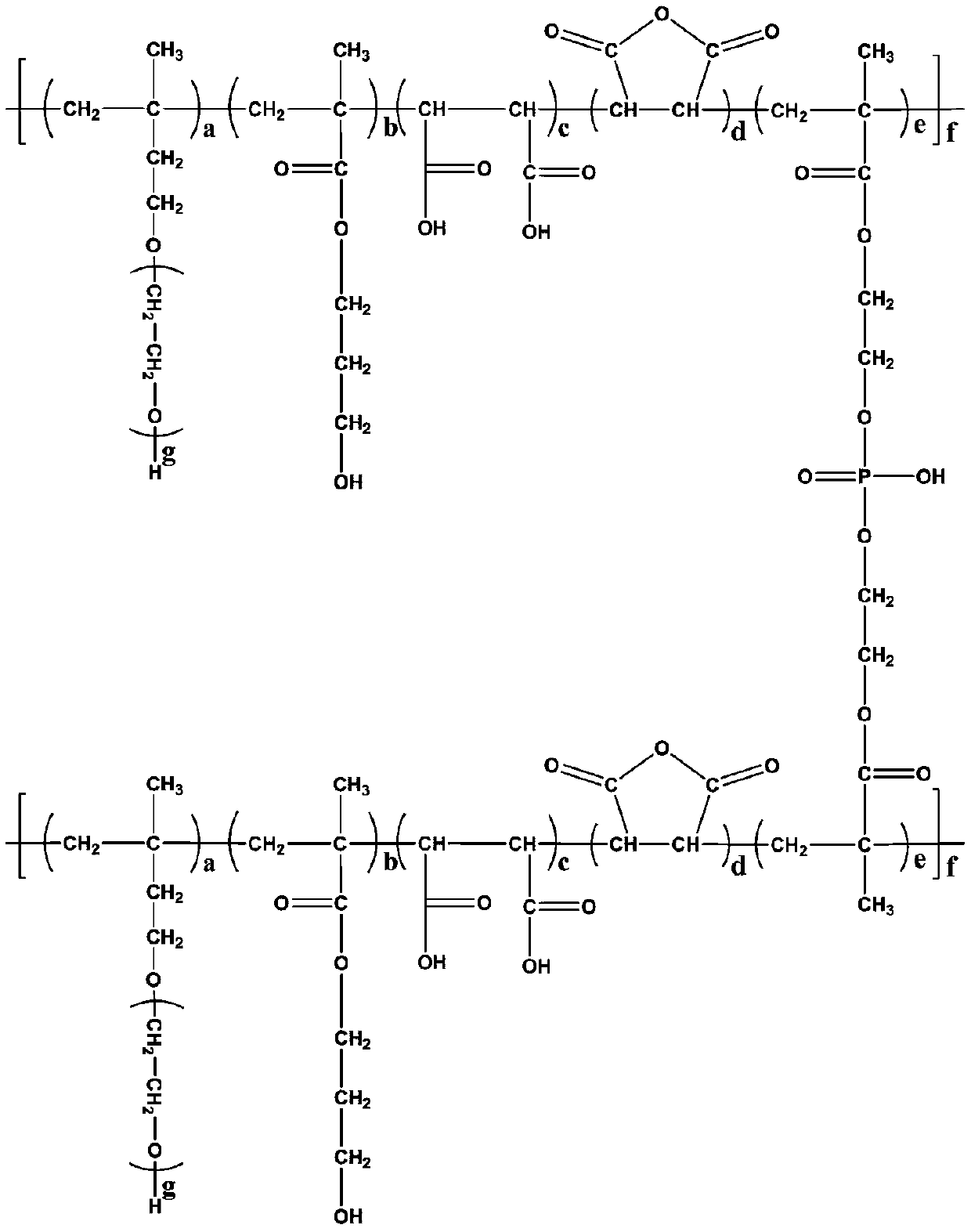

Viscosity reduction type polycarboxylate superplasticizer with microcrosslinking structure and preparation method of viscosity reduction type polycarboxylate superplasticizer

ActiveCN110790872AImprove molecular structureIncreasing the thicknessPolymer scienceSuperplasticizer

