Preparation method of electric-conductive macromolecule polymer nanoparticles with good water phase dispersibility

A technology for conducting polymers and nanoparticles, applied in the field of preparation of polymer nanoparticles, can solve the problems affecting the conductivity of materials, high surface energy, particle coagulation, agglomeration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

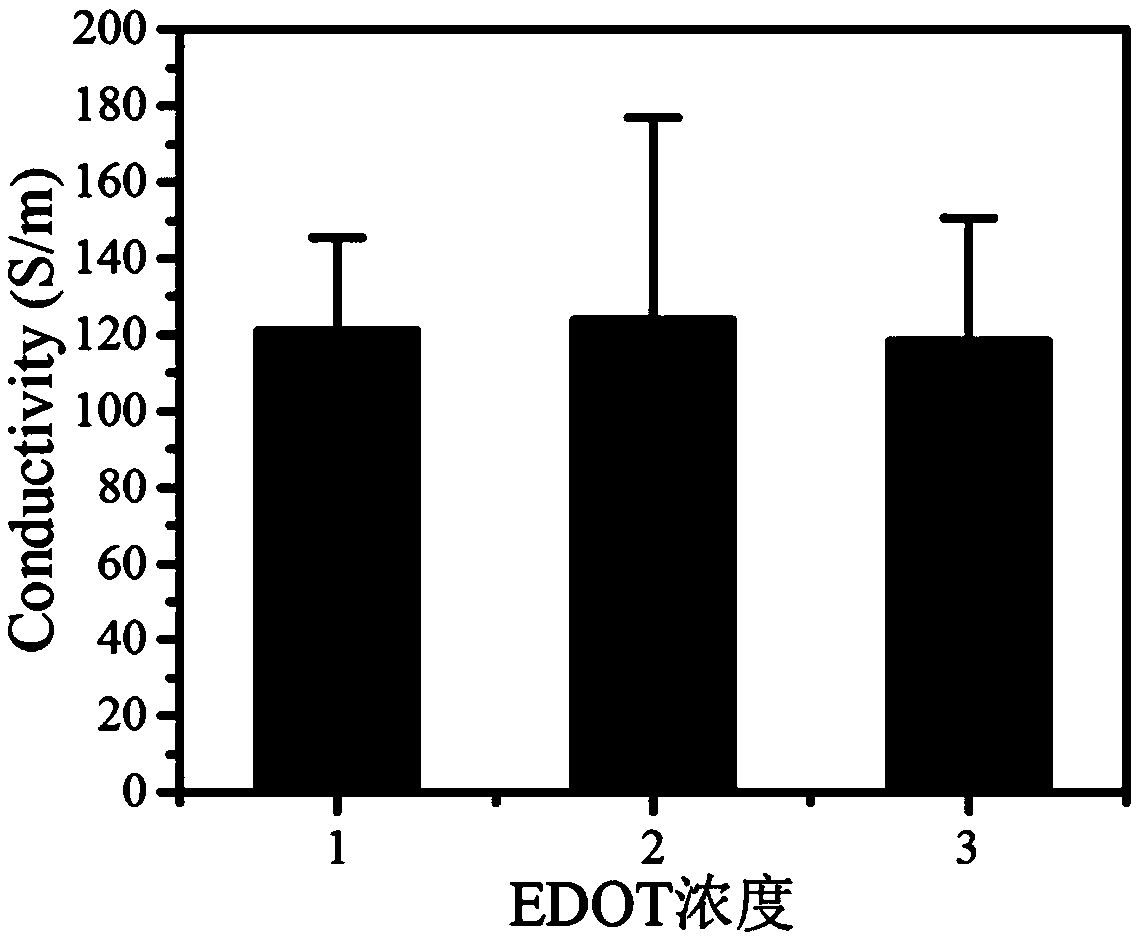

[0033] A. Preparation of 3,4-ethylenedioxythiophene monomer solution:

[0034] Add 3,4-ethylenedioxythiophene monomer into absolute ethanol and stir thoroughly to obtain a 3,4-ethylenedioxythiophene monomer solution with a mass concentration of 0.85%.