The invention discloses a viscosity reduction type polycarboxylate superplasticizer with a microcrosslinking structure. The viscosity reduction type polycarboxylate superplasticizer is prepared from unsaturated acids, unsaturated anhydride, isopentene polyoxyethylene ether, a crosslinking agent and a reactive cosolvent as polymerization raw materials through free radical pauperization under actions of an initiator and chain transfer, components and structures take mutual synergetic effects into play, and compared with a viscosity reduction type polycarboxylate superplasticizer synthesized in the prior art, the viscosity reduction type polycarboxylate superplasticizer has an excellent viscosity reduction effect and has collapse prevention and regulation and control on early strength functions as well; meanwhile, due to introduction of the structure, the thickness of an adsorption layer on the surface of cement granules can be increased, the cement granule surface covering rate can be increased, the concentration of the polycarboxylate superplasticizer retained in a cement pore liquid can be reduced, surface activation performance of the polycarboxylate superplasticizer can be enhanced, and a good viscosity reduction effect can be achieved. Due to adoption of the reactive cosolvent, the intermiscibility of monomers can be effectively improved, and the polymerization efficiency ofa polymer and structure arrangement of effective molecules can be improved. Due to adoption of a bifunctionality crosslinking agent in the polycarboxylate superplasticizer, the molecular structure ofthe polycarboxylate superplasticizer can be improved, and the viscosity reduction performance of the polycarboxylate superplasticizer can be improved.

Owner:CHINA WEST CONSTR GRP +2

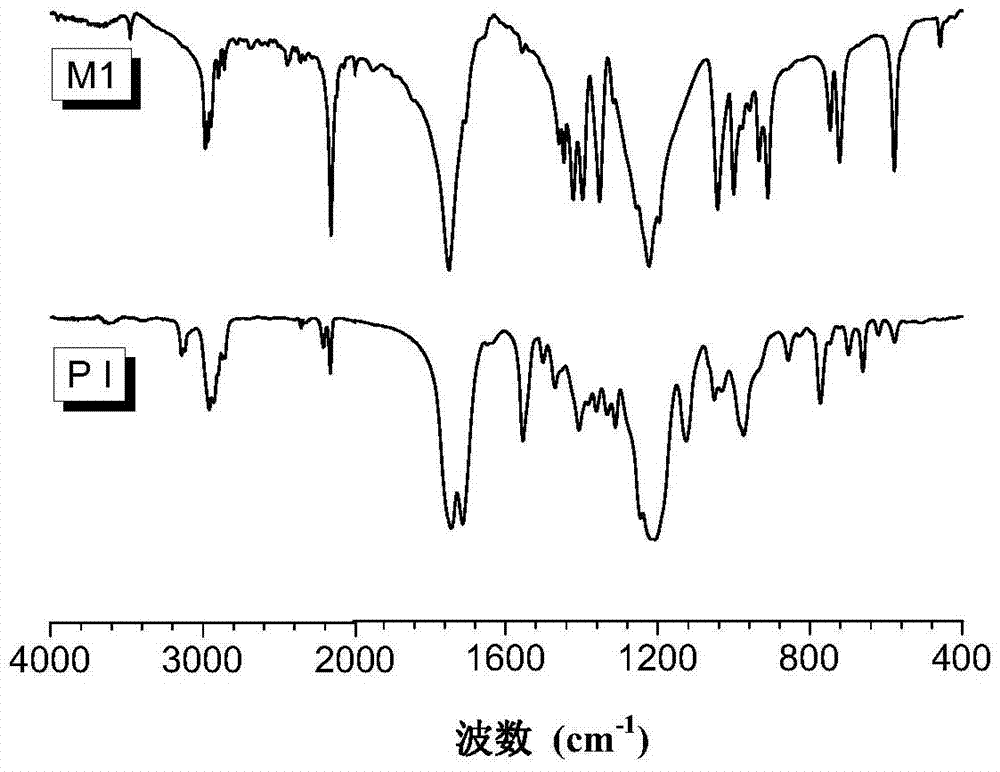

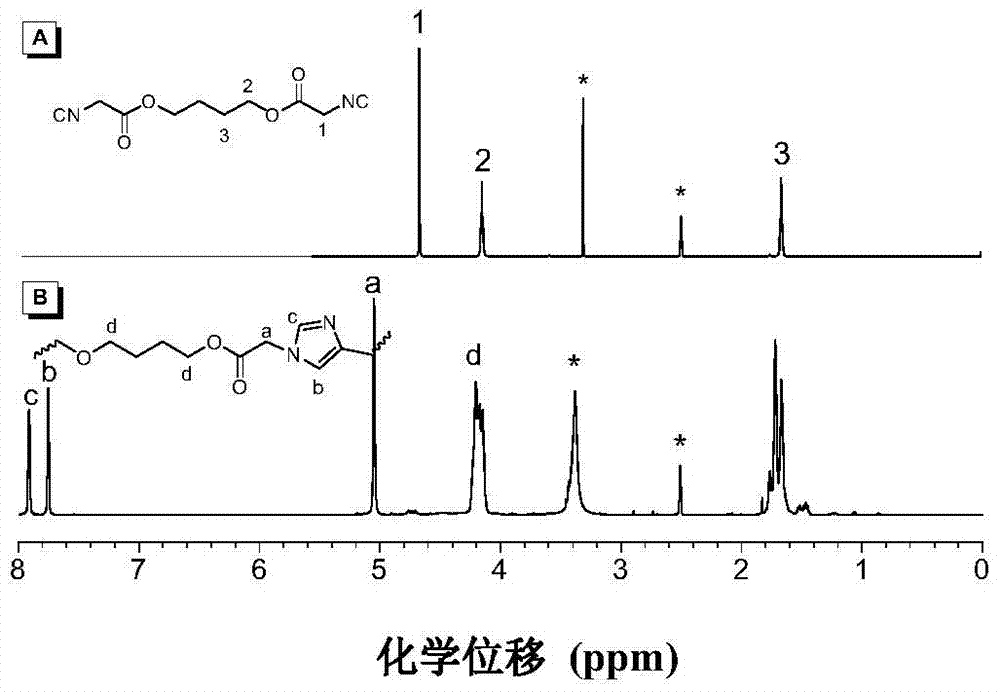

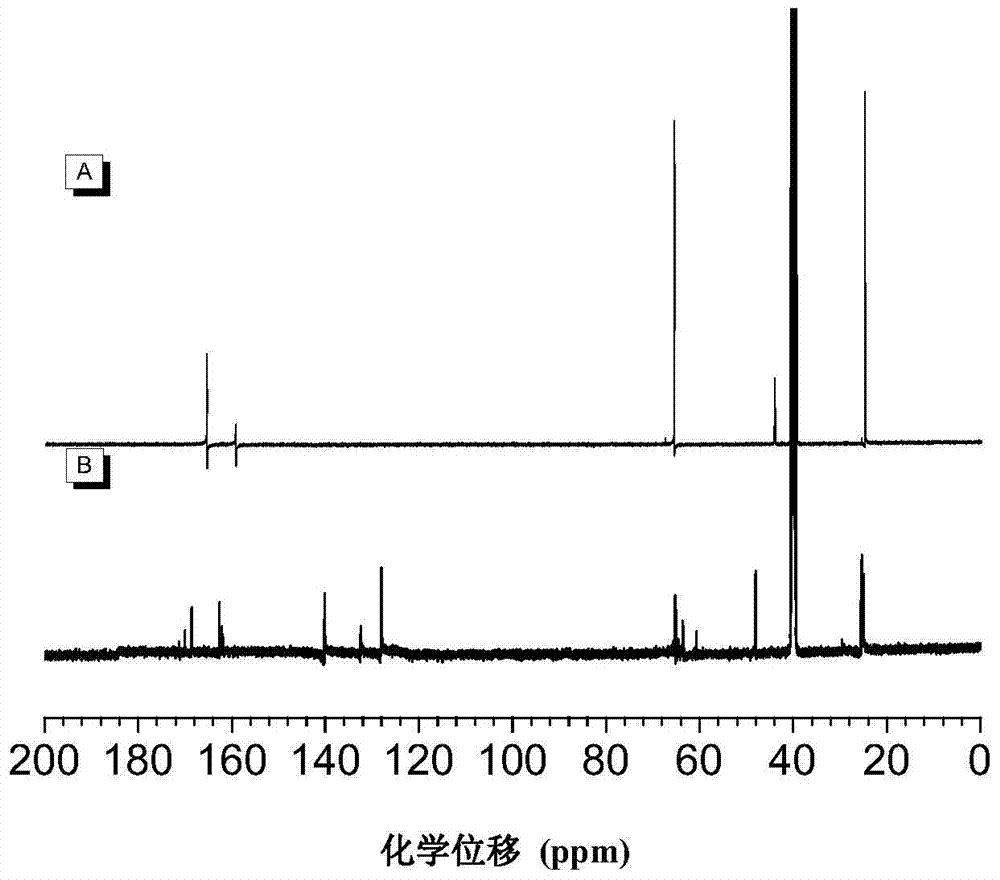

Polyimidazole compound, in-situ preparation method and applications thereof

InactiveCN106967217AEfficient Polymerization MethodSimple substrateIn situ polymerizationEnergy conservation