[0035] B. Preparation of persulfate aqueous solution:

[0036] A certain amount of ammonium persulfate was weighed and dissolved in deionized water to obtain an aqueous solution of ammonium persulfate with a mass concentration of 9.1%.

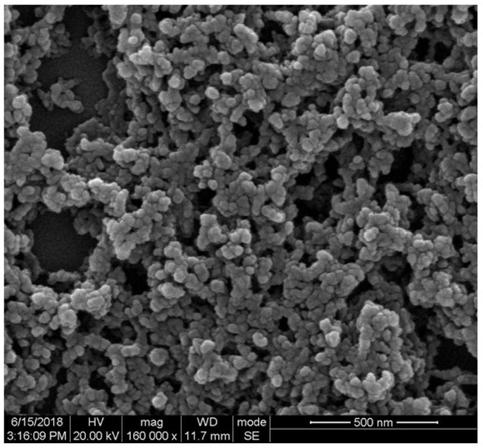

[0037] C. Preparation of poly-3,4-ethylenedioxythiophene nanoparticles:

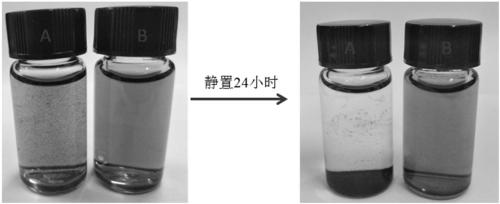

[0038] Add ammonium persulfate aqueous solution to 3,4-ethylenedioxythiophene monomer solution, the mass ratio is 3,4-ethylenedioxythiophene monomer:ammonium persulfate=1:5, after stirring evenly, weigh ferric chloride , with a mass ratio of 3,4-ethylenedioxythiophene monomer: ferric chloride = 1:20, added to the above mixed solution, the color of the solution immediately turned blue-black, and stirred for 9 days under ...

Embodiment 2

[0040] A. Preparation of pyrrole monomer solution:

[0041] The pyrrole monomer was added into methanol and stirred thoroughly to obtain a pyrrole monomer solution with a mass concentration of 1.2%.

[0042] B. Preparation of persulfate aqueous solution:

[0043] A certain amount of sodium persulfate was weighed and dissolved in deionized water to obtain an aqueous sodium persulfate solution with a mass concentration of 15%.

[0044] C. Preparation of Polypyrrole Nanoparticles:

[0045] Add sodium persulfate aqueous solution to the pyrrole monomer solution, the mass ratio is pyrrole monomer: sodium persulfate = 1:3, after stirring evenly, weigh the ferric sulfate. The mass ratio is pyrrole monomer: ferric sulfate = 1:15, when added to the above mixed solution, the color of the solution immediately turns blue-black, and it is stirred for 7 days in an ice bath. Then, centrifuge and wash 3 times with deionized water. The obtained black polypyrrole monomer nanoparticles are di...

Embodiment 3

[0047] A. Preparation of aniline monomer solution:

[0048] Adding the aniline monomer into glycerol and stirring thoroughly to obtain an aniline monomer solution with a mass concentration of 0.5%.

[0049] B. Preparation of persulfate aqueous solution:

[0050] A certain amount of potassium persulfate was weighed and dissolved in deionized water to obtain an aqueous solution of potassium persulfate with a mass concentration of 7.2%.

[0051] C. Preparation of polyaniline nanoparticles:

[0052]Add potassium persulfate aqueous solution to the aniline monomer solution, the mass ratio is aniline monomer: potassium persulfate=1:10, after stirring evenly, take iron nitrate, the mass ratio is aniline monomer: iron nitrate=1:7, add To the above mixed solution, the color of the solution turned black immediately, and stirred for 2 days under ice-bath conditions. Then, centrifuge and wash 3 times with deionized water. The obtained black polyaniline nanoparticles are dispersed in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com