The present invention discloses a polyimidazole compound, an in-situ preparation method and applications thereof, wherein a binary isocyano compound is subjected to a cyclization polymerization reaction in an organic solvent under the action of a cyclization polymerization catalyst to obtain the polyimidazole compound. According to the present invention, the imidazole unit in the prepared polyimidazole compound is formed by carrying out in-situ polymerization on the imidazole-unit-free monomer so as to make up the gaps in the prior art; the cyclization polymerization reaction is the one-component polymerization reaction, the monomer ratio is not required to be considered, the process is simple, the reaction raw materials and the catalyst are easy to obtain, the polymerization reaction conditions are mild, the polymerization can be performed at the room temperature, and the energy source is saved; and the polymerization efficiency of the polymerization reaction is high, the high molecular weight polymer can be obtained after the reaction is performed for a short time, the polymerization reaction has excellent region selectivity and excellent stereoselectivity, no by-product is generated during the polymerization process, and the atom economy is met.

Owner:SOUTH CHINA UNIV OF TECH

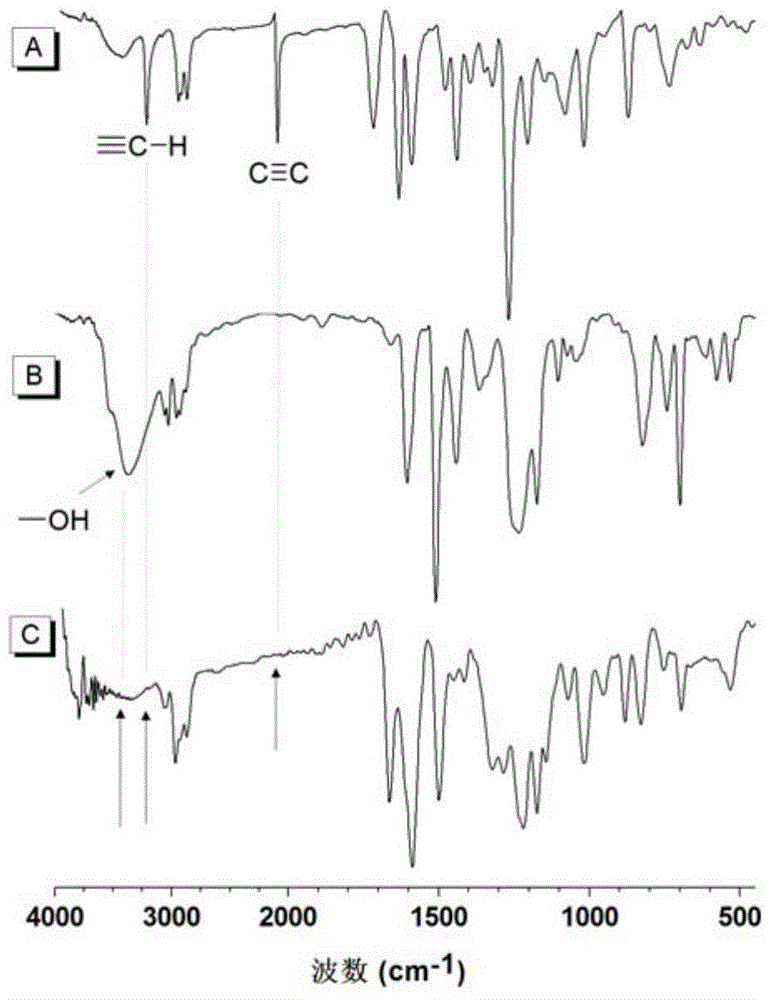

Polyvinylene sulfide and preparation method thereof

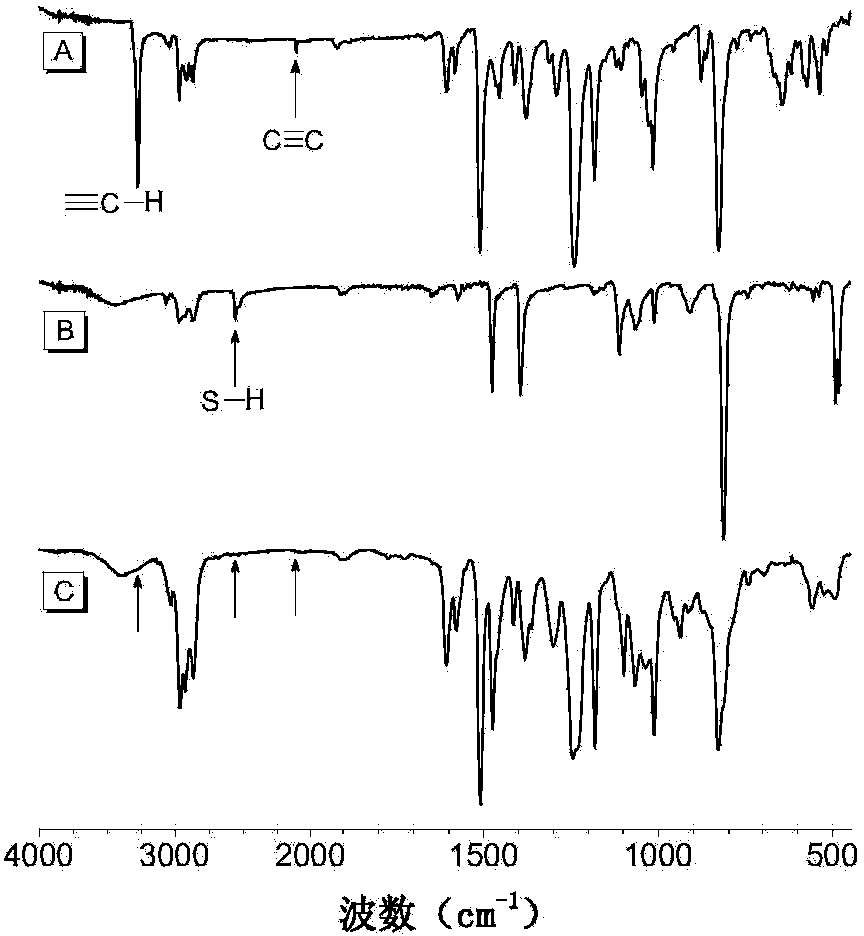

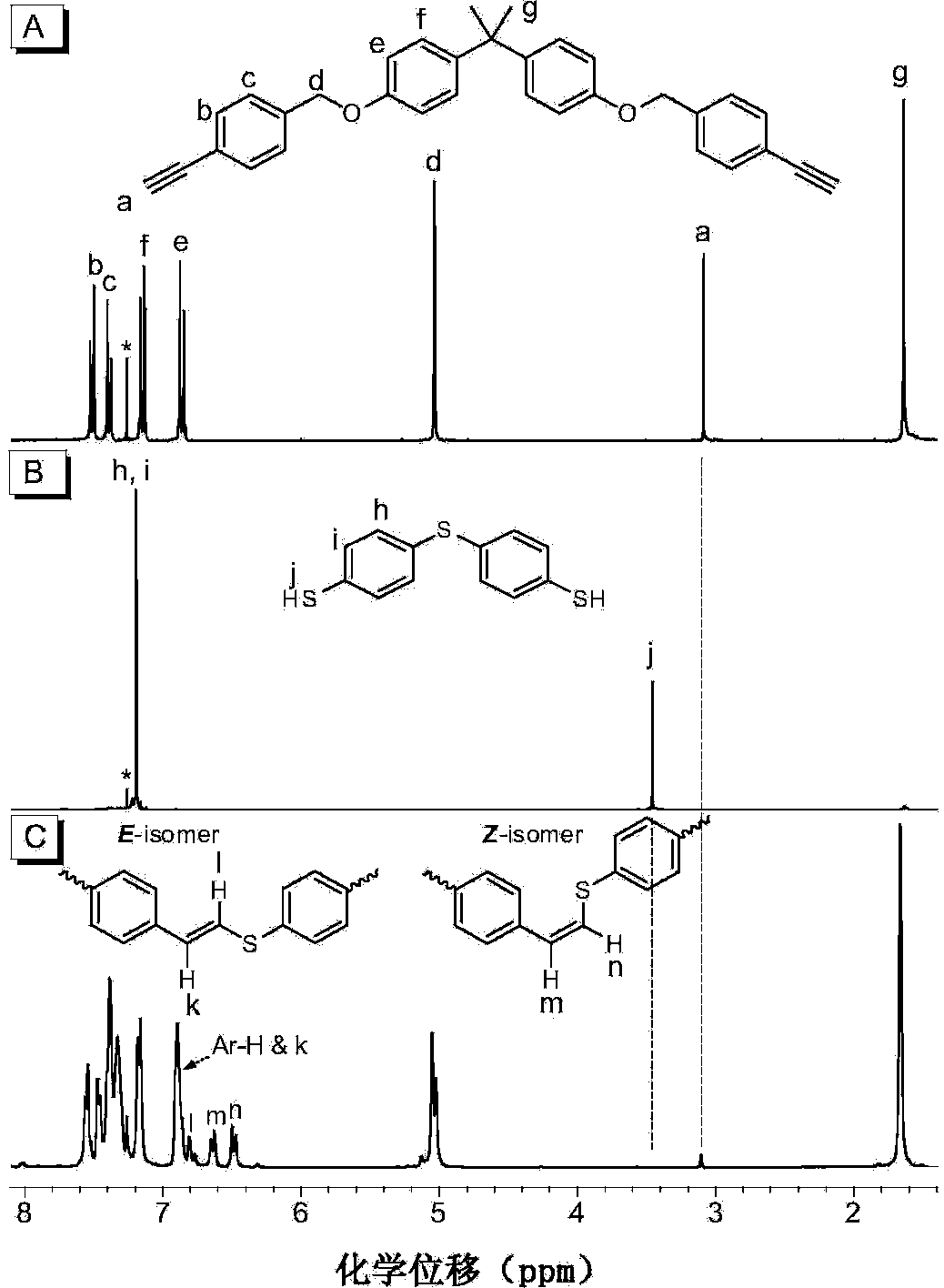

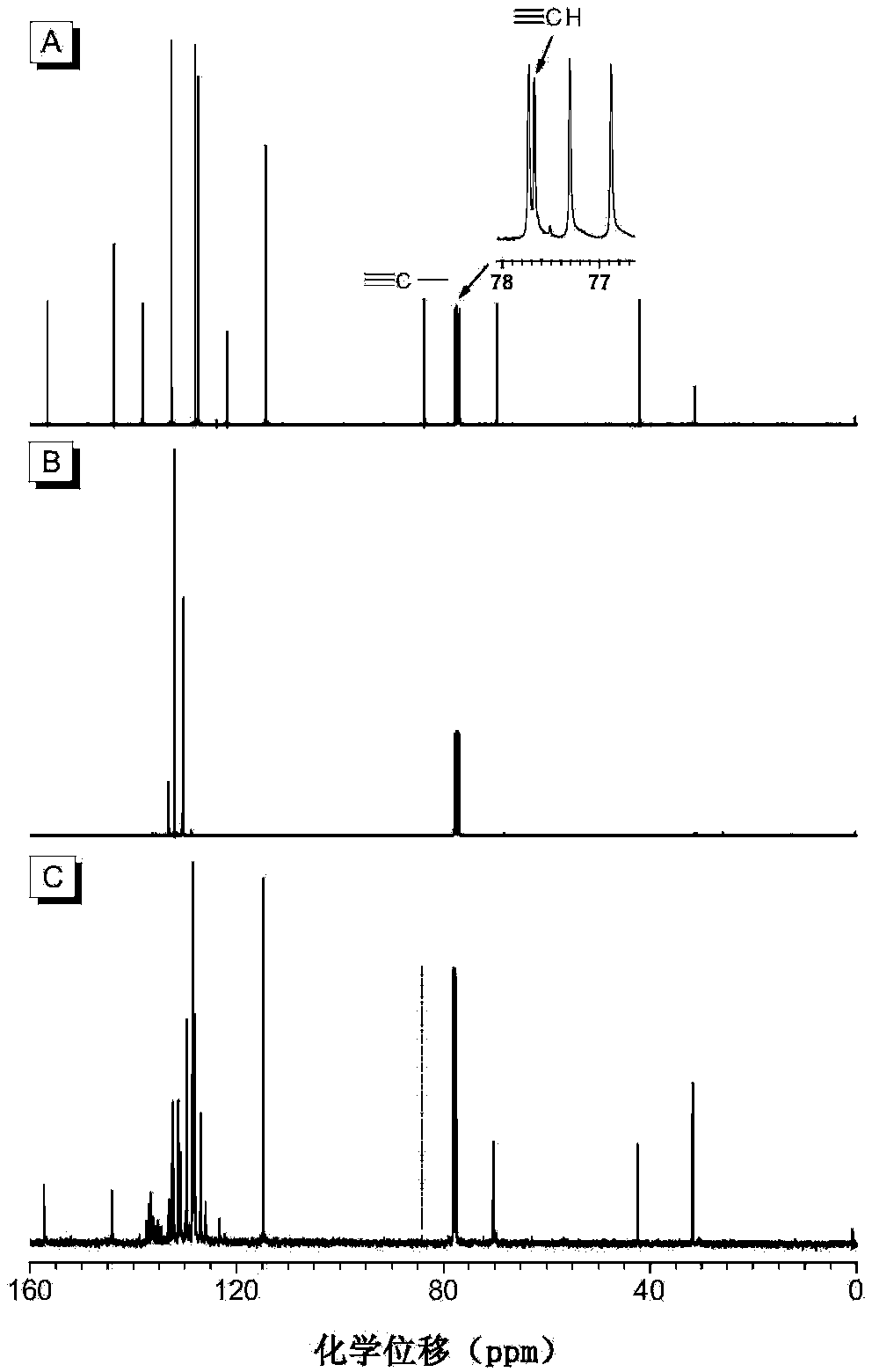

The invention discloses a preparation method of polyvinylene sulfide. The preparation method comprises the following step of performing click polymerization reaction on a binary alkynyl compound and a binary mercapto-compound in an organic solvent to obtain the polyvinylene sulfide. The obtained polyvinylene sulfide comprises an internal unit shown in a formula (I), the step of polymerization is shown in a formula (IV), wherein n is more than 1 and is selected from organic groups. The preparation method does not need heating or any catalyst, is simple and efficient in process, and has excellent space selectivity. The invention also discloses the polyvinylene sulfide obtained through the preparation method, and the polyvinylene sulfide has good workability and film-forming property, high heat stability and refractive index and aggregation induced luminescent property.

Owner:ZHEJIANG UNIV

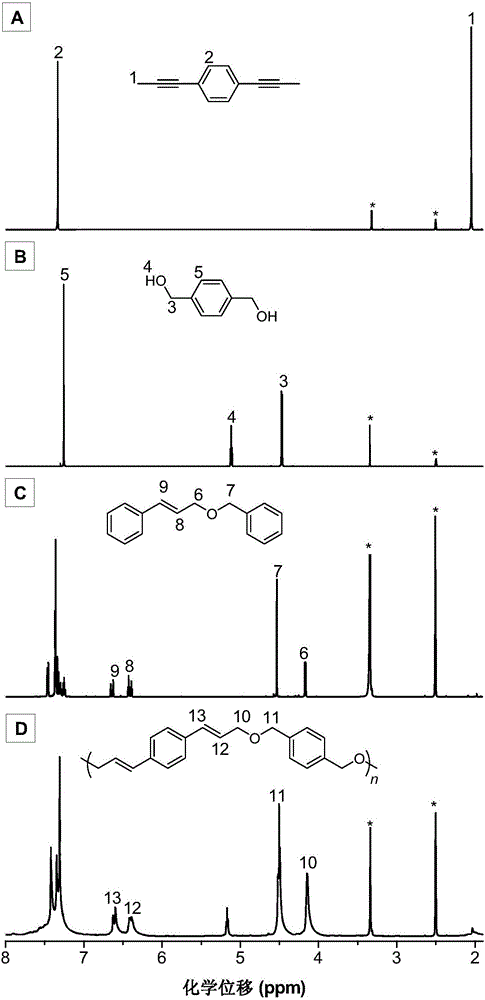

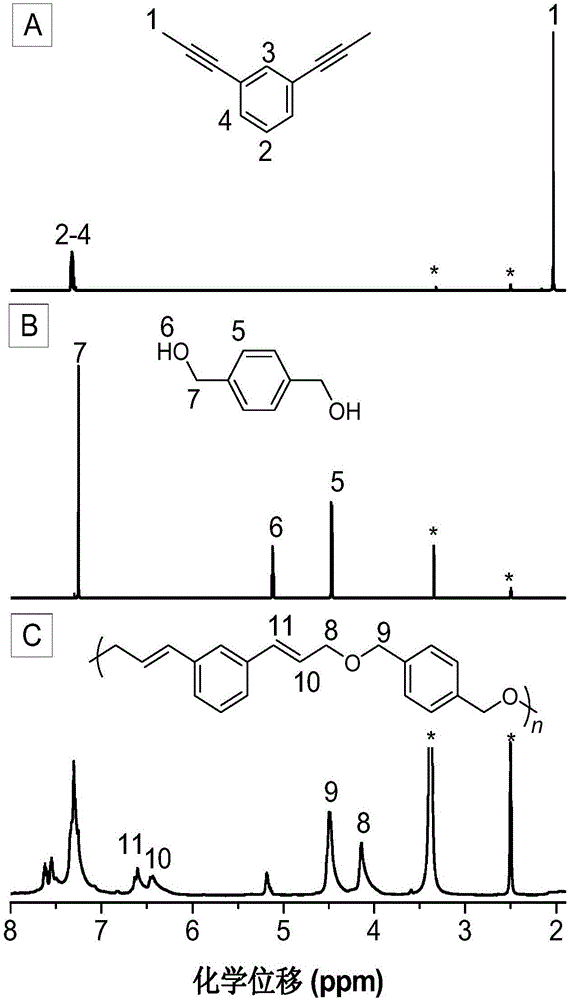

Poly(allyl ether) compound, and preparation method and application thereof

The invention belongs to the fields of high polymer chemistry and material science, and discloses a poly(allyl ether) compound, and a preparation method and application thereof. The method comprises the following steps: (1) performing polymerization reaction on a binary propinyl compound and a binary hydroxyl compound in organic solvent in an inert gas protective atmosphere to obtain a crude product; and (2) performing post-treatment on the crude product to obtain the poly(allyl ether) compound. The poly(allyl ether) compound has a structure shown in Formula (I), wherein n is an integer of 2-200, and R2 is a same or different organic group. The method disclosed by the invention has the advantages of mild conditions, simple and accessible polymerizable monomers, high polymer yield, high molecular weight, high atom economy and excellent regioselectivity; and the poly(allyl ether) compound disclosed by the invention has excellent processability and high thermal stability. The Formula (I) is shown in the specification.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing organic silicon modified propenoic ester copolymer emusion by fine emulsion polymerizing method

The present invention discloses fine emulsion polymerizing process to prepare organosilicon modified acrylate copolymer emulsion. The process includes the following steps: 1) dissolving emulsifier in 0.01-10 weight portions in water of 50-400 weight portions to form water phase solution; 2) mixing two or more kinds of vinyl monomers in 10-200 weight portions and organosilicon monomer in 1-30 weight portions to form oil phase solution; 3) mixing the water phase solution and the oil phase solution, and crushing in a high shearing field for 2-30 min to form fine emulsion; and 4) transferring the fine emulsion into a reactor, heating to 40-160 deg.c and adding initiator in 0.05-10 weight portions to initiate polymerization for 2-18 hr, and cooling slowly to room temperature before discharging. The process is simple, efficient and environment friendly, and may have organosilicon introduced in relatively high content.

Owner:ZHEJIANG UNIV

Method for synthesizing polyacrylate soap-free emulsion through micro-reactor

The invention discloses a method for synthesizing polyacrylate soap-free emulsion through a micro-reactor. The micro-reactor is used for carrying out synthesis; the micro-reactor is composed of a micro-mixer and a staying reaction tube which are communicated with each other; the method comprises the following specific steps: taking a double-bond acrylic monomer as an oil phase and an alkyl vinyl sulfate sulfonate water solution as a water phase; pumping the oil phase and the water phase into the micro-mixer of the micro-reactor and carrying out emulsifying to obtain a pre-emulsified solution;preparing an initiator water solution; pumping the pre-emulsified solution and the initiator water solution into the micro-reactor and reacting; and after reaction is finished, discharging in a cold water bath, so as to obtain the polyacrylate soap-free emulsion. The micro-reactor is adopted to realize controllable multi-phase micro-scale flowing, and mixing, mass transfer and heat transfer processes of a polymerization reaction process are strengthened, the reaction time is greatly shortened and the polymerization efficiency is improved; the micro-reactor has an excellent heat conduction capability, so that heat released by the reaction is dissipated in time and the control of temperature is realized; and the polymerization and explosion problem caused by the fact that the temperature ofa traditional method is too high is overcome.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